Patents

Literature

1616 results about "Nano copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

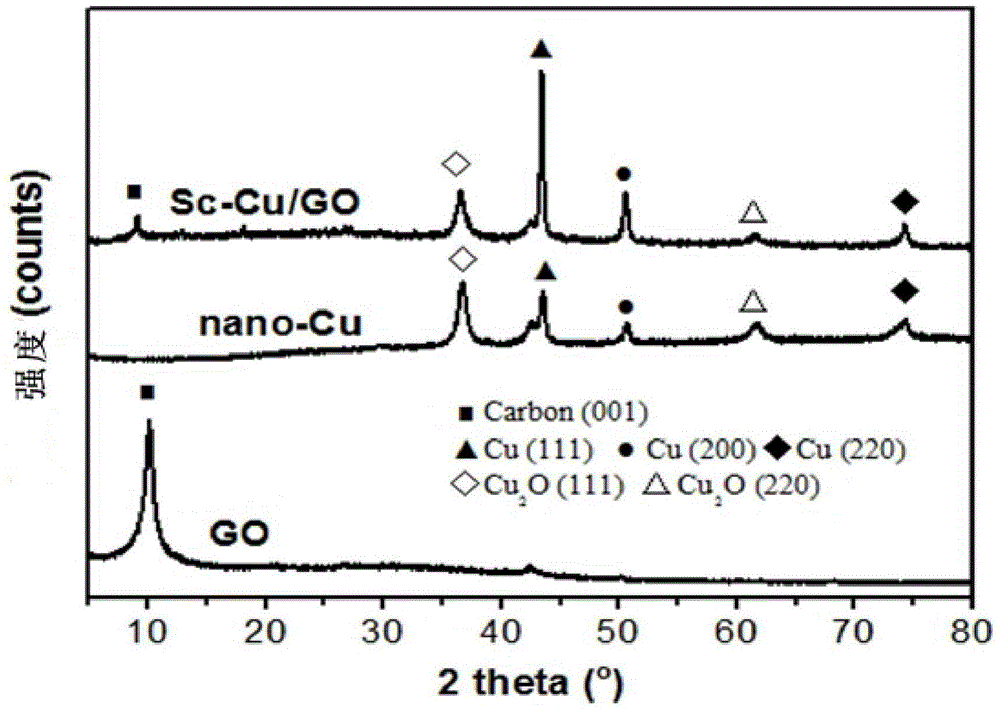

High-strength and high-conductivity graphene copper-based composite material and preparation method thereof

The invention discloses a high-strength and high-conductivity graphene copper-based composite material and a preparation method thereof, wherein the graphene copper-based composite material comprises 0.01wt.%-6.0wt% of graphene and the balance of copper; the preparation method comprises the following steps: firstly, adding graphene oxide to a copper sulfate solution, adding a hydrazine hydrate solution to reduce nano-copper powder and graphene, drying and then reducing in H2 atmosphere, and finally, preparing the graphene copper-based composite material from the reduced composite powder by use of the Spark Plasma Sintering (SPS) technology. The graphene copper-based composite material shows excellent electric conductivity and thermal conductivity and outstanding wear resistance and corrosion resistance, and thus has a wide application prospect in the field of the frame leads and the electrical contact materials.

Owner:JIANGXI UNIV OF SCI & TECH

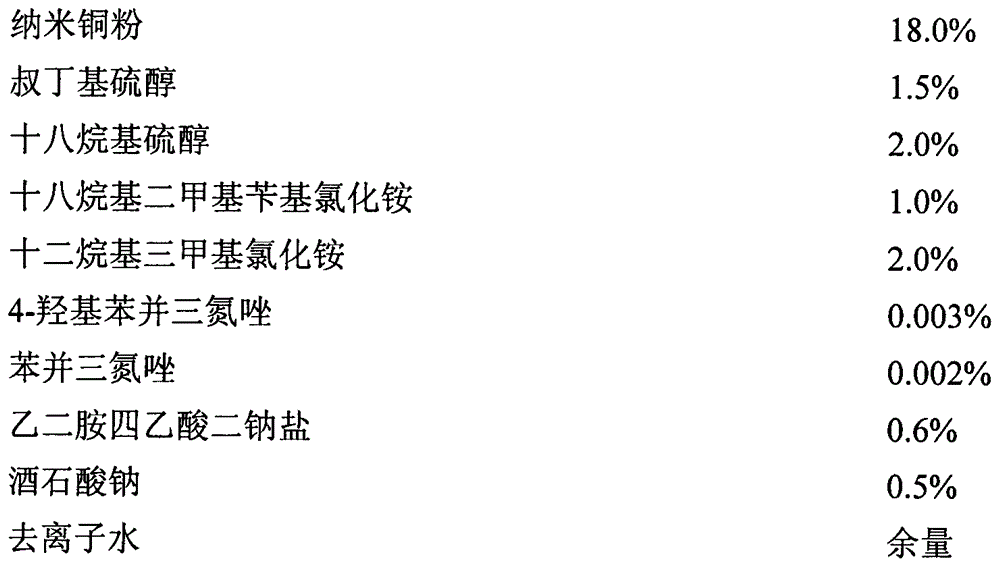

Cold-rolled sheet rolling emulsified oil containing modified nano copper and preparation method thereof

The invention relates to a cold-rolled sheet rolling emulsified oil containing a modified nano copper and preparation method thereof, which belong to the field of organic chemistry. The emulsified oil comprises the following components, in percentage by weight: 54-80% of a base oil, 15-32% of an oiliness agent, 0.1-1% of a modified nano copper particle, 2-4% of an extreme pressure agent, 0.5-2% of an anti-rusting agent, 2-6% of an emulsifier, 0.4-1% of an anti-oxidant, 0.03-0.1% of an anti-foaming agent, and 0.2-0.6% of an anti-mildew agent. The cold-rolled sheet rolling emulsified oil containing the modified nano copper is diluted with water into a 2-6 wt% emulsion, and the emulsion is directly used in the cold rolling process of the strip steel and has very good lubrication, cleaning property of the rolling mill and annealing cleaning property, after annealing, the steel plate not subjected to degreasing has a clean surface without pollutants, so as to satisfy rolling production requirement under high pressure at high speed.

Owner:NORTHEASTERN UNIV

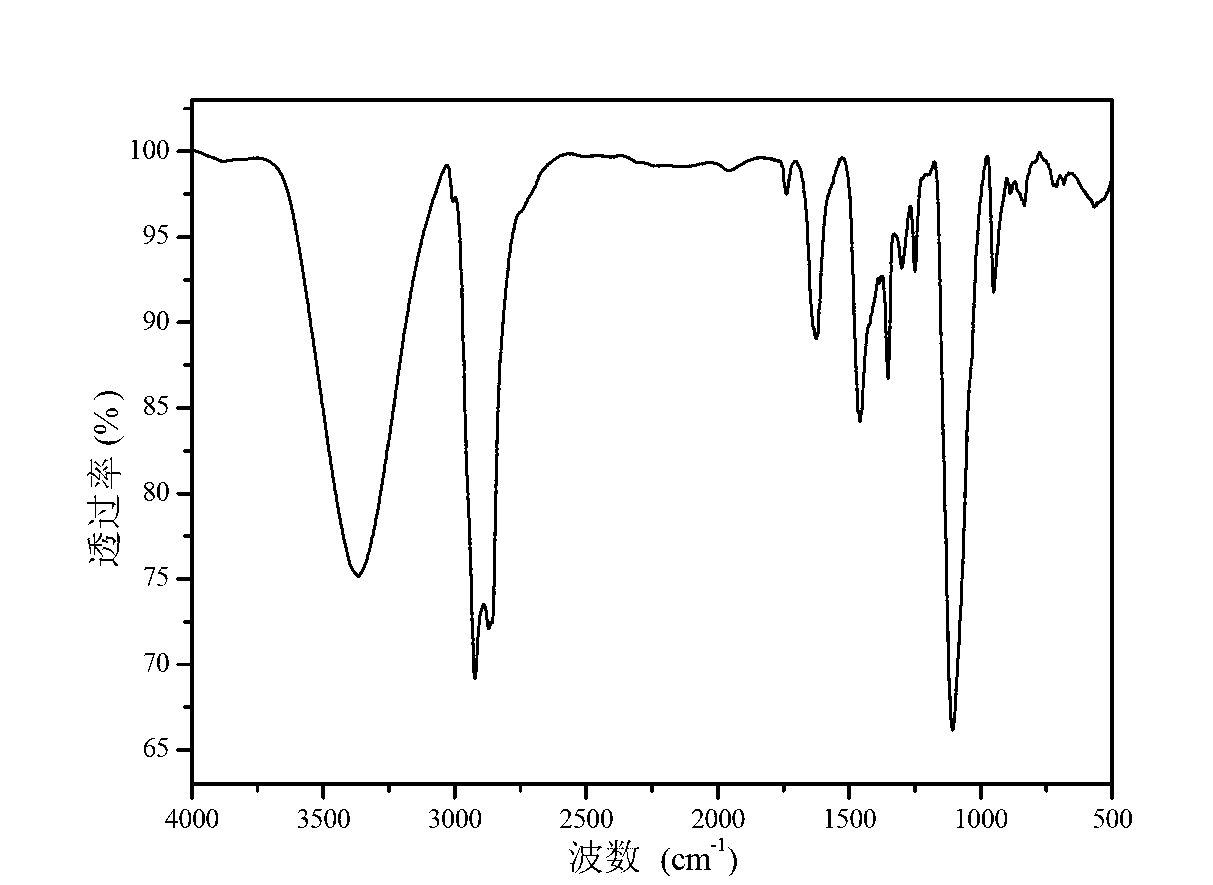

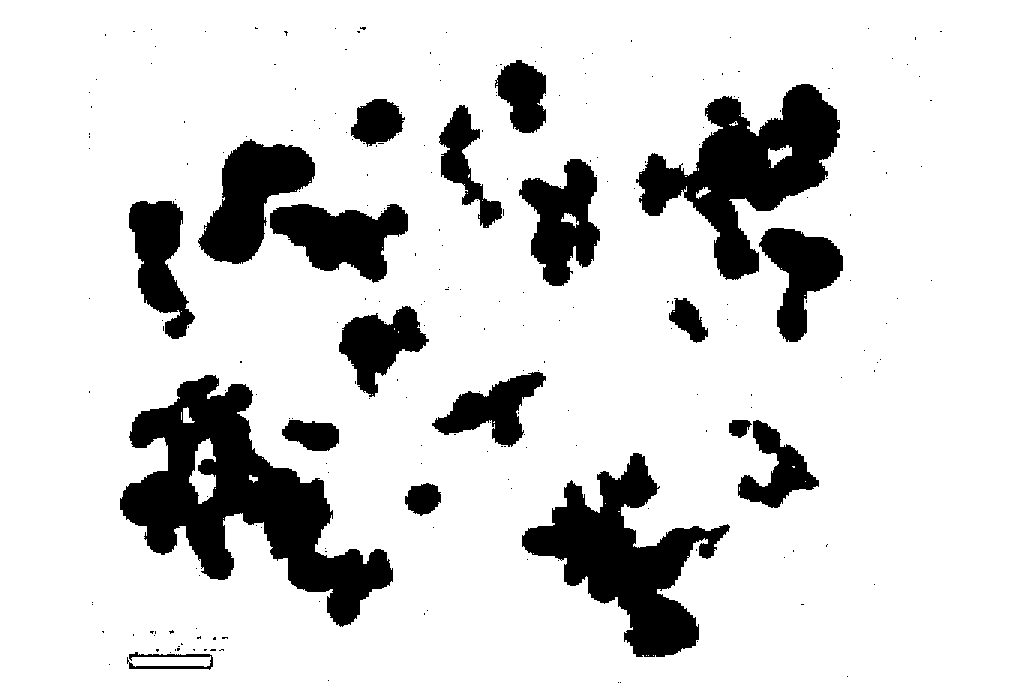

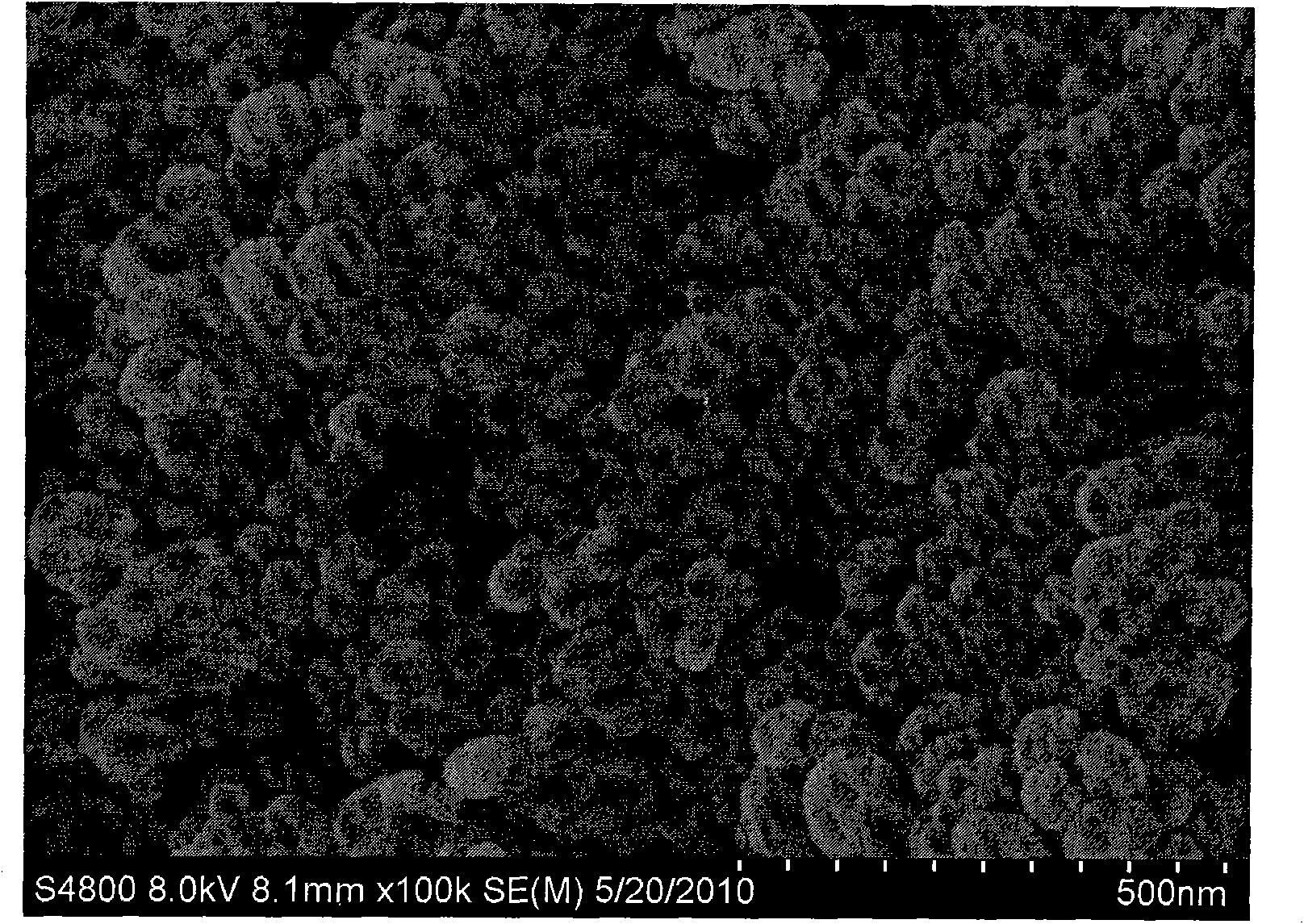

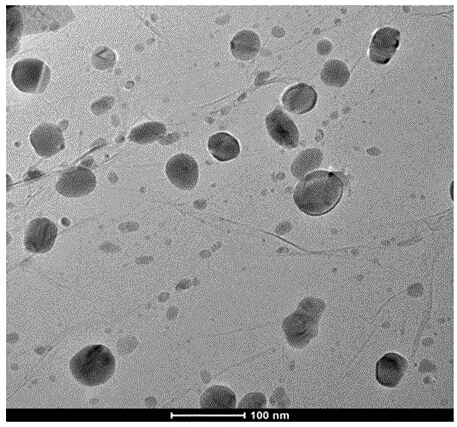

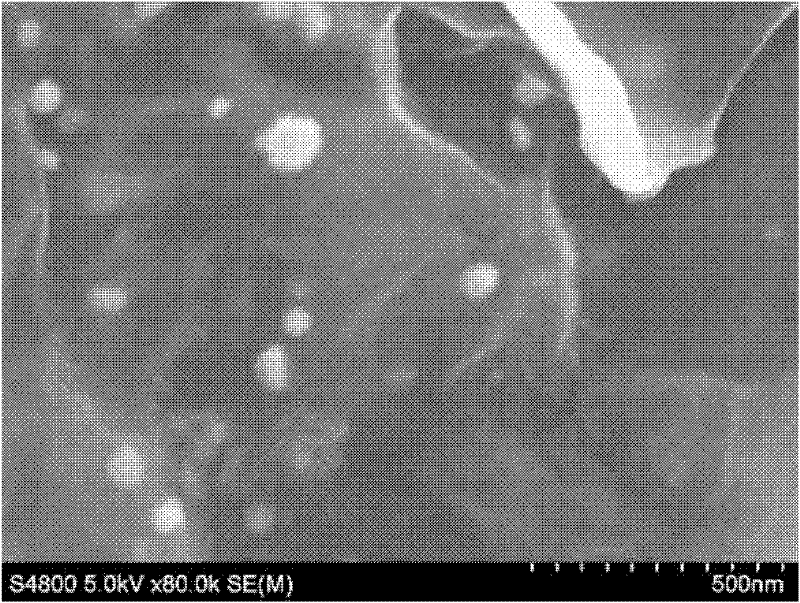

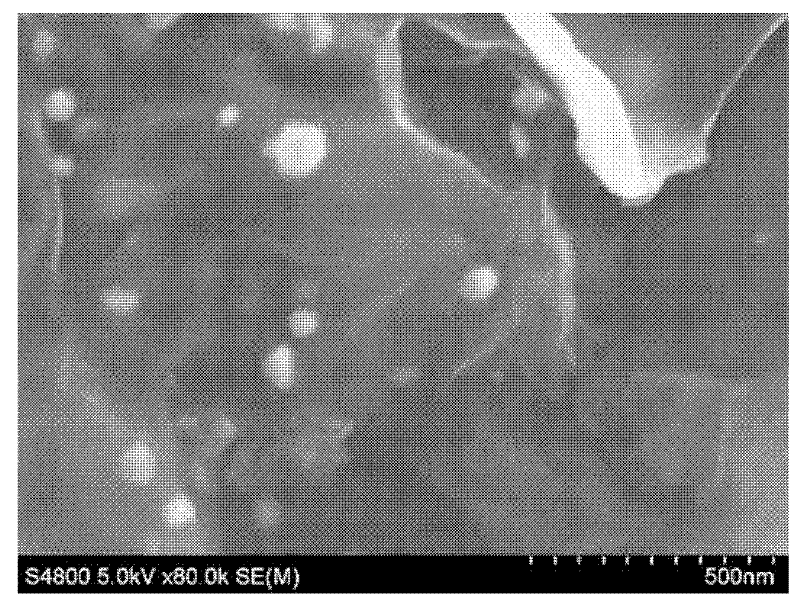

Nanometer copper/graphene composite material and preparation method and application thereof

InactiveCN104479804AThe preparation method is simple and quickShort processing timeAdditivesOil additiveSurface-active agents

The invention belongs to the technical field of new material preparation and lubricating oil additives, and discloses a nanometer copper / graphene composite material and a preparation method and application thereof. The preparation method comprises the following steps of: firstly dissolving a copper precursor compound, a surface active agent and a complexing agent into reducing alcohol, then adding graphene oxide, and carrying out ultrasonic dispersion to obtain a mixed solution; then adding a reducing agent to the mixed solution, transferring into a reaction kettle, introducing CO2 gas, and controlling gas pressure and temperature so that CO2 achieves a supercritical state; stirring the mixed solution inside the reaction kettle for reacting, cooling, decompressing, washing by centrifuging, and carrying out vacuum drying to obtain the nanometer copper / graphene composite material. The preparation method disclosed by the invention is simple, saved in time and fast. The prepared nanometer copper / graphene composite material has the characteristics of single phase, controllability in loading capacity, small nanometer copper particle size, uniformity in nanometer copper distribution on the surface of a graphene nanometer layer, and the like, has a synergetic lubricating effect, and can be used for outstandingly improving the antifriction and abrasion-resistant property of basic lubricating oil.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing nano copper conductive ink

