Patents

Literature

995results about How to "Improve combustion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

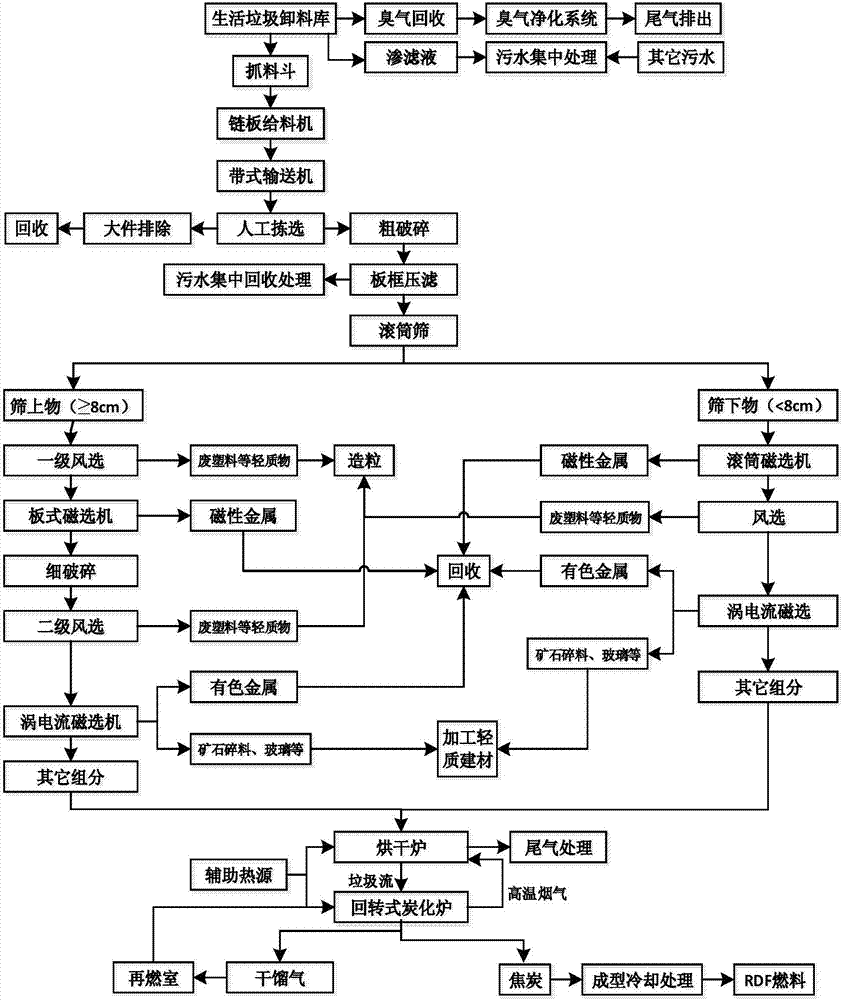

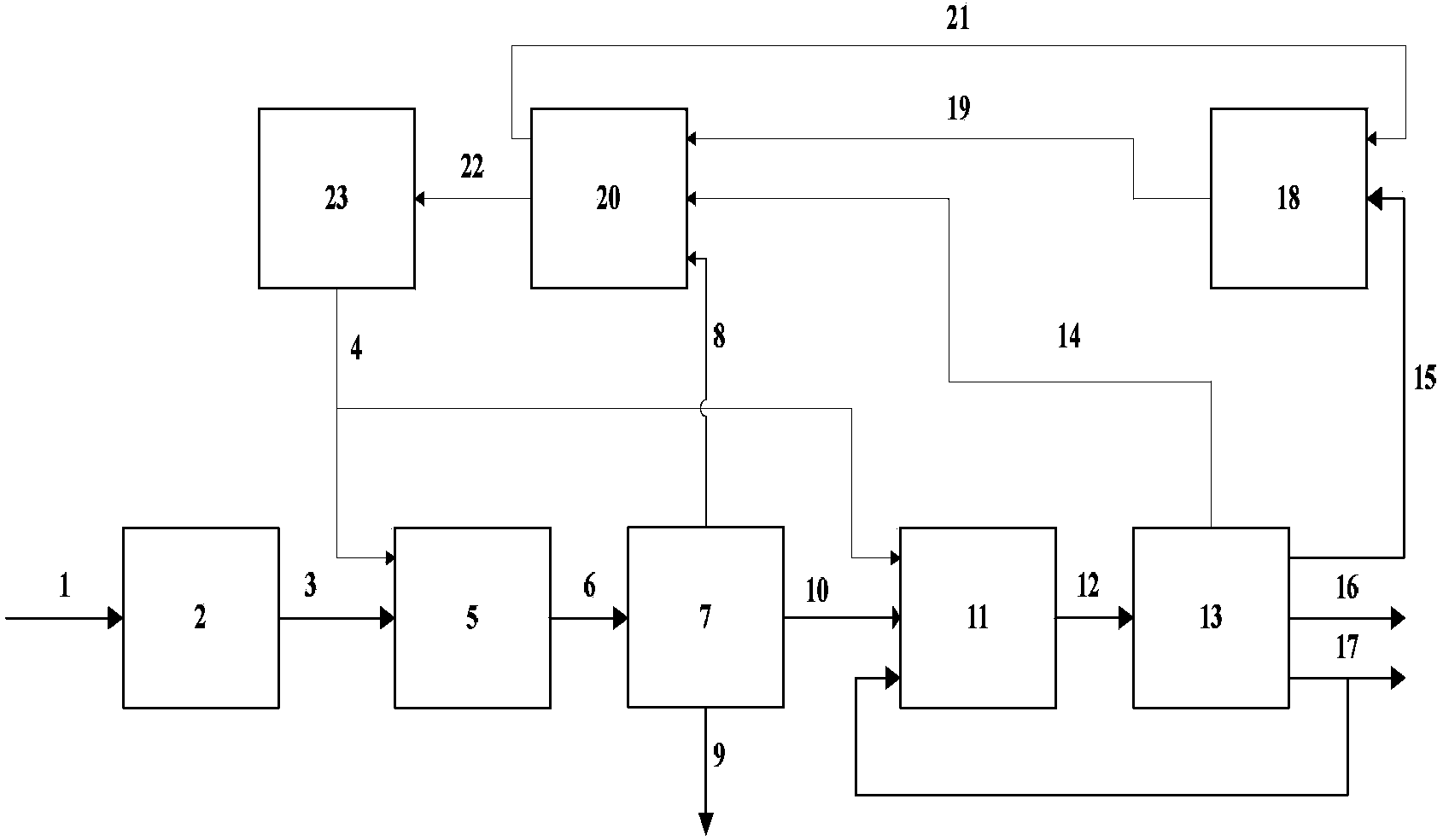

Urban household garbage sorting and charring comprehensive treatment resource recovery method

InactiveCN107497831AHigh degree of automationImprove sorting efficiencyTransportation and packagingSolid waste disposalSolid carbonResource recovery

A urban household garbage sorting and charring comprehensive treatment resource recovery method comprises the first step of garbage sorting treatment, wherein original household garbage is subjected to uniform feeding, manual large garbage sorting, coarse crushing, plate-frame pressure filtering, rolling cylinder screening, full-closed mechanical selecting by winnowing, plate-type magnetic separator treating, eddy current magnetic separator treating and fine crushing process treatment; the second step of garbage drying treatment; the third step of garbage charring treatment, wherein a rotary charring furnace is adopted, and garbage charring is carried out in a normal-pressure low-temperature and low-oxygen atmosphere so that solid carbon can be prepared; the fourth step of coke forming and cooling treatment; the fifth step of bad smell purifying treatment, wherein bad smell generated in a household garbage discharging warehouse and bad smell generated in all treatment process links are collected to a bad smell purifying system through a negative pressure induced draught system; and the sixth step of waste water purifying treatment. The urban household garbage sorting and charring comprehensive treatment resource recovery method is relatively high in automation degree, sorting efficiency and recovery utilization rate and has more sorting functions.

Owner:李新方

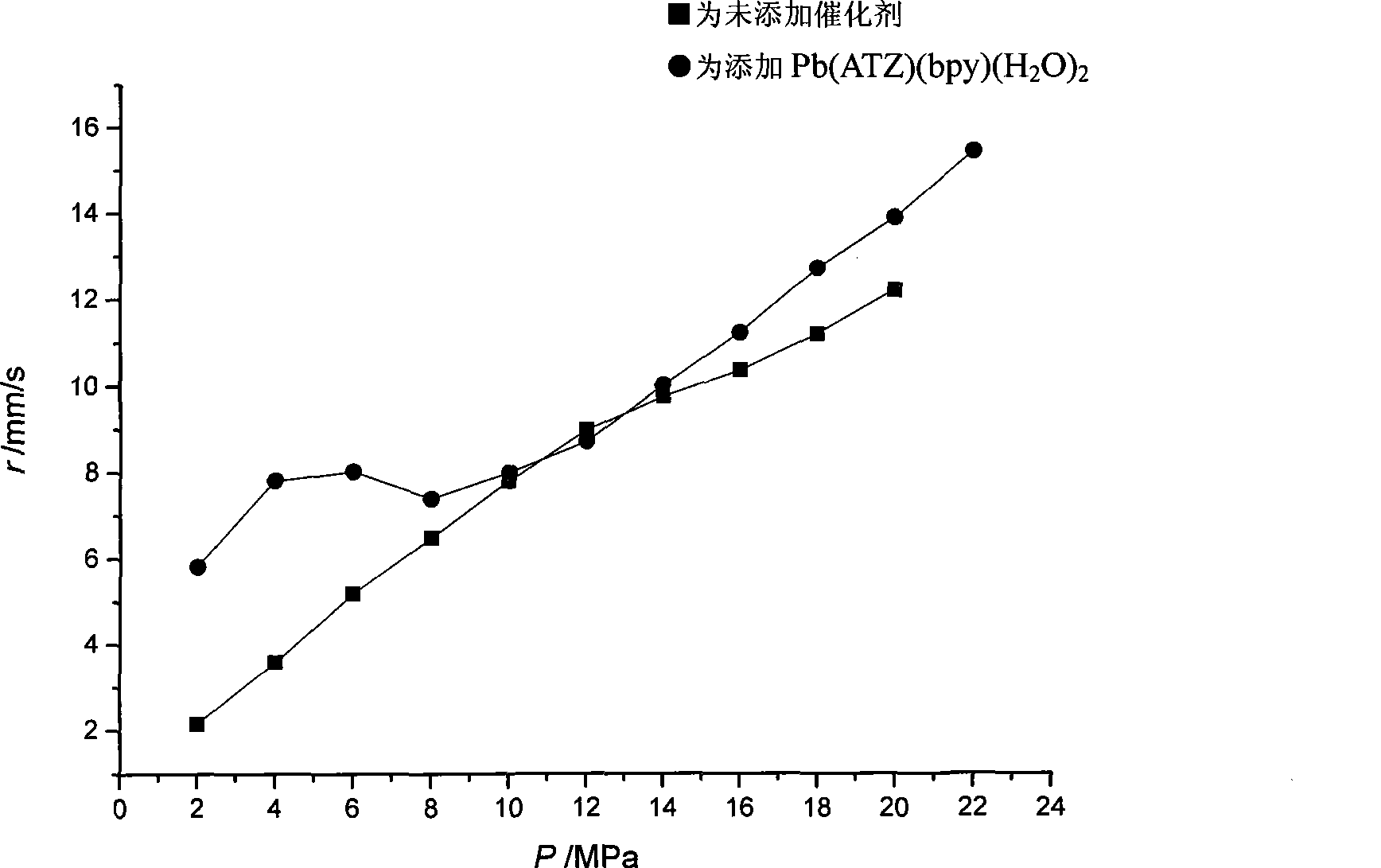

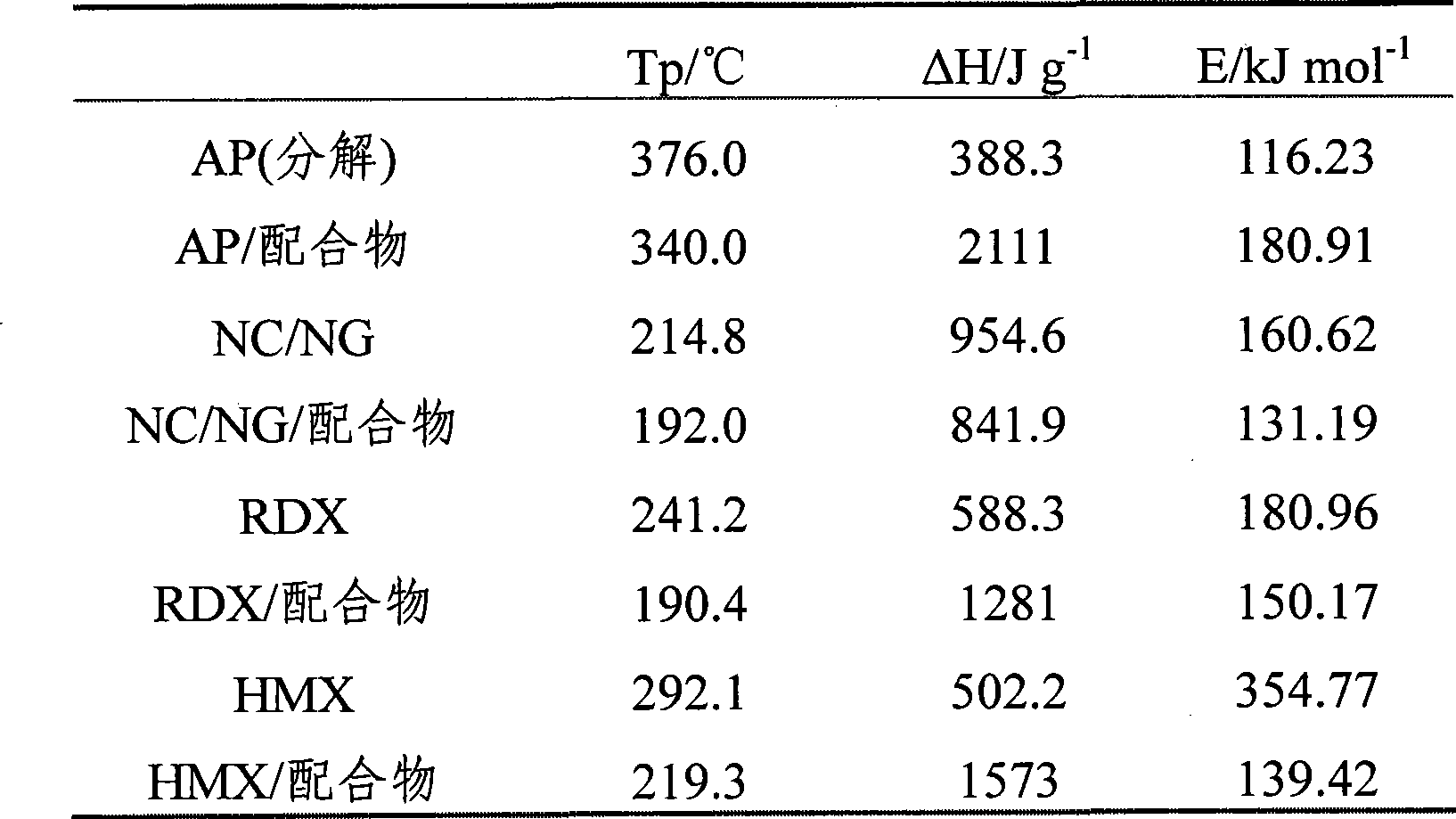

Energetic coordination complex based on azo tetrazole azotetrazole and use thereof

InactiveCN101434617AImprove combustion performanceAchieve high energyOrganic-compounds/hydrides/coordination-complexes catalystsCopper organic compoundsTetrazoleO-PHENANTHROLINE

The invention discloses an azotetrazole-based energetic compound with the composition of M(ATZ)(L)n question mark mH2O, wherein, M refers to Mn, Co, Ni, Cu, Zn or Pb; ATZ refers to 5, 5'-azotetrazole ion, L refers to 1, 10-o-phenanthroline or 2, 2'-dipyridyl, n refers to 1 or 2, and m refers to an integer or a decimal between 0 and 10. In the invention, the 1, 10-o-phenanthroline or the 2, 2'-dipyridyl is introduced into the M(ATZ) as an ancillary ligand to obtain a novel compound, thus integrating the characteristics of high efficiency, insensibility and environmental protection of a catalyst on the premise of the combustibility improvement of composite propellants. The azotetrazole-based energetic compound has the advantages of simple preparation method and accessible raw materials.

Owner:NORTHWEST UNIV(CN)

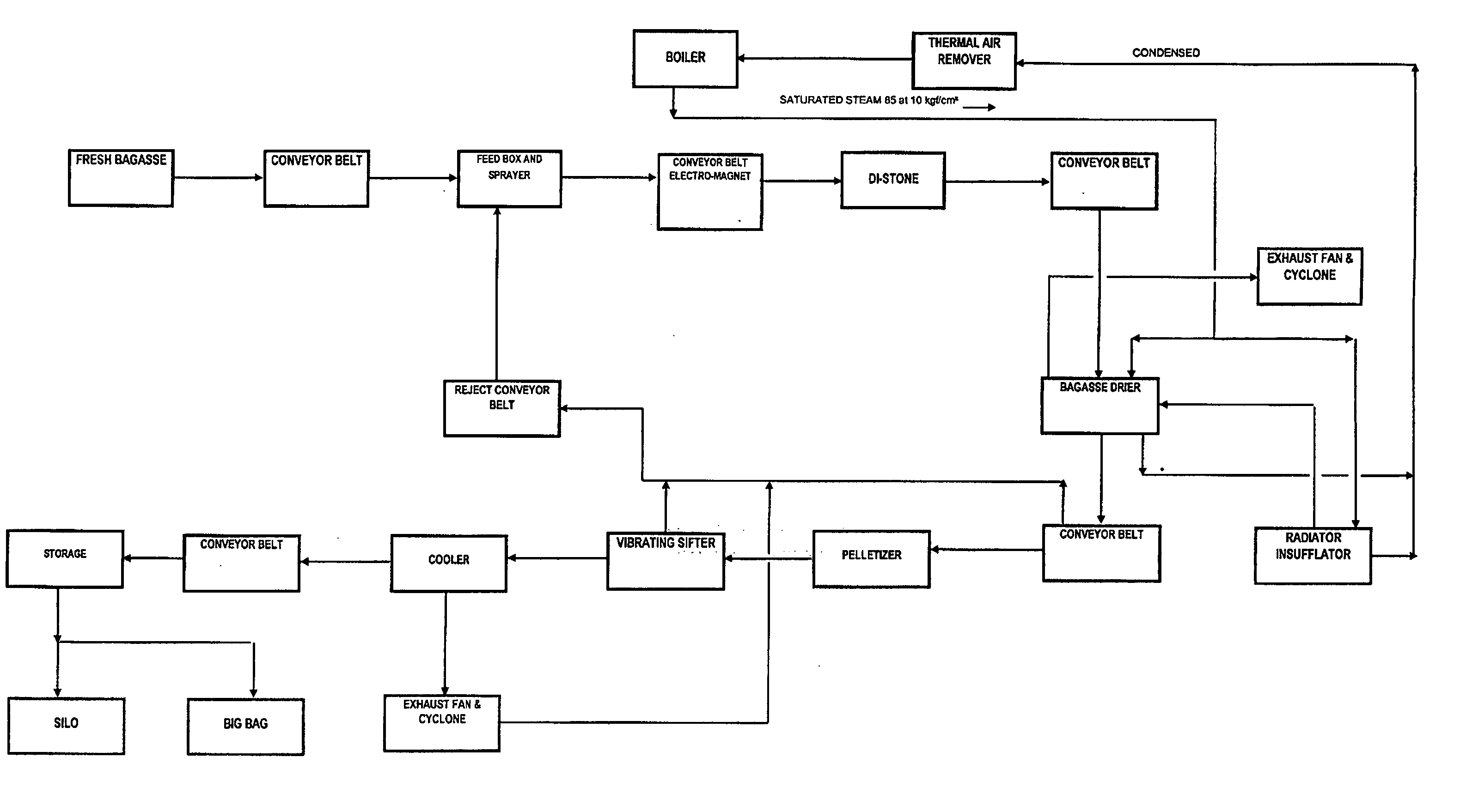

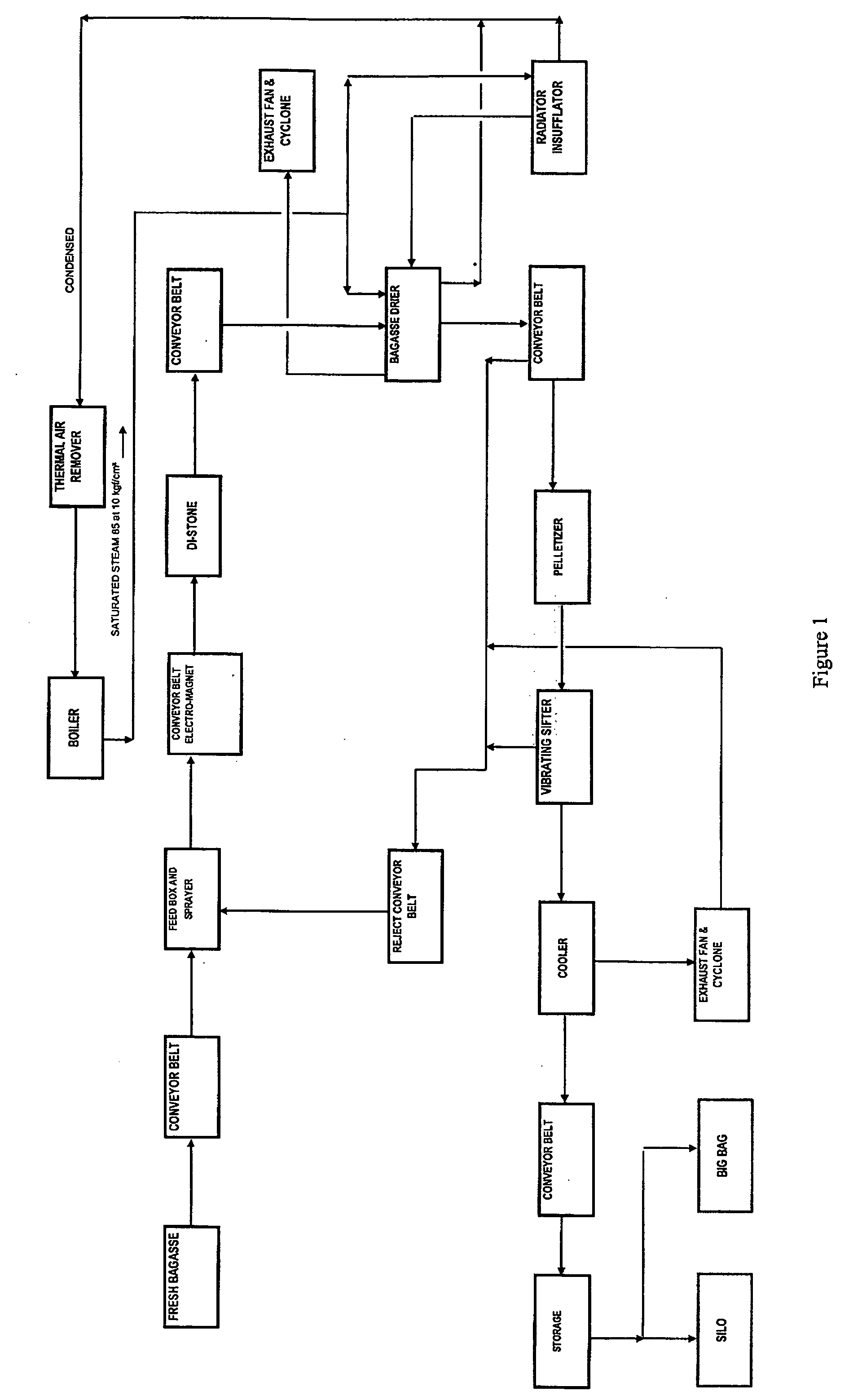

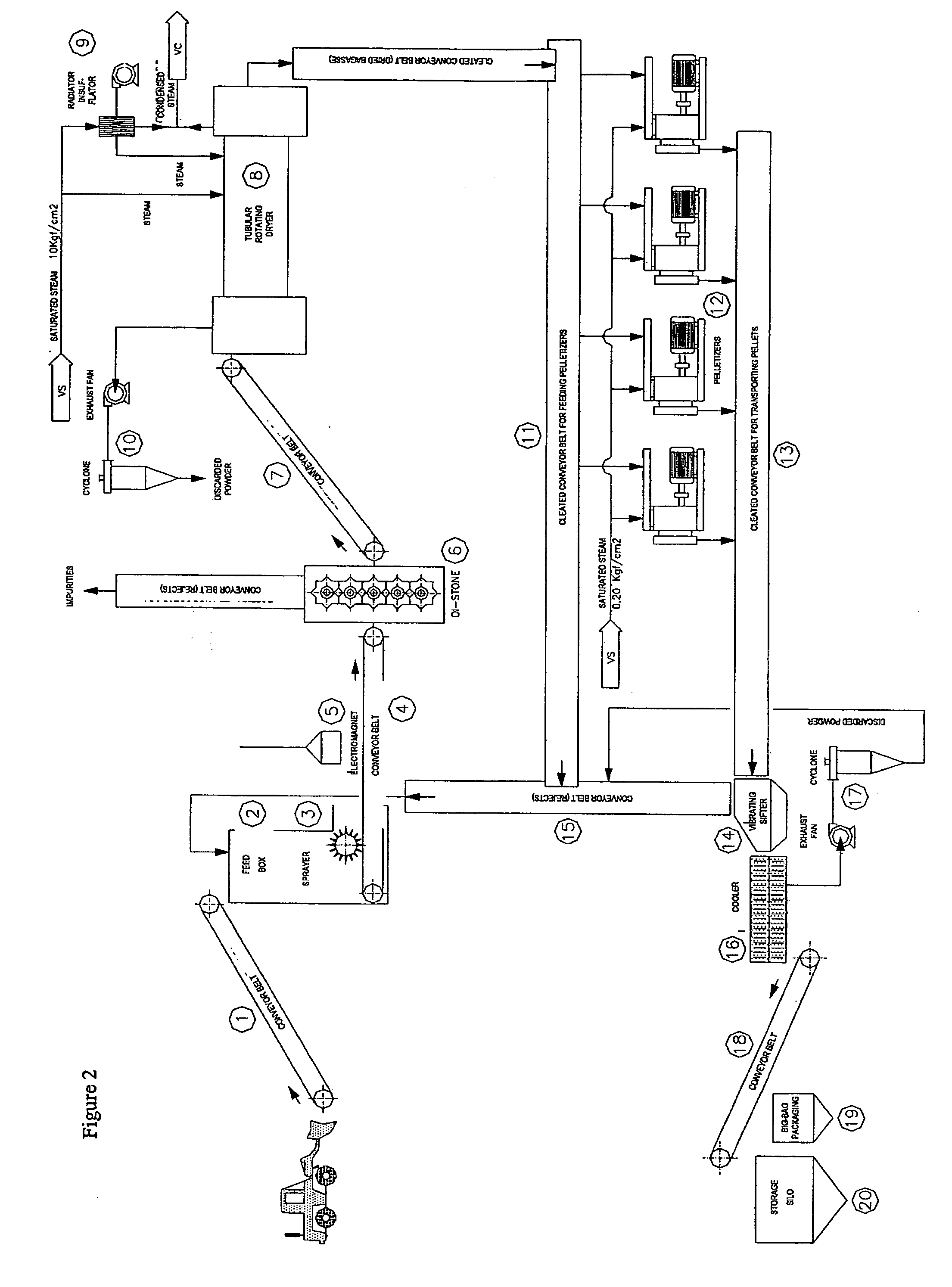

Method and device for pelletizing unprocessed cellulosic fibrous material

InactiveUS20070084385A1High risk of fireHigh calorific valueBiofuelsGranulation in rotating drumsPulp and paper industryCellulose fiber

The present invention relates to a method and a device for pelletizing unprocessed cellulosic fibrous material on an industrial scale, and in particular to the use of said unprocessed cellulosic fibrous material pellets as a combustible fuel product.

