Manufacturing method of light aerofoil with super-high aspect ratio and high lift-drag ratio and aerofoil manufactured thereby

A technology with a high lift-to-drag ratio and a manufacturing method, applied in the field of aircraft, can solve problems such as poor effect, limited lifting space, and increased weight of the wing structure, and achieve the effects of light weight, improved rigidity and strength, and increased stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment is based on the "Helios" (Helios) solar-powered aircraft.

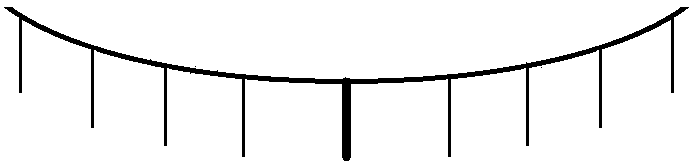

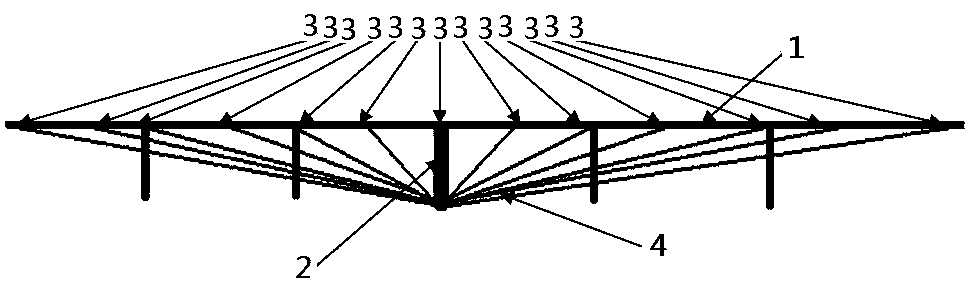

[0056] 1. Determine the span length and aspect ratio of the wing according to the overall design requirements of the aircraft. Select the wing span length of 130m, the chord length of 4m, and the aspect ratio of 30. The airfoil is selected as the "Helios" (Helios) solar aircraft. airfoil.

[0057] 2. According to the overall design requirements of the aircraft, determine the upper limit of the elastic deformation of the wing and the upper limit of the torsional deformation, set the ratio of the deflection at the wing tip to the half-span length to be less than 0.6, and the torsion angle of the wing to be less than 6 degrees.

[0058] 3. According to the overall design requirements of the aircraft, calculate the aerodynamic loads of the aircraft under different flight conditions, and the aerodynamic loads caused by external forces during the flight of the aircraft.

[0059] Under all poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com