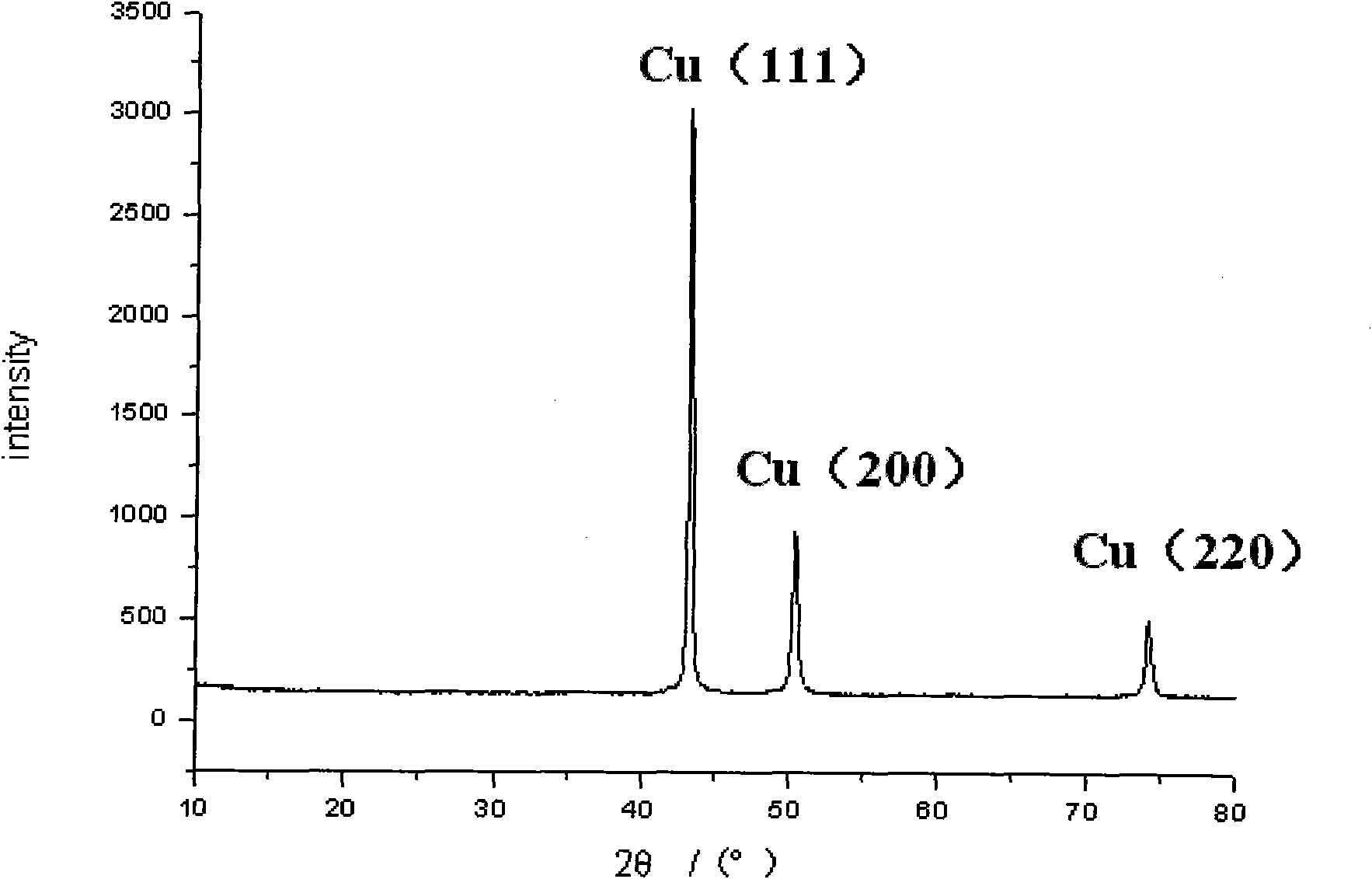

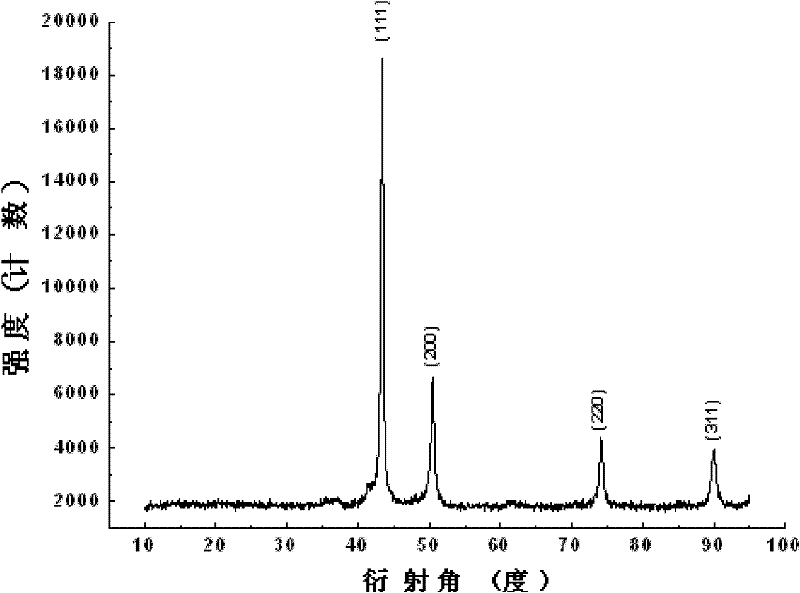

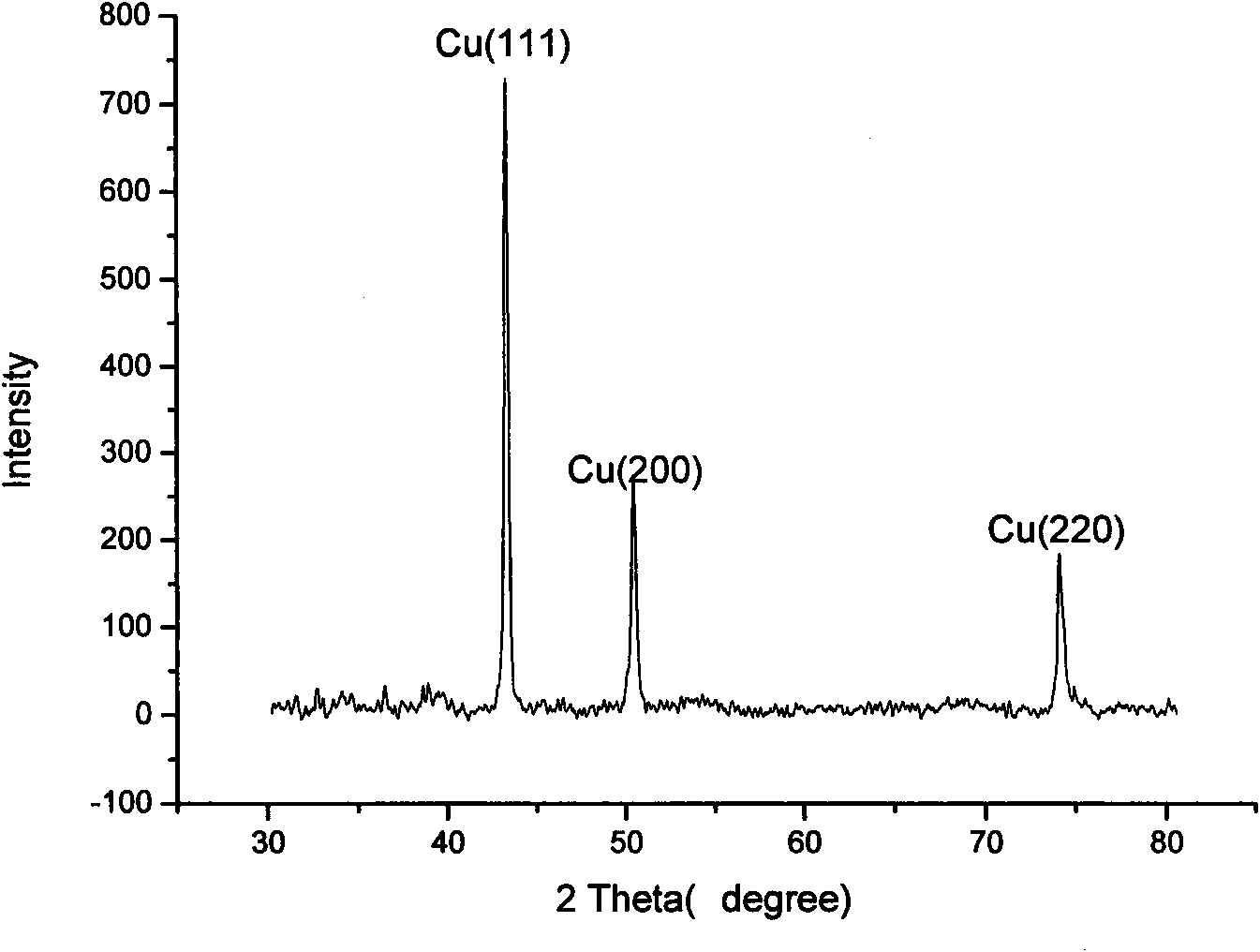

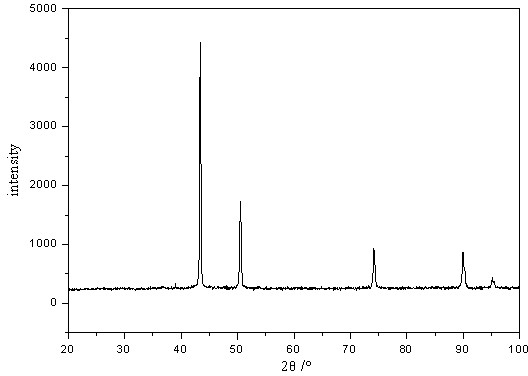

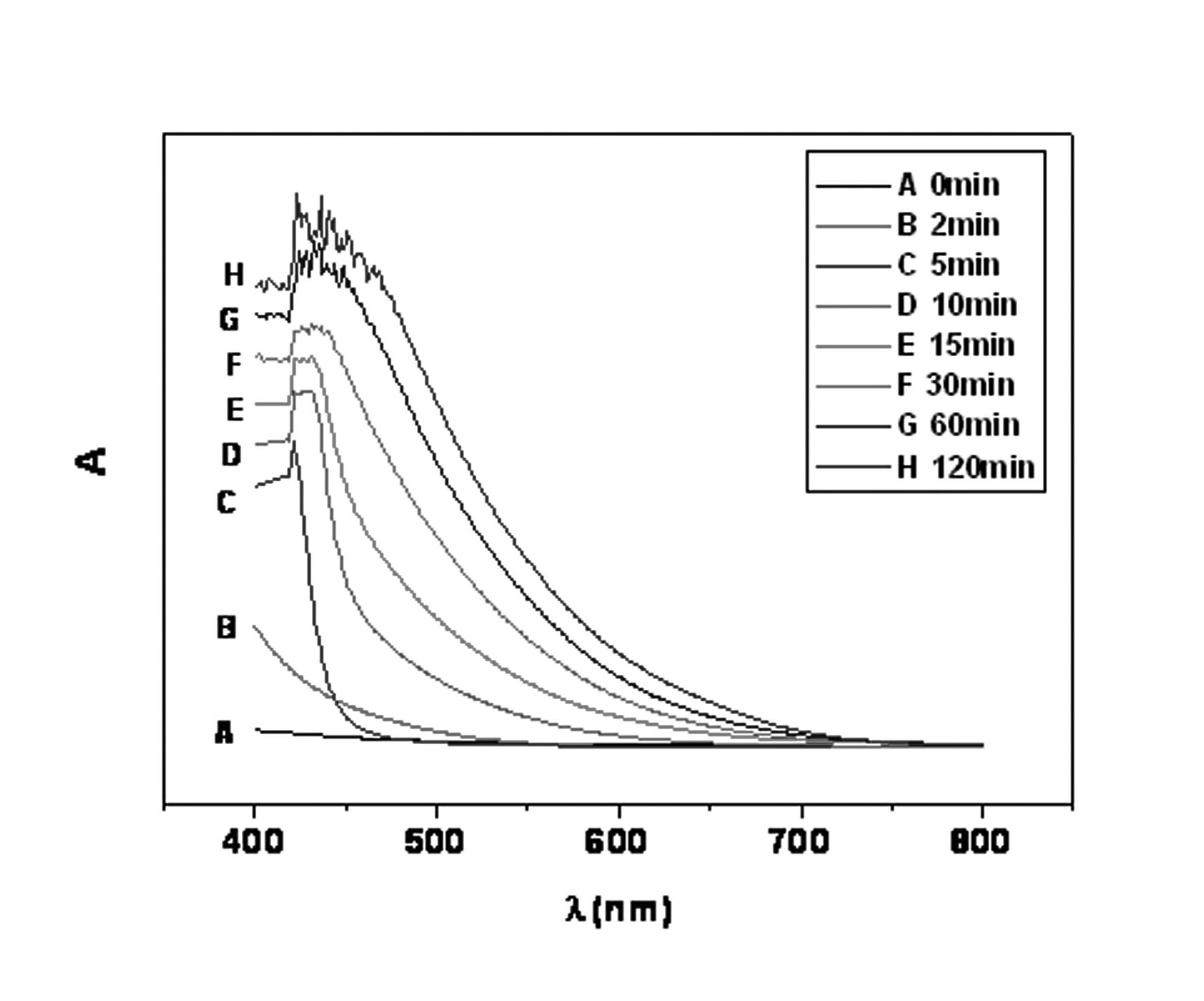

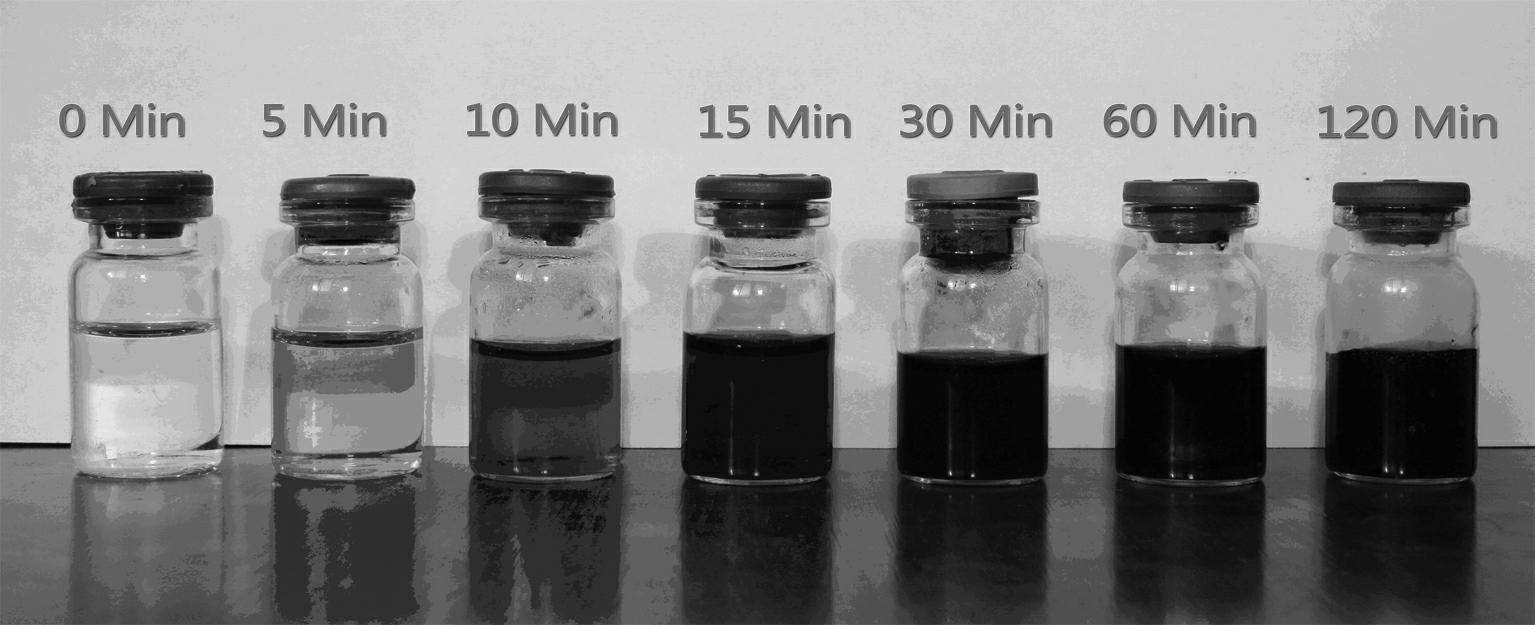

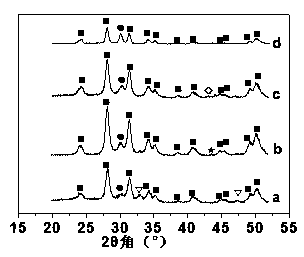

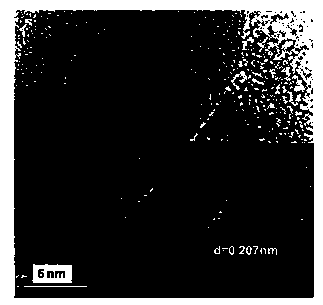

ActiveCN101880493AGood dispersionCharacteristic peaks are obviousInksNon-conductive material with dispersed conductive materialOrganic solventRoom temperature

The invention discloses a method for preparing nano copper conductive ink, which can be applied in the field of printing electronic technology, in particular ink jet printing technology. The preparation method comprises the following steps of: dissolving copper salt and protective agent into a solvent, heating and stirring the solution, adding a small amount of alkali solution to adjust the pH ofthe solution to between 7 and 10, dripping a reducing agent into the solution, continuously stirring the solution to react for 30 to 60 minutes, and then cooling the reaction solution to room temperature to obtain nano copper dispersion; performing centrifuging, washing and vacuum drying at room temperature on the nano copper dispersion to obtain nano copper granules; and dispersing the nano copper granules into an organic solvent, and ultrasonically treating the solution to obtain the nano copper conductive ink. The method solves the problems of complex preparation process and long preparation period in the prior art, has the advantages of simple and convenient operation, low production cost, short flow and no harmful waste generation, and realizes the goals of environmental protection and economy; and the prepared nano copper conductive ink has good dispersion property and high stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

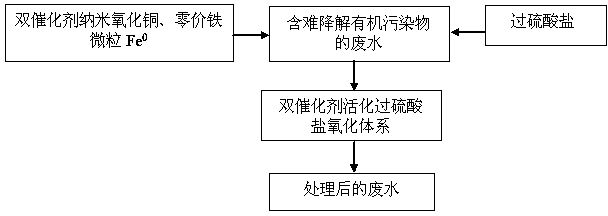

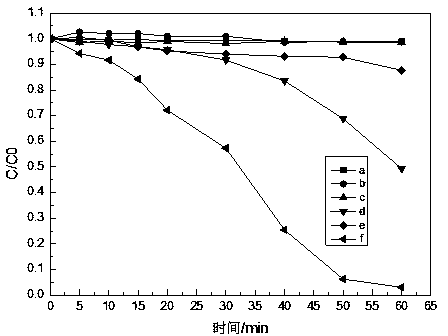

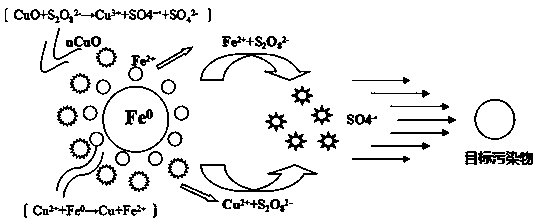

Method for treating organic wastewater by using double catalysts to heterogeneously activate persulfates

ActiveCN103896388AHigh catalytic activityIncrease profitWater/sewage treatment by oxidationSulfate radicalsBiological activation

The invention discloses a method for treating organic wastewater by using double catalysts to heterogeneously activate persulfates, belonging to the technical field of water pollution control. According to the method, nano copper oxide and zero-valent iron particles are used as a combined catalyst to activate the persulfates to generate free sulfate radicals with strong oxidizing property, so that refractory organics are removed from the wastewater. Compared with a homogeneous persulfate water treatment technology, the method has the advantage that the heterogeneous catalysts can efficiently and continuously activate the persulfates to achieve a heterogeneous activation effect due to the properties of relatively large specific surface area, relatively high catalytic activity and the like. The double-catalyst heterogeneous persulfate activation water treatment technology established by the method disclosed by the invention is applicable to treatment of various kinds of organic wastewater, is high in efficiency, good in durability and convenient in operation, can efficiently remove toxic and harmful pollutants from the wastewater within a relatively wide pH range, provides a broad prospect for treating toxic, harmful and non-biodegradable organic wastewater, and has a great application potential in the field of environmental pollution treatment.

Owner:SOUTH CHINA UNIV OF TECH

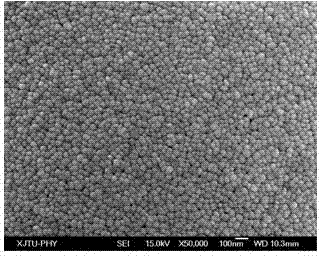

Nano copper powder for electronic paste and preparation process

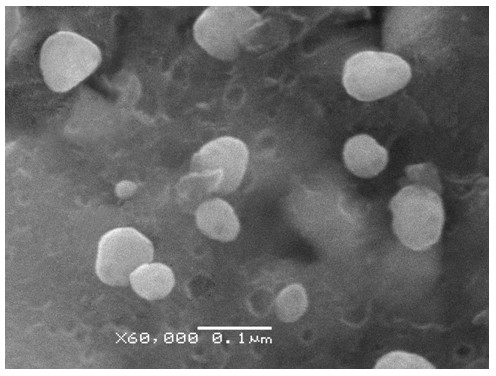

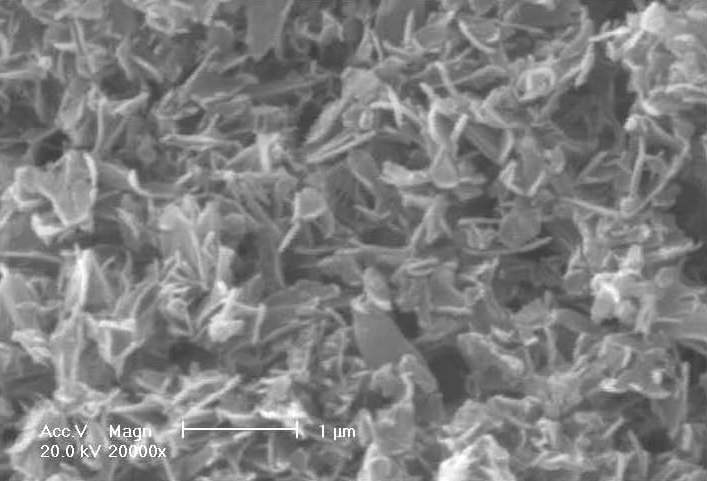

InactiveCN102205422AUniform particle size distributionGranularity controllableHigh surfaceVacuum drying

The invention discloses nano copper powder for electronic paste and a preparation process. The process is characterized in that: nano copper powder is prepared through the reduction of a reducing agent under the condition of the temperature and the pressure which are produced by a hydrothemal method, and nano copper powder with different appearances and grain diameters can be prepared under the conditions of different temperatures, pressures, reducing agents and dispersing agents. The method comprises the following steps of: adding aqueous solution of a complexing agent into aqueous solution of water soluble copper salt to form the complex aqueous solution of copper; adding an appropriate amount of dispersing agent, stirring to uniformly disperse the mixture, adding an appropriate amount of reducing agent, and adding the finally-obtained mixed solution into a stainless steel high-temperature reaction kettle with a polytetrafluoroethylene lining; heating to a certain temperature; preserving heat for certain time; naturally reducing temperature to room temperature; filtering off precipitate; cleaning by using deionized water and ethanol for multiple times; and performing vacuum drying to finally obtain high-purity nano copper powder with high surface activity and controllable granularity.

