Patents

Literature

1397results about How to "Improve combustion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing high-density aviation fuel by using cyclopentanone as raw material

ActiveCN104232140AImprove combustion effectIncreased carrying energyLiquid hydrocarbon mixture productionBio-feedstockCarbon numberSolvent free

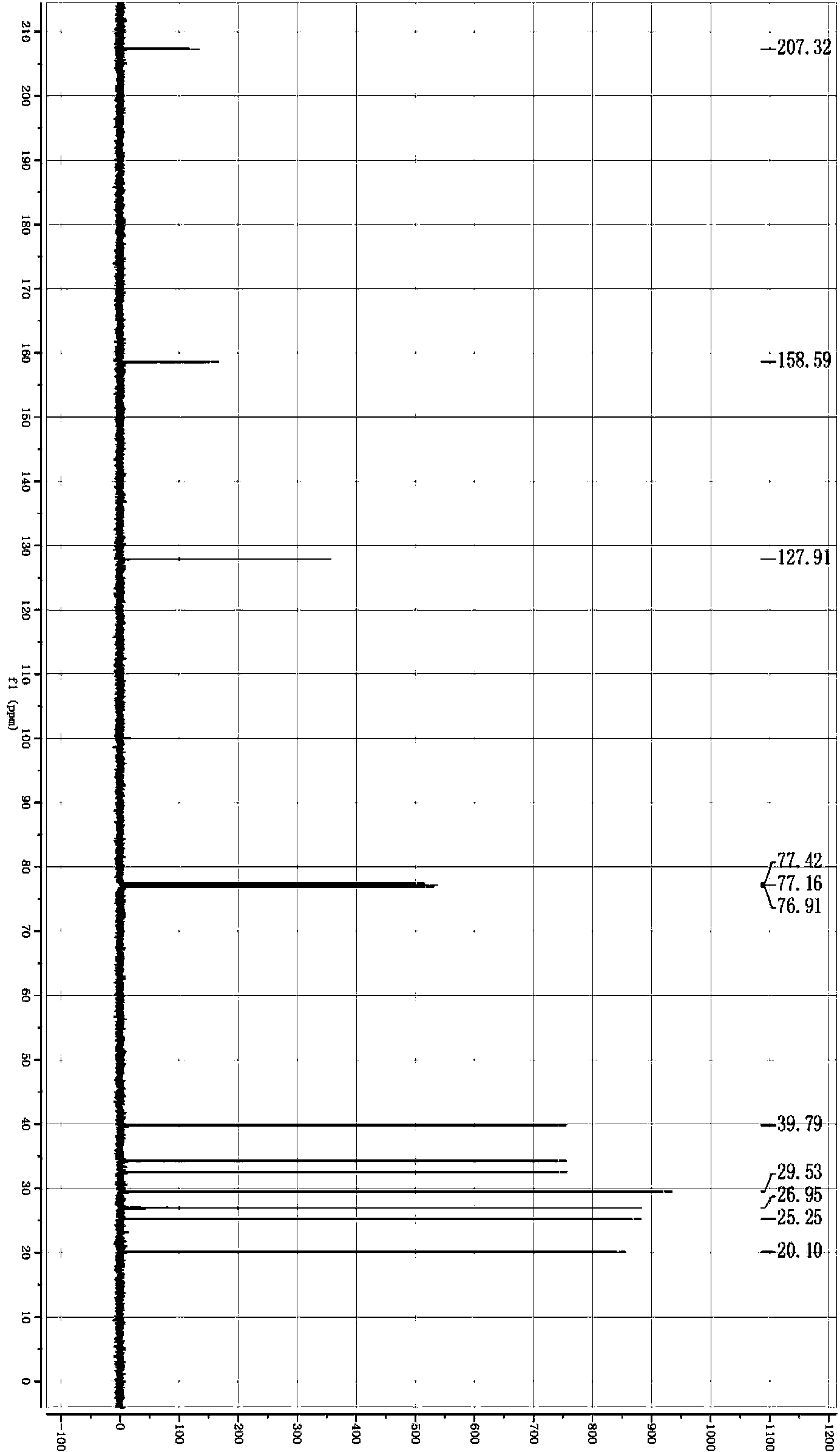

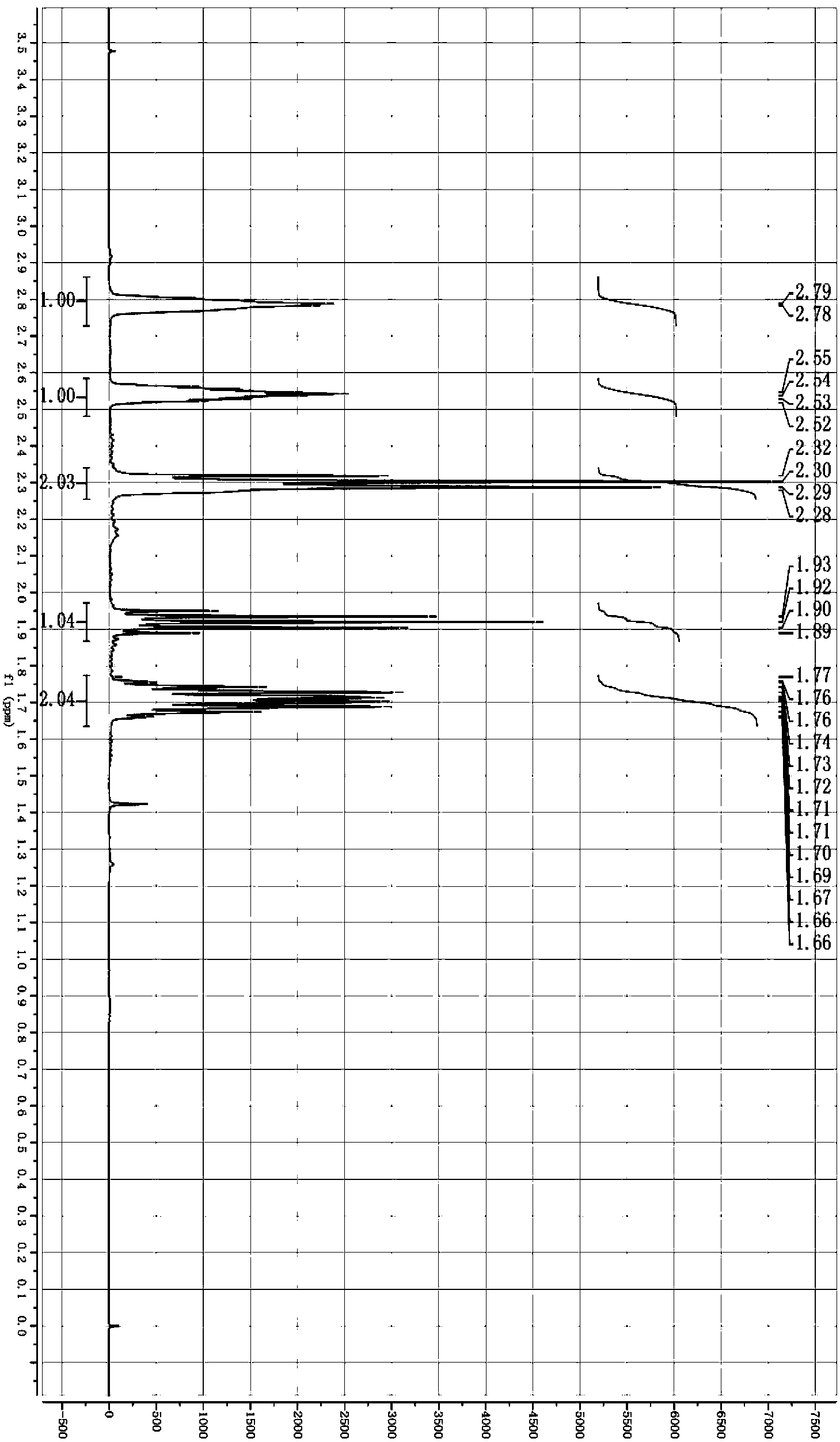

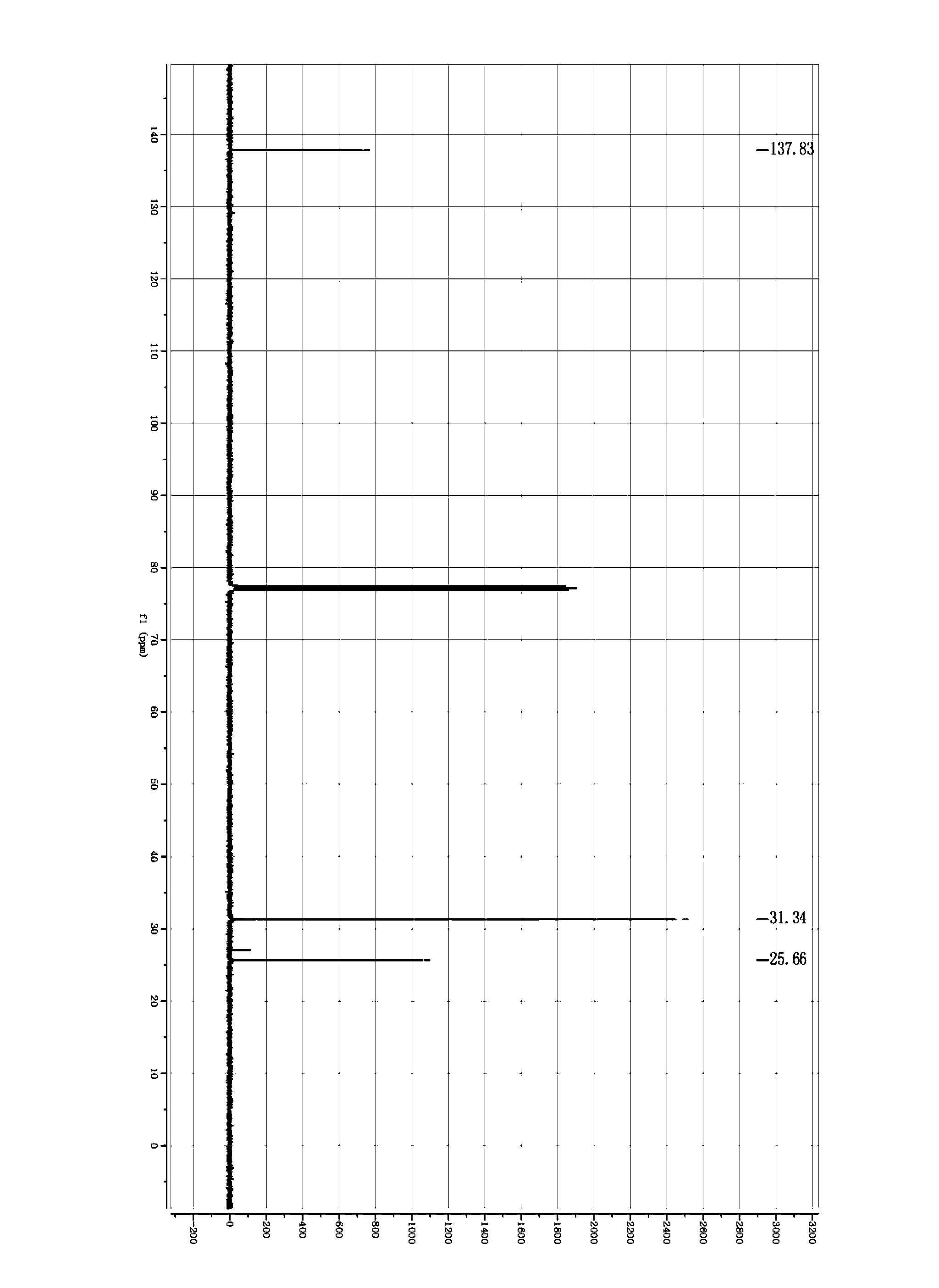

The invention relates to a synthetic route of a hydrocarbon fuel with high density and high volumetric calorific value by using a lignocelluloses-based platform chemical compound as a raw material and completely independent of fossil energy. A liquid fuel obtained by the method can be used in various aircrafts or used as an additive to raise combustion performance of aviation fuel. The method is divided into two parts: 1) under the promotion action of an acid / base catalyst, cyclopentanone (furfural selective hydrogenation product) is subjected to an aldol self-condensation reaction to synthesize unsaturated organic compounds with C10 and C15 polycyclic structures; and 2) a metal loaded A / X catalyst is used to carry out a one-step hydrodeoxygenation and hydrogenation reaction on products generated from the step 1 under low-temperature solvent-free conditions, so as to obtain polycyclic hydrocarbon fuel with carbon number being 10 and 15. The liquid fuel has high density (C10: 0.92g / cm<3>; C15: 1.12g / cm<3>), can be used to effectively raise carrying energy of an aircraft and reduce fuel consumption rate, and meets requirements of high navigational speed, large load and long range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

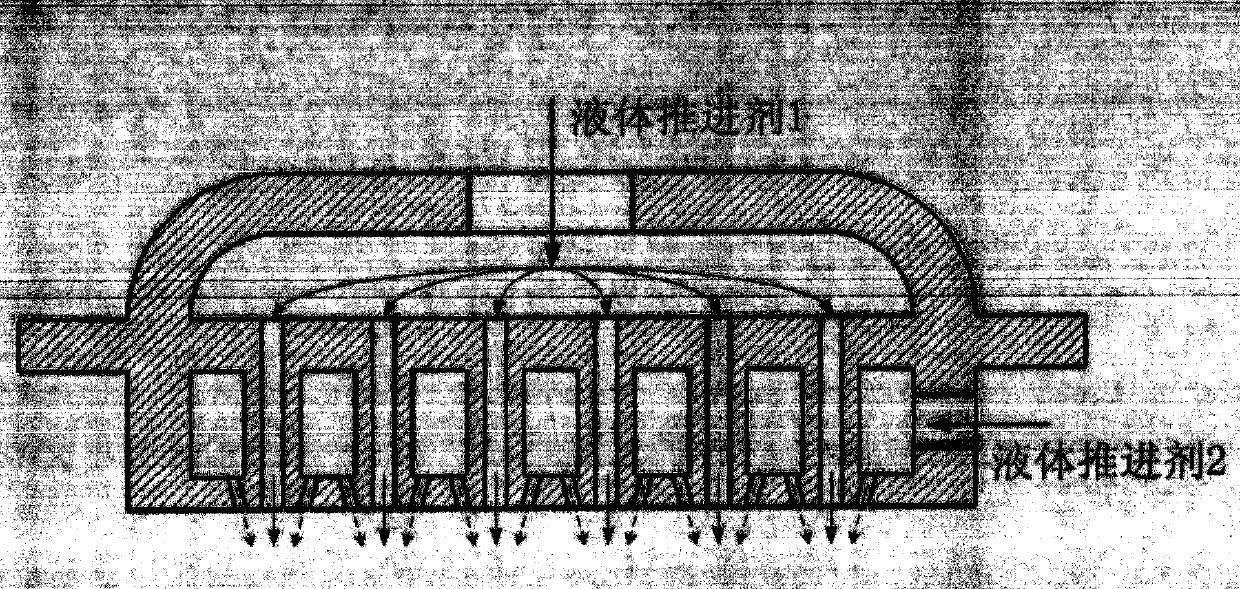

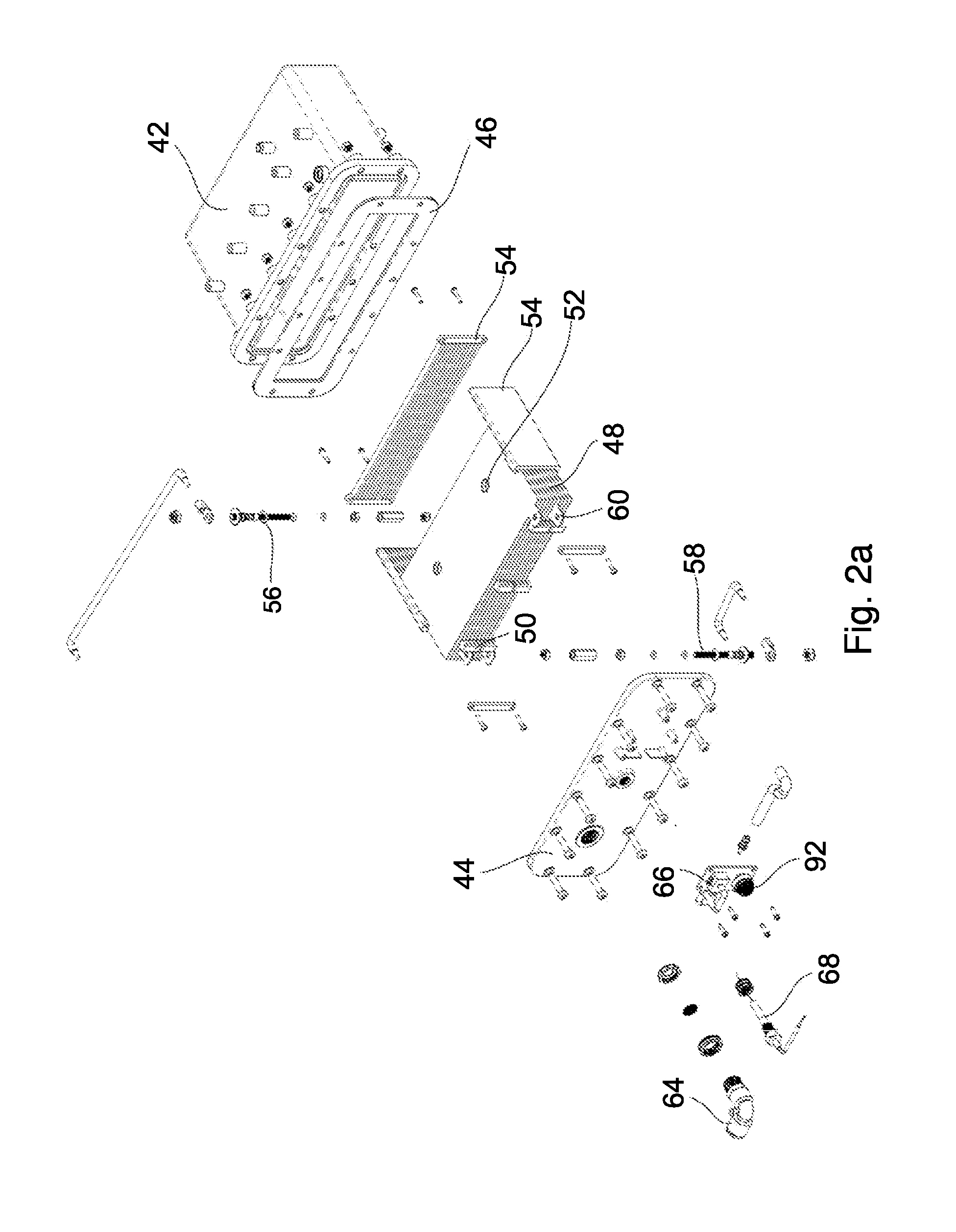

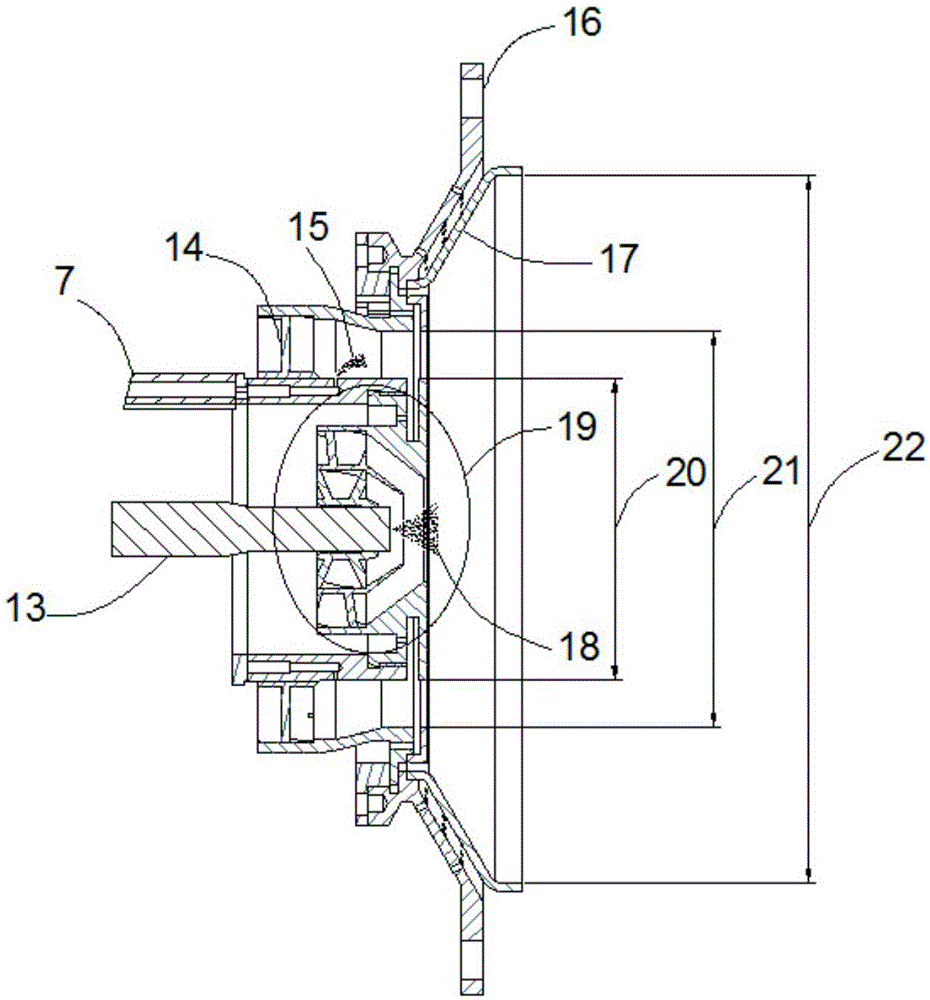

Dual-rotational-flow inspirator

ActiveCN103867340AStrong interactionGood atomization performanceRocket engine plantsHollow cylinderEngineering

The invention provides a dual-rotational-flow inspirator, which comprises a top cover, a nozzle, an upper bottom, a middle bottom, a gas whirlcone and an inspirator cavity, wherein the inspirator cavity is a barrel-shaped hollow cylinder; a fuel cavity is formed between the top cover and the upper bottom of the inspirator; a gas oxidizing agent cavity is formed between the upper bottom and the middle bottom of the inspirator; a water cavity is formed between the middle bottom of the inspirator and the base of the inspirator; an inner nozzle passes through mounting holes in the upper bottom, the middle bottom and the inspirator cavity and is fixedly arranged on the upper bottom via a thread; the gas whirlcone is installed on the nozzle by a thread; water nozzles are water holes evenly distributed on the circumstance on the base of the inspirator. The inspirator provided by the invention has the characteristics of simple structure, low cost, good atomization performance and stable flame.

