Patents

Literature

1750 results about "Biofuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A biofuel is a fuel that is produced through contemporary processes from biomass, rather than a fuel produced by the very slow geological processes involved in the formation of fossil fuels, such as oil. Since biomass technically can be used as a fuel directly (e.g. wood logs), some people use the terms biomass and biofuel interchangeably. More often than not however, the word biomass simply denotes the biological raw material the fuel is made of, or some form of thermally/chemically altered solid end product, like torrefied pellets or briquettes. The word biofuel is usually reserved for liquid or gaseous fuels, used for transportation. The EIA (U.S. Energy Information Administration) follow this naming practice. If the biomass used in the production of biofuel can regrow quickly, the fuel is generally considered to be a form of renewable energy.

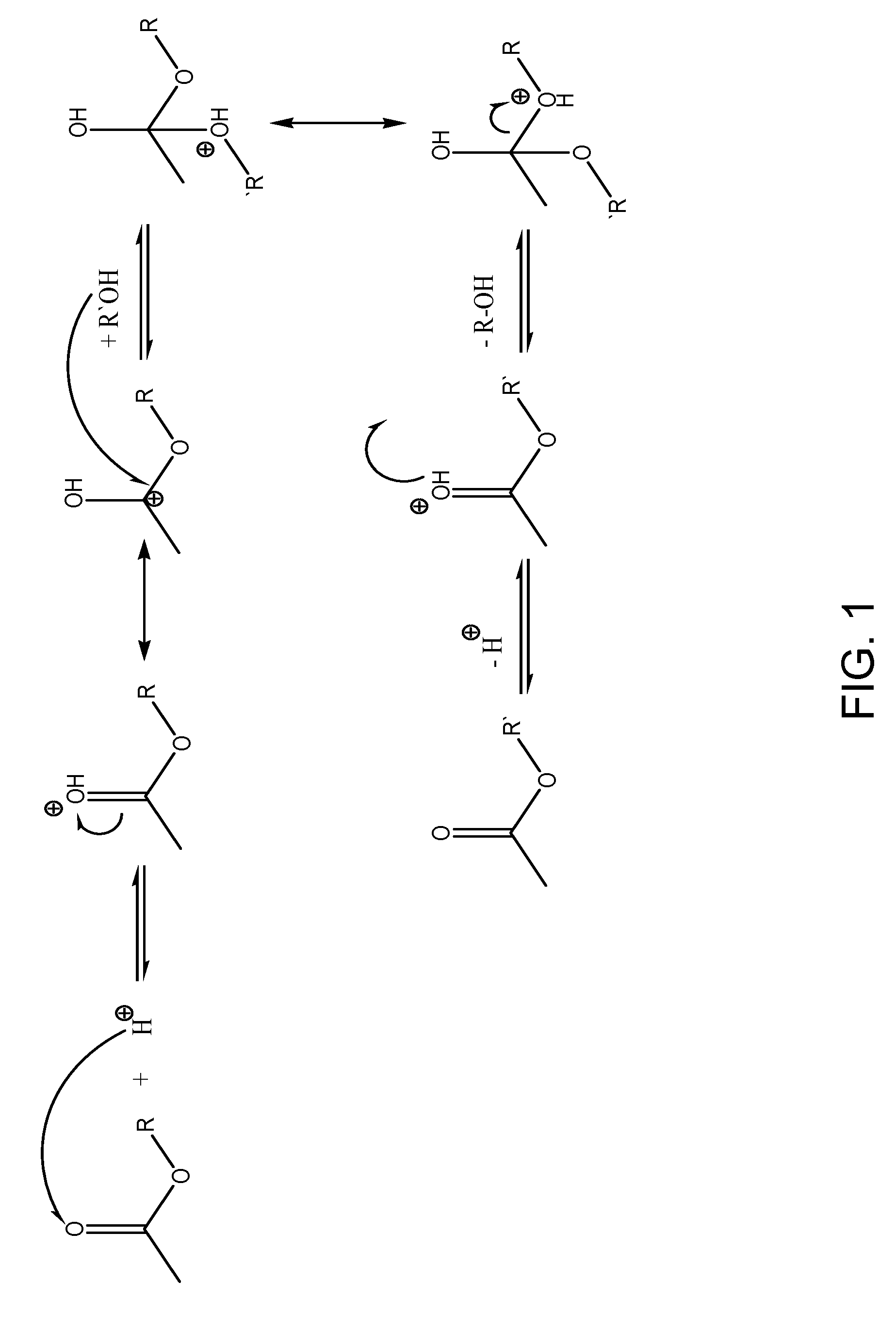

Methods and compositions for extraction and transesterification of biomass components

InactiveUS20090234146A1Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationBiofuel

Methods and compositions are disclosed for the direct transesterification and extraction of bio-lipids and bio-oils in the production of biofuel, particularly fatty acid methyl ester products.

Owner:UNIV OF HAWAII

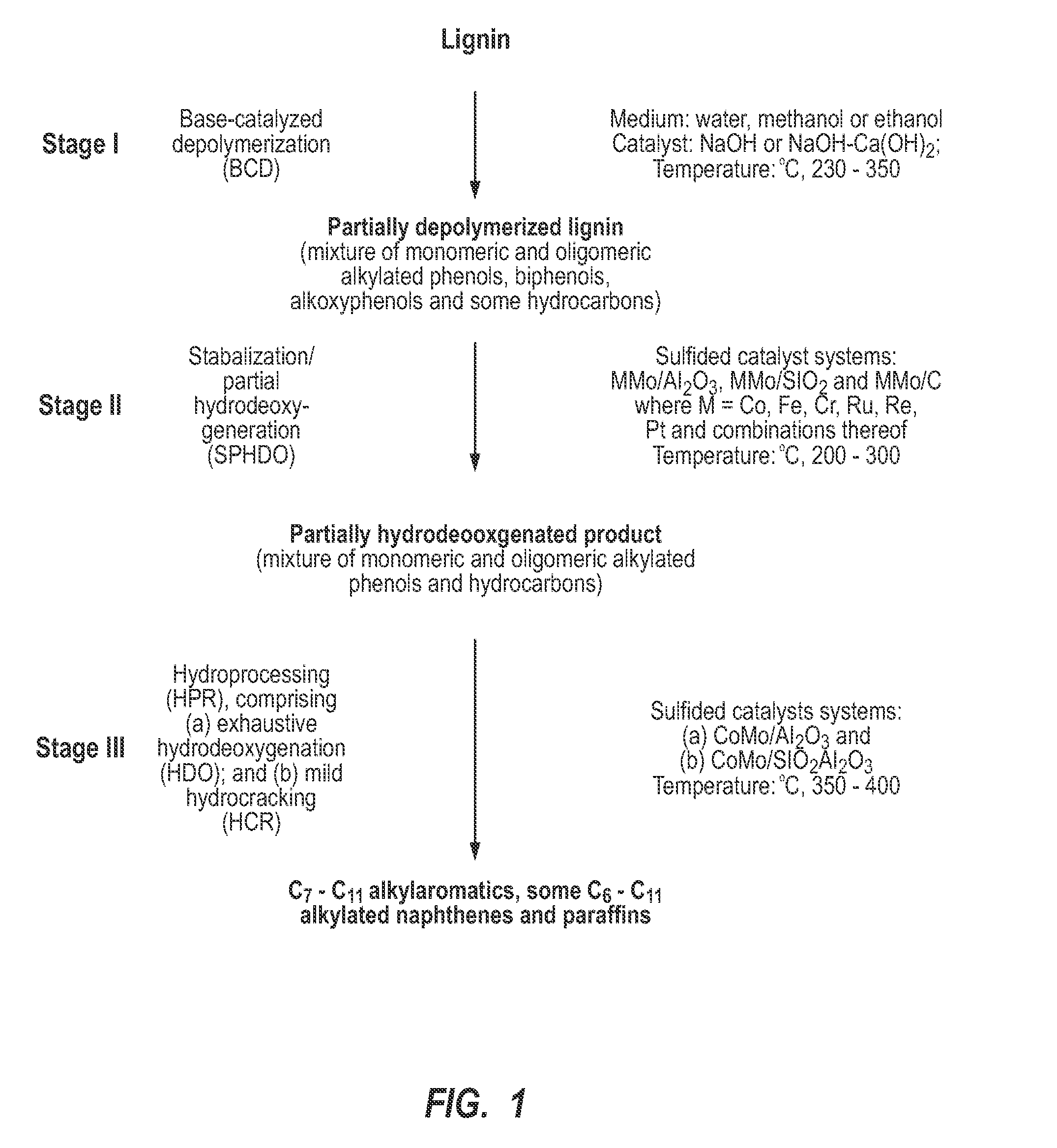

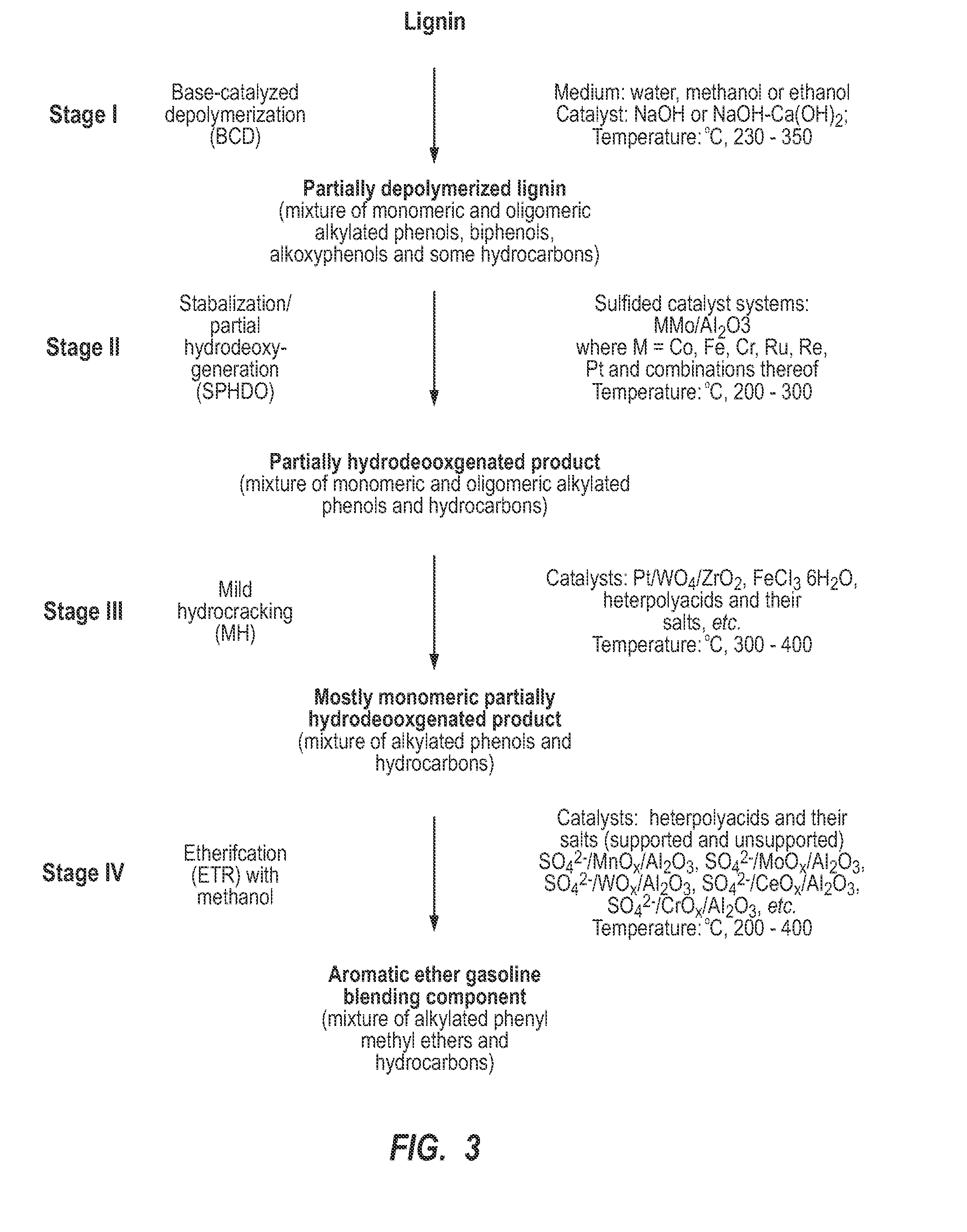

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

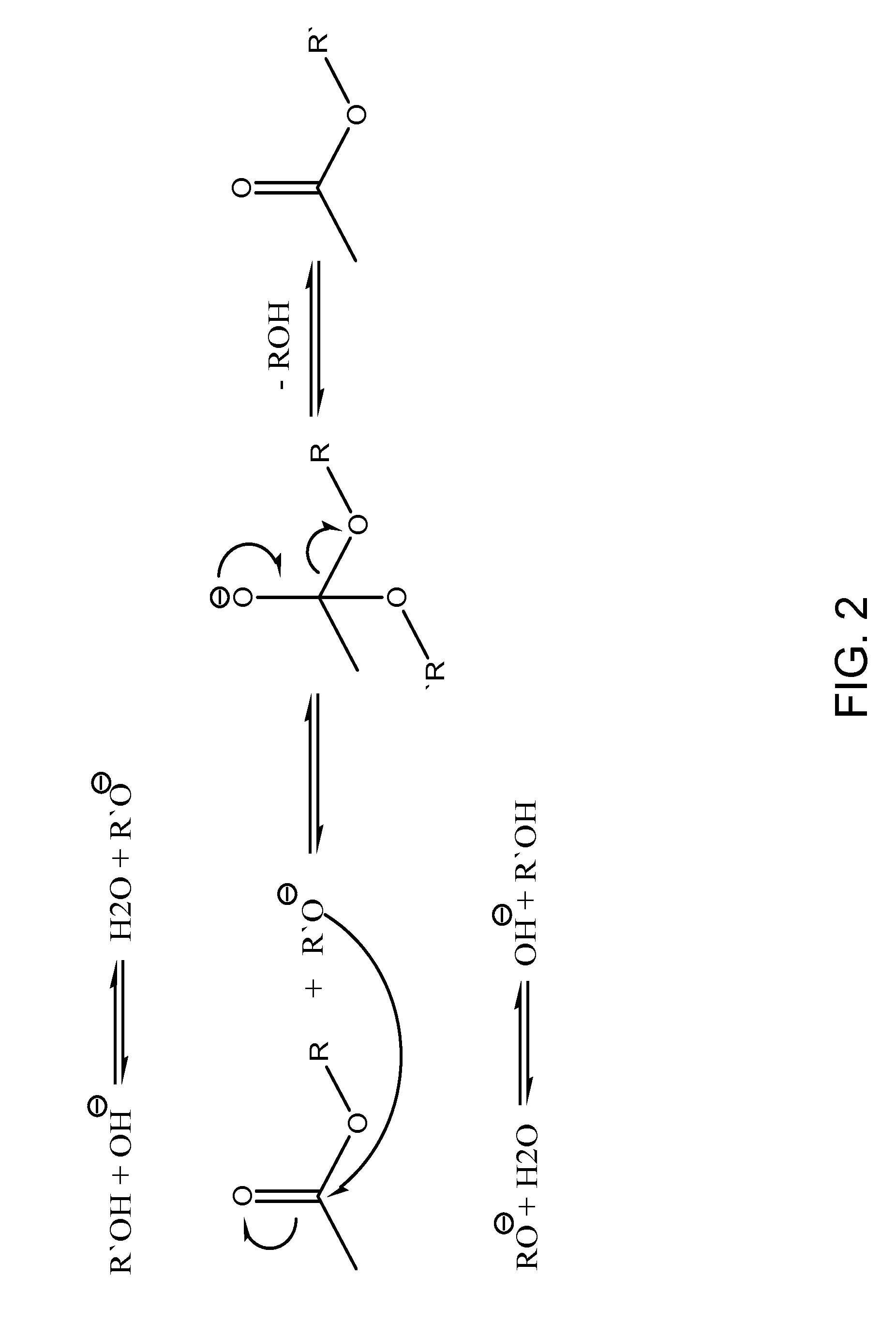

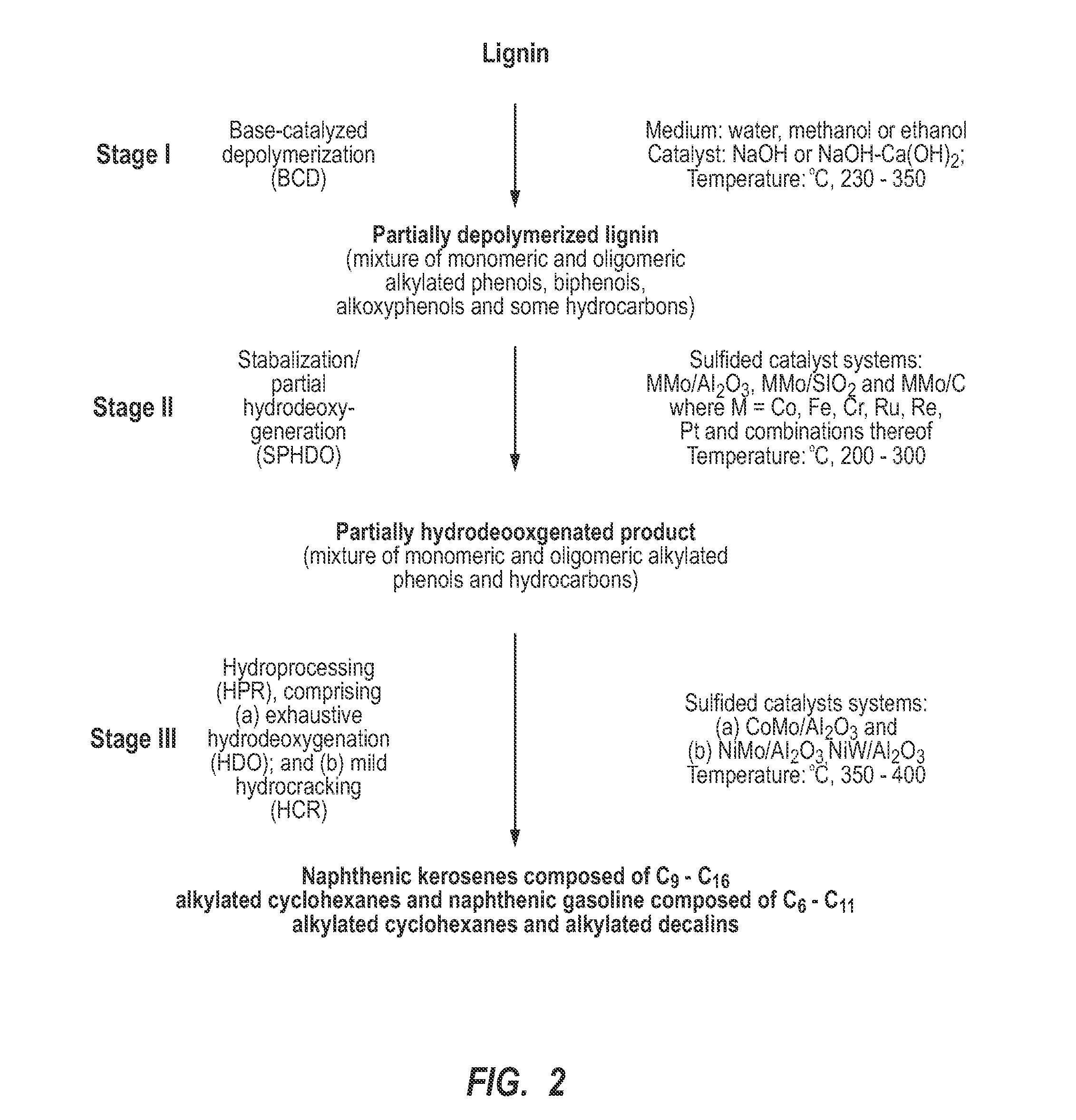

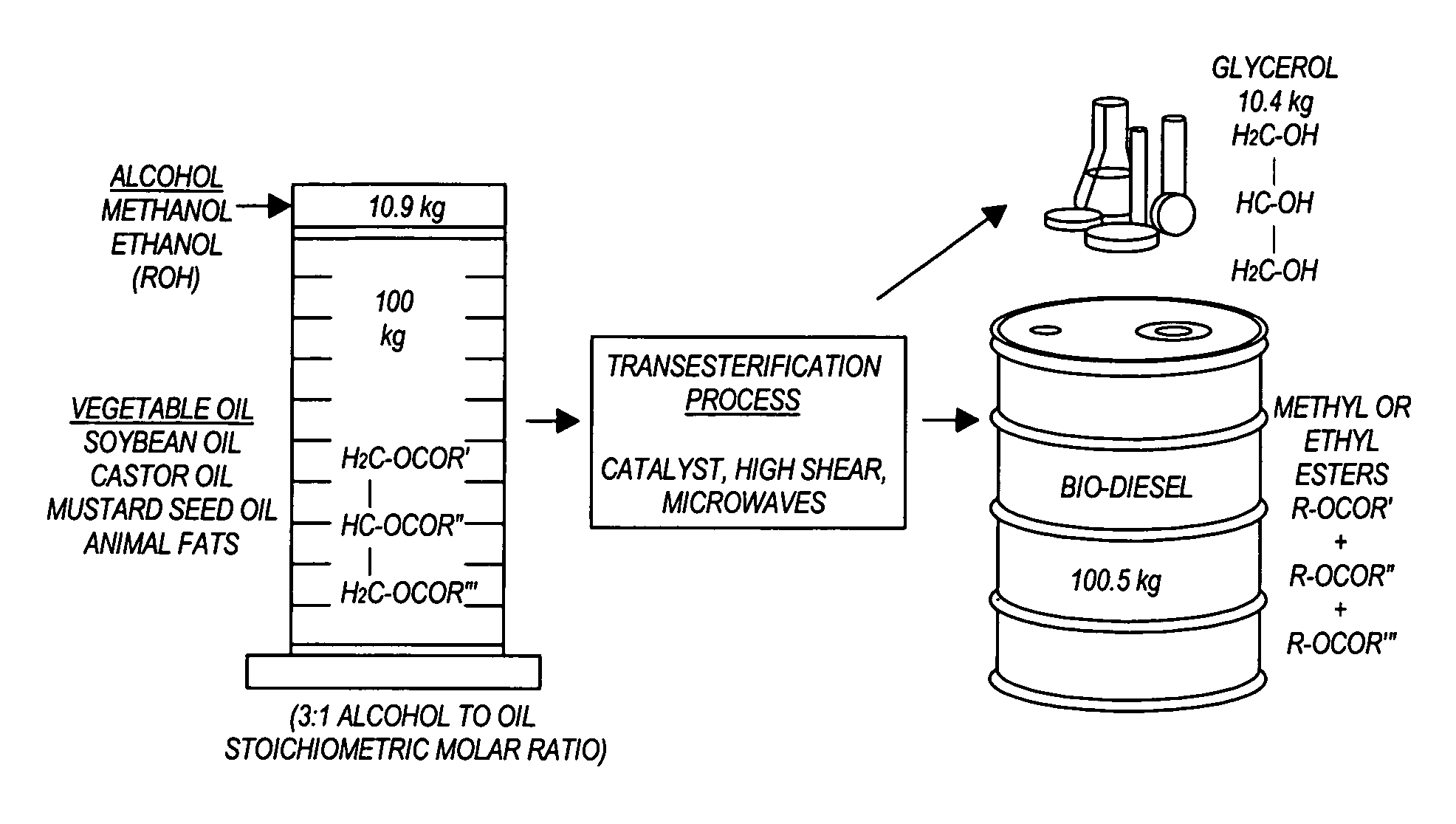

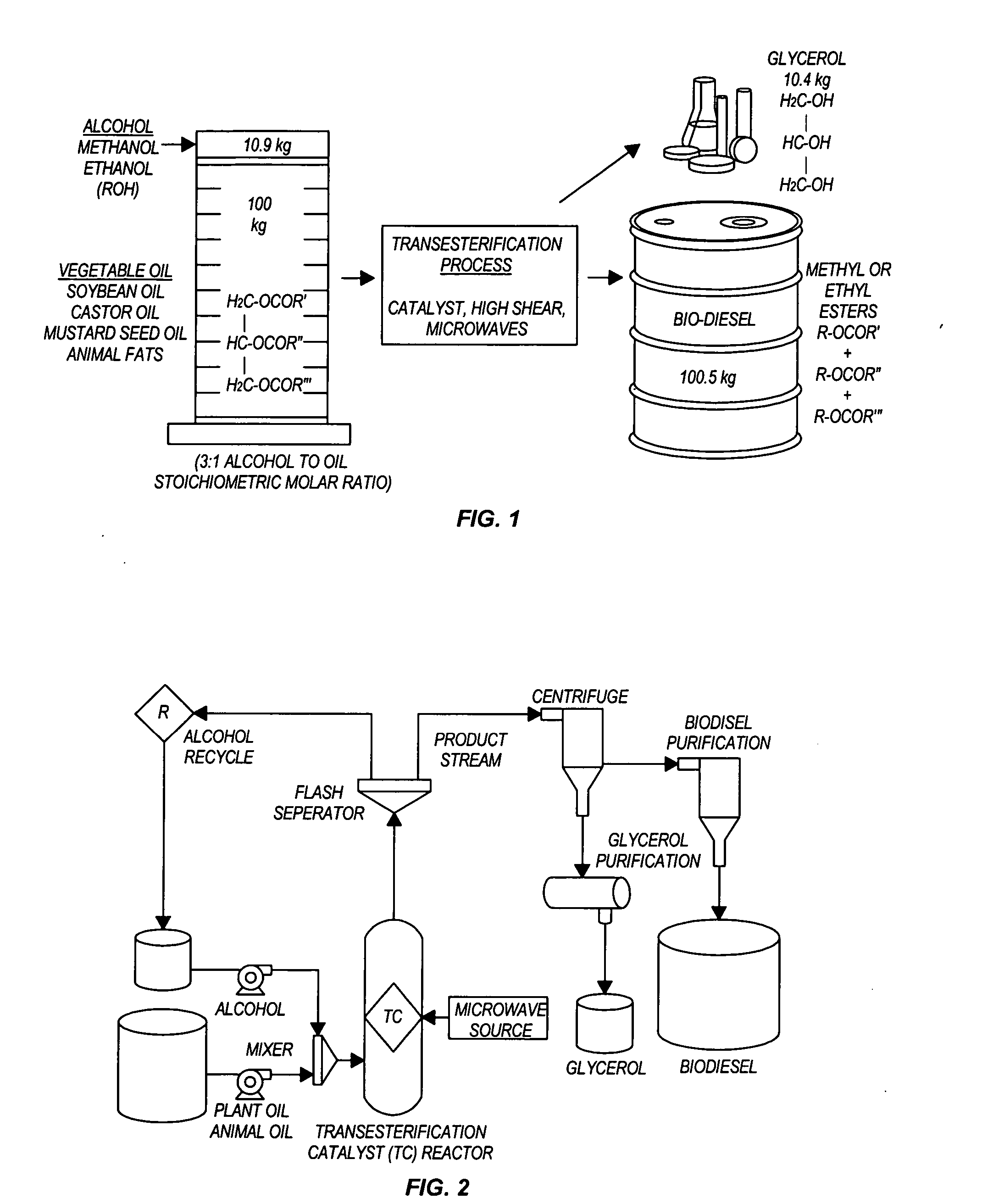

Methods for producing biodiesel

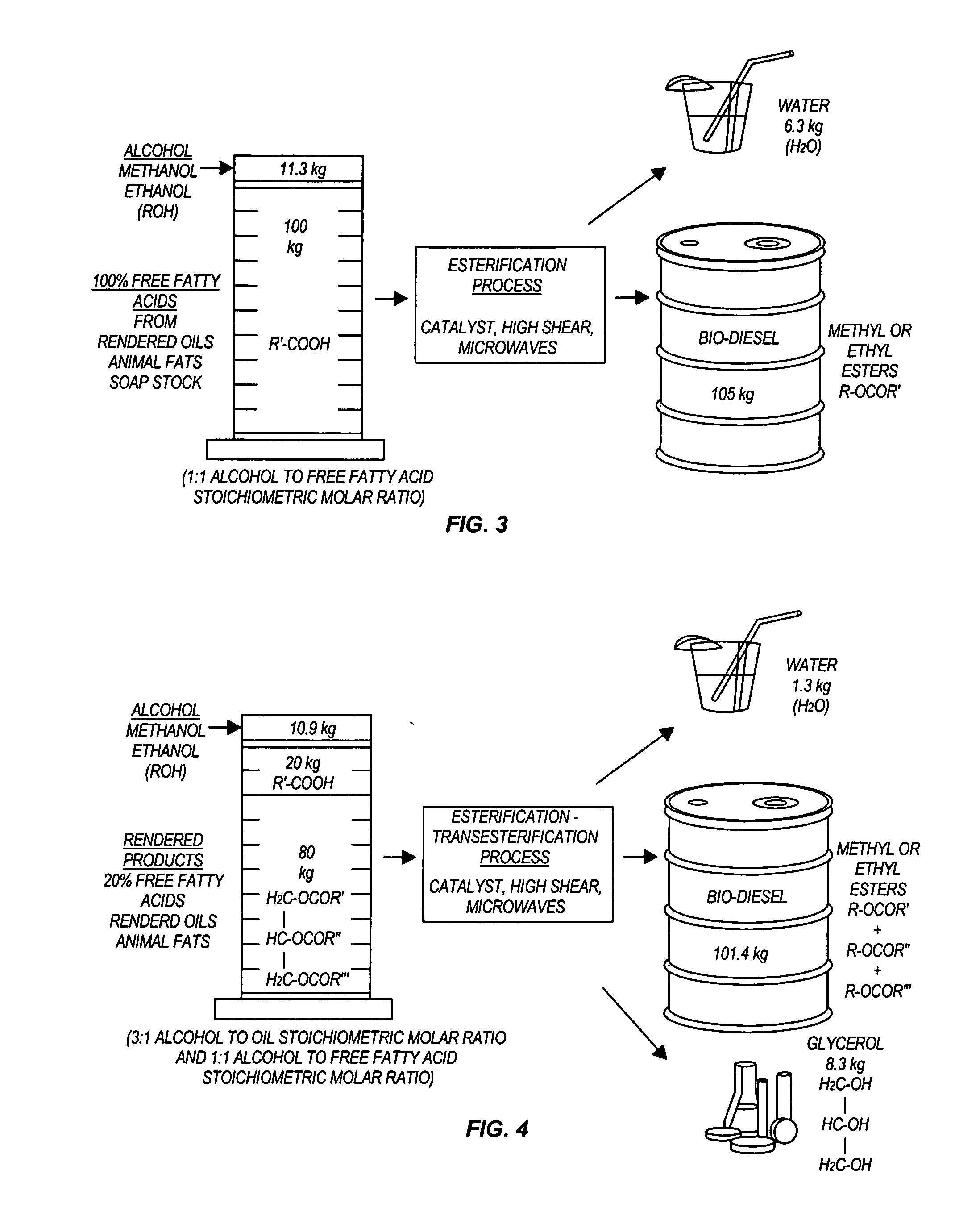

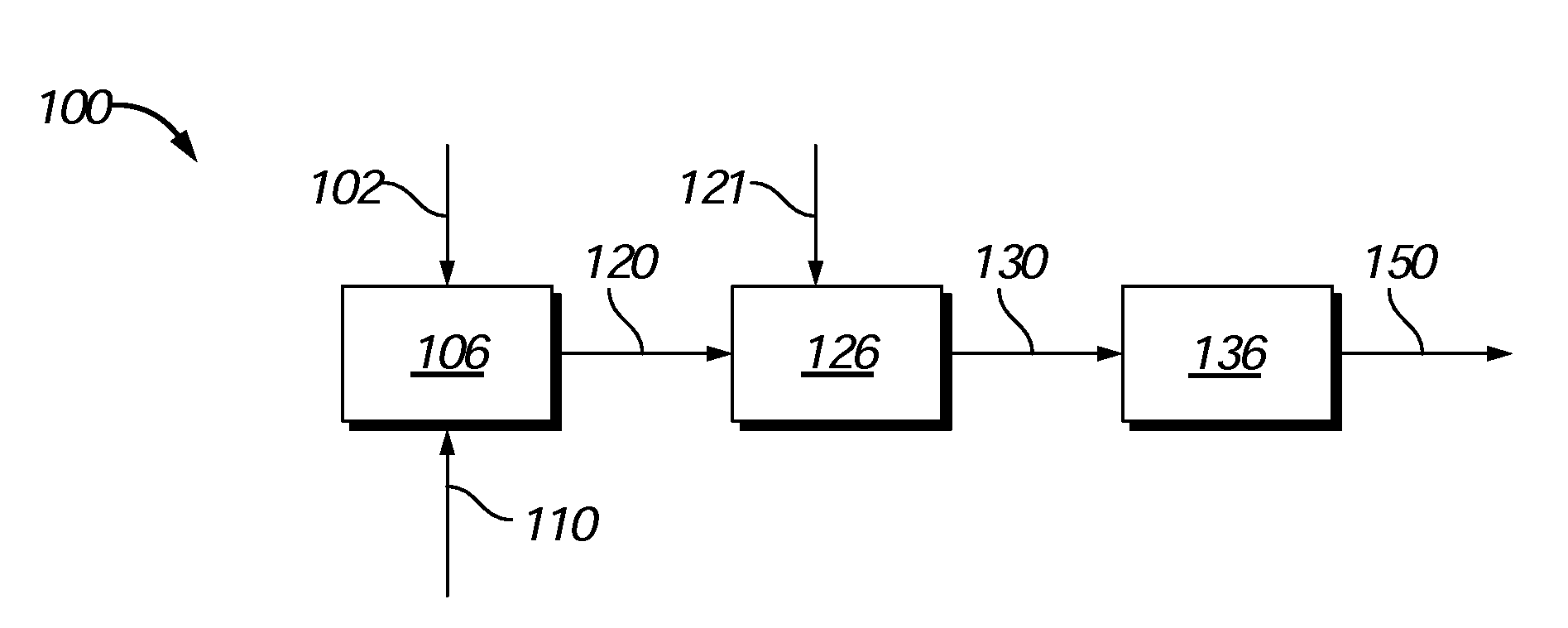

InactiveUS20050274065A1Fatty acid esterificationPreparation by ester-hydroxy reactionMicrowaveTransesterification

Transesterification, esterification, and esterification-transesterification (both one-step and two-step) for producing biofuels. The process may be enhanced by one or more of the following: 1) applying microwave or RF energy; 2) passing reactants over a heterogeneous catalyst at sufficiently high velocity to achieve high shear conditions; 3) emulsifying reactants with a homogeneous catalyst; or 4) maintaining the reaction at a pressure at or above autogeneous pressure. Enhanced processes using one or more of these steps can result in higher process rates, higher conversion levels, or both.

