Patents

Literature

20779 results about "Siloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

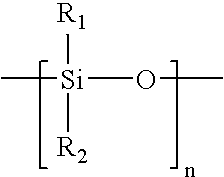

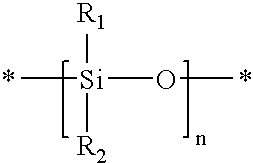

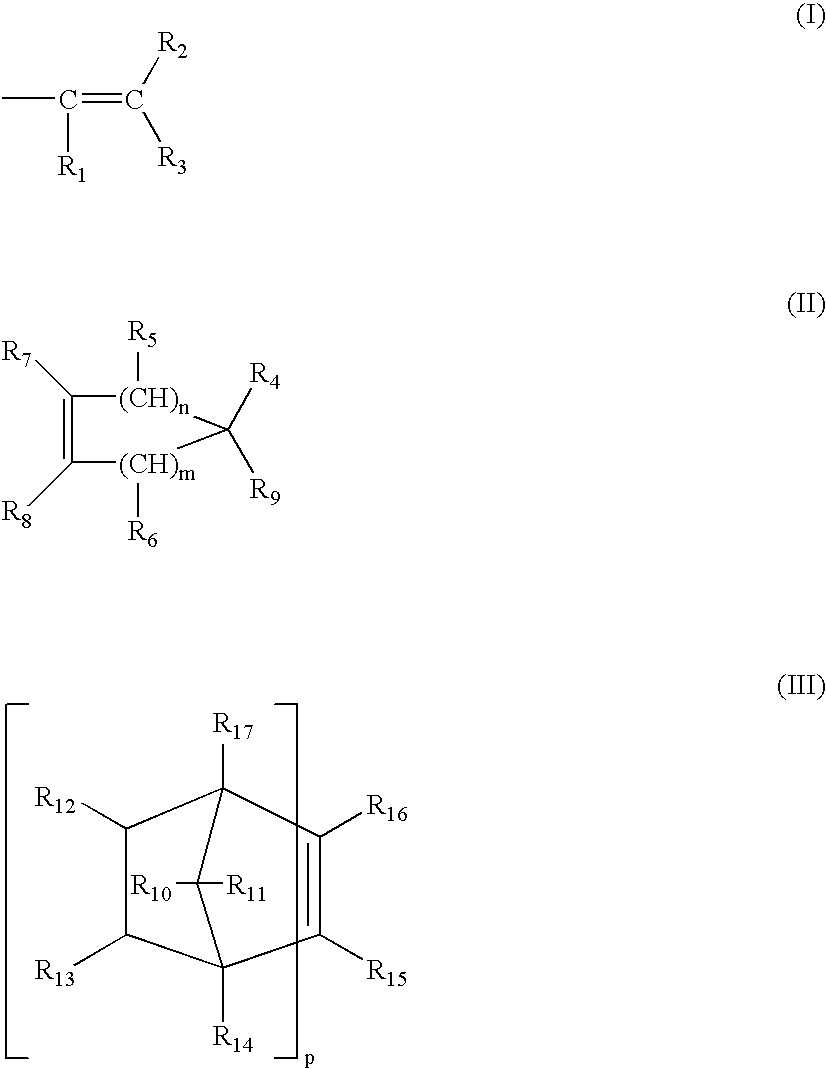

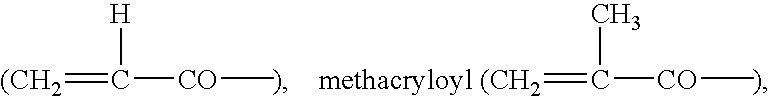

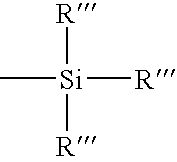

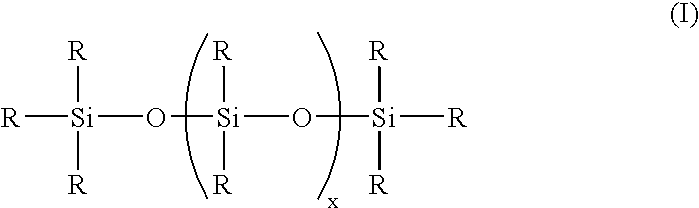

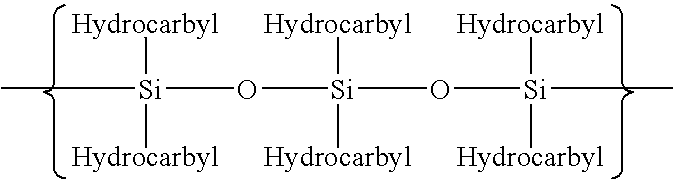

A siloxane is a functional group in organosilicon chemistry with the Si–O–Si linkage. The parent siloxanes include the oligomeric and polymeric hydrides with the formulae H(OSiH₂)ₙOH and (OSiH₂)ₙ. Siloxanes also include branched compounds, the defining feature of which is that each pair of silicon centres is separated by one oxygen atom. The siloxane functional group forms the backbone of silicones, the premier example of which is polydimethylsiloxane. The functional group R₃SiO- (where the three Rs may be different) is called siloxy. Siloxanes are manmade and have many commercial and industrial applications because of the compounds’ hydrophobicity, low thermal conductivity, and high flexibility.

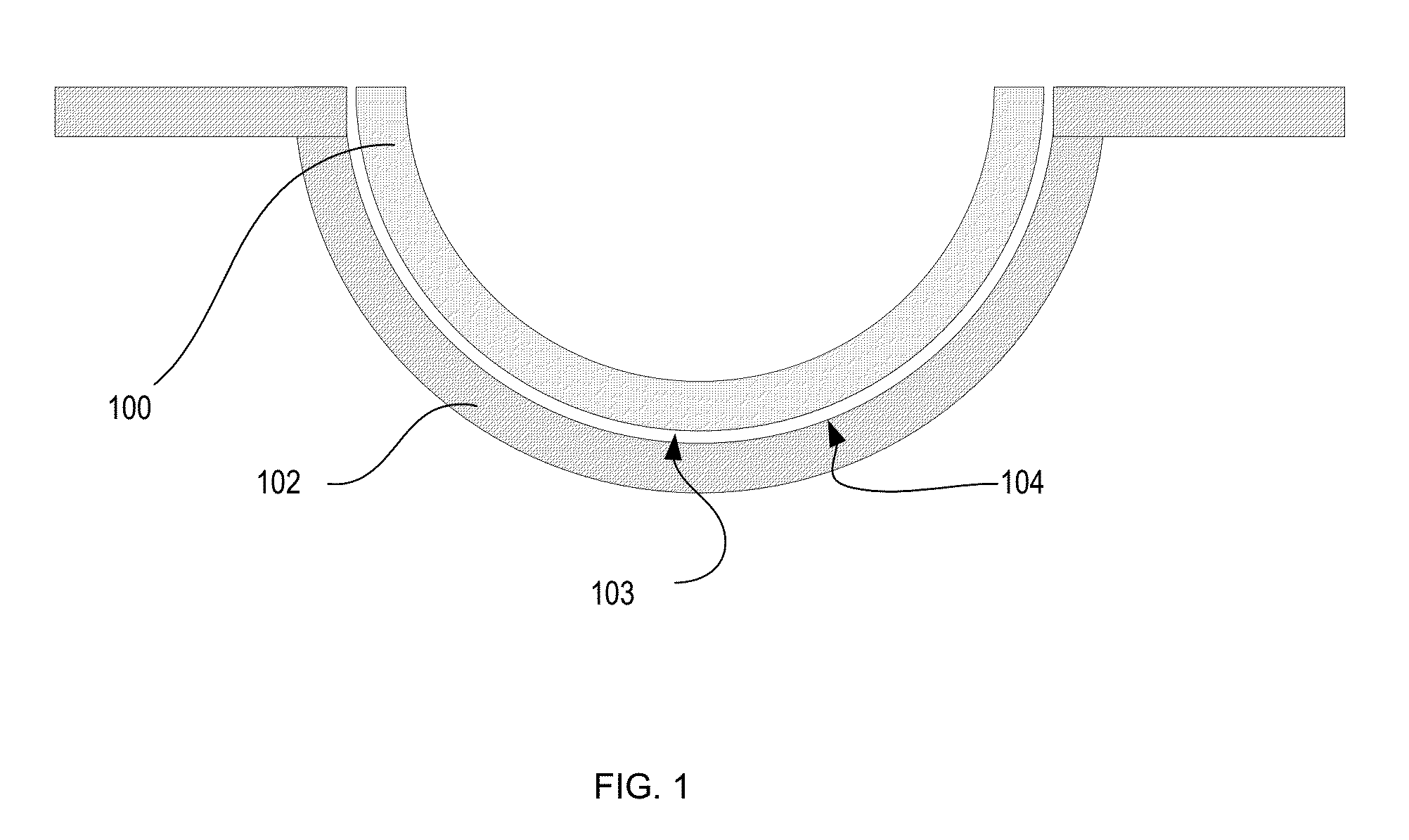

Long wearable soft contact lens

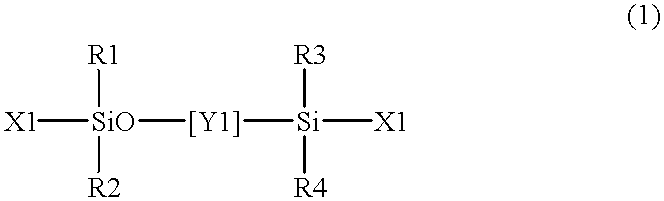

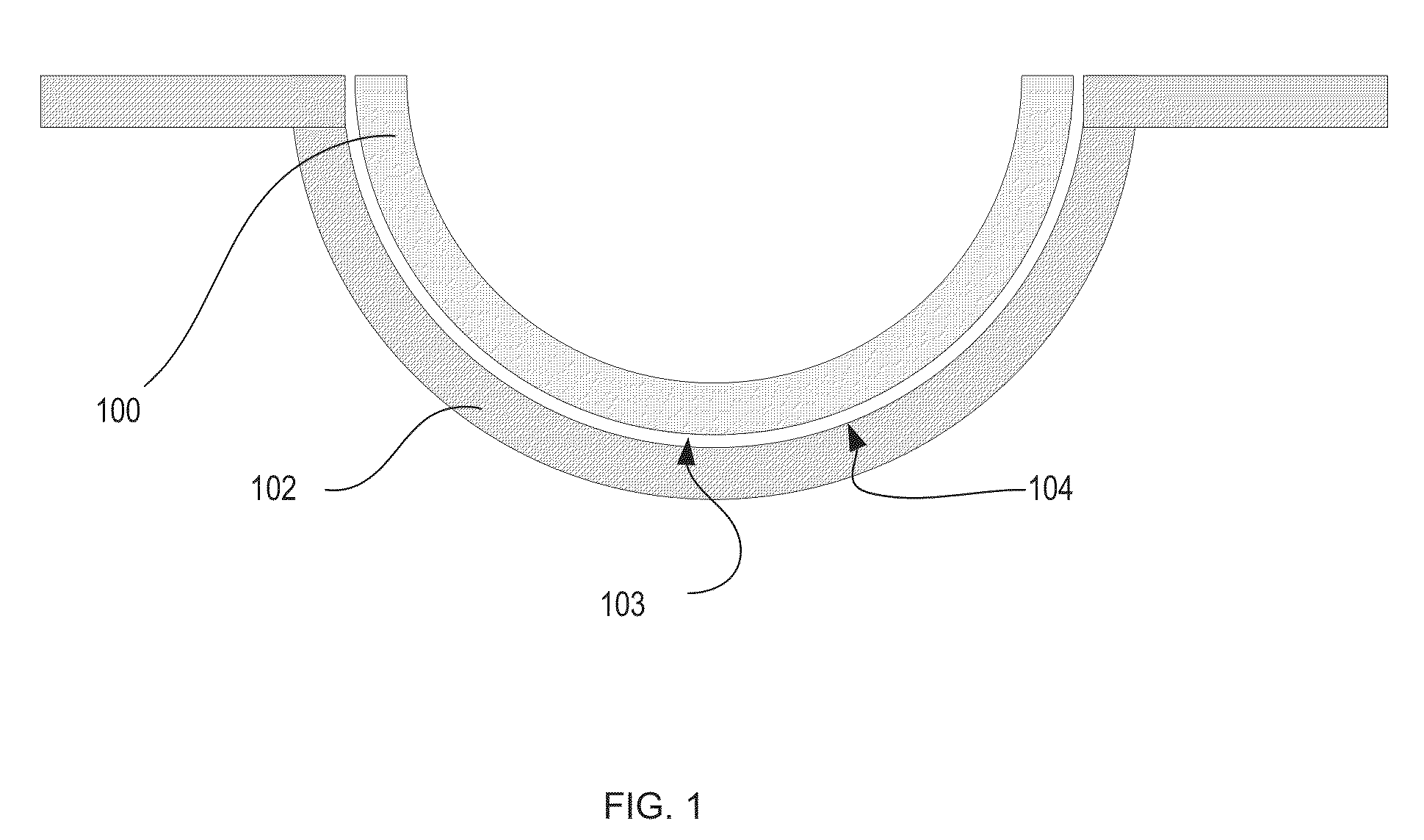

The present invention relates to a soft contact lens, and provides a contact lens which shows small and stable contact angle to water at its surface in water as well as in air, little deposition in wearing, high oxygen permeability, no adhesion of lens to a cornea and superior extended-wearing characteristics. The present invention provides a hydrogel soft contact lens which has contact angle at a lens surface in a range of 10-50° by the captive bubble method in water and 30-90° by the sessile drop method in air, oxygen permeability of not less than 30 and water content of not less than 5%, and also a hydrogel soft contact lens consisting of a polymer comprising a hydrophilic siloxanyl monomer shown by a specified general formula.

