Patents

Literature

57results about How to "Extended crystallization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

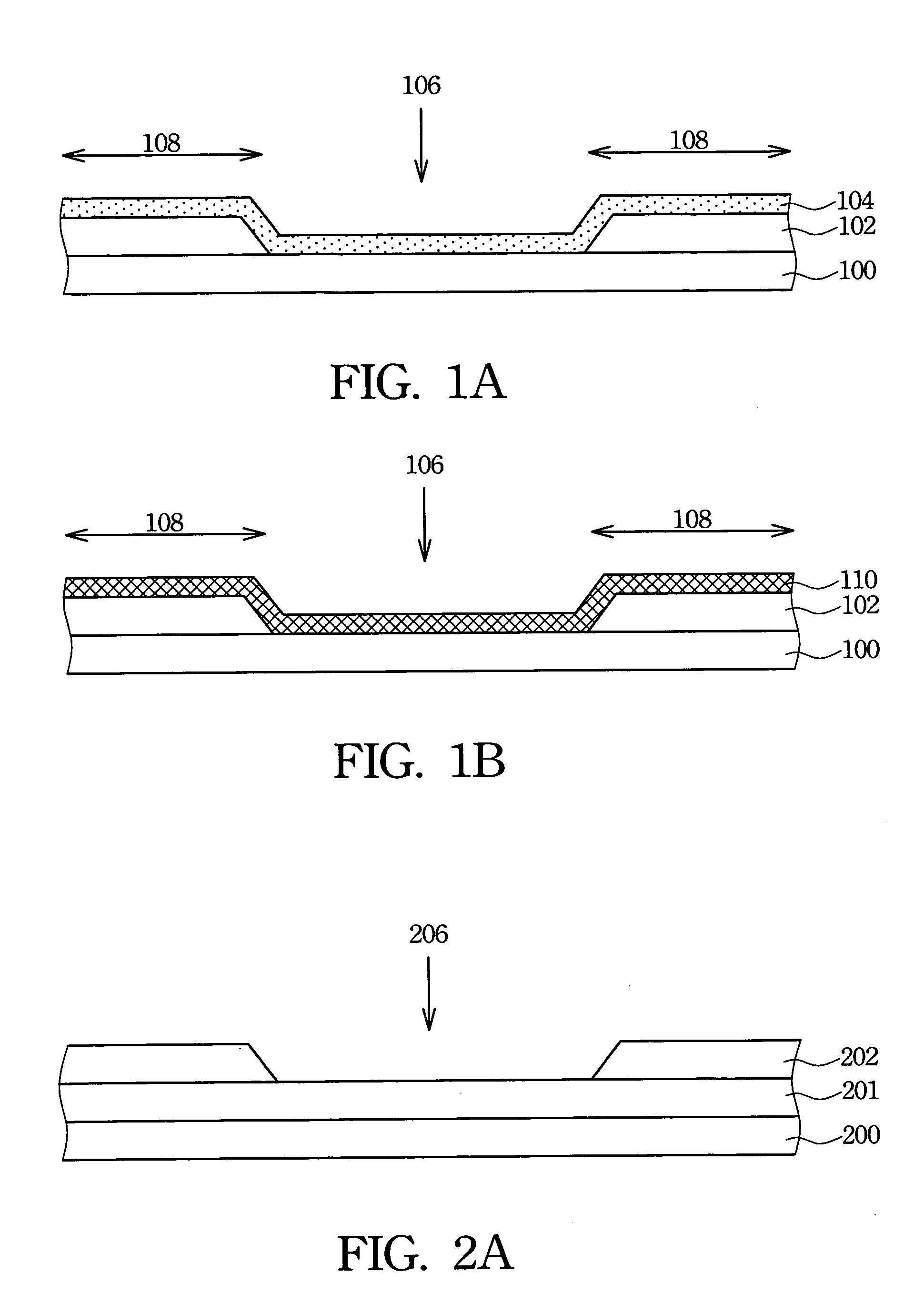

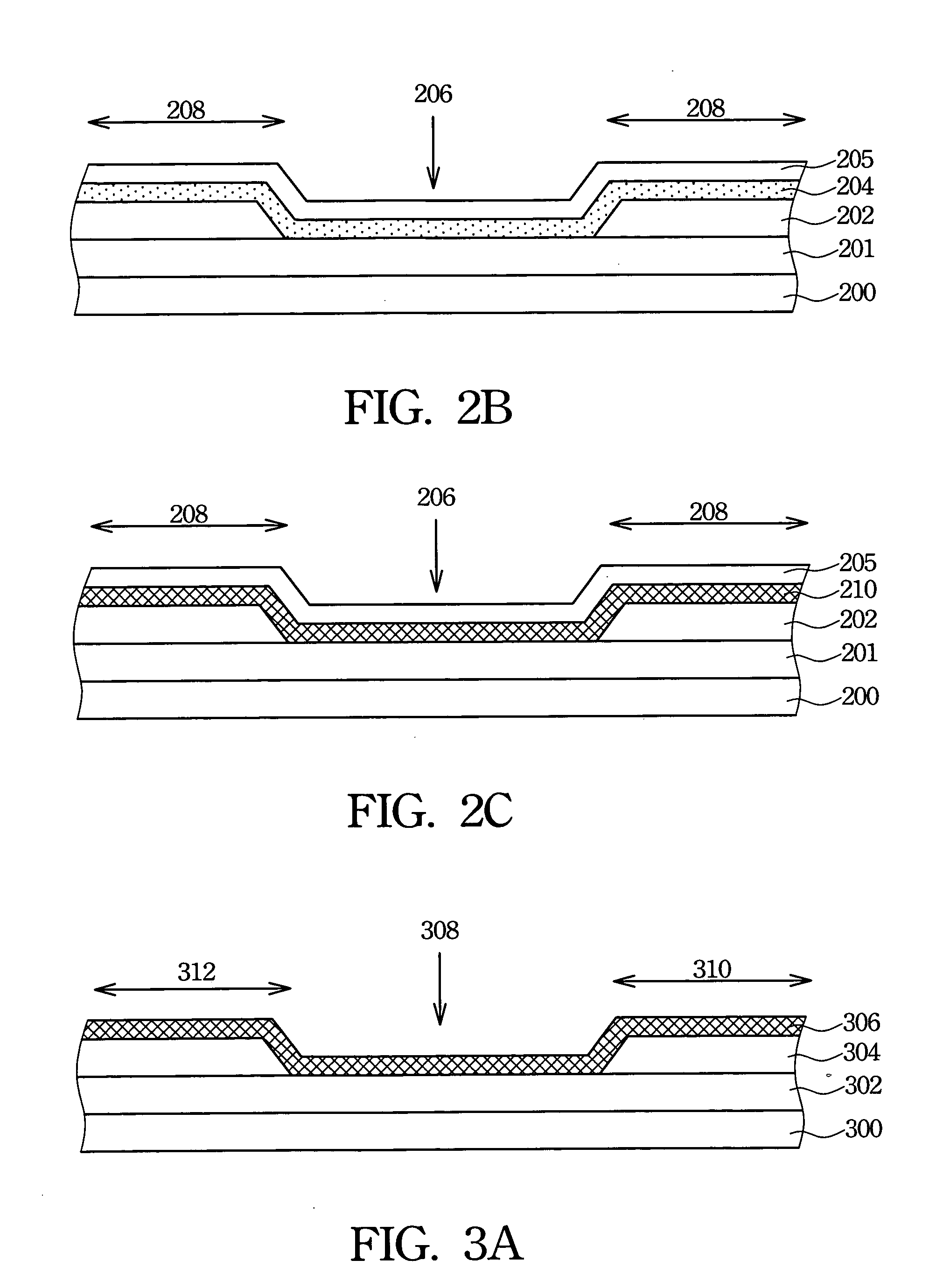

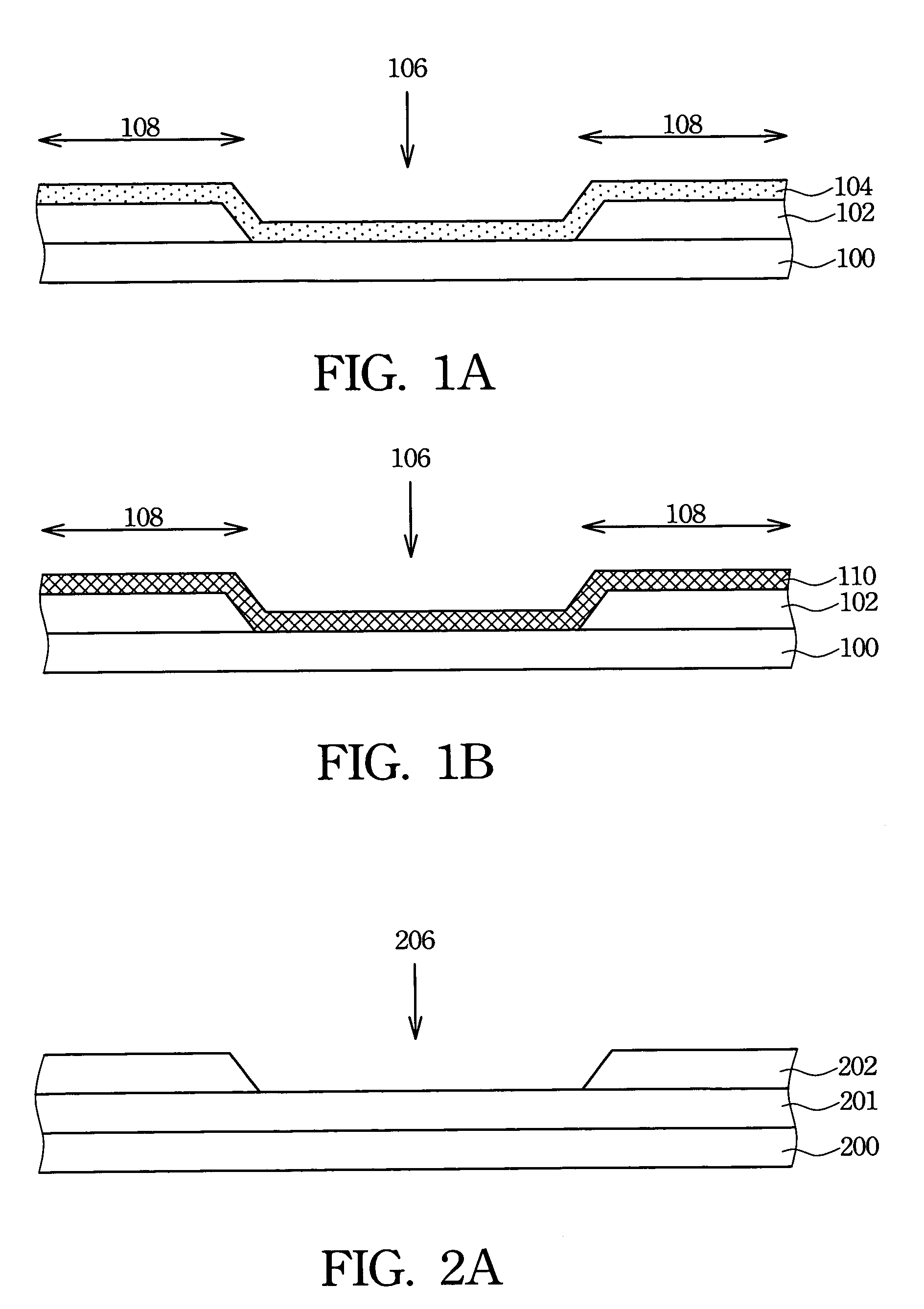

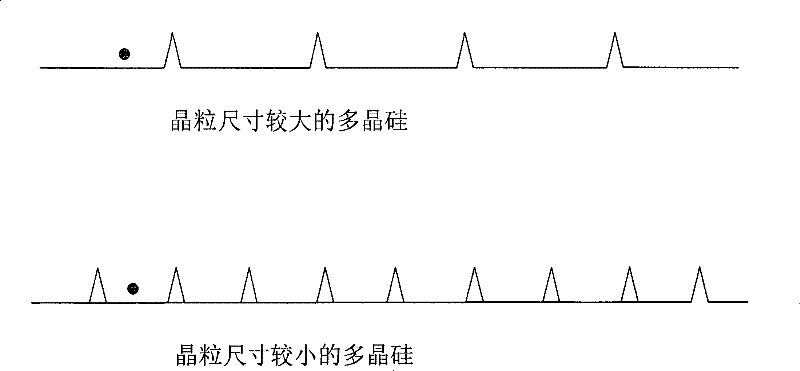

Method of controlling polysilicon crystallization

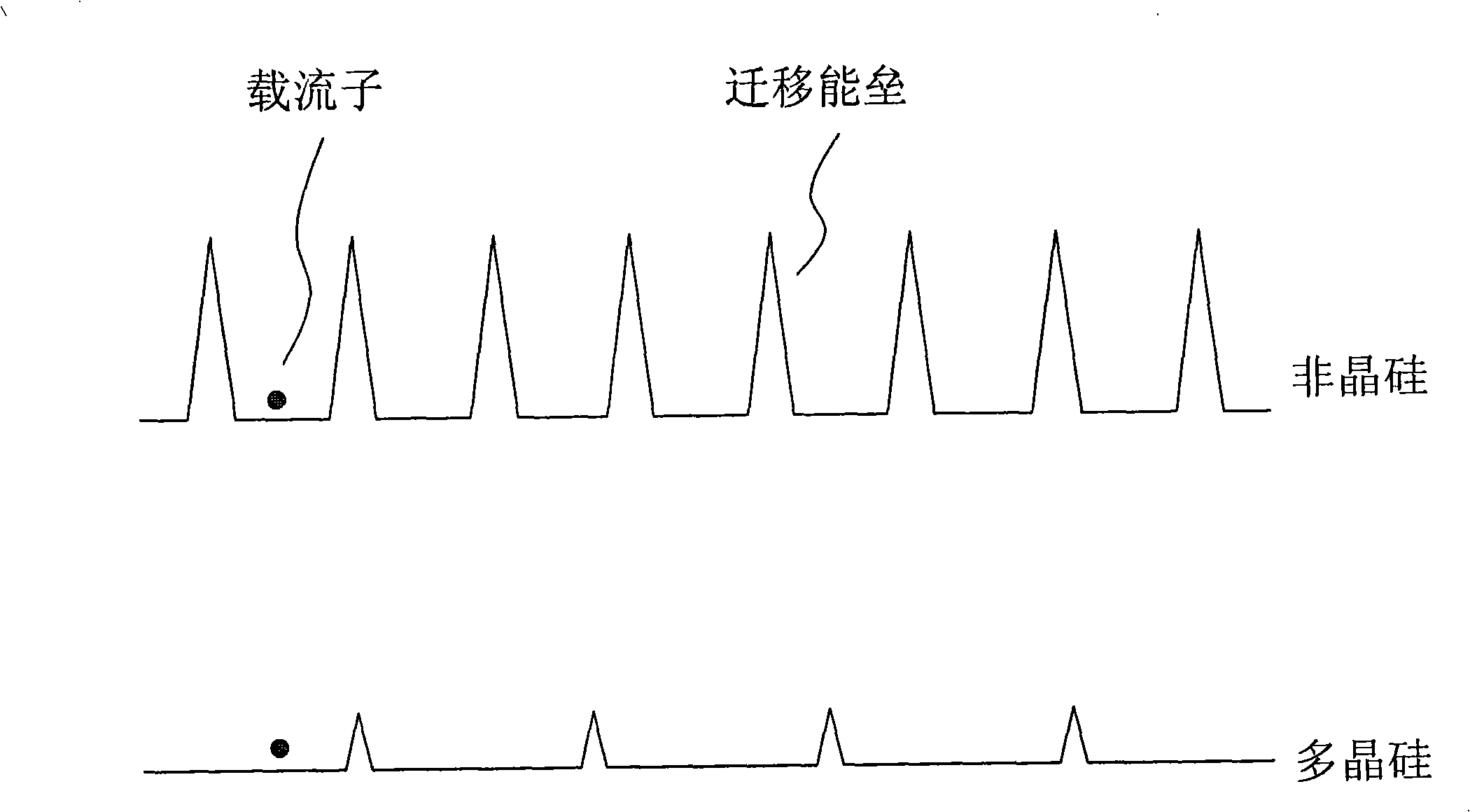

InactiveUS20050079294A1High grain orderEnergy transfer uniformRadiation applicationsBy zone-melting liquidsMicrometerAmorphous silicon

A heat sink layer is formed on portions of a substrate, and then an amorphous silicon layer is formed thereon. The heat coefficient of the heat sink layer is greater than that of the substrate. When an excimer laser heats the amorphous silicon layer to crystallize the amorphous silicon, nucleation sites are formed in the amorphous silicon layer on the heat sink layer. Next, laterally expanding crystallization occurs in the amorphous silicon layer on the substrate to form polysilicon having a crystal size of a micrometer.

