Patents

Literature

134results about How to "Shorten evaporation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

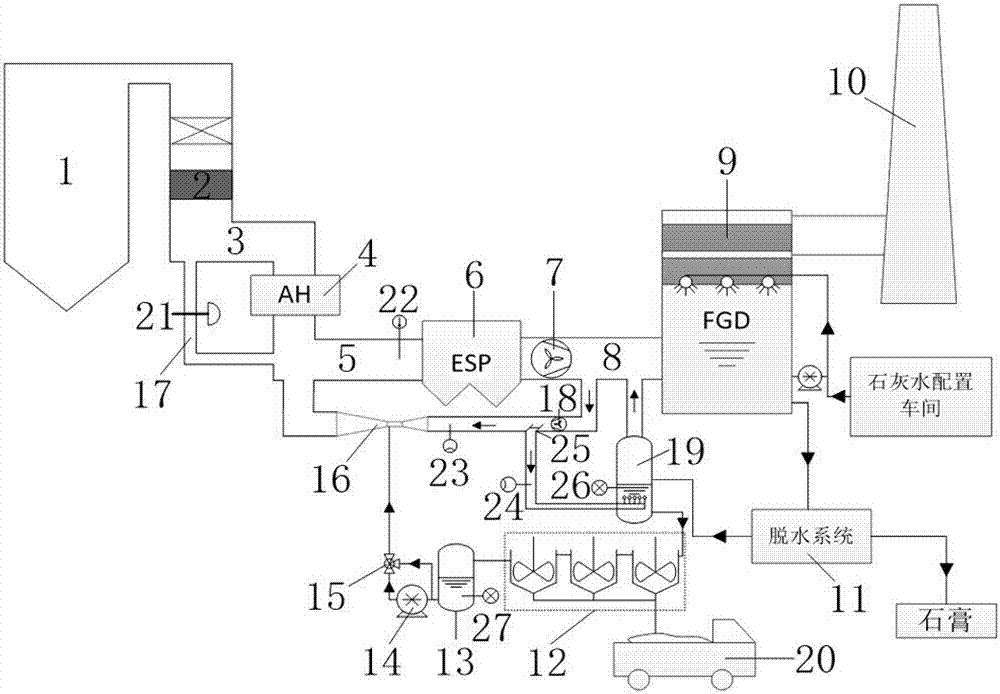

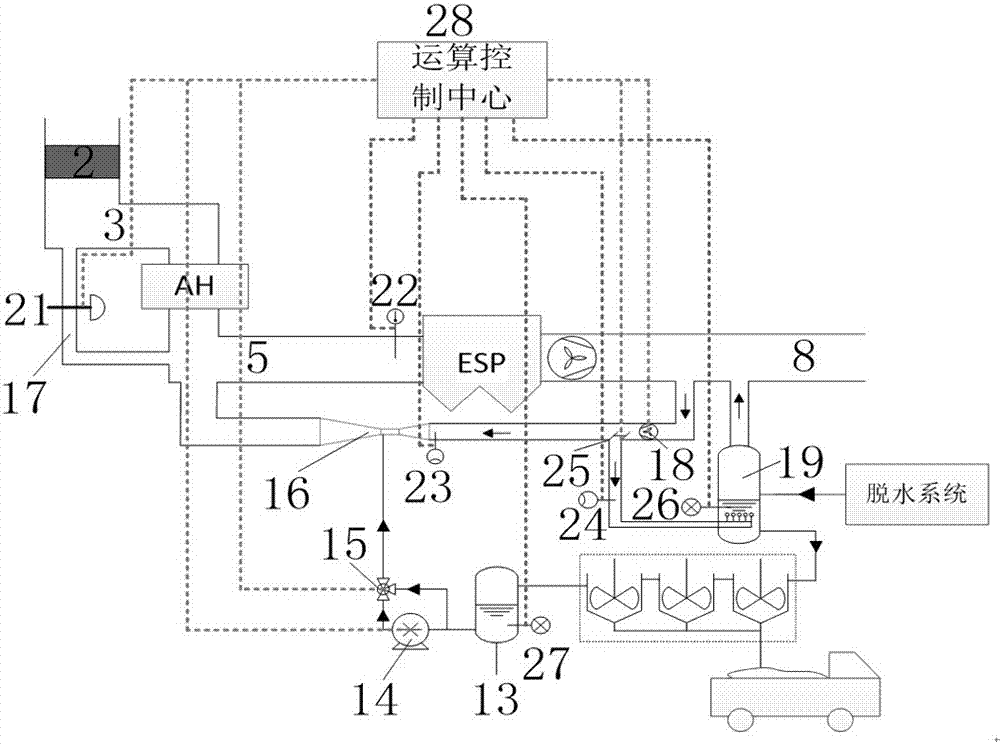

Method and device for achieving desulfurization wastewater zero discharging with full flue gas

PendingCN108006683ATo achieve the effect of reduction treatmentAvoid problems with temperatures below the acid dew pointGas treatmentEmission preventionEvaporationSlurry

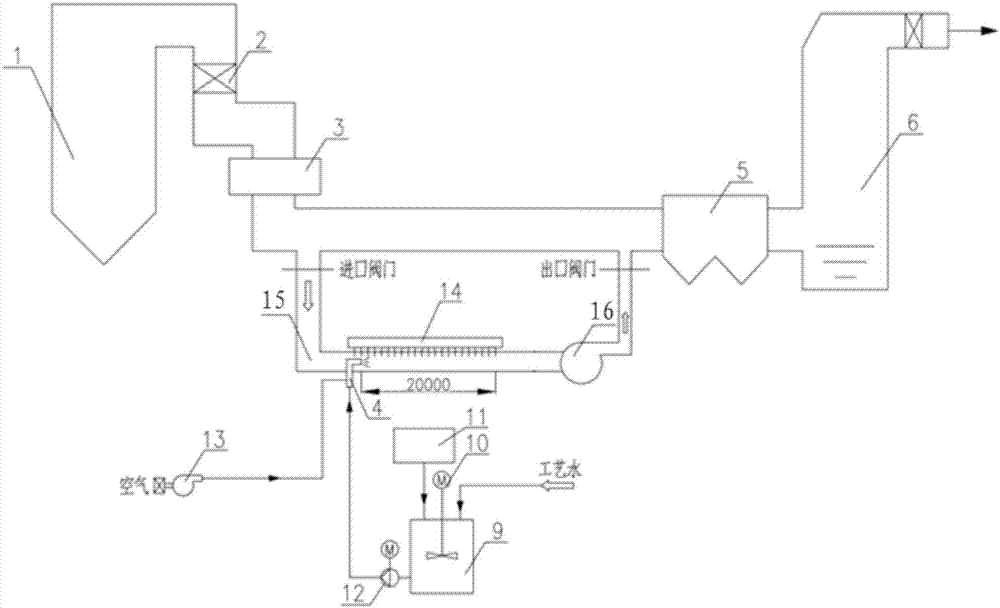

The invention discloses a method and device for achieving desulfurization wastewater zero discharging with full flue gas. The method includes the steps that desulfurization wastewater discharged froma coal-fired power plant slurry dewatering system is directly fed into a bypass bubble tower in front of a desulfurizing tower, and then is subjected to reducing concentration with hot flue gas in front of the desulfurizing tower; desulfurization wastewater concentrated water is fed into three connection tanks for charging treatment; settled supernatant liquid is fed into a wastewater tank to be buffered and stored; part of waste heat flue gas is led out behind an electrostatic dust collector and is further pressurized through a high-pressure fan to be fed into an inlet of a Venturi atomizingtube; the desulfurization wastewater stored in the wastewater tank is led into the Venturi tube through negative pressure at a pipe opening of the Venturi tube, high-speed airflow at the throat position of the Venturi tube can impact and atomize the led-in desulfurization wastewater, and meanwhile the waste heat flue gas and liquid drops are subjected to forceful heat transfer so that the pre-evaporation effect on the liquid drops can be achieved; and solid evaporated products are captured by the follow-up electrostatic dust collector or a bag-type dust remover, and therefore low-cost zero discharging of the desulfurization wastewater can be realized.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

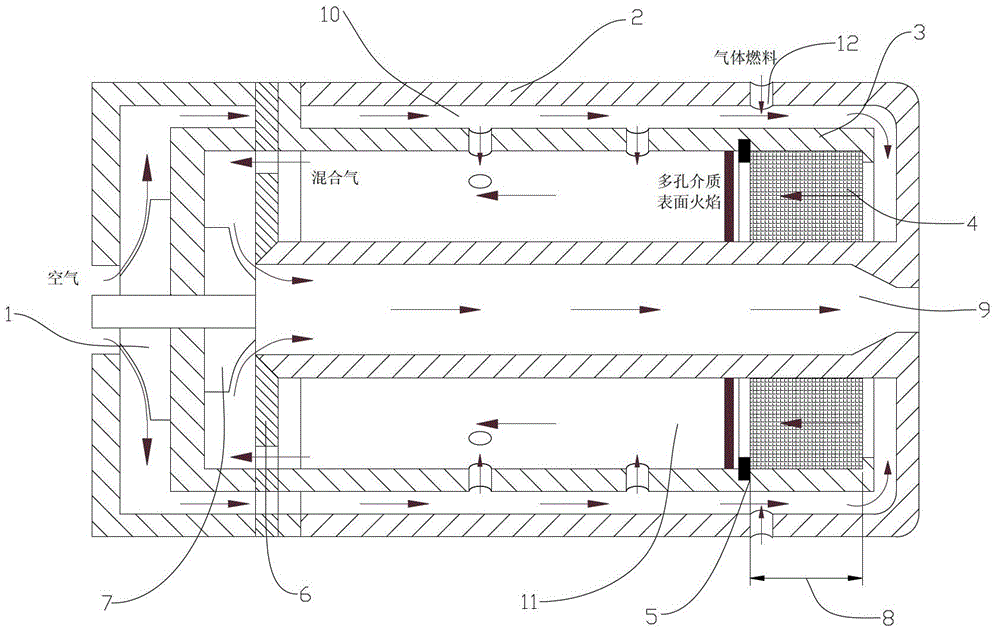

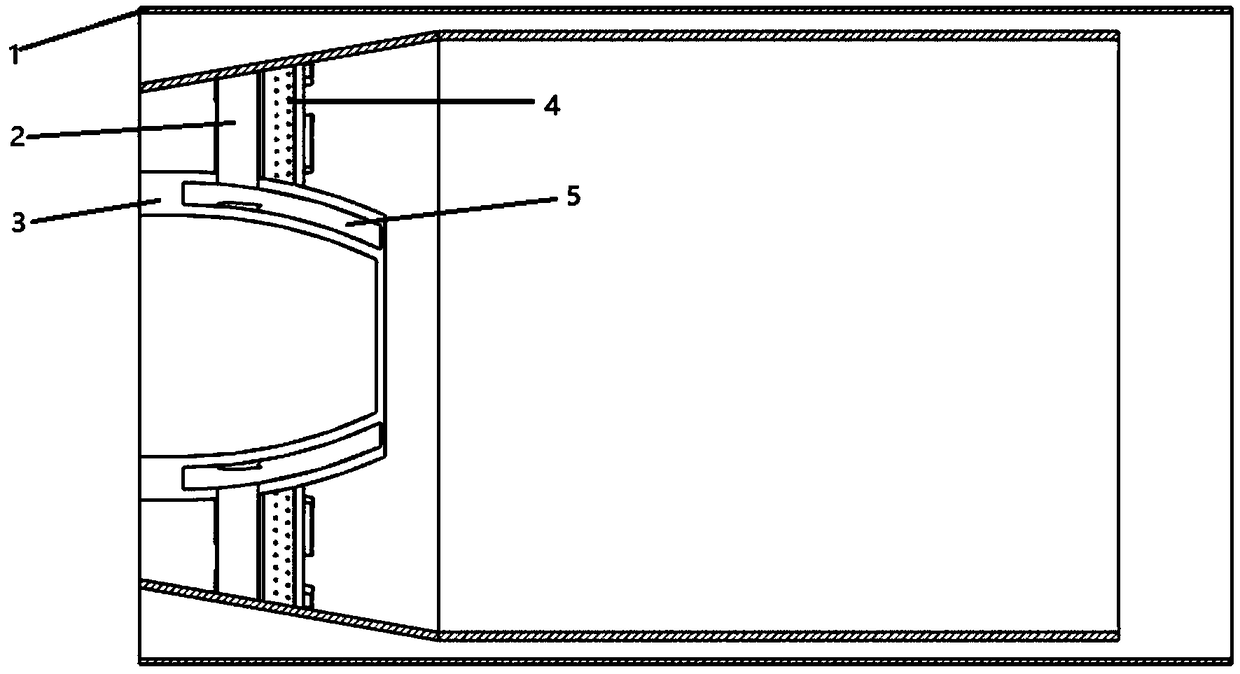

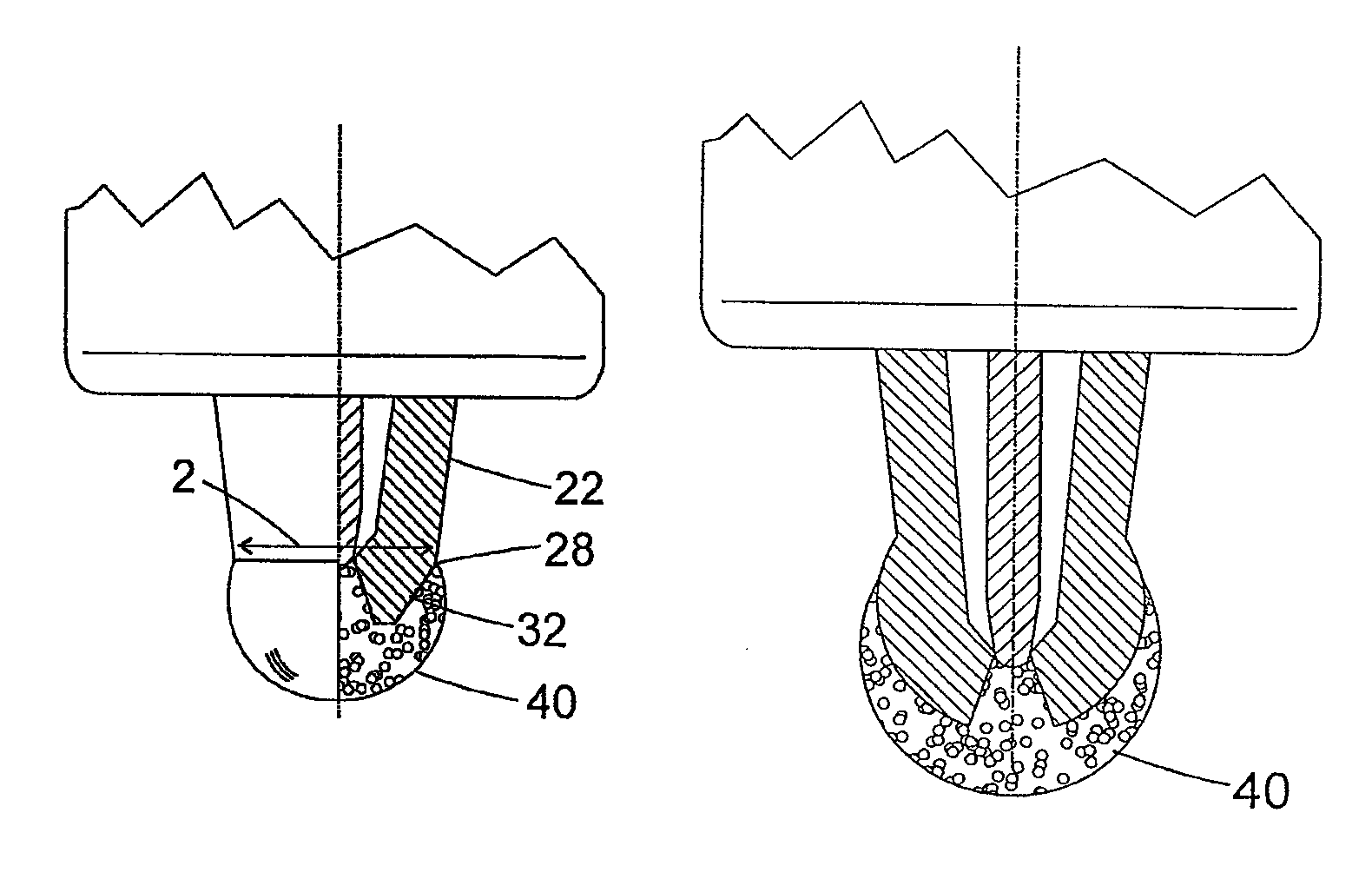

Rear-placed combustor with annular porous medium head for ultramicro turbojet engine

ActiveCN102878579AOvercoming short stay timeReduce foggingContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

Disclosed is a rear-placed combustor with an annular porous medium head for an ultramicro turbojet engine. An annular reflux structure is adopted for the combustor which is formed by a combustor box, a flame tube wall, a combustor outlet and the annular porous medium head. Air flow passes through a centrifugal compressor of the engine for compression, enters an annular cavity channel of the combustor, and then is mixed with gas fuel which is jetted in horizontally; premixed gas is pre-heated through the flame tube wall and then flows back to enter a flame tube through the annular porous medium head, and stable ignition is achieved; the whole mixed gas combustion process is finished in the flame tube, and high-temperature gas is discharged from the outlet of the rear-placed combustor; and then the high-temperature gas is discharged into air through a tail pipe after turbine blades of an impact engine does work. The combustor box, the flame tube wall and the combustor outlet are connected through bolts with high temperature glue sprayed on annular edges to guarantee the sealing. According to the combustor, features and advantages of stable flame of the annular porous medium head can be adapted to and played to the greatest extent, proneness to flameout of ultramicro combustors can be improved, so that the combustor can work for the ultramicro turbojet engine reliably and stably.

