Patents

Literature

6174 results about "High rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low water methanol carbonylation process for high acetic acid production and for water balance control

ActiveUS7005541B2High acetic acid production rateIncrease chanceOrganic compound preparationCarboxylic preparation from carbon monoxide reactionWater methanolAcetic anhydride

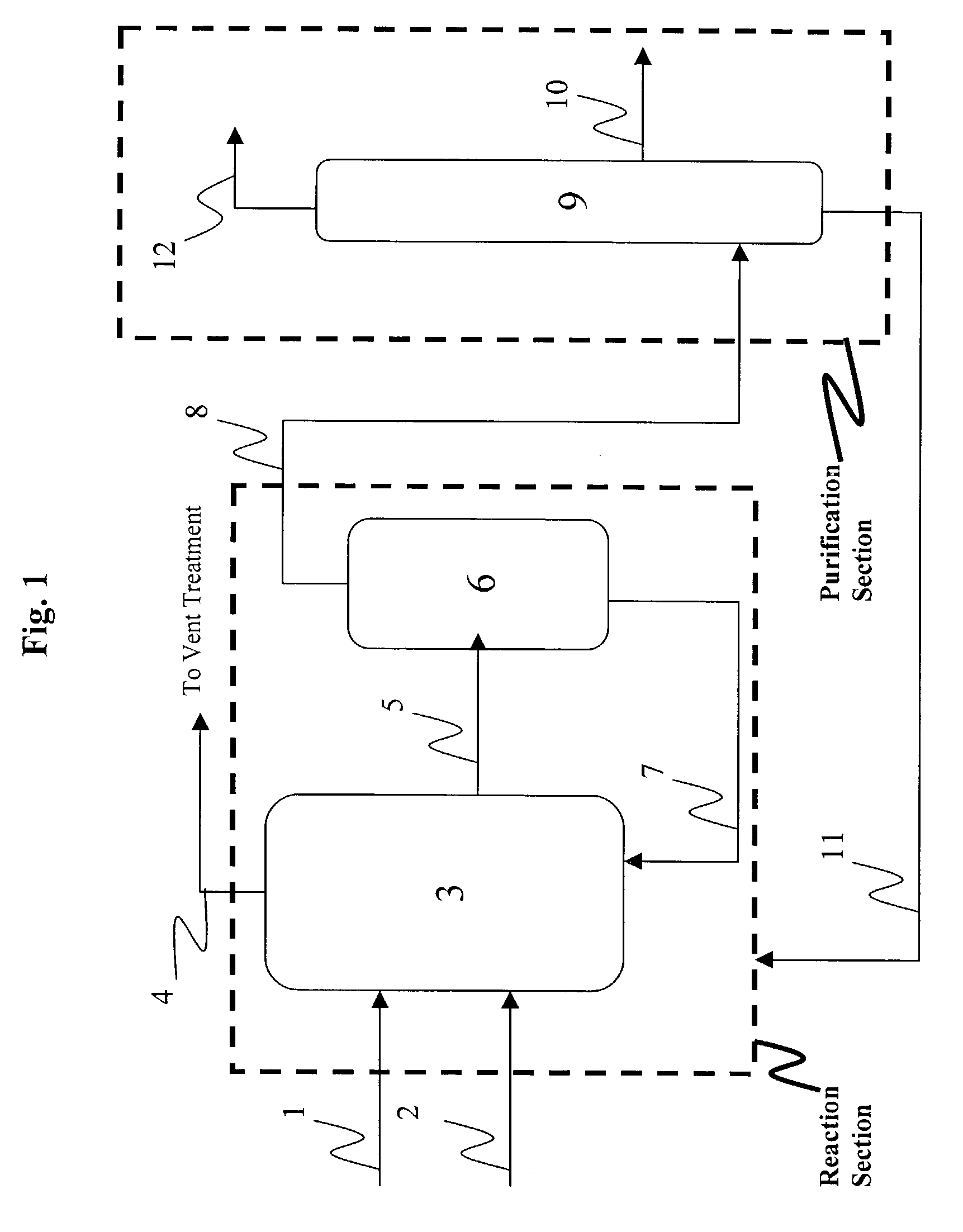

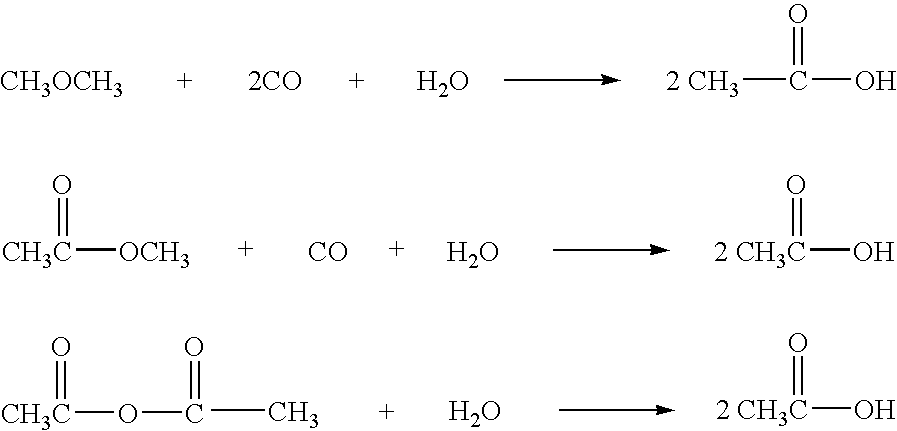

The invention relates to a process for the production of acetic acid by carbonylation of methanol, and reactive derivatives thereof, in a reaction mixture using a rhodium-based catalyst in low water conditions. The process is used to achieve reaction rates of at least 15 g mol / l / hr. The high rate reactions proceed at water concentrations of less than 2.0 wt. %. Under certain conditions, the water concentration in the reaction mixture of the process is maintained at a desired concentration by at least one process step including adding a compound such as methyl acetate, dimethyl ether, acetic anhydride, or mixtures of these compounds to the reaction system. The process step of adding the components to the reaction mixture may be combined with other process steps for controlling water concentrations in reaction mixtures for the carbonylation of methanol.

Owner:CELANESE INT CORP

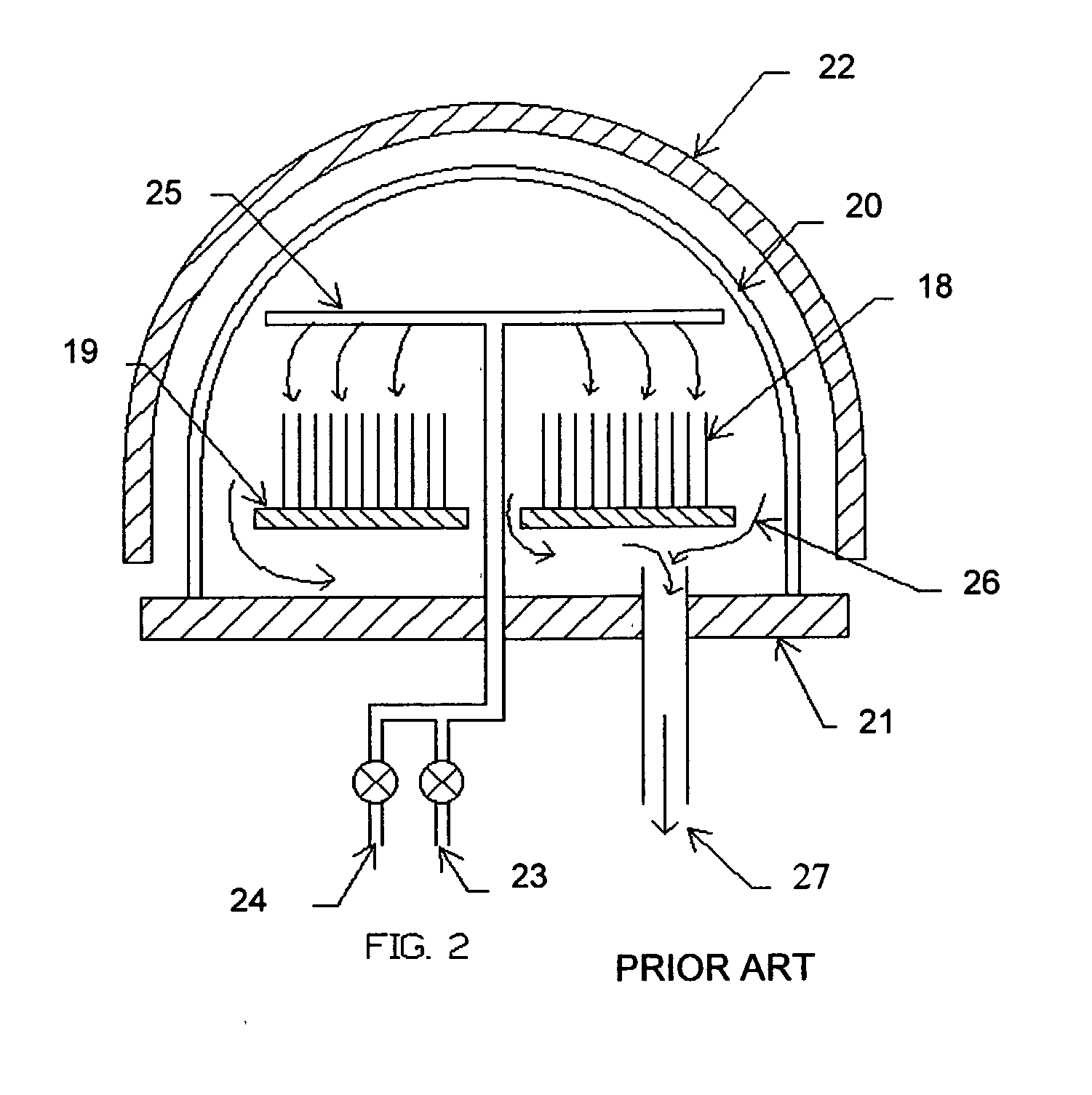

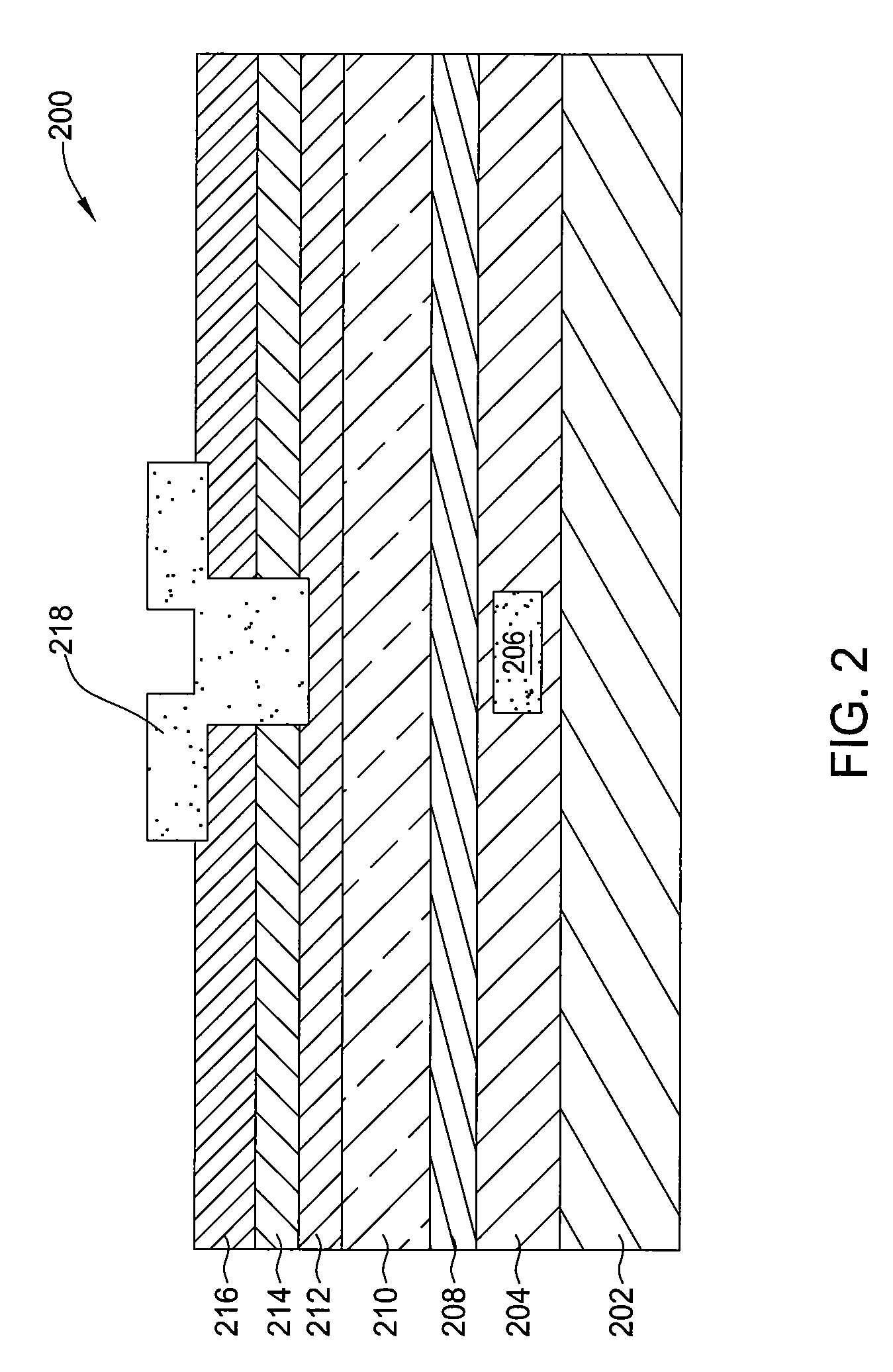

High rate deposition at low pressures in a small batch reactor

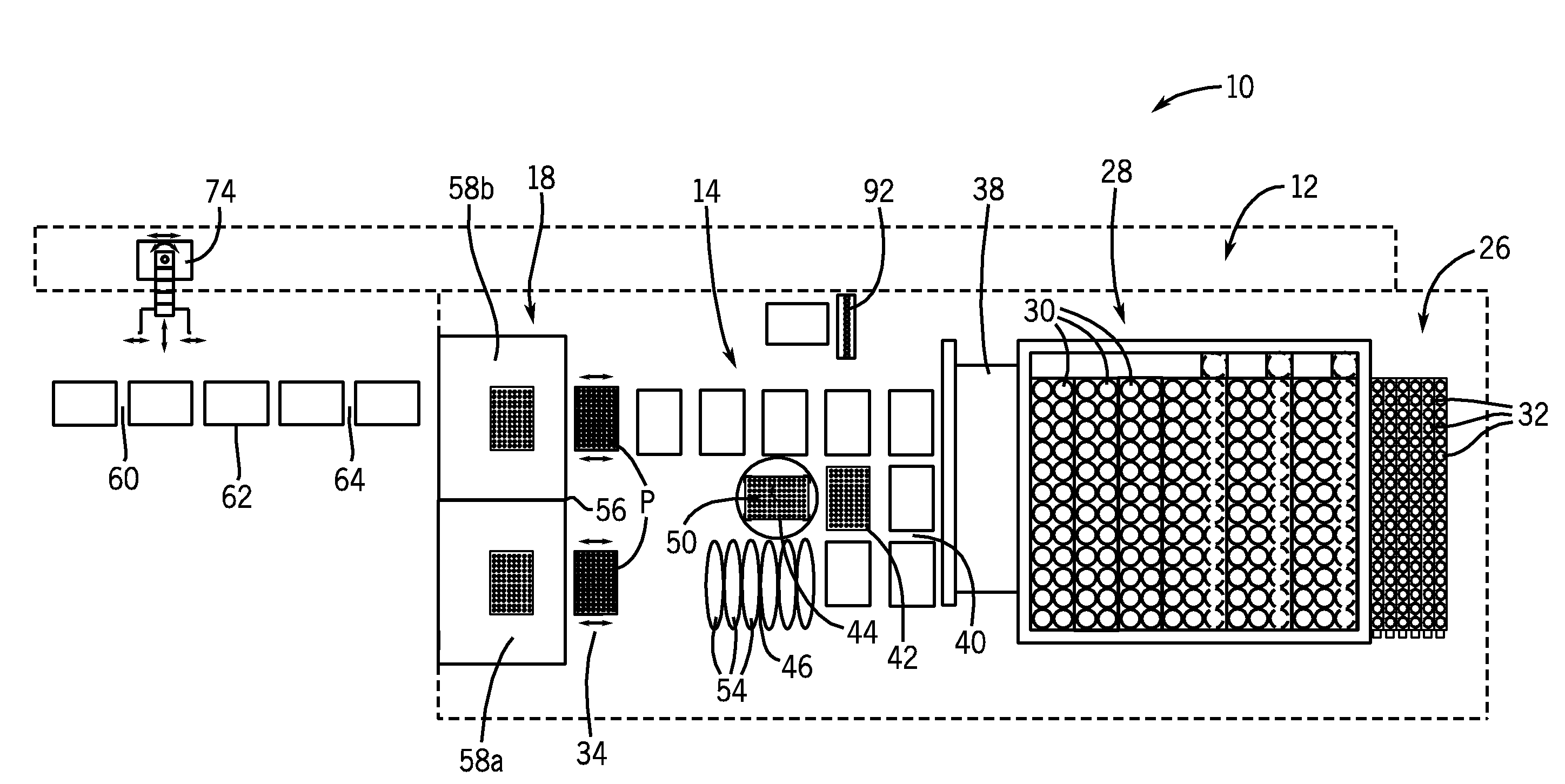

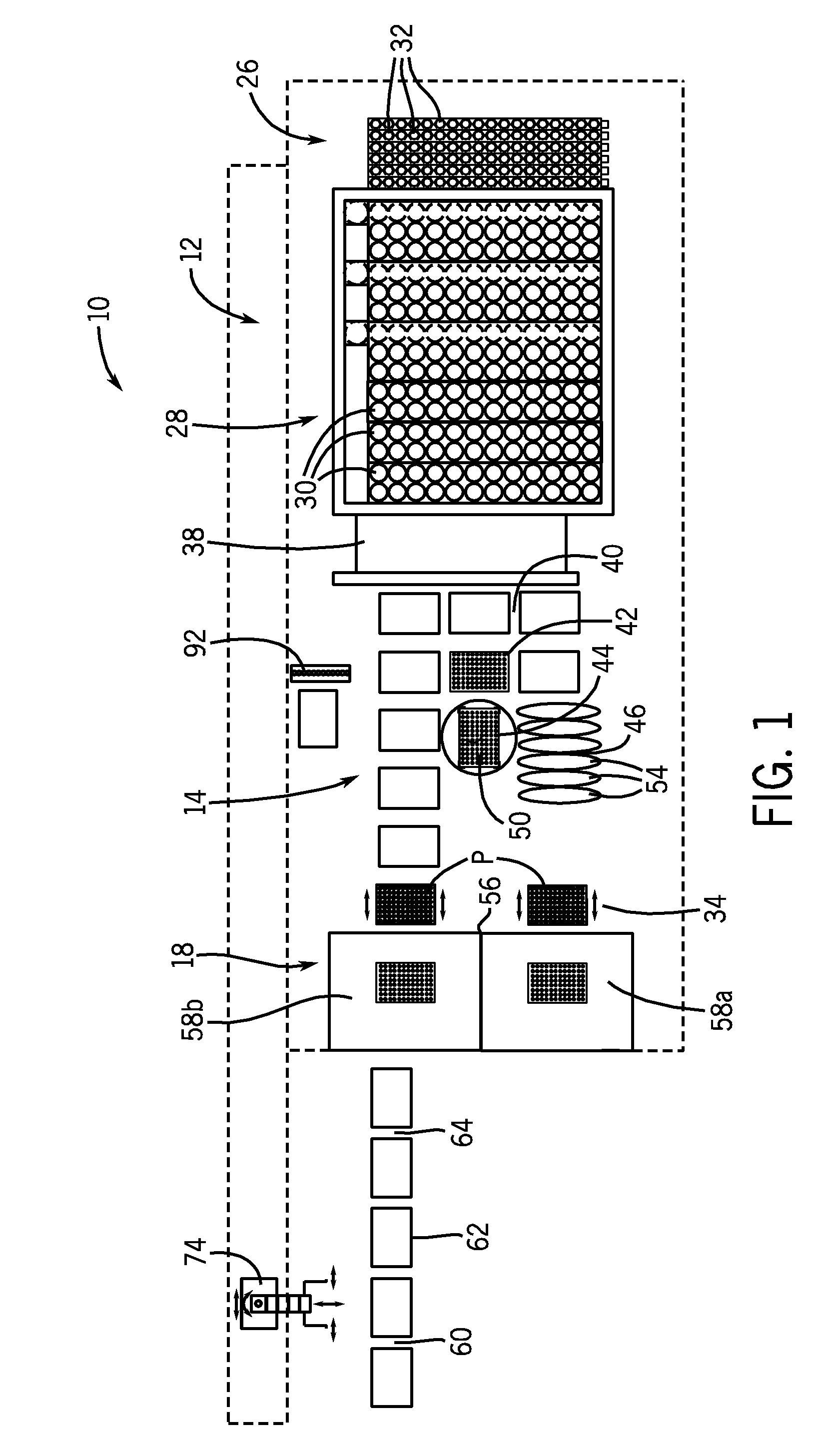

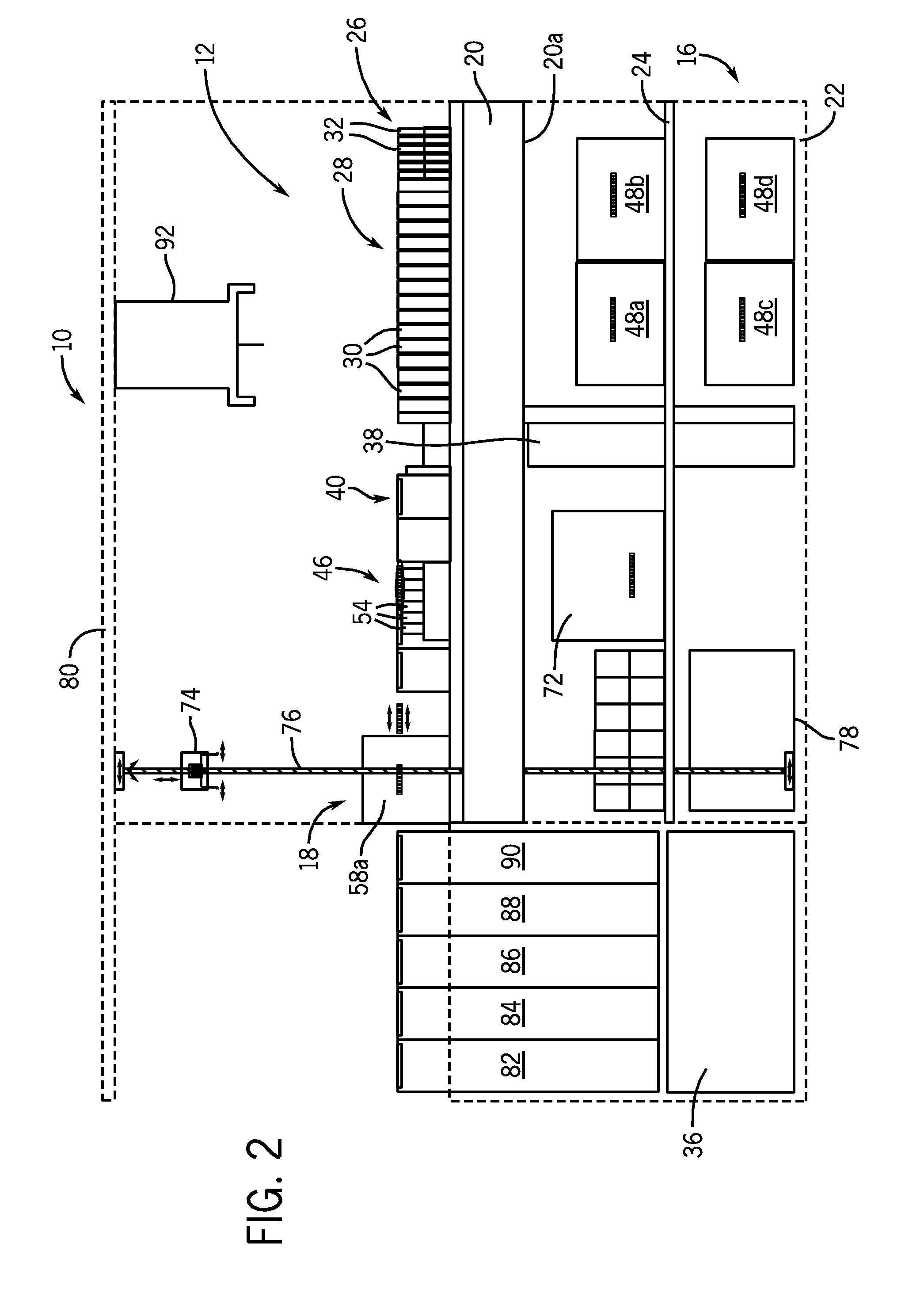

InactiveUS20030049372A1Increase ratingsRapid and uniform deposition of materialElectric discharge tubesSemiconductor/solid-state device manufacturingHigh rateSusceptor

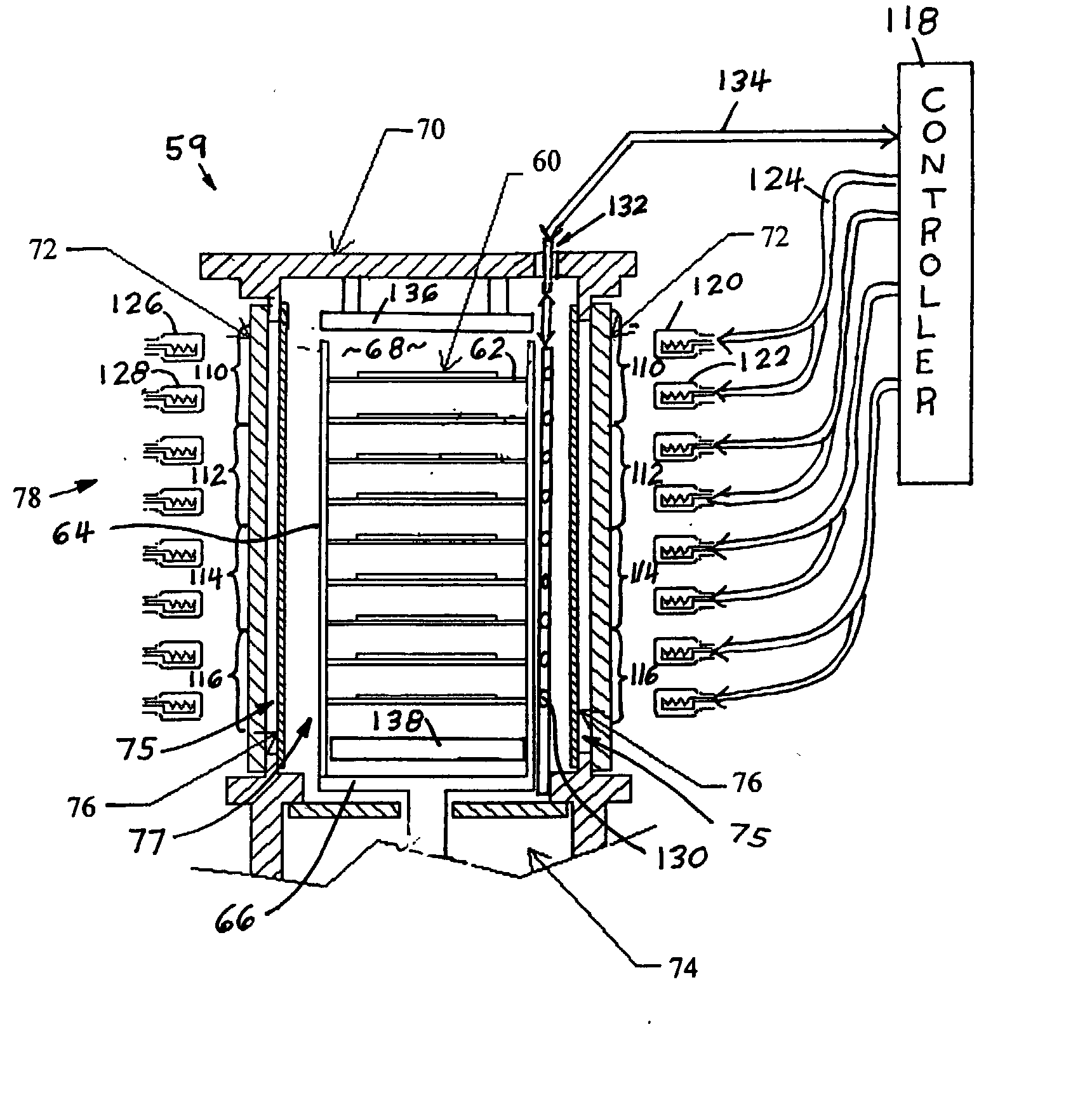

A chemical vapor deposition reactor including a wafer boat with a vertical stack of horizontally oriented susceptors serving as thermal plates and each having pins extending upward for suspending a wafer between a pair of susceptors. Reactant gas injector and exhaust apparatus are positioned to concentrate a forceful supply of reactant gas across each wafer at a speed in excess of 10 cm / sec. The pressure is held in the range of 0.1 to 5,000 mTorr. The forceful gas flow avoids gas depletion effects, thinning the boundary layer and resulting in faster delivery of reactants to substrate surfaces, resulting in surface rate reaction limited operation. A plurality of individually controllable heaters are spaced vertically around the sides of the boat. Temperature sensors monitor the temperature along the boat height and provide input to a controller for adjusting the heater drive to optimize the temperature uniformity.

Owner:APPLIED MATERIALS INC

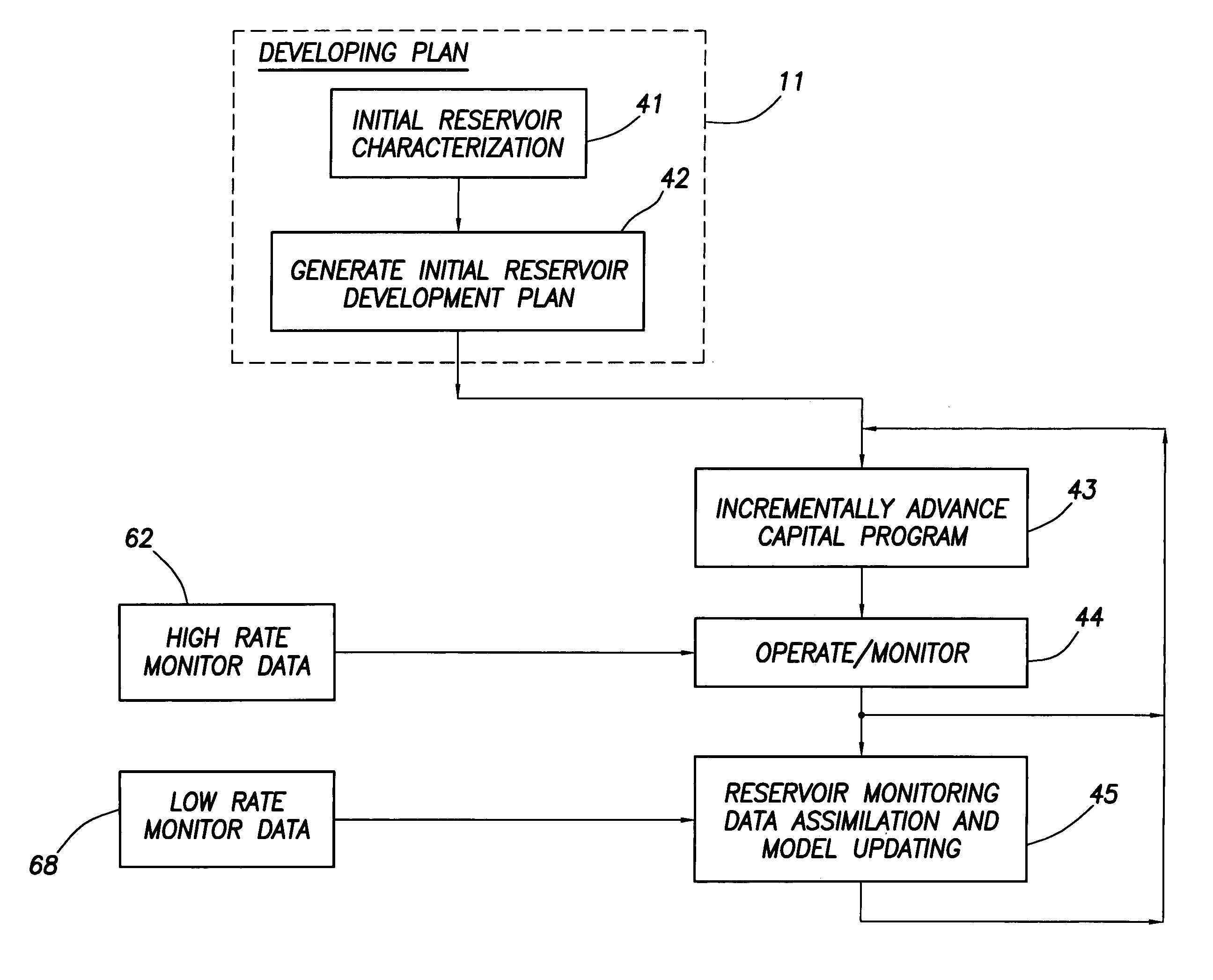

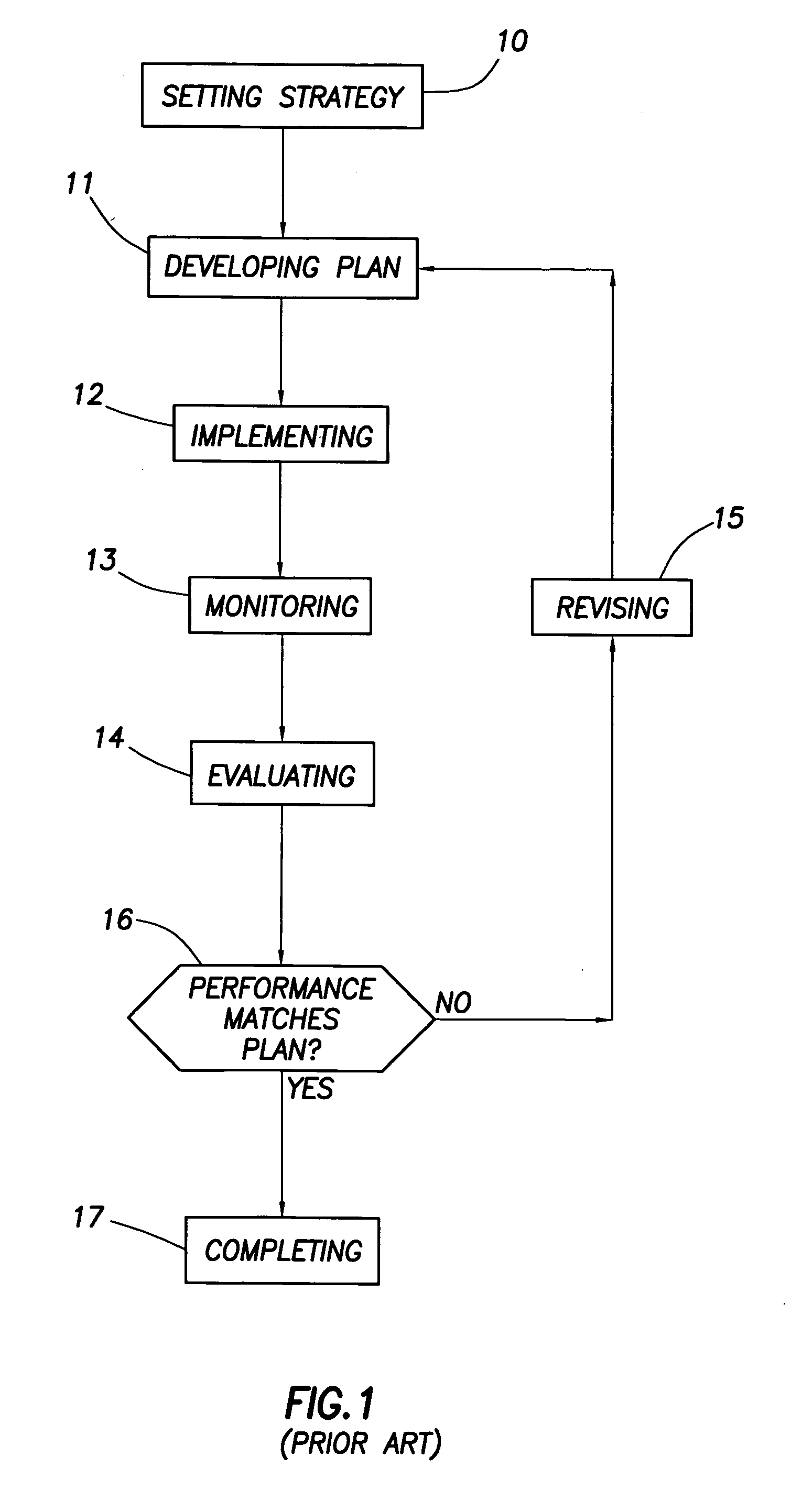

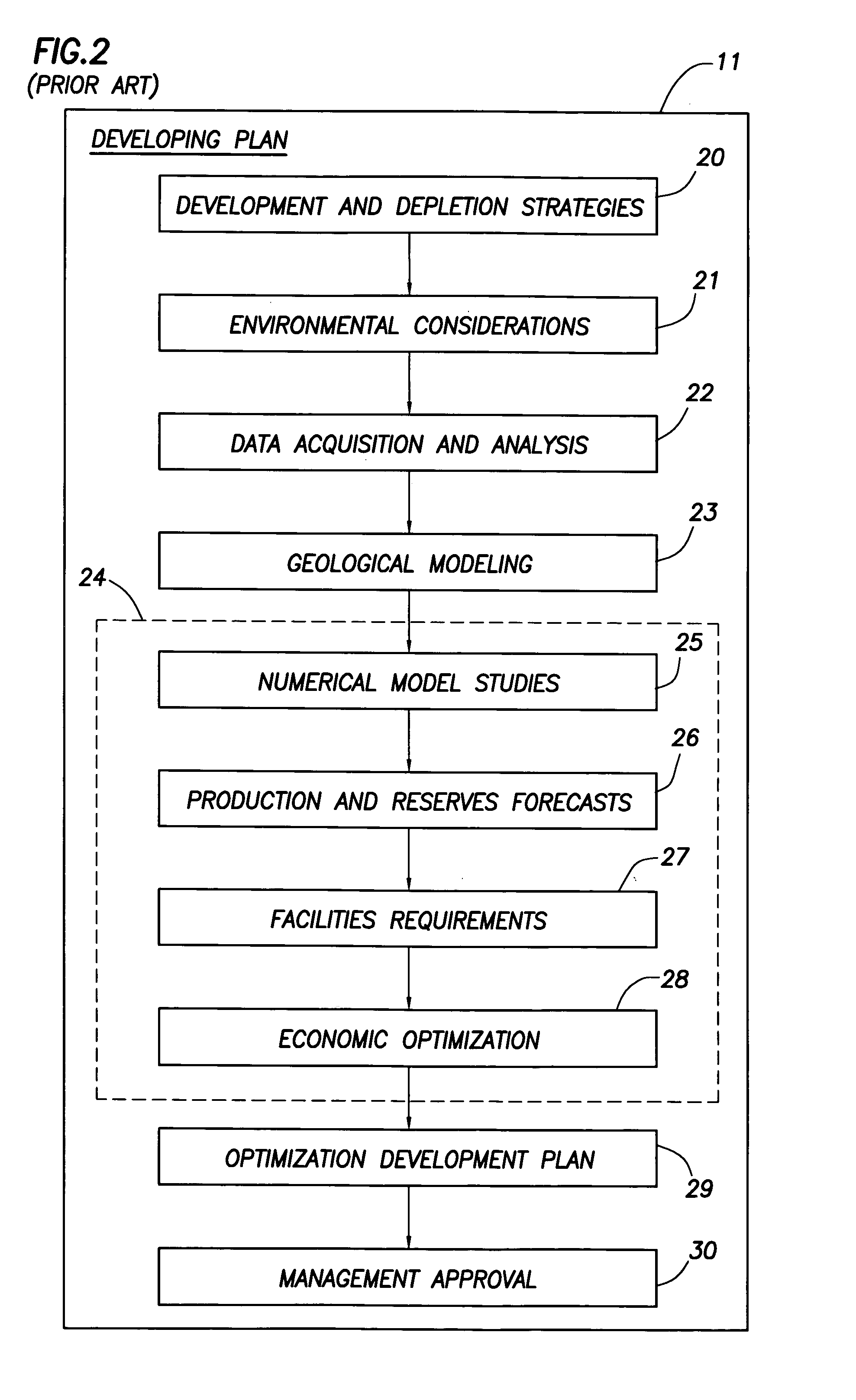

Intergrated reservoir optimization

A method of managing a fluid or gas reservoir is disclosed which assimilates diverse data having different acquisition time scales and spatial scales of coverage for iteratively producing a reservoir development plan that is used for optimizing an overall performance of a reservoir. The method includes: (a) generating an initial reservoir characterization, (b) from the initial reservoir characterization, generating an initial reservoir development plan, (c) when the reservoir development plan is generated, incrementally advancing and generating a capital spending program, (d) when the capital spending program is generated, monitoring a performance of the reservoir by acquiring high rate monitor data from a first set of data measurements taken in the reservoir and using the high rate monitor data to perform well-regional and field-reservoir evaluations, (e) further monitoring the performance of the reservoir by acquiring low rate monitor data from a second set of data measurements taken in the reservoir, (f) assimilating together the high rate monitor data and the low rate monitor data, (g) from the high rate monitor data and the low rate monitor data, determining when it is necessary to update the initial reservoir development plan to produce a newly updated reservoir development plan, (h) when necessary, updating the initial reservoir development plan to produce the newly updated reservoir development plan, and (i) when the newly updated reservoir development plan is produced, repeating steps (c) through (h). A detailed disclosure is provided herein relating to the step (a) for generating the initial reservoir characterization and the step (b) for generating the initial reservoir development plan.