Owner:NAT UNIV OF DEFENSE TECH

Straw densification briquetting fuel preparation method for biomass power generation and boiler combustion

InactiveCN101768494ARaise the ash melting pointImprove combustion effectBiofuelsSolid fuelsSolid fuelPotassium ions

The invention provides a straw densification briquetting fuel (SDBF) preparation method for biomass power generation and boiler combustion, solving problems of low ash fusion point, easily coking, serious corrosion to boilers and the like of direct straw combustion. In the invention, straw is pre-processed through steam explosion or with diluted acid then is subjected to enzyme hydrolysis with cellulose, and the enzyme hydrolysis residue is briquetted to be used as fuel for biomass power generation or boiler combustion. The pre-processed and enzyme-hydrolysis straw can be briquetted easily; cellulose and hemicellulose in the pre-processed and enzyme-hydrolysis straw are removed basically, lignin content and calorific value increase, potassium ion, sodion and chloridion are removed, thereby improving ash fusion point of straw, reducing coking and boiler corrosion in combustion process, and improving combustion performance of straw. The straw solid fuel prepared by the invention can be used as fuel for common domestic boilers. Sugar produced by enzymolysis can be used as a fermentation carbon source for large-amount fermented products, so as to improve comprehensive utilization value of straw.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

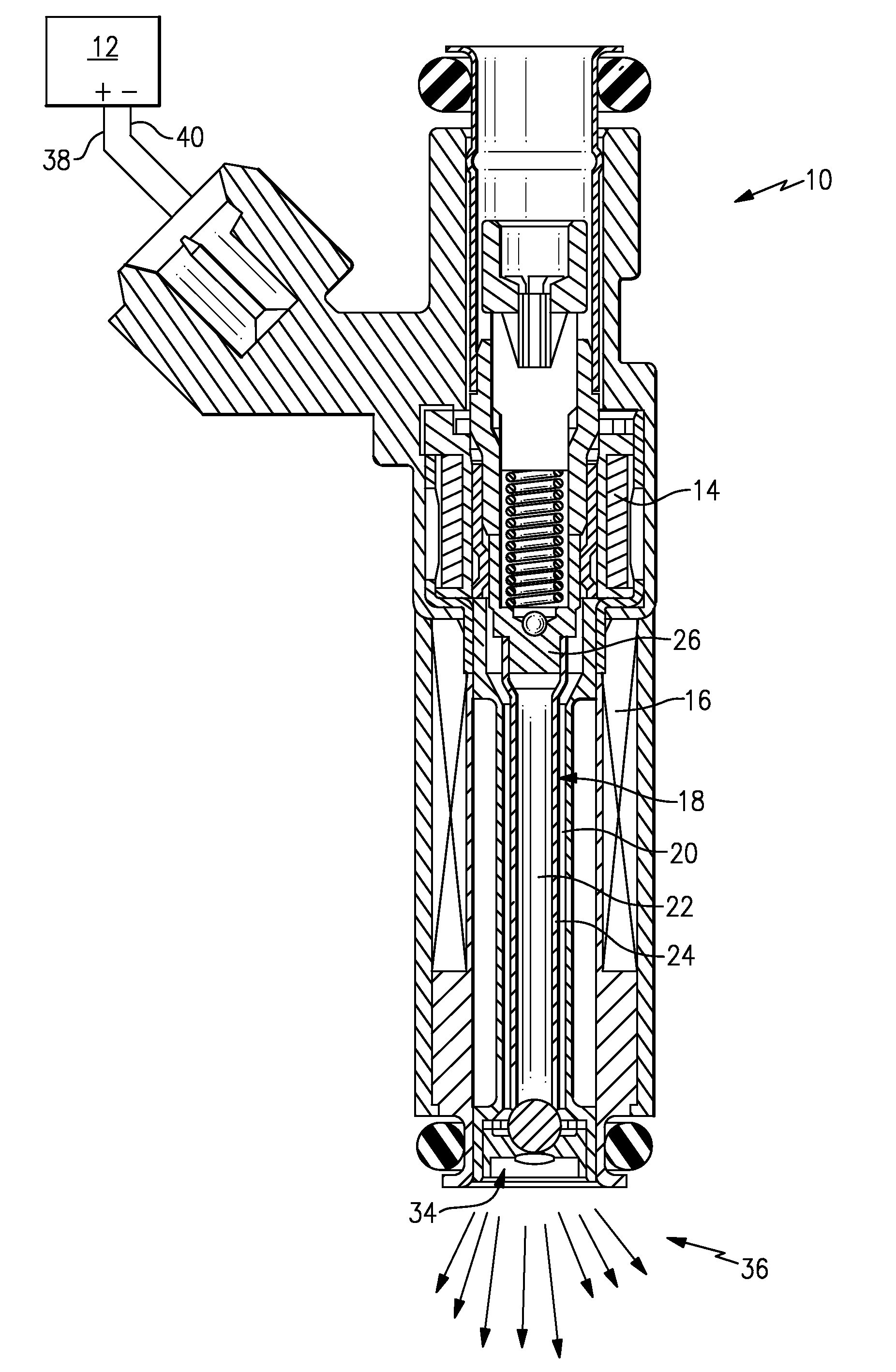

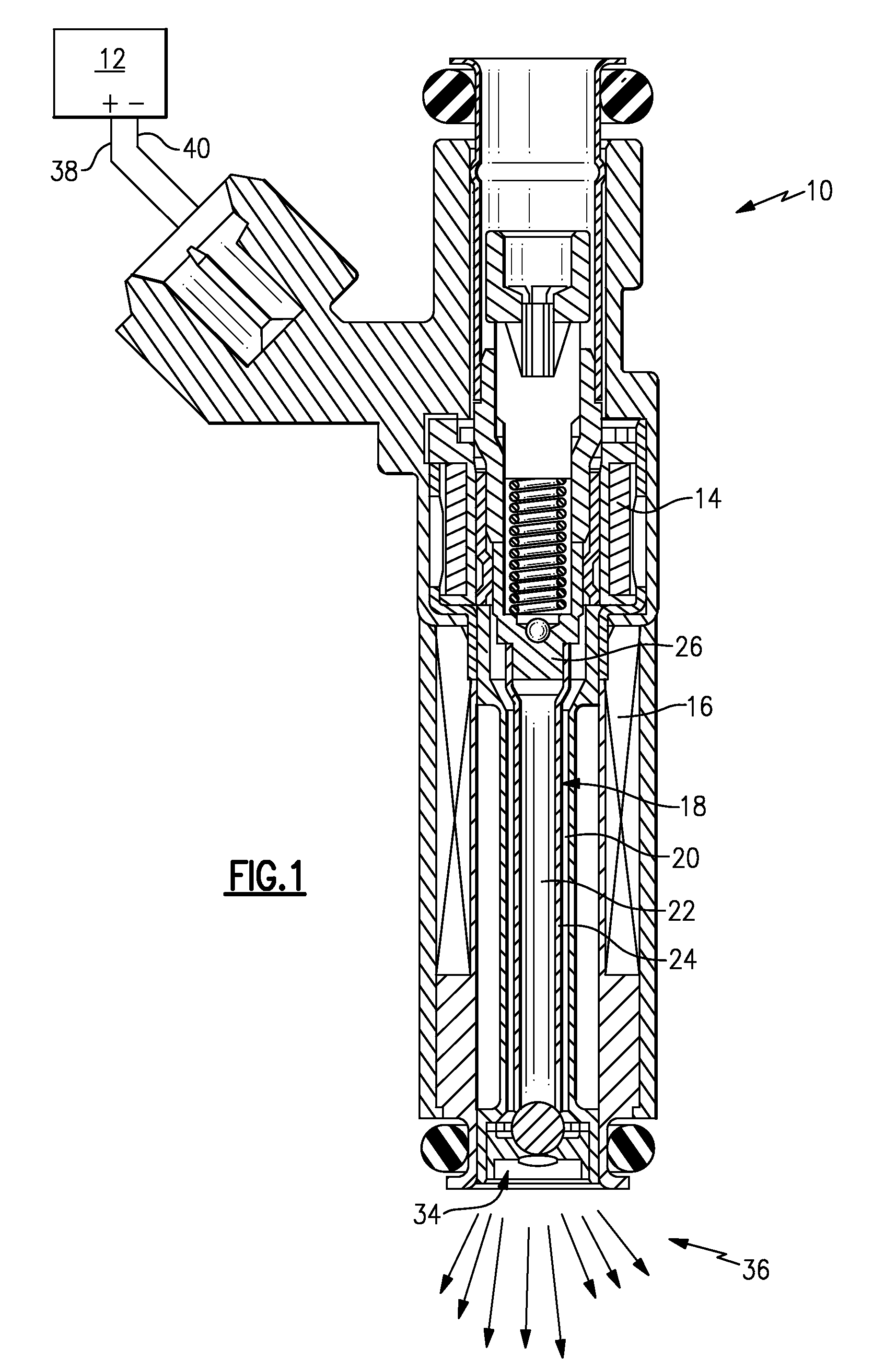

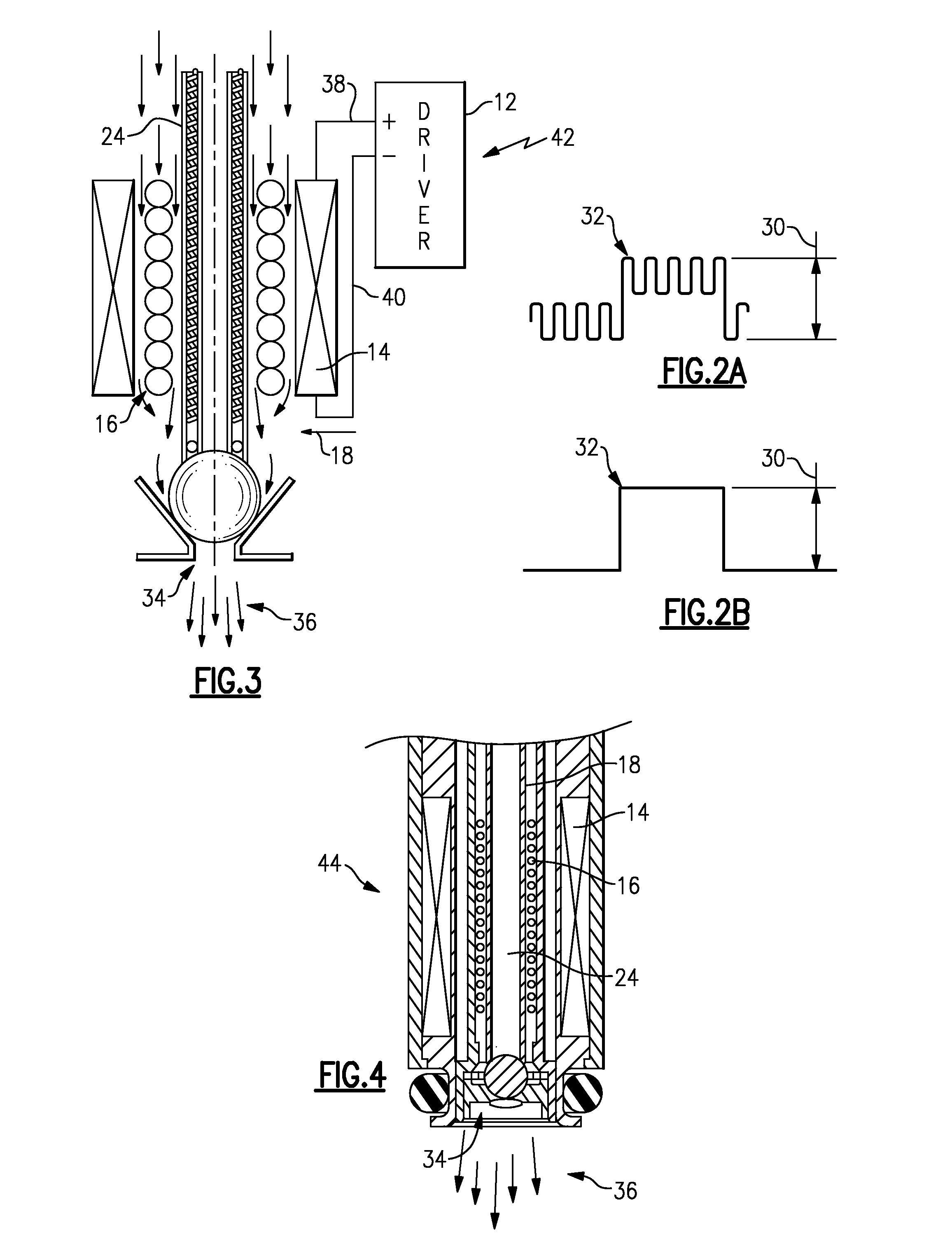

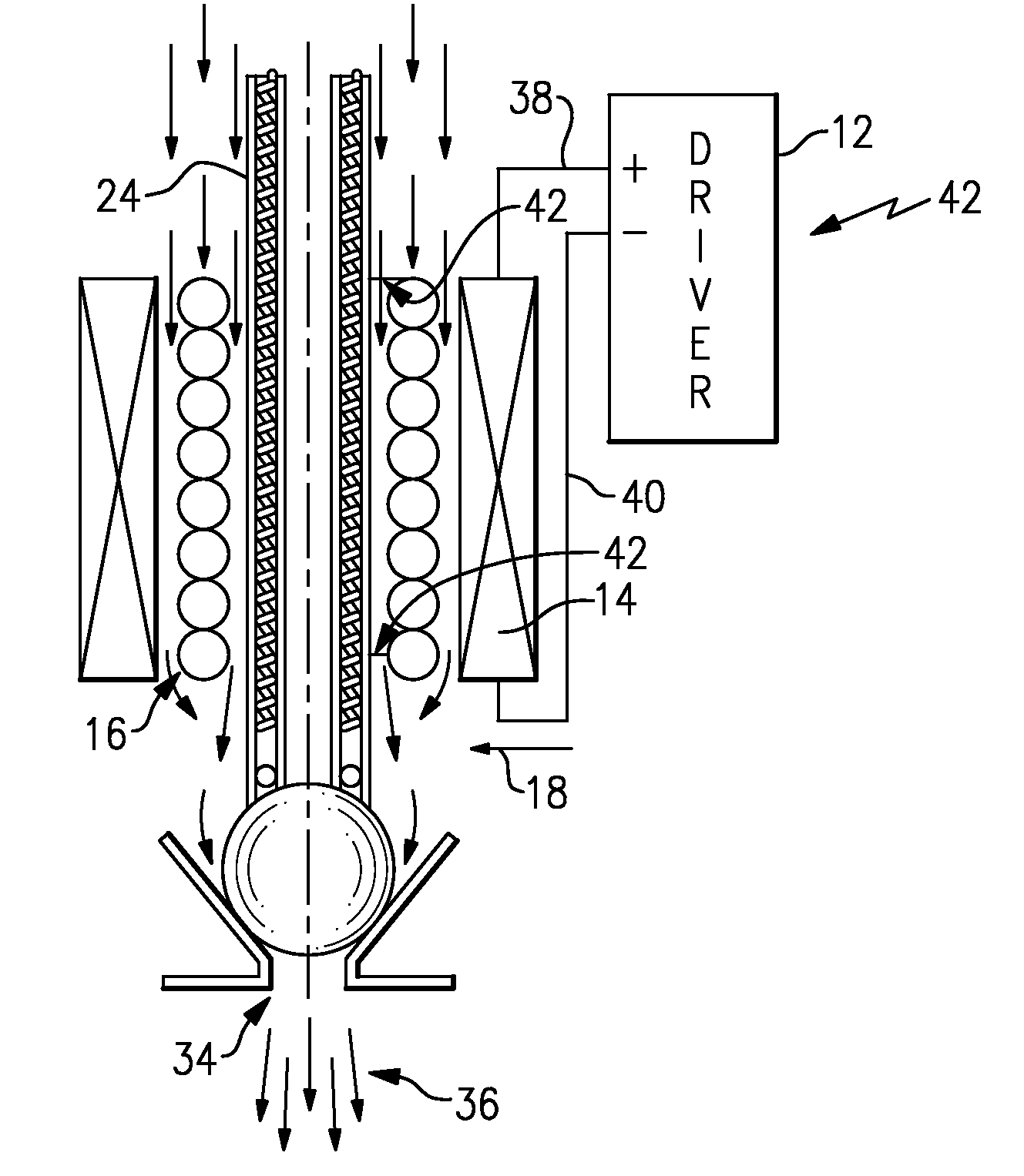

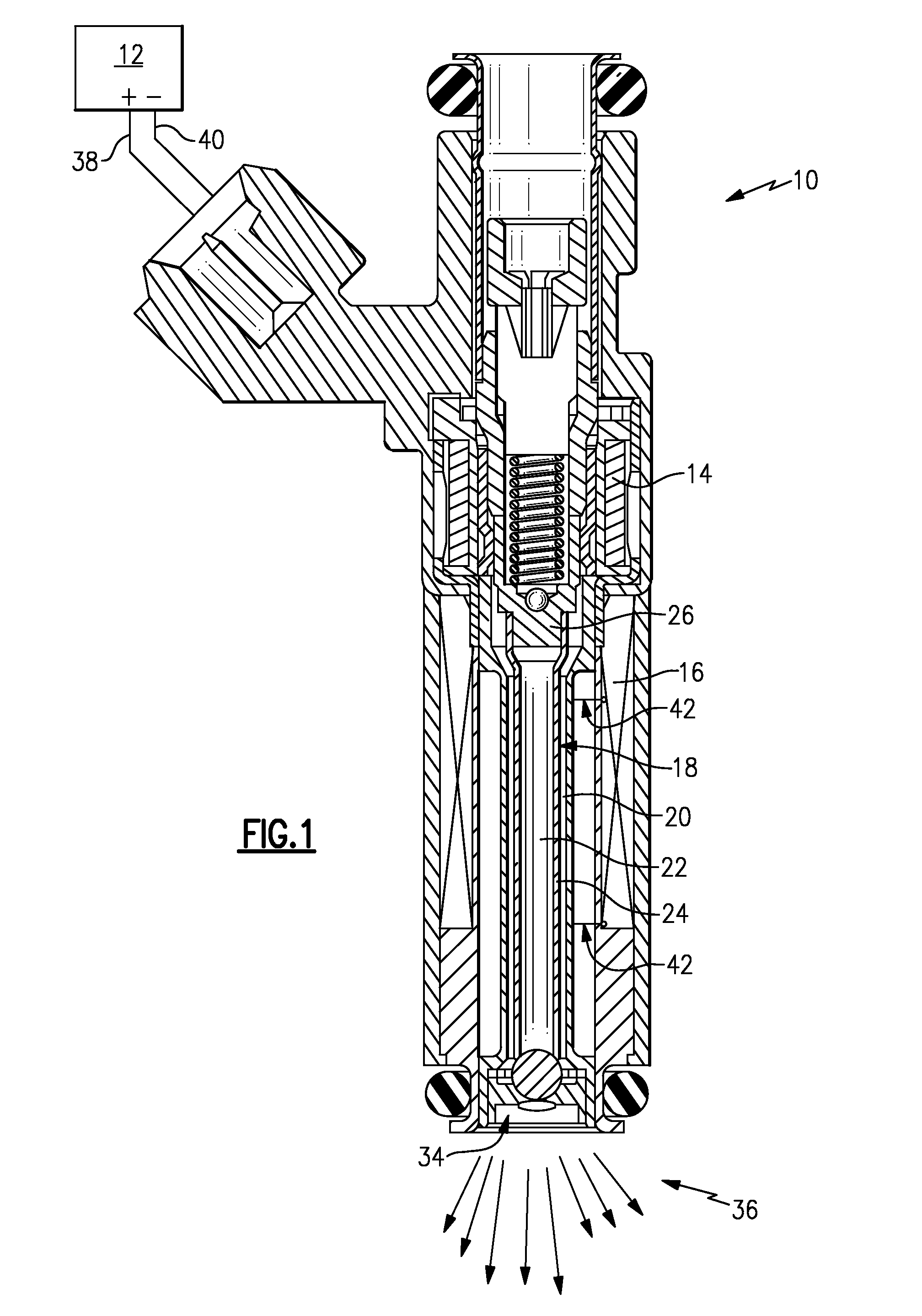

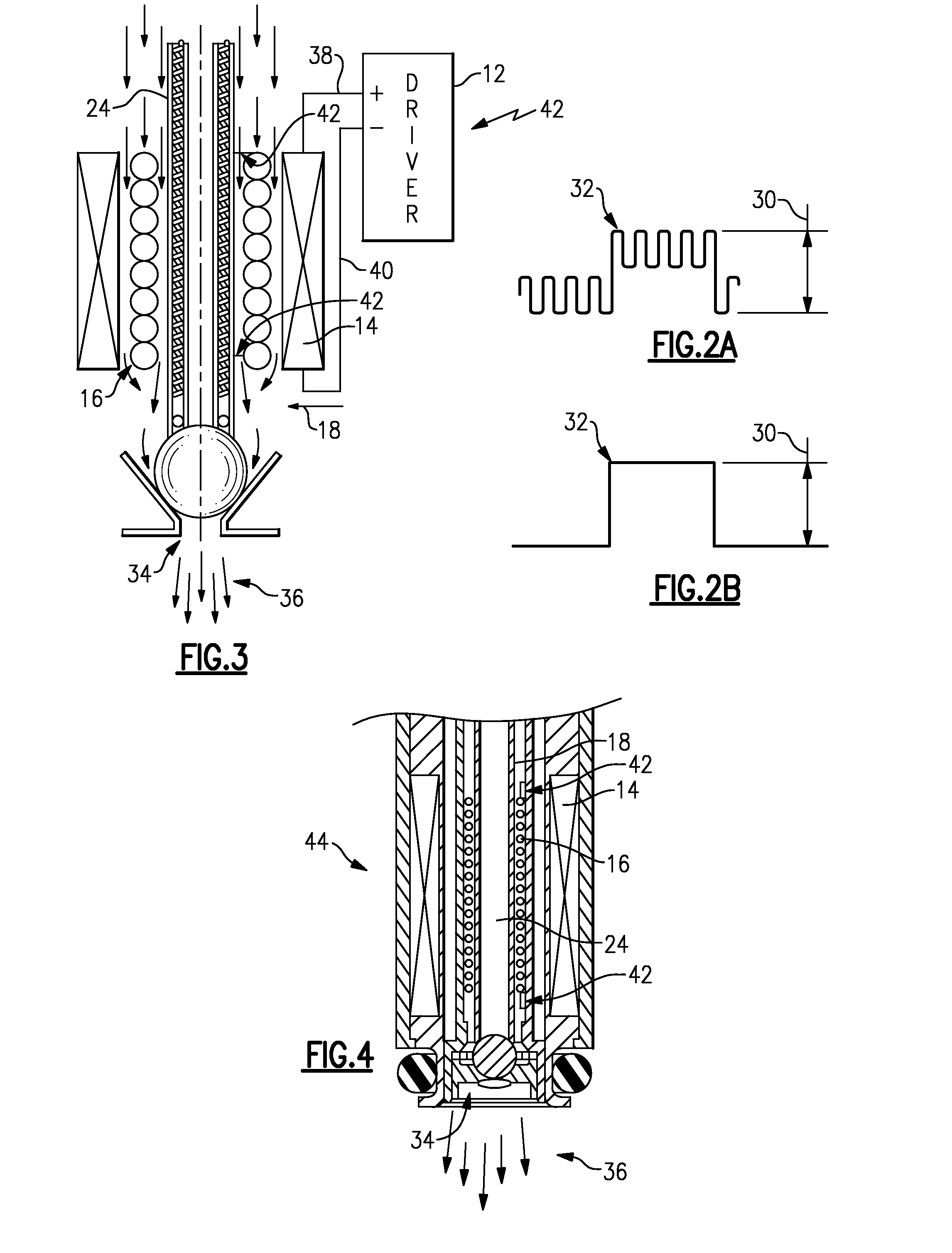

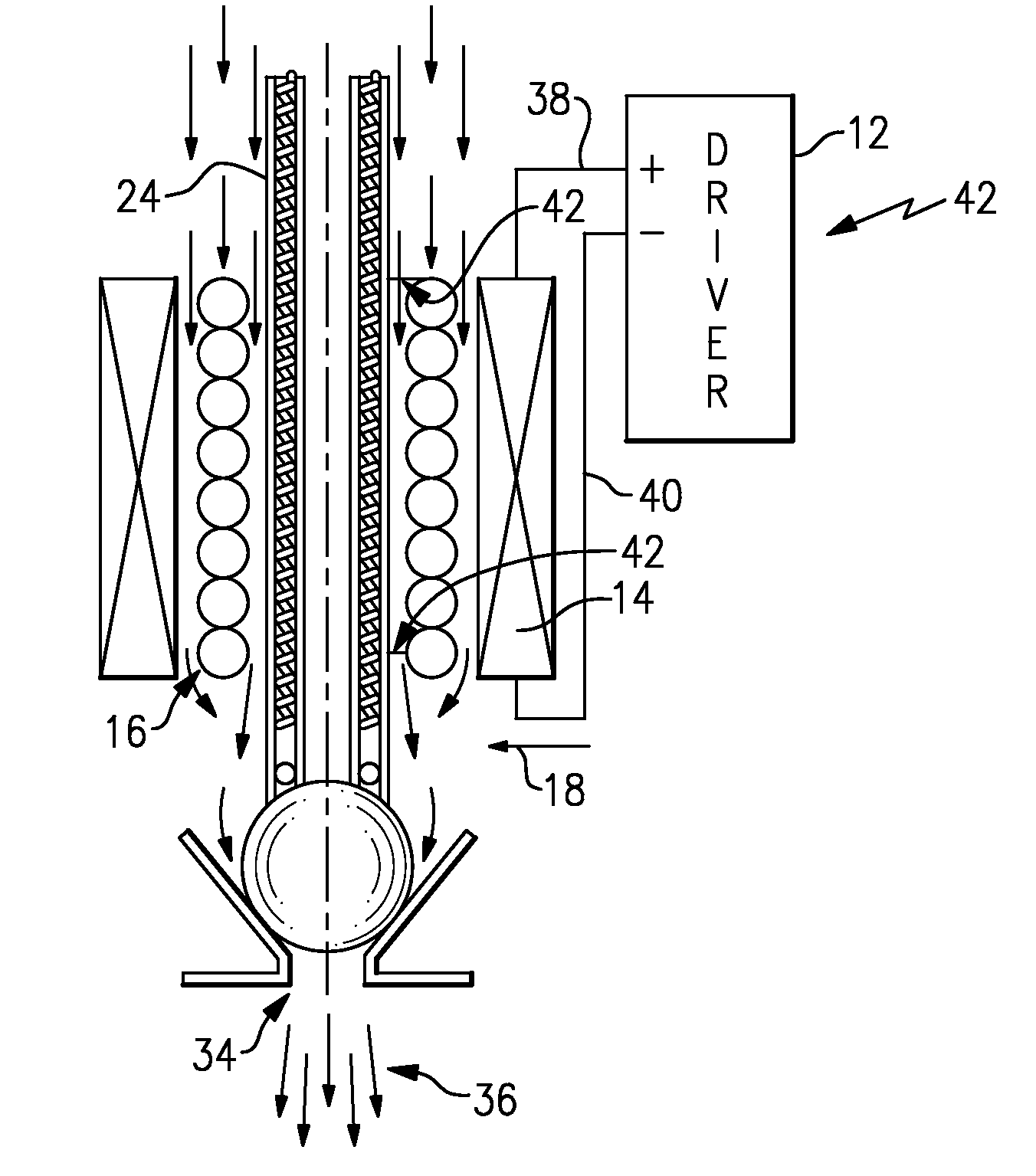

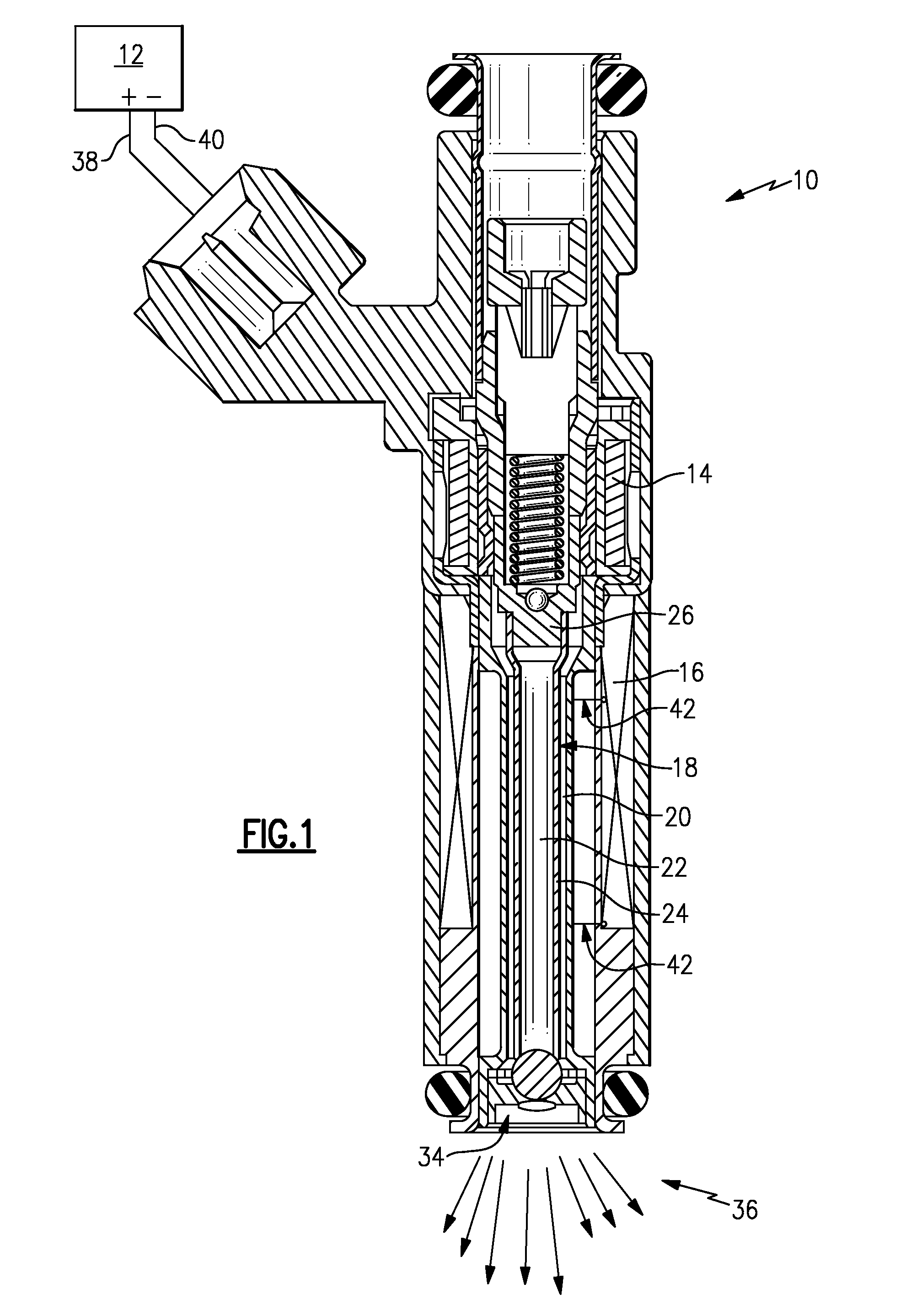

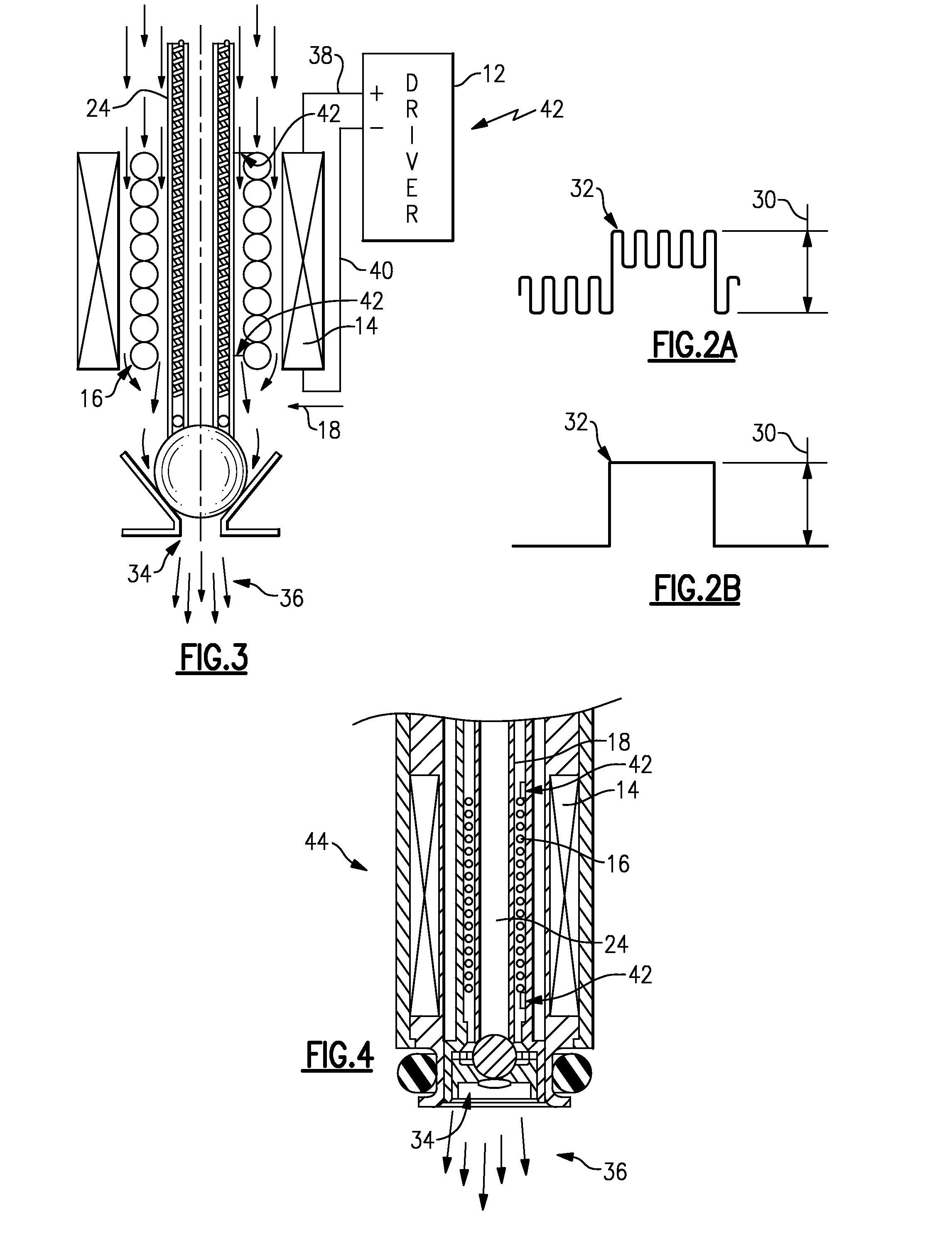

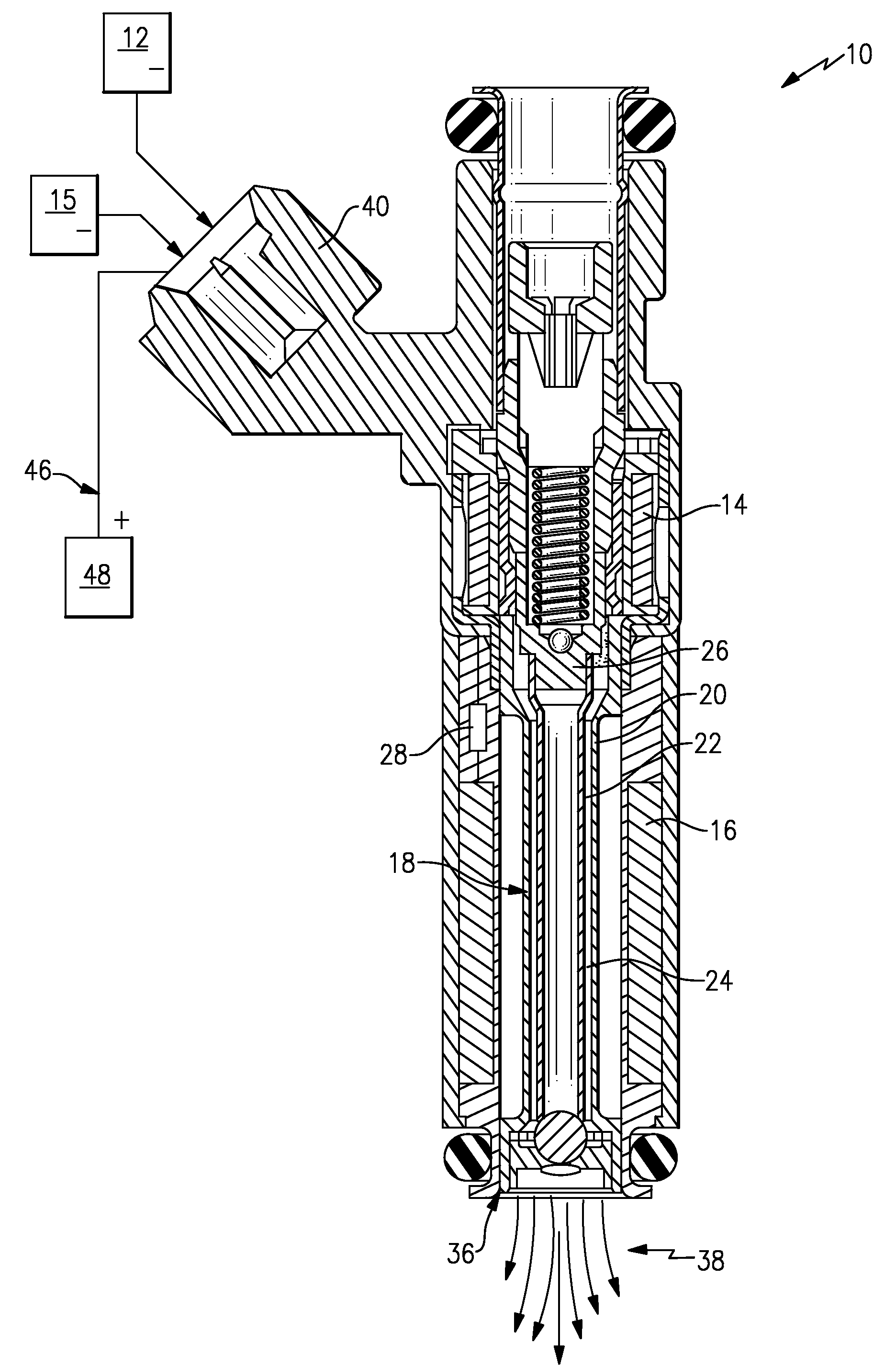

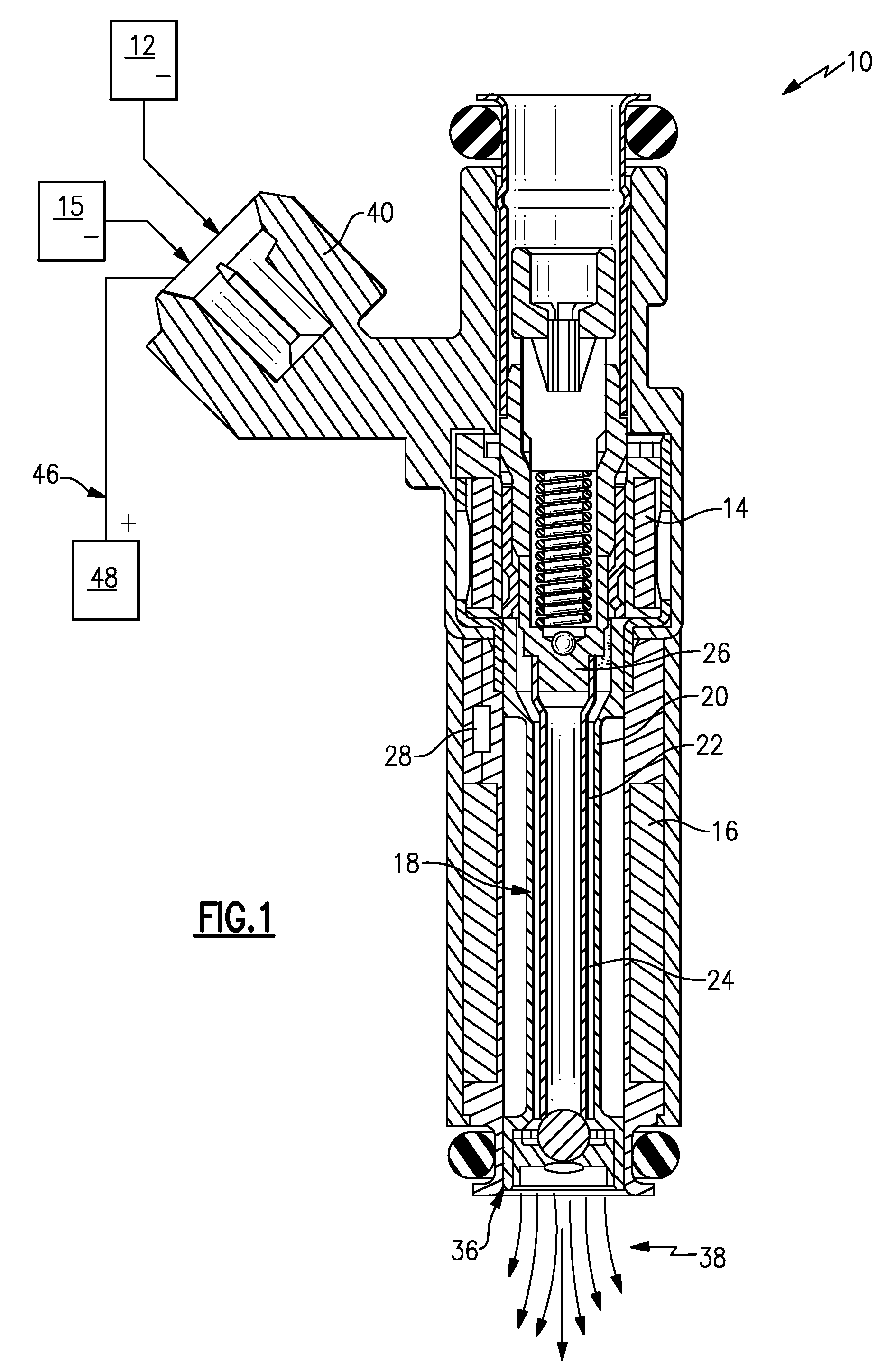

Inductive heated injector using voltage transformer technology

InactiveUS20070221874A1Desired performanceImprove the level ofLiquid surface applicatorsOperating means/releasing devices for valvesTransformerActive component

A fuel injector assembly includes a first coil that induces a time varying magnetic field into a second coil that is utilized to heat fuel flowing through the fuel injector. A first coil receives a first signal from a driver to generate a first magnetic field that moves an armature between an open and closed position. The second coil generates a second magnetic field generated by a current induced by the first coil into the second coil. The induced current is generated by an alternating current signal that is interposed onto a direct current signal sent to the first coil. The alternating current signal produces a time varying second magnetic field that induces heating of a magnetically active component with the fuel flow that in turn heats the fuel.

Owner:VITESCO TECH USA LLC

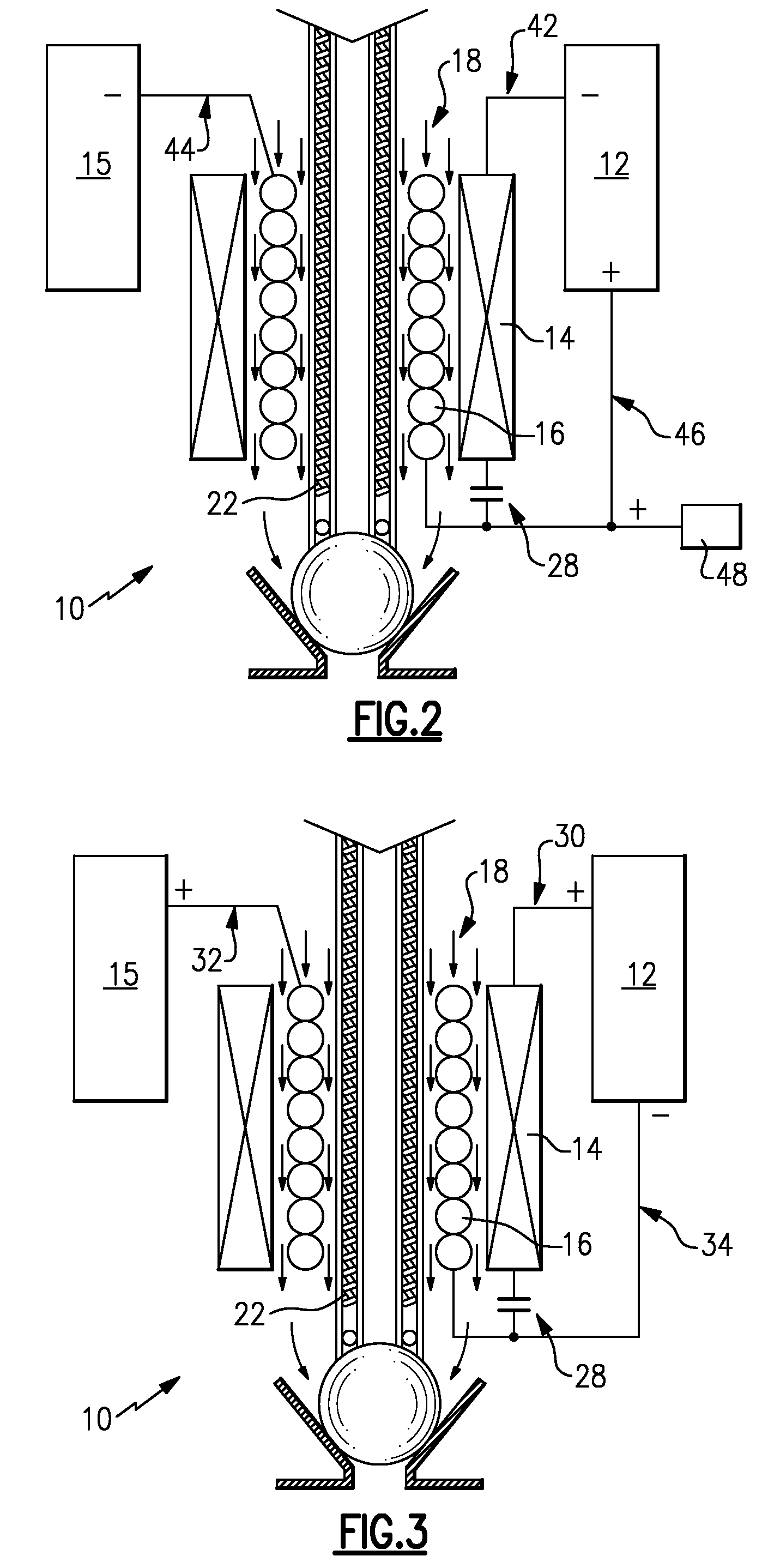

Inductive heated injector using additional coil