Owner:COOPERVISION INT LTD

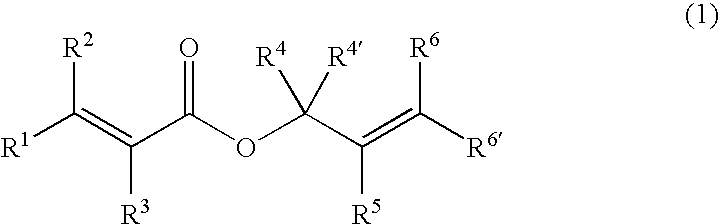

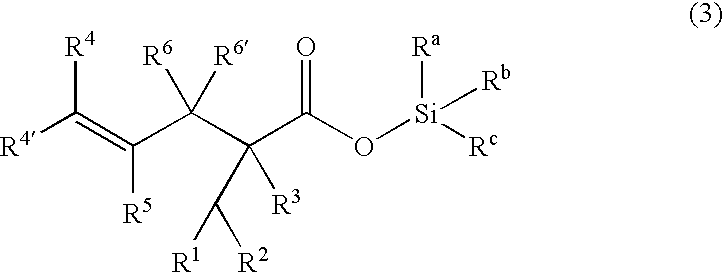

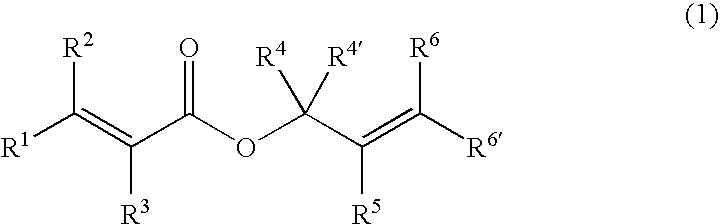

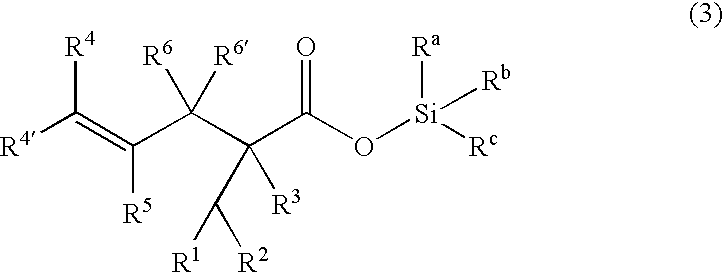

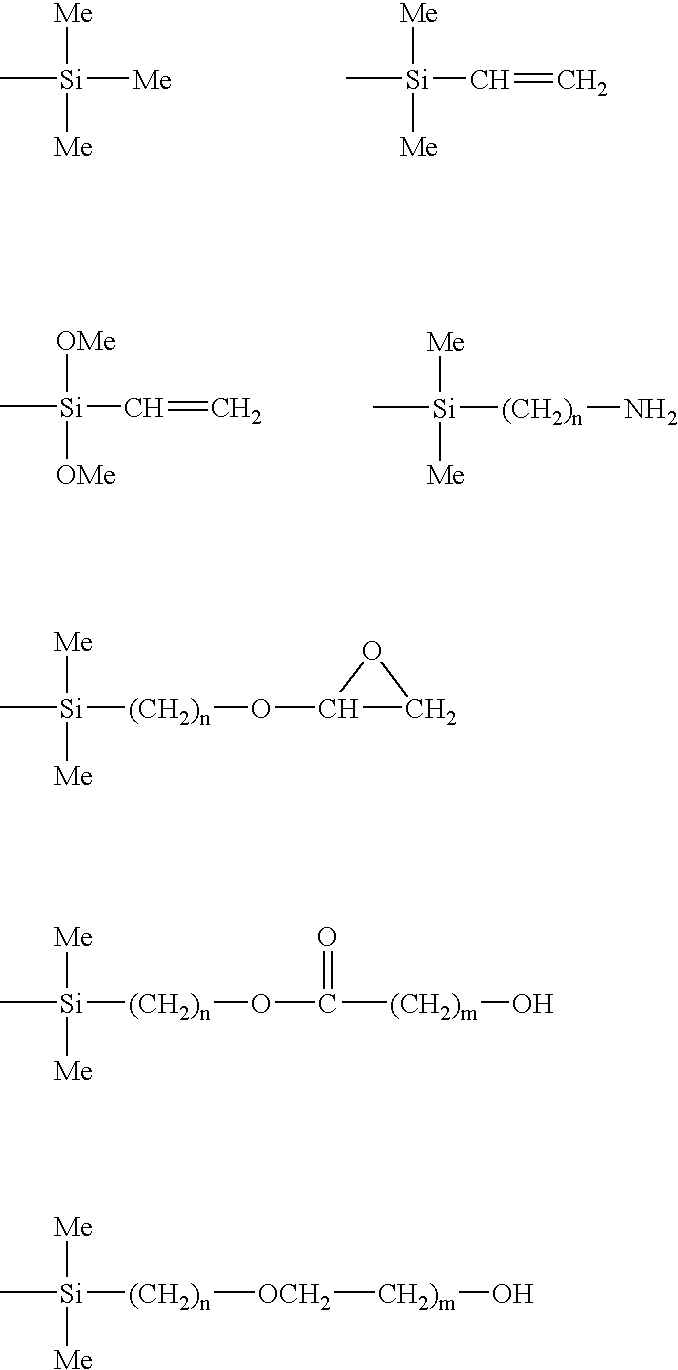

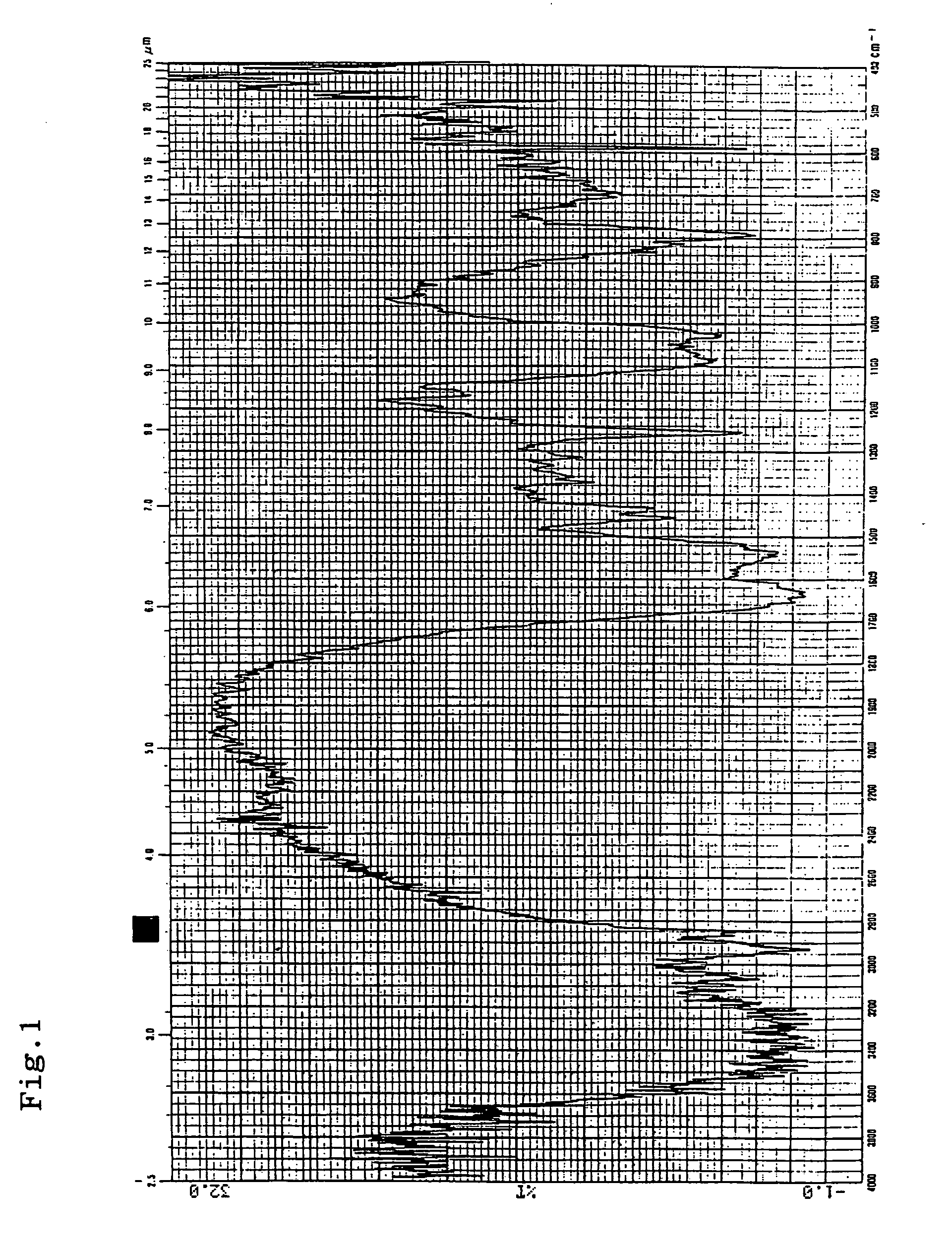

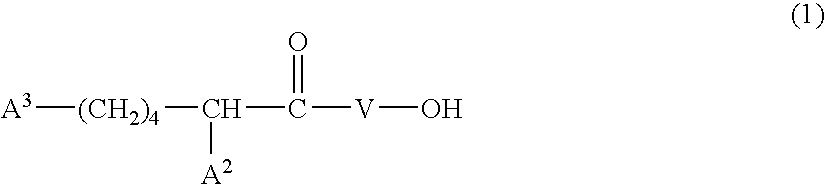

Processes of making gamma,delta-unsaturated carboxylic acid and silyl ester thereof, carboxyl group-containing organosilicon compound and process of making

ActiveUS7307178B2Few stepsHigh yieldSilicon organic compoundsPreparation from carboxylic acid esters/lactonesCarboxyl radicalPerylene derivatives

A γ,δ-unsaturated carboxylic acid silyl ester is prepared by reacting an α,β-unsaturated carboxylic acid ester with a hydrosilane or hydrosiloxane in the presence of tris(pentafluorophenyl)borane. γ,δ-Unsaturated carboxylic acid derivatives are readily prepared through fewer steps and in high yields.

Owner:SHIN ETSU CHEM CO LTD

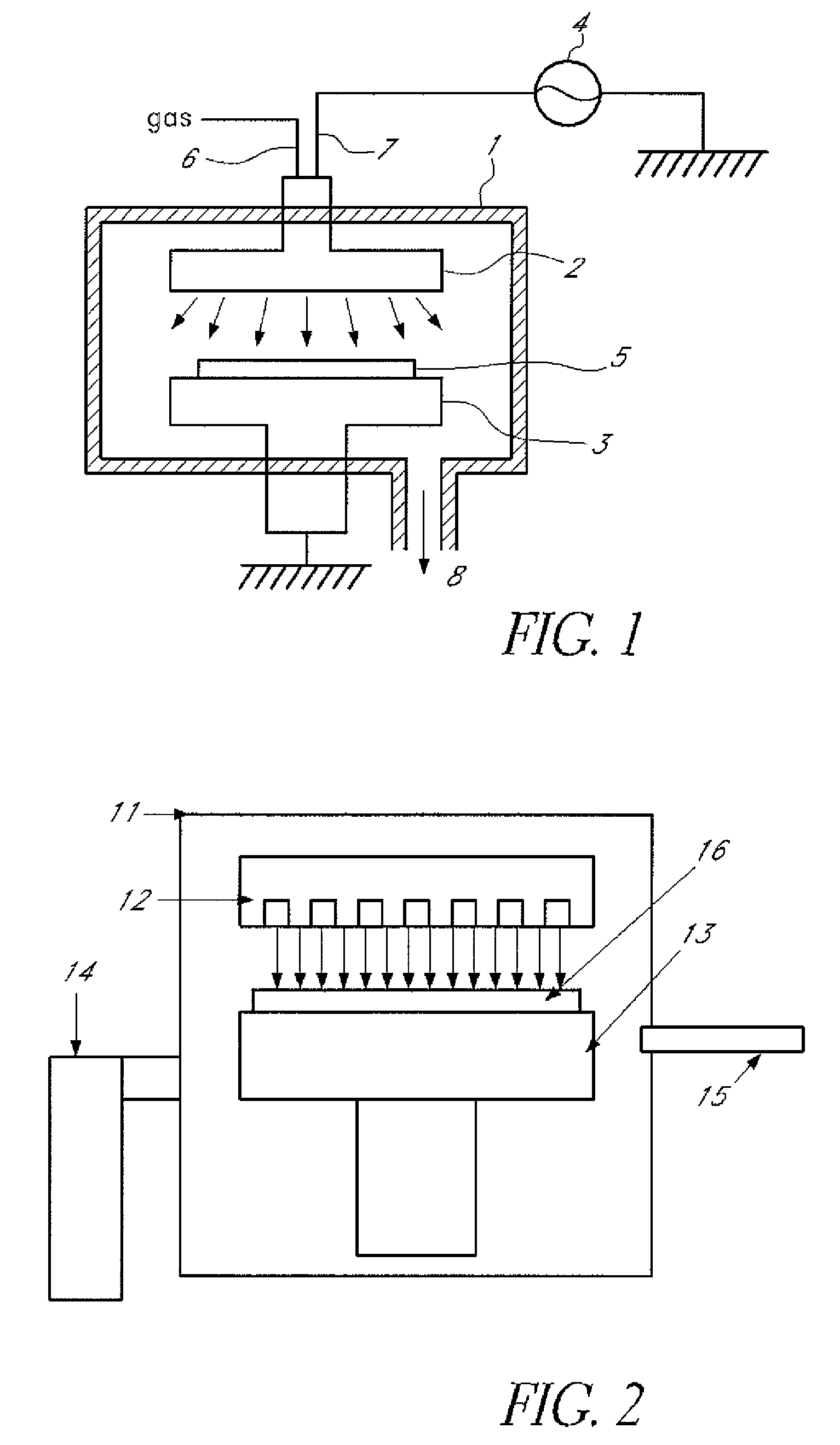

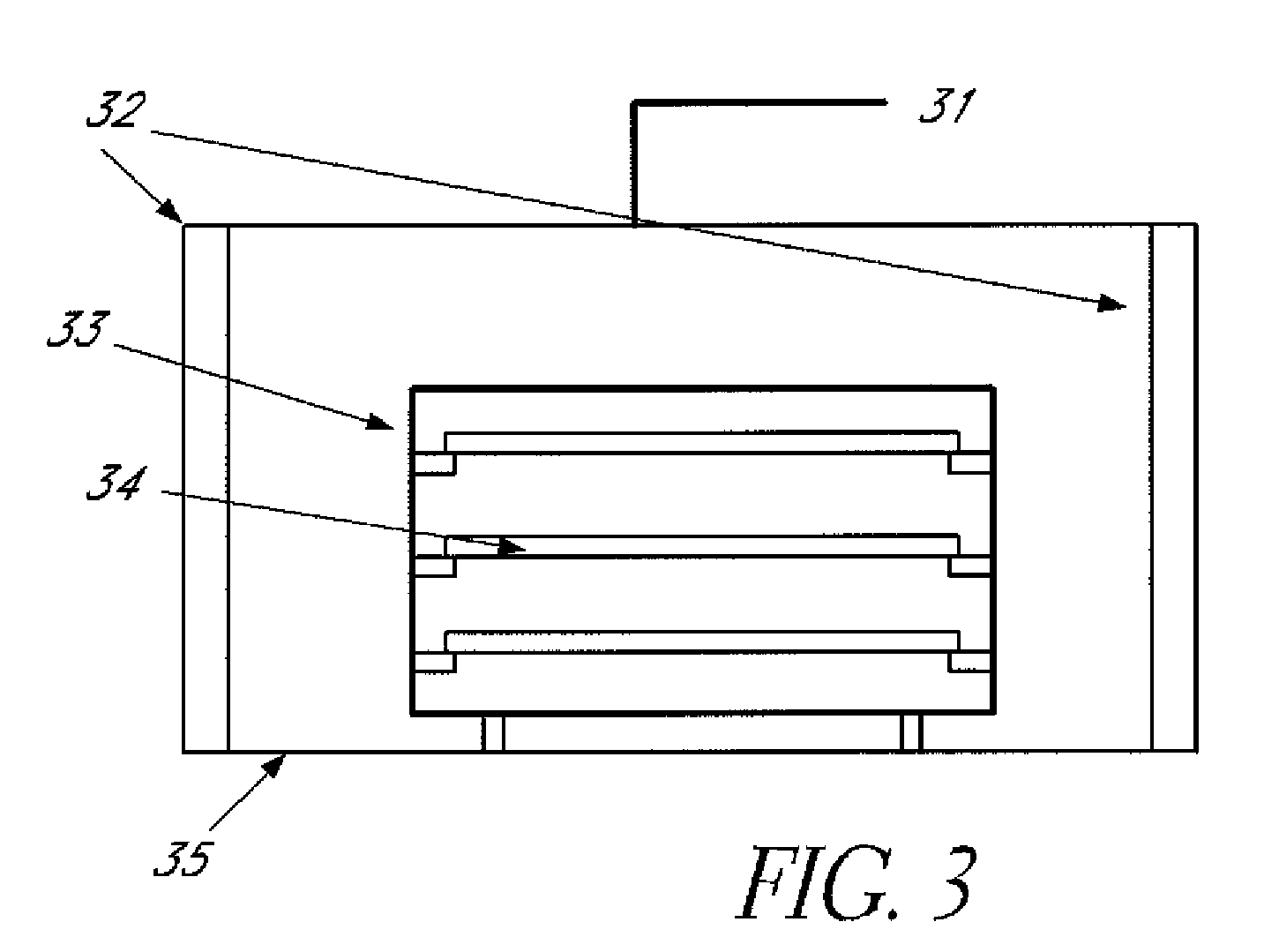

Method for forming dielectric film using siloxane-silazane mixture

ActiveUS8003174B2High densityHigh strengthPretreated surfacesSemiconductor/solid-state device manufacturingSilazaneMetallurgy

Owner:ASM JAPAN

Processes of making gamma,delta-unsaturated carboxylic acid and silyl ester thereof, carboxyl group-containing organosilicon compound and process of making

ActiveUS20050070729A1High yieldFew stepsSilicon organic compoundsPreparation from carboxylic acid esters/lactonesCarboxyl radicalPerylene derivatives

A γ,δ-unsaturated carboxylic acid silyl ester is prepared by reacting an α,β-unsaturated carboxylic acid ester with a hydrosilane or hydrosiloxane in the presence of tris(pentafluorophenyl)borane. γ,δ-Unsaturated carboxylic acid derivatives are readily prepared through fewer steps and in high yields.

Owner:SHIN ETSU CHEM IND CO LTD

Home and personal care compositions comprising silicon-based lubricants

InactiveUS7465439B2Cosmetic preparationsOrganic detergent compounding agentsPersonal carePolymer science

A composition for personal, home, or laundry treatment comprising a polymer made up of one or more crosslinked rake or comb silicone copolymer segments. A process for making copolymers for use in such compositions involves hydrosilylation in the presence of a catalyst.

Owner:CONOPCO INC D B A UNILEVER

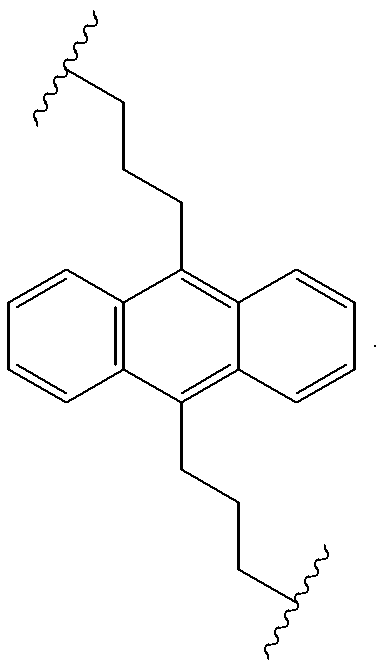

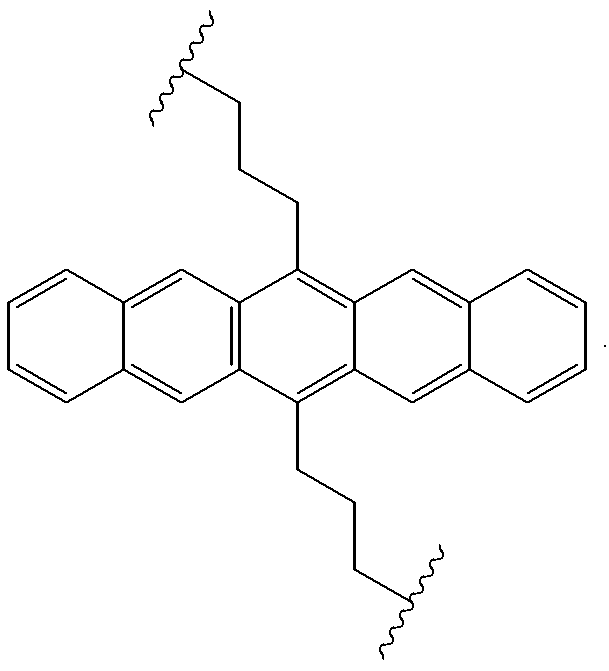

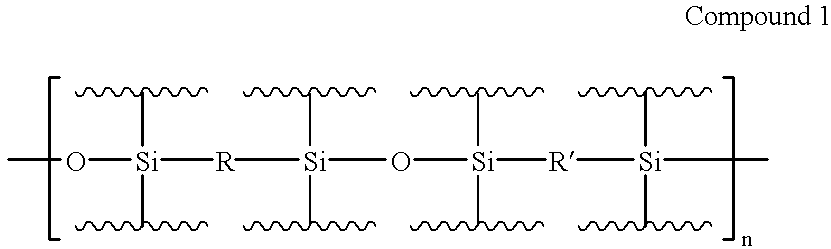

Organic electroluminescent materials and device made from such materials

Electroluminescent devices and materials including an electroluminescent organo-siloxane polymer. The main chain of the organo-siloxane polymer comprises an organic component that can be alkenyl, alkynyl, aralkyl, aryl, heteroaralkyl, and heteroaryl which can be substituted optionally with hydrogen, alkyl, aryl, heteroalkyl, heteroaralkyl, nitro, cyano, hydroxy, alkoxy, aryloxy, thio, alkylthio, arylthio, amino, halogen, dialkylamino, diarylamino, diaralkylamino, arylamino, alkylamino, arylalkylamino, carbonyloxy, carbonylalkoxy, carbonylalkyloxy, alkylcarbonyloxy, arylcarbonyloxy, alkoxylcarbonyloxy, sulfonyl, or sulfonyloxy. The organic component includes at least two covalent bonds coupling the organic component to the main chain of the organo-siloxane polymer. Such devices provide superior performance and mechanical stability compared with conventional organic electroluminescent materials and devices made from such materials.