Owner:SCHLUMBERGER TECH CORP

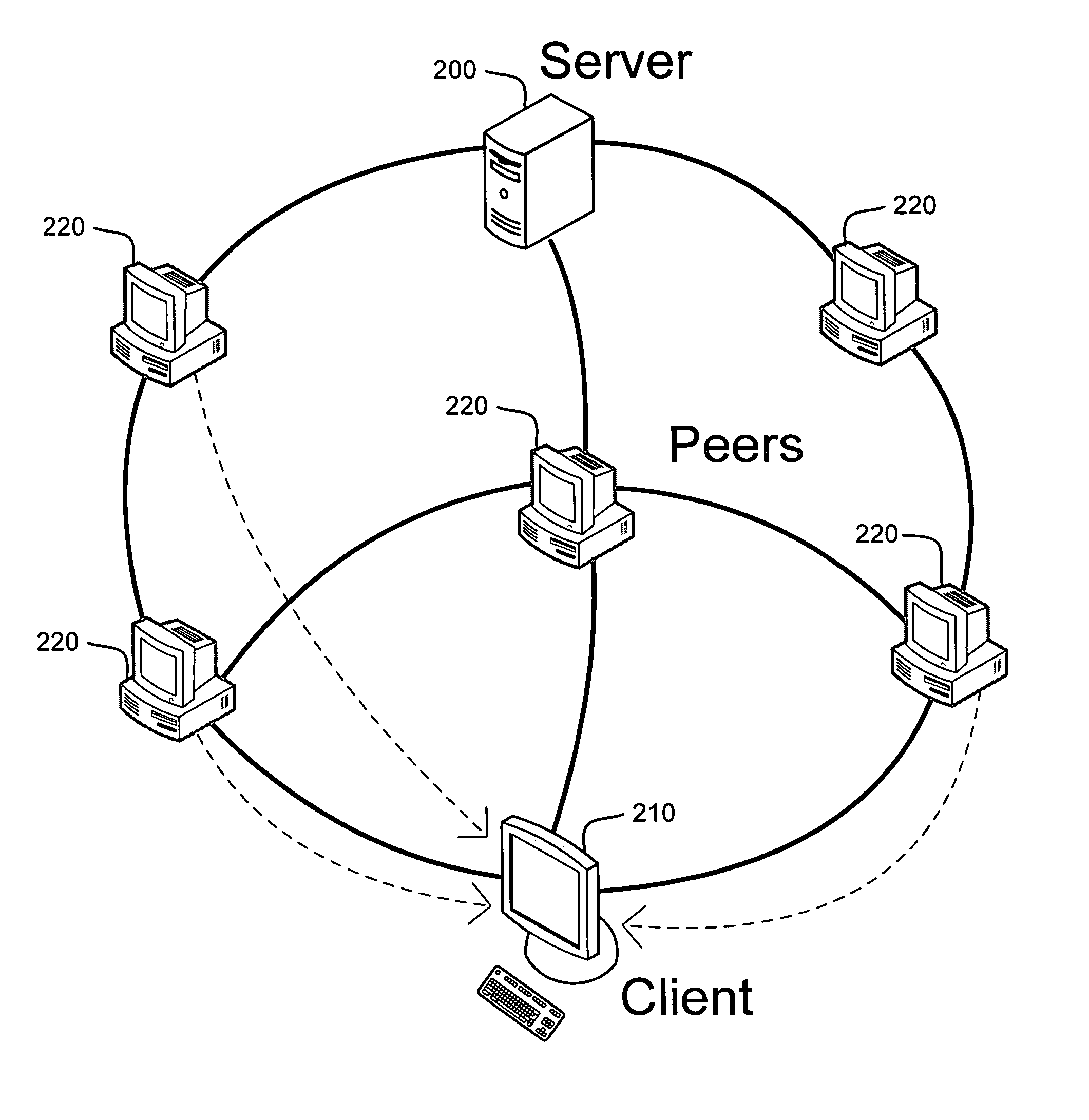

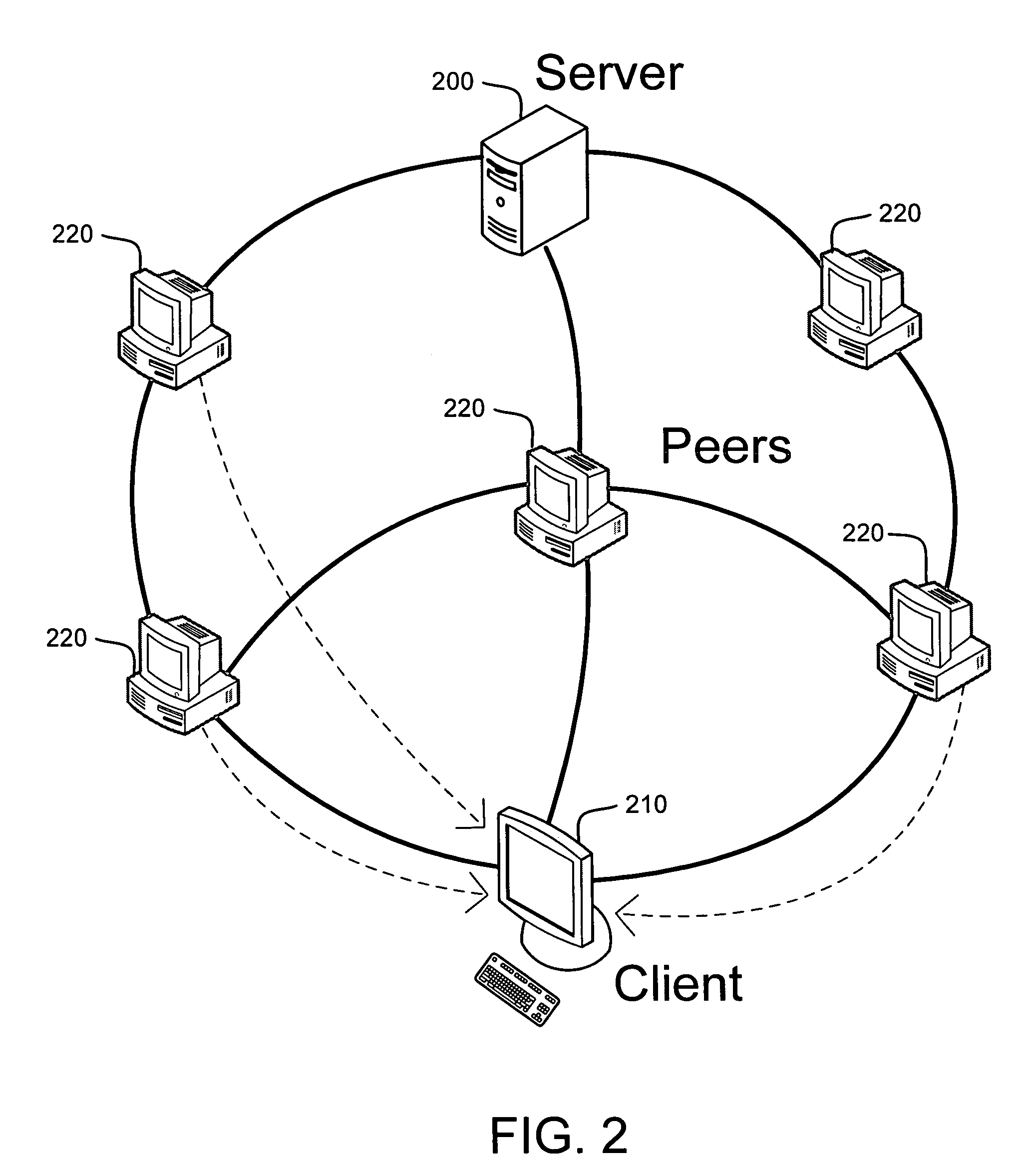

System and method for receiver-driven streaming in a peer-to-peer network

ActiveUS7174385B2Combat network packet loss and jitterMultiple digital computer combinationsTransmissionHigh rateClient-side

A “PeerStreamer” provides receiver-driven peer-to-peer (P2P) media streaming for loosely coupled P2P networks. Peers in the network perform only simple operations, may cache all or part of the streaming media, do not collaborate with other peers, may be unreliable, and may drop offline or come online during any given streaming session. Clients in the network operate in real-time to coordinate peers, stream media from multiple peers, perform load balancing, handle online / offline states of peers, and perform decoding and rendering the streaming media. In one embodiment, the PeerStreamer uses high rate erasure resilient coding to allow multiple serving peers to hold partial media without conflict, such that clients simply retrieve fixed numbers of erasure coded blocks regardless of where and what specific blocks are retrieved. In another embodiment, the PeerStreamer uses embedded coded media to vary streaming bitrates according to available serving bandwidths and client queue status.

Owner:ROVI TECH CORP

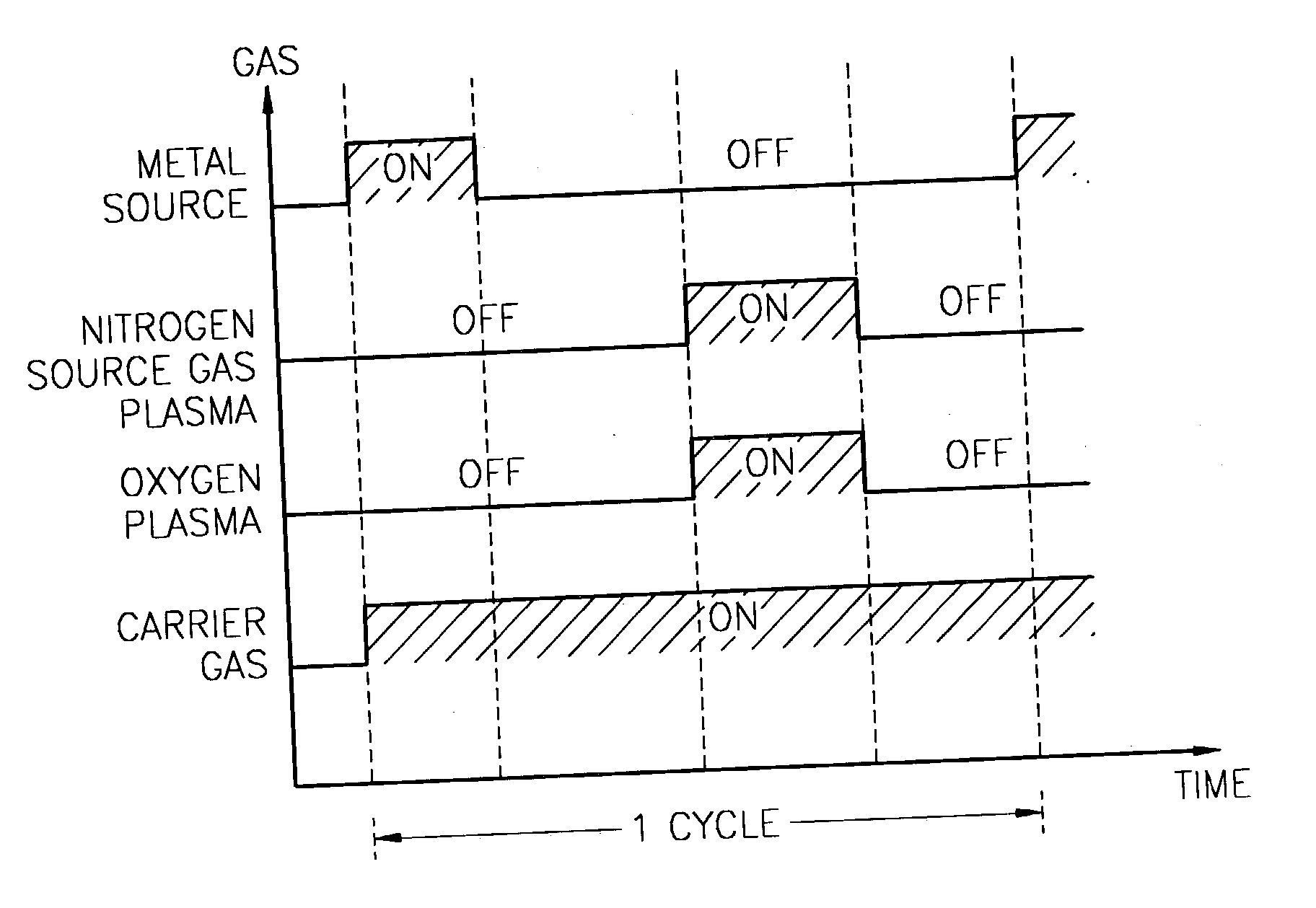

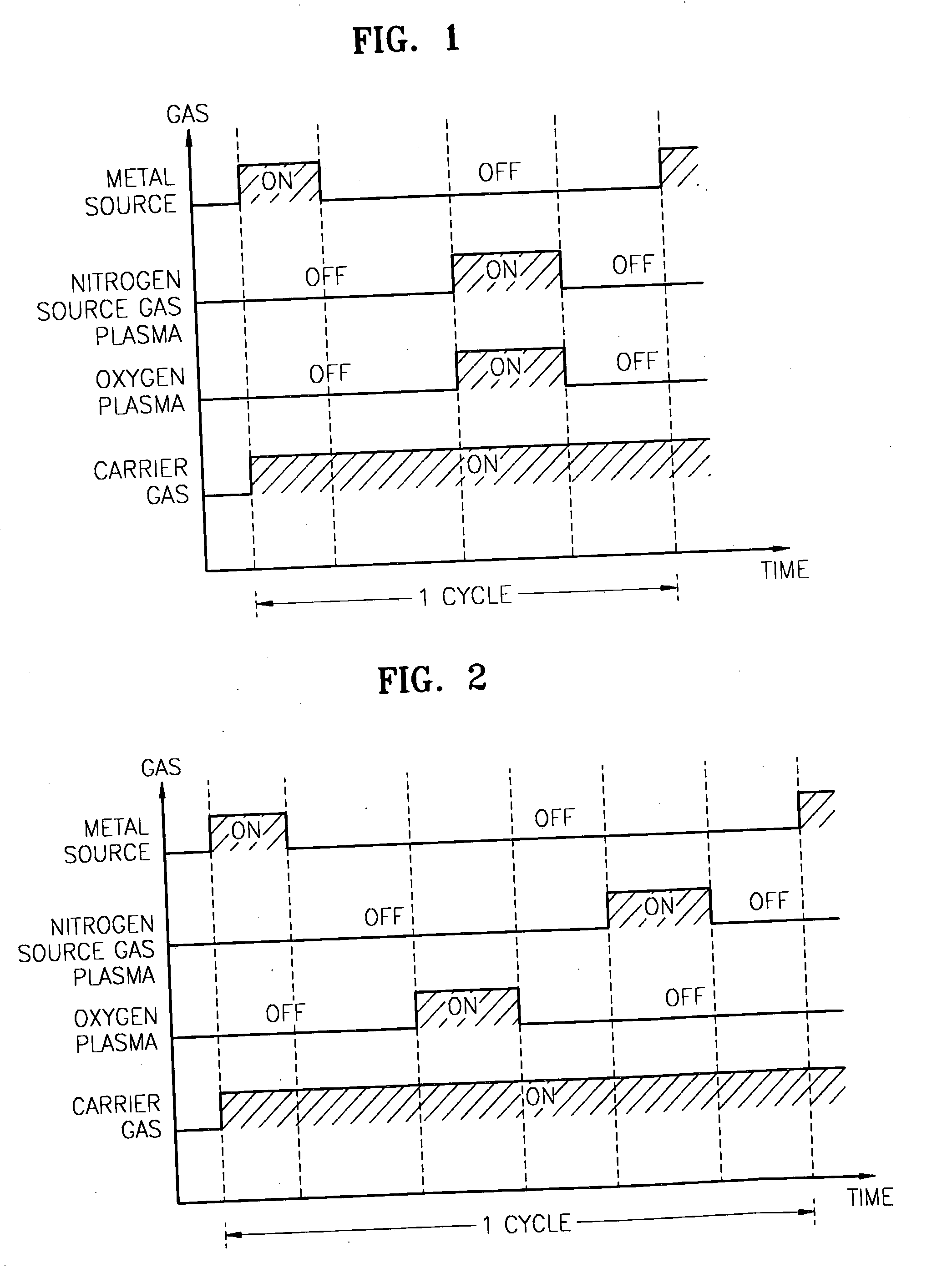

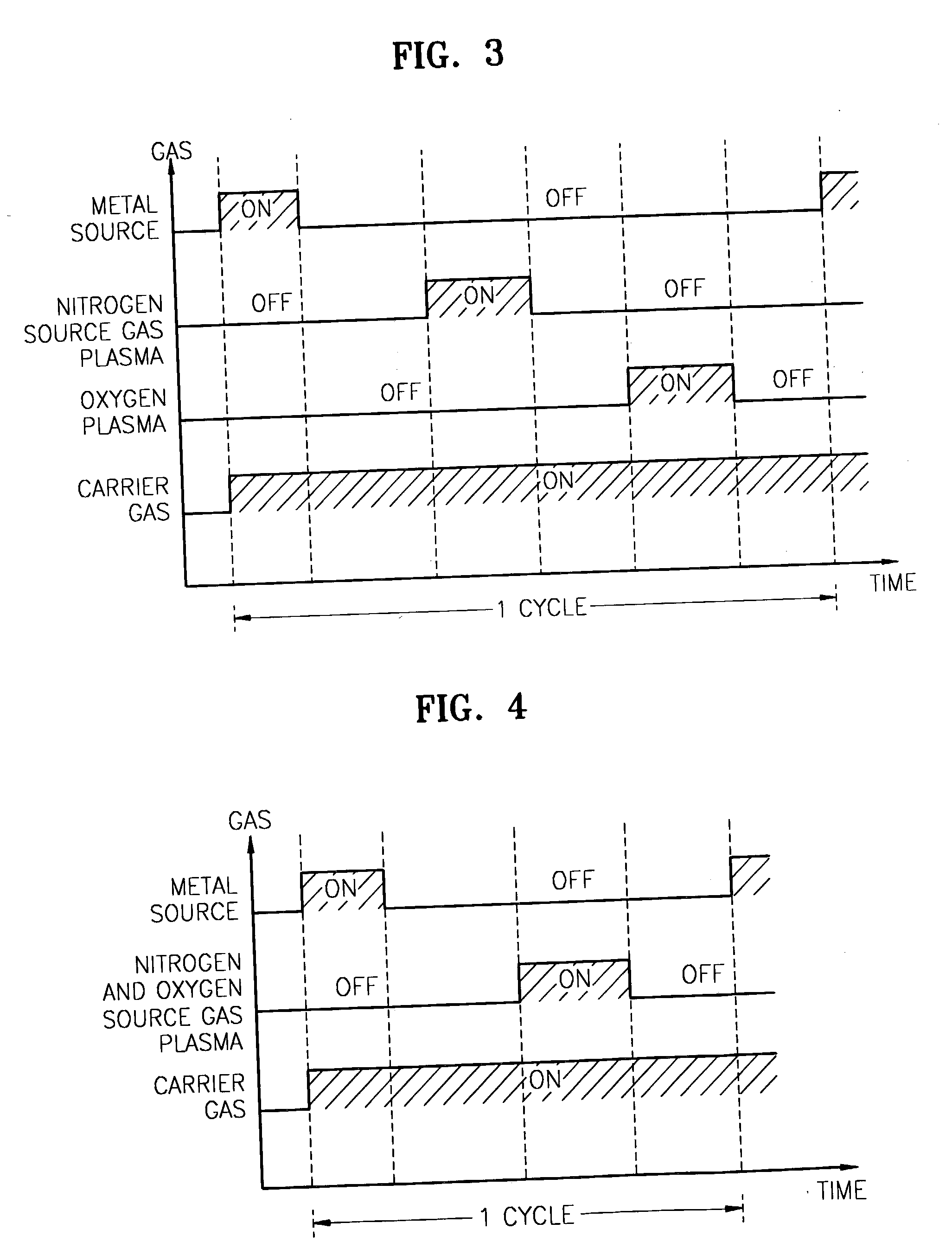

Method for forming introgen-containing oxide thin film using plasma enhanced atomic layer deposition

InactiveUS20040077182A1Density of thinThin rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh rateNitrogen source

A method for forming a nitrogen-containing oxide thin film by using plasma enhanced atomic layer deposition is provided. In the method, the nitrogen-containing oxide thin film is deposited by supplying a metal source compound and oxygen gas into a reactor in a cyclic fashion with sequential alternating pulses of the metal source compound and the oxygen gas, wherein the oxygen gas is activated into plasma in synchronization of the pulsing thereof, and a nitrogen source gas is further sequentially pulsed into the reactor and activated into plasma over the substrate in synchronization with the pulsing thereof. According to the method, a dense nitrogen-containing oxide thin film can be deposited at a high rate, and a trace of nitrogen atoms can be incorporated in situ into the nitrogen-containing oxide thin film, thereby increasing the breakdown voltage of the film.

Owner:ELECTRONICS & TELECOMM RES INST

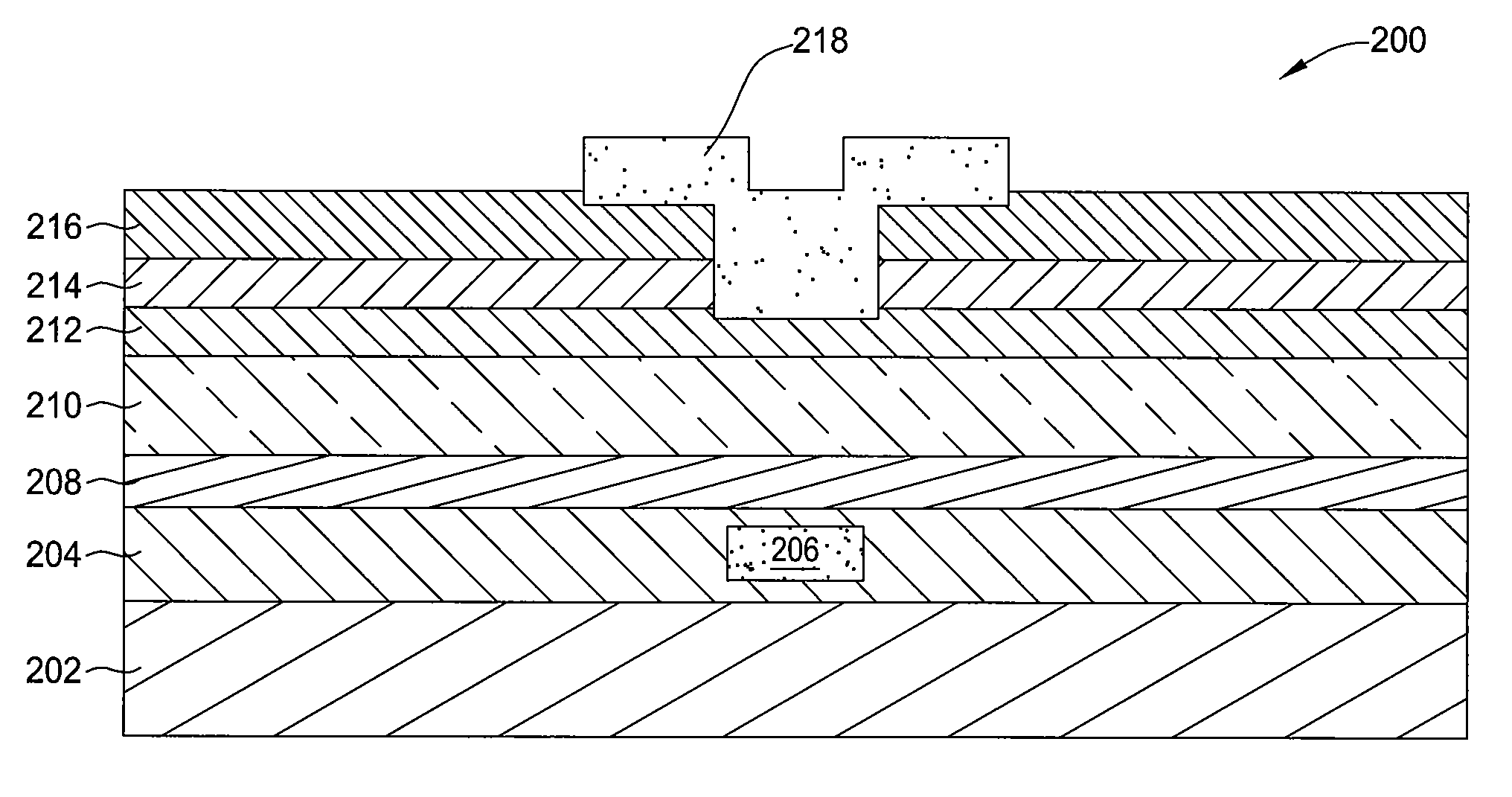

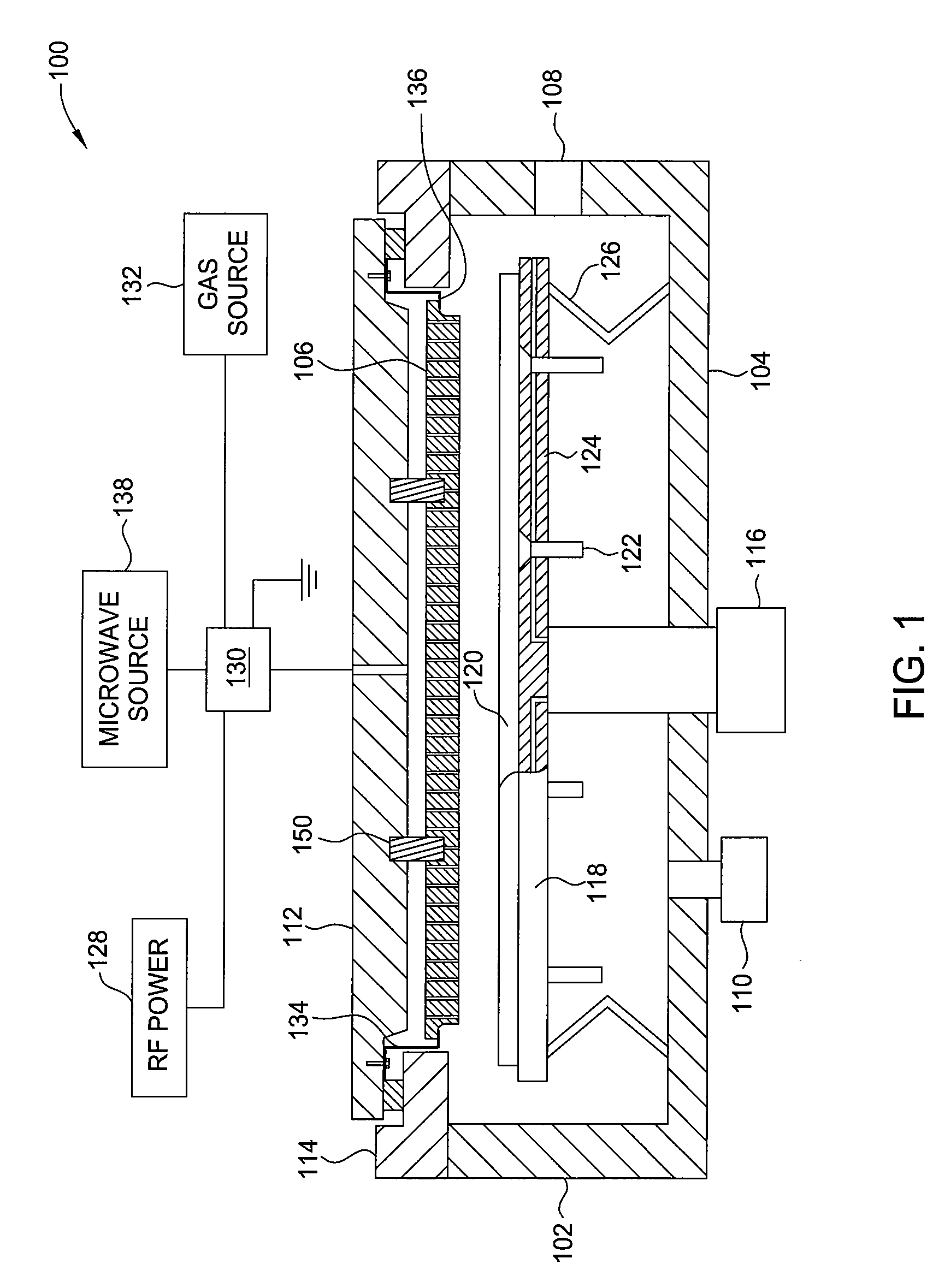

Low temperature thin film transistor process, device property, and device stability improvement

InactiveUS20090261331A1Low deposition rateIncrease deposition rateTransistorSemiconductor/solid-state device manufacturingDevice PropertiesHigh rate

A method and apparatus for forming a thin film transistor is provided. A gate dielectric layer is formed, which may be a bilayer, the first layer deposited at a low rate and the second deposited at a high rate. In some embodiments, the first dielectric layer is a silicon rich silicon nitride layer. An active layer is formed, which may also be a bilayer, the first active layer deposited at a low rate and the second at a high rate. The thin film transistors described herein have superior mobility and stability under stress.

Owner:APPLIED MATERIALS INC

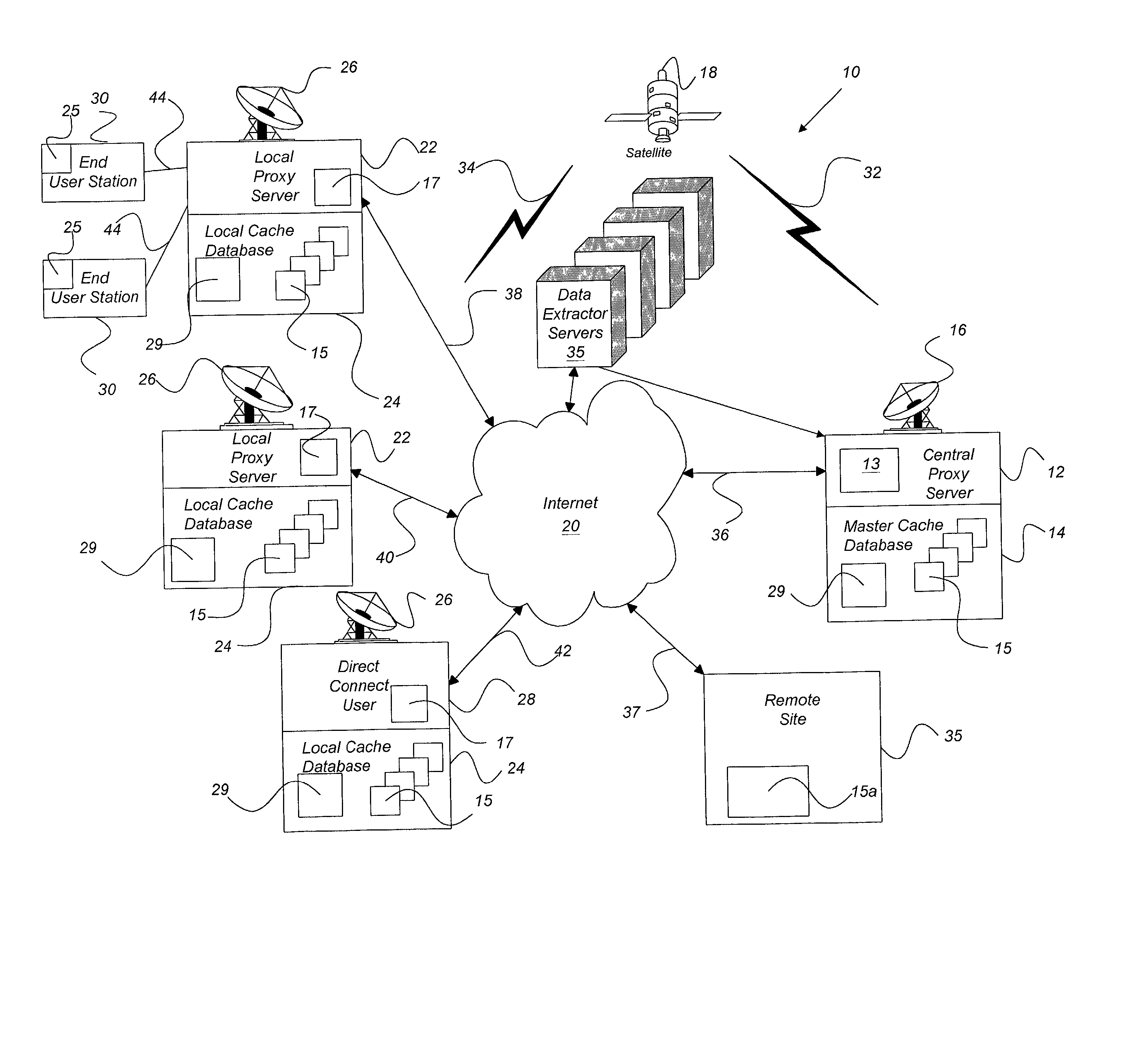

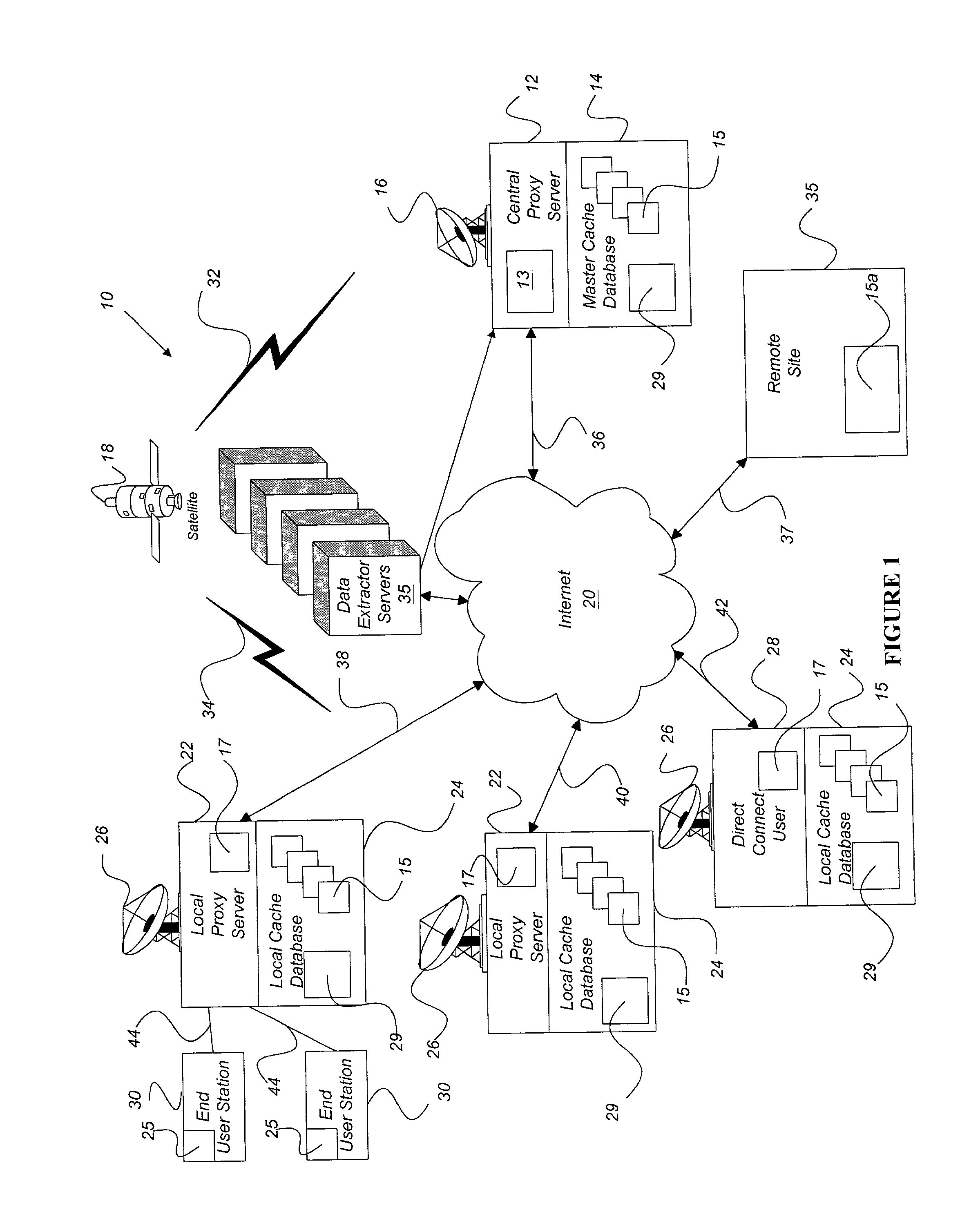

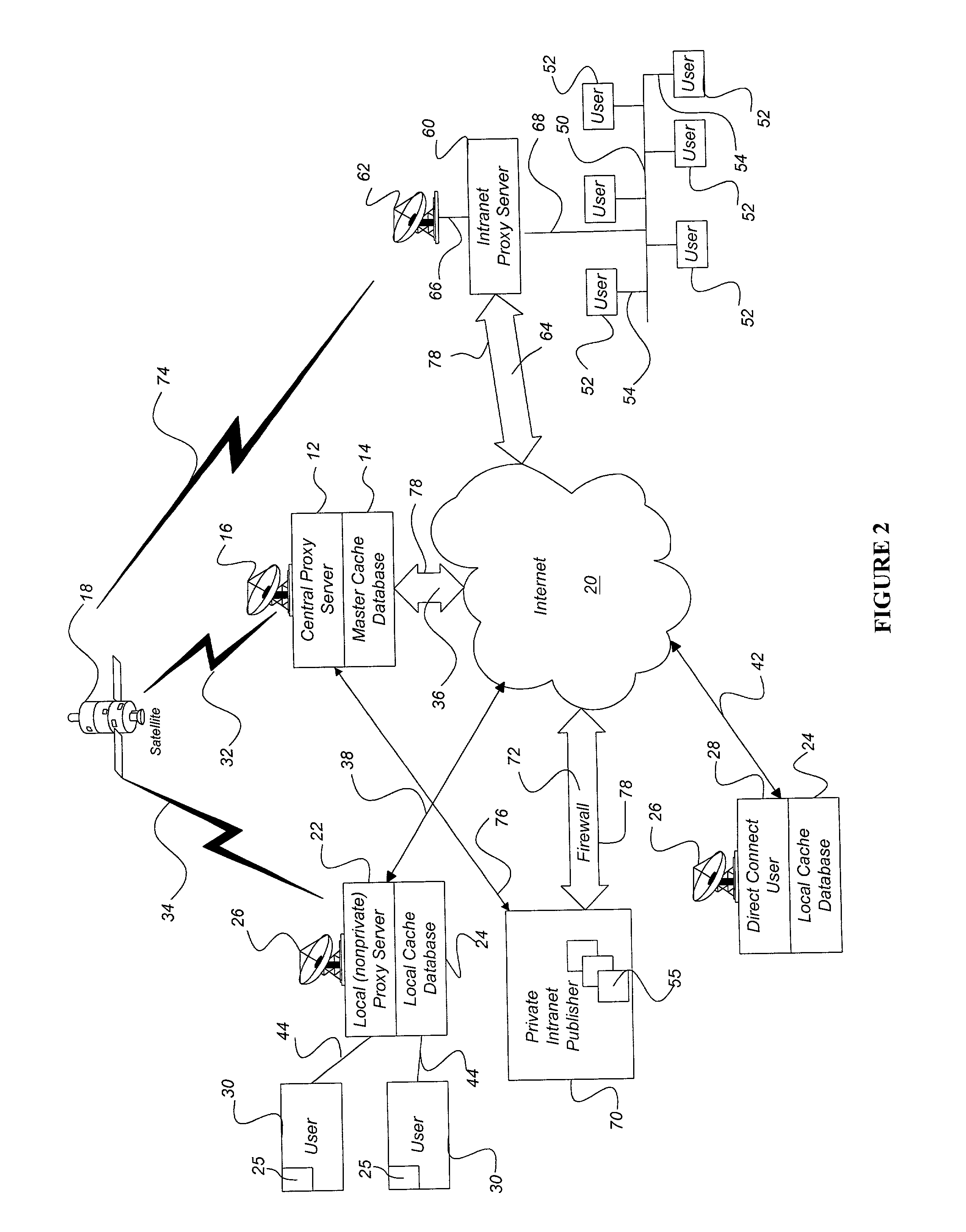

Internet content delivery acceleration system employing a hybrid content selection scheme

InactiveUS20020073167A1Facilitates very efficient reportingMultiple digital computer combinationsRadio transmissionInternet contentHigh rate

A system and method accelerates the distribution of digital content of a global communications network such as the Internet. A central proxy server selects popular digital objects for transmission over a communication medium to provide content filling of cache databases attendant to local proxy servers. The communication medium may comprise satellite transmission using an IP multicast protocol. The local proxy servers concurrently receive the digital objects at a high rate of speed and store the digital objects in the attendant local cache databases. The local proxy servers may utilize a localized priority determination scheme to determine whether to keep or discard the transmitted digital objects. The priority determination scheme may utilize global demand data and / or local demand data. The demand data may include hits and / or misses on digital objects and may also include quantitative data about the digital objects. The priority determination scheme may be driven by feedback regarding the needs and interests of subscribing users of the local cache database. Consequently, the priority determination scheme and ultimately, the contents of a local cache database, may be unique to that local cache database.

