Patents

Literature

5640 results about "Structural stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, structural stability is a fundamental property of a dynamical system which means that the qualitative behavior of the trajectories is unaffected by small perturbations (to be exact C¹-small perturbations).

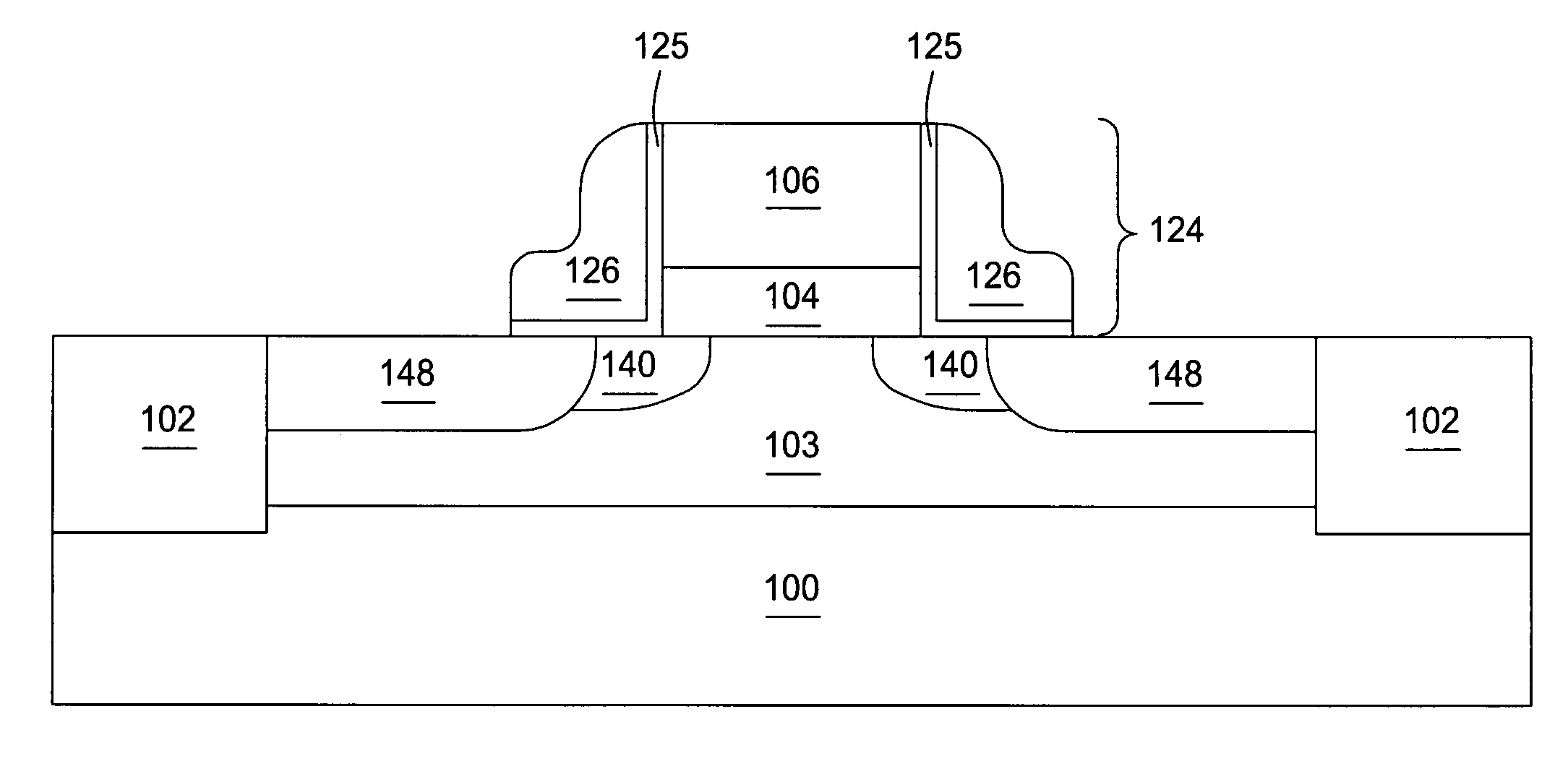

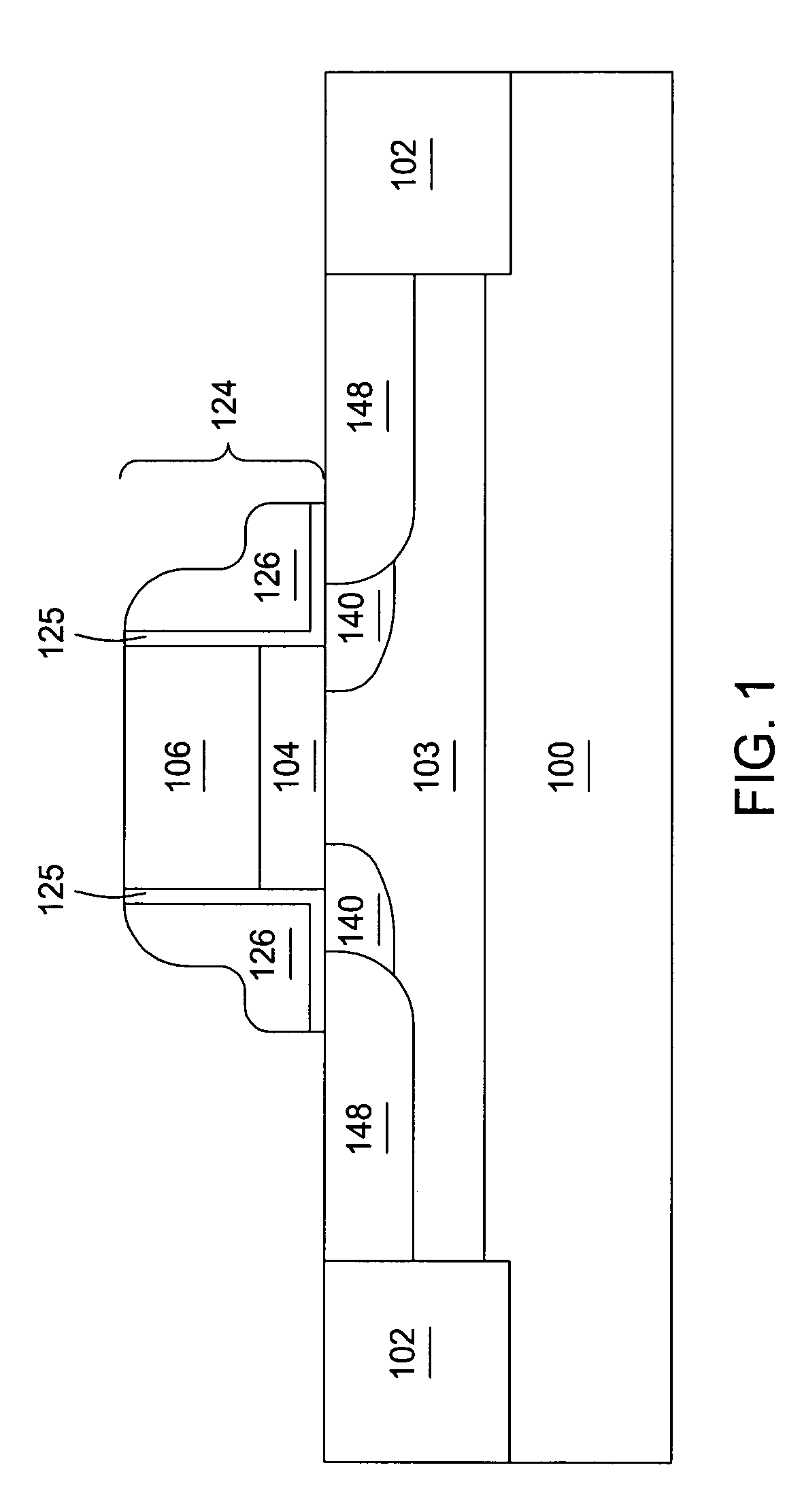

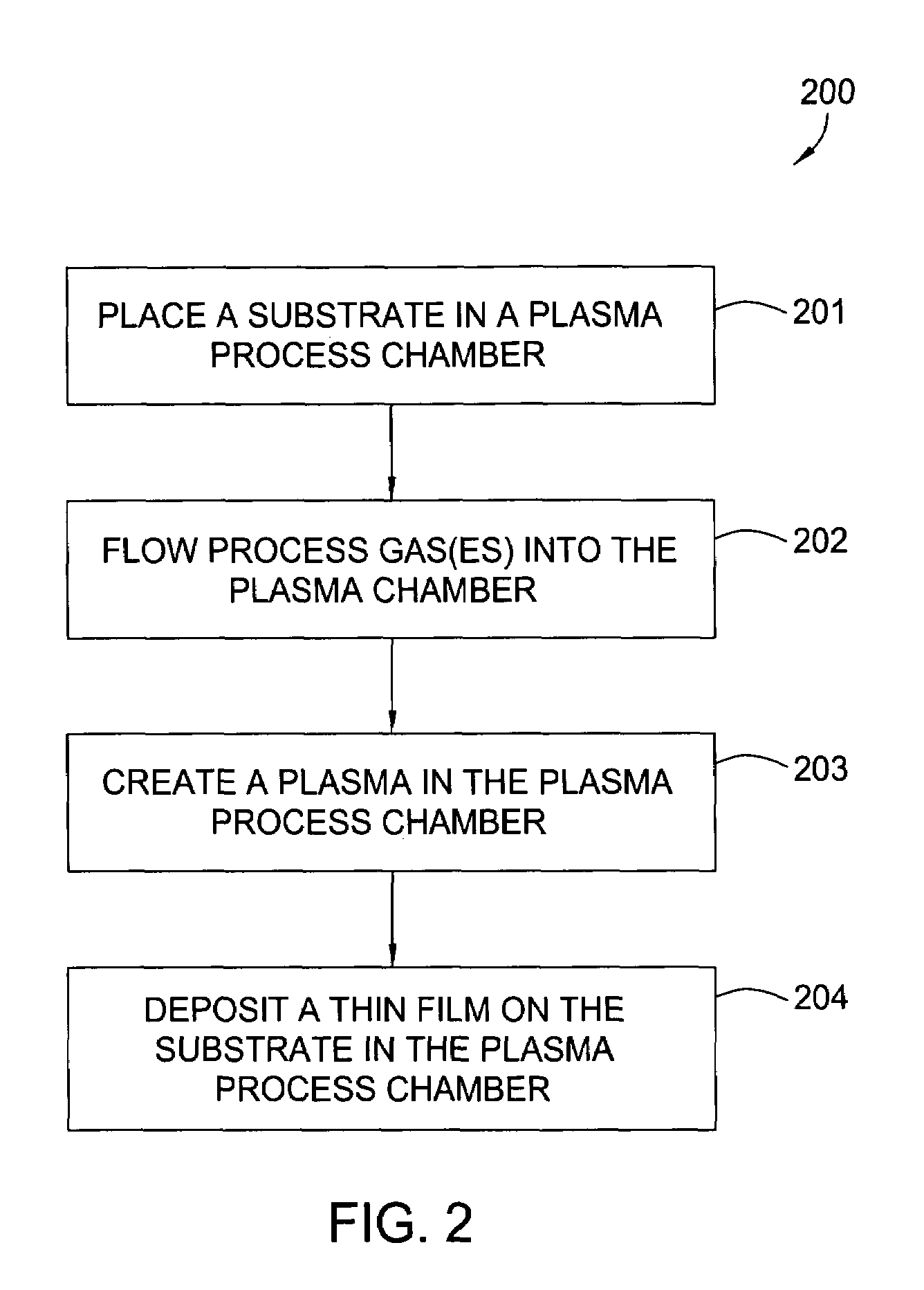

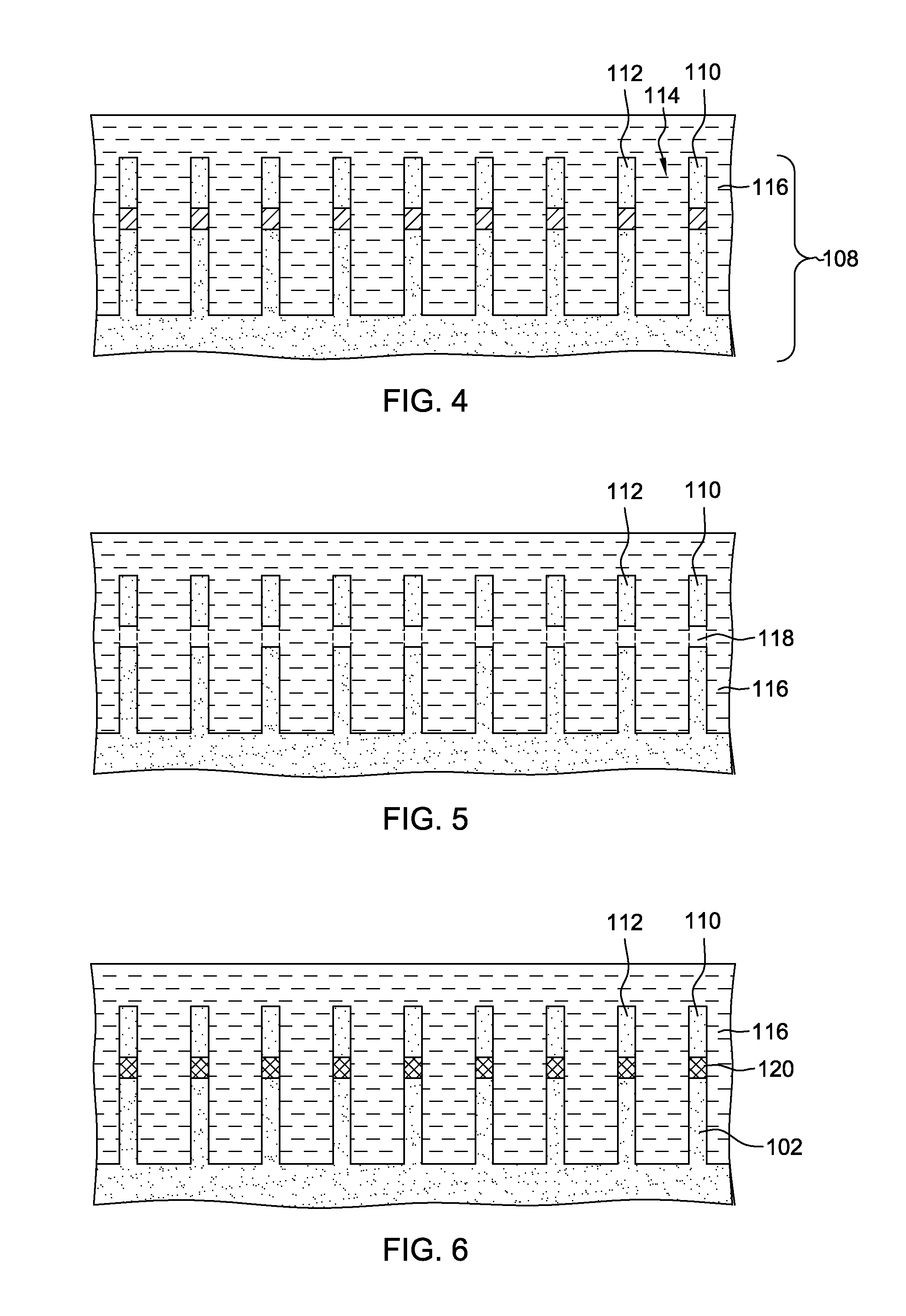

Method for producing gate stack sidewall spacers

A method for forming sidewall spacers on a gate stack by depositing one or more layers of silicon containing materials using PECVD process(es) on a gate structure to produce a spacer having an overall k value of about 3.0 to about 5.0. The silicon containing materials may be silicon carbide, oxygen doped silicon carbide, nitrogen doped silicon carbide, carbon doped silicon nitride, nitrogen doped silicon oxycarbide, or combinations thereof. The deposition is performed in a plasma enhanced chemical vapor deposition chamber and the deposition temperature is less than 450° C. The sidewall spacers so produced provide good capacity resistance, as well as excellent structural stability and hermeticity.

Owner:APPLIED MATERIALS INC

Two-dimensional fiber cloth reinforced composite material and preparation method thereof

InactiveCN101224989AImprove fracture toughnessImprove use reliabilityMetal powderStructural stability

The invention discloses a two-dimensional fiber cloth reinforced ceramics based composite material and the preparation technique, which adopts the two-dimensional fiber cloth as the reinforcing phase and the ceramic powder or the refractory metal powder as the stuffing, and the carbon and the carborundum as the base. The process steps are following: first the sizing agent with different ceramic powder and metal powder is coated on the two-dimensional fiber cloth, and then overlapping, puncturing and repeated densification are carried out. The preparation method has the advantages of lowering preparation cost and shortening preparation cycle, and the two-dimensional fiber cloth reinforced ceramics based composite material has the advantages of high shear strength between layers, structural stability and high reliability. The types of fiber cloth and the base can be adjusted and optimized in a wider range according to the applications, so as to be applicable for different fields.