Owner:ORGANIC DISPLAY TECH

Cosmetic composition and production thereof

InactiveUS20060018867A1Efficient use ofReduce the amount requiredCosmetic preparationsHair cosmeticsEpsilon-PolylysineEmulsion

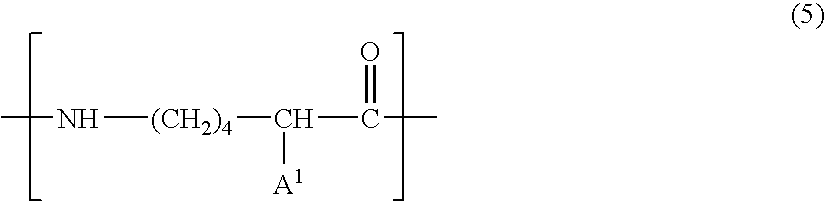

It has been desired to develop a highly preservative and antibacterial cosmetic composition that can easily be applied to both emulsion and non-emulsion type cosmetics. It has also been desired to develop a method of improving a preservative and / or antibacterial effect(s) of a cosmetic composition comprising polyorganosiloxane-containing epsilon-polylysine and thereby reducing the amount of antibacterial preservative agent to be used. There is provided a cosmetic composition comprising one or a combination of two or more of polyorganosiloxane-containing epsilon-polylysine compounds obtained by reacting epsilon-polylysine with polyorganosiloxane or a physiologically acceptable salt thereof, and polyhydric alcohol.

Owner:CHISSO CORP

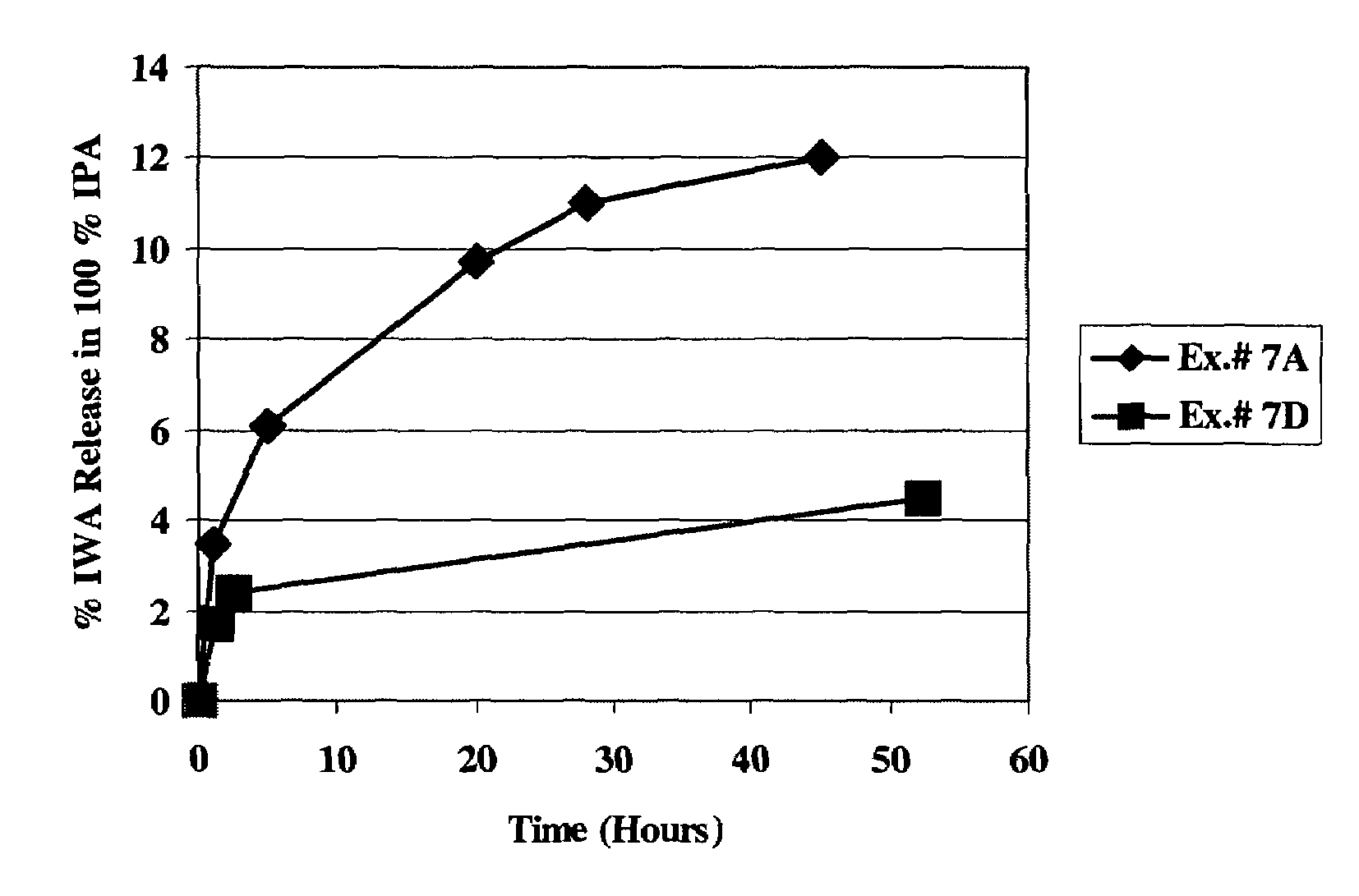

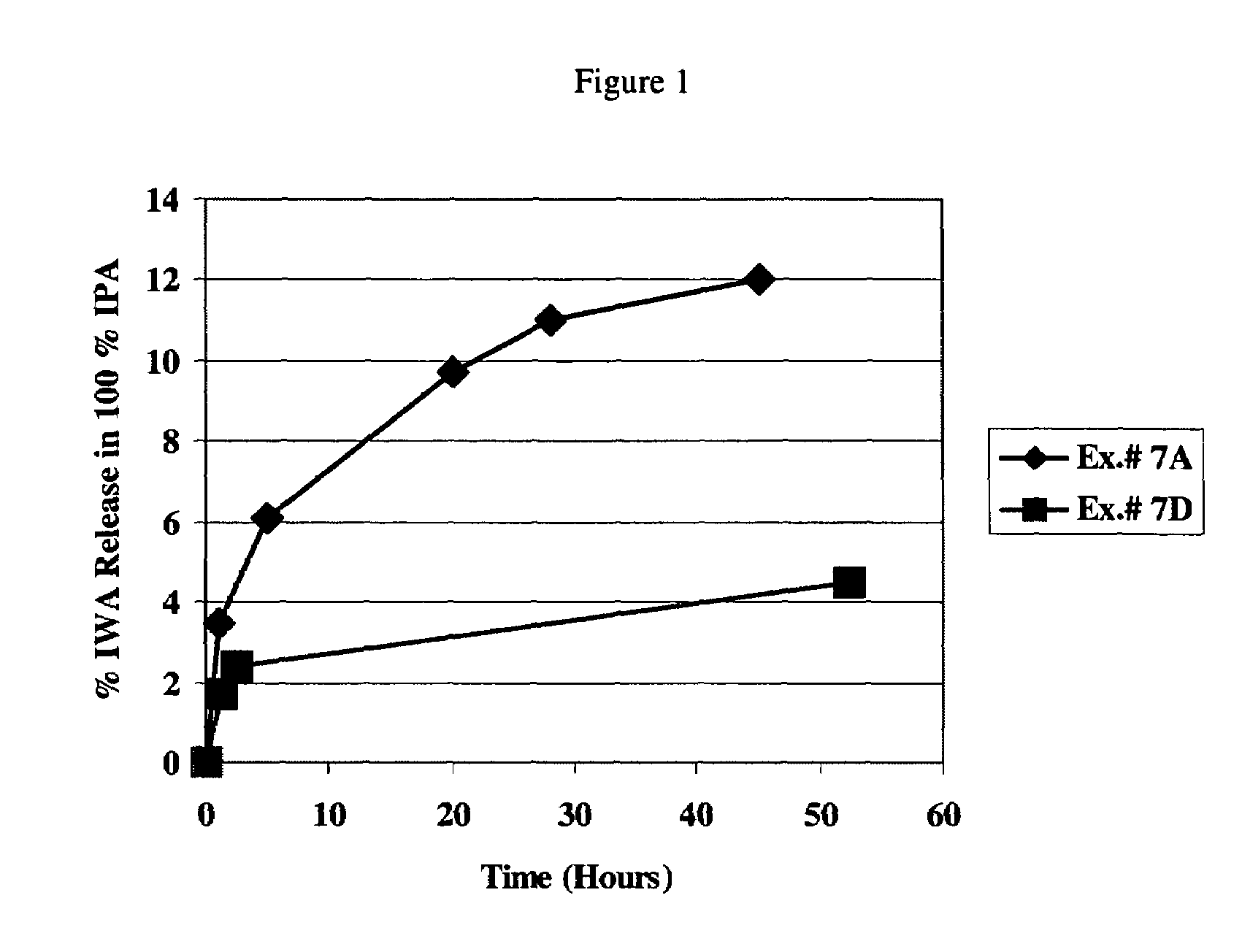

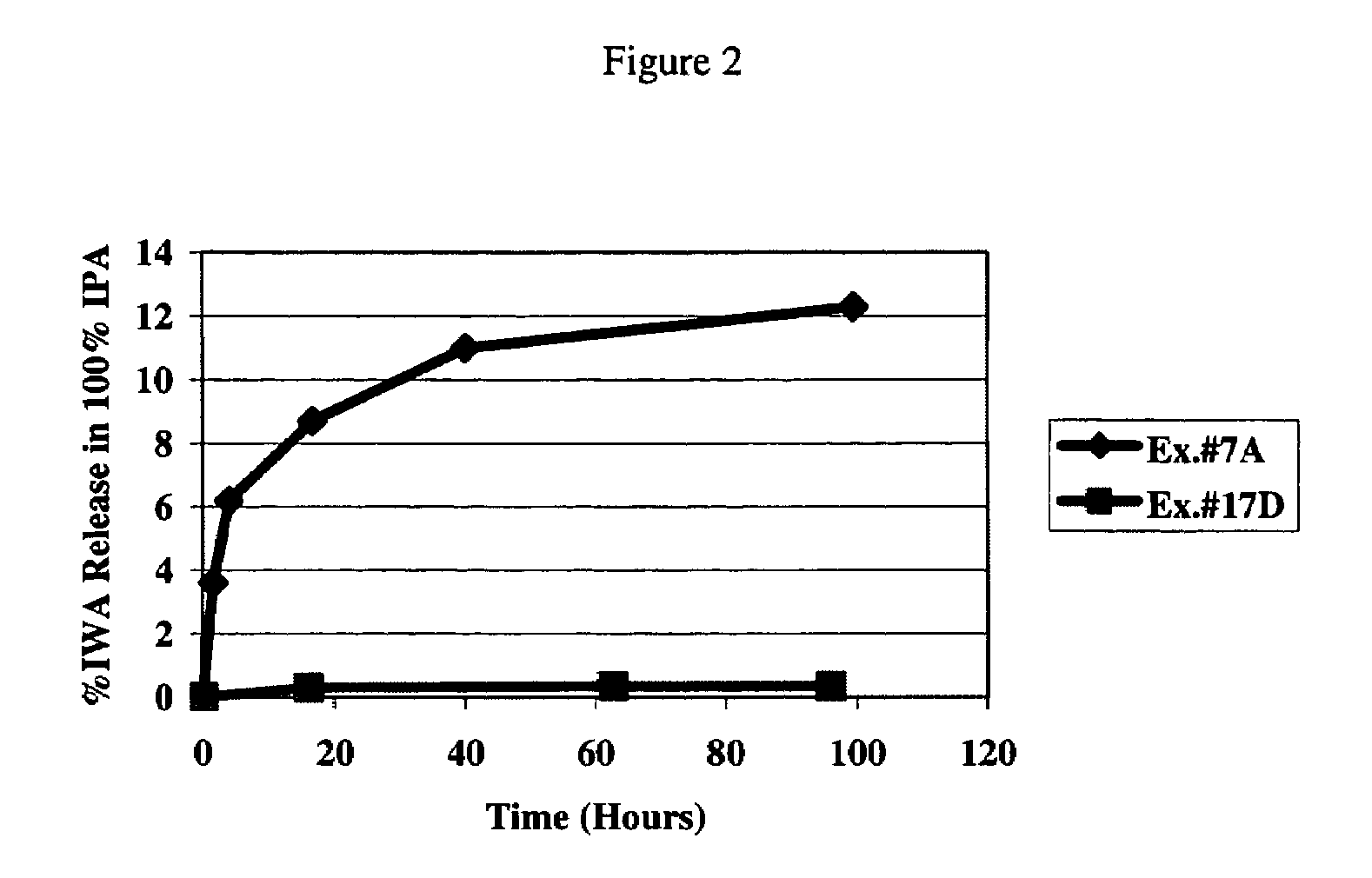

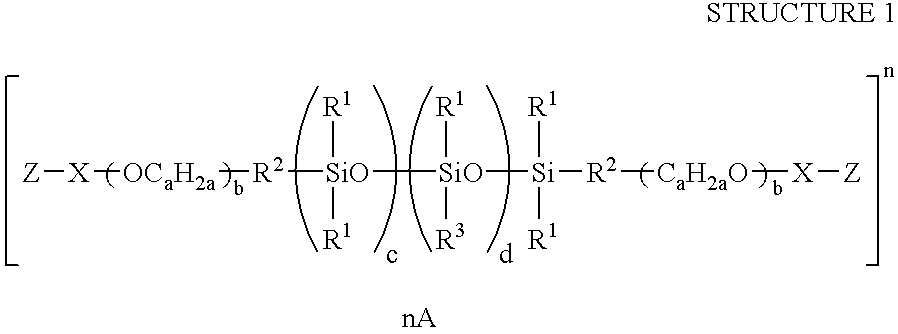

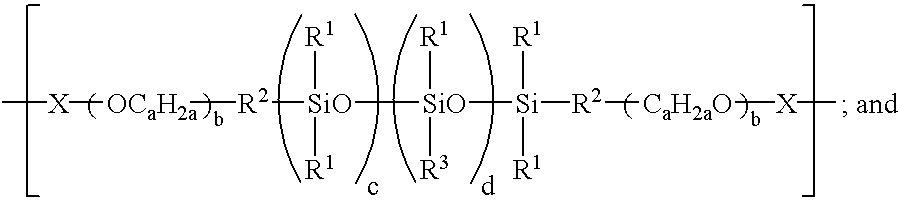

Wettable hydrogels comprising reactive, hydrophilic, polymeric internal wetting agents

The present invention relates to wettable silicone hydrogels comprising the reaction product of at least one siloxane containing component and at least one reactive, hydrophilic polymeric internal wetting agent. The present invention further relates to silicone hydrogel contact lenses comprising at least one oxygen permeable component, and an amount of reactive, hydrophilic polymeric internal wetting agent sufficient to impart wettability to said device.

