Patents

Literature

4645 results about "Copper salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition, method of making, and treatment of wood with an injectable wood preservative slurry having biocidal particles

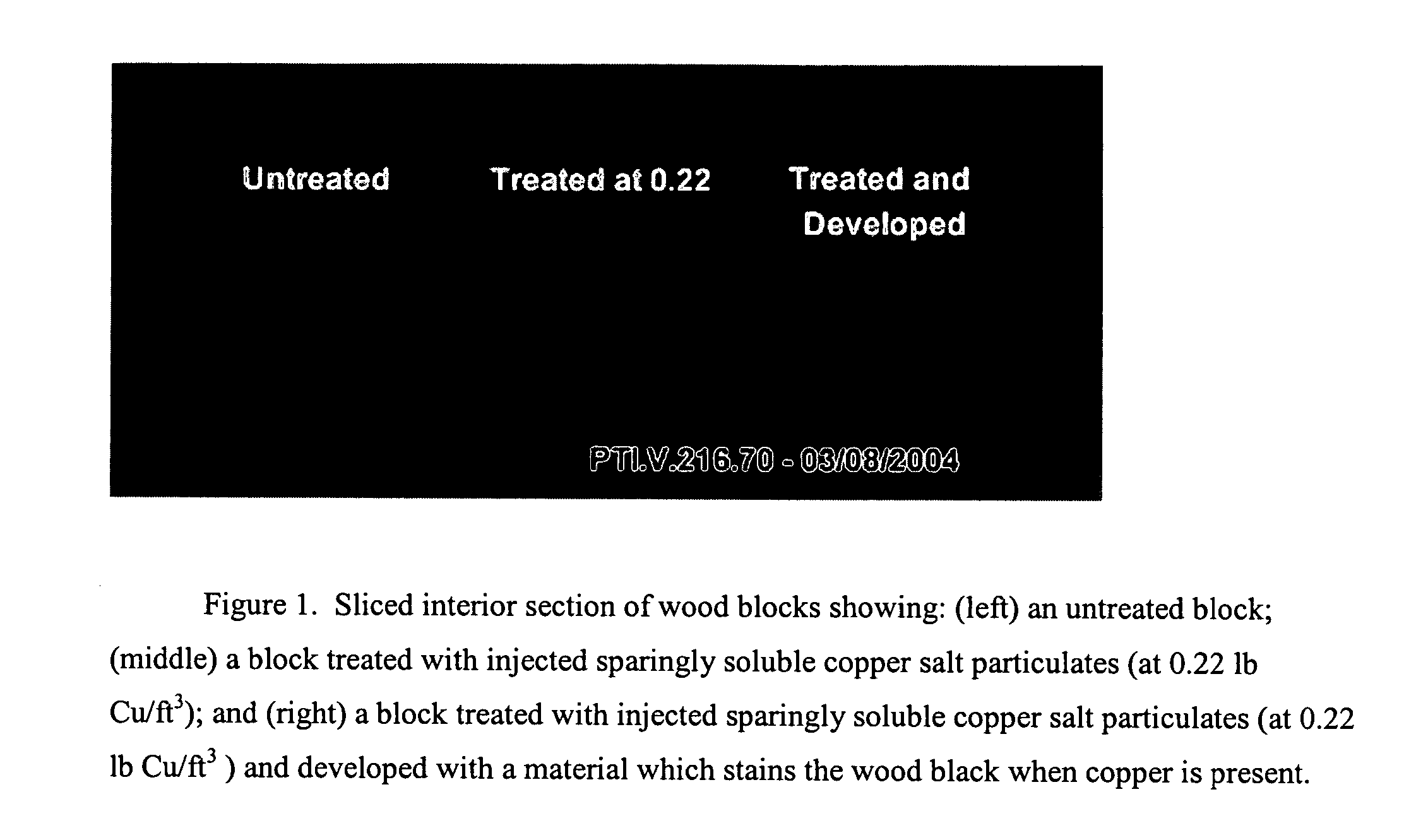

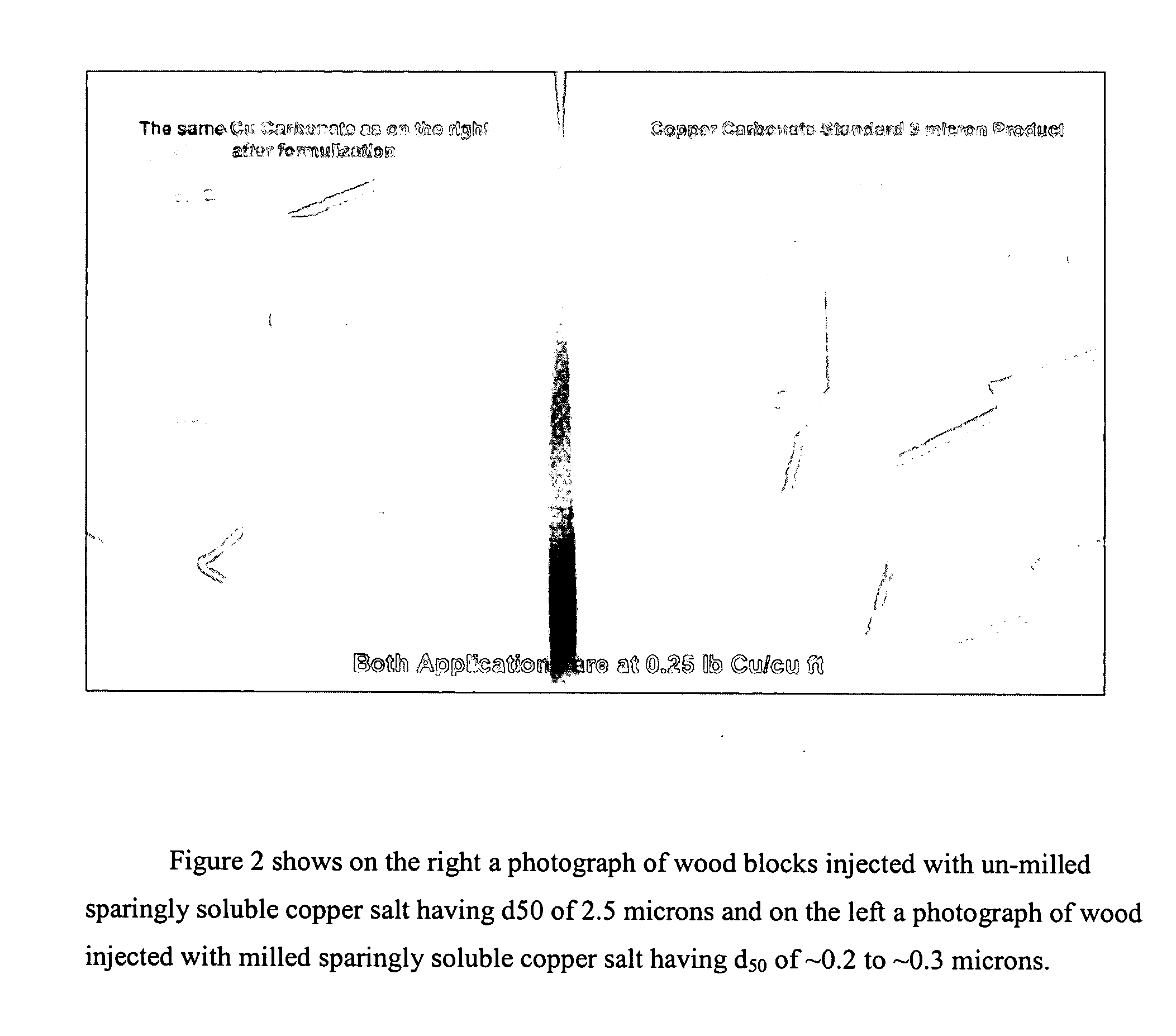

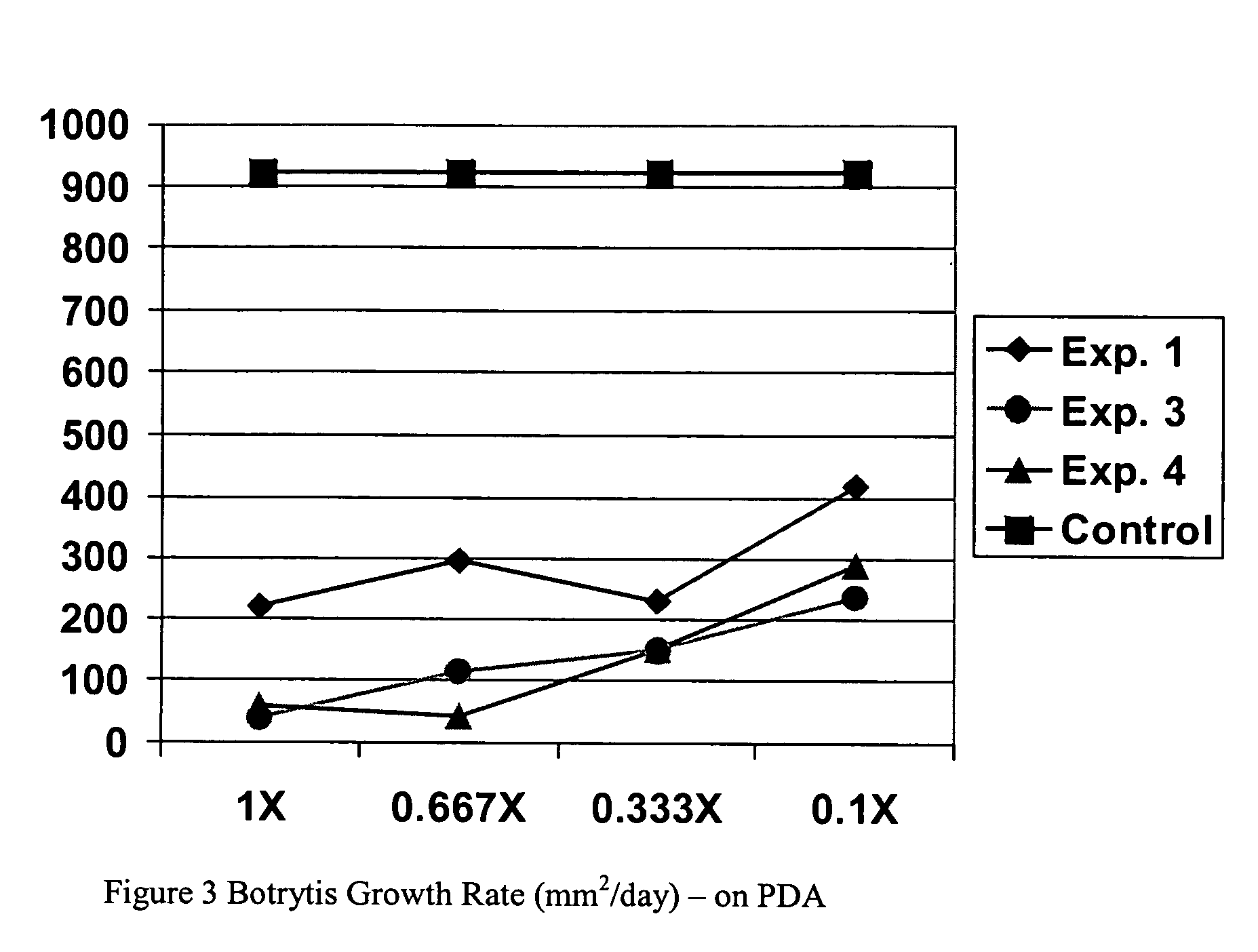

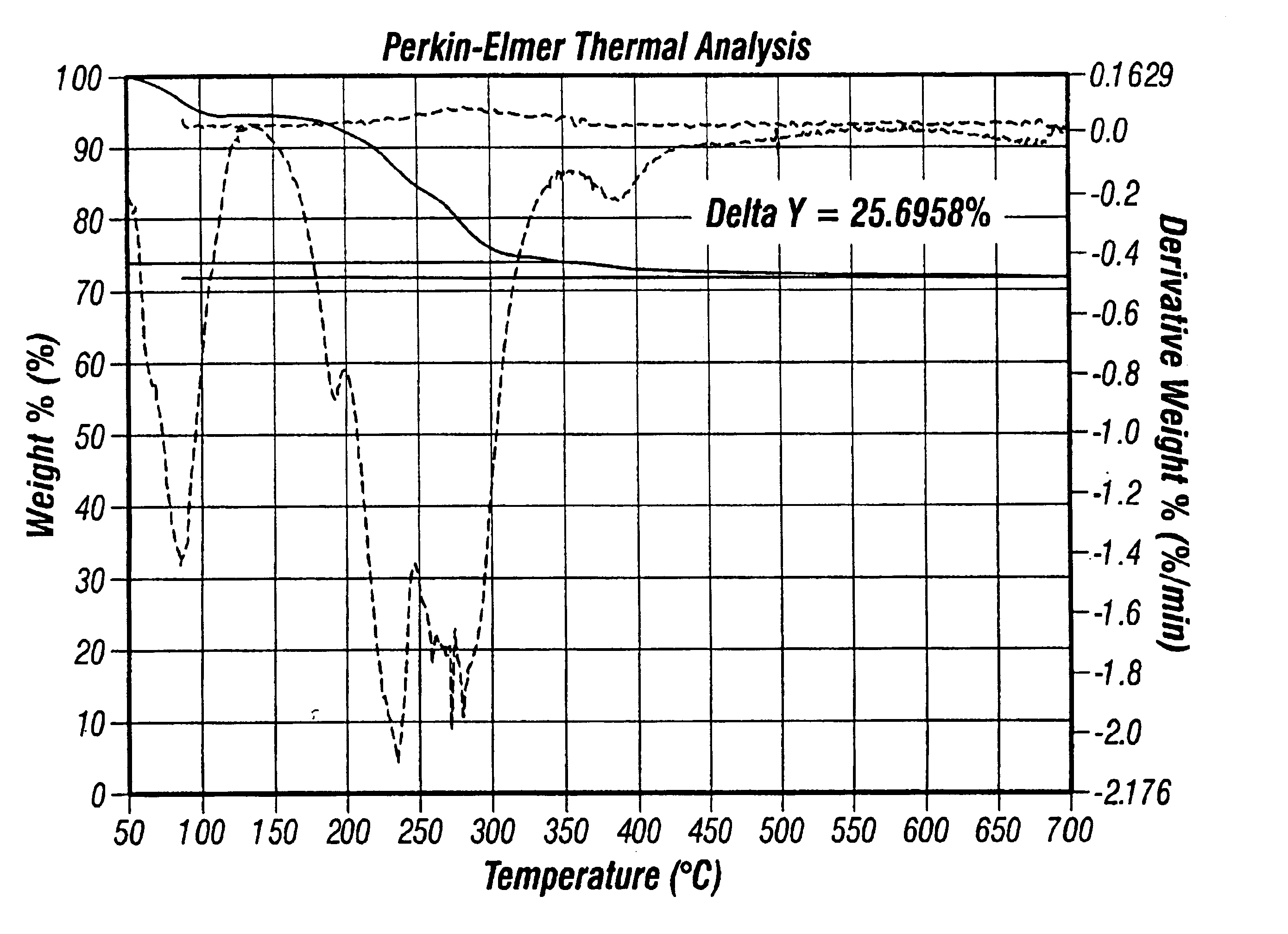

A method of preserving wood includes injecting into the wood an effective amount of a aqueous wood-injectable biocidal slurry, said a wood-injectable biocidal slurry containing dispersants and sub-micron biocidal particles selected from at least one of the following classes: 1) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble salts selected from copper salts, nickel salts, tin salts, and / or zinc salts; 2) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble metal hydroxides selected from copper hydroxide, nickel hydroxide, tin hydroxide, and / or zinc hydroxide; 3) a plurality of particles containing at least 25% by weight of a solid phase comprising a substantially-insoluble organic biocide selected from triazoles, chlorothalonil, iodo-propynyl butyl carbamate, copper-8-quinolate, fipronil, imidacloprid, bifenthrin, carbaryl, strobulurins, and indoxacarb; 4) a plurality of particles containing on the outer surface thereof a substantially-insoluble organic biocide; 5) a plurality of particles containing a solid phase of a biocidal, partially or fully glassified composition comprising at least one of Zn, B, Cu, and P. The particles may advantageously contain metallic copper, a leachability barrier, pigments, dyes, or other adjuvants disposed on the outer surface thereof.

Owner:OSMOSE

Golf ball

The invention provides a golf ball composed of, at least in part, a molded and crosslinked material obtained from a rubber composition made of a base rubber, a filler, an organic peroxide, an α,β-unsaturated carboxylic acid and / or metal salt thereof, and a copper salt of a saturated or unsaturated fatty acid. The molded rubber composition has a very high rebound, and is thus useful as a golf ball core for achieving an excellent flight performance.

