Patents

Literature

1435results about How to "High elastic modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

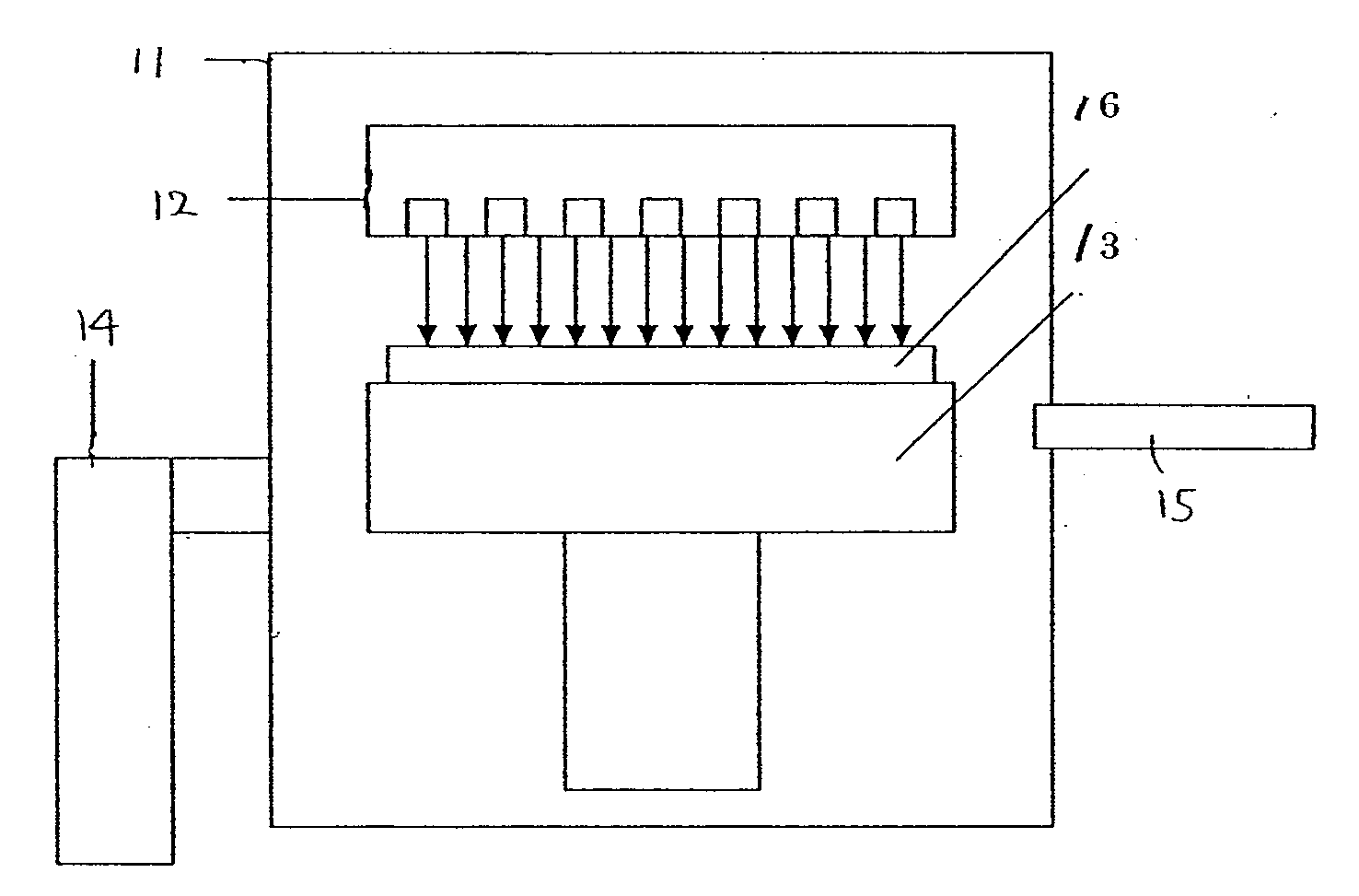

Plasma curing process for porous silica thin film

InactiveUS6558755B2Low dielectric constantHigh elastic modulusSilicaSemiconductor/solid-state device manufacturingSilicon dioxideHeat treated

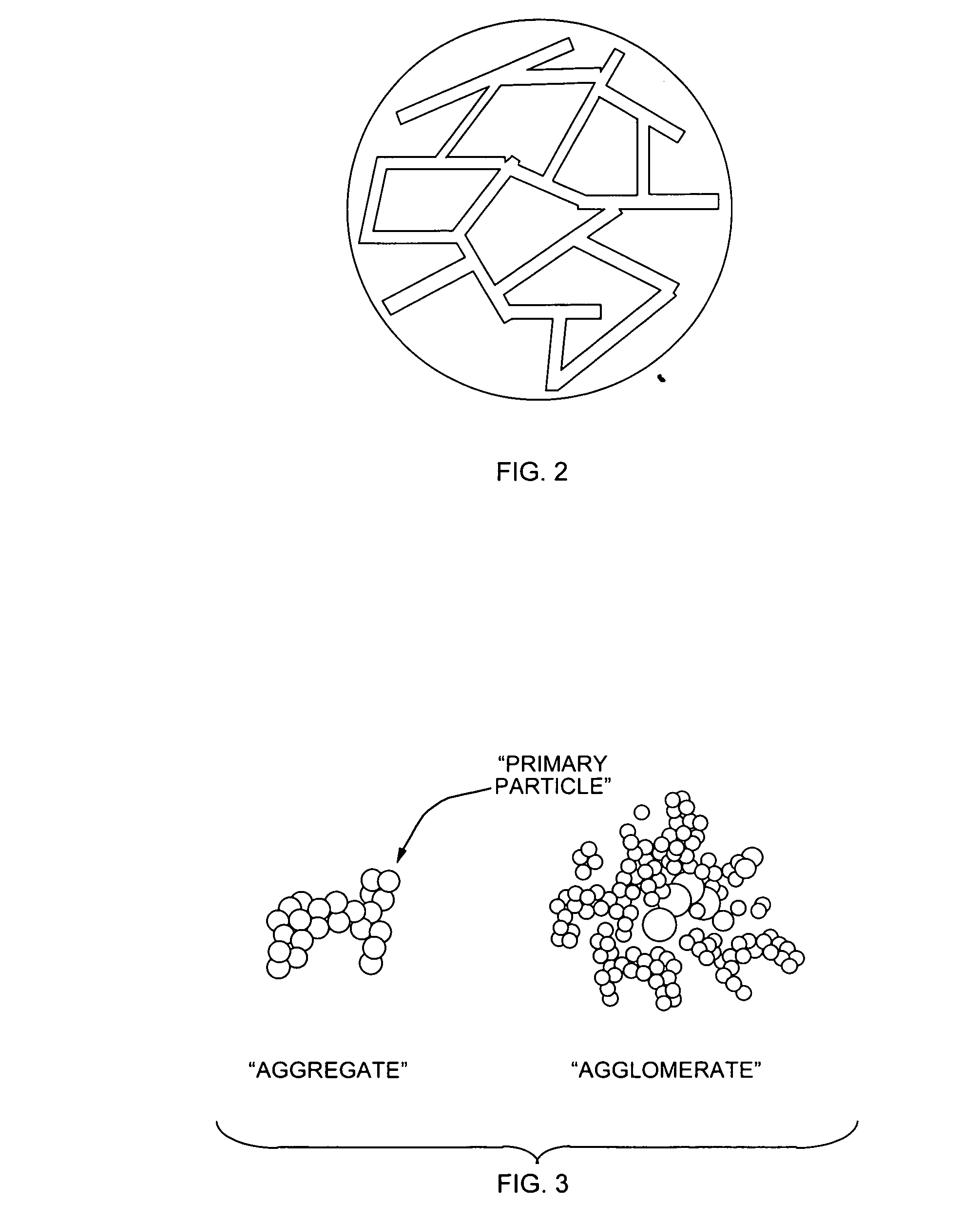

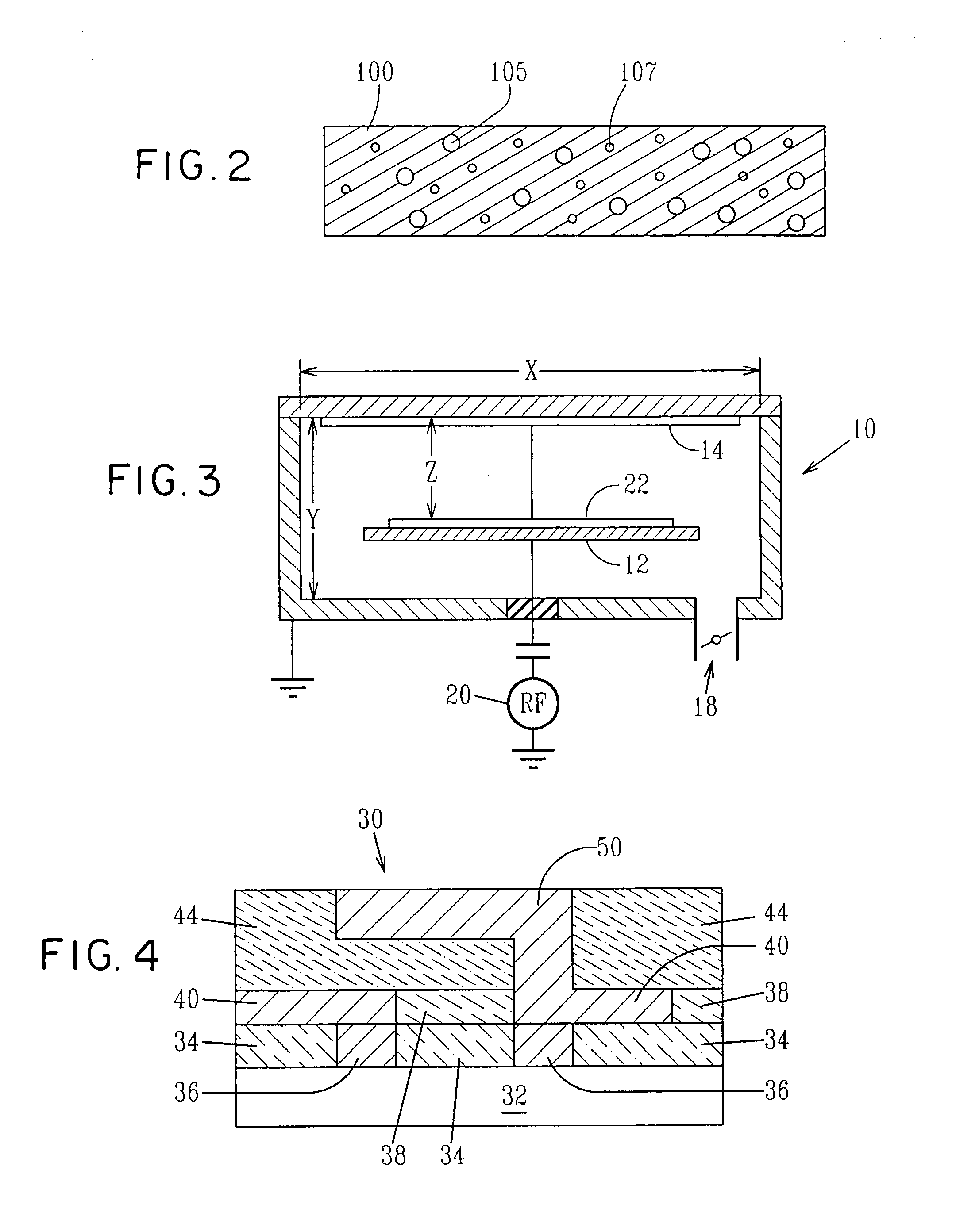

Low dielectric constant films with improved elastic modulus. The method of making such coatings involves providing a porous network coating produced from a resin containing at least 2 Si-H groups and plasma curing the coating to convert the coating into porous silica. Plasma curing of the network coating yields a coating with improved modulus, but with a higher dielectric constant. The costing is plasma cured for between about 15 and about 120 seconds at a temperature less than or about 350° C. The plasma cured coating can optionally be annealed. Rapid thermal processing (RTP) of the plasma cured coating reduces the dielectric constant of the coating while maintaining an improved elastic modulus as compared to the plasma cured porous network coating. The annealing temperature is typically loss than or about 475° C., and the annealing time is typically no more than or about 180 seconds. The annealed, plasma cured coating has a dielectric constant in the range of from about 1.1 to about 2.4 and an improved elastic modulus.

Owner:AXCELIS TECHNOLOGIES +1

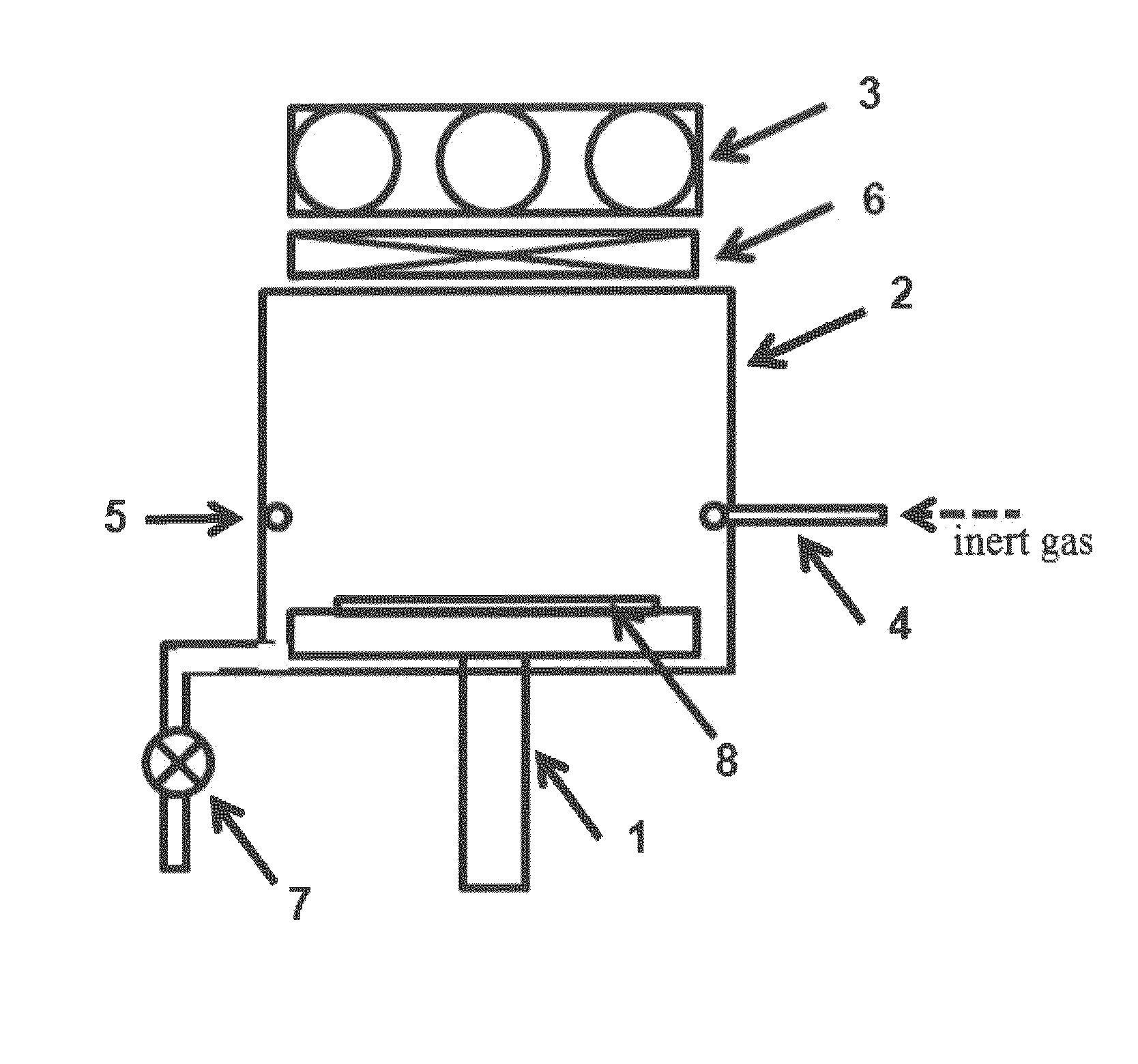

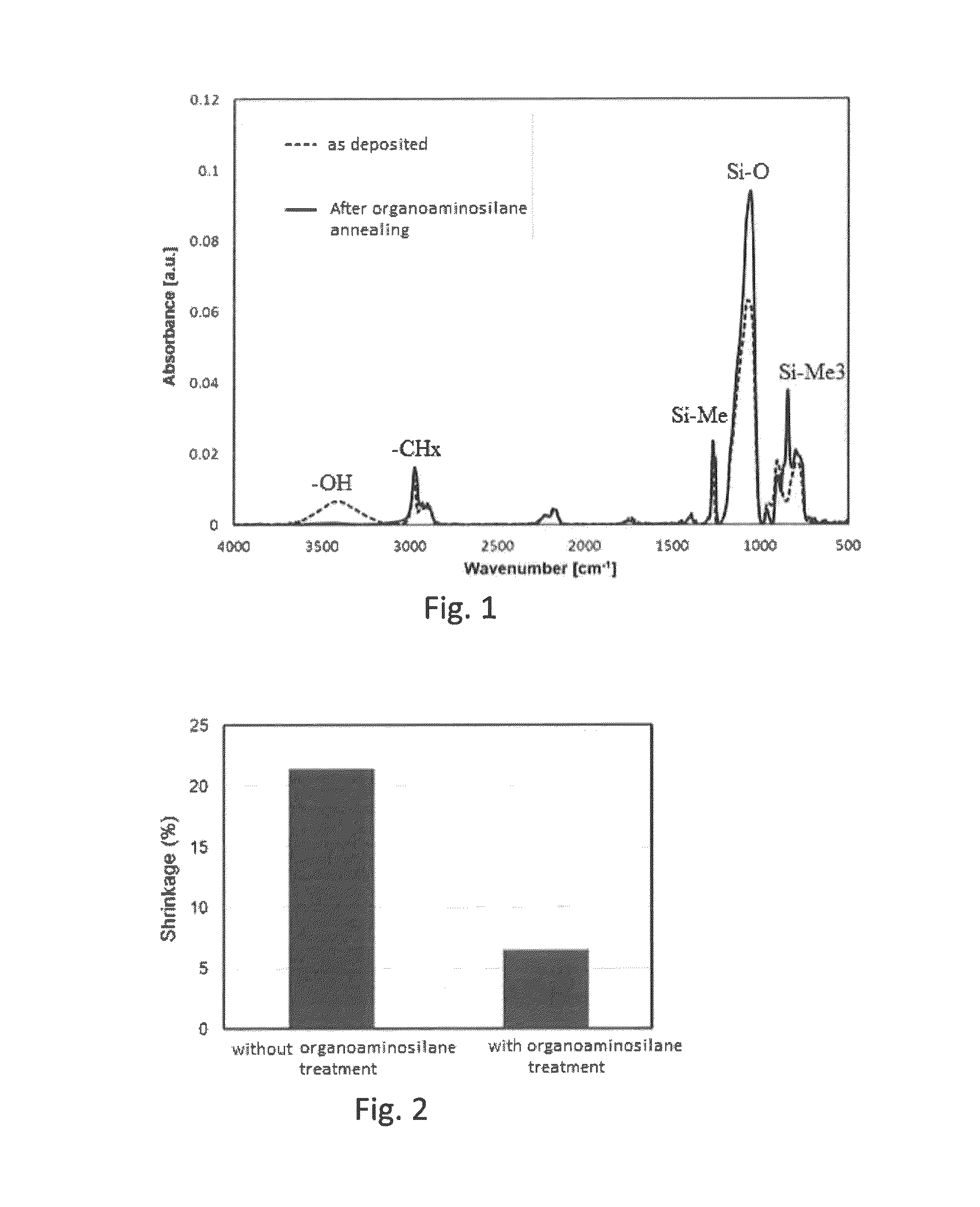

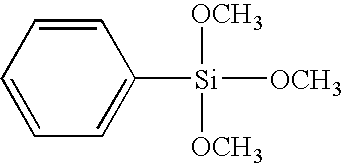

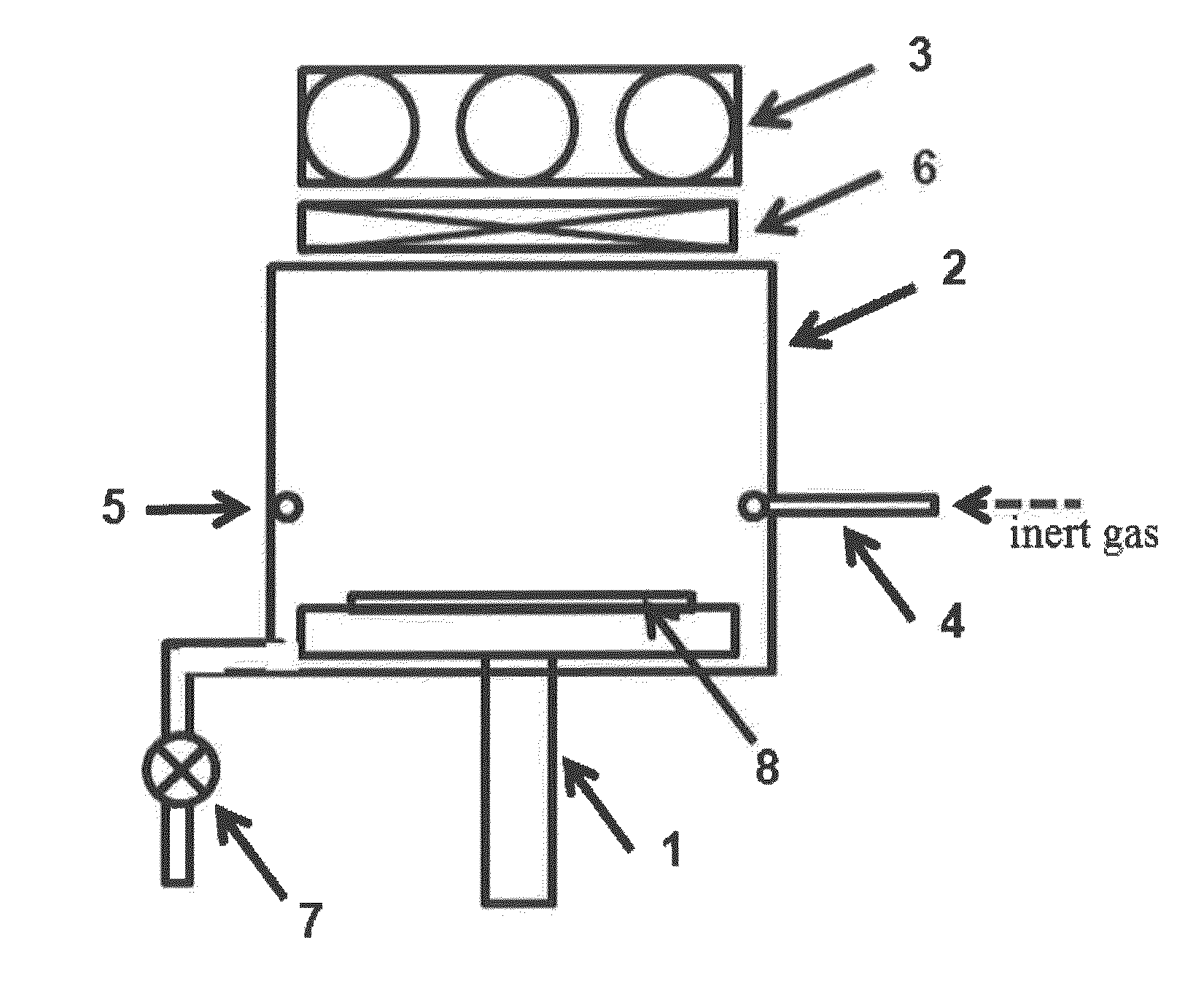

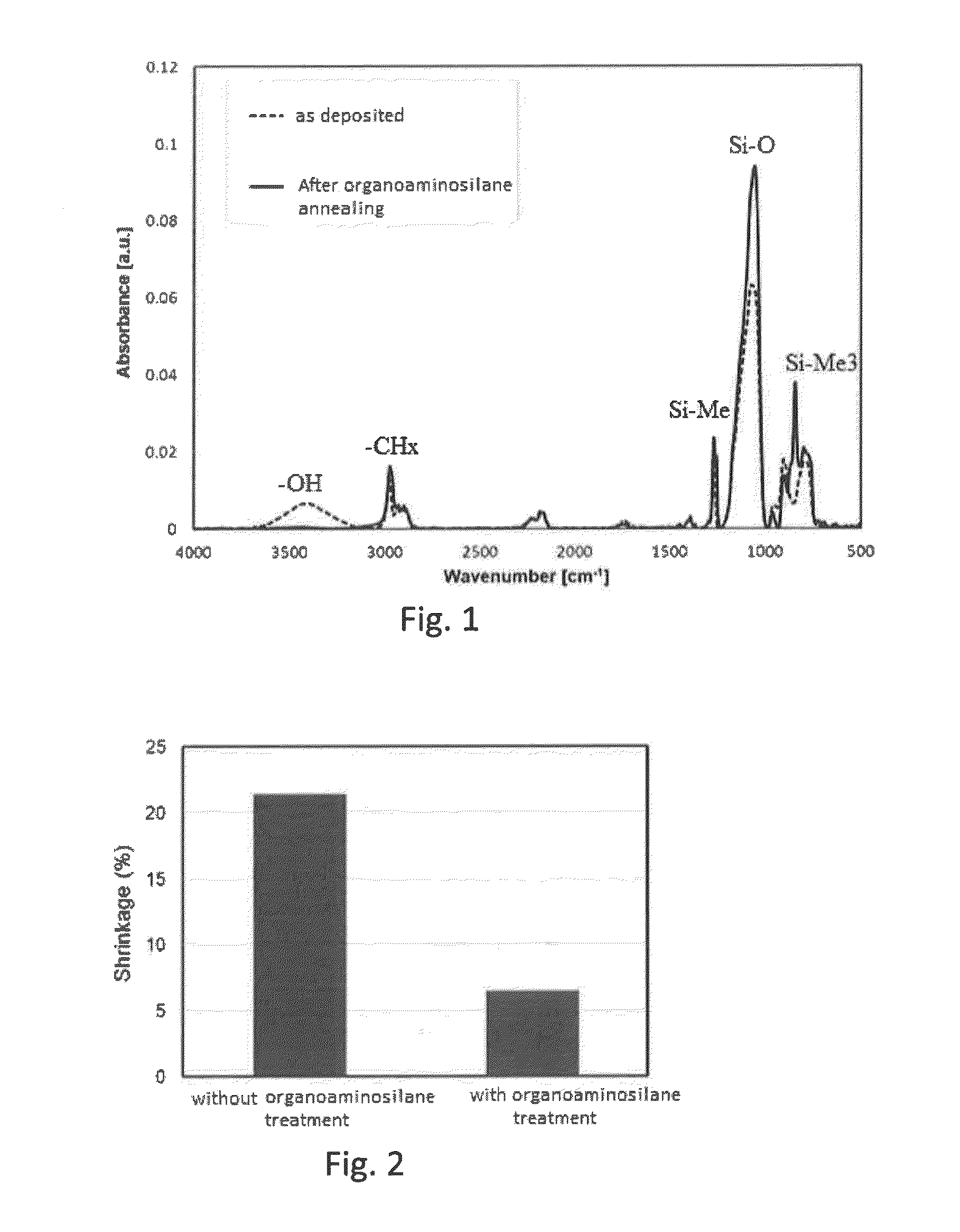

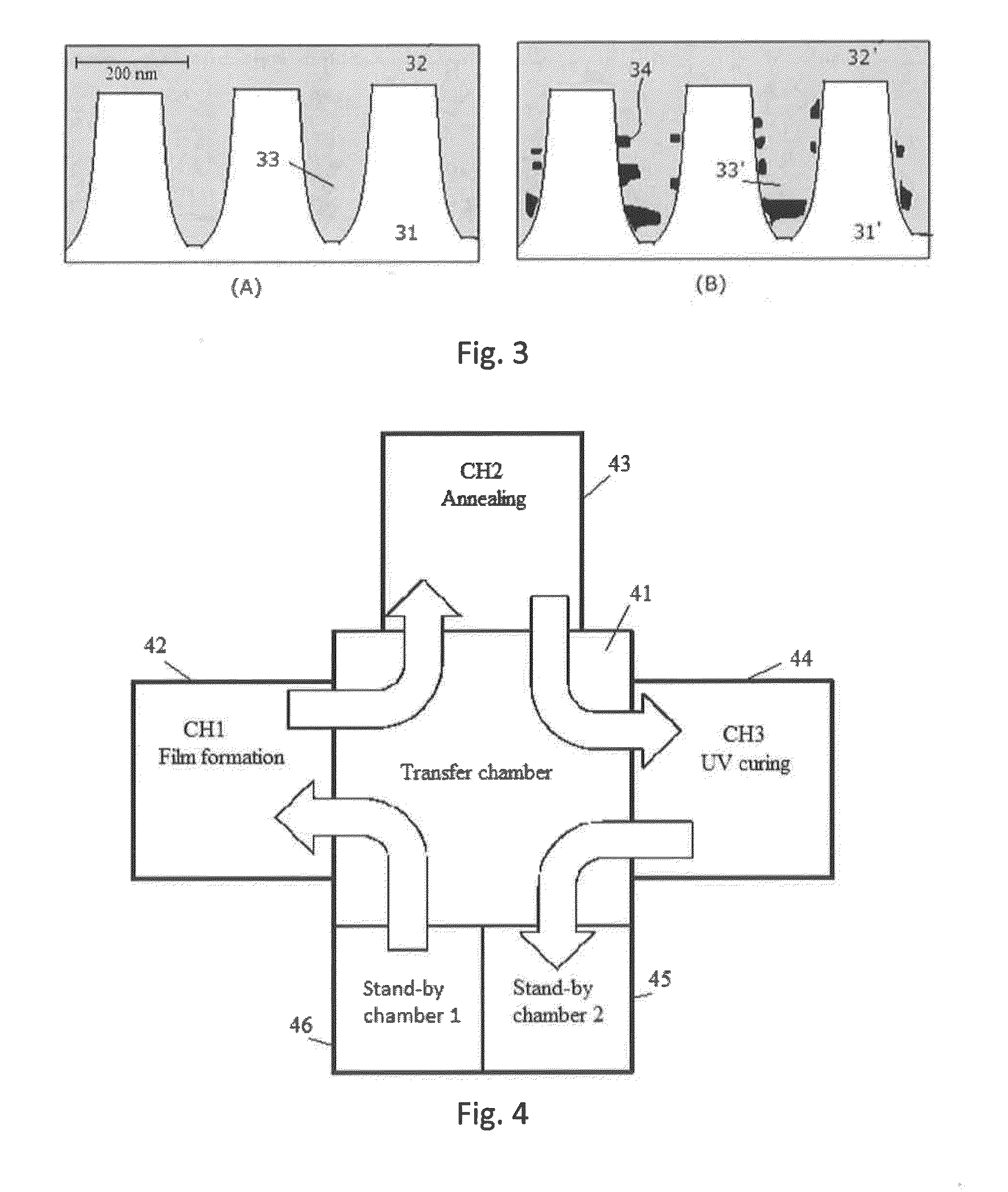

Method for forming SiOCH film using organoaminosilane annealing

ActiveUS9190263B2Improve liquidityReduce the amount requiredSemiconductor/solid-state device manufacturingPolymer scienceSilanes