Owner:JOHNSON & JOHNSON VISION CARE INC

Silsesquioxane polymers, method of synthesis, photoresist composition, and multilayer lithographic method

InactiveUS6087064AReduce usageAvoid pollutionPhotosensitive materialsRadiation applicationsResistPolymer science

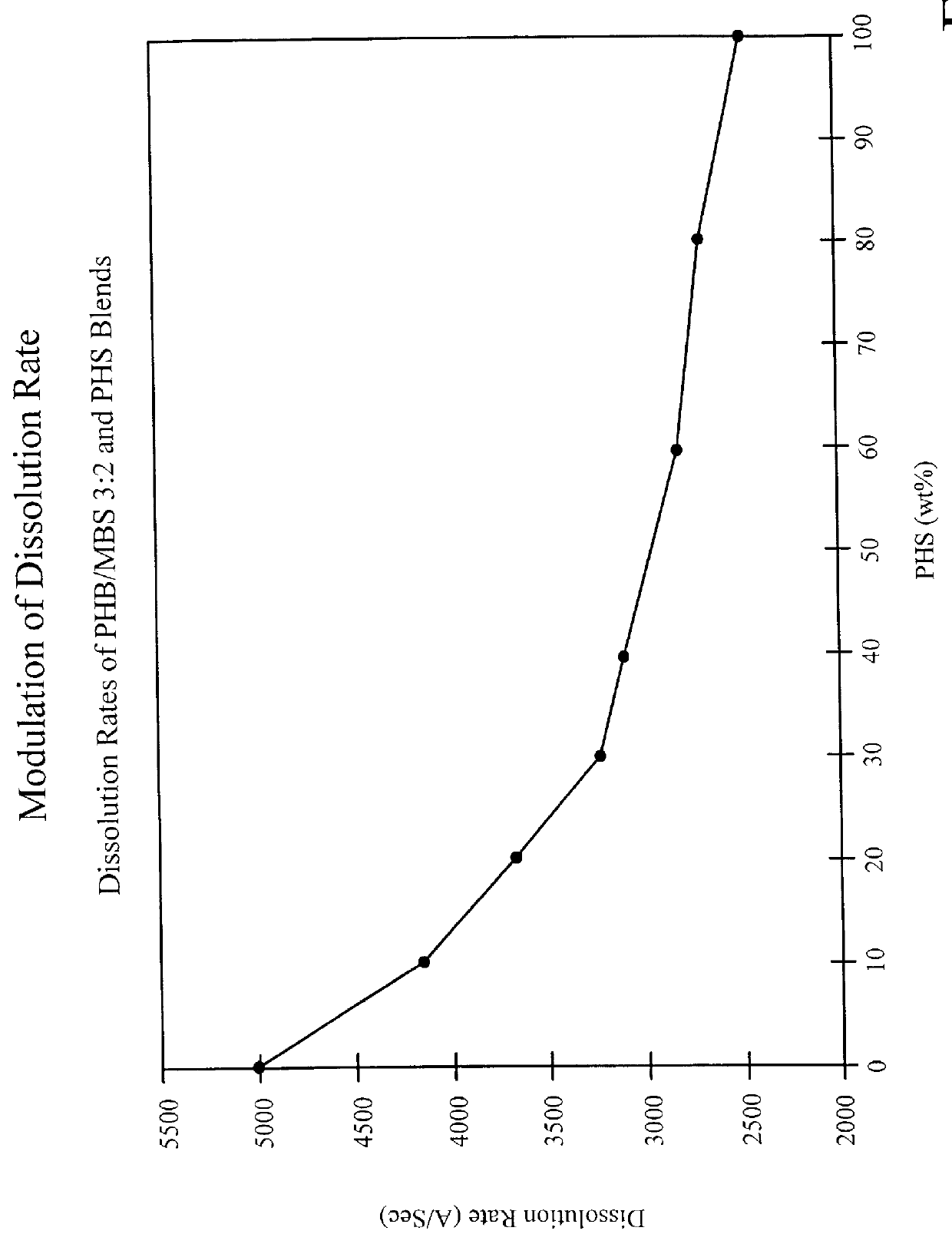

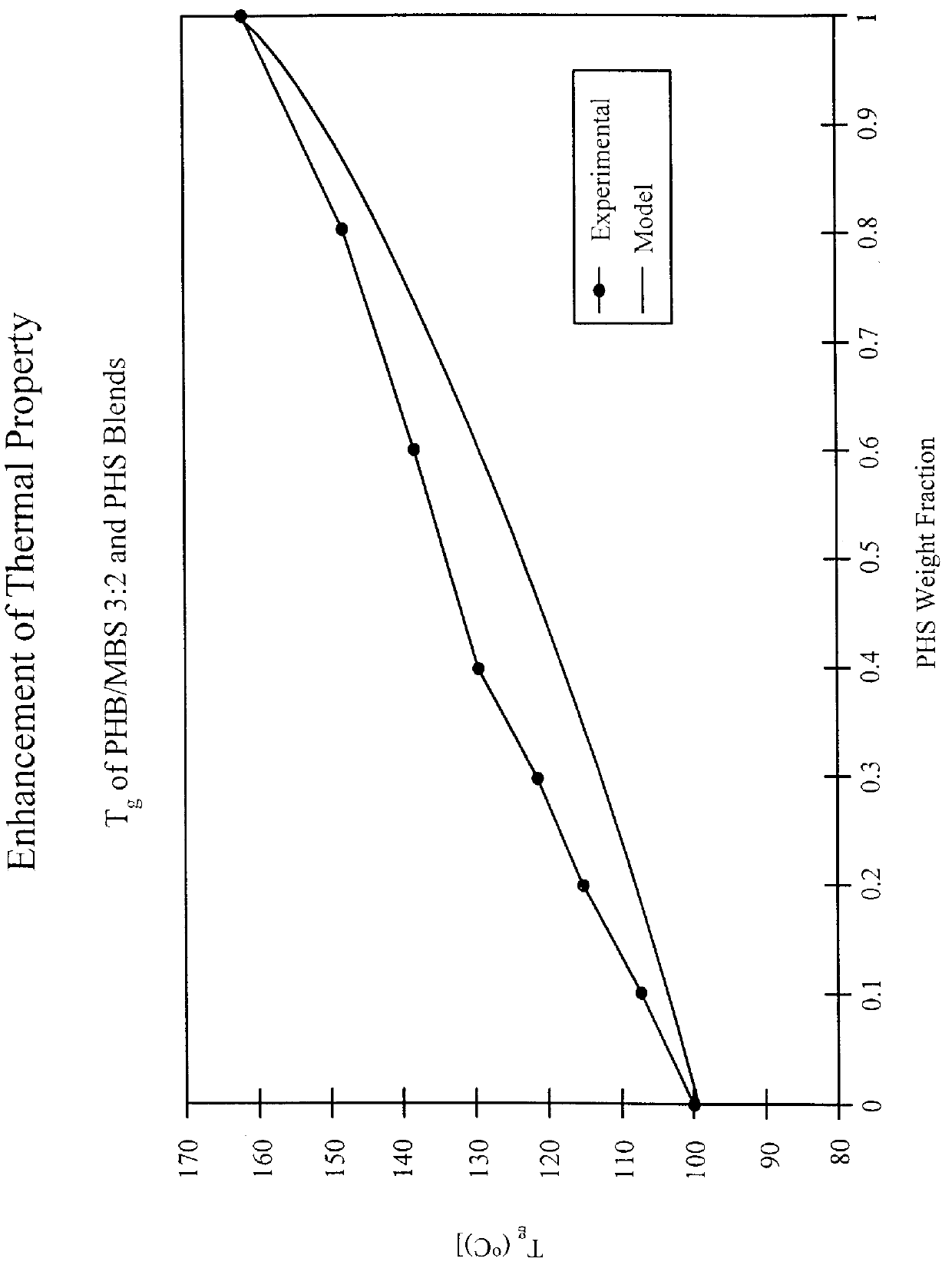

Novel silsesquioxane polymers are formed by methods which avoid the use of BBr3. The novel silsesquioxane polymers are especially useful in negative photoresist compositions and photolithographic processes. Alternatively, improved silsesquioxane polymer-containing negative photoresist compositions are obtained by using a polymer component containing a blend of silsesquioxane polymer and non-silsesquioxane polymer. The photoresist compositions provide improved dissolution characteristics enabling the use of 0.26 N TMAH developer. The photoresist compositions also provide improved thermal characteristics enabling use of higher processing temperatures. The photoresist compositions are especially useful in a multilayer photolithographic processes and are capable of producing high resolution.

Owner:GLOBALFOUNDRIES INC

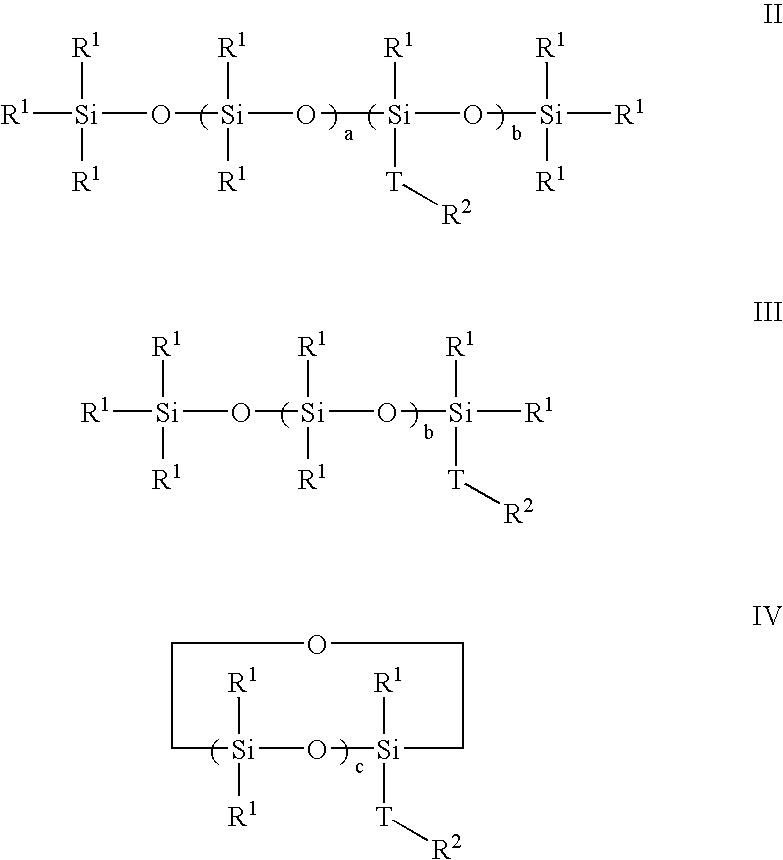

Prepolymers with dangling polysiloxane-containing polymer chains

The invention provide a new class of silicone-containing prepolymers containing dangling polysiloxane-containing polymer chains. This class of silicone-containing prepolymer is capable of being actinically crosslinked to form a silicone hydrogel material with a relatively high oxygen permeability, a reduced elastic modulus, and a relatively high ion permeability. The present invention is also related to silicone hydrogel contact lenses made from this class of silicone-containing prepolymers and to methods for making the silicone hydrogel contact lenses.