Owner:IND TECH RES INST

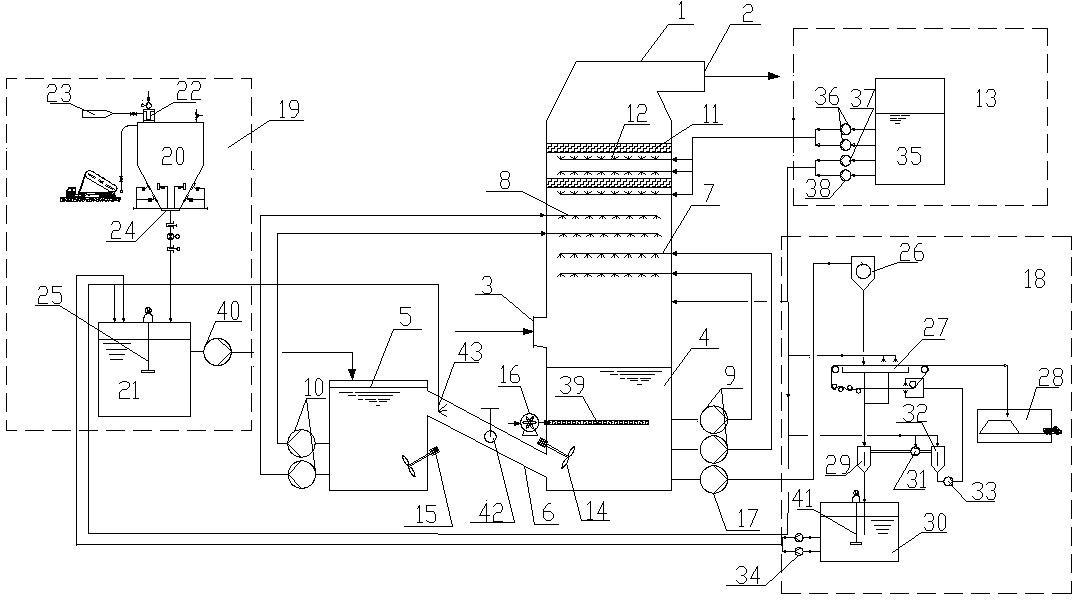

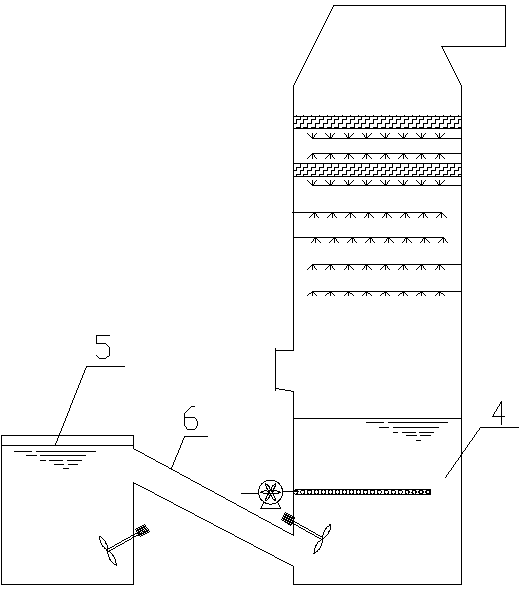

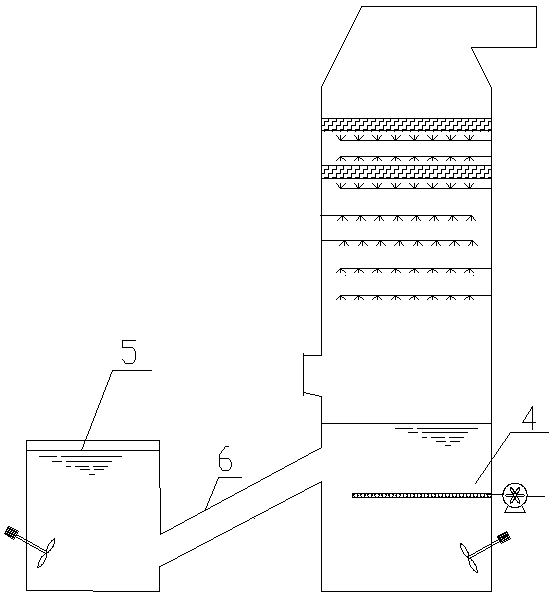

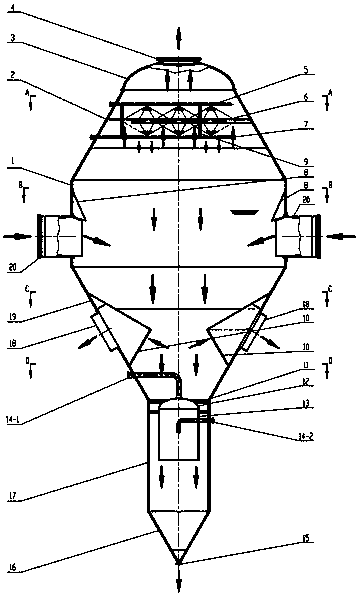

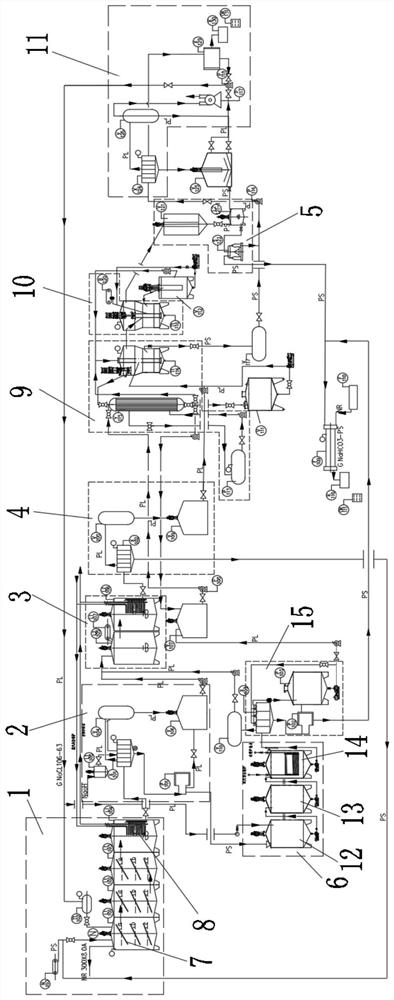

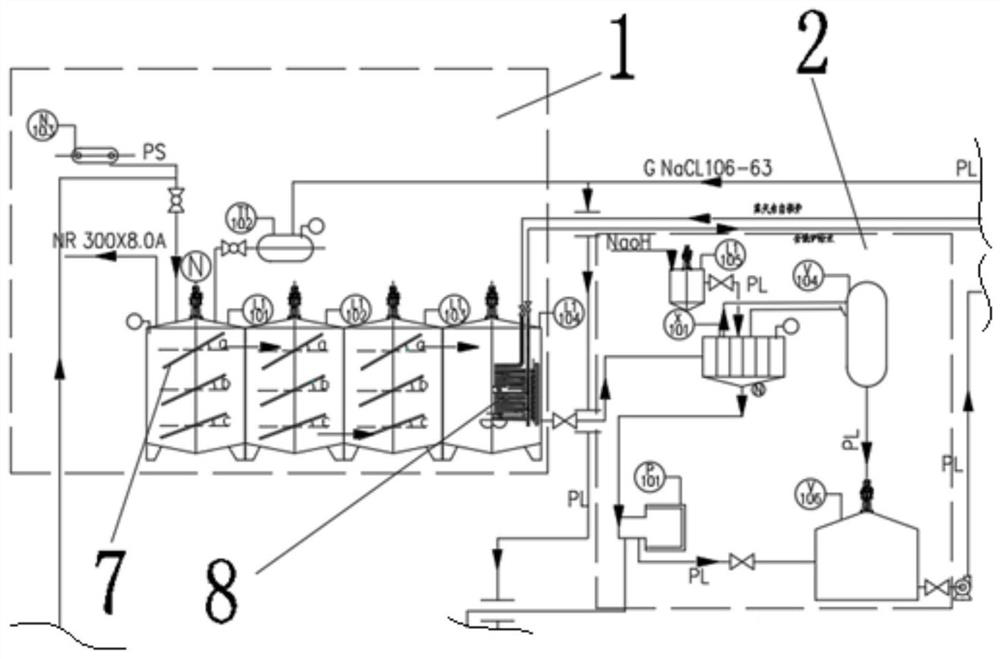

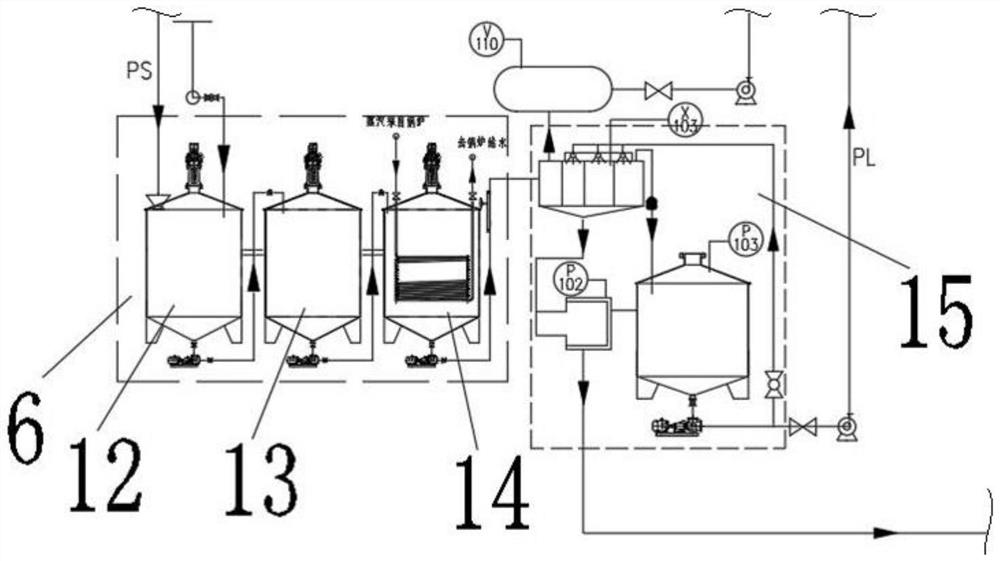

Efficient desulfurization single-tower double-circulation system and method

InactiveCN104226099APromote crystallizationImprove dehydration rateDispersed particle separationPh controlEngineering

The invention discloses an efficient desulfurization single-tower double-circulation system and method. The efficient desulfurization single-tower double-circulation system comprises a primary slurry pool in a desulfurization tower and a secondary slurry pool outside the desulfurization tower, and the two slurry pools are connected by virtue of a pipeline, so as to form a multiregion pH control double-circulation desulfurization system, wherein limestone slurry is supplemented from the secondary slurry pool to the primary slurry pool, and cypsum slurry is discharged from the primary slurry pool of the desulfurization tower. According to the efficient desulfurization single-tower double-circulation system, the region control can be performed on the pH of the two slurry pools, the slurry at different spraying layers is respectively supplied by the two slurry pools, the slurry with a high pH value is favorable for absorbing SO2, so that the desulphurization efficiency of a desulfurization system is more than 99%, and the slurry with a low pH value is favorable for sulfite oxidation and gypsum crystallization, so that the gypsum dehydration rate and the gypsum purity are increased.

