Patents

Literature

153 results about "Fuel conservation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

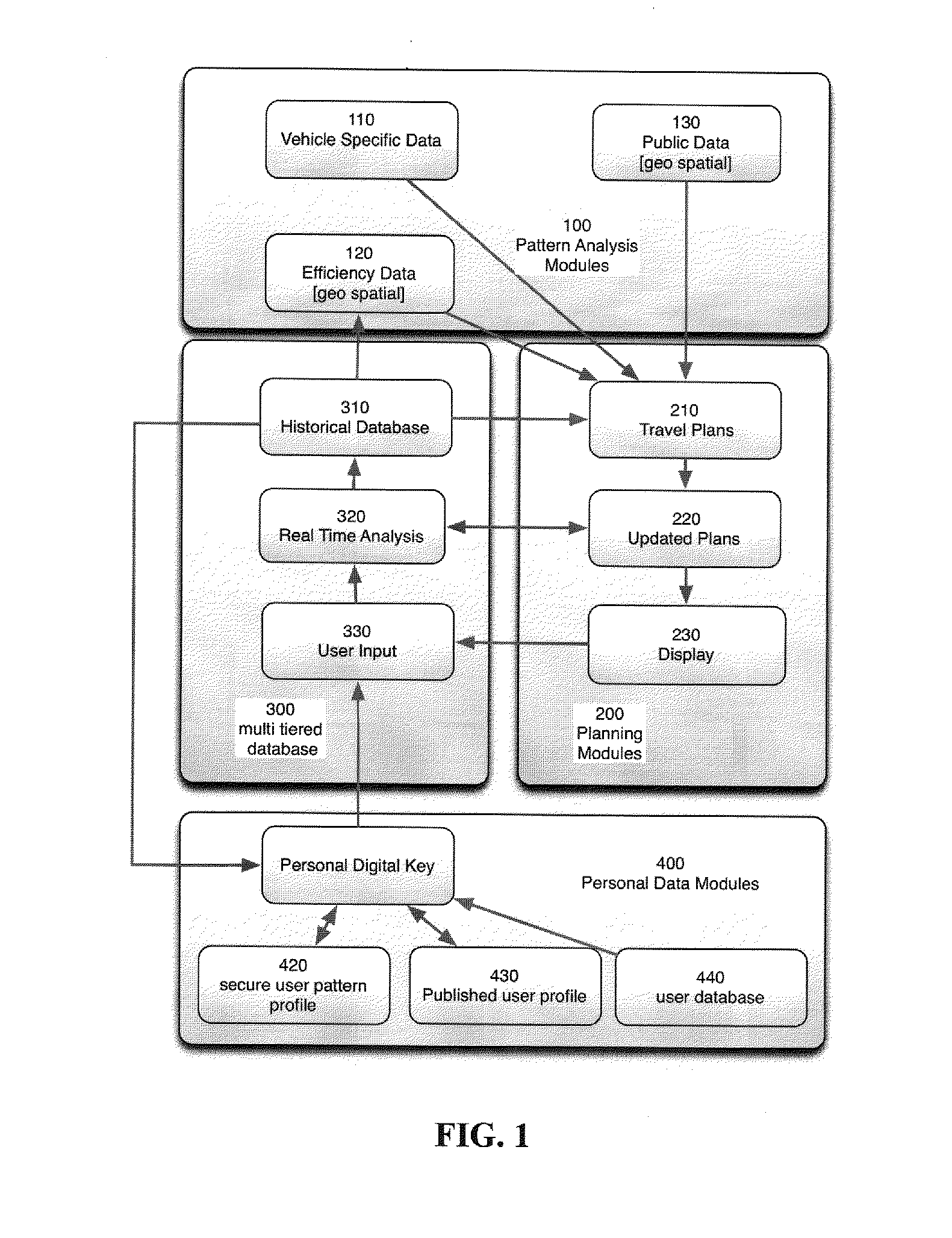

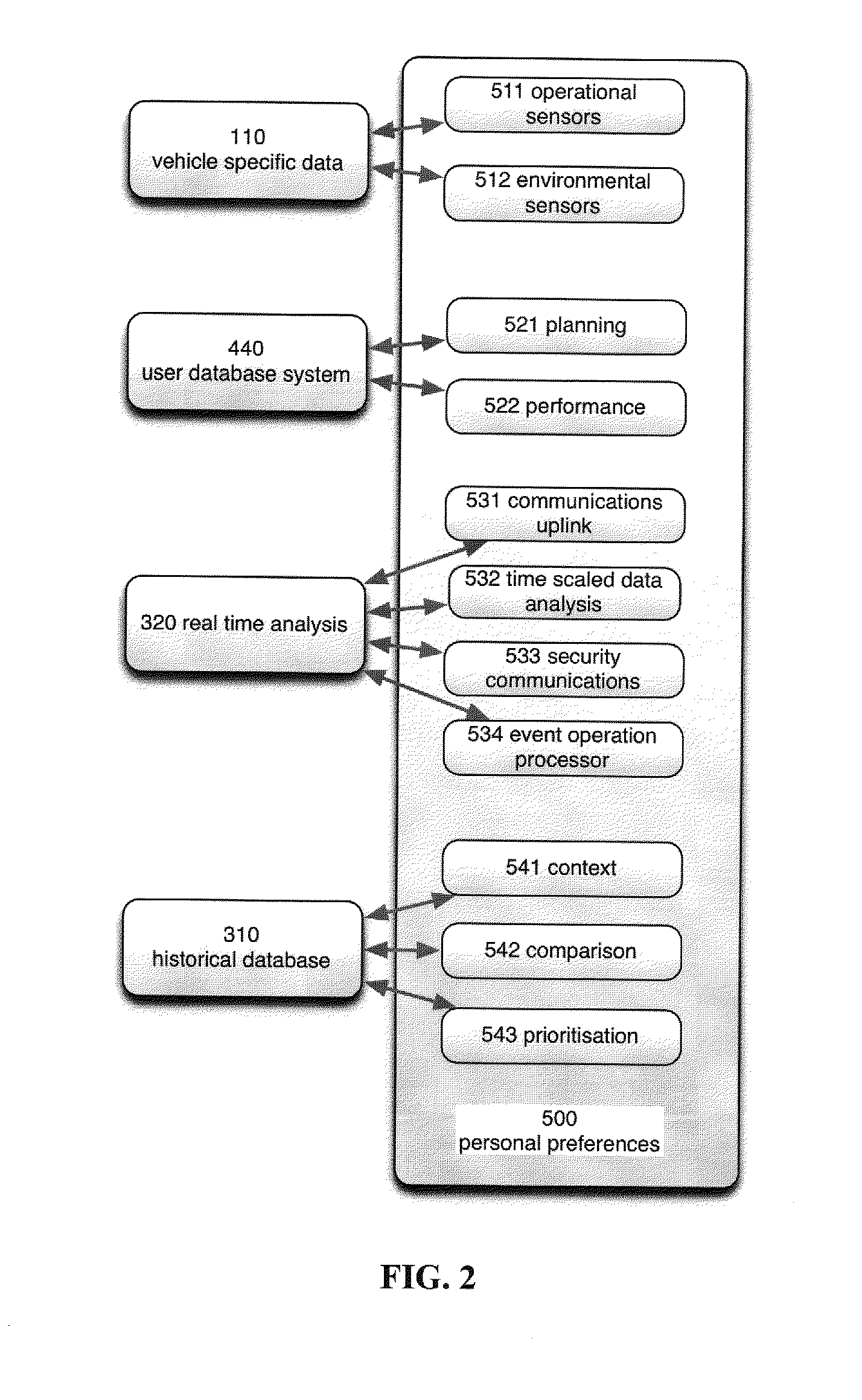

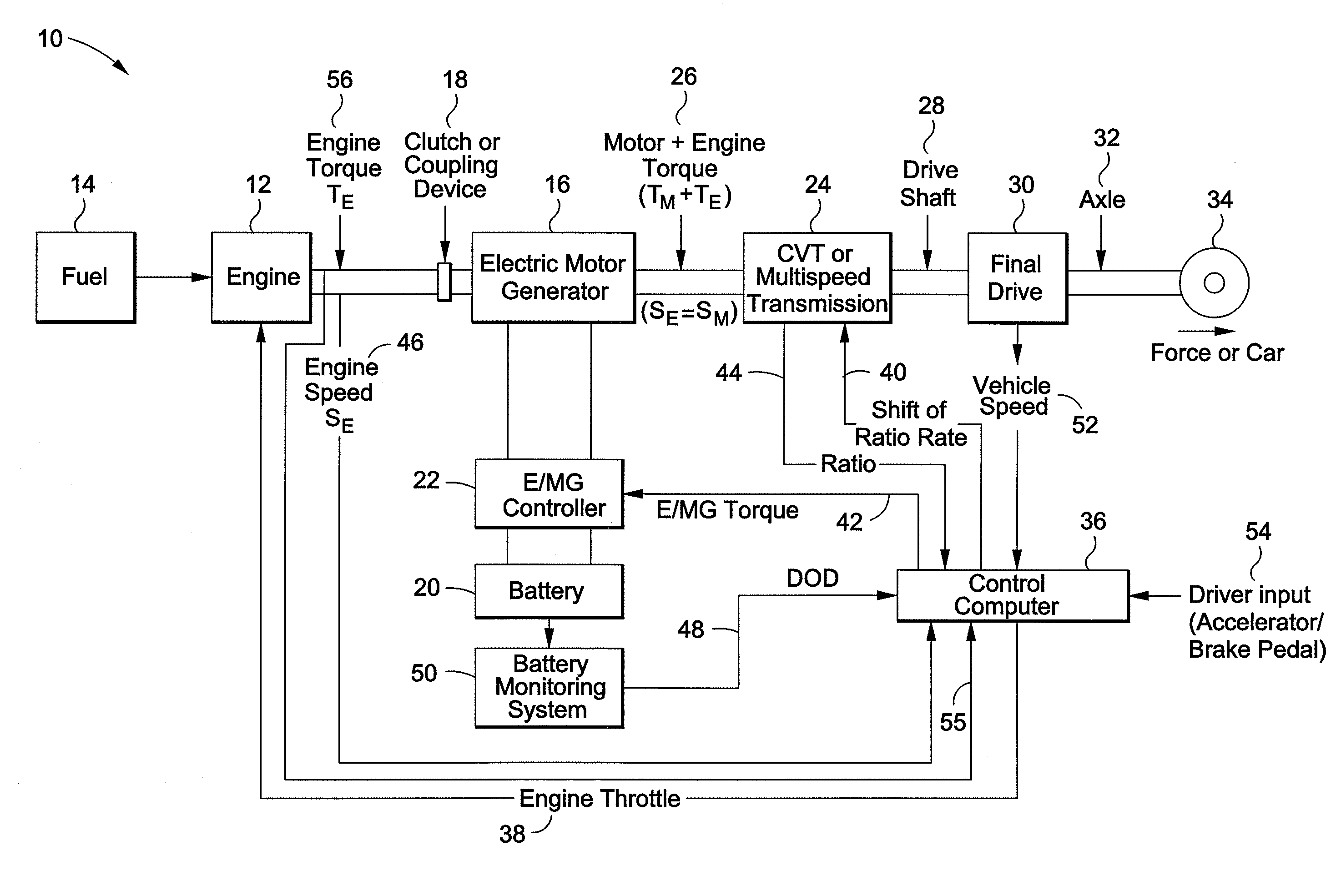

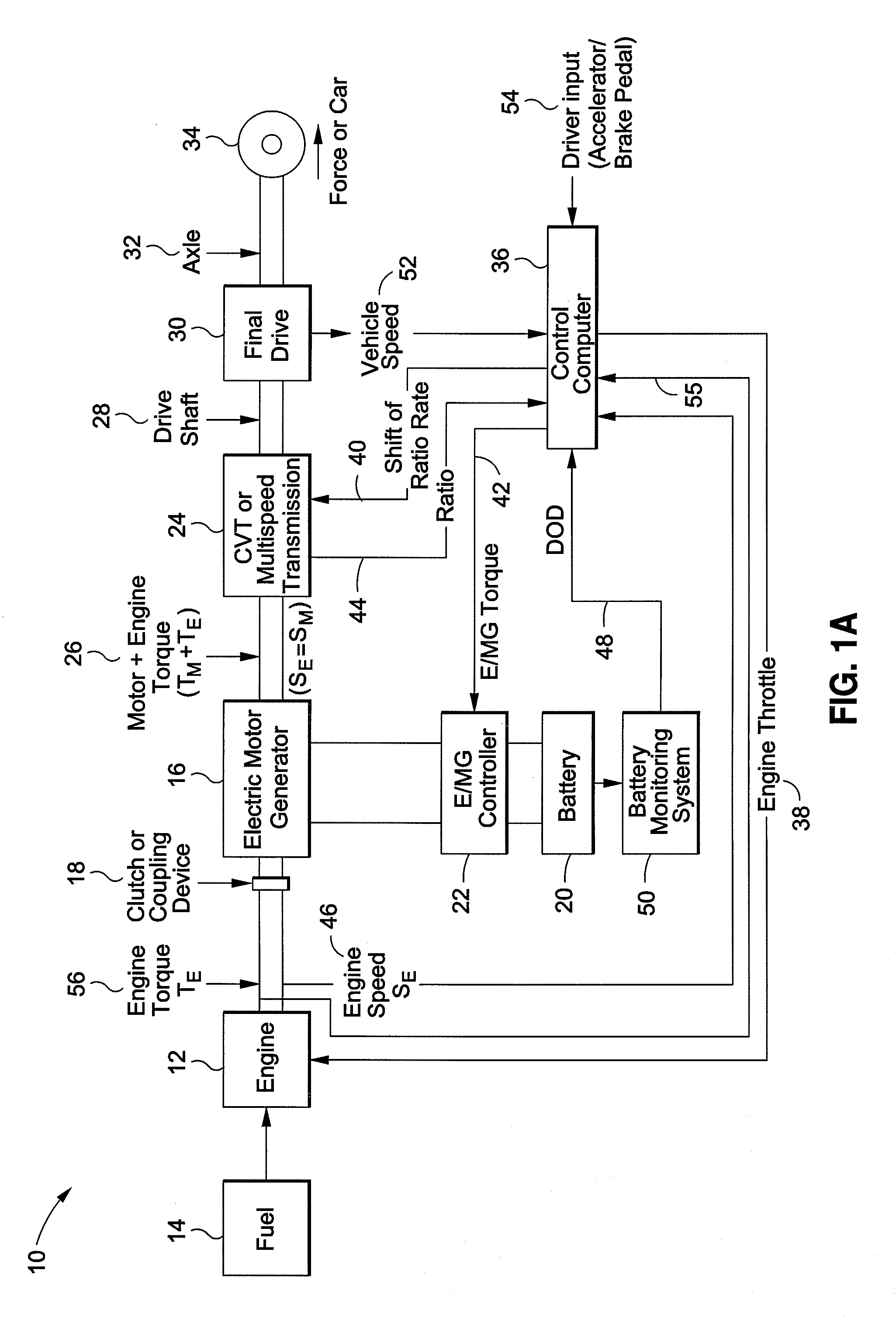

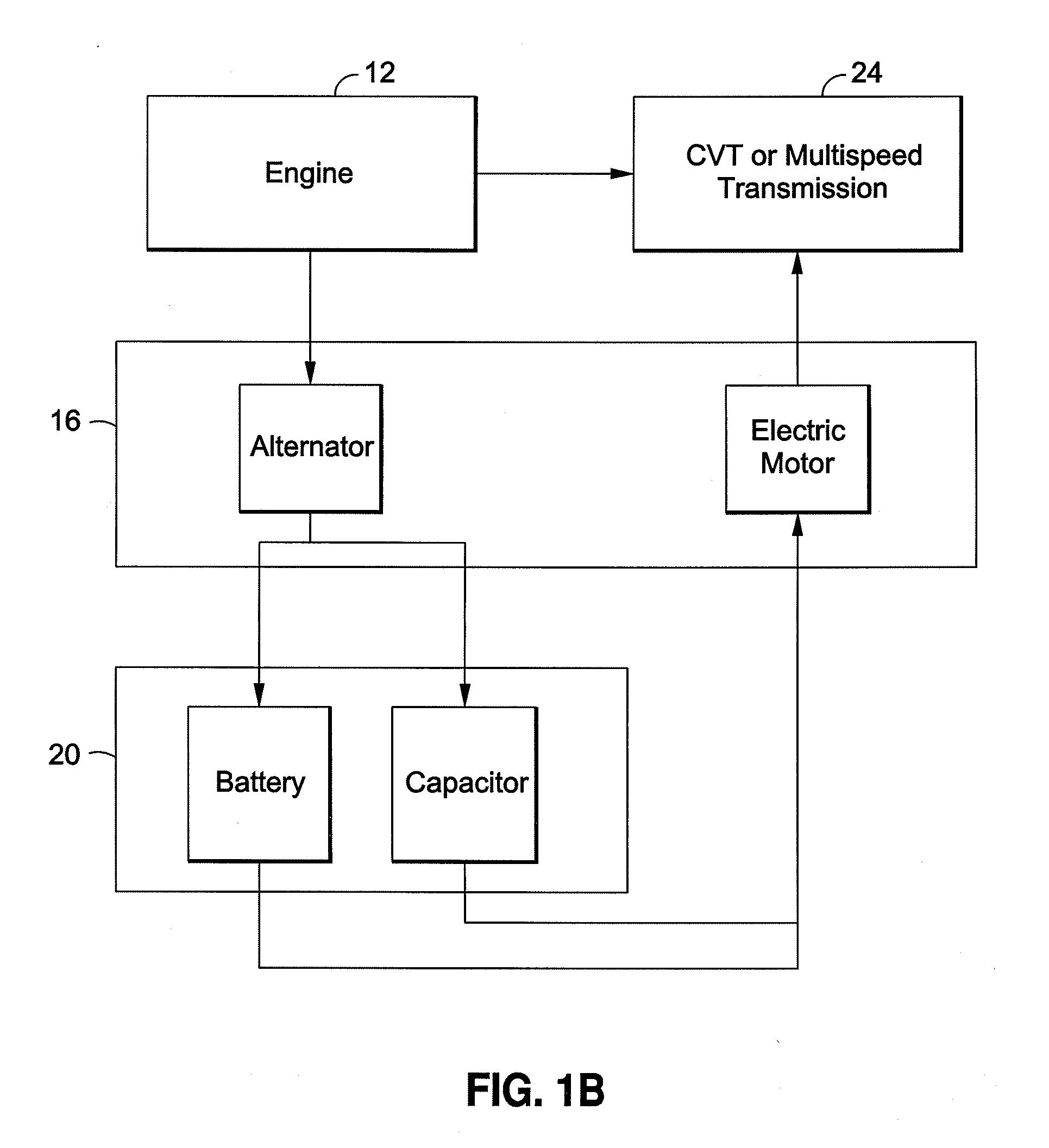

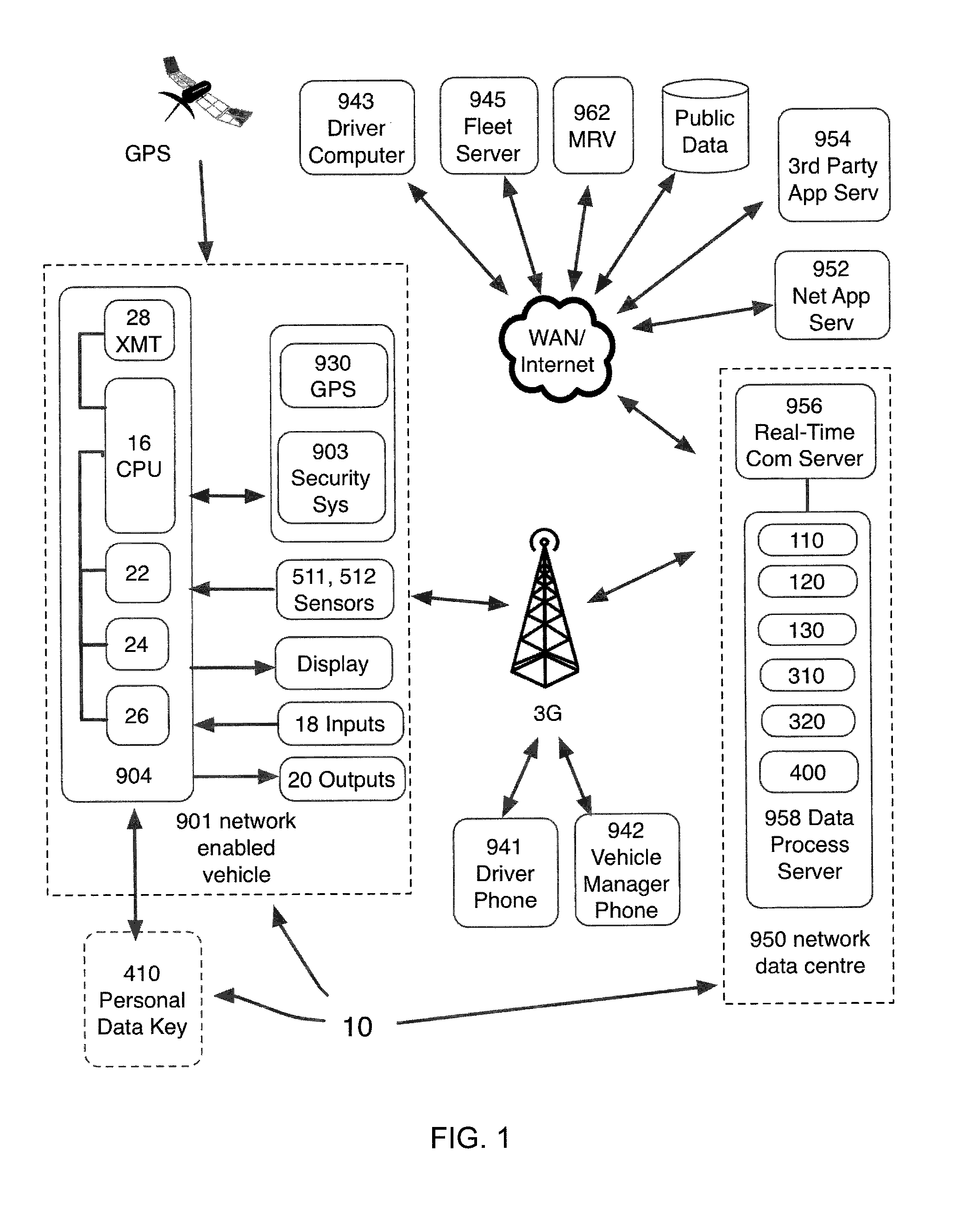

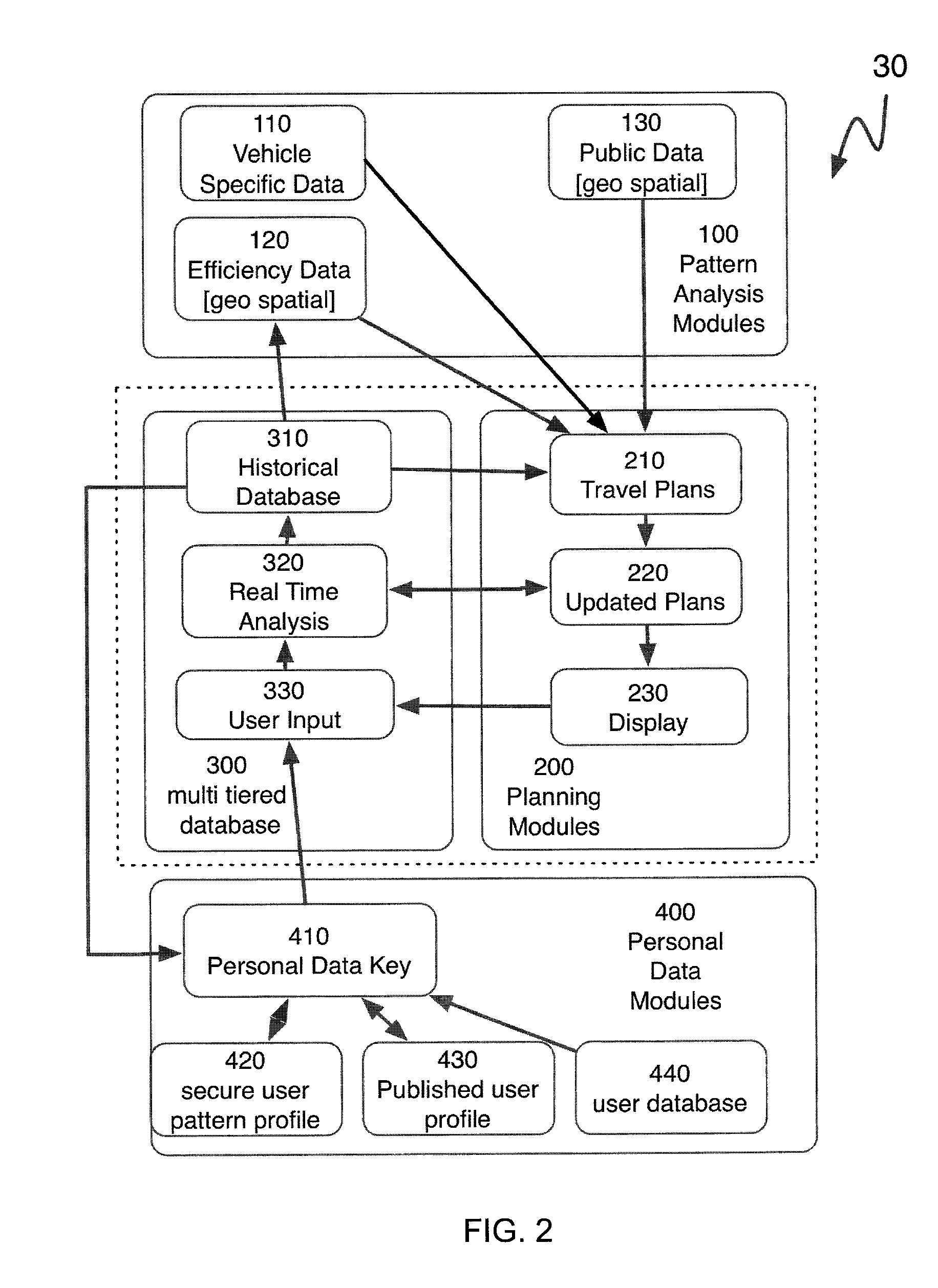

Vehicle communication, analysis and operation system

InactiveUS20130024060A1Instruments for road network navigationDigital data processing detailsFuel conservationOperational system