Owner:CARNEGIE MELLON UNIV

Process to produce biofuels from biomass

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates; (iii) contacting the pretreated biomass with hydrogen in the presence of a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co and / or Ni incorporated into a suitable support to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

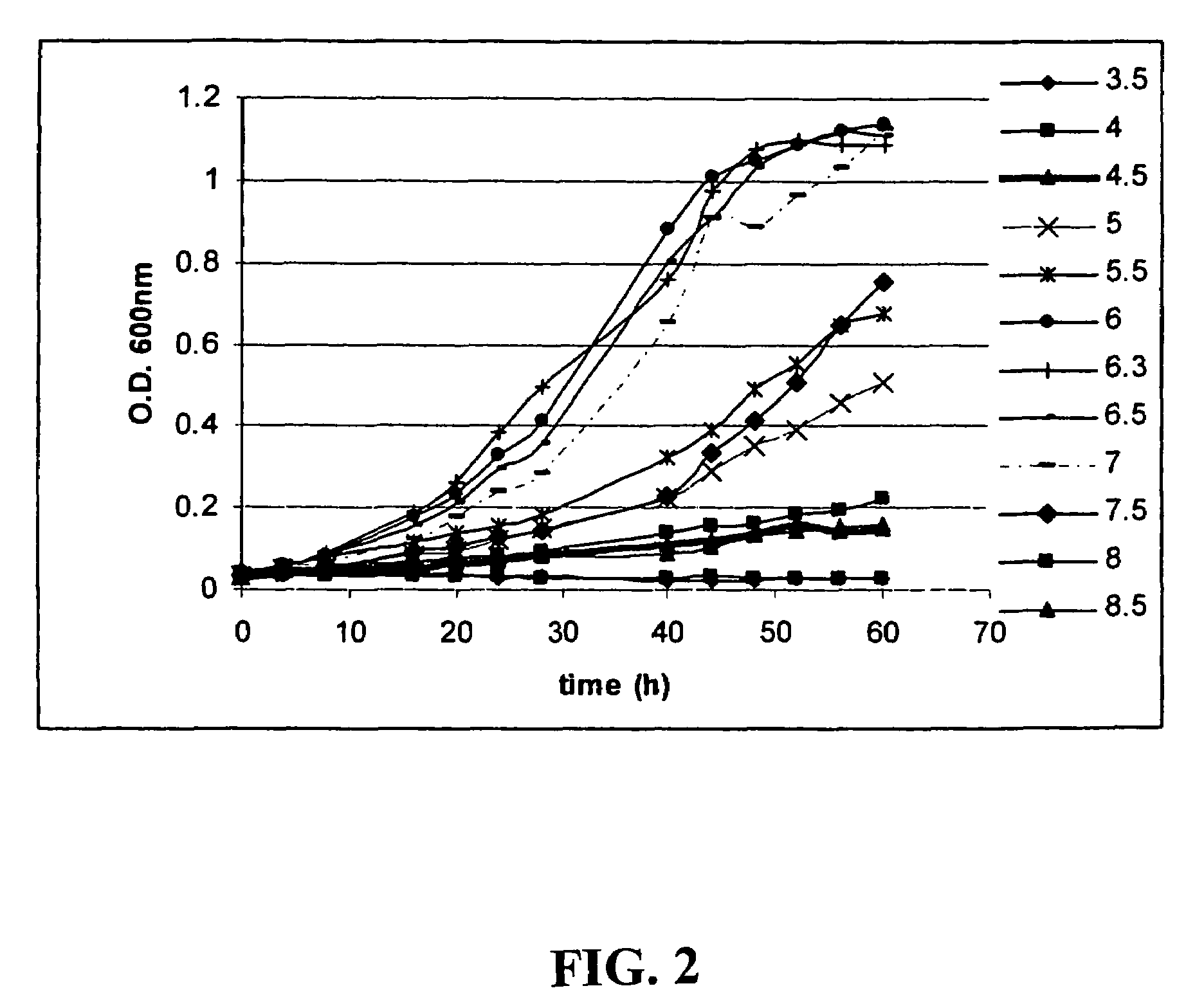

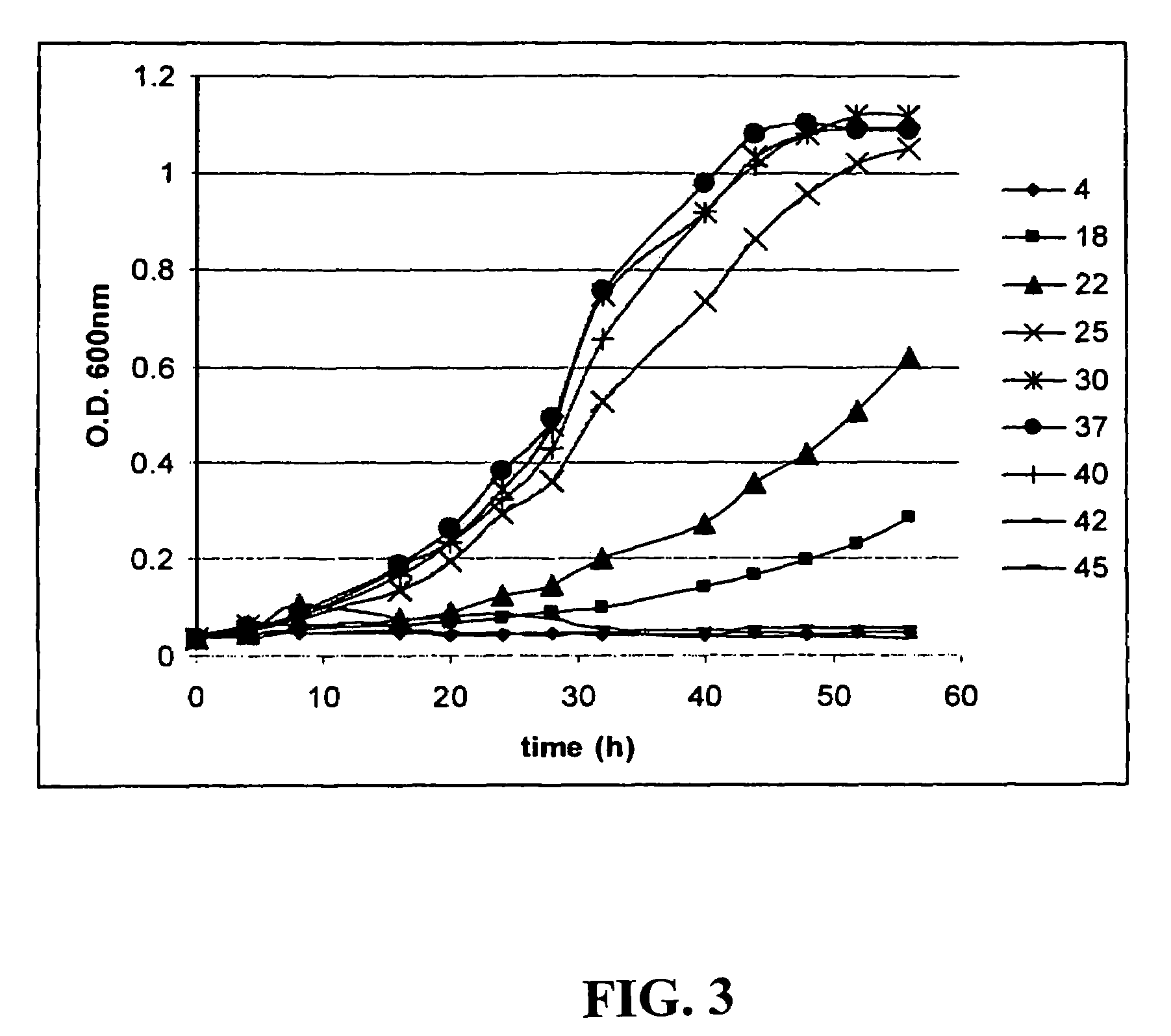

Isolation and characterization of novel clostridial species

InactiveUS7704723B2High yieldReadily availableBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasAcetic acid

A novel clostridia bacterial species (Clostridium ragsdalei, ATCC BAA-622, “P11”) is provided. P11 is capable of synthesizing, from waste gases, products which are useful as biofuel. In particular, P11 can convert CO to ethanol. Thus, this novel bacterium transforms waste gases (e.g. syngas and refinery wastes) into useful products. P11 also catalyzes the production of acetate.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY +1

Process to produce biofuels via organic phase thermal hydrocatalytic treatment of biomass

Biofuels can be produced via an organic phase hydrocatalytic treatment of biomass using an organic solvent that is partially miscible with water. An organic hydrocarbon-rich phase from the hydrocatalytically treated products can be recycled to form at least a portion of the organic phase.

Owner:SHELL OIL CO

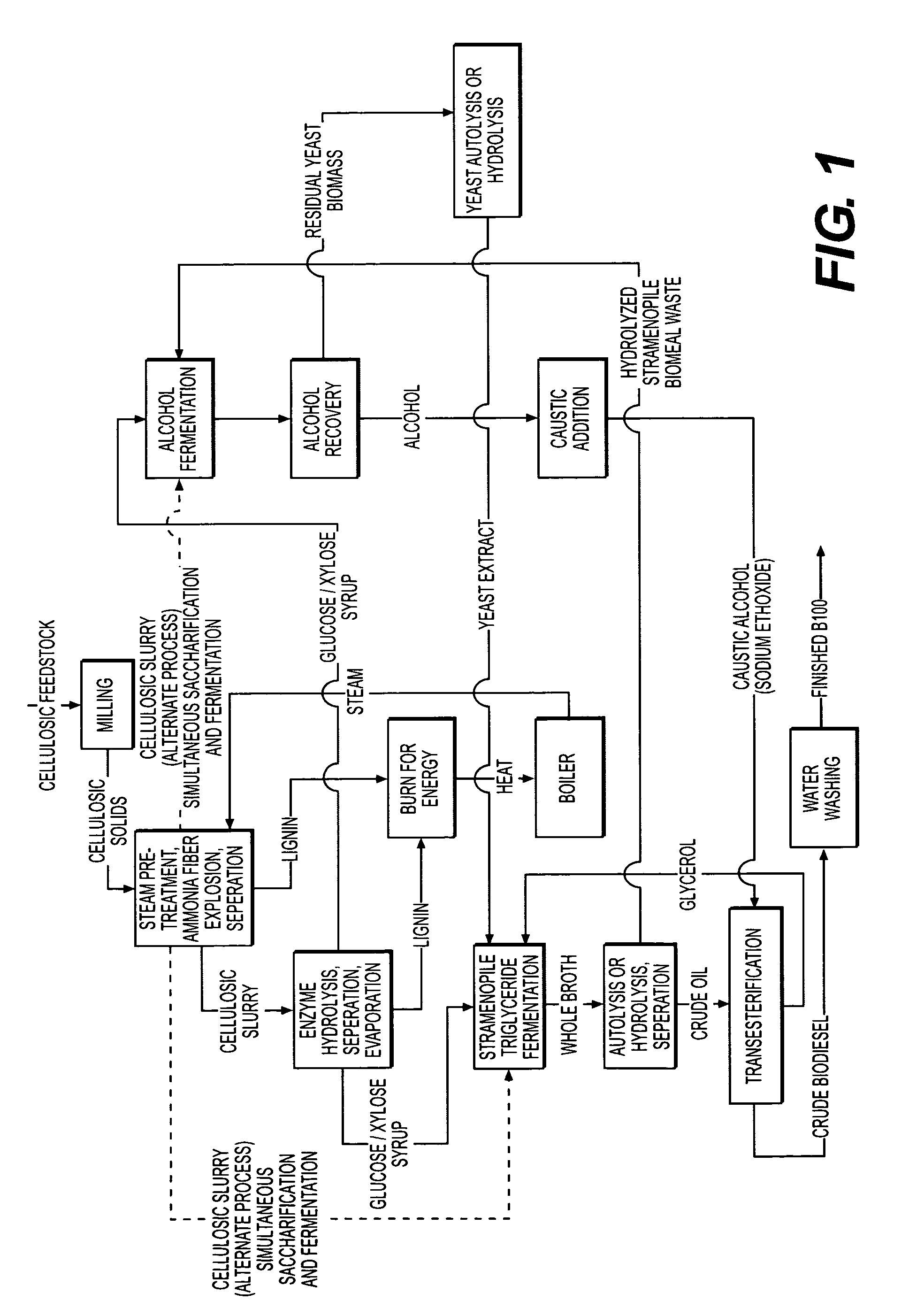

Biological oils and production and uses Thereof

The present invention provides biological oils and methods and uses thereof. The biological oils are preferably produced by heterotrophic fermentation of one or more microorganisms using cellulose-containing feedstock as a main source of carbon. The present invention also provides methods of producing lipid-based biofuels and food, nutritional, and pharmaceutical products using the biological oils.

Owner:MARTEK BIOSCIENCES CORP

Isolation and characterization of novel clostridial species

InactiveUS20080057554A1High yieldReadily availableBioreactor/fermenter combinationsBiological substance pretreatmentsBacteroidesAcetic acid

A novel clostridia bacterial species (Clostridium ragsdalei, ATCC BAA-622, “P11”) is provided. P11 is capable of synthesizing, from waste gases, products which are useful as biofuel. In particular, P11 can convert CO to ethanol. Thus, this novel bacterium transforms waste gases (e.g. syngas and refinery wastes) into useful products. P11 also catalyzes the production of acetate.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY +1

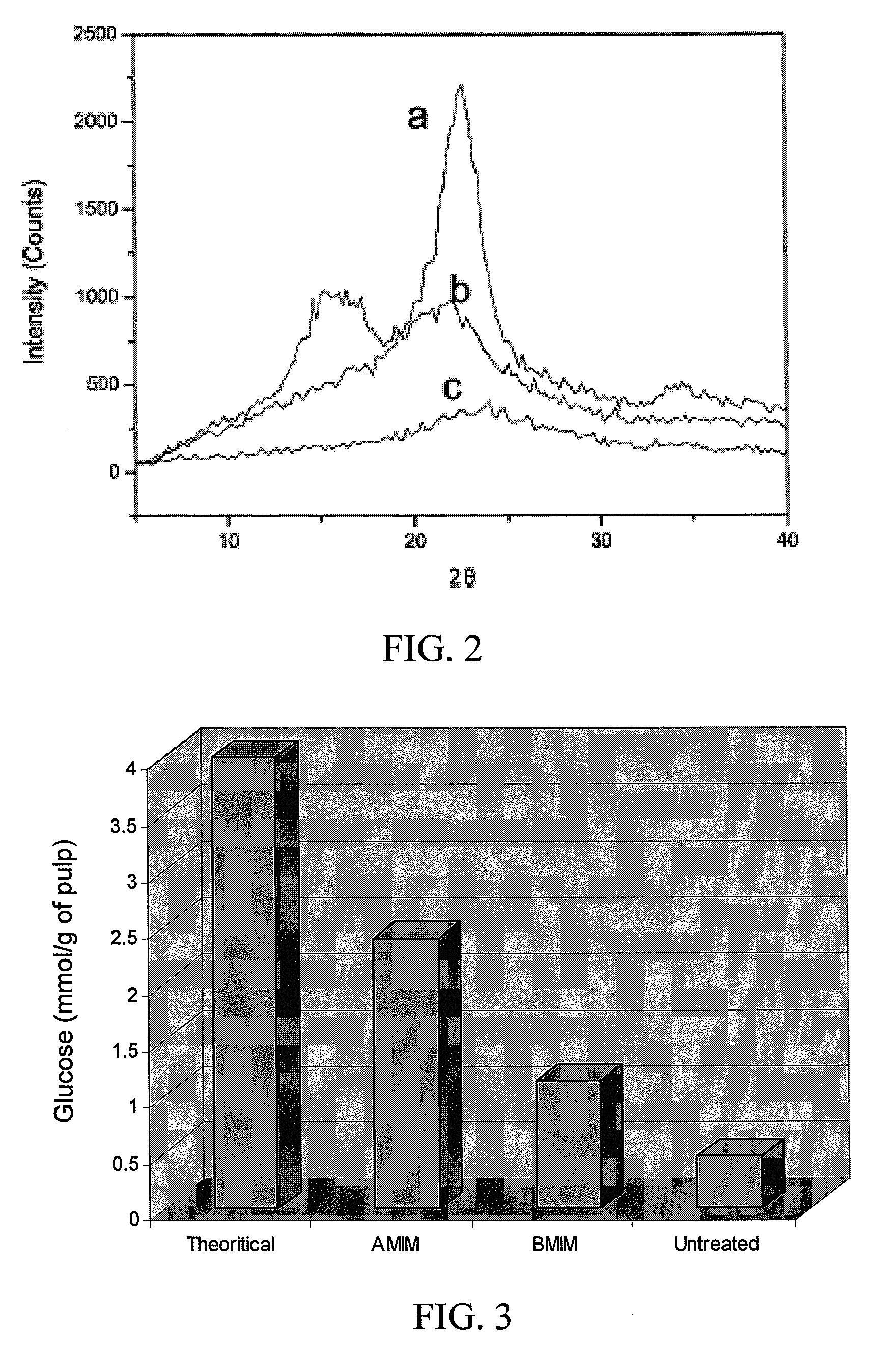

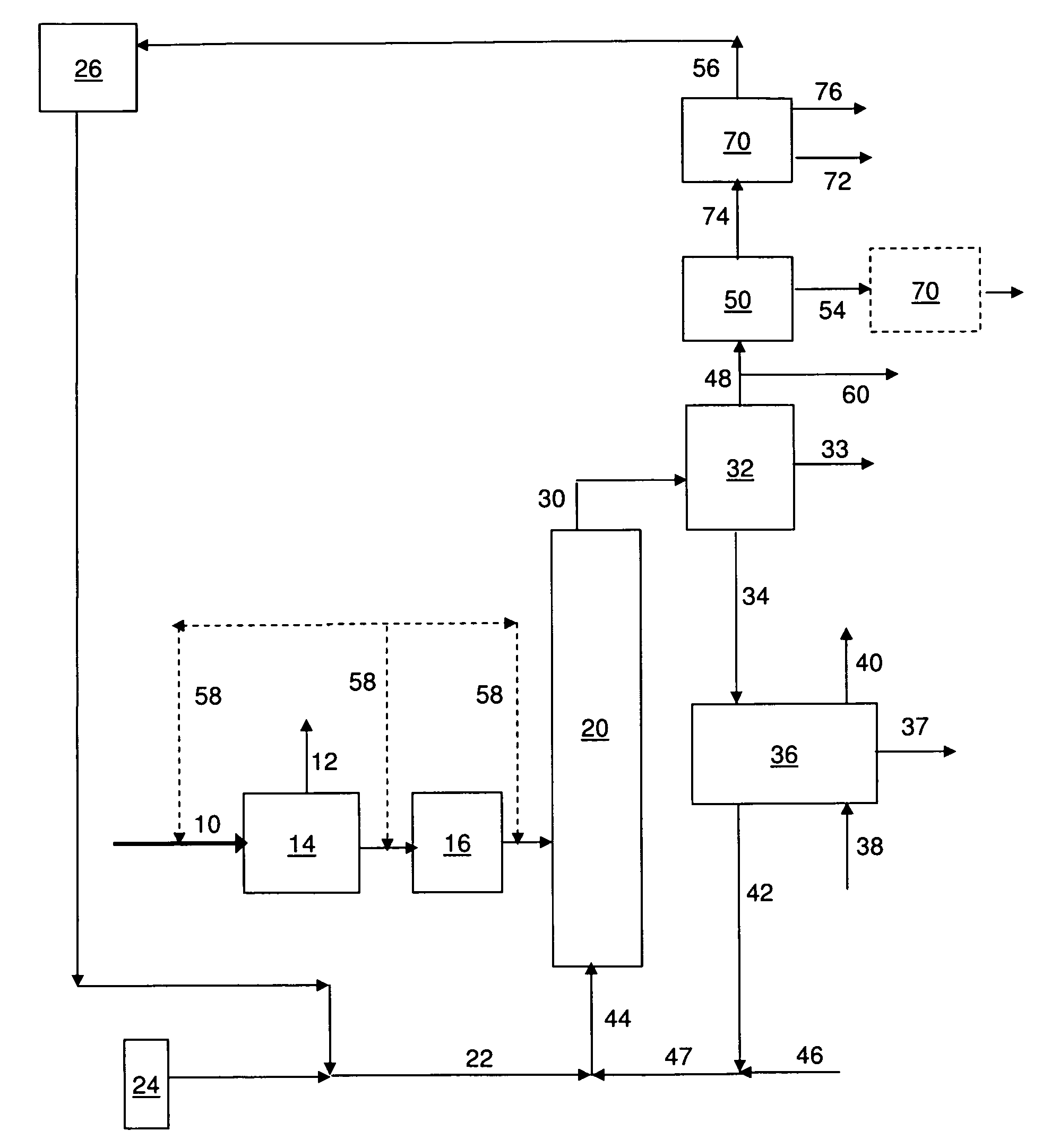

Use of lignocellulosics solvated in ionic liquids for production of biofuels

InactiveUS20080190013A1Guaranteed economic efficiencyReduced availabilityCellulosic pulp after-treatmentSugar productsBiofuelEvaporation

The present invention provides a method for converting lignocellulosic material into biofuel. In particular embodiments, the method comprises pre-treating lignocellulosic material by dissolving the material in ionic liquids. The pretreated lignocellulosic material can be isolated, such as by precipitation with a regenerating solvent (e.g., water), and be used directly in the formation of biofuel, including undergoing hydrolysis to form sugar and fermentation to form fuel, such as bioethanol. The ionic liquid can be recycled for further use, such as by evaporation of the water introduced during precipitation, and the recycling provides a route to a hemicellulose rich fraction and an ionic liquid of consistent quality and wood dissolution characteristics. The recovered hemicelluloses are of significant utilization potential toward commodity and specialty applications.

Owner:NORTH CAROLINA STATE UNIV

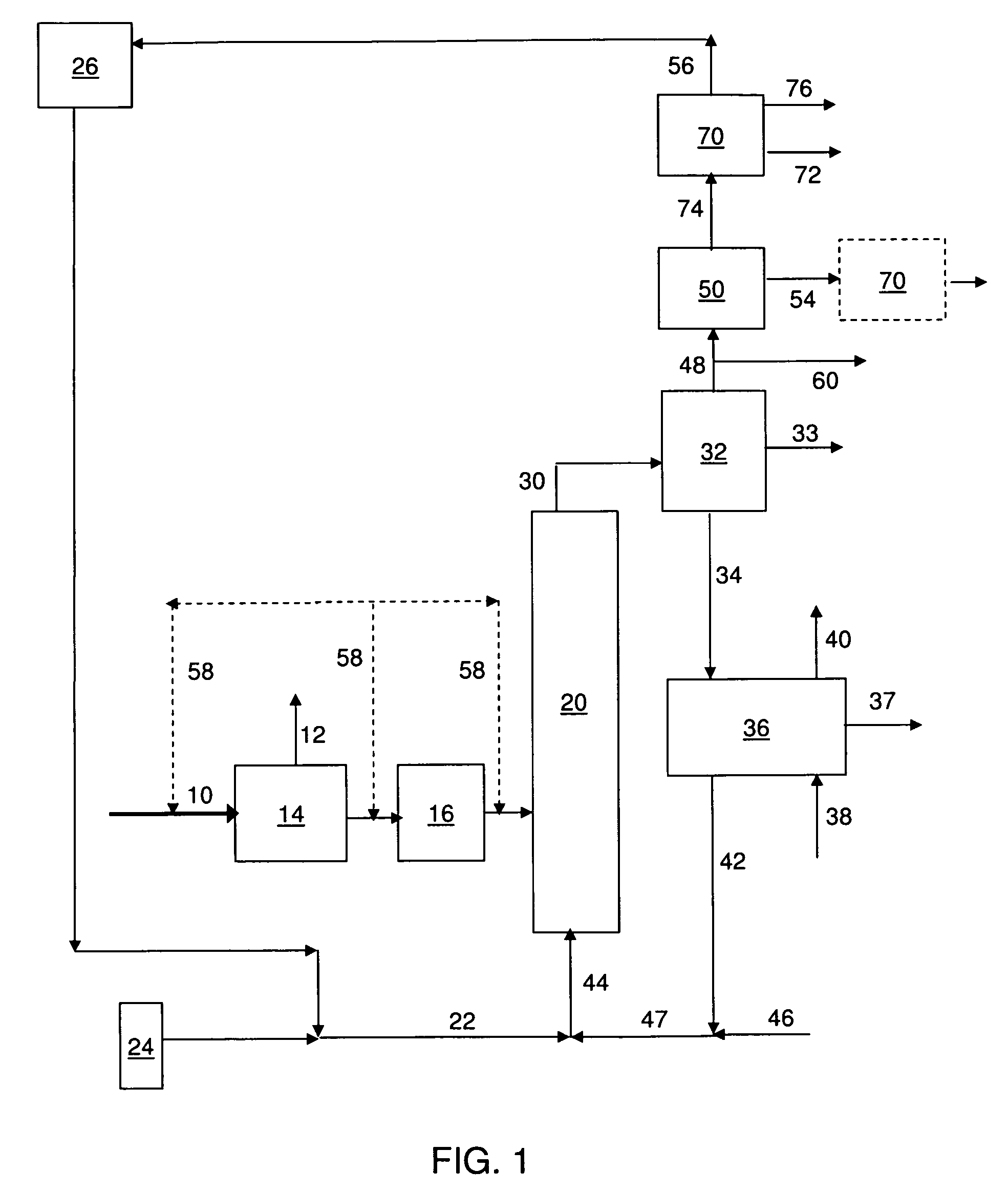

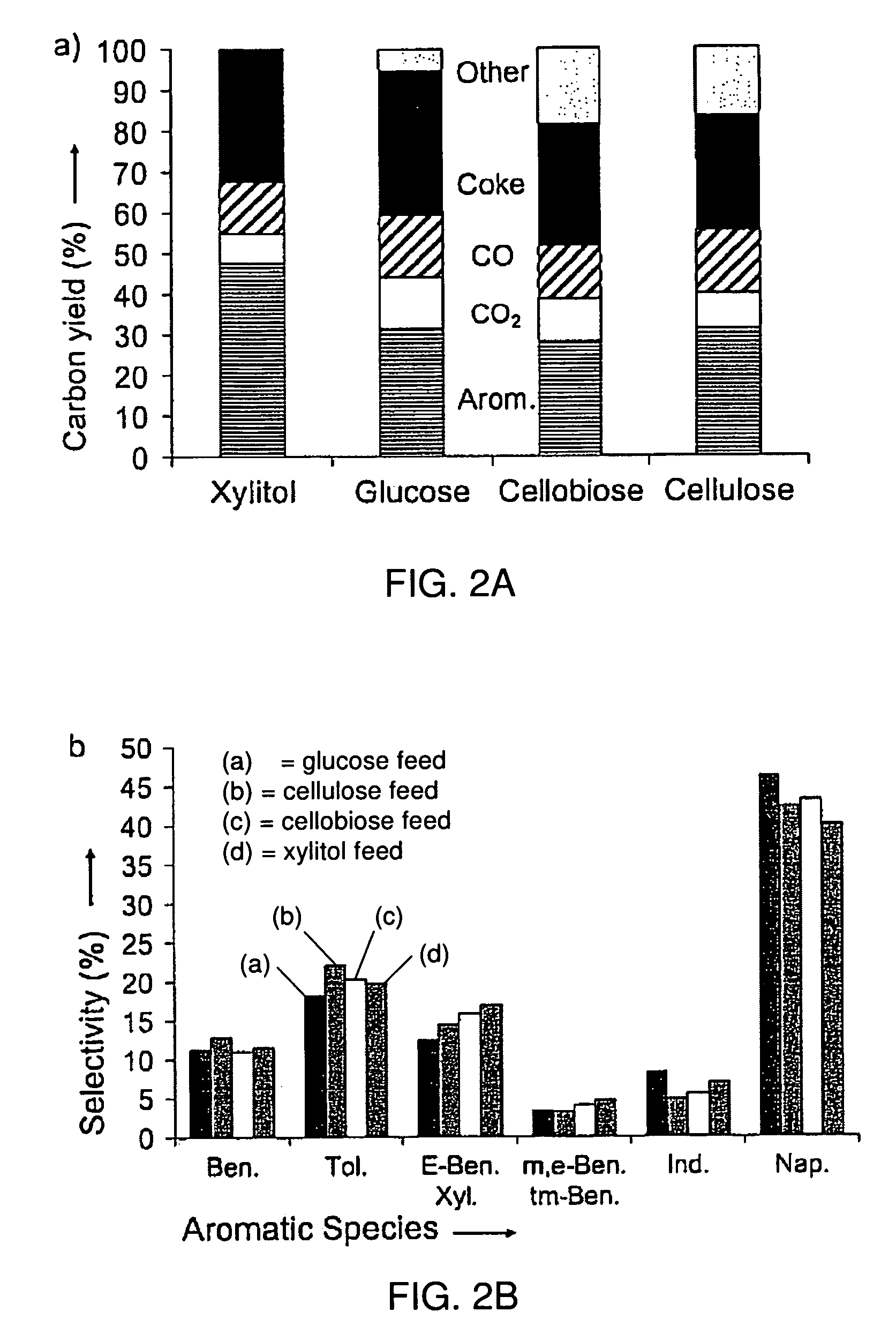

Catalytic pyrolysis of solid biomass and related biofuels, aromatic, and olefin compounds

ActiveUS8277643B2Minimize coke productionSolid fuelsHydrocarbon from oxygen organic compoundsCatalytic pyrolysisHigh rate

This invention relates to compositions and methods for fluid hydrocarbon product, and more specifically, to compositions and methods for fluid hydrocarbon product via catalytic pyrolysis. Some embodiments relate to methods for the production of specific aromatic products (e.g., benzene, toluene, naphthalene, xylene, etc.) via catalytic pyrolysis. Some such methods may involve the use of a composition comprising a mixture of a solid hydrocarbonaceous material and a heterogeneous pyrolytic catalyst component. In some embodiments, the mixture may be pyrolyzed at high temperatures (e.g., between 500° C. and 1000° C.). The pyrolysis may be conducted for an amount of time at least partially sufficient for production of discrete, identifiable biofuel compounds. Some embodiments involve heating the mixture of catalyst and hydrocarbonaceous material at high rates (e.g., from about 50° C. per second to about 1000° C. per second). The methods described herein may also involve the use of specialized catalysts. For example, in some cases, zeolite catalysts may be used; optionally, the catalysts used herein may have high silica to alumina molar ratios. In some instances, the composition fed to the pyrolysis reactor may have a relatively high catalyst to hydrocarbonaceous material mass ratio (e.g., from about 5:1 to about 20:1).

Owner:UNIV OF MASSACHUSETTS

Process for producing biodiesel, lubricants, and fuel and lubricant additives in a critical fluid medium

InactiveUS6887283B1Limited mass transferImprove reaction speedFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

A process for producing alkyl esters useful in biofuels and lubricants by transesterifying glyceride- or esterifying free fatty acid-containing substances in a single critical phase medium is disclosed. The critical phase medium provides increased reaction rates, decreases the loss of catalyst or catalyst activity and improves the overall yield of desired product. The process involves the steps of dissolving an input glyceride- or free fatty acid-containing substance with an alcohol or water into a critical fluid medium; reacting the glyceride- or free fatty acid-containing substance with the alcohol or water input over either a solid or liquid acidic or basic catalyst and sequentially separating the products from each other and from the critical fluid medium, which critical fluid medium can then be recycled back in the process. The process significantly reduces the cost of producing additives or alternatives to automotive fuels and lubricants utilizing inexpensive glyceride- or free fatty acid-containing substances, such as animal fats, vegetable oils, rendered fats, and restaurant grease.