Owner:ASM IP HLDG BV

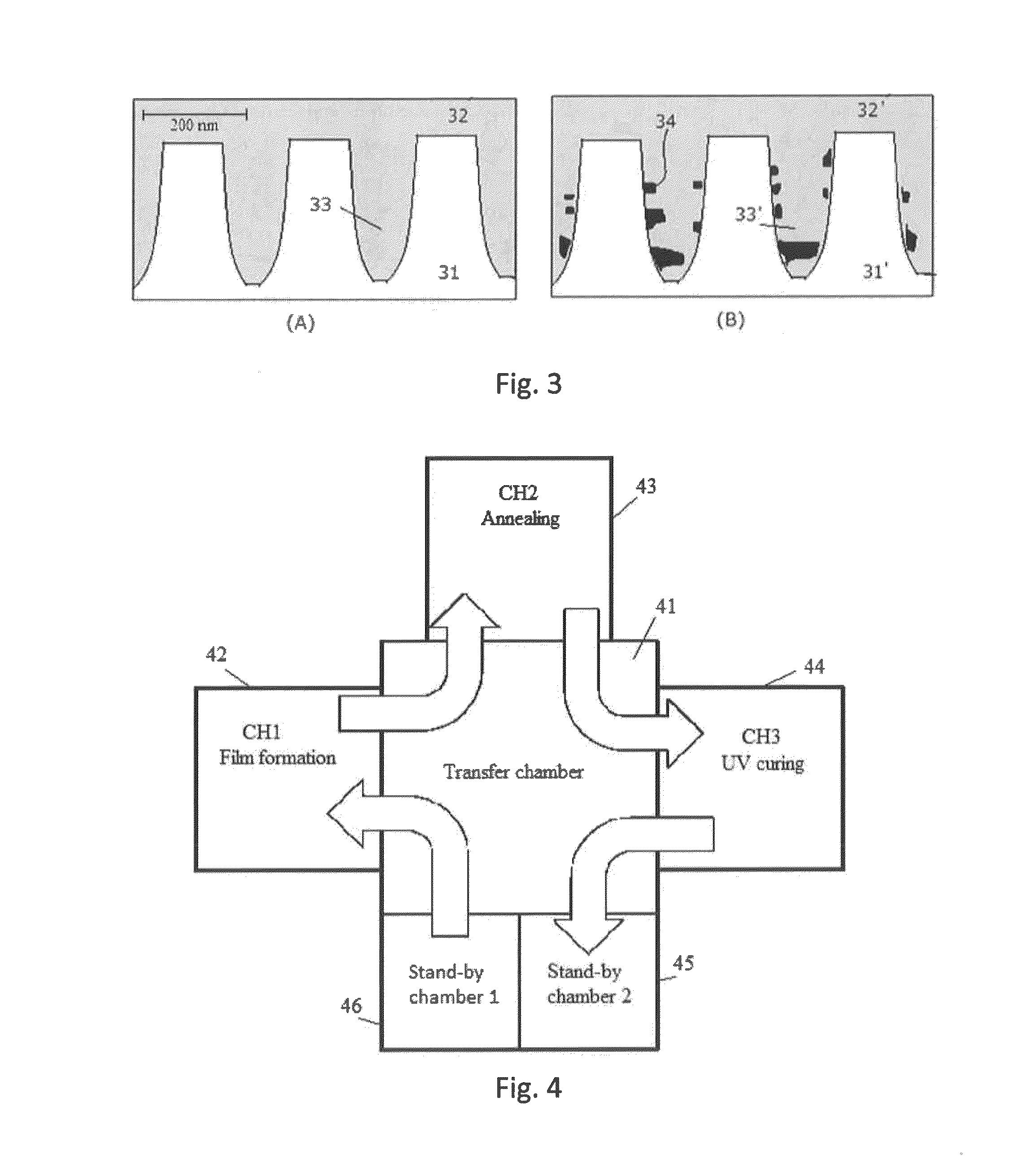

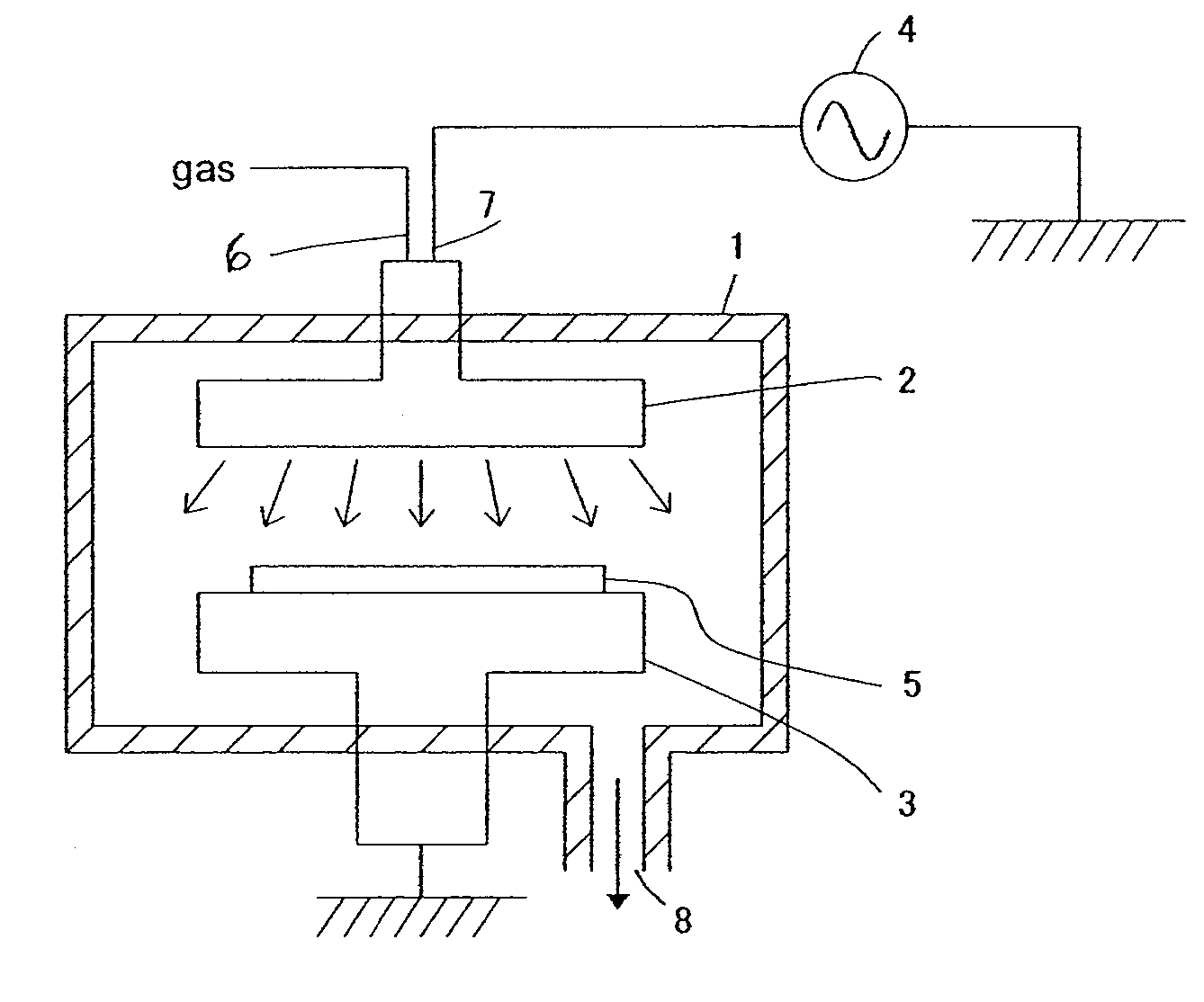

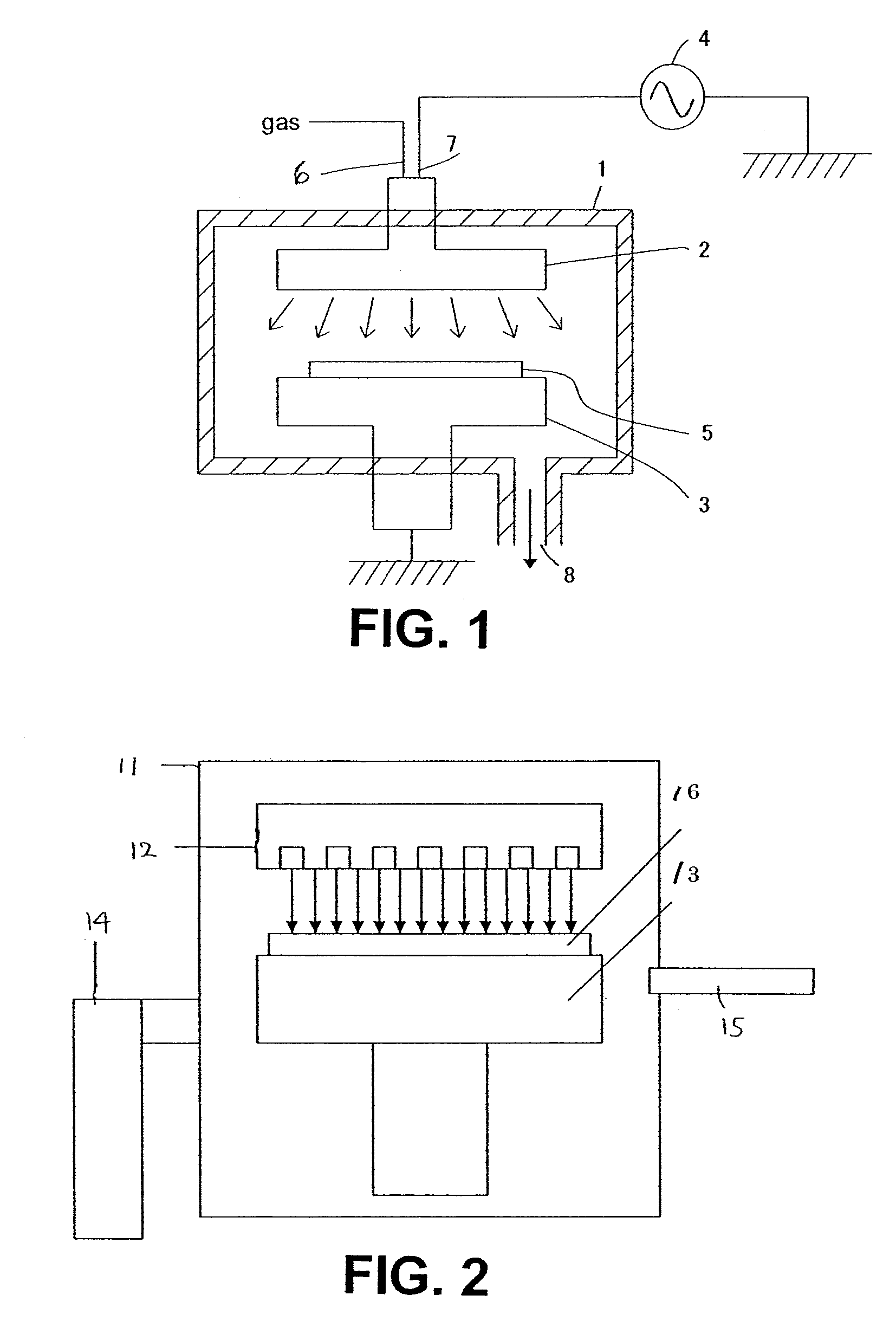

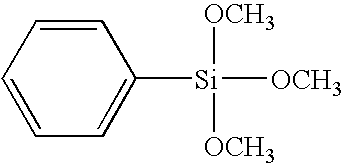

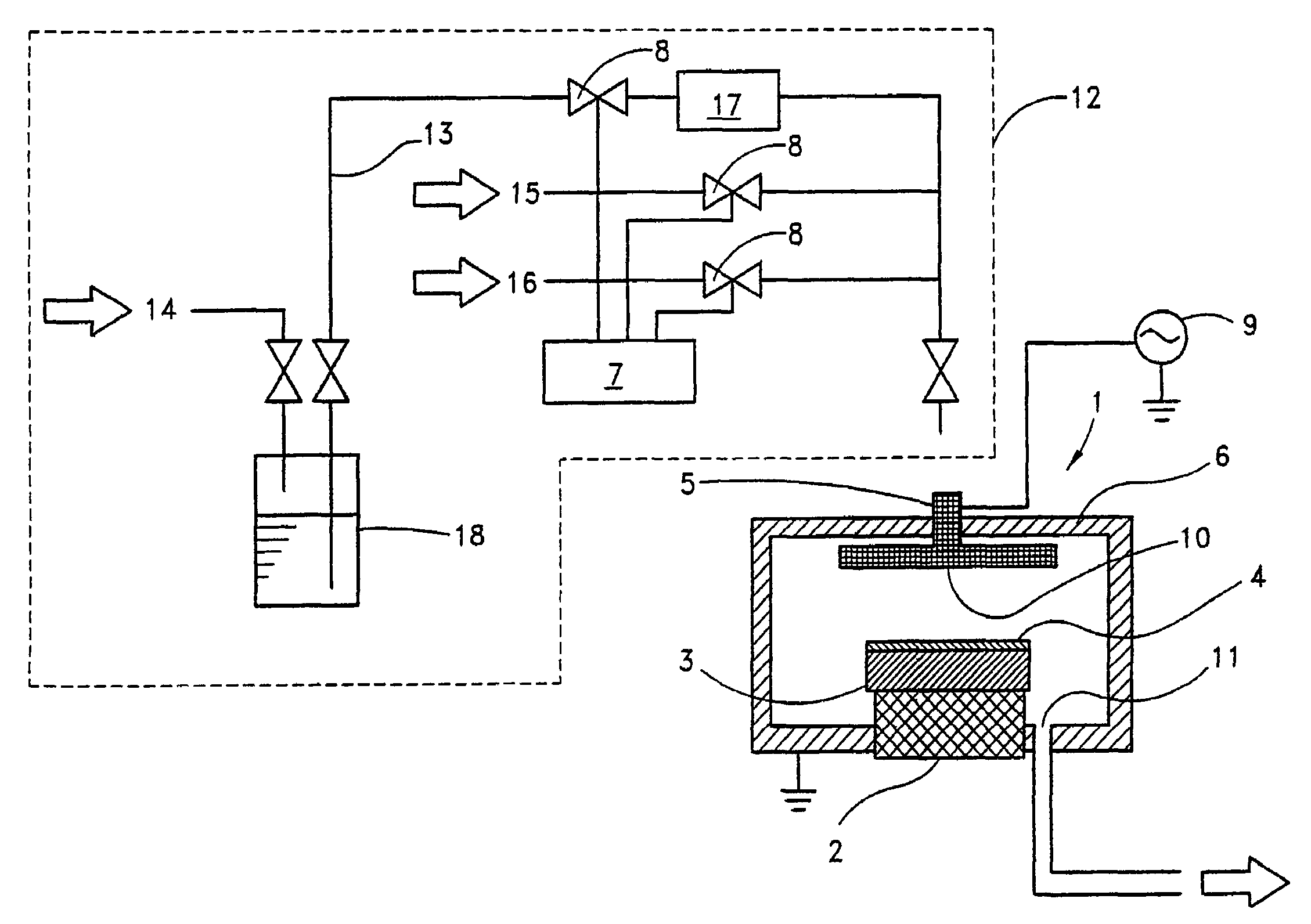

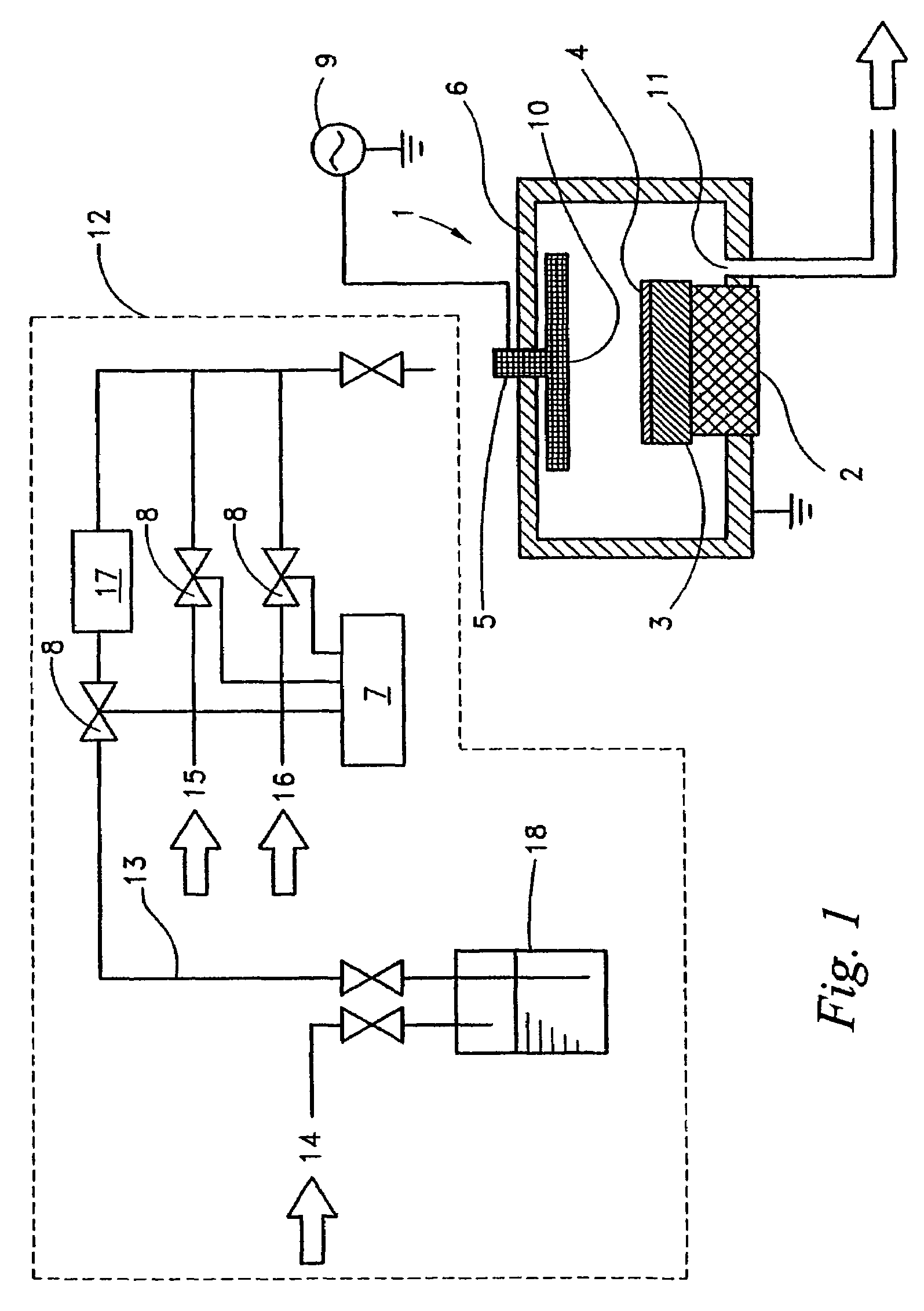

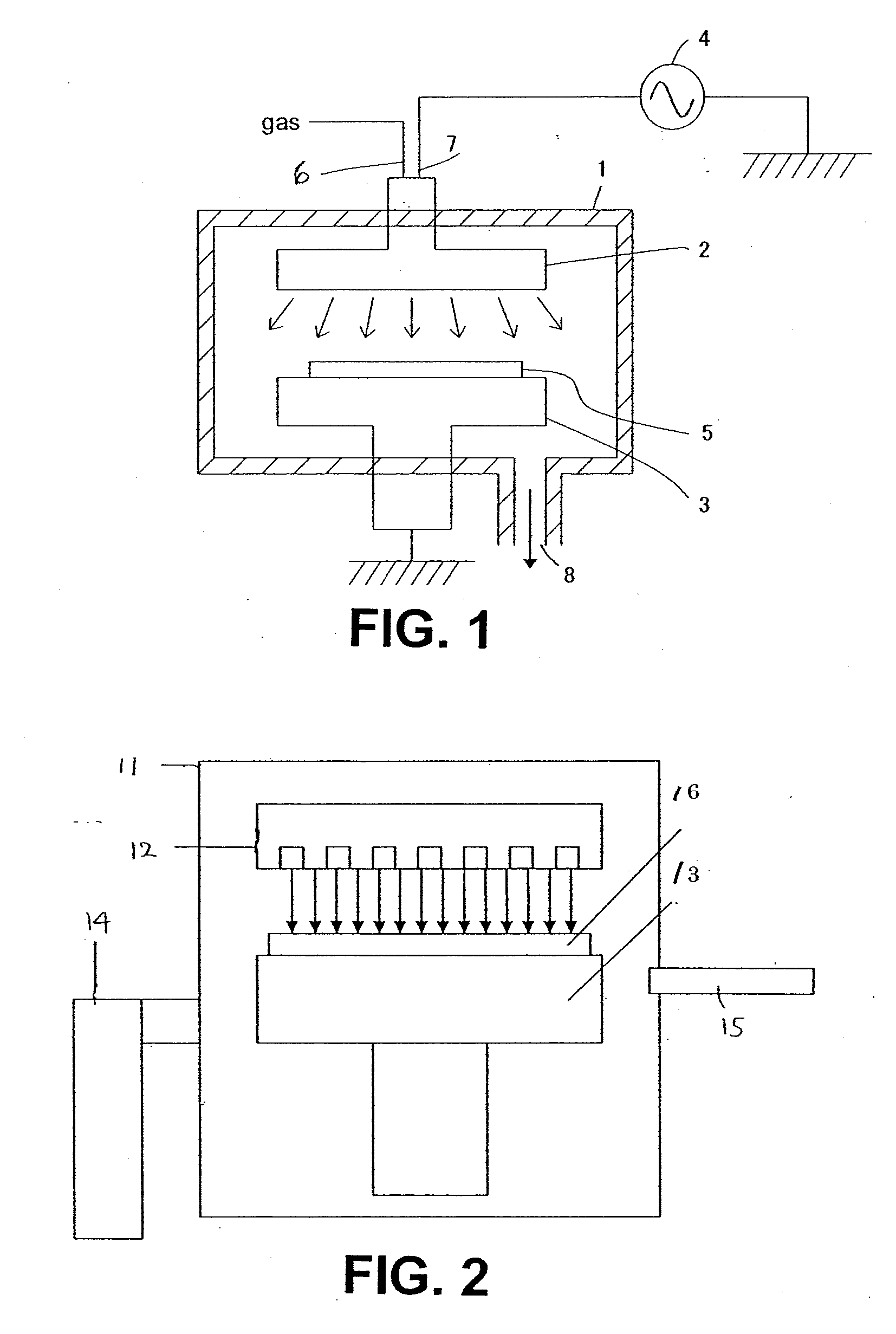

Method for forming insulation film

InactiveUS7354873B2Reduce distanceGood film densitySolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