Owner:NAT UNIV OF DEFENSE TECH

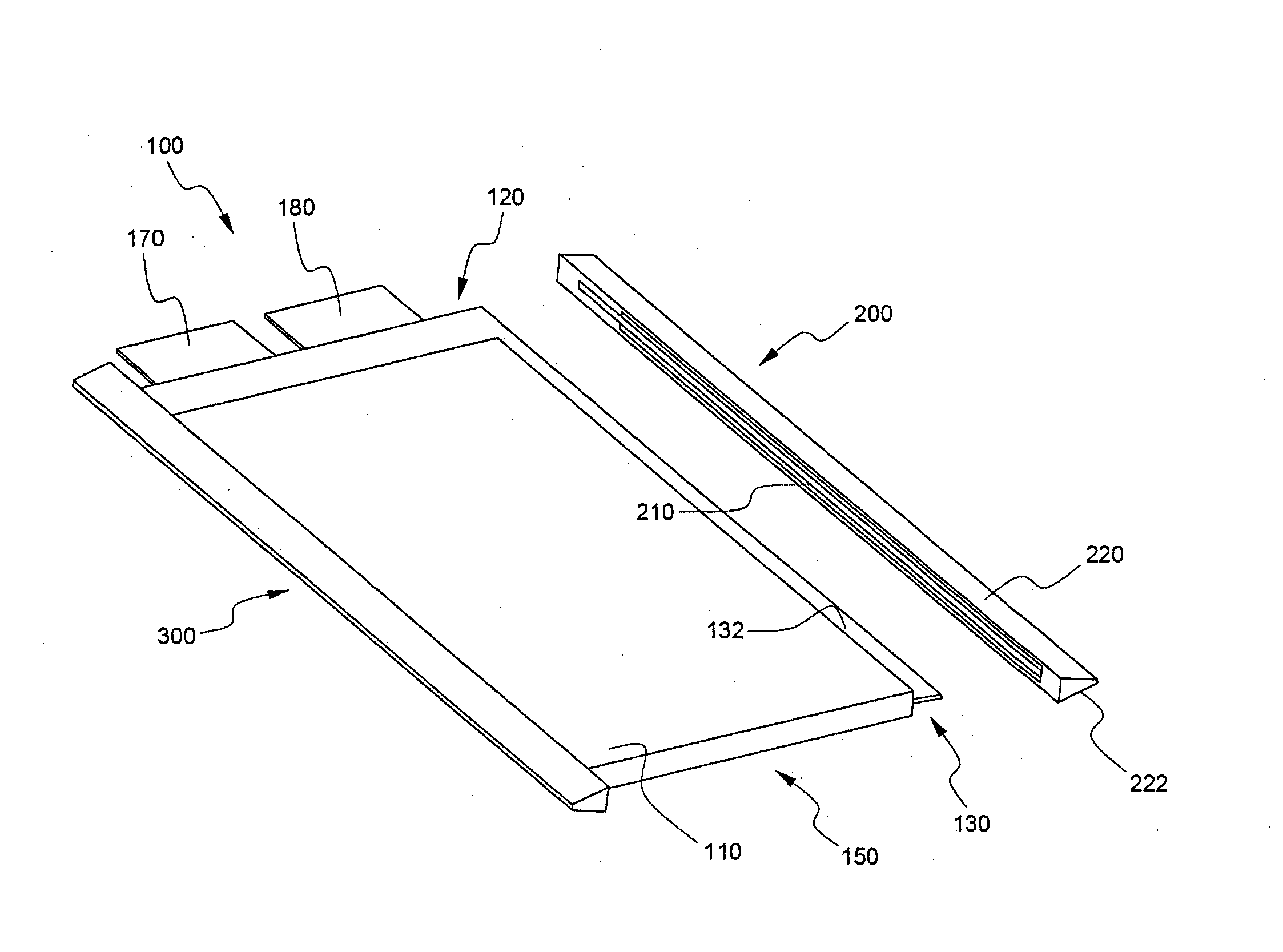

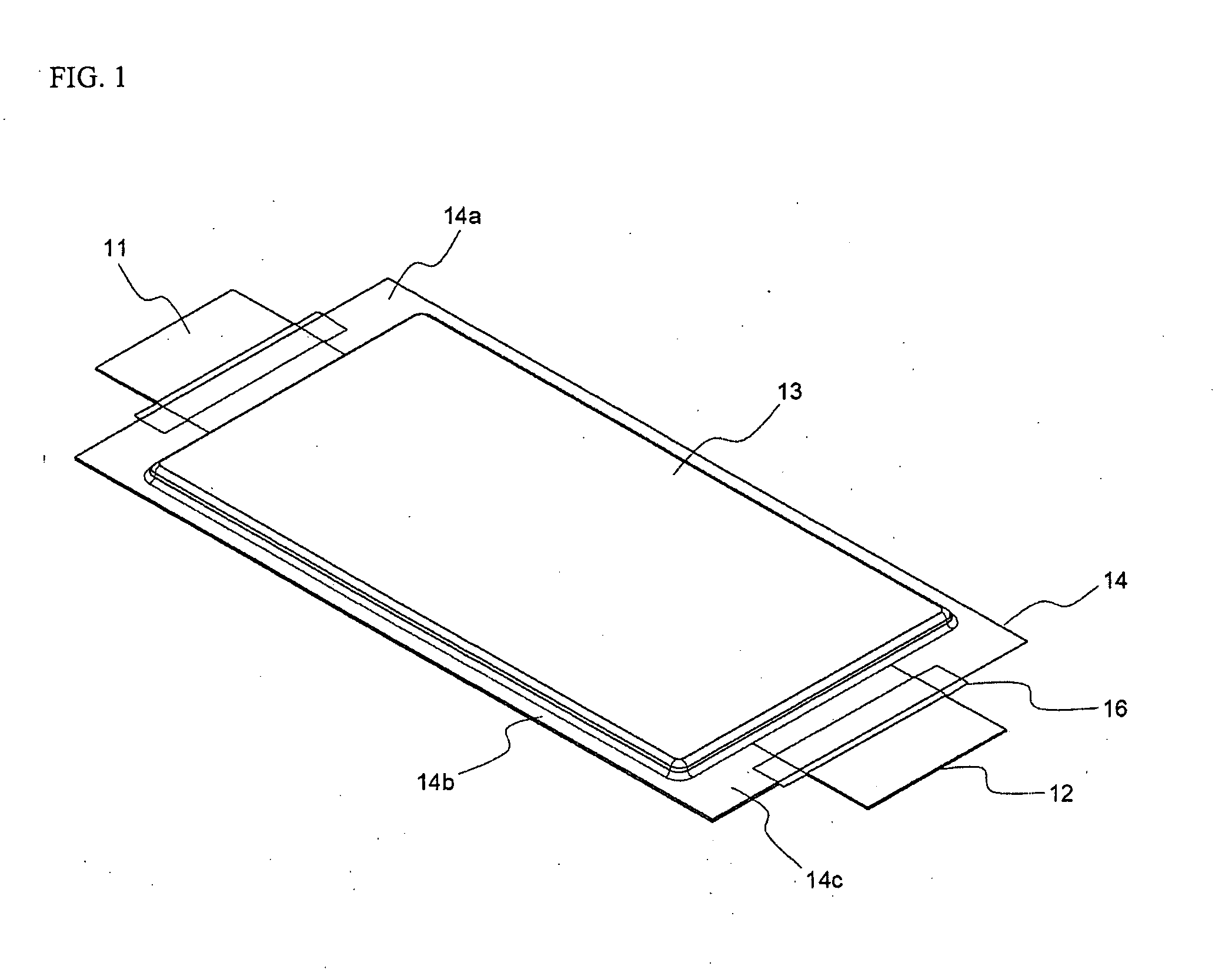

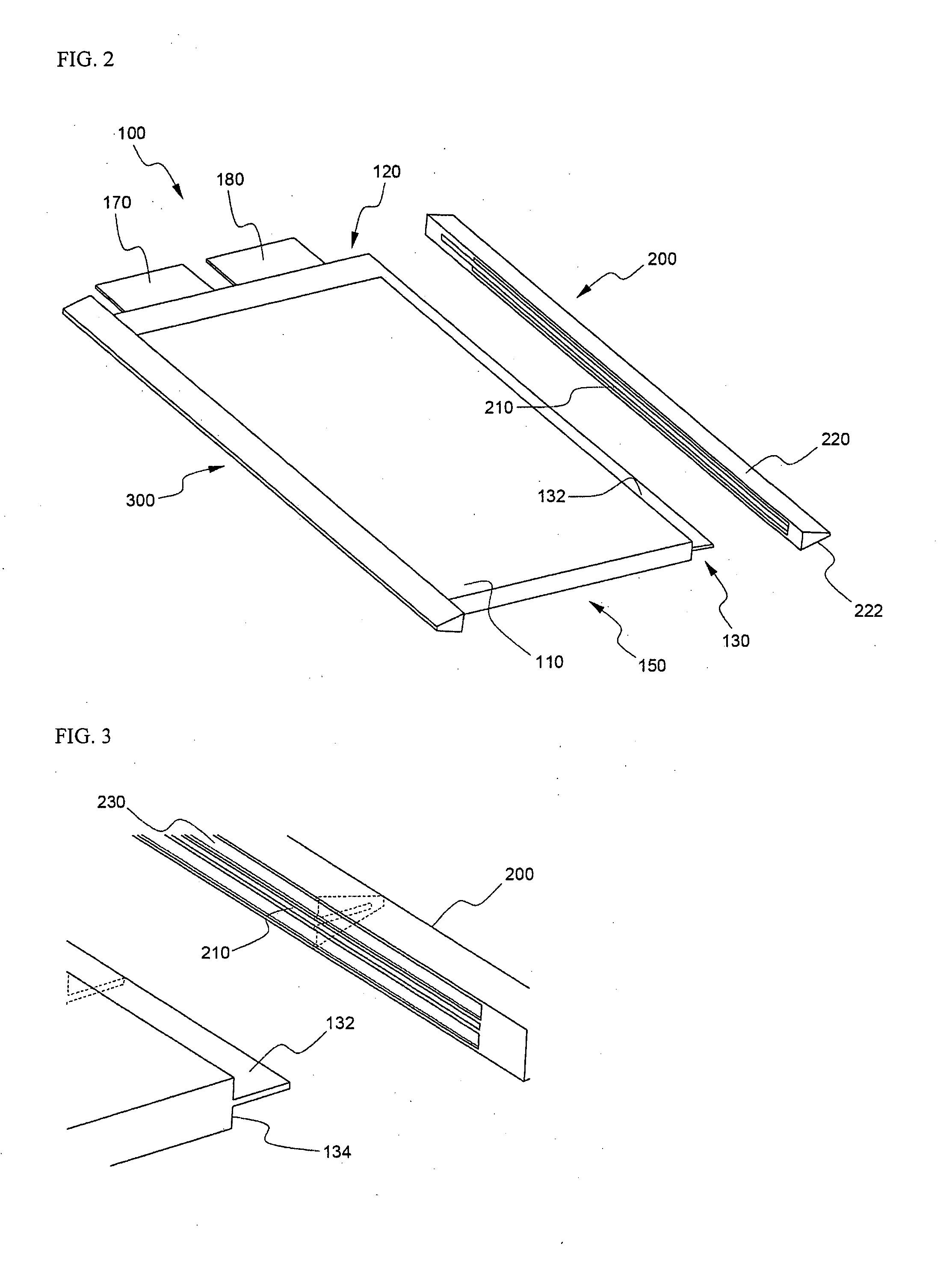

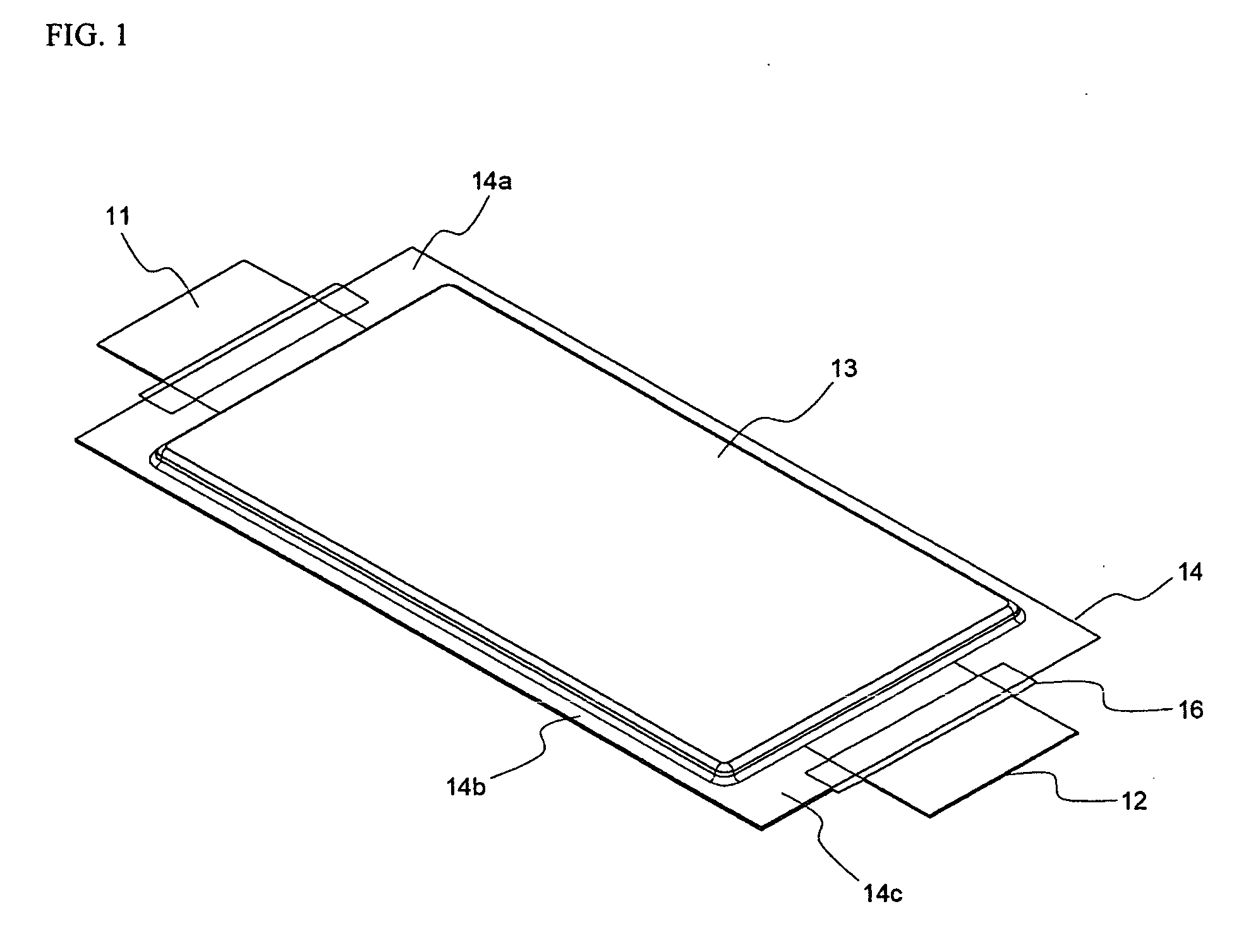

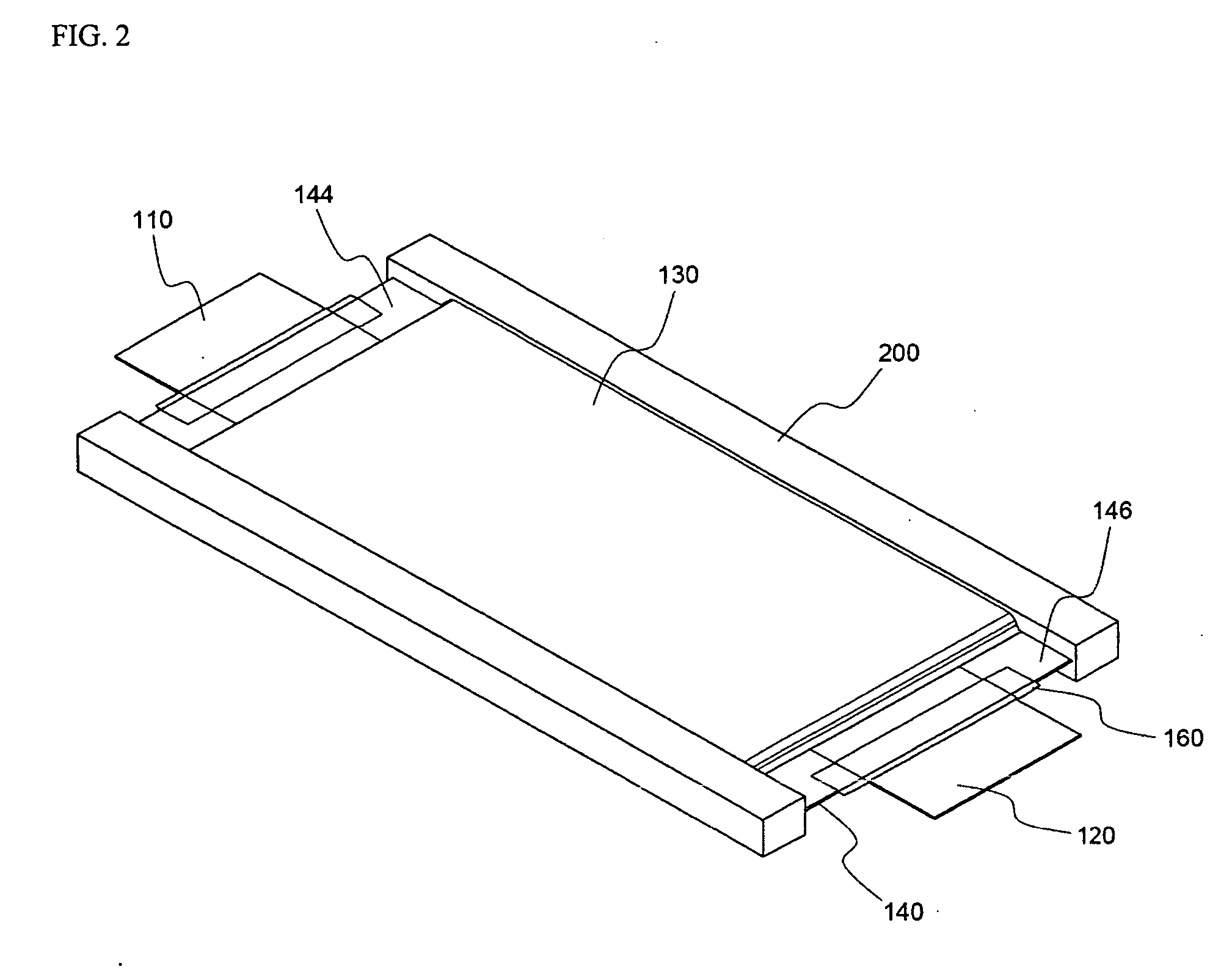

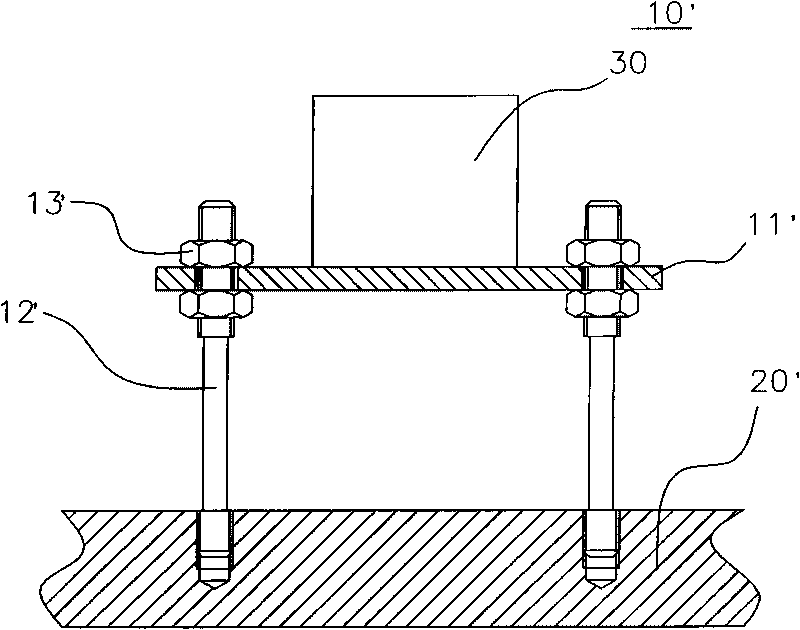

Secondary battery and battery module having the same

ActiveUS20070207377A1Increase productionLarge capacityLarge-sized flat cells/batteriesSmall-sized cells cases/jacketsElectricityElectrical battery

Disclosed herein are a secondary battery, which is formed in the shape of a plate and has an electrode assembly mounted in a battery case made of a laminated sheet including a metal layer and a resin layer, wherein the secondary battery is constructed in a structure in which independent coupling type frame members are mounted to the outside part of a sheathing member serving as the battery case, and a medium- or large-sized battery module including the same as a unit cell. Consequently, the secondary battery has a high mechanical strength and a large sealing force. Furthermore, the electrical connection is accomplished without bending the electrode leads. Also, the battery module, which is constructed with the secondary battery as a unit cell, can be manufactured with a compact structure and a relatively light weight. Furthermore, the assembly process of the battery module is greatly simplified. The structural stability of the battery module according to the present invention is very high, and therefore, the battery module can be preferably used as a power source for electric vehicles, hybrid electric vehicles, electric motor cycles, and electric bicycles.

Owner:LG ENERGY SOLUTION LTD

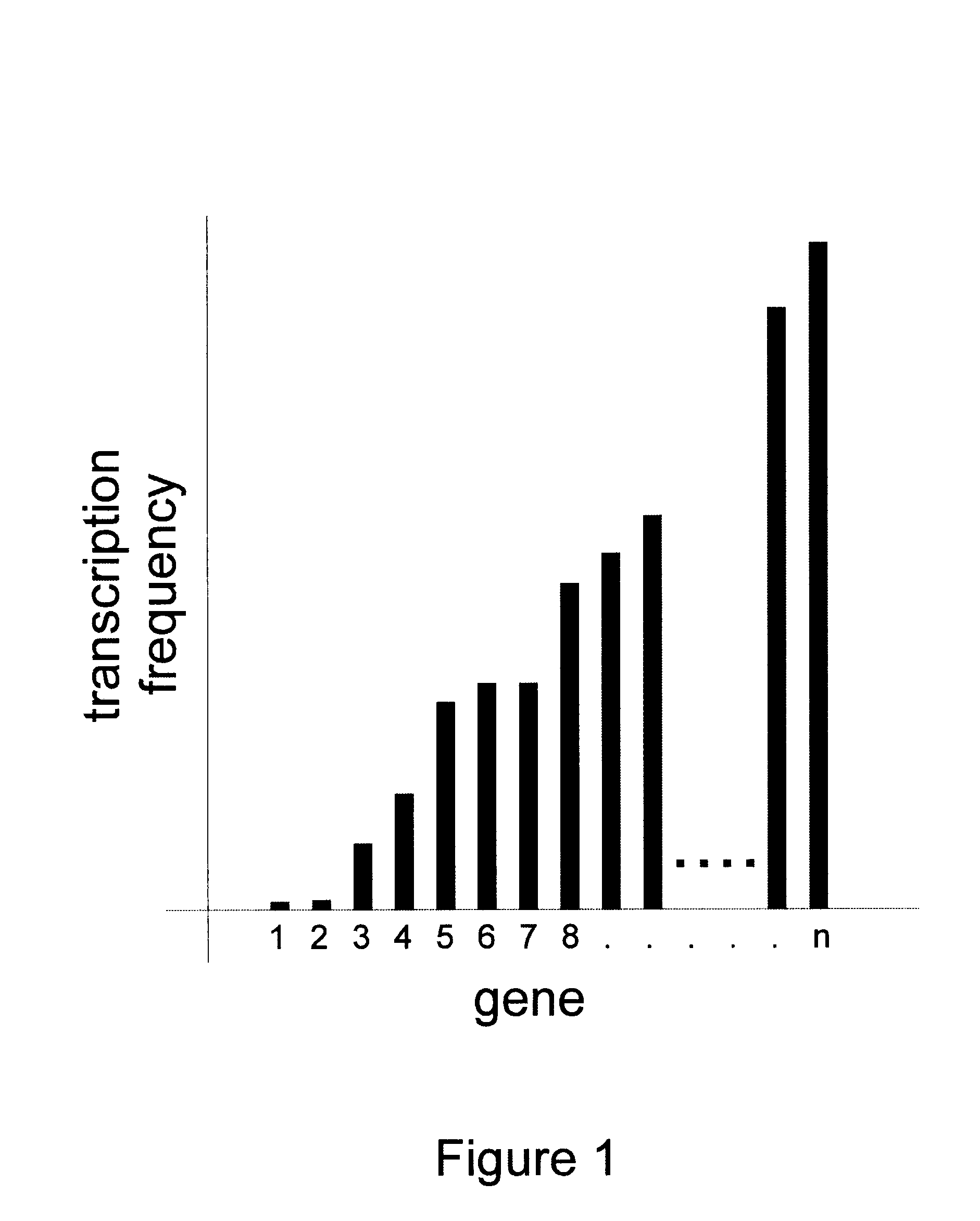

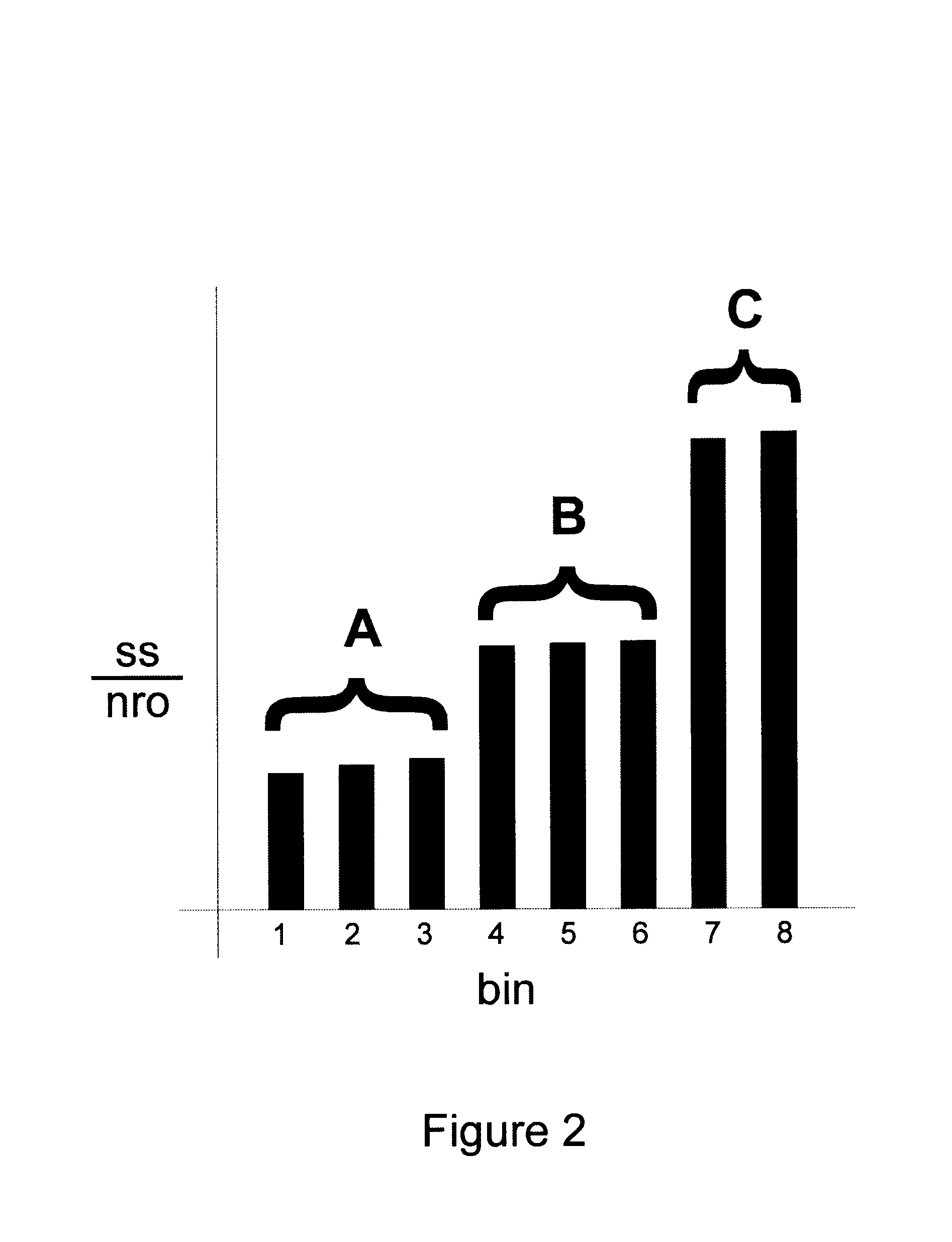

Methods for gene array analysis of nuclear runoff transcripts

InactiveUS6617112B2Rapid and efficient and extensive analysisAccurate predictionSugar derivativesMicrobiological testing/measurementStructure functionOrganism

Methods for determining transcription rate of mRNA in eukaryotic cells using nuclear runoff transcription where labeled RNA molecules are hybridized against an array of at least 500 nucleic acid molecule probes representing at least part of the genome of the native eukaryotic organism to identify the quantity of nascent mRNA transcripts in said cells. The method can be used to simultaneously identify the quantity of a large number of mRNA transcripts. A rate of degradation for distinct mRNA in a eukaryotic cell rate is determined by comparing a steady state mRNA with nuclear runoff mRNA. Steady state to nuclear runoff ratios are used to determine gene and mRNA structure function relations that leads to gene expression and mRNA stability, predict structural determinants for mRNA stability and predict regulatory motifs for transcription rates. Methods of constructing recombinant organisms with enhanced stability for mRNA expressed from a gene of interest comprise introducing into the genome of an organism a gene containing one or more sequence elements that confer structural stability on mRNA transcribed from said gene.

Owner:MONSANTO TECH LLC

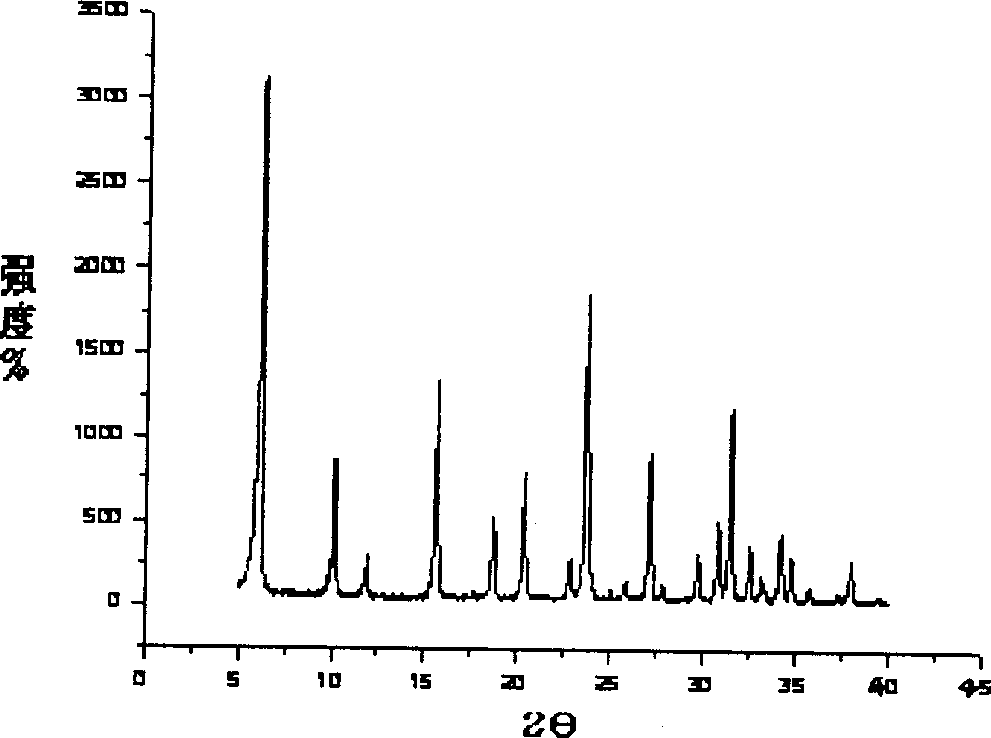

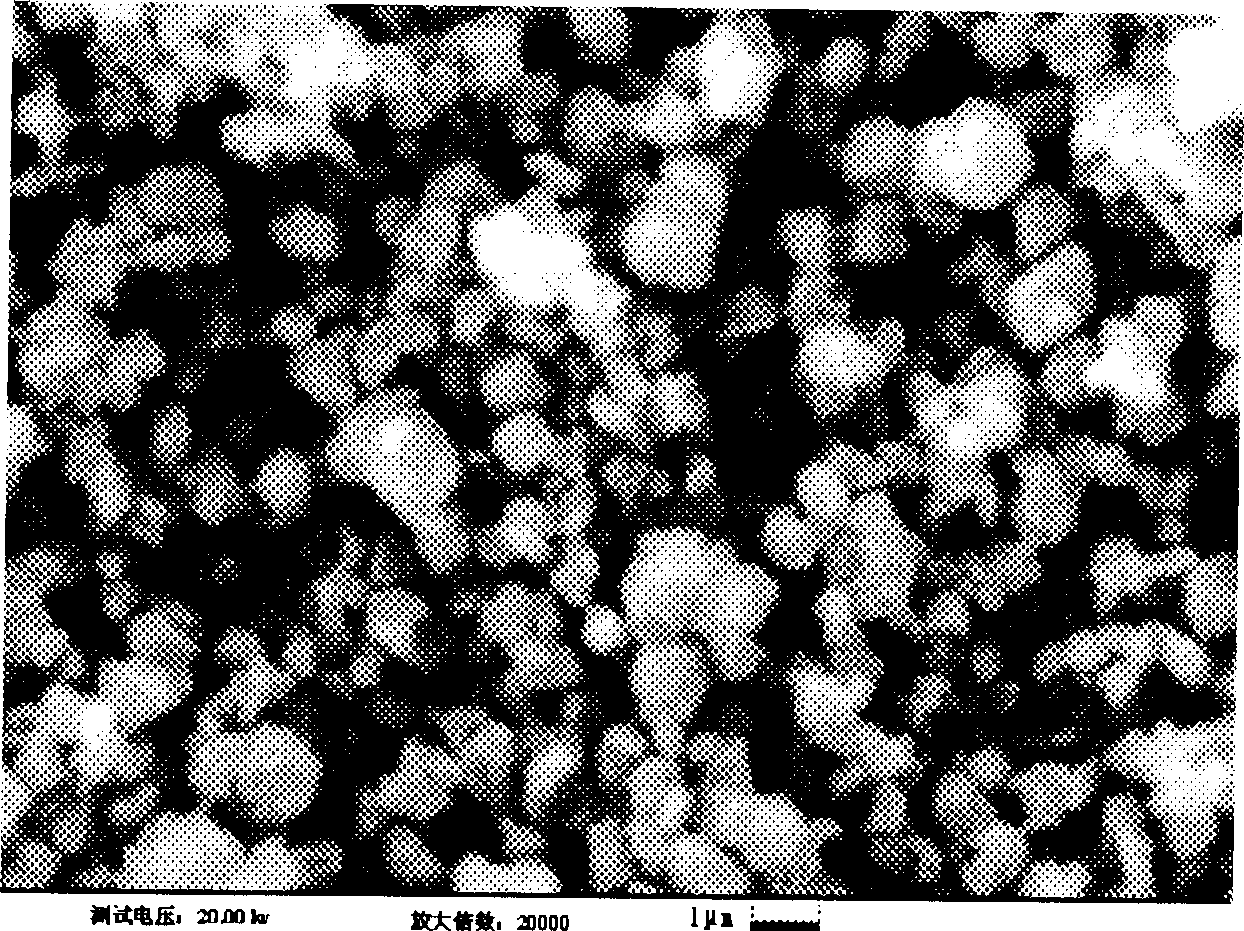

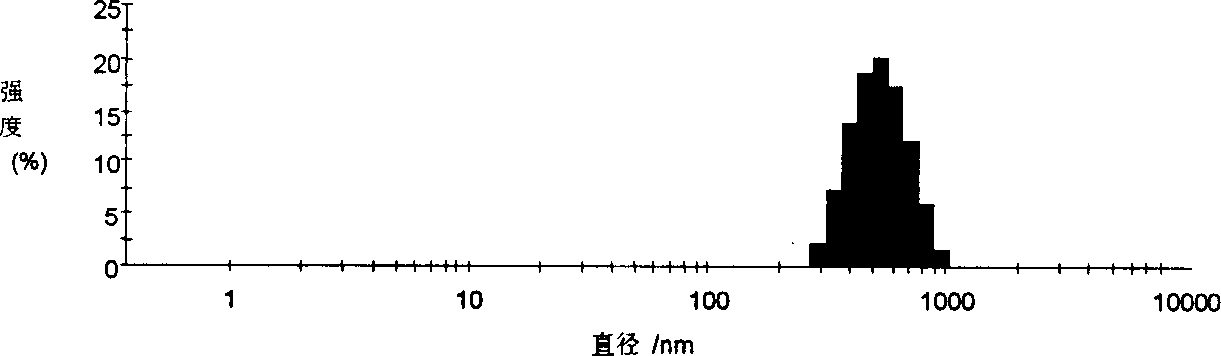

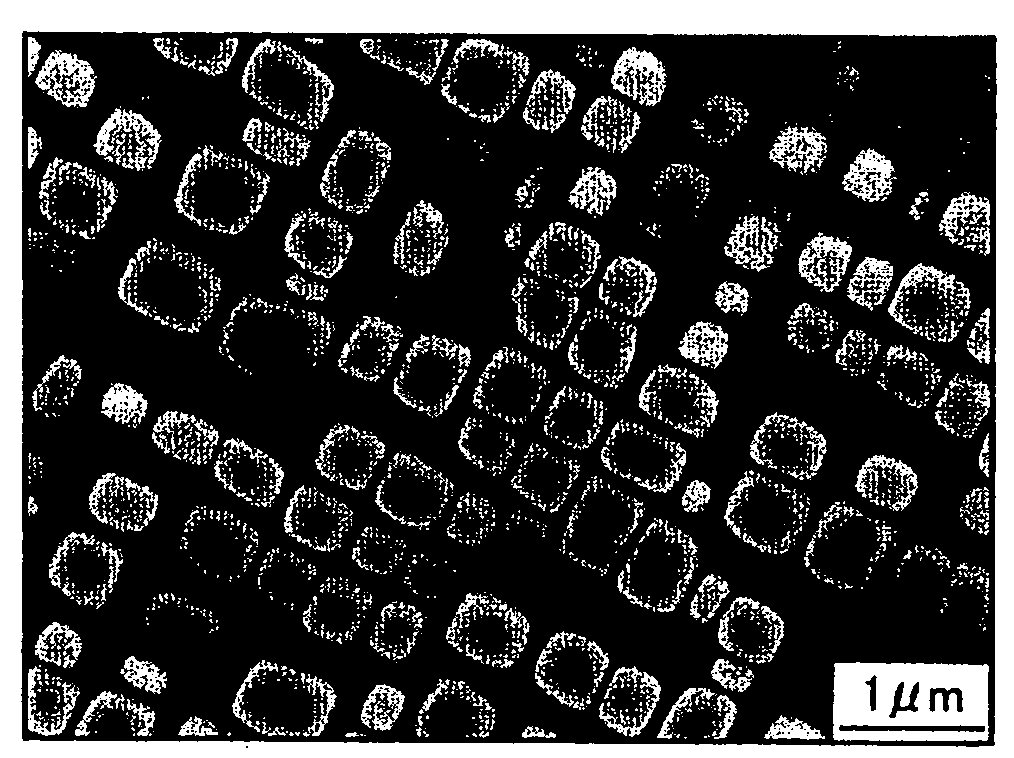

High silicon aluminium ratio small crystal NaY molecular sieve

ActiveCN1785807ALow costReduce manufacturing costFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The present invention provides a high silica-alumina ratio small crystal grain NaY molecular sieve. The skeleton silica-alumina ratio of NaY molecular sieve, namely. SiO2 / Al2O3 mole ratio is 6.0-7.0, and the average grain size is 300-800 nm. It can be made up by adopting non-template agent direct synthesis process. Its preparation method includes the following steps: firstly, stirring and ageing for 0.5-48 hr at 15-60deg.C to obtain crystallization guide agent, then mixing said guide agent, water, silicon source and aluminium source to obtain reaction mixture, then crystallizing said mixture at twice, first steps is dynamic crystallization and second step is static crystallization, finally, filtering, washing and drying so as to obtain the invented high silica-alumina ratio small crystal grain NaY molecular sieve whose relative crystallinity is greater than 80%.