Owner:SHENZHEN SENLONT ELECTRONICS

Efficient and environmentally-friendly antibacterial and mildewproof inorganic composite nano-powder slurry and its preparation method

Relateing to the field of antibacterial materials, the invention specifically provides an efficient and environmentally-friendly antibacterial and mildewproof inorganic composite nano-powder slurry obtained through compounding nano-magnesium oxide and other nano-inorganic materials and its preparation method. The nano-powder slurry takes nano-magnesium oxide as the main body, which is then compounded with one or more inorganic materials of nano-zinc oxide, nano-titanium oxide, nano-copper oxide, nano-cuprous oxide, nano-silver oxide, nano-zinc sulfide, nano-zirconium oxide, nano-yttrium oxide, nano-alumina, and nano-calcium oxide so as to form the nano-powder slurry, which comprises, by weight percent: 0.1-40% of nano-magnesium oxide, 0.01-40% of other inorganic materials, 0.5-12% of a polymeric dispersant, and the balance a solvent. In the method, a nano-inorganic material enters a solution composed of the polymeric dispersant and the solvent by means of high speed dispersion according to a predetermined proportion, and after ball milling, the composite nano-powder slurry can be obtained. The composite nano-powder slurry can be applied in antibacterial coatings, deodorants, textiles, paper products, plastics, rubbers, water treatment agents, ship protective agents, cosmetics and other aspects.

Owner:广东腐蚀科学与技术创新研究院

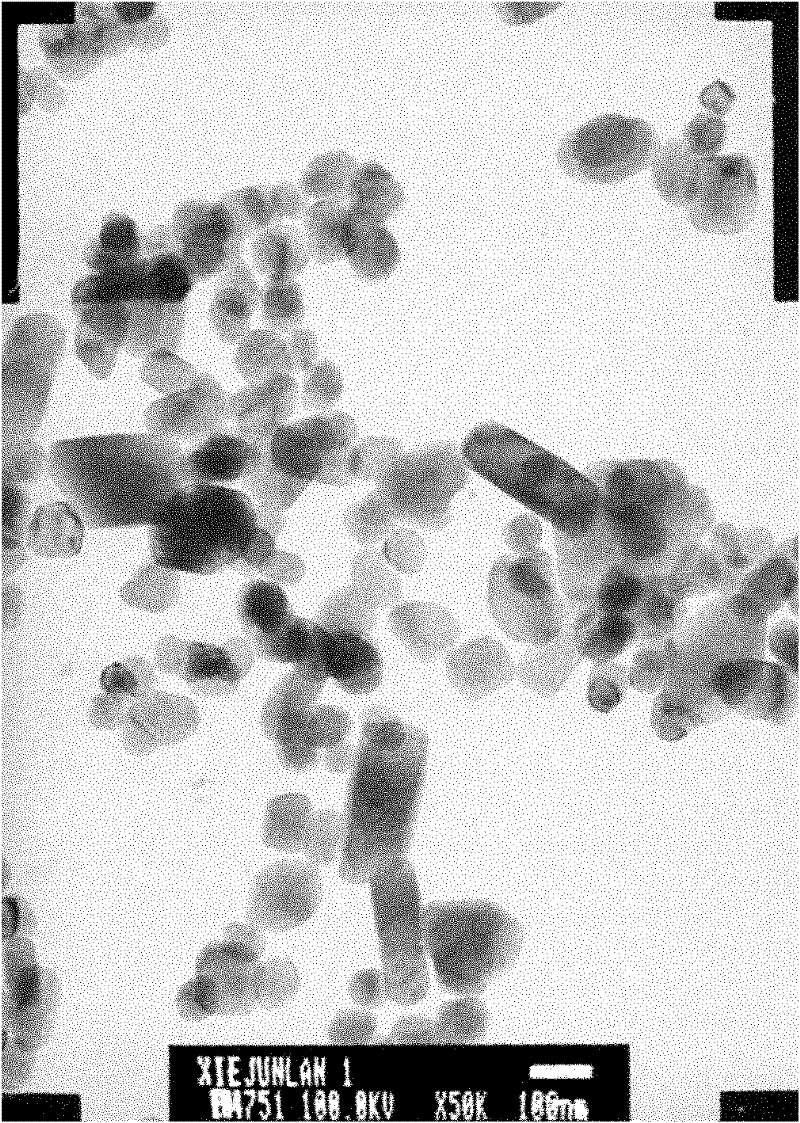

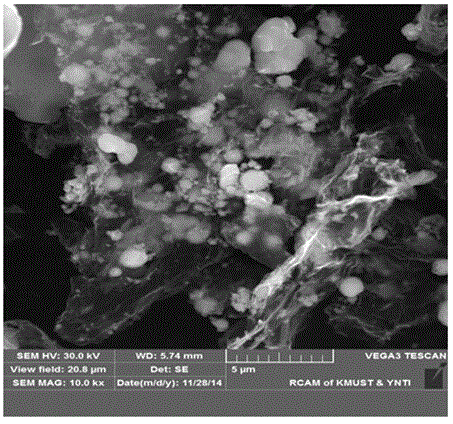

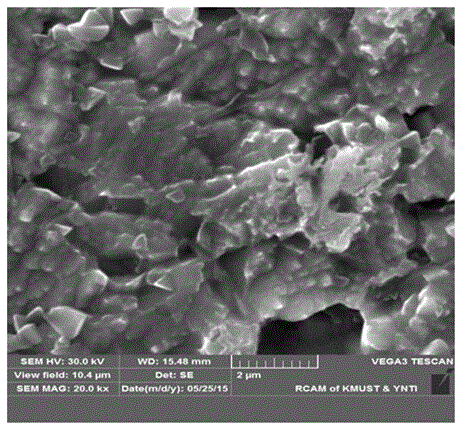

Preparation method of graphene-reinforced copper-based composite

ActiveCN105624445AImprove performanceEasy to organizeTransportation and packagingMetal-working apparatusSlurryCobalt

The invention discloses a preparation method of a graphene-reinforced copper-based composite and belongs to the field of preparation of high-strength and high-conductivity composites. The method comprises steps as follows: graphene, nano copper powder and cobalt powder in the required mass ratio are mixed in absolute ethyl alcohol, the mixture is physically dispersed under electromagnetic stirring, and then physically dispersed mixed slurry is added to a ball milling tank for mechanical ball milling; after evenly mixed slurry is centrifugally dried, obtained mixed powder is annealed and then subjected to hot-pressing SPS (spark plasma sintering) forming; an obtained block blank is annealed and then subjected to hot extrusion, and the graphene-reinforced copper-based composite is obtained. The graphene-reinforced copper-based composite prepared through the method has the good mechanical property, uniform structure and good heat and electricity conductivity.

Owner:KUNMING UNIV OF SCI & TECH

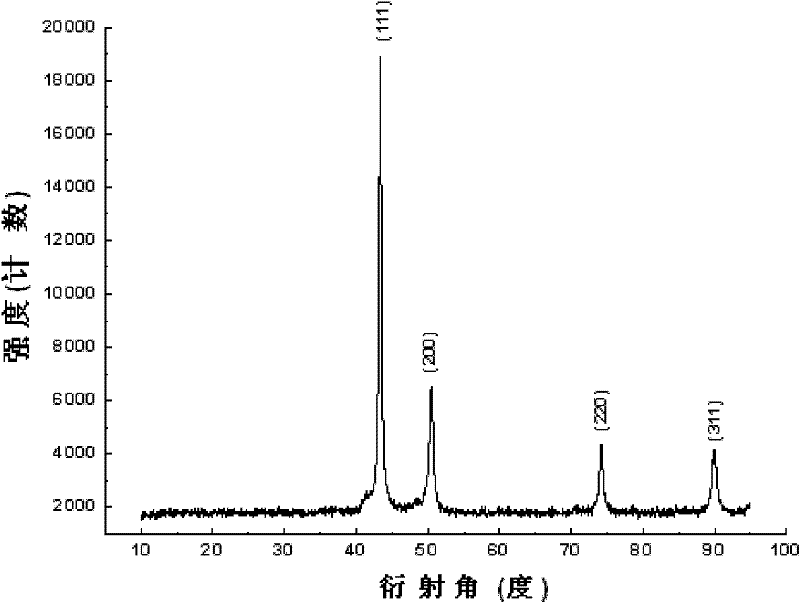

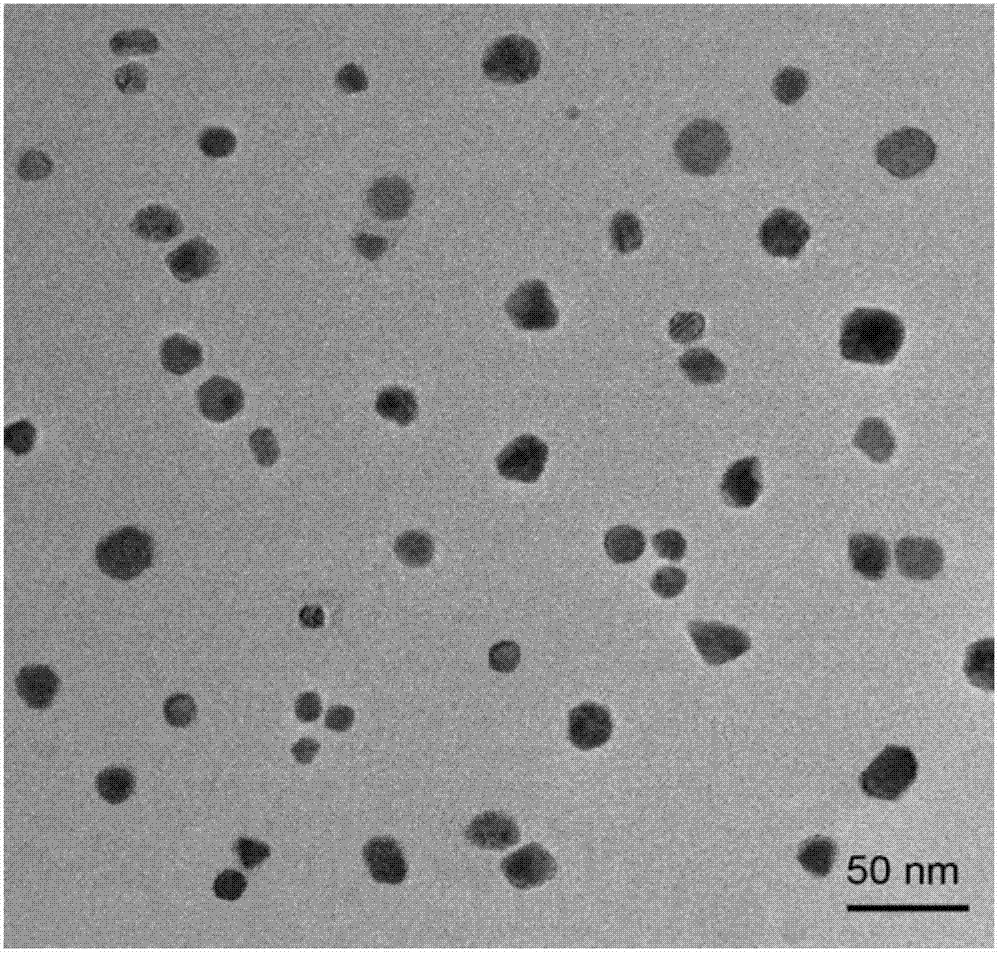

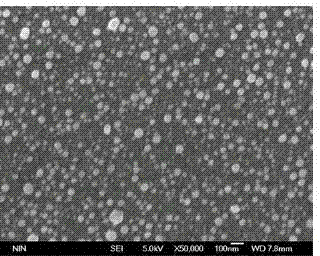

Preparation method of low-temperature sintering nano copper conductive ink

InactiveCN103087582AImprove antioxidant capacityImprove conductivityInksConductive pattern formationCopper wireSolvent

The invention provides a preparation method of low-temperature sintering nano copper conductive ink. The preparation method comprises the steps of: dissolving a copper salt and a protective agent in an organic solvent, heating until the copper salt and the protective agent are completely dissolve, regulating the pH value to be 8.6-10.5 by using ammonia water, dropping a reducing agent in a reaction system, reacting for 10-60minutes and continuously stirring, gradually cooling; carrying out centrifuging, washing and vacuum drying to obtain high-purity nano copper particles; and dispersing the nano copper particles in solvents with different proportions to obtain stable nano copper conductive ink. The preparation method has the advantages that the particle size of nano copper powder in the prepared nano copper conductive ink is 5-30nm, and the prepared nano copper conductive ink has high oxidization resistance and can not be oxidized after stored for above one year in air; the nano copper conductive ink has high conductivity, the resistivity of the sintered electronic device is only 2-5 times that of the conventional copper wire and can be kept unchangeable after being placed for a long time in air; and the preparation method is suitable for preparing various printed electronic devices, is simple in process, and can realize massive production.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Loaded nano-copper magnetic catalyst used for catalysis of solution of formaldehyde for preparing hydrogen and preparation method thereof

InactiveCN101862656AHigh activityImprove reuse efficiencyCatalyst carriersHydrogenHydrazine compoundFORMALDEHYDE SOLUTION

The invention relates to a loaded nano-copper magnetic catalyst used for catalytic conversion of aqueous solution of formaldehyde for preparing hydrogen and a preparation method thereof. The method comprises the following steps of: preparing magnetic Fe3O4 from low-cost FeCl2.4H2O and FeCl3.6H2O; coating a layer of SiO2 on the surface of the Fe3O4 to prepare a magnetic Fe3O4@SiO2 catalyst carrier; dispersing the magnetic Fe3O4@SiO2 in a copper ammonia complex; and reducing the dispersed substance by using a hydrazine hydrate to obtain a Cu / Fe3O4@SiO2 magnetic catalyst having a nano-scale Cu active ingredient. High-purity hydrogen can be obtained under a room temperature condition by applying the Cu / Fe3O4@SiO2 magnetic catalyst to the catalytic reaction of the solution of formaldehyde for preparing hydrogen and the separation of the catalyst from reactants can be realized easily by adding a magnetic field outside. Simultaneously, the catalyst can be reused repeatedly.

Owner:BEIJING UNIV OF CHEM TECH

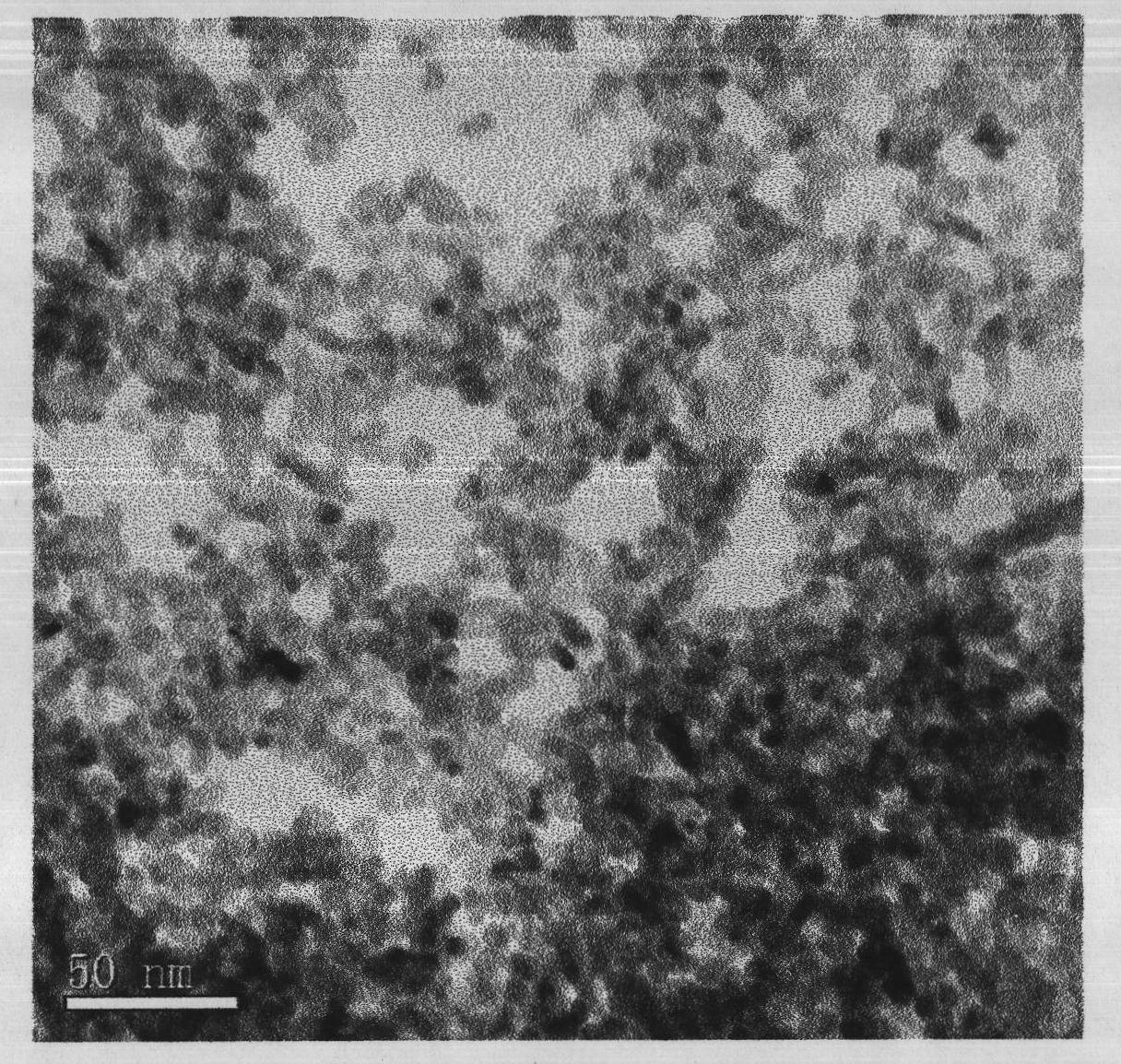

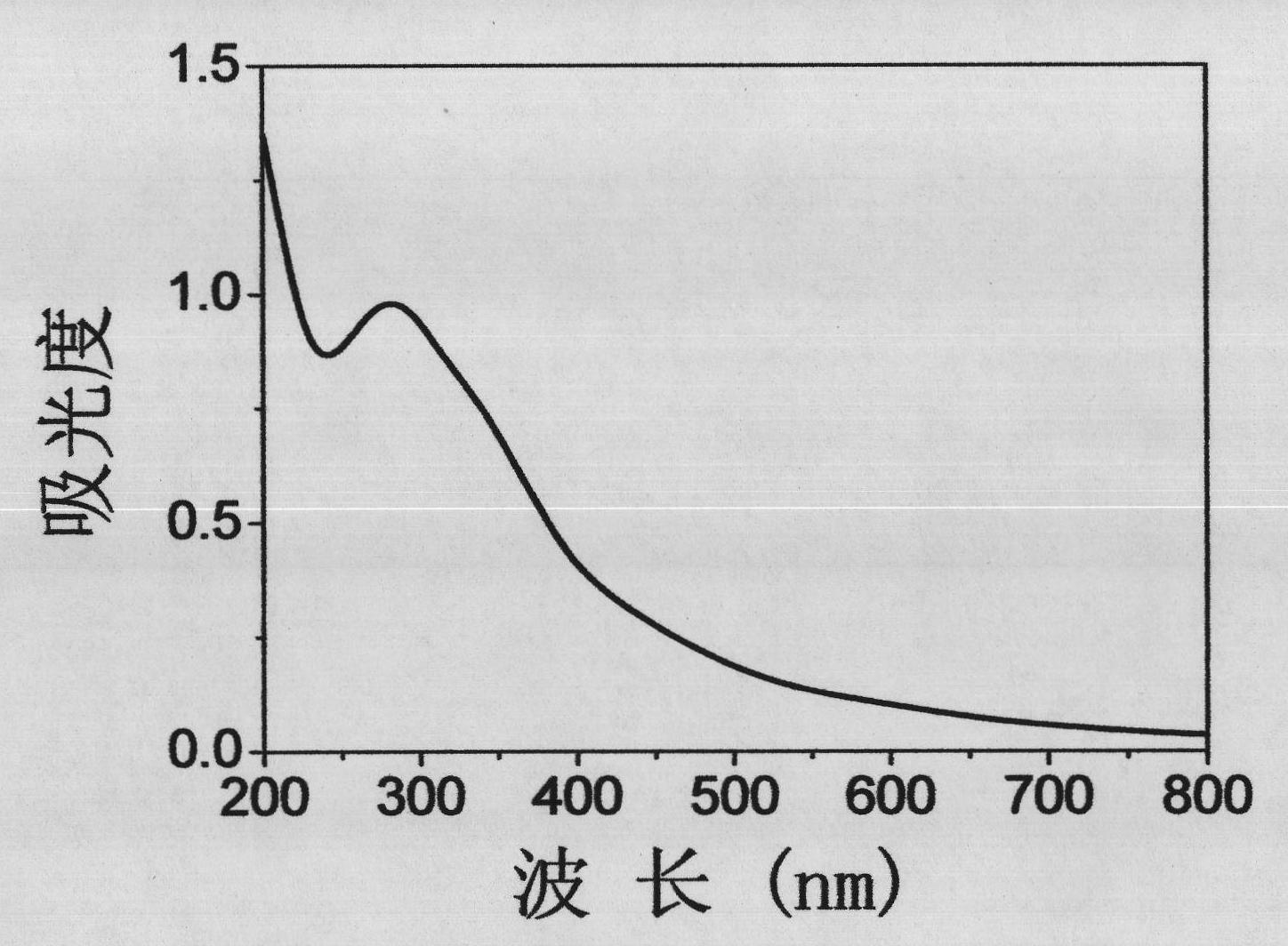

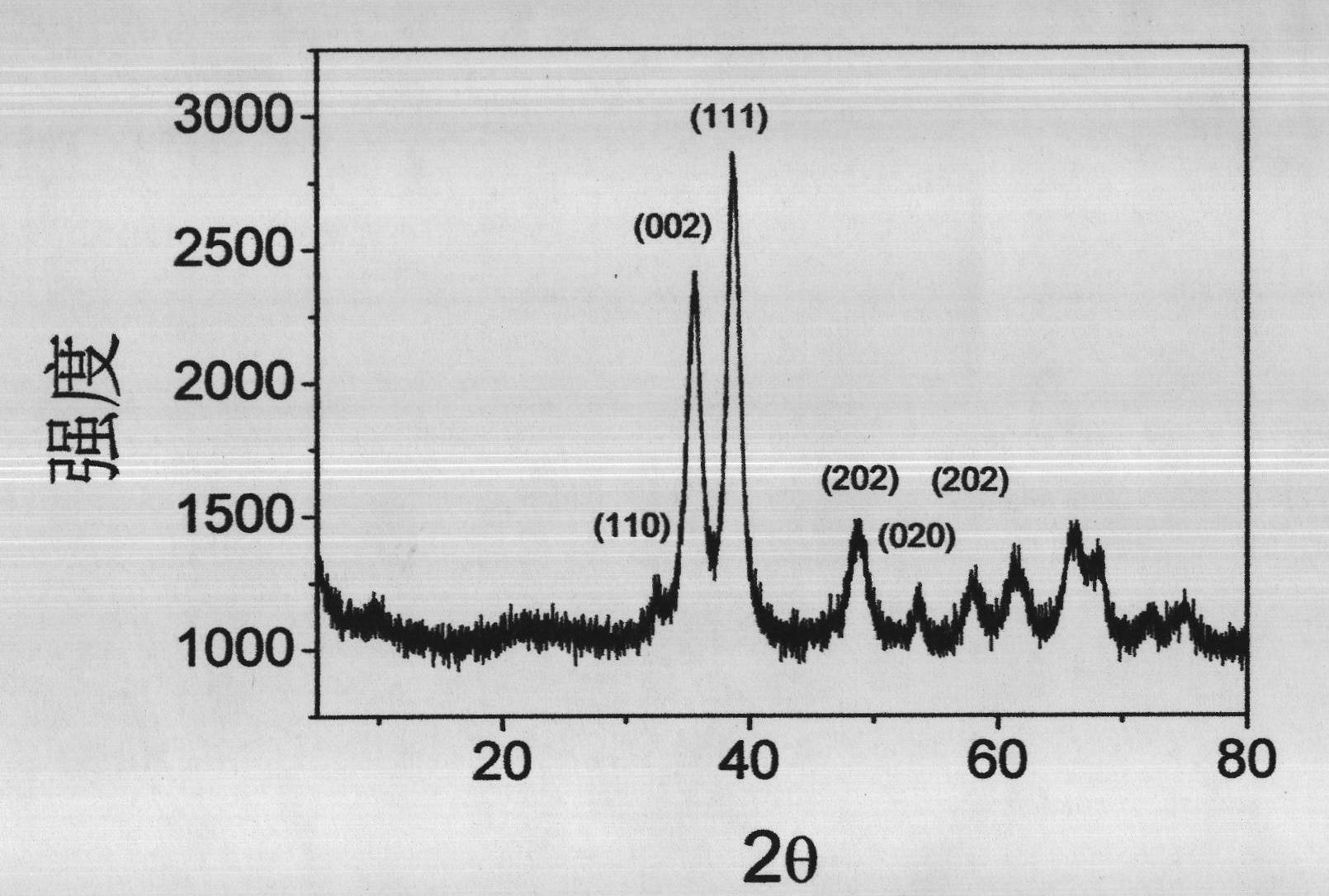

Nano copper oxide analogue enzyme and method for measuring hydrogen peroxide by using nano copper oxide analogue enzyme as peroxide analogue enzyme

