Patents

Literature

4834results about How to "Uniform particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal nano particle and method for manufacturing them and conductive ink

InactiveUS20060254387A1Uniform particle size distributionHigh yield rateMaterial nanotechnologyBiocideSolventIon

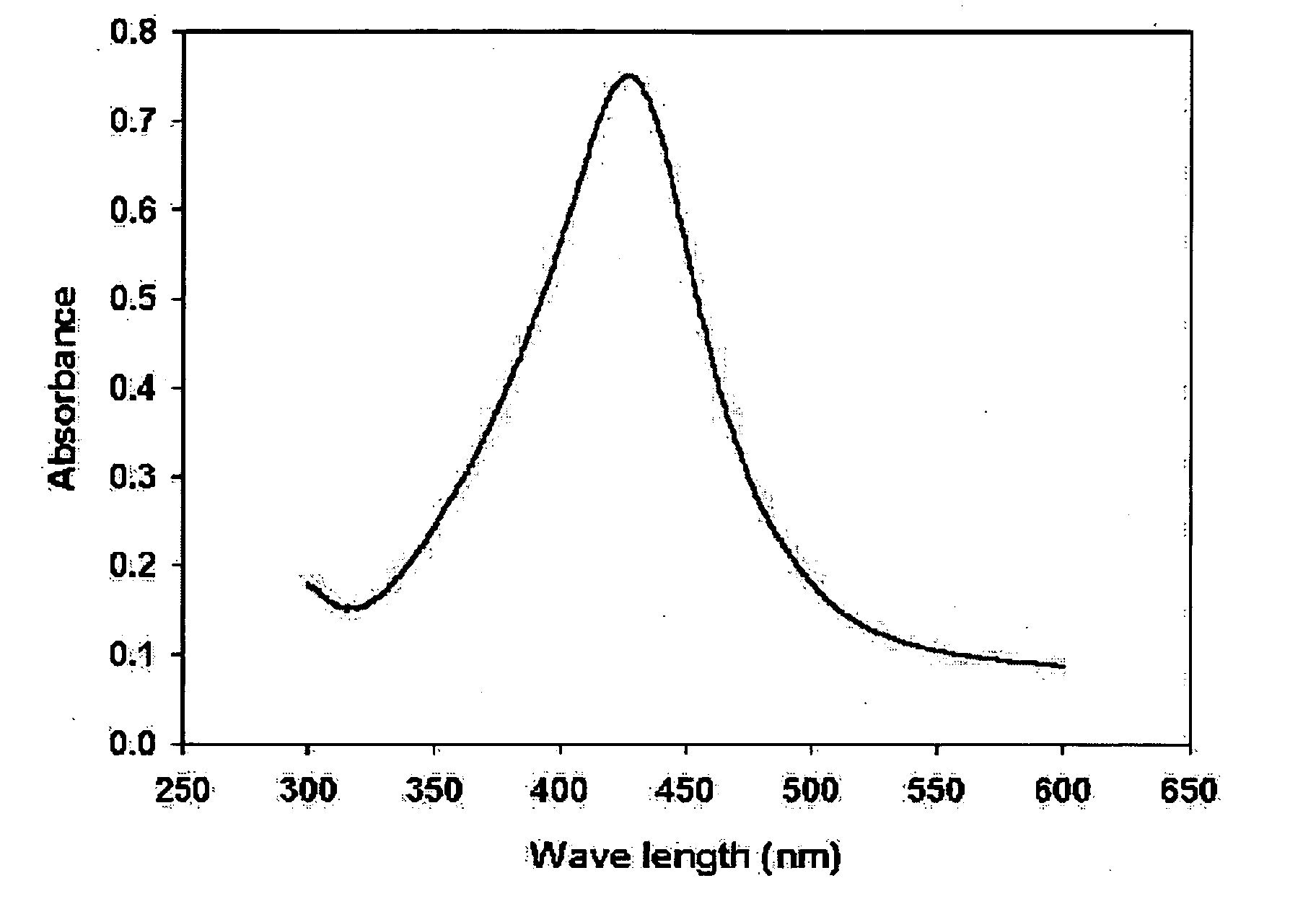

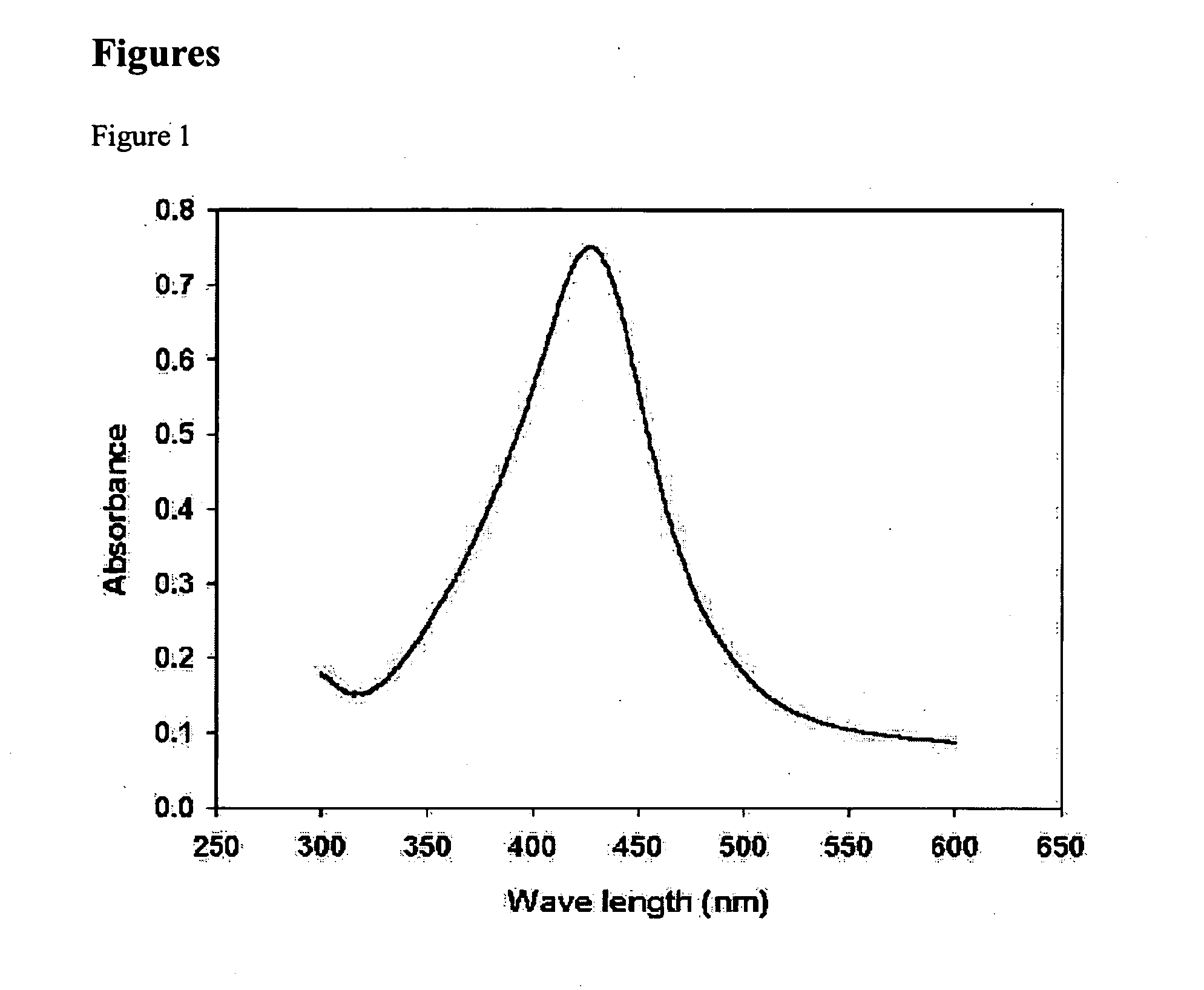

A method of producing hydrophobic metal nanoparticles using a hydrophobic solvent, having uniform particle size distribution and high yield rate to allow mass production; the metal nanoparticles thus produced; and conductive ink including the metal nanoparticles are disclosed. According to one aspect of the invention, a method of producing metal nanoparticles is provided, comprising dissociating a metal compound with an amine-based compound, and adding a hydrocarbon-based compound and either one of an alkanoic acid or a thiol-based compound to the dissociated metal ion solution.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

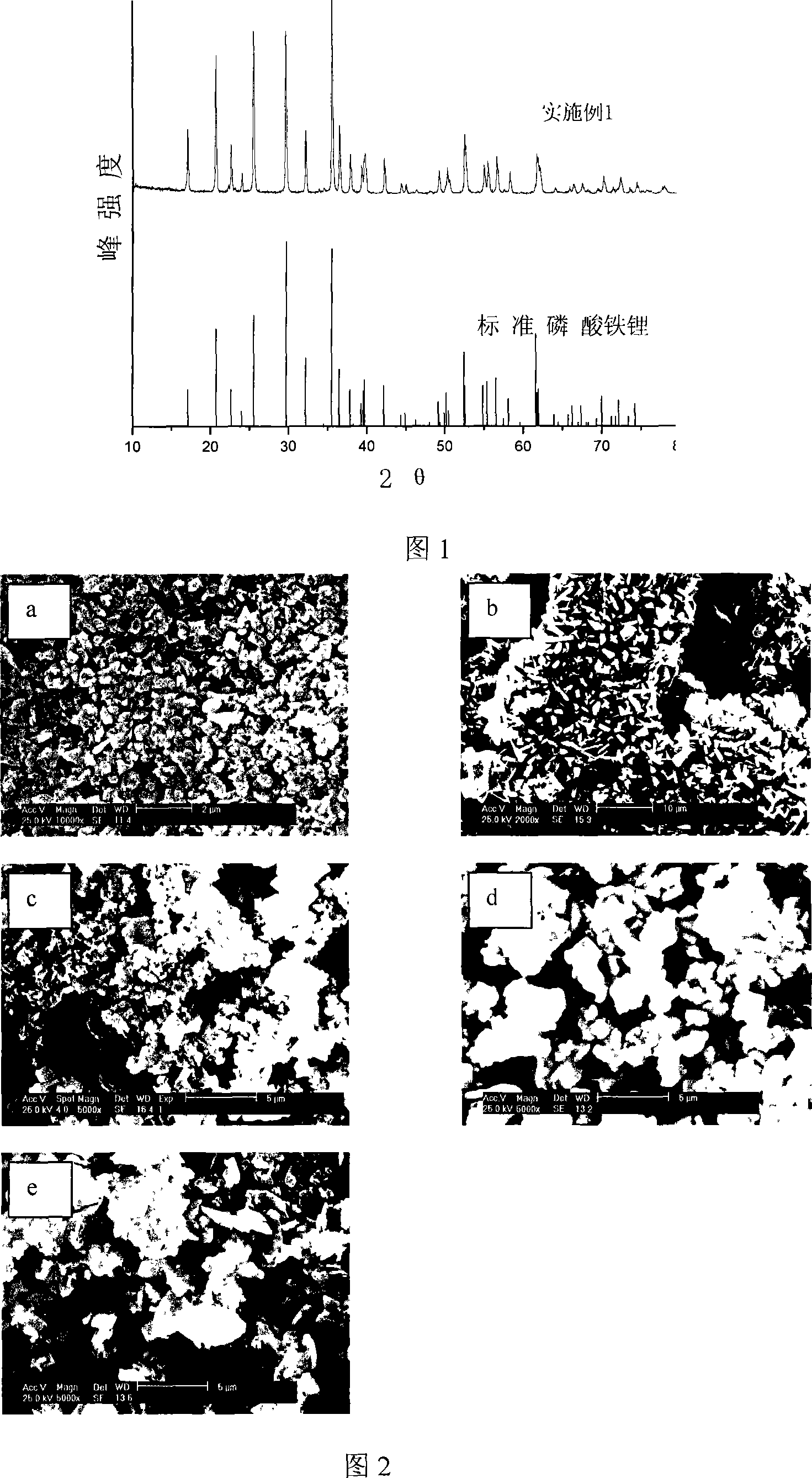

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

Method for preparing nanometer silver powder with accurately controlled particle size

The invention relates to a method for preparing nanometer silver powder with accurately controlled particle size, which comprises the following steps of: taking silver nitrate as a starting material, and reacting with a precipitant to form a uniform silver-containing precursor precipitate; and adding a reducing agent for reducing the silver-containing precursor precipitate while adding a silver crystal seed to obtain simple substance silver. The obtained silver powder particle is polyhedral or almost spherical, the powder body has good dispersity and uniformly distributed particle size, and particle size of the silver powder can be accurately controlled in the range of 20-300nm by controlling crystal seed size and addition. The invention is the method for preparing water solution system of nanometer silver powder which has accurately controlled particle size and is suitable for large scale production under normal temperature and normal pressure condition. The preparation method has moderate reaction condition and is simple and convenient, and the nanometer silver powder has low cost and stable quality.

Owner:山东建邦集团有限公司

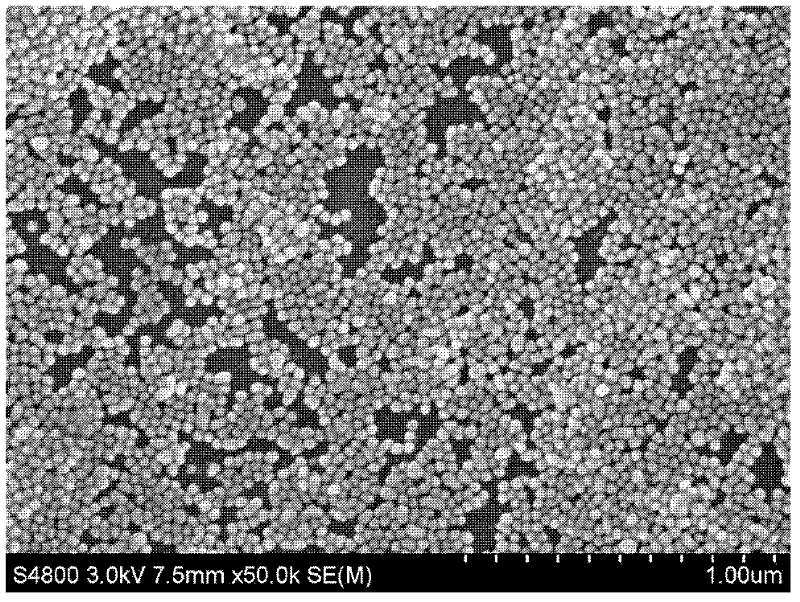

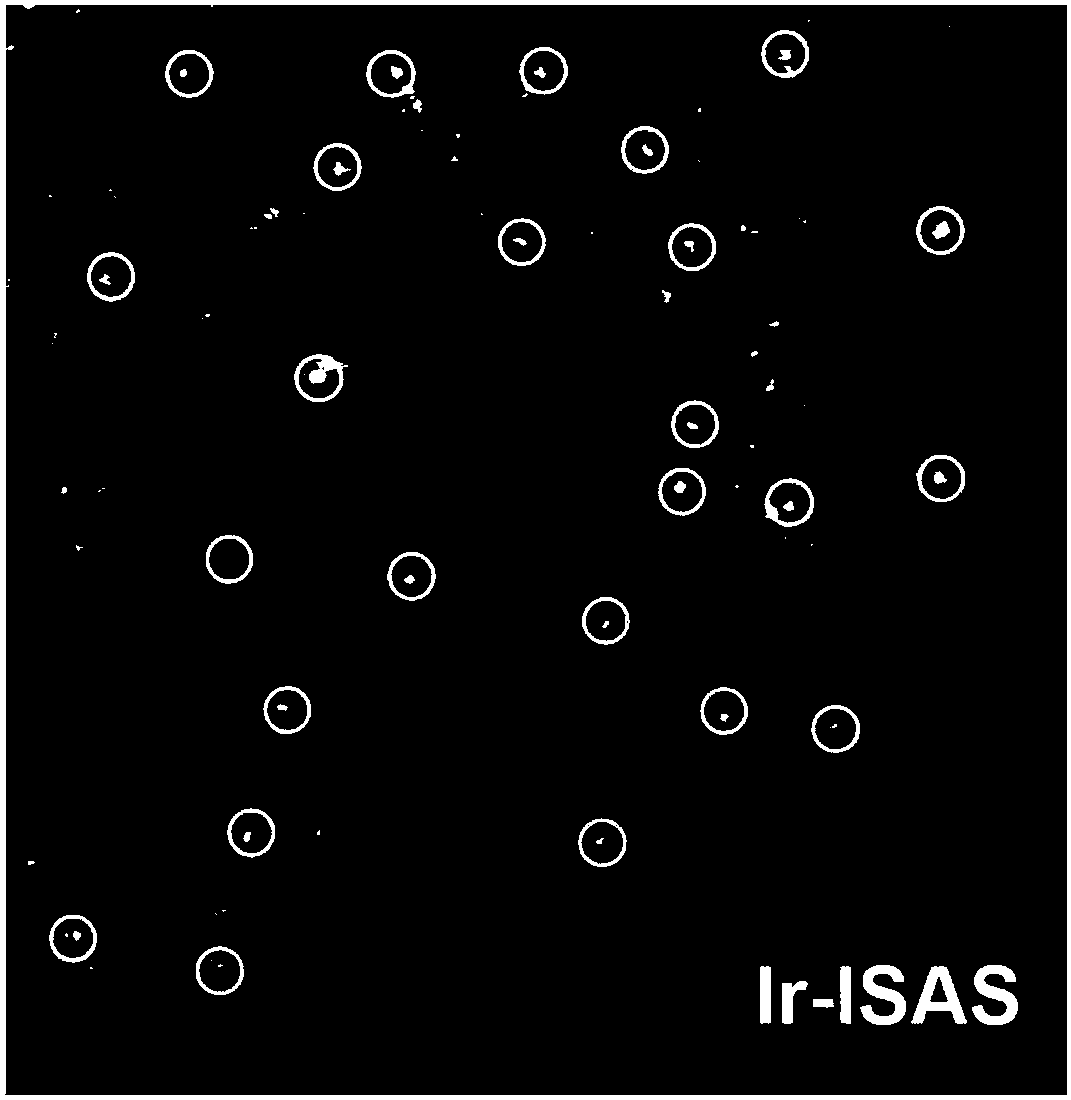

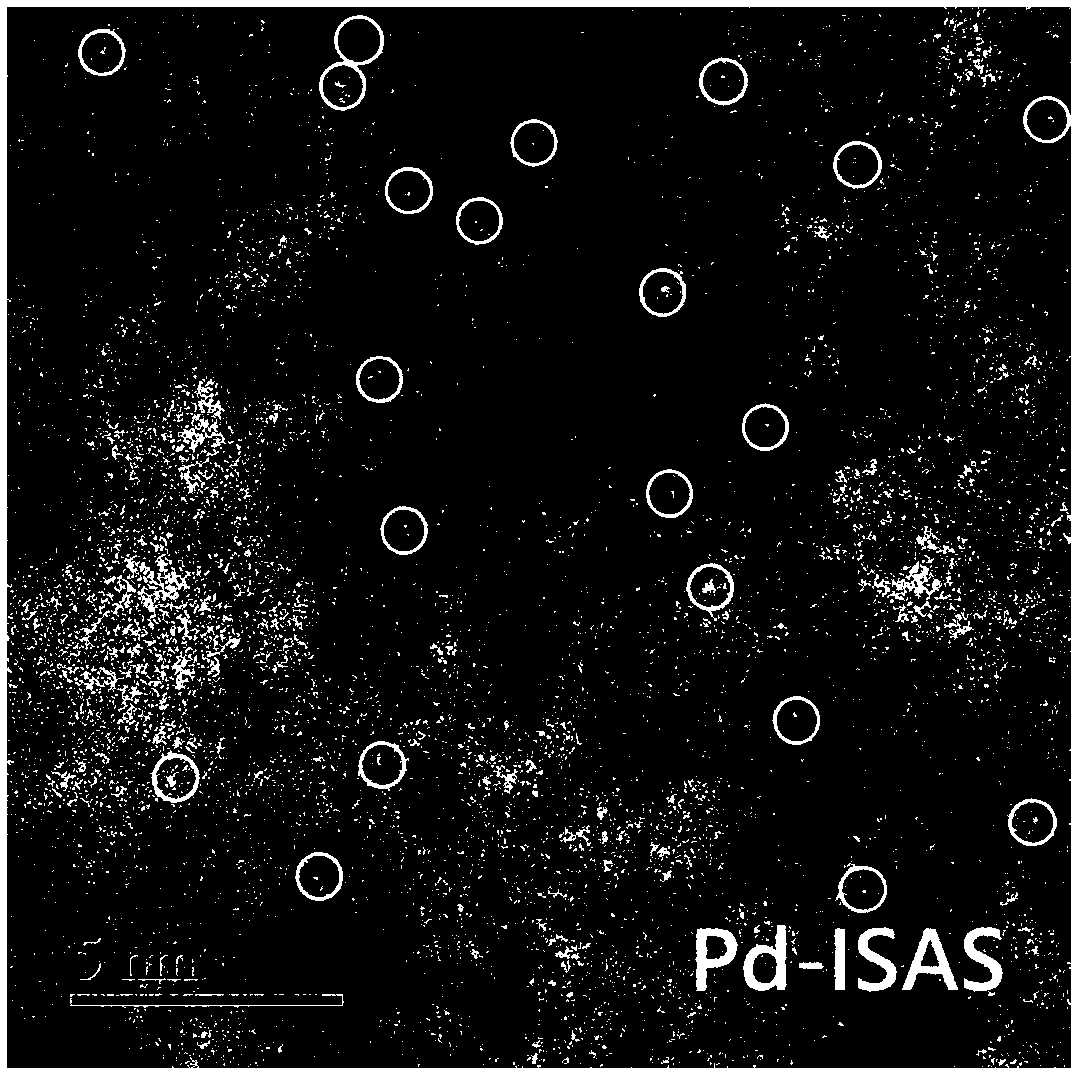

Preparation method of metal monatomic site catalyst

ActiveCN107626294ASmall particlesUniform particle size distributionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsPorous carbon

The invention provides a preparation method of a metal monatomic site catalyst. According to the synthetic strategy, a porous complex composite material coated with an acetylacetone metal salt is formed from a zinc compound and an imidazole organic ligand through coordination in a methanol solution of the acetylacetone metal salt, and then a porous carbon support doped with nonmetal heteroatomic nitrogen is formed from the imidazole organic ligand through a high-temperature pyrolytic reaction in an inert gas atmosphere, wherein metal atoms interact with surrounding nonmetal heteroatomic nitrogen and exist in the form of single atoms. The method is simple, safe, low in cost and applicable to synthesis of various noble metal and non-noble metal monatomic site catalysts, and the obtained metal monatomic site catalyst is high in metal concentration and good in heat stability, can be applied to the fields of energy, catalysis, medicine, biology and the like and has quite broad market prospect.