Owner:PETROCHINA CO LTD +1

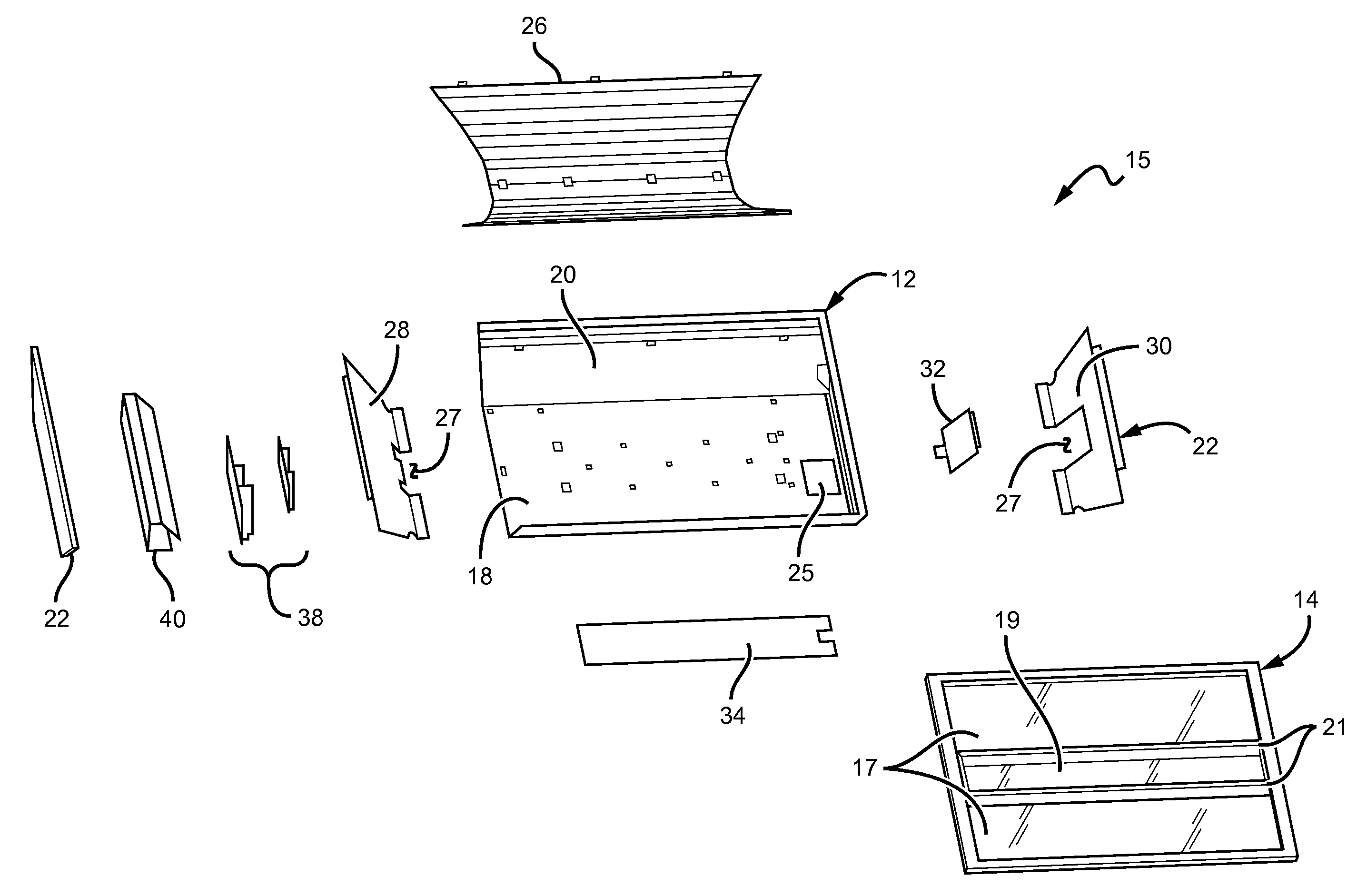

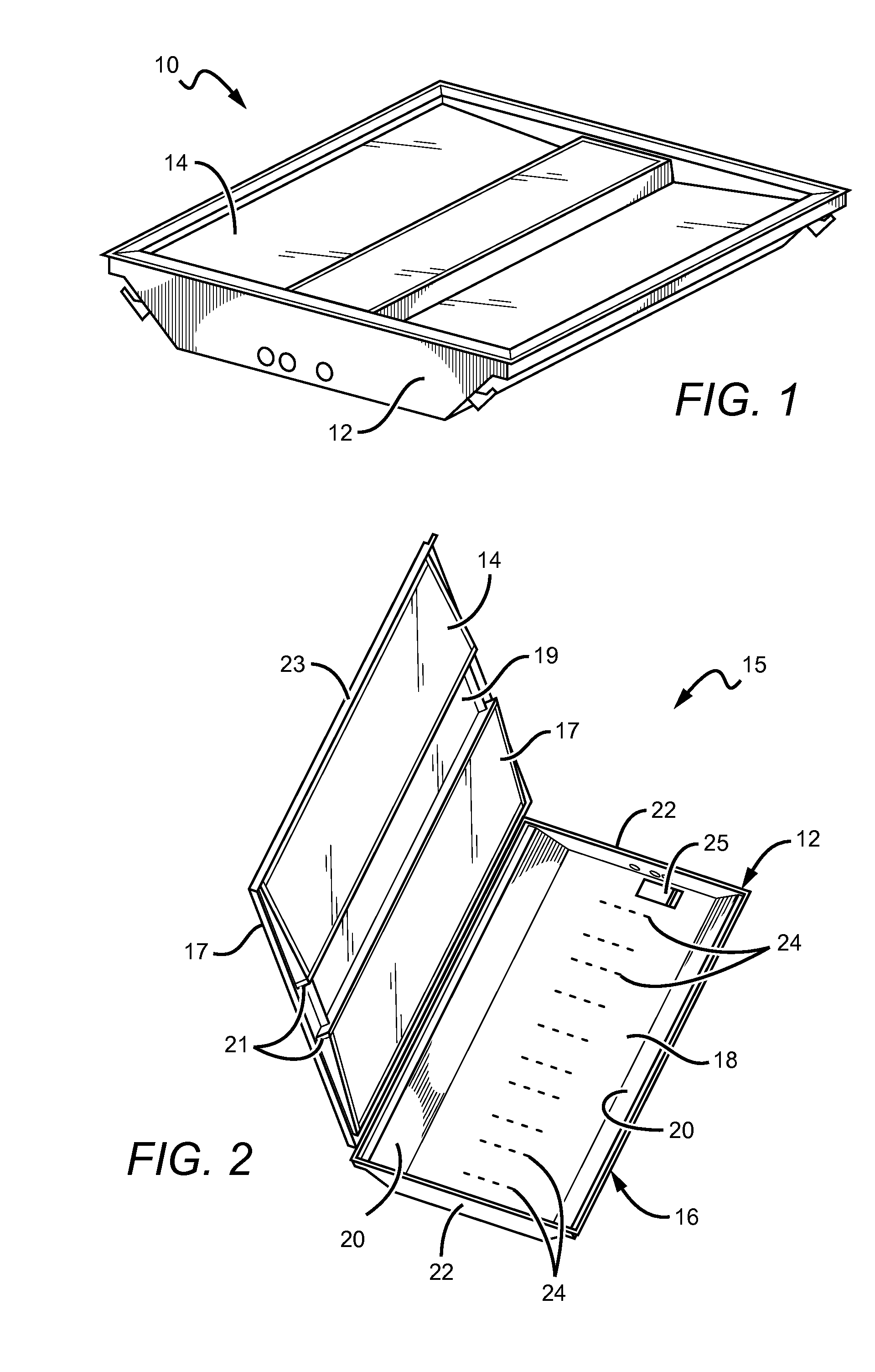

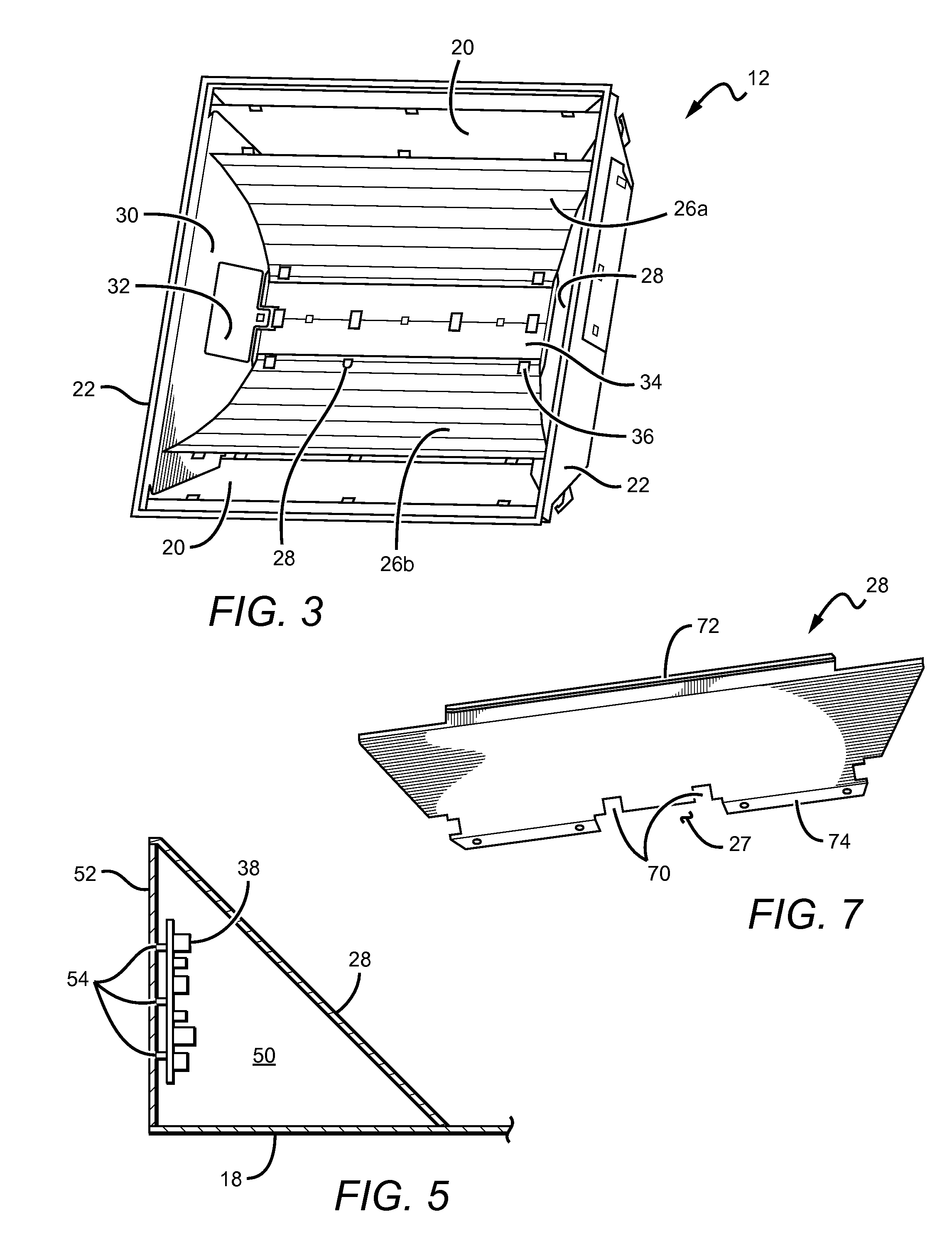

Standardized troffer fixture

A direct troffer-style fixture for solid state light sources and pan structures for use in these fixtures. The fixture comprises a door frame assembly that is attached to the pan. The pan housing is defined by a base and two angled side walls. End caps are attached to the side walls. End reflectors extend at an angle away from the end caps and attach to the base. The end caps, the end reflectors, and the base define compartments at both ends of the housing in which components can be housed. A light board is attached to the base using alignment holes in the base and cutout portions of the end reflectors. The multifunctional end reflectors retain elements within the compartments, provide added structural stability to the pan, aid in aligning a light board, and they reflect light that impinges on them toward the open end of the fixture.

Owner:IDEAL IND LIGHTING LLC

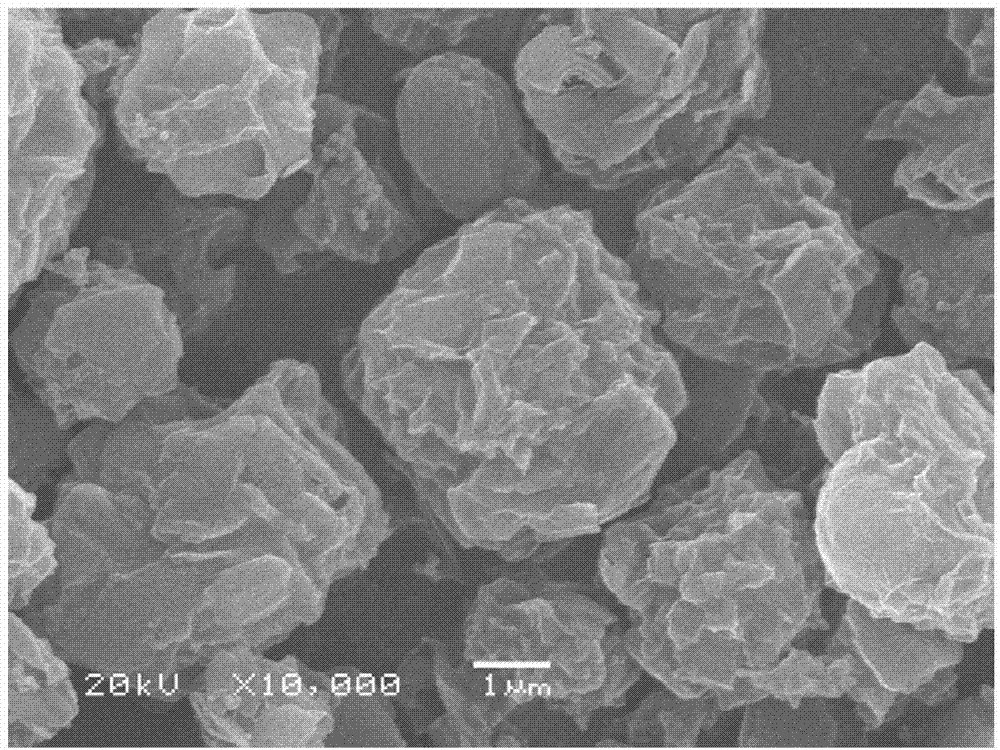

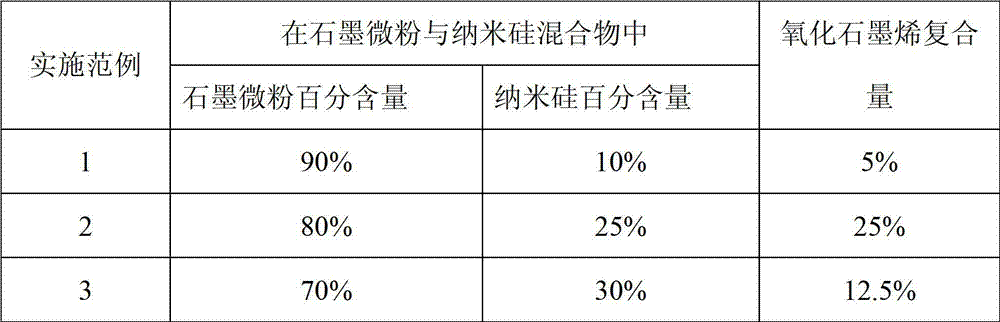

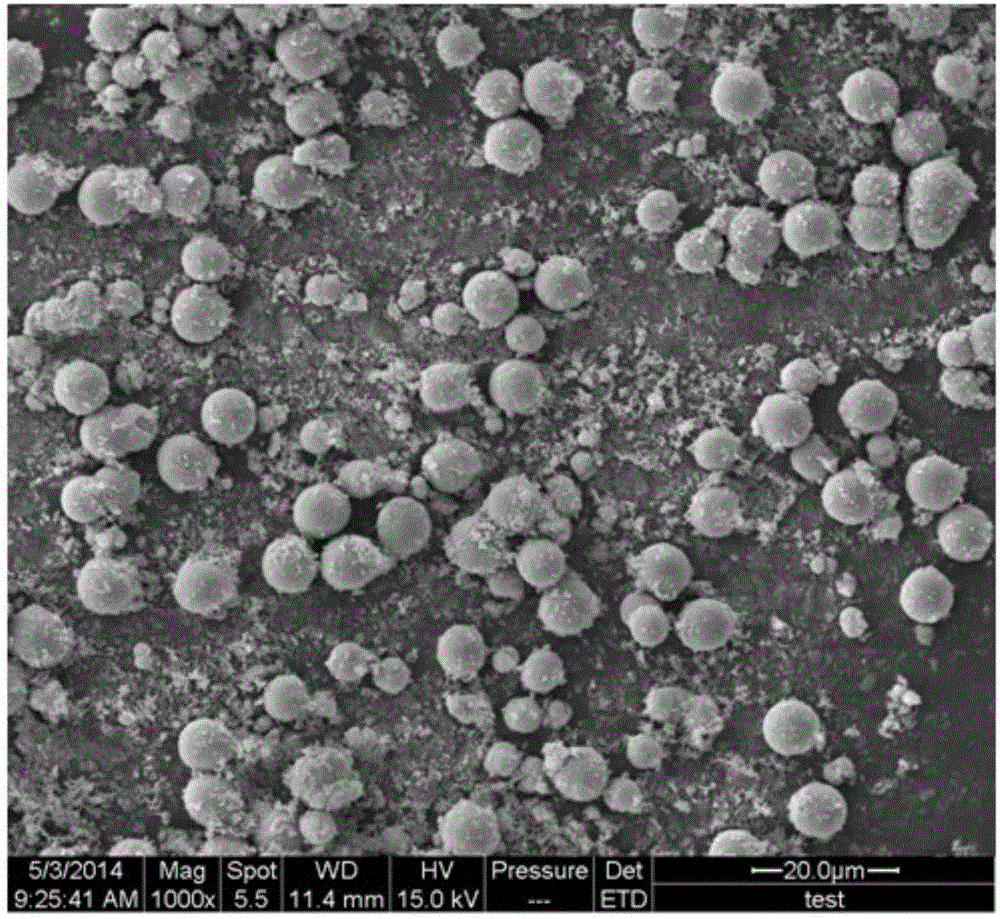

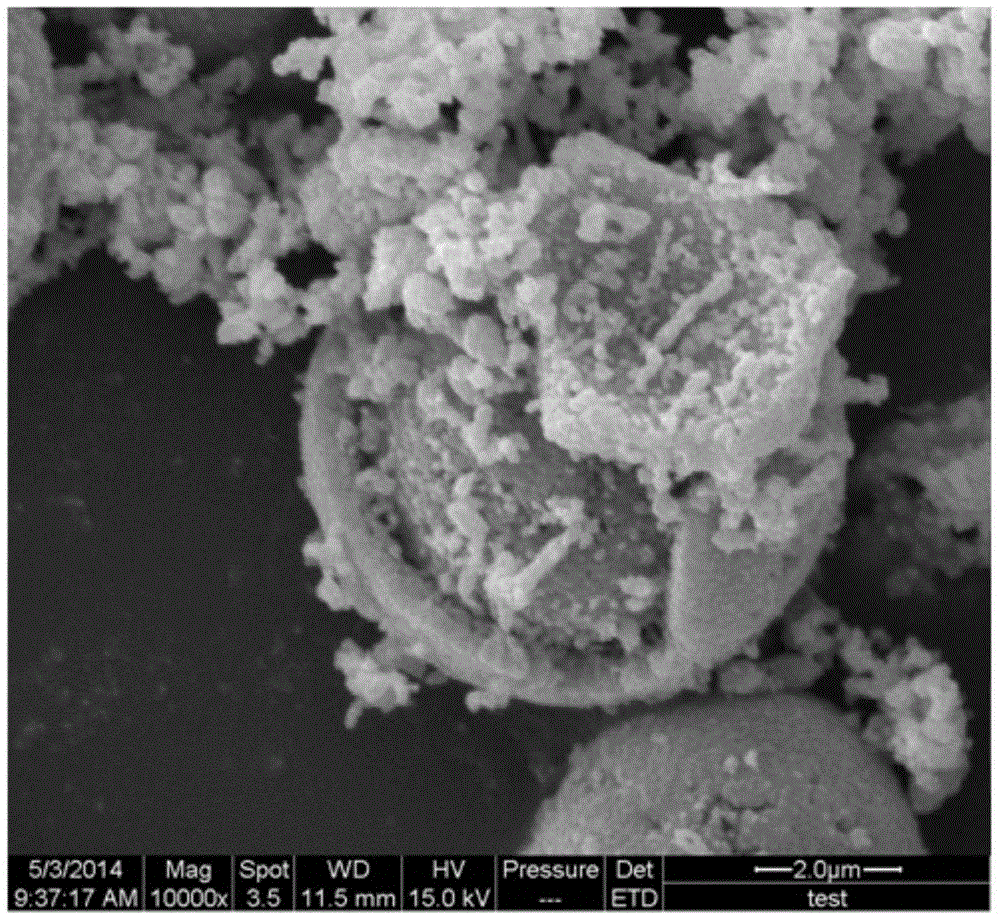

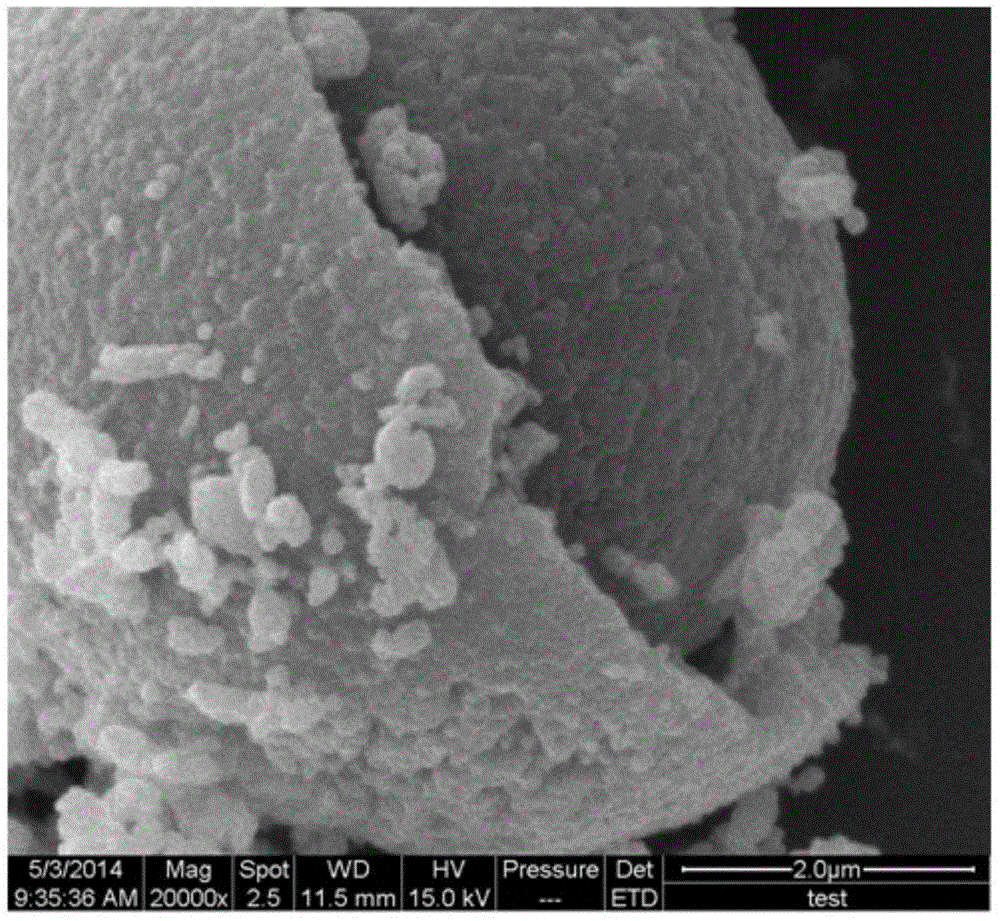

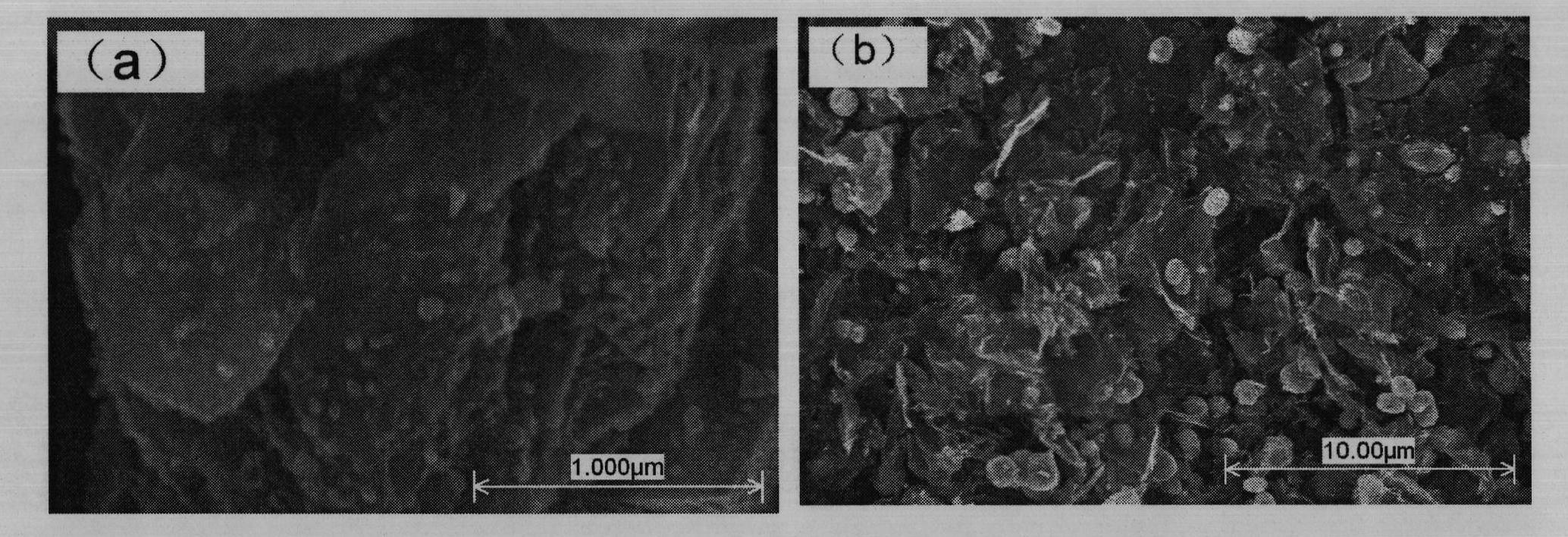

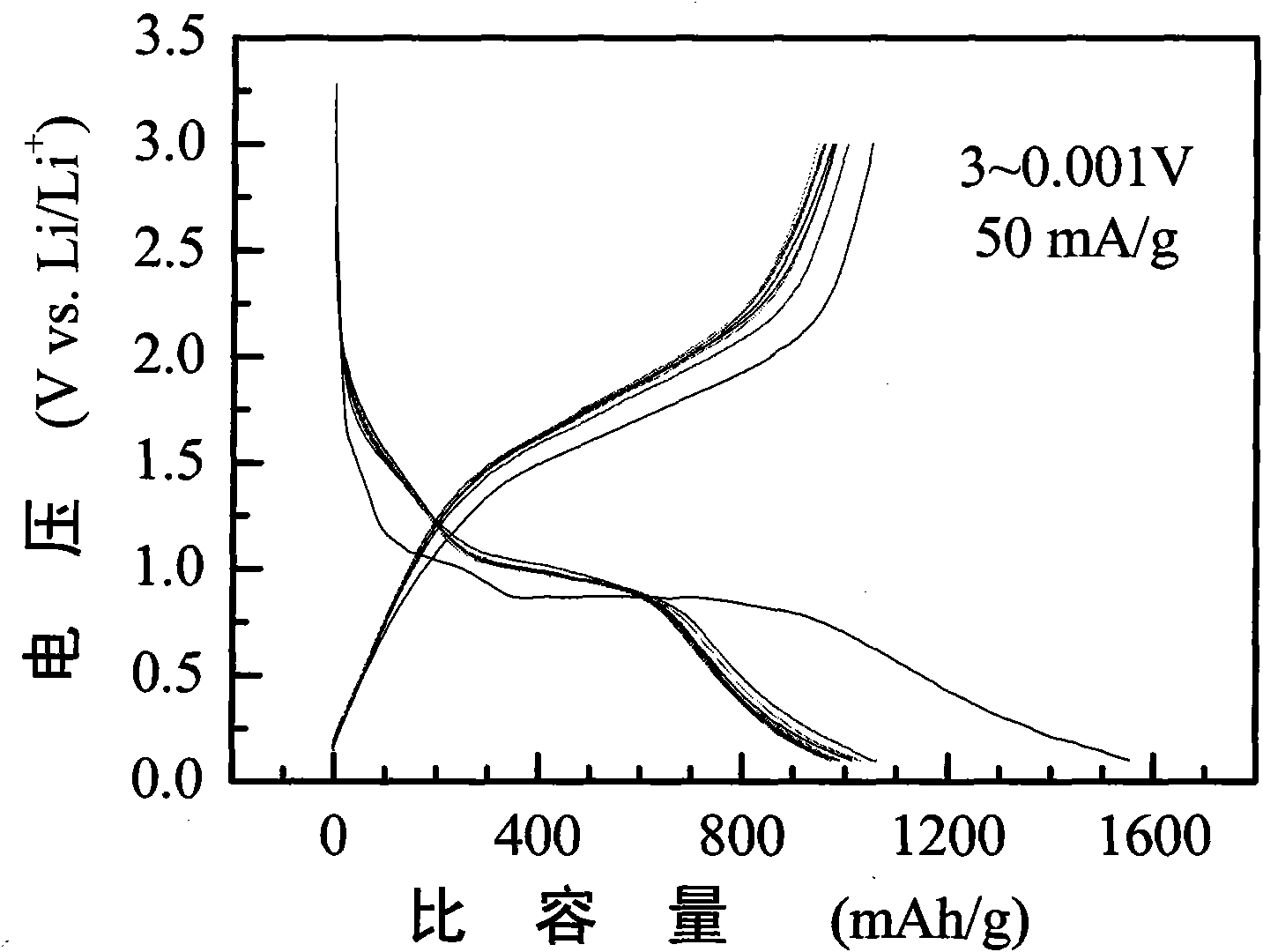

Preparation method of silicon and carbon-coated graphene composite cathode material

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

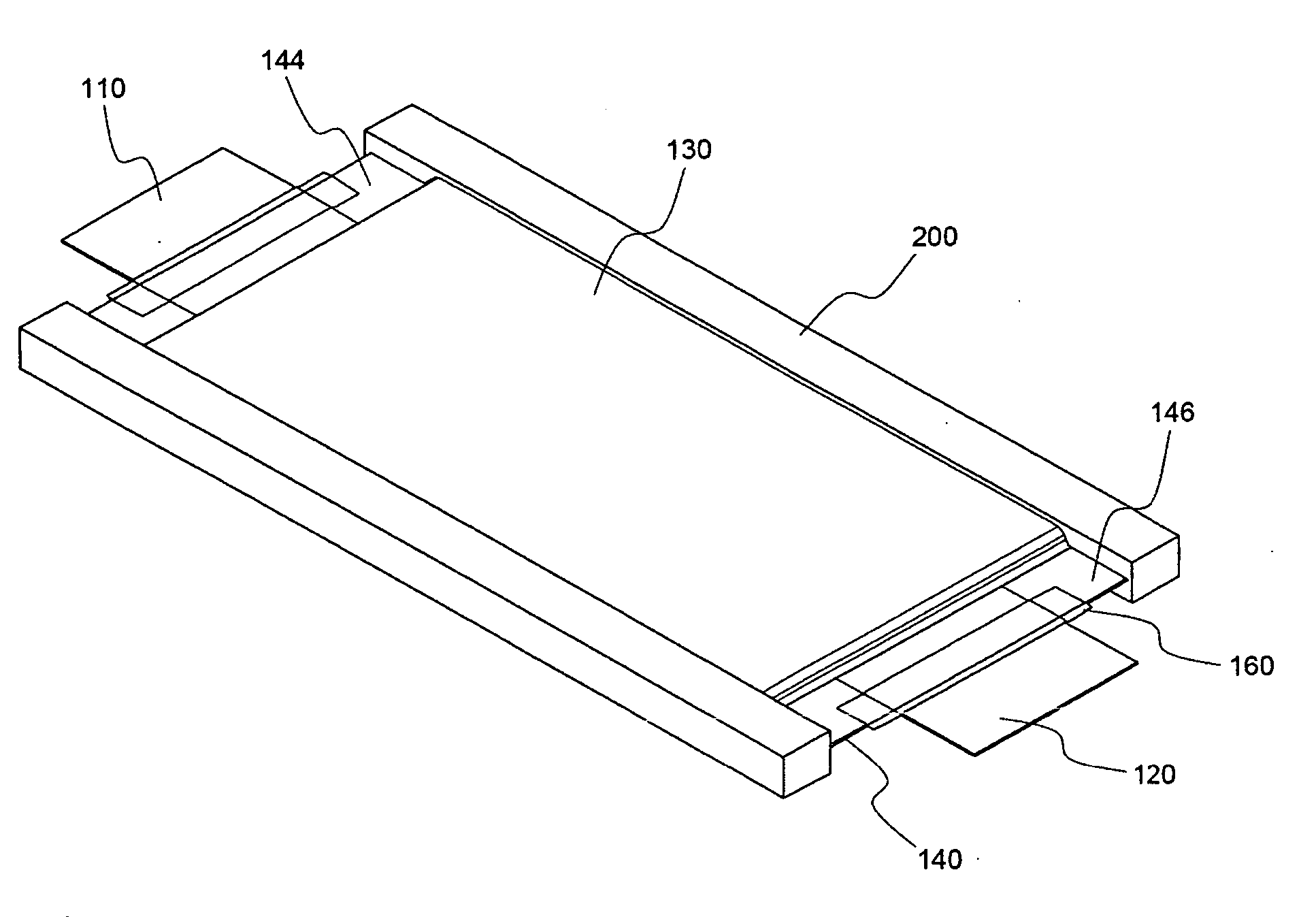

Secondary battery of novel structure and battery pack having the same

ActiveUS20060286450A1Increase productionLarge capacityLarge-sized flat cells/batteriesSmall-sized cells cases/jacketsShell moldingElectric vehicle

Disclosed herein are a secondary battery including an electrode assembly for charging and discharging mounted in a sheathing member including a metal layer and a resin layer, wherein the secondary battery further includes a secondary battery having a molding part of a predetermined thickness at least partially formed at the outside of a sheathing member, preferably, at a sealing region of the sheathing member, and a medium- or large-sized battery pack including the same. The molding part is formed at the outside of the sheathing member of the secondary battery. Consequently, the secondary battery according to the present invention has high mechanical strength, and therefore, it is possible to construct a battery pack without using addition members, such as cartridges. When the molding part is formed at the sealing region, which is weak, the molding part increases the mechanical strength and the sealing force of the secondary battery. Consequently, a battery pack including the secondary batteries as unit cells can be manufactured generally in a compact structure and with relatively small weight, and the assembly process of the battery pack is greatly simplified. The battery pack according to the present invention has high structural stability. Consequently, the battery pack can be preferably used as a power source for electric vehicles, hybrid electric vehicles, electric motorcycles, and electric bicycles.

Owner:LG ENERGY SOLUTION LTD

Reflection layer or semi-transparent reflection layer for use in optical information recording media, optical information recording media and sputtering target for use in the optical information recording media

InactiveUS20020150772A1Improve stabilityIncreased durabilityCellsVacuum evaporation coatingRare-earth elementAlloy

A novel reflective layer or semi-transparent reflective layer for use in optical information recording media with suppressed growth of Ag crystal grains and having a high reflectivity and excellent structural stability comprising an Ag based alloy containing from 0.1 to 3.0% of Nd in total of at least one element selected from the group consisting of Nd, Sn and Ge; and / or containing 0.1% or more of at least one rare earth element.