Owner:ZHEJIANG UNIV

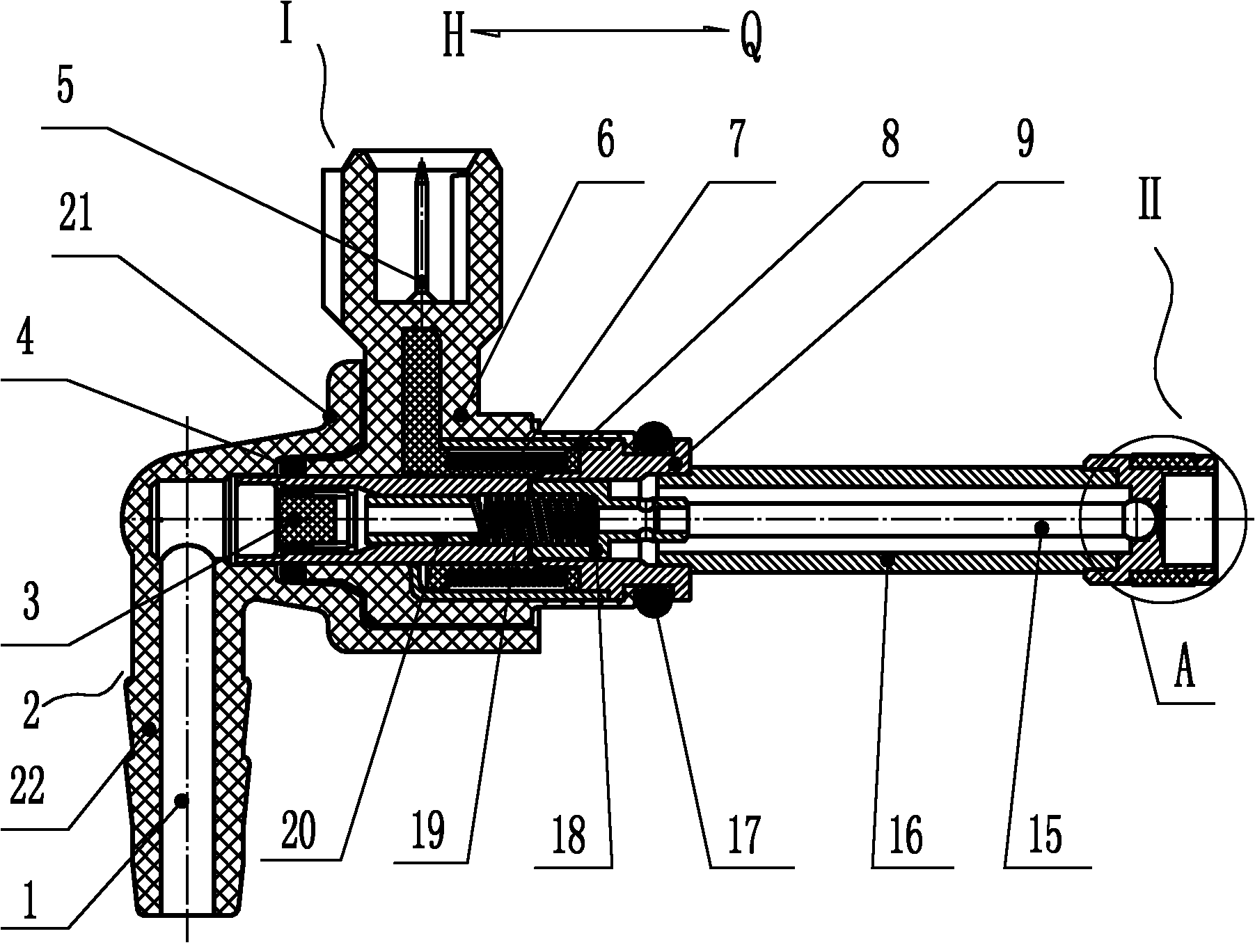

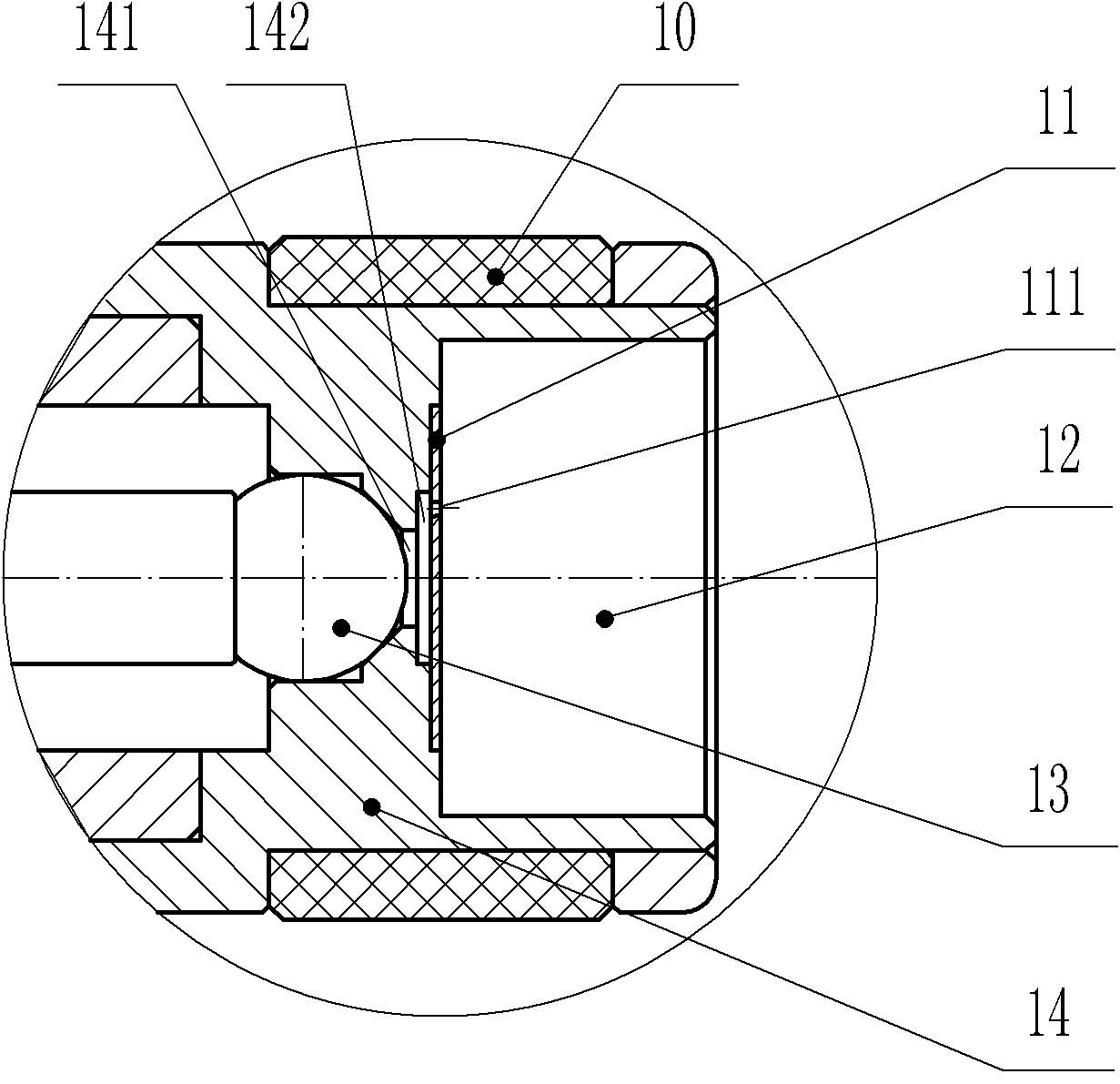

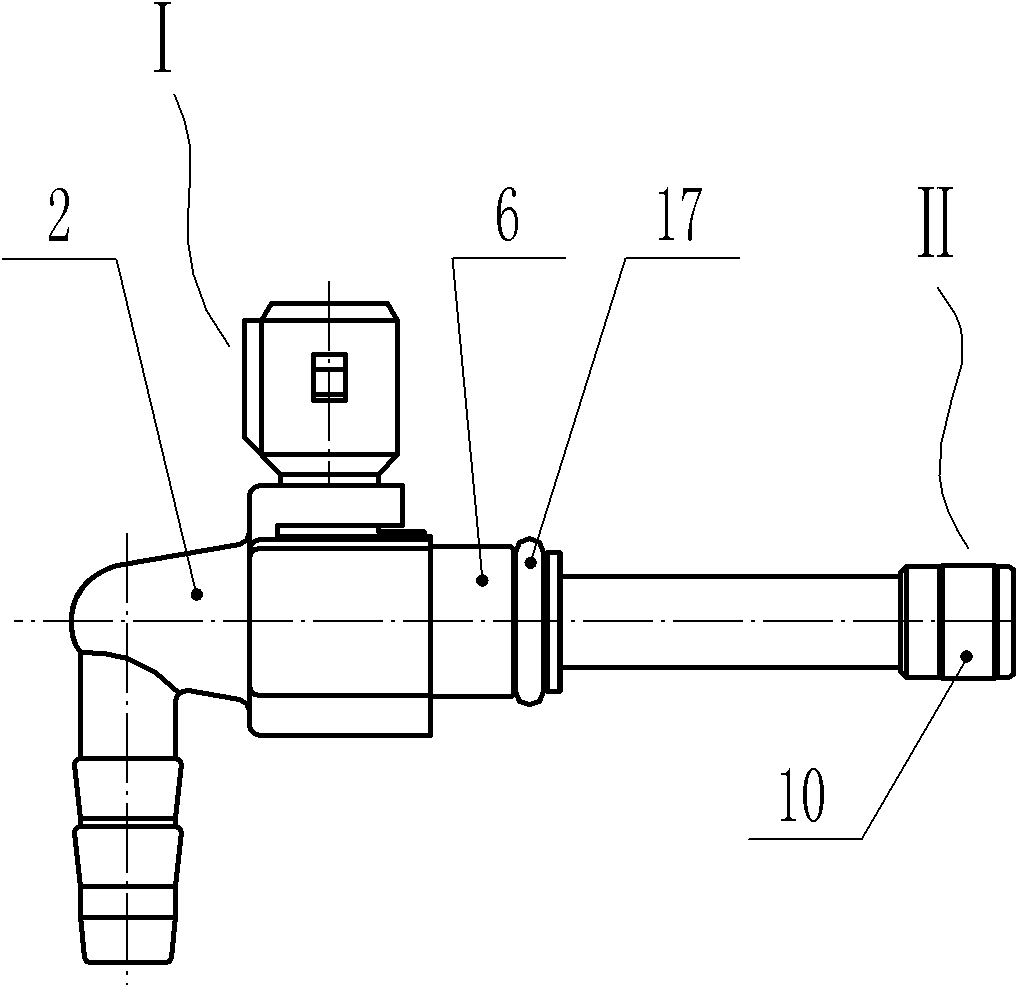

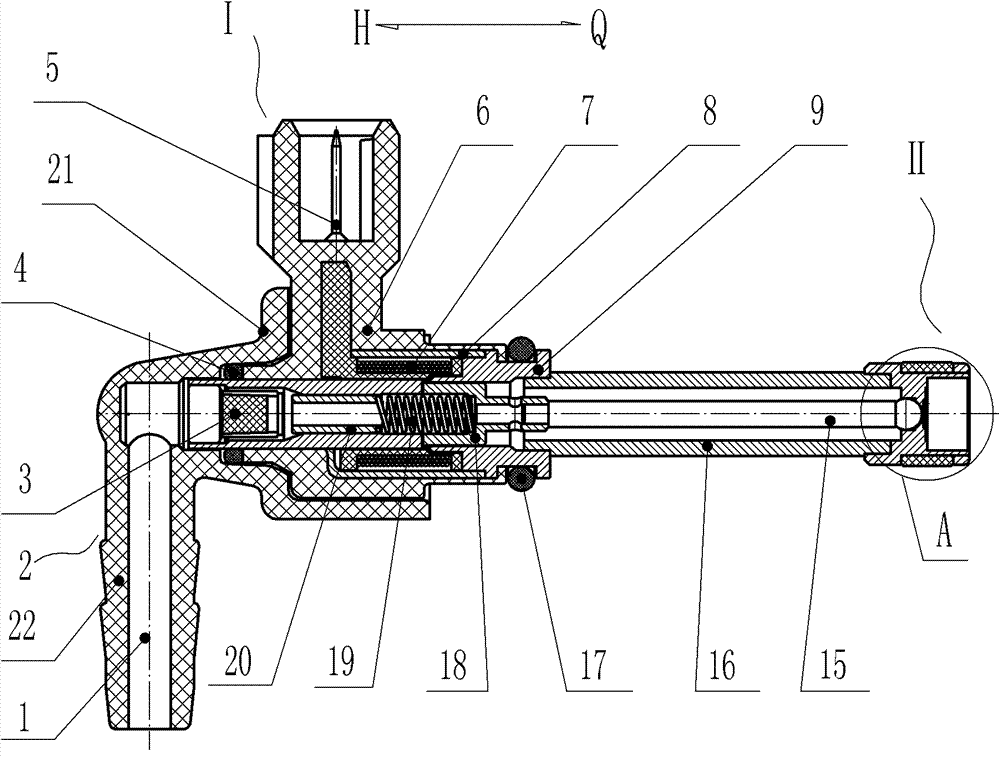

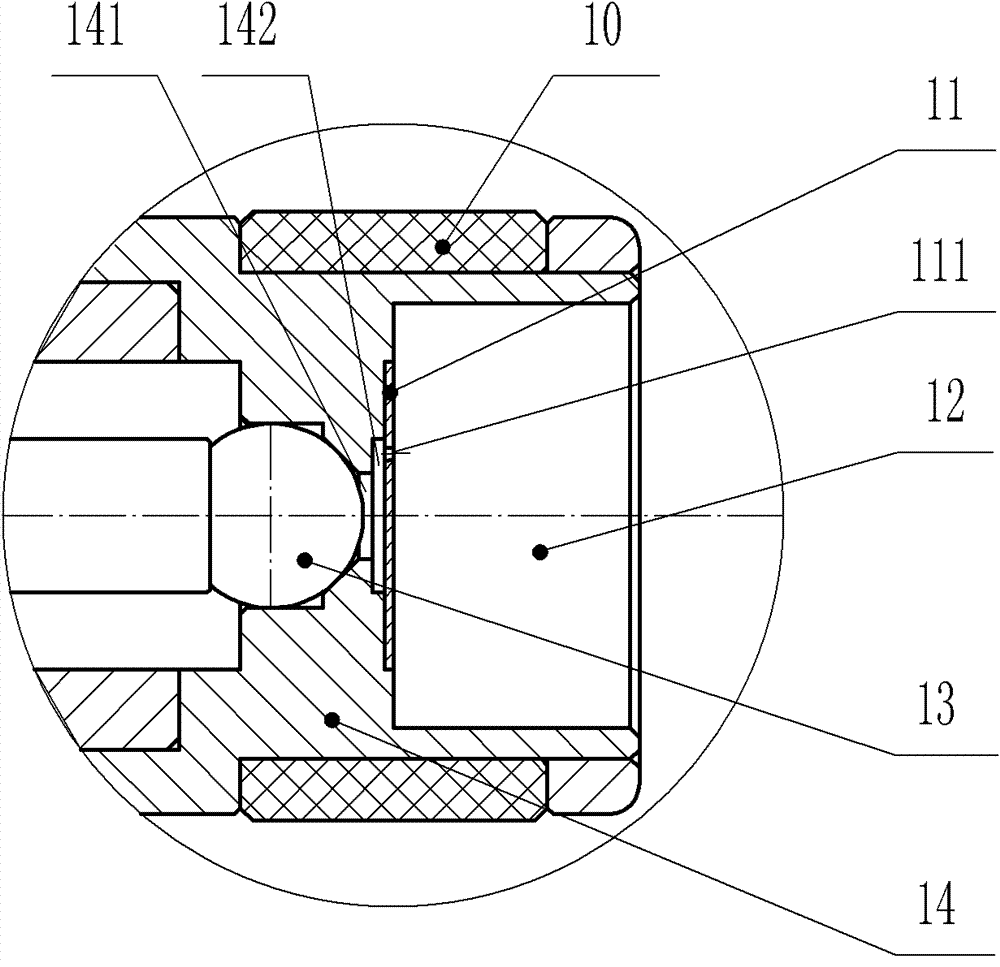

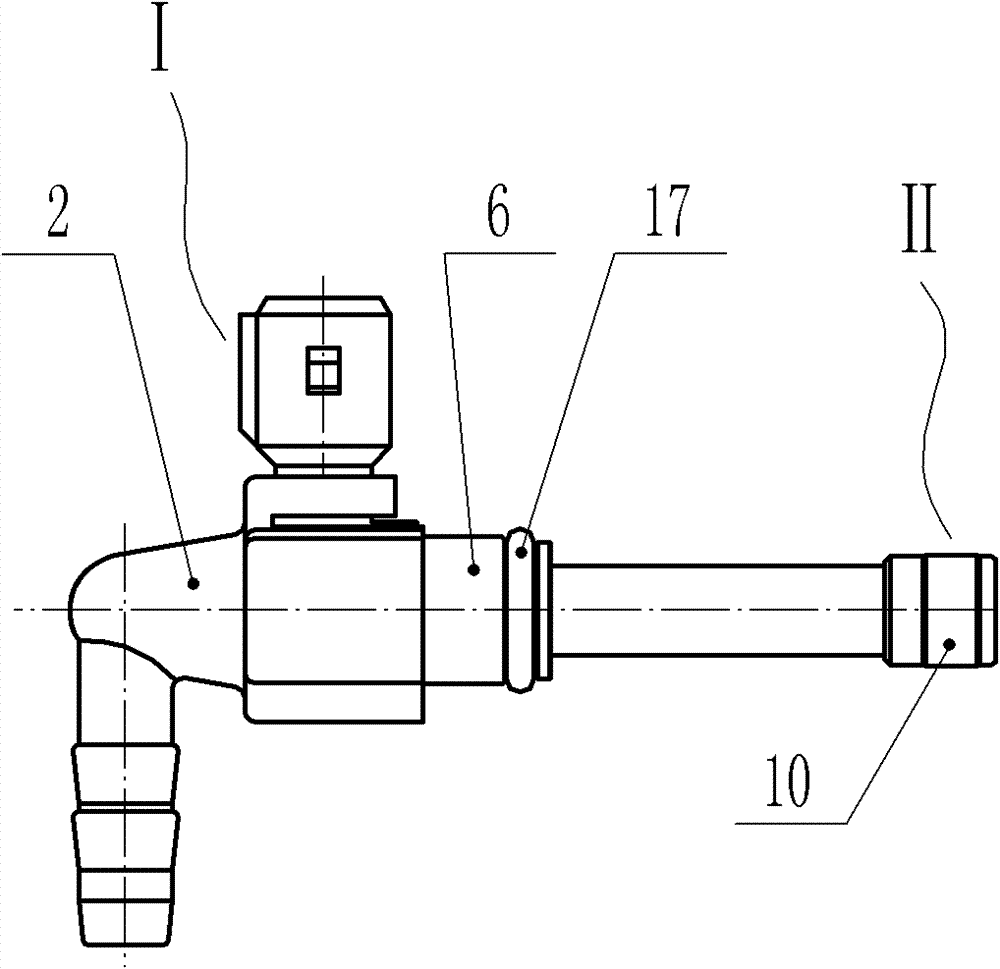

Electromagnetic valve type urea solution injector

ActiveCN102108891AStable jobSolve the deformationExhaust apparatusDispersed particle separationThermal energySteel ball

An electromagnetic valve type urea solution injector relates to an injector, and comprises an electromagnetic valve type injecting body, and an injecting nozzle, wherein the electromagnetic valve type injecting body and the injecting nozzle are connected into a whole through an injecting nozzle connecting rod; the injecting nozzle comprises a valve seat, a sealing steel ball mounted at a valve, a spraying orifice plate provided with a spraying orifice and mounted at the front end of the valve, and a step hole is formed between the front end part of the valve seat and the spraying orifice plate to form a turbulent cavity A ; a heat-insulating sleeve is arranged on an excircle at the front end of the valve seat for preventing heat energy of a tail gas discharge pipe from passing into the injecting nozzle; and a single-orifice atomization structure is arranged in the injecting nozzle. The electromagnetic valve type urea solution injector can work in high-temperature and high-speed gas with long-term stability and very high reliability, has low possibility of blockage, and better solves the problem that the spraying orifice can be blocked up by urea crystals. The invention also has the advantages of low manufacturing cost, short maintenance time of the product, reasonable structure and convenience in installation, etc.

