Patents

Literature

1370results about How to "Improve film quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

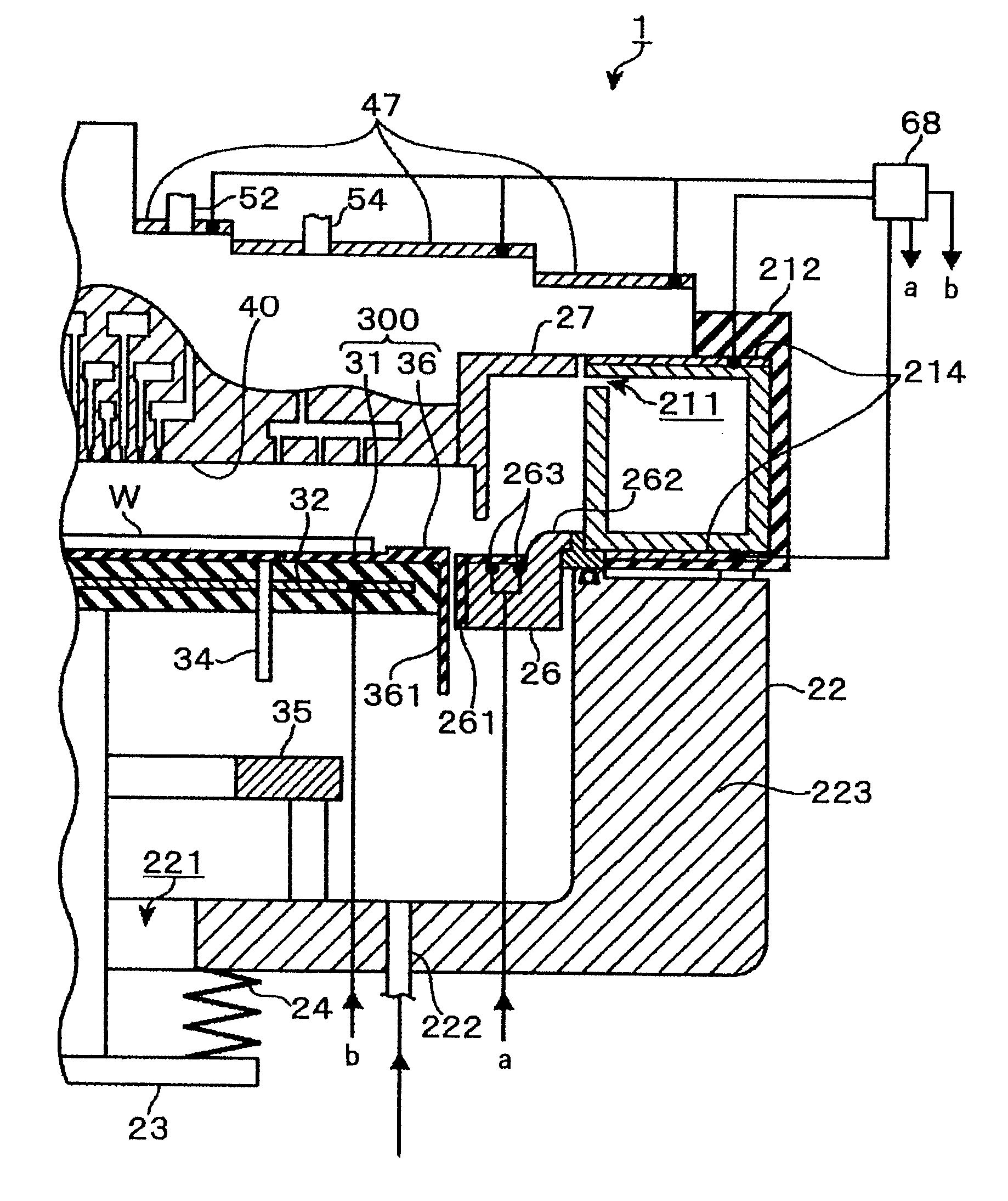

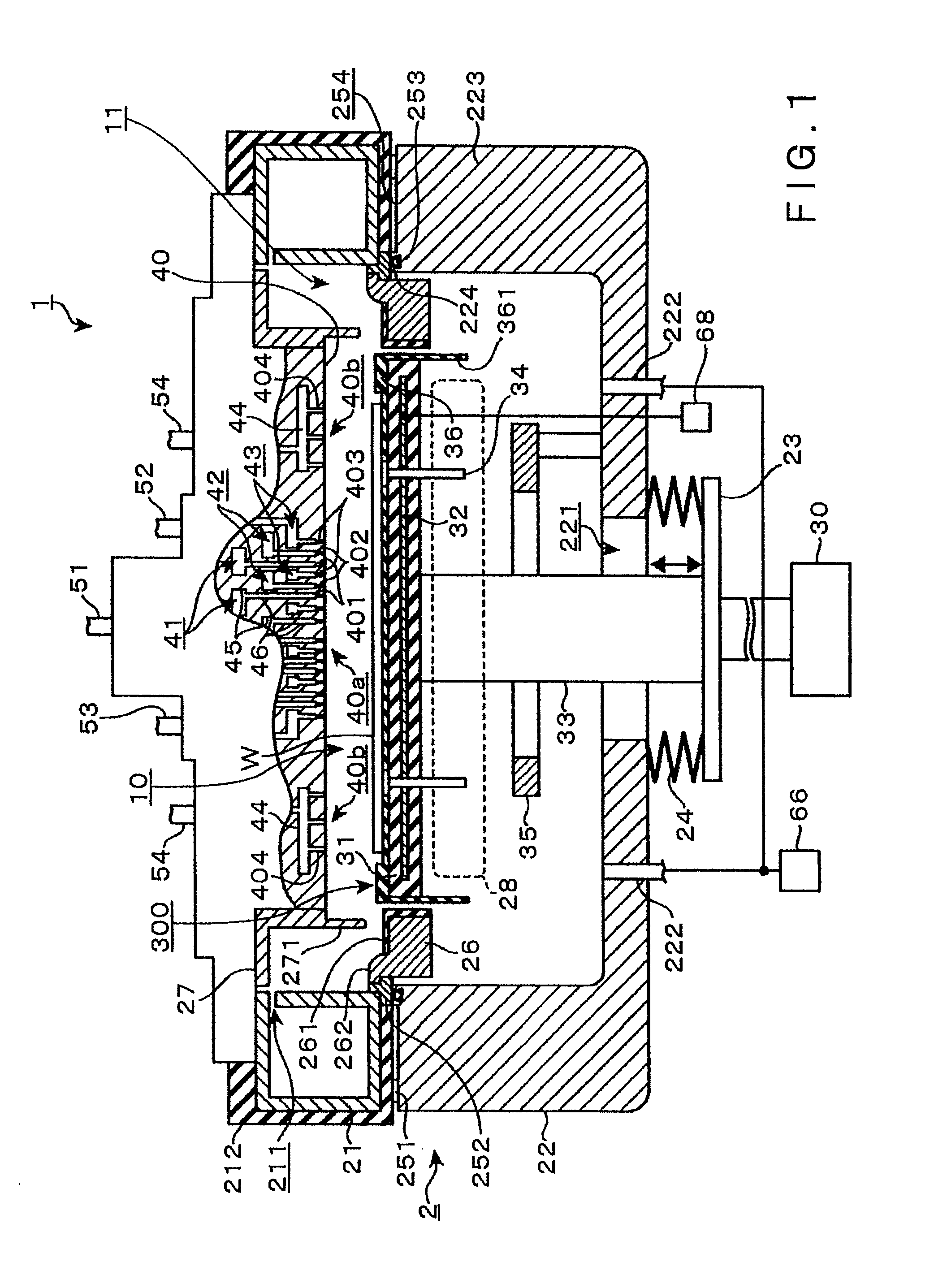

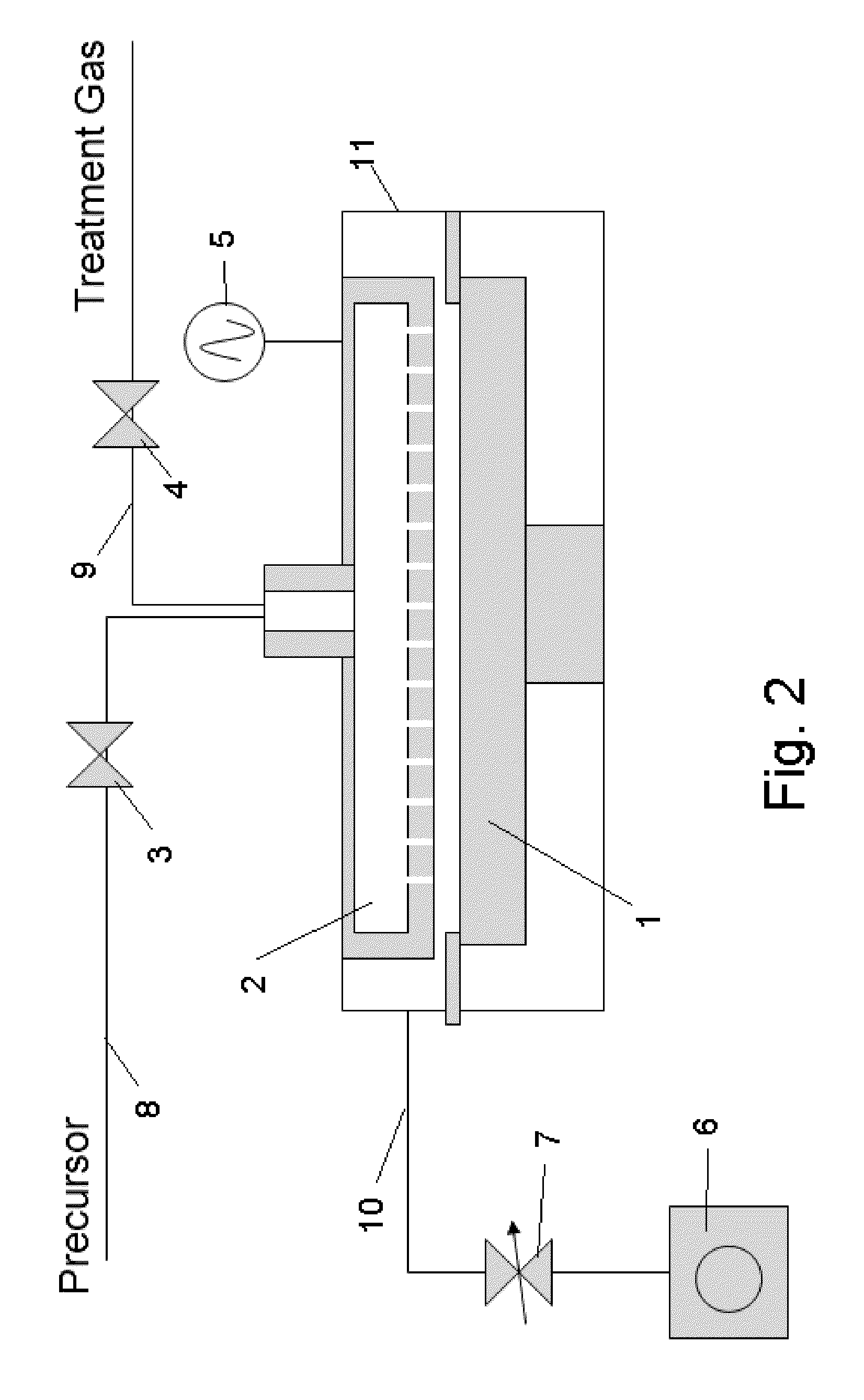

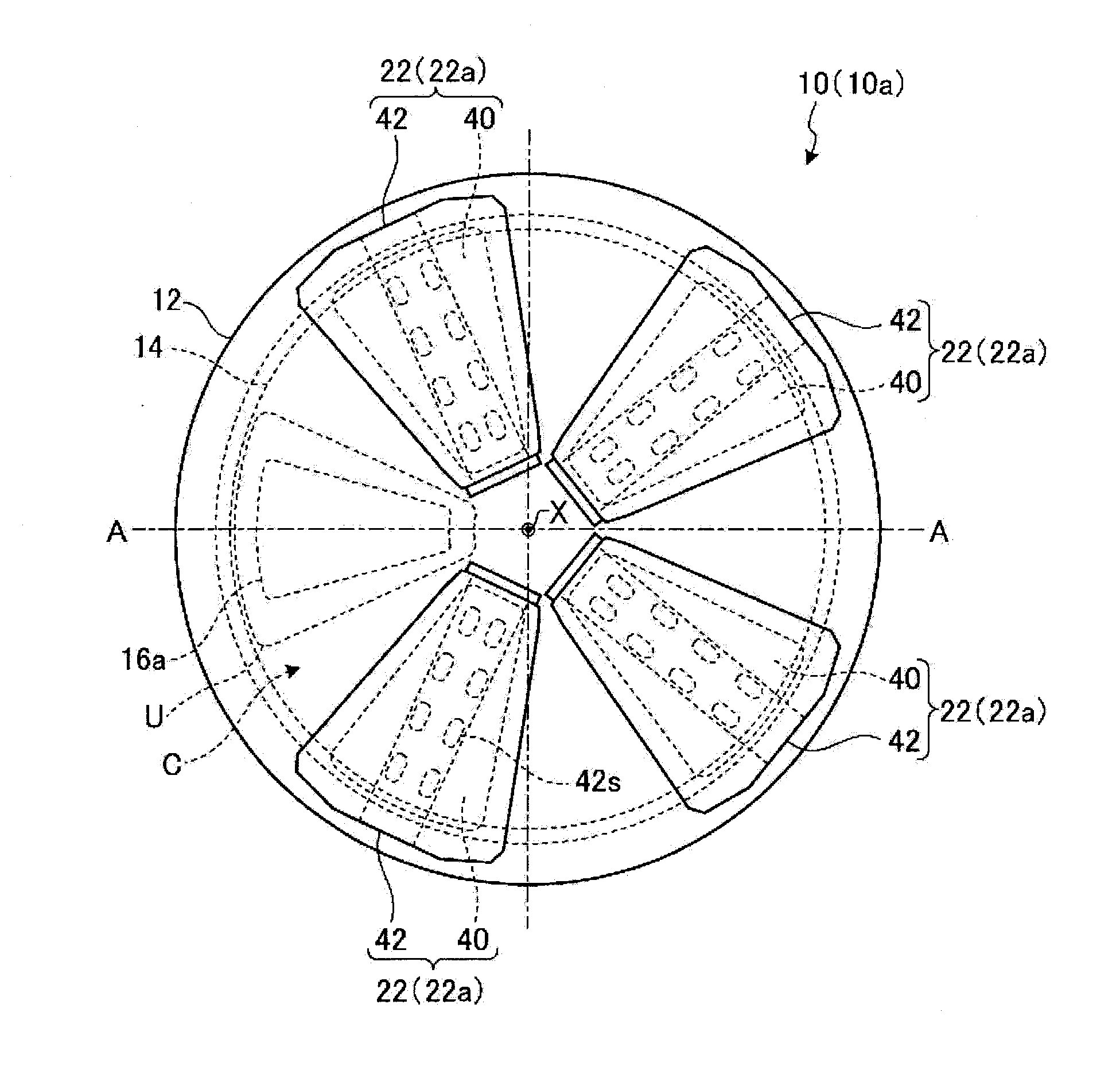

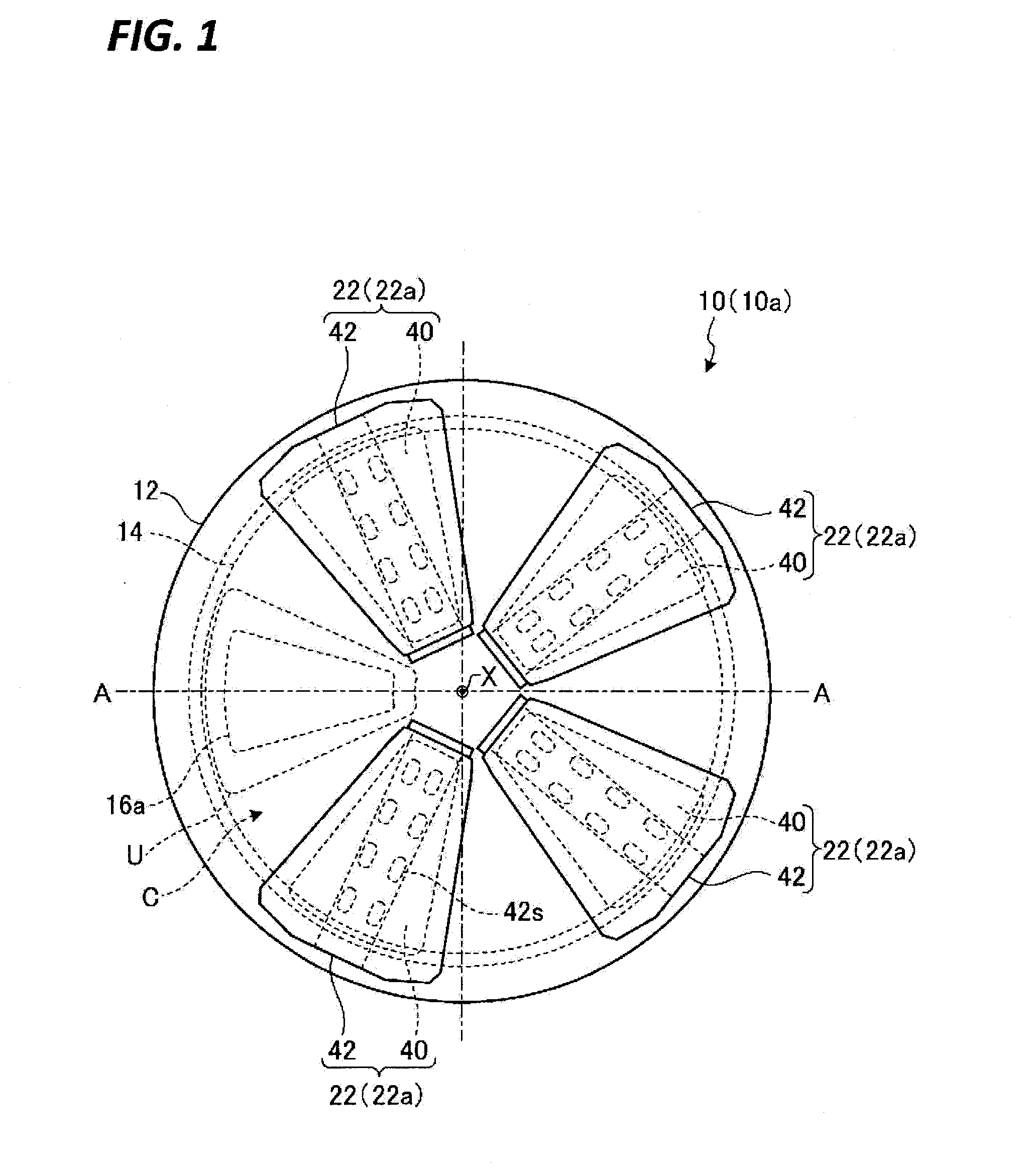

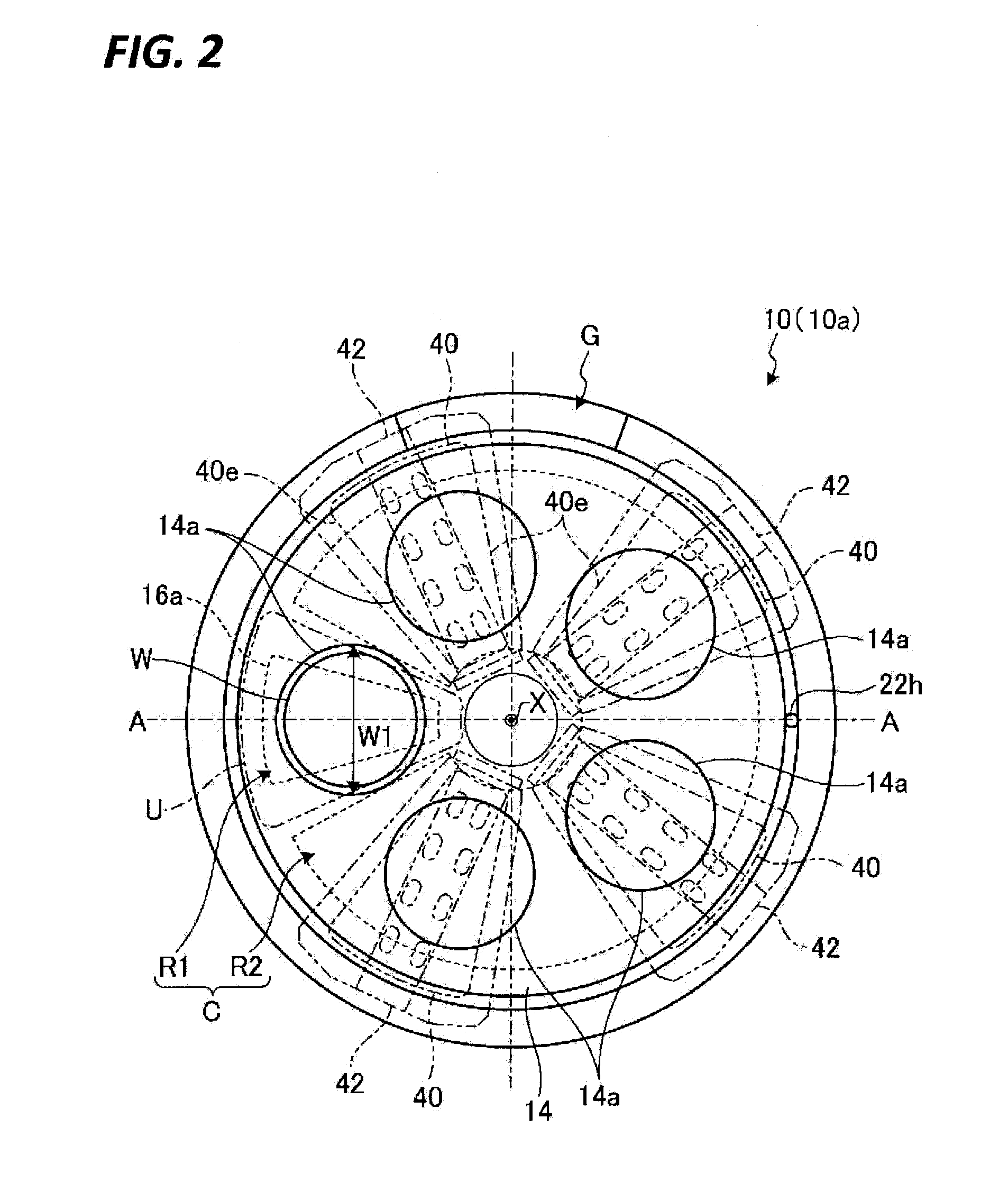

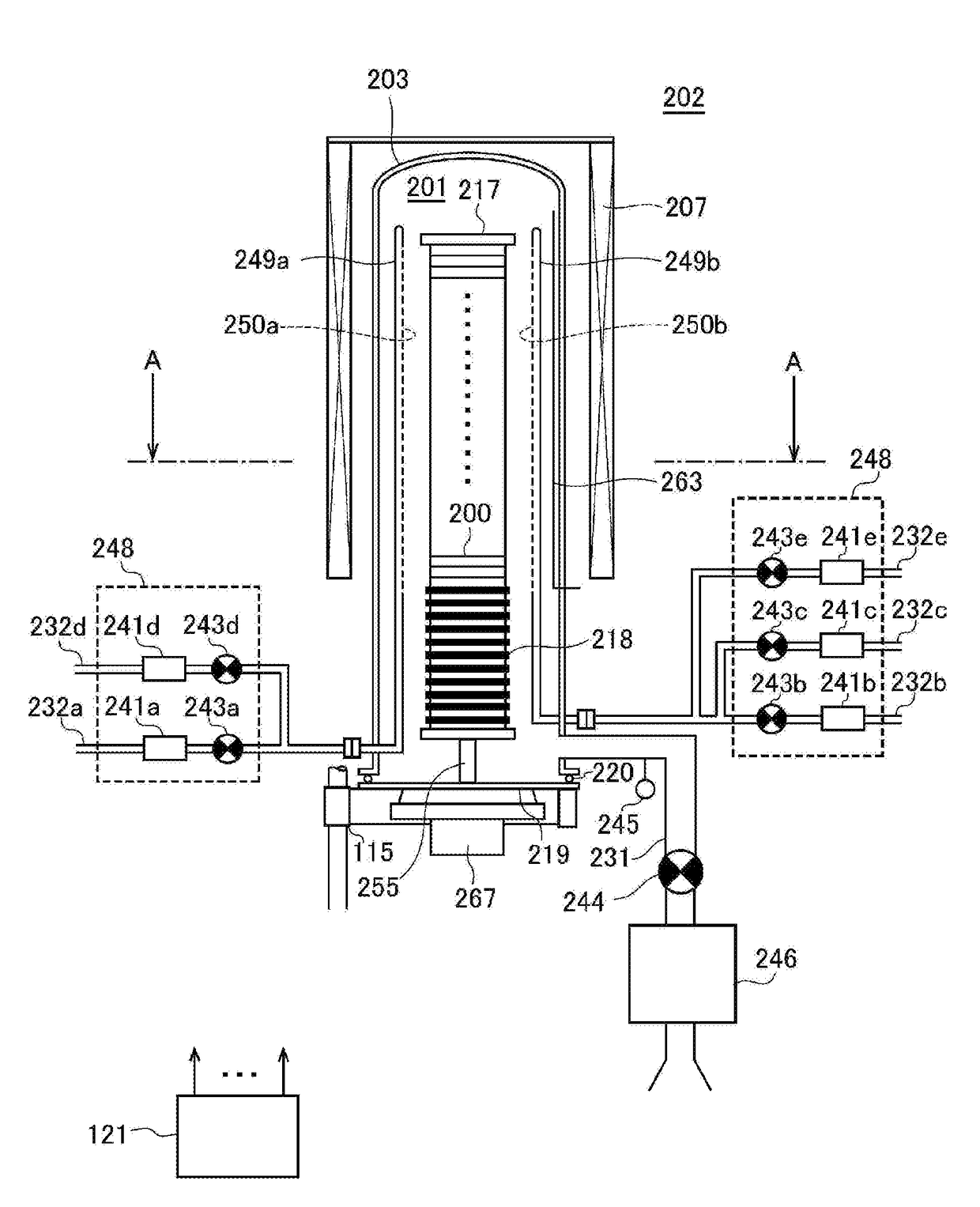

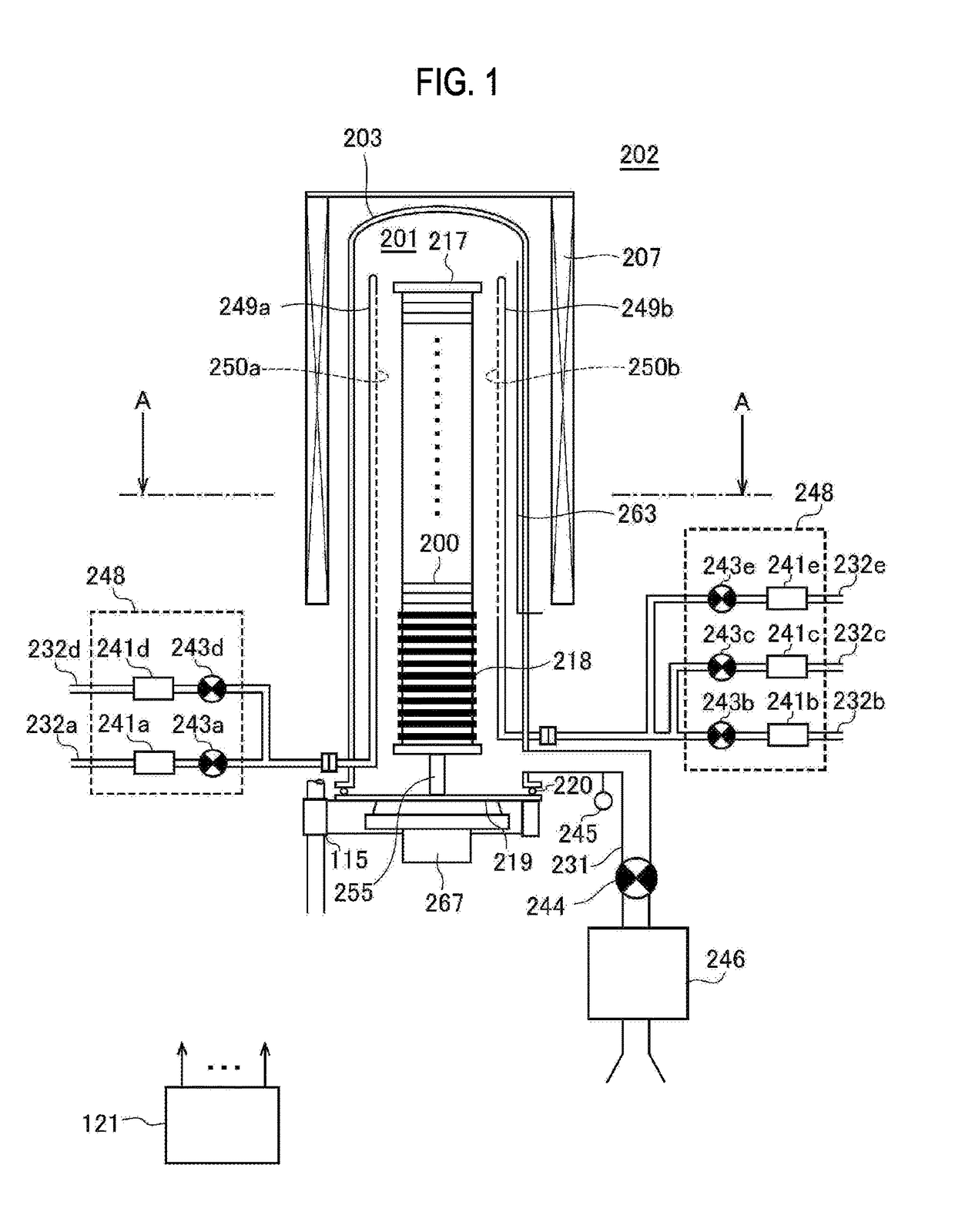

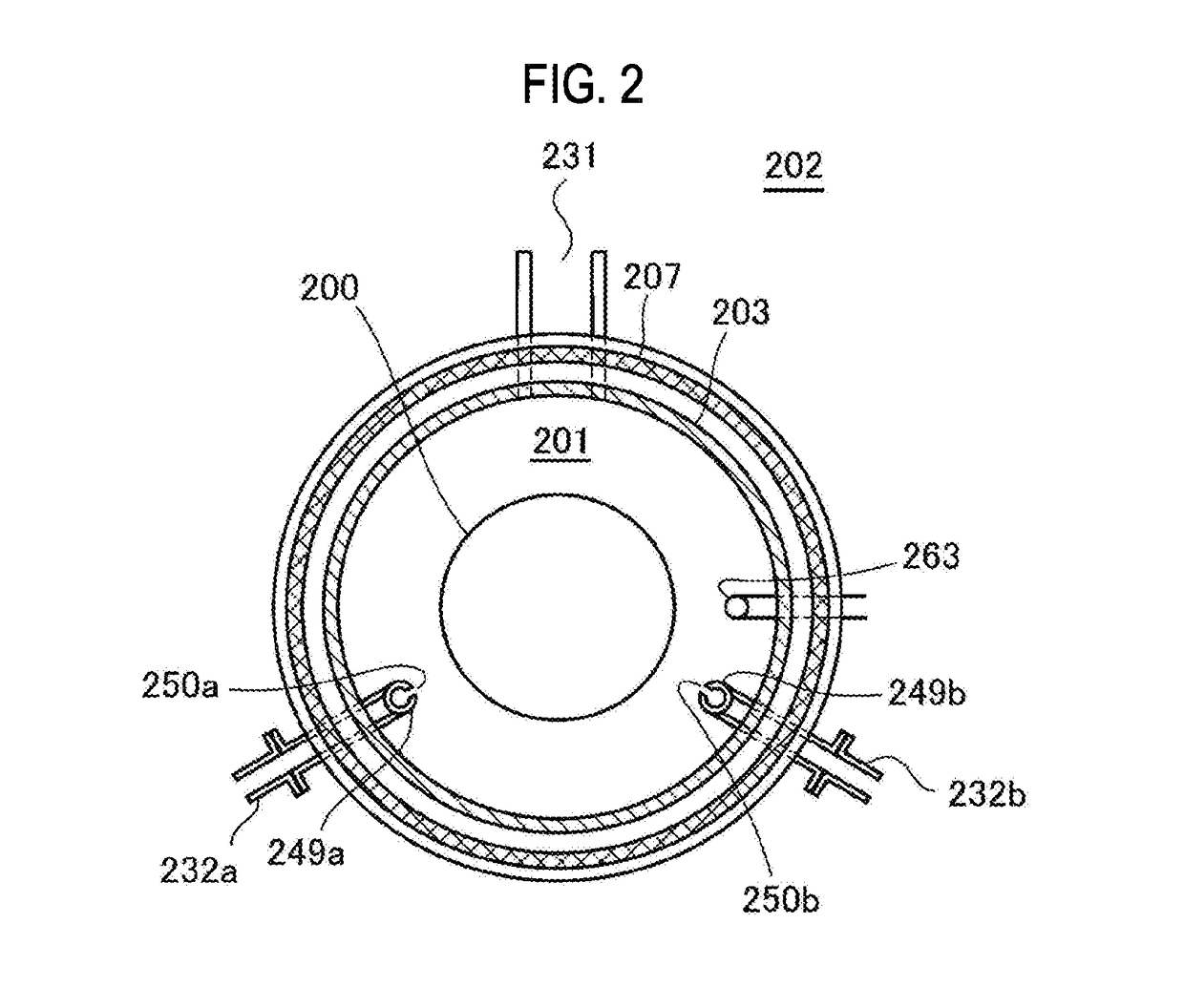

Film deposition apparatus and film deposition method

ActiveUS8506713B2Efficient solutionImprove uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