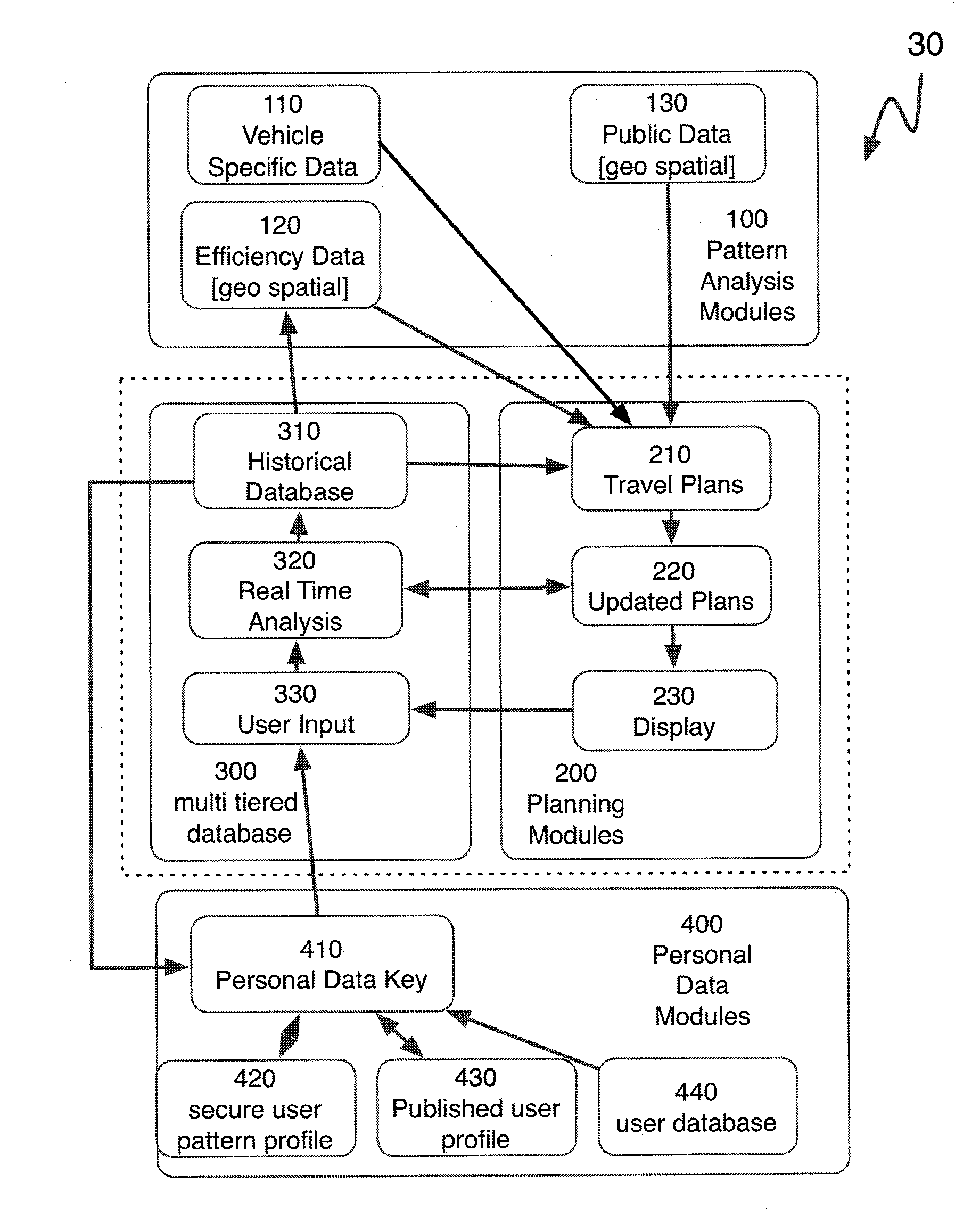

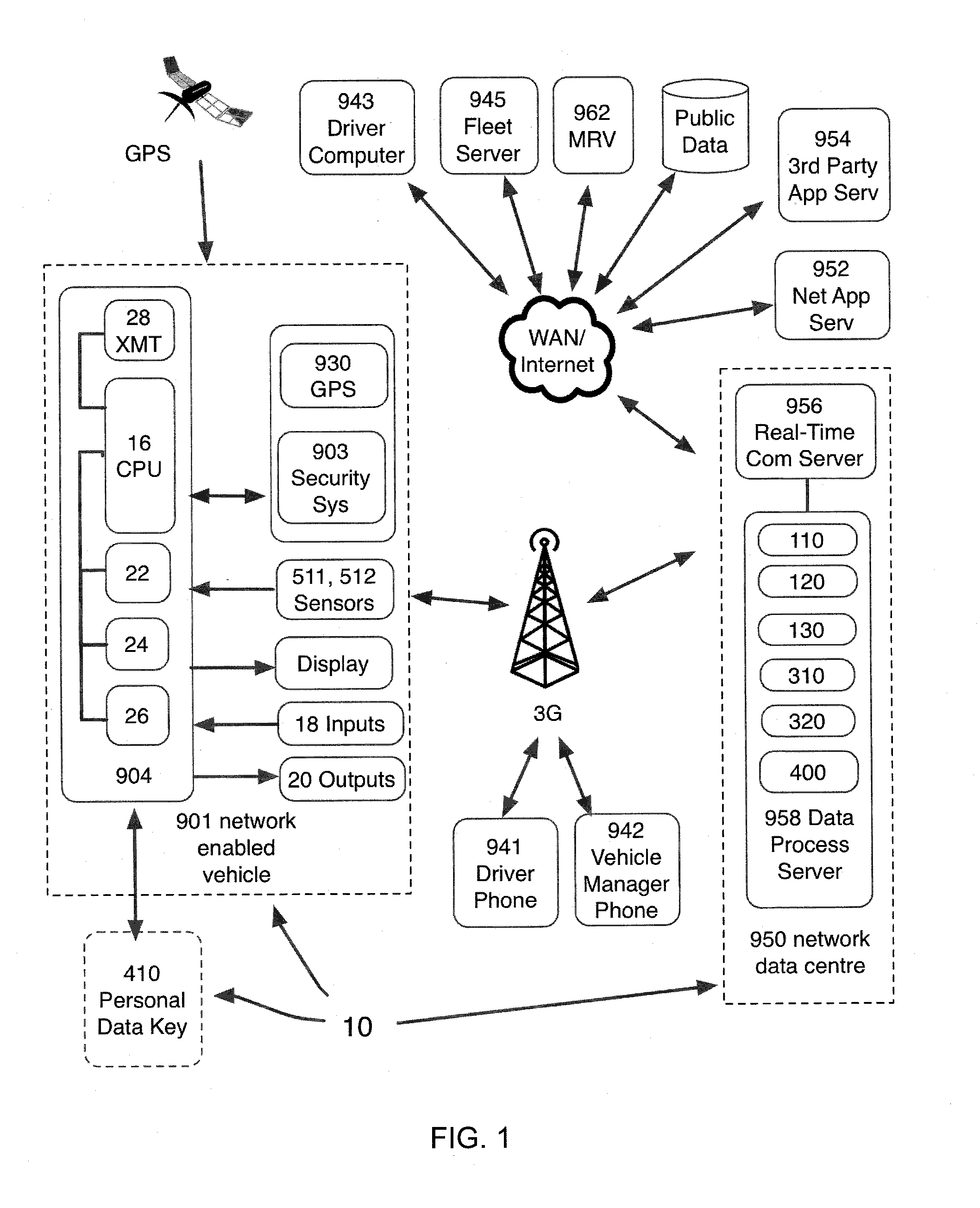

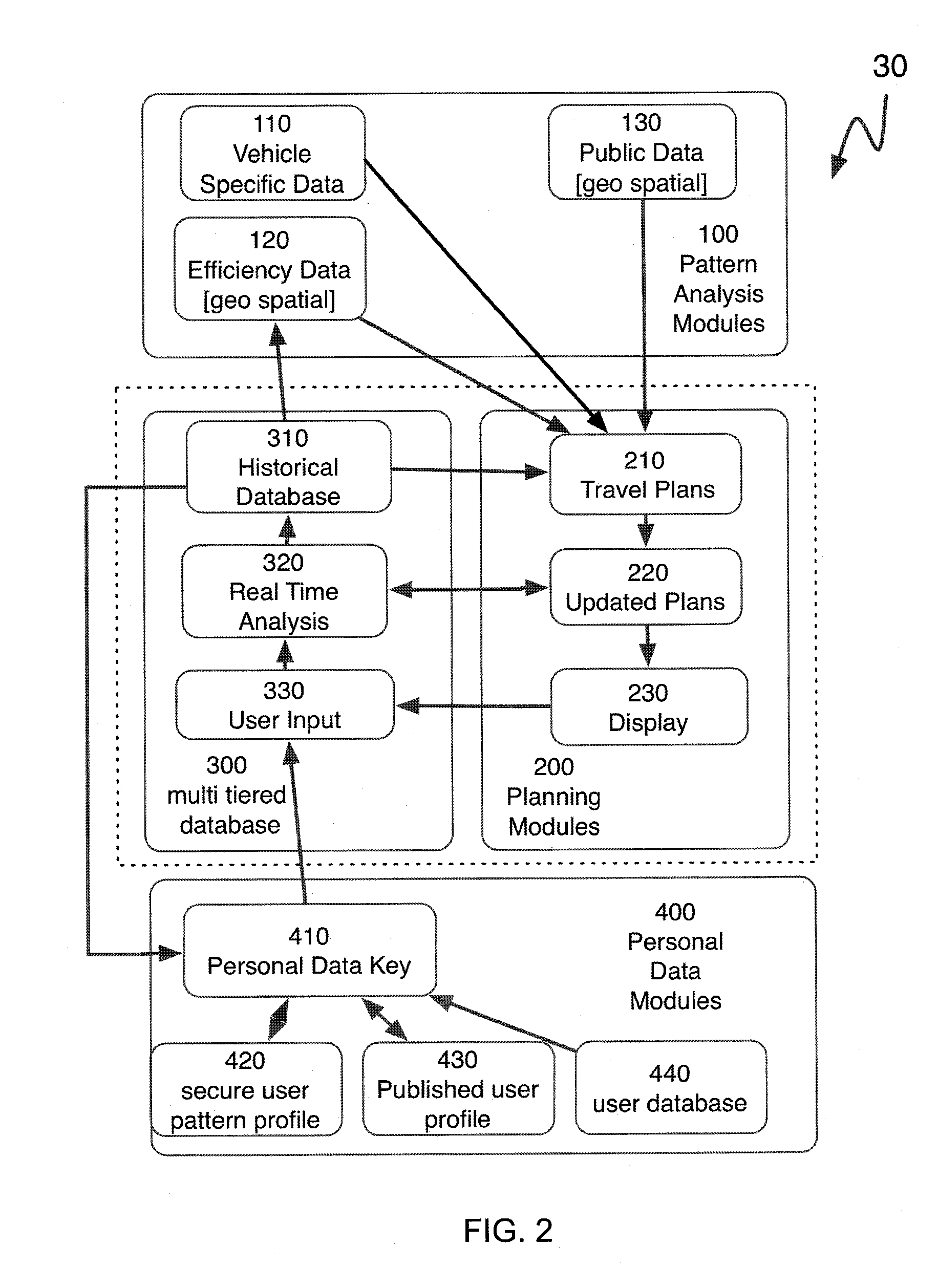

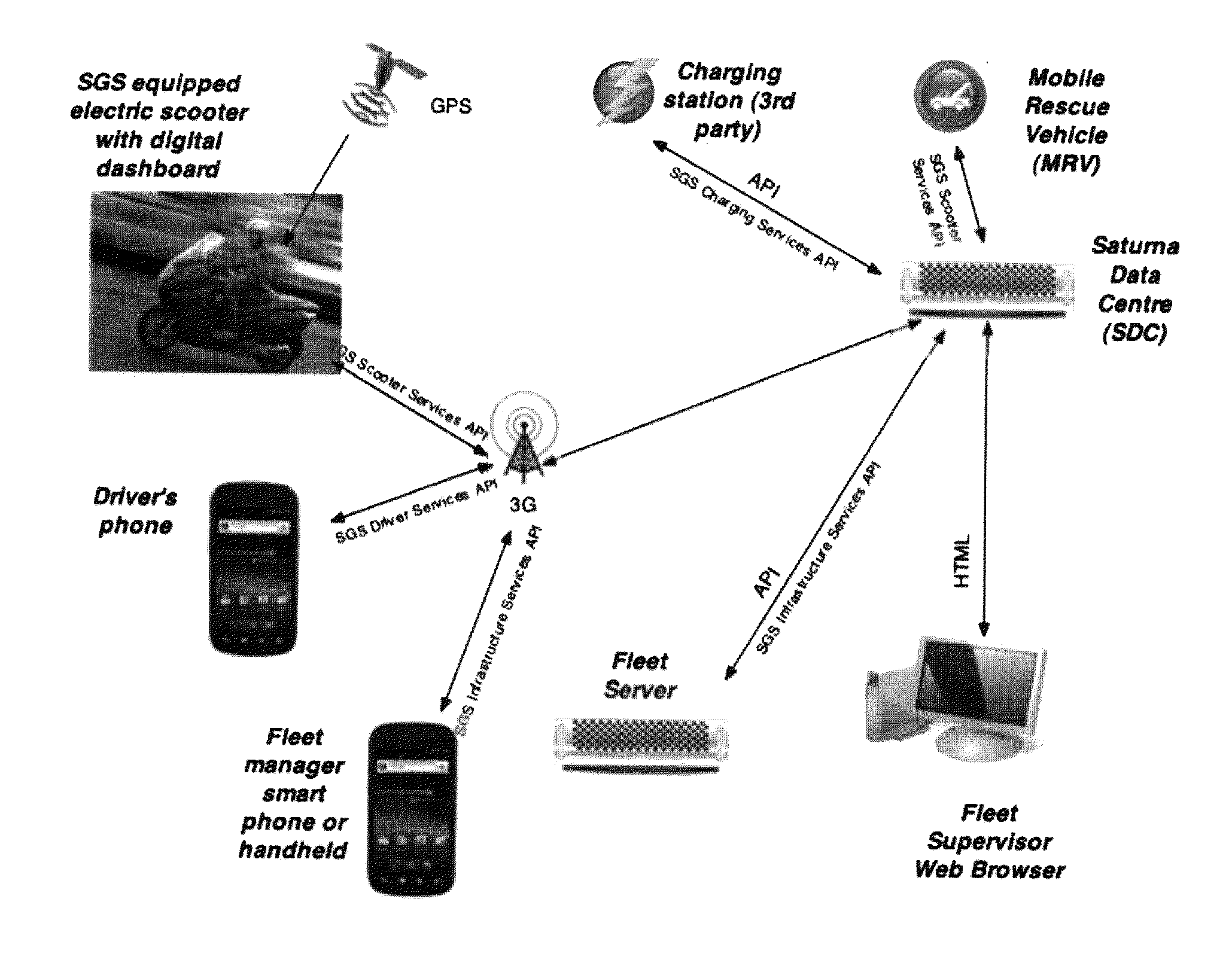

A communication and analysis system can manage data operations with a vehicle centric system. A vehicle that is in a communications link with a network can also manage its activities based on real-time, historical and predictive knowledge, without having this knowledge processing on-board. Such data processing includes the geo-spatial, internal functions and operator specific requirements. The rule based system also incorporates the use patterns of a specific vehicle, or a specific user. A use pattern can be transferred from one operator to another or be shared to assist with navigation and operations. A vehicle operator or vehicle multiple operators can share or upload information that can assist with efficient operations, including fuel conservation and time management. Use patterns can be assigned to geospatial regions and be used for comparative analysis for such activities as efficient operation, safe travel and navigation.

Owner:SATURNA GREEN SYST

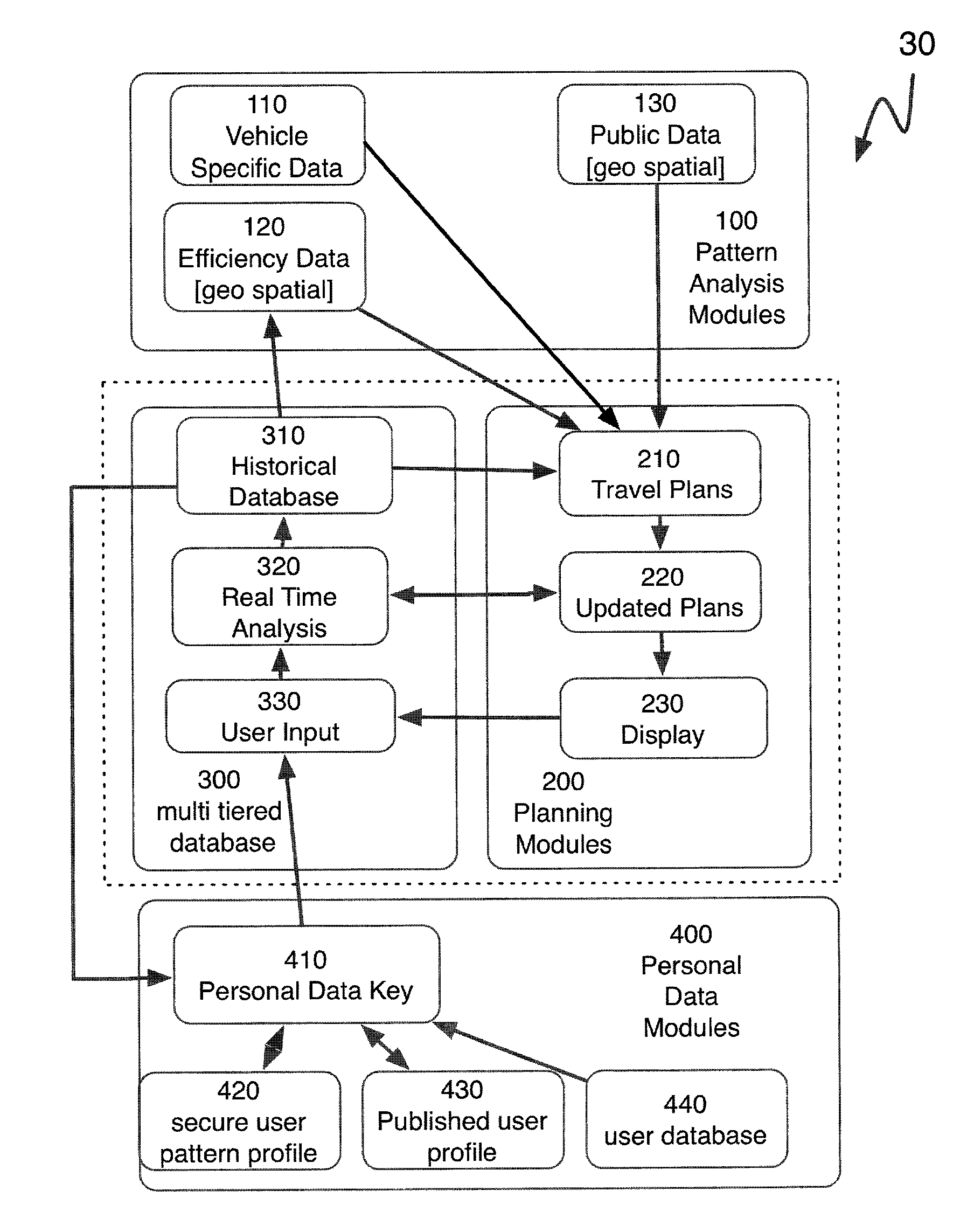

Vehicle communication, analysis and operation system

InactiveUS20130079964A1Minimizes computation loadLoad minimizationDigital data processing detailsNavigation instrumentsFuel conservationOperational system

The present invention provides a communication and analysis system that can manage data operations with a vehicle centric system with a planned route path. A vehicle that is in a communications link with a network can also manage its activities based on real time, historical and predictive knowledge, without having this all knowledge processing on board. Such data processing would include a cluster analysis of geo-spatial, internal functions and operator specific requirements. The rule based system would also incorporate the use patterns of a specific vehicle, or a specific user. A vehicle operator or vehicle multiple operators could share or upload information that would assist with efficient data processing and display, including fuel conservation and time management. Cluster weighting patterns can be assigned based on activities as efficient operation, safe travel and navigation.

Owner:SATURNA GREEN SYST

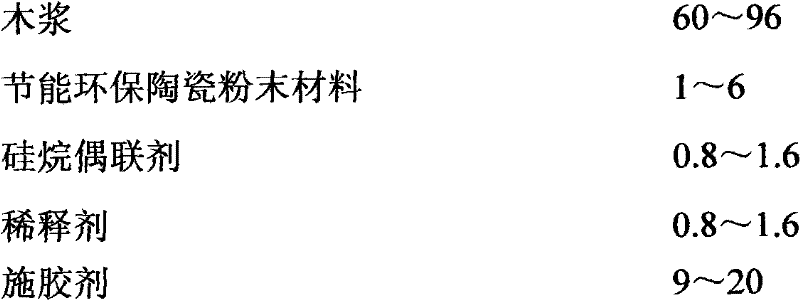

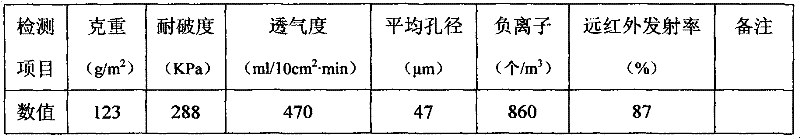

Filter paper of energy-saving and environment-friendly filter and making method thereof

ActiveCN102199903AHigh filtration precisionHigh burst resistanceInorganic fibres/flakesFiltration separationAir filterFuel filter

The invention relates to filter paper of an energy-saving and environment-friendly filter and a making method thereof. The filter paper is made from an energy-saving and environment-friendly ceramic powder material, a silane coupling agent, a dilute, a sizing agent and wood pulp. The filter paper can be made into an air filter and a fuel filter so as to improve the power performance by 6-12%, save the fuel by 2-5% and reduce pollutants in discharged tail gas by 16-47%.

Owner:北京联飞翔科技股份有限公司

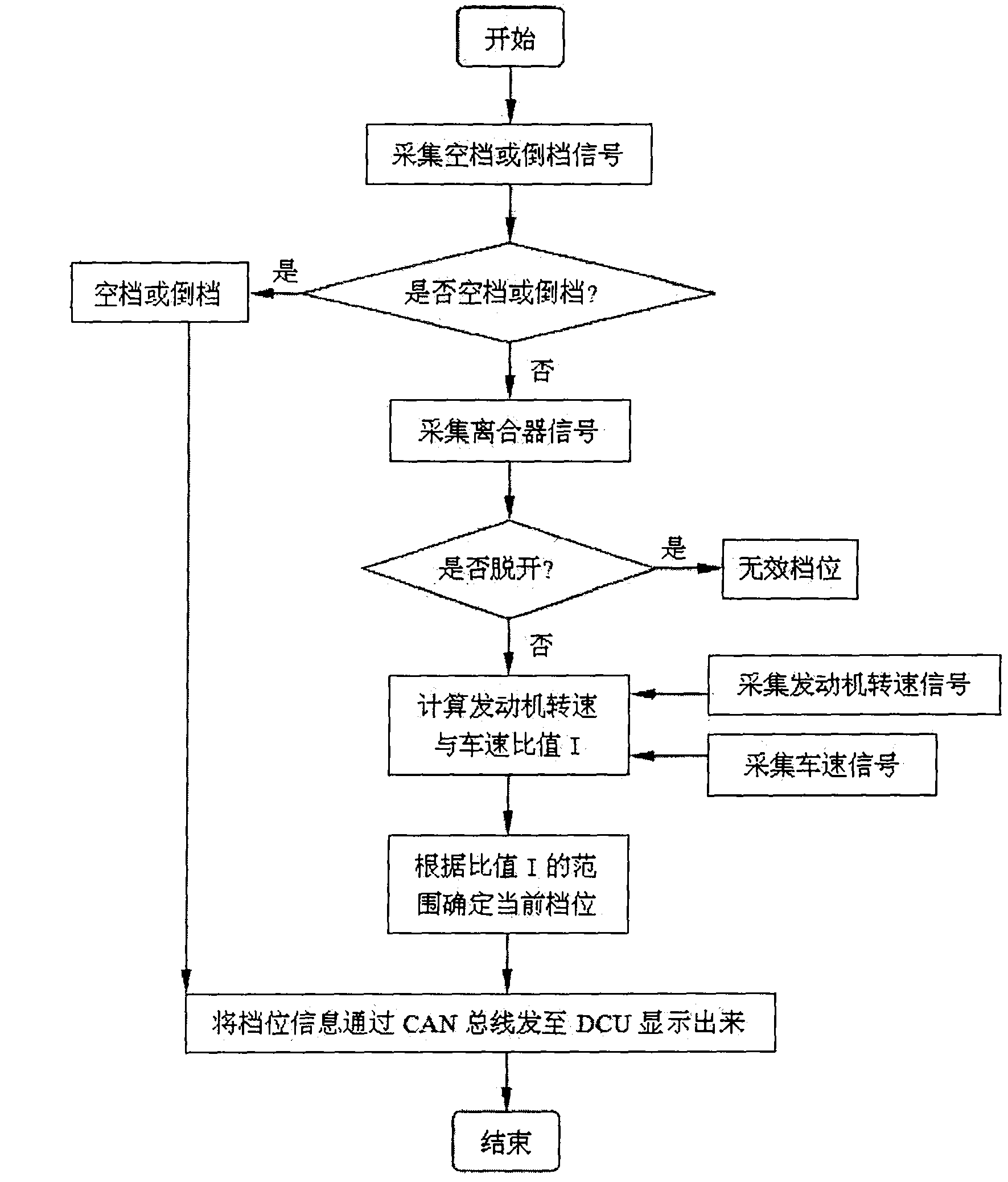

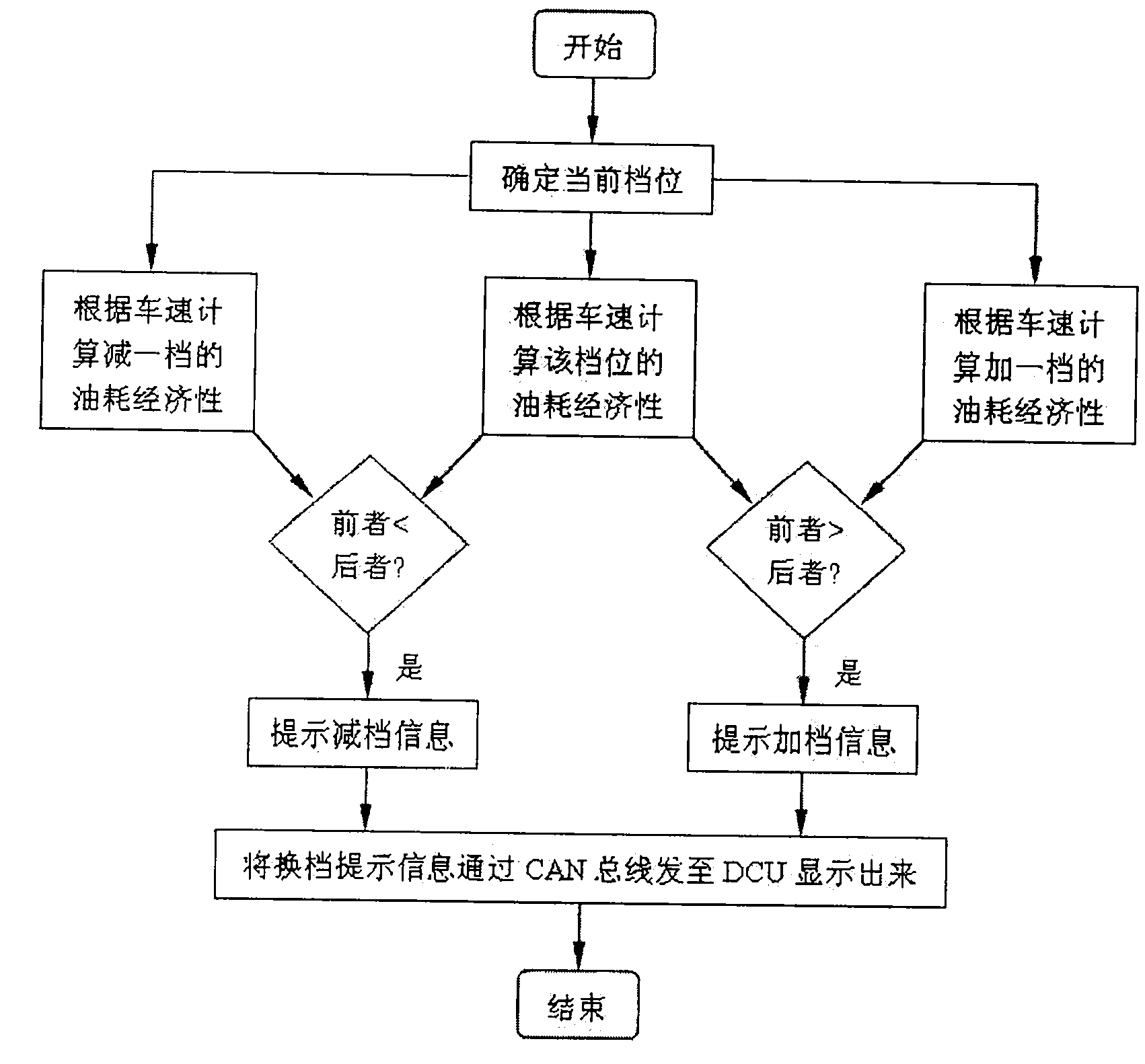

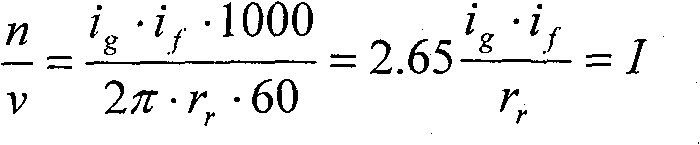

Method for gear information display and gear shift prompt of hybrid electric vehicle

ActiveCN101870279ATimely replacementLearn about healthElectric/fluid circuitFuel conservationElectric vehicle

The invention provides a method for gear information display and gear shift prompt of a hybrid electric vehicle. The gear information can be obtained through calculation according to the proportional relation of the vehicle speed and the engine speed when no gear sensor is used, and can then be displayed, and the gear shift prompt information can be obtained through calculation of upward or downward gear shifting based on fuel conservation when the vehicle is running within a certain speed range, and can then be displayed. Therefore, the invention can help the driver to learn about the running of the vehicle so that the driver can promptly shift the gear, thereby improving the economical efficiency of the fuel.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Fuel conservation systems and methods

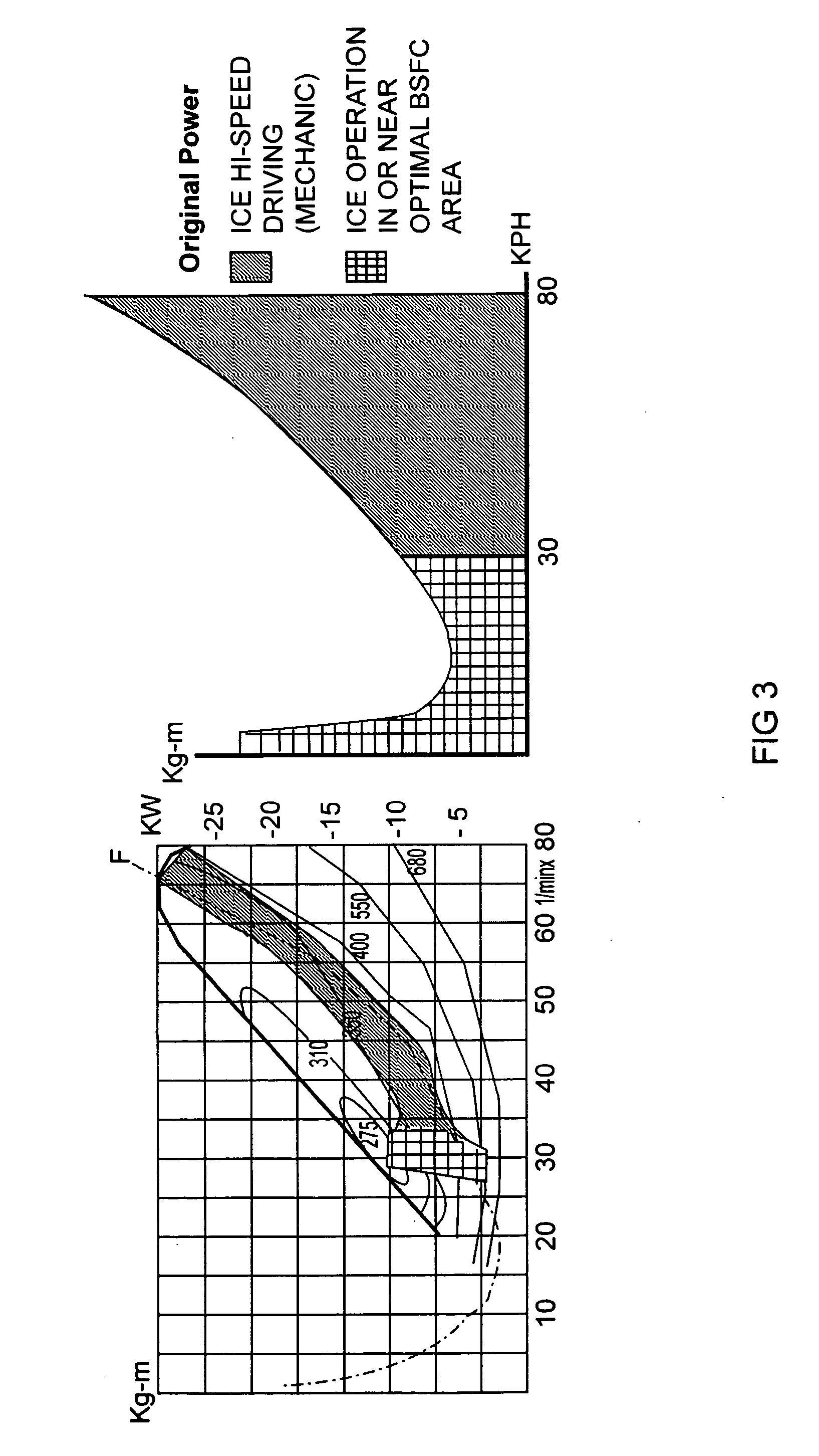

ActiveUS20100004843A1Dampen and cut fuel deliveryGreat amount of output powerAnalogue computers for vehiclesElectrical controlFuel conservationAutomotive engineering

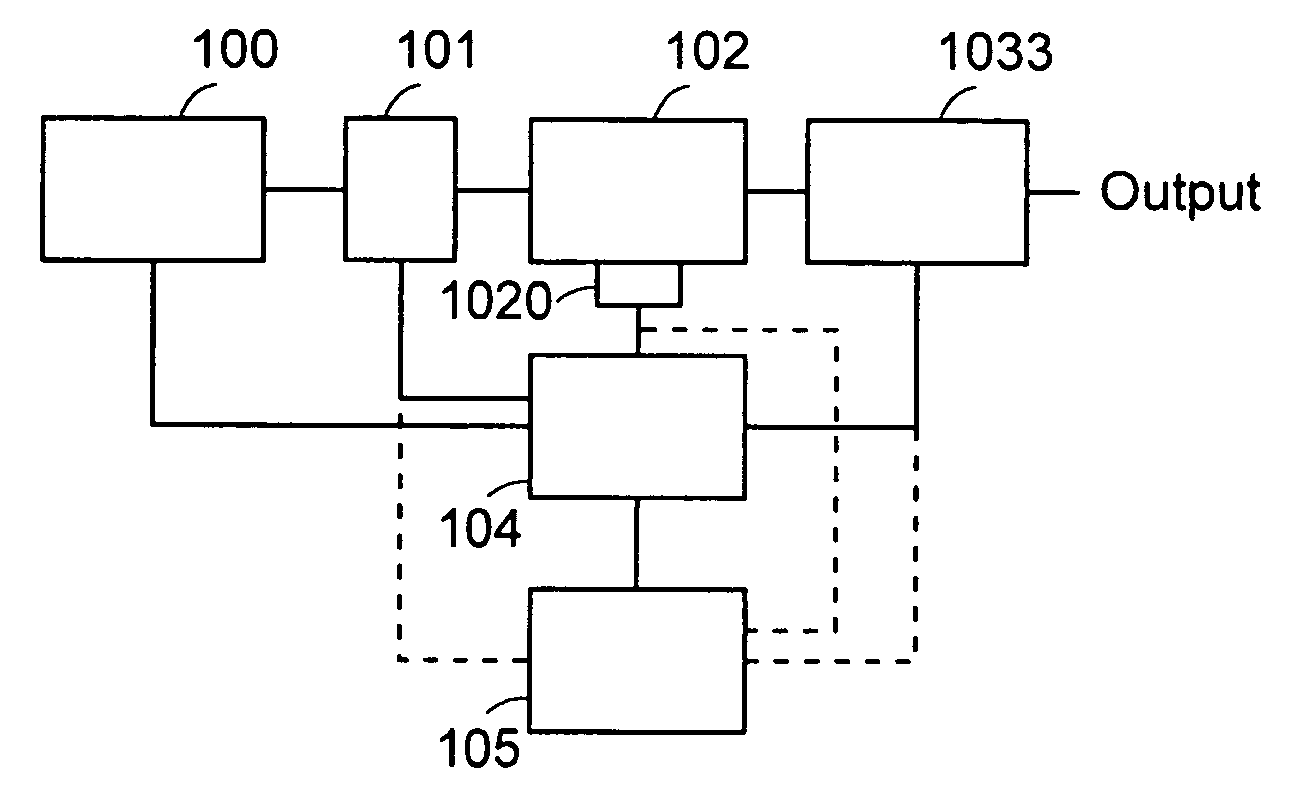

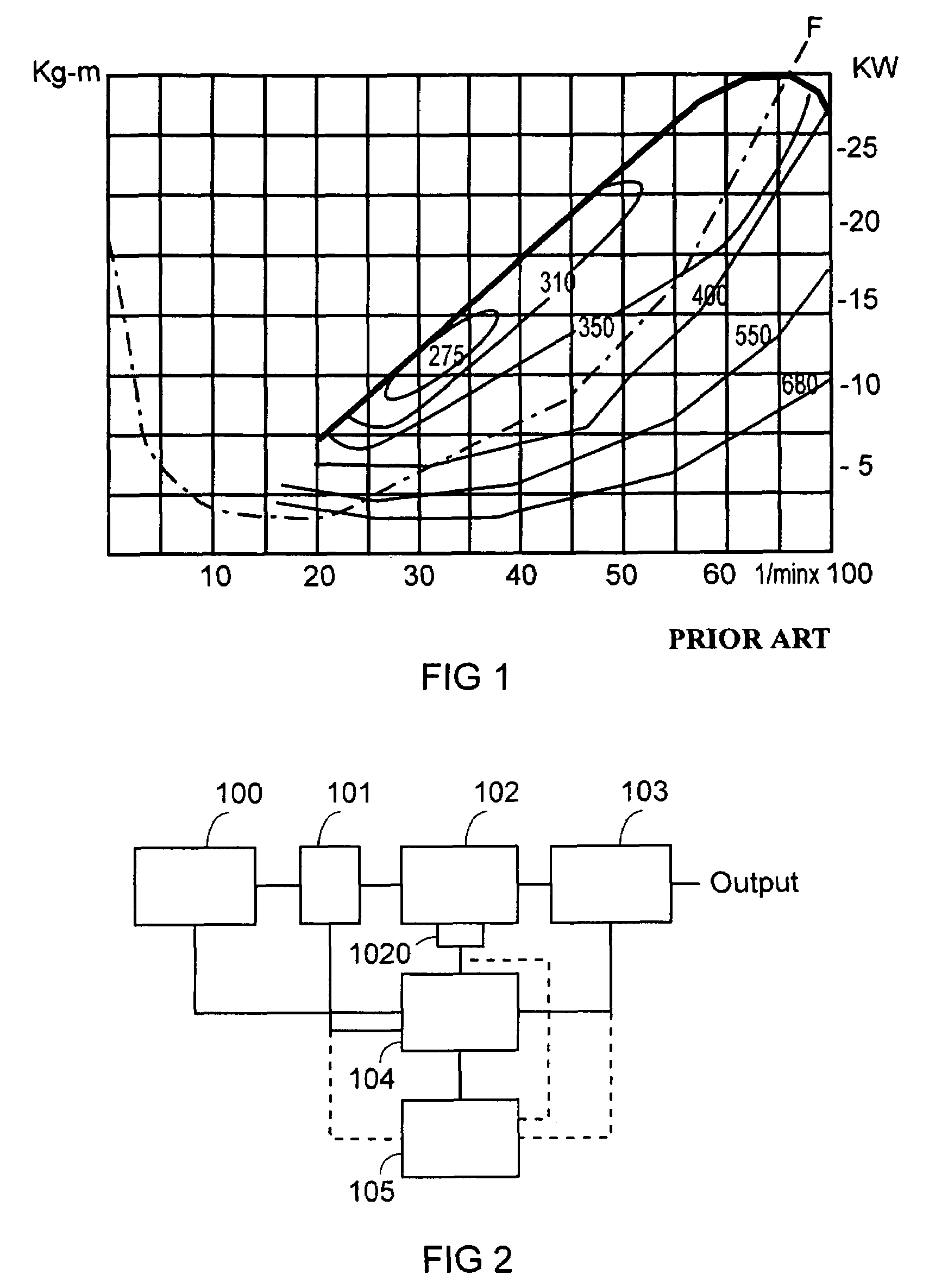

Methods and systems are described for conserving fuel used by an engine. In some embodiments a control module processes a user-provided input, as a first function, into a second function. The second function can be used to direct the engine with a directive output power. The directive output power may have regions equal to, greater than, and / or less than what the power output would be if the engine were controlled using the user-provided input.