Owner:BEIHANG UNIV

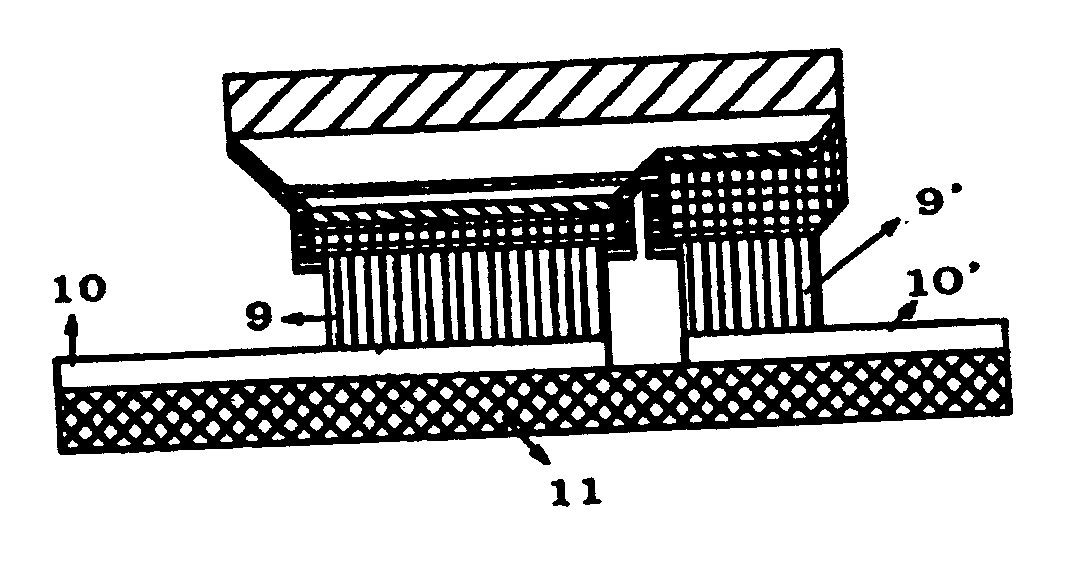

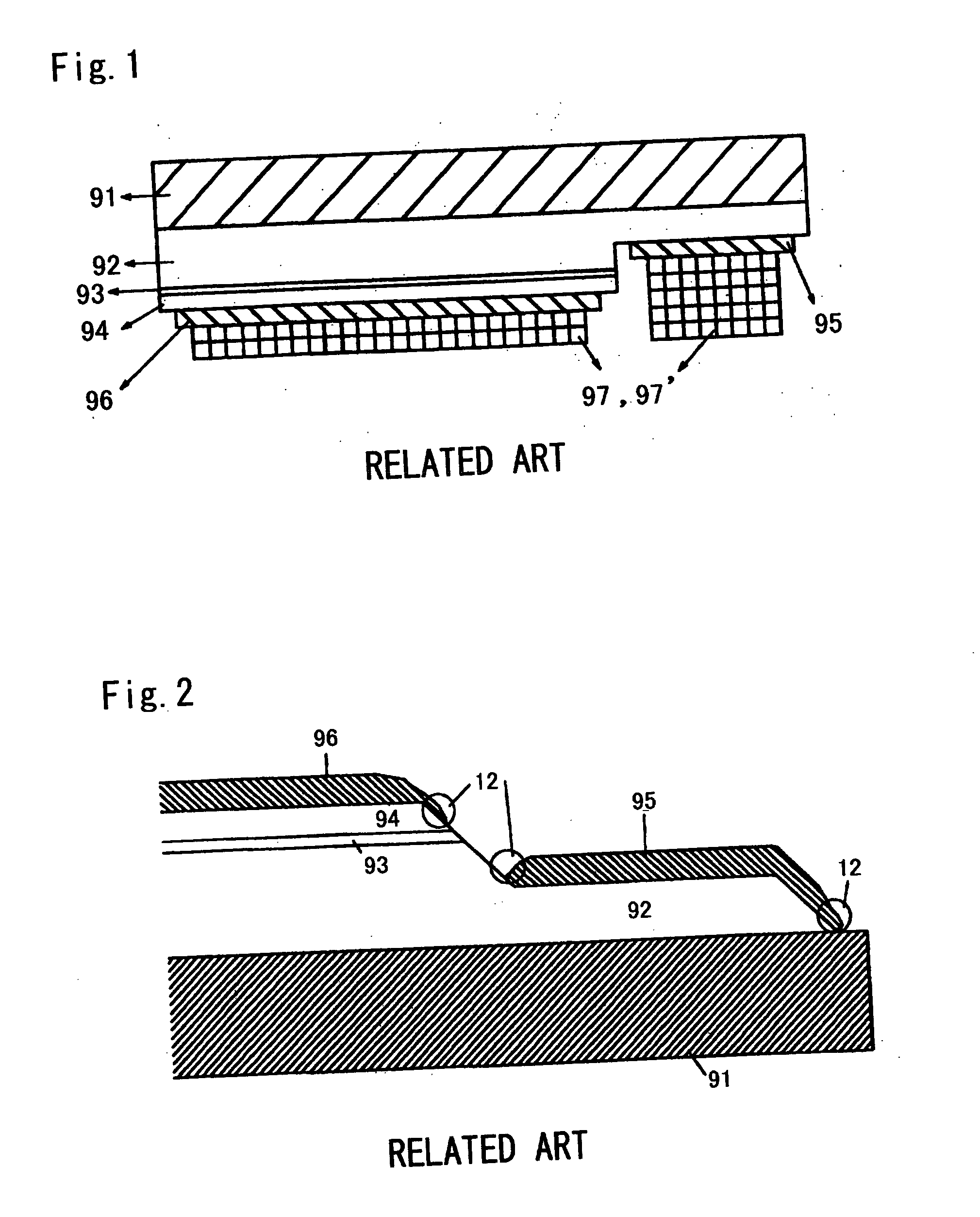

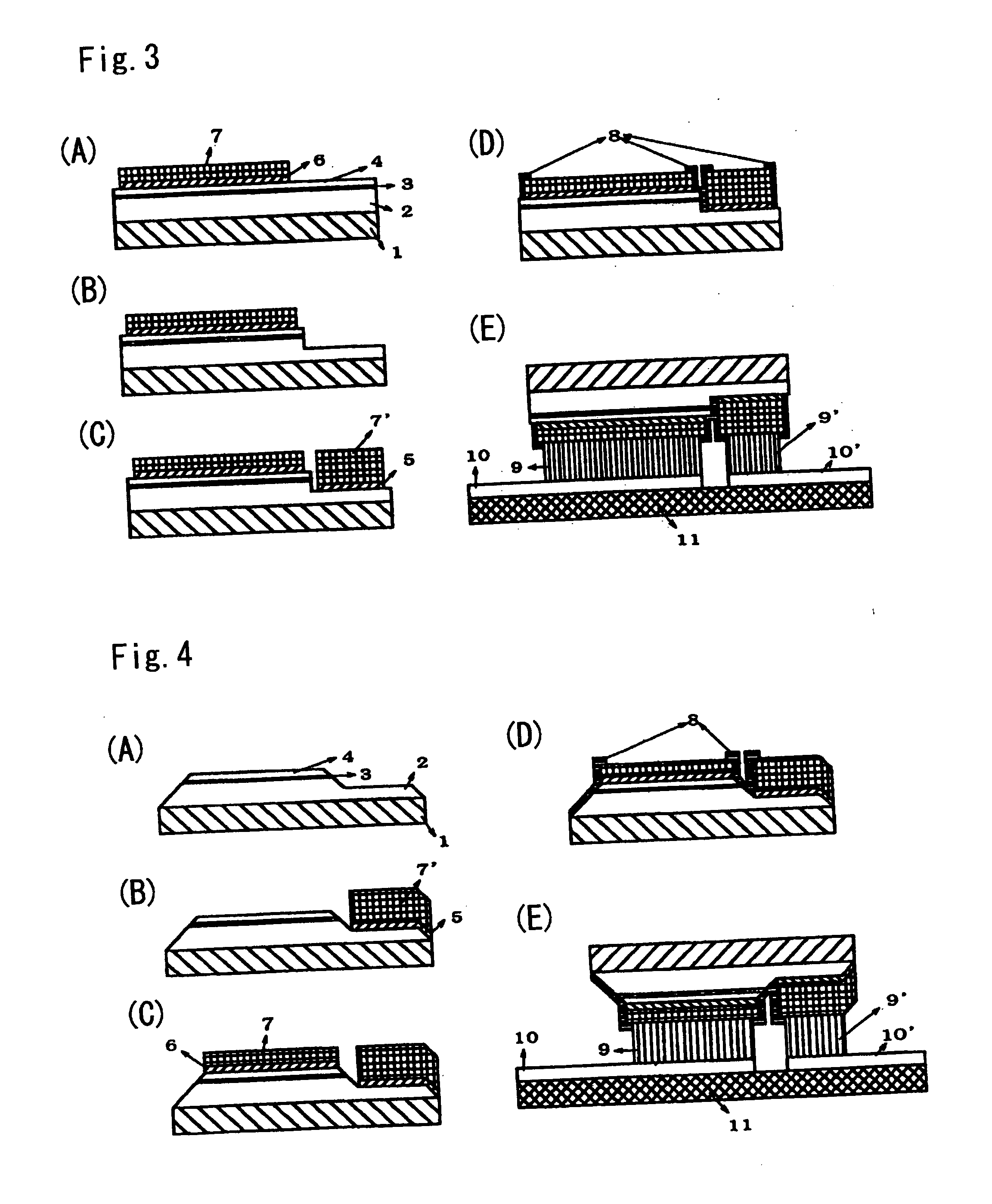

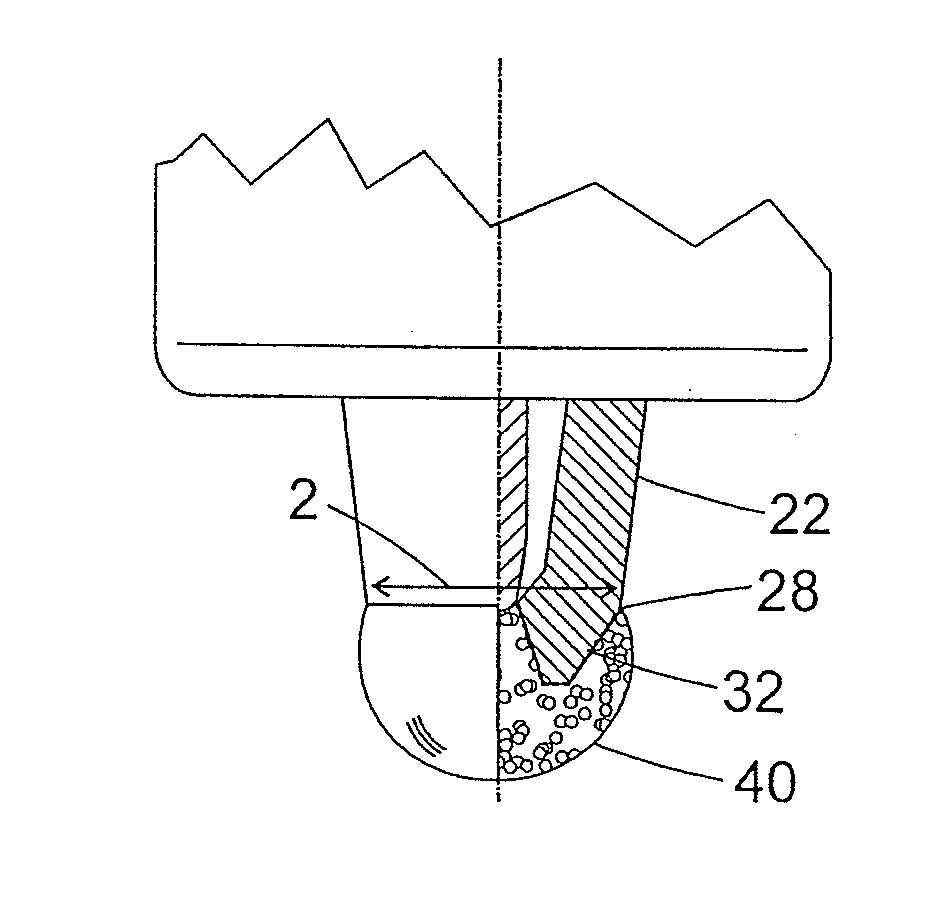

Gallium nitride compound semiconductor device and method of manufacturing the same

ActiveUS20050056865A1Deteriorating in characteristicDeteriorating in reflectivityInking apparatusSolid-state devicesDevice materialOhmic contact

A GaN compound semiconductor device can be capable of free process design and can have optimum device characteristics. The device can include a group III nitride compound semiconductor laminate structure including an n-type GaN compound semiconductor layer and a p-type GaN compound semiconductor layer. An n electrode can be formed on the n-type GaN compound semiconductor layer, and a p electrode can be formed on the p-type GaN compound semiconductor layer. The n electrode preferably includes an Al layer of 1 to 10 nm, in contact with the n-type GaN compound semiconductor layer, and any metal layer of Rh, Ir, Pt, and Pd formed on the Al layer. The p electrode can be made of a 200 nm or less layer of of Pd, Pt, Rh, Pt / Rh, Pt / Ag, Rh / Ag, Pd / Rh, or Pd / Ag, in contact with the p-type GaN compound semiconductor layer. Both electrodes can make ohmic contact with respective n-type / p-type GaN semiconductors without application of active annealing.