Owner:TOKYO ELECTRON LTD

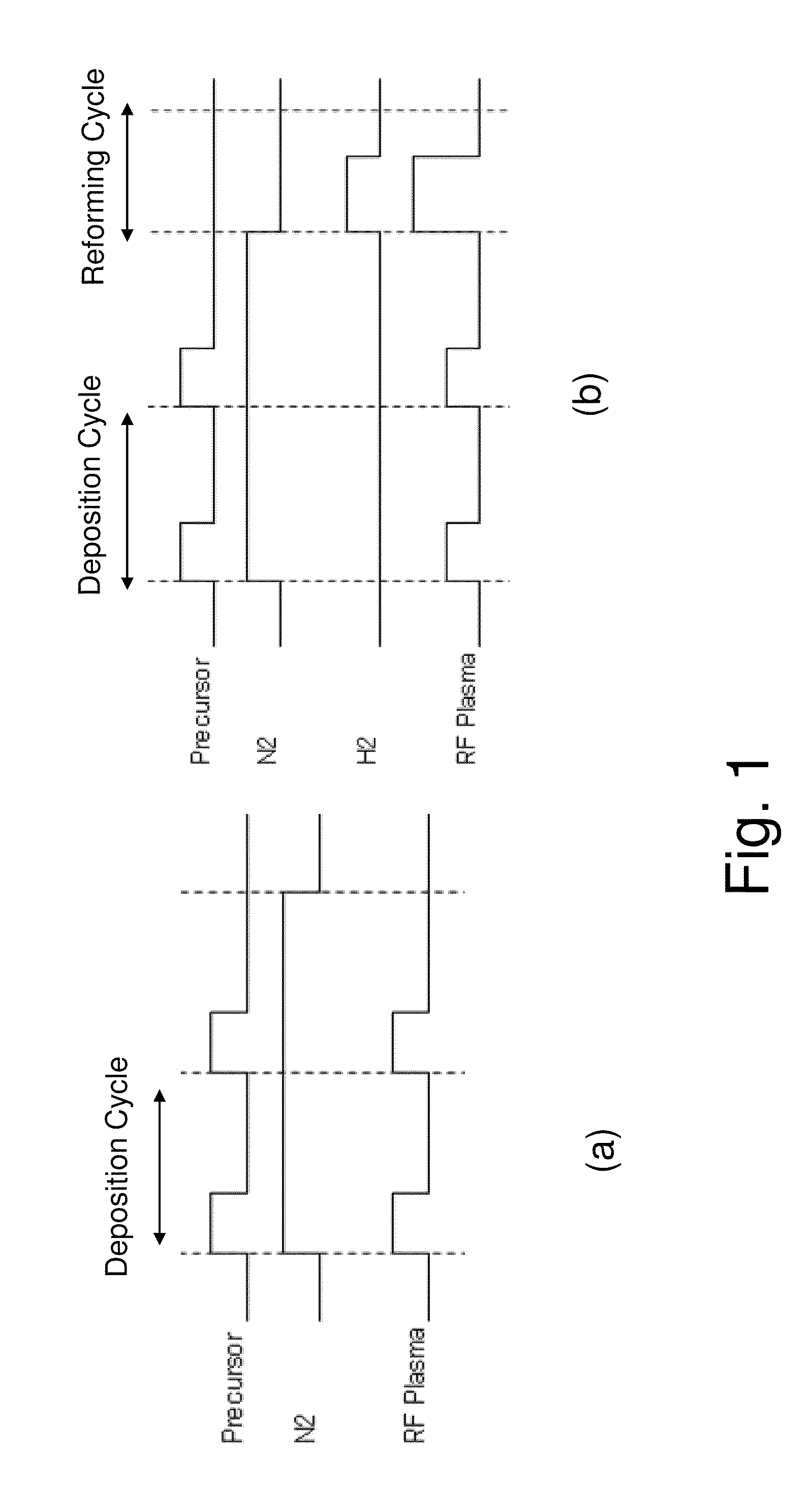

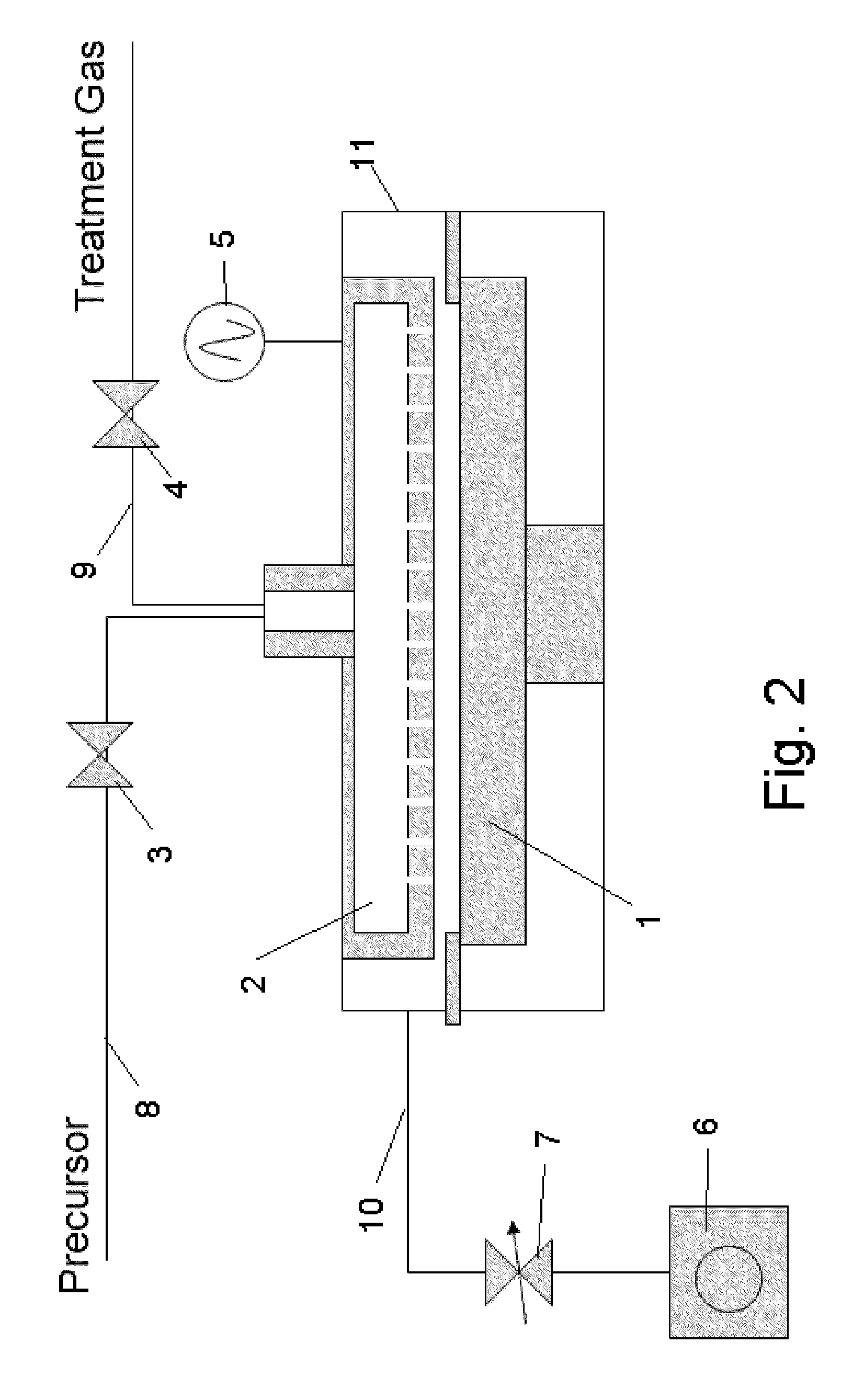

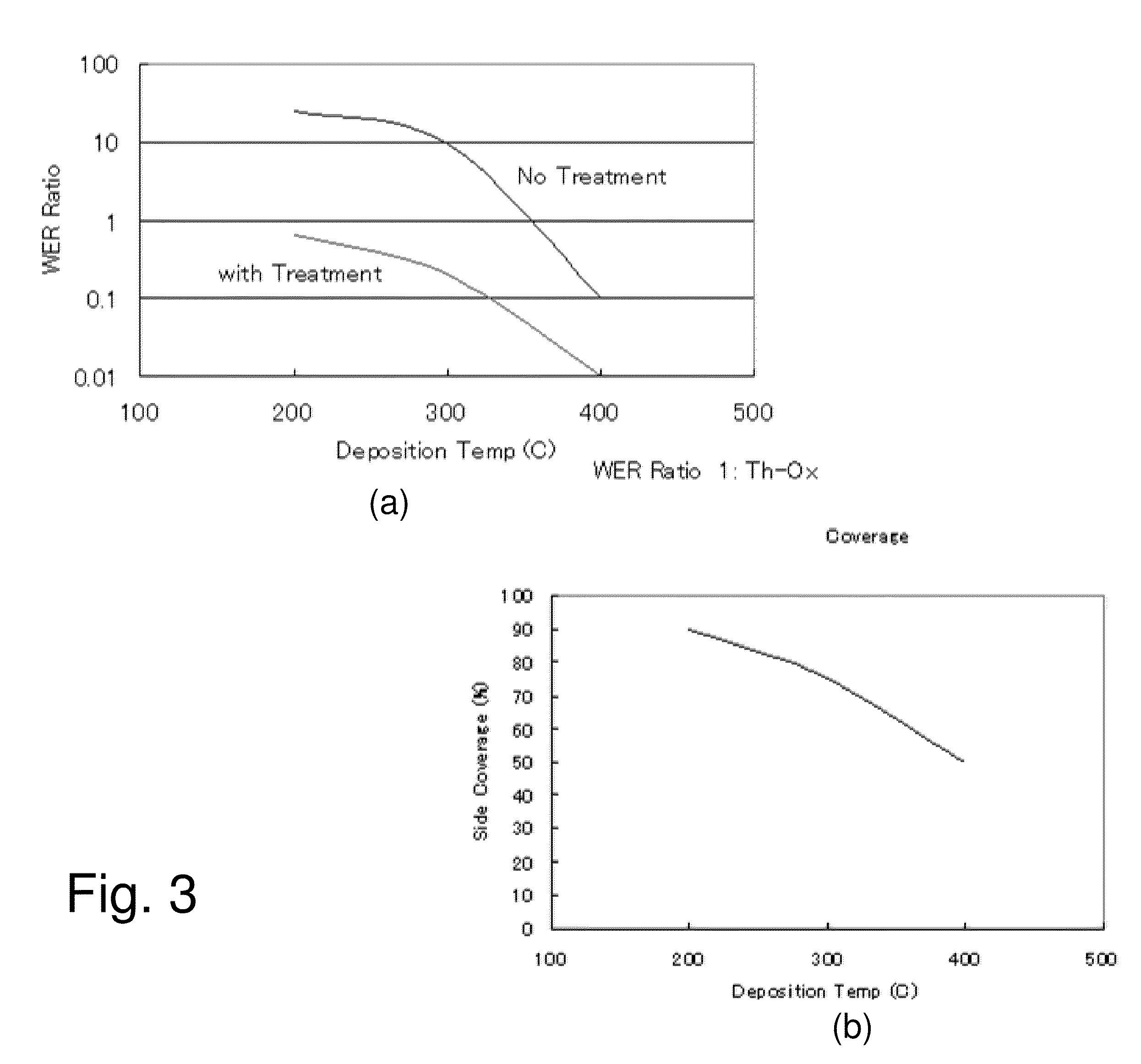

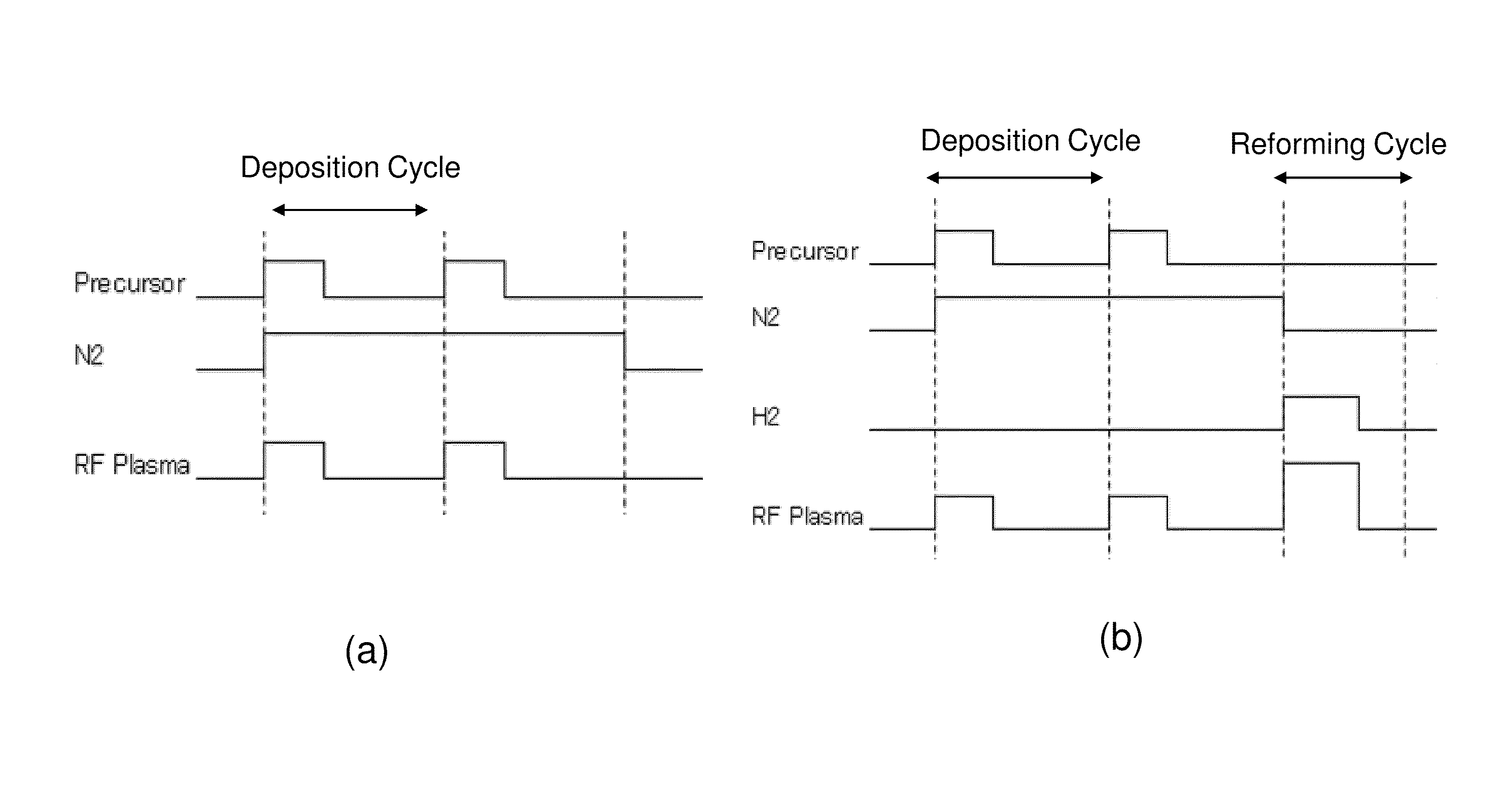

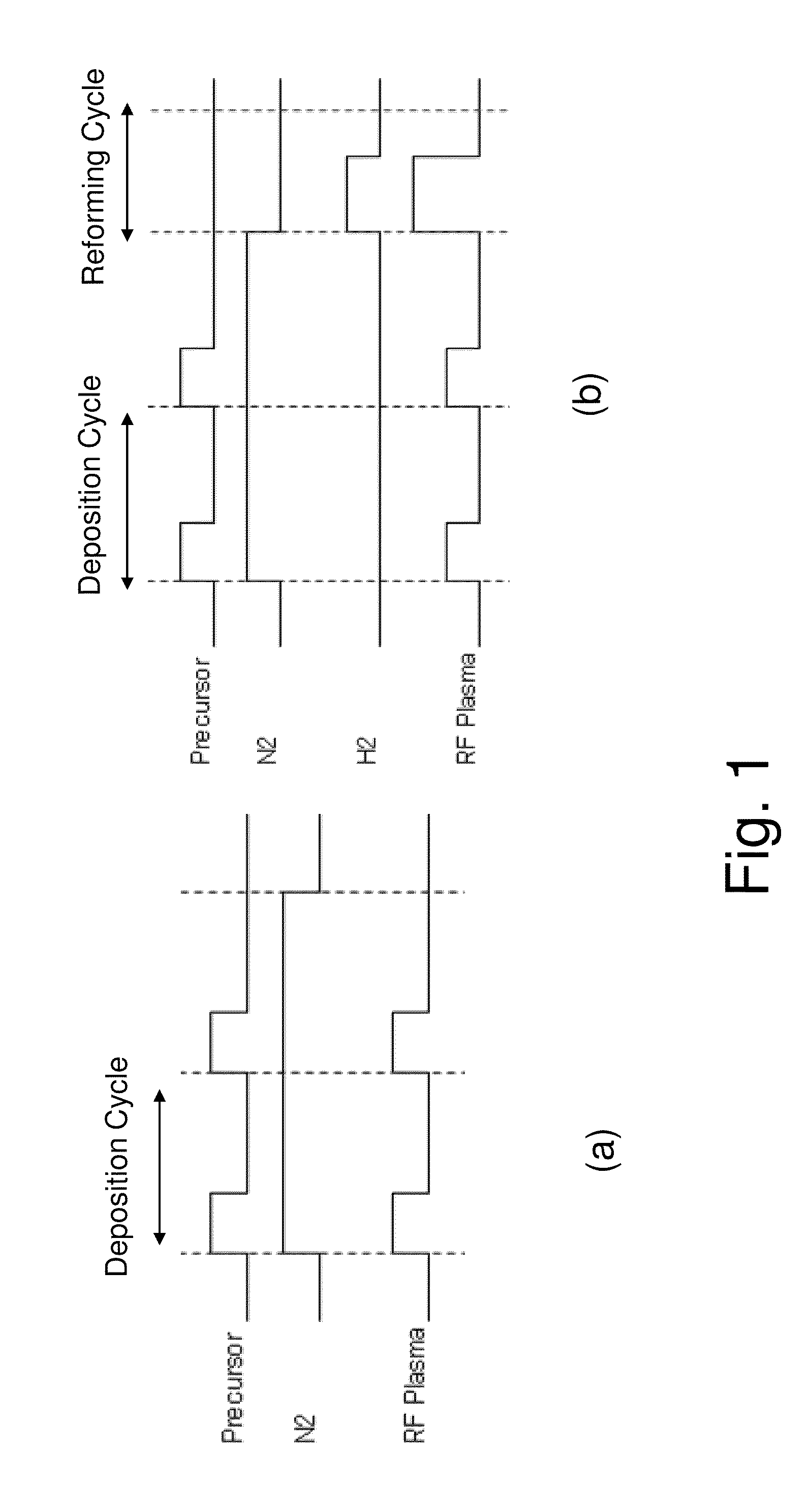

Method of Forming Insulation Film Using Plasma Treatment Cycles

ActiveUS20100124618A1Good coverageGood film qualityPretreated surfacesChemical vapor deposition coatingPlasma treatmentEngineering

A film forming cycle based on pulse CVD or ALD is repeated multiple times to form a single layer of insulation film, while a reforming cycle is implemented in the aforementioned process, either once or multiple times per each film forming cycle, by treating the surface of formed film using a treating gas that has been activated by a plasma.

Owner:ASM JAPAN

Method of forming insulation film using plasma treatment cycles

ActiveUS8647722B2Improve film qualityIncrease coverageChemical vapor deposition coatingPlasma techniqueEngineeringMono layer

A film forming cycle based on pulse CVD or ALD is repeated multiple times to form a single layer of insulation film, while a reforming cycle is implemented in the aforementioned process, either once or multiple times per each film forming cycle, by treating the surface of formed film using a treating gas that has been activated by a plasma.

Owner:ASM JAPAN

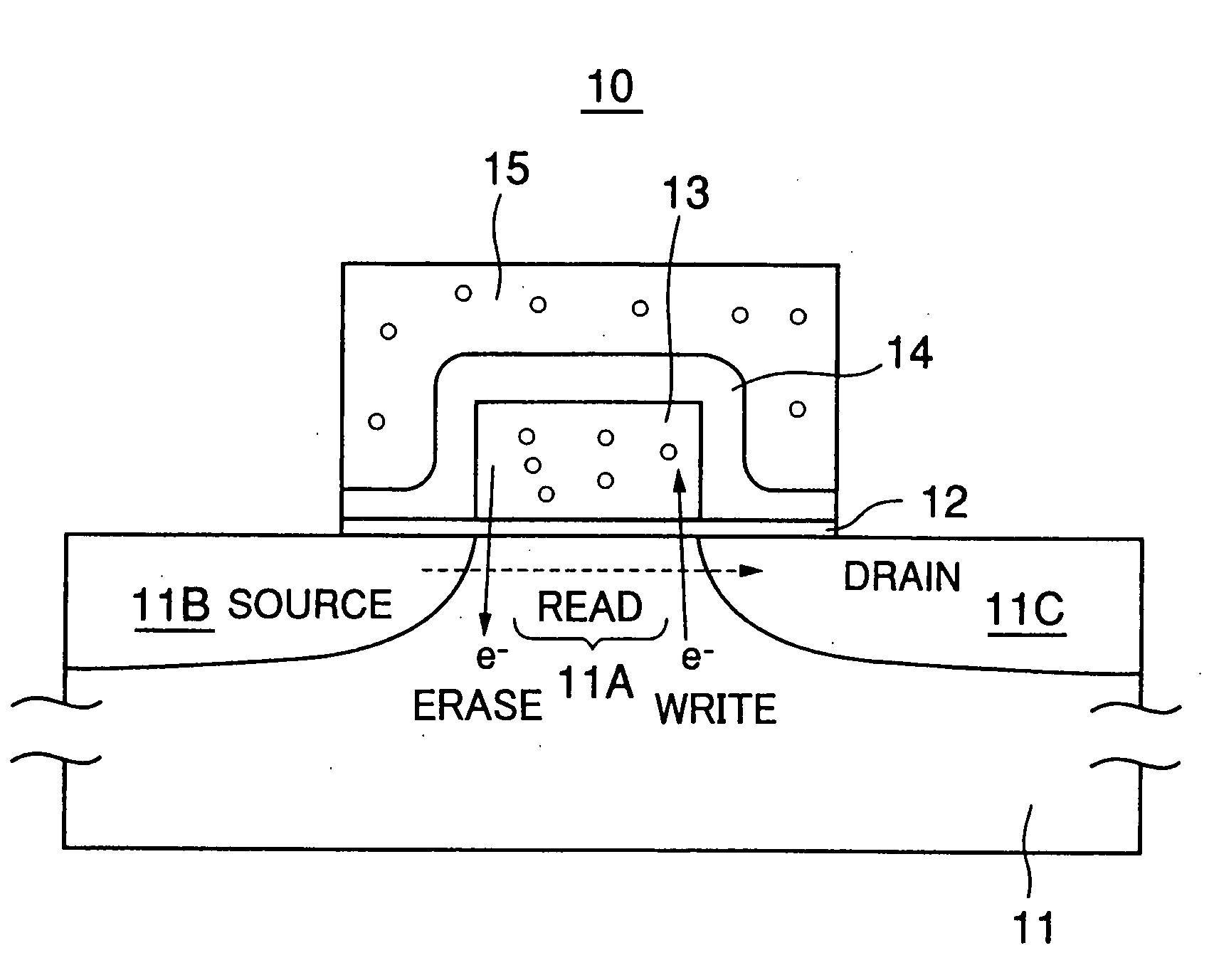

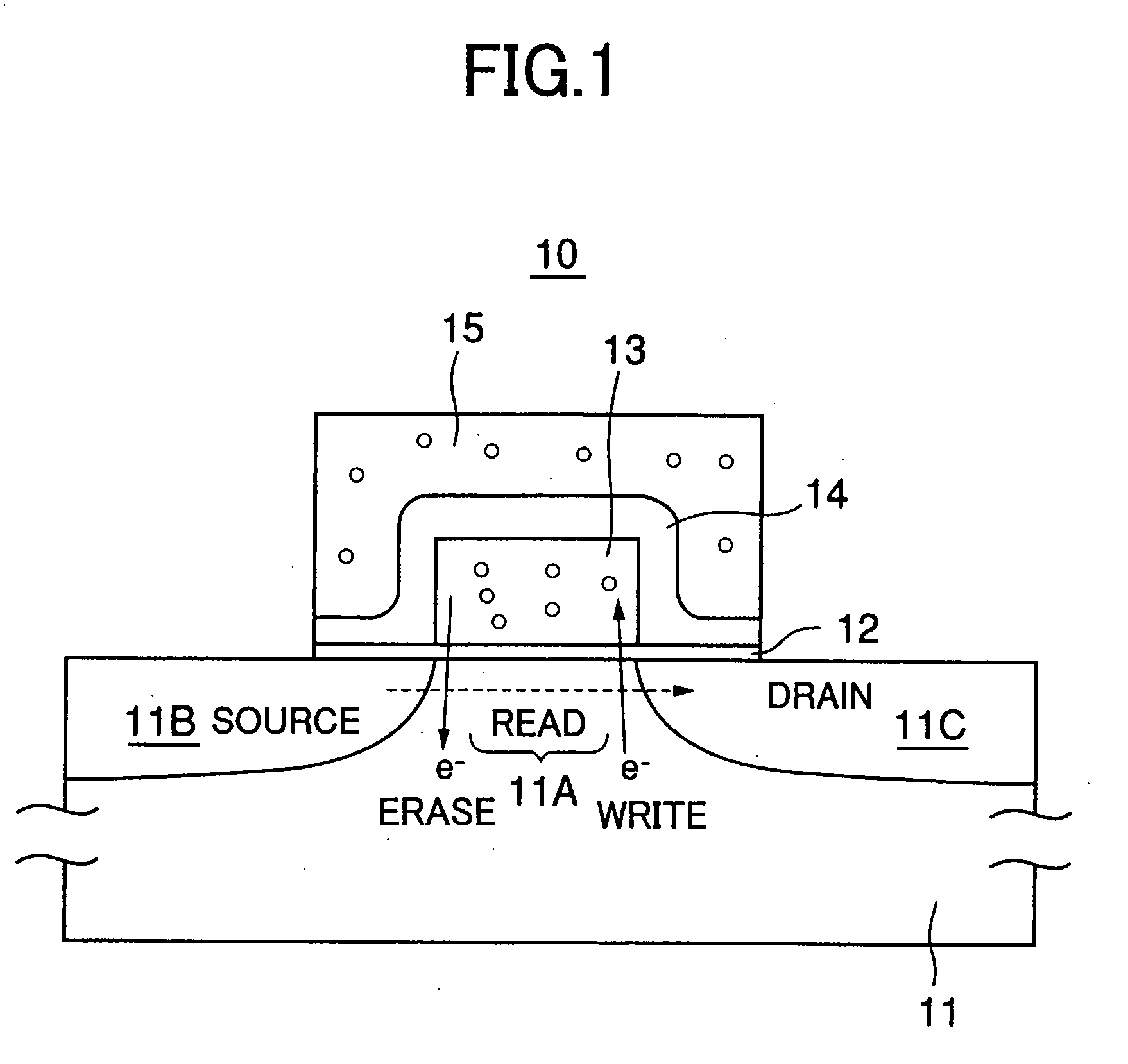

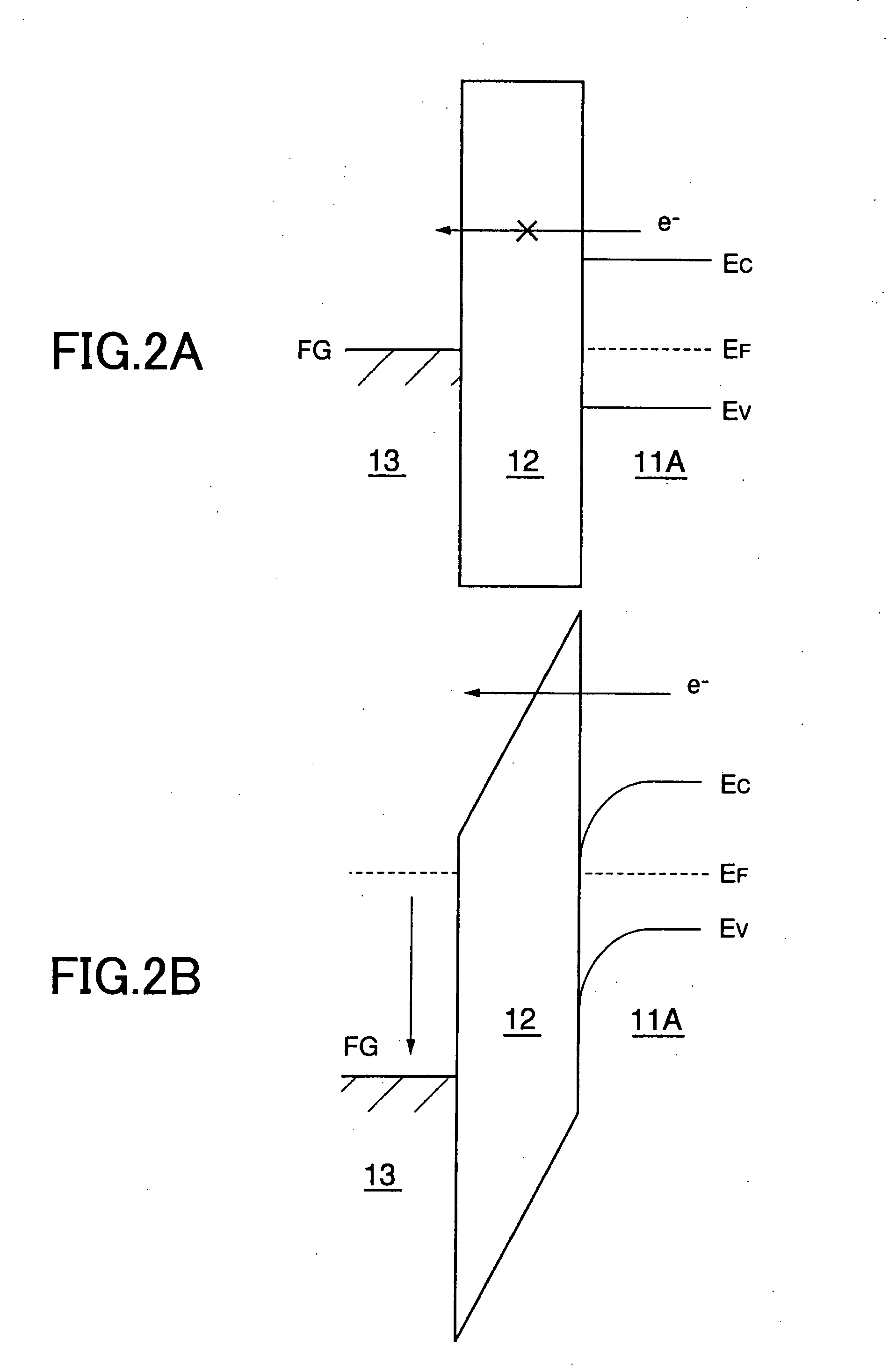

Dielectric film and formation method thereof, semiconductor device, non-volatile semiconductor memory device, and fabrication method for a semiconductor device

InactiveUS20080277715A1Improve wiring speedLow working voltageTransistorSemiconductor/solid-state device detailsDielectricHydrogen

Owner:FOUND FOR ADVANCEMENT OF INT SCI

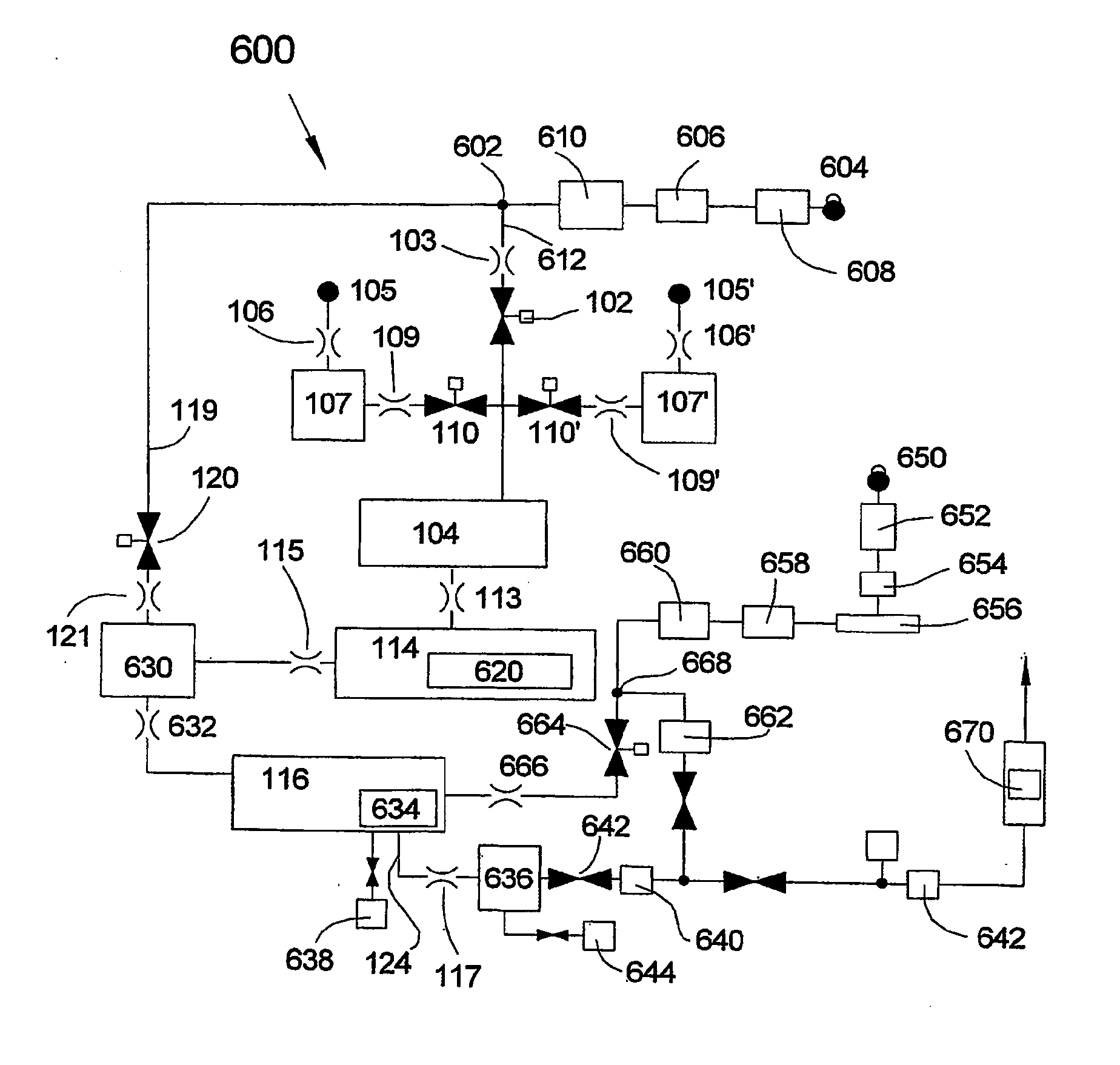

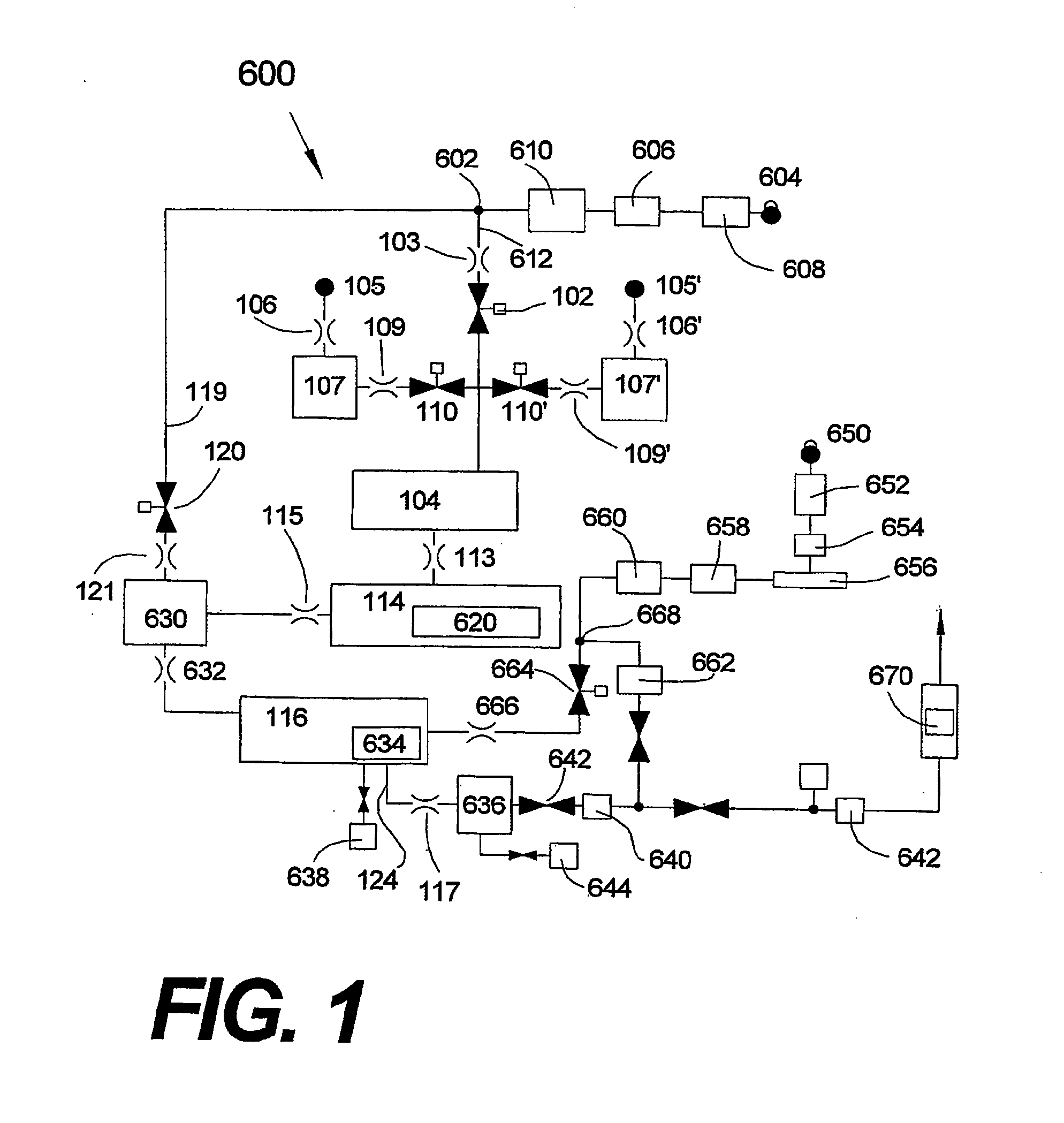

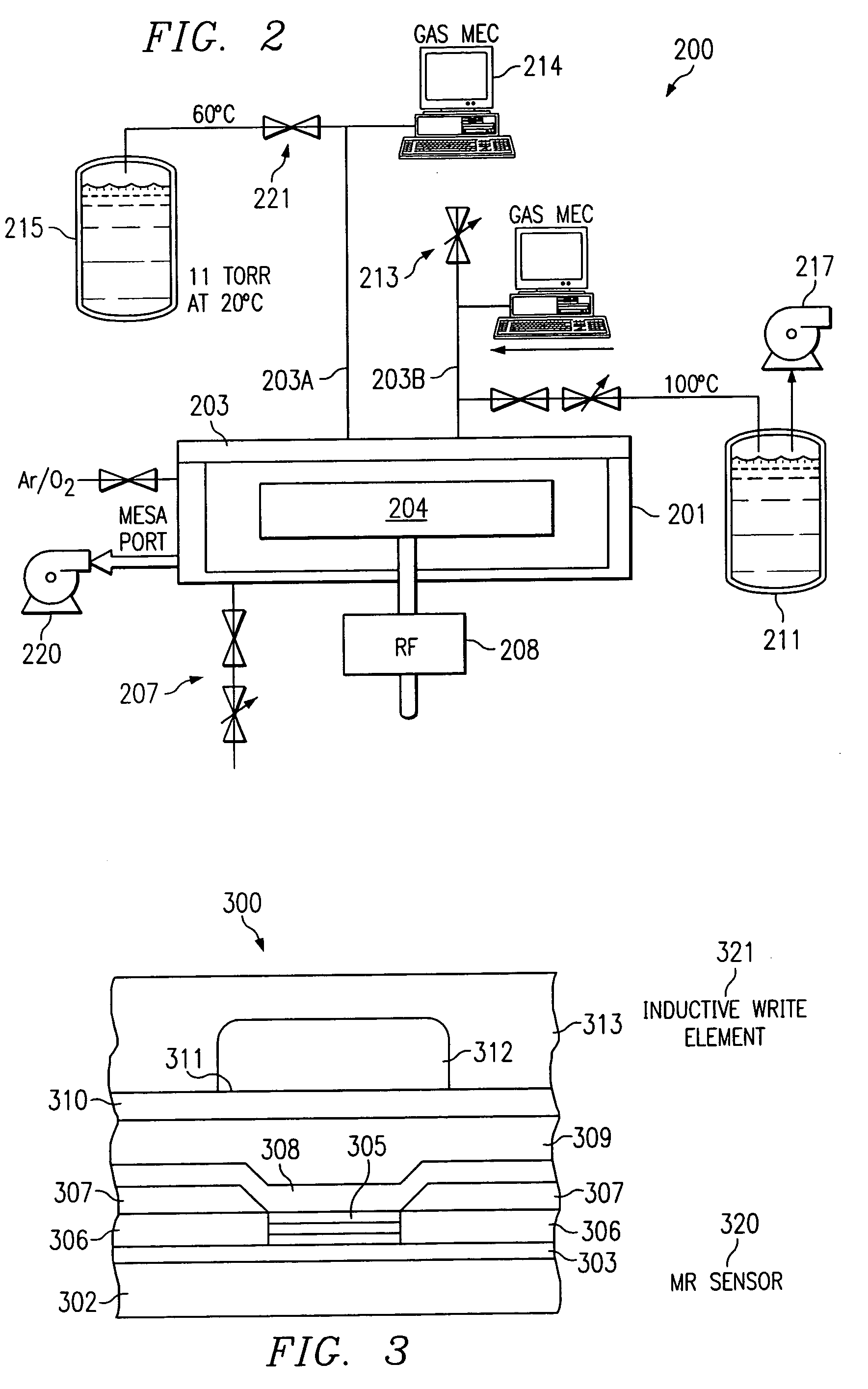

Ald Apparatus and Method

InactiveUS20070269983A1Enhanced advantageMaterial utilization efficiency is increasedLiquid surface applicatorsBy zone-melting liquidsCompound (substance)Engineering