Owner:BRIDGESTONE SPORTS

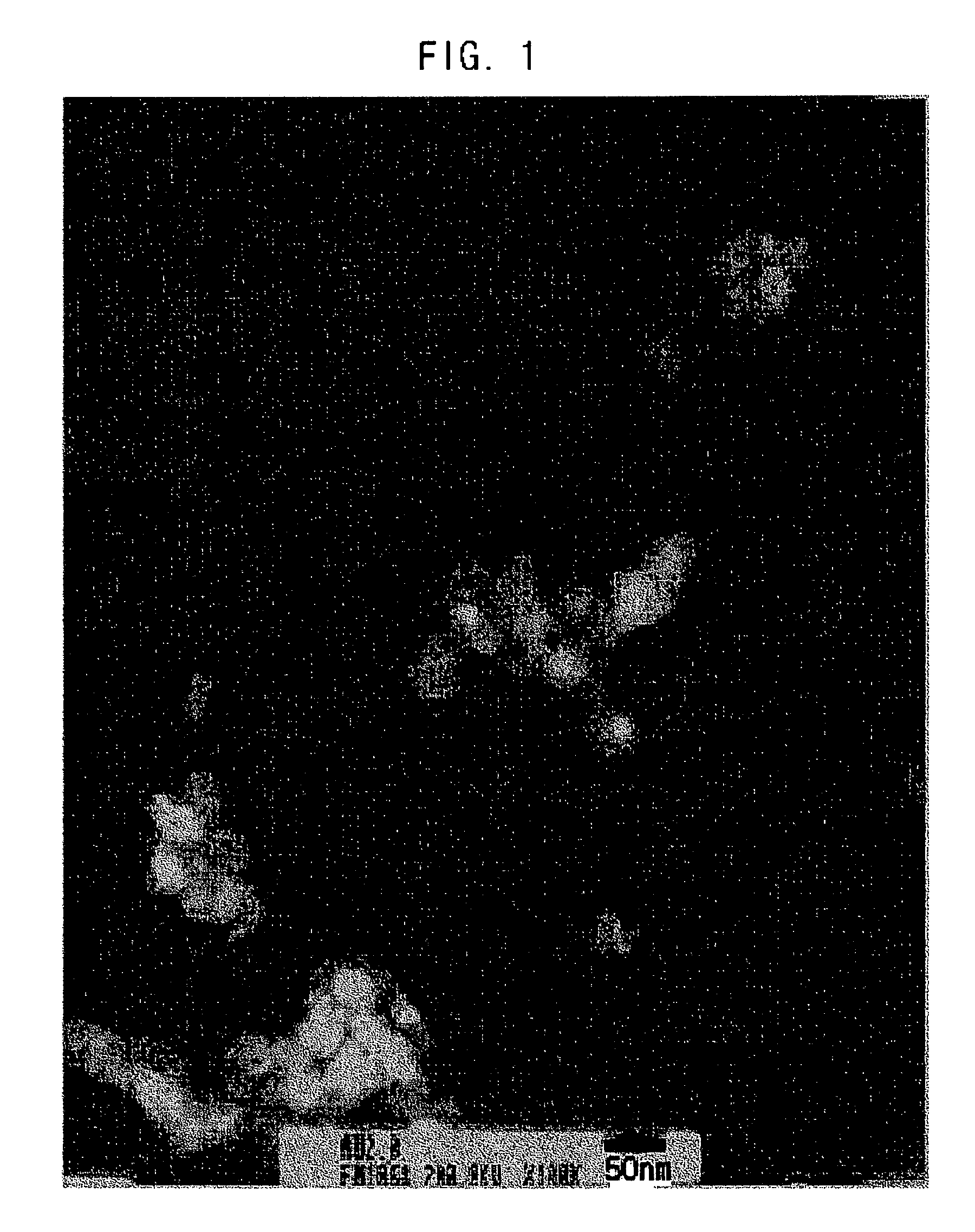

Copper nanocrystals and methods of producing same

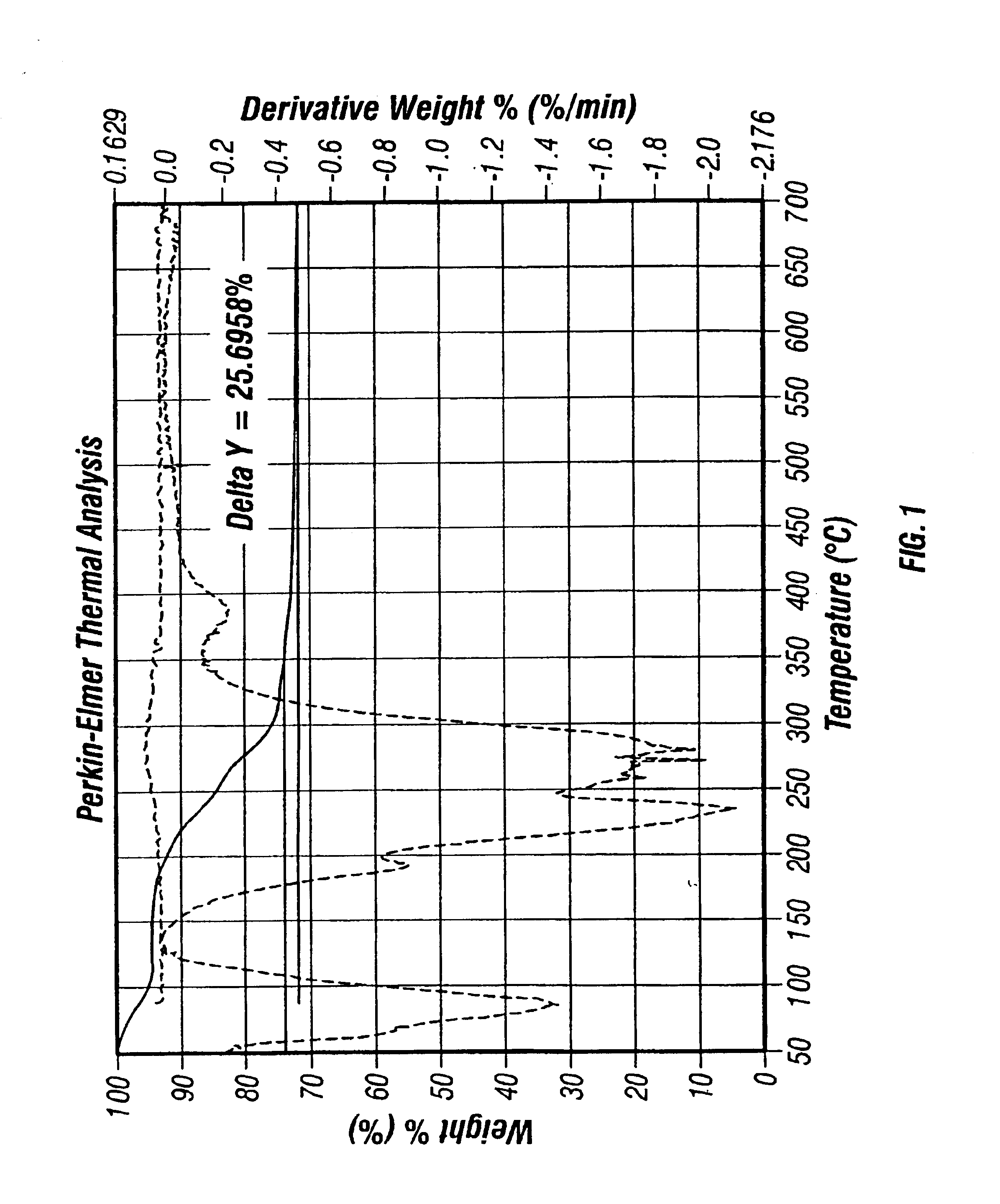

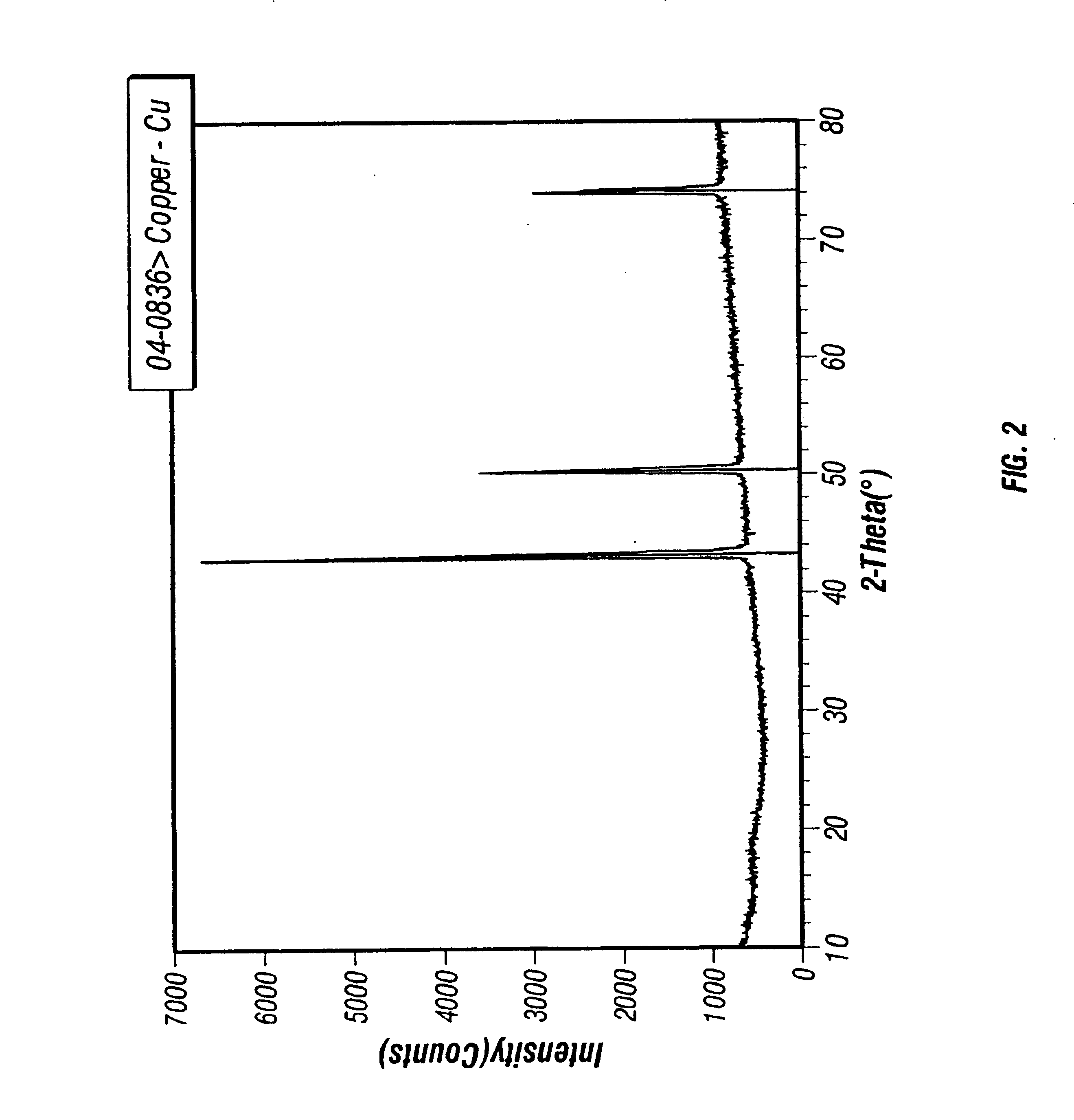

The invention relates to methods of making monodisperse nanocrystals comprising the steps of reducing a copper salt with a reducing agent, providing a passivating agent comprising a nitrogen and / or an oxygen donating moitey and isolating the copper nanocrystals. Moreover, the invention relates to methods for making a copper film comprising the steps of applying a solvent comprising copper nanocrystals onto a substrate and heating the substrate to form a film of continuous bulk copper from said nanocrystals. Finally, the invention also relates to methods for filling a feature on a substrate with copper comprising the steps of applying a solvent comprising copper nanocrystals onto the featured substrate and heating the substrate to fill the feature by forming continuous bulk copper in the feature.

Owner:WAYNE STATE UNIV

Copper bismuth catalyst and preparation method thereof

ActiveCN102658158AImprove wear performanceExtended service lifeOrganic compound preparationHydroxy compound preparationCooking & bakingAlcohol

The invention relates to a copper bismuth catalyst for combining chemically into 1, 4-butynediol with formaldehyde and ethyne and a preparation method thereof. The preparation method comprises the following steps of: preparing mixed solution which contains copper salt, bismuth salt, magnesium salt and dispersant; dropping alcoholic solution with an organic silicon source into the mixed solution; adjusting a pH value of the mixed solution with alkaline solution to obtain mixed precipitate; and further aging, washing, drying and baking in inert atmosphere to obtain the copper bismuth catalyst with C-MgO-SiO2 a carrier, in the catalyst, the content of CuO accounts for 25-50 weight percent, and the content of Bi2O3 accounts for 2-6 weight percent. The catalyst is applied in a reaction of combining chemically into 1, 4-butynediol with formaldehyde and ethyne, and has high catalytic activity and high selectivity.

Owner:SHANXI UNIV

Supported catalyst for use in production of 1, 4-butynediol by Reppe method, preparation method thereof and application thereof

ActiveCN102125856AGood sustained response timeOrganic compound preparationHydroxy compound preparationSlurryCopper oxide

The invention relates to a supported catalyst for use in the production of 1, 4-butynediol by a Reppe method, a preparation method thereof and application thereof, in particular to a method for preparing a catalyst for use in the synthesis of1, 4-butynediol by formaldehyde and acetylene in a slurry bed and application. The method is characterized by comprising the steps of: taking 40 to 60 mass percent of treated kaolin as a carrier, and depositing soluble copper salt and soluble bismuth salt on the carrier by a method for depositing sediments, so that the catalyst contains 57 to 37 mass percent of copper oxide. The catalyst prepared by the method has high activity and selectivity, and compared with similar catalysts without the carrier, the catalyst is wear-resistance and saves copper resources.