Owner:LIUZHOU YUANCHUANG EFI TECH

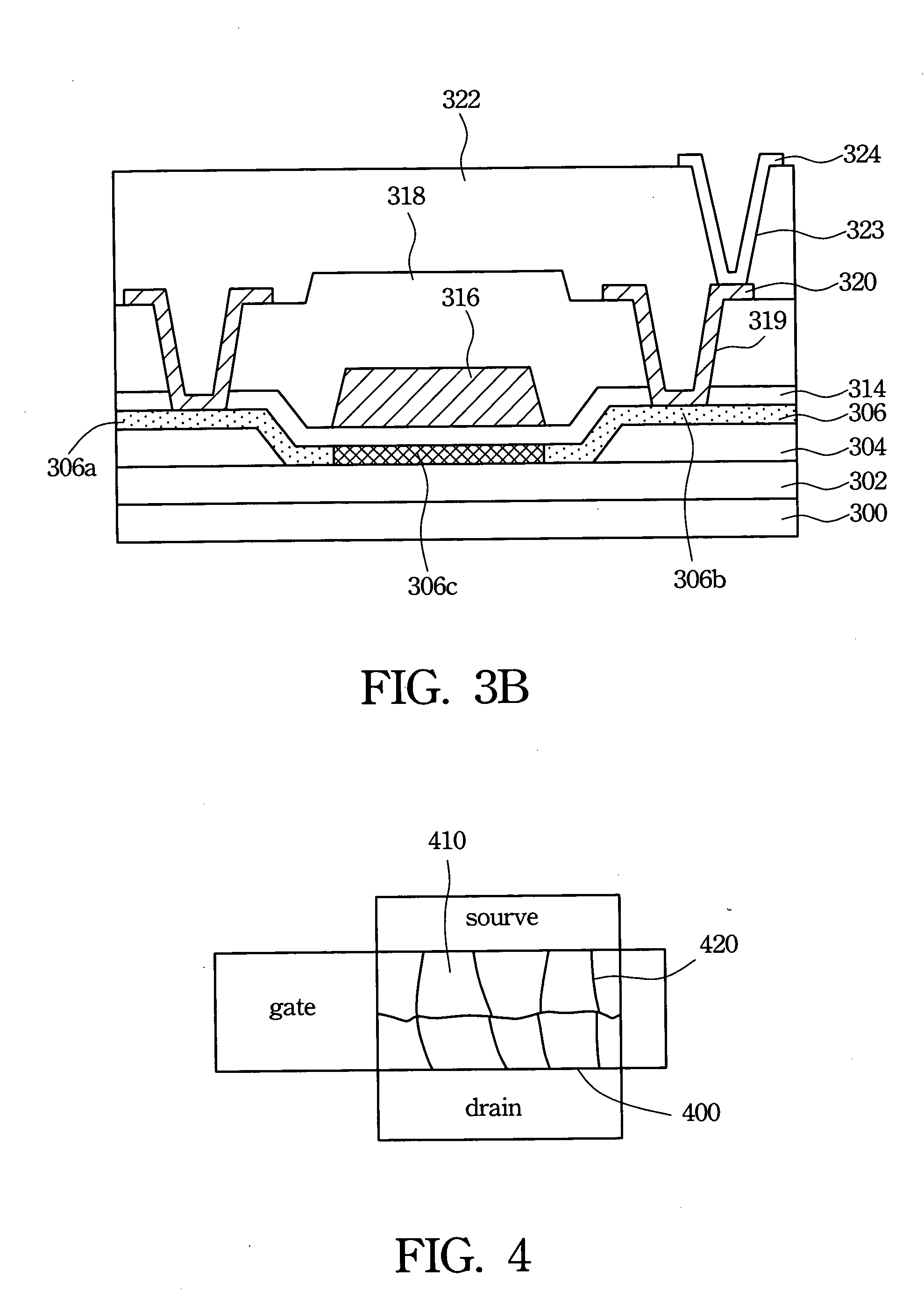

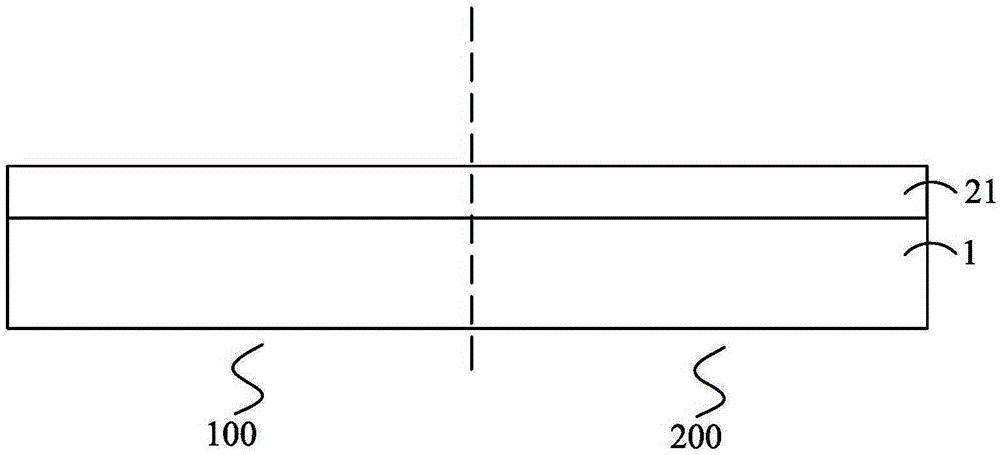

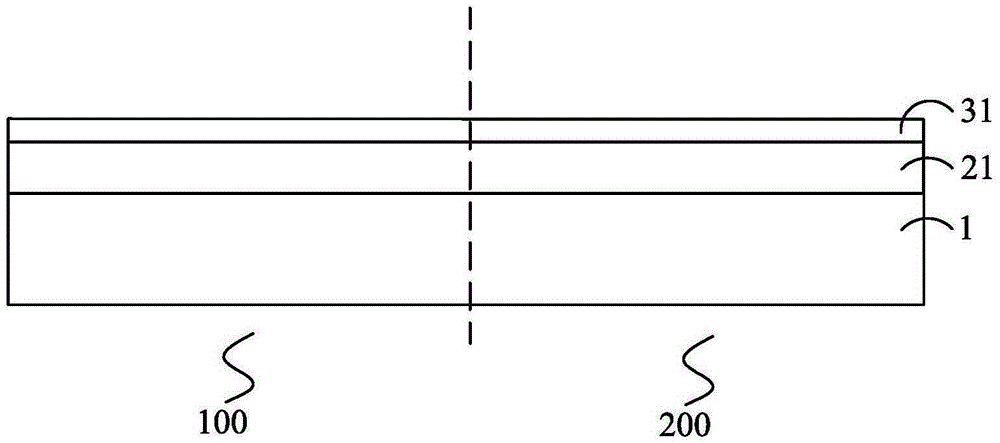

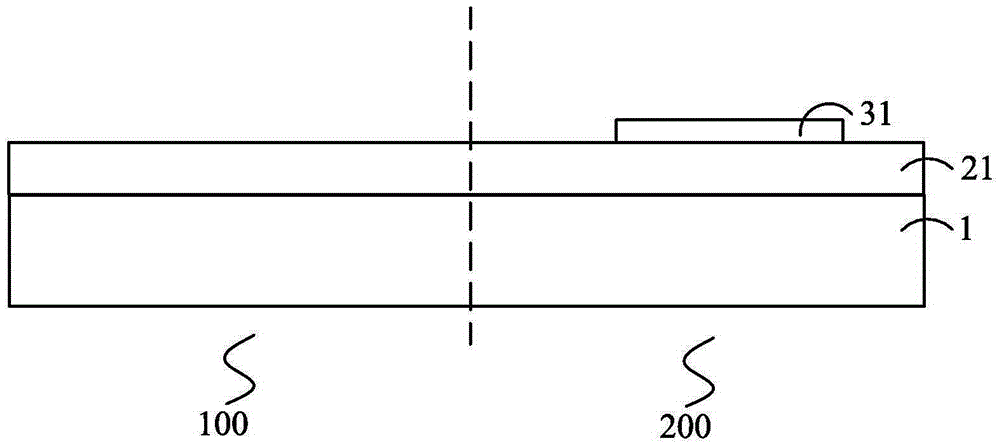

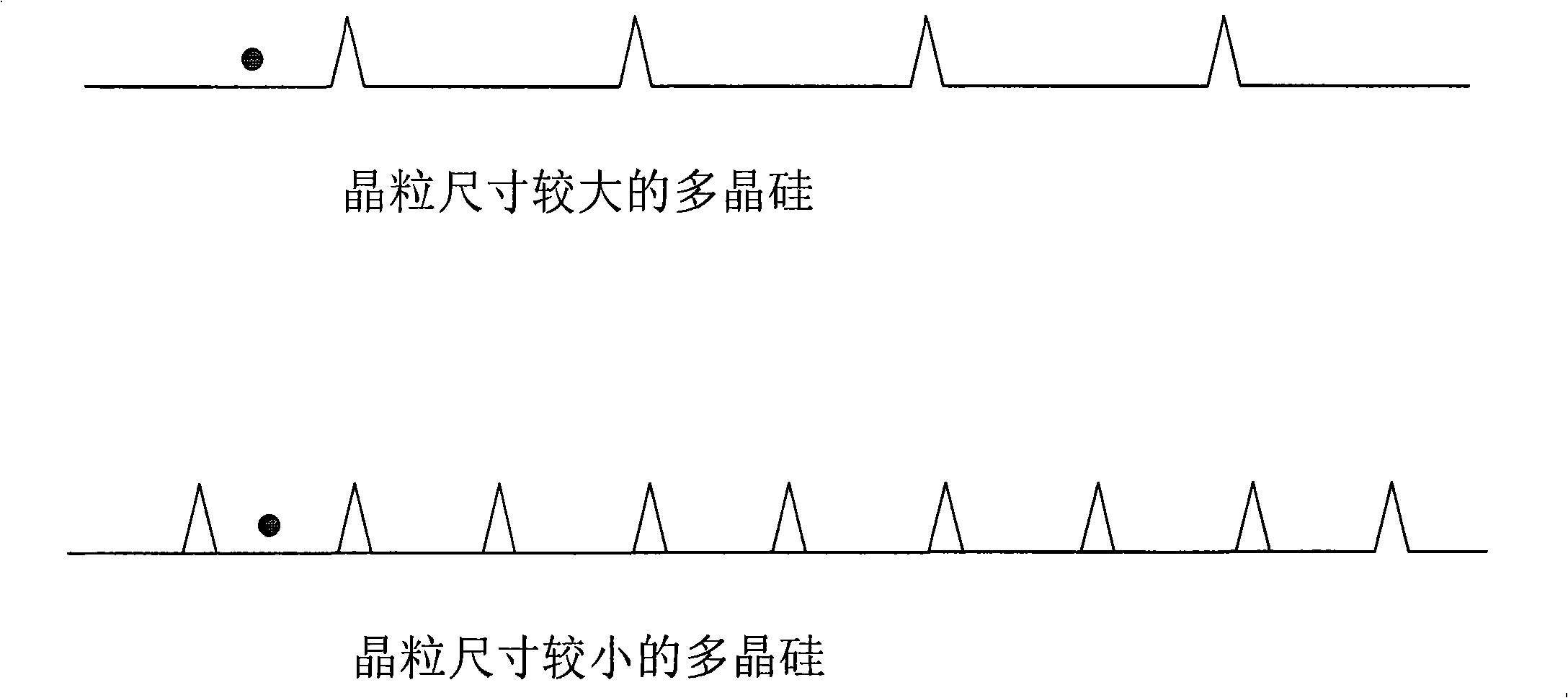

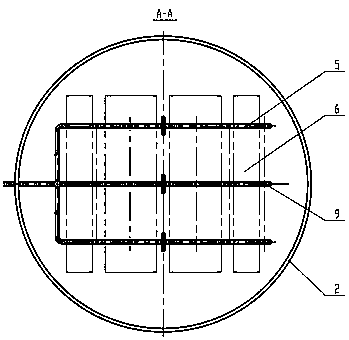

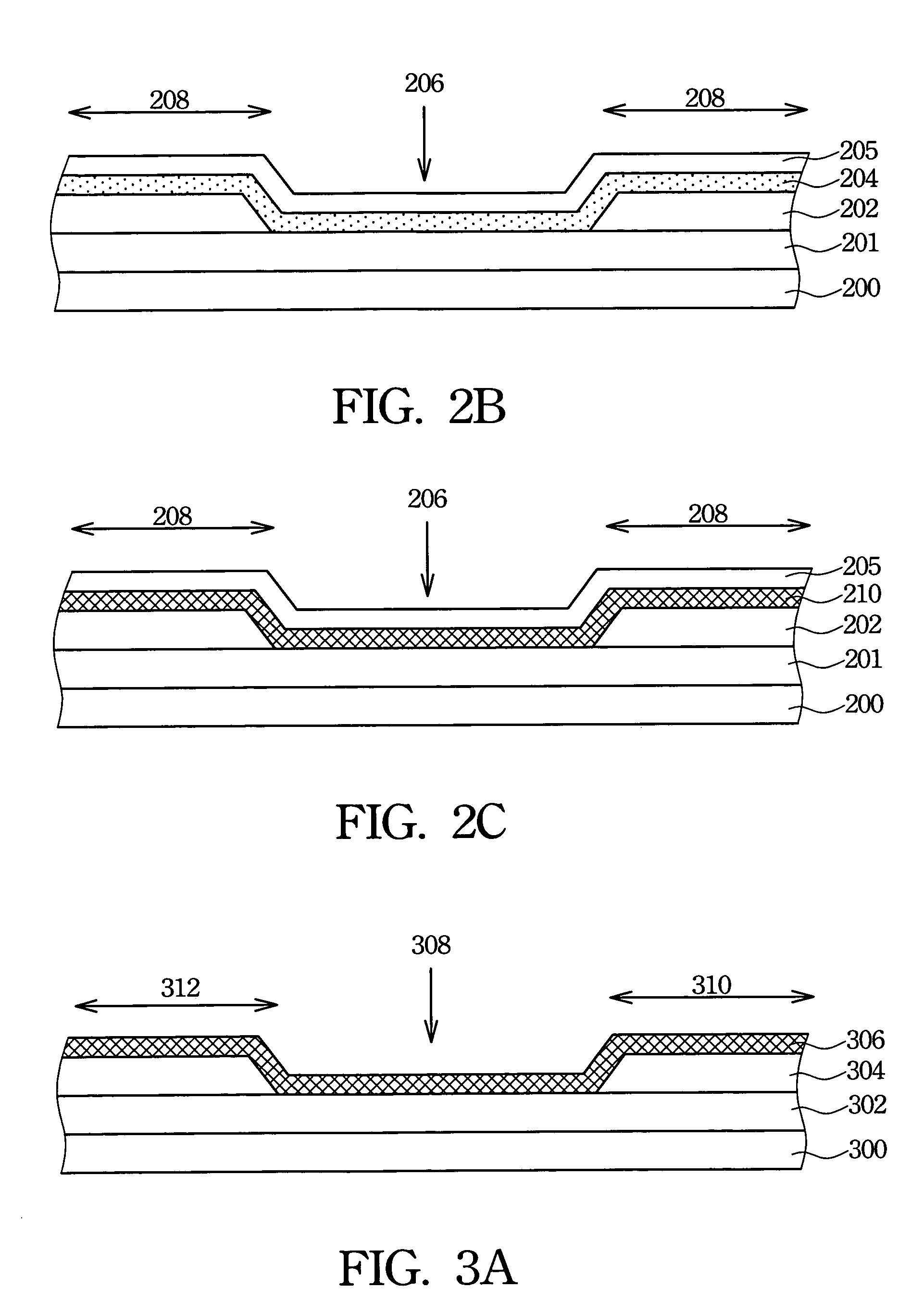

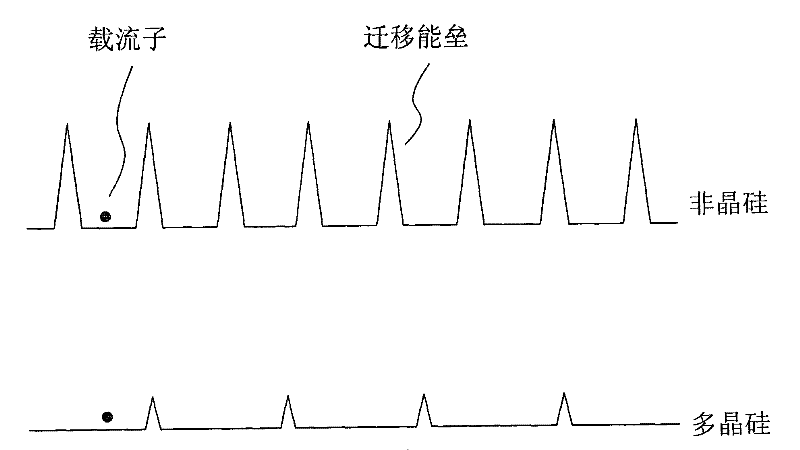

Low-temperature polycrystalline silicon thin film transistor and preparation method thereof

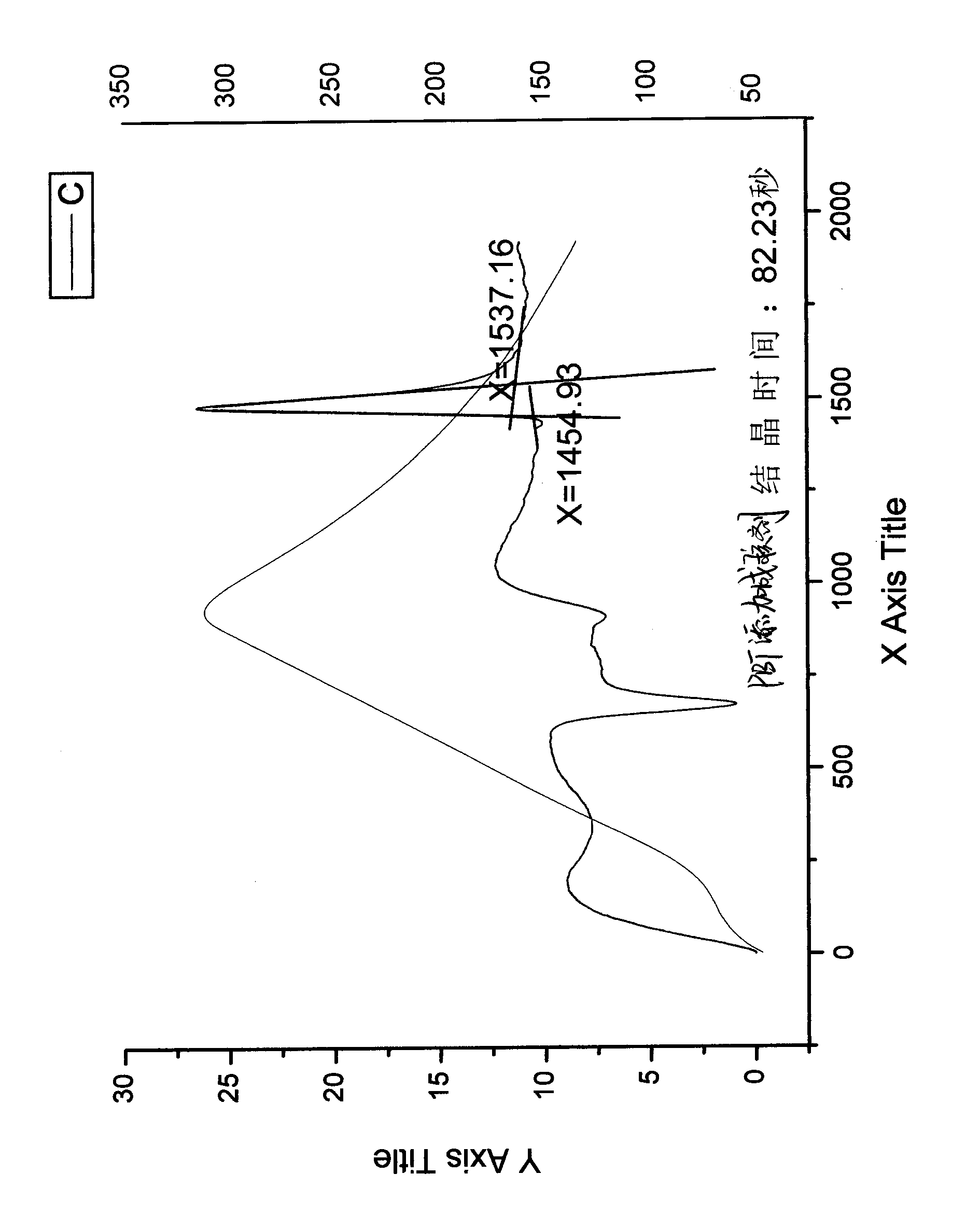

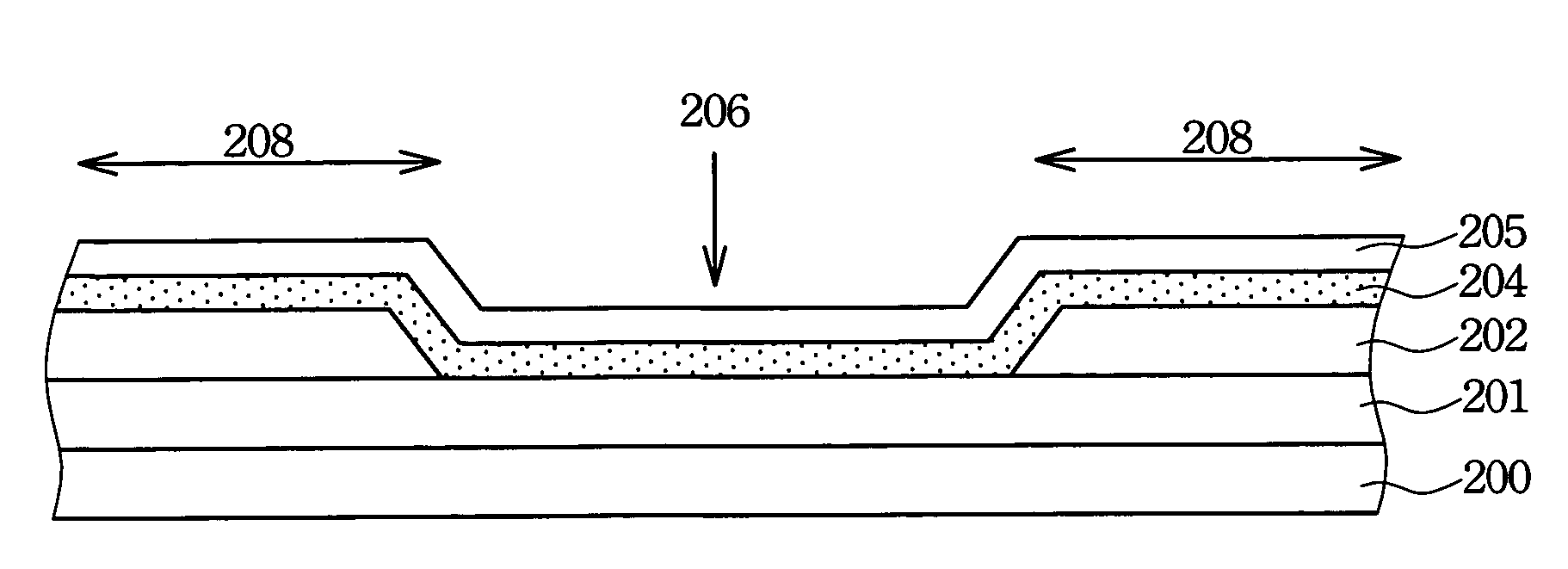

InactiveCN105374882AExtended crystallization timeIncrease in crystal sizeTransistorSolid-state devicesInsulation layerElectron mobility

The invention relates to a low-temperature polycrystalline silicon thin film transistor. The low-temperature polycrystalline silicon thin film transistor comprises a substrate, a buffer layer formed on the substrate, a semiconductor layer formed on the buffer layer, a gate insulation layer formed on the buffer layer and the semiconductor layer, gate electrodes formed on the gate insulation layer, a dielectric layer formed on the gate insulation layer and the gate electrodes, and a passivation layer formed on the dielectric layer; first contact holes and second contact holes are formed in the passivation layer, the dielectric layer and the gate insulation layer, a source electrode and a drain electrode are respectively formed on the first contact holes, and a source electrode and a drain electrode are respectively formed on the second contact holes; and the semiconductor layer is a low-temperature polycrystalline silicon layer, and a reflection layer and / or a heat insulation layer are further disposed between the buffer layer and the semiconductor layer. The invention further relates to a preparation method of the thin film transistor, and the thin film transistor is prepared mainly through utilization of deposition, photoetching, etching, laser irradiation and the other process methods. According to the low-temperature polycrystalline silicon thin film transistor, the large dimensions of polycrystalline silicon grains can be obtained, and obtaining of the large electron mobility is facilitated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

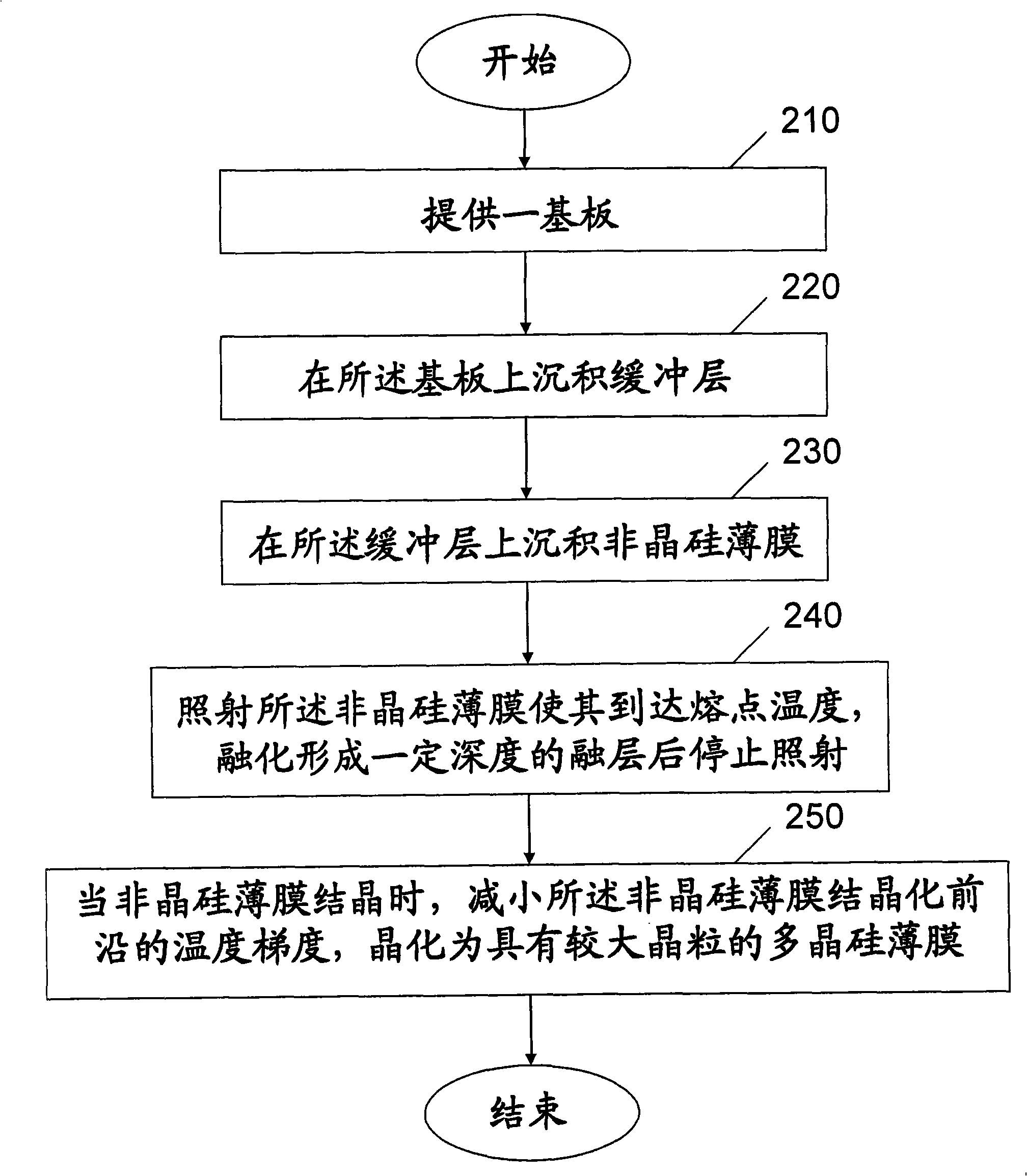

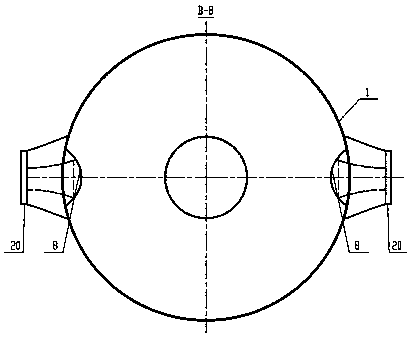

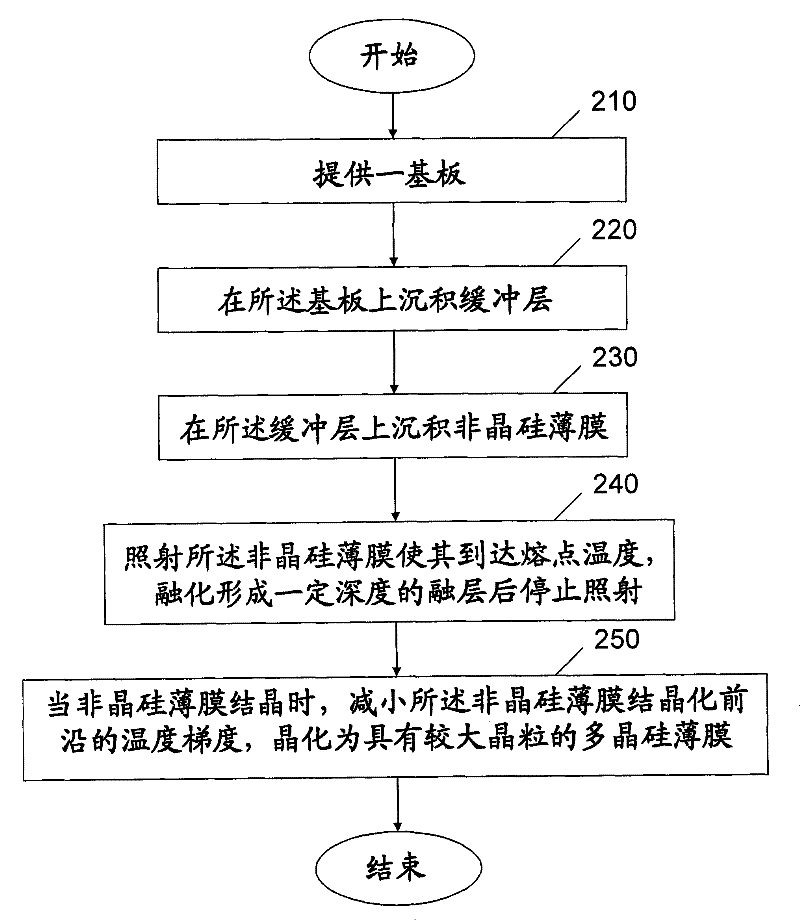

Method and device for preparing polysilicon thin-film solar battery

InactiveCN101325156ASmall temperature differenceExtended crystallization timeFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsSolar battery

The invention provides a method for preparing polycrystalline silicon thin-film solar cell and a device thereof. The method comprises the steps of providing a substrate; depositing a front electrode and conducting etching on the substrate; depositing a non-crystalline silicon film on the front electrode; irradiating the non-crystalline silicon film to allow the non-crystalline silicon film to reach the melting point temperature thereof until the non-crystalline silicon film is melted to formed a molten layer with a certain depth; reducing the temperature difference between the non-crystalline silicon film and the substrate when the non-crystalline silicon film crystallizes, so as to obtain a polycrystalline silicon film with larger crystal grains; etching the polycrystalline silicon film; depositing a back electrode on the polycrystalline silicon film; etching the polycrystalline silicon film and the back electrode; and packaging the substrate, the front electrode, the polycrystalline silicon film and the back electrode to obtain a solar cell. The obtained solar cell by using the inventive method has low cost and high photoelectric transformation efficiency.