Owner:FUEL SAVING TECH

Vehicle communication, analysis and operation system

InactiveUS9014888B2Instruments for road network navigationDigital data processing detailsFuel conservationOperational system

Owner:SATURNA GREEN SYST

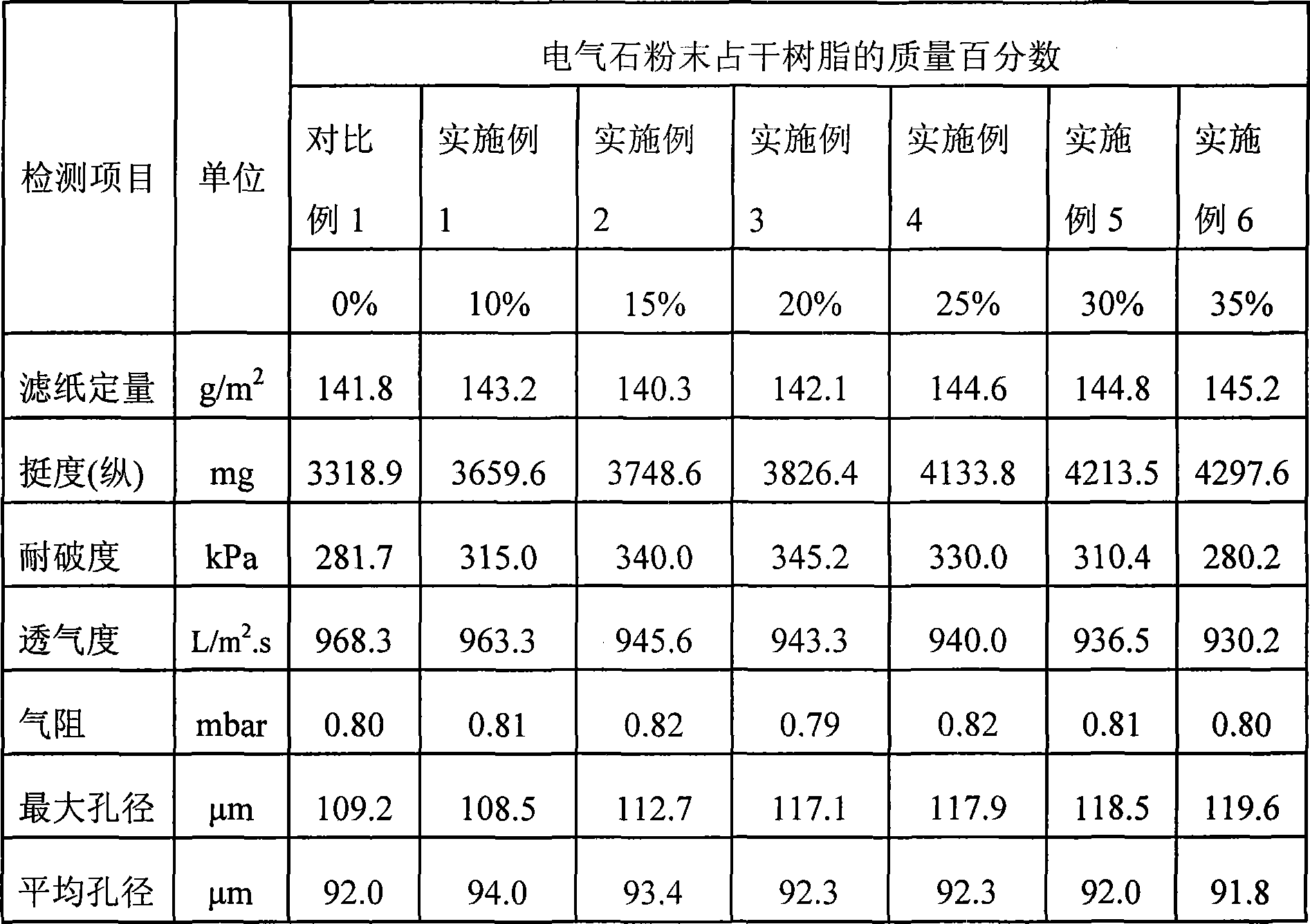

Filter paper of air filter for saving fuel and method for manufacturing same

ActiveCN101392703AReduce resistanceEasy to useWater-repelling agents additionMachines/enginesWater basedFuel conservation

The invention provides filter paper of an air filter of fuel conservation and a manufacture method thereof. The filter paper consists of base paper and a sizing agent which is coated on a single side or double sides of the base paper gram weight of between 110 and 160 gram / meter<2>, and water-base resin (butt) is 5 to 30 percent of mass of the base paper. The sizing agent comprises the following components in weight percentage: 2 to 20 percent of the water-base resin (butt), 1 to 20 percent of powder functional material, and 60 to 80 percent of water. The powder functional material is more than one of tourmaline ore powder with far infrared emitting property and releasing anion property, molten mass powder of rare-earth zirconium oxide and alumina, molten mass powder of rare-earth zirconium oxide, titanium oxide or rare-earth zirconium oxide, zinc oxide and the like. With the filter paper, fuel can be saved by 3 to 10 percent, but power of the engine is increased by 5 to 20 percent; noise of the engine is reduced by over 10 decibels, and exhaust emission pollutants are reduced by over 10 to 30 percent.

Owner:湖北国鼎华明纳米新材料有限公司

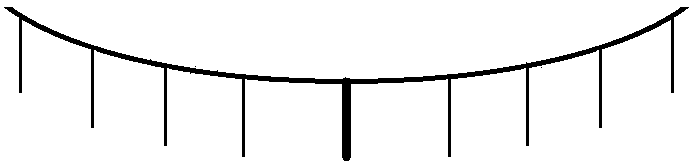

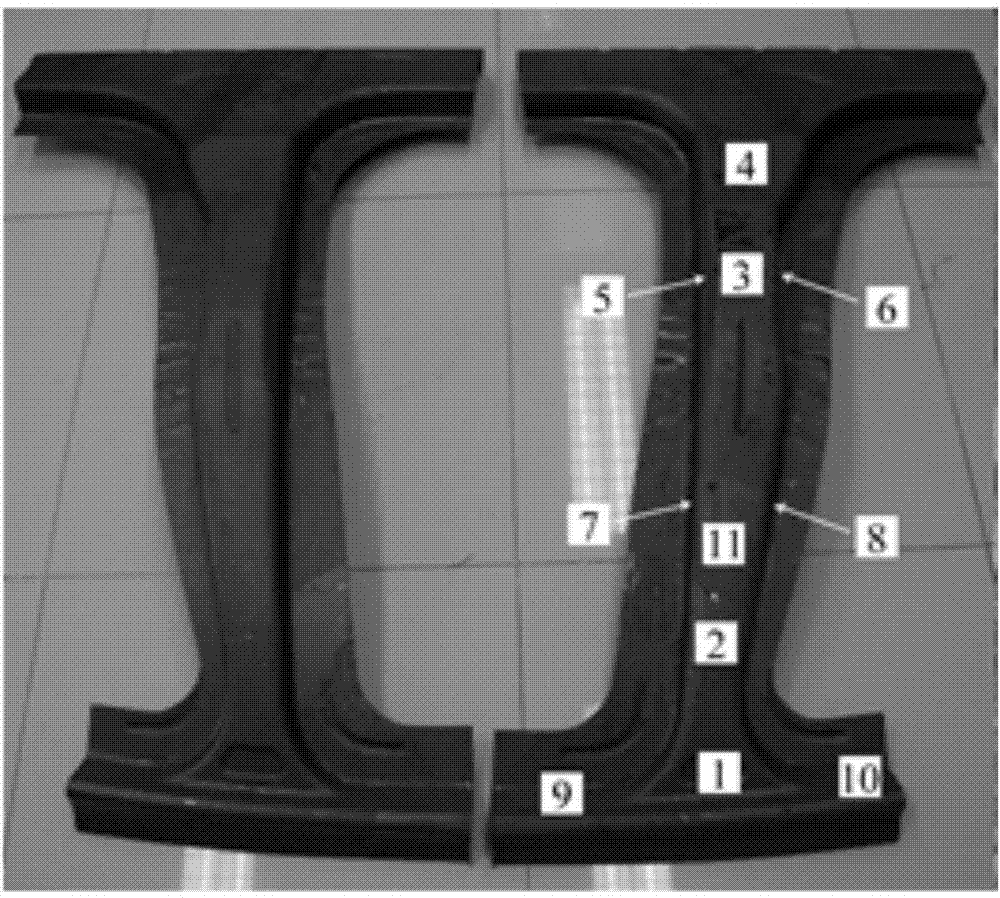

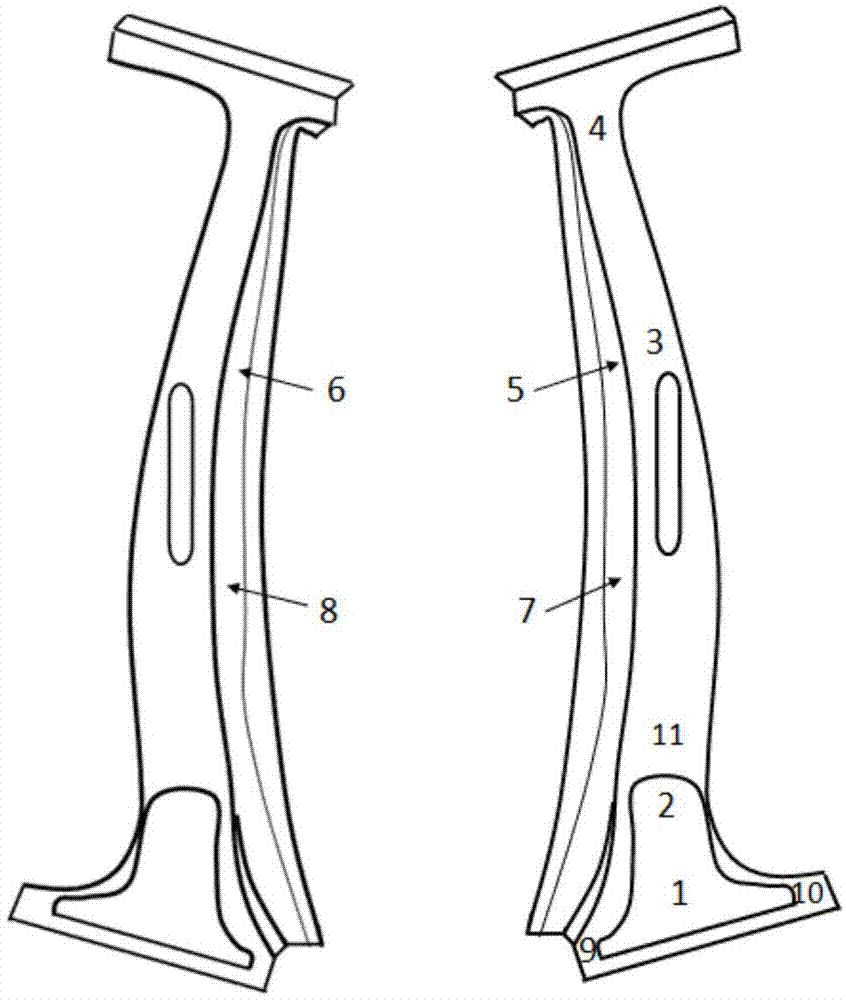

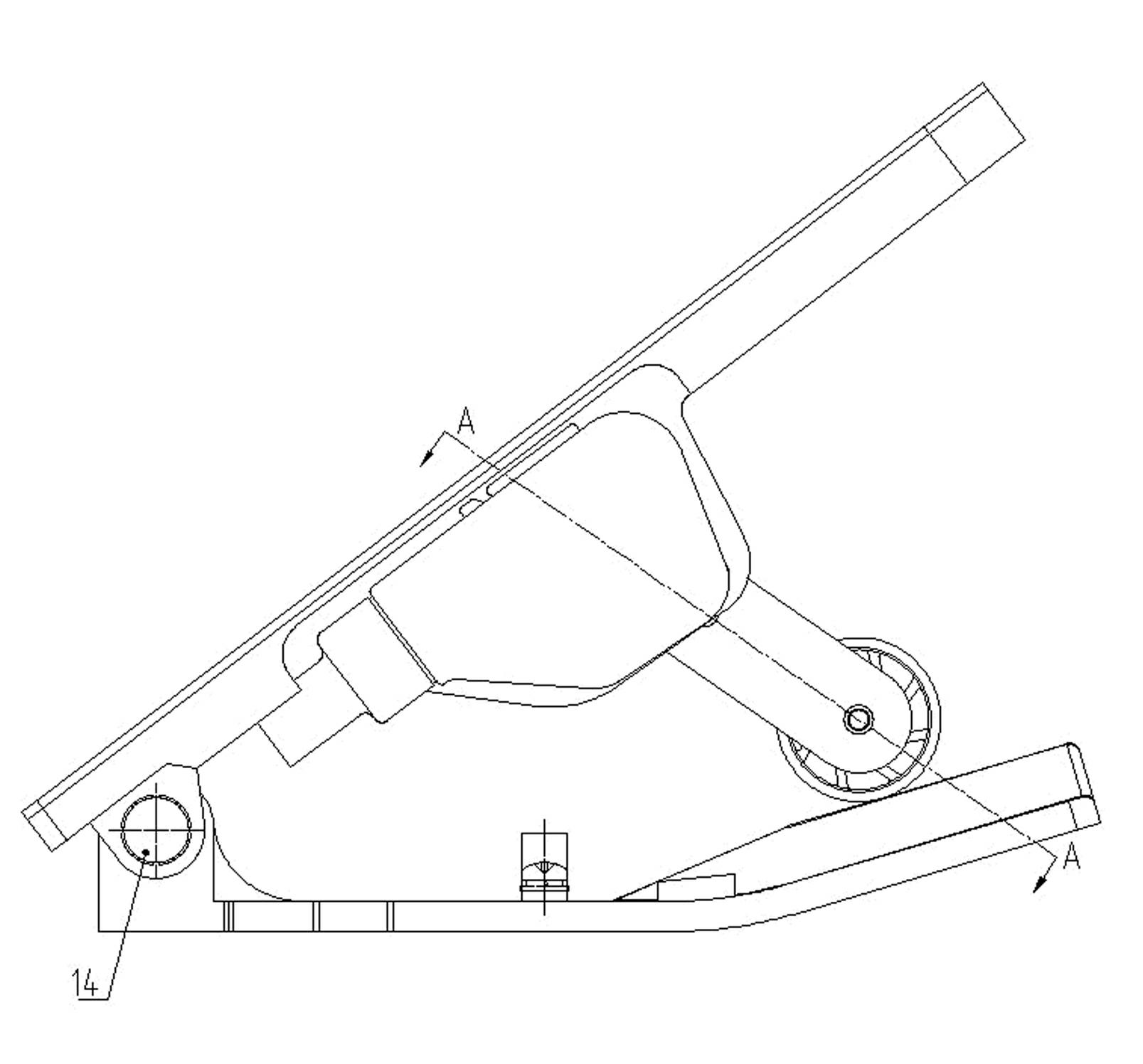

Manufacturing method of light aerofoil with super-high aspect ratio and high lift-drag ratio and aerofoil manufactured thereby

The invention discloses a manufacturing method of a light aerofoil with super-high aspect ratio and high lift-drag ratio and an aerofoil manufactured thereby. At present, some used optimized design methods for improving the strength and the rigidity of the aerofoil with the high aspect ratio have the limited improvement space; and if a method for increasing geometrical characteristic parameters of the sections of the plasmodium is adopted, the structure weight of the aerofoil needs to be increased and the effect is poor. By the manufacturing method adopted by the invention, these problems are solved. According to the overall configuration of an aircraft, the aerofoil is divided into a plurality of sections; tensile wires are arranged according to a certain mode section by section. The research result shows that the original bending function of the aerofoil is replaced by the tension of the tensile wires and the impaction of the aerofoil, and under the premise that the structure weight is basically not increased, the rigidity and the strength of the aerofoil with the high aspect ratio are greatly improved, and the pneumatic elastic deformation is reduced to be within 10 percent of the traditional aerofoil. The manufacturing method is very important for the practical application of the aerofoil with super-high aspect ratio, the cruising efficiency of the aircraft can be greatly improved, and the fuel consumption and the cost are reduced.