Owner:TSINGHUA UNIV

Coprecipitation method for preparing ultra fine zinc oxide powder possessing high electric conductivity

ActiveCN1590302AImprove conductivityVolume resistivity is stableZinc oxides/hydroxidesIndiumGas phase

The invention relates to a preparation method for preparing nano-scale oxidized zinc powder with high conductivity. The method simultaneously drip mixed salt solution of zincic soluble salt and doping elements such as aluminum, gallium, indium, Yt, scandium, tin, germanium, silicon, as well as precipitating agent into water, to generate coprecipitation to generate doped zinc bloom precursor basic zinc carbonate in condition of controlling temperature and PH value of entire reaction system, and at last, calcining the product in mixed gas atmospheres of hydrogen gas and argon gas, doped superfine zinc bloom conductive powder material can be obtained. The powder material prepared by the invention has small particle-size, uniform grain fineness distribution, and which mean particle diameter is about 10 to 80 nanometer. The electric volume resistivity of the powder can reach 2.5*10^-3 omega.cm, thus its electro conductivity is better than the sample prepared by plasma method and gas-phase method in current market. The preparation method further enhances whiteness degree and conductivity of the oxidized zinc powder, and further reduces the cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

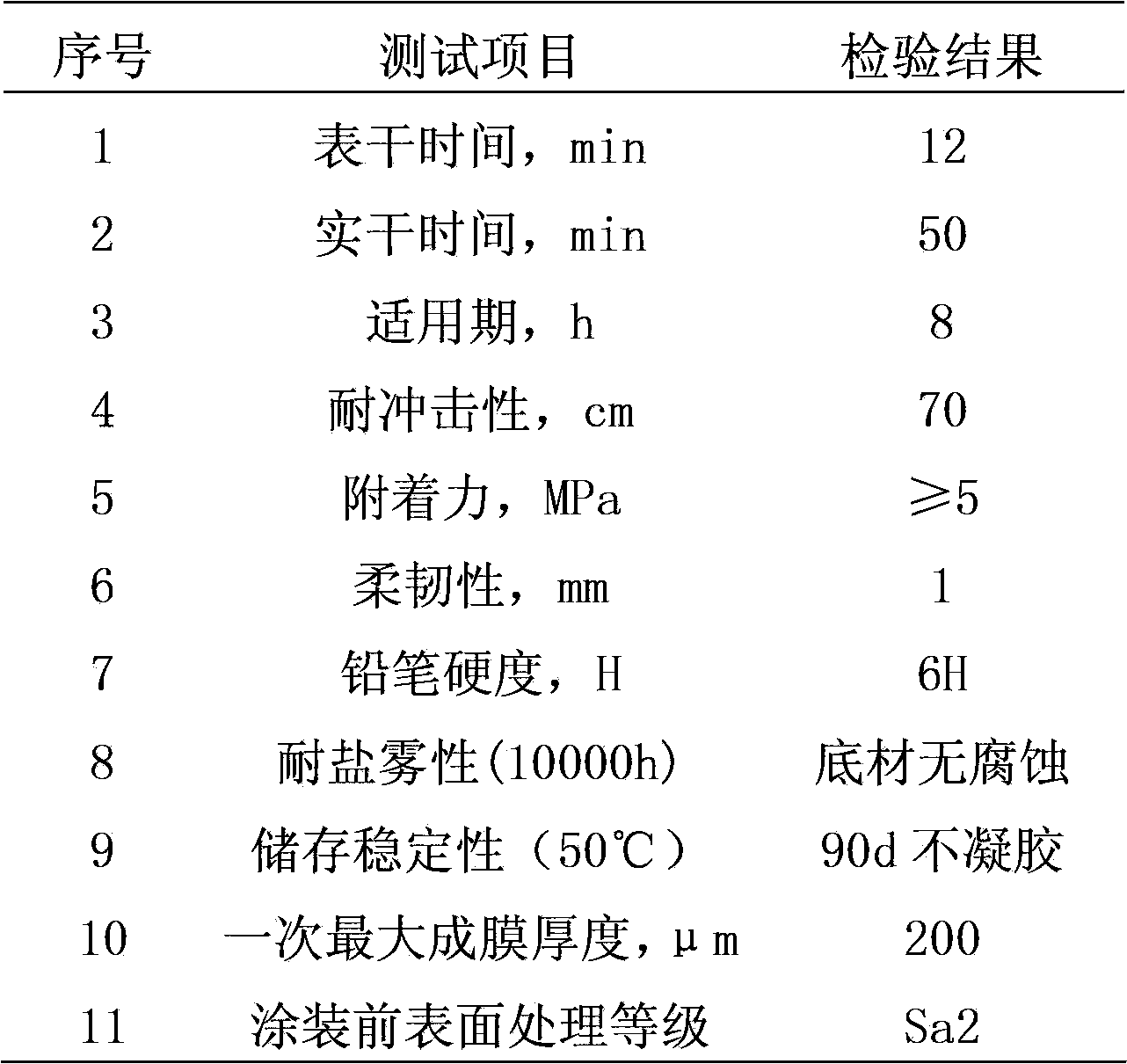

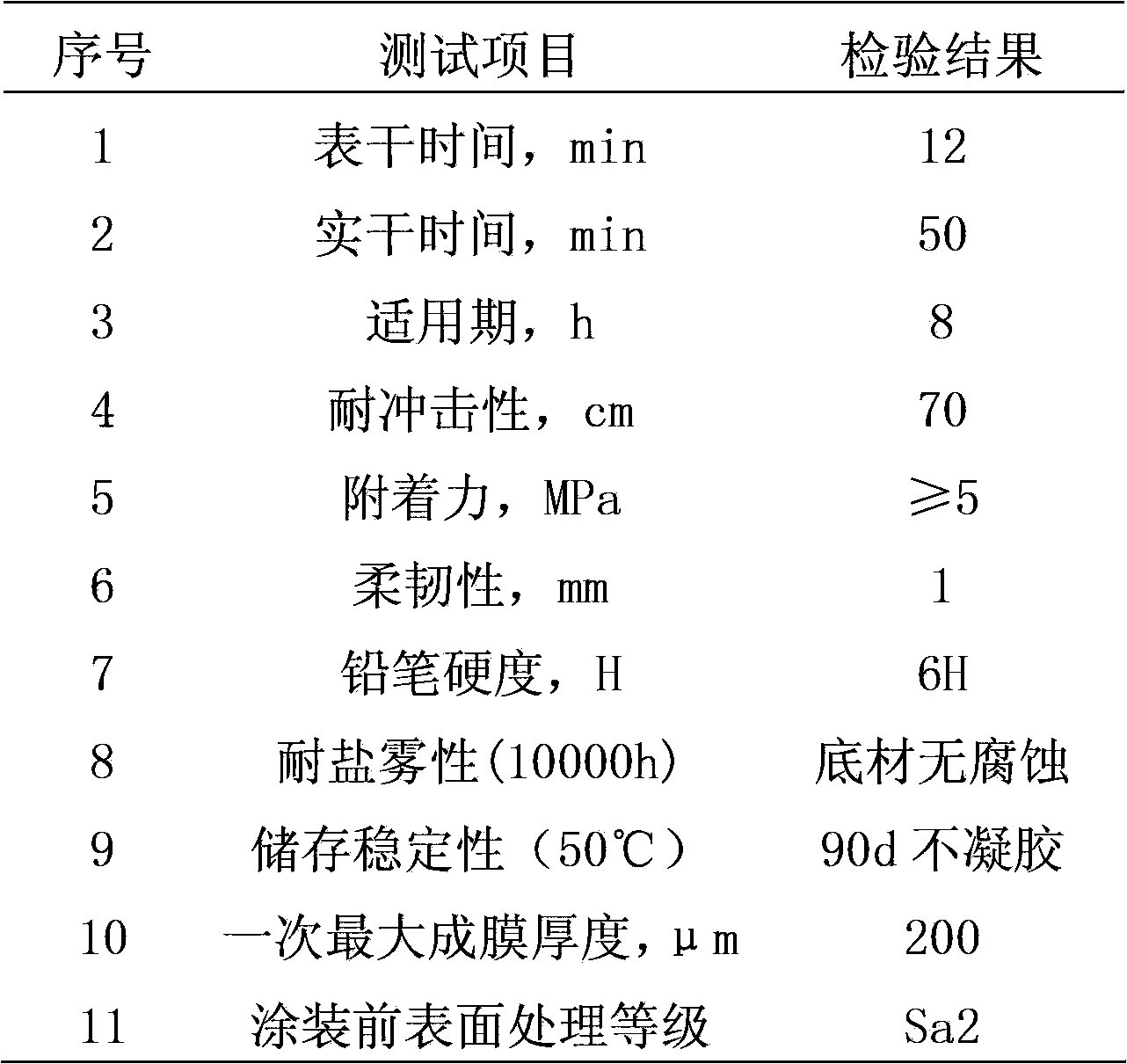

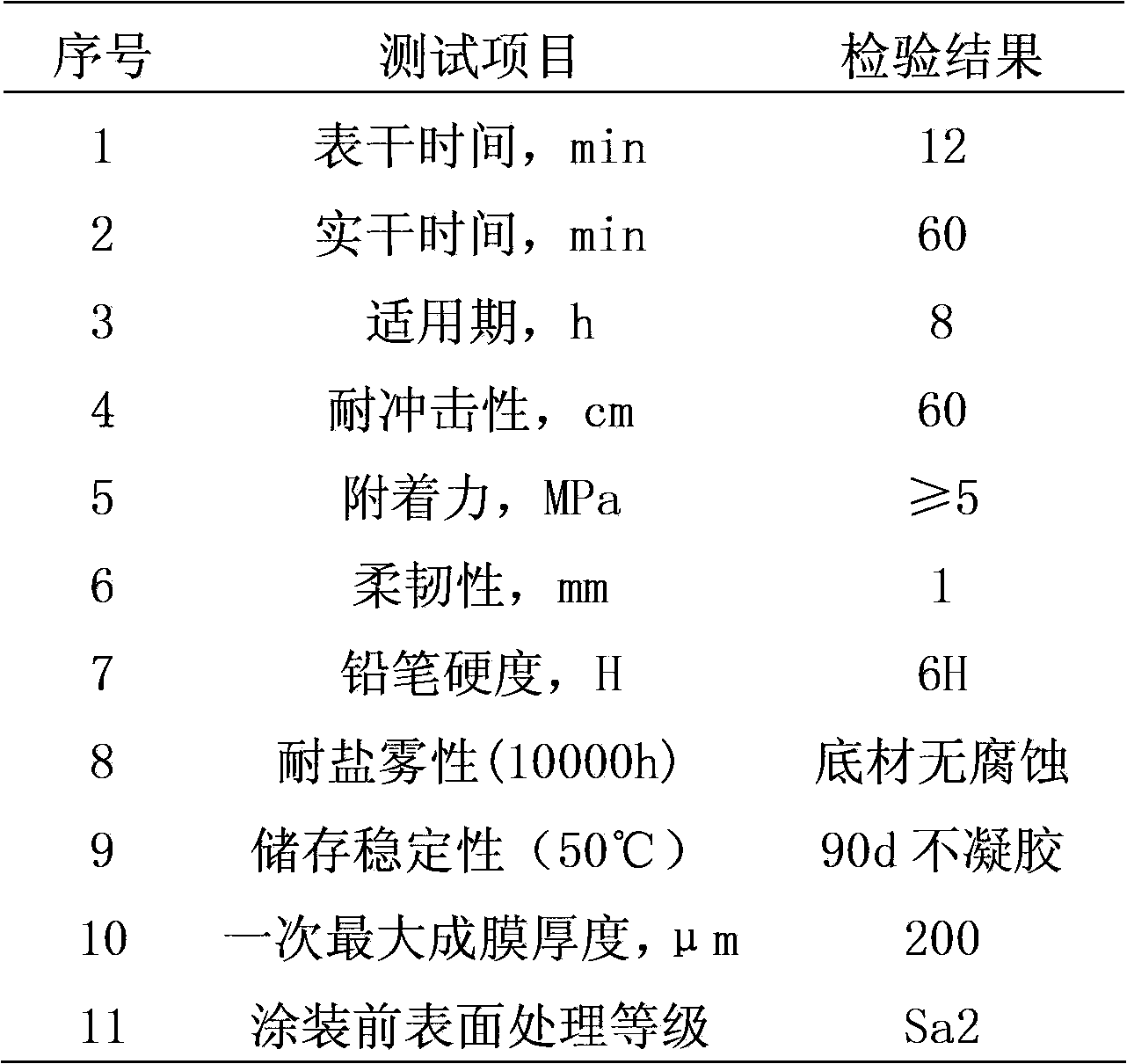

Water-soluble inorganic zinc-rich paint and preparation method thereof

ActiveCN103788734AUniform particle size distributionUniform reaction rateAlkali metal silicate coatingsStress concentrationPowder mixture

The invention provides a water-soluble inorganic zinc-rich paint and a preparation method thereof. The preparation method comprises the following steps: dropwise adding aluminum-modified silica sol into potassium silicate solution with low modulus, so as to obtain a high-modulus potassium silicate solution as a binder; and adding a catalyst, a siloxane oligomer and a modifier to ensure that the high-modulus potassium silicate solution are uniform in size distribution, and does not have gelatinization reaction for a long time, wherein after the high-modulus potassium silicate solution and a zinc powder mixture are stirred uniformly, the zinc-rich paint has the advantages that reaction rates of all parts of a coating are uniform, and no stress concentration phenomenon exist. Proved by experiments, the zinc-rich paint provided by the invention has no gel after being stored for 90 days at 50 DEG C, the thickness of a film formed once can reach 200 mu m, no cracking or bubbling phenomenon exists, construction can be carried out after the treatment level of the steel surface reaches Sa2, and the salt fog resistance of the coating can reach 10000 hours.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

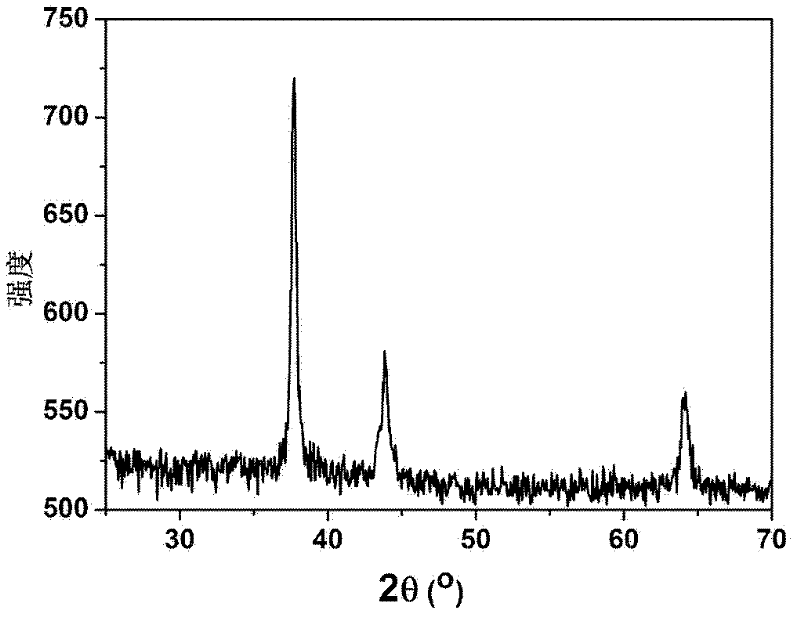

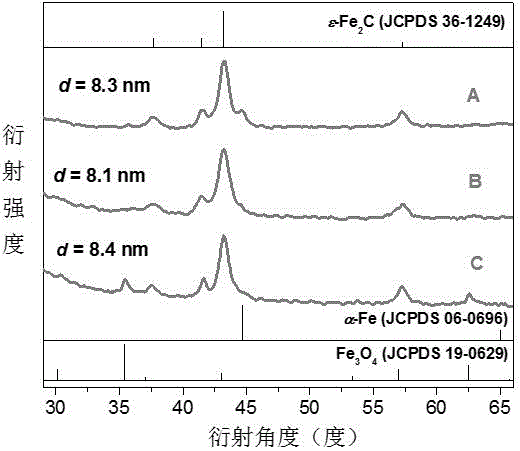

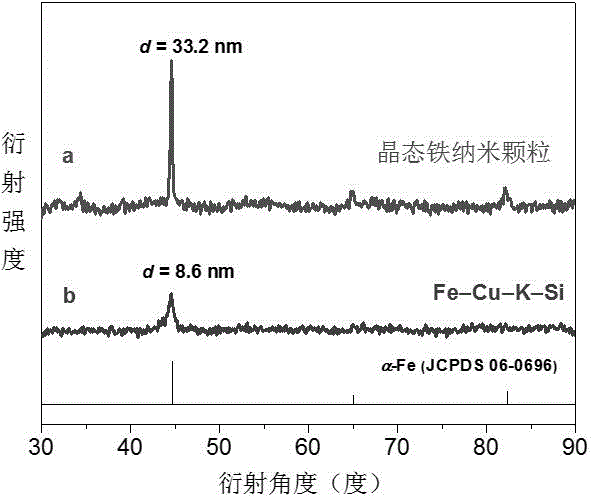

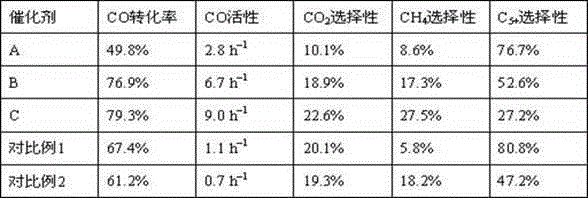

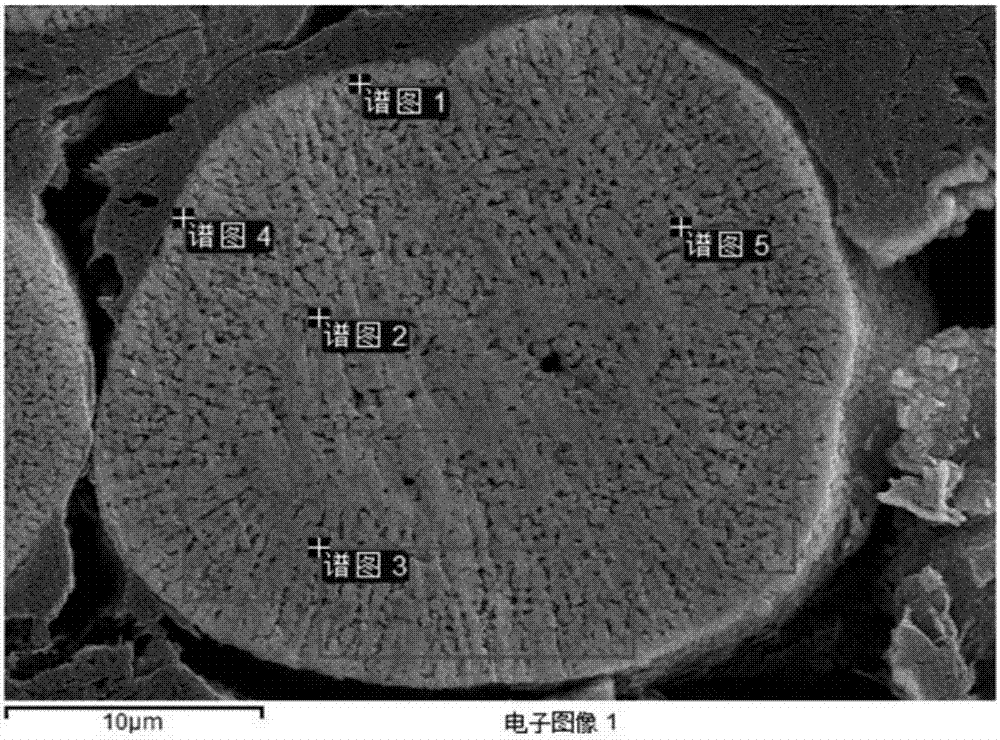

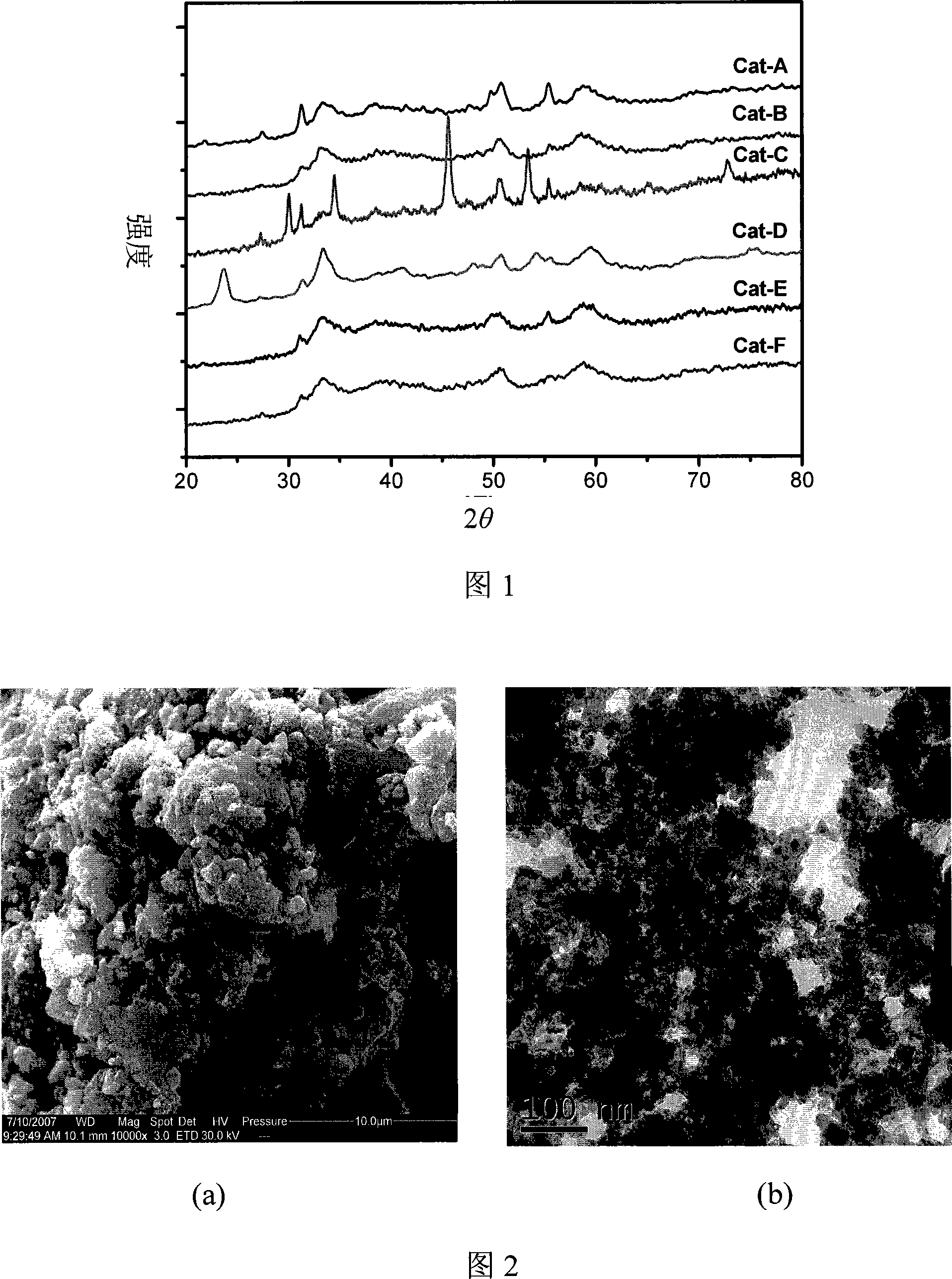

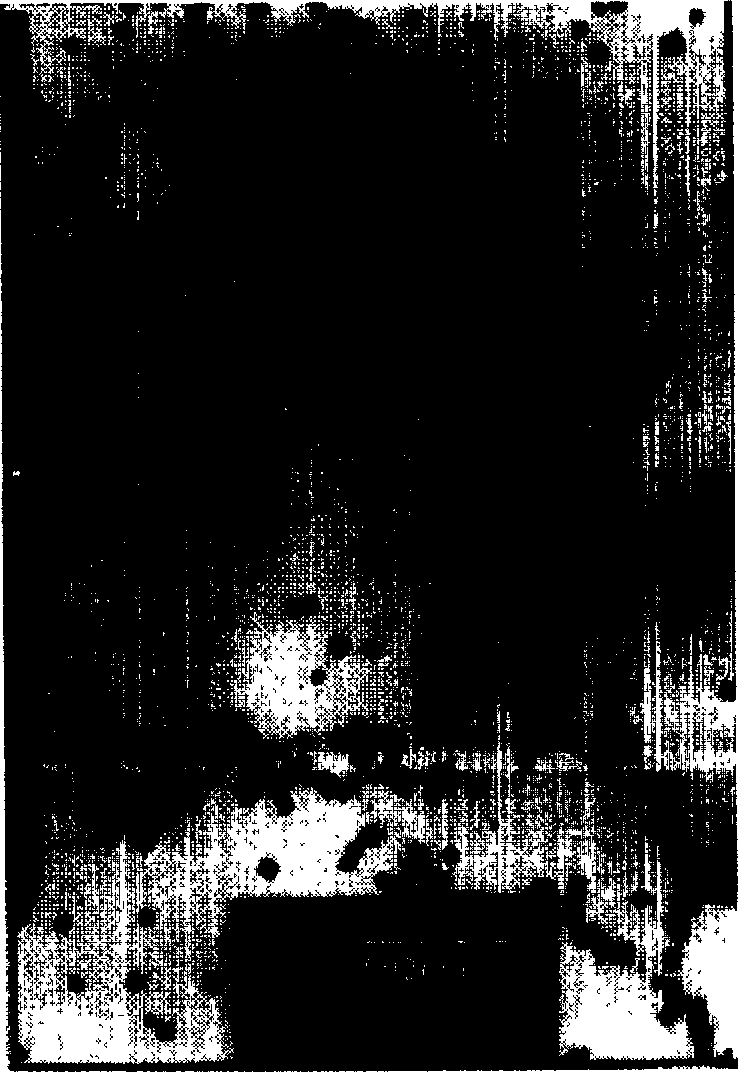

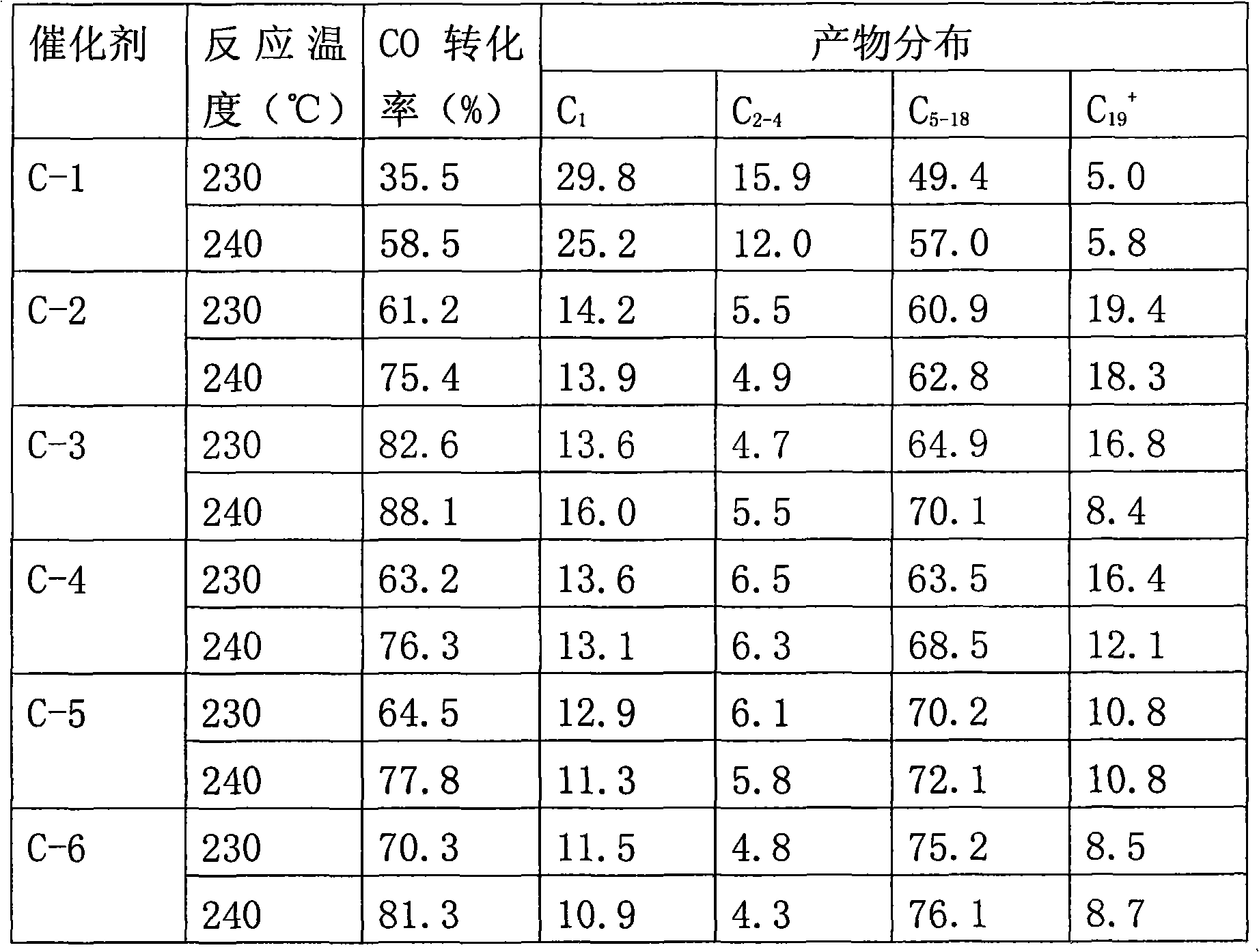

High-activity iron-based low-temperature Fischer-Tropsch synthesis catalyst and preparation method thereof

InactiveCN104399501AEasy to prepareSuitable for mass productionPhysical/chemical process catalystsHydrocarbon from carbon oxidesPtru catalystNanoparticle

The invention belongs to the field of chemical catalysts, and specifically relates to a high-activity iron-based low-temperature Fischer-Tropsch synthesis catalyst and a preparation method thereof. The low-temperature Fischer-Tropsch synthesis iron-based catalyst is prepared by subjecting a skeleton iron material to low-temperature carbonization at a low temperature under a high carbon monoxide partial pressure and contains high-activity epsilon-Fe2C nano particles. The provided Fischer-Tropsch synthesis catalyst has an extremely high catalytic activity at a low temperature (less than 200 DEG C), wherein the catalytic activity is prominently higher than that of reported low-temperature iron-based Fischer-Tropsch synthesis catalysts. At the same time, the stability of the provided catalyst is high, and thus the catalyst can meet the production requirements.