Owner:HAISO TECH

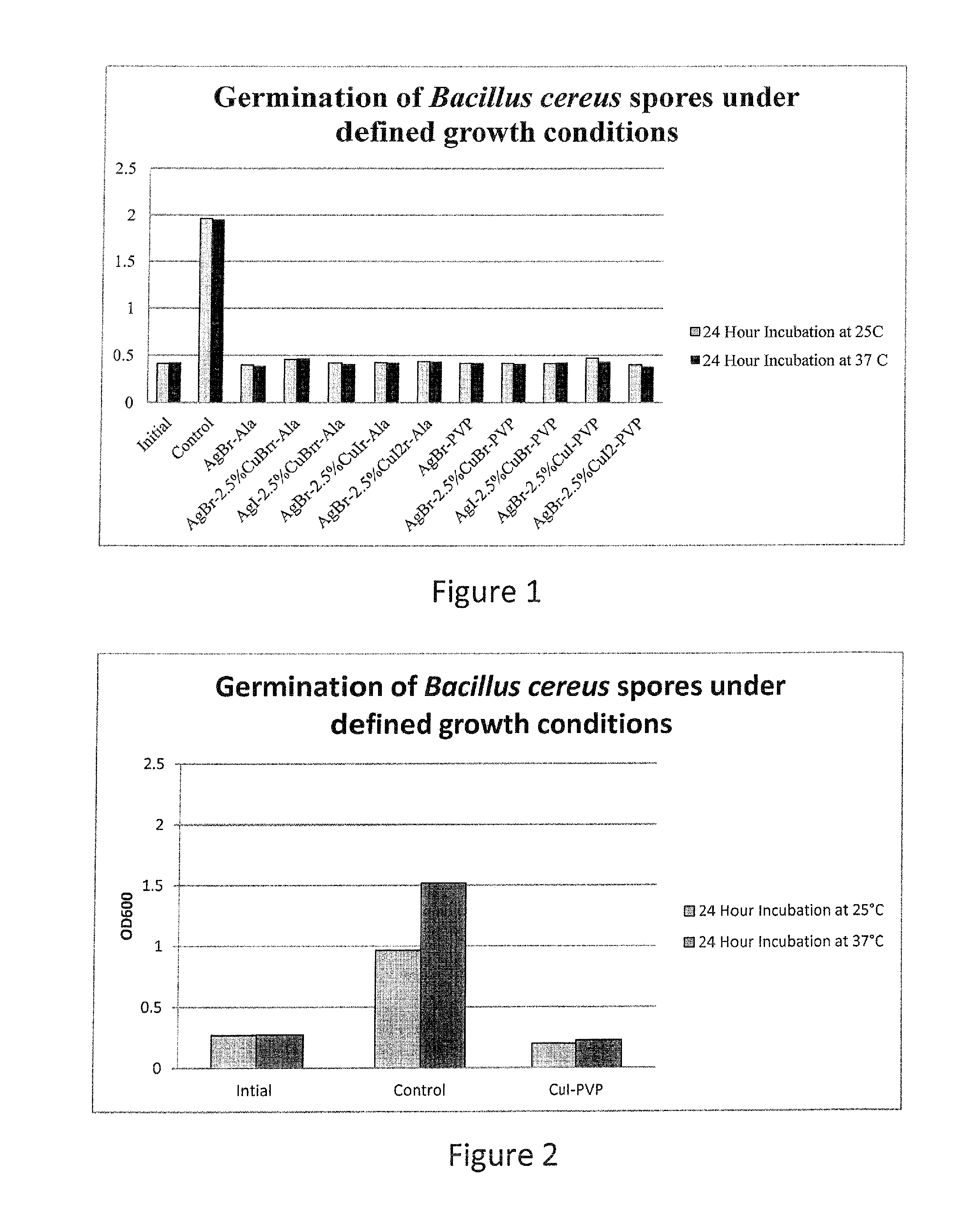

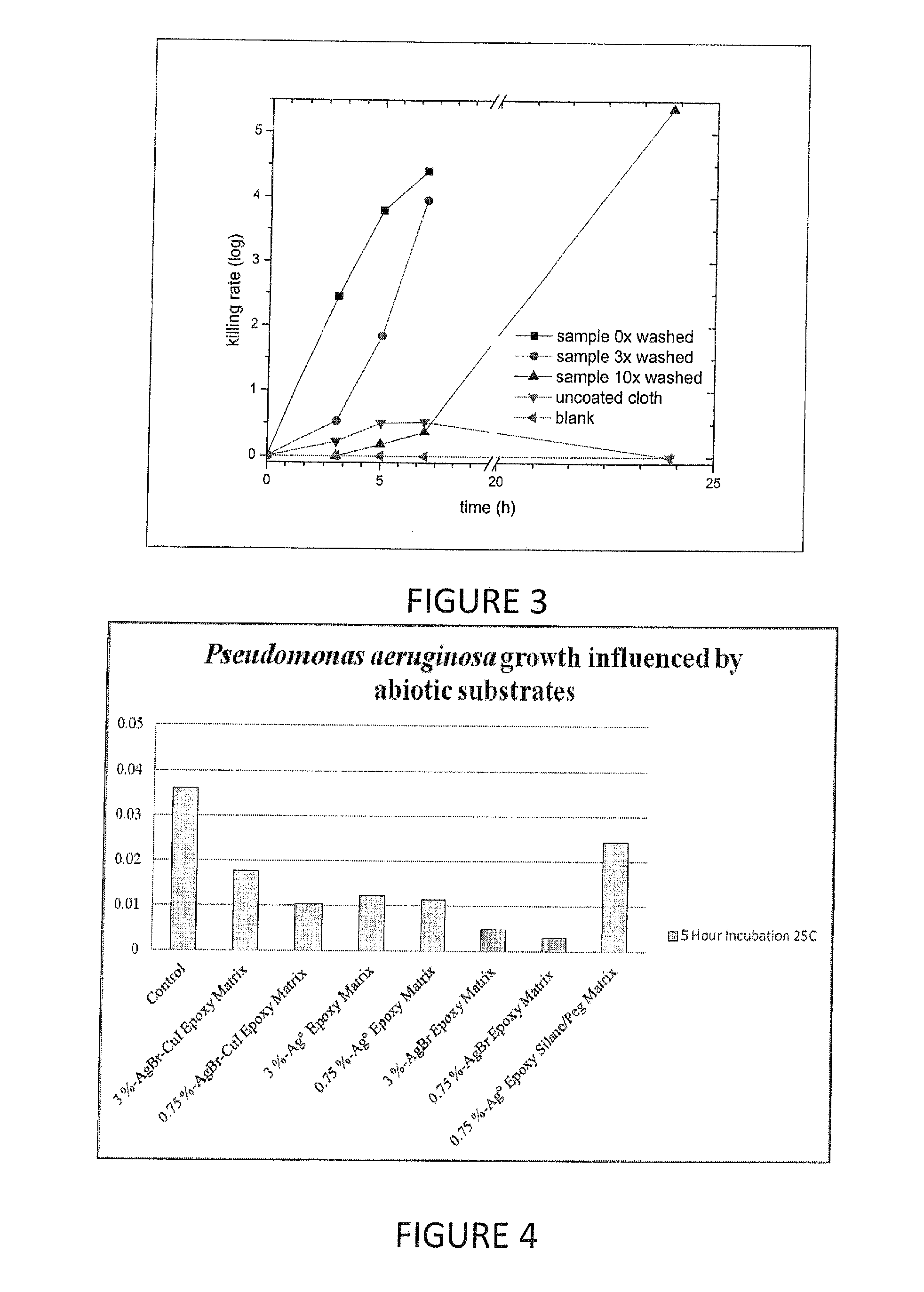

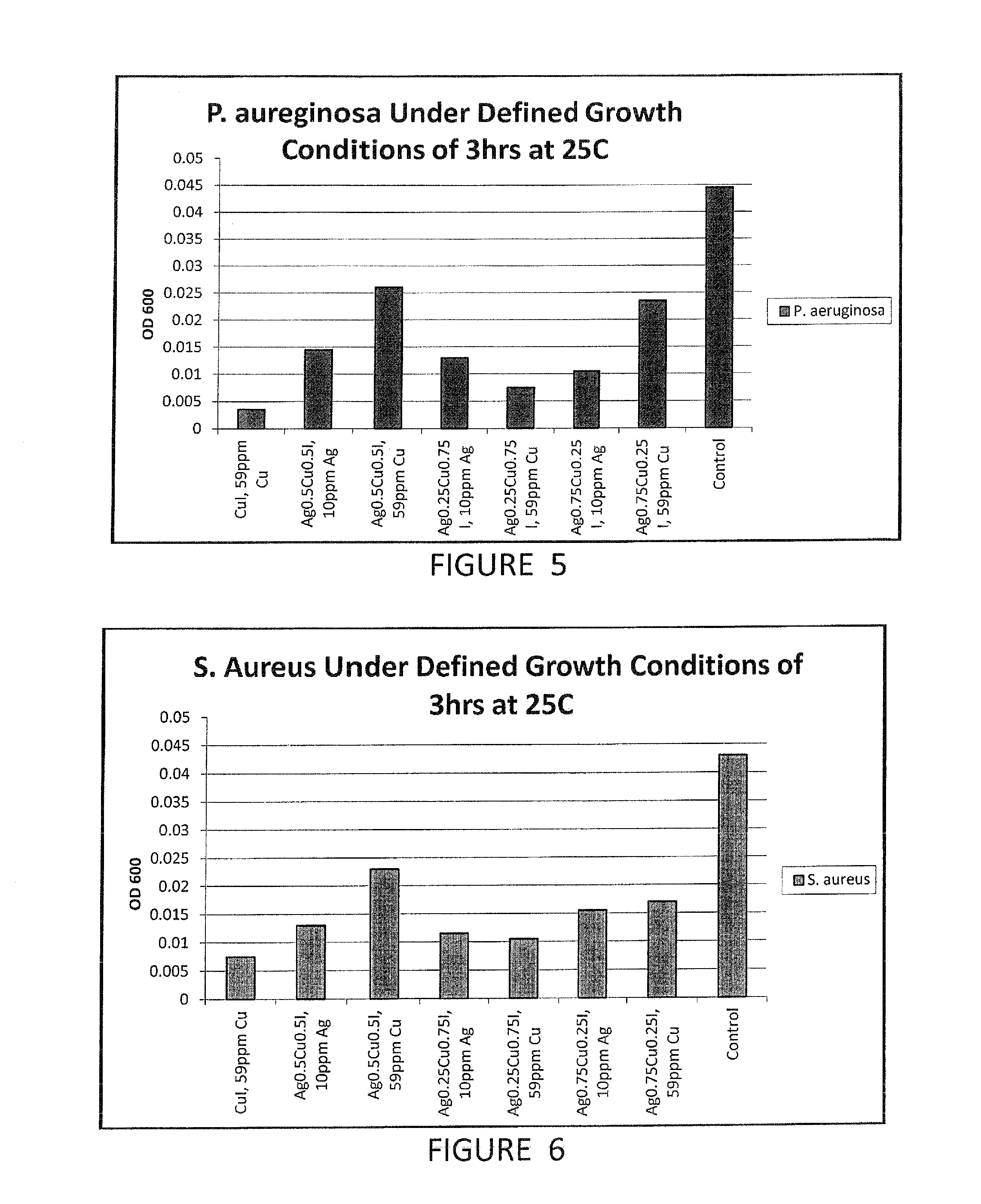

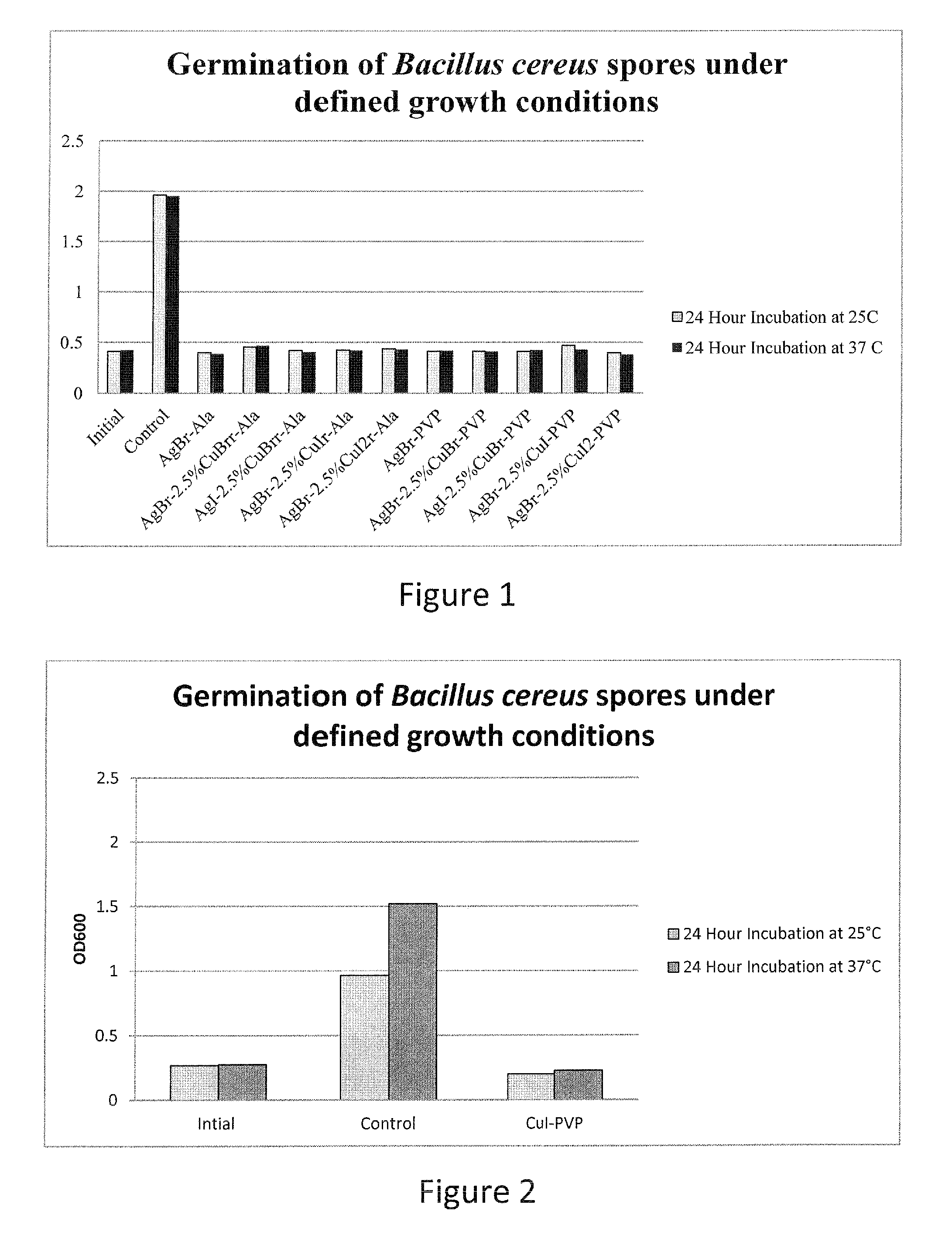

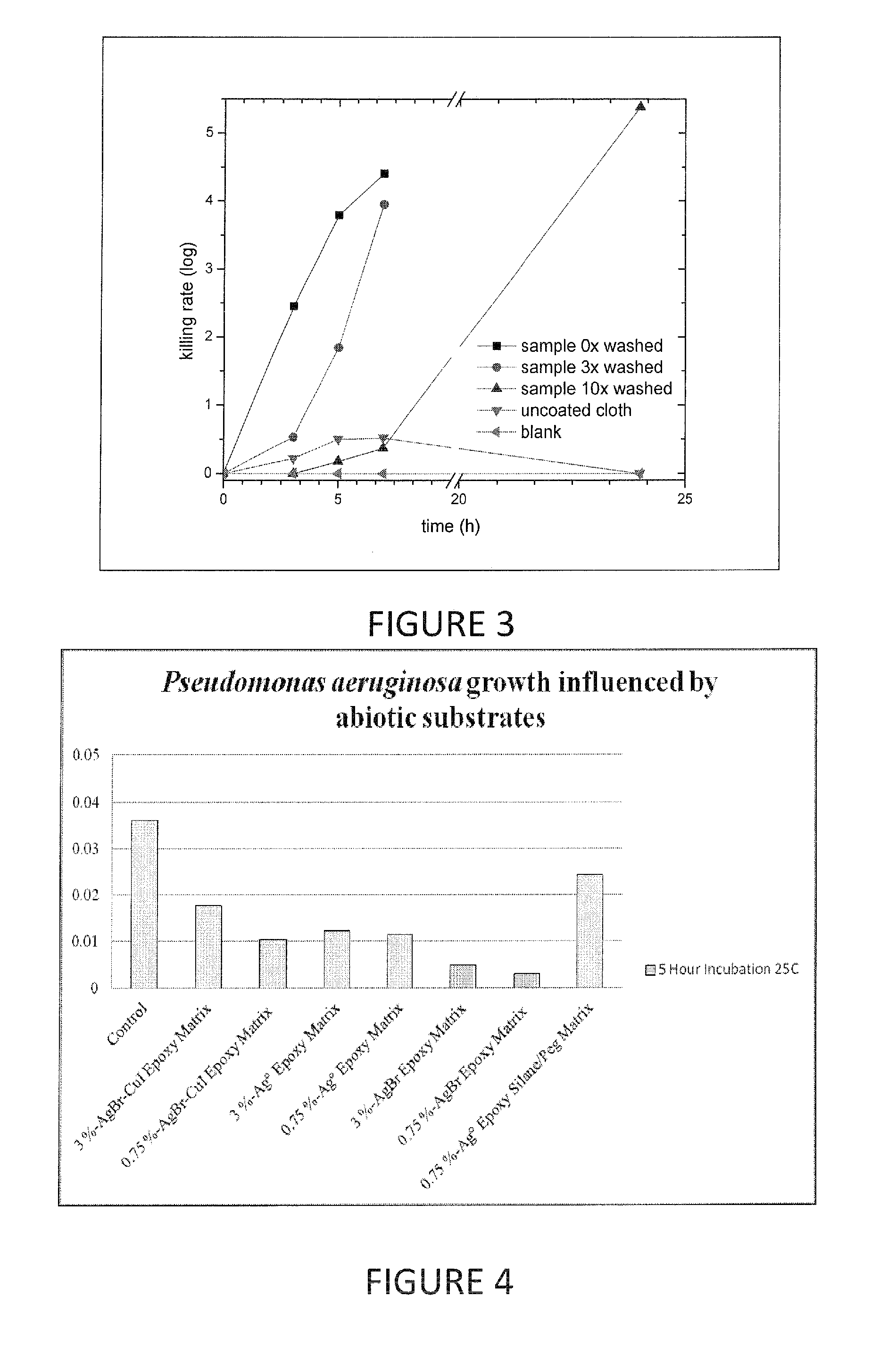

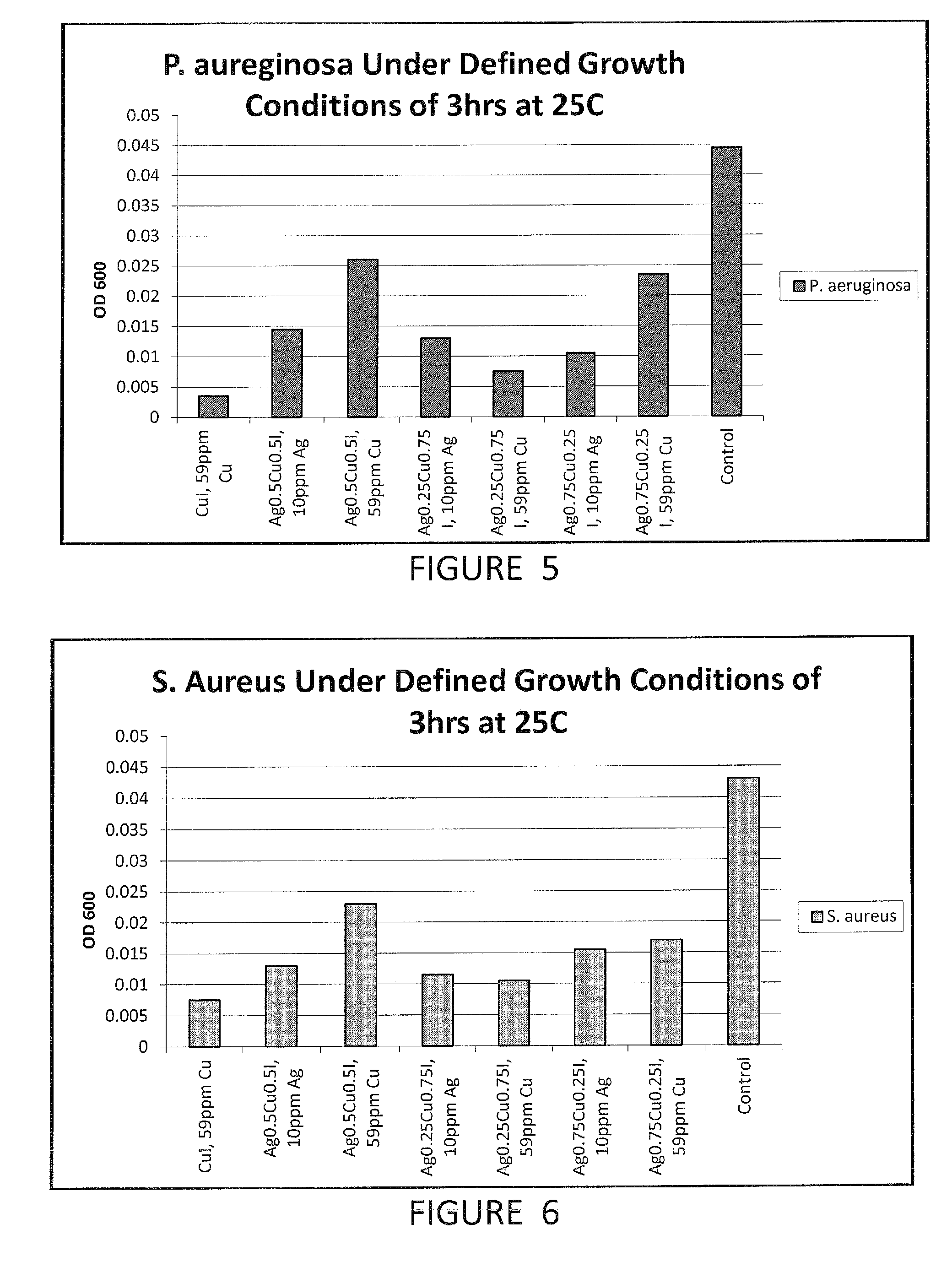

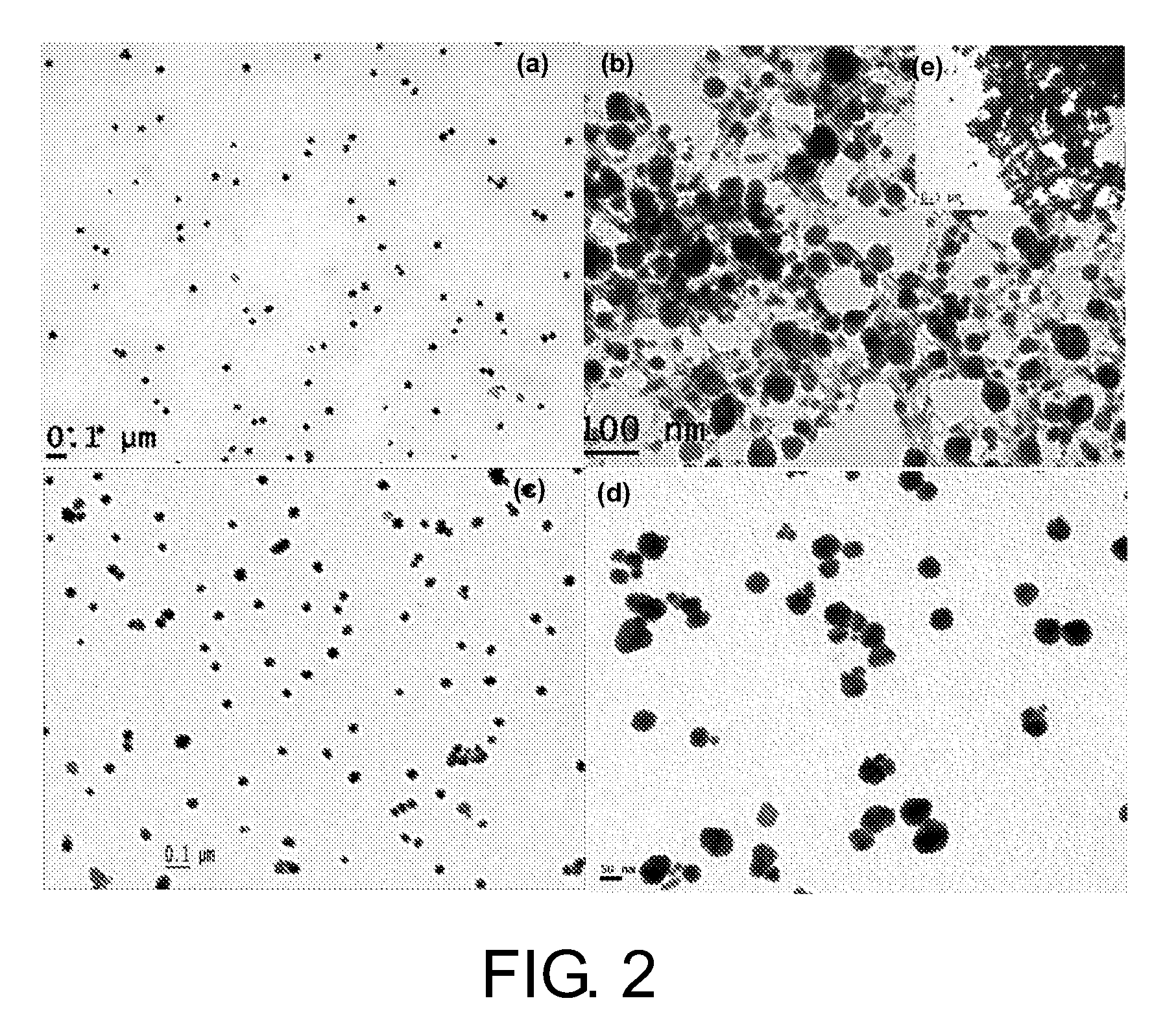

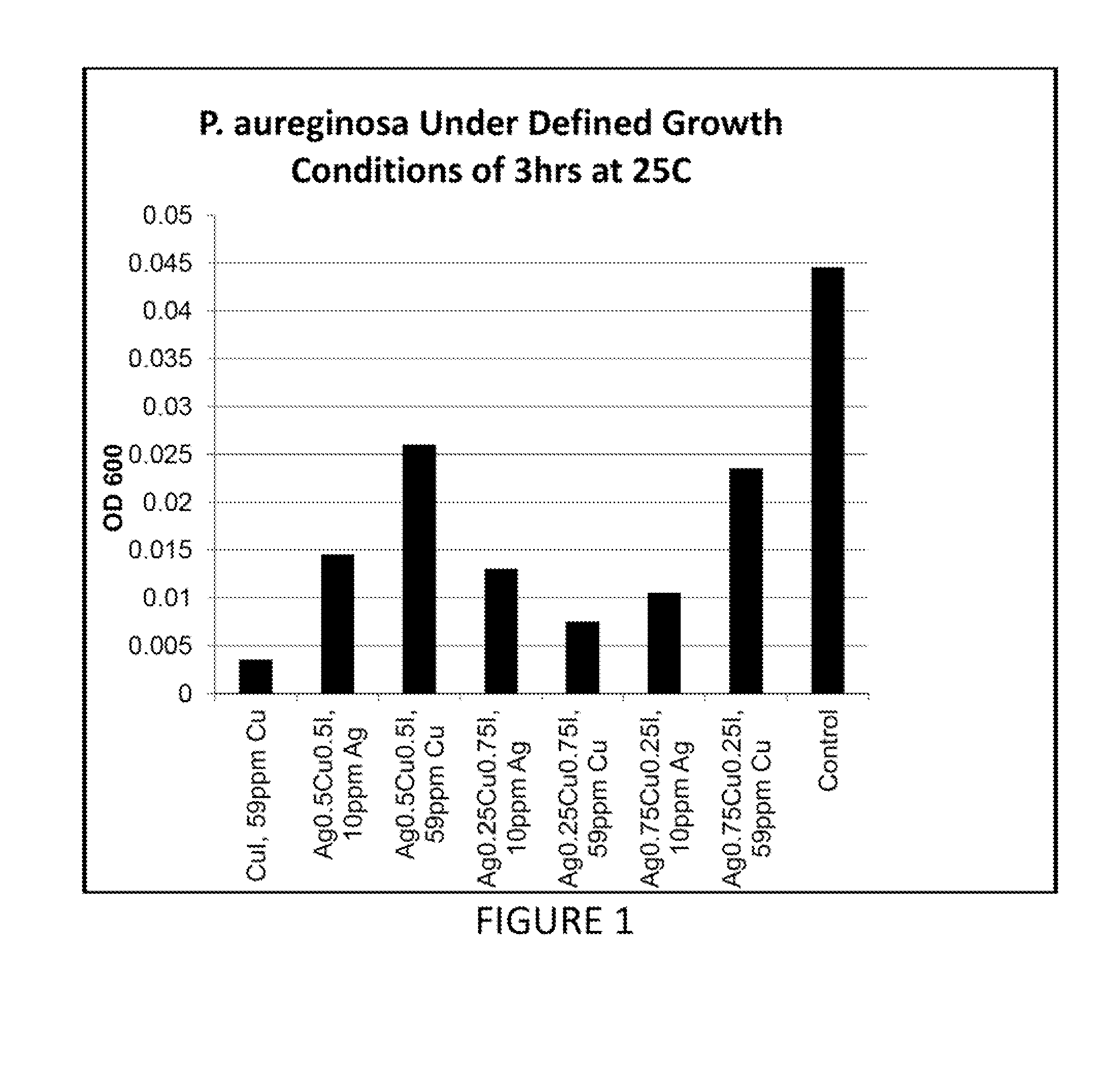

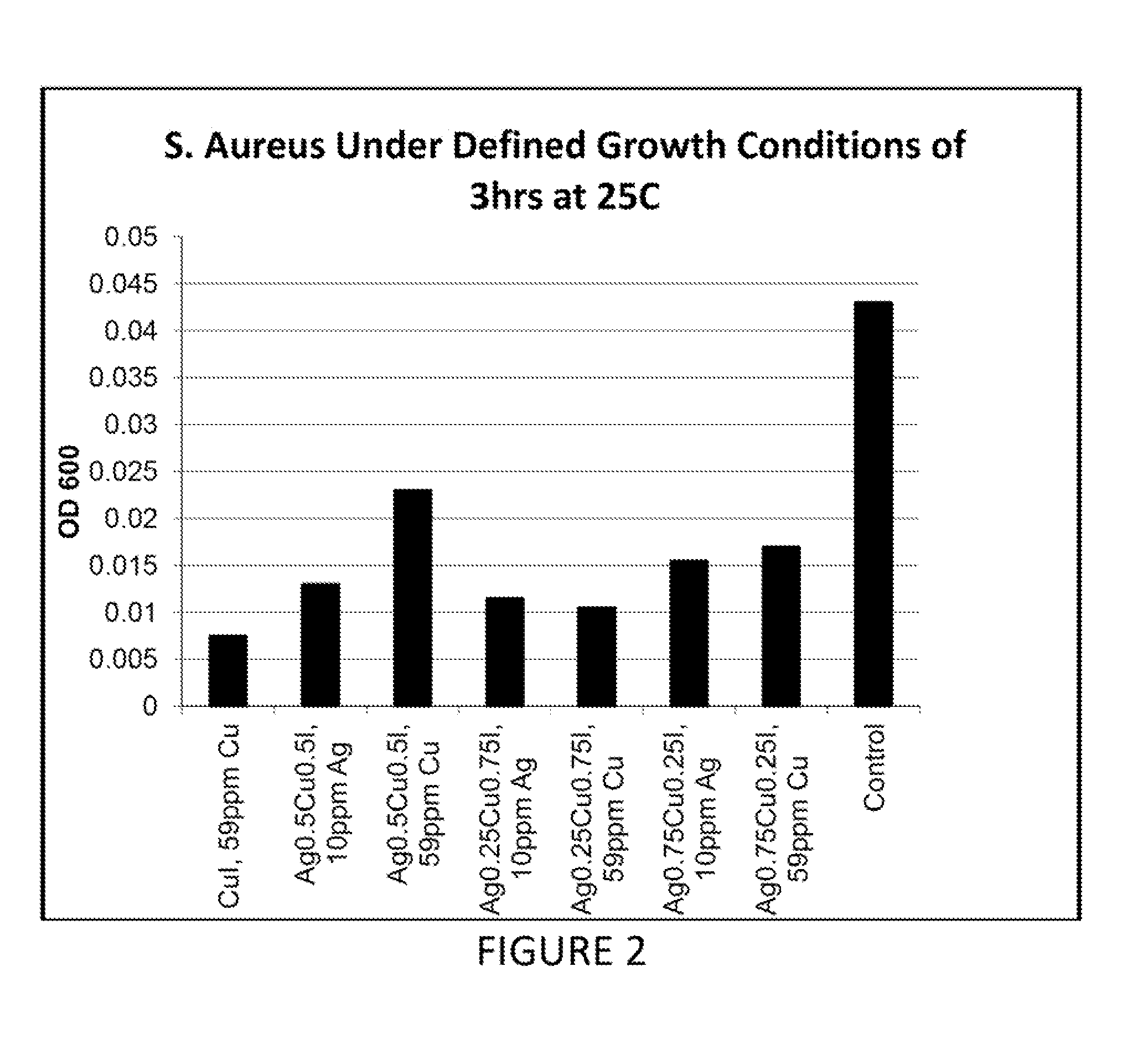

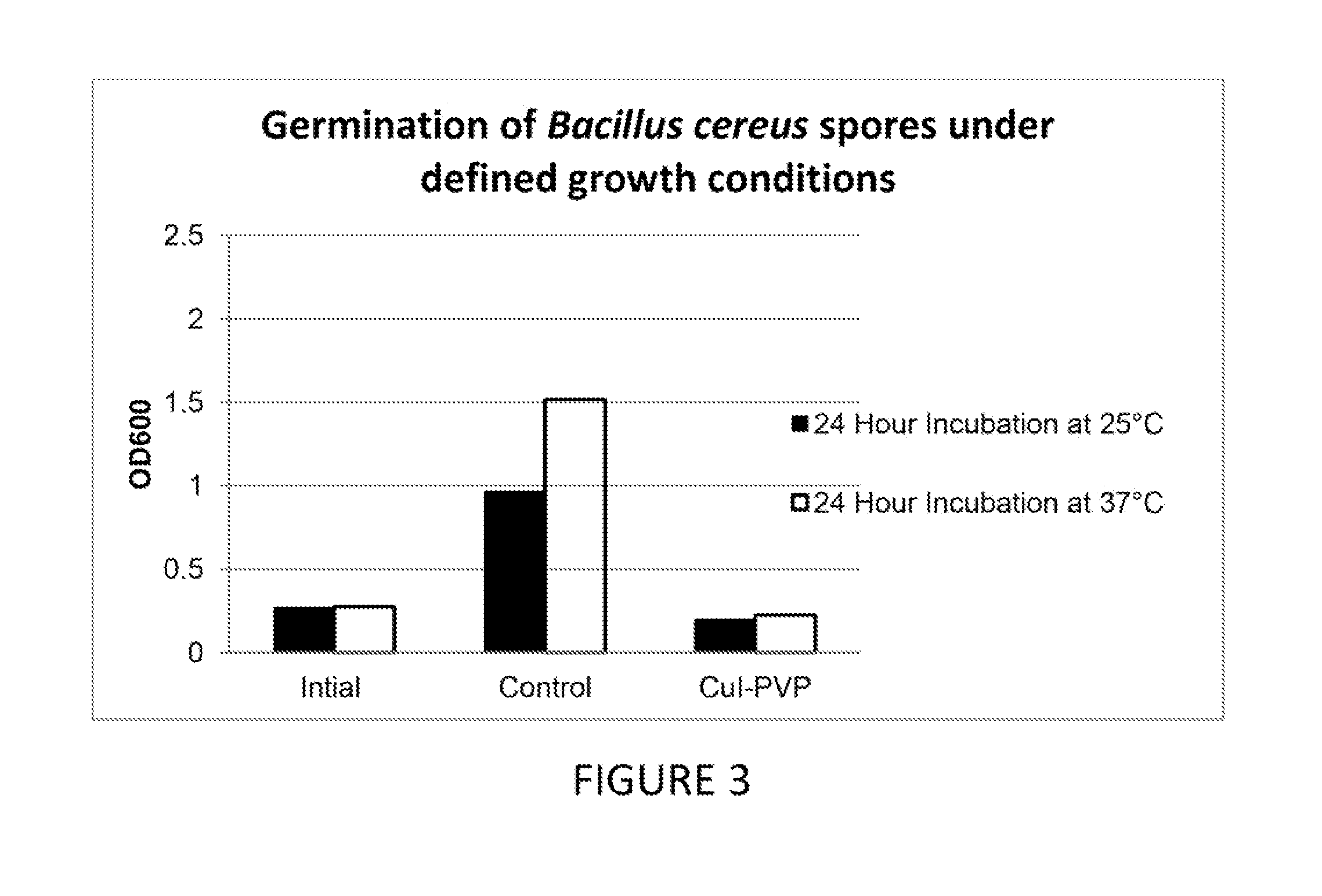

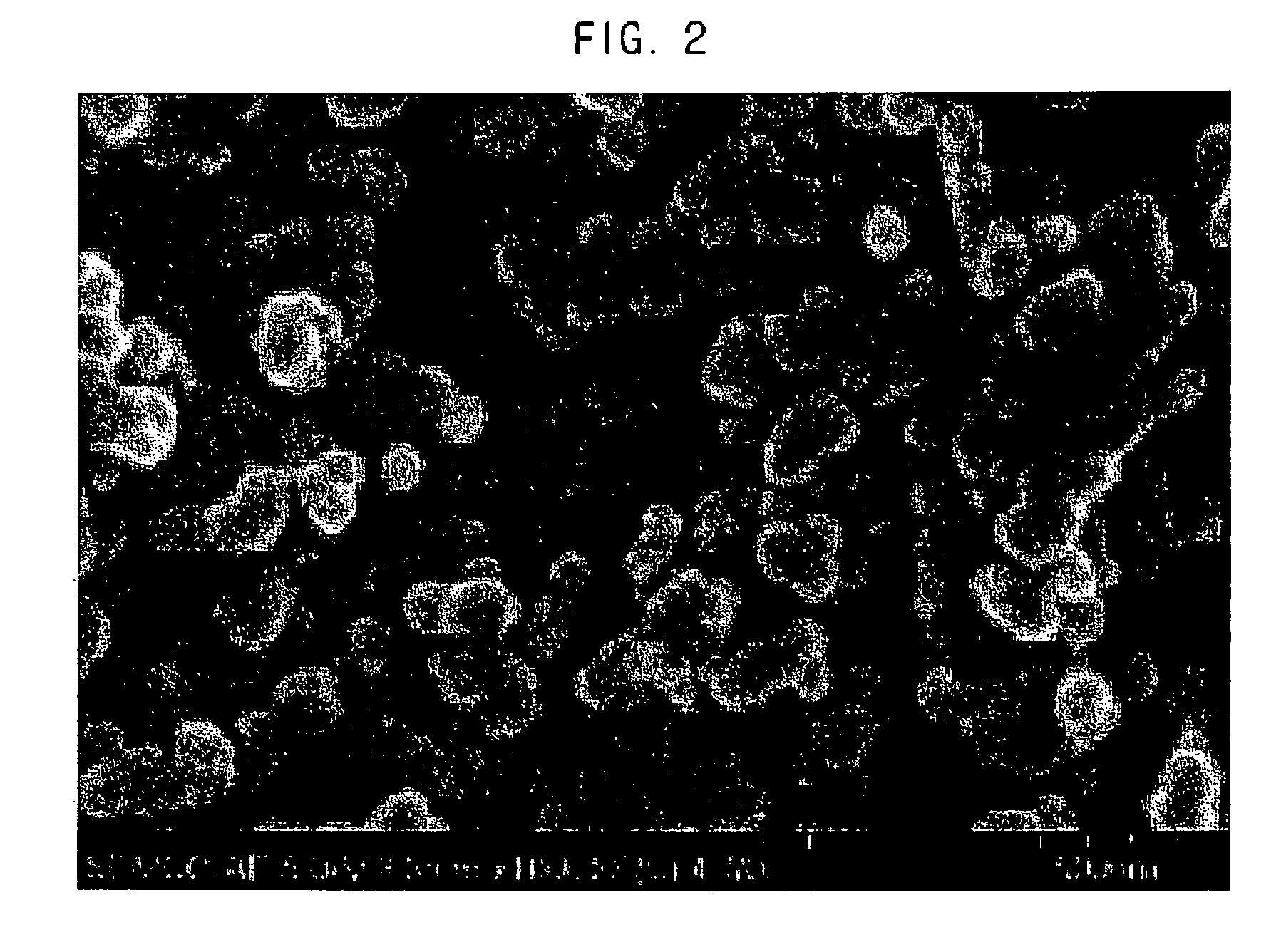

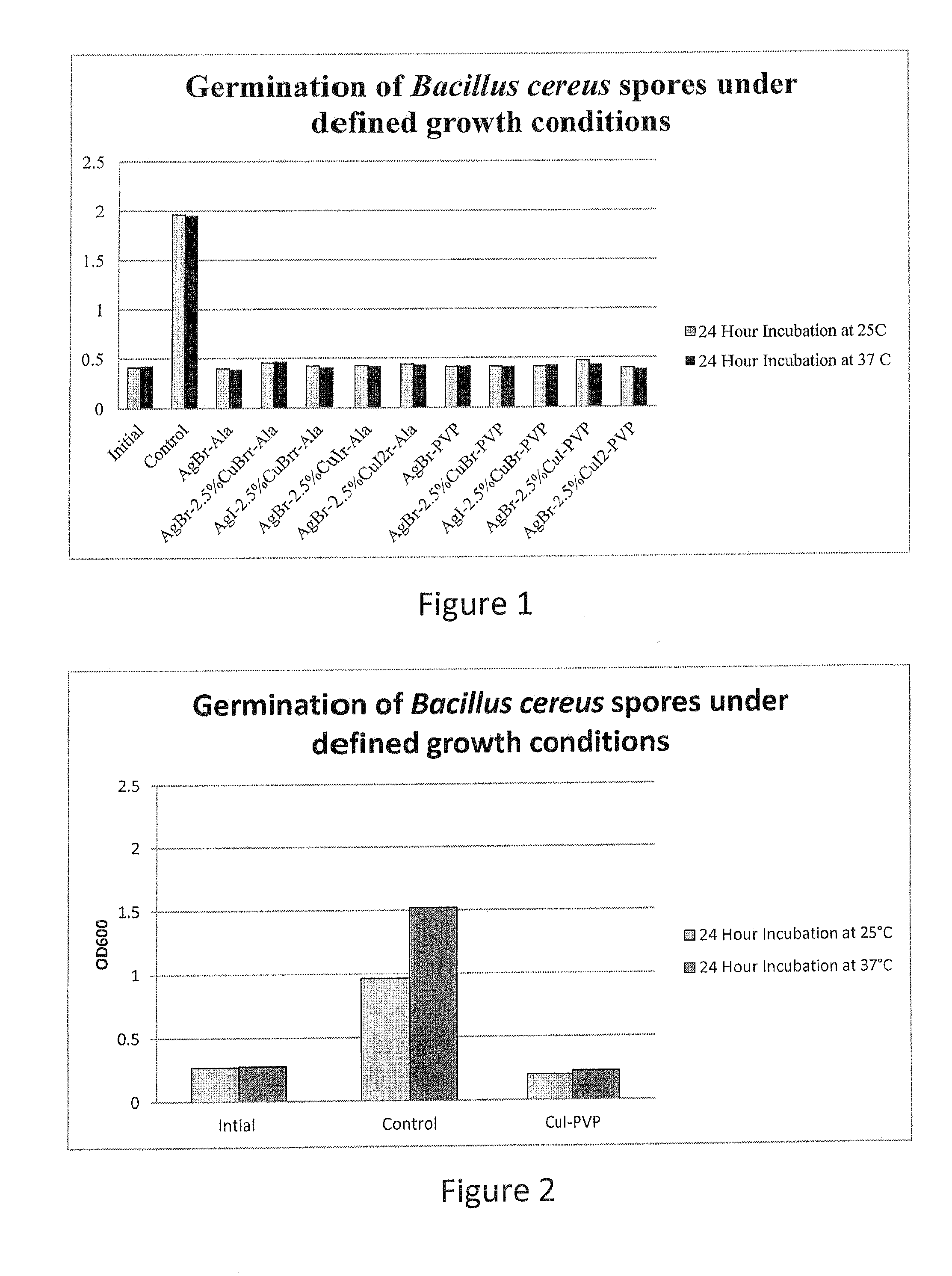

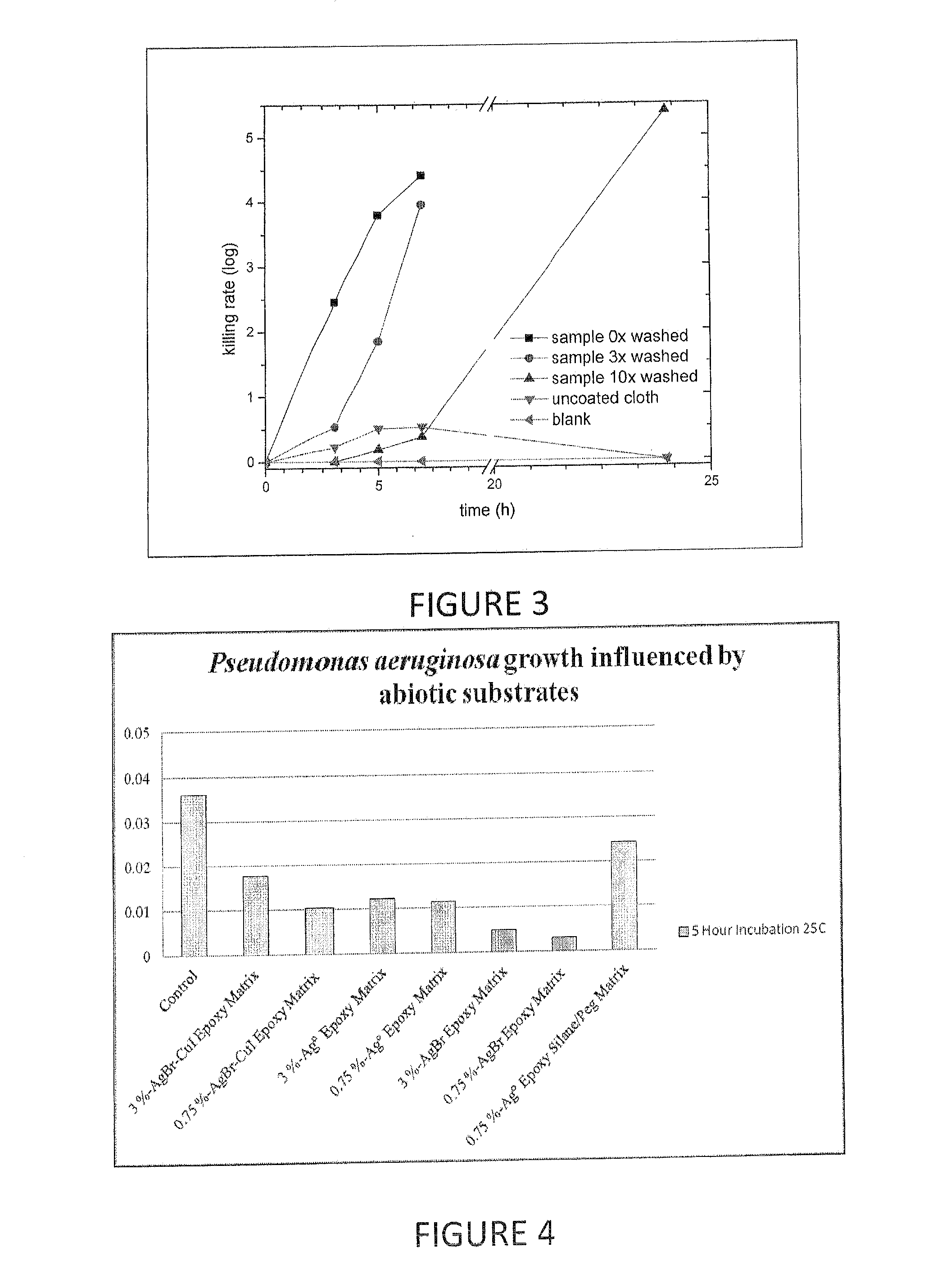

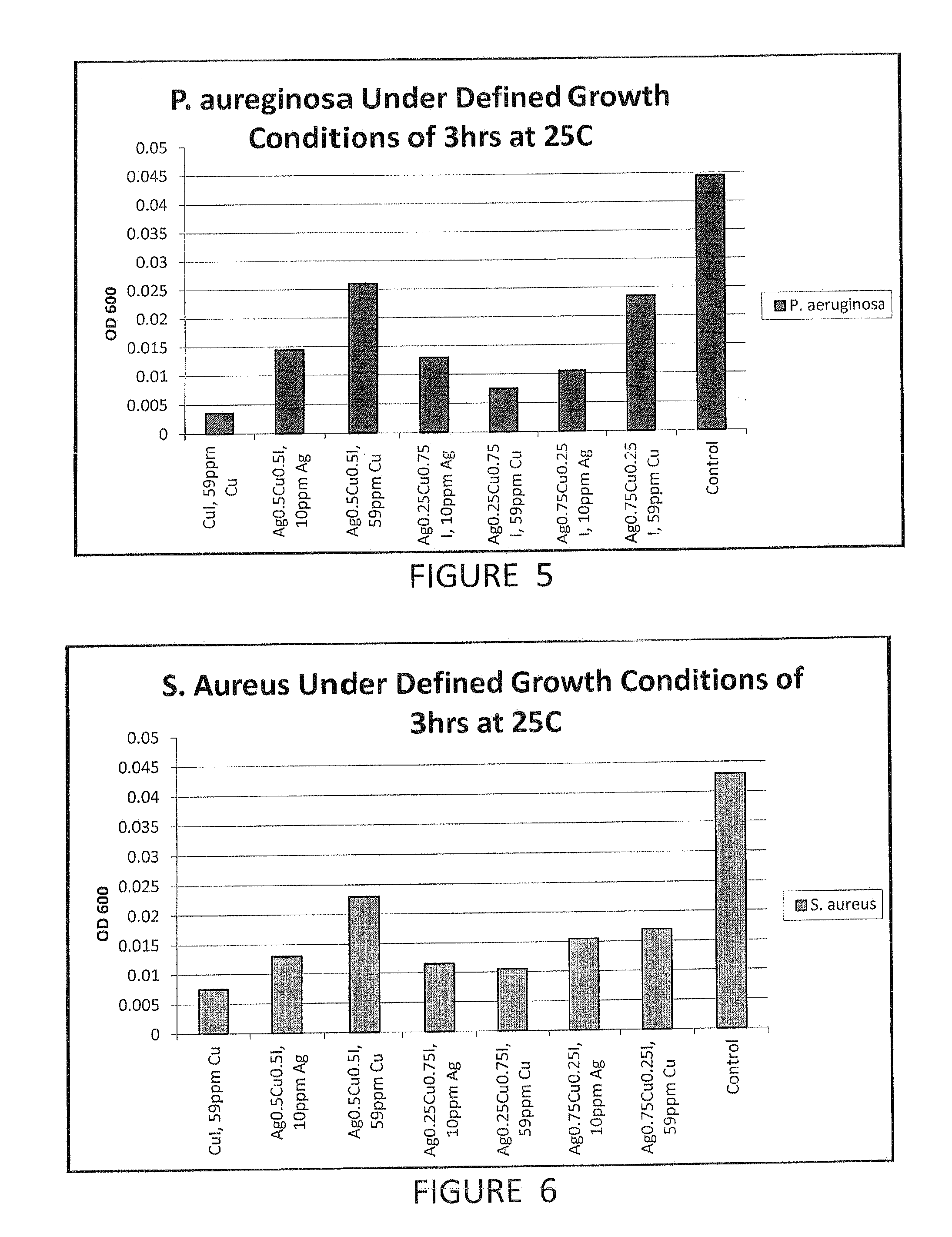

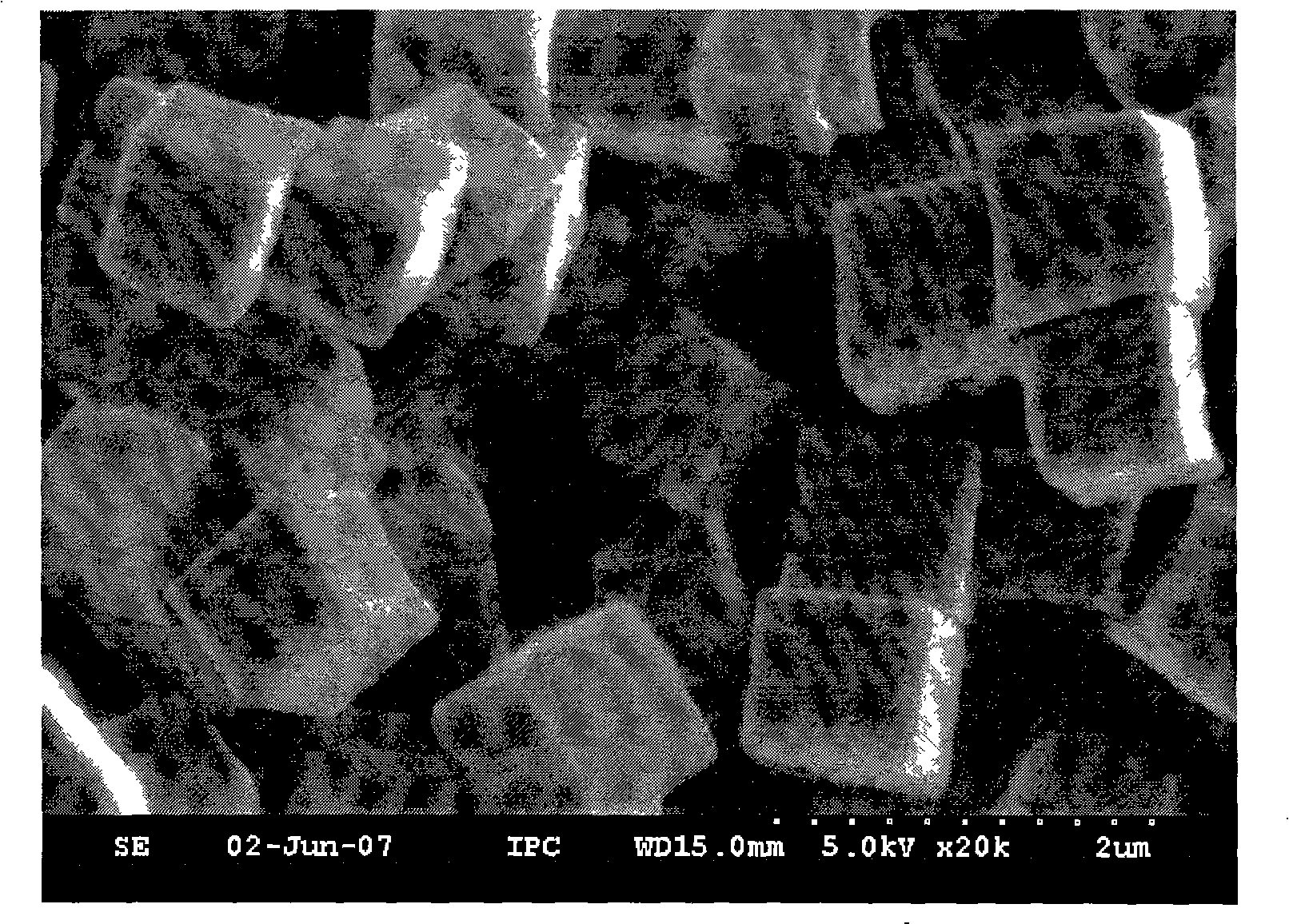

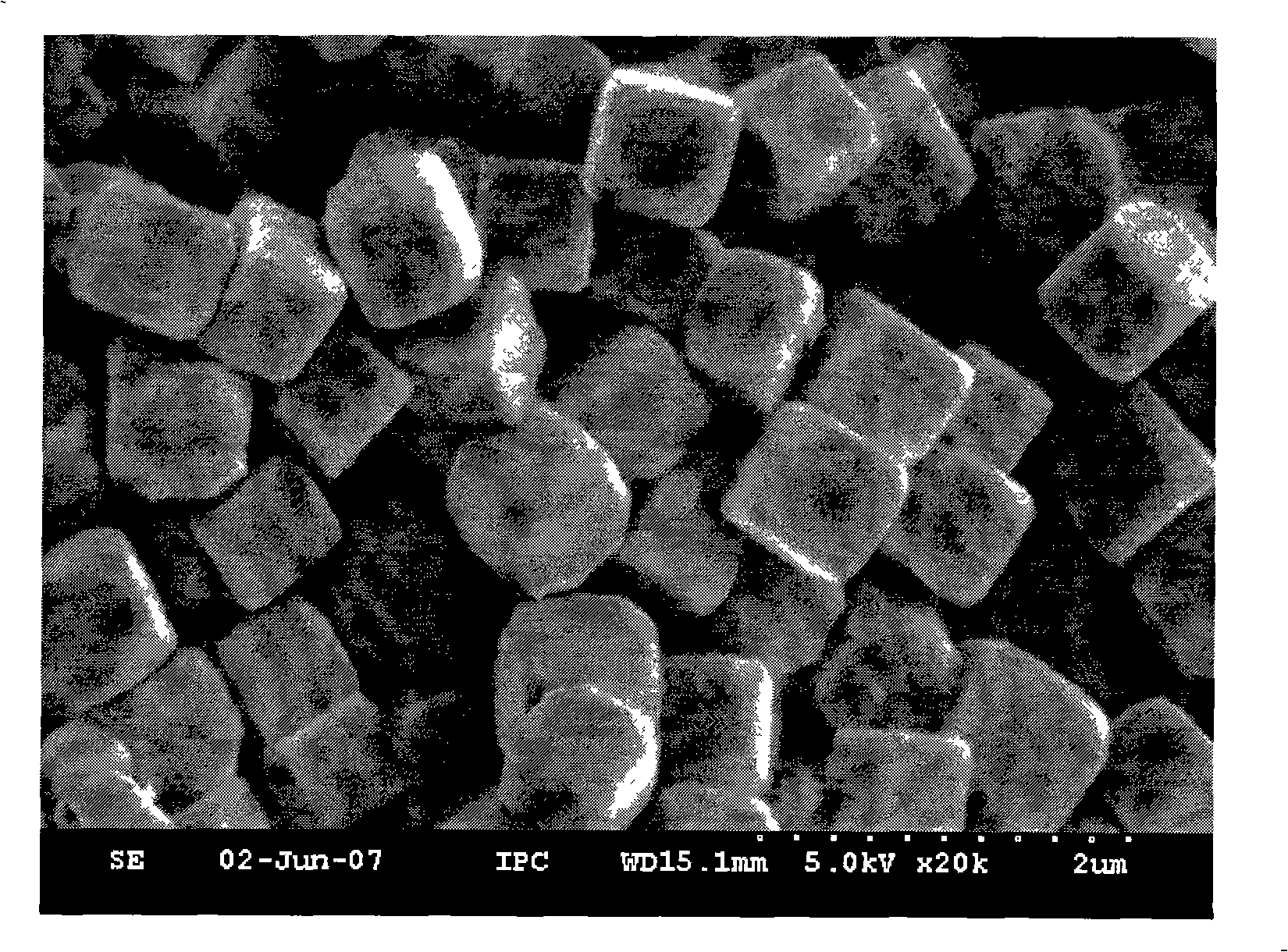

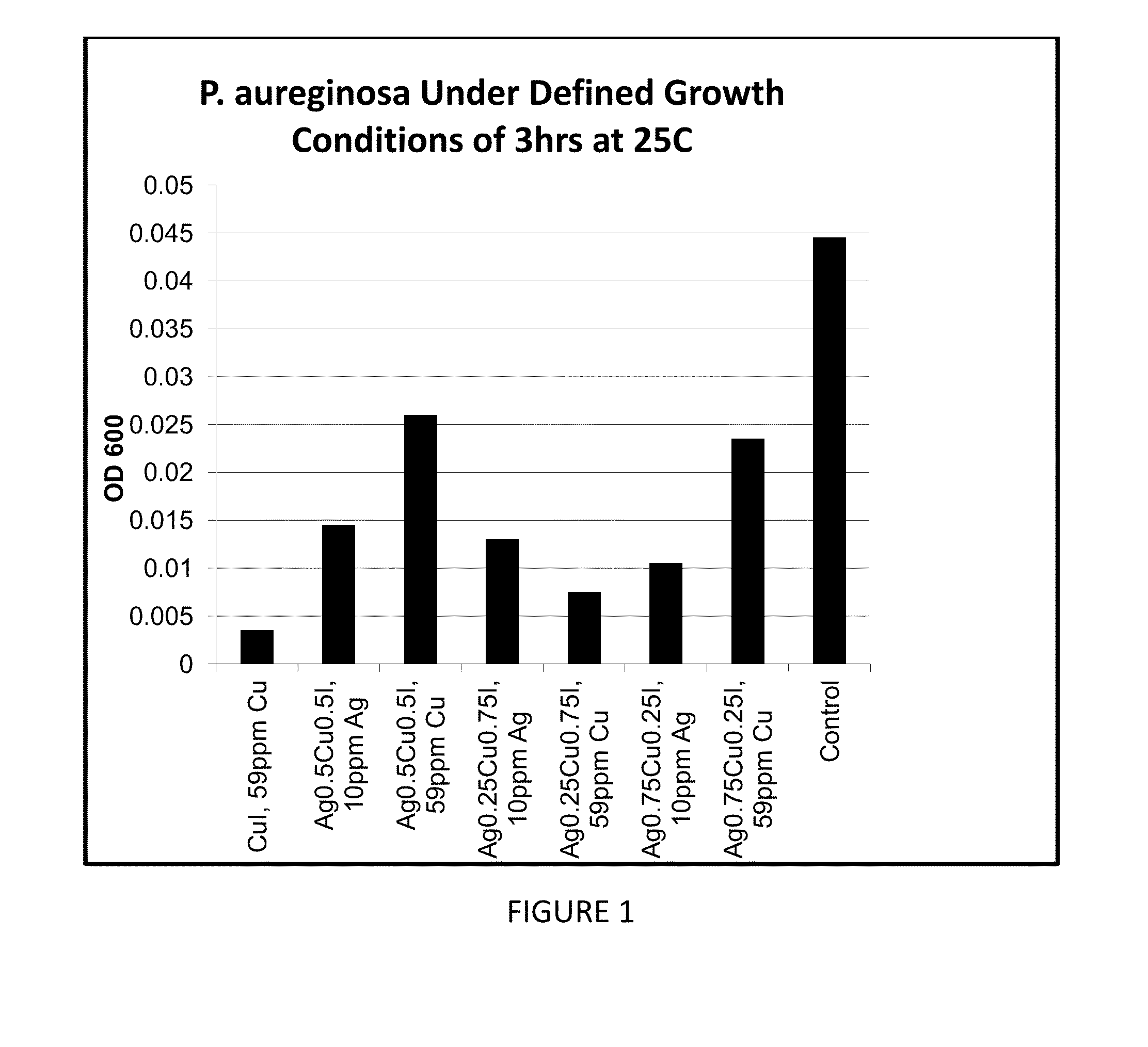

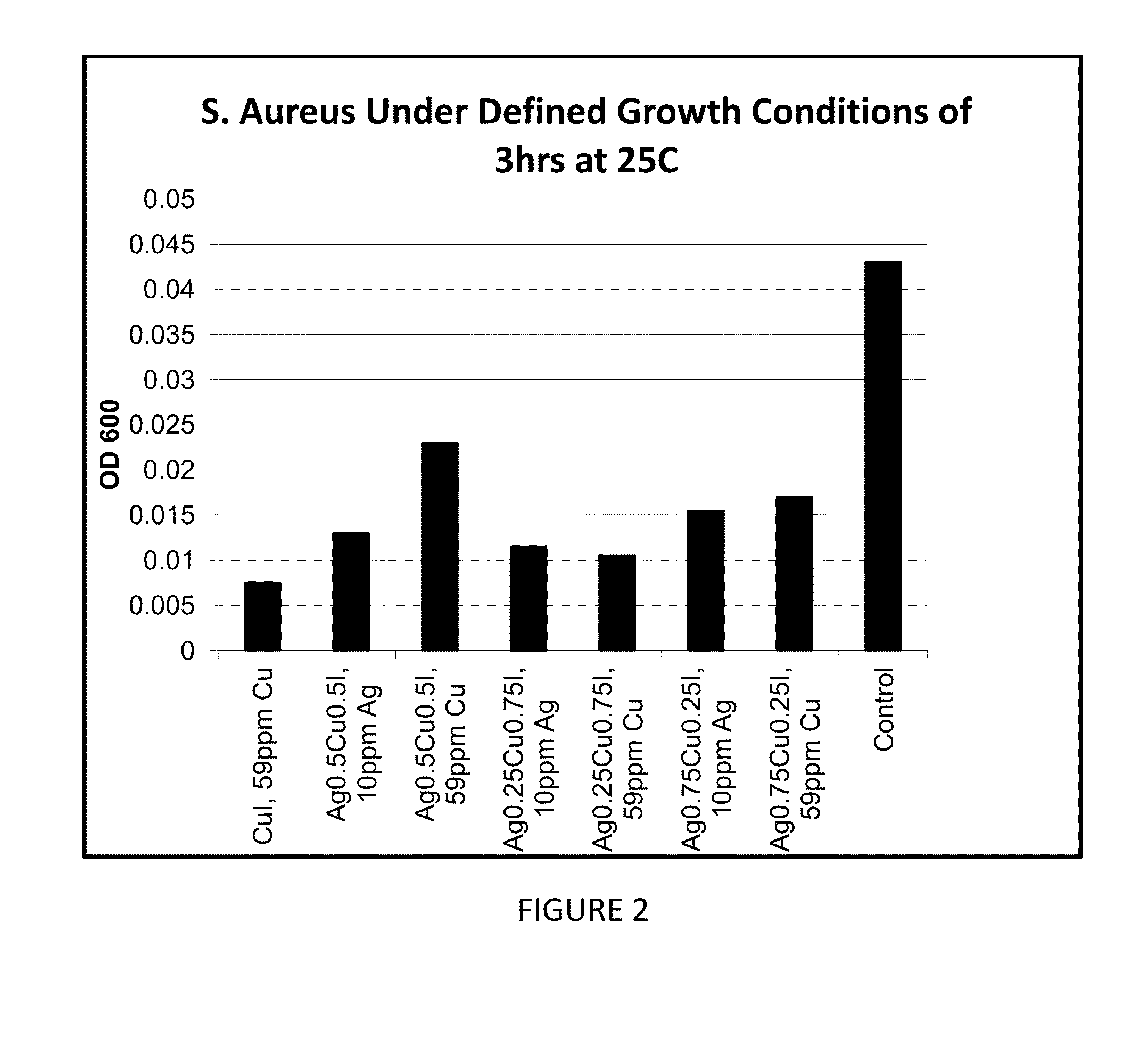

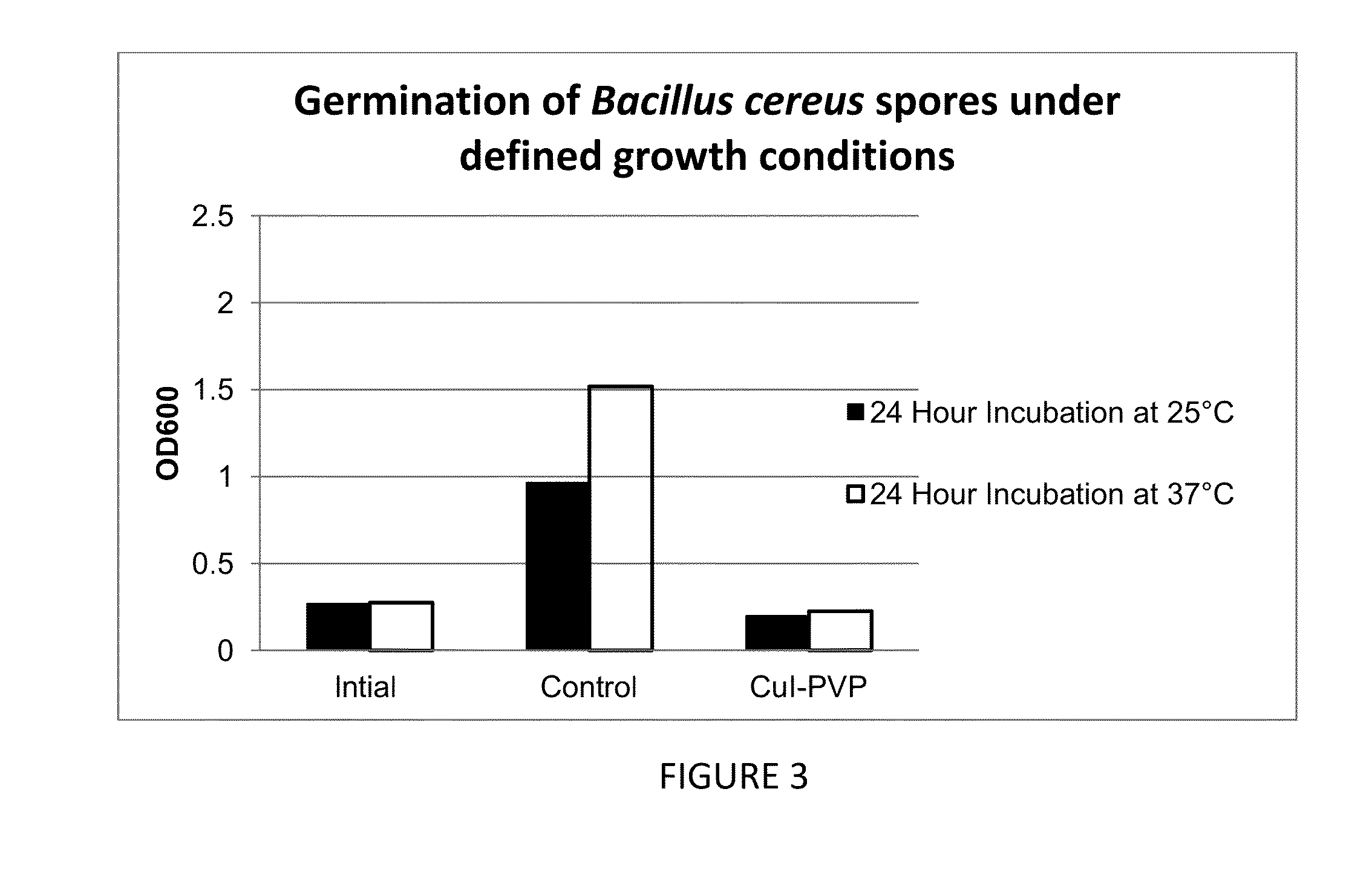

Compositions and methods for antimicrobial metal nanoparticles

InactiveUS20130315972A1Improve efficacyImprove utilizationBiocideInorganic active ingredientsHydrophilic polymersHydrophobic polymer

Compositions having antimicrobial activity contain particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 3 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride, most preferred being copper iodide. Preferred functionalizing agents comprise materials with a molecular weight of 60 or above, which include amino acids, other acidic materials, thiols, hydrophilic polymers, emulsions of hydrophobic polymers and surfactants. The functionalized particles are preferably made by a grinding process.