Owner:EDGIX CORP

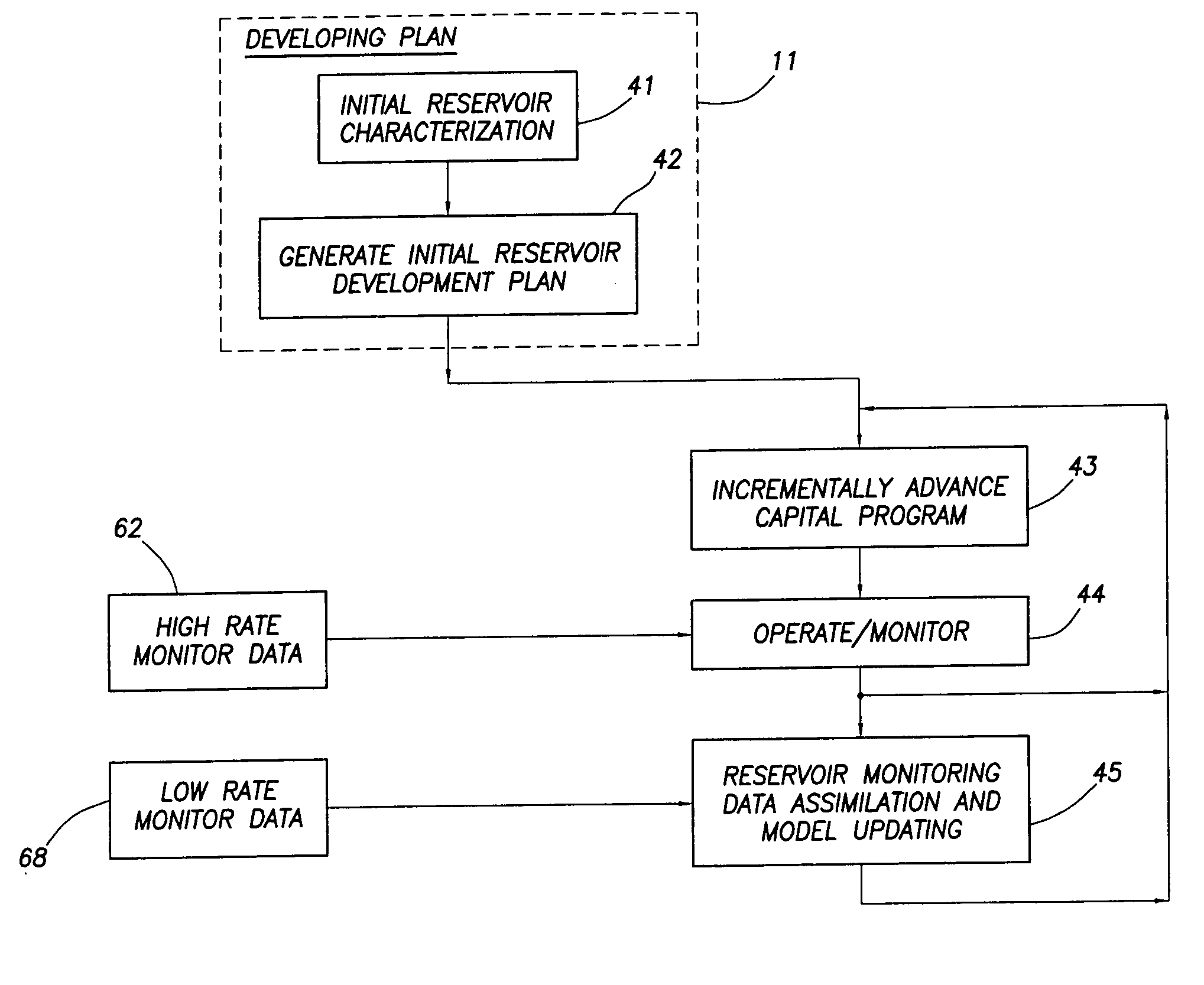

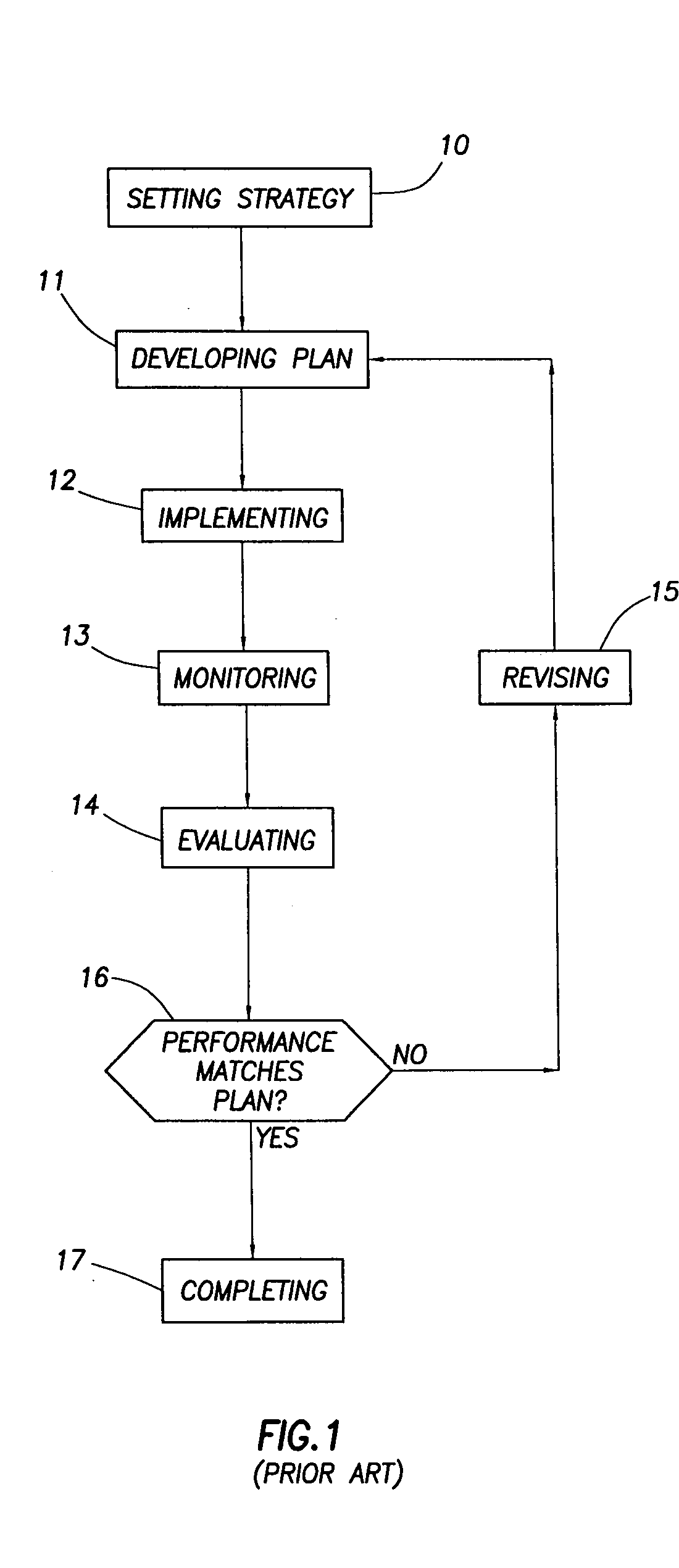

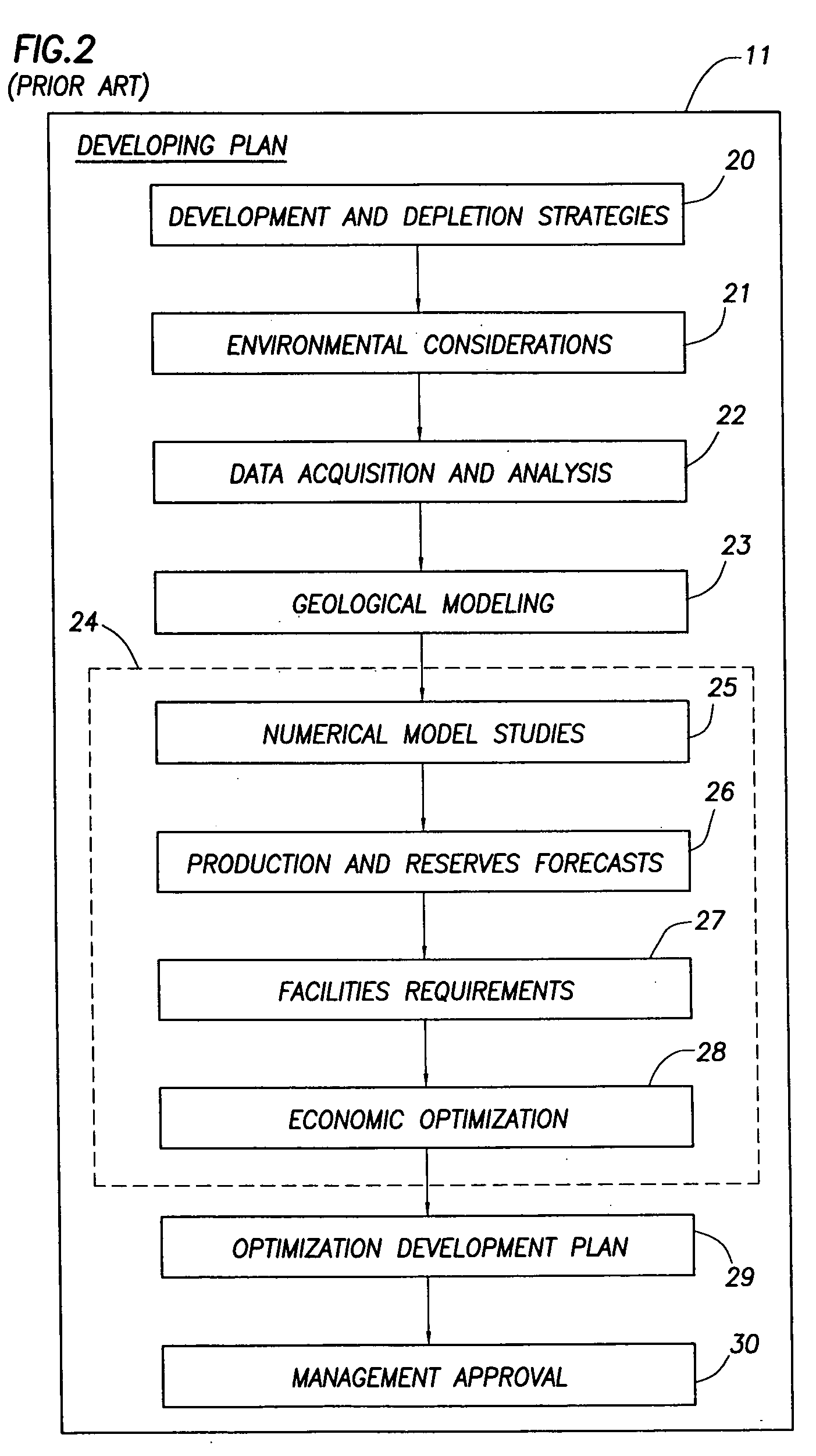

Integrated reservoir optimization

InactiveUS20050149307A1Maximize productionMaximizing value of propertyElectric/magnetic detection for well-loggingSurveyHigh rateAcquisition time

A method of managing a fluid or gas reservoir is disclosed which assimilates diverse data having different acquisition time scales and spatial scales of coverage for iteratively producing a reservoir development plan that is used for optimizing an overall performance of a reservoir. The method includes: (a) generating an initial reservoir characterization, (b) from the initial reservoir characterization, generating an initial reservoir development plan, (c) when the reservoir development plan is generated, incrementally advancing and generating a capital spending program, (d) when the capital spending program is generated, monitoring a performance of the reservoir by acquiring high rate monitor data from a first set of data measurements taken in the reservoir and using the high rate monitor data to perform well-regional and field-reservoir evaluations, (e) further monitoring the performance of the reservoir by acquiring low rate monitor data from a second set of data measurements taken in the reservoir, (f) assimilating together the high rate monitor data and the low rate monitor data, (g) from the high rate monitor data and the low rate monitor data, determining when it is necessary to update the initial reservoir development plan to produce a newly updated reservoir development plan, (h) when necessary, updating the initial reservoir development plan to produce the newly updated reservoir development plan, and (i) when the newly updated reservoir development plan is produced, repeating steps (c) through (h). A detailed disclosure is provided herein relating to the step (a) for generating the initial reservoir characterization and the step (b) for generating the initial reservoir development plan.

Owner:SCHLUMBERGER TECH CORP

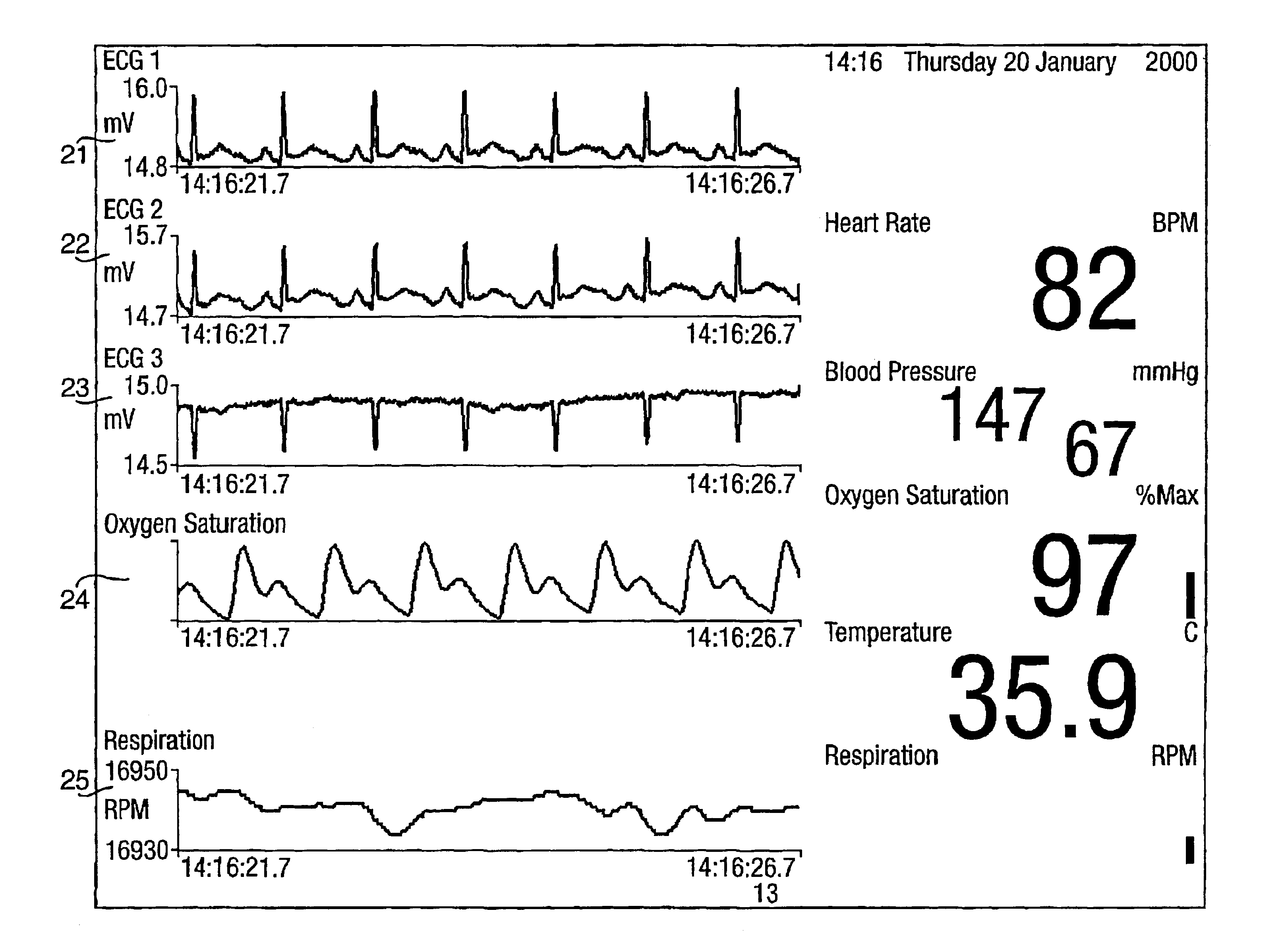

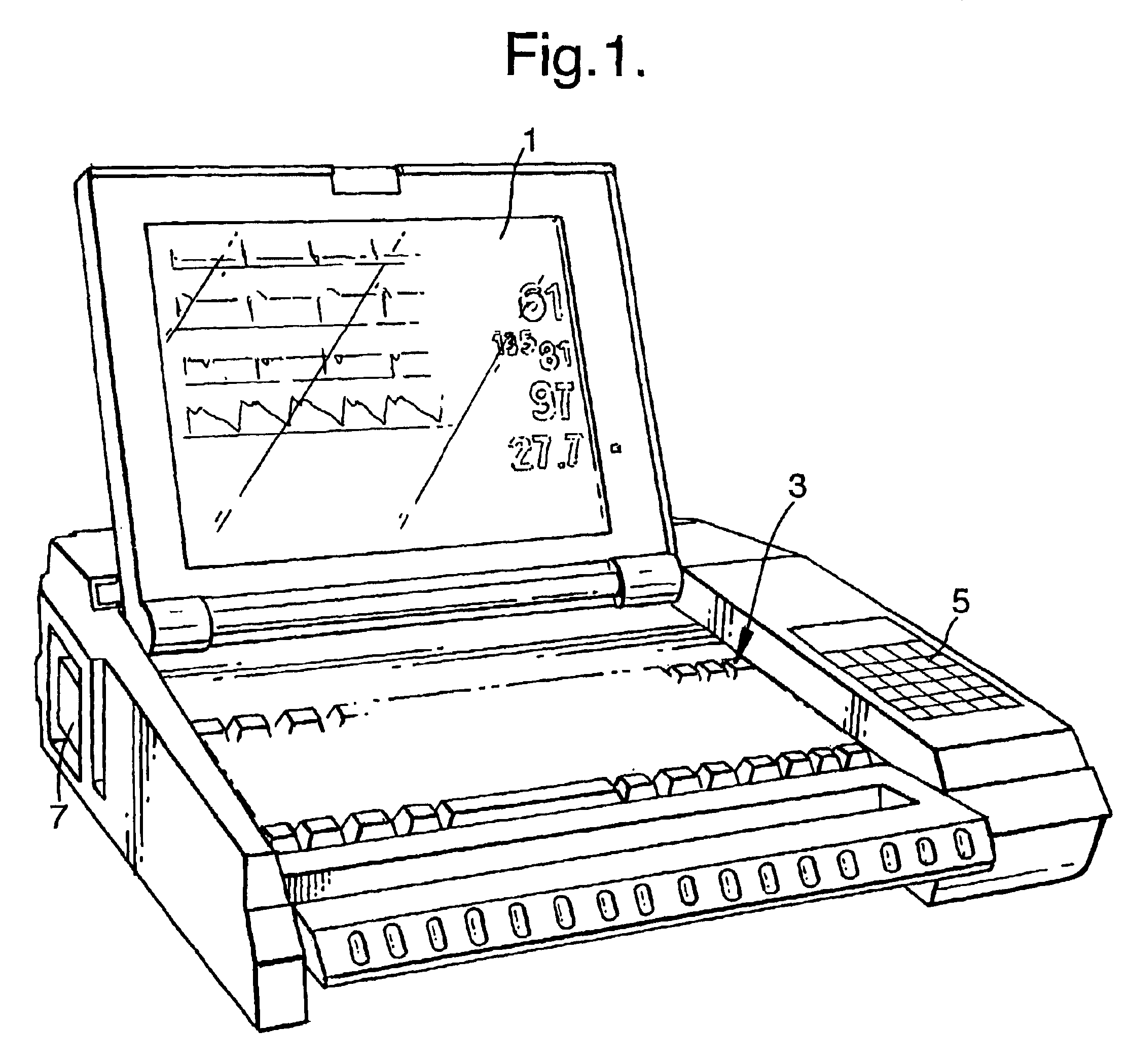

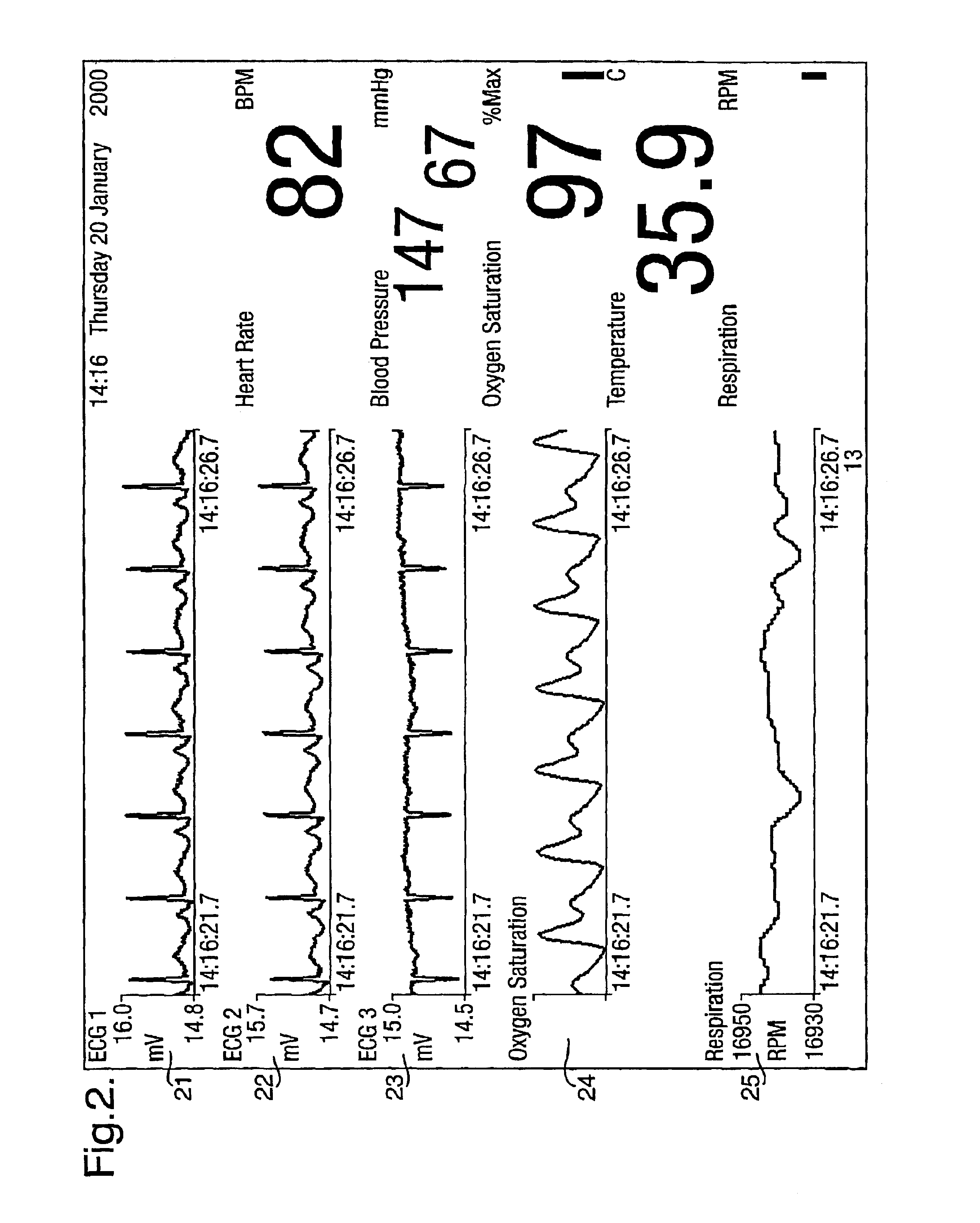

System and method for acquiring data

InactiveUS6839659B2Easy to carryImprove clarityAngiographyData acquisition and loggingData connectionHigh rate

A system for acquiring, and displaying, data such as physiological data, from a plurality of data connection devices, each of which monitor one or more different parameters and output data at different sampling frequencies based on their own system clocks. The system receives the data signals at different sampling frequencies and associates each sample of each signal with a time stamp derived from a single master clock. Low rate and high rate data are treated differently. Low rate data is associated with the current value of the master clock, where as high rate data is time stamped by giving the first sample a time stamp equal to the current value of the current master clock, subsequent samples being given an estimated time stamp based on the expected interval between samples derived from the sampling frequency of the data collection device, and the timescale given to the first example. The estimated time stamp may be periodically corrected, and the estimation calculation can be improved by correcting the value used for the interval between samples. The different signals can be displayed together on a display aligned with respect to a time axis. The system can display, the data in two different timescales, one showing a few seconds of data and one showing a few hours of data. The data traces are scrolled across the time axis, new data being added to one end of the trace.

Owner:ISIS INNOVATION LTD

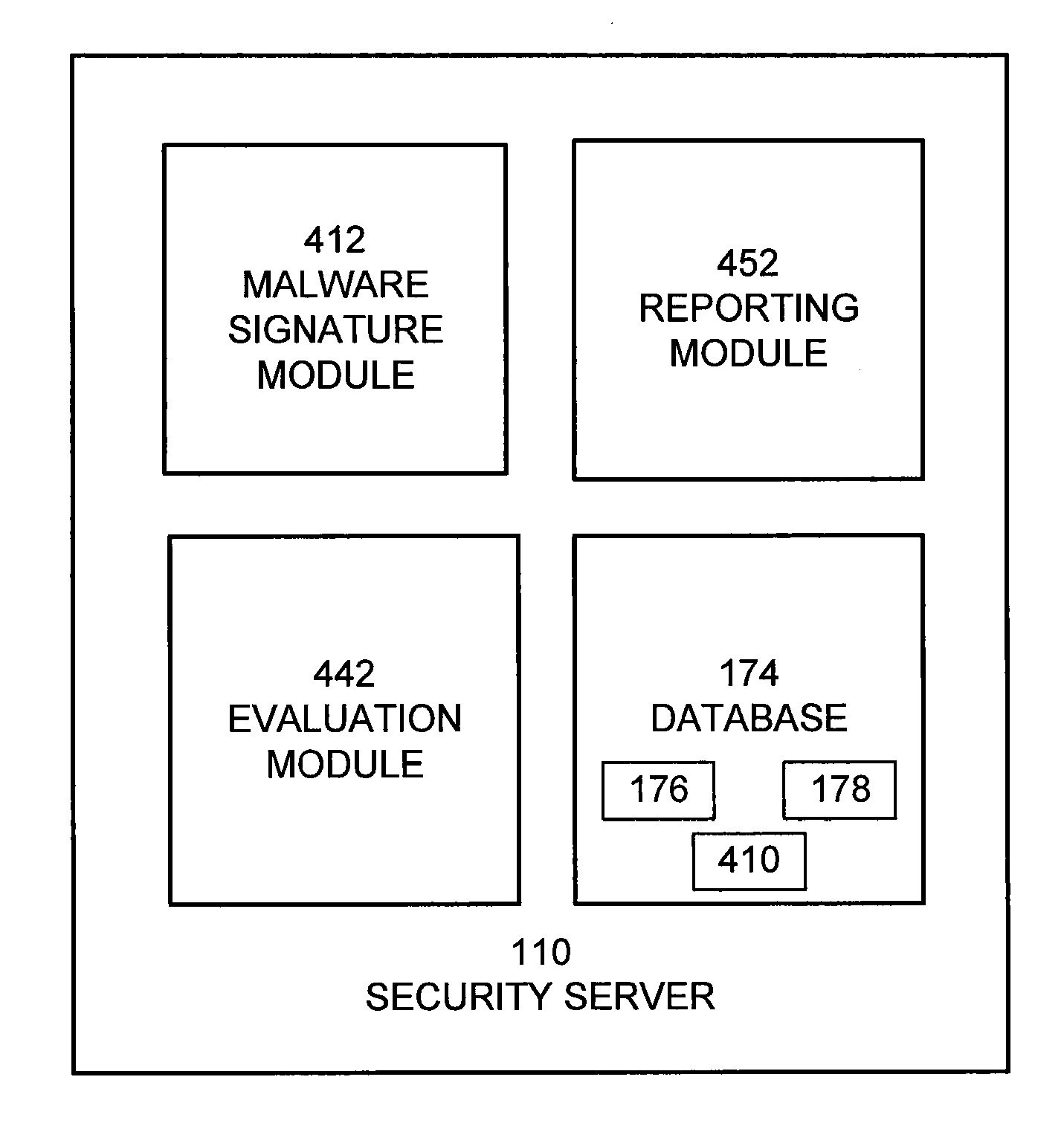

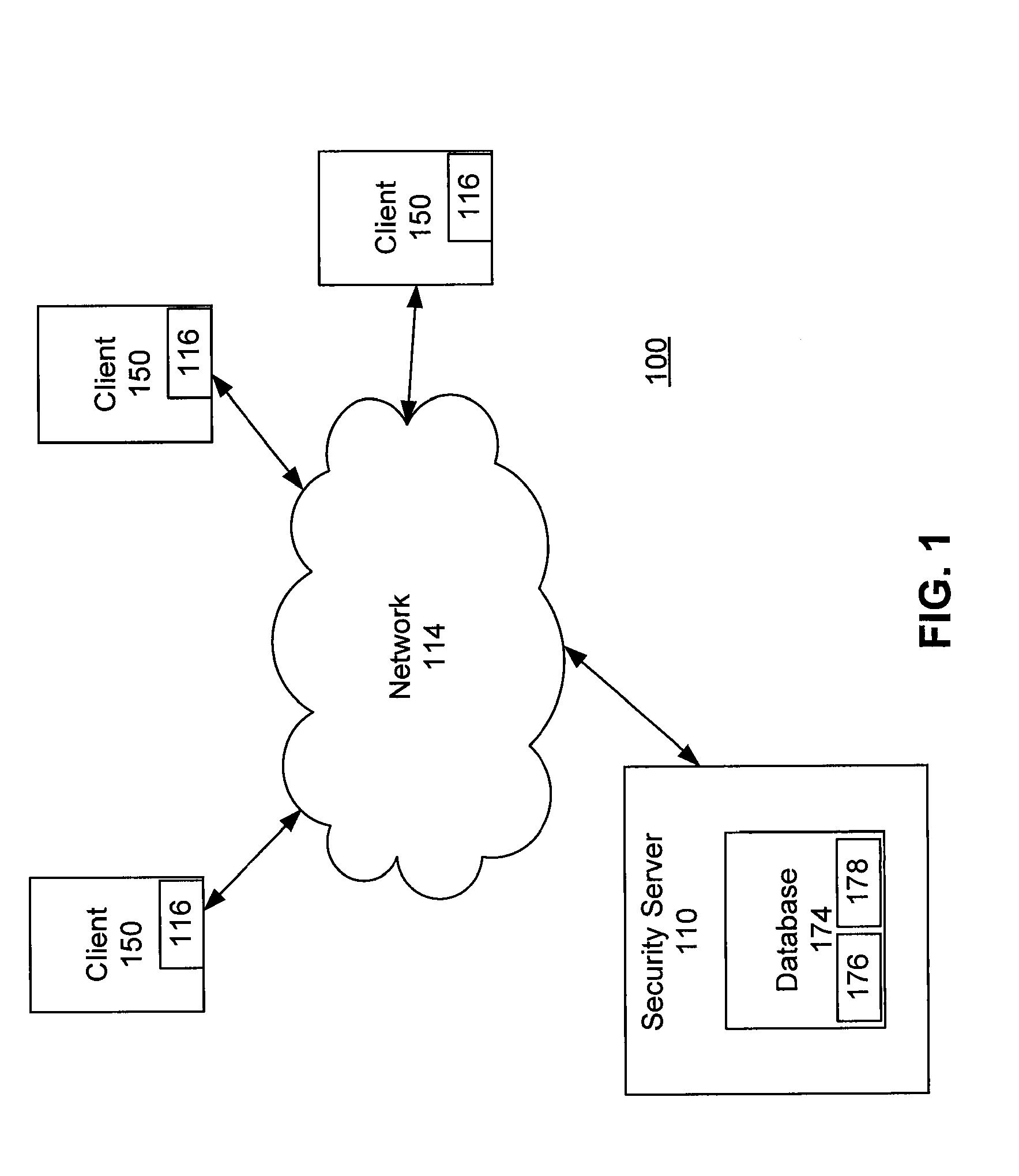

Reducing malware signature set size through server-side processing

A server provides a reduced set of malware signatures to clients. The reduced set of malware signatures has the same scope of coverage as a comprehensive set of malware signatures stored on the server, but with a higher rate of false positive detections. The server receives signature detection event reports from the clients. A signature detection event report identifies the signature in the reduced set that was detected, and includes information describing the suspicious entity in which the signature was detected. Upon receiving a signature detection event report from a client, the server evaluates the information describing the suspicious entity using one or more signatures in the comprehensive set to determine whether the signature detection event is a false positive or a legitimate malware detection. The security server provides the result of the evaluation to the client from which the report was received.

Owner:CA TECH INC

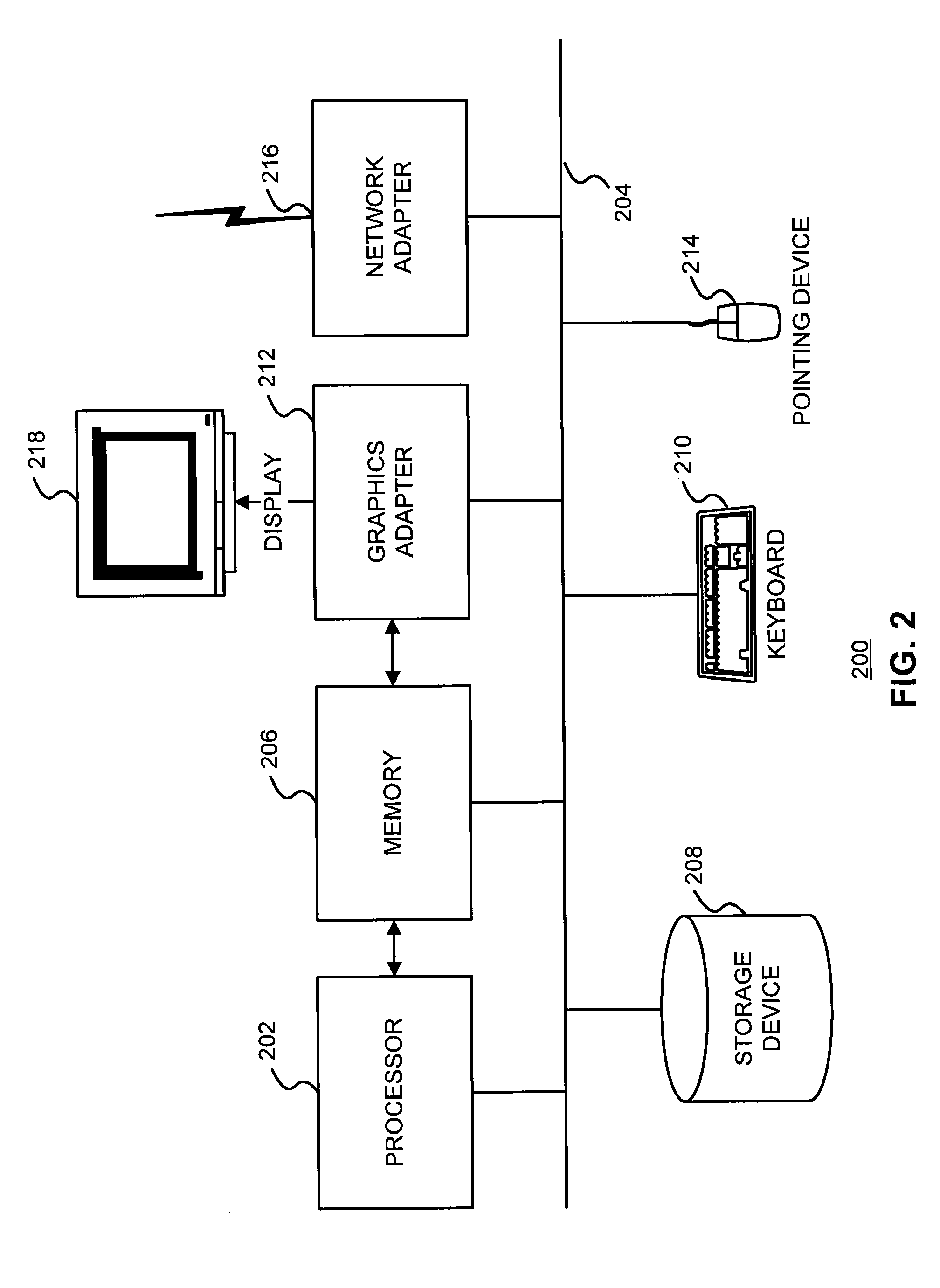

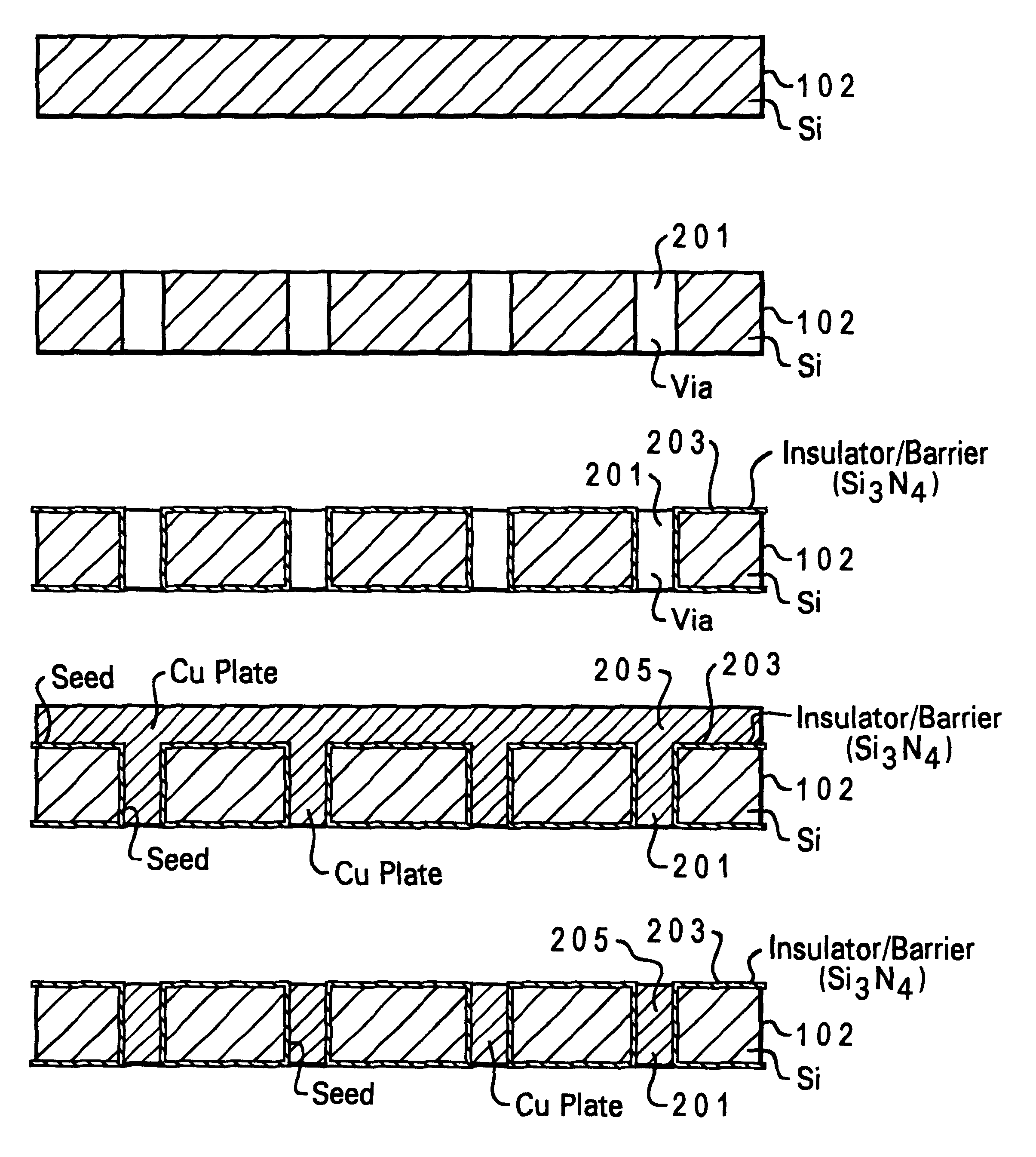

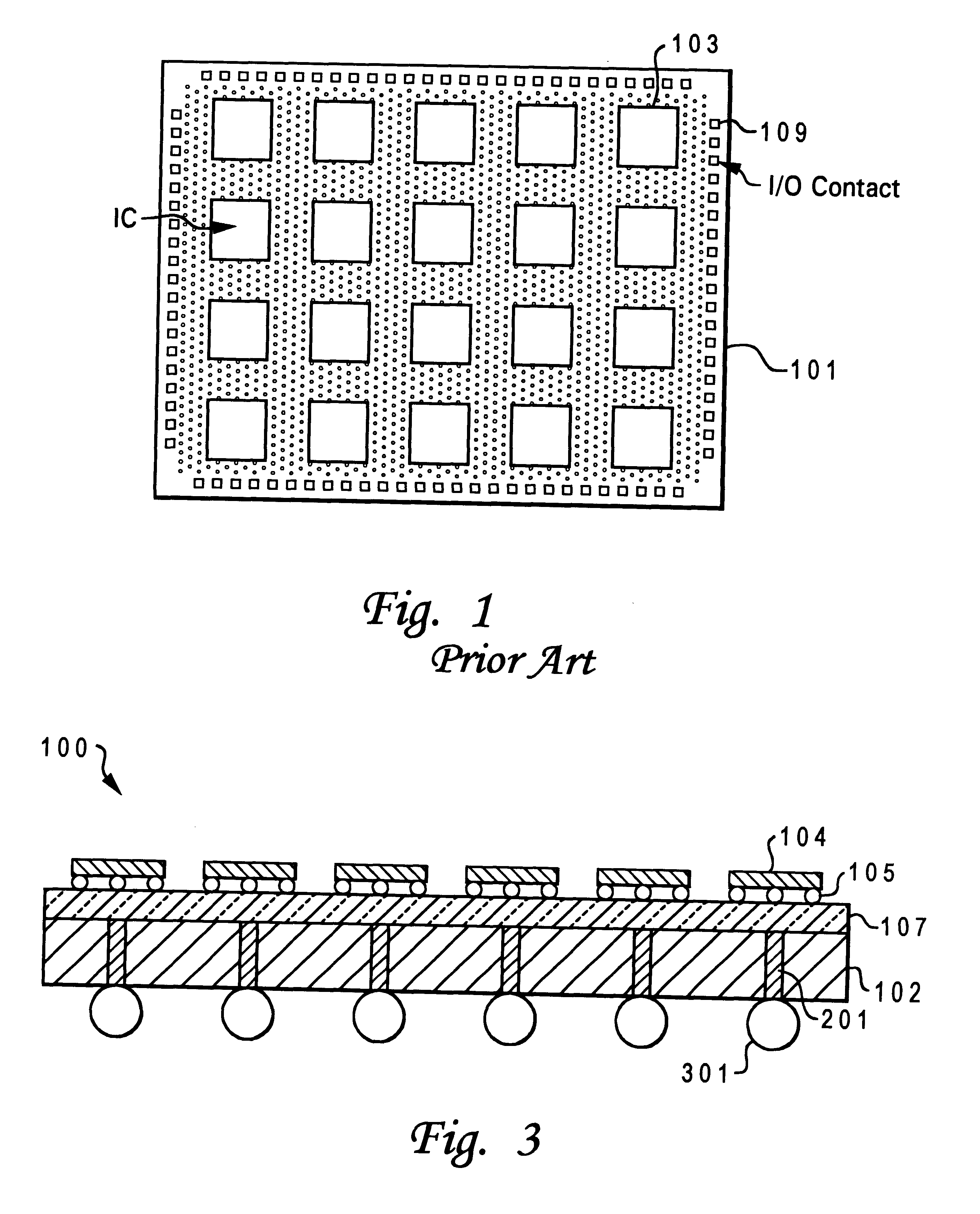

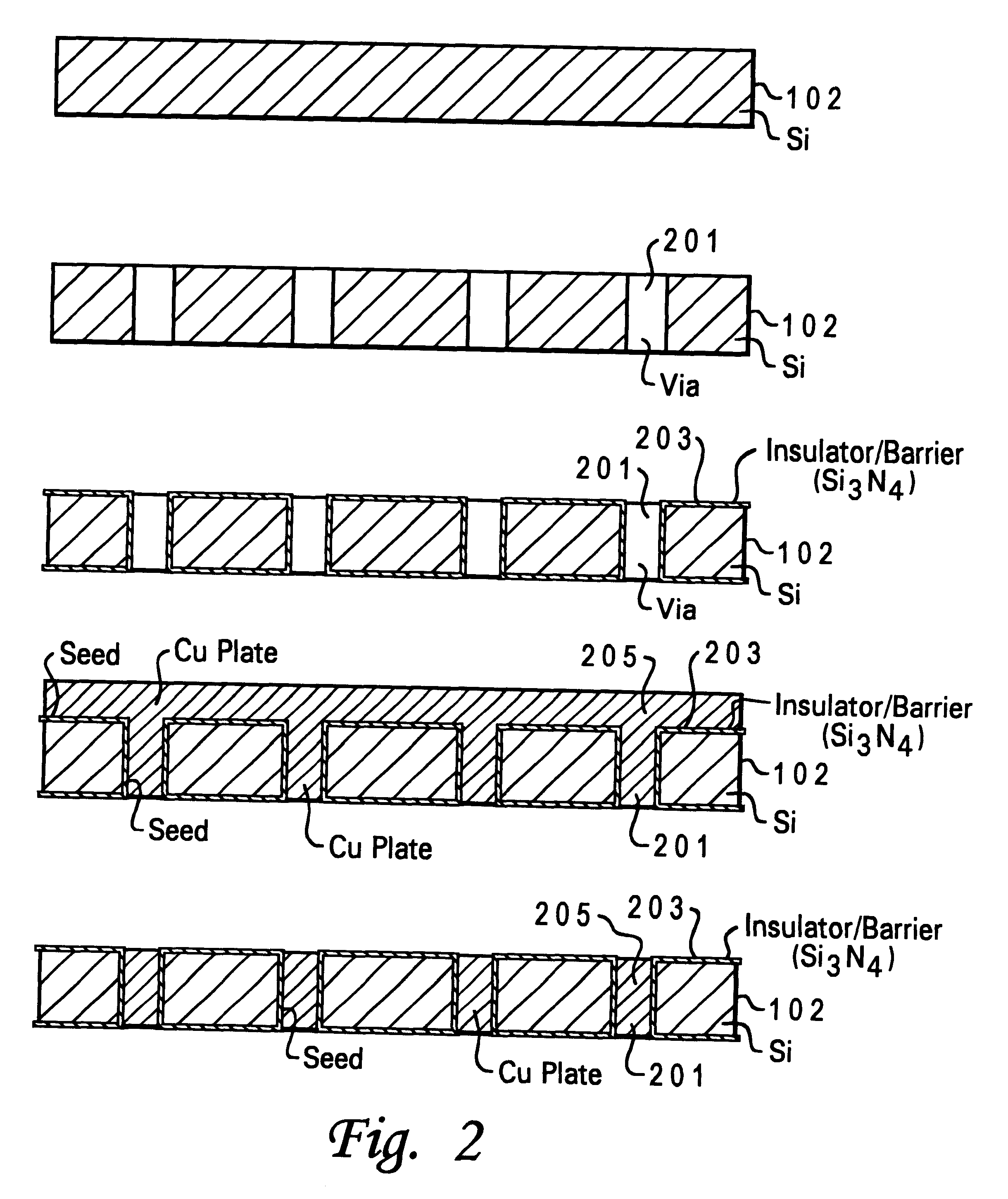

Method for integrated circuit power and electrical connections via through-wafer interconnects

InactiveUS6221769B1Solid-state devicesSemiconductor/solid-state device manufacturingHigh rateElectrical connection

A method for providing a through wafer connection to an integrated circuit silicon package. A hole is first created in the silicon package with an inner surface area extending from the bottom surface of the silicon package to the top surface of the silicon package. The hole is created by one of two methods. The first involves mechanical drilling with a diamond bit rotated at a high rate of speed. The second involves ultrasonically milling utilizing a slurry and steel fingers. The inner surface area of the hole is covered with an insulating material to insulate the conductive material which is later deposited and to serve as a diffusion barrier, then a seed material is placed in the hole. Finally, the hole is filled with a conductive material which is utilized to provide large power inputs or signaling connections to the integrated circuit chips.