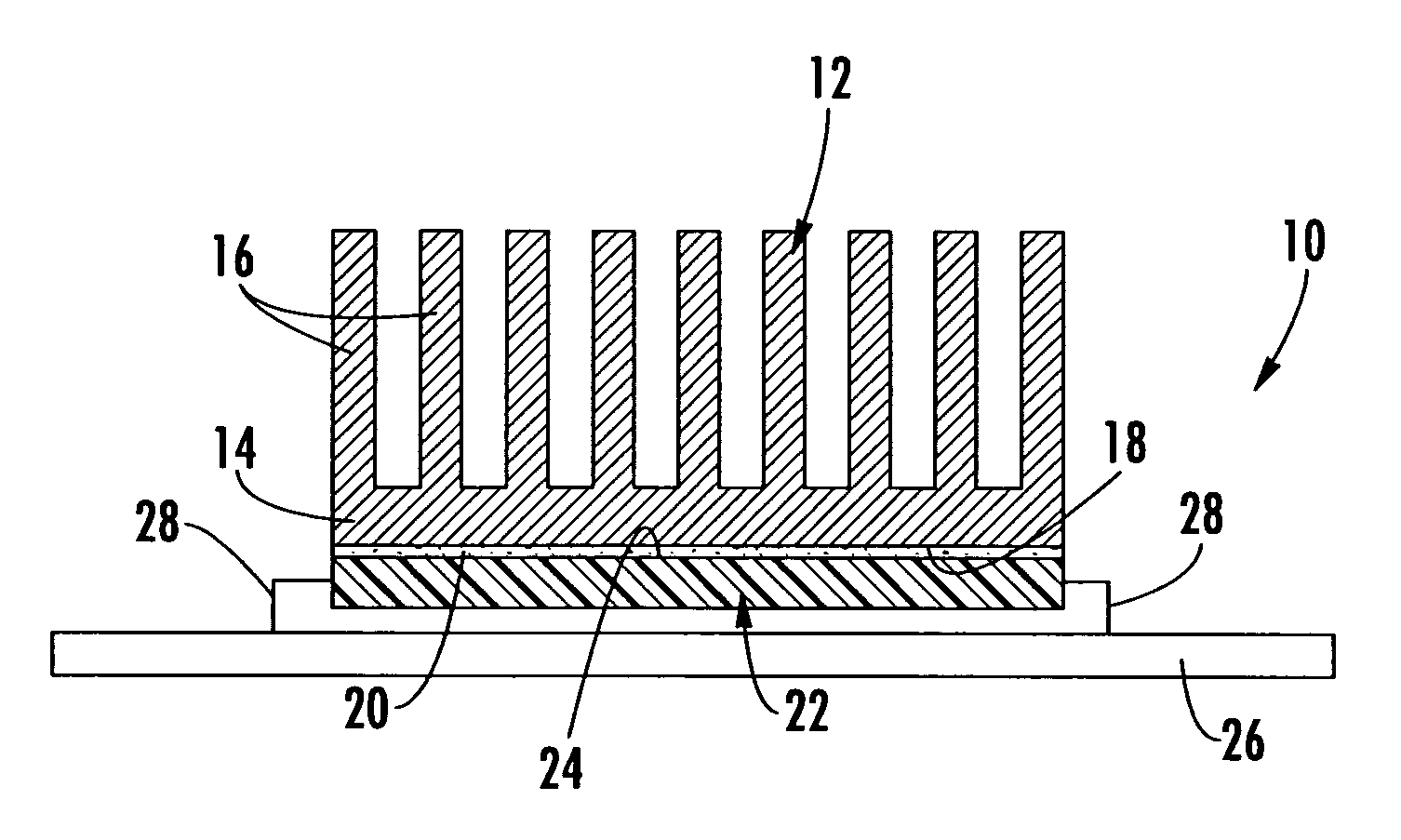

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Method for forming insulation film

InactiveUS7582575B2Reduce trafficReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Method for Forming SiOCH Film Using Organoaminosilane Annealing

ActiveUS20150056821A1Improve liquidityReduce the amount requiredSemiconductor/solid-state device manufacturingPolymer scienceSilanes

Owner:ASM IP HLDG BV

Method for forming insulation film

InactiveUS20070004204A1Reduce trafficDecrease in flow volumeSolid-state devicesSemiconductor/solid-state device manufacturingProduct gasPlasma reaction

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

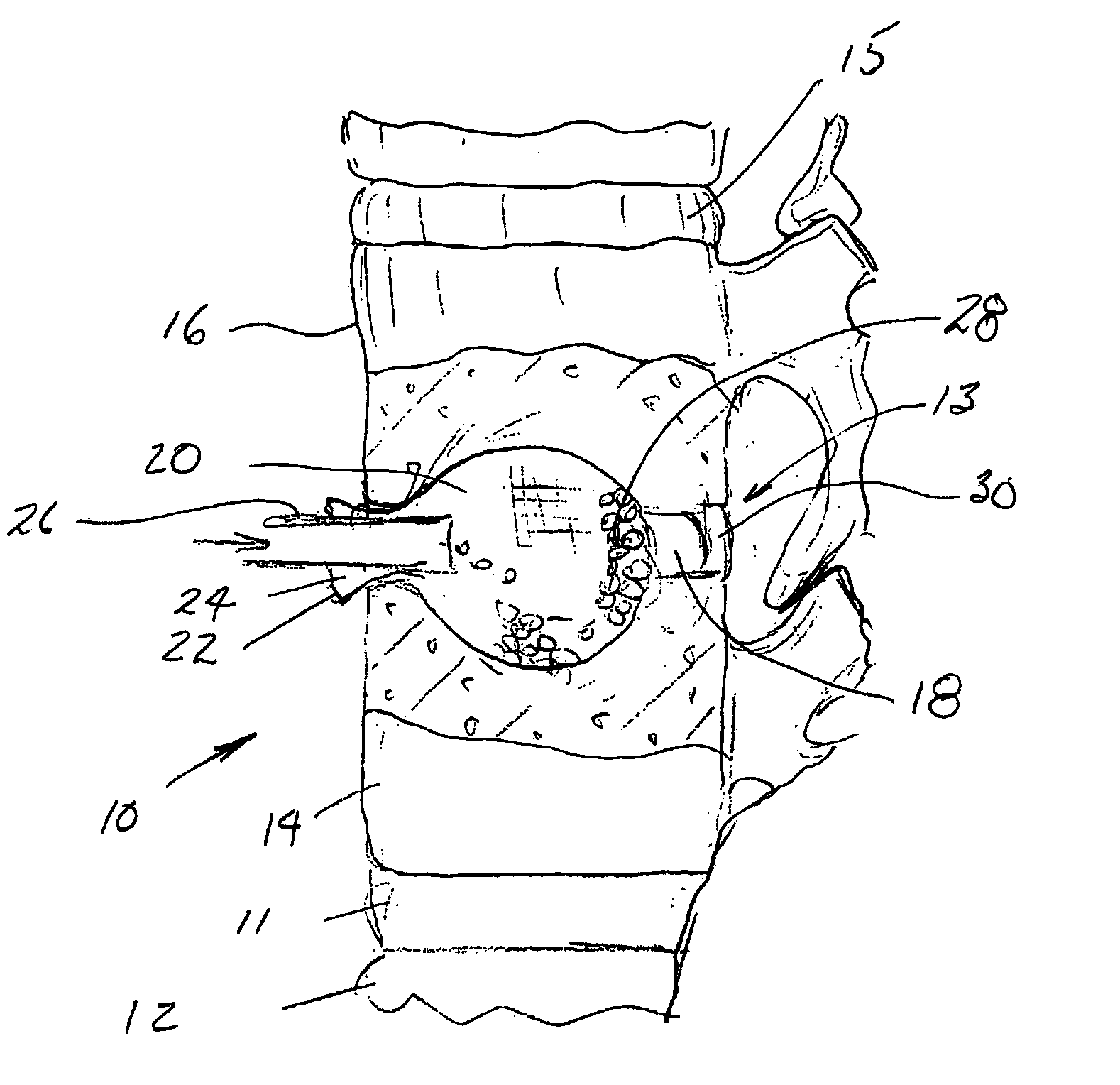

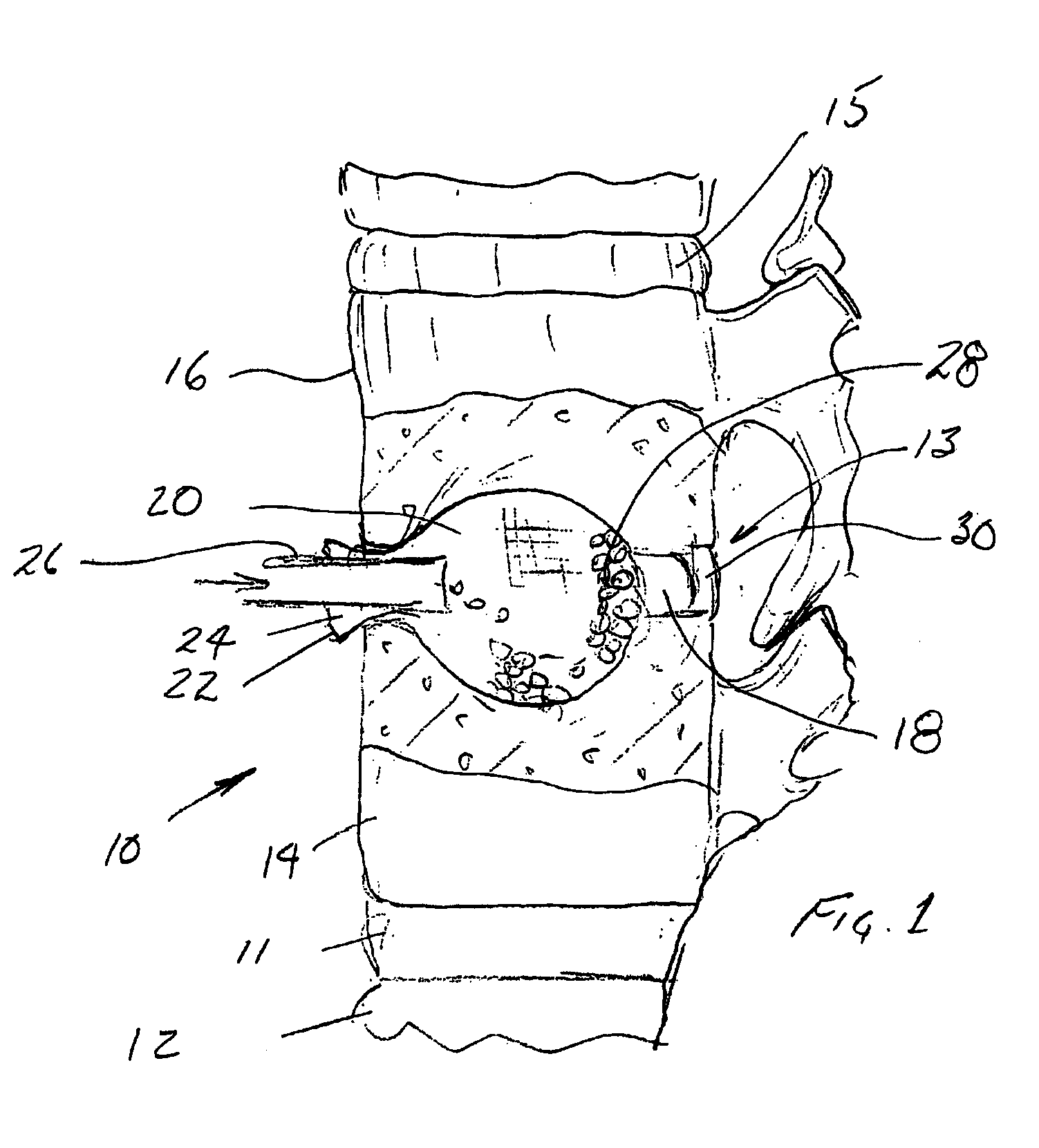

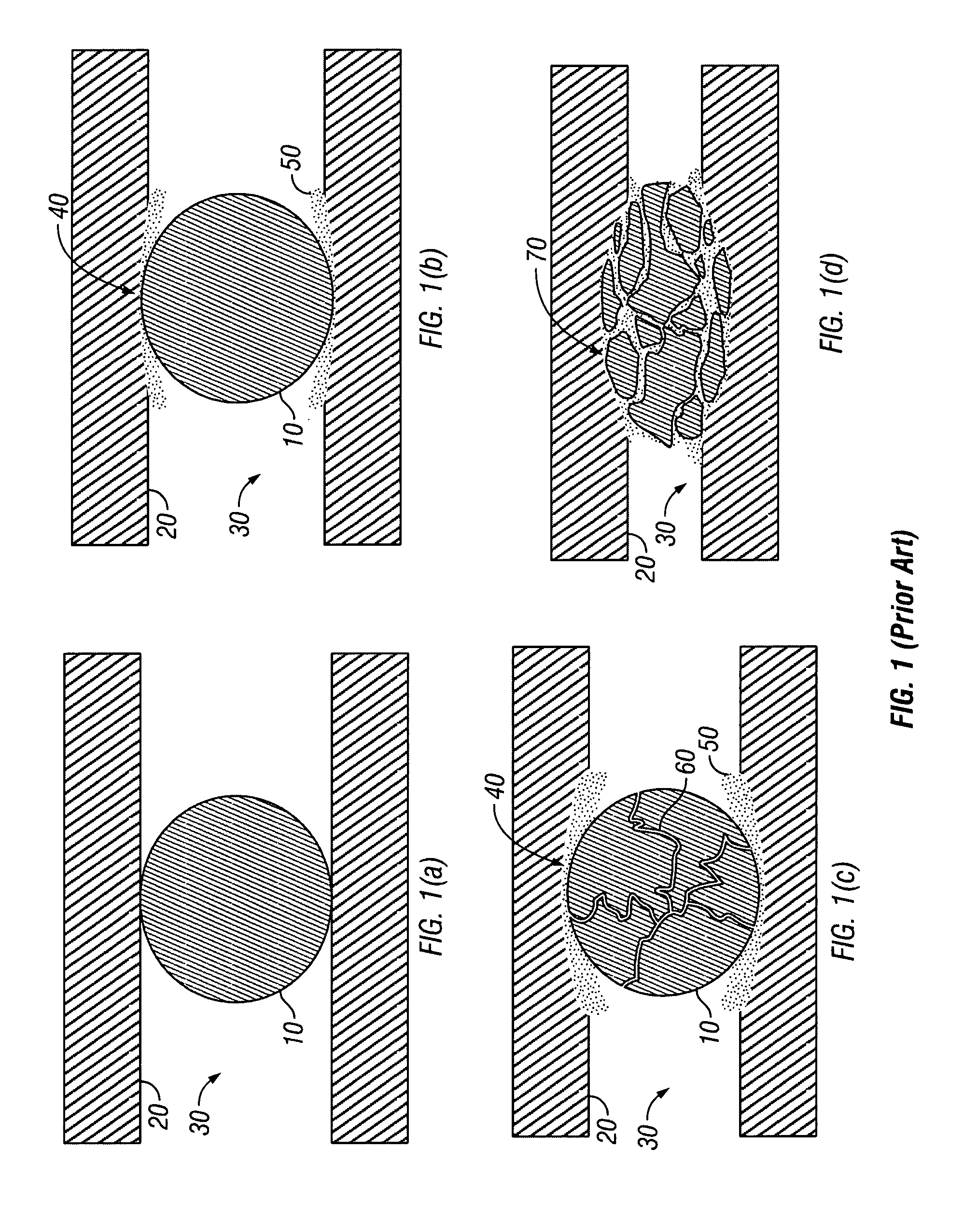

Packable ceramic beads for bone repair

InactiveUS6869445B1Less friableHigh elastic modulusBone implantJoint implantsHydroxyapatitesPhosphate

Adherent packed beds of ceramic beads, each comprising a ceramic body coated with a biodegradable polymer, and fabric bags containing such beads in a packed, self-supporting configuration. The polymeric coating provides some resilience to a packed bed of the ceramic beads, and prevents the beads from moving with respect to each other when placed under stress, leading to reduced breakage. The ceramic beads desirably are osteoconductive, and preferably are formed of a ceramic material that is resorbed during bone growth, such as hydroxyapatite, tricalcium phosphate, or mixtures of these materials. The beads may contain, either internally or on their surfaces or both, a bone morphogenic protein, and the latter may also be included in the biodegradable polymer coatings on the beads.

Owner:PHILLIPS PLASTICS

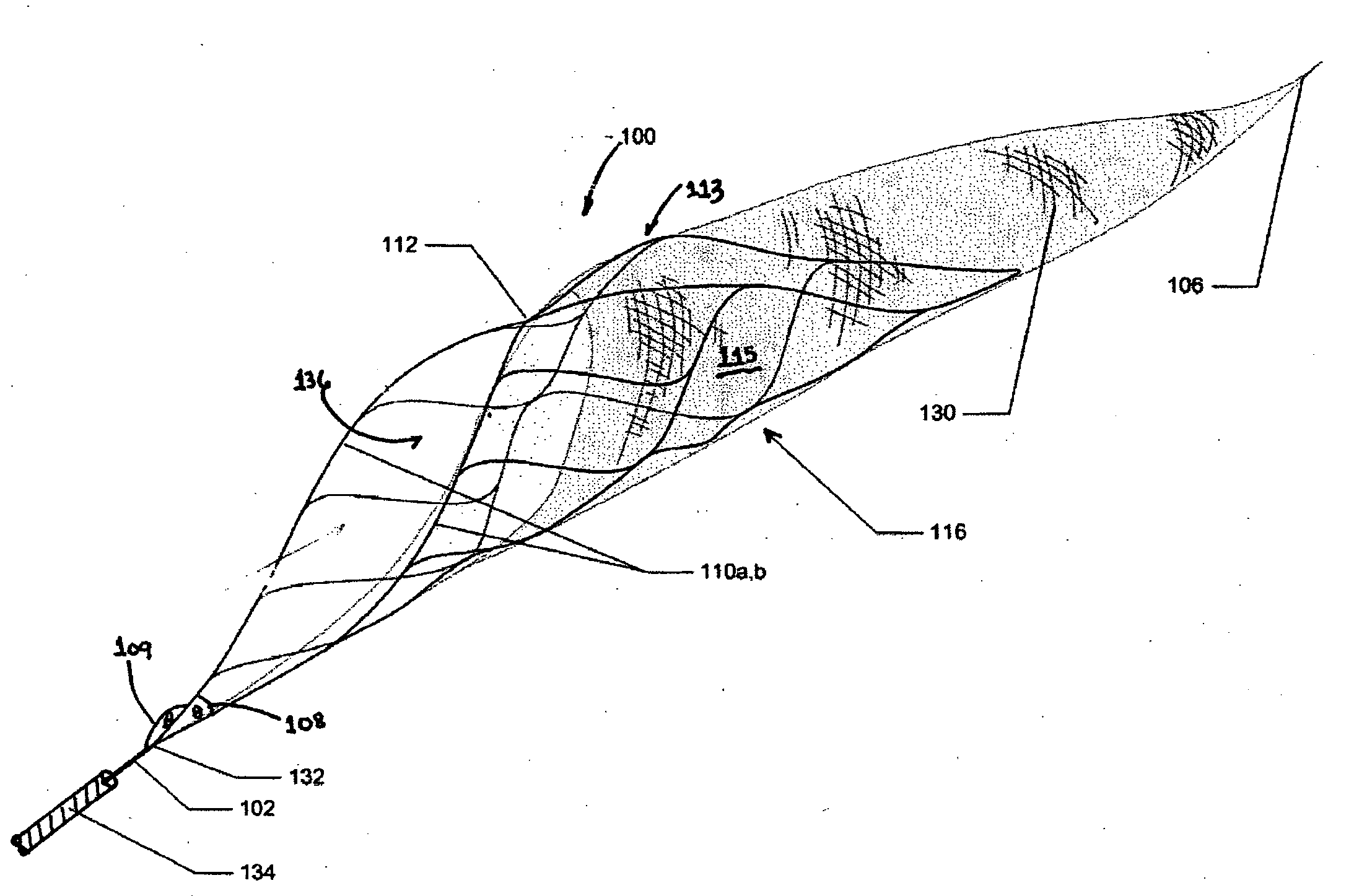

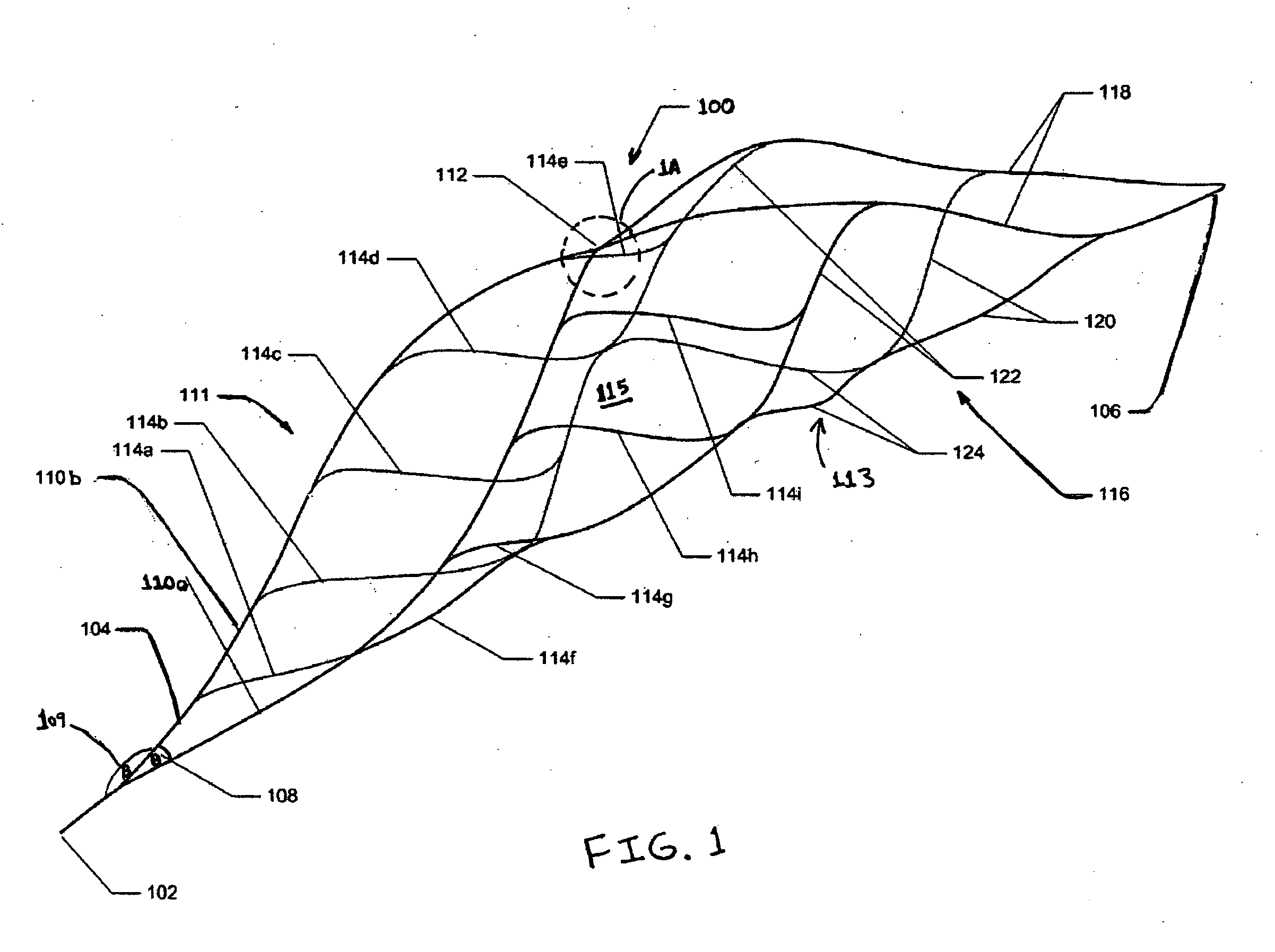

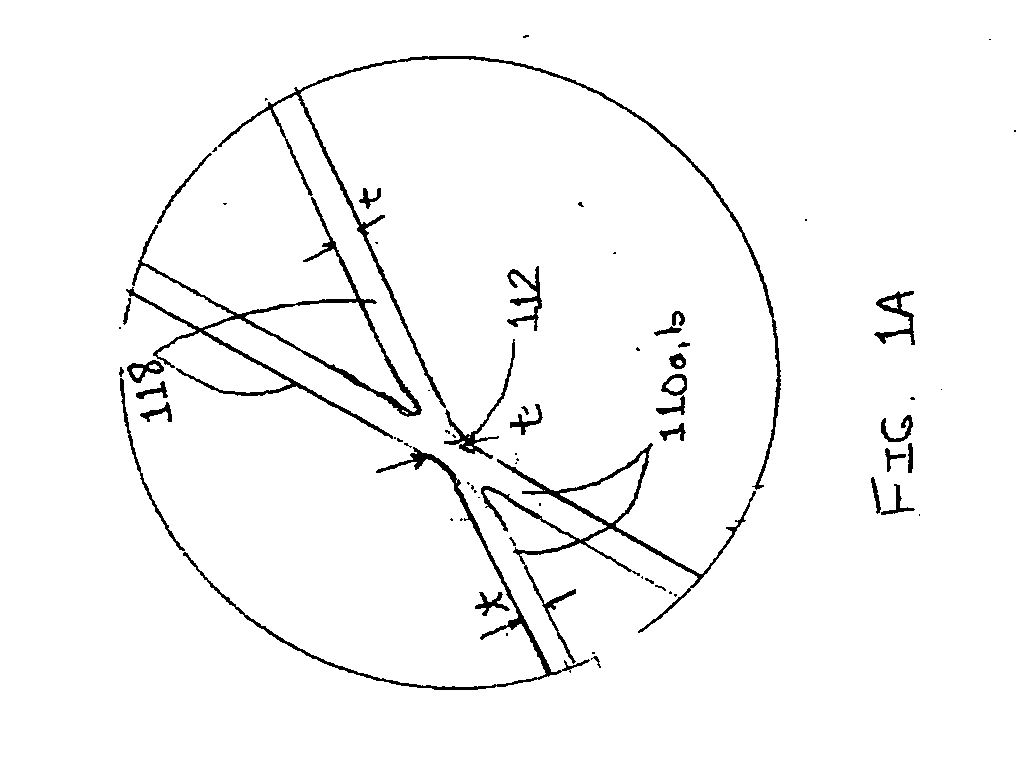

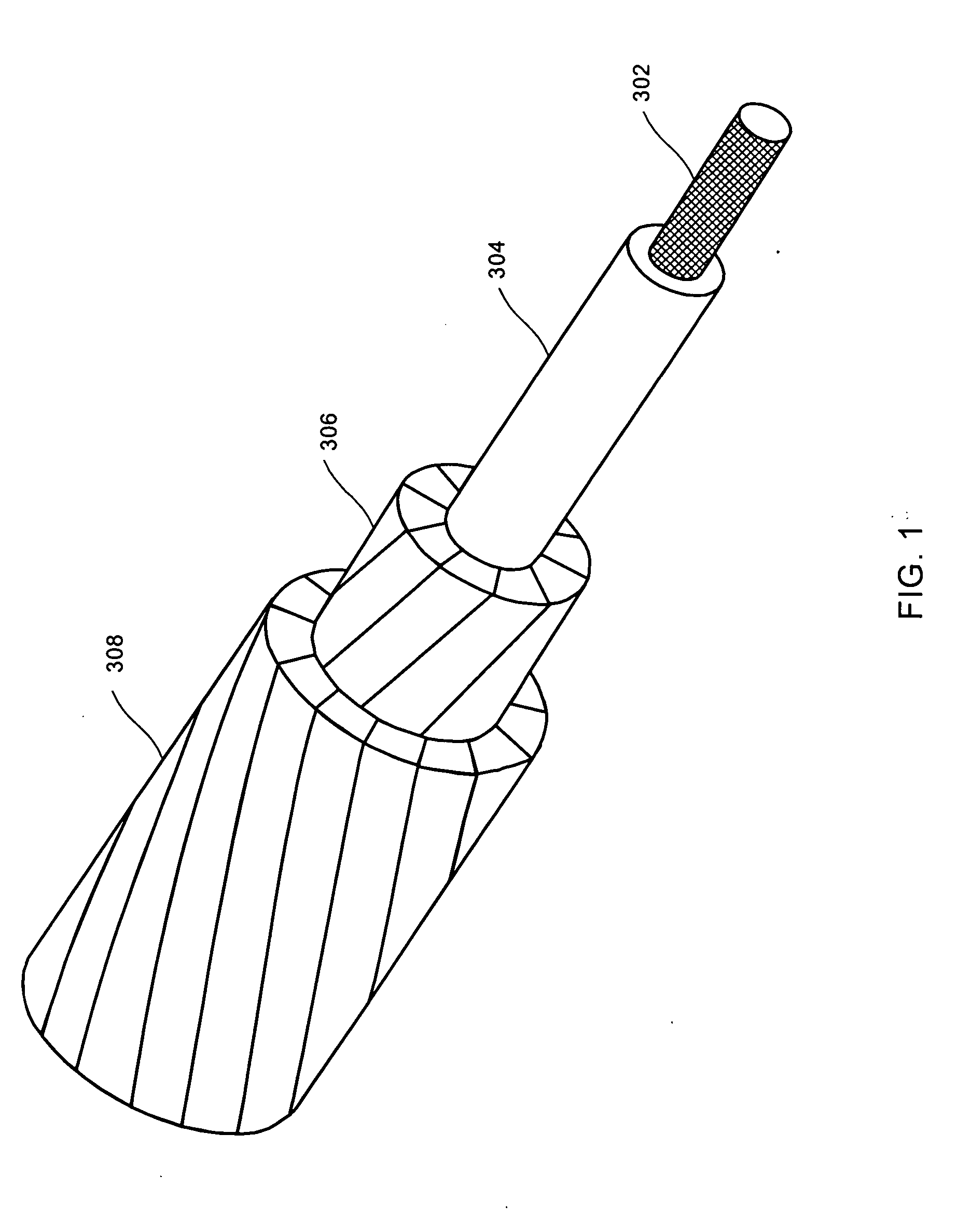

Vascular thrombectomby apparatus and method of use

InactiveUS20070288054A1Modulus of elasticityStay flexibleSurgeryDilatorsMembrane configurationBlood vessel

An apparatus is provided for removing matter from within a conduit. The apparatus generally comprises a separation edge attached to a wire at its proximal end, a frame attached to the distal end of the separation edge, and a membrane attached to the wire and disposed over the frame enclosing its interior. The membrane generally comprises a net constructed from a vaporized metal deposited on a mandrel. Alternatively, the membrane may comprise a braided tube constructed from wire. The apparatus may be employed as a filter or as a means for actively dislodging matter from the wall of a conduit. When employed as a filter, the apparatus is positioned downstream of the matter where it ensures that matter does not escape downstream as it is being removed. When employed to actively remover matter from a conduit, the apparatus is positioned downstream of the matter. The apparatus is then pulled proximally whereby it engages the matter and dislodges it from the wall of the conduit

Owner:CORDIS CORP

Method of making a product with improved material properties by moderate heat-treatment of a metal incorporating a dilute additive

InactiveUS6150186AStable mechanical propertiesImprove conductivitySemiconductor/solid-state device testing/measurementFinal product manufactureUltimate tensile strengthMechanical property

Deposition of metal in a preferred shape, including coatings on parts, or stand-alone materials, and subsequent heat treatment to provide improved mechanical properties. In particular, the method gives products with relatively high yield strength. The products often have relatively high elastic modulus, and are thermally stable, maintaining the high yield strength at temperatures considerably above 25 DEG C. This technique involves depositing a material in the presence of a selected additive, and then subjecting the deposited material to a moderate heat treatment. This moderate heat treatment differs from other commonly employed "stress relief" heat treatments in using lower temperatures and / or shorter times, preferably just enough to reorganize the material to the new, desired form. Coating a shape and heat treating provides a shaped deposit with improved material properties. Coating a shape with a portion connected to a base and a portion detached therefrom can provide a resilient, conductive contact useful for electronic applications.