Owner:AGIENIC

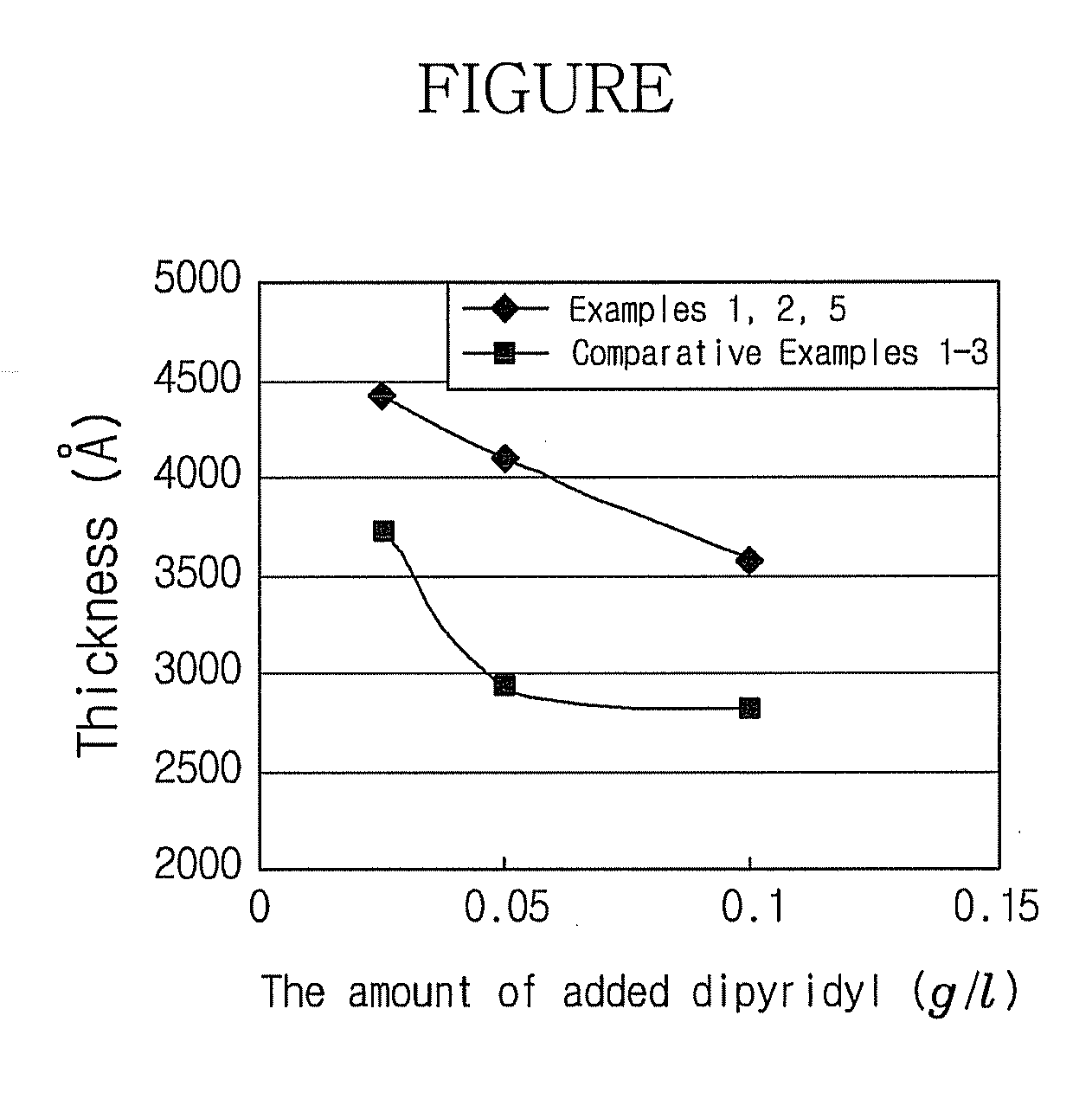

Electroless copper plating solution, method of producing the same and electroless copper plating method

ActiveUS20080223253A1Improve adhesionLower resistanceLiquid surface applicatorsAnti-corrosive paintsCopper platingHydrogen-Ion Concentrations

Disclosed herein is an electroless copper plating solution, including a copper salt, a completing agent, a reductant and a pH adjuster, in which the plating solution includes a 2,2-dipyridyl acid solution and the hydrogen ion concentration (pH) thereof is about 11.5 to about 13.0, a method of producing the same, and an electroless copper plating method. According to the plating solution of the present invention, an electroless copper plating film having stable and improved adhesivity and low electrical resistance can be obtained. Further, display devices including a metal pattern formed with the electroless copper plating solution can improve the reliability and price competitiveness of products prepared therefrom.

Owner:SAMSUNG DISPLAY CO LTD

Compositions and methods for antimicrobial metal nanoparticles

InactiveUS20120301528A1Good effectBiocideCosmetic preparationsHydrophilic polymersHydrophobic polymer