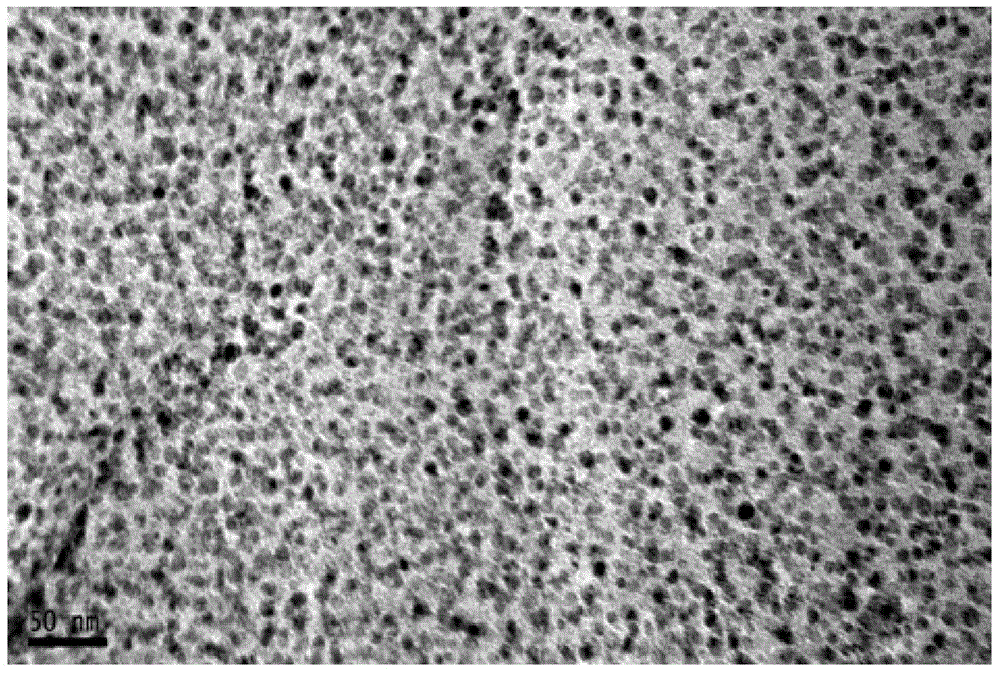

InactiveCN102020308AImprove dispersion stabilitySimple preparation processNanotechnologyCopper oxides/halidesPeroxidaseNano copper

The invention discloses a nano copper oxide analogue enzyme and a method for measuring hydrogen peroxide by using the nano copper oxide analogue enzyme as a peroxide analogue enzyme. The nano copper oxide analogue enzyme is nano copper oxide powder with a grain diameter ranging from 5 to 8 nanometers; the nano copper oxide is Cuo of a monoclinic system, the space group is C2 / c; and the maximum absorption peaks of the typical ultraviolet-visible absorption spectra of the prepared nano copper oxide are at 280-nanometer positions. The nano copper oxide analogue enzyme is obtained by a chemical precipitation process. The nano copper oxide analogue enzyme has a catalytic property similar to that of peroxidase. When the nano copper oxide analogue enzyme is used in a 4-aminoantipyrine-ol system, the colorimetric detection of hydrogen peroxide can be realized, the hydrogen peroxide detection limit is 0.02mmol / L, and the linear range is 1mmol / L.

Owner:FUJIAN MEDICAL UNIV

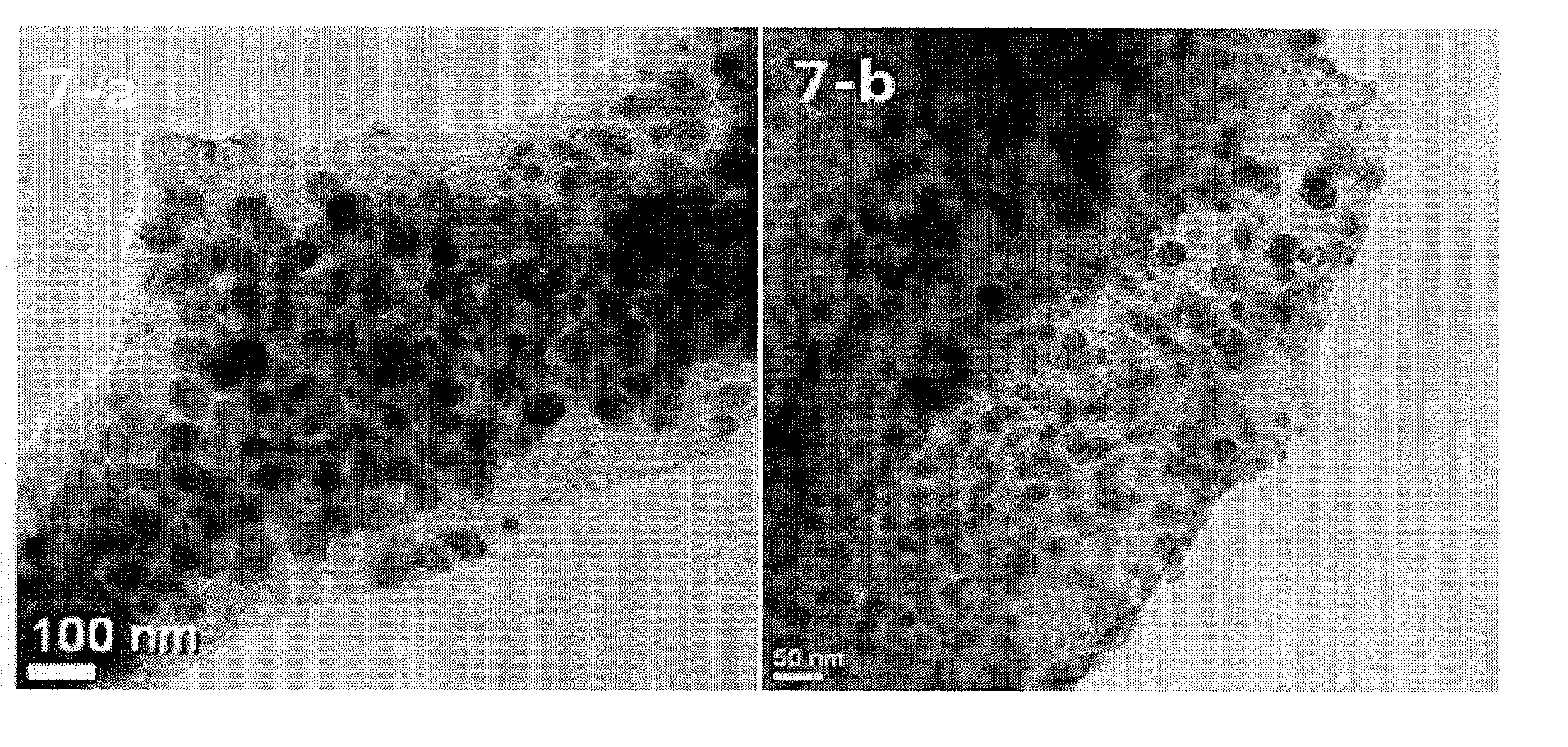

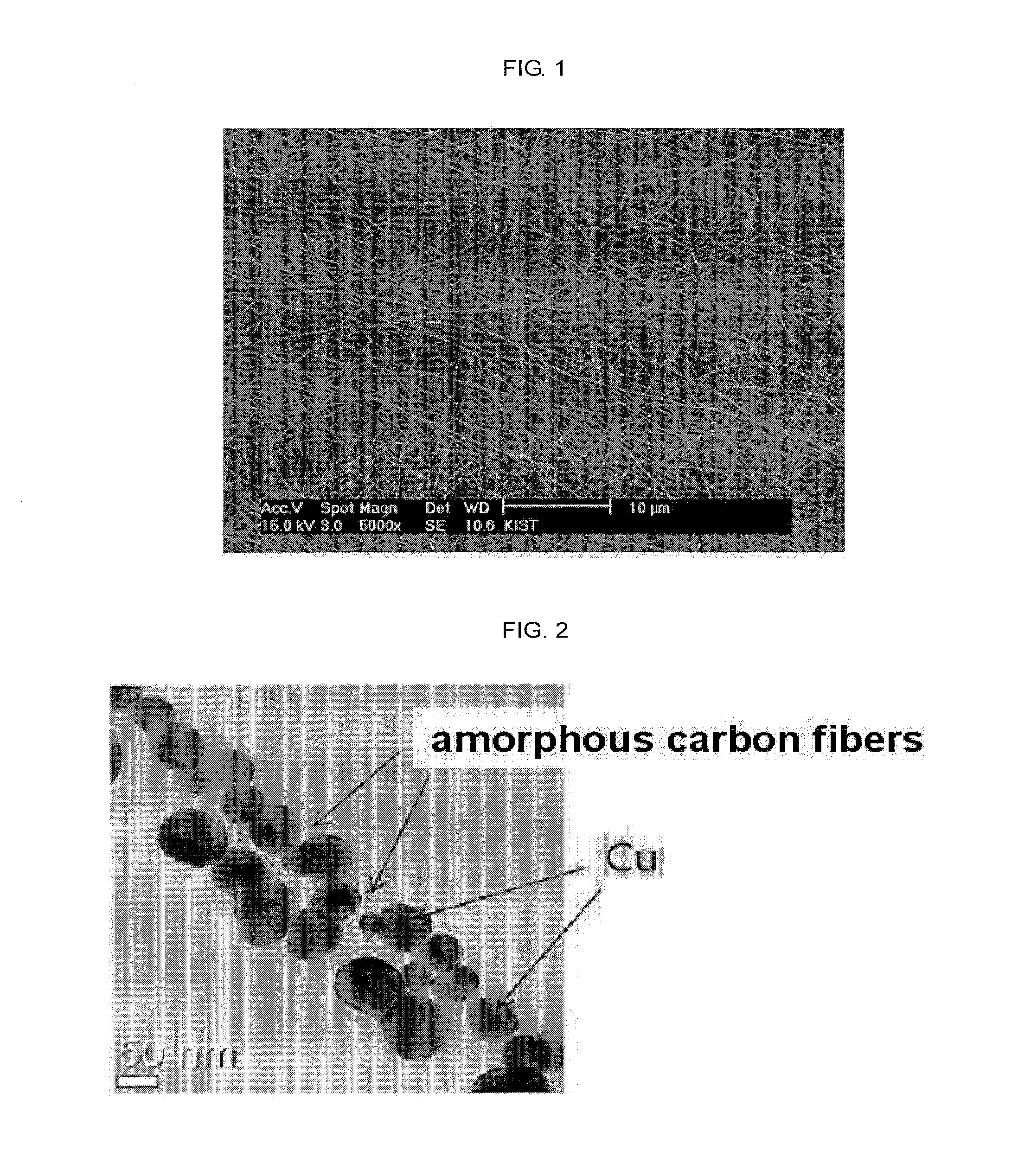

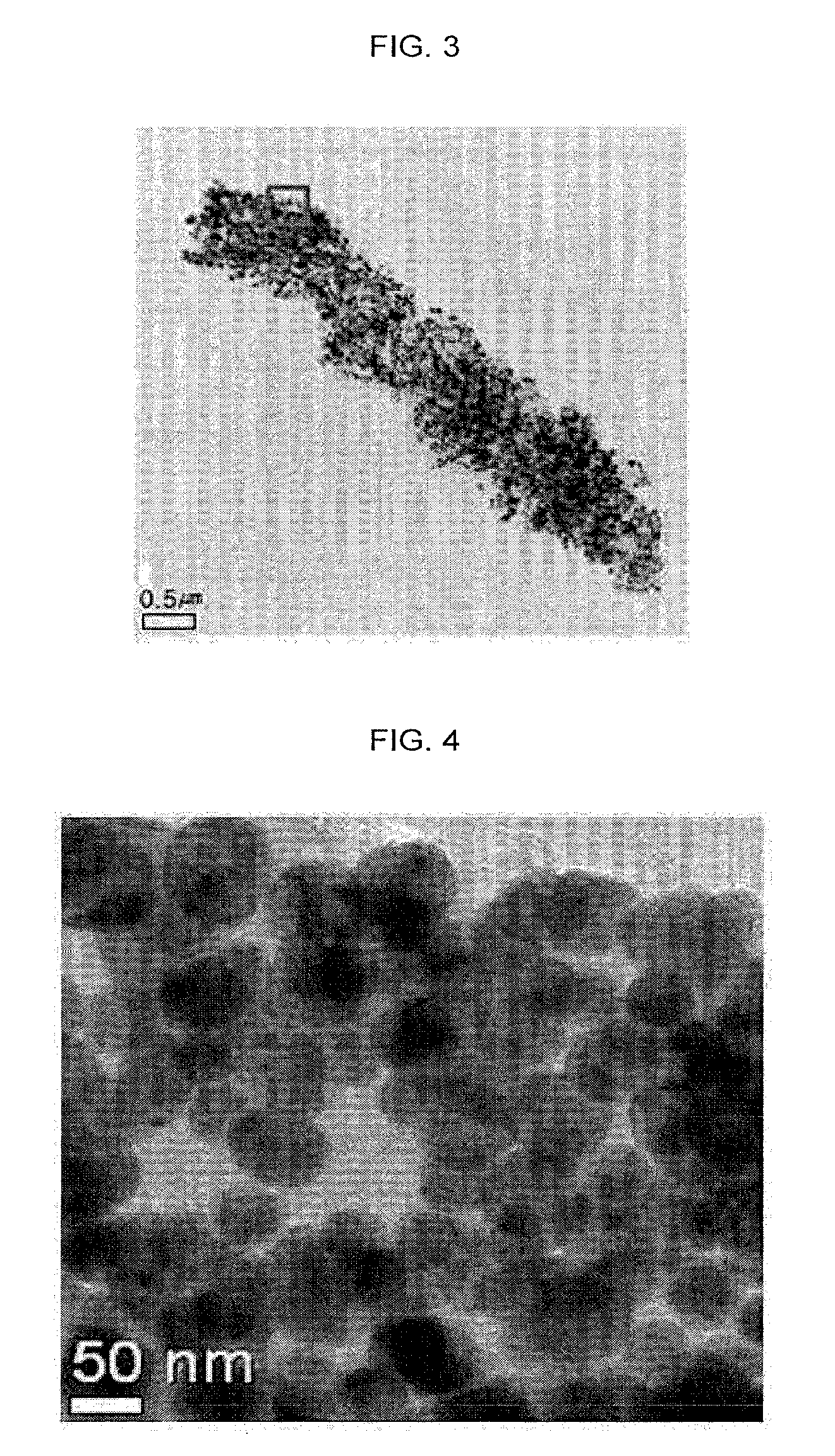

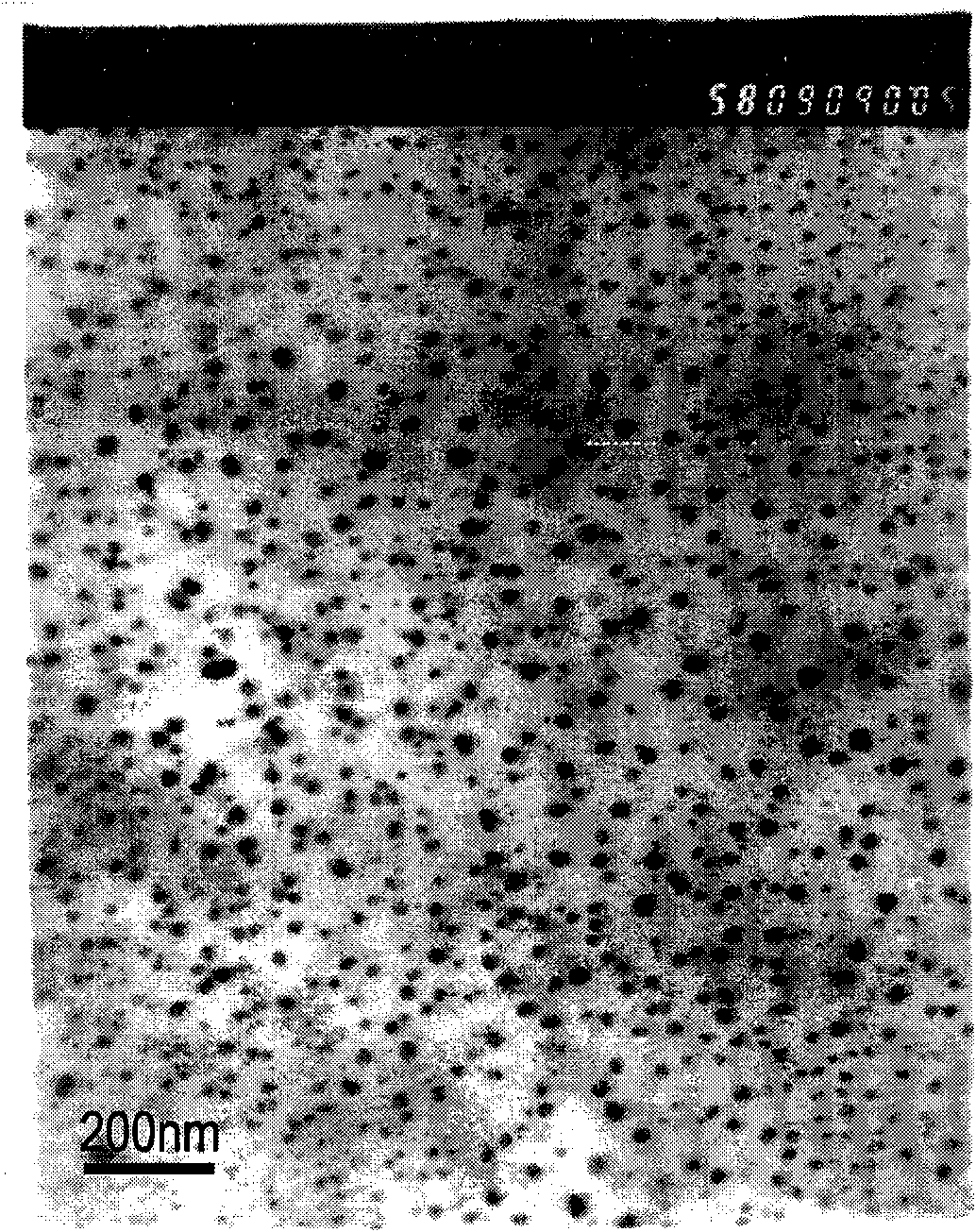

Carbon nanofiber including copper particles, nanoparticles, dispersed solution and preparation methods thereof

ActiveUS20120100303A1Improve conductivityUniform particle sizeMaterial nanotechnologyRadiation applicationsFiberNanofiber

Disclosed are amorphous carbon nanofibers including copper nanoparticles or copper alloy nanoparticles, copper composite nanoparticles prepared by grinding the amorphous carbon nanofibers and implemented as surfaces of Cu-included particles are partially or wholly coated with amorphous carbons, a dispersed solution including the copper composite nanoparticles, and preparation methods thereof and the amorphous carbon nanofibers include nanoparticles including copper, copper nanoparticles or copper alloy nanoparticles, and, the copper composite nanoparticles are implemented as surfaces of Cu-included particles are partially or wholly coated with amorphous carbons.