Owner:IBM CORP

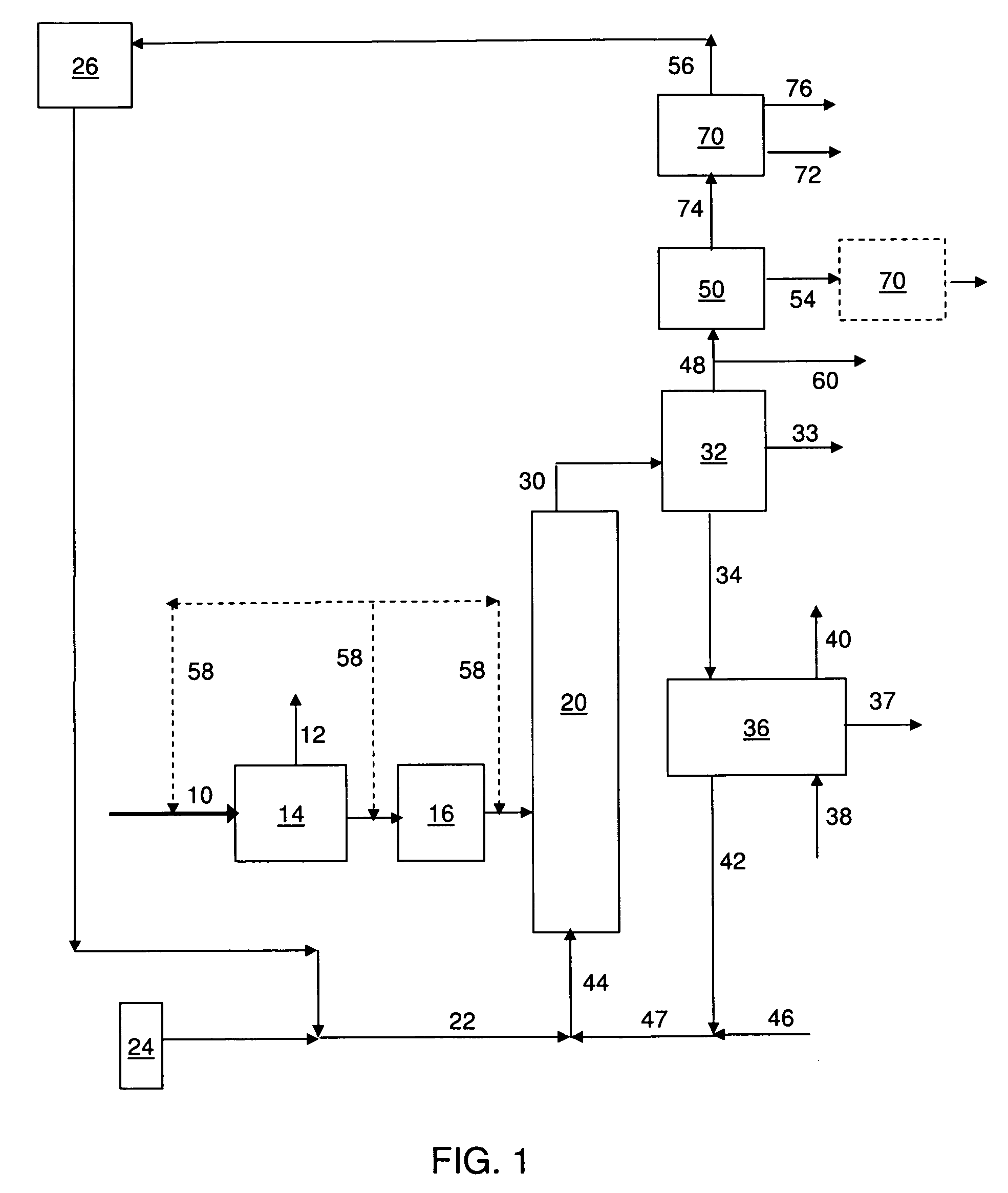

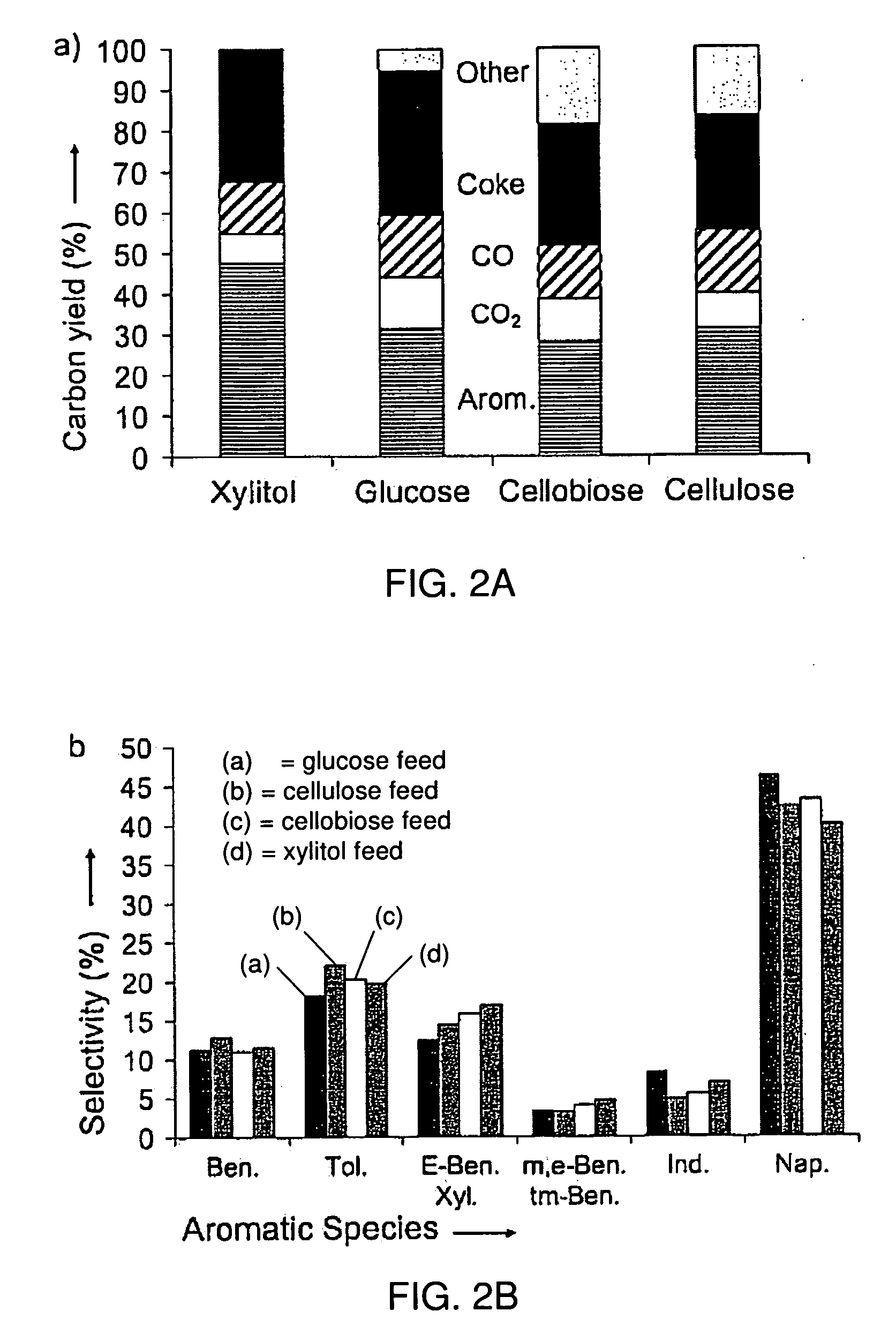

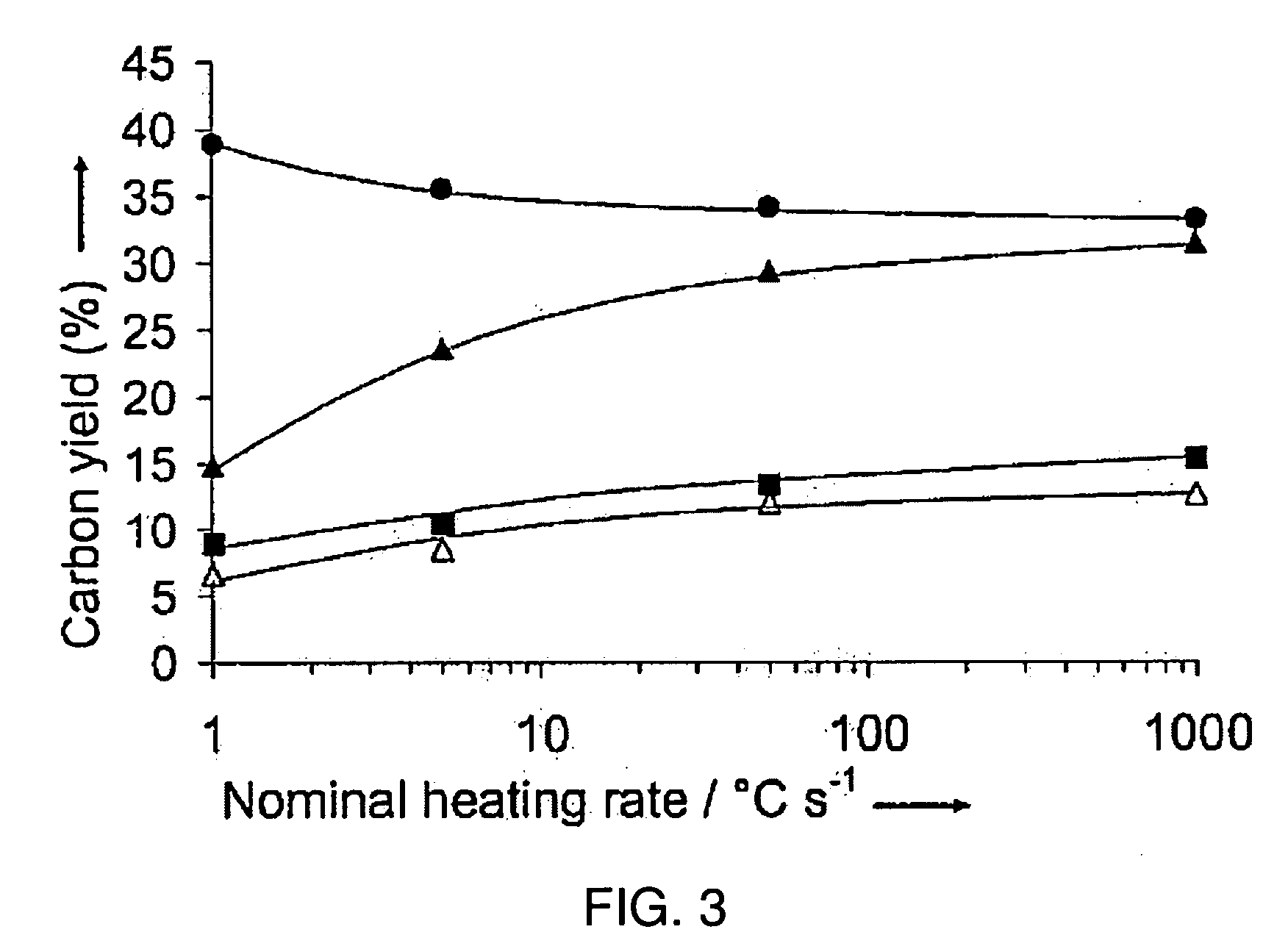

Catalytic pyrolysis of solid biomass and related biofuels, aromatic, and olefin compounds

ActiveUS20090227823A1Minimize coke productionLiquid hydrocarbon mixture productionHydrocarbonsHigh rateCatalytic pyrolysis

This invention relates to compositions and methods for fluid hydrocarbon product, and more specifically, to compositions and methods for fluid hydrocarbon product via catalytic pyrolysis. Some embodiments relate to methods for the production of specific aromatic products (e.g., benzene, toluene, naphthalene, xylene, etc.) via catalytic pyrolysis. Some such methods may involve the use of a composition comprising a mixture of a solid hydrocarbonaceous material and a heterogeneous pyrolytic catalyst component. In some embodiments, the mixture may be pyrolyzed at high temperatures (e.g., between 500° C. and 1000° C.). The pyrolysis may be conducted for an amount of time at least partially sufficient for production of discrete, identifiable biofuel compounds. Some embodiments involve heating the mixture of catalyst and hydrocarbonaceous material at high rates (e.g., from about 50° C. per second to about 1000° C. per second). The methods described herein may also involve the use of specialized catalysts. For example, in some cases, zeolite catalysts may be used; optionally, the catalysts used herein may have high silica to alumina molar ratios. In some instances, the composition fed to the pyrolysis reactor may have a relatively high catalyst to hydrocarbonaceous material mass ratio (e.g., from about 5:1 to about 20:1).

Owner:UNIV OF MASSACHUSETTS

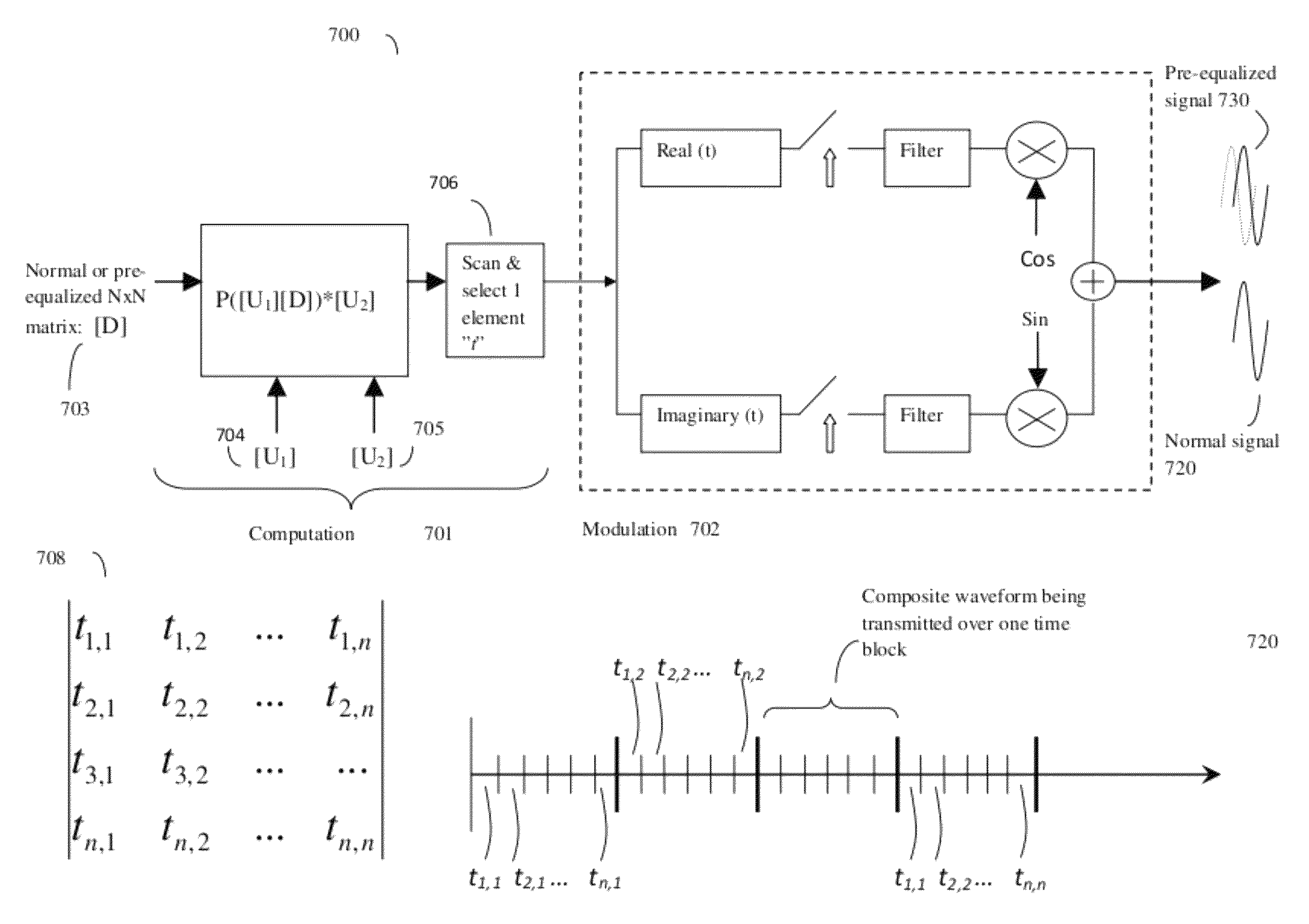

Signal modulation method resistant to echo reflections and frequency offsets

ActiveUS9083595B2Improve performancePromote decompositionNetwork traffic/resource managementMulti-frequency code systemsHigh rateEngineering

A method of modulating communications signals, such as optical fiber, wired electronic, or wireless signals in a manner that facilitates automatic correction for the signal distortion effects of echoes and frequency shifts, while still allowing high rates of data transmission. Data symbols intended for transmission are distributed into N×N matrices, and used to weigh or modulate a family of cyclically time shifted and cyclically frequency shifted waveforms. Although these waveforms may then be distorted during transmission, their basic cyclic time and frequency repeating structure facilitates use of improved receivers with deconvolution devices that can utilize the repeating patterns to correct for these distortions. The various waveforms may be sent in N time blocks at various time spacing and frequency spacing combinations in a manner that can allow interleaving of blocks from different transmitters. Applications to channel sounding / characterization, system optimization, and also radar are also discussed.

Owner:COHERE TECH

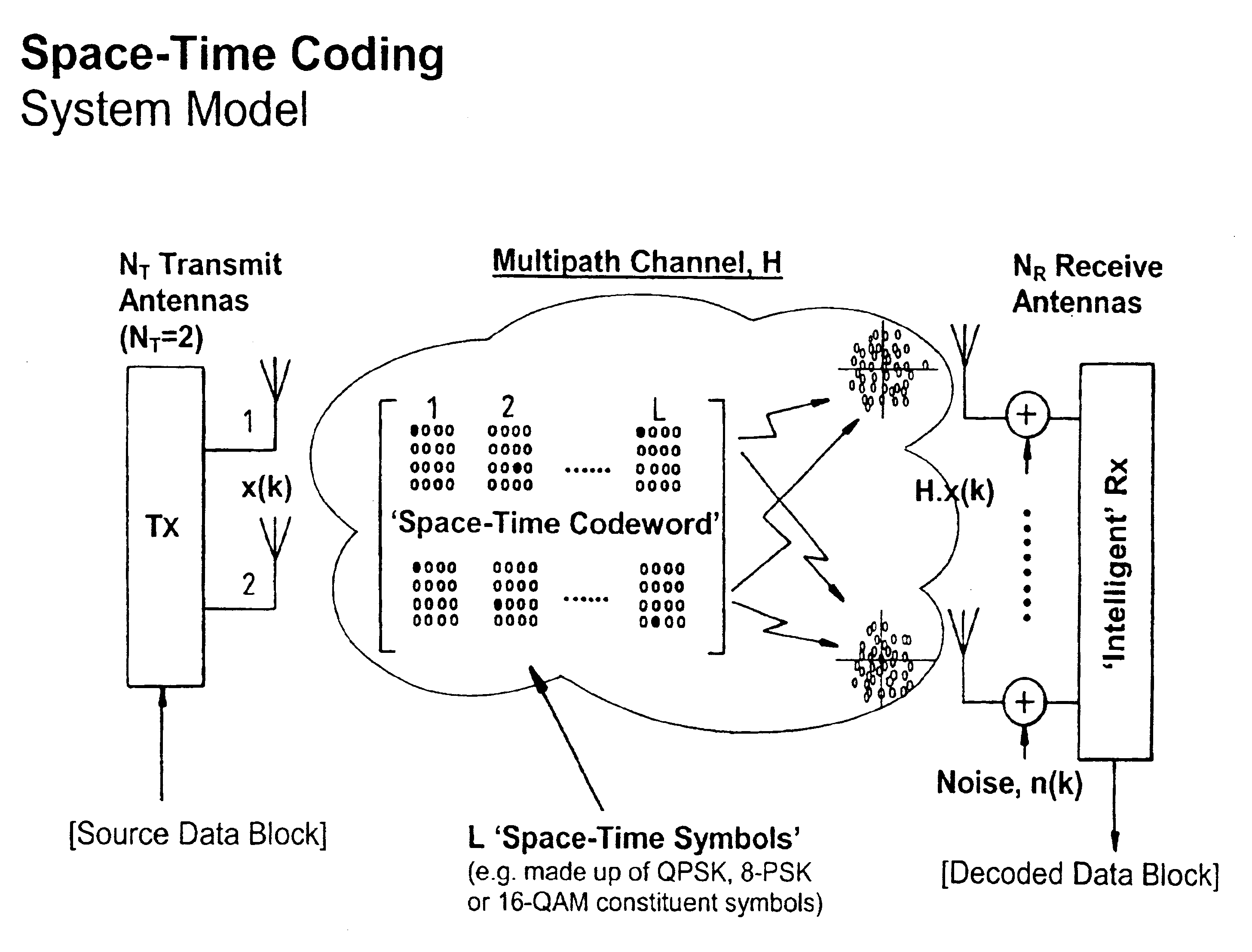

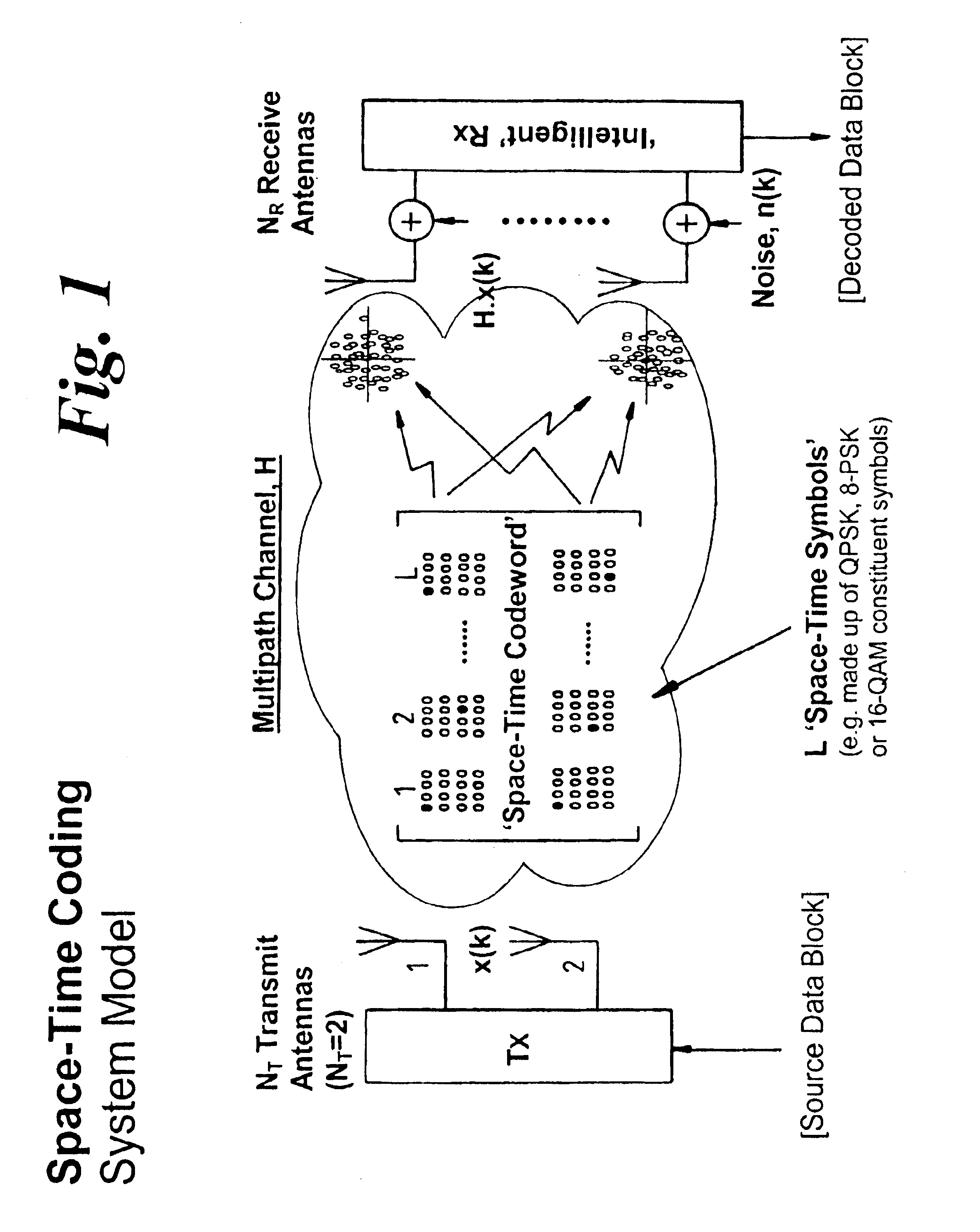

Space-time coding and channel estimation scheme, arrangement and method

InactiveUS6891897B1Improve spectral efficiencyIncreased improved bandwidth efficiencySpatial transmit diversityChannel estimationHigh rateFrequency spectrum

The evolution of high rate data services within future wireless networks will call for new RF access technologies to enable substantial increases in overall system spectral efficiency at an acceptably low cost to the user. Space-Time Coding (STC) is an antenna array processing technology currently simulating considerable Interest across the wireless industry. The invention provides a space-time coding apparatus having an input, a trellis encoder, a modulator, a demultiplexer, and a set of signal outputs wherein the input is operable to receive a stream of data. This allows de-multiplexing to take place after coding and modulation has been performed. The trellis encoder comprises a convolutional encoder operable to sequentially group data to provide coded bits to provide QPSK symbols. By the selection of convolutional encoder rates and / or modulation alphabets STCs of any desired dimensionality may be produced including multi-dimensional codes.

Owner:APPLE INC

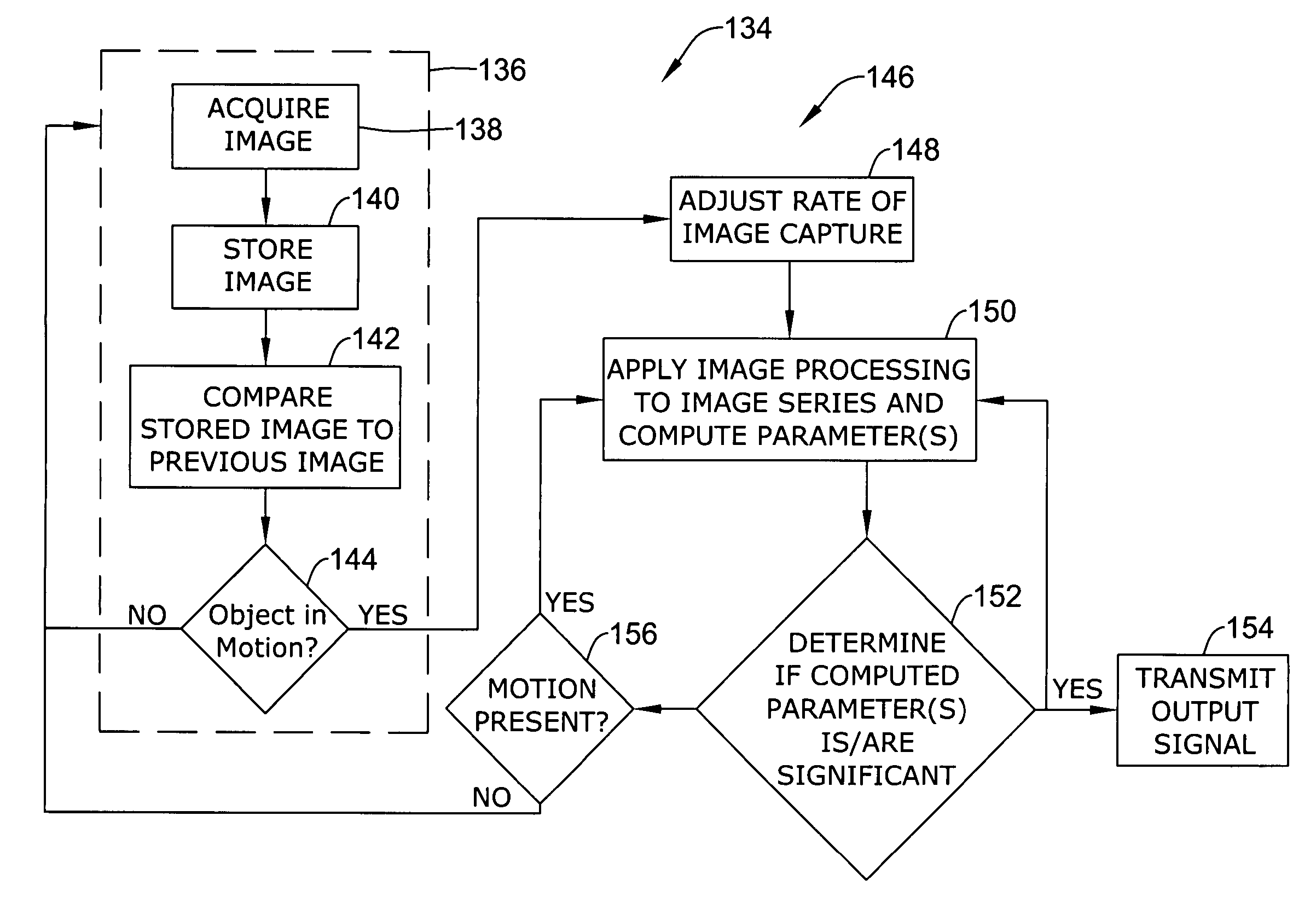

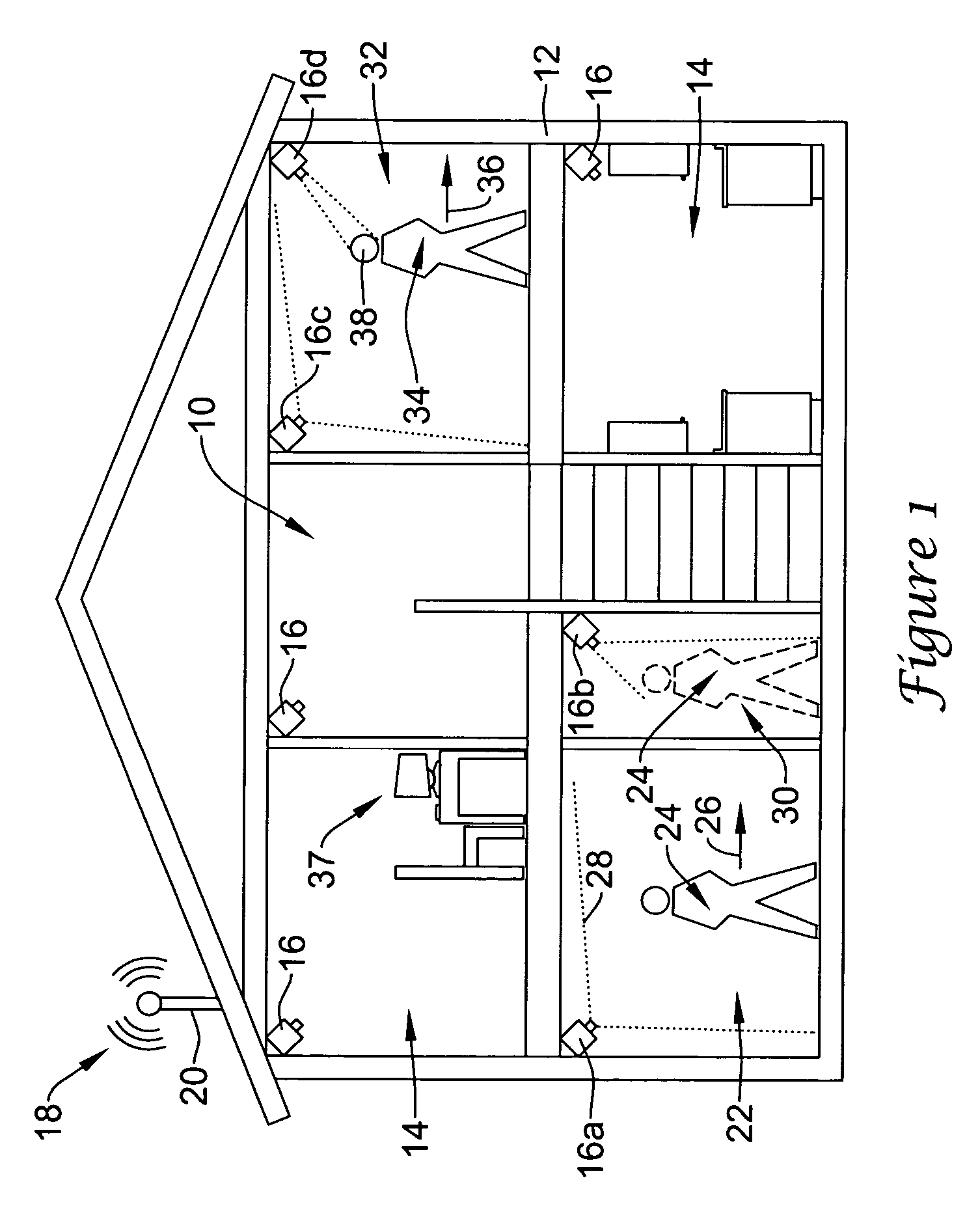

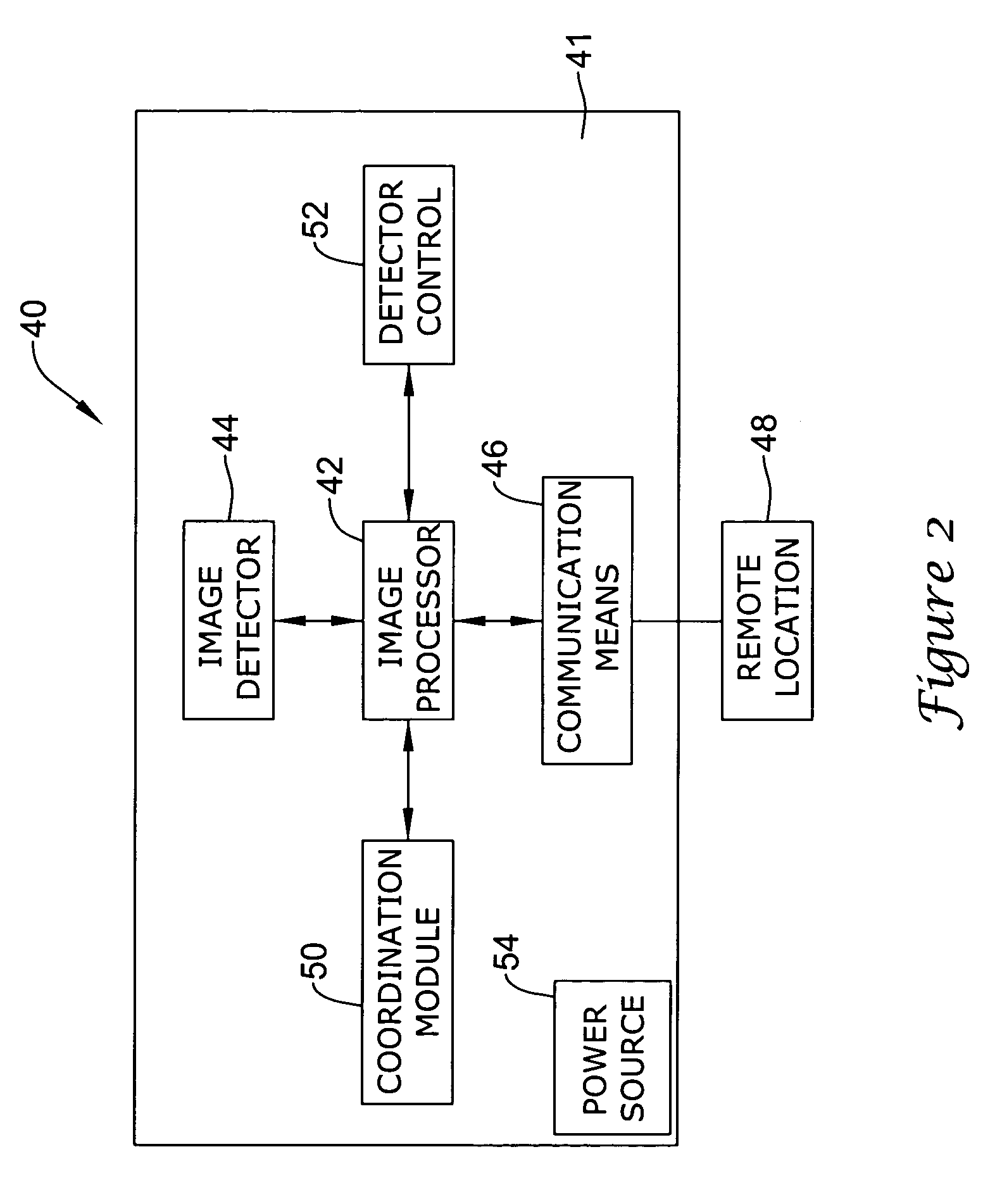

Monitoring devices

Monitoring systems, devices, and methods for monitoring one or more objects within an environment are disclosed. An illustrative monitoring device in accordance with the present invention can include an image detector, an on-board image processor, and communication means for transmitting an imageless signal to a remote location. The image processor can be configured to run one or more routines that can be used to determine a number of parameters relating to each object detected. In some embodiments, the monitoring device can be configured to run an image differencing routine that can be used to initially detect the presence of motion. Once motion is detected, the monitoring device can be configured to initiate a higher rate mode wherein image frames are processed at a higher frame rate to permit the image processor to compute higher-level information about the moving object.