Owner:FUDAN UNIV

Preparation method of Co3O4 with large grain size and uniformly doped with aluminum

ActiveCN108011101AEvenly distributedUniform particle size distributionCell electrodesCobalt oxides/hydroxidesCobalt(II,III) oxideMicrometer

The invention relates to a preparation method of Co3O4 with large grain size and uniformly doped with aluminum. The invention provides the preparation method of the Co3O4 which is uniformly doped withaluminum and is large in grain size and uniform in particle distribution, and the obtained Co3O4 with the large grain size and uniformly doped with aluminum can completely conform to the requirementof preparation of 4.45V high-voltage lithium cobalt oxide. According to the method, the large-grain size and aluminum-doped cobalt carbonate is synthesized by a wet method, and the problems of difficulty in enlargement of cobalt hydroxide (or hydroxyl cobalt) system grain size and non-uniform particle distribution are solved; with the regard to the problem of uniform aluminum doping of a cobalt carbonate system, a parameter is set from principle, an aluminum compound is prevented from being independently separated out and gathered, the doped Al element can be uniformly distributed in the Co3O4, the grain size reaches 15 micrometers or above, and the particle distribution is uniform; and the lithium cobalt oxide prepared from the aluminum-doped Co3O4 has high specific capacity and excellentcycle property under 4.45V.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

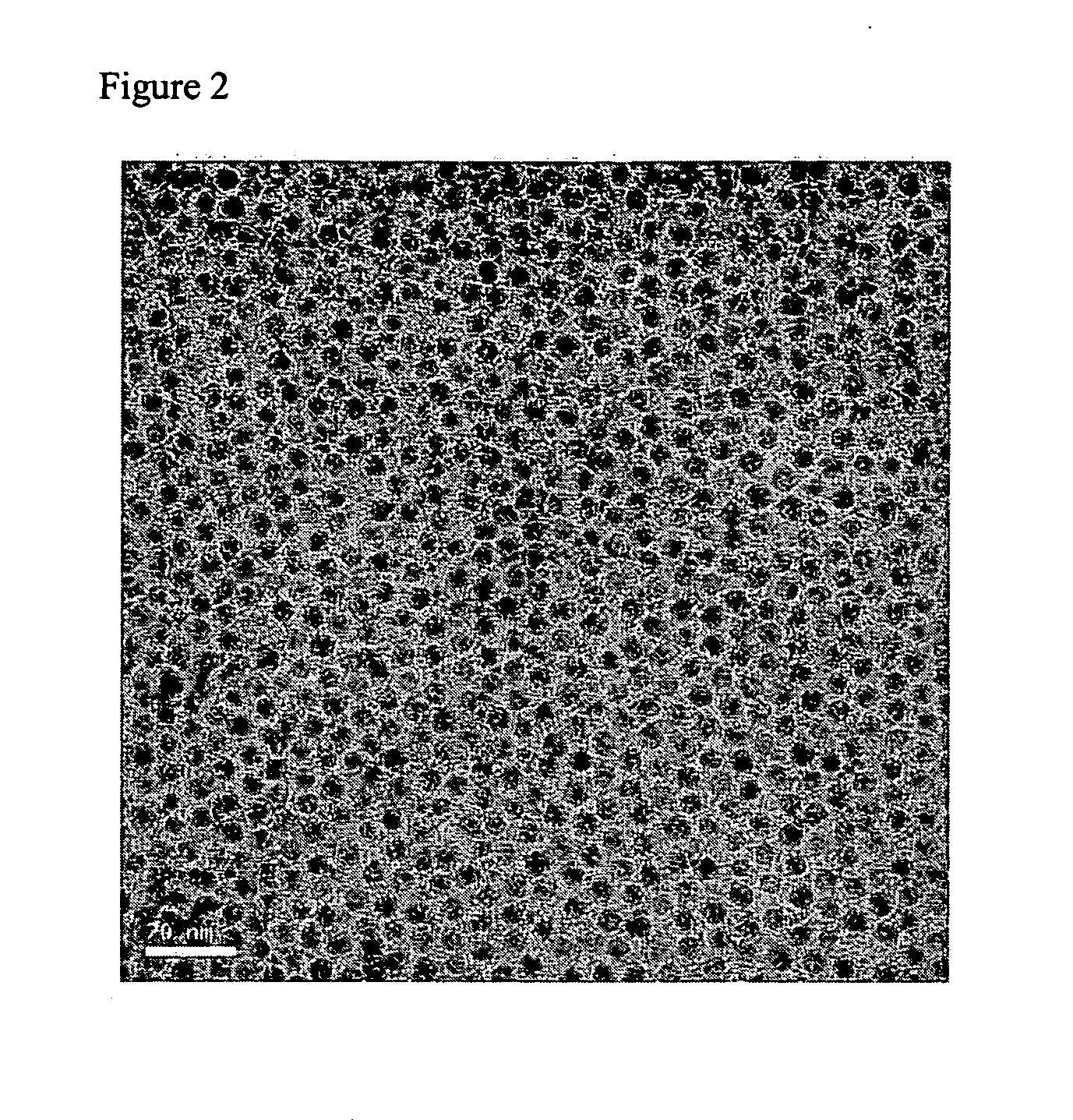

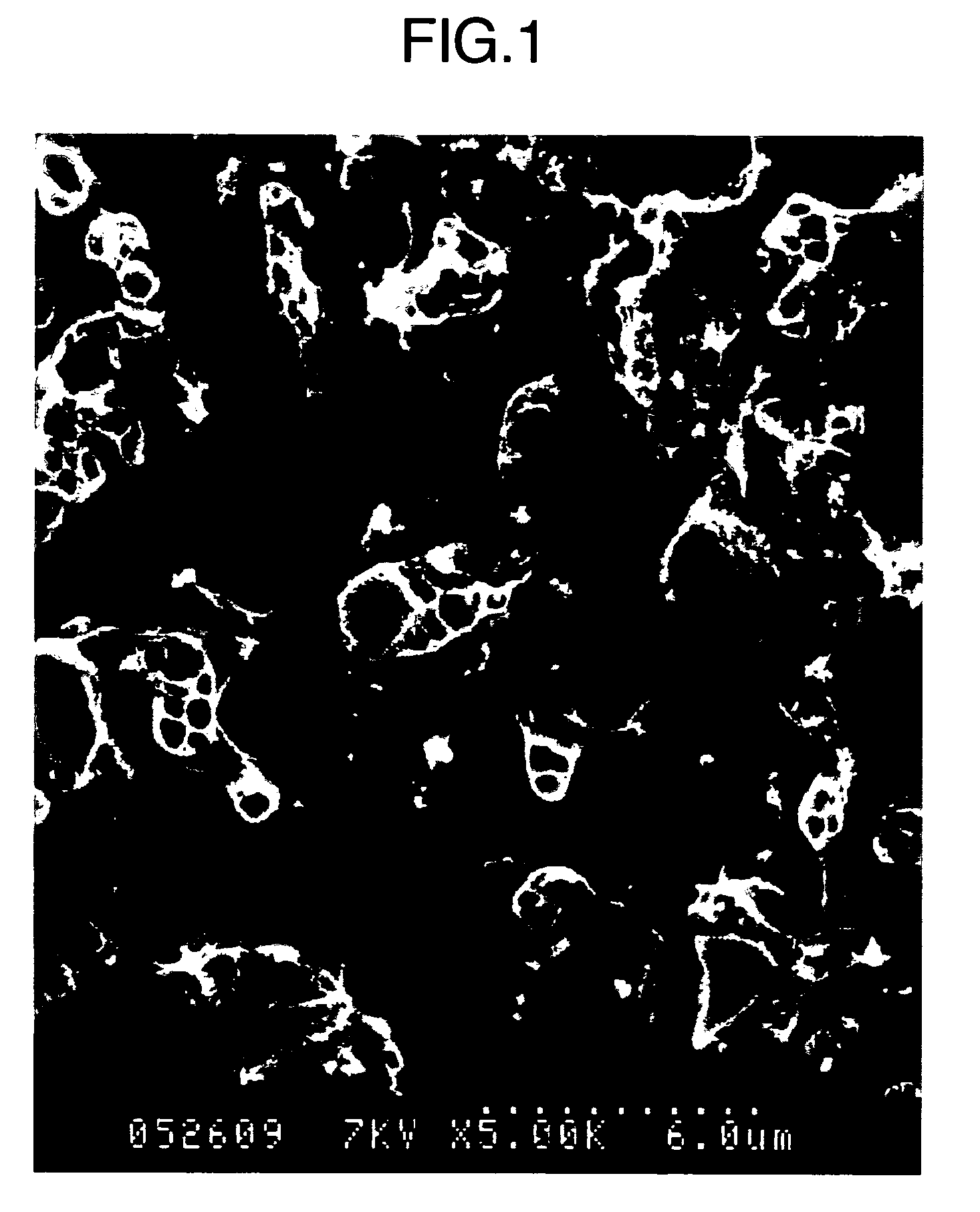

Porous formed article and method for production thereof

ActiveUS20070128424A1High opening rateIncreasing treatment speedLayered productsSolid sorbent liquid separationIonFiber

A porous formed article which comprises an organic polymer resin and an inorganic ion absorbing material, and has communicating pores opening at an outer surface, wherein it has cavities in the interior of a fibril forming a communicating pore, at least a part of said cavities opens at the surface of the fibril, and the inorganic ion absorbing material is carried on the outer surface of said fibril and on the surface of inner cavities.

Owner:ASAHI KASEI CHEM CORP

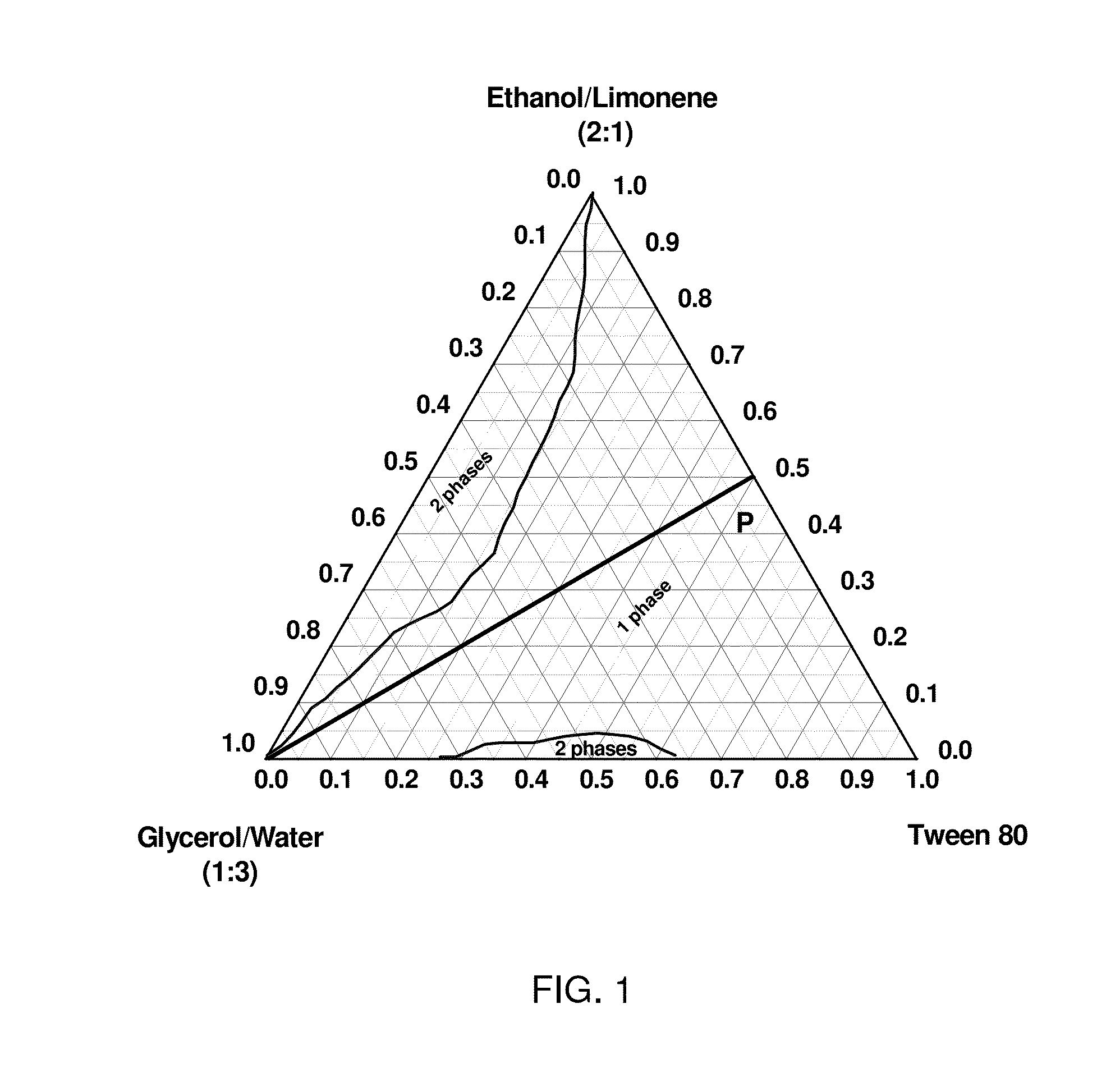

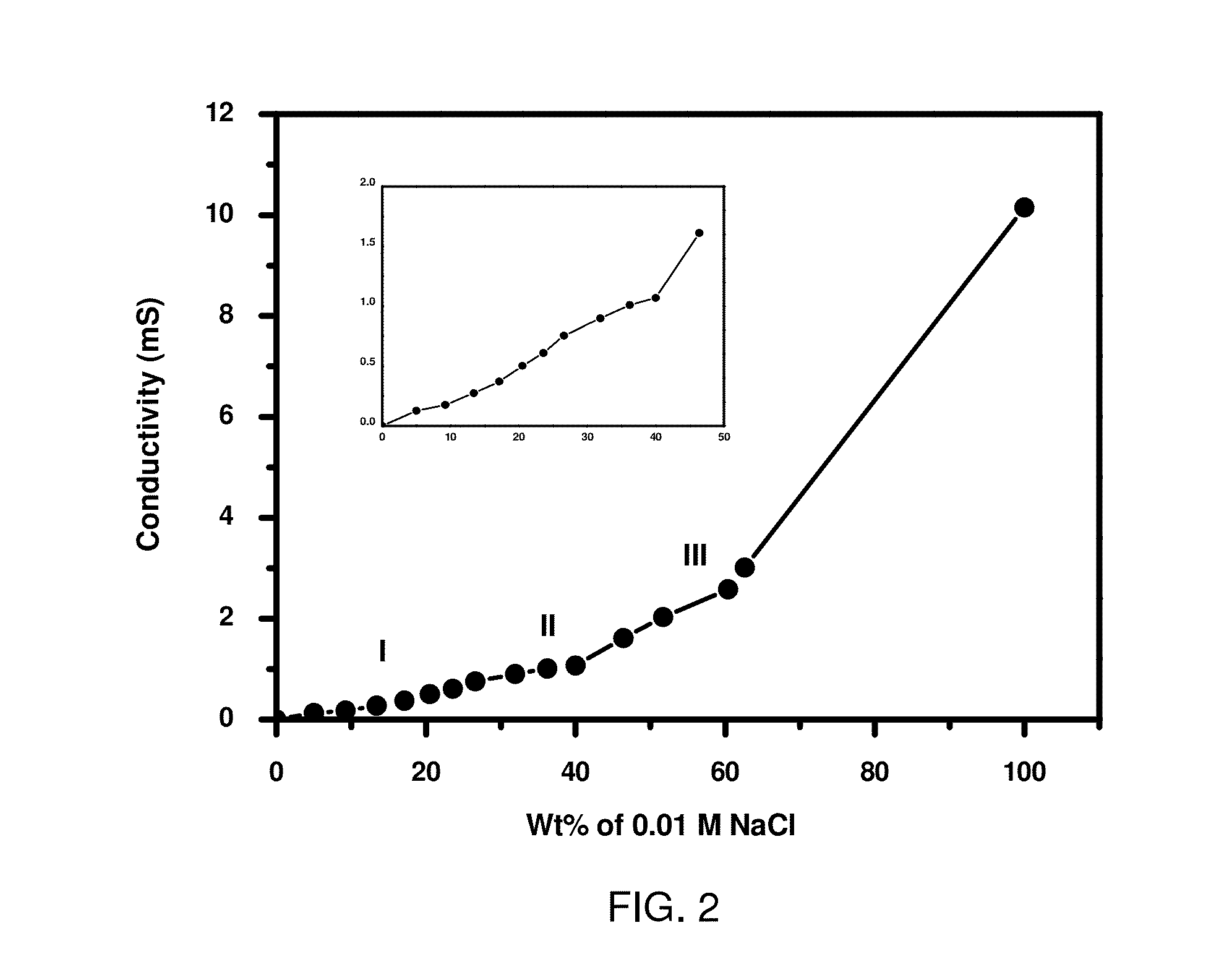

Method of Forming Encapsulated Compositions with Enhanced Solubility and Stability

InactiveUS20130004619A1Easy to makeEasy to operateEdible oils/fats ingredientsLiquid surface applicatorsSolubilityWater soluble

A method of forming an encapsulated composition with enhanced solubility and stability. A bicontinuous or Winsor Type III microemulsion is formed using an emulsifier, a solvent and a co-emulsifier. An active composition is added to the microemulsion resulting in a micellar network of the active composition within the microemulsion. The active composition can be either water-soluble or oil-soluble or both.