Owner:KOREA INST OF SCI & TECH

Nano-copper conductive ink preparation method

InactiveCN101608077ASimple processMild reaction conditionsInksNon-conductive material with dispersed conductive materialDistillationSolvent

The invention belongs to the nanometer material technical field, in particular to a nano-copper conductive ink preparation method, comprising the following steps: dissolving copper salt and organic protective agents in a solvent, heating the solution to 30-100 DEG C, simultaneously adding reducing agent in the reaction system to react while stirring for 20-30min, then cooling gradually; finally obtaining stable nano-copper conductive ink through electrodialysis separation and reduced pressure distillation. The invention has simple process, mild reaction conditions and short reaction time; the conductibility of the product is good, the particle size of nano-copper is 20-70nm, the nano-copper can not be oxidized for one month in the air; the production cost is low and no hazardous waste can be generated, thus meeting the demand of 'green production'.

Owner:FUDAN UNIV

Nano copper-tin alloy conductive ink and preparation method and usage of nano copper-tin alloy conductive ink

ActiveCN102675960ALower sintering temperatureImprove antioxidant capacityInksMetallic pattern materialsRare earthElectron scattering

The invention belongs to the technical field of material chemistry, relates to conductive ink, and particularly relates to nano copper-tin alloy conductive ink and a preparation method and usage of the nano copper-tin alloy conductive ink. Nano copper-silver alloy is replaced by nano copper-tin alloy to be used as conductive filler in the conductive ink, sintering temperature of the conductive ink is lowered, and when the nano copper-tin alloy conductive ink is compared with nano copper-silver alloy conductive ink, antioxidant capacity of the conductive ink during sintering is improved, mechanical property and solderability of a conductive circuit formed after sintering of the conductive ink are improved, and the problem of silver ion migration is avoided. Further, since rare earth metal elements are doped in the nano copper-tin alloy, grain boundary of the nano copper-tin alloy is increased, electron scattering power is increased, and conductivity is improved as compared with that of nano copper alloy. On the other hand, tin is much cheaper than silver, so that raw material cost of the nano copper-tin alloy conductive ink is reduced.

Owner:深圳市尊业纳米材料有限公司

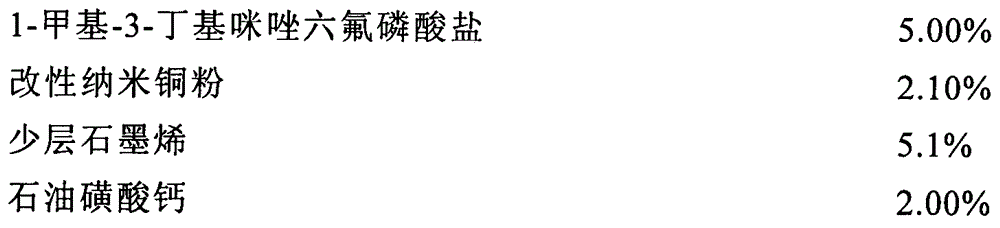

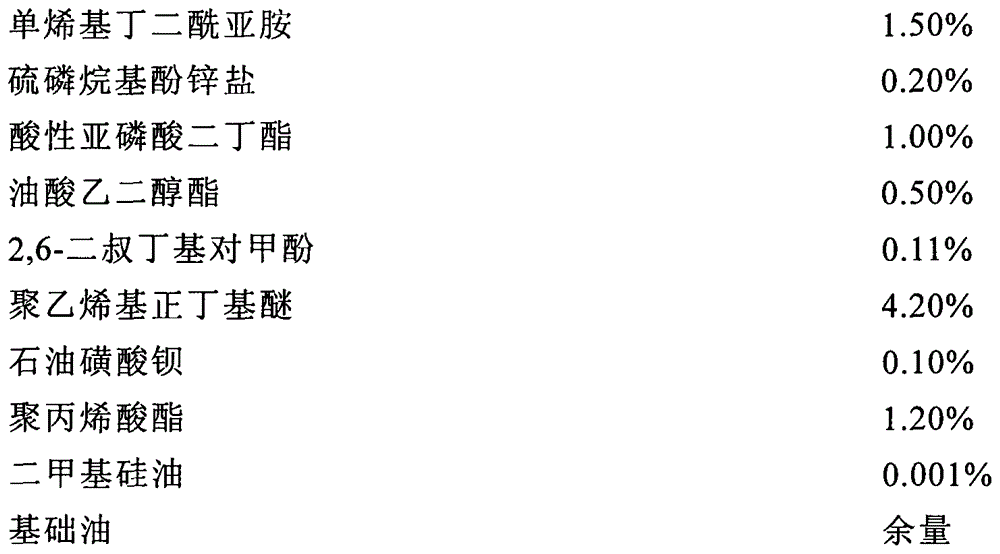

Preparation method for lubricating oil composition containing ionic liquid, modified nanometer copper powder and graphene

The invention discloses a preparation method for a lubricating oil composition containing ionic liquid, modified nanometer copper powder and graphene. The method comprises the following steps: compounding base oil, a detergent, a dispersant, a preservative, an extreme-pressure antiwear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirusting agent, a depressant, an antifoamer, the ionic liquid, the modified nanometer copper powder and the graphene so as to obtain the lubricating oil composition containing the ionic liquid, the modified nanometer copper powder and the graphene. The method in the invention has the advantages of simple and practicable production process, small equipment investment and low energy consumption, is pollution-free to the environment and is favorable for popularization and application. The lubricating oil composition prepared by using the method in the invention can be widely applied in the industrial fields of mechanical industry, automobile industry, precision instruments, electric power industry, metallurgy industry, die manufacturing and application industry, iron and steel industry, machine tool industry, etc., and has broad application prospects.

Owner:烟台广和润滑油有限公司

Method for preparing nano-metallic copper powder

A method for preparing nano-metallic copper powder relates to methods for preparing chemical materials and comprises the preparation processes: adding copper salt serving as raw materials into a reactor, adding solvents and chelating agents into the reactor, adjusting pH (potential of hydrogen) value with ammonia water, stirring liquor, controlling reaction temperature and reaction time to transform the liquor into sol, and controlling drying temperature and drying time to transform the sol into gel; and calcining the gel under the protection of inert atmosphere at the temperature of 200-400 DEG C for 0.5-2h, and cooling the gel to reach room temperature after calcining to obtain the nano-copper powder. The nano-copper powder is prepared by a sol-gel method, the reaction time is short, and the reaction temperature is low. Operation is simple and practical in the preparation processes, the preparation method is highly applicable to the raw materials, the raw materials and reagents are low in cost and easy to obtain, products in the preparation procedures are easy to obtain, and the obtained nano-copper powder is pure.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

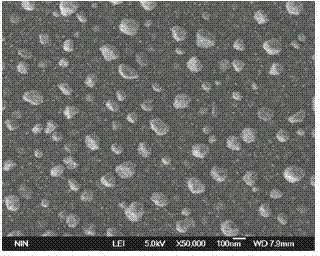

Water-soluble nano-copper and preparation method thereof

ActiveCN102554217AEffective dispersionSimple preparation processMaterial nanotechnologyNano copperMicroparticle

The invention belongs to the technical field of nanometer materials, and particularly relates to water-soluble nano-copper and a preparation method of the water-soluble nano-copper, wherein the water-soluble nano-copper is nano-copper clusters which are surface-modified by stable organic single molecules formed in a way that organic compound surface modifier containing sulfydryl is bonded on the surface of copper nanoparticles. The invention can obtain copper nanoparticles which can be effectively dispersed in water phases and can exist stably, and is simple in preparation process and preparation devices, low in raw material cost, low in the production cost, high in yield, and suitable for large-scale industrial production, and the raw materials are easily accessible.

Owner:HENAN UNIVERSITY

Positive electrode material of lithium ion cell and its preparation method

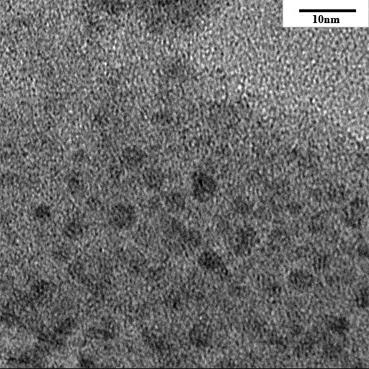

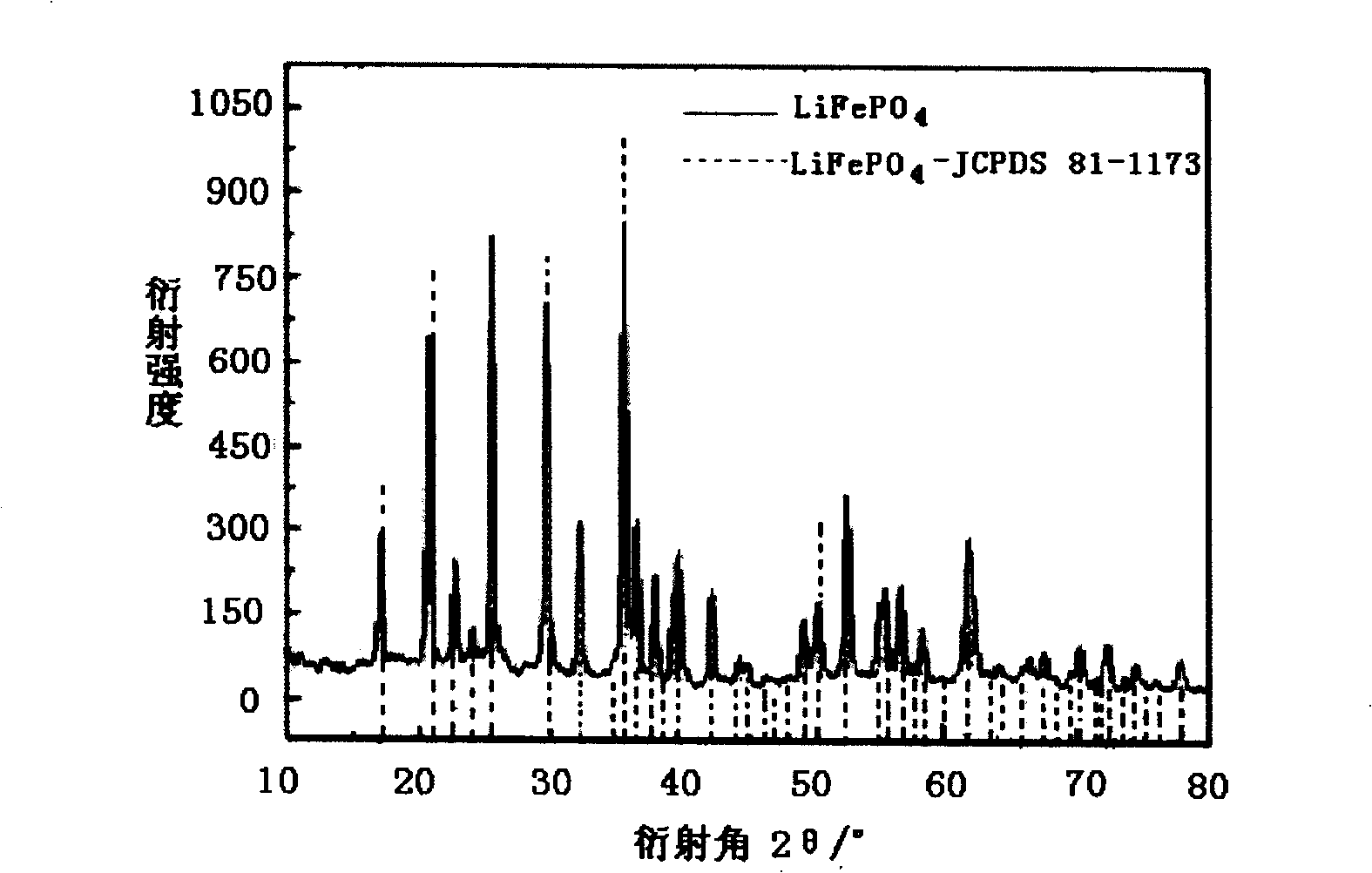

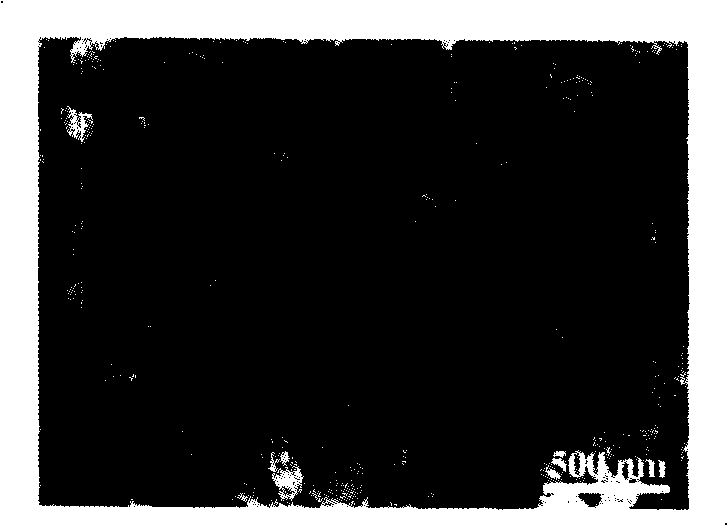

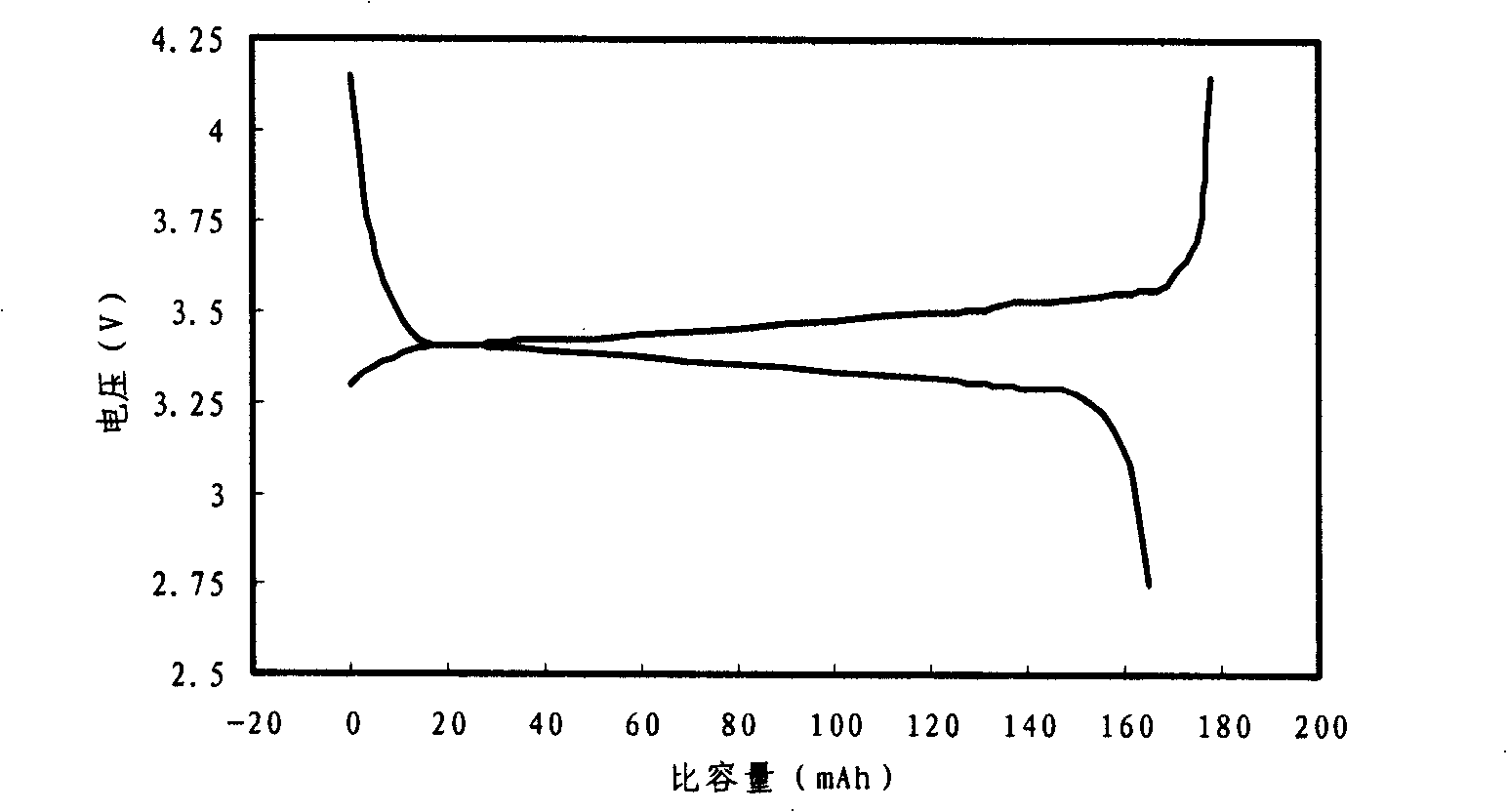

InactiveCN101339988ASolve the control puzzleWell mixedElectrode manufacturing processesPhosphorus compoundsPhosphateCopper nitrate

The invention discloses an electrode material of a lithium-ion battery and a preparation method thereof. The electrode material is lithium iron phosphate (LiFePO4) with the surface coated with nano-copper and is prepared by using the following method: water solution of ferrous phosphate and lithium phosphate is evenly mixed according to a chemical formula, and is added with a stabilizer OP-10 water solution for mixing and stirring, the mixed solution is controlled at a certain temperature for precipitation, and then the precipitate is filtered, rinsed and aired. Heat treatment is carried out for an aired precursor obtained from the previous step at high temperature, therefore a lithium iron phosphate semi-finished product is obtained. The problem of the imperfect particle size of the lithium iron phosphate is solved by controlling the process conditions. Copper nitrate solution is mixed with the lithium iron phosphate semi-finished product and is added with vitamin C for reducing to obtain the copper; metal copper is evenly clad on the surface of the lithium iron phosphate particles. The preparation method has simple operational procedure; the lithium-ion battery anode material of the prepared lithium-ion battery electrode material has high ionic conductivity and electron conductivity, the 1C initial specific capacity is not less than 162mAh / g and the lC tap density is not less than 1.5g / cm<3>.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

