Electrolyte for rechargeable lithium battery and rechargeable lithium battery

A technology for electrolytes and lithium batteries, applied in the field of electrolytes for rechargeable lithium batteries and rechargeable lithium batteries, can solve problems such as poor safety, high-temperature performance degradation, and large amounts of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

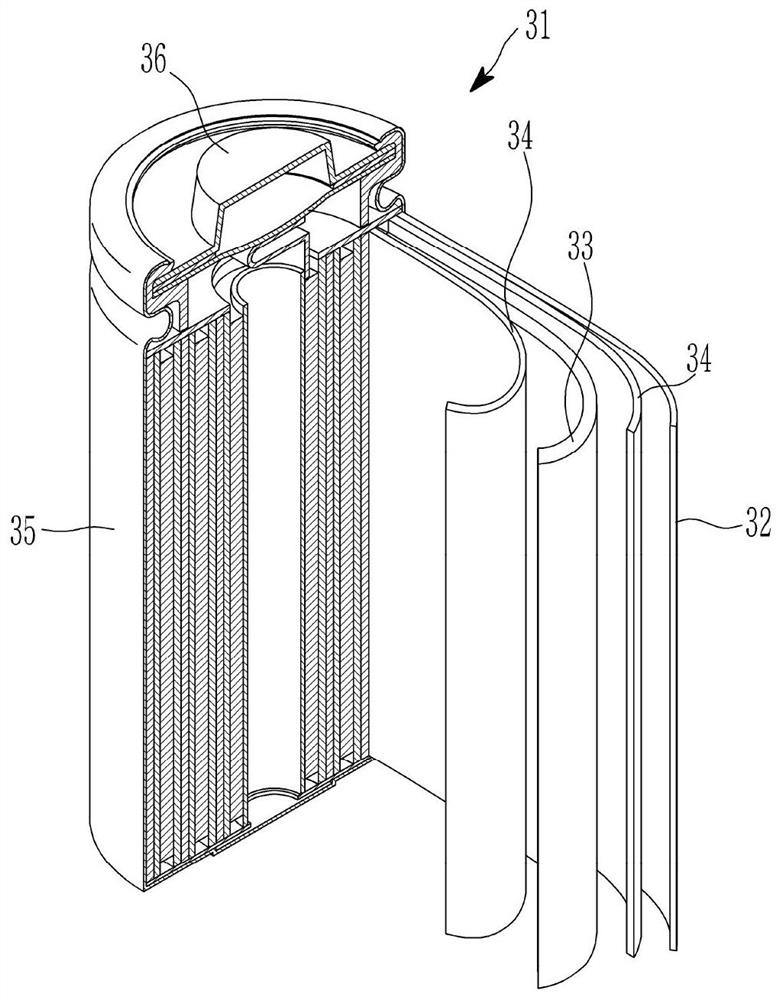

[0125] LiNi will be used as the positive electrode active material 0.8 Co 0.15 Al 0.05 O 2 , polyvinylidene fluoride as a binder, and carbon black as a conductive material were mixed in a weight ratio of 92:4:4, respectively, and then, dispersed in N-methylpyrrolidone to prepare a positive electrode active material slurry.

[0126] The positive electrode active material slurry was coated on Al foil to a thickness of 15 μm, dried at 100° C., and pressed to manufacture a positive electrode.

[0127] Graphite as an anode active material, polyvinylidene fluoride as a binder, and Ketjen black as a conductive material were mixed in a weight ratio of 98:1:1, and then, dispersed in N-methylpyrrolidone to A negative electrode active material slurry was prepared.

[0128] The negative electrode active material slurry was coated on Cu foil to a thickness of 10 μm, dried at 100° C., and pressed to manufacture a negative electrode.

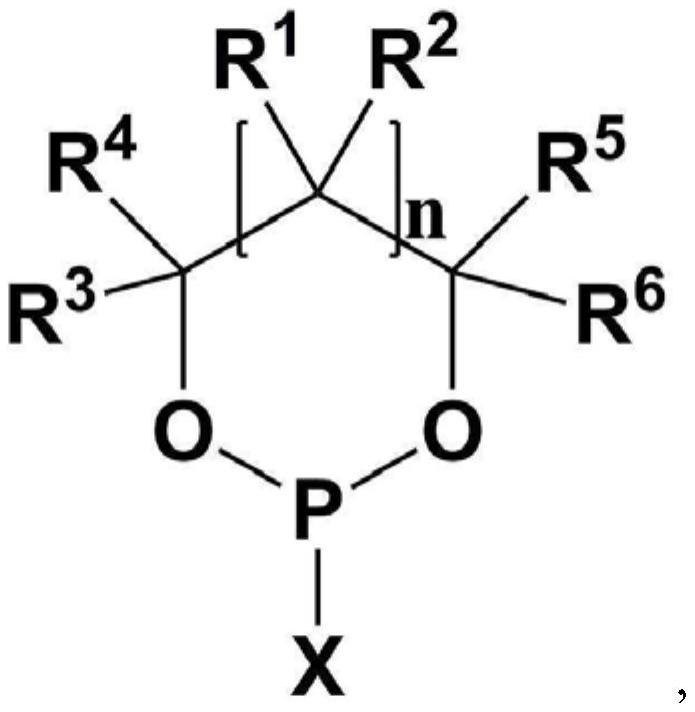

[0129] The fabricated positive and negative electro...

Embodiment 2

[0138] A rechargeable lithium battery cell was fabricated according to substantially the same method as Example 1 except that the content (eg, amount) of the compound represented by Chemical Formula 1 was changed to 0.75 wt %.

Embodiment 3

[0140] A rechargeable lithium battery cell was fabricated according to substantially the same method as Example 1 except that the content (eg, amount) of the compound represented by Chemical Formula 1 was changed to 1 wt %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com