InactiveUS7677468B2Improve the level ofImprove combustion effectLiquid surface applicatorsInternal combustion piston enginesElectricityPower flow

A fuel injector assembly includes a first coil that induces a time varying magnetic field into a second coil that is utilized to heat fuel flowing through the fuel injector. The second coil generates a second magnetic field generated by a current induced by the first coil into the second coil. The induced current is generated by an alternating current signal that is interposed onto a direct current signal sent to the first coil. The second coil also is electrically connected to pass current induced from the first coil into a component in thermal contact with the flowing fuel. The current from the secondary coil resistibly heats the component to provide an alternate mode of heating fuel flow.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Halogen-free intumescent flame-retardant polypropylene/ethylene vinyl acetate cable material

ActiveCN101649088AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesExtensibilityUv absorber

The invention relates to a halogen-free intumescent flame-retardant polypropylene / ethylene vinyl acetate cable material which is characterized by comprising the following components by weight part: 20-40 parts of polypropylene, 60-80 parts of ethylene vinyl acetate, 45-65 parts of compound flame retardant, 5-15 parts of grafting agent, 1.0-2.0 parts of antioxidizer, 1.0-2.0 parts of ultraviolet absorbent and 1.0-3.0 of processing aid. With the advantages of favorable flexibility, high breakage extensibility, favorable tensile strength, excellent electrical insulating property and good flame retardant, the material favorably meets the requirements on the burning property, the mechanical property and the heat property of the cable material and is mainly used as the outer coating material ofcables.

Owner:应急管理部四川消防研究所

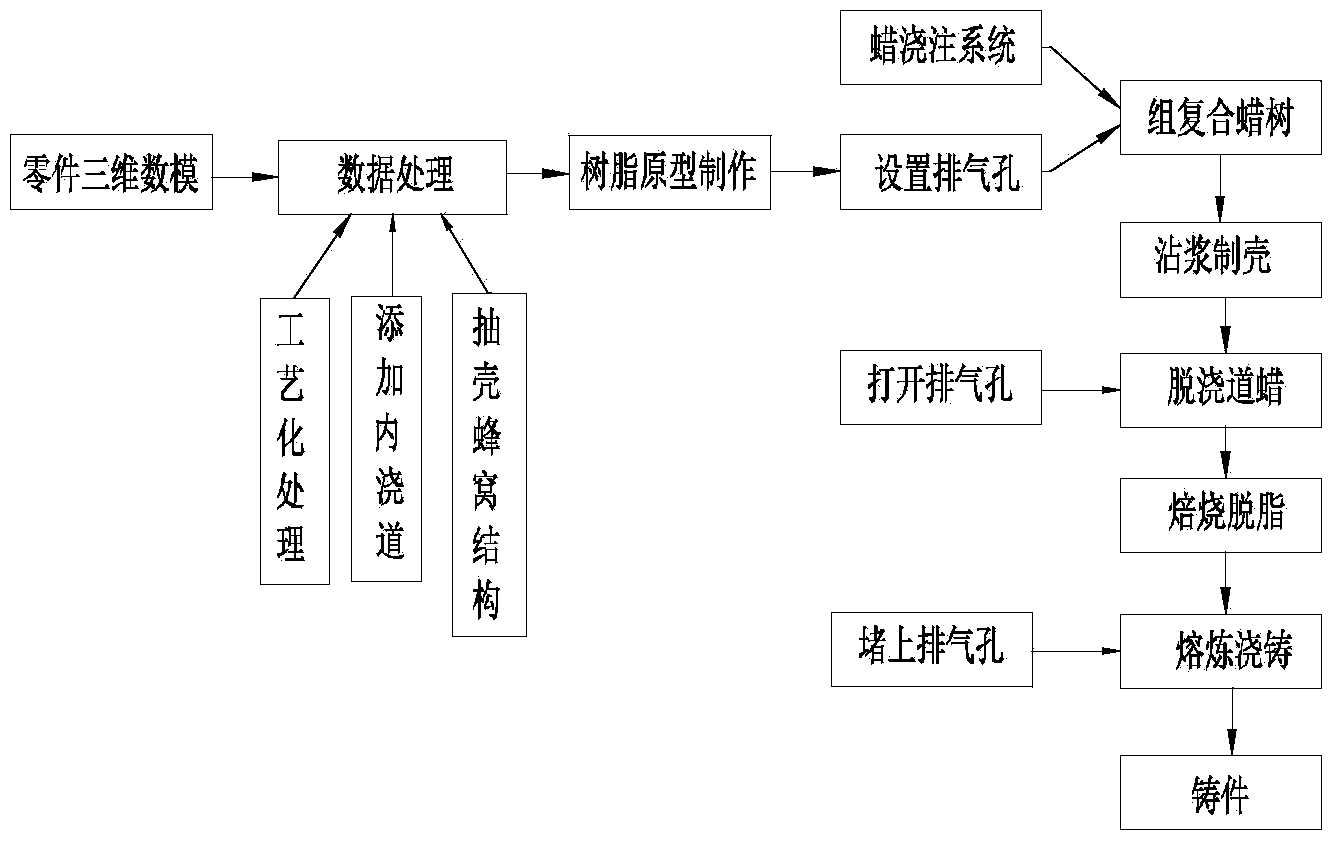

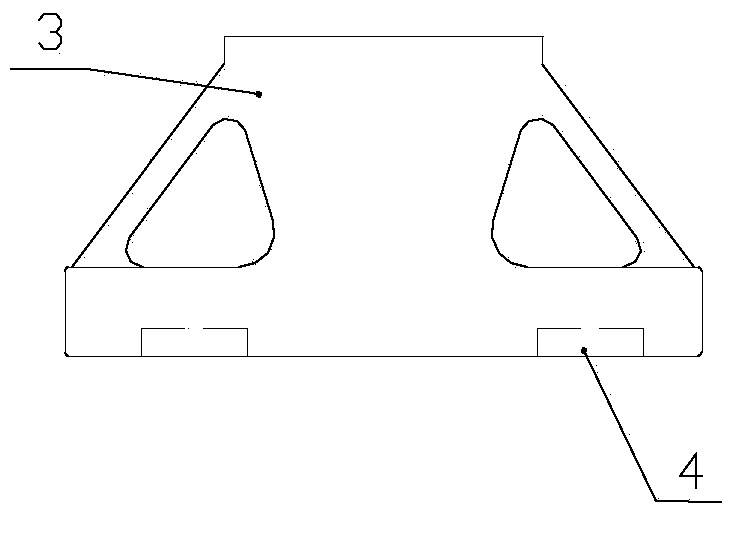

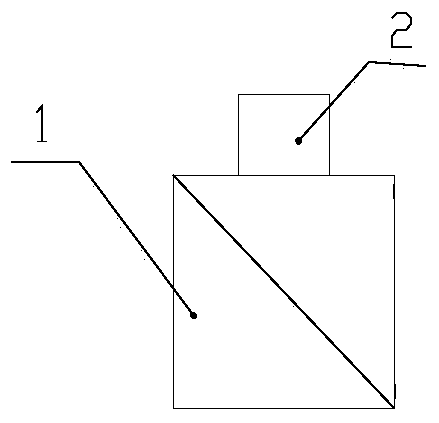

Rapid investment casting method based on stereolithography (SL)

Owner:无锡市交大增智增材制造技术研究院有限公司

Blow molding type halogen-free flame-retardant polypropylene material

InactiveCN102286171AOvercome strengthOvercoming problems such as brittleness at low temperaturesBlow moldingHalogen

The invention provides a blow molding type halogen-free flame-retardant polypropylene material, which comprises the following components in part by weight: 100 parts of polypropylene, 40 to 85 parts of phosphorus-nitrogen series expanded halogen-free composite flame retardant, 3 to 20 parts of resin modifier, 0.05 to 0.5 part of pigment, 0.4 to 2.0 parts of antioxidant, 0.3 to 2.0 parts of ultraviolet absorbent, 0.3 to 2.0 parts of light stabilizer, and 1.0 to 3.0 parts of other processing aids. The material has good tensile strength, high impact strength, good low-temperature performance and excellent flame-retardant performance, and is particularly suitable for hollow blow molding type small and large components of automobiles, furniture and the like.