Owner:东莞晨真光伏有限公司

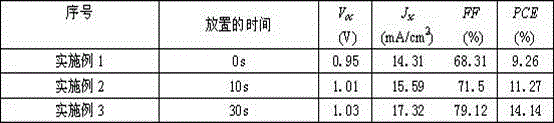

Perovskite thin film, preparation method thereof and perovskite solar cell

ActiveCN106784322AShorten evaporation timeExtended crystallization timeSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellSpins

The invention discloses a perovskite thin film, a preparation method thereof and a perovskite solar cell. The method comprises the following steps: firstly spin-coating a perovskite precursor solution on a substrate, wherein the solvent selectively used in the perovskite precursor solution is one or more of DMF, DMSO and gamma-GBL, then rotating the substrate spin-coated with the perovskite precursor solution, stopping rotation when the perovskite precursor solution is not completely volatilized, and placing for a certain period of time; rotating the substrate spin-coated with the perovskite precursor solution again, then dropping an inversion solvent again, annealing for 5 to 15 minutes at the temperature of 80 to 120 DEG C, and thus preparing the perovskite thin film. In the perovskite film-forming process, when the solvent in the perovskite precursor solution is not completely volatilized, the rotation of a spin coater is stopped, and the spin coater stands for a certain period of time, and the film-forming quality of the perovskite thin film is increased by prolonging the film-forming time of the perovskite thin film, so that the device performance of the prepared perovskite solar cell is improved.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

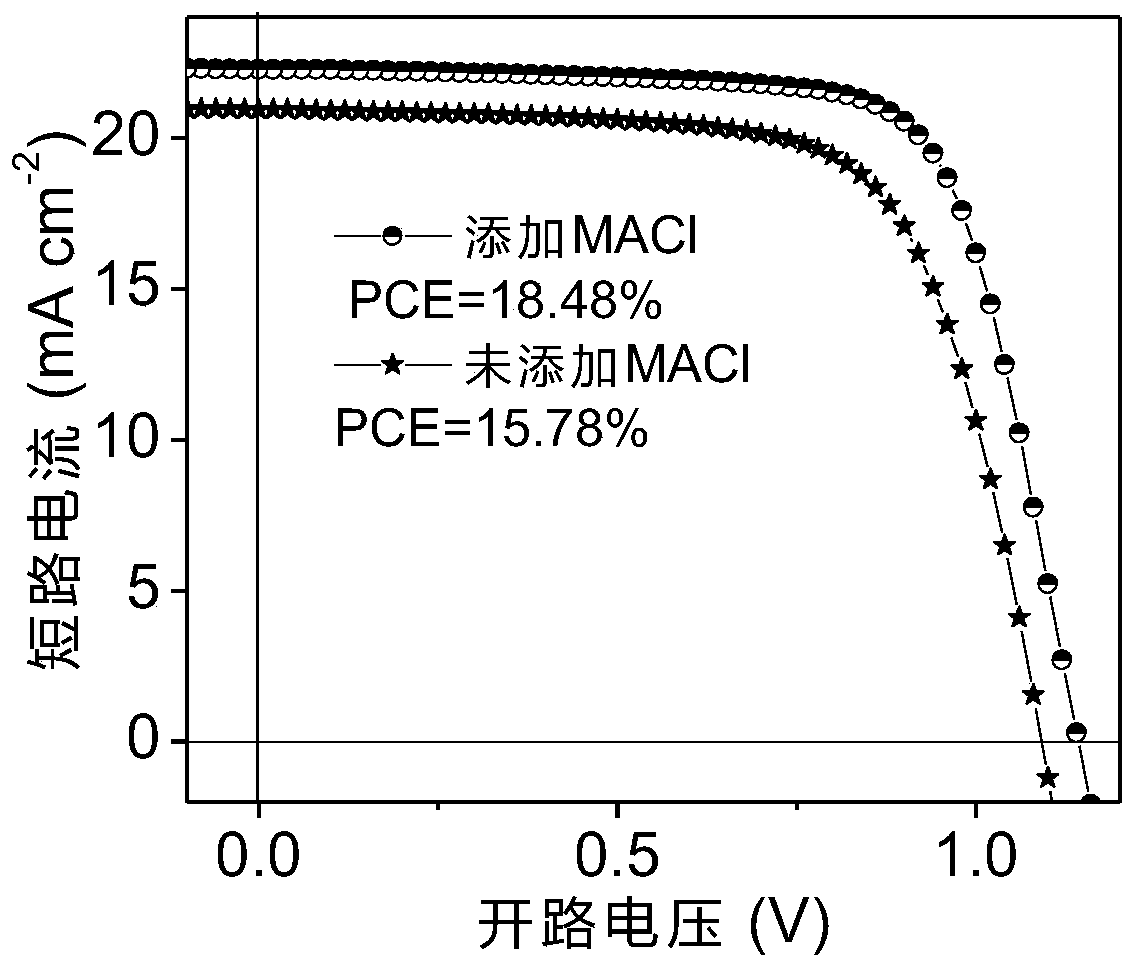

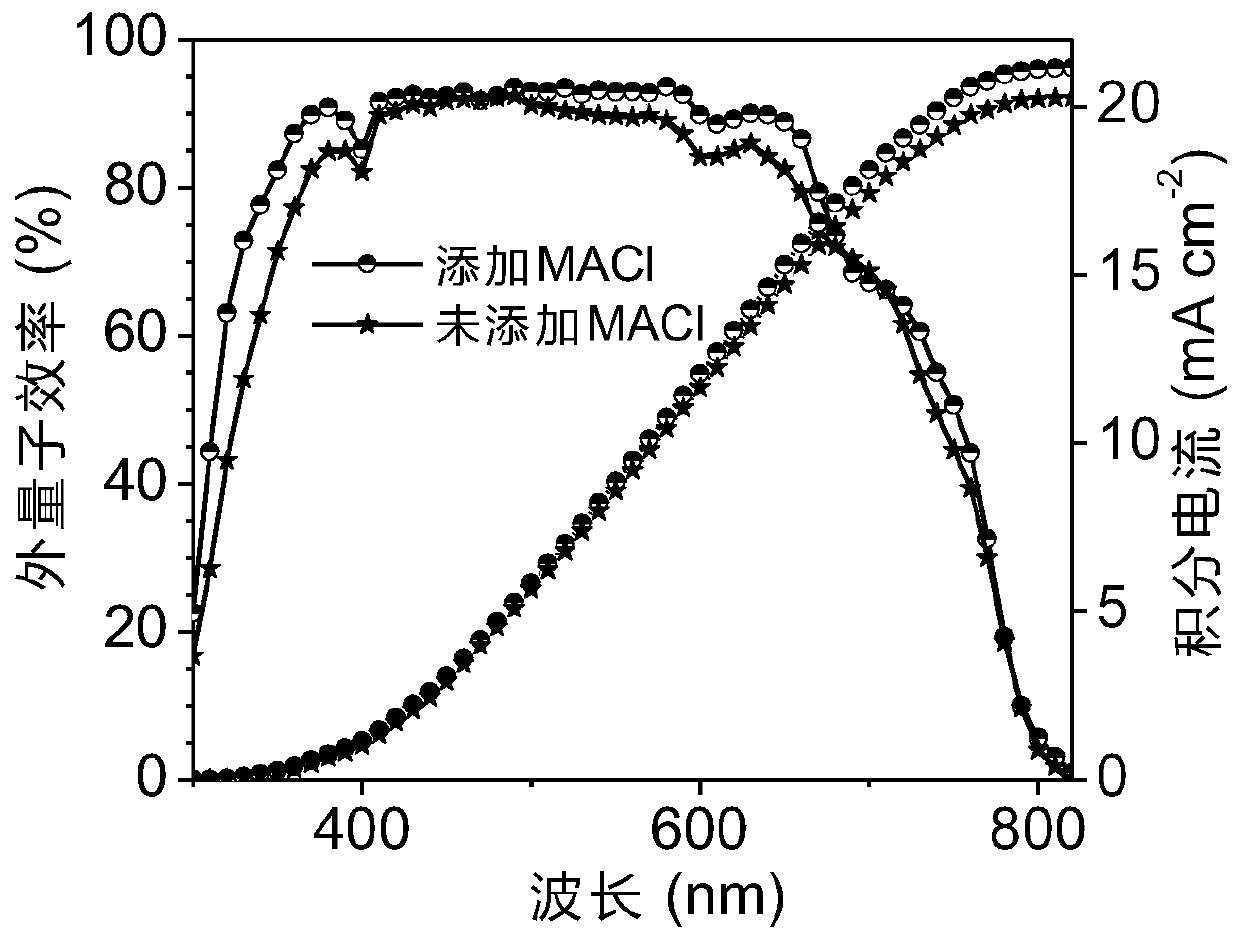

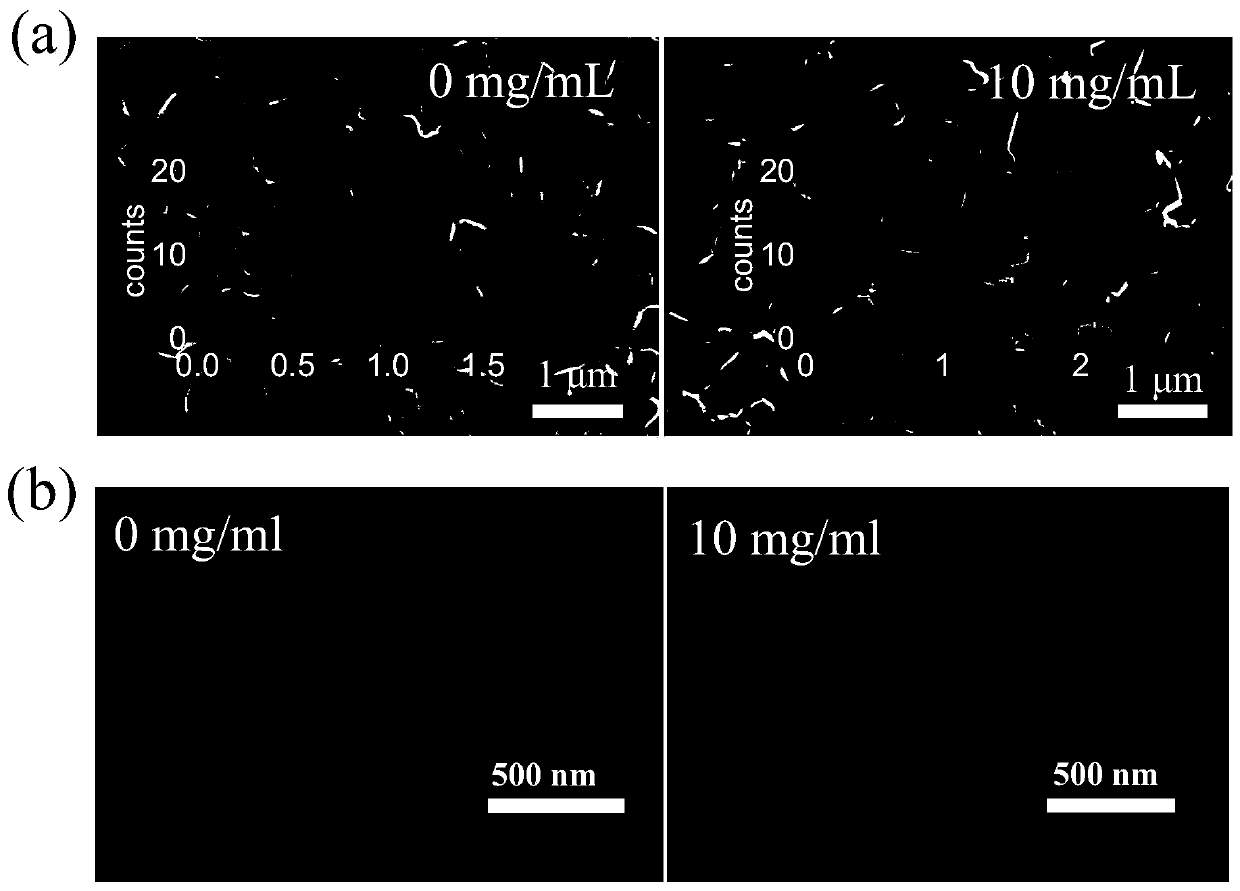

ACI type two-dimensional perovskite solar cell and preparation method thereof

ActiveCN110518128ASlow crystallization rateExtended crystallization timeFinal product manufactureSolid-state devicesPerovskite solar cellGrain boundary

The invention discloses an ACI type two-dimensional perovskite solar cell and a preparation method thereof. The perovskite absorption layer of the solar cell is a mixture of C(NH2)3I, CH3NH3I and PbI2. In the preparation process, CH3NH3Cl is added to serve as an additive. Compared with the conventional two-dimensional perovskite device, the addition of CH3NH3Cl greatly improves the crystallizationquality of the perovskite thin film, increases the grain size, reduces the carrier recombination loss caused by defects at the grain boundary, and prolongs the carrier service life. Meanwhile, effective gradient distribution of different n values is increased, the charge transmission efficiency is improved, the improvement of the photoelectric conversion efficiency of the perovskite battery device is finally directly determined, the series-parallel resistance of the device is improved, and the photoelectric conversion efficiency of 18.48% is finally obtained. The excellent photoelectric properties and device efficiency of the perovskite solar cell are helpful for promoting the commercial application of the perovskite solar cell.

Owner:SHAANXI NORMAL UNIV

Method for treating magnesium sulfate mather slution after producing boric acid by sulfuric acid method

InactiveCN1554595AFast productionLess coal consumptionSolution crystallizationWater/sewage treatment by freezingSulfurNitrogen

The technological scheme of the present invention is the magnesium sulfate mother solution treating process including: heating the mother solution to 95-100 deg.c, adding solid ammonium sulfate into the mother solution to produce magnesium ammonium sulfate with the weight ratio between ammonium sulfate and magnesium sulfate being 1-1.4, filtering the produced solution, lowering the temperature to crystallize and separate magnesium ammonium sulfate, and drying. The said process needs no concentration while extracting over 80% of magnesium sulfate, and has fast production speed, low power consumption and low cost. In addition, the said process has reduced loss of barium and less environmental pollution. The produced magnesium ammonium sulfate is one excellent fertilizer with nitrogen, magnesium and sulfur.

Owner:尹德文

Production method of sodium citrate

ActiveCN103044239AFully crystallizedShort reaction timeCalcium/strontium/barium carbonatesCarboxylic acid salt preparationSodium bicarbonateCalcium bicarbonate

The invention relates to a production method of sodium citrate. The method comprises the main steps that limestone powder and citric acid fermentation liquor are reacted, filtered and crystallized, and then are conducted to at least one time of neutralization and crystallization, so that calcium hydrogen citrate crystal is continuously and directly obtained; and the calcium hydrogen citrate crystal is reacted with the mixed solution of sodium hydroxide and sodium carbonate, so that sodium citrate and calcium carbonate are obtained. The method increases the content of carbonate in a whole system, reduces the hydrolysis rate of the carbonate, avoids the affect to finished products by calcium bicarbonate, and prevents the calcium ion in the finished products from exceeding standard. Part of sodium in the sodium citrate is provided by ionic membrane caustic soda, and compared with the traditional one-step method for producing sodium citrate, the production method has the advantages that the purity of solution is high, contents of calcium ion, iron ion and chloride ion are low, and return rate of sodium citrate mother liquor is greatly reduced.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Method for improving production efficiency of vacuum crystallization for titaniferous solution

ActiveCN102757100ARaise feed temperatureShorten the boil timeSolution crystallizationIron sulfatesPhysical chemistryCrystallization

The invention discloses a method for improving the production efficiency of vacuum crystallization for titaniferous solution, wherein the method comprises a titaniferous solution vacuum crystallization process and a titaniferous solution hot concentration process; the hot concentration discharging temperature is higher than the feeding titaniferous solution temperature for the titaniferous solution vacuum crystallization; heat exchange is carried out between feeding titaniferous solution for the titaniferous solution vacuum crystallization and discharging material for the titaniferous solution hot concentration; and then the feeding titaniferous solution that is processed through heat exchange is conveyed to a titaniferous solution vacuum crystallization container for crystallization. The method adopts the technical scheme that the conventional production temperatures and negative pressure conditions are utilized to perform the heat exchange between the feeding material for the titaniferous solution vacuum crystallization and the discharging material for the hot concentration, and the feeding temperature for the titaniferous solution vacuum crystallization is raised, so that the time for titaniferous solution boiling is shortened without changing the negative pressure conditions, the crystallization time of titaniferous solution in the vacuum crystallization container is shortened, and the production efficiency of vacuum crystallization for titaniferous solution can be improved further.

Owner:LOMON BILLIONS GRP CO LTD

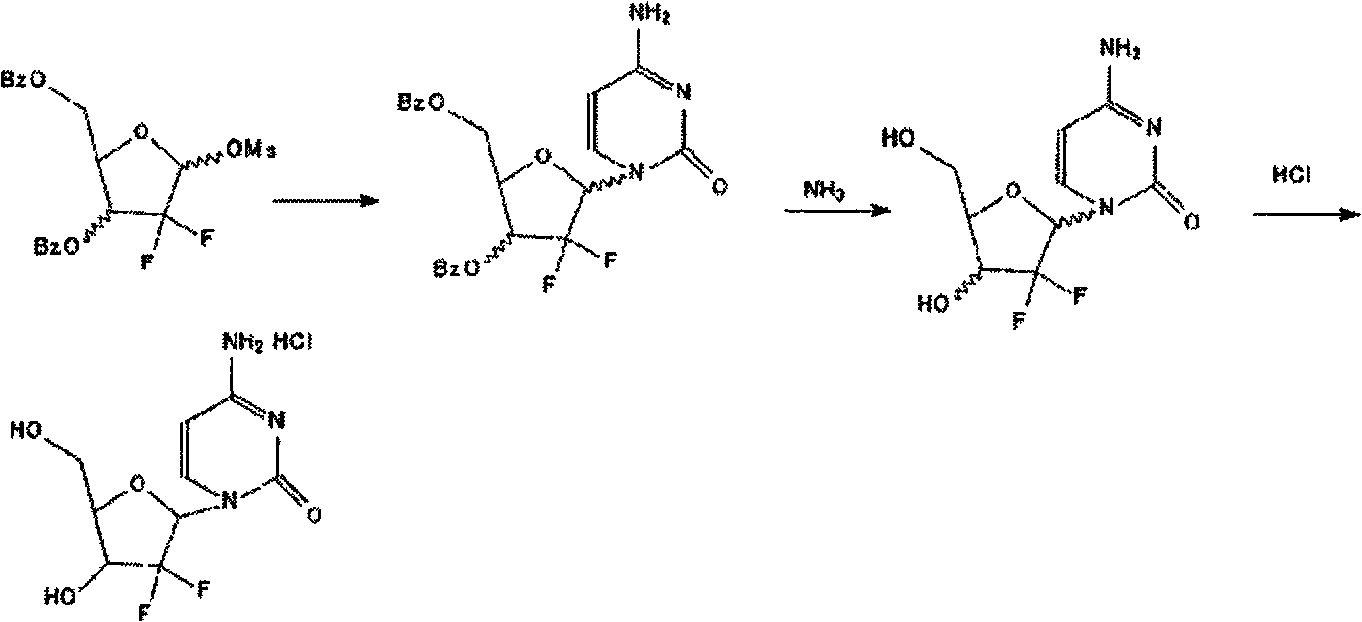

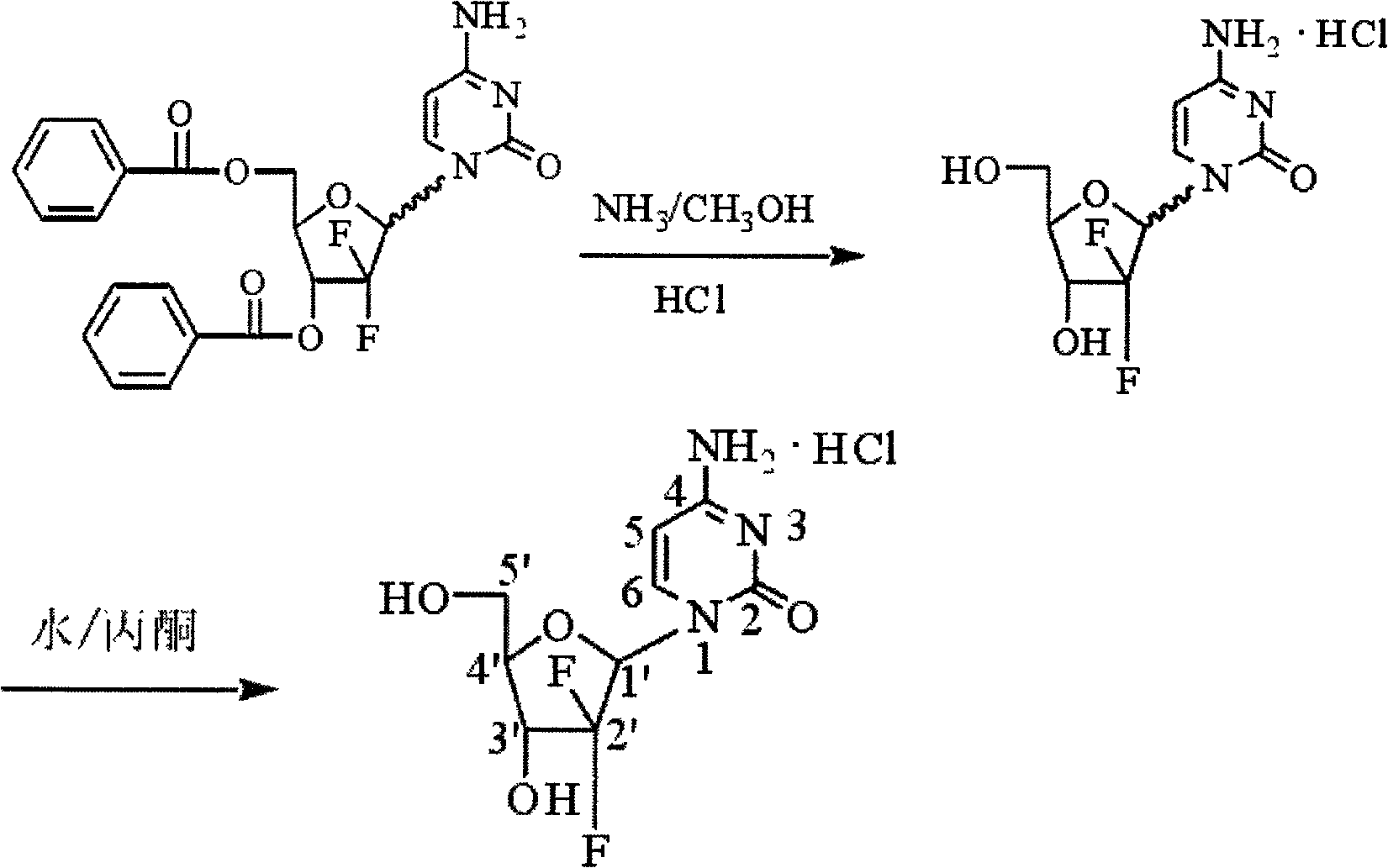

Industrialized gemcitabine hydrochloride synthesis method

InactiveCN103232508AExtended crystallization timeHigh reaction yieldSugar derivativesSugar derivatives preparationGemcitabine HydrochlorideSynthesis methods