Owner:CARGILL INC

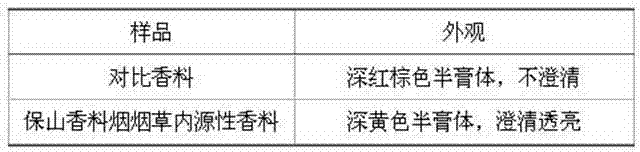

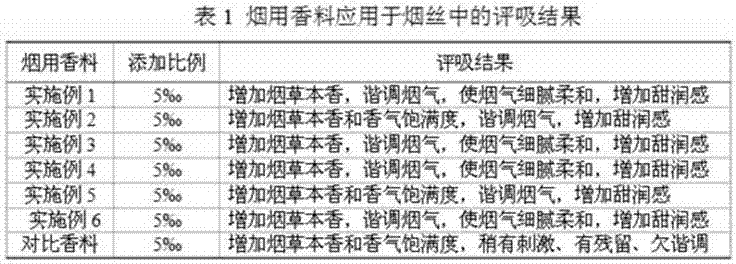

Preparation method and application of tobacco endogenous spice of Boshan aromatic tobacco

ActiveCN102952638ATake advantage ofHigh value of potent aromatizing ingredientsTobacco preparationTobacco treatmentFlavorHigh pressure

The invention discloses a preparation method and application of a tobacco endogenous spice of Boshan aromatic tobacco. According to the preparation method, the crushed Boshan aromatic tobacco is placed in an extra-high pressure extracting tank for extra-high pressure extraction and then is subjected to column separation by using macroporous resin, and finally, the tobacco endogenous spice of the Boshan aromatic tobacco is obtained. The spice is clear in appearance, and thus the spice is more suitable for being added in cigarettes to bring remarkable effect of improving the quality of cigarettes. The preparation method disclosed by the invention is simple and practical, convenient for operation and lower in cost; resin can be repeatedly used; the time is greatly saved; the value of the extracted effective aroma components is high; and tobacco raw materials are utilized more fully.