Owner:BANK OF AMERICA N A

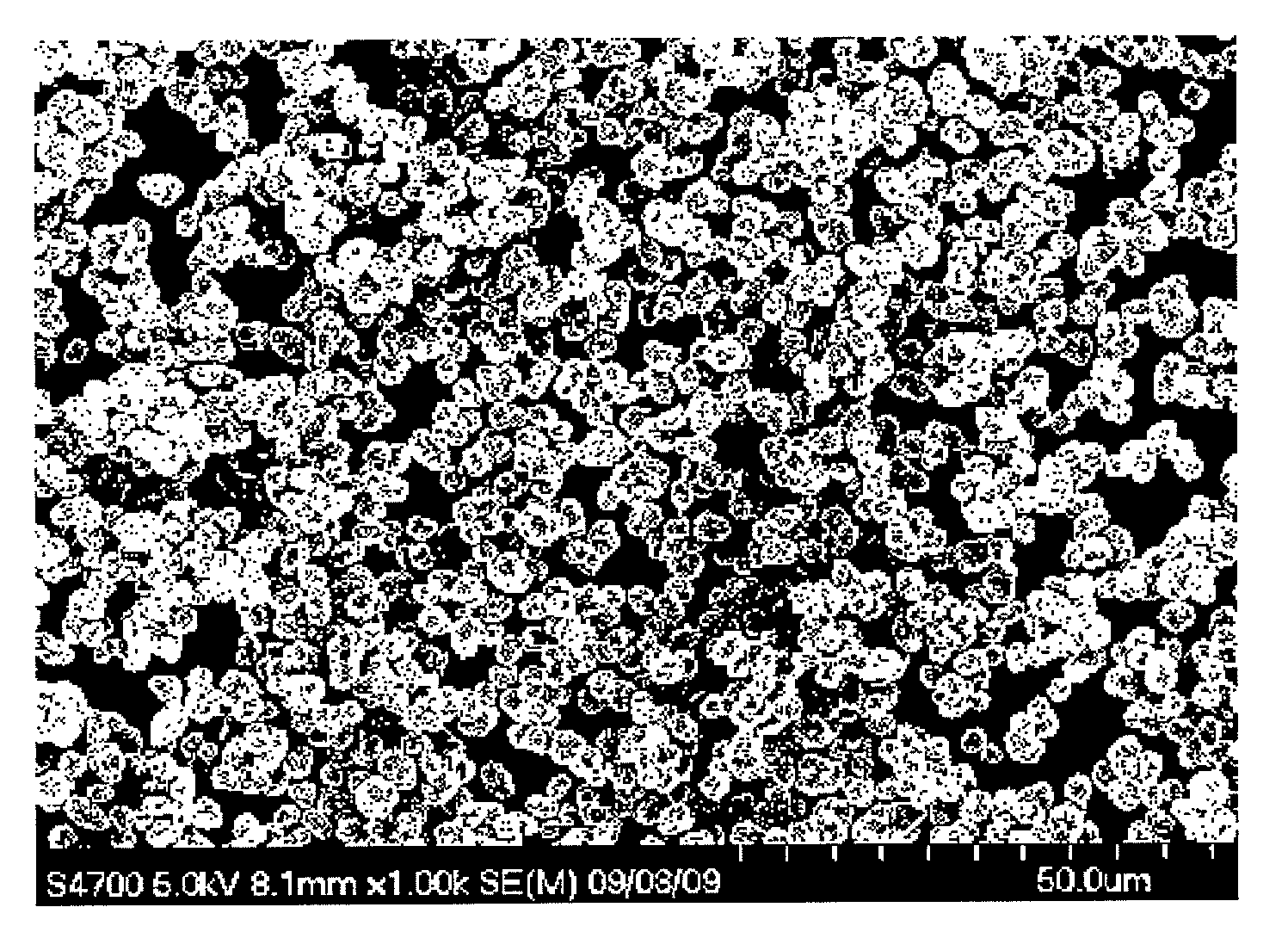

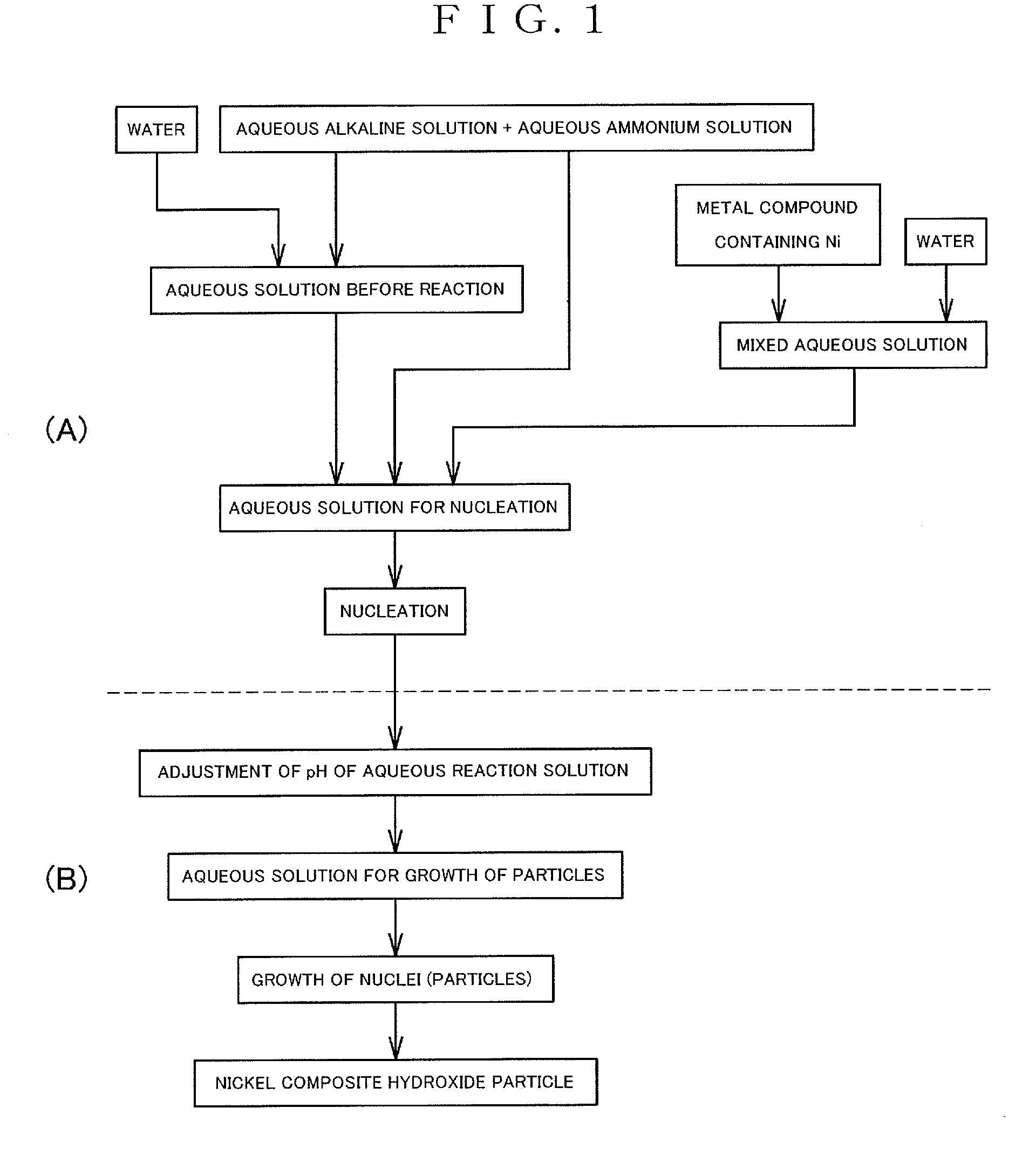

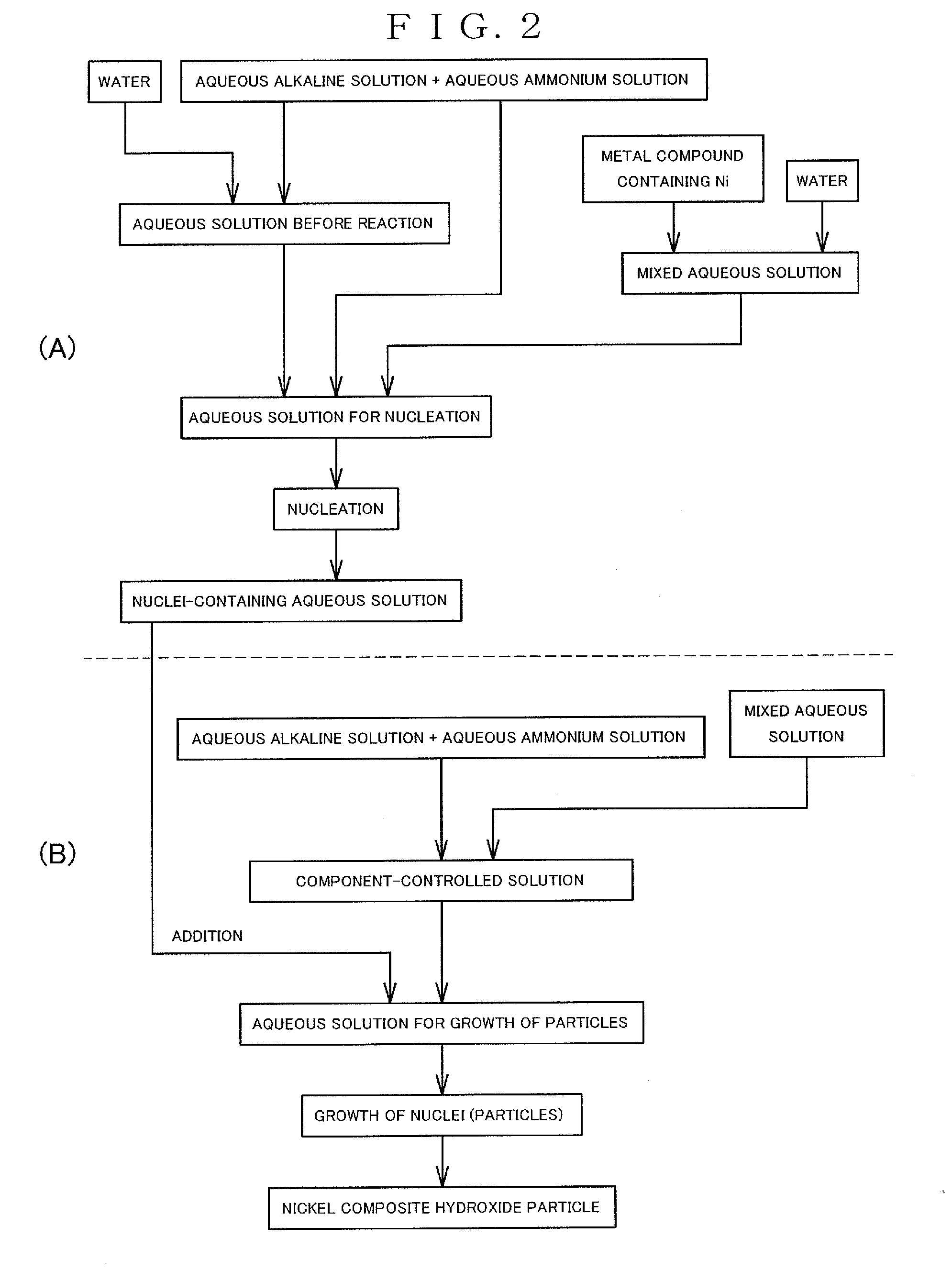

Nickel complex hydroxide particles and nonaqueous electrolyte secondary battery

ActiveUS20120276454A1Formation of new can be suppressedGrowth inhibitionOther chemical processesSynthetic resin layered productsLiquid temperatureParticle growth

Disclosed are: nickel complex hydroxide particles that have small and uniform particle diameters; and a method by which the nickel complex hydroxide particles can be produced. Specifically disclosed is a method for producing a nickel complex hydroxide by a crystallization reaction, which comprises: a nucleation step in which nucleation is carried out, while controlling an aqueous solution for nucleation containing an ammonium ion supplying material and a metal compound that contains nickel to have a pH of 12.0-13.4 at a liquid temperature of 25° C.; and a particle growth step in which nuclei are grown, while controlling an aqueous solution for particle growth containing the nuclei, which have been formed in the nucleation step, to have a pH of 10.5-12.0 at a liquid temperature of 25° C. In this connection, the pH in the particle growth step is controlled to be less than the pH in the nucleation step.

Owner:SUMITOMO METAL MINING CO LTD

Preparation method for starch nanospheres

InactiveCN104785179AEasy to operateEasy to controlMicroballoon preparationMicrocapsule preparationFood additiveMicrosphere

The invention discloses a preparation method for starch nanospheres. The method comprises the following steps: (1) dissolving amylase in an alkaline solution, and stirring to obtain suspension; (2) completely freezing the suspension obtained in the step (1); (3) thawing a product obtained in the step (2), and obtaining a starch solution; (4) dialyzing the starch solution obtained in the step (3), and obtaining starch dispersion liquid; (5) filtering the starch dispersion liquid obtained in the step (4), and drying to obtain the starch nanospheres. The preparation method is energy-saving, environment-friendly and simple to operate, and a process is easy to control; the preparation method only adopts a general chemical reagent and simple experimental equipment, can realize large-scale production and is easy for industrialized promotion; the starch nanospheres prepared with the method are high in purity, and the starch structure is not changed; the starch nanospheres prepared with the method are controllable in particle size and uniform in particle size distribution, can be stably dispersed in water, and can be used for biomedical carriers and food additives.

Owner:INST OF CHEM CHINESE ACAD OF SCI

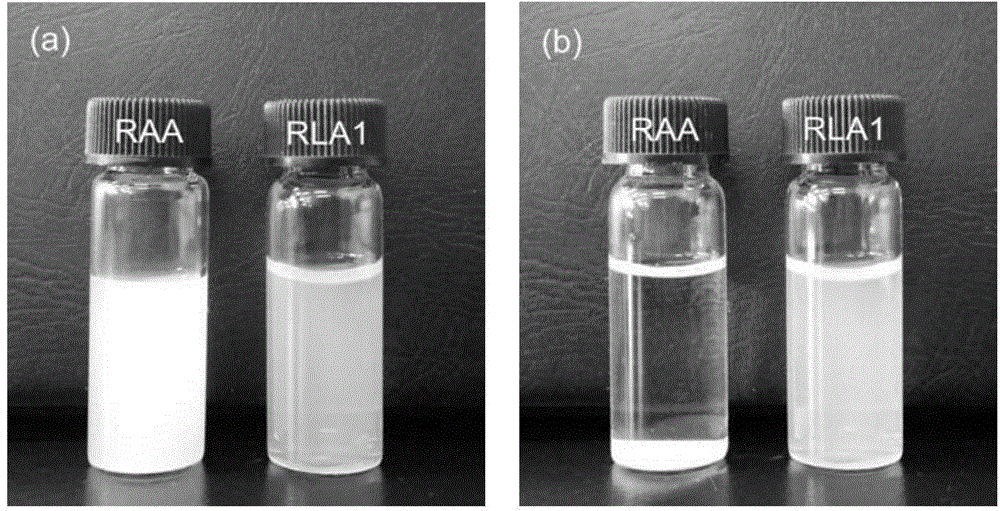

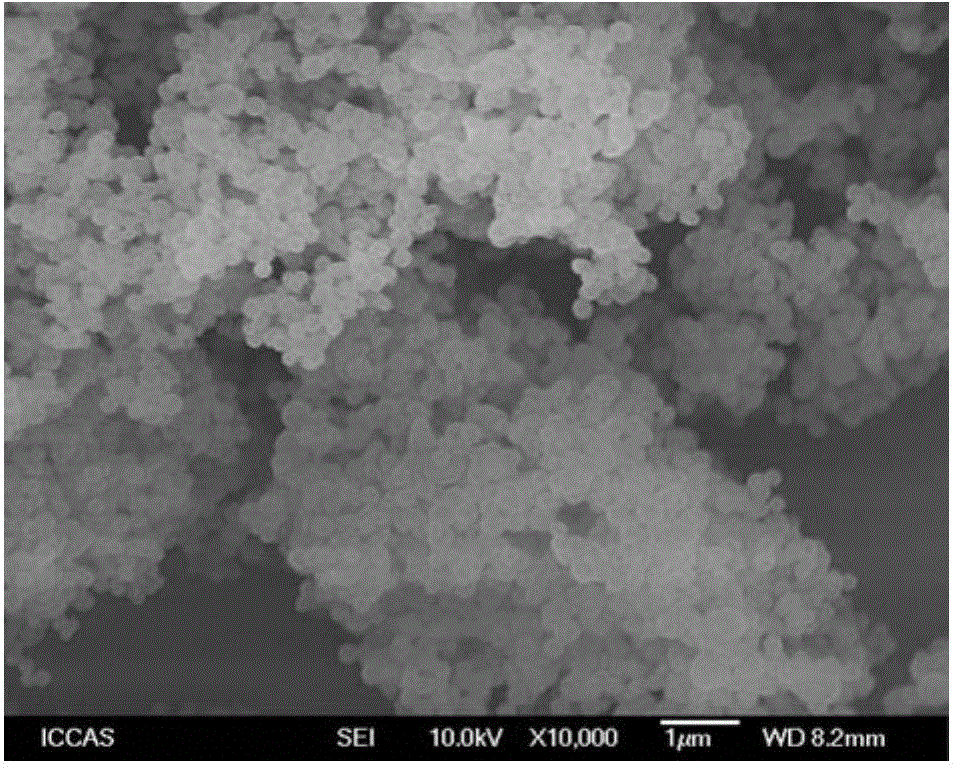

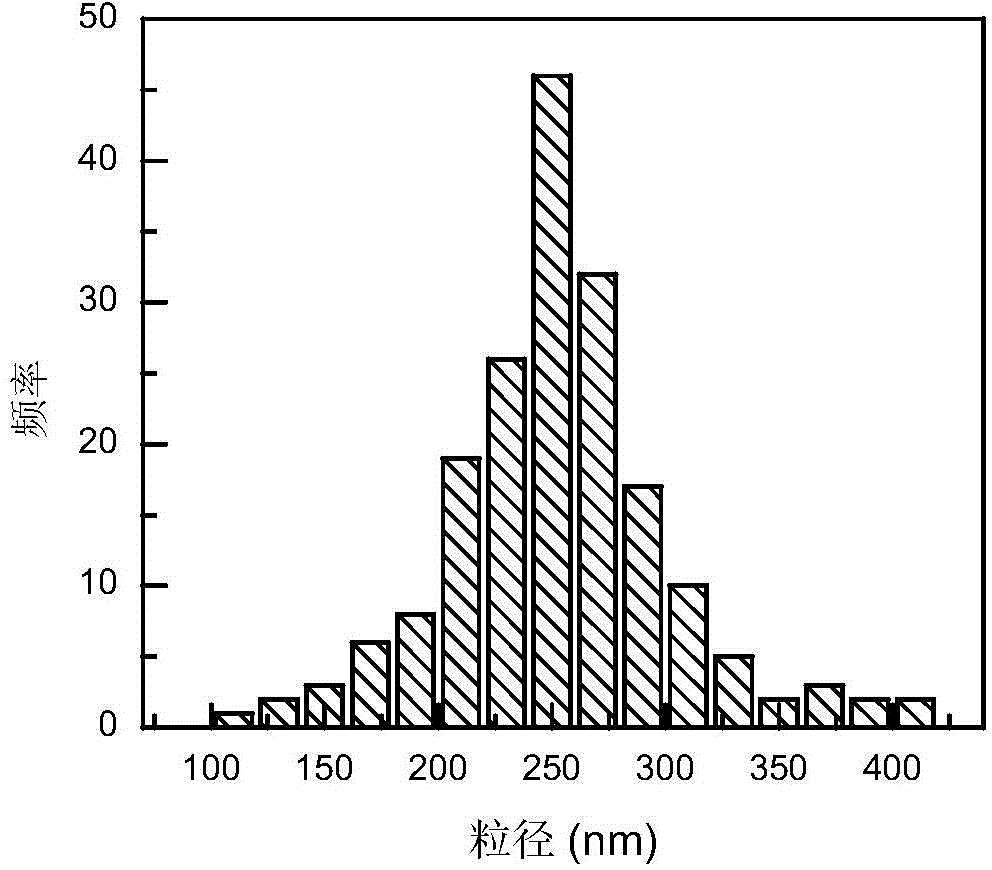

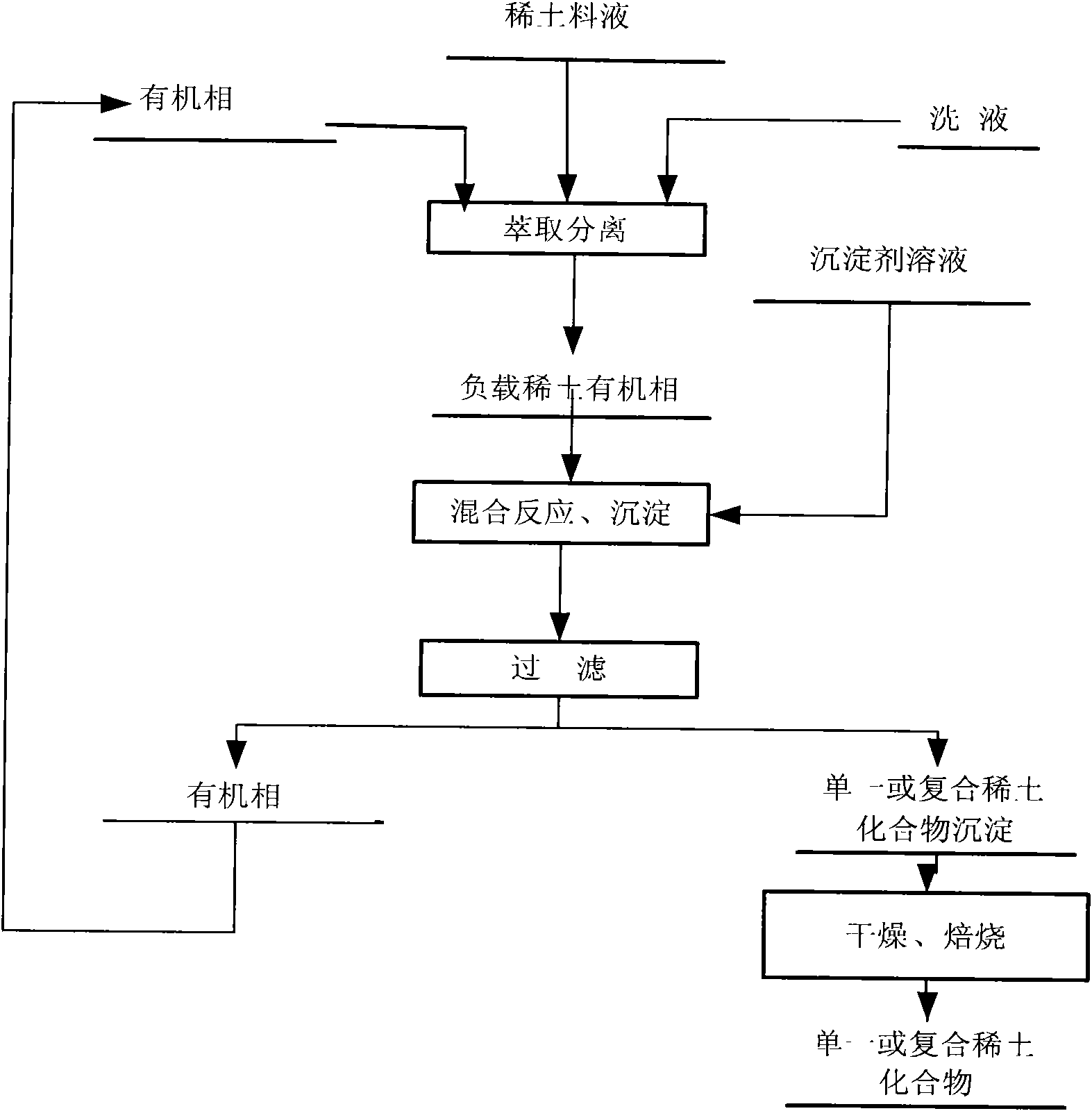

Process of directly preparing rare-earth compound from extraction separation load organic phase

InactiveCN101602519ASolve the problem of high residual acid and large acid consumptionEliminate the step of stripping rare earthRare earth metal compoundsProcess efficiency improvementDispersityRare earth

The invention provides a process of directly preparing a rare-earth compound from an extraction separation load organic phase. The process comprises following steps: carrying out a mixed precipitation reaction between a precipitator solution and the load organic phase which is obtained from extraction separation and contains rare-earth; post-treating the filter cake obtained by filtering slurry liquid so as to obtain the rare-earth compound with good dispersity and uniform particle size distribution; and returning the organic phase to the extraction separation working procedure for recycling use. The process of extracting and separating rare-earth omits the rare-earth stripping step, saves a great amount of acid needed by the rare-earth in a stripping load organic phase and solves the problems of stripping difficulty of medium-heavy rare-earth, high spent acid of a stripping solution, and the like. The invention uses the precipitator to precipitate the rare-earth from the organic phase, and the whole precipitation reaction is carried out on an oil-water interface to effectively control the grain size. Meanwhile, a trace organic phase is attached to grain surfaces and is used as a surface active agent to reduce the mutual adsorption action of grains for deflocculation. The invention can obtain products with good dispersity and uniform grain size distribution, thereby being a new method for preparing a high-quality rare-earth compound material. The invention has simple process, is easy to realize the industrialized production and has low production cost.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Multi-metal noumenon catalyzer for hydrodesulphurization of diesel oil, producing method and application of the same

InactiveCN101153228ARaw materials are simple and cheapEasy to operateRefining to eliminate hetero atomsHydrodesulfurizationSolvent

A polymetallic bulk catalyst for diesel oil hydrodesulfurization is provided. The particle diameter of the present invention is 10-100 nm, and the present invention consists of a species of VIII metal and two species of VIB metal, wherein, the mole ratio of the VIII metal and the VIB metal is 1:9-9:1, while the mole ratio of two species of VIB metal is 1:5-5:1. The preparation method is that: a) the basic carbonate of VIII metal is led to dissolve in solvent to form suspension liquid; b) two species of metal salts of the VIB metal are led to dissolve in the solvent, and surfactant is added into the solvent, stirred and heated to 50-250 DEG C; c) the suspension liquid in step a is added into the solvent in step b and led to react in reflux for 4-25 hours under 50-250 DEG C; d) the product obtained in step c is filtered, washed and dried to obtain target product. The catalyst of the present invention is used in the ultra-deep hydrodesulfurization of diesel oil and shows extremely high hydrodesulfurization activity. Under the same operating conditions, the activity of the present invention is 5.9 times as much as industrial reference agent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparing method for cubic silver nanometer grain

InactiveCN1552547AGood electrical conductivityGood self-assembly performanceAg nanoparticlesNanometre

A process for preparing the cubic silver nanocrystals includes such steps as proportionally dissolving surfactant and silver nitrate in organic solvent while stirring, slowly adding to an organic solvent at 150-180 deg.C to obtain the saturated solution of Ag nanoparticles, continuous reacting, and slow cooling while stirring to obtain the sol of cubic silver nanocrystals. Its advantage is high purity and dispersity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

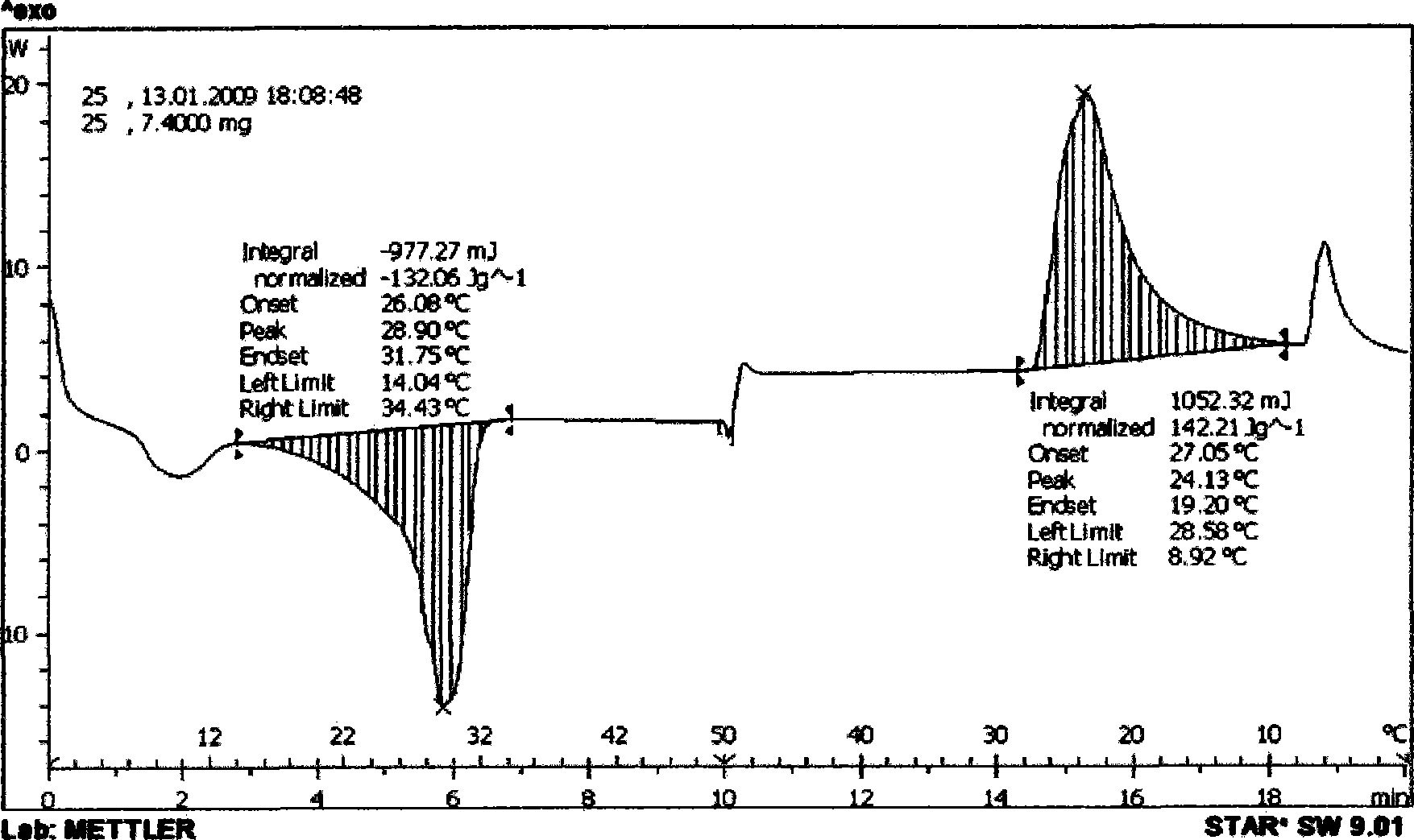

Preparing method for phase transited stored energy microcapsule covered with an organic polymer material