Owner:FORMFACTOR INC

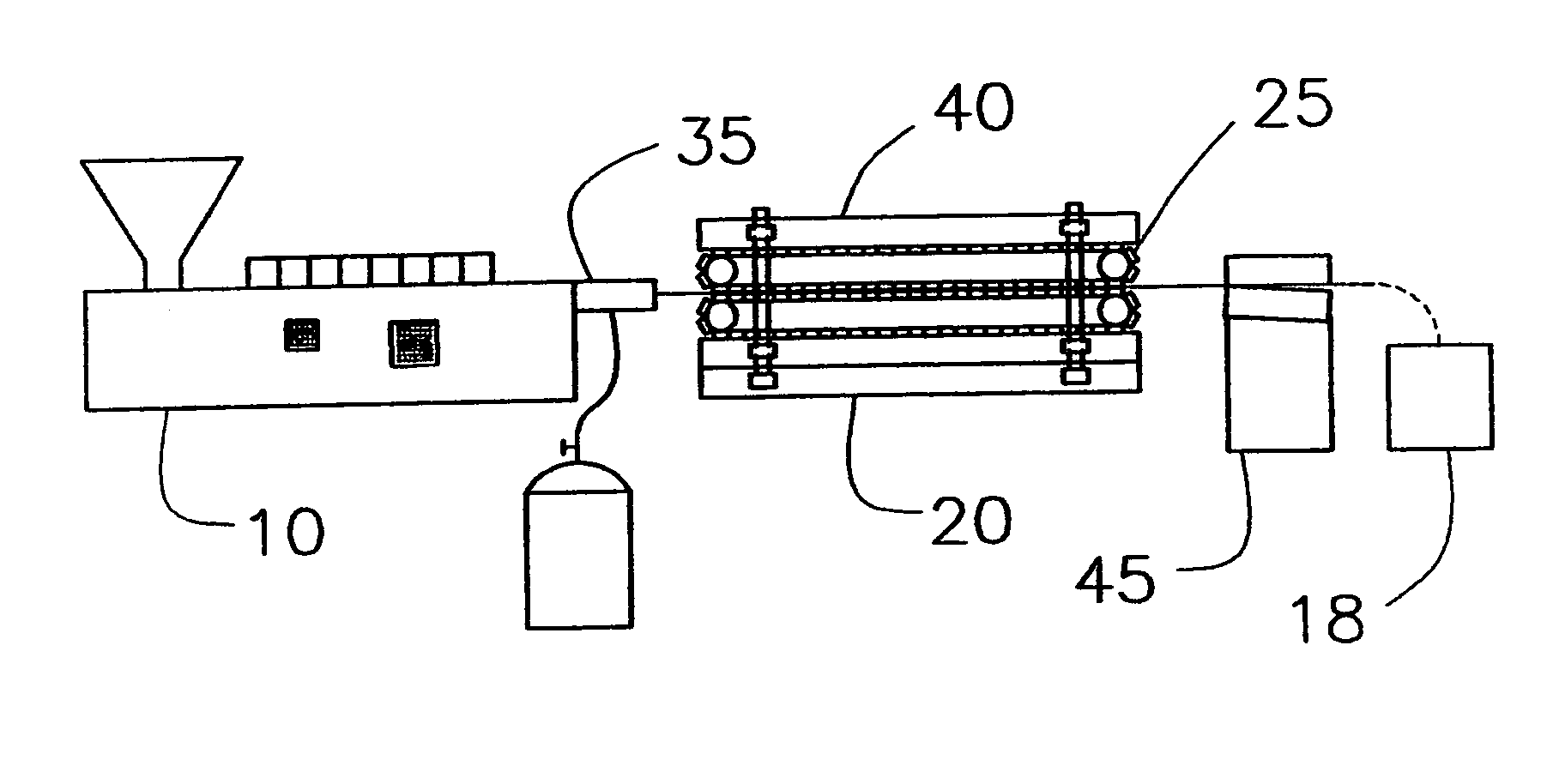

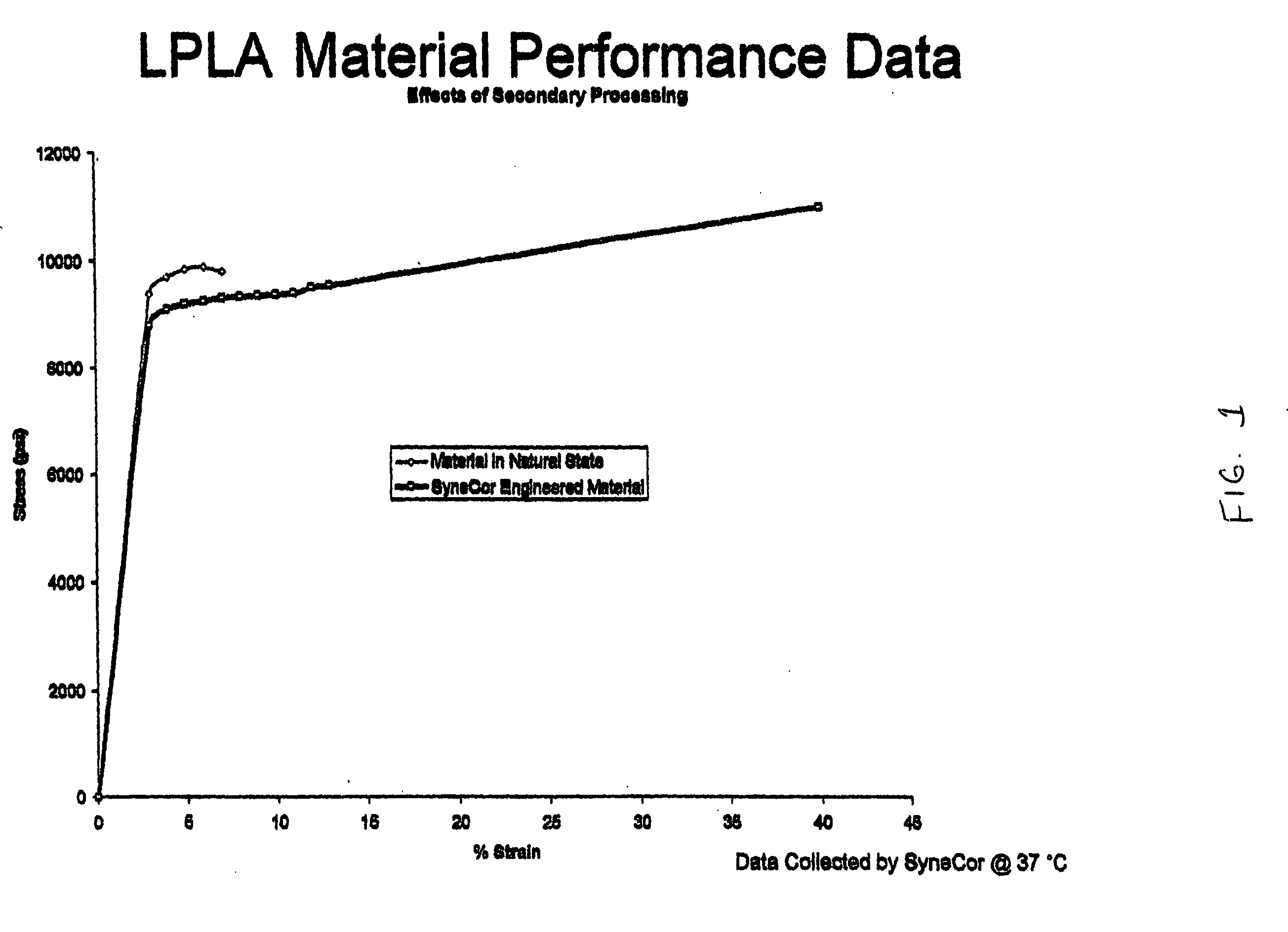

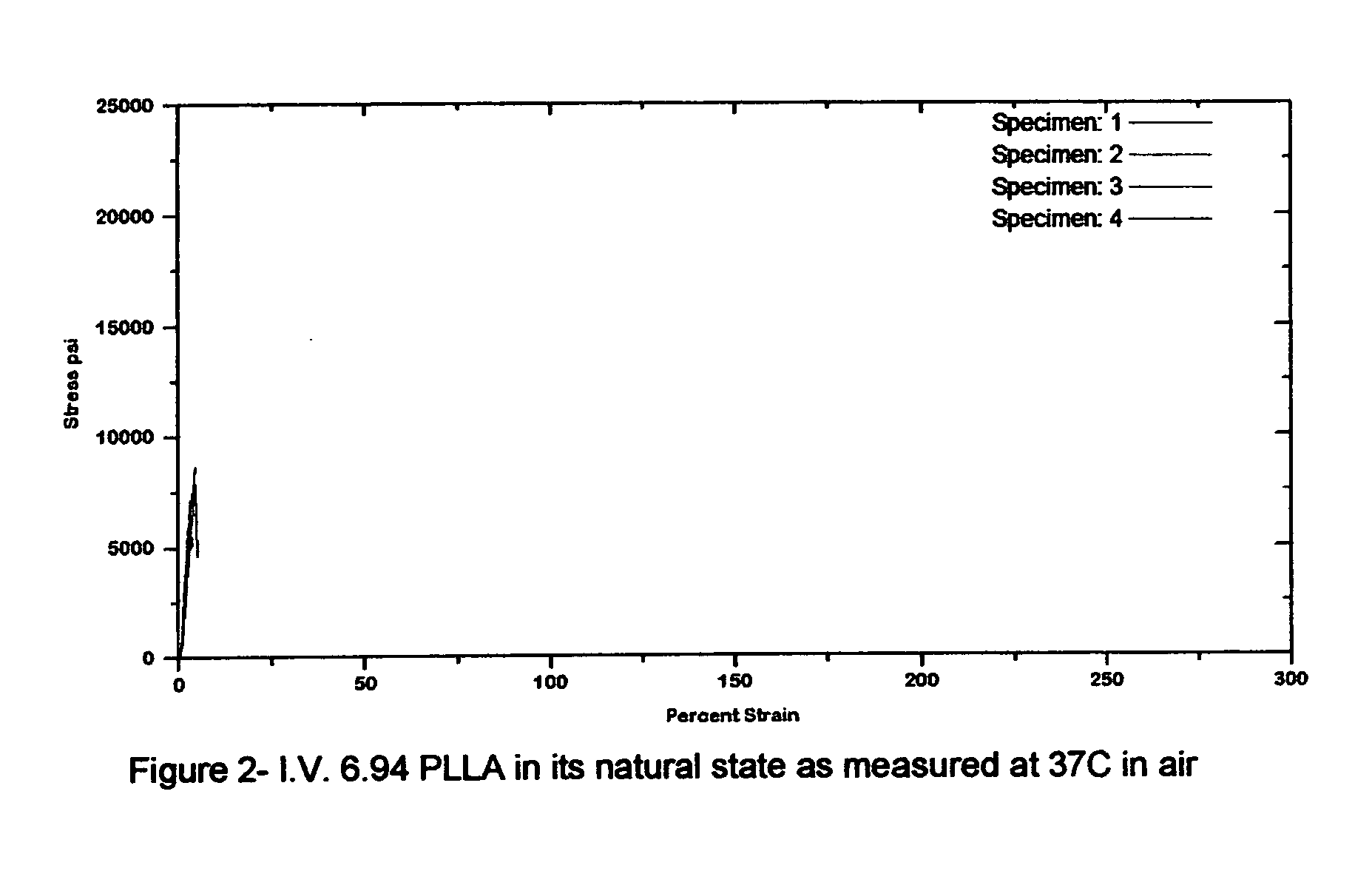

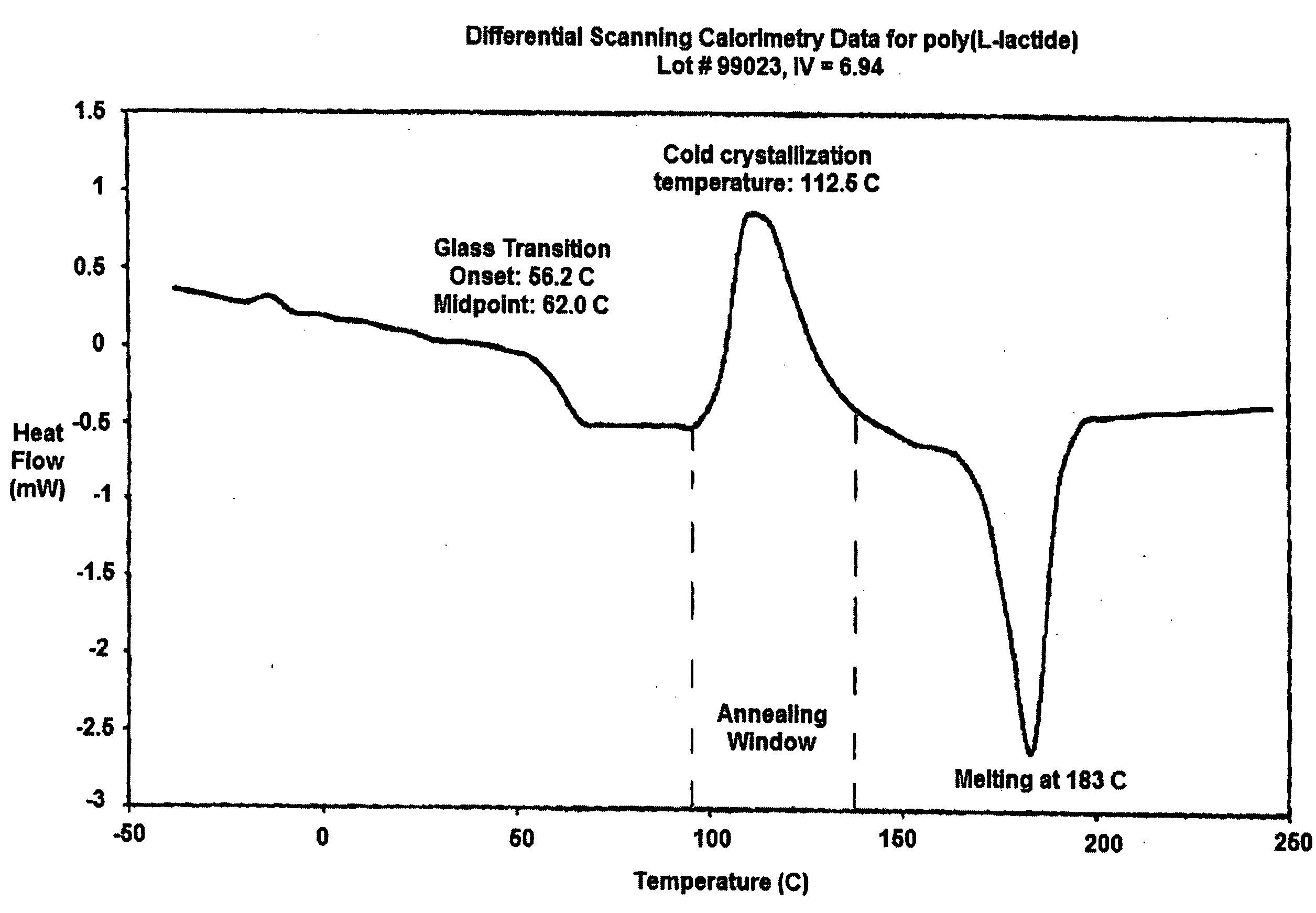

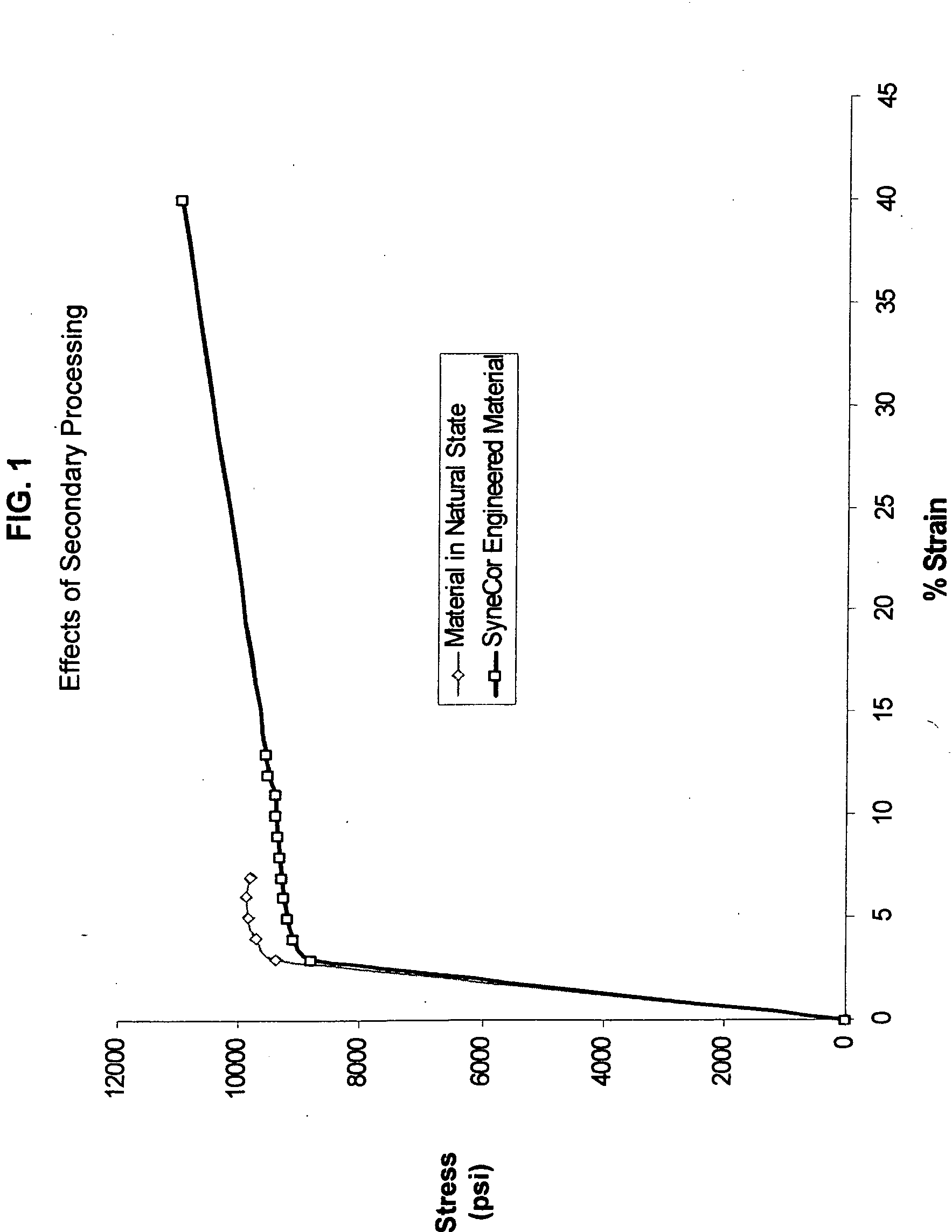

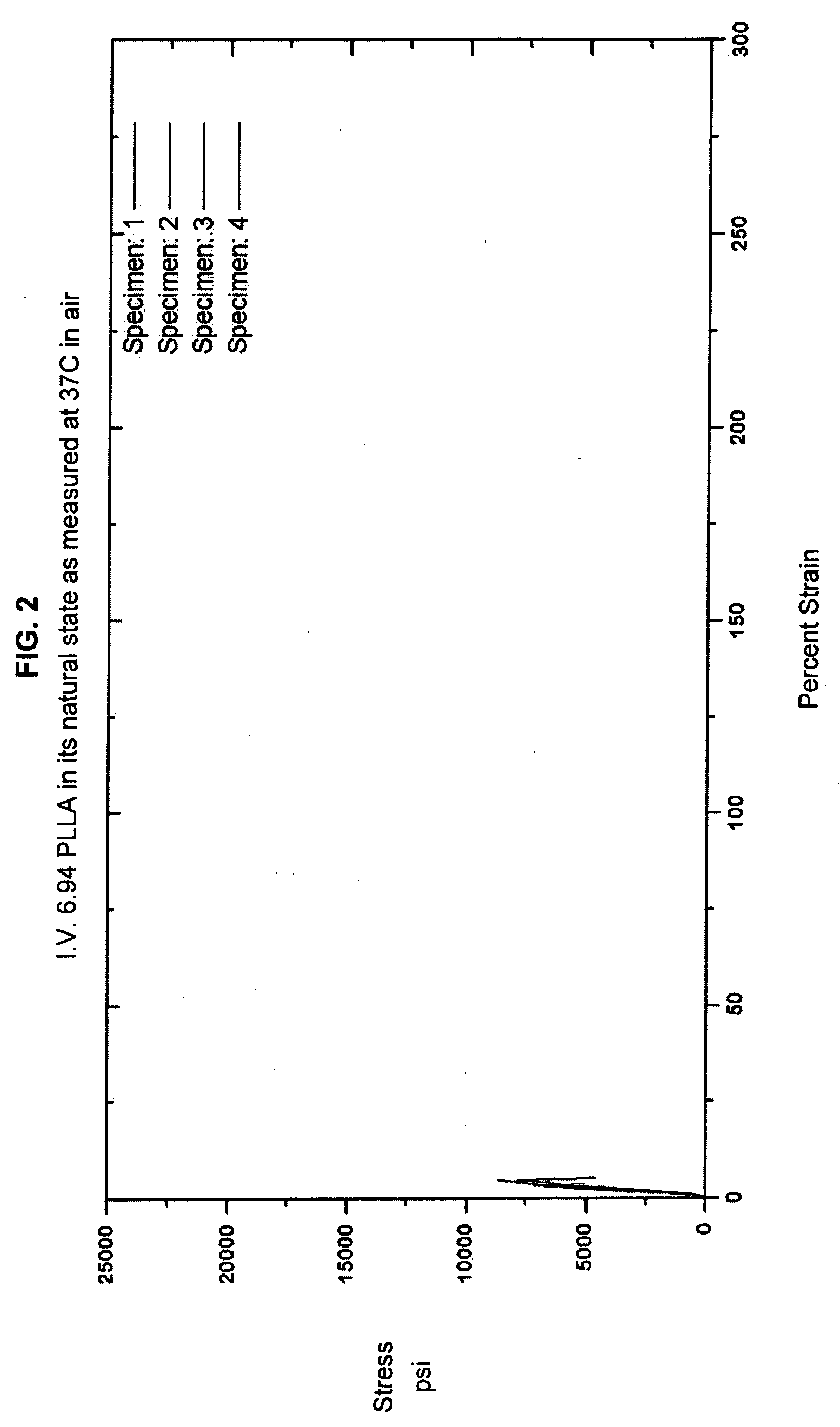

Polymeric endoprostheses with enhanced strength and flexibility and methods of manufacture

InactiveUS20050187615A1Reduce surface roughnessHigh elastic modulusStentsLayered productsPolymer scienceProsthesis

Improved polymeric endoprostheses and methods of manufacturing endoprostheses are disclosed herein. The endoprostheses may comprise one or more polymers wherein the polymer chains are substantially aligned circumferentially, and comprising increased radial strength and flexibility. An endoprosthesis according to the invention may comprise a smooth surface. Endoprostheses disclosed herein may be used in the treatment of strictures in lumens of the body. Alternatively, endoprostheses disclosed herein may be used as anchors to secure medical devices within lumens of the body. The endoprostheses disclosed herein may comprise one or more erodible polymer.