Owner:CHINA TOBACCO GUANGDONG IND

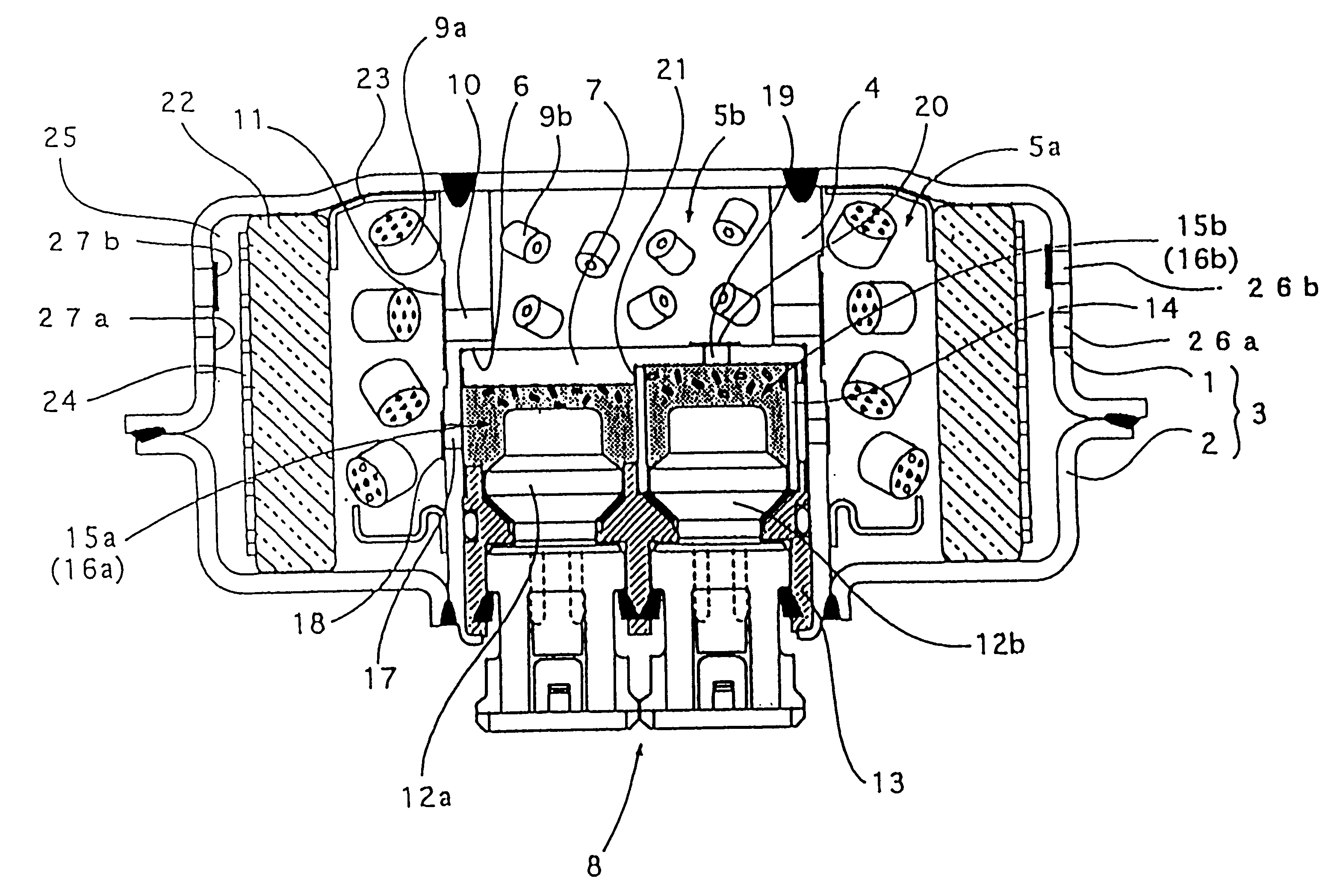

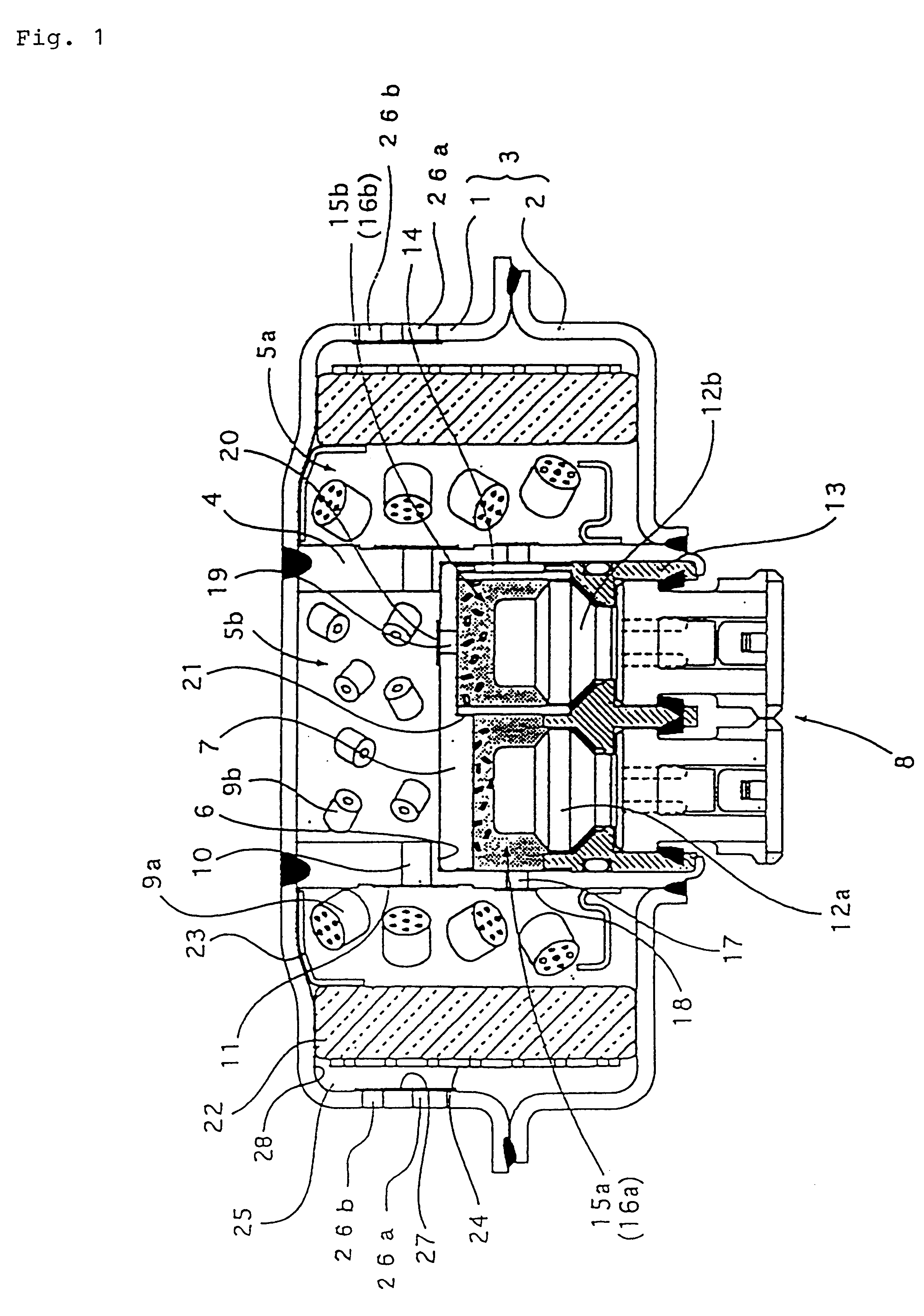

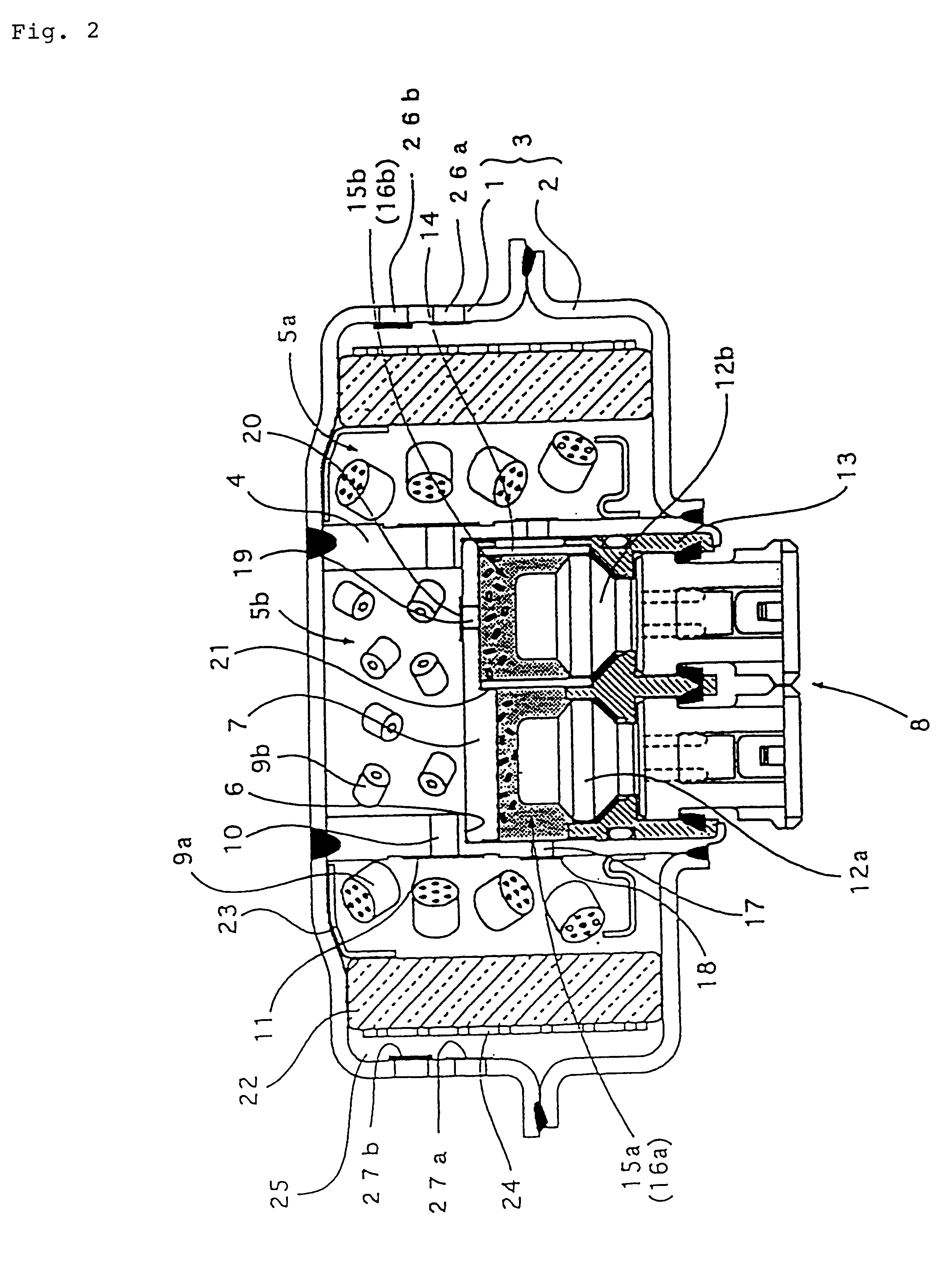

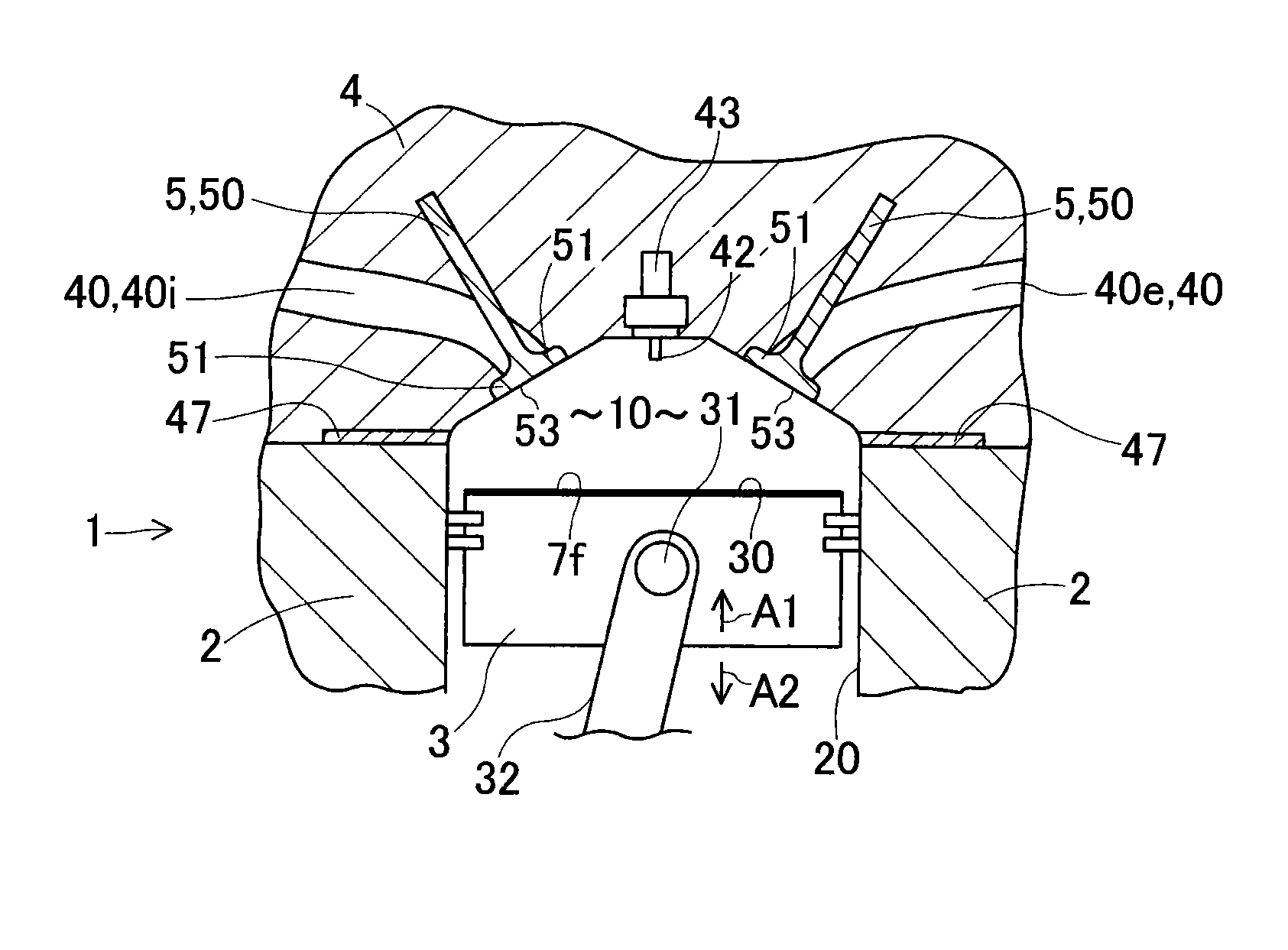

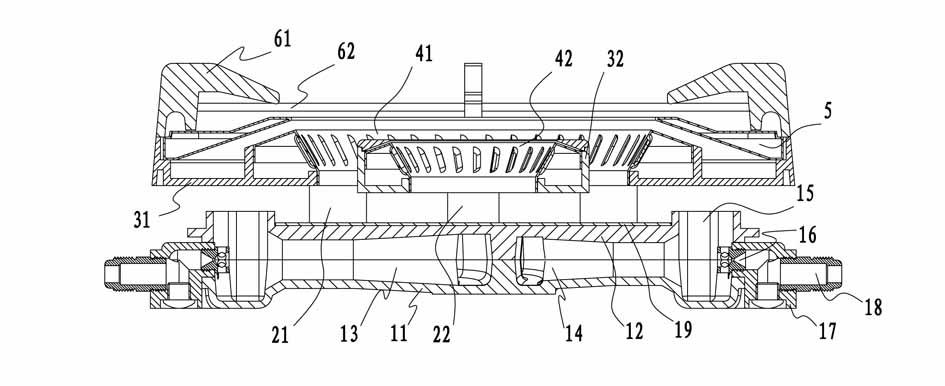

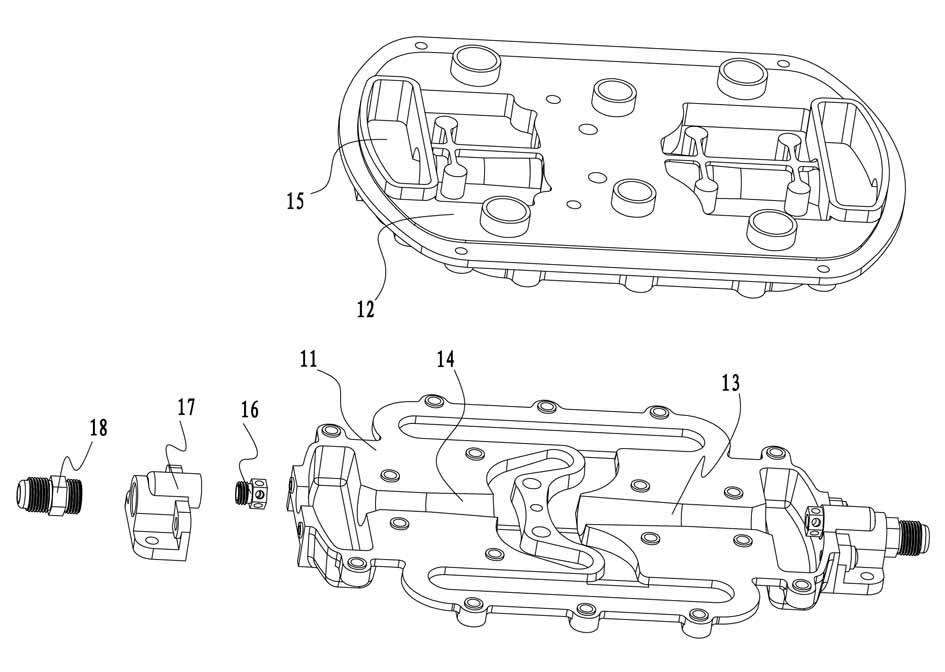

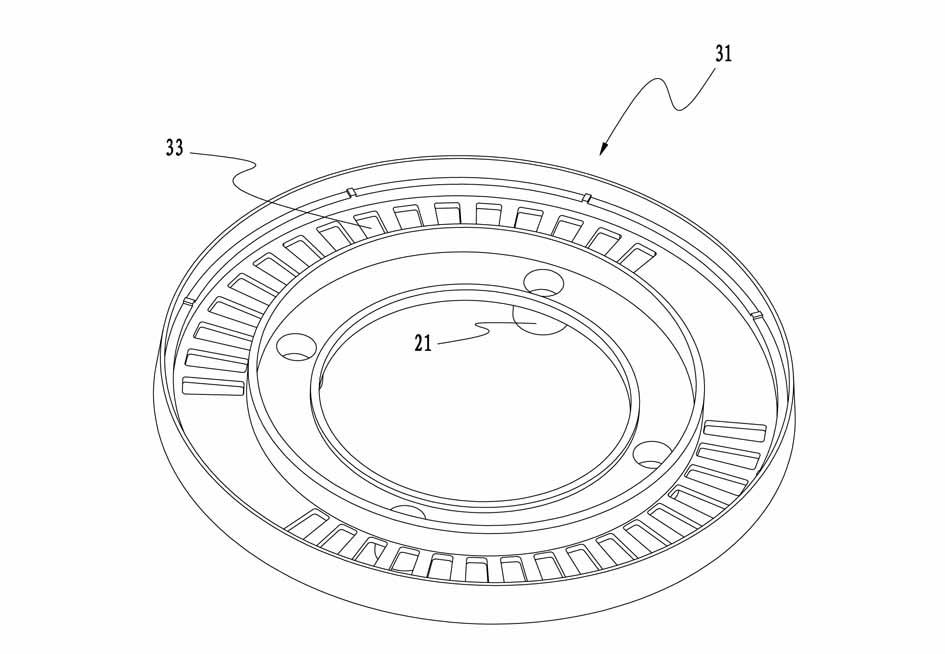

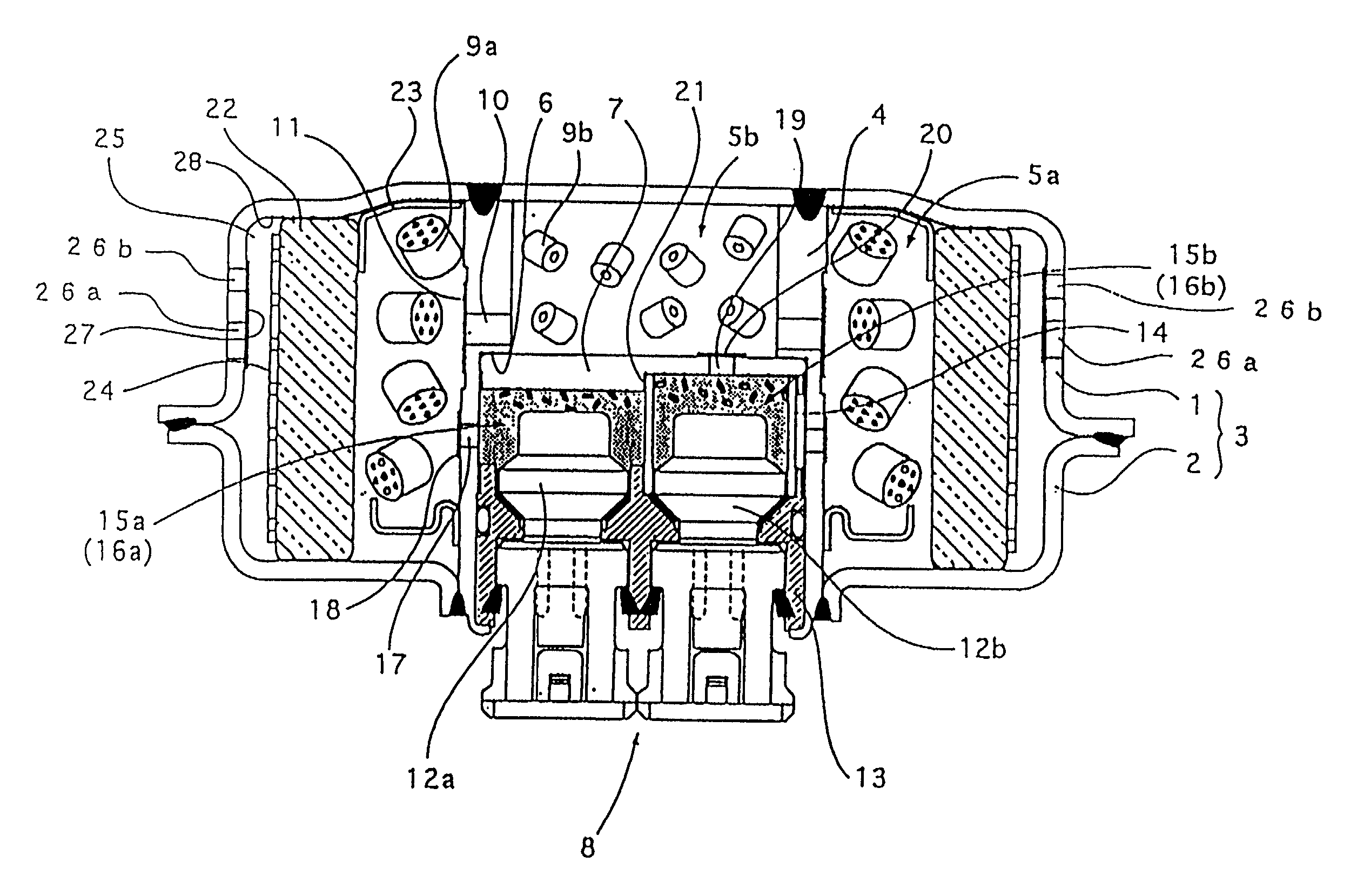

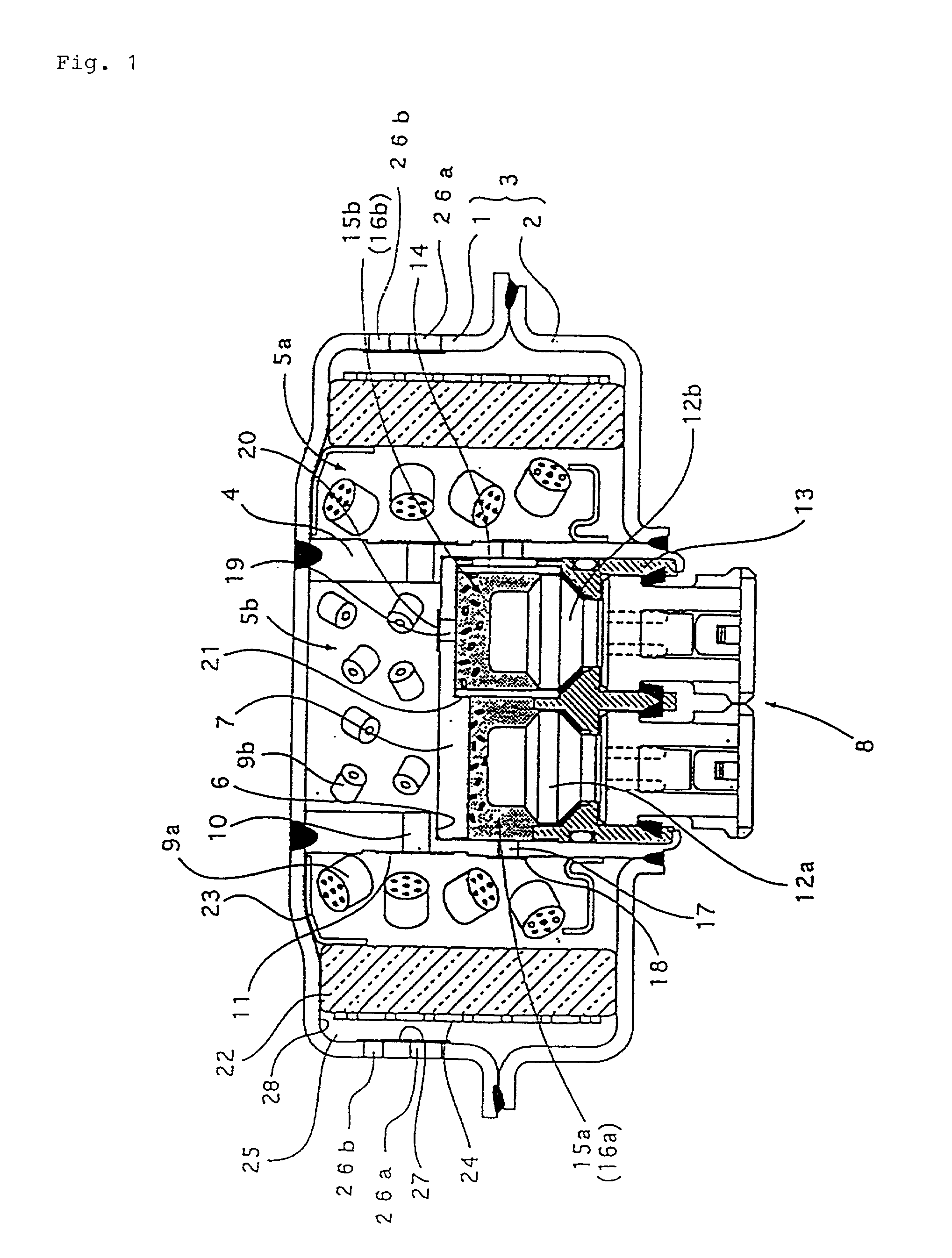

Air bag gas generator and air bag device

InactiveUS6547275B2Improve combustion performanceEasy to shapeGas treatmentDispersed particle filtrationInternal pressureGas-discharge lamp

A gas generator small in size and which can be produced easily with a simple structure is provided. The output of a gas generator is equalized so that an occupant can be safely restrained, and the combustion performance can be stably adjusted. The gas generator comprises a housing forming an outer shell container and accommodating two or more ignition units to ignite upon an impact and two or more gas generating agents which are independently ignited and burnt by the ignition units to generate a combustion gas for inflating an air bag, and a plurality of gas discharge ports which are formed in the housing, wherein the gas discharge ports are closed by sealing units for maintaining an internal pressure of the housing to the given pressure, a breaking pressure for breaking the sealing units is adjusted in multiple stages by controlling gas discharge ports and / or sealing units, and a difference of the maximum internal pressures in the housing at activation of the respective igniters is suppressed.