Owner:应急管理部四川消防研究所

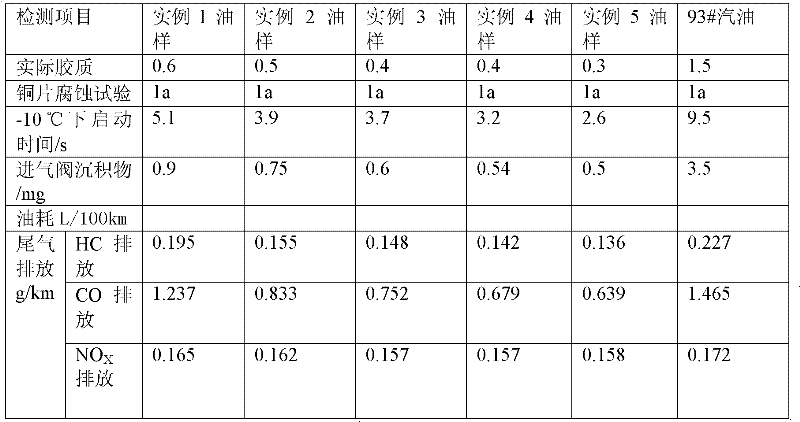

Gasoline compound additive

ActiveCN102643691AImprove detergencyImprove antioxidant capacityLiquid carbonaceous fuelsFuel additivesEngineeringFuel oil

The invention provides a multifunctional gasoline compound additive which is capable of reducing fuel consumption and decreasing the pollution caused by tail gas emission. The additive comprises a gasoline cleaning agent, a combustion improver, a low temperature start improving agent, an antiknock agent, an anti-oxidizing and anti-gum agent and a metal corrosion inhibitor. By adopting the gasoline compound additive, the cleanness, oxidation resistance and anti-corrosion performance of gasoline can be improved; and meanwhile, the combustion performance of fuel oil can be improved, the fuel consumption is reduced, and the automobile tail gas pollutants can be reduced.

Owner:山东京博众诚清洁能源有限公司

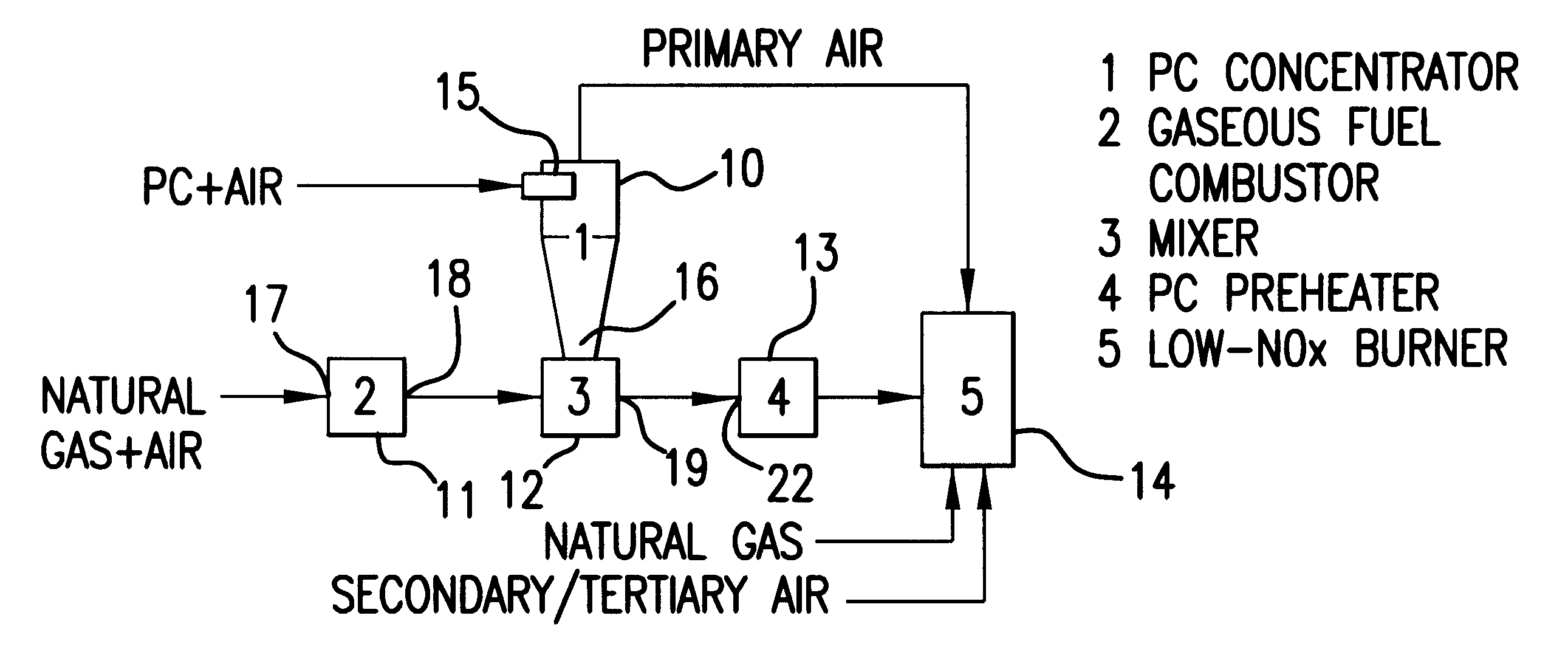

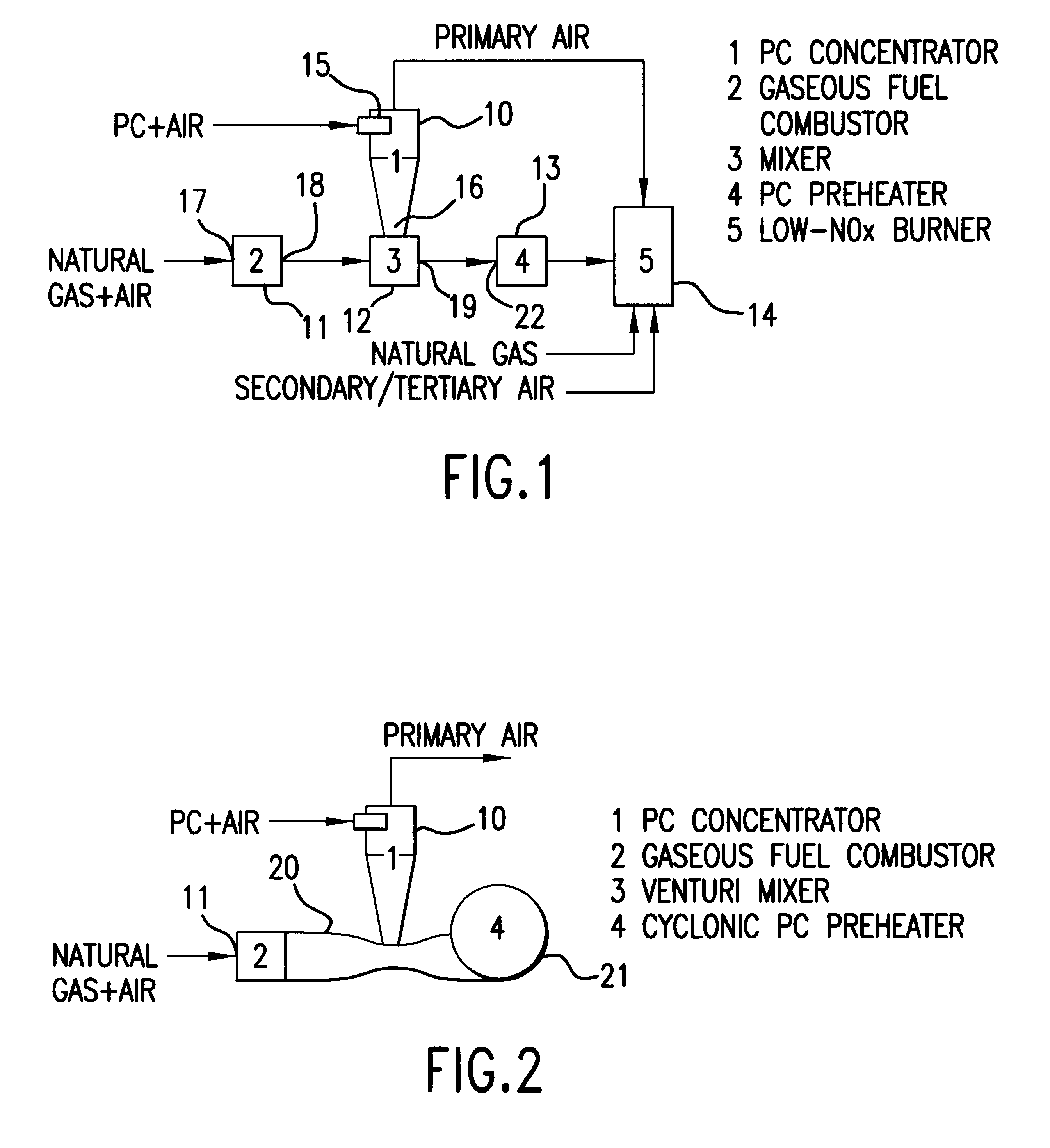

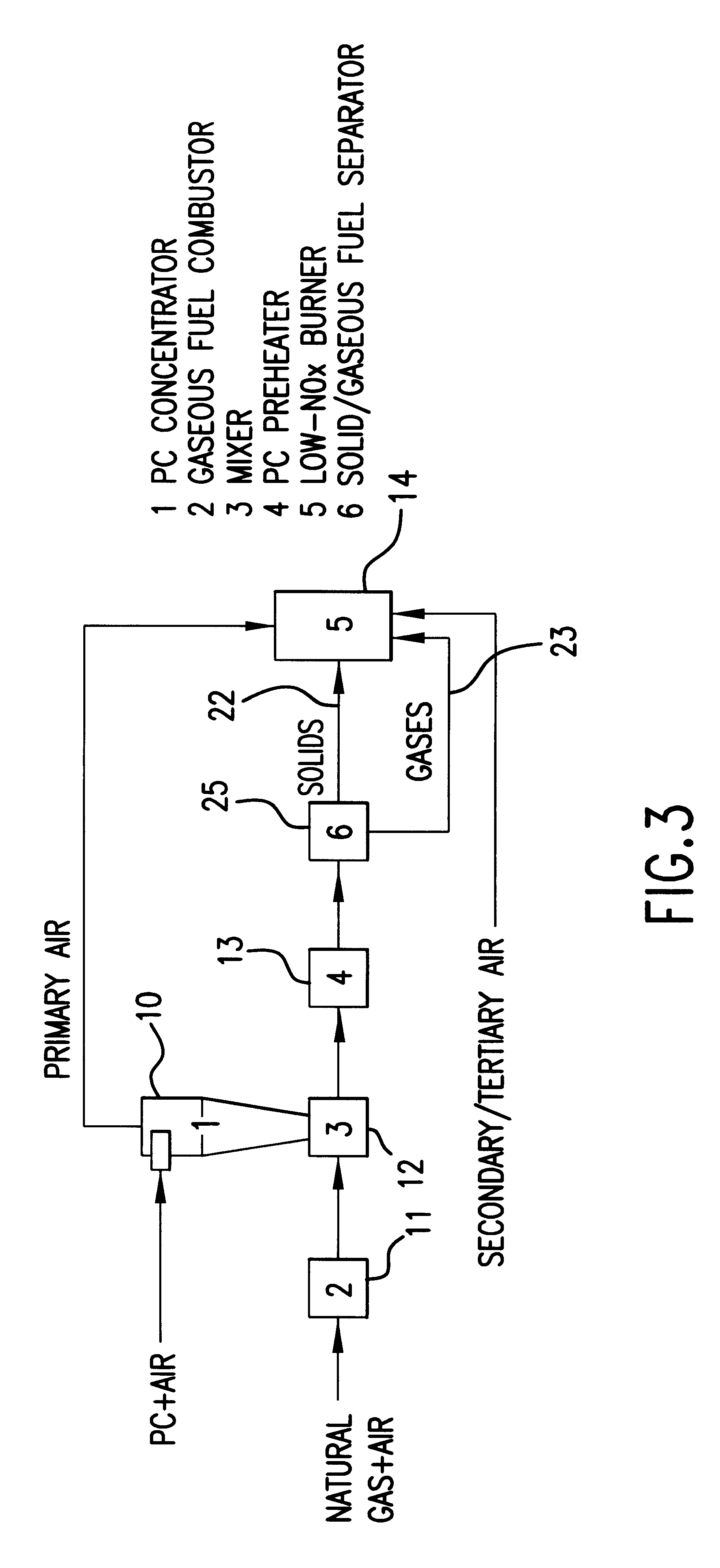

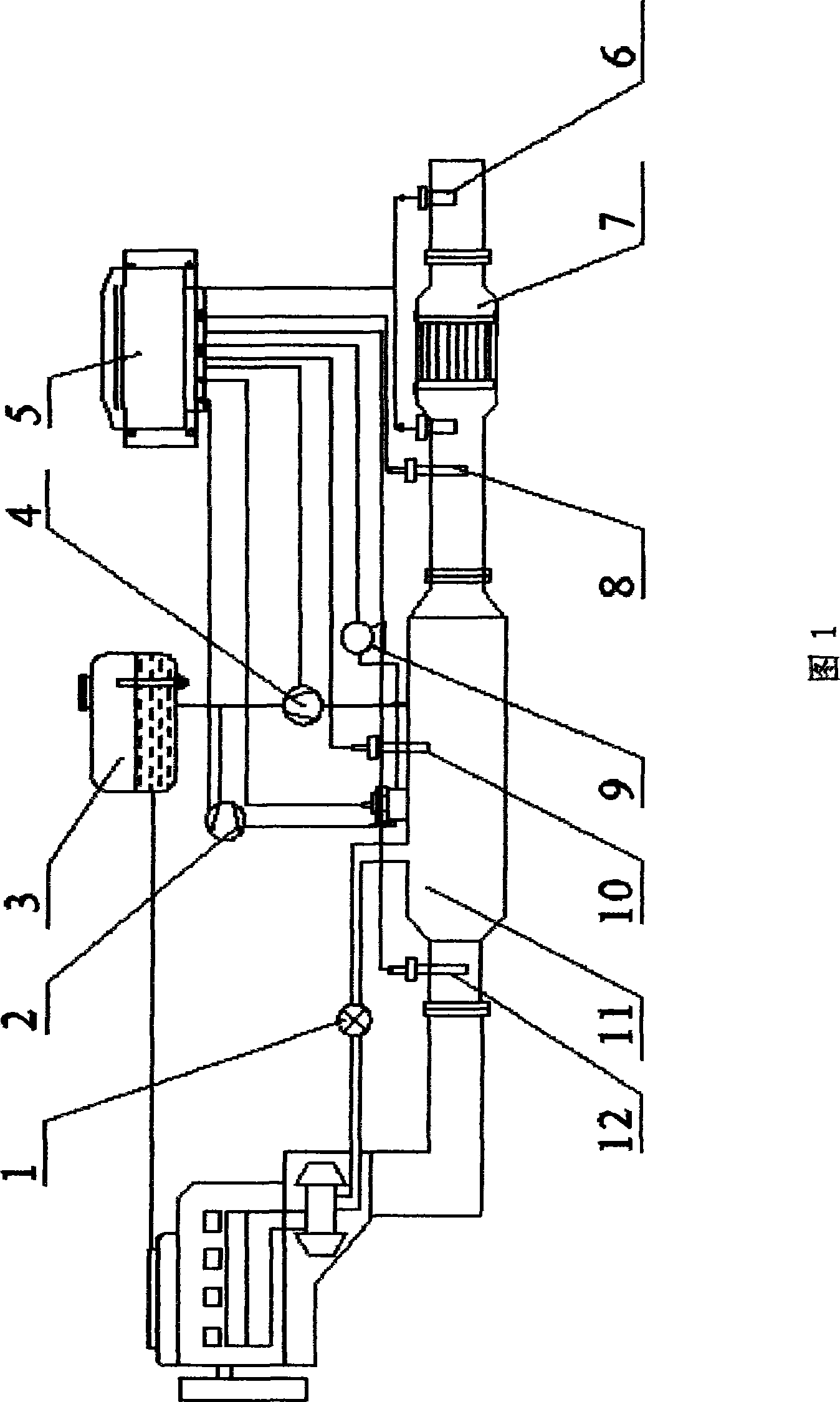

Low NOx pulverized solid fuel combustion process and apparatus

InactiveUS6244200B1Reduce the amount requiredImprove combustion effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberPartial oxidation

A method and apparatus for low-NOx combustion of a pulverized solid fuel in which combustion products from a partial oxidation combustor are mixed with a pulverized solid fuel, thereby preheating the pulverized solid fuel and resulting in devolatilization of at least a portion of the pulverized solid fuel. The preheated pulverized solid fuel and the devolatilization products are then burned in a burner firing directly into a combustion chamber.

Owner:INST OF GAS TECH

Inductive Heated Injector Using Additional Coil

InactiveUS20070221748A1Improve the level ofImprove combustion effectLiquid surface applicatorsInternal combustion piston enginesElectricityPower flow

A fuel injector assembly includes a first coil that induces a time varying magnetic field into a second coil that is utilized to heat fuel flowing through the fuel injector. The second coil generates a second magnetic field generated by a current induced by the first coil into the second coil. The induced current is generated by an alternating current signal that is interposed onto a direct current signal sent to the first coil. The second coil also is electrically connected to pass current induced from the first coil into a component in thermal contact with the flowing fuel. The current from the secondary coil resistibly heats the component to provide an alternate mode of heating fuel flow.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

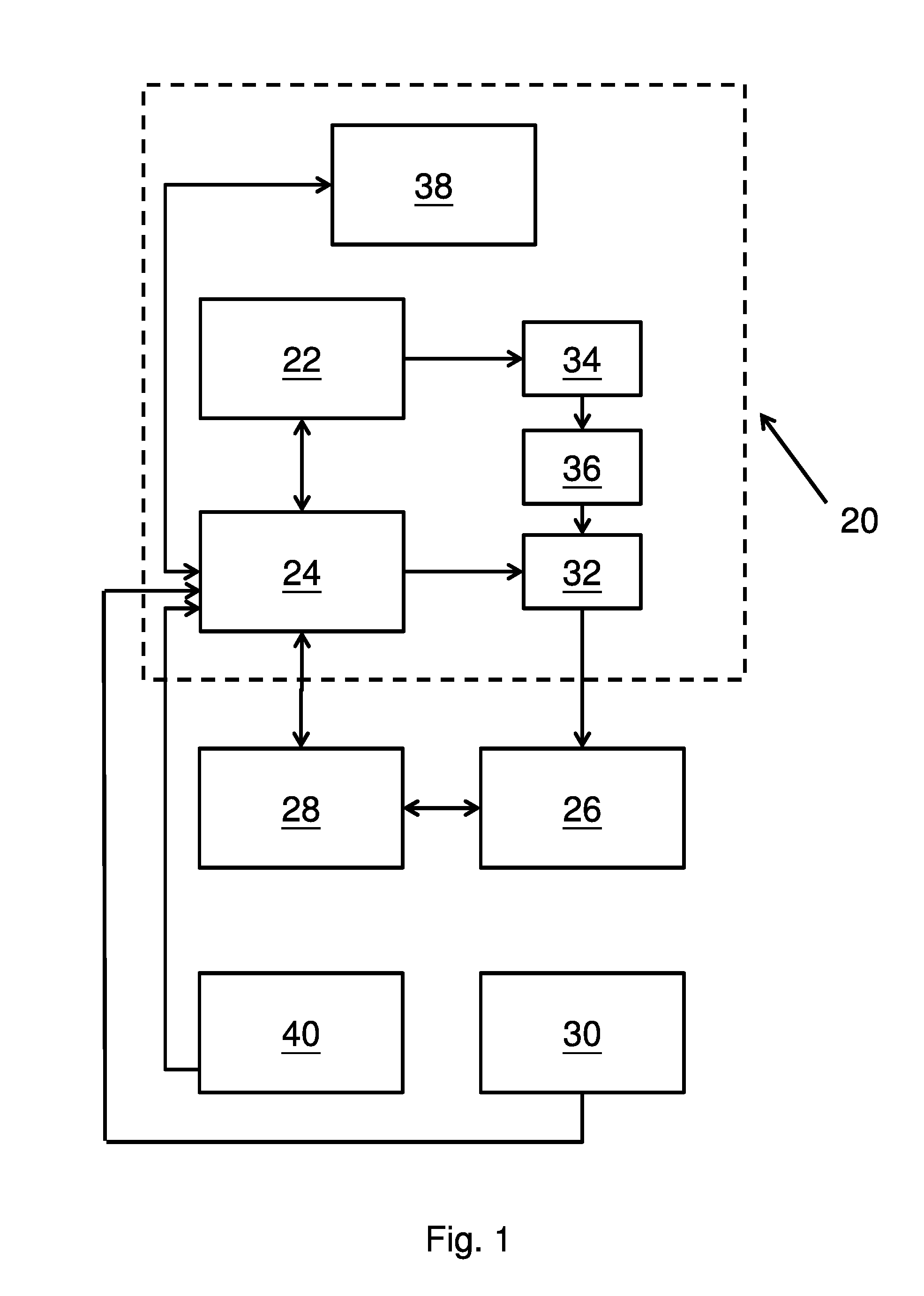

System and method of improving efficiency of combustion engines

InactiveUS20110303194A1Less fuelEfficient combustionInternal combustion piston enginesNon-fuel substance addition to fuelCombustionInternal combustion engine

A system for improving the performance of a combustion engine comprising a system control unit is disclosed. The system control unit comprises an input module, a transform module and a control module all interconnected to each other. The input module obtains a first set of combustion parameters of the engine through at least one sensor. The transform module transforms the first set of combustion parameters into a second set of combustion parameters. The control module controls fuel injection of the engine based on the second set of combustion parameters, and controls oxyhydrogen production and injection based on the second set of combustion parameters. The controlled fuel injection and the controlled oxyhydrogen production and injection contribute to an improved performance of said engine during combustion. A method of improving the performance of a combustion engine and a method of injecting oxyhydrogen into a combustion engine are also disclosed.