Owner:STANLEY ELECTRIC CO LTD

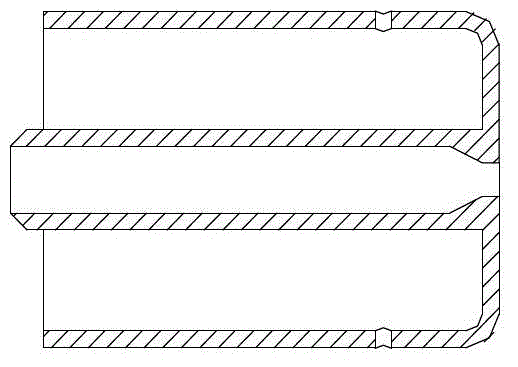

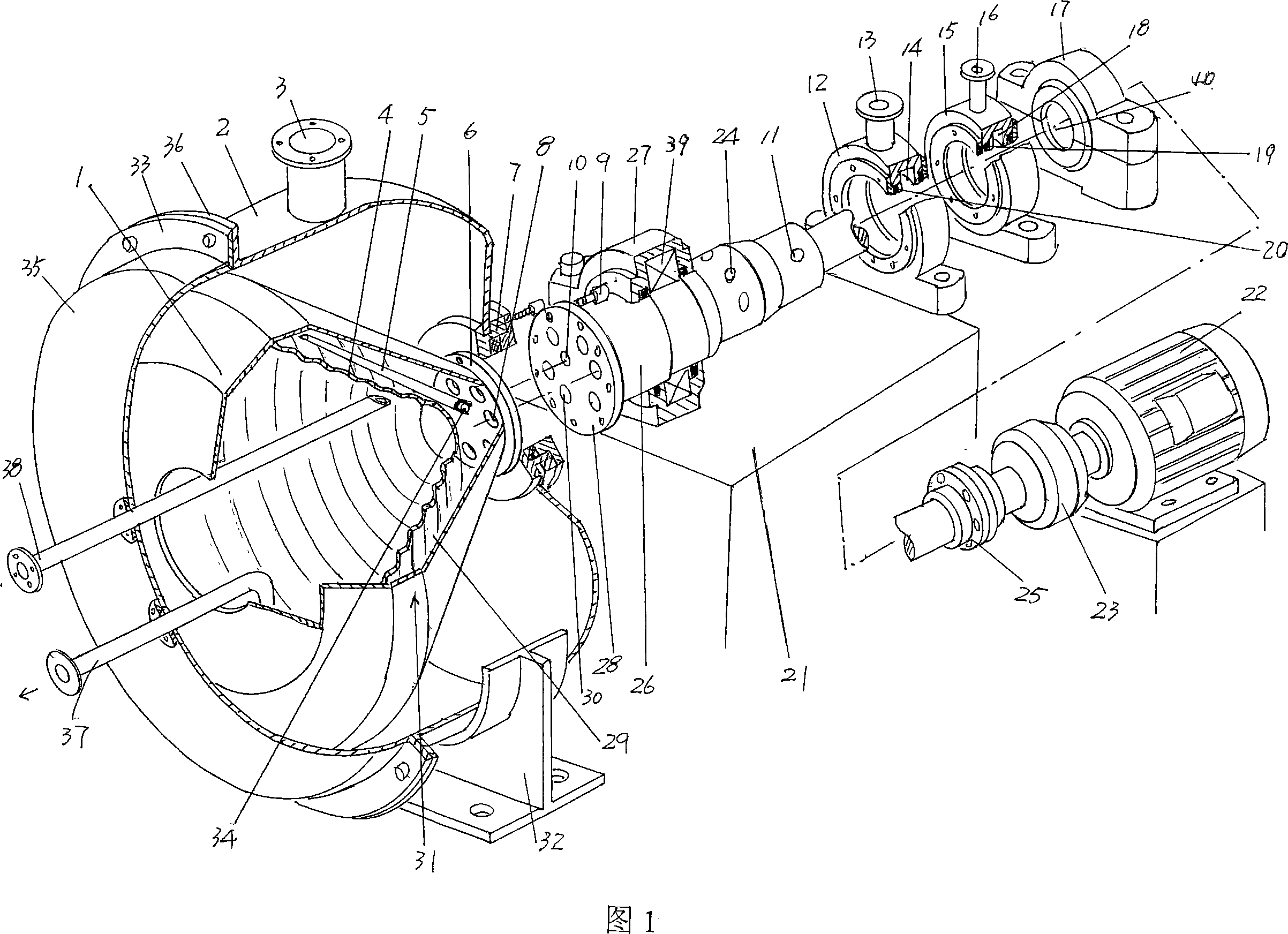

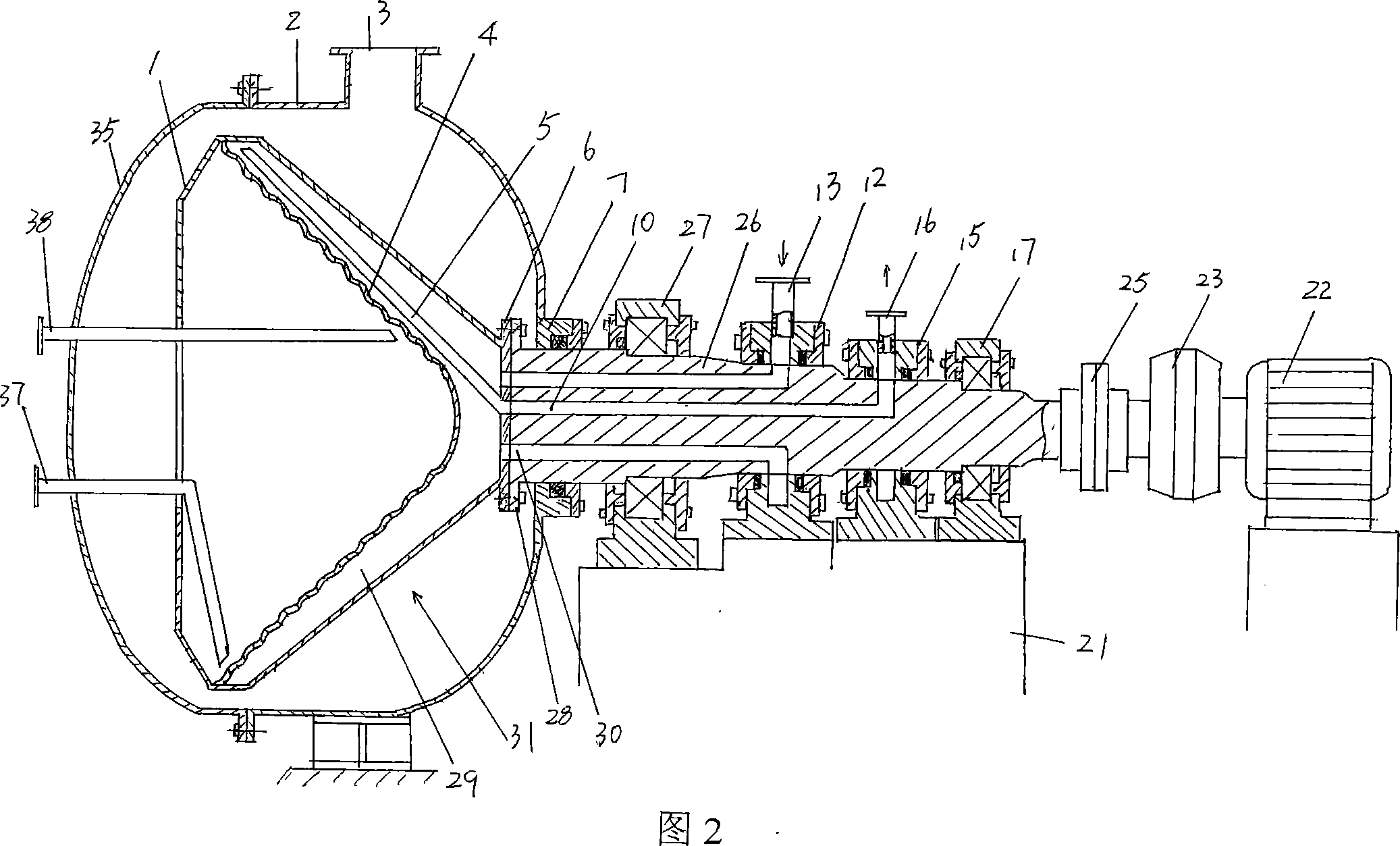

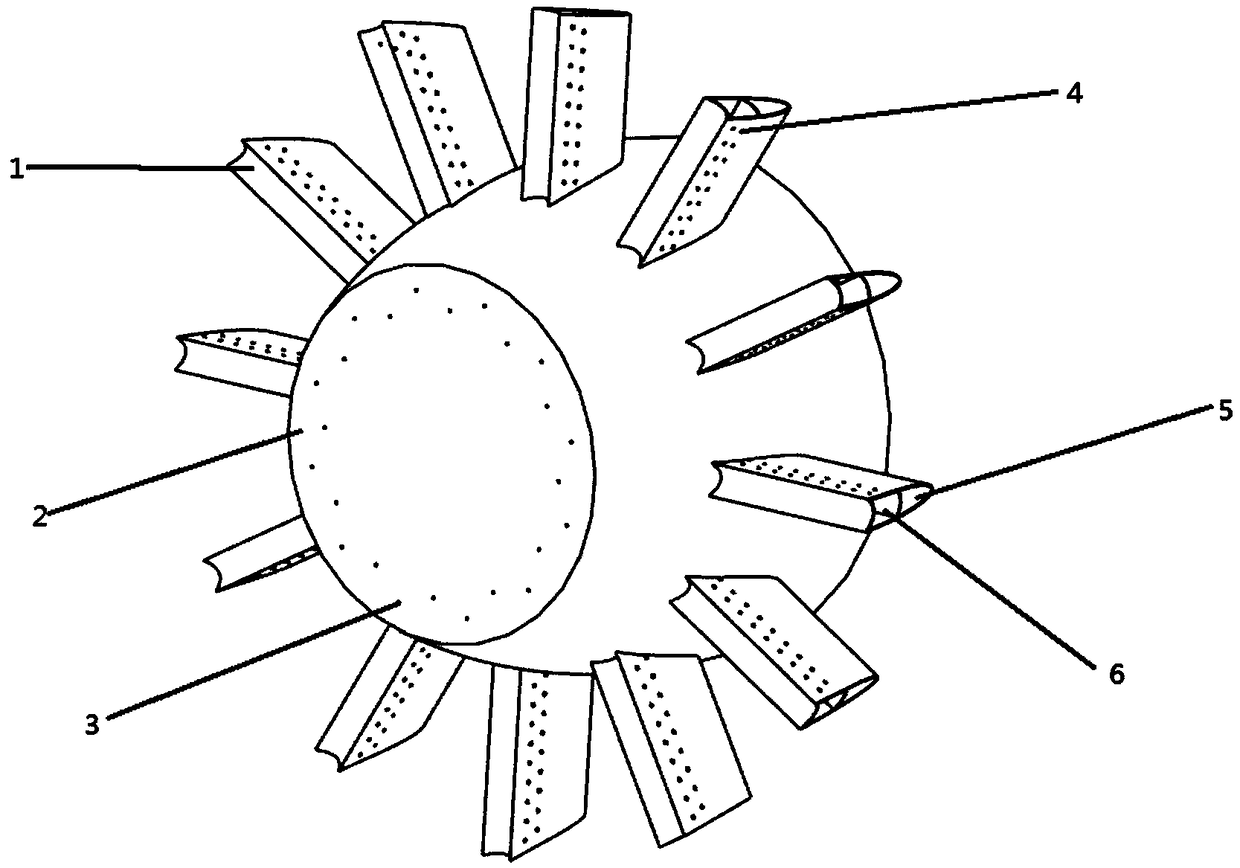

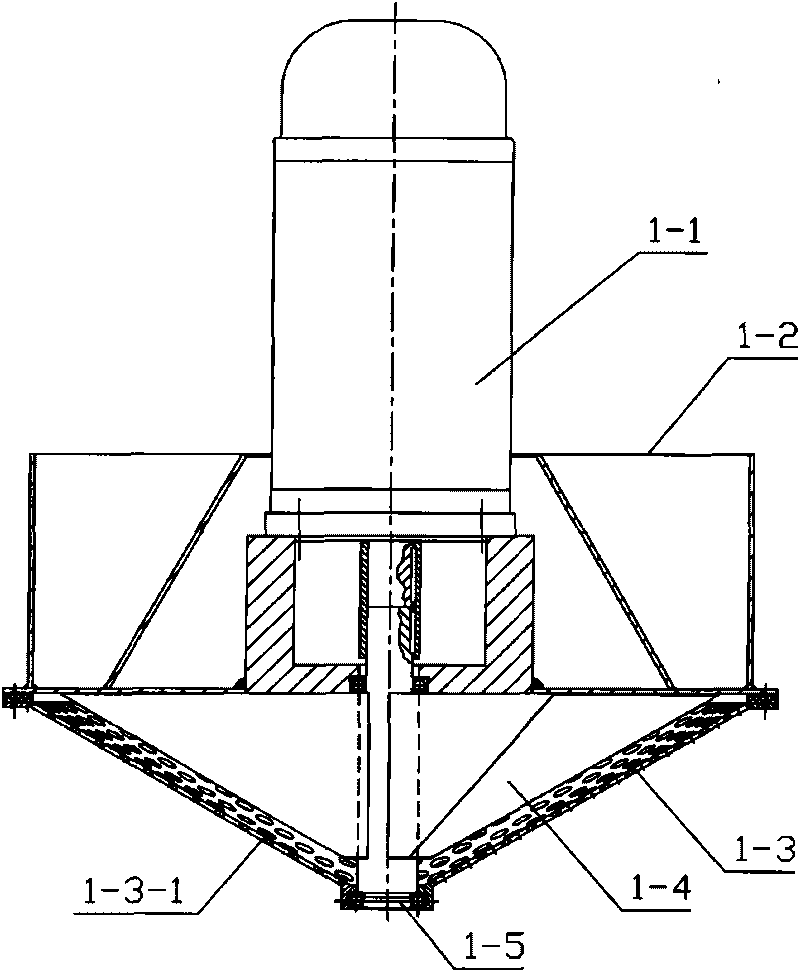

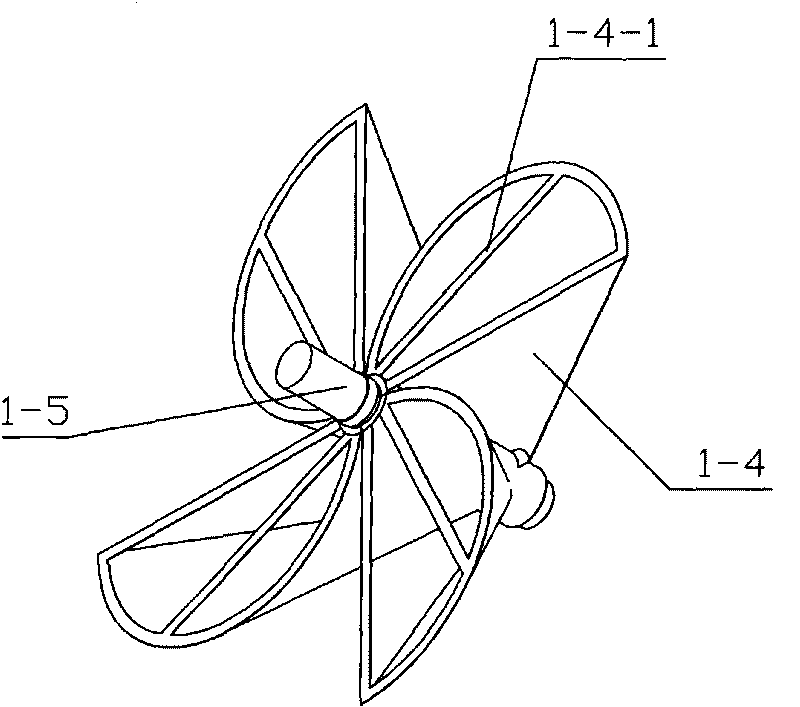

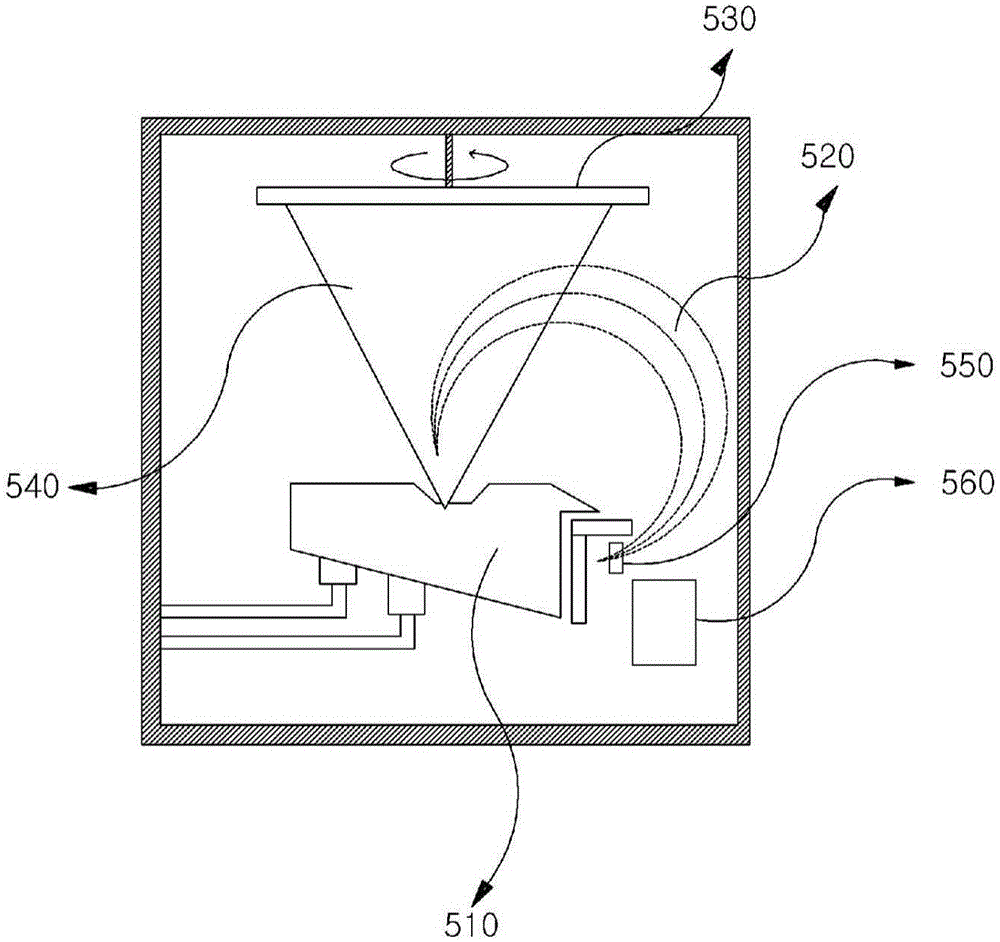

Centrifugal film evaporator

InactiveCN101058039AShorten evaporation timeImprove evaporation efficiencyEvaporationEvaporationEngineering

The invention relates to a centrifugal thin film evaporator for fluid even distribution in fluid film for evaporation and condensation, comprising a power and a main shaft connected to the power drive with evaporation channel and condensation return duct, evaporation introducer and condensation fluid extractor on the main shaft, a barrel with evaporator return opening equipped at the end of the main shaft, an isolation sleeve inside the barrel cavity and connected to the main shaft, an evaporator inside the isolation sleeve and fixed with the said isolation sleeve with evaporator cavity formed by the evaporator and the wall of the isolation sleeve and the evaporator cavity connecting to the evaporator channel and condensation duct respectively. It can shorten the evaporation period of material on the evaporator, with even fluid film, conducive to the improvement of evaporation efficiency and effect with energy conservation.

Owner:常熟市春来机械有限公司

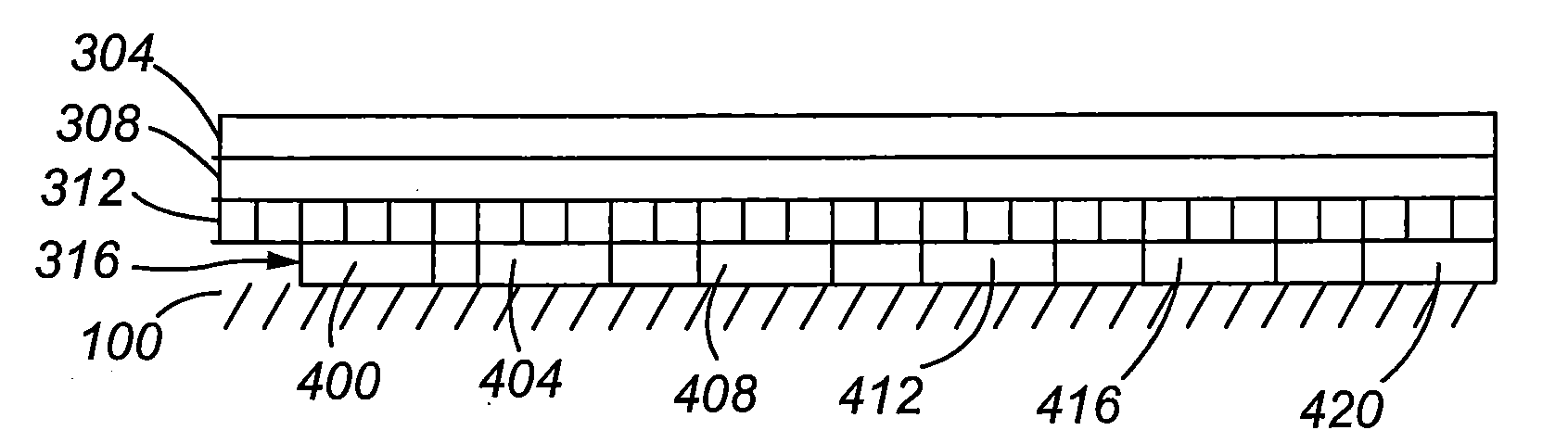

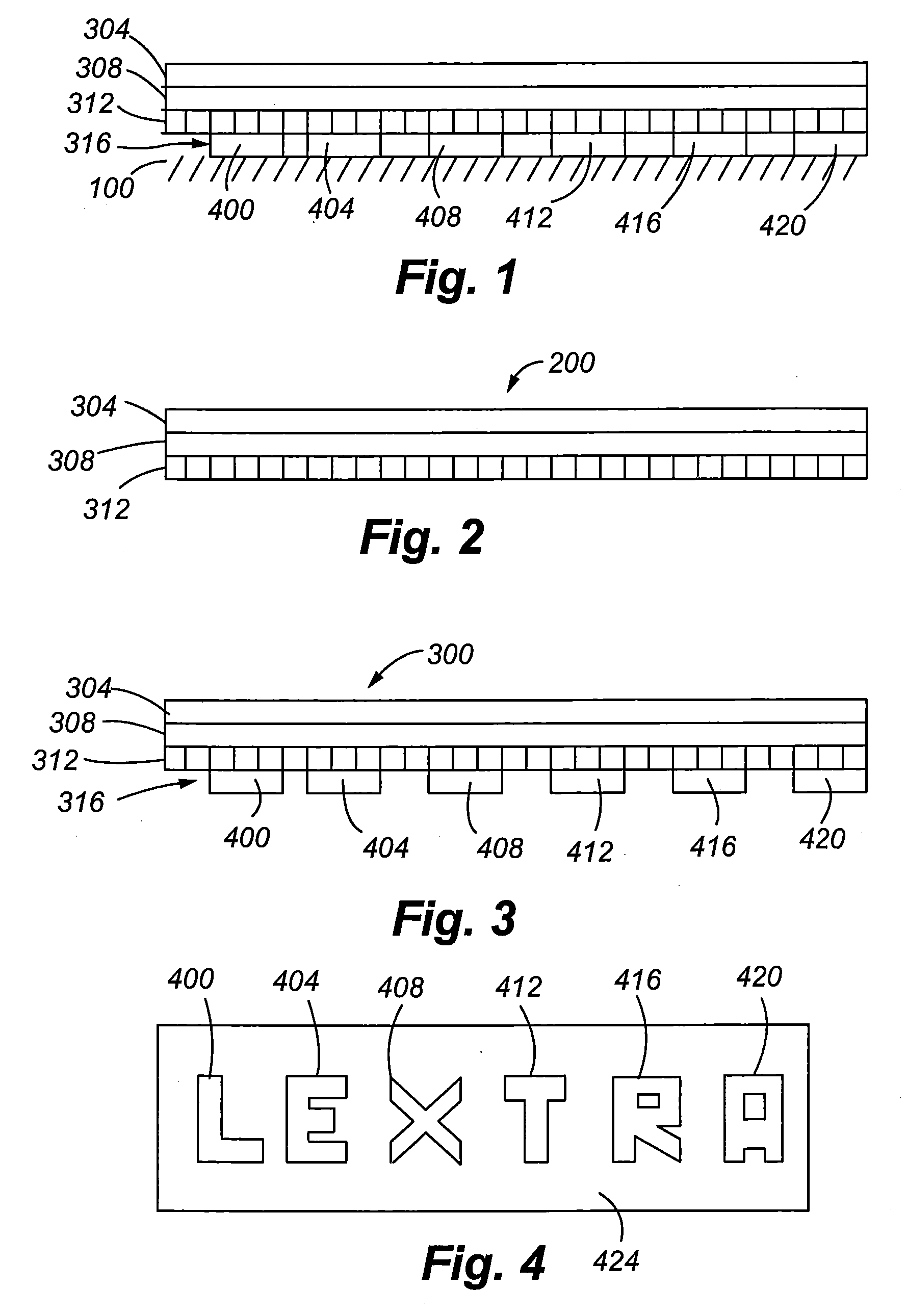

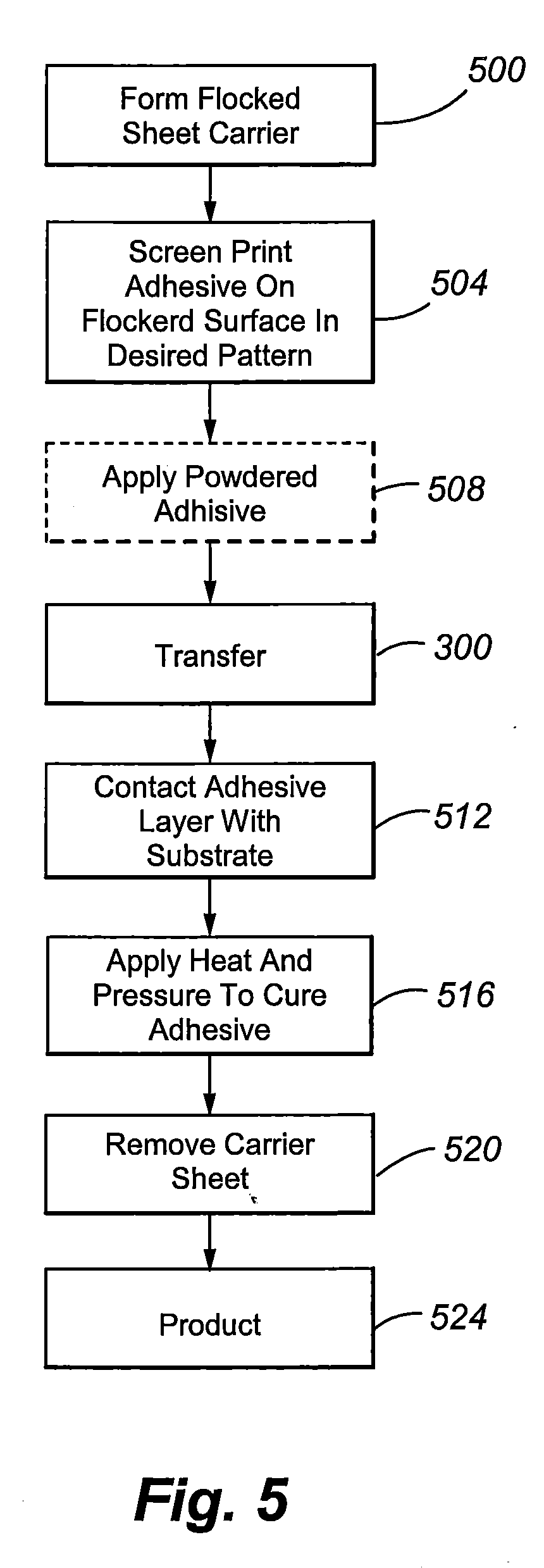

Flocked slurried thermosetting adhesive article

InactiveUS20100068447A1Good chemical resistanceRelease lessPattern printingCoatingsEngineeringSlurry

Owner:HIGH VOLTAGE GRAPHICS

Composition and method for remediation of heavy metal contaminated substances

InactiveUS20110116872A1Avoid spreadingReduce dustOrganic detergent compounding agentsContaminated soil reclamationPhosphateChloride

The present invention relates to a composition and method for remediation of heavy metal contaminated substances. More particularly, the present invention relates to a composition and method for remediating soil, paint chips, paint dusts, surfaces, and other substances contaminated with heavy metals by application of an aqueous suspension of phosphate compound. Even more particularly, the present invention relates to remediating soil, paint chips, paint dusts, surfaces, and other substances contaminated with lead by at least one application of an aqueous suspension of tricalcium phosphate, surfactant, thixotrope, and a chloride source.

Owner:RESTORATION PRODS

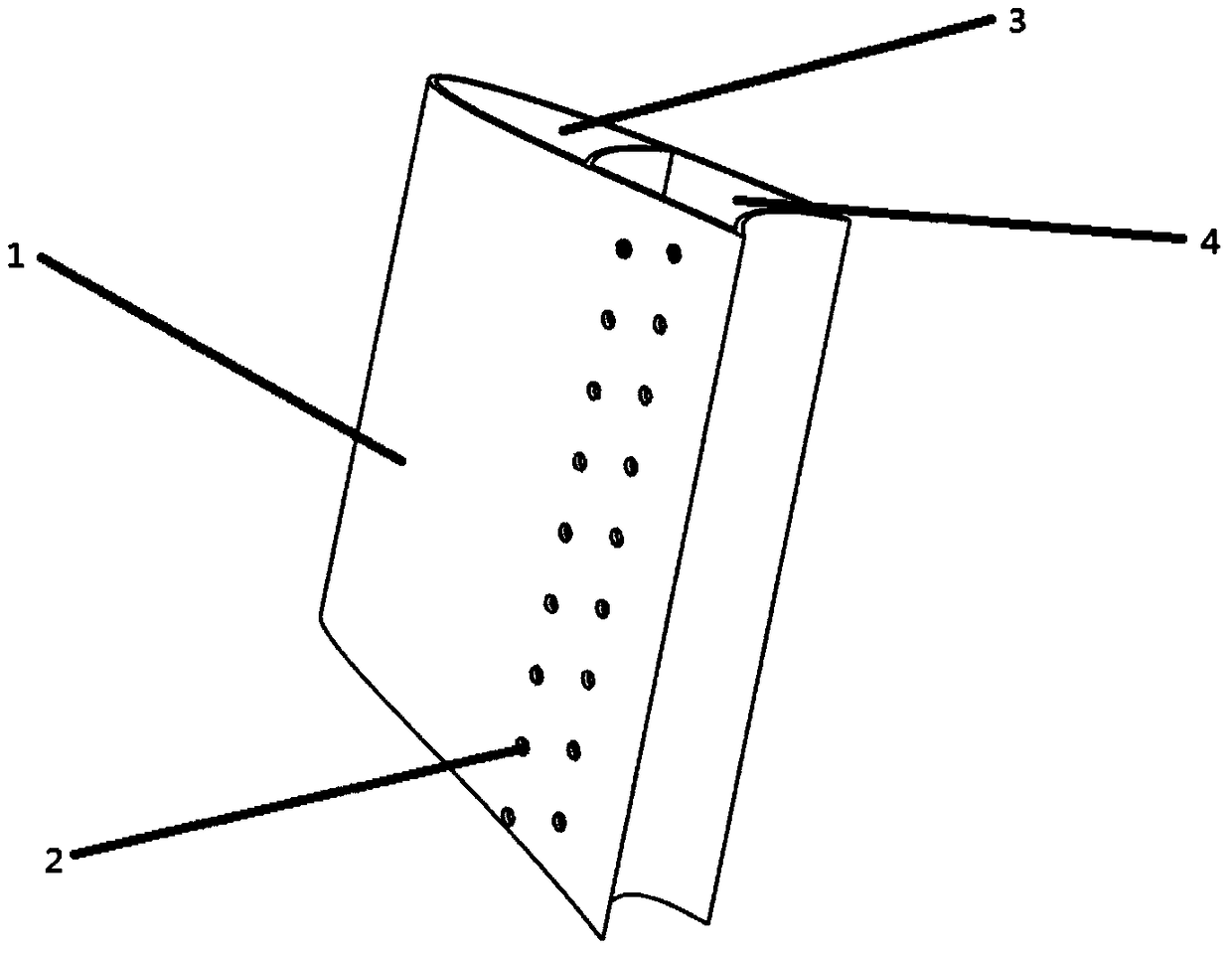

Integrated afterburner with double oil circuits and truncated central cone structure

InactiveCN108758693AIncrease temperatureShorten evaporation timeContinuous combustion chamberCombustion chamberFuel oil

The invention provides an integrated afterburner with double oil circuits and a truncated central cone structure, so that a fuel oil atomization effect can be effectively improved, the oil-gas mixturedegree is improved, the mixed gas staying time is prolonged, and the combustion efficiency is improved. The fuel oil is divided into two streams so as to enter a main oil circuit fuel oil channel andan auxiliary oil circuit fuel oil channel in a rectifying support plate flame stabilizer; the fuel oil of the main oil circuit is sprayed out through small oil spray holes in the surface of the rectifying support plate flame stabilizer; and the fuel oil of the auxiliary oil circuit absorbs heat in the fuel oil channel and is finally sprayed out through small oil spray holes in the surface of a truncated central cone. Due to the structure design of the truncated central cone, an airflow circulation area is enlarged suddenly, and mixed gas of inner and outer duct parts is entrained to the center area after flowing through the truncated central zone so as to form a strong return flow zone structure and is sufficiently mixed and burned with the fuel oil sprayed by the auxiliary oil circuit inthe zone. Due to the long staying time, an oil-gas atomization effect is good, and the burning efficiency and the stability are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

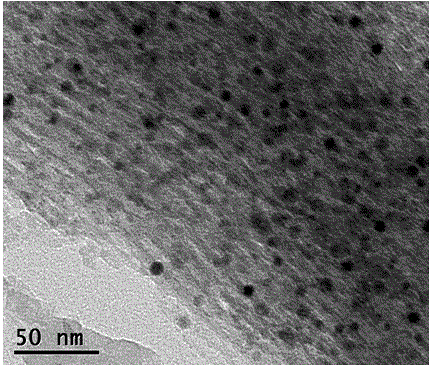

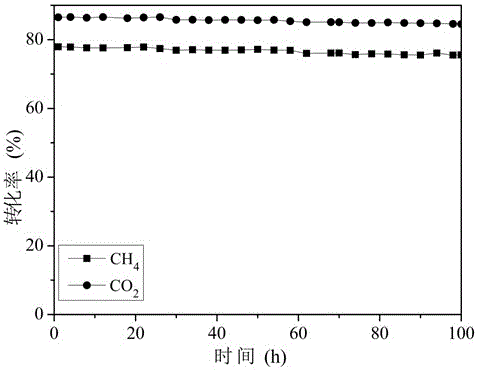

Preparation method for rapidly preparing highly-dispersed nickel-based catalyst for methane reforming with carbon dioxide

InactiveCN106000444ASimple preparation processShorten evaporation timeHydrogenMolecular sieve catalystsNickel catalystHigh carbon

The invention discloses a preparation method for rapidly preparing a highly-dispersed nickel-based catalyst for methane reforming with carbon dioxide. A high-temperature-resistant mesoporous material with a large specific surface area and ordered mesoporous passages is adopted as a carrier of the catalyst, a nickel precursor salt and the mesoporous material are ground and stirred to uniformly disperse the nickel precursor salt on the surface of the mesoporous material carrier which is not de-molded by adopting a solid-state grinding method, and during drying, the nickel precursor salt enters the passages to obtain a nickel catalyst with highly-dispersed active ingredients and high carbon deposition resistance and sintering resistance by calcination and H2 reduction. The preparation method has the advantages of simple preparation process, high catalysis efficiency, energy saving (calcination is not required during preparation of the carrier), uniform distribution of the active ingredients and the like.