Owner:DAICEL CHEM IND LTD

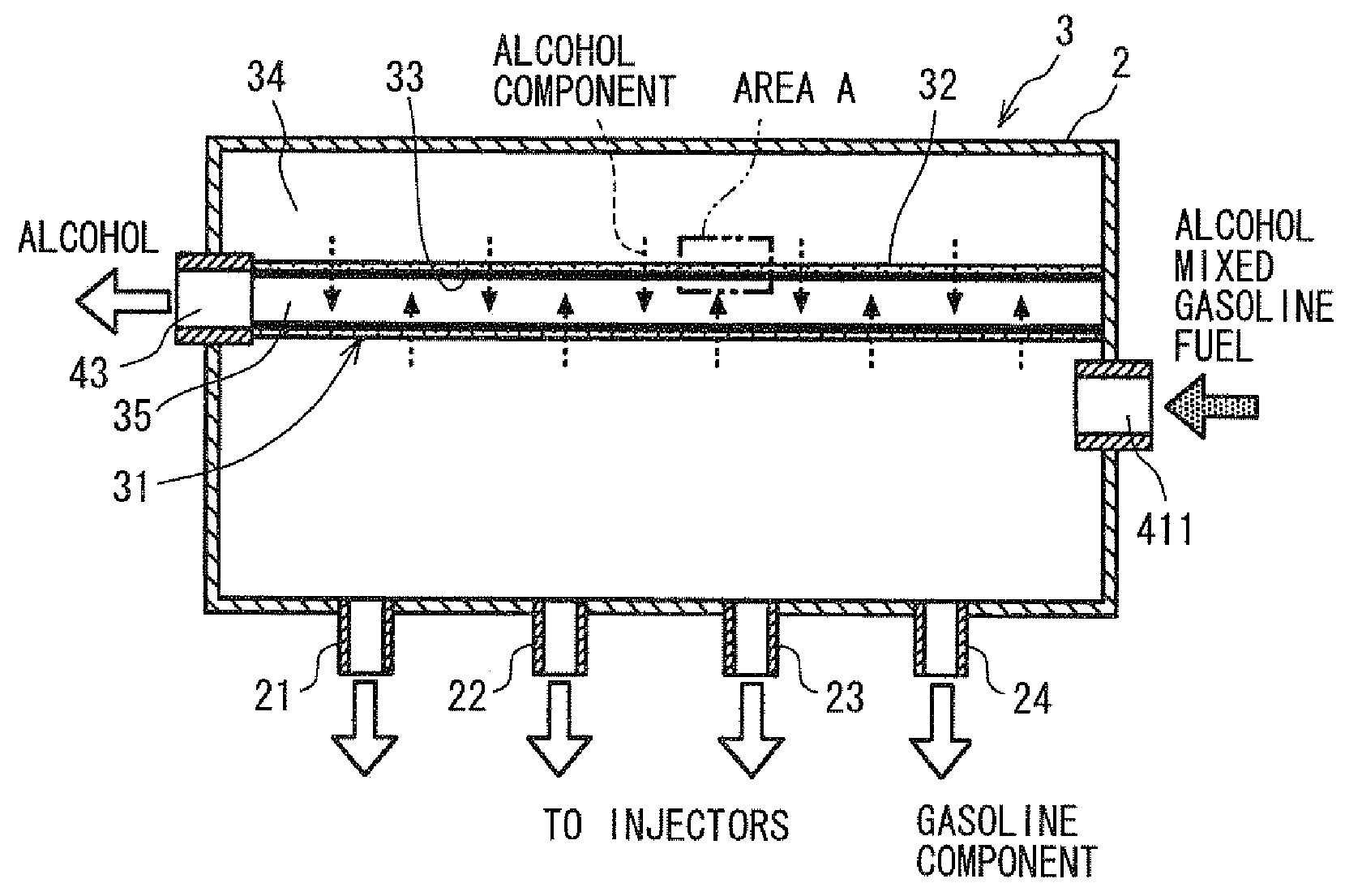

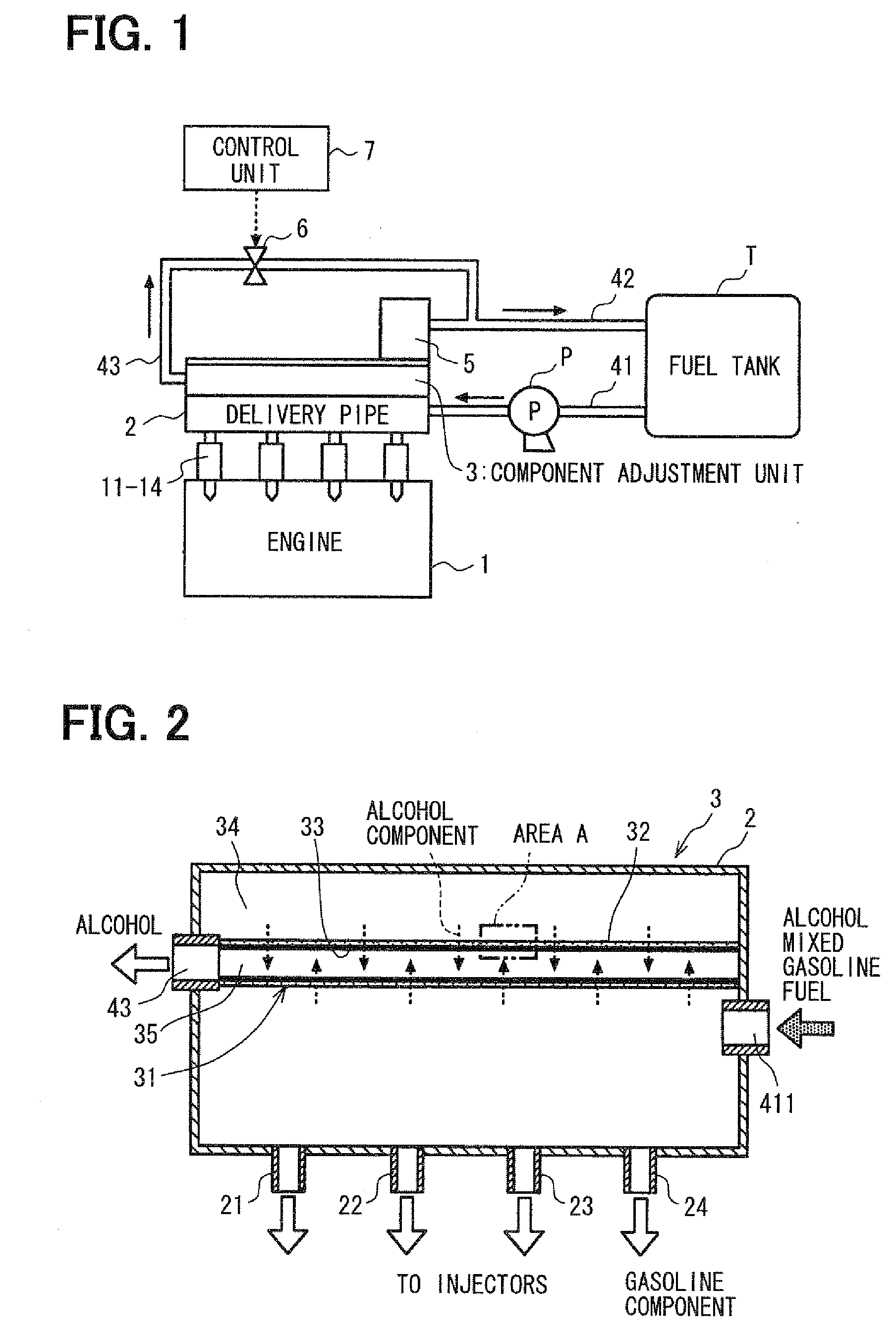

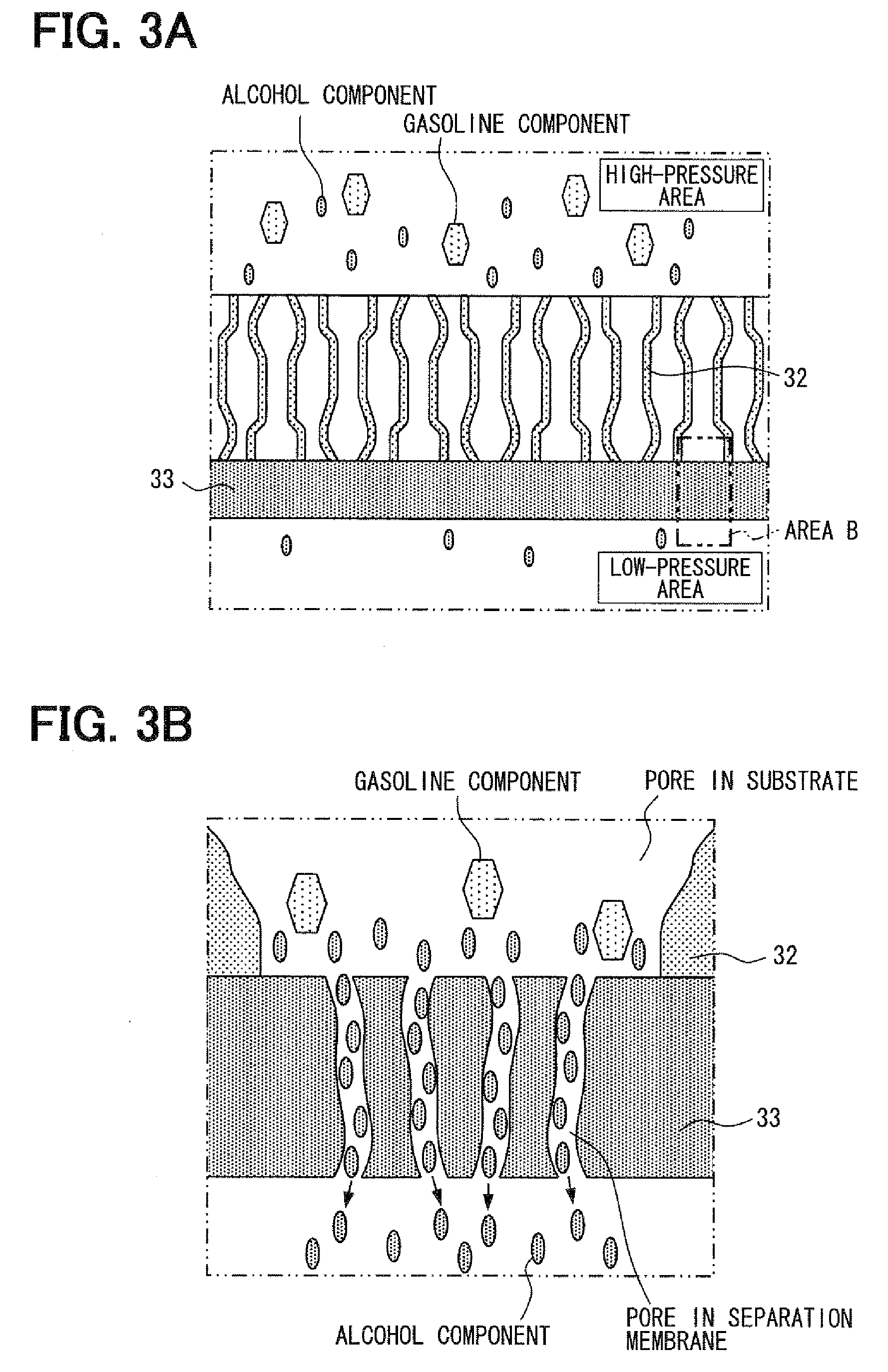

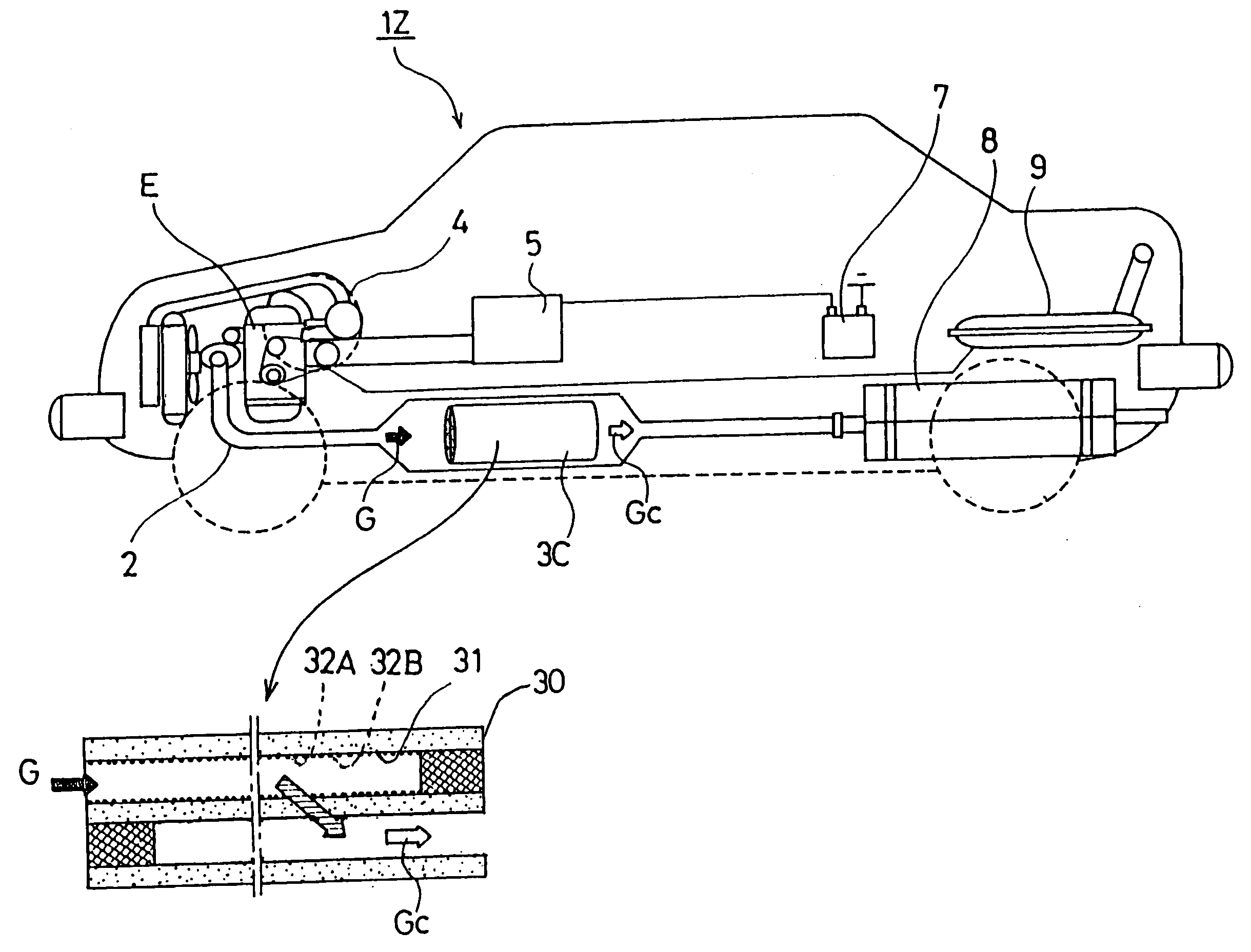

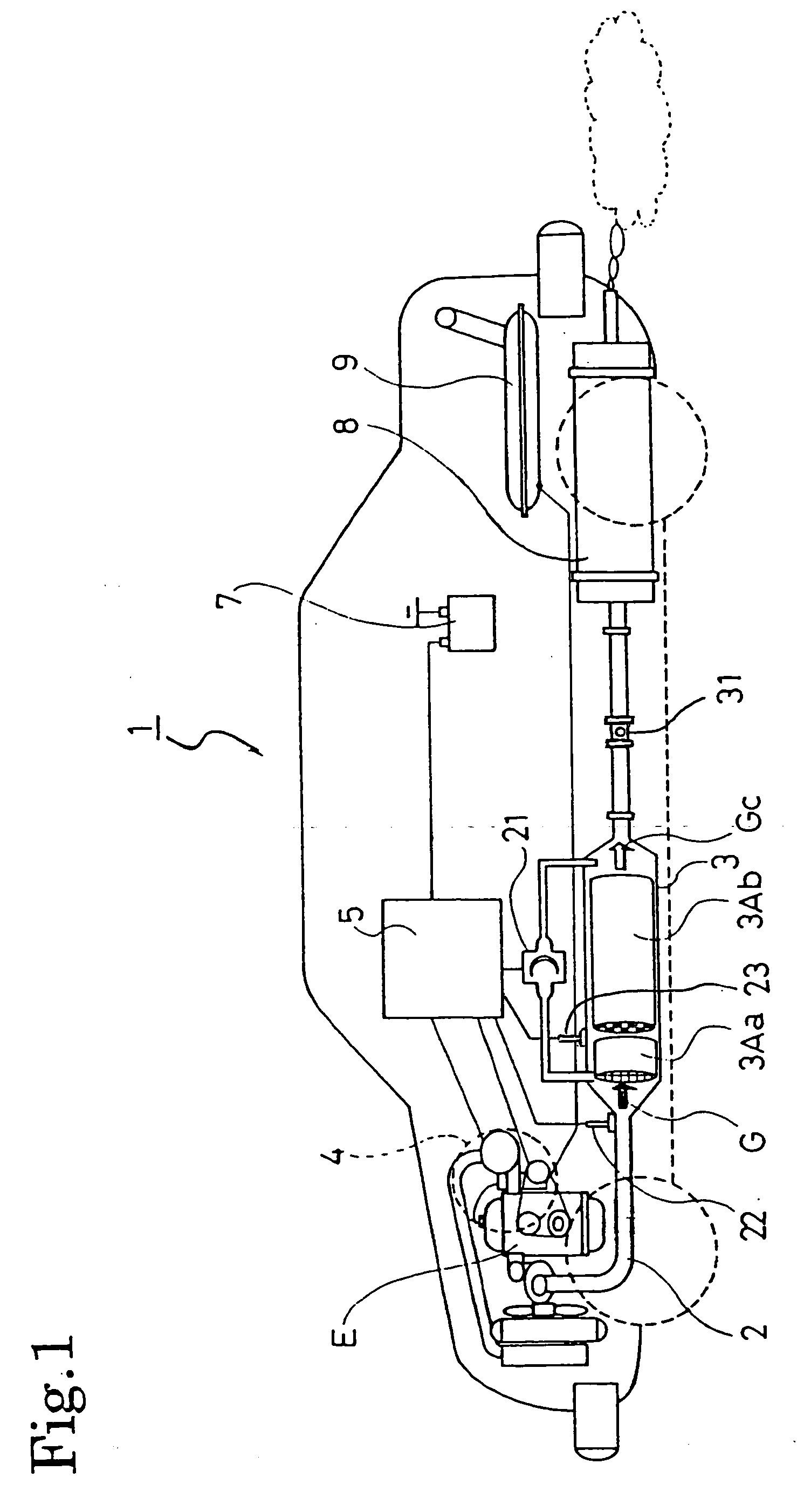

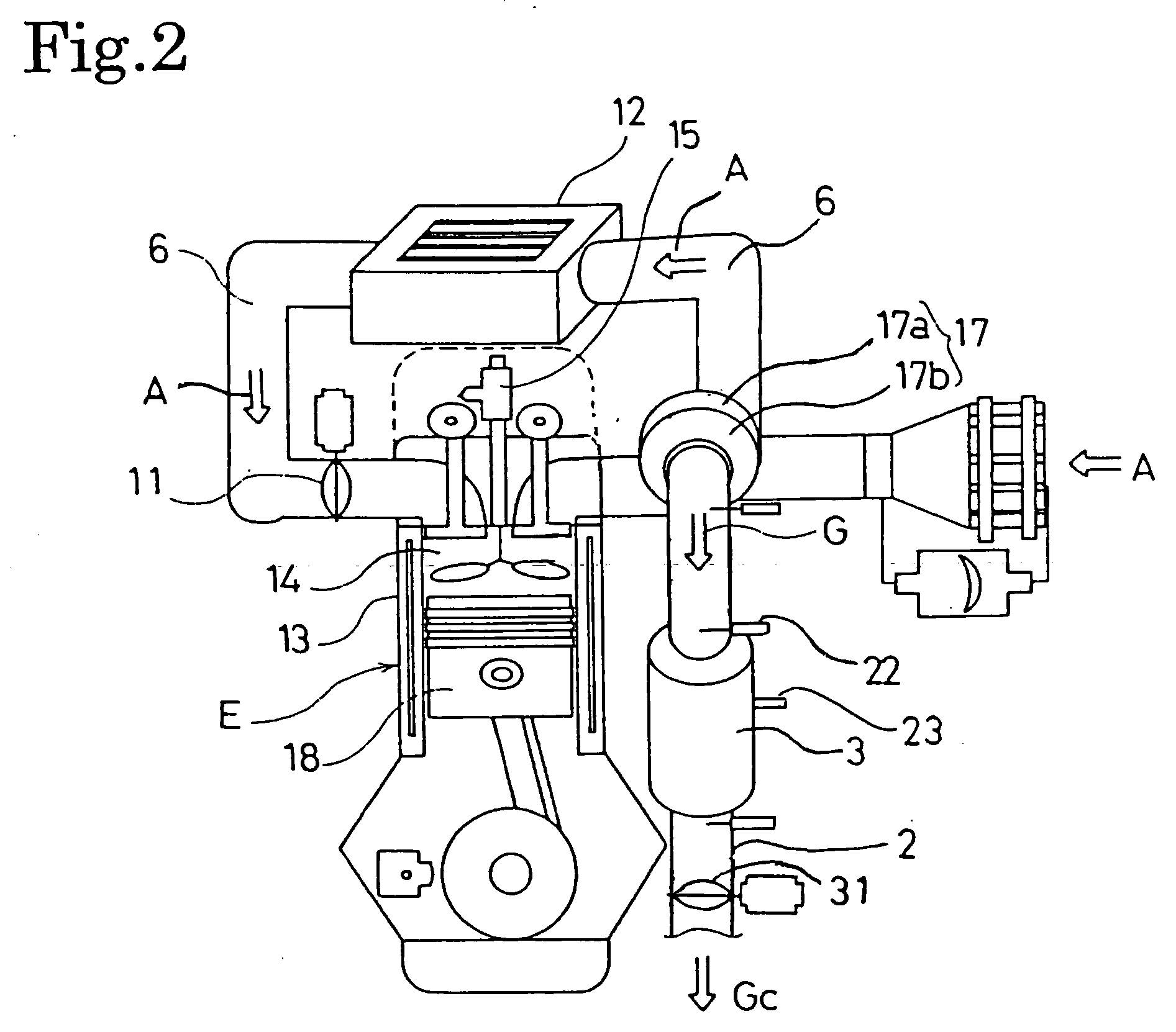

Fuel supply apparatus and fuel supply control apparatus for internal-combustion engine

InactiveUS20080092851A1Startability is improvedSimple configurationSemi-permeable membranesCombustion enginesFuel supplyComponent separation

A fuel supply apparatus includes a component adjustment unit, a low-pressure side passage, and a valve. The unit adjusts component composition of fuel by separating a particular component from fuel. The unit includes a component separation wall, which divides an interior of a portion of a fuel supply passage between an anterior chamber and a posterior chamber. The wall includes a separation membrane, which the particular component of fuel in the anterior chamber selectively permeates to be separated. The particular component after passing through the wall is temporarily stored in the posterior chamber. When the low-pressure side passage connected to the posterior chamber is opened by the valve, the particular component is separated. Fuel, from which the particular component is separated, is supplied to an injection valve from the anterior chamber. When the low-pressure side passage is closed by the valve, the separation of the particular component is restricted.

Owner:DENSO CORP

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

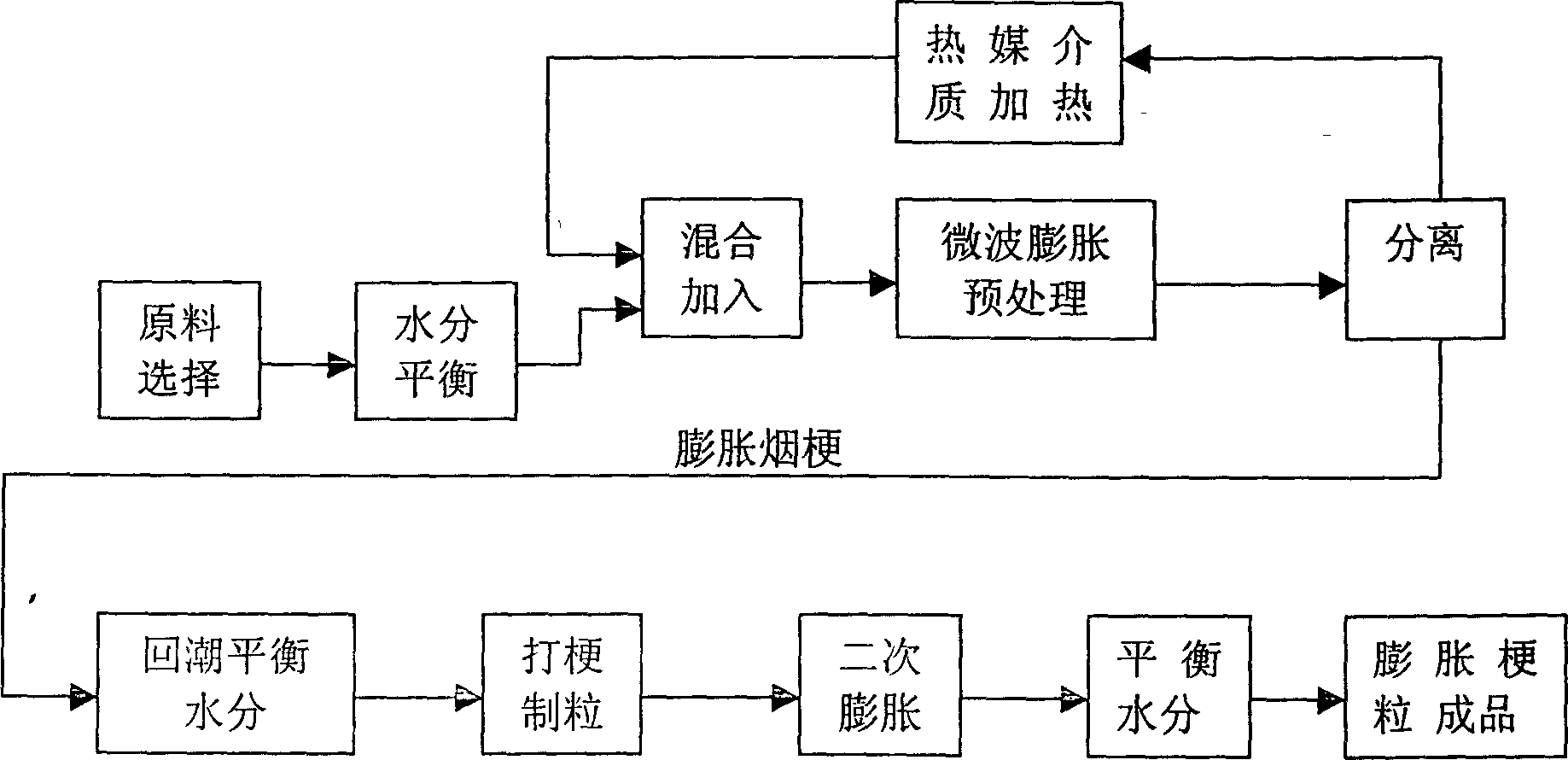

Preparation method of cigarette expansion cabo granule filling material

The invention discloses a preparation method of cigarette expansion cabo granule filling material, which comprises subjecting expanded cabo containing 5-9% of water to moisture regaining and balanced water treatment, loading into wind separation cabo beating machine, conveying bulked cabo particles into drying equipment for quick-speed drying till the moisture content is 7-14%, resulting cabo particles reexpansion, finally balancing water content of the cabo particles to 13+-0.5%.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

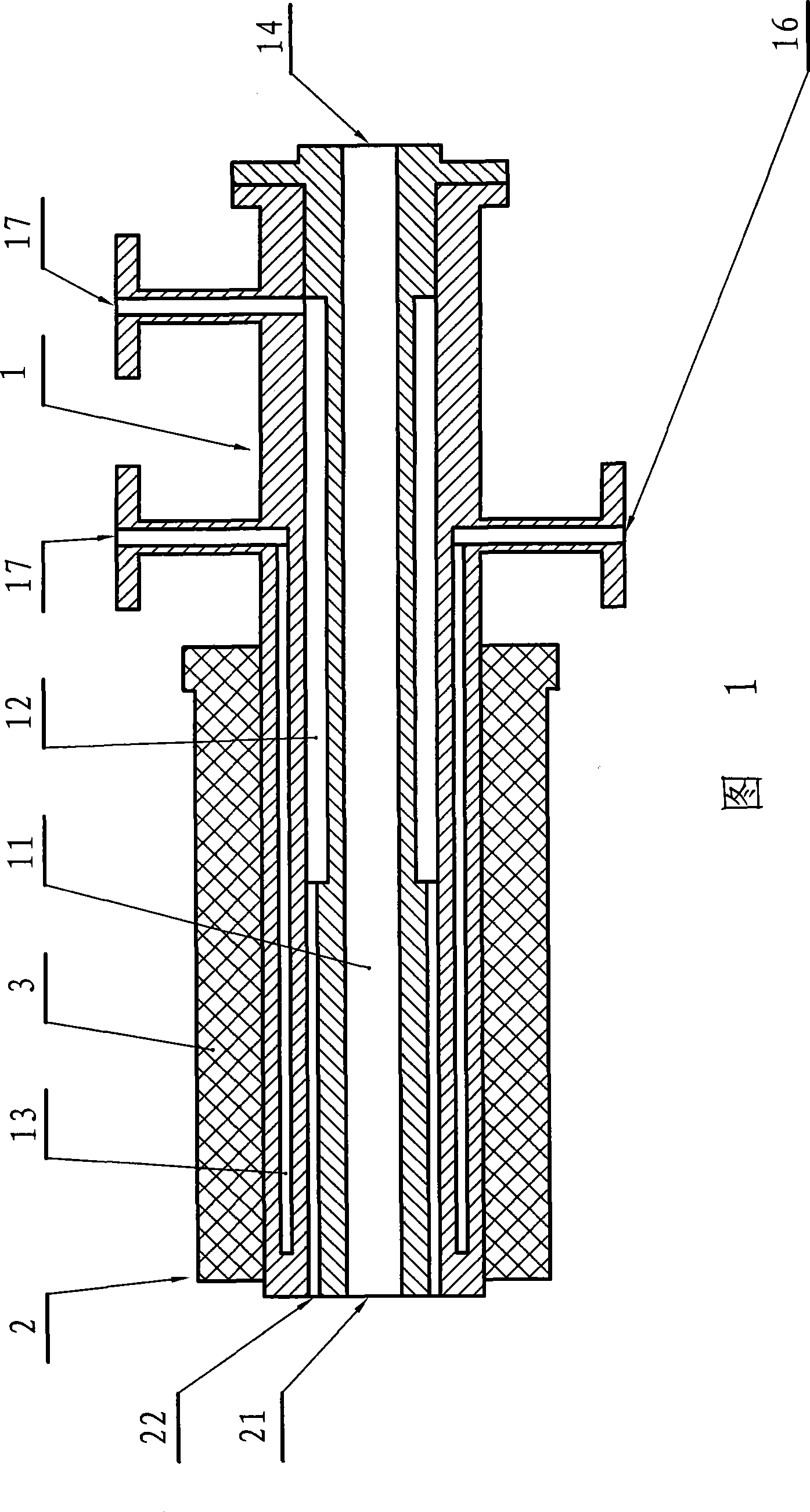

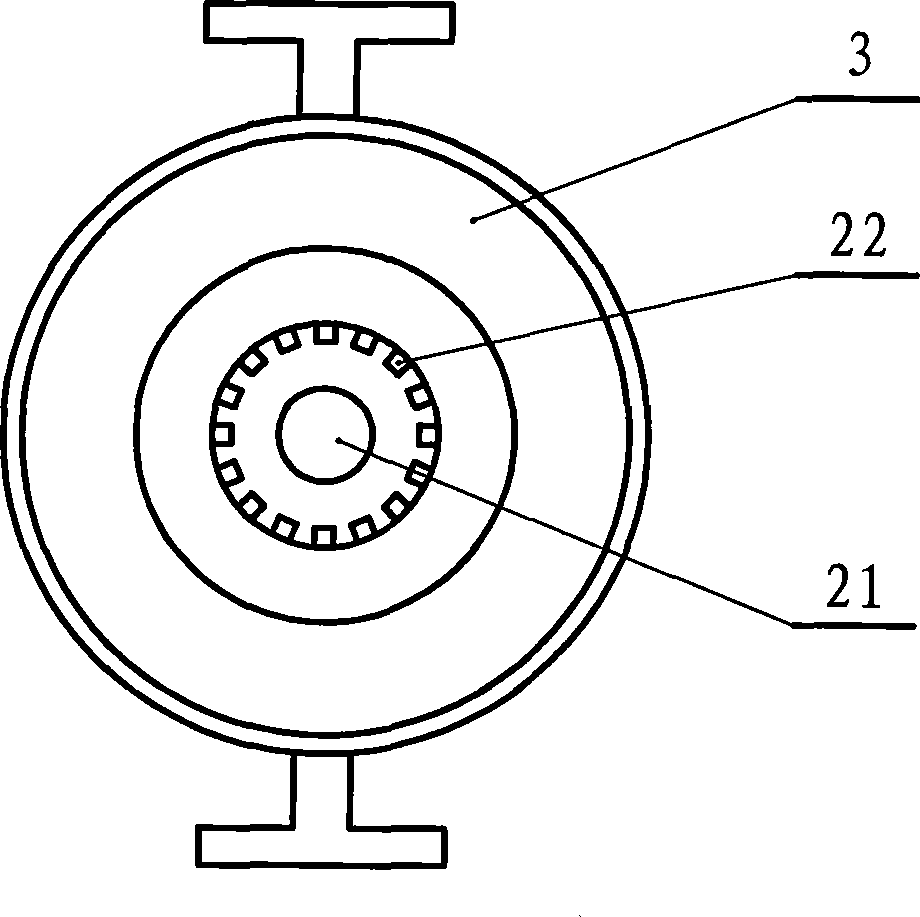

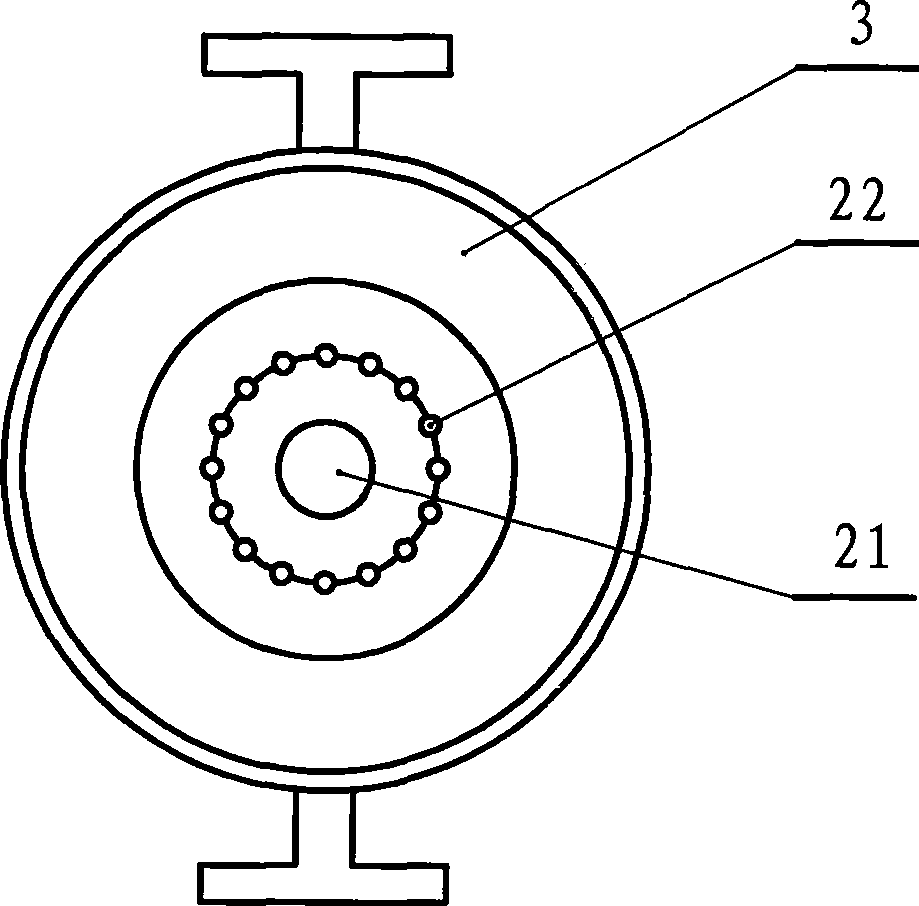

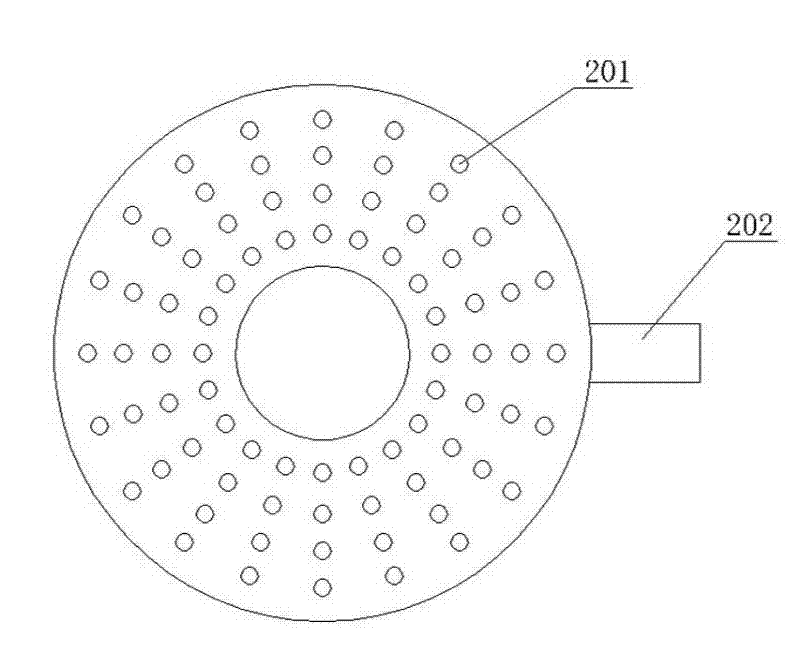

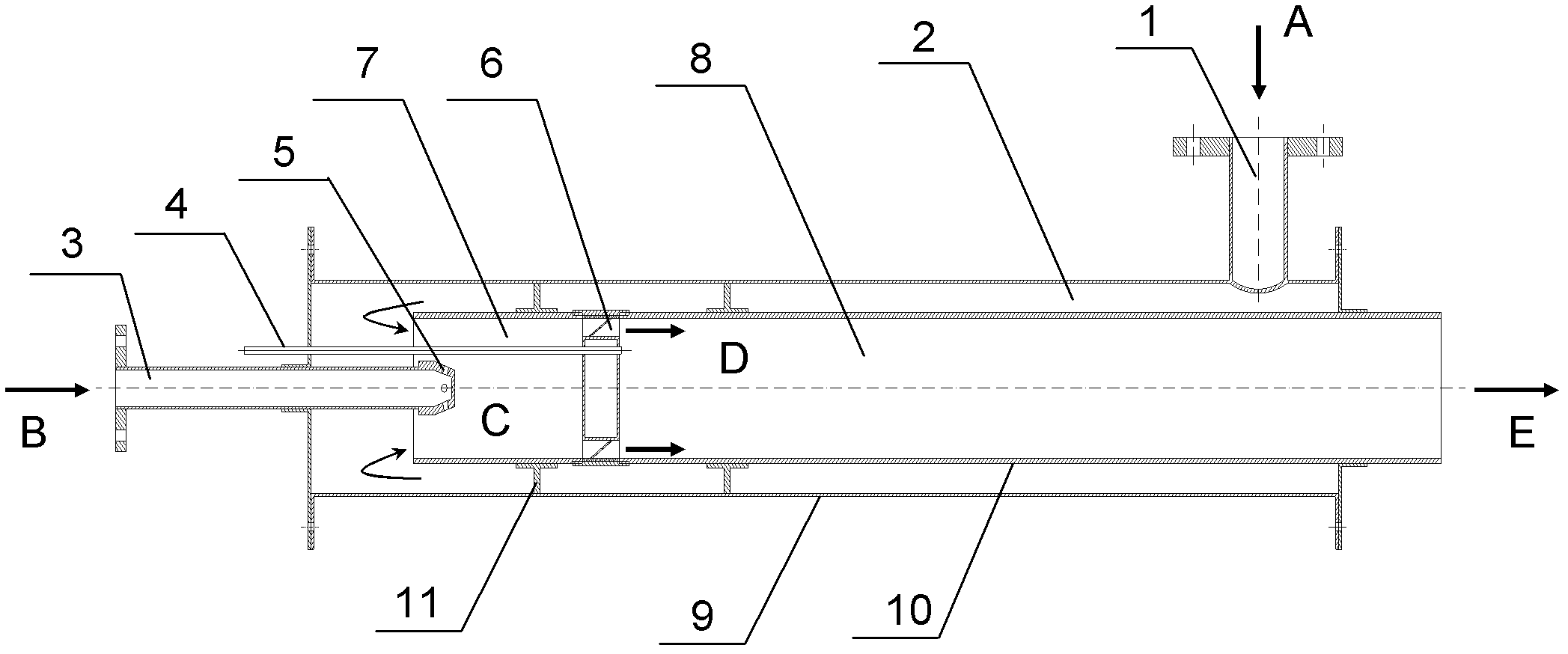

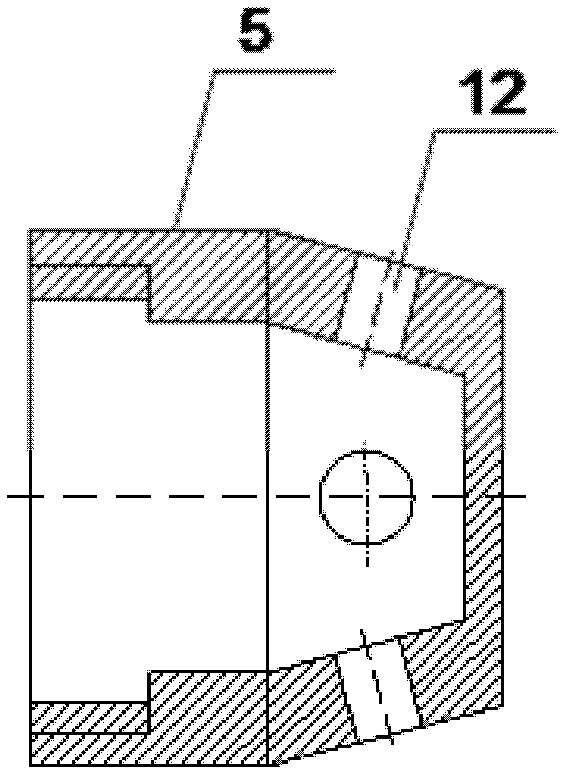

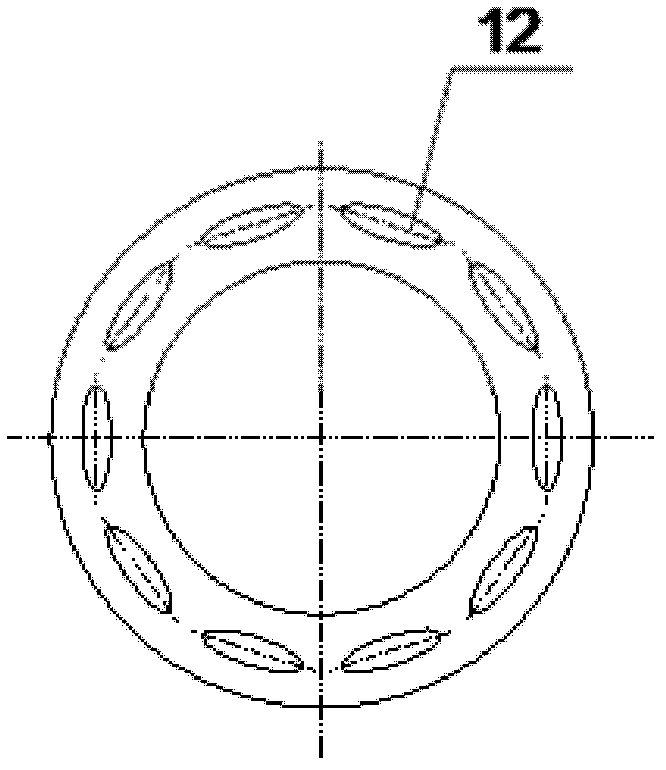

Spray gun of side-blown converter for smelting non-ferrous metal

ActiveCN101382387AImprove combustion performanceSpeed up redox reactionsCharge manipulationCombustionNonferrous metal

The invention discloses a novel side-converter spray gun for smelting nonferrous metals, comprising a spray gun body with a sleeve structure and a spray gun head at the front end of the spray gun body; a central pipeline of the sleeve structure is provided with a connecting interface connected with a fuel conveyor; a sandwich ring channel of the sleeve structure is provided with a connecting interface connected with combustion-supporting gas; the spray gun head is provided with a fuel nozzle which is matched with the central pipeline and a combustion-supporting gas nozzle which is matched with the sandwich ring channel; and the combustion-supporting gas nozzle is provided with a through hole nozzle array.