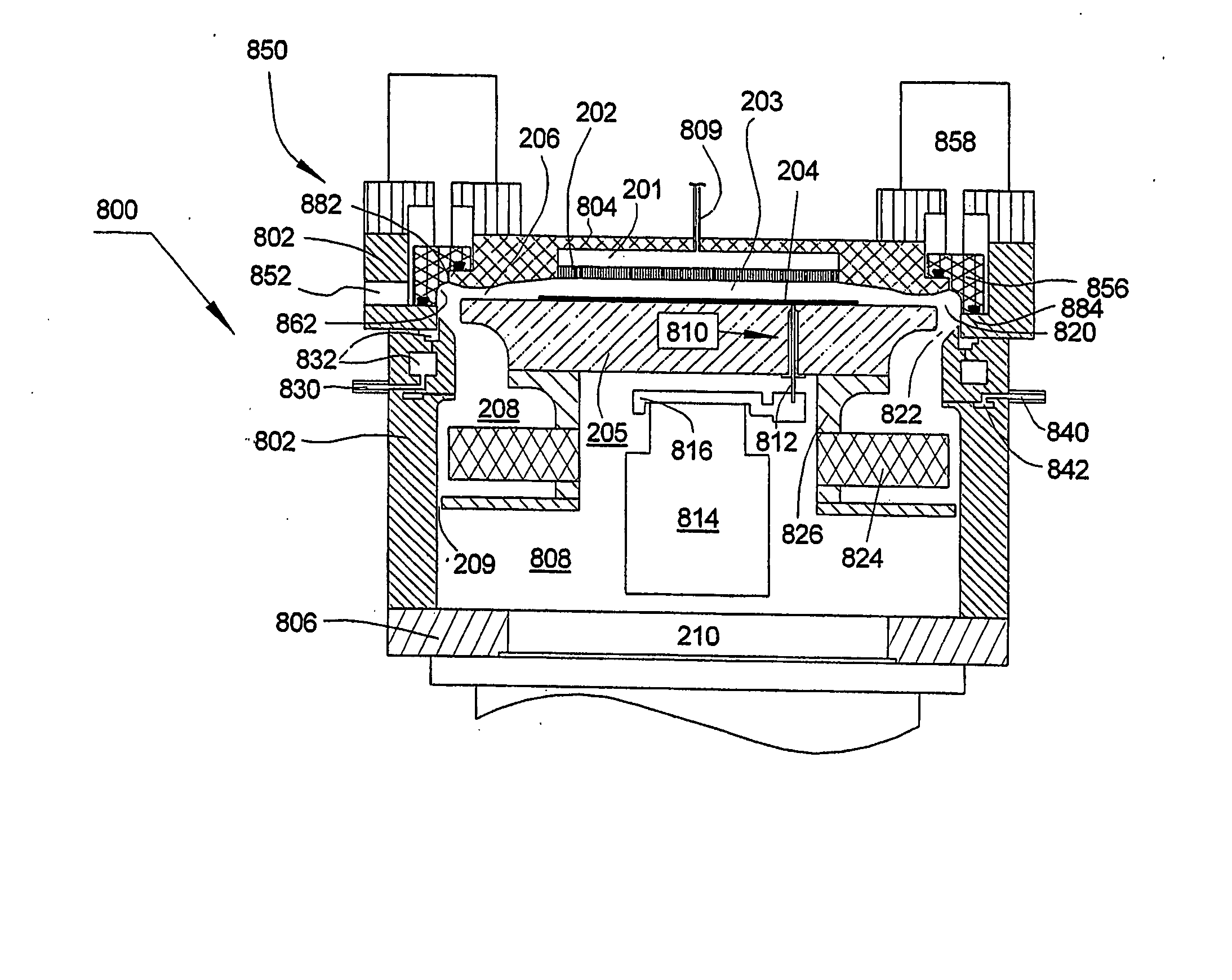

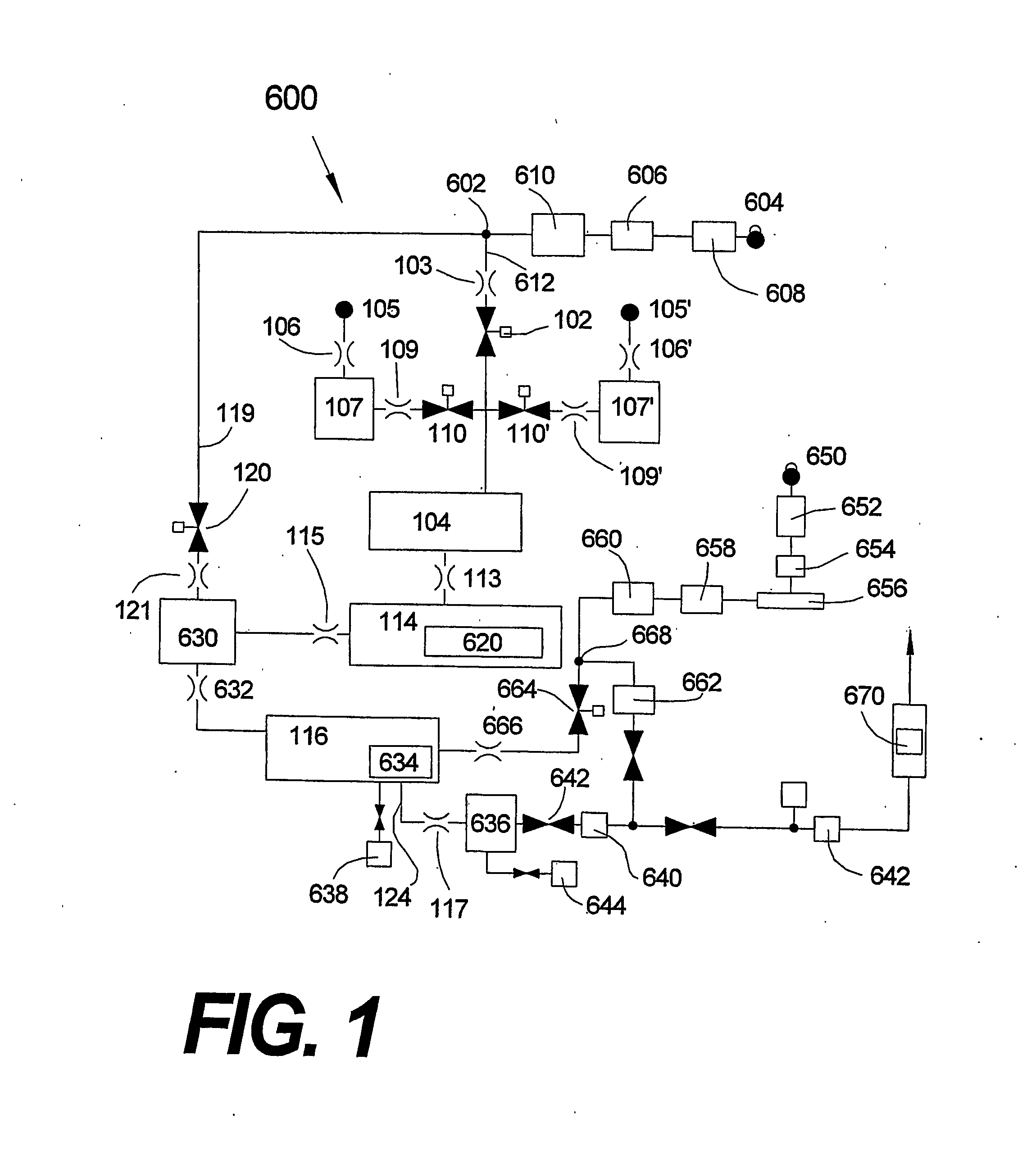

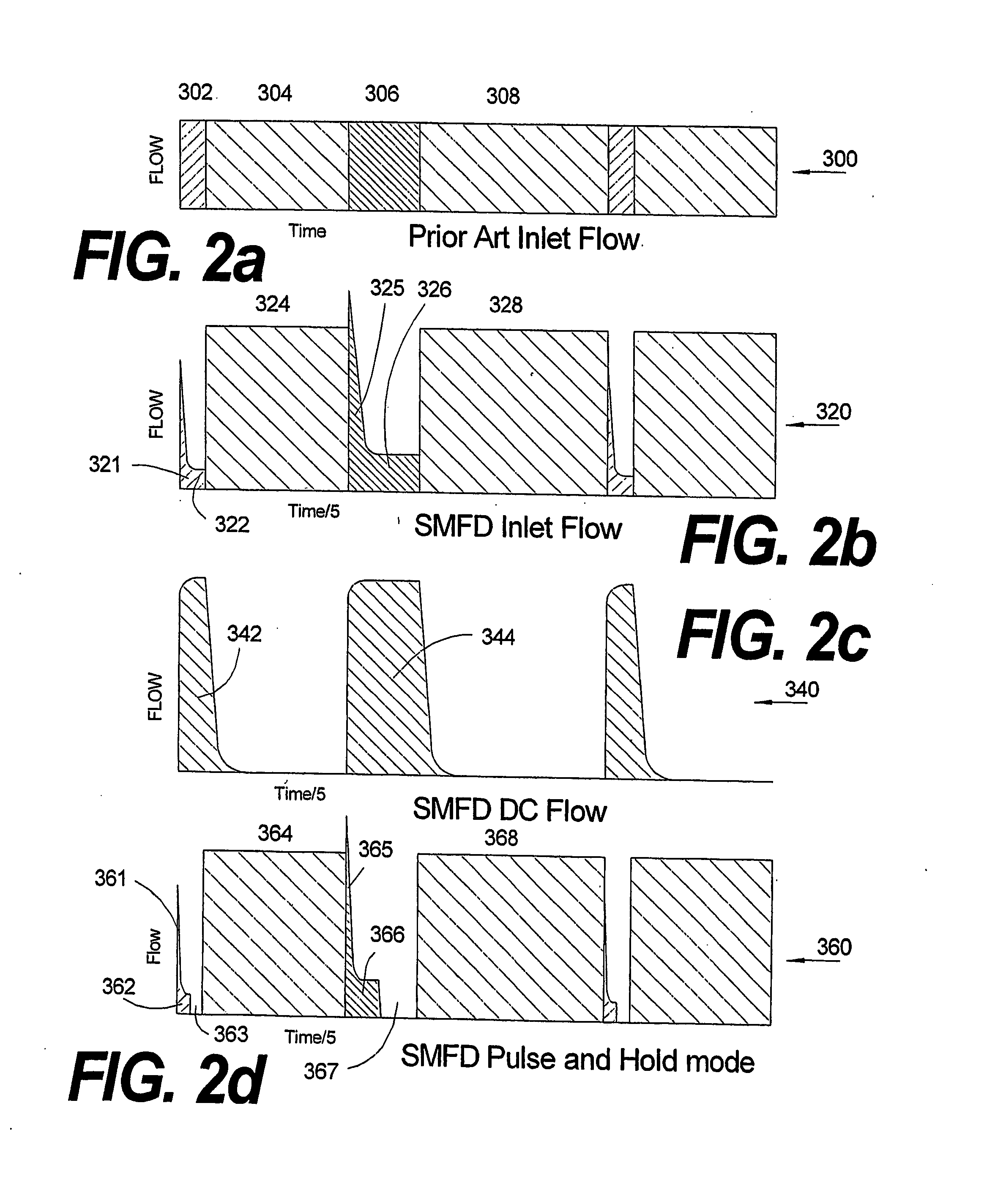

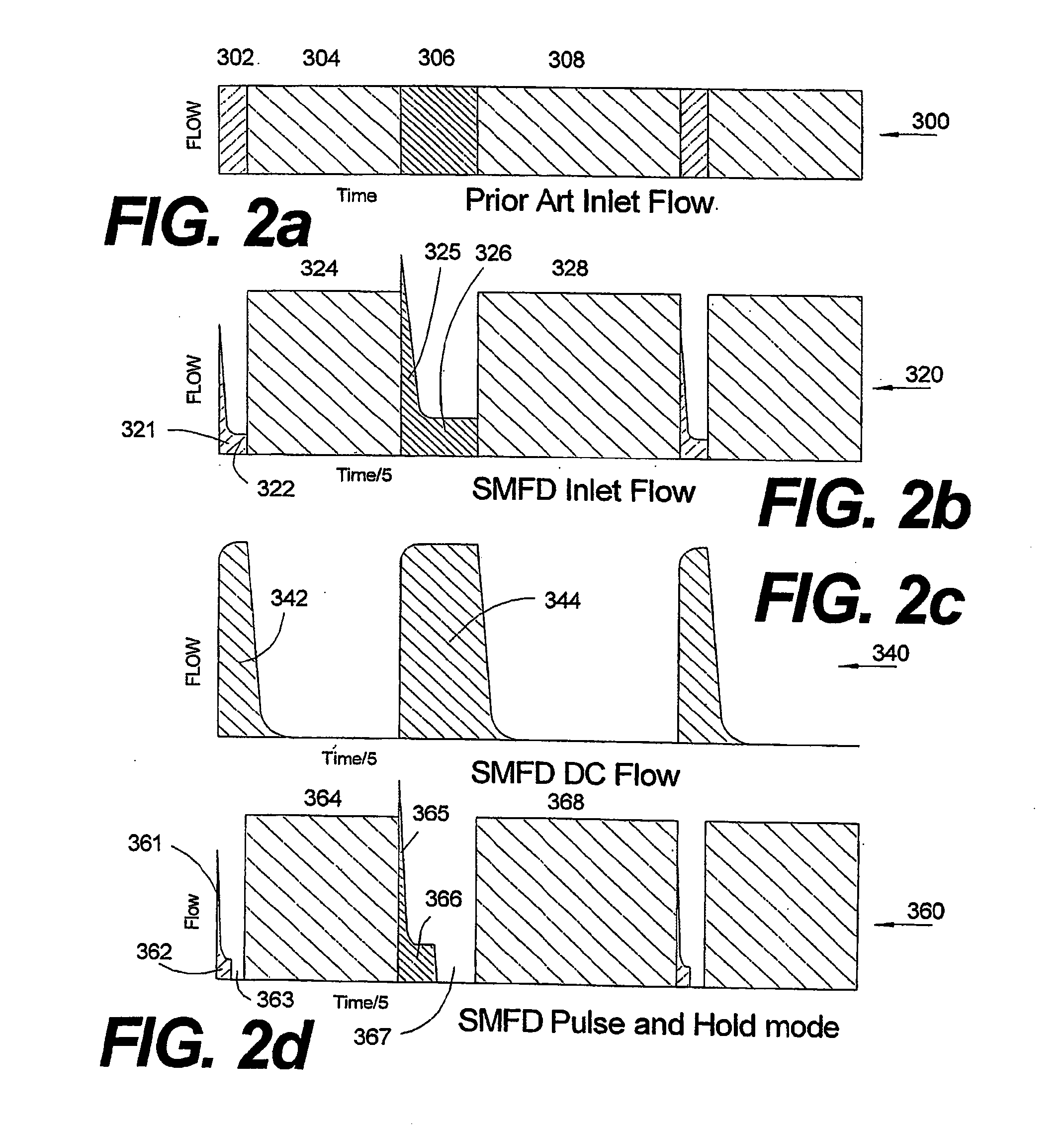

Improved apparatus and method for SMFD ALD include a method designed to enhance chemical utilization as well as an apparatus that implements lower conductance out of SMFD-ALD process chamber while maintaining full compatibility with standard wafer transport. Improved SMFD source apparatuses (700, 700′, 700″) and methods from volatile and non-volatile liquid and solid precursors are disclosed, e.g., a method for substantially controlling the vapor pressure of a chemical source (722) within a source space comprising: sensing the accumulation of the chemical on a sensing surface (711); and controlling the temperature of the chemical source depending on said sensed accumulation.

Owner:SUNDEW TECH

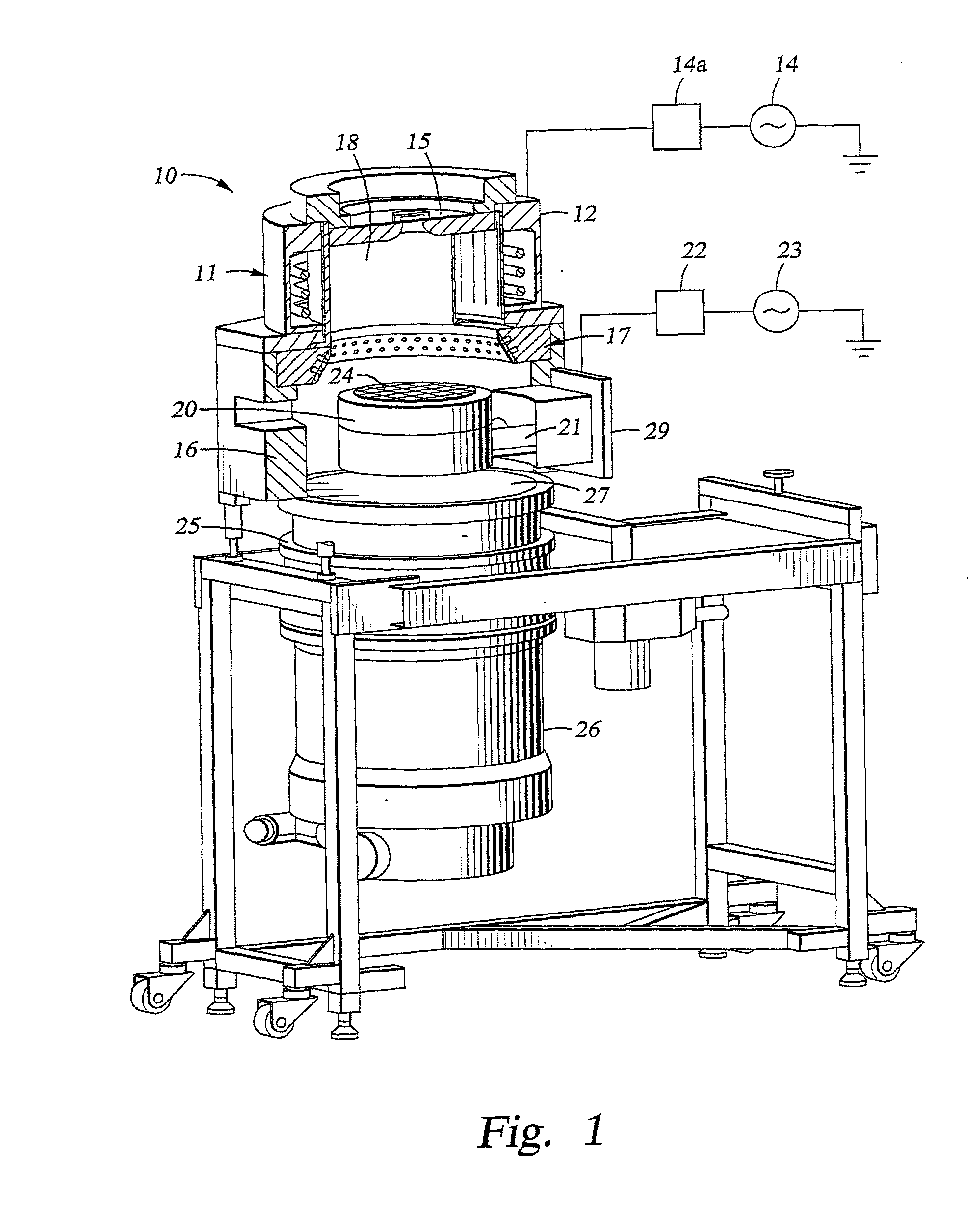

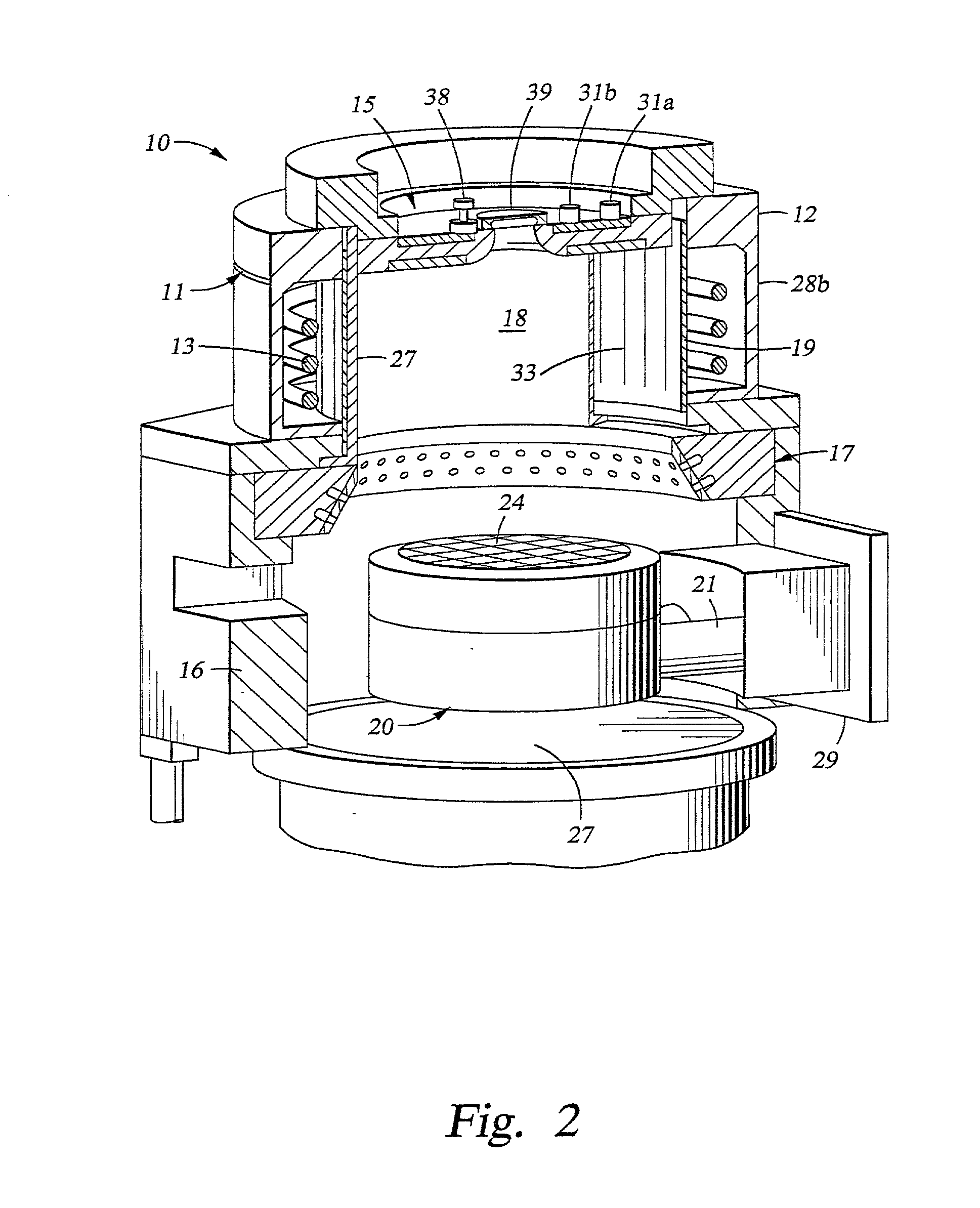

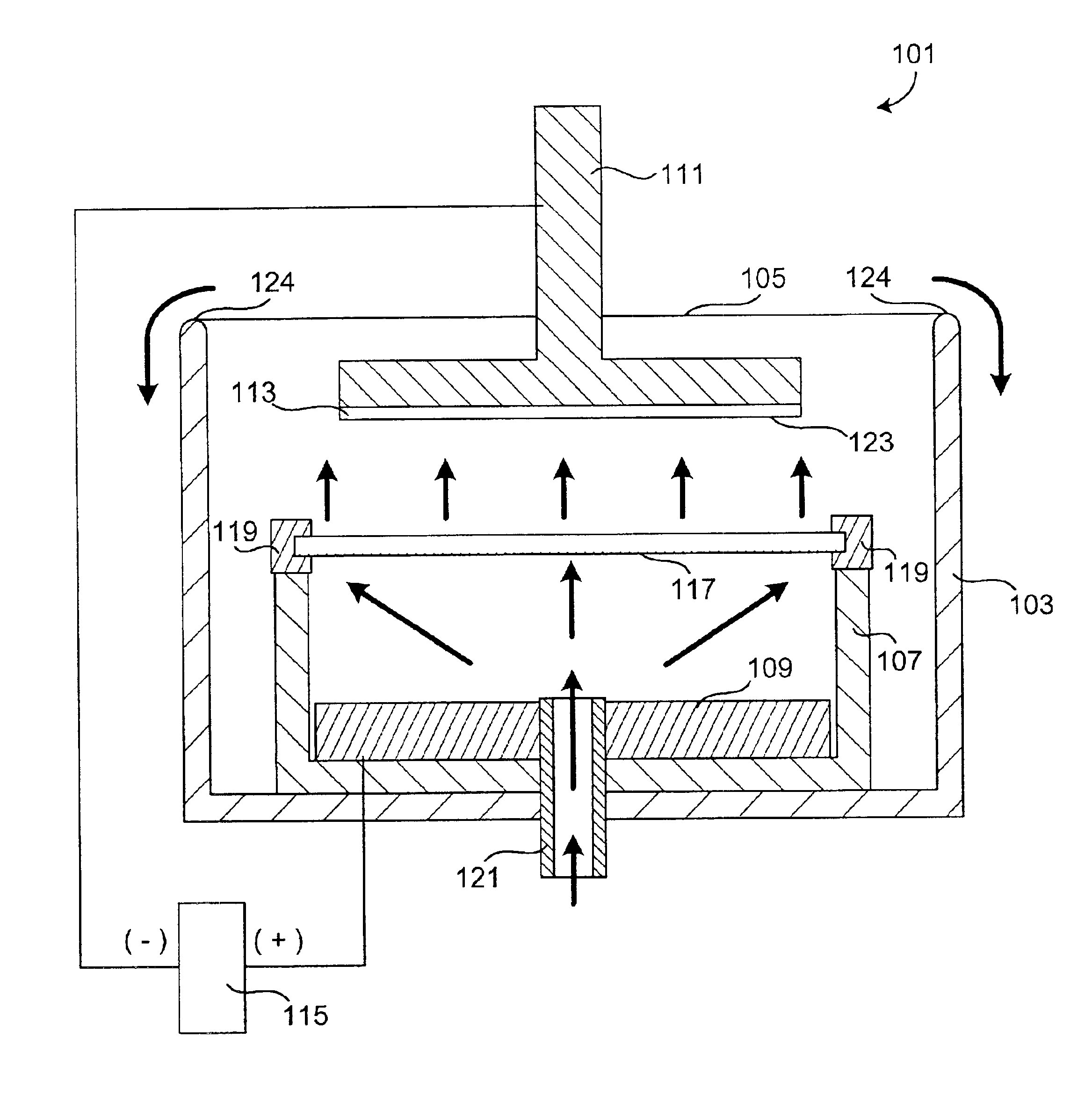

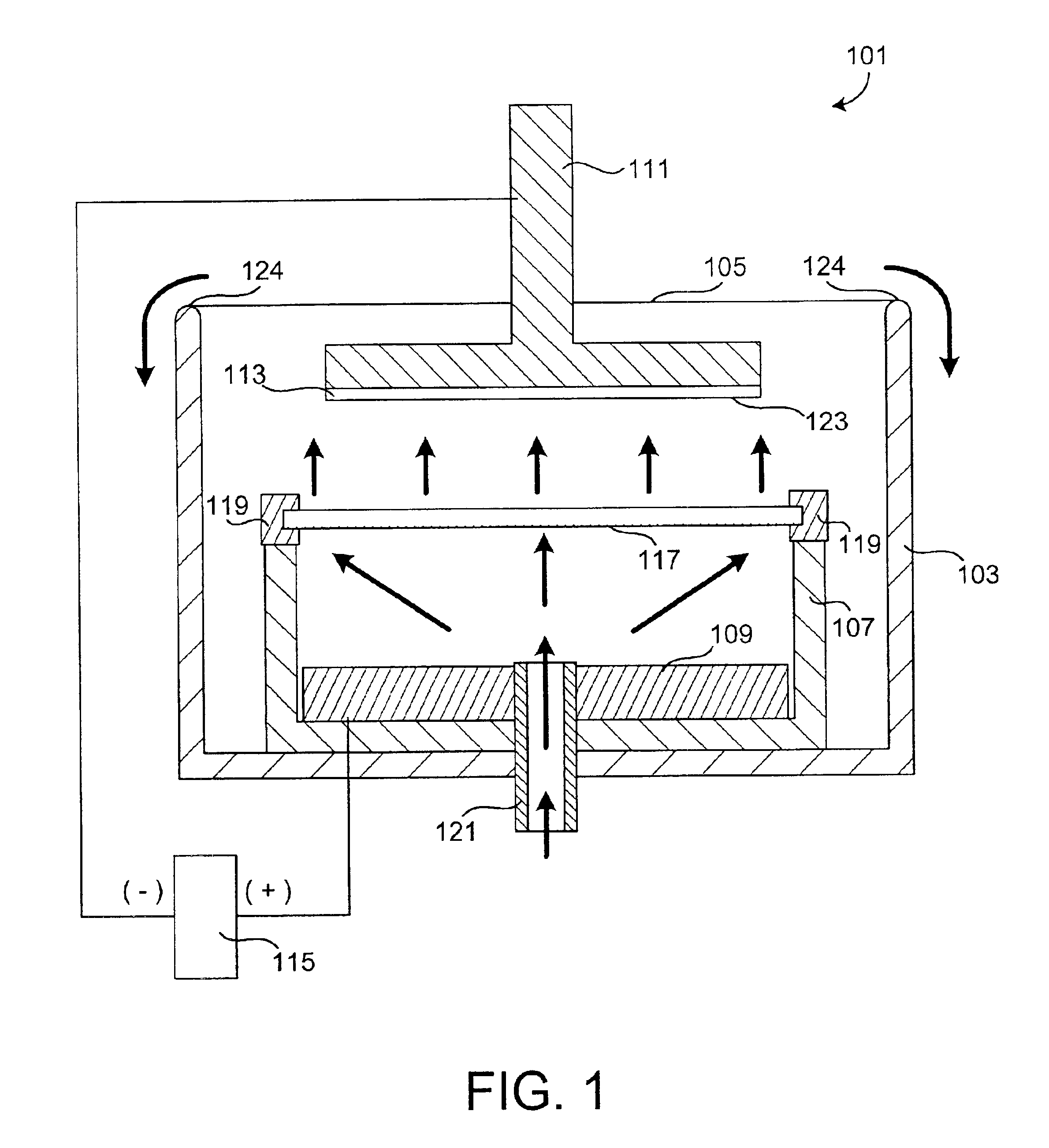

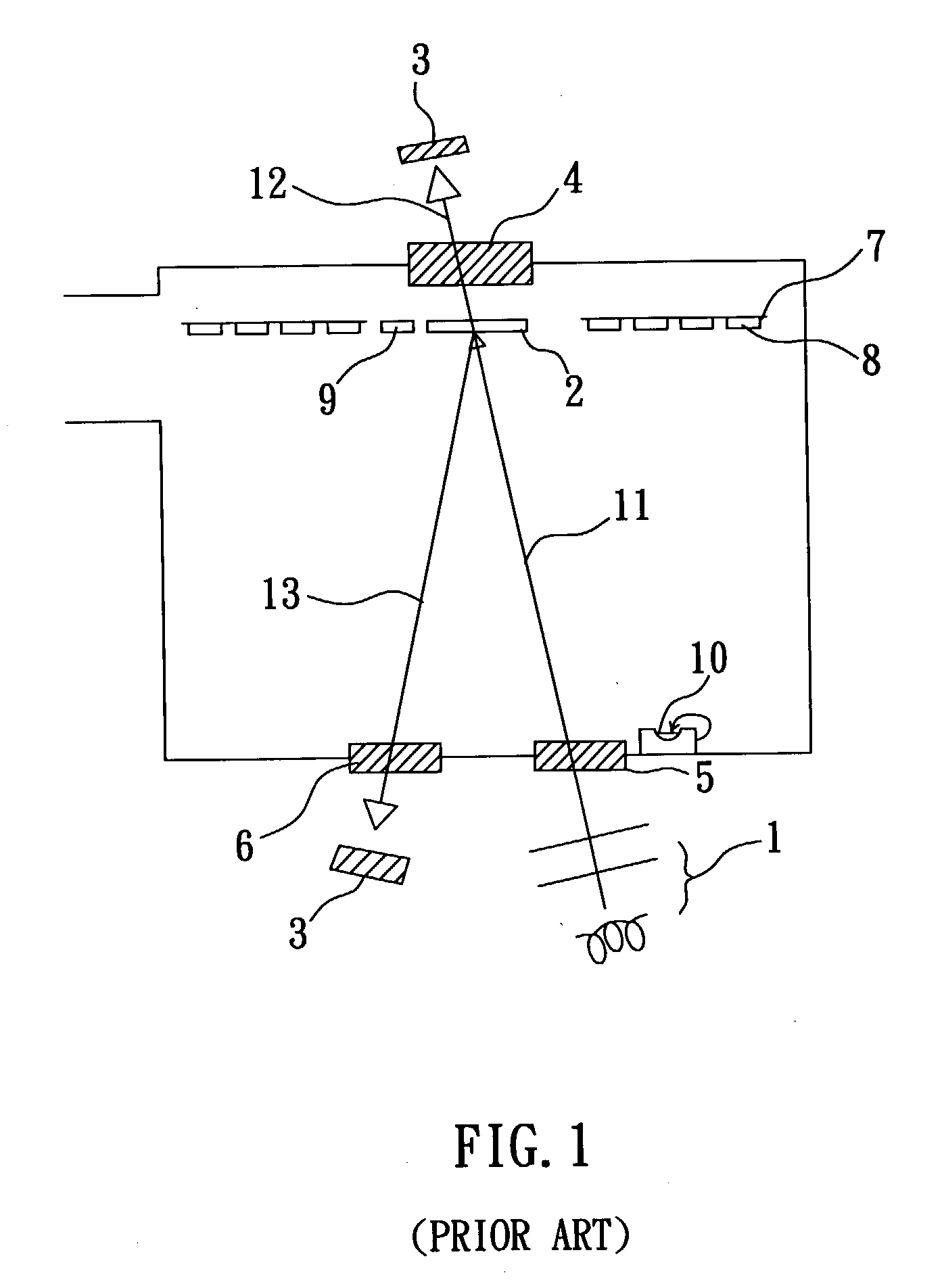

Plasma enhanced chemical processing reactor and method

InactiveUS20020078893A1Improve film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingChemical treatmentReactive gas

A plasma enhanced chemical processing reactor and method. The reactor includes a plasma chamber including a first gas injection manifold and a source of electromagnetic energy. The plasma chamber is in communication with a process chamber which includes a wafer support and a second gas manifold. The plasma generated in the plasma chamber extends into the process chamber and interacts with the reactive gases to deposit a layer of material on the wafer. The reactor also includes a vacuum system for exhausting the reactor. The method includes the steps of generating a plasma within the plasma chamber, introducing at least one gaseous chemical into the process chamber proximate to the wafer support and applying r.f. gradient to induce diffusion of the plasma to the area proximate the wafer support.

Owner:APPLIED MATERIALS INC

Low-Oxidation Plasma-Assisted Process

ActiveUS20150315704A1Improve film qualitySuppressing of layerElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringOxide

A method for forming an oxide film by plasma-assisted cyclic processing, includes: (i) supplying a precursor to a reaction space wherein a substrate is placed; (ii) applying a first RF power to the reaction space for a first period of time without supplying a precursor; and (iii) applying a second RF power to the reaction space for a second period of time without supplying the precursor, wherein the first RF power is lower than the second RF power, and / or the first period of time is shorter than the second period of time.