Owner:KUNMING UNIV OF SCI & TECH

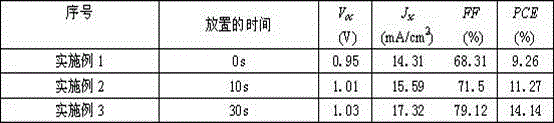

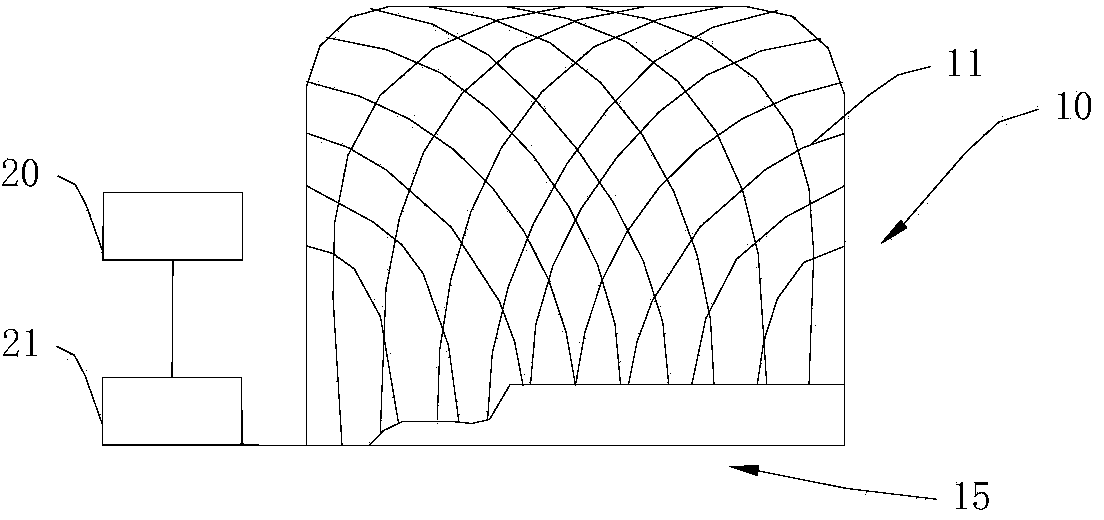

Perovskite thin film, preparation method thereof and perovskite solar cell

ActiveCN106784322AShorten evaporation timeExtended crystallization timeSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellSpins

The invention discloses a perovskite thin film, a preparation method thereof and a perovskite solar cell. The method comprises the following steps: firstly spin-coating a perovskite precursor solution on a substrate, wherein the solvent selectively used in the perovskite precursor solution is one or more of DMF, DMSO and gamma-GBL, then rotating the substrate spin-coated with the perovskite precursor solution, stopping rotation when the perovskite precursor solution is not completely volatilized, and placing for a certain period of time; rotating the substrate spin-coated with the perovskite precursor solution again, then dropping an inversion solvent again, annealing for 5 to 15 minutes at the temperature of 80 to 120 DEG C, and thus preparing the perovskite thin film. In the perovskite film-forming process, when the solvent in the perovskite precursor solution is not completely volatilized, the rotation of a spin coater is stopped, and the spin coater stands for a certain period of time, and the film-forming quality of the perovskite thin film is increased by prolonging the film-forming time of the perovskite thin film, so that the device performance of the prepared perovskite solar cell is improved.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

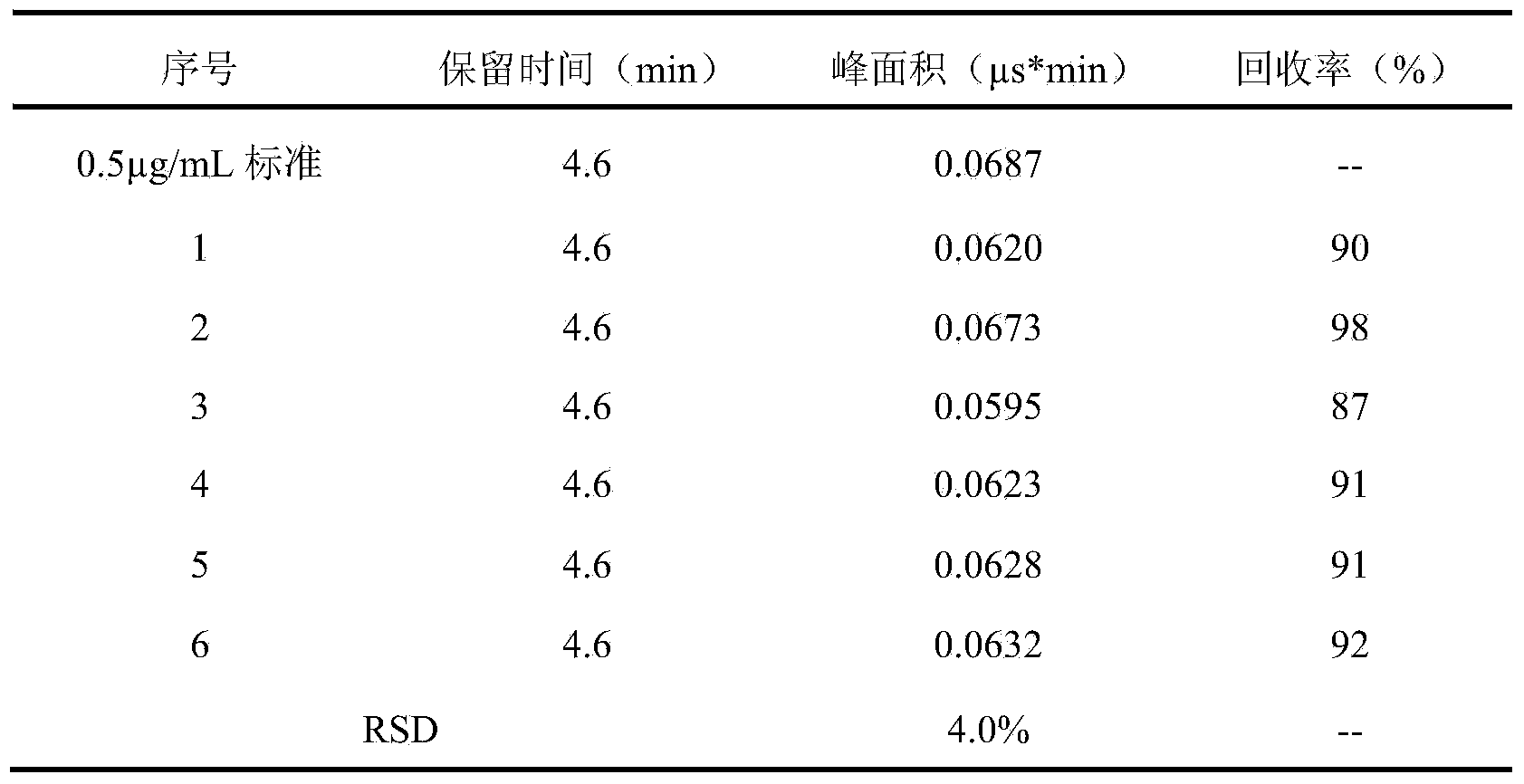

Analysis method for trace oxalic acid root in mother liquor of plutonium oxalate precipitation

ActiveCN103760273AHigh sensitivityImprove accuracyComponent separationFuel reprocessingIon chromatography

The invention belongs to the technical field of spent fuel reprocessing, and discloses an analysis method for a trace oxalic acid root in a mother liquor of plutonium oxalate precipitation. The analysis method comprises the following steps that: (1) the mother liquor of plutonium oxalate precipitation is diluted by 10 to 20 times, and a reducing agent is added to destroy potassium permanganate in the mother liquor of plutonium oxalate precipitation; (2) the test solution prepared in the step (1) is placed on an IC - H column to remove the positive ions in the solution; (3) the solution collected in the step (2) is placed into a container and heated under a temperature condition of less than 60 DEG C, and a gas is used to purge the upper surface of the solution to full dry at the same time; (4) a beaker is washed with deionized water for many times, the washing liquor is collected for fixing a volume, and the content of the oxalic acid root in the solution is measured by an ion chromatography. The analysis method has the characteristics of small interference of matrix, high accuracy and simple device adopted.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

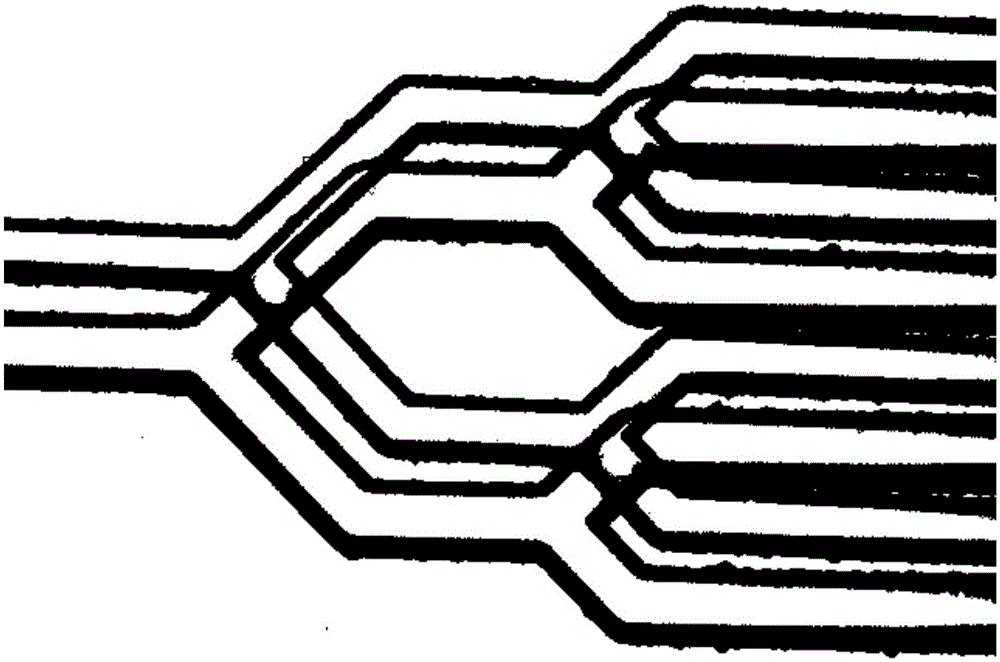

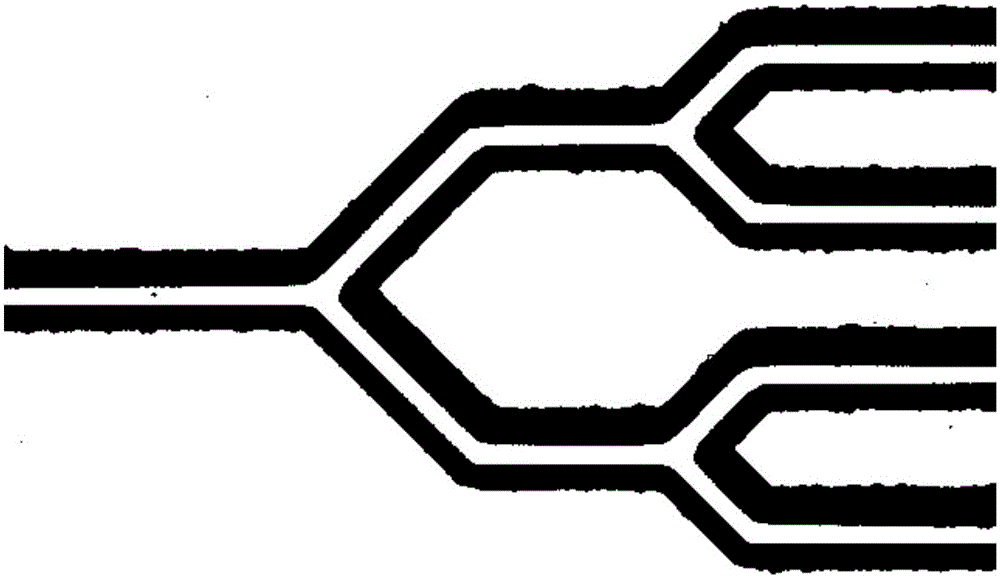

Plasma-assisted glass or quartz chip microstructure alignment and pre-bonding method

ActiveCN105161437AShorten the soaking timeFlexible moving processSolid-state devicesSemiconductor/solid-state device manufacturingSurface cleaningMicroscopic observation

The invention provides a plasma-assisted glass or quartz chip microstructure alignment and pre-bonding method and belongs to the chip micromachining and bonding technology. The method comprises the following steps: removing a glass or quartz chip optical cement layer and a chromium layer, and fully cleaning the surface by utilizing detergent and a lot of ultrapure water; carrying out surface cleaning and activation by utilizing a plasma cleaner to enable the surface to have high hydrophilia; under an anhydrous condition, carrying out observation with a microscope, and moving the cleaned substrate and cover plate to finish perfect alignment; dripping minute quantity of ultrapure water in edge cracks to carry out bonding, and after carrying out full pressing to squeeze out the excessive water, discharging all of the water in the chip by utilizing a vacuum function of the plasma cleaner, and finishing glass or quartz chip microstructure alignment and pre-bonding; and furthermore, finishing permanent bonding of the chip by utilizing a thermal bonding method. The method enables the overall alignment and pre-bonding operation to be finished within 30 min; and the method is quick and efficient, simple and convenient to carry out, safe to operate and wide in application.

Owner:BEIJING UNIV OF TECH

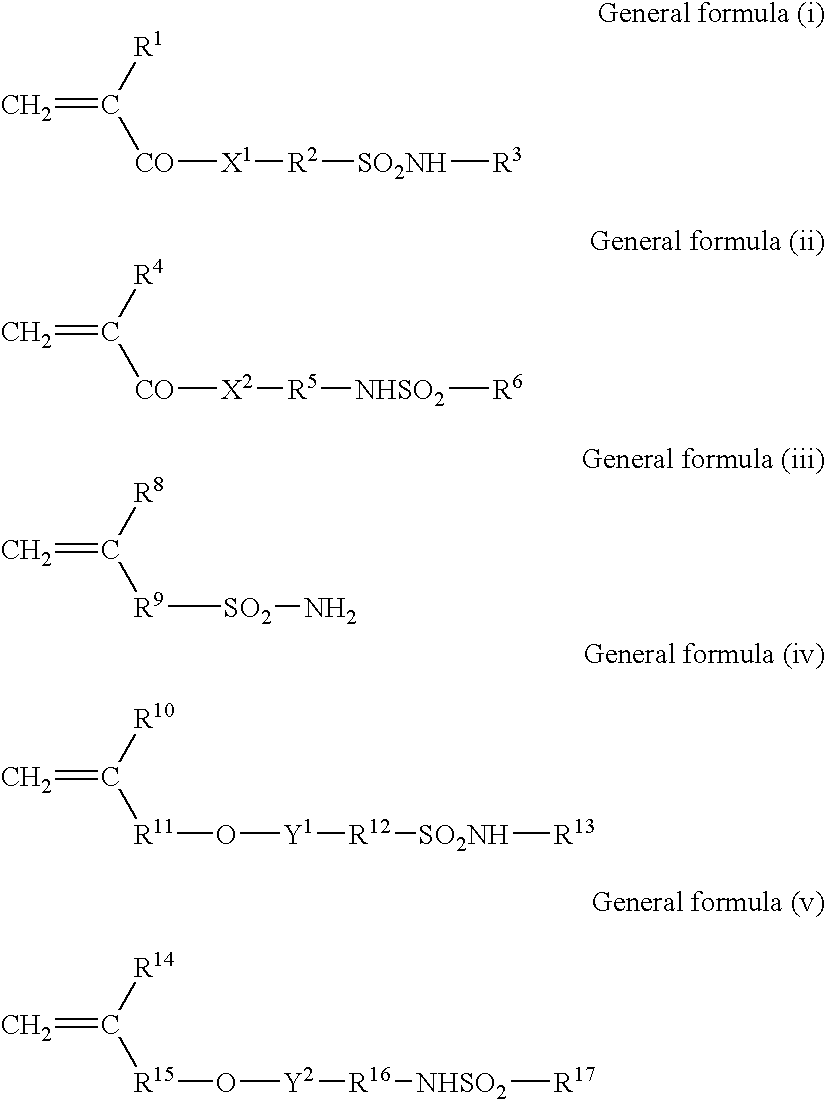

Planographic printing plate precursor and method of producing the same

InactiveUS20060216639A1Inhibit developmentIncrease solubilityPhotosensitive materialsPhotomechanical apparatusLaser lightSolubility

A planographic printing plate precursor of the present invention comprises: a support and a positive recording layer arranged on the support. the positive recording layer containing resin and an infrared absorber and being constituted of two or more sub-layers, wherein the solubility of the positive recording layer to an aqueous alkali solution is increased by exposure to infrared laser light, and for the positive recording sub-layer of the two or more positive recording sub-layers that is nearest to the support (the lower layer), the ratio of the dissolution speed to an aqueous alkali solution in the lateral direction to the dissolution speed in the depth direction is less than 1. Such a ratio of the dissolution speeds can be achieved by forming a dispersed phase in the lower layer and / or high-temperature drying when forming the lower layer. According to the invention, there is provided a positive planographic printing plate precursor for infrared laser for direct plate making, which is excellent in scratch resistance and in discrimination of formed images.