Owner:CHINA ENFI ENGINEERING CORPORATION

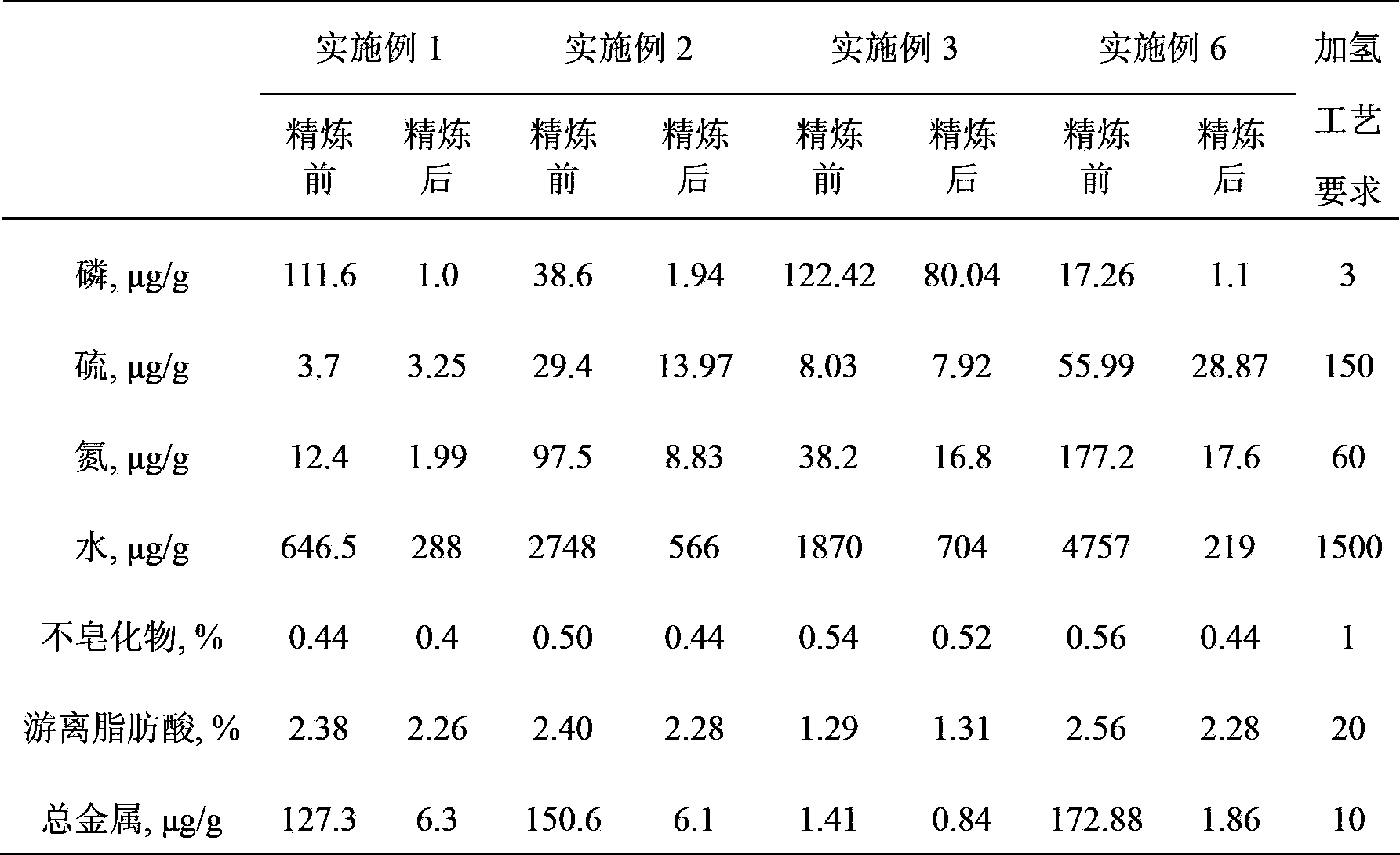

Method for production of diesel oil fraction and aviation fuel fraction by use of animal and plant oils and fats

The invention relates to a method for production of a diesel oil fraction and an aviation fuel fraction by use of animal and plant oils and fats, and the method comprises the following steps: a) performing refining processing on the animal and plant oils and fats; b) performing catalytic hydrogenation and deoxidation to obtain saturated linear alkanes and propane; c) performing hydroisomerization and hydrocracking processing to obtain an alkane material flow with higher branched chain degree; d) separating to obtain liquid hydrocarbons and gaseous hydrocarbons with the boiling point within the boiling point range of diesel oil, aviation fuels and naphtha; e) directly collecting the diesel oil fraction as a product, or cycling in whole or in part to continue isomerization and cracking reaction to increase production of the aviation fuel fraction; and f) mixing propane gaseous hydrocarbon and naphtha for steam reforming hydrogen production reaction, separating and purifying the obtained hydrogen to enter into a circulating hydrogen system; the method is used in the production of the renewable diesel oil and aviation fuels with excellent combustion performance and cold flow performance, and meanwhile efficient utilization of by-products and in-system supplement of hydrogen consumption can be realized.

Owner:PETROCHINA CO LTD

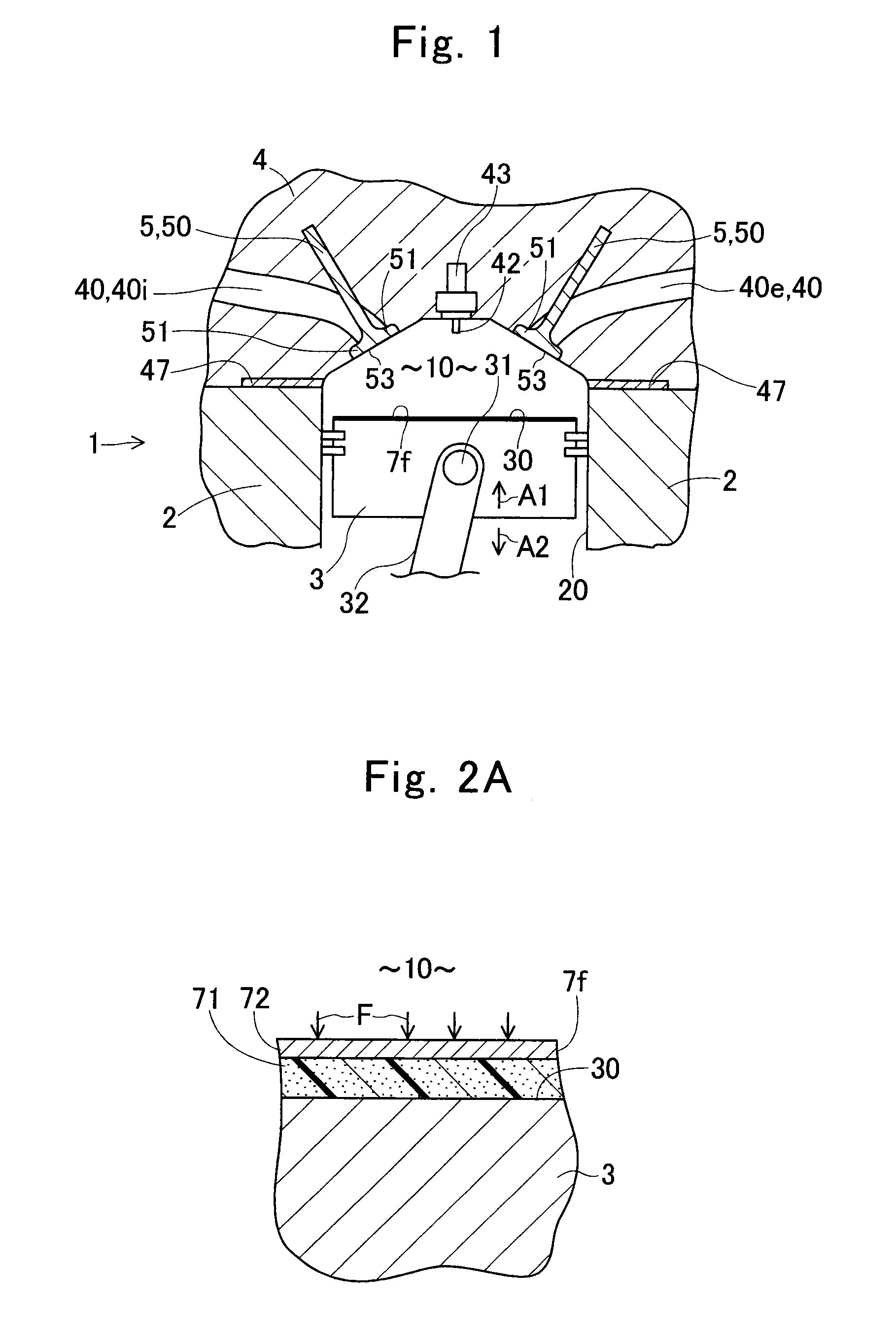

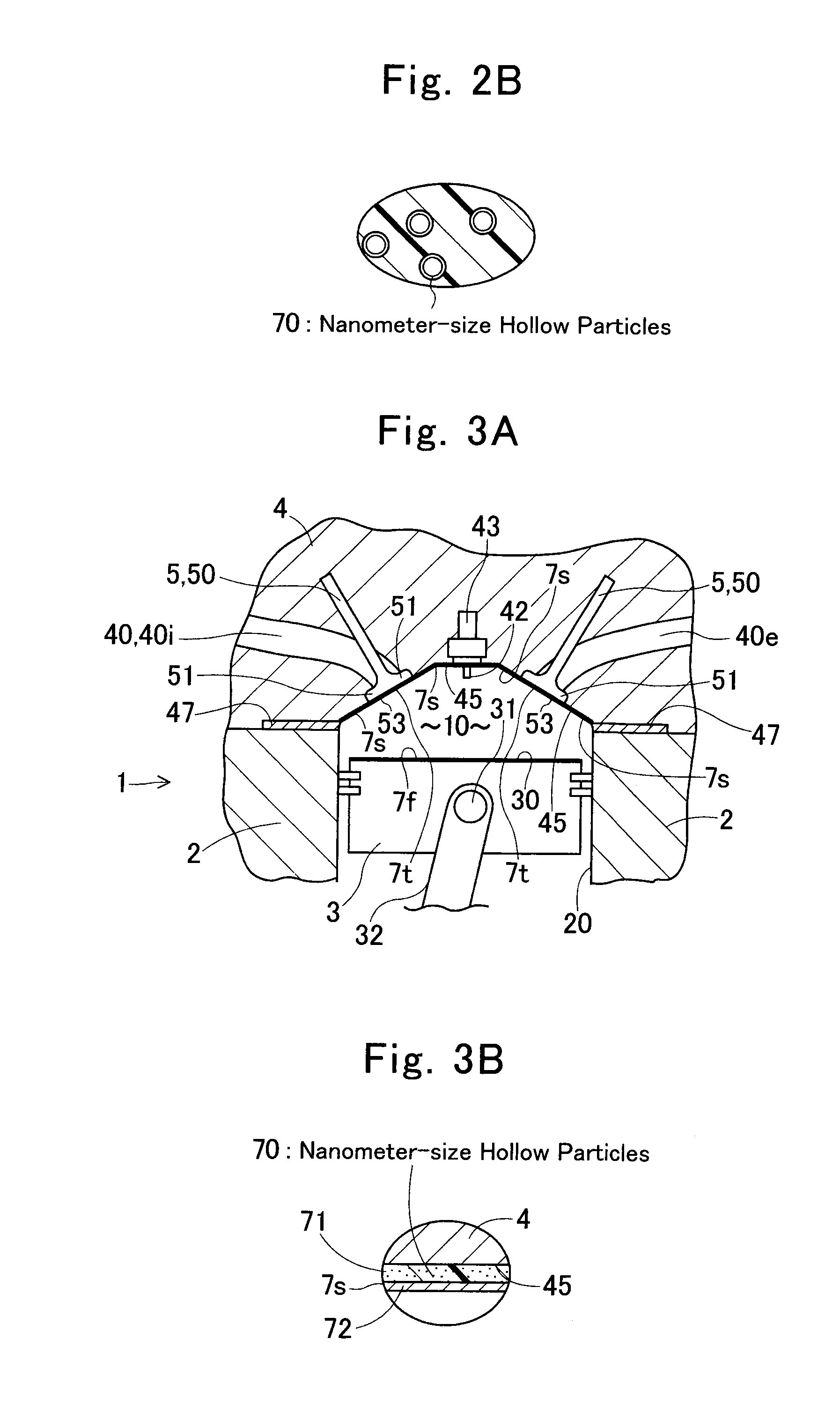

Engine and piston

ActiveUS20150204269A1Improve insulation performanceUpgrading mileagePlungersCylinder headsCombustion chamberCylinder head

Any one or more members of an engine, that is, a piston, a cylinder head and a valve, has a wall face disposed face-to-face to a combustion chamber, and the wall face is coated by a heat-insulation coating film. The heat-insulation coating film includes a heat-insulative layer formed on a surface of the wall face, and an inorganic-system coated-film layer formed on a surface of the heat-insulative layer. The heat-insulative layer includes a resin, and first hollow particles buried inside the resin and exhibiting an average particle diameter being smaller than a thickness of the heat-insulative layer. The inorganic-system coated-film layer includes an inorganic compound.

Owner:AISIN SEIKI KK +1

Top-intake burner of gas cooker

InactiveCN102661606AImprove combustion performanceImprove combustion thermal efficiencyDomestic stoves or rangesStoves/ranges topsFuel gasGas stoves

The invention relates to a top-intake burner of a gas cooker. The top-intake burner comprises a burner support, a fire distribution seat and fire caps. The top-intake burner is characterized in that the burner support is combined by an lower support and an upper cover, at least two Venturi ejector pipes are formed, the openings of the Venturi ejector pipes are correspondingly communicated with primary air inlets with an upward opening, a single gas nozzle is mounted in the primary air correspondingly and is disposed right against the center of one of the the Venturi ejector pipes, the other end of the gas nozzle is communicated with a gas inlet pipe, one Venturi ejector pipe is communicated with a fire distribution chamber of the fire distribution seat through one gas guide pipe or multiple gas guide pipes, and an air passage is reserved between the upper cover of the burner support and the fire distribution seat. The top-intake burner is reasonable in structural design, efficient and energy saving, is capable of realizing precision supply of primary and secondary air and complete and stable burning of the gas, and is especially suitable for embedded household gas stoves.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI +1

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

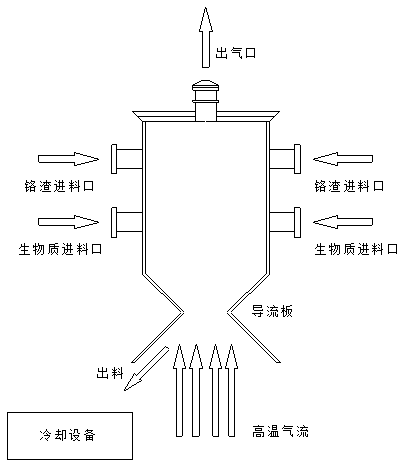

Fluidized bed type of harmless chromium slag pyrolysis process

The invention relates to a fluidized bed type of harmless chromium slag pyrolysis process. The process is characterized in that biomass and chromium slag into are respectively added into a high temperature fluidized bed pyrolysis furnace, wherein the biomass rapid melts and pyrolyses to release a lot of pyrolysis gas in the process, so as to reduce Cr (VI); at the same time pyrolysis carbon residue attaches to fluidization process the chromium slag surface to protect the reduced Cr (III) reduction in chromium residue from secondary oxidation, and the chromium slag conducts effectively catalytic cracking on be produced pyrolysis gas to avoid generation of a lot of high-pollution tar gas. Compared with the traditional pyrolysis technology, the technology greatly shortens the residence time, at the same time produces energy tail gas with high heat value, and avoids the disposal of the exhaust.

Owner:光大理工环境技术研究院(青岛)有限公司

Exhaust gas cleaning system

ActiveUS20060201144A1Improve fuel efficiencyReduce exhaust temperatureElectrical controlInternal combustion piston enginesLower limitCombustion

An exhaust gas purifying system causes less torque fluctuation and is capable of preventing the occurrence of white smoke in a regeneration control operation for regenerating a continuous regeneration DPF 3. When the continuous regeneration DPF 3 with an oxidation catalyst 3Aa on the upstream side of a filter 3Ab is controlled to regenerate, an exhaust throttle valve 31 provided in an exhaust passage 2 is closed and a delay multi-step injection control is performed to increase the temperature of the exhaust gas if an exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa is less than the activation temperature Ta of the oxidation catalyst. After the exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa has risen to the activation temperature Ta of the oxidation catalyst or higher, the exhaust throttle valve 31 is opened in a stepwise or continuous manner so that the exhaust temperature T2 at the inlet of the filter 3Ab rises to a lower limit temperature of PM forced combustion Tb1 or higher.

Owner:ISUZU MOTORS LTD

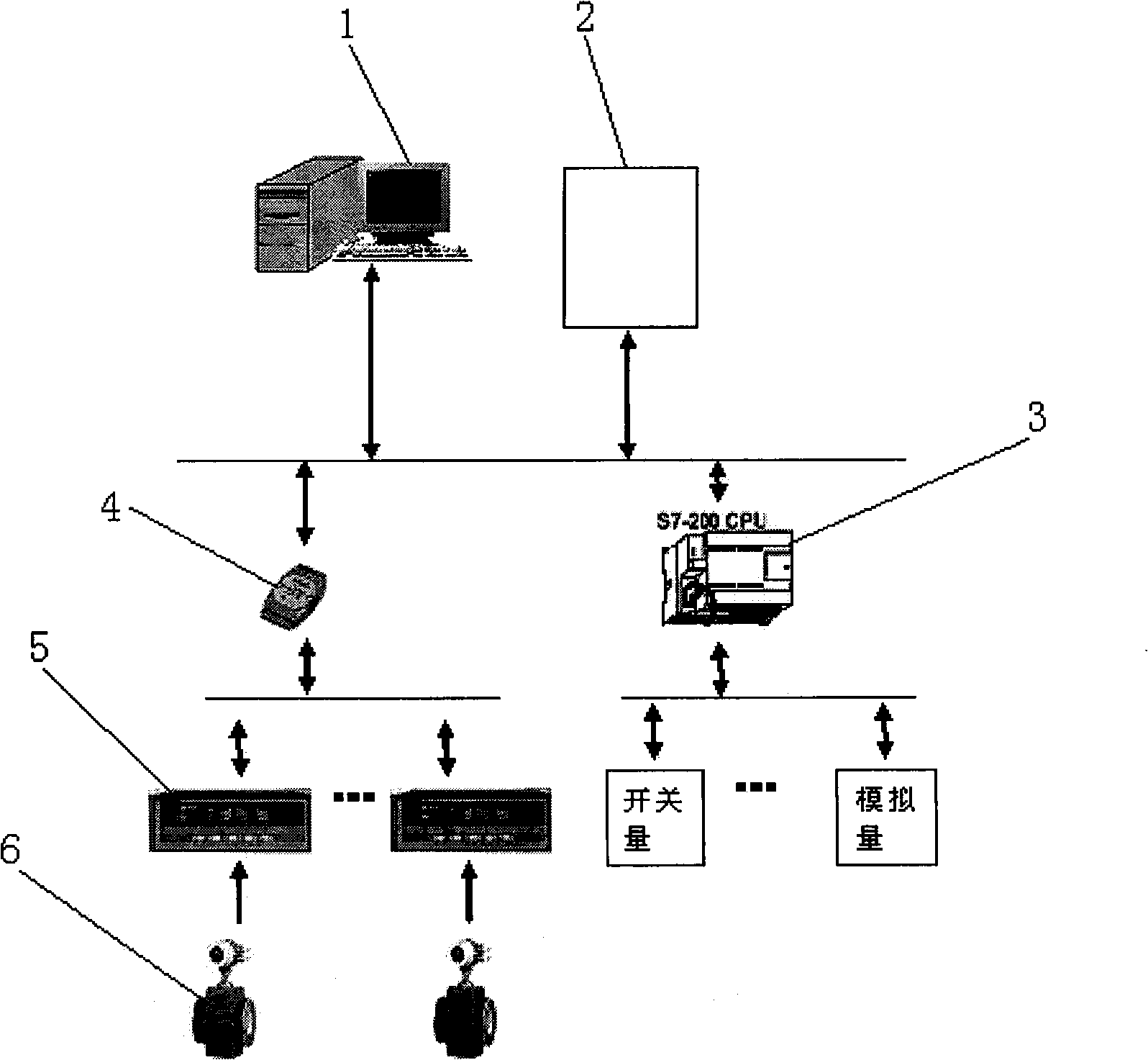

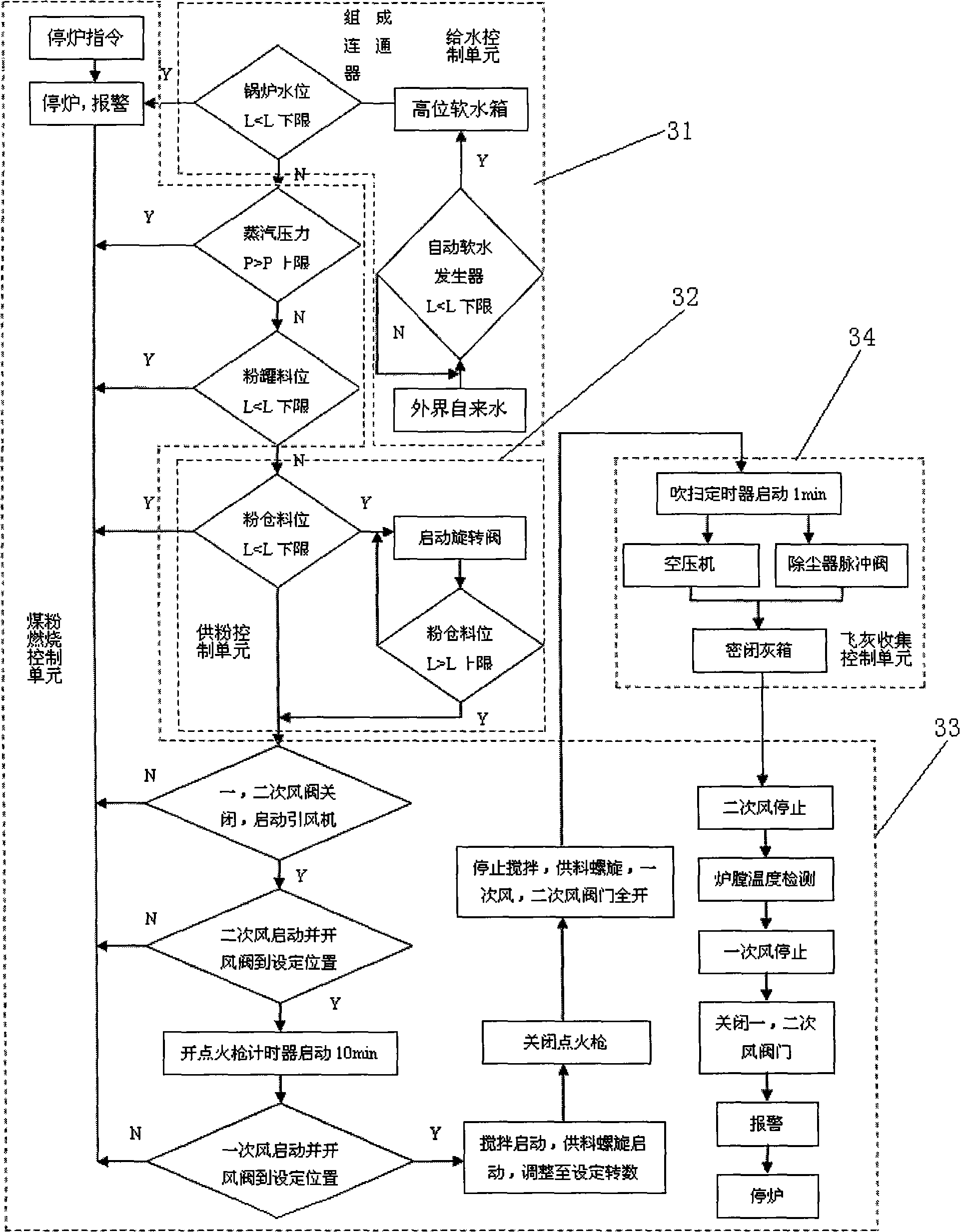

Automatic control system for industrial coal powder boiler

ActiveCN101576247AGuaranteed uptimeWith self-diagnosis functionBoiler controlWater feed controlAuto regulationAutomatic train control