Owner:AERODYNAMICS NAT KEY LAB

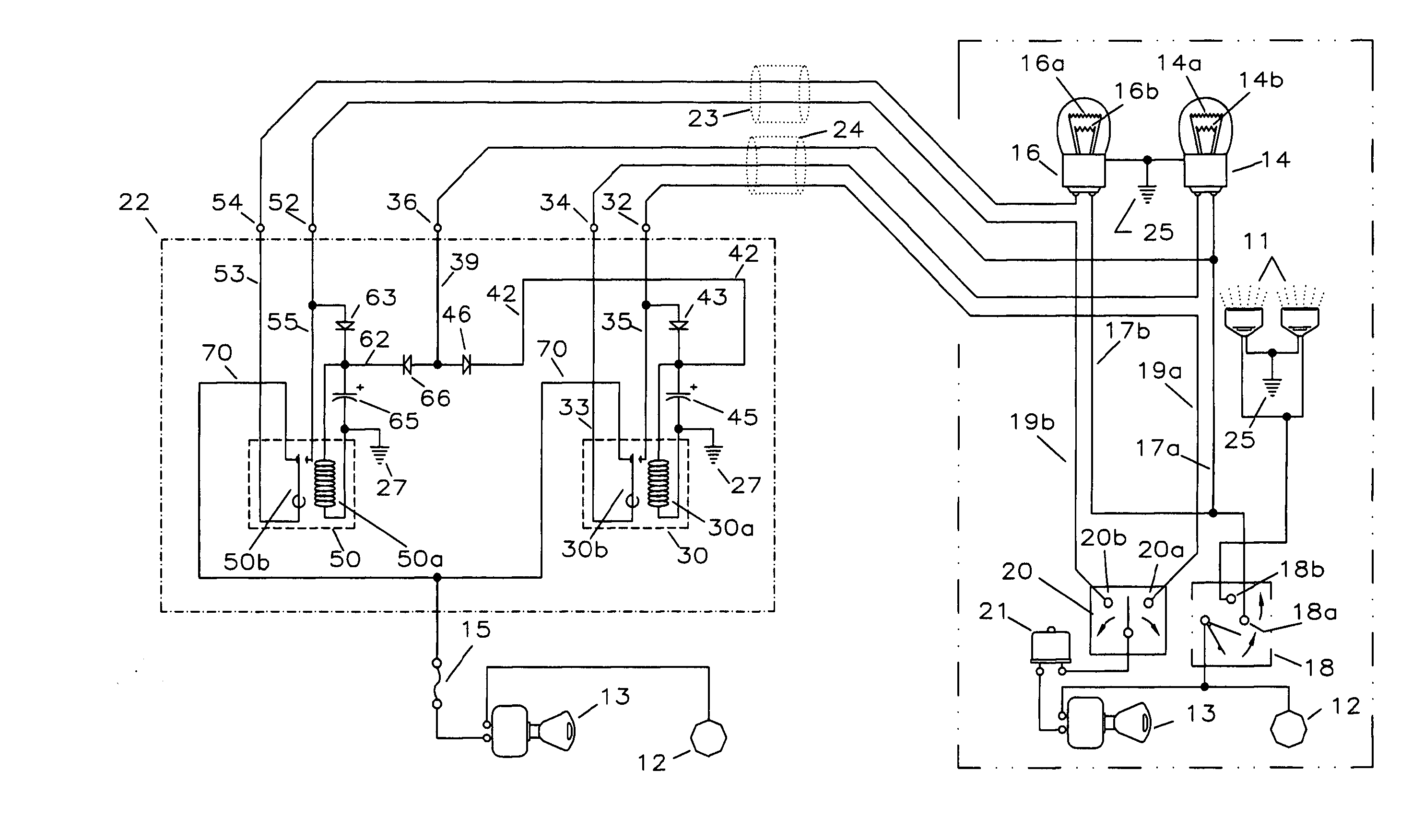

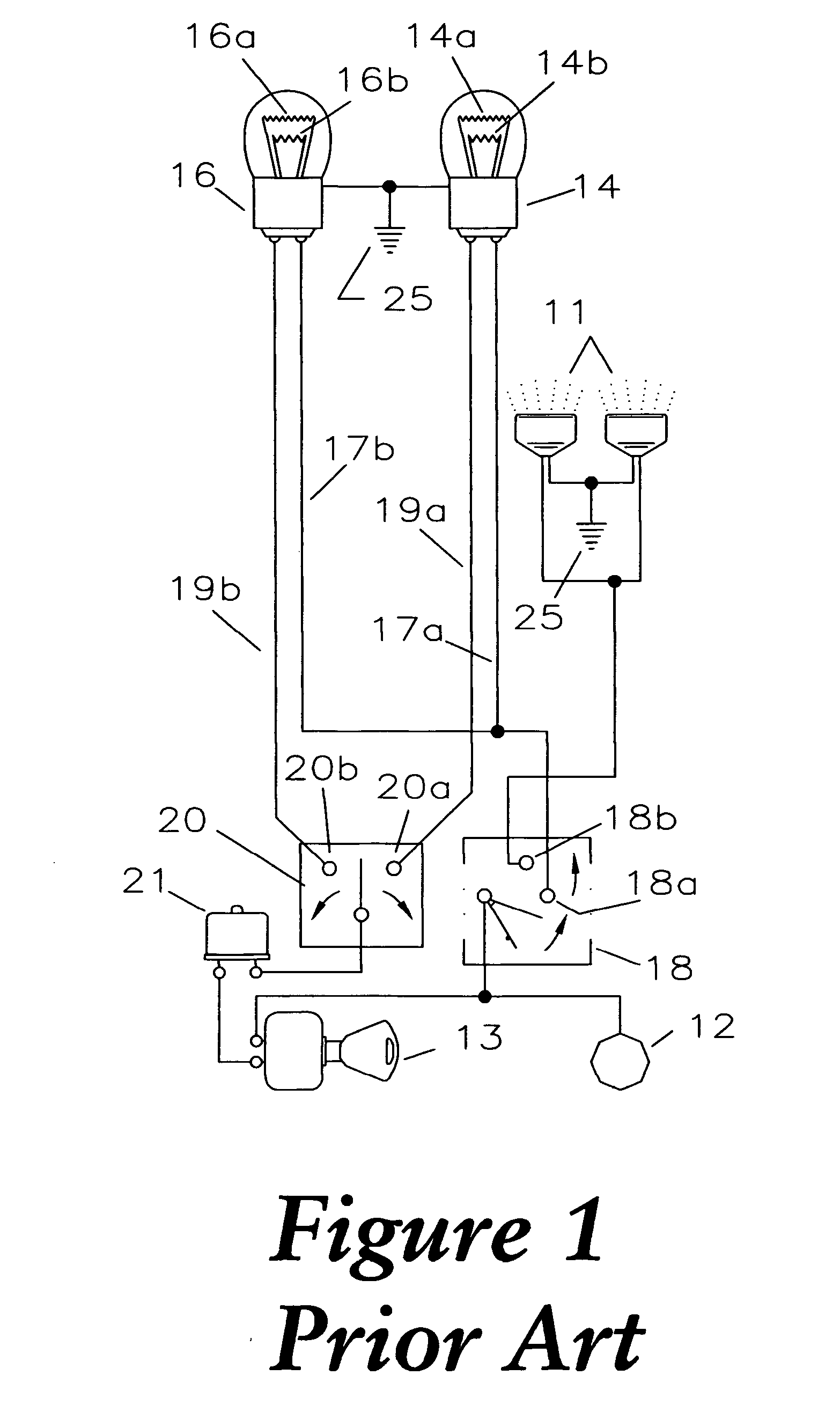

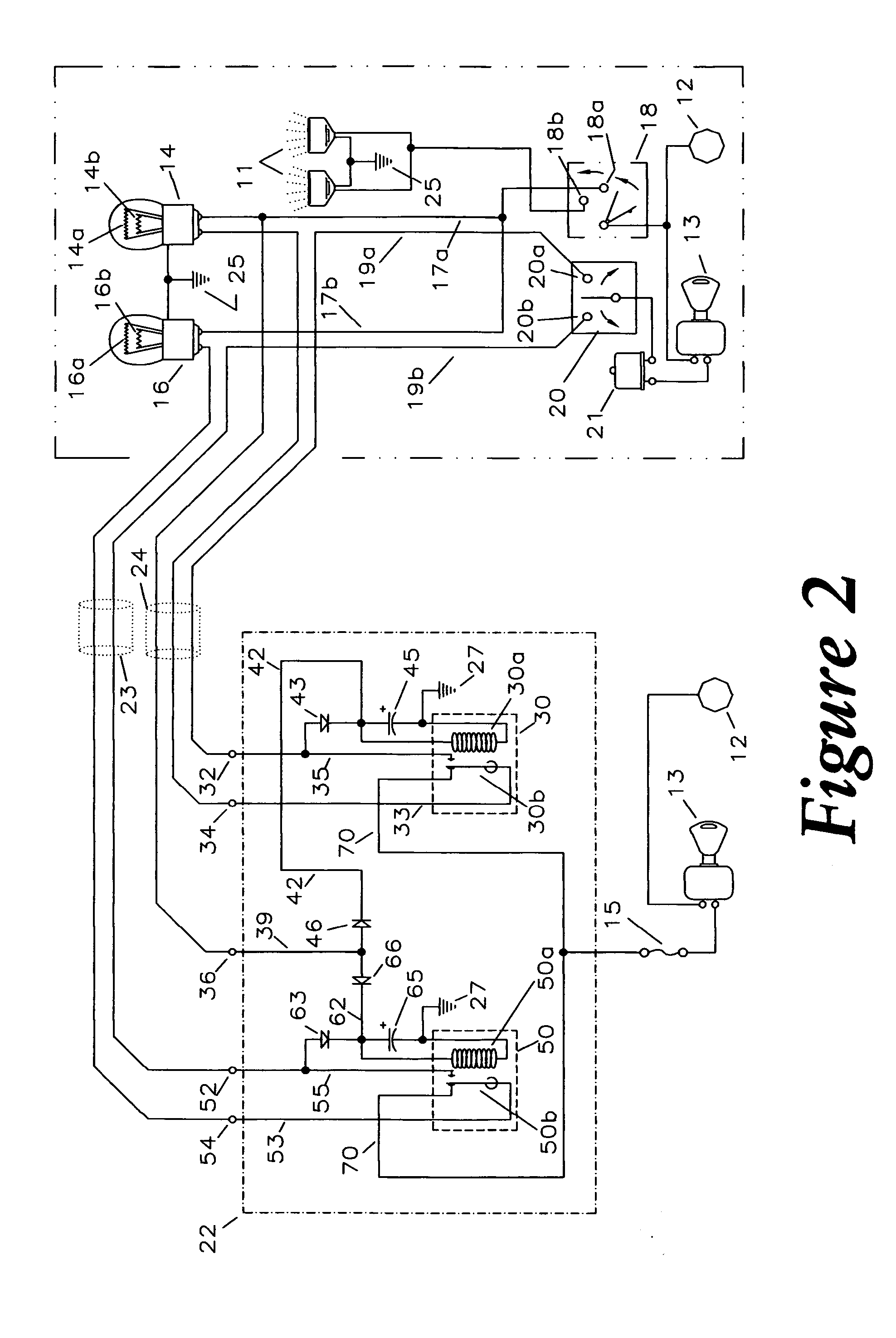

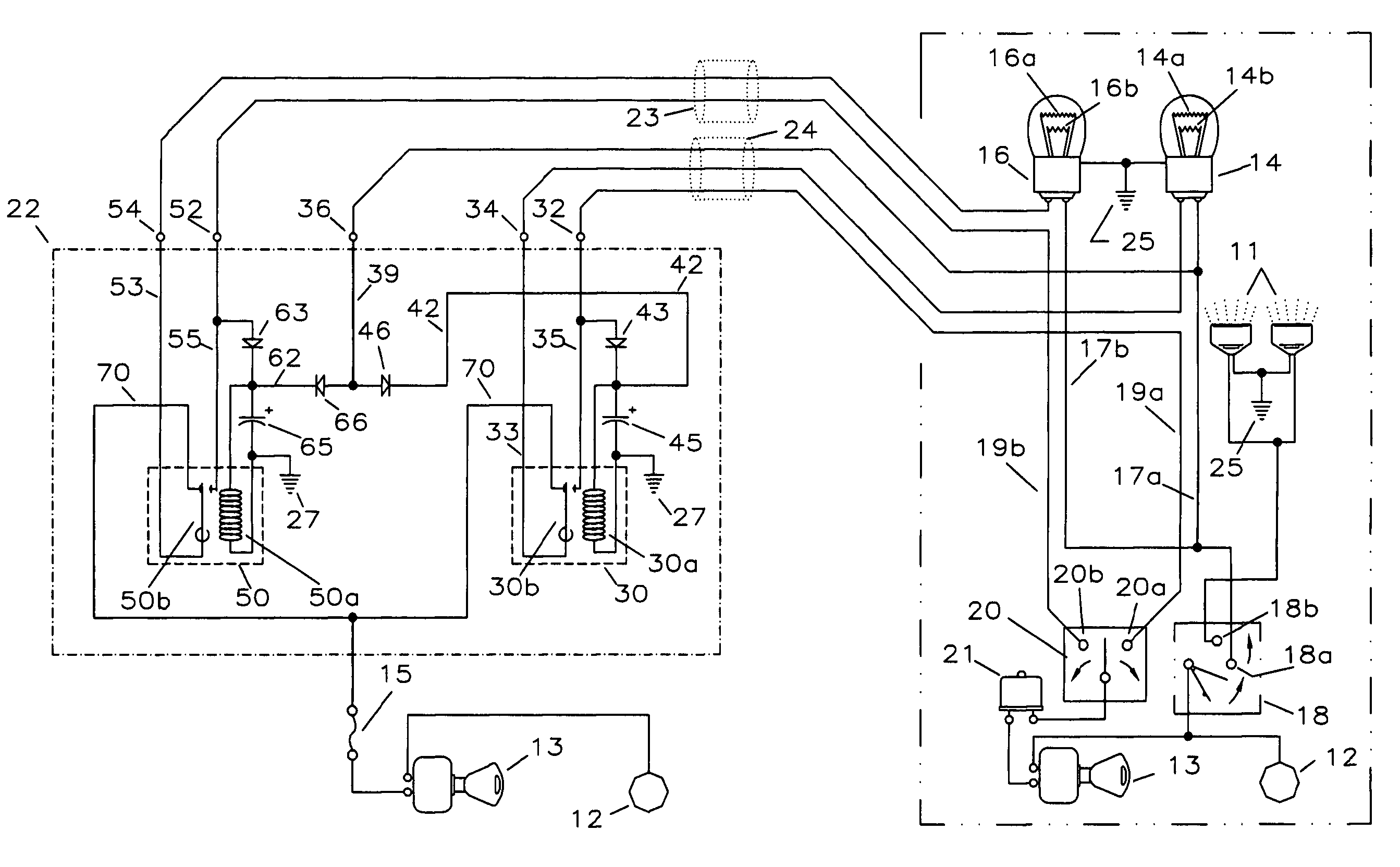

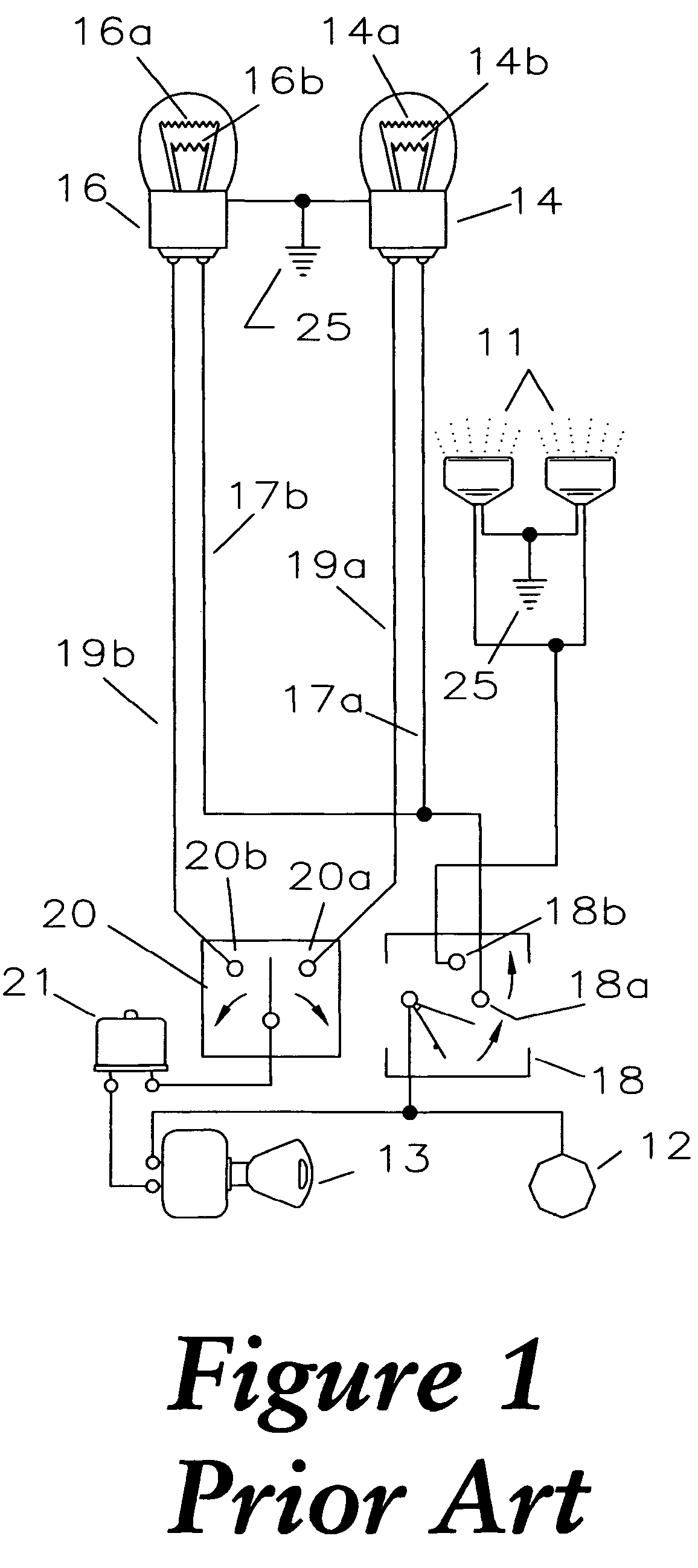

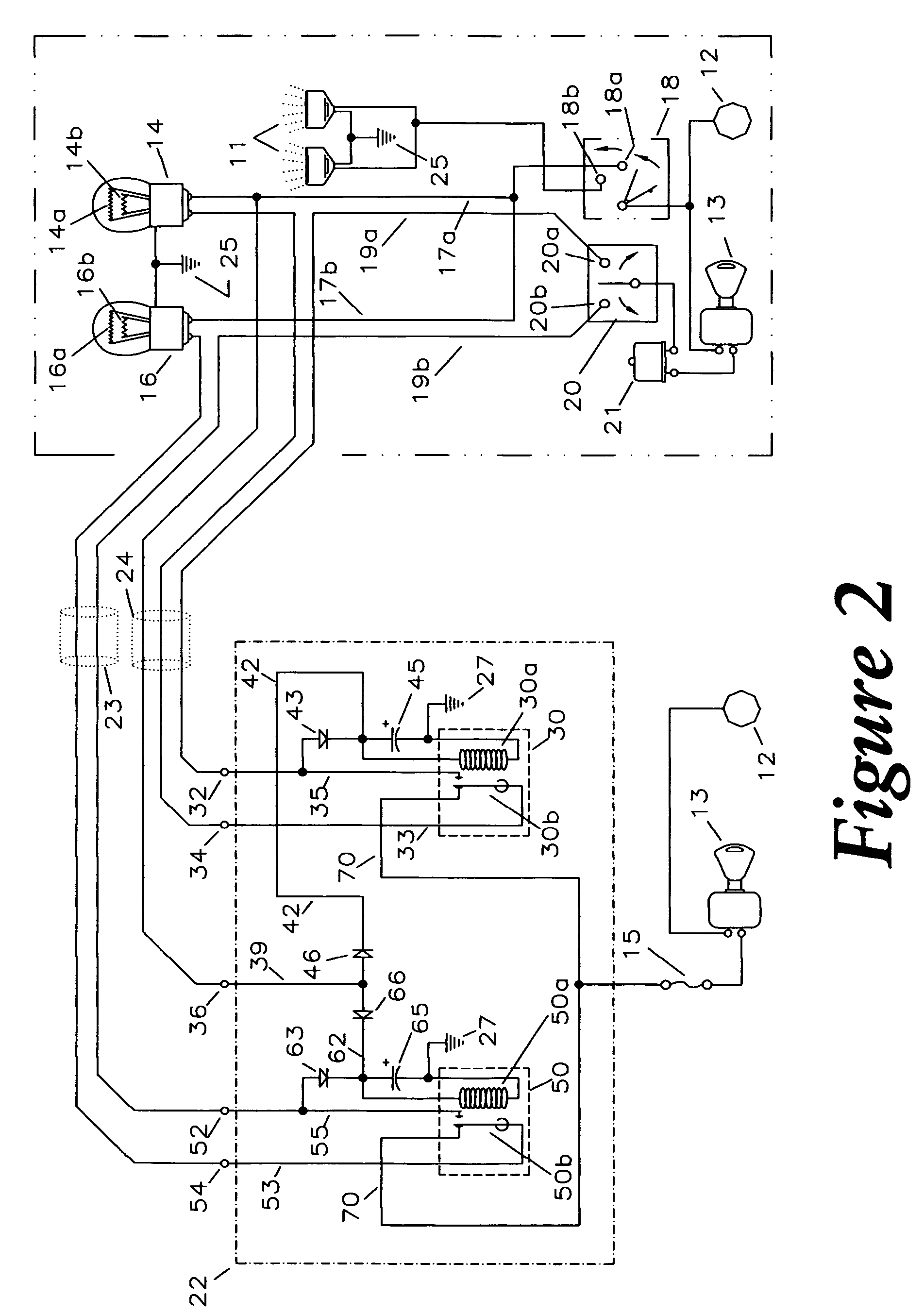

Directional lamp daytime running light module and vehicular turn signal control system

A vehicular lighting control system for controlling the illumination of a vehicle's external directional / turn signaling and / or hazard lighting, by controlling continuous illumination of pairs of the brightest filaments of single or dual filament bulb designed vehicles. The system controls to operate the brightest filaments when the operator wishes to draw attention to the vehicle for safety, or for visibility purposes, without the same system negatively affecting normal operation of existing turn signal / hazard warning systems. The system automatically and manually controls the light output as desired by the vehicle operator, incorporates the vehicle's internal turn signal bulb-failure indication subsystem to continuously monitor the target bulbs for any failure event, and employs a dynamic safety reconnect feature, an attribute which reconnects factory wiring with factory bulbs instantaneously with any signaling or hazards activation. The device employs a zero-system current drain, actual dual bulb activation / current consumption notwithstanding, for minimum environmental impact / maximum fuel conservation.

Owner:KESTERSON RAYMOND

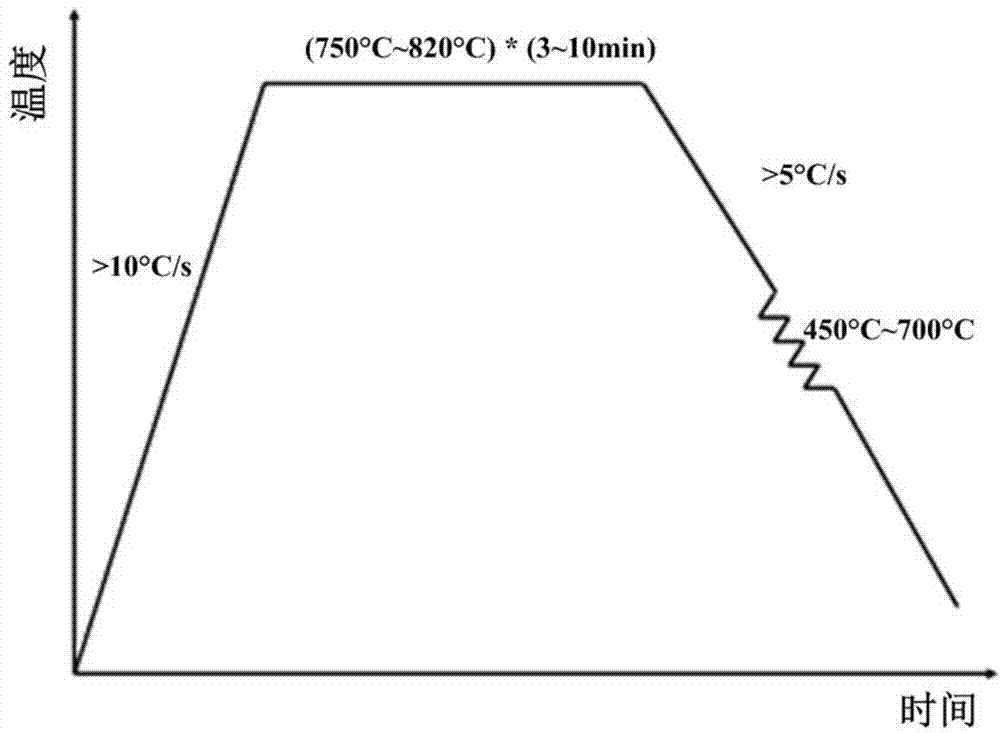

Warm-hot forming method for boron-free medium-manganese steel

InactiveCN104726762ALow austenitizing heating temperatureLow stamping temperatureShaping toolsManufacturing cost reductionFuel conservation

The invention discloses a warm-hot forming method for boron-free medium-manganese steel. The method is characterized by comprising the following steps: austenitizing pretreatment, namely heating a sheet to 750-820 DEG C at the heating rate of not lower than 10 DEG C / s, and carrying out heat preservation for 3-10 minutes; a sheet transferring process, namely cooling the sheet to a stamping temperature of 450-700 DEG C at the cooling rate of not lower than 5 DEG C / s, and transferring to a stamping mold; heat-resistant stamping and pressurizing-quenching treatment, namely transporting the sheet below the stamping mold, forming, and simultaneously carrying out heat-retaining quenching, wherein the quenching cooling rate is greater than 5 DEG / s; and the pressurizing time is 5-20s; and post-treatment, namely carrying out shot blasting on a formed sample piece, and anti-rust oil coating treatment. The warm-hot forming method provided by the invention conforms to industrial production of the boron-free medium-manganese steel, and has the advantages that the manufacture cost is reduced and the strength and plasticity of a steel part are improved; the new generation of automobile is promoted to reach a relatively high step in the aspects of light weight, fuel conservation and safety; and the warm-hot forming method is simple in technological process and convenient to operate.

Owner:DALIAN UNIV OF TECH

Directional lamp daytime running light module and vehicular turn signal control system

InactiveUS7482756B2Improve efficiencySave fuelBoards/switchyards circuit arrangementsWelding electric supplyFuel conservationEffect light

A vehicular lighting control system for controlling the illumination of a vehicle's external directional / turn signaling and / or hazard lighting, by controlling continuous illumination of pairs of the brightest filaments of single or dual filament bulb designed vehicles. The system controls to operate the brightest filaments when the operator wishes to draw attention to the vehicle for safety, or for visibility purposes, without the same system negatively affecting normal operation of existing turn signal / hazard warning systems. The system automatically and manually controls the light output as desired by the vehicle operator, incorporates the vehicle's internal turn signal bulb-failure indication subsystem to continuously monitor the target bulbs for any failure event, and employs a dynamic safety reconnect feature, an attribute which reconnects factory wiring with factory bulbs instantaneously with any signaling or hazards activation. The device employs a zero-system current drain, actual dual bulb activation / current consumption notwithstanding, for minimum environmental impact / maximum fuel conservation.

Owner:KESTERSON RAYMOND

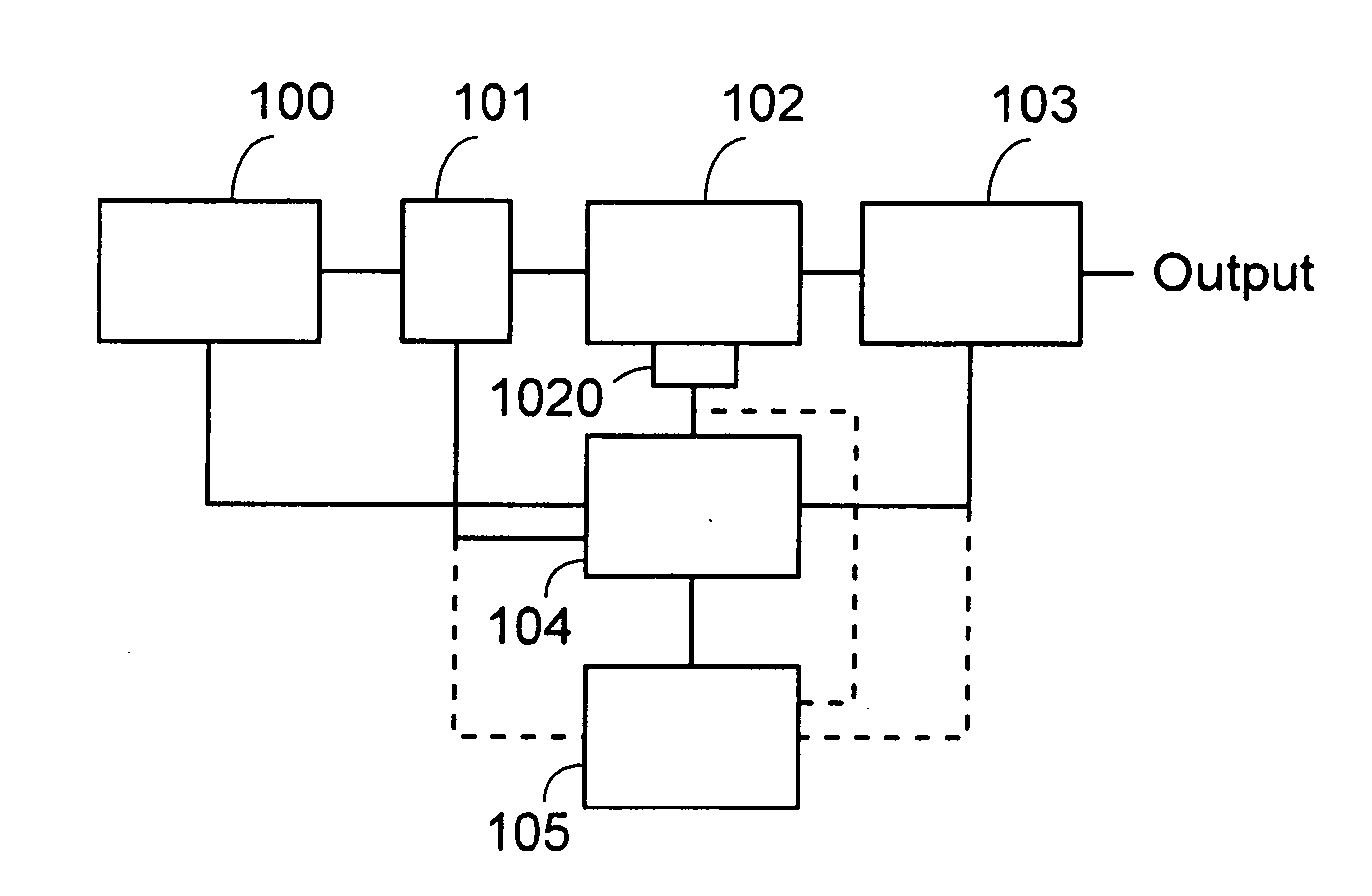

Fuel conservation systems and methods

ActiveUS7983830B2Dampen and cut fuel deliveryGreat amount of output powerAnalogue computers for vehiclesElectrical controlFuel conservationComputer module

Methods and systems are described for conserving fuel used by an engine. In some embodiments a control module processes a user-provided input, as a first function, into a second function. The second function can be used to direct the engine with a directive output power. The directive output power may have regions equal to, greater than, and / or less than what the power output would be if the engine were controlled using the user-provided input.

Owner:FUEL SAVING TECH

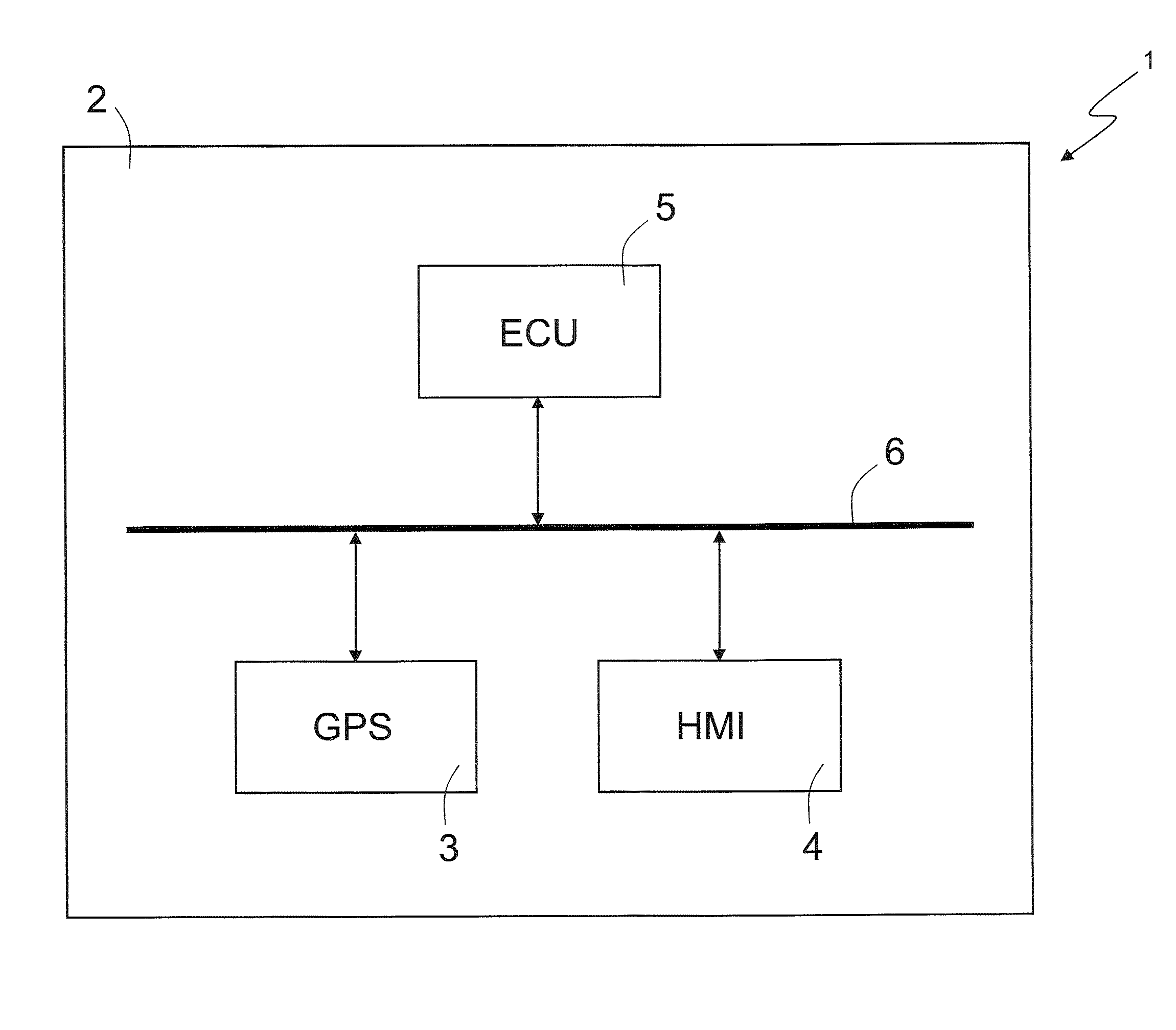

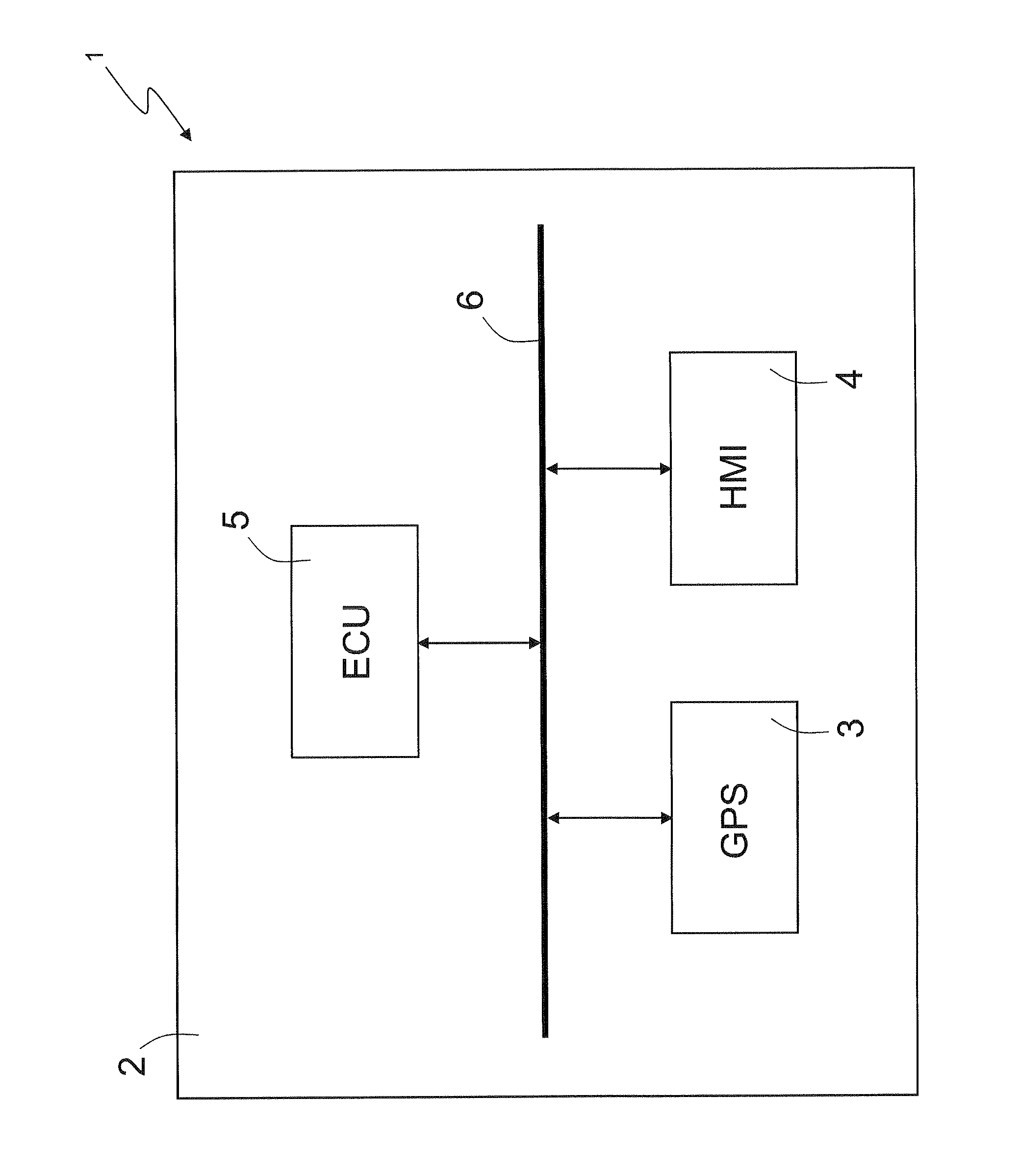

Preventive fuel saving-aimed motor vehicle driver assistance

ActiveUS20160123755A1Instruments for road network navigationAnalogue computers for trafficMotor vehicle drivingHuman–machine interface

A fuel saving-aimed motor vehicle driver assistance system configured to receive and process motor vehicle-related data and motor vehicle position-related data to identify recurrent routes of a motor vehicle and to provide a motor vehicle driver, via an automotive human-machine interface, with motor vehicle driving assistance recommendations for fuel saving along the routes. The motor vehicle driver assistance system is configured to identify recurrent routes of the motor vehicle by determining a succession of geographic points, referred to as Waypoints, along a route of the motor vehicle, at which values of a series of physical quantities are determined and recorded, which define the attributes of the Waypoints. The Waypoint attributes are then updated when the vehicle travels through them. For each current motor vehicle position, a search is made for the Waypoint spatially closest to the current motor vehicle position and having certain characteristics, such that if such a Waypoint is not found, then a new Waypoint is defined, or else, if such a Waypoint is found, then variable Waypoint attributes are updated. The so-defined Waypoints are then concatenated so as to form an ordered list of Waypoints belonging to the same recurrent route. The characteristic points of the routes, such as bends, roundabouts and traffic lights, are identified and optimal speed profiles and primary controls for the motor vehicle at the characteristic points are computed. Based on the computed optimal speed profiles and primary controls and by means of the automotive human-machine interface, the motor vehicle driver is then provided with motor vehicle driving recommendations for fuel saving along the routes.

Owner:CENT RECERCHE FIAT S PA

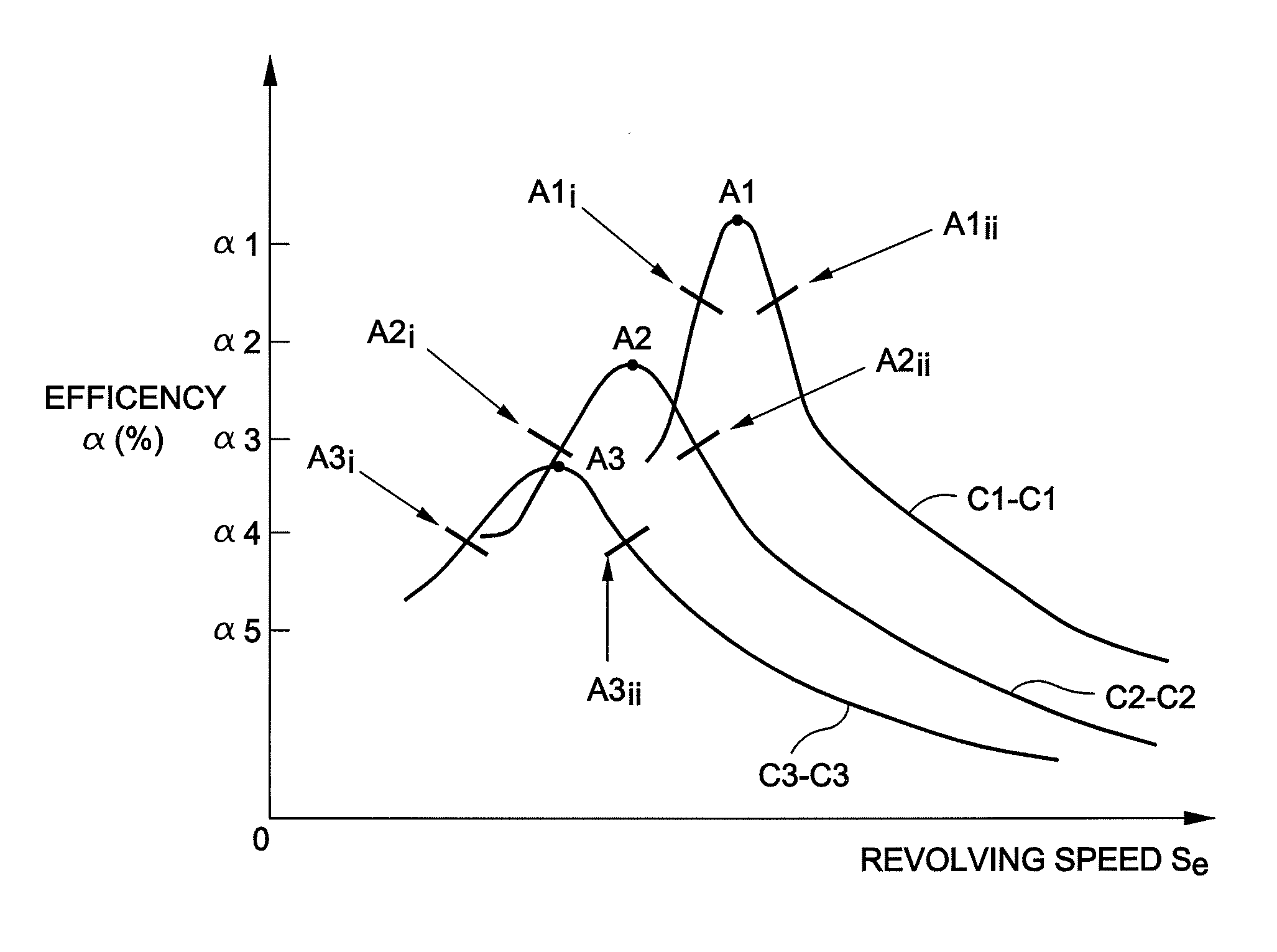

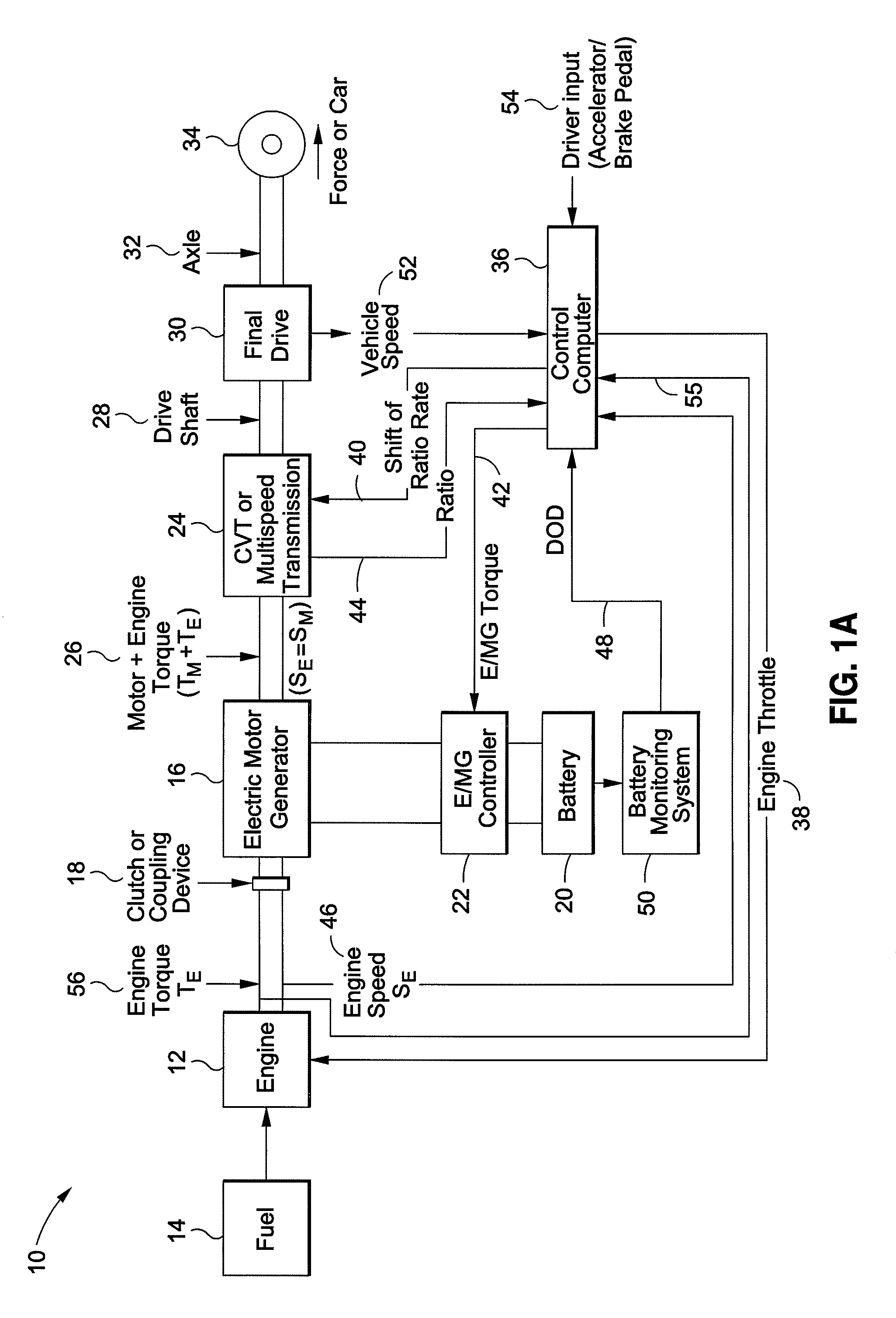

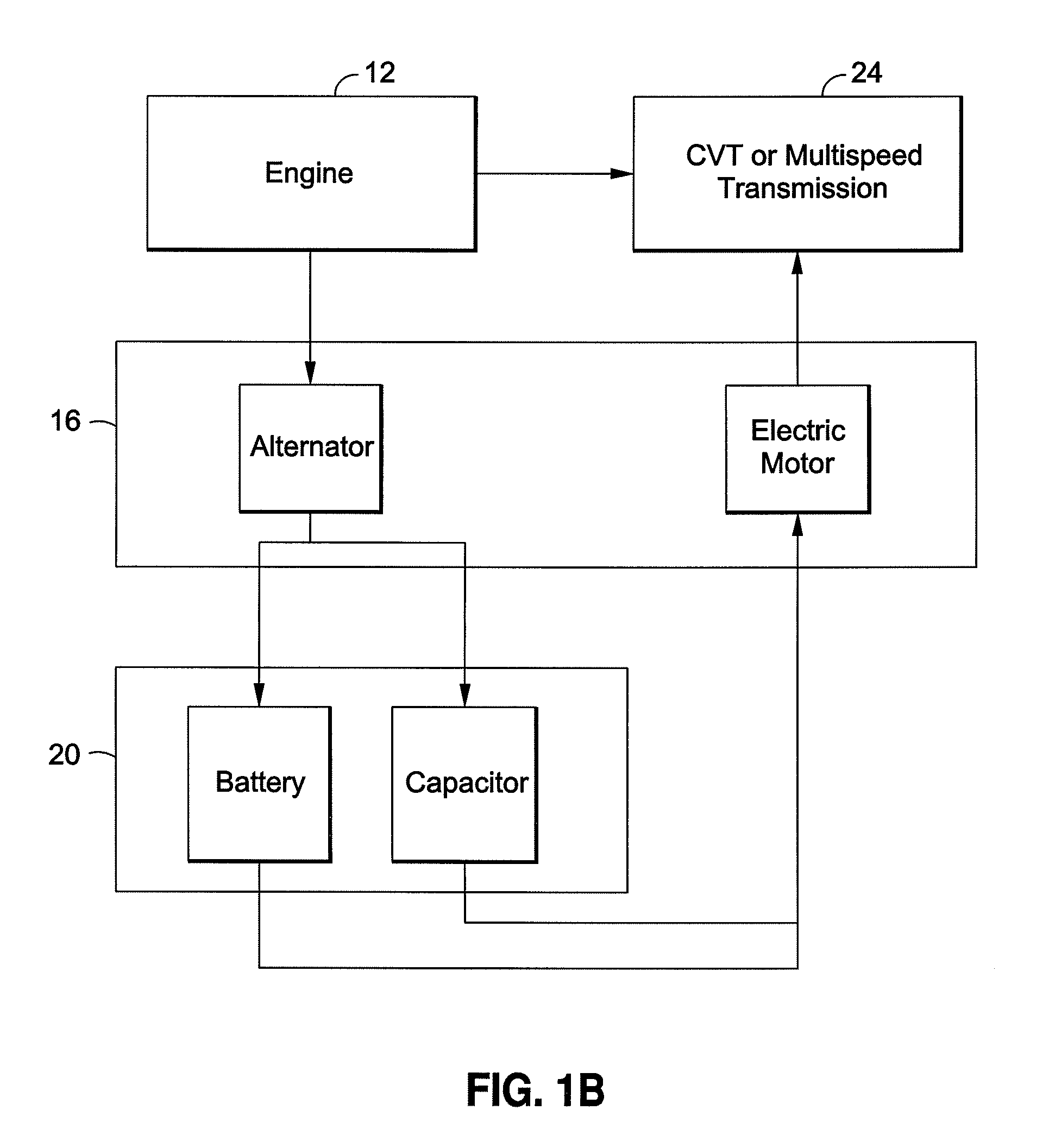

Engine running at fixed speed incorporated controllable transmission power system