Owner:KOBE STEEL LTD

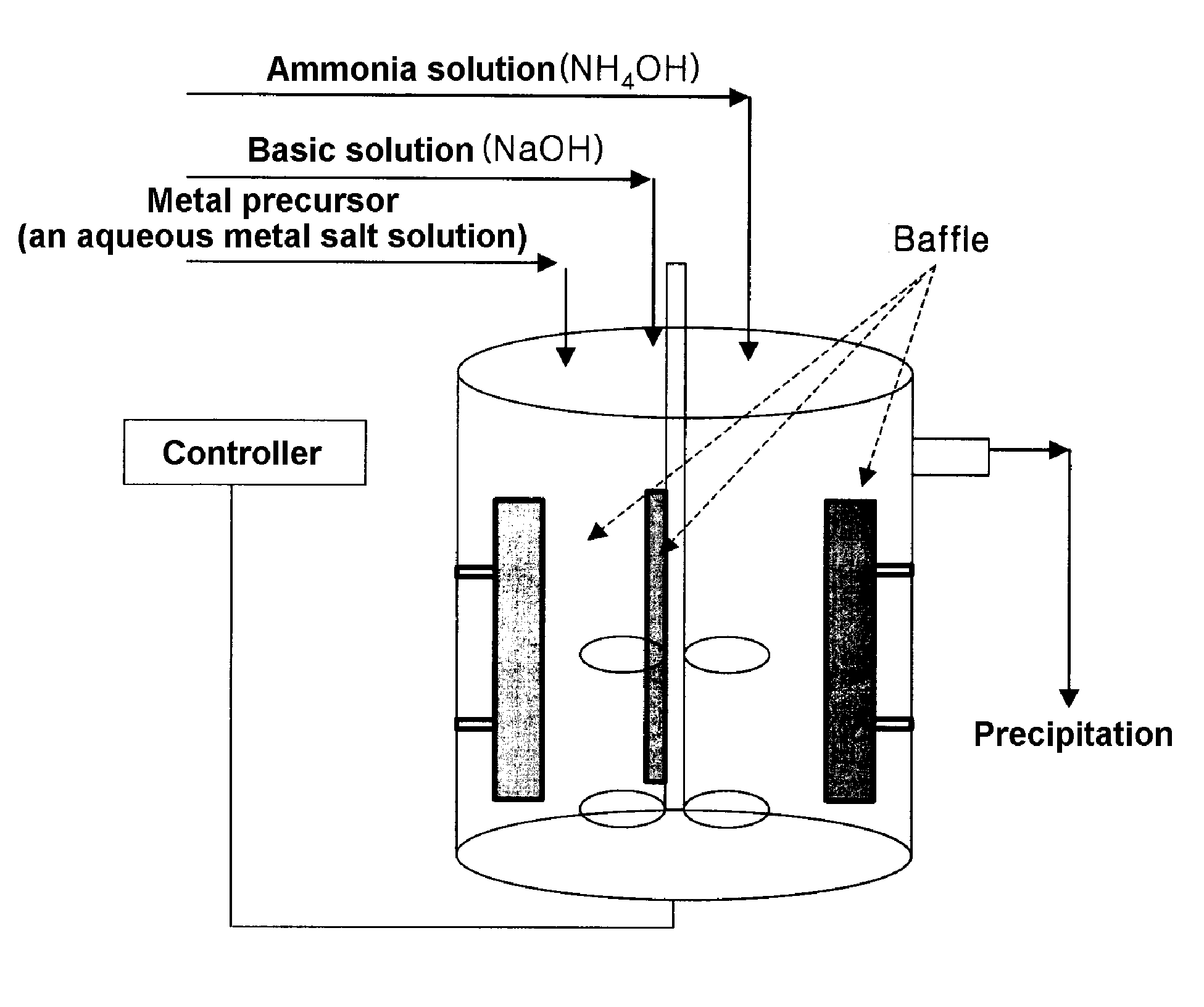

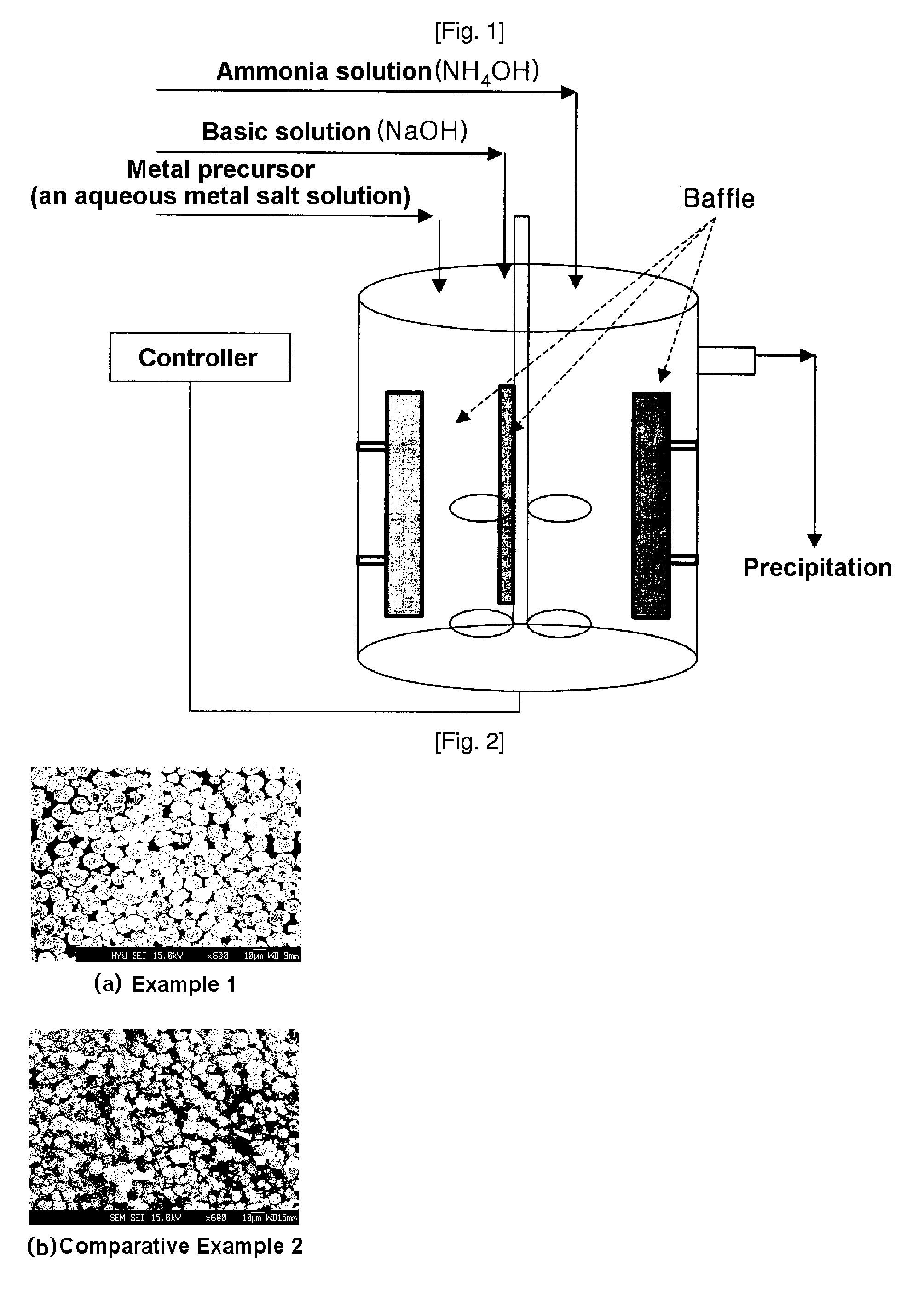

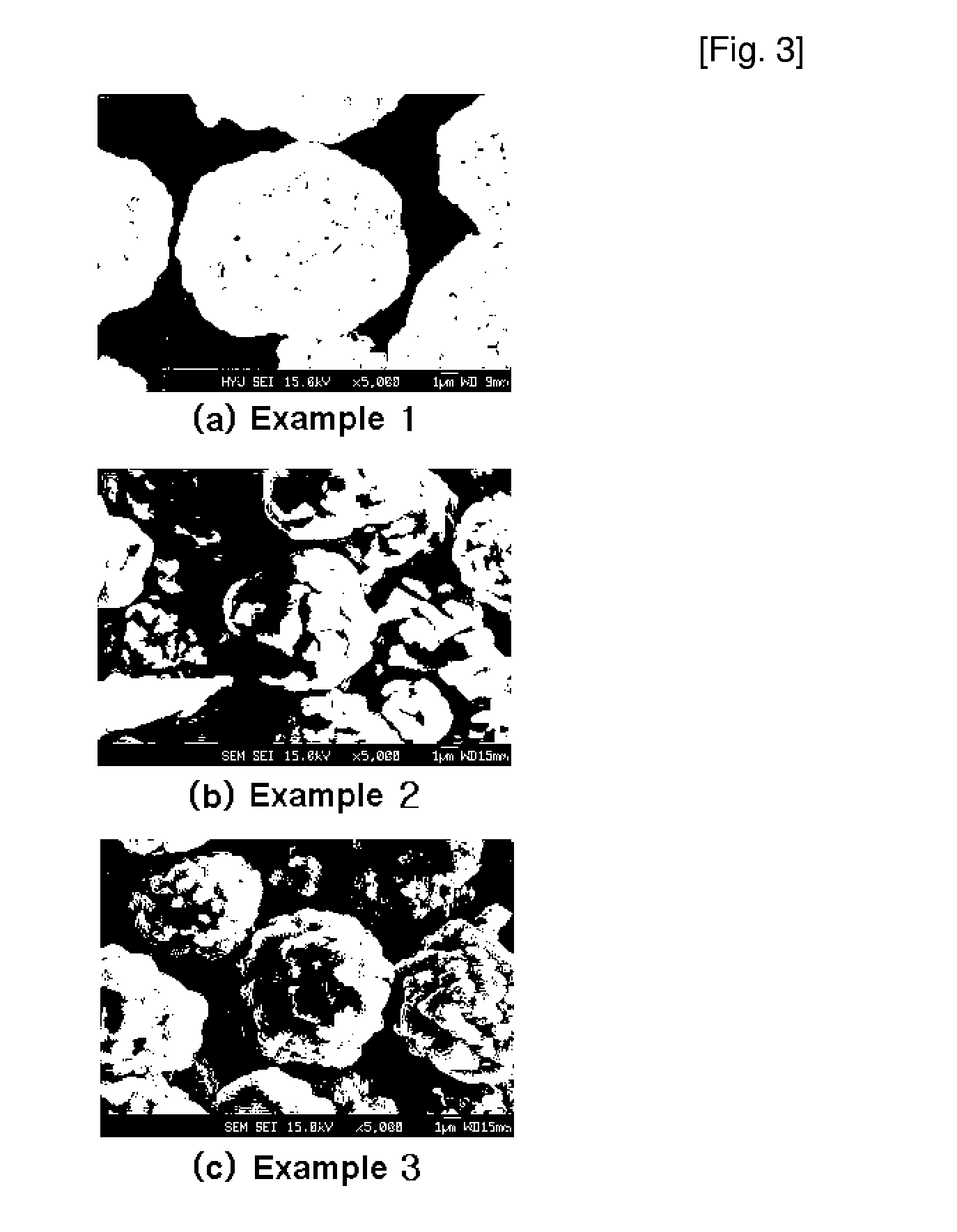

Cathode active material for lithium secondary battery, process for preparing the same and reactor for use in the same process

ActiveUS20070111098A1Large capacityHigh tap densityElectrode manufacturing processesPhosphatesLithiumHigh rate

The present invention relates to a cathode active material for a lithium secondary battery and a process for preparing the same. In accordance with the present invention, the cathode active material having a high packing density was designed and synthesized and thus provided is a cathode active material for a lithium secondary battery exhibiting structural stability such as improved characteristics for charge / discharge, service life and high-rate and thermal stability, by modifying surface of the electrode active material with amphoteric or basic compounds capable of neutralizing acid produced around the cathode active material.

Owner:LG CHEM LTD

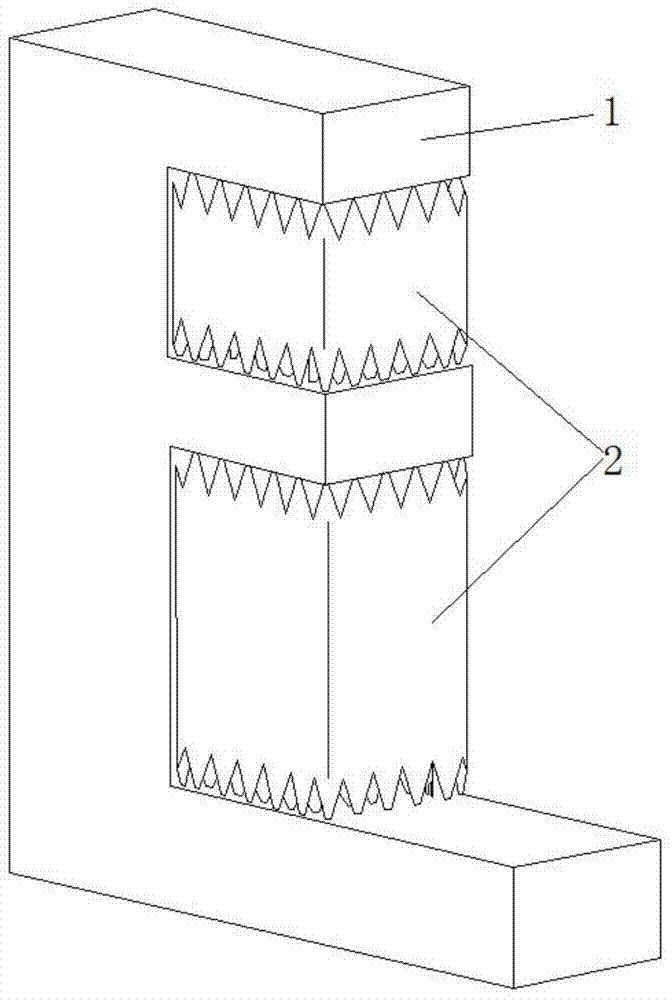

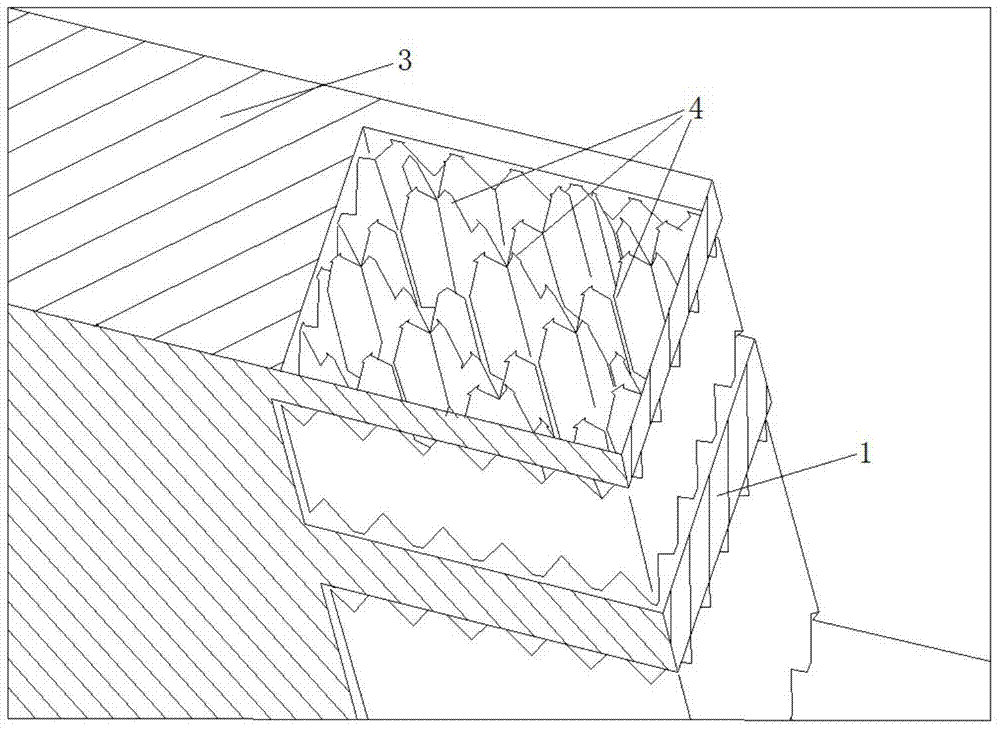

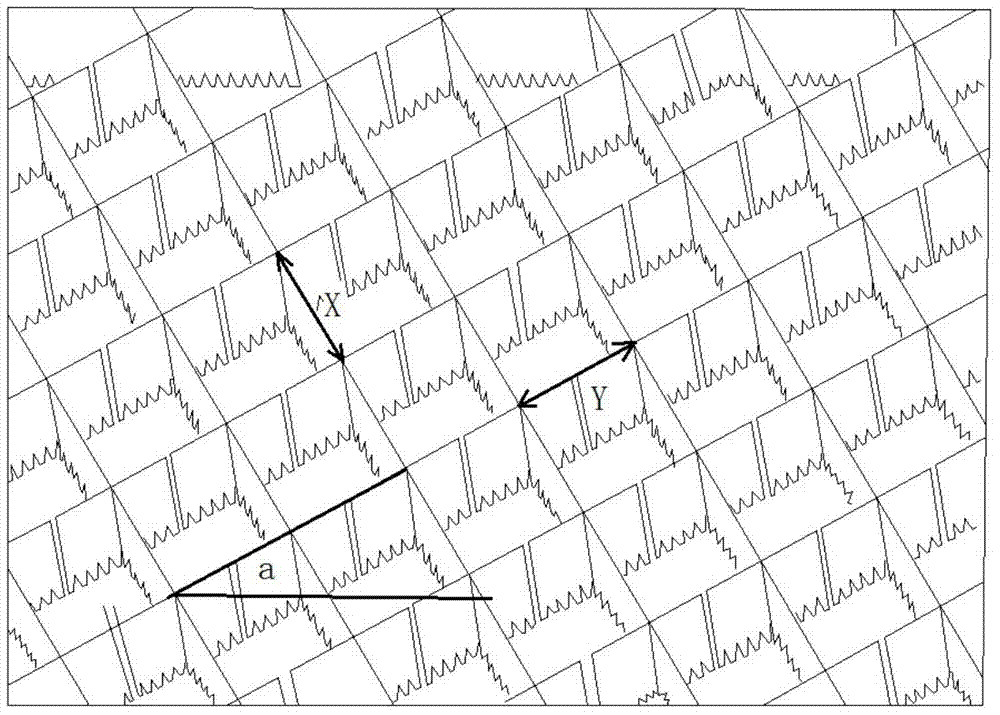

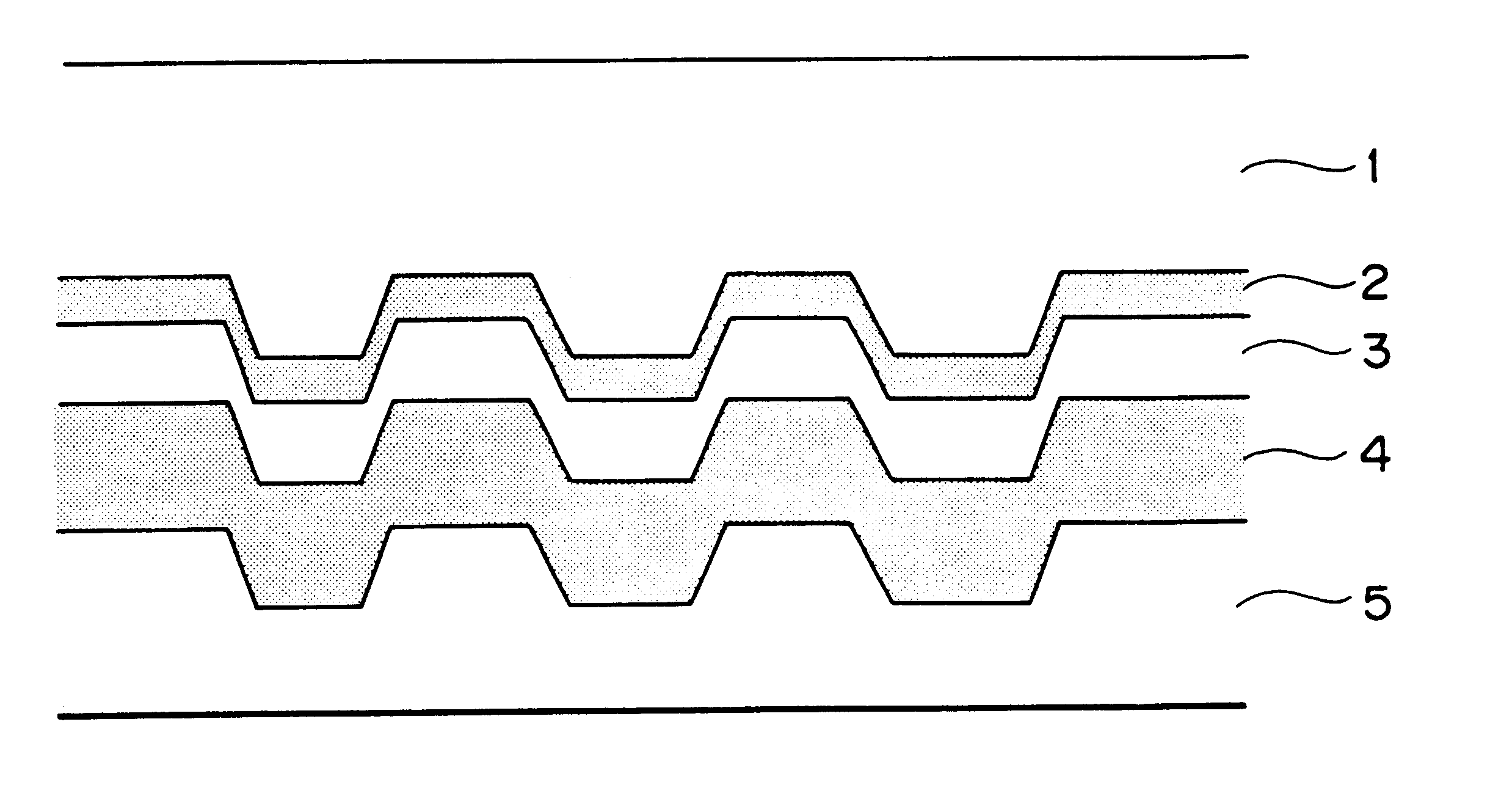

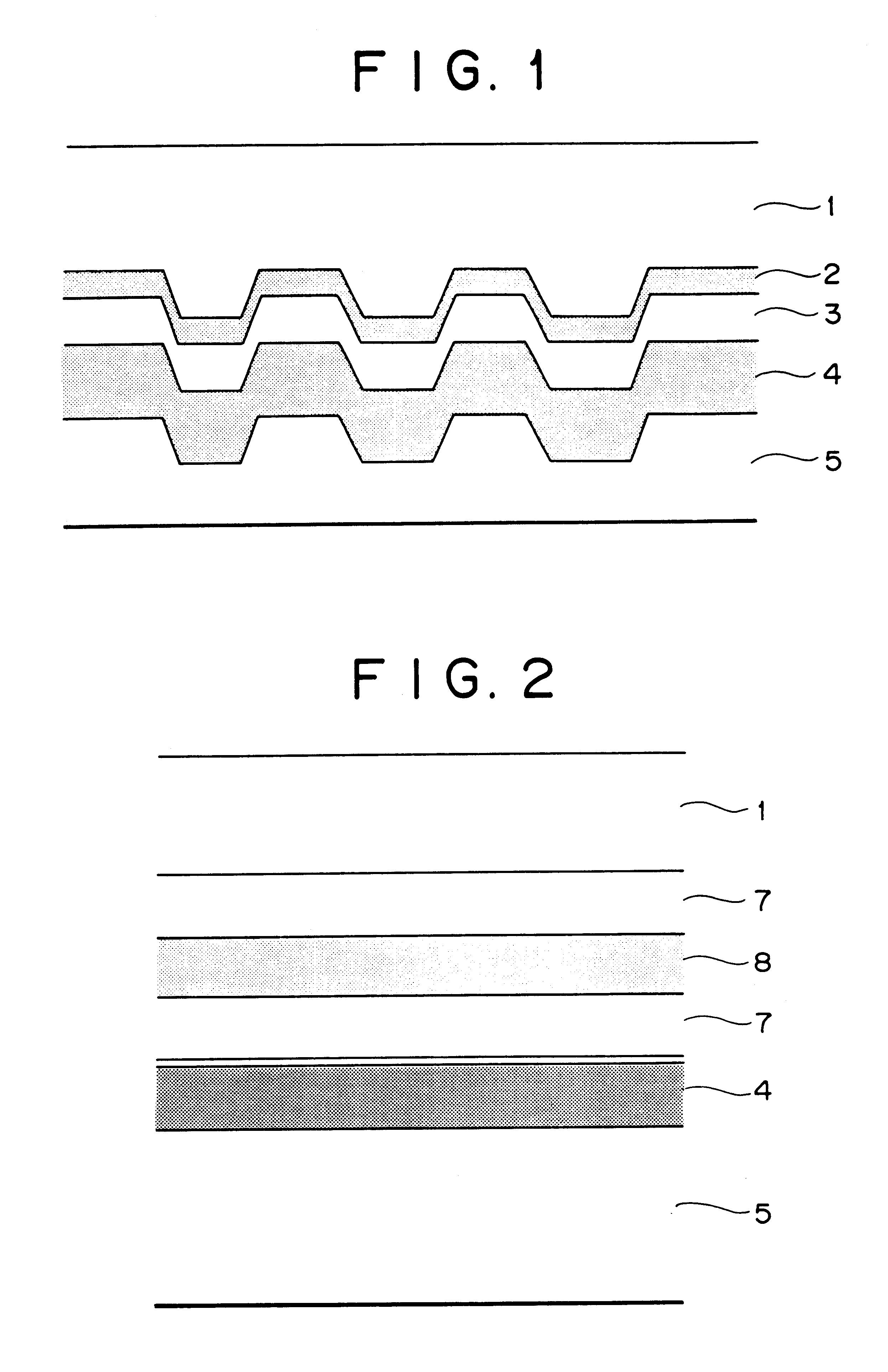

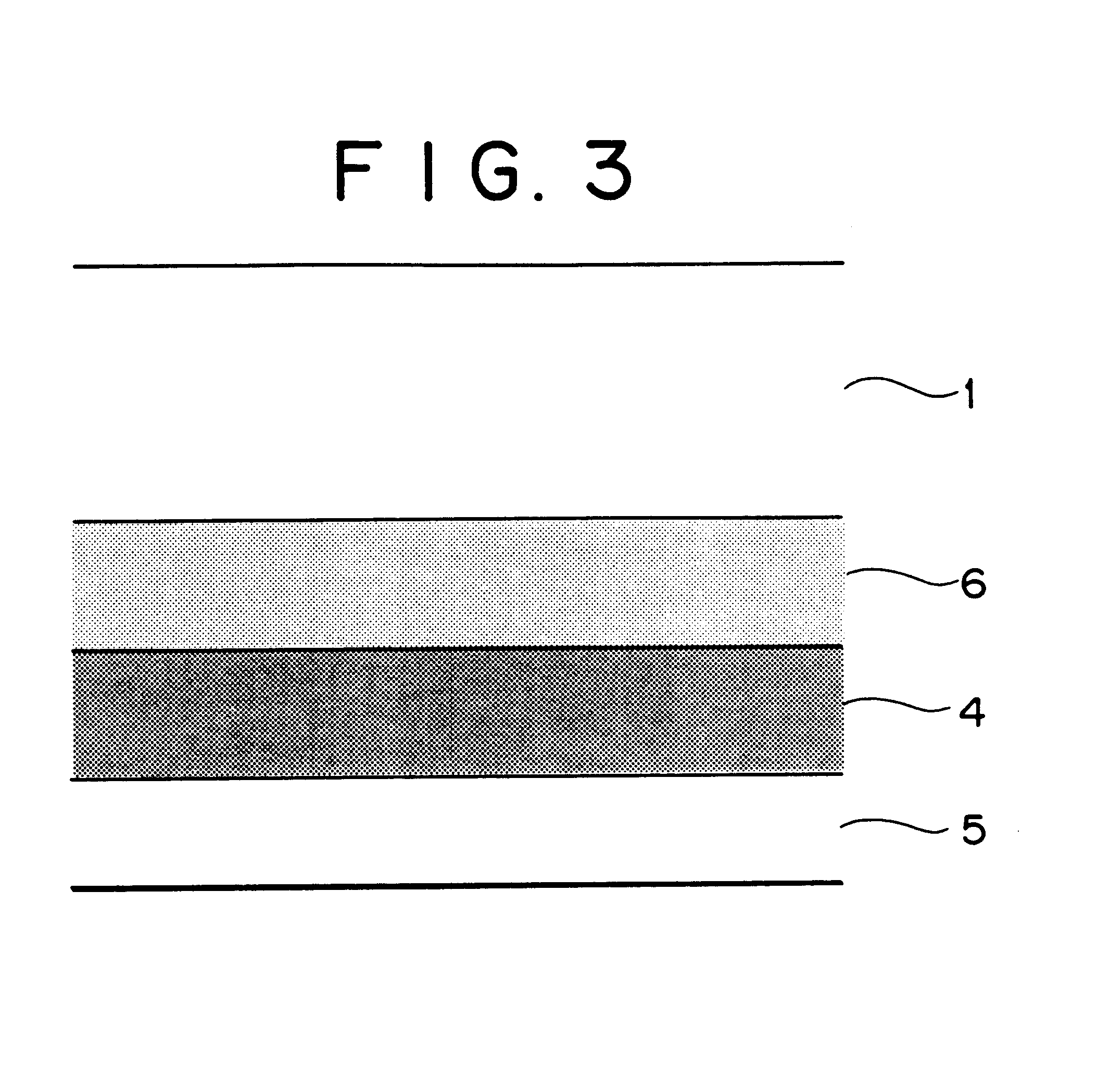

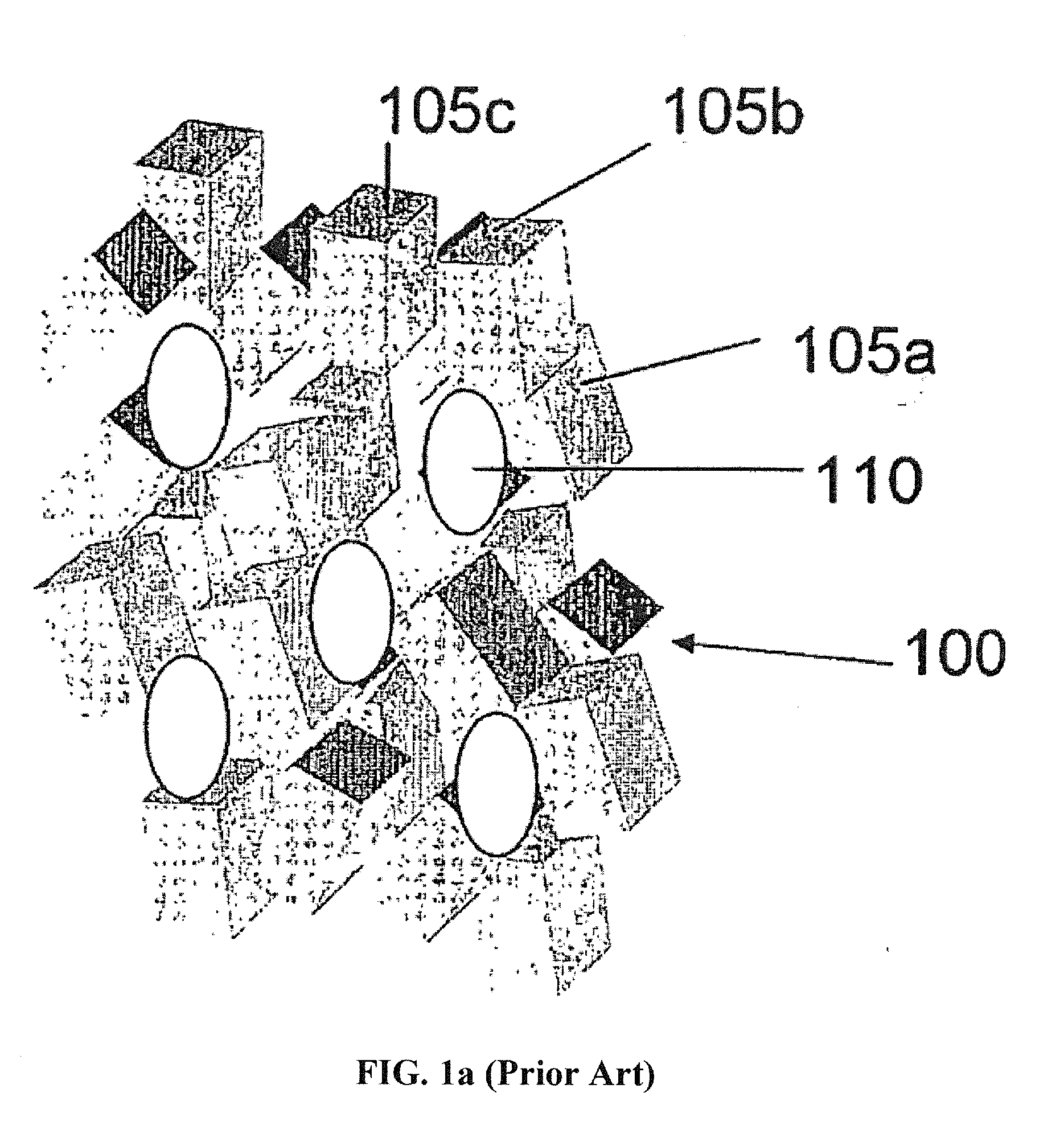

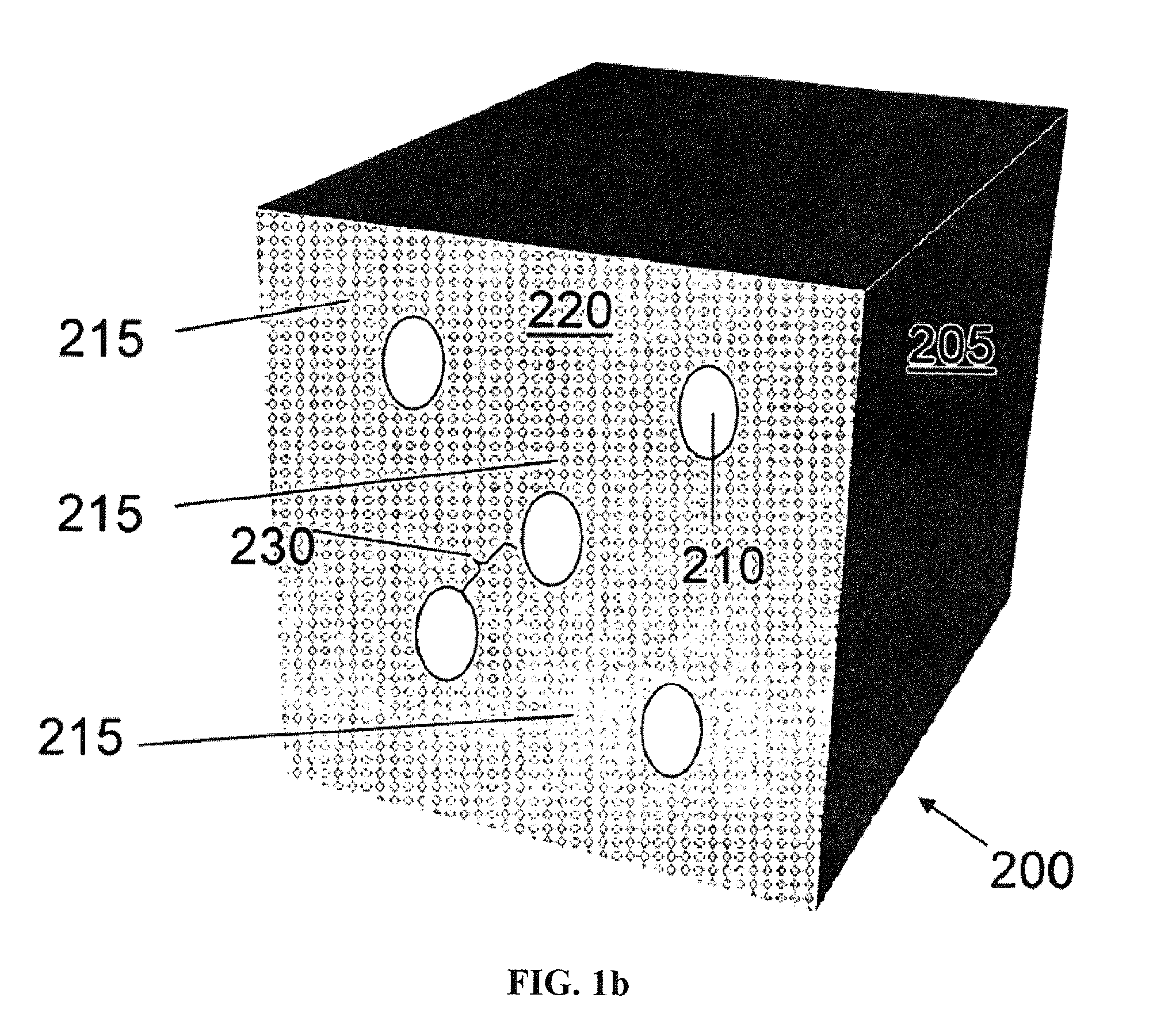

Design method of easily-removable support structure for SLM-manufactured metal parts

ActiveCN103920877AThe process is easy to realizeGenerate easyIncreasing energy efficiencySelective laser meltingSurface roughness

A design method of an easily-removable support structure for SLM-manufactured metal parts is applied to the design of supports for the structures such as suspended planes and surfaces in the process of producing metal parts by SLM (selective laser melting), so that the surfaces can be formed, and stability of the structures on the surfaces and forming quality can meet the technical requirements. A meshed thin-walled structure support is designed by the design method; a saw-toothed structure is designed at the connection of a support and a solid body. The meshed thin-walled structure support has the advantages that weight of the support and even consumption of powder are decreased; forming strength of the support suspended surfaces is met, and the support is easy to remove by mechanical methods; manufacturing time of the support is shortened, and efficiency is improved. The saw-toothed structure has the advantages that strength of the connection of the support with the solid body is decreased, and the influence of many supports upon the surface quality of the formed surfaces after removal is avoided. The support structure is easy to impellent and to produce and is easy to remove during the post-treatment process, the surface roughness of the support faces can be minimized, and the design method is suitable for mass production.