Owner:ALCON INC

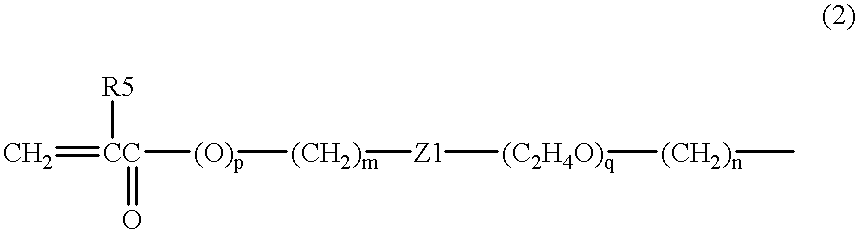

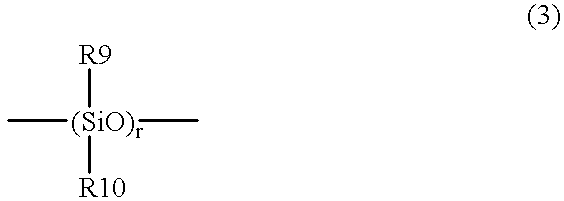

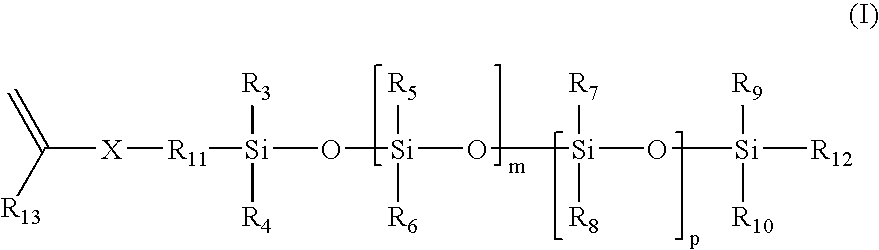

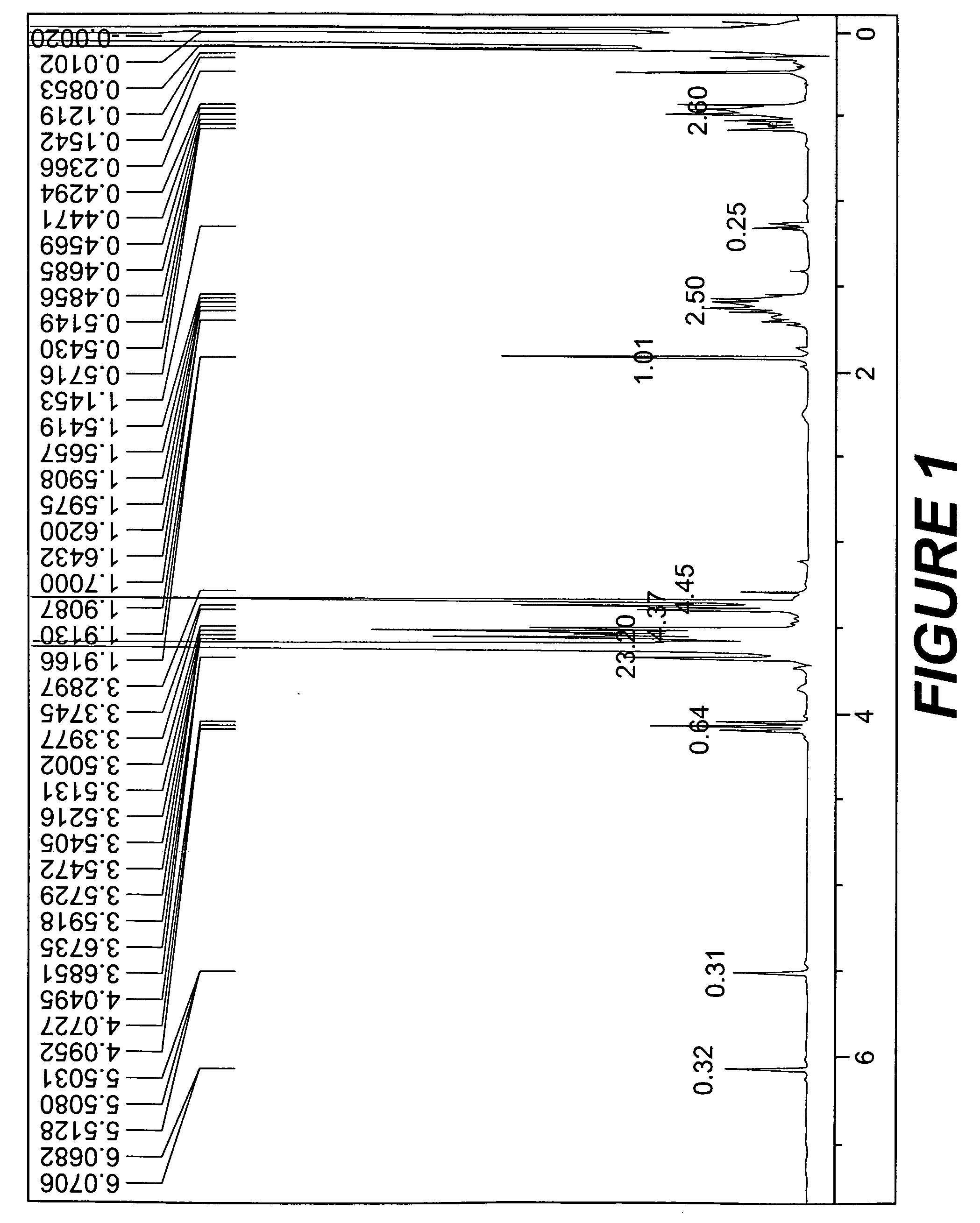

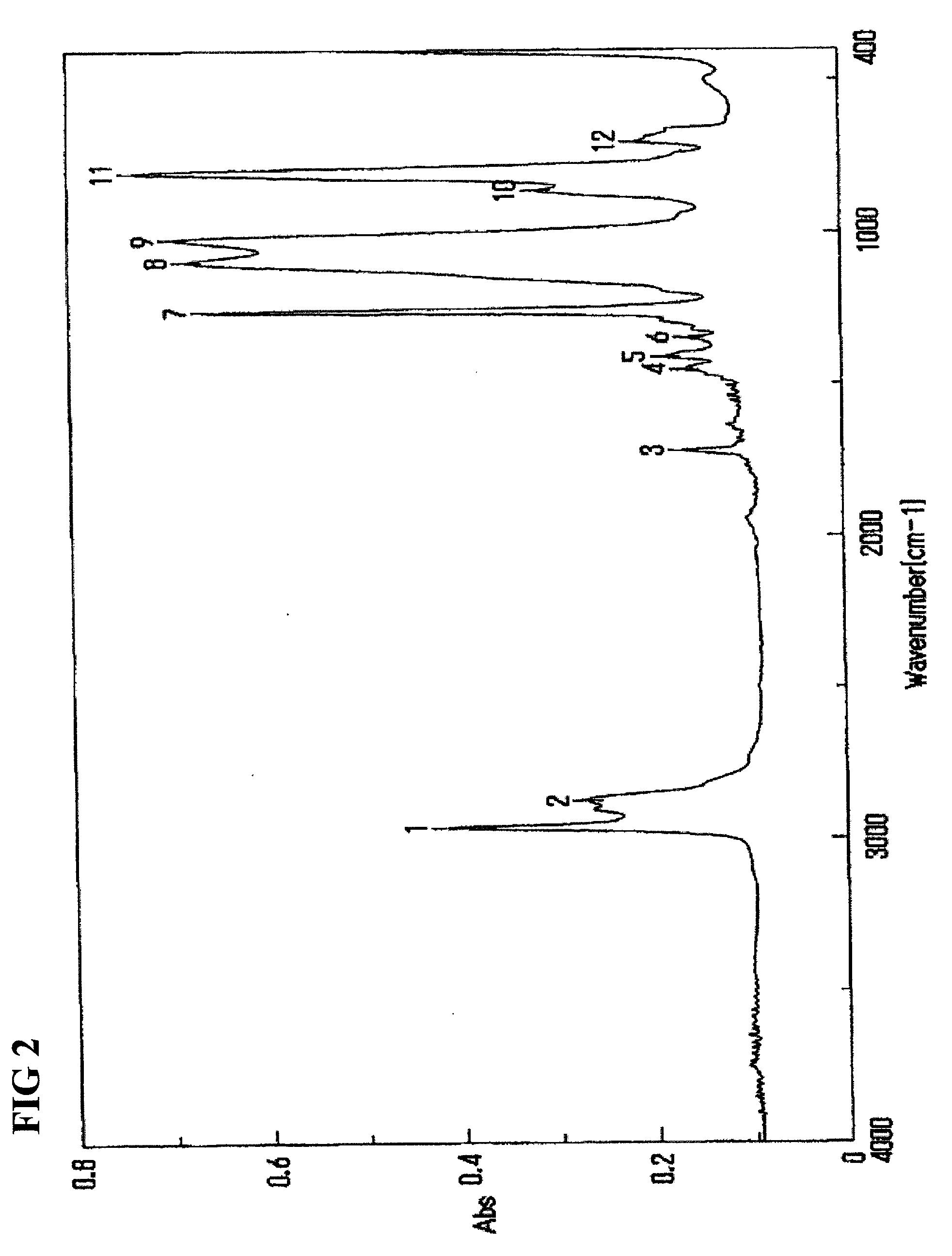

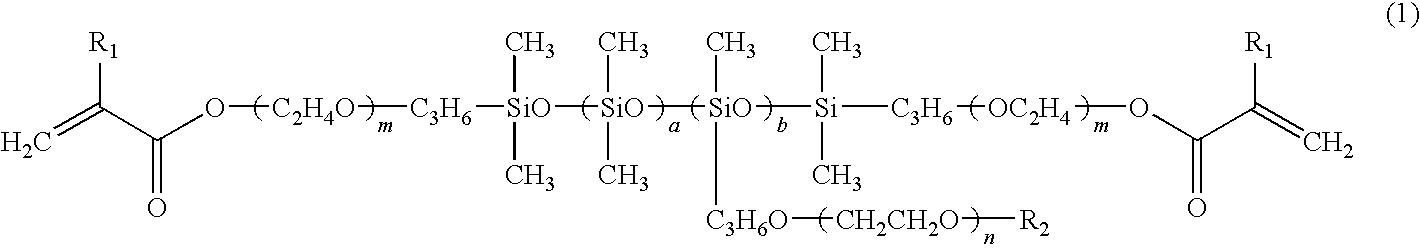

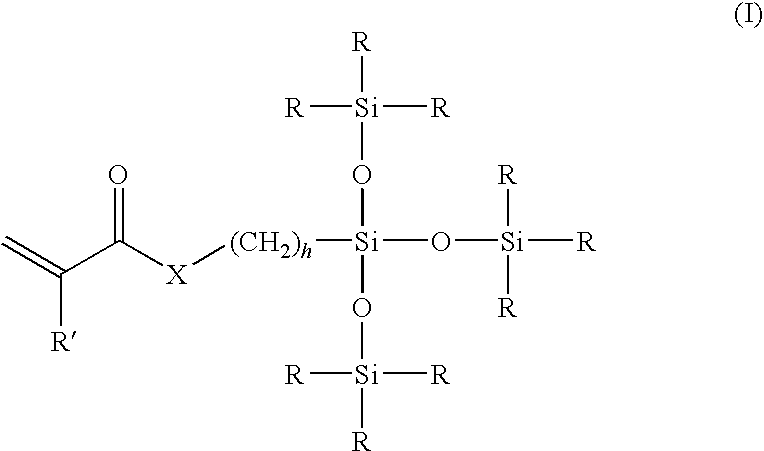

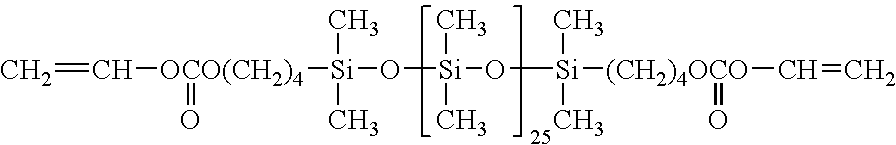

Hydrophilic Polysiloxane Macromonomer, and Production and Use of the same

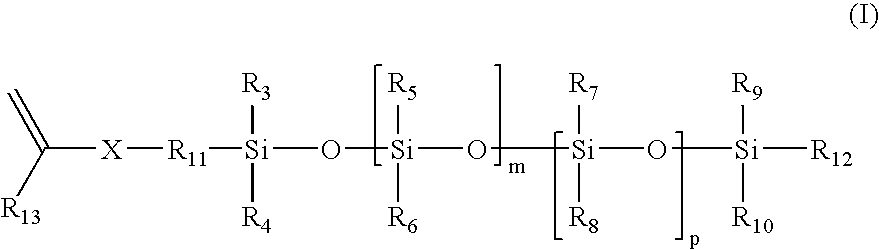

ActiveUS20090234089A1Improve compatibilityHigh oxygen permeabilitySilicon organic compoundsOptical articlesSide chainHydrophile

Problem to be Solved To provide an ophthalmic lens, which can be more safely worn, that is, to provide a material, which is transparent and has high oxygen permeability and a high hydrophilic property, and to provide a novel monomer to be a raw material thereof.Solution A hydrophilic polysiloxane macromonomer contains polyoxyethylene as a hydrophilic side chains in a polysiloxane main chain, wherein transparency, oxygen permeability, and hydrophilic properties of the material are controlled by regulating the length of the polysiloxane main chain, the length of the hydrophilic polyoxyethylene side chains, and the number of the side chains.

Owner:COOPERVISION INT LTD

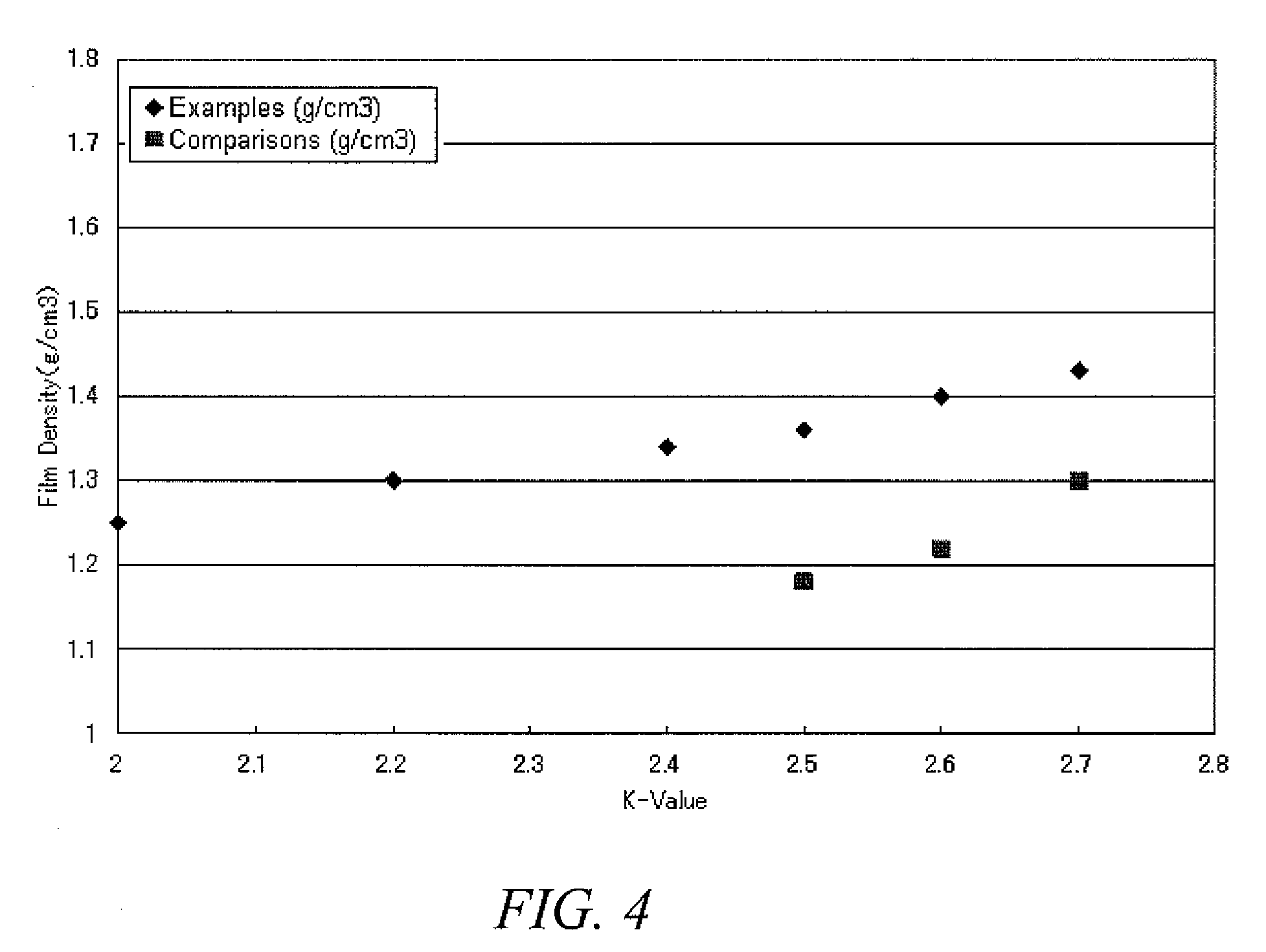

Low dielectric constant materials and method

InactiveUS6051321AImprove rotational flexibilityTightly boundSemiconductor/solid-state device detailsSynthetic resin layered productsElectrical conductorCopper

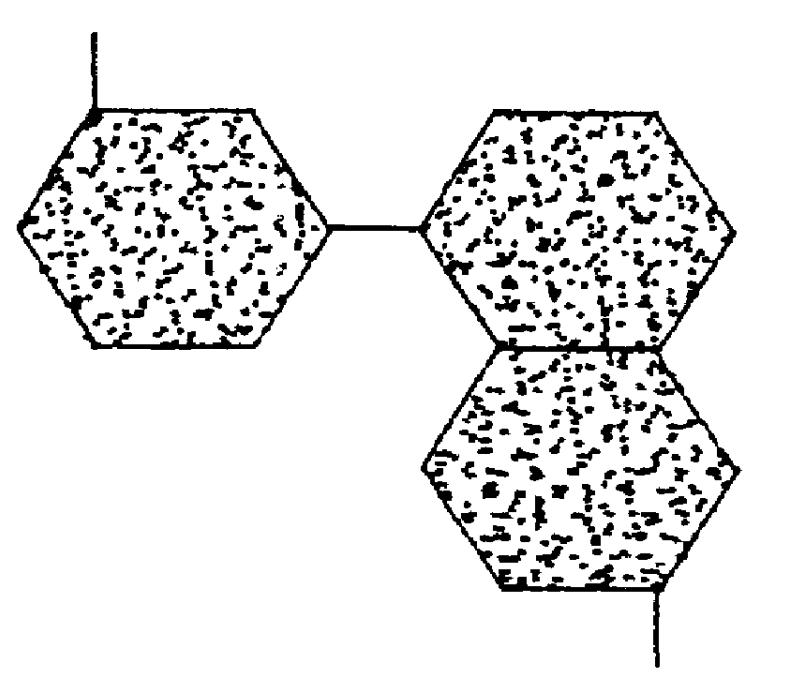

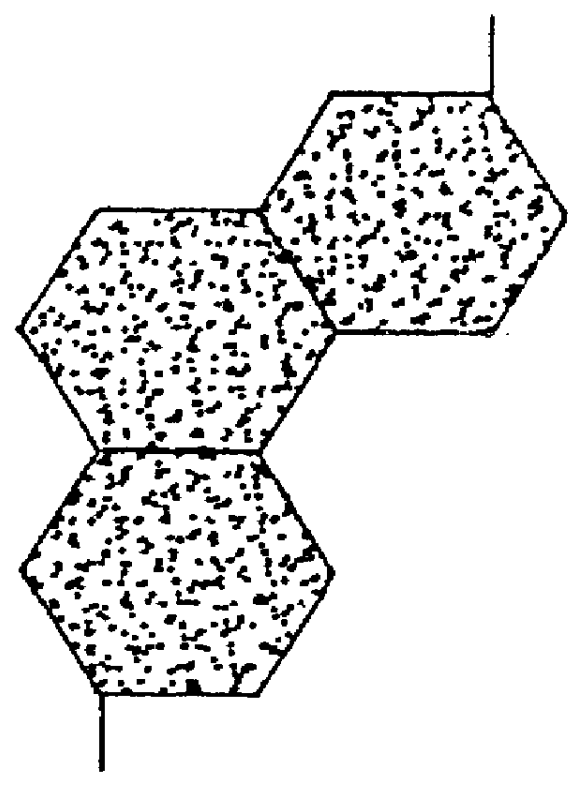

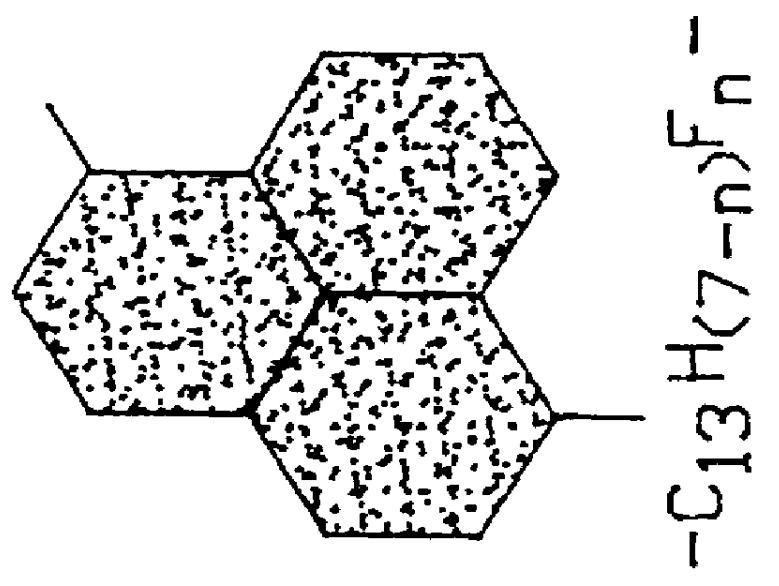

Intermetal dielectric (IMD) and interlevel dielectric (ILD) that have dielectric constants (K) ranging from 2.0 to 2.6 are prepared from plasma or photon assisted CVD (PACVD) or transport polymerization (TP). The low K dielectric (LKD) materials are prepared from PACVD or TP of some selected siloxanes and F-containing aromatic compounds. The thin films combine barrier and adhesion layer functions with low dielectric constant functions, thus eliminating the necessity for separate adhesion and barrier layers, and layers of low dielectric constant. The LKD materials disclosed in this invention are particularly useful for <0.18 .mu.m ICs, or when copper is used as conductor in future ICs.

Owner:CANON USA

Silicone-containing prepolymers with dangling hydrophilic polymer chains

ActiveUS20080234457A1Reduce molecular weightHigh molecular weightOptical articlesProsthesisPolymer scienceHydrophilic polymers

The invention provide a new class of silicone-containing prepolymers containing dangling hydrophilic polymer chains. This class of silicone-containing prepolymer is capable of being actinically crosslinked to form a silicone hydrogel material with a hydrophilic surface without post curing surface treatment. The present invention is also related to silicone hydrogel contact lenses made from this class of silicone-containing prepolymers and to methods for making the silicone hydrogel contact lenses.