Owner:FUJIFILM CORP +1

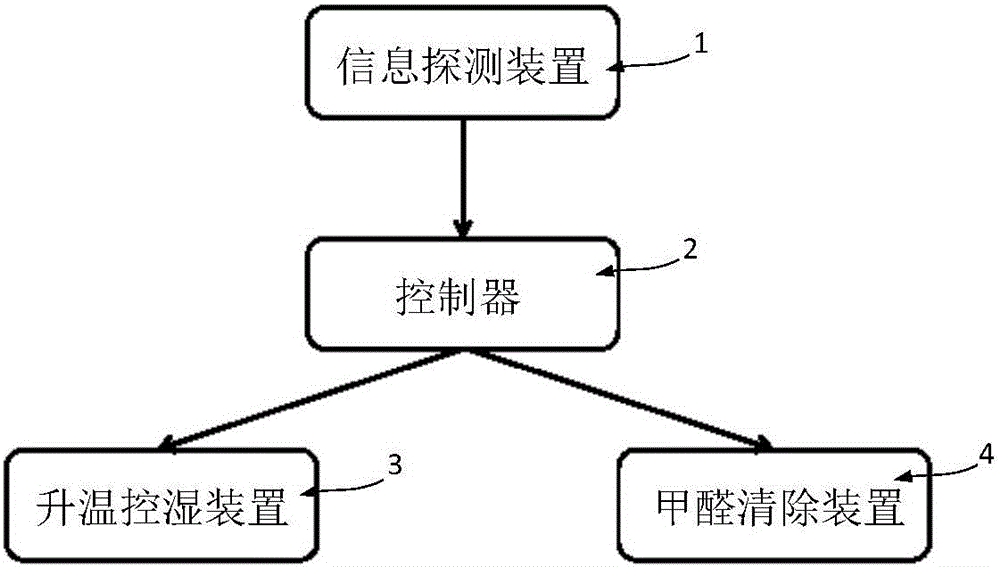

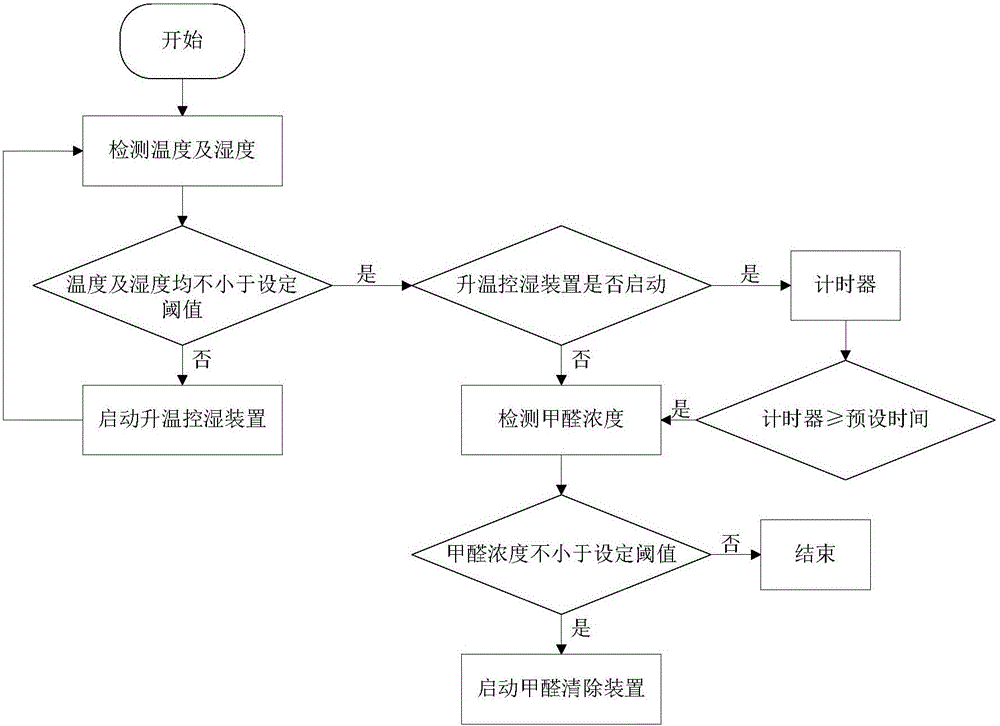

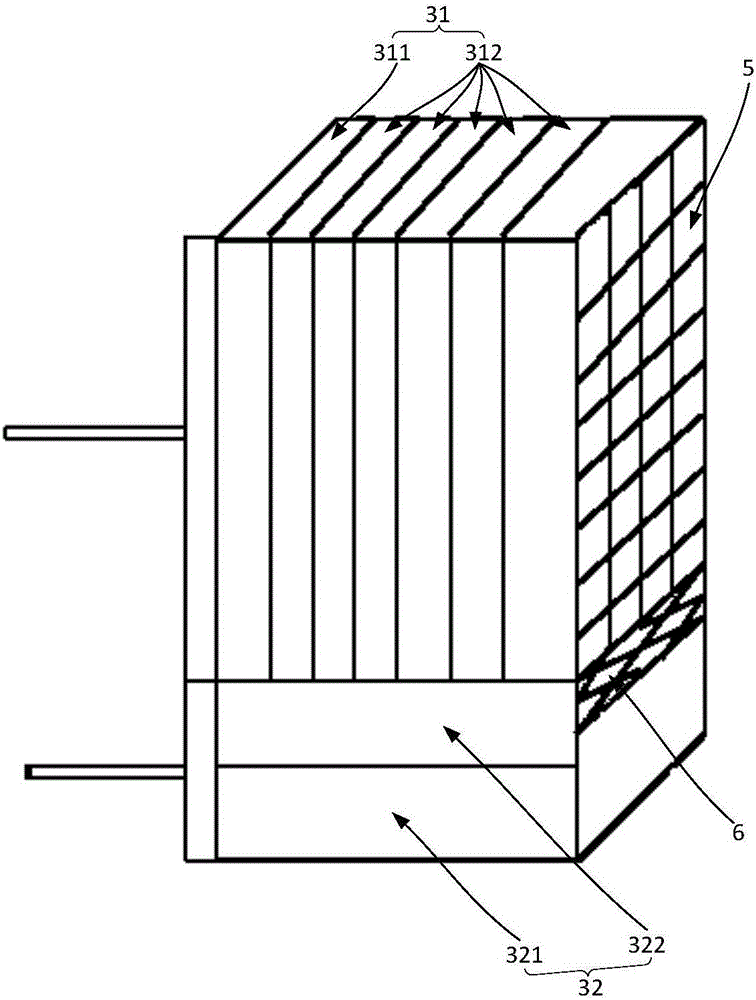

Formaldehyde remover

InactiveCN106440226AShorten evaporation timeImprove cleanlinessMechanical apparatusSpace heating and ventilation safety systemsEngineeringStart up

The invention discloses a formaldehyde remover. The formaldehyde remover comprises an information detection device, a heating and humidity control device, a formaldehyde removal device and a controller, wherein the information detection device is used for detecting the temperature, the humidity and the formaldehyde concentration of the indoor environment, the controller is used for starting up the heating and humidity control device when the detected temperature value is lower than a preset temperature threshold and / or the detected humidity value is lower than a preset humidity threshold, and starting up the formaldehyde removal device when the detected temperature value is not lower than the preset temperature threshold, the detected humidity value is not lower than the preset humidity threshold, and the detected formaldehyde concentration value is not lower than the preset formaldehyde concentration threshold, and when the detected formaldehyde concentration value is lower than the preset formaldehyde concentration threshold, the formaldehyde removal device is shut down by the controller. With the formaldehyde remover, firstly, formaldehyde volatilization is accelerated by increasing the temperature and humidity of the environment, the formaldehyde in the neglected corners of a house and the formaldehyde hidden in the inner layers of furniture and other positions volatilize as soon as possible so that the efficiency of treatment can be improved, the volatilization time of formaldehyde is shortened, the effect of removing formaldehyde is enhanced, the amount of residual formaldehyde is reduced, and therefore, the purpose of protecting the health of people is achieved.

Owner:SOUTHWEST UNIVERSITY

Disease-resistant peanut cultivation method

InactiveCN108243891AImprovement of drainage structureSimple structureBiocideCalcareous fertilisersBiologySowing

The invention relates to the technical field of cultivation, and particularly relates to a disease-resistant peanut cultivation method, comprising the following steps: 1) planning peanut cultivation lines and uniformly sprinkling lime powder; 2) digging cultivation slots with cross section being V-shaped in the cultivation lines, and arranging drainage ditches; 3) soaking peanut seeds with a soaking soup and performing seed dressing by using a seed dressing agent; 4) screening peanuts in a staged manner and sowing; 5) applying basal fertilizer for the peanuts; and 6) sprinkling disease-resistant agent once after needle dropping of the peanut, wherein the disease-resistant agent is prepared from thidiazuron, copper hydroxide, bacillus megaterium, bacillus laterosporus and water. The disease-resistant peanut cultivation method can effectively improve the disease resistant capacity of peanuts, and inhibit bacterial virus of the soil, and can improve the stress resistance of the peanuts.

Owner:广西壮族自治区农业科学院经济作物研究所

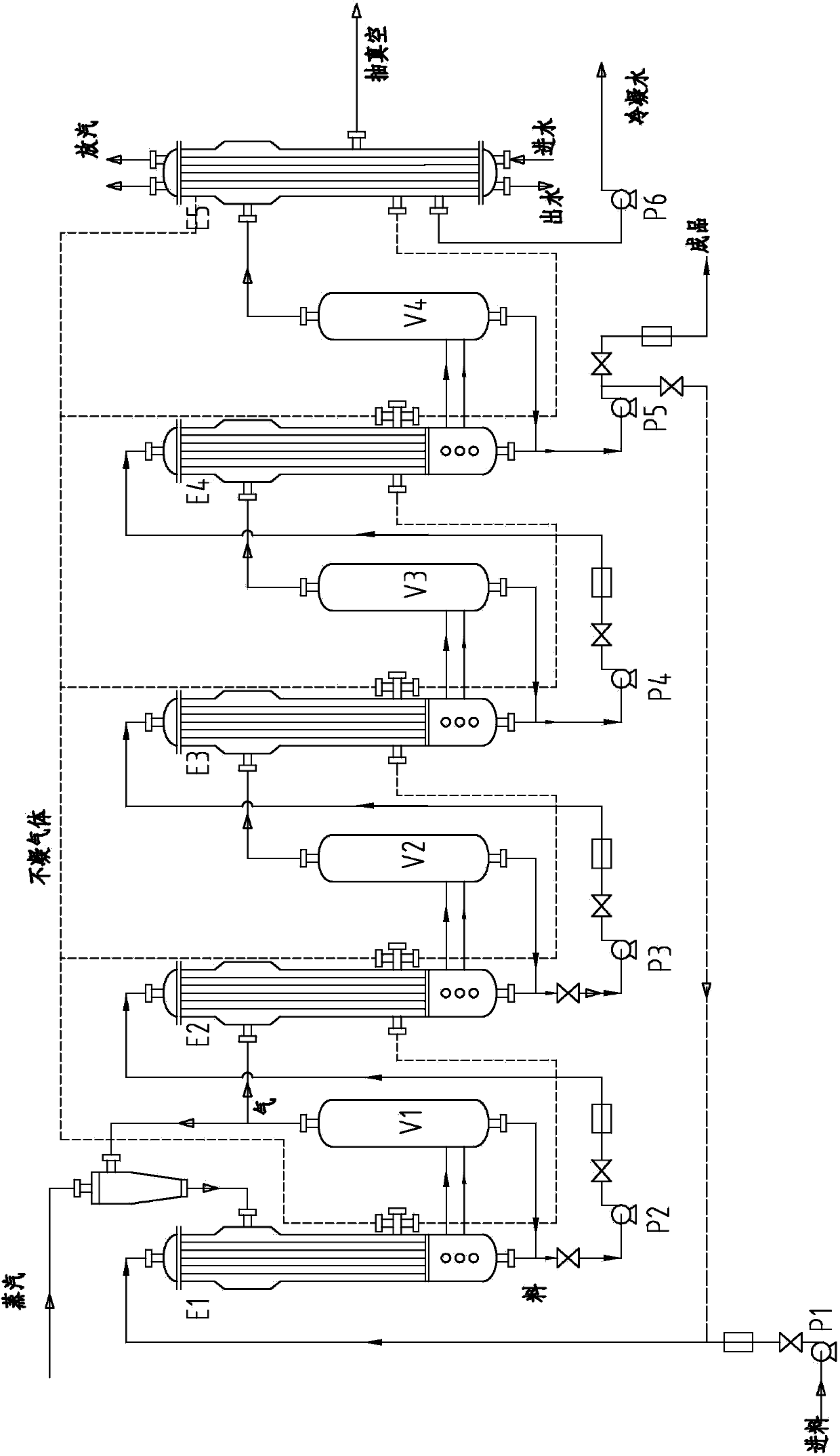

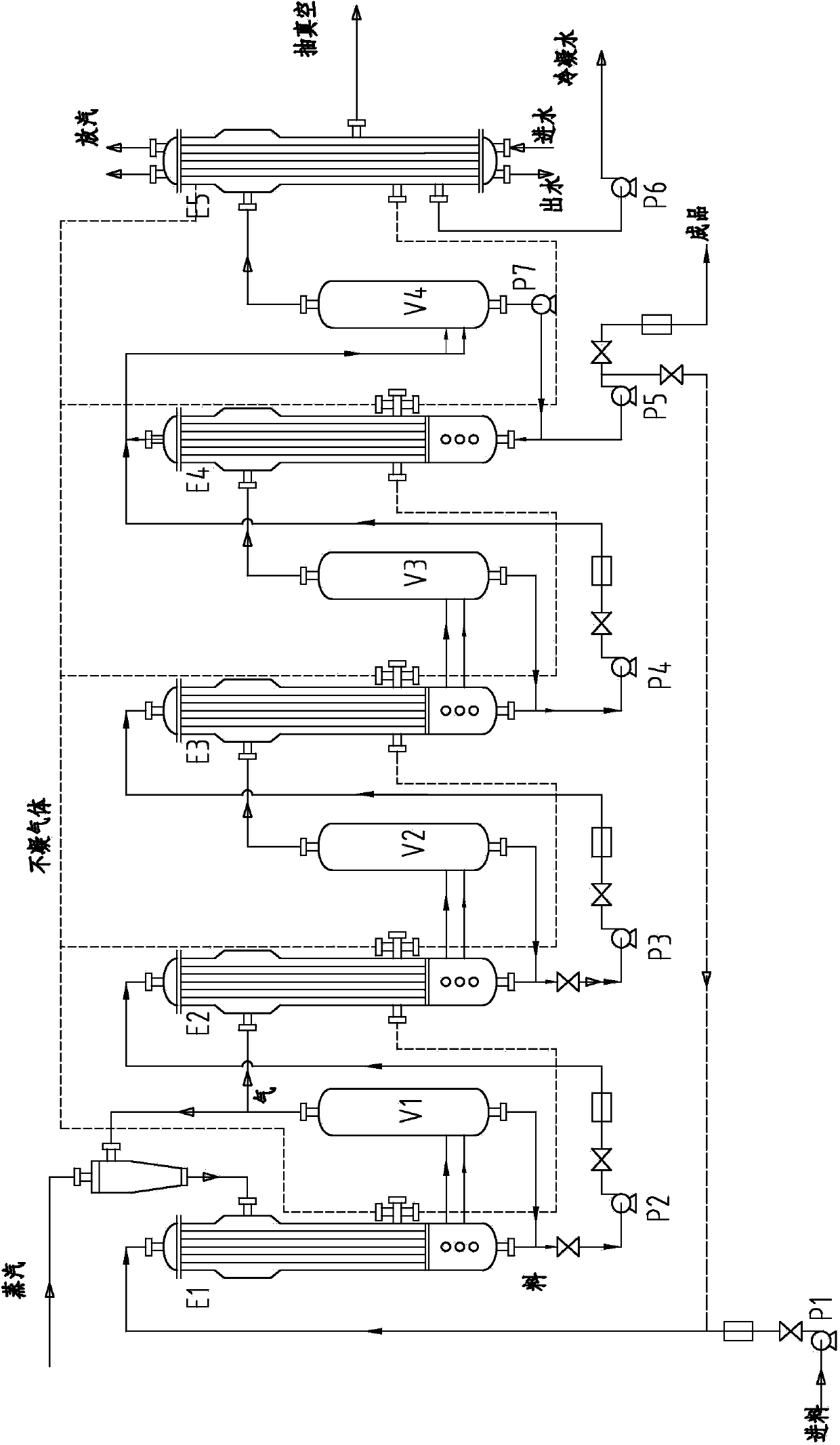

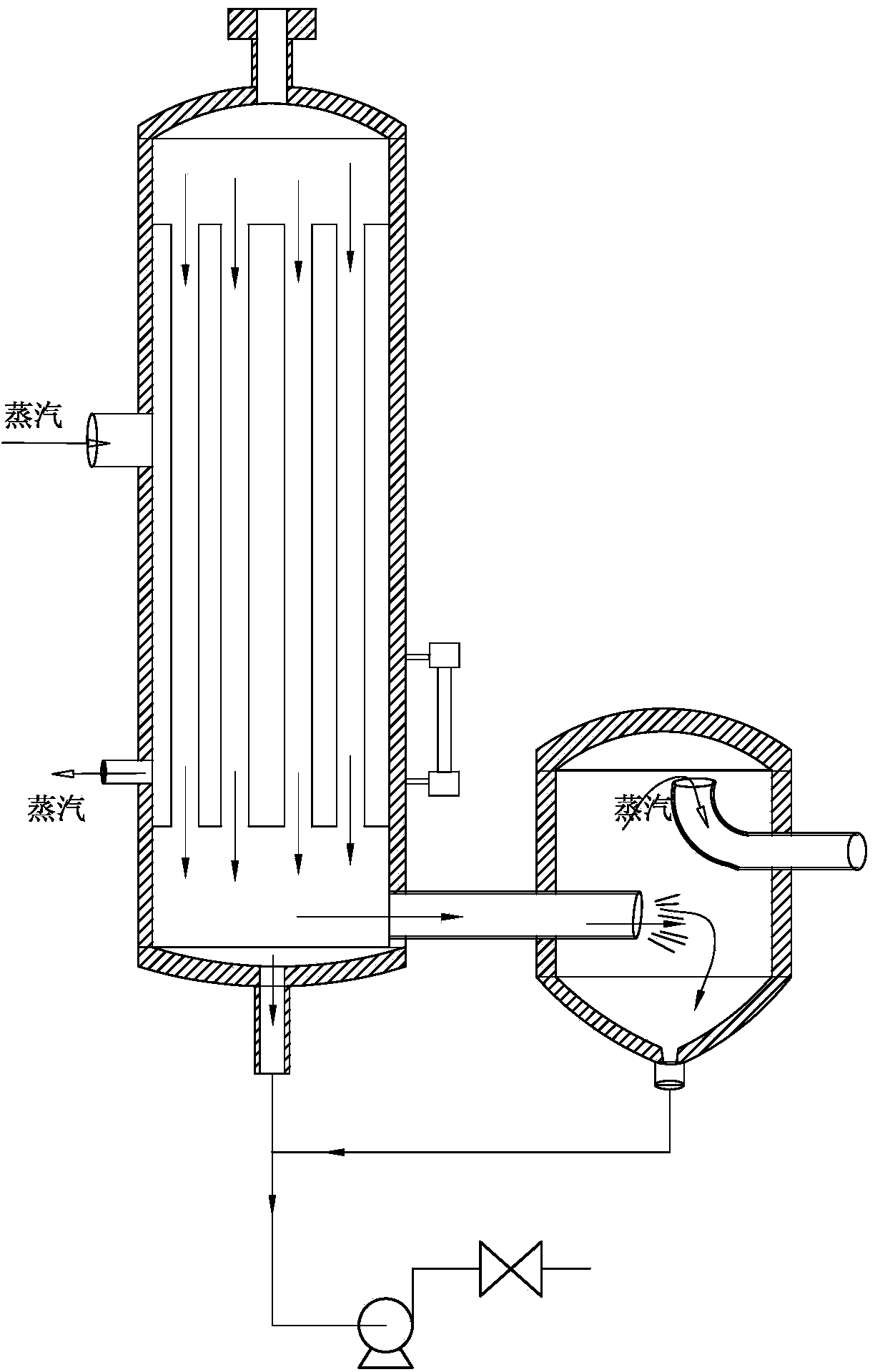

Improved type four-effect rising film evaporator and concentration method

ActiveCN103585776AImprove evaporation efficiencyReduce usageMultiple-effect evaporationThermal energyEnrichment methods

The invention relates to an improved type four-effect rising film evaporator and a concentration method, the evaporator comprises a four-effect heater and a separator, the material outlets in a three-effect heater and a three-effect separator are merged and connected to the four-effect separator through a three-effect charging pump, the material outlet of the four-effect separator is connected to the material outlet at the bottom of the four-effect heater through a pressure pump, and the material outlet at the top of the four-effect heater is connected to the four-effect separator through a pipeline. The material is orderly passed through the heater and the separator and then is directly sent to the four-effect separator, then the material in the four-effect separator is sent to a cavity at the bottom of the four-effect heater by the pressure pump from the bottom of the four-effect heater, so that the material flows from top to down by pressurizing, and flows back to the four-effect separator from the cavity at the top of the four-effect heater to form a complete cycle. According to the improved type four-effect rising film evaporator, through multitime cycle, the concentration of concentration limit can increase to 35-37%, heat energy utilization rate is increased, steam can be saved by 30%, and the consumption time is not changed.