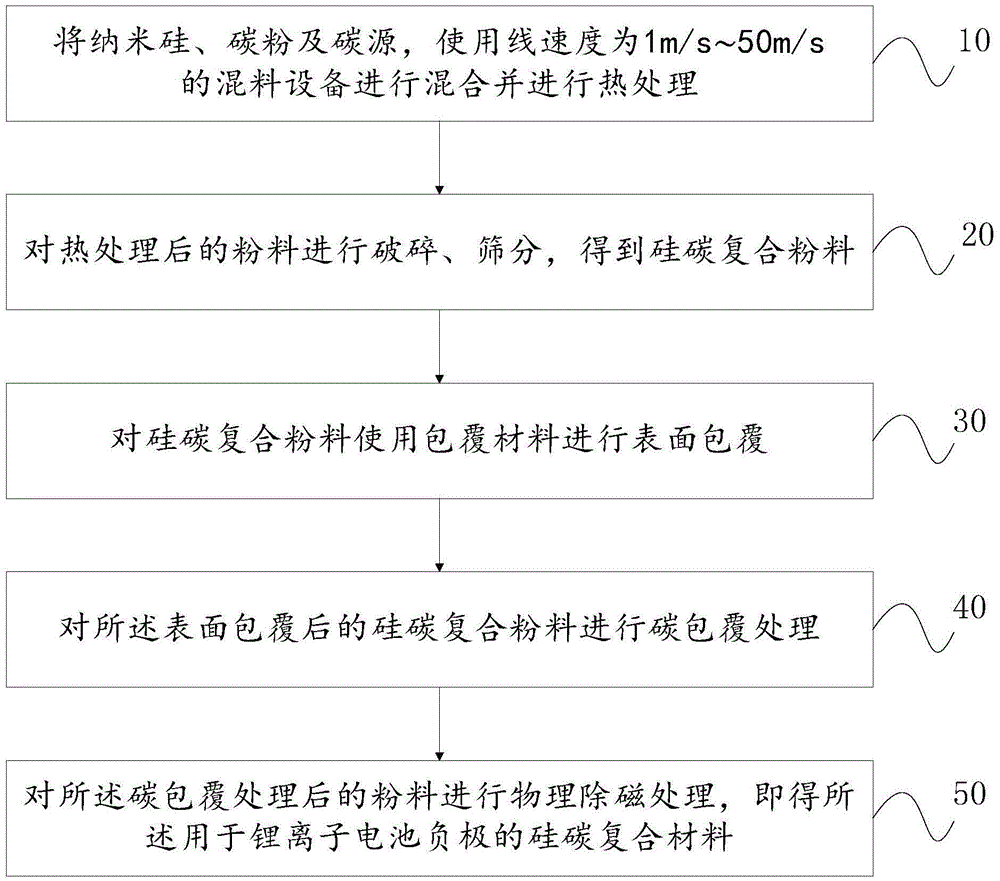

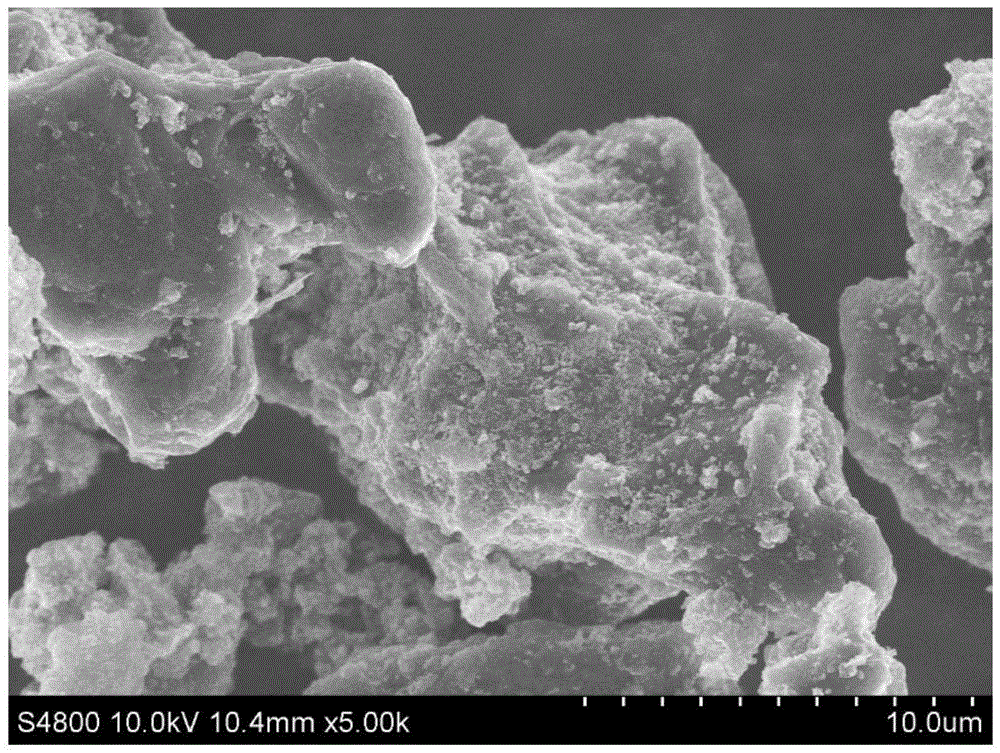

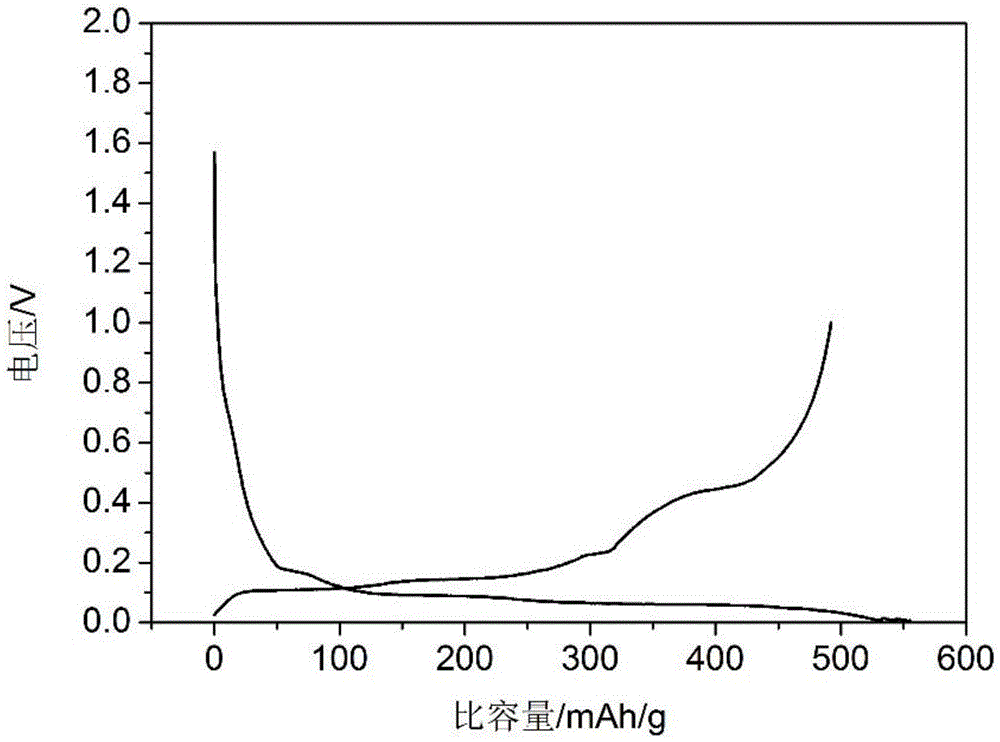

Silicon and carbon composite material for lithium ion battery anode and preparation method thereof

ActiveCN105576210AHas first week efficiencySimple processNegative electrodesSecondary cellsCarbon coatingCarbon composites

The invention discloses a silicon and carbon composite material for a lithium ion battery anode and a preparation method thereof. The method comprises following steps: mixing nano silicon, carbon powder and a carbon source by a piece of mixing equipment with a linear speed of 1m / s-50m / s, carrying out heat treatment, wherein the mass ratio of the nano silicon is (0 %, 50 %], the mass ratio of the carbon powder is (0 %, 80 %], the mass ratio of the carbon source is (0 %, 80 %]; crushing and sieving the powder materials after the heat treatment, thus obtaining silicon and carbon composite powder materials; carrying out surface coating to the silicon and carbon composite powder materials by a clad material, wherein the clad material comprises one or the mixture of multiple of the following materials: nano copper oxide, nano magnesium oxide, nano titanium oxide, nano aluminium oxide, nano graphite, graphite flakes or graphene with mass ratio of 1%-10%; carrying out carbon coating treatment to the surface coated silicon and carbon composite powder materials; and carrying out physical magnetism removing treatment to the carbon coated powder materials, thus obtaining the silicon and carbon composite material for the lithium ion battery anode.

Owner:江西紫宸科技有限公司 +2

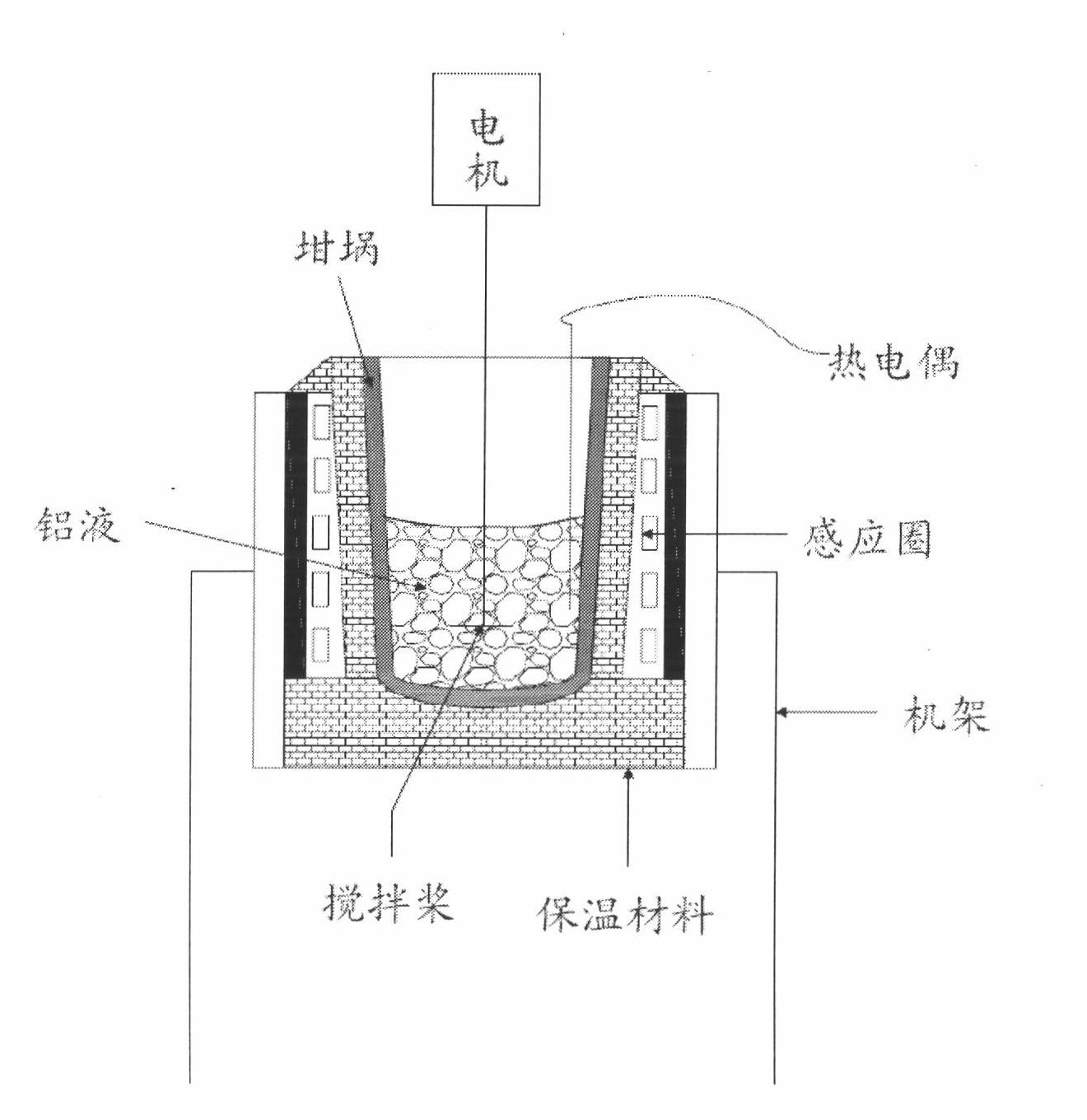

Micro-nano particle reinforced aluminum-based composite material and preparation method thereof

The invention relates to a micro-nano particle reinforced aluminum-based composite material and a preparation method thereof. The aluminum-based composite material takes aluminum or an aluminum alloy as a substrate material; micron-scale silicon carbide particles and nano alumina particles are uniformly dispersed in the substrate material; and the nano alumina particles are generated by undergoing a thermit reaction on nano copper oxide particles and a substrate alloy on the surfaces of the silicon carbide particles, so that a micron silicon carbide / nano alumina reinforced aluminum-based composite material is formed. The preparation method of the aluminum-based composite material comprises the following steps of: undergoing a reaction on micron-scale silicon carbide powder and soluble copper salt in an alkaline solution; filtering, baking and grinding to obtain silicon carbide / copper oxide composite powder; and undergoing a thermit reaction on the composite powder and an aluminum melt, and casting and molding to obtain a target product. By adopting the method, composite reinforcement of the substrate is realized by particles of multiple scales and multiple types, the obtained aluminum-based composite material has the advantages of high intensity, high wear resistance and the like, the bending resistance and Brinell hardness of the aluminum-based composite material are increased by over 50 percent and 73 percent compared with those of the conventional aluminum alloy respectively, and the friction coefficient is lowered by over 25 percent.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