InactiveCN101530772ALess light fastnessSmall smellHeat-exchange elementsMicroballoon preparationPolymer chemistryPhase-change material

A preparing method for phase transited stored energy microcapsule covered with an organic polymer material adopts the following steps: (1) mixing the 10 weight organic phase transited material and 0.5-2.5 weight nonionic surfactant under the condition of heating and blending; (2) picking the organic polymer material monomer A, B 2-3 weight to add to 40-60 weight water, blending and mixing as the water phase; (3) adding the oil phase to the water phase, blending the material as the creaming liquid at 30-50 centigrade, adding the free radical to the initiator for the poly-reaction 1-8h at 35-90 centigrade; then adjusting the low temperature as blending the material and adding the cross linker, filtering, washing and drying to obtain the finished products. The organic polymer material achieves the phase transited capsule envelopment via the creaming polymer reaction of the wall material; the microcapsule is the spherical; the granule is distributed evenly; the polymer wall material has a stable intensity, great tightness and great mechanical performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

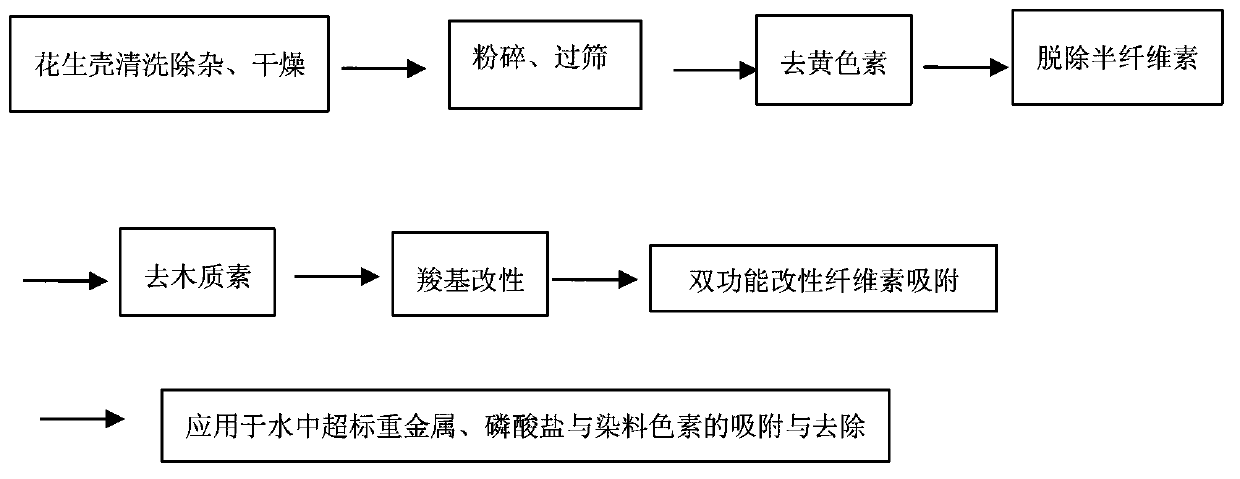

Method for preparing bifunctional modified cellulose adsorbing agent from peanut shells and application of method

InactiveCN103272568AGood biocompatibilityAchieve adsorptionOther chemical processesWater/sewage treatment by sorptionPhosphateSorbent

The invention discloses a method for preparing a bifunctional modified cellulose adsorbing agent from peanut shells and application of the method. The method comprises the following preparation steps of: washing, drying and crushing waste peanut shells, which are taken as raw materials, and removing flavochrome, hemicellulose and xylogen from the crushed peanut shells so as to obtain peanut shell cellulose; and performing surface functional modification on the materials through substitution and amidation further so as to finally obtain the amino and carboxy bifunctional modified peanut shell cellulose adsorbing material. The product is powdery and light brownish yellow, and the particle size of the product is 1.5-2.5 microns. The bifunctional modified peanut shell cellulose adsorbing material has a good adsorption effect for excessive heavy metals such as copper, chrome and mercury, phosphate, methylthionine chloride dye, and the like in water. The adsorbing agent is simple in preparation method, low in cost, cheap, easily available, good in biological compatibility and environment-friendly, contains a great deal of functional chelation groups, can realize simultaneous adsorption and removal of negative ions and positive ions, and has the advantages of being recyclable and the like.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

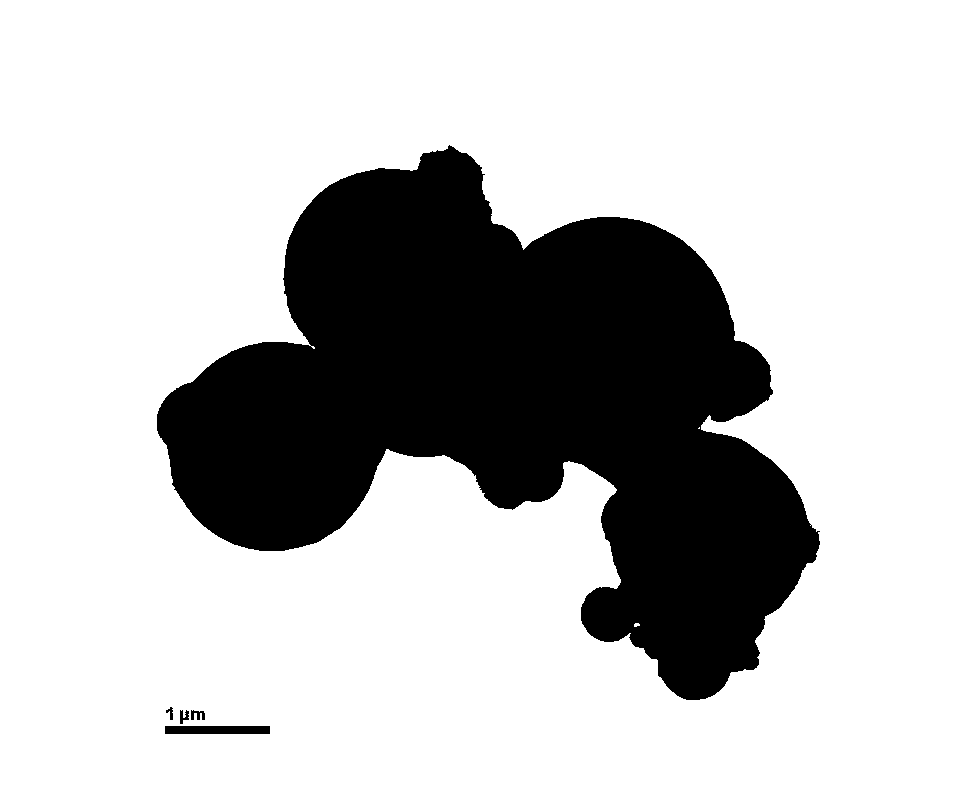

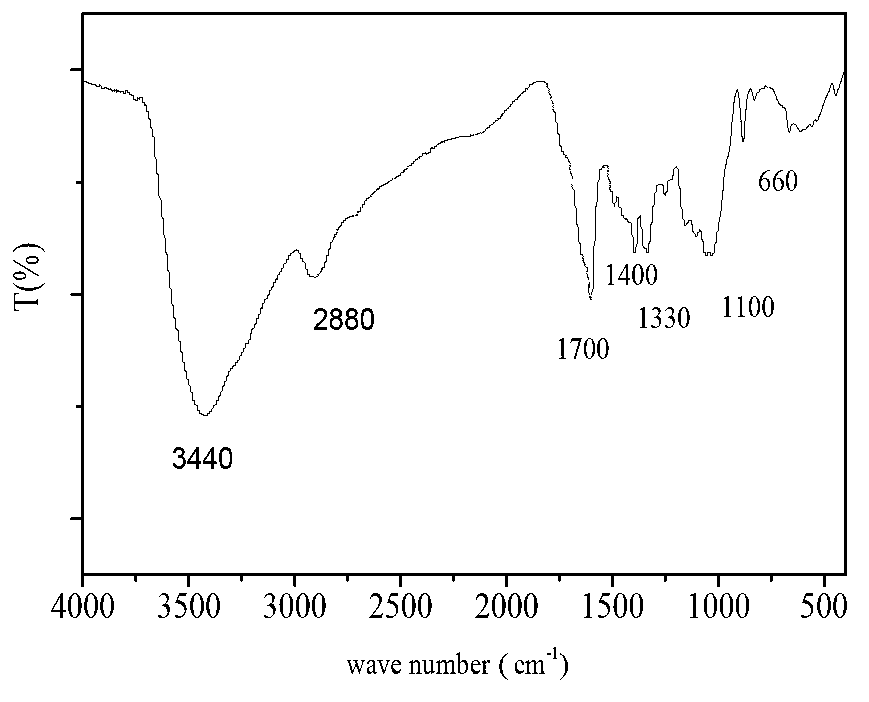

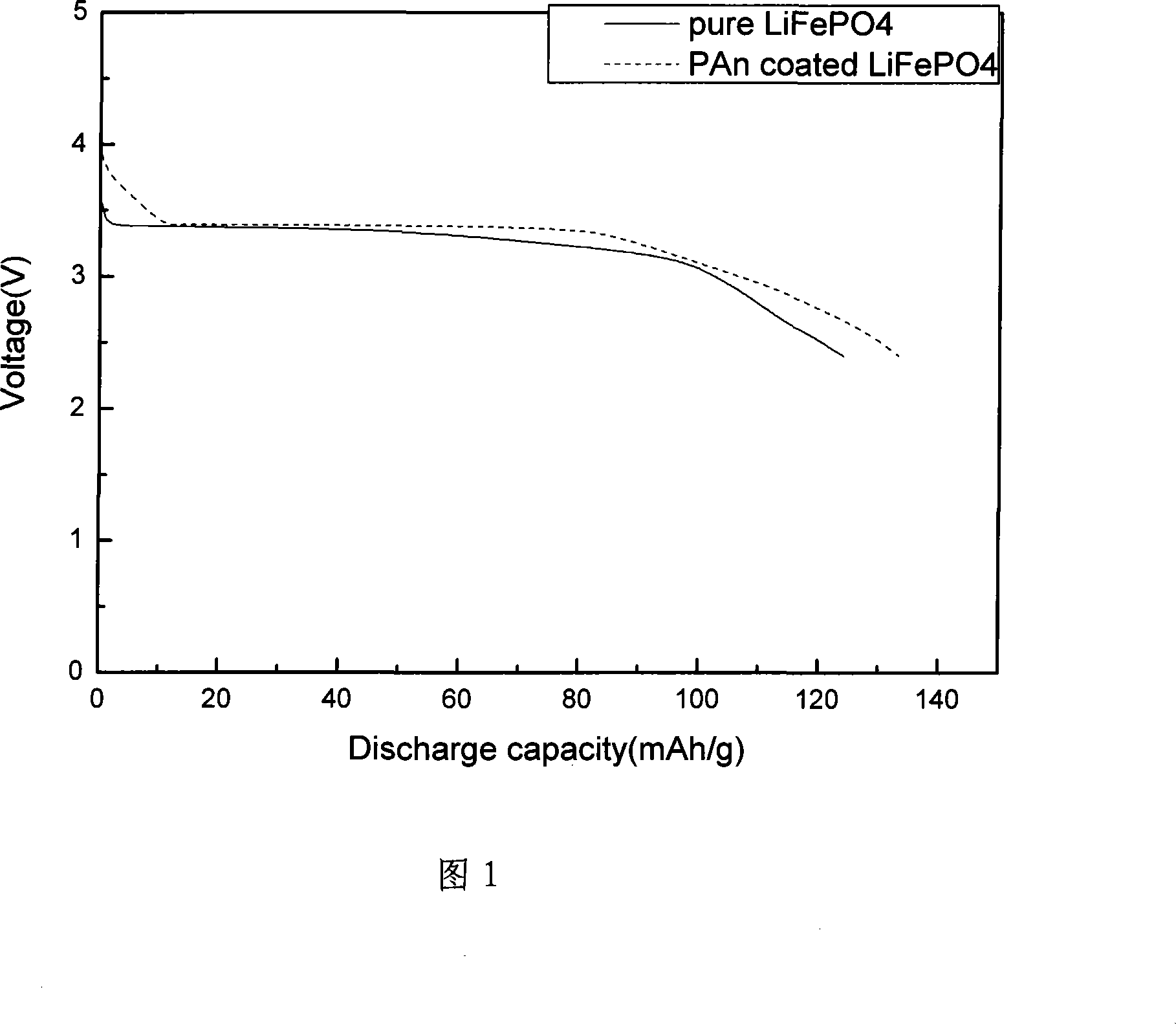

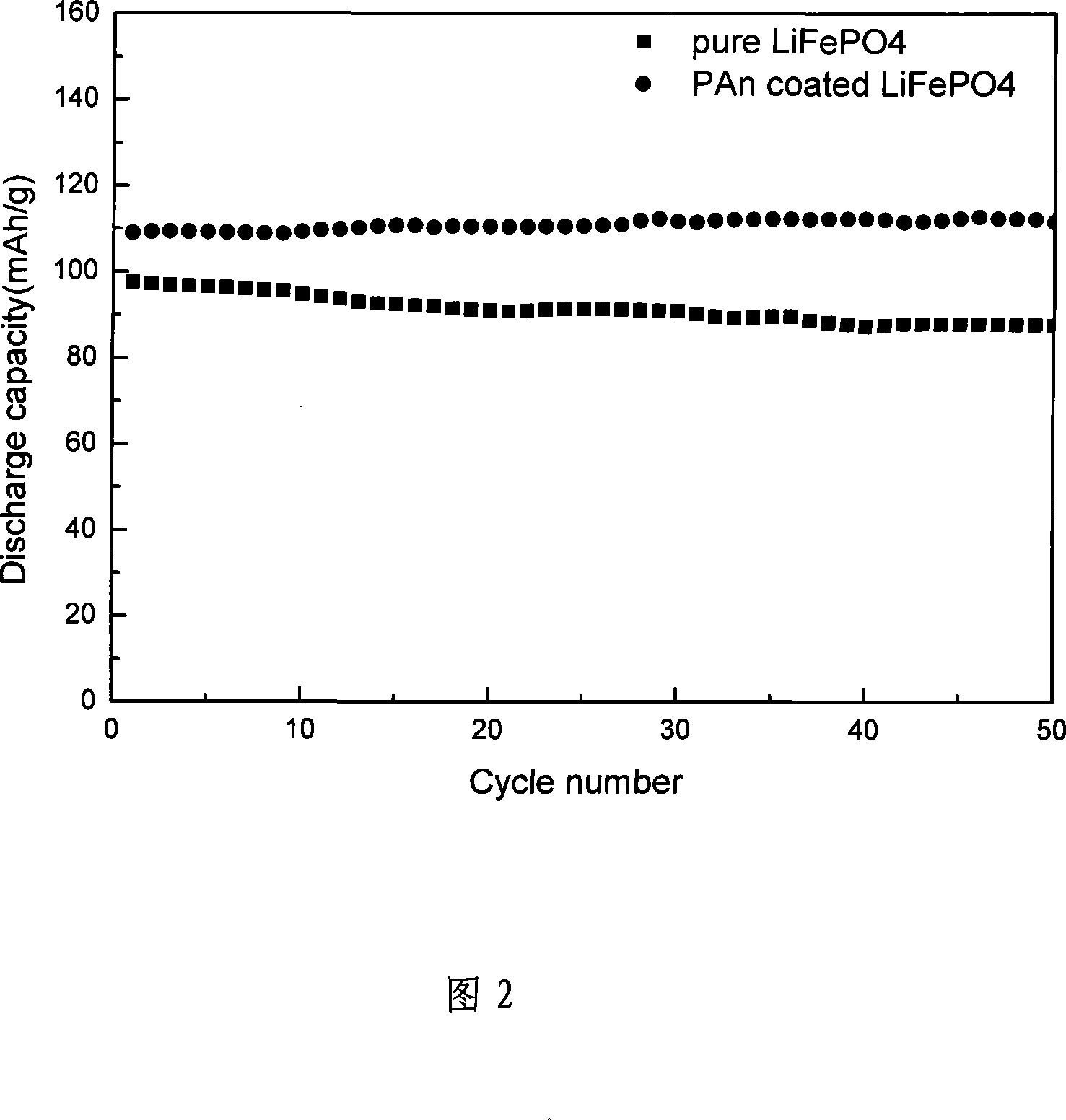

Making method for positive material LiFePO4 of poly-aniline coated lithium ion battery

InactiveCN101237036AStable discharge voltage platformHigh specific capacityElectrode manufacturing processesPhosphorus compoundsGranularitySodium-ion battery

The invention discloses a method for preparing polyaniline coating Li-ion battery anode material LiFePO4. The method is coating polyaniline on the in-situ surface of the powder of Li-ion battery anode material LiFePO4. The method has the following favorable effects: the discharging voltage platform of the polyaniline coating anode material LiFePO4obtained is stable, the battery has higher specific capacity up to one hundred and forty point three mAh / g, the granularity is distributed evenly, the grains are in good appearance and high in discharging capacity and long in cycling life, etc.

Owner:XIANGTAN UNIV

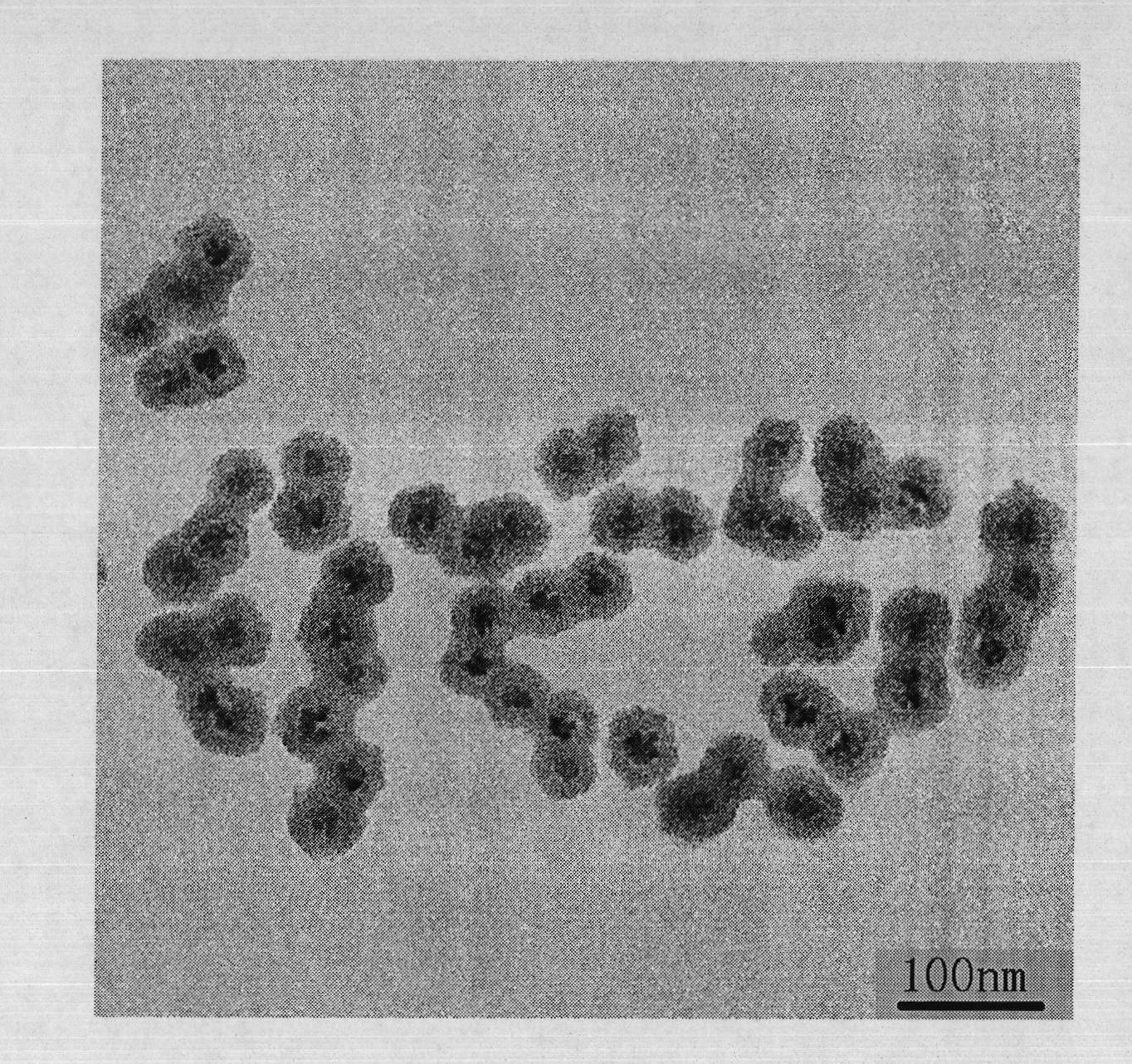

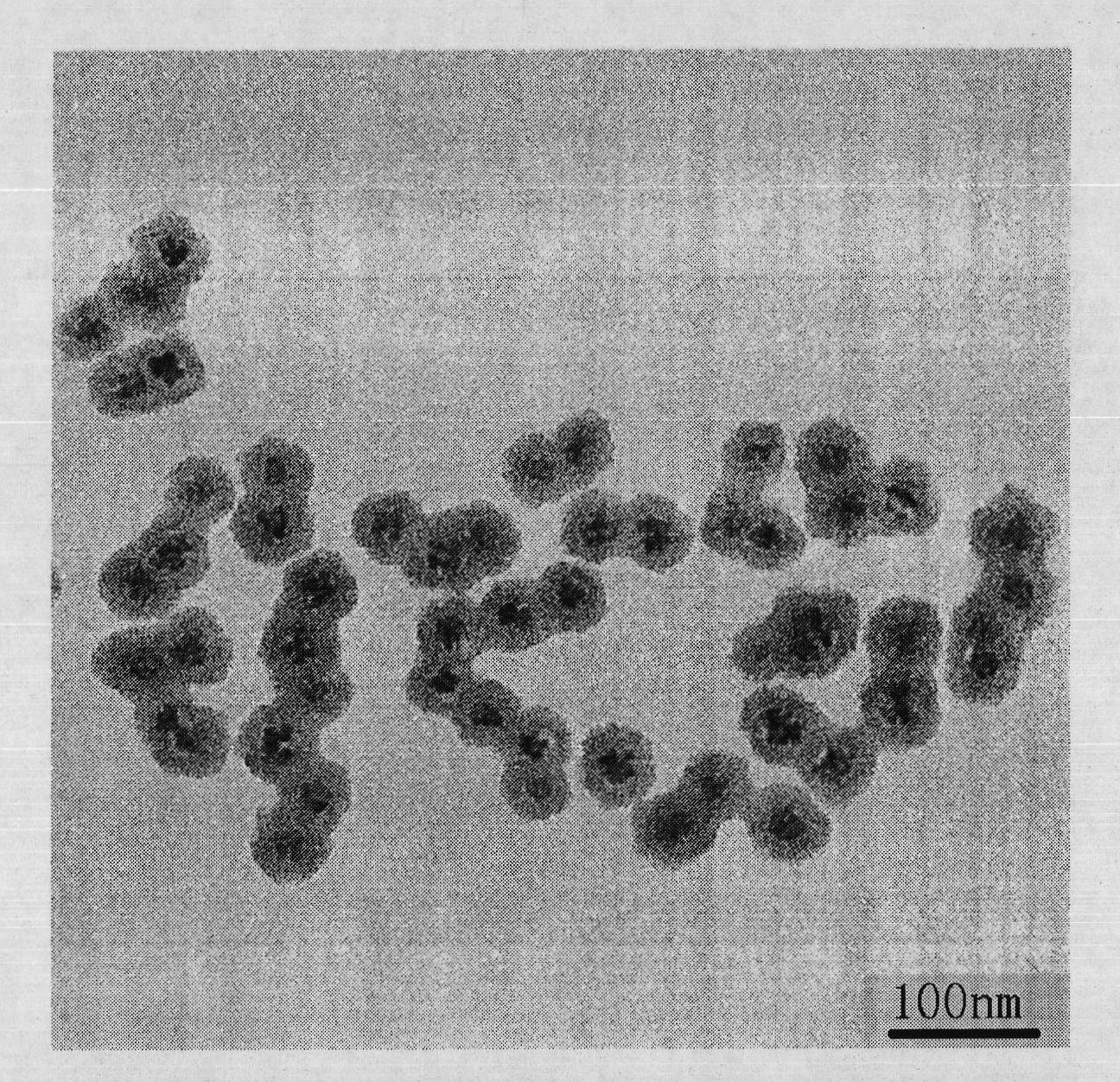

Preparation method and application of core-shell structure cobalt-base catalyst of middle distillate for synthesis gas preparation

ActiveCN101804351AUniform particle size distributionGood dispersionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSyngasNanometre

The invention relates to a core-shell structure cobalt-base catalyst of a middle distillate for synthesis gas preparation, which comprises the following components in percentage by weight: 5 to 30 percent of cobalt and 70 to 95 percent of silica. The catalyst has the following physical properties: the specific surface area is 200 to 1400m<2> / g, the pore volume is 0.5 to 1.3cm<3> / g, the average pore size is 2.0 to 18nm, the cobalt crystallite dimension is 12 to 25nm, and the particle size of the core-shell structure cobalt-base catalyst is less than 100nm, and cobaltosic oxide nano particles are coated in a mesoporous silicon shell to form a core-shell structure. The invention has the advantages of simple operation, high yield, high activity and high selectivity of the middle distillate.