Owner:SYNECOR LLC

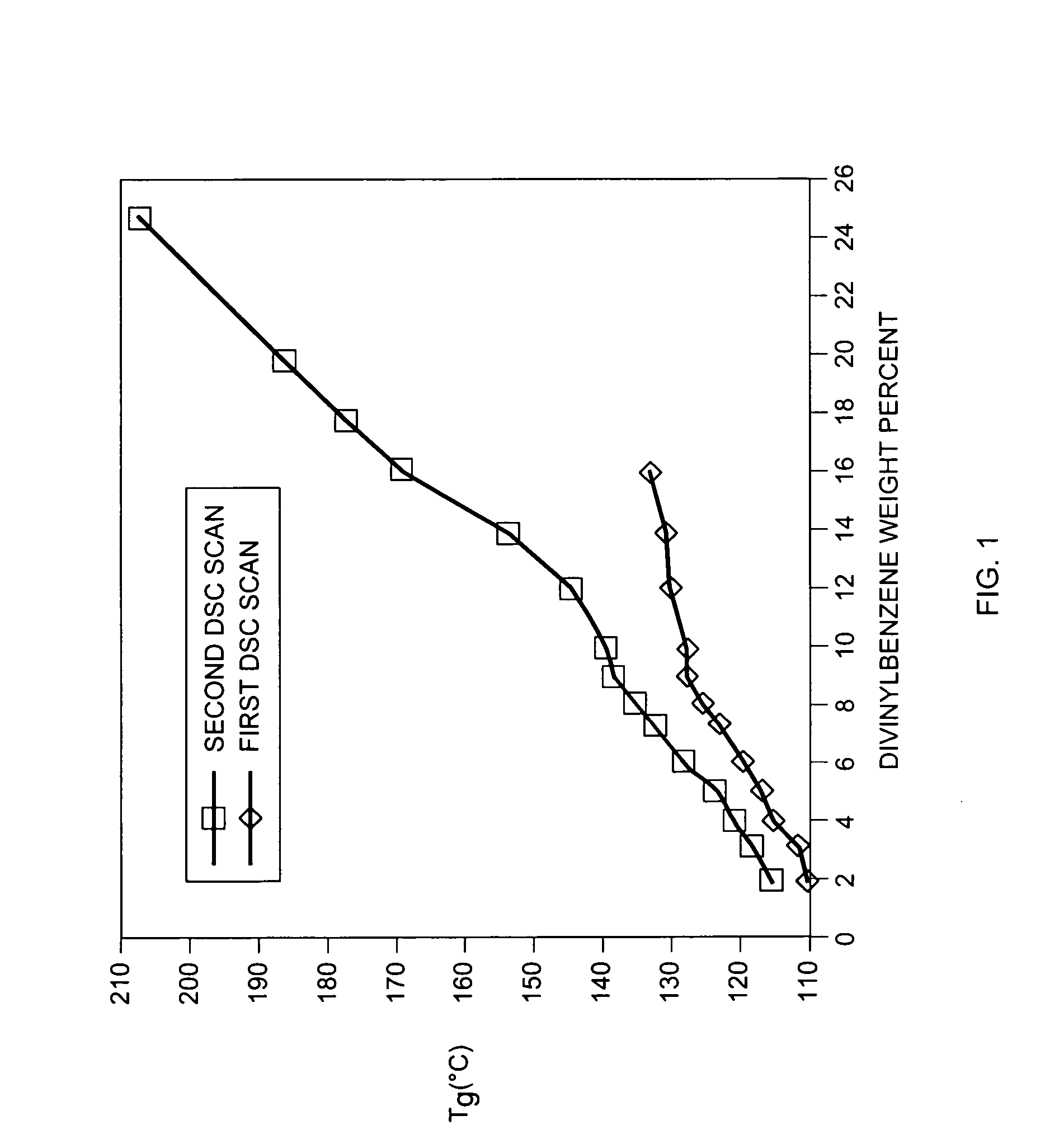

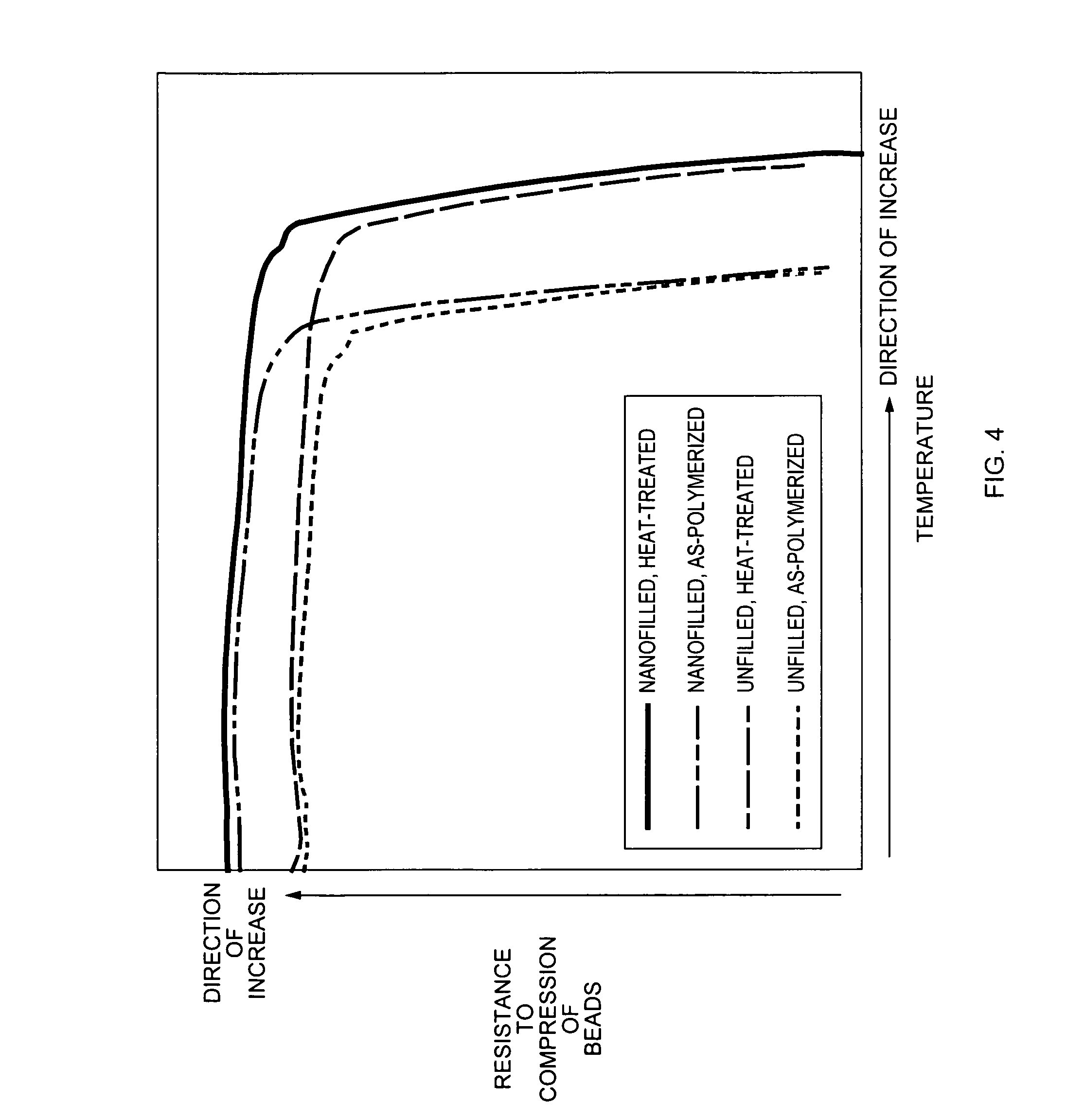

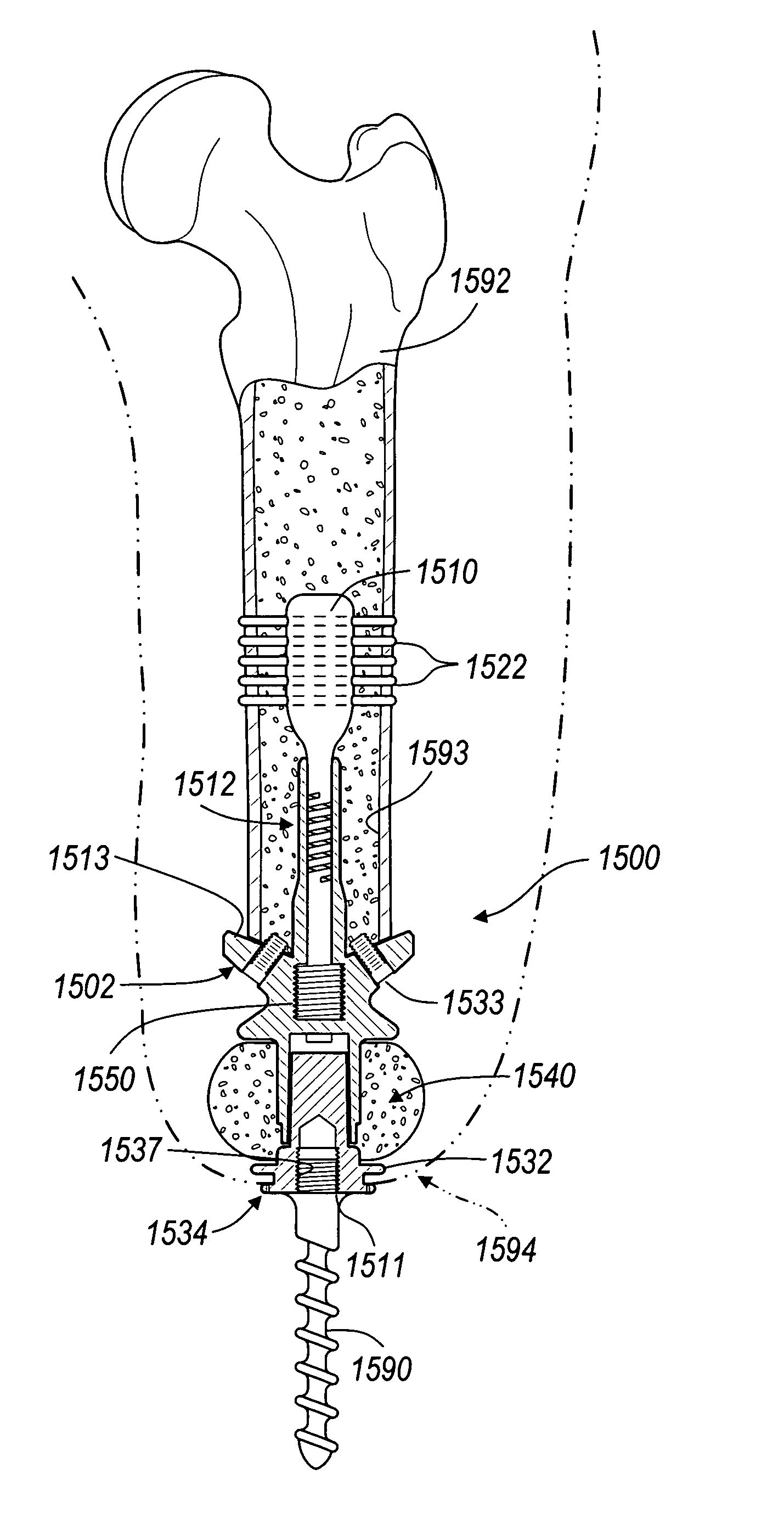

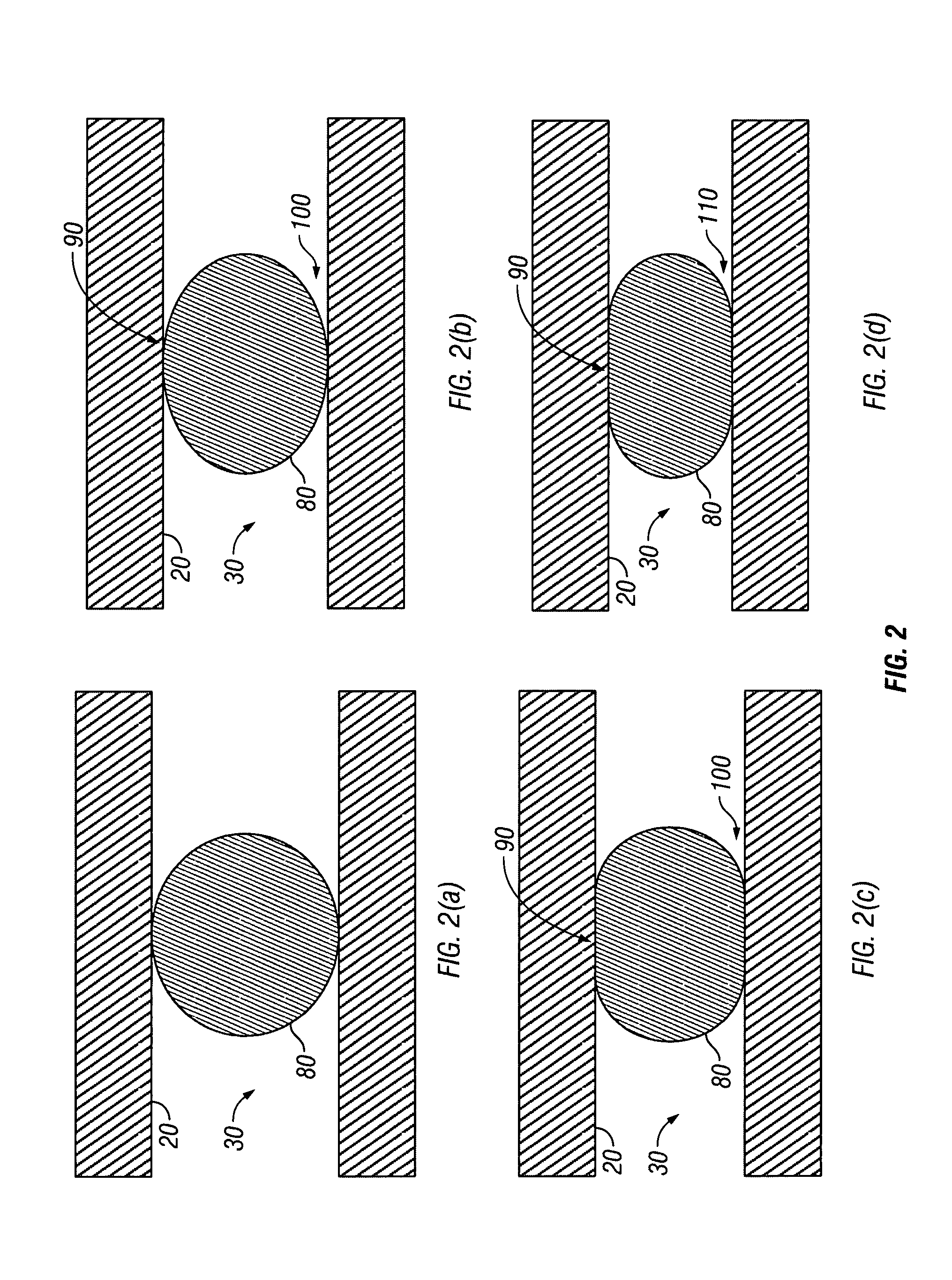

Thermoset nanocomposite particles, processing for their production, and their use in oil and natural gas drilling applications

ActiveUS20070066491A1Improve curingImprove heat transfer performanceMaterial nanotechnologySynthetic resin layered productsEnvironmental resistanceBall bearing

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of two different methods, either each by itself or in combination, to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method is the application of post-polymerization process steps (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. In general, its main benefits are the enhancement of the maximum possible use temperature and the environmental resistance. The other method is the incorporation of nanofillers, resulting in a heterogeneous “nanocomposite” morphology. In general, its main benefits are increased stiffness and strength. Nanofiller incorporation and post-polymerization heat treatment can also be combined to obtain the benefits of both methods simultaneously. The present invention relates to the development of thermoset nanocomposite particles. It also relates to the optional further improvement of the heat resistance and environmental resistance of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

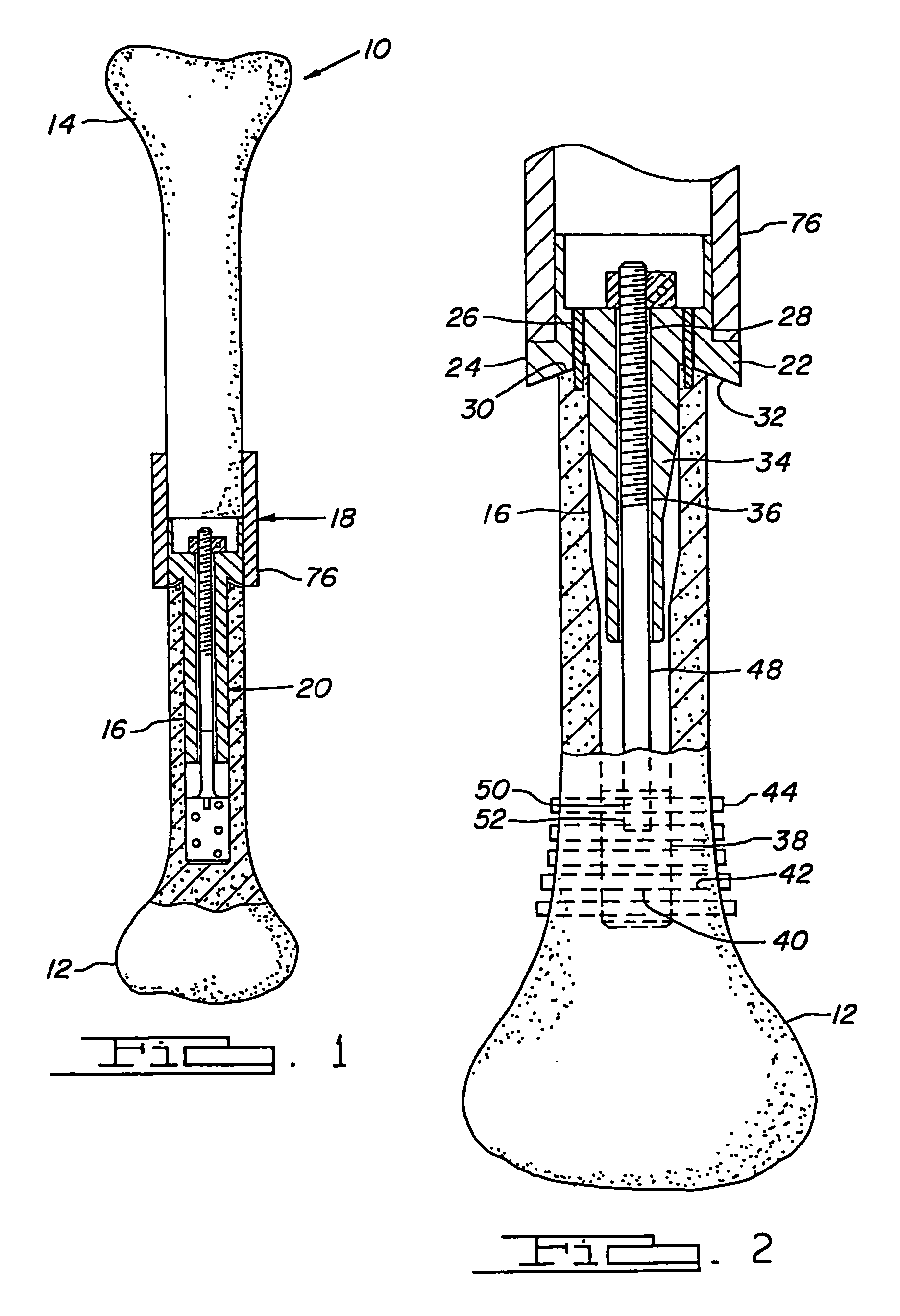

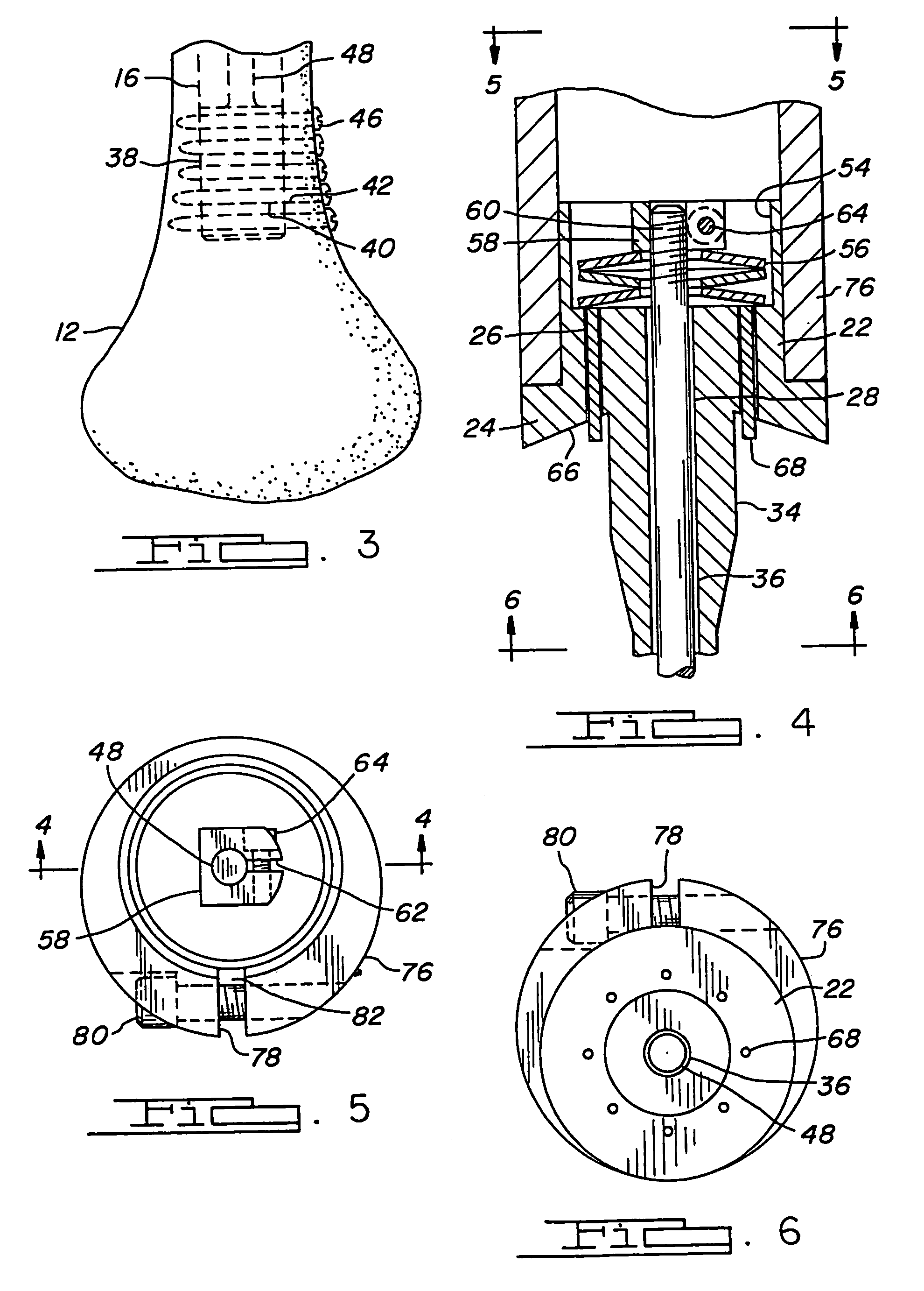

Compliant fixation of external prosthesis

InactiveUS7141073B2Improve securityPreventing secure wedgingInternal osteosythesisBone implantBiomedical engineeringExternal prosthesis

A fixation device and method for attaching an external prosthesis to a bone. The fixation device includes a main body having a compliant portion operable to be expanded and contracted. The main body has a first end fixedly retained in the bone and a second end coupled to an extension for receiving the external prosthesis. The main body and the extension define respectively first and second engagement surfaces for constraining a bone graft therebetween.

Owner:BIOMET MFG CORP

Method for the fracture stimulation of a subterranean formation having a wellbore by using impact-modified thermoset polymer nanocomposite particles as proppants

ActiveUS20070161515A1Heat distortion be greatGreat stiffnessSynthetic resin layered productsCellulosic plastic layered productsChemistryPolymer nanocomposite

A method for fracture stimulation of a subterranean formation includes providing a thermoset polymer nanocomposite particle precursor composition comprising a polymer precursor mixture, dispersed within a liquid medium, containing at least one of an initiator; at least one of a monomer, an oligomer or combinations thereof, said monomer and oligomer having three or more reactive functionalities capable of creating crosslinks between polymer chains; at least one of an impact modifier; and nanofiller particles substantially dispersed within the liquid medium; subjecting the nanocomposite particle precursor composition to suspension polymerizing conditions; subjecting the resulting nanocomposite particles to heat treatment; forming a slurry comprising a fluid and a proppant that includes the heat-treated nanocomposite particles; injecting the slurry into a wellbore; and emplacing the proppant within a fracture network in the formation.

