Filter paper of air filter for saving fuel and method for manufacturing same

An air filter and filter paper technology, applied in fuel air filter, combustion air/combustion-air treatment, papermaking, etc., can solve the problems of little increase in combustion efficiency, influence of air permeability, long cycle, etc., and achieve reduction Effect of carbon monoxide generation, increase of oil and gas contact area, and reduction of harmful emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 100g of functional tourmaline solid powder (particle size D50<0.5μm, D90<1.0μm) emitting far infrared and releasing negative ions, 2000g of polyacrylate emulsion (solid content 45%, equivalent to 900g of dry resin, average particle size 0.149 μm, D90<0.177μm), 4500g of water, stir and mix evenly to obtain the sizing agent slurry required for coating.

[0037] And preheat it to 60°C, and then apply the above-mentioned coating sizing agent slurry to a quantitative rate of 110g / m 2 both sides of the filter paper.

[0038] After drying the above-mentioned filter paper coated with functional solid powder capable of emitting far-infrared and releasing negative ions in a segmented electric blast drying oven with a temperature distribution between 100 and 145°C for 5 minutes, the filter paper with the ability to emit far-infrared and release Functional filter paper for motor vehicle engines with negative ions.

[0039] The above-mentioned sizing of the motor vehicle engine ai...

Embodiment 2-6

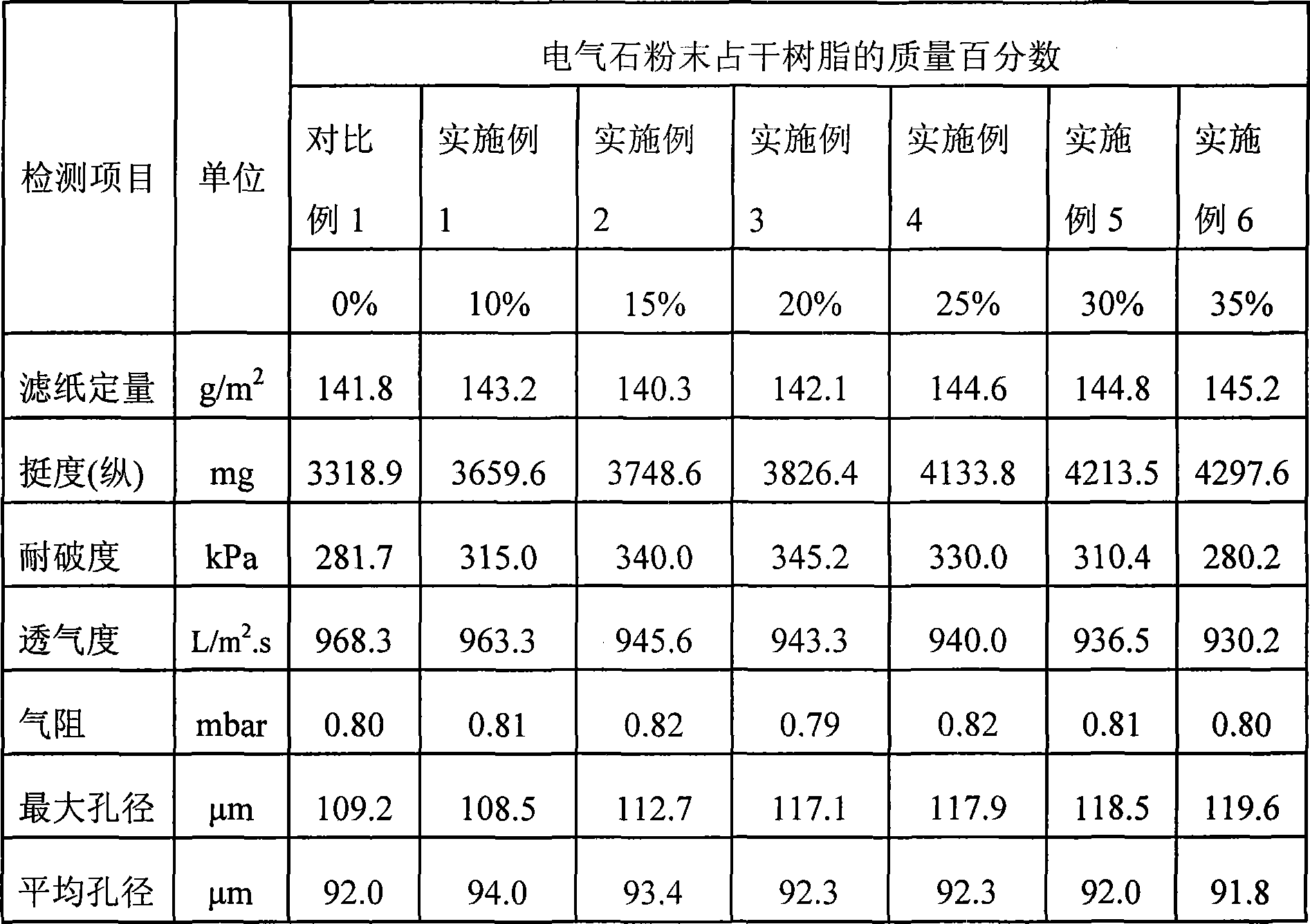

[0041] According to the same method and steps of Example 1, the difference is that the amount of tourmaline powder is different from that of Example 1, and the amount of tourmaline powder and the properties of the resulting filter paper are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com