Owner:中科潞安能源技术有限公司

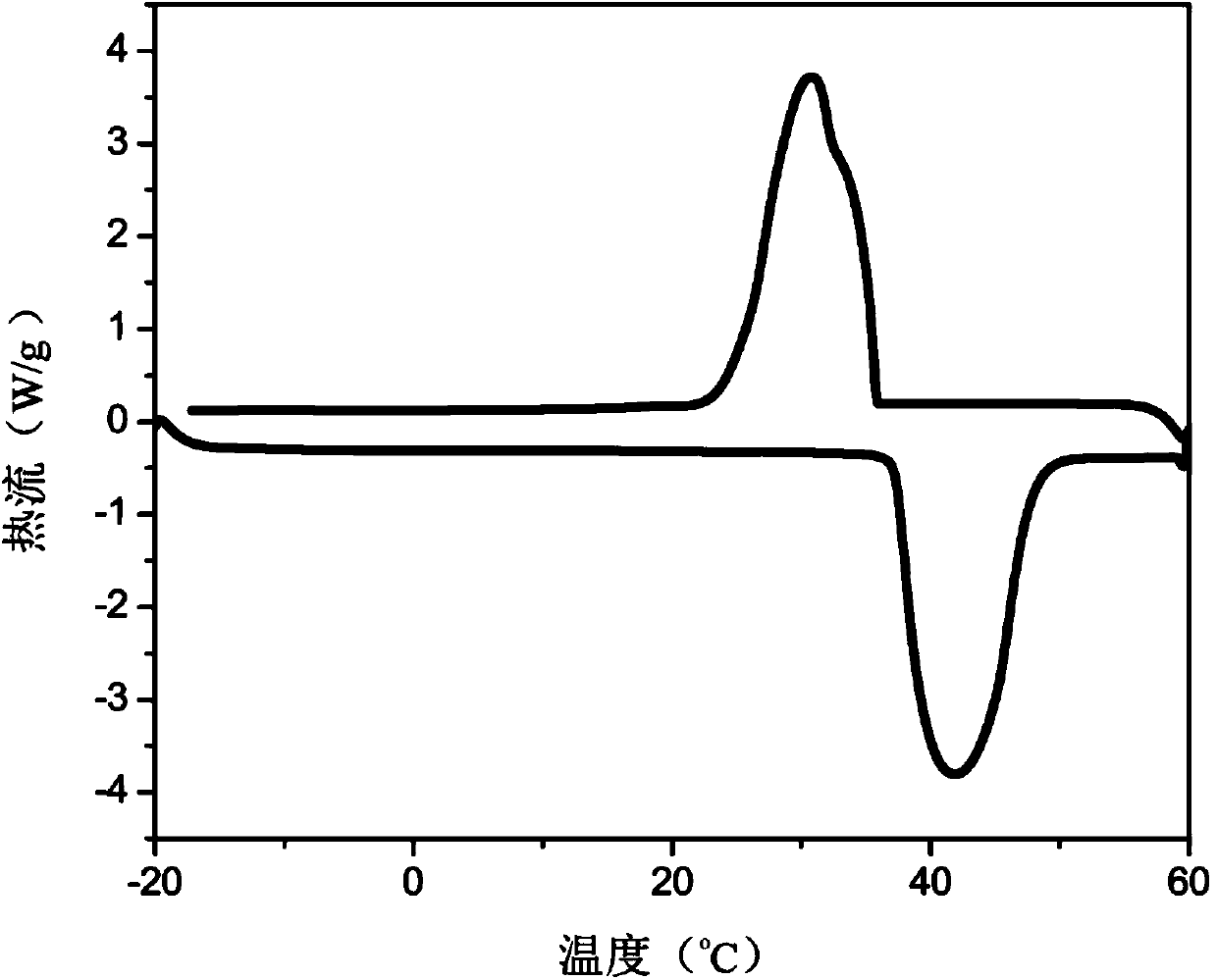

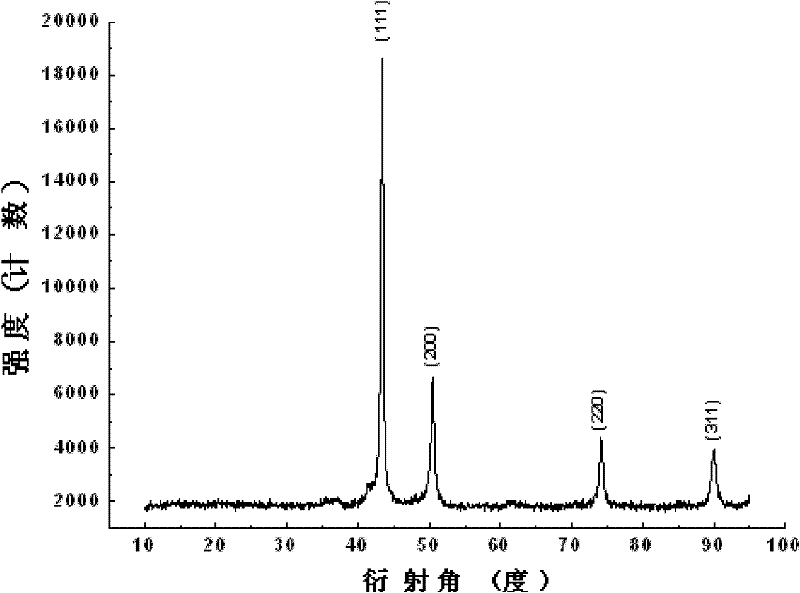

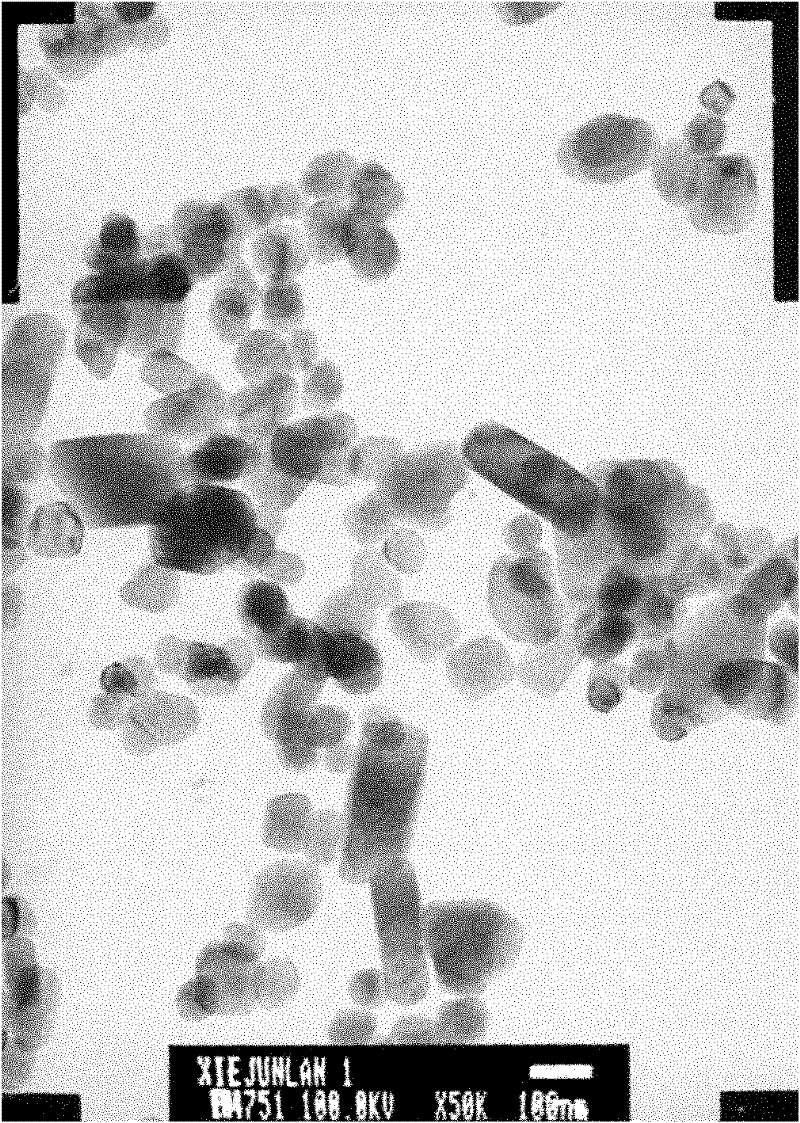

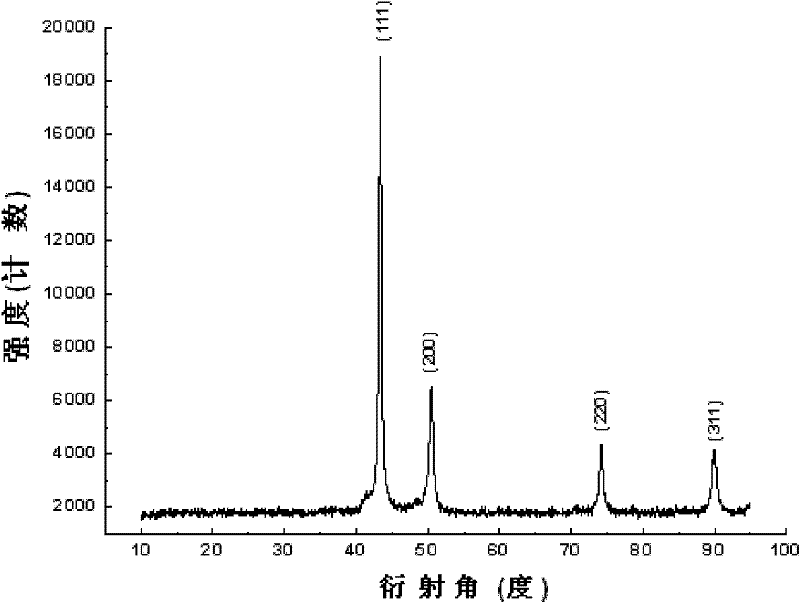

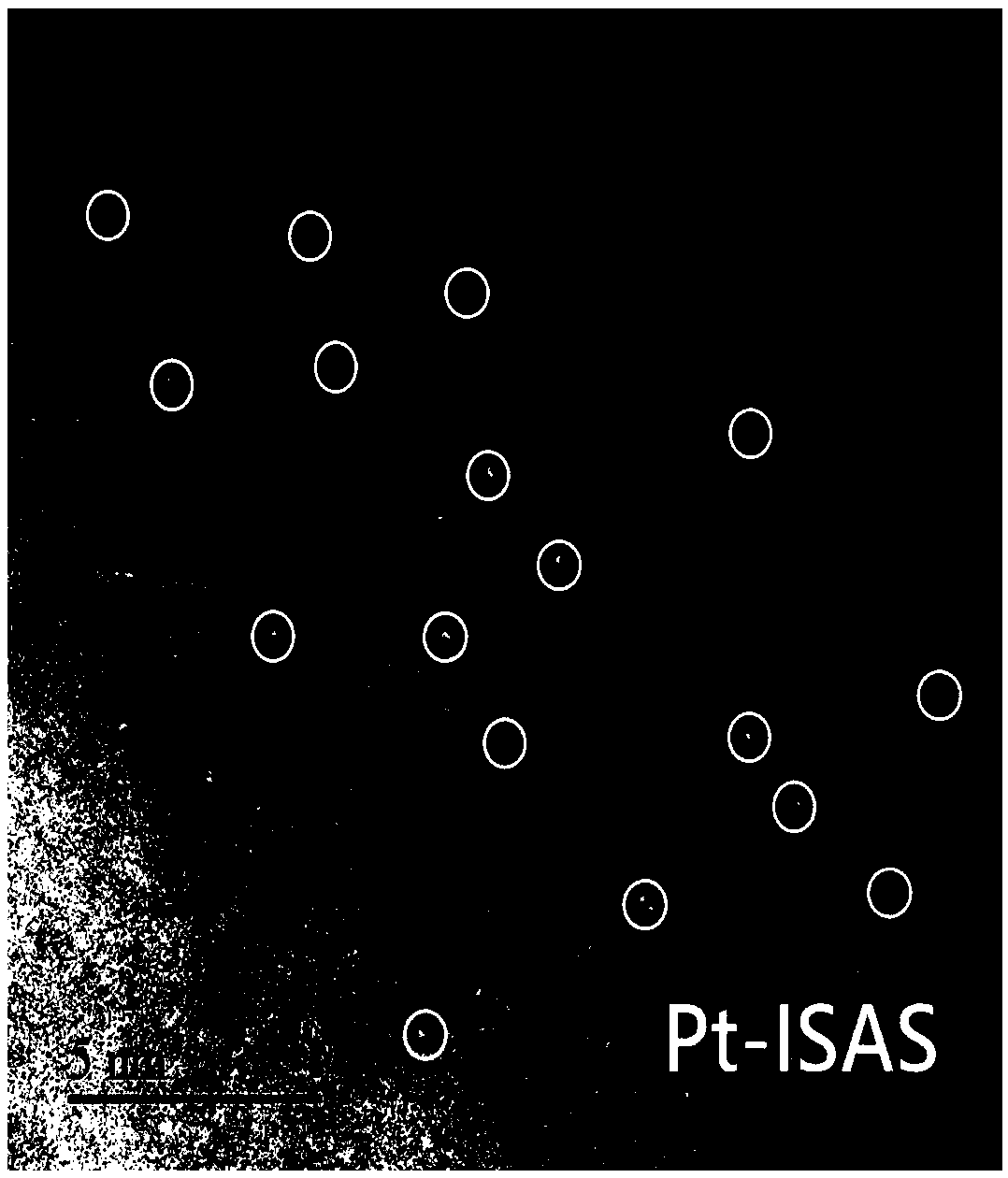

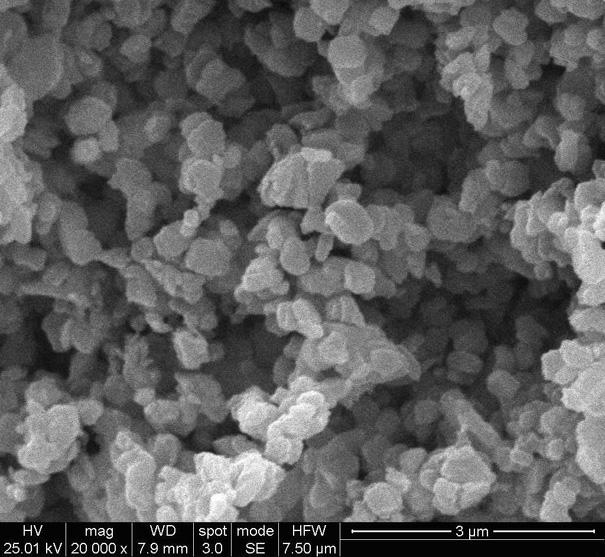

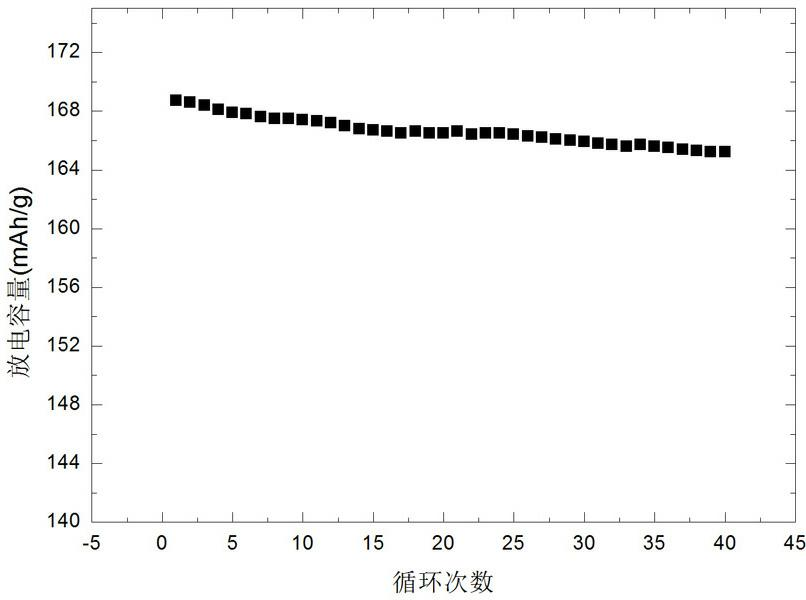

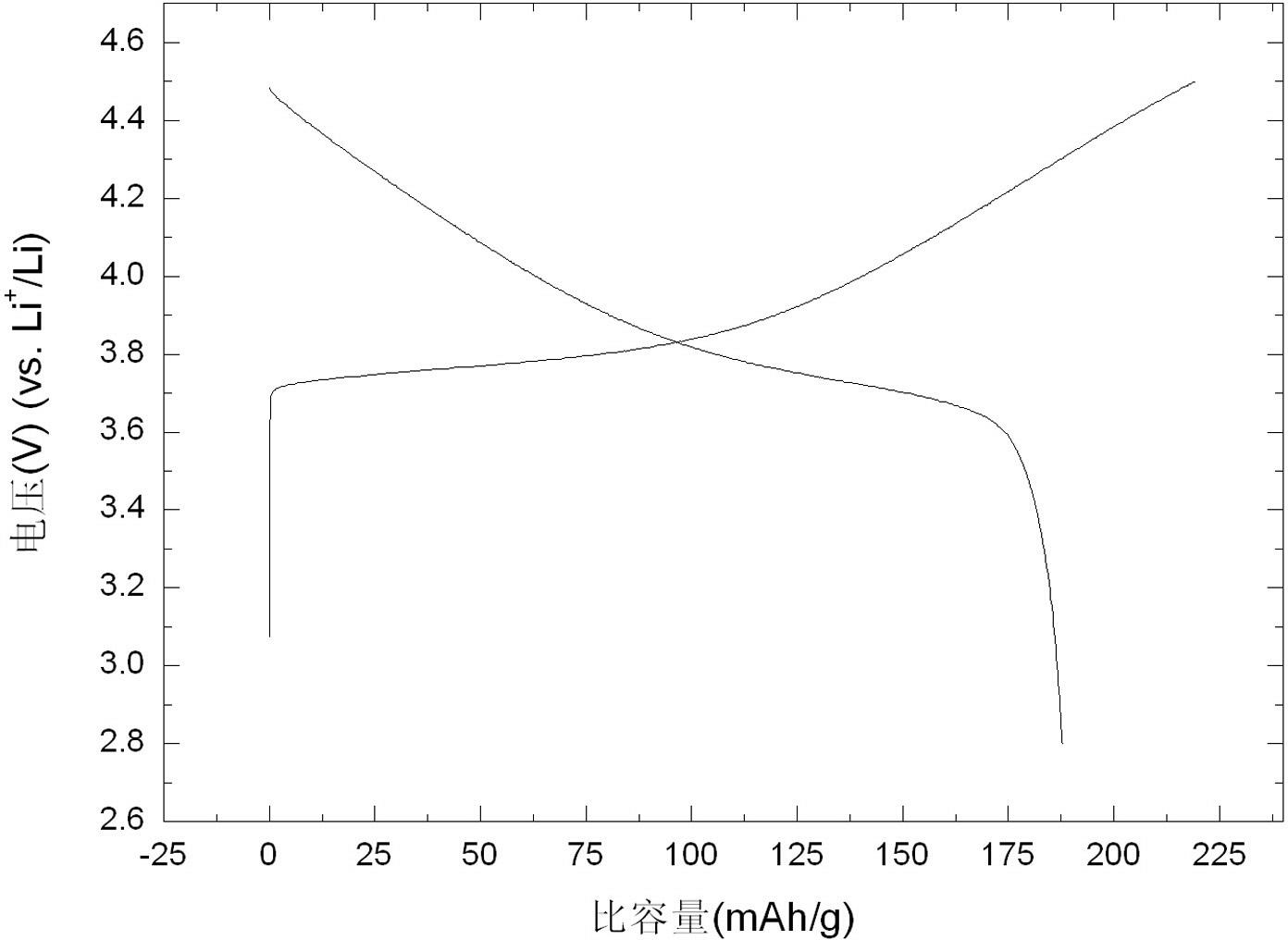

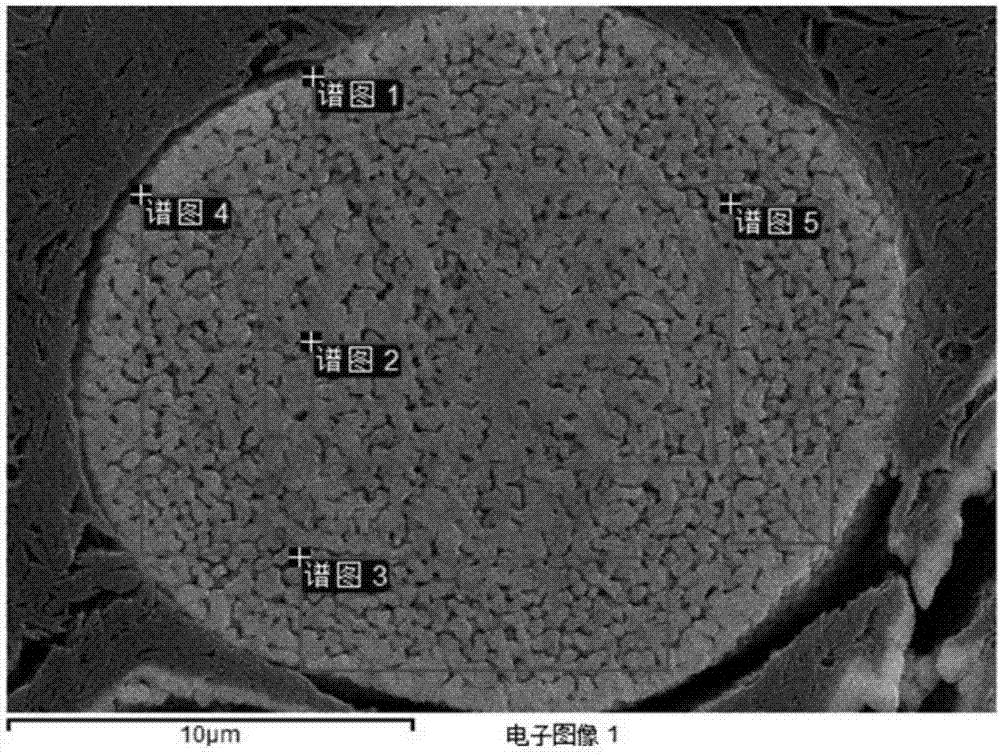

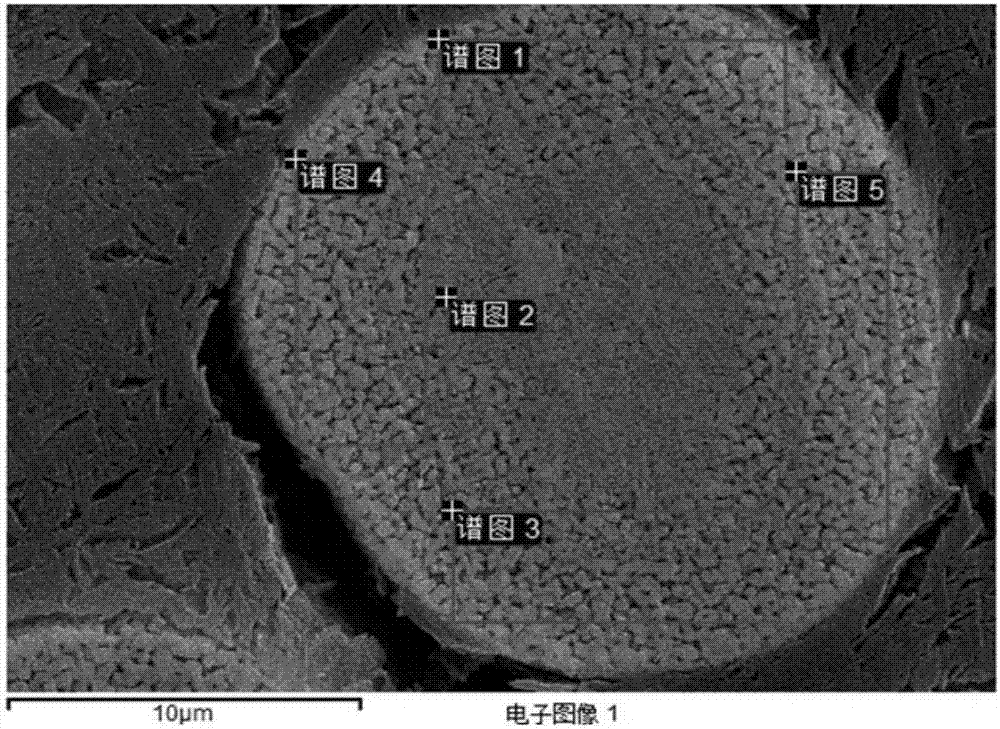

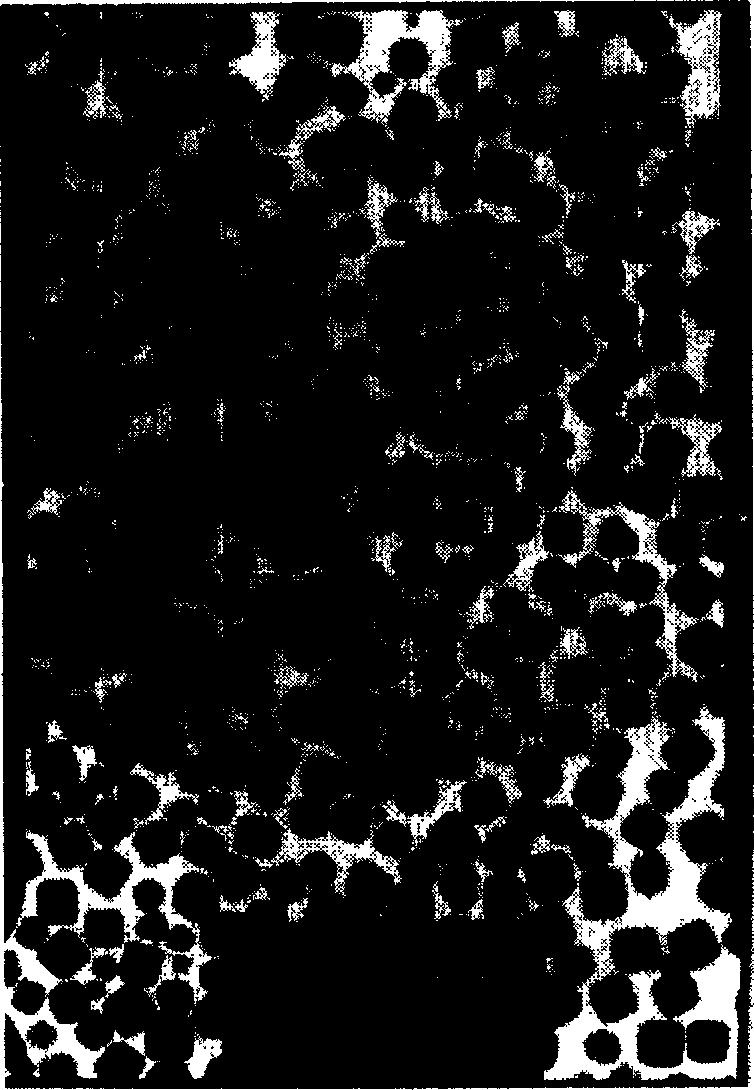

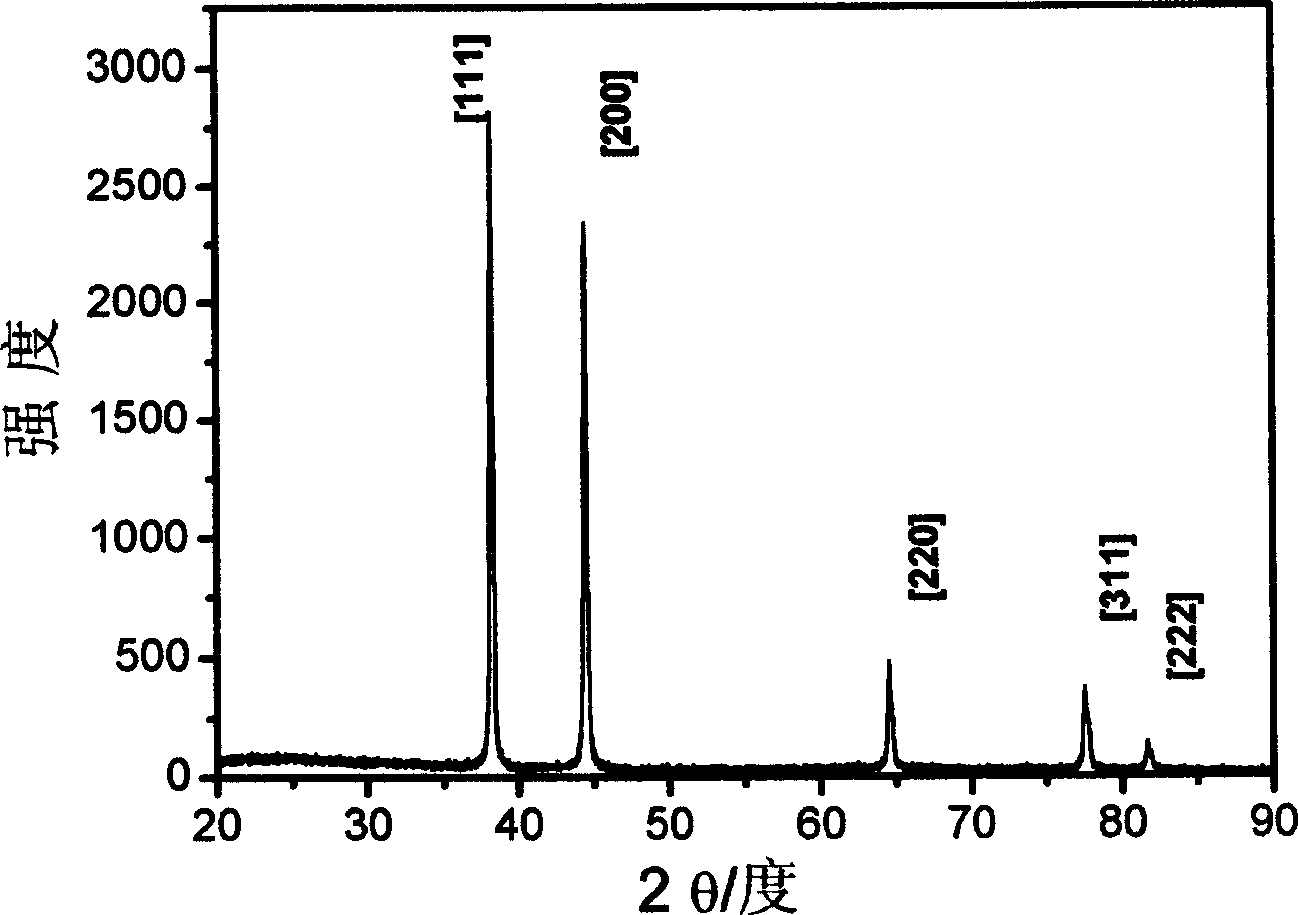

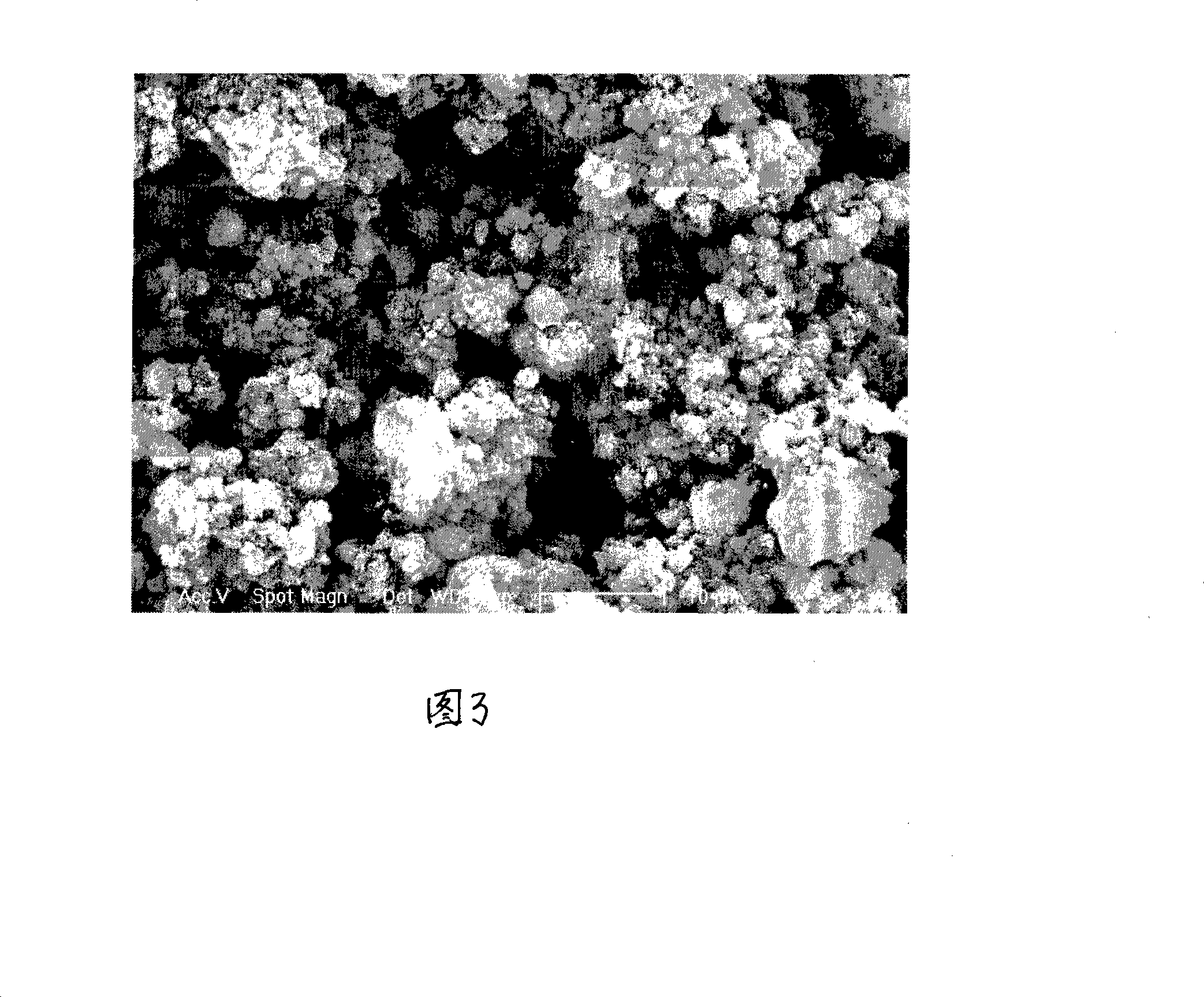

Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material

InactiveCN102013475AEasy to processImprove performanceCell electrodesNanotechnologyLithium iron phosphatePhosphor

The invention discloses a method for preparing a porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y] / 3) / C material, comprising the specific steps of: dissolving a lithium-containing compound, an iron-containing compound, a phosphor-containing compound and a element-doped compound additive in a dispersing agent to form a sizing agent; dispersing a mixture of a pore-forming agent, a cladding agent and a stabilizer in a dispersing agent through ultrasound, then adding into the sizing agent and mixing to form a new sizing agent; carrying out a physical method or a chemical method on the new sizing agent to obtain a sizing agent with the primary particles in nano grade; carrying out spraying drying and granulating on the obtained sizing agent with the primary particles in nano scale to obtain a dry mixed material with secondary particles with spherical appearances; then carrying out a sintering process on the dry mixed material to obtain the product of the invention. The method has the advantages that besides that the primary particles reach the nano scale, the particle diameters are more uniform in distribution and more regular in appearance, an iron phosphate product synthesized from the material has the particle diameters with uniform distribution, and the material has favorable processability, good electric conductivity, excellent power multiplication performance and higher actual capacity.