Owner:SUN DRILLING PRODS

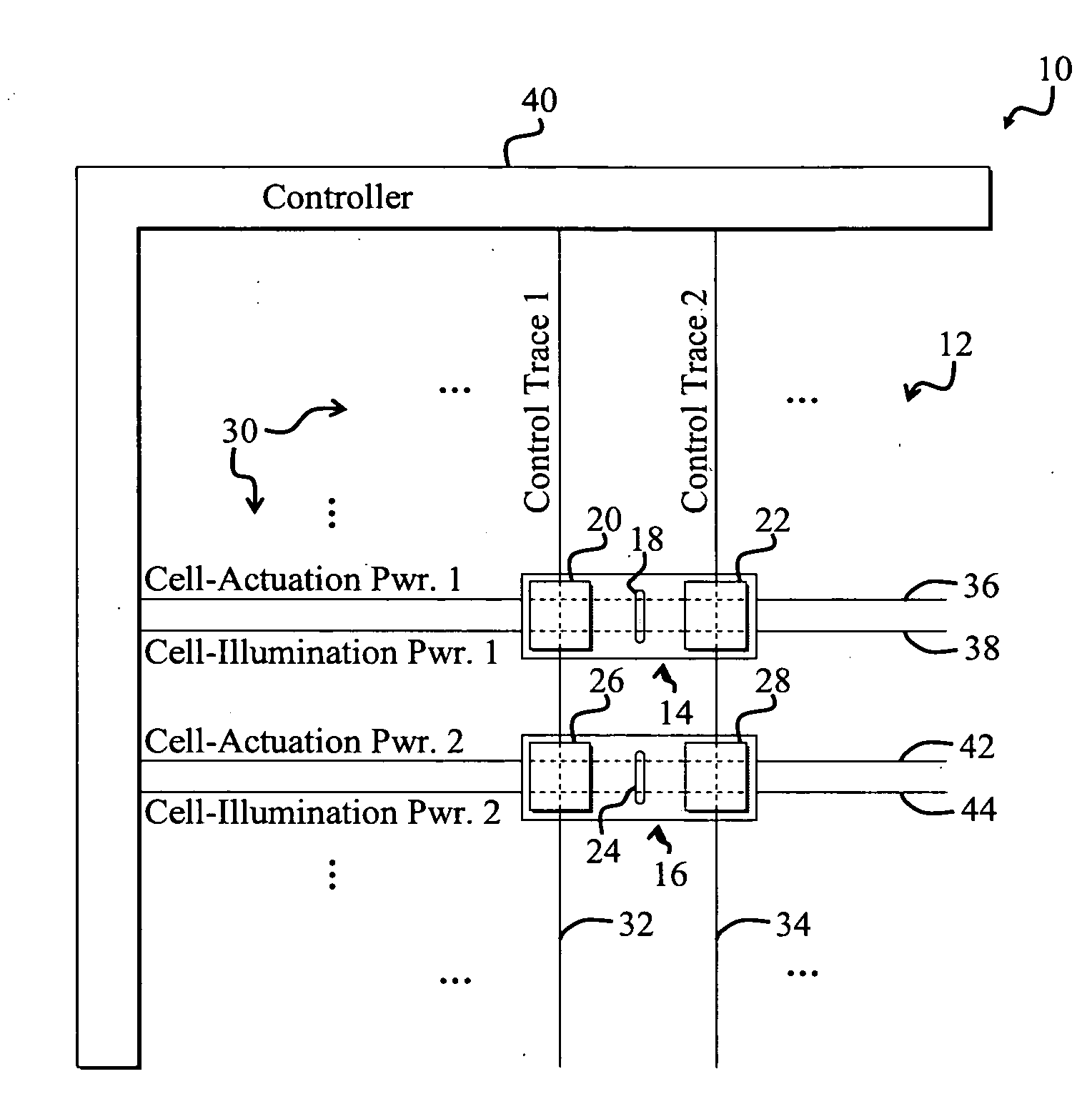

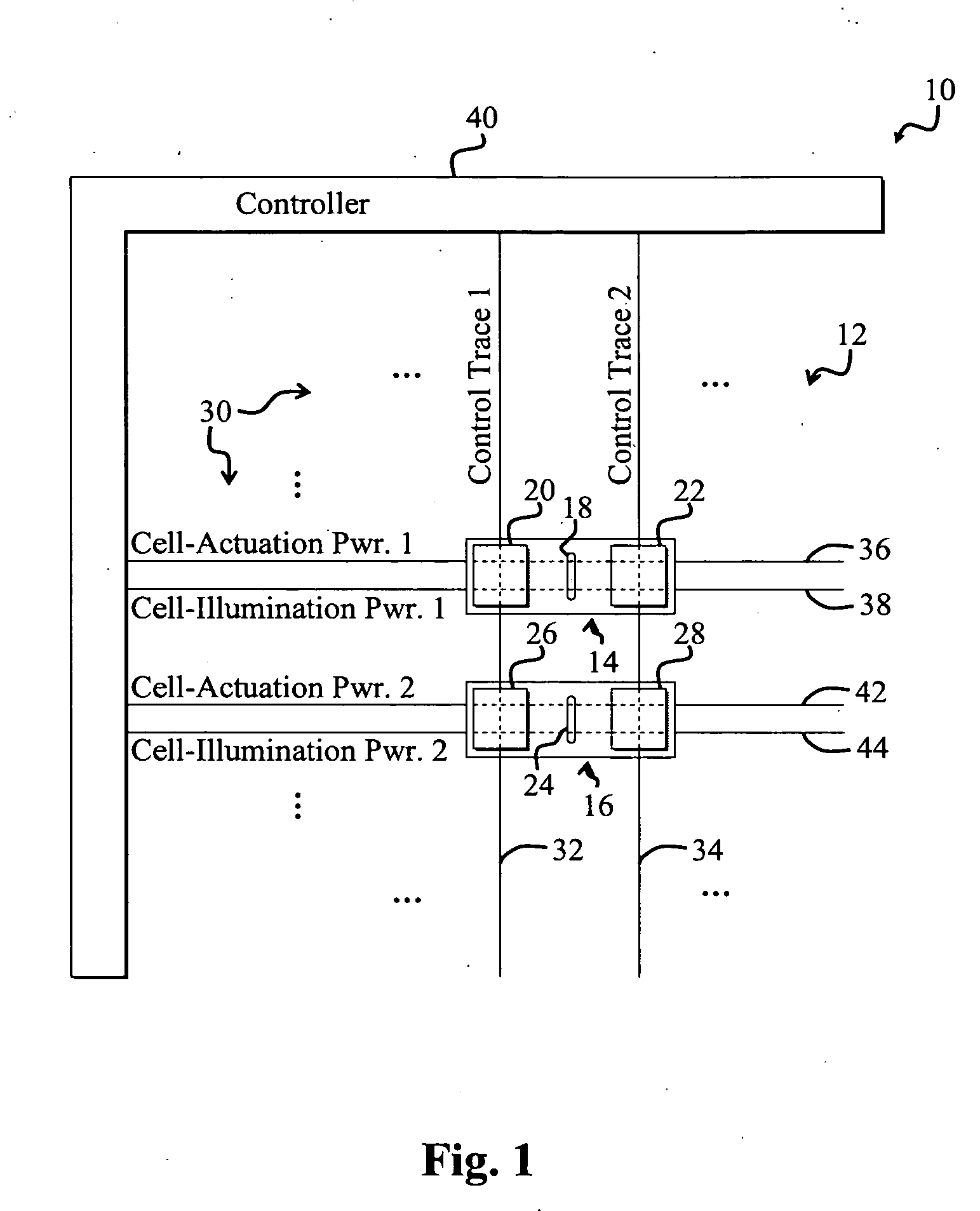

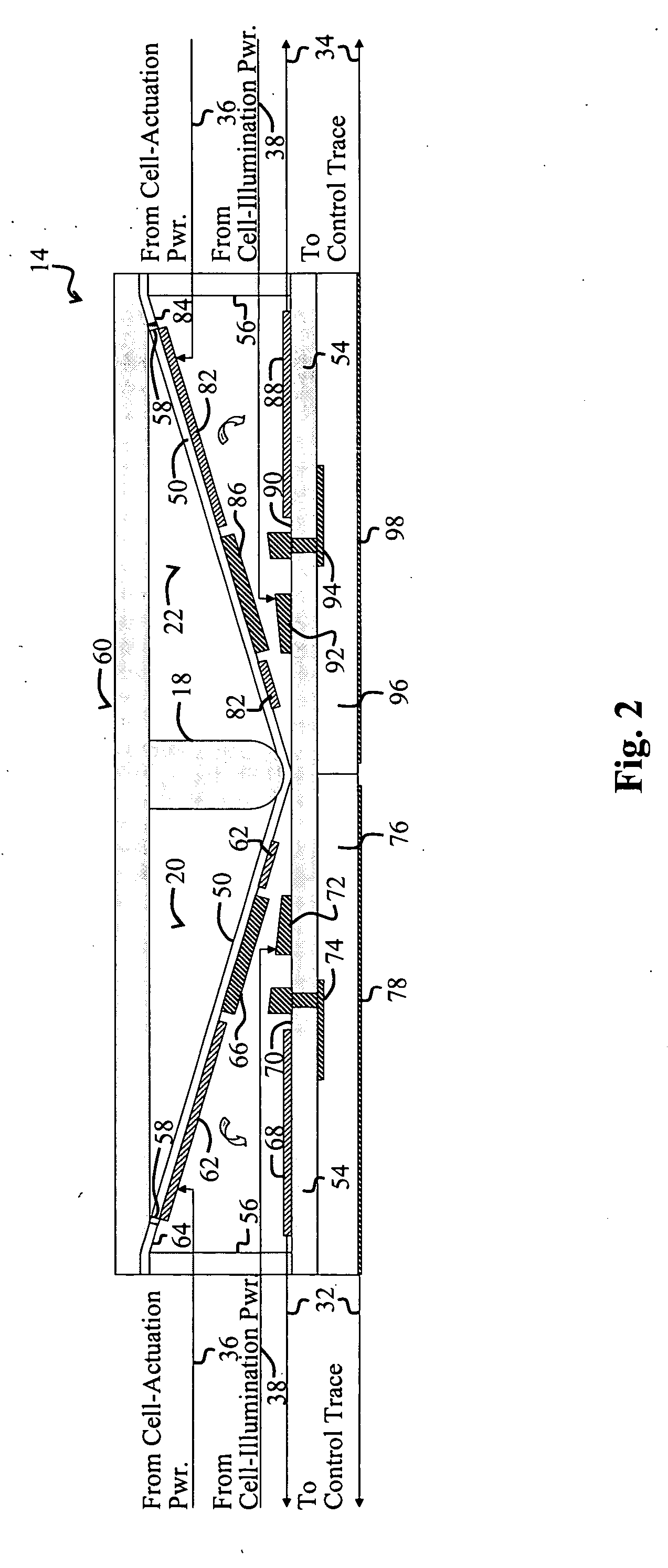

Picture element using microelectromechanical switch

InactiveUS20060202933A1Quality improvementImproved off-axis contrast contrastElectrostatic/electro-adhesion relaysStatic indicating devicesDisplay deviceEngineering

A robust microelectromechanical switch. In an illustrative embodiment, the switch is adapted for use in a display and includes a first flexible surface and a second surface. The second surface is angled relative to the first surface, forming a wedge the first surface and the second surface. A first terminal and a second terminal are positioned relative to the first flexible surface and the second surface so that selective flexing of the flexible surface electrically couples or uncouples the first terminal to the second terminal. In a more specific embodiment, the switch further includes a first mechanism for selectively applying an electrostatic force between the first flexible surface and the second surface. The first surface is positioned on a first elastic flexible layer, and the second surface is positioned on a second layer. The first mechanism includes a first actuator electrode that is coupled to the first surface, and a second actuator electrode that is coupled to the second surface. A sufficient charge differential applied between the first actuator electrode and the second actuator electrode will attract the first electrode to the second electrode, thereby flexing the flexible layer toward the second layer. The sidewalls define a perimeter of a cell that houses the switch. A protrusion extends from a third layer between the sidewalls, thereby indenting the first layer, and thereby forming the wedge.

Owner:SEERTECH CORP

Methods and compositions of a storable relatively lightweight proppant slurry for hydraulic fracturing and gravel packing applications

InactiveUS20080087429A1Improve system performanceHigh elastic modulusFluid removalDrilling compositionParticulatesMetallurgy

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that utilize relatively lightweight and / or substantially neutrally buoyant particulates. Particles that may be employed include particulates of naturally occurring materials that may be optionally strengthened or hardened by exposure to a modifying agent; porous materials including selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials; and well treating aggregates composed of an organic lightweight material and a weight modifying agent. The relatively lightweight particulate may be suspended as a substantially neutral buoyant particulate and stored with a carrier fluid as a pumpable slurry.

Owner:BAKER HUGHES HLDG LLC

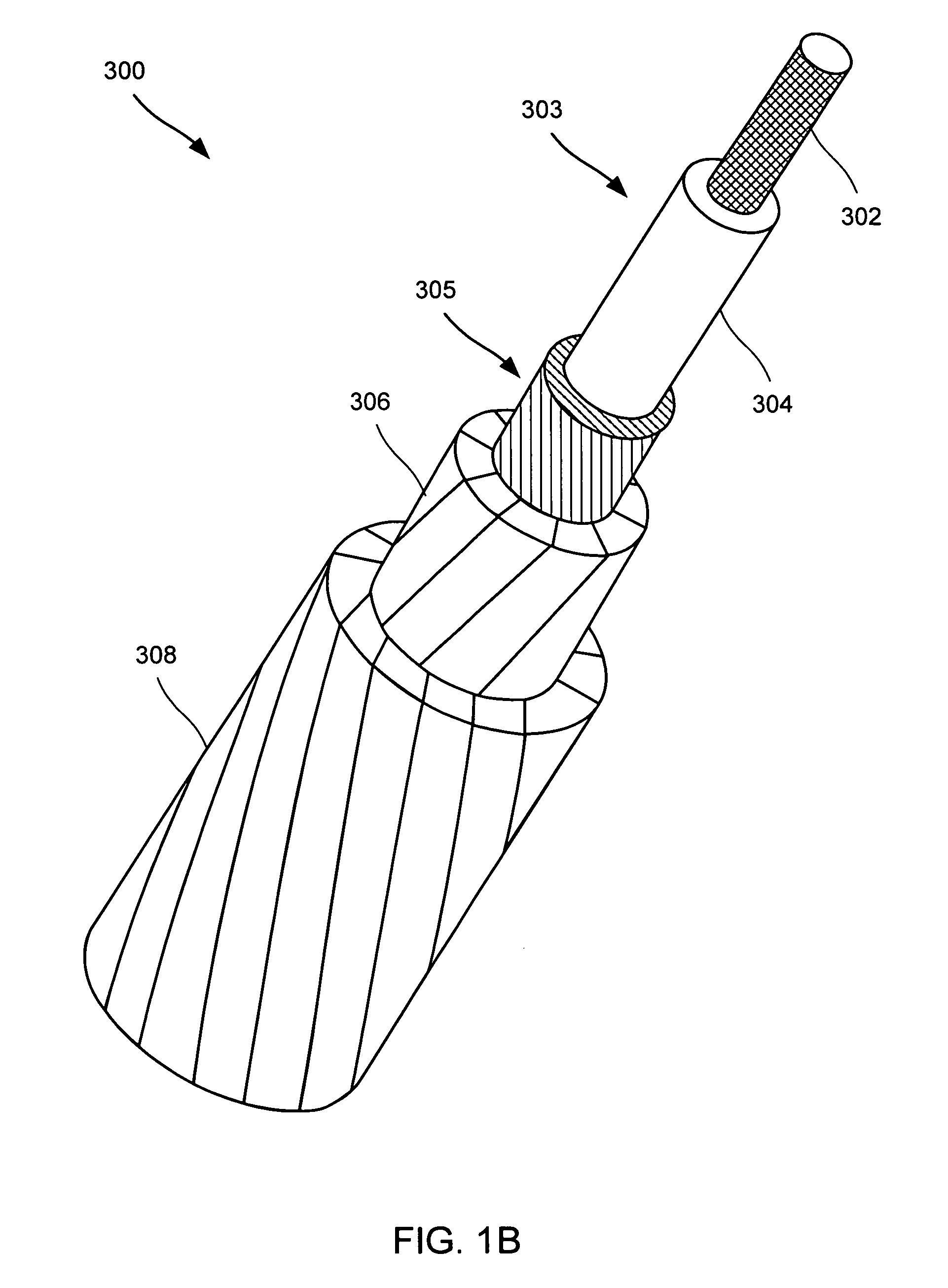

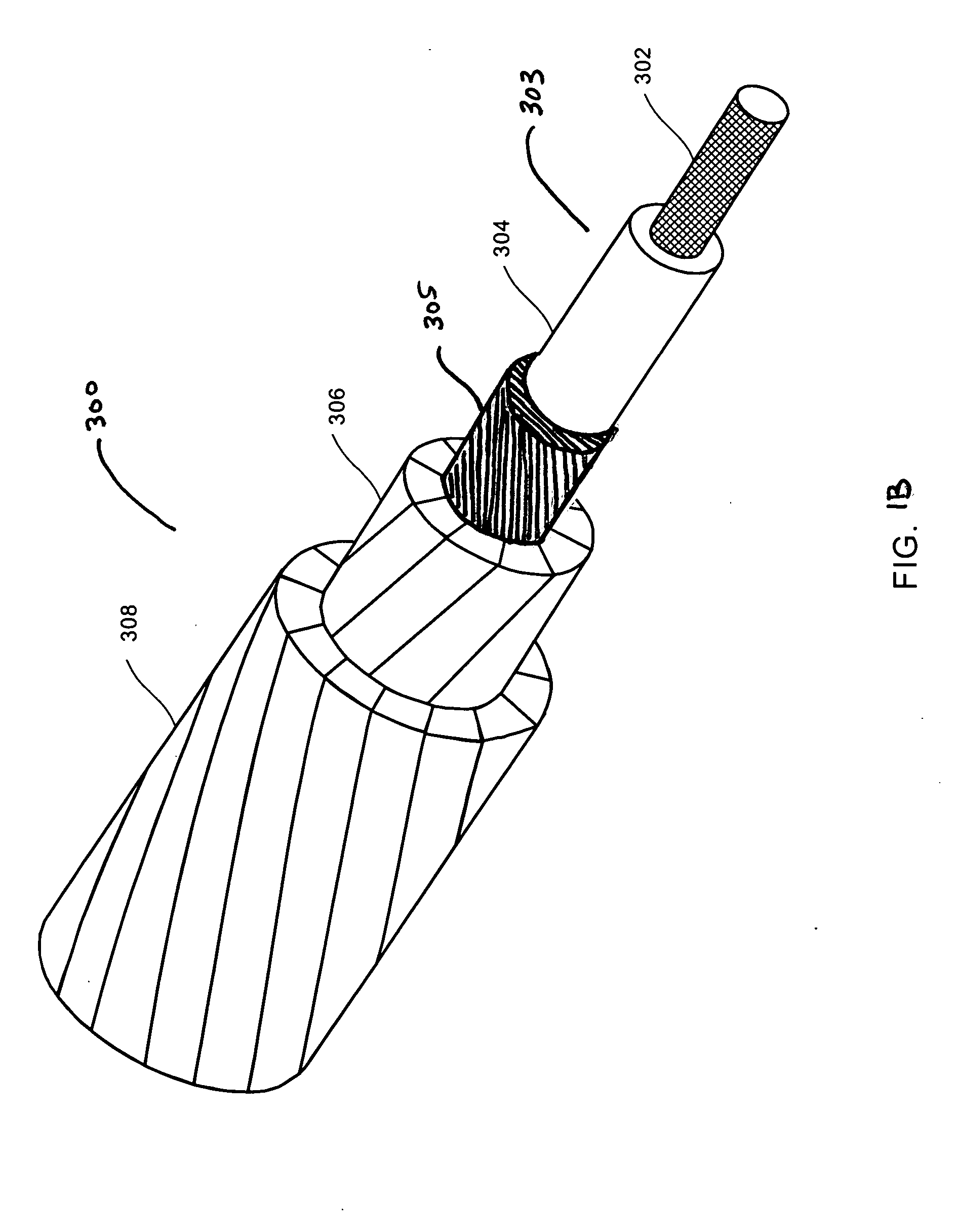

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS7179522B2Change in weightMaintain stable propertiesNon-insulated conductorsSynthetic resin layered productsElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about −45° C. to about 240° C. or higher, at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about −0.6×10−6 per deg. C. to about 1.0×10−5 per deg. C. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

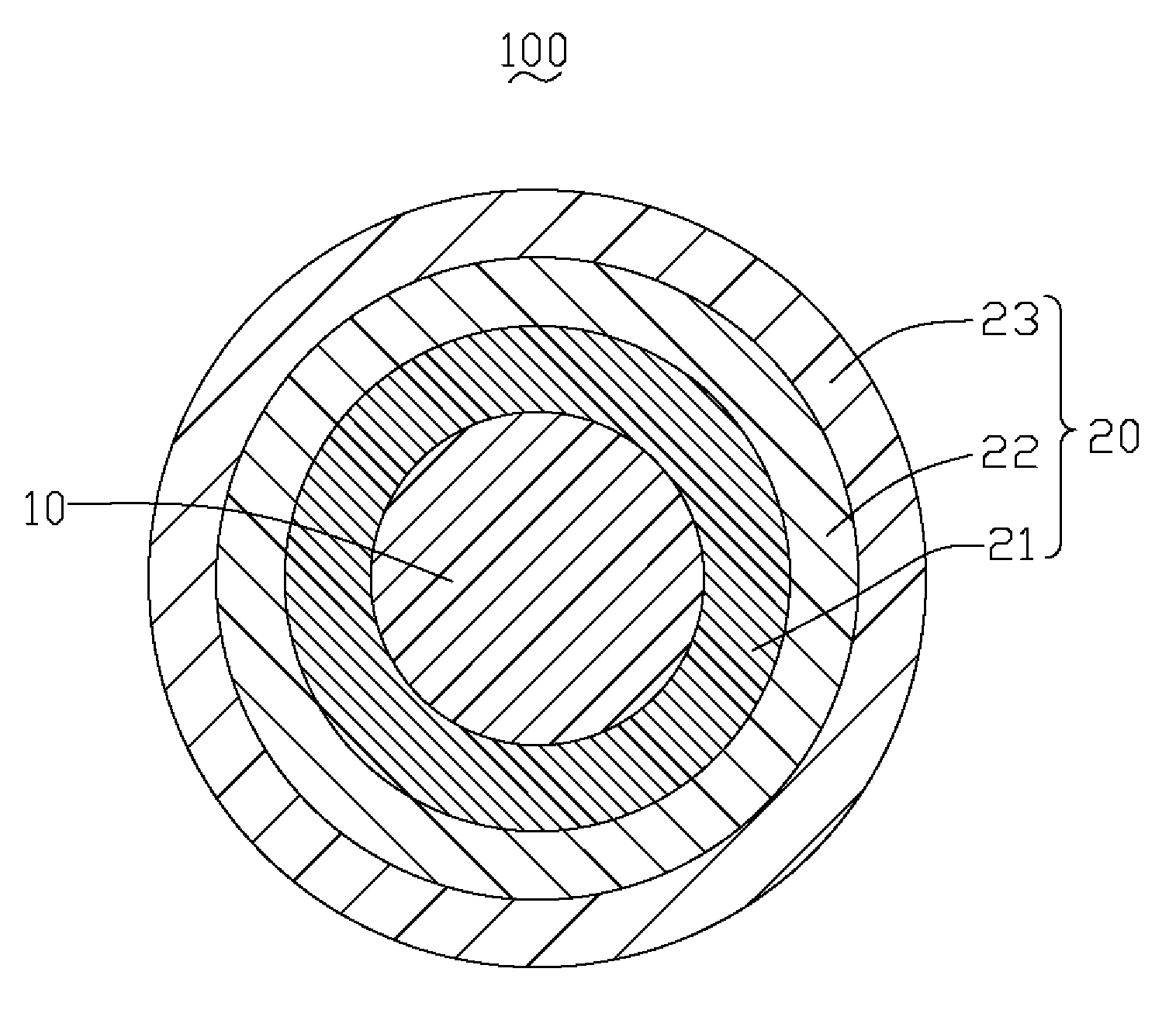

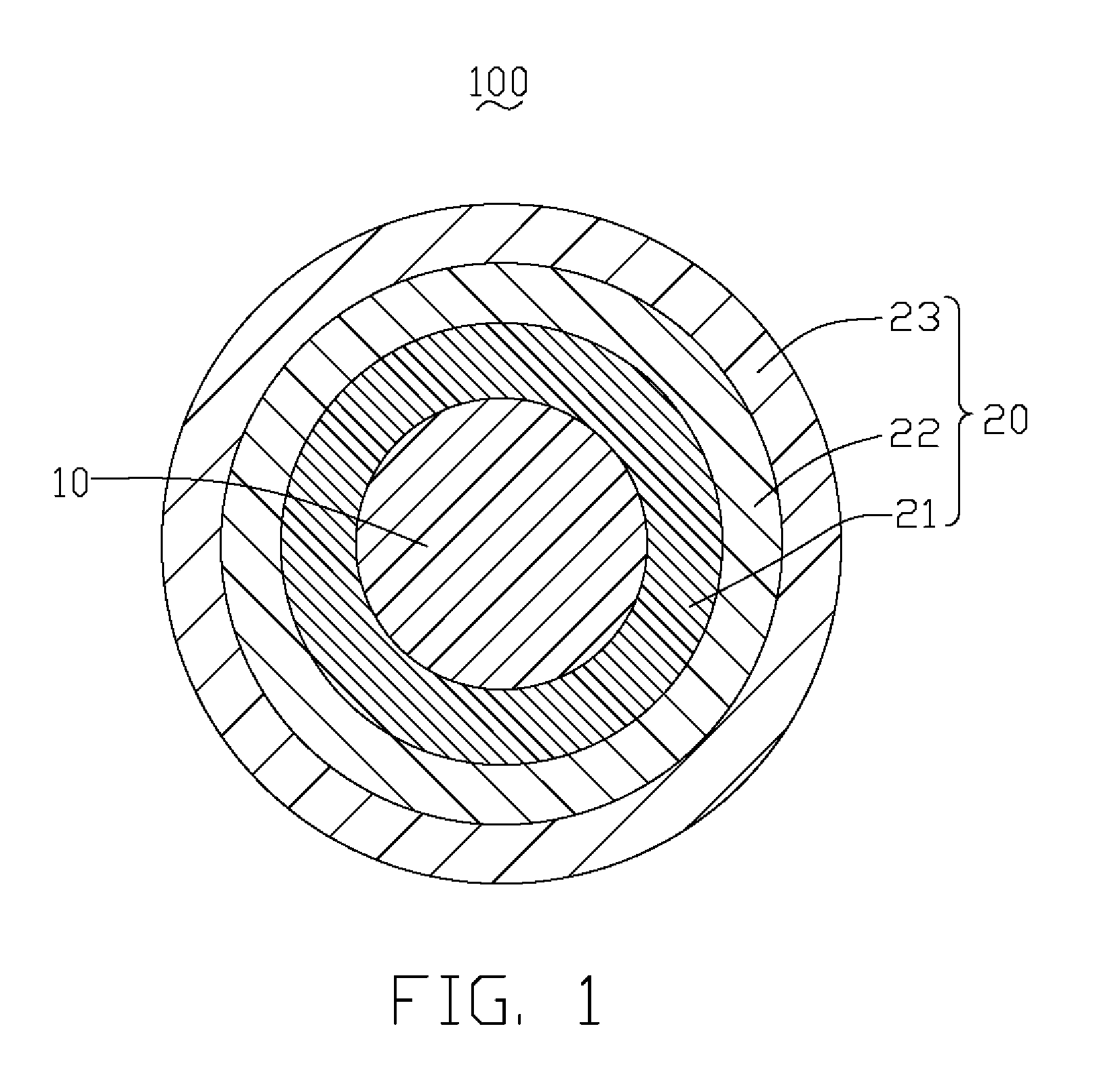

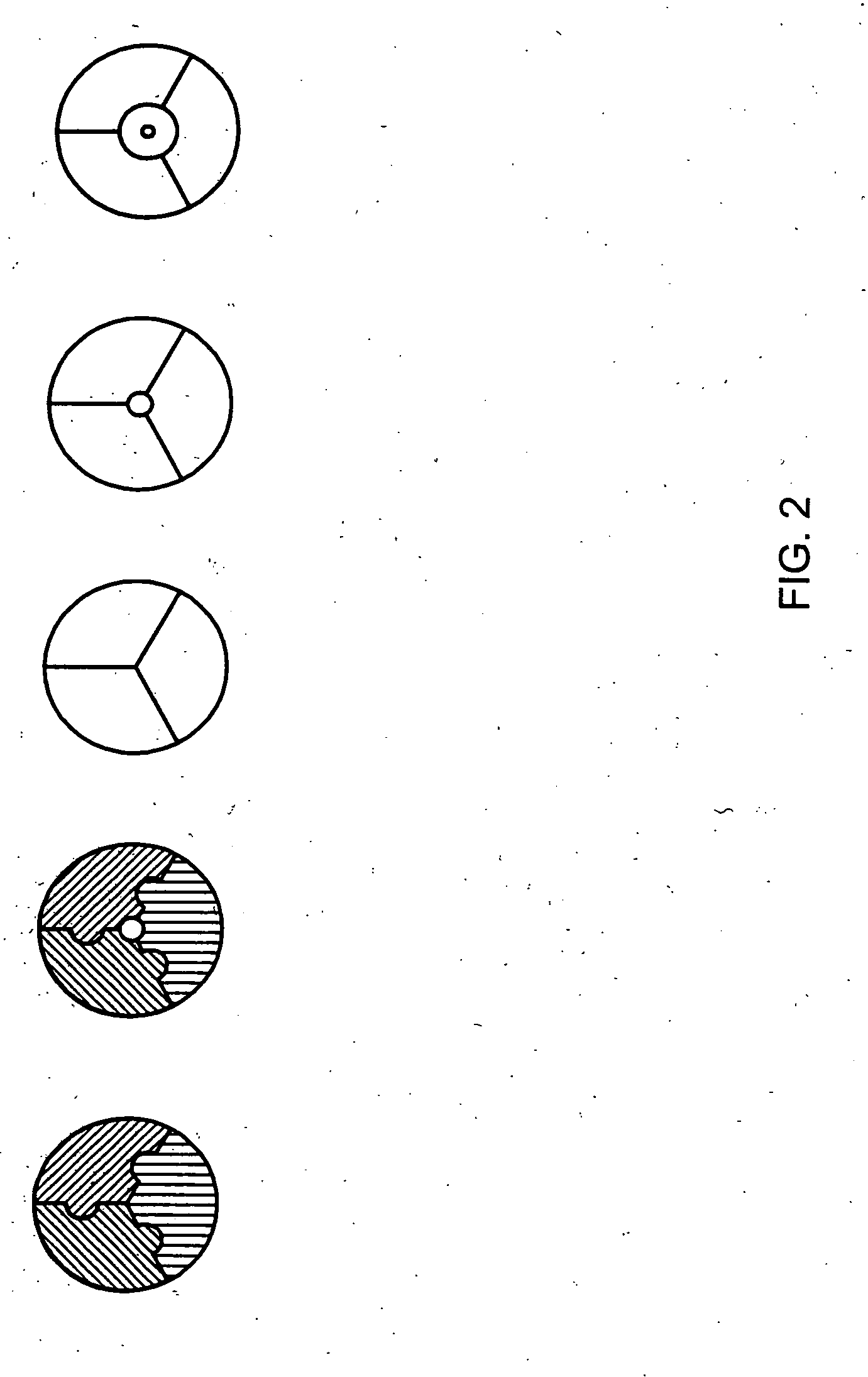

Electrical composite conductor and electrical cable using the same

InactiveUS20070151744A1Good electrical conductorImprove mechanical propertiesPlastic/resin/waxes insulatorsConductive materialElectrical conductorAlloy

A composite conductor includes a metal matrix and a certain amount of carbon nanotubes. The metal matrix is comprised of a material selected from the group consisting of copper, zinc, silver and any combination alloy thereof. A percentage by mass of the carbon nanotubes is in an approximate range from 0.2 percent to 2 percent. An electrical cable (100) includes an interior composite conductor core (10) and an exterior layer (20). The exterior layer further includes an insulating layer (21), a shielding layer (22) and a protective layer (23). The insulating layer is comprised of nanoclay and Teflon. The shielding layer is comprised of carbon nanotubes, carbon nanotube yarn and copper. The protective layer is comprised of nanoclay.