Owner:ALCON INC

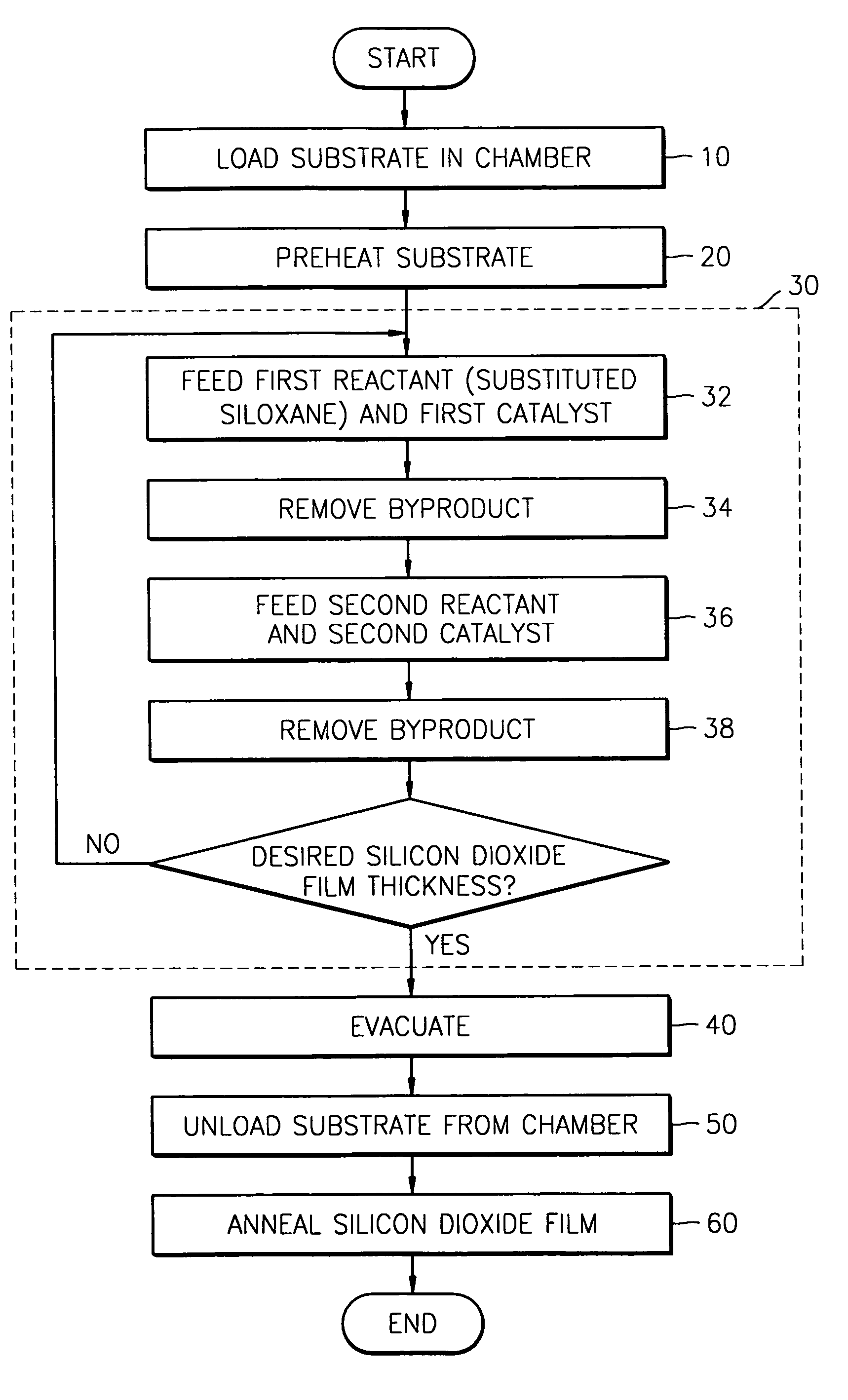

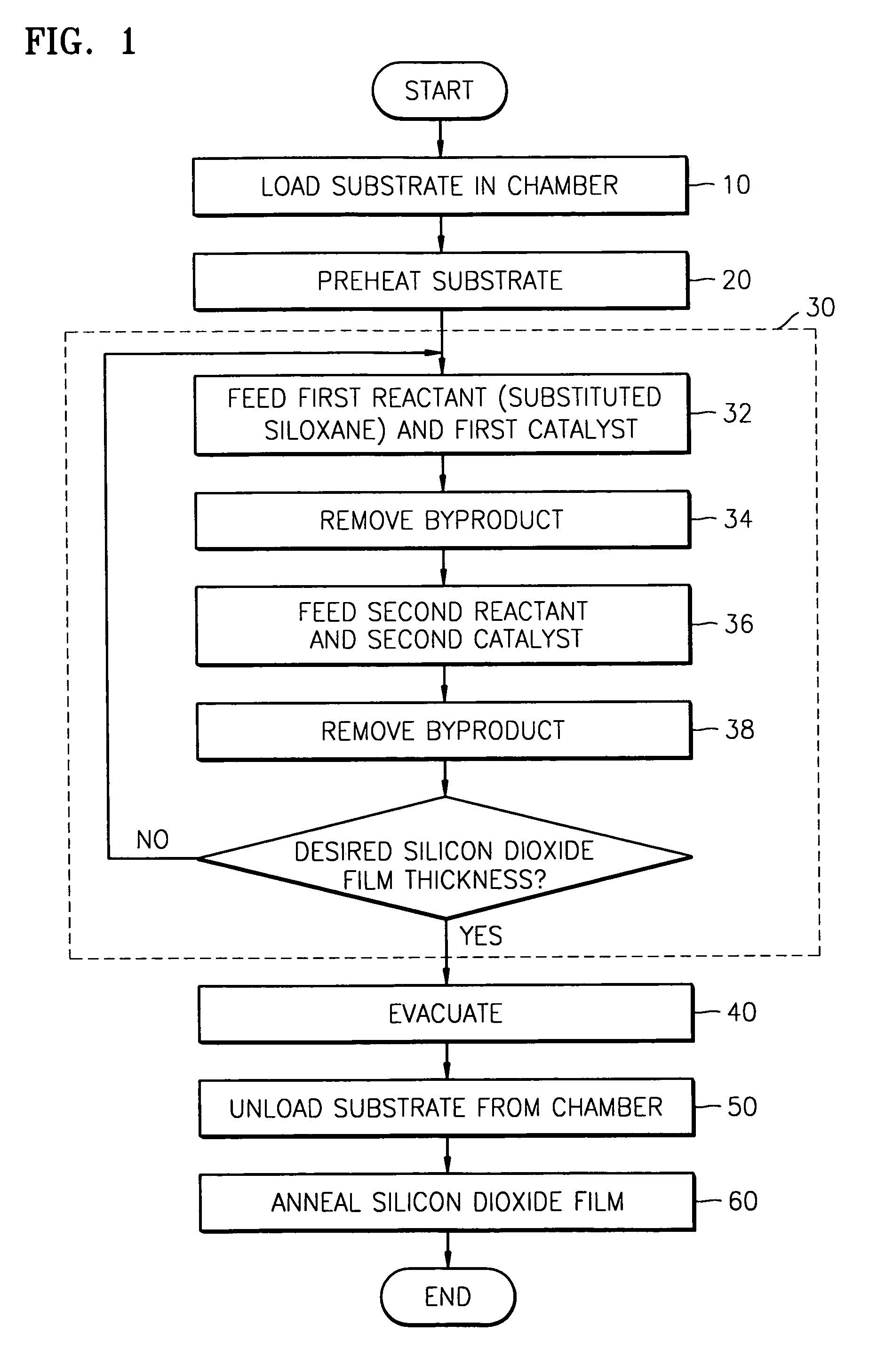

Method for forming silicon dioxide film using siloxane

InactiveUS7084076B2Improve film qualityReduce the presence of impuritiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenHalogen

Owner:SAMSUNG ELECTRONICS CO LTD

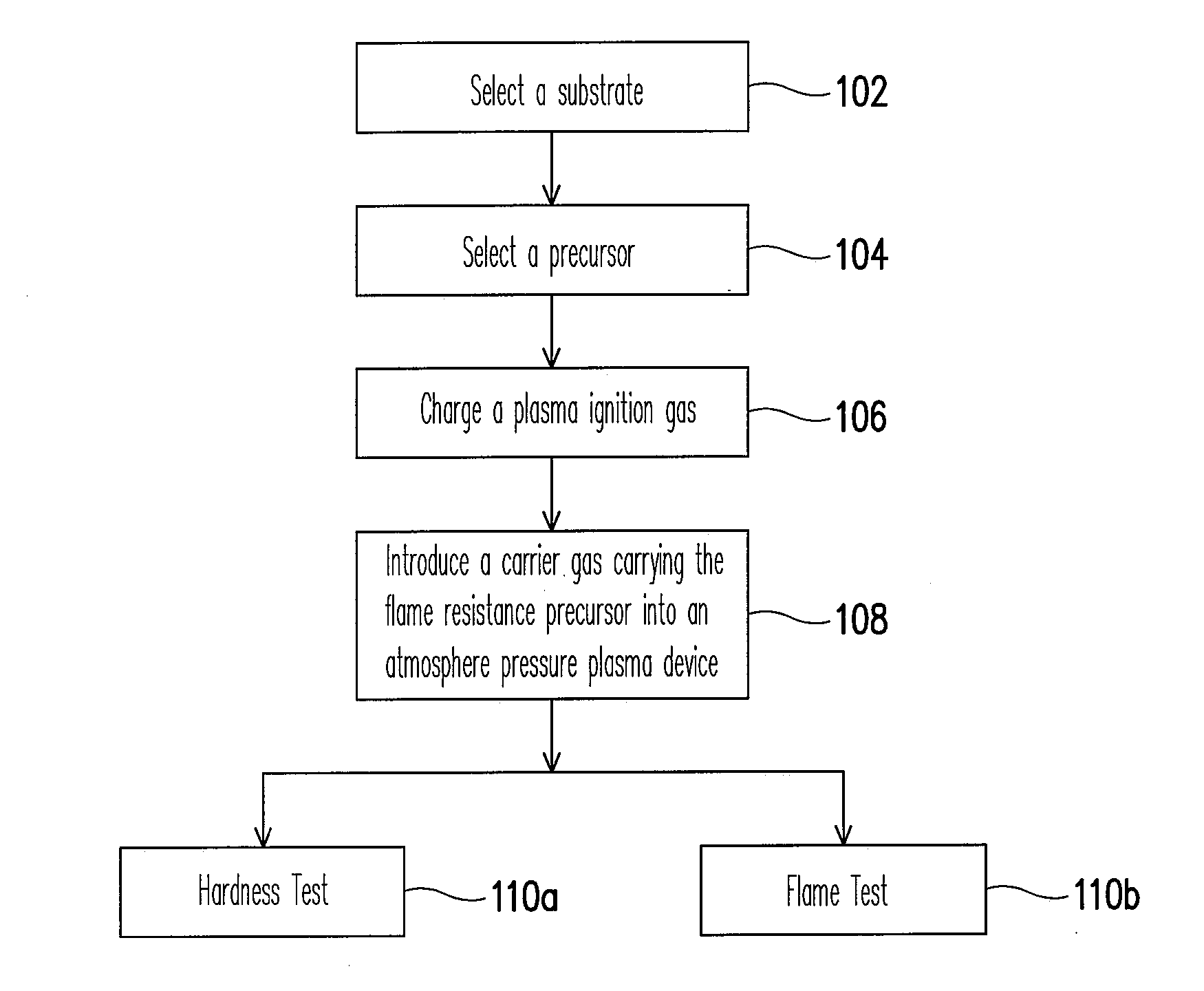

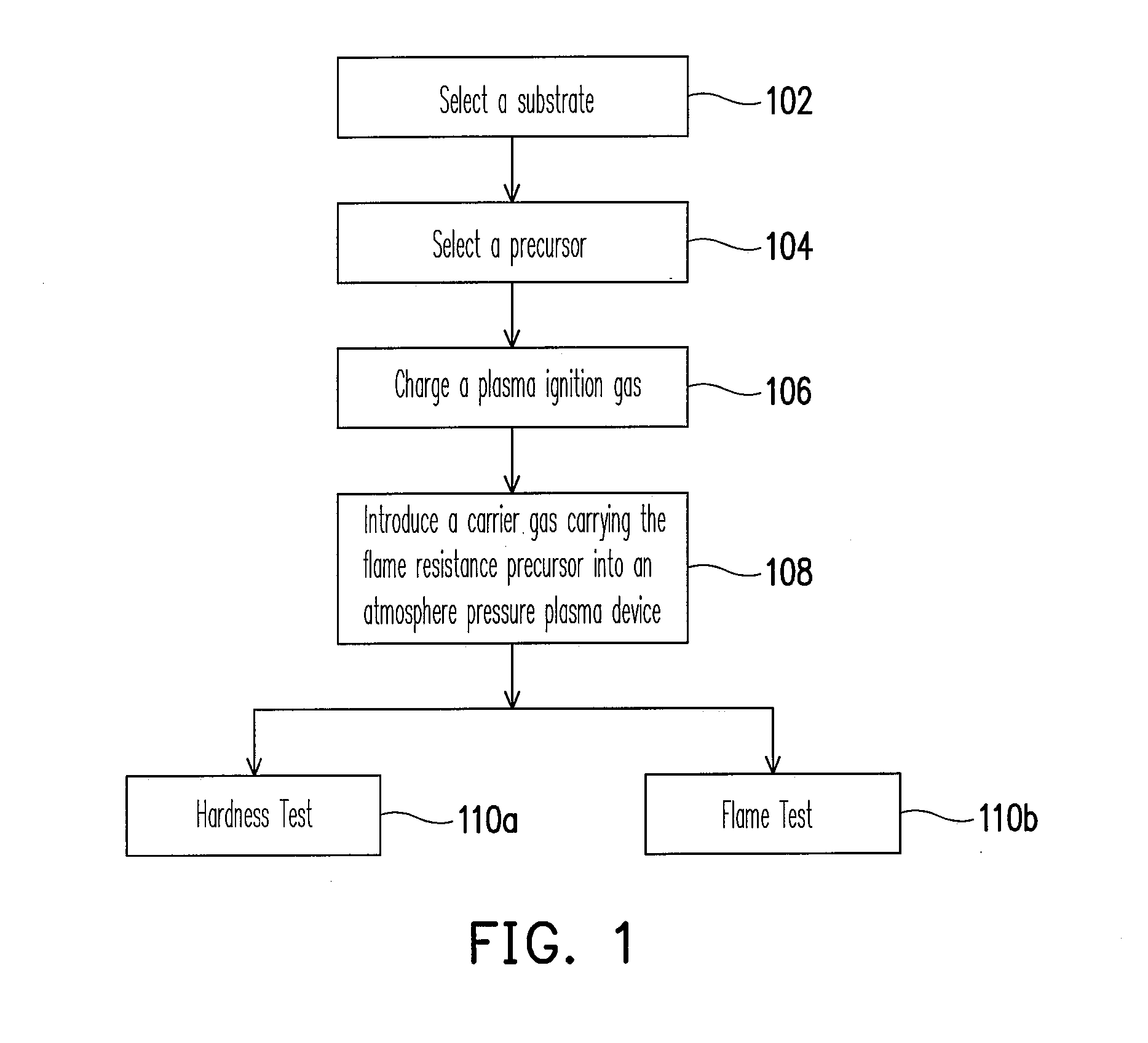

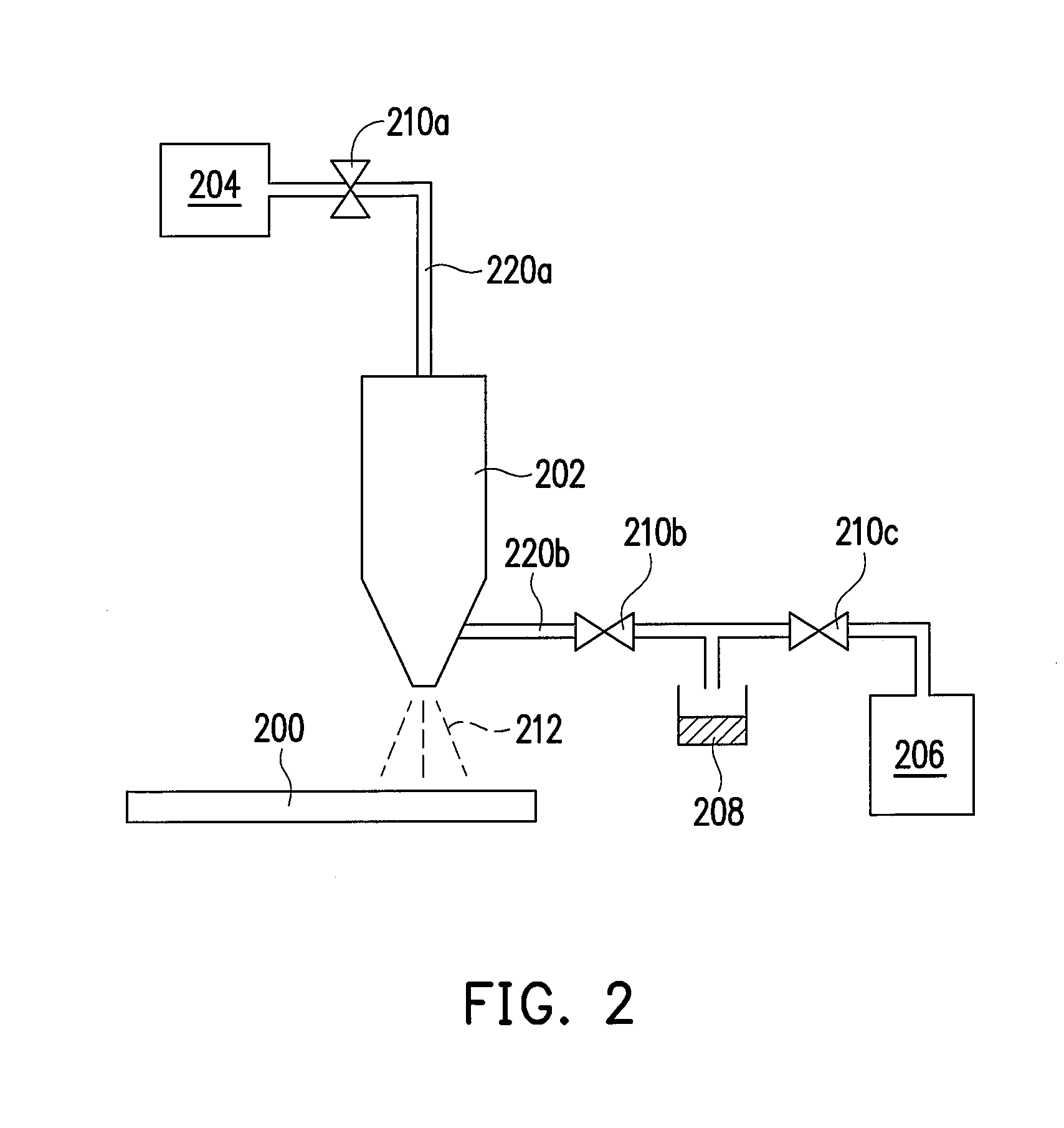

Method of improving surface flame resistnace of substrate

InactiveUS20080105276A1Improve flame retardant performanceSurface cleaningElectrostatic cleaningChemical vapor deposition coatingPlasma ignitionAtmosphere

A method of improving surface flame resistance of a substrate is provided. A substrate is provided. An atmosphere pressure plasma process is performed on the surface of the substrate to form an inorganic film layer on the surface of the substrate, wherein a process gas of the atmosphere plasma process includes a flame resistance precursor, a carrier gas, and a plasma ignition gas. Particularly, the flame resistance precursor is selected from a siloxane compound, an inorganic alkoxide compound and a combination thereof. The siloxane compound has a formula of Si(OCnH2(n+1))4, n=1˜5, and the inorganic alkoxide compound has a formula of A(OCmH2m+1)4, where A represents Sn, Ti, Zr, Ce and m=2.

