Nano-copper conductive ink preparation method

A conductive ink and nano-copper technology, applied in the field of nano-materials, can solve the problems of difficult dispersion of conductive media, difficulty in achieving conductivity, and high heating temperature, and achieve the effects of good conductivity, short reaction time, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

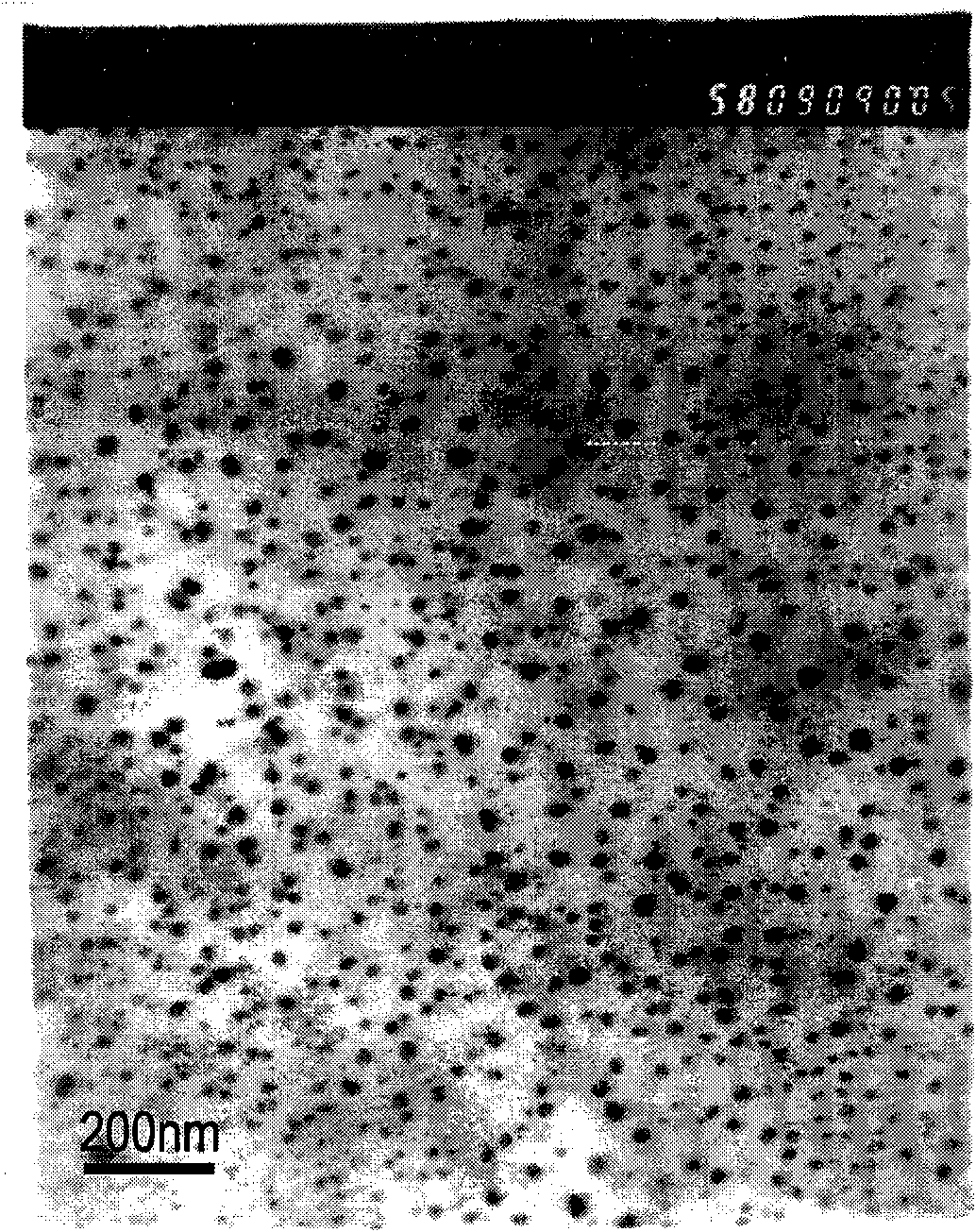

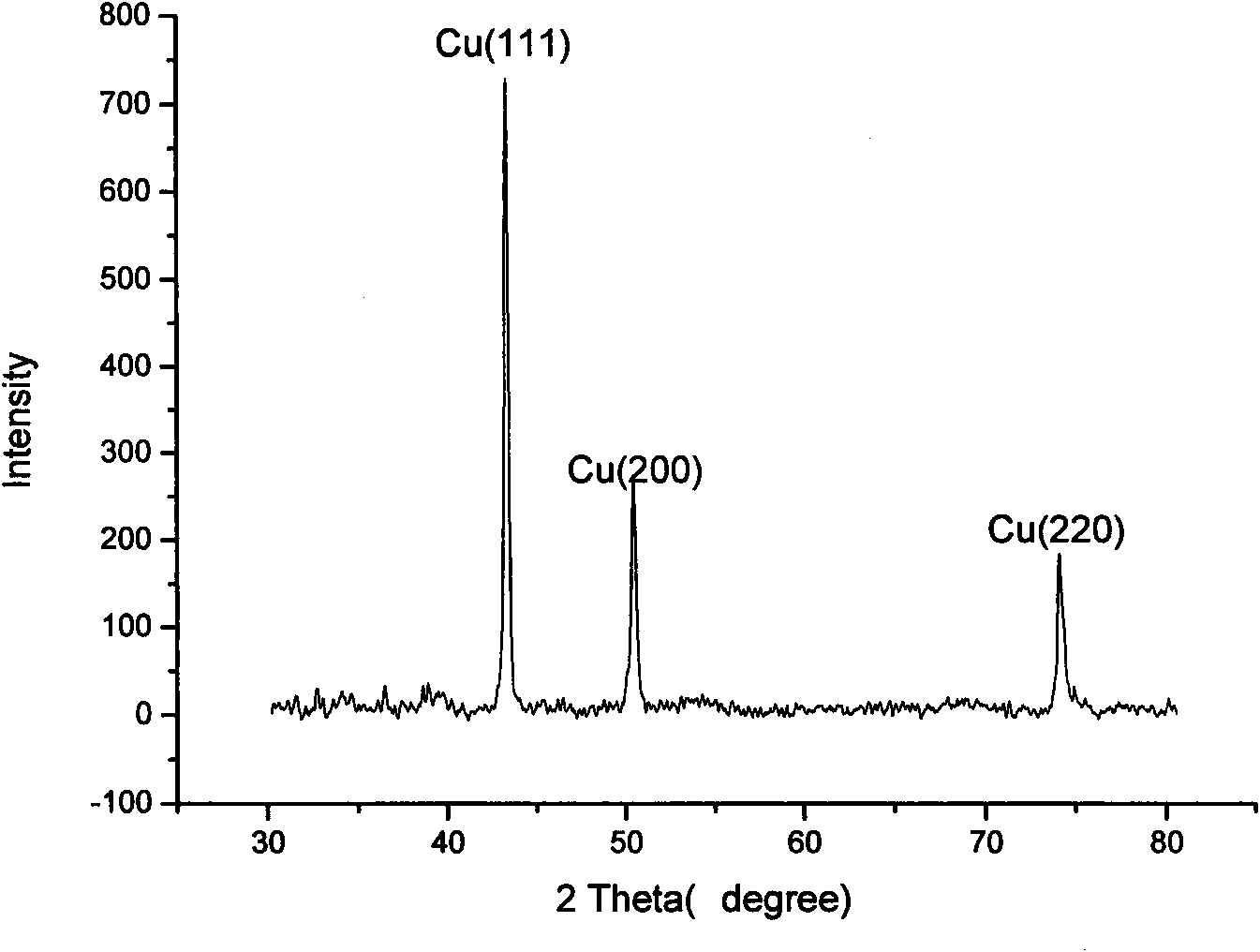

[0025] Example 1: Dissolve 0.01mol of copper sulfate pentahydrate in 100ml of ethanol, add 5ml of oleic acid and 0.5g of polyvinylpyrrolidone (K30), stir to dissolve, and heat up to 50°C. Slowly add 10ml of hydrazine hydrate solution, stir vigorously, the solution gradually turns deep red, indicating the generation of nano-copper, and stop heating after 20 minutes.

Embodiment 2

[0026] Example 2: The cooled solution was left to stand, and the electrodialysis was maintained for 20 hours with a voltage of 4-8V, which can effectively remove impurities. See Table 1 for the effect of removing impurities.

Embodiment 3

[0027] Embodiment 3: The nano-copper conductive ink prepared in Example 2 was subjected to vacuum distillation, and the concentration of the final nano-copper was controlled to be about 40wt% according to the amount of fractions.

[0028] The impurity element content analysis result of table 1 nanometer copper ink

[0029] the element

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com