Patents

Literature

301results about How to "High combustion value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

Technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and photothermal catalyst

InactiveCN104016825AReduce energy consumptionHigh reactivityHydrocarbon from carbon oxidesOrganic compound preparationSynthesis methodsUltraviolet lights

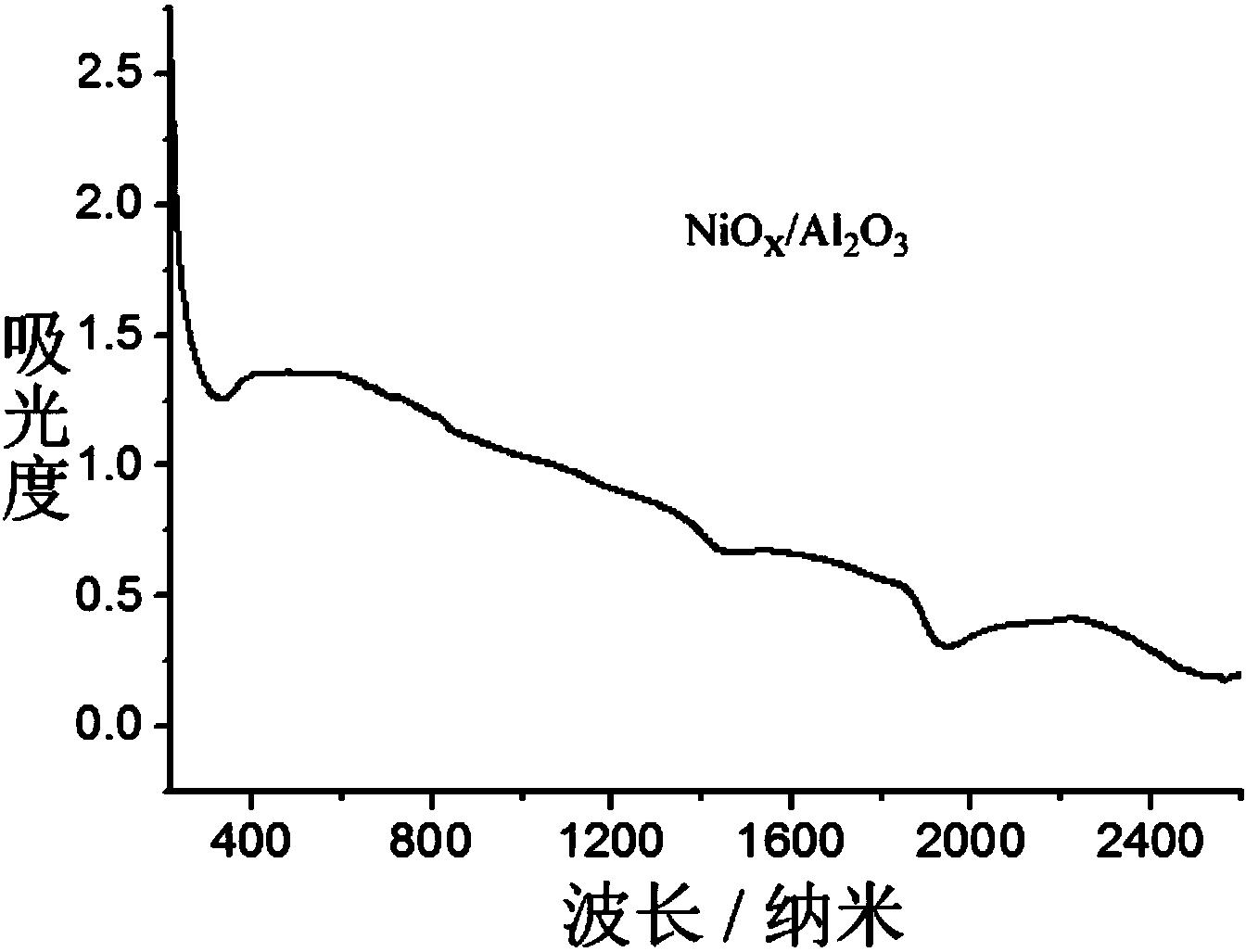

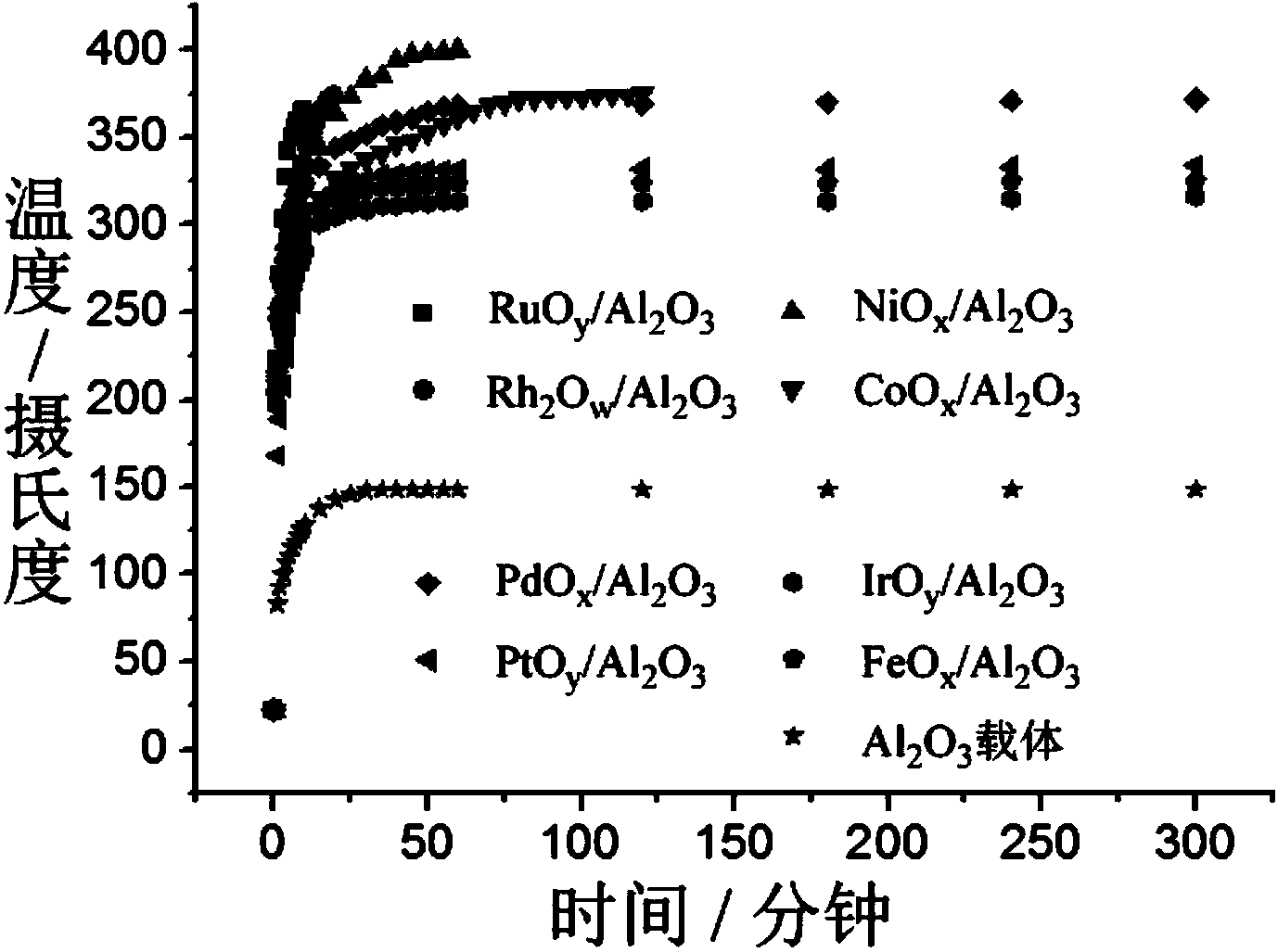

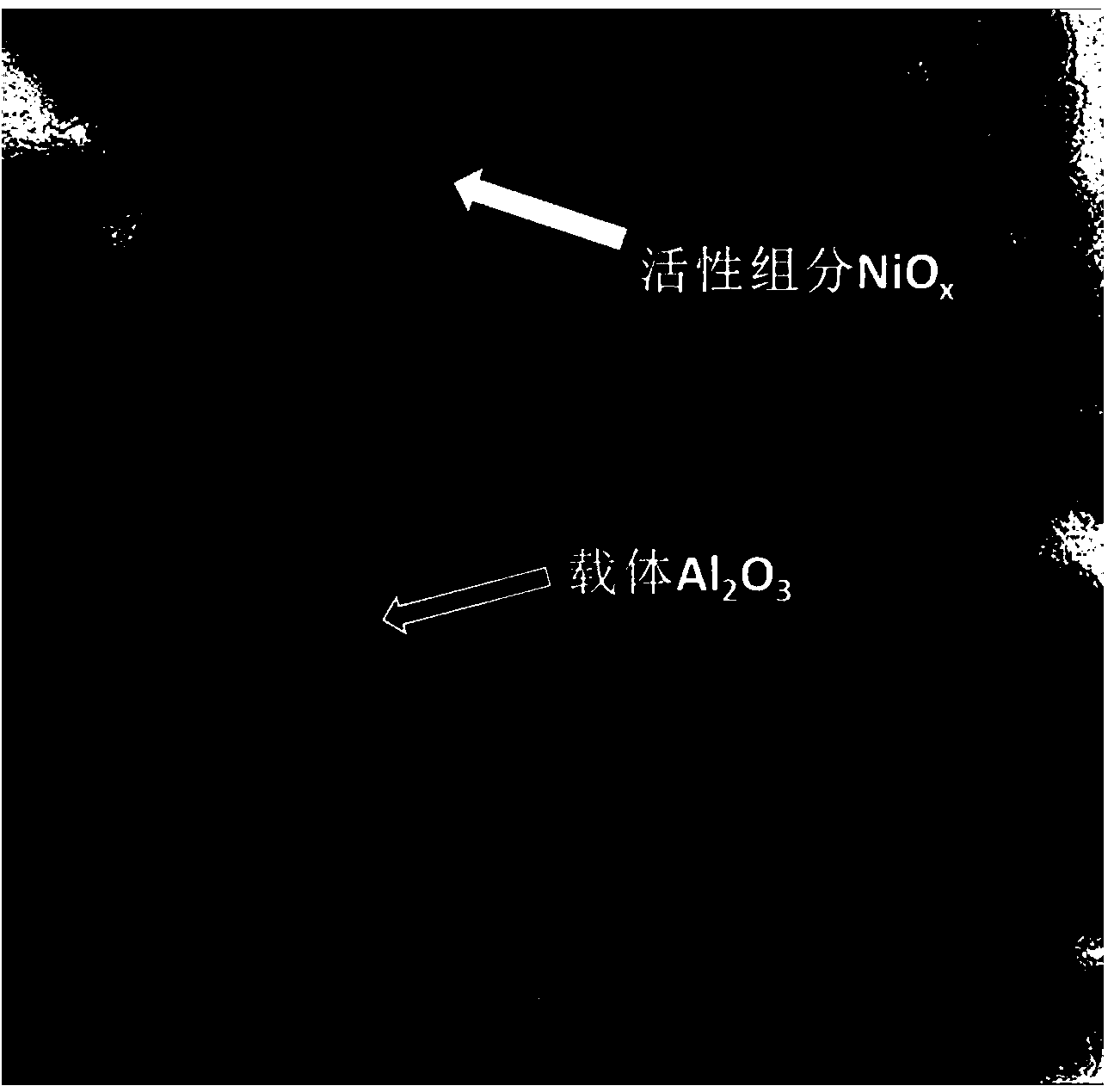

The invention discloses a technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and a photothermal catalyst. Sunlight is utilized to supply light and heat for the synthesis and catalytic process of the photothermal catalyst, and the photothermal catalyst can simultaneously absorb and utilize ultraviolet light, visible light and infrared light parts in sunlight, so that a phtothermal catalytic reaction is induced to prepare the organic fuel through reducing carbon dioxide by using hydrogen. The photothermal catalyst comprises the following components: an active component which is a 2-30 nano-scale non-stoichiometric oxide belonging to a VIII-family element in a transition family and a carrier material which is an oxide or carbon material with the specific surface area of 30-1000cm<2> / g, alkaline resistance, high heat conductivity or photocatalytic activity. A steeping and in-situ sintering method or photodepositing and in-situ sintering method is used as a synthesis method so that the energy consumption is low, and the photothermal catalyst has high activity and long service life by using a solar-assisted in-situ sintering technology. The technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and the photothermal catalyst is low in energy consumption in the catalytic process, high in organic fuel production efficiency and stable in catalyst activity.