Owner:HONEYWELL INT INC

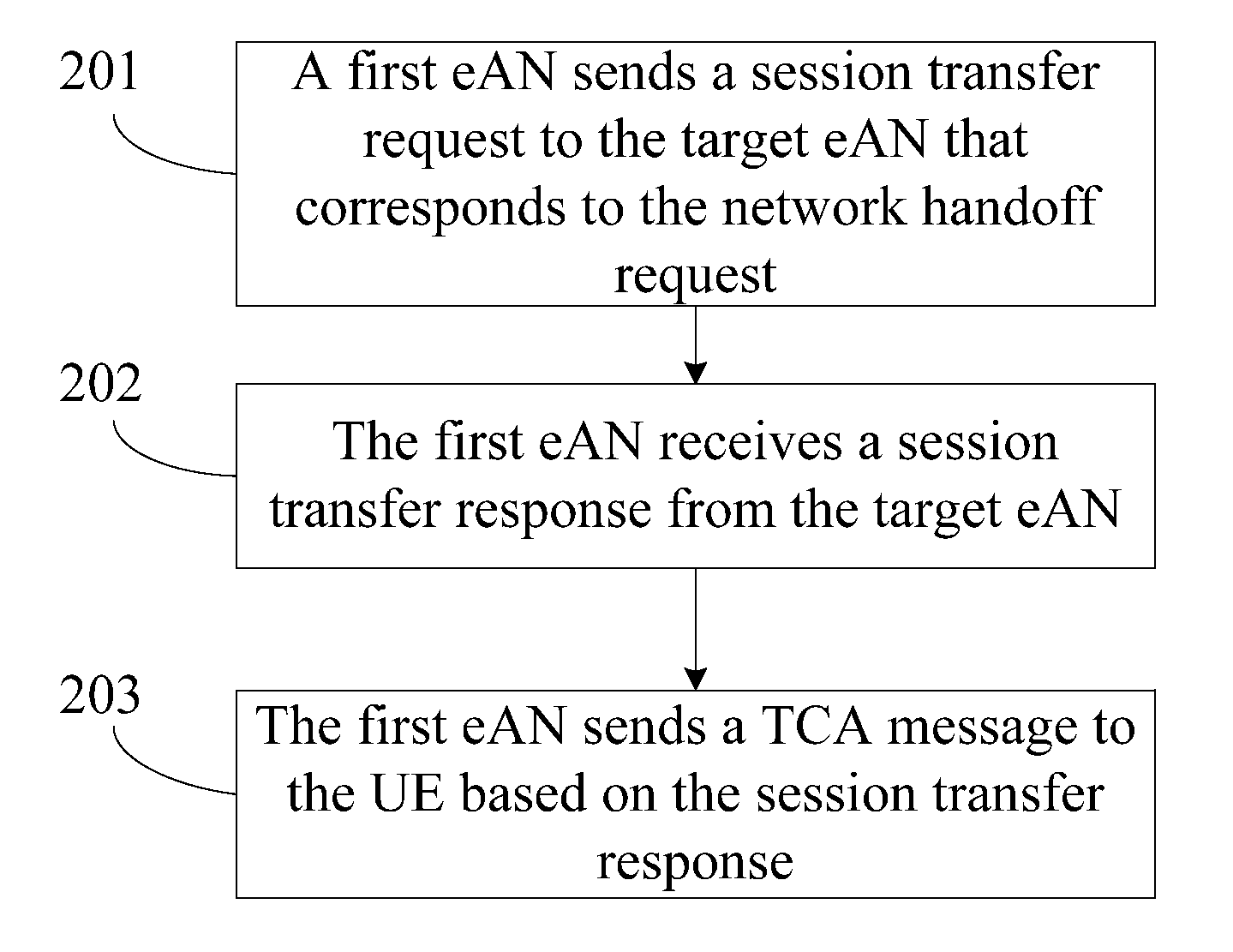

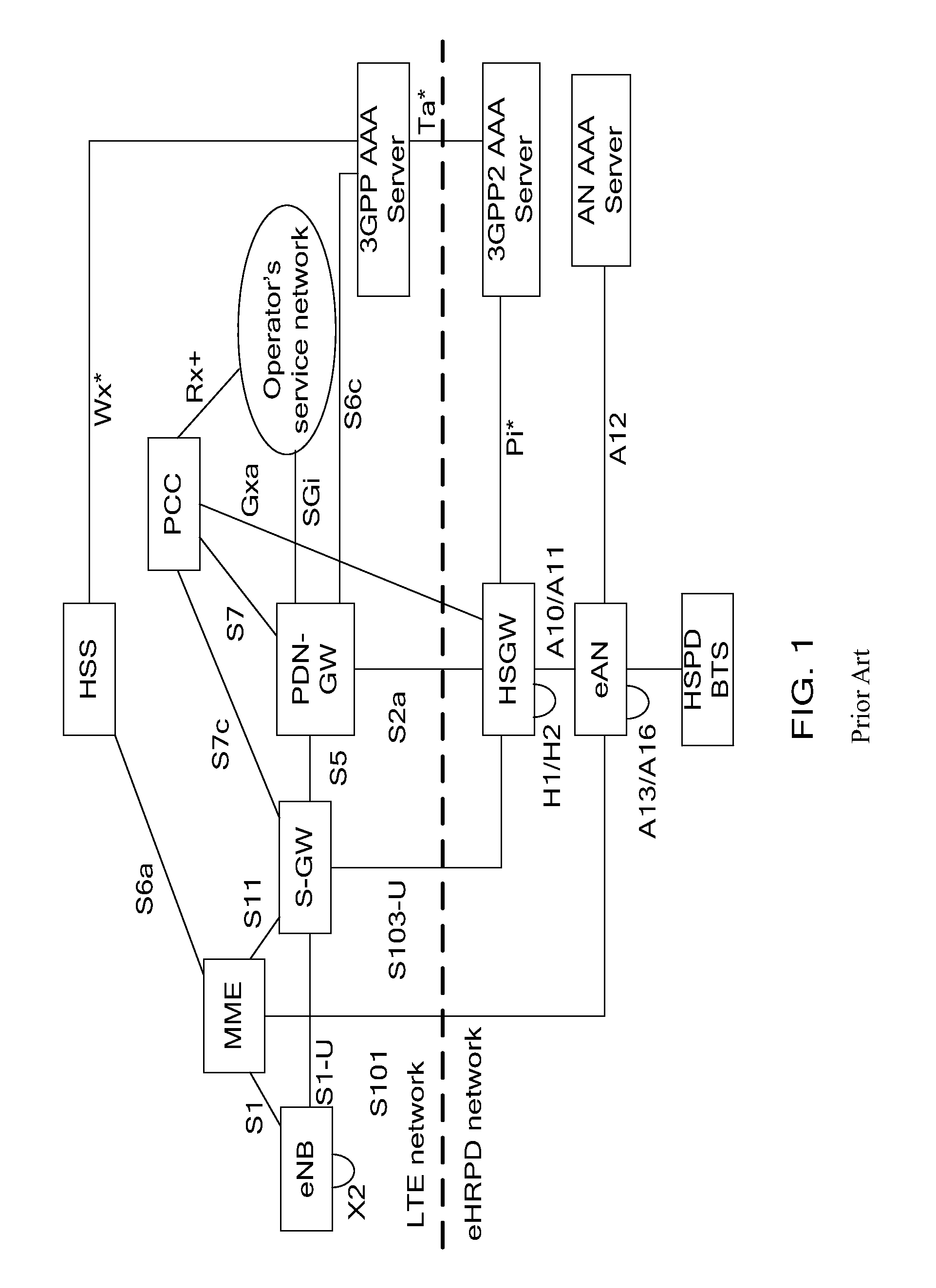

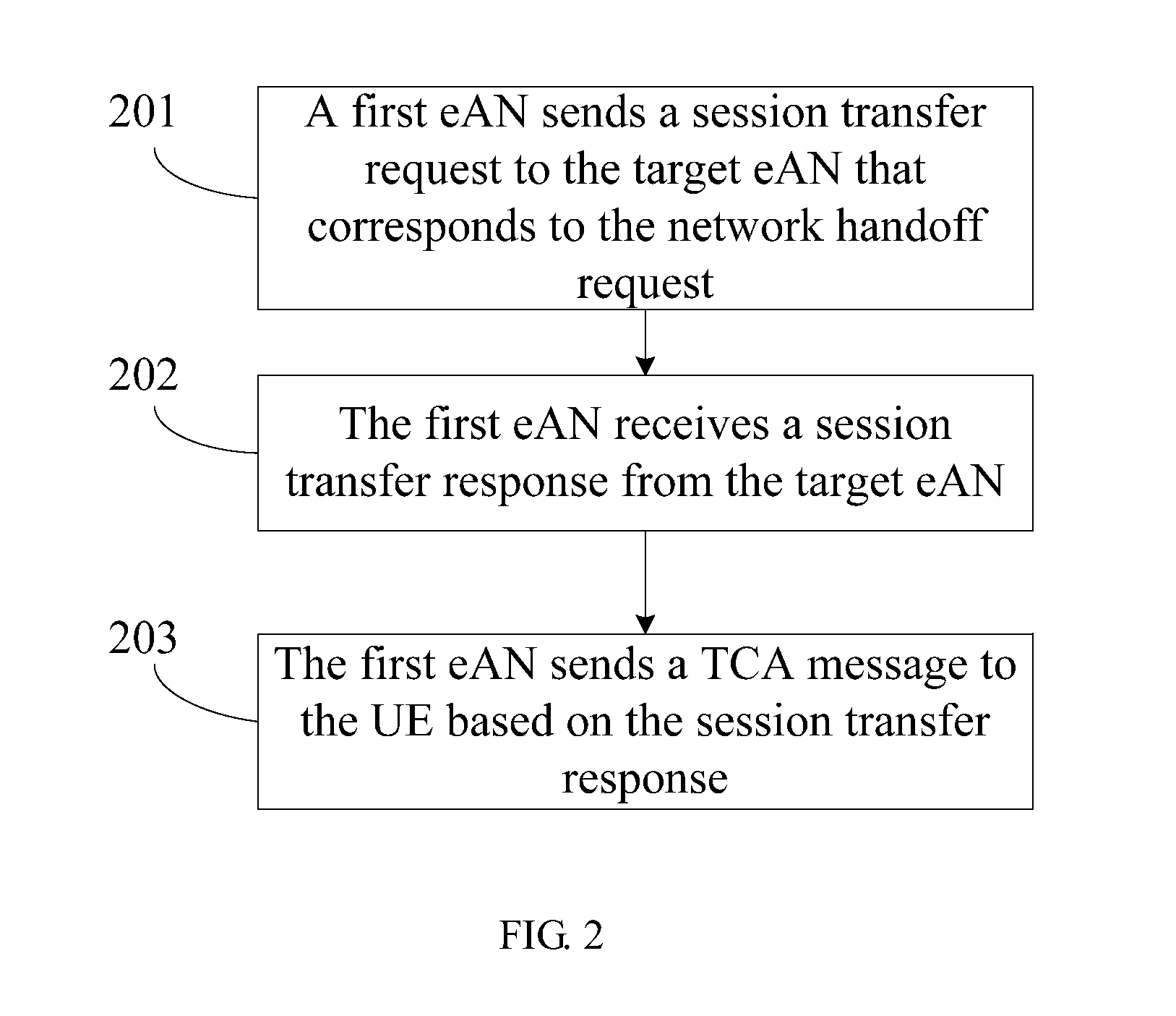

Method, system, and device for network handoff

ActiveUS8532046B2Data switching by path configurationWireless commuication servicesAccess networkHigh rate

A method, a system, and a device for network handoff is disclosed. A first evolved Access Network (eAN) sends a session transfer request to the target eAN that corresponds to the network handoff request. The first eAN receives a session transfer response from the target eAN. The first eAN sends a Traffic Channel Assignment (TCA) message to a User Equipment (UE) based on the session transfer response, so that the UE can switch from a Long Term Evolution (LTE) network to an evolved High Rate Packet Data (eHRPD) network based on the TCA message.

Owner:HUAWEI TECH CO LTD

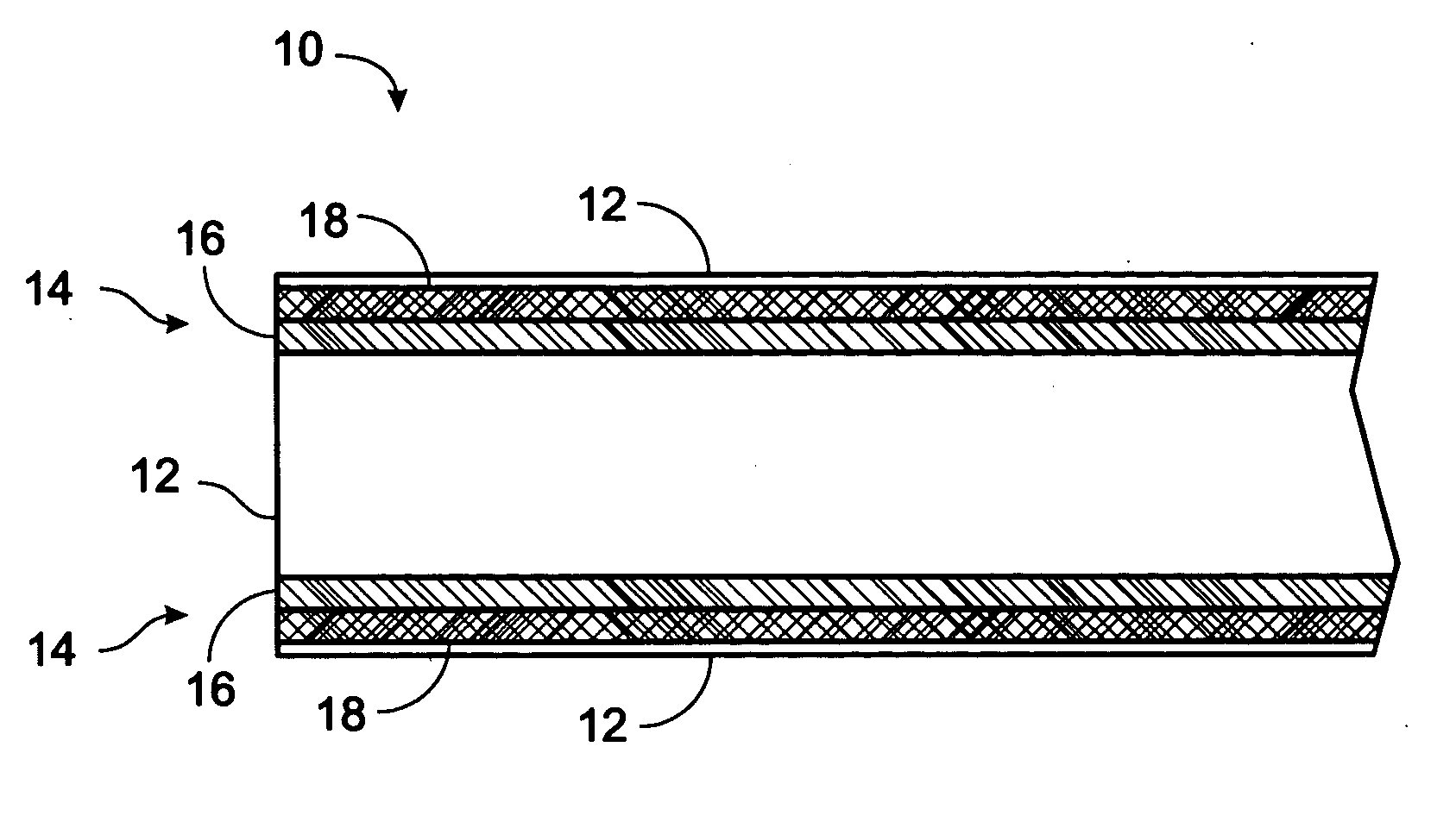

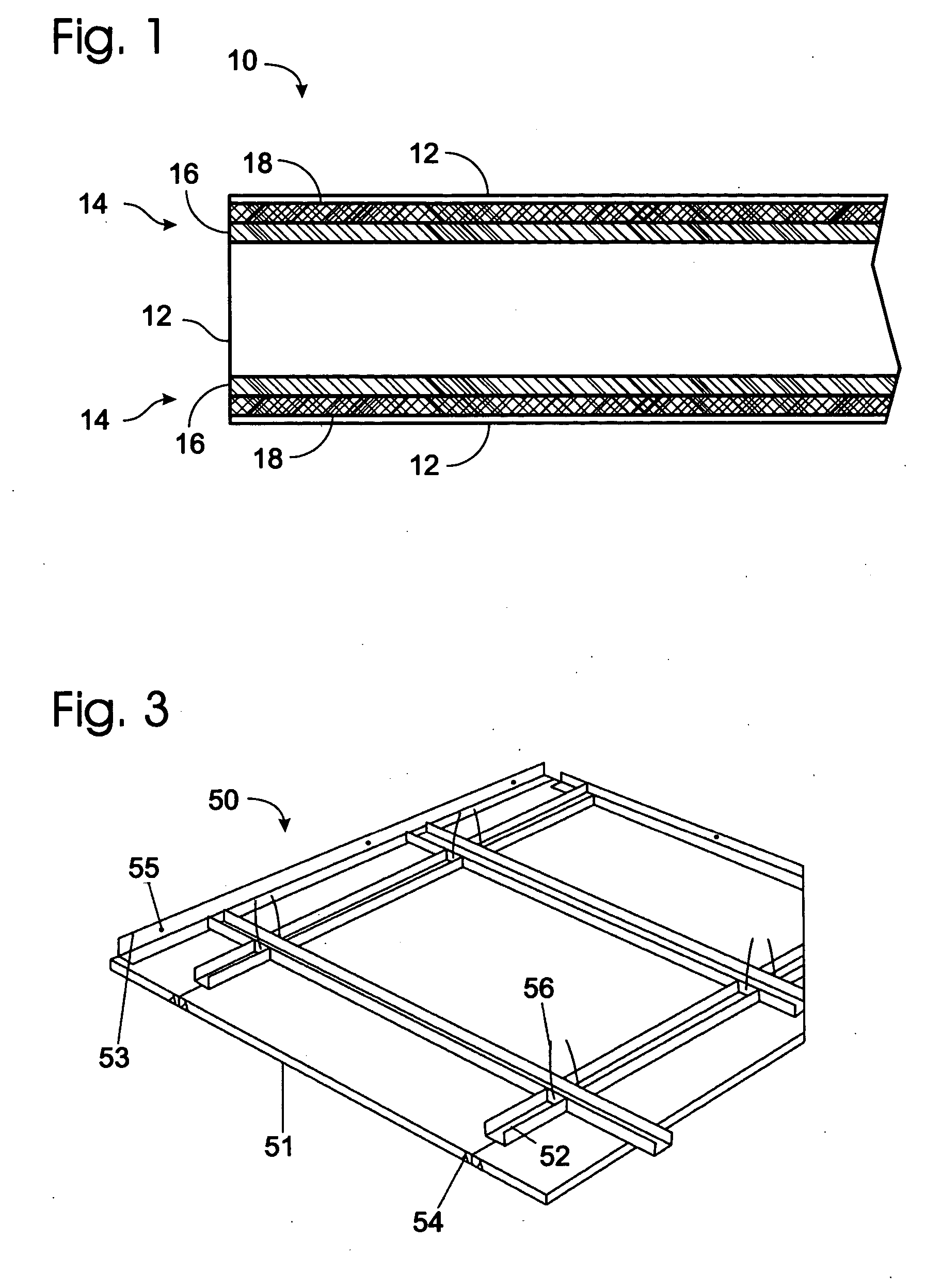

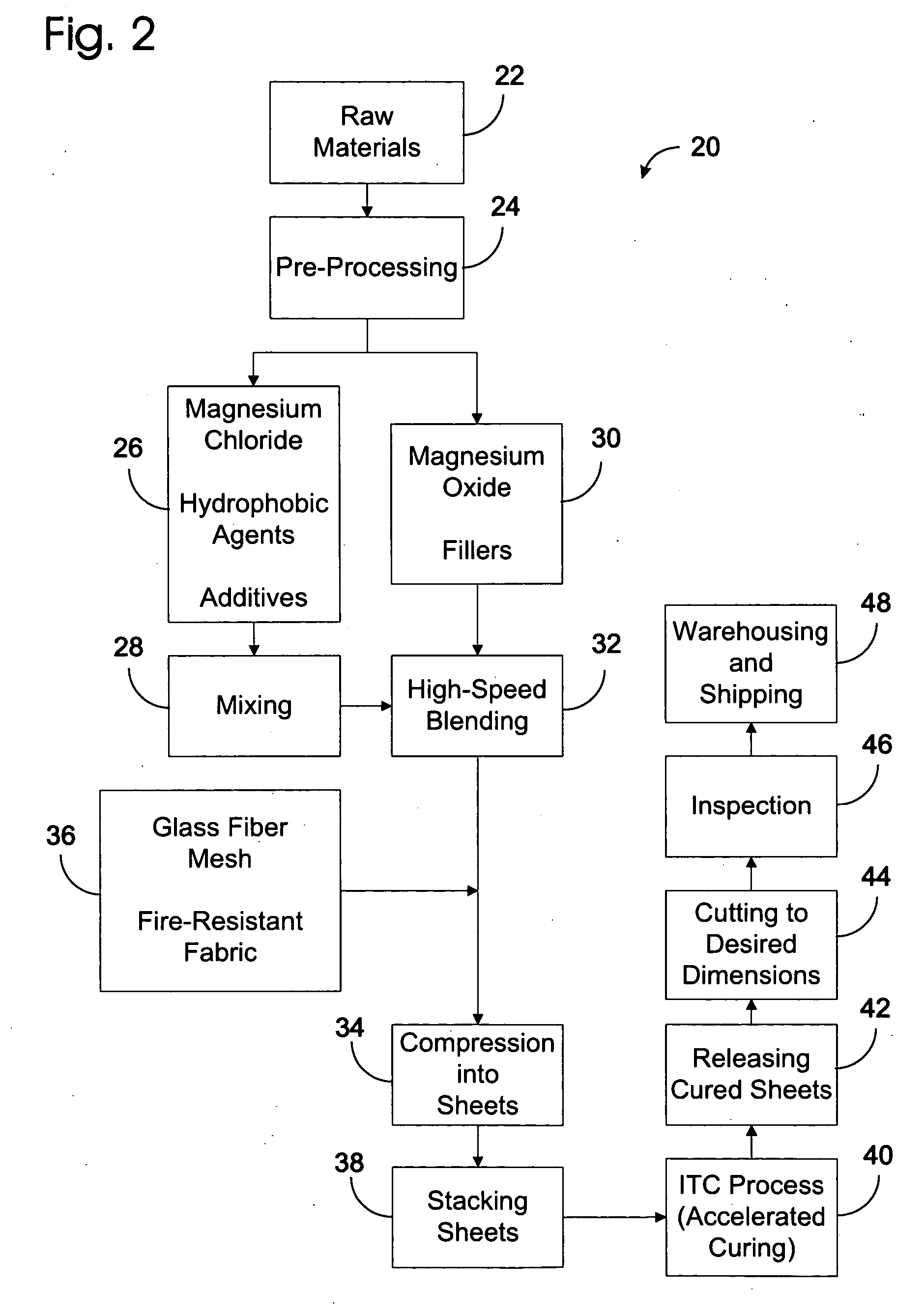

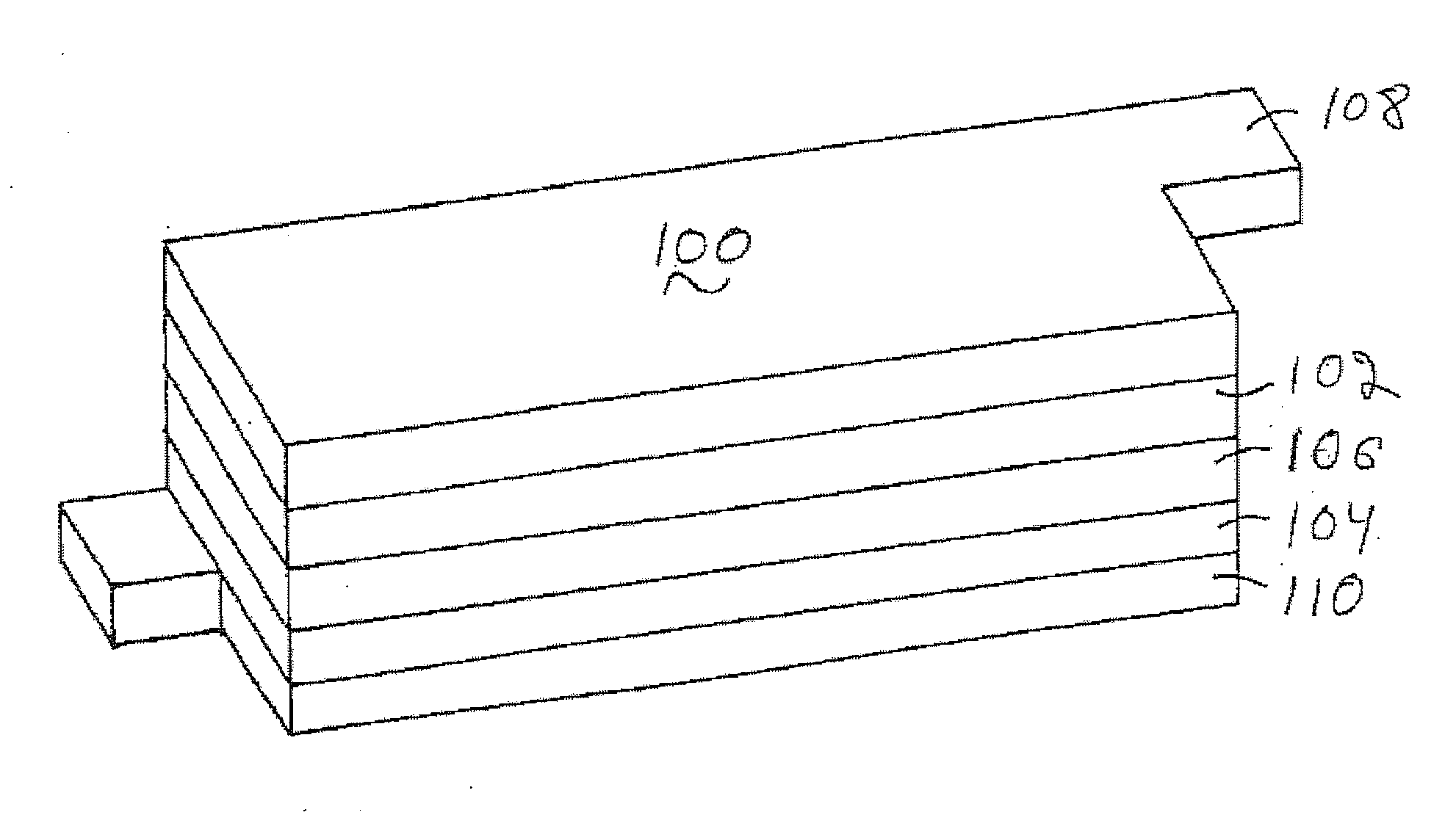

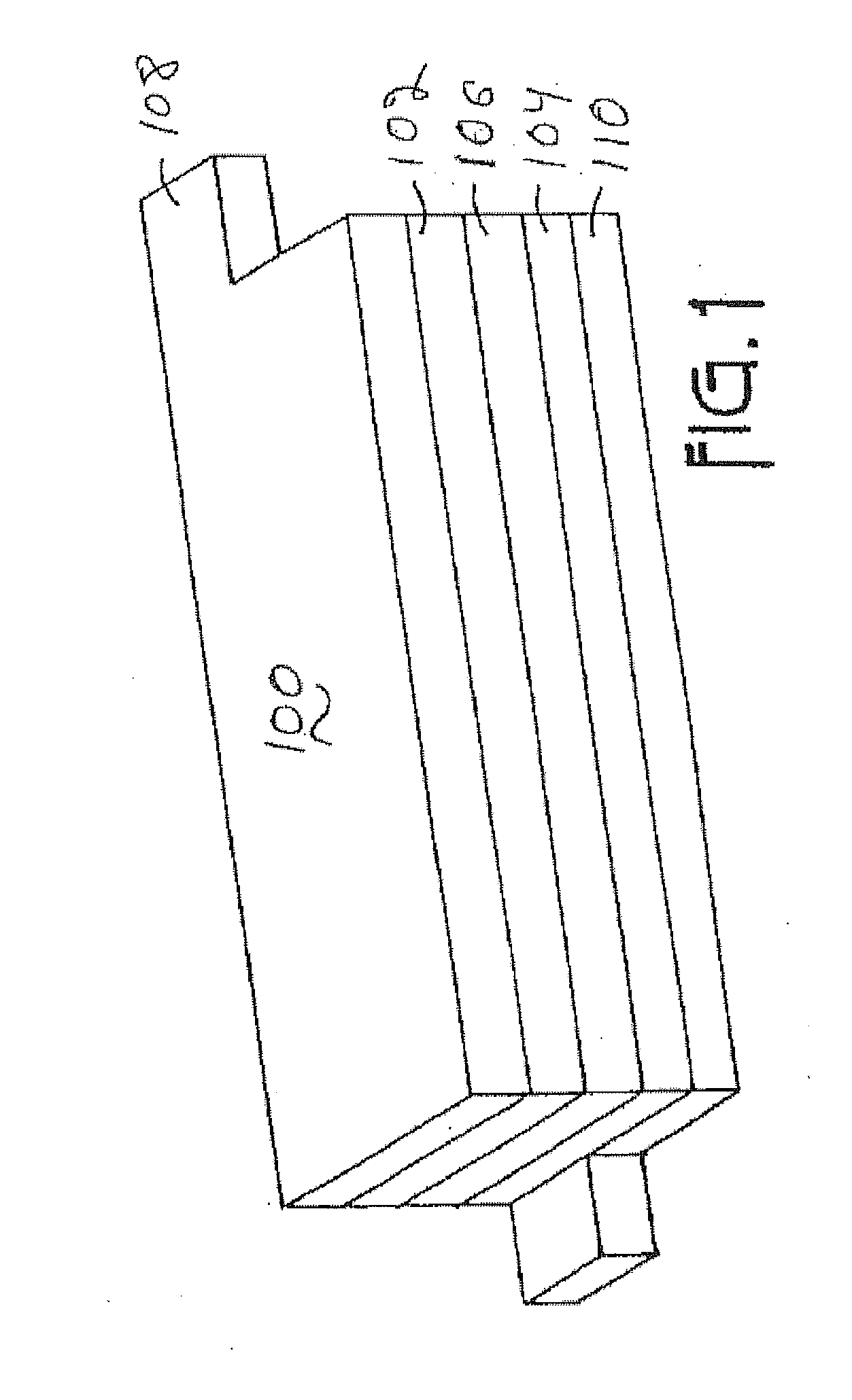

Fire-resistant panel and method of manufacture

A highly fire-resistant and environmentally-friendly panel of 2 mm to 28 mm may be manufactured by a blending of magnesium compounds, sodium silicate, kaolin, fillers, and additives to form the core materials, reinforced by 4 layers of fire-resistant glass fiber meshes and fabrics. Using a proprietary ITC process that accelerates the chemical reactions of the ingredients to generate sufficient heat without external supply of energy, the panels may be completely cured within 24 hours instead of 10 days. The use of waste materials, energy-saving curing system and no gas emission manufacturing process combined to make this panel an eco-friendly product which offers the world's highest-rated fire resistance of 5 hours, high flexural strength, low density, durability and effective water-resistance.

Owner:REP TECH

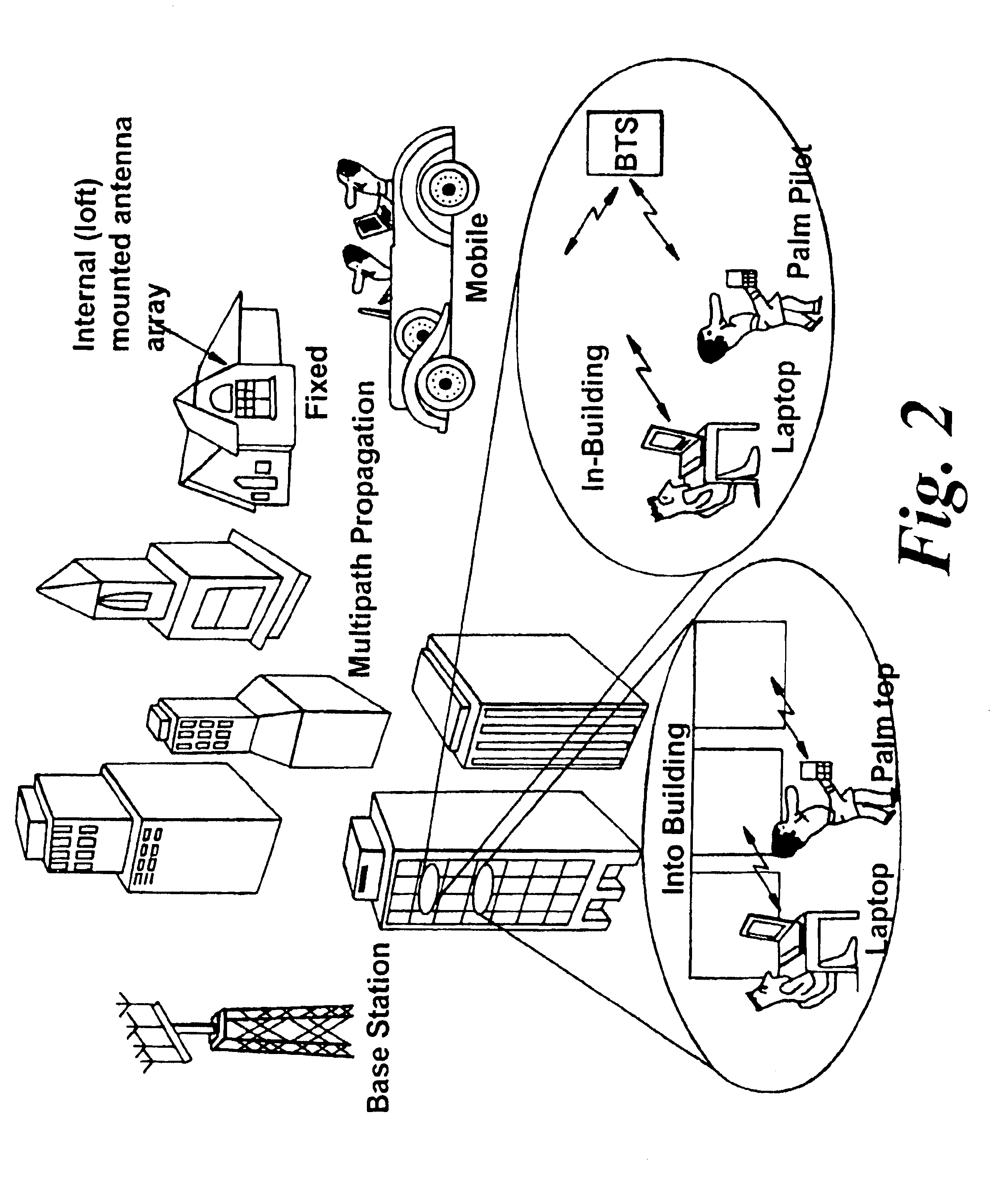

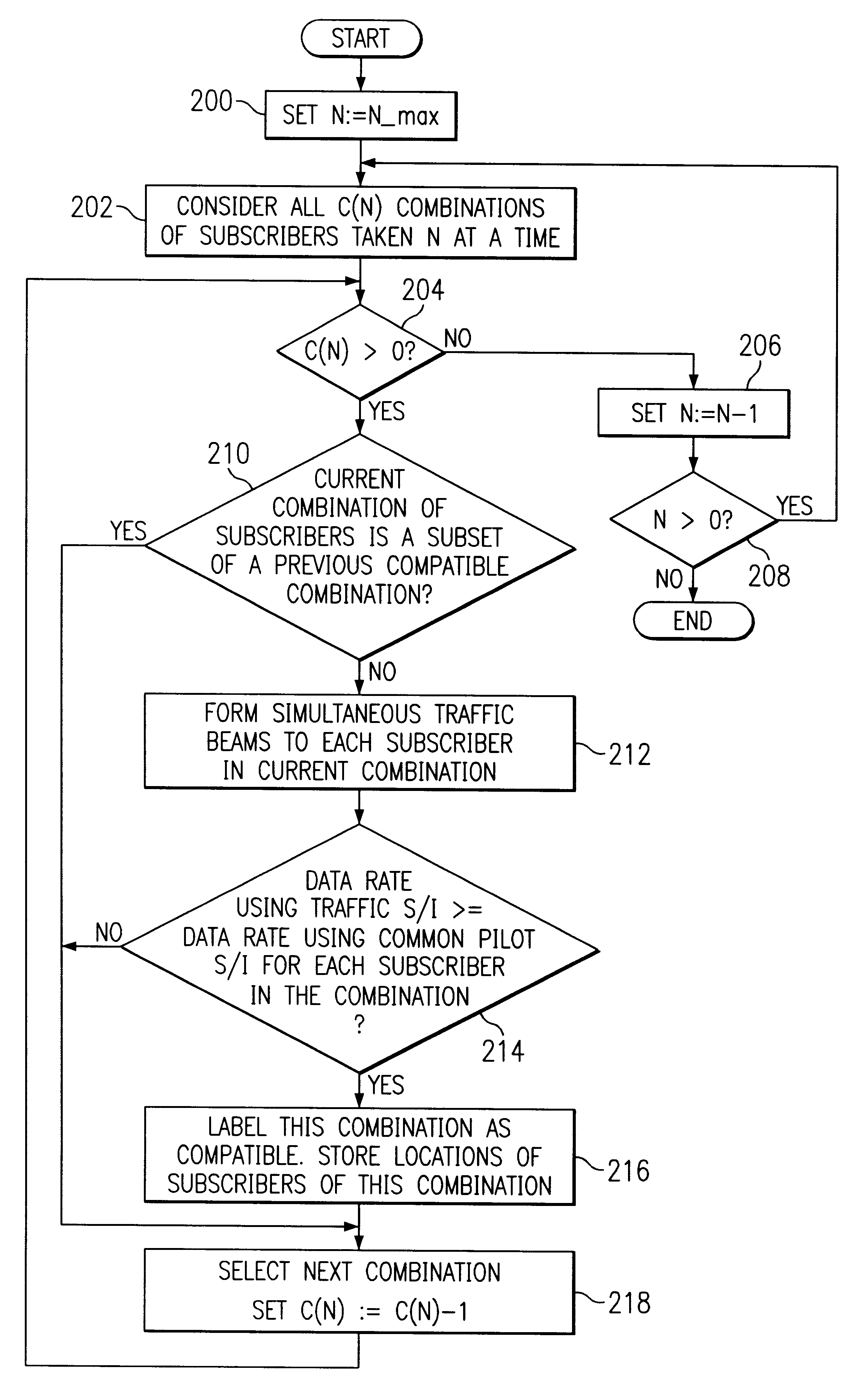

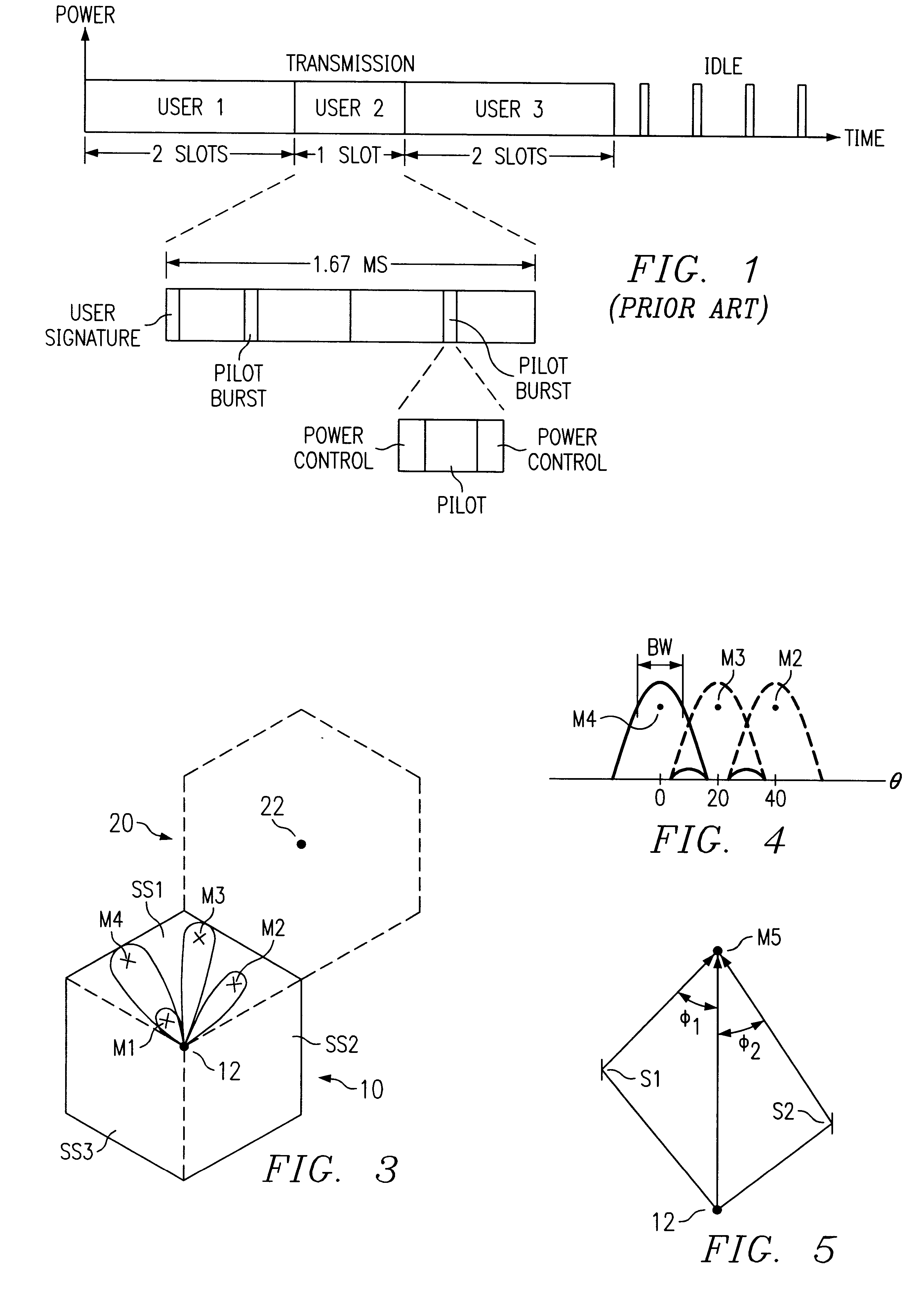

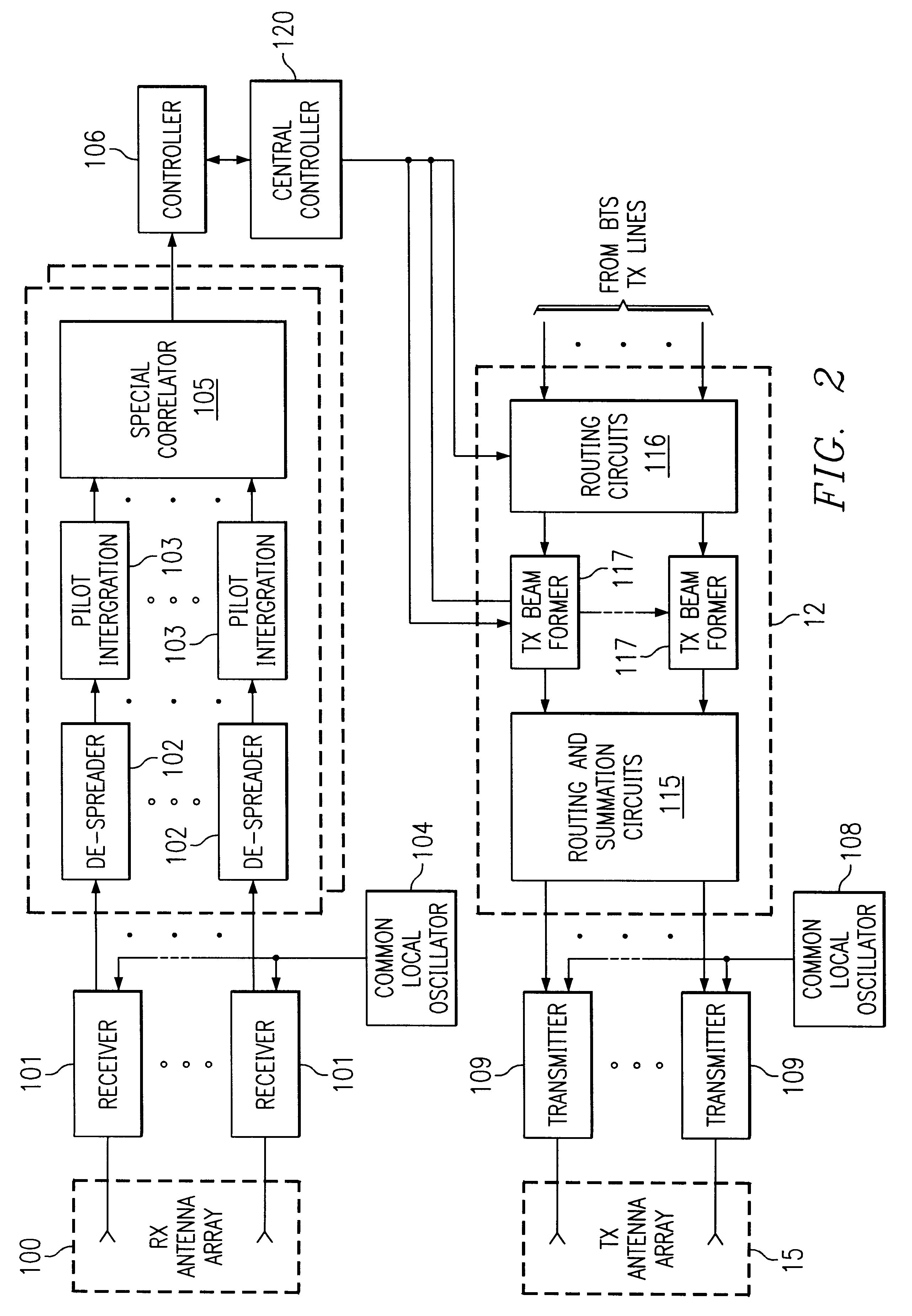

Simultaneous forward link beam forming and learning method for mobile high rate data traffic

InactiveUS6330460B1Increase aggregate digital data packet throughputImprove data transfer ratePower managementSpatial transmit diversityHigh rateCommunications system

Disclosed is a base station of a wireless communications system including an adaptive antenna array and beam forming means for forming simultaneous multiple forward link beams. Preferably mobile stations are separated into groups of mobile stations corresponding to a maximum number of simultaneous forward link beams for determining which of said groups can be served by compatible simultaneous forward link beams. Preferably, if mobiles remain outside of a compatible group, the number of simultaneous forward link beams is increased and grouping of the mobile stations is repeated until all the mobile stations are included in compatible groups. Preferably simultaneous data beams are formed to mobiles of a said group during a time interval accorded to said group, such that every mobile station receives service data during a full cycle of said time intervals at a rate equal to or in excess of a target service data rate for that mobile.