Embodiments of the invention are directed to a composition having antimicrobial activity comprising particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 4 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride. Preferred functionalizing agents include amino acids, thiols, hydrophilic polymers, emulsions of hydrophobic polymers and surfactants.

Owner:AGIENIC

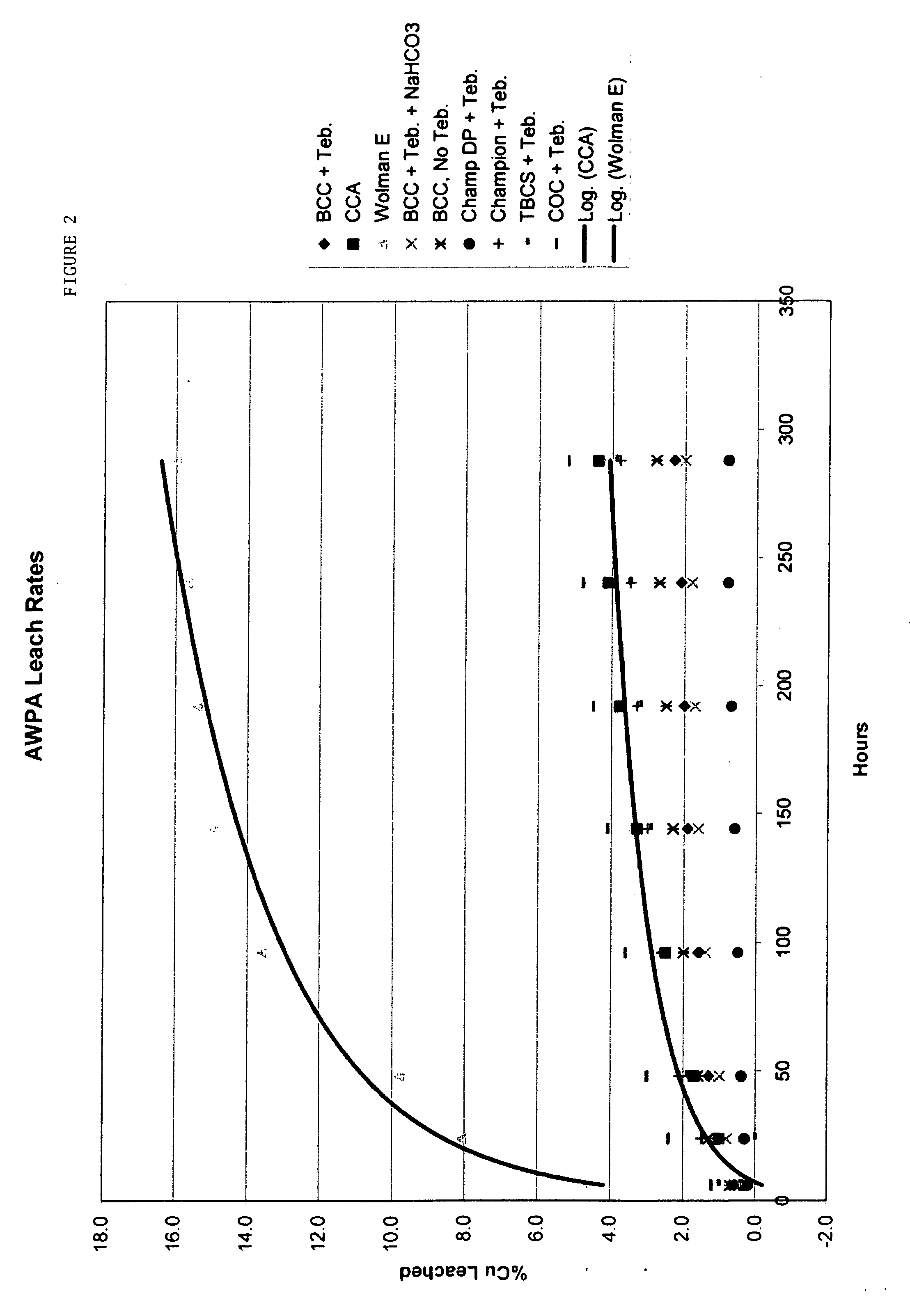

Use of sub-micron copper salt particles in wood preservation

InactiveUS20060062926A1Little dangerSmall particle sizeBiocideLiquid surface applicatorsPhosphateCopper nitrate

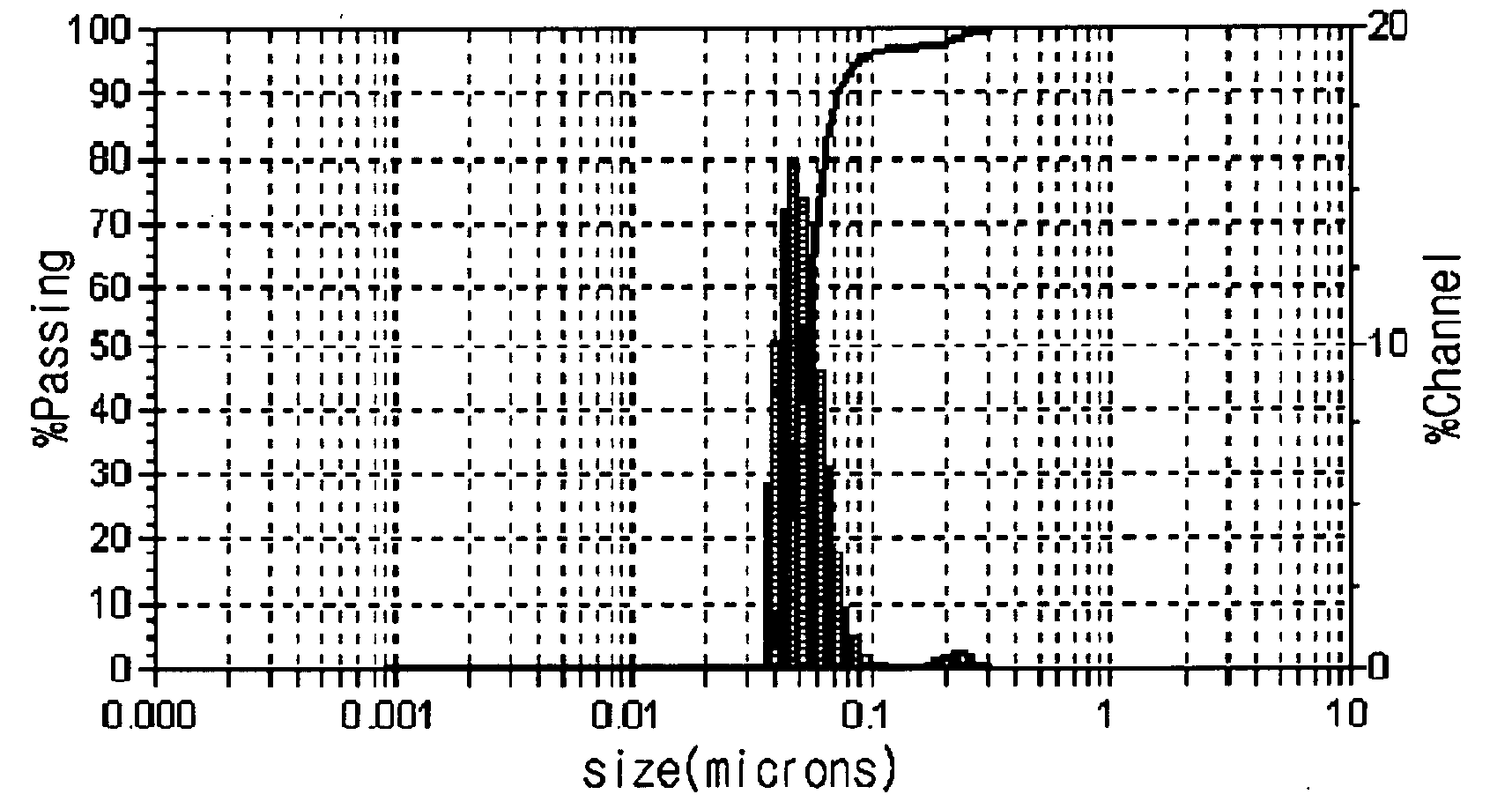

A method for preserving wood by injecting into the wood a slurry having: particles of a sparingly soluble copper salt, copper hydroxide, or both, wherein the weight average diameter d50 of the particles in the slurry is between 0.1 microns and 0.7 microns and the d98 of the particles in the slurry is less than about 1 micron; a dispersant; and water. The dispersant is anionic or a mix of anionic and non-ionic. Advantageously, less than 20% by weight of the particles have a diameter less than 20 nanometers. Useful copper salts include basic copper carbonate, tri-basic copper sulfate, copper oxychloride, basic copper nitrate, basic copper borate, copper borate, basic copper phosphate, or copper silicate. The slurry most preferably includes copper hydroxide particles. The slurry further advantageously includes at least one organic biocide, wherein at least a portion of the organic biocide is coated on the particles.