Owner:TIANJIN UNIV

A method for underground coal gasification

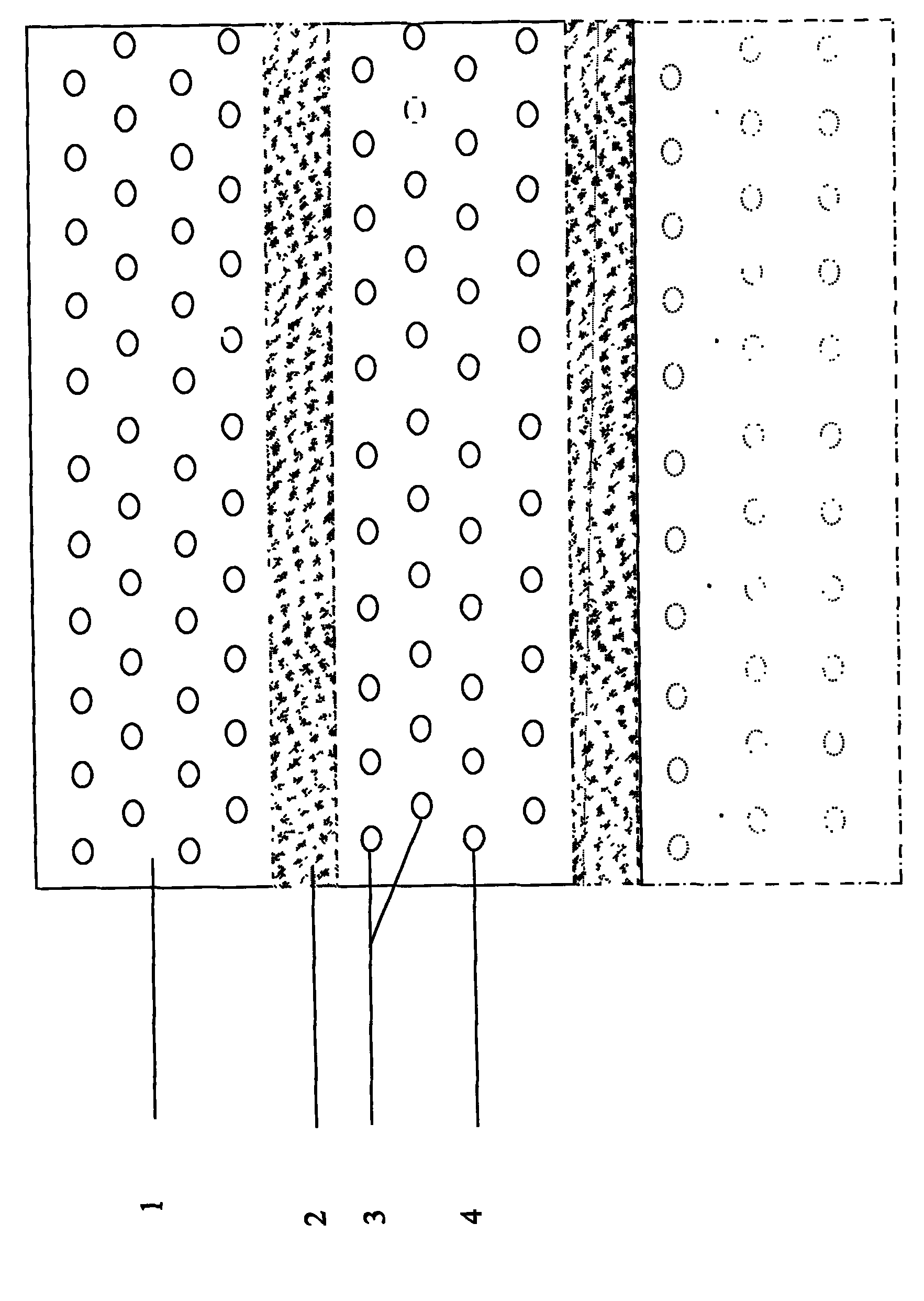

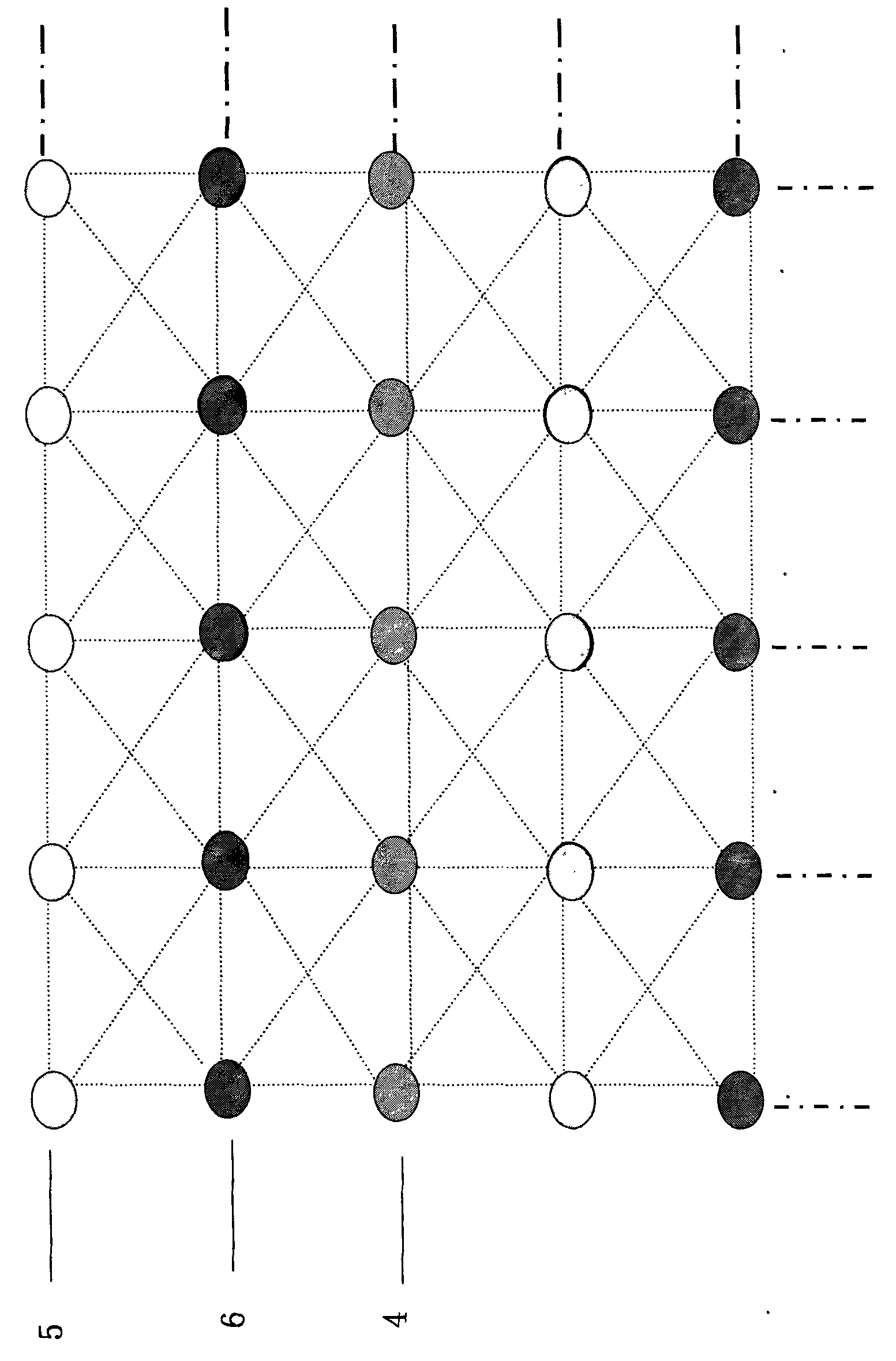

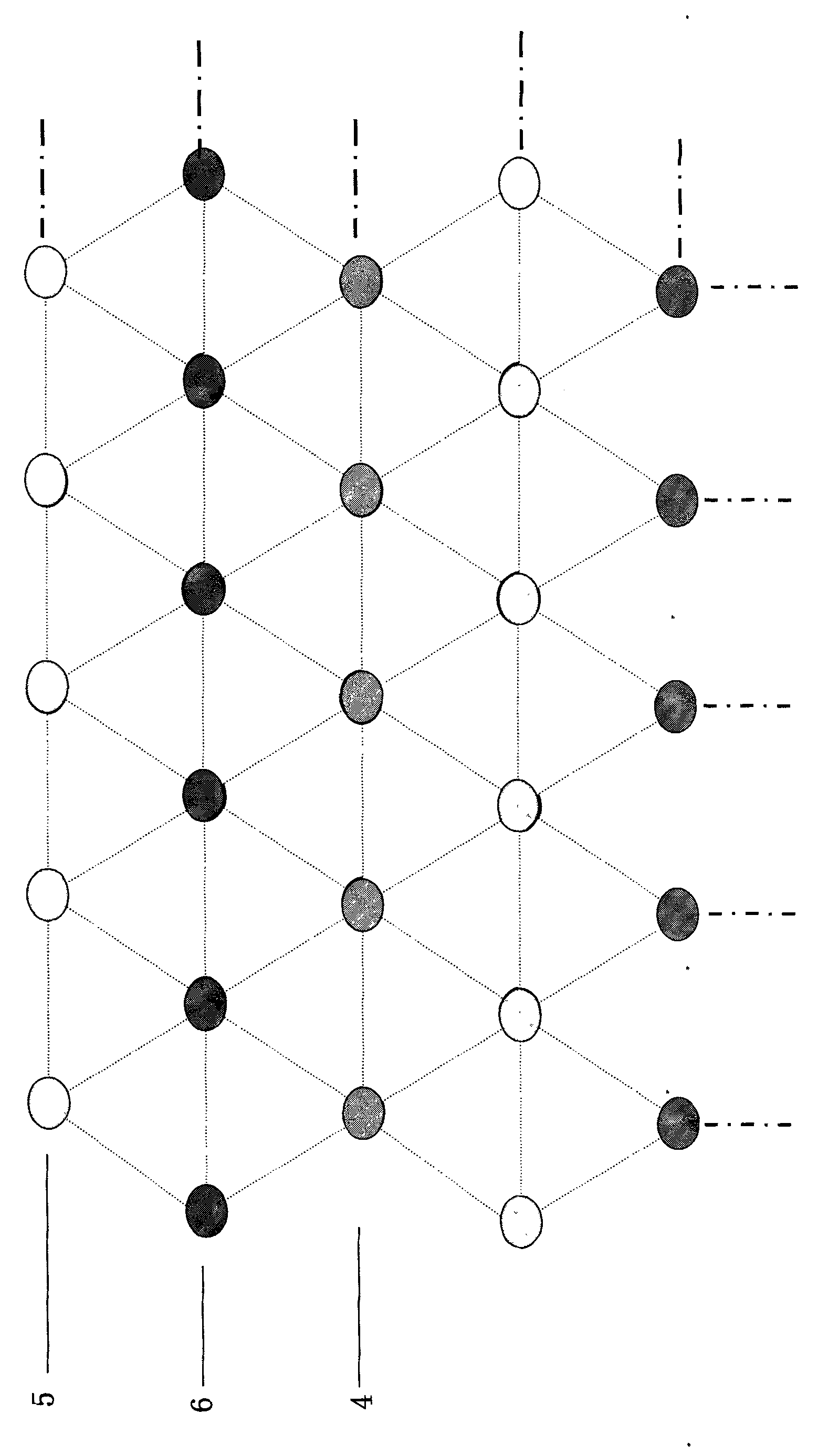

InactiveCN102287177AEfficient developmentChange areaConstructionsFluid removalMultiple injectionChemical reaction

An underground coal gasification method. The method comprises disposing multiple injection wells (3) and gas collection wells (4) in a gasification operation zone; adding a catalyst and a propping agent into injection wells and gas collection wells by means of a fluid medium; fracturing and reforming the coal layer using a fracturing device to form large areas of fissures and cracks; forming gasification paths in the form of directional wells between the injection wells and gas collection wells; adding a gasification agent, a catalyst, and water through the injection wells to cause coal layer combustions and chemical reactions; collecting at the gas collection wells the gas produced by means of collection devices. The fissure paths between the wells formed by reforming large fractures, and the metal mineral particles used as a propping agent for the paths between wells effectively enable the maintenance of the effective communication in the injection well network for long durations; the metal mineral particles also function as a catalyst and an aggregating agent during gasification, thereby substantially enhancing the coal gasification volume.