The invention relates to an industrialized gemcitabine hydrochloride synthesis method, and belongs to the field of chemical product synthesis process. According to the invention, 2'-deoxy-2',2'-difluorocytidine-3',5'-dibenzoate is subjected to benzoyl protecting group removing in a methanol solution comprising ammonia water, and salt-formation is proceeded, such that 2'-deoxy-2',2'-difluorocytidine hydrochloride is formed; and crystallization and separation is carried out in an acetone-water mixed solvent, such that a gemcitabine hydrochloride pure product is obtained. According to the invention, a commonly used method for adding ammonia gas in the step 1 is changed into adding concentrated ammonia water; and a freezing crystallization overnight operation is adopted in subsequent purification process, such that process operability is increased, and reaction yield is improved. The synthesized process product has high refined rate. The purity of the product is maintained above 99.8%.

Owner:湖北一半天制药有限公司

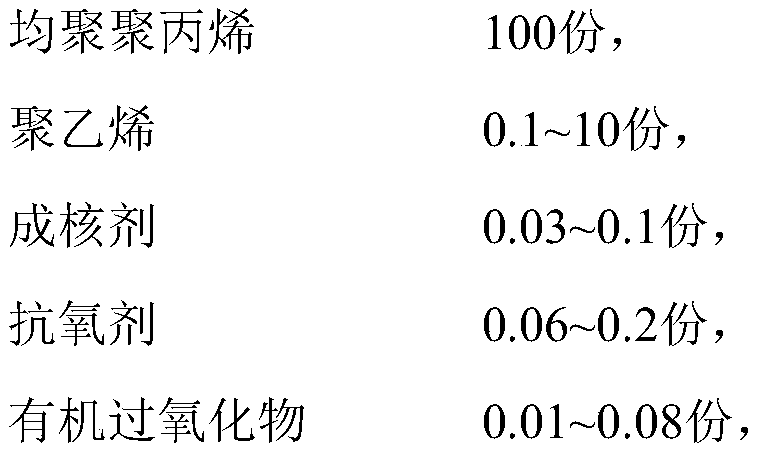

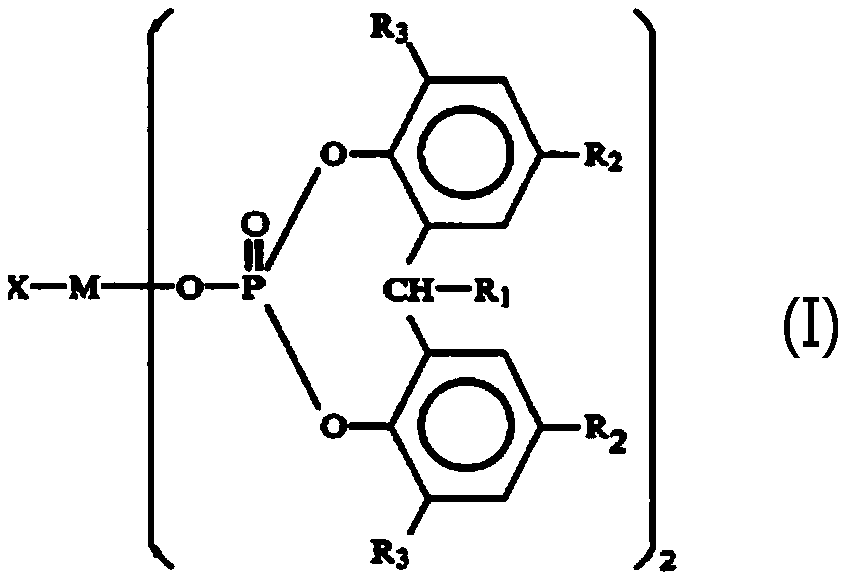

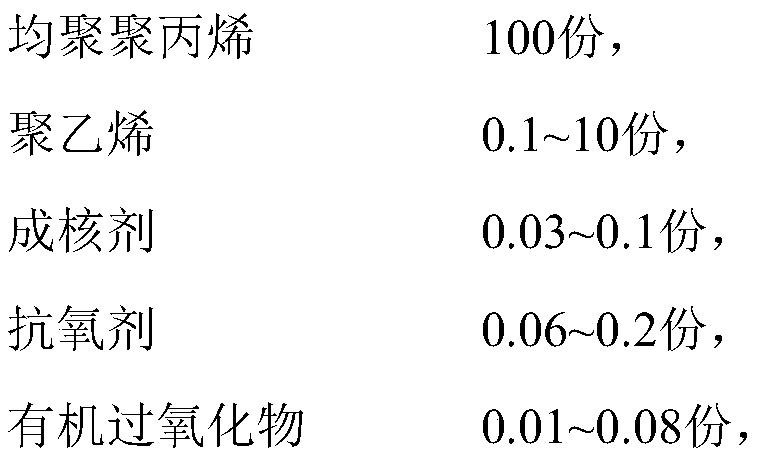

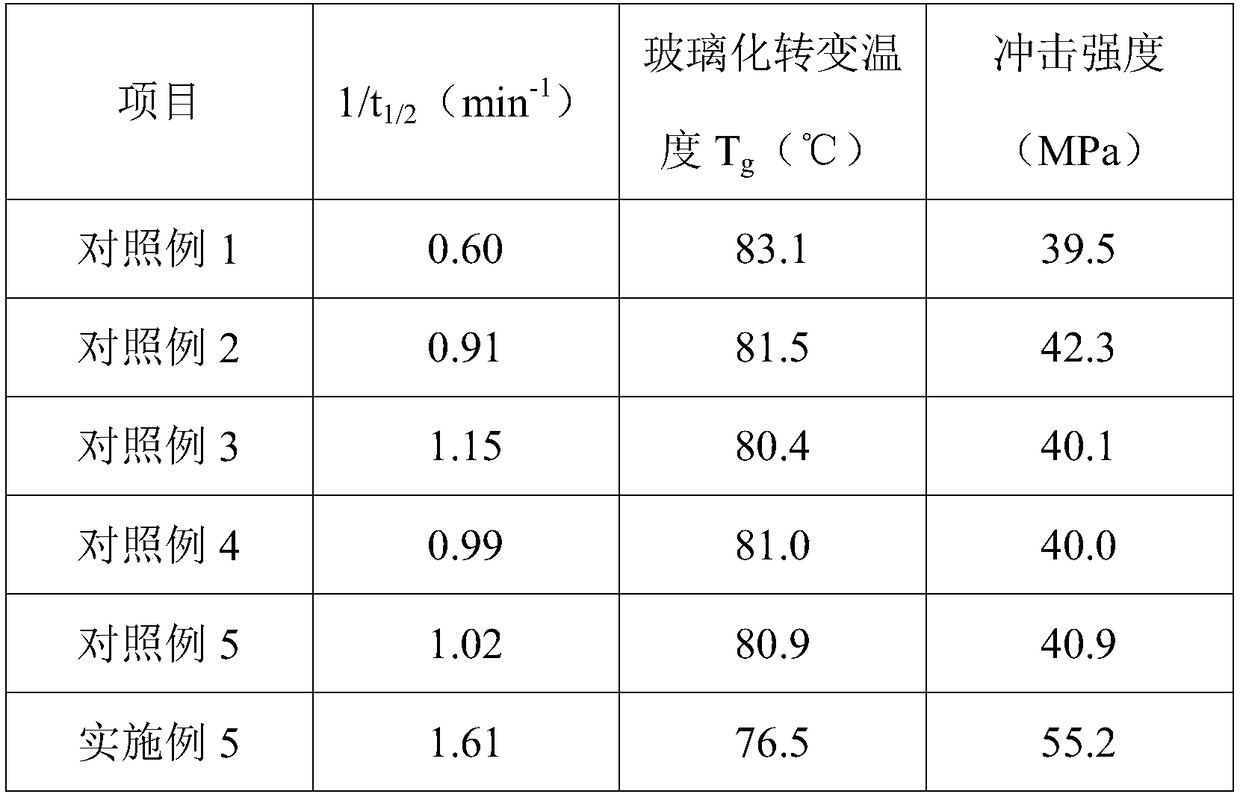

Toughening polypropylene material and preparation method thereof

ActiveCN109851913ALower crystallization temperature and longer crystallization timeIncrease production costPolypropyleneCrystallite

The invention discloses a toughening polypropylene material, comprising the following components in parts by weight: 100 parts of homo-polypropylene, 0.1-10 parts of polyethylene, 0.05-0.2 part of nucleating agent, 0.04-0.3 part of antioxygen, and 0.01-0.04 part of organic peroxide. The invention also discloses a preparation method of the toughening polypropylene material, and the preparation method includes the following steps: adding homo-polypropylene, polyethylene, a nucleating agent, an antioxygen and an organic peroxide into a high speed mixer for mixing, and conducting melting blendingextruding pelletizing on the uniformly mixed premix by a twin screw extruder, so as to obtain the final product. According to the invention, a low proportion of polyethylene is added into the formulacomponents and is used as a toughening agent of polypropylene, thereby realizing impact modification of polypropylene, refining grain size of polypropylene crystal, increasing impact resistance of thepolypropylene material, enhancing low-temperature resistance, and decreasing the melting point of the polypropylene material, decreasing the processing temperature and correspondingly reducing energyconsumption.

Owner:东华能源(宁波)新材料有限公司 +2

Electromagnetic valve type urea solution injector

ActiveCN102108891BStable jobSolve the deformationExhaust apparatusDispersed particle separationThermal energySteel ball

Owner:LIUZHOU YUANCHUANG EFI TECH

Crystallizer for MVR (Mechanical Vapor Recompression) sewage treatment system

ActiveCN107930175AReduce flow rateIncrease the cross-sectional areaCrystallization preventionSolution crystallizationSprayerSewage treatment

The invention discloses a crystallizer for an MVR (Mechanical Vapor Recompression) sewage treatment system. According to the crystallizer, the problems that an inlet solution is not uniformly dispersed, a steam outlet channel has small clearance, great resistance drop, easiness in blockage and poor separation effect, as well as a crystalloid in a container easily enters a connected pipeline, so that the service life of a pump in the connected pipeline is shortened in the prior art are solved. The crystallizer is characterized in that guide diverters are welded at an interface positions of theinner wall of a cylinder body and solution inlet pipes; a multichannel folded plate type demisting device is arranged in an upper cone; sprayers on an upper layer and a lower layer are arranged on themultichannel folded plate type demisting device; outlet grids are welded at an solution outlet; multifunctional grids are also arranged in a lower cone. The crystallizer has the beneficial effects that the inlet solution is uniformly distributed, the vapor-liquid separating efficiency of a steam outlet is high, and a crystal mush solution in a salt leg is uniformly distributed, so that vortex formed in the sinking process of the crystal mush solution can be prevented and a crystallizing effect is improved; the crystalloid in the container can be prevented from entering the connected pipelineat the solution outlet, and the service life of a circulating pump in the connected pipeline is prolonged.

Owner:沈阳东方钛业股份有限公司

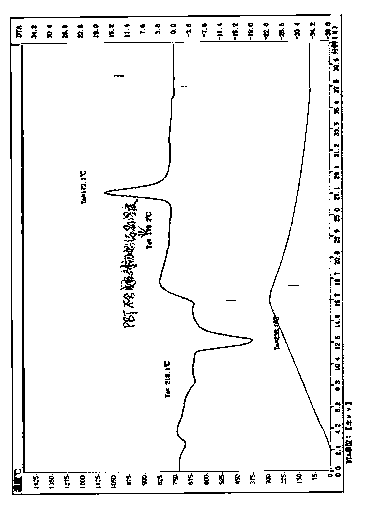

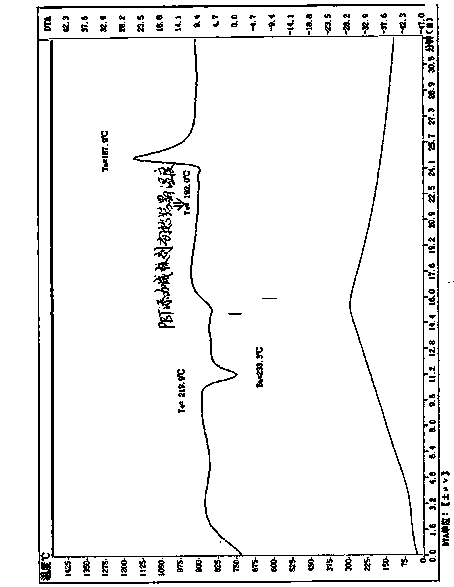

Processing technology of PBT (Polybutylene Terephthalate) blue color masterbatch

InactiveCN103525045ARaise the crystallization temperatureExtended crystallization timeChemistryPolypropylene

The invention relates to a processing technology of a PBT (Polybutylene Terephthalate) blue color masterbatch. The processing technology comprises the steps of adding a polypropylene nucleating agent and a PVC (Polyvinyl Chloride) heat stabilizer while matching the colors of PBT and a blue pigment and blending PBT and the blue pigment, wherein the polypropylene nucleating agent accounts for 5-20% of the total weight of a material, and the PVC heat stabilizer accounts for 5-20% of the total weight of the material; then, mixing to obtain the PBT blue color masterbatch. The processing technology has the advantages that (1) the polypropylene nucleating agent is added, so that the crystallization temperature is raised, the crystallization time is shortened, the formation is promoted, and the extra length of an optical fiber is controlled within an allowable range when a loose tube is cabled; (2) the PVC heat stabilizer is added, so that the heat resistance and the moving resistance are remarkably improved in petroleum butter at the same temperature, and the optical fiber / cable distinguishing effect is improved; (3) all indexes of the blue color masterbatch produced through the measures meet enterprise standard requirements through test detection, the extra length of the optical fiber / cable used by an optical fiber / cable production enterprise meets a specification requirement, the heat resistance and the petroleum butter resistance meet requirements, and the original defects of linear expansion coefficients, heat resistance and petroleum butter moving resistance are overcome.

Owner:YANGZHOU JINSEN OPTOELECTRONICS

Method for preparing ammonium chloride through co-production of baking soda

PendingCN114132950AHigh yieldReduce contentAmmonium chlorideCarbonate preparationSodium bicarbonateSodium salt

The invention discloses a method for preparing ammonium chloride by co-production of baking soda, which comprises the following steps: 1) performing primary precipitation of baking soda to obtain crude baking soda and crude mother liquor M1; 2) sodium precipitation: adding sodium chloride into the crude mother liquor M1 to enable residual ammonium bicarbonate and sodium chloride in the crude mother liquor M1 to be subjected to double decomposition reaction again, filtering to obtain fine mother liquor M1 and baking soda, and returning the baking soda to the step 1); (3) cold separation crystallization; 4) salting-out crystallization; 5) secondary separation of baking soda; and 6) mother liquor circulation. According to the sodium precipitation step, residual ammonium bicarbonate in the crude mother liquor M1 further reacts with sodium chloride, and ammonium bicarbonate is decomposed before subsequent cold separation crystallization; the method avoids the phenomenon that sodium bicarbonate generated by reacting ammonium bicarbonate with sodium chloride in the subsequent cold separation process is difficult to separate from ammonium chloride at low temperature due to high content of ammonium bicarbonate in the crude mother liquor, further reduces the content of sodium salt in ammonium chloride, improves the content of ammonia, and also effectively improves the yield of sodium bicarbonate.

Owner:衡阳爱洁科技股份有限公司

Process for producing electronic-grade barium hydroxide by recovering high-purity barium chloride mother liquor

PendingCN112758969AEfficient removalRestricted reuseAlkali metal chloridesCalcium/strontium/barium oxides/hydroxidesProcess engineeringMother liquor

The invention discloses a process for producing electronic-grade barium hydroxide by recovering high-purity barium chloride mother liquor. The process comprises the following steps: adding a sodium hydroxide solution into the recovered high-purity barium chloride mother liquor to react, controlling the reaction temperature to be 80-100 DEG C and the reaction time to be 0.1-0.5 hour, performing filtering while hot after the reaction is finished, cooling and crystallizing filtrate, and performing centrifugal separation, and obtaining the crude barium hydroxide; adding distilled water into the crude barium hydroxide, heating until the crude barium hydroxide is completely dissolved, carrying out vacuum evaporation concentration, cooling, recrystallizing, filtering, washing crystals with absolute ethyl alcohol, and drying to obtain the electronic-grade barium hydroxide. According to the method, the high-purity barium chloride mother liquor is successfully utilized to produce the electronic-grade barium hydroxide, so that the additional value of the product is improved, the waste of resources is avoided, and the pollution to the environment is also avoided.