Owner:HON HAI PRECISION IND CO LTD

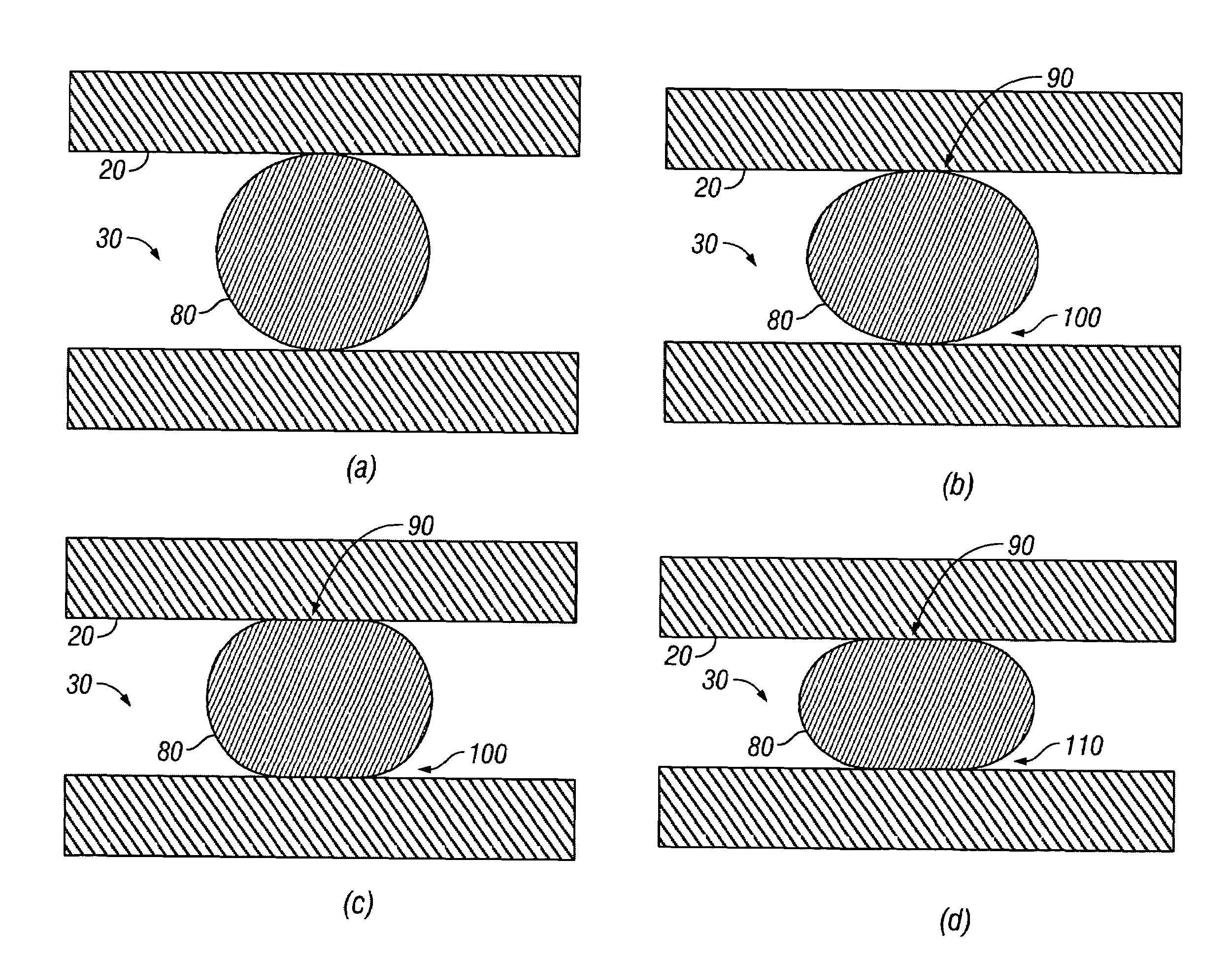

Method of stimulating oil and gas wells using deformable proppants

ActiveUS7322411B2Reduce cloggingMinimize damageFluid removalDrilling compositionFracturing fluidDolomite

A method of fracturing using deformable proppants minimizes proppant pack damage, without compromising the fracturing fluid's proppant transport properties during pumping, by use of deformable proppants. Selection of proppant is dependent upon the mechanical properties of the formation rock. The strength of the deformable proppant is dependent upon the modulus of the formation rock being treated such that the proppant is capable of providing, at the very least, a minimum level of conductivity in in-situ stress environments. The maximum elastic modulus of the deformable proppant is less than the minimum modulus of the formation rock which is being treated. The method is particularly applicable in fracturing operations of subterranean reservoirs such as those comprised primarily of coal, chalk, limestone, dolomite, shale, siltstone, diatomite, etc.

Owner:BAKER HUGHES HLDG LLC

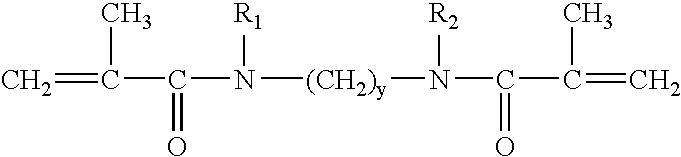

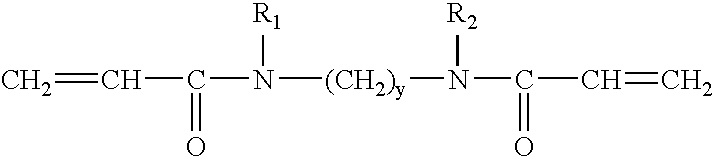

Biodegradable and biocompatible crosslinked polymer hydrogel prepared from PVA and/or PEG macromer mixtures

InactiveUS20050271727A1High elastic modulusLow elongationPowder deliverySurgical adhesivesWound dressingBlood vessel

Biodegradable and biocompatible polymeric hydrogels based on the mixtures of poly(vinyl alcohol) and poly(ethylene glycol) macromers, and methods for their preparation and use, are disclosed. The polymerization may be carried out in situ on organs or tissues or outside the body. Applications for such biocompatible crosslinked hydrogels include prevention of post-operative adhesions, surgical sealants, embolic therapies, controlled delivery of drugs, coating of medical devices such as vascular grafts, wound dressings and other medical applications.

Owner:CALLISYN PHARMA

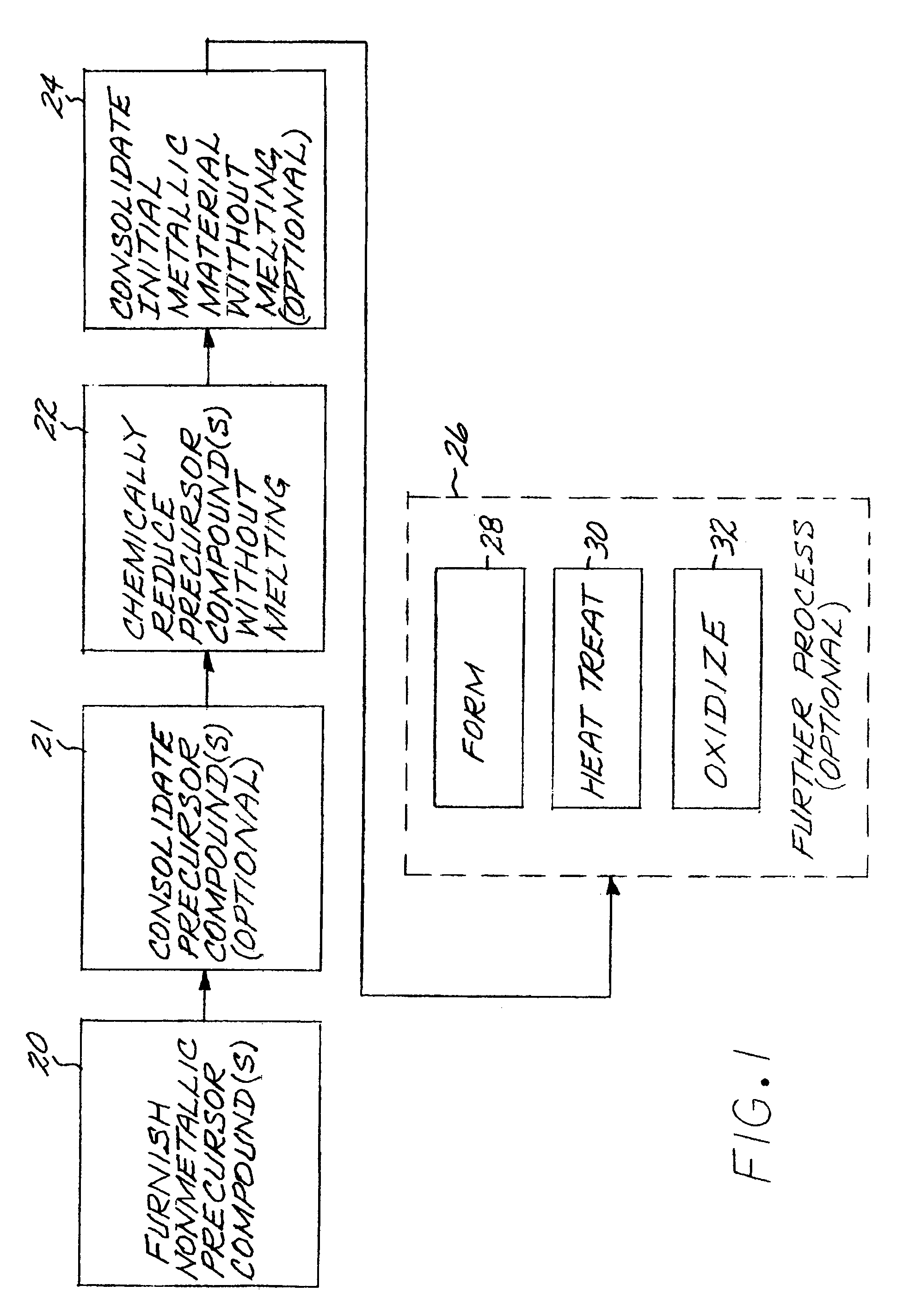

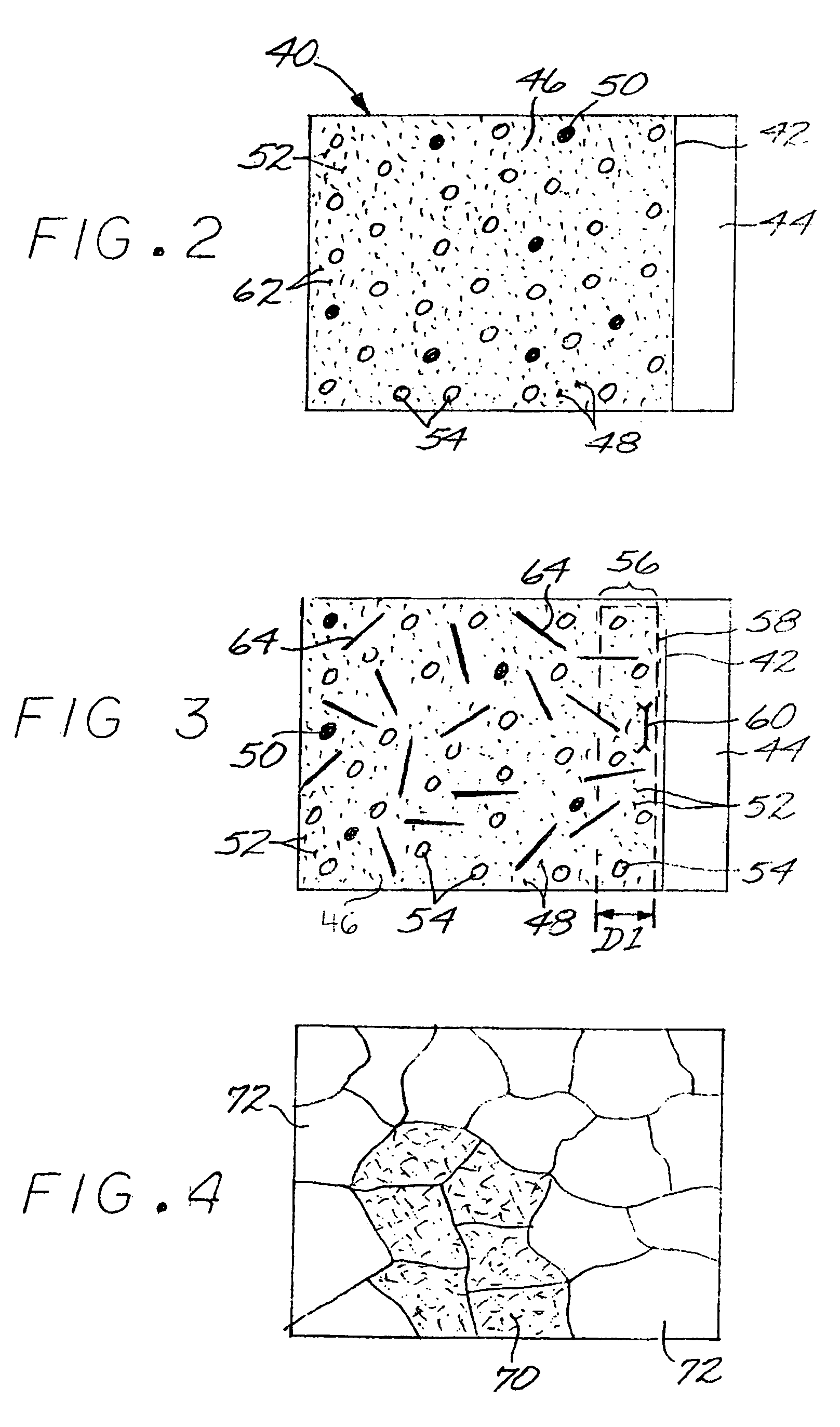

Method for producing a titanium metallic composition having titanium boride particles dispersed therein

InactiveUS7410610B2Reduce incidenceMaintain good propertiesPump componentsBlade accessoriesElemental compositionRoom temperature

An article made of constituent elements is prepared by furnishing at least one nonmetallic precursor compound, wherein all of the nonmetallic precursor compounds collectively contain the constituent elements. The constituent elements include a titanium-base metallic composition, boron present at a level greater than its room-temperature solid solubility limit, and, optionally, a stable-oxide-forming additive element present at a level greater than its room-temperature solid solubility limit. The precursor compounds are chemically reduced to produce a material comprising a titanium-base metallic composition having titanium boride particles therein, without melting the titanium-base metallic composition. The titanium-base metallic composition having the titanium boride particles therein is consolidated without melting.

Owner:GENERAL ELECTRIC CO

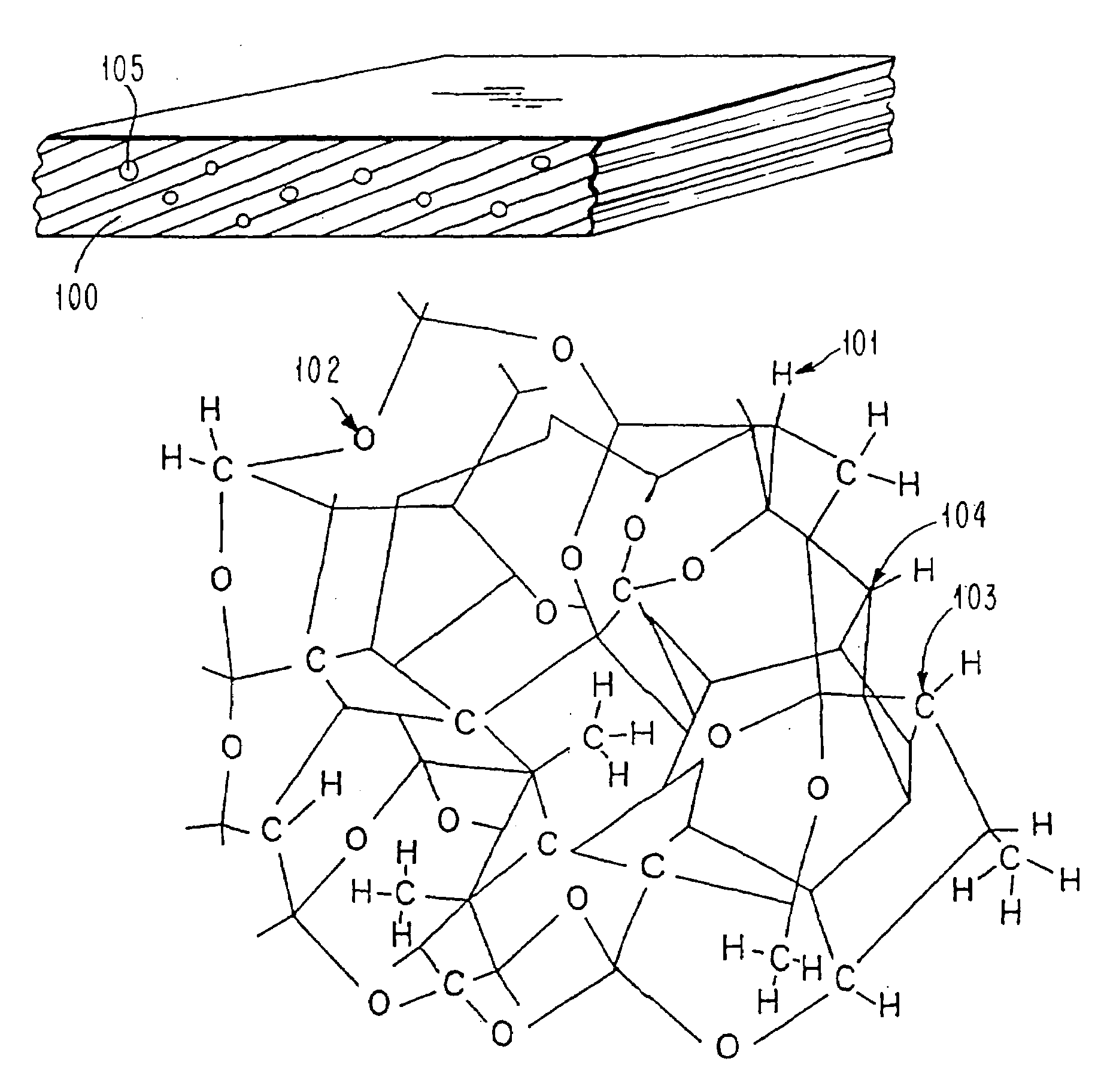

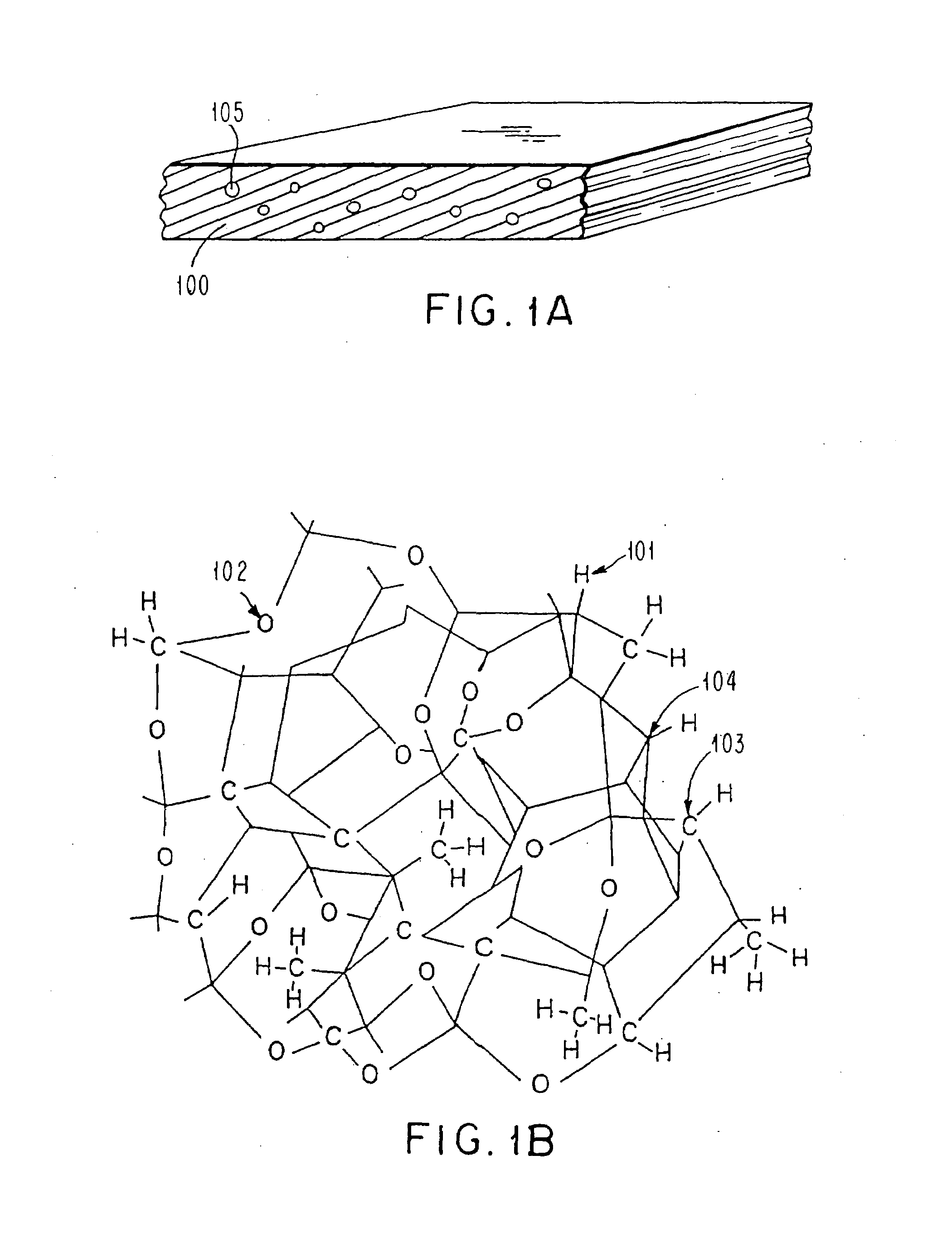

Carbon fiber prepreg, and a production process thereof

InactiveUS6117551AImprove impact resistanceHigh tensile strengthDecorative surface effectsAdhesive processes with surface pretreatmentHigh concentrationFiber bundle

PCT No. PCT / JP97 / 04642 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Dec. 16, 1997 PCT Pub. No. WO98 / 26912 PCT Pub. Date Jun. 25, 1998The present invention relates to a carbon fiber prepreg. The carbon fiber prepreg of the present invention is characterized in that a carbon fiber bundle comprising a plurality of continuous carbon filaments and having a hook drop value of 10 cm or more as the degree of fiber entanglement is impregnated with a base resin mainly composed of a thermosetting resin, and that particles of 150 mu m or less in particle size made of a thermoplastic resin account for 20 wt % or less based on the weight of the entire prepreg and distributed at a higher concentration in the surface zone than in the inside. The carbon fiber prepreg of the present invention is good in tackiness and less changing in tackiness with the lapse of time, and can form a composite with an excellent compression interlaminar shear strength (CILS) at high temperature after moisture absorption while maintaining good impact resistance. It also allows the production of a composite very higher than the conventional composite in the compressive strength (LCS) of a cross laminated panel. The carbon fiber prepreg of the present invention can be preferably used as a structural member in such areas as aerospace area, sporting area and civil engineering and architecture area.

Owner:TORAY IND INC

Method of stimulating oil and gas wells using deformable proppants

ActiveUS20060151170A1Minimizing proppant pack damageImproves retained proppant pack permeabilityFluid removalDrilling compositionFracturing fluidUltimate tensile strength

A method of fracturing using deformable proppants minimizes proppant pack damage, without compromising the fracturing fluid's proppant transport properties during pumping, by use of deformable proppants. Selection of proppant is dependent upon the mechanical properties of the formation rock. The strength of the deformable proppant is dependent upon the modulus of the formation rock being treated such that the proppant is capable of providing, at the very least, a minimum level of conductivity in in-situ stress environments. The maximum elastic modulus of the deformable proppant is less than the minimum modulus of the formation rock which is being treated. The method is particularly applicable in fracturing operations of subterranean reservoirs such as those comprised primarily of coal, chalk, limestone, dolomite, shale, siltstone, diatomite, etc.