Owner:ASM IP HLDG BV

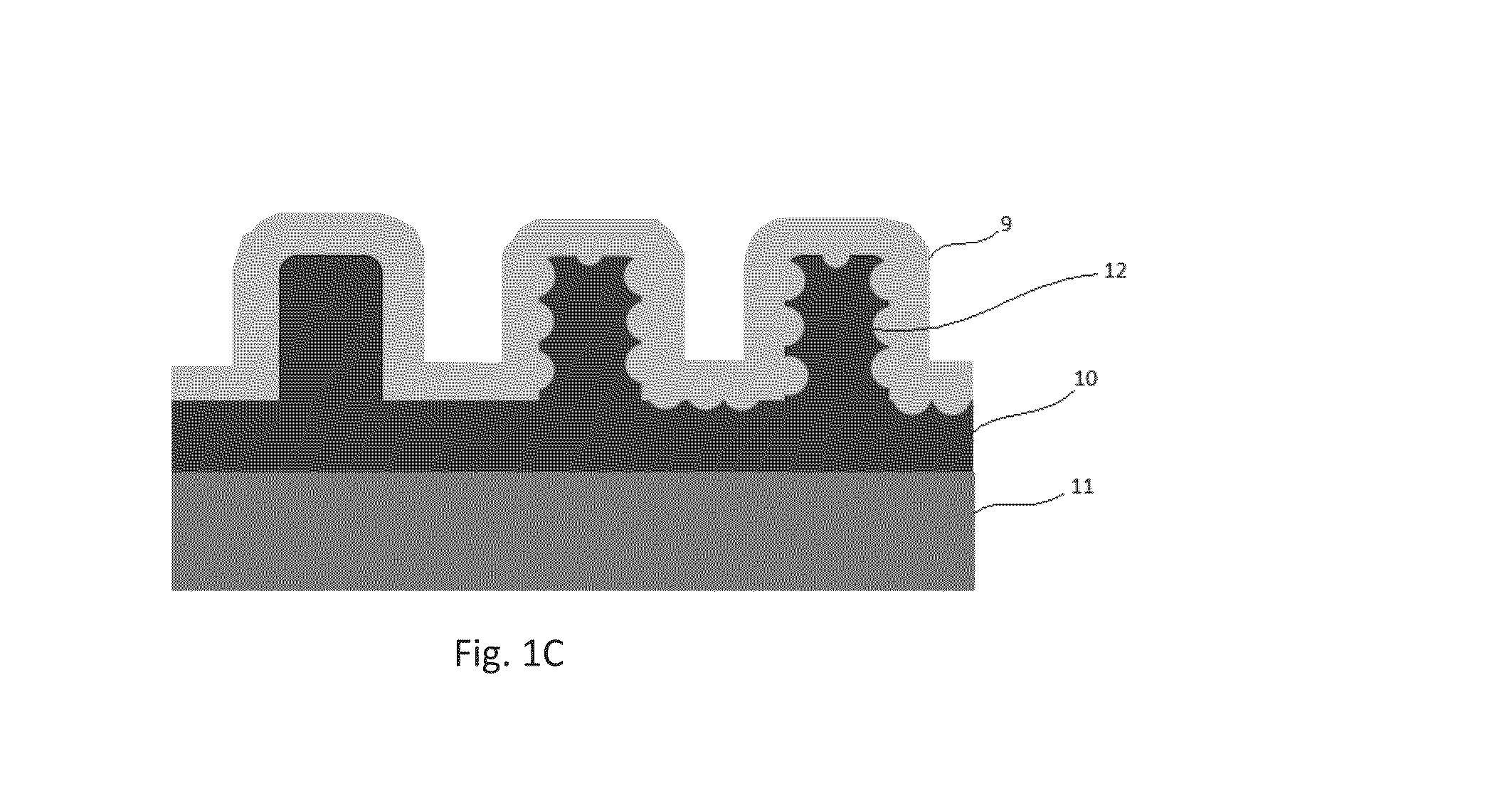

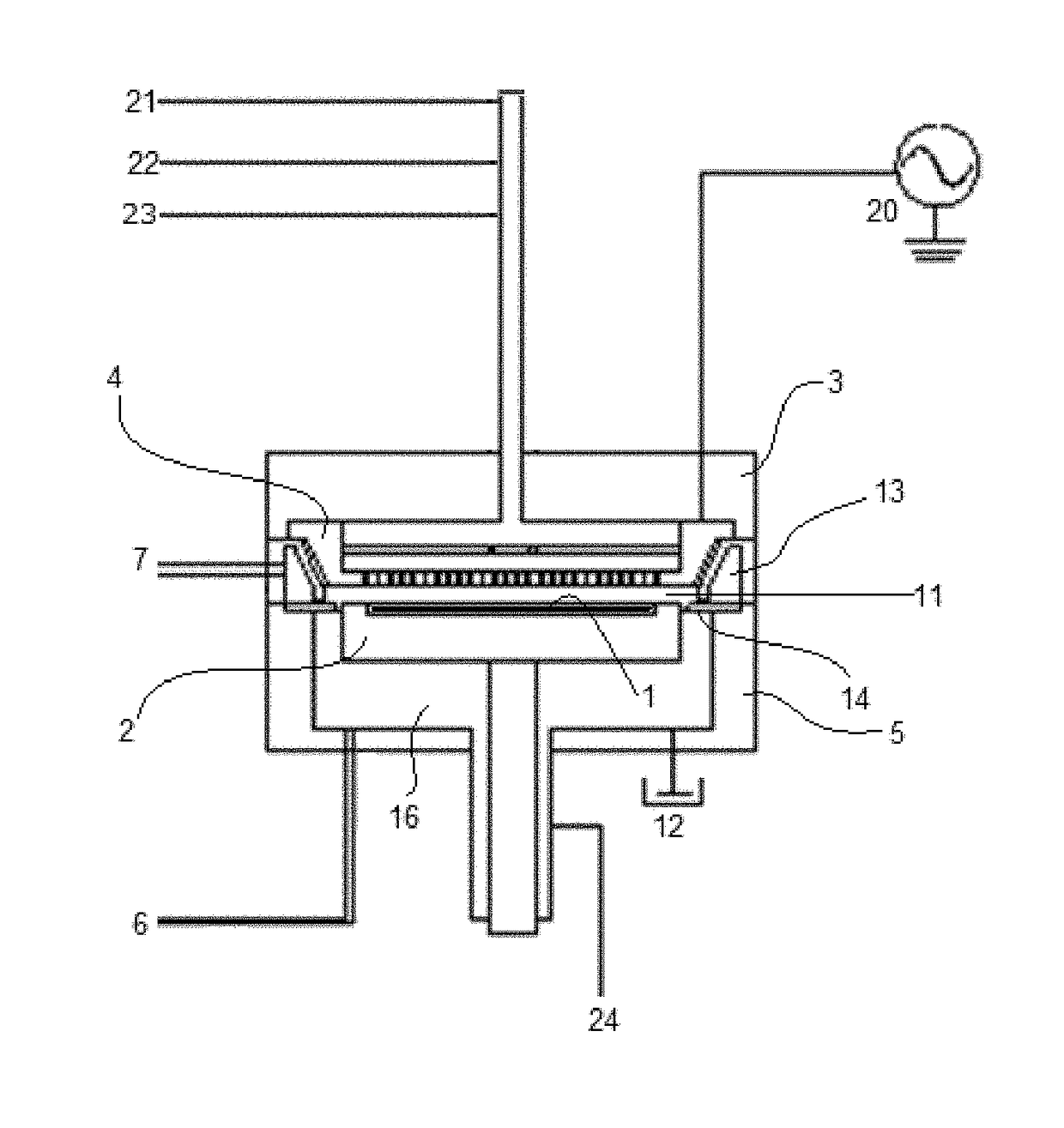

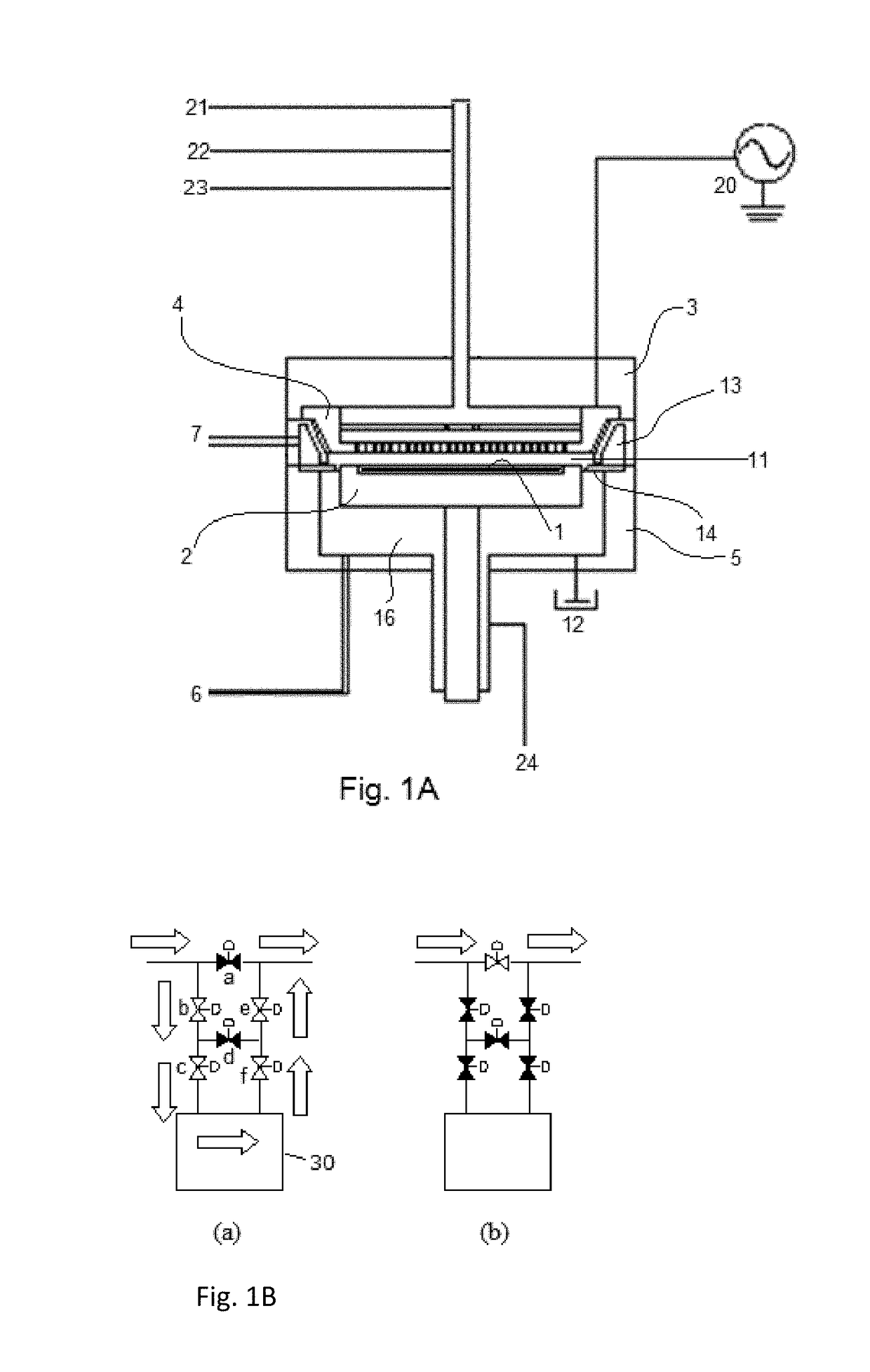

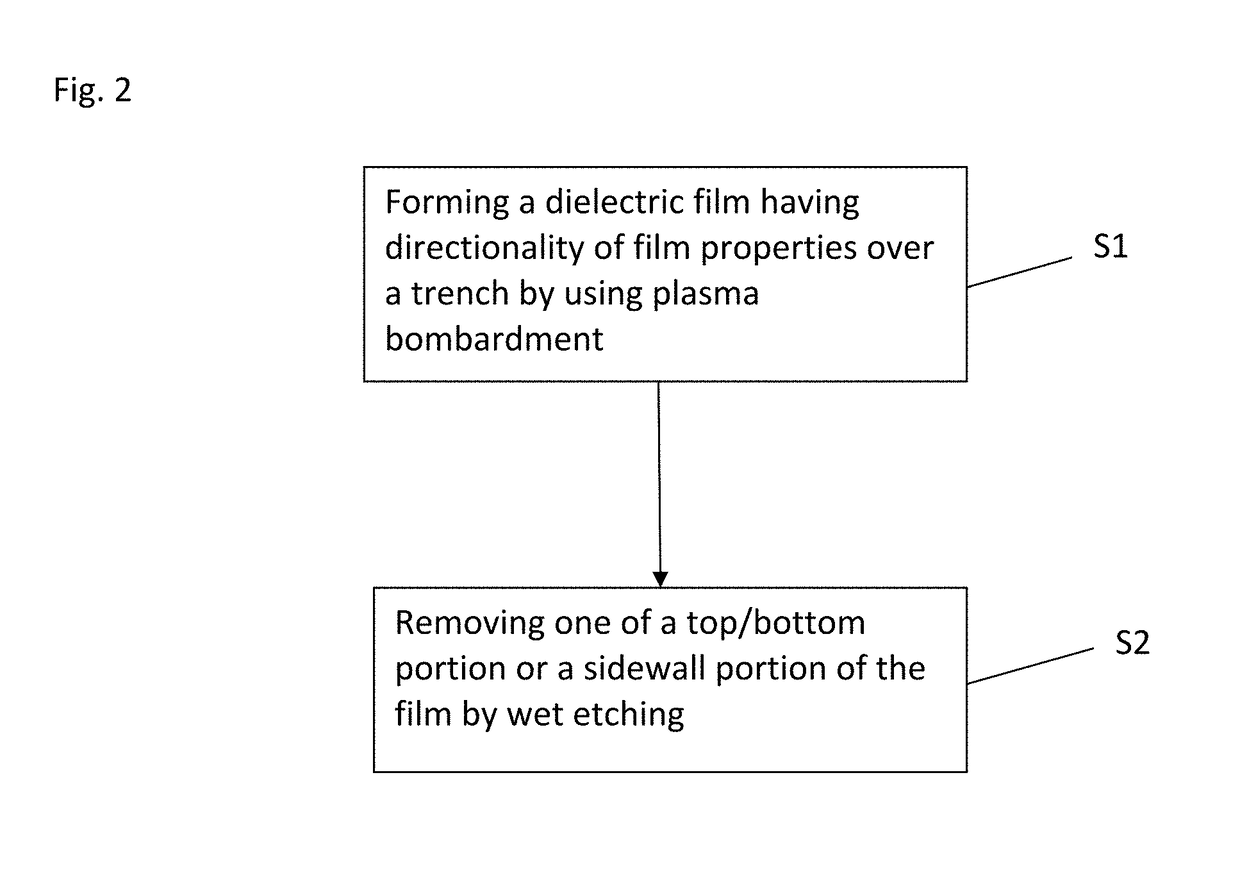

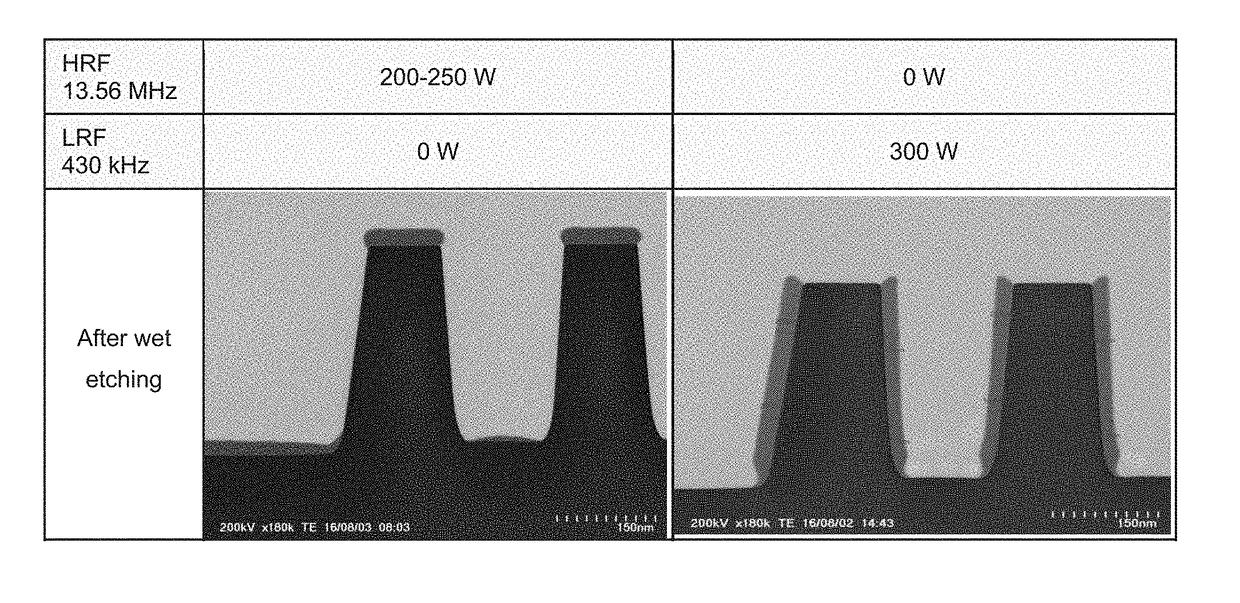

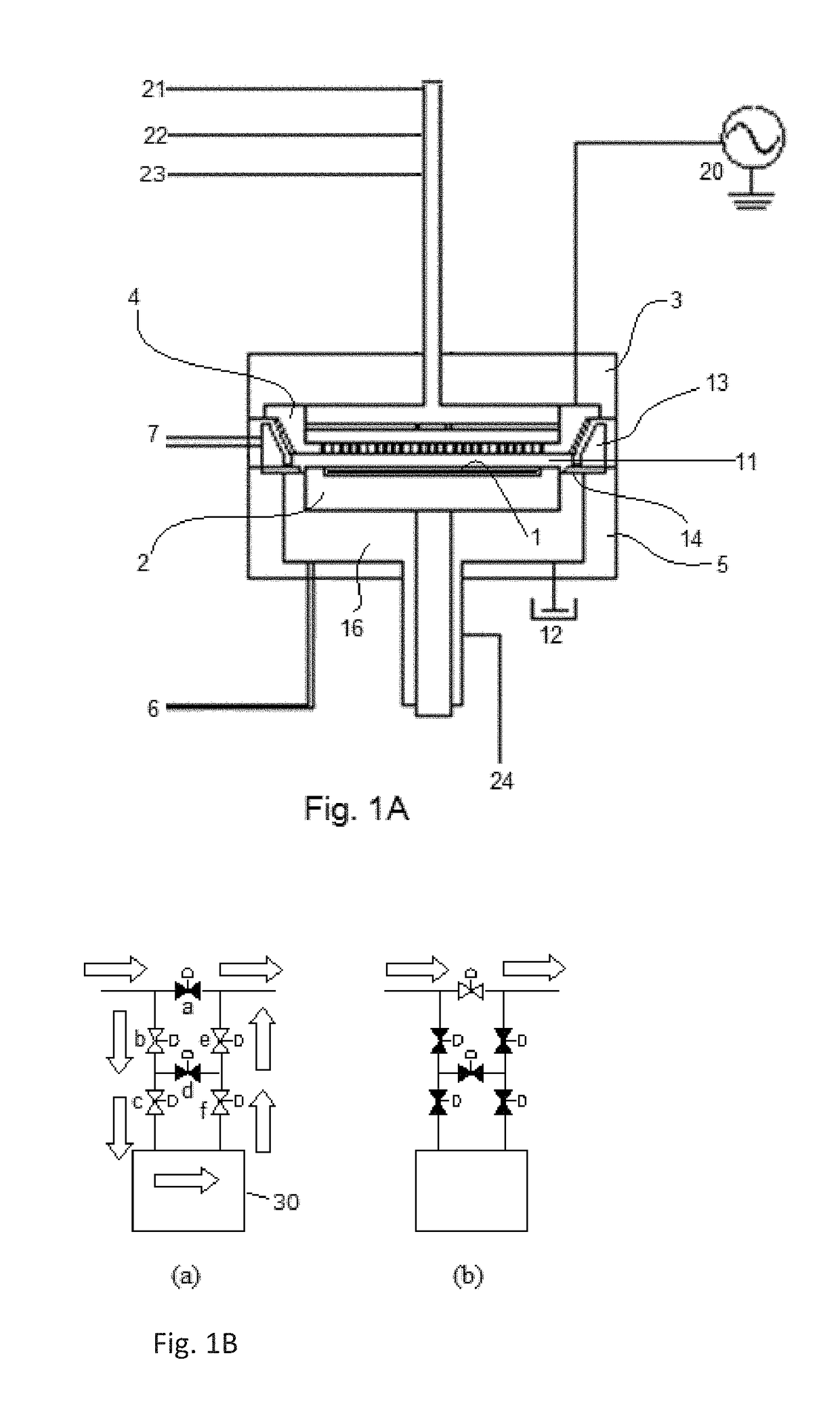

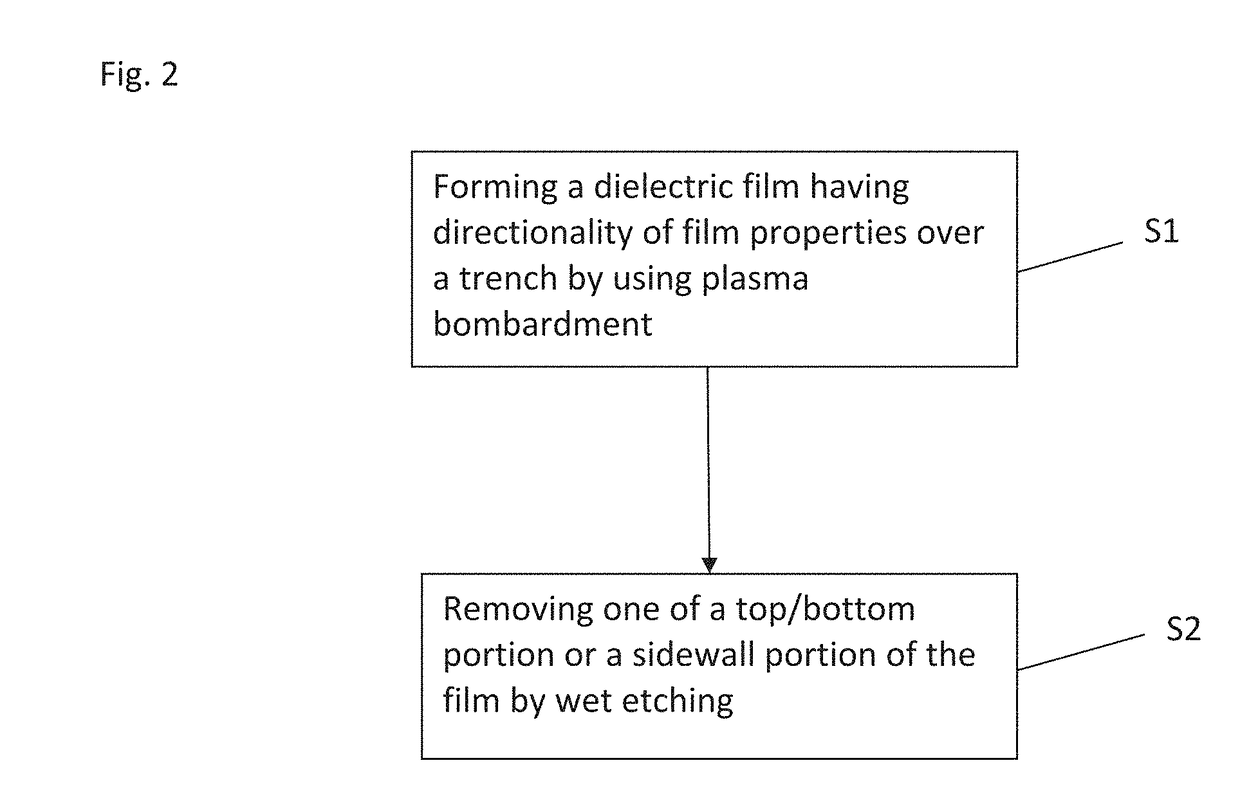

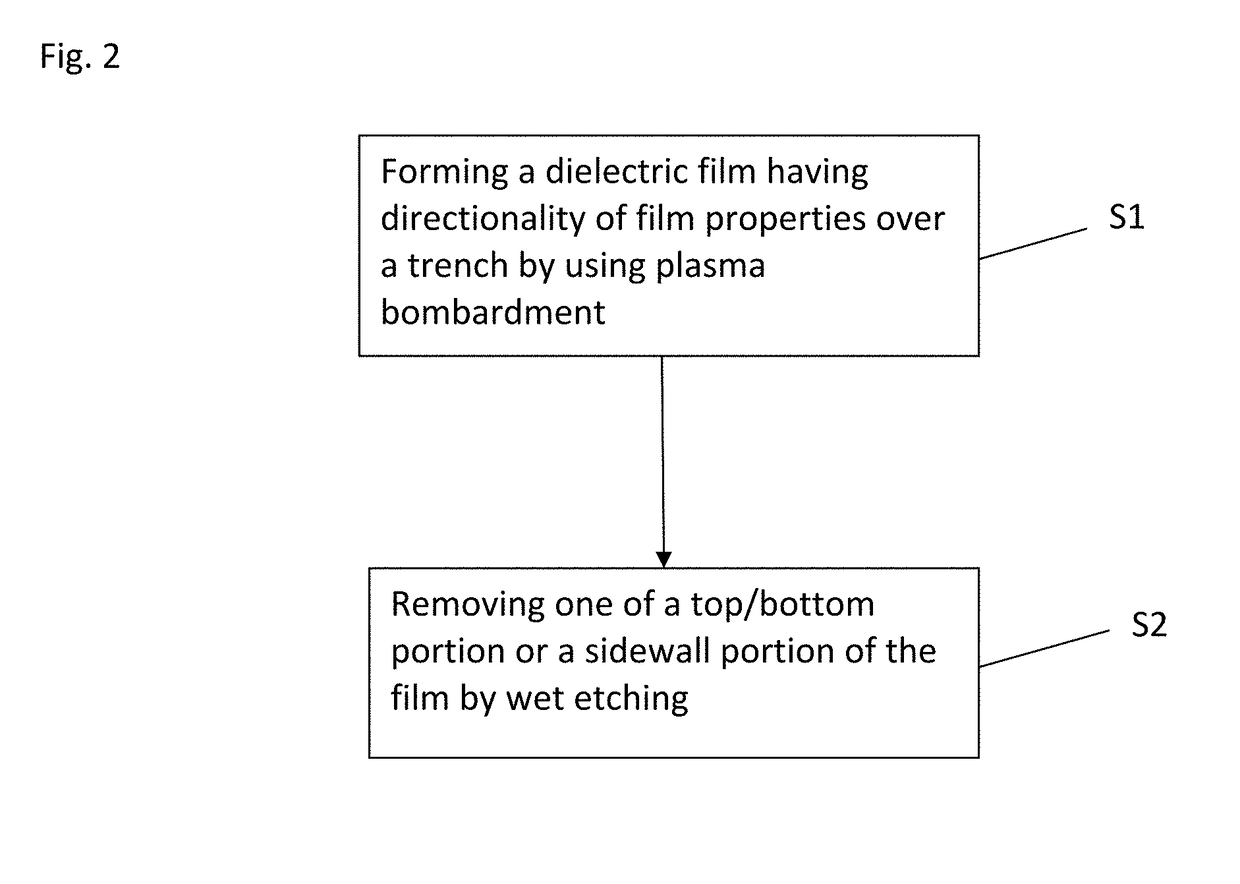

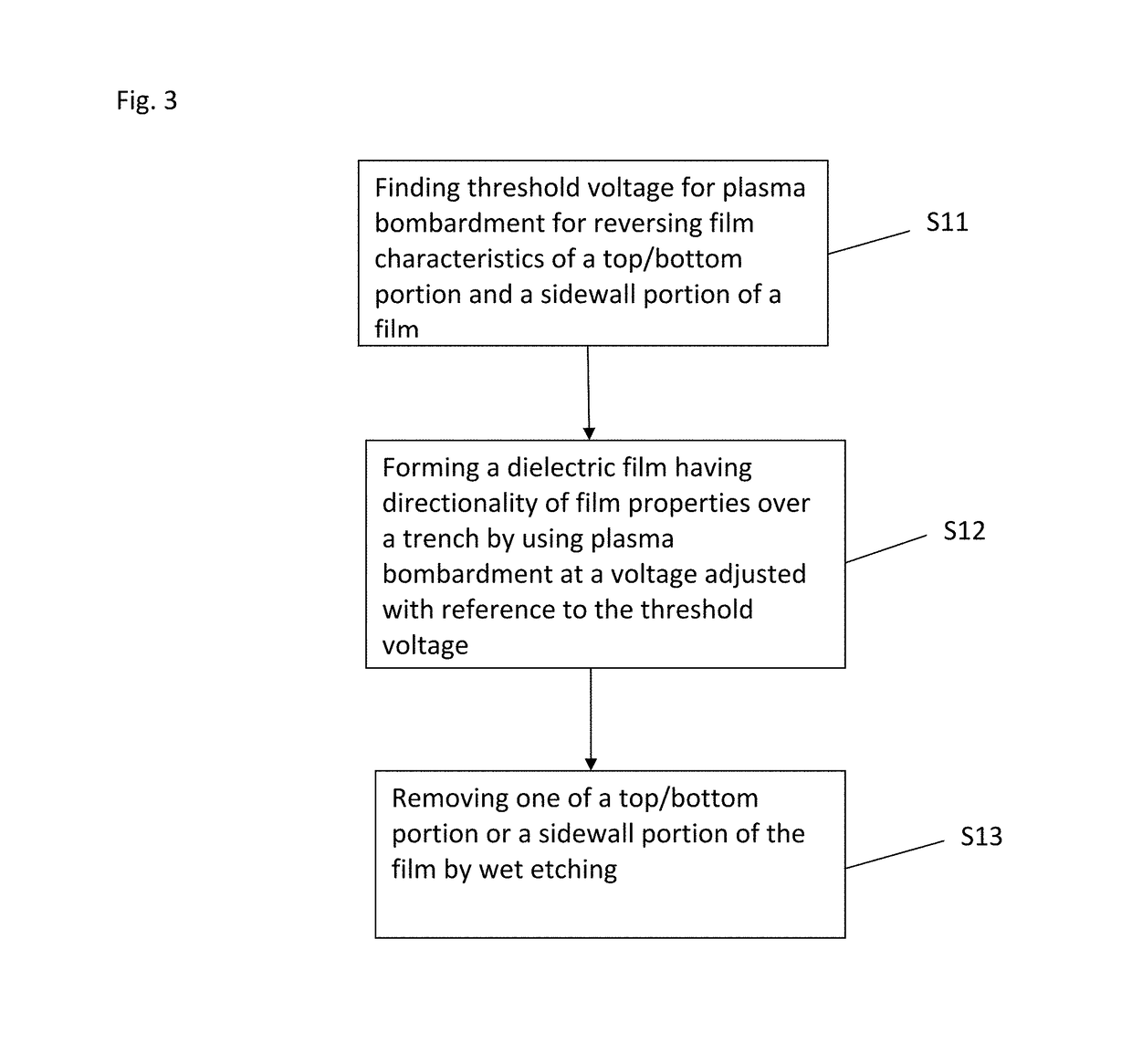

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS9754779B1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

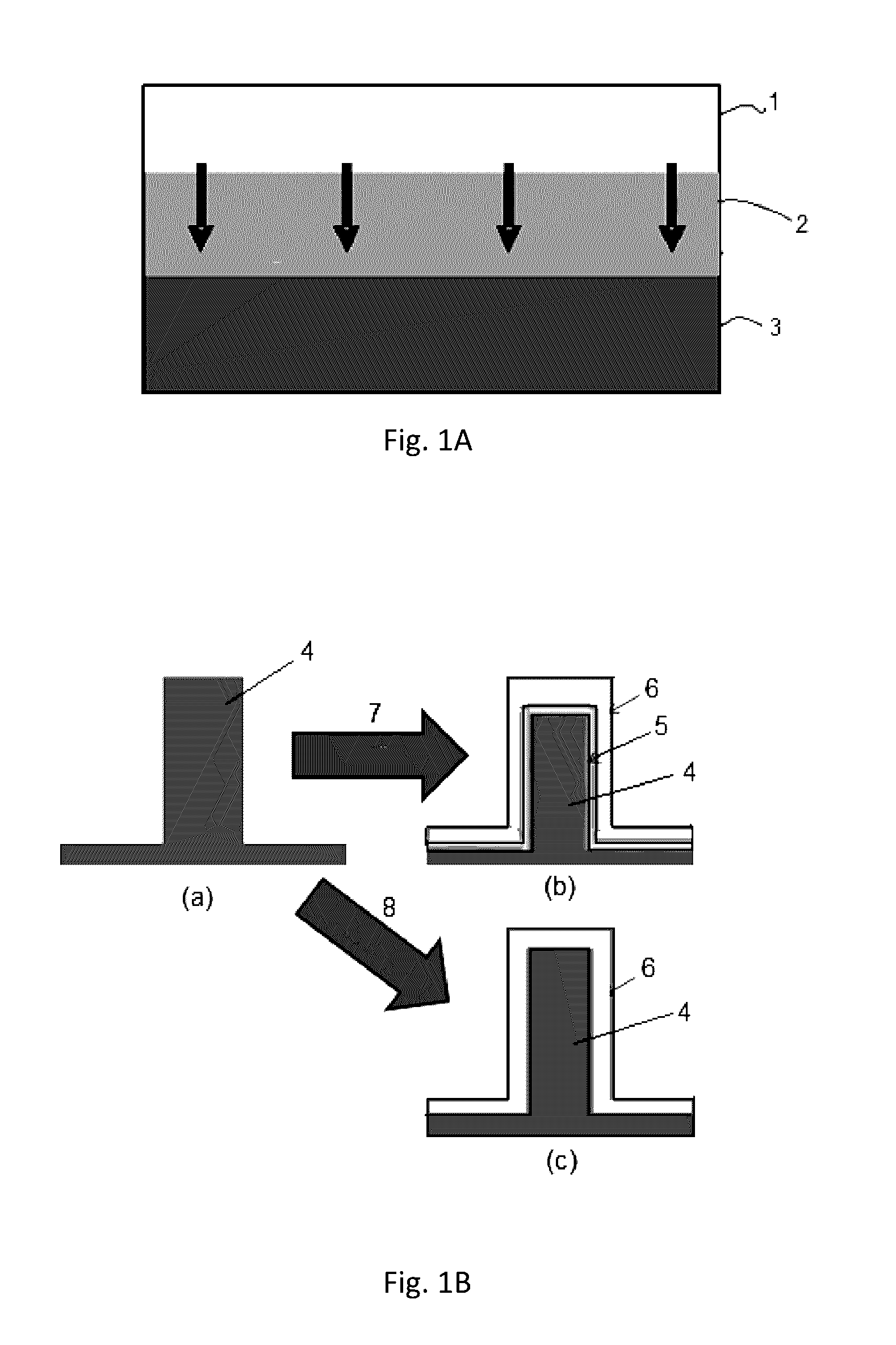

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Low-oxidation plasma-assisted process

ActiveUS9464352B2Suppressing of layerImprove film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingPhysical chemistryRadio frequency

A method for forming an oxide film by plasma-assisted cyclic processing, includes: (i) supplying a precursor to a reaction space wherein a substrate is placed; (ii) applying a first RF power to the reaction space for a first period of time without supplying a precursor; and (iii) applying a second RF power to the reaction space for a second period of time without supplying the precursor, wherein the first RF power is lower than the second RF power, and / or the first period of time is shorter than the second period of time.