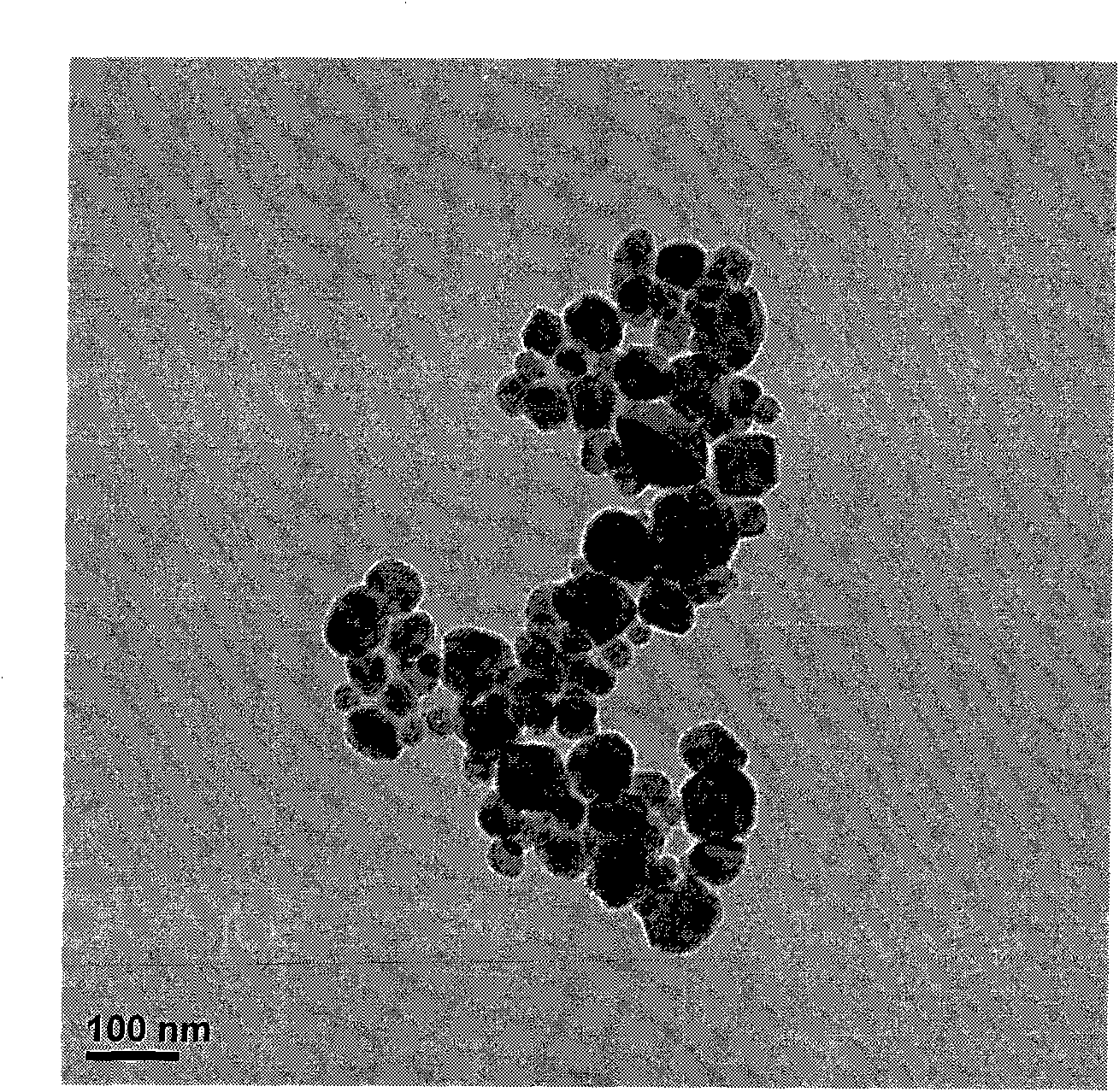

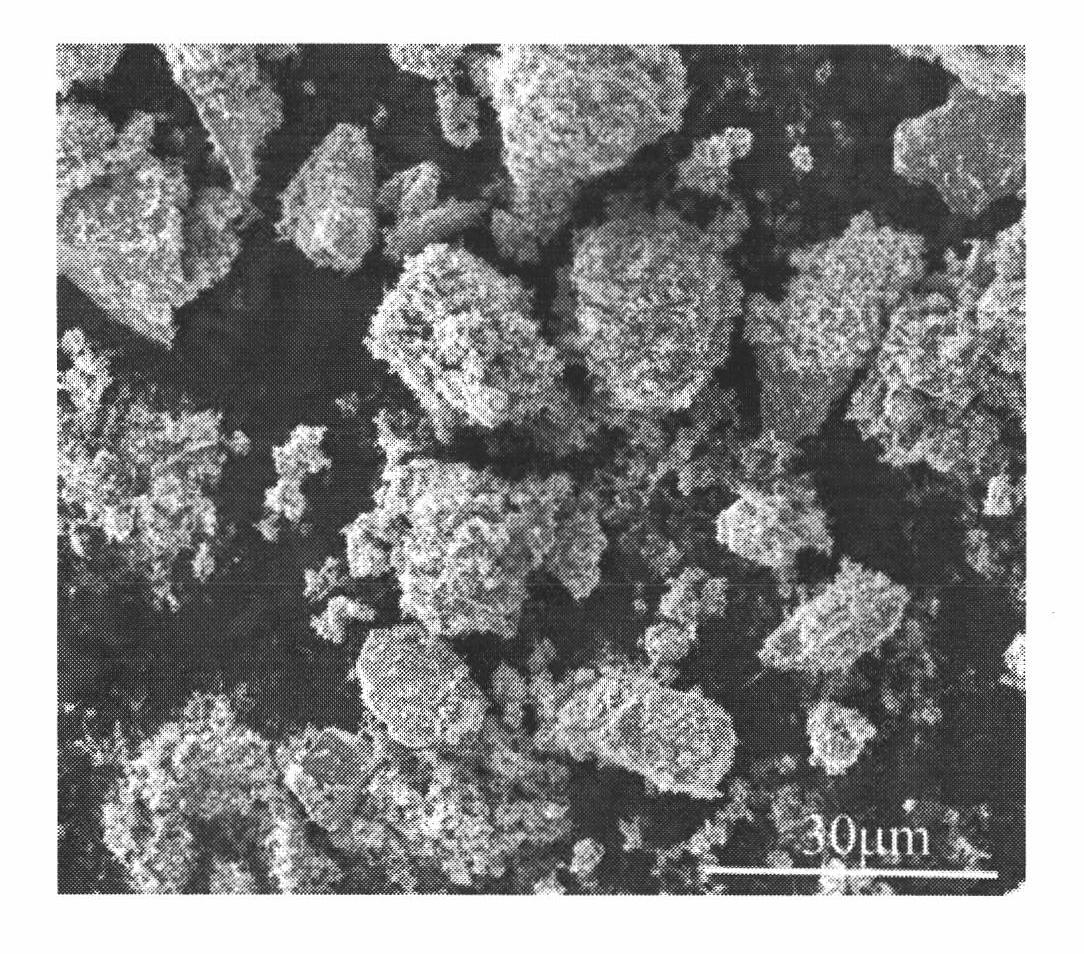

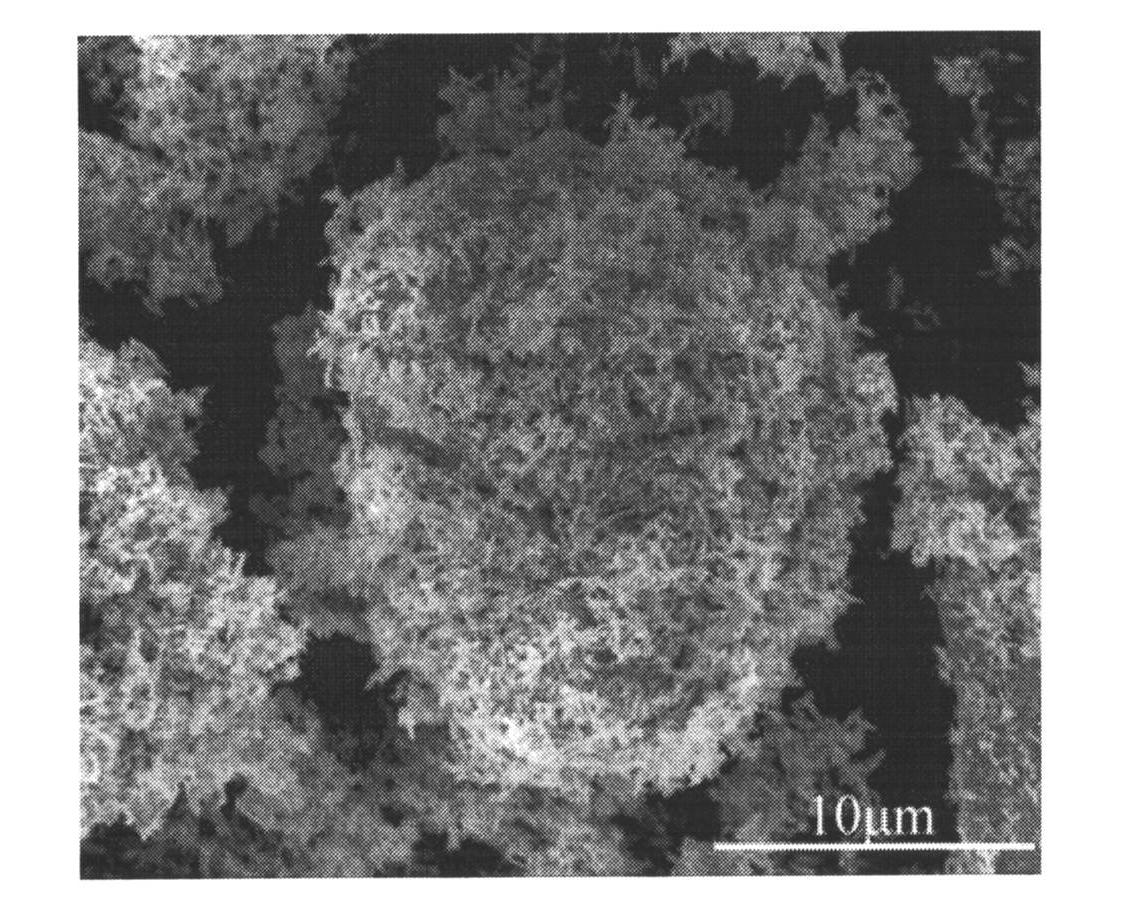

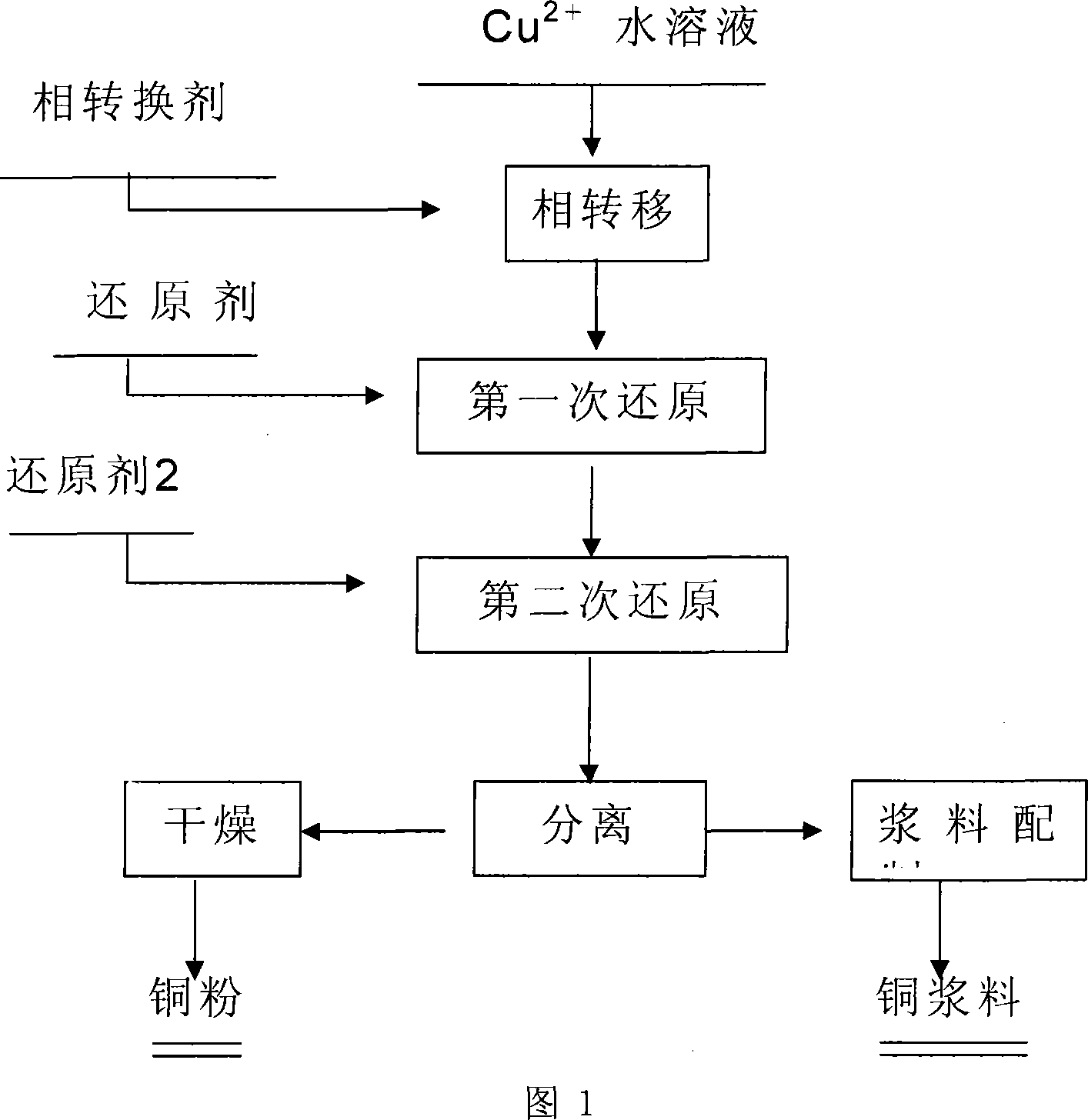

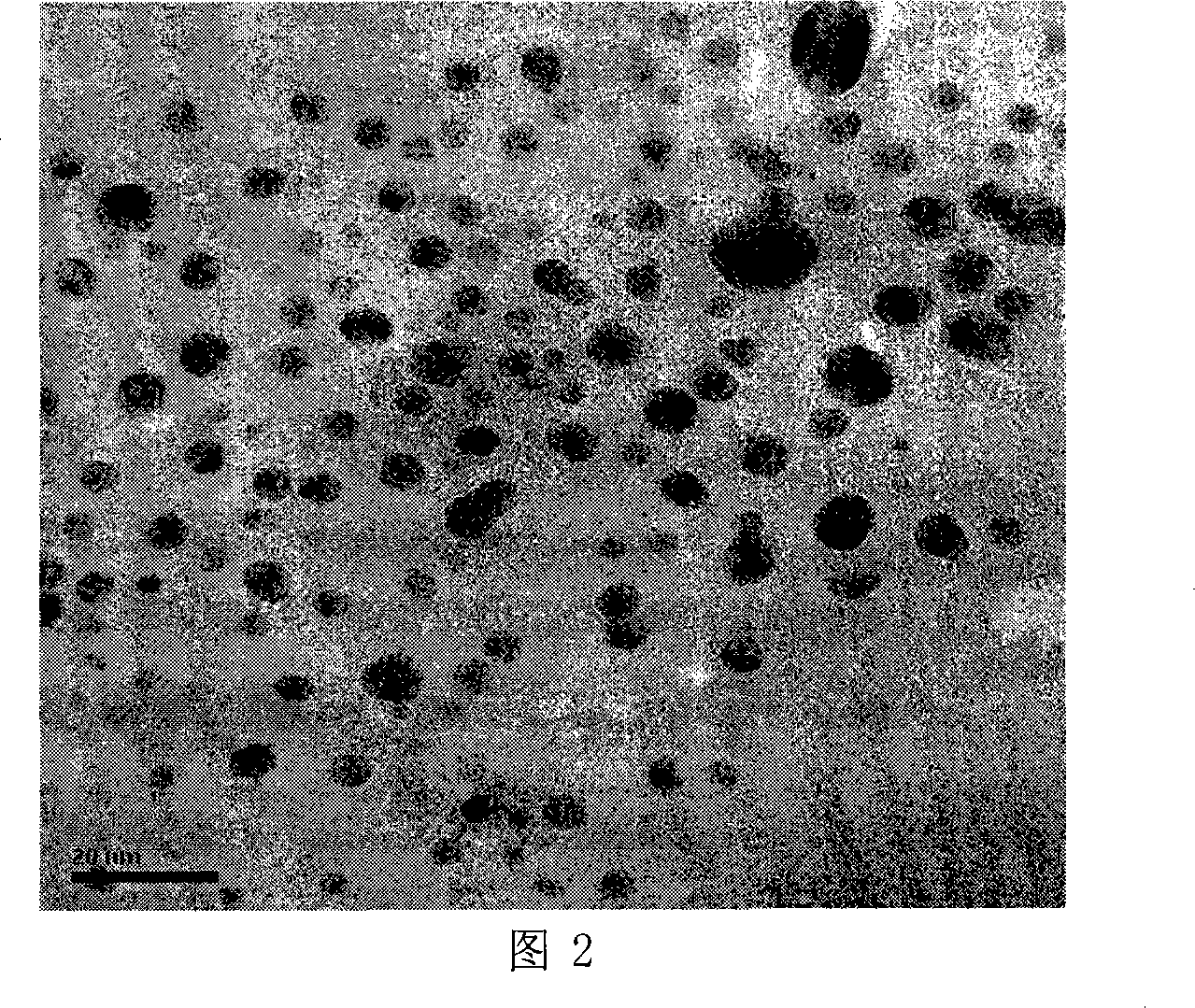

Method for preparing nano copper powder and copper slurry

InactiveCN101077529ASmall particle sizeImprove antioxidant capacityChemical compositionCeramic capacitor

The present invention is process of preparing nanometer copper powder and copper slurry with high antioxidant performance. The process includes solvent replacement, the first reduction, the second reduction, separation, drying and other steps. The present invention has the features of simple preparation process at normal temperature and normal pressure, low production cost, the effective protection of produced nanometer copper particle in organic phase, small copper powder size, environment friendly preparation process, etc. The prepared nanometer copper powder and copper slurry may be applied in producing large scale PCB, conducting ink, multilayer ceramic capacitor, etc.

Owner:CENT SOUTH UNIV +1

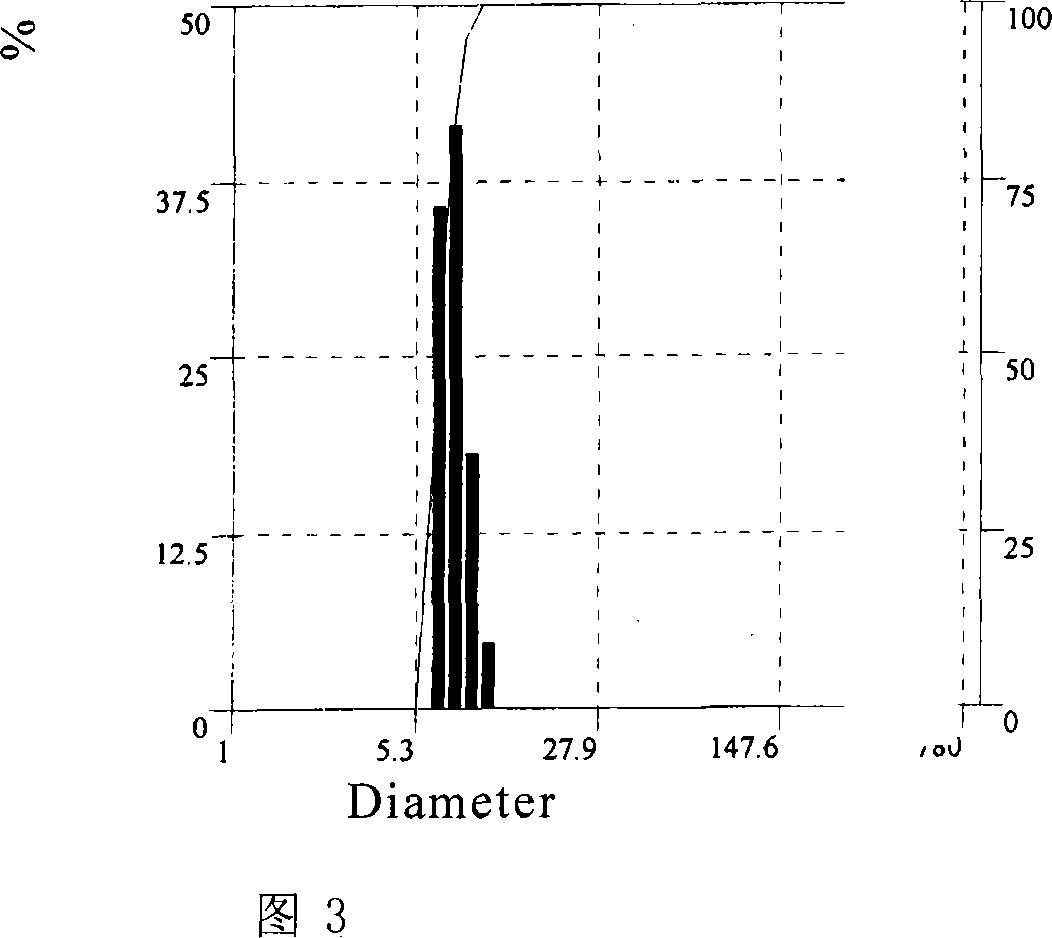

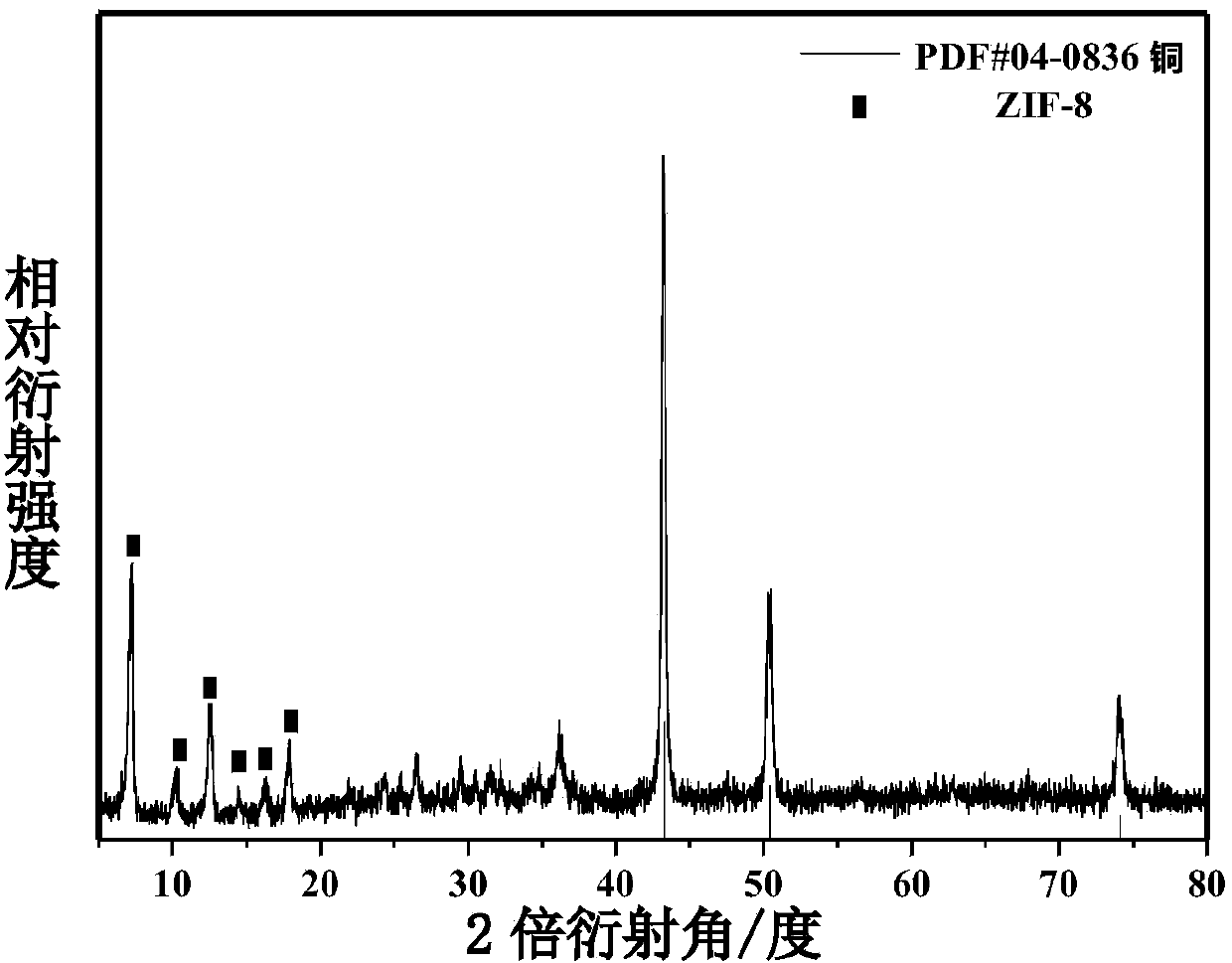

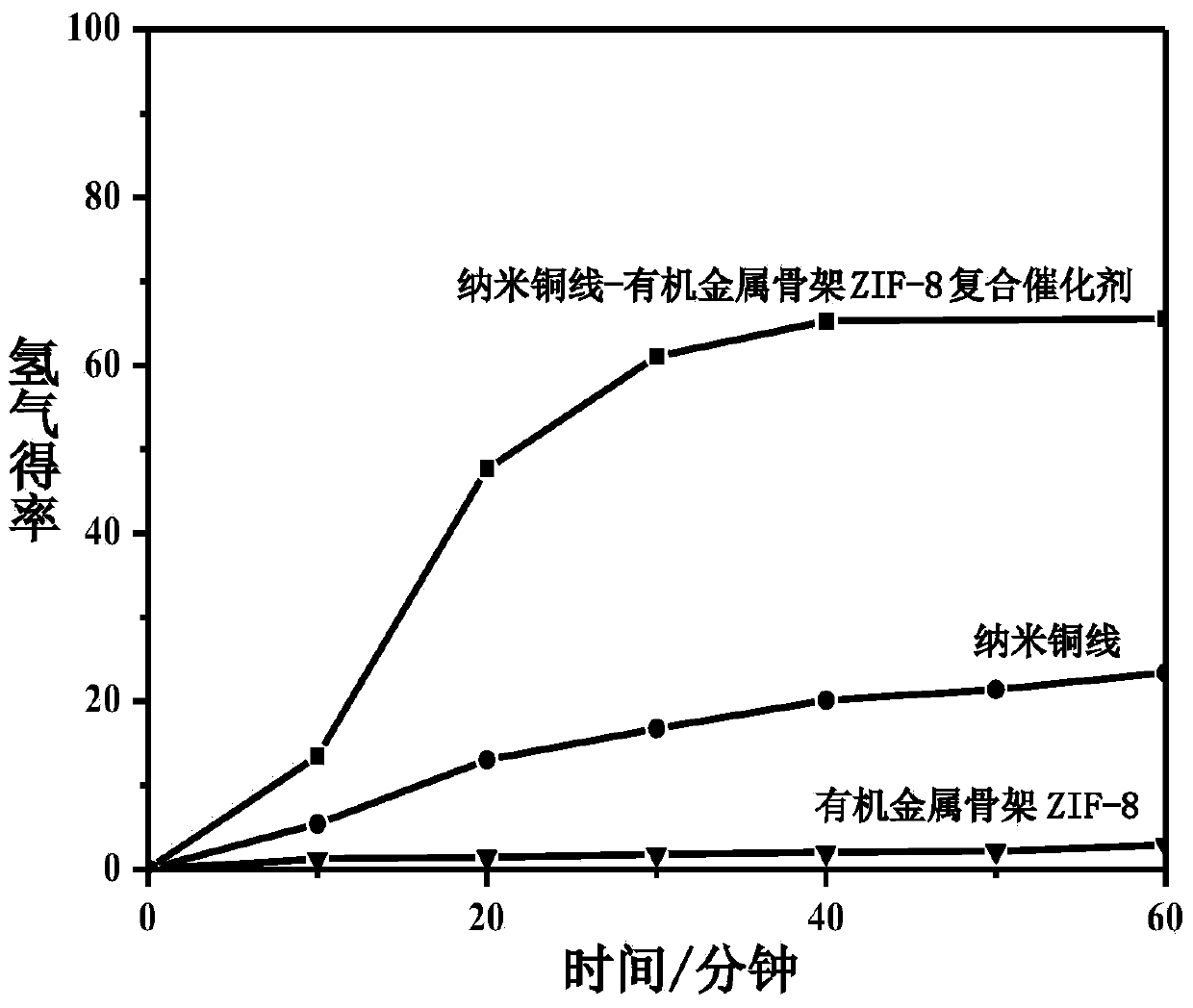

Preparation method and application of environment-friendly core shell one-dimensional nanometer copper wire-organic metallic framework ZIF-8 composite catalyst

InactiveCN104001547AImprove stabilityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionN dimethylformamideSynthesis methods

The invention discloses an environment-friendly core shell one-dimensional nanometer copper wire-organic metallic framework ZIF-8 composite catalyst and a preparation method and application of the environment-friendly core shell one-dimensional nanometer copper wire-organic metallic framework ZIF-8 composite catalyst. A microwave induction coring heating synthesis method is adopted, N, N-dimethylformamide is used as a solvent, polyvinylpyrrolidone is used as a trapping agent, a copper wire is used as a one-dimensional structure loading carrier, the environment-friendly core shell one-dimensional nanometer copper wire-organic metallic framework ZIF-8 composite catalyst is synthesized fast, the decomposition rate of the catalyst on ammonia borane in an ammonia borane decomposition catalytic reaction is 71 percent, and the good catalytic activity is shown. The preparation method of the catalyst is simple, and environmental pollution is small. An organic metallic framework ZIF-8 is combined with a non-precious metal copper nanometer wire with the good conductivity and certain catalytic performance, and the catalytic performance of the material of this kind is greatly improved. The material is potentially applied to energy storage, pollution gas absorption, sewage treatment, new energy development and other fields.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for preparing flaky nano copper powder

The invention discloses a method for preparing flaky nano copper powder, comprising the following steps: compounding a copper salt aqueous solution with a surfactant to obtain a mixed solution A, wherein the water in the copper salt aqueous solution and the surfactant form a surfactant compound system; (2) compounding a reducing agent aqueous solution with the surfactant which is the same as that used in step (1) to obtain a mixed solution B, wherein the water in the reducing agent aqueous solution and the surfactant form the surfactant compound system; (3) mixing the mixed solution B obtained in step (2) and the mixed solution A obtained in step (1) by stirring at the temperature of 20 DEG C to 80 DEG C, and reacting completely with stirring; and (4) carrying out solid and liquid separation on the product, washing the solid, and carrying out vacuum drying to obtain the flaky nano copper powder. The method of the invention has mild condition, simple process, short production period, low equipment investment and low preparation cost, and is easy to realize industrial production. The prepared flaky nano copper powder has consistent appearance, uniform size and good dispersibility.

Owner:尊领科技集团有限公司 +1

Nano-copper-cobalt bimetallic catalyst as well as preparation method and application thereof

ActiveCN103721721AEnhanced interactionGood dispersionOrganic compound preparationHydroxy compound preparationDispersityBULK ACTIVE INGREDIENT

The invention discloses a nano-copper-cobalt bimetallic catalyst as well as a preparation method and an application thereof. The catalyst takes SiO2, ZrO2, CeO2 or Al2O3 as a carrier and La2O3 as an aid, and is loaded with an active ingredient Cu[x]Co[1-x]. The preparation method comprises the following steps: soaking a mixed solution of lanthanum ions, copper ions, cobalt ions, citric acid and a chelating agent in the SiO2, ZrO2, CeO2 or Al2O3 carrier, drying and roasting to obtain a catalyst precursor; reducing the precursor through H2, CO or CH4 reducing gas or mixed gas containing the H2, CO or CH4 reducing gas and inert gas to obtain the loaded copper-cobalt bimetallic catalyst taking lanthanum oxide as the aid. The preparation method has the advantages that the interaction among Cu, Co and the lanthanum oxide is facilitated in the process of obtaining the catalyst through the precursor, and the components such as the Cu, the Co and the lanthanum oxide are high in dispersity and good in stability. The catalyst is used in reaction for preparing low-carbon alcohol from synthetic gas, and is relatively high in selectivity, activity and stability on alcohols each with 2-6 carbon atoms.

Owner:TIANJIN UNIV

Method for generating nano-copper particles on the surface of copper alloy film

InactiveCN102274973AIncrease the areaHigh densityVacuum evaporation coatingSputtering coatingHigh densityDisplay device

The method for generating nano-copper particles on the surface of a copper alloy film adopts the following steps: 1. First, deposit a Cu-Zr alloy film on a polyimide PI substrate to form a Cu-Zr / PI film-based system; 2. Then prepare the Cu-Zr alloy film The film-based system, under the condition that the vacuum degree is better than 1*10-3, the temperature is 100-400 ° C, annealed for 5-10 minutes, so that pure Cu particles with nanometer or submicron scale are formed on the surface of the polyimide matrix film. ; or by oxidizing the prepared copper particles to achieve copper oxide particles. The beneficial effects of the present invention: the method is simple, the cost is low, and it is easy to prepare large-area, high-density, and scale-controllable nano-scale pure Cu particles or oxide particles on the surface of the film; the prepared pure Cu particles or oxide particles can be used to prepare Flexible electronic devices and photoelectric display devices; the preparation method of the present invention can also provide reference for the preparation of other metal particles with similar properties.