The invention relates to an automatic control system for an industrial coal powder boiler, which is characterized by comprising an industrial computer, a control cabinet, a core controller, an RS signal converter, an intelligent display instrument and a plurality of sensors; the output terminals of the sensors are connected with the input terminal of the intelligent display instrument, the output terminal of the intelligent display instrument is connected with the input terminal of the RS signal converter, and the output terminal of the RS signal converter is connected with the industrial computer and the control cabinet; the core controller is directly connected with the industrial computer and the control cabinet; and the core controller comprises a water supply controlling unit, a powder supply controlling unit, a pulverized-coal combustion controlling unit and a fly ash collection controlling unit. The invention not only can finish the acquisition of the related technical parameters of the boiler, ensure the normal running of the boiler, and achieve the optimum burning effect, but also can realize the automatic regulation and control of water supply, powder supply, starting and stopping and dust removal and ensure the normal running of the boiler under the condition without being monitored by a person.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

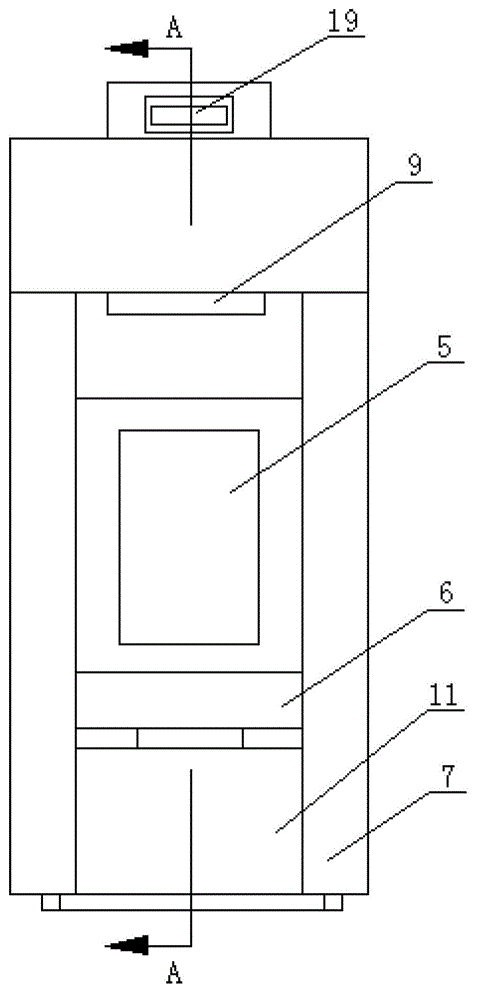

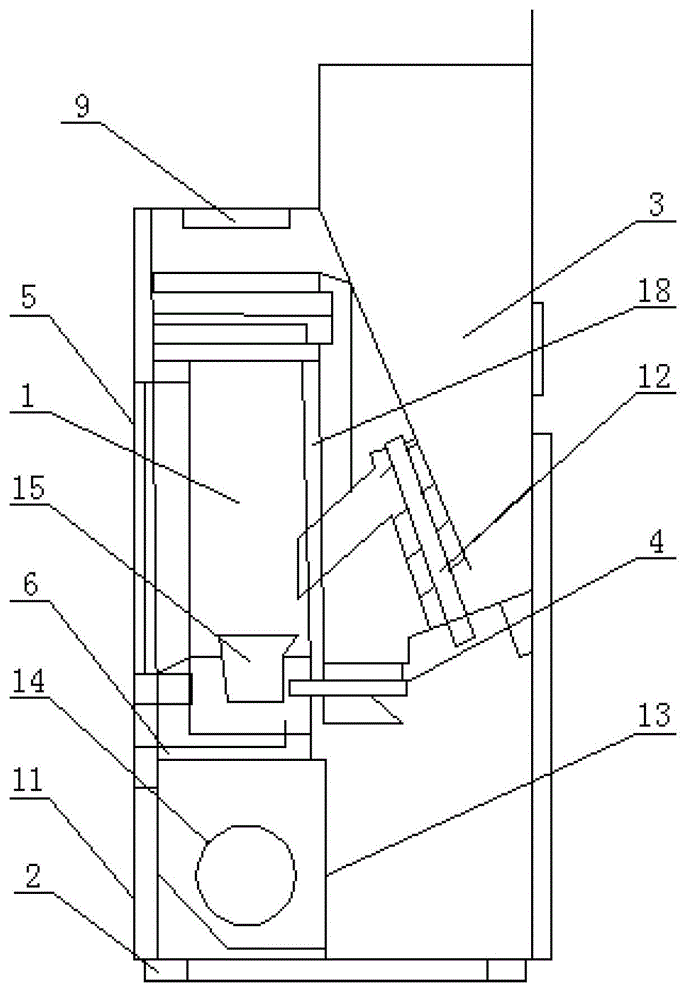

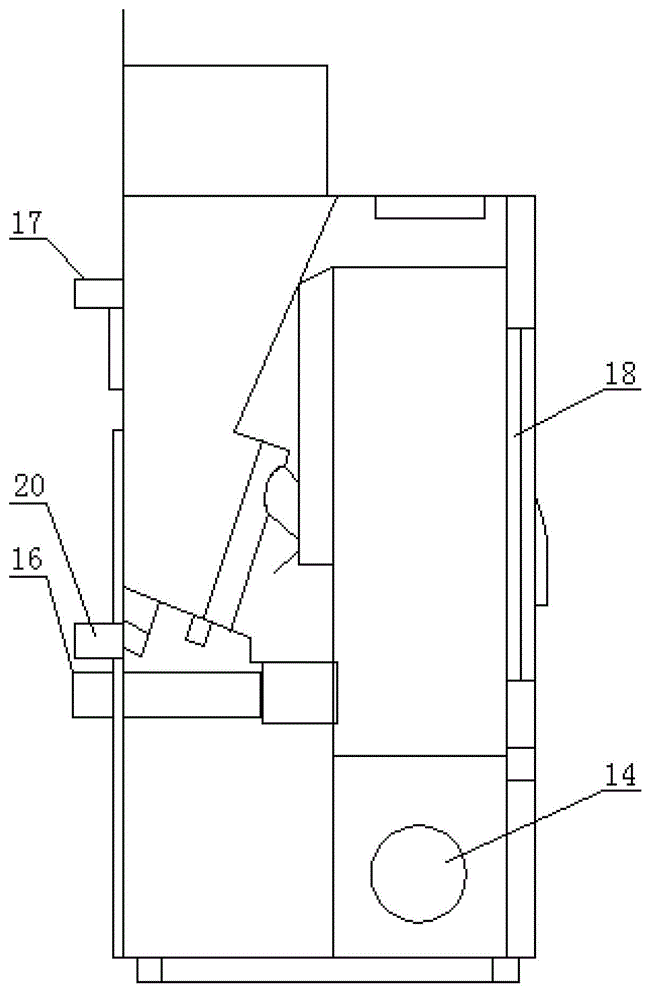

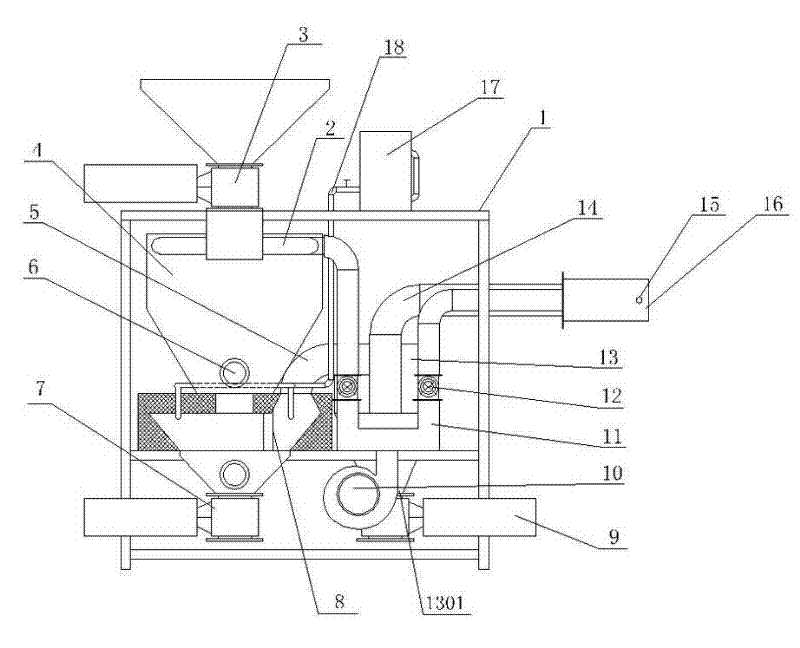

Automatic biofuel-combustion multipurpose furnace

InactiveCN102721169AFull and efficient combustionLow costStove/ranges for heating waterWater heatersAutomatic controlCombustion

An automatic biofuel-combustion multipurpose furnace comprises a furnace body, wherein the furnace body consists of a combustion furnace, a fuel bucket, a feeding device and an automatic control device, the fuel bucket is positioned above the combustion furnace which is obliquely provided with a feeding pipe and internally provided with a combustion pool, the lower port of the feeding pipe is positioned above the combustion pool, the feeding device is arranged between the upper port of the feeding pipe and the combustion bucket, the furnace body is provided with an automatic igniter, the front end of the automatic igniter is contacted with the combustion bucket, a water drum wall is arranged on the side wall of the combustion furnace, a water inlet and a water outlet corresponding to the water drum wall are arranged on the combustion furnace, a water boiling port is arranged at the upper end of the combustion furnace and provided with a water boiling tray, a slag collection box is arranged under the combustion furnace, the combustion furnace is provided with an air inlet under the automatic igniter, an air outlet is arranged at the lower part of the furnace body and provided with an exhaust fan. The automatic biofuel-combustion multipurpose furnace can save non-renewable resources by combusting biofuel, and has the advantages of environment friendliness and safety.

Owner:烟台市宜和环保设备有限公司

Fire coal efficient catalysis combustion-supporting agent and preparation method and use method thereof

InactiveCN102061212AImprove combustion performanceImprove burnout rateSolid fuelsBasic copper carbonateUrea

The invention provides a fire coal efficient catalysis combustion-supporting agent and a preparation method and use method thereof. The combustion-supporting agent provided by the invention comprises the following components in parts by weight: 20-40 parts of basic copper carbonate, 10-25 parts of calcium oxide, 5-20 parts of citric acid, 5-10 parts of ammonium metavanadate, 5-10 parts of urea, 5-10 parts of potassium carbonate and 5-10 parts of borax. The combustion-supporting agent can also contain 5-10 parts of lanthanide oxide, 5-15 parts of magnesium powder and 0-10 parts of iron nitrate. The invention has the following beneficial effects: the components of the combined combustion-supporting agent release or transfer active oxygen at the high temperature; the macromolecular structures of coal are damaged to break the bridge bonds between the connecting structure units, improve the combustibility of fire coal and increase the burn-off rate of coal, thus fire coal can be fully utilized and the aim of energy saving can be achieved; and the combustion-supporting agent performs combination reactions with the combustion products of coal such as SO2 and the generated solids which are difficult to volatilize enter ash, thus the emissions of gaseous pollutants can be reduced.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

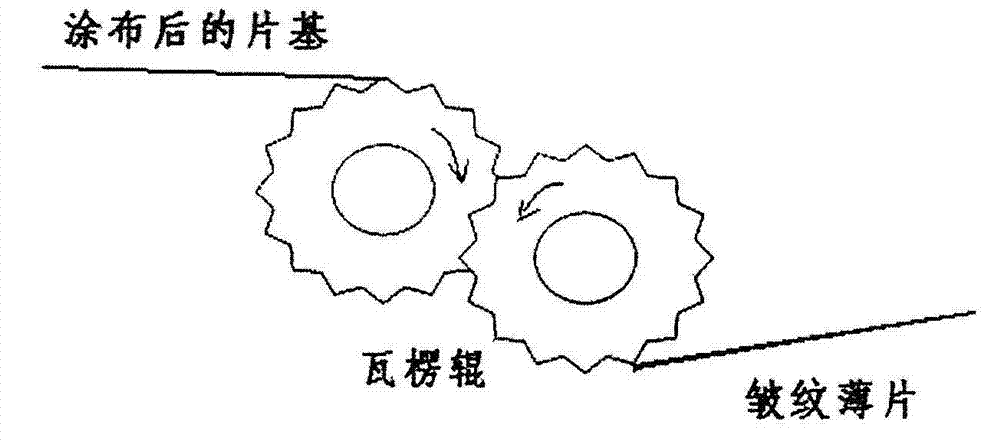

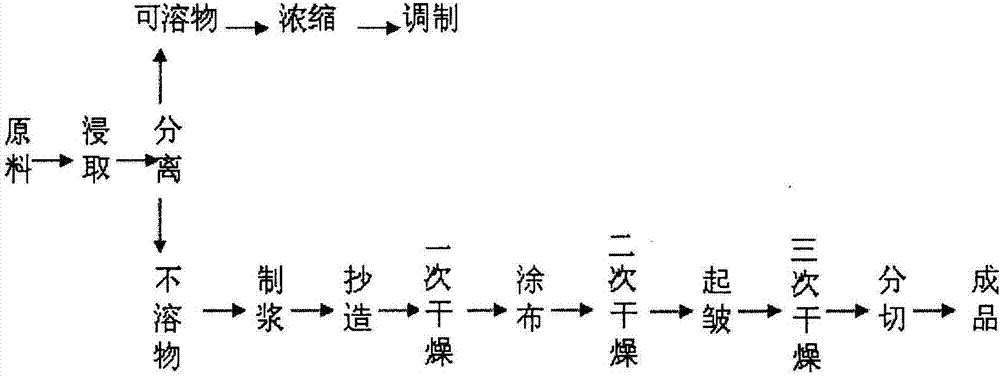

Manufacturing technique of tobacco remaking with fold paper-making method

InactiveCN103082396AEasy to fillGood size controllabilityTobacco preparationCombustionInsoluble fiber

The invention provides a manufacturing technique of tobacco remaking with a fold paper-making method. The manufacturing technique of tobacco remaking with the fold paper-making method comprises the following steps: raw materials of tobacco are soaked and extracted through extraction agent, insolubility fiber materials are separated from soluble substances, film base is made of insoluble substances through pulping, coating liquid is made of the soluble substances by concentration in a modulation mode, and the coating liquid is dip-coated or spray-coated on a slice film base, and enters a drying machine to dry. The manufacturing technique of tobacco remaking with the fold paper-making method is characterized in that slice film base after being dried is made to be diamond-shaped through a pair of corrugated rollers reversely rotating, and is made into a fold tobacco slice after being dried and cut. The manufacturing technique of tobacco remaking with the fold paper-making method is not limited by drying modes, is simple in manufacturing technique, and capable of being widely applied to the production of tobacco remaking with the fold paper-making method, and facilitates improving padding performance of remade tobacco, and reducing consumption of raw materials and production cost. According to measurement and calculation, compared with the prior ordinary tobacco remaking, the manufacturing technique of tobacco remaking with the fold paper-making method can save the consumption of the raw materials by 1.0% or so, improve combustion performance of cigarettes, reduce suction resistance and improve suction quality of the cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

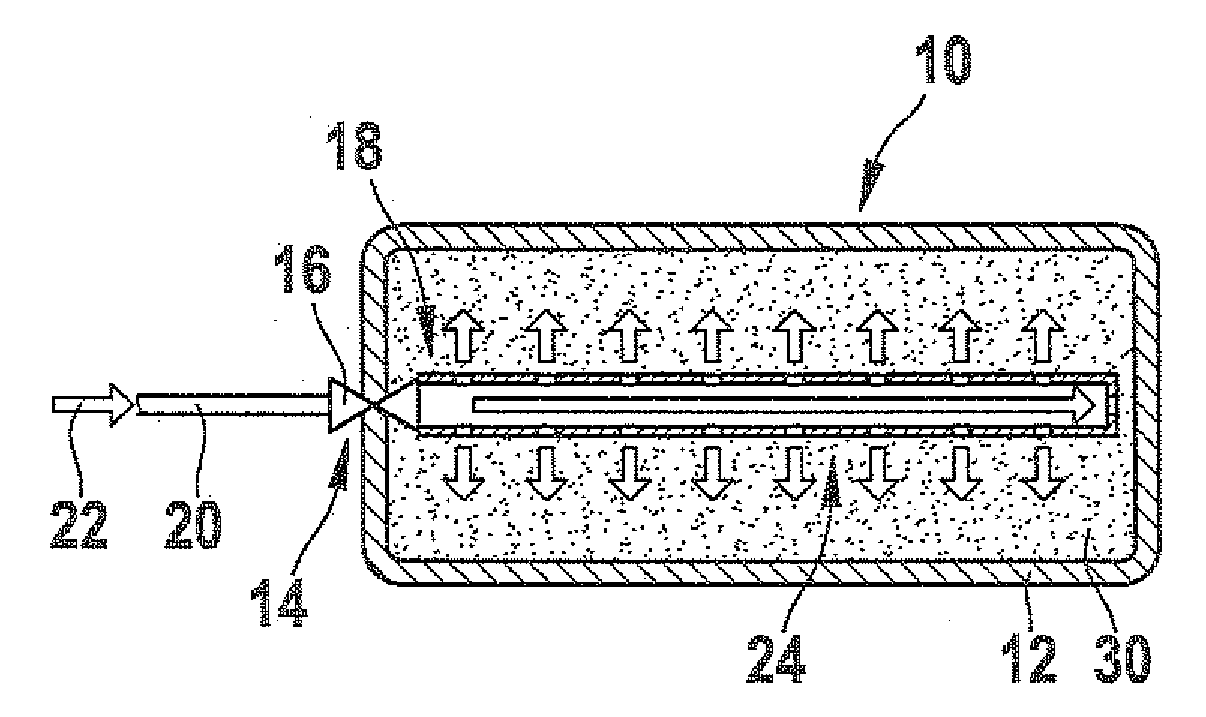

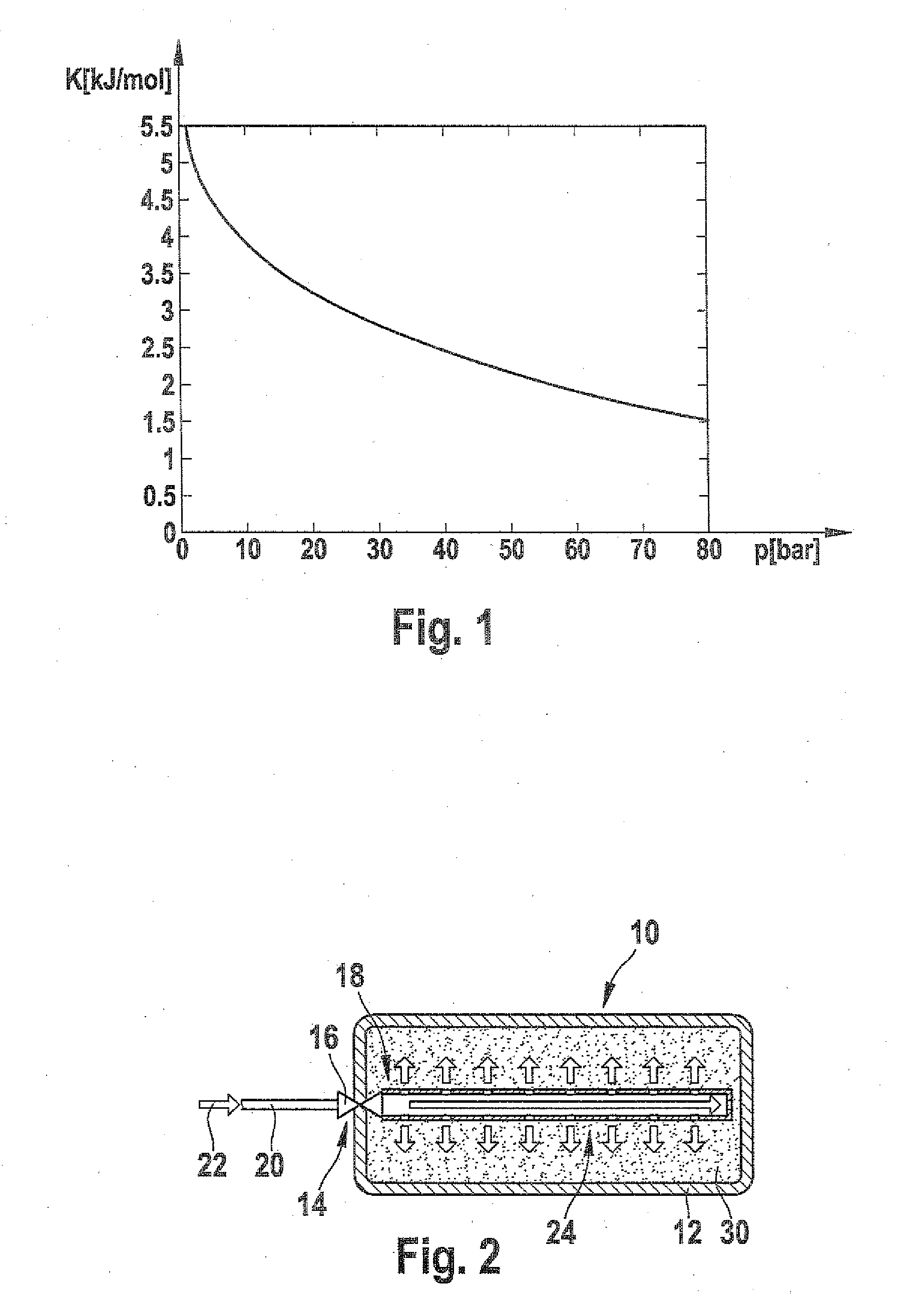

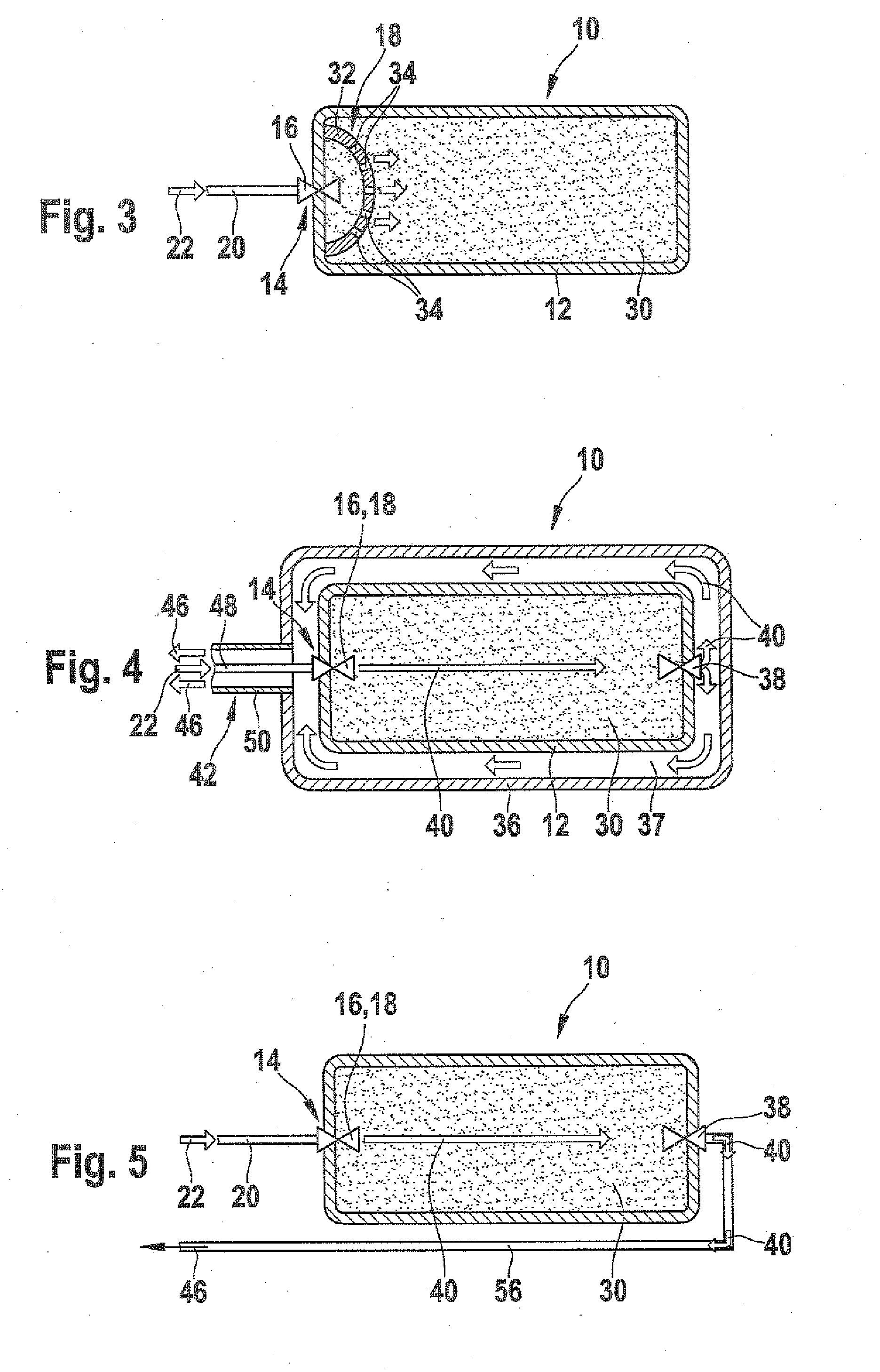

Gas absorption reservoir with optimized cooling

ActiveUS20100006454A1Reduced pressure levelHigh potential for dangerCheck valvesLarge containersNuclear engineeringInlet valve

The invention relates to a fuel reservoir for gaseous fuel in a vehicle, in particular a sorption reservoir. The fuel reservoir is delimited by at least one wall and includes a sorption material that is contained in its interior. The fuel reservoir has a tank inlet valve containing a shut-off valve and a throttle restriction valve. The restriction of the gaseous fuel takes place inside the fuel reservoir.