Owner:ASM IP HLDG BV

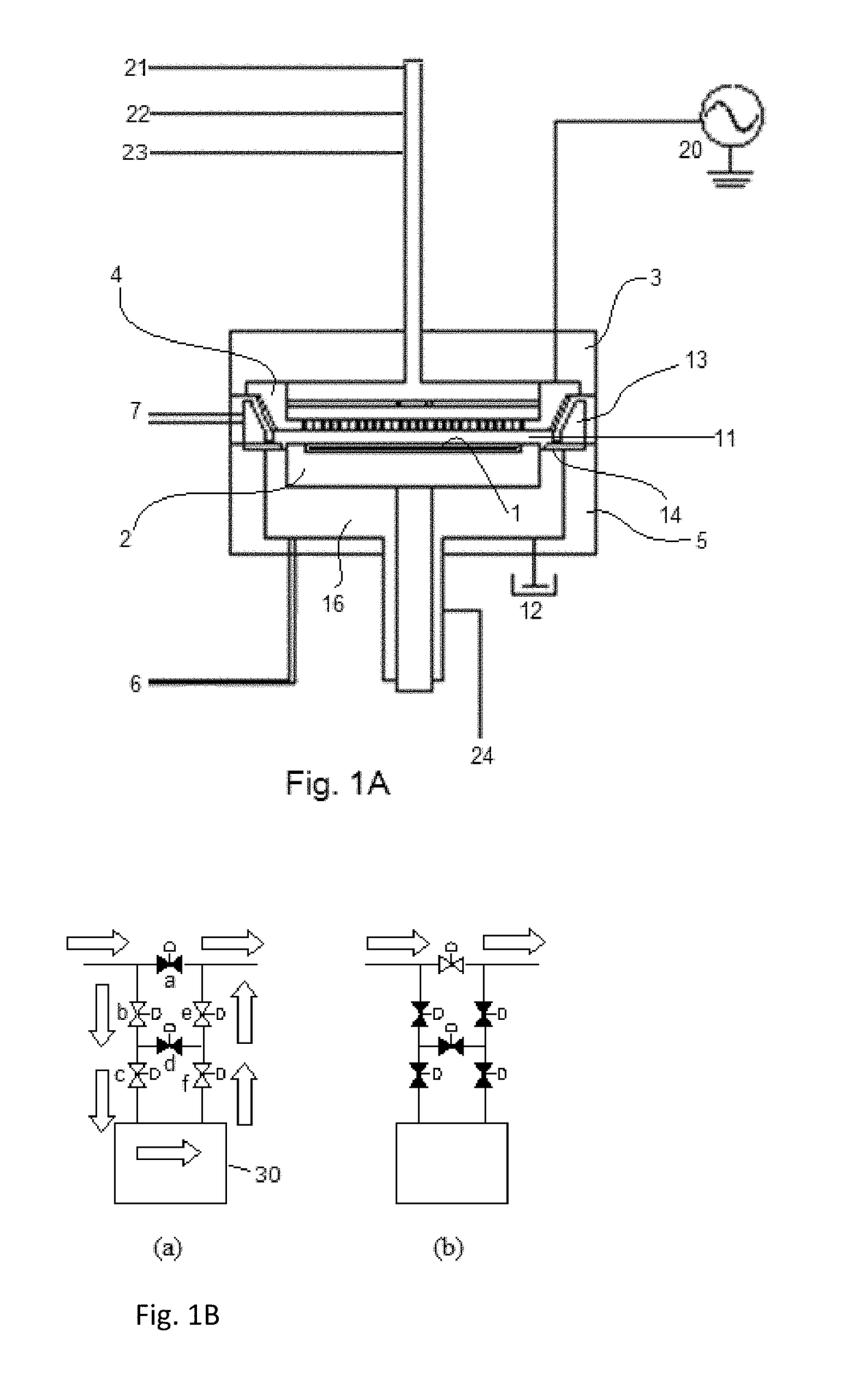

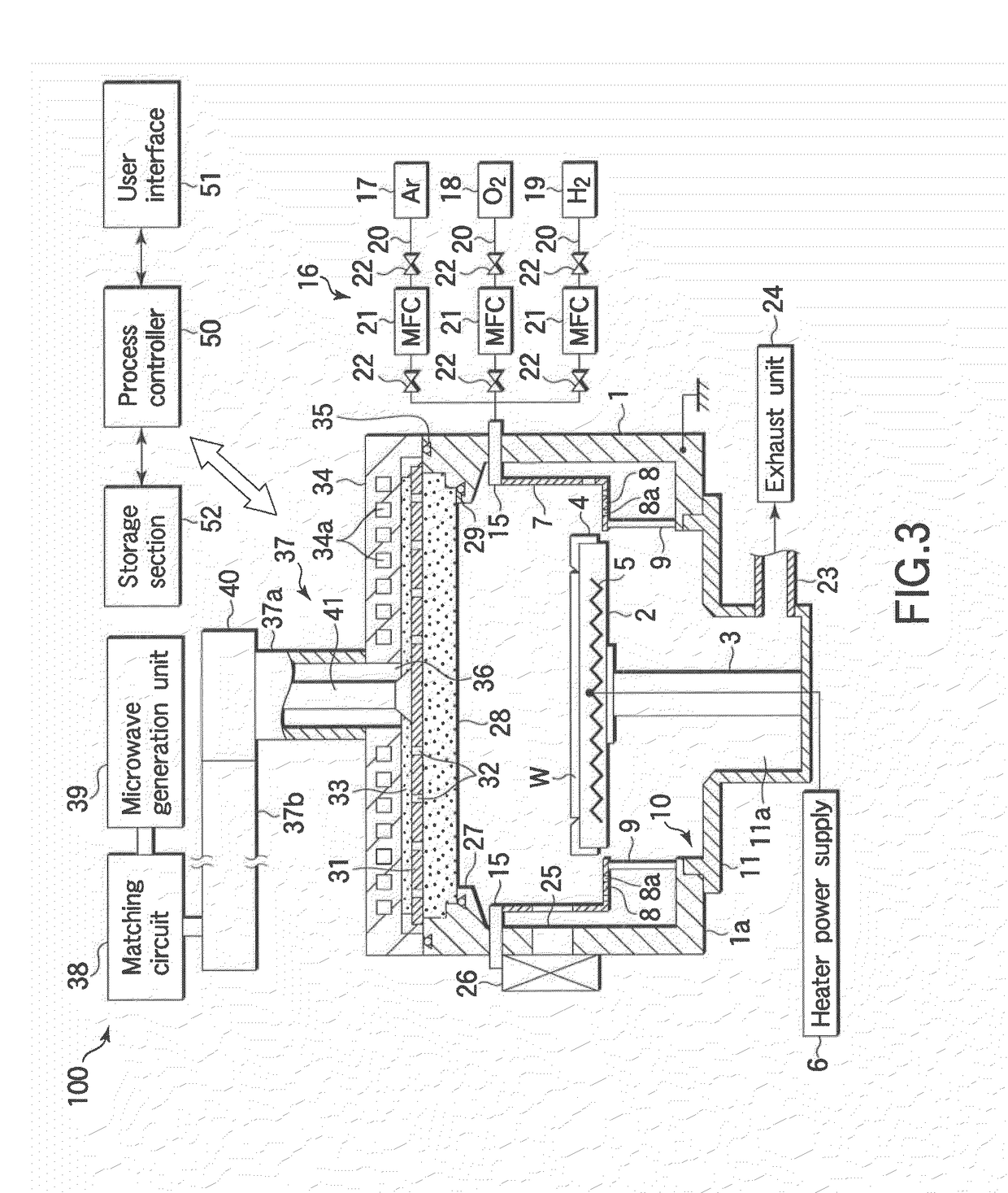

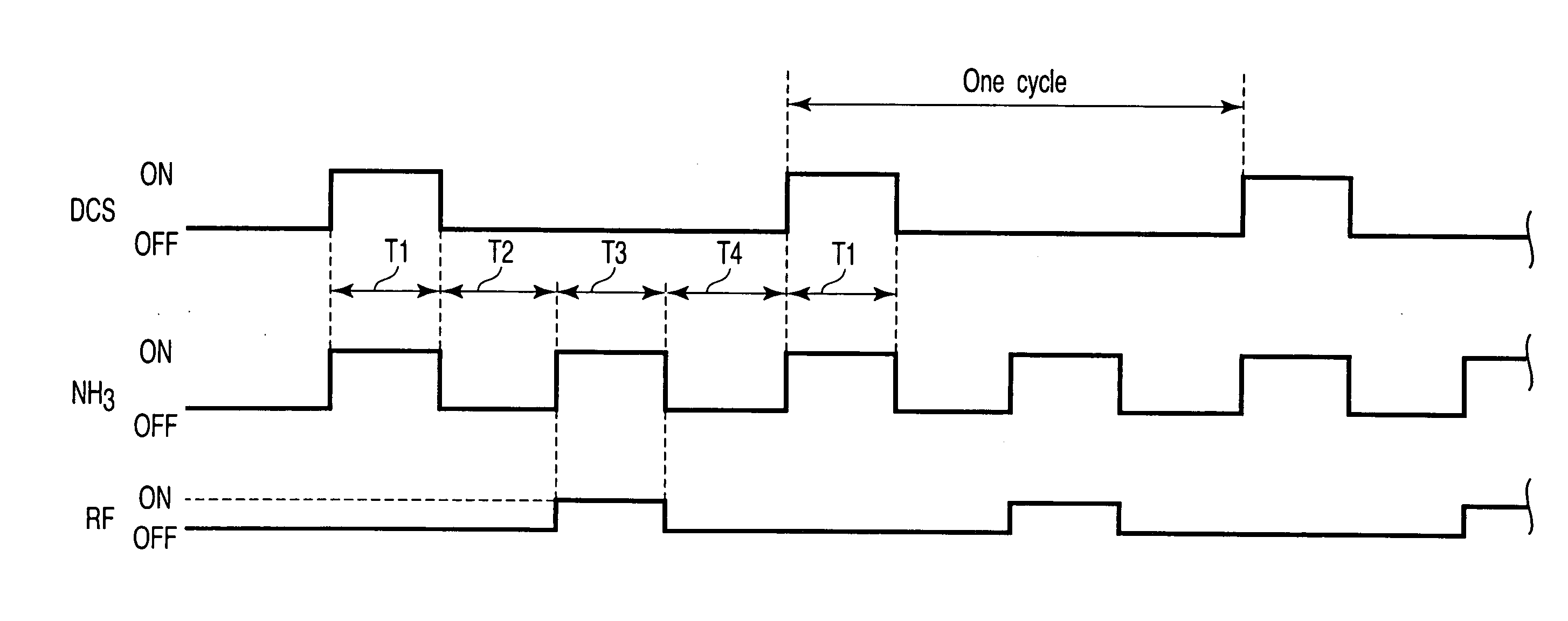

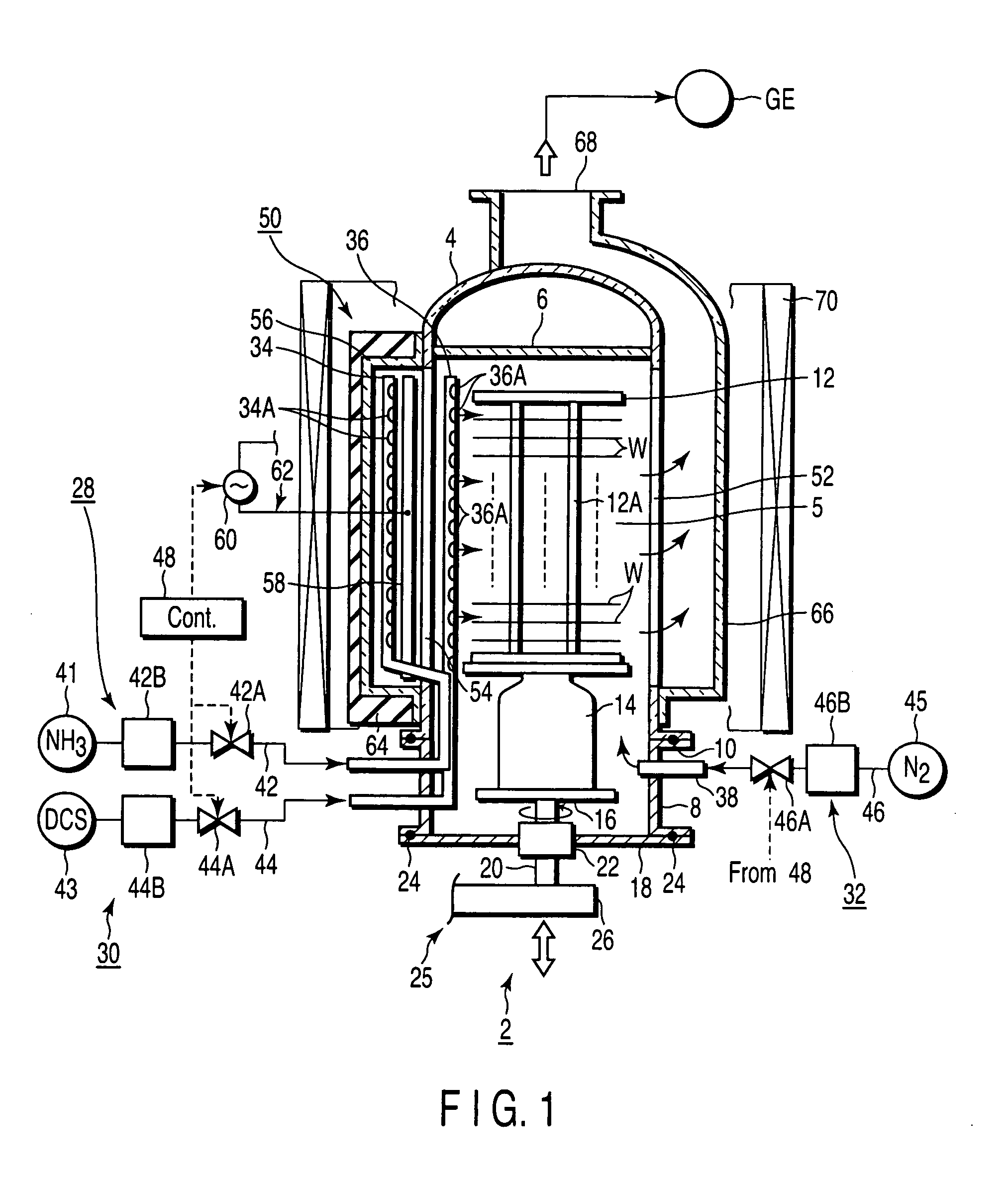

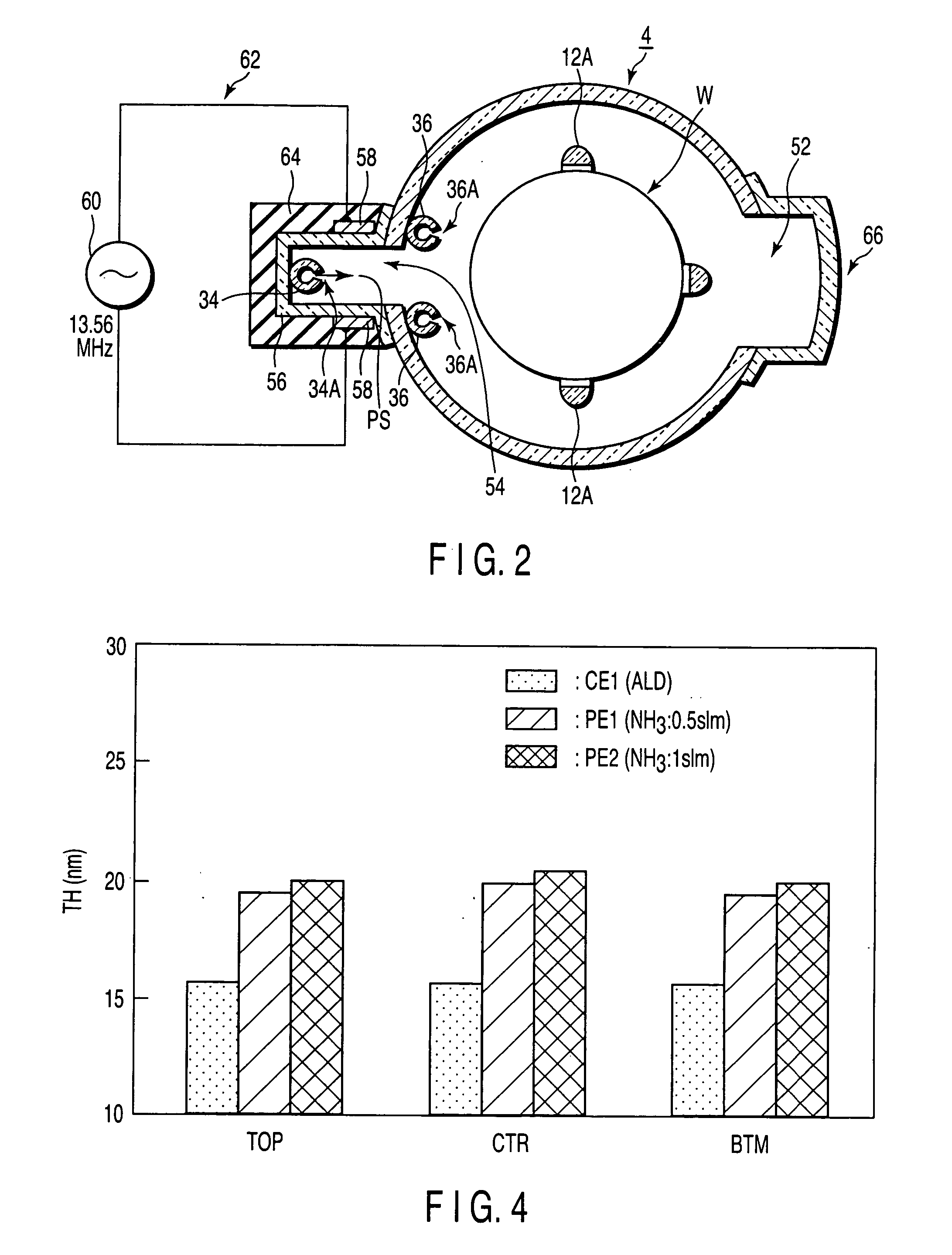

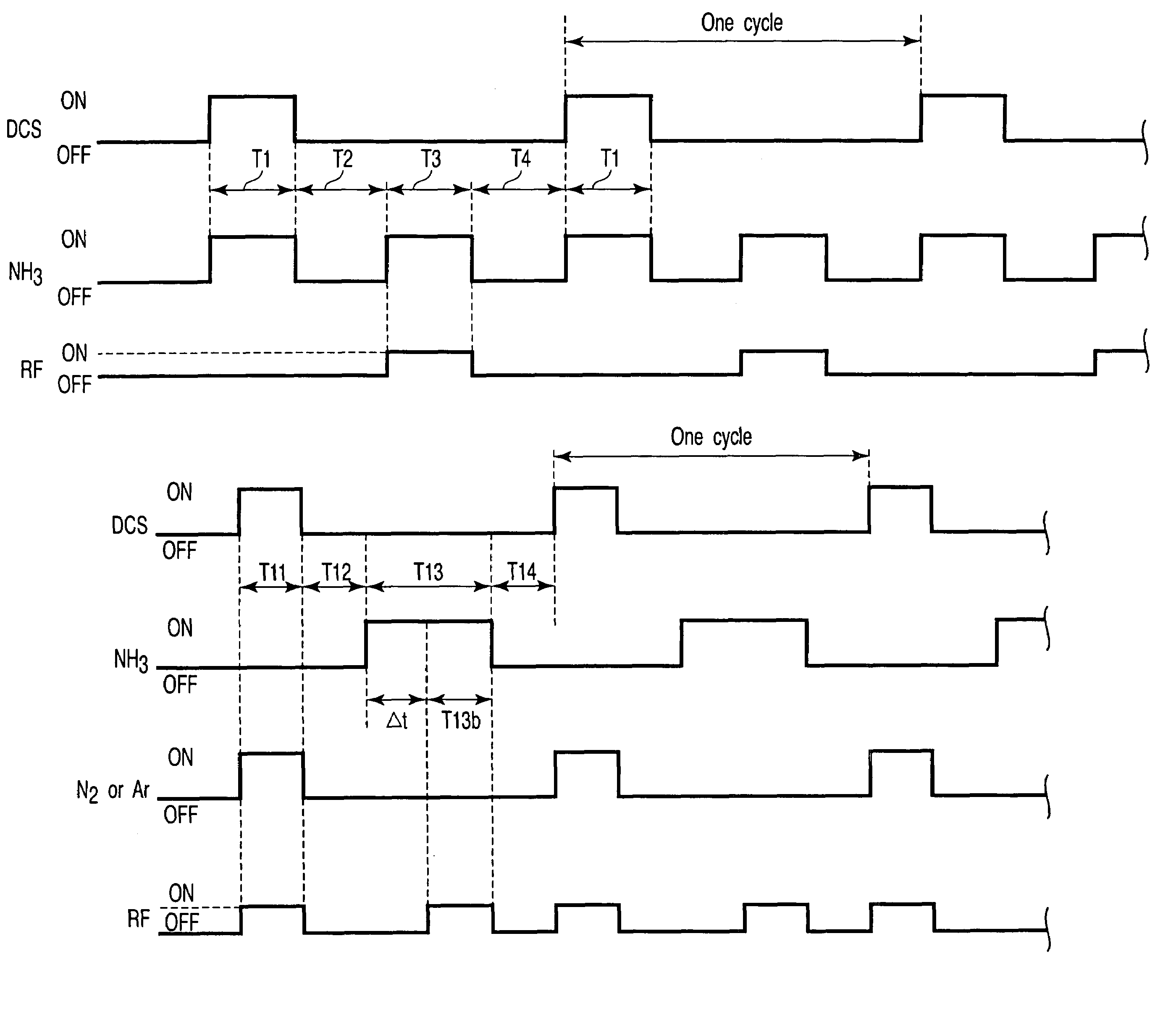

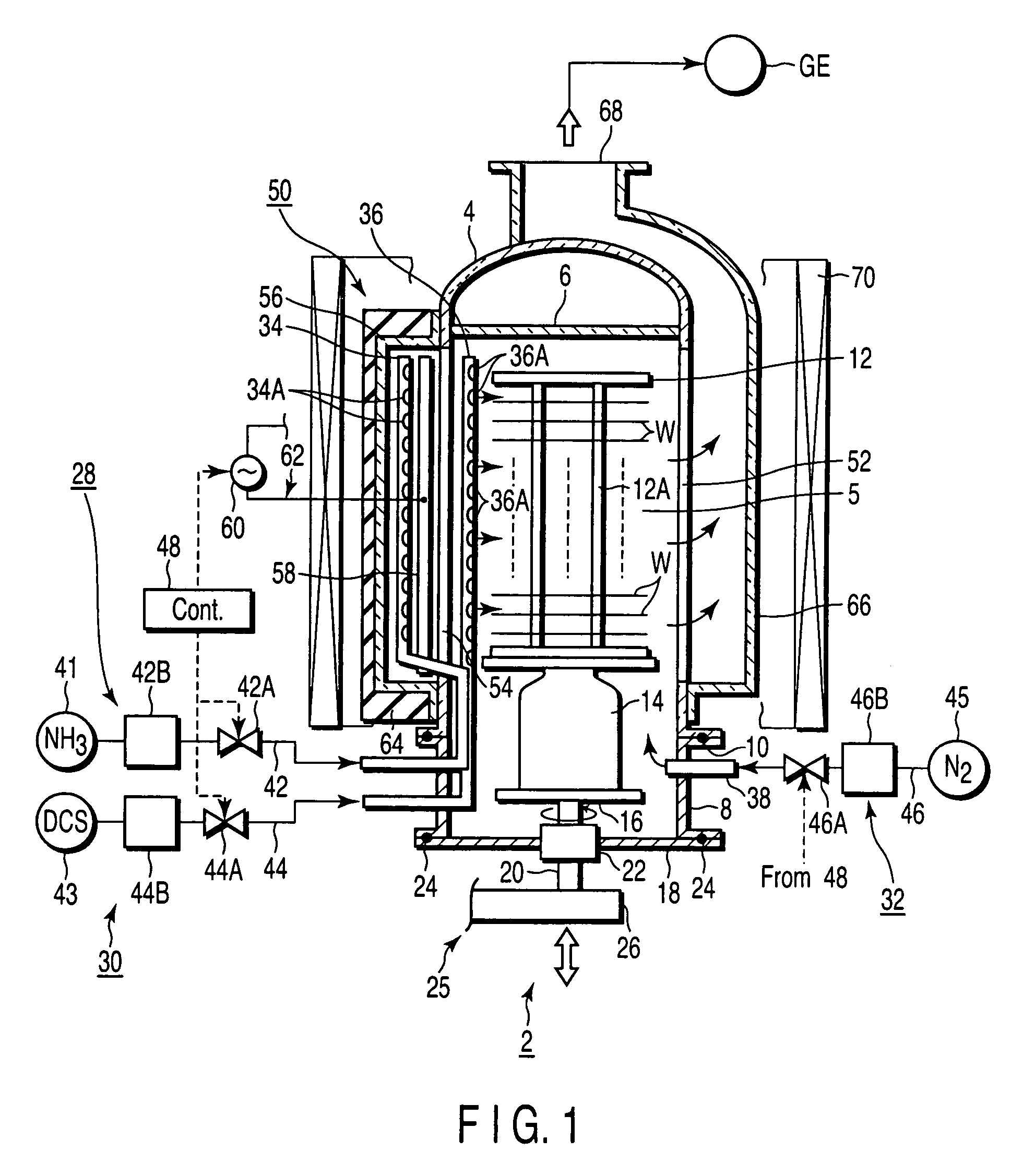

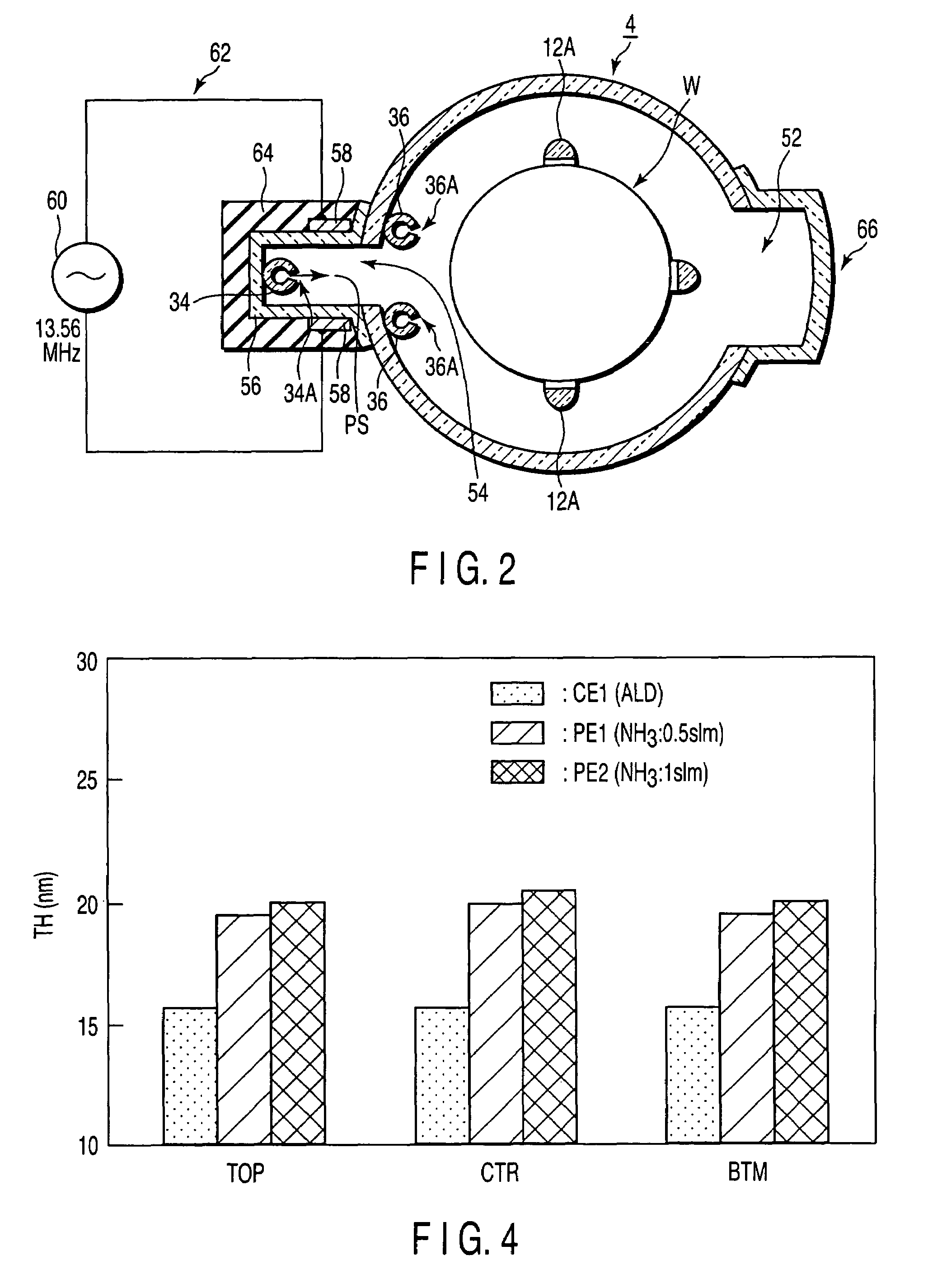

Film forming process and film forming apparatus

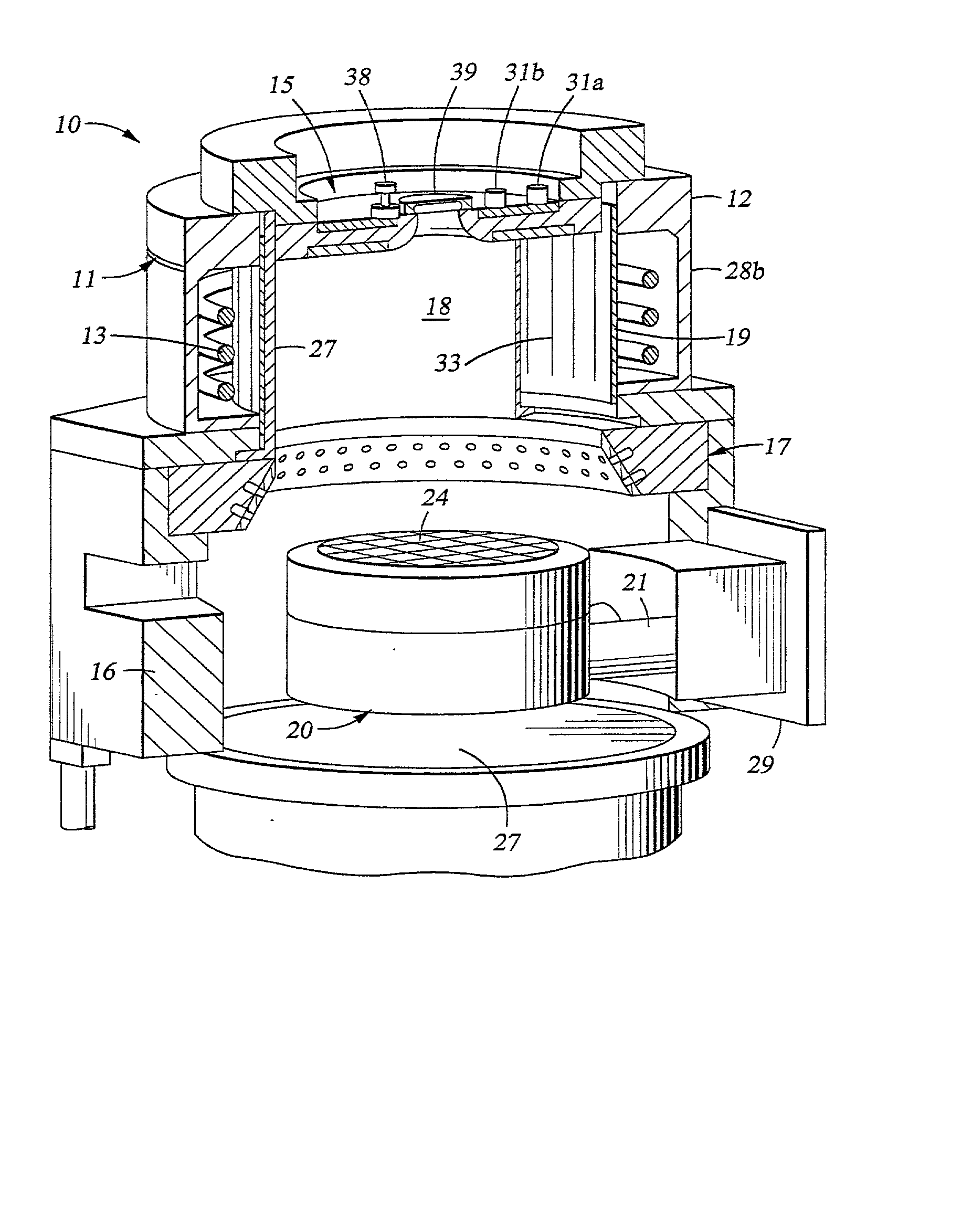

InactiveUS20150031218A1Improve quality of filmImprove film qualityLiquid surface applicatorsSemiconductor/solid-state device manufacturingProduct gasForming processes

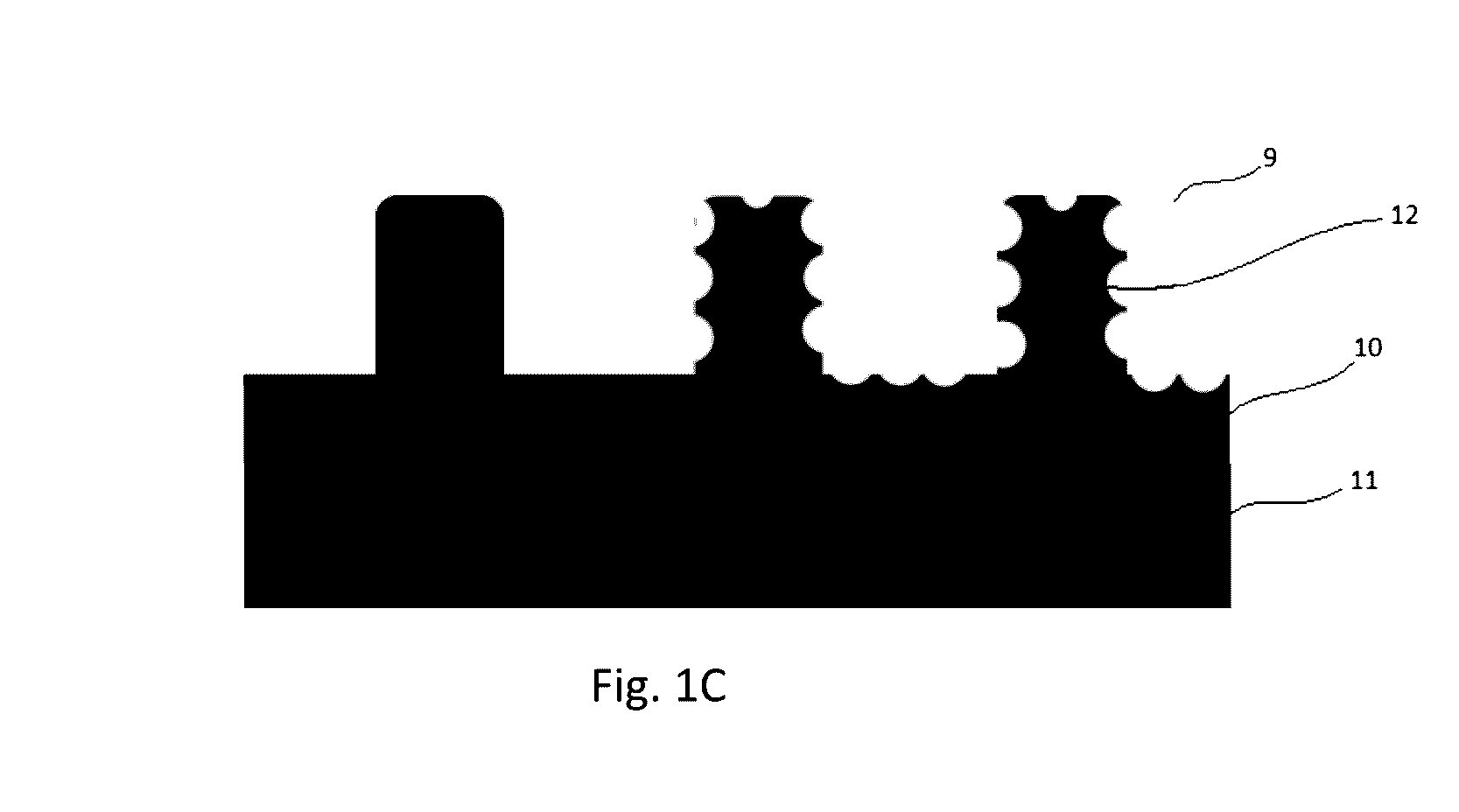

In a film forming apparatus (10), plasma-assisted ALD sequences are carried out to form a nitride film on a substrate (W) through the nitration of the silicon (Si) resulting from dichlorosilane (DCS), and then the first to fourth gas-feeding processes and plasma-feeding processes are successively carried out as plasma-assisted post-treatment. The gas to be fed in the first to fourth gas-feeding processes in the plasma-assisted post-treatment is a modifier gas consisting of either a gas selected from among N2, NH3, Ar and H2 or a mixed gas obtained by suitably mixing some of these gases. After the completion of the plasma-assisted ALD sequences, a plasma formed from the modifier gas is fed onto the nitride film on the substrate (W) to improve the film quality of the nitride film.

Owner:TOKYO ELECTRON LTD

Ald apparatus and method

InactiveUS20100129548A1Enhanced advantageImprove utilization efficiencyLiquid surface applicatorsFrom chemically reactive gasesEngineeringElectric conductance

Improved apparatus and method for SMFD ALD include a method designed to enhance chemical utilization as well as an apparatus that implements lower conductance out of SMFD-ALD process chamber while maintaining full compatibility with standard wafer transport. Improved SMFD source apparatuses and methods from volatile and non-volatile liquid and solid precursors are disclosed, e.g., a method for substantially controlling the vapor pressure of a chemical source within a source space comprising: sensing the accumulation of the chemical on a sensing surface; and controlling the temperature of the chemical source depending on said sensed accumulation.

Owner:SUNDEW TECH

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS20170250068A1Improve film qualityDecreasing density of filmElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon nitrideEtching

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Production Method for Semiconductor Device and Substrate Processing Apparatus

ActiveUS20080124945A1Deterioration of film qualityQuality improvementLiquid surface applicatorsSemiconductor/solid-state device manufacturingChemistrySemiconductor

Disclosed is a producing method of a semiconductor device comprising a first step of supplying a first reactant to a substrate to cause a ligand-exchange reaction between a ligand of the first reactant and a ligand as a reactive site existing on a surface of the substrate, a second step of removing a surplus of the first reactant, a third step of supplying a second reactant to the substrate to cause a ligand-exchange reaction to change the ligand after the exchange in the first step into a reactive site, a fourth step of removing a surplus of the second reactant, and a fifth step of supplying a plasma-excited third reactant to the substrate to cause a ligand-exchange reaction to exchange a ligand which has not been exchange-reacted into the reactive site in the third step into the reactive site, wherein the first to fifth steps are repeated predetermined times.

Owner:KOKUSA ELECTRIC CO LTD

Method for forming silicon nitride film selectively on sidewalls of trenches

ActiveUS20190057857A1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing the sidewall portion of the film by wet etching which removes the sidewall portion of the film more predominantly than the top / bottom portion according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

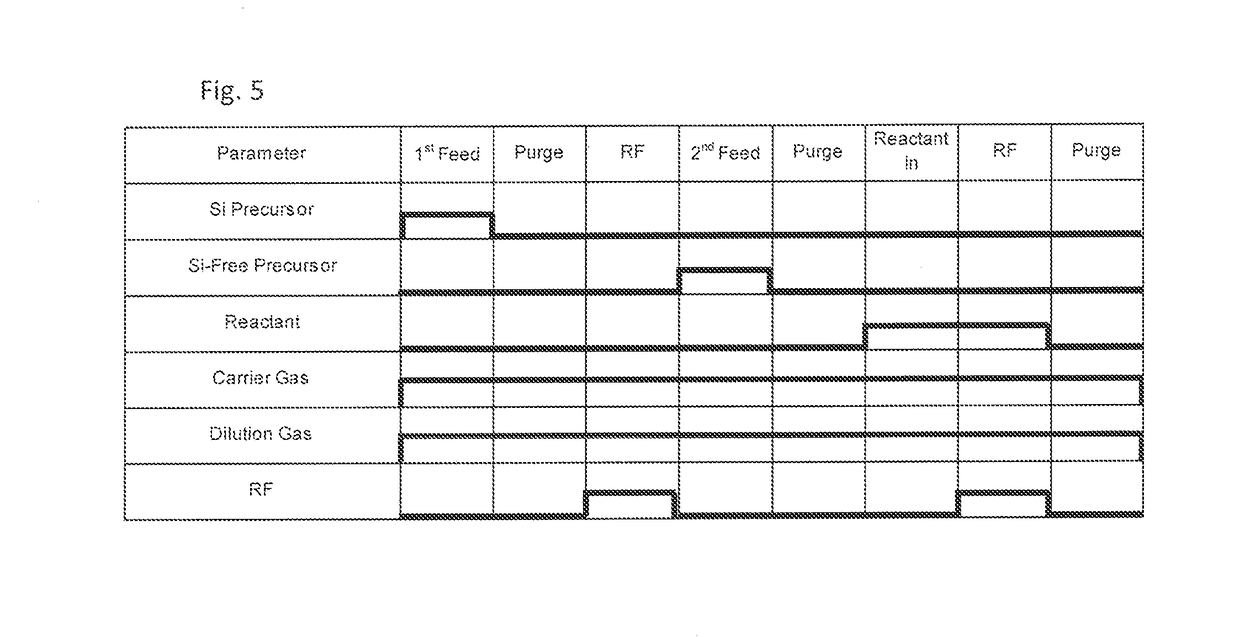

Method for forming conformal nitrided, oxidized, or carbonized dielectric film by atomic layer deposition

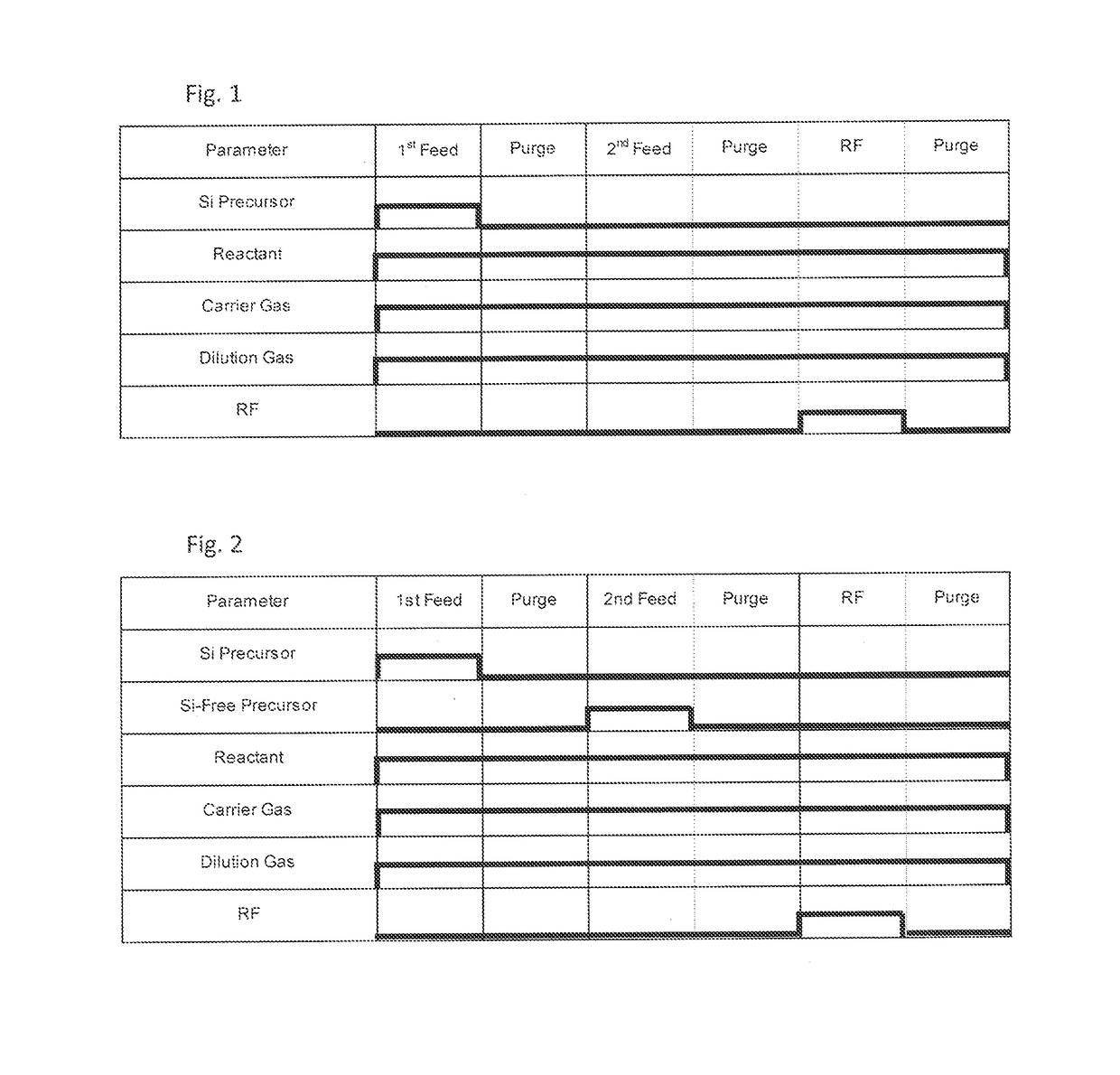

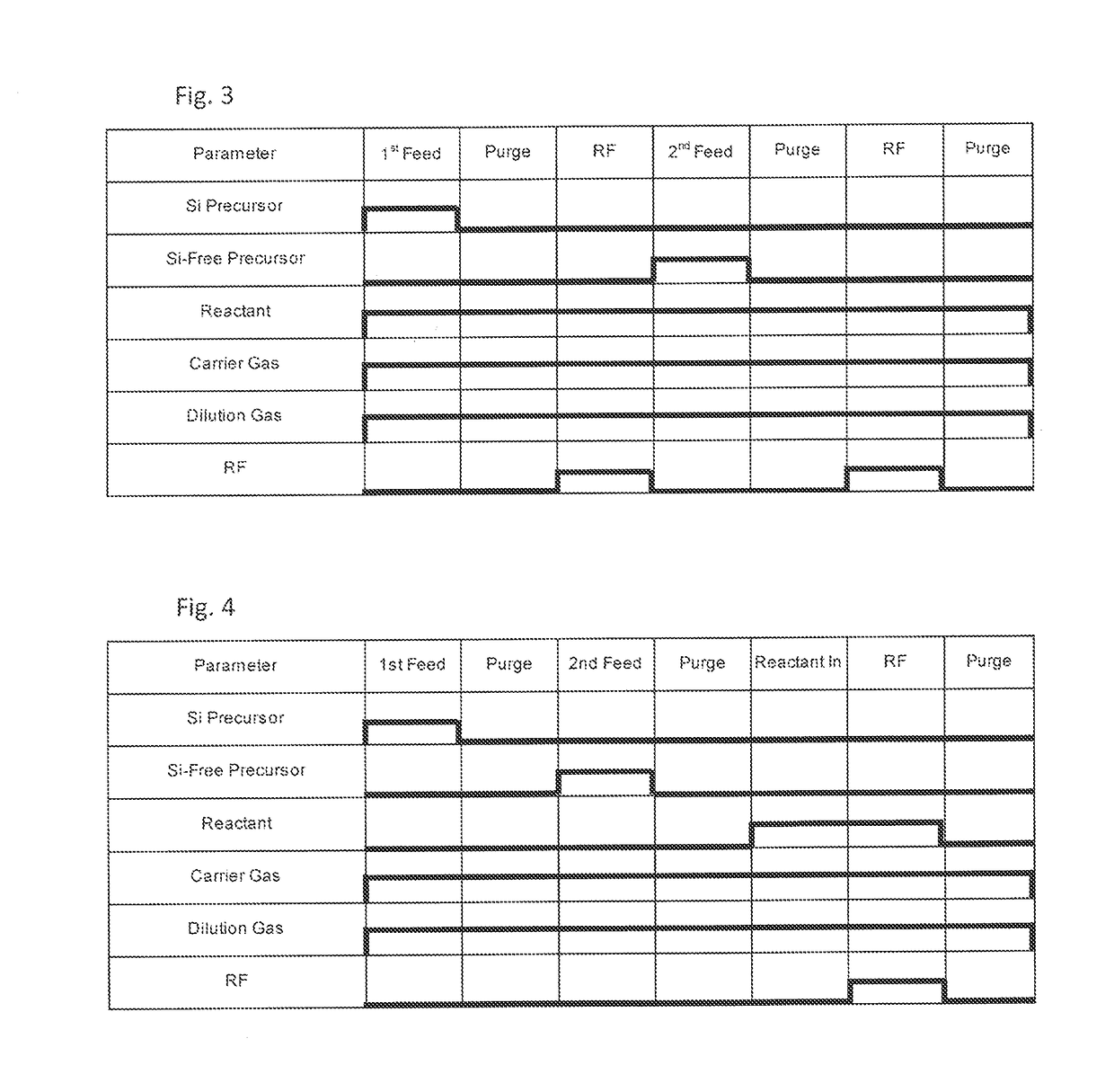

ActiveUS10179947B2Easy to oxidizeEasily and nitridedChemical vapor deposition coatingPlasma techniqueDielectric membraneThin membrane

A method for forming a film on a patterned surface of a substrate by atomic layer deposition (ALD) processing includes: adsorbing onto a patterned surface a first precursor containing silicon or metal in its molecule; adsorbing onto the first-precursor-adsorbed surface a second precursor containing no silicon or metal in its molecule; exposing the second-precursor-adsorbed surface to an excited reactant to oxidize, nitride, or carbonize the precursors adsorbed on the surface of the substrate; and repeating the above cycle to form a film on the patterned surface of the substrate.

Owner:ASM IP HLDG BV

Method of manufacturing semiconductor device, substrate processing apparatus, and recording medium

ActiveUS20170365467A1Improve film qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHalogenEngineering

There is provided a method of manufacturing a semiconductor device, which includes: forming a first seed layer containing silicon and germanium on a substrate by performing, a predetermined number of times, a cycle which includes supplying a first process gas containing silicon or germanium and containing a halogen element to the substrate, supplying a second process gas containing silicon and not containing a halogen element to the substrate, and supplying a third process gas containing germanium and not containing a halogen element to the substrate; and forming a germanium-containing film on the first seed layer by supplying a fourth process gas containing germanium and not containing a halogen element to the substrate.

Owner:KOKUSA ELECTRIC CO LTD

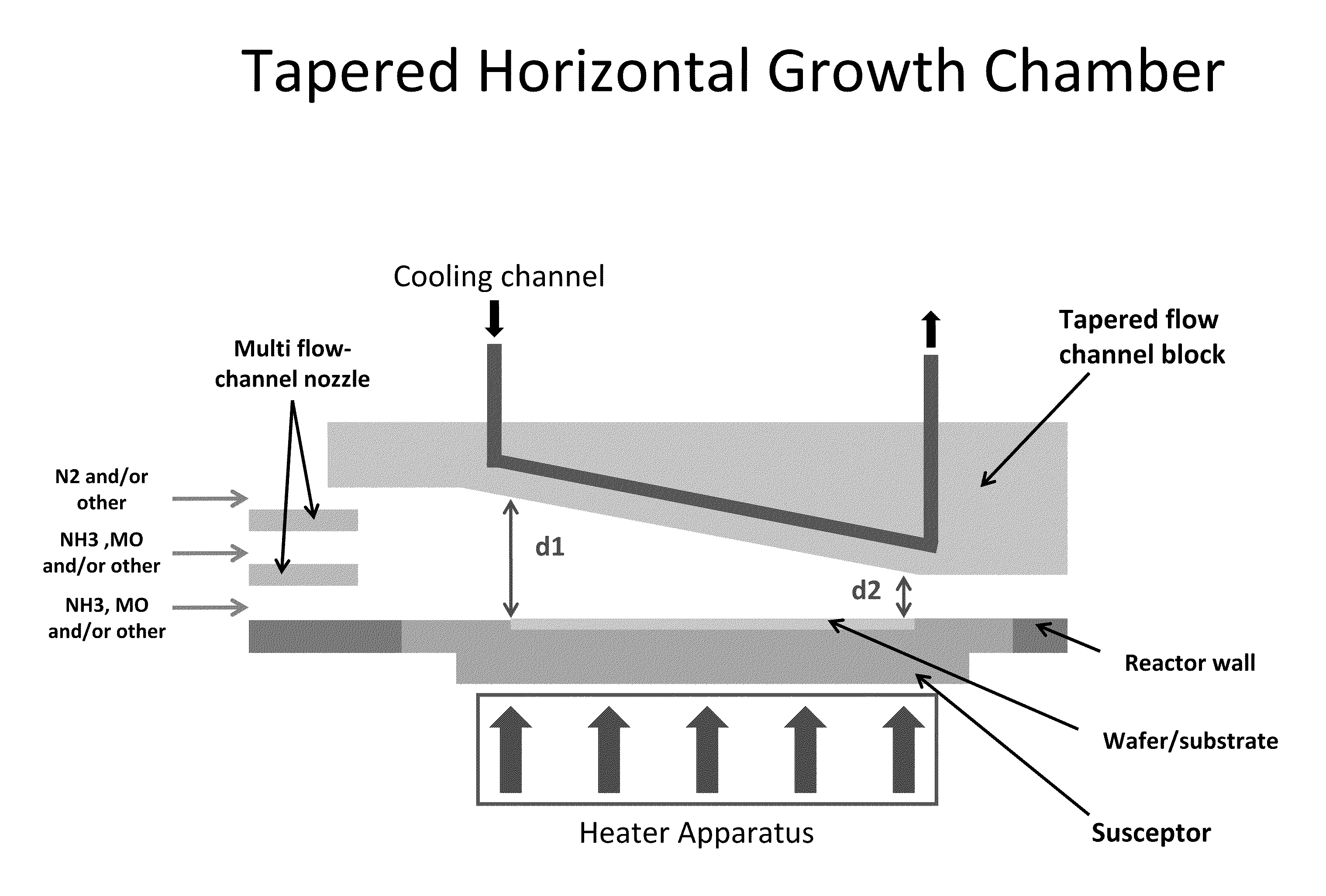

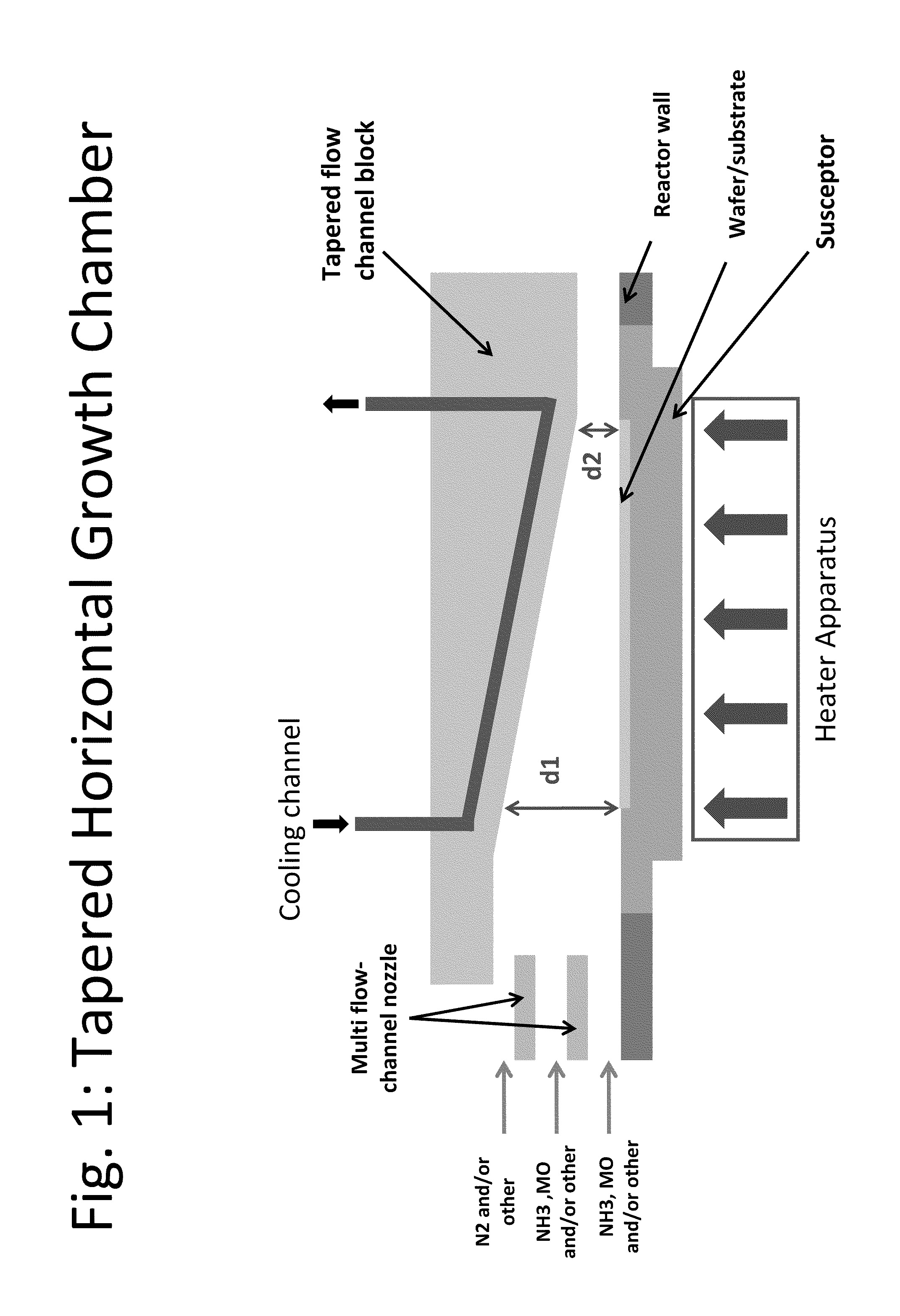

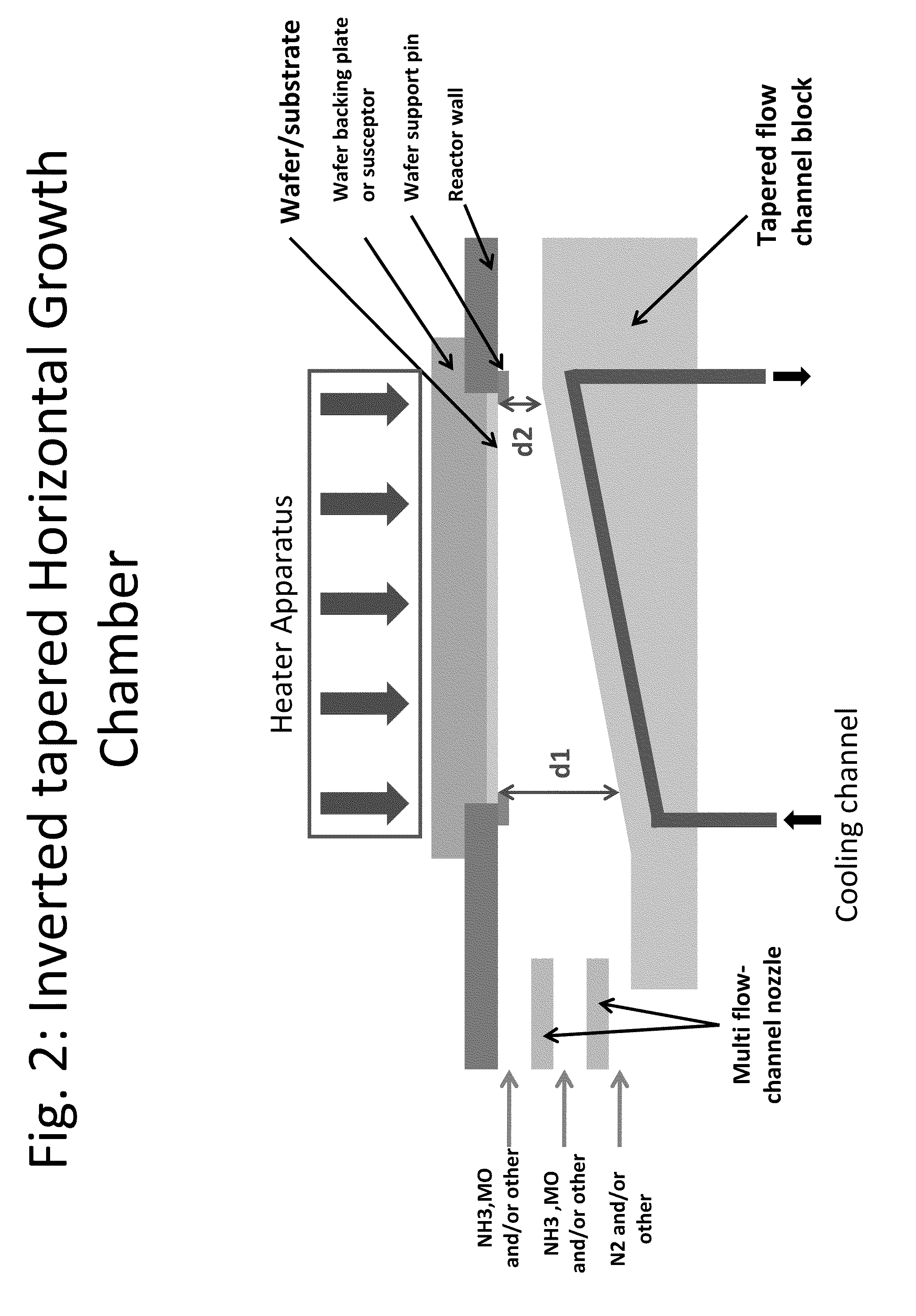

Tapered Horizontal Growth Chamber

InactiveUS20110247556A1Guaranteed efficient growthEfficient reactionPolycrystalline material growthLiquid surface applicatorsSusceptorEngineering

A system and techniques for performing deposition having a tapered horizontal growth chamber which includes a susceptor and a tapered channel flow block. A tapered chamber is formed between the susceptor and the tapered channel flow block. Gaseous species introduced are forced by the tapered channel block to flow toward the susceptor to enhance the efficiency of reactions between the gases species and a wafer on the susceptor.