Owner:秦勇 +2

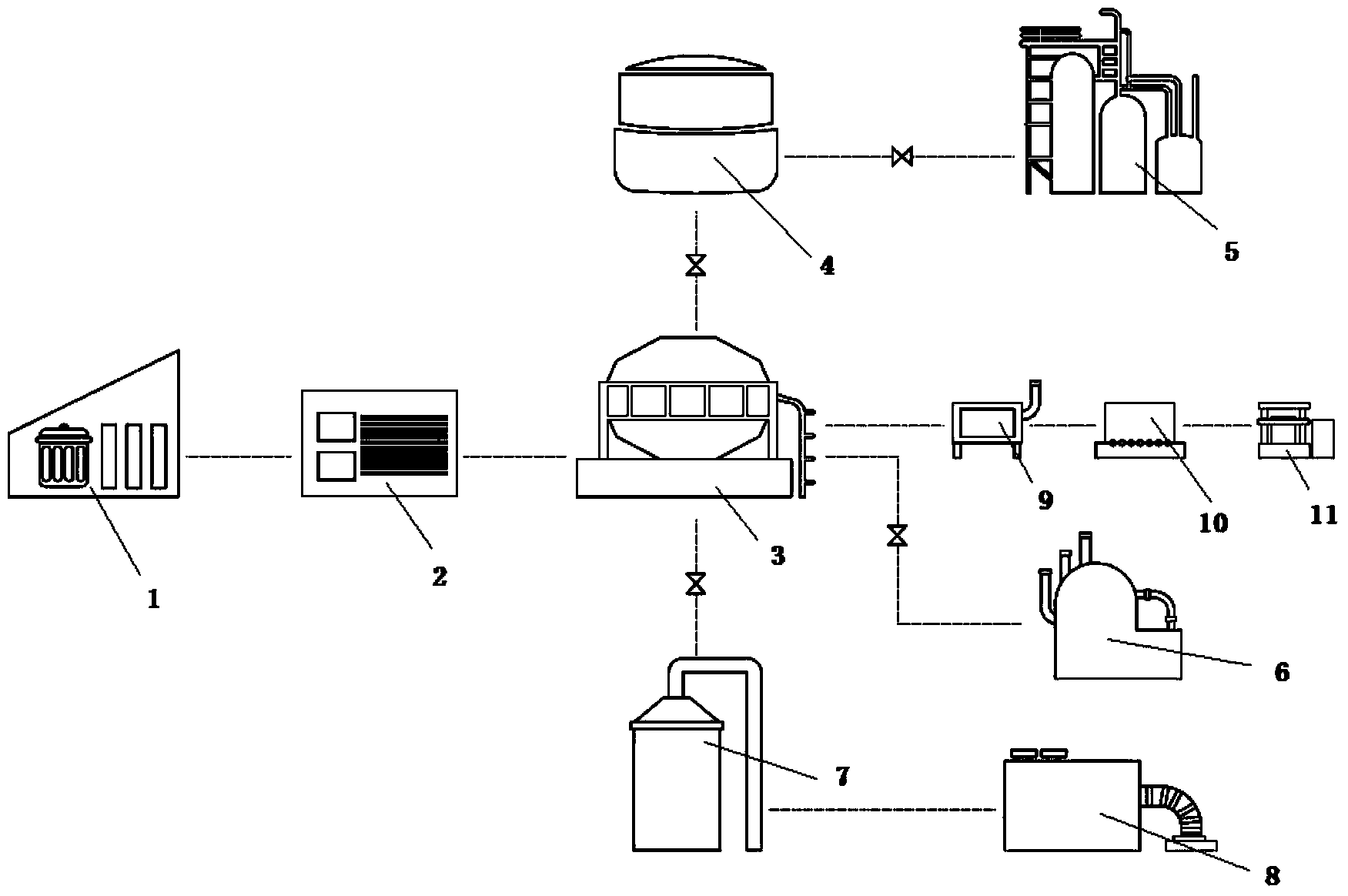

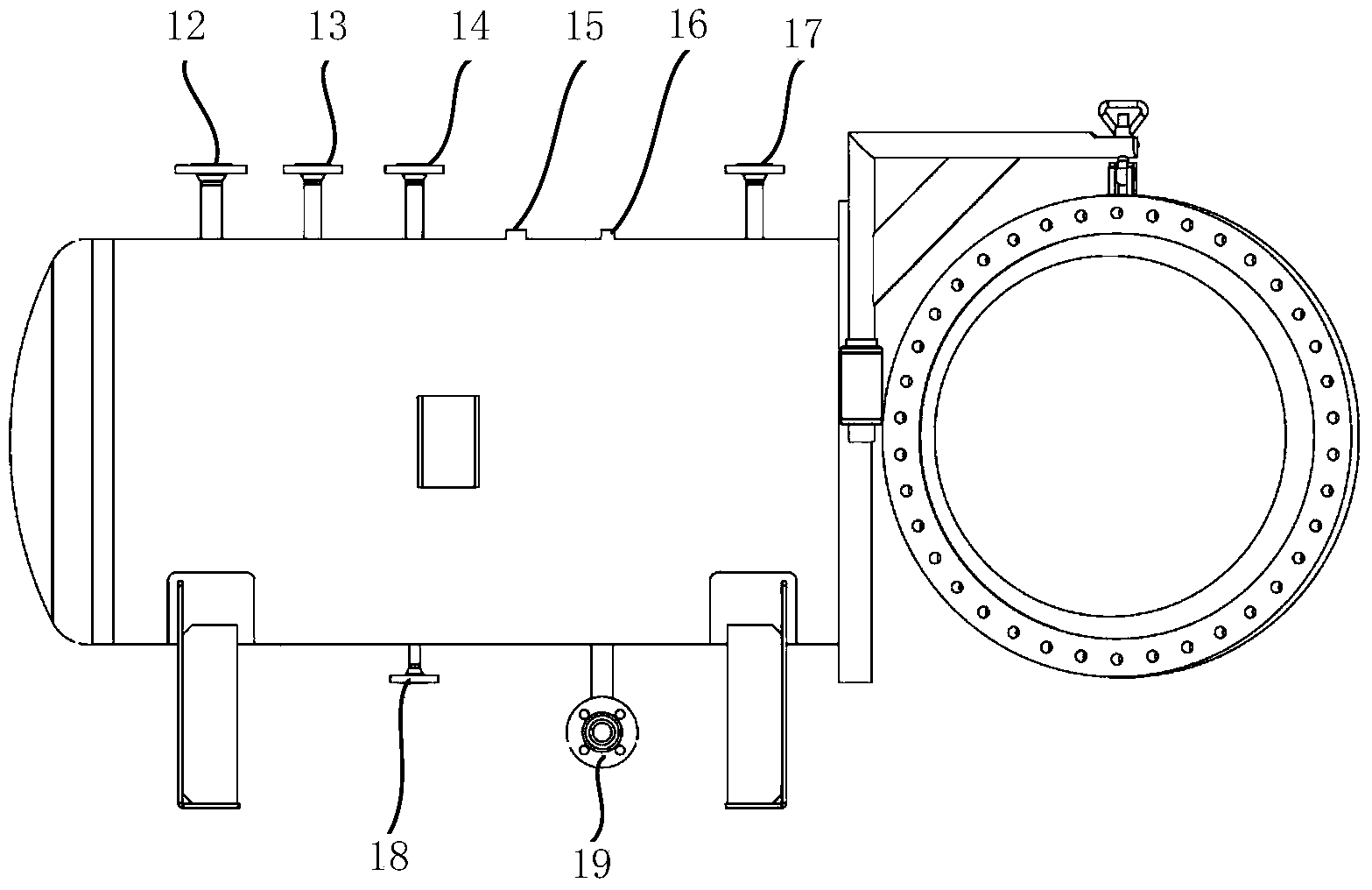

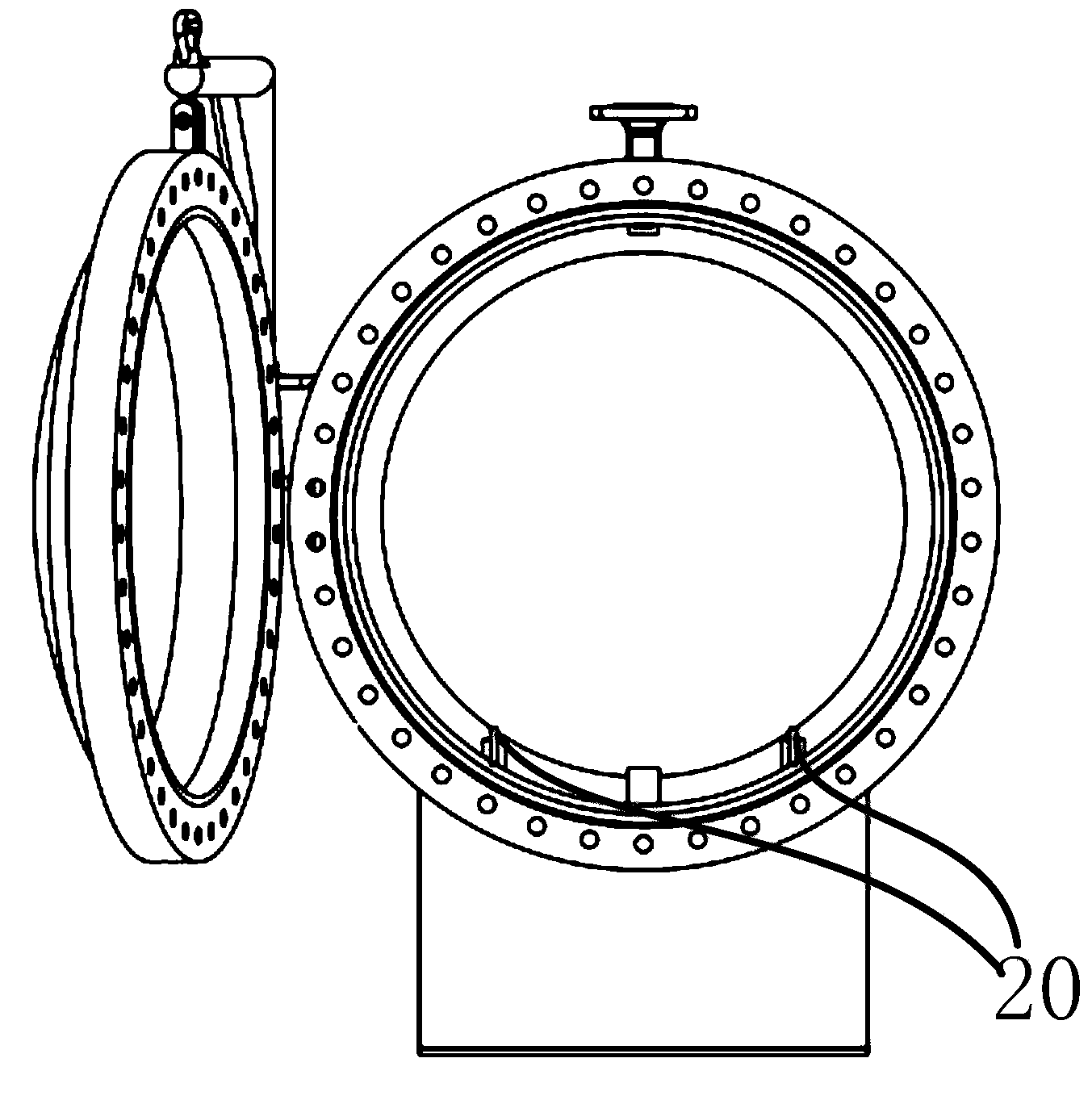

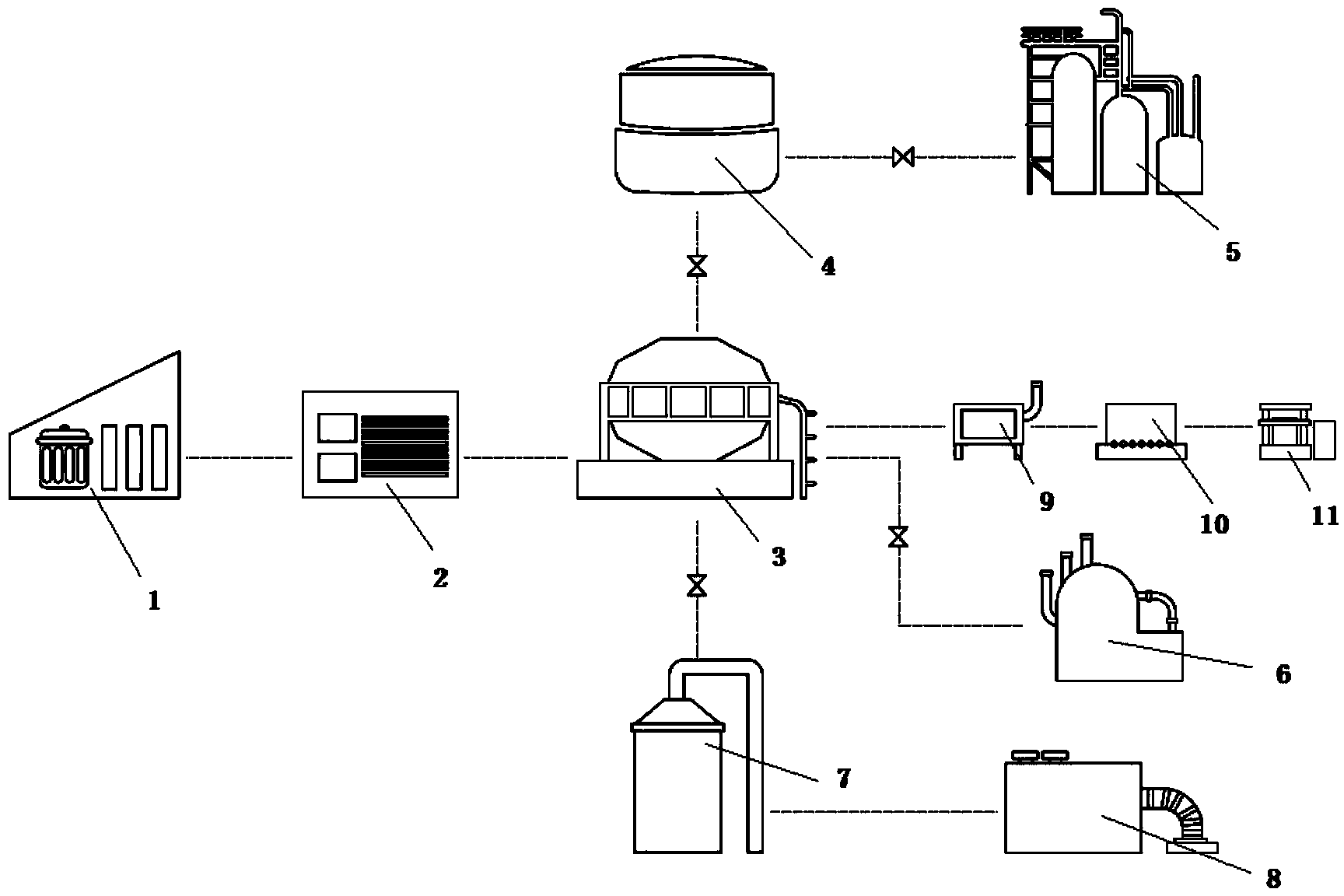

Garbage carbonization reacting system

ActiveCN104263388AClassification requirements are lowHarmlessSolid waste disposalDirect heating destructive distillationLitterCarbonization

The invention provides a garbage carbonization reacting system. The system comprises a reaction still, a reaction tank, a vapor generator and a control device, wherein the vapor generator is connected with the reaction still, and the vapor generator is used for supplying vapor to the reaction still; the reaction tank is used for placing garbage. When a reaction is carried out, the reaction tank is pushed into the reaction still to react to generate a carbonization mixture; after the reaction is completed, the reaction tank is pulled out of the reaction still. The reaction still comprises a still body and a still cover, wherein the still body is connected with the still cover in a sealing manner; the control device is connected with the reaction still, and the control device is used for controlling the change of the pressure and the temperature in the reaction still and the reaction time; a first guide rail which extends in the length direction of the still body is arranged in the still body. The system disclosed by the invention has the advantages that the structural scheme is reasonable, the device is advanced, the degree of automation is high, the investment cost of equipment is low, the occupation area of a required plant is small, and burning value of prepared biomass fuel is high, and the discharge is low.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

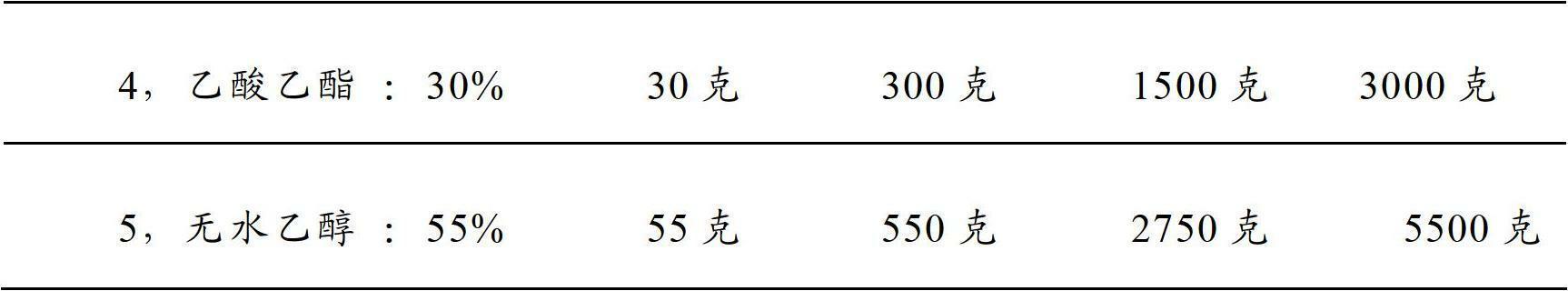

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

High-efficiency fire coal catalyst

InactiveCN101269339AHigh thermal efficiencyHas a defocusing effectSolid fuelsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAdditive ingredient

The invention discloses a coal-fired catalyst with high efficiency, the coal-fired catalyst essentially comprises the following components in accordance with the mass percentage content: 20 to 40 percent of potassium salt, 10 to 25 percent of industrial grade sodium chloride, 15 to 30 percent of quicklime, 9 to 15 percent of bauxite, 1 to 4 percent of rare earth elements, and 0.1 to 1 percent of ferric oxide, wherein, the main ingredients of the invention are monovalent and divalent alkali metal salts, bauxite and rare earth elements. The coal-fired catalyst has catalytic combustion, sulfur fixing and improvement of the properties of coal combustion, and therefore, the coal-fired catalyst plays a comprehensive role of coal conservation and emission reduction of pollutants, and is suitable for a variety of large-scale civic or industrial coal-fired boilers. The catalyst has simple use, adequate raw materials supply, simple preparation, low price, stable performance and pollution-free for the environment, therefore, the catalyst as an ideal coal-fired catalyst has obvious social and economic benefits.