Owner:F POSZAT HU

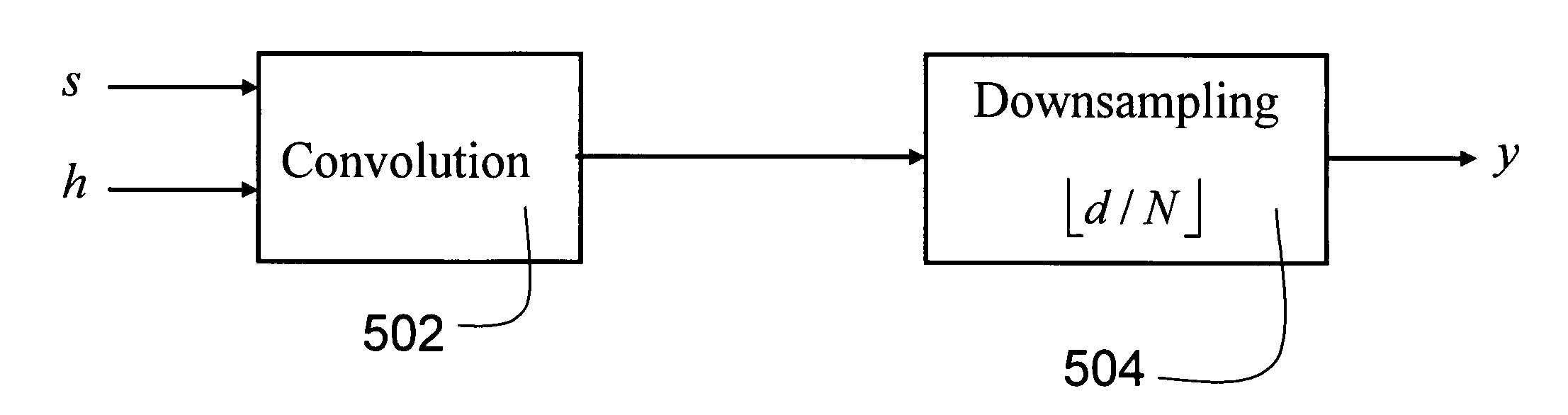

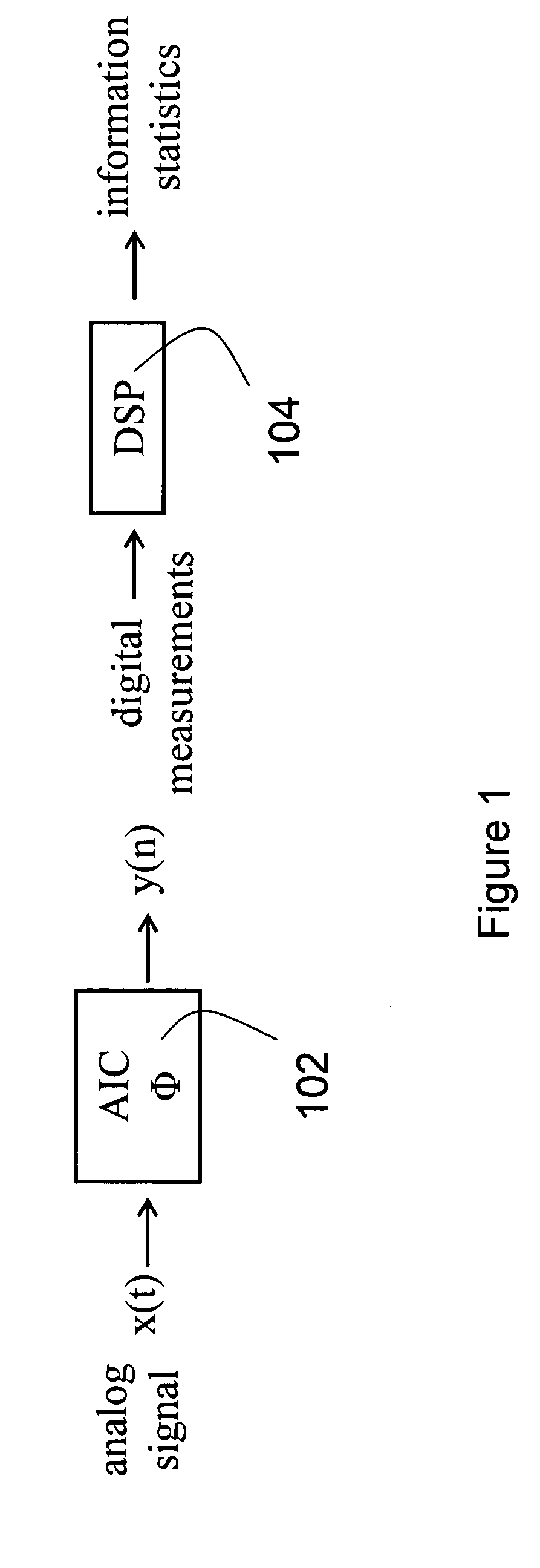

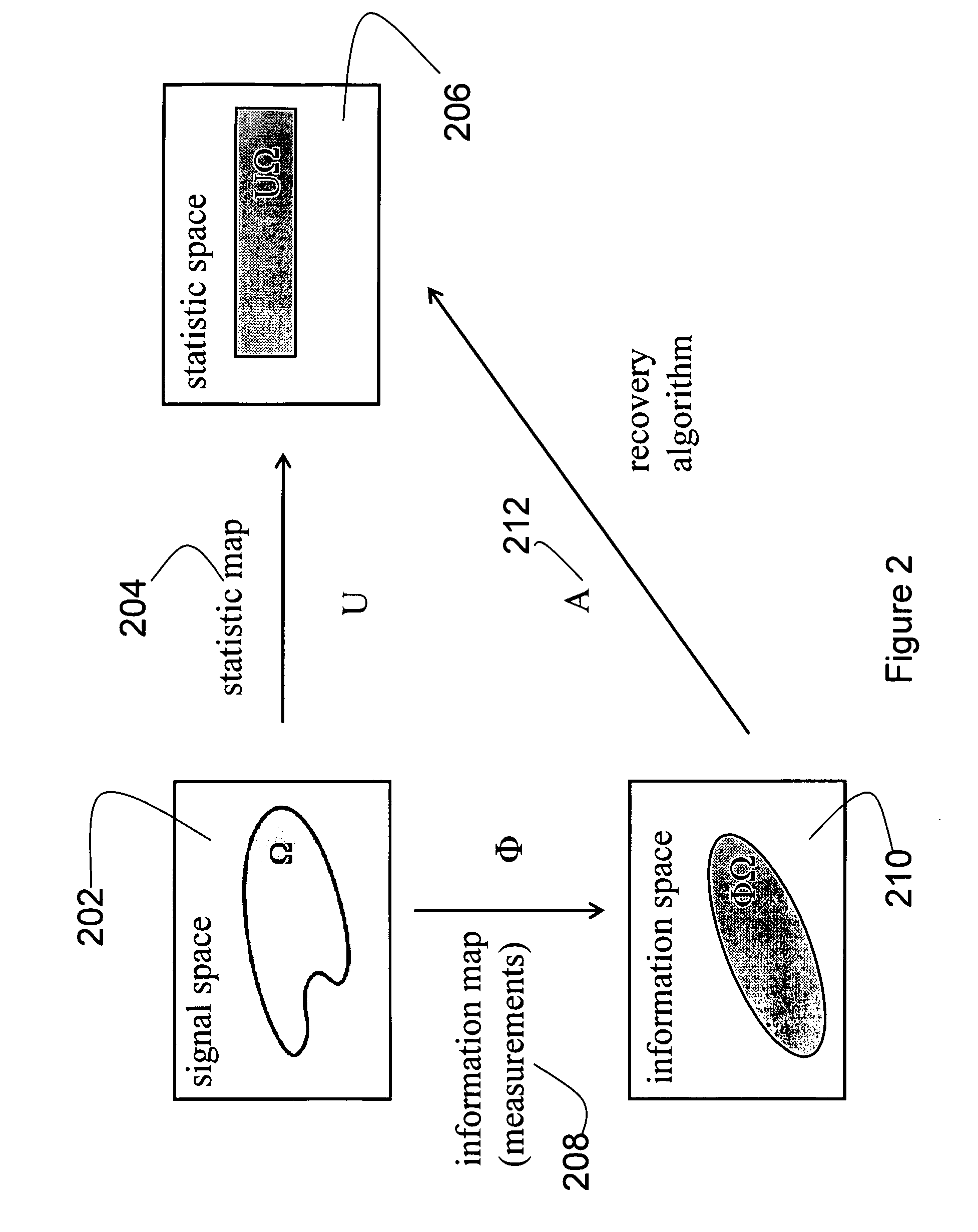

Method and Apparatus for On-Line Compressed Sensing

ActiveUS20090222226A1Improve system performanceAnalogue/digital conversionError correction/detection using multiple parity bitsHigh rateDiscrete-time signal

A typical data acquisition system takes periodic samples of a signal, image, or other data, often at the so-called Nyquist / Shannon sampling rate of two times the data bandwidth in order to ensure that no information is lost. In applications involving wideband signals, the Nyquist / Shannon sampling rate is very high, even though the signals may have a simple underlying structure. Recent developments in mathematics and signal processing have uncovered a solution to this Nyquist / Shannon sampling rate bottlenck for signals that are sparse or compressible in some representation. We demonstrate and reduce to practice methods to extract information directly from an analog or digital signal based on altering our notion of sampling to replace uniform time samples with more general linear functionals. One embodiment of our invention is a low-rate analog-to-information converter that can replace the high-rate analog-to-digital converter in certain applications involving wideband signals. Another embodiment is an encoding scheme for wideband discrete-time signals that condenses their information content.

Owner:RGT UNIV OF MICHIGAN +1

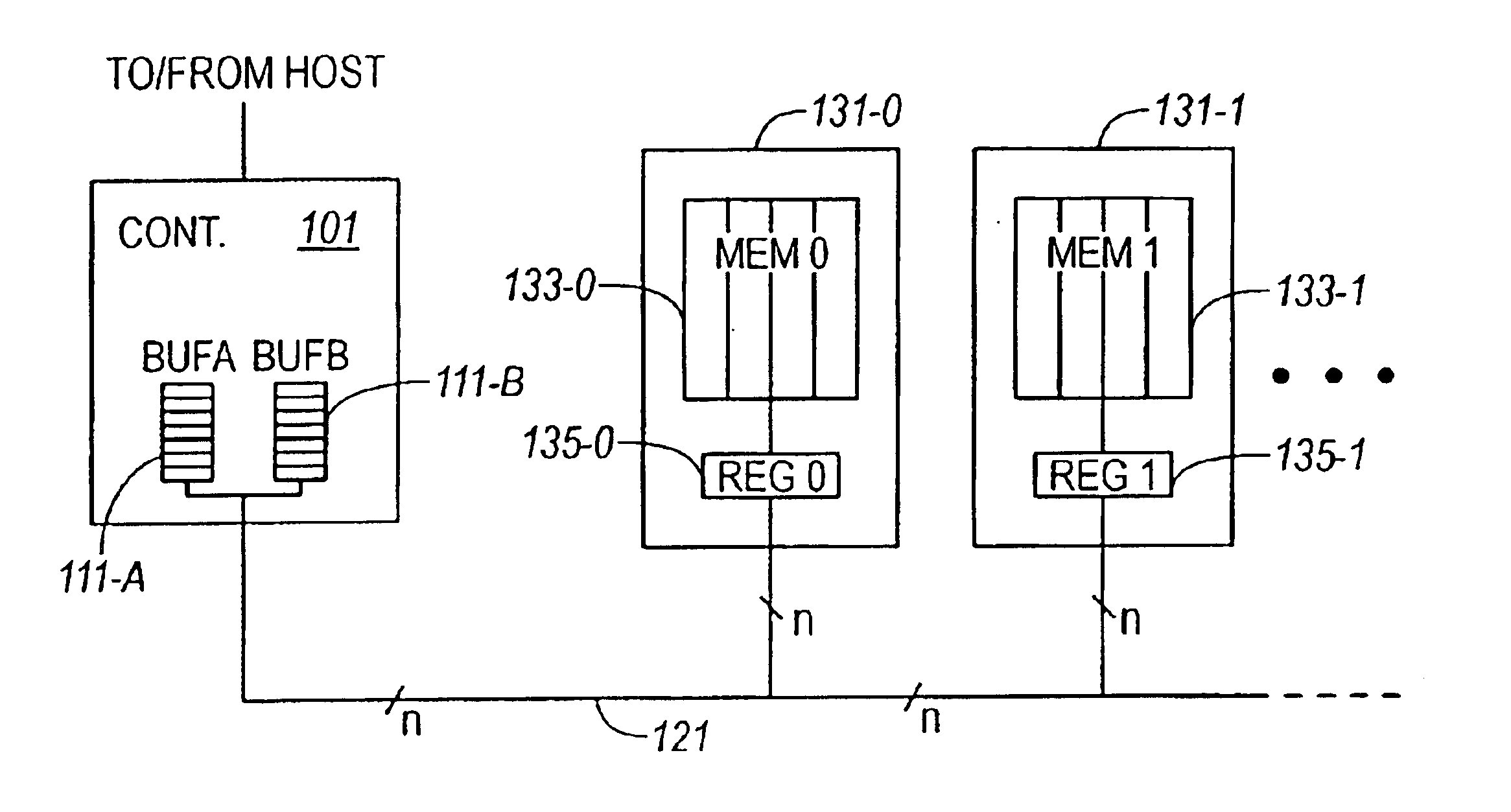

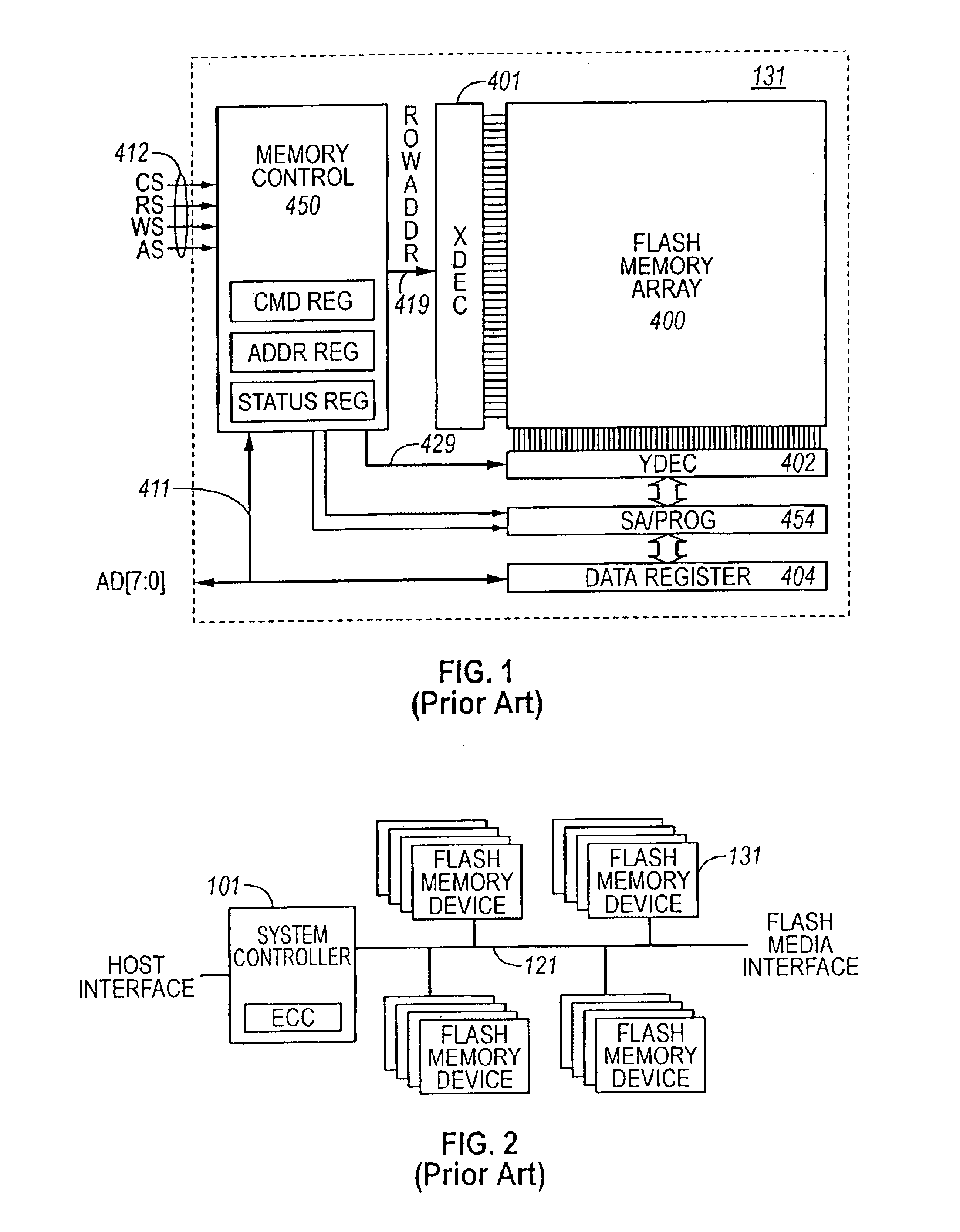

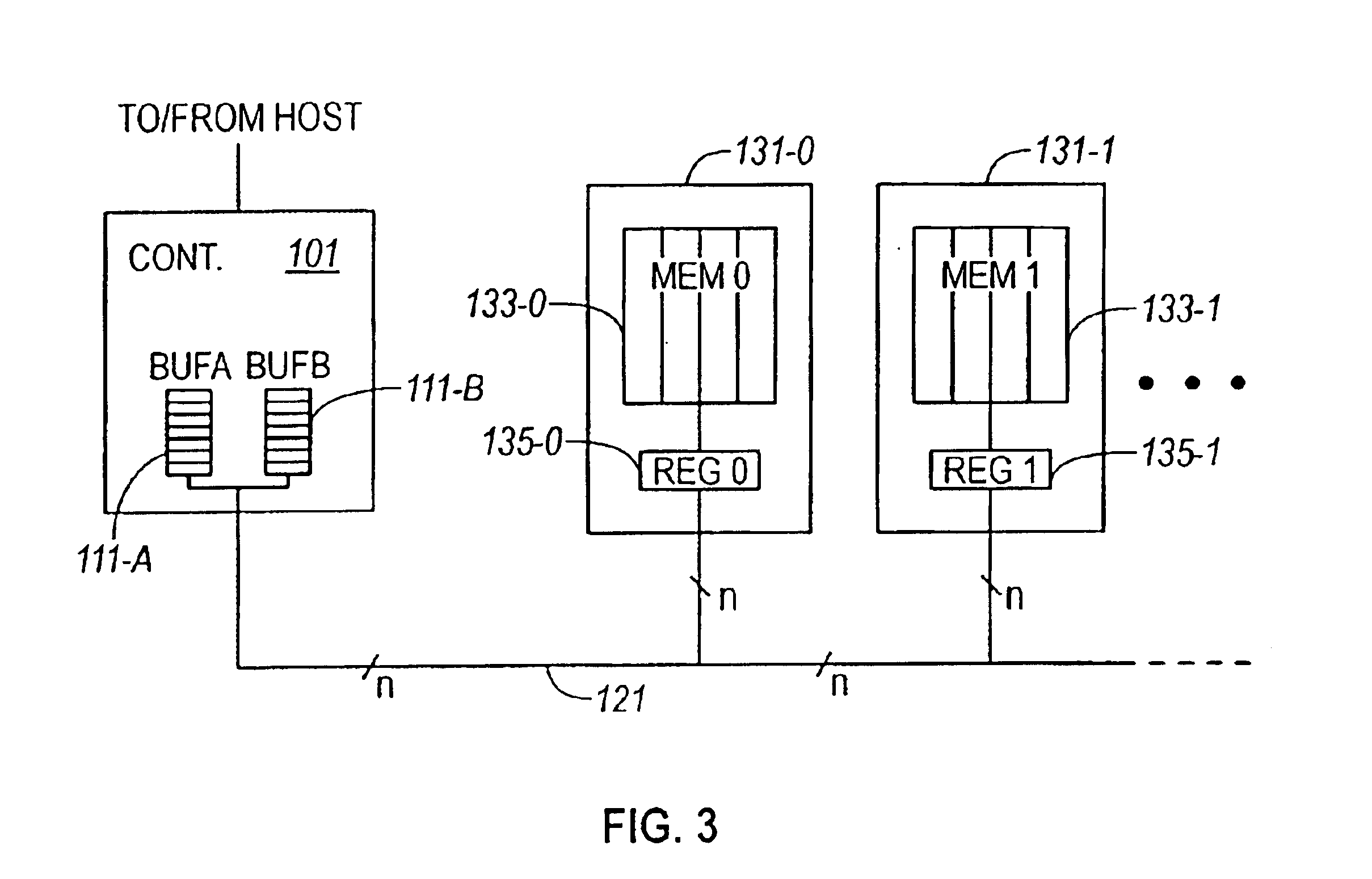

Pipelined parallel programming operation in a non-volatile memory system

InactiveUS6871257B2High degree of parallelismEasy to liftRead-only memoriesDigital storageMemory chipHigh rate

The present invention allows for an increase in programming parallelism in a non-volatile memory system without incurring additional data transfer latency. Data is transferred from a controller to a first memory chip and a programming operation is caused to begin. While that first memory chip is busy performing that program operation, data is transferred from the controller to a second memory chip and a programming operation is caused to begin in that chip. Data transfer can begin to the first memory chip again once it has completed its programming operation even though the second chip is still busy performing its program operation. In this manner high parallelism of programming operation is achieved without incurring the latency cost of performing the additional data transfers. Two sets of embodiments are presented, one that preserves the host data in a buffer until successful programming of that data is confirmed and one that does not require that success be achieved and that does not preserve the data thus achieving a higher rate of data programming throughput.

Owner:SANDISK TECH LLC

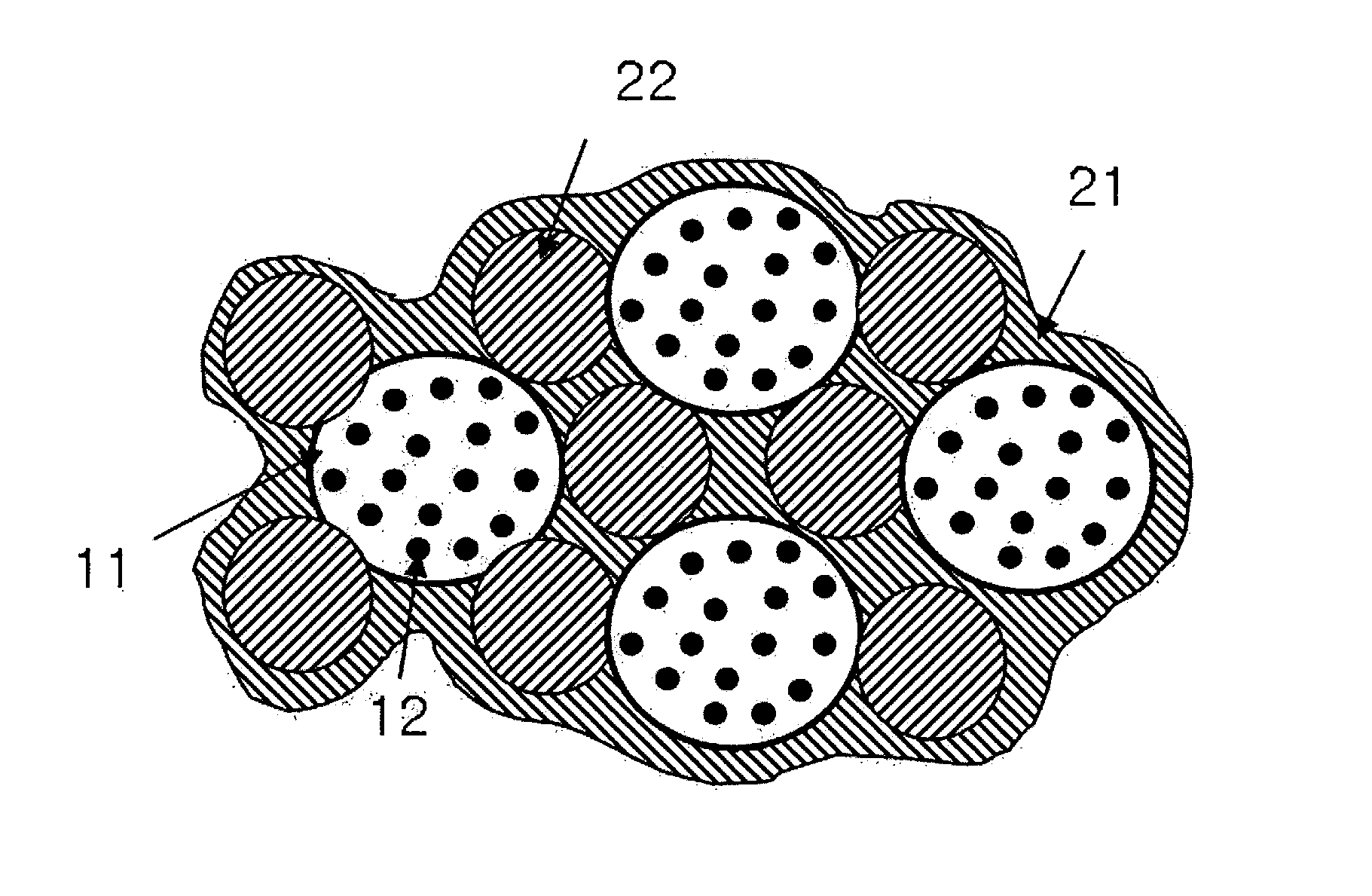

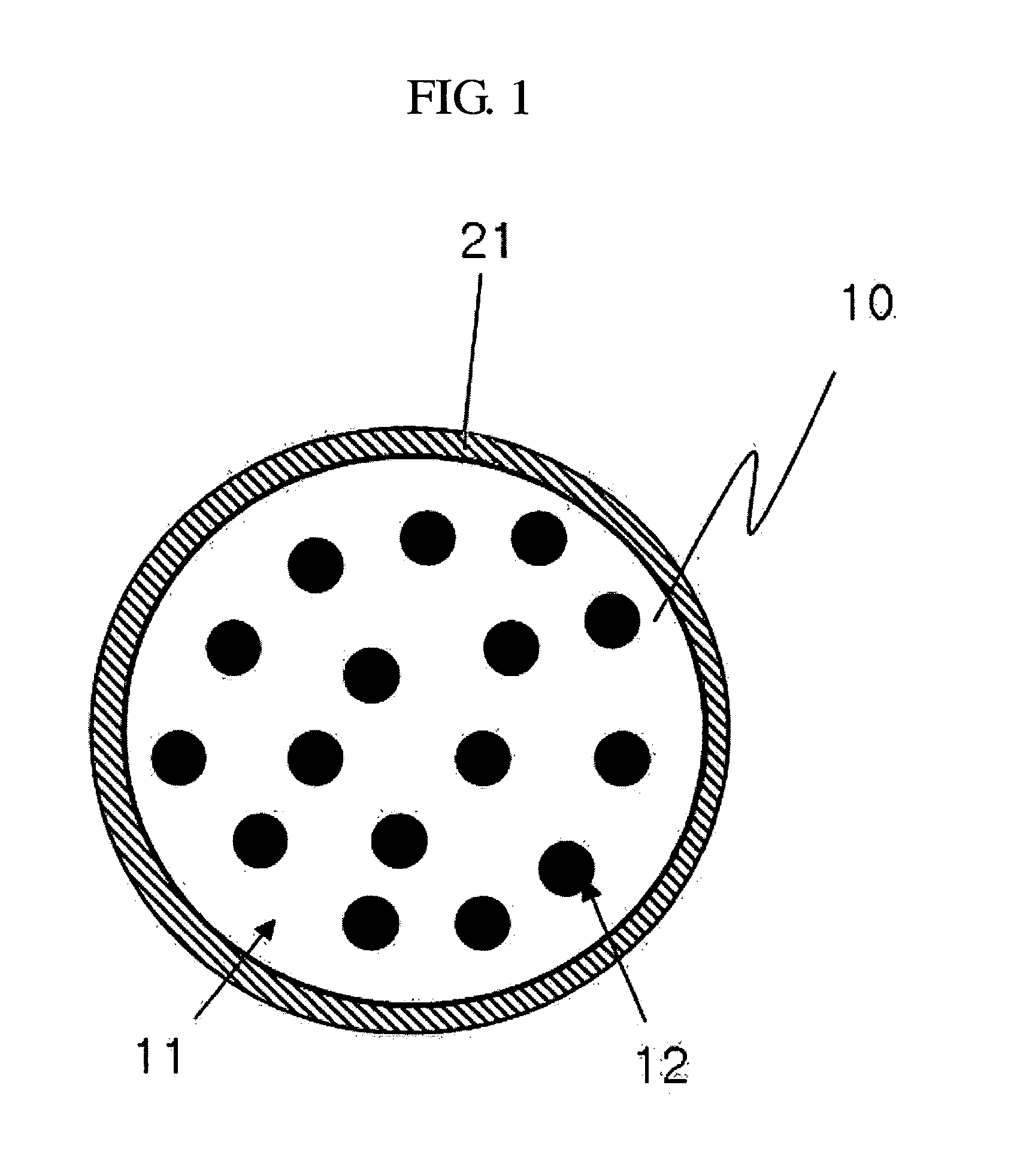

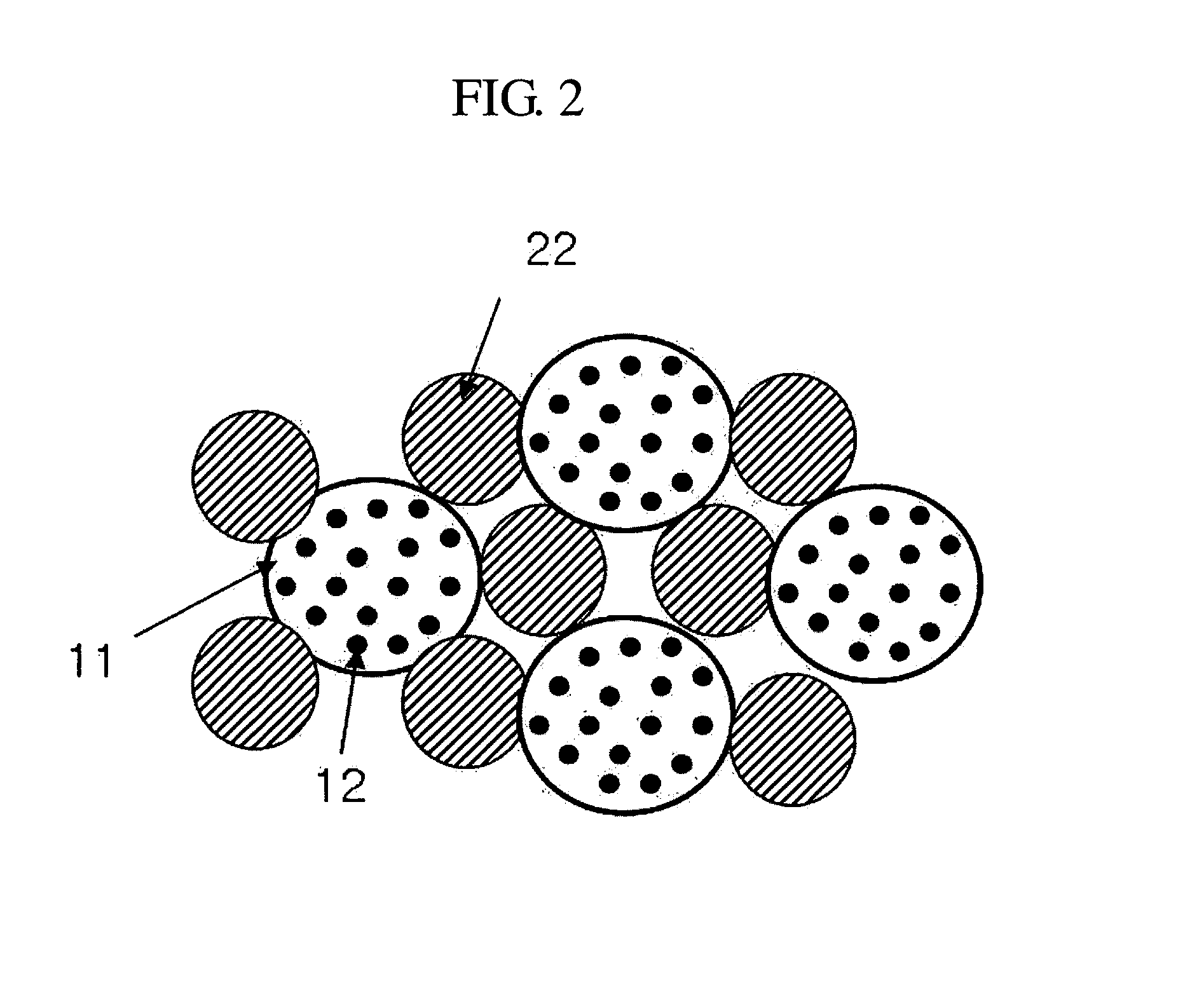

Negative active material for a rechargeable lithium battery, a method of preparing the same, and a rechargeable lithium battery comprising the same

ActiveUS20050233213A1Improved cycle-life characteristic and charge and discharge characteristicIncrease chanceElectrode manufacturing processesNon-aqueous electrolyte accumulatorsHigh rateSilicon oxide

The present invention relates to a negative active material for a rechargeable lithium battery, which includes a silicon-based composite having a silicon oxide of the form SiOX where x≦1.5 and at least one element selected from the group consisting of B, P, Li, Ge, Al, and V, and a carbonaceous material. The negative active material of the present invention can improve the cycle-life and high-rate charge / discharge characteristics of a rechargeable lithium battery.

Owner:SAMSUNG SDI CO LTD

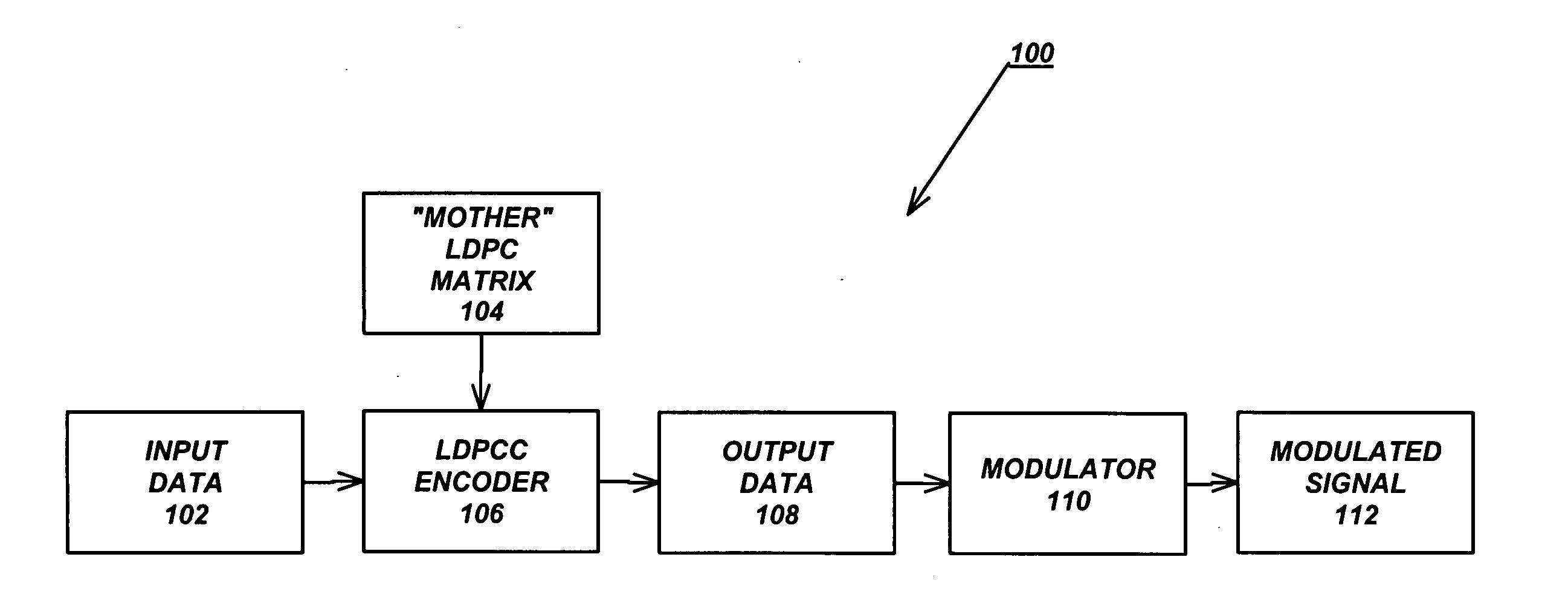

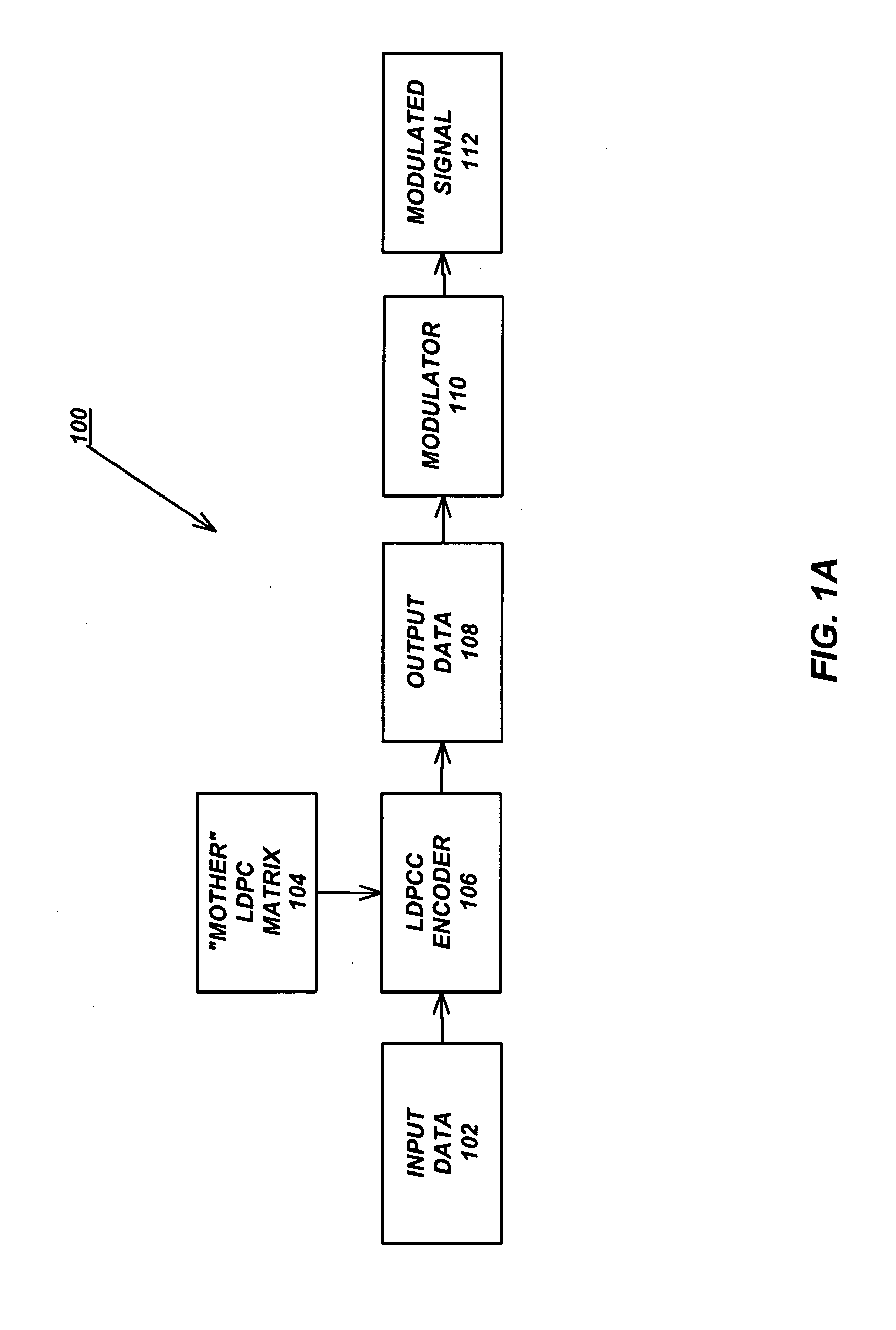

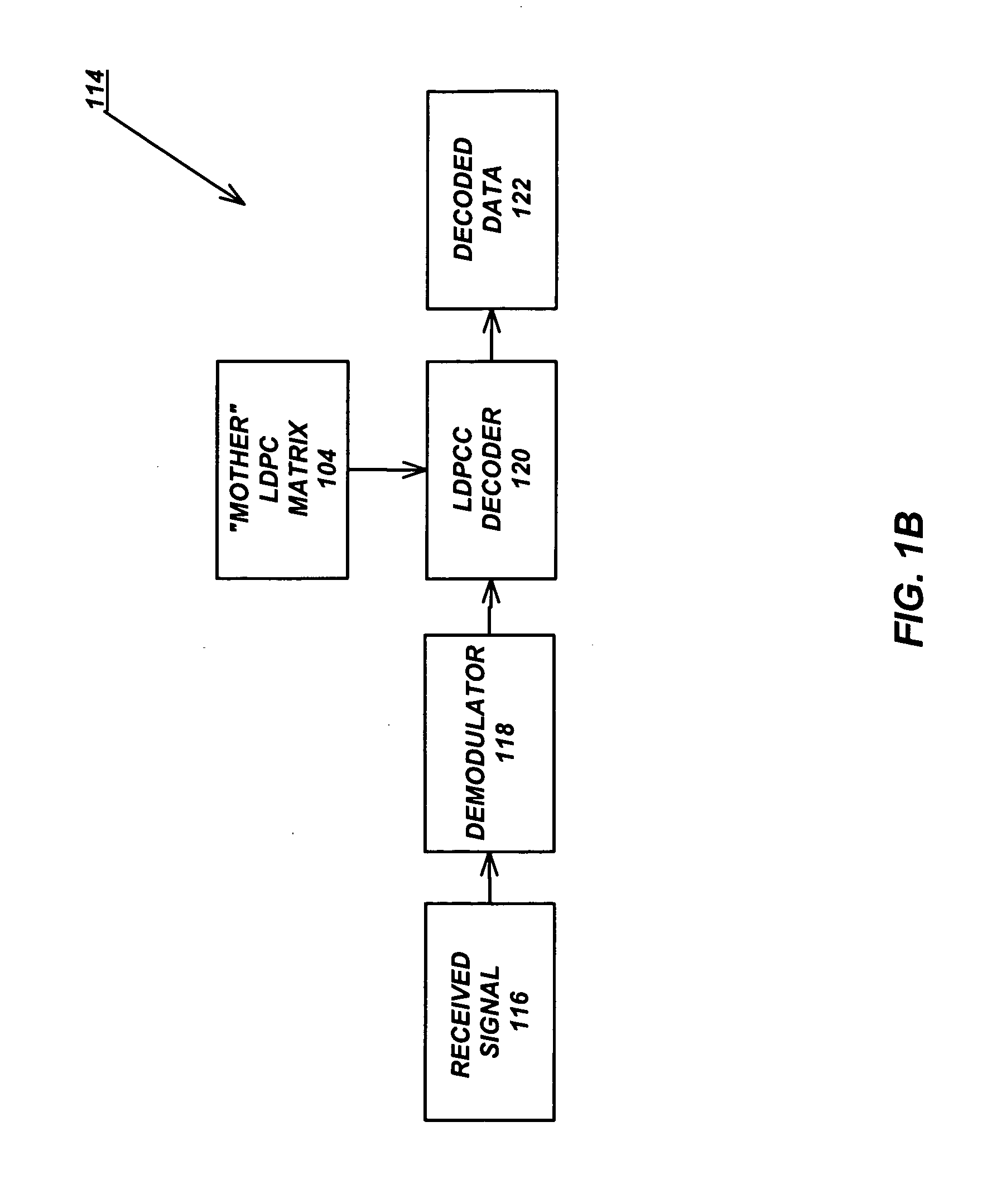

Variable-rate low-density parity check codes with constant blocklength

Low density parity check (LDPC) codes (LDPCCs) have an identical code blocklength and different code rates. At least one of the rows of a higher-rate LDPC matrix is obtained by combining a plurality of rows of a lower-rate LDPC matrix with the identical code blocklength as the higher-rate LDPC matrix.