Owner:OSMOSE

Particulate wood preservative and method for producing same

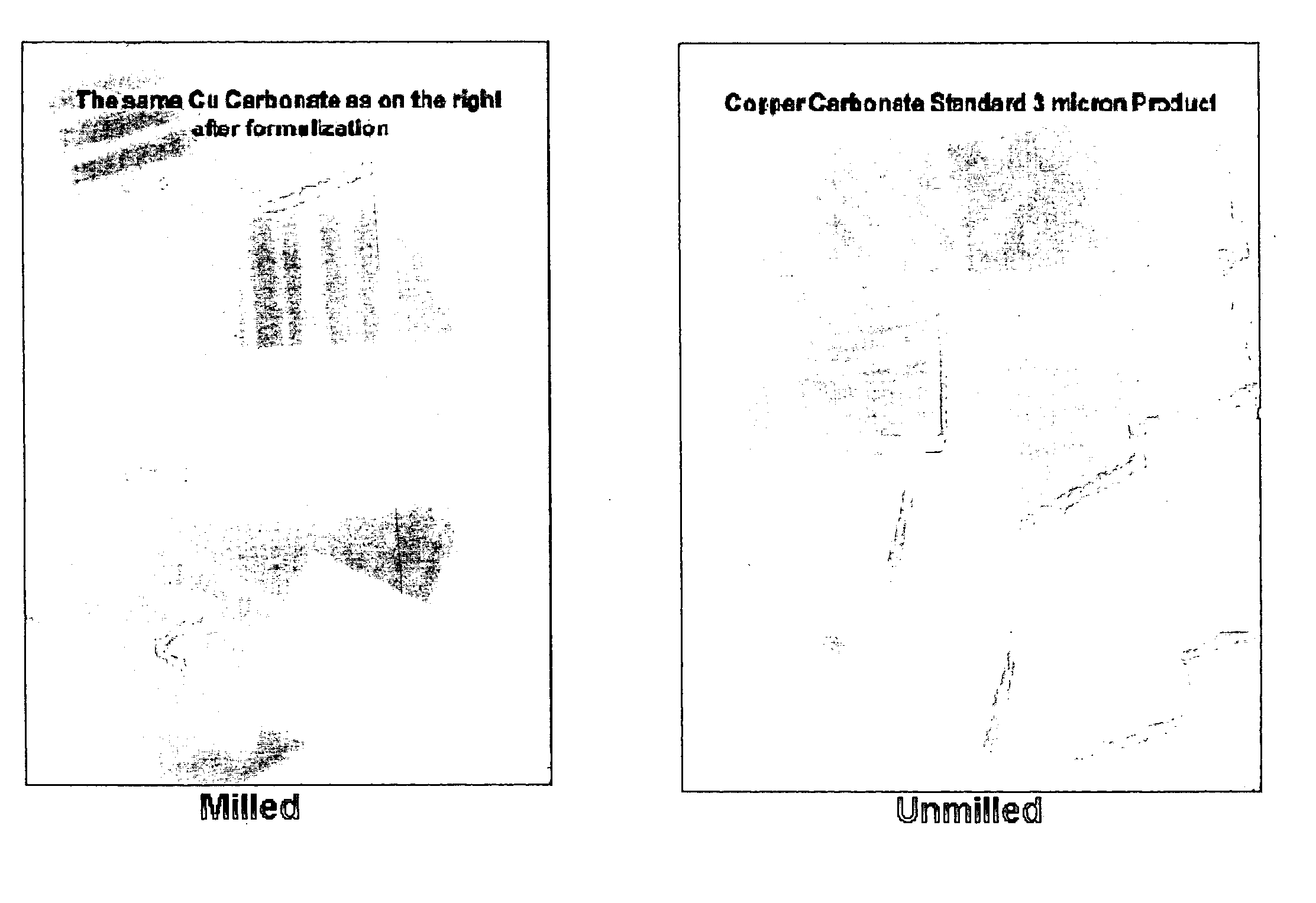

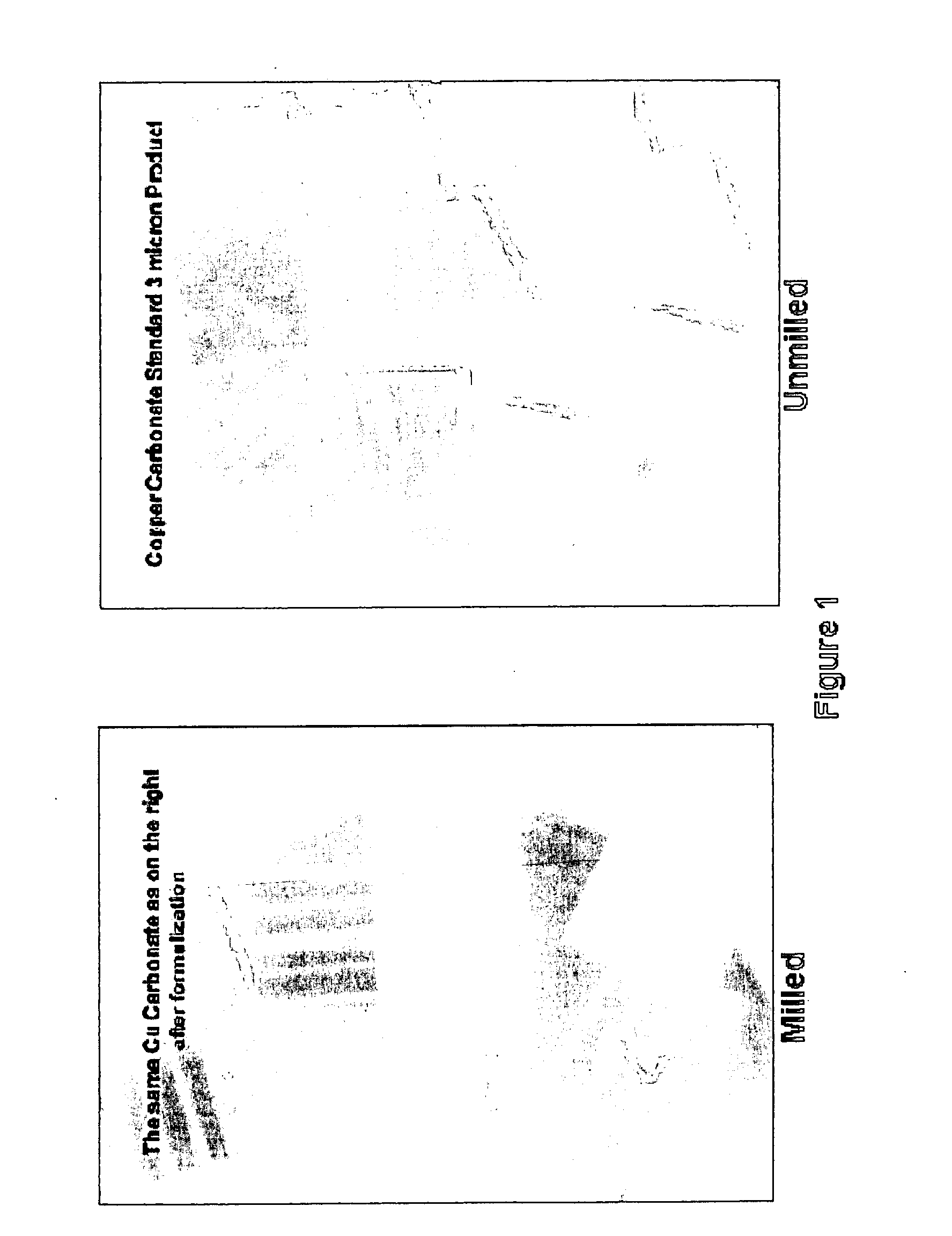

InactiveUS20050252408A1Reduce the amount requiredWide particle size distributionBiocideAntifouling/underwater paintsCopper(II) hydroxideBasic copper carbonate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:OSMOSE

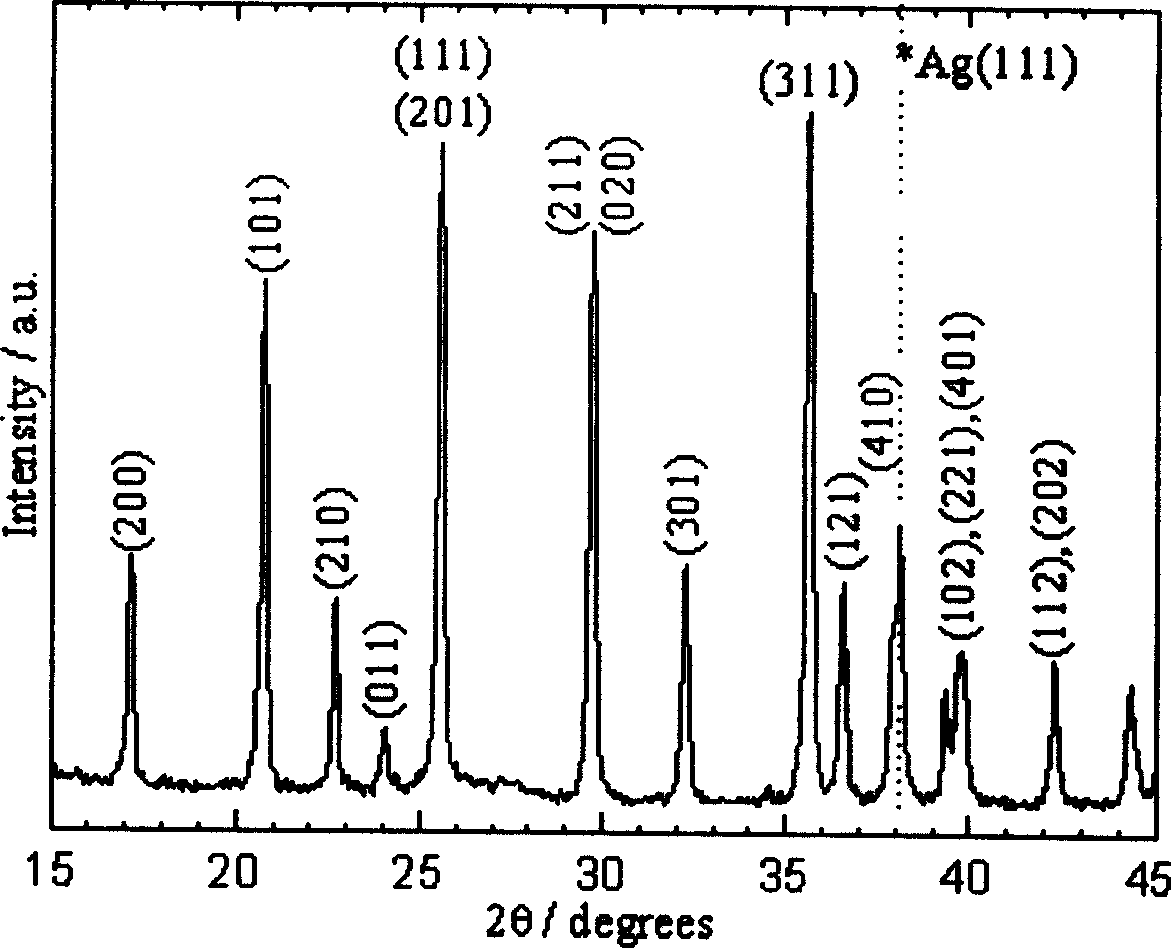

Preparation of supported catalyst for 1,4-butynediol

InactiveCN103157500AImprove stabilityHigh activityMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention relates to preparation of a supported catalyst for 1,4-butynediol. The supported catalyst used is characterized in that a mesoporous molecular sieve is used as a carrier, and soluble copper salt and bismuth are loaded on the carrier by an impregnation method so that the mass content of copper in the catalyst is 15-30%, and the mass content of bismuth is 1-6%. In the prepared catalyst, the particle size of copper oxide is 10-80nm, and the bismuth oxide is amorphous powder; the copper oxide and the bismuth oxide are uniformly distributed on the carrier and interact with the carrier; and the catalyst has high activity and high selectivity in producing 1,4-butynediol through an alkyne hydroformylation reaction, is more stable and wear-resistant than similar catalysts, and saves copper resources.

Owner:XINJIANG UNIVERSITY

Preparation method of chelate coating with copper ions capable of controllably catalyzing release of nitrogen monoxide and polyphenol complex

ActiveCN104194460ALong-term antibacterialImprove antibacterial propertiesAntifouling/underwater paintsSurgeryBiocompatibility TestingPhenol

The invention discloses a preparation method of a chelate coating with copper ions capable of controllably catalyzing release nitrogen monoxide and a polyphenol complex. The preparation method comprises the following steps: soaking a target modified material or an instrument in a mixed aqueous solution consisting of soluble metal salt, soluble copper salt and a compound having an o-phenol structure; and depositing a layer of chelate coating with copper ions with a function of catalyzing nitrogen monoxide and the polyphenol complex on the surface. The chelate coating with the copper ions and the polyphenol complex, which is obtained by the preparation method disclosed by the invention, not only has excellent biocompatibility and bacterial resistance, but also has a function of inducing catalysis of endogenous nitrogen monoxide to release in a blood environment. In addition, the coating is nearly applicable to surface modification of materials of all textures, complex geometrical shapes and different topological structures.

Owner:GUANGZHOU NANCHUANG EVEREST MEDICAL TECH CO LTD

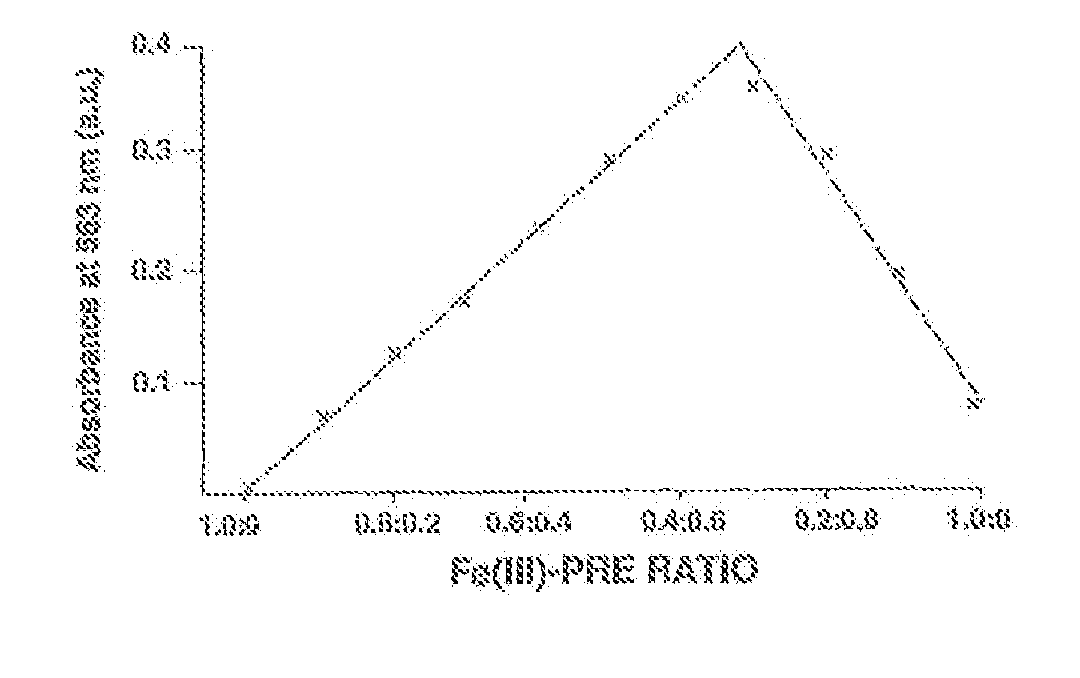

Antimicrobial Composition

Disclosed herein are antimicrobial compositions comprising an effective concentration of a metal salt combined with a plant extract. In some embodiments the composition comprises a copper salt and / or an iron salt and / or a nickel salt and / or a cobalt salt; and an extract of a plant selected from a group consisting of Punka granatum, Viburnum plicatum, Camellia sinensis, and Acer spp. The invention extends to uses of such compositions as medicaments, and to methods of treating microbial infections. The invention extends to methods for preventing microbial infections by coating objects and surfaces with the compositions.

Owner:NATURE THERAPEUTICS

Method for Making Nanoparticles

InactiveUS20080264205A1Cheap methodEasily reduces metalNanotechElectrolysis componentsOxidation-Reduction AgentRedox

A method for making nanoparticles includes the steps of dipping a metal element in a solution that contains metallic ions or ions with a metal, wherein the metal element has a lower electronegativity or redox potential than that of the metal in the ions, and rubbing the metal element to make nanoparticles. Another method for making nanoparticles includes the steps of dipping a metal element in a solution that contains metallic ions or ions with a metal, wherein the metal element has a lower electronegativity or redox potential than that of the metal in the ions, and applying sonic energy to at least one of the metal element and solution. A further method for making copper nanoparticles includes the step of adding ascorbic acid to a copper salt solution.

Owner:ZENG TAOFANG

Maintenance method for alkaline non-cyanide plating copper

The invention discloses a maintaining method for an alkalescent non-cyanide cuprodine. The method uses indissoluble anode, cathode in the alkalescent non-cyanide cuprodine liquor as the galvanized workpiece, adds cupric salt, complexing agents and additives and adjusts the pH value of the galvanizing liquor to control the current dense range between 0.1-7A / dm2; the galvanizing time is between 1min to 72h; then the galvanizing liquor is filtered; the galvanizing liquor is processed air bend or moves the workpiece while galvanizing. The invention uses the indissoluble anode comprising stainless steel, DSA coating, titanium, platinum, graphite which is simple to use, innoxious, harmless; the invention has a low production cost and even, smooth and shining fine galvanizing layer by using the indissoluble anode. The technique maintaining method of the invention has a simple operation, great stability of galvanizing liquor and convenient maintenance for the galvanizing liquor.

Owner:广州市二轻研究所股份有限公司

Antimicrobial compositions for use in products for petroleum extraction, personal care, wound care and other applications

ActiveUS20140271757A1Improve viabilityProvide benefitsBiocideCosmetic preparationsSolubilityPersonal care

Compositions having antimicrobial activity contain surface functionalized particles comprising an inorganic copper salt which has low water solubility. These types of inorganic salts may also be introduced in porous particles to yield antimicrobial compositions. The compositions may optionally comprise additional antimicrobial agents, salts with high water solubility, organic acids, salts of organic acids and their esters. The compositions may be added to various fluids used in the petroleum extraction industry, or used as coatings on components used in this industry. These antimicrobial materials may be used for reducing both anaerobic and aerobic bacteria and are also useful for reducing corrosion of ferrous components caused by anaerobic bacteria. Although such compositions may be used for any antimicrobial application, and some of the other important uses of these compositions are in wound care, personal care and waste processing.

Owner:AGIENIC

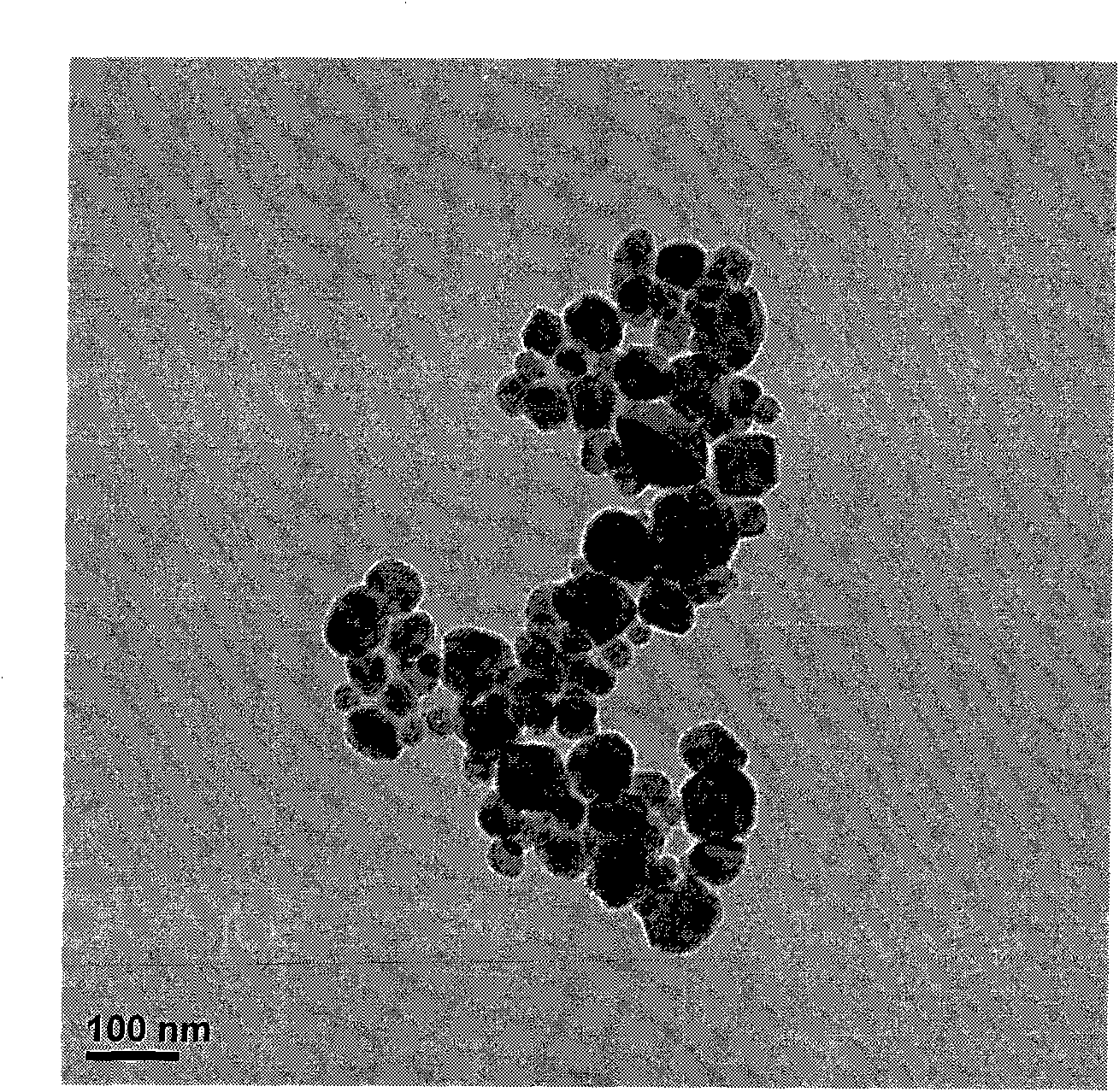

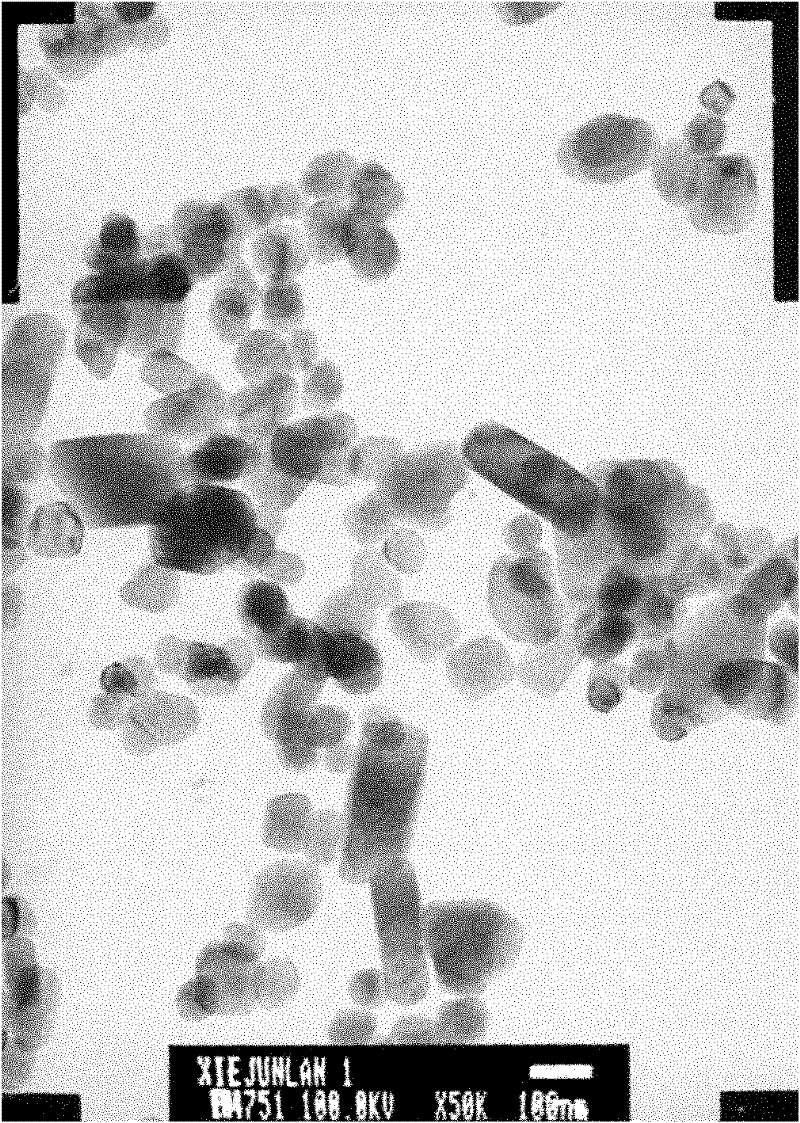

Method for manufacturing copper nanoparticles using microwaves

InactiveUS20080072706A1Good dispersionNarrow particle size distributionMaterial nanotechnologyPolycrystalline material growthMicrowaveOrganic solvent

The present invention relates to a method for manufacturing copper nanoparticles, in particular, to a method for manufacturing copper nanoparticles, wherein the method includes preparing a mixture solution including a copper salt, a dispersing agent, a reducing agent and an organic solvent; raising temperature of the mixture solution up to 30-50° C. and agitating; irradiating the mixture solution with microwaves; and obtaining the copper nanoparticles by lowering temperature of the mixture solution.According to the present invention, several tens of nm of copper nanoparticles having a narrow particle size distribution and good dispersibility can be synthesized in mass production.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