Owner:BATTELLE ENERGY ALLIANCE LLC

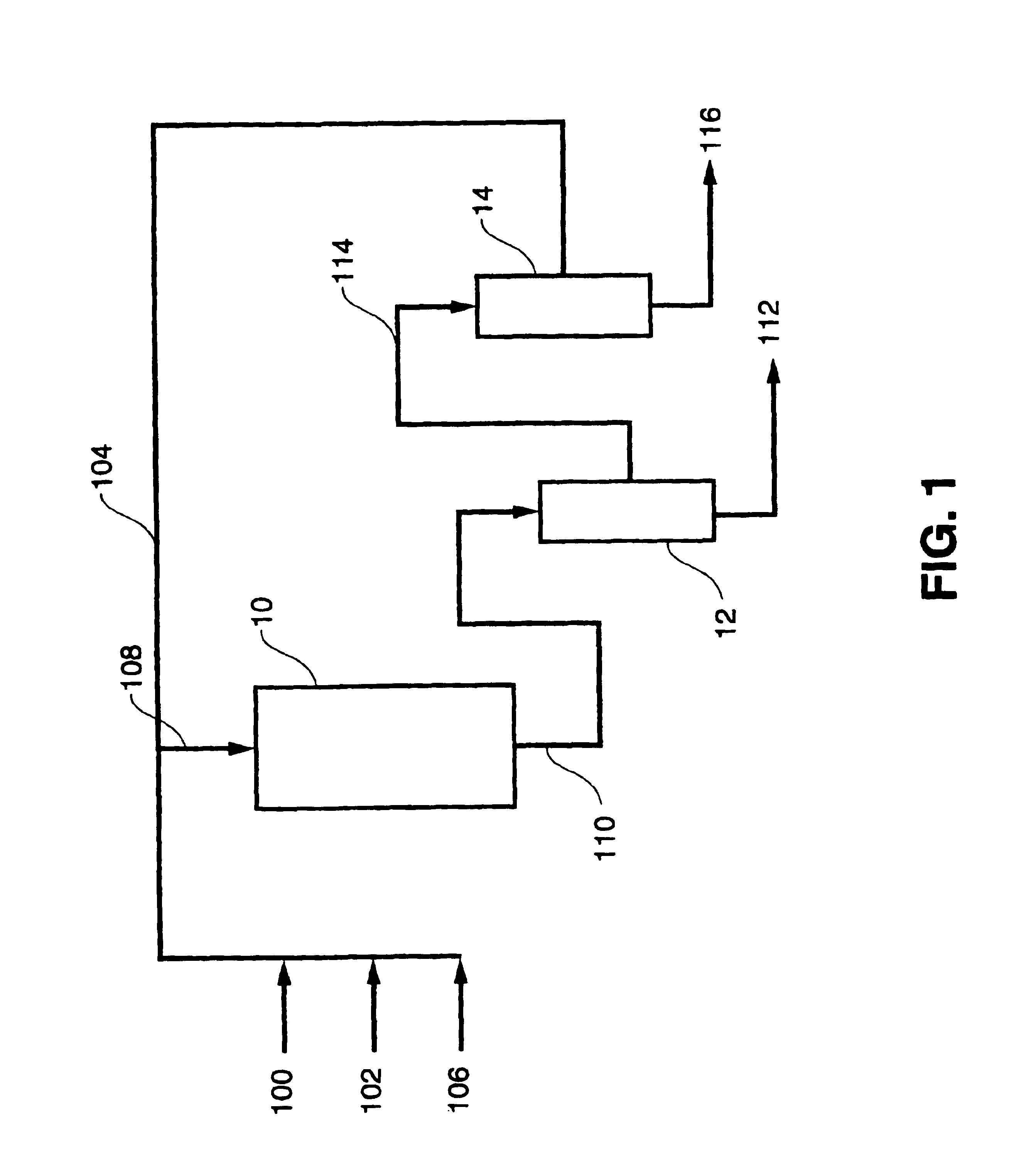

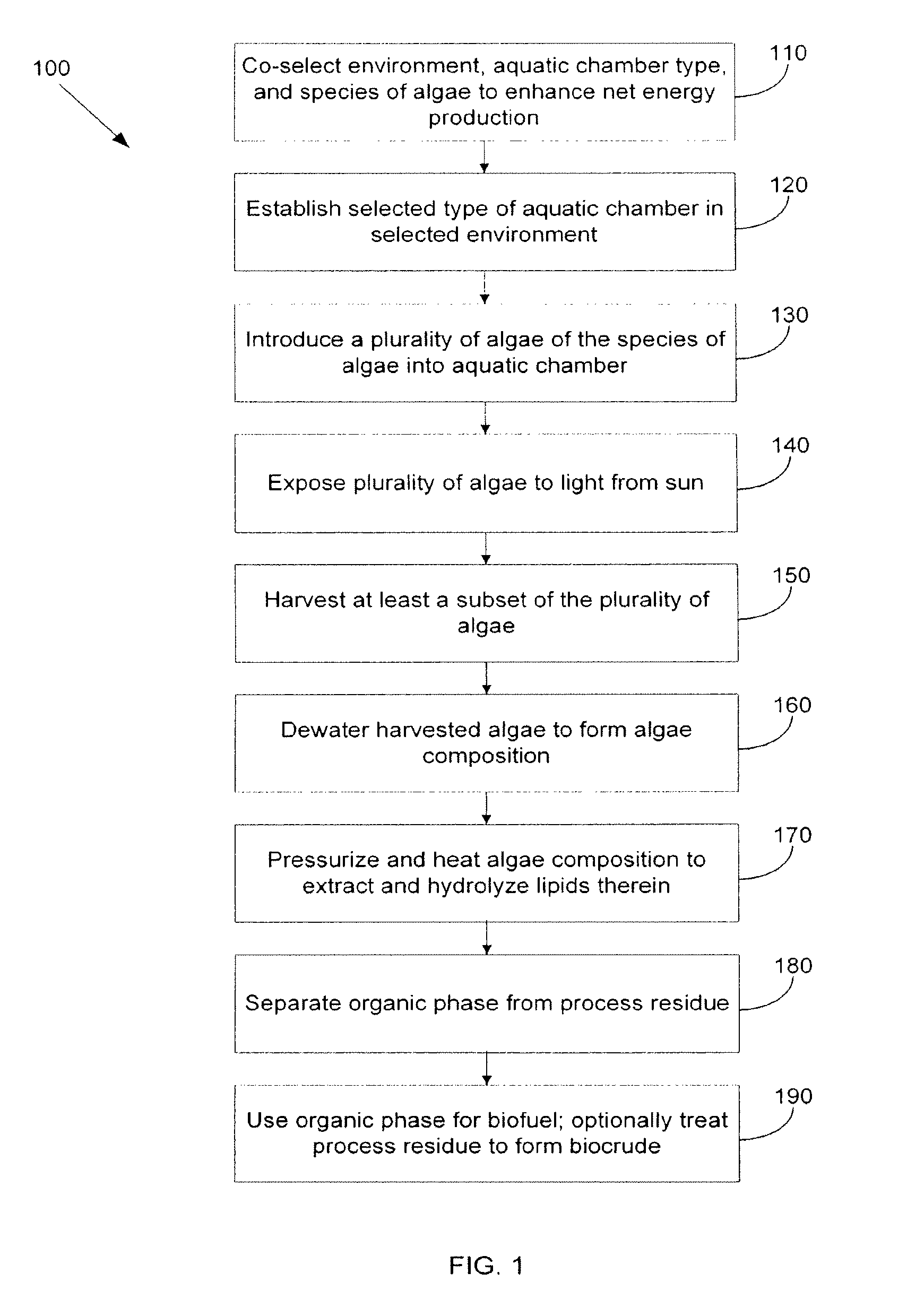

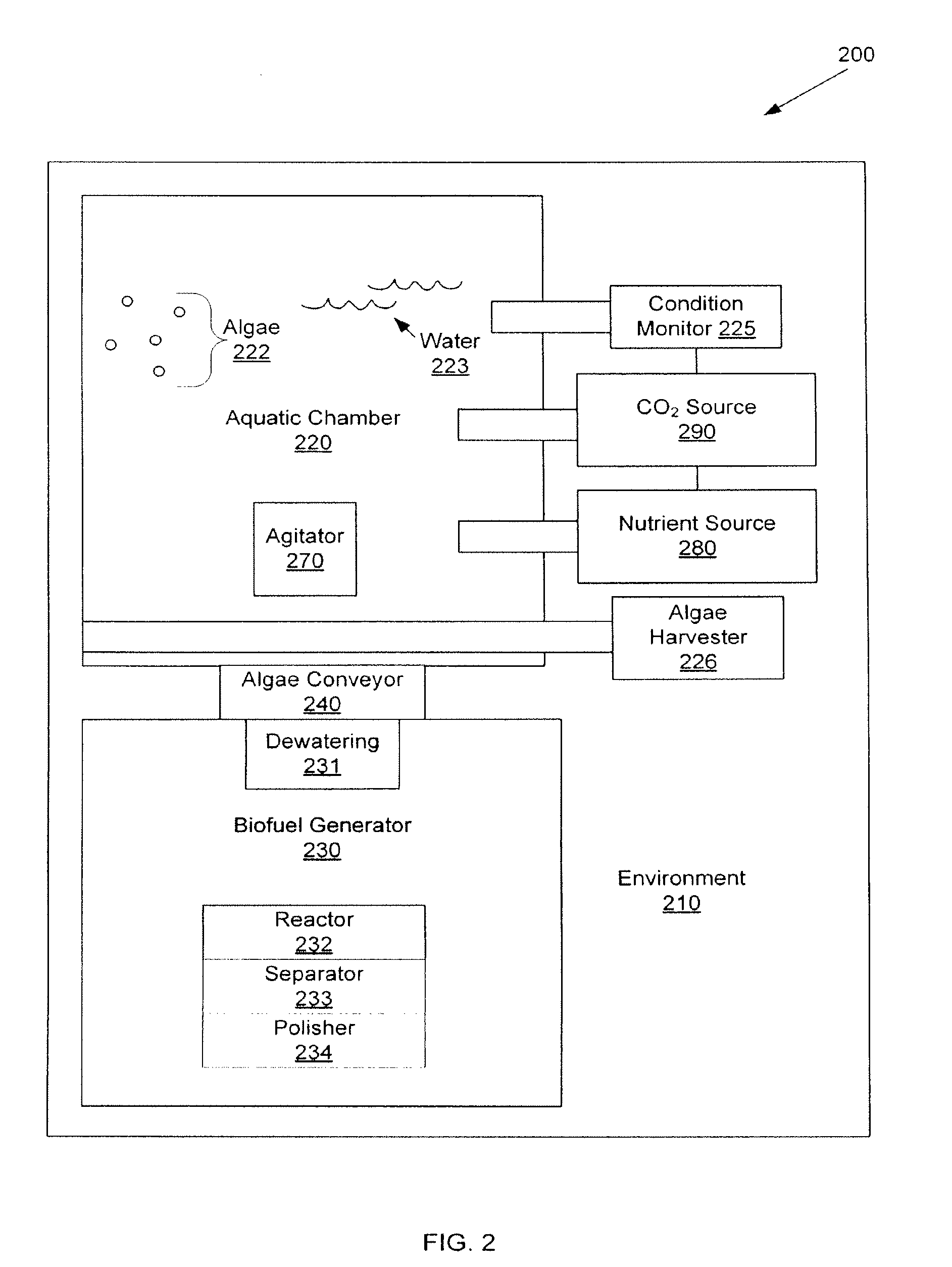

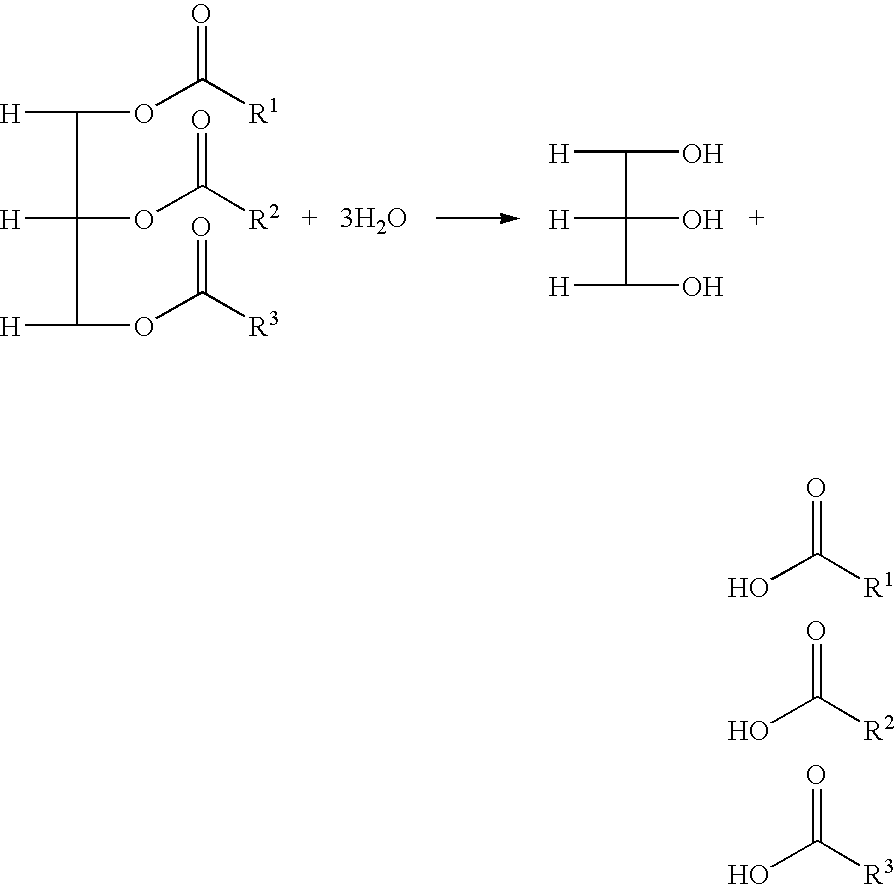

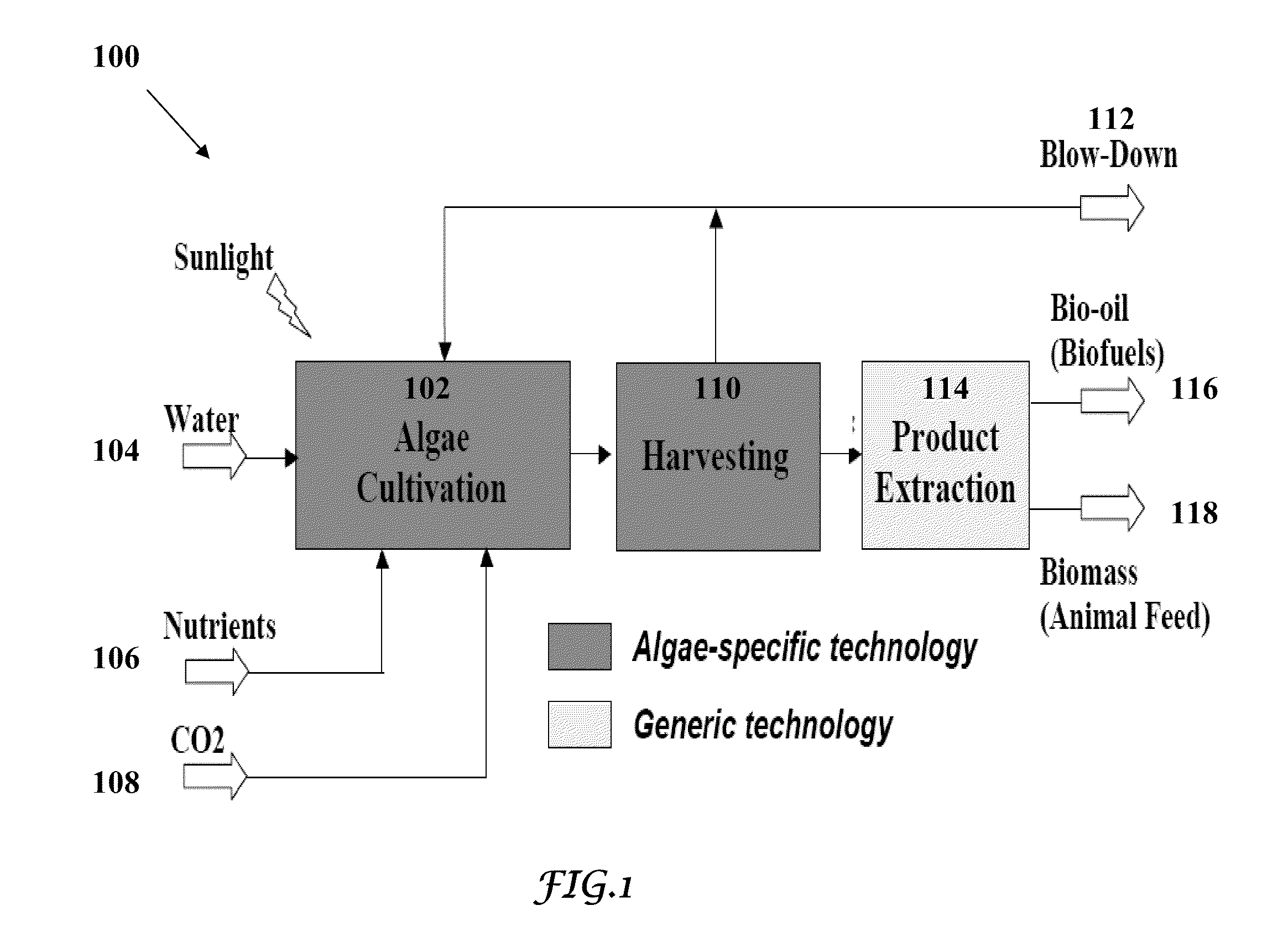

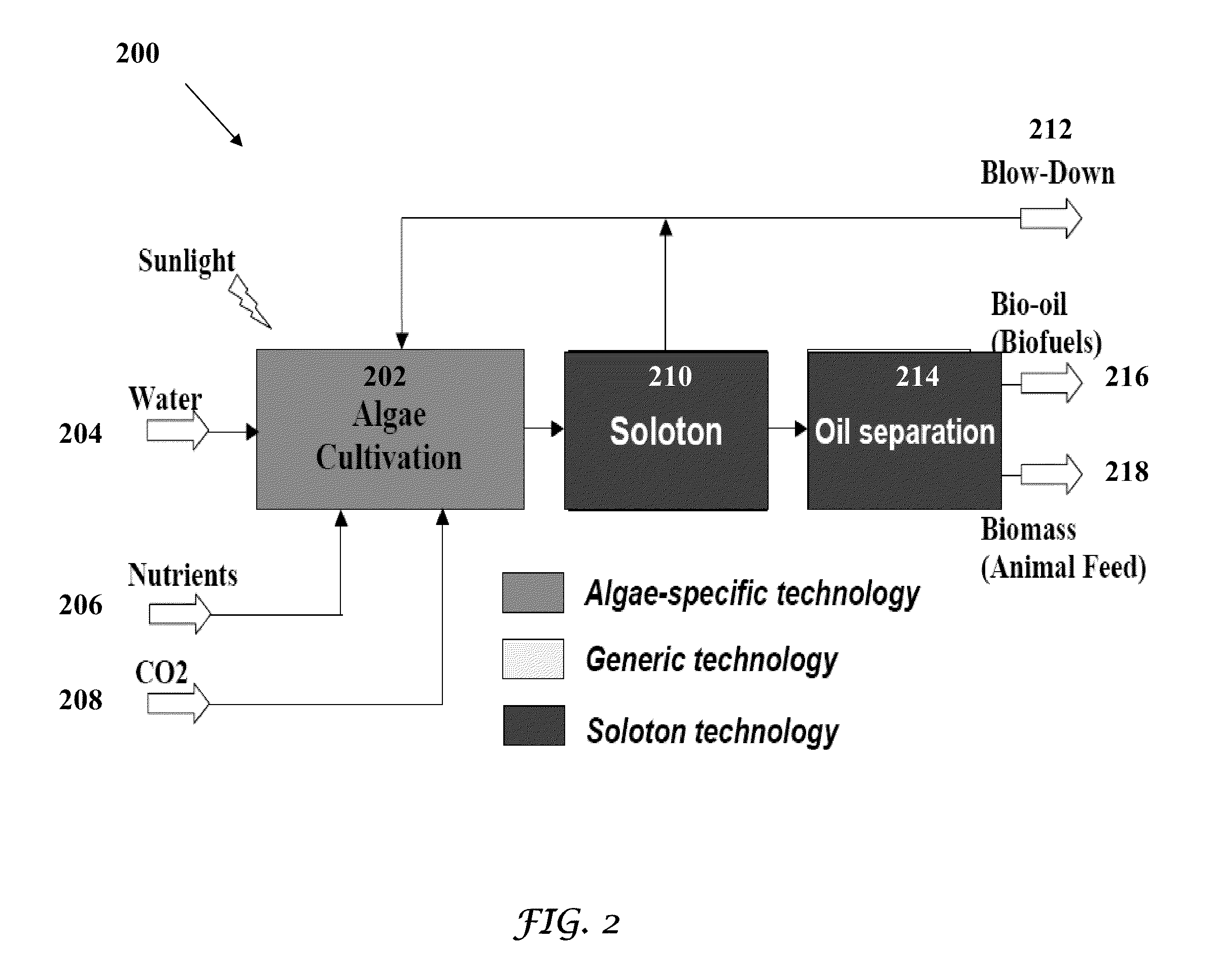

Systems and methods for hydrothermal conversion of algae into biofuel

InactiveUS20100050502A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelAlgae

The invention provides a system for obtaining biofuel from an algae composition comprising algae and water. The system comprises a pump for pressurizing the algae composition to a predefined pressure and a heater for heating the algae composition to a predefined temperature. Lipids in the algae are extracted and / or hydrolyzed to form fatty acids at a set of predefined temperature and pressure. The water may be in a subcritical or supercritical state at the predefined pressure and predefined temperature. The system further comprises a separator for partitioning the treated algae composition into an organic phase which includes the lipids and / or fatty acids, an aqueous phase, and a solid phase with biomass residue, and for collecting the organic phase. The organic phase can be upgraded to biofuel.

Owner:LIVEFUELS

Process to produce biofuels from biomass

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) removing sulfur compounds and nitrogen compounds from the biomass by contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates and having less than 35% of the sulfur content and less than 35% of the nitrogen content of untreated biomass on a dry mass basis; (iii) contacting the pretreated biomass directly with hydrogen in the presence of a hydrogenolysis catalyst to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

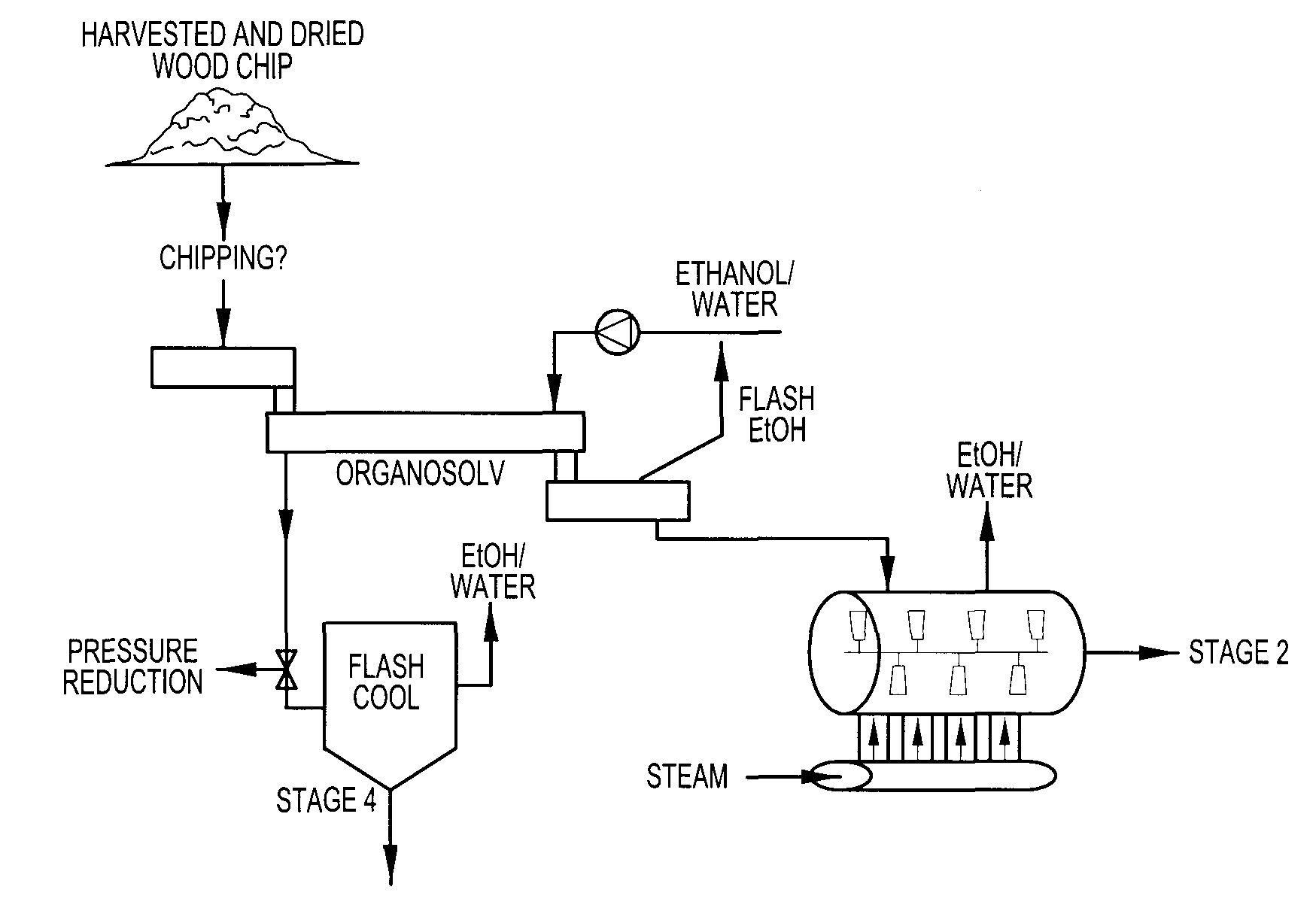

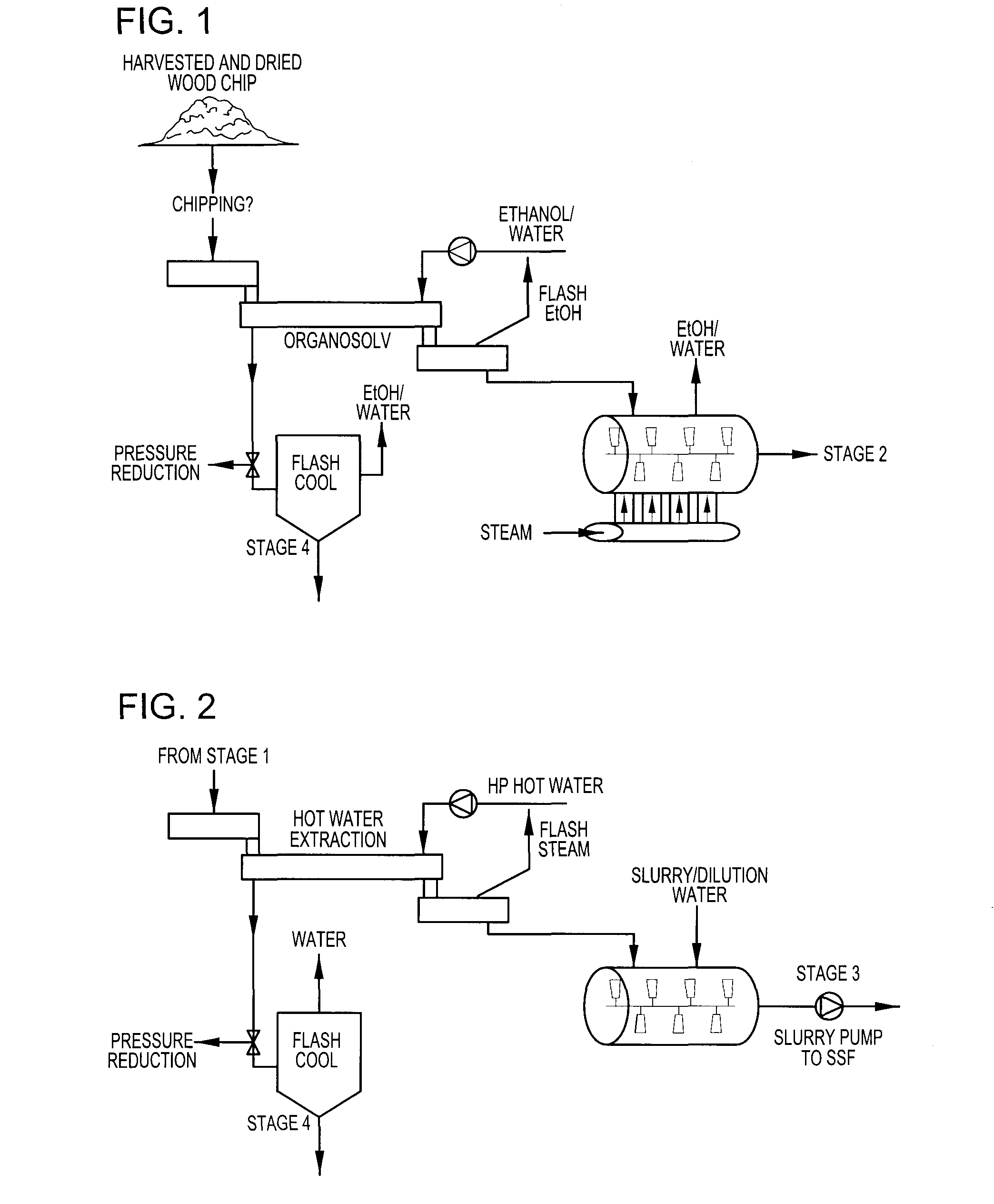

Process for the production of biofuel from plant materials

InactiveUS20070259412A1Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseBiofuel

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

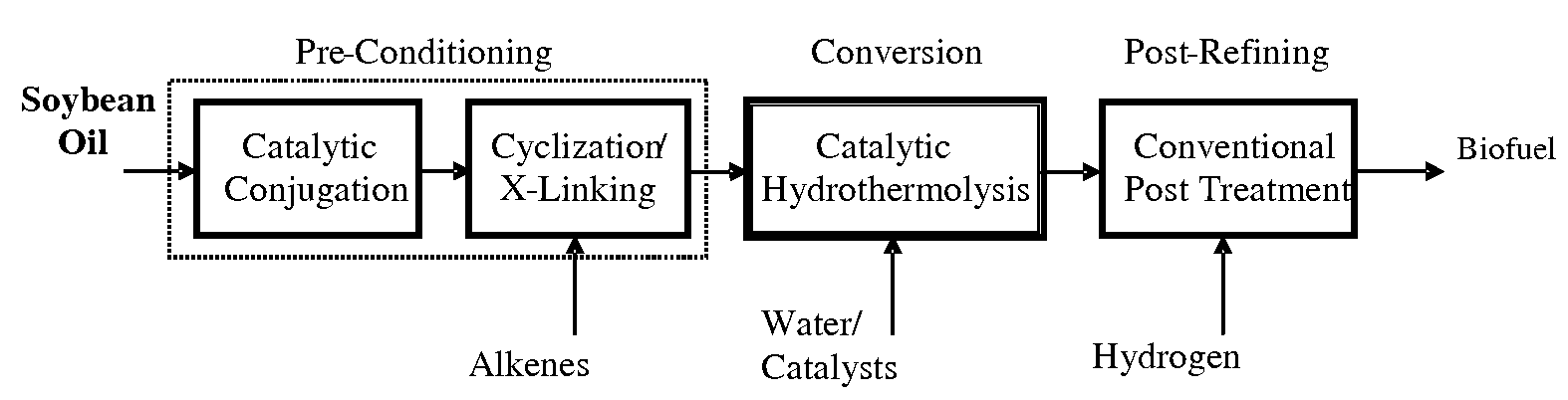

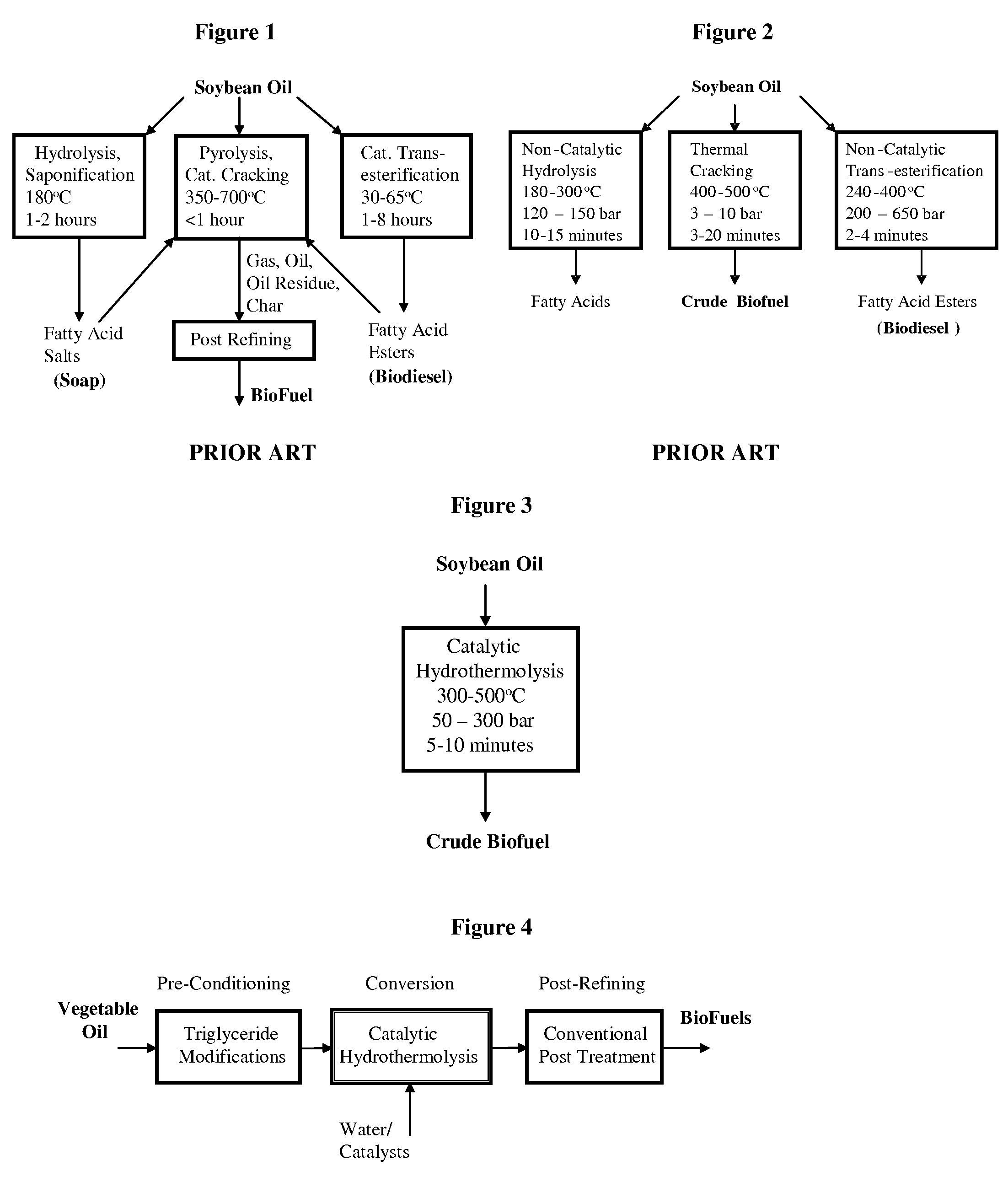

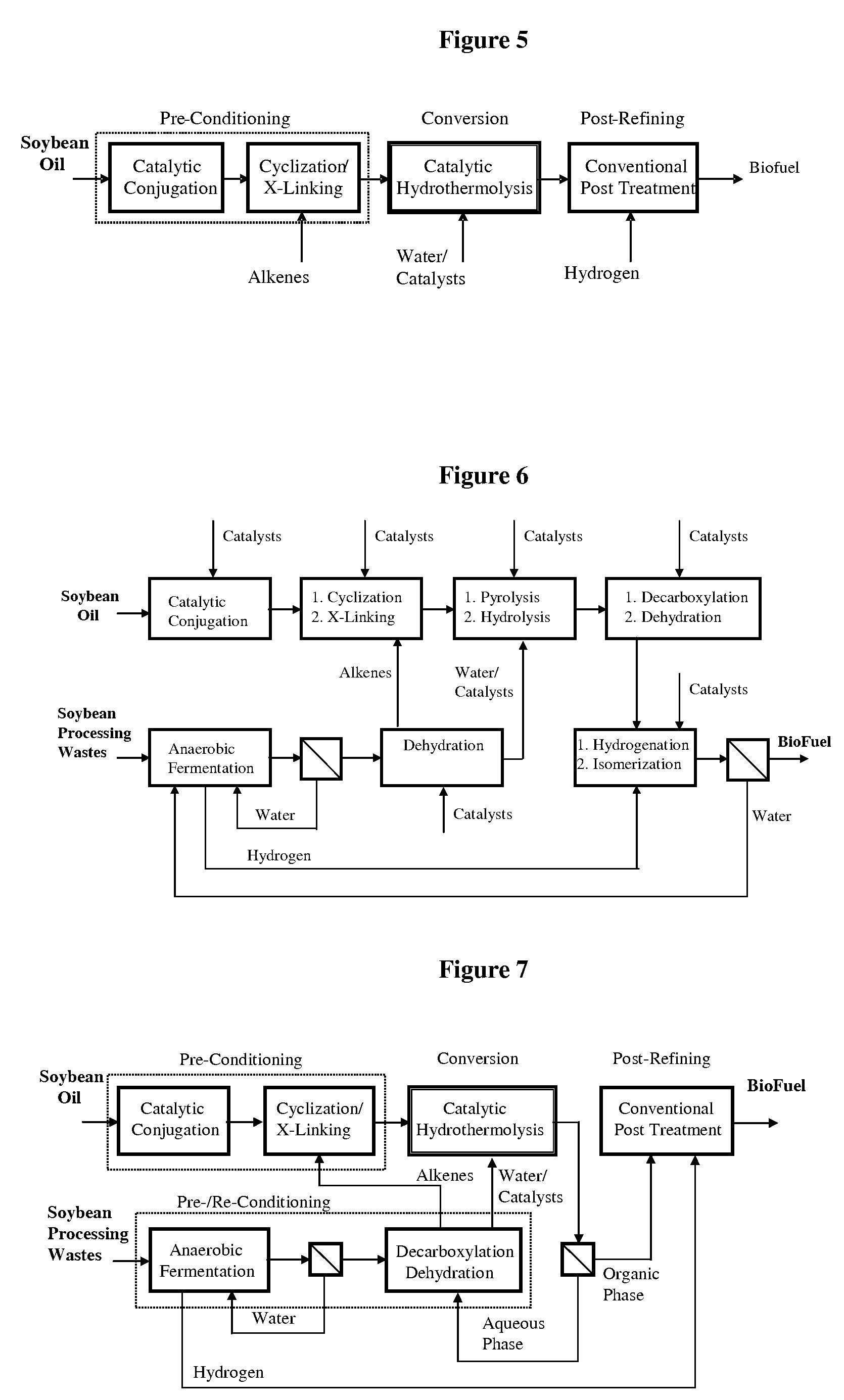

Method of converting triglycerides to biofuels

ActiveUS7691159B2Improve chemical and physical and combustion qualityImprove thermal stabilityFatty acid chemical modificationOrganic compound preparationCross-linkIsomerization

A triglyceride-to-fuel conversion process including the steps of (a) preconditioning unsaturated triglycerides by catalytic conjugation, cyclization, and cross-link steps; (b) contacting the modified triglycerides with hot-compressed water containing a catalyst, wherein cracking, hydrolysis, decarboxylation, dehydration, aromatization, or isomerization, or any combination thereof, of the modified triglycerides produce a crude hydrocarbon oil and an aqueous phase containing glycerol and lower molecular weight molecules, and (c) refining the crude hydrocarbon oil to produce various grades of biofuels. A triglyceride-to-fuel conversion process further including the steps of (a) carrying out anaerobic fermentation and decarboxylation / dehydration, wherein the anaerobic fermentation produces hydrogen, volatile acids, and alcohols from fermentable feedstocks, and the decarboxylation / dehydration produces alkenes from the volatile acids and alcohols, respectively; (b) feeding the alkenes to the cyclization process; (c) feeding the hydrogen to the post refining process; and (d) recycling the aqueous phase containing glycerol to the decarboxylation / dehydration process. A biofuel composition including straight-chain, branched and cyclo paraffins, and aromatics. The paraffins are derived from conversion of triglycerides. The aromatics are derived from conversion of either triglycerides, petroleum, or coal.