Owner:ROBERT BOSCH GMBH 50 +1

Composite modifying alcohol ether fuel and catalytic fuel agent

InactiveCN1944596AImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCombustion

The composite modifying catalyst for alcohol-ether fuel is compounded with zinc peroxide 5-15 weigh portions, dimethyl carbonate 15-35 weigh portions, vat yellow GCN 5-15 weigh portions, cyclohexylamine 3-10 weigh portions, and isooctyl nitrate 15-30 weigh portions, and through mixing at normal temperature. The alcohol-ether fuel with the composite modifying catalyst may have great methanol adding ratio while ensuring the combustion efficiency, fuel consumption, dynamic performance and other indexes.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

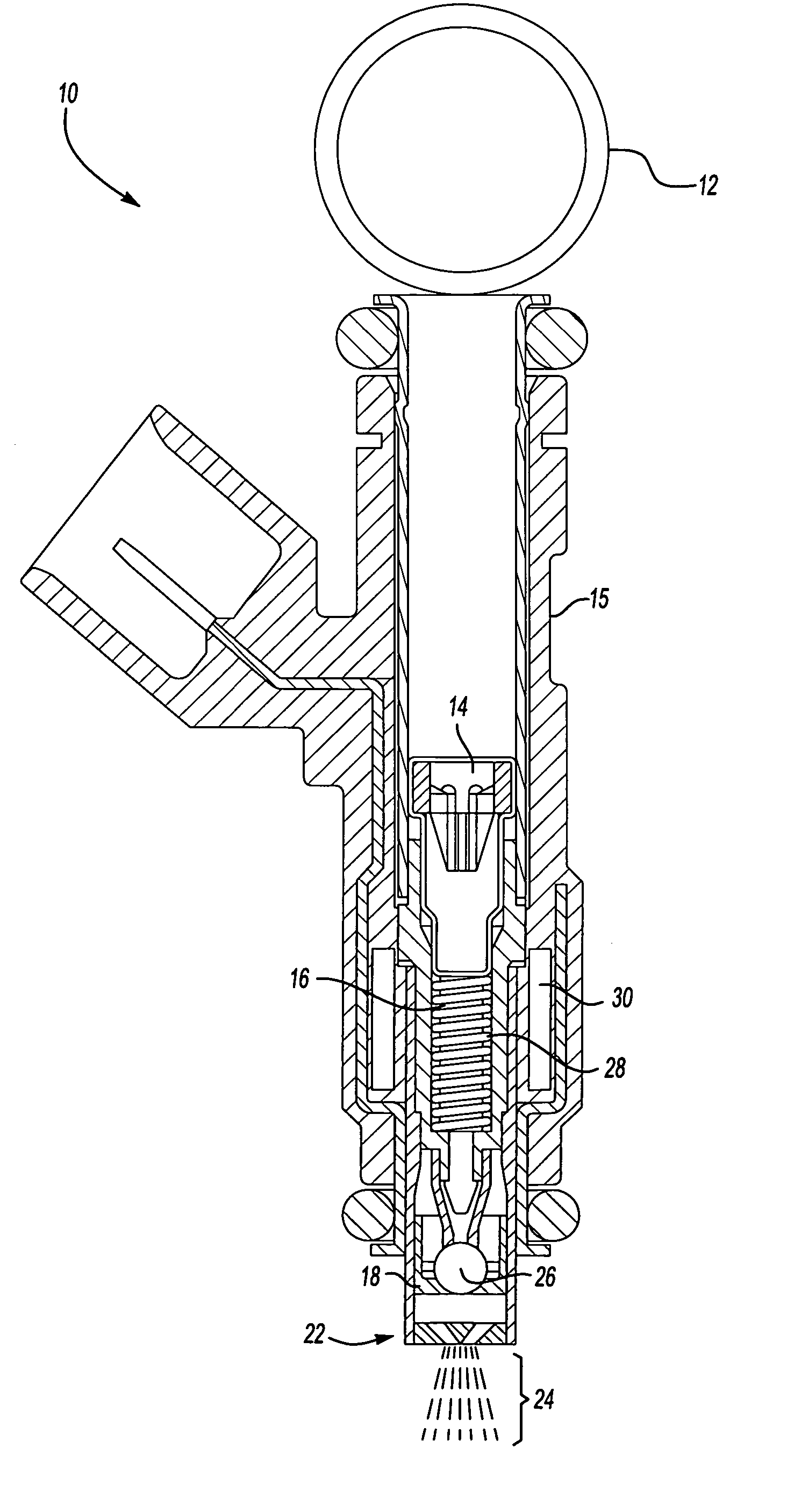

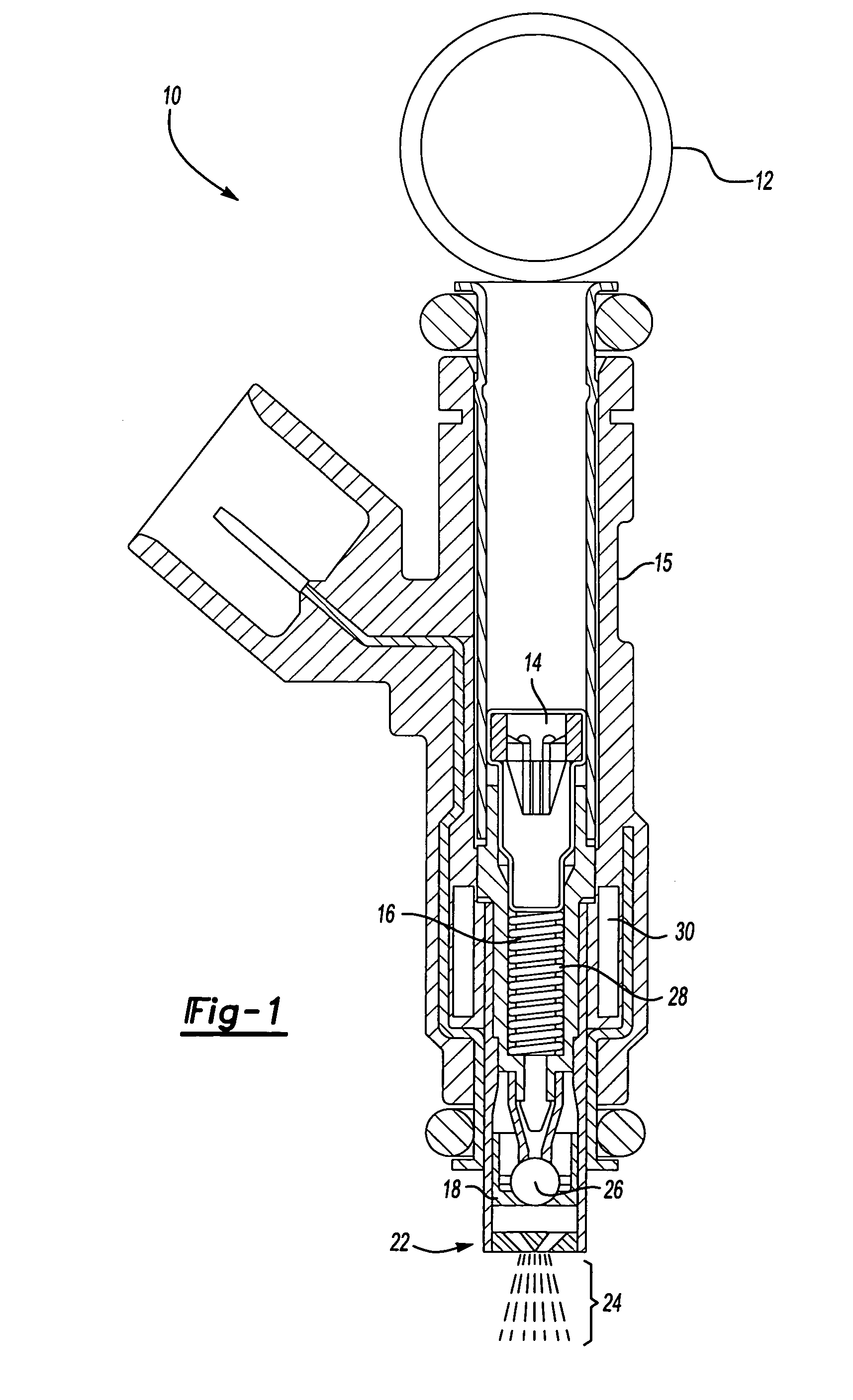

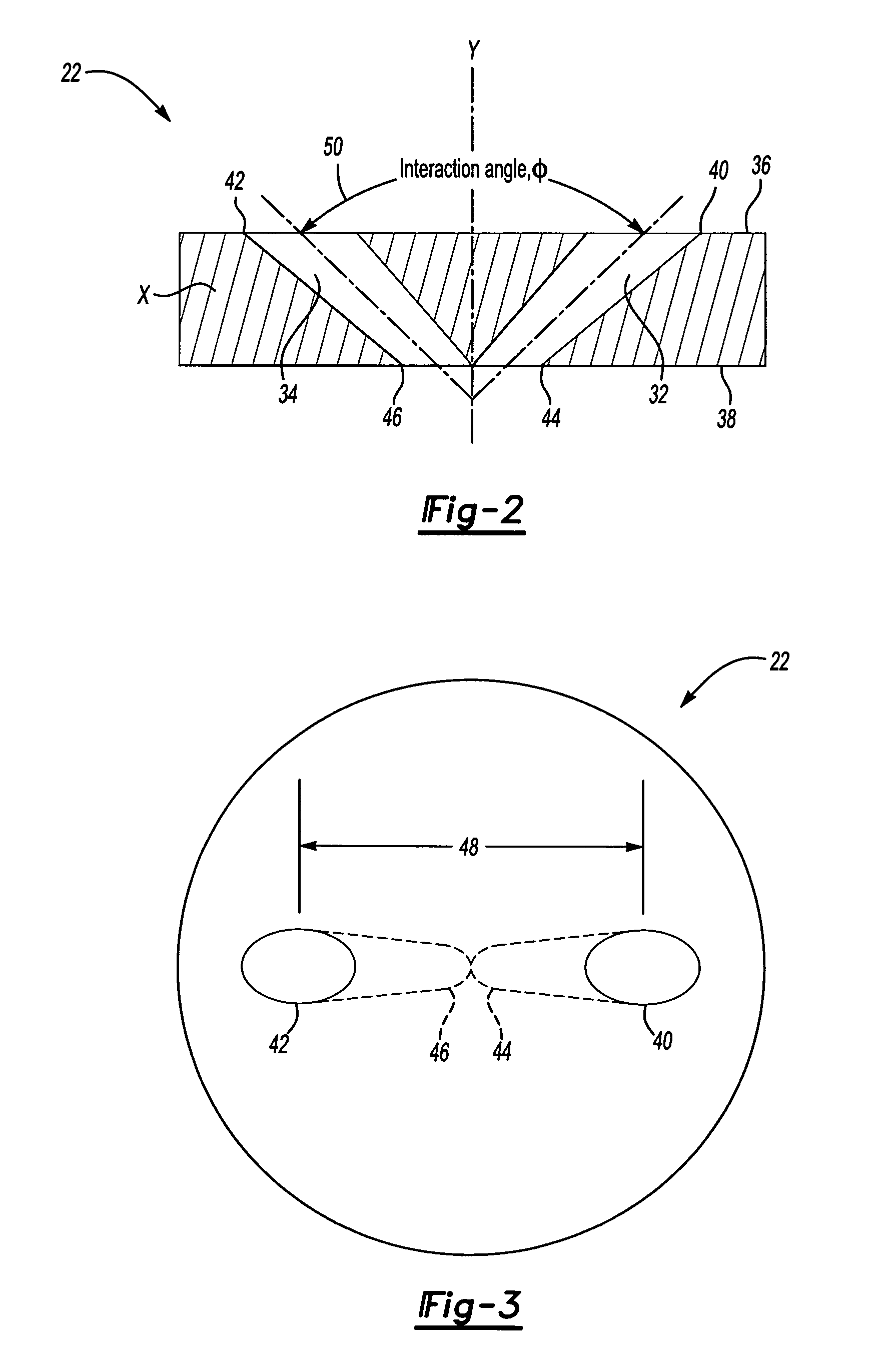

Orifice disc for fuel injector

InactiveUS20060202062A1Atomization of fuel be increaseImprove combustion performanceBurnersSpray nozzlesInjectorEngineering

An orifice disc for a fuel injector includes two orifices that provide a desired interaction between two fuel flows to increase fuel atomization and improve combustion performance. The orifice disc includes a first orifice and a second orifice that are disposed at an interaction angle relative to each other. The orifices are orientated relative to each other such that fuel flow exiting the outlets impinges on each other to further reduce the size of fuel droplets. Large dramatic changes in momentum caused by the impingement of fuel flows disintegrates fuel droplets into much smaller finer fuel droplets that provided enhanced atomization.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

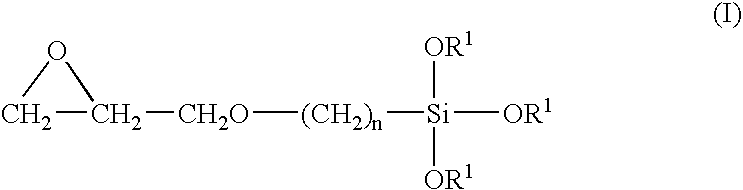

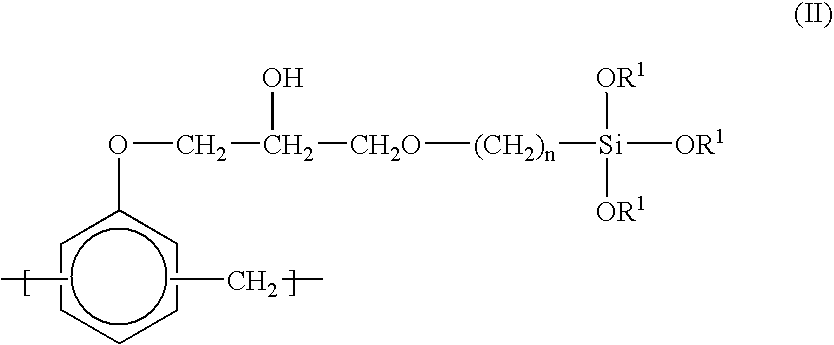

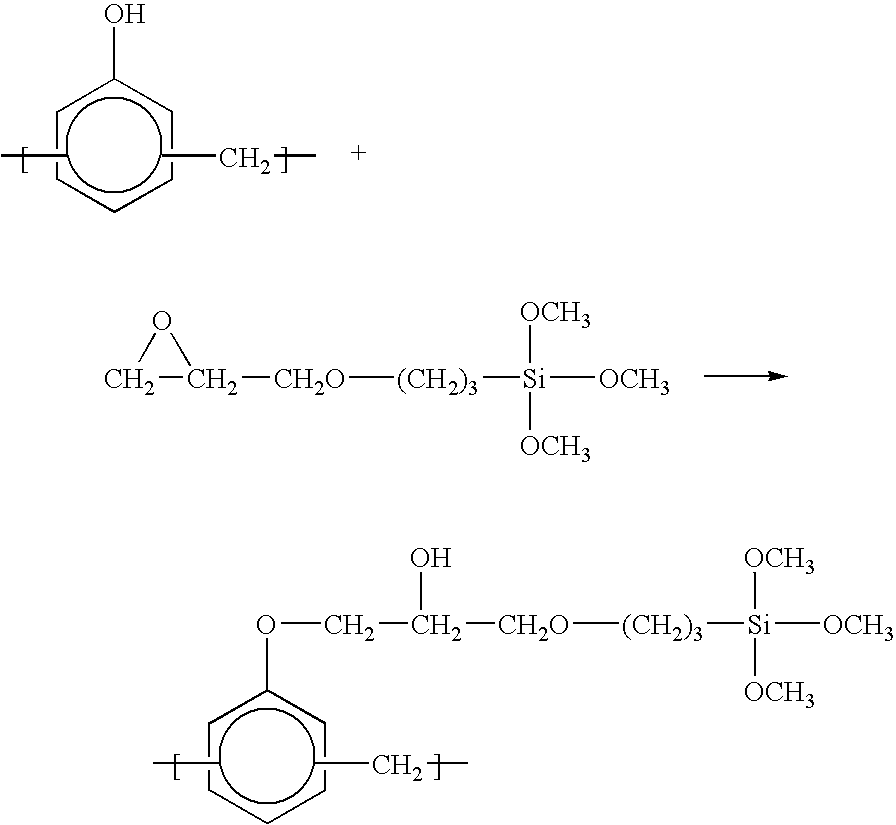

Method for preparing a novolac phenolic resin/silica hybrid organic-inorganic nanocomposite

ActiveUS20050284087A1Improve thermal stabilityMaintain stable propertiesMaterial nanotechnologyBuilding constructionsOrganic solventSilanes

The method of the present invention includes grafting a glycidyl alkylene trialkoxy silane to a novolac phenolic resin in an organic solvent to form a modified novolac phenolic resin; mixing a tetralkoxy silane, an acid and water with the resulting organic solution containing the modified novolac phenolic resin, wherein hydrolysis and condensation reactions are carried out to form a —Si—O—Si— bonding; adding a curing agent for novolac phenolic resin to the resulting reaction mixture; evaporating the organic solvent and acid from the resulting mixture and heating the resulting mixture to form a novolac phenolic resin / silica hybrid organic-inorganic nanocomposite.