Owner:袁柏安

Biomass pellet fuel and preparation method thereof

ActiveCN105542893AReduce moisture contentHigh lignin contentBiofuelsSolid fuelsPropanoic acidSodium Bentonite

The invention provides a biomass pellet fuel and a preparation method thereof. The biomass pellet fuel comprises the following components, by weight: herbivorous animal manure, agricultural waste, illegal cooking oil, calcium oxide, calcium sulfate, propionic acid, kaolin, diatomaceous earth, bentonite, calcium peroxide, aluminum hydroxide, propylene glycol, polyvinyl alcohol, an oxygenate, an antiknock agent, a combustion improver, and a bulking agent. The biomass pellet fuel has low water content and high lignin content. According to the invention, a large amount of agricultural waste and animal manure are utilized. Air pollution caused by the activities of burning agricultural waste is greatly reduced, and animal manure can be effectively treated, such that recycling application value is improved, and the fuel is more environment-friendly. Compared to conventional biomass pellet fuels, the biomass pellet fuel provided by the invention has the advantages of high combustion value, long combustion time, no harmful gas emission after combustion, and no corrosion to combustion equipment.

Owner:太仓东浔生物科技有限公司

Biomass fuel and preparation method therefor

The present invention provides biomass fuel and a preparation method therefor. The biomass fuel comprises the following ingredients in parts by weight: lignin, agricultural wastes, sea mud, sepiolite flocking, aluminum oxide, silane coupling agents, ammonium chloride, dimethyl silicone oil, yeast extract powder, capsaicin, di-tert-butyl hydroquinone, oxygenates, a shock-resistant and antiknock agent, a combustion improver, and a bulking agent. The biomass fuel has low moisture content and high lignin content. With the use of a large amount of agricultural wastes, air pollution caused by burning agricultural wastes and other activities is greatly reduced, and recycling utilization value is improved, so that the biomass fuel is more environmentally friendly. Compared with conventional biomass fuel particles, the biomass fuel provided by the present invention has a high fuel value, a long burning time, no discharge of harmful gas after combustion, and no corrosion on a combustion device.

Owner:太仓东浔生物科技有限公司

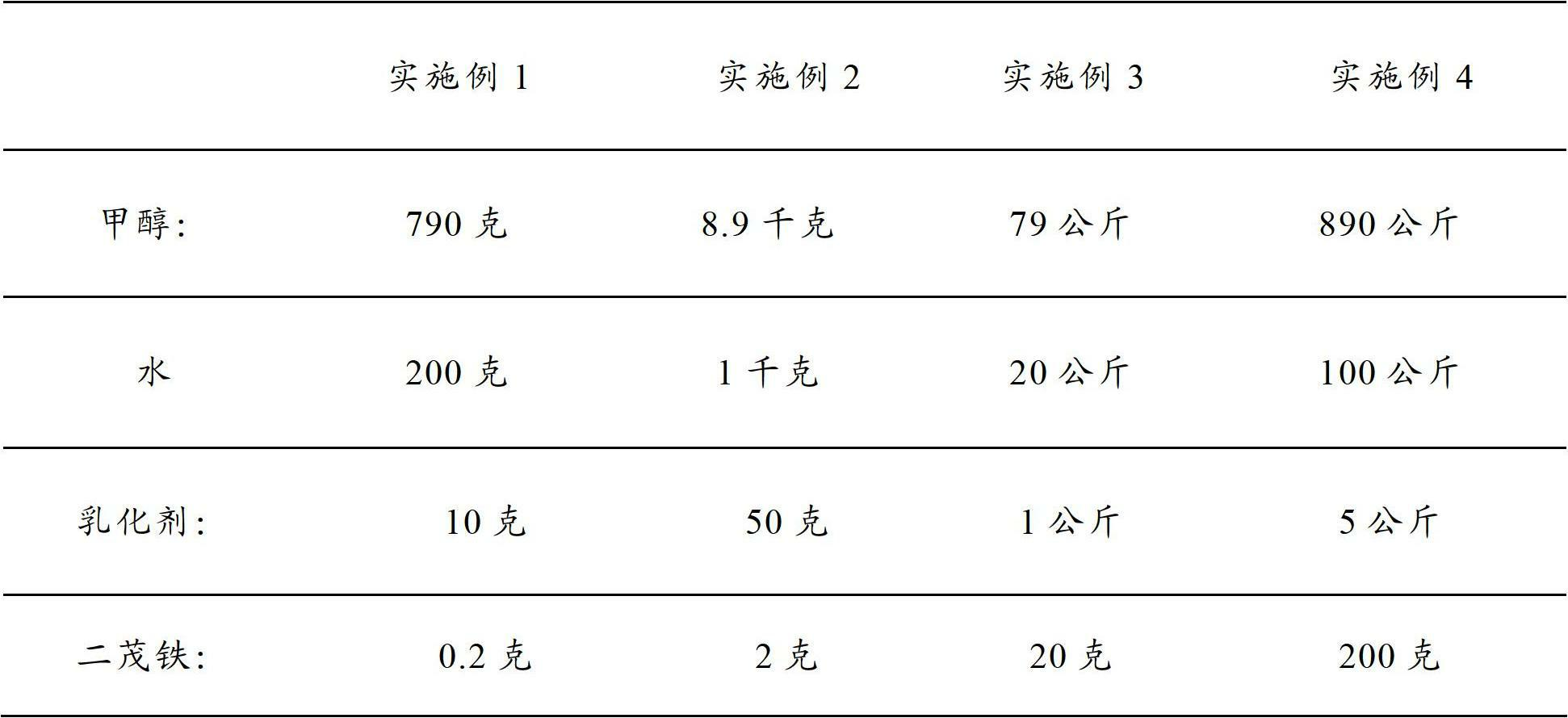

Novel environmental protection and energy saving biological alcohol oil

InactiveCN102358853AHigh combustion valueAvoid situations where you mistakenly drink it for waterLiquid carbonaceous fuelsCombustionAlcohol

Relating to a biofuel, the invention provides novel environmental protection and energy saving biological alcohol oil, which is a biofuel with methanol as the main component. The novel environmental protection and energy saving biological alcohol oil of the invention is characterized by comprising, by weight percent: 75-95 parts of methanol, 0.2-1.0 part of an emulsifier, 0.01-0.5 part of ferrocene, and 5-25 parts of water. Characterized by complete combustion, high calorific value, stable performance, nonvolatility, low condensation point, difficult ignition, an ignition temperature higher than 200DEG C, no pressure, no explosion, and extinguishability by water in an accidental fire, the novel environmental protection and energy saving biological alcohol oil provided in the invention is nontoxic, odorless, smokeless and dust-free renewable green new energy, and has quality reaching the national primary standards of alcohol-based fuels.

Owner:刘一江

Civil use synthetic liquid fuel and its preparation method

A synthetic liquid fuel for civil purpose is prepared from alcohol, H2O2, acetone, camphor extract or essence, and multifunctional additive through proportioning, sequentially mixing and stirring for 3-8 min. Its advantages are low cost, high heat value and no carbon deposit.

Owner:黄海静

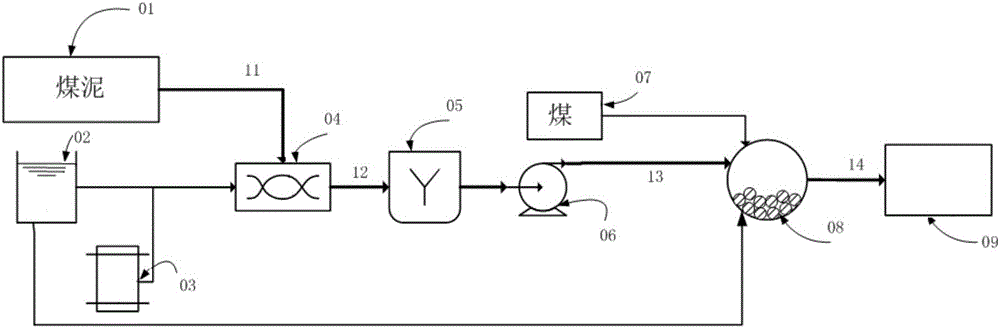

Preparation method for coal water slurry used for gasification

InactiveCN106085524AEasy to realize transportationImprove economyLiquid carbonaceous fuelsFuel additivesCoal waterCoal slurry

The invention provides a preparation method for coal water slurry used for gasification. The preparation method comprises the following steps: step S1, adding water to dilute slime so as to obtain coal slime; step S2, adding coal and water into the coal slime and carrying out mixing so as to obtain mixed coal slurry; and step S3, grinding the mixed coal slurry so as to obtain the coal water slurry for gasification. According to the invention, the slime is diluted with water to prepare the coal slime, which facilitates transportation; then coal and water are added and mixing is carried out so as to prepare the mixed coal slurry; and the coal water slurry for gasification is eventually obtained through grinding. The method prepares the coal water slurry for gasification with an appropriate concentration through dilution at first and supplementation of coal to adjust coal concentration of a product next, so transport of slime according to needs of practical utilization distance is realized, the coal water slurry for gasification with a high combustion value is prepared, and the economic performance of utilization of slime is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