Owner:KYOCERA SLD LASER INC

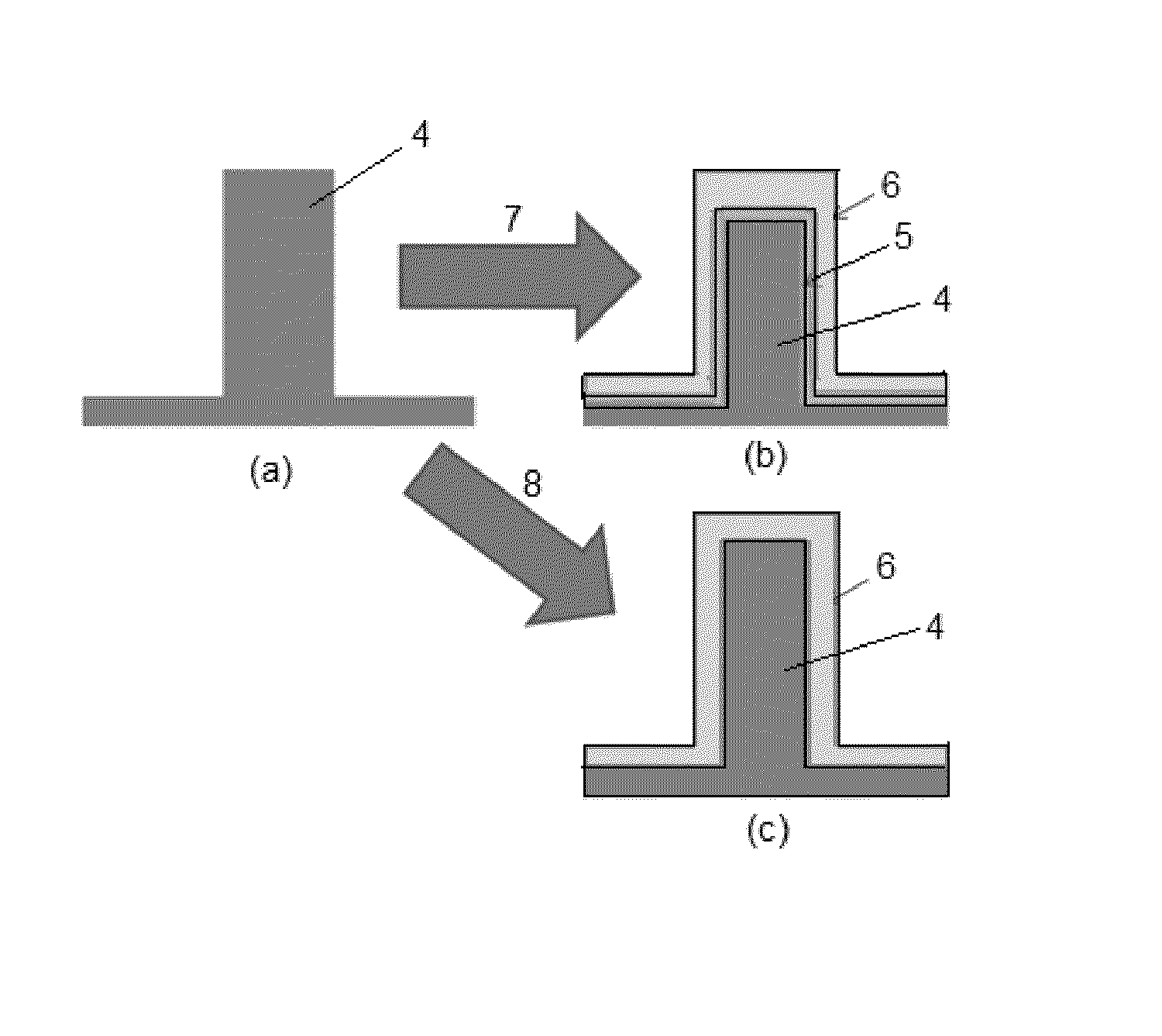

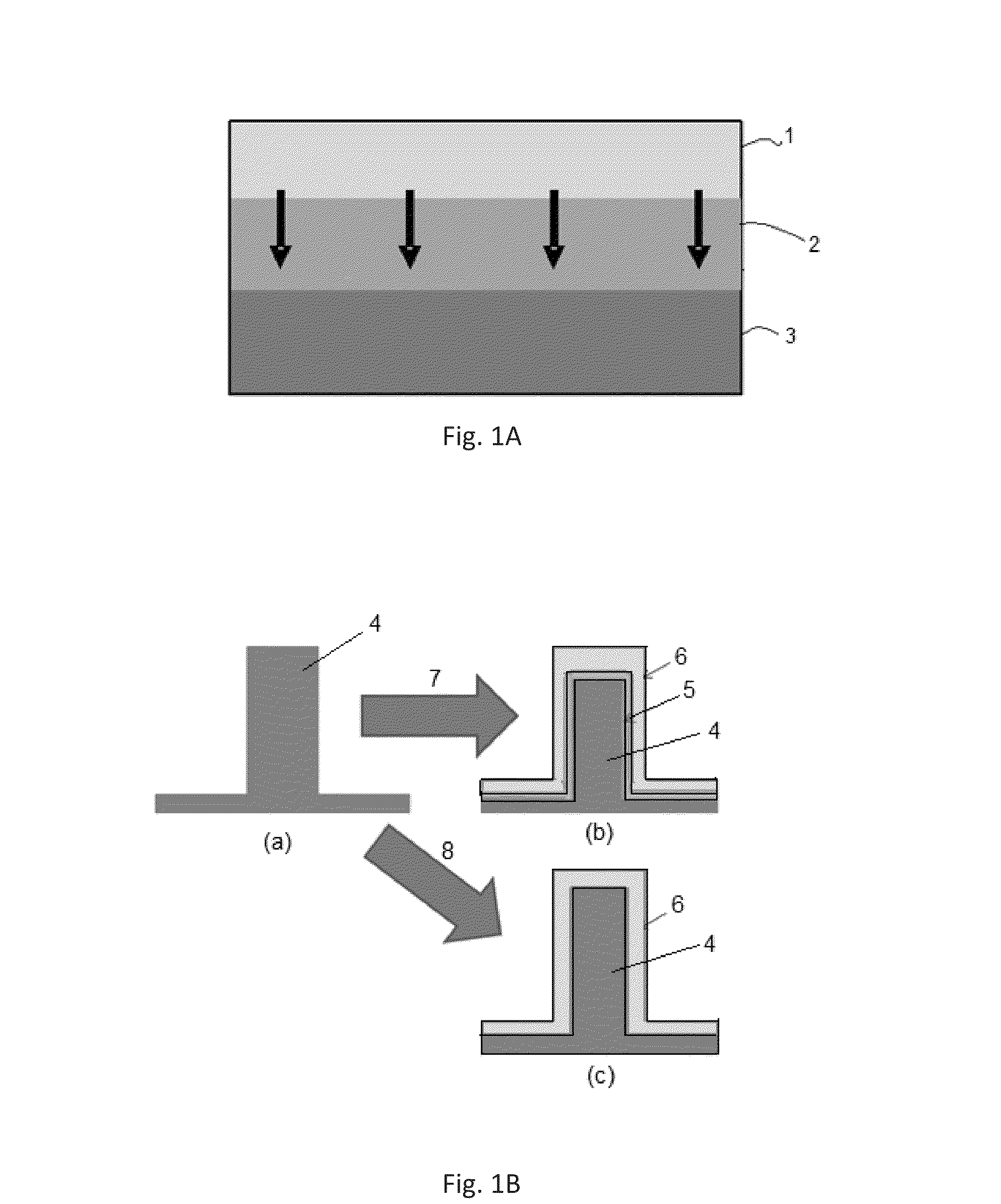

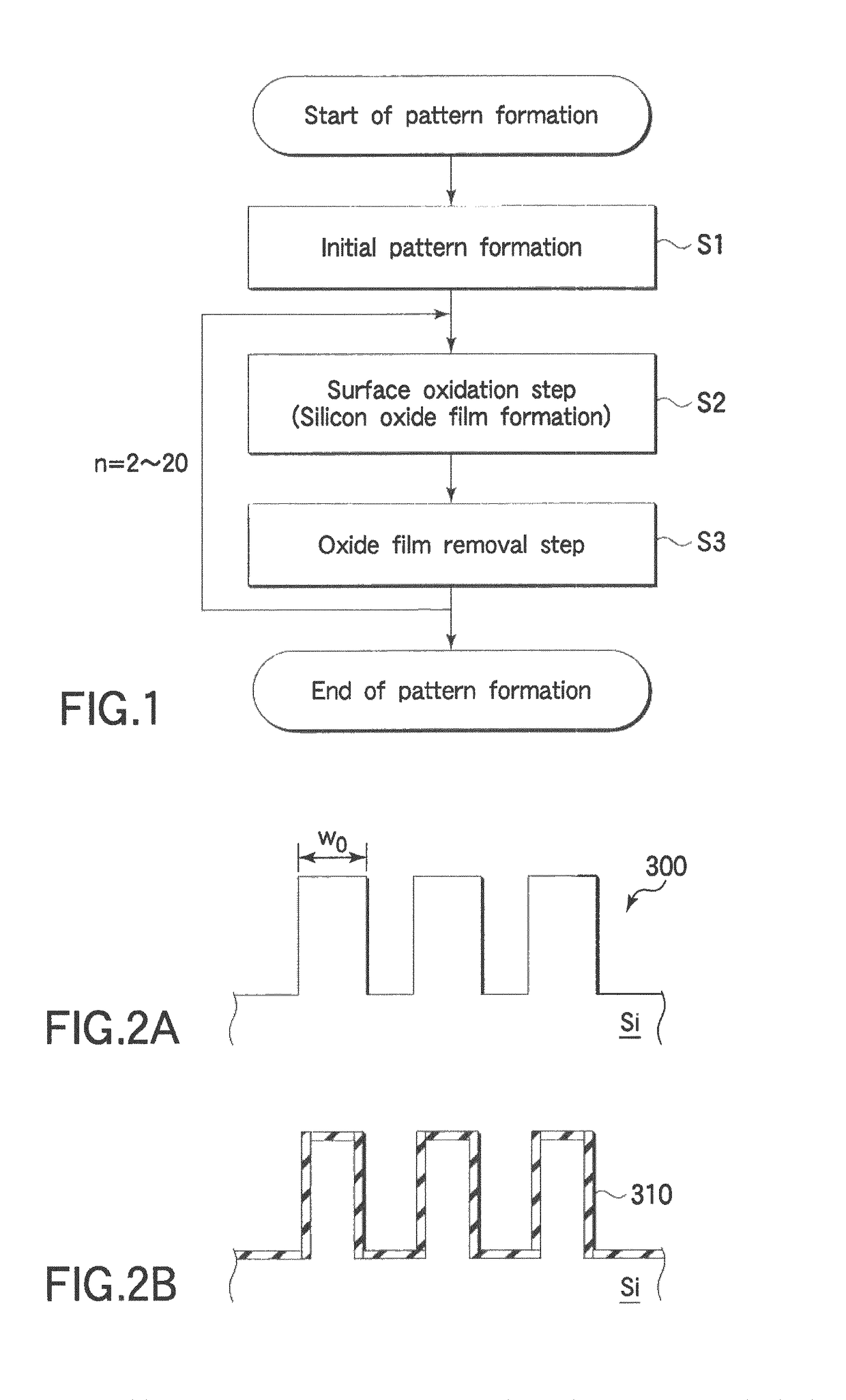

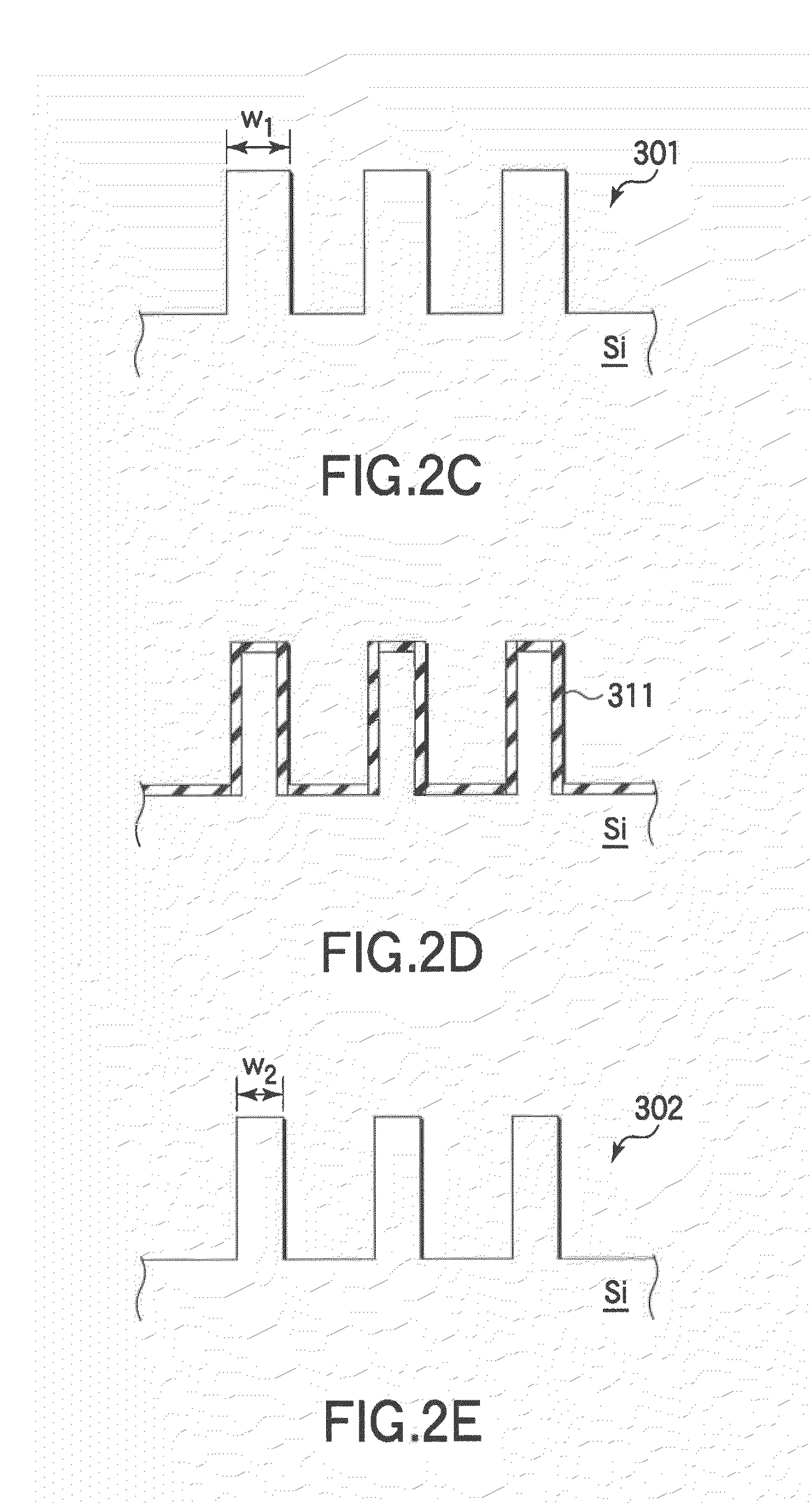

Pattern forming method and semiconductor device manufacturing method

ActiveUS8119530B2Not easy to damageImprove film qualitySemiconductor/solid-state device manufacturingSemiconductor devicesLine widthSilicon oxide

A pattern forming method includes preparing a target object including silicon with an initial pattern formed thereon and having a first line width; performing a plasma oxidation process on the silicon surface inside a process chamber of a plasma processing apparatus and thereby forming a silicon oxide film on a surface of the initial pattern; and removing the silicon oxide film. The pattern forming method is arranged to repeatedly perform formation of the silicon oxide film and removal of the silicon oxide film so as to form an objective pattern having a second line width finer than the first line width on the target object.

Owner:NAGOYA UNIVERSITY +1

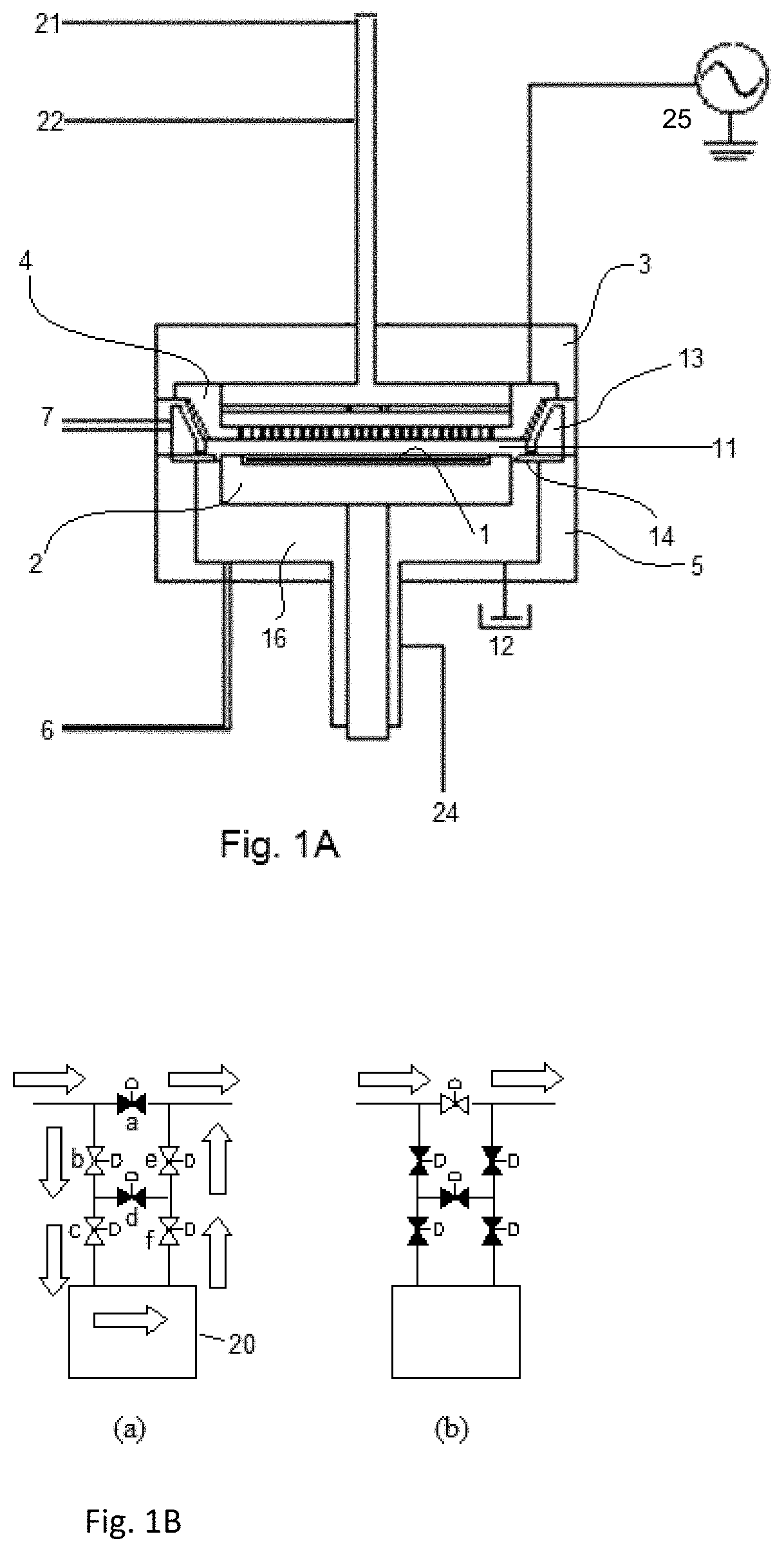

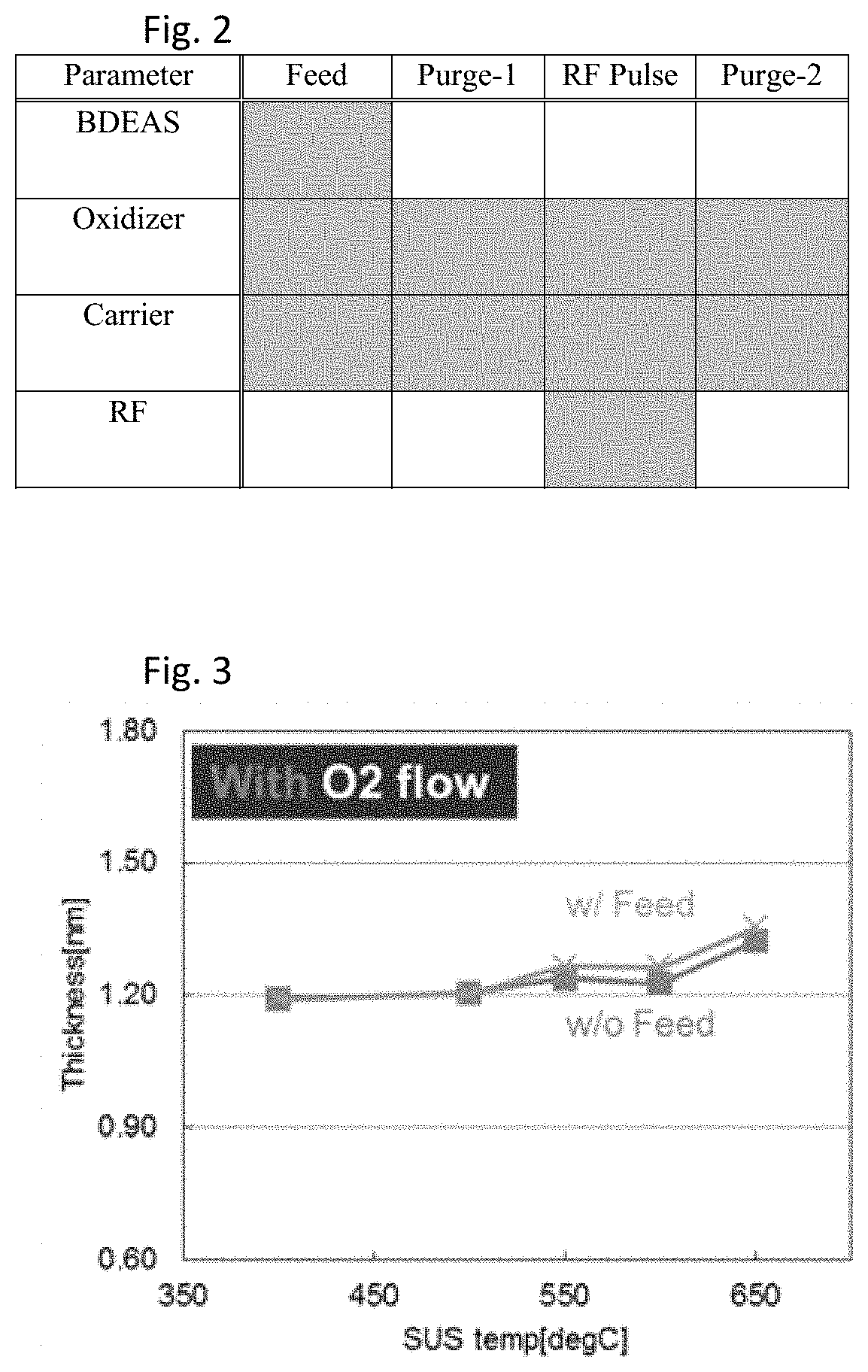

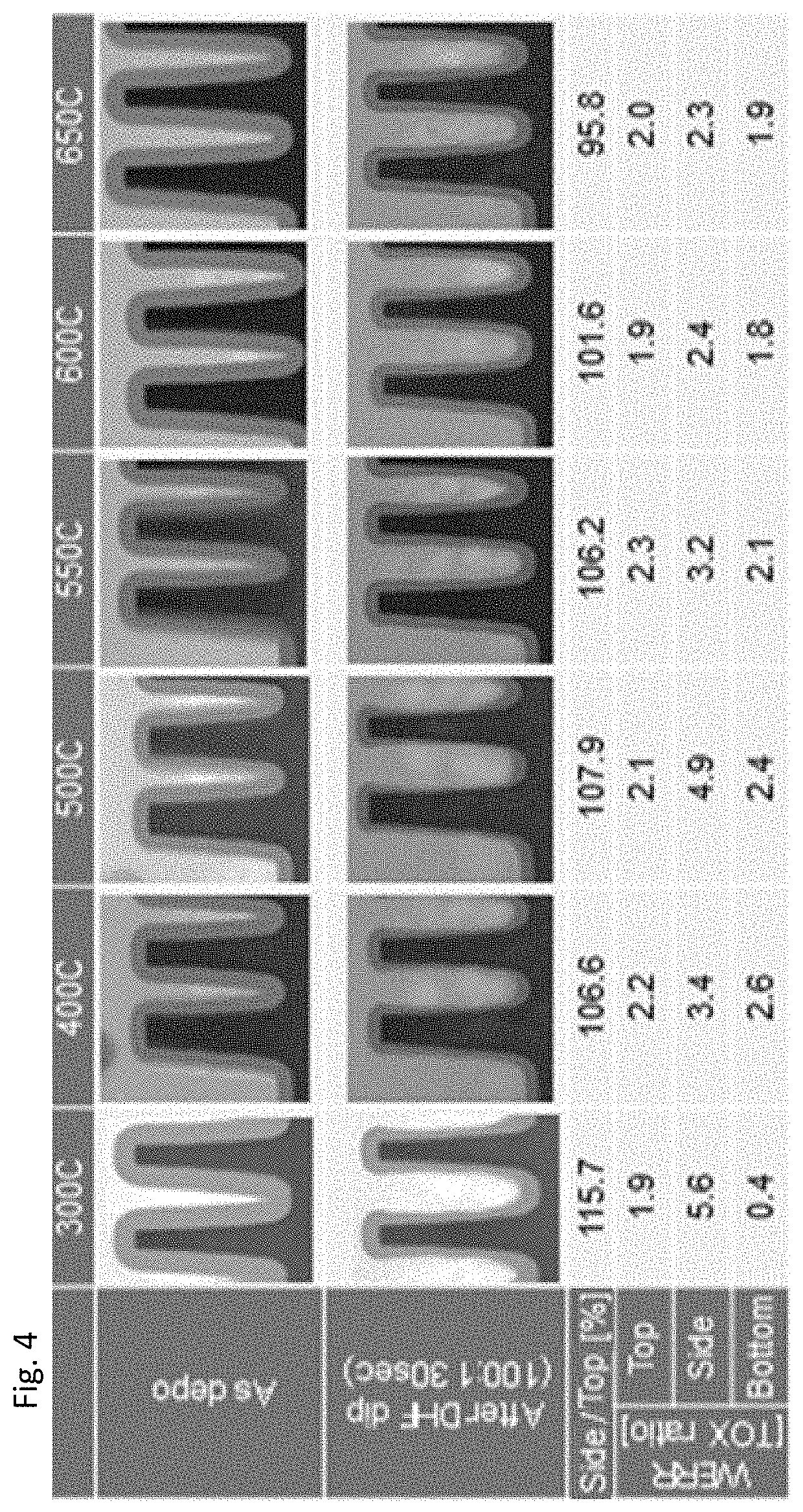

Method for depositing silicon oxide film having improved quality by peald using bis(diethylamino)silane

ActiveUS20210057214A1Avoid thermal decompositionImprove film qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorOxygen plasma

In a method of depositing a silicon oxide film using bis(diethylamino)silane (BDEAS) on a substrate in a reaction space by plasma-enhanced atomic layer deposition (PEALD), each repeating deposition cycle of PEALD includes steps of: (i) adsorbing BDEAS on the substrate placed on a susceptor having a temperature of higher than 400° C. in an atmosphere substantially suppressing thermal decomposition of BDEAS in the reaction space; and (ii) exposing the substrate on which BDEAS is adsorbed to an oxygen plasma in the atmosphere in the reaction space, thereby depositing a monolayer or sublayer of silicon oxide.

Owner:ASM IP HLDG BV

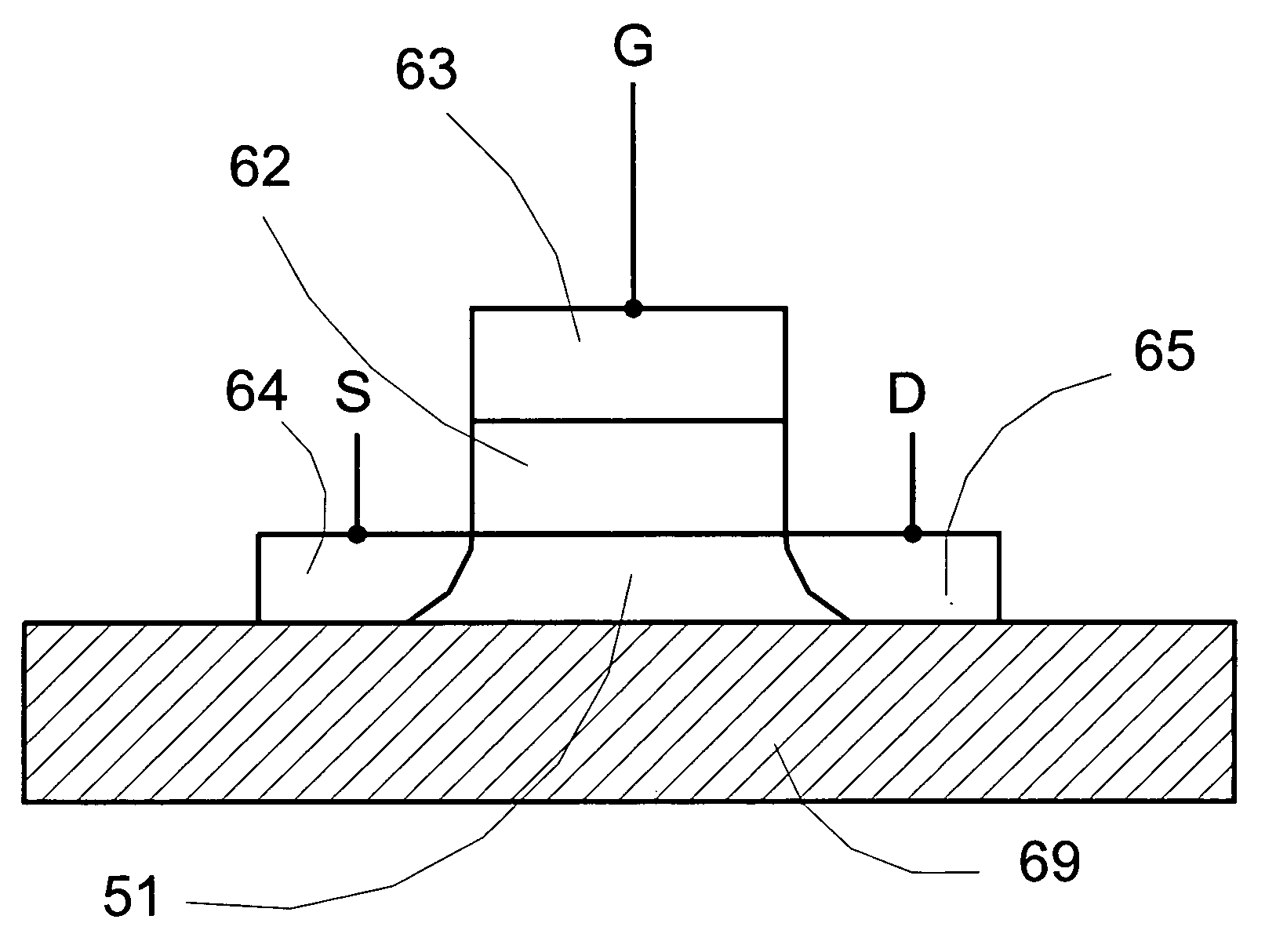

Semiconductive metal oxide thin film ferroelectric memory transistor

InactiveUS20060038242A1Simplify the manufacturing processHigh densitySemiconductor/solid-state device manufacturingSemiconductor devicesDielectricGate dielectric

The present invention discloses a novel transistor structure employing semiconductive metal oxide as the transistor conductive channel. By replacing the silicon conductive channel with a semiconductive metal oxide channel, the transistors can achieve simpler fabrication process and could realize 3D structure to increase circuit density. The disclosed semiconductive metal oxide transistor can have great potential in ferroelectric non volatile memory device with the further advantages of good interfacial properties with the ferroelectric materials, possible lattice matching with the ferroelectric layer, reducing or eliminating the oxygen diffusion problem to improve the reliability of the ferroelectric memory transistor. The semiconductive metal oxide film is preferably a metal oxide exhibiting semiconducting properties at the transistor operating conditions, for example, In2O3 or RuO2. The present invention ferroelectric transistor can be a metal-ferroelectric-semiconductive metal oxide FET having a gate stack of a top metal electrode disposed on a ferroelectric layer disposed on a semiconductive metal oxide channel on a substrate. Using additional layer of bottom electrode and gate dielectric, the present invention ferroelectric transistor can also be a metal-ferroelectric-metal (optional)-gate dielectric (optional)-semiconductive metal oxide FET.

Owner:SHARP KK

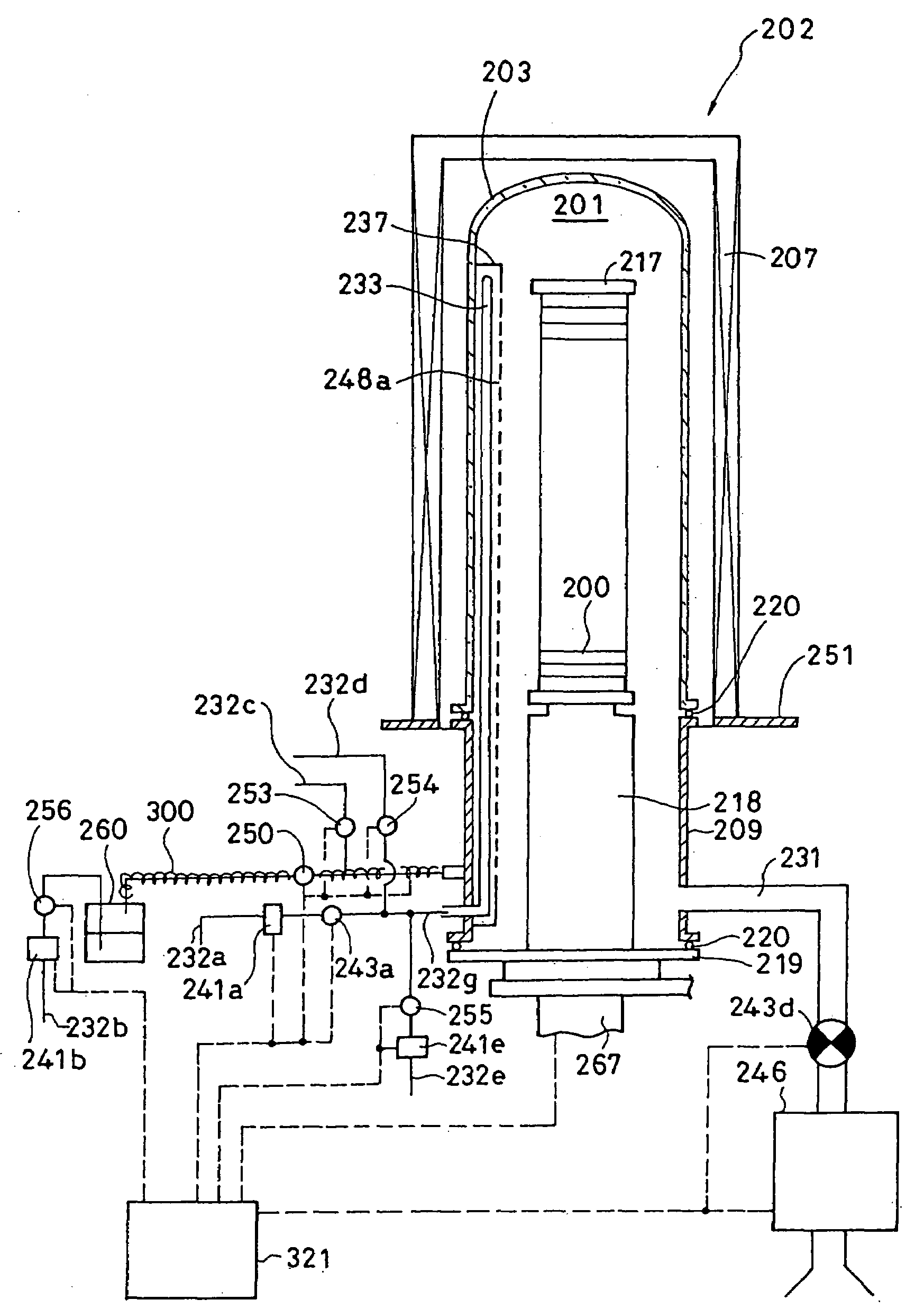

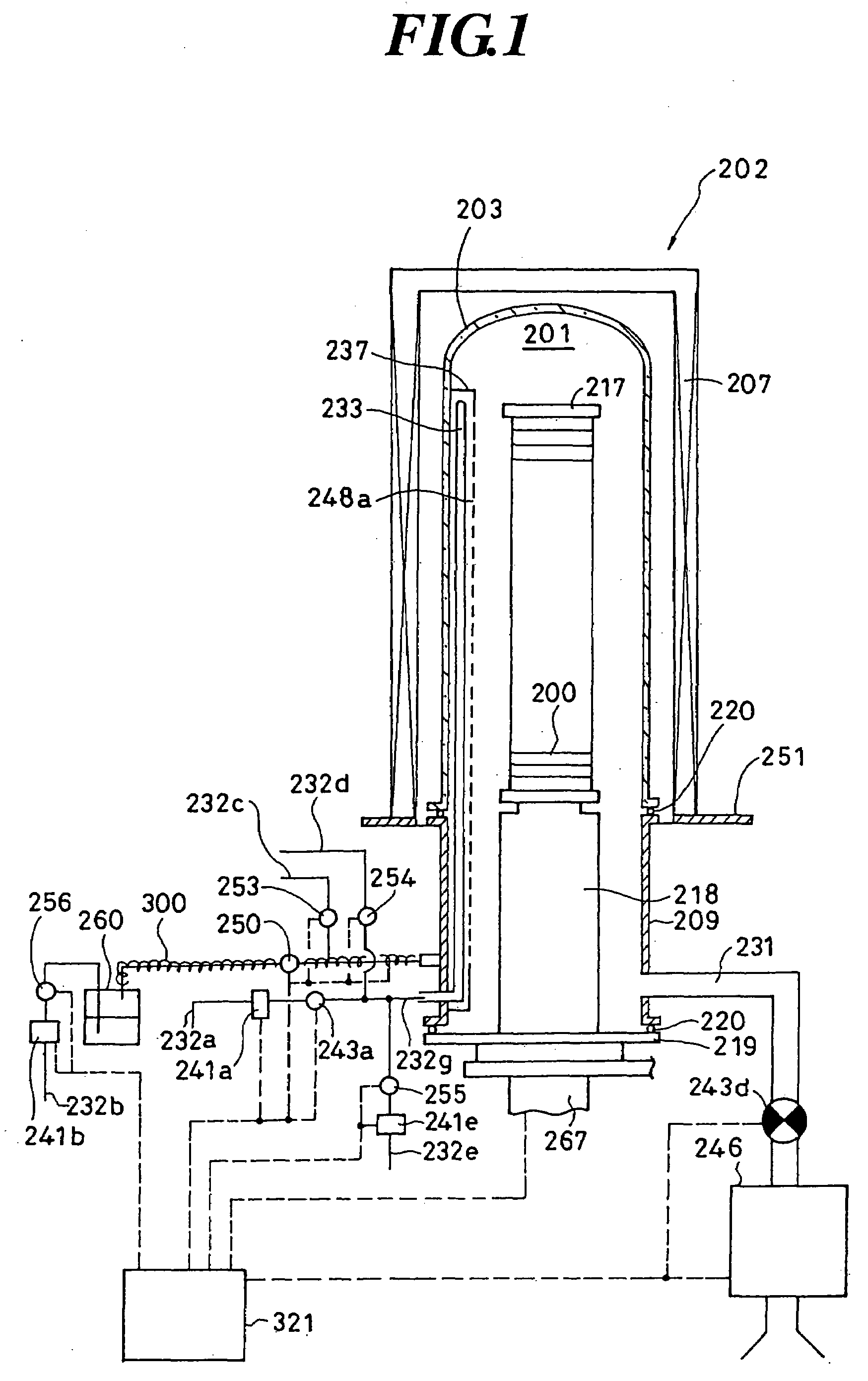

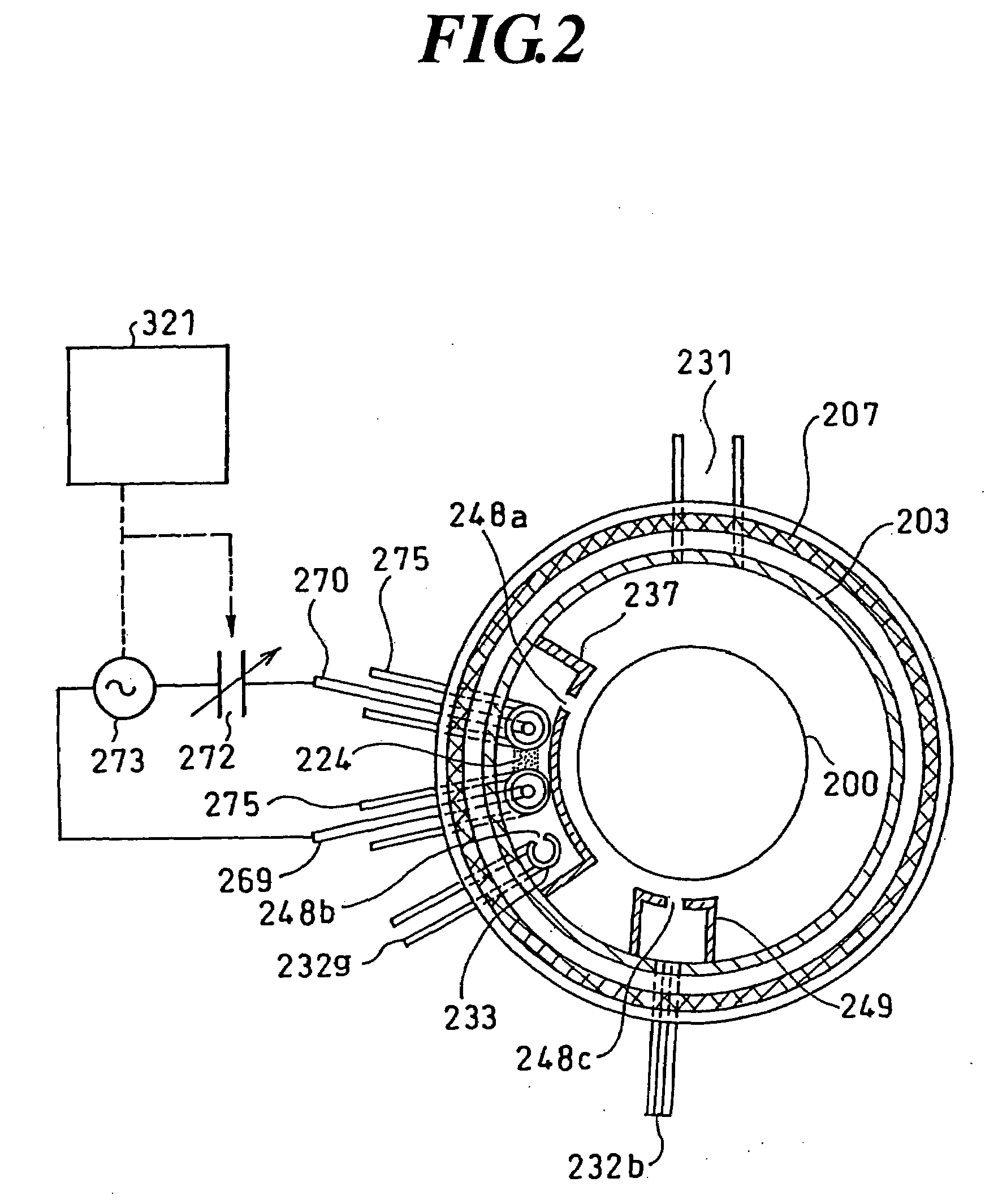

Film formation apparatus and method for semiconductor process

ActiveUS20050287775A1Increase ratingsImprove film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingProcess regionProcess engineering

A film formation method for a semiconductor process is arranged to form a thin film on a target substrate by CVD, while supplying a first process gas for film formation and a second process gas for reacting with the first process gas to a process field accommodating the target substrate. The method alternately includes first to fourth steps. The first step performs supply of the first and second process gases to the process field. The second step stops supply of the first and second process gases to the process field. The third step performs supply of the second process gas to the process field while stopping supply of the first process gas to the process field. The fourth step stops supply of the first and second process gases to the process field.

