Electrolyte of lithium-ion battery and lithium-ion battery containing electrolyte

A lithium ion battery and electrolyte technology, applied in the field of lithium ion batteries, can solve the problems of high temperature storage of electrolyte and poor cycle performance, and achieve the effects of excellent high temperature cycle performance, reducing dissolution and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Electrolyte preparation:

[0039] In a glove box filled with argon (moisture content 6 , and stirred until it was completely dissolved, that is, the lithium-ion battery electrolyte of Example 1 was obtained.

[0040] Preparation of lithium-ion batteries:

[0041] The positive electrode active material LiNi 0.6 co 0.2 mn 0.2 o 2 , the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) in the N-methylpyrrolidone solvent system in a mass ratio of 95:3:2 are fully stirred and mixed evenly, and then coated on Al foil, dried, and cooled. Press to obtain the positive electrode sheet, and its compacted density is 3.5g / cm 3 .

[0042] Negative electrode active material graphite, conductive agent acetylene black, binder styrene-butadiene rubber (SBR), thickener sodium carboxymethyl cellulose (CMC) were mixed in a deionized water solvent system according to the mass ratio of 96:2:1:1 After fully stirring and mixing evenly, it is coated on Cu foi...

Embodiment 2~22

[0045] The preparation of embodiment 2~22 and comparative example 1~6 electrolyte:

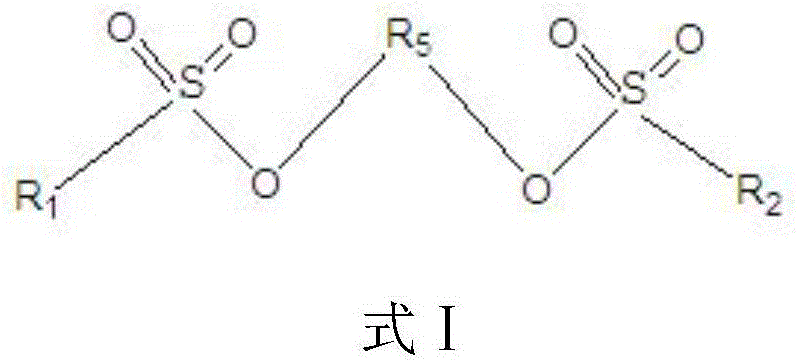

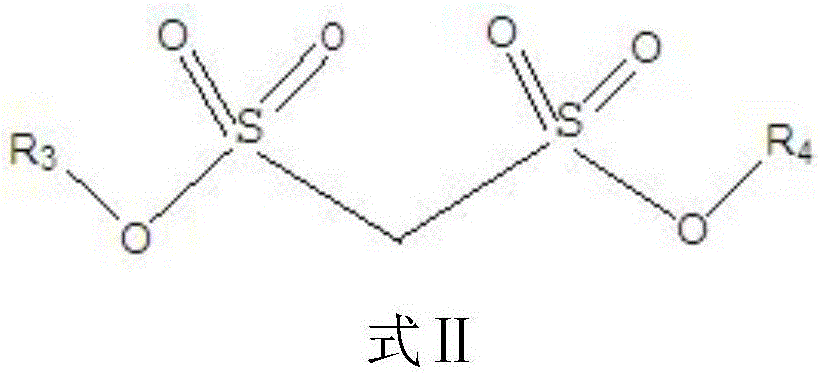

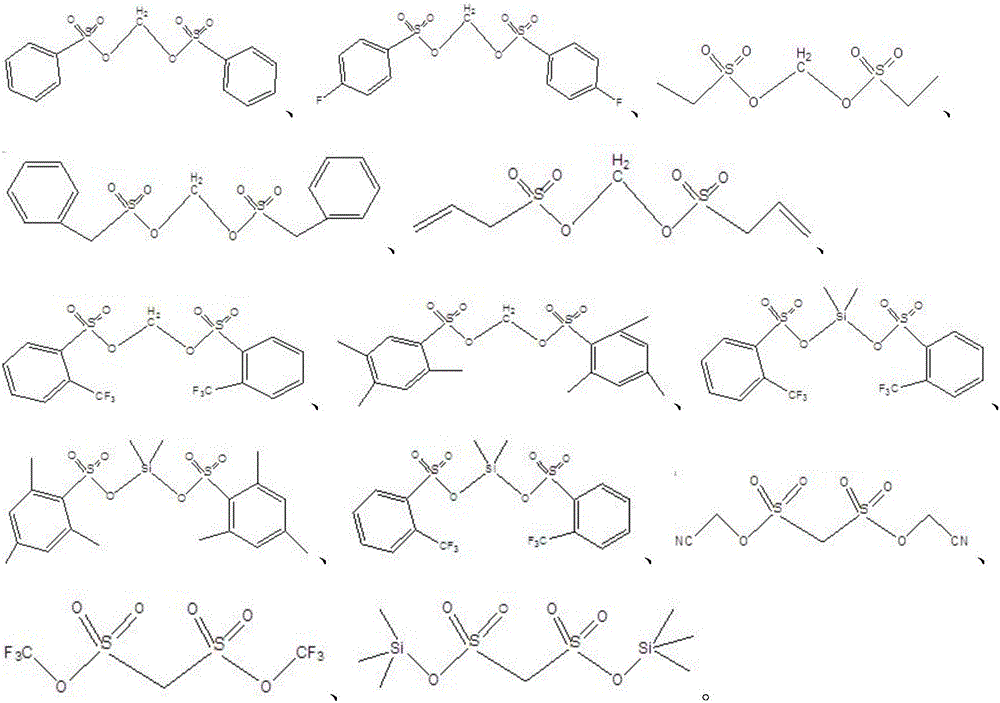

[0046] The preparation method of the electrolyte solution of Examples 2-22 and Comparative Examples 1-6 is similar to the preparation method of the electrolyte solution of Example 1, that is, in a glove box (moisture content<10ppm, oxygen content<1ppm) filled with argon, according to The solvents listed in Table 1 and the proportions of various additives were prepared, wherein the addition amount of lithium hexafluorophosphate was 12.5%. Wherein, the listed additives of B1-B13 respectively correspond to the following compounds:

[0047] i.e. R 1 = R 2 = phenyl, R 5 = methylene;

[0048] i.e. R 1 = R 2 = p-fluorophenyl, R 5 = methylene;

[0049] i.e. R 1 = R 2 = ethyl, R 5 = methylene;

[0050] i.e. R 1 = R 2 = benzyl, R 5 = methylene;

[0051] i.e. R 1 = R 2 = Allyl, R 5 = methylene;

[0052] i.e. R 1 = R 2 =2-trifluoromethylphenyl, R 5 = methylene;

[0053]...

Embodiment 2~18

[0060] Preparation of Li-ion batteries (ternary NCM batteries) in Examples 2-18 and Comparative Examples 1-5:

[0061] The preparation method of the lithium-ion battery of Examples 2-18 and Comparative Examples 1-5 is similar to that of Example 1, and the positive electrode active material used is consistent with the ternary positive electrode material (NCM) used in Example 1, and then Inject the electrolytes corresponding to Examples 2-18 and Comparative Examples 1-5 respectively, and undergo processes such as packaging, shelving, chemical formation, aging, secondary packaging, and volume separation to obtain Examples 2-18 and Comparative Examples 1-5 High-nickel ternary cathode material soft pack lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com