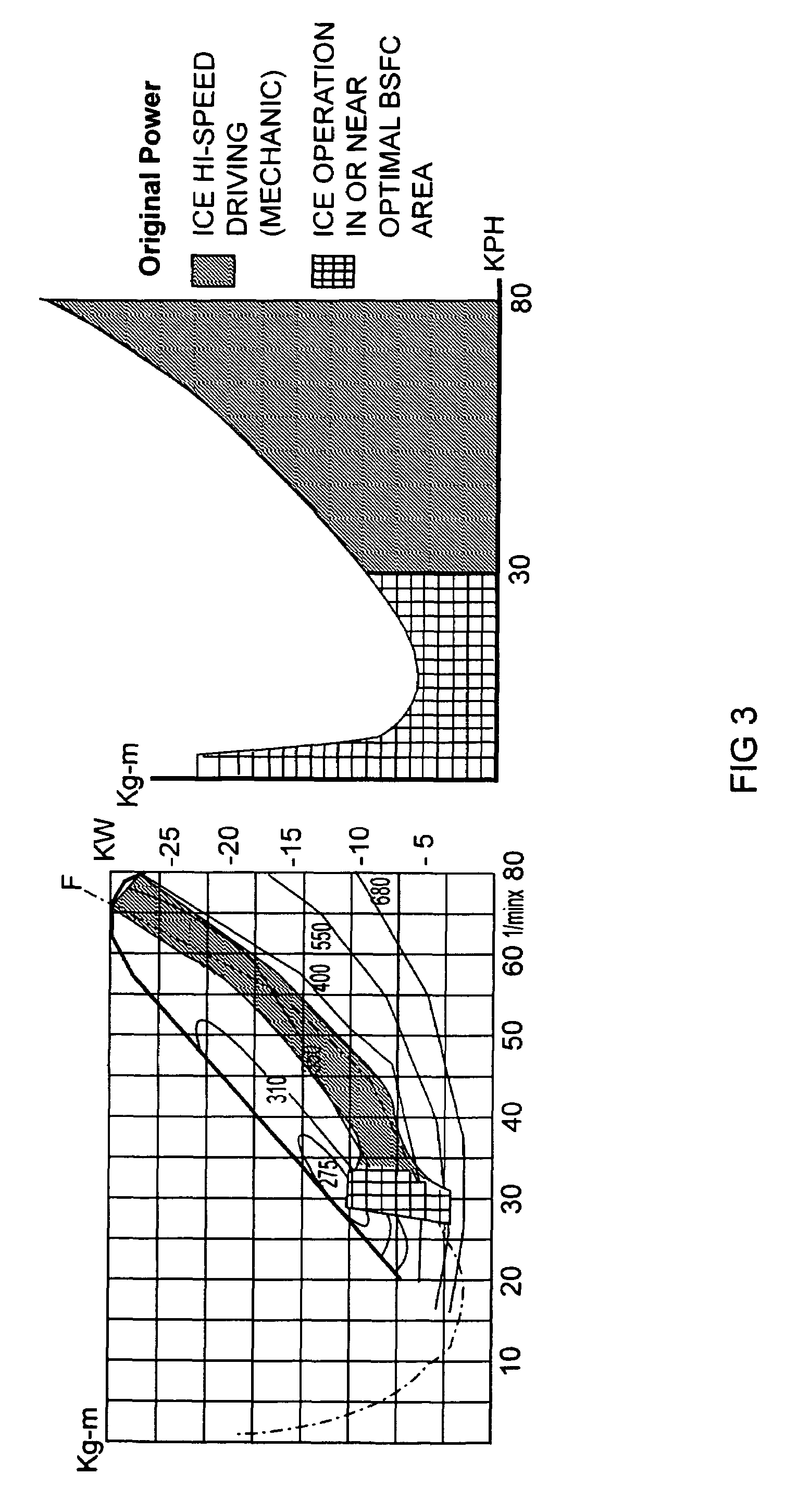

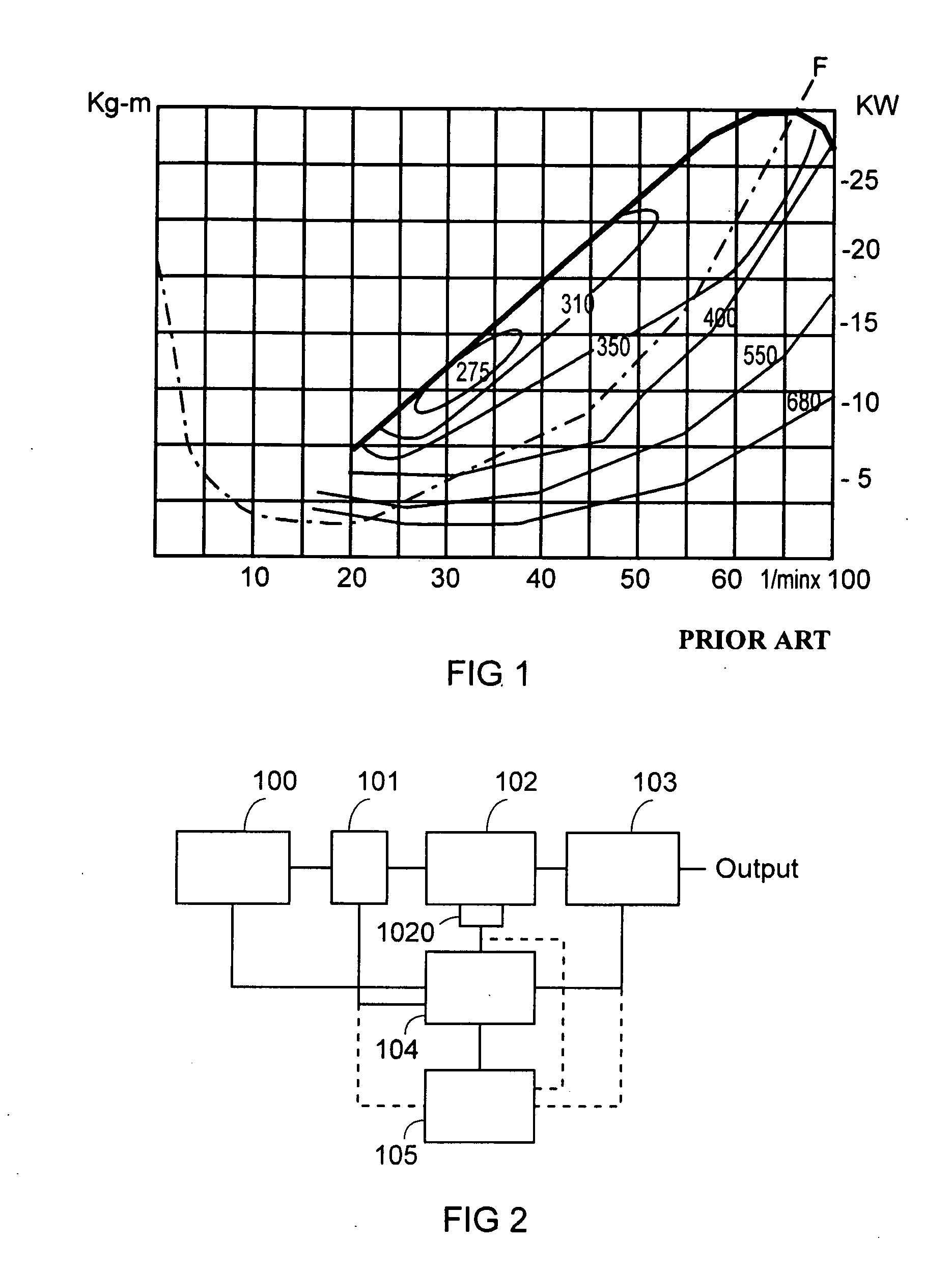

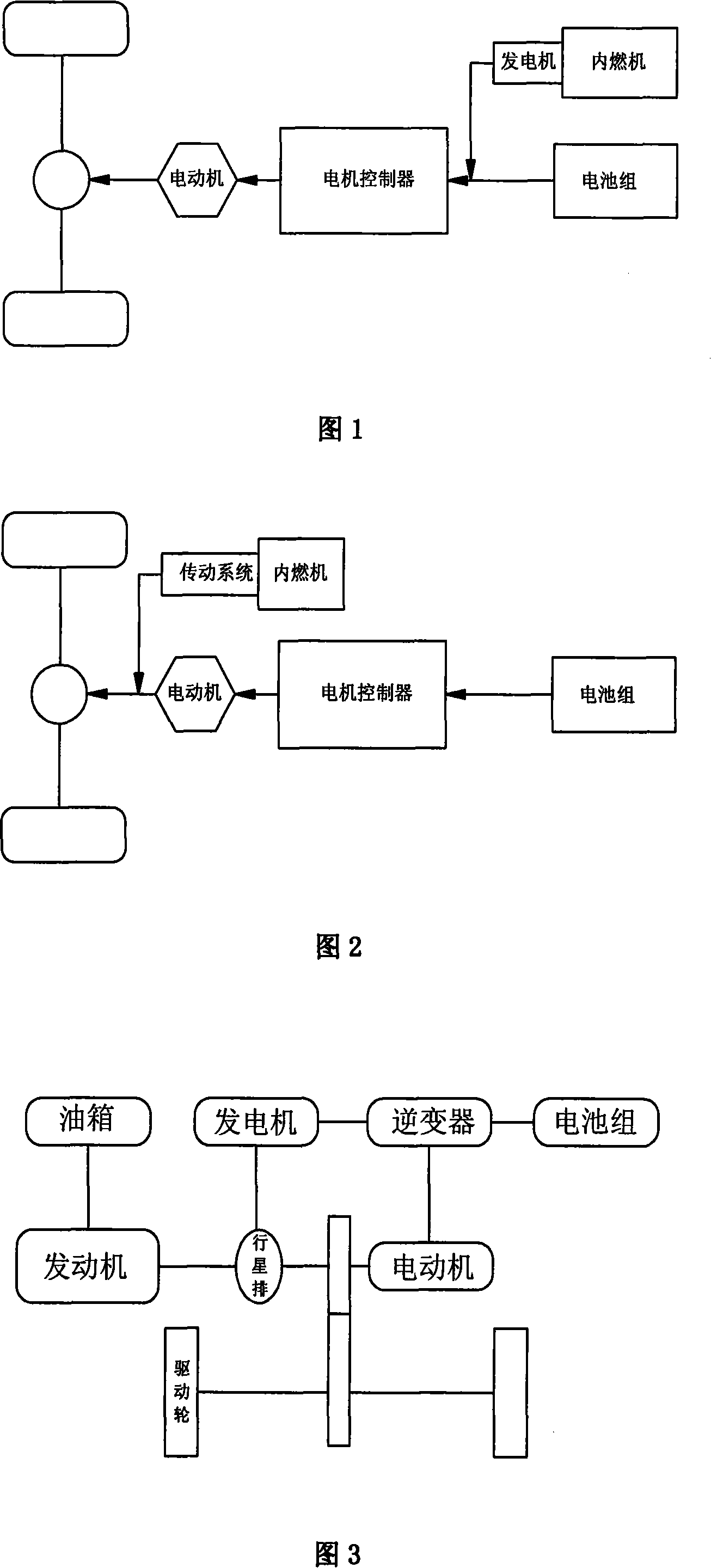

InactiveUS7479091B2Improve efficiencySave fuelVehicle fittingsInternal combustion piston enginesFuel conservationBrake specific fuel consumption

A power system of controllable transmission incorporated with an engine running at fixed speed that controls the engine to run at a fixed speed or approaching a fixed speed within an rpm range with higher BSFC (braking specific fuel consumption) when the engine is started up from static status and in the accelerated drive from low rpm, the output end of the engine drives to achieve active control of the controllable front-end gearbox that is capable of executing variable or invariable gear shift so to activate the output end to execute accelerated drive output from low to high rpm; meanwhile, in the course of start-up and acceleration from lower to high rpm and in driving operation, the engine runs in an rpm range with higher BSFC for saving fuel.

Owner:YANG TAI HER

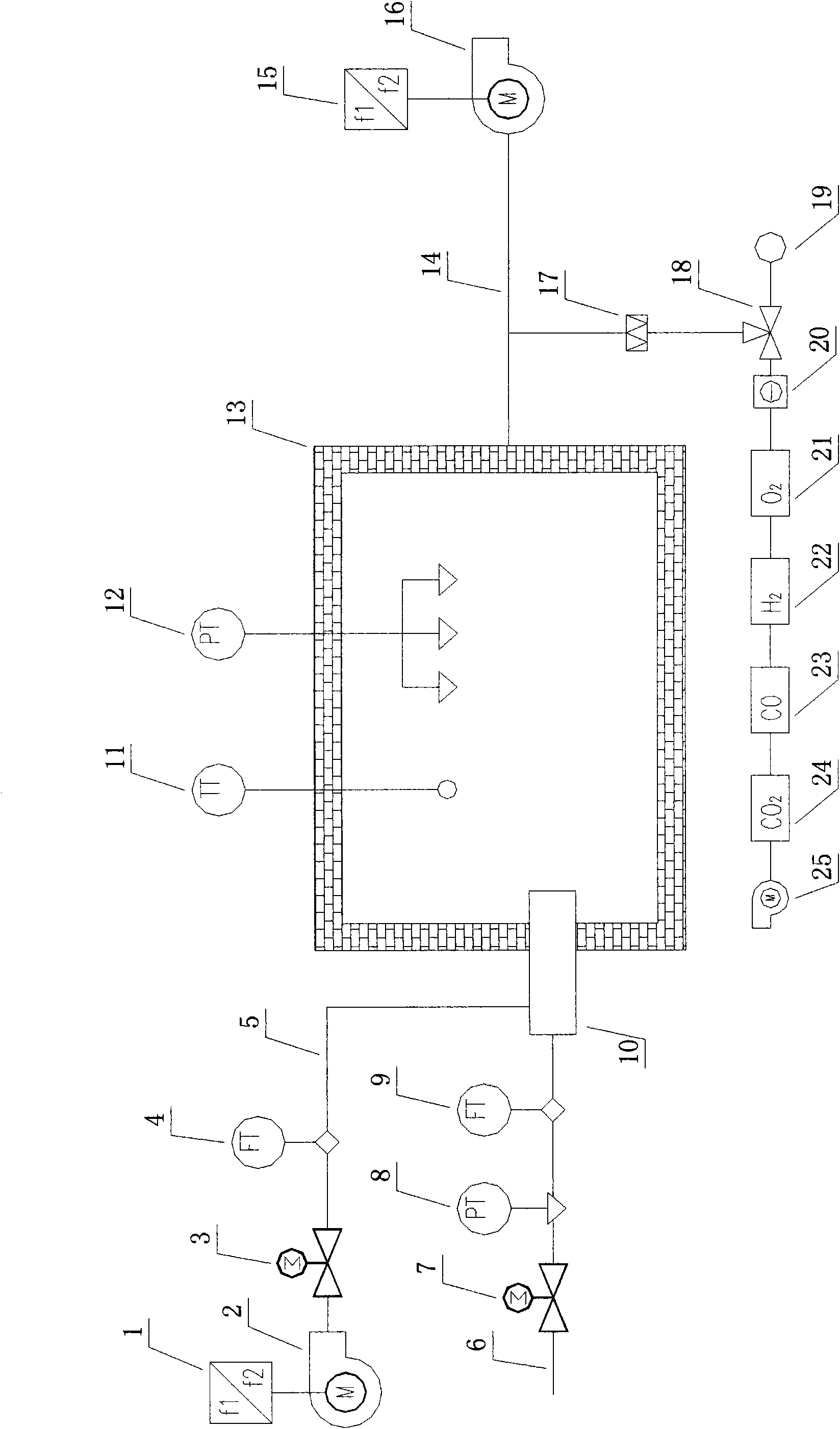

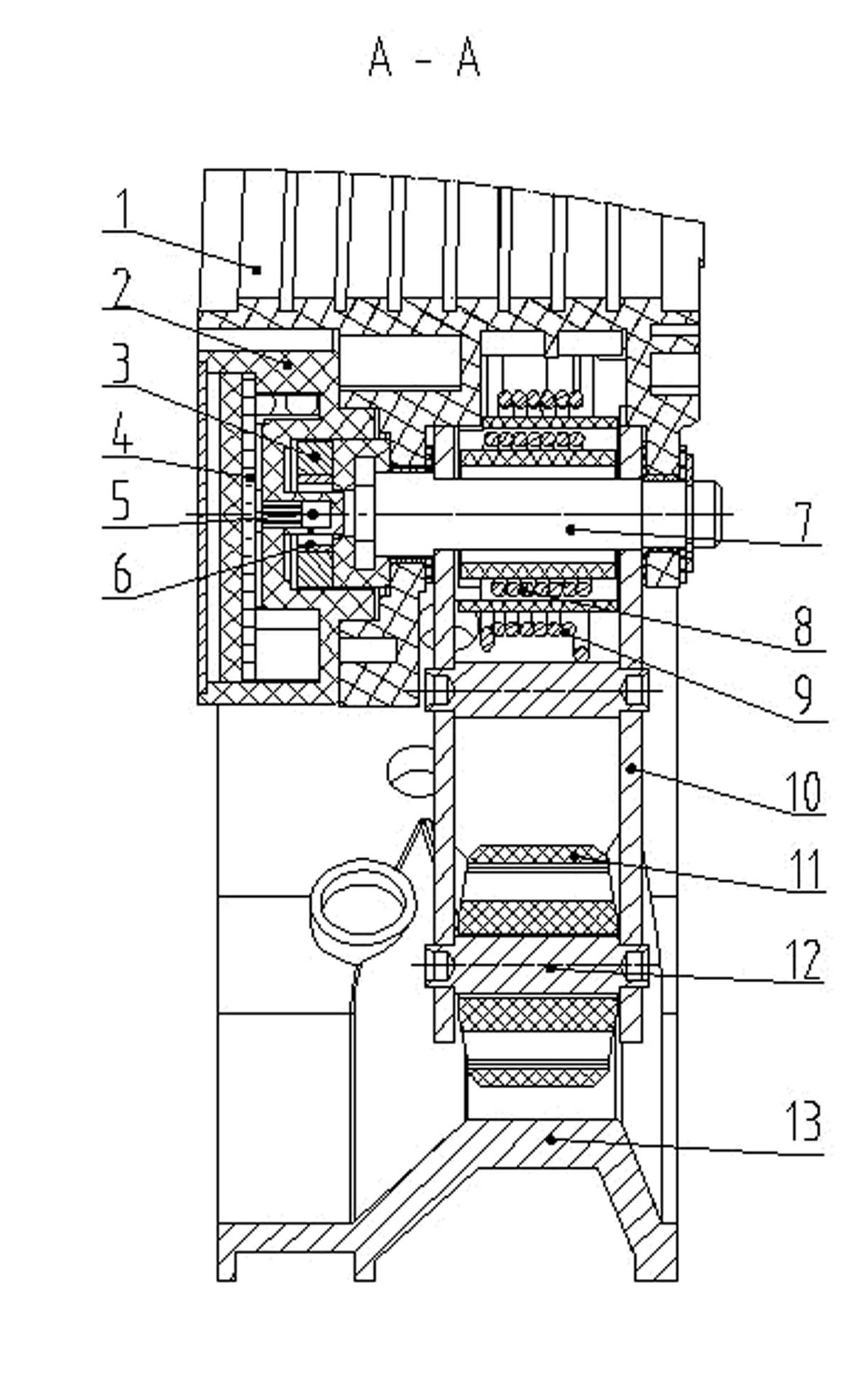

Method and device for industrial furnace atmosphere automatic combustion control

InactiveCN103134328AEasy to handleAvoid distractionsMaintainance of heating chambersControl devices for furnacesFuel conservationAutomatic control

The invention relates to the technical field of industrial furnace combustion control, and particularly provides a method and a device for industrial furnace atmosphere automatic combustion control. The method comprises the following steps: measuring contents of O2, CO2, H2, and CO in flue gas which is after being burned by using an on-line real-time sampling detection method, analyzing combustion atmosphere data, adjusting industrial furnace combustion-supporting wind-fuel flow and induced air flue gas flow by using an industrial furnace combustion atmosphere mathematical model, controlling the combustion atmosphere and controlling furnace chamber pressure to enable the combustion to be carried out in a controllable atmosphere on the premise that industrial furnace manufacturing technique requirements are met, and controlling a combustion flue gas flow direction and the furnace chamber pressure to be in stable conditions. Compared with the prior art, the method and the device for the industrial furnace atmosphere automatic combustion control have the advantages that self-adjusting and automatic control of the combustion atmosphere can be achieved, disturbance pipe network fuel fluctuations to the control can be automatically corrected, no manual intervention is needed in a control process, and due to the fact that the combustion atmosphere of a heating furnace can be automatically controlled, effects of stable combustion, combustion quality improvement, fuel conservation, control of heating furnace oxidation burning loss, reduction of flue gas emission and improvement of industrial furnace thermal efficiency are achieved.

Owner:WUXI KAITIAN ENVIRONMENTAL PROTECTION TECH

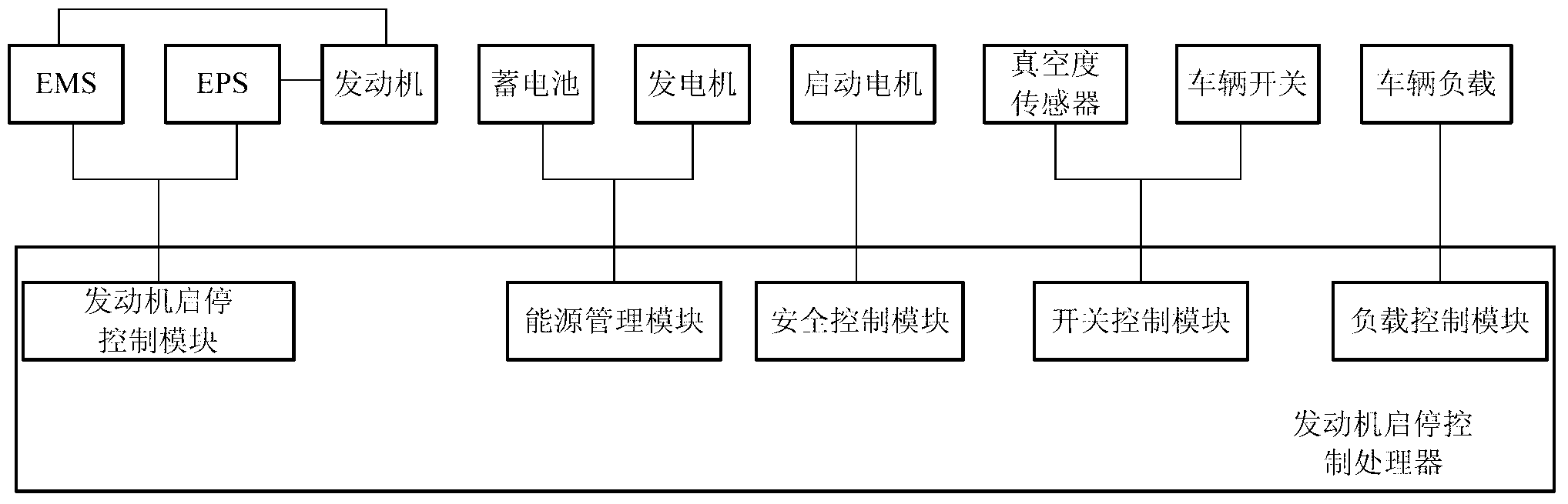

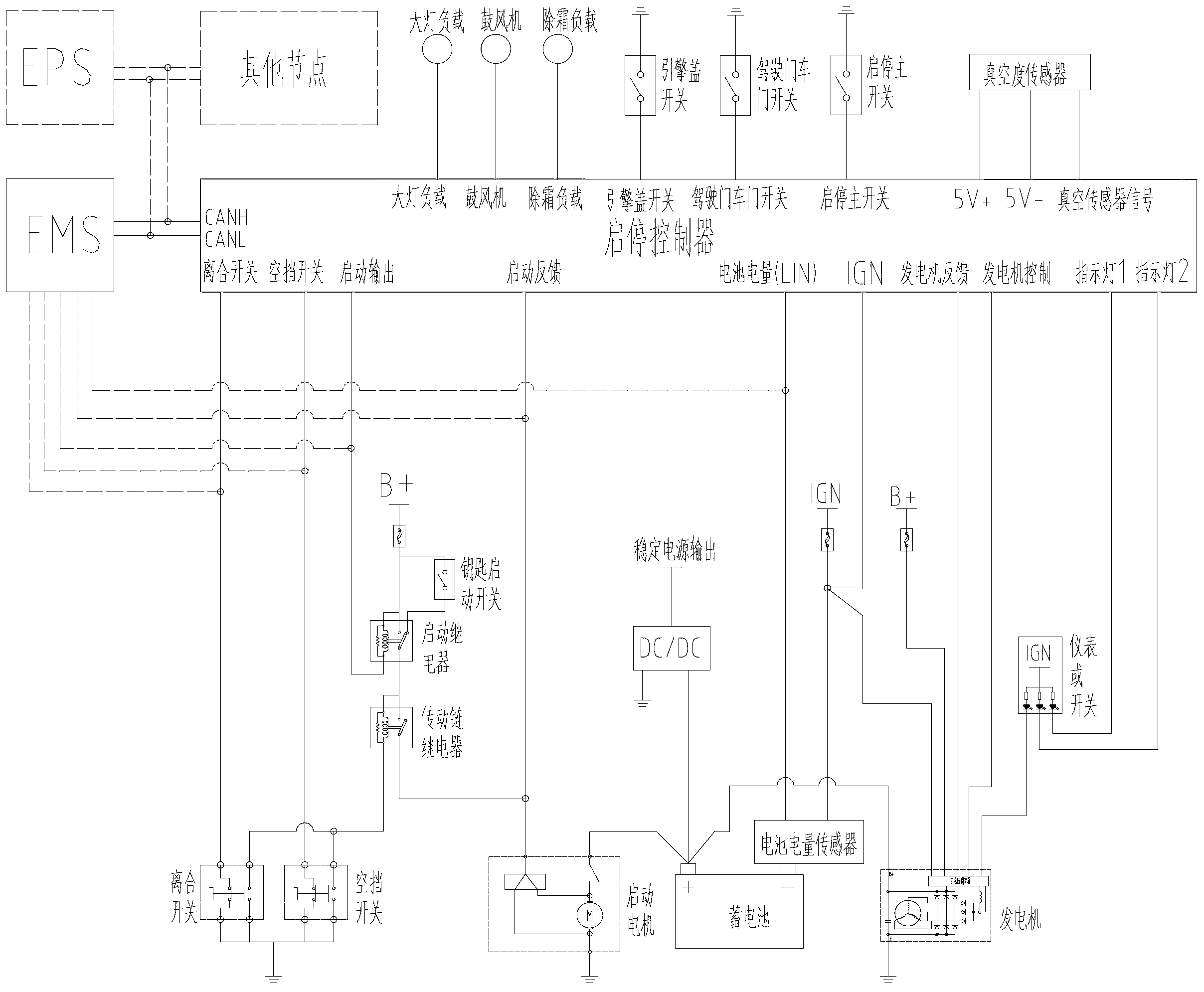

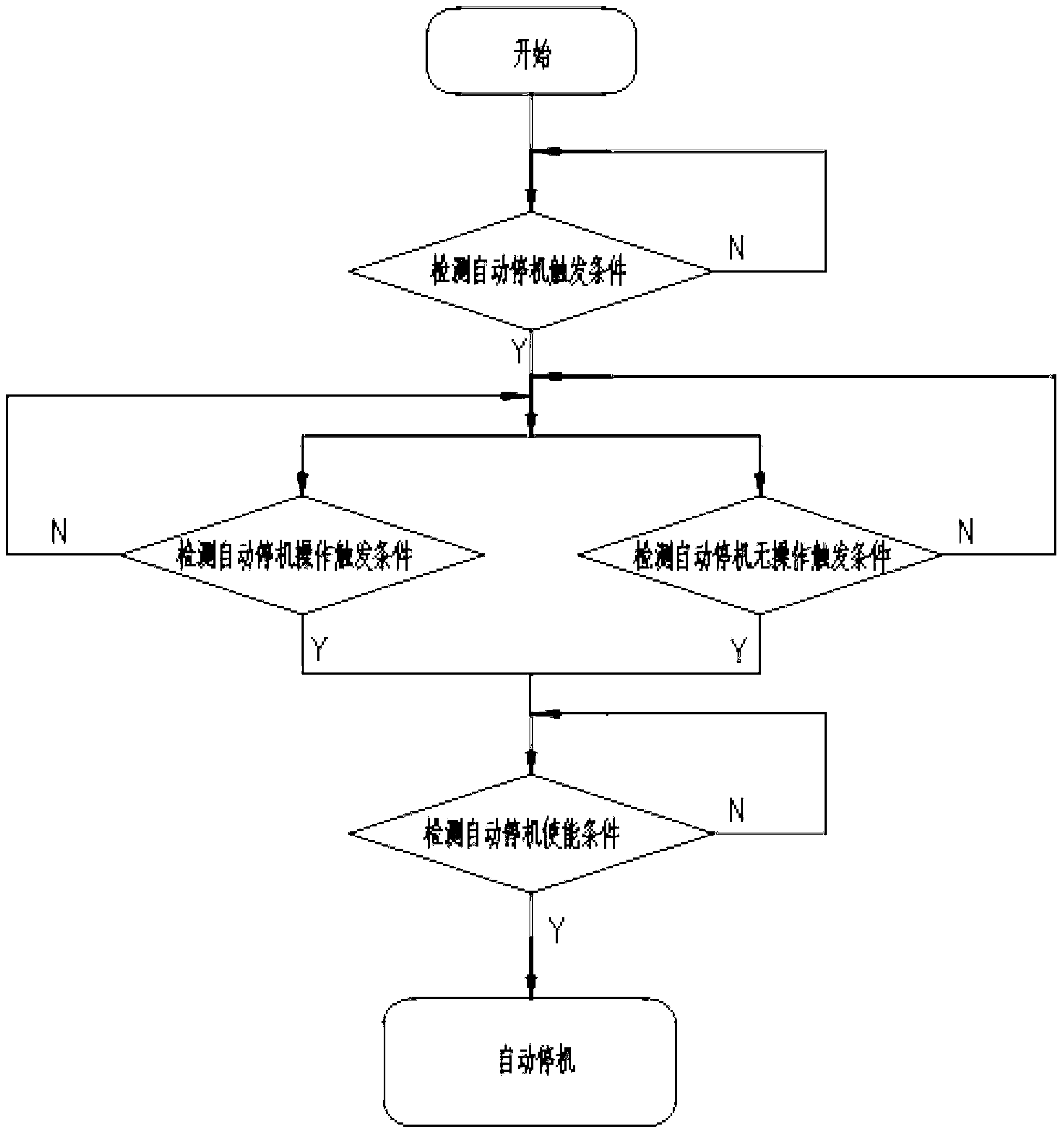

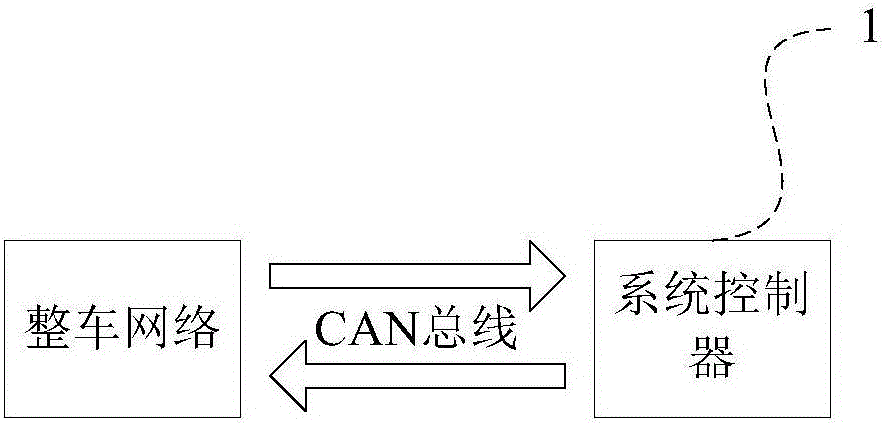

Independent type engine start and stop control system and control method thereof

InactiveCN103287361ASave fuelSimple Calibration VerificationElectric/fluid circuitFuel conservationControl system

The invention discloses an independent type engine start and stop control system and a control method thereof. The control system comprises an EMS, an EPS, a storage battery, a generator, a starting engine, a vacuum sensor, vehicle switches, vehicle loads and an engine start and stop control module. According to the independent type engine start and stop control system, the engine start and stop control system is separated from the EMS and forms a special control module, the special module collects information of multiple sources and is communicated with the engine through a CAN bus under the calibration conditions of a vehicle, then the engine is started or stopped, and therefore the purpose of fuel conservation is achieved. The independent type engine start and stop control system and the control method thereof have the advantages that the basic framework of the electrical system of the vehicle is not changed, the special module is communicated with the engine, calibration verification is simple, the development period is short, calibration cost is low, hardware cost is lowered, and the control method is suitable for multiple standards of vehicles. According to the engine start and stop control method, the independent engine start and stop control module is used for starting and stopping the engine automatically, the hardware cost is lowered, and safety and reliability are guaranteed.