Owner:宜昌华昊新材料科技有限公司

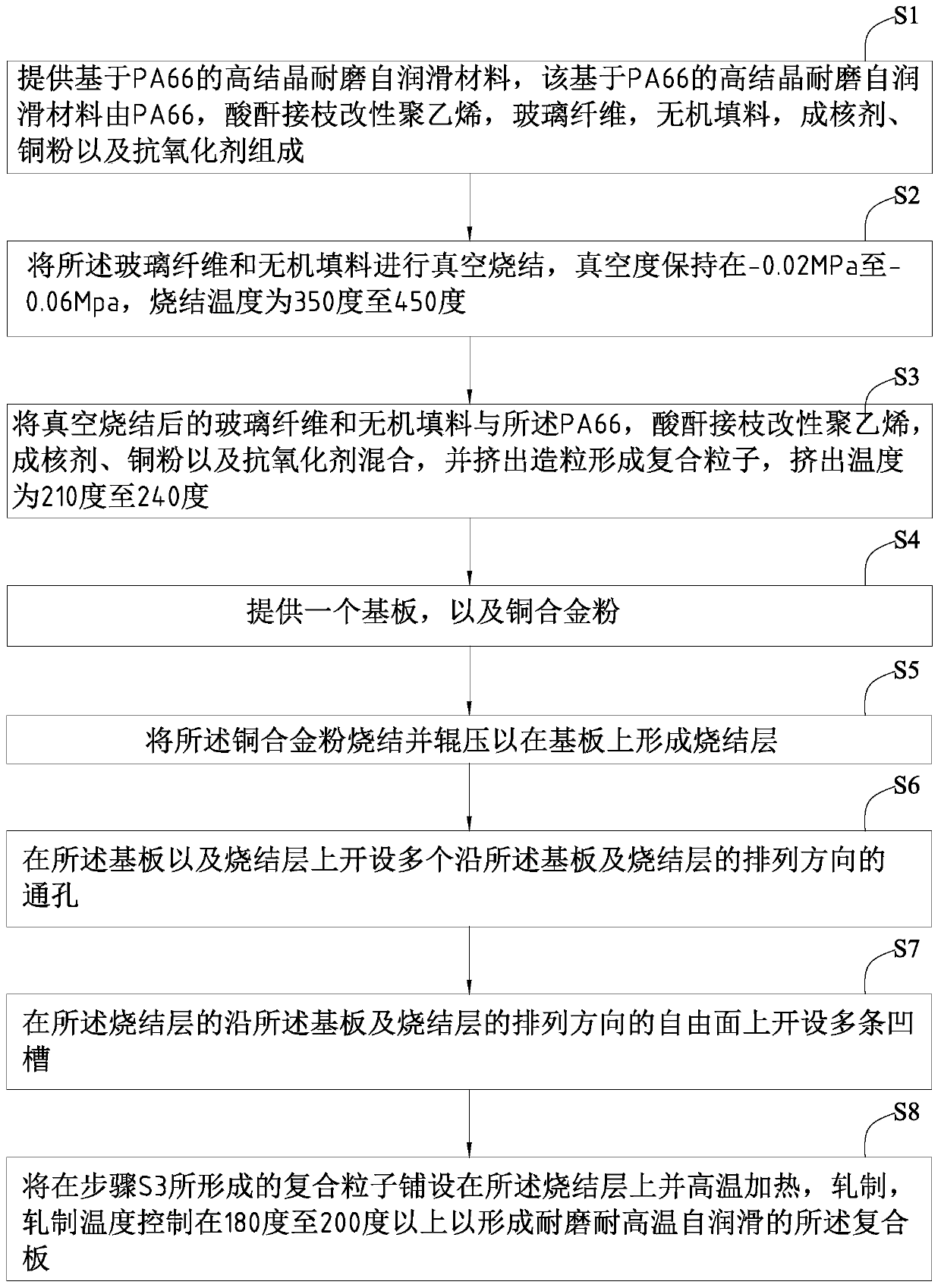

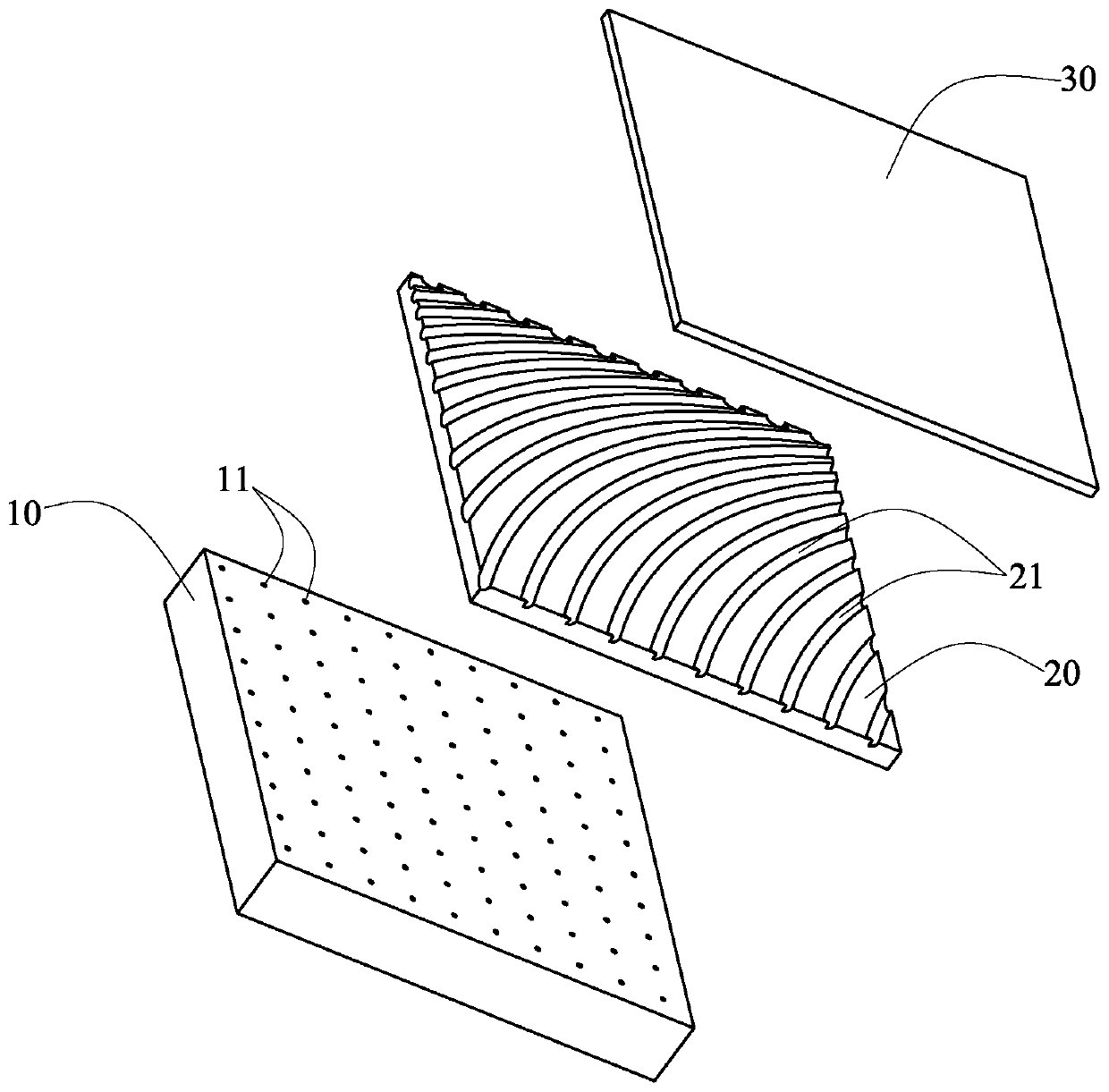

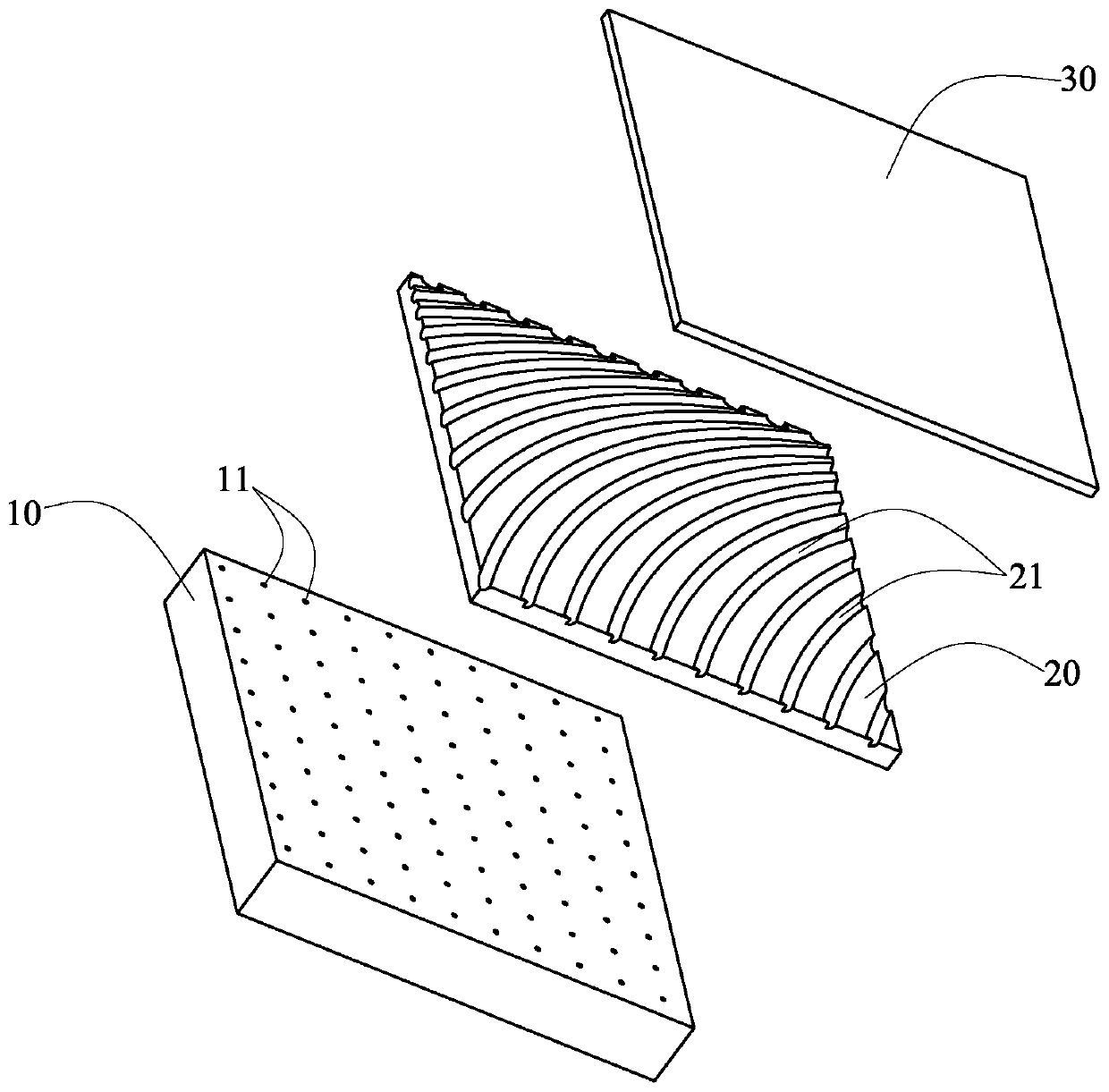

High-crystallized and high-temperature-resistant self-lubricating material based on PA66, composite board and preparation method of composite board

The invention discloses a high-crystallized and high-temperature-resistant self-lubricating material based on PA66, a composite board and a preparation method of the composite board. The composite board comprises a base board, a sintering layer and a wear-resistant and high-temperature-resistant self-lubricating layer. The base board and the sintering layer comprise multiple trough holes extendingin the arrangement direction of the base board, the sintering layer and the wear-resistant and high-temperature-resistant self-lubricating layer. Multiple grooves are formed in the contact surface, adjacent to the wear-resistant and high-temperature-resistant self-lubricating layer, of the sintering layer. The wear-resistant and high-temperature-resistant self-lubricating layer is made of the high-crystallized and high-temperature-resistant self-lubricating material based on PA66. The high-crystallized and high-temperature-resistant self-lubricating material based on PA66 consists of PA66, acid anhydride grafted modified polyethylene, glass fiber, inorganic filler, a nucleating agent and an antioxidant. The high-crystallized and high-temperature-resistant self-lubricating material based on PA66 is loaded on the sintering layer in a hot rolling manner. The cooling rate of PA66 becomes lower due to roller heating, so that PA66 obtains longer crystallization time, crystal grains grow sufficiently, and PA66 has better wear resistance and water absorption resistance.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

Method of controlling polysilicon crystallization

InactiveUS7435667B2Good uniformity of lateral growthExtended crystallization timeTransistorPolycrystalline material growthMicrometerAmorphous silicon

A heat sink layer is formed on portions of a substrate, and then an amorphous silicon layer is formed thereon. The heat coefficient of the sink layer is greater than that of the substrate. When an excimer laser heats the amorphous silicon layer to crystallize the amorphous silicon, nucleation sites are formed in the amorphous silicon layer on the heat sink layer. Next, laterally expanding crystallization occurs in the amorphous silicon layer on the substrate to form polysilicon having a crystal size of a micrometer.

Owner:IND TECH RES INST

Polyformaldehyde thin film and preparation method thereof

ActiveCN107722550AReduce coefficient of frictionGood stretchabilityFlat articlesCrystallinityUltimate tensile strength

The invention discloses a polyformaldehyde thin film and a preparation method thereof. The polyformaldehyde thin film comprises the following components by weight: 94-98 parts of a polyformaldehyde resin, 1-5 parts of a linear phenolic resin, and 0.5-1 part of an anti-oxidant. In allusion to the problem that the film formation is difficult because the crystallization speed of the polyformaldehydeis rapid and the crystallinity degree is high, the linear phenolic resin is introduced as a crystallization interference agent, the crystallization speed is reduced, and the crystallization time is prolonged, so the film-forming property of the polyformaldehyde is improved. In addition, a synchronous two-way stretching method is used, so the problem that the crosswise stretching film-formation isdifficult because of the rapid crystallization after the longitudinal stretching is prevented. In the raw material and technology aspect, the problem that the uniformity is bad because fracture and afine neck are easily generated in the stretching process of the polyformaldehyde thin film is overcome, and the high-strength polyformaldehyde thin film is prepared.

Owner:TANGSHAN KAILUAN CHEM TECH CO LTD

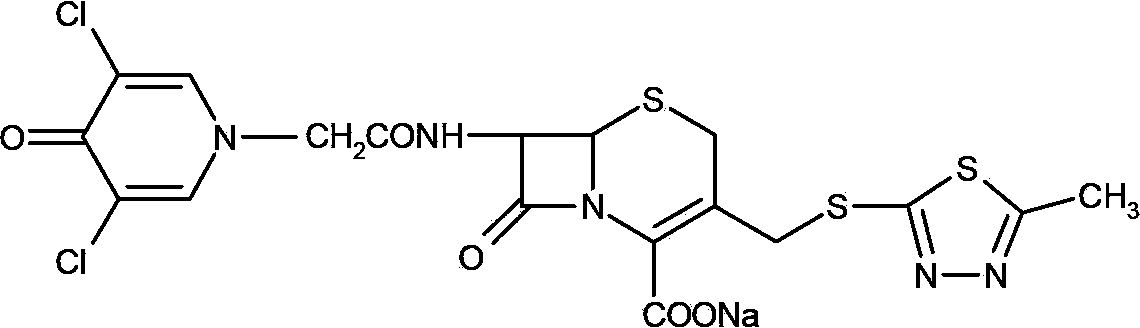

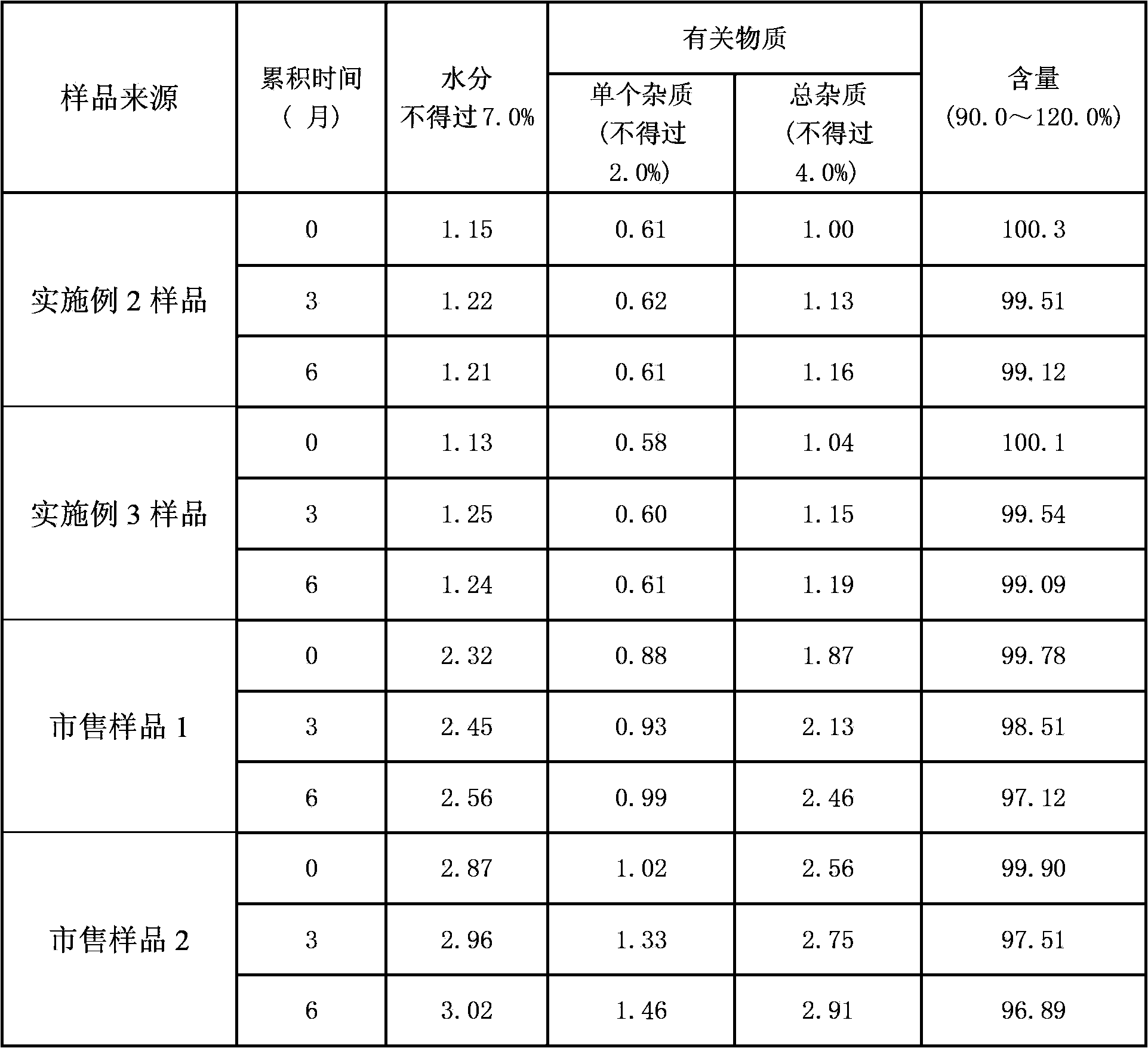

Preparation method for cefazedone sodium with low water content

The invention relates to a preparation method for cefazedone sodium with low water content. The method includes the following steps: performing salifying: placing cefazedone and sodium methoxide into dried methyl alcohol for a salifying reaction, and cooling a reaction solution to 10-30DEG C when the cefazedone is completely dissolved; decoloration: adding activated carbon into the reaction solution, stirring for decoloration, filtering out the activated carbon, and then performing ultrafiltration; crystallization; and drying: filtering and washing filter cake to obtain the cefazedone sodium with low water content. According to the method, the cefazedone and sodium methoxide are placed into the dried methyl alcohol for the salifying reaction so as to obtain cefazedone sodium with low water content, and simultaneously, ultrafiltration and ultrasonic crystallization technologies are adopted to produce the cefazedone sodium which is low in water content, few in impurities, uniform in particles, good in liquidity and high in stability.

Owner:天津新丰制药有限公司

Method for preparing hard xylitol candy

InactiveCN108208285AReduce the temperatureReduce energy consumptionFood thermal treatmentConfectionerySugarEnergy consumption

The invention discloses a method for preparing hard xylitol candy. The method comprises the following steps: weighing 90% of a formula amount of xylitol, heating the weighed xylitol to 100 DEG C in order to melt the xylitol, and performing heat insulation at 93-95 DEG C; adding other raw materials and auxiliary materials to the obtained sugar solution in a heat insulation state, and performing heat insulation; stirring all above materials, adding the remaining 10% of the formula amount of xylitol, and performing uniform stirring; allowing the obtained sugar solution to automatically flow intoa casting trough through a 92-96 DEG C interlayer heat insulation pipeline; and cooling, demolding and packaging the sugar solution. The method solves a problem that the hard xylitol candy cannot be continuously produced for a long term. The casting temperature is increased, so the crystallizing and demolding time is prolonged, the obtained product has fine particles, a uniform size and a beautiful appearance, the yield is large, and the energy consumption is low.

Owner:李圣仓

Plastic material for beverage bottle

The invention discloses a plastic material for a beverage bottle. The plastic material is prepared from the following raw materials in parts by weight: 80 to 120 parts of polyethylene glycol terephthalate, 25 to 35 parts of fillers, 0.1 to 0.3 part of antioxidants, 1 to 3 parts of compatilizers, 2 to 4 parts of nucleating agents, 1 to 3 parts of plasticizers and 2 to 4 parts of lubricating agents,wherein the nucleating agents are Na-based montmorillonite, nanometer magnesia, sodium chloride and polyoxyethylene. The plastic material has the advantages that the crystallization speed is high; the crystallization time consumption is short; the anti-impact performance is good.