Owner:BEIJING UNIV OF TECH

Reflection layer or semi-transparent reflection layer for use in optical information recording media, optical information recording media and sputtering target for use in the optical information recording media

InactiveUS6689444B2Improve stabilityIncreased durabilityCellsVacuum evaporation coatingRare-earth elementAlloy

Owner:KOBE STEEL LTD

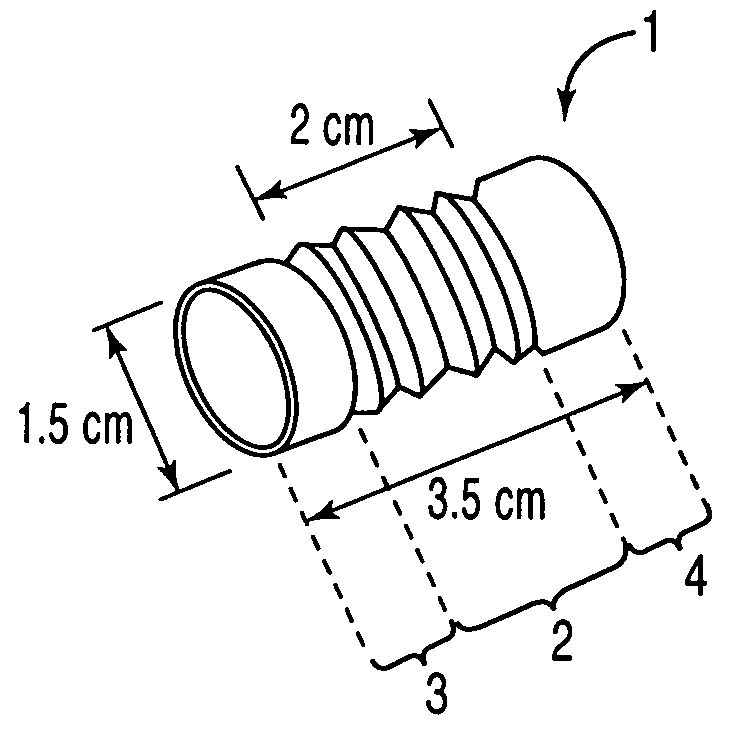

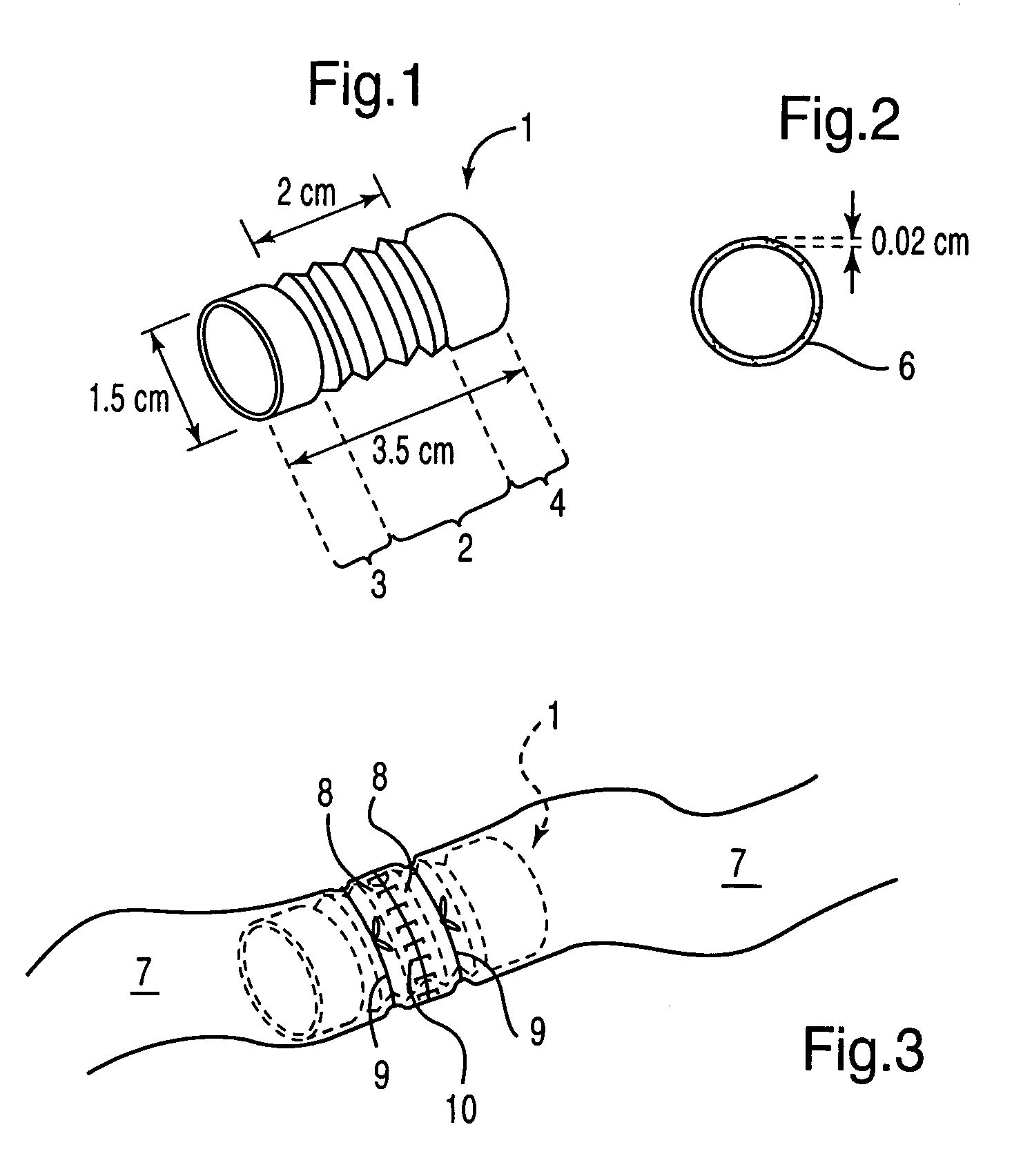

Visceral anastomotic device and method of using same

InactiveUS6926724B1Compromising strengthEasy to reconnectBlood vesselsSurgical staplesInsertion stentPERITONEOSCOPE

A temporary biocompatible stent and method for visceral anastomosis. The stent is provided with integral means for maintaining the structural stability of the stent while providing substantial flexibility. The method comprises fitting the luminal stumps of the viscus over either end of a stent of the invention, and joining the ends of each stump together. A short time after completion of the anastomosis, the stent dissolves and is absorbed safely into the body. The stent and method can be beneficially used in laparoscopic or more invasive traditional surgical procedures. The stent and method are particularly well suited for anastomosis of the bowel.

Owner:CITY OF HOPE

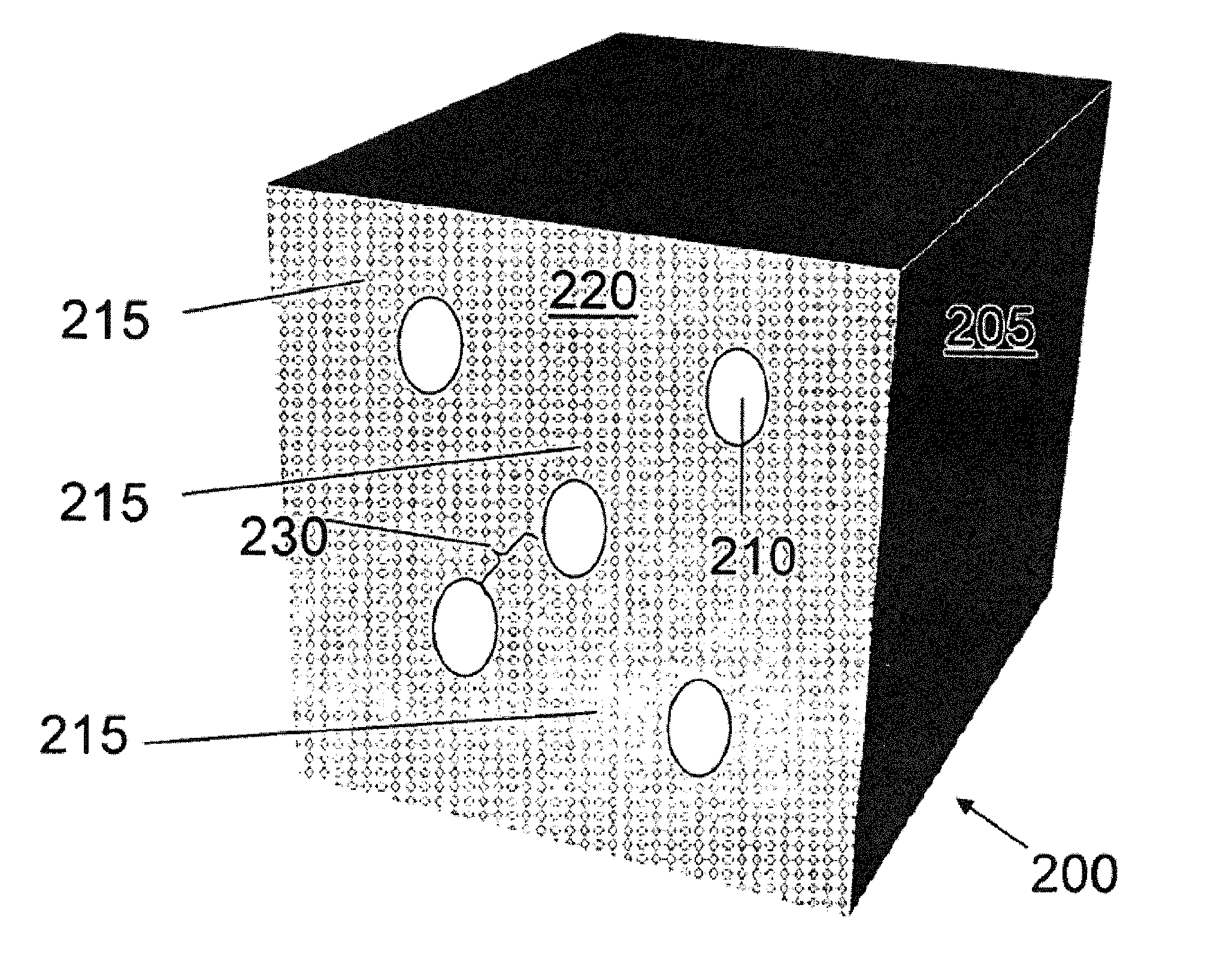

Compositions and methods for making stabilized mesoporous materials

InactiveUS20110171121A1Aluminium compoundsFaujasite aluminosilicate zeoliteMesoporous materialAmmonia

Compositions and methods for making stabilized mesoporous materials. Surfactant-treated mesoporous precursor materials can be heat-treated in the presence of steam and / or ammonia in a heat-treating environment. The steam and / or ammonia can be introduced into the heat-treating environment via in situ and / or ex situ sources. Such stabilized mesoporous materials can have increased structural stability.

Owner:RIVE TECH

Spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with core-shell structure and preparation method thereof

ActiveCN104157831APromote circulationRaise the ratioCell electrodesSecondary cellsComposite cathodeMaterial synthesis

The invention relates to a spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with a core-shell structure and a preparation method thereof, which belongs to the technical field of material synthesis. The prepared lithium ion composite cathode material takes a layered lithium-rich manganese-based Li[Lia(NixCoyMnz)]O2 as a core material, takes spinel nickel manganese acid lithium LiNi0.5Mn1.5O4 as a shell material; a coprecipitation method is employed to obtain a core-shell precursor, the core-shell precursor and the lithium source are uniformly mixed and calcined to obtain the spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with the core-shell structure. According to the invention, the layered lithium-rich manganese-based is taken as the core material, and the spinel nickel manganese acid lithium is taken as the shell material; under the prerequisite that material gram capacity is kept, material structural stability is increased, material cycle, multiplying power and safety performances are improved, function composite and complementation of the core material and the shell layer material can be realized, and the problem that high capacity and high security can not be achieved simultaneously is solved. The composite cathode material has the advantages of simple process and obviously increased performance.

Owner:南京时拓能源科技有限公司

High silicon Y-type zeolite containing rare-earth and its preparing method

ActiveCN1281493CThe initial unit cell constant is smallThe equilibrium cell constant is largeFaujasite aluminosilicate zeoliteGasolineRare earth

A rare-earth-containing high-silicon Y-type zeolite, the zeolite contains rare earths, is characterized in that the silicon-aluminum ratio of the zeolite is 5-30, the initial unit cell constant is 2.430-2.465 nanometers, and the balance unit cell constant and the initial unit cell constant The ratio is at least 0.985. The zeolite has the characteristics of small initial unit cell constant and large equilibrium unit cell constant. It has high structural stability and hydrothermal stability. The cracking catalyst containing this zeolite is not easy to deactivate. The choice of gasoline, diesel oil, dry gas and coke Good sex.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lithium ion battery gradient core shell cathode material and synthetic method thereof

ActiveCN103236537AGuaranteed cycle performanceGuaranteed rate performanceCell electrodesNickel compoundsElectrical batteryPhysical chemistry

The invention provides a lithium ion battery gradient core shell cathode material and synthetic method thereof, and relates to a lithium ion battery cathode material and synthetic method thereof. The lithium ion battery gradient core shell cathode material provided by the present invention may have two kinds of core shell structures as follows: a two-layer structure: a ternary material is used as a core material, and a binary material or a unitary material is casing material, and the ternary material external layer is covered by the binary material or the unitary material; three-layer structure: the ternary material is used as a core material, and the binary material and the unitary material are casing materials, and the ternary material external layer is covered with the binary material, and the binary material is covered with the unitary material. The synthetic method includes: employing a coprecipitation method for obtaining a precursor, and then adding lithium source, calcining and coating to obtain the ternary gradient core shell material. Under the prerequisite that the structure stability of the material is kept, the cost is reduced, and the gram capacity of the material is improved, and the material circulating performance and rate capability of the material are improved, and the safety performance and low temperature performance of the ternary cathode material are increased, and the preparation technology is optimized and improved.

Owner:HARBIN INST OF TECH

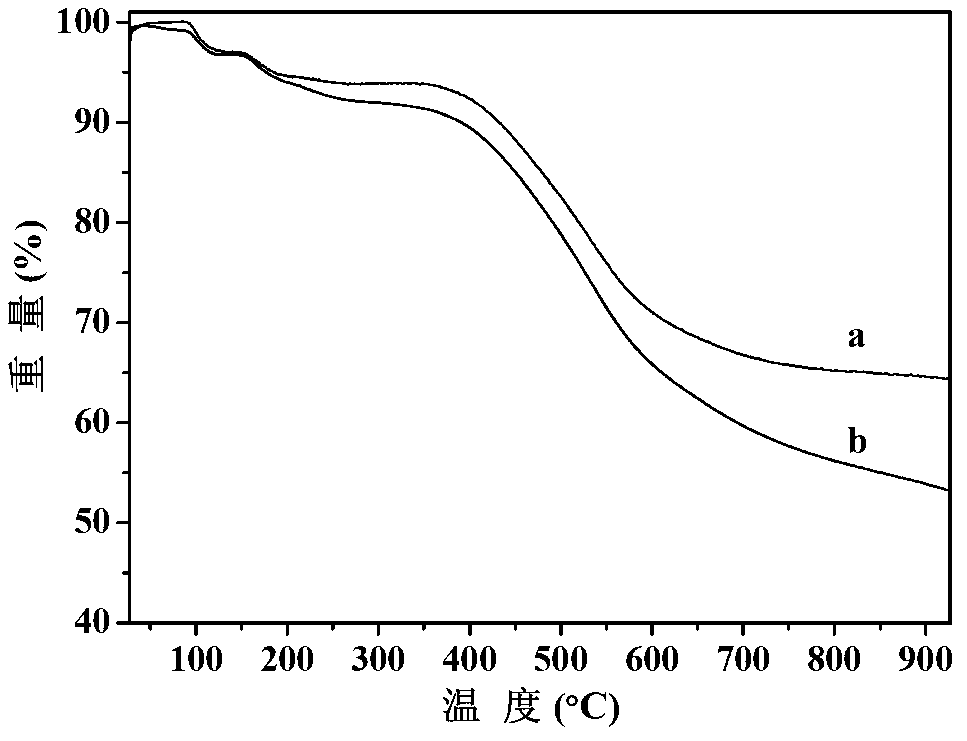

Graphene-based porous macroscopic carbon material and preparation method thereof

The invention relates to a graphene-based porous macroscopic carbon material and a preparation method thereof, belonging to the technical field of porous macroscopic carbon materials. The material comprises graphene and carbon from polyvinyl alcohol and has large specific surface area. The preparation method comprises the following processes of: mixing a graphene oxide water solution and a polyvinyl alcohol solution, and placing the uniformly mixed solution into a hydro-thermal reaction kettle to obtain a graphene-based hydrogel; freezing and drying the hydrogel to obtain a graphene-based aerosol; and carrying out thermal treatment on the aerosol under the protection of an argon gas atmosphere to obtain the graphene-based porous macroscopic carbon material. The invention has the following advantages of simple preparation process and wide raw material source scope; and the prepared porous macroscopic carbon material has the following advantages of well-developed pore structure, extra-large specific surface area, favorable structural stability and wide application range.

Owner:深圳清研紫光科技有限公司

Armature for an electromotive device

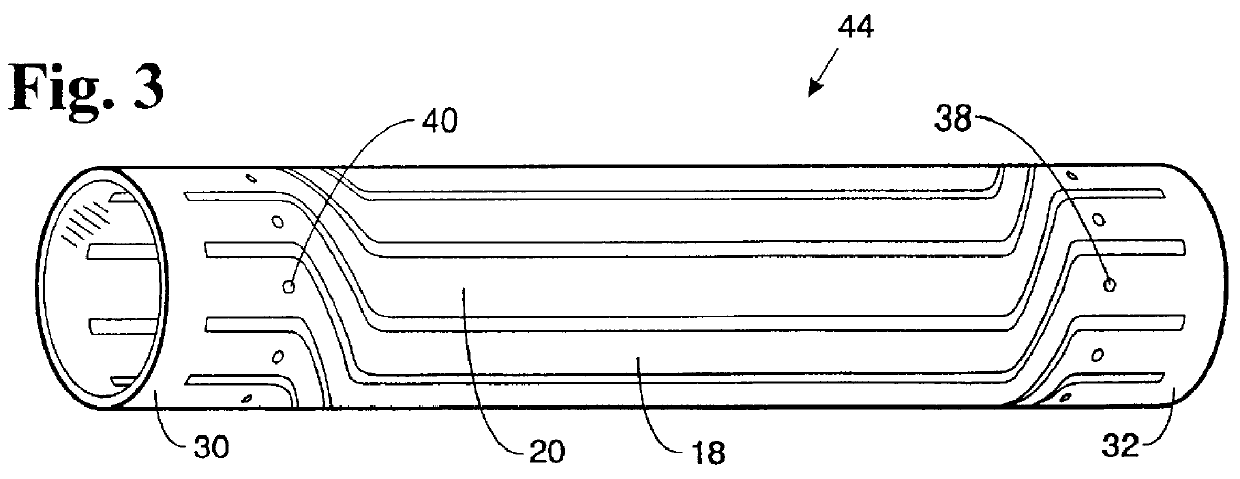

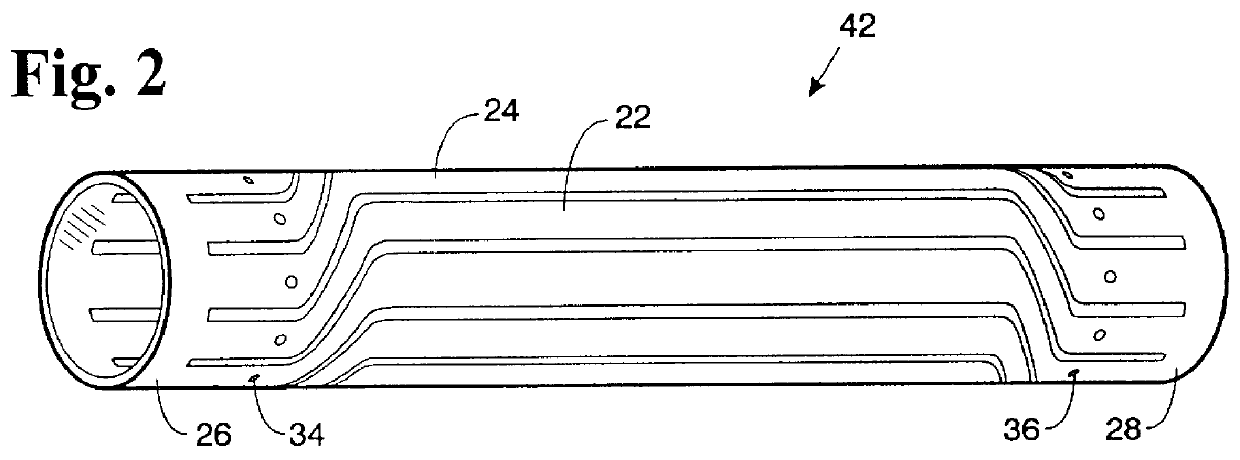

InactiveUS6111329AMaximize conductor-packing factorMaximize conductor volume to gap ratioWindings insulation shape/form/constructionMagnetic circuit rotating partsGlass fiberEngineering

An armature for an electric motor is constructed from a pair of precision machined copper plates cut in a pattern to produce a series of axially extending surface conductive bands with each band separated from the other by an insulated cutout. The precision machined plates are rolled to form two telescoping, hollow cylinders with each cylinder having a pattern of conductive bands representing a half-electric circuit. The outer surface of the inner cylinder is wrapped with several layers of fiberglass strands for structural stability and insulation. The fiberglass wrapped inner cylinder is telescoped inside the outer cylinder. The outer surface of the telescoped structure is also wrapped with several layers of fiberglass strands for structural stability. The conductive bands from the outer cylinder being the near mirror image of the conductive bands of the inner cylinder are helically coupled to form a complete electrical circuit. The resulting tubular structure is encapsulated in a potting material for further structural stability and insulation. The result is a freestanding ironless core inductive armature coil for a DC motor with brushes. The armature also has a commutator, which is mounted at one end of the coil and is in electrical contact with the helically coupled conductive bands. An insulated flywheel and shaft assembly is mounted inside the coil with the flywheel behind the commutator for motor mounting and operation.

Owner:THINGAP

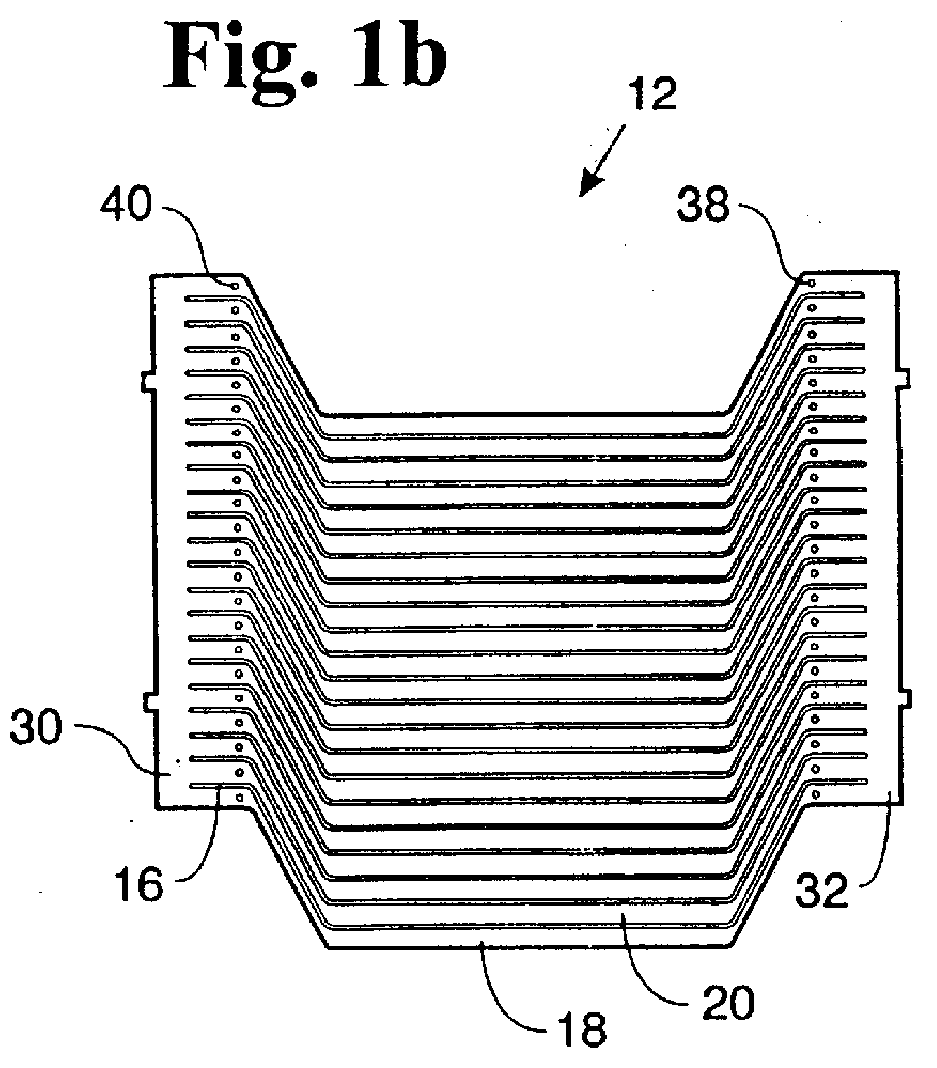

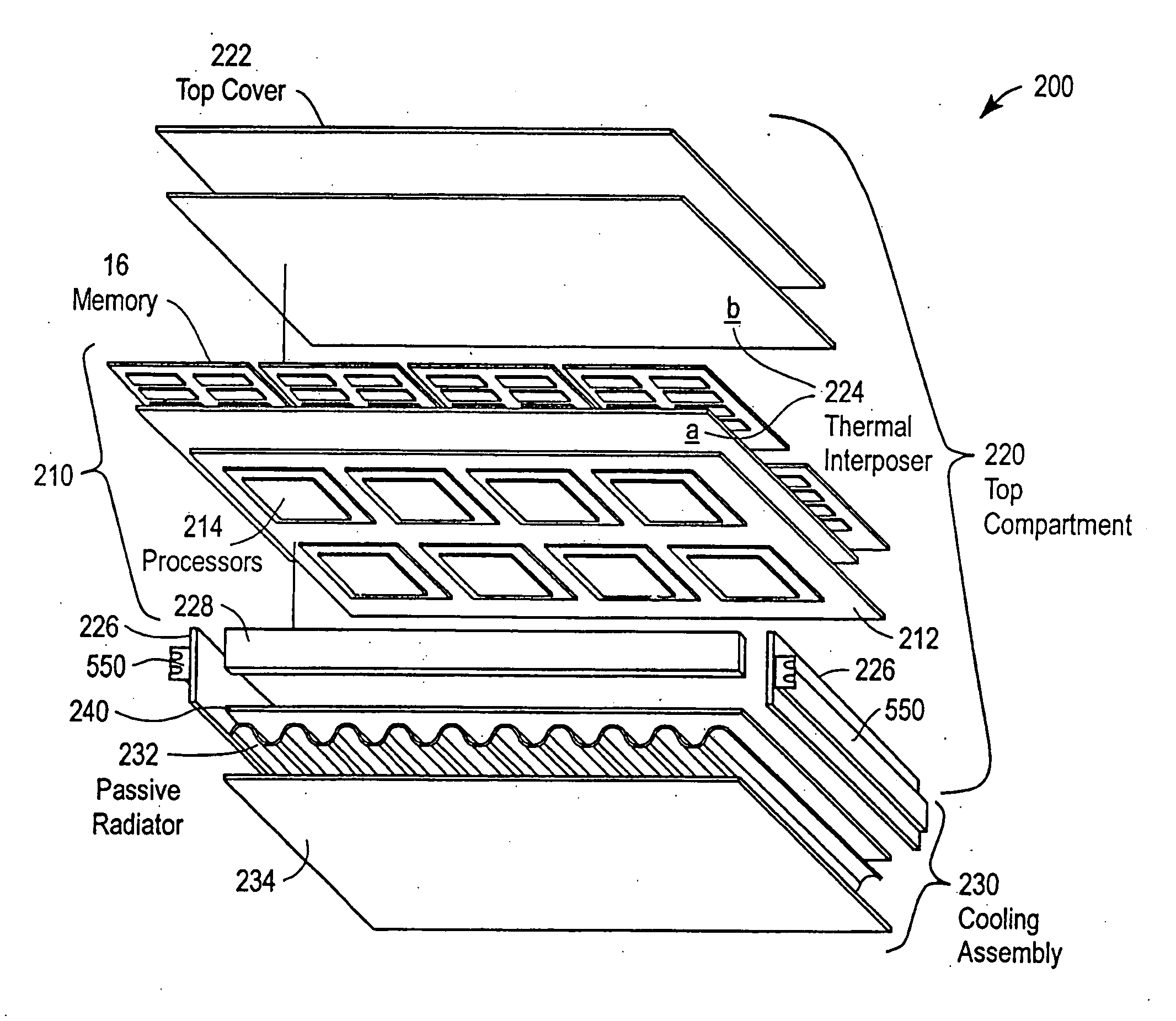

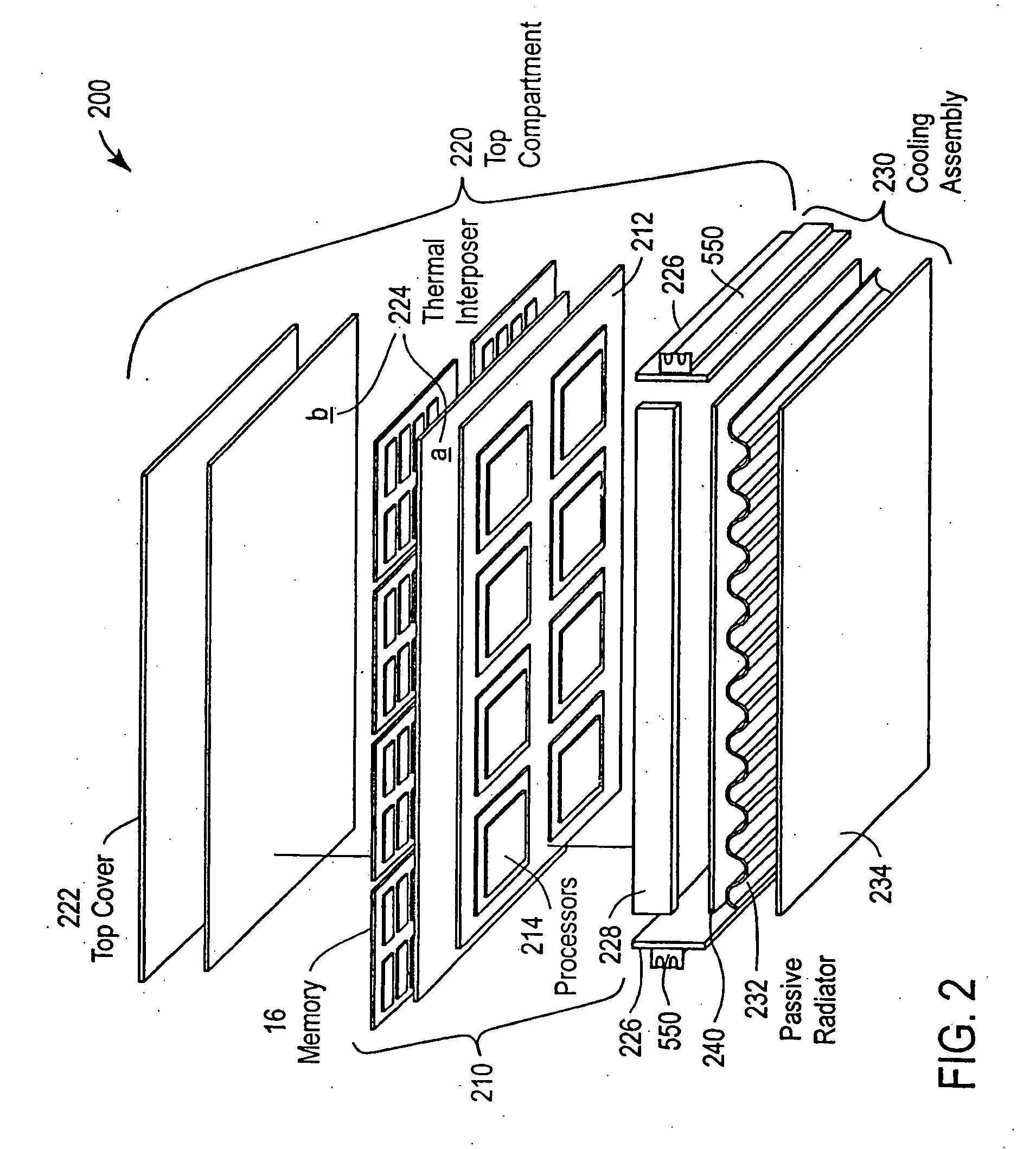

Thermal management for a ruggedized electronics enclosure

InactiveUS20070041160A1High strength to weight ratioEfficient heat dissipationCooling/ventilation/heating modificationsEngineeringElectronic component

