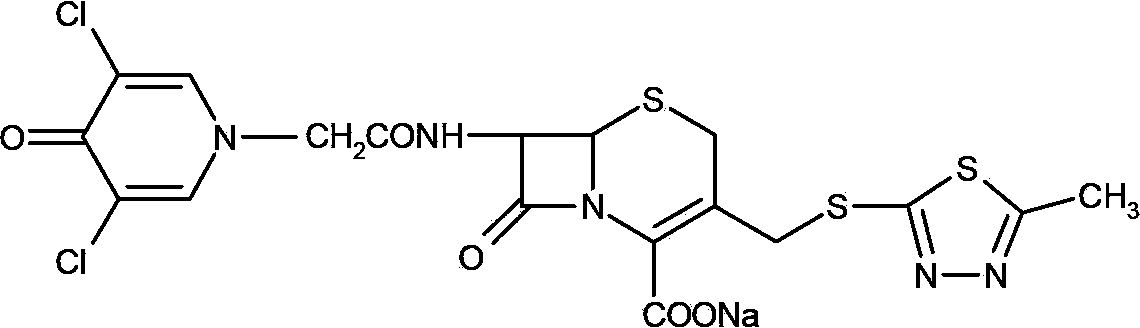

Preparation method for cefazedone sodium with low water content

A technology of cefazedone sodium and water content, which is applied in the field of medicine, can solve the problems of low drying efficiency and difficulty in reproducing product moisture control, and achieve the effects of long crystallization time, ensuring reproducible consistency, and reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of low water content cefazedone sodium, the steps are as follows:

[0035] (1) Liquid dosing: the reaction kettle, filter and utensils used are carried out aseptic treatment, 2000g (3.65mol) cefazedone, 296g (5.48mol) sodium methylate and 20.36L anhydrous methanol are added in the 50L reaction kettle, Stir to dissolve completely, and cool the reaction solution to 10-30°C;

[0036] (2) Decolorization: Then add 80g of activated carbon, stir and adsorb for 30 minutes, decarbonize through titanium rod filtration, and the filtrate is further decarburized and sterilized through a 0.22 μm microporous membrane; and wash the place where the reaction solution passes through with anhydrous methanol, and combine the filtrate and washing liquid and keep the temperature at 15-25°C, and use a filter membrane with a molecular cut-off of 1000 Daltons for ultrafiltration;

[0037] (3) Crystallization: The filtrate was transferred to a 50L crystallization tan...

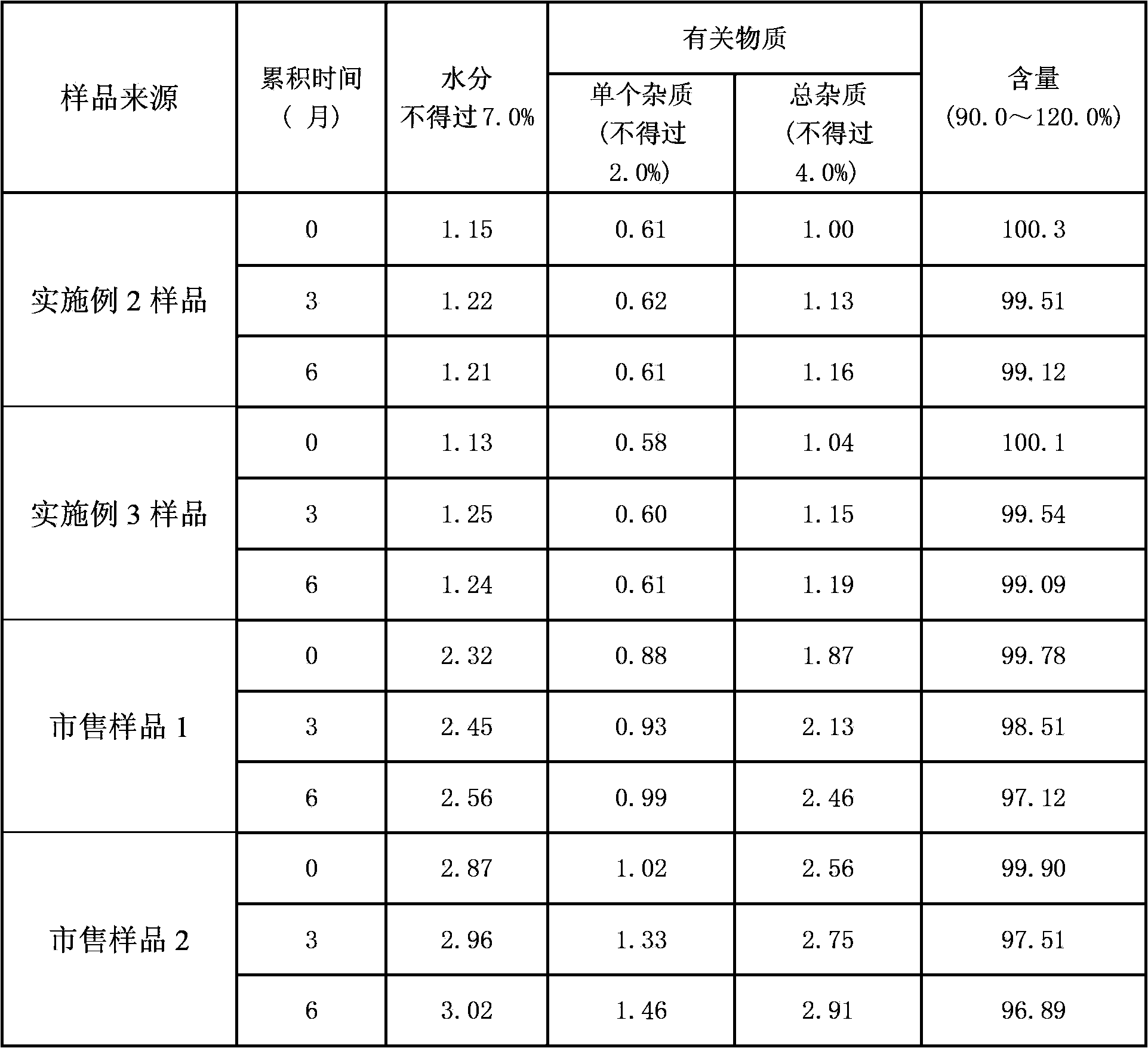

Embodiment 2

[0040] A kind of preparation method of low water content cefazedone sodium, the steps are as follows:

[0041] (1) Dosing: carry out aseptic treatment to used reactor, filter, utensil, 2100g (3.83mol) cefoxizone, 228g (4.21mol) sodium methylate and 21.37L anhydrous methanol are added in 50L reactor, Stir to dissolve completely, and cool the reaction solution to 10-30°C;

[0042] (2) Decolorization: Then add 73.5g of activated carbon, stir and adsorb for 30 minutes, decarbonize through titanium rod filtration, and further decarburize and sterilize the filtrate through a 0.22 μm microporous membrane; wash the place where the reaction solution passes through with anhydrous methanol, combine and filter liquid and washing liquid and keep the temperature at 15-25°C, and use a filter membrane with a molecular cut-off of 1000 Daltons for ultrafiltration;

[0043] (3) Crystallization: The filtrate was transferred to a 50L crystallization tank in a 10,000-class local clean area, 26.75L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com