Preparation method of cigarette expansion cabo granule filling material

A technology of expanded stems and fillers, which is applied in the field of preparation of expanded tobacco stem particles, can solve the problems that expanded tobacco stems cannot be added directly, and achieve the effects of simple composition, less woody gas, and high filling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

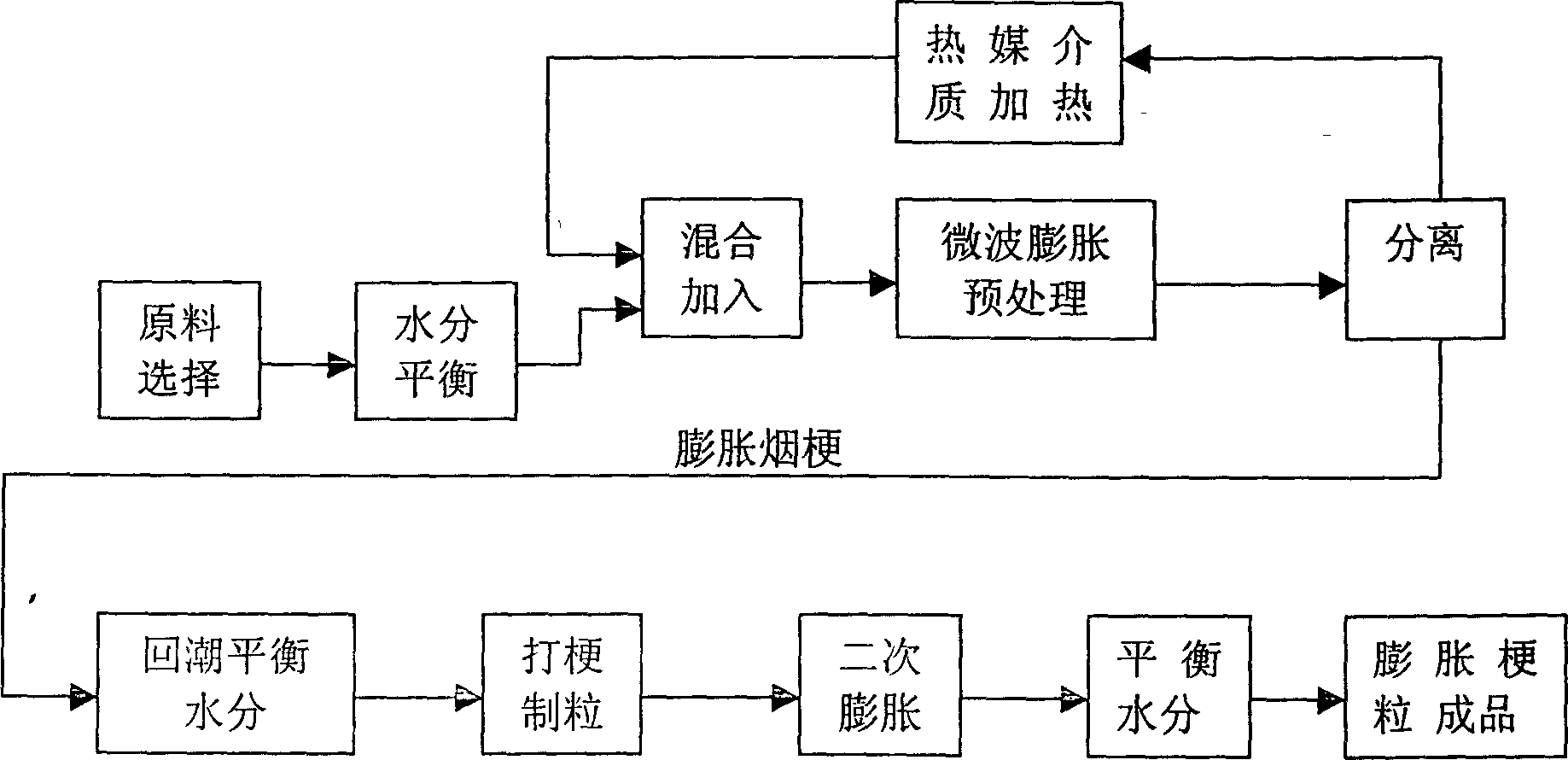

[0027] A method for preparing cigarette expanded stem granule fillers, comprising preparing expanded tobacco stems, regaining moisture, balancing moisture, stalk granulation, secondary expansion, and rebalancing moisture, characterized in that the specific process steps are as follows:

[0028] A. Preparation of expanded tobacco stems: the process method of patent application No. 03117228.8 applied by the applicant is used to prepare expanded tobacco stems with a moisture content of 5-9%.

[0029] B. Moisture regain and moisture balance: In the moisture regain and balance moisture equipment, the expanded tobacco stems with a moisture content of 5-9% are subjected to moisture regain and moisture balance treatment, so that the moisture content of the expanded tobacco stems is humidified to 13-35%, and the same batch Secondary moisture deviation ≤ 1%.

[0030] C. Stem granulation: the expanded tobacco stems with a moisture content of 13-35% and balanced moisture content are crush...

Embodiment 2

[0034] A method for preparing cigarette expanded stem granule filling material, which is to humidify the expanded tobacco stem with a moisture content of 5-9% to 13-35% in moisture regain equipment and balance moisture equipment prepared by the process method of patent application number 03117228.8 % (adjustable, batch moisture deviation ≤ 1%), and then continuously sent to the air separation and stalking equipment for stalking, the stalks are separated and removed, and the particle size is 1mm 3 ~70mm 3 The expanded stalk granules are air-separated and transported to the HT vibrating tank for rapid drying until the moisture content is 7-14%, so that the stalk granules are expanded twice, and the volume increases by 15-30%. In the moisture balance equipment, the moisture is balanced to 13%±0.5 to obtain the finished product of expanded stem particles that can be blended and added to cigarettes.

Embodiment 3

[0036] A method for preparing cigarette expanded stem granule filling material, which is to humidify the expanded tobacco stem with a moisture content of 5-9% to 13-35% in moisture regain equipment and balance moisture equipment prepared by the process method of patent application number 03117228.8 % (adjustable, batch moisture deviation ≤ 1%), and then continuously sent to the air separation and stalking equipment for stalking, the stalks are separated and removed, and the particle size is 1mm 3 ~70mm 3 The expanded stalk particles are separated by air and transported to the STS flash evaporation equipment for rapid drying to a moisture content of 7-14%, so that the stalk granules are expanded twice, and the volume increases by 15-30%. The expanded stalk particles after the second expansion Finally, the moisture is balanced to 13%±0.5 in the moisture balance equipment to obtain the finished product of expanded stem particles that can be blended and added to cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com