Owner:安徽洋龙塑业有限公司

Method and device for preparing polysilicon thin-film solar battery

InactiveCN101325156BSmall temperature differenceExtended crystallization timeFinal product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconTemperature difference

The invention provides a method for preparing polycrystalline silicon thin-film solar cell and a device thereof. The method comprises the steps of providing a substrate; depositing a front electrode and conducting etching on the substrate; depositing a non-crystalline silicon film on the front electrode; irradiating the non-crystalline silicon film to allow the non-crystalline silicon film to reach the melting point temperature thereof until the non-crystalline silicon film is melted to formed a molten layer with a certain depth; reducing the temperature difference between the non-crystallinesilicon film and the substrate when the non-crystalline silicon film crystallizes, so as to obtain a polycrystalline silicon film with larger crystal grains; etching the polycrystalline silicon film;depositing a back electrode on the polycrystalline silicon film; etching the polycrystalline silicon film and the back electrode; and packaging the substrate, the front electrode, the polycrystallinesilicon film and the back electrode to obtain a solar cell. The obtained solar cell by using the inventive method has low cost and high photoelectric transformation efficiency.

Owner:东莞晨真光伏有限公司

PET material for beverage bottle caps

InactiveCN109467893AAvoid degradation of mechanical propertiesPromote crystallizationPolyethylene terephtalateSodium benzoate

The invention discloses a PET material for beverage bottle caps. The PET material comprises the following raw materials in parts by weight: 70-90 parts of polyethylene terephthalate, 10-20 parts of aPOE resin, 20-30 parts of a filler, 0.05-0.1 part of an antioxidant, 2-4 parts of a compatilizer, 1-3 parts of a nucleating agent, 1-1.5 parts of a plasticizer and 1-3 parts of a lubricant, wherein the nucleating agent is hydrotalcite, magnesium carbonate, sodium benzoate and PEG4000. The PET material is high in crystallization speed, short in crystallization time and high in impact resistance.

Owner:安徽洋龙塑业有限公司

Method for recycling boric acid and magnesium sulfate from boric acid mother solution

InactiveCN109809443AFast productionLess coal consumptionMagnesium carbonatesBoron-oxygen compoundsDiammonium carbonateCarbonate

The invention discloses a method for treating a magnesium carbonate mother solution obtained after the production of boric acid by a carbonation method. The method disclosed by the invention is characterized by comprising the following steps: treating the magnesium carbonate mother solution, obtained after the production of the boric acid by the carbonation method, through the following technological processes: firstly, heating the mother solution to 95 to 100 DEG C; adding a proper amount of solid ammonium carbonate into the mother solution, wherein the weight ratio of the ammonium carbonateto magnesium carbonate is (1 to 1) to (1.4 to 1); dissolving and reacting to generate magnesium ammonium carbonate; filtering and cooling a generated solution; and crystallizing and separating out themagnesium ammonium carbonate, and then carrying out spin-drying treatment. By adopting the method disclosed by the invention, 80 percent or above of the magnesium carbonate in the mother solution canbe extracted without the need of concentrating the mother solution; the production speed is accelerated; coal and power are saved; the cost is reduced; compared with a traditional concentration method, the amount of the treated mother solution is reduced by one half and equipment is saved; meanwhile, the loss caused by the fact that boron is volatilized along with steam when the mother solution is concentrated and the pollution to environment are greatly reduced; and when the method is used, a lot of low-grade boron rocks also can be sufficiently utilized and the obtained magnesium ammonium carbonate is also a very good nitrogen magnesium carbon fertilizer in agriculture.

Owner:王娟

Preparation method of low-melting-point capsicum-flavored butter

The invention relates to a preparation method of low-melting-point capsicum-flavored butter. The preparation method comprises the following steps: (1) drying capsicum at 40-60 DEG C until the water content <= 10%, and pulverizing the dried capsicum so as to obtain capsicum powder; (2) increasing the temperature of butter to 110-130 DEG C; (3) adding the capsicum powder obtained in the step (1) tothe butter obtained in the step (2) at a mass ratio of (10-25):100; and (4) performing frying at the temperature of 110-130 DEG C for 5-20 min so as to obtain the low-melting-point capsicum-flavored butter. The method has simple operation, and the finished product low-melting-point capsicum-flavored butter has bright color, has obvious and special aroma of butter and frying aroma compared with capsicum oil which is prepared from vegetable oil, and has mellow spicy taste, so that the product is popular with customers.

Owner:TIANJIN AGRICULTURE COLLEGE

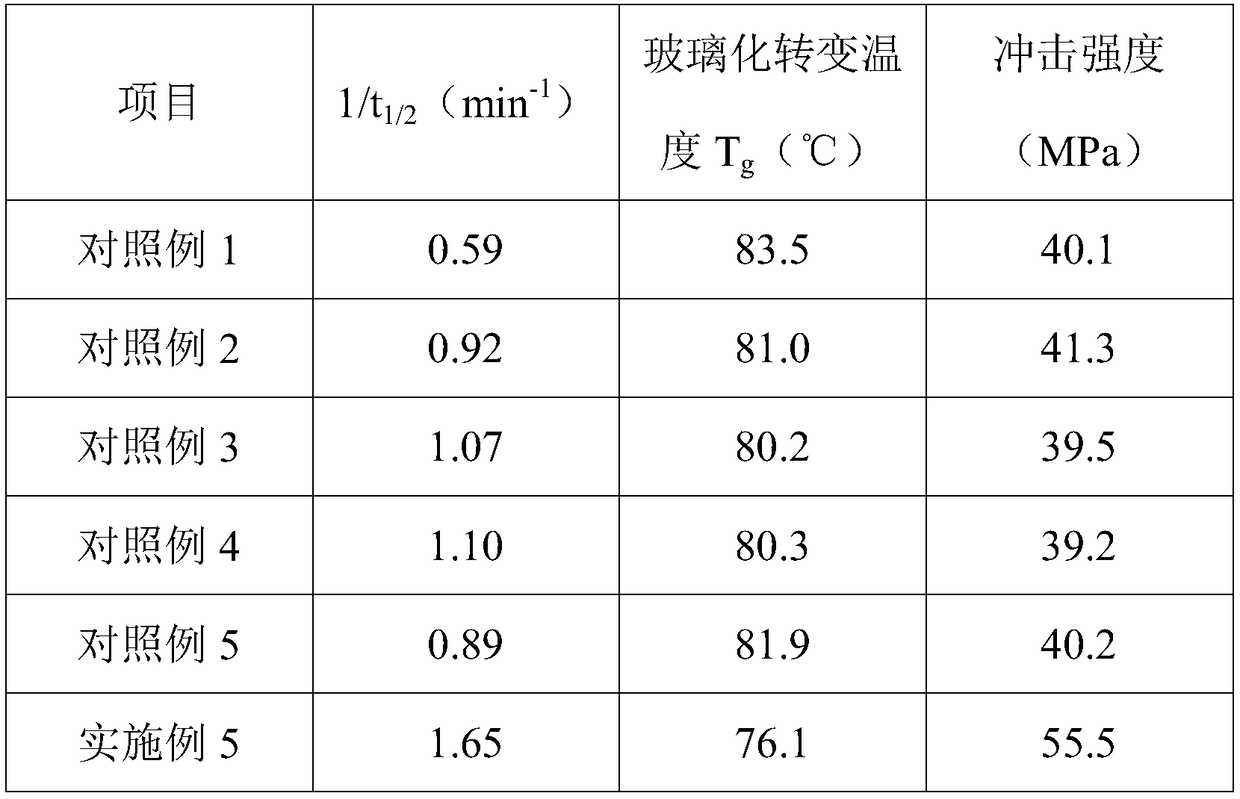

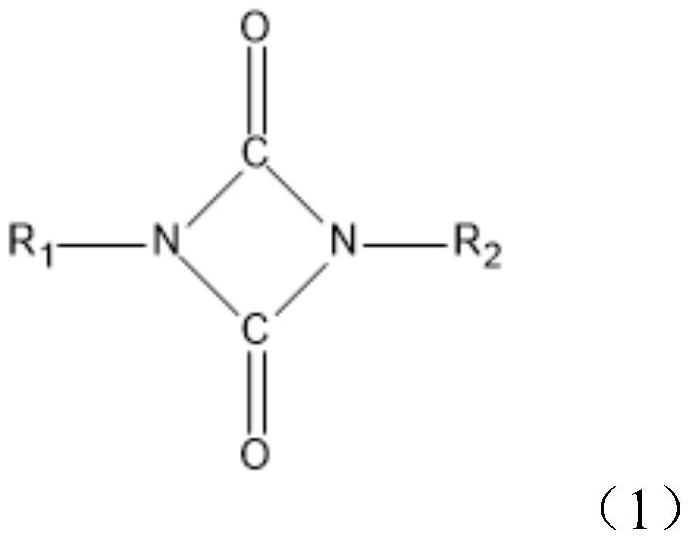

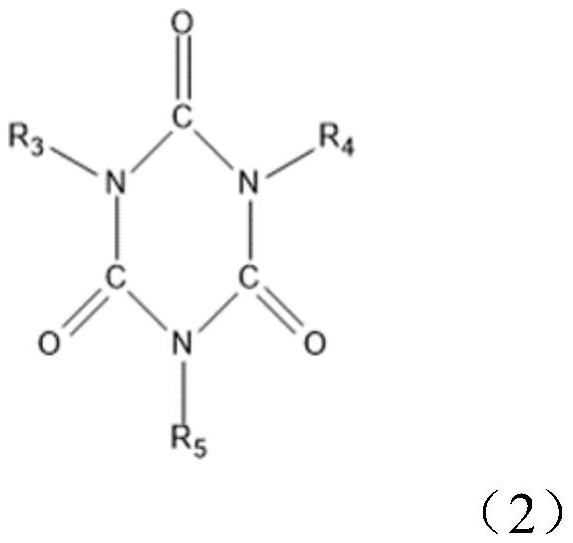

Storage-stable liquid pure MDI composition as well as preparation method and application thereof

The invention discloses a storage-stable liquid pure MDI composition as well as a preparation method and application of the liquid pure MDI composition. The liquid pure MDI composition is prepared from diphenylmethane diisocyanate, diazacyclobutanedione (formula 1) and / or an isocyanurate six-membered heterocyclic compound (formula 2) and an antioxidant. According to the present invention, the diazacyclobutanedione or isocyanurate six-membered heterocyclic compound having the specific structure is added to the liquid pure MDI, such that the solubility of the liquid pure MDI on the dimer is improved, the storage period of the liquid pure MDI at the temperature of 40-45 DEG C can be prolonged to 100 days or more, and the turbidity increase in the storage period is less than 0.1 NTU. When being used for preparing the isocyanate prepolymer, the compound can also improve the crystallization property of the isocyanate prepolymer and enhance the crystallization resistance of the prepolymer.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

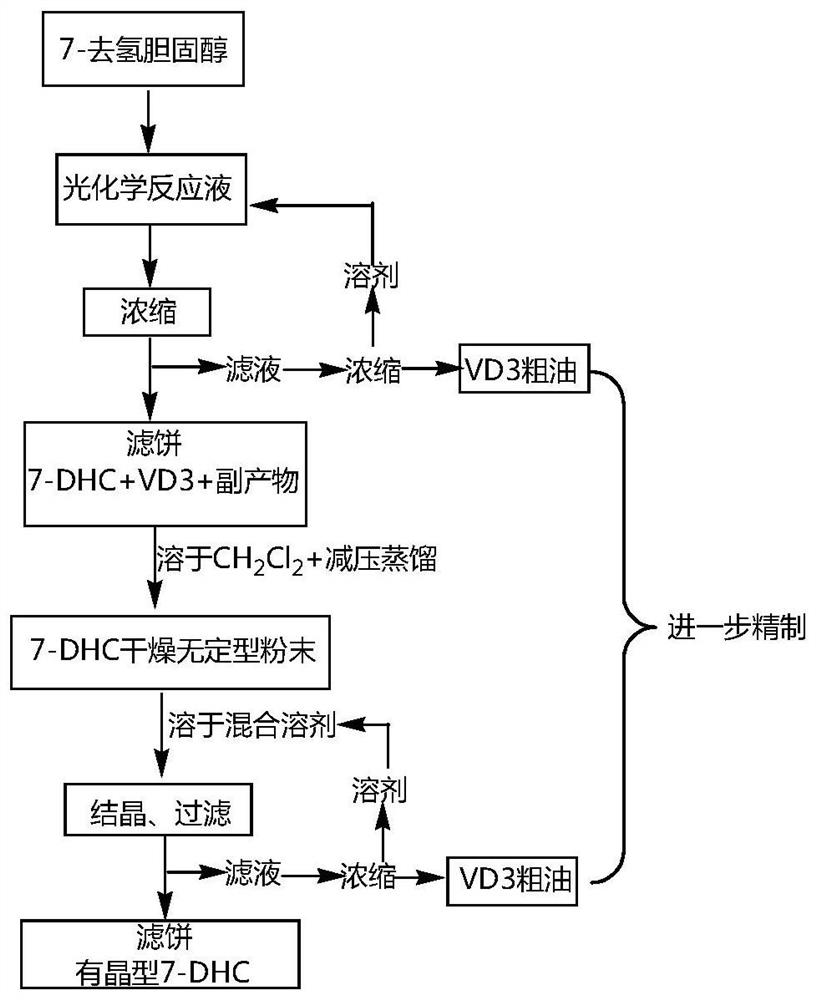

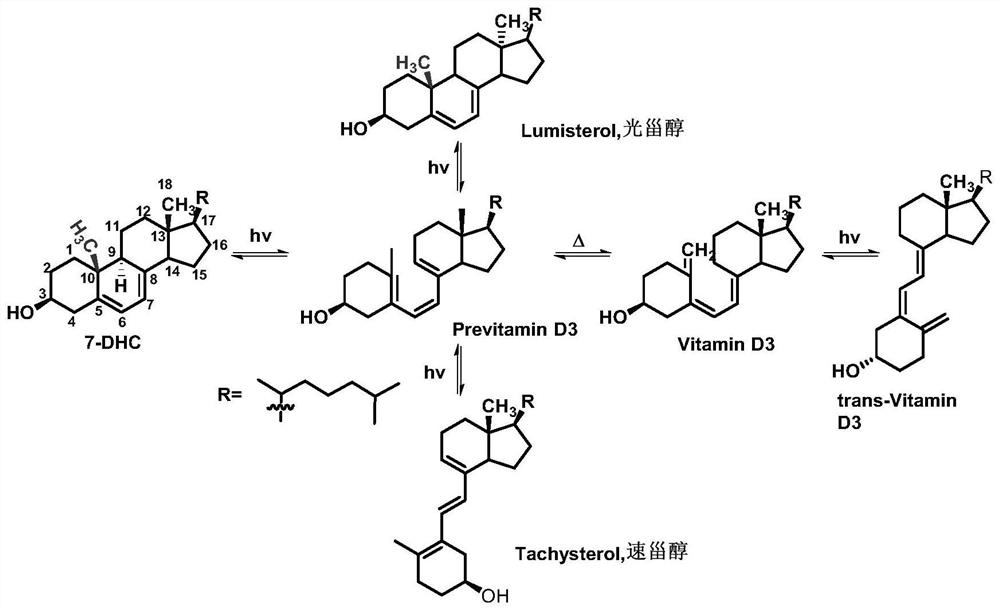

A kind of crystallization purification method of 7-dehydrocholesterol and its application in the production of vd3

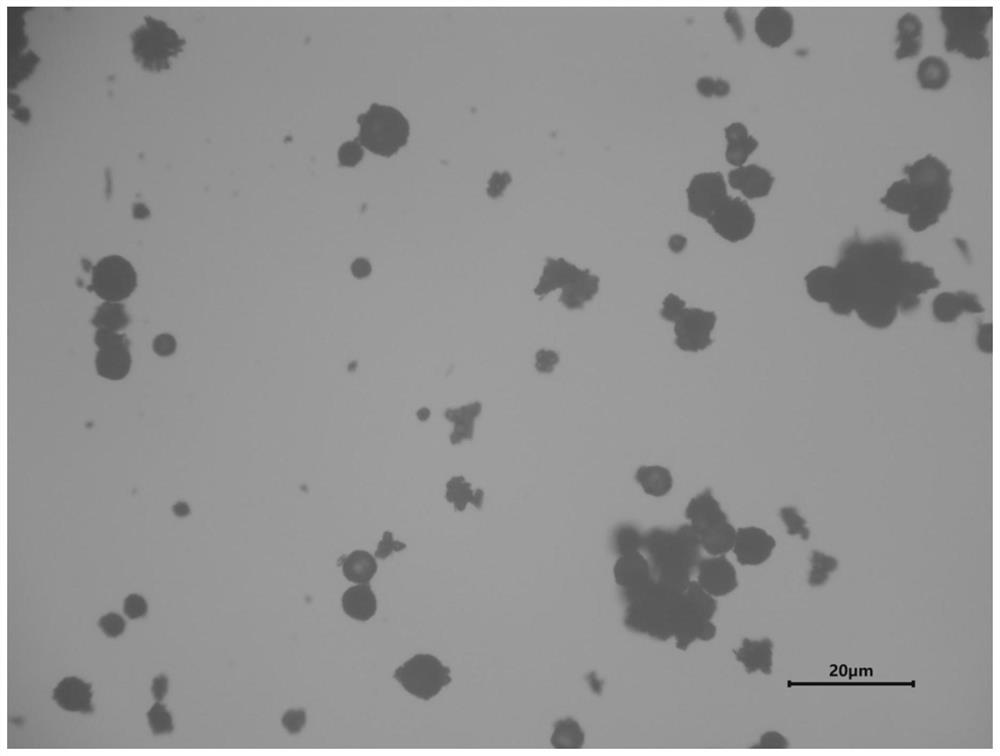

The invention discloses a method for crystallization and purification of 7-dehydrocholesterol and its application in the production of VD3. The method for crystallization and purification comprises the following steps: (1) dissolving crude 7-dehydrocholesterol in a halogenated hydrocarbon solvent, The solvent is then removed to obtain amorphous 7-dehydrocholesterol powder; (2) the 7-dehydrocholesterol powder obtained in step (1) undergoes crystal transformation in a mixed solvent system composed of a polar solvent and a non-polar solvent Form 7-dehydrocholesterol with a crystal form, and after the crystallization is completed, the pure product of 7-dehydrocholesterol is obtained through post-processing; the polar solvent is an alcohol solvent; the non-polar solvent is a hydrocarbon solvent. The method can improve the inclusion and entrainment problem of VD3 in the separation process of 7-dehydrocholesterol, thereby increasing the yield of VD3.

Owner:ZHEJIANG NHU CO LTD +2

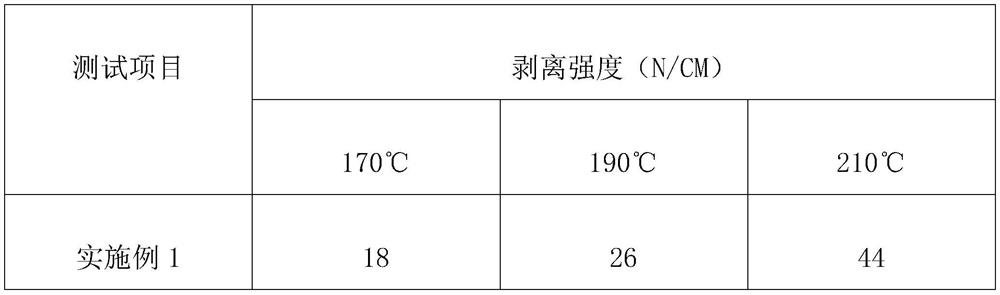

A kind of modified polypropylene hot melt adhesive and preparation method thereof

The invention discloses a modified polypropylene hot-melt adhesive, which is prepared from the following components in parts by weight: 5-30 parts of functionalized modified polypropylene; 50-90 parts of a first random copolymerized polypropylene; a first 5-20 parts of ethylene-α-olefin copolymer; 0.05-0.5 part of antioxidant. The invention also discloses a preparation method of the above-mentioned modified polypropylene hot-melt adhesive. The modified polypropylene hot-melt adhesive of the invention has high bonding strength; especially under low temperature conditions, it can bond quickly and has strong bonding force, and can also help to reduce production cost and improve production efficiency.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com