Patents

Literature

50results about How to "Improve wiring speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

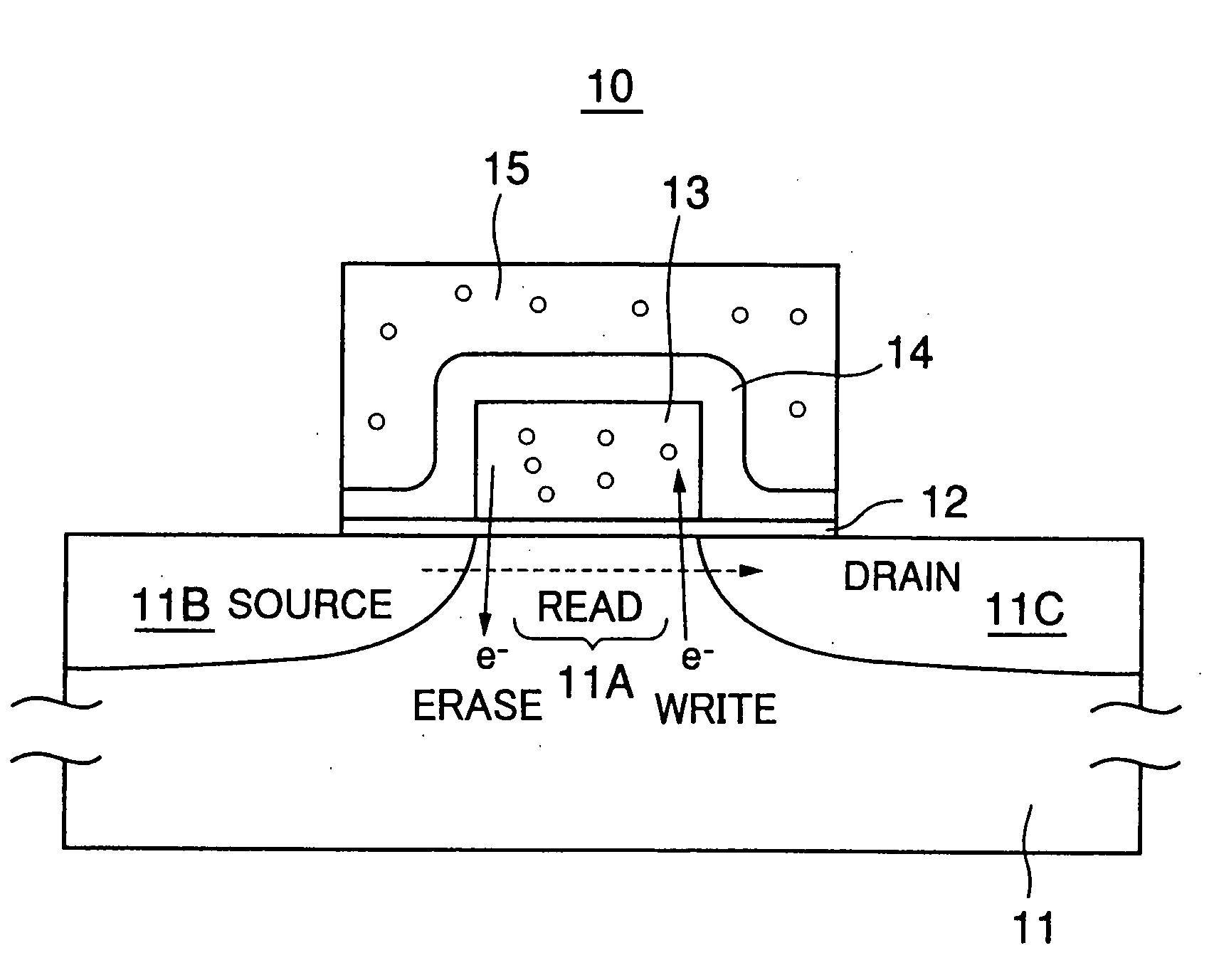

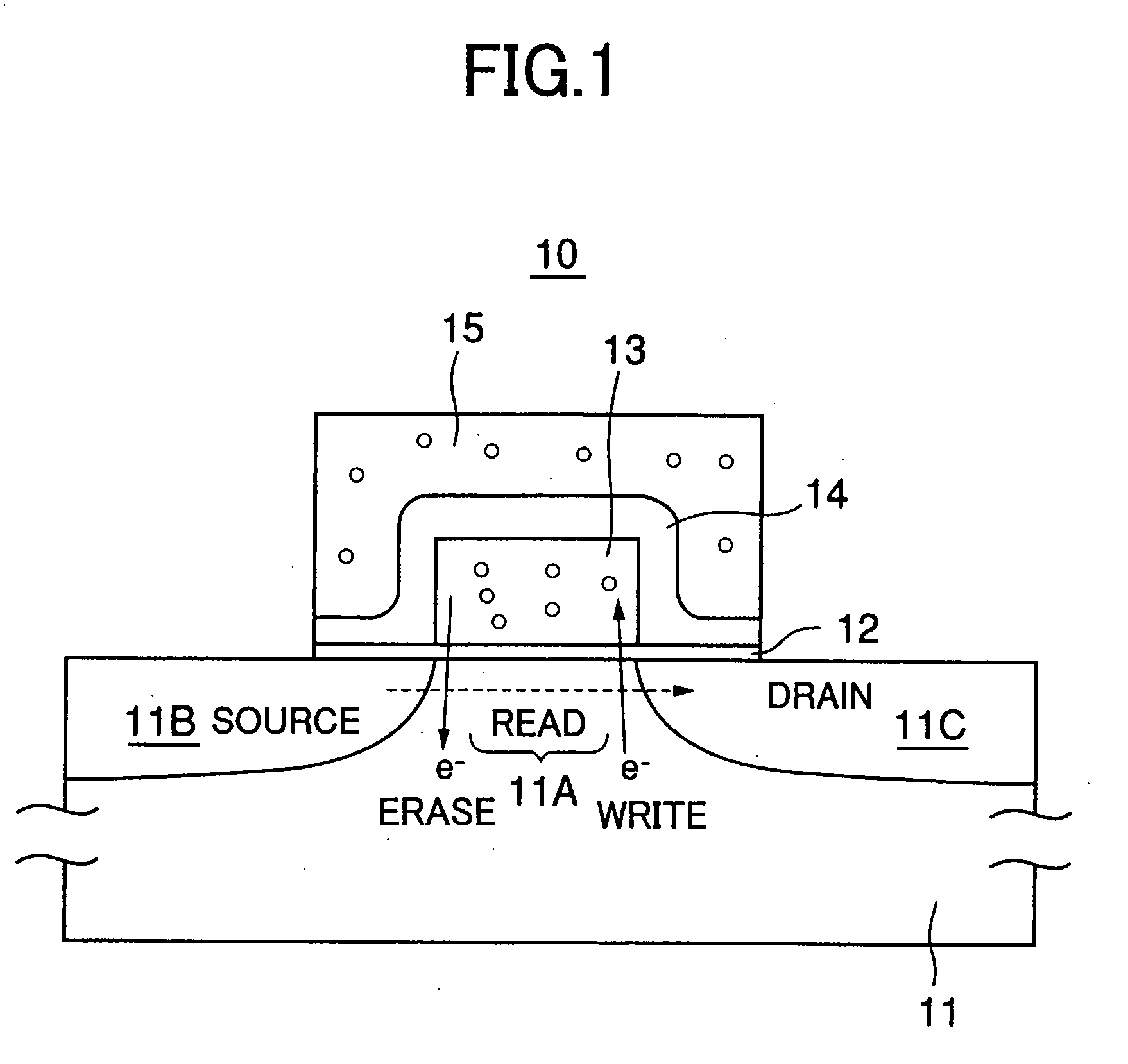

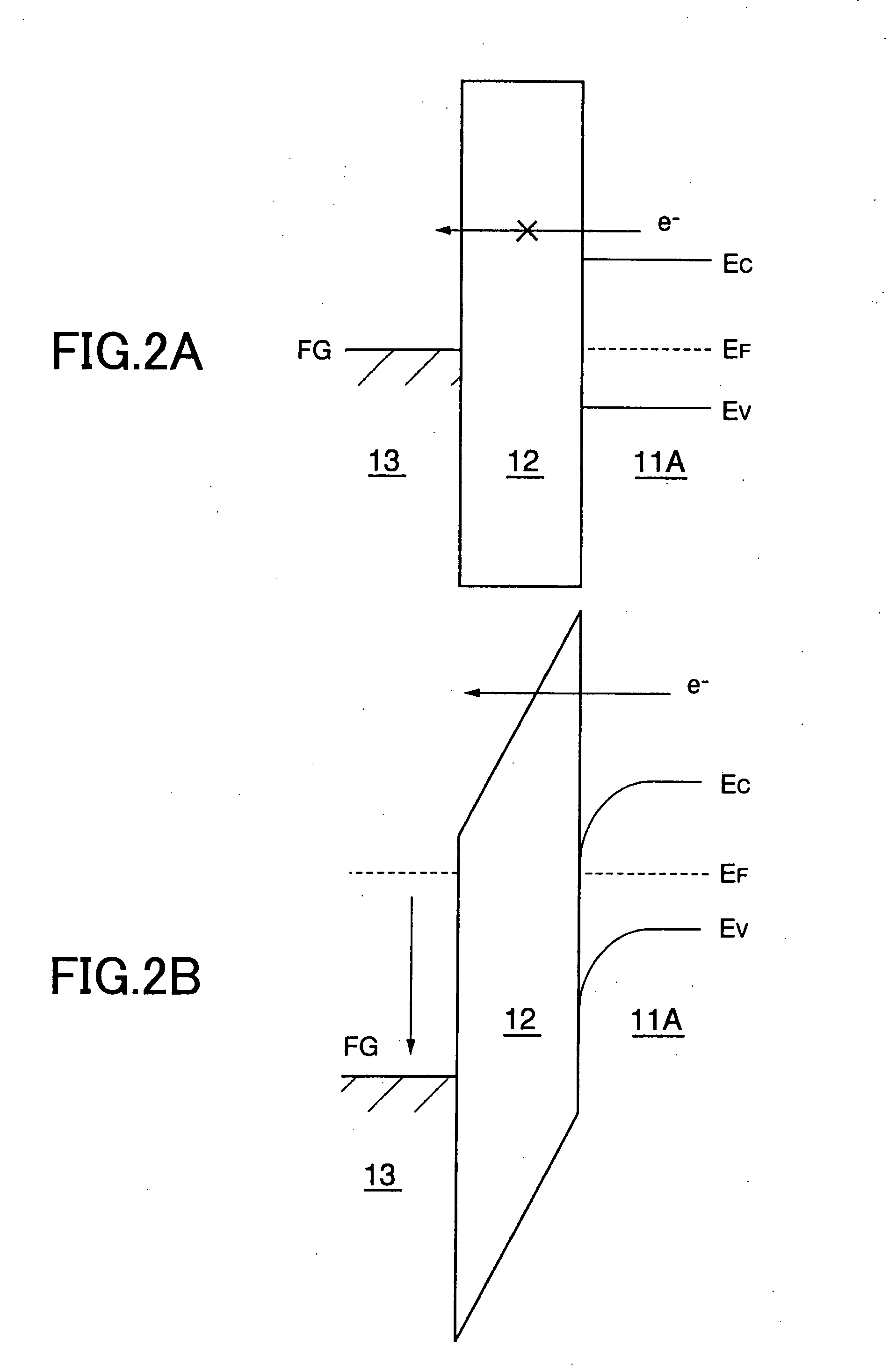

Dielectric film and formation method thereof, semiconductor device, non-volatile semiconductor memory device, and fabrication method for a semiconductor device