Owner:APPLIED RES ASSOCS INC

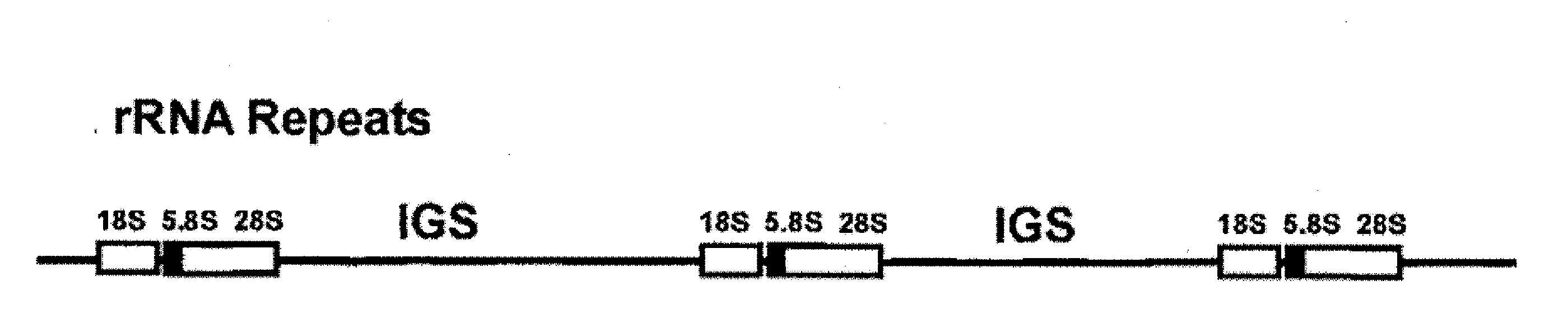

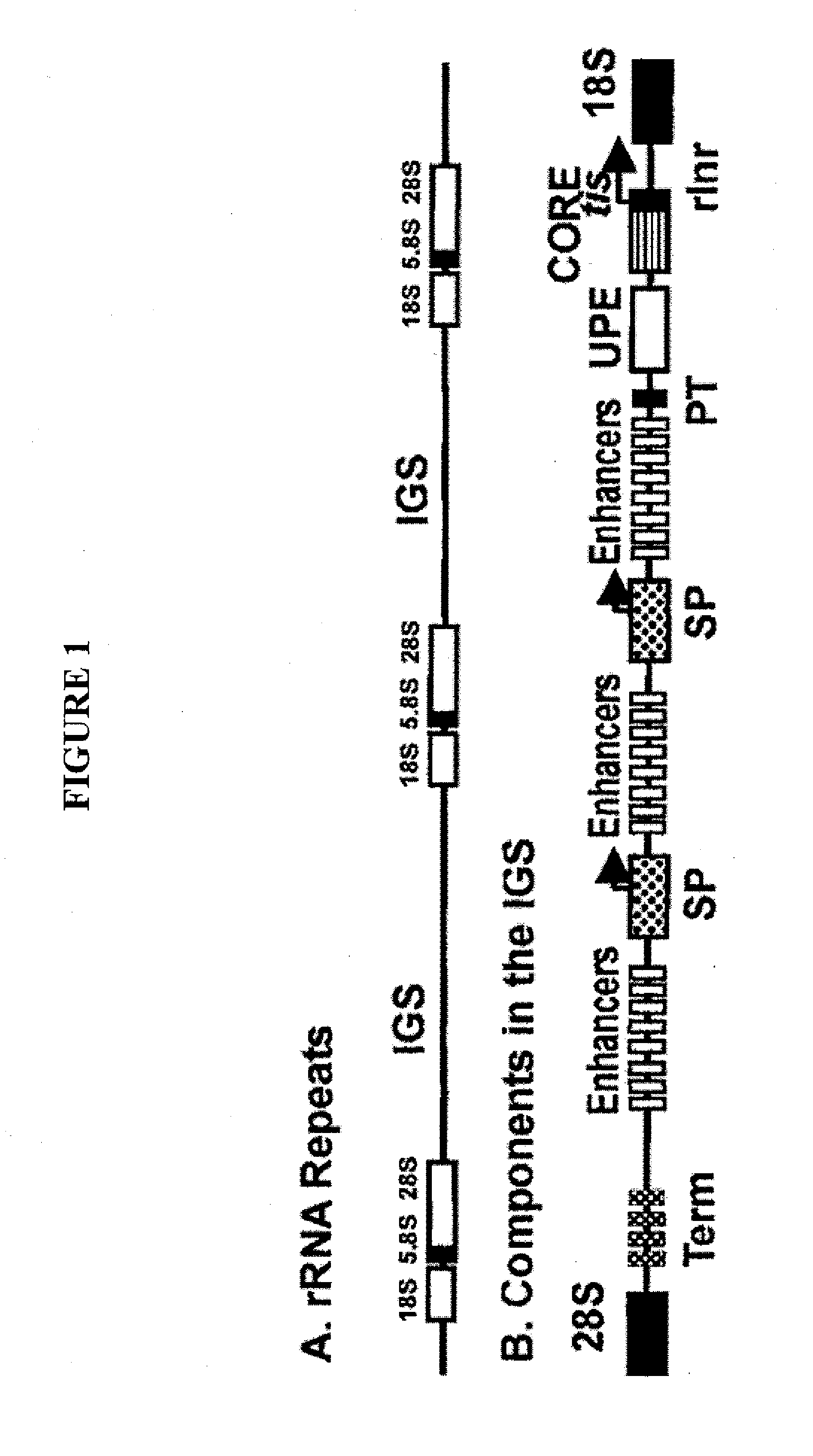

Nuclear based expression of genes for production of biofuels and process co-products in algae

Various embodiments provide, for example, vectors, expression cassettes, and cells useful for transgenic expression of nucleic acid sequences. In various embodiments, vectors can contain nuclear-based sequences of unicellular photosynthetic bioprocess organisms for the production of food- and feed-stuffs, oils, biofuels, starches, raw materials, pharmaceuticals or fine chemicals.

Owner:KUEHNLE AGROSYST

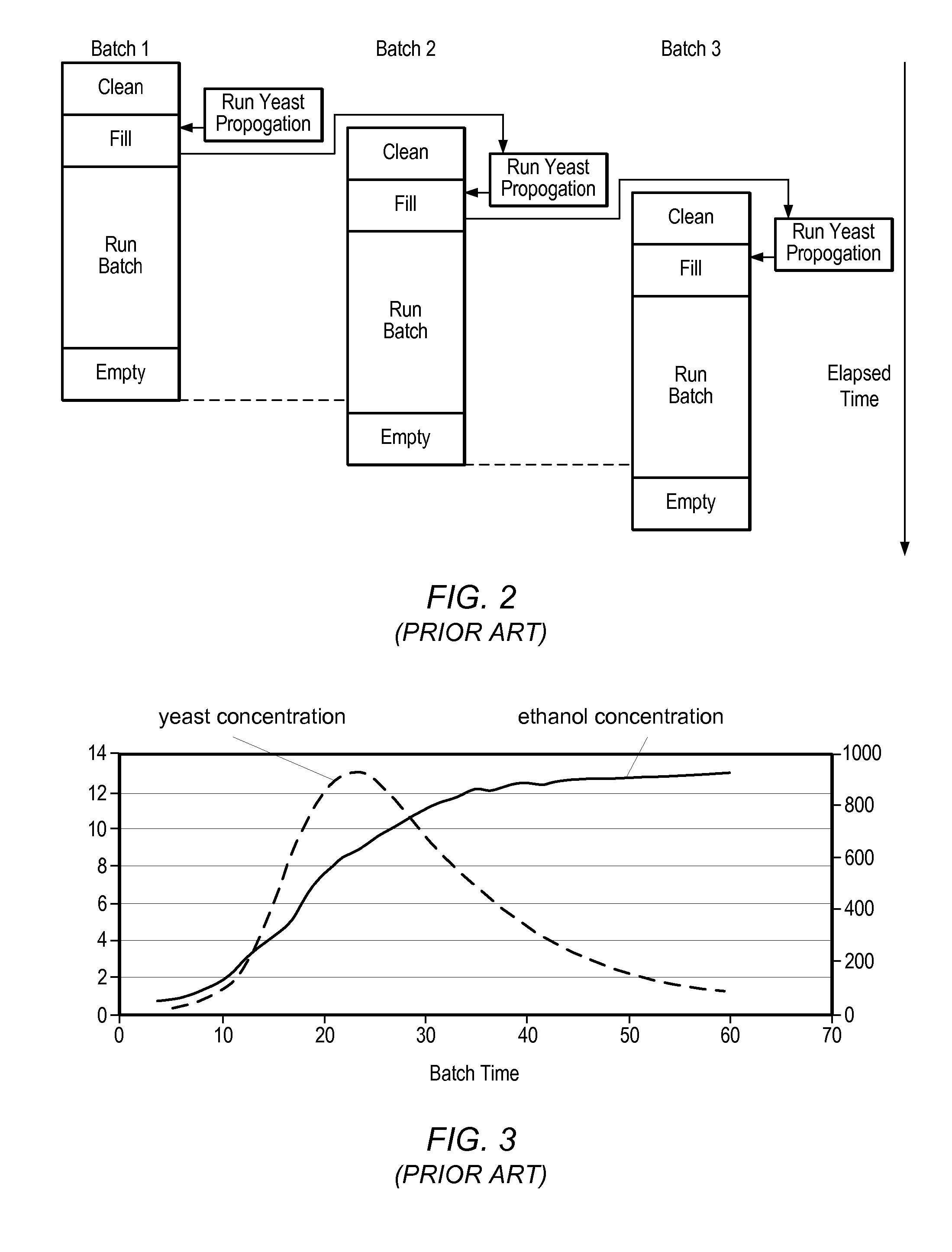

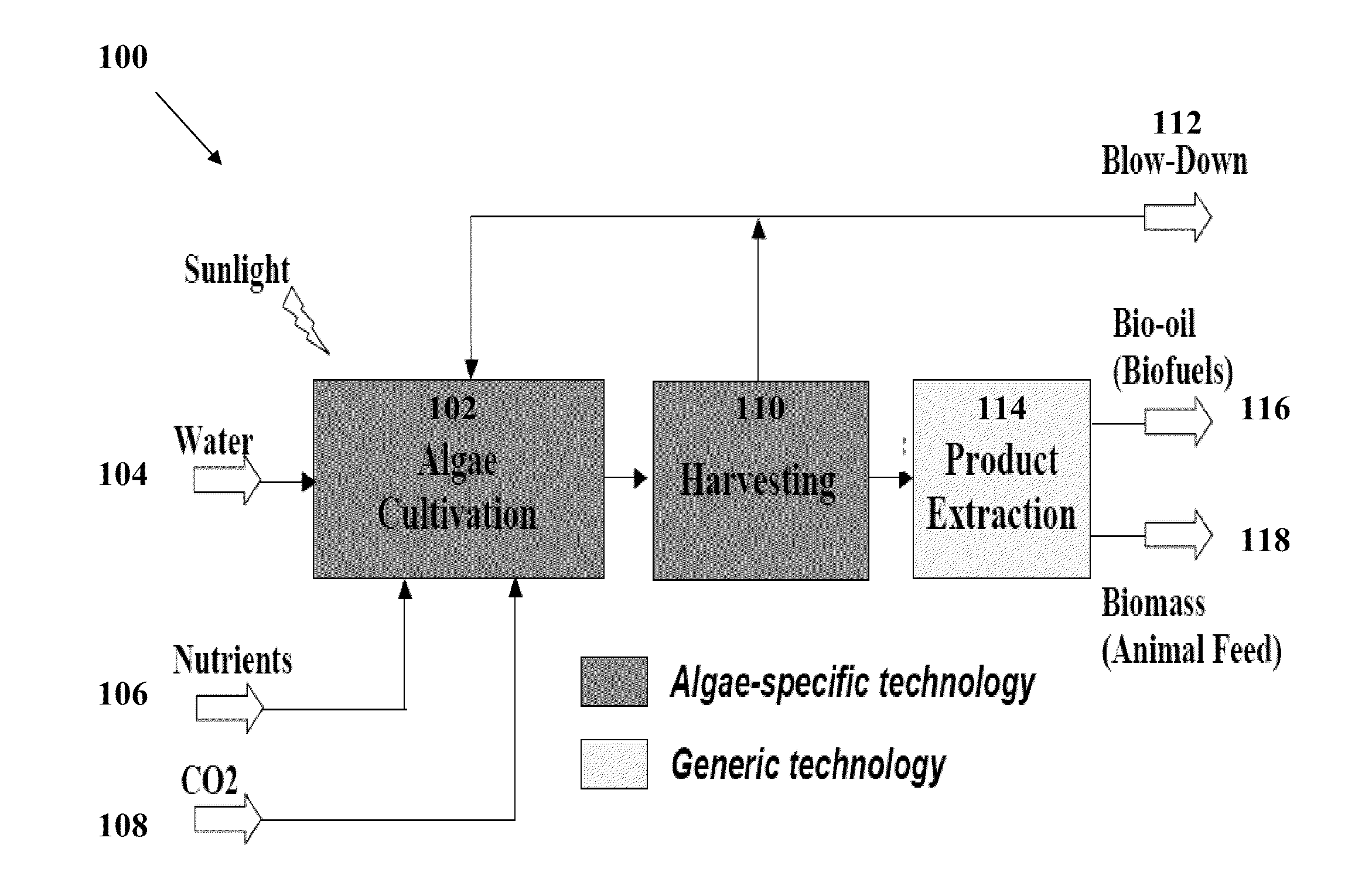

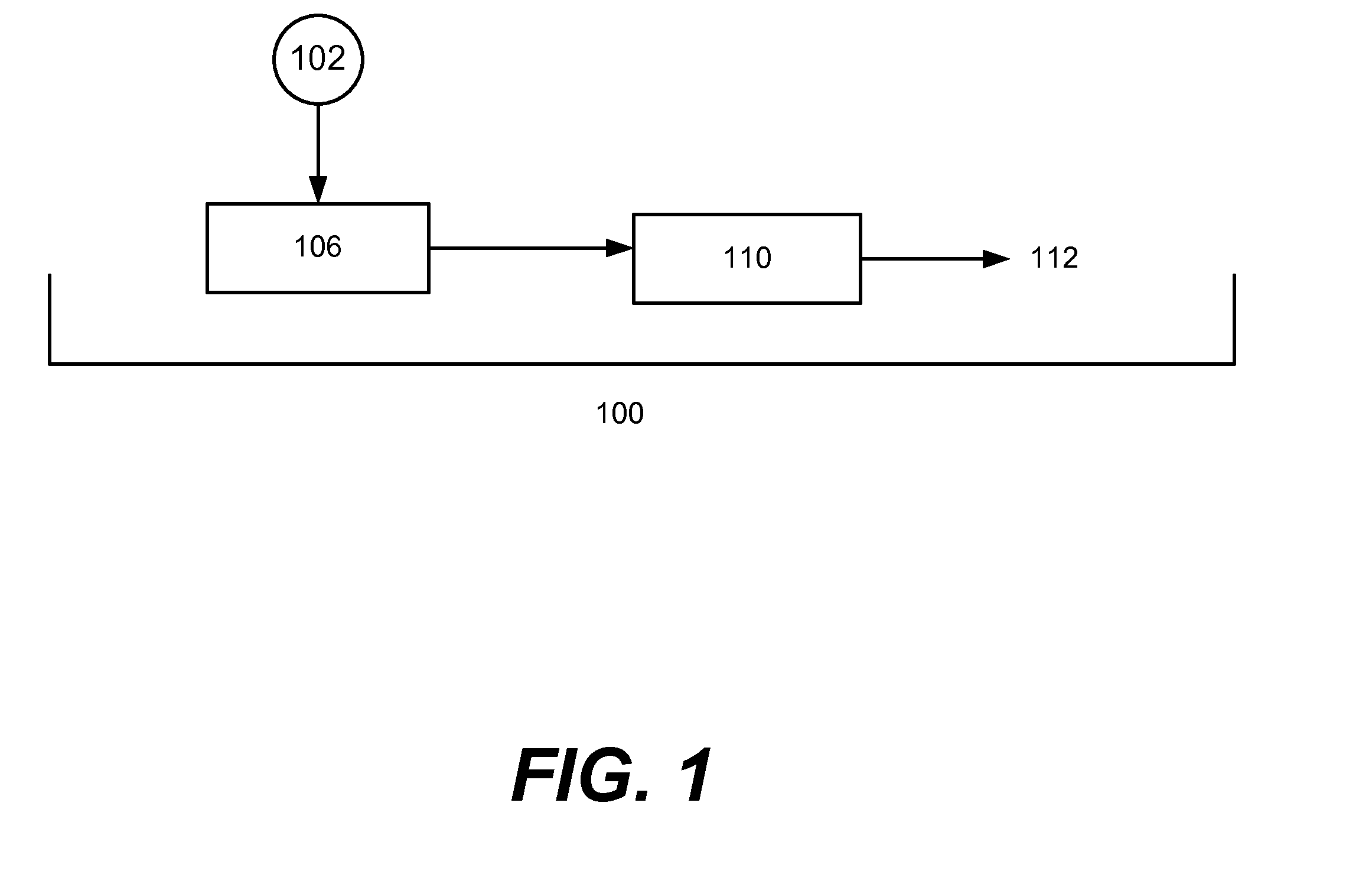

Model predictive control of fermentation in biofuel production

ActiveUS20080109100A1Easy to controlImprovement in biofuel yieldBiological substance pretreatmentsTemperatue controlHorizonBiofuel

System and method for managing batch fermentation in biofuel production. An optimizer executes a nonlinear multivariate predictive model of a batch fermentation process in accordance with an end of batch objective specifying a target end of batch biofuel concentration to determine an optimal batch trajectory over a temporal control horizon specifying a biofuel and / or sugar concentration trajectory over the batch fermentation process. A nonlinear control model for the batch fermentation process that includes the temporal control horizon driven by biofuel concentration during the batch fermentation process is executed per the determined optimal batch trajectory using received process information as input, thereby generating model output including target values for manipulated variables for the batch fermentation process, including batch fermentation temperature. The batch fermentation process is controlled per the target values to produce biofuel in accordance with the determined optimal batch trajectory, to substantially optimize the end of batch biofuel yield.

Owner:ROCKWELL AUTOMATION TECH

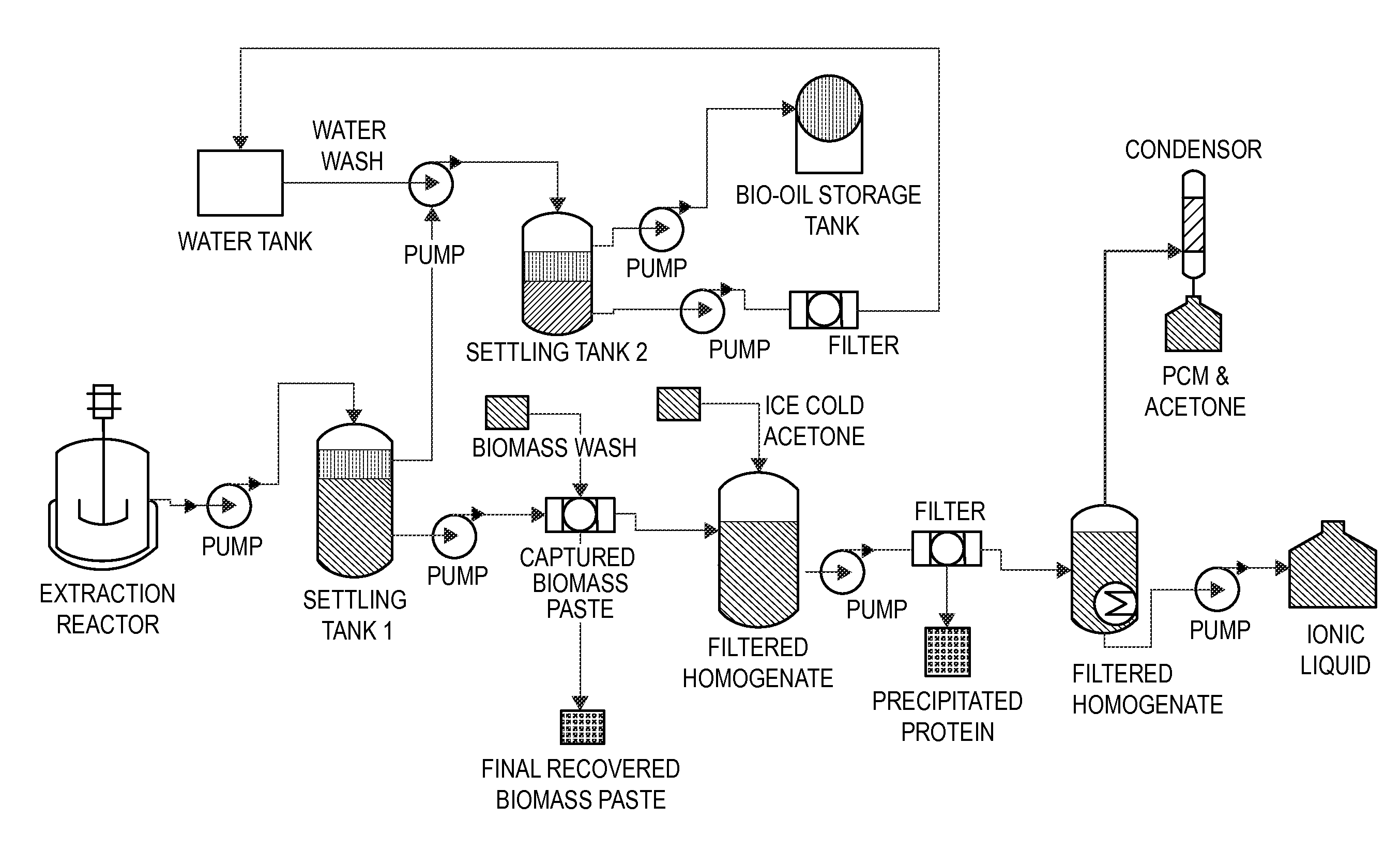

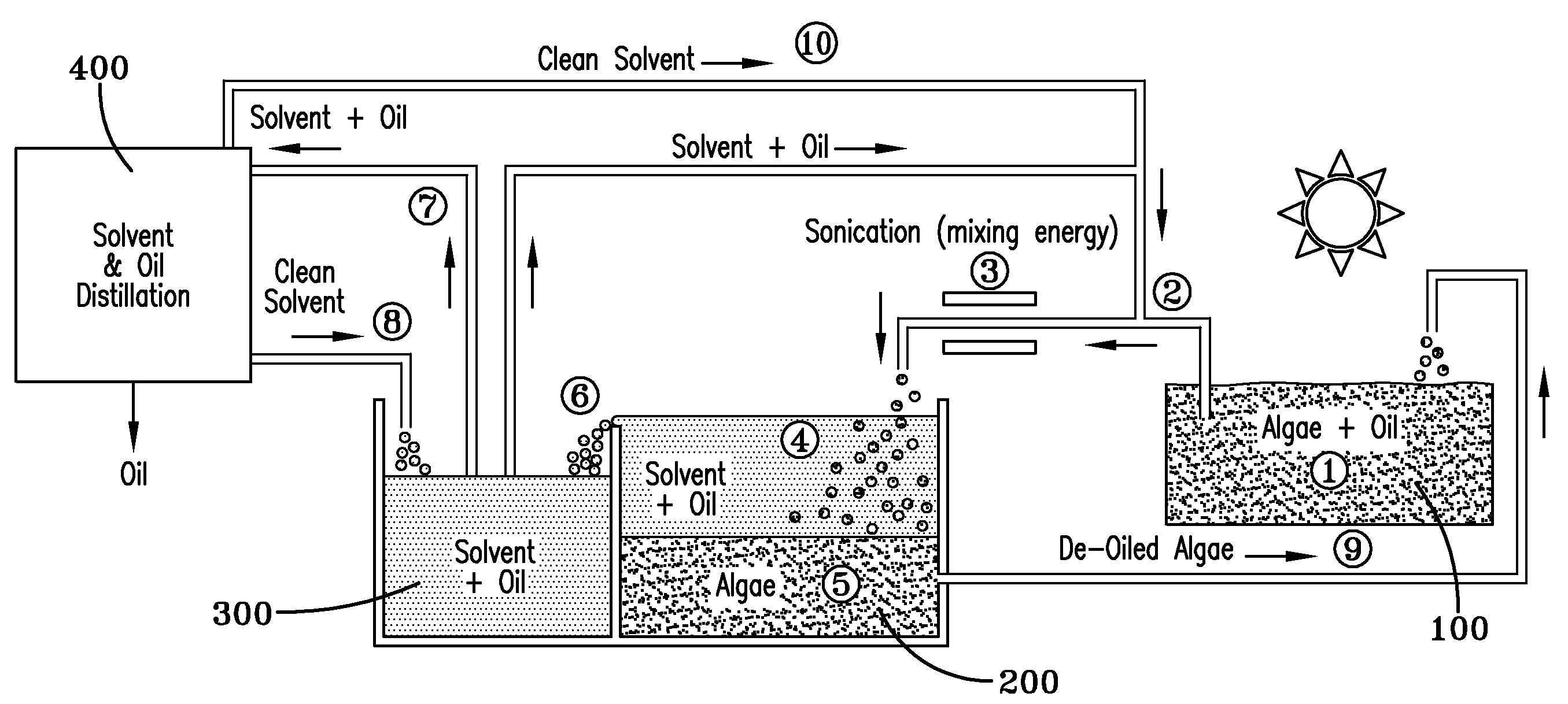

Novel Process for Separating Lipids From a Biomass

InactiveUS20100261918A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelAlgae

A novel low cost separation process for separating lipid oil from an algal biomass for biofuel production is described herein. The process of the present invention comprises of two steps: (i) breaking the algae cells and (ii) separation of the lipid oils from the broken cells. The separated lipids are extracted by conventional techniques followed by conversion to a biofuel.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