The present invention relates to a liquid cooling assembly for cooling electronic components. The liquid cooling assembly contains a heat spreader plate rigidly coupled to a structural foam layer for providing mechanical support and thermal dissipation for the electronic components. A fluid channel, rigidly coupled to the structural foam, is provided for directing a cooling fluid in the plane of the heat spreader and a bottom plate rigidly coupled to the structural foam to protect the electronic components against one or more destructive shock events and to provide thermal dissipation of heat generated by the electronic components. The present invention also provides a maze structure in the liquid cooling assembly to increase structural stability against destructive shock events. The present invention relates to a ruggedized electronics enclosure for housing electronic components containing a top compartment configured to house the electronic components. The top compartment contains a first electronics layer and a second electronics layer adjacent to said first electronics layer and a cooling assembly, rigidly coupled to the top compartment. A thermal shunt is configured to channel heat from the first and second electronics layers to the cooling assembly and to provide additional mechanical support to protect against potentially destructive shock events.

Owner:THEMIS COMP

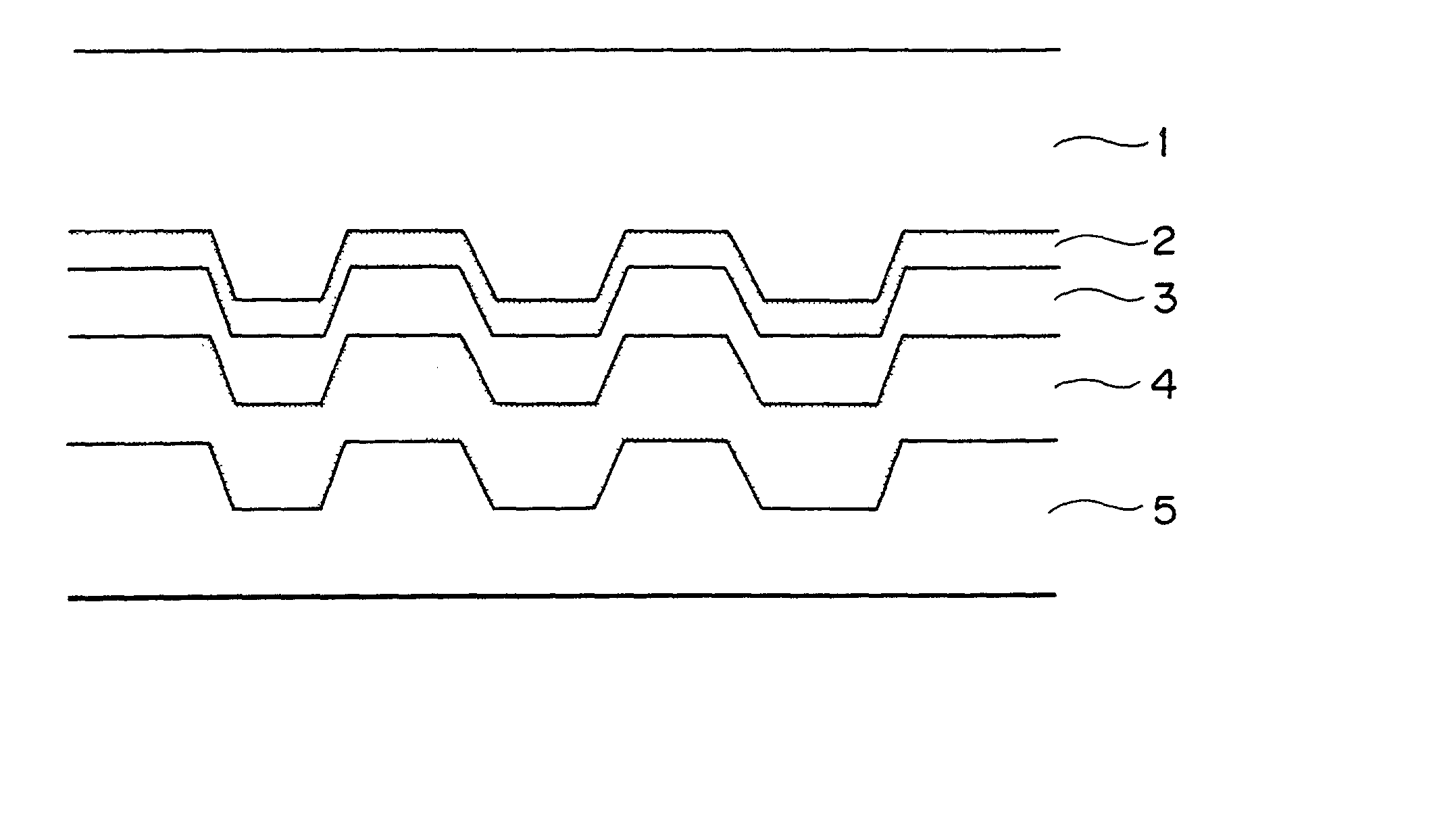

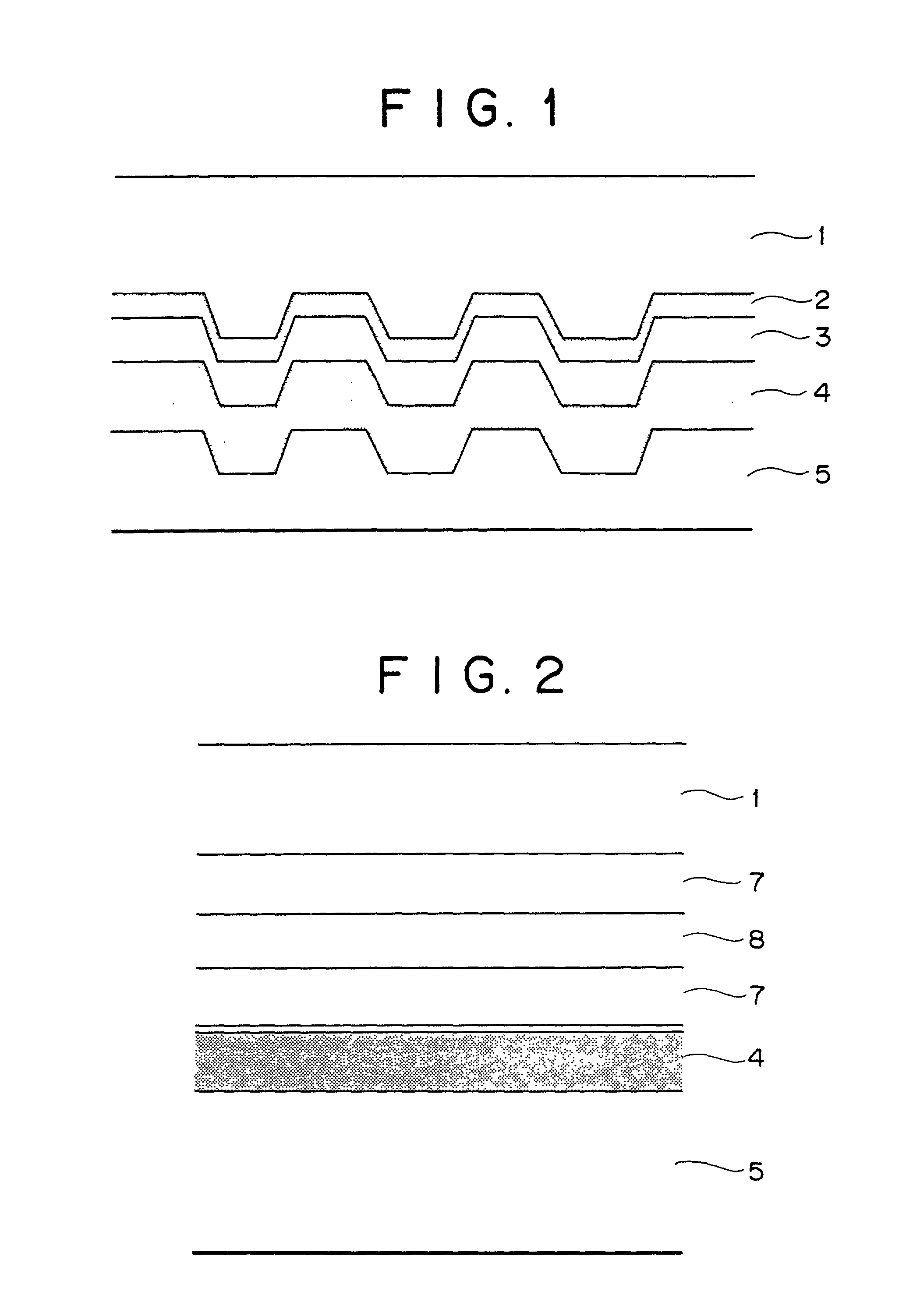

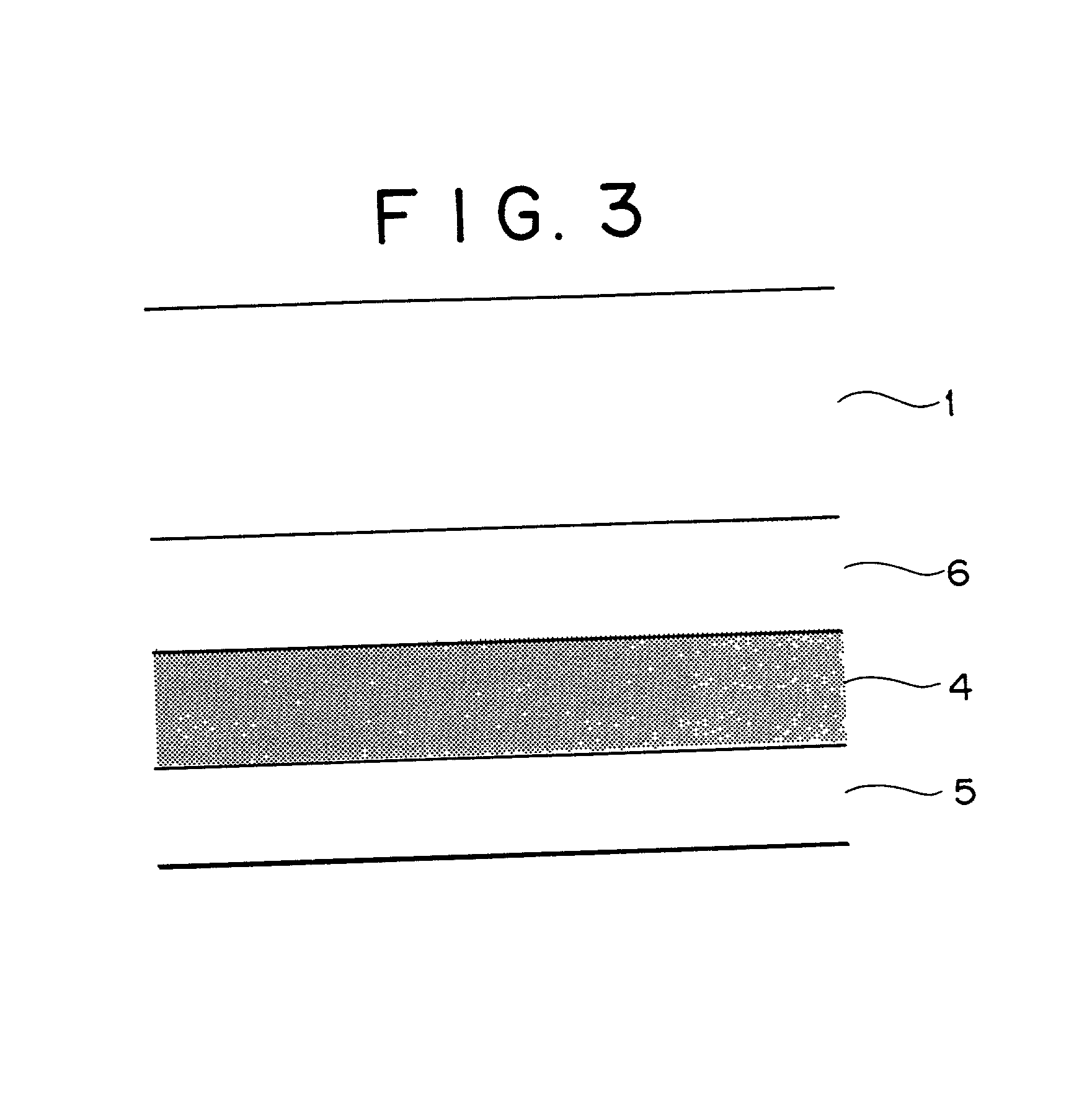

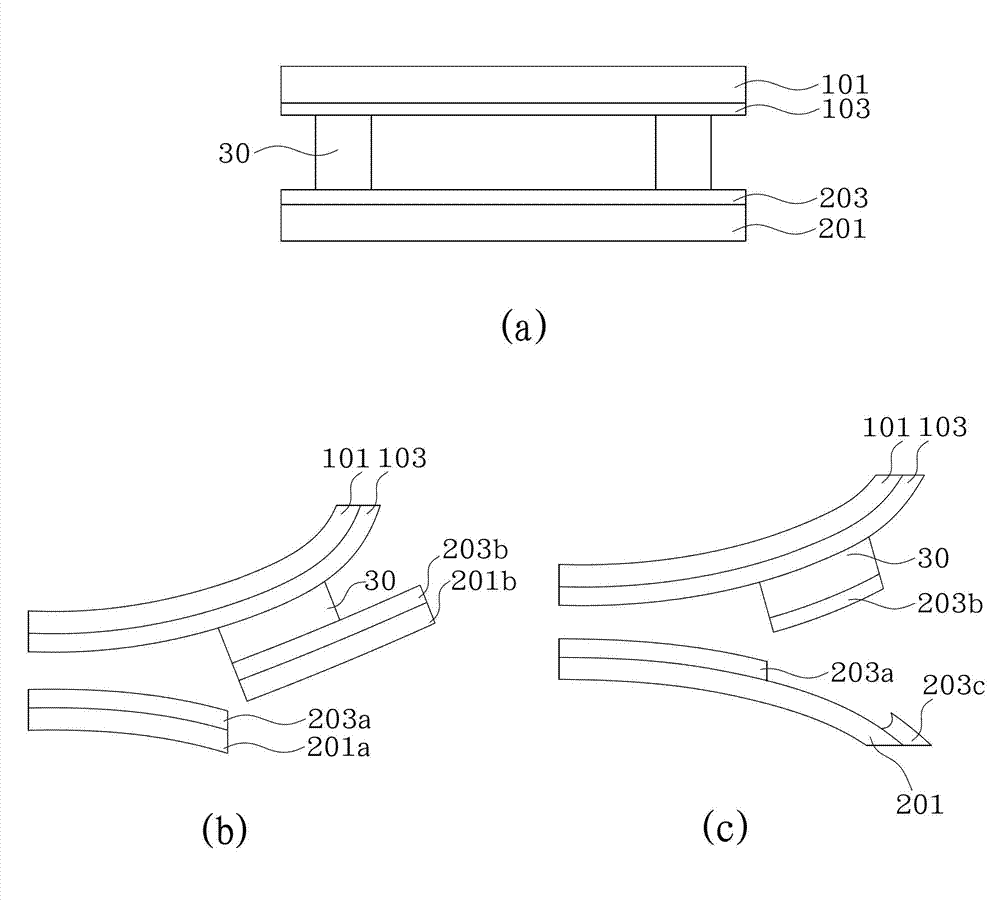

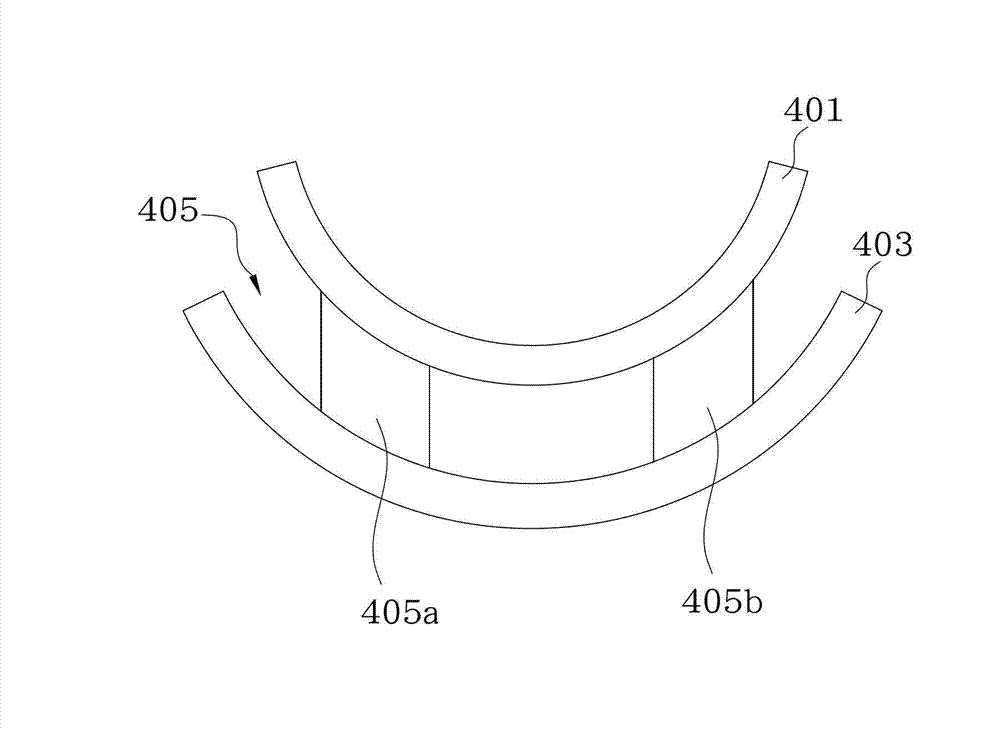

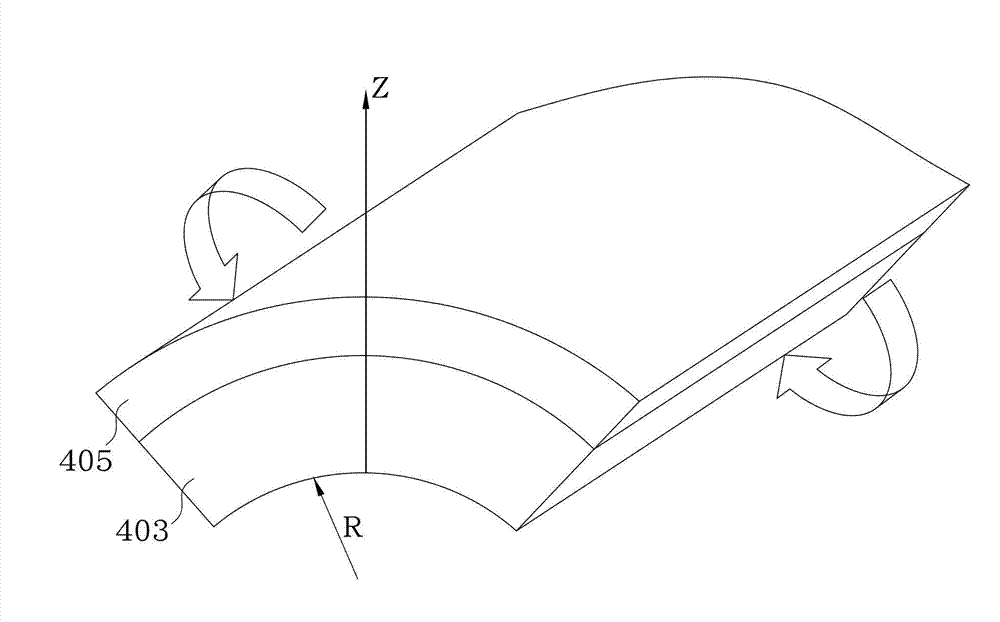

Flexible display panel

InactiveCN102902109AImprove structural stabilitySolid-state devicesSemiconductor/solid-state device manufacturingYoung's modulusFlexible display

The invention provides a flexible display panel, which comprises a first flexible substrate, a second flexible substrate and a frame sealant, wherein the second flexible substrate is arranged opposite to the first flexible substrate; the frame sealant is positioned between the first flexible substrate and the second flexible substrate for adhering the first flexible substrate and the second flexible substrate and is made of an elastic material; the flexible display panel has a curvature radius; and the young modulus numerical value of the frame sealant corresponds to the size of the curvature radius. By using the flexible display panel, the frame sealant of the elastic material is arranged between the two substrates; and when a flexible element in the flexible display panel bends, stress between the frame sealant and the substrates can be buffered by the elastic frame sealant material, and the structural stability of the flexible element can be improved.

Owner:AU OPTRONICS CORP

Cobalt-base alloy with high heat resistance and high strength and process for producing the same

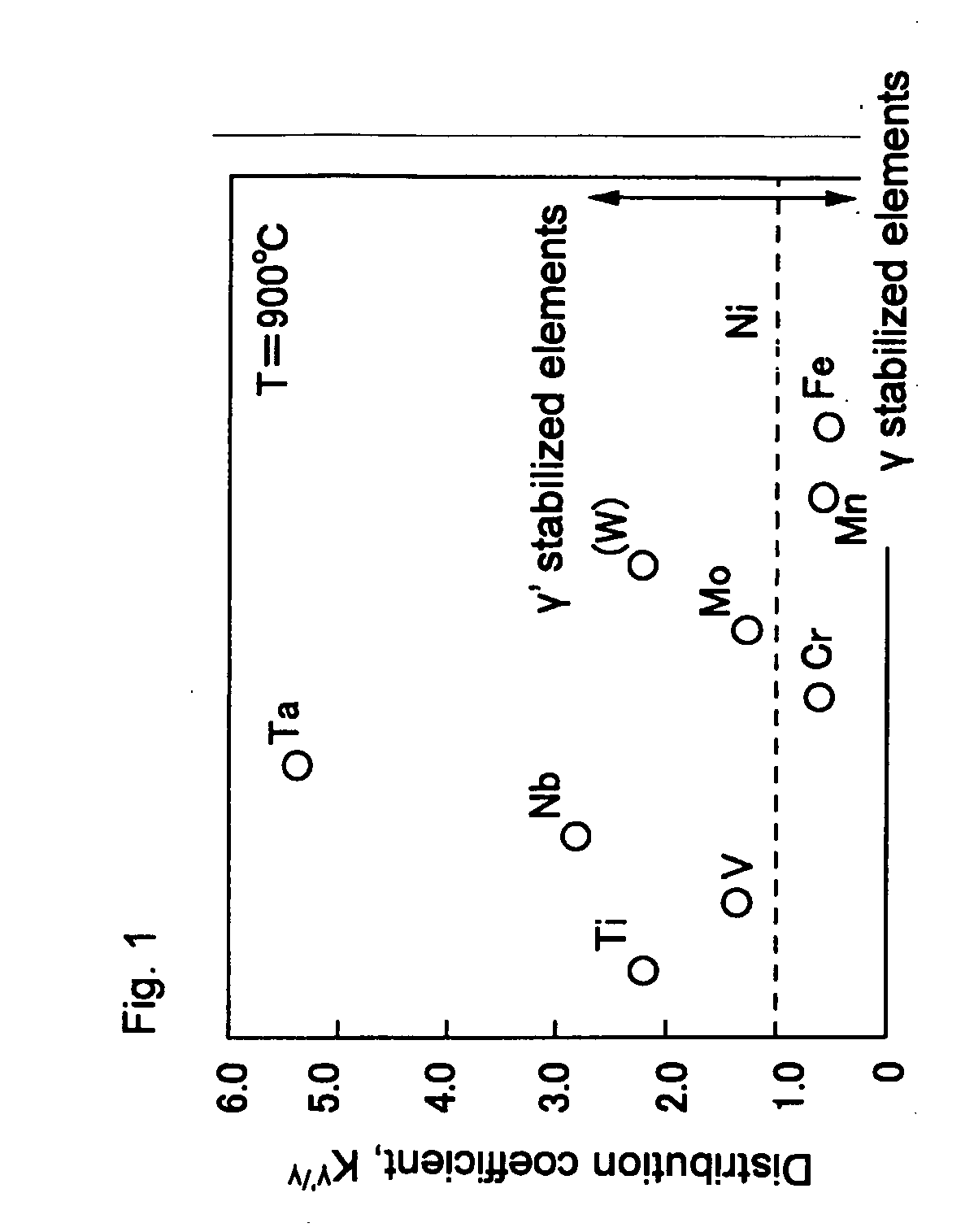

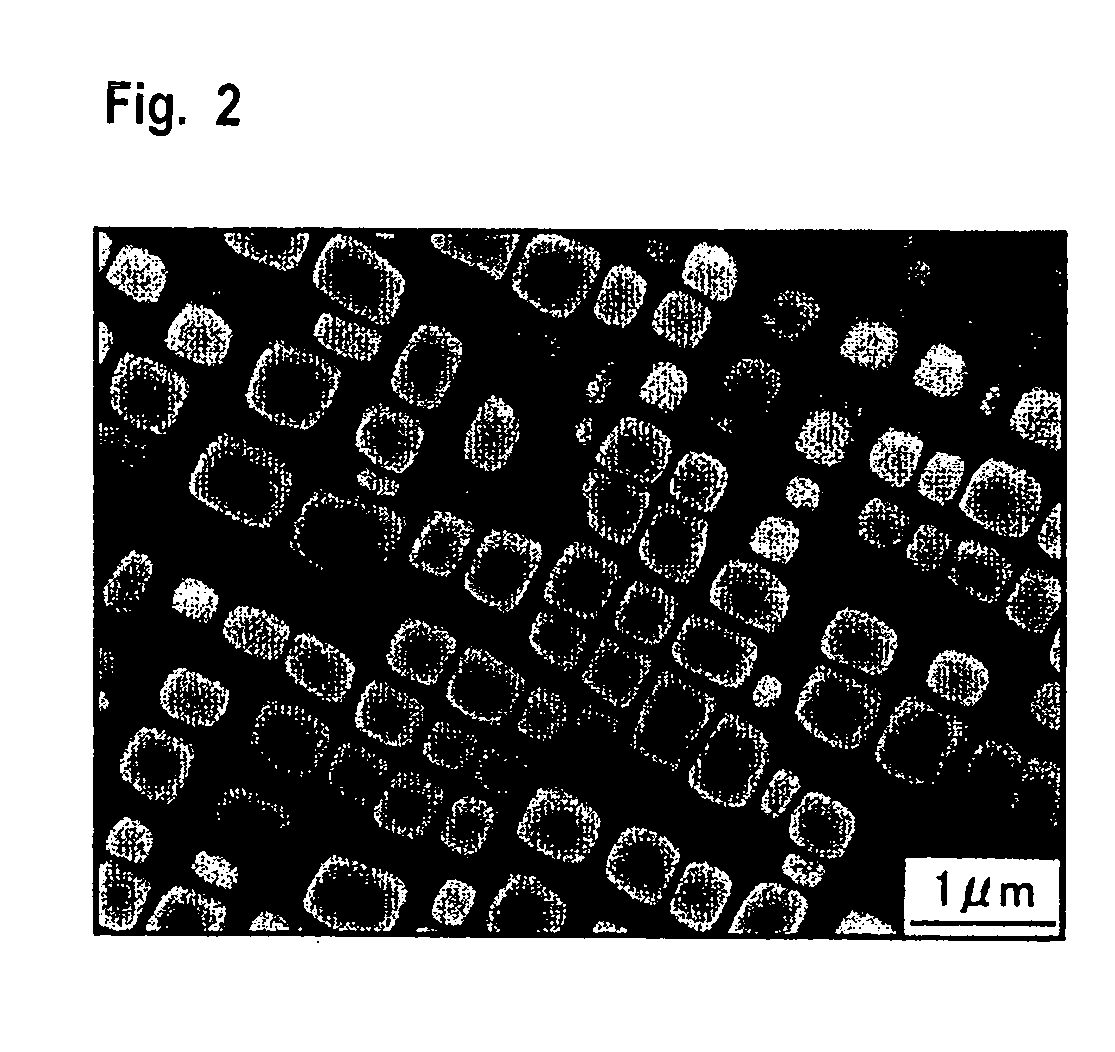

A Co-base alloy which has a basic composition including, in terms of mass proportion, 0.1%-10% Al, 3.0-45% W, and Co as the remainder and has an intermetallic compound of the Ll2 type [Co3(Al,W)] dispersed and precipitated therein. Part of the Co may be replaced with Ni, Ir, Fe, Cr, Re, or Ru, while part of the Al and W may be replaced with Ni, Ti, Nb, Zr, V, Ta or Hf. The intermetallic compound [Co3(Al, W)] has a high melting point, and this compound and the matrix are mismatched little with respect to lattice constant. Thus, the cobalt-base alloy can have high-temperature strength equal to that of nickel-base alloys and excellent structure stability.