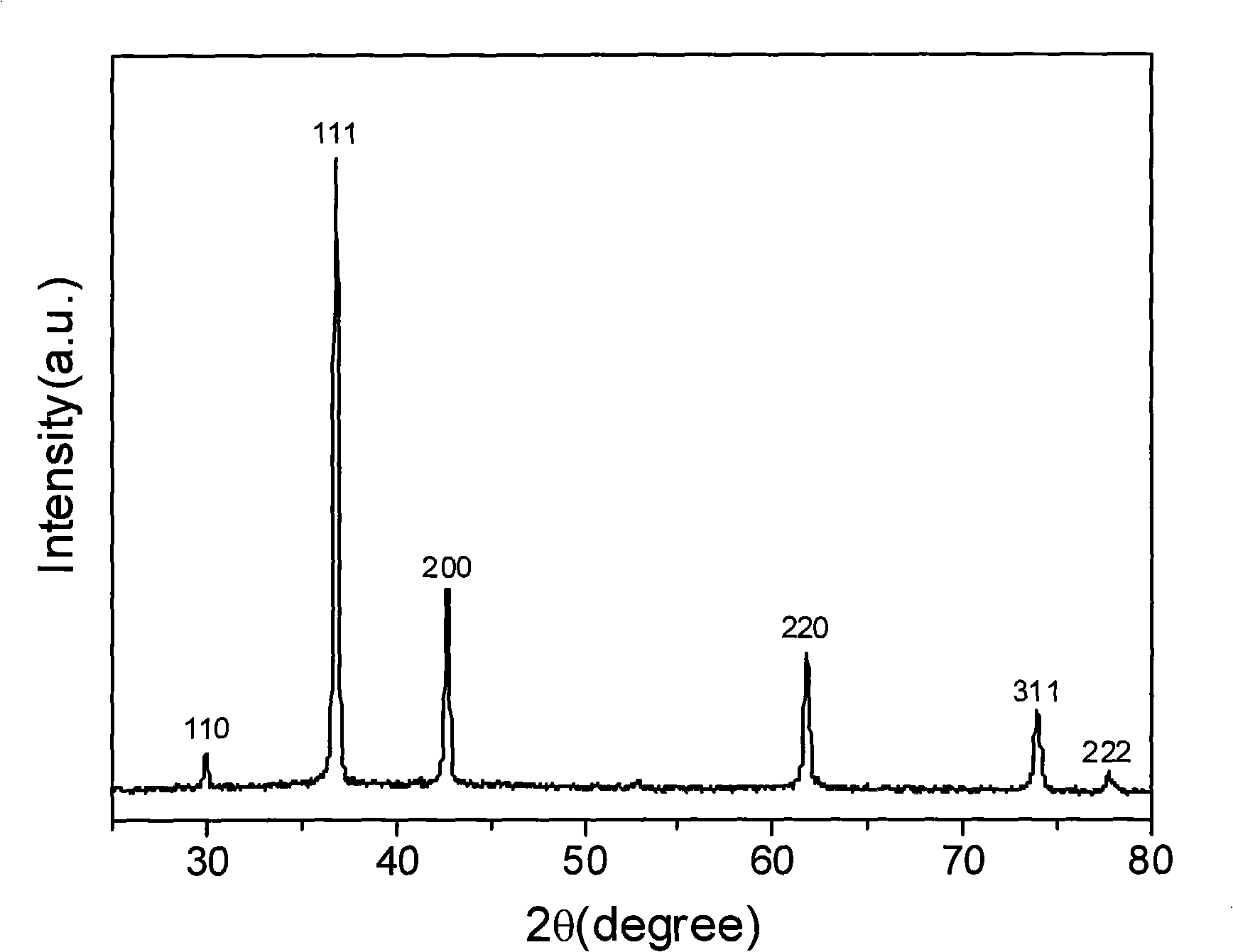

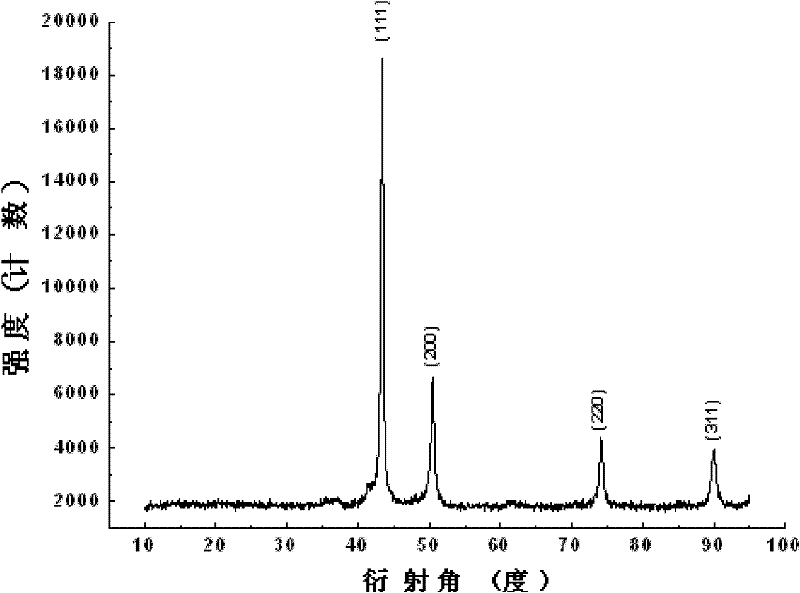

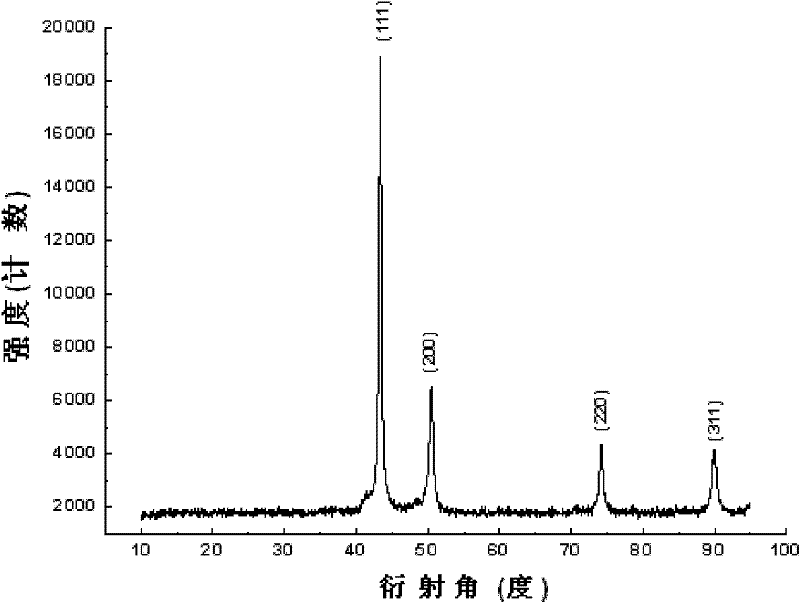

Method for preparing nano copper conductive ink

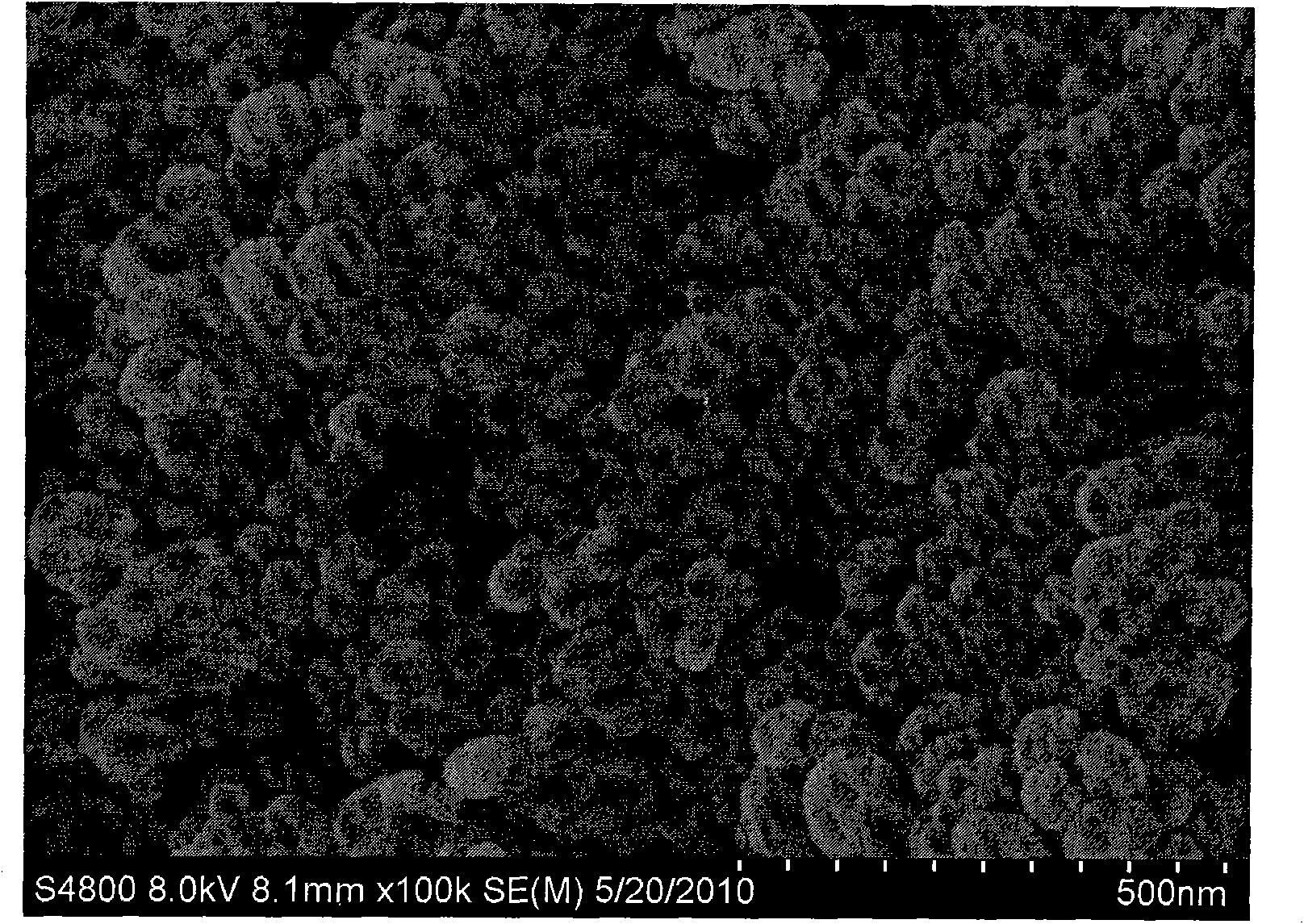

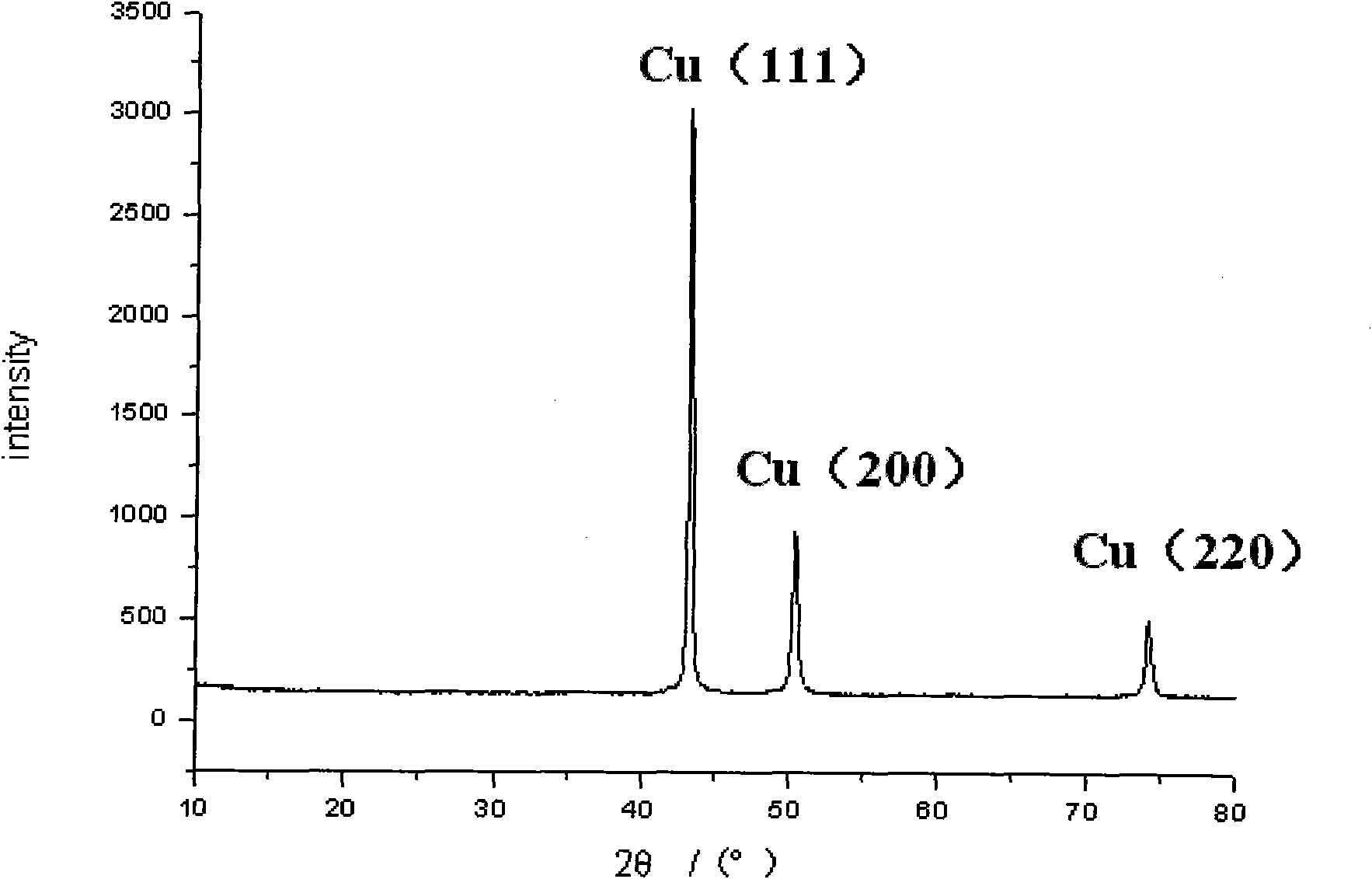

ActiveCN101880493AGood dispersionCharacteristic peaks are obviousInksNon-conductive material with dispersed conductive materialOrganic solventRoom temperature

The invention discloses a method for preparing nano copper conductive ink, which can be applied in the field of printing electronic technology, in particular ink jet printing technology. The preparation method comprises the following steps of: dissolving copper salt and protective agent into a solvent, heating and stirring the solution, adding a small amount of alkali solution to adjust the pH ofthe solution to between 7 and 10, dripping a reducing agent into the solution, continuously stirring the solution to react for 30 to 60 minutes, and then cooling the reaction solution to room temperature to obtain nano copper dispersion; performing centrifuging, washing and vacuum drying at room temperature on the nano copper dispersion to obtain nano copper granules; and dispersing the nano copper granules into an organic solvent, and ultrasonically treating the solution to obtain the nano copper conductive ink. The method solves the problems of complex preparation process and long preparation period in the prior art, has the advantages of simple and convenient operation, low production cost, short flow and no harmful waste generation, and realizes the goals of environmental protection and economy; and the prepared nano copper conductive ink has good dispersion property and high stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

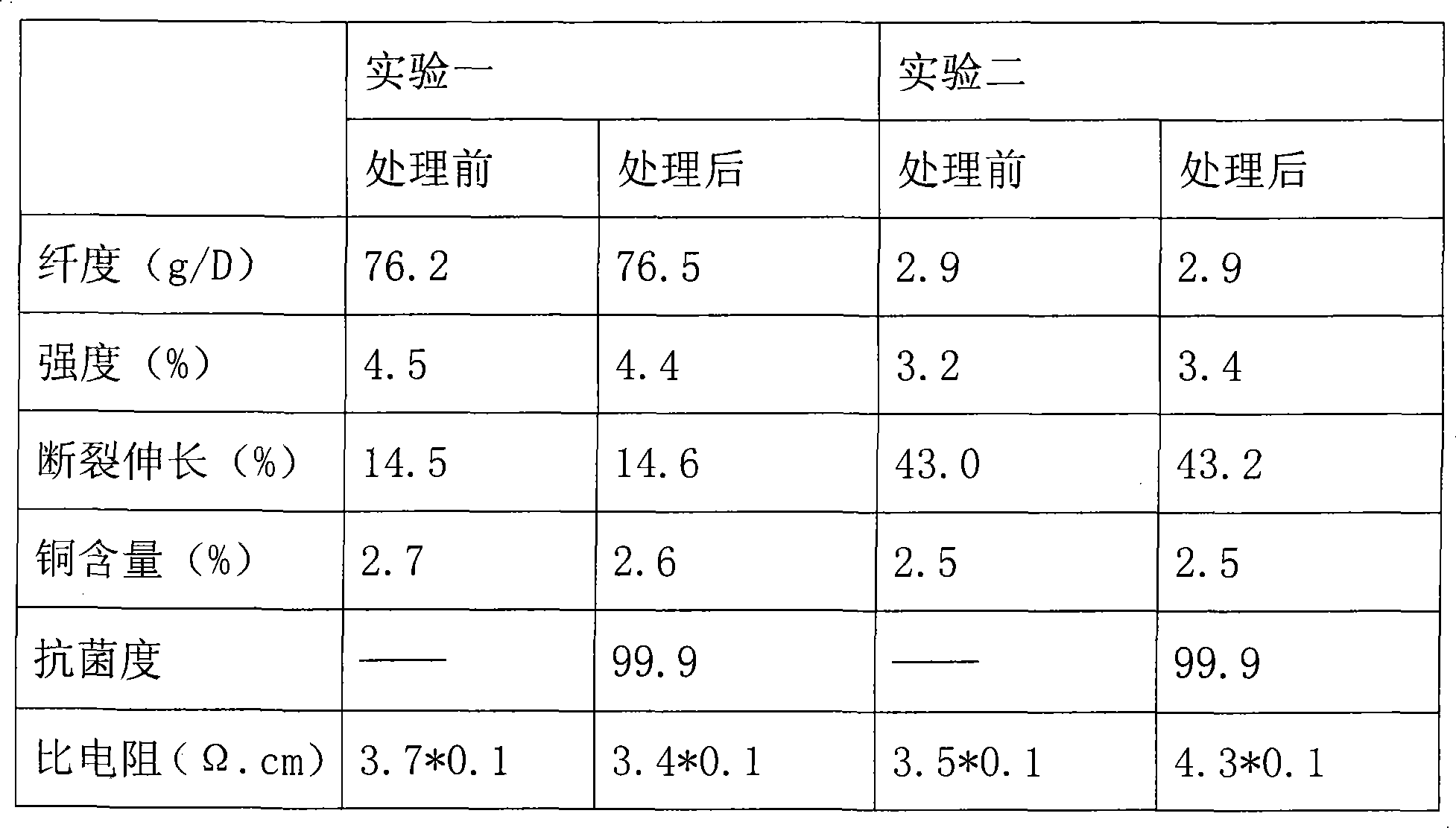

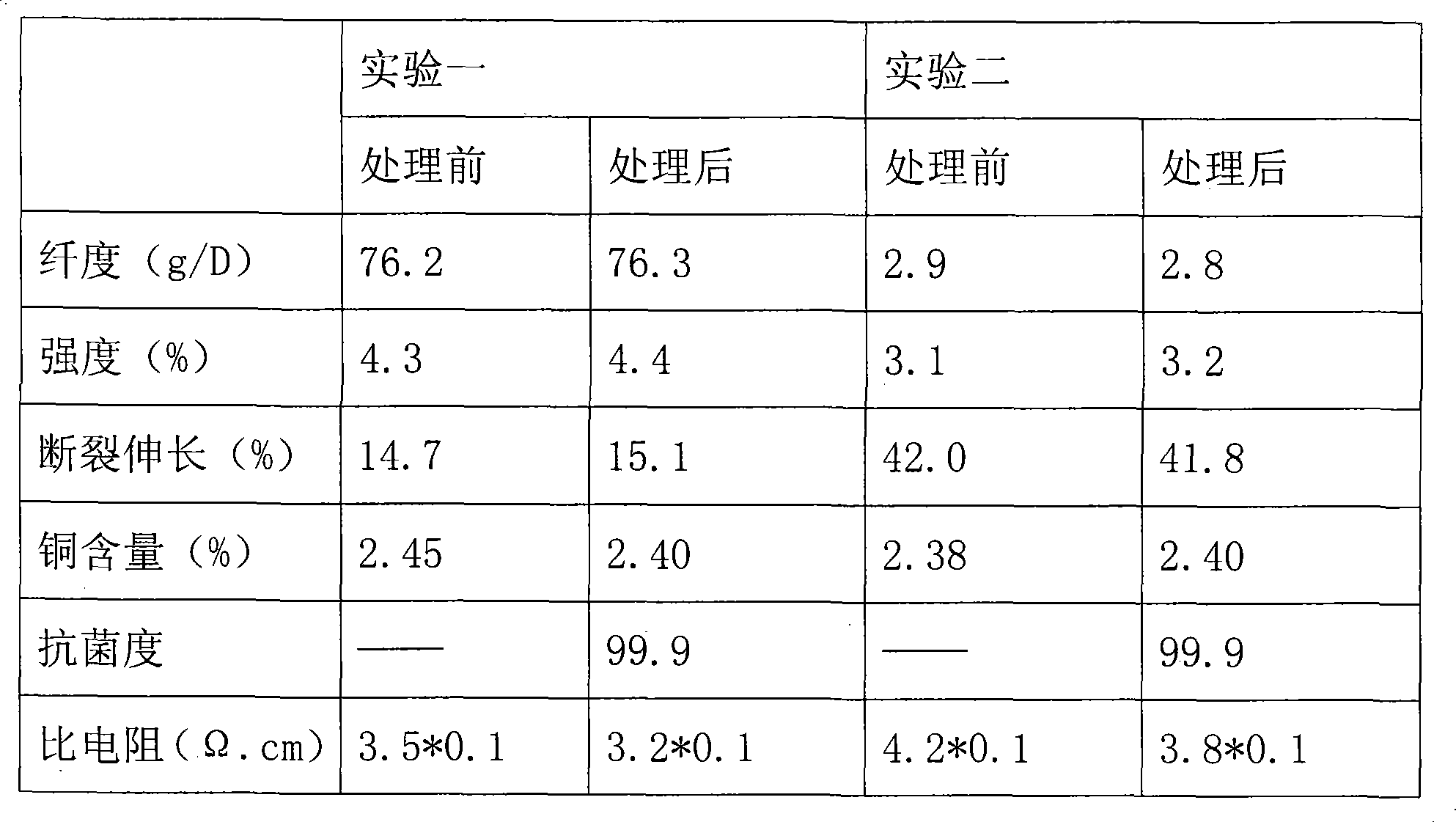

Process for manufacturing antimicrobial conductive acrylic fibre fibre

The invention belongs to a manufacture method of an antibacterial conductive acrylic fiber, which is characterized by being composed of the following steps: (1) arranging the acrylic fiber into a reaction vessel, then pouring a solvent into the reaction vessel, dissolving copper salt containing Cu<2+> into the solvent, adjusting the pH valve of the solution to be between 1.5 to 3.0, then adding a reducer and heating, maintaining the temperature of the solution to be between 90 to 100 DEG C, carrying out reduction on the Cu<2+> by utilizing the reducer to generate Cu<+> and lead the Cu<+> to be absorbed on the acrylic fiber; (2) adjusting the pH value of the solution to be between 1.5 to 3.0 and then maintaining the temperature of the solution to be between 40 to 120 DEG C, adding salt containing sulfur atoms and leading a great amount of Cu<+> to be oxidized to generate the Cu<2+> after the reaction time lasts 2 to 4 hours; thereby generating a sulfide of copper that is not easy to be dissolved in the solvent to lead the sulfide of copper to be sufficiently and uniformly dispersed on the surface of the whole fiber. The copper sulphide in the acrylic fiber manufactured by utilizing the method is dispersed on the surface of the whole fiber. The self physical and chemical characteristics of the copper sulphide lead the fiber to have excellent antibacterial property and conductibility; the copper sulphide on the fiber surface is not easy to fall off and has excellent anti-washing property.

Owner:金素娟

Compositions and methods for antimicrobial metal nanoparticles

InactiveUS20120301531A1Good effectAntibacterial agentsBiocideHydrophilic polymersHydrophobic polymer

Embodiments of the invention are directed to a composition having antimicrobial activity comprising particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 4 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride. Preferred functionalizing agents include amino acids, thiols, hydrophilic polymers emulsions of hydrophobic polymers and surfactants.

Owner:UHLMANN DONALD R +3

Iron-base catalyst for Fischer-Tropsch synthesis and its preparation method

ActiveCN1597105AReduce manufacturing costLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIron sulfatePotassium silicate

A Fe-based catalyst for the Fischer-Tropsch synthesis contains Re2O3, Fe3O4, La2O3, CuO, K2O and SiO2. It is prepared through using oxidant to oxidize partially the ferrous sulfate to obtain the mixed solution of iron sulfate and ferrous sulfate, mixing with the mixed solution of lanthanum nitrate and copper salt, fast depositing by alkaline compound, washing the deposited slurry, adding potassium silicate-water glass solution, and spray drying.