Owner:HANDSOME VIVA INVESTMENTS

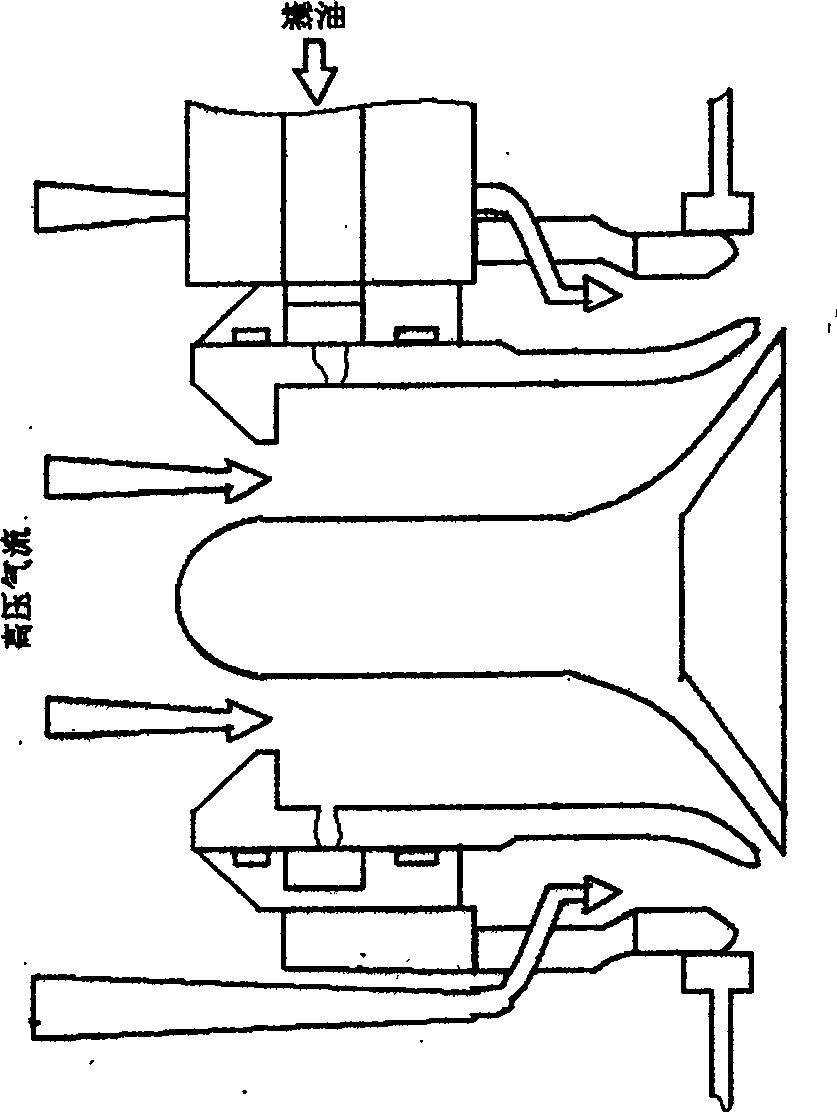

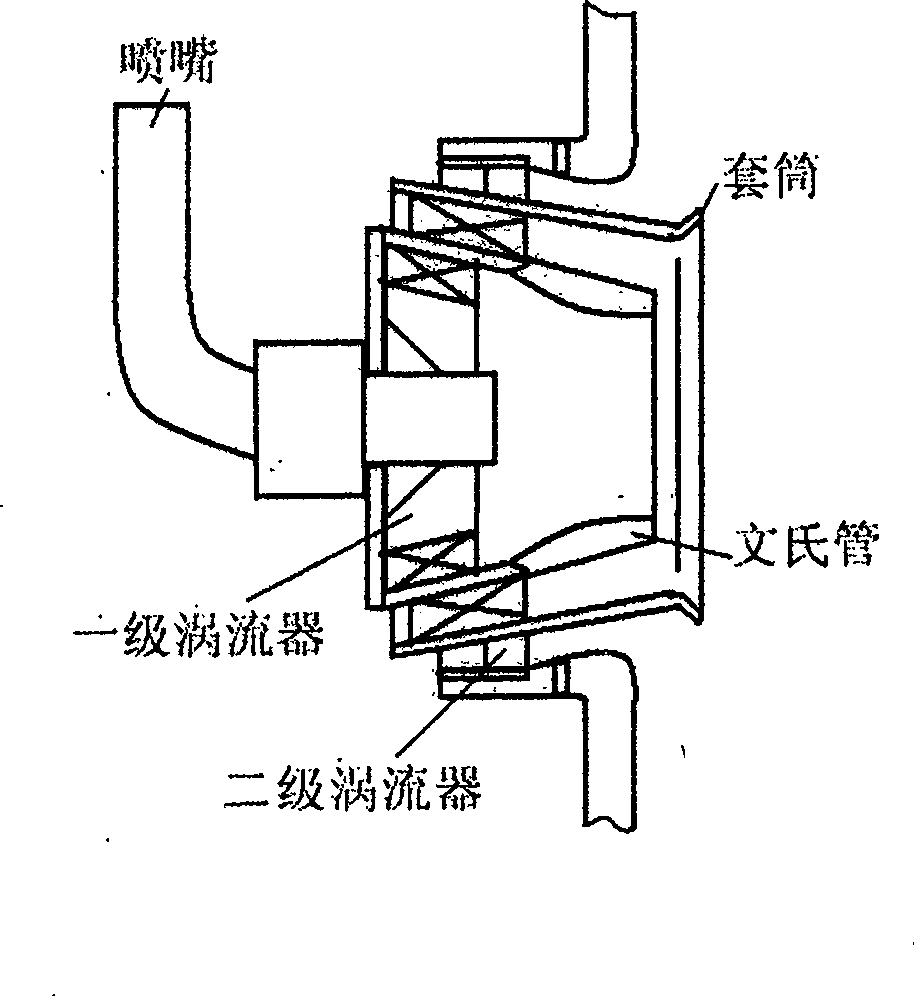

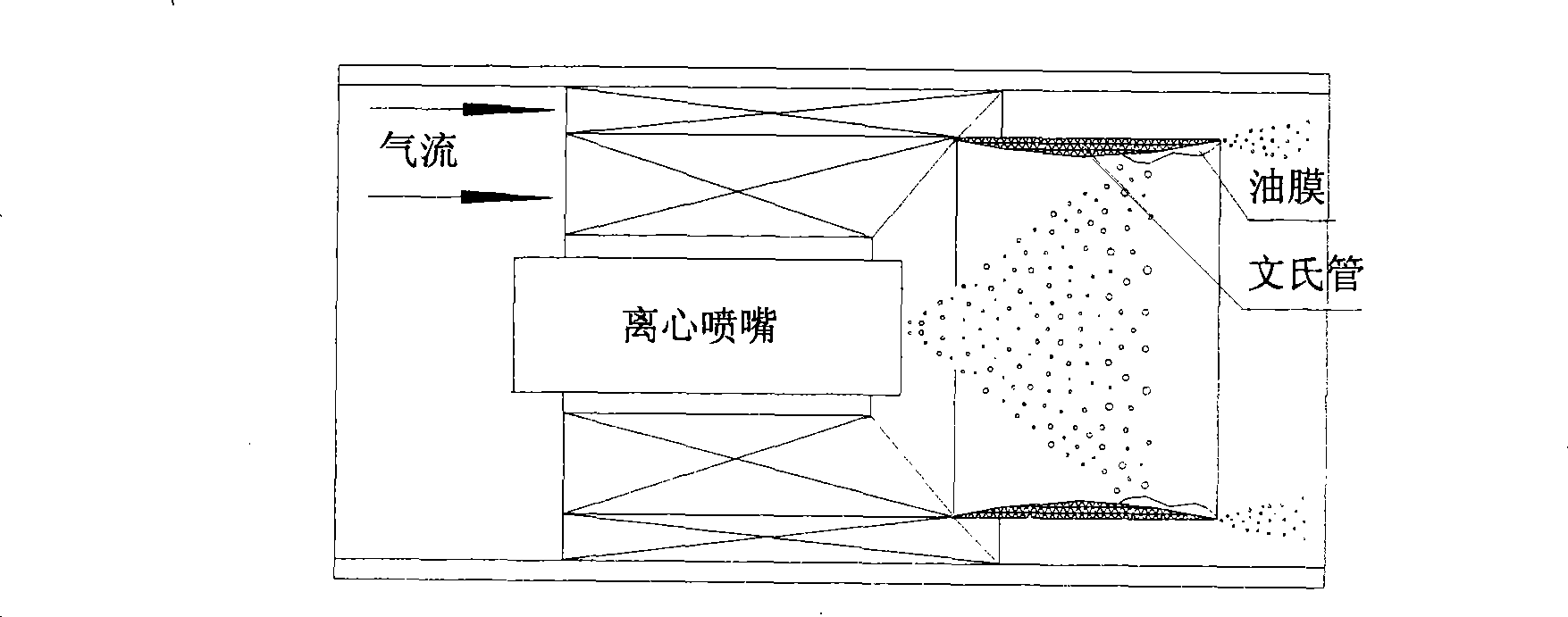

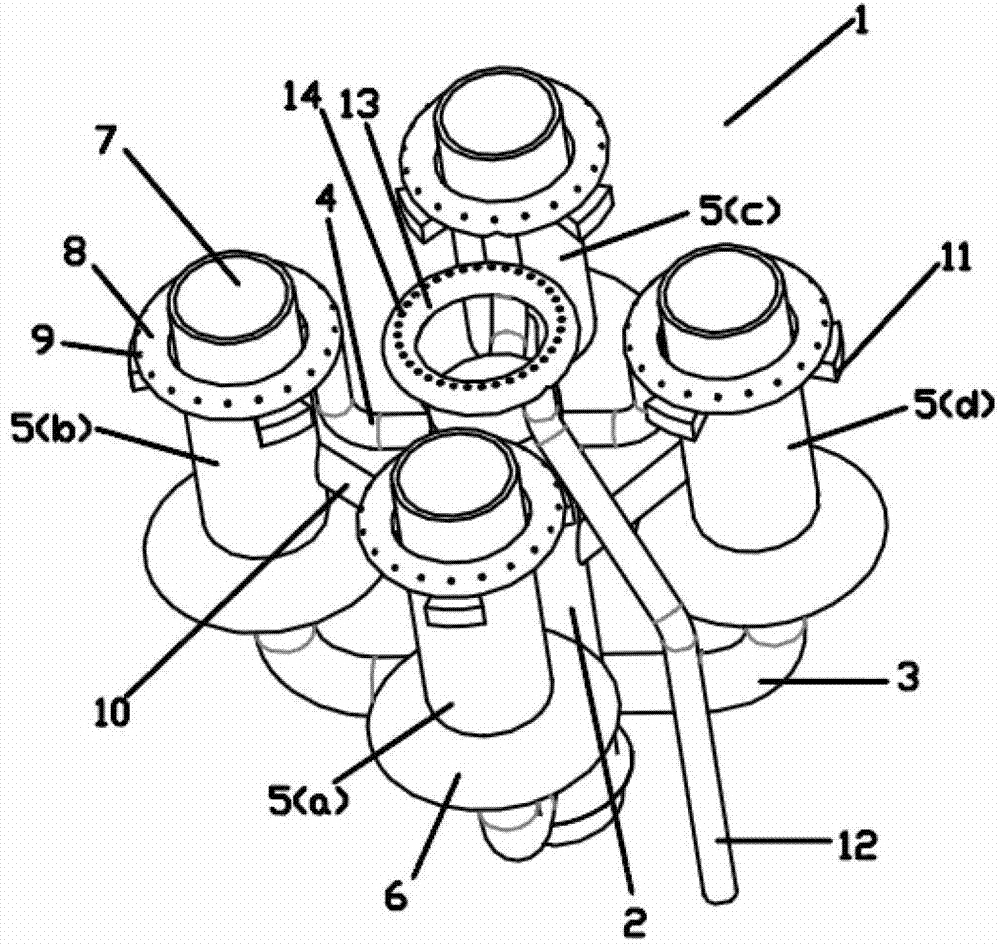

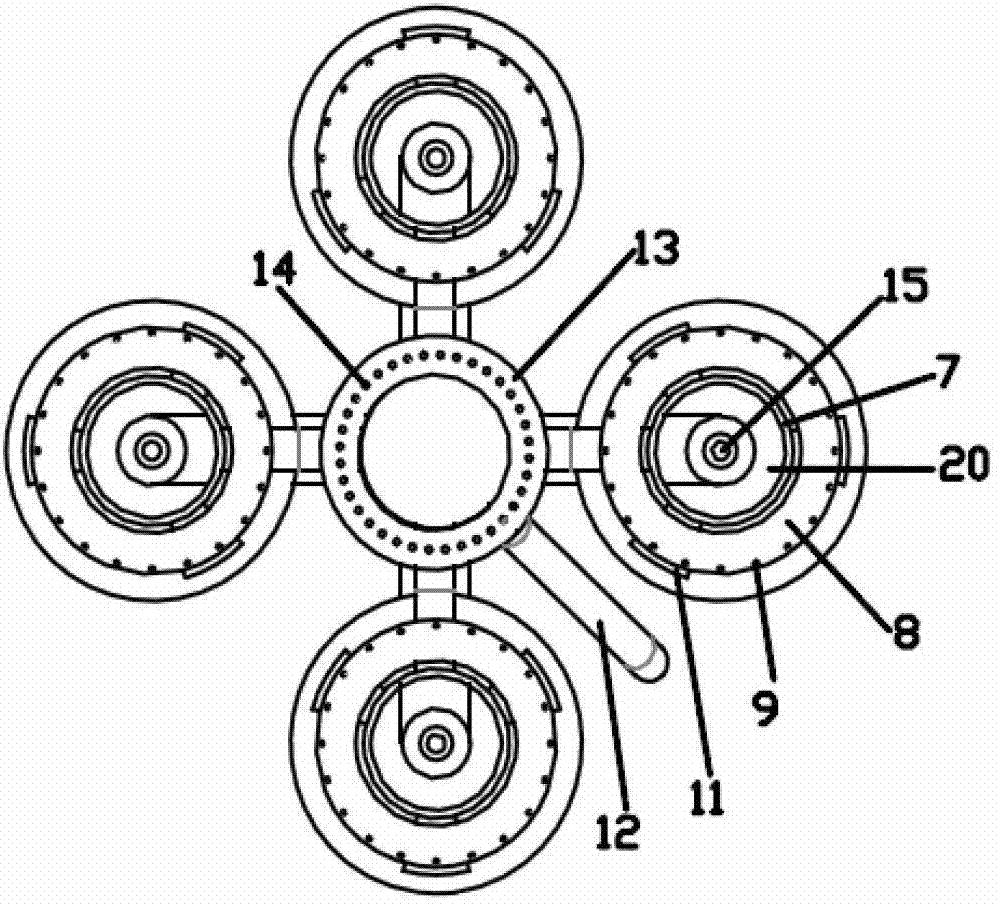

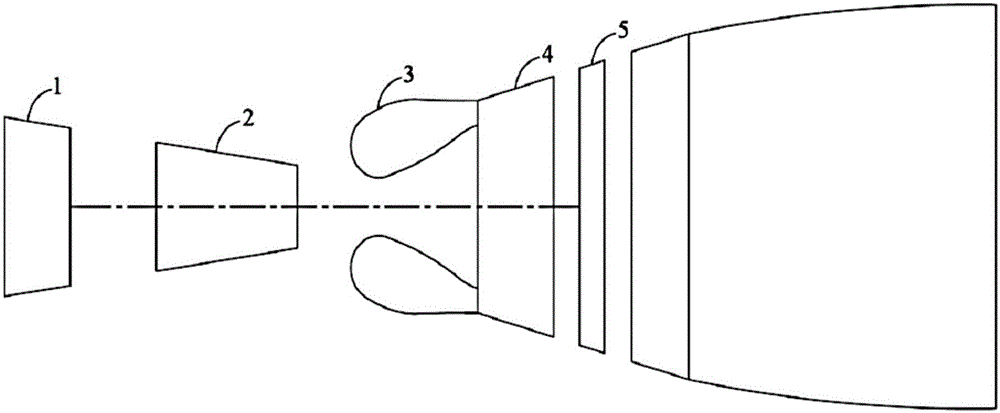

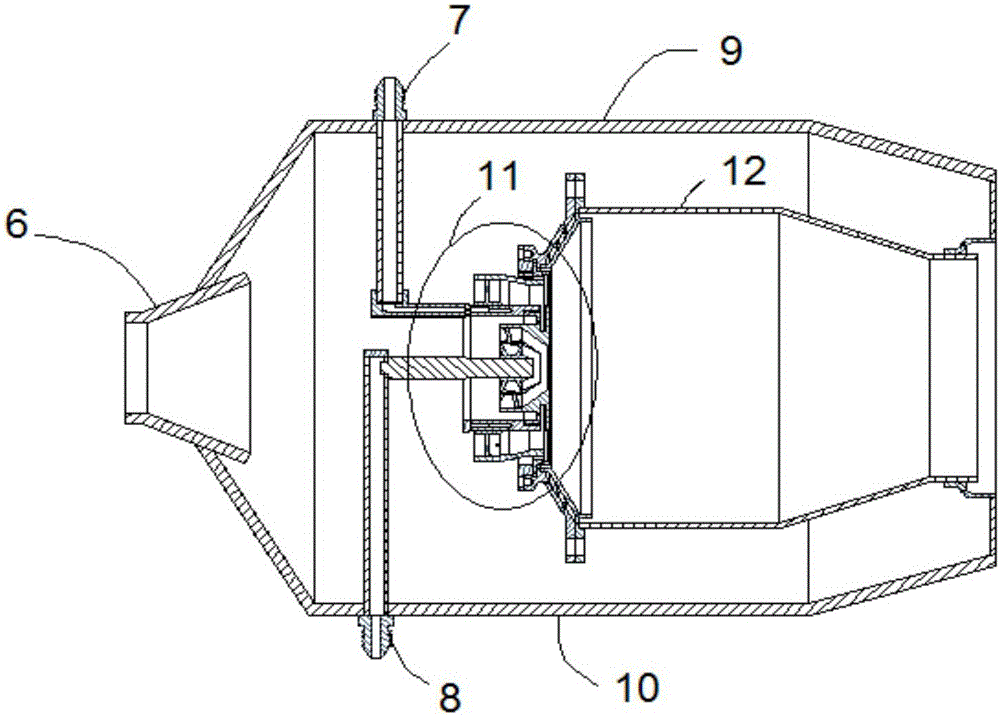

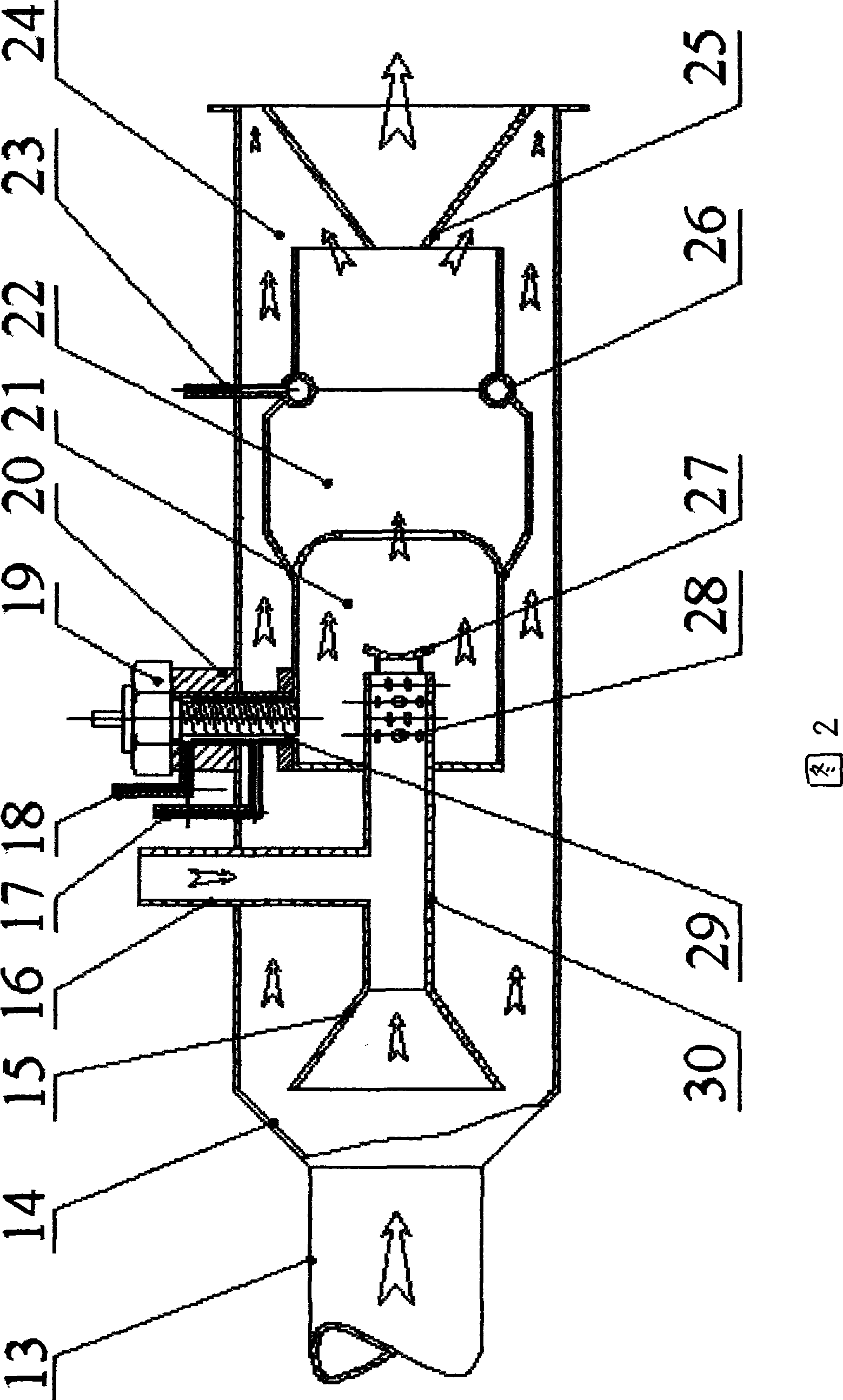

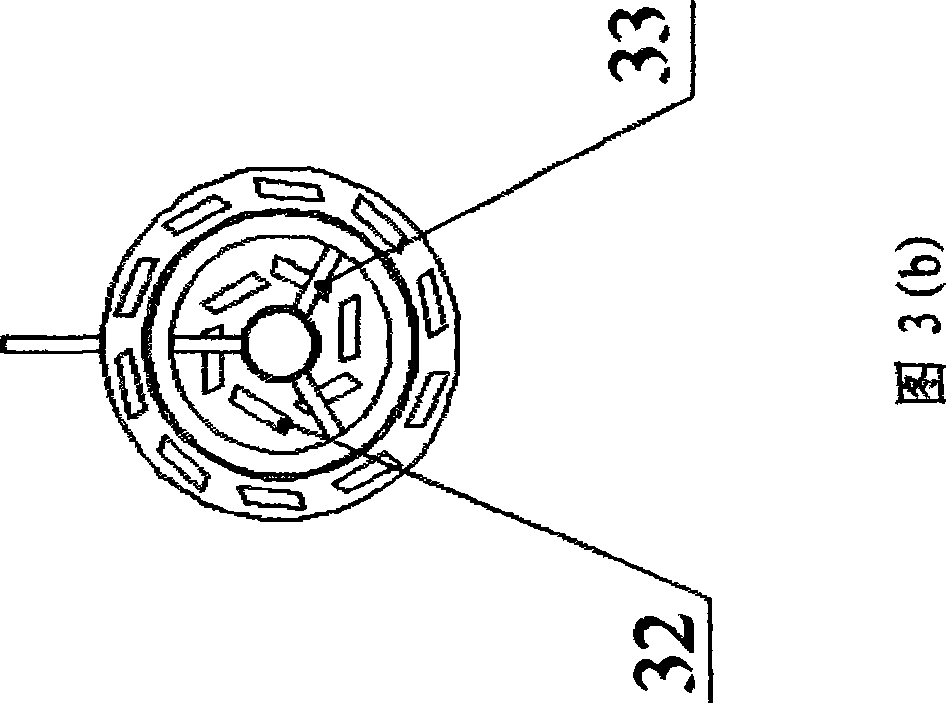

Gas turbine combined type fuel evaporating and atomizing combustion apparatus

InactiveCN101435585AIncrease the pre-mixed pre-evaporation processImprove atomization and evaporationContinuous combustion chamberAviationCyclone

The invention provides a combined fuel oil atomizing, evaporating and combusting device for a gas turbine, relates to an air inlet device of the gas turbine, a fuel oil atomizing, evaporating and blending device, and core technology of organized combustion and stable flame, and belongs to the power field of an aeronautic power propulsion system and a ground gas turbine. A nozzle 1 is arranged at a central position of an inlet of a premixing chamber 2; an evaporator 3 is fixed in an inner cavity of the premixing chamber 2; double cyclones 4 are arranged at the inside of the outlet end of the premixing chamber 2 and connected hermetically; a centrifugal nozzle 5 is arranged at a central position of the double cyclones 4; a venturi 6 is welded at a transition position of an outlet of internal and external cyclones of the double cyclones 4; a sleeve 7 is hermetically welded with the outside of an outlet of the premixing chamber 2; and the head of a combustion chamber 8 is hermetically welded with the sleeve 7. Compared with the prior fuel oil combined nozzle, the device has the advantages of improving properties of fuel oil atomizing, evaporating and blending and evenness of oil-gas space distribution, improving combustion performance, shortening flame length and reducing discharge of pollutant, and is a comparatively ideal combined fuel oil atomizing and combusting device for a high-performance gas turbine.

Owner:PEKING UNIV

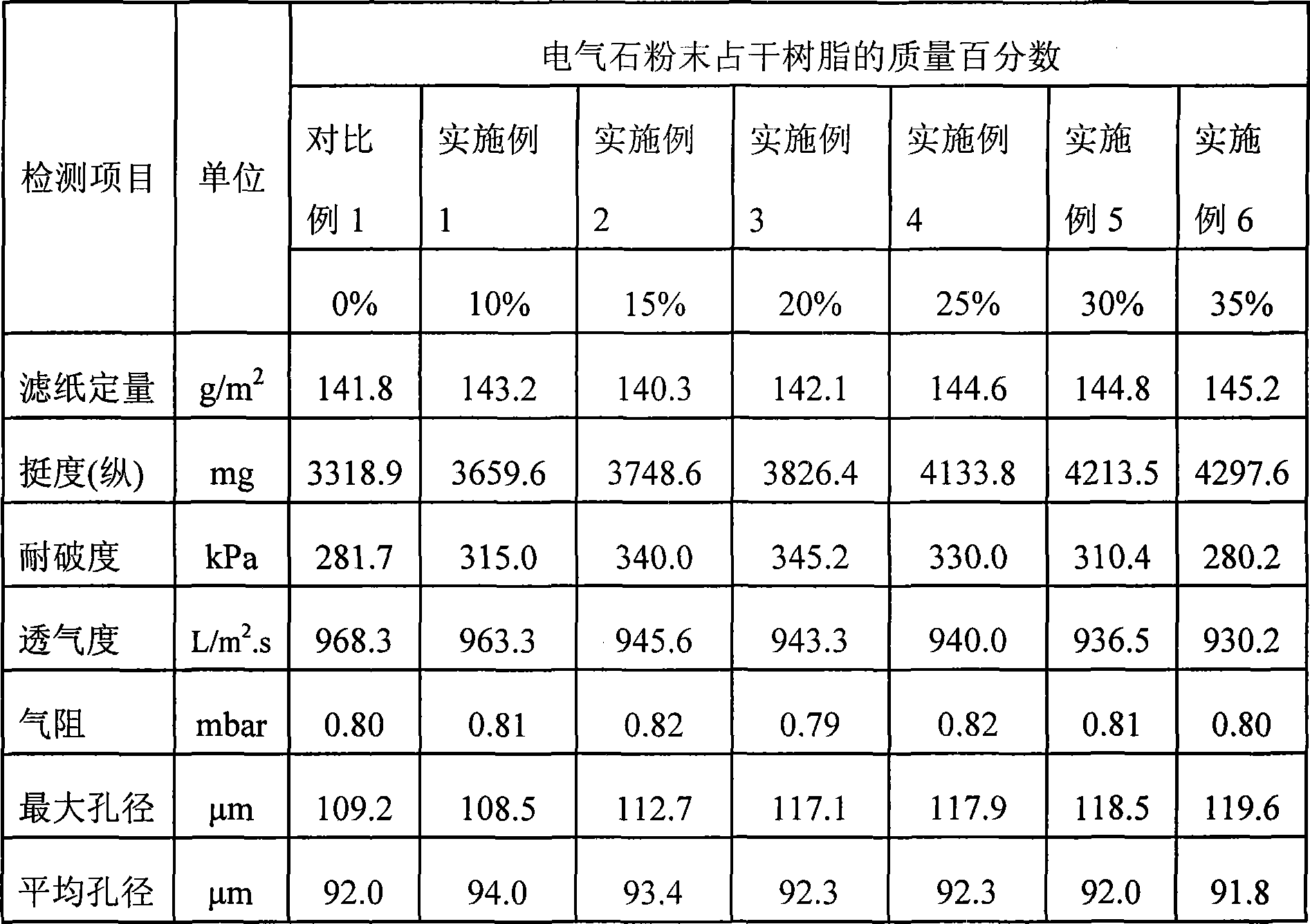

Filter paper of air filter for saving fuel and method for manufacturing same

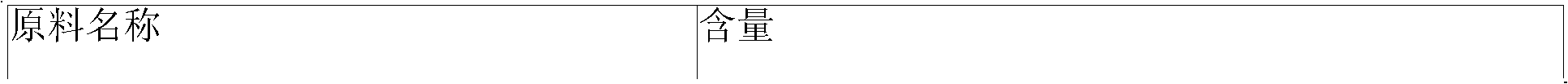

ActiveCN101392703AReduce resistanceEasy to useWater-repelling agents additionMachines/enginesWater basedFuel conservation

The invention provides filter paper of an air filter of fuel conservation and a manufacture method thereof. The filter paper consists of base paper and a sizing agent which is coated on a single side or double sides of the base paper gram weight of between 110 and 160 gram / meter<2>, and water-base resin (butt) is 5 to 30 percent of mass of the base paper. The sizing agent comprises the following components in weight percentage: 2 to 20 percent of the water-base resin (butt), 1 to 20 percent of powder functional material, and 60 to 80 percent of water. The powder functional material is more than one of tourmaline ore powder with far infrared emitting property and releasing anion property, molten mass powder of rare-earth zirconium oxide and alumina, molten mass powder of rare-earth zirconium oxide, titanium oxide or rare-earth zirconium oxide, zinc oxide and the like. With the filter paper, fuel can be saved by 3 to 10 percent, but power of the engine is increased by 5 to 20 percent; noise of the engine is reduced by over 10 decibels, and exhaust emission pollutants are reduced by over 10 to 30 percent.