Owner:力帆科技(集团)股份有限公司

Engine running at fixed speed incorporated controllable transmission power system

InactiveUS20070037661A1Save fuelImprove efficiencyVehicle fittingsInternal combustion piston enginesBrake specific fuel consumptionStart up

A power system of controllable transmission incorporated with an engine running at fixed speed that controls the engine to run at a fixed speed or approaching a fixed speed within an rpm range with higher BSFC (braking specific fuel consumption) when the engine is started up from static status and in the accelerated drive from low rpm, the output end of the engine drives to achieve active control of the controllable front-end gearbox that is capable of executing variable or invariable gear shift so to activate the output end to execute accelerated drive output from low to high rpm; meanwhile, in the course of start-up and acceleration from lower to high rpm and in driving operation, the engine runs in an rpm range with higher BSFC for saving fuel.

Owner:YANG TAI HER

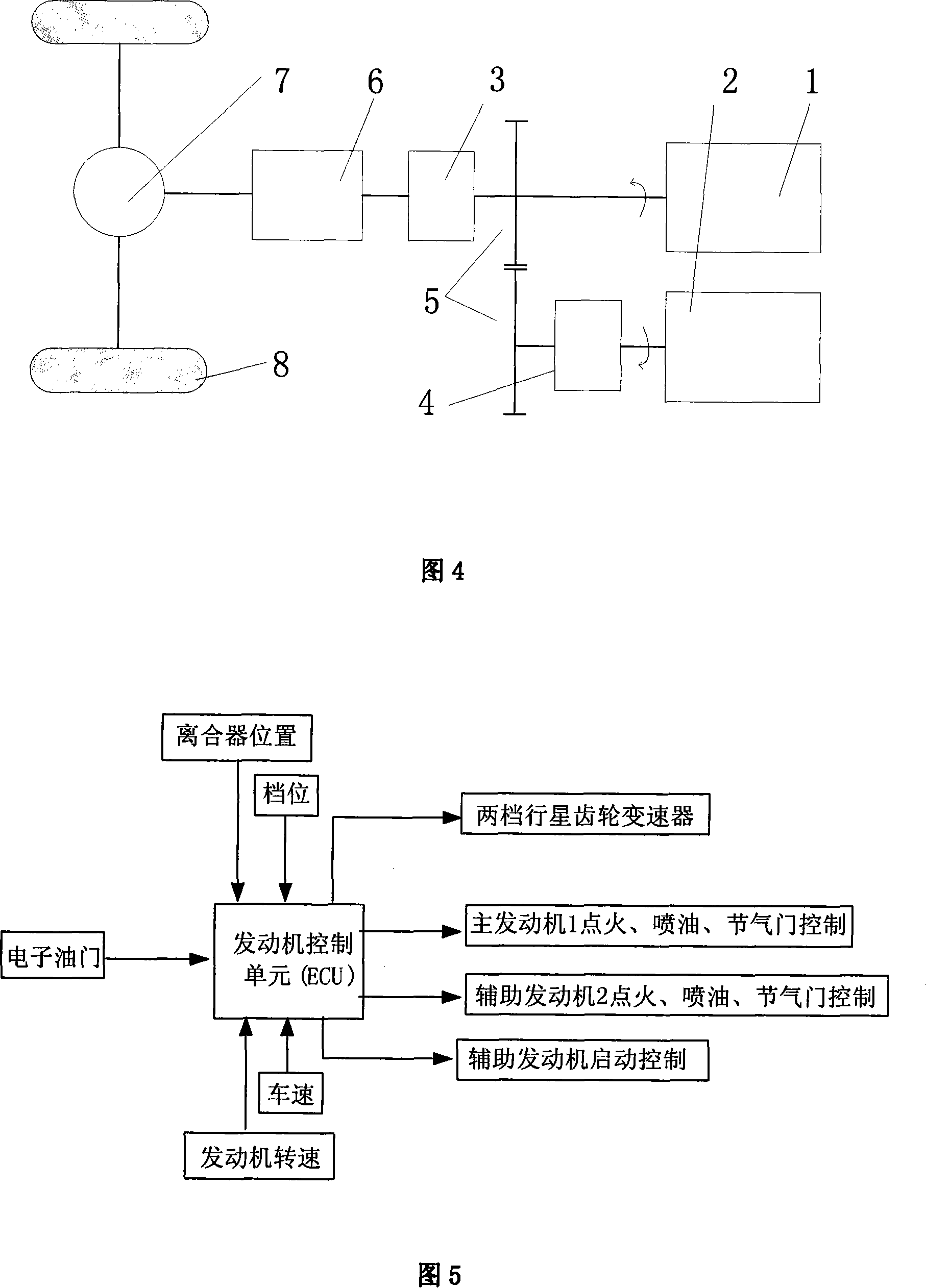

Automobile power system with double-engine and its control method

InactiveCN101148145AEasy loadingIncrease weightJet propulsion mountingInternal combustion mountingFuel oilAuxiliary power unit

The present invention discloses one kind of double engine automobile power system, which includes one main engine, one main clutch, one main speed variator, one differential gear and wheels connected successively to constitute one main power system, as well as one auxiliary engine and one auxiliary speed variator connected to constitute one auxiliary power system. The auxiliary power system has an output shaft connected through one gear train to the output shaft of the main engine. The present invention can save fuel oil, reduce emission and lower cost effectively. The present invention also discloses the control method of the double engine automobile power system.

Owner:SAIC MOTOR

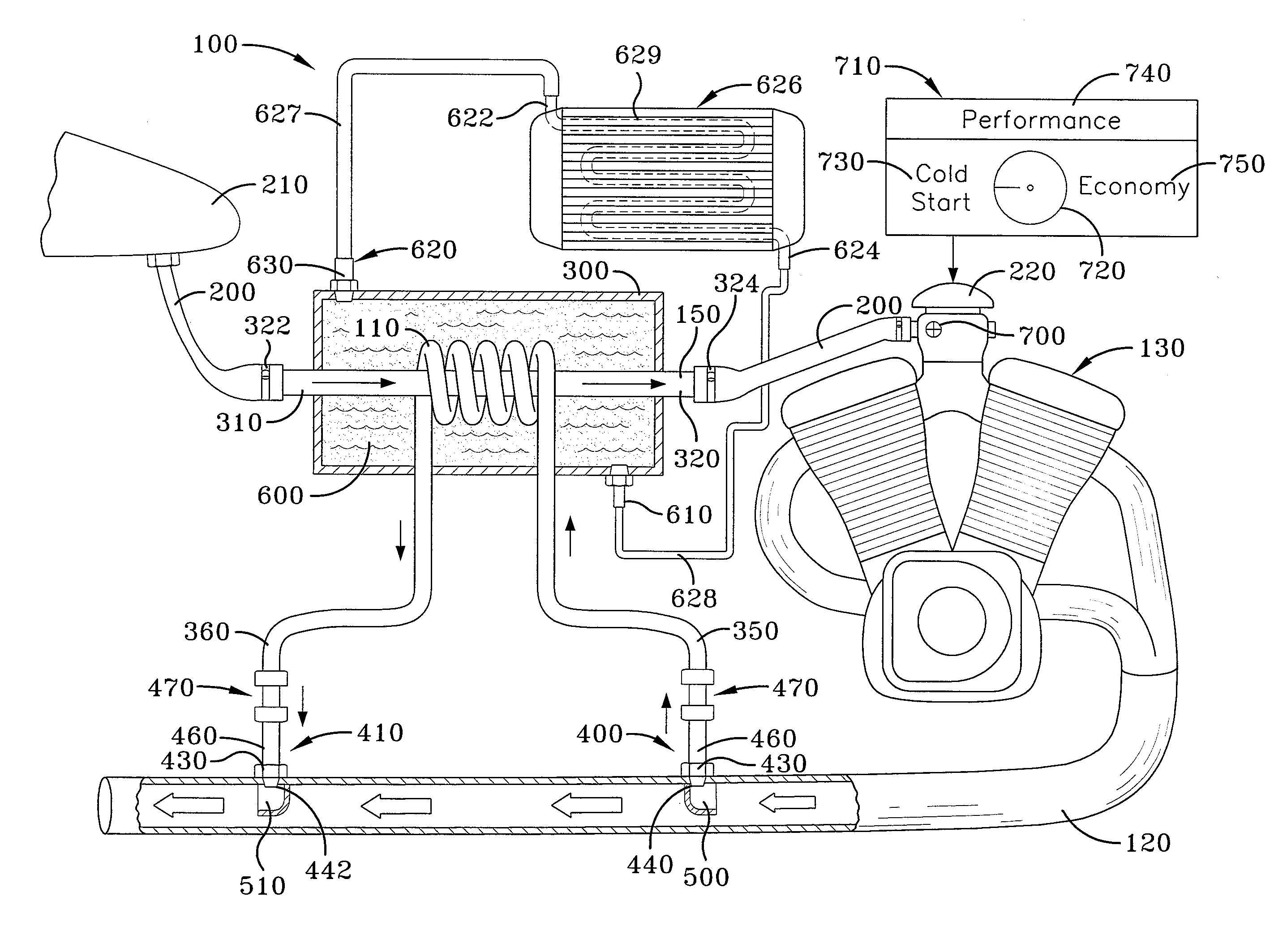

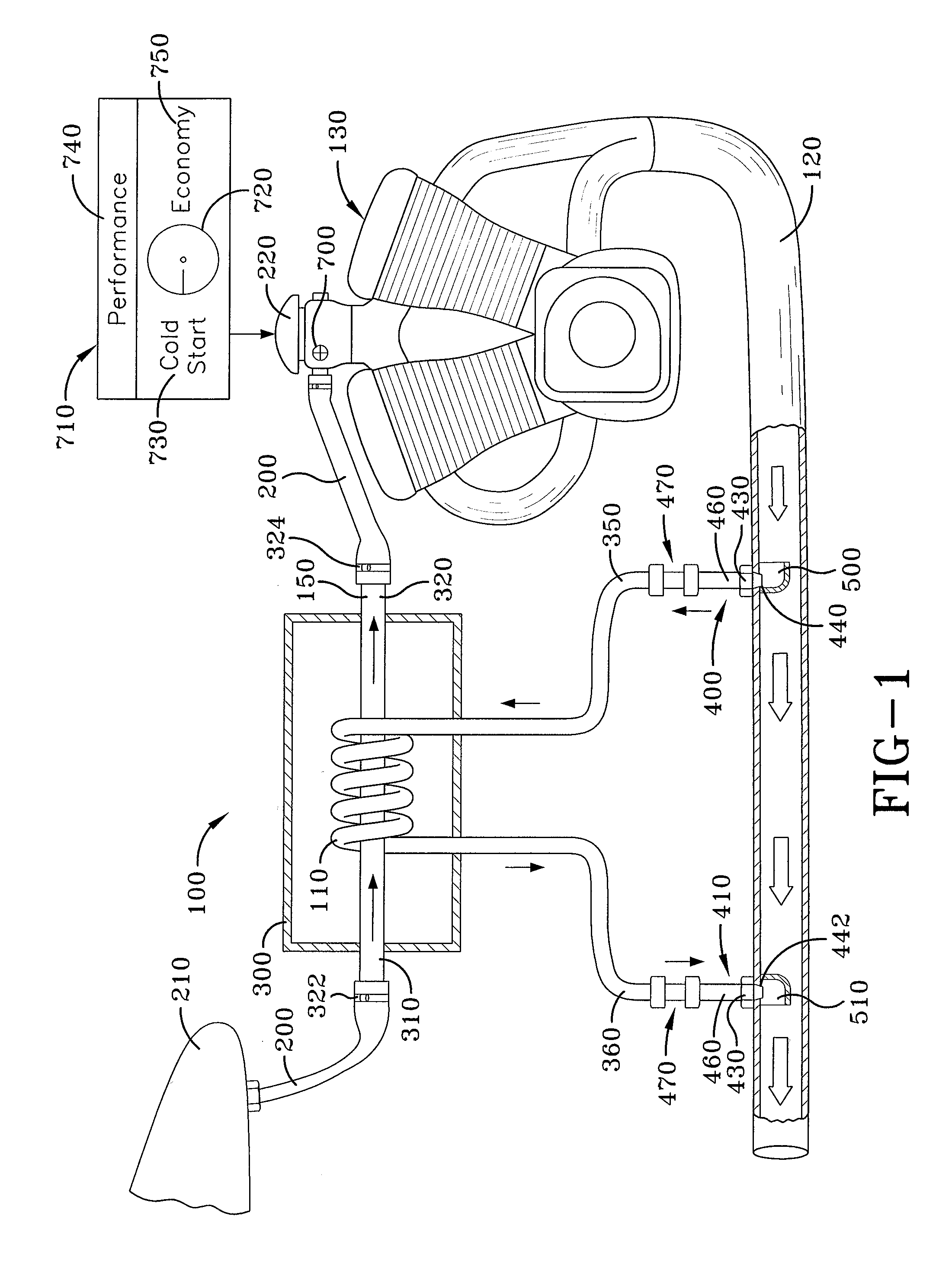

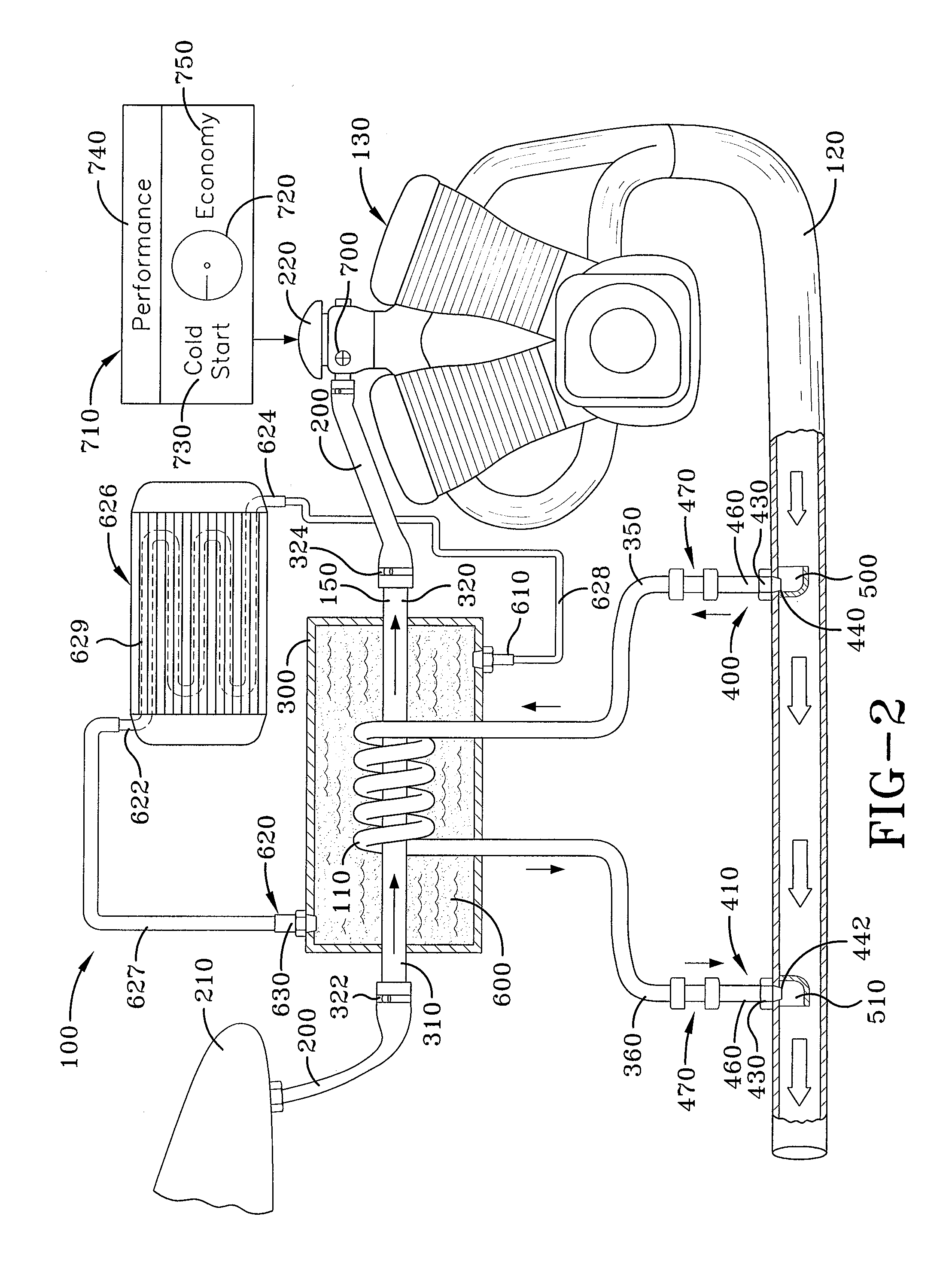

Fuel conservation device

ActiveUS20100288245A1Internal combustion piston enginesThermal treatment of fuelFuel conservationLine tubing

A fuel conservation device for a combustion engine includes a heat-exchanging tube disposed through a heating coil that is contained within a housing containing coolant. The heat-exchanging tube is adapted to be coupled inline with a fuel line used to supply fuel from a gas tank to a fuel management device, such as a carburetor provided by the engine. In addition, the heating coil is configured to be coupled to an exhaust pipe coupled to the engine, so as to be heated by the hot exhaust gases generated as it operates. A radiator fluidly coupled to the housing cools the coolant, so that the fuel passing through the fuel line is maintained at a temperature just below the boiling point of the fuel.