Owner:TOKYO ELECTRON LTD

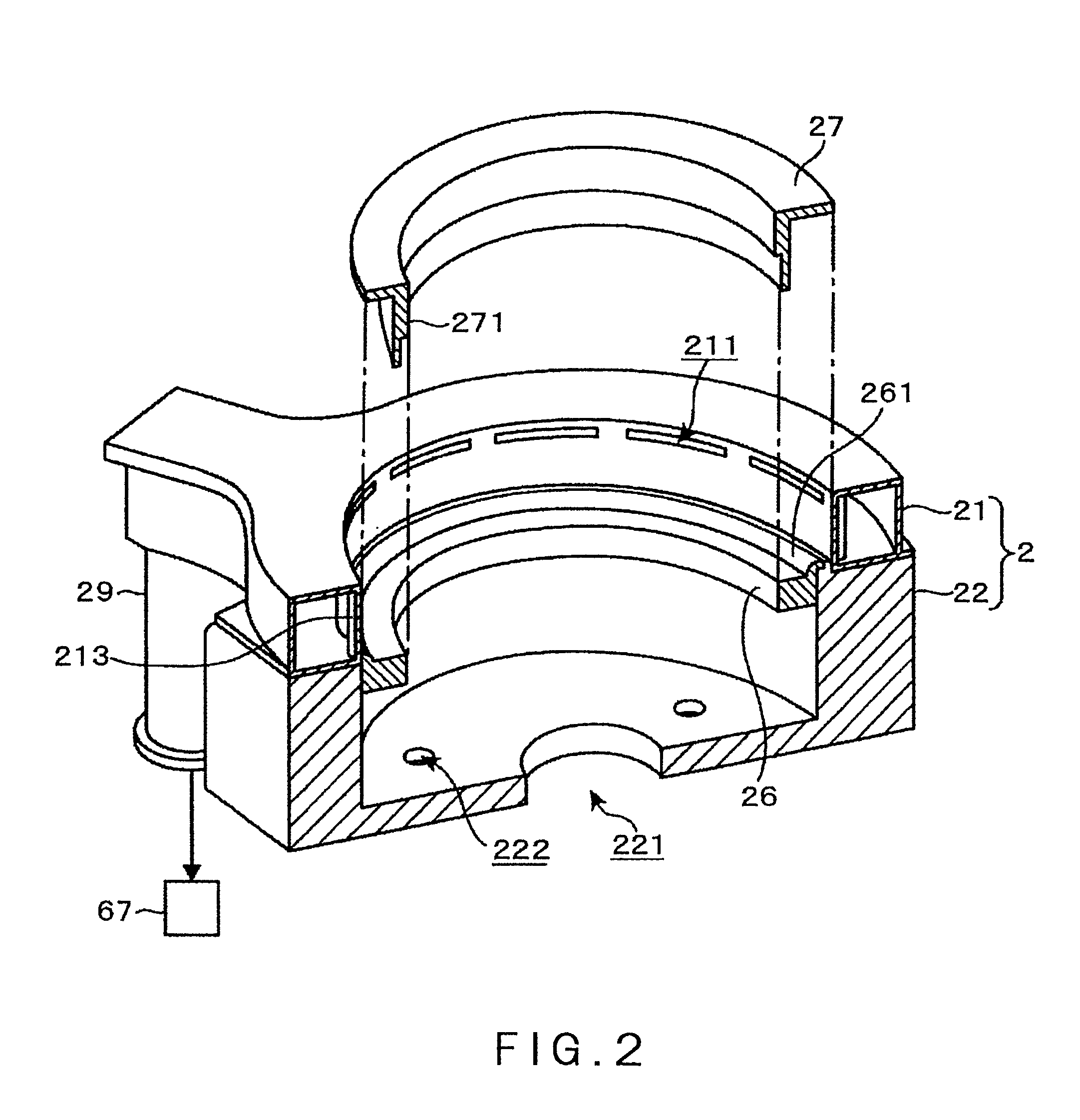

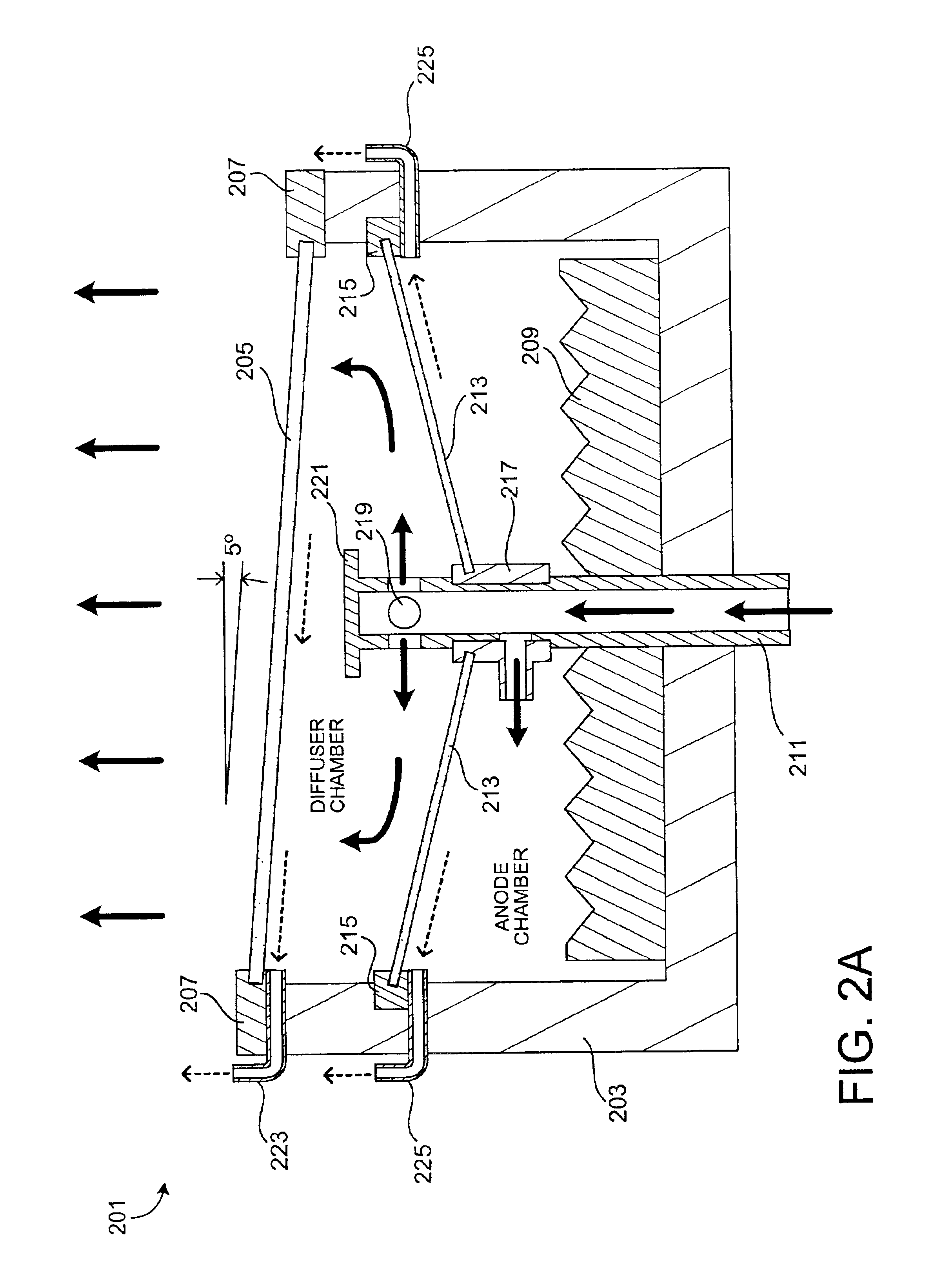

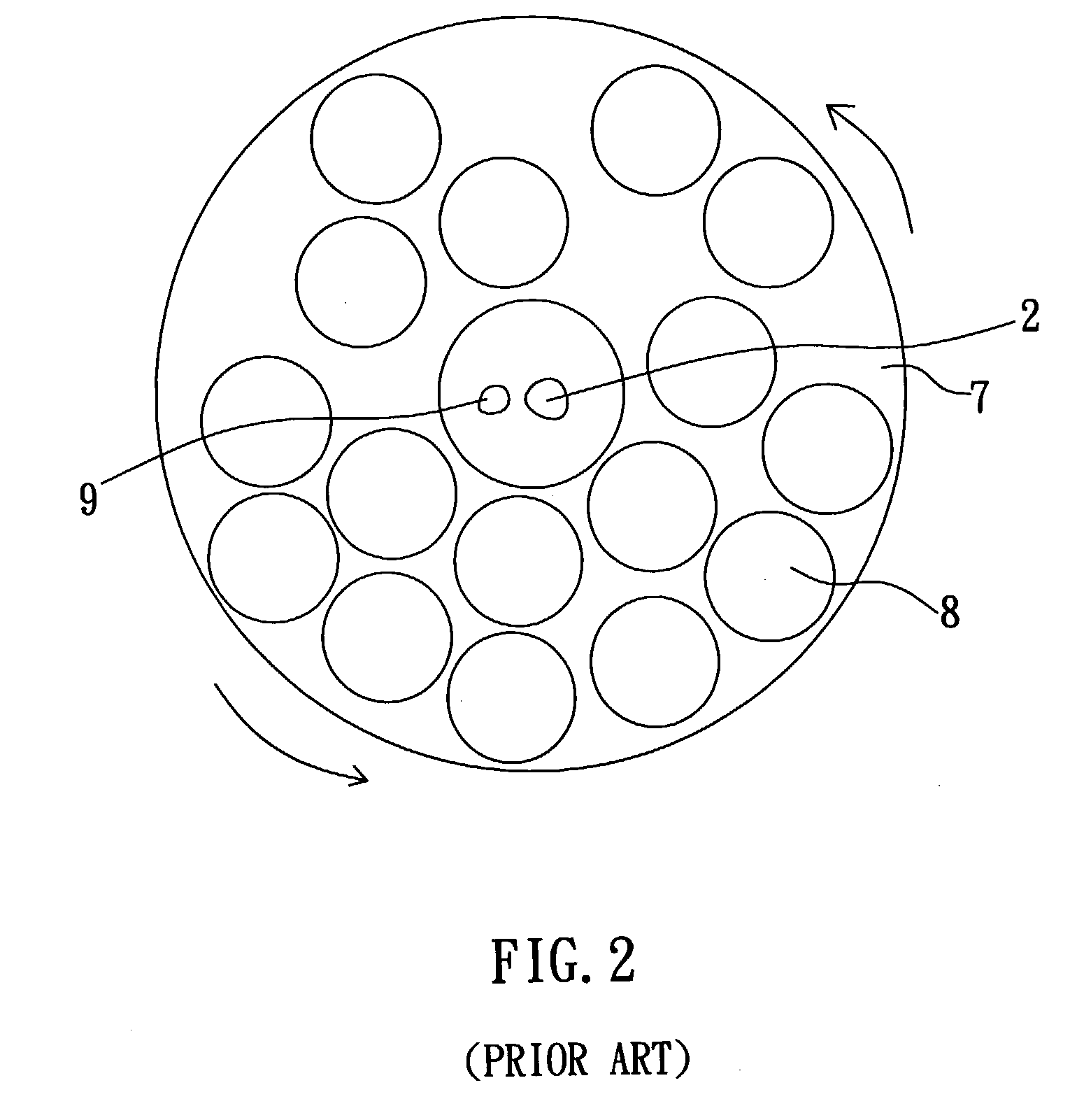

Methods and apparatus for controlling electrolyte flow for uniform plating

InactiveUS6964792B1Prevent movementQuality improvementCellsLiquid surface applicatorsControl flowFluid control

The present invention provides apparatus and methods for controlling flow dynamics of a plating fluid during a plating process. The invention achieves this fluid control through use of a diffuser membrane. Plating fluid is pumped through the membrane; the design and characteristics of the membrane provide a uniform flow pattern to the plating fluid exiting the membrane. Thus a work piece, upon which a metal or other conductive material is to be deposited, is exposed to a uniform flow of plating fluid.

Owner:NOVELLUS SYSTEMS

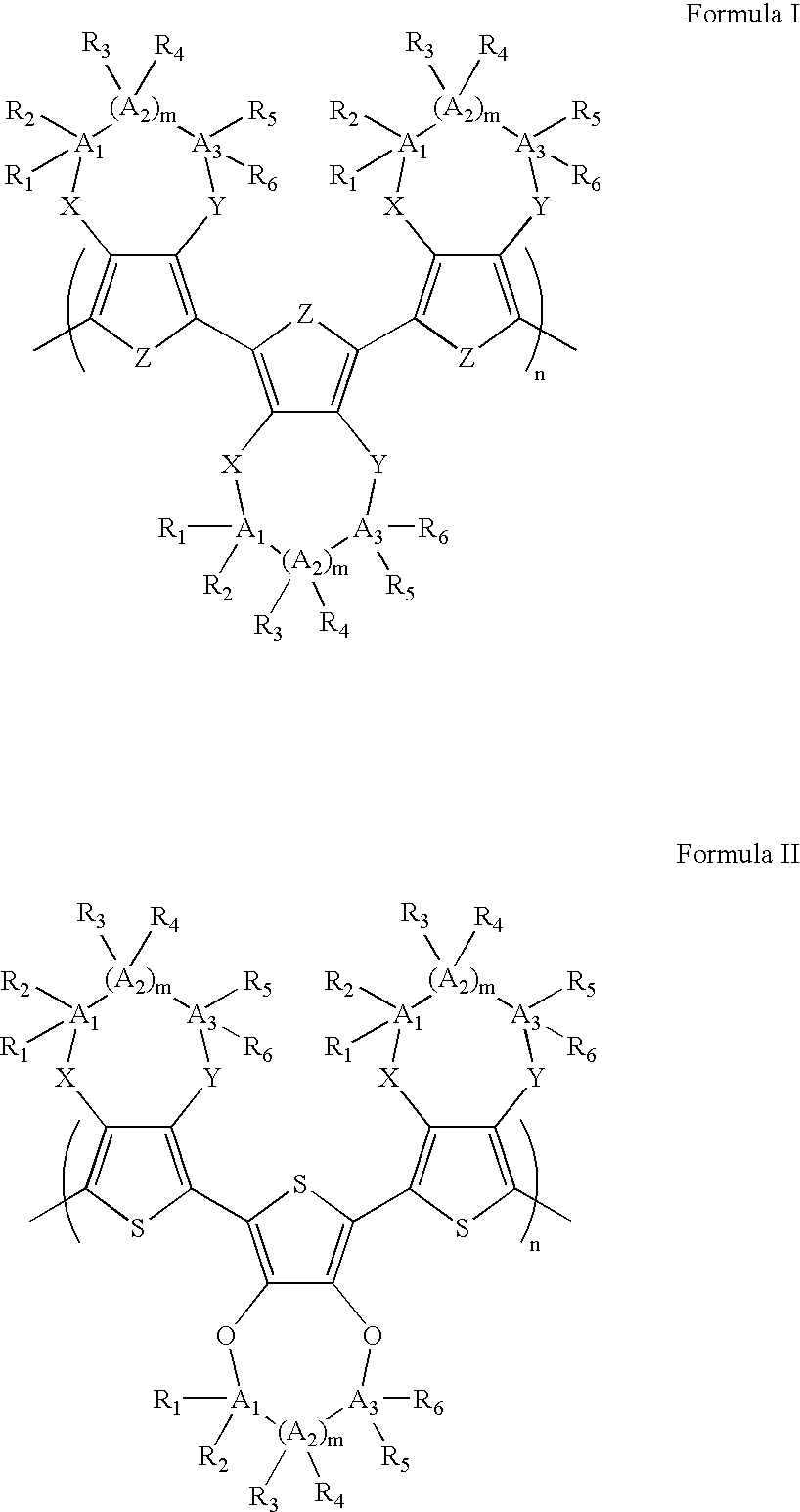

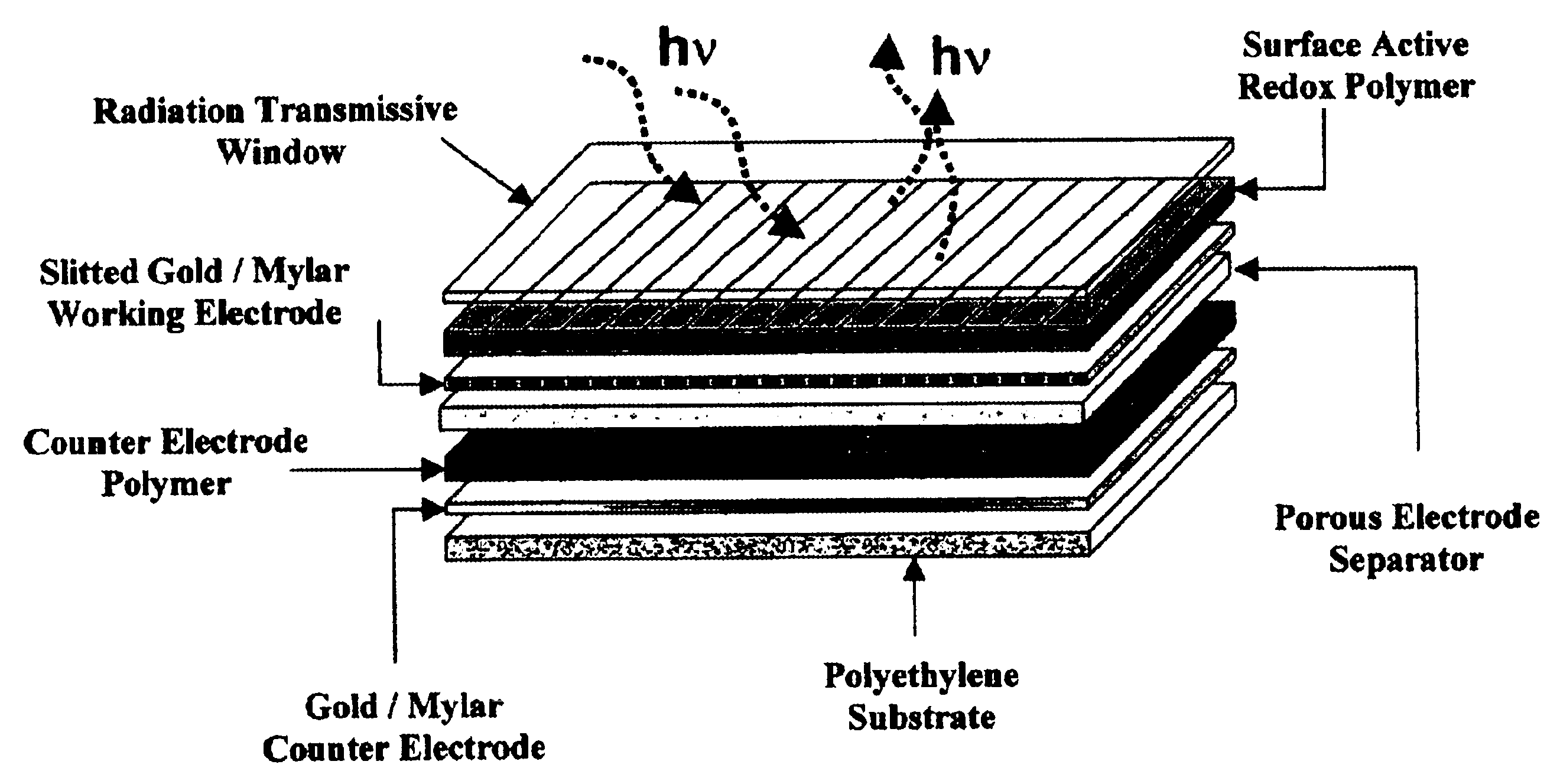

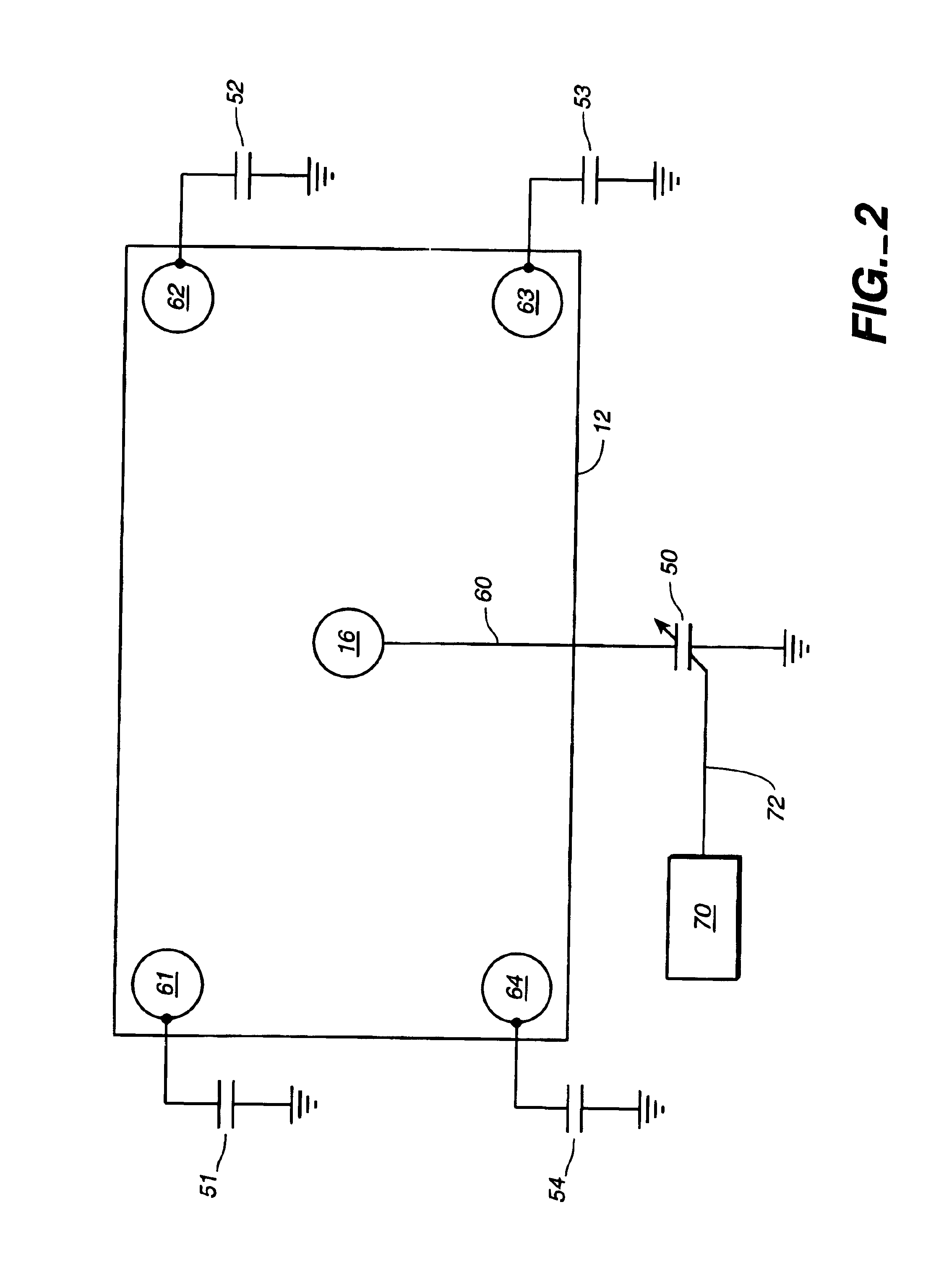

Electrochromic polymers and polymer electrochromic devices

InactiveUS6791738B2Increase the gapLess structural defectsPhotosensitive materialsElectrography/magnetographyPolymer scienceGas phase

The subject invention pertains to electrochromic polymers and polymer electrochromic devices. In a specific embodiment, two complementary polymers can be matched and incorporated into dual polymer electrochromic devices. The anodically coloring polymers in accordance with the subject invention can allow control over the color, brightness, and environmental stability of an electrochromic window. In addition, high device contrast ratios, high transmittance changes, and high luminance changes can be achieved, along with half-second switching times for full color change. Also provided are electrochromic devices such as advertising signage, video monitors, stadium scoreboards, computers, announcement boards, warning systems for cell phones, warning / information systems for automobiles, greeting cards, electrochromic windows, billboards, electronic books, and electrical wiring. The subject invention also provides for the use of complementary electrochromic polymers in the manufacture of electrochromic devices. In some embodiments, the devices of the invention can be prepared using metal vapor deposition or line patterning.

Owner:FLORIDA UNIV OF A FLORIDA

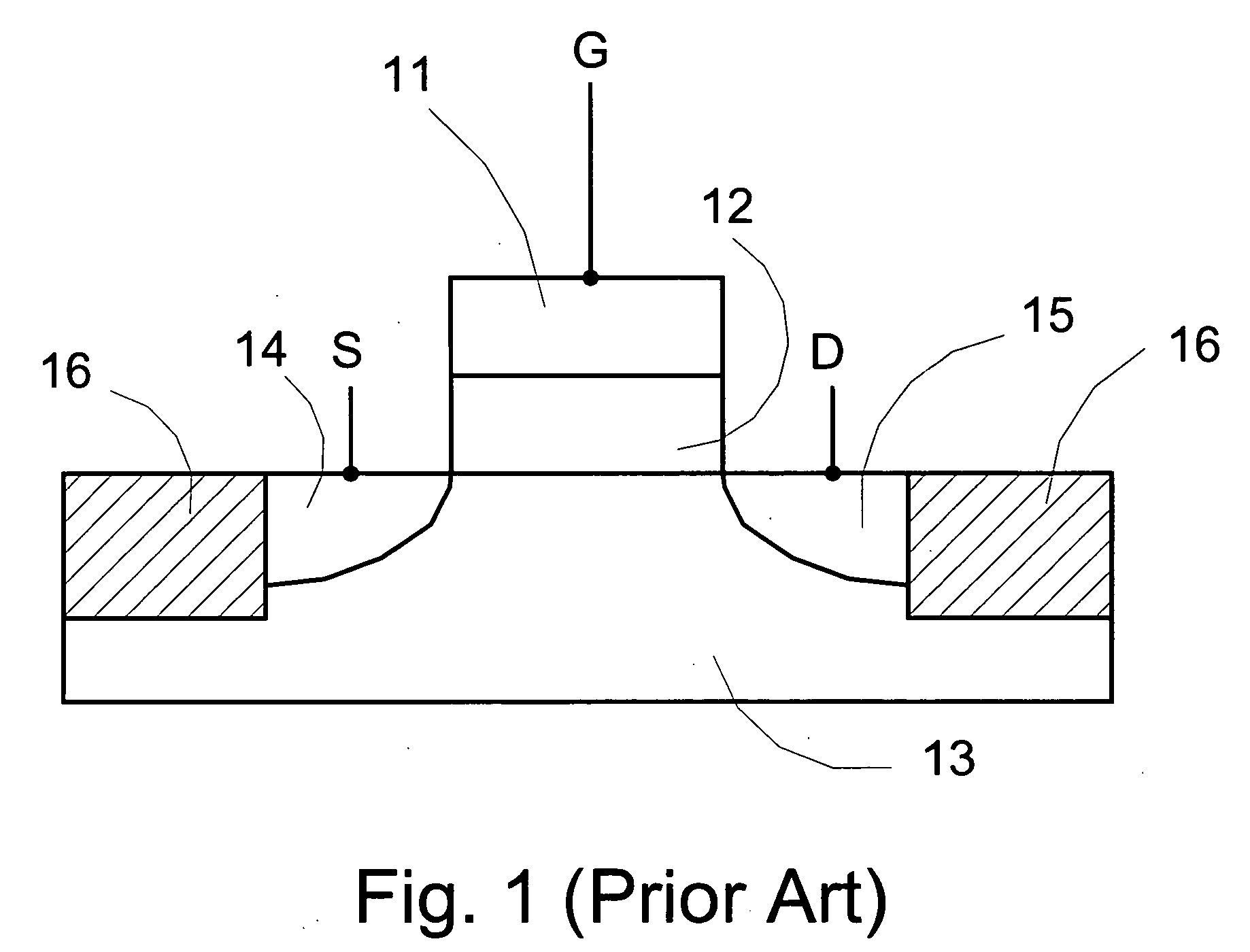

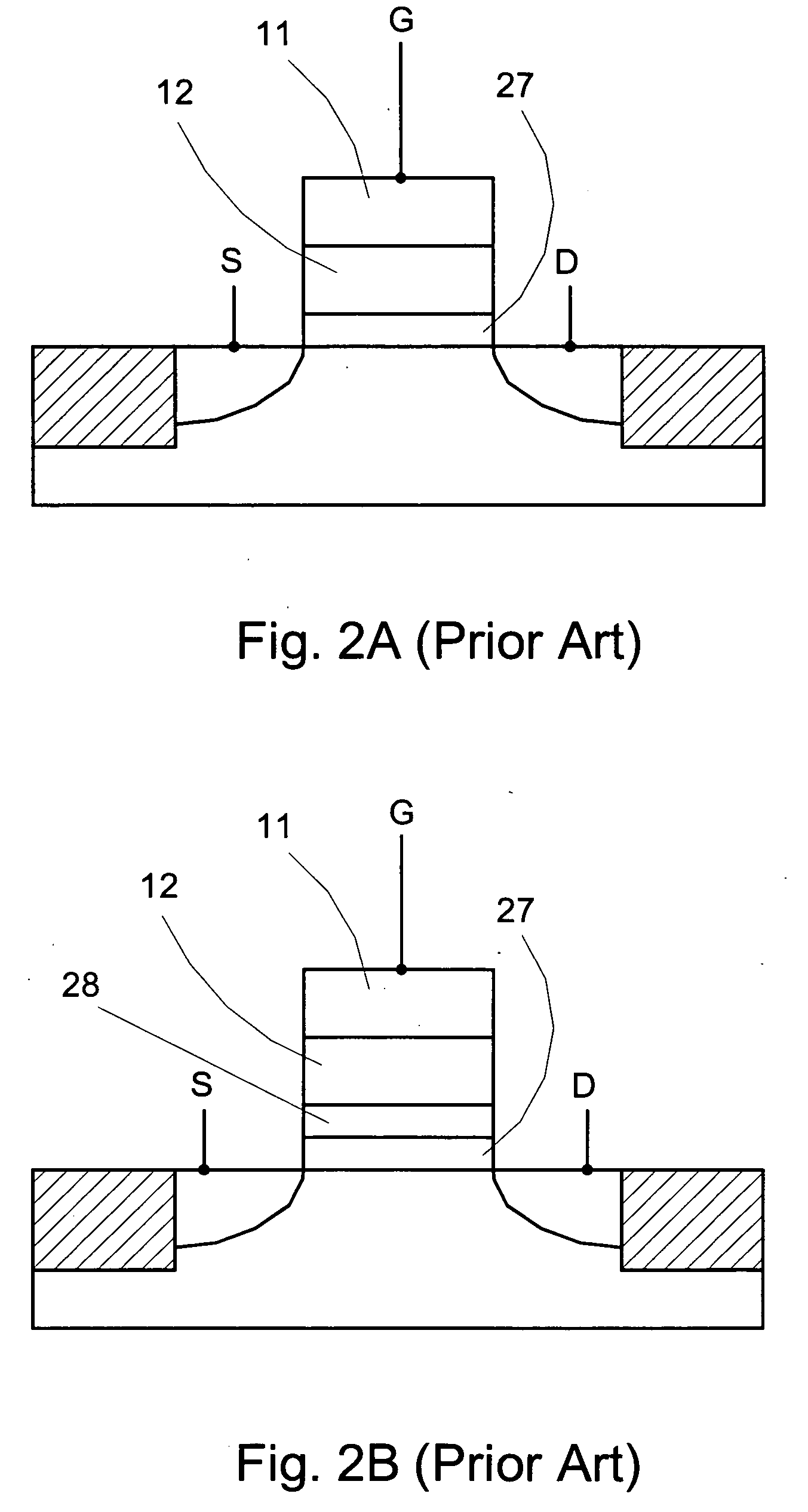

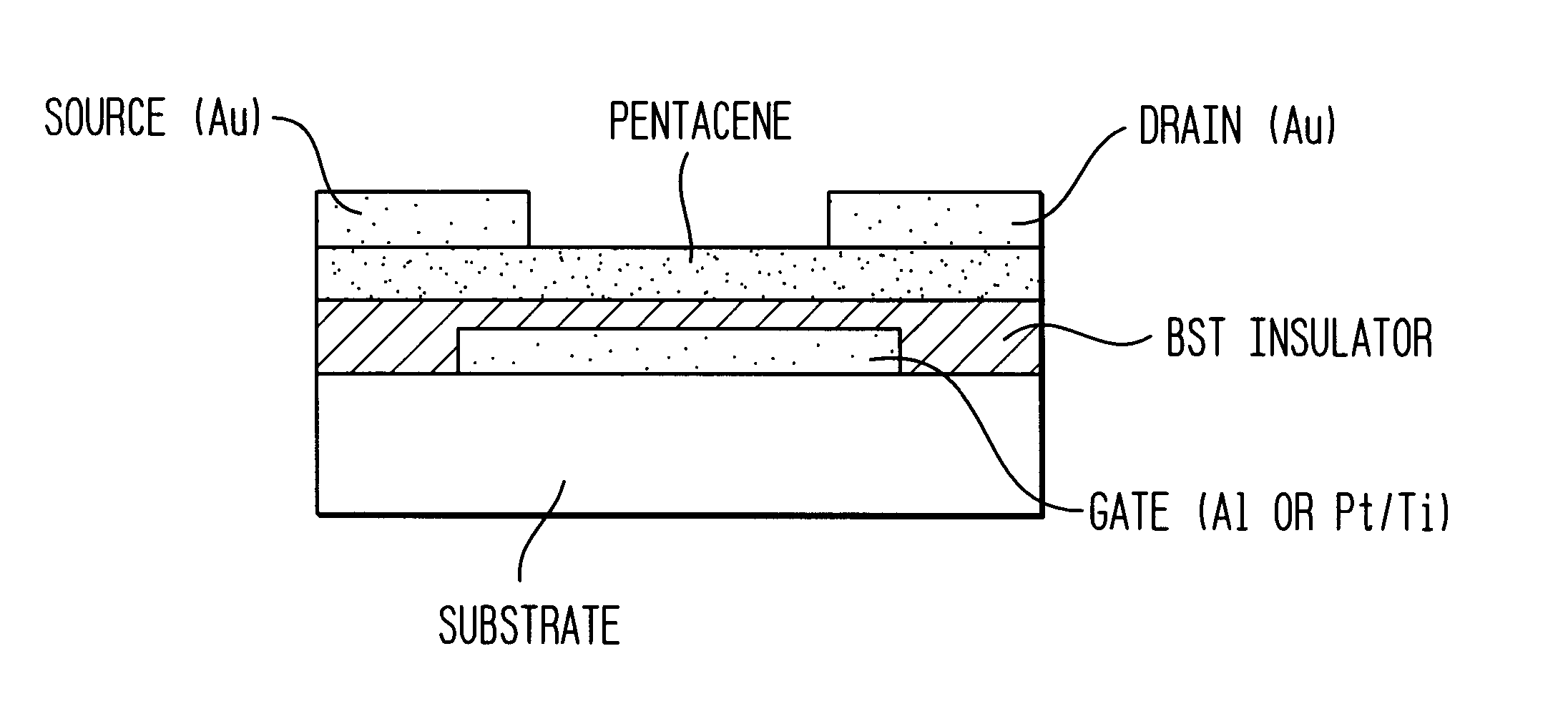

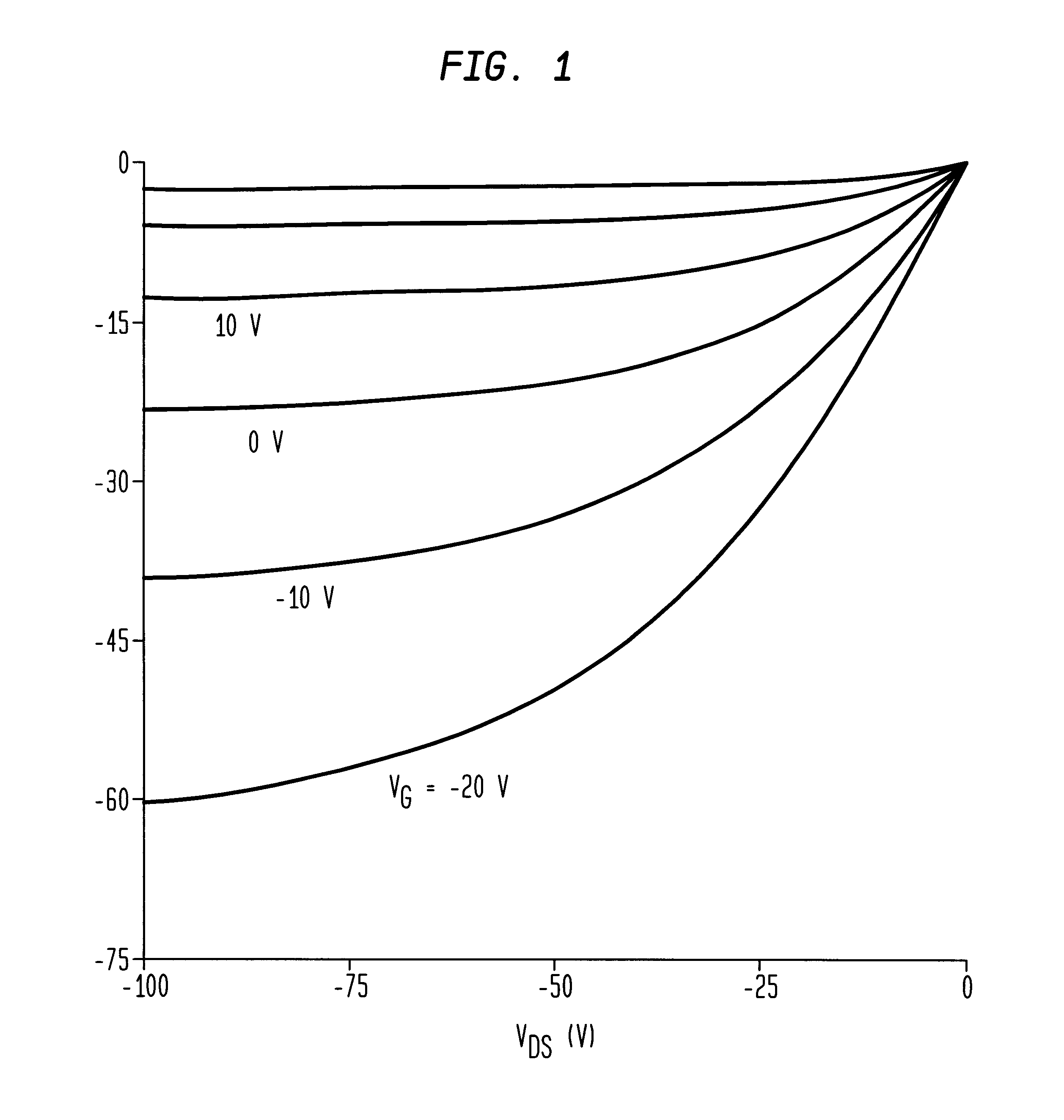

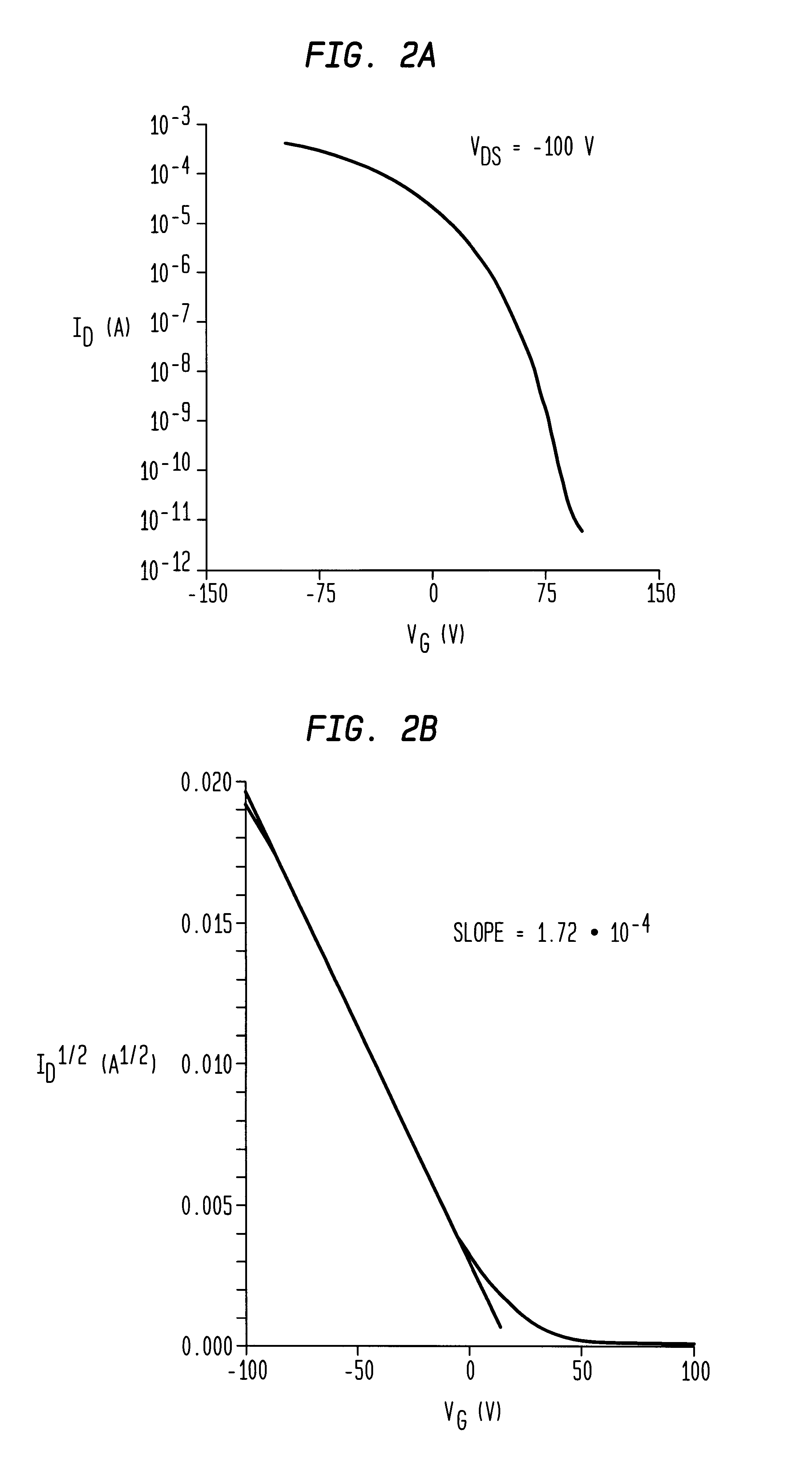

Thin-film field-effect transistor with organic semiconductor requiring low operating voltages

InactiveUS6344660B1Reduce thicknessImprove mobilityTransistorSolid-state devicesDisplay deviceFlat panel display

A thin film transistor (TFT) device structure based on an organic semiconductor material, that exhibits a high field effect mobility, high current modulation and a low sub-threshold slope at lower operating voltages than the current state of the art organic TFT devices. The structure comprises a suitable substrate disposed with he following sequence of features: a set of conducting gate electrodes covered with a high dielectric constant insulator, a layer of the organic semiconductor, sets of electrically conducting source and drain electrodes corresponding to each of the gate lines, and an optional passivation layer that can overcoat and protect the device structure. Use of high dielectric constant gate insulators exploits the unexpected gate voltage dependence of the organic semiconductor to achieve high field effect mobility levels at very low operating voltages. Judicious combinations of the choice of this insulator material and the means to integrate it into the TFT structure are taught that would enable easy fabrication on glass or plastic substrates and the use of such devices in flat panel display applications.