Owner:湖北国鼎华明纳米新材料有限公司

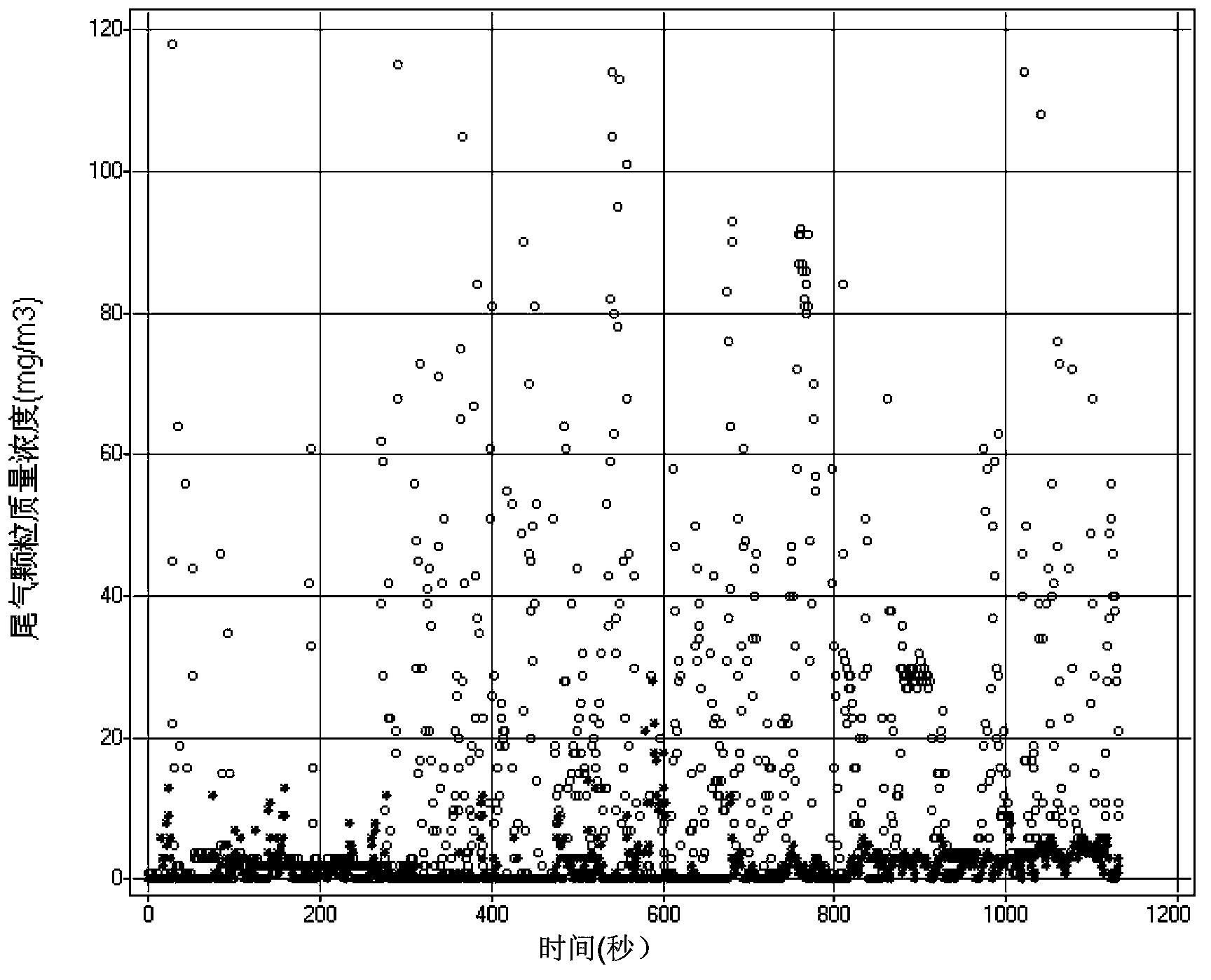

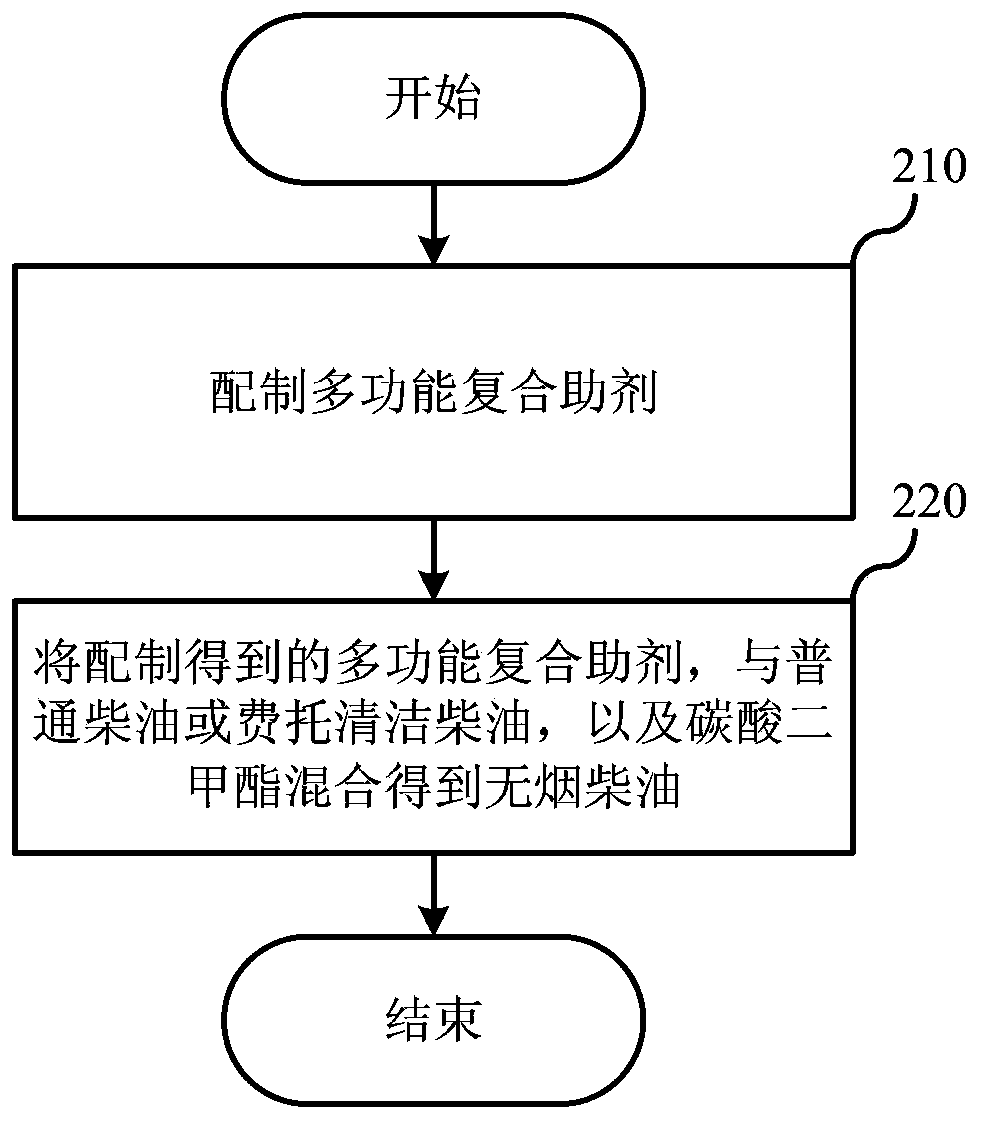

Smokeless diesel oil and preparation method thereof

ActiveCN103805297AEliminate emissionsImprove combustion effectLiquid carbonaceous fuelsParticulatesMethyl carbonate

The invention relates to the field of fuels, and discloses smokeless diesel oil and a preparation method thereof. The smokeless diesel oil comprises 70-95wt% of common diesel oil, 2-25wt% of dimethyl carbonate and 0-10wt% of a multifunctional compound additive. According to the smokeless diesel oil provided by the invention, particulate matter emission in the using process of means of conveyance (comprising various motor vehicles and ships) taking diesel oil as a fuel and machinery for engineering, mining and agriculture and forestry taking diesel engines as power can be greatly reduced or even eliminated without affecting other emission indexes. The smokeless diesel oil is clean and environment-friendly diesel oil, and is simple and convenient and feasible. The fuel system of the diesel engine needs not to be changed.

Owner:YASHENTECH CORP

Inductive heated injector using a three wire connection

ActiveUS20070221761A1Reduce numberReduce in quantitySpray nozzlesMachines/enginesInjectorEngineering

A fuel injector assembly includes a first coil driven by a direct current driver and a second coil driven by an alternating current driver where both the first coil and the second coil share a common connection to reduce the number of external terminal connections. The second coil generates a second magnetic field that is utilized to heat a component in thermal contact with the fuel flow that in turn heats fuel before exiting the fuel injector.

Owner:VITESCO TECH USA LLC

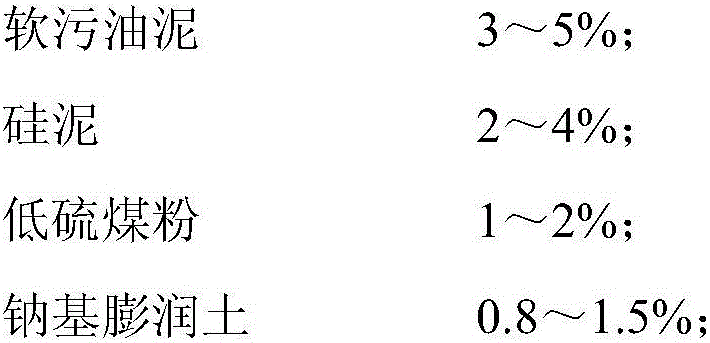

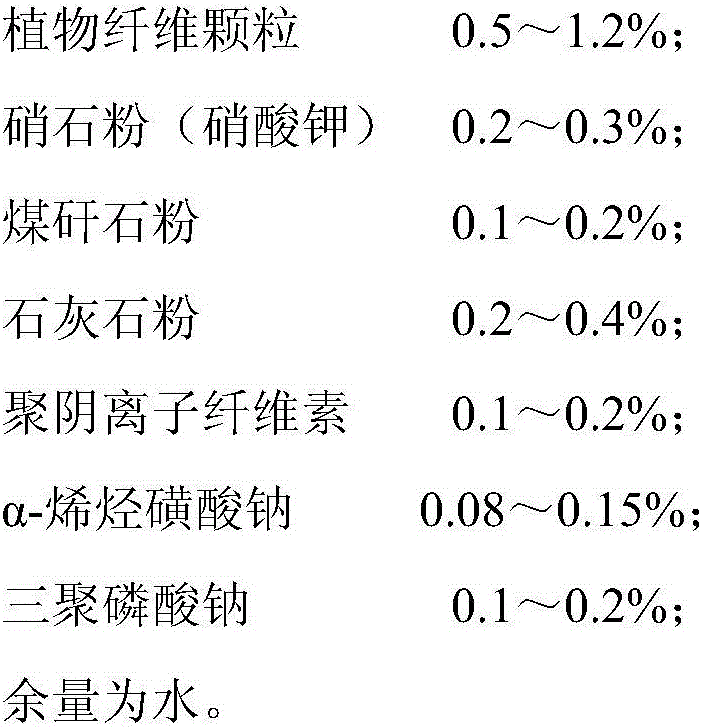

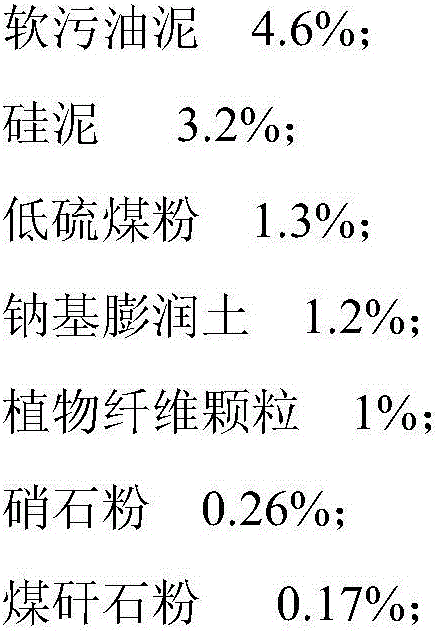

Sulfur-fixing combustion-supporting high-temperature profile control agent, and preparation method and application thereof

ActiveCN106833588AImprove temperature resistanceImprove seal strengthDrilling compositionFiberCellulose

The invention provides a sulfur-fixing combustion-supporting high-temperature profile control agent, and a preparation method and application thereof. By taking the total weight of the sulfur-fixing combustion-supporting high-temperature profile control agent as 100%, the profile control agent is prepared from the following raw materials in percentage by weight: 3-5% of soft oil sludge, 2-4% of silicon sludge, 1-2% of low sulfur coal powder, 0.8-1.5% of sodium bentonite, 0.5-1.2% of plant fiber particle, 0.2-0.3% of saltpetre powder, 0.1-0.2% of coal gangue powder, 0.2-0.4% of limestone powder, 0.1-0.2% of polyanionic cellulose, 0.08-0.15% of alpha-sodium olefinsulfonate, 0.1-0.2% of sodium tripolyphosphate and the balance of water. The profile control agent has favorable stratum compatibility, causes no damage to the oil reservoir, does not pollute the stratum, and has favorable temperature tolerance; and meanwhile, the profile control agent has sulfur-fixing and combustion-supporting functions, thereby being completely applicable to a profile control technology for a thick oil fireflood chemical profile control gas injection well.

Owner:PETROCHINA CO LTD

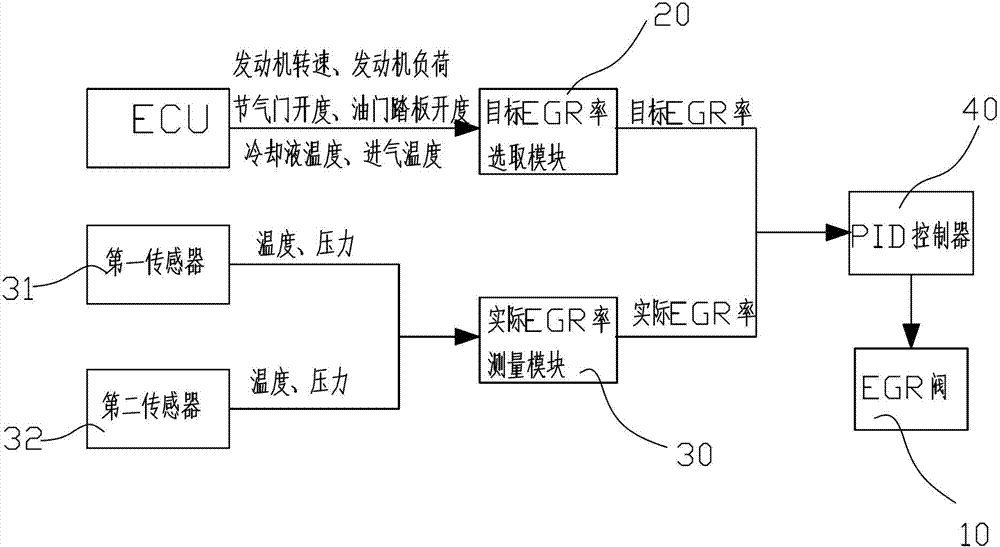

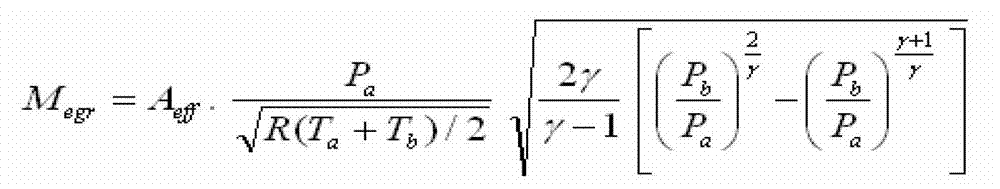

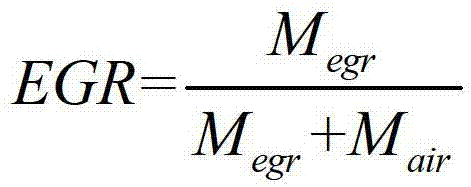

Engine exhaust gas recirculation (EGR) valve closed-loop control system

InactiveCN103089460AImprove combustion effectEngine controllersMachines/enginesRate measurementLoop control

The invention relates to the field of engine exhaust gas recirculation rate control, in particular to an engine exhaust gas recirculation (EGR) valve closed-loop control system which comprises an EGR valve, a target EGR rate selection module, an actual EGR rate measurement module and a proportion integration differentiation (PID) controller. The target EGR rate selection module stores target EGR rates under different work conditions, the actual EGR rate measurement module can measure the actual EGR rate of an EGR valve under the current work condition, the actual EGR rate measurement module can send the actual EGR rate under the current work condition to the PID controller, and the target EGR rate selection module can send a target EGR rate corresponding to the current work condition to the PID controller. If the actual EGR rate and the target EGR rate are identical, the EGR valve remains valve core opening degree. If the actual EGR rate and the target EGR rate are different, the valve core opening degree of the EGR valve is adjusted so as to adjust the EGR rate. The system can monitor the EGR rate in real time, guarantees that the actual EGR rate and the target EGR rate are identical, enables an engine to be in the best condition and improves gasoline combustion performance.

Owner:CHERY AUTOMOBILE CO LTD

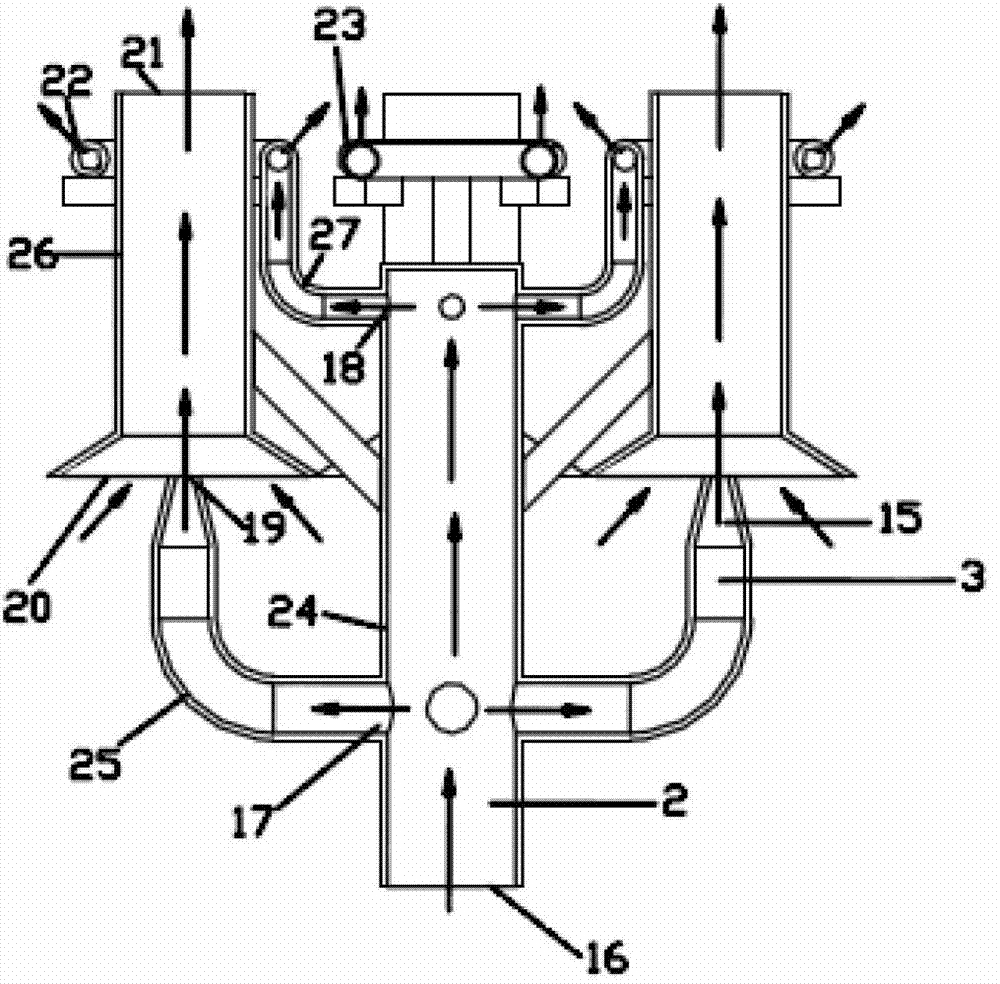

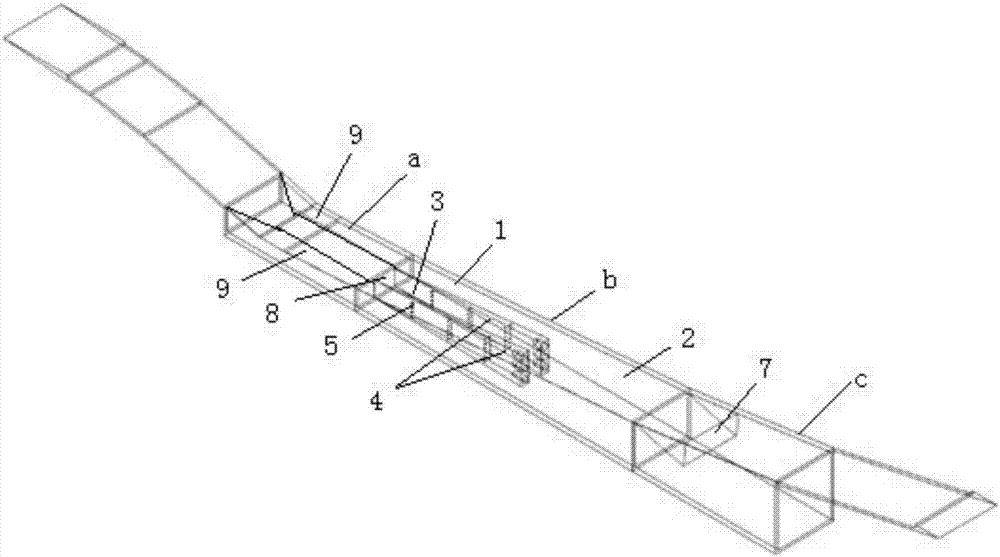

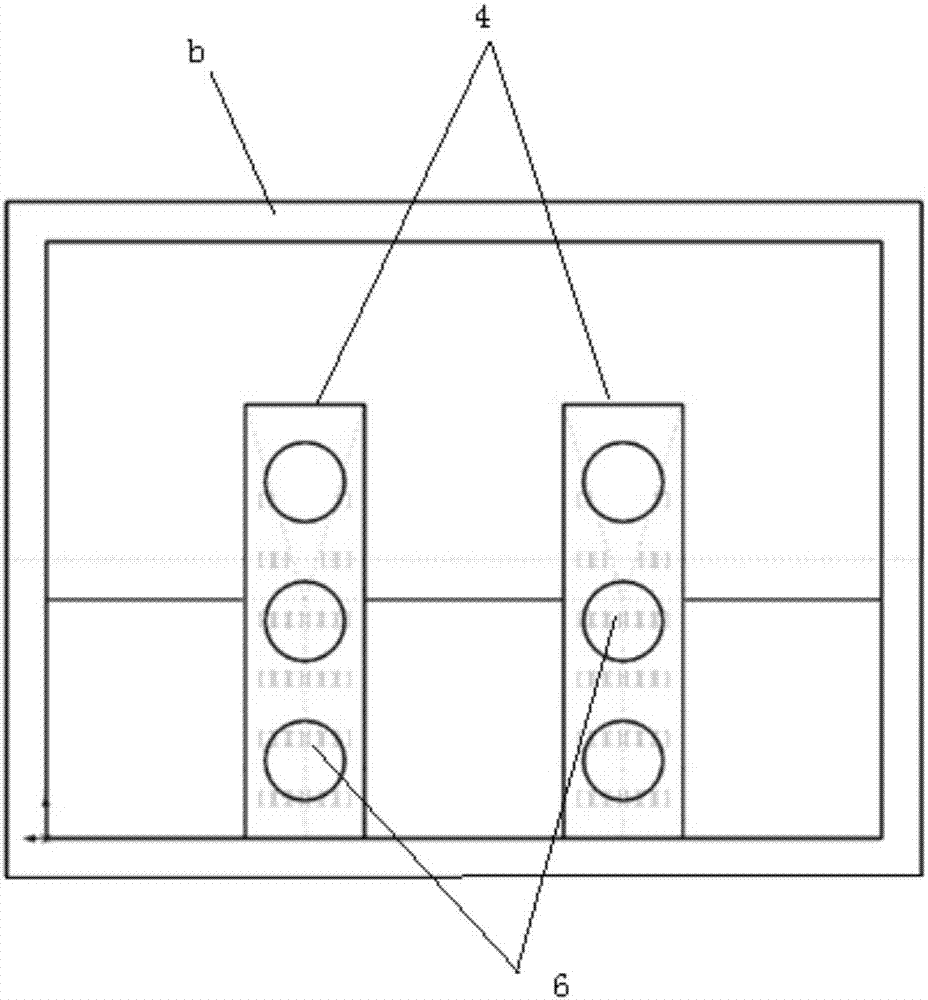

Multi-head efficient pre-mixing type combustion system of ground flare

The invention discloses a multi-head efficient pre-mixing type combustion system of a ground flare. The multi-head efficient pre-mixing type combustion system of the ground flare comprises an air conveying header pipe (2), wherein the air conveying header pipe (1) is connected with at least two lower air distributing branch pipes (3) and at least two upper air distributing branch pipes (4); each lower air distributing branch pipe is provided with a nozzle (15); each nozzle is provided with a pre-mixing chamber (5) which is composed of a gradually shrinking air inlet pipe (6) and a cylindrical pipe; the gradually shrinking air inlet pipe (6) is hooded on each nozzle; the small end of each gradually shrinking air inlet pipe (6) is communicated with the lower end of each cylindrical pipe; the upper end of each cylindrical pipe is a pre-mixed air outlet (7) and is provided with a lighter (11); an air outlet end of each air distributing branch pipe is communicated with an annular pipe (8); the annular pipe is provided with a spraying hole (9); a top annular pipe (13) is arranged at the outlet end of the air conveying header pipe; the top annular pipe is communicated with a steam conveying pipe (12); and the top annular pipe is provided with a steam nozzle (14) for adding the mixed air and improving smoke-removing performance. The multi-head efficient pre-mixing type combustion system of the ground flare, disclosed by the invention, has the advantages of improving pre-mixing proportion and improving combustion efficiency.