Owner:FERTIG ANDREW L

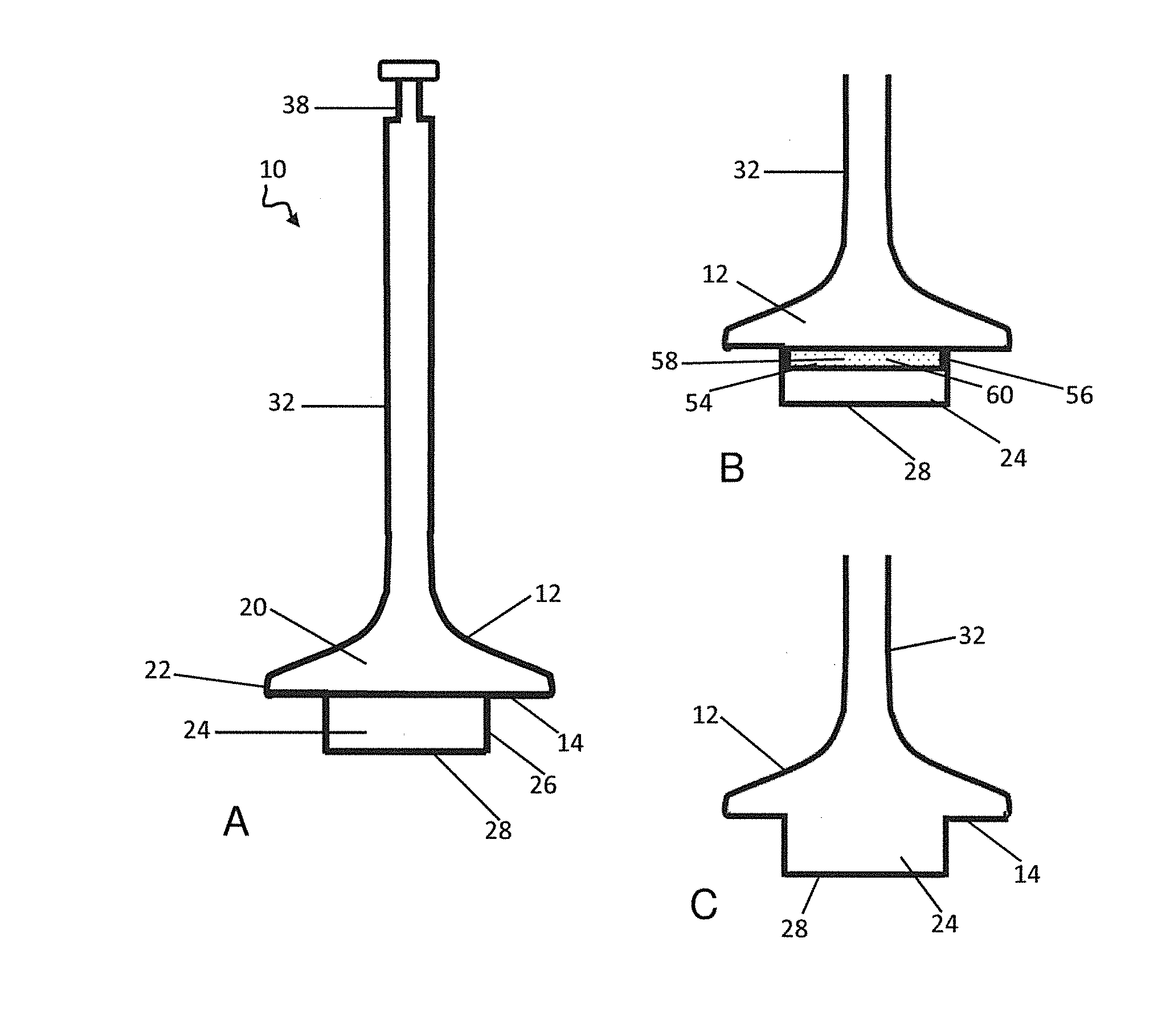

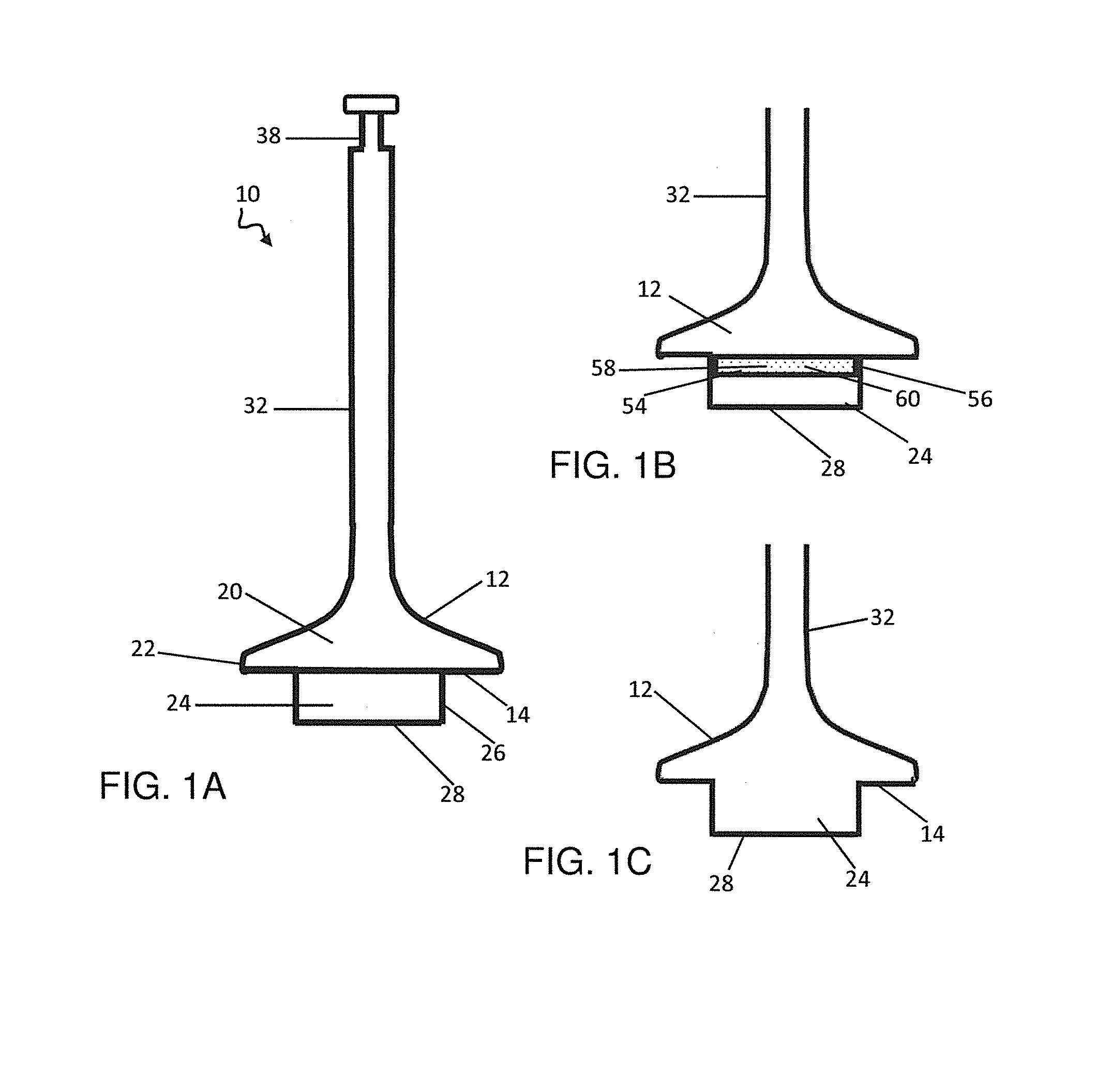

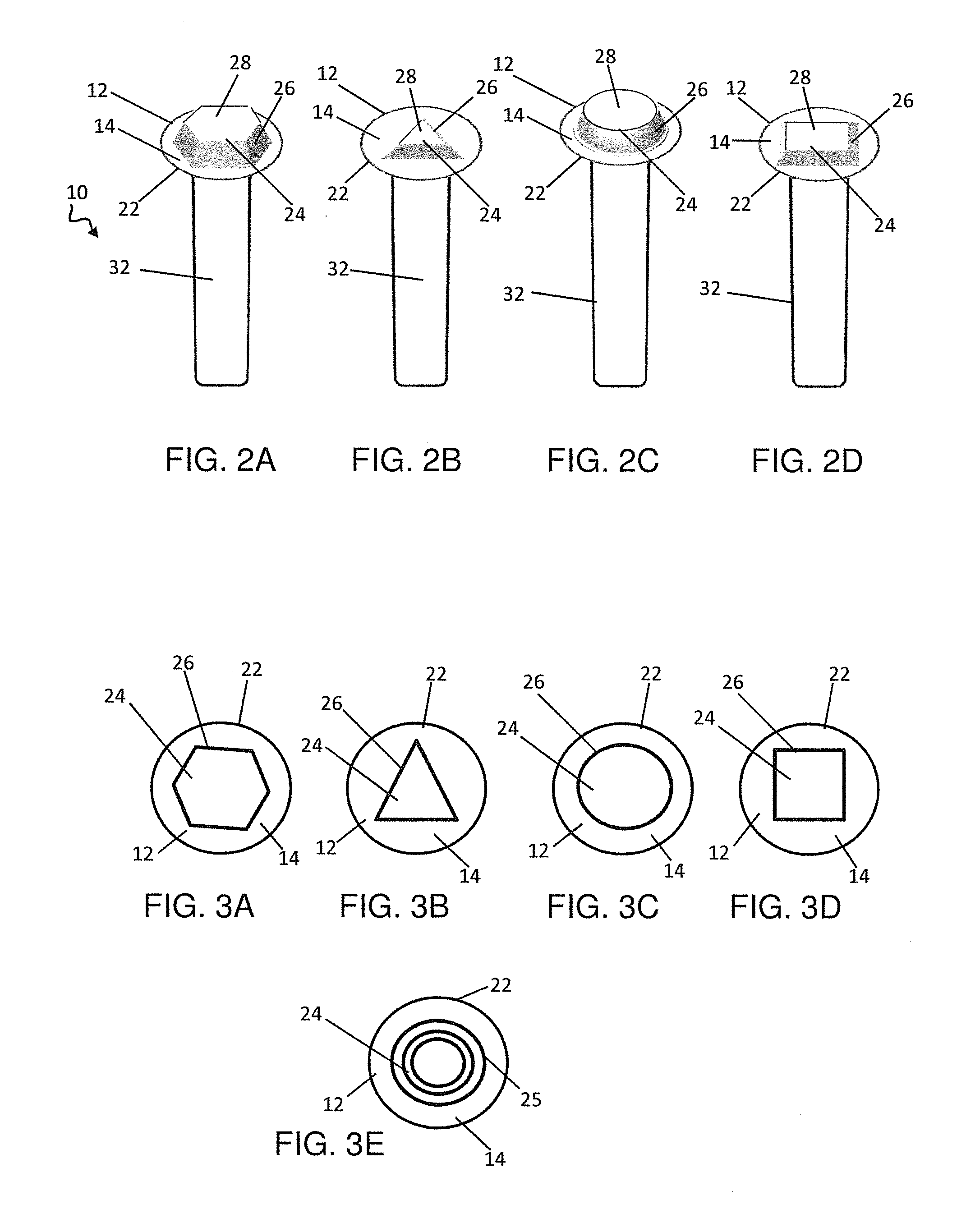

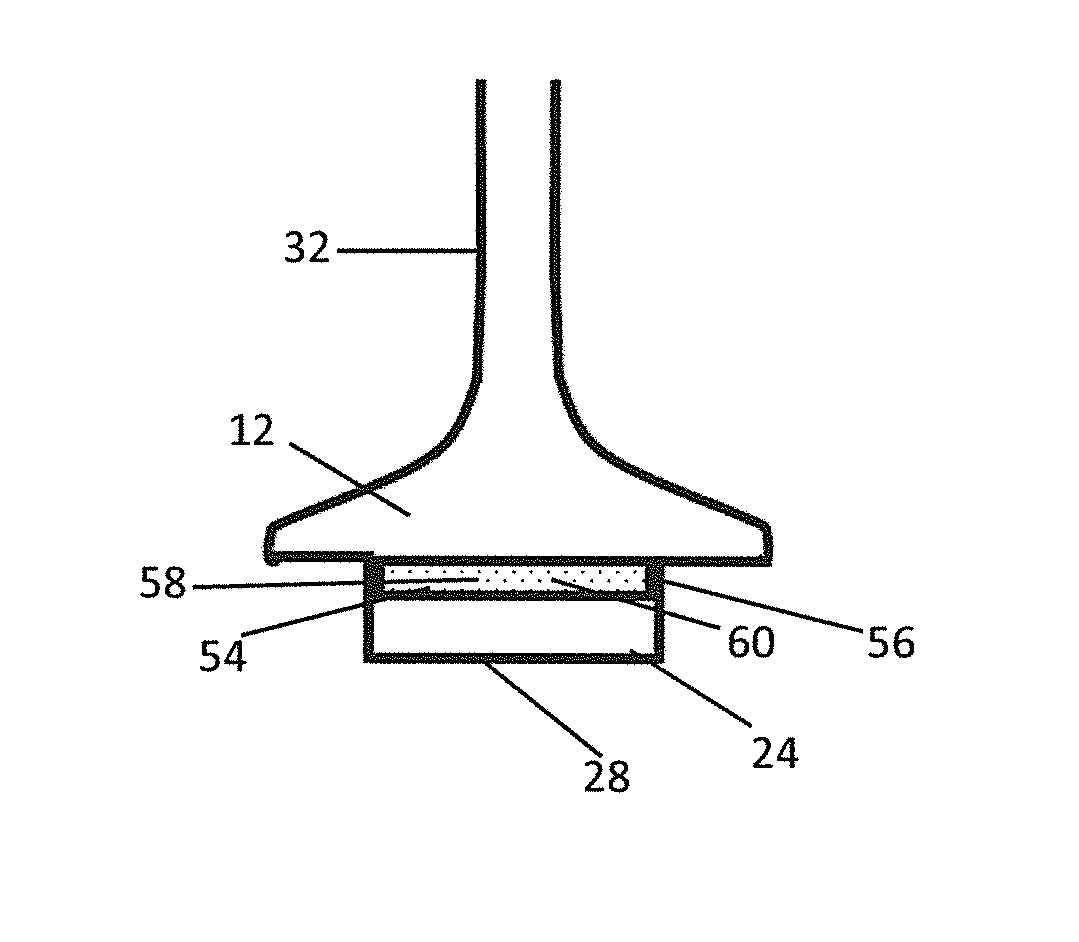

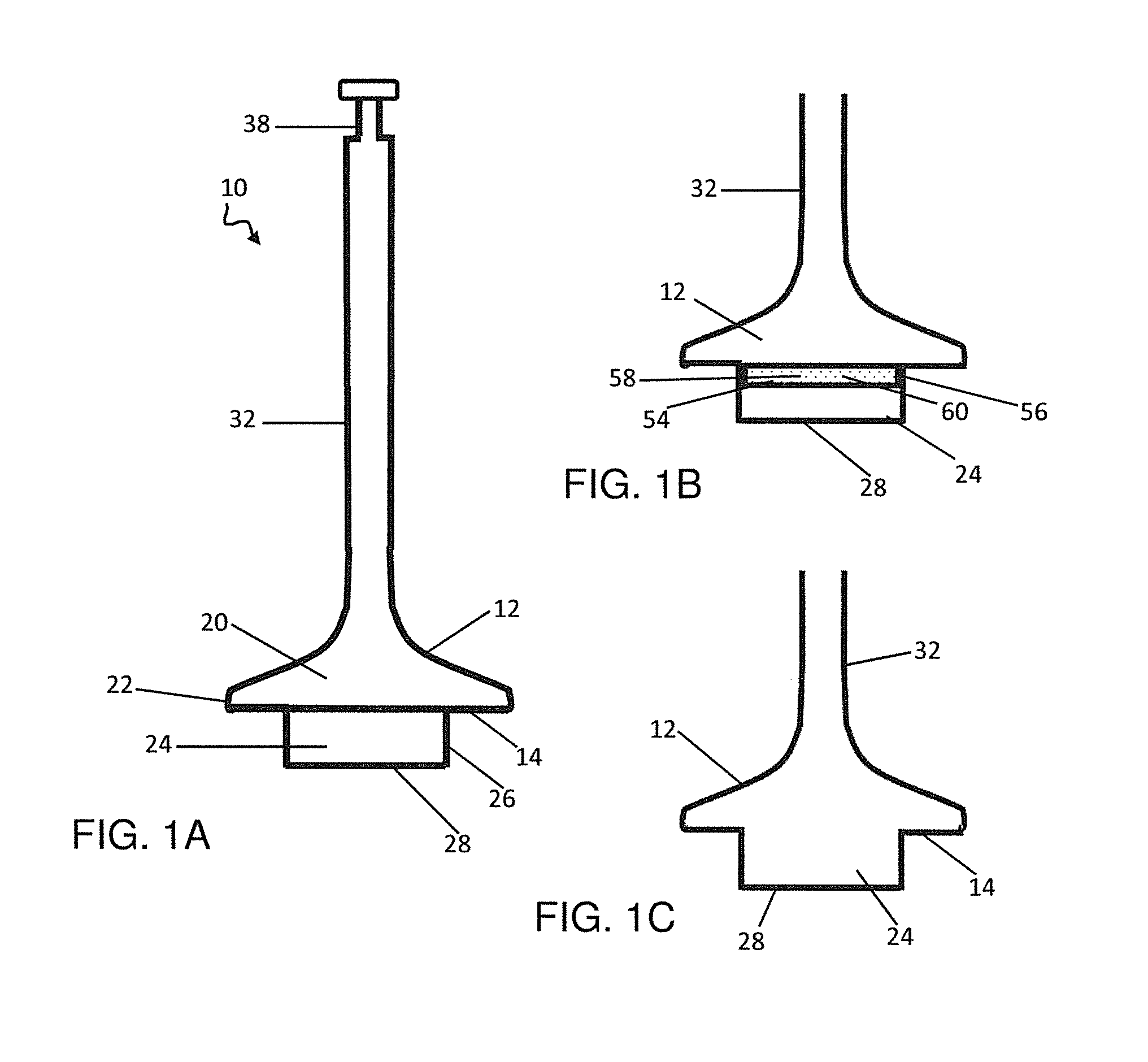

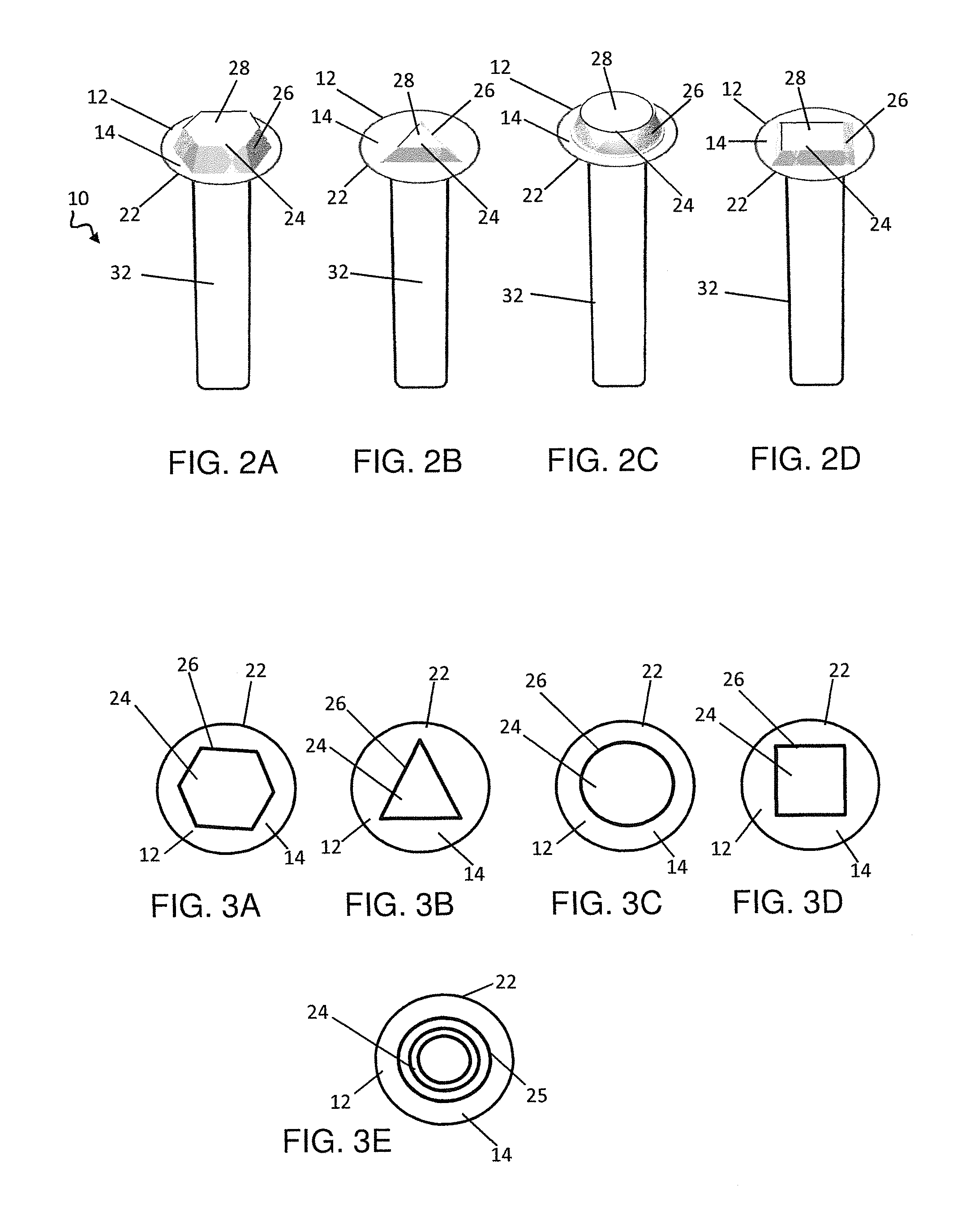

Heat transferring engine valve for fuel conservation

InactiveUS20140014057A1Improve combustion efficiencyMachines/enginesSlide valveFuel conservationCombustion chamber

A heat transferring engine valve for an internal combustion engine to increase the combustion efficiency and fuel economy of the engine. The heat transferring valve includes a valve head and a heat transferring member situated at the combustion surface of the valve head and extending toward the combustion chamber. The heat transferring member absorbs heat of combustion during the power stroke of an engine cycle and releases the heat into the combustion chamber during the compression stroke of a succeeding engine cycle, thereby raising the temperature of fuel at the start of combustion. A method for increasing the efficiency of combustion in an internal combustion engine by incorporating at least one heat transferring valve into the engine.

Owner:MCGINNIS GEORGE

Energy-saving cooling fluid

The invention discloses an energy-saving cooling fluid. The energy-saving cooling fluid comprises the following raw material components in parts by weight: 40-45 parts of 1,2-propylene glycol, 25-30 parts of glycerol, 20-22 parts of ethanol, 15-21 parts of ethyl acetate, 8-10 parts of polyethylene glycol, 5-6 parts of polyvinyl alcohol, 3-5 parts of hydroxyethyl cellulose, 2-5 parts of sodium alginate, 4-6 parts of sodium polyacrylate, hexametaphosphate, 3-5 parts of isocaprylic acid, 3-5 parts of sodium benzoate, 4-6 parts of adipic acid, 3-5 parts of azelaic acid, 1-2 parts of salicylic acid, 2-3 parts of tartaric acid, 2-4 parts of lauric acid, 2-5 parts of pentanoic acid, 4-5 parts of malonic acid, 4-6 parts of sodium hydroxide, 3-4 parts of aluminum hydroxide, 3-5 parts of thiourea and 20-25 parts of deionized water. By virtue of the energy-saving cooling fluid, the safety performance of the engine can be greatly improved, the fuel conservation is achieved, the engine damage caused by high temperature is prevented and the heat conduction and cooling effects are remarkable.

Owner:张慧玲

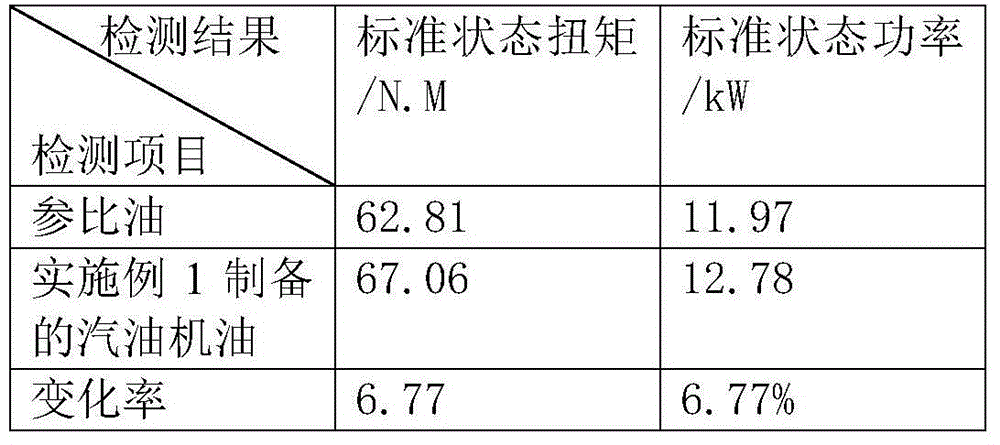

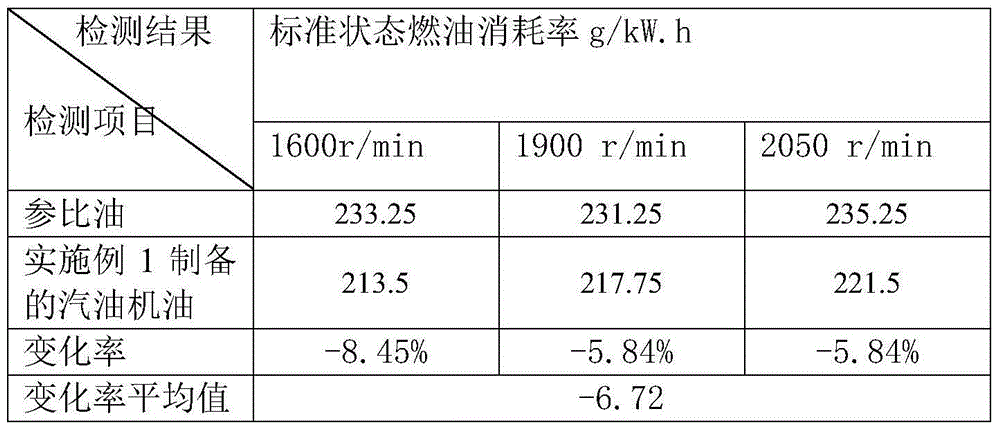

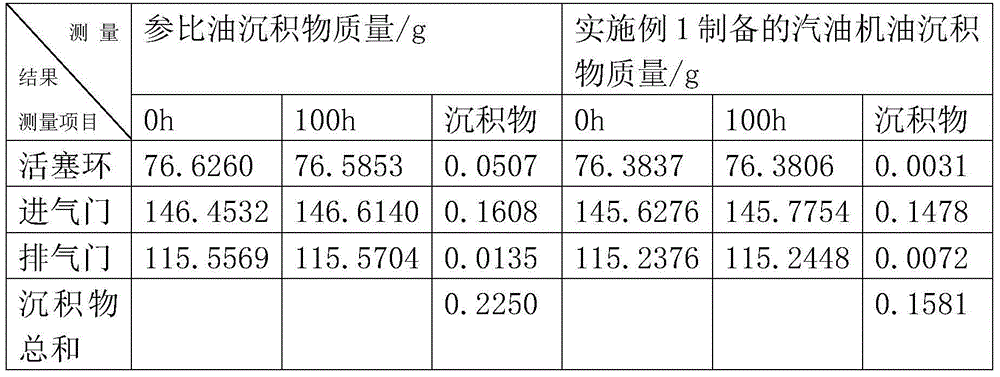

Energy-saving emission-reducing type gasoline engine oil and preparation method thereof

The invention discloses energy-saving emission-reducing type gasoline engine oil and a preparation method thereof. The gasoline engine oil (API SN SAE 5W / 40 specification requirements) is prepared from the following components in percentage by weight: 20-25% of 100N, 45-55% of 150N, 8-12% of PAO-4, 6.0-12.0% of a viscosity index improver SCR-261, 7-10% of a gasoline engine oil composite additive H9089, 0.001-0.01% of a defoaming agent T901, and 0.3-3% of a nano friction improver TND001. A nano functional material in the gasoline engine oil disclosed by the invention can be kept in a stable and uniform state for a long time without generating any layer chromatography and failure phenomenon. The product disclosed by the invention can be used for a gasoline engine of a high-class car, and the like, fuel oil can be reduced by 4-15%, pollutants can be reduced by 10-40%, power is increased by more than 6%, and cold-starting abrasion of the engine is avoided.

Owner:湖北长天通信科技有限公司枣阳分公司

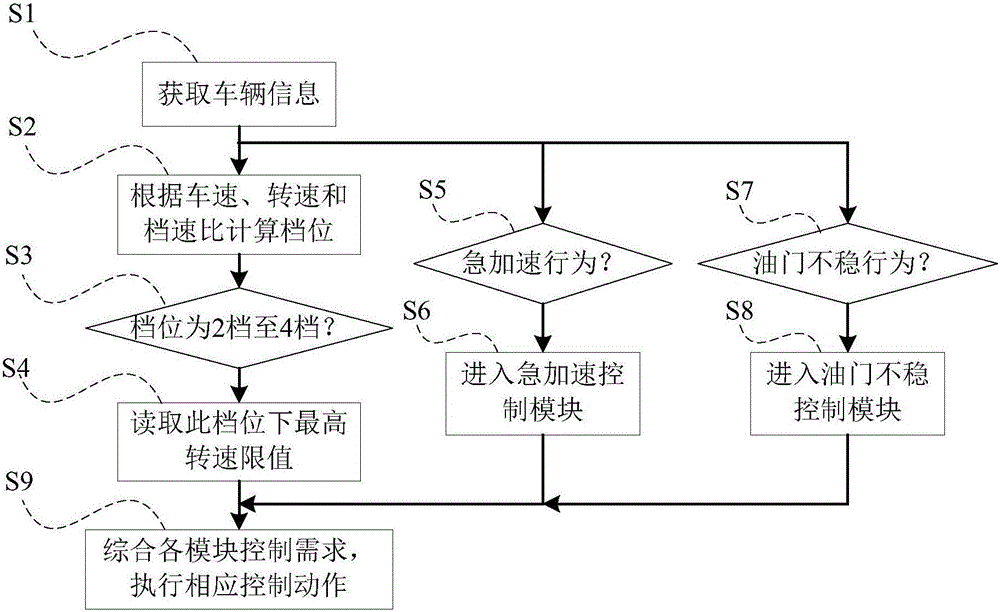

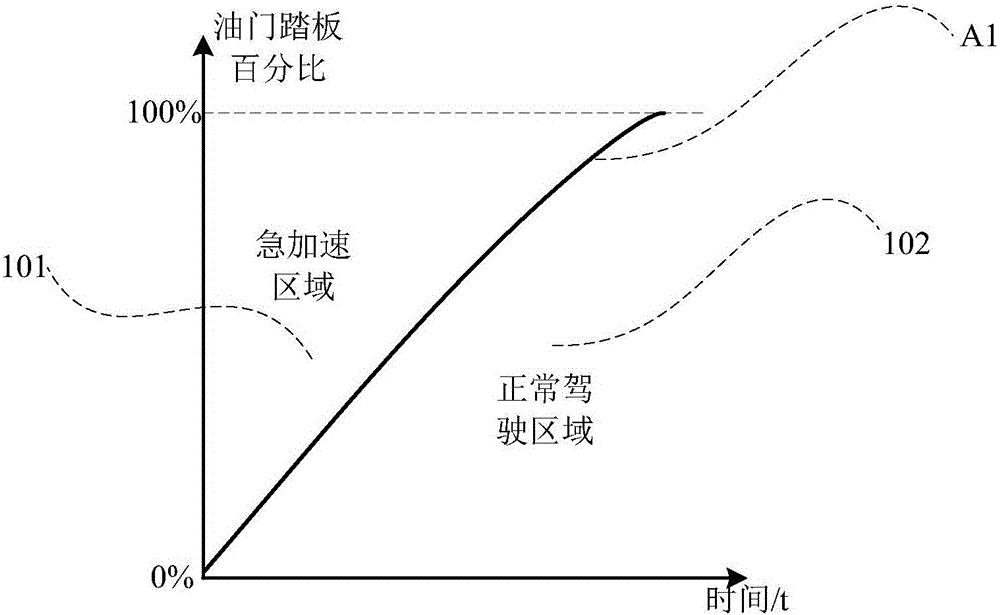

Automatic driving behavior optimizing method

ActiveCN105857302ABad driving behavior optimizationFix bad drivingData processing managementFuel conservationHigh velocity

The invention relates to an automatic driving behavior optimizing method which can judge bad driving behaviors. The bad driving behaviors comprise at least one of high-speed driving at a low gear, abrupt acceleration and unsteady stepping on an accelerator, and corresponding control algorithms are adopted to relieve the bad driving behaviors: when the driving behavior of high-speed driving at a low gear occurs, the highest rotation speed of an engine of a vehicle is limited to be at a preset highest rotation speed value; when the behavior of abrupt acceleration occurs, an actual accelerator pedal value is limited, and an output accelerator pedal value is acquired and does not exceed the actual accelerator pedal value under a normal driving condition; when the behavior of unsteady stepping on the accelerator occurs, the engine is controlled to output a power value according to an engine torque value corresponding to a set accelerator pedal value. According to the method, power output of the engine is directly controlled, active correction and optimization are performed when a driver has a bad driving behavior, the bad driving problem is fundamentally solved, and the driving safety and the fuel conservation effect are improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Tourmaline additive for saving energy and reducing emission

InactiveCN104232184AStrong NMR CapabilityNon-corrosiveLiquid carbonaceous fuelsFuel conservationCombustion chamber

The invention provides a tourmaline additive for saving energy and reducing emission, and particularly relates to a liquid fuel additive used for saving energy and reducing emission, increasing output power of an engine, improving anti-explosion performance of fuel and reducing engine noise and water temperature. The additive comprises moisture and tourmaline micro-powder or tourmaline nano-powder. According to the tourmaline additive, the synergetic effect of moisture particle explosion and nuclear magnetic resonance is utilized, high voltage electrodes (tourmaline micro-powder or tourmaline nano-powder) are intensively distributed inside a combustion chamber of the engine in a diffusing manner and are capable of inevitably generating over 10000 volts of strong discharge inside a cylinder under a condition of high temperature and extreme pressure, and combustion is enforced to burst in an absolutely uniform manner, so that insufficient combustion modes can be completely eliminated, fuel is remarkably saved by 10-48 percent, power is remarkably improved to enable a vehicle to climb at a higher gear, the anti-explosion performance of fuel can be remarkably improved, noise and vibration can be reduced, over-high water temperature even boiling water of the engine can be balanced, and the electronic lighting function, which is lost because of aging, of certain engines can be recovered.

Owner:罗琮贵

Fuel cell system and method for operating the same

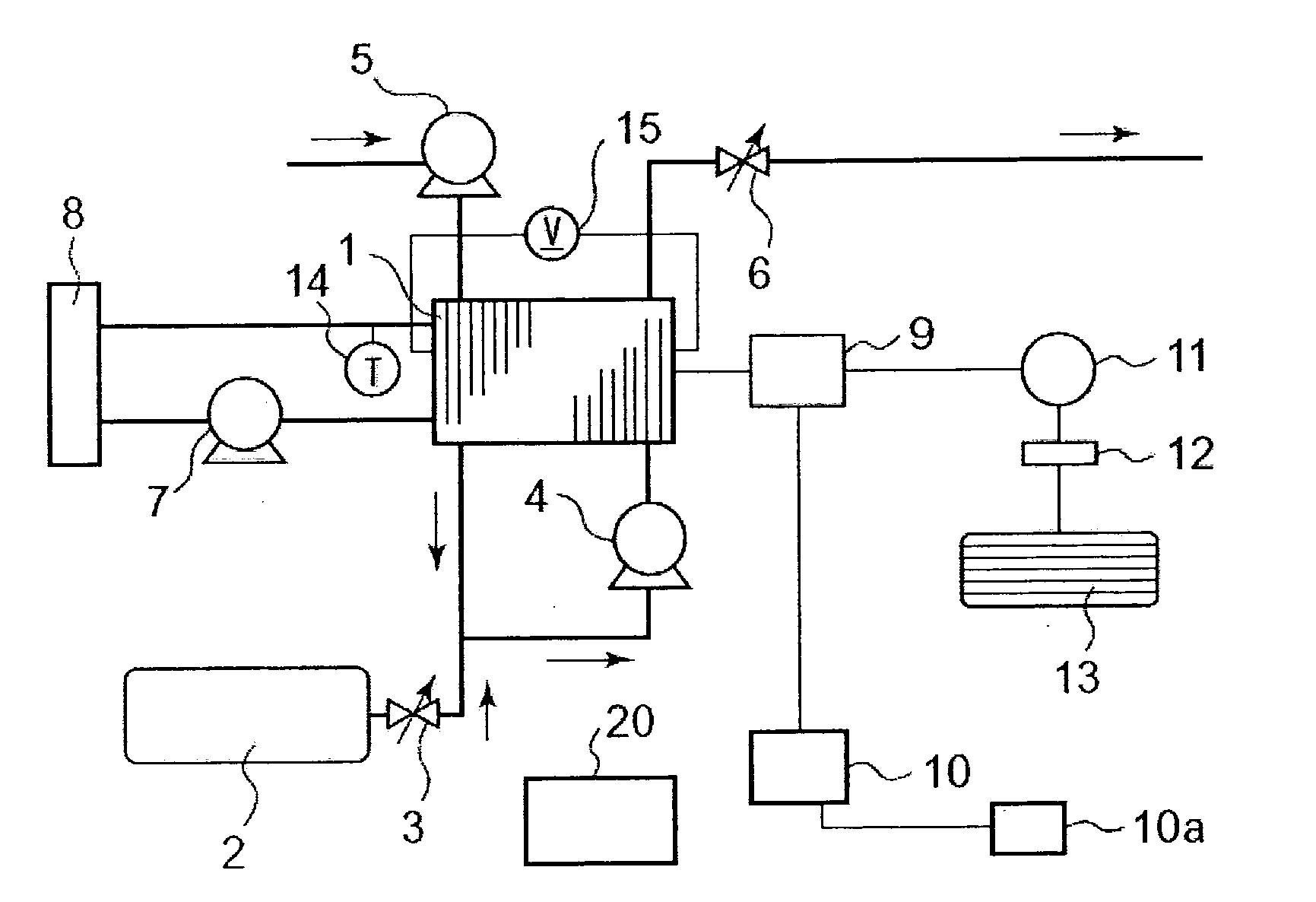

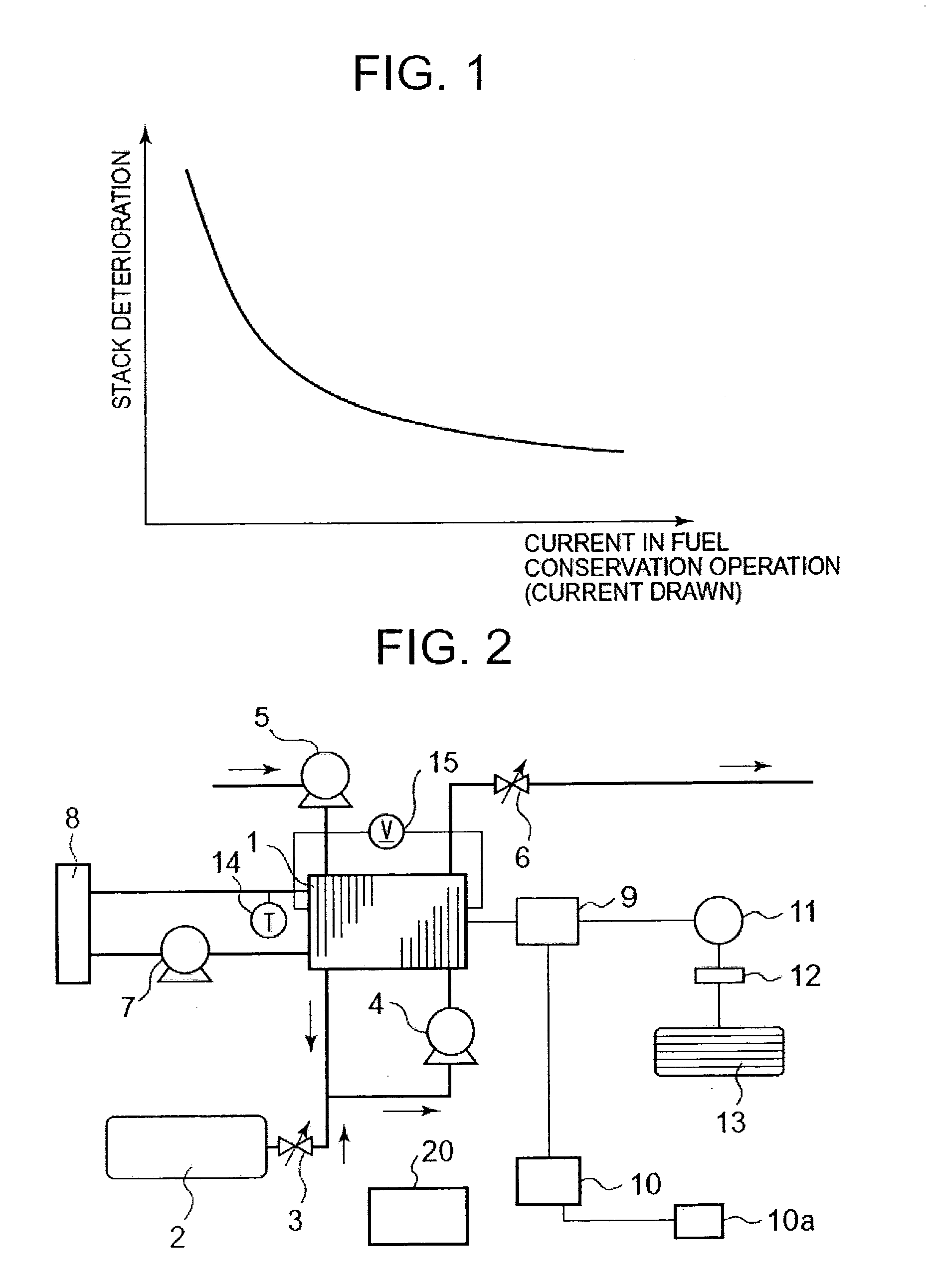

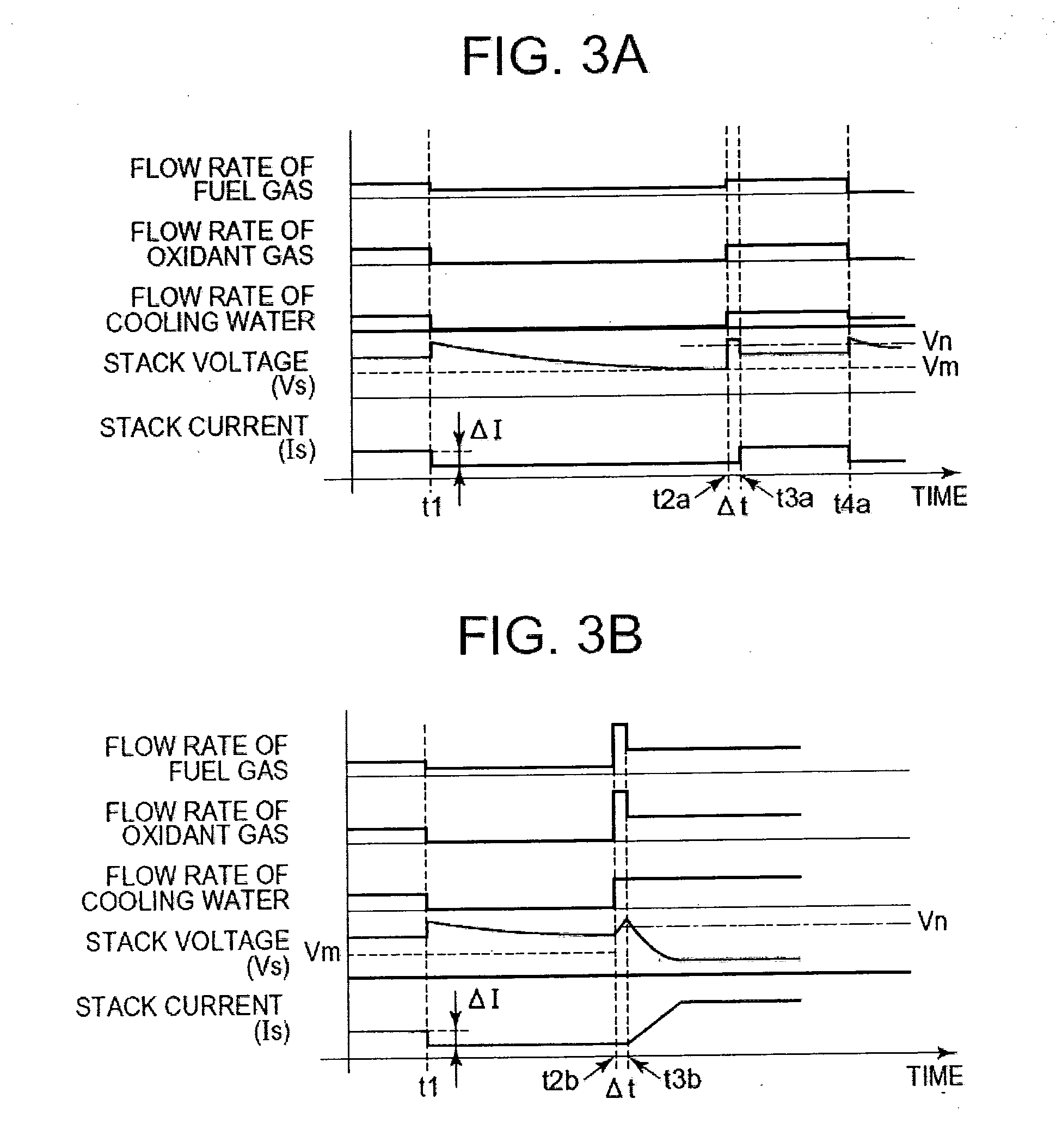

A fuel cell system which prevents the deterioration of the fuel cell stack when feeding of the oxidant gas is paused under a load to perform a fuel conservation operation. Controller shuts down oxidant gas compressor and cooling water circulating pump to execute fuel conservation operation at a low fuel cell system load. The controller gives a current draw instruction to electric power controller. In the fuel conservation operation, electric power controller draws a current larger than zero from fuel cell stack, and keeps the total charge drawn per unit time constant or substantially constant.