Owner:秦波

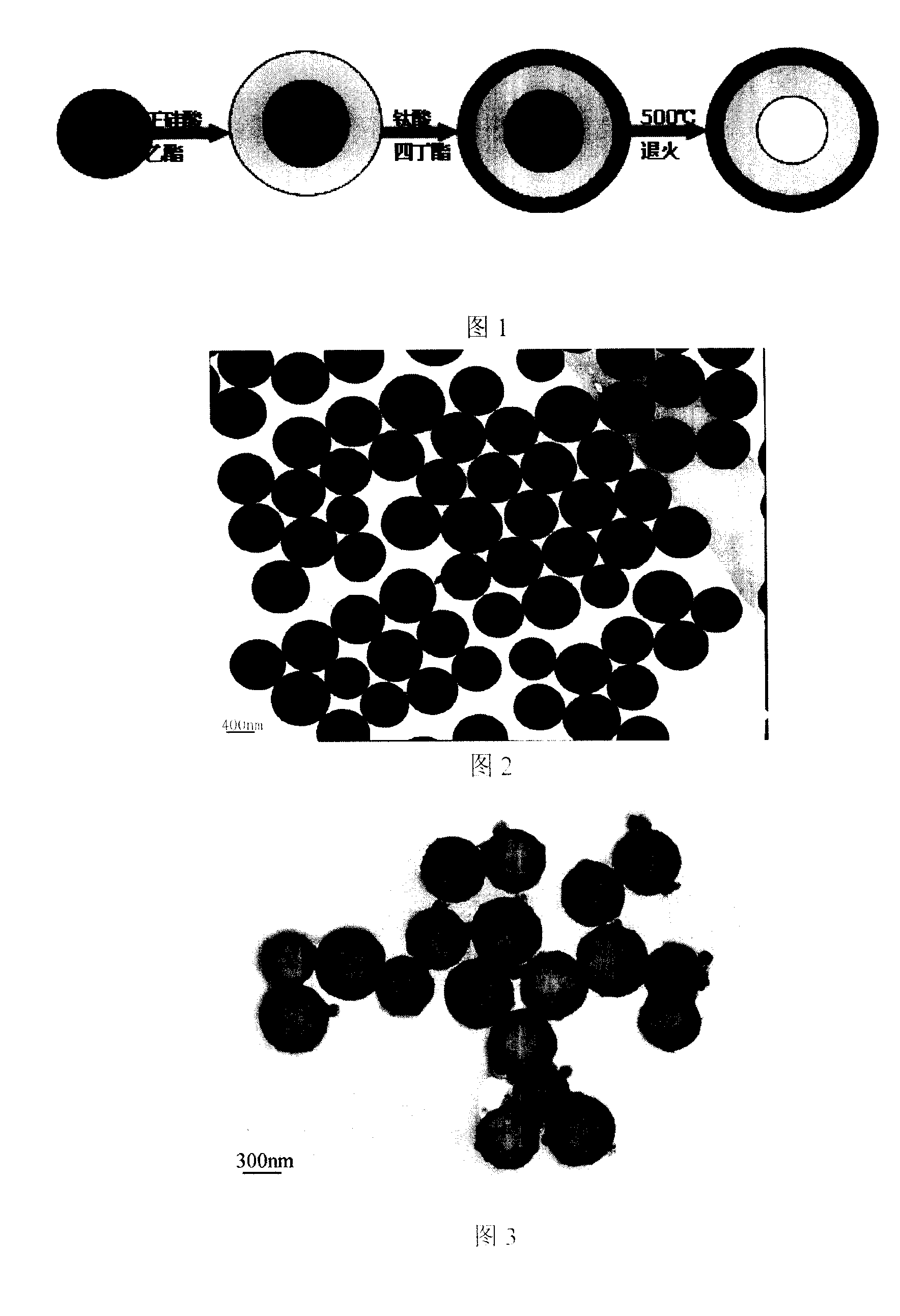

SiO2/TiO2 hollow compound structural material as well as preparation method and uses thereof

InactiveCN101229957AGood monodispersityUniform particle size distributionStructural materialGreenhouse

The invention relates to a hollow material with a composite structure of SiO2 / TiO2 and a preparation method and application thereof. By applying hydrothermal reaction, glucose solution is carbonized at 160 to 200 DEG C to obtain carbon nanometer spheres with a particle size of 200nm to 1um; the carbon nanometer spheres are used as hard templates; hydrolysis of ethyl orthosilicate and tetrabutyl titanate are used for wrapping the SiO2 and TiO2 on the surfaces of the carbon spheres; the obtained product is annealed for an hour at the temperature of 450 to 500 DEG C; the carbon spheres are removed, and the hollow structure of silicon dioxide / titanium dioxide is obtained; then the obtained product is prepared into membranes with different layers by applying a czochralski method and a spin coating method respectively. The method is reasonable in design and simple in technology; besides, the hollow structure has even size-distribution and controllable particle size; the hollow silicon dioxide can remarkably improve the transmission rate of the membranes; the composite membranes are widely applied to fields such as windshields, various lenses and agricultural greenhouses.

Owner:SHANDONG UNIV

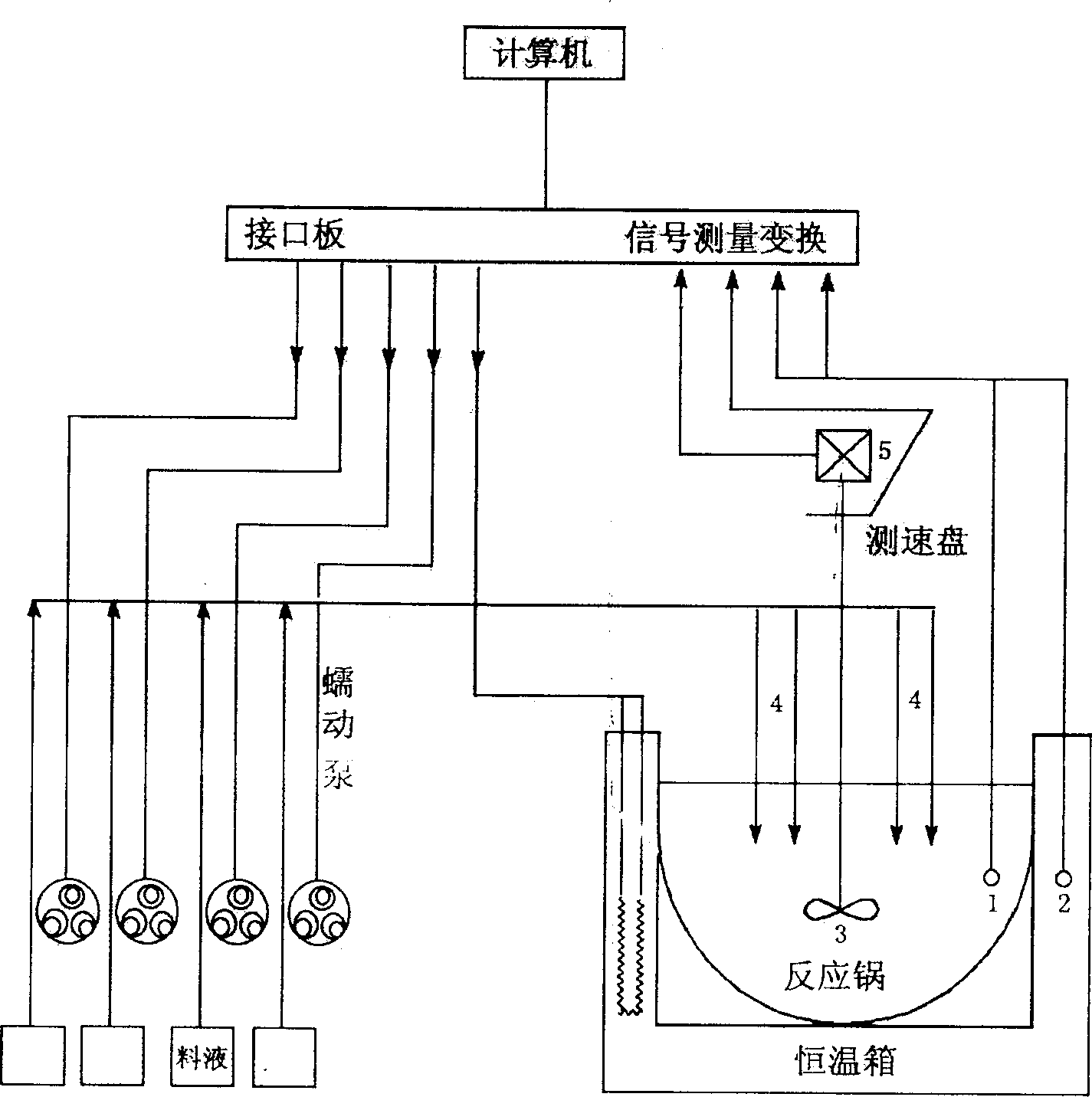

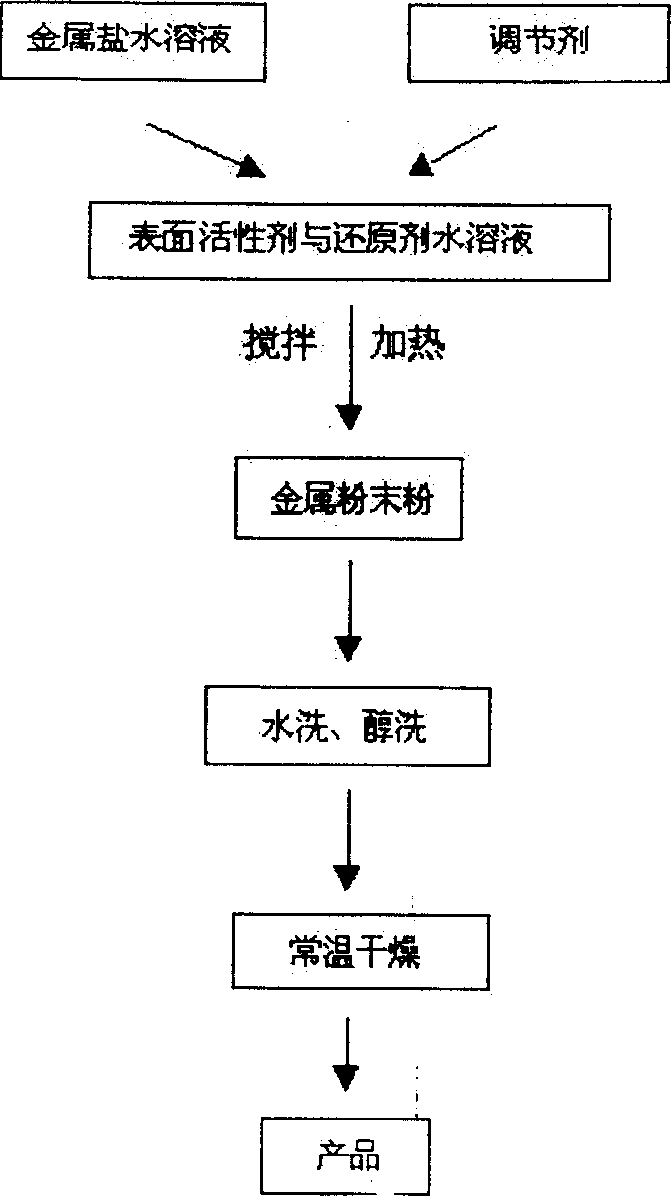

Preparation method of metallic nano powder

A process for preparing nano-class metal particles by dual-pouring method features that under the existance of protector and regulator, the metallic salt is reduced by reducing agent to obtain one ormore (30-100 nm) metallic particles. Its advantages are high dispersity, easy control of diameter, high output rate up to 95%, and preparing the particles of more metals by a single equipment.