Owner:JIANGSU SUNPOWER TECH

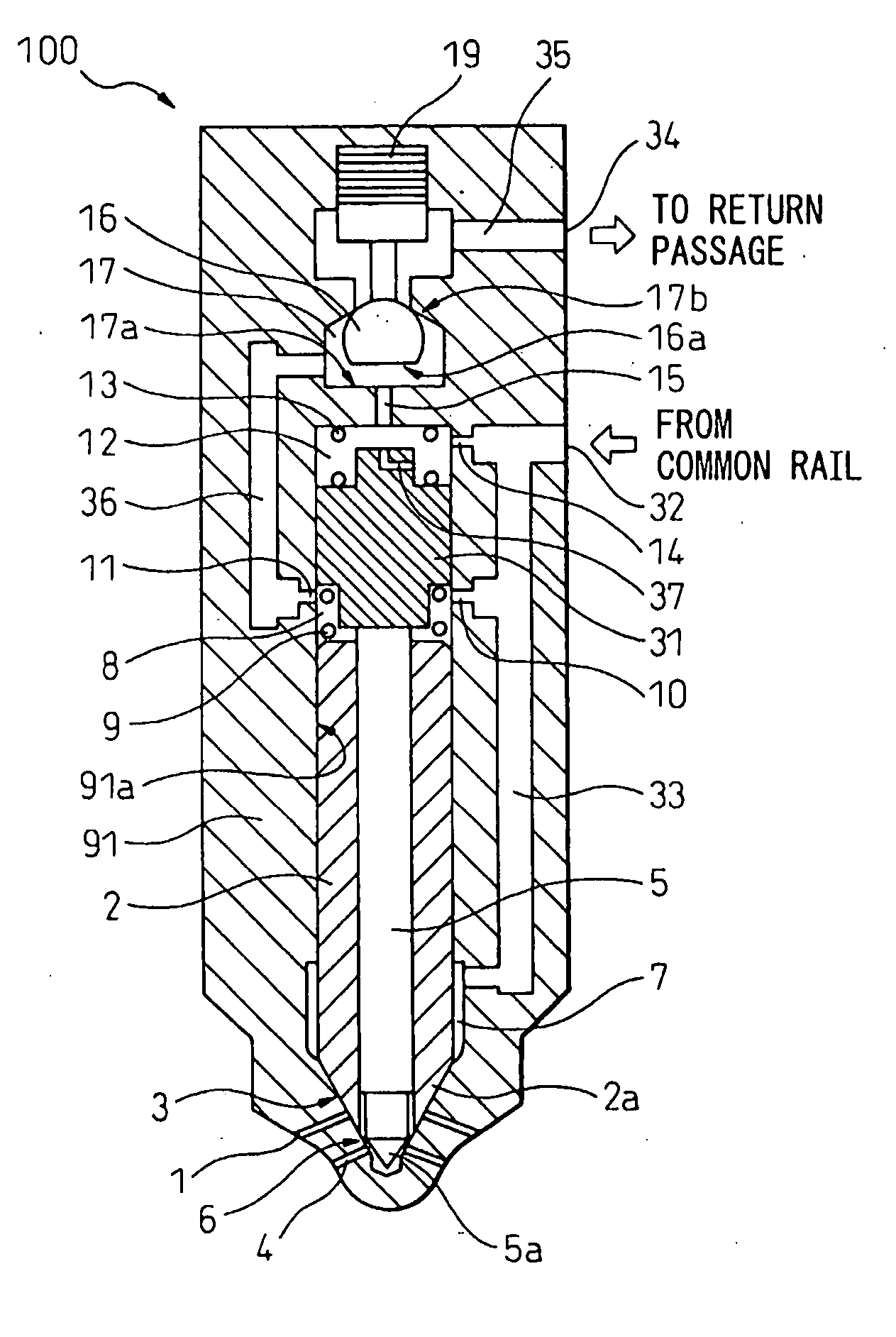

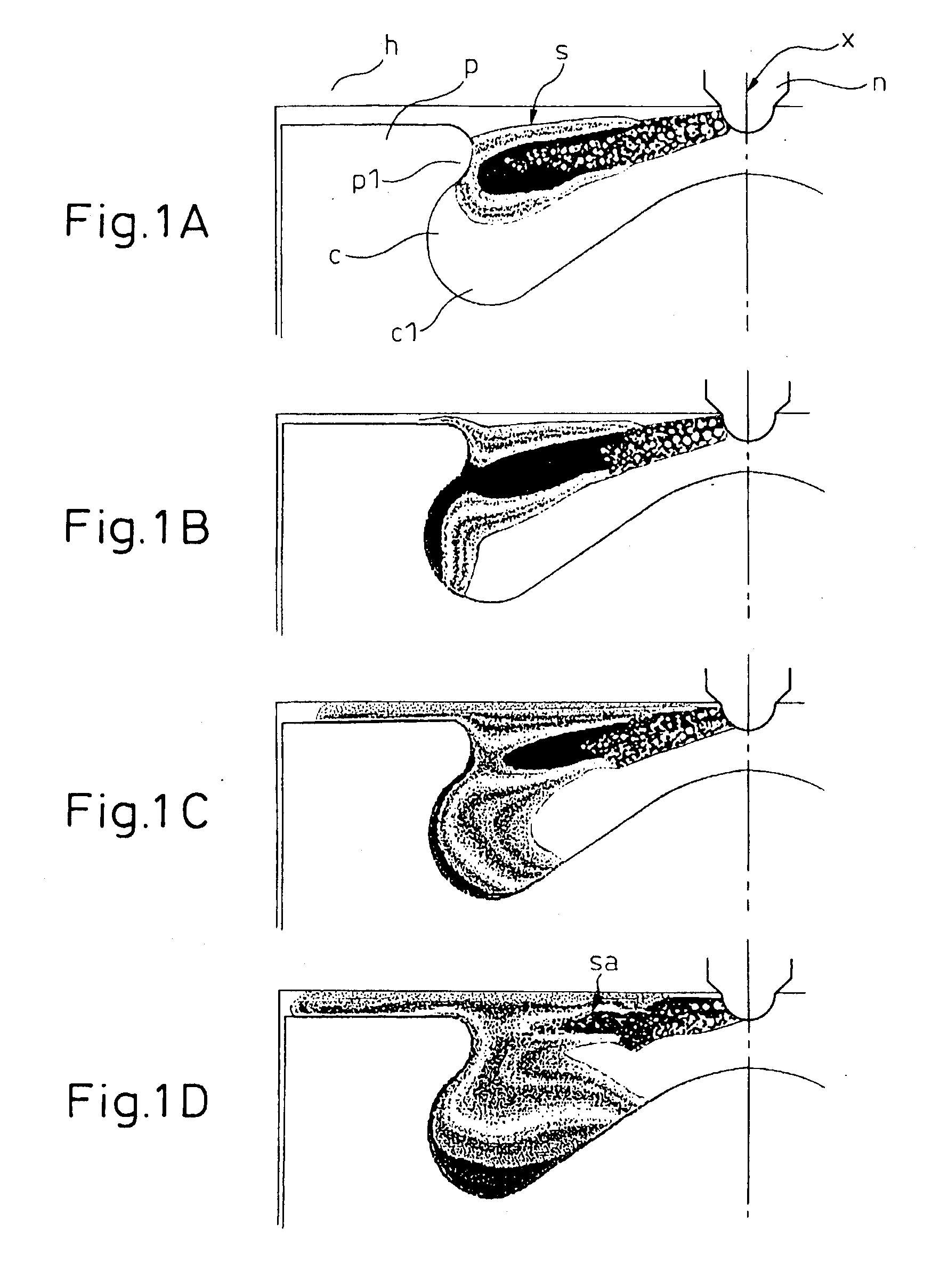

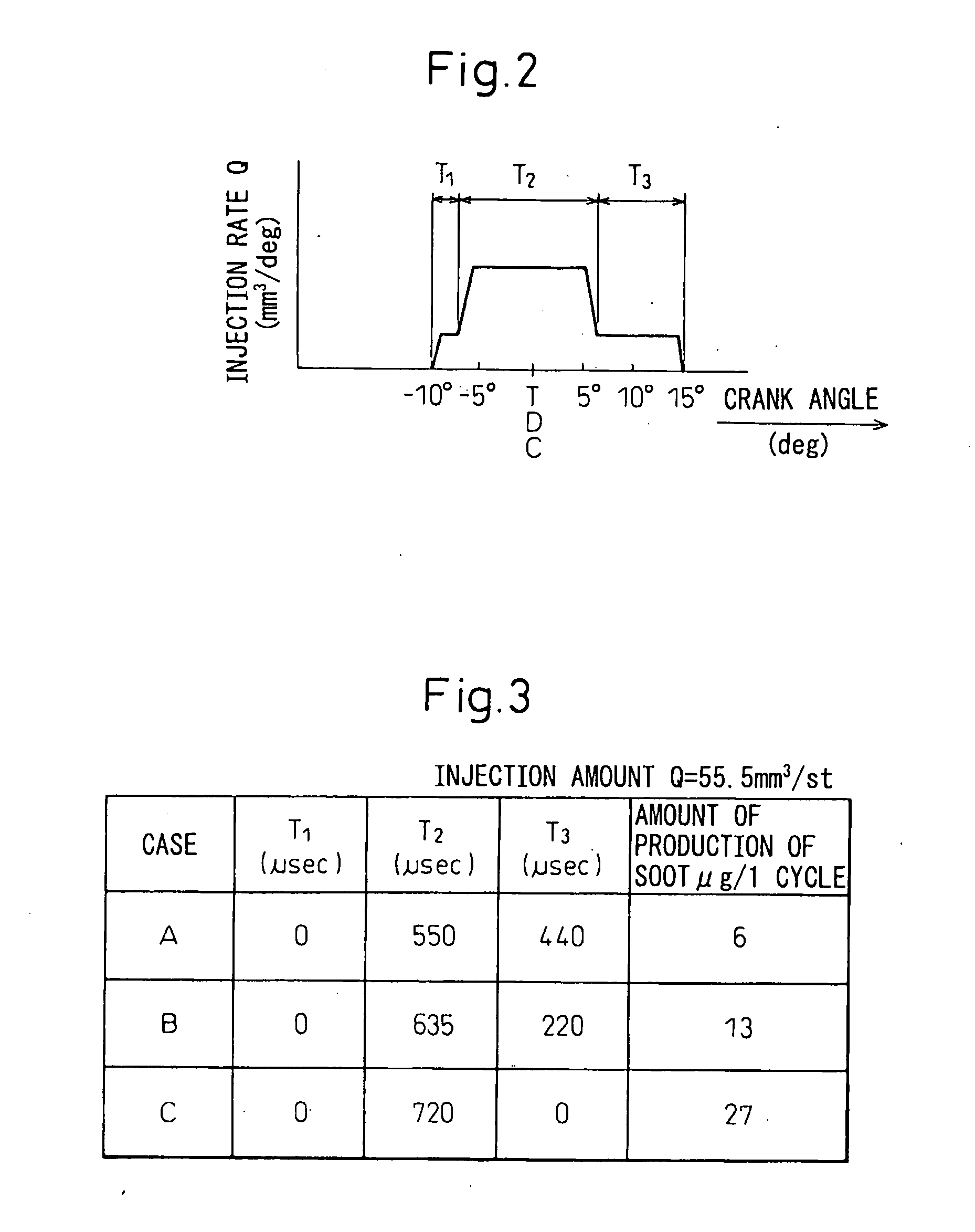

Fuel Injection System of Internal Combustion Engine

InactiveUS20080053408A1Improve combustionReduce NOxElectrical controlInternal combustion piston enginesInjection pressureInjection port

A fuel injection system deliberately utilizing after injection so as to improve the engine combustion and reduce soot and NOx, wherein at least one operating valve is provided for operating a first injection port group and second injection port group, after injection is performed consecutively after main injection in a high load region, fuel is injected from the first injection port group and second injection port group at the time of main injection, fuel is injected from the first injection port group at the time of after injection, the actual injection pressure near the first injection port during the after injection period is higher than the actual injection pressure near the first injection port during the main injection period, the operating valve opens the first injection port group to start the injection, then the operating valve opens the second injection port group simultaneously or in a short time as well to perform the main injection, the operating valve closes the second injection port group, then performs the after injection, and the operating valve closes the first injection port group and ends the injection after the elapse of a time longer than simultaneously or a short time from after start of after injection.

Owner:TOYOTA JIDOSHA KK

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

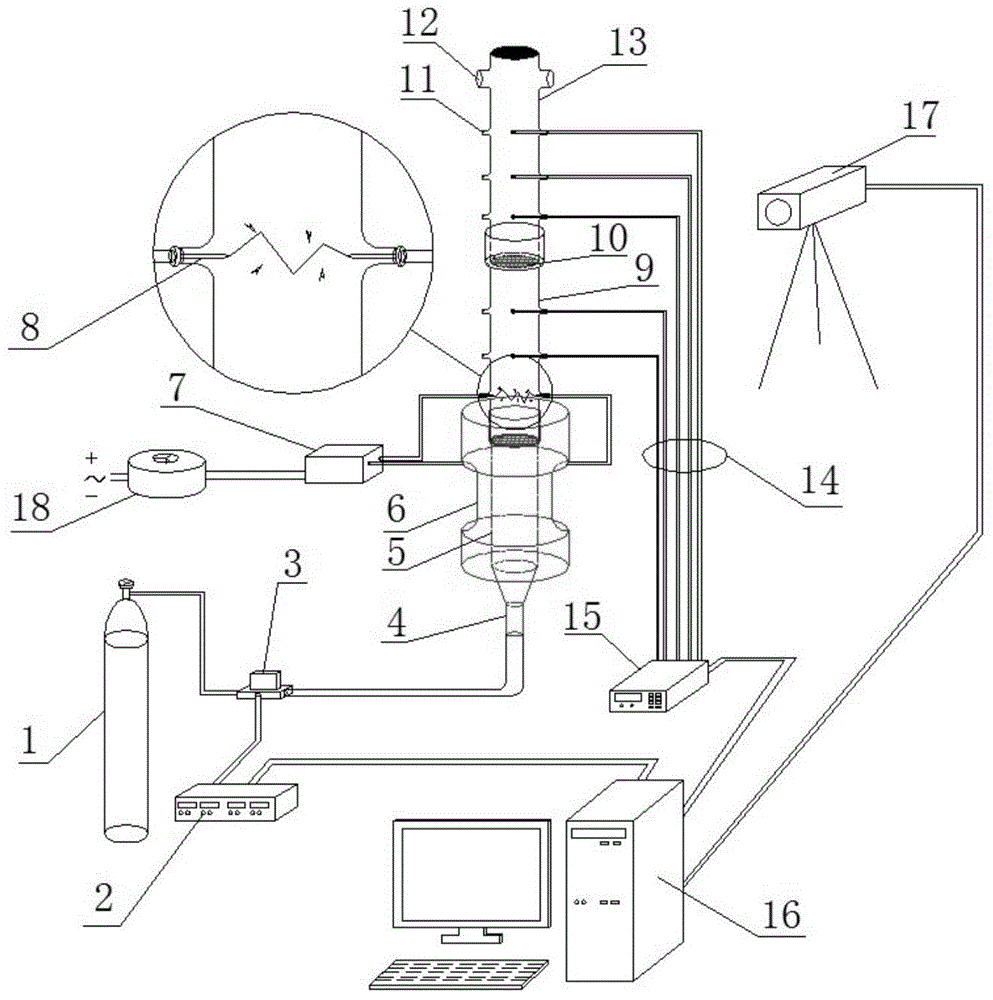

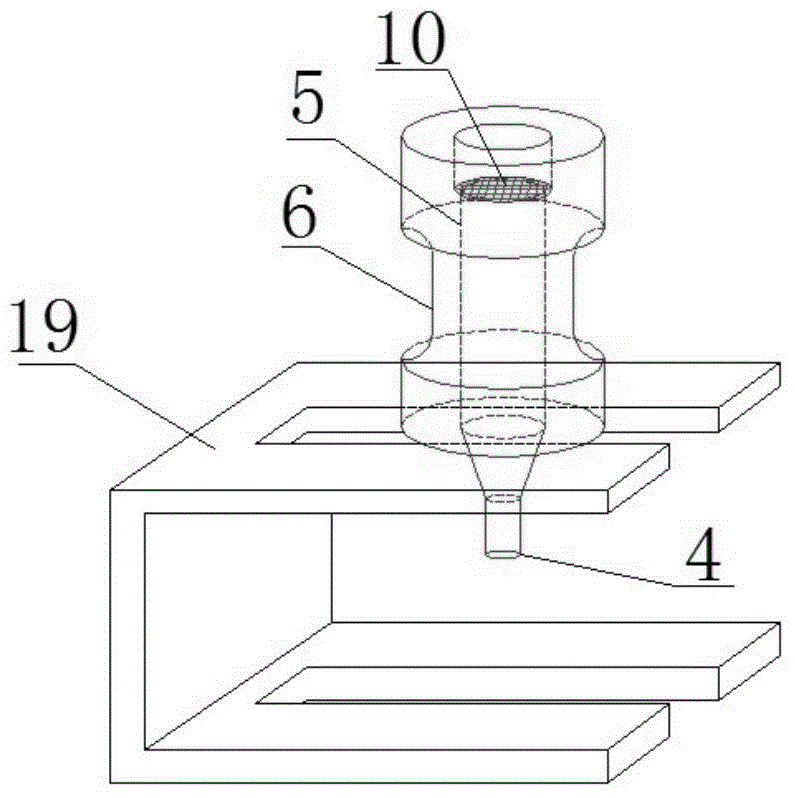

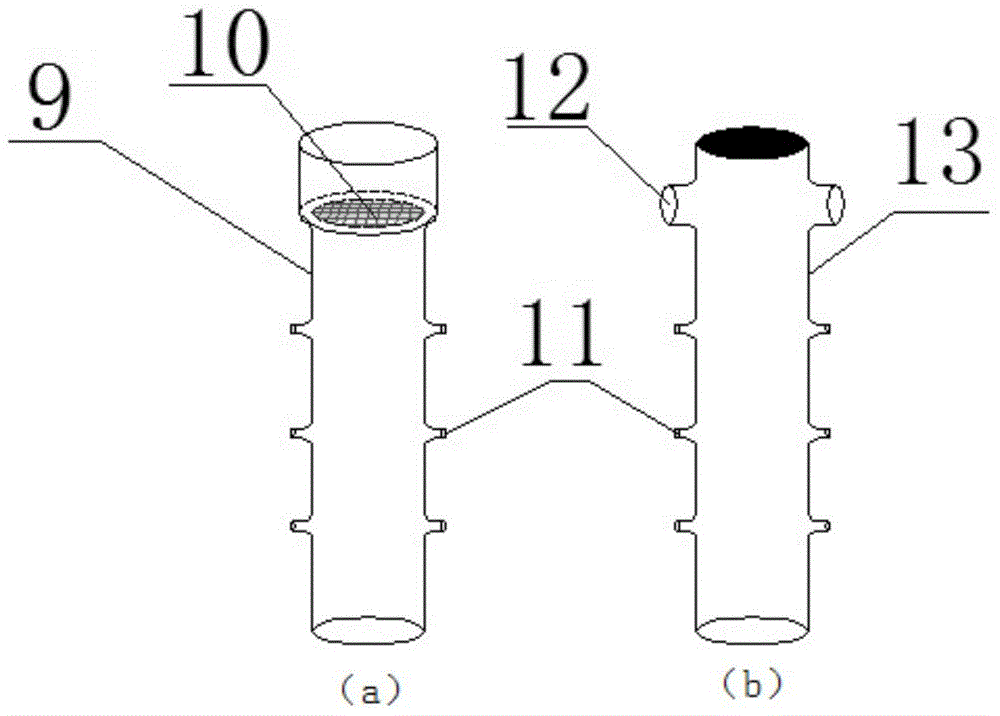

Detachable solid fuel suspension combustion experiment testing device and detachable solid fuel suspension combustion experiment testing method

ActiveCN104634922ASolve the problem of not easy to igniteEasy to igniteChemical analysis using combustionData acquisitionSolid fuel

The invention discloses a detachable solid fuel suspension combustion experiment testing device and a detachable solid fuel suspension combustion experiment testing method, belonging to the technical field of a solid fuel combustion experiment. The testing device comprises a suspension combustion mechanism, a combustion data acquisition mechanism, a gas supply mechanism and an ignition mechanism; a base is arranged on a base bracket; the lower end hole of a primary combustion pipe is communicated and in detachable connection with the upper end hole of an inner pipe of the base; the lower end hole of a secondary combustion pipe is communicated and in detachable connection with the upper end hole of the primary combustion pipe; two porous metal plates are respectively arranged at the upper end hole of the inner pipe of the base and the upper end hole of the primary combustion pipe. The testing method comprises the steps of placing fuel; enabling the fuel to suspend; burning; acquiring combustion data; finishing the experiment. The device and the method mainly have the functions of realizing visualization of a combustion state, realizing uniform combustion at a suspended state, carrying out a combustion test on multiple samples for once and enabling the large-particle samples to be easily ignited.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Low-emission combustion chamber with double-layer axial hydrocyclone adopted at precombustion stage

InactiveCN105157062AImprove combustion effectAvoid lossContinuous combustion chamberCombustion chamberPollutant emissions

The invention discloses a low-emission combustion chamber with a double-layer axial hydrocyclone at a precombustion stage. The combustion chamber is of a single annular cavity structure and structurally comprises a pressure expander, a combustion chamber exterior casing, a combustion chamber interior casing, a flame tube and a combustion chamber head; all combustion-used air enters the flame tube through the combustion chamber head, a staged combustion scheme is adopted, and the combustion is divided into into the precombustion stage and a primary combustion stage; a premixed combustion mode is adopted at the primary combustion stage, and a diffusive combustion mode serves as the main mode of the precombustion stage; the double-layer axial hydrocyclone is adopted at the precombustion stage, two blasts of rotational flow can maintain individual flowing through a partition plate, and momentum loss due to the fact that the two blasts of rotational flow make contact with each other too early is avoided; the two blasts of rotational flow are utilized for reinforcing fuel oil atomization and mixing, meanwhile, reasonable recirculating zone distribution is generated, efficient and stable combustion under small working conditions is guaranteed, and meanwhile pollutant emission is lowered; the combustion chamber is simple in structure at the precombustion stage and easy to machine and install, combustion chamber emission under small working conditions can be lowered, and thereby the low emission performance of a total landing and taking-off cycle of the combustion chamber is improved.