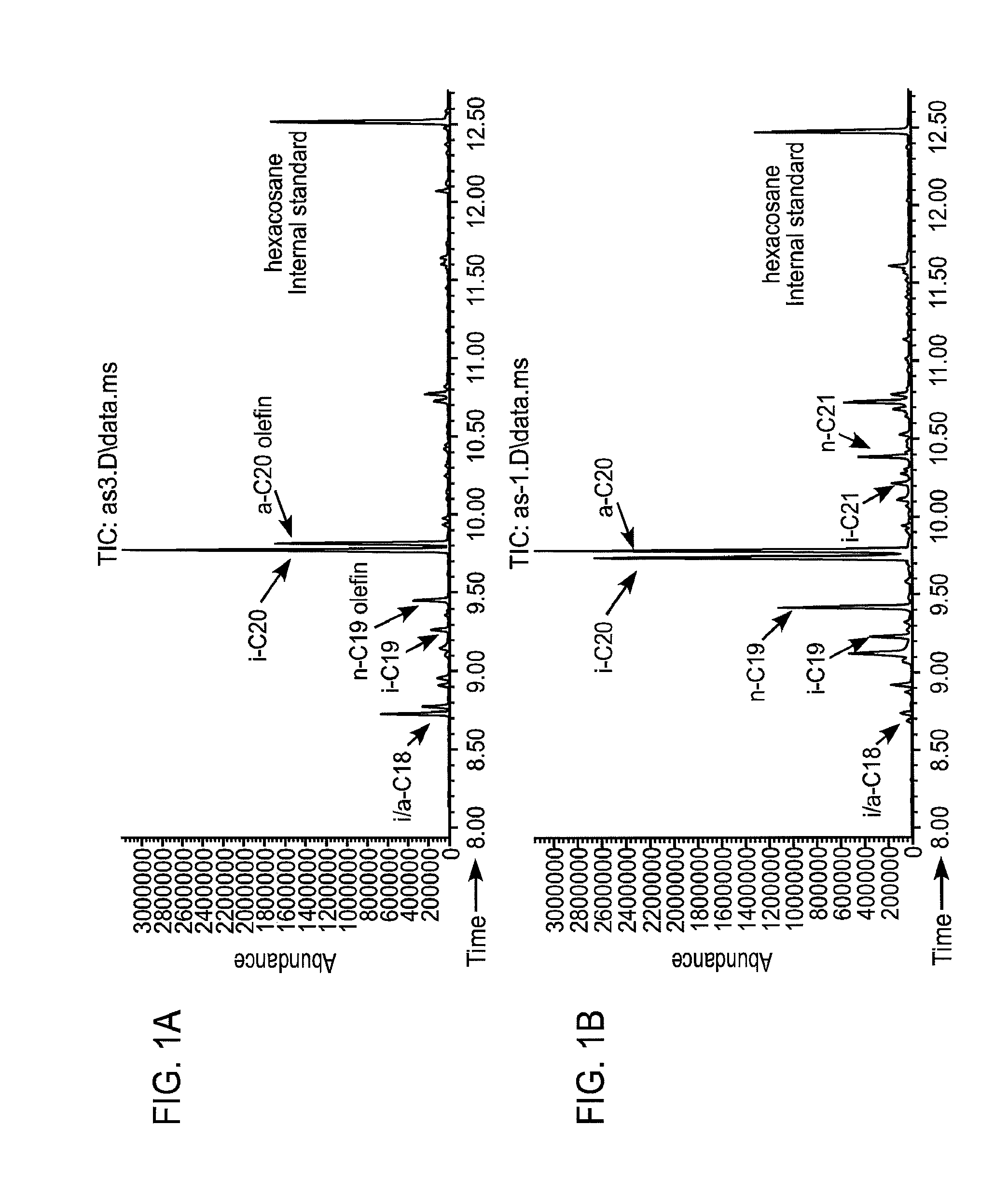

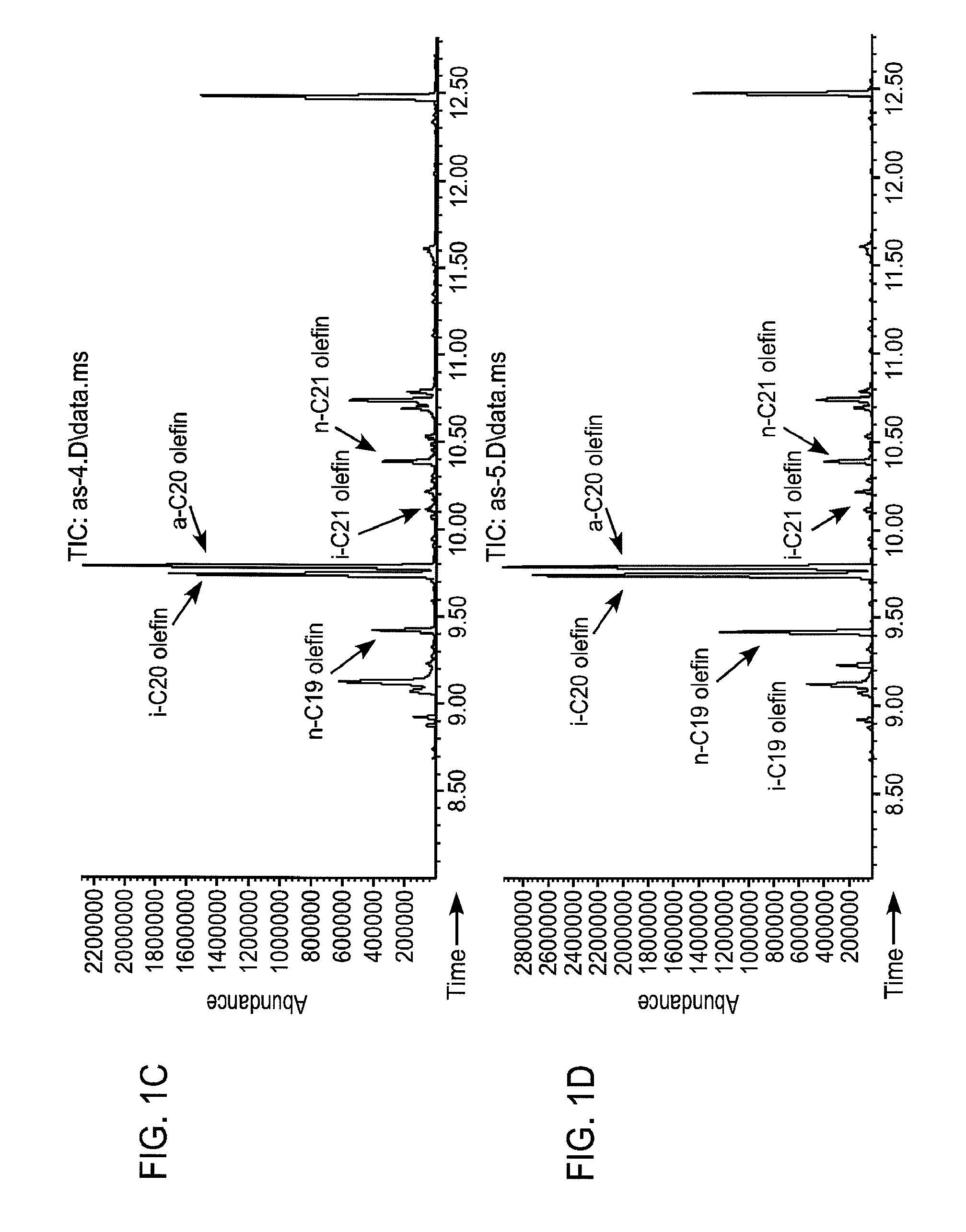

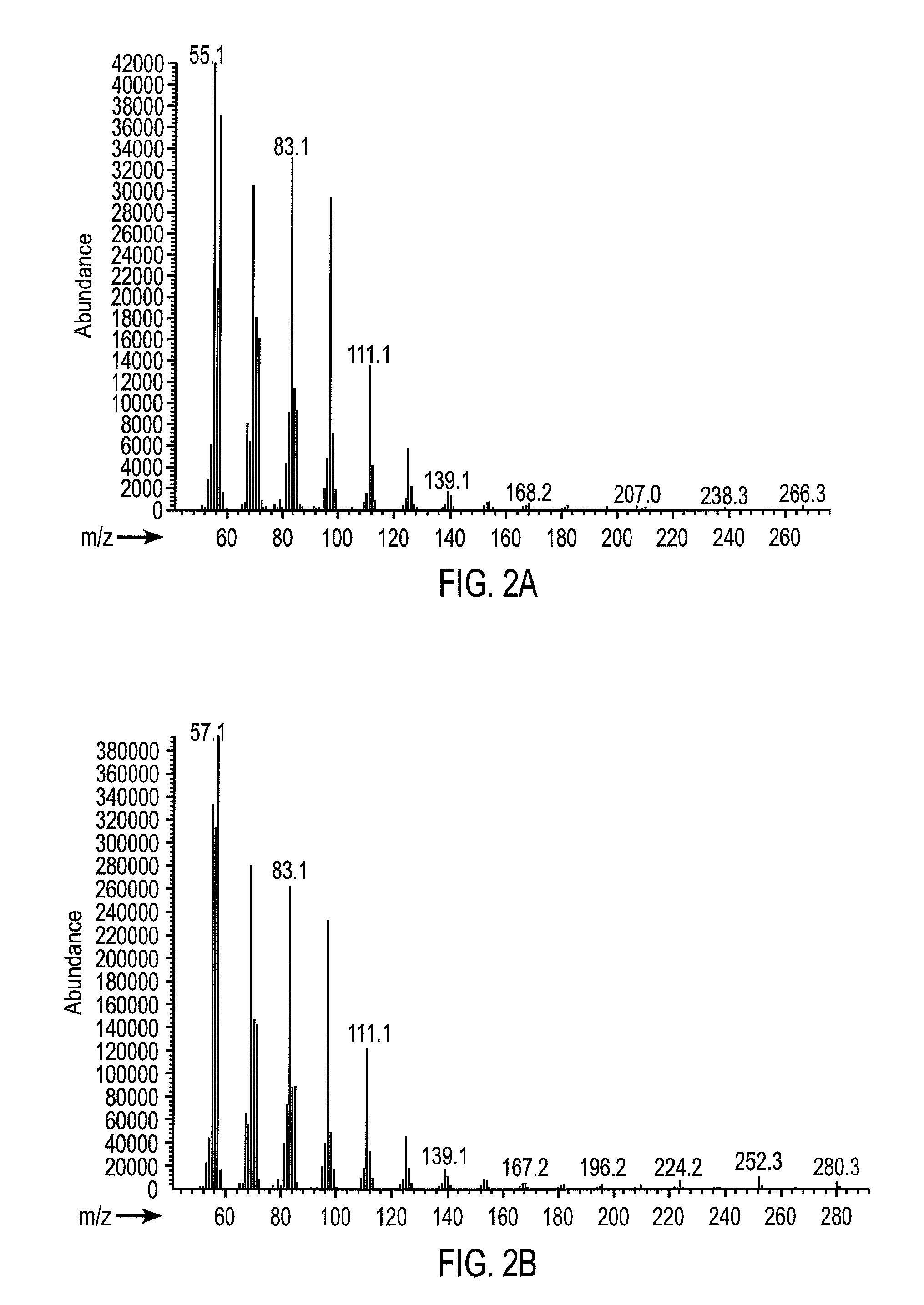

Methods and compositions for producing olefins

Owner:LS9 INC +1

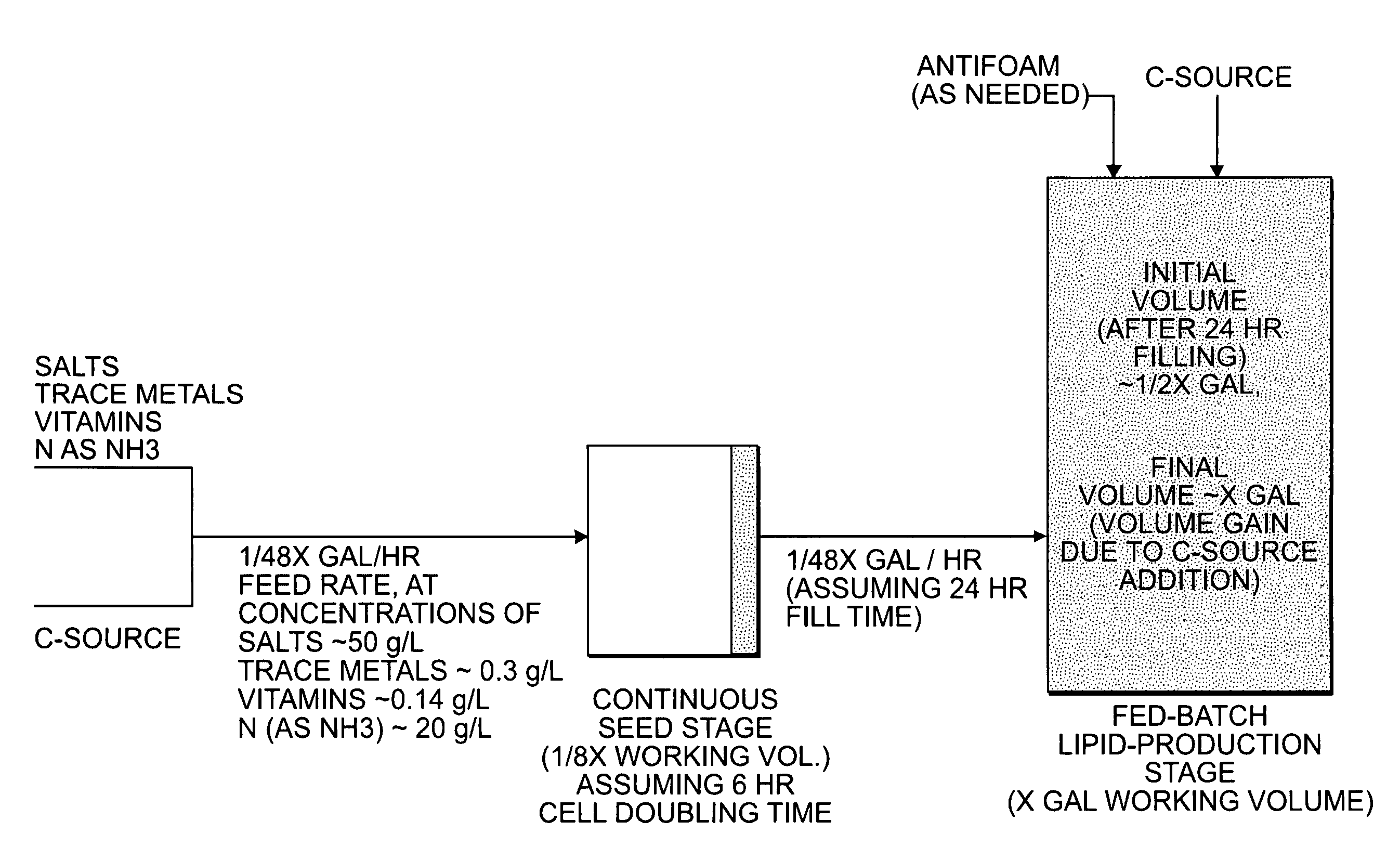

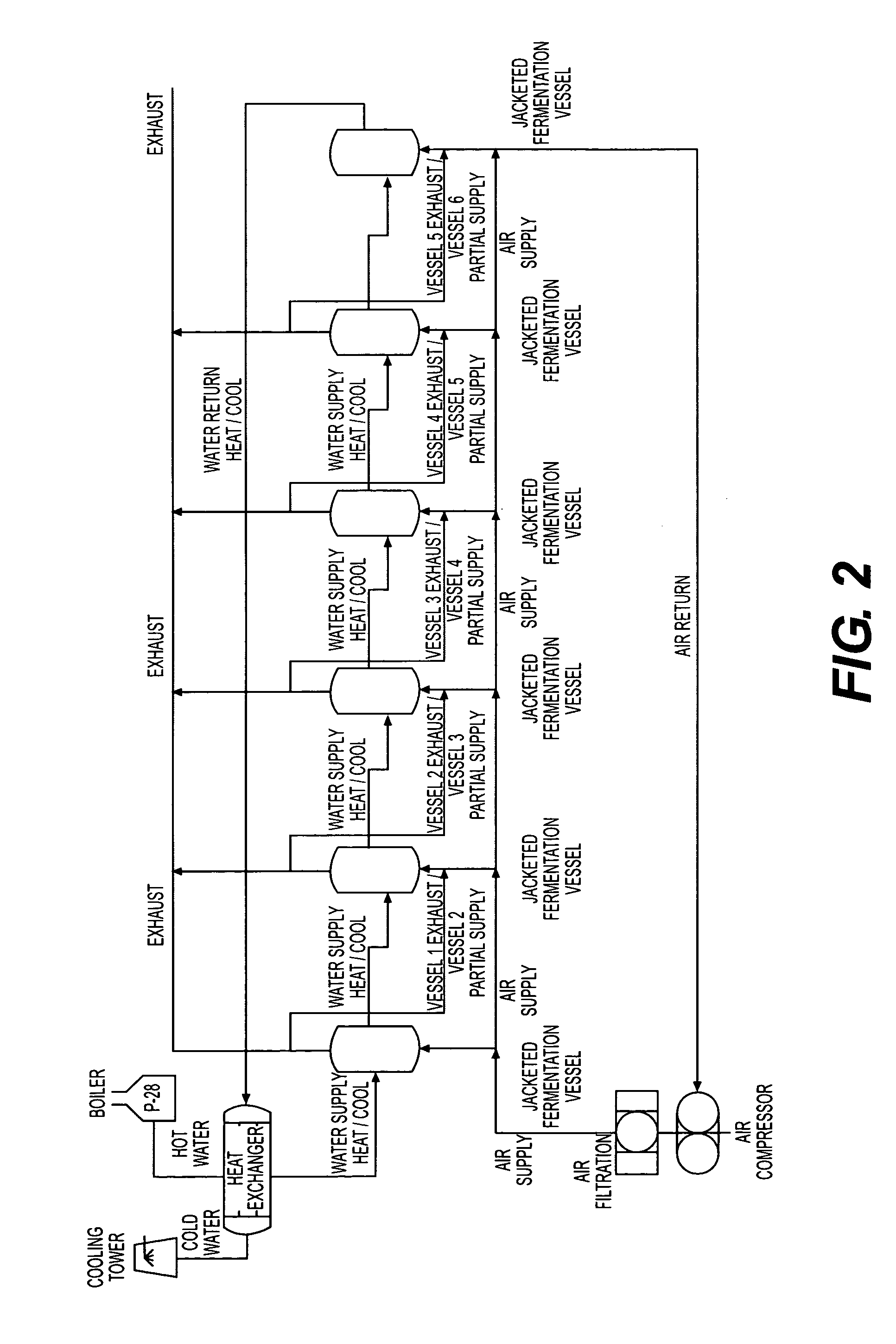

Optimization of biofuel production

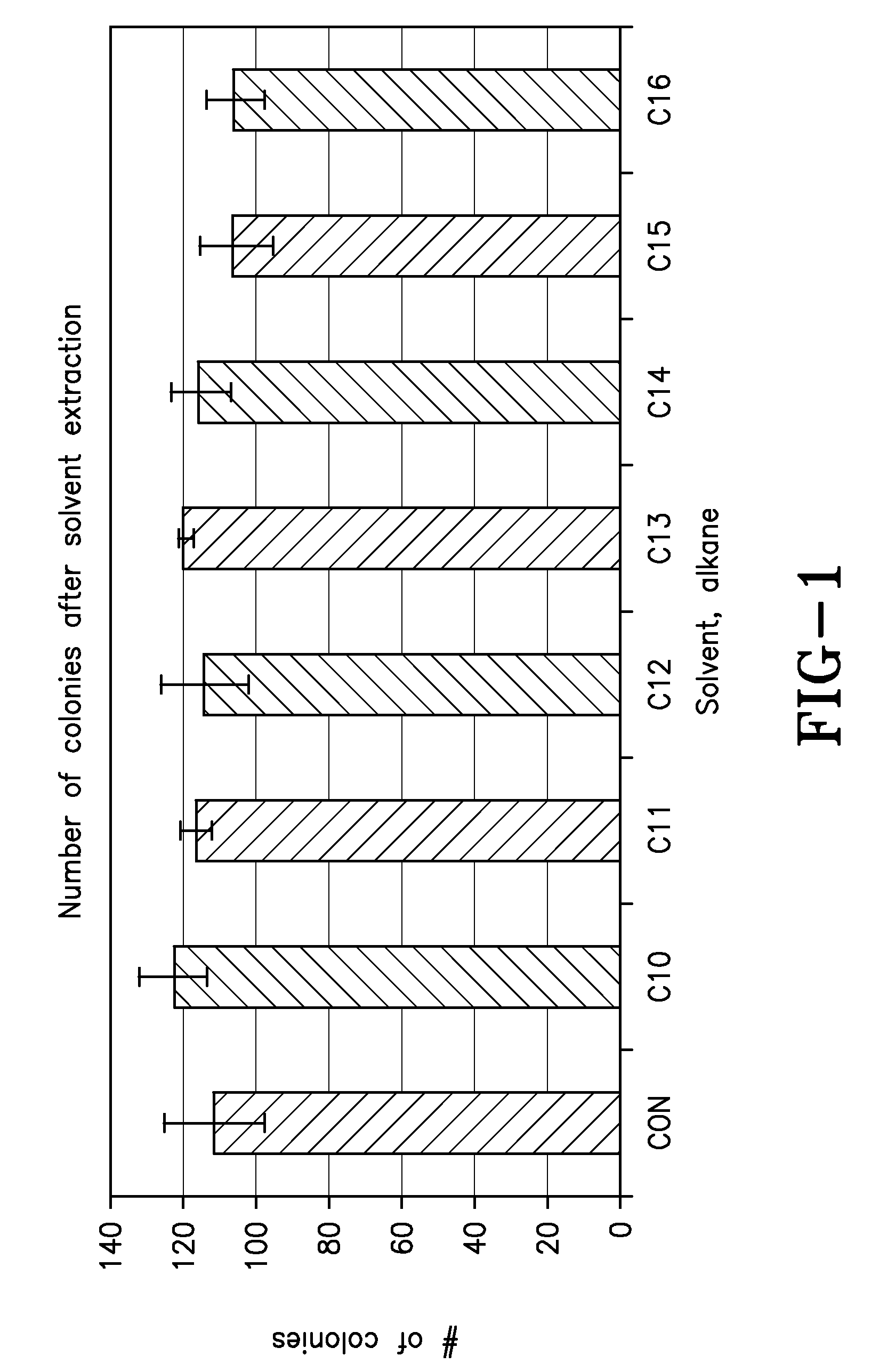

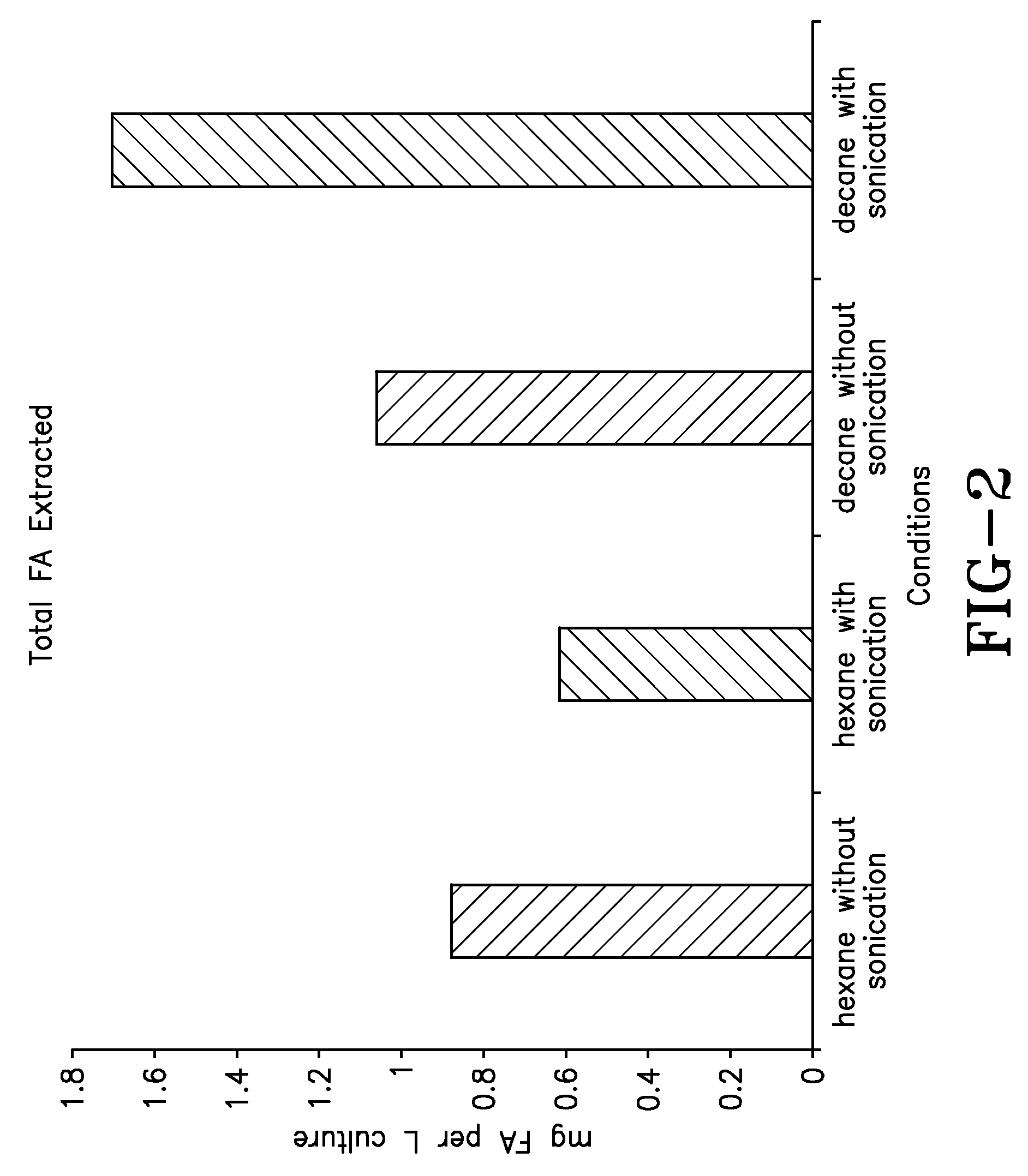

InactiveUS20090181438A1Enhance lipid productionEnhance oil extractionBioreactor/fermenter combinationsBiological substance pretreatmentsNon destructiveBiofuel

Embodiments of the present invention includes an apparatuses, compositions, and methods utilizing mechanical and chemical engineering strategies to achieve even greater efficiencies in biofuels production from oleaginous organisms. These increased efficiencies may be achieved through the application of targeted and well-designed chemical and mechanical engineering methods disclosed herein to achieve a non-destructive extraction process (NDEP).

Owner:THE OHIO STATE UNIV RES FOUND

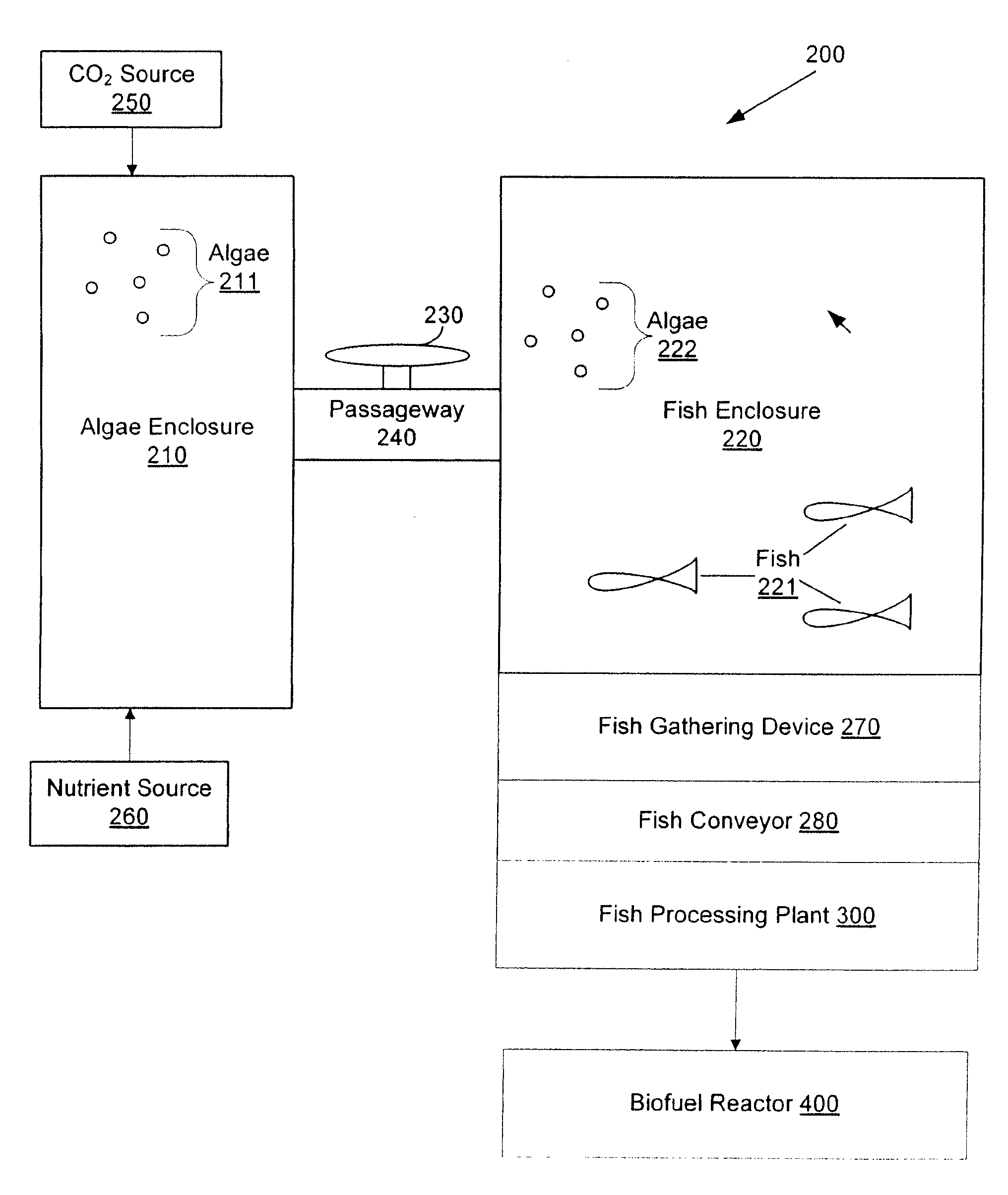

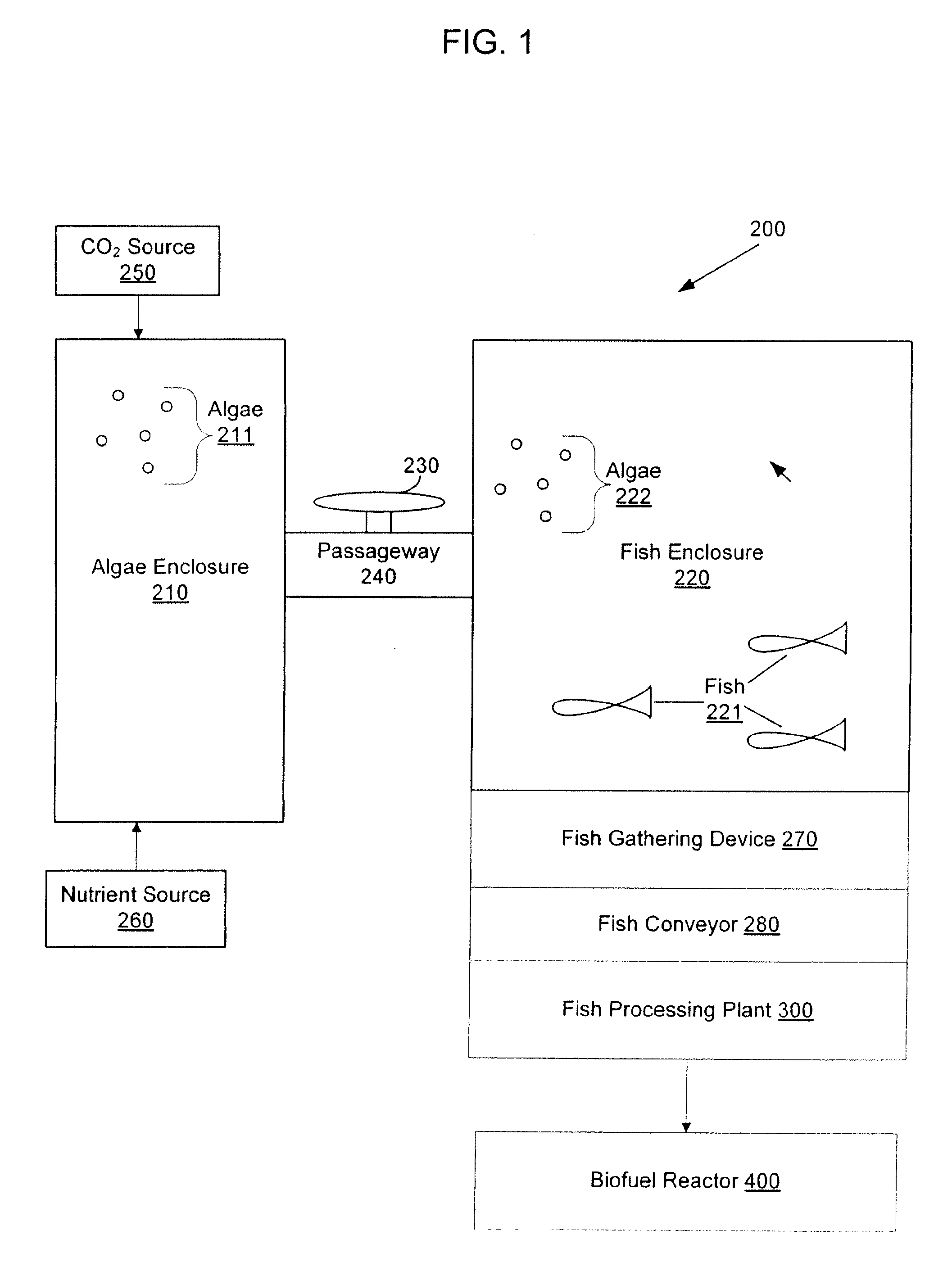

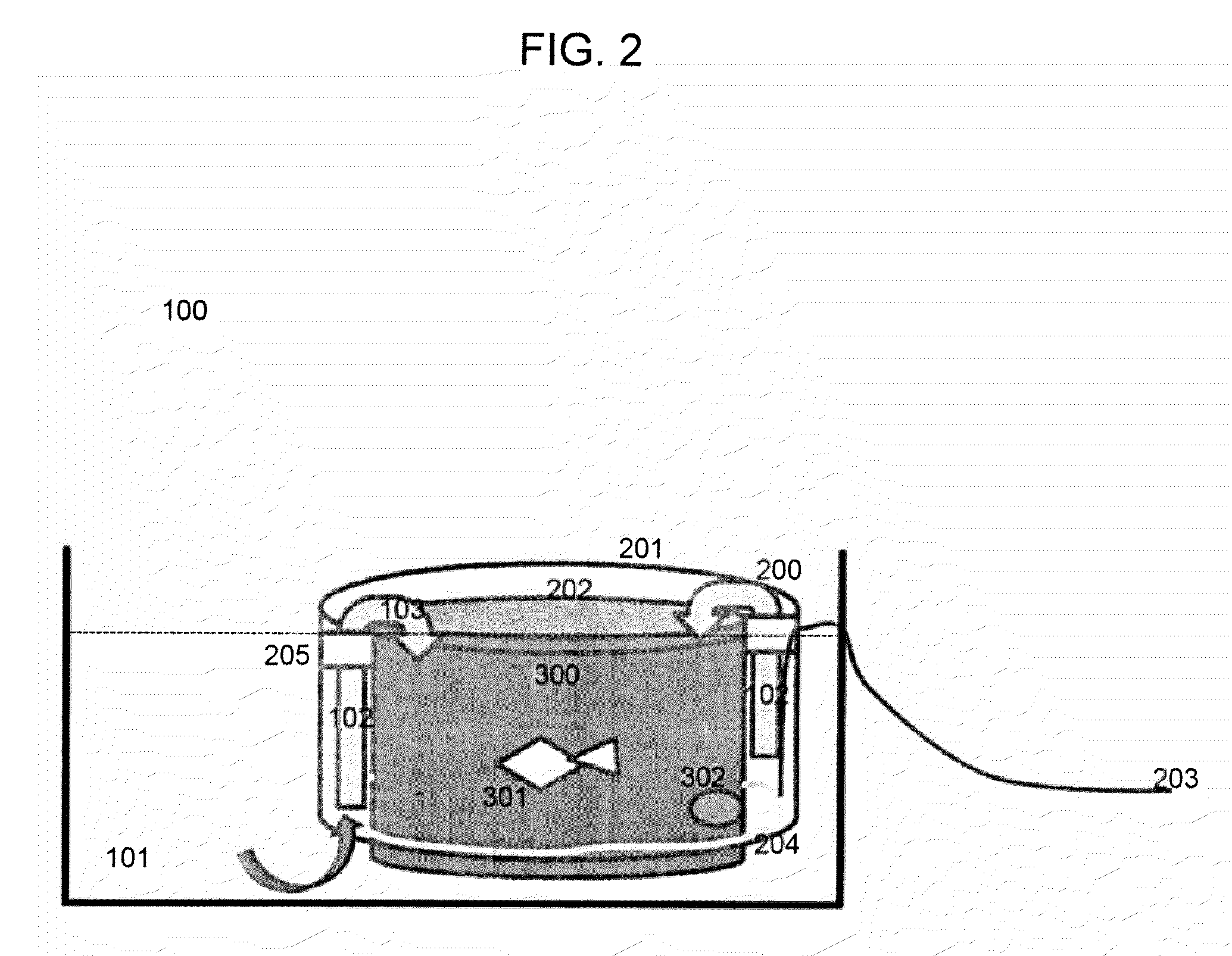

Systems and methods for producing biofuels from algae

The invention provides systems and methods for producing biofuel from algae that use cultured fish to harvest algae from an algal culture. The methods further comprise gathering the fish, extracting lipids from the fish, and processing the lipids to form biofuel. The multi-trophic systems of the invention comprises at least one enclosure that contains the algae and the fishes, and means for controllably feeding the algae to the fishes. The lipid compositions extracted from the fishes are also encompassed.