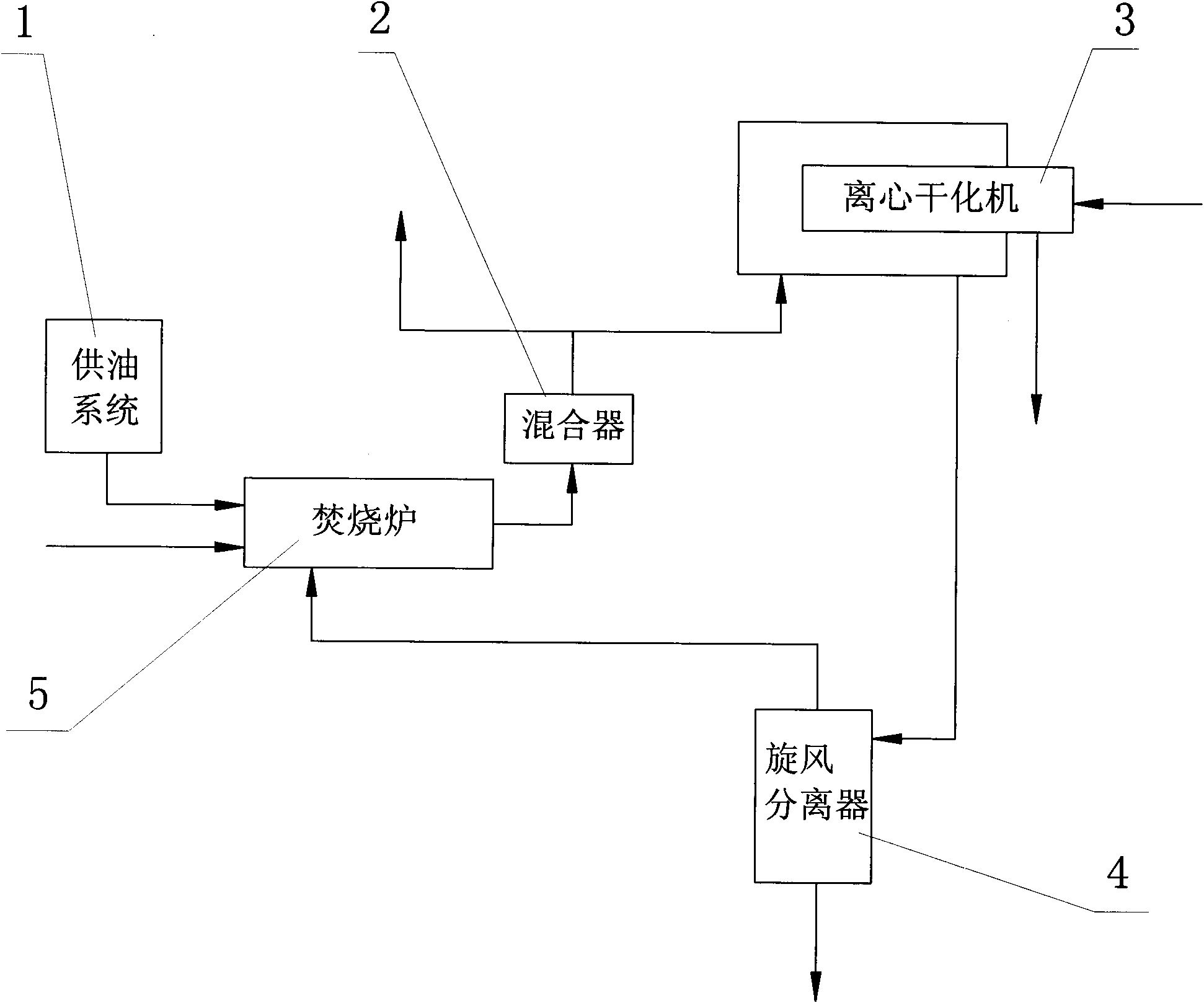

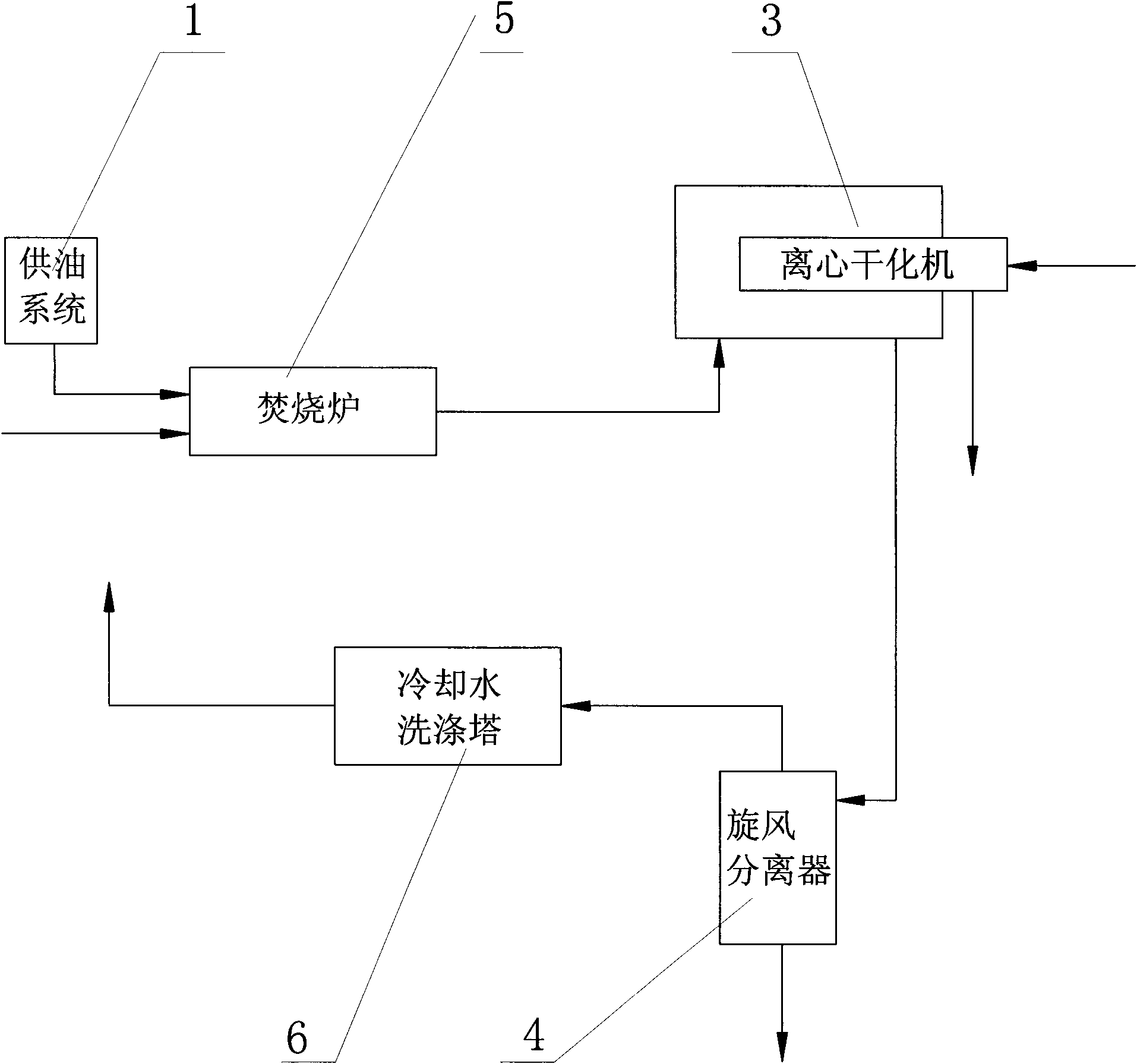

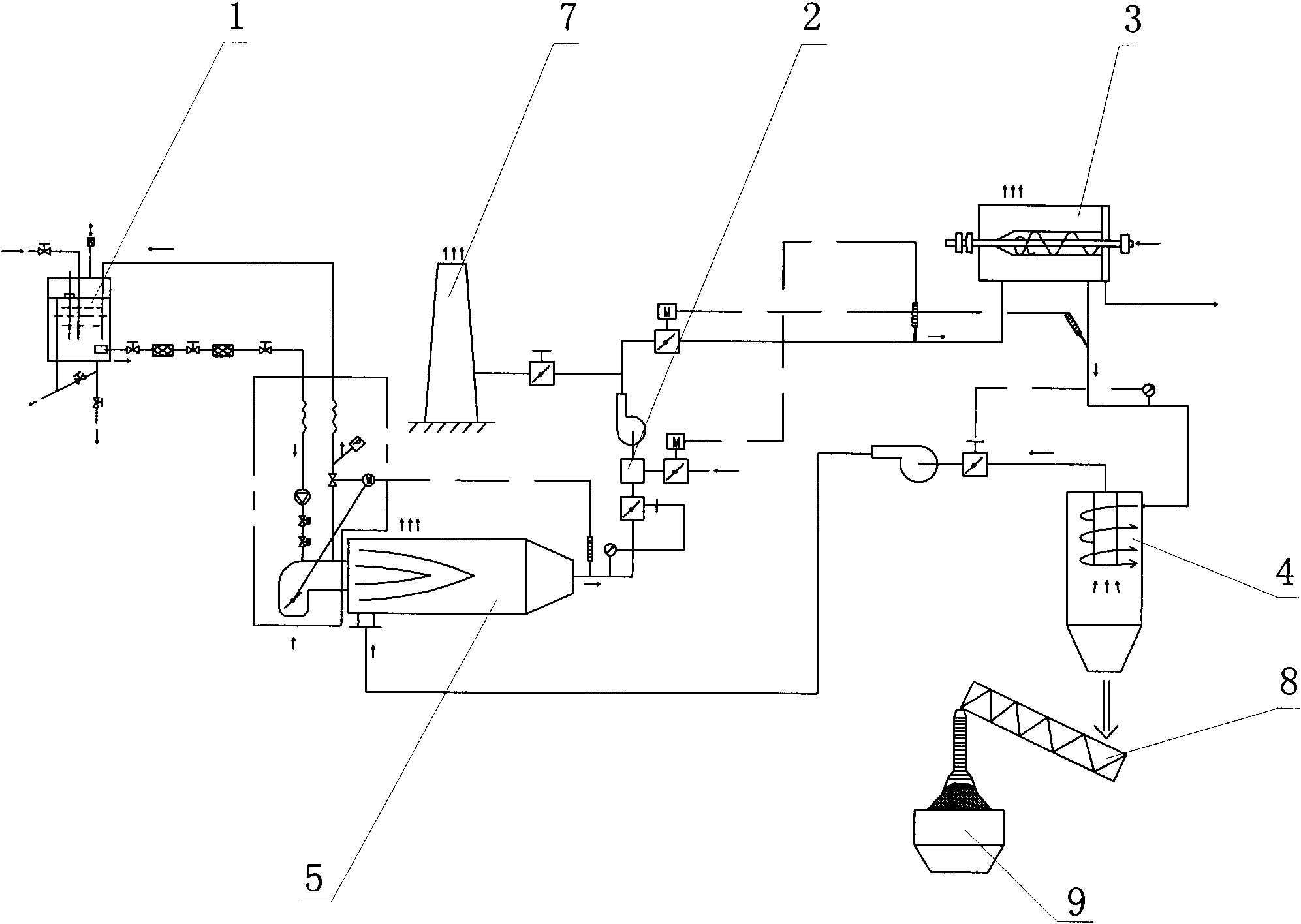

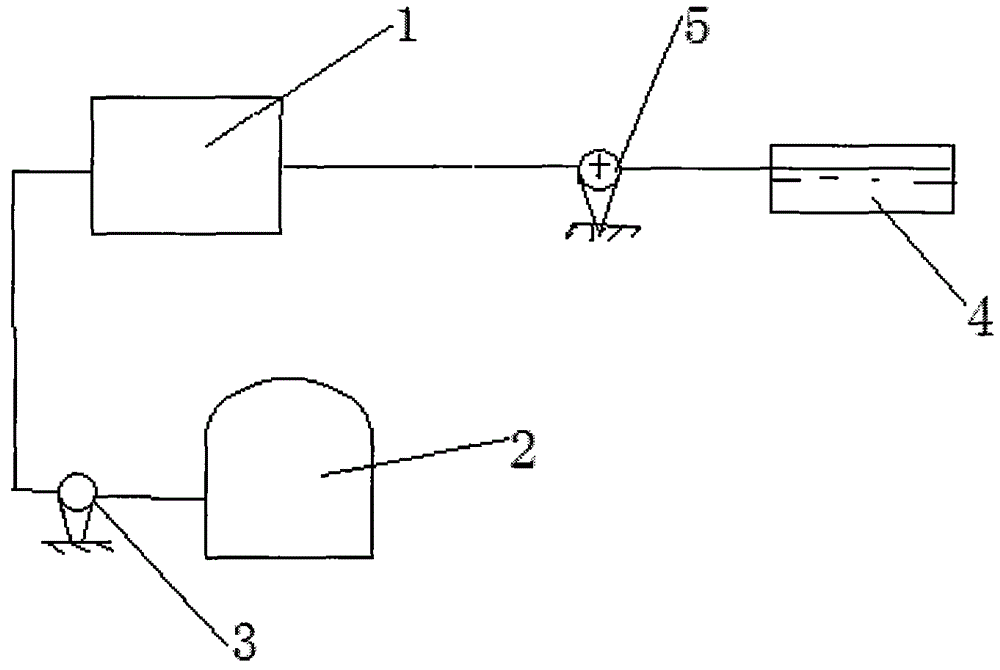

Method for sludge dehydration and drying

InactiveCN102372410AAdequate adaptabilityGuaranteed operational safetySludge treatment by de-watering/drying/thickeningSolid particleMoisture

Relating to the field of sludge treatment, the invention provides a method for sludge dehydration and drying. The method comprises the steps of: sending the sludge to be treated and a hot dry gas into a centrifugal desiccation machine (3), and sending out separated clear water and a gas / liquid mixture respectively from the centrifugal desiccation machine (3); delivering the gas / liquid mixture into a cyclone separator (4), and sending out dried clean solid particles from the lower part of the cyclone separator (4); pumping out moisture-containing exhaust gas from the upper part of the cyclone separator (4); delivering the moisture-containing exhaust gas into an incinerator (5), the fuel of which is provided by an oil supply system (1), and combusting the exhaust gas in the incinerator (5) for 2sec at a temperature of 900DEG C, and sending the combusted high temperature purified gas into high-low temperature gas mixer (2) for mixing so as to obtain a purified gas of 280DEG C, providing part of the purified gas to the centrifugal desiccation machine (3) for drying, and discharging the other part of the purified gas into air through a chimney (7). In the invention, the moisture-containing exhaust gas pumped out dose not need cleaning treatment by cooling water, so that the water resource is substantially saved, and environmental protection treatment to the cooling and cleaning water is avoided. And dual application of one incinerator can improve the incinerator work efficiency. The method provided in the invention has the advantages of less equipment, simplified structure, reduced investment cost, and higher economic benefits.

Owner:SHANGHAI CENTRIFUGE INST

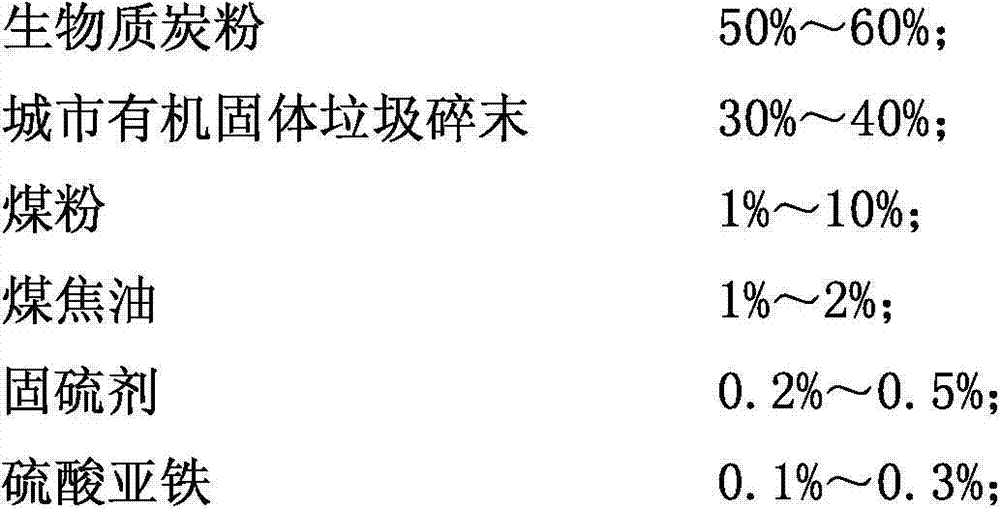

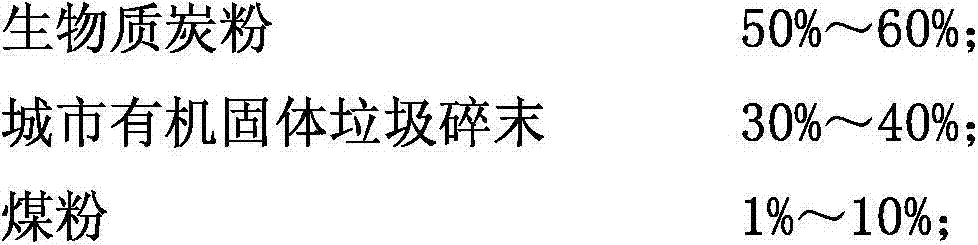

Biomass granular fuel

ActiveCN103937574AEasy to store and transportImprove adhesionBiofuelsSolid fuelsPolyesterEcological environment

The invention discloses a biomass granular fuel. The biomass granular fuel is prepared via uniform mixing of following materials and compression moulding of an obtained mixture. The materials comprise, by mass, 50 to 60% of biomass carbon powder, 30 to 40% of municipal organic solid garbage fragment, 1 to 10% of coal dust, 1 to 2% of coal tar, 0.2 to 0.5% of a sulfur fixing agent, and 0.1 to 0.3% of ferrous sulphate. The outer surface of the biomass granular fuel is coated with a layer of biomass polyester. According to the biomass granular fuel, organic combination of biomass energy, mineral fuel, and municipal organic solid garbage is realized; the obtained biomass granular fuel is excellent in caking ability, high in combustion value, and low in combustion pollution, and is beneficial for construction of ecological environment; sulfur dioxide and fly ash are hardly generated; and the outer surface of the biomass granular fuel is coated with a layer of biomass polyester, so that storage and transportation of the biomass granular fuel is convenient, and fragmentation of particles is not easily caused.

Owner:泗洪新创源木业有限公司

Method for generating electricity using cow dung as fuel

InactiveCN102444435AHigh combustion valueHigh densityBiofuelsSolid fuelsCombustion chamberFuraldehyde

The invention discloses a method for generating electricity using cow dung as fuel. The method comprises the following steps of: burning the cow dung in a steam boiler to prepare high-pressure steam; using the high-pressure steam to drive a steam turbine to rotate; and using the steam turbine to drive an electric generator to rotate for generating electric current, wherein the cow dung needs pre-treatment before being fed to a boiler furnace, and the pre-treatment comprises the following steps of: carrying out solid-liquid separation to fresh cow dung, so that the moisture content of the cow dung is smaller than or equal to 55%, and then wet cow dung is obtained; mixing and uniformly stirring the wet cow dung with furaldehyde residue to acquire the dung residue mixture; drying the dung residue mixture to acquire the dry dung residue mixture; thermoforming the dry dung residue mixture to acquire the cow dung electricity-generating fuel. The method uses the cow dung as the fuel to produce high-temperature and high-pressure steam which drives the steam turbine to rotate, so that the steam turbine drives the electric generator to rotate and generate electricity, thus the purpose of using cow dung to replace non-renewable resources such as coal or petroleum and the like to generate electricity is achieved.