Owner:JINAN MINGXIN PHARMA

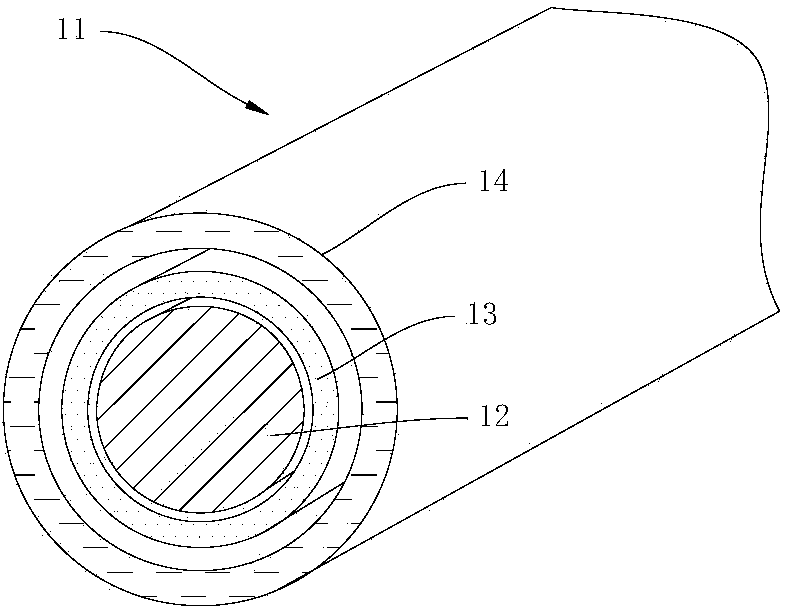

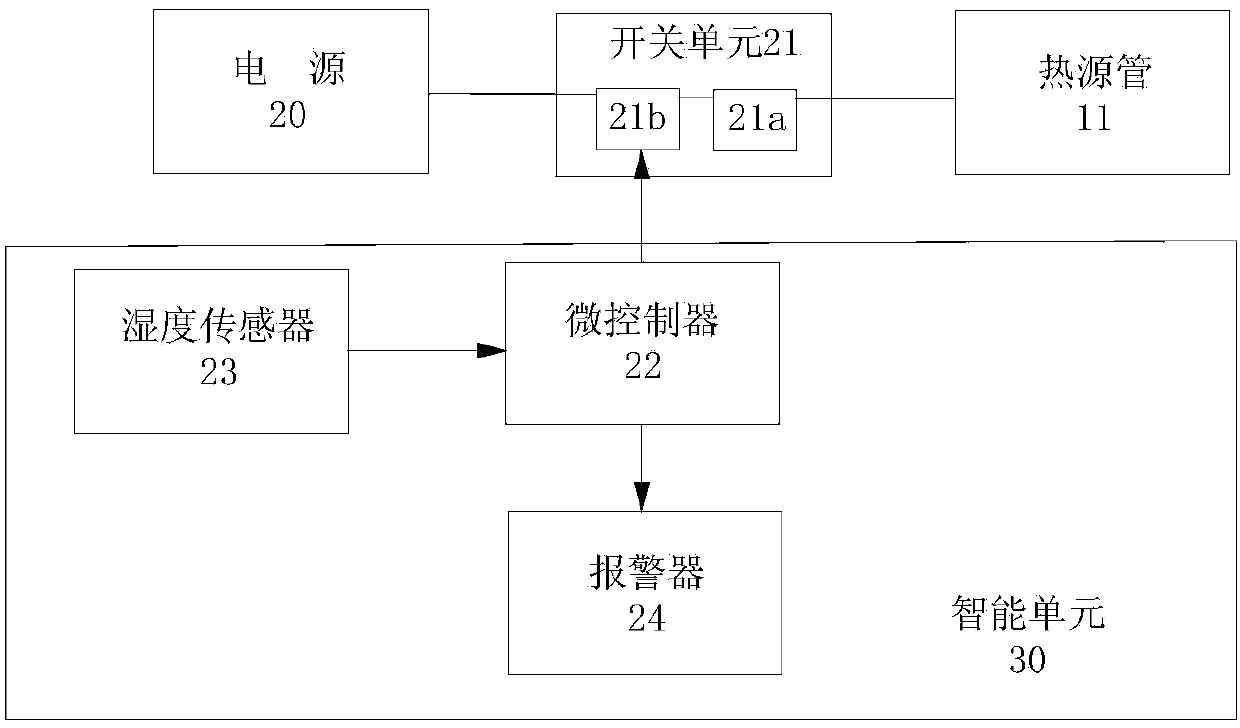

Hair drying cap

ActiveCN103504770AShorten evaporation timeRaise the evaporation temperatureHair dryingHeating timeEvaporation

The invention relates to the technical field of hair drying appliances, in particular to a hair drying cap used for drying the hair. The hair drying cap comprises a cap body, wherein the cap body is formed by winding and lapping a plurality of heat source pipes; the heat source pipes give out heat after being connected with a power supply, comprise electric heating wires, insulating layers and water absorption layers from the inside out, and are mutually staggered to be reticular; an intelligent unit is further arranged on the outer side of an opening of the cap body of the hair drying cap. The hair drying cap has the advantages that on one hand, the heat source pipes are wound and lapped to form the cap body directly, so that the efficiencies of exchange and circulation of air inside and outside the hair drying cap can be improved, and the air permeability of the cap body can be increased, and on the other hand, due to the design of each heat source pipe, water in hair can be close to the heat source area to the maximum extent, then the evaporating temperature can be increased, and the water evaporation time can be shortened. After the intelligent unit is introduced, the heating time can be regulated and controlled according to the dryness condition of the hair.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

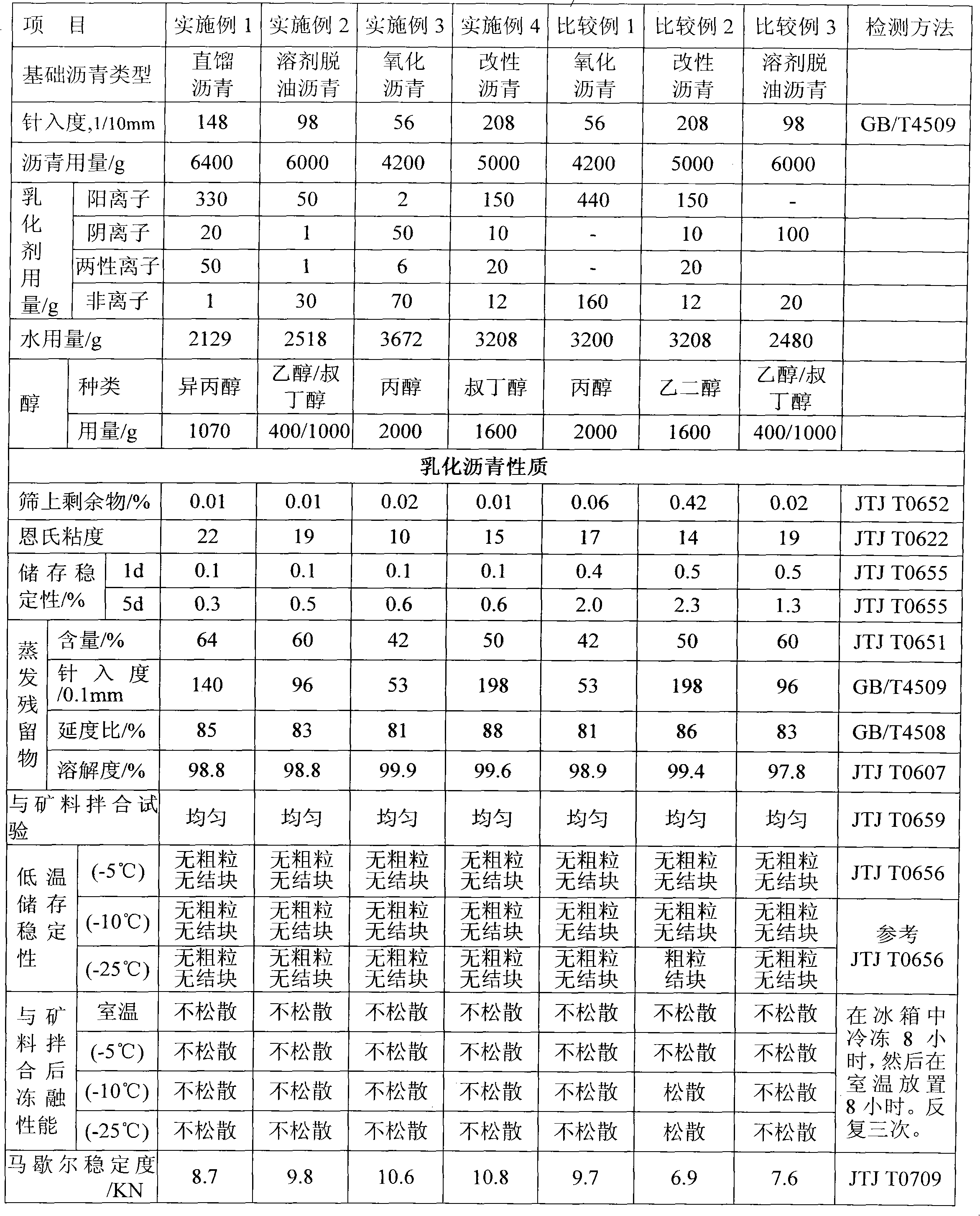

Frost resistant emulsified bitumen prepared from composite emulsifier, and preparation method thereof

ActiveCN102234435AReduce the amount requiredGood emulsifying effectWorking-up pitch/asphalt/bitumenBuilding insulationsFreeze thawingPropanol

The invention discloses frost resistant emulsified bitumen which is prepared from a composite emulsifier, and a preparation method thereof. The emulsified bitumen comprises bitumen, a cationic emulsifier, an anionic emulsifier, an amphoteric emulsifier, a nonionic emulsifier, an alcohol and water. The alcohol comprises one or more selected from ethanol, propanol, isopropanol and tert butyl alcohol. With the present invention, a combination of the composite emulsifier and the low molecular weight fatty alcohol is adopted for the emulsified bitumen while diluents such as diesel oil or kerosene and the like are not added, such that time of water evaporation is shortened, a hardening rate of mixture is increased, frost resistance is improved (the emulsified bitumen cannot be frozen at a temperature of -5 to -25 DEG C), original excellent properties such as bonding performance of the bitumen and the like are maintained, and shrinkage and cracking of the mixture due to a low temperature in winner or surface loosening of the mixture due to freeze thawing is avoided. The frost resistant emulsified frost resistant can be used for road curing and road maintenance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of household paper with fragrance

ActiveCN103431805AKeep for a long timeNot perishableEssential-oils/perfumesDomestic applicationsAlcoholMass ratio

The invention relates to the technical field of household paper, and particularly relates to a preparation method of household paper with fragrance. The preparation method comprises the following steps of: step A. preparing formula essential oil: uniformly mixing lemon-scented gum essential oil, orange flower essential oil and sandalwood essential oil in an arbitrary mass ratio; step B. preparing perfume:, placing tasteless alcohol in a clean container, adding the formula essential oil, fully dissolving, adding purified water, diluting, and sealing for later usestandby application, wherein the mass percentages of the tasteless alcohol, the formula essential oil and the purified water are respectively 70-87%, 8-15% and 5-16%; step C. putting the perfume in an atomization device, and spraying the household paper passing through the atomization device; and step D. sealing and packaging the household paper on which the perfume is sprayed, thus obtaining finished products. The preparation method has the advantages that the holding time of fragrance is long, the household paper is comfortable to use, and the process is simple.

Owner:GUANGDONG BILUN HOUSEHOLD PAPER IND

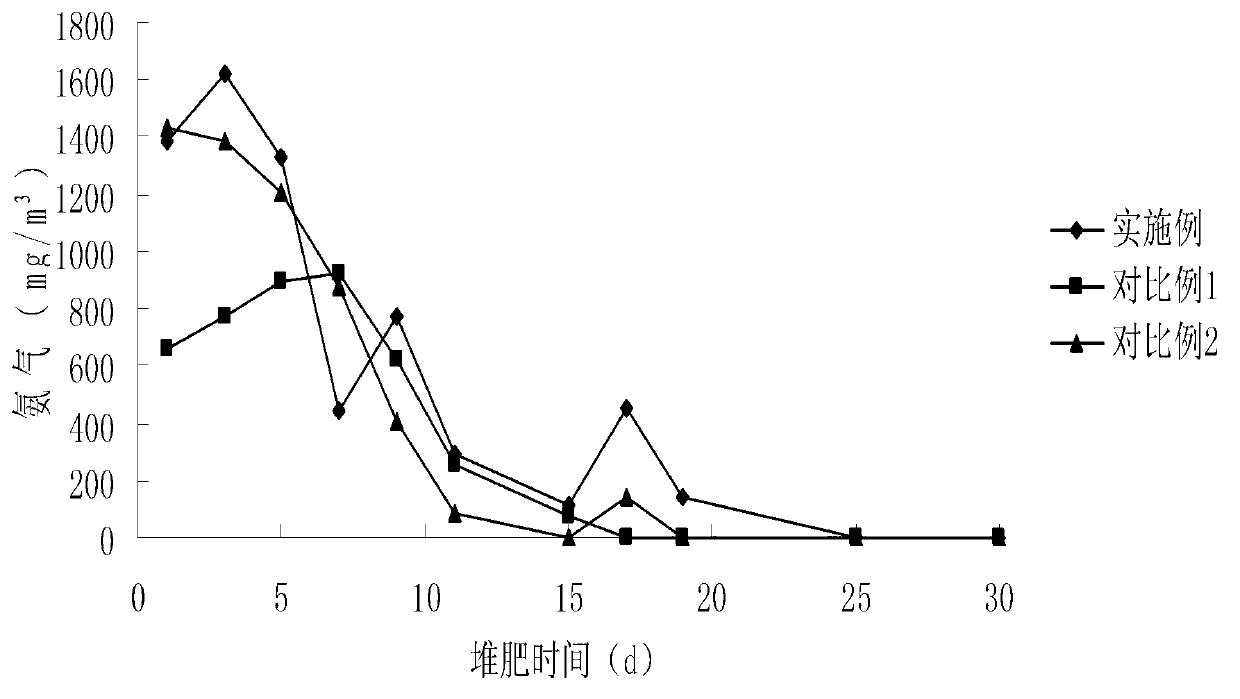

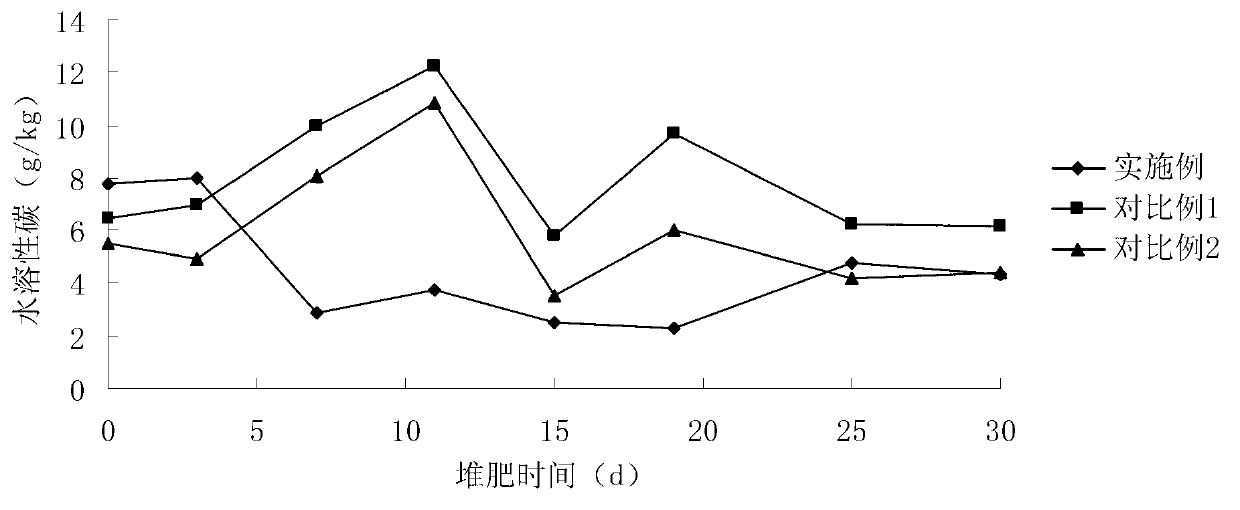

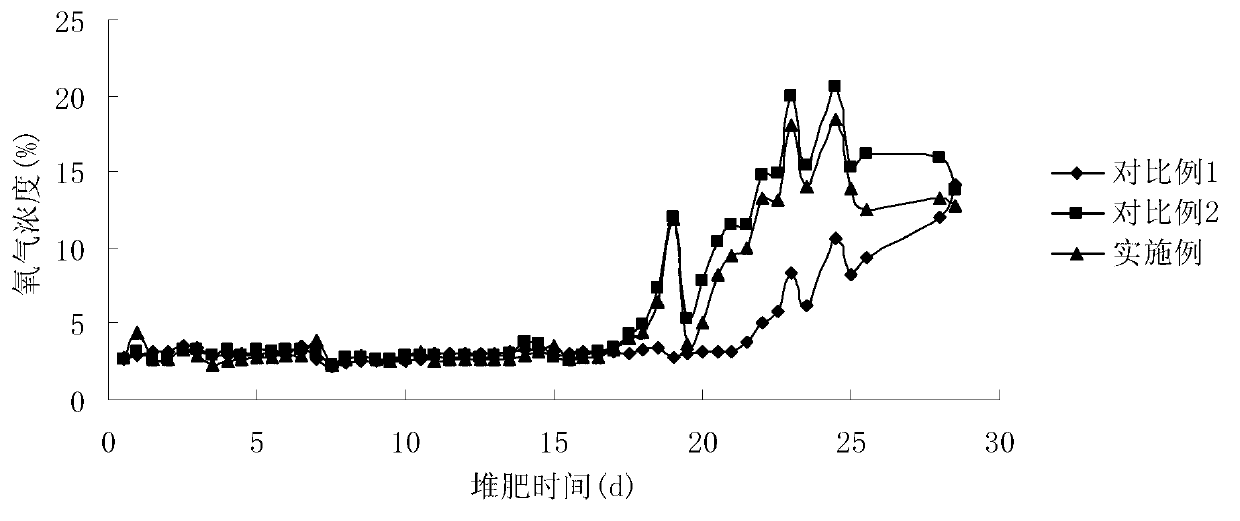

Laying hen excrement composting method capable of reducing compost raw material ammonia production amount

InactiveCN102992831AReduce volatility peakShorten evaporation timeBio-organic fraction processingClimate change adaptationDecompositionAmmonia production

The invention discloses a laying hen excrement composting method capable of reducing compost raw material ammonia production amount. The method comprises the following steps of: taking straw; cutting the straw into sections of 2-3 meters; mixing the laying hen excrement with rice bran and the straw sections according to a mass ratio of 28: 9: 1 to ensure that the initial water content of the compost raw material is 55-65 percent; composting for 30 days to finish a composting process to obtain fertilizers; and turning over the compost on 3rd, 7th, 11th, 15th, 19th and 25th days from the beginning of compositing. By the laying hen excrement composting method, the straw is added into the laying hen excrement-rice bran compost, so that the ammonia volatilization peak value is lowered, the volatilization time of the ammonia is shortened, and the ammonia production amount is reduced; the straw is added to promote the decomposition and utilization of soluble carbon, boost the temperature rise of the compost, improve the temperature of the compost, and relatively shortens the ripening time of the compost. The method is easy to operate, wide in sources of the raw materials, low in cost and high in practical value; the nitrogen loss is 8 percent; and the nitrogen loss of the conventional laying hen composting method is up to 23-65 percent.

Owner:SOUTH CHINA AGRI UNIV

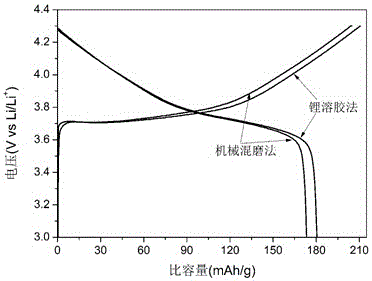

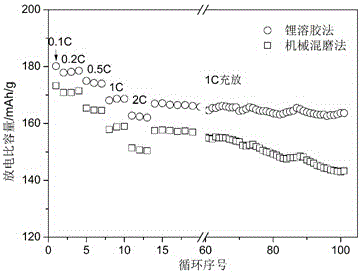

Preparation method for positive electrode material of lithium ion battery

ActiveCN105742596AWill not precipitate outWill not corrodeCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention provides a preparation method for a positive electrode material of a lithium ion battery. A complexing agent is added to a lithium source solution firstly; the pH of the lithium source solution is adjusted to 5-7 to obtain lithium salt sol; a positive electrode material precursor is added to the lithium salt sol to be mixed to obtain paste; the solution is evaporated while stirring and heating to obtain dried gel; and the dried gel is calcined to obtain the positive electrode material of the lithium ion battery. According to the preparation method, the contact area between the lithium salt sol and the positive electrode material precursor is large, so that the uniform mixing between the lithium salt sol and the positive electrode material precursor can be facilitated; the rapid implementation of the reaction can be promoted in the high-temperature roasting process, so that the cost is saved; the prepared positive electrode material elements are uniform in distribution; and a more excellent electrochemical performance of the positive electrode material is realized.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

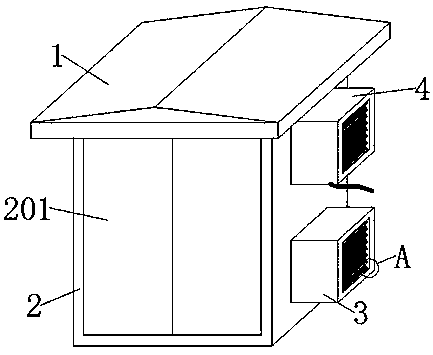

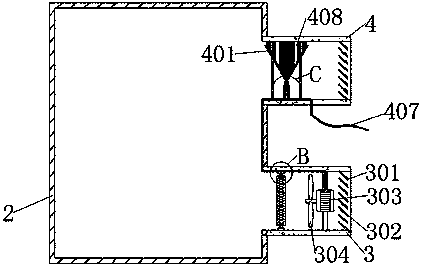

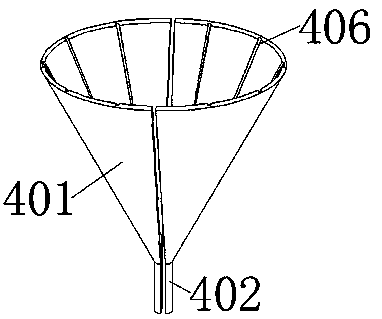

Automatic dehumidification power transformation box

ActiveCN109713587AReduce air humidityAutomatic dehumidification realizedSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsMotor driveEngineering

The invention provides an automatic dehumidification power transformation box, which comprises a top plate, a dehumidification cylinder, a control cylinder and a box body. The top plate is welded to the top of the box body. The dehumidification cylinder and the control cylinder are welded to the right side of the box body in an embedded mode. The dehumidification cylinder is located right over thecontrol cylinder. Two cabinet doors are hinged to the front surface of the box body through hinges. According to the invention, when the air humidity in the box body is increased, the heat of the aqueous vapor can be quickly absorbed by metal water collecting barrels when the aqueous vapor gets in contact with the metal water collecting barrel. Therefore, the aqueous vapor in the metal water collecting barrels can be quickly liquefied on the inner wall of the metal water collecting barrels to form water drops. After the water drops are accumulated to a certain extent, the water drops flow down along the inner wall of the metal water collecting barrel and flow towards water running plates. When water on the water running plates comes up together, the two water running plates can form a current loop. In this way, a power supply for a motor and an electric heating pipe is switched on by an electric wire. The electric heating pipe starts heating to dry the air. The motor drives fan bladesto rotate to form the airflow and the airflow is driven to blow into the box body. The air humidity in the box body is reduced, and the automatic dehumidification is achieved.