Owner:BEIHANG UNIV

Fire coal combustion improver

InactiveCN102191110AImprove operational safetyExtended service lifeSolid fuelsChromium trioxideDolomite

The invention relates to an improvement of a fire coal combustion improver. The improved fire coal combustion improver is characterized by being prepared by compounding and mixing the following components: 20 to 30 weight percent of dolomite powder, 5 to 15 weight percent of dicyclopentadieny iron, 3 to 10 weight percent of chromium trioxide, 3 to 10 weight percent of manganese dioxide, 3 to 15 weight percent of magnesium nitrate, 3 to 15 weight percent of sodium dichromate and / or potassium dichromate, 3 to 18 weight percent of zinc oxide, 15 to 30 weight percent of active clay. The fire coal combustion improver has a plurality of functions of combustion acceleration, sulfur solidification, smoke abatement and the like; the thermal efficiency of a boiler can be improved by 3 to 8 percent; the coal-saving efficiency is up to 5 to 15 percent; the Ringelmann smoke blackness is less than 1; the total removal rate of SO2, NOx and the like is 25 to 60 percent, and the combustion improver has remarkable coal-saving and environmental-protection effect. Since the combustion effect is improved, the inferior coal (such as coal gangue), which is difficult to combust normally, is combusted and comes into play. After the long use, the boiler is not corroded, the scaling of the calcium sulfate in the boiler can be reduced, the operation safety of the boiler can be improved and the service life of the boiler can be prolonged.

Owner:YIXING KEQI CHEM

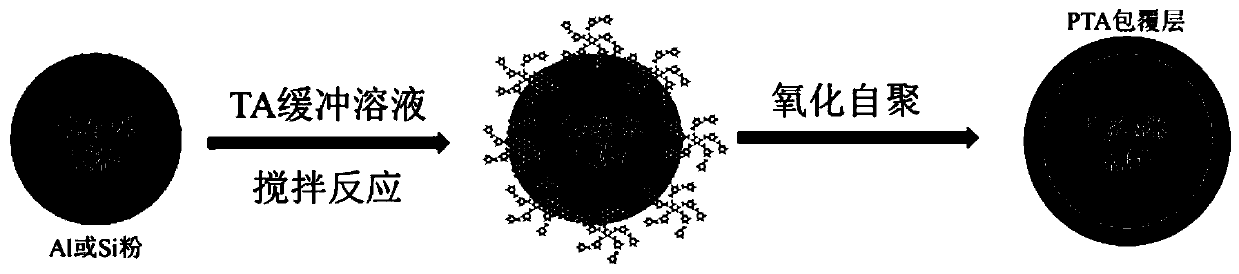

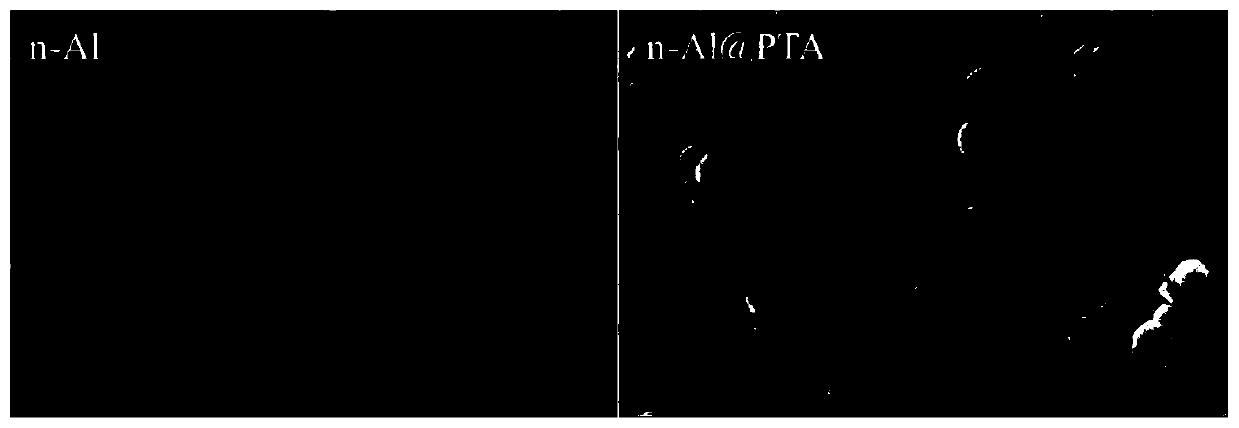

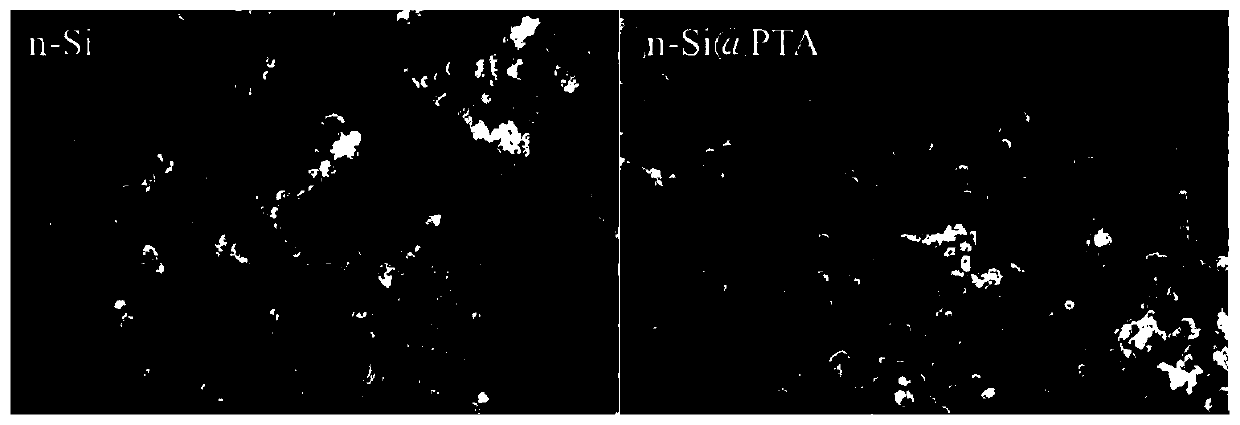

Preparation method of polymerized tannic acid coated high-activity aluminium powder/silicon powder

ActiveCN110550990AHigh activityRapid combustion reactionNon-explosive/non-thermic compositionsPressure gas generationHigh activityPolymerization

The present invention discloses a preparation method of polymerized tannic acid coated high-activity aluminium powder / silicon powder. The method comprises the following steps: firstly, dissolving a buffer reagent in an organic solution, adding tannic acid, carrying out stirring for dissolving to obtain a tannic acid-buffer solution, then dispersing aluminum powder or silicon powder into the tannicacid-buffer solution, and carrying out stirring to carry out a self-polymerization reaction to obtain the polymerized tannic acid coated high-activity aluminium powder or silicon powder. The raw material of the preparation method is wide in resource and is green, environmentally friendly and safe, and the preparation method is simple and convenient and is suitable for industrial production. The aluminum or silicon@polymerized tannic acid core-shell-structure composite material prepared by the method can effectively prevent rapid oxidation of surfaces of aluminum / silicon particles and protectactivity of aluminum powder or silicon powder. When the aluminum or silcon@polymerized tannic acid core-shell-structure composite material is added into a solid propellant for high-temperature combustion, the coating polytannic acid is rich in carbon, and additional combustion heat can be provided, so that rapid combustion reactions of aluminum powder or silicon powder are promoted, and then combustion performance of the solid propellant is improved.

Owner:NANJING UNIV OF SCI & TECH

Wide-range working rocket stamping combined full flow channel

ActiveCN106968835AShort blending distanceIncrease penetration depthContinuous combustion chamberGas turbine plantsExtensibilityInlet channel

The invention discloses a wide-range working rocket stamping combined full flow channel comprising an air inlet channel inner compression section, a combustion chamber and a tail spraying pipe which are sequentially connected from front to back. The combustion chamber comprises a supersonic combustion chamber section and a subsonic combustion chamber section from front to back; the supersonic combustion chamber section is divided into three independent flow channel bodies in the longitudinal direction of the supersonic combustion chamber section; and the flow channel bodies all communicate with the subsonic combustion chamber section. The front ends of the flow channel bodies are the air inlet ends, and three independent air inlets are formed correspondingly; the three independent flow channel bodies are formed by enclosing of two central supporting plates arranged in the supersonic combustion chamber section in a spaced mode and the two side walls of the supersonic combustion chamber section; the rear ends of the central supporting plates are provided with a plurality of rocket ejecting spraying pipe mounting holes communicating with cavities; the interiors of the central supporting plates are the hollow cavities used for communicating with a fuel storage tank; and a plurality of fuel nozzles communicating with the cavities are formed in the two side faces of the central supporting plates from front to back at intervals. The wide-range working rocket stamping combined full flow channel multimode flow channel capable of being shared is high in flow channel extensibility and simple in structure changing style.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Air discharge heating apparatus, system and method for diesel engine under full operating condition

InactiveCN101440735ALow ignition temperatureReduce accumulation rateInternal combustion piston enginesExhaust apparatusCombustion chamberAir pump

The invention relates to a device, a system and a method for exhausting and heating under all operating conditions of a diesel engine, and belongs to the technical field of pollution control of tail gas particle. The heating device comprises a first-stage combustion chamber, a second-stage combustion chamber and a third-stage combustion chamber orderly connected in series with a shell, a whirlpool groove, a tapered spoiler, a spoiler groove, a triangular support of the tapered spoiler, a first-stage combustion oil supply pipe, a circular fuel oil evaporating pipe, a third-stage combustion oil supply pipe, an air intake guide cylinder, a fresh air guide cylinder, an exhaust tapered air inlet, an air inlet and an air intake baffle. An electronic control unit judges whether to regenerate by monitoring exhaust temperature and pressure at two ends of a particle catcher; when regeneration is needed, oxygen content in the exhausted air is judged, and when the oxygen content is lower than a preset value, an air pump is controlled to provide little air so as to reliably ignite under all operating conditions. The device, the system and the method have the advantages of low energy consumption, simple operation method, high combustion efficiency and reliable operation, and can work under all the operating conditions of an engine.

Owner:MILITARY TRANSPORTATION UNIV PLA

Pulverized coal combustion improver for thermal power plant

InactiveCN102559331ALow ignition pointImprove combustion effectSolid fuelsCombustionEconomic benefits

The invention discloses a pulverized coal combustion improver for a thermal power plant. The pulverized coal combustion improver comprises components with weight percentages as follows: 50 to 80 percent of manganese ore, 10 to 40 percent of chemical activator, 5 to 15 percent of clinker sintering agents and smaller than 2 percent of water, wherein the chemical activator is sodium aluminosilicate or potassium aluminum silicate. Raw materials of the chemical activator in the pulverized coal combustion improver are easy to obtain and an effect of saving more than 13 percent of coal can be achieved, so that the pulverized coal combustion improver has great economic benefits and is worthy of popularization.

Owner:洛阳大泽节能环保科技有限公司

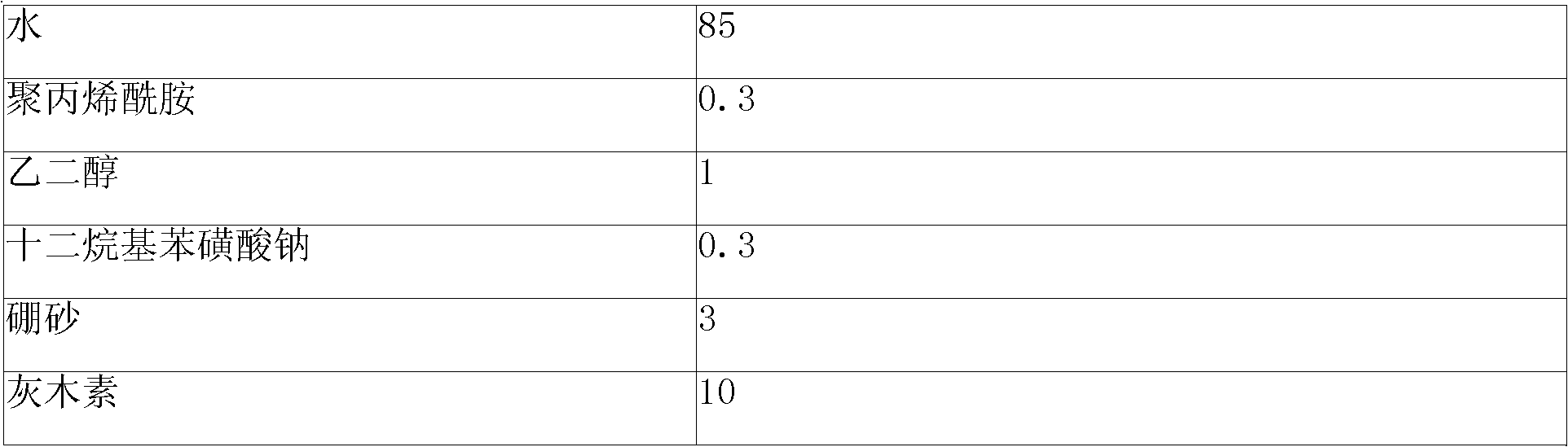

Fireproof interface agent for polystyrene foam heat insulation material and preparation method thereof

InactiveCN101787236AImprove flame retardant performanceImprove combustion effectFireproof paintsConjugated diene hydrocarbon coatingsFiberPolystyrene

The invention discloses a fireproof interface agent for a polystyrene foam heat insulation material and a preparation method thereof. The fireproof interface agent is compounded by components A and B, wherein the mass ratio of the components A to B is 1: 1.2 to 1.4. The fireproof interface agent comprises the following raw materials in percentage by mass: the component A: 40 to 50 percent of butyl benzene emulsion, 35 to 40 percent of water glass, 1 to 3 percent of water glass stabilizing agent, 3.4 to 8 percent of ammonium polyphosphate fireproof aid, 10 to 15 percent of stable thickening agent and 0.2 to 0.4 percent of preservative; and the component B: 25 to 30 percent of water, 0.2 to 0.4 percent of preservative, 3 to 5 percent of antimonous oxide, 7 to 11 percent of chlorinated paraffin, 15 to 20 percent of fireproof paper fiber pulp, 3 to 5 percent of mica, 15 to 20 percent of aluminum hydroxide, 20 to 25 percent of fly ash, 0.5 to 1 percent of expanded perlite and the like. The fireproof interface agent has good flame-retardant property, and can greatly improve the combustion performance of the polystyrene foam heat insulation material.

Owner:北京振利节能环保科技股份有限公司

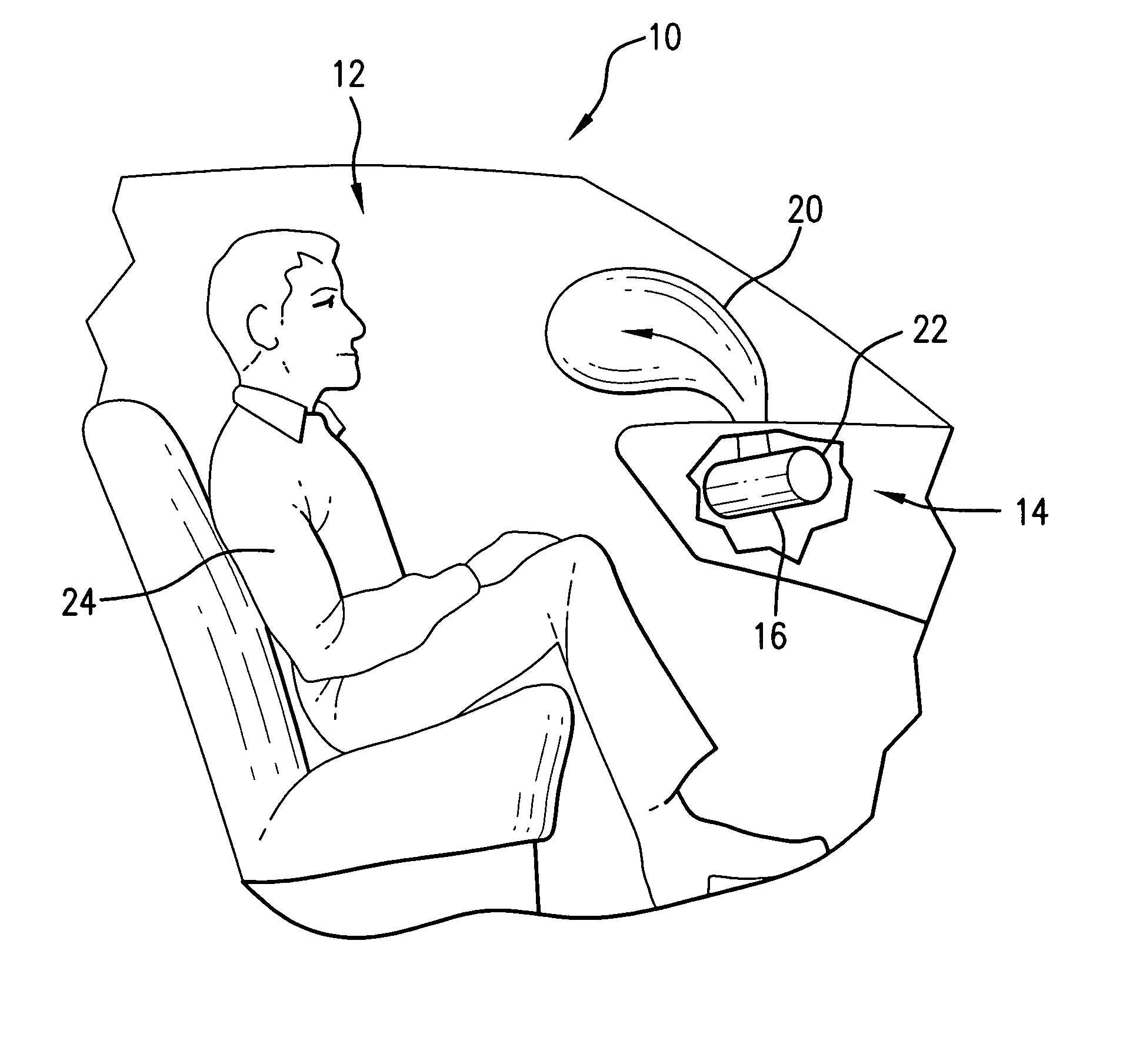

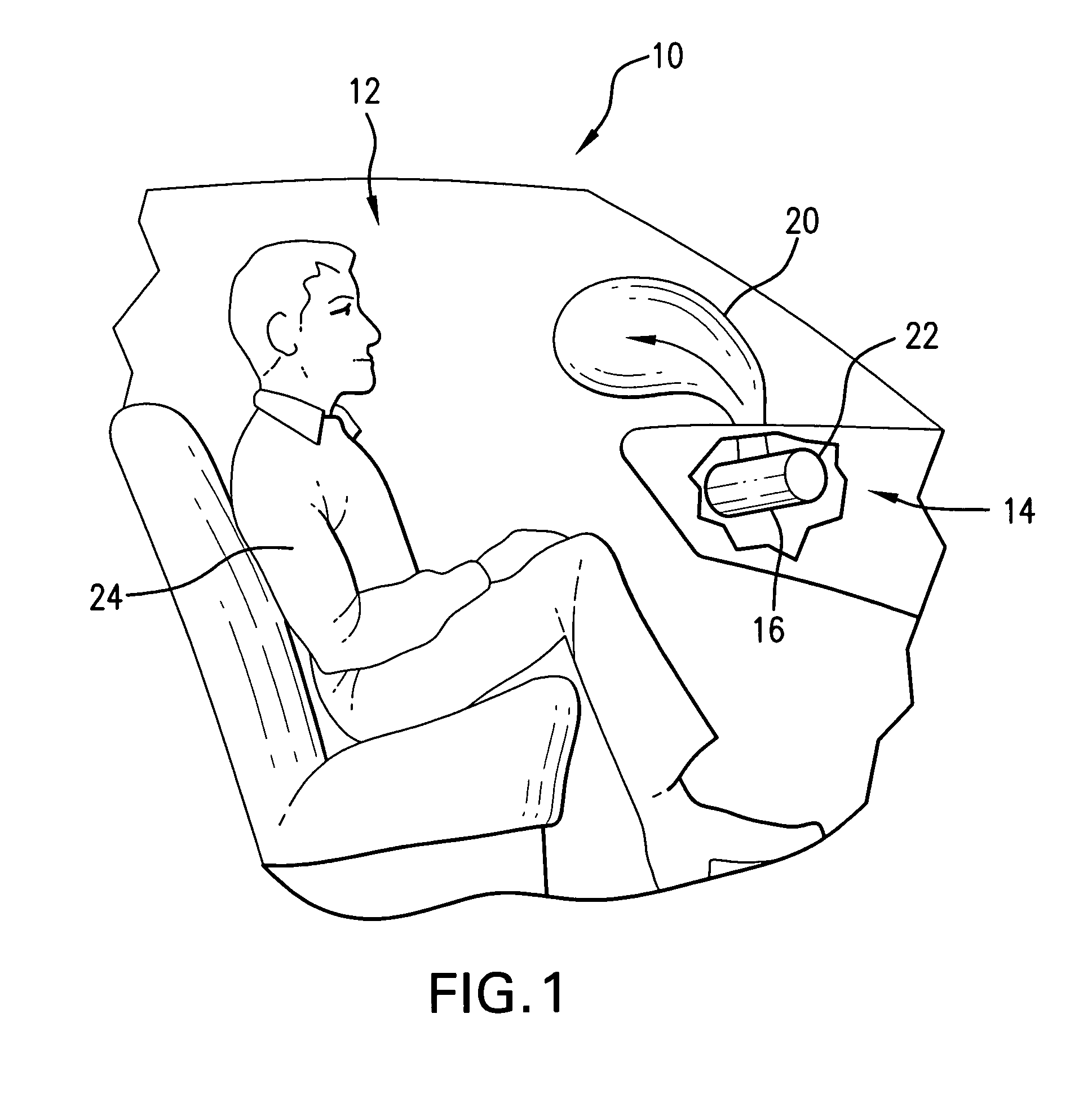

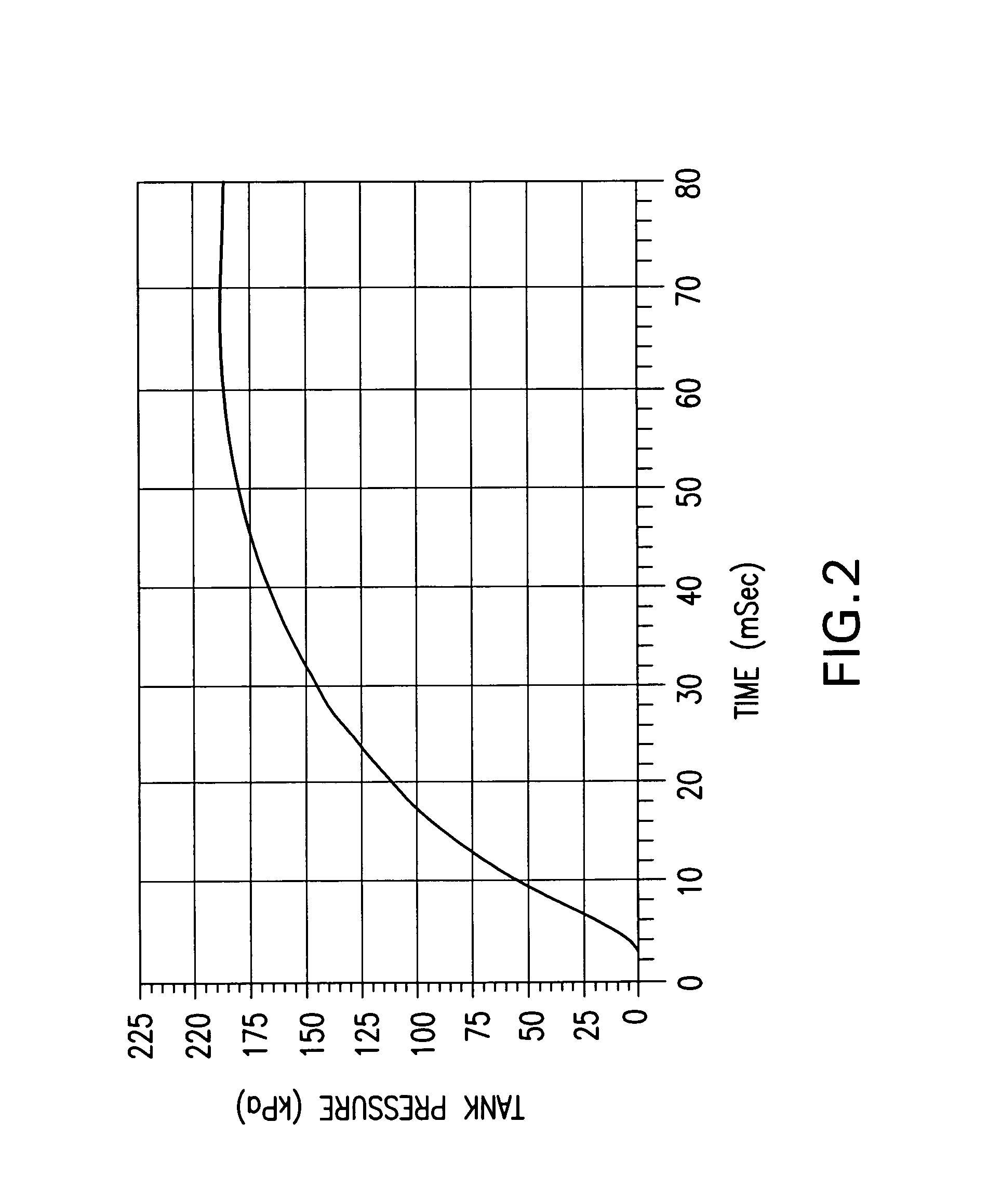

Gas generation with copper complexed imidazole and derivatives

InactiveUS20070240797A1Improve combustion effectImprove flammabilityNon-explosive/non-thermic compositionsPressure gas generationNitrogenBurn rate

A compound including at least one copper II complex of a material selected from the group of imidazole and imidazole derivatives is provided for use in a gas generant composition. An associated burn rate enhanced gas generant composition, in addition to such copper complex-containing compound, also includes a nitrogen-containing non-azide fuel. Additionally provided are methods for improving the combustion performance of a non-azide gas generant composition in at least one aspect selected from the group consisting of ignitability, burn rate and burn rate pressure sensitivity, through the addition of such copper complex-containing compound to the non-azide gas generant composition.

Owner:AUTOLIV ASP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com