Owner:LIVEFUELS

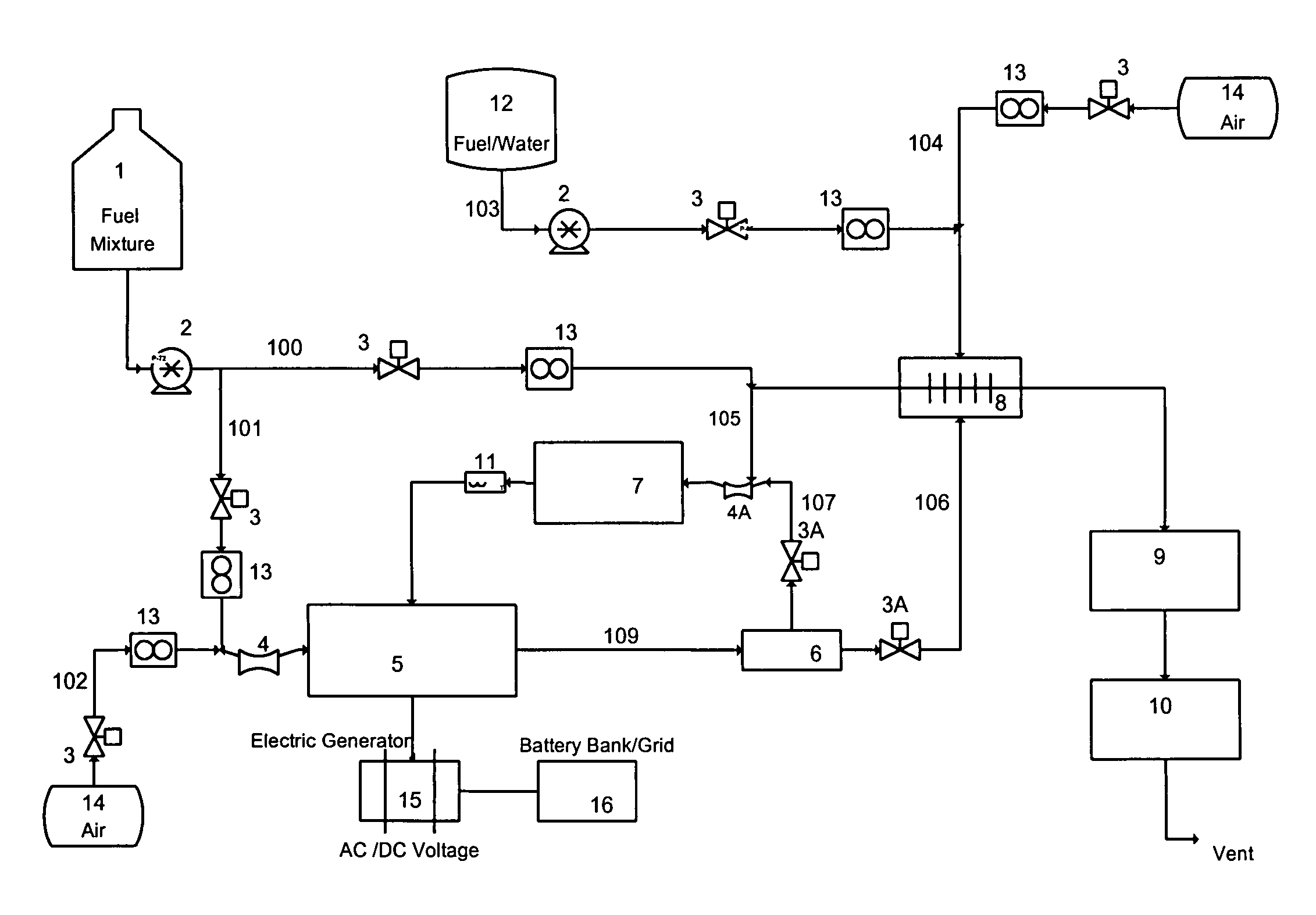

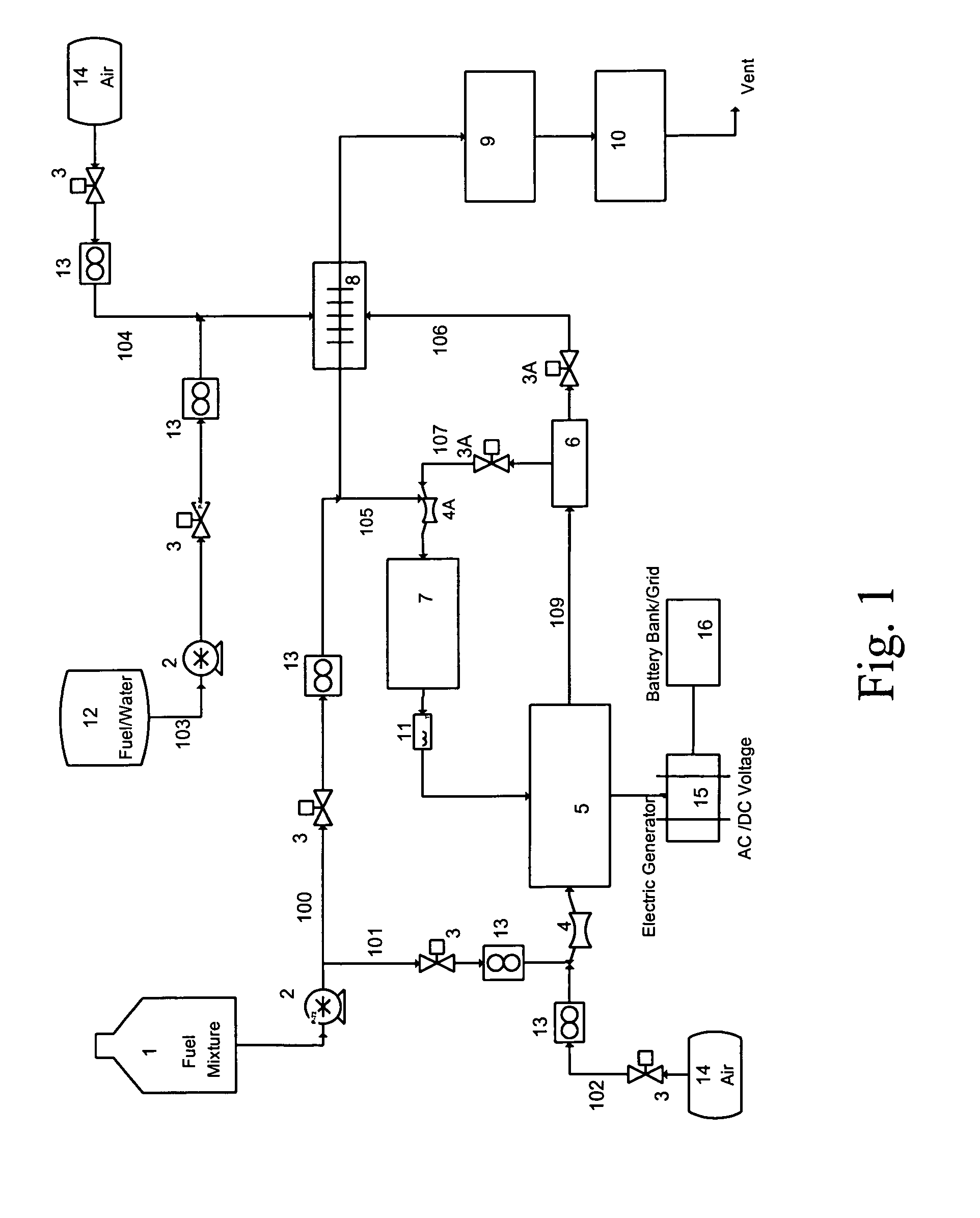

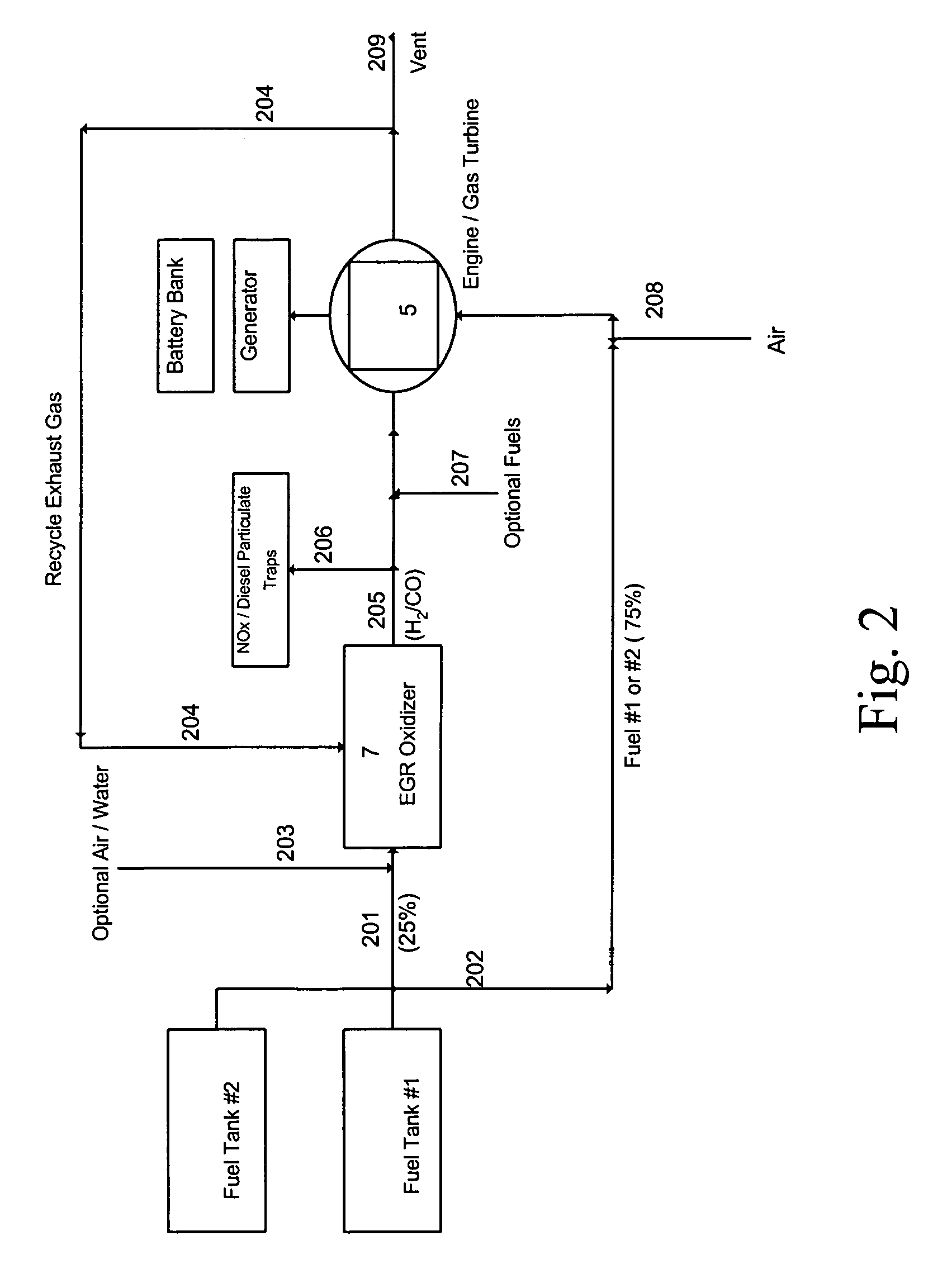

Catalytic EGR oxidizer for IC engines and gas turbines

InactiveUS8061120B2Increased durabilityProlong lifeCombination devicesInternal combustion piston enginesElectricityPartial oxidation

By using catalytic partial oxidation or autothermal reforming process, a catalytic oxidizer installed in the engine's Exhaust Gas Recycle (EGR) line can be used to produce from fossil fuels or bio-fuels a reformate gas containing H2 and CO for an IC engine or a gas turbine. Thus, a system consisting of an EGR Oxidizer and an IC engine / gas turbine can be used by itself as a driving device, or can be combined with an electric generator and a battery bank to produce, store and transmit electricity to be used in stationary or mobile power generation, transportation and utility etc.The Oxidizer can also be used to provide reducing gases to regenerate the NOx or diesel particulate traps, so that the traps can continuously be used for reducing emissions from IC engine, diesel truck, gas turbine, power plant etc.

Owner:HWANG HERNG SHINN

Method for producing bio-fuel that integrates heat from carbon-carbon bond-forming reactions to drive biomass gasification reactions

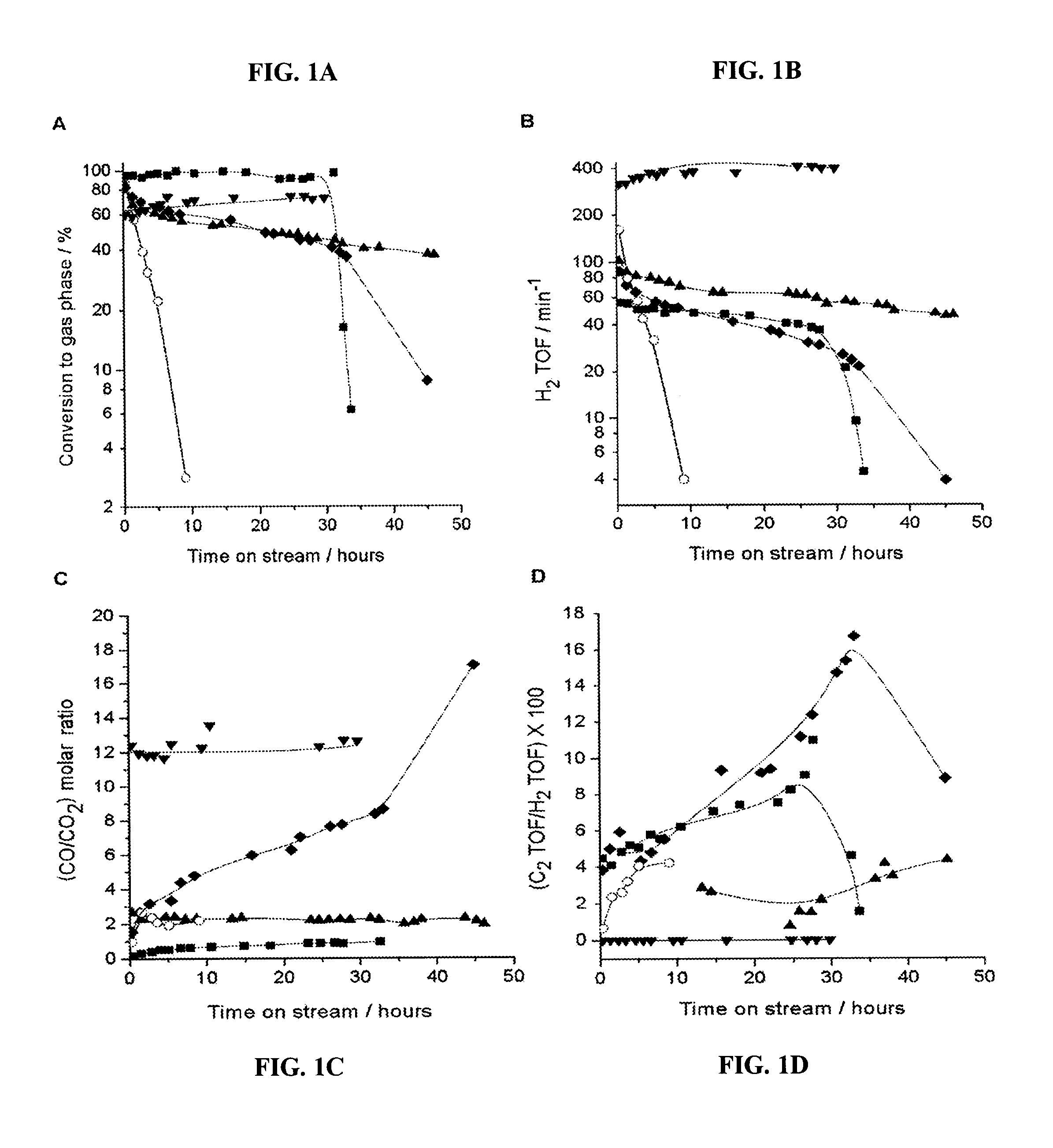

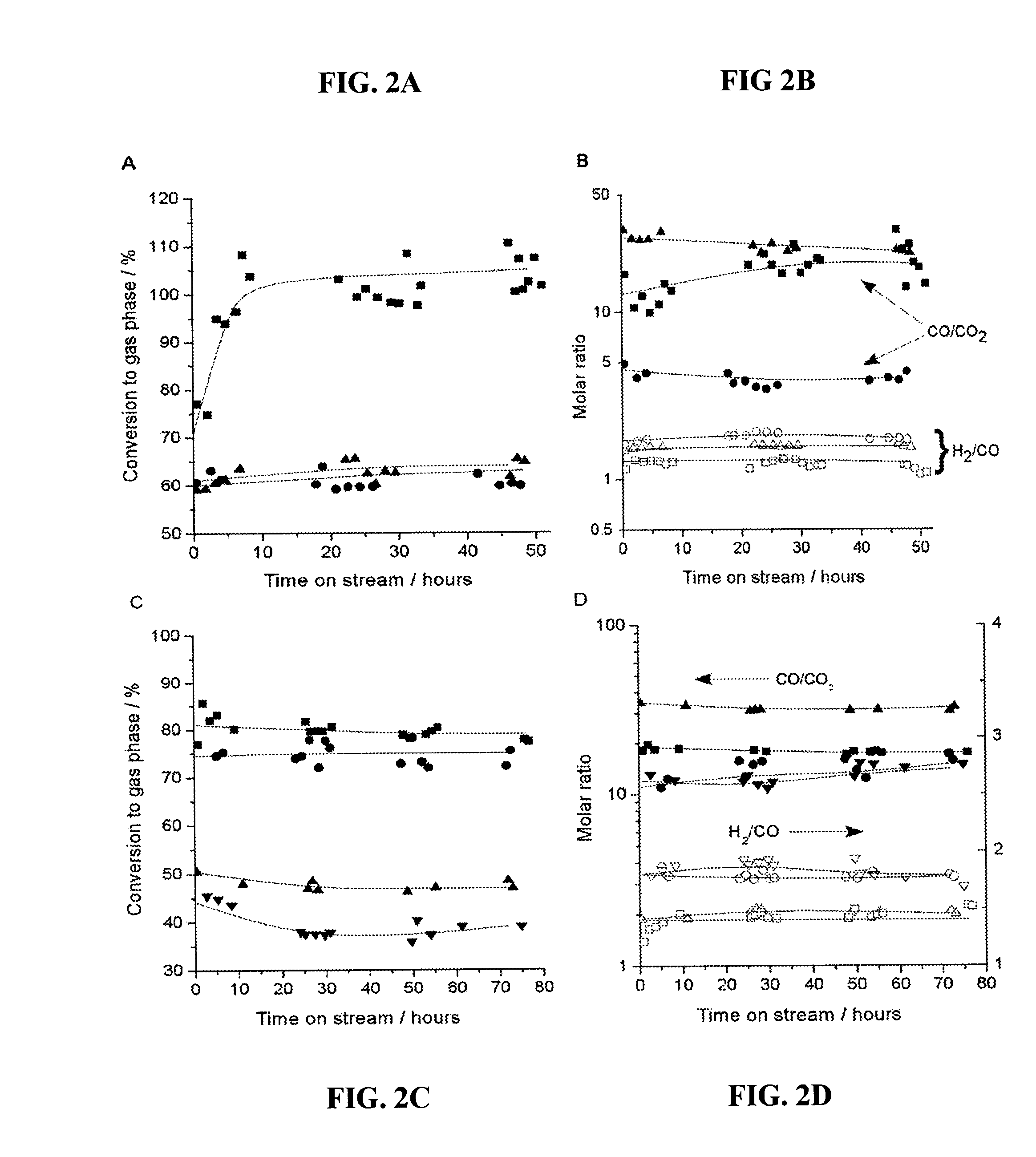

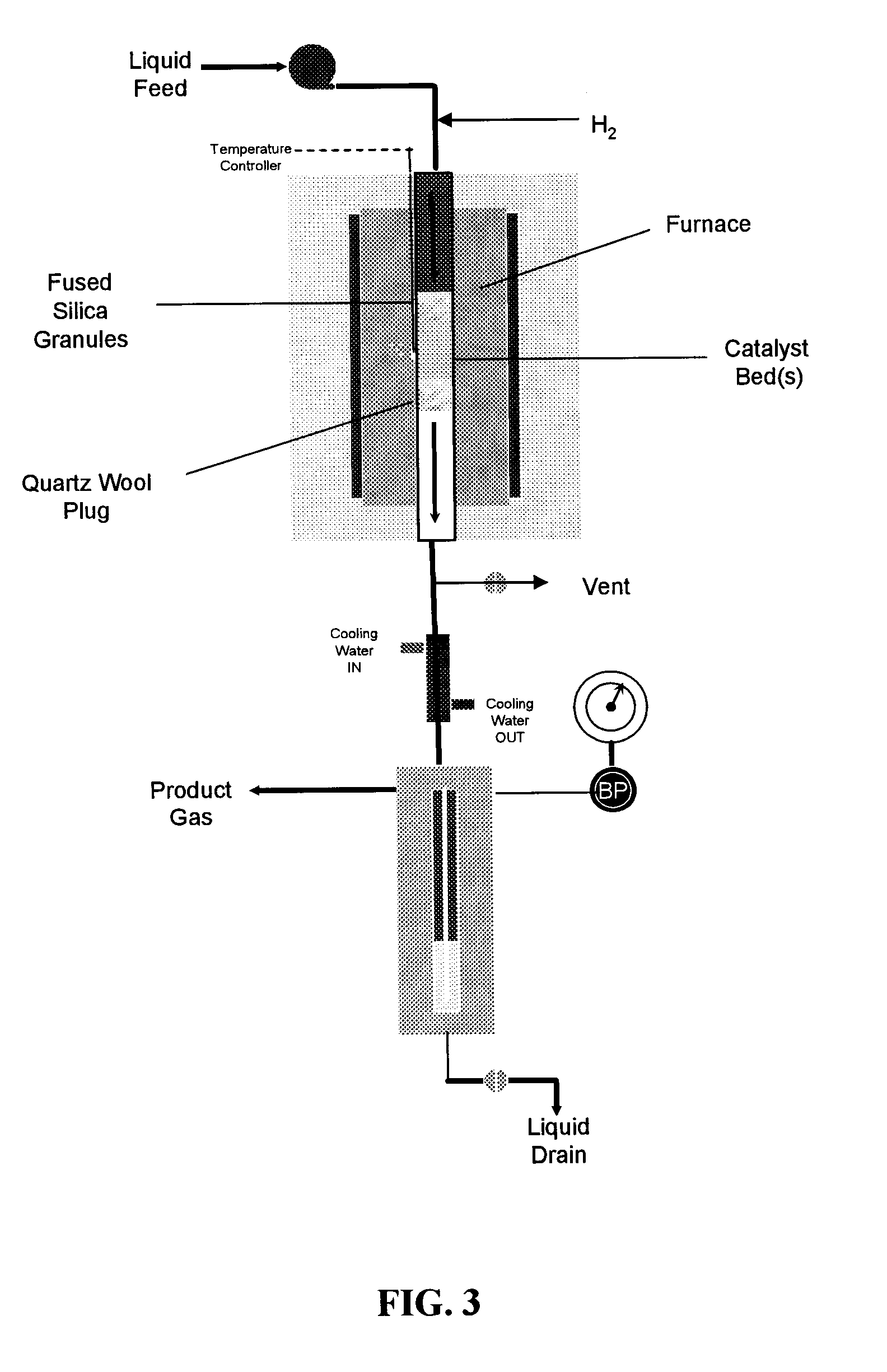

ActiveUS20070225383A1Improve thermal efficiencyImprove economyCatalytic crackingBiofuelsSyngasBiodiesel

A low-temperature catalytic process for converting biomass (preferably glycerol recovered from the fabrication of bio-diesel) to synthesis gas (i.e., H2 / CO gas mixture) in an endothermic gasification reaction is described. The synthesis gas is used in exothermic carbon-carbon bond-forming reactions, such as Fischer-Tropsch, methanol, or dimethylether syntheses. The heat from the exothermic carbon-carbon bond-forming reaction is integrated with the endothermic gasification reaction, thus providing an energy-efficient route for producing fuels and chemicals from renewable biomass resources.

Owner:VIRENT +1

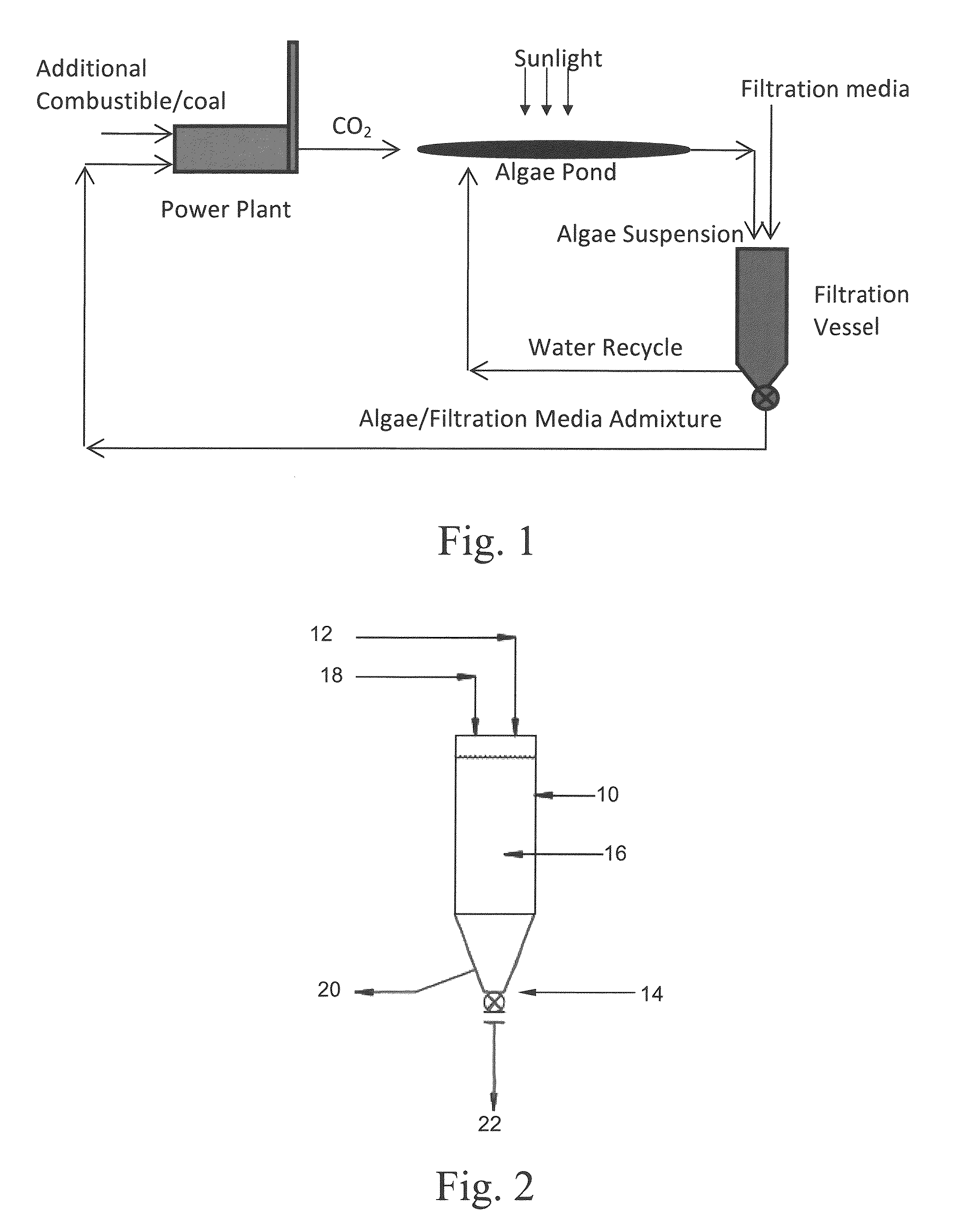

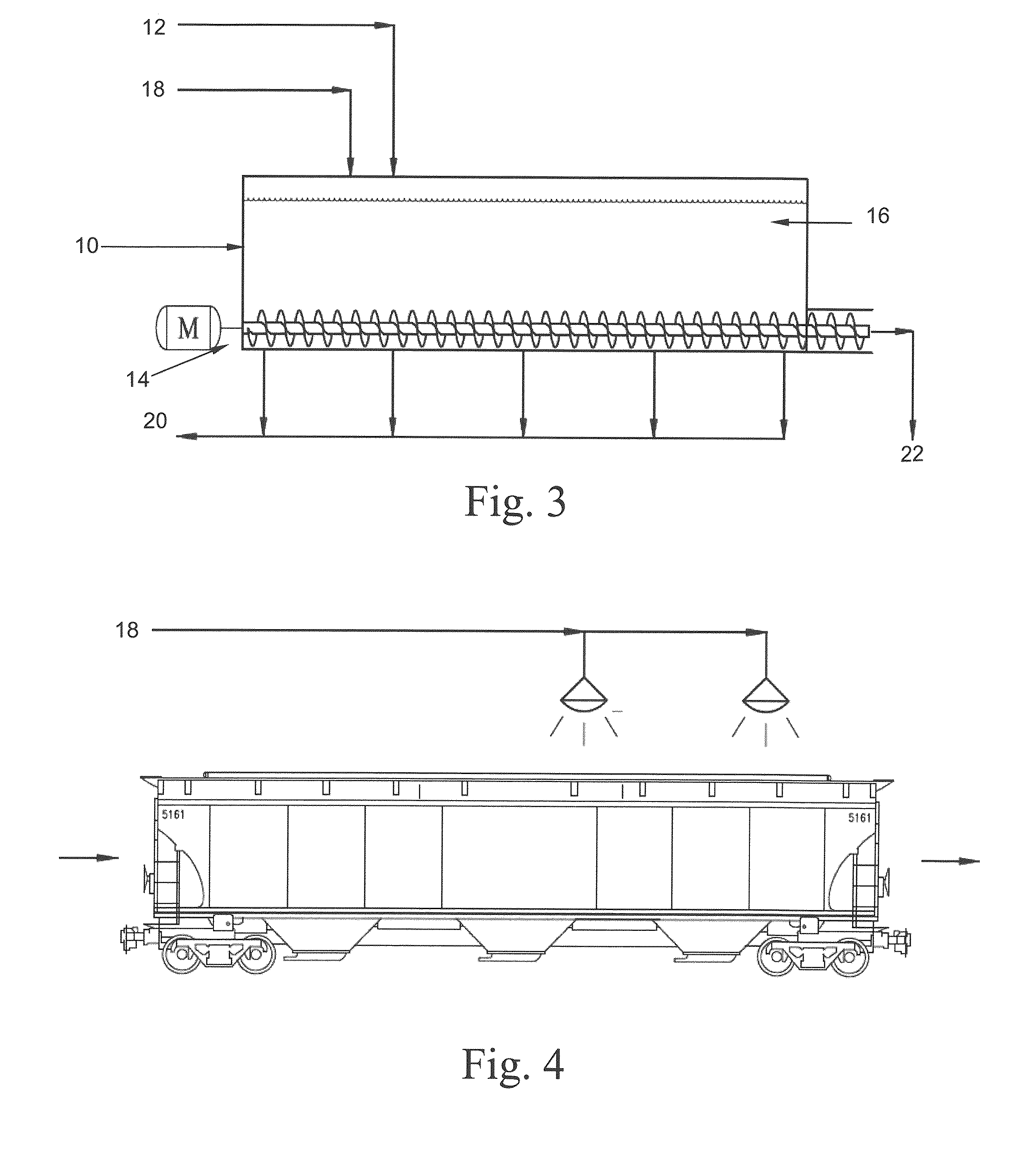

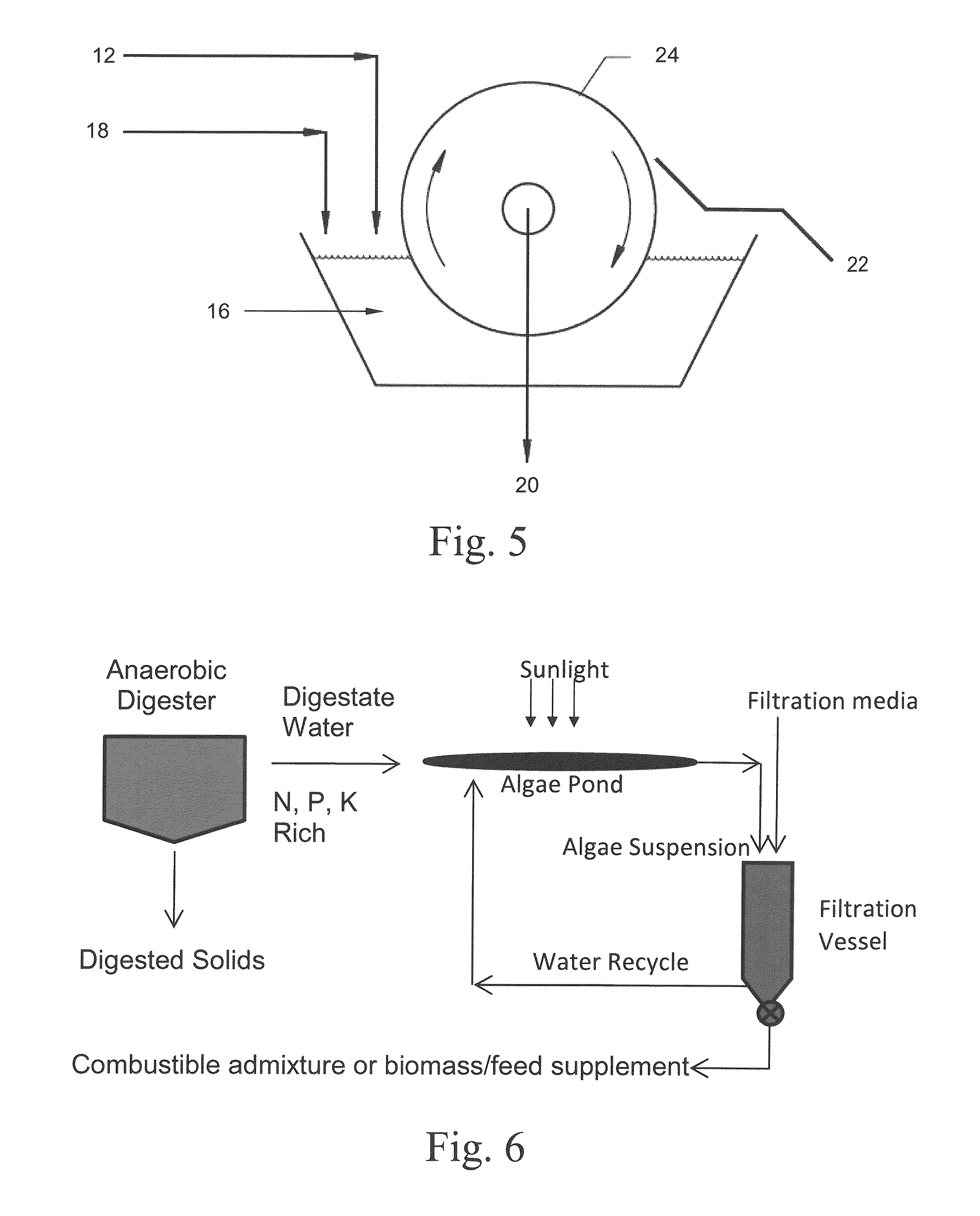

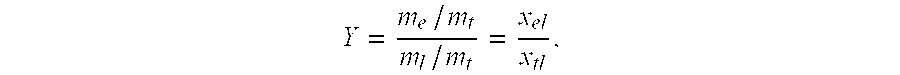

Methods of algae harvesting utilizing a filtering substance and uses therefor

InactiveUS20110143012A1High combustion valueHigh nutritional valueFatty oils/acids recovery from wasteLiquid separation auxillary apparatusFood supplementFiltration

Methods of harvesting algae, and using algae as a biofuel, livestock feed, or food supplement are provided. The methods comprise contacting liquid algae suspensions with a filtration media. Depending upon the filtration media, the resulting algae and filtration media admixture is then utilized as a biofuel, livestock feed, food supplements, or for the extraction of algae oil. Admixtures comprising a combustible filtration media, such as coal, are particularly preferred. The methods are suitable for use with any algae species. Compositions for use as a biofuel, livestock feed, or food supplement are also provided. These compositions comprise an admixture of algae and a filtration media.