Owner:刘明全

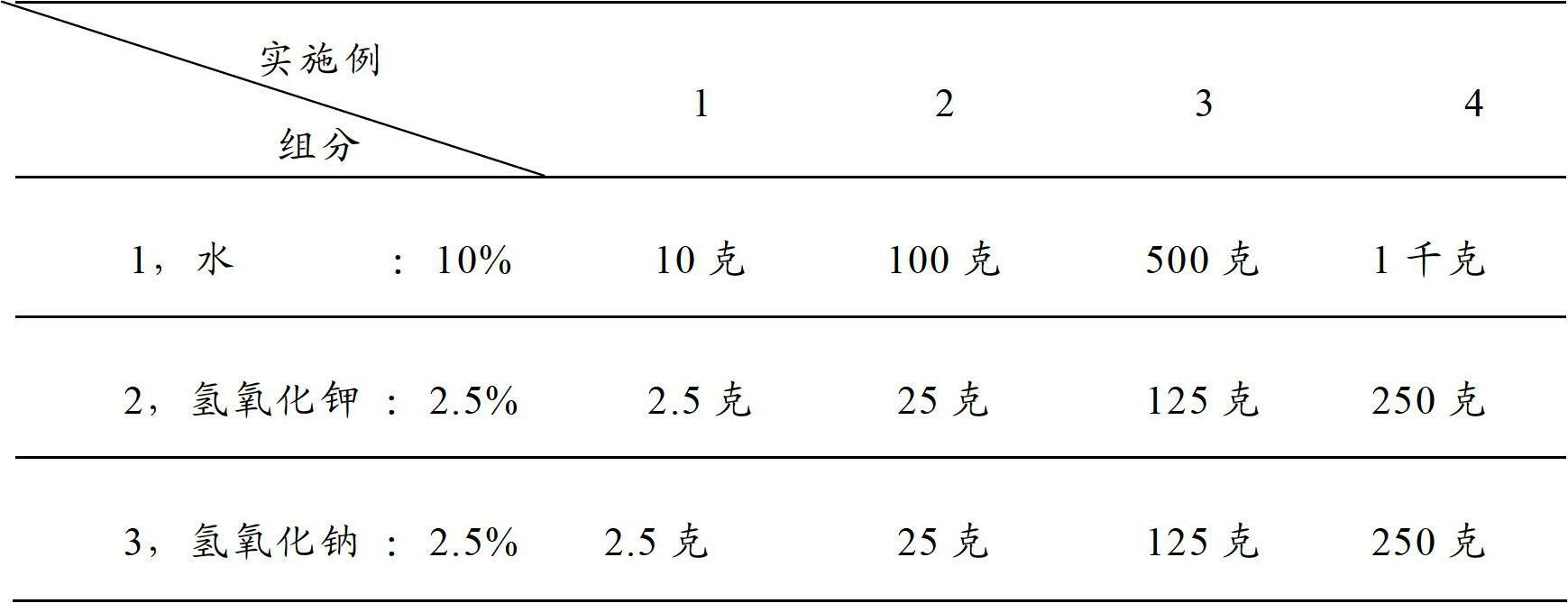

Biological alcohol oil and preparation method thereof

InactiveCN102660334ABurn fullyHigh combustion valueLiquid carbonaceous fuelsPotassium hydroxideEthyl acetate

The invention provides a biological alcohol oil composition which is characterized by comprising the following materials in parts by weight: 79 to 89 parts of methanol, 10 to 20 parts of water, 5 to 10 parts of mixed emulsifier and 0.2 to 0.5 part of ferrocene. The mixed emulsifier comprises water, potassium hydroxide, sodium hydroxide, ethyl acetate, ethanol and inevitable impurities. The biological alcohol oil composition provided by the invention has a high combustion value, can be burned completely and does not pollute air. The invention provides a preparation method of the biological alcohol oil composition.

Owner:王国平

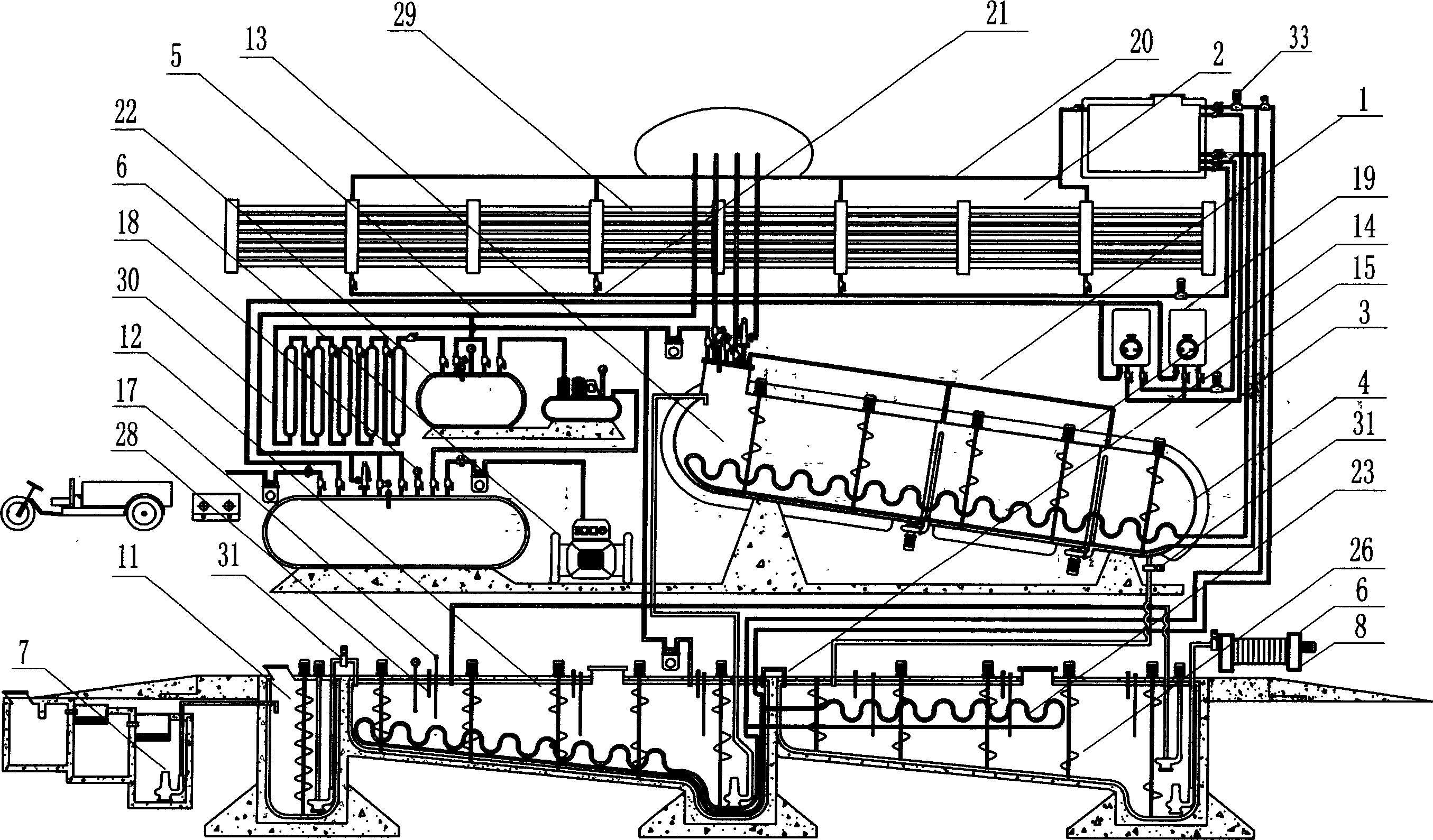

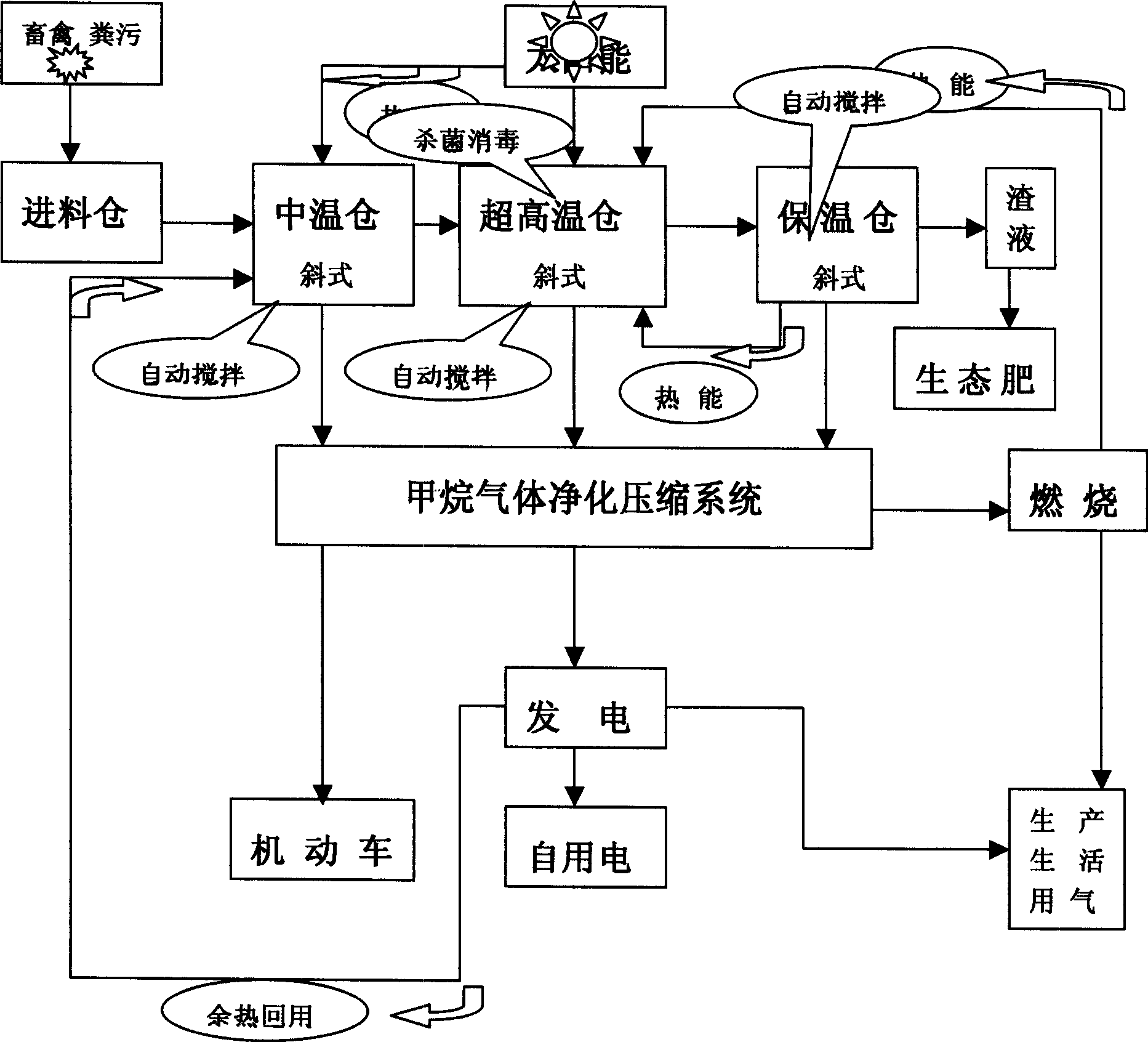

Fast disinfectant anti-epidemic system with super-high temperature for bird and animal manure anaerobe and treatment

InactiveCN1817370AEfficient killingEfficient disseminationLavatory sanitoryDisinfectionThermal energyFowl

A biologic fast disinfecting and anti-epidemic system for treating the droppings and dung of fowls and animals is composed of ultrahigh-temp anaerobic biologic fermenting system, solar energy and self heat feedback and compensation system, full-automatic control system PLC, inertial gas insulating system, marsh gas cleaning and storing system, electric generation system, sewage treating system, and the system for treating the residual liquid and dregs of marsh gas to obtain organic fertilizer. Its method is also disclosed.

Owner:钟亚伟

Biomass particle fuel

The invention relates to biomass particle fuel which comprises the following components in parts by weight: 40-70 parts of animal waste, 50-80 parts of biomass, 20-35 parts of gangue powder, 12-20 parts of bulking agent and 20-28 parts of combustion improver. The biomass particle fuel is low in water content and high in lignin content; and the abundant animal waste and the abundant biomass are utilized, so that pollution of activities such as animal waste incineration to air is greatly reduced, the biomass is effectively treated, a recycling value is increased, and the biomass particle fuel ismore environment-friendly. Compared with the conventional biomass particle fuel, the biomass particle fuel is high in combustion value and long in combustion time, has no harmful gas discharge aftercombustion, and cannot corrode combustion equipment.

Owner:桂林市安琪玫瑰农业发展有限公司

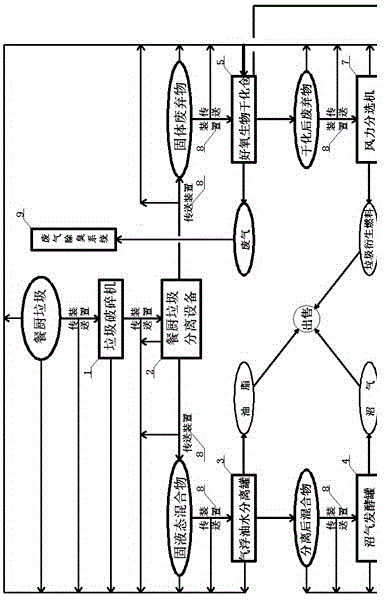

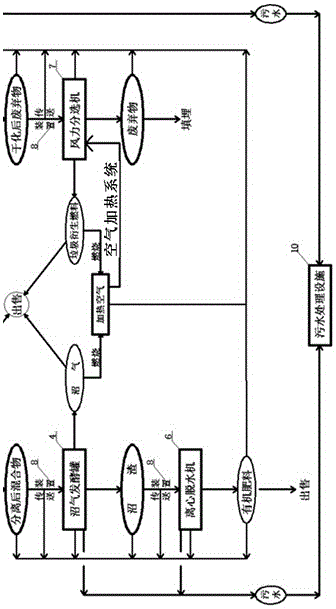

Comprehensive treatment device and method for kitchen waste

The invention discloses a comprehensive treatment device and method for kitchen waste. The comprehensive treatment device and method are used for kitchen waste treatment. By the adoption of the comprehensive treatment device and method, a solid-liquid mixture (the mixture of original food, grease, water and the like) in the kitchen waste and solid waste (such as original food packaging materials and containing materials) are separated and then treated respectively; the grease in the solid-liquid mixture is separated to be used for producing biodiesel, the solid-liquid mixture without the grease is fermented for producing methane, and biogas residues form organic fertilizer finally; aerobic bio-drying and wind separation are conducted on the solid waste to form waste derived fuel; and waste leachate generated in the comprehensive treatment process is treated through a sewage treatment device and then drained. After the kitchen waste is treated through the comprehensive treatment technology, the purpose of recycling, reducing and harmless treatment is achieved.

Owner:SOUTH CHINA UNIV OF TECH +1

Novel sludge deep dehydration rinsing agent

InactiveCN103332849AGood conditioning effectHigh strengthSludge treatment by de-watering/drying/thickeningSludge cakeAluminium chloride

The invention discloses belongs to the technical field of sludge deep dehydration and relates to a novel sludge deep dehydration rinsing agent. The rinsing agent comprises the following substance according to weight percentage: 5 to 30 percent of activated charcoal powder, 30 to 70 percent of fly ash, 5 to 30 percent of quicklime powder, and 1 to 20 percent of polyaluminum ferric chloride. The invention further discloses a using method of the rinsing agent. In the invention, the rinsing agent added is cheap material, and replaces rinsing agents such as conventional polyacrylamide flocculating agent, iron trichloride, calcium oxide and the like, and after dehydration, sludge cakes can be used as raw material for building material and fuel.