Owner:JAPAN SCI & TECH CORP

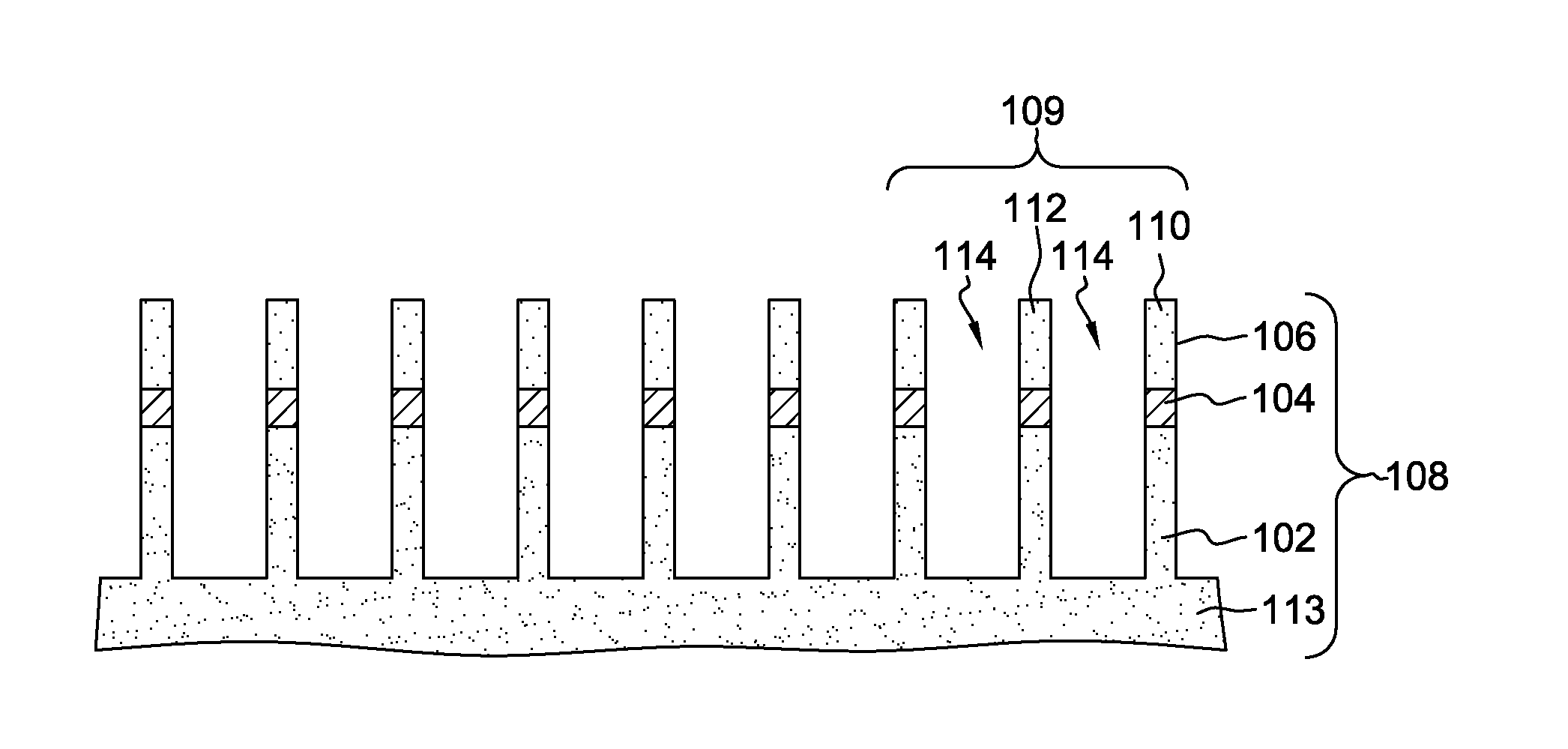

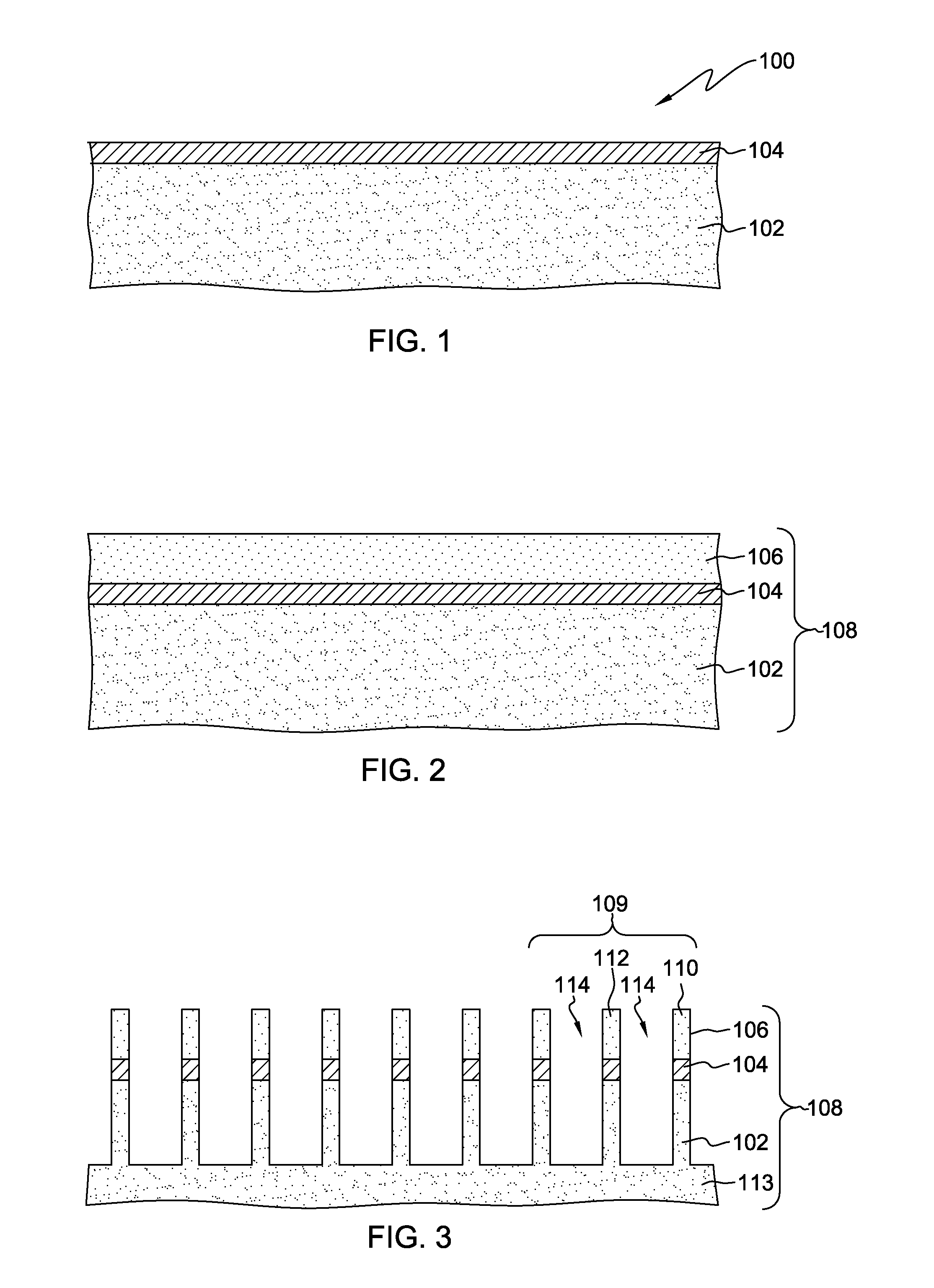

Finfet with electrically isolated active region on bulk semiconductor substrate and method of fabricating same

ActiveUS20150021691A1Overcomes shortcomingEnhanced advantageTransistorSemiconductor/solid-state device manufacturingActive layerStructural stability

A semiconductor stack of a FinFET in fabrication includes a bulk silicon substrate, a selectively oxidizable sacrificial layer over the bulk substrate and an active silicon layer over the sacrificial layer. Fins are etched out of the stack of active layer, sacrificial layer and bulk silicon. A conformal oxide deposition is made to encapsulate the fins, for example, using a HARP deposition. Relying on the sacrificial layer having a comparatively much higher oxidation rate than the active layer or substrate, selective oxidization of the sacrificial layer is performed, for example, by annealing. The presence of the conformal oxide provides structural stability to the fins, and prevents fin tilting, during oxidation. Selective oxidation of the sacrificial layer provides electrical isolation of the top active silicon layer from the bulk silicon portion of the fin, resulting in an SOI-like structure. Further fabrication may then proceed to convert the active layer to the source, drain and channel of the FinFET. The oxidized sacrificial layer under the active channel prevents punch-through leakage in the final FinFET structure.

Owner:GLOBALFOUNDRIES US INC

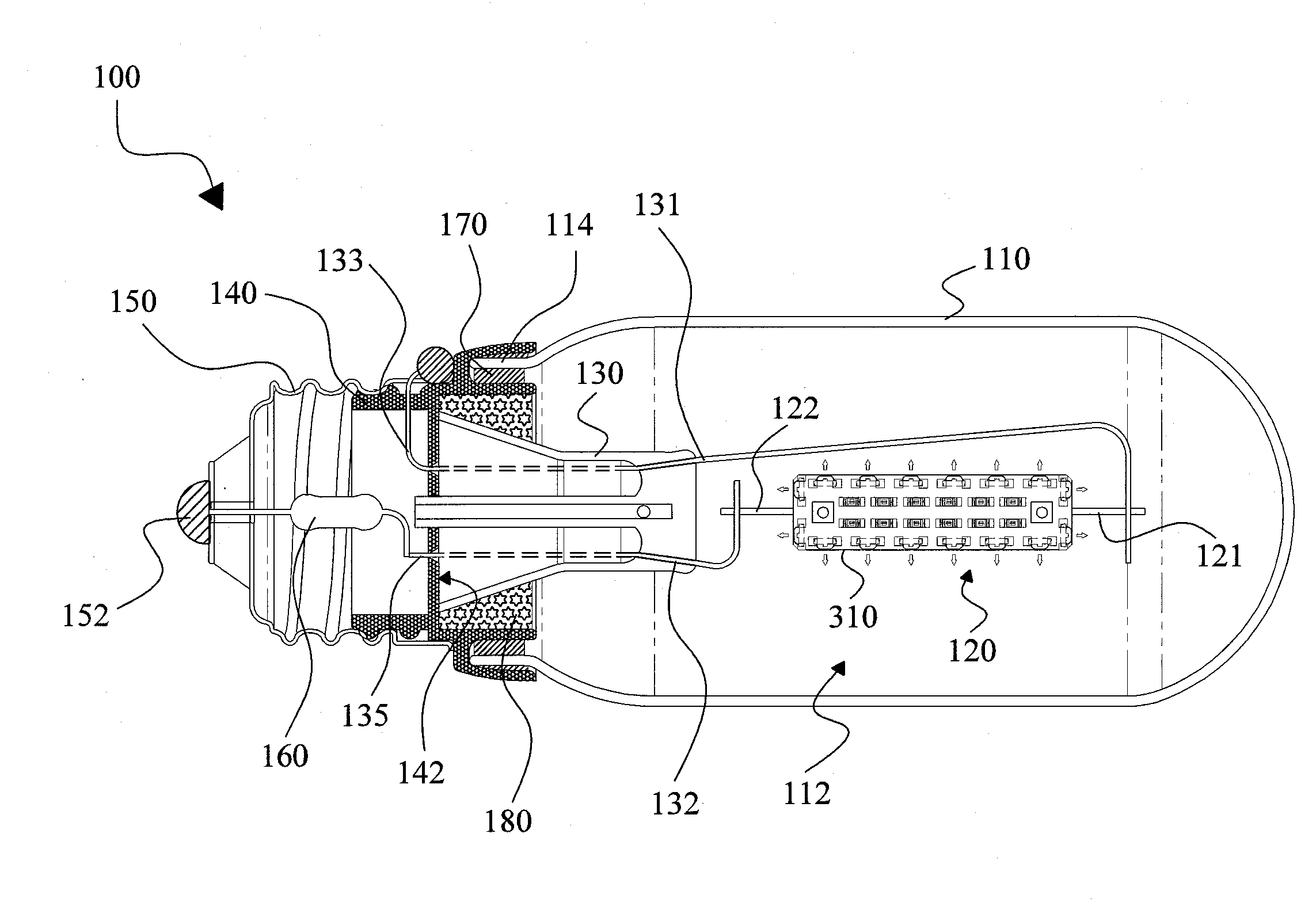

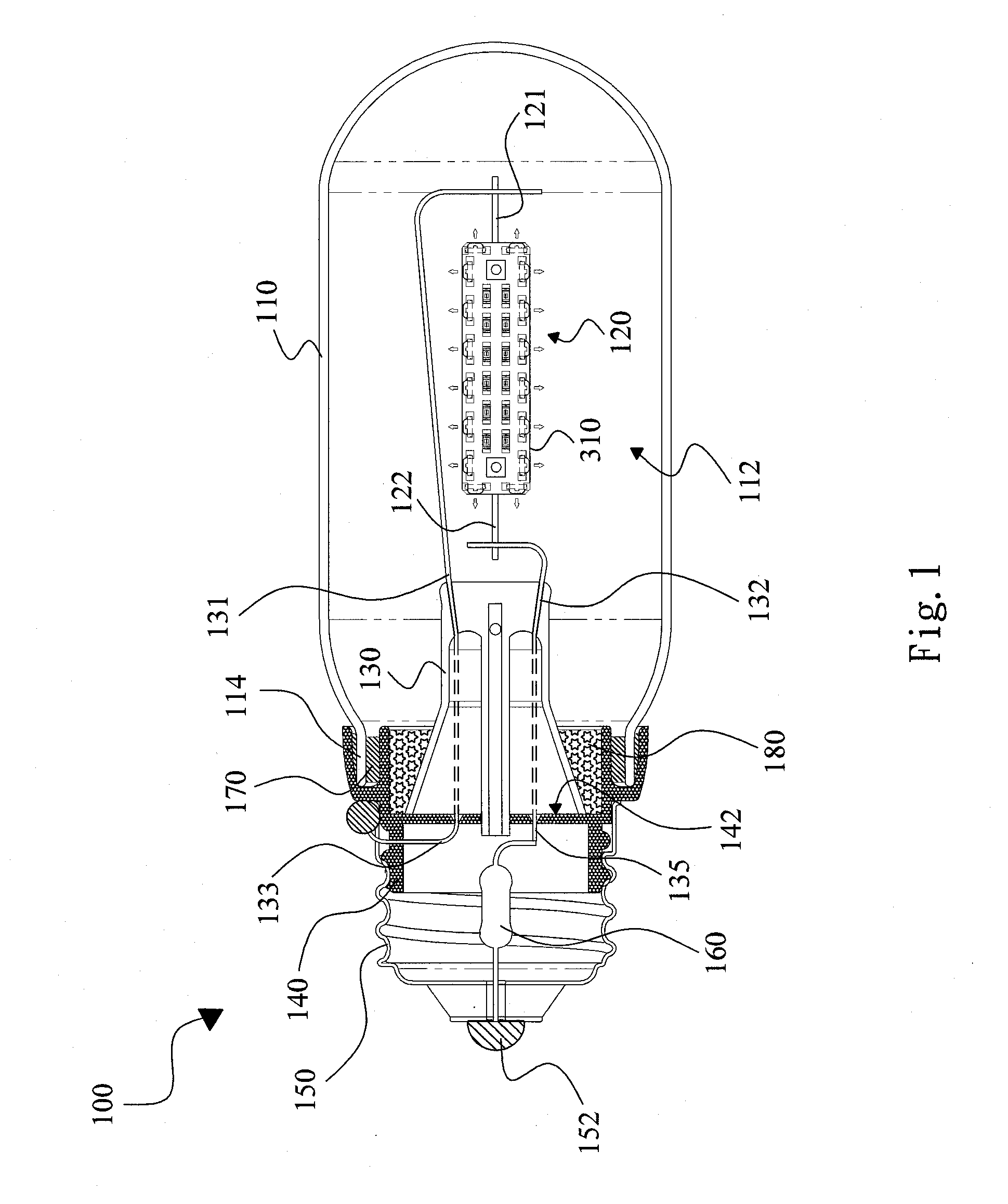

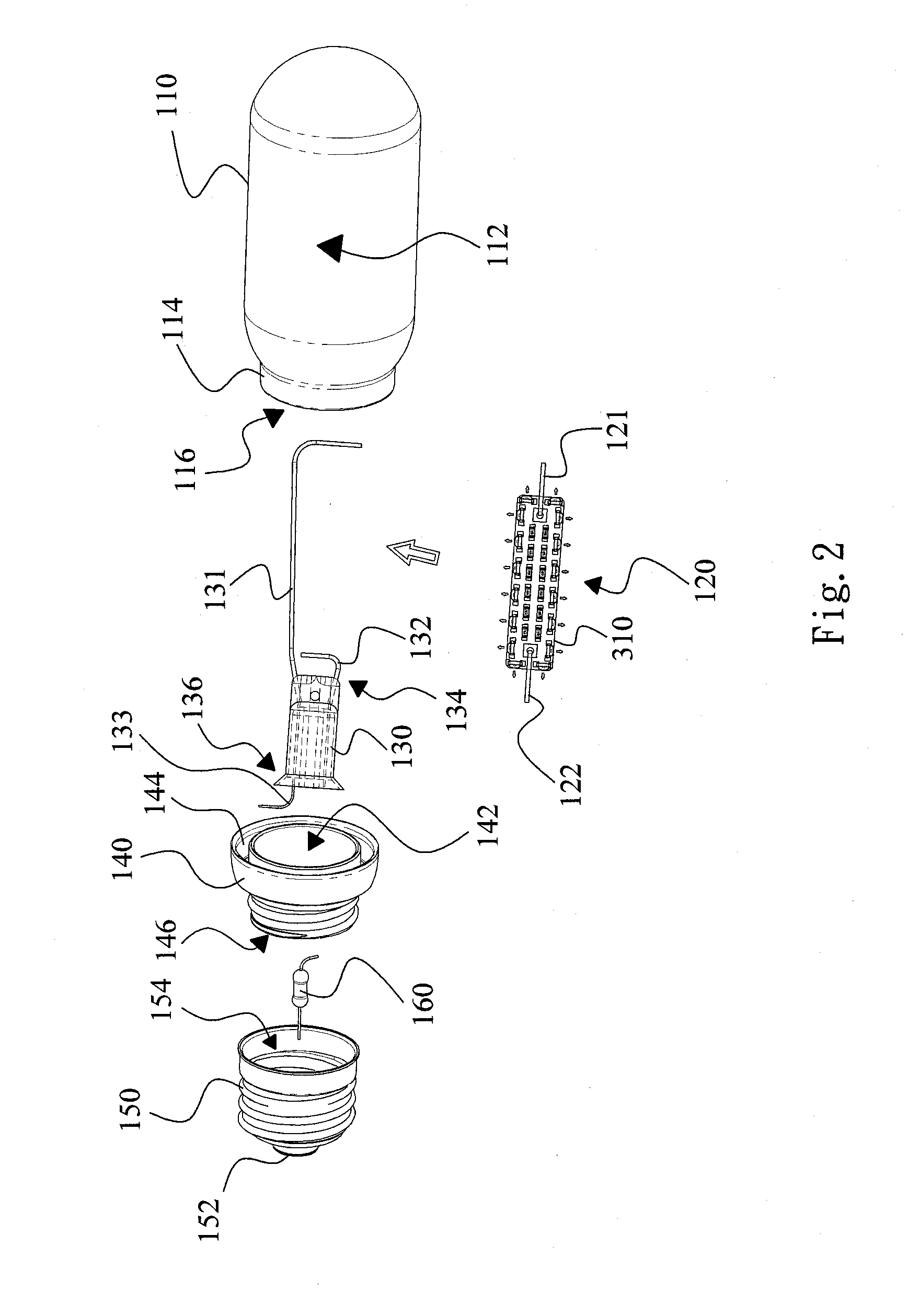

LED bulb

InactiveUS20100253221A1Wide and uniform illuminationImprove reliabilityCoupling device connectionsPoint-like light sourceElectrical connectionEngineering

An LED bulb uses an LED strip suspended between two lead frames of a stem as a light source to provide uniform illumination with wider angles. The lead frames of the stem provide an improved structural stability to the LED strip while maintaining a reliable electrical connection between the components of the stem and the LED strip. The utilization of both top-emitting and side-emitting LEDs on the LED strip further allows lights emitted in directions substantially parallel and perpendicular to the LED strip to cover a wide angle of illumination from the LED bulb.

Owner:LIQUIDLEDS LIGHTING

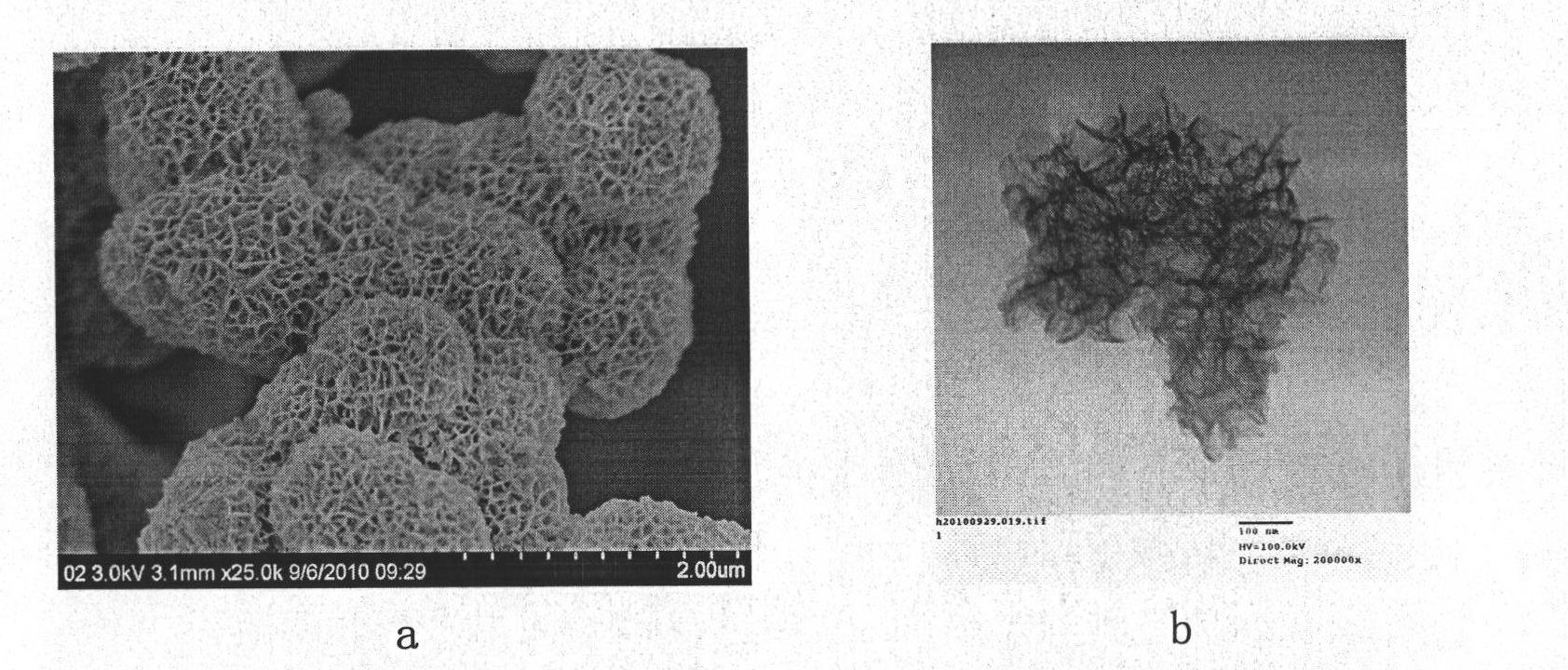

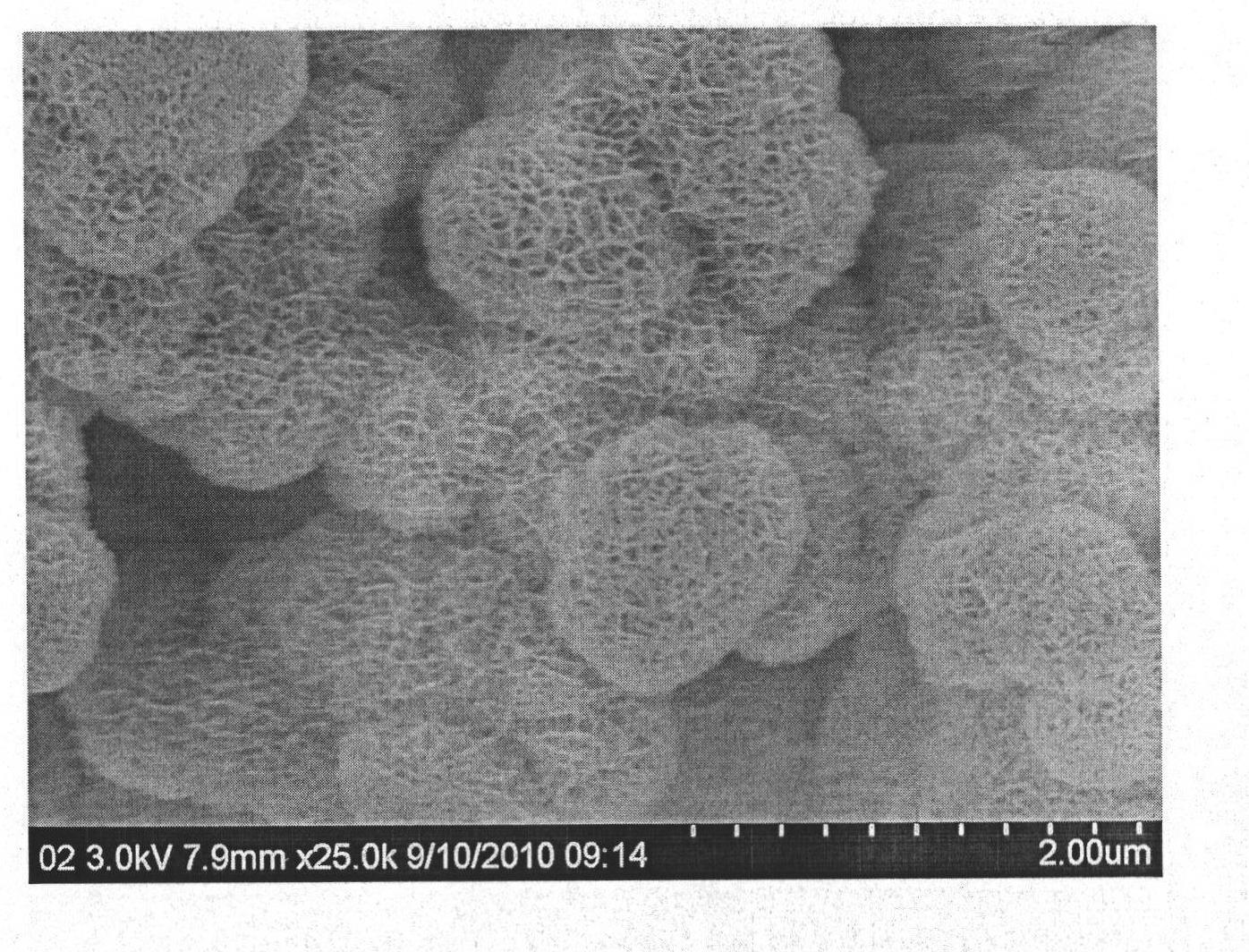

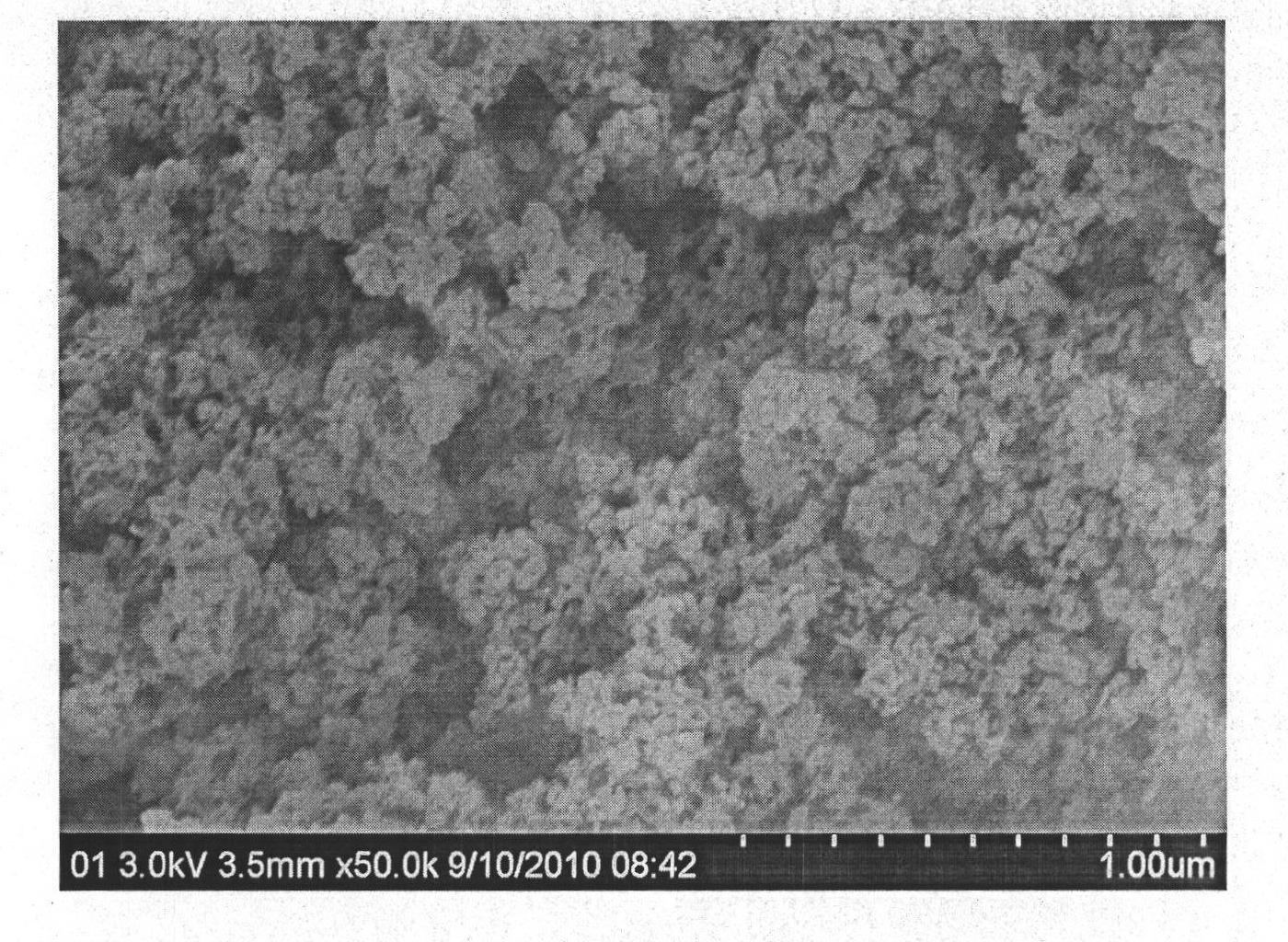

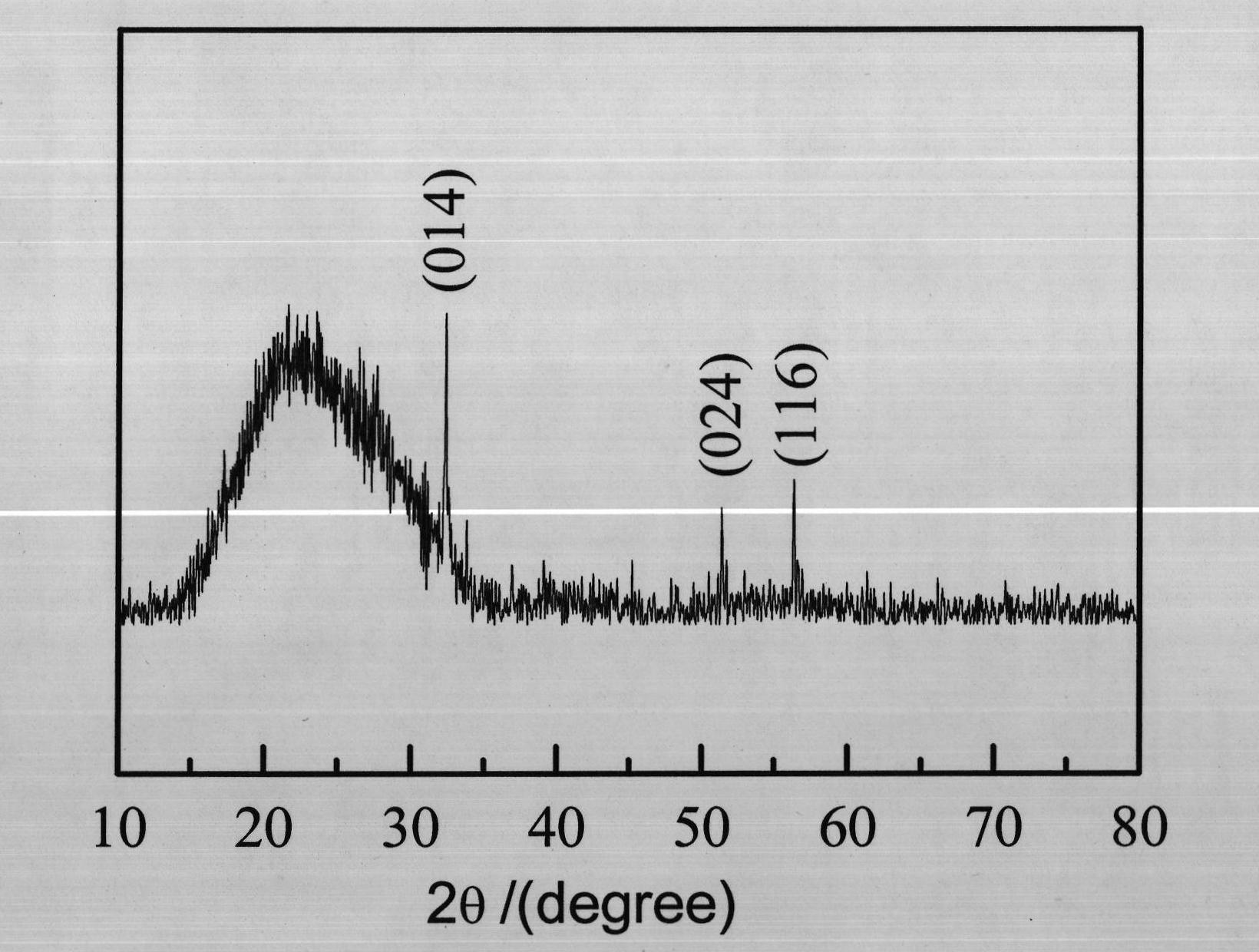

Preparation method of brain-coral-shaped birnessite type manganese dioxide

InactiveCN102120619AImprove structural stabilityShape unchangedNanotechnologyManganese oxides/hydroxidesStructural stabilityPotassium permanganate