Owner:源洲电气有限公司

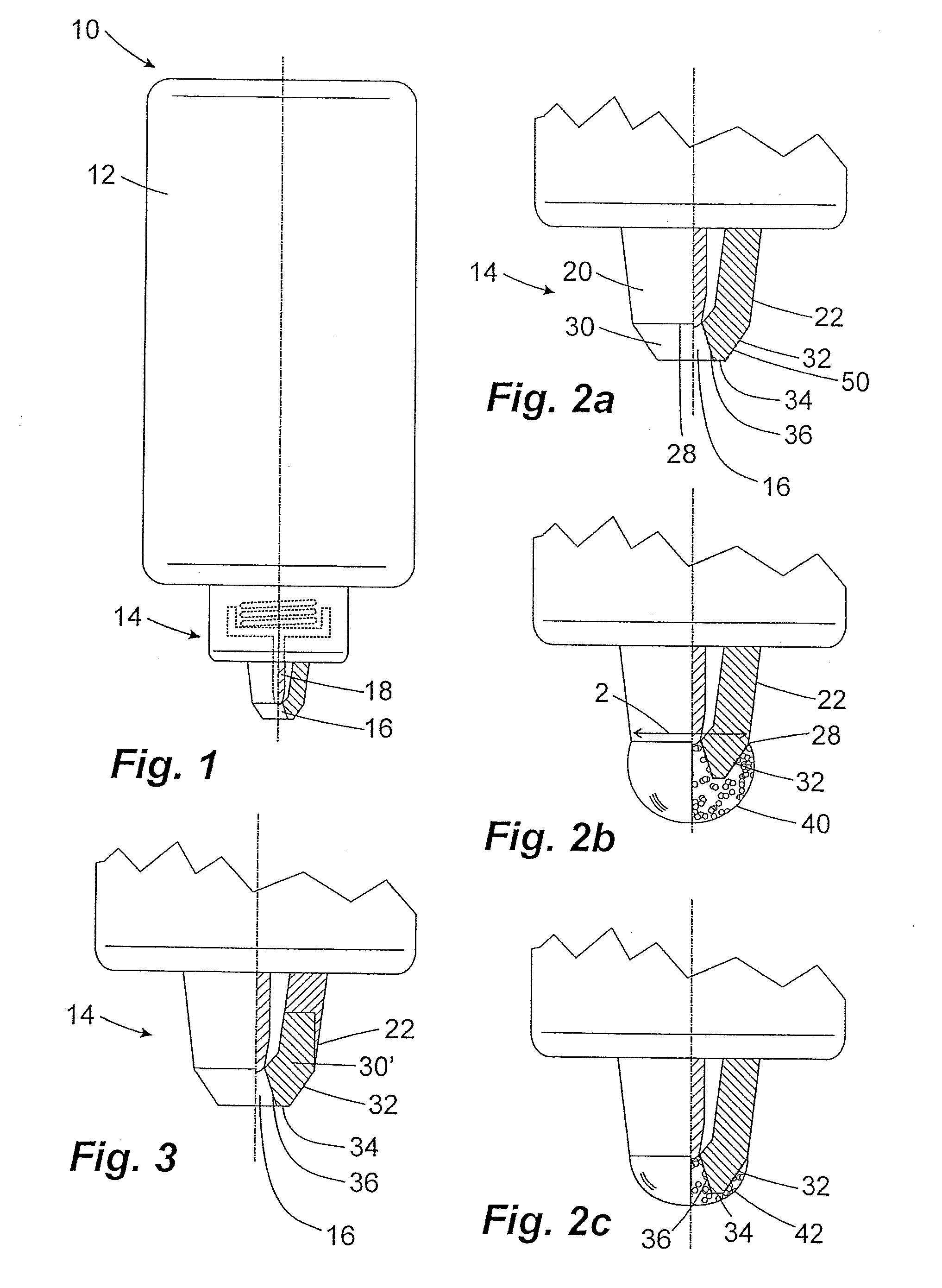

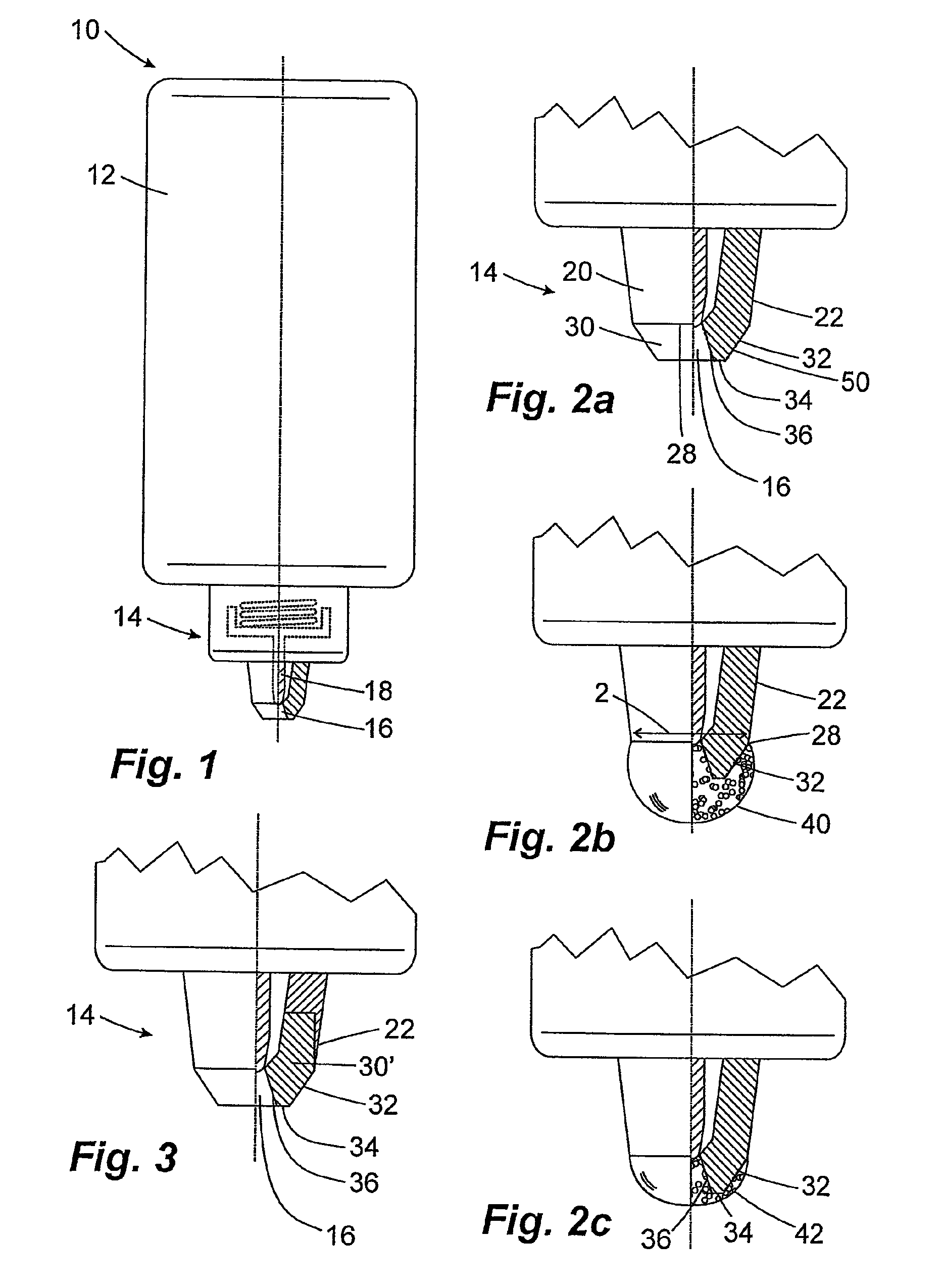

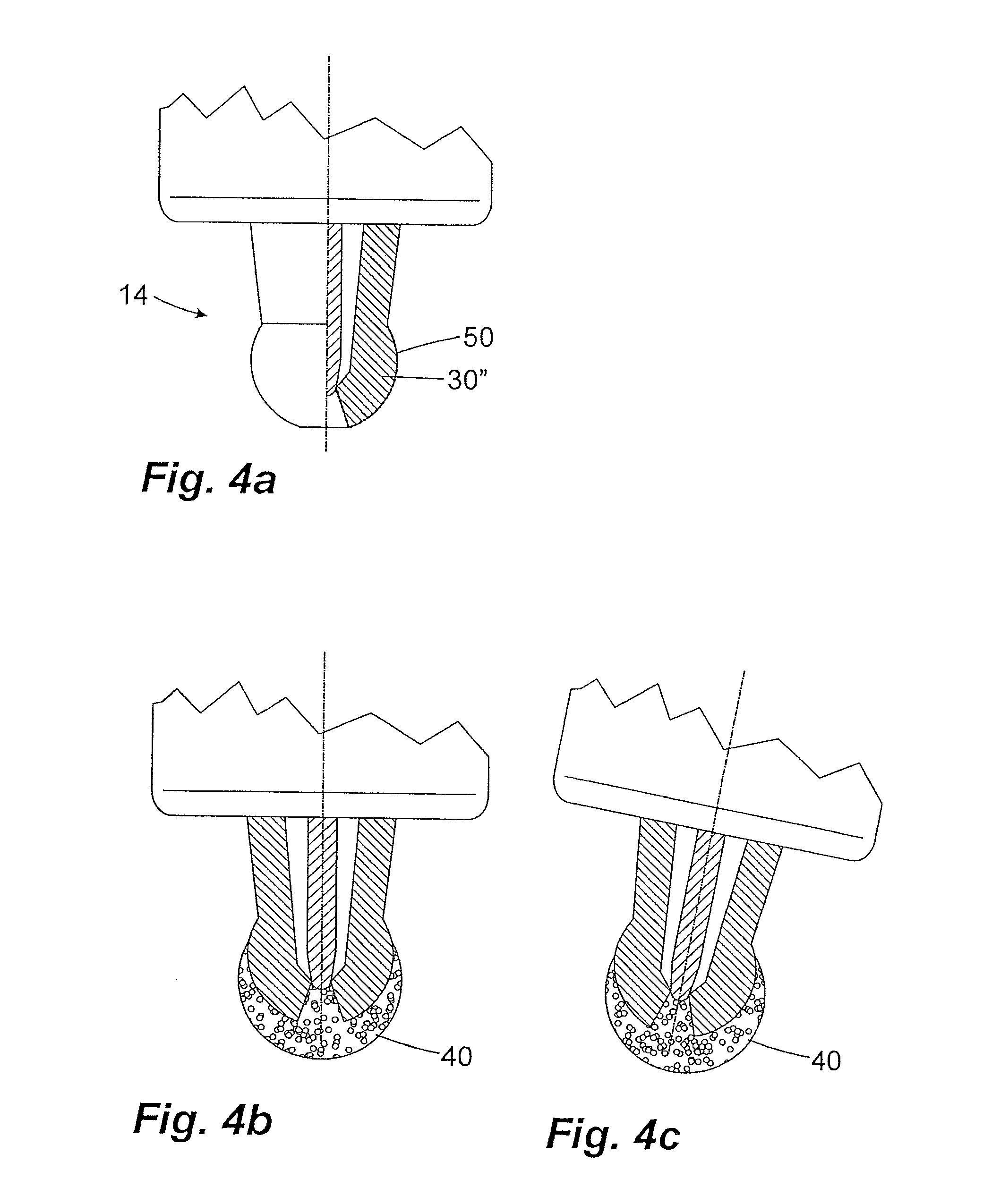

Drop dispenser

ActiveUS20130075431A1Constant drop sizeSmall volumeClosuresLaboratory glasswaresEngineeringDrying time

Drop dispenser for releasing a pharmaceutical liquid in drop form, with a housing, a liquid storage and a discharge opening, which penetrates a wall of the housing and to which an outlet valve is assigned, for extracting the liquid. The discharge opening is surrounded by a drop-formation area on the outside of the housing, wherein this drop-formation area, at least in an outer region with respect to an alignment of the drop dispenser with the discharge opening pointing vertically downwards, has a shape tapering downwards and towards the discharge opening. The drop dispenser allows the release of drops with a constant size and shortens drying time.

Owner:APTAR RADOLFZELL

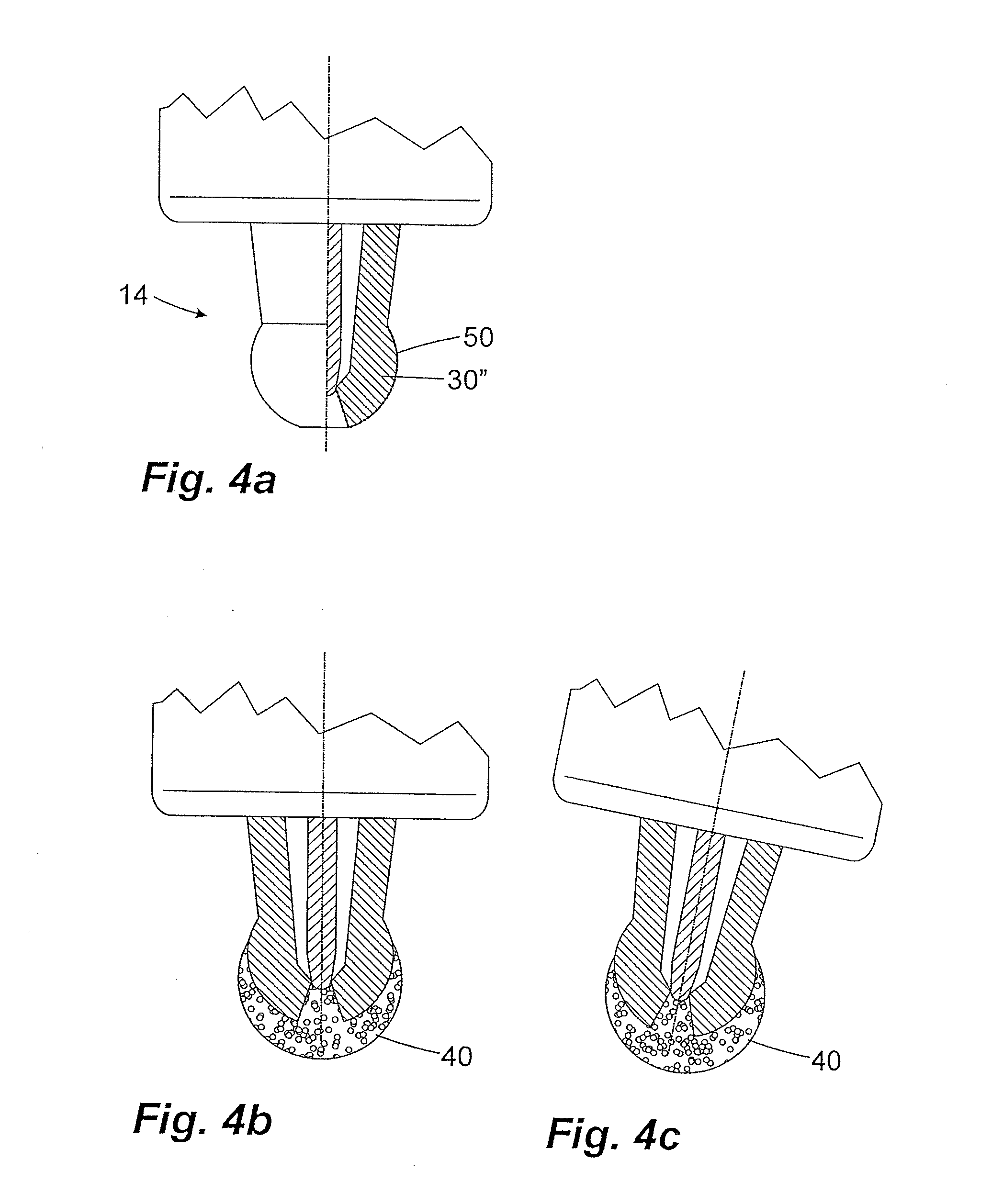

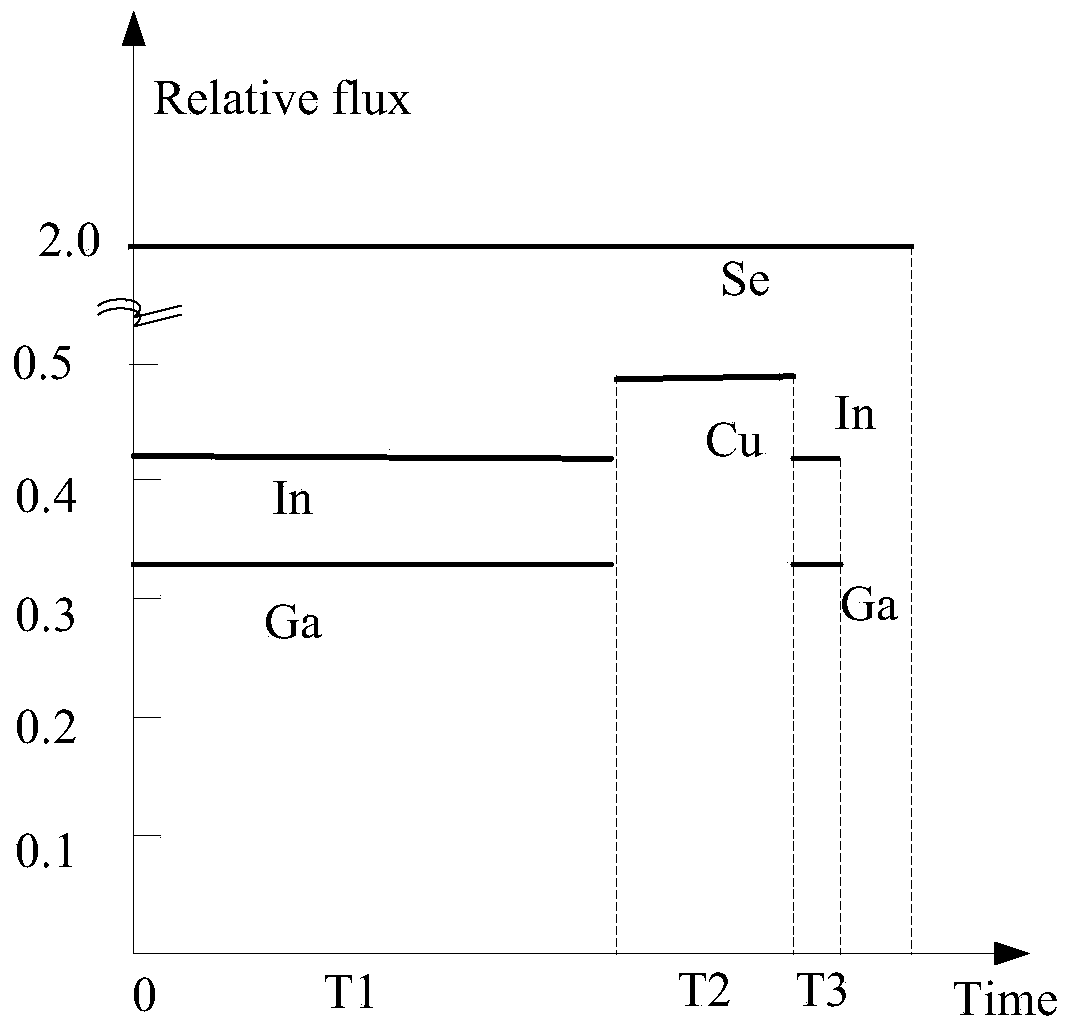

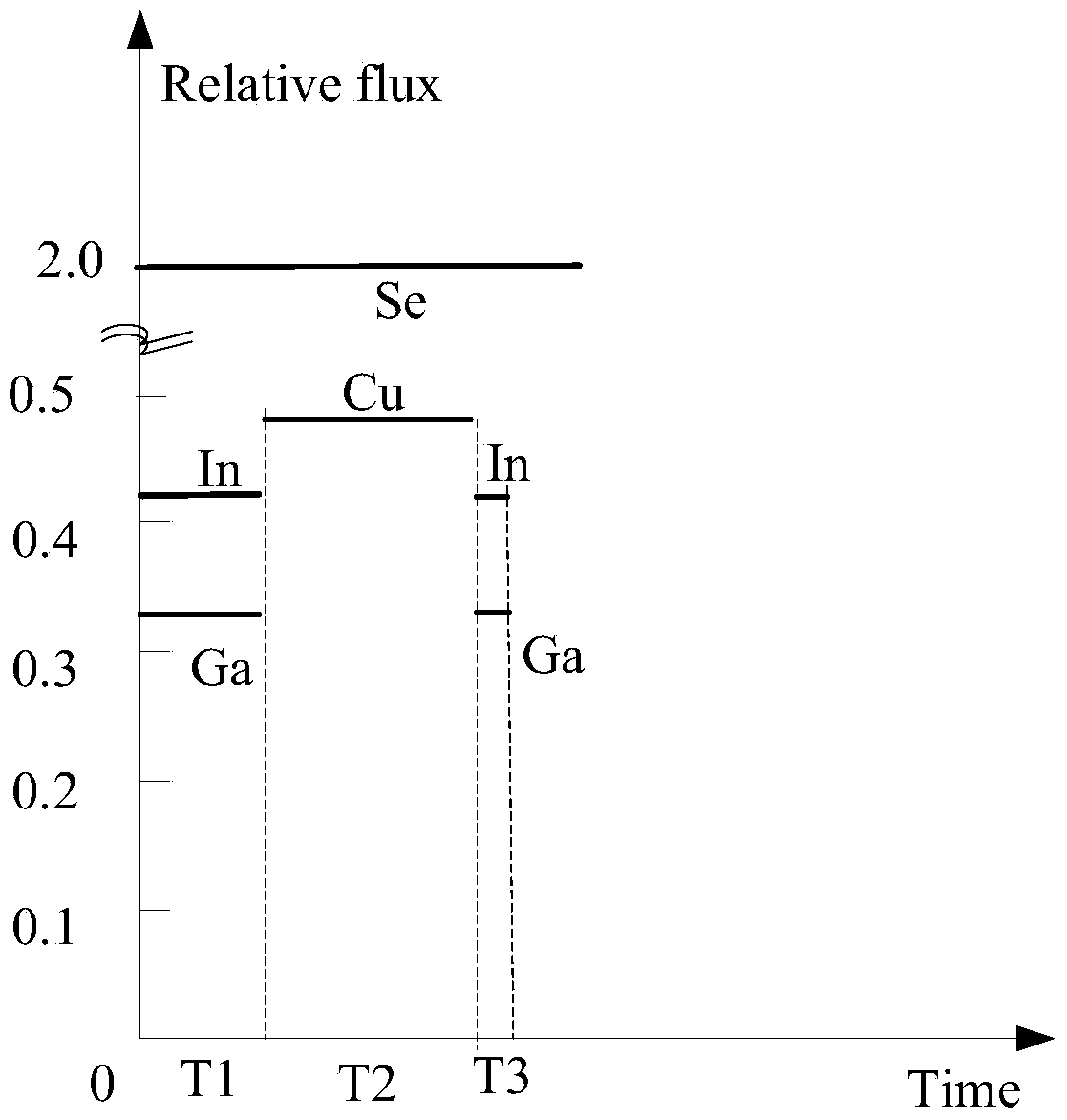

Preparation method for copper indium gallium diselenide thin film

ActiveCN103710668AQuality improvementRaise the evaporation temperatureFinal product manufactureVacuum evaporation coatingIndiumDiselenide

The invention relates to a preparation method for a copper indium gallium diselenide thin film. The preparation method for the copper indium gallium diselenide thin film comprises the steps of 1, co-evaporating gallium and indium in a selenium atmosphere to enable the selenium, the gallium and the indium to be deposited on a substrate; 2, heating the substrate, and evaporating copper in the selenium atmosphere to enable the selenium and the copper to be deposited on the substrate; 3, preserving the temperature of the substrate, and co-evaporating the gallium and the indium in the selenium atmosphere to form the copper indium gallium diselenide thin film. A ratio of the co-evaporating time in the step 1 to the co-evaporating time in the step 3 is (5:1)-(7:1). By virtue of rising of the evaporating temperature of the hot gallium and the indium, acceleration of thin film deposition and setting of the ratio relation between the evaporation amount in the step 1 and the evaporation amount in the step 3, the much indium can enter the thin film, and the gallium content of the surface of the thin film can be increased; therefore, the gradient distribution of all the elements can be obviously improved, defects on the surface of the copper indium gallium diselenide thin film can be reduced, the quality of the copper indium gallium diselenide thin film can be improved, and the energy consumption is reduced.