Owner:NAT CHUNG SHAN INST SCI & TECH

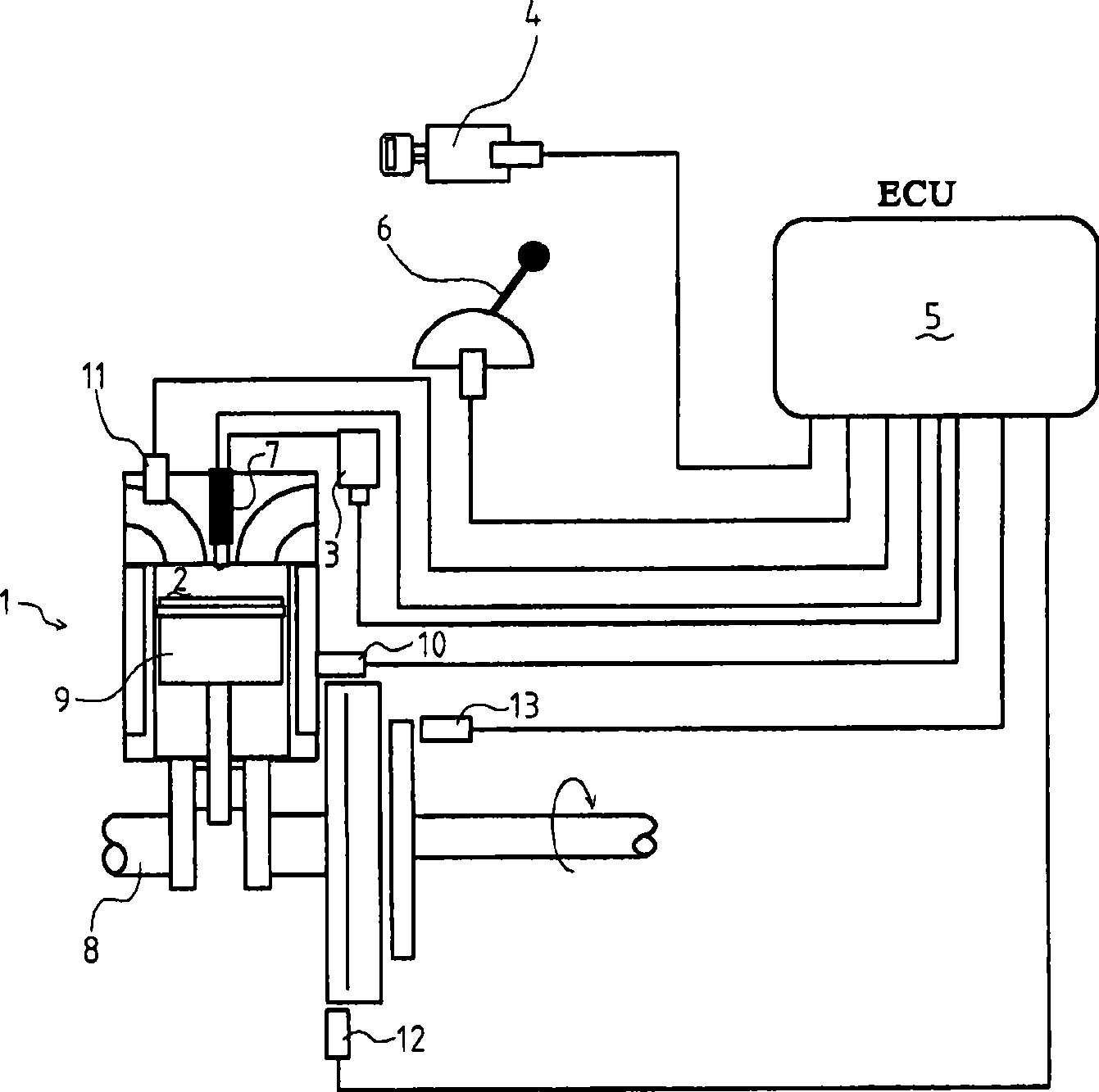

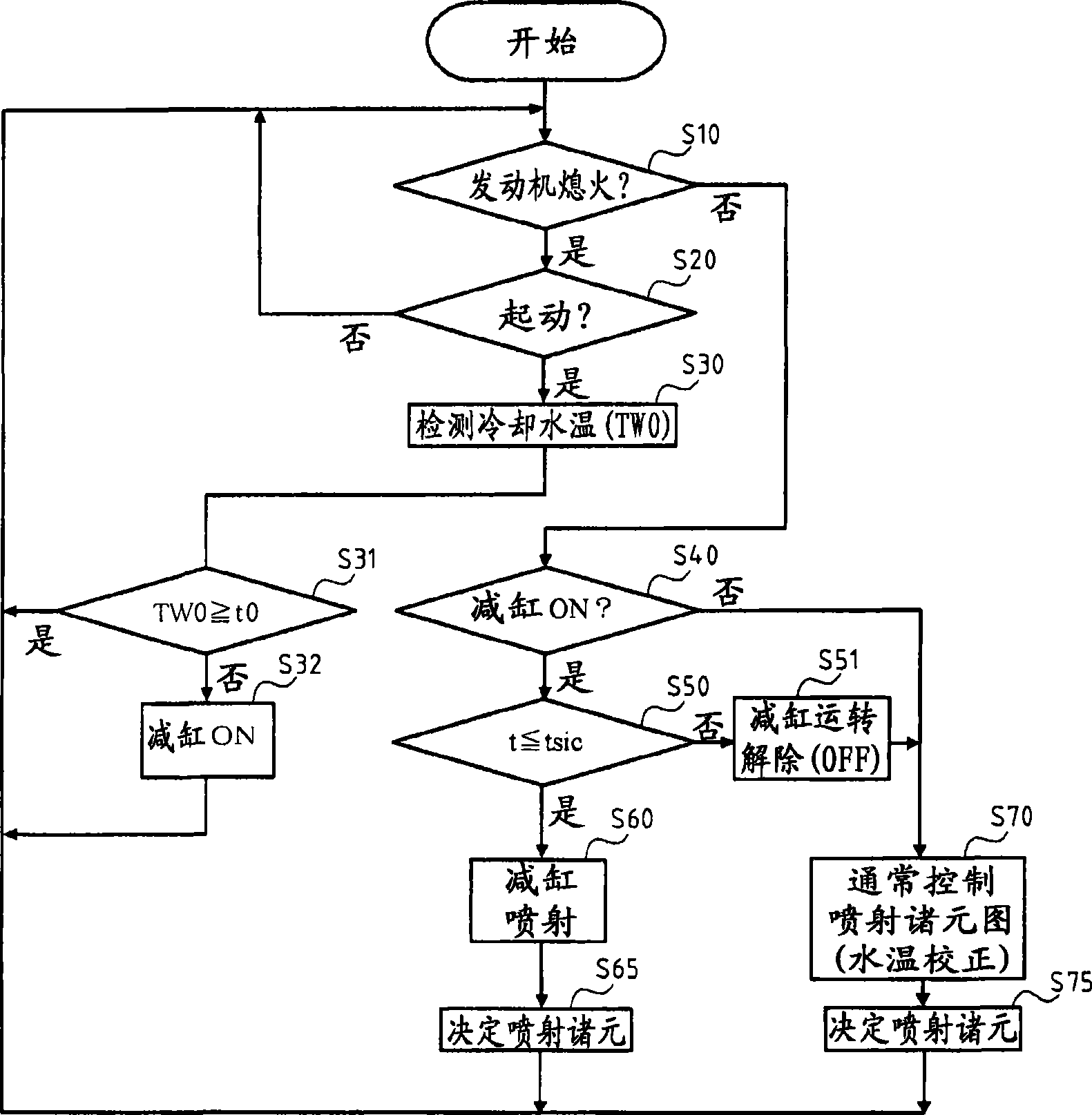

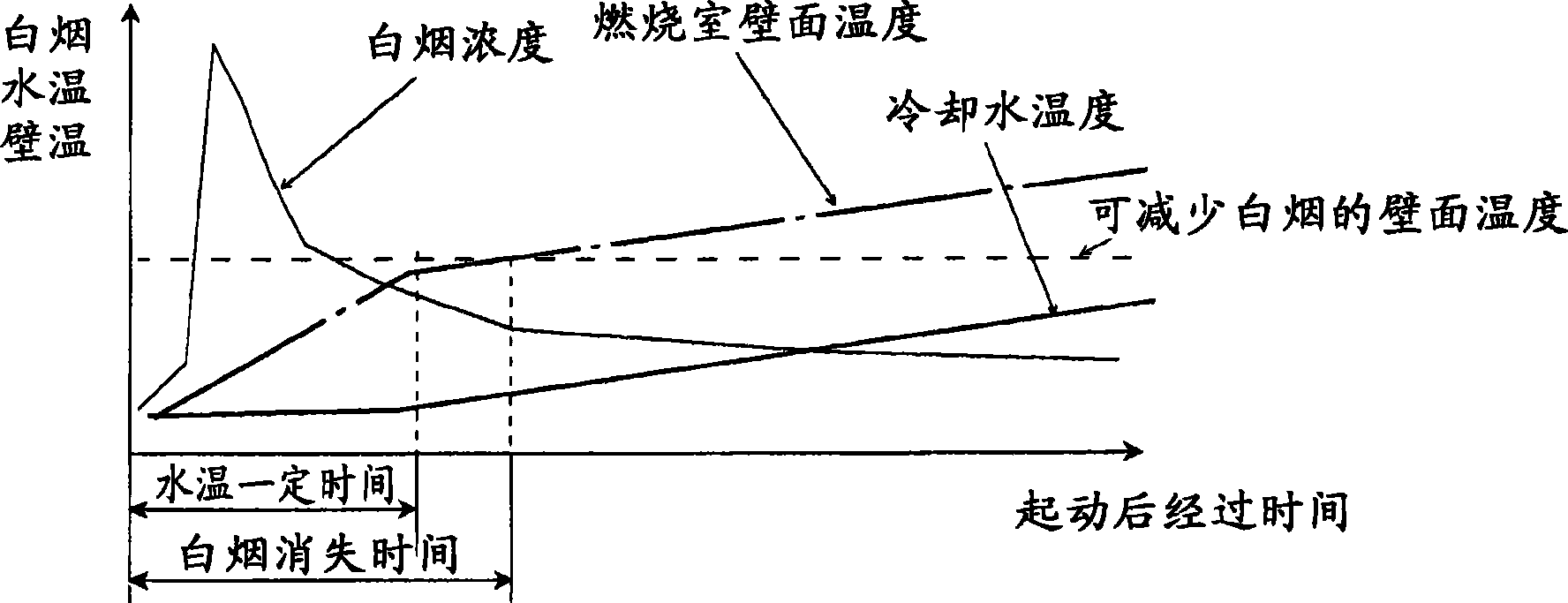

Method of controlling internal combustion engine

InactiveCN101535614ALarge injection volumeRaise the combustion temperatureElectrical controlInternal combustion piston enginesTime lagExternal combustion engine

A method of controlling an internal combustion engine, in which engine operation with a reduced number of cylinders is controlled according to an idling speed after starting the engine to thereby minimize discharge of white smoke during a time lag for temperature equilibrium immediately after a cold start. The method uses a coolant temperature detection means (10) for detecting the temperature of the coolant of the internal combustion engine (1), an engine speed detection means (12) for detecting the speed of the engine, and control means (5) for controlling operation of the engine according to the temperature of the coolant and the engine speed. When the engine is determined to be in a cold start, engine operation with a reduced number of cylinders is started, and in this engine operation, fuel is injected into the cylinders for a predetermined time period after the speed of the engine reaches a predetermined level after the start of the engine.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Gasification combustor for biomass granules

ActiveCN102252317APrevent compactionFully vaporizedSolid fuel combustionCombustion apparatusCombustorCarbonization

The invention relates to a gasification combustor for biomass granules. The gasification combustor comprises a shell, wherein a filler device is arranged on the shell; an inner container and a blast blower are arranged in the shell; and an ignition tuyere and a fire grate is formed on the lower part of the inner container. The gasification combustor is characterized in that: an annular air diffuser is arranged on the upper part in the inner container; a carbonization area corresponds to the ignition tuyere in the inner container, a reduction area is positioned between the carbonization area and the fire grate, and a gasification area is positioned outside the fire grate; the gasification area is connected with a filter by a connection pipe; a gas pipe is arranged at an outlet of the filter; an ash discharge opening is formed at the bottom of the filter; a burner and an ignition device are arranged at the lead-out end led out of the filter and the shell on the gas pipe; and the blast blower is connected with the air diffuser and the burner respectively by a pipeline and a valve arranged on the pipeline. The gasification combustor can gasify the biomass granules fully, is good in combustion effect, high in heat efficiency and heat value, energy-saving, low-carbon, environment-friendly and low in discharge, can replace fuel oil, gas and fire coal, and does not have oil tar, wastewater and smoke dust; and the gasification combustor has a compact structure, and is easy and convenient to mount, small in space occupation and wide in application range.

Owner:穆壮荣

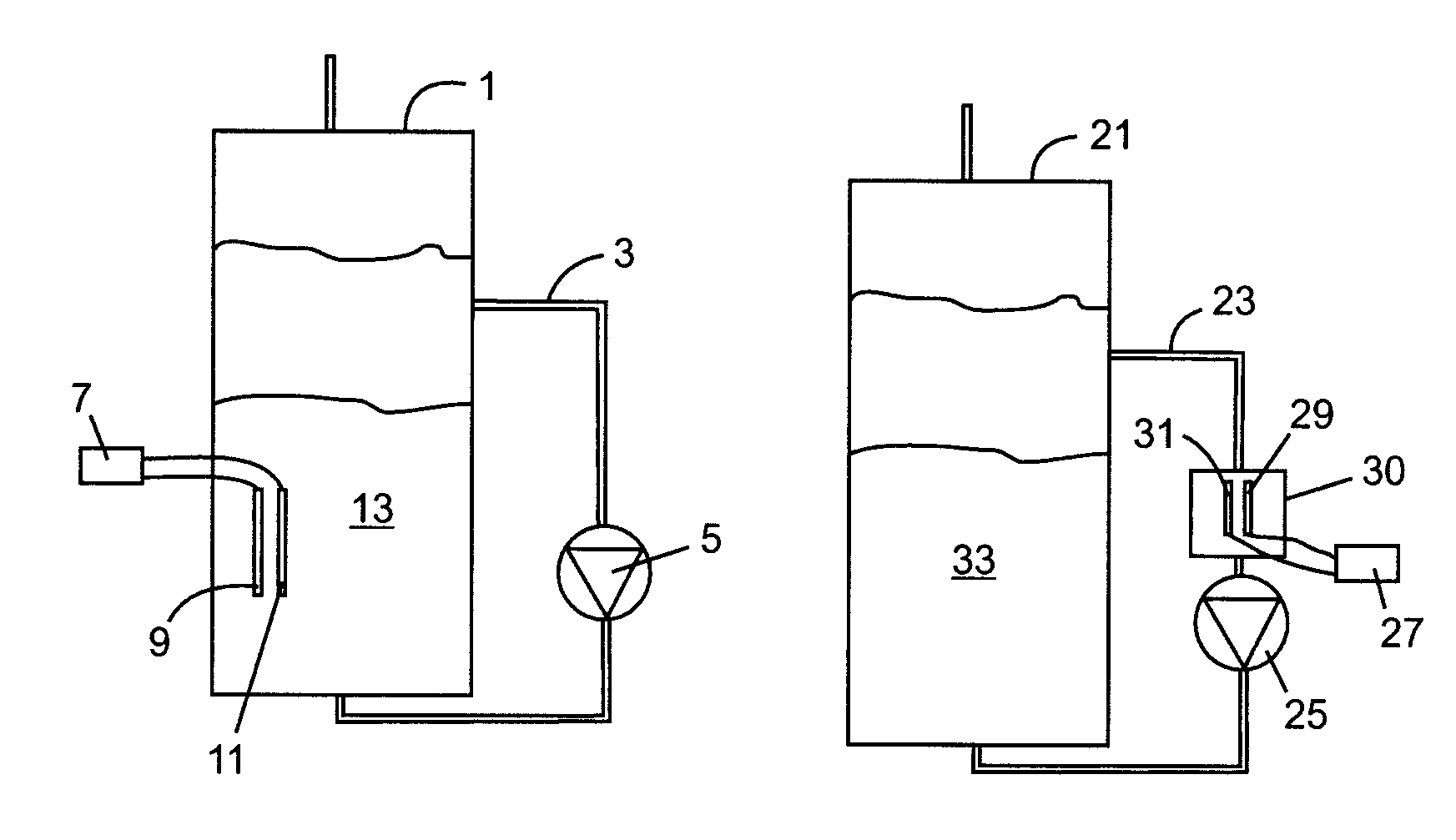

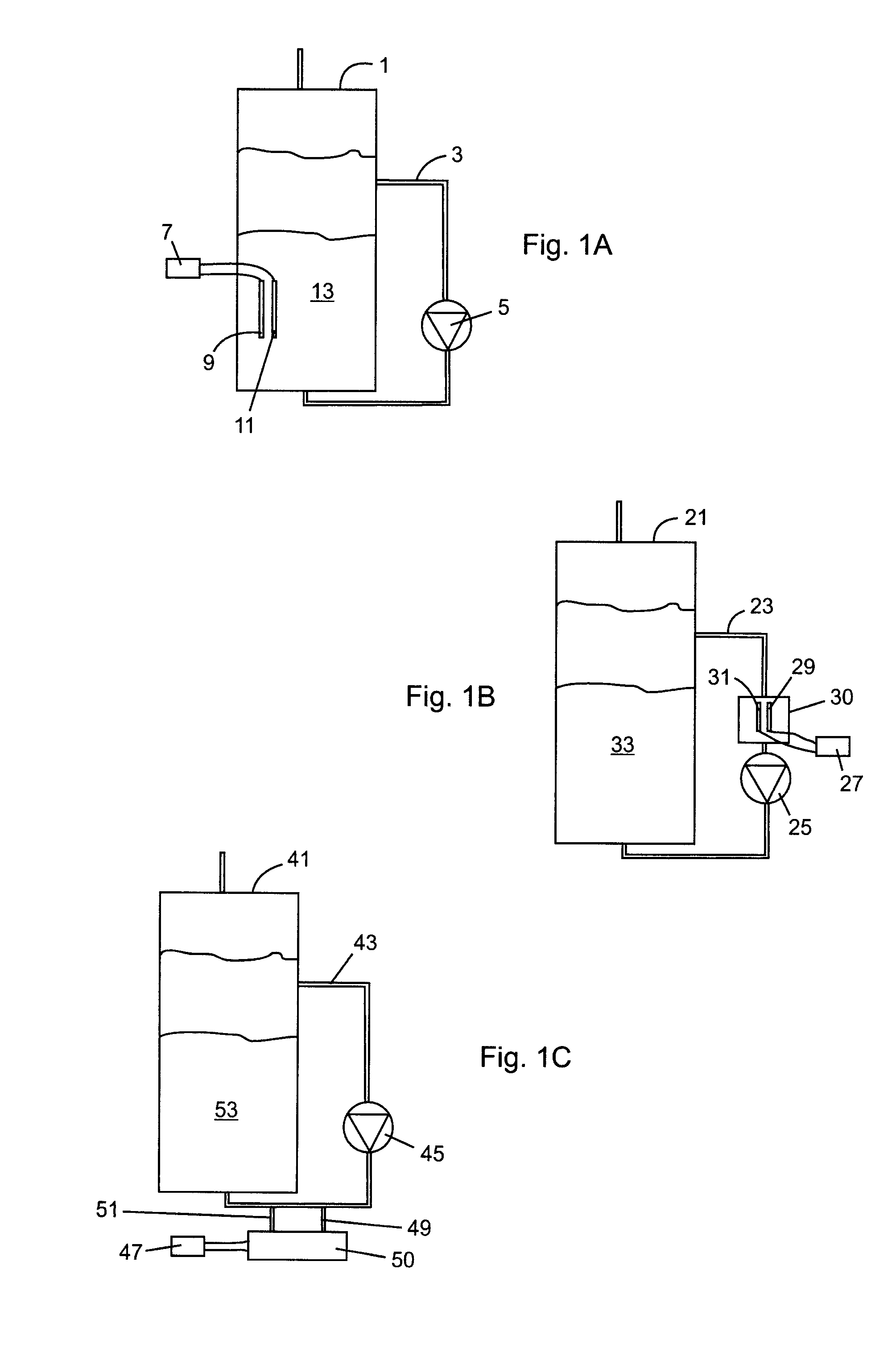

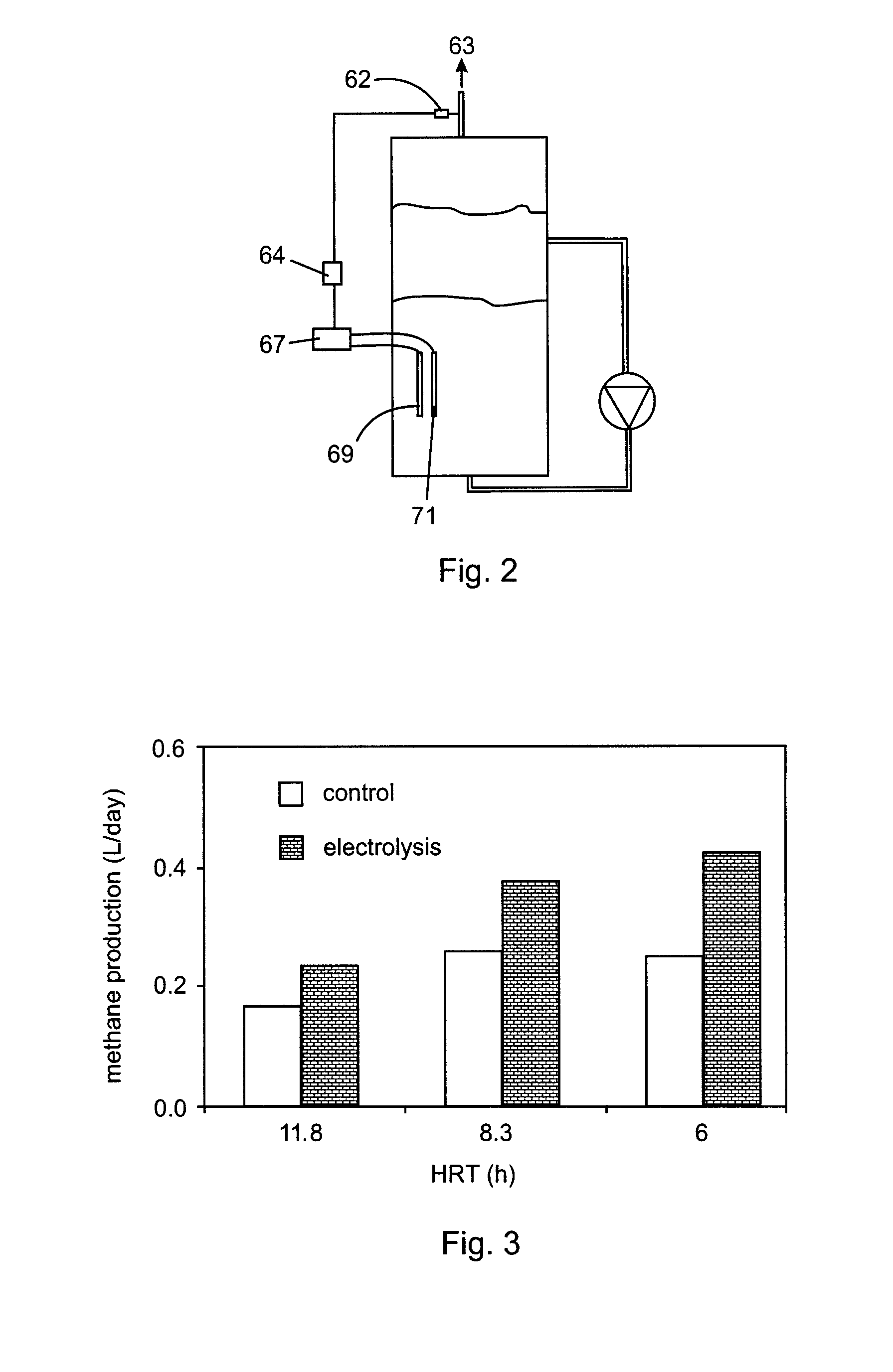

Microbially-assisted water electrolysis for improving biomethane production

InactiveUS20120100590A1Increase surface areaReduce the amount requiredBioreactor/fermenter combinationsElectrolysis componentsElectrochemistryAnaerobic microorganisms

A method of producing in a bioreactor a biogas rich in methane involves electrolyzing water in an aqueous medium at a voltage in a range of from 1.8 V to 12 V in the presence of electrochemically active anaerobic microorganisms that biocatalyze production of hydrogen gas, and, contacting a species of hydrogenotrophic methanogenic microorganisms with the hydrogen gas and carbon dioxide to produce methane. Volumetric power consumption is in a range of from 0.03 Wh / LR to 0.3 Wh / LR. Current density is 0.01 A / cmE2 or lower. The voltage is sufficient to electrolyze water without destroying microbial growth. Such a method results in improved electrolysis efficiency while avoiding the use of noble metal catalysts. Further, a combination of water electrolysis with anaerobic degradation of organic matter results in increased biogas quality and in increased biogas quantity and yield. Oxidation of hydrogen sulfide contributes to the increased quality, while an increase in the rate of organic matter hydrolysis and an increase in the production of methane from hydrogen contributes to the increased quantity and yield.

Owner:NAT RES COUNCIL OF CANADA

Inorganic material-modified phenolic foam insulation material with low water absorption and preparation method thereof

An inorganic material-modified phenolic foam insulation material with low water absorption and a preparation method thereof are disclosed. According to the invention, 0.1-50 parts by weight of an inorganic modifier with the surface coated by a water repellent, 1-10 parts by weight of a coupling agent, 3-15 parts by weight of an organic modifier, 2-18 parts by weight of a foaming agent, 6-20 parts by weight of a curing agent and 0-5 parts by weight of a powdery water repellent are added into 100 parts by weight of foamable phenolic resin. The preparation method provided by the invention comprises the following steps: uniformly mixing the foamable phenolic resin, the inorganic modifier processed by surface hydrophobic treatment, the coupling agent, the organic modifier, the foaming agent, the curing agent and the powdery water repellent, foaming at 18-90 DEG C, curing, carrying out thermal insulation for 2-18 h, standing at room temperature for 7-20 days, and slaking to obtain the inorganic material-modified phenolic foam insulation material with low water absorption. The foam material provided by the invention has fine and uniform cells and high porosity by closed pore. In addition, a light inorganic material undergoes hydrophobic cover treatment so as to achieve the purpose of reducing water absorption of the material.

Owner:CHINA BUILDING MATERIALS ACAD

Self-backheating swirling burner for fuel gas with low heat value

InactiveCN102425793ARaise the initial temperatureImprove combustion performanceGaseous fuel burnerPetrochemicalPower engineering

The invention discloses a self-backheating swirling burner for a fuel gas with a low heat value. The structure comprises an outer barrel of a burner, an inner tube of the burner and a swirling generation device, wherein the outer barrel of the burner and the inner tube of the burner are coaxially configured, and the swirling generation device is arranged in the inner tube of the burner. The self-backheating swirling burner is characterized in that combustion air exchanges heat with the high-temperature smoke of a combustion chamber by virtue of an inner pipe wall to improve the temperature of the combustion air; and then after the combustion air enters a mixing chamber to be mixed with the fuel gas with a low heat value, the mixture begins rotating by virtue of the swirling generation device to obviously improve the combustion stability of the fuel gas with a low heat value to realize complete combustion. The burner can be applied to the technical field of thermal power engineering, can fully utilize various types of fuel gases generated in the industrial processes, such as metallurgy, petrochemical industry, biomass pyrogenation, waste gasification treatment and the like, and also can be used for burning a common fuel gas.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

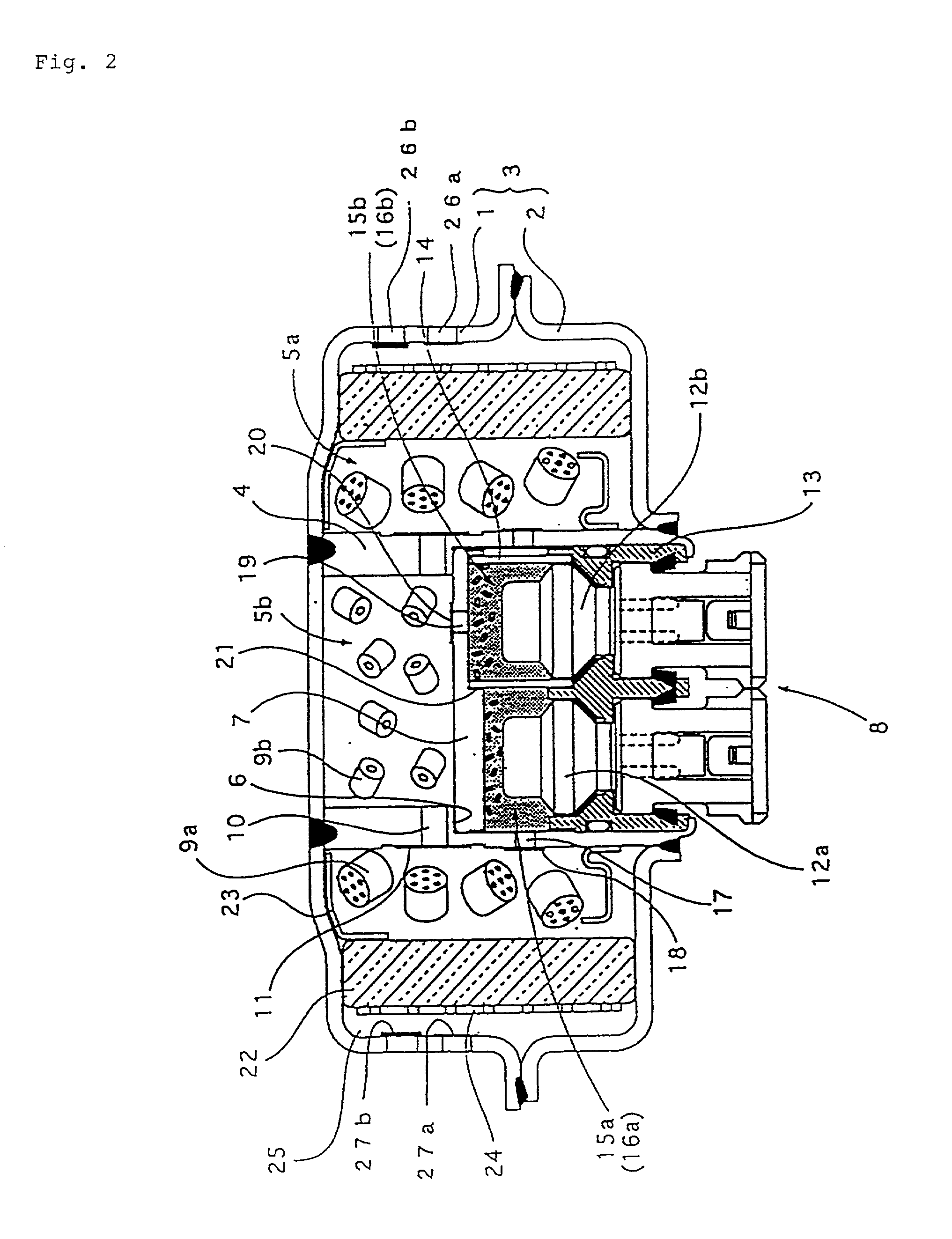

Gas generator for air bag and air bag apparatus

InactiveUS20020056976A1Improve combustion performanceEasy to shapeGas treatmentDispersed particle filtrationInternal pressureGas-discharge lamp

A gas generator small in size and which can be produced easily with a simple structure is provided. The output of a gas generator is equalized so that an occupant can be safely restrained, and the combustion performance can be stably adjusted. The gas generator comprises a housing forming an outer shell container and accommodating two or more ignition units to ignite upon an impact and two or more gas generating agents which are independently ignited and burnt by the ignition units to generate a combustion gas for inflating an air bag, and a plurality of gas discharge ports which are formed in the housing, wherein the gas discharge ports are closed by sealing units for maintaining an internal pressure of the housing to the given pressure, a breaking pressure for breaking the sealing units is adjusted in multiple stages by controlling gas discharge ports and / or sealing units, and a difference of the maximum internal pressures in the housing at activation of the respective igniters is suppressed.

Owner:DAICEL CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com