Owner:HEBEI NORMAL UNIV

Graphene-based nano iron oxide composite material and preparation method thereof

InactiveCN102130334AAvoid reunionPrevent heavy stackingMaterial nanotechnologyCell electrodesNano compositesFreeze-drying

The invention discloses a graphene-based nano iron oxide composite material and a preparation method thereof. By the method, iron oxide nano granules with uniform diameter and controllable shape and components can be loaded on graphene. The method comprises the following steps of: uniformly dispersing graphite oxide into deionized water by adopting an ultrasonic method to obtain graphene oxide solution; adding an iron salt precursor into the obtained solution and mixing the precursor and the solution uniformly, adjusting the pH of the solution, and hydrolyzing the iron salt; putting the mixed solution into a reaction kettle and performing hydrothermal reaction; and finally, cleaning and freeze-drying the obtained product to obtain the graphene-based nano iron oxide composite material. The raw materials are common and easily obtained, the cost is low, and the preparation process is simple, safe and environmentally-friendly; the prepared graphene-based nano iron oxide composite material has good structural stability and monodispersity; when the composite material is used as a lithium iron battery electrode material, the charge / discharge capacity can reach over 1,000mAh / g; and the composite material has good multiplying power performance and cycle life.

Owner:CHINA UNIV OF MINING & TECH

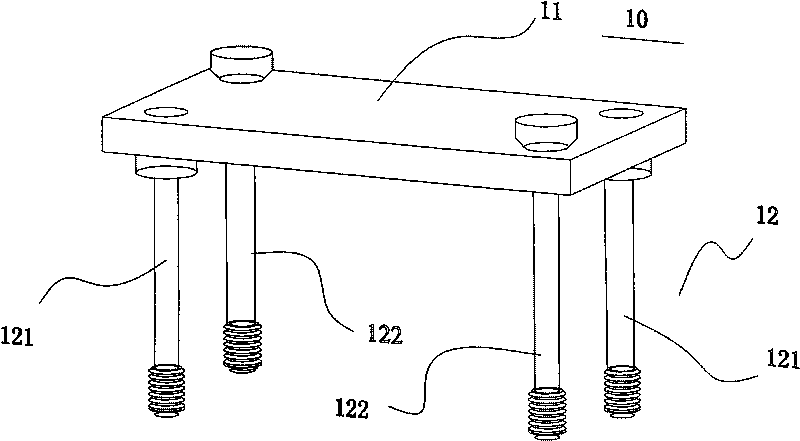

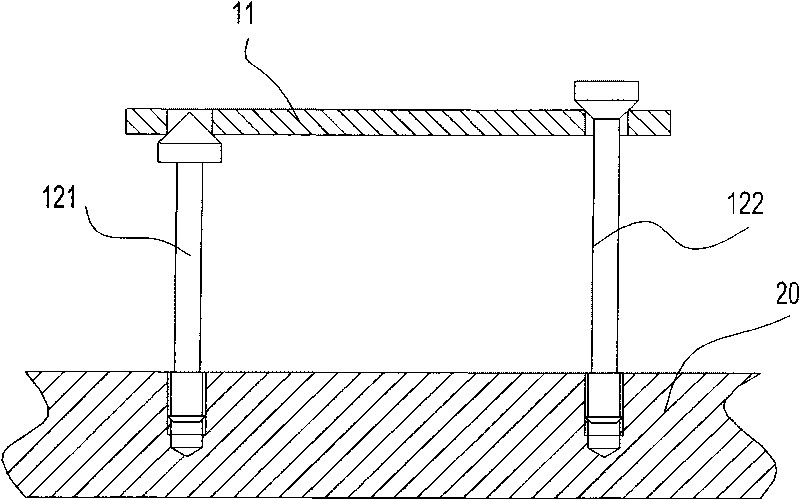

Adiabatic supporting device

ActiveCN101738127AGuaranteed stabilityReduce thermal contact areaHeat exchanger casingsEngineeringVacuum chamber

An adiabatic supporting device is used for supporting low temperature devices in a low temperature vacuum system. The supporting device comprises a cold platform with a plurality of mounting holes and support bars used for supporting the cold platform. The bottoms of the support bars are fixedly connected with a vacuum chamber. The support bars comprise upward ejecting support bars and downward pressing support bars. The upper parts of the upward ejecting support bars are matched with the mounting holes by way of point contact or line contact and the upward ejecting support bars provide upward ejecting force to the cold platform. After the downward pressing support bars pass through the mounting holes, the tops of the downward pressing support bars are matched with the mounting holes by way of point contact or line contact and the downward pressing support bars provide downward pressing force to the cold platform. The upward ejecting force reaches equilibrium with the downward pressing force. The supporting device furthest reduces the heat contact area under the premise of ensuring the stability of the mechanical structure and changes from the original nut surface contact to the current line contact or point contact, thus reducing heat leakage from the vacuum chamber to the cold platform and greatly reducing heat load.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

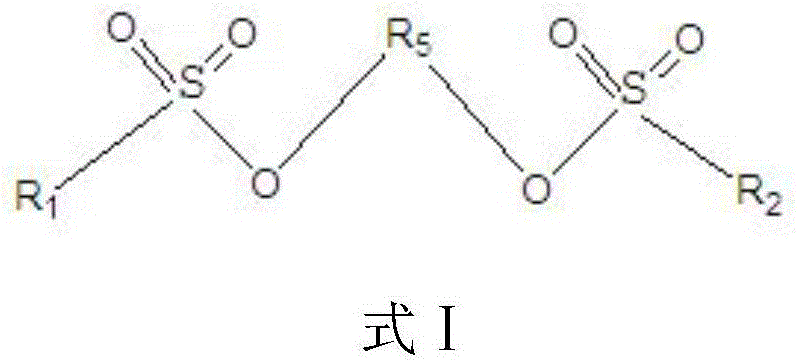

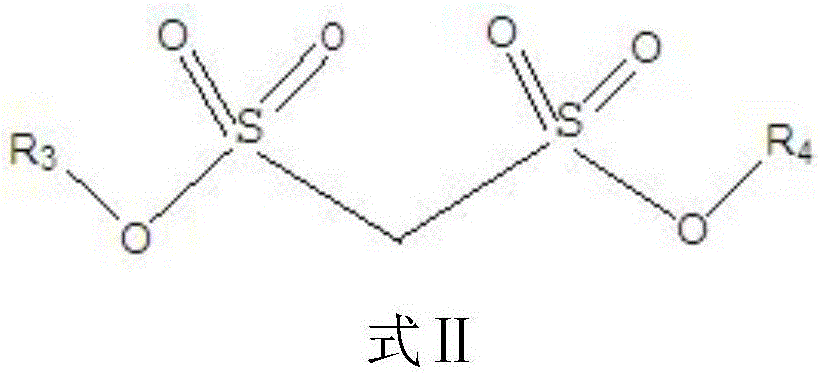

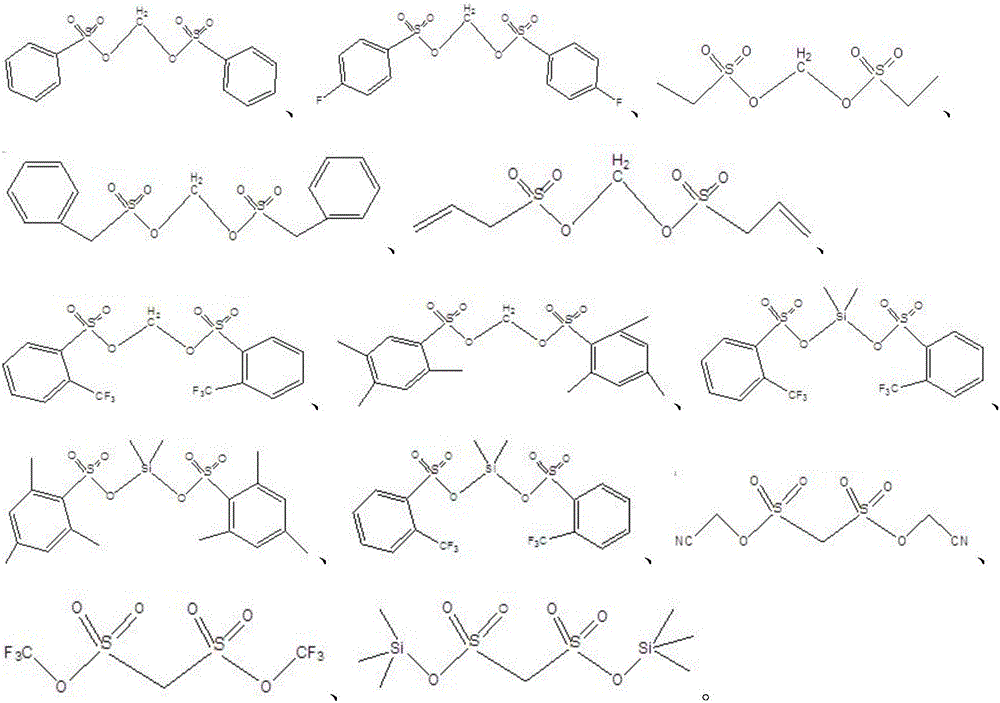

Electrolyte of lithium-ion battery and lithium-ion battery containing electrolyte

ActiveCN106505249AExcellent high temperature storageExcellent high temperature cycle performanceSecondary cells servicing/maintenanceOrganic electrolytesHigh temperature storageSide reaction

The invention relates to the technical field of lithium-ion batteries, in particular to an electrolyte of the lithium-ion battery and the lithium-ion battery containing the electrolyte. The electrolyte comprises a lithium salt, a non-aqueous organic solvent and an additive, wherein the additive comprises a film-forming additive A and a stabilizing additive B; the stabilizing additive B is a chainlike disulfonic acid ester compound as shown in a formula I and / or a formula II; and the film-forming additive A forms an SEI film on a negative electrode surface of the battery and the side reaction of a negative electrode interface and the electrolyte is reduced, so that the film-forming additive A is an necessary precondition that the battery has relatively good cycle performance. The stabilizing additive B can form a CEI film on a positive electrode surface, the activity of a positive electrode interface and the electrolyte is inhibited, direct contact oxidation of a positive electrode and the electrolyte is reduced, meanwhile, the structure stability of a positive electrode material is improved and the structure is not easy to collapse and crush due to generation of the stress, so that the electrolyte has excellent high-temperature storage performance and high-temperature cycle performance through combination of the additive A and the additive B.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

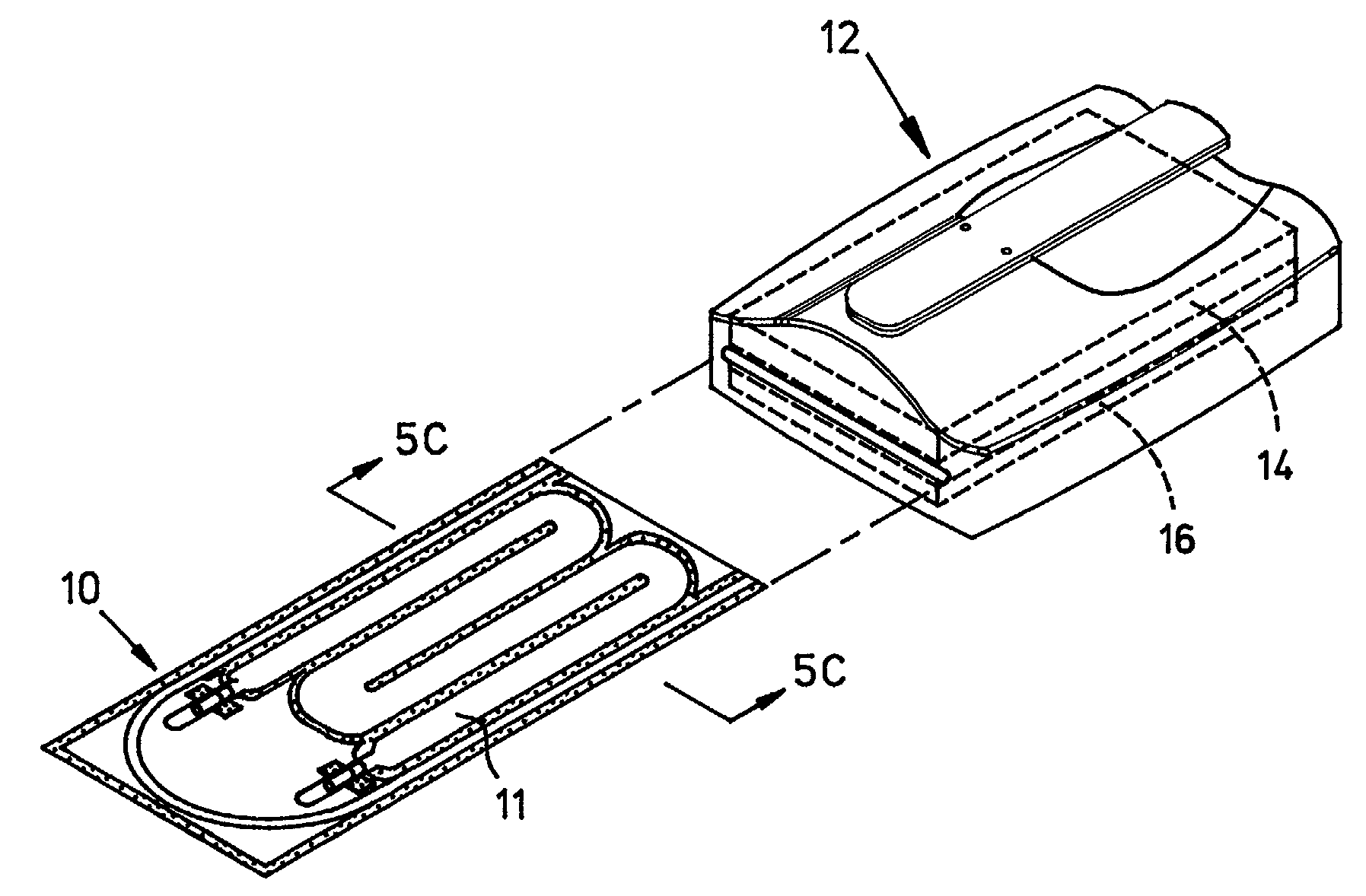

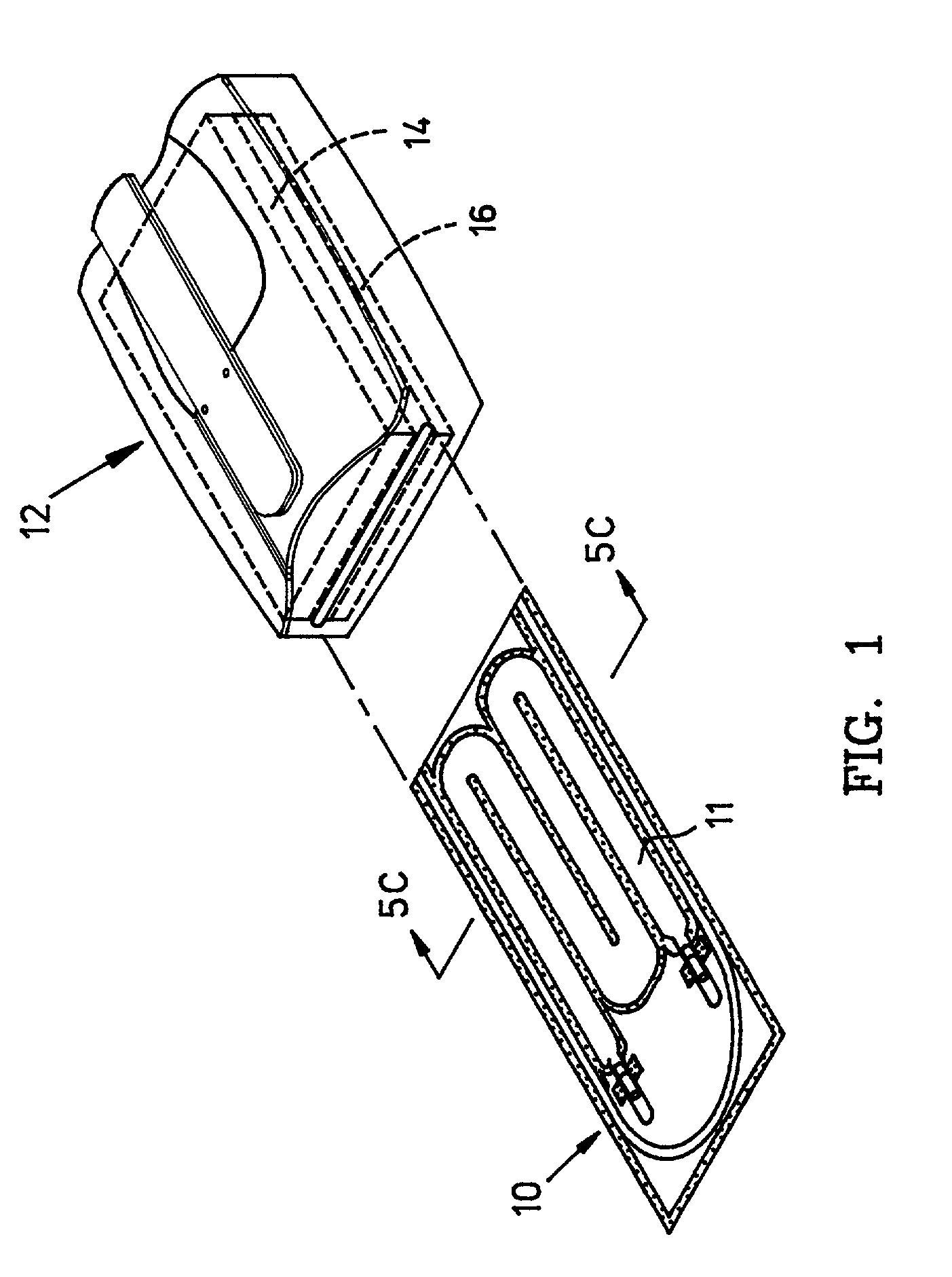

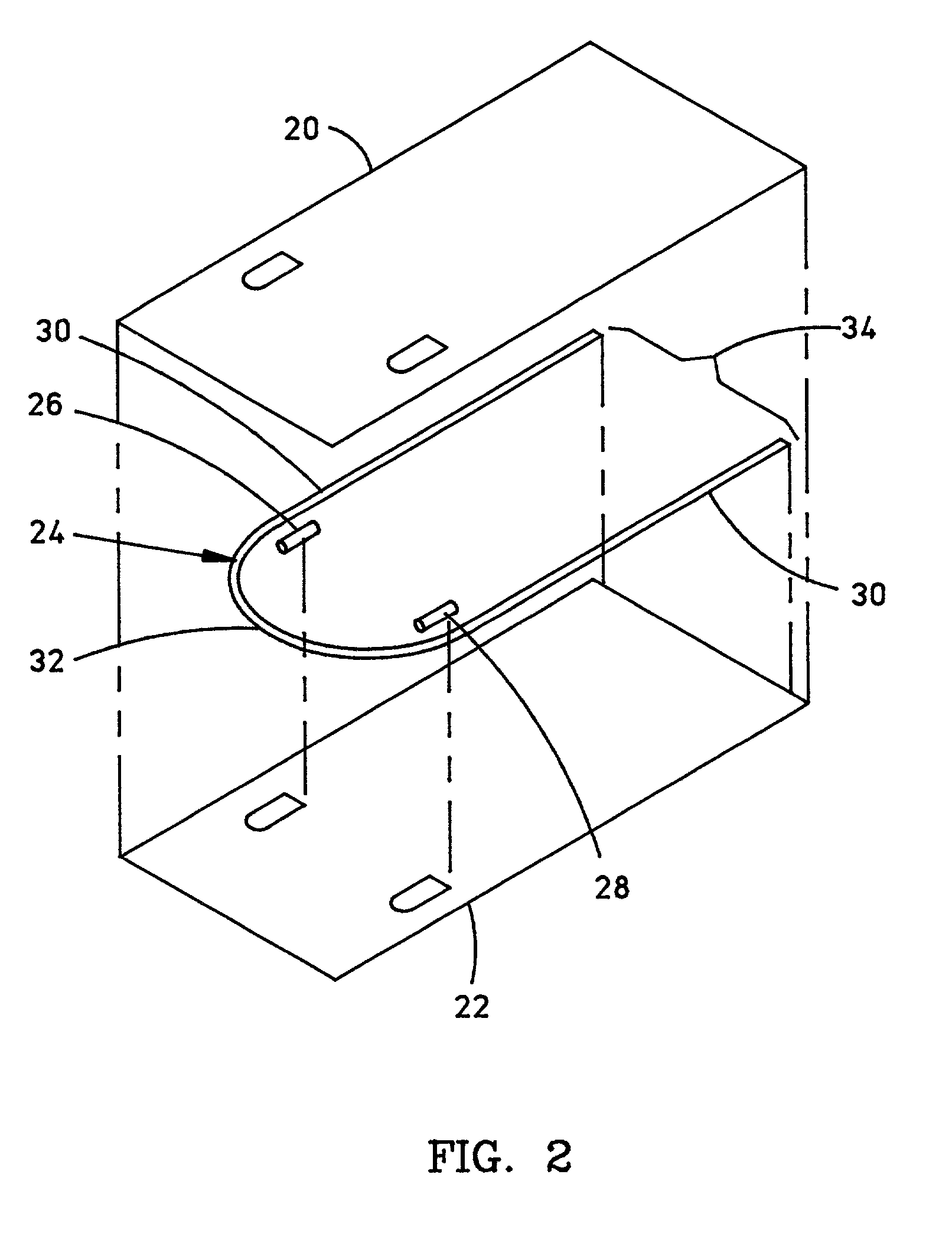

Fluid warming cassette with a tensioning rod

A fluid warming cassette for use in a fluid warming system includes a first sheet and second sheet joined with a flexed tensioning rod to form a fluid container with a periphery in which the flexed tensioning rod is disposed to tension the fluid container. The fluid container includes a fluid channel with inlet and outlet ports in fluid communication with the fluid channel. Preferably, the rod is flexed into an open-ended shape such as a “U” shape. So flexed, the rod tensions the fluid container, adding structural stability to the fluid warming cassette.

Owner:GEN ELECTRIC CAPITAL +1

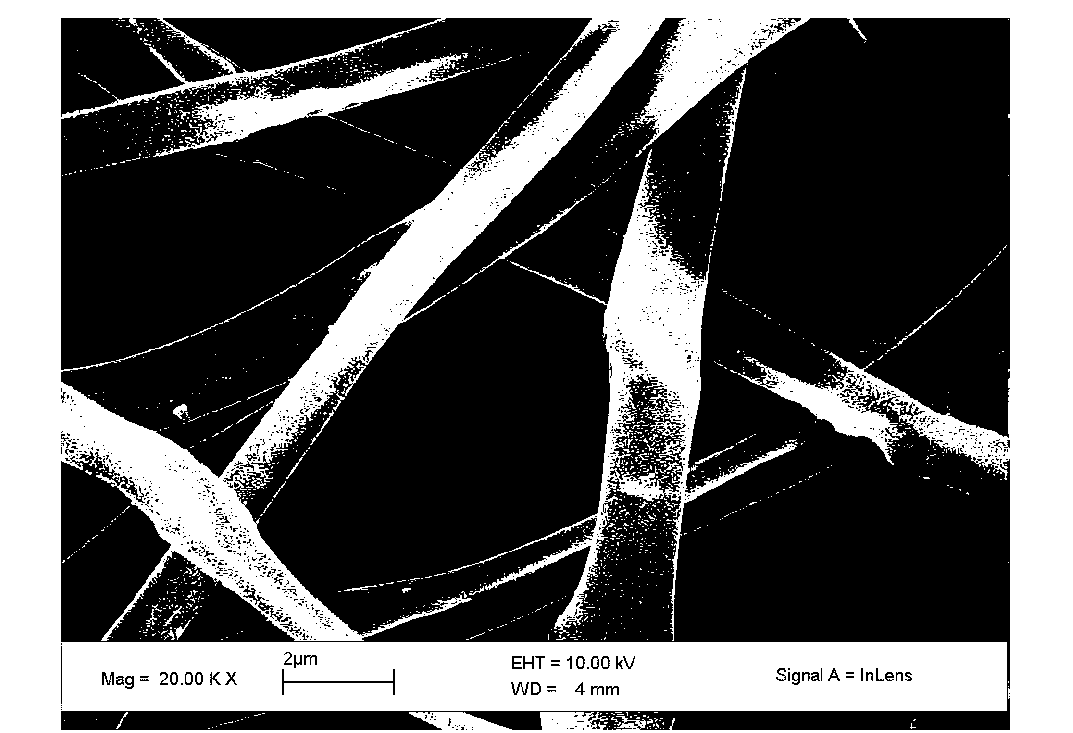

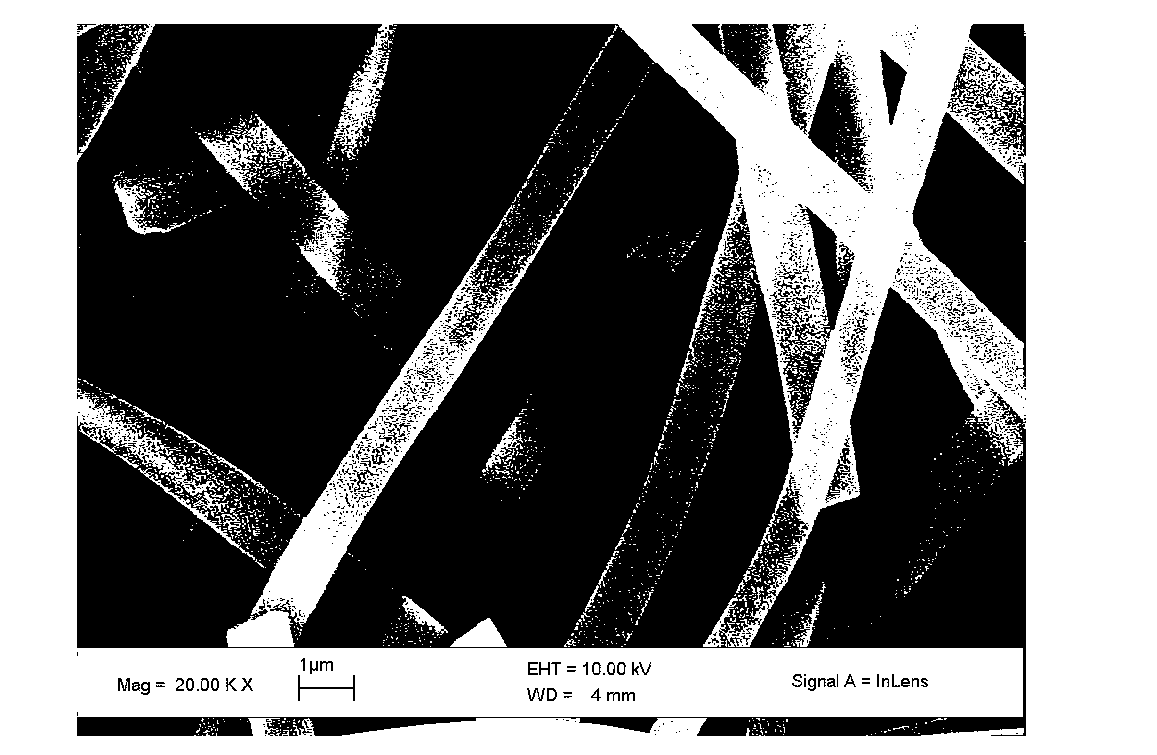

Graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and preparation method thereof

ActiveCN103215693AEvenly dispersedGood flexibilityFibre chemical featuresOrganic solventPorous carbon

The invention relates to graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and a preparation method thereof. The diameter of the fiber is in a range of 0.3-1.7mum, and the specific surface area of the fiber is 500-900m<2> / g. The fiber has a porous structure which is formed by microporous mainly. Micro-pore volume is 0.20-0.50cm<3> / g, and surface oxygen atomic ratio is lower than 10%. The preparation method comprises the steps that: graphene oxide is added into an organic solvent and is subjected to ultrasonic dispersion, such that a graphene oxide solution is formed; termosetting phenolic resin and a high-molecular-weight linear polymer are added into the graphene oxide organic solution, and are completely dissolved by stirring; the mixed solution is spun into composite fiber, and solidification and carbonization are carried out, such that porous phenolic-resin-based carbon / graphite oxide composite ultrafine fiber is obtained. The sources of adopted raw materials are rich. The prepared composite fiber has the advantages of high structural stability, good flexibility, developed pore structure, controllable surface oxygen content, and suitability for practical application.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com