Owner:GLOBALFOUNDRIES INC

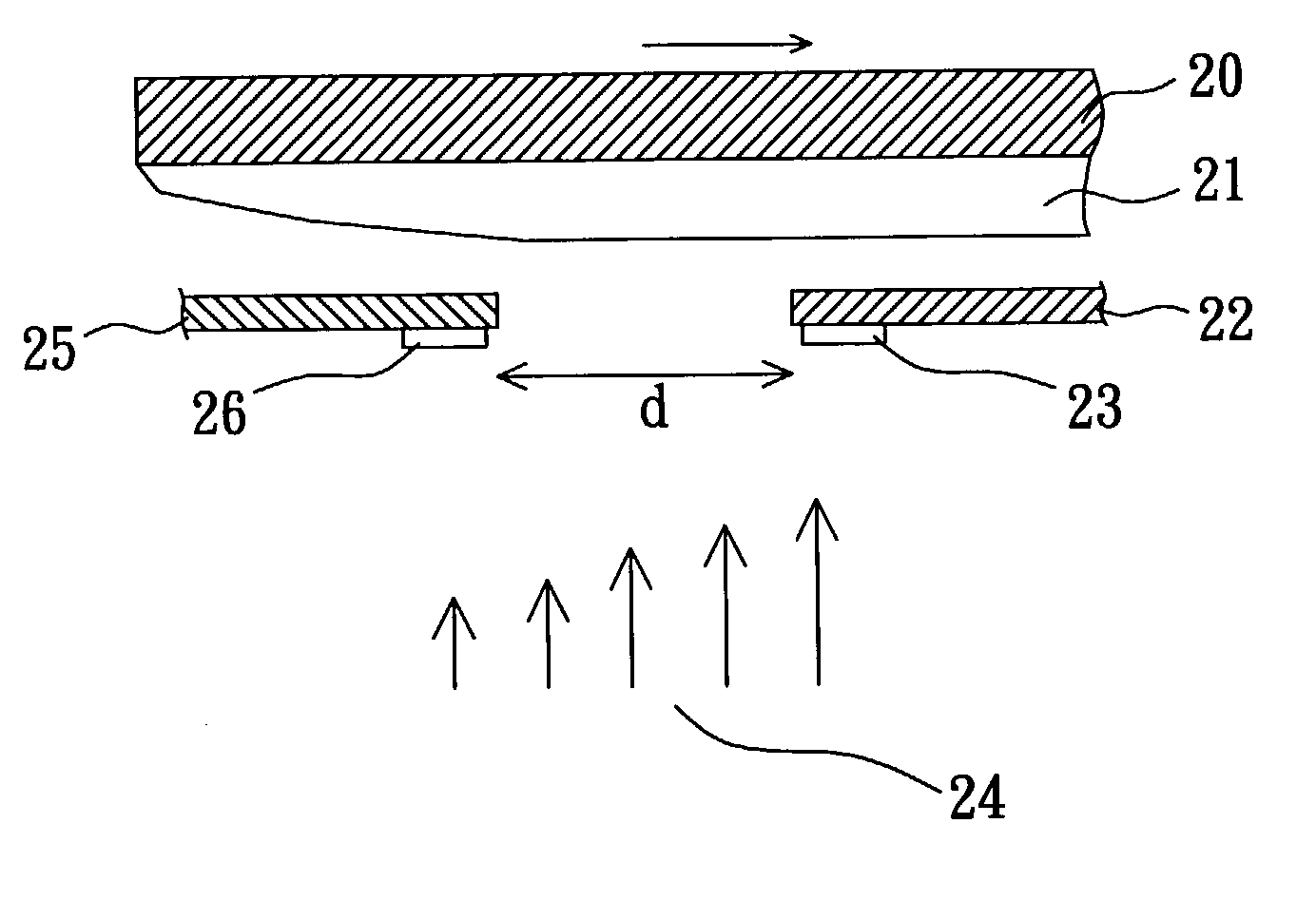

Dynamic film thickness control system/method and its utilization

InactiveUS20080216741A1Effectively afford controlEffectivelyLiquid surface applicatorsVacuum evaporation coatingControl systemEngineering

A dynamic film thickness control system / method and its utilization consisting of a minimum of one mask plate arranged between a substrate and a vapor source. A film thickness control device is utilized for real-time control over deposited film thickness and gradually moves the mask plate according to the film thickness control value acquired by the film thickness control device, enabling the mask plate to mask film zones on the said substrate to achieve the film thickness of a design objective. When the required zones of deposition are masked, the deposition of a particular film layer is completed.

Owner:HERMOSA THIN FILM

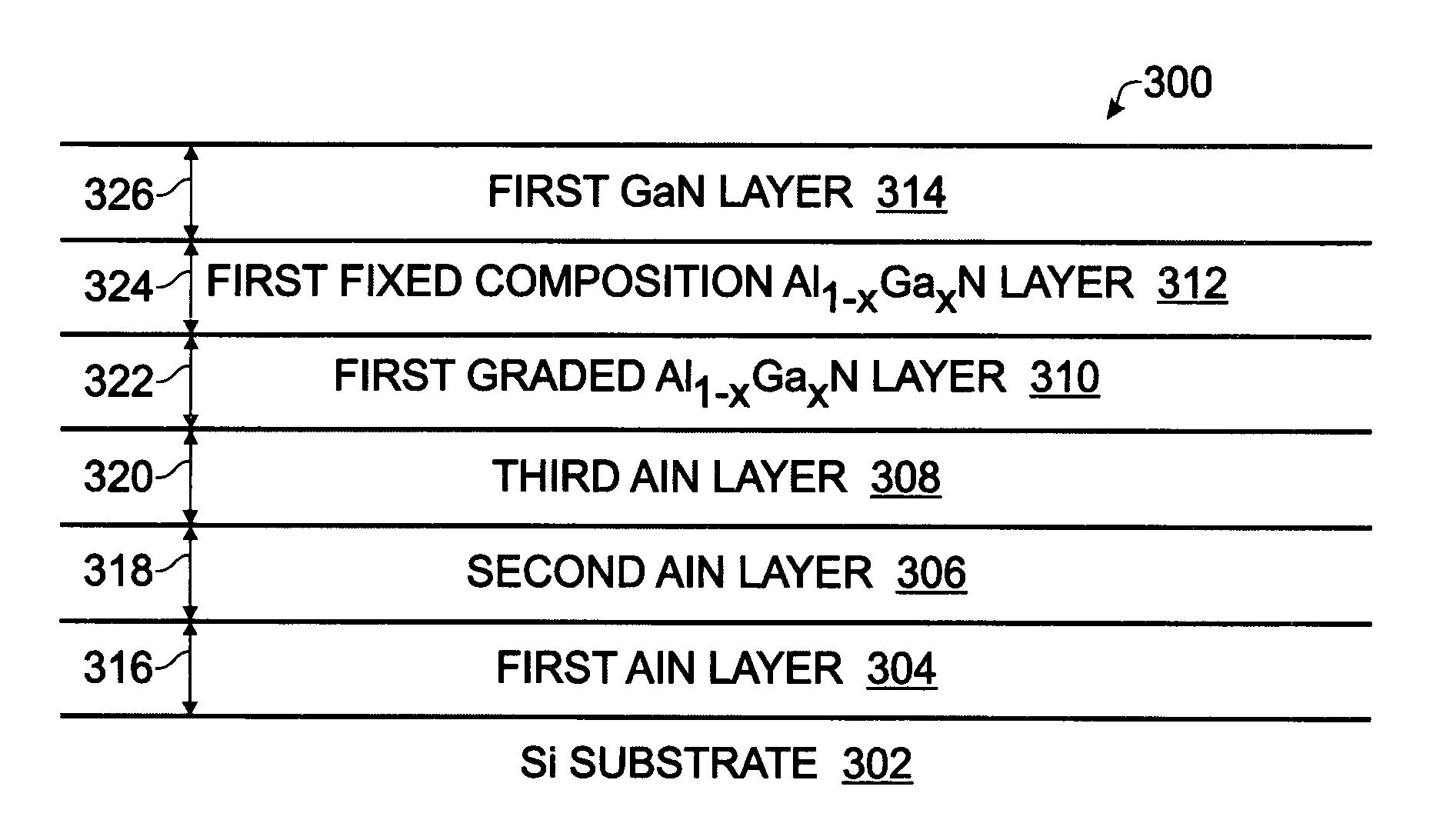

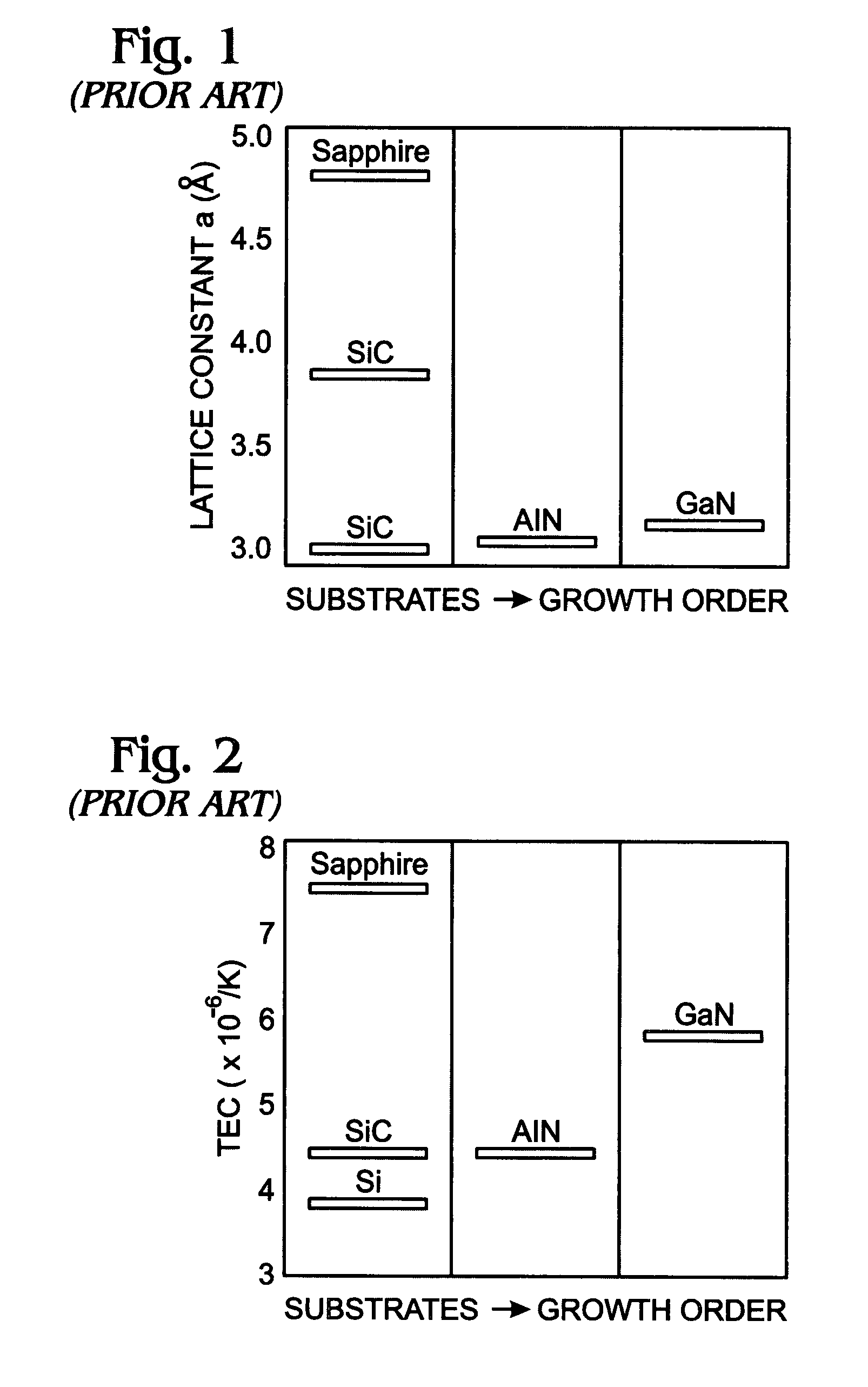

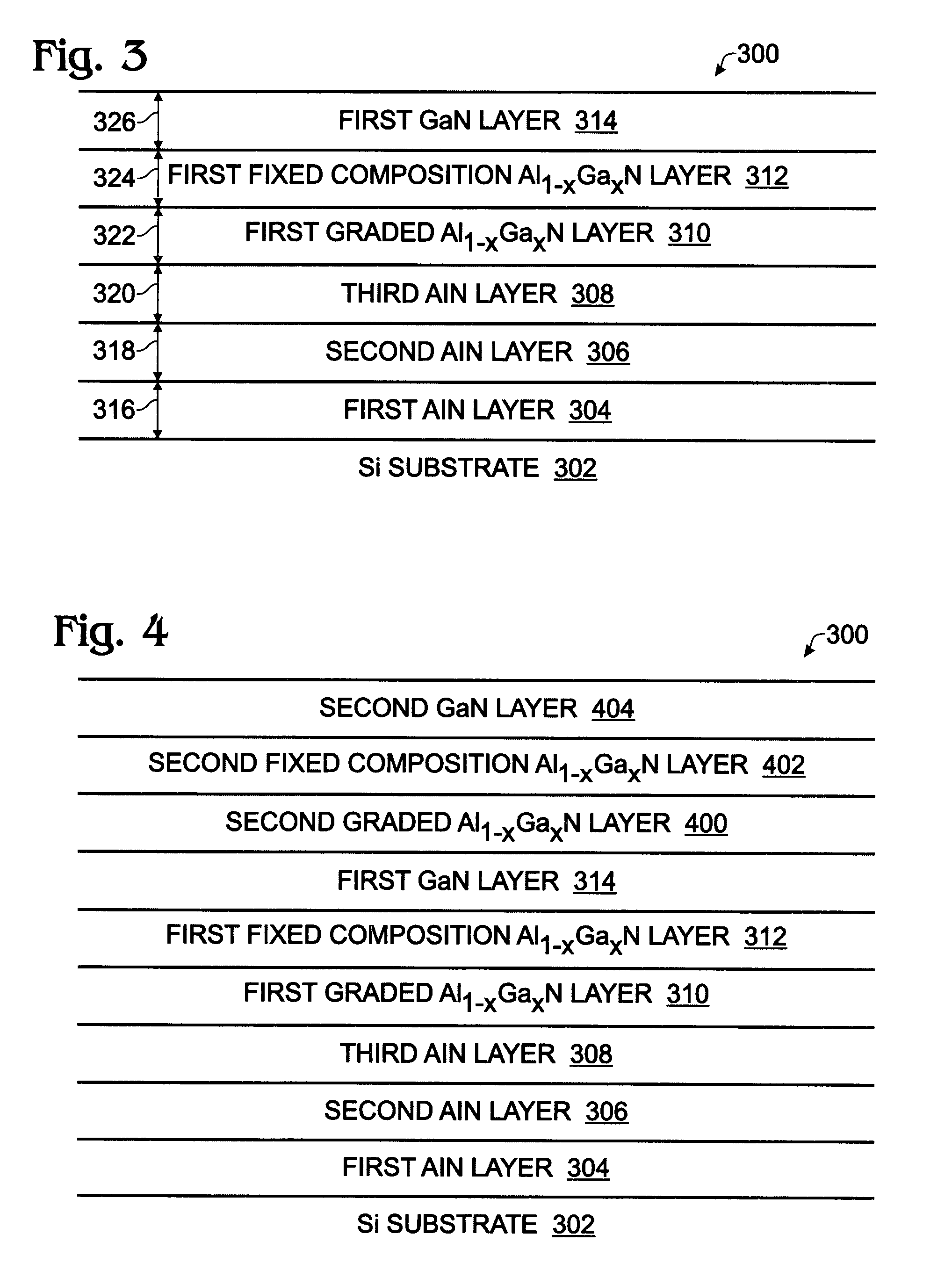

Gallium nitride-on-silicon interface using multiple aluminum compound buffer layers

InactiveUS7598108B2Thermal conductivityIncrease powerSemiconductor/solid-state device manufacturingSemiconductor devicesThermal expansionGallium nitride

A thermal expansion interface between silicon (Si) and gallium nitride (GaN) films using multiple buffer layers of aluminum compounds has been provided, along with an associated fabrication method. The method provides a (111) Si substrate and deposits a first layer of AlN overlying the substrate by heating the substrate to a relatively high temperature of 1000 to 1200° C. A second layer of AlN is deposited overlying the first layer of AlN at a lower temperature of 500 to 800° C. A third layer of AlN is deposited overlying the second layer of AlN by heating the substrate to the higher temperature range. Then, a grading Al1-XGaXN layer is formed overlying the third layer of AlN, where 0<X<1, followed by a fixed composition Al1-XGaXN layer overlying the first grading Al1-XGaXN layer. An epitaxial GaN layer can then be grown overlying the fixed composition Al1-XGaXN layer.

Owner:SHARP KK

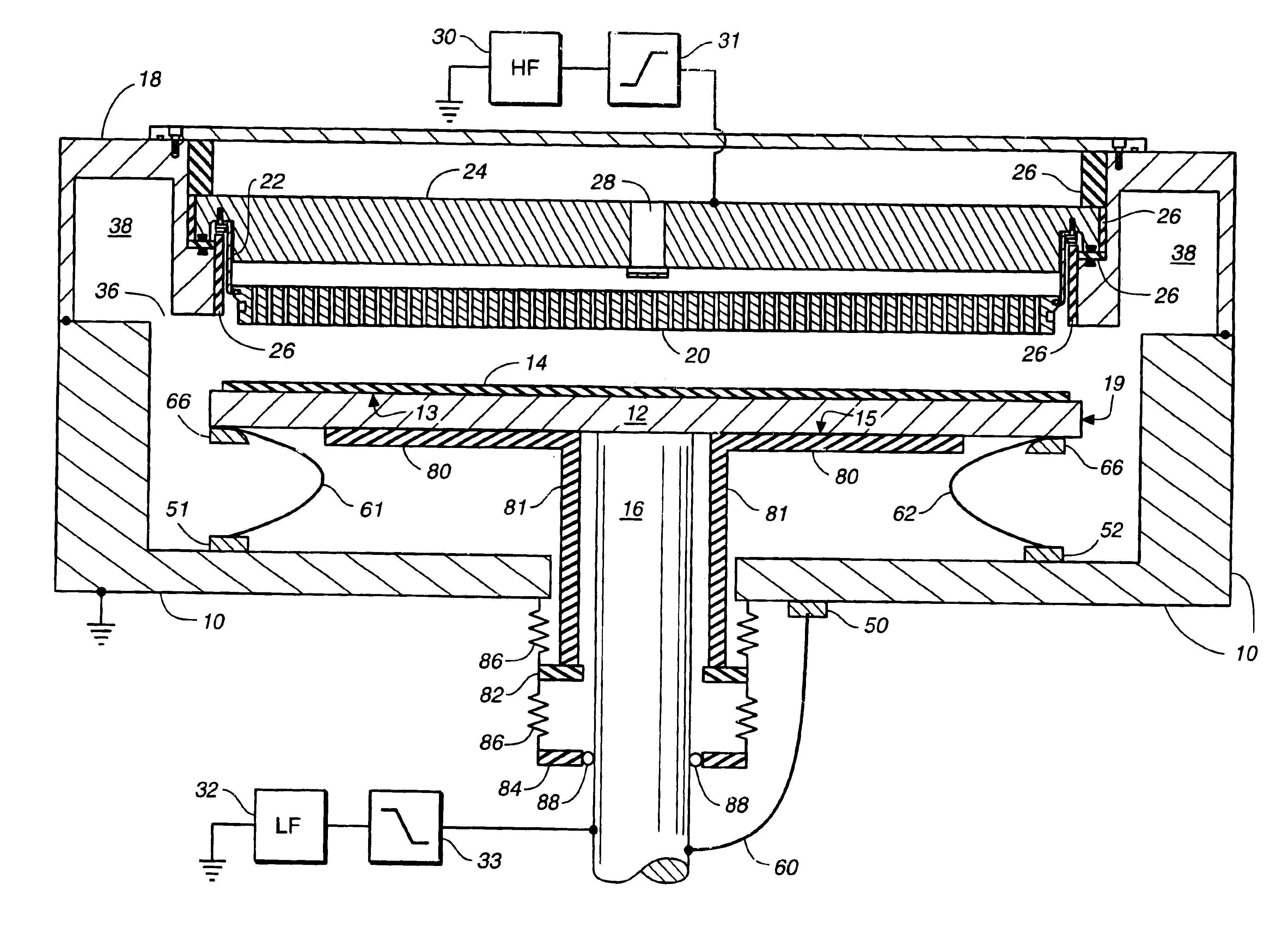

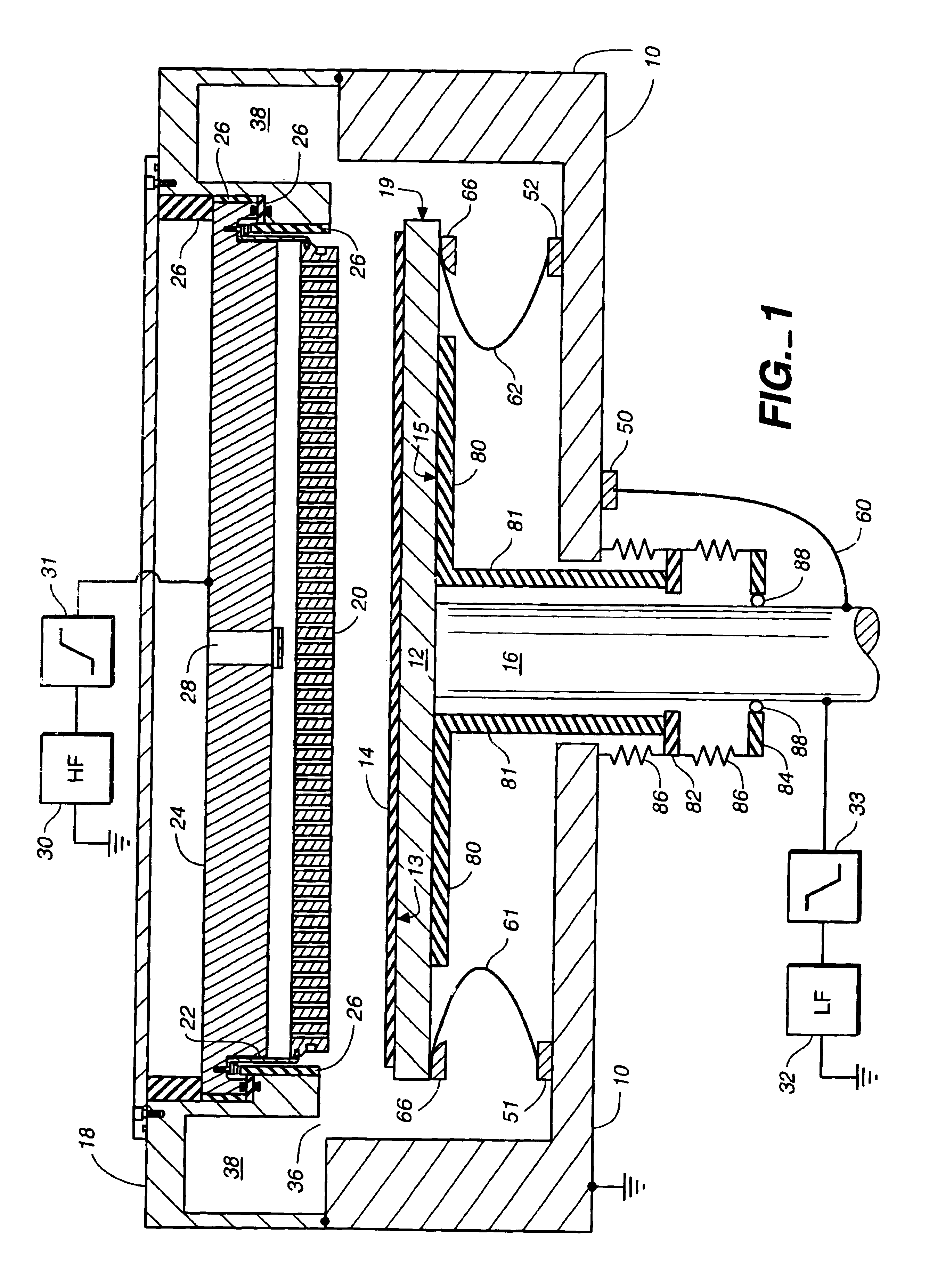

Multiple frequency plasma chamber with grounding capacitor at cathode

InactiveUS6857387B1Reduce and eliminate couplingImprove performanceElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityCoupling

An apparatus and method for fabricating an electronic workpiece in which first and second electrodes within a plasma chamber are respectively connected to low frequency and high frequency RF power supplies. At least one capacitor is connected between the first electrode and electrical ground. The one or more capacitors can reduce or eliminate the coupling of high frequency RF power to any plasma outside the region directly between the two electrodes. Consequently, the invention can improve the performance of the plasma process by concentrating more of the RF power in the region between the two electrodes.

Owner:APPLIED MATERIALS INC

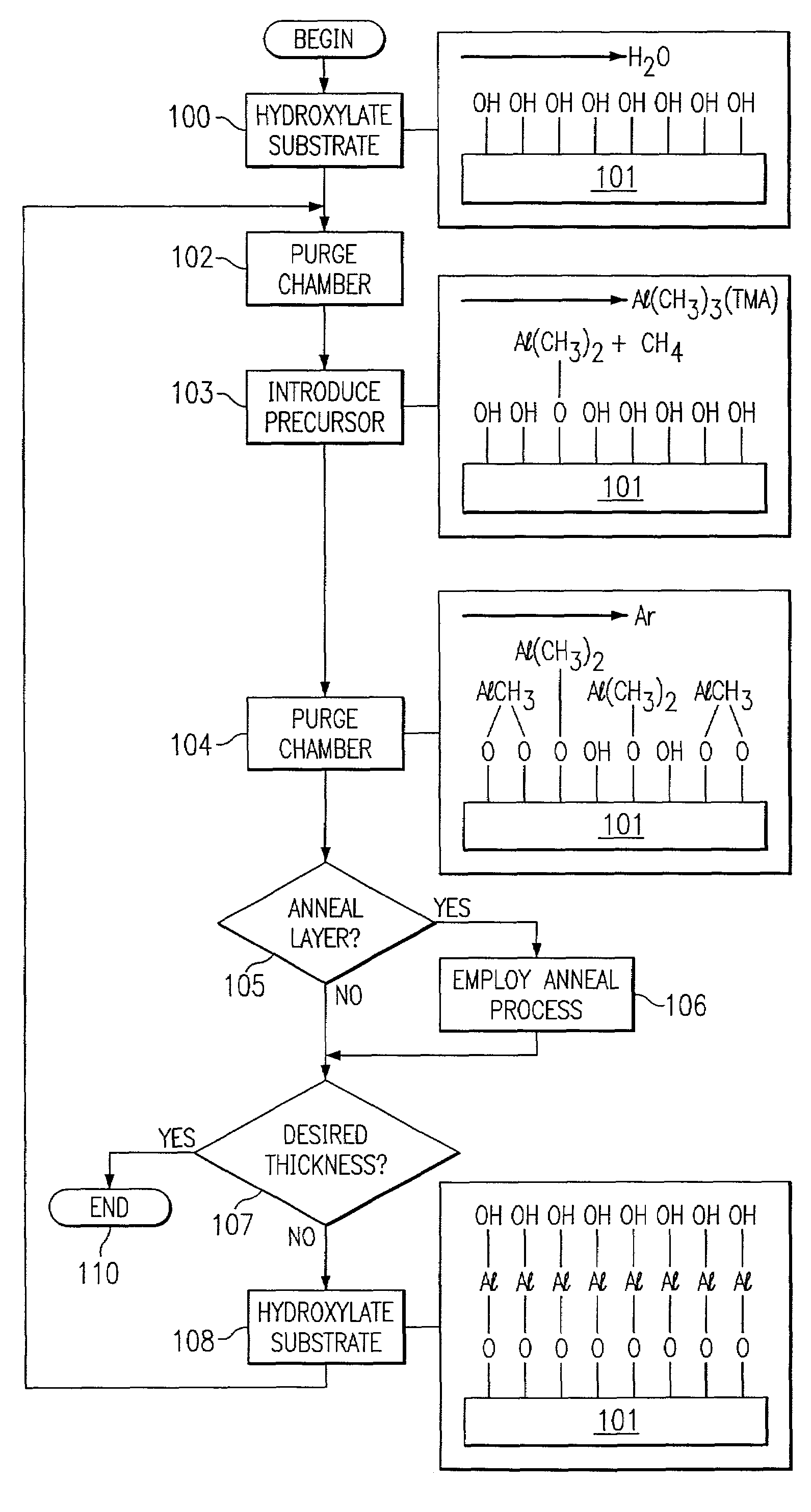

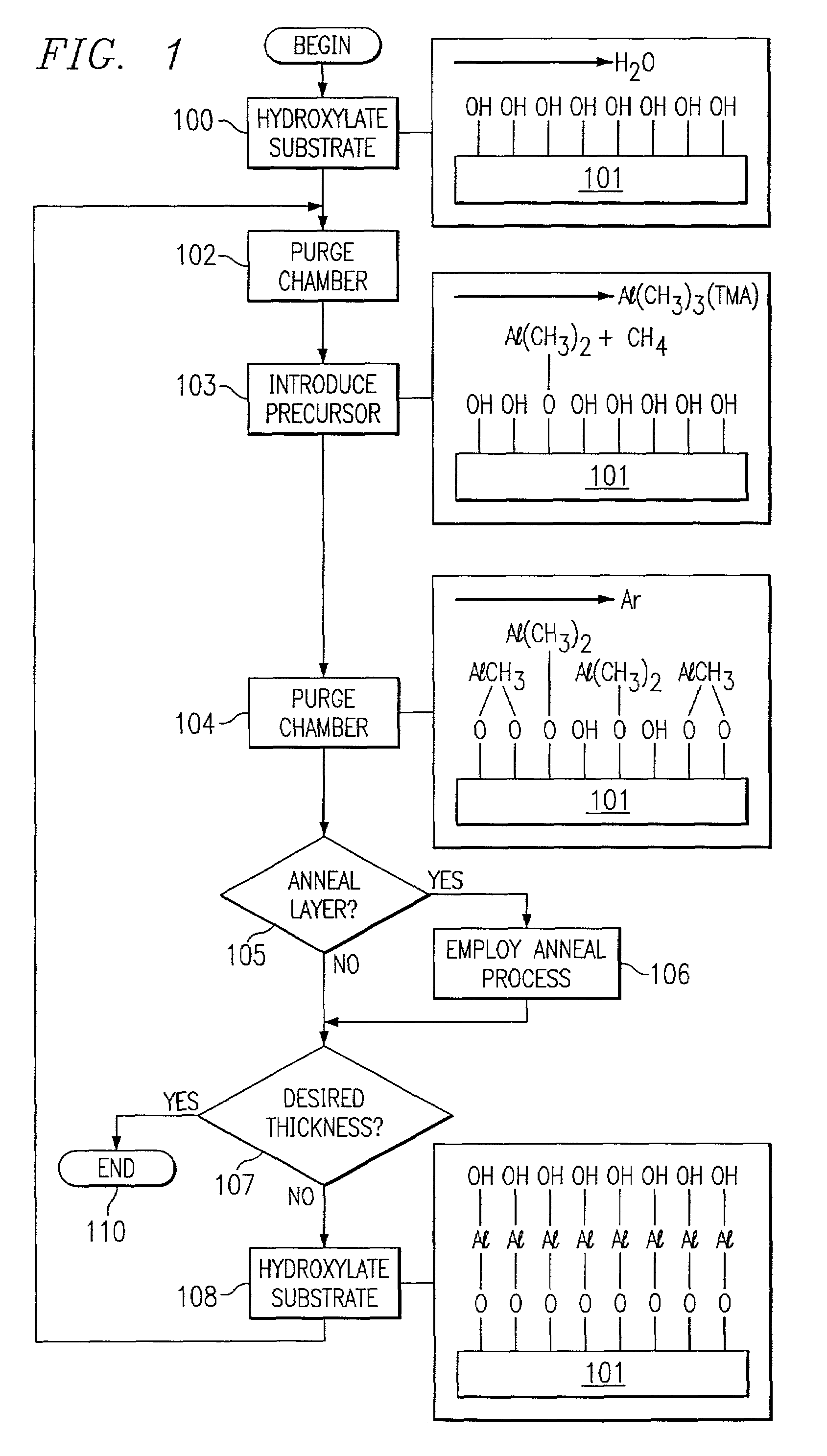

Atomic layer deposition for fabricating thin films

InactiveUS7037574B2High breakdown strengthImprove breakdown voltageNanostructure applicationLiquid surface applicatorsElectronic structureBreakdown strength

An atomic layer deposition (ALD) process deposits thin films for microelectronic structures, such as advanced gap and tunnel junction applications, by plasma annealing at varying film thicknesses to obtain desired intrinsic film stress and breakdown film strength. The primary advantage of the ALD process is the near 100% step coverage with properties that are uniform along sidewalls. The process provides smooth (Ra˜2 Å), pure (impurities<1 at. %), AlOx films with improved breakdown strength (9–10 MV / cm) with a commercially feasible throughput.

Owner:CVC PRODS

Film formation apparatus and method for semiconductor process

ActiveUS7300885B2Increase ratingsImprove film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingProcess regionSemiconductor package

A film formation method for a semiconductor process is arranged to form a thin film on a target substrate by CVD, while supplying a first process gas for film formation and a second process gas for reacting with the first process gas to a process field accommodating the target substrate. The method alternately includes first to fourth steps. The first step performs supply of the first and second process gases to the process field. The second step stops supply of the first and second process gases to the process field. The third step performs supply of the second process gas to the process field while stopping supply of the first process gas to the process field. The fourth step stops supply of the first and second process gases to the process field.

Owner:TOKYO ELECTRON LTD

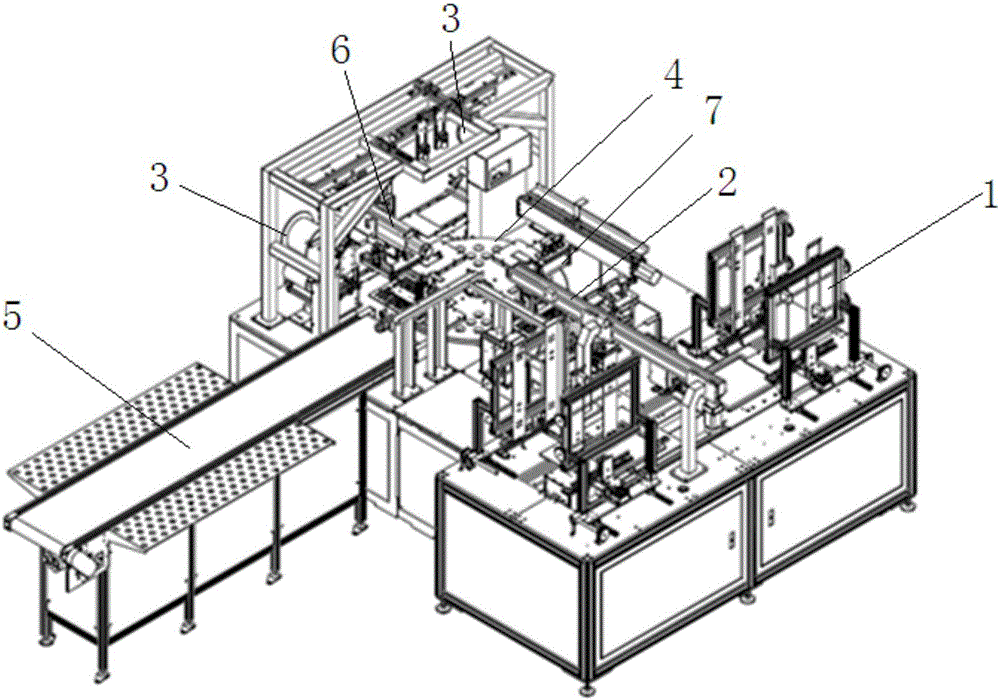

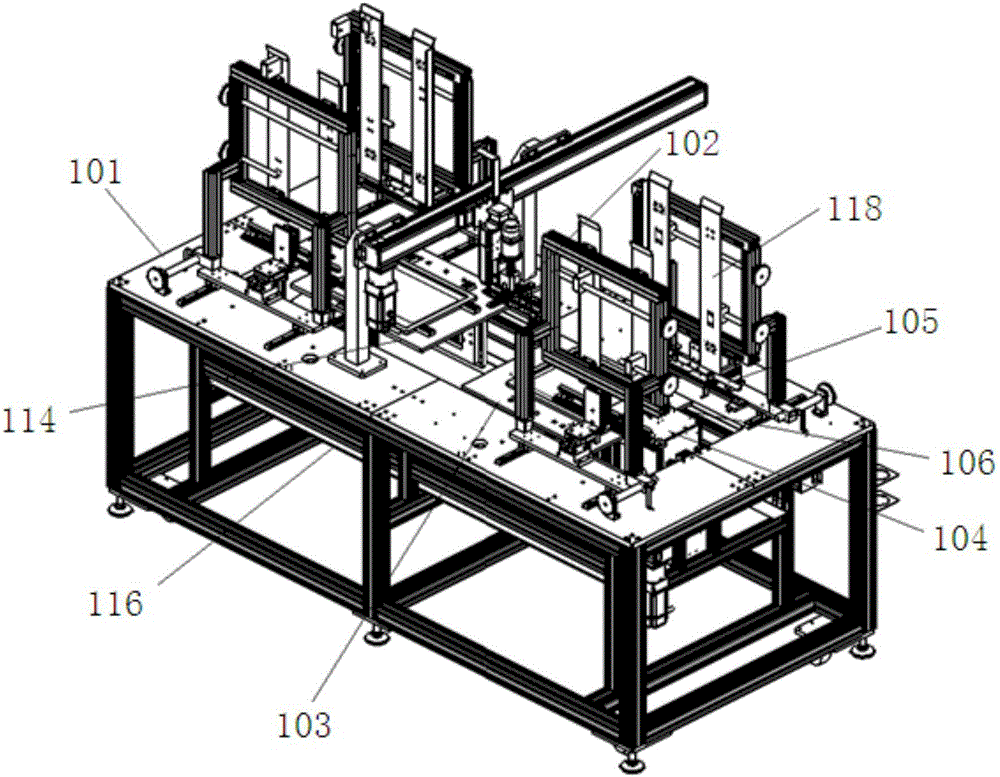

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com