Owner:IND TECH RES INST

Method for forming dielectric film using siloxane-silazane mixture

ActiveUS20090156017A1High densityHigh strengthPretreated surfacesSemiconductor/solid-state device manufacturingSilazaneMetallurgy

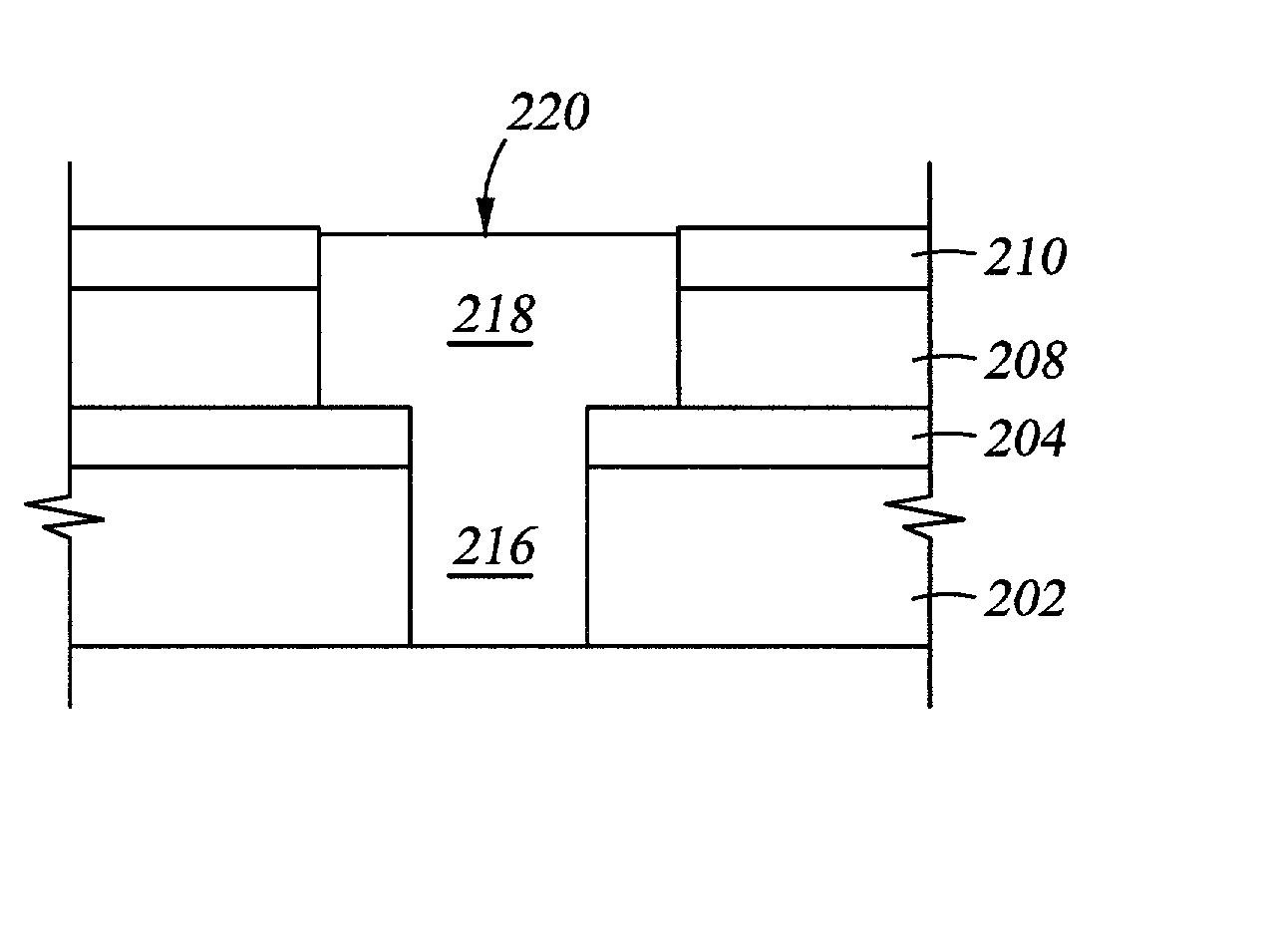

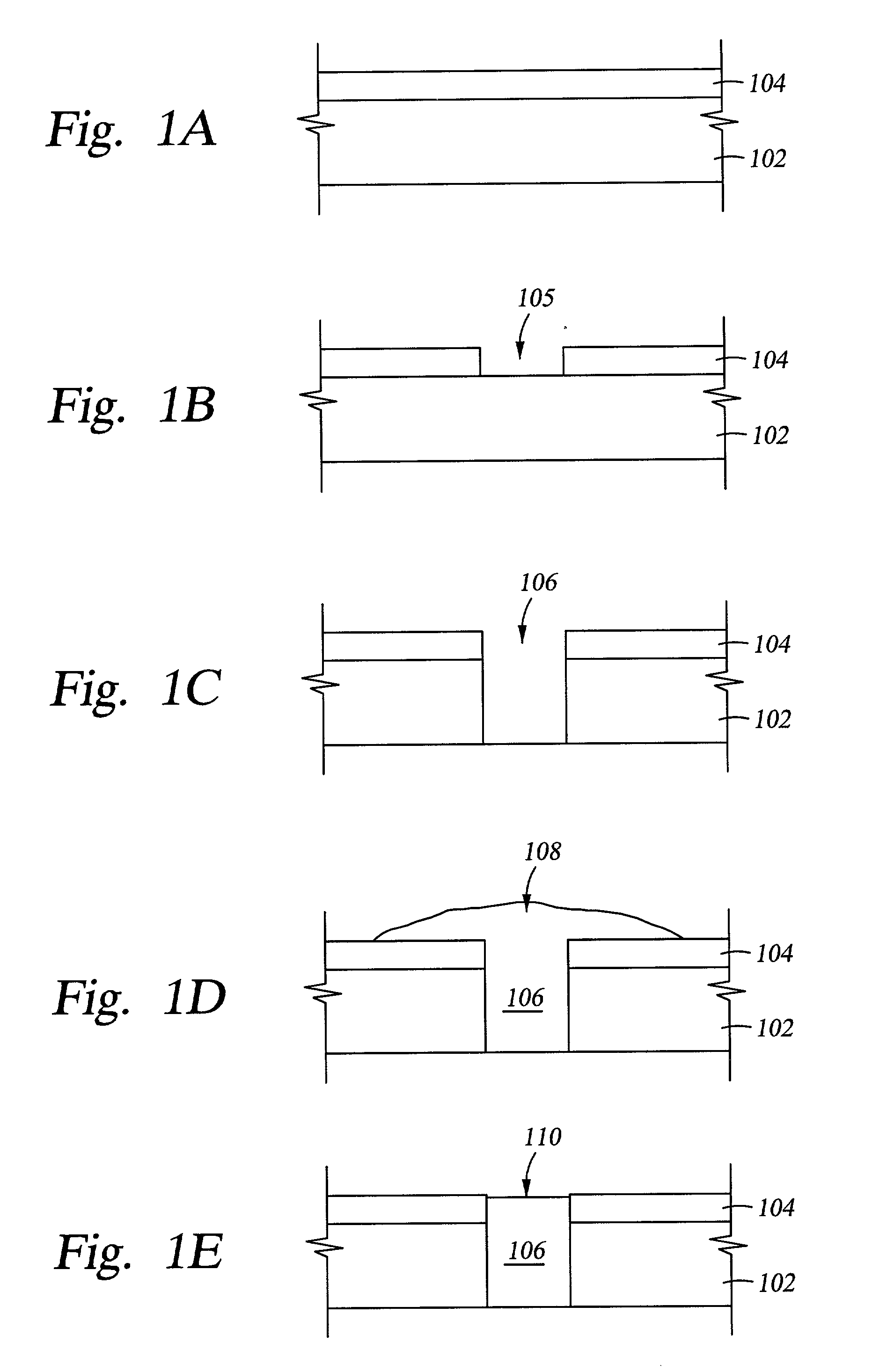

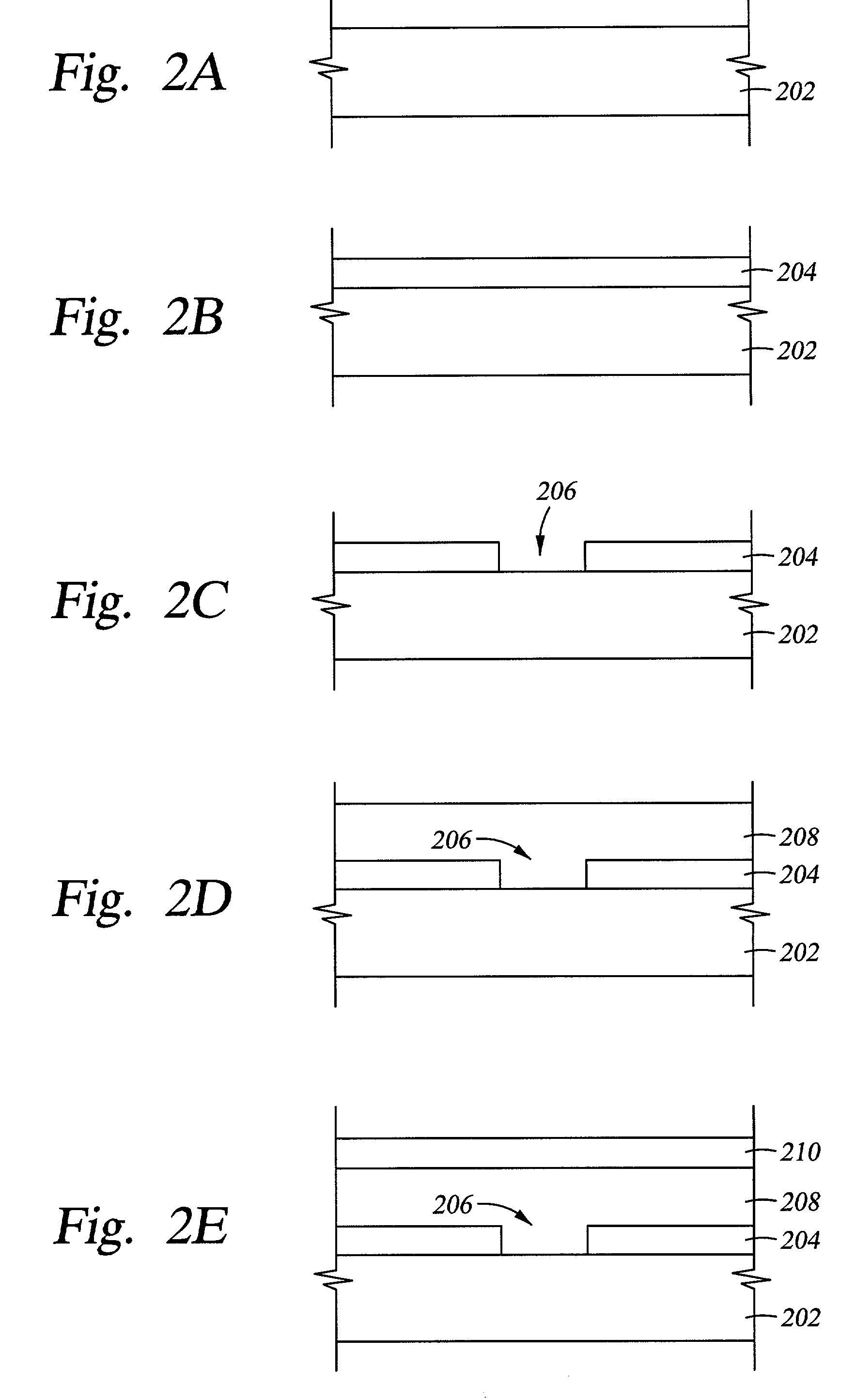

A method of forming a dielectric film, includes: introducing a siloxane gas essentially constituted by Si, O, C, and H and a silazane gas essentially constituted by Si, N, H, and optionally C into a reaction chamber where a substrate is placed; depositing a siloxane-based film including Si—N bonds on the substrate by plasma reaction; and annealing the siloxane-based film on the substrate in an annealing chamber to remove Si—N bonds from the film.

Owner:ASM JAPAN

Dicarboxylic acid foamable vehicle and pharmaceutical compositions thereof

ActiveUS20080044444A1Convenient vehicle for topical deliveryGood treatment effectPowder deliveryBiocideDicarboxylic acidCarboxylic acid

The present invention teaches a foamable pharmaceutical carrier comprising a benefit agent, selected from the group consisting of a dicarboxylic acid and a dicarboxylic acid ester; a stabilizer selected from the group consisting of at least one surface-active agent; at least one polymeric agent and mixtures thereof; a solvent selected from the group consisting of water, a hydrophilic solvent, a hydrophobic solvent, a potent solvent, a polar solvent, a silicone, an emollient, and mixtures thereof, wherein the benefit agent, stabilizer and solvent are selected to provide a composition that is substantially resistant to aging and to phase separation and or can substantially stabilize other active ingredients. The invention further relates to a foamable composition further containing a liquefied hydrocarbon gas propellant.

Owner:VYNE THERAPEUTICS INC

Method for depositing a low k dielectric film (k<3.5) for hard mask application

InactiveUS20030113995A1Semiconductor/solid-state device detailsSolid-state devicesOptoelectronicsDielectric thin films

A method for depositing a silicon oxycarbide hard mask on a low k dielectric layer is provided. Substrates containing a silicon oxycarbide hard mask on a low k dielectric layer are also disclosed. The silicon oxycarbide hard mask may be formed by a processing gas comprising a siloxane.

Owner:APPLIED MATERIALS INC

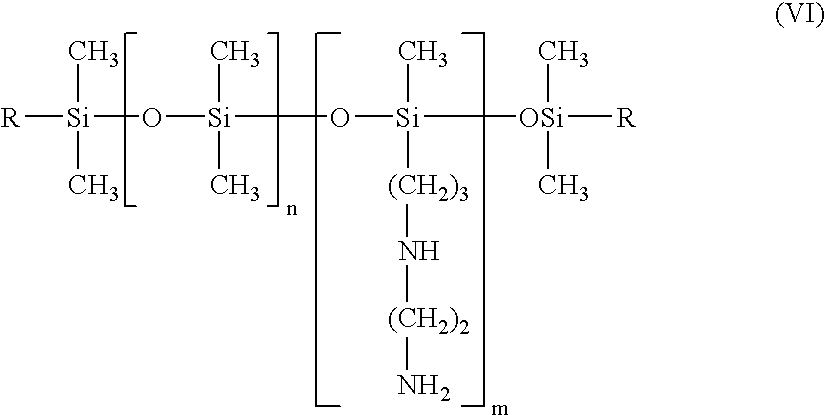

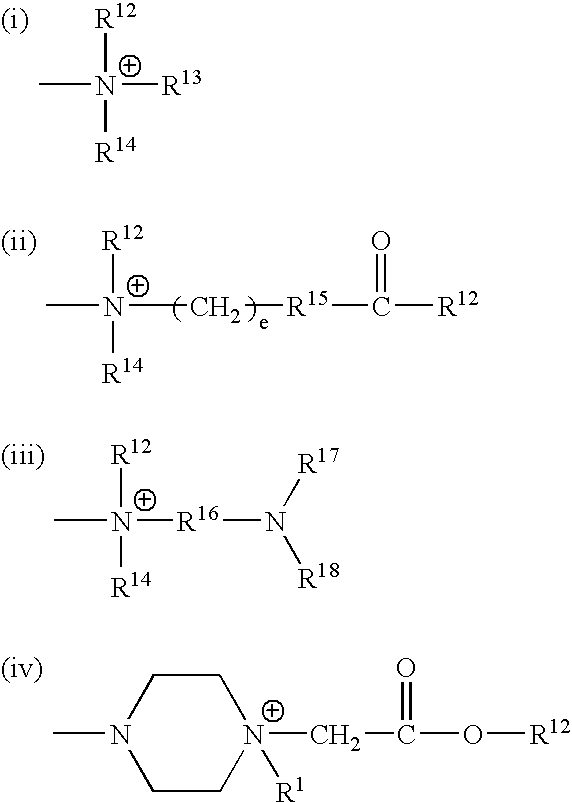

Perfumed liquid laundry detergent compositions with functionalized silicone fabric care agents

InactiveUS20060003913A1Organic detergent compounding agentsNon-surface-active detergent compositionsLiquid laundry detergentNitrogen

The invention is directed to aqueous liquid laundry detergent compositions for cleaning and imparting fabric care benefits to fabrics laundered therewith and to methods for preparing such compositions. Such compositions comprise (A) at least one textile-cleaning surfactant; (B) droplets of miscible silicones comprising both a polarly-functionalized, preferably nitrogen-containing amino or ammonium functionalized, polysiloxane component and a nitrogen-free non-functionalized or non-polarly-functionalized polysiloxane component; and (C) a perfume component comprising fragrant aldehydes and / or ketones or a pro-perfume capable of providing such aldheyde and / or ketone perfume materials in situ. Incorporation of a polarly-functionalized polysiloxane fabric care agent into liquid laundry detergent compositions by miscibly combining it with a non-functionalized or non-polarly functionalized polysiloxane minimizes the undesirable interaction such polarly-functionalized silicone material might otherwise have with aldehyde and / or ketone perfume compounds.

Owner:THE PROCTER & GAMBLE COMPANY

High water content silicone hydrogels

ActiveUS7934830B2Increase moisture contentSuitable oxygen permeability propertyLayered productsThin material handlingHydration reactionHydrophilic monomer

Owner:BAUSCH & LOMB INC

Fabric care and perfume compositions and systems comprising cationic silicones and methods employing same

InactiveUS6903061B2Superior fabric careGood lookingInorganic/elemental detergent compounding agentsCationic surface-active compoundsSiliconeChemistry