Owner:KANGTAI JIANGSU ENVIRONMENTAL PROTECTION LTD BY SHARE LTD

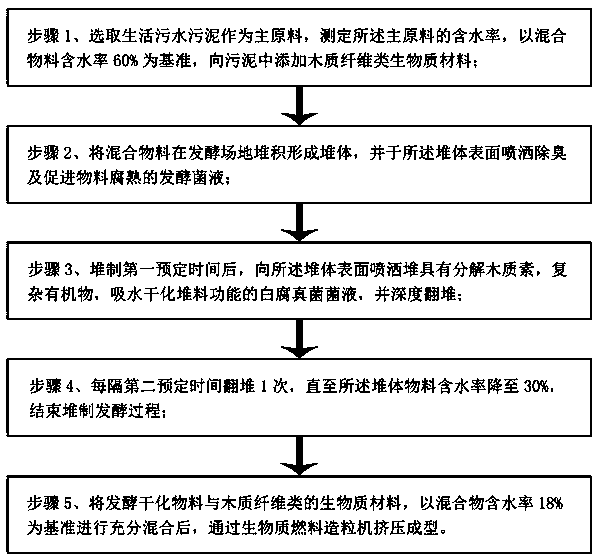

Manufacturing method of sludge biomass compact briquette fuel

InactiveCN103805304AThe pre-processing process is simpleAvoid the pitfalls of large fluctuations in moisture contentBiofuelsSolid fuelsFiberEnvironmental resistance

The invention provides a manufacturing method of a sludge biomass compact briquette fuel. The traditional method has different weaknesses. The manufacturing method comprises the following steps: selecting the domestic sewage sludge as a main raw material; stacking the mixed material on a fermentation field to form a stack body, and spraying a deodorized fermentative bacteria liquid capable of promoting the rotting of the material on the surface of the stack body; spraying white-rot fungi liquid containing decomposed lignin and composite organism and having a function for absorbing the water and drying the stacked material on the surface of the stack body after the stack body is stacked for a first predetermined time, and deeply turning the stack body; turning the stack body one time every a second predetermined time until the moisture content of the stack body material is reduced to 30 percent, and ending the stacking fermentation process; adequately mixing the fermented dry material and the wood fiber biomass material by adopting the water content of the mixture of 18 percent as a benchmark, and extruding and forming the mixture. The method is simpler to operate, the technological parameters are stable and easy to control, the energy consumption is greatly reduced, no non-biomass additive is added, and the product is cleaner and more environment-friendly.

Owner:汪兴华

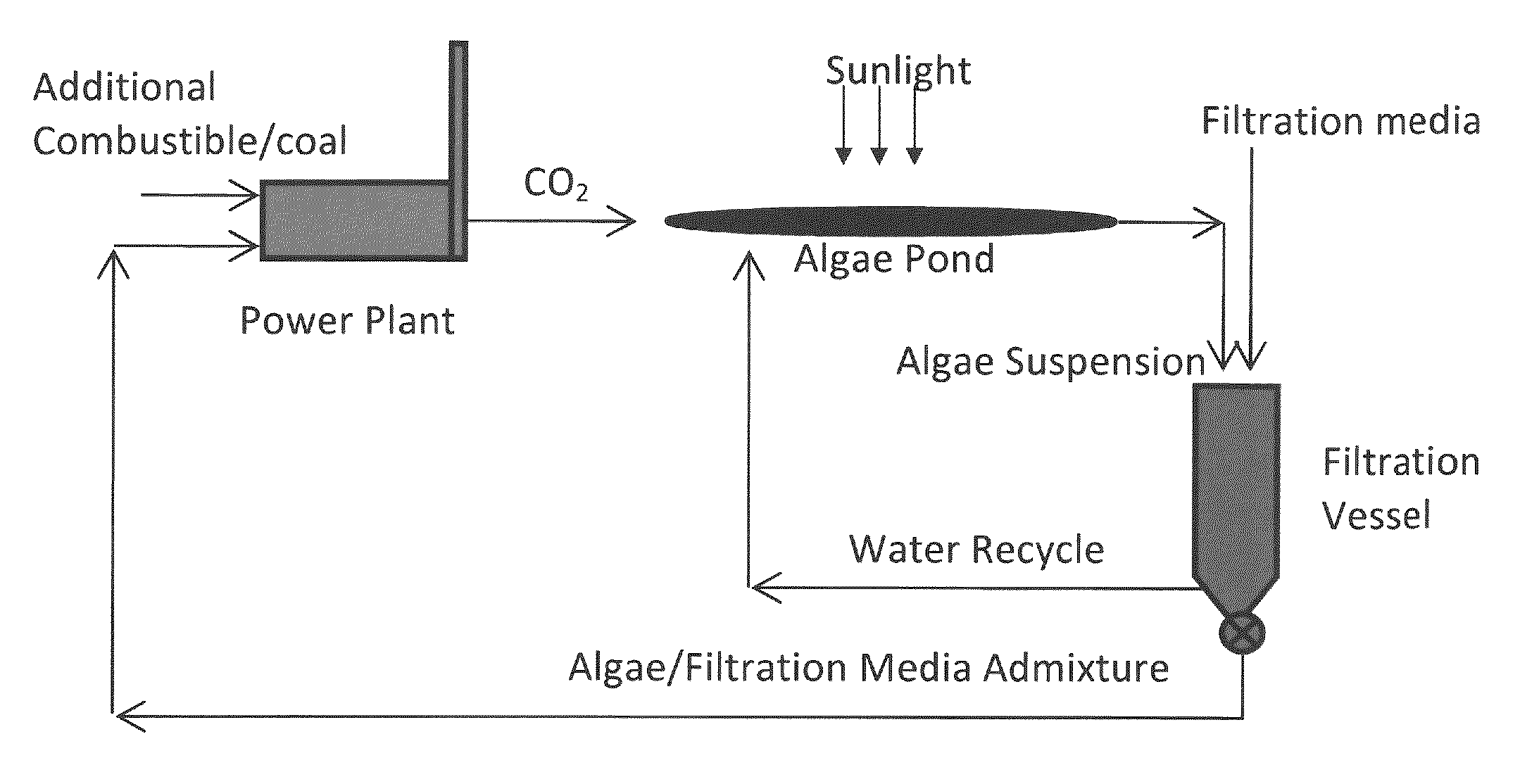

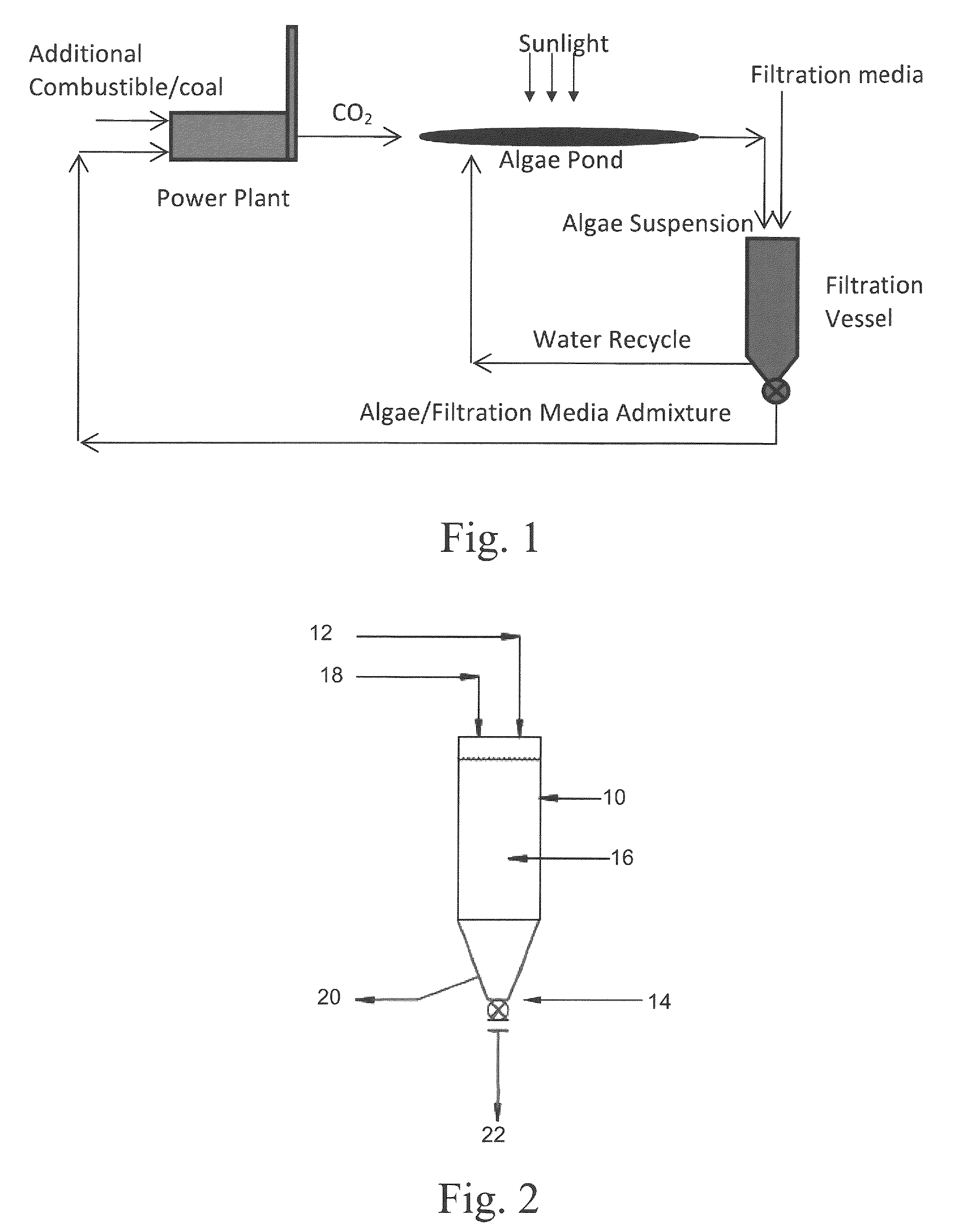

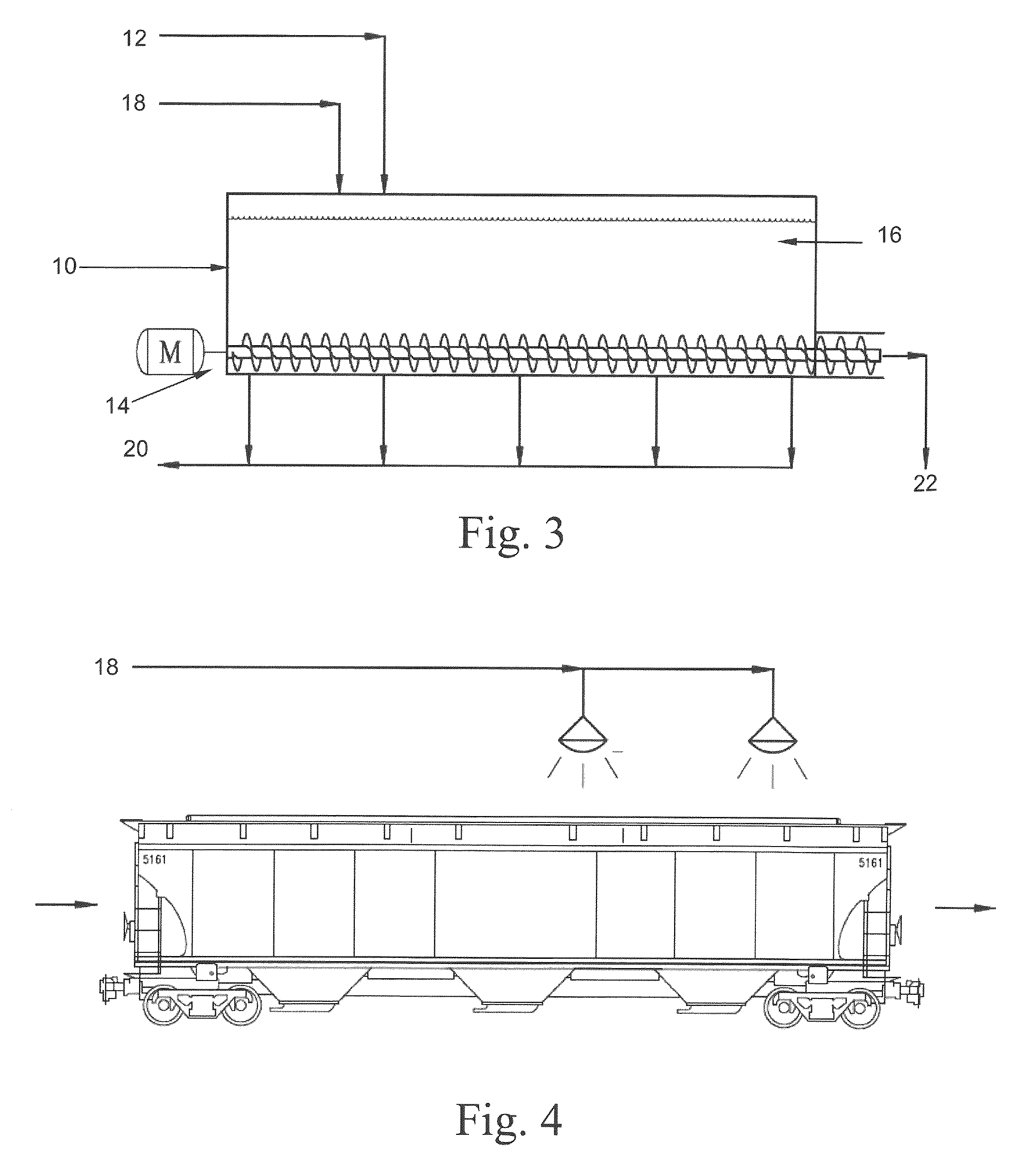

Methods of algae harvesting utilizing a filtering substance and uses therefor

InactiveUS8518132B2Reduce energy inputHigh salinityFatty oils/acids recovery from wasteLiquid separation auxillary apparatusFood supplementFiltration

Owner:RETTENMAIER ALBERT C

Environment-friendly liquid fuel with high heating value and preparation method

InactiveCN101531927AReduce consumption costReduce consumptionLiquid carbonaceous fuelsParaffin waxLiquid fuel

The invention relates to an environment-friendly liquid fuel with high heating value, comprising the ingredients with the following weight ratio contents: 70-75 of methanol, 10-15% of water, 13-16 turpentine oil and 1-4 of additive. The additive is prepared by hydrogen peroxide with weight percent concentration of 30%, cyclohexane, ferrocene, liquid paraffin and ethanol. The preparation method comprises the following steps: firstly preparing the additive, then adding the methanol, water and turpentine oil into an agitated tank, finally adding the prepared additive in proportion to obtain the product after agitating. The invention has the advantages of low fuel cost, simple and convenient production technique, high heat value of combustion, easy procurement of raw materials, no pollution and saved energy, produces no harmful gases in the process of combustion, thus being convenient, practical, safe and environment-friendly.