Owner:NISSAN MOTOR CO LTD

Heat transferring engine valve for fuel conservation

InactiveUS8960148B2Improve combustion efficiencyMuscle operated startersMachines/enginesFuel conservationCombustion chamber

Owner:MCGINNIS GEORGE

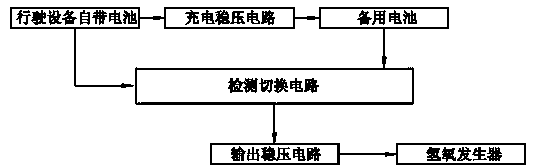

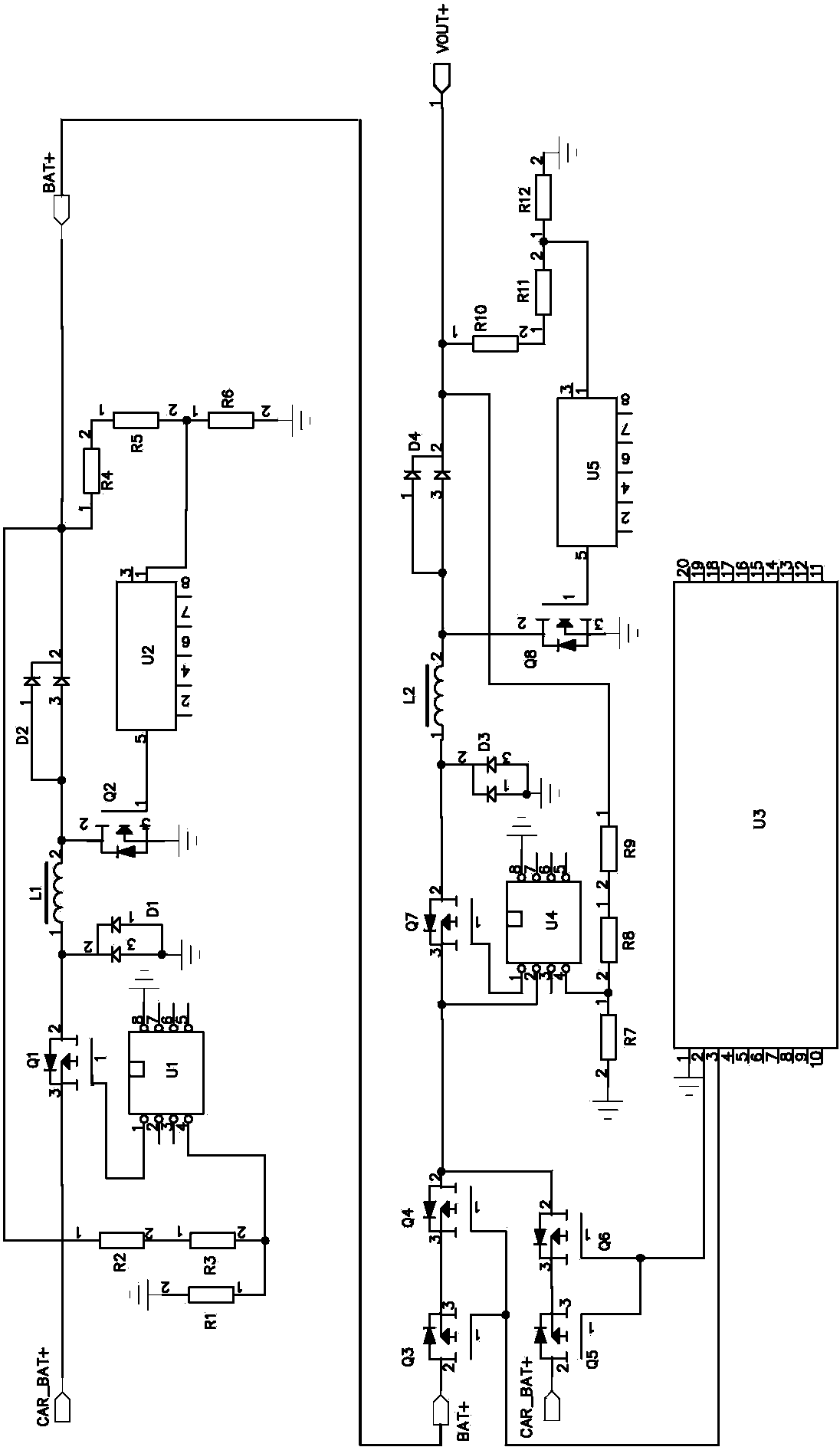

Energy-saving current voltage stabilization auxiliary system for oxyhydrogen machine

InactiveCN104348240AExtended service lifeGuaranteed uptimeBatteries circuit arrangementsCharging stationsFuel conservationFuel oil

The invention discloses an energy-saving current voltage stabilization auxiliary system for an oxyhydrogen machine. The energy-saving current voltage stabilization auxiliary system for the oxyhydrogen machine comprises a standby battery, a charge voltage stabilization circuit, a detection switching circuit and an output voltage stabilization circuit. The energy-saving current voltage stabilization auxiliary system is reasonable in structure layout, and is capable of simultaneously charging and discharging; excessive generating capacity of a running equipment generator is supplied to a hydrogen-oxygen generator and replenished to the standby battery with stable current voltage; when the generating capacity is not enough, a working power supply is lastingly provided for the hydrogen-oxygen generator by automatically switching into the standby battery, and the power supply current voltage is stable, so that the working stability of the hydrogen-oxygen generator is effectively ensured; hydrogen and oxygen with constant flow are provided for an engine of running equipment; the reliability is high; the power of the engine is effectively improved; fuel oil is saved; the energy-saving current voltage stabilization auxiliary system is energy-saving and environment-friendly; meanwhile, the service life of a built-in battery of the running equipment is prolonged; normal operation of the running equipment is ensured; the energy-saving current voltage stabilization auxiliary system is wide in application range, can be applied to running equipment, such as saloon cars, buses, trucks and steamships with fuel oil, natural gas and the like.

Owner:东莞市绿麒麟环保科技有限公司

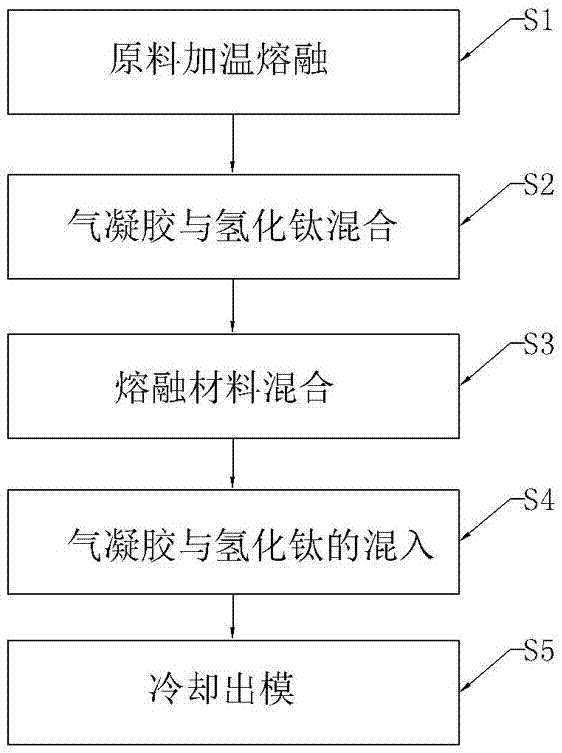

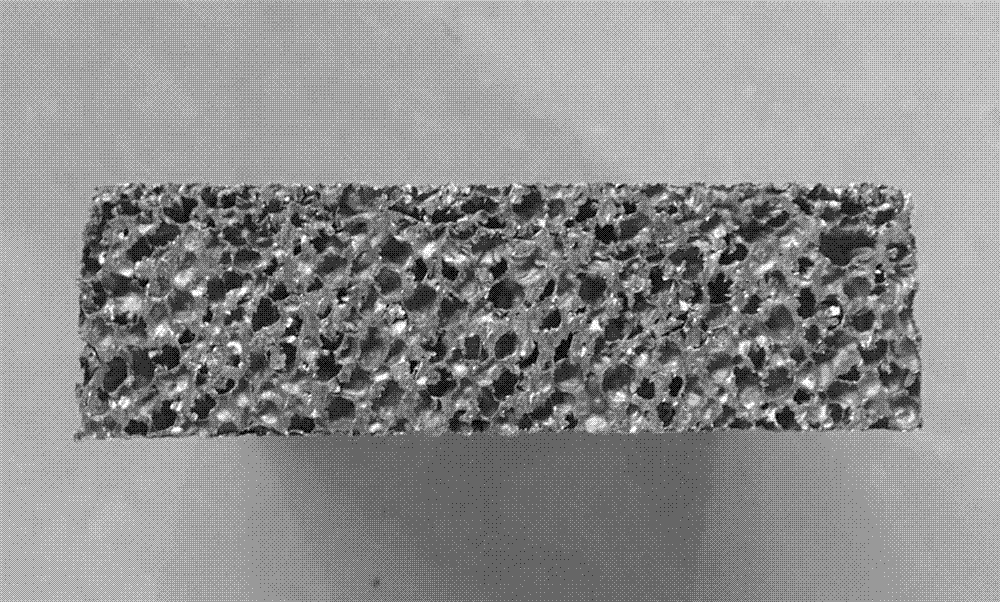

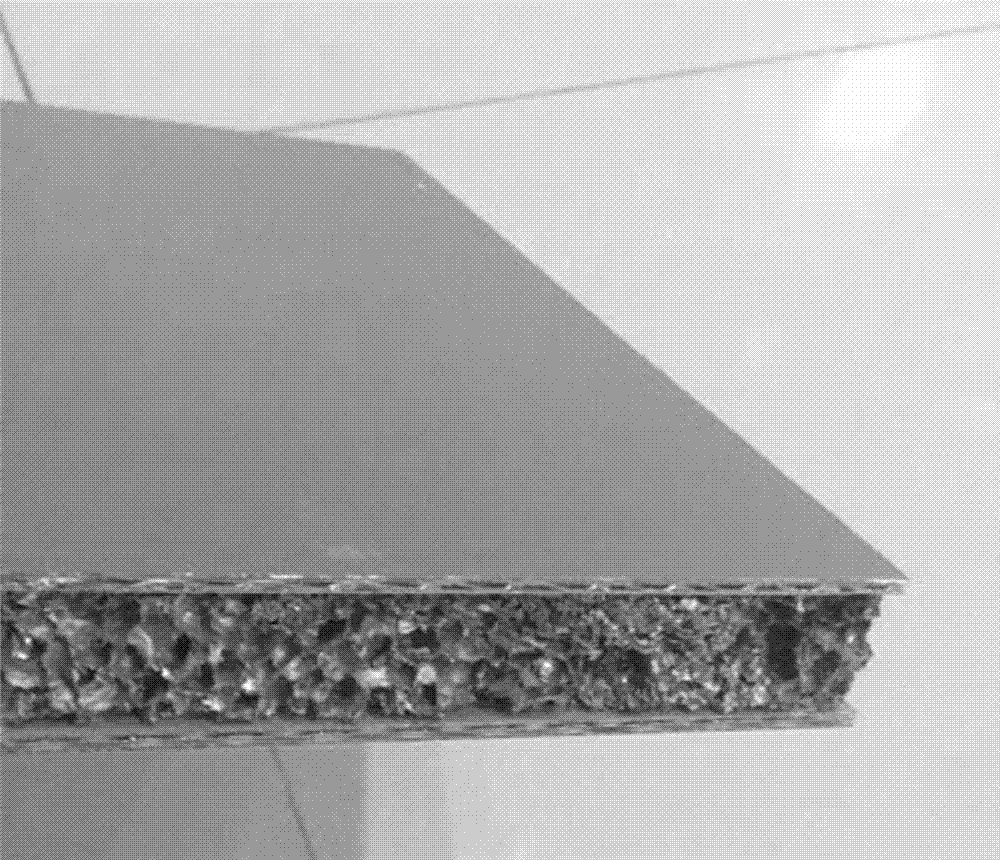

Modified composite metal truck loading plate and manufacturing method thereof

The invention discloses a modified composite metal truck loading plate and a manufacturing method thereof. The metal bridge plate comprises the following components in parts by mass: 55 to 75 parts of an aluminium material, 10 to 20 parts of an iron material, 3 to 8 parts of a magnesium material, 0.1 to 0.3 part of a graphene material, 3 to 8 parts of feldspar powder, 1 to 2 parts of fumed silica, 0.2 to 0.4 part of aerogel and 6 to 10 parts of titanium hydride powder. The modified composite metal truck loading plate manufactured from the aluminium material, the iron material, the magnesium material, the graphene material, feldspar powder, fumed silica and aerogel is light in mass, high in strength and good in toughness, and has good pressure resistant, stretching resistant, antiseismic, rustproof and anticollision functions; and the truck loading plate is a porous plate and is provided with countless fulcrums and pores, compressive resistance and stretching resistance are balanced, bearing capacity is improved by 10 times or above, fuel oil can be saved, the modified composite metal truck loading plate can bear tons of cargo, and economic benefits are increased.

Owner:何新桥

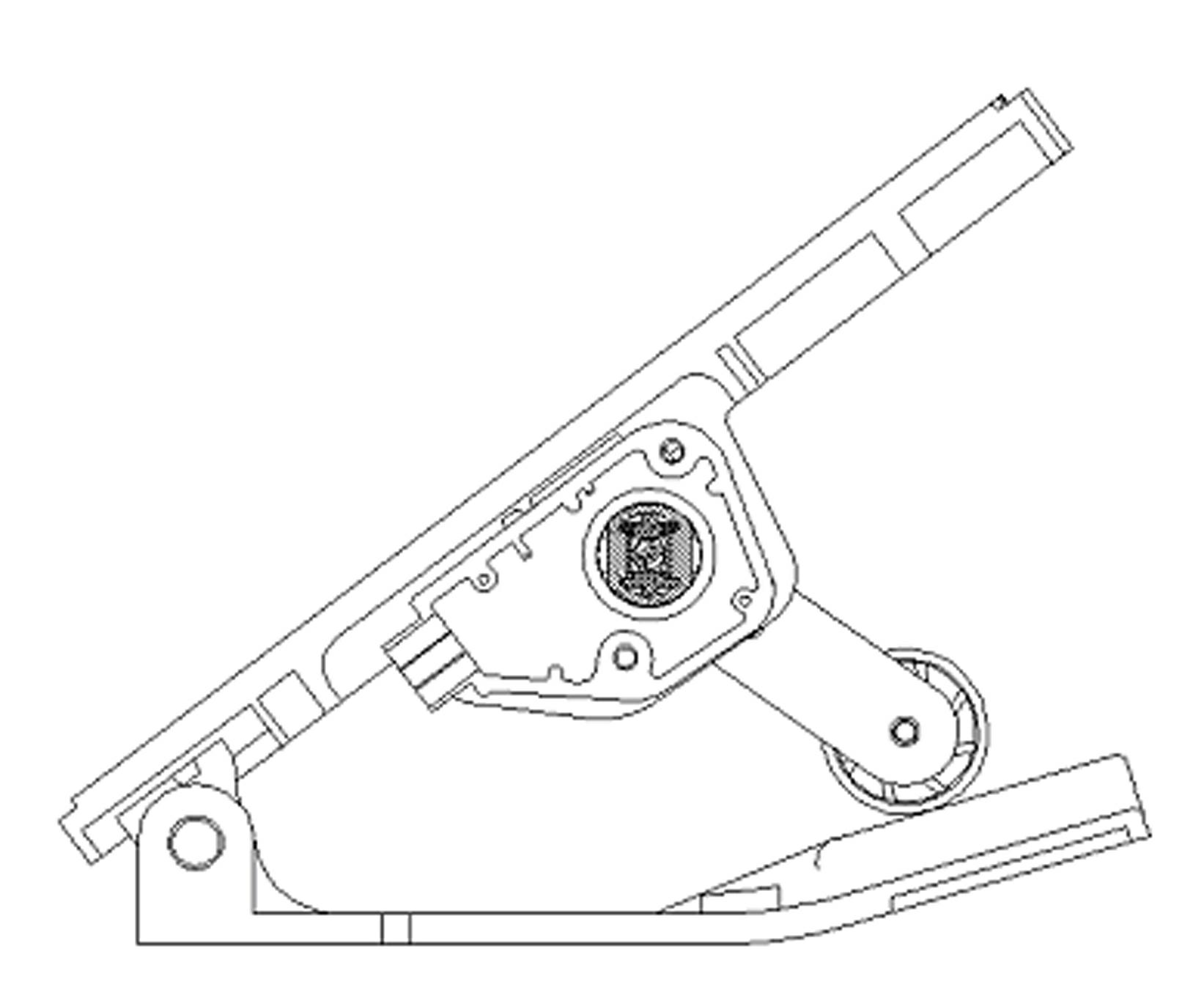

Electronic accelerator pedal with high-linearity output signal

ActiveCN102121421AImprove linearityImprove comfortEngine controllersMachines/enginesFuel conservationElectronic throttle

The invention relates to an electronic accelerator pedal with a high-linearity output signal, which belongs to an accelerator control device of a motor vehicle and relates to a non-contact electronic accelerator pedal for oil inlet amount of an engine cylinder of the motor vehicle. The conventional non-contact electronic accelerator pedal is improved by setting the direction of magnetic steel in a Hall sensor when the engine is in different states and setting the angle of the Hall sensor between 26 degrees and 40 degrees at an idle speed position. Based on the improvement, the electronic accelerator pedal assembly in the invention solves the problems of difficulty in accurate control over the initial position of the conventional electronic accelerator pedal sensor, poorer linearity of a voltage output signal responding to the electronic accelerator pedal and poor operational reliability of an electronic accelerator so that the accelerator control accuracy of the engine is improved, fuel oil is saved and the environment is protected.

Owner:WENZHOU RUILI KEMI AUTOMOTIVE ELECTRONICS CO LTD

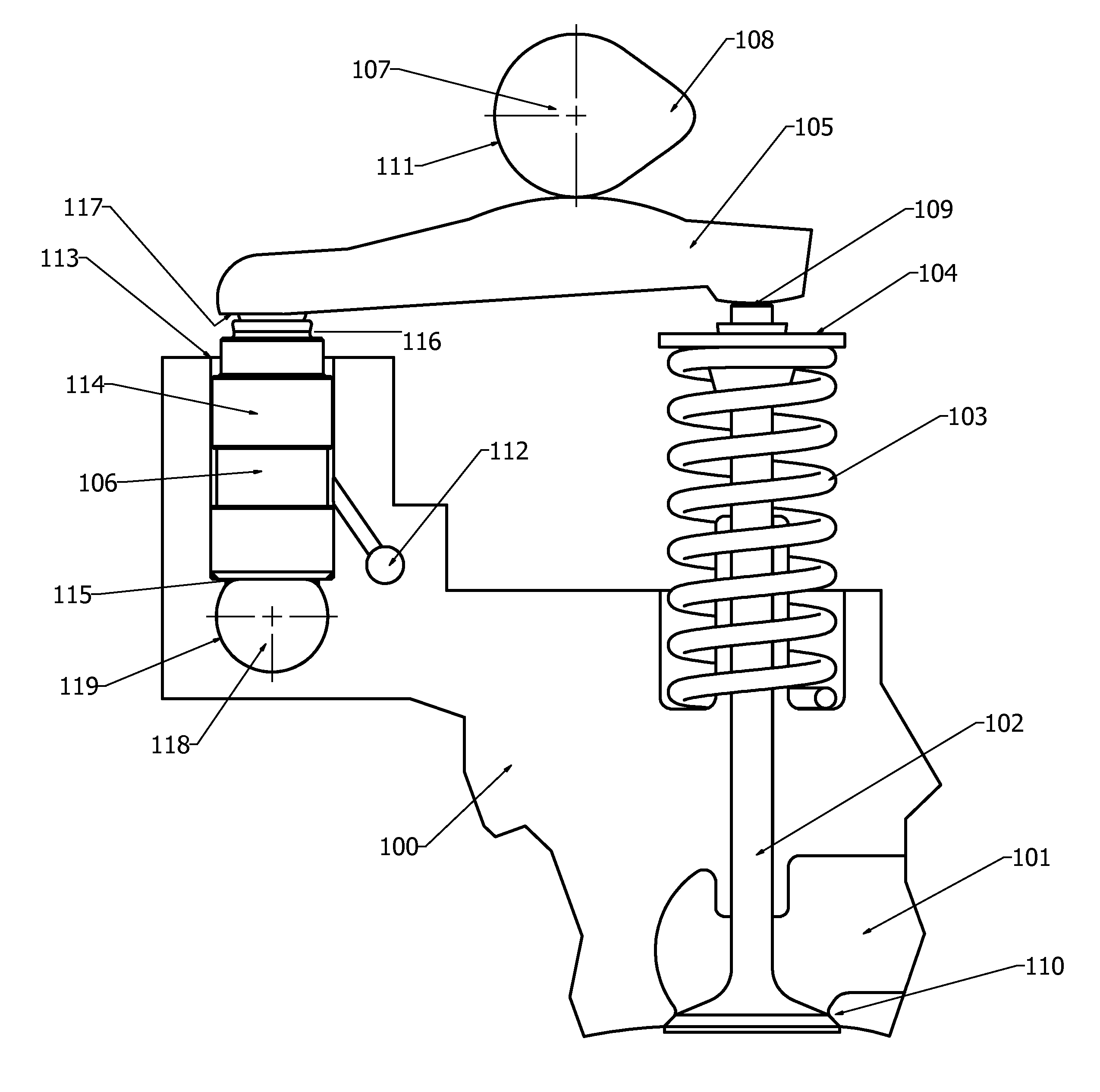

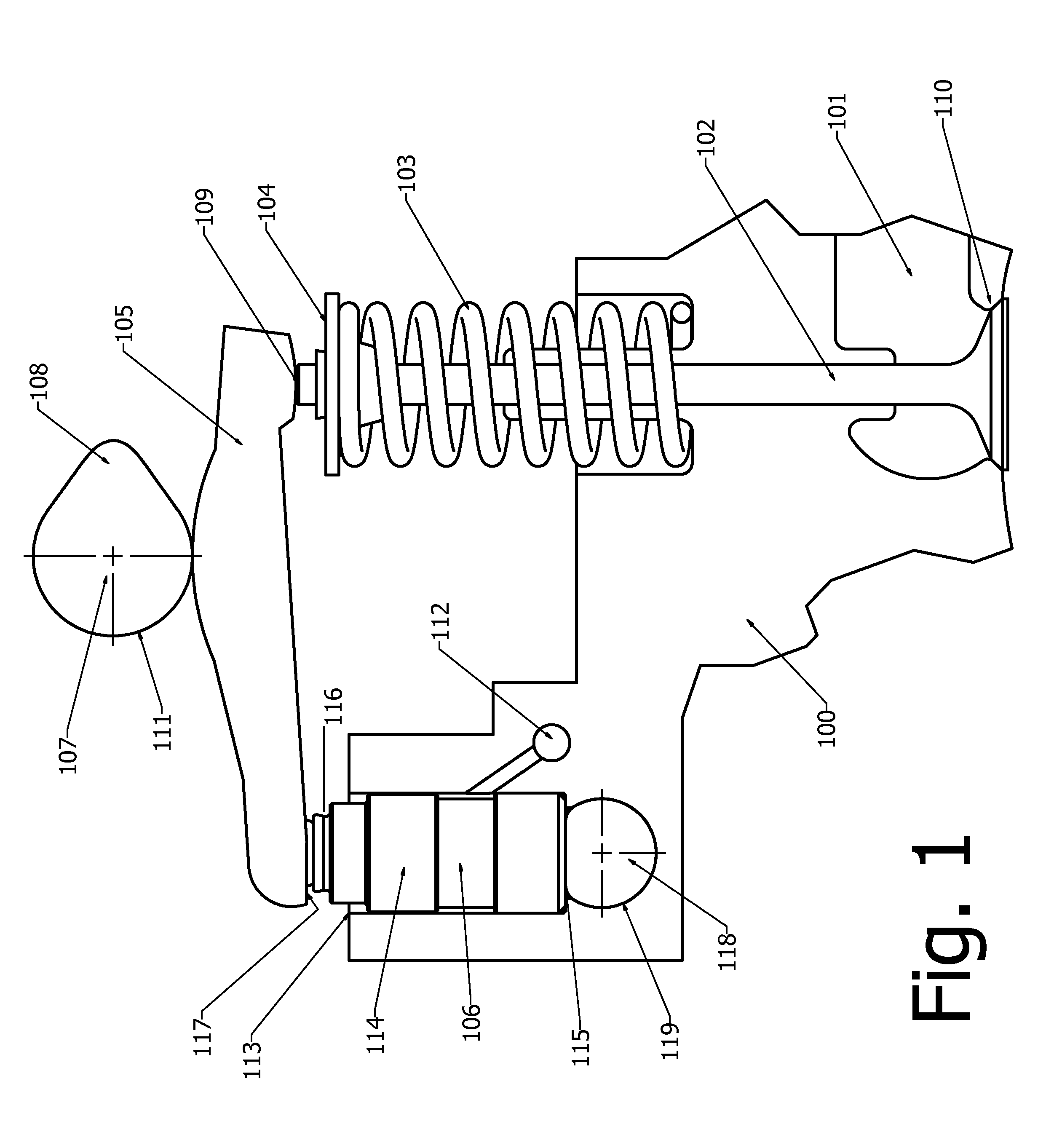

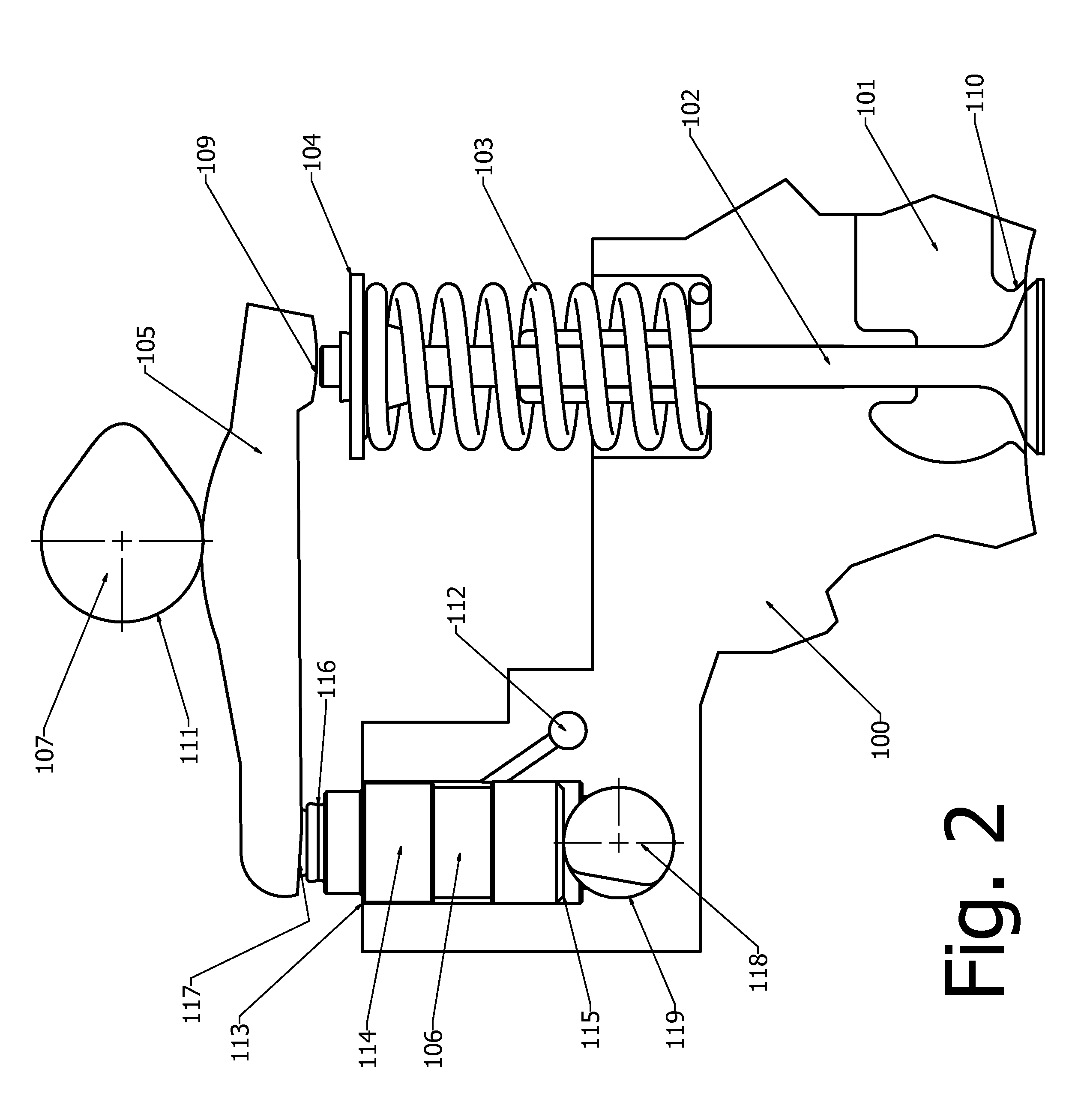

Engine compression release method and apparatus

The present invention comprises apparatus and methods for releasing internal combustion engine compression during cranking to reduce cranking effort and the size and weight of the starter motor and battery. It is particularly suitable for fuel conservation systems that stop the engine when the vehicle is stopped in traffic, and restart the engine when the driver steps on the accelerator petal, since such systems place heavy demands on the starter motor and battery. The apparatus provides a means for automatically shifting the valve gear such that exhaust and / or inlet valves are held slightly open during the intake compression strokes to reduce compression torque during initial cranking, and restoring the valves to normal operation before the first firing event. The method provides a sequence of steps executed by the engine electronic control module to control the compression release apparatus to carry out the engine starting process safely and reliably.

Owner:MEACHAM G B KIRBY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com