Owner:RGT UNIV OF CALIFORNIA +1

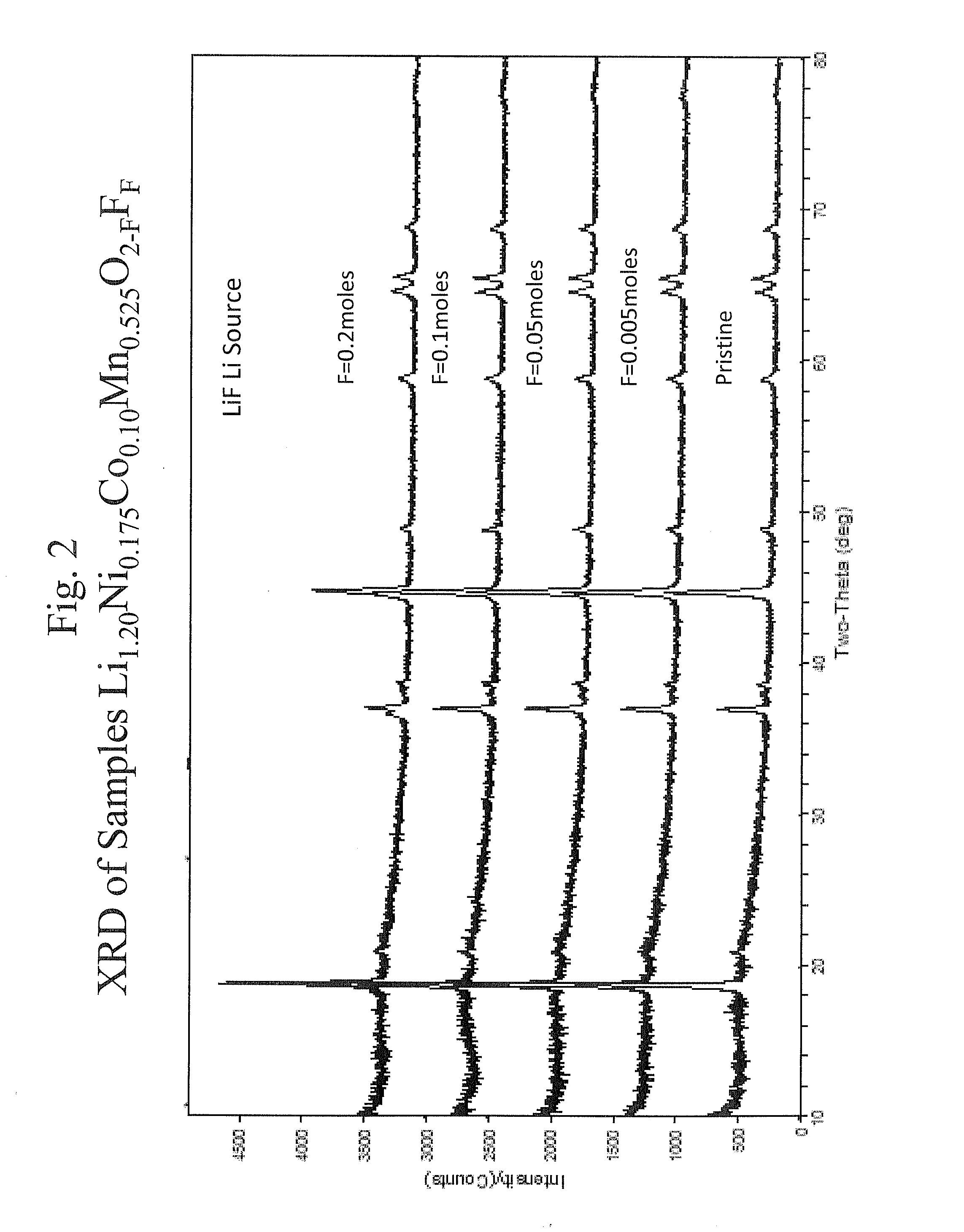

Fluorine doped lithium rich metal oxide positive electrode battery materials with high specific capacity and corresponding batteries

ActiveUS20100086854A1Desirable battery performanceElectrode manufacturing processesFinal product manufactureLithiumDopant

Lithium rich metal oxyfluorides are described with high specific capacity and, good cycling properties. The materials have particularly good high rate capabilities. The fluorine dopant can be introduced in a low temperature process to yield the materials with desirable cycling properties. In some embodiments, the positive electrode active materials have a composition represented approximately by the formula Li1+xNiαMnβCoγAδO2−zFz where:x is from about 0.02 to about 0.19,α is from about 0.1 to about 0.4,β is from about 0.35 to about 0.869,γ is from about 0.01 to about 0.2,δ is from 0.0 to about 0.1 andz is from about 0.01 to about 0.2,where A is Mg, Zn, Al, Ga, B, Zr, Ti, Ca, Ce, Y, Nb or combinations thereof.

Owner:IONBLOX INC

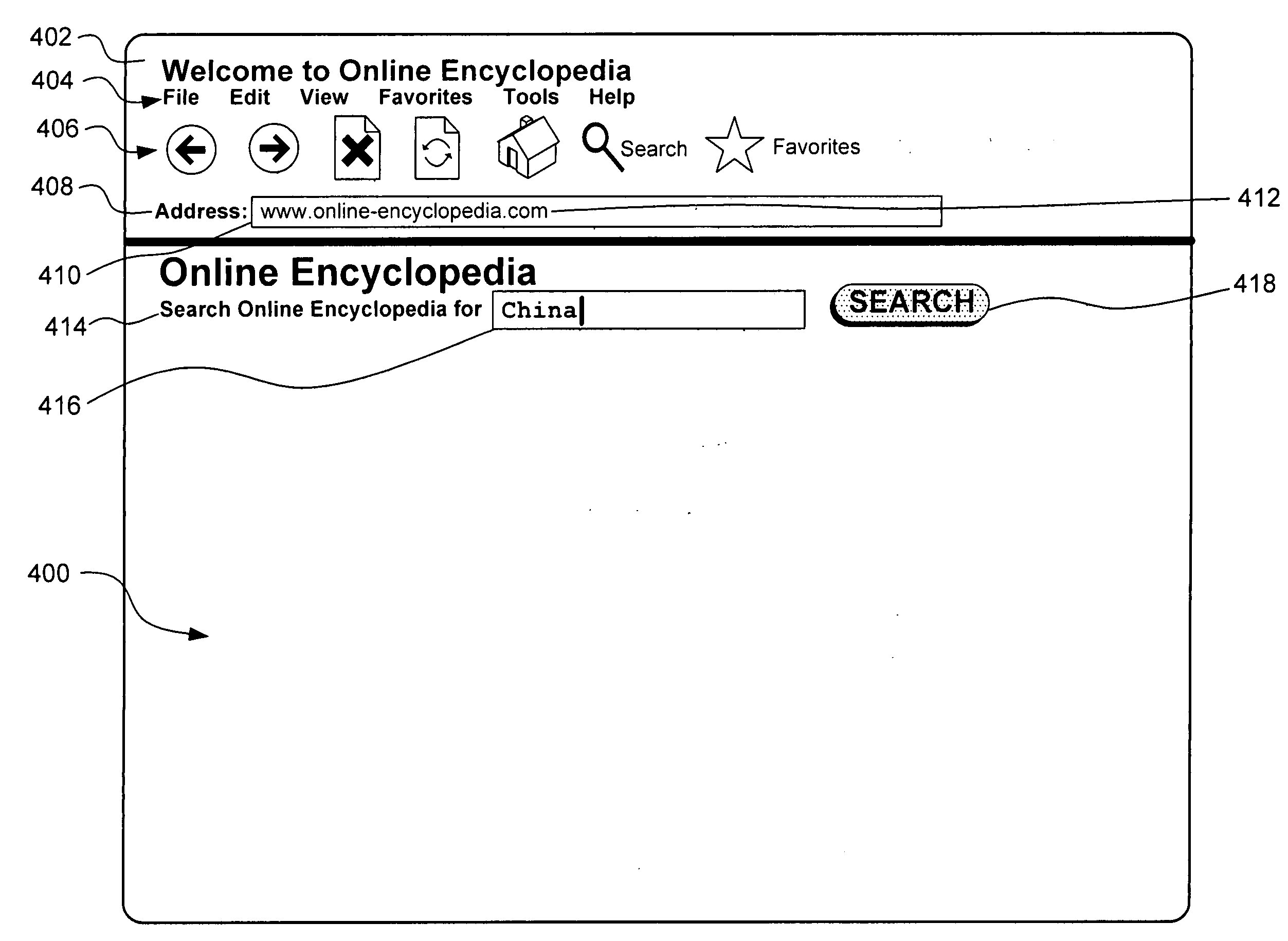

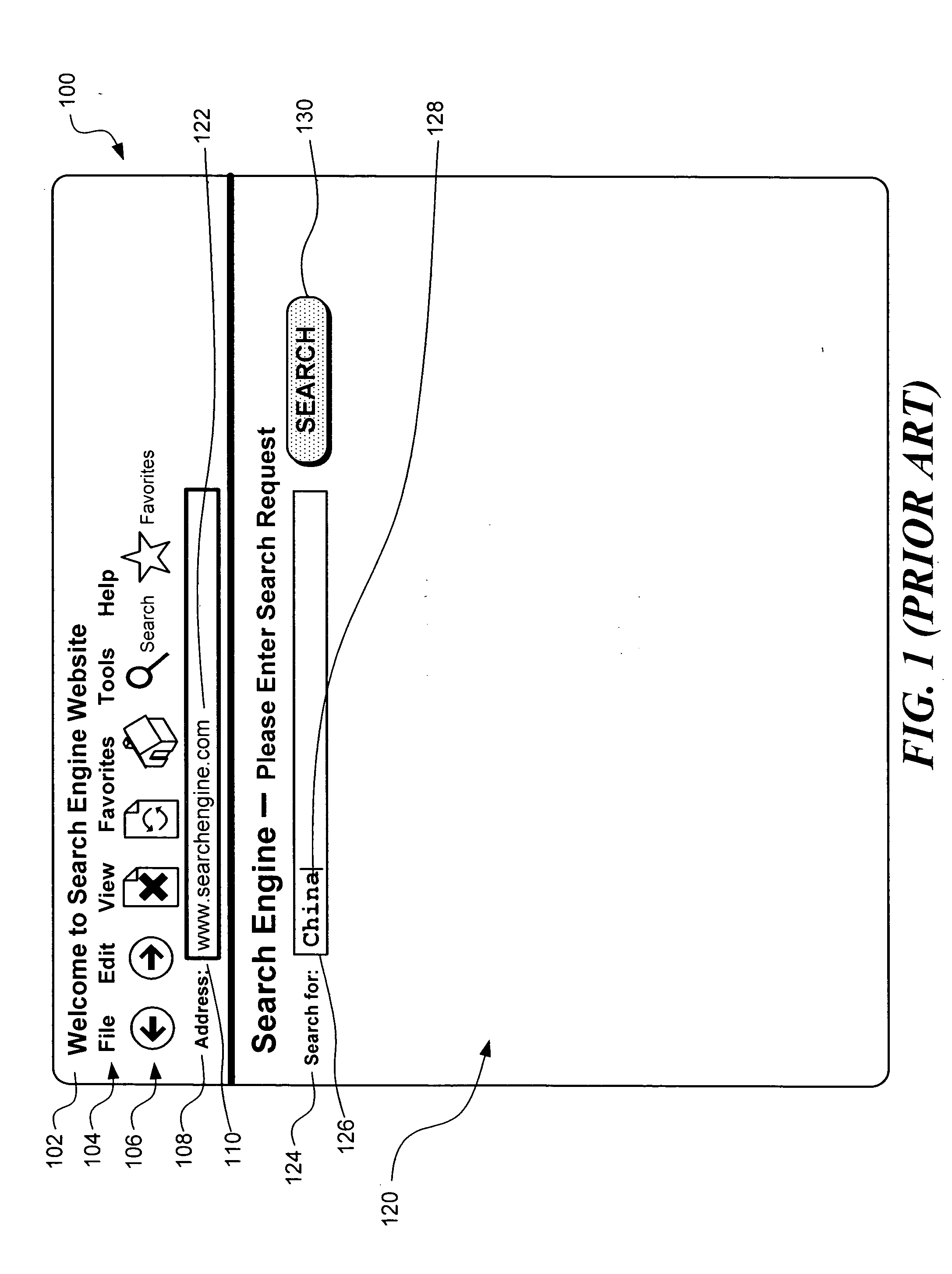

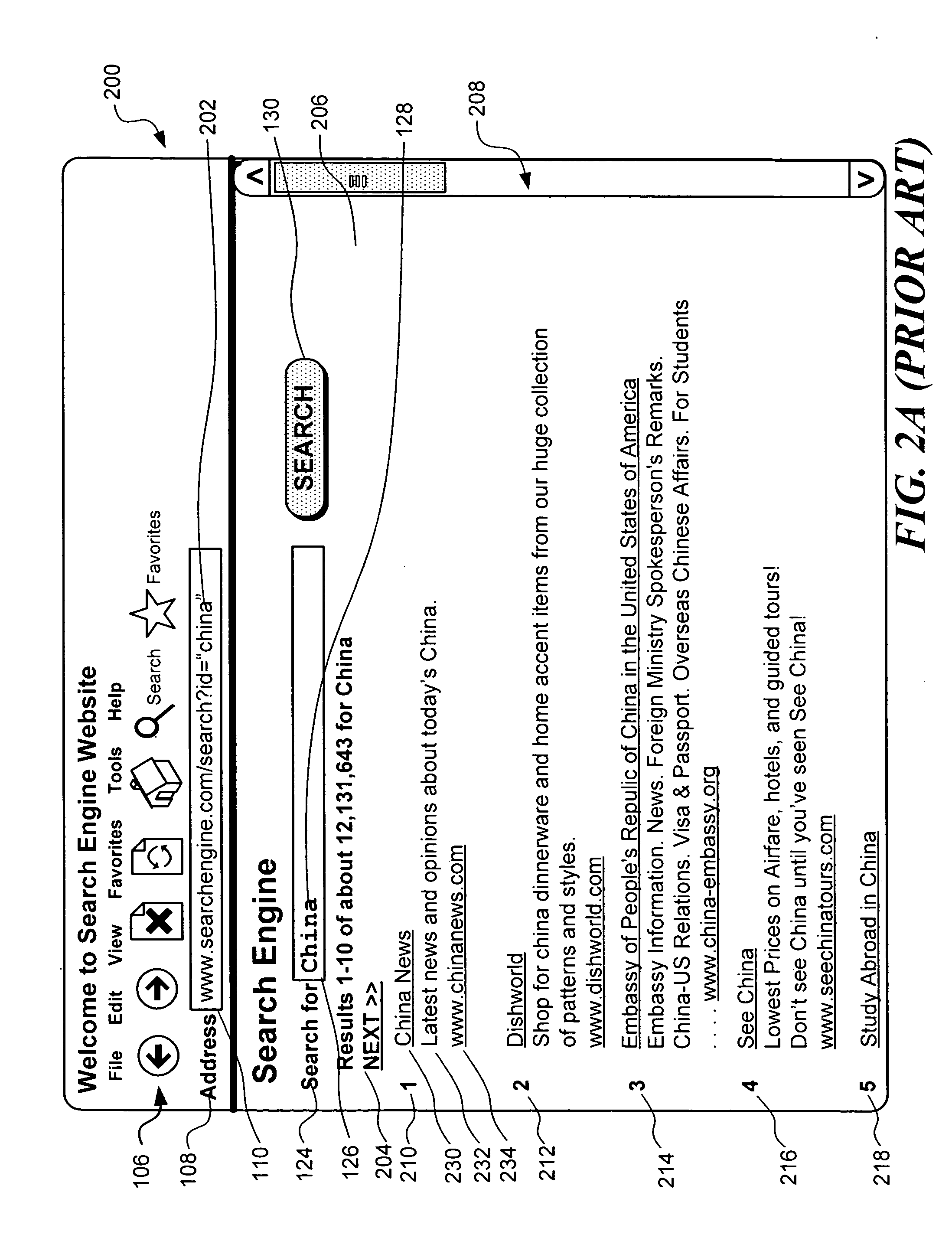

Method and system for adaptive categorial presentation of search results

ActiveUS20060031214A1Higher perceived relevance of that categoryData processing applicationsWeb data indexingHigh rateInformation retrieval

Search results are classified and presented by groups based on the type of each search result. Within the groups, the search results are ranked according to a rating, such as the relevancy of the result to the search request. The groups are also ordered, e.g., based upon the highest rated search result included in each group. The relative number of search results presented in the groups can vary, based upon the relative values of the highest rated search results in successive groups. When additional search results associated with a group are not initially presented for display, the group is selectively expandable to display additional search results. The expanded group, if not already first in the list, is moved to the first position, while other groups are displayed below the expanded group.

Owner:MICROSOFT TECH LICENSING LLC

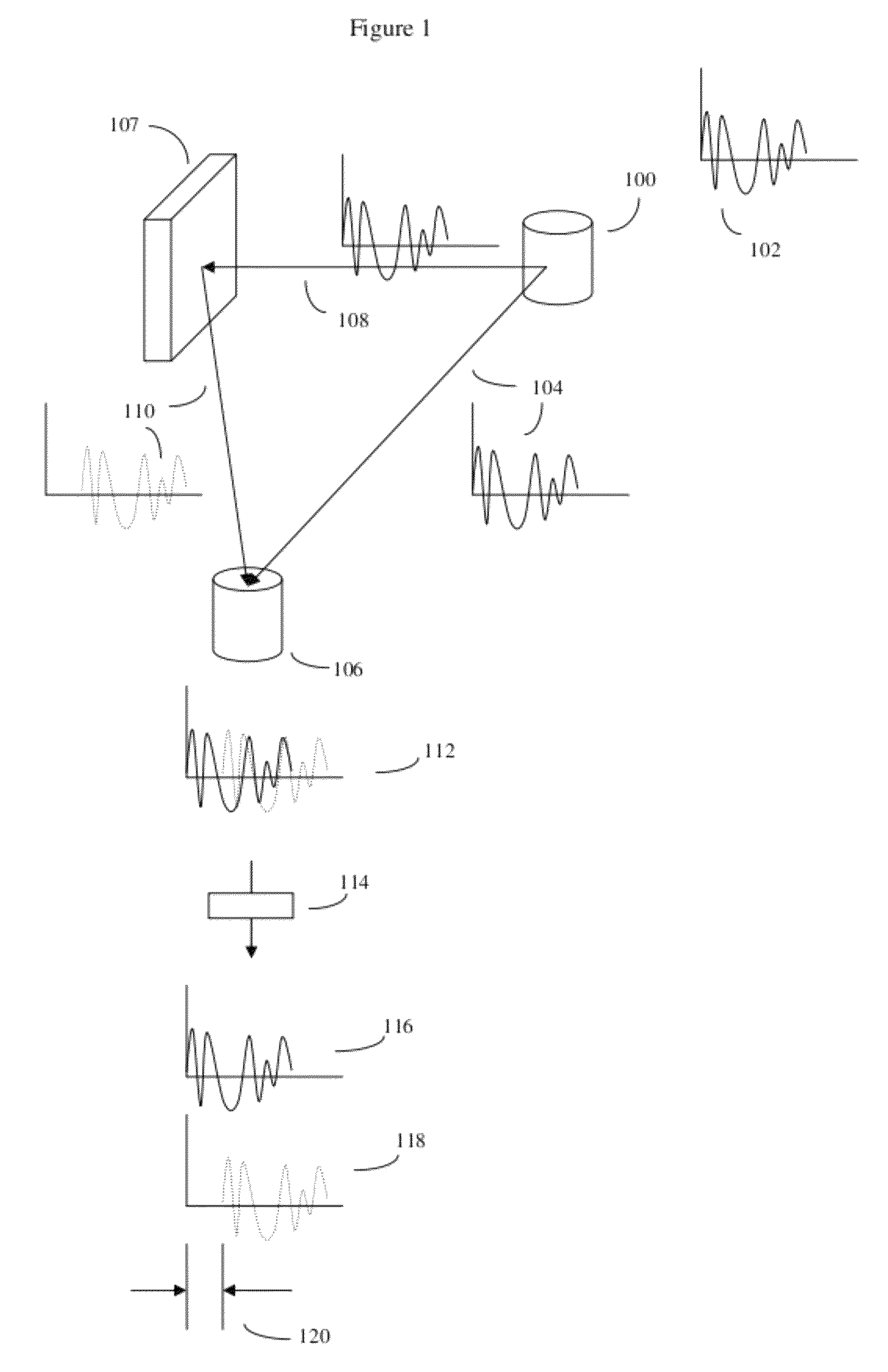

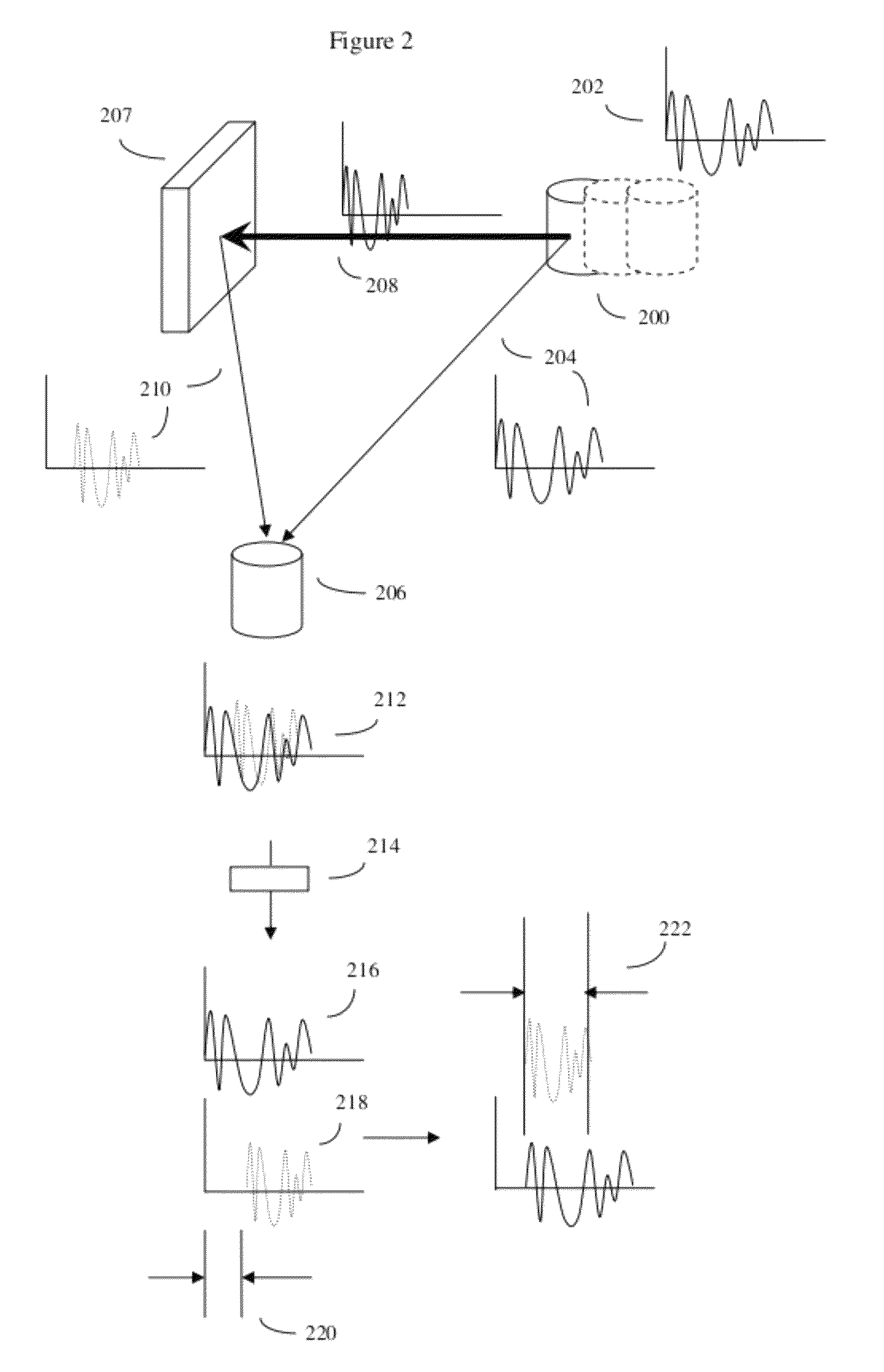

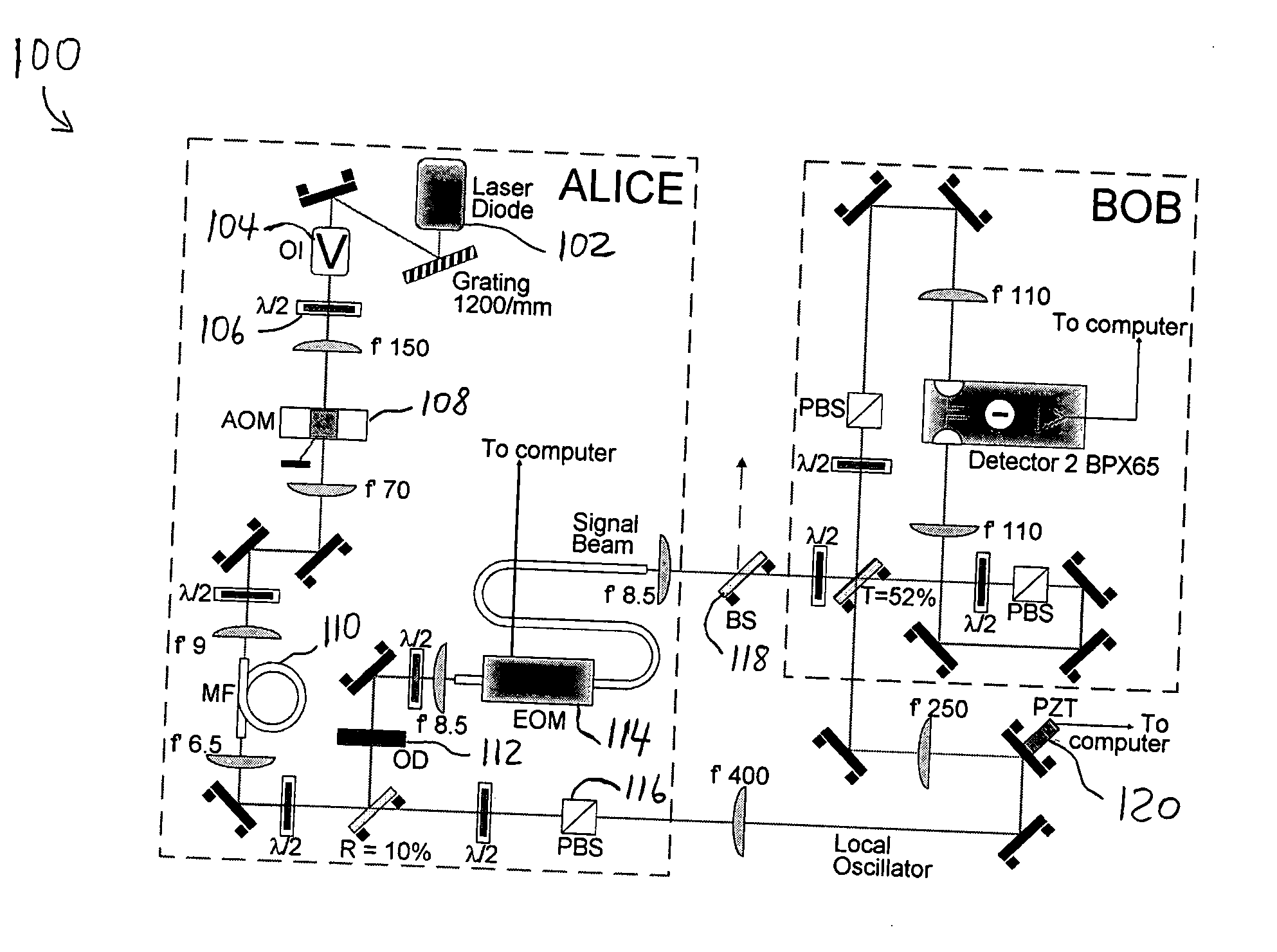

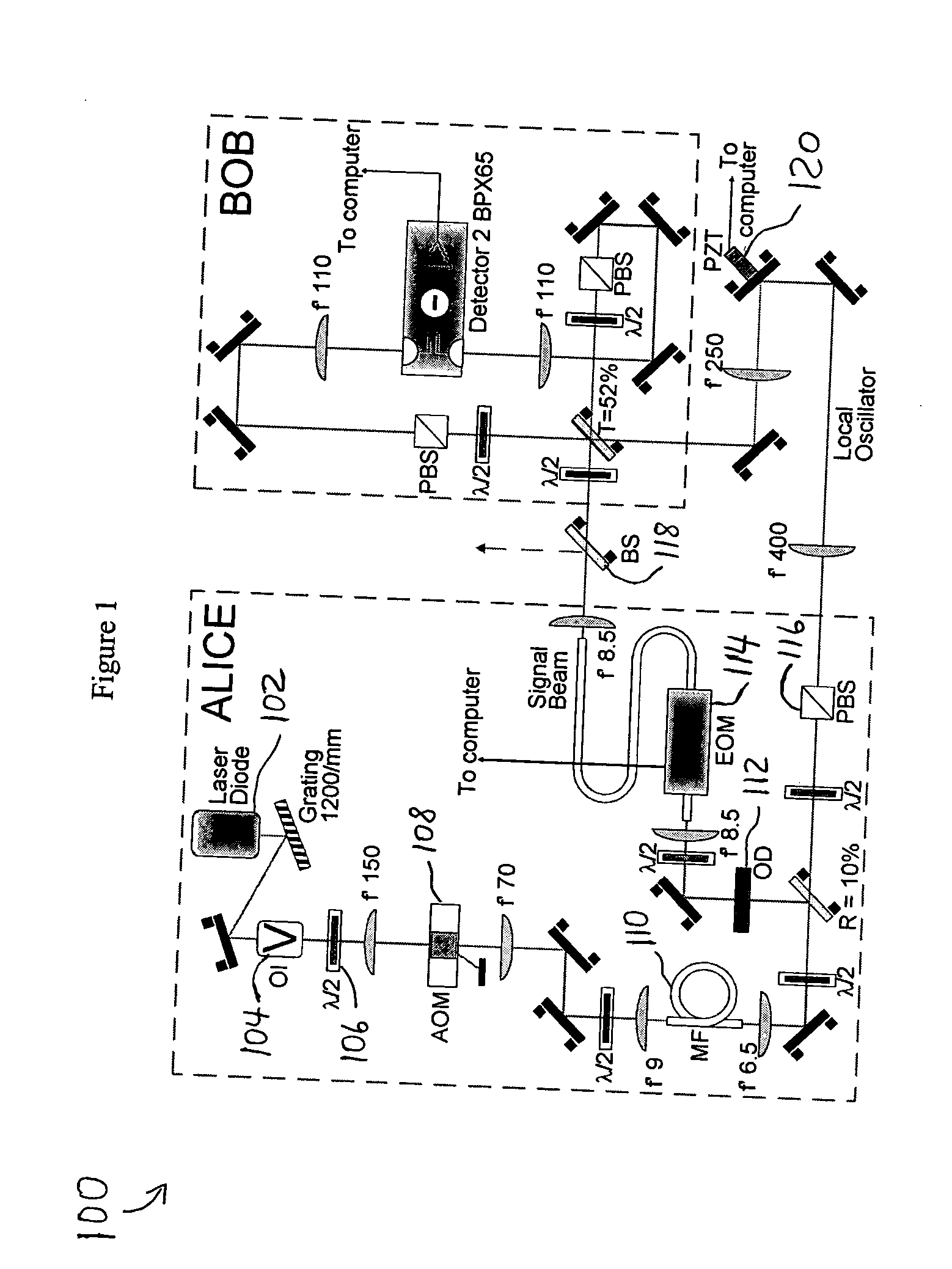

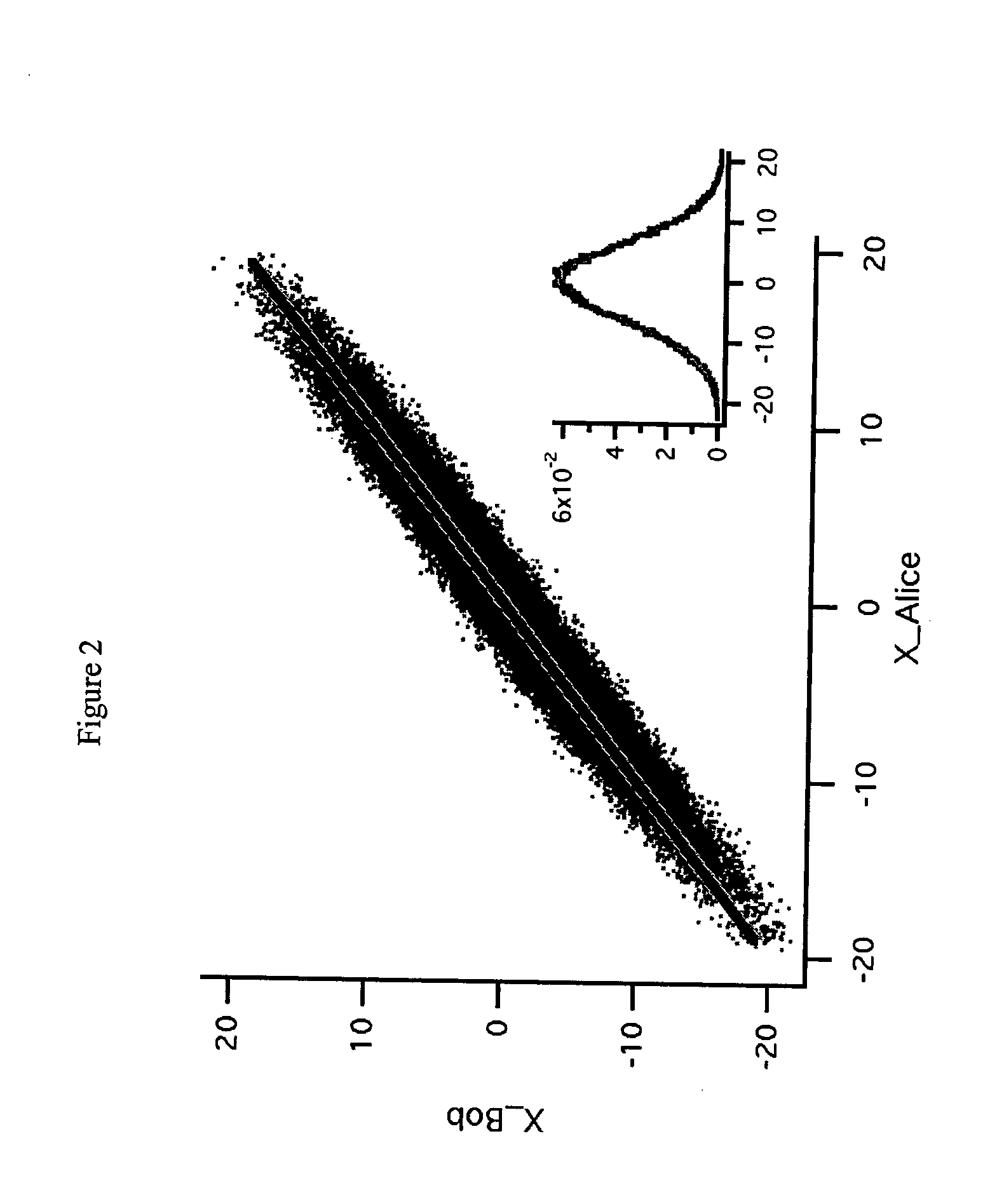

High-rate quantum key distribution scheme relying on continuously phase and amplitude-modulated coherent light pulses

InactiveUS20040109564A1Level of securityIncrease chanceKey distribution for secure communicationSecret communicationHigh rateCoherent states

One aspect of the present invention is related to a quantum cryptographic scheme comprising at least one sending unit including a physical means of encoding and distributing a raw key in the quadrature components of quantum coherent states that are continuously modulated in phase and amplitude, at least one receiving unit containing a physical means of performing homodyne detection of the quantum coherent states in order to measure the quadrature components of the states, a quantum channel for connecting the sending unit to the receiving unit, a two-way authenticated public channel for transmitting non-secret messages between the sending unit and the receiving unit, a quantum key distribution protocol ensuring that the information tapped by a potential eavesdropper can be estimated from the quantum channel parameters, and a direct or reverse reconciliation protocol that converts the raw continuous data into a common binary key.