Owner:HENAN UNIV OF SCI & TECH

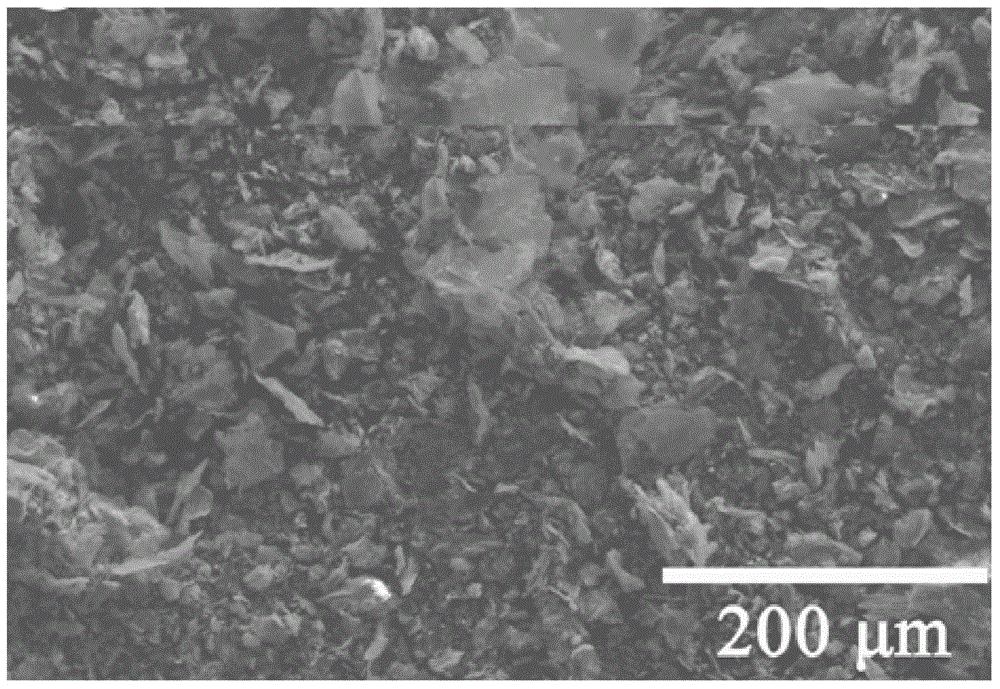

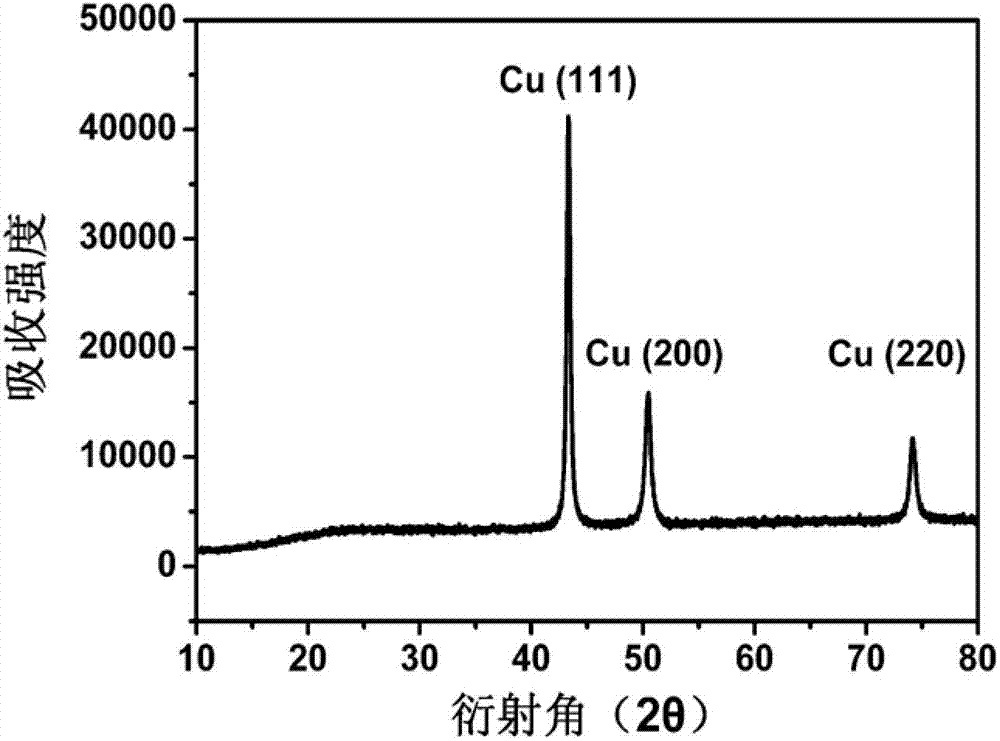

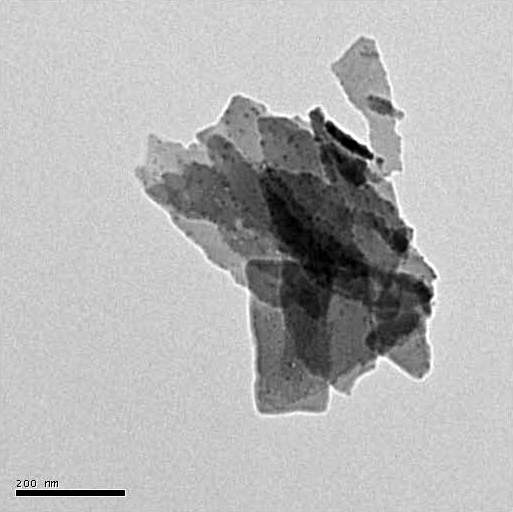

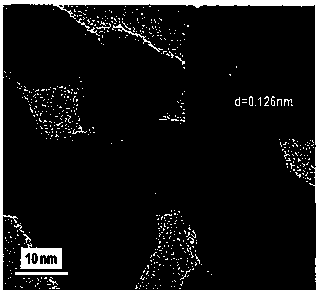

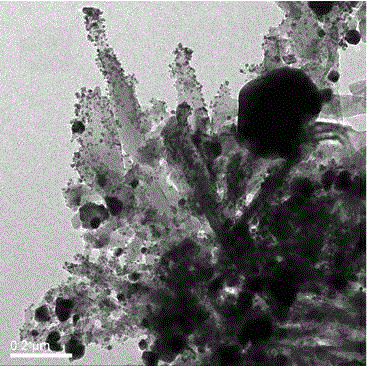

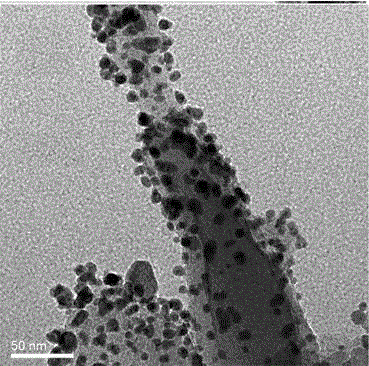

Method of using liquid-phase reduction method to prepare nano copper powder loaded graphene

InactiveCN102581295AEvenly distributedSimple methodGrapheneNanotechnologyMetal particleSurface modification

The invention relates to a method of using a liquid-phase reduction method to prepare nano copper powder loaded graphene, which solves the problems of complexity and high cost of existing graphene preparation methods. The method includes: taking graphite, adding concentrated sulphuric acid and mixing to obtain a mixture A; adding potassium permanganate, bathing in water, adding distilled water for diluting, adding hydrogen peroxide solution and diluted hydrochloric acid, cooling to the room temperature, leaching to obtain solid, adding distilled water to the solid, and placing in a semipermeable membrane for dialyzing until neutral to obtain sol; adding distilled water into the sol, adding copper sulfate pentahydrate, ultrasonically mixing, sequentially adding hydrazine hydrate solution and NaOH solution, mixing, centrifuging to obtain the product, washing and drying to obtain the nano copper powder loaded graphene. The method is simple and low in cost, no surface dressing agent is needed, and metal particles on the surface of graphene are uniform in distribution and stable in chemical performance.

Owner:HEILONGJIANG UNIV

Strong magnetic core-shell structural nano copper-based hydrotalcite catalyst and preparation method thereof

InactiveCN101927165ASimple production processLow costOrganic chemistryOrganic compound preparationNano catalystMagnetization

The invention discloses a strong magnetic core-shell structural nano copper-based hydrotalcite catalyst and a preparation method thereof, and belongs to the technical field of nano catalysts. The catalyst consists of a strong magnetic core-shell structural nano copper-based hydrotalcite catalyst CuM2+Al hydrotalcite shell and a Fe3O4 magnetic nano particle core; the strong magnetic core-shell structural nano copper-based hydrotalcite catalyst is expressed as Fe3O4@CuM2+Al-LDH and consists of 60 to 80 percent of Fe3O4 magnetic nano particles and 20 to 40 percent of CuM2+Al-LDH hydrotalcite in percentage by mass; the particle size of the core-shell structural magnetic nano catalyst is 500 to 540 nanometers; the specific saturation magnetization intensity sigma s is 40.2 to 60.7emu / g; and the phenolic conversion rate is 38.28 to 55.47 percent. The preparation method has the advantages of simple catalyst preparation process, low cost, suitability for phenolic hydroxylation reaction and phenol-containing wastewater treatment, and convenient enrichment, reclamation and reutilization through an additional magnetic field after the reaction is finished.

Owner:BEIJING UNIV OF CHEM TECH

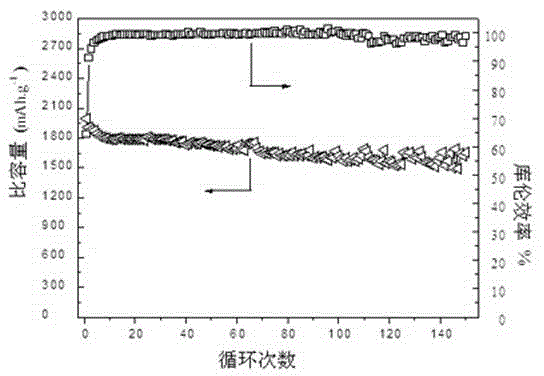

Nano-copper coated porous nano silicon composite material as well as preparation method and application thereof

InactiveCN104979559AOvercoming the disadvantage of low electronic conductivityLow costCell electrodesAcid etchingCopper plating

The invention discloses a nano-copper coated porous nano silicon composite material as well as a preparation method and application thereof. The method comprises the following steps: (1) performing activating pretreatment on a porous nano silicon powder material prepared from an acid etching silicon allay; and (2) dispersing the porous nano silicon powder material after being subjected to activating pretreatment in an electroless copper plating solution, performing electroless copper plating, filtering, washing and drying so as to obtain the nano-copper coated porous nano silicon composite material. As being used as a negative material of a lithium ion battery, the nano-copper coated porous nano silicon composite material provided by the invention has very high specific discharge capacity, charge-discharge cycling stability and excellent charge-discharge power characteristic; the specific discharge capacity of the material used as a negative material is far higher than that of a graphite negative material in an existing lithium ion battery; as the cost of preparation of porous nano silicon powder and the cost of electroless copper plating are low, the preparation method of the material is simple and easy to operate, the low-cost continuous and large-scale production is realized, and the method is suitable for being used in the production of a new-generation high-performance lithium ion battery silicon negative material.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

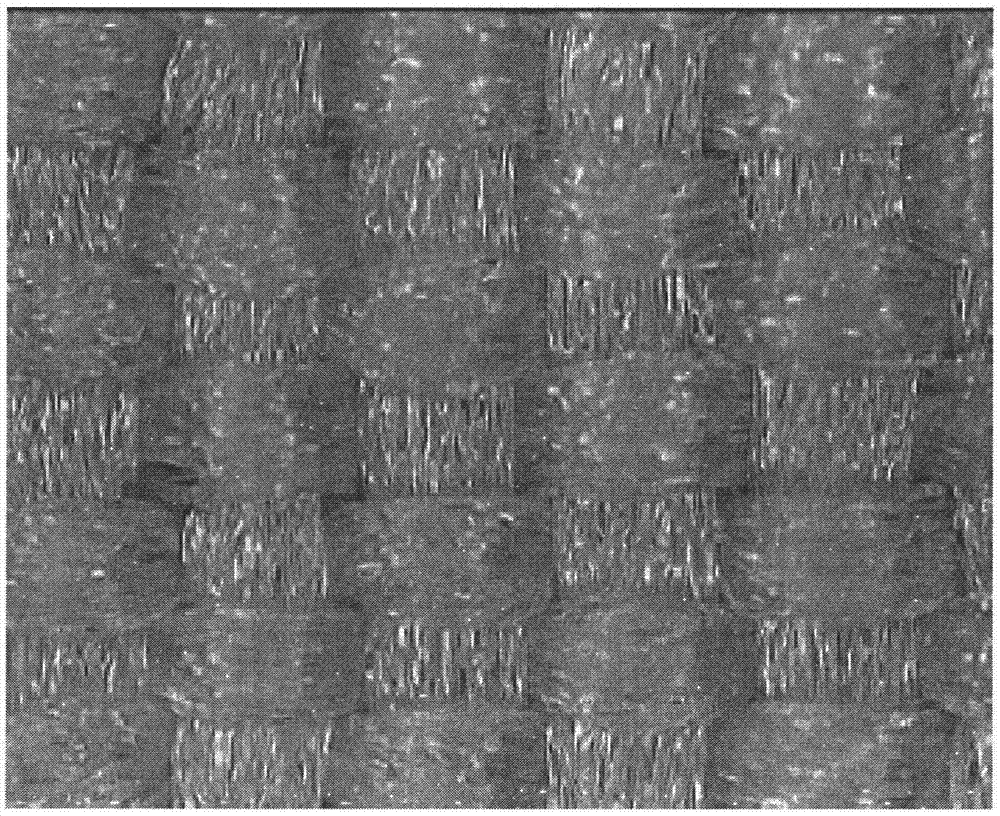

Novel electromagnetic shielding textile fabric and preparation method thereof

InactiveCN104727139ASimple preparation processLow costPhysical treatmentVacuum evaporation coatingFiberHeat conducting

The invention discloses novel electromagnetic shielding textile fabric and its preparation method and belongs to the field of textile processing. By a magnetron sputtering technology, nano-silver, nano-copper and nanometer titania particles are respectively sputtered onto a fabric base material to form an uniform nanocomposite film so as to obtain the electromagnetic shielding fabric. The electromagnetic shielding fabric for children's garments has advantages of simple preparation technology, low cost, high binding strength of the film and the base material, uniformly and compactly distributed film, strong adhesive force and no environmental pollution, and has excellent electrical conductivity and electromagnetic shielding performance. Resistance can be less than 10 omega / cm, SE value reaches about 28dB, and more than 99% of electromagnetic wave is shielded. By means of rapid heat-conducting property of metal, the fiber fabric can have effects of regulating body temperature and making the winter warm and the summer cool. In addition, the fabric feels very soft and has excellent resistance to water washing.

Owner:JIANGNAN UNIV +1

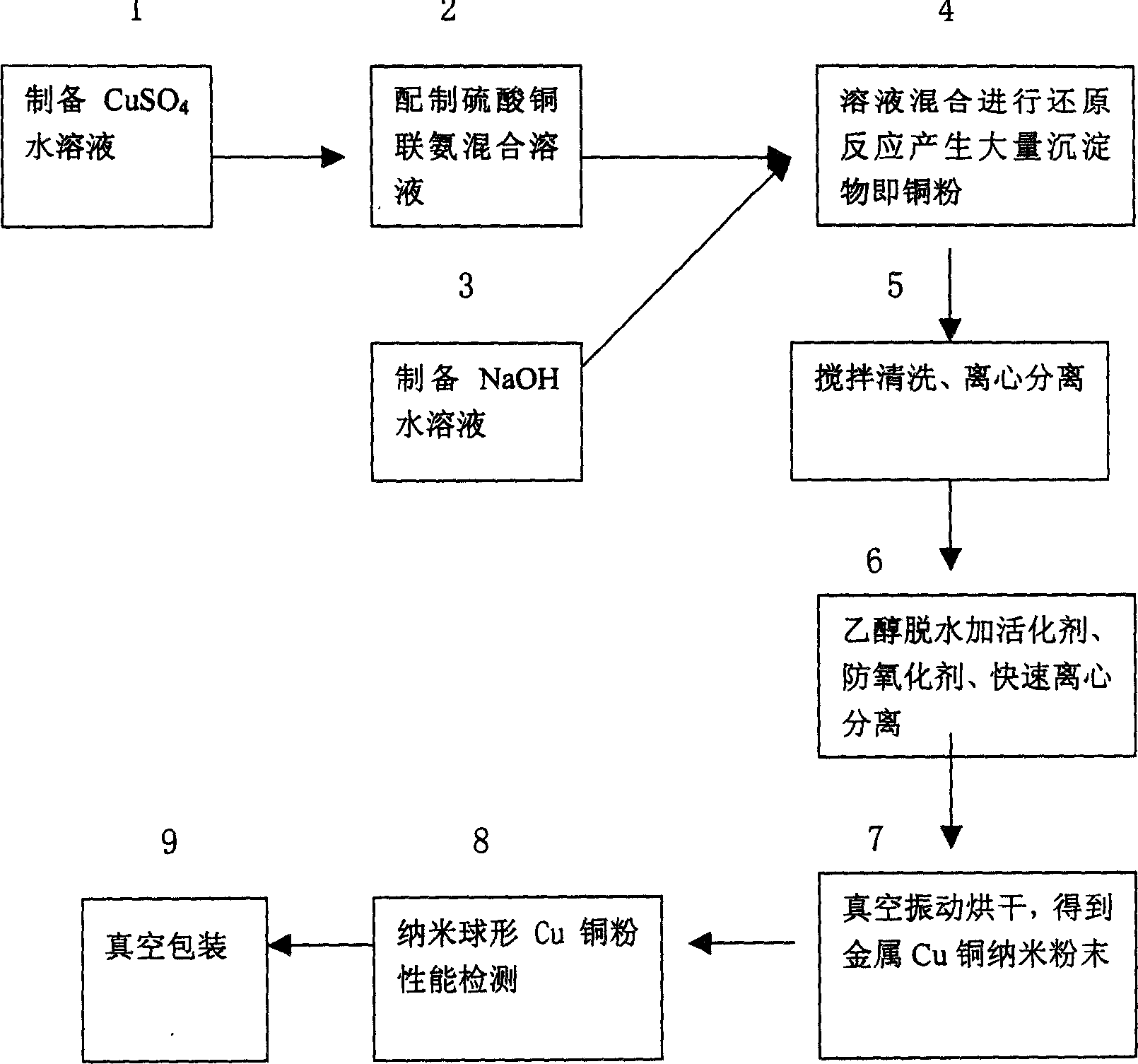

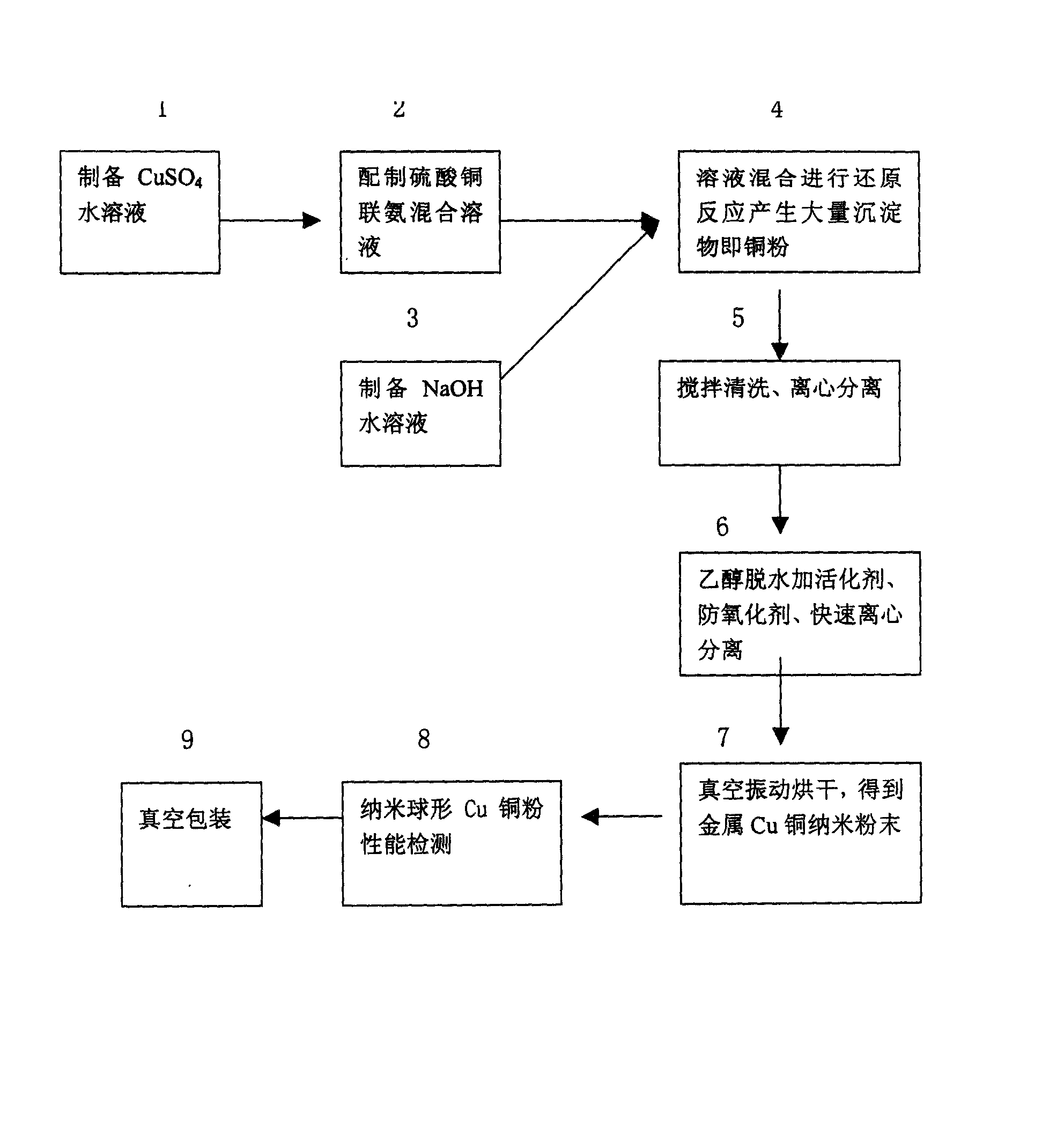

Method for mfg nano copper powder

THe present invention provides a method for preparing nano-grade ultrafine copper powder, and its preparation process. Said process includes the following steps: dissolving CuSO4 containing copper ion in water, and using hydrazine to make CU(2+) ion be reduced into supperfine Cu granules, and in the reaction product using water to clean out SO4(2-) radical ion, and using ethyl alcohol to remove residual water and adopting the continuous rapid centrifugal separation method to separate waste liquor from precipitate, finally low-temp. drying in vacuum vibration drying machine so as to obtain nano Cu powder.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com