Owner:SYNFUELS CHINA TECH CO LTD

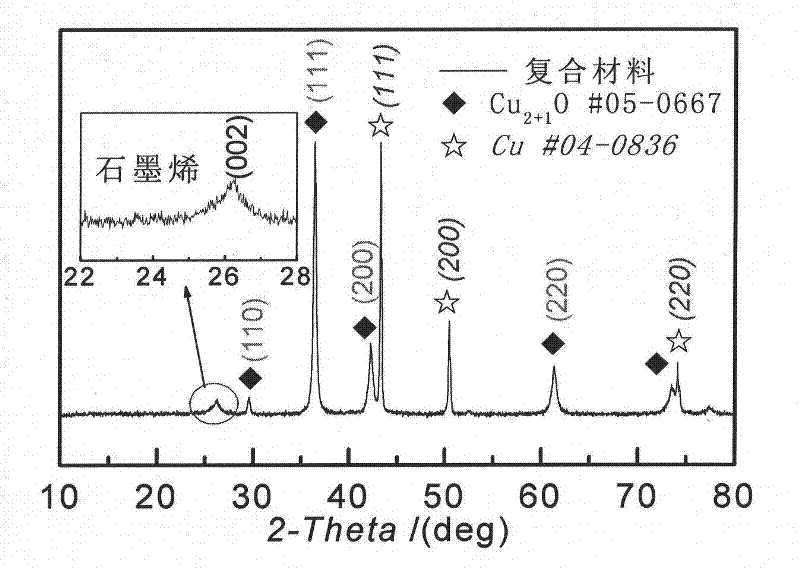

Graphene loaded Cu-CuxO composite material and preparation method thereof

InactiveCN102315433AImprove crystal structureAvoid reunionMaterial nanotechnologyElectrode manufacturing processesLithium-ion batteryStructural stability

The invention discloses a graphene loaded Cu-CuxO composite material and a preparation method thereof. Through the preparation method, Cu-CuxO composite particles with uniform particle size and controllable morphology and components can be loaded on graphene. The preparation method comprises the following steps of dispersing uniformly oxidized graphite in deionized water by supersonic waves to obtain an oxidized graphene solution, adding a copper salt into the oxidized graphene solution, mixing uniformly, adjusting a pH value of the mixed solution obtained by the previous step to an appropriate pH value, putting the mixed solution into a reactor for a hydro-thermal reaction, carrying out separation and calcination of reaction products obtained by the hydro-thermal reaction to obtain the graphene loaded Cu-CuxO composite material. The preparation method has the advantages of common and easily available raw materials, low cost, and simple and safe preparation processes. The prepared graphene loaded Cu-CuxO composite material has good structural stability, excellent physicochemical properties, and potential application values in the fields of lithium ion batteries, photoelectric conversion, catalytic degradation and electron devices.

Owner:CHINA UNIV OF MINING & TECH

Electroplating solution for acid copper-plating for printed circuit board as well as preparation method and application method for same

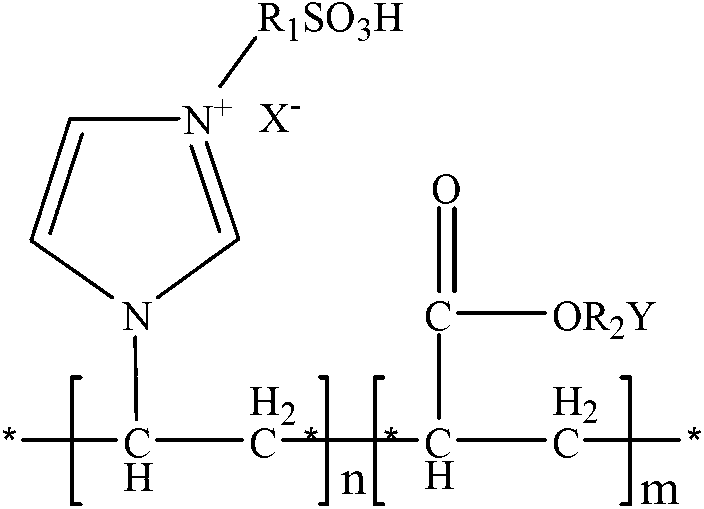

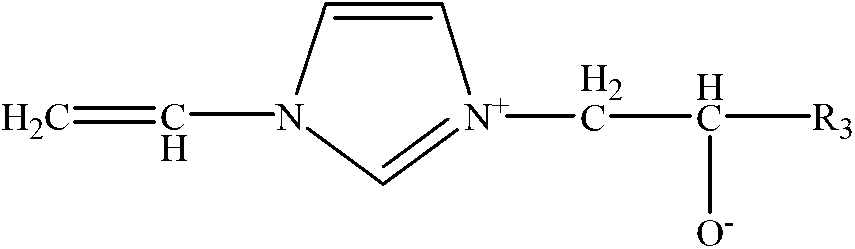

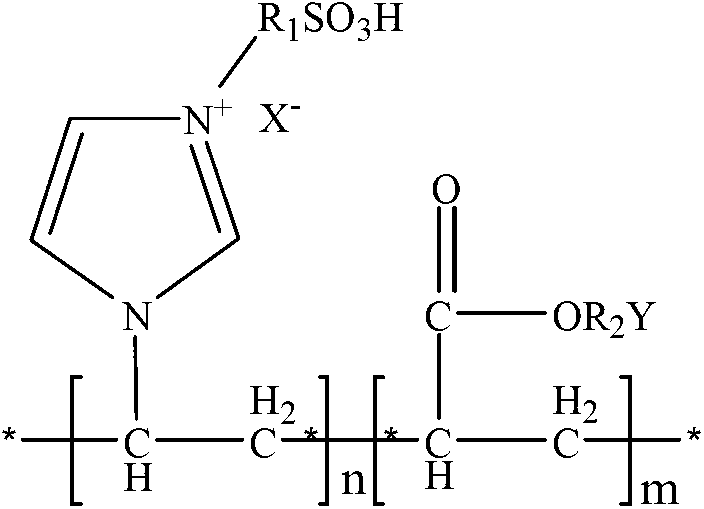

The invention discloses an electroplating solution for acid copper-plating for a circuit board as well as a preparation method and an application method for the same. The electroplating solution disclosed by the invention is characterized in that a home-made synthesised levelling agent is added, and the levelling agent is matched with water-soluble copper salt, sulphuric acid, a brightening agent, chloride ions, a gloss agent and a surfactant to form the electroplating solution. The home-made levelling agent is one or more of the copolymer of N-vinyl imidazole onium salt and propenyl esters, and the polymer of N-vinyl imidazole and epoxides. The electroplating solution containing the home-made synthesised levelling agent is great in covering power and the dispersing power, capable of improving the uniform distribution of copper layers in the through holes of the printed circuit board, and capable of effectively reducing the ratio of the thickness of the surface copper layers to the thickness of the copper layers in the centres of the holes.

Owner:CENT SOUTH UNIV

Method for preparing carbon coated lithium ferrous phosphate composite material including metal conductive agent

InactiveCN1649189AImprove electronic conductivityImprove protectionElectrode manufacturing processesPhosphatePhosphoric acid

This invention relates to a preparation method for LiFe PO4 / M / C compound positive material, the precursor of Li-Fe-PO4-M is synthesized with Li salt, Fe compound, phosphate, silver salt and organic acid as the raw materials by the sol-coagel method. Then the precursor mixed with pyrogenic-decomposed in inert atmosphere to get LiFePO4 / M / C compound positive material.

Owner:ZHEJIANG UNIV

Preparation of polyhedral cuprous oxide nano particle

The invention provides a method for preparing polyhedral cuprous oxide nanometer granules. The method adopts a chemical solution method to prepare polyhedral cuprous oxide nanometer granules comprising cubes, chamfered cubes, cubic octahedrons, chamfered octahedrons or octahedral series. The method comprises the following concrete steps: copper salt is dissolved in water and stirred at a temperature between 50 and 60 DEG C; polyvinyl pyrrolidone, strong base solution and ascorbic acid solution are orderly added, stirred at a constant temperature between 50 and 60 DEG C and kept for 1 to 3 hours; after the reaction is over, the centrifugation is carried out; and a large amount of the deionized water is used for washing, and the cuprous oxide nanometer granules can be obtained after vacuum drying. By regulating the adding amount of the polyvinyl pyrrolidone, the polyhedral cuprous oxide nanometer granules comprising the cubes, the chamfered cubes, the cubic octahedrons, the chamfered octahedrons or the octahedral series are obtained. The method has the advantages of moderate condition, simple operation, low cost, high yield, controllable shape, and so on.

Owner:BEIHANG UNIV

Antimicrobial compositions for use in wound care products

Compositions having antimicrobial activity contain surface functionalized particles comprising an inorganic copper salt which has low water solubility. These types of inorganic salts may also be introduced in porous particles to yield antimicrobial compositions. The compositions may optionally comprise additional antimicrobial agents, salts with high water solubility, organic acids, salts of organic acids and their esters. The above compositions can be incorporated in a variety of wound care products to provide antimicrobial properties.

Owner:AGIENIC

Nano copper powder for electronic paste and preparation process

InactiveCN102205422AUniform particle size distributionGranularity controllableHigh surfaceVacuum drying

The invention discloses nano copper powder for electronic paste and a preparation process. The process is characterized in that: nano copper powder is prepared through the reduction of a reducing agent under the condition of the temperature and the pressure which are produced by a hydrothemal method, and nano copper powder with different appearances and grain diameters can be prepared under the conditions of different temperatures, pressures, reducing agents and dispersing agents. The method comprises the following steps of: adding aqueous solution of a complexing agent into aqueous solution of water soluble copper salt to form the complex aqueous solution of copper; adding an appropriate amount of dispersing agent, stirring to uniformly disperse the mixture, adding an appropriate amount of reducing agent, and adding the finally-obtained mixed solution into a stainless steel high-temperature reaction kettle with a polytetrafluoroethylene lining; heating to a certain temperature; preserving heat for certain time; naturally reducing temperature to room temperature; filtering off precipitate; cleaning by using deionized water and ethanol for multiple times; and performing vacuum drying to finally obtain high-purity nano copper powder with high surface activity and controllable granularity.

Owner:SHENZHEN SENLONT ELECTRONICS

Chemical copper-plating solution and chemical copper-plating method

InactiveCN102191491AImprove stabilityImprove yieldLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention provides chemical copper-plating solution. The chemical copper-plating solution is the aqueous solution containing copper salt, N-methylmorpholine, formaldehyde, complexing agent, stabilizer and pH regulator and the pH value of the chemical copper-plating solution is 12-13. The invention also provides a chemical copper-plating method. The method comprises the following steps: directly contacting a part to perform chemical copper plating with the chemical copper-plating solution, cleaning and drying to obtain the plated part. By adopting the chemical copper-plating solution, the stability of the copper-plating solution can be greatly increased and the plating speed can be increased. By adopting the chemical copper-plating method provided by the invention to plate copper on the part to be plated, the yield of the copper-plating product can be increased largely and the work efficiency of chemical plating can be increased, thus the method is good for industrialized mass production.

Owner:BYD CO LTD

High-chloride-capacity liquid-phase dechlorinating agent as well as preparation method and application thereof

InactiveCN104437342ASmooth appearanceAvoid crackingOther chemical processesHydrocarbon oils refiningHas active ingredientAlkaline earth metal

The invention provides a high-chloride-capacity liquid-phase dechlorinating agent as well as a preparation method and an application thereof. The high-chlorine-capacity liquid-phase dechlorinating agent is suitable for removing inorganic chlorine from an oil product and is particularly suitable for removing hydrogen chloride from reformate. A carrier of the dechlorinating agent is a carbon molecular sieve, active ingredients of the dechlorinating agent comprise an alkali metal and an alkali earth metal oxide, and an auxiliary agent component is copper oxide, ferric oxide or zinc oxide. The preparation method of the solid dechlorinating agent provided by the invention comprises the following steps: dipping soluble copper salt, calcium salt, magnesium salt, barium salt and the like to a cylindrical carbon molecular sieve, drying, and performing stabilizing treatment to obtain the dechlorinating agent. The dechlorinating agent provided by the invention has the advantages of being relatively high in chloride capacity, low-price and easily available in raw material, having active ingredients uniformly distributed on the carrier, good in thermal stability, strong in water resistance, high in mechanical strength and the like, and the dechlorinating agent has desulfurization and denitrification effects at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

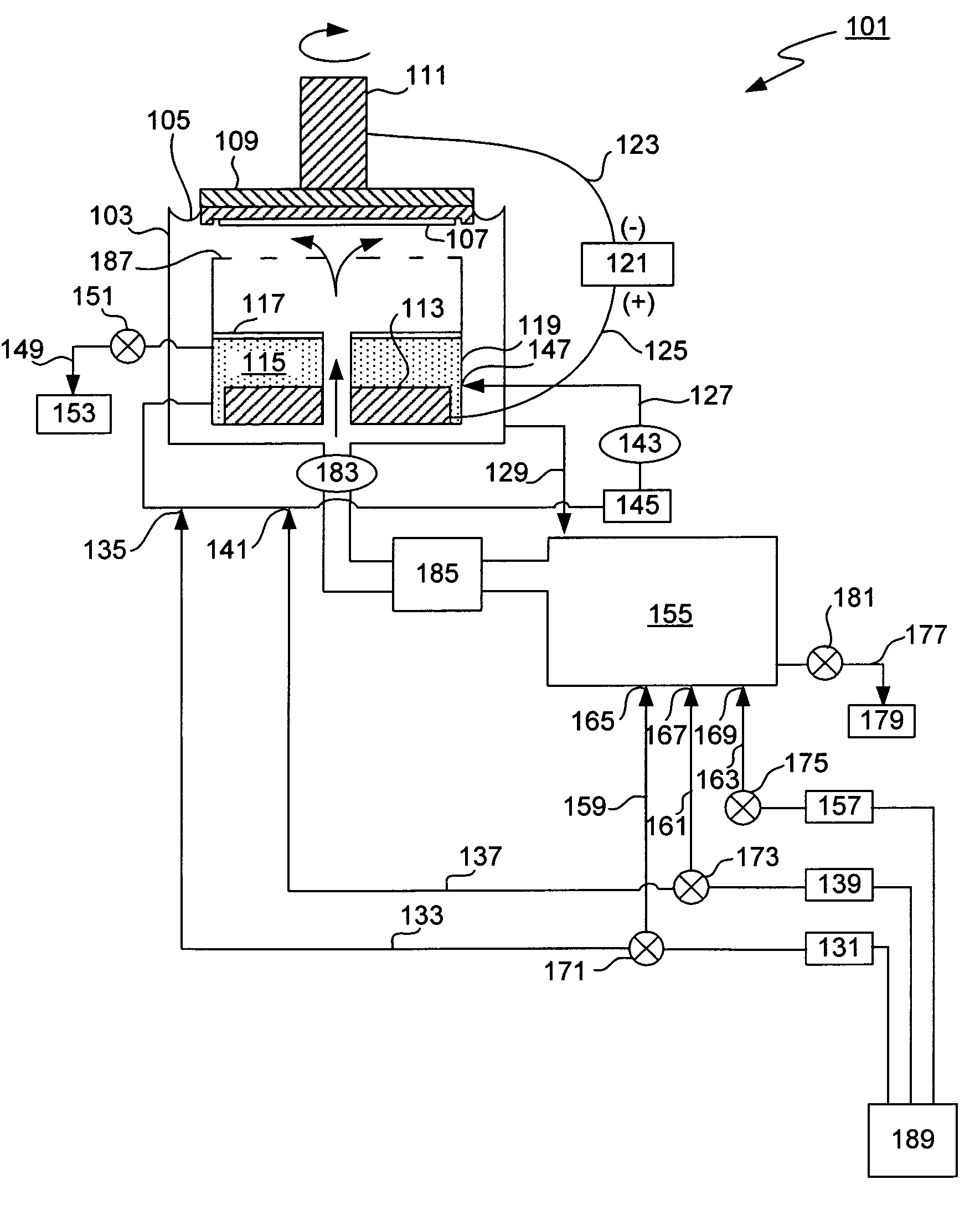

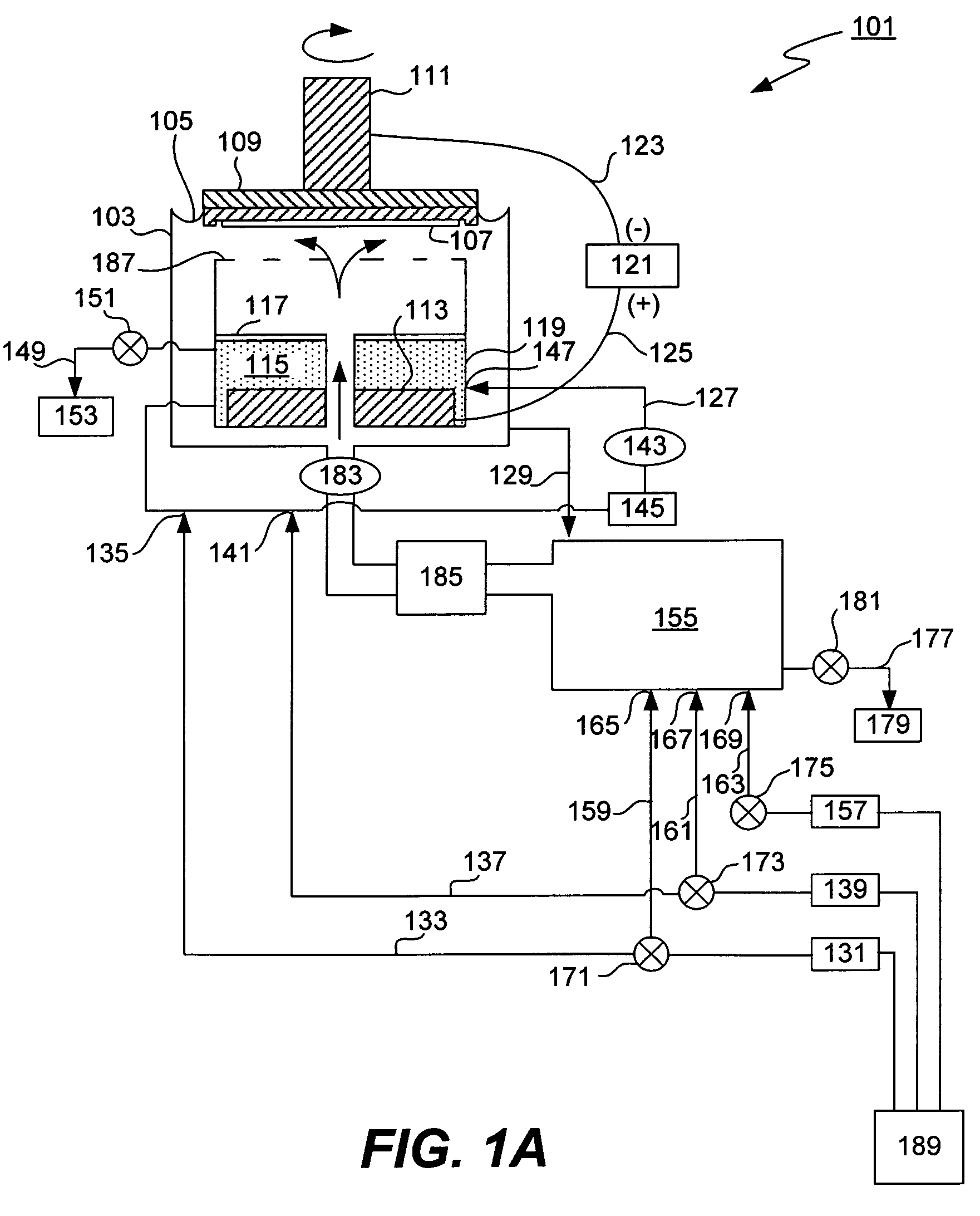

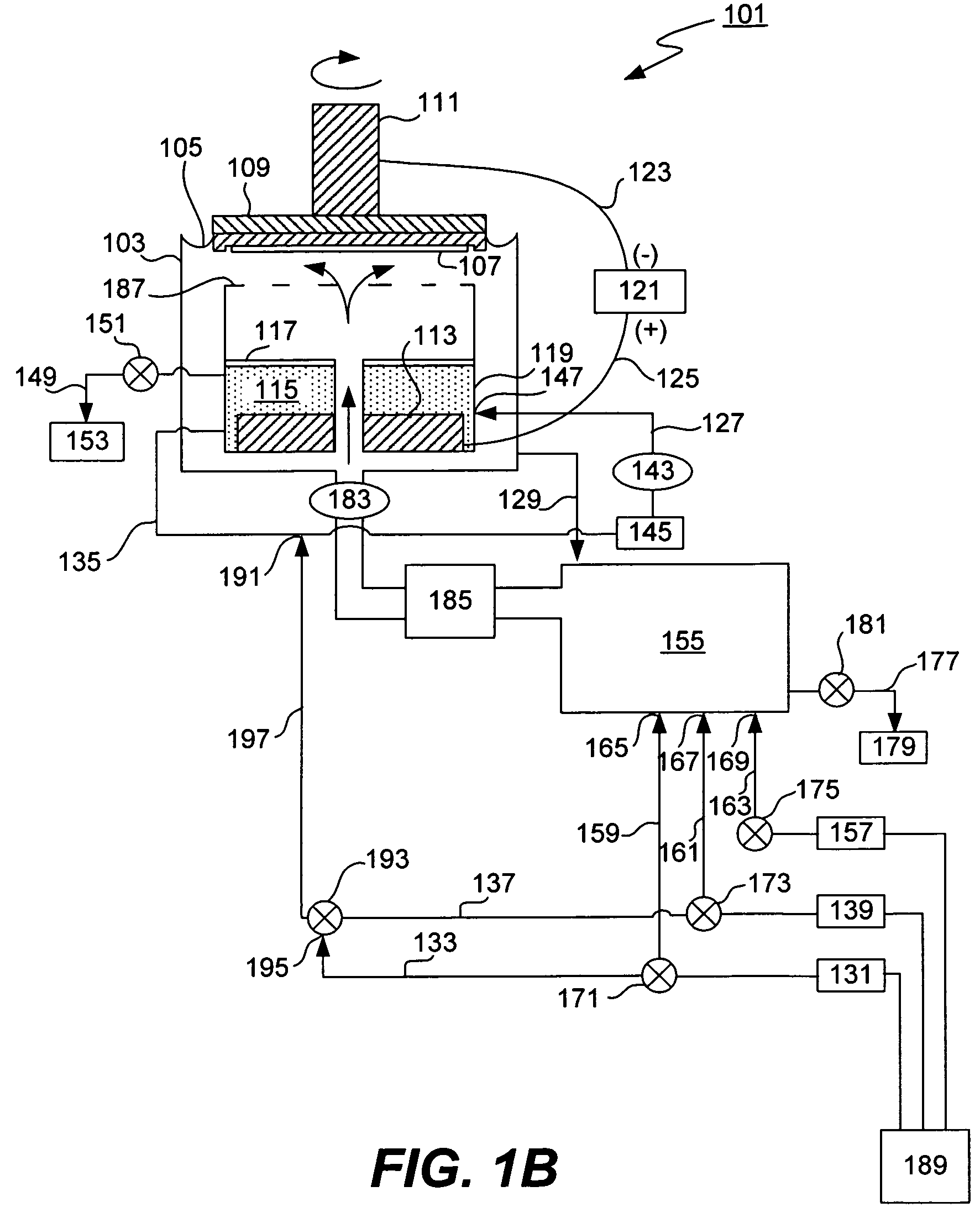

Control of electrolyte composition in a copper electroplating apparatus

ActiveUS8128791B1Prevent precipitationPrevent saltingCellsElectrophoretic coatingsElectrolyte compositionDiluent

In a copper electroplating apparatus having separate anolyte and catholyte portions, the concentration of anolyte components (e.g., acid or copper salt) is controlled by providing a diluent to the recirculating anolyte. The dosing of the diluent can be controlled by the user and can follow a pre-determined schedule. For example, the schedule may specify the diluent dosing parameters, so as to prevent precipitation of copper salt in the anolyte. Thus, precipitation-induced anode passivation can be minimized.

Owner:NOVELLUS SYSTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com