Owner:THE PROCTER & GAMBLE COMPANY

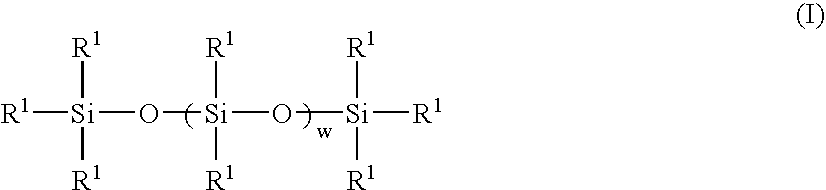

Silanol-functionalized compounds for the preparation of polyurethane foams

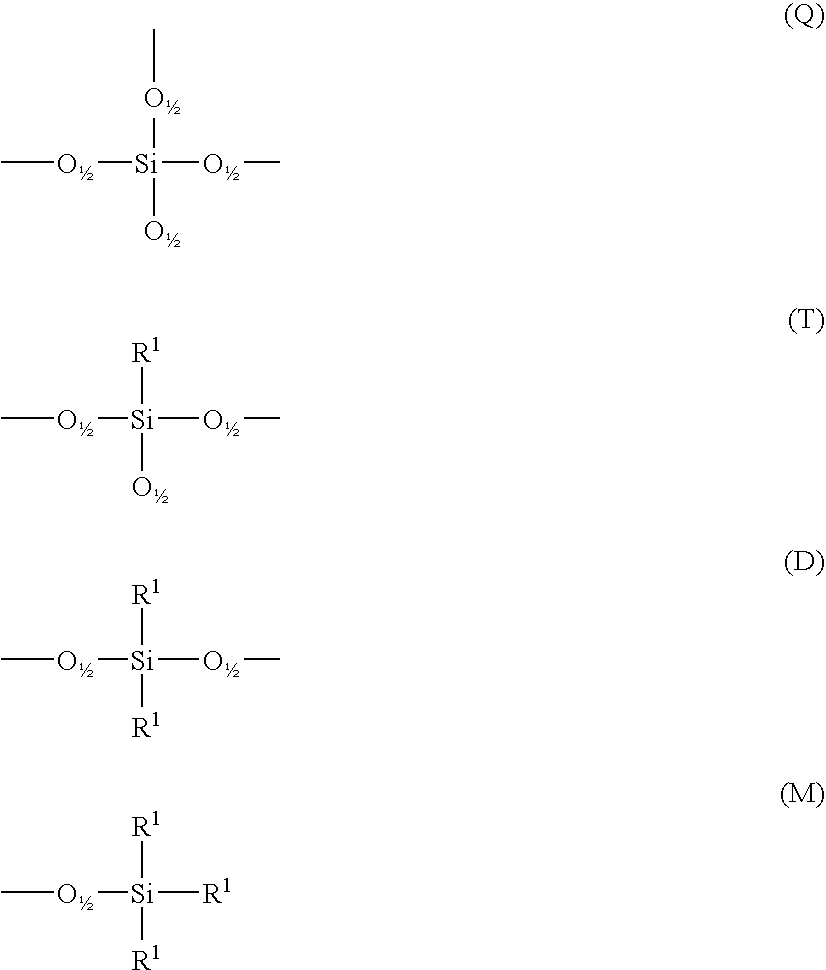

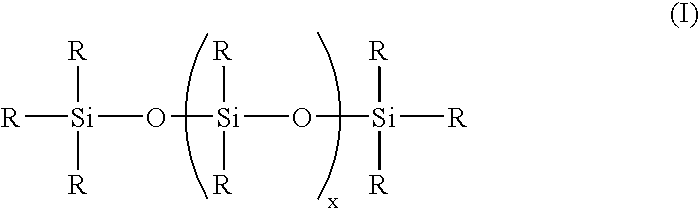

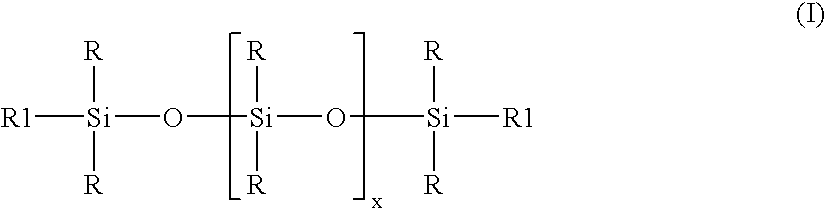

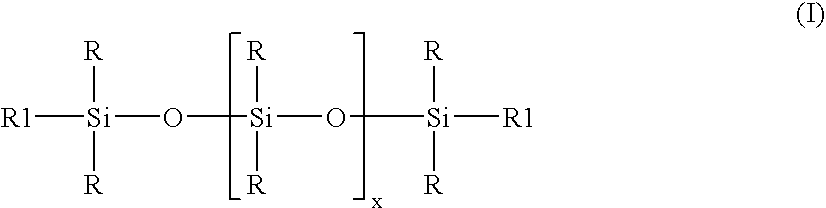

Methods for preparing polyurethane flexible foam are described, wherein an organic polyisocyanate is reacted with an active hydrogen-containing component such as an organic polyol, in the presence of a urethane catalyst, a blowing agent, optionally a cell opener, and a siloxane-based surfactant composition as a stabilizer for the foam. The siloxane-based surfactant composition comprises a silanol-functionalized organosiloxane having general formula (I), wherein: the R groups are independently a C1-C3 alkyl, phenyl, or —OSi(R)3; provided that at least one R group is a hydroxyl (—OH) bonded directly to any silicon atom and X is an integer from 0-200.

Owner:EVONIK OPERATIONS GMBH

Silicone hydrogels comprising n-vinyl amides and hydroxyalkyl (meth)acrylates or (meth)acrylamides

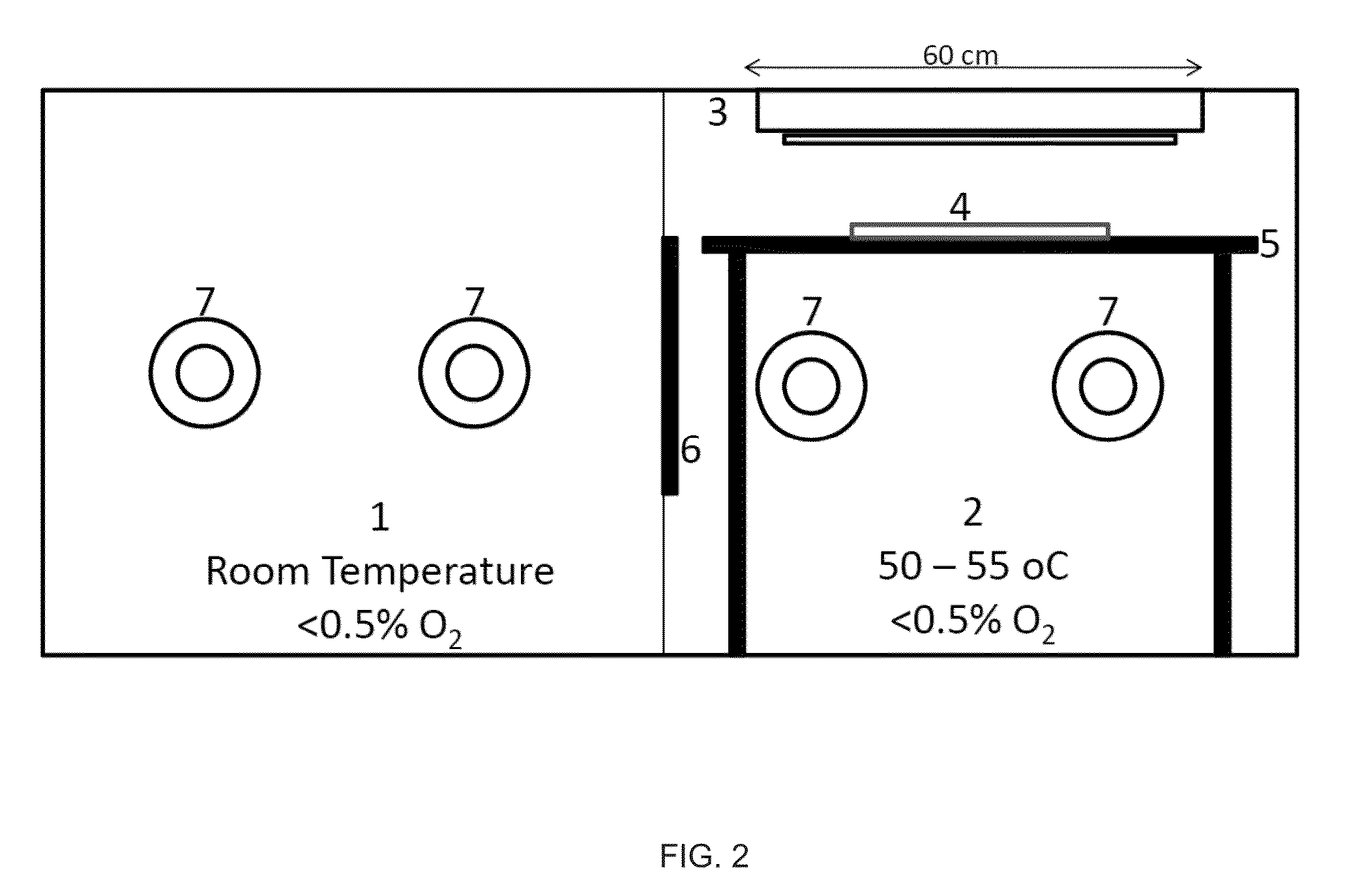

The present invention relates to a process comprising the steps of reacting a reactive mixture comprising at least one silicone-containing component, at least one hydrophilic component, and at least one diluent to form an ophthalmic device having an advancing contact angle of less than about 80°; and contacting the ophthalmic device with an aqueous extraction solution at an elevated extraction temperature, wherein said at least one diluent has a boiling point at least about 10° higher than said extraction temperature.

Owner:JOHNSON & JOHNSON VISION CARE INC

Polymerization of halogen-containing monomers using siloxane surfactant

Halogenated polymers are prepared by a process comprising polymerizing at least one halogen-containing monomer in an aqueous medium containing monomer, radical initiator, and siloxane surfactant. The medium may optionally contain one or more of an antifoulant, a buffering agent and a chain-transfer agent.

Owner:ARKEMA INC

Ionic silicone hydrogels

Owner:JOHNSON & JOHNSON VISION CARE INC

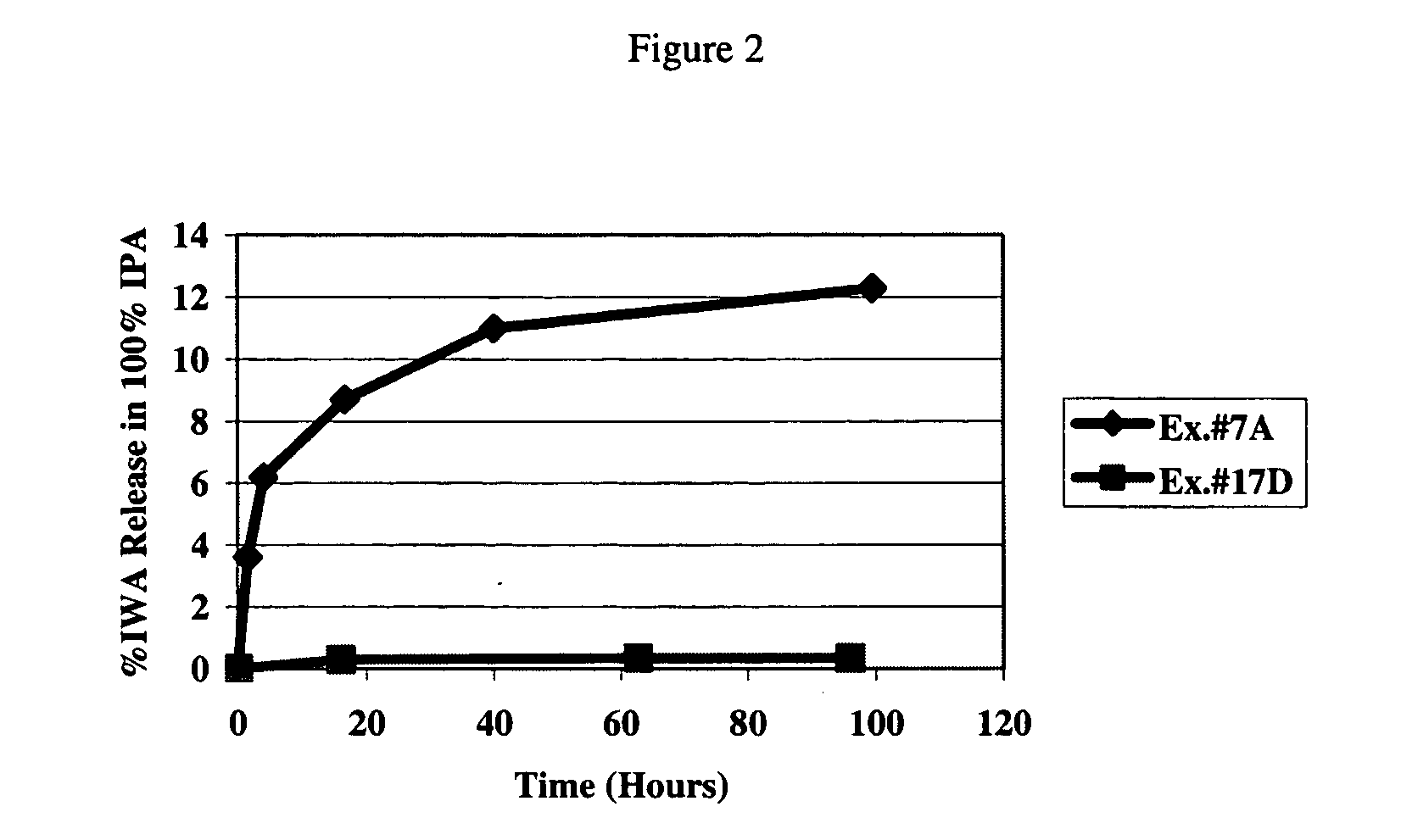

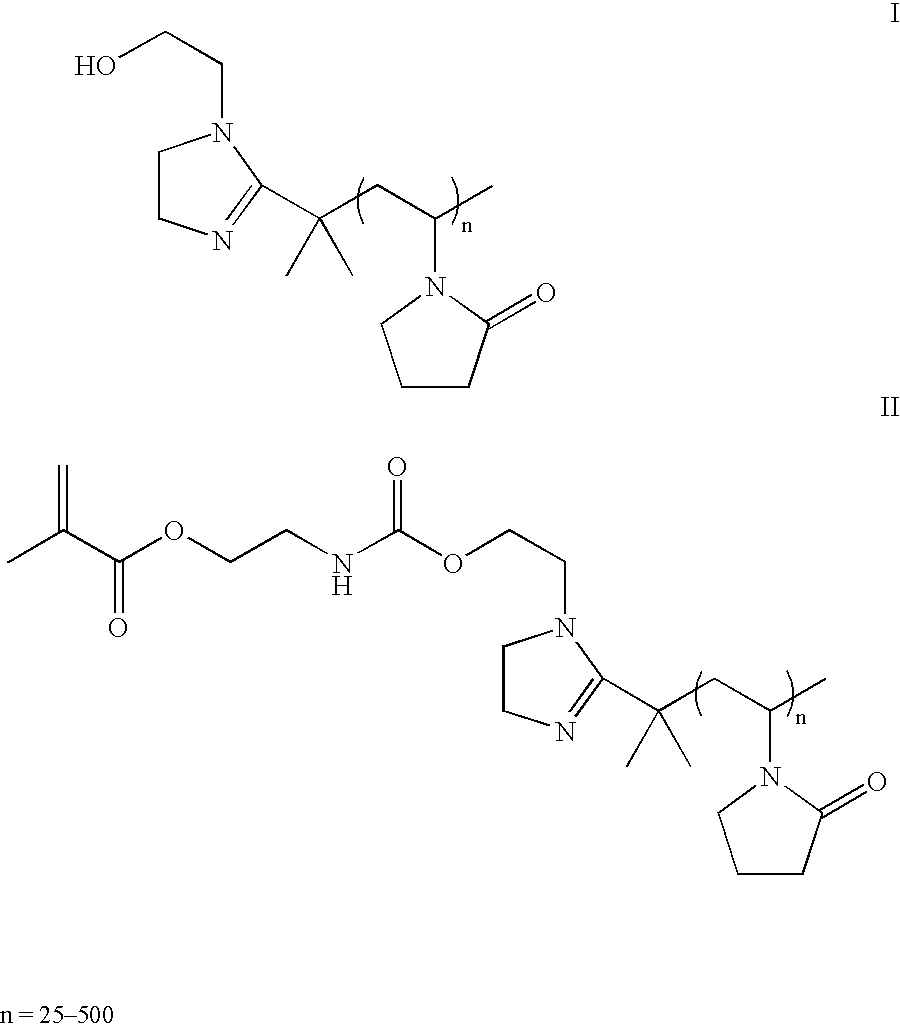

Wettable hydrogels comprising reactive, hydrophilic, polymeric internal wetting agents

The present invention relates to wettable silicone hydrogels comprising the reaction product of at least one siloxane containing component and at least one reactive, hydrophilic polymeric internal wetting agent. The present invention further relates to silicone hydrogel contact lenses comprising at least one oxygen permeable component, and an amount of reactive, hydrophilic polymeric internal wetting agent sufficient to impart wettability to said device.

Owner:JOHNSON & JOHNSON VISION CARE INC

Amine organoborane complex initiated polymerizable compositions containing siloxane polymerizable components

InactiveUS6777512B1Easy to useBroaden applicationOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsAminosilochromeOligomer

In one embodiment the invention is a polymerizable composition comprising a) an organoborane amine complex; b) one or more of monomers, oligomers or polymers having olefinic unsaturation which is capable of polymerization by free radical polymerization; c) one or more compounds, oligomers or prepolymers having a siloxane backbone and reactive moieties capable of polymerization; and d) a catalyst for the polymerization of the one or more compounds, oligomers or prepolymers having a siloxane backbone and reactive moieties capable of polymerization. This composition may further comprise a compound which causes the organoborane amine complex to disassociate. In a preferred embodiment, the two part composition further comprises a compound which is reactive with both the b) one or more of monomers, oligomers or polymers having olefinic unsaturation which is capable of polymerization by free radical polymerization; and the c) one or more compounds, oligomers or prepolymers having a siloxane backbone and reactive moieties capable of polymerization. This composition can be polymerized by contacting the two parts of the composition. In another embodiment the invention is an organoborane amine complex comprising an alkyl borane having ligands which are alkyl, cycloalkyl or both and an amino siloxane.

Owner:DOW GLOBAL TECH LLC

Manufacture of stable low particle size organopolysiloxane emuslion

ActiveUS20070276087A1Rapid emulsificationReduce polymerization timeMaterial nanotechnologyOther chemical processesPolymer scienceEmulsion

Stable high viscosity organopolysiloxane emulsions with particle sizes up to 150 nanometer may be made in a simple and cost-effective manner employing a standard homogenizer, and optional subsequent polymerization of the organopolysiloxan at controlled temperature. A combination of non-ionic emulsifier together with an at least one anionic emulsifier is employed, having an HLB value 12-15, while maintaining a temperature up to 50° C.

Owner:WACKER CHEM GMBH

Hydrophilic polysiloxane compositions

The instant invention provides a method for improving the miscibility of the lower molecular weight unsaturated siloxane-polyether copolymers with the alpha , omega -divinylpolysiloxanes without loss of storage stability, or delay of cure at the vulcanization temperature, or loss of permanent hydrophilicity or other desirable features of the cured polysiloxane. The compositions of the present invention comprise one or more alpha , omega -divinylpolysiloxanes, unsaturated polysiloxane-polyether copolymers having from 2 to 5 silicon atoms per molecule which are preferably trisiloxanes, and a compatibilizing additive. The permanently hydrophilic, rapidly wettable polysiloxane compositions yield static water contact angles <50 DEG dynamic advancing contact angles of less than about 100.

Owner:GENERAL ELECTRIC CO

Ionic silicone hydrogels

The present invention relates to a process comprising the steps of reacting a reactive mixture comprising at least one silicone-containing component, at least one hydrophilic component, and at least one diluent to form an ophthalmic device having an advancing contact angle of less than about 80°; and contacting the ophthalmic device with an aqueous extraction solution at an elevated extraction temperature, wherein said at least one diluent has a boiling point at least about 10° higher than said extraction temperature.

Owner:JOHNSON & JOHNSON VISION CARE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com