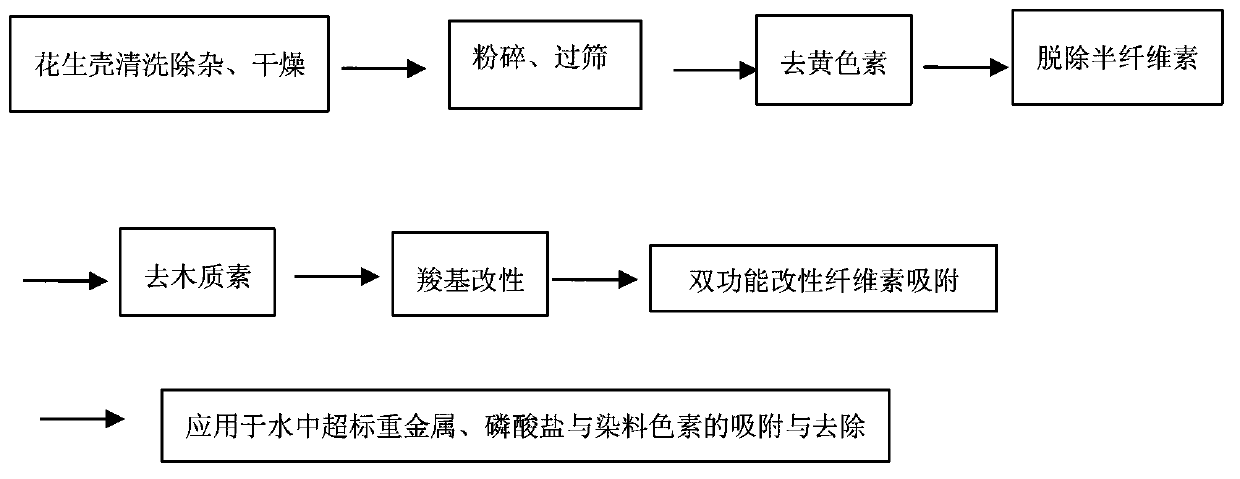

Method for preparing bifunctional modified cellulose adsorbing agent from peanut shells and application of method

A peanut shell and cellulose technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of difficult control of functional group ratio, long reaction cycle, application limitations, etc., and achieve stable properties and low cost. Effect of low cost and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Washing and removing impurities from waste peanut shells, crushing them after natural air drying, and passing through a 100-mesh sieve to obtain pretreated peanut shell powder;

[0041] (2) Weigh 12g of the pretreated peanut shell powder obtained in step (1), and immerse it in 100mL of a mixed solution of ethanol and acetic acid with a volume fraction of 50% for 2 hours, and filter with suction, and filter the residue with a small amount of % ethanol and acetic acid mixed solution, and then washed with water until neutral to remove the yellow pigment. After suction filtration, the samples were dried in a drying oven at 50°C. store for later use;

[0042] (3) Weigh 10 g of the de-yellow peanut shell powder obtained in step (2), disperse it in 100 mL of NaOH solution with a mass fraction of 4%, stir at about 55°C for 2 hours, and remove half of the peanut shell. Cellulose: After the reaction, centrifugal separation at 4000 rpm, the solid was rinsed with distilled wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com