Owner:RETTENMAIER ALBERT C

Enrichment of process feedstock

InactiveUS20110124034A1Fit for consumptionUnicellular algaeBiomass after-treatmentMicroorganismBiofuel

The subject invention relates to novel methods for treating microbial biomass and uses thereof. In particular, this invention provides methods for production of lipids using ionic liquid solutions, and subsequent uses of biomass components in food, biofuels, and as chemical precursors. Further, this invention provides methods for recovering the ionic liquids using an antisolvent, thus enables subsequent reuse of the ionic liquids In addition, this invention provides practical methods for determining the lipid content of a biomass and screening potential lipid-producing microbial classes. This invention also provides a method of chemical dewatering the lipid-rich algae cells by ionic liquids with its subsequent reuse.

Owner:KUEHNLE AGROSYST

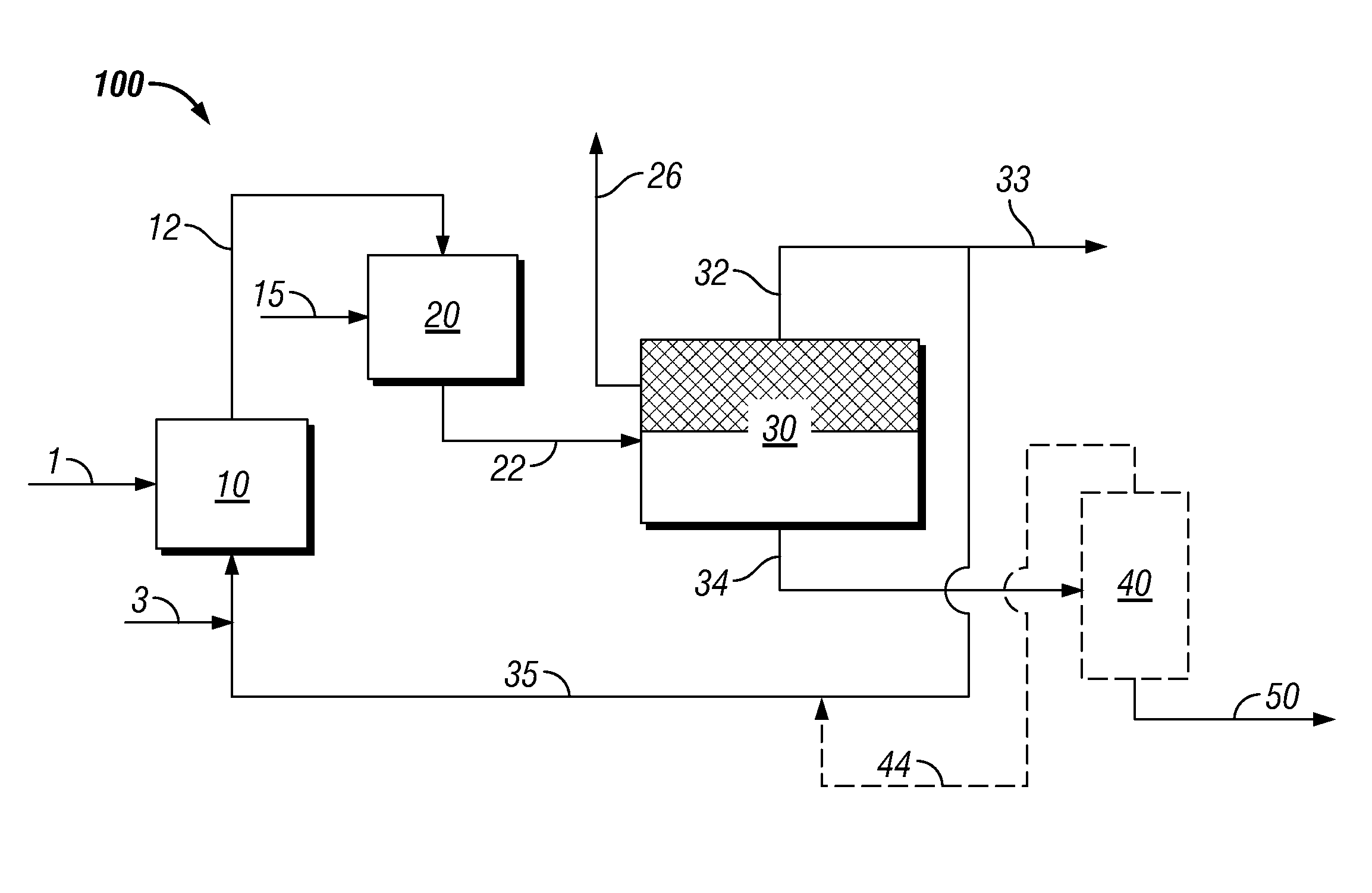

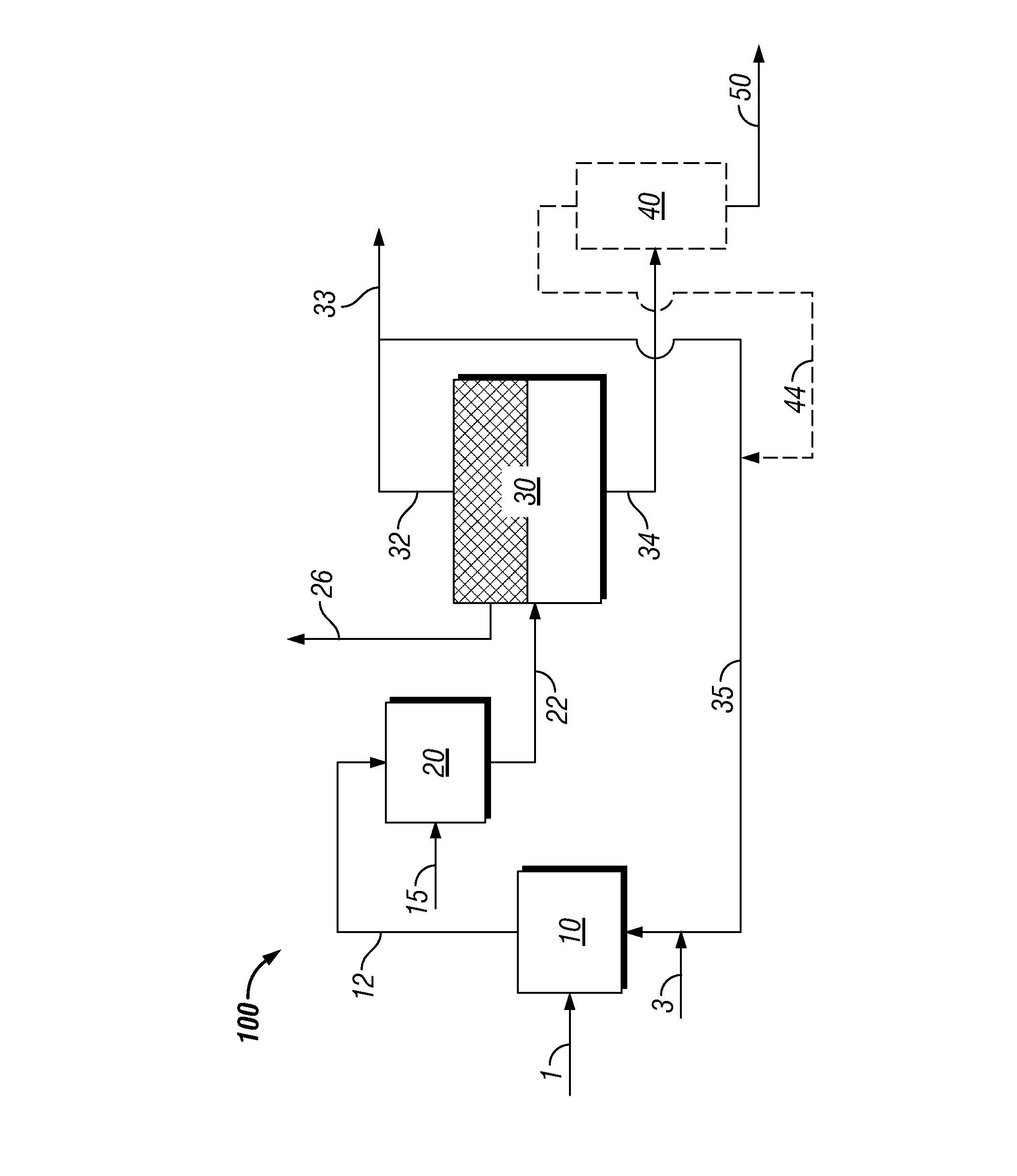

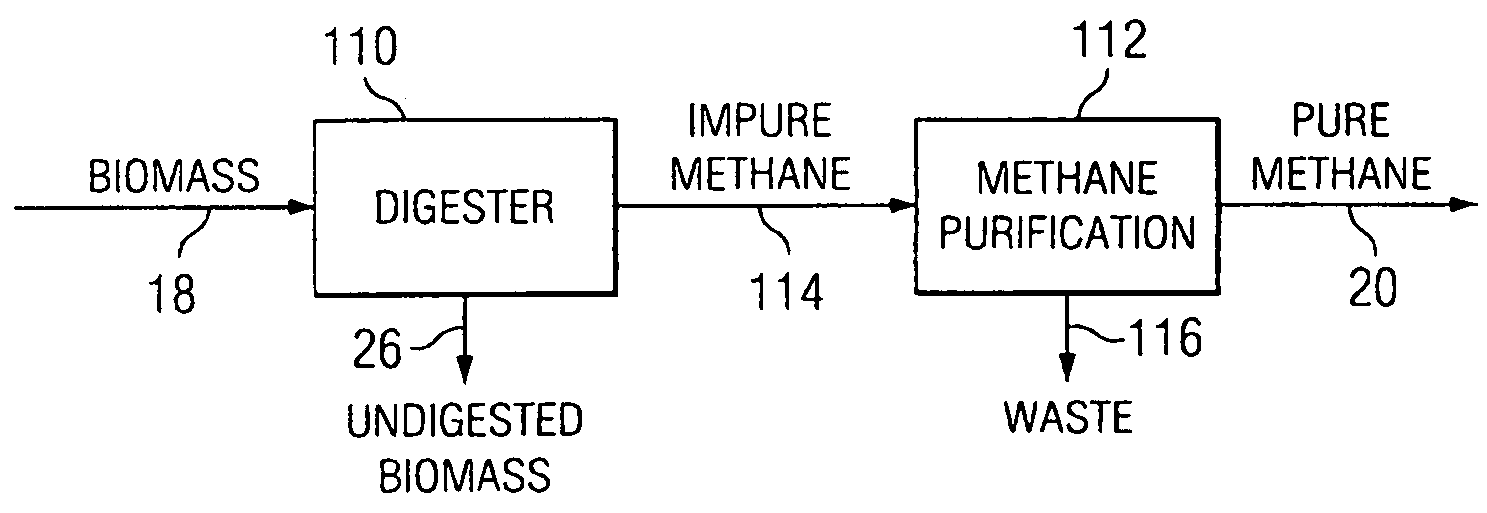

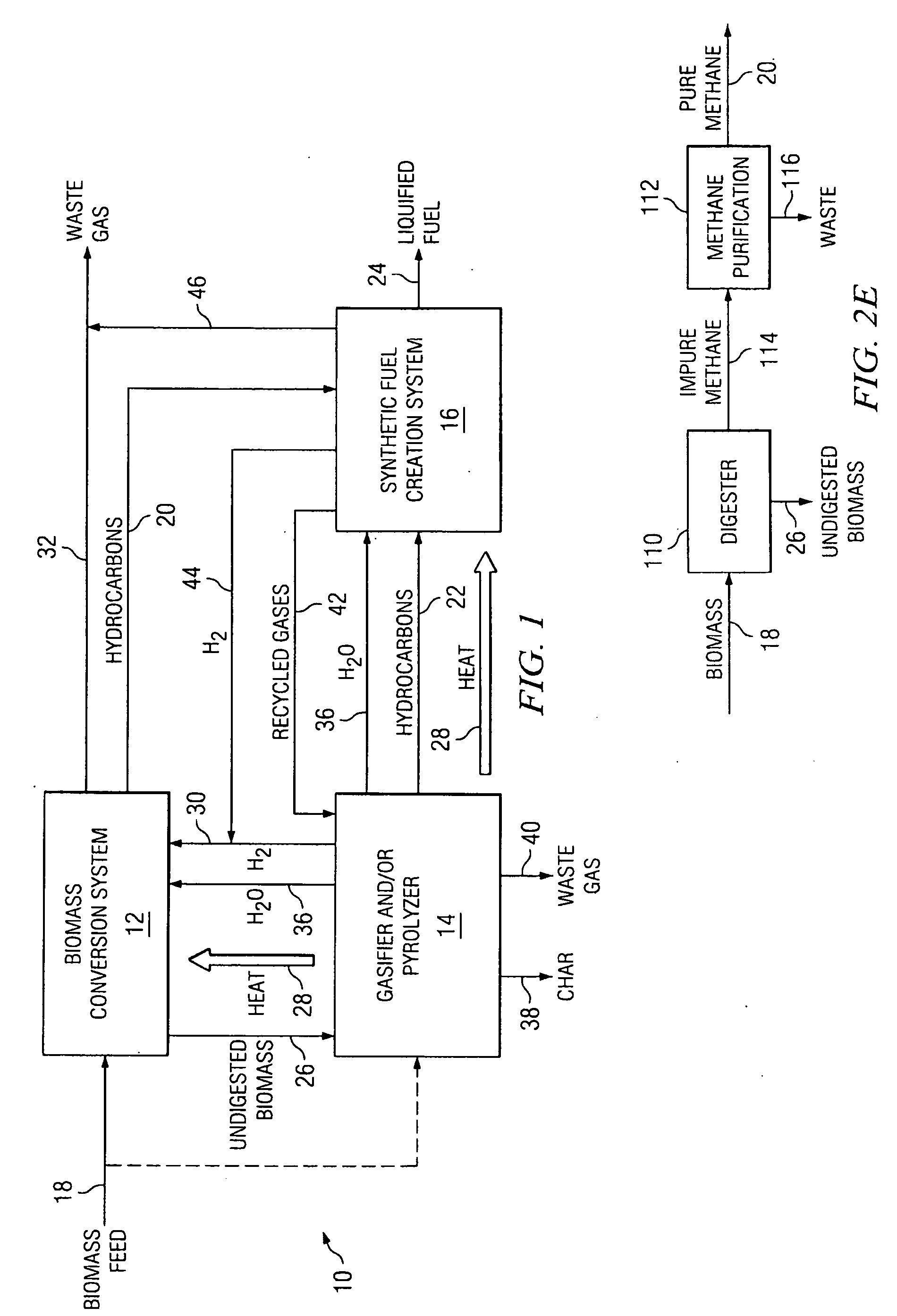

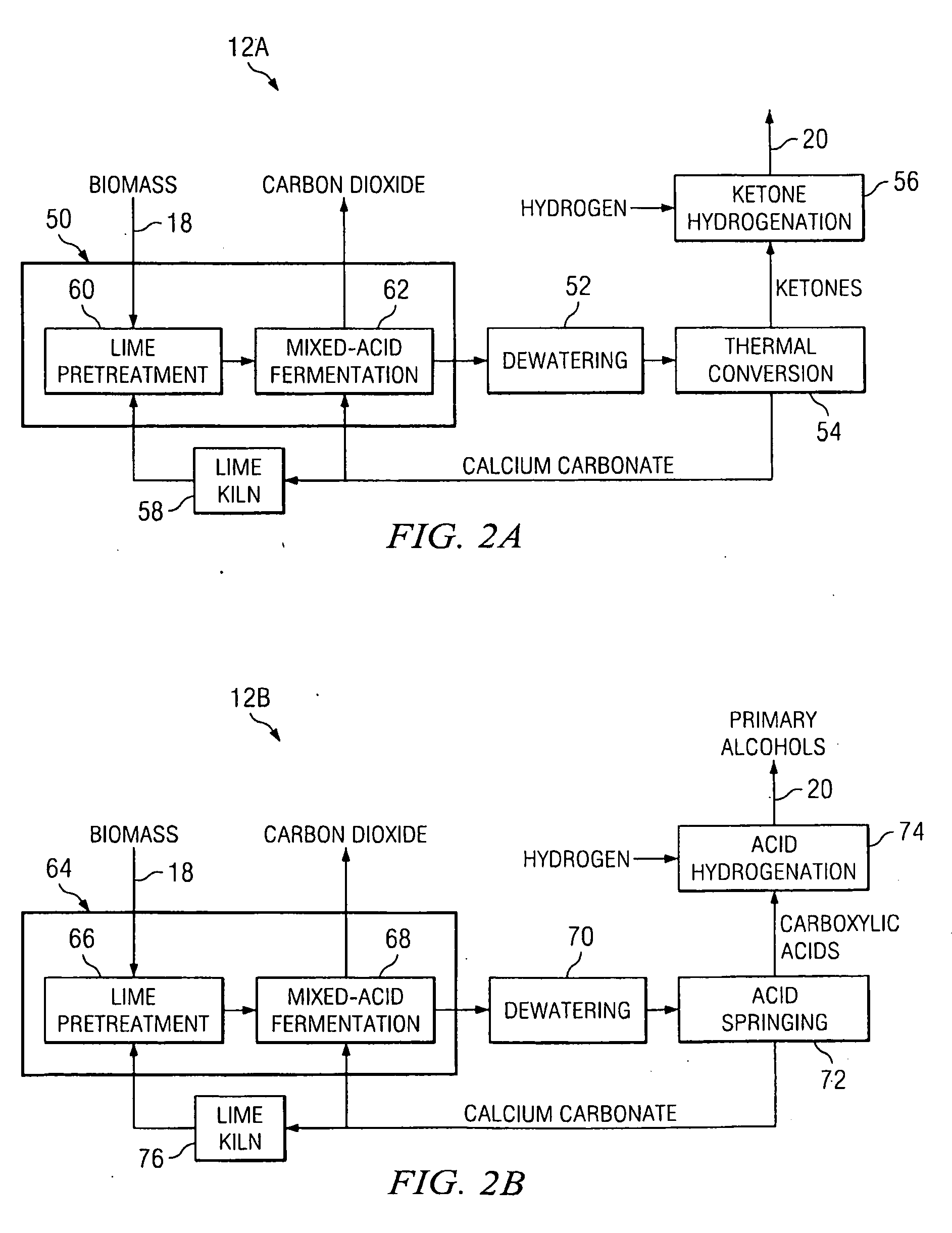

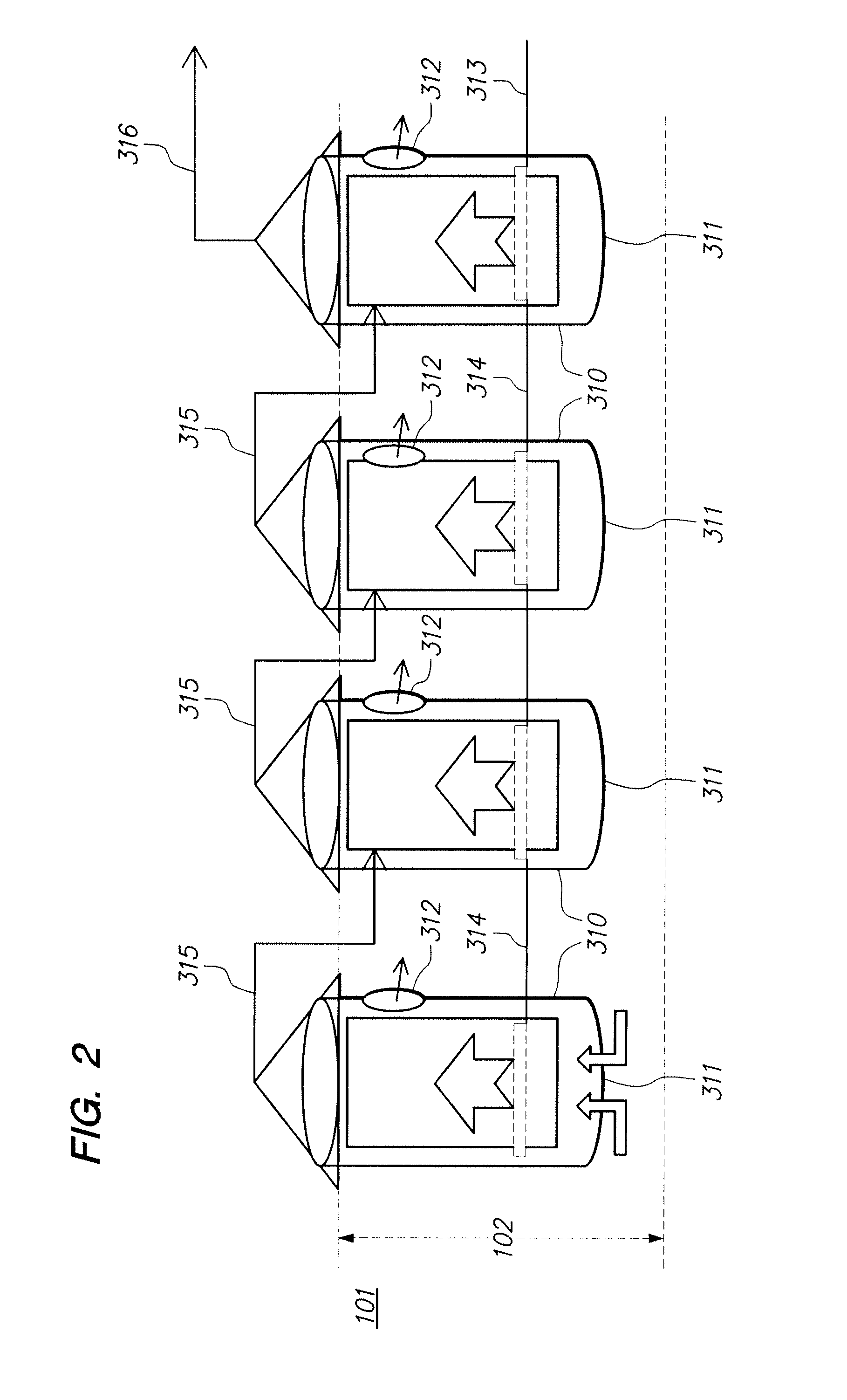

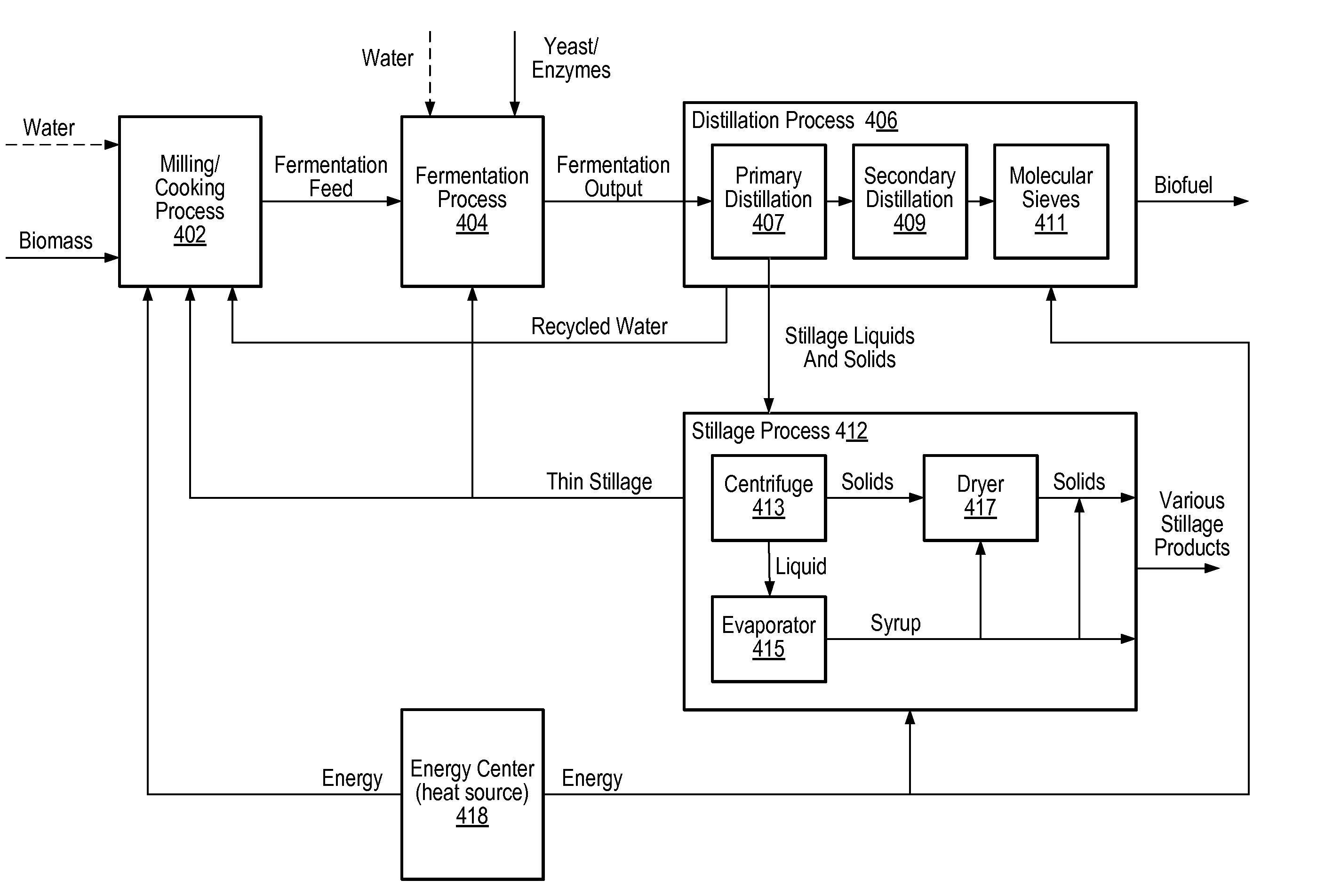

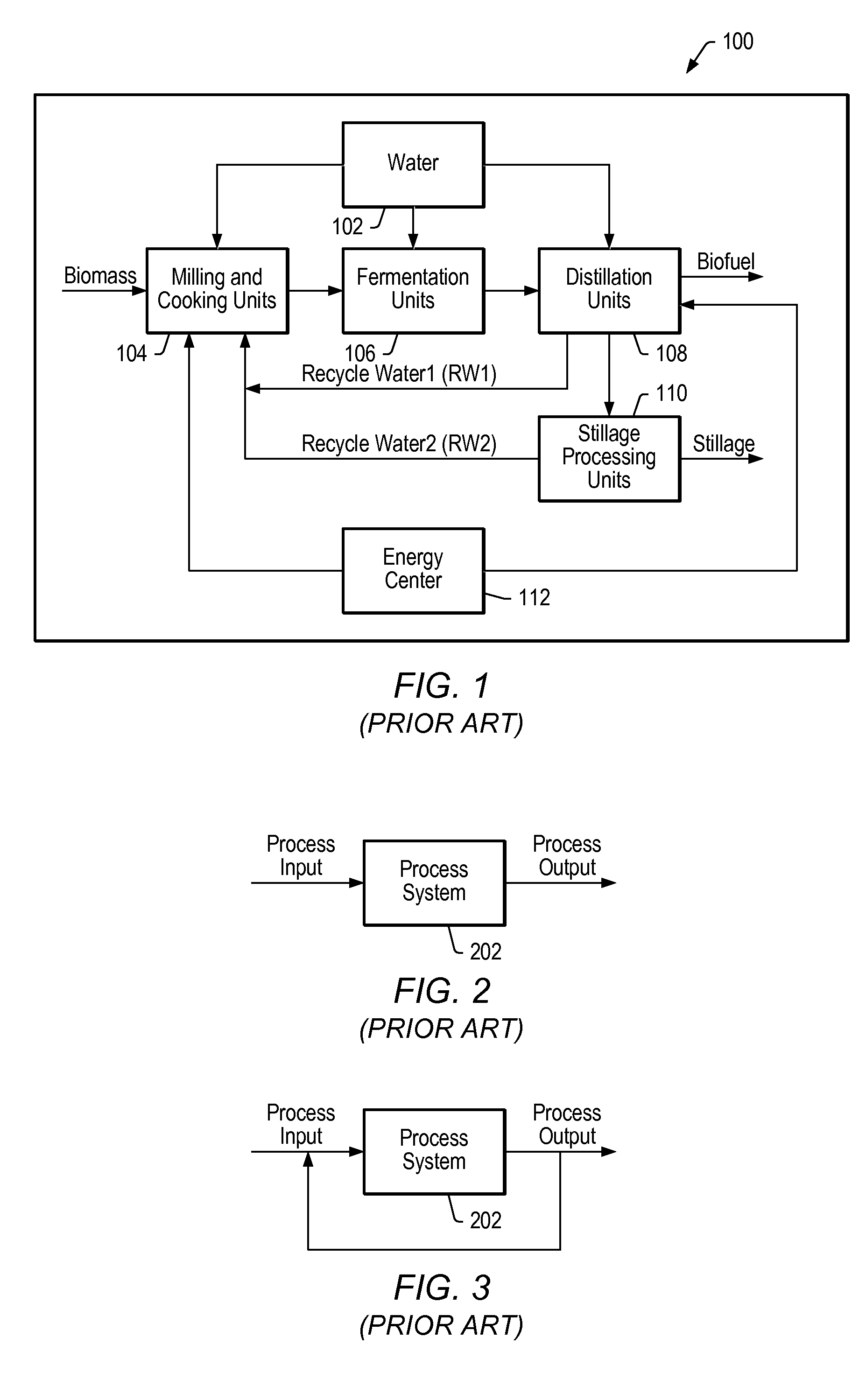

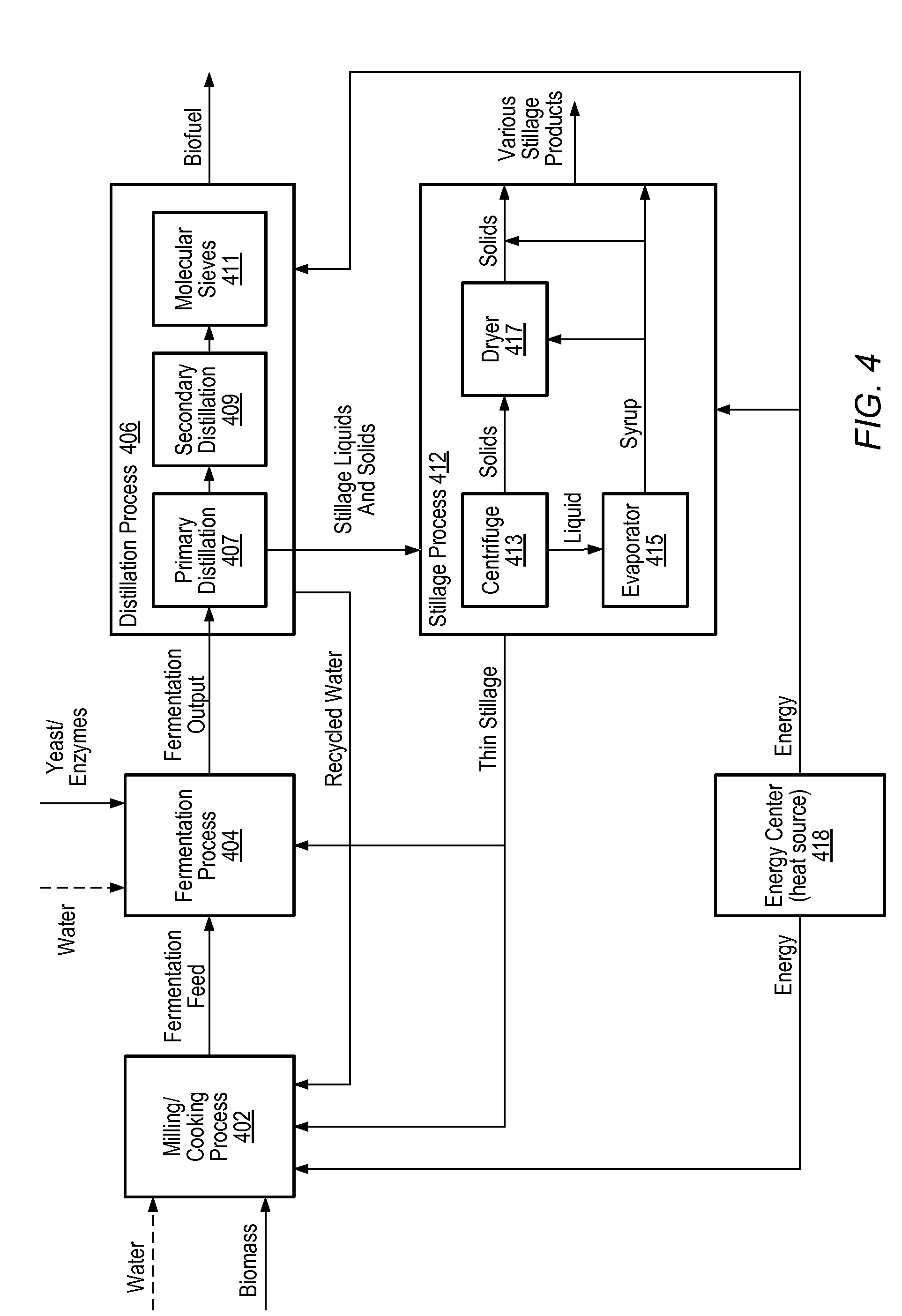

Integrated Biofuel Production System

InactiveUS20090239279A1Increase energy densityImprove conversion efficiencyWaste based fuelSedimentation separationThermal energyResidual biomass

According to an embodiment, a biomass conversion subsystem produces methane and / or alcohol and residual biomass. A pyrolysis or a gasification subsystem is used to produce thermal energy and / or process gasses. The thermal energy may be stored thermal energy in the form of a pyrolysis oil. A fuel conversion subsystem produces liquid hydrocarbon fuels from the methane and / or alcohol using thermal energy and / or process gasses produced by the gasification or pyrolysis subsystem. Because the biomass production system integrates the residual products from biomass conversion and the residual thermal energy from pyrolysis or gasification, the overall efficiency of the integrated biomass production system is greatly enhanced.