Owner:TIANJIN ZHONGKE PHYSICAL & CHEM NEW MATERIAL TECH CO LTD

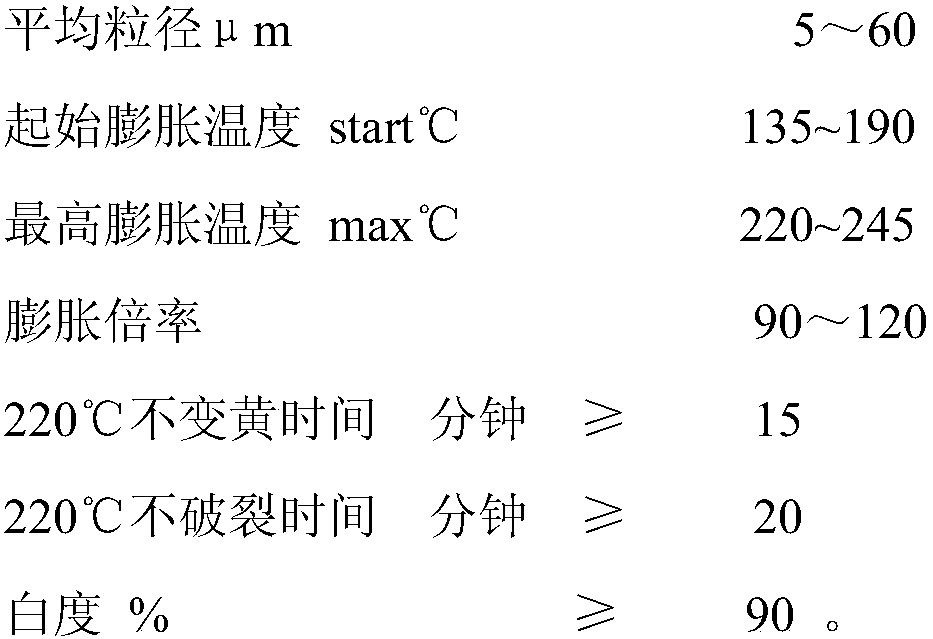

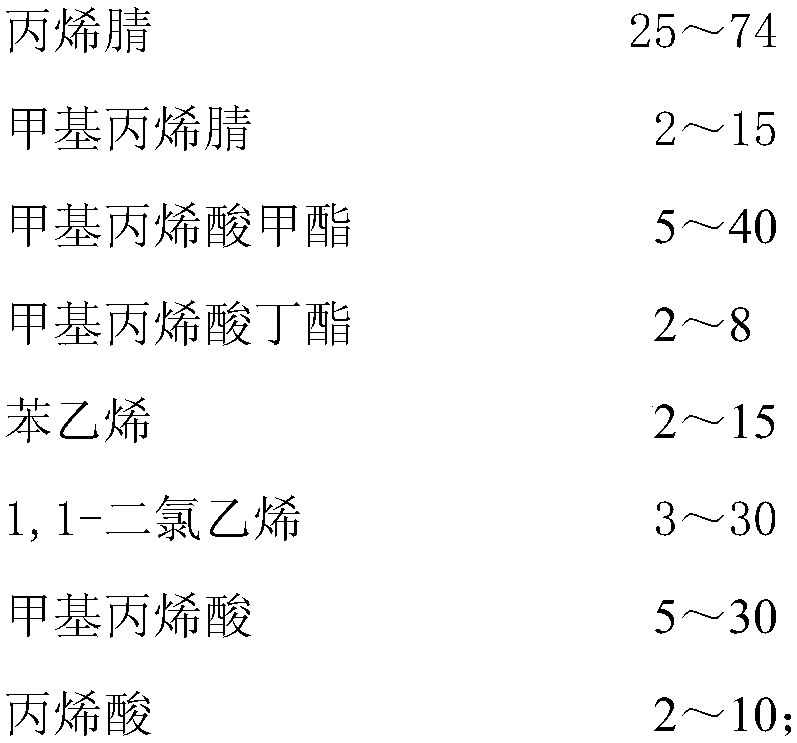

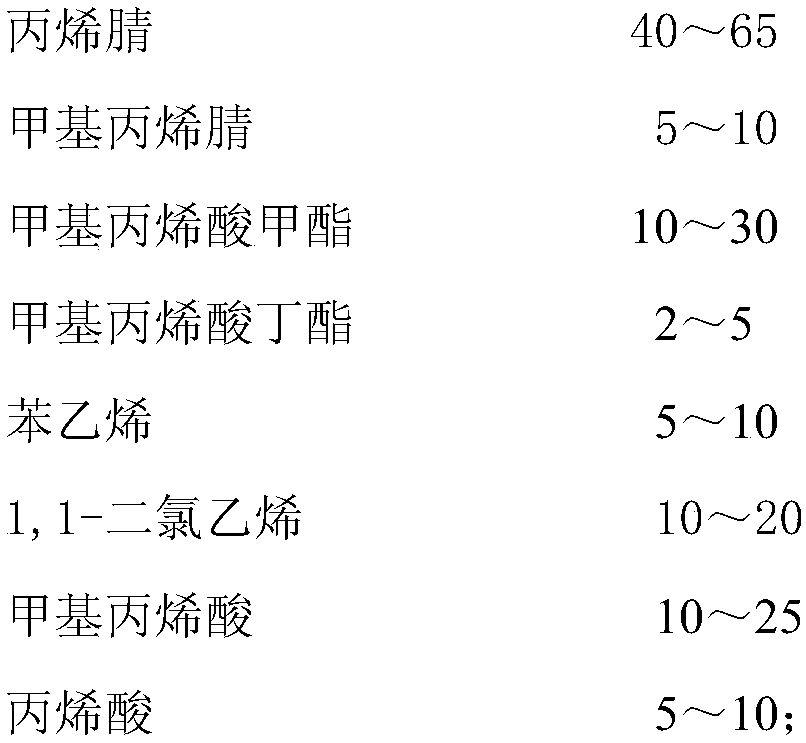

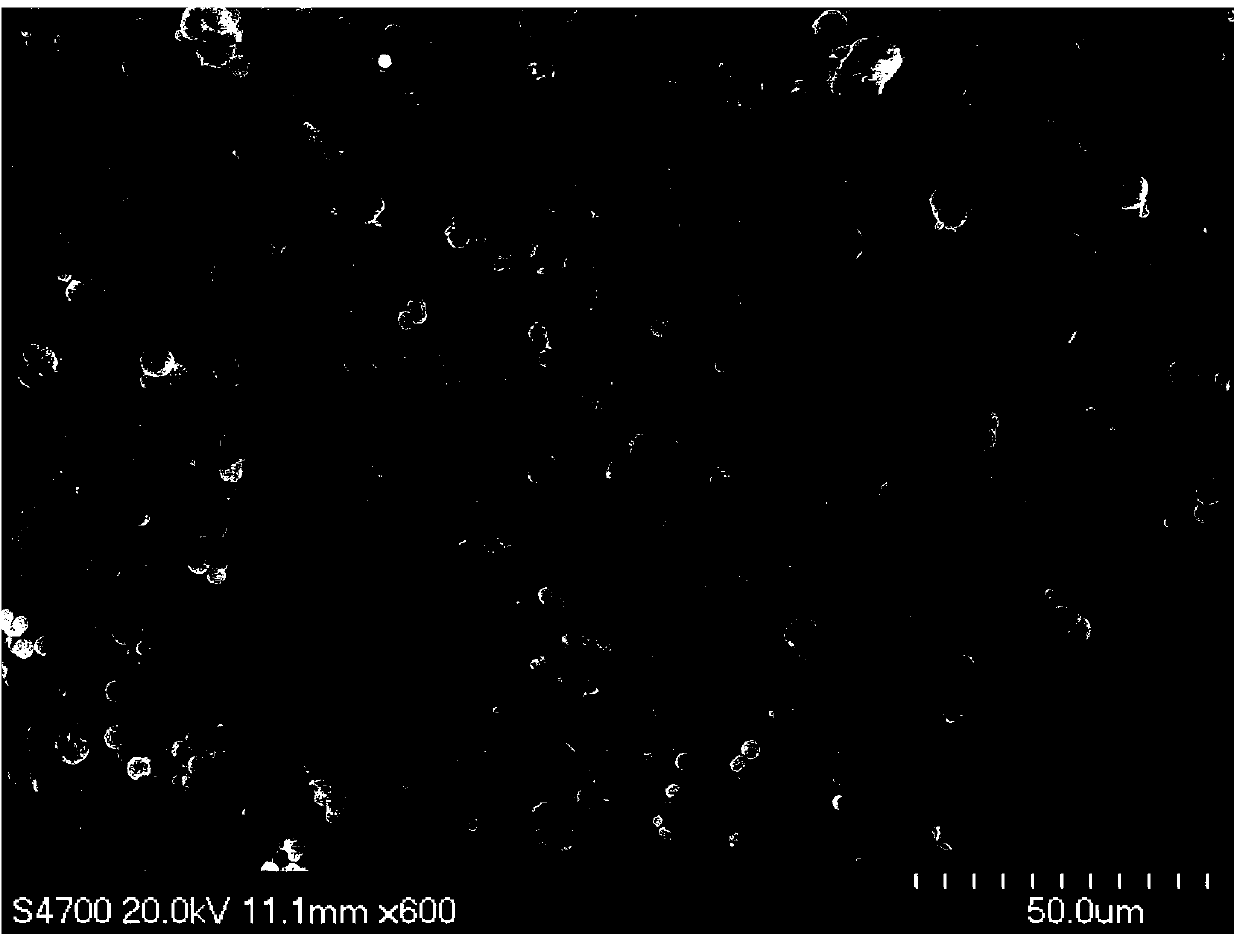

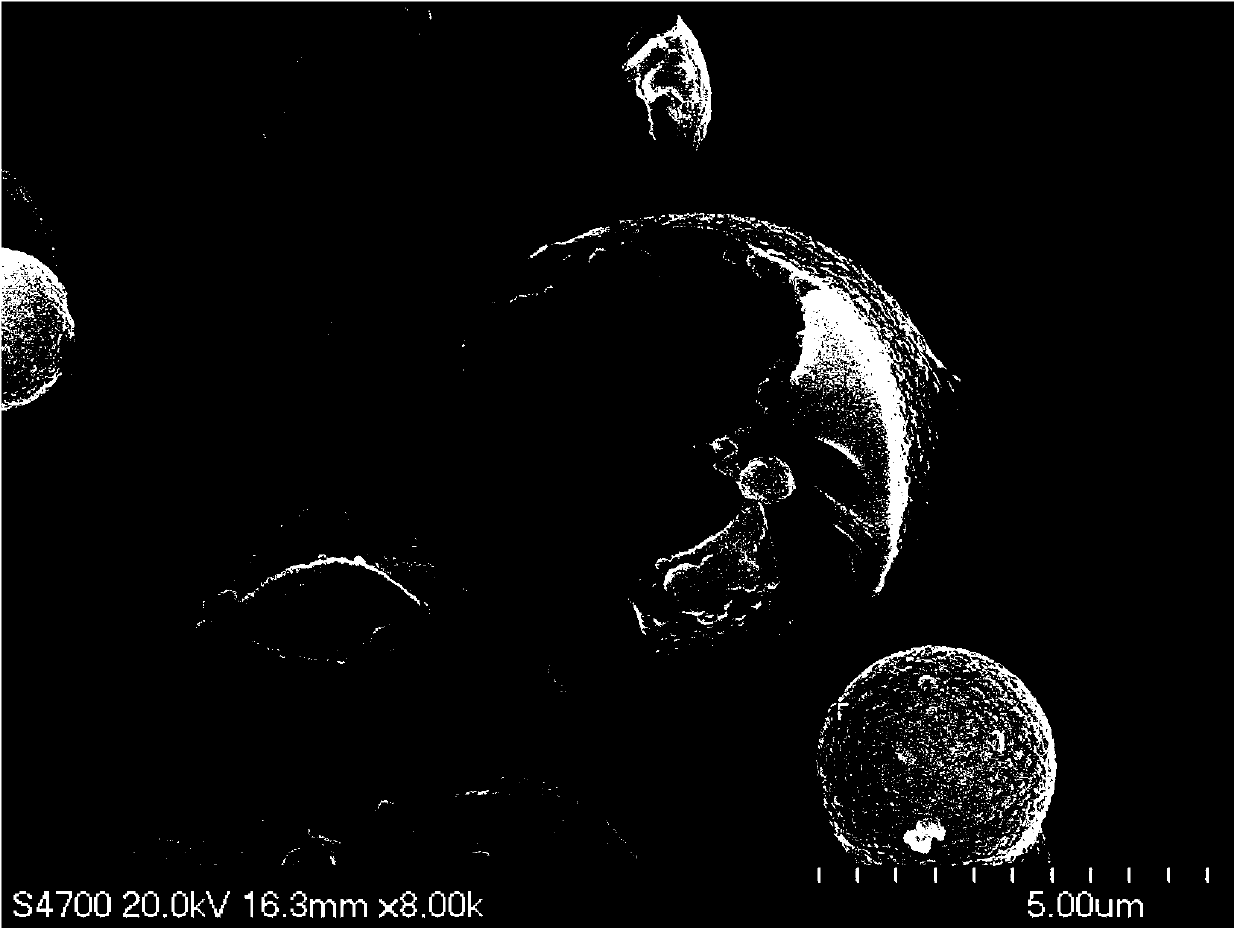

High-temperature expanded polymer microspheres and preparation method thereof

The invention provides high-temperature expanded polymer microspheres and a preparation method thereof and belongs to expandable particles. The high-temperature expanded polymer microspheres are prepared from a thermoplastic resin shell body and a foaming agent packaged in the shell body, wherein an oil-phase composition composed of a polymerizable monomer and a crosslinking agent can be dispersedinto a water-phase dispersed composition; in the presence of the foaming agent, the polymer microspheres coated with the foaming agent are directly prepared through carrying out suspension polymerization reaction and coating the foaming agent in situ; the high-temperature expanded polymer microspheres are characterized in that the oil-phase composition contains the polymerizable monomer and the crosslinking agent, and also comprises a silane coupling agent; the foaming agent is a mixture of isopentane, isooctane and n-octane; the high-temperature expanded polymer microspheres provided by theinvention have the advantages of complete core-shell structure, uniform grain diameter distribution, high foaming agent coating efficiency, good heat resistance of a shell-layer polymer, relatively high initial temperature in an expansion process, relatively high highest expansion temperature and high foaming ratio, have a relatively wide foam stabilizing temperature range, and are suitable for being applied to a thermoplastic resin, rubber or thermoplastic elastomer foaming and processing technology.

Owner:SHANDONG RUIFENG CHEM

Magnetic microencapsulated phase change energy storage material and preparation method thereof

ActiveCN103992774AUniform particle size distributionAchieve dual functionHeat-exchange elementsMicroballoon preparationThermal energyThermal energy storage

The invention discloses a magnetic microencapsulated phase change energy storage material with magnetic and thermal energy storage functions and a preparation method thereof. A wall material of microcapsules is a magnetic ferrite / silica inorganic hybrid material with the magnetic function and a core material can be paraffin and a higher fatty alcohol, acid and ester type organic phase change energy storage material. The preparation method of the magnetic microencapsulated phase change energy storage material disclosed by the invention comprises the steps of firstly synthesizing magnetic ferrite nanoparticles and further assembling the magnetic ferrite nanoparticles in a solvent to the surfaces of suspended oil droplets of the organic phase change energy storage material through a Pickering emulsion technology; finally forming silica gel on the surface of the phase change energy storage material through an interfacial polymerization technology to fix the magnetic ferrite nanoparticles on the surfaces of the oil droplets of the organic phase change energy storage material so as to form the microcapsules using the magnetic ferrite / silica hybrid wall material to coat the phase change energy storage material.

Owner:上海弈峋科技有限公司

Nano copper powder for electronic paste and preparation process

InactiveCN102205422AUniform particle size distributionGranularity controllableHigh surfaceVacuum drying

The invention discloses nano copper powder for electronic paste and a preparation process. The process is characterized in that: nano copper powder is prepared through the reduction of a reducing agent under the condition of the temperature and the pressure which are produced by a hydrothemal method, and nano copper powder with different appearances and grain diameters can be prepared under the conditions of different temperatures, pressures, reducing agents and dispersing agents. The method comprises the following steps of: adding aqueous solution of a complexing agent into aqueous solution of water soluble copper salt to form the complex aqueous solution of copper; adding an appropriate amount of dispersing agent, stirring to uniformly disperse the mixture, adding an appropriate amount of reducing agent, and adding the finally-obtained mixed solution into a stainless steel high-temperature reaction kettle with a polytetrafluoroethylene lining; heating to a certain temperature; preserving heat for certain time; naturally reducing temperature to room temperature; filtering off precipitate; cleaning by using deionized water and ethanol for multiple times; and performing vacuum drying to finally obtain high-purity nano copper powder with high surface activity and controllable granularity.

Owner:SHENZHEN SENLONT ELECTRONICS

Tungsten carbide particle-enhanced iron-based powder metallurgy material and preparation method thereof

The invention relates to plastic forming technology and powder metallurgy technology, in particular to a tungsten carbide particle-enhanced iron-based powder metallurgy material and a preparation method thereof. According to a specific formula, the iron-based powder metallurgy material comprises the following components in percentage by mass: 85.0 to 90.0 percent of matrix material and 10.0 to 15.0 percent of enhanced phase tungsten carbide, wherein the matrix material comprises the following components in percentage by mass: 1.4 to 2.0 percent of copper, 1.7 to 2.0 percent of nickel, 0.9 to 1.2 percent of molybdenum, 0.7 to 1.6 percent of carbon and the balance of iron. In the invention, quick spark plasma sintering is adopted; and the obtained material has the characteristics of nearly full densification, high hardness, high indoor temperature bending strength, high high-temperature mechanical property and the like, can be used as a wear-resistant material, a tool material and the like, and can reduce the dependency of Chinese tool material production on import of precious metals such as vanadium, chromium and the like. The material has high cost performance and a good industrial production prospect.

Owner:SOUTH CHINA UNIV OF TECH

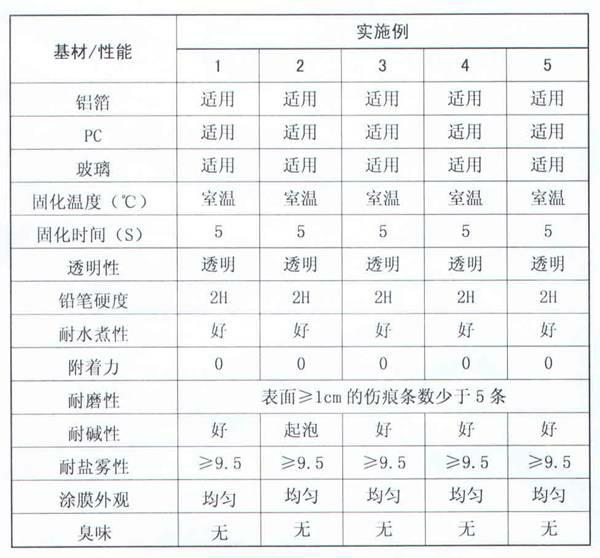

Organosilicon-modified polyurethane-acrylic ester photocurable coating and preparation method thereof

InactiveCN102559038AUniform particle size distributionSmall particle sizePolyurea/polyurethane coatingsPolymer scienceUrethane acrylate

The invention relates to an organosilicon-modified polyurethane-acrylic ester photocurable coating and a preparation method thereof. The photocurable coating comprises the following components in percentage by weight: 25 to 60 percent of polyurethane-acrylic ester, 20 to 55 percent of organic polysilane, 5 to 15 percent of solvent, 1 to 5 percent of photoinitiator and 0.05 to 4.5 percent of aid. The preparation method comprises the following steps of: weighing the organic polysilane according to the amount of a formula, putting into a container, sequentially adding a polyurethane-acrylic ester photocurable resin, the solvent and the aid, mixing uniformly, adding the photoinitiator, stirring uniformly to obtain an ultraviolet-photocurable coating, and preserving in a dark place. The ultraviolet-photocurable coating composition can be coated on base materials such as plastics, metals, glass and the like; a coating subjected to ultraviolet photocuring has excellent wear resistance and mechanical properties; and meanwhile, the coating has excellent adhesion, water resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

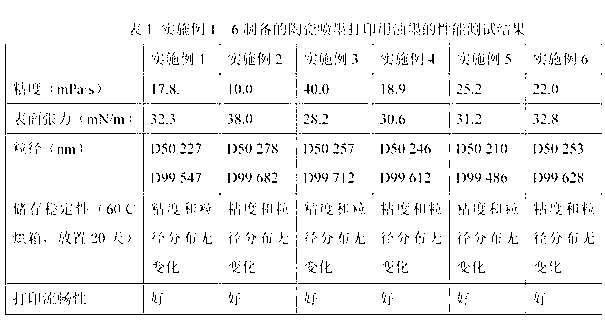

Ink for ceramic ink-jet printing and method for preparing same

ActiveCN102964920AGood quality and stabilitySimple manufacturing methodInksAcrylate esterDefoaming Agents

The invention discloses an ink for ceramic ink-jet printing and a method for preparing the same, wherein the ink comprises the following components by mass percent: 20-50% of ceramic pigment, 3-8% of resin, 2-10% of dispersant, 0.1-0.2% of flatting agent, 0.3-0.7% of defoamer, 0.08-0.12% of anti-settling agent and the balance of solvent; and the dispersant is a high-molecular-weight polyurethane type dispersant or a high-molecular-weight polyacrylate type dispersant. The ink for ceramic ink-jet printing provided by the invention is good in quality stability and thereby can be stored for a long time; the ink is excellent in ink-jet printing performance, low in ink viscosity and even in particle size distribution; the viscosity of the ink is between 10.0 and 40.0 mPa.s and is controllable; and the surface tension of the ink is 28-38 mN / m, while the average particle size is 200-300 nm and the maximum particle size is less than 800 nm. The method for preparing the ink for ceramic ink-jet printing provided by the invention is simple and efficient; and a one-step mill base grinding process and an ink performance regulation process are carried out, so that the production cost is greatly saved.

Owner:GUANGDONG DOWSTONE TECH

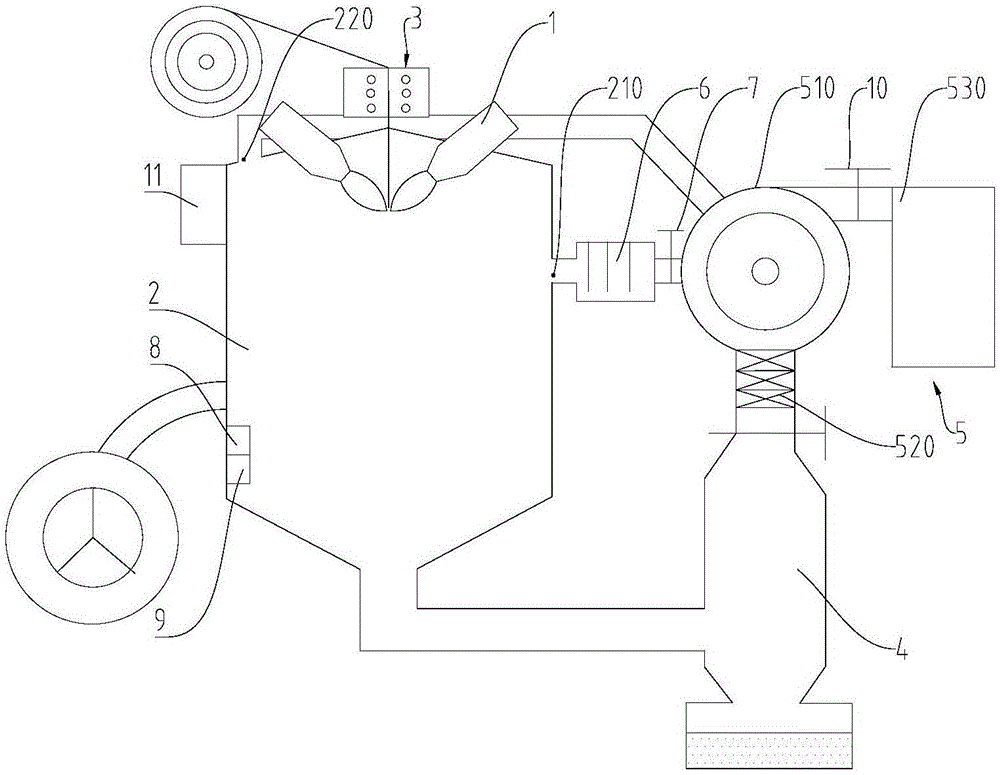

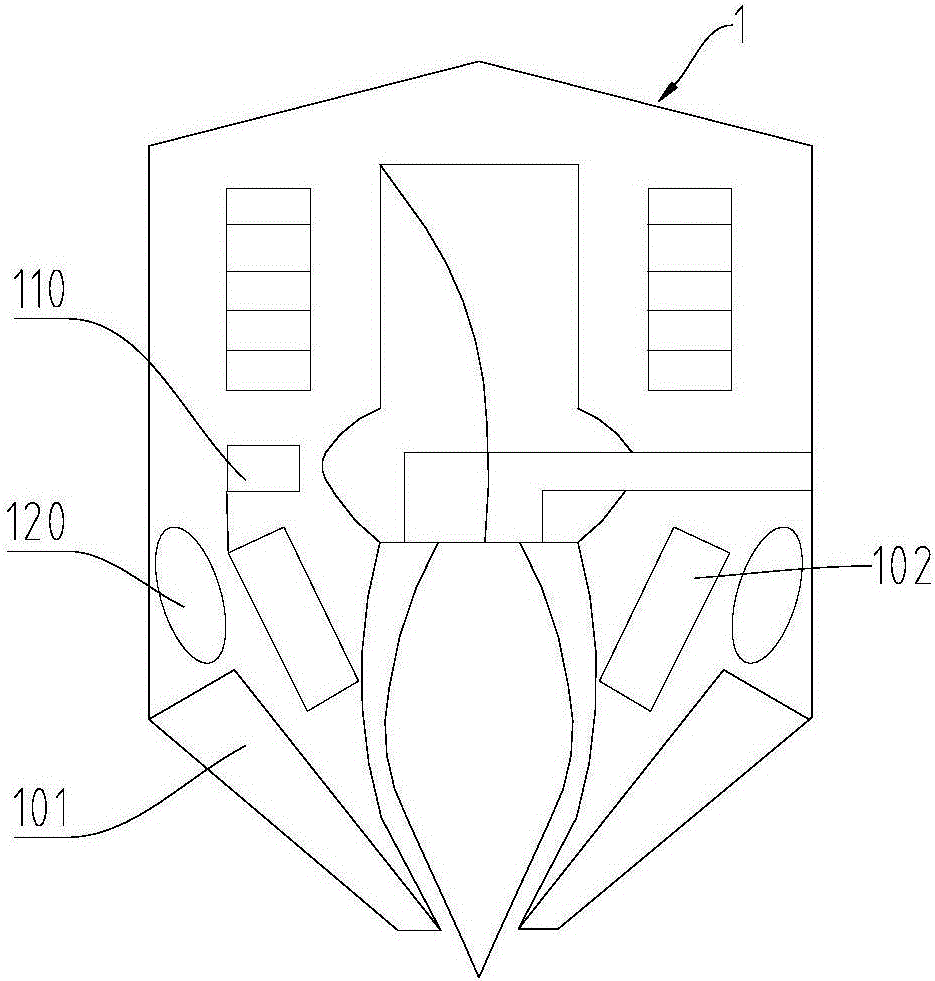

Plasma atomization method and apparatus for preparing pure titanium or titanium alloy powder

The invention relates to a plasma atomization method and apparatus for preparing spherical pure titanium or titanium alloy powder, and belongs to the technical field of preparation of titanium or titanium alloy powder. The plasma atomization method for preparing pure titanium or titanium alloy powder comprises the following steps of (1) preparing a titanium wire or titanium alloy wire with the diameter ranging from 3 millimeters to 20 millimeters, (2) using a plasma torch to fuse and atomize the titanium wire or titanium alloy wire in an atomization bin with an argon atmosphere to obtain atomized pure titanium particles or titanium alloy particles, and (3) feeding argon flow with the temperature ranging from 300 DEG C to 500 DEG C into the atomization bin, carrying out laminar cooling on the atomized pure titanium particles or titanium alloy particles to obtain pure titanium or titanium alloy powder. The obtained powder is good in degree of sphericity and low in the content of satellite balls, and has the advantages of being uniform in size distribution, high in purity and degree of sphericity, good in liquidity, low in oxygen content and impurity content, free of bond or cluster phenomenon and the like. The prepared titanium powder can be widely applied to the forming manners such as metal additive manufacturing, powder injection moulding and hot isostatic pressing for manufacturing parts with high precision.

Owner:OPTIMAL MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000011.PNG)

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000012.PNG)

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000013.PNG)