InactiveUS20080277715A1Improve wiring speedLow working voltageTransistorSemiconductor/solid-state device detailsDielectricHydrogen

Owner:FOUND FOR ADVANCEMENT OF INT SCI

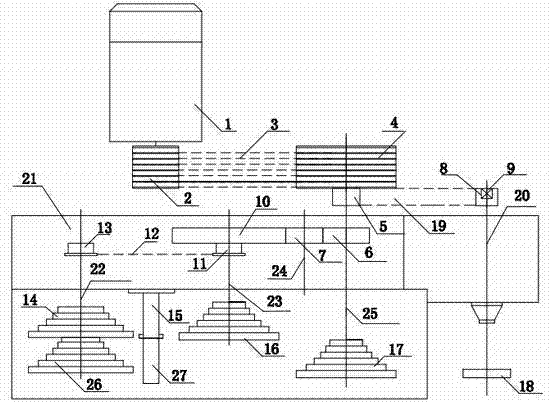

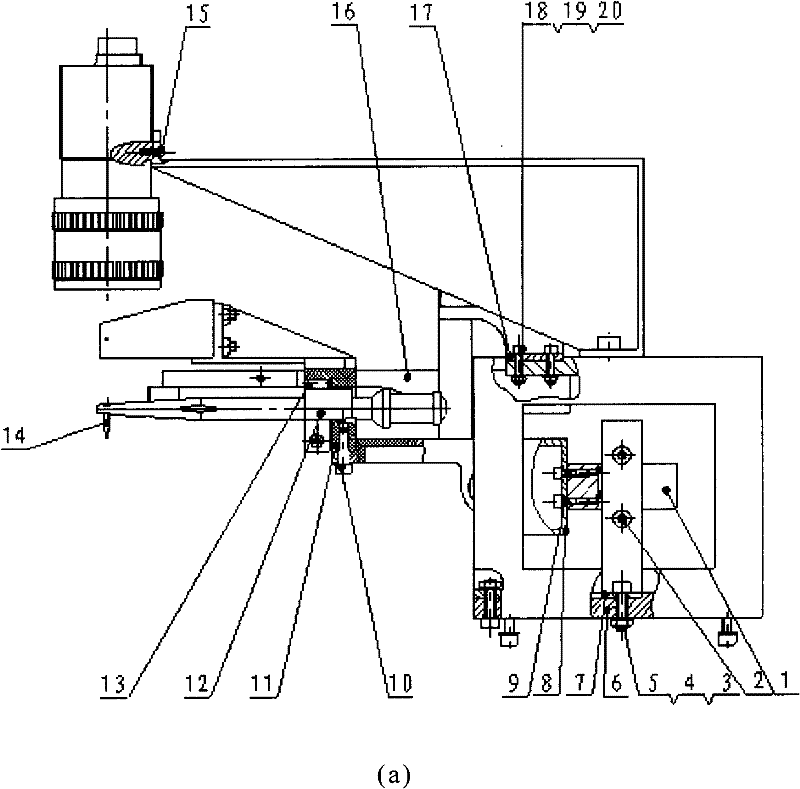

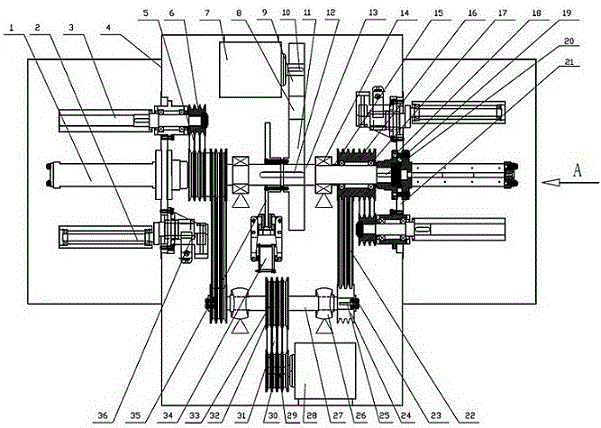

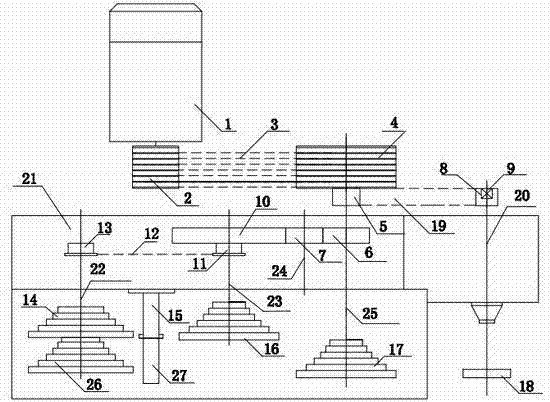

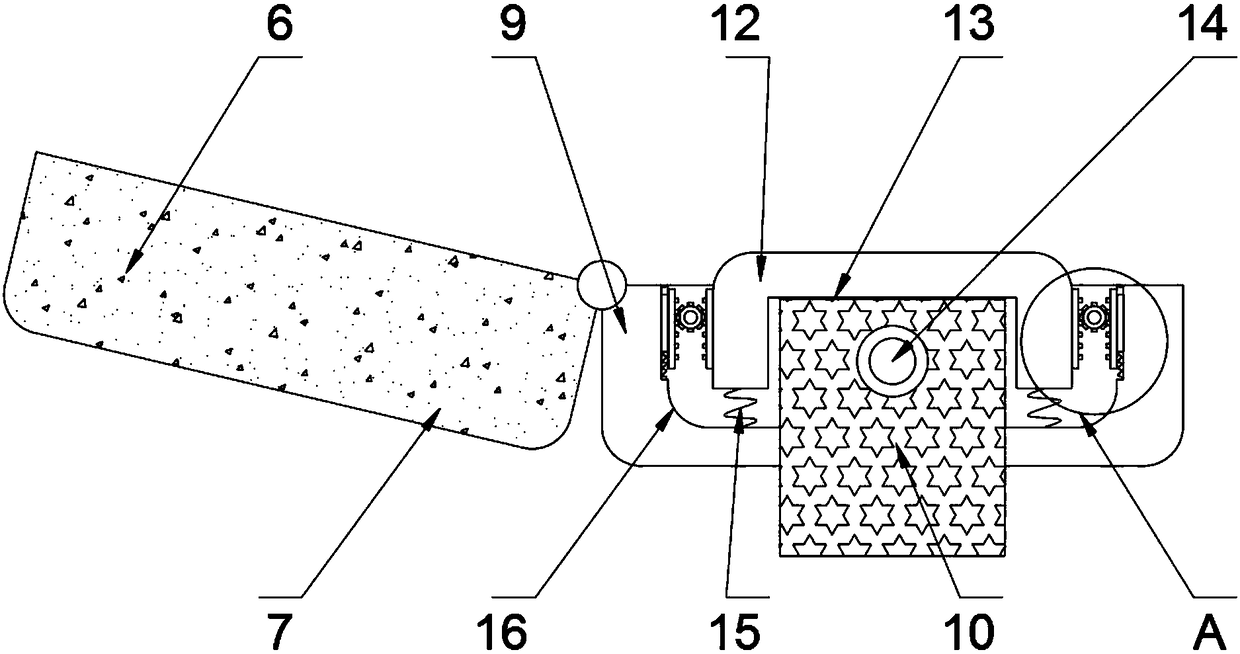

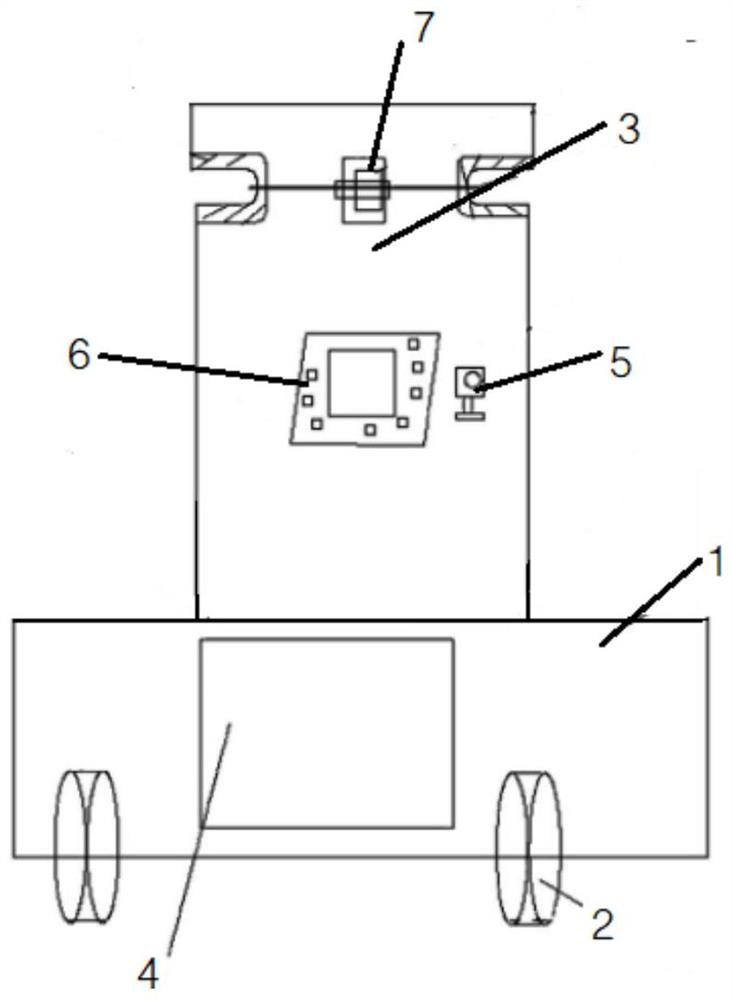

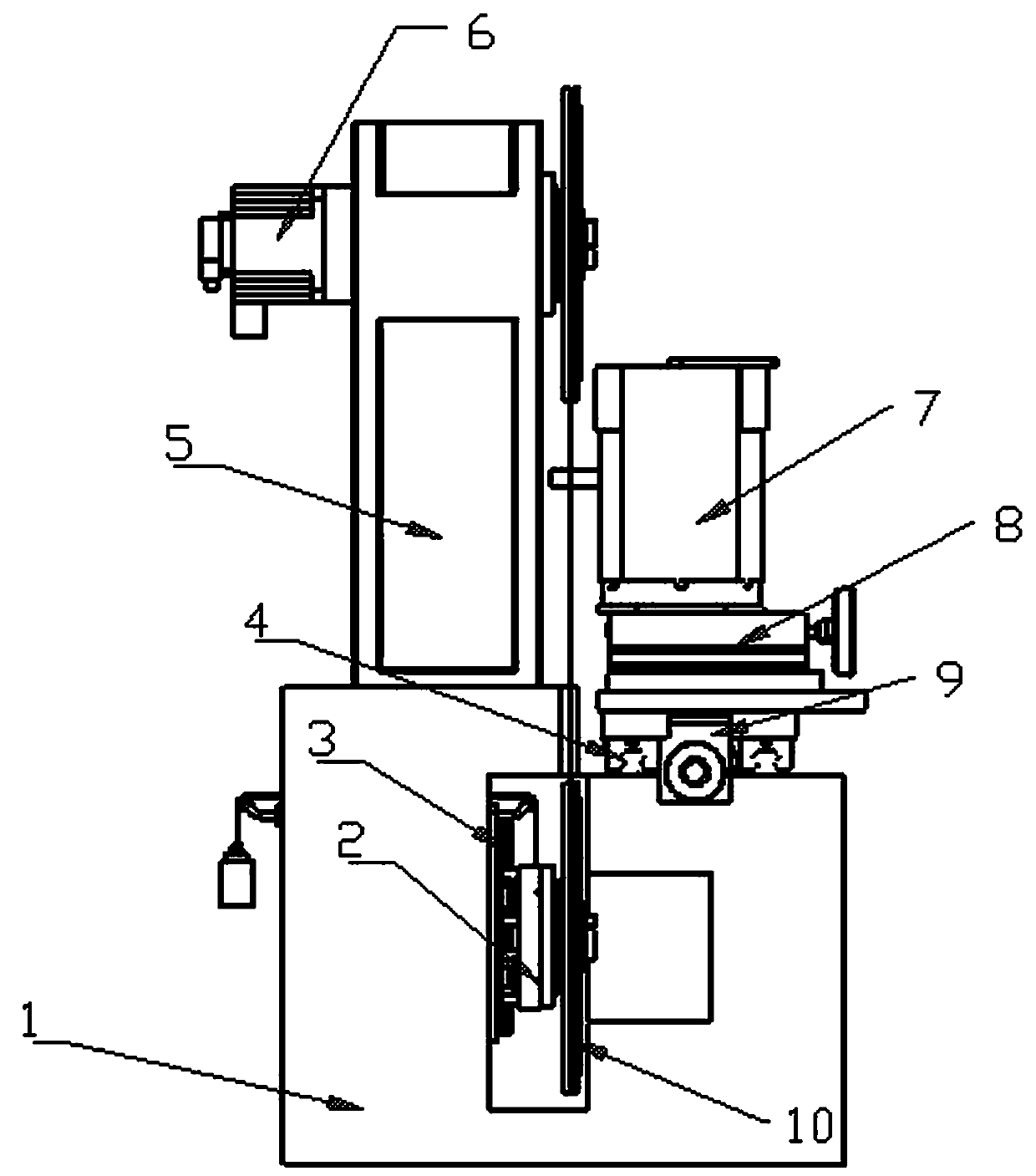

High-speed metal wire drawing machine

The invention relates to a high-speed metal wire drawing machine, and belongs to the technical field of a metal wire drawing machine. The high-speed metal wire drawing machine comprises a rack and a motor, wherein a low-speed guide wheel set, a low-speed mould base, a high-speed guide wheel set, a high-speed mould base and the like are arranged on the rack; the motor is sequentially connected with a driving pulley, a driven pulley and a high-speed cone pulley set; the high-speed cone pulley set is in transmitted connection with a constant-speed wheel and is in meshed and transmitted connection with a low-speed cone pulley set; the low-speed guide wheel set is connected with the low-speed cone pulley set. The chain or gear transmission of the constant-speed wheel and the high-speed cone pulley set is changed into synchronous belt transmission, synchronous belt wheels are connected with shafts through taper locks, the replacement is convenient, and therefore the different speed ratios between the constant-speed wheel and the high-speed cone pulley set is obtained, so that only one mould is needed when customers draw a variety of specifications of metal wires. The mould cost is greatly reduced. The high-speed metal wire drawing machine has the advantages of simple design, high wire drawing speed, low energy consumption, good economic benefit and strong practicality, greatly reduces transmission noises, and brings security assurance to the personal safety of operating personnel.

Owner:HANGZHOU XINGGUAN MACHINERY