Owner:SHAOGUAN FUDE ENVIRONMENTALLY FRIENDLY FUELS

Low-chlorine value biomass briquette fuel and production method thereof

The invention discloses a low-chlorine value biomass briquette fuel. According to the invention, the pretreated corn straws are taken as a raw material for anaerobic fermentation for 10-20 days, so that mechanical endurance of the briquette fuel is increased, magnesium carbonate is taken as an anti-slagging agent, during a combustion process, the Mg element and elements such as Si, K, and Na which are inherent in the corn straws and are capable of slagging are subjected to a reaction, a novel compound K2Mg(SO4)2 is generated and provides anti-slagging performance to the briquette fuel, and the produced briquette fuel has the advantages of low chlorine value and high combustion value, no harmful gas is discharged after combustion is carried out, and a boiler is not easily corroded.

Owner:蚌埠华东石膏有限公司

Biogas composite material

InactiveCN103103216AShort startup timeIncrease gas productionWaste based fuelFermentationDecompositionPoultry litter

The invention discloses a biogas composite material, which is characterized by comprising 70-80kg of excrements of livestocks, 10-15kg of mushroom dreg, 10g of biological bacteria and 5kg of biogas residue by mass. The excrements of livestocks comprise 30kg of dried poultry litter, 10-40kg of dried pig litter and 10-40kg of dried cow litter. The biogas residue is a product which obtained by sediments in a biogas digester through drying and crushing. The biogas composite material has the advantages that the aerogenesis duration is long, the biogas production rate is high, the biogas production speed is fast, the decomposition of cellulose and hemicellulose can be promoted so that the utilization ratio of material can be enhanced, the methane content in biogas is obviously increased, the biogas is convenient for industrialized production and transportation, the usage is convenient for the farmers, the raw materials are easy to be obtained, the rural pollution can be effectively solved, and the waste can be comprehensively used.

Owner:营山县朗润创新能源有限公司

Straw shaped fuel and preparation thereof

InactiveCN1424385AOvercoming the disadvantage of low utilizationAvoid missingBiofuelsSolid fuelsEngineeringCoal gangue

Owner:孙永章

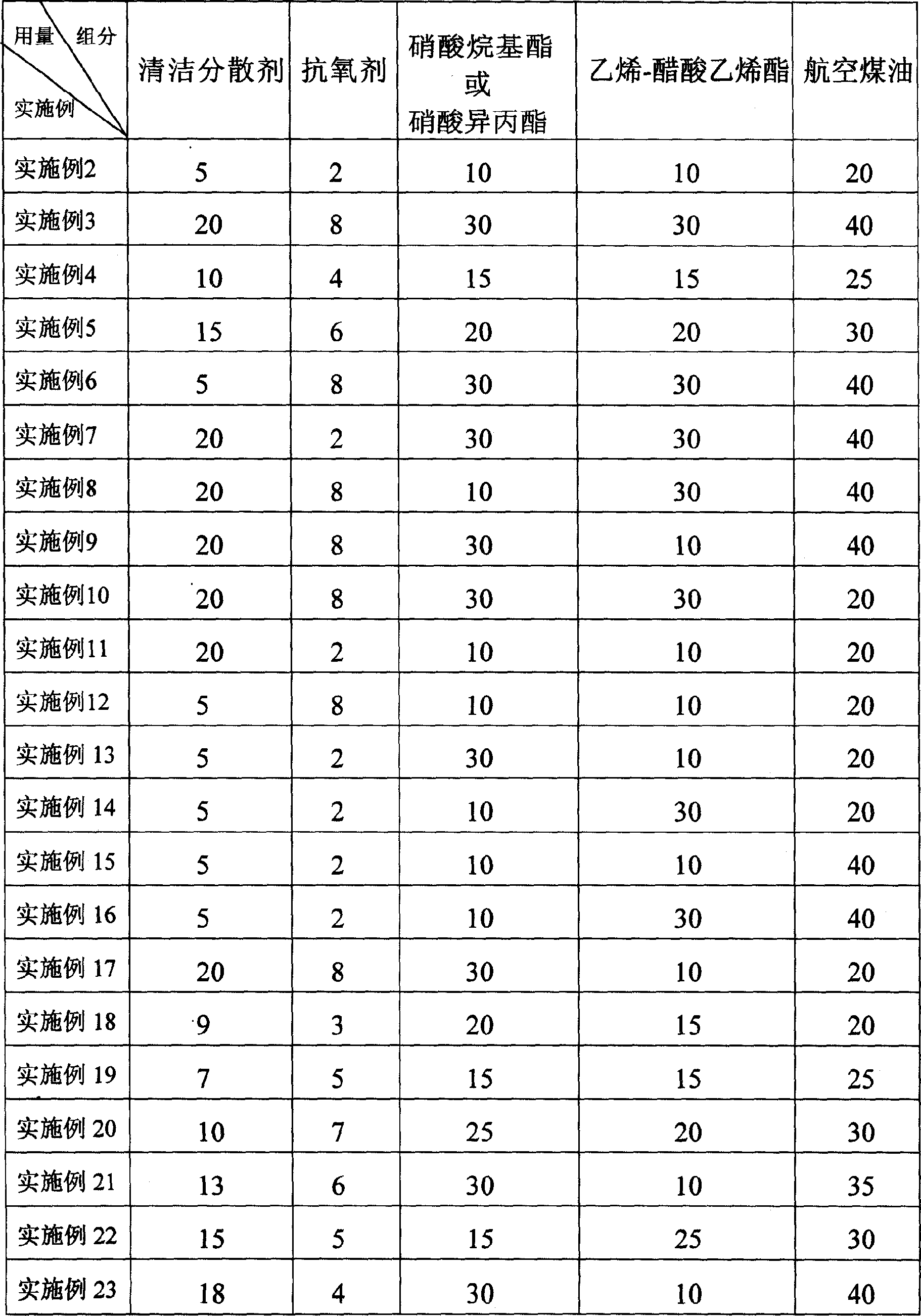

Smoke abatement anti-freeze agent for diesel fuel

The invention provides an environment-friendly type diesel smoke abatement and anti-freeze agent for purifying emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate or ethylene / vinyl acetate and high grade plane kerosene through high-shearing mixing and emulsion process. The invention can realize good intensified smoke abatement property and fluidity for diesel under low-temperature.

Owner:牛云龙

Highly efficient alcohol-based fuel emulsifier

InactiveCN103484178AHigh combustion valueEmission reductionLiquid carbonaceous fuelsAlcoholLiquid gas

Under the effect of a highly efficient alcohol-based fuel emulsifier, environmentally friendly biological alcohol oil with calorific value improved by about one time compared with low calorific value of chemical crude alcohol can be used in the fields of restaurants, metal heat treatment and the like for replacement of diesel oil and liquefied gas. The advantages are as follows: high calorific value (8800 kcal / kg), easily purchasable raw materials, economy and environmental friendliness, less investment, simple process and wide development prospects.

Owner:包寅戈

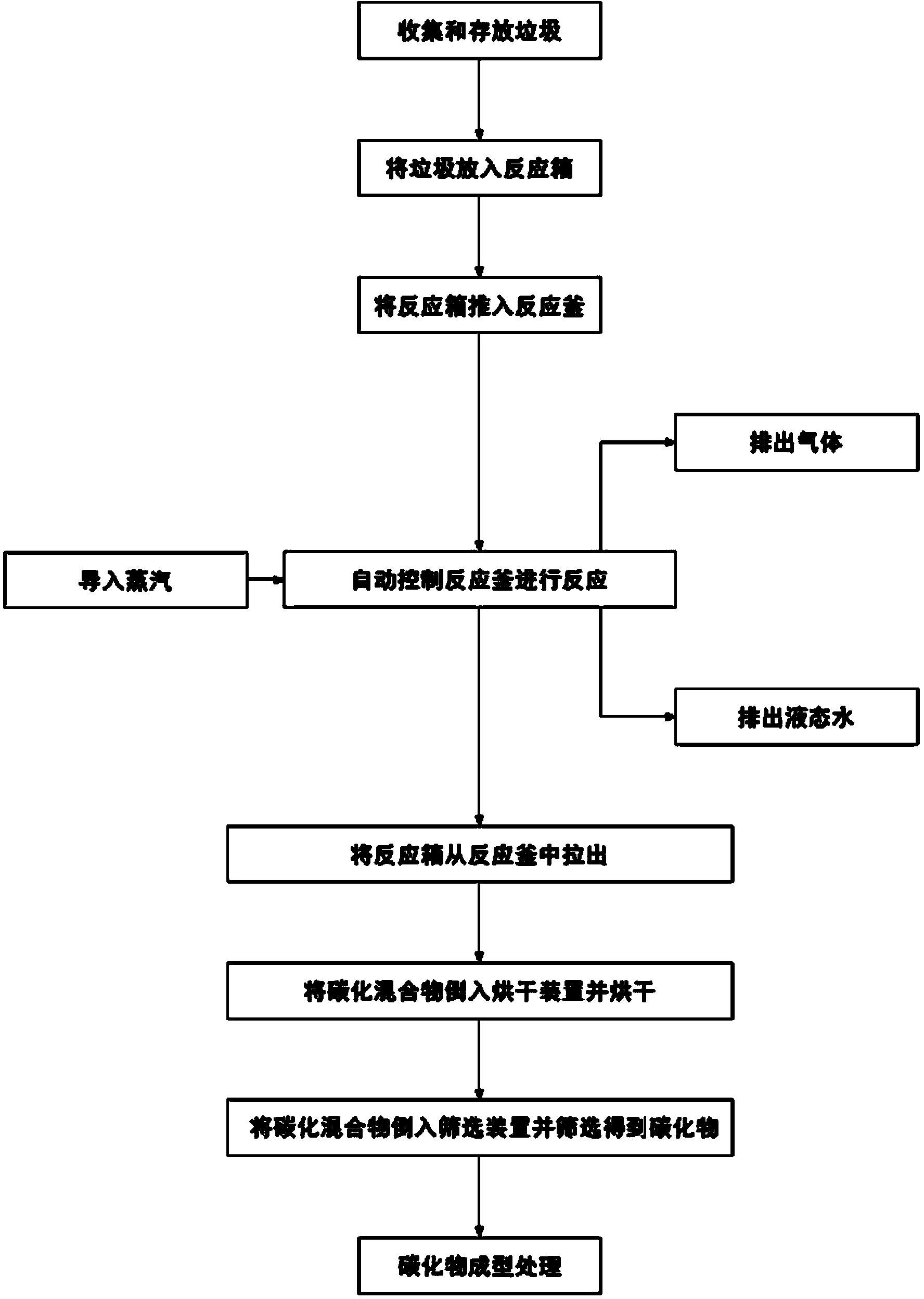

Manufacturing method of pollution-free coal with high combustion value by household garbage

InactiveCN104031713AClassification requirements are lowAdvanced and reasonable process routeSolid waste disposalBiofuelsCombustionCarbide

The invention relates to a manufacturing method of pollution-free coal with a high combustion value by household garbage. The manufacturing method specifically comprises the following steps: S1, conveying garbage from dispersing points to a garbage storage area; S2, conveying the garbage from the garbage storage area to a reaction kettle automatically or manually, and completely sealing the reaction kettle; S3, introducing steam into the reaction kettle and dynamically controlling time-dependent temperature and pressure of the garbage to form a carbonized mixture; S4, reducing the temperature and pressure in the reaction kettle and discharging liquefied water and gases formed in reaction; and S5, pouring the carbonized mixture formed in the step 3 into a screening device which screens incombustible matters out of the carbonized mixture, and finally obtaining the carbide. The manufacturing method provided by the invention is pollution-free in processing process and low in processing cost, and the prepared garbage coal is high in combustion value and low in emission.

Owner:沙嫣 +1

Environmentally-friendly biomass granule fuel

The invention discloses an environmentally-friendly biomass granule fuel. The environmentally-friendly biomass granule fuel comprises sawdust, crop straw, anthracite smalls, sludge garbage, tea leaf residues, rice hull powder, attapulgite clay, montmorillonite and red mud. According to the environmentally-friendly biomass granule fuel, treatment of the sludge garbage is more environmentally friendly and economical, and the cost of the environmentally-friendly biomass granule fuel is low; compared with biomass granule fuels of the same type which are not compatible with the sludge garbage, theenvironmentally-friendly biomass granule fuel has higher heat value; moreover, the environmentally-friendly biomass granule fuel overcomes the phenomenon of slag-bonding, and discharging of harmful air is greatly reduced.

Owner:安徽盛昌生物能源科技开发有限公司

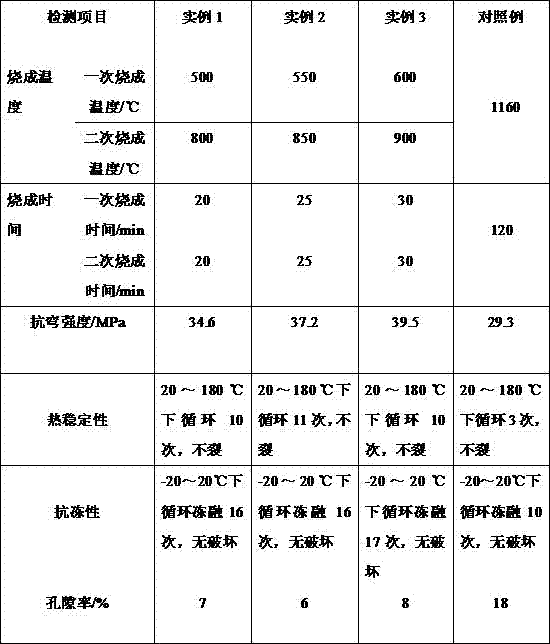

Low-temperature-fired antique glazed tile and its preparation method

InactiveCN107417254ALow melting pointEvenly heatedCeramic materials productionClaywaresFree coolingRoom temperature

The invention discloses a low-temperature-fired antique glazed tile and a preparation method thereof, belonging to the field of building materials. The method comprises the following steps: weighing the raw materials of the low-temperature-fired antique glazed tile, adding water for batch mixing and carrying out aging so as to obtain an aged mixture; compacting the aged mixture to form a blank and carrying out demolding so as to obtain a tile blank; subjecting the tile blank to drying and pre-firing so as to obtain a pre-fired tile blank; then carrying out fumigation, cooling and drying so as to obtain a fumigated tile blank; weighing raw materials for a glaze of the low-temperature-fired antique glazed tile and carrying out batch mixing so as to obtain the glaze; coating the surface of the fumigated tile blank with the obtained glaze and carrying out drying so as to obtain a glazed tile blank; and carrying out heating and heat preservation twice and then carrying out natural cooling to room temperature so as to obtain the low-temperature-fired antique glazed tile. The invention has the beneficial effects that the low-temperature-fired antique glazed tile is low in firing temperature, short in firing time, low in energy consumption, high in product density and good in mechanical properties, has excellent application prospects, and is worthy of promotion and application.

Owner:YUHUAN DEGU NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com