Owner:TEXAS A&M UNIVERSITY

Systems and methods for producing biofuels from algae

InactiveUS20100077654A1Promotes algae growthEnergy efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelOedogonium

The invention provides systems and methods for producing biofuel from algae wherein the algae and fishes are co-cultured in a body of water. The methods further comprise inducing the algae to accumulate lipids by environmental stress, and concentrating the algae prior to extraction of the algal oil. The systems of the invention comprise at least one growth enclosure, means for concentrating algae, and means for subjecting algae to environmental stress.

Owner:LIVEFUELS

Biofuels via hydrogenolysis-condensation

ActiveUS20110154721A1Easy to oxidizePromote hydrolysis reactionBiofuelsEfficient propulsion technologiesHydrogenPolyol

A method comprises a providing a carbohydrate; reacting the carbohydrate directly with hydrogen in the presence of a hydrogenolysis catalyst to produce a reaction product comprising a polyol; and then processing at least a portion of the reaction product to form a fuel blend.

Owner:SHELL USA INC

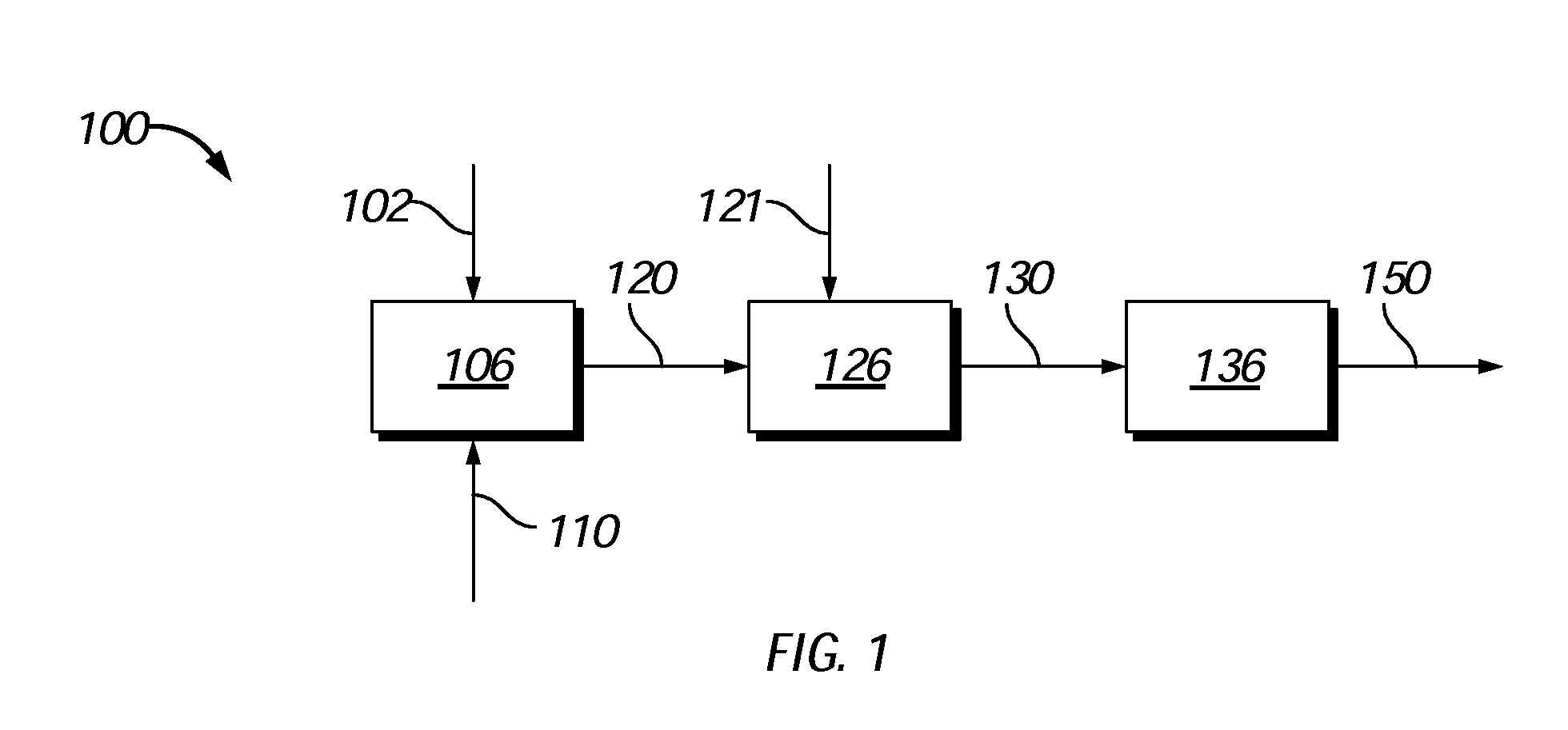

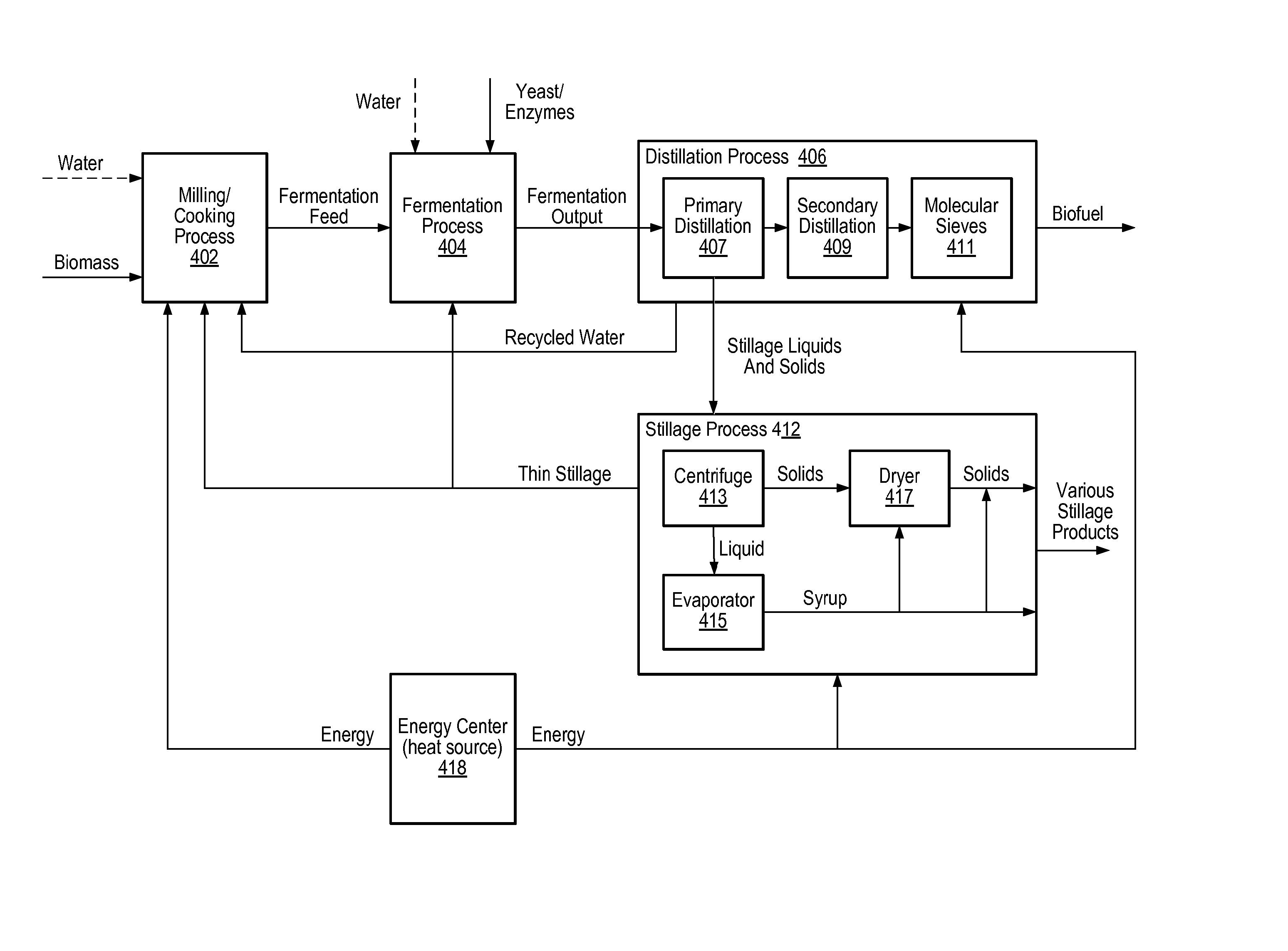

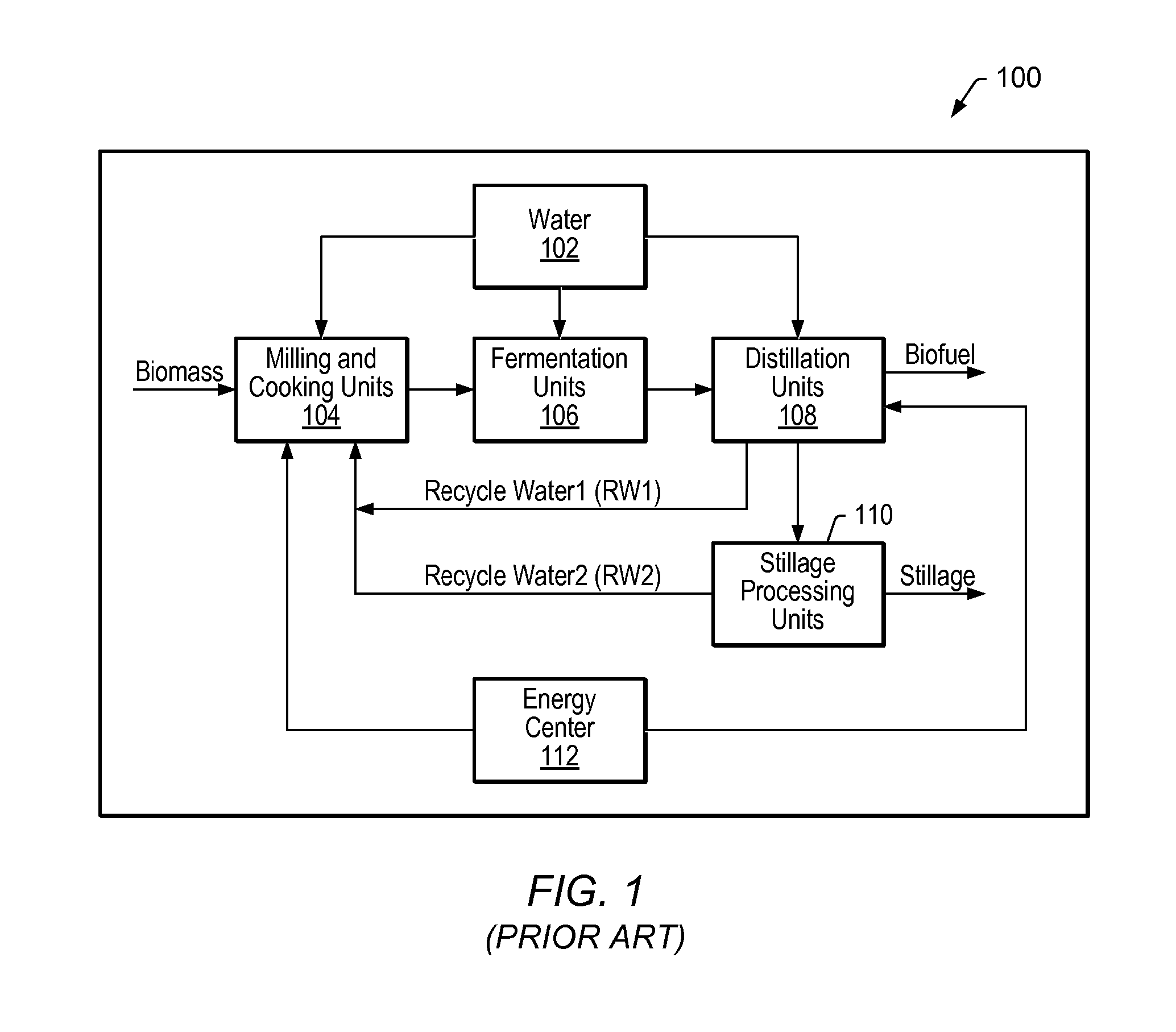

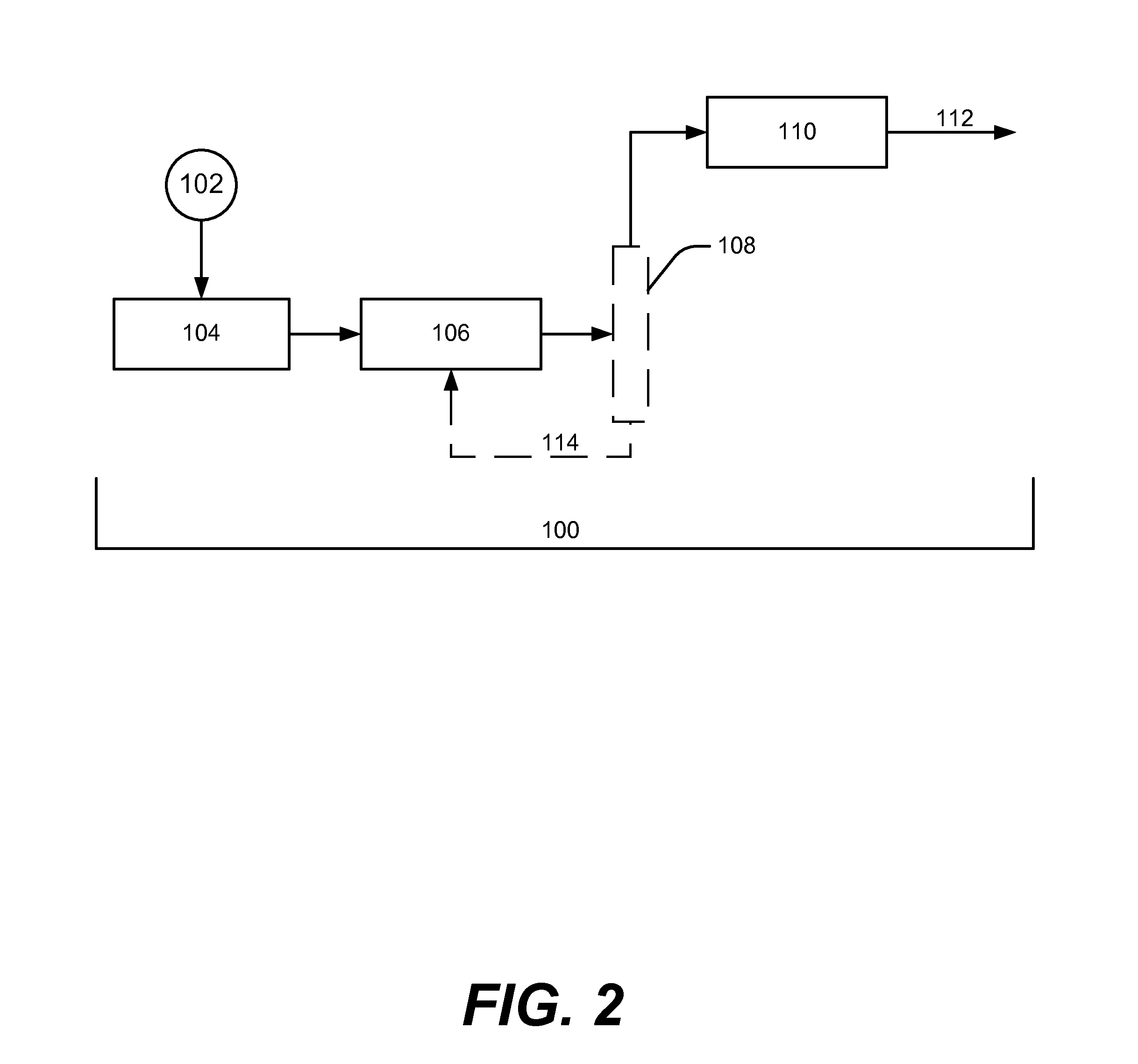

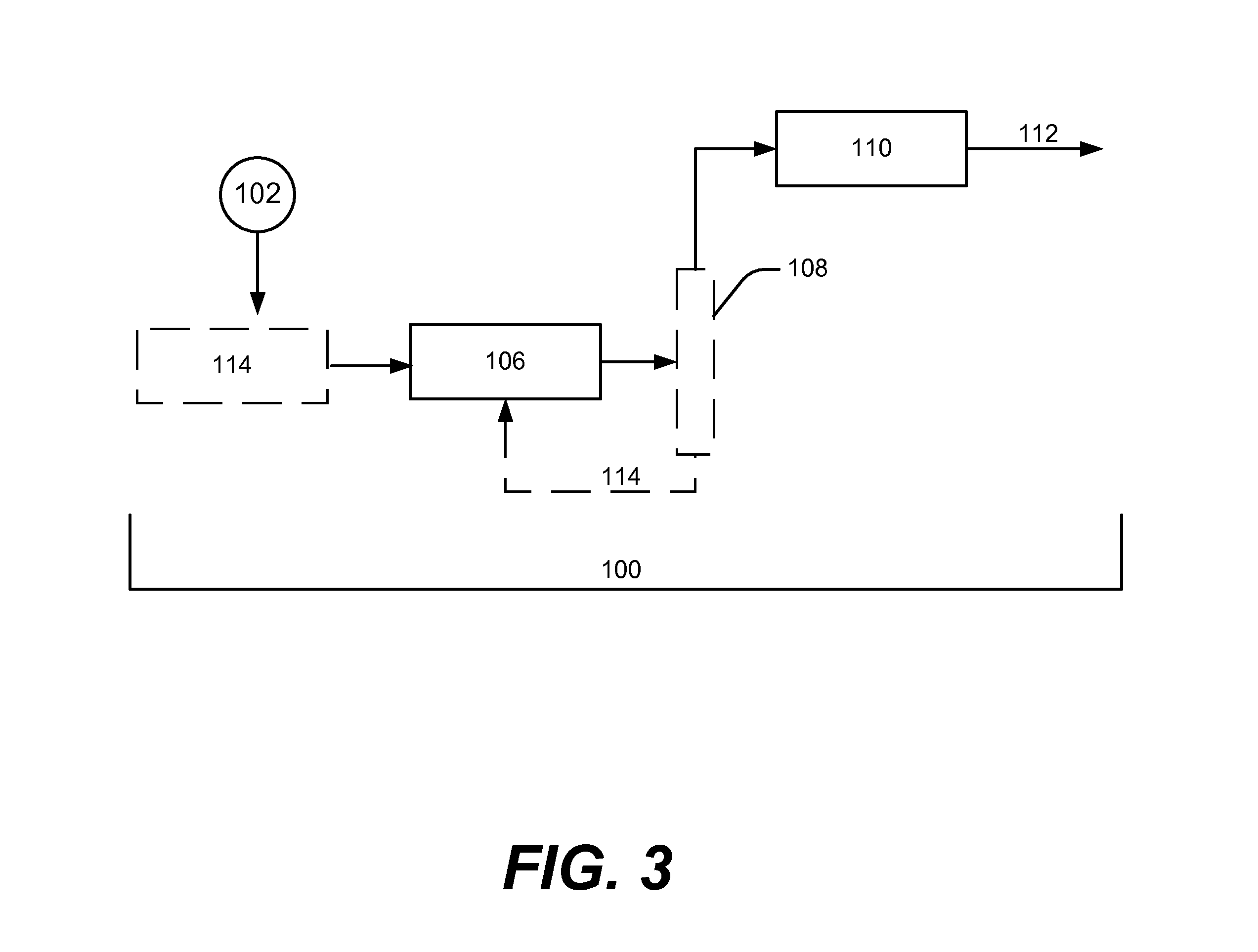

Model predictive control of a fermentation feed in biofuel production

ActiveUS20080104003A1Guaranteed balance and stabilityBioreactor/fermenter combinationsSimulator controlBiofuelModel based controller

System and method for managing fermentation feed in a biofuel production process, comprising a dynamic multivariate predictive model-based controller coupled to a dynamic multivariate predictive model. The model is executable to: receive process information, including water inventory and biomass information, from the biofuel production process; receive a specified objective for the fermentation feed specifying a target biomass concentration; and generate model output comprising target values for a plurality of manipulated variables of the biofuel production process, including target flow rates of water and / or biomass contributing to the fermentation feed in accordance with the specified objective. The controller is operable to dynamically control the biofuel production process by adjusting the plurality of manipulated variables to model-determined target values to stabilize water / biomass balance in the fermentation feed in accordance with the specified objective, including the specified target biomass concentration.

Owner:ROCKWELL AUTOMATION TECH

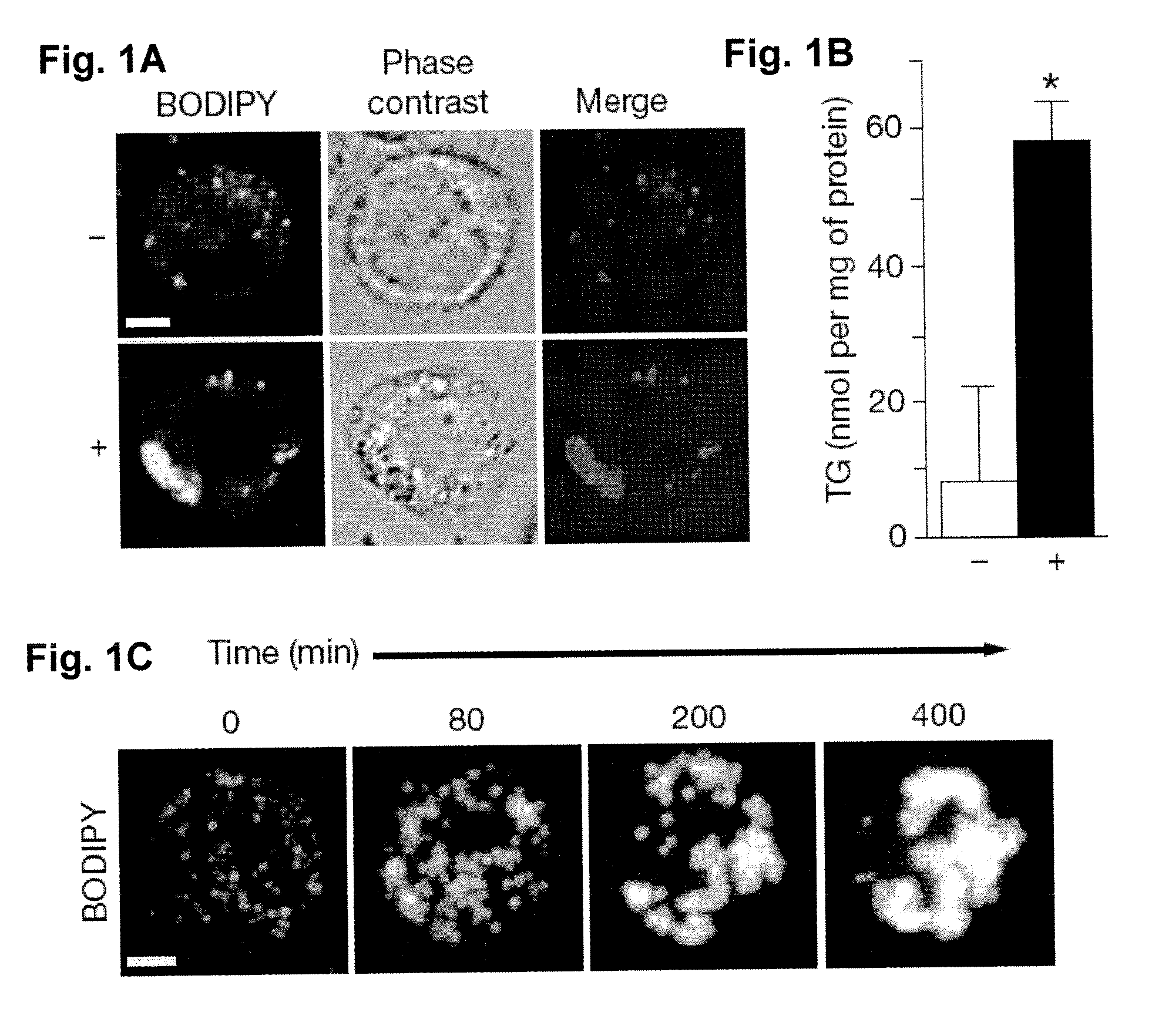

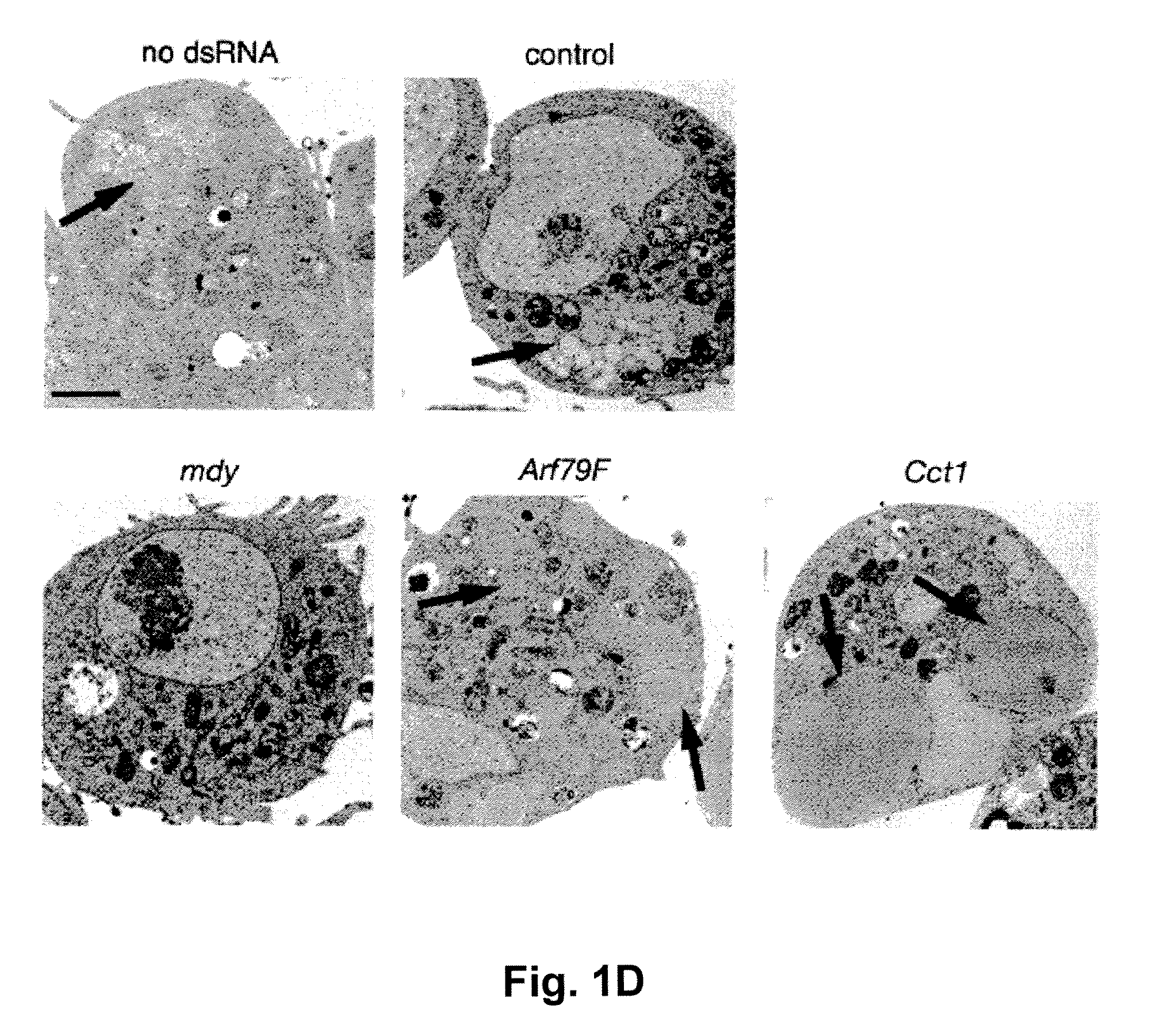

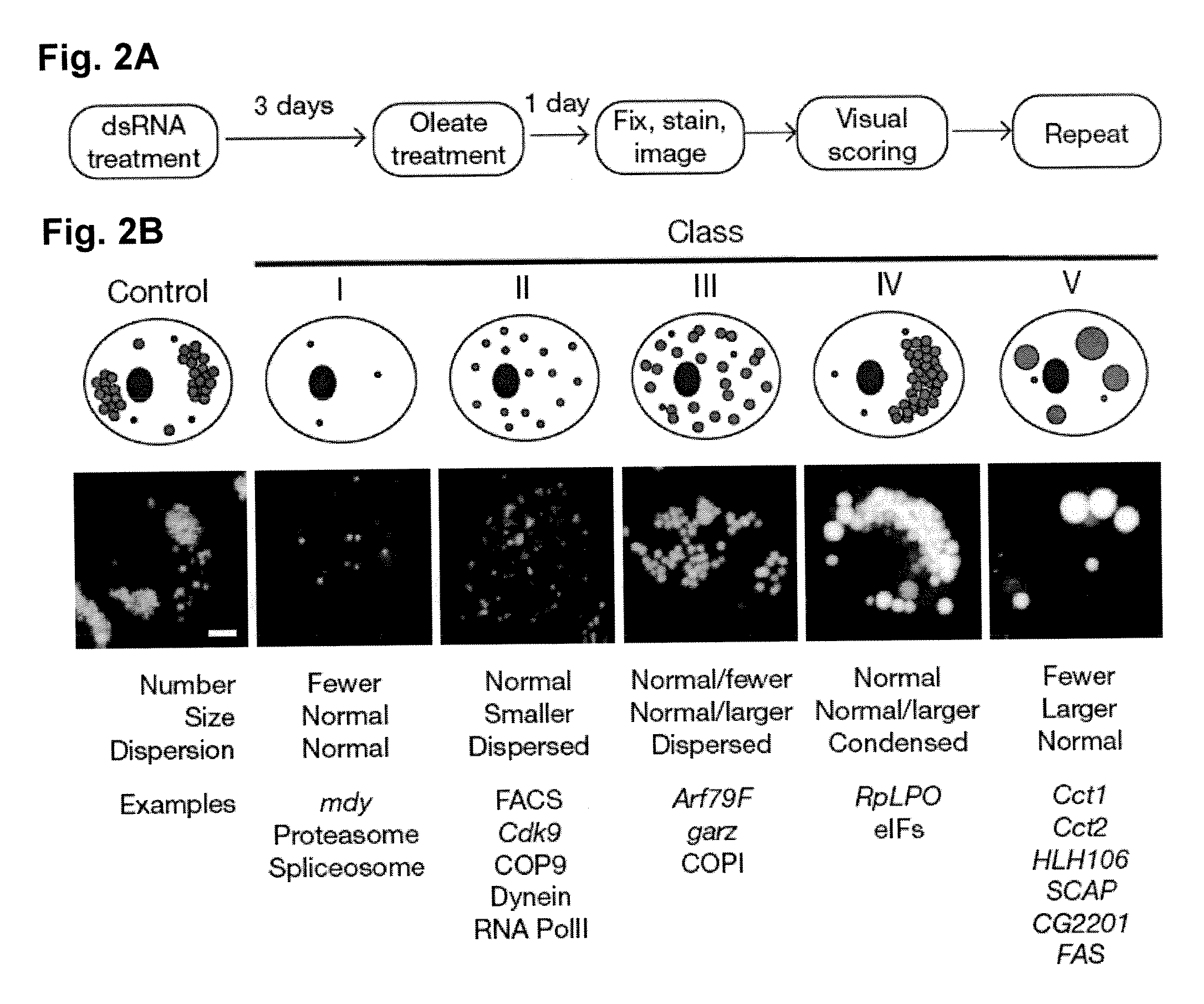

Methods of Modulating Lipid Concentrations in Eukaryotic Cells

ActiveUS20100021912A1Decreasing lipid concentrationIncreasing and decreasing gene expressionFungiMicrobiological testing/measurementLipid storageLipid formation

The present invention is based on the discovery of a set of genes that are involved in lipid-droplet formation and regulation. Accordingly, the present invention provides methods of increasing or decreasing lipid concentrations in eukaryotic cells by decreasing or increasing expression of one of these genes. Increased lipid concentrations may be useful, for example, in the generation of biofuels. Decreased lipid concentration may be useful in the treatment of diseases characterized by excessive lipid storage. In addition, the invention provides methods of identifying markers of diseases characterized by excessive lipid storage.

Owner:RGT UNIV OF CALIFORNIA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com