Owner:BAKER HUGHES INC

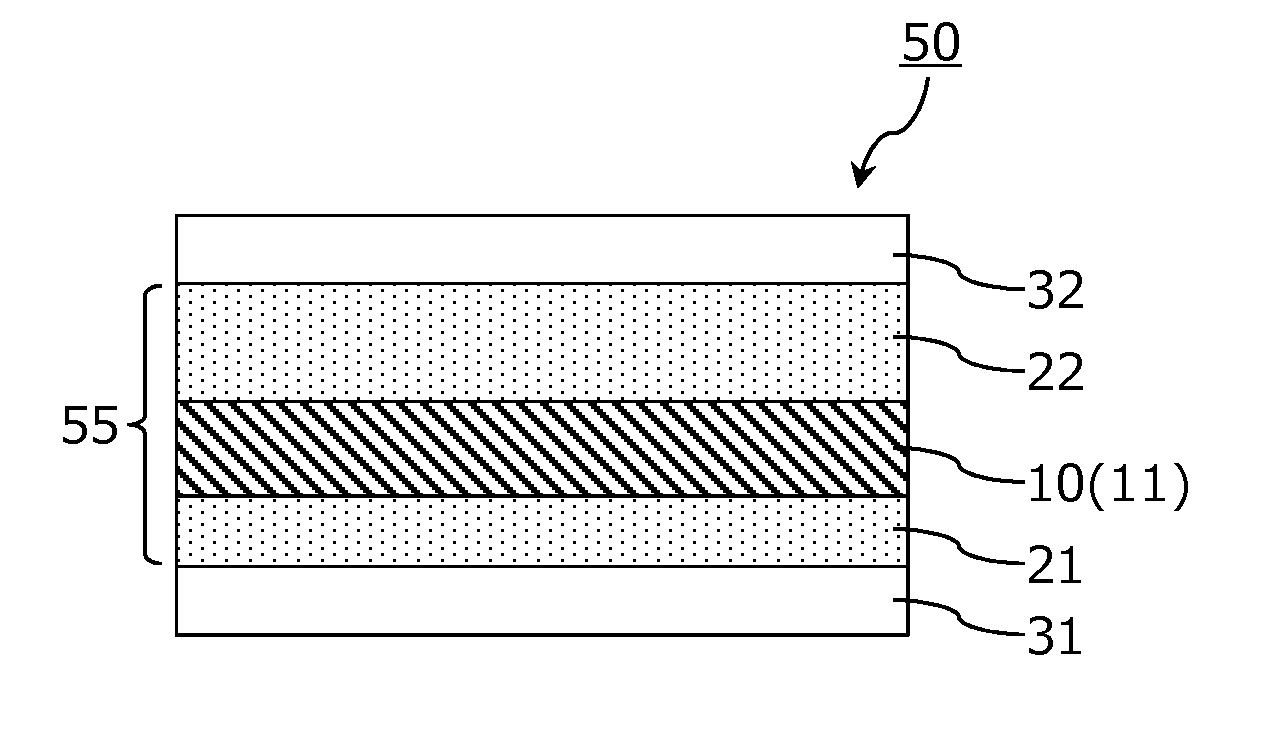

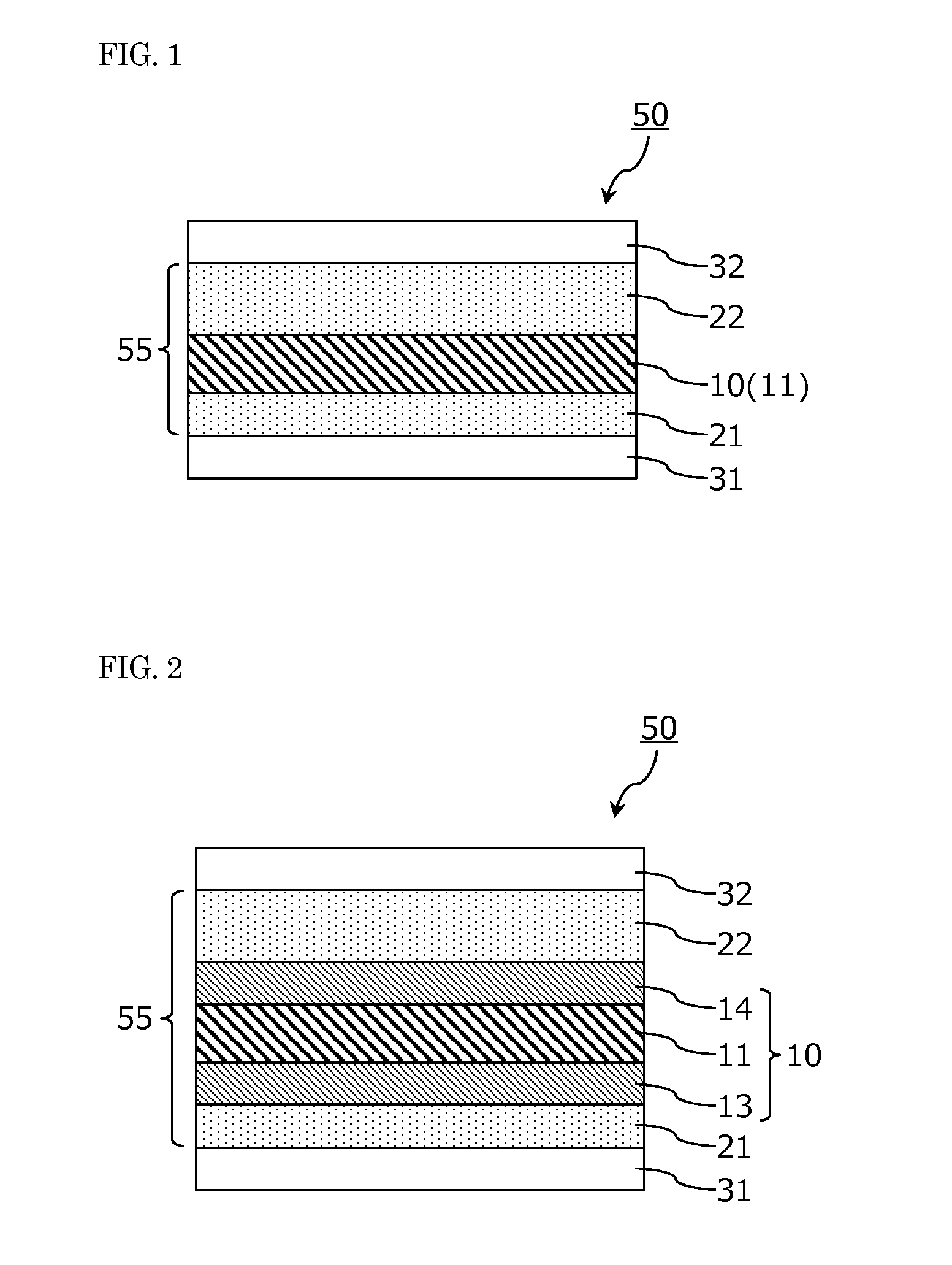

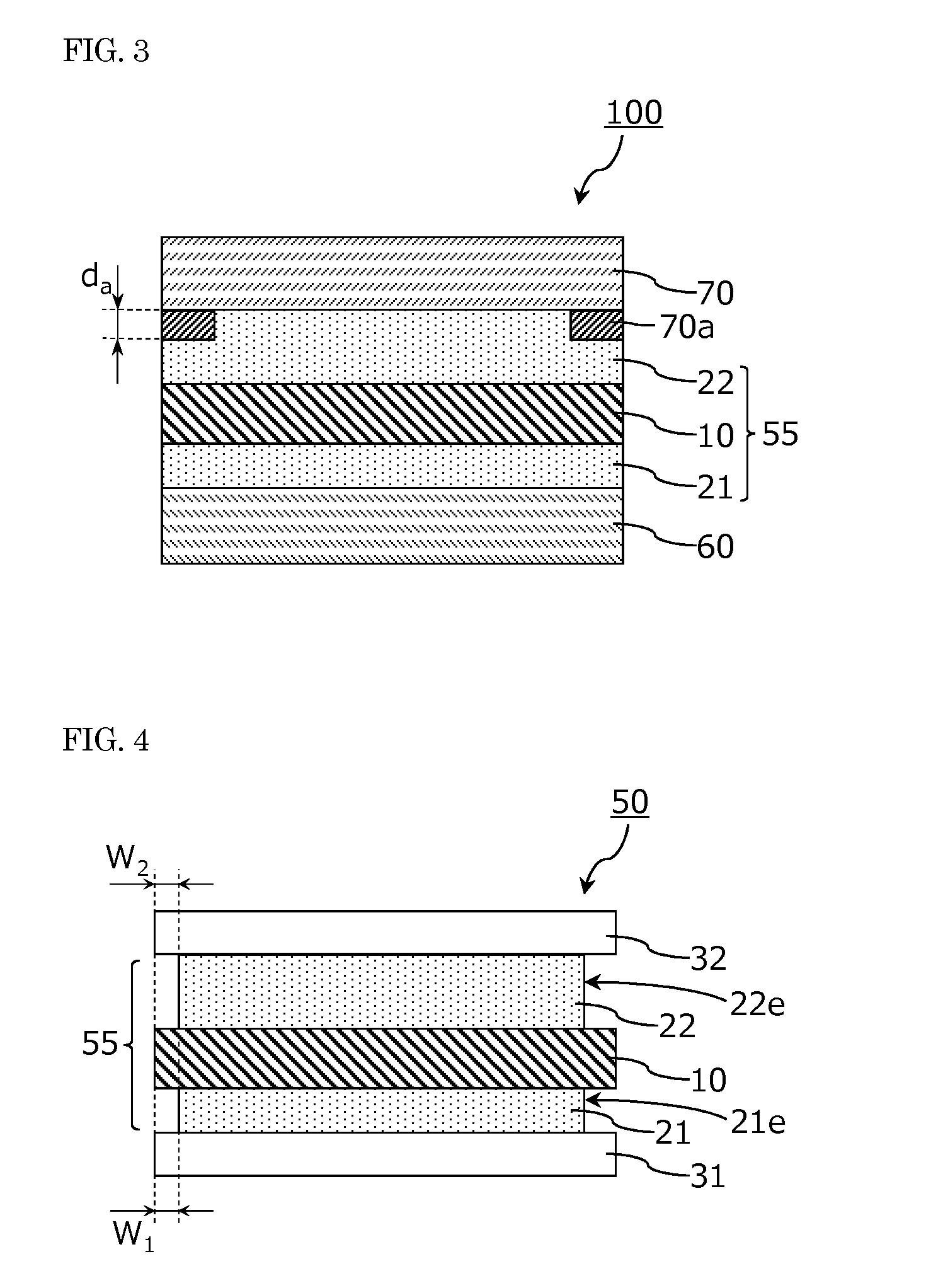

Optical film with pressure sensitive adhesive on both sides and method for producing image display device using same

InactiveUS20150346408A1Simple processAvoid pollutionLamination ancillary operationsElectrical apparatusDisplay devicePolarizer

According to the invention, an optical film with adhesive on both sides comprises: an optical film including a polarizing plate; a first pressure sensitive adhesive layer provided on a surface of the optical film at a side configured to be bonded to an image display cell; and a second pressure sensitive adhesive layer provided on a surface of the optical film at a side configured to be bonded to a transparent plate or the touch panel. Further, a protective sheet is releasably attached on each of the first pressure sensitive adhesive layer and the second pressure sensitive adhesive layer. A thickness of the second pressure sensitive adhesive layer is preferably 30 μm or more. In a practical use, the optical film with adhesive on both sides according to the present invention is, for example, disposed between a front transparent plate or a touch panel and an image display cell.

Owner:NITTO DENKO CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20050129942A1Change in weightMaintain stable propertiesNon-insulated conductorsSynthetic resin layered productsProduction rateElectrical conductor

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about −45° C. to about 240° C. or higher, at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about −0.6×10−6 per deg. C. to about 1.0×10−5 per deg. C. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

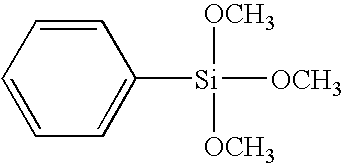

Ultra low k (ULK) SiCOH film and method

InactiveUS7288292B2Improve mechanical propertiesHigh elastic modulusPigmenting treatmentSemiconductor/solid-state device detailsNano sizeGas phase

The present invention provides a multiphase, ultra low k film which exhibits improved elastic modulus and hardness as well as various methods for forming the same. The multiphase, ultra low k dielectric film includes atoms of Si, C, O and H, has a dielectric constant of about 2.4 or less, nanosized pores or voids, an elastic modulus of about 5 or greater and a hardness of about 0.7 or greater. A preferred multiphase, ultra low k dielectric film includes atoms of Si, C, O and H, has a dielectric constant of about 2.2 or less, nanosized pores or voids, an elastic modulus of about 3 or greater and a hardness of about 0.3 or greater. The multiphase, ultra low k film is prepared by plasma enhanced chemical vapor deposition in which one of the following alternatives is utilized: at least one precursor gas comprising siloxane molecules containing at least three Si—O bonds; or at least one precursor gas comprising molecules containing reactive groups that are sensitive to e-beam radiation. Electronic structures including the multiphase, ultra low k film are also disclosed.

Owner:GLOBALFOUNDRIES INC

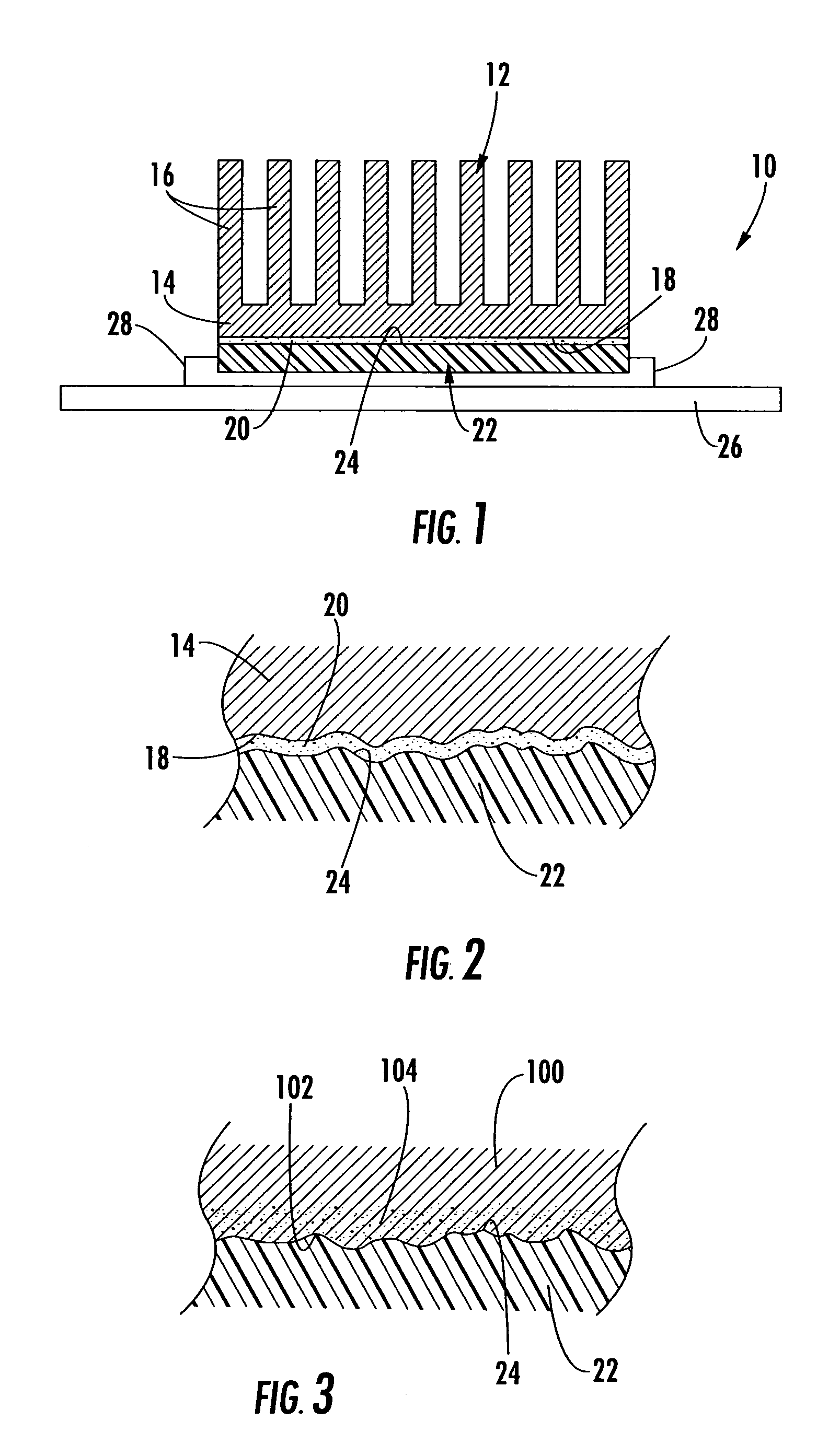

Elastomeric heat sink with a pressure sensitive adhesive backing

InactiveUS6886625B1Improved thermal interfaceLower thermal resistivityCooling/ventilation/heating modificationsLaminated elementsElastomerEngineering

The present invention discloses a net-shape molded elastomeric heat-dissipating device that includes an integrally formed conformable interface surface. A base elastomeric matrix material is loaded with thermally conductive filler and injected into a mold cavity to form the completed device. Further, a layer of thermally conductive pressure sensitive adhesive material is applied to the conformable interface surface to allow the device to be securely fastened to a heat-generating surface. The present invention provides superior sealing and elimination of voids and air gaps that are typically found between the thermal transfer surfaces thereby facilitating enhanced thermal transfer properties. In addition, the present invention provides a method of manufacturing an elastomeric heat sink device as described above.

Owner:TICONA POLYMERS INC

Polymeric endoprostheses with enhanced strength and flexibility and methods of manufacture

InactiveUS20090096137A1High elastic modulusImprove visualizationStentsLayered productsPolymer scienceProsthesis

Improved polymeric endoprostheses and methods of manufacturing endoprostheses are disclosed herein. The endoprostheses may comprise one or more polymers wherein the polymer chains are substantially aligned circumferentially, and comprising increased radial strength and flexibility. An endoprosthesis according to the invention may comprise a smooth surface. Endoprostheses disclosed herein may be used in the treatment of strictures in lumens of the body. Alternatively, endoprostheses disclosed herein may be used as anchors to secure medical devices within lumens of the body. The endoprostheses disclosed herein may comprise one or more erodible polymer.

Owner:SYNECOR LLC

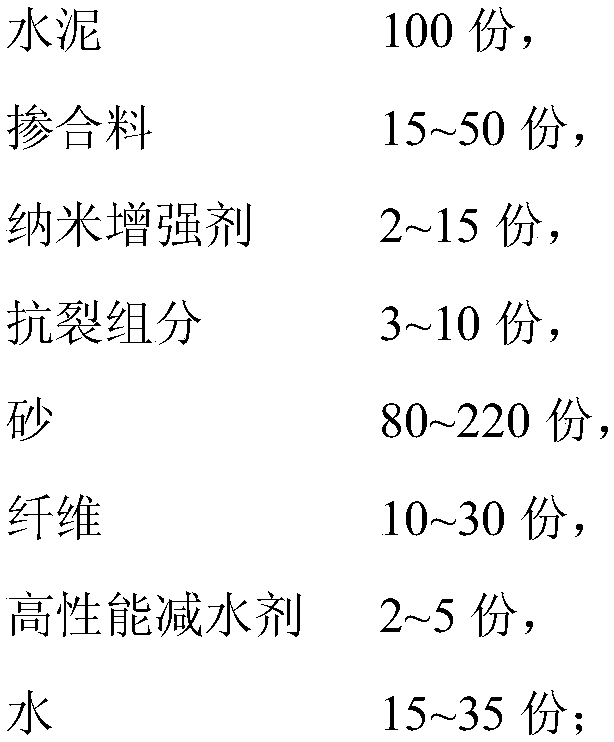

Super-high-performance cement base repairing material and preparing method thereof

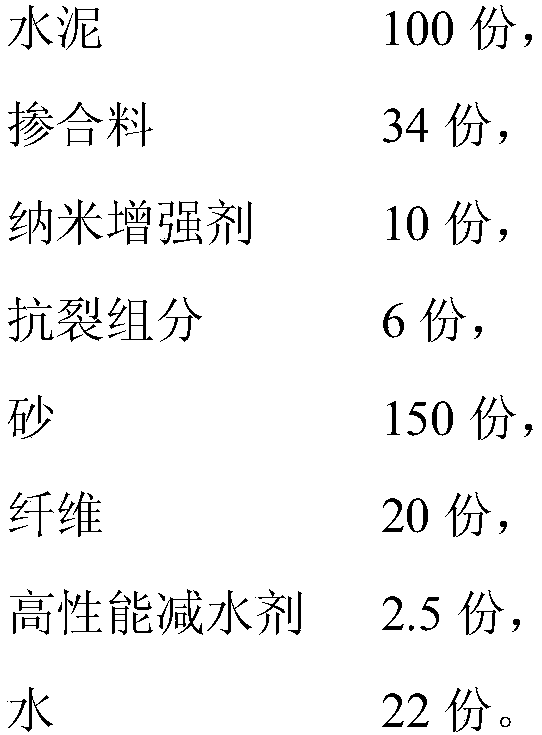

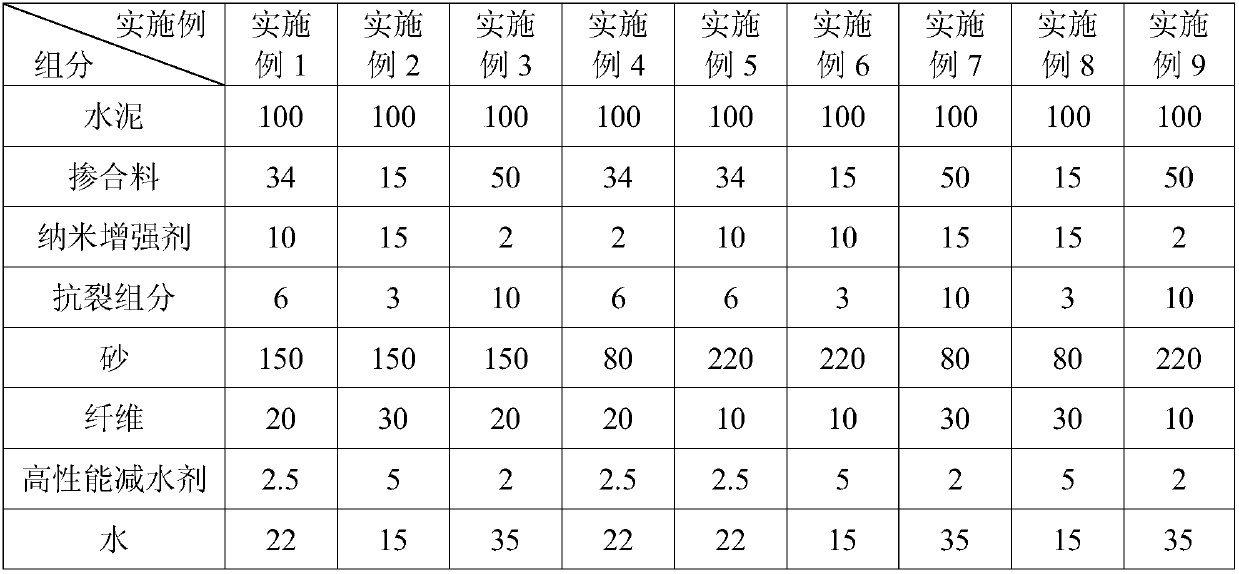

The invention discloses a super-high-performance cement base repairing material and a preparing method thereof. The repairing material is prepared from, by mass, 100 parts of cement, 15-50 parts of admixture, 2-15 parts of nanometer reinforcing agent, 3-10 parts of crack resistance component, 80-220 parts of sand, 10-30 parts of fiber, 2-5 parts of high-performance water reducing agent and 15-35 parts of water. The super-high-performance cement base repairing material has super-high tensile strength, bending resistance and adhesive strength and extremely low shrinkage performance, and has excellent construction performance, high elasticity modulus and super-high durability. The material has effects of repairing, reinforcing, seepage preventing, preventing and the like, and therefore the service life of the repairing material and a structure is prolonged. In addition, the material can be used as a joint material of a structural joint.

Owner:JIANGSU SOBUTE NEW MATERIALS

Supporting material for medical purposes

InactiveUS6555730B1High elastic modulusHigh strengthWeft knittingSynthetic resin layered productsEngineeringMedical treatment

The invention relates to the use of a non-woven fabric which is over-stitched by means of stitching threads as a supporting material for medical purposes. The invention is characterized in that the maximum tensile force of supporting material is equal to at least 30 N / cm and at least one side of the supporting material is partially or completely coated with a self-adhesive mass.

Owner:BEIERSDORF AG

Polyurethane composition and polishing pad

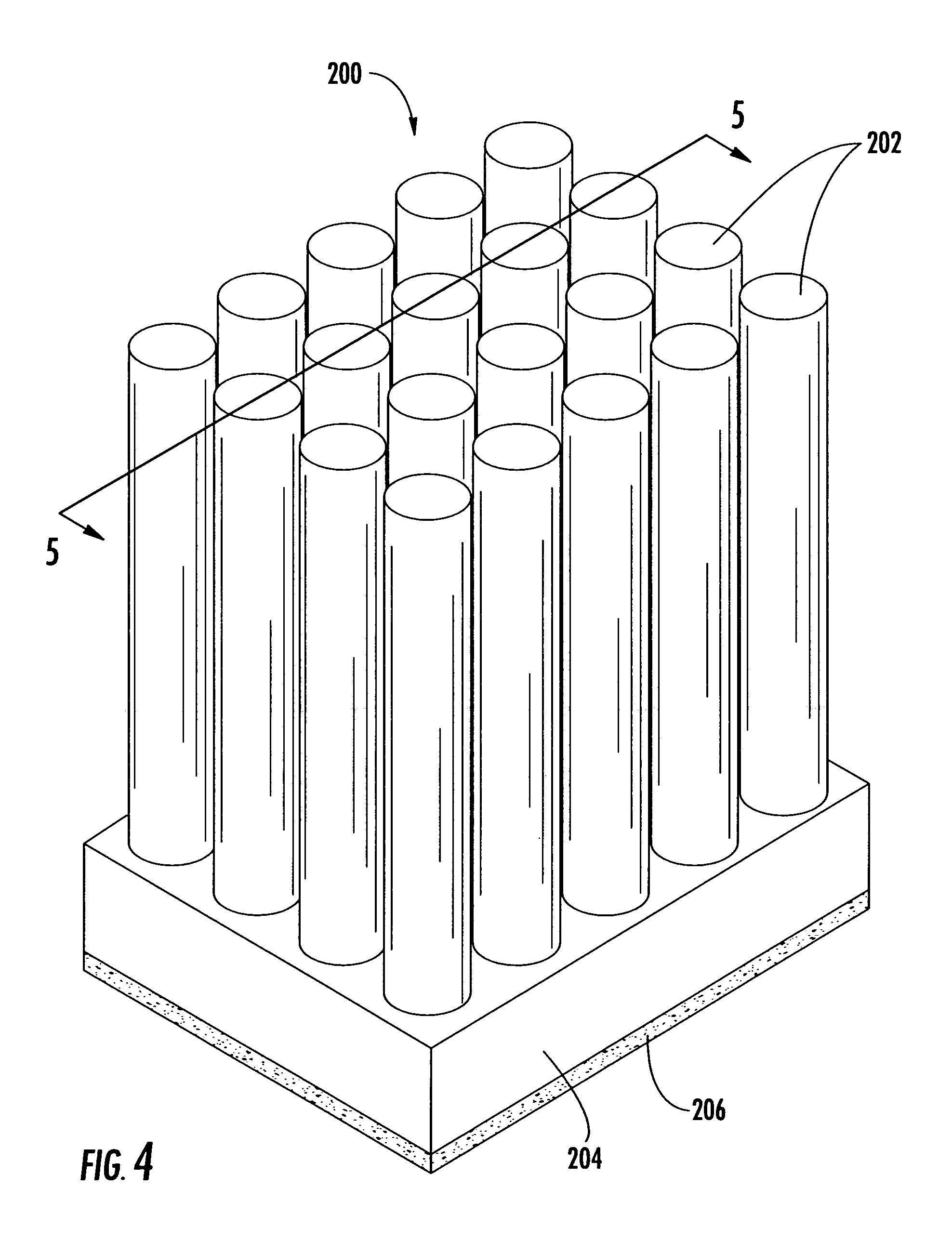

InactiveUS20040157985A1Stable productionImprove compatibilityFlexible-parts wheelsLapping toolsAqueous mediumPolymer chemistry

A polyurethane composition containing solid beads dispersed therein, characterized in that the polyurethane is a microcellular polyurethane foam and the composition has a storage modulus of elasticity at 40° C. of 270 MPa or more as measured by means of a dynamic elasticity measuring device: and a polyurethane composition containing solid beads dispersed therein, characterized in that the solid beads are capable of swelling with or being soluble in an aqueous medium. The former composition has excellent flattening capability, and the latter composition can provide a polished surface which combines good flatness and good uniformity and can also reduce scratches on the surface.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com