Owner:UNIV LIBRE DE BRUXELIES +1

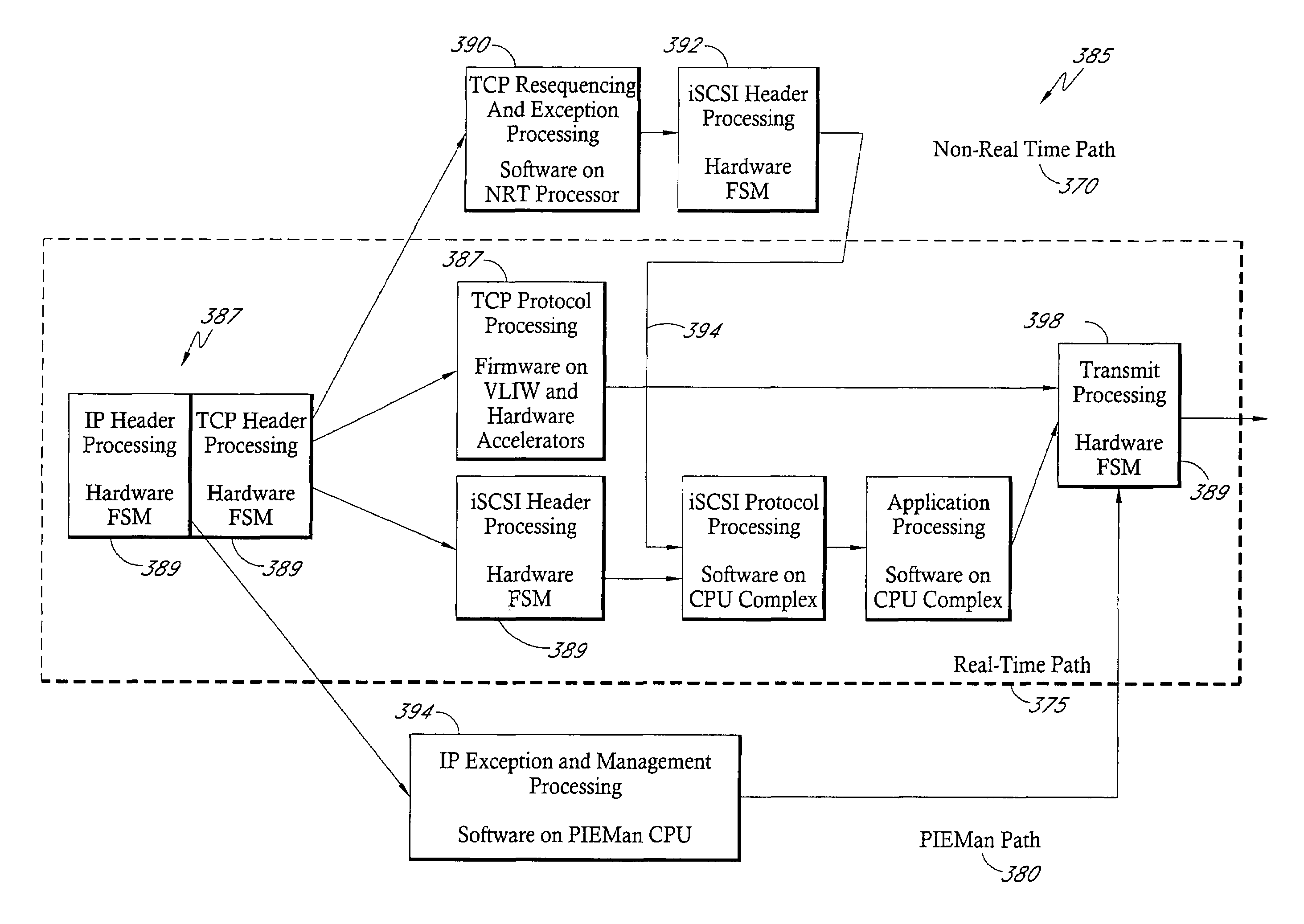

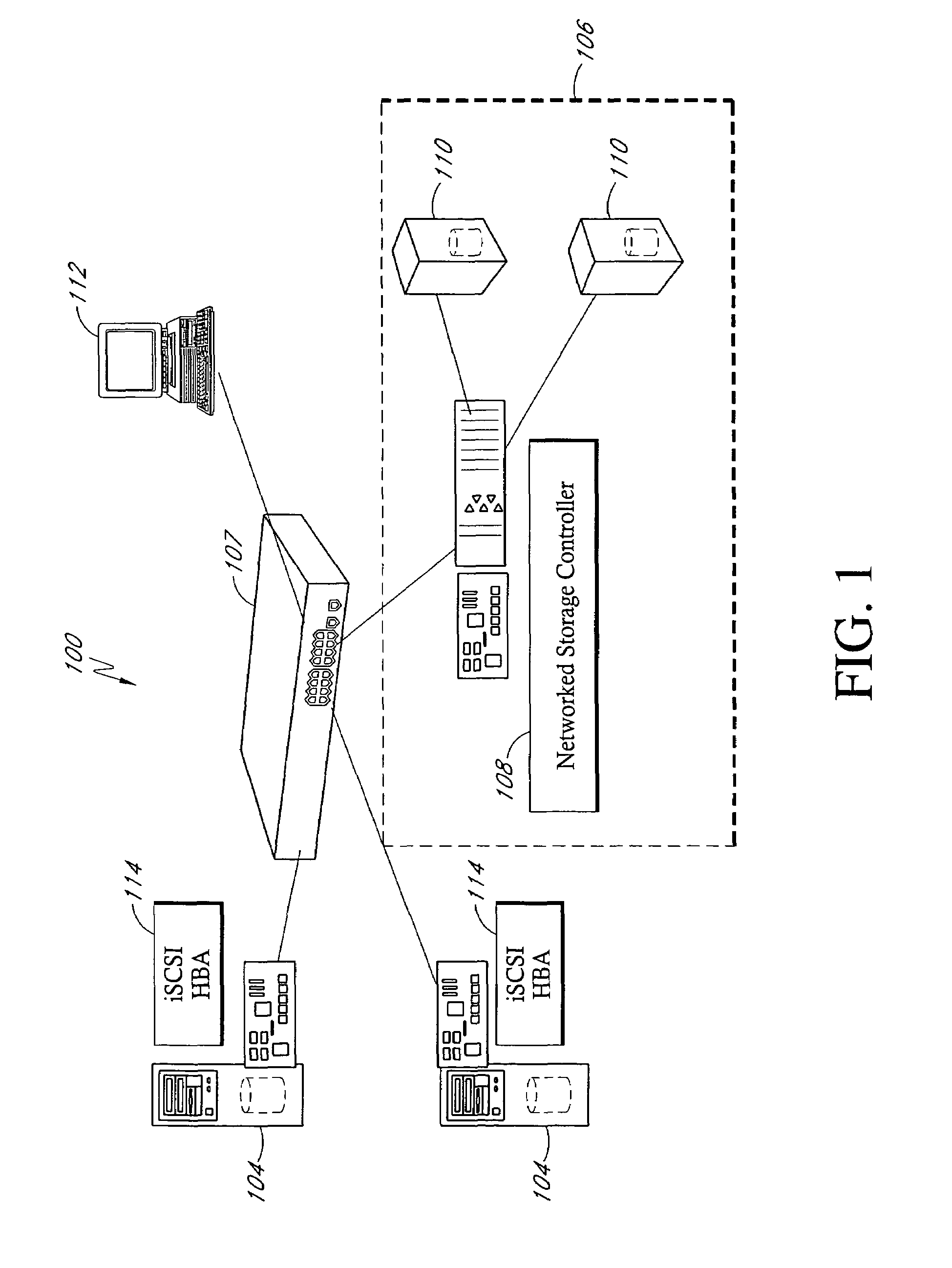

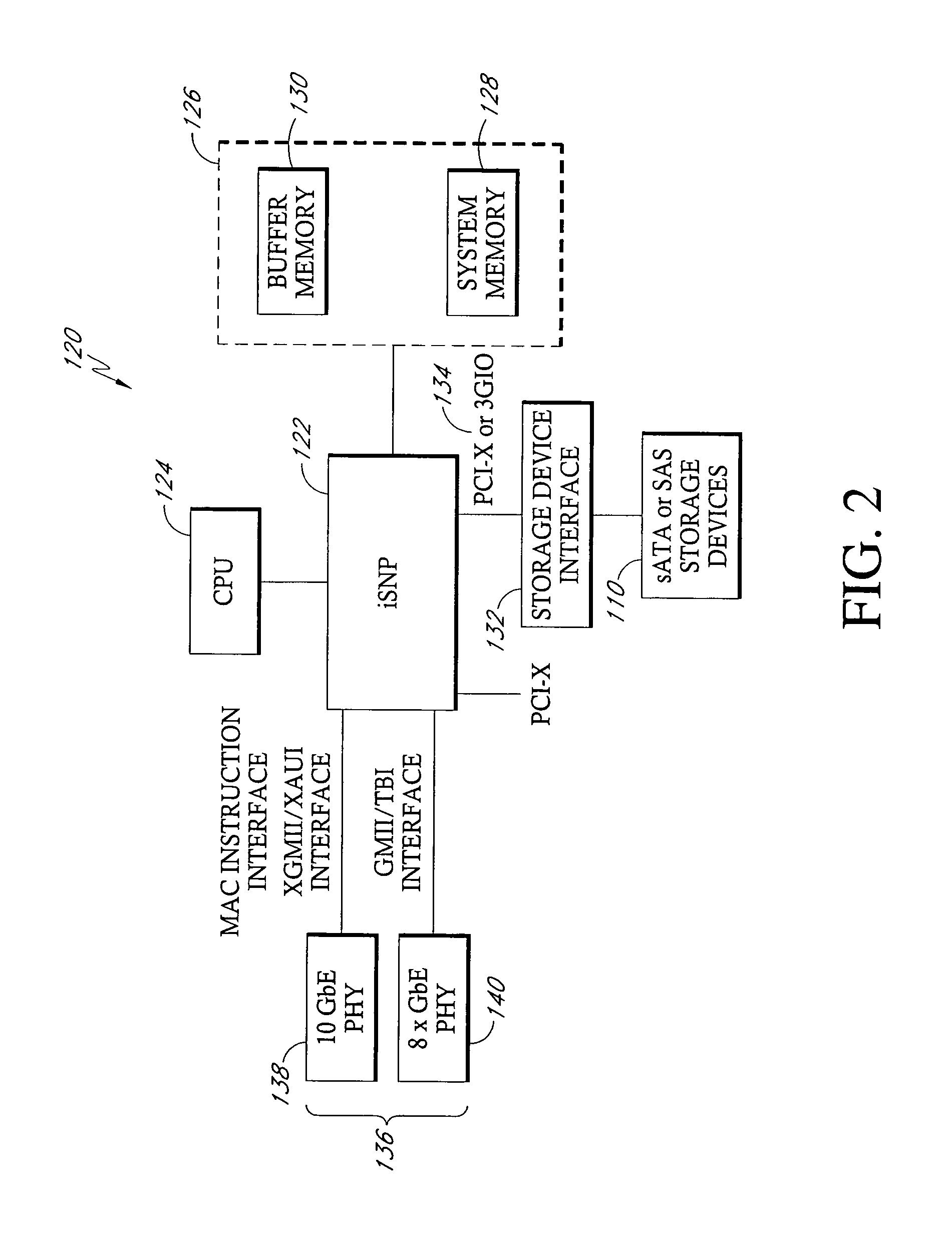

System and methods for high rate hardware-accelerated network protocol processing

InactiveUS7389462B1Improve network performanceImprove storage performanceError prevention/detection by using return channelTransmission systemsTraffic capacityHigh rate

Disclosed is a system and methods for accelerating network protocol processing for devices configured to process network traffic at relatively high data rates. The system incorporates a hardware-accelerated protocol processing module that handles steady state network traffic and a software-based processing module that handles infrequent and exception cases in network traffic processing.

Owner:PROMISE TECHNOLOGY

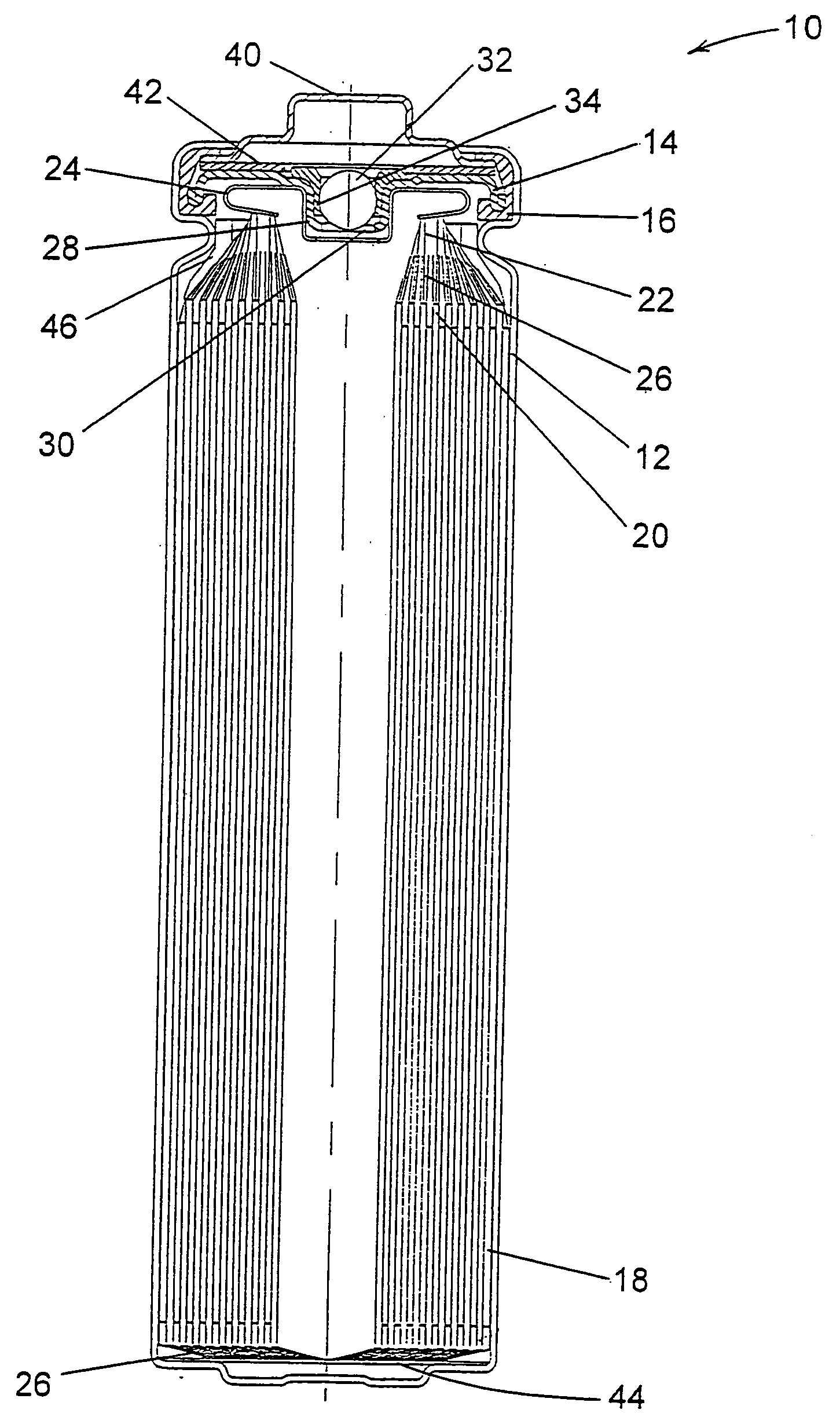

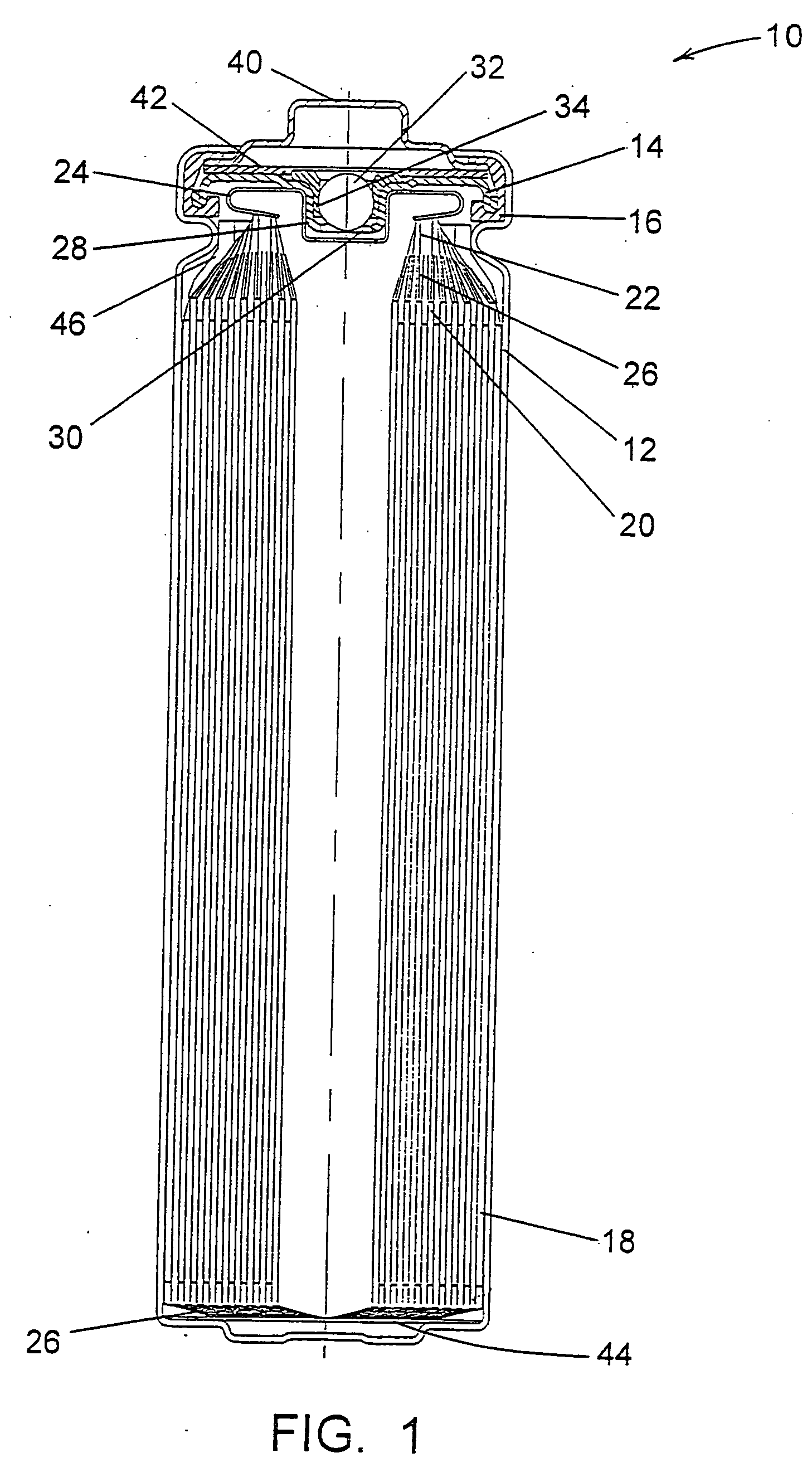

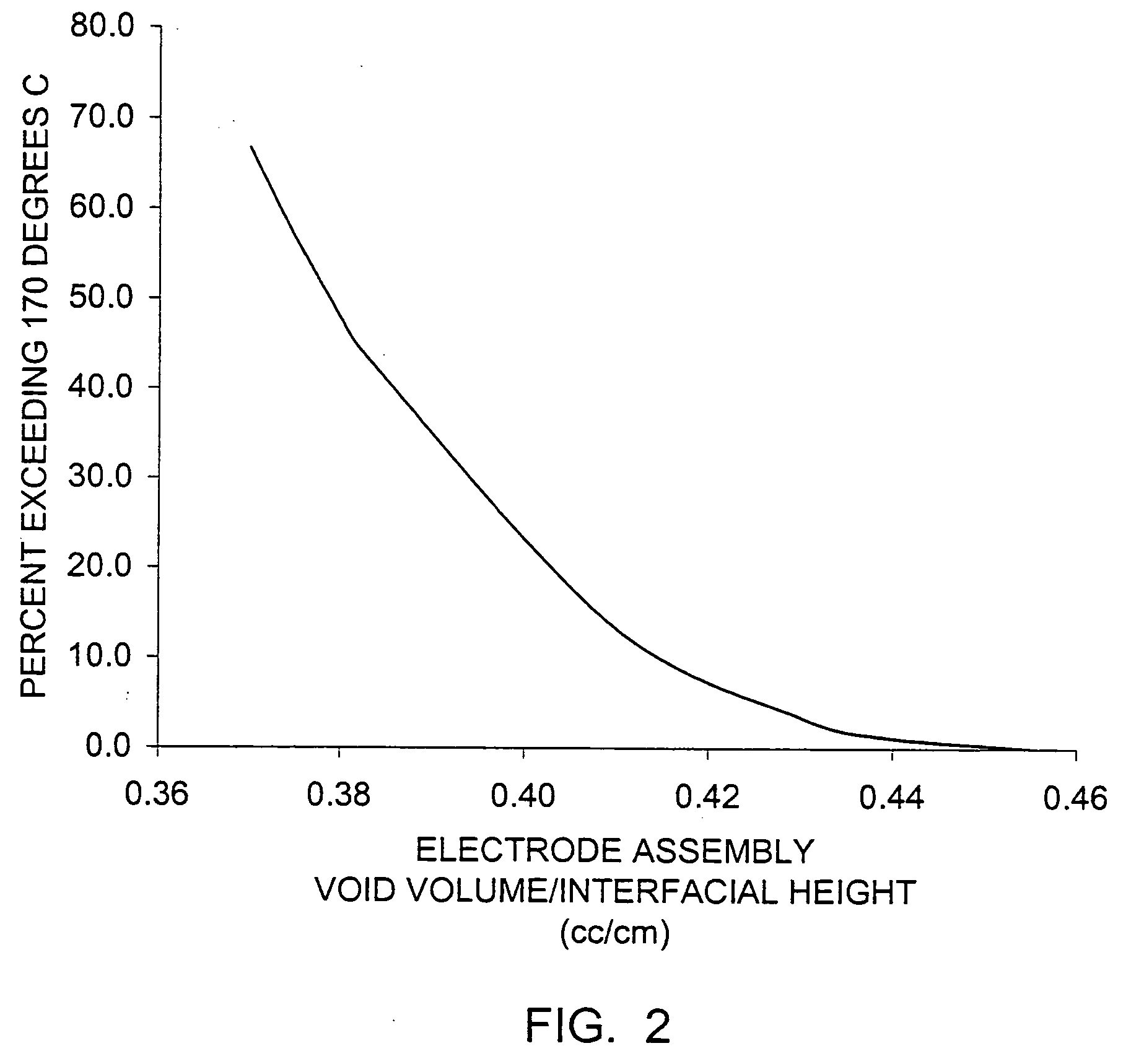

High discharge capacity lithium battery

InactiveUS20050233214A1Improve discharge performanceIncrease energy densityFinal product manufactureOrganic electrolyte cellsHigh rateIron disulfide

A lithium / iron disulfide electrochemical battery cell with a high discharge capacity. The cell has a lithium negative electrode, an iron disulfide positive electrode and a nonaqueous electrolyte. The iron disulfide of the positive electrode has a controlled average particle size range which allows the electrochemical cells to exhibit desired properties in both low and high rate applications. In various embodiments, the iron disulfide particles are wet milled, preferably utilizing a media mill or milled utilizing a non-mechanical mill such as a jet mill, which reduces the iron disulfide particles to a desired average particle size range for incorporation into the positive electrode.

Owner:EVEREADY BATTERY CO INC

System for managing inventory of bulk liquids

ActiveUS20100322822A1Read intuitivelyReduce laborPreparing sample for investigationMaterial analysis by optical meansHigh ratePipette

A system for managing bulk liquids for an automated clinical analyzer. The system comprises (a) at least one local reservoir for storing a bulk liquid for impending use, (b) at least one container for holding a bulk liquid before the liquid is transferred to a local reservoir, and (c) a controller for monitoring the level of a bulk liquid in a local reservoir. The local reservoir for storing a bulk liquid for impending use can be a trough. The use of troughs for storing a reagent, a diluent, or some other treating agent for impending use enables an aspirating / dispensing device having a plurality of pipettes to aspirate and dispense the reagent, diluent, or other treating agent at a high rate of throughput. The controller can monitor the level of a liquid in (a) a local reservoir for storing a bulk liquid for imminent use and the level of liquid in a (b) container for holding a bulk liquid before the liquid is transferred to a local reservoir. In the laboratory automation system described herein, the container for holding a bulk liquid before the liquid is transferred to a local reservoir can be a bottle. Other desirable features in the system include, but are not limited to, pump(s), valves, liquid level sensors.

Owner:ABBOTT LAB INC

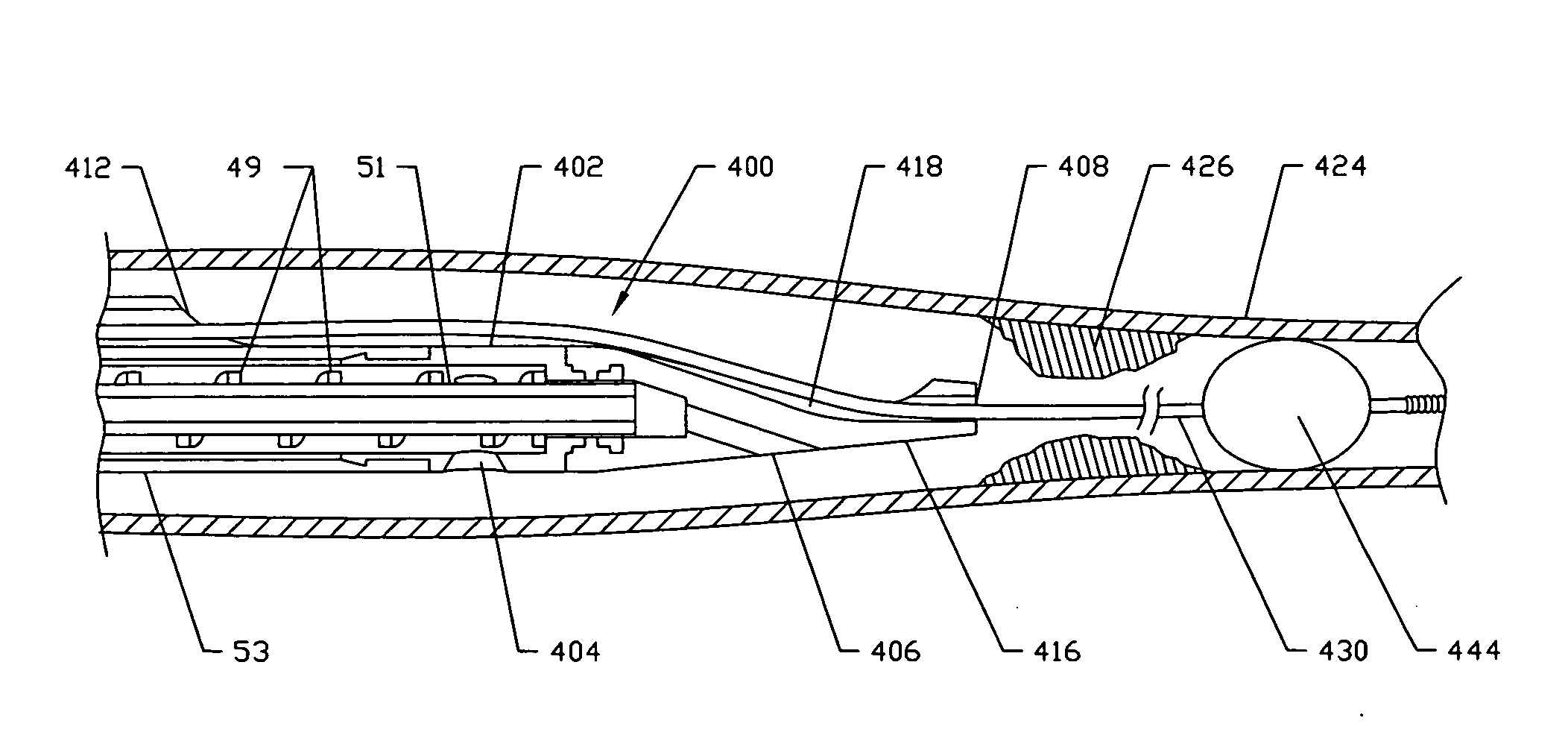

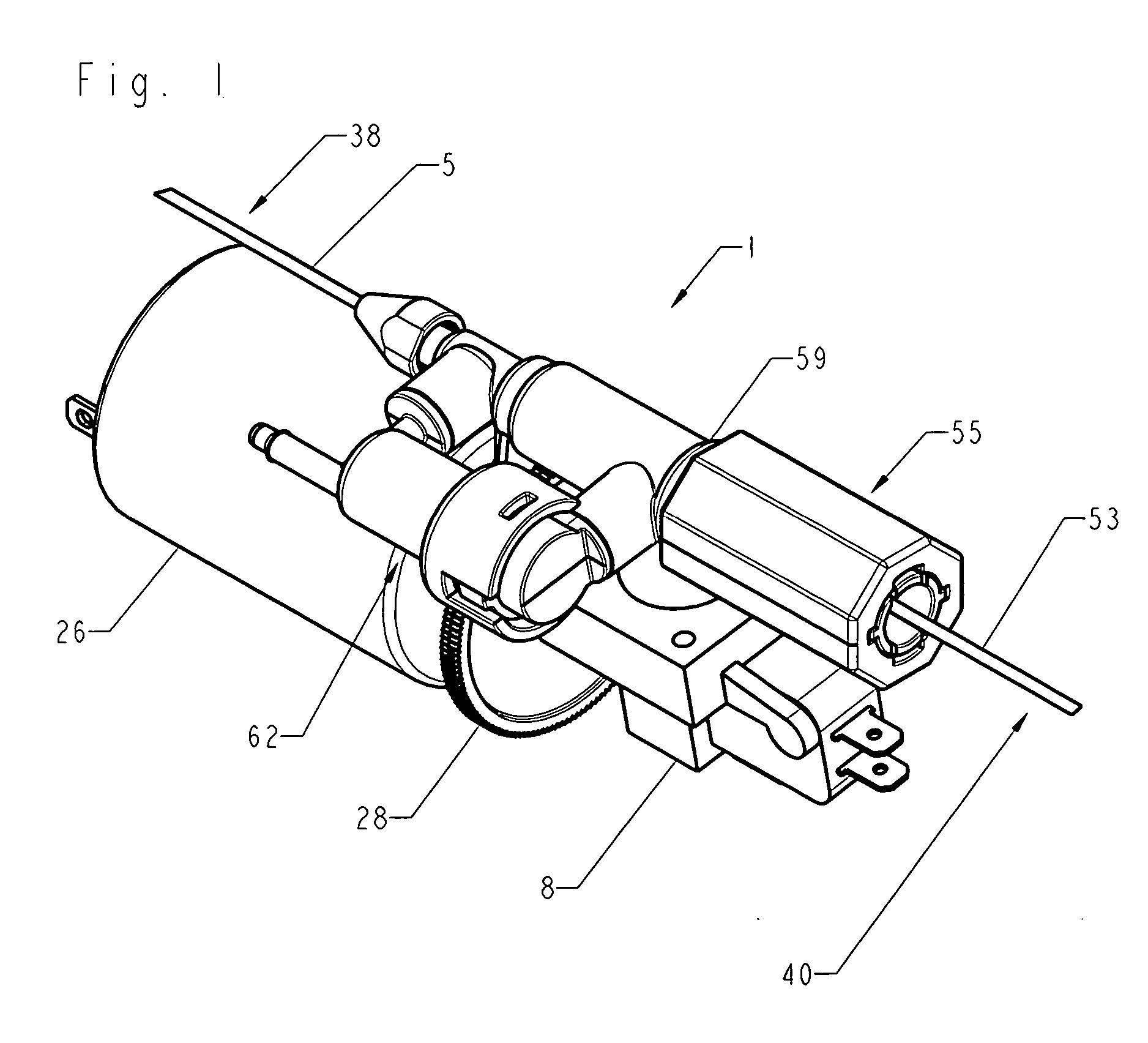

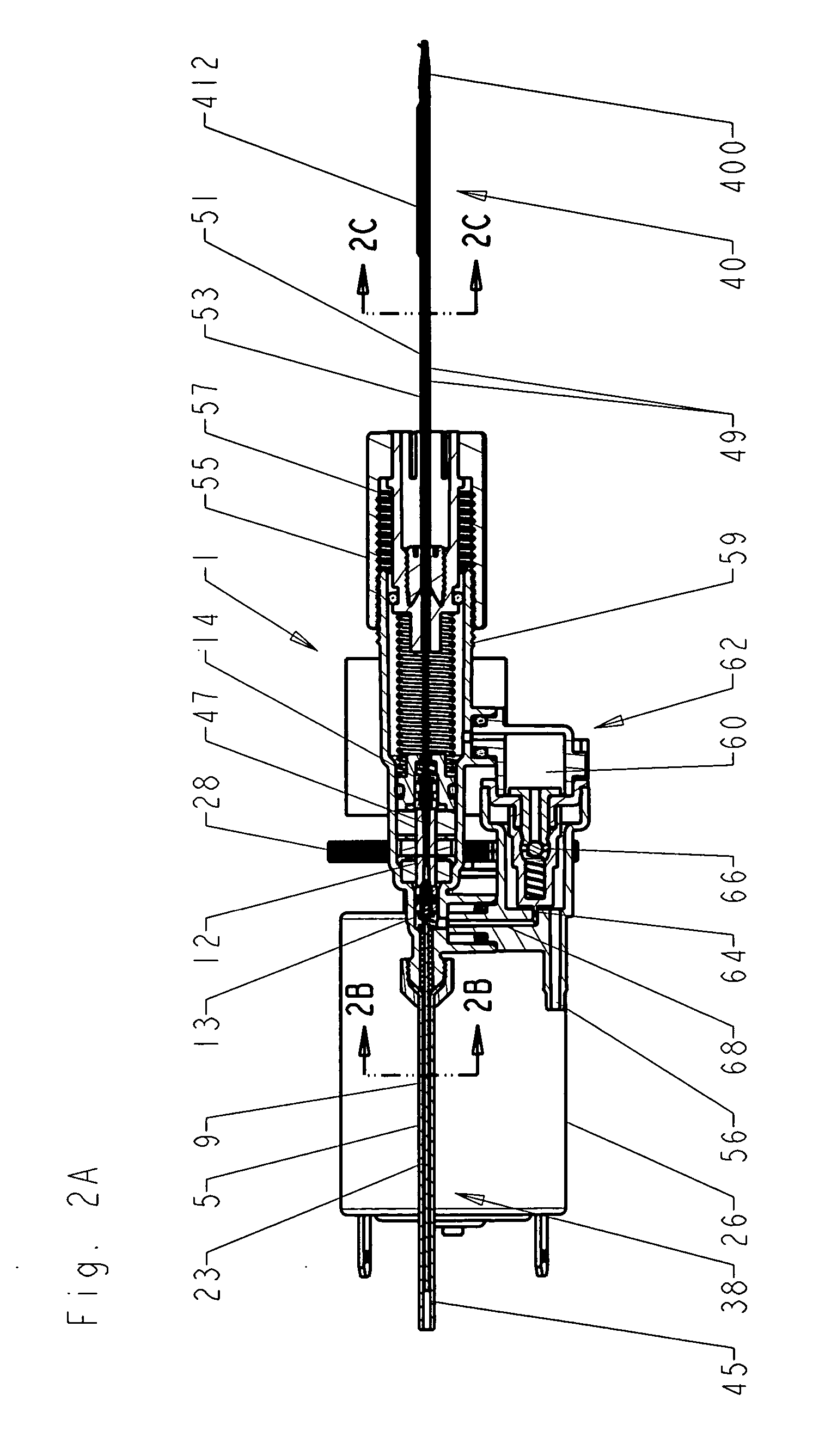

Thrombectomy and soft debris removal device

ActiveUS20050240146A1Efficient removalMinimize associated blood lossStentsBalloon catheterBiological bodyHigh rate

A device suitable for removing material from a living being is provided, featuring an infusate pump, and an aspiration pump, both powered by a motor. The aspiration pump and infusate pump preferably feature a helical pumping mechanism, and operate at a high rate of rotation, thereby ensuring adequate pumping performance and flexibility. Additionally, a narrow crossing profile is maintained, ensuring that the device may reach more tortuous regions of the vasculature.

Owner:SPECTRANETICS

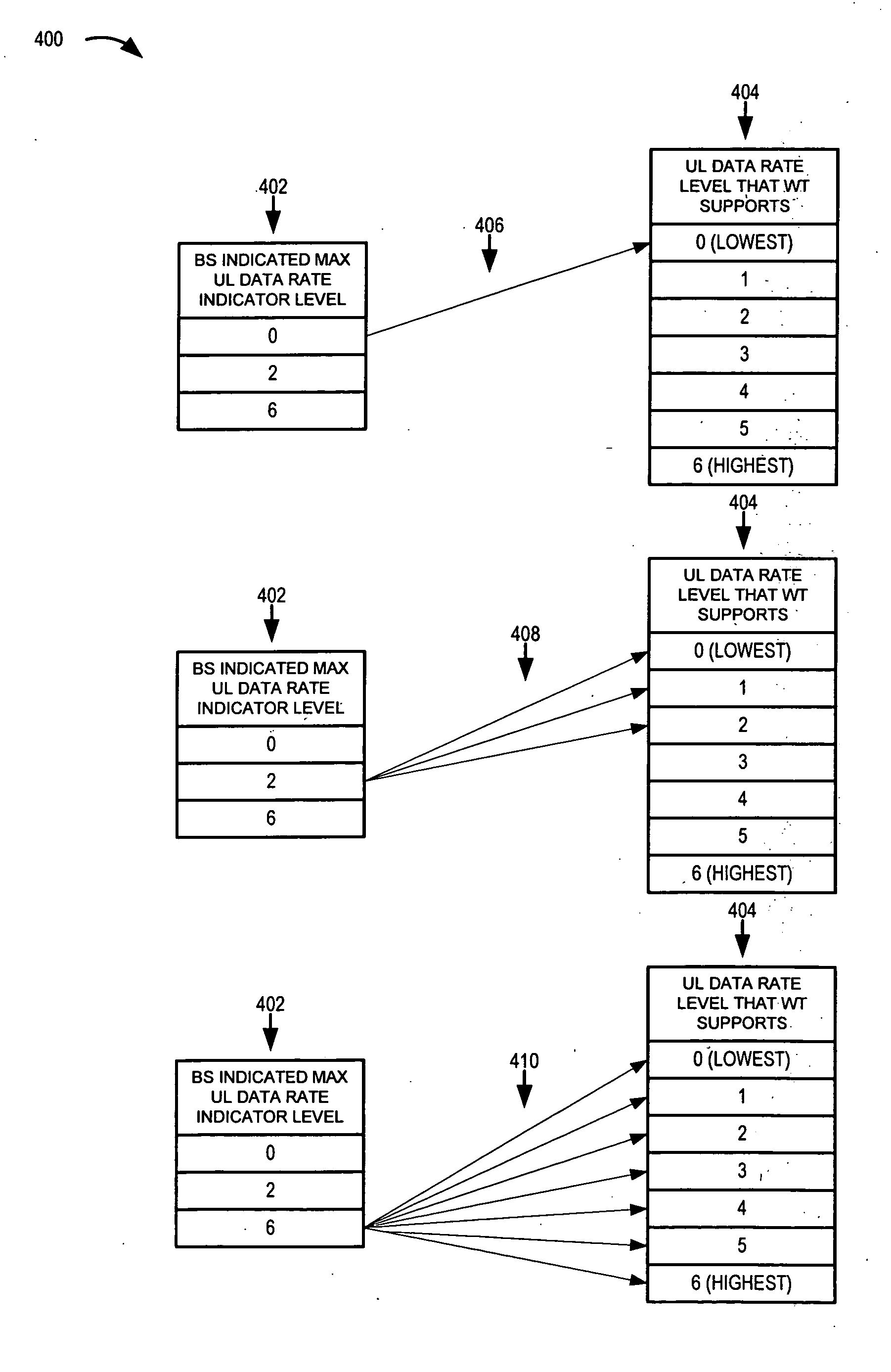

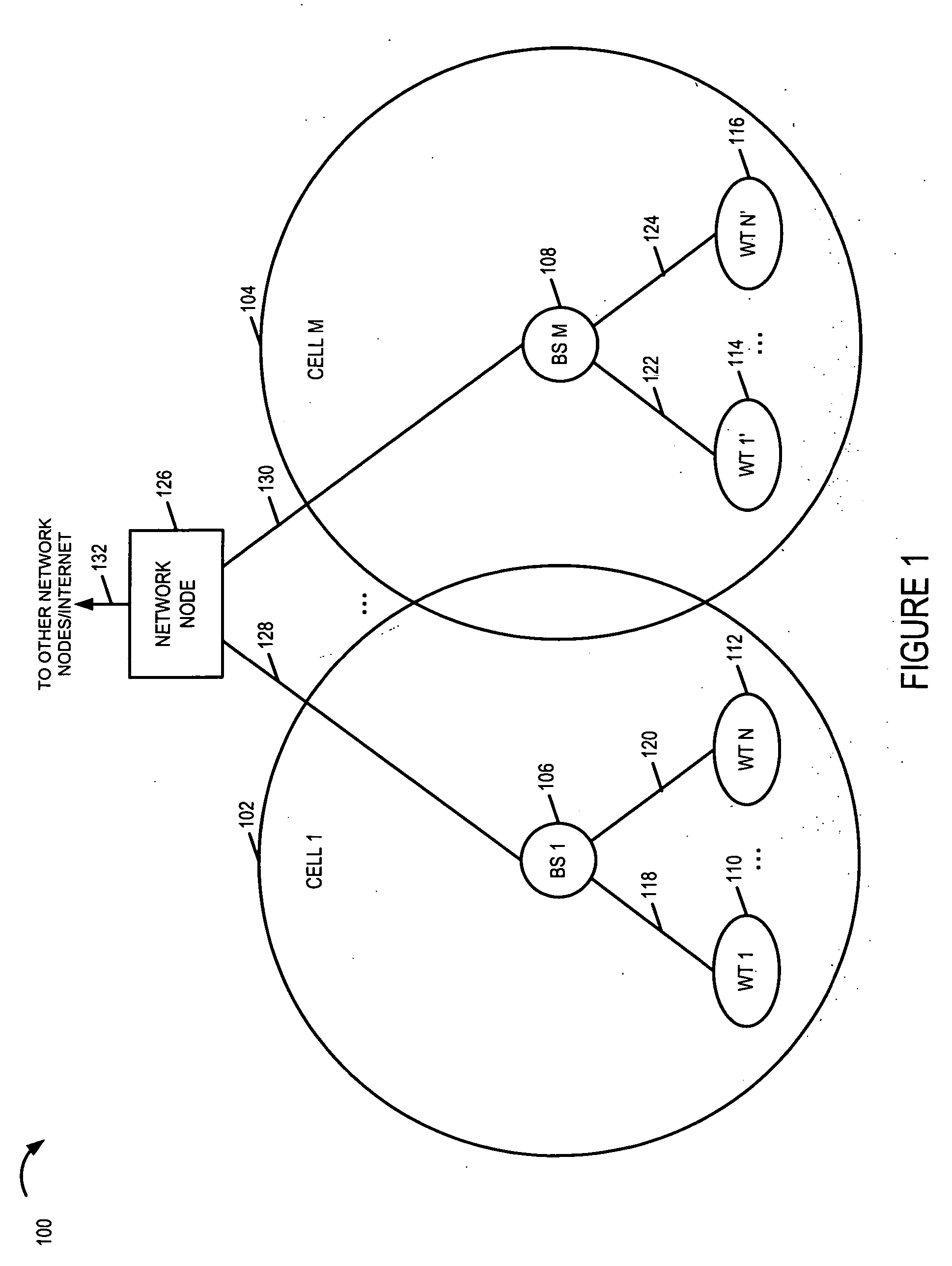

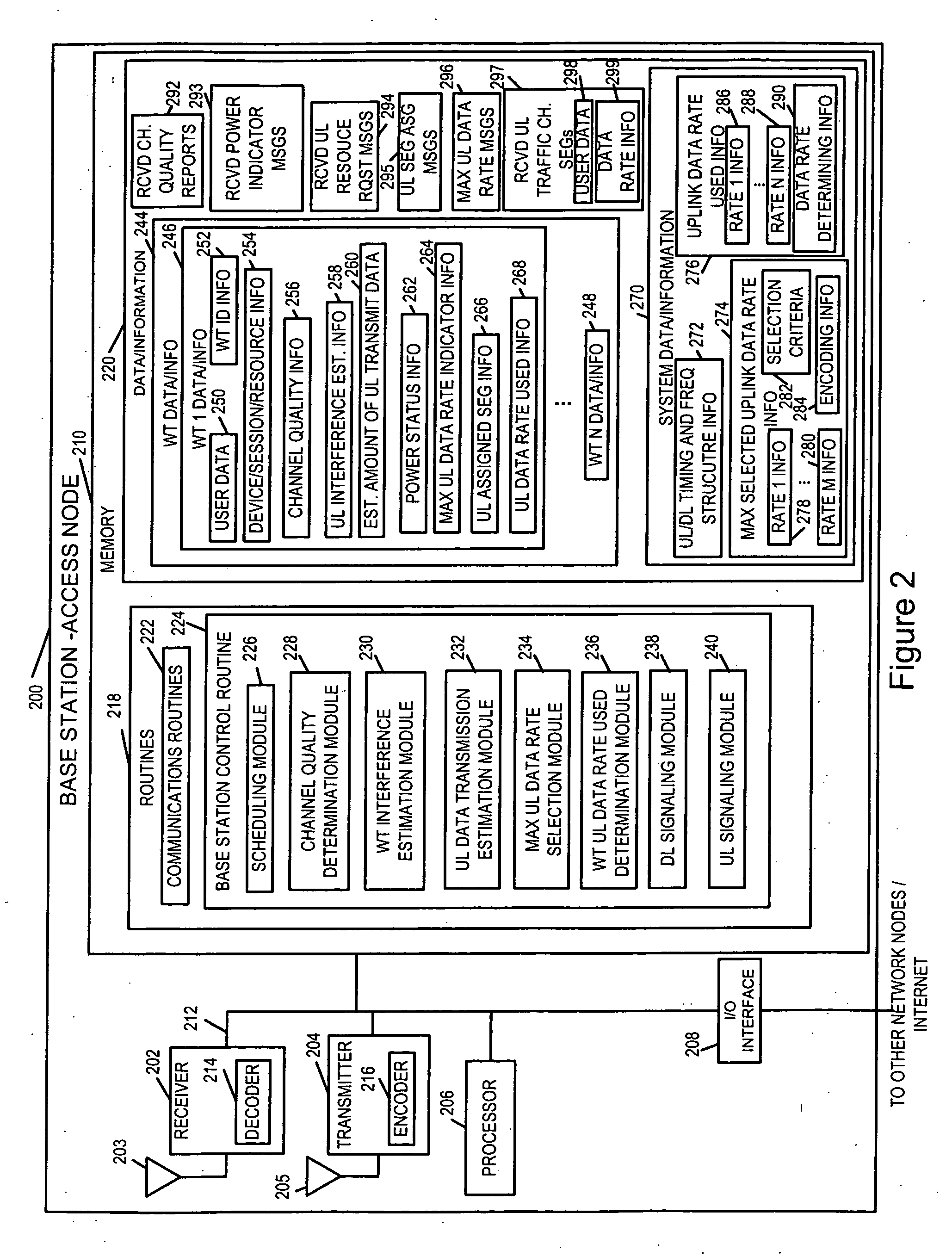

Data rate methods and apparatus

ActiveUS20060203765A1Improving uplink communicationNetwork traffic/resource managementData switching by path configurationHigh rateMaximum rate

A wireless terminal receives an uplink traffic channel segment assignment including a maximum uplink rate option indicator. Each uplink rate option corresponds to a number of information bits, coding rate and modulation method. The maximum rate option indicator indicates the highest rate option that the wireless terminal is permitted to use when transmitting in the assigned traffic channel segment from the perspective of the base station. In some embodiments, the wireless terminal uses interference measurements to further quality, e.g., conditionally reduce, the maximum uplink rate option that may be used. Then, the wireless terminal selects an uplink rate option to use which is less than the determined allowed maximum uplink rate option, e.g., based on the amount of user data to communicate. The wireless terminal transmits data in the assigned uplink traffic channel segment in accordance with the wireless terminal selected uplink rate.

Owner:QUALCOMM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com