Owner:SHENZHEN INST OF ADVANCED TECH +1

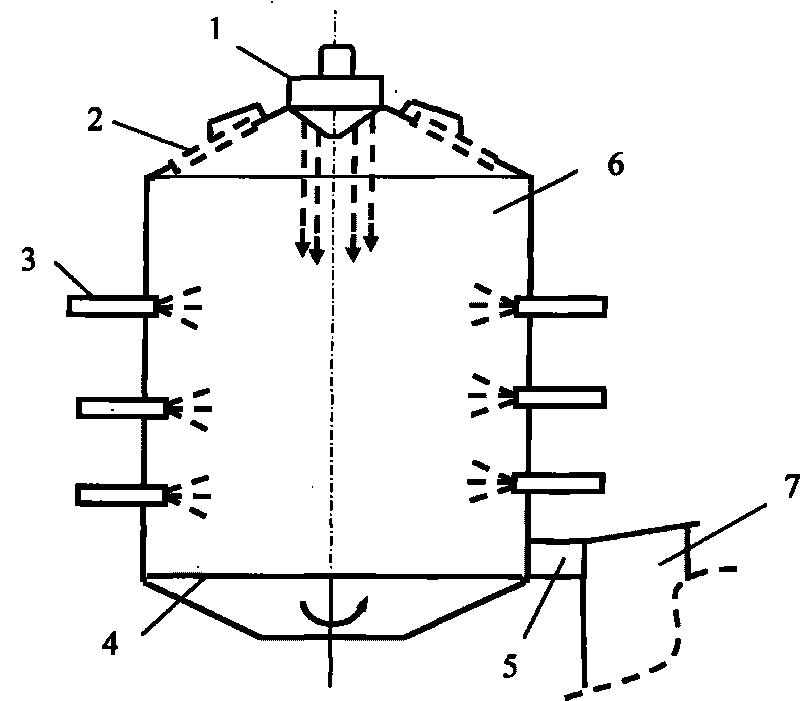

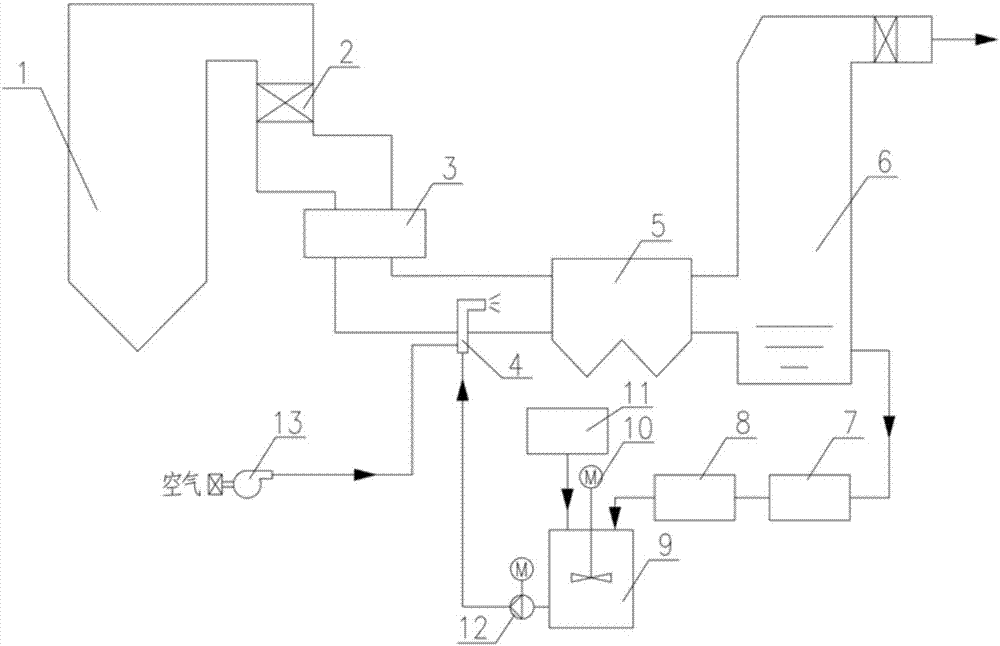

Method and equipment for granulating wet sludge soft particles

InactiveCN101703907AFine grainReduce drying costsSludge treatment by de-watering/drying/thickeningGranulation in rotating dishes/pansCombustionSludge

The invention discloses a method for granulating wet sludge soft particles. Sludge after being pressed and filtered is extruded into sludge strings by a sludge string extrusion machine at the top of a mixing tank, combustible powder is sprayed to the sludge strings for serving as an isolator by adopting a powder spraying machine of a powder spraying gun which is fixedly connected on the side wall of the mixing tank in the process that the sludge strings fall from top to bottom, the sludge strings coated with the combustible powder fall on a turntable granulating machine of which the bottom is laid with the combustible powder, and soft body granulation is carried out under the rotation of the turntable granulating machine to form dispersive wet sludge soft particles. The invention also discloses equipment for realizing the method. The invention simplifies a subsequent sludge drying process; the sprayed combustible powder can be used as the isolator, which is beneficial to sludge granulation and solves the problems of sludge caking and wall sticking effectively; moreover, the sprayed combustible powder can also act as a combustion-supporting function when sludge is incinerated; and the invention has simple equipment, low energy consumption and high benefit, is safe and sanitary, is convenient for popularization and use and can promote the industrialization progress of the drying incineration of the sludge.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

High-yield peanut planting method

InactiveCN108633672AImprove drainage capacityImprove fertilityExcrement fertilisersFabaceae cultivationSquare meterArachis hypogaea

The invention relates to the technical field of planting and particularly relates to a high-yield peanut planting method. The method comprises the following steps: 1) planning peanut planting rows, and uniformly spreading lime powder; 2) forming planting slots with V-shaped cross sections in the planting rows, and forming drainage ditches; 3) subjecting peanut seeds to grading screening, and sowing the seeds to bottoms of the V-shaped planting slots; 4) applying a base fertilizer to the peanut seeds in the step 3) in accordance with that 1.5kg to 2.8kg of base fertilizer is applied to the planting slots per square meter; and 5) applying a seedling-stage fertilizer once or twice every 15 days at a seedling stage of peanuts, and applying a pin-dropping-stage fertilizer once or twice every 10days at a pin-dropping stage of the peanuts, wherein the seedling-stage fertilizer is prepared from a base fertilizer and seedling-stage additives. According to the high-yield peanut planting methoddisclosed by the invention, the pin forming rate of the peanuts can be effectively increased, the vacant shell rate of the peanuts can be effectively reduced, the yield of the peanuts can be increased, and the ripening time can be shortened.

Owner:广西壮族自治区农业科学院经济作物研究所

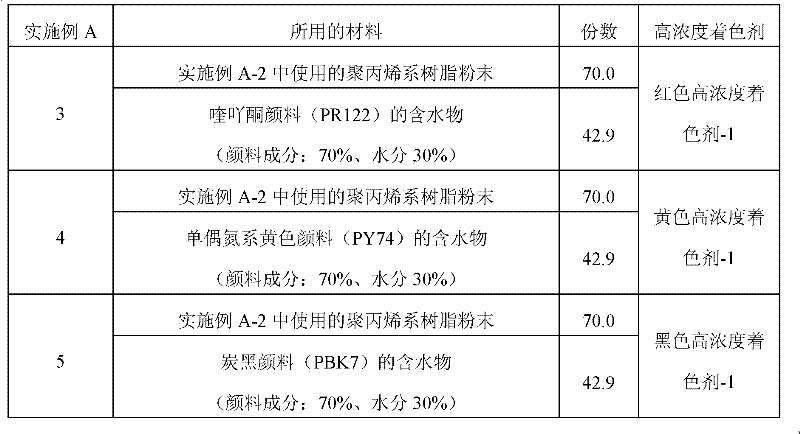

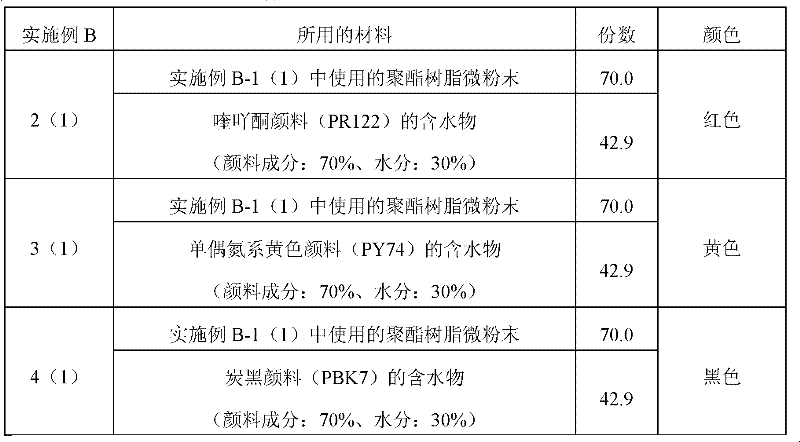

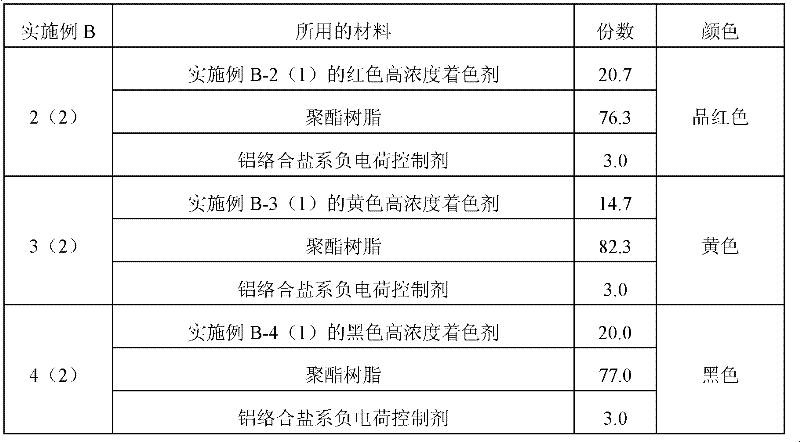

Process for production of pigment/resin composition, coloring agent and coloring method

InactiveCN102203679AShorten heating and kneading timeGood dispersionInksOrganic dyesColor imageImage recording

Disclosed are a process for the production of a pigment / resin composition, a coloring agent, and a coloring method. The process is characterized by introducing both a pigment and a heat-meltable resin continuously into a kneading extruder provided with at least one vent hole in the presence of moisture in an amount of 3 to 70mass% of the sum of the pigment and the resin, kneading the pigment and the resin together at a temperature not lower than the melting point of the resin while discharging steam produced from both separated moisture and remaining moisture through the vent hole, and thus dispersing the pigment in the molten resin. According to the process for the production of a pigment / resin composition, the coloring agent and the coloring method, a coloring agent useful in coloring plastics or in coloring image recording agents can be produced with flexible accommodation to an increase in demand, while enhanced production efficiency, shortened processing time, man-power saving, and streamlining can be attained in charging and in steps subsequent to kneading.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Drop dispenser

Drop dispenser for releasing a pharmaceutical liquid in drop form, with a housing, a liquid storage and a discharge opening, which penetrates a wall of the housing and to which an outlet valve is assigned, for extracting the liquid. The discharge opening is surrounded by a drop-formation area on the outside of the housing, wherein this drop-formation area, at least in an outer region with respect to an alignment of the drop dispenser with the discharge opening pointing vertically downwards, has a shape tapering downwards and towards the discharge opening. The drop dispenser allows the release of drops with a constant size and shortens drying time.

Owner:APTAR RADOLFZELL

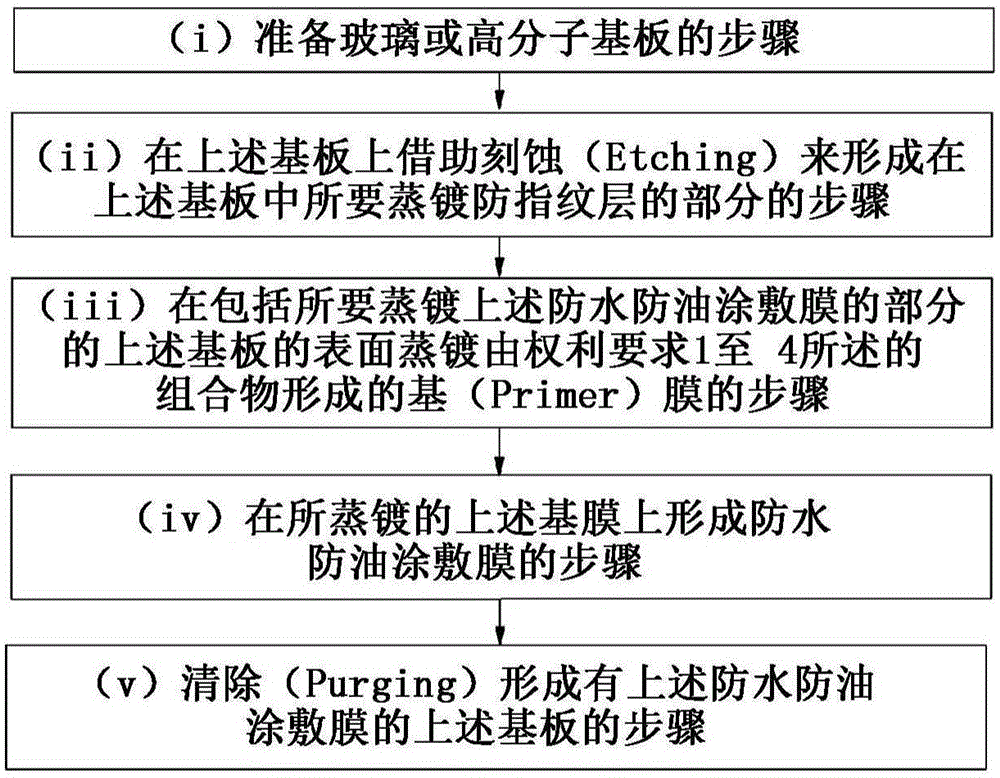

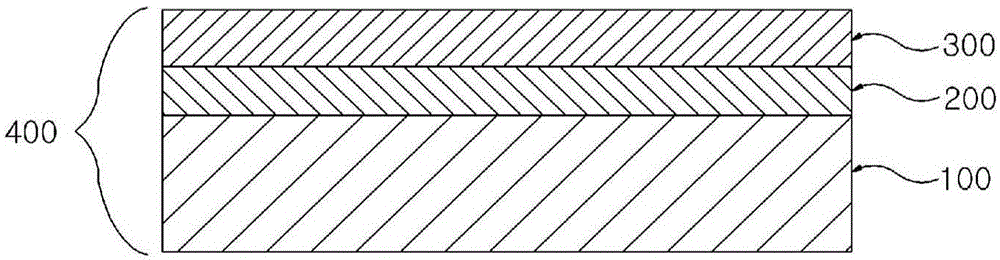

Composition of fingerprint-resistant layer consisting of a plurality of thin films and preparation method therefor

ActiveCN105209568AWear-resistantSalt water resistantAntifouling/underwater paintsOther chemical processesPolymer substrateChemical compound

A composition for primer layer coating of a water- and oil-repellent coating layer, which is deposited so as to enhance the durability of the water- and oil-repellent coating layer, is characterized by being a mixture which comprises at least one of a silicon oxide (SiOx), a titanium (Ti) compound, an aluminum (Al) compound, and a zirconium (Zr) compound. A preparation method therefor may comprise: a step for preparing a glass or polymer substrate; a step for forming, on the substrate, a portion on which a fingerprint-resistant layer is to be deposited within the substrate by etching; a step for depositing a primer layer consisting of the composition on the surface of the substrate which comprises a portion on which the water- and oil-repellent coating layer is to be deposited; a step for forming the water- and oil-repellent coating layer on the deposited primer layer; and a step for purging the substrate on which the water- and oil-repellent coating layer is formed. The method of the present invention has an effect of having excellent wear-resistance, salt water resistance, chemical resistance and cosmetics resistance, compared to the conventional deposition.

Owner:GAEMA TECH

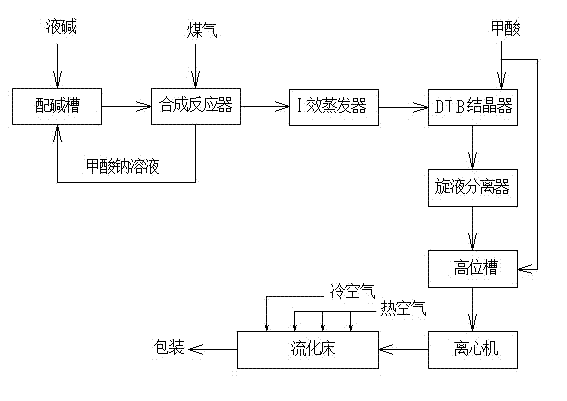

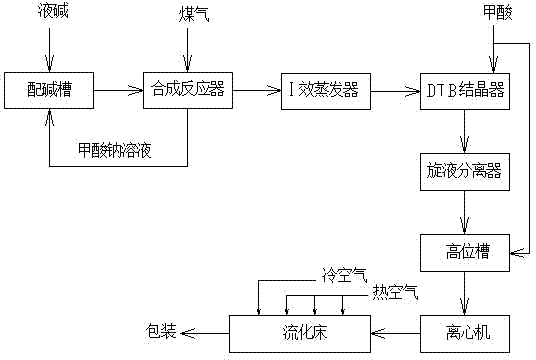

Method for producing sodium formate by using coal gas

InactiveCN102516059AReduce consumptionHigh purityCarboxylic preparation from carbon monoxide reactionCarboxylic compound separation/purificationSocial benefitsEvaporation

The invention discloses a method for producing sodium formate by using coal gas. The method comprises the steps that: a production raw material liquid is prepared; coal gas is added to the raw material liquid, and a synthesis reaction is carried out, such that a reaction product liquid is obtained; and sodium formate in the reaction product liquid is evaporated, crystallized, separated, dried, and packaged. According to the invention, a limitation of a low concentration of produced sodium formate is broken. Under a condition that current raw material concentration, reaction temperature and reaction pressure are not changed, the concentration of sodium formate in the reaction product liquid is no lower than 500g / L, such that vapor consumption is saved. Also, with a method that formic acid is added, the purity of sodium formate is higher than 99.5%. Also, evaporation, crystallization, drying and packaging manners are changed, such that sodium formate is prevented from moisture absorbing and caking. With the method provided by the invention, apparatus productivity is greatly improved, vapor consumption is reduced, system operation stability is improved, continuous production is realized, and product quality is improved. Therefore, economic, environmental and social benefits are ensured.

Owner:YIBIN TIANYUAN GRP CO LTD

Desulfurization wastewater treatment system

PendingCN107344788AIncrease disturbanceShorten evaporation timeDispersed particle separationWater/sewage treatmentWater treatment systemFluid phase

The invention provides a desulfurization wastewater treatment system. The desulfurization wastewater treatment system comprises a wastewater buffer tank, a pretreatment system, a bicarbonate medication device and a dual-fluid atomizing nozzle, wherein the pretreatment system is arranged at an inlet end of the wastewater buffer tank; the bicarbonate medication device is used for adding bicarbonate into the wastewater buffer tank; and an air compressor is connected to an air inlet of the dual-fluid atomizing nozzle, and a water inlet of the air compressor is connected with a water outlet of the wastewater buffer tank. After entering a flue, desulfurization wastewater is evaporated under the action of waste heat of flue gas; the desulfurization wastewater reacts with SO3 in flue gas; the desulfurization wastewater easily generates decomposition reaction when being heated; by virtue of carbon dioxide generated in two reactions, the perturbation of liquid drops cane be further accelerated, and secondary fog drops are easily generated, and meanwhile, the heat and mass transfer processes of fog drops and flue gas must be accelerated by virtue of reaction between gas and liquid phases; and besides, generated carbonate can rapidly react with a small amount of soluble calcium and magnesium ions in the desulfurization wastewater so as to form a core and release heat, so that the evaporation time of the fog drops can be effectively shortened, and a wastewater zero discharging effect is improved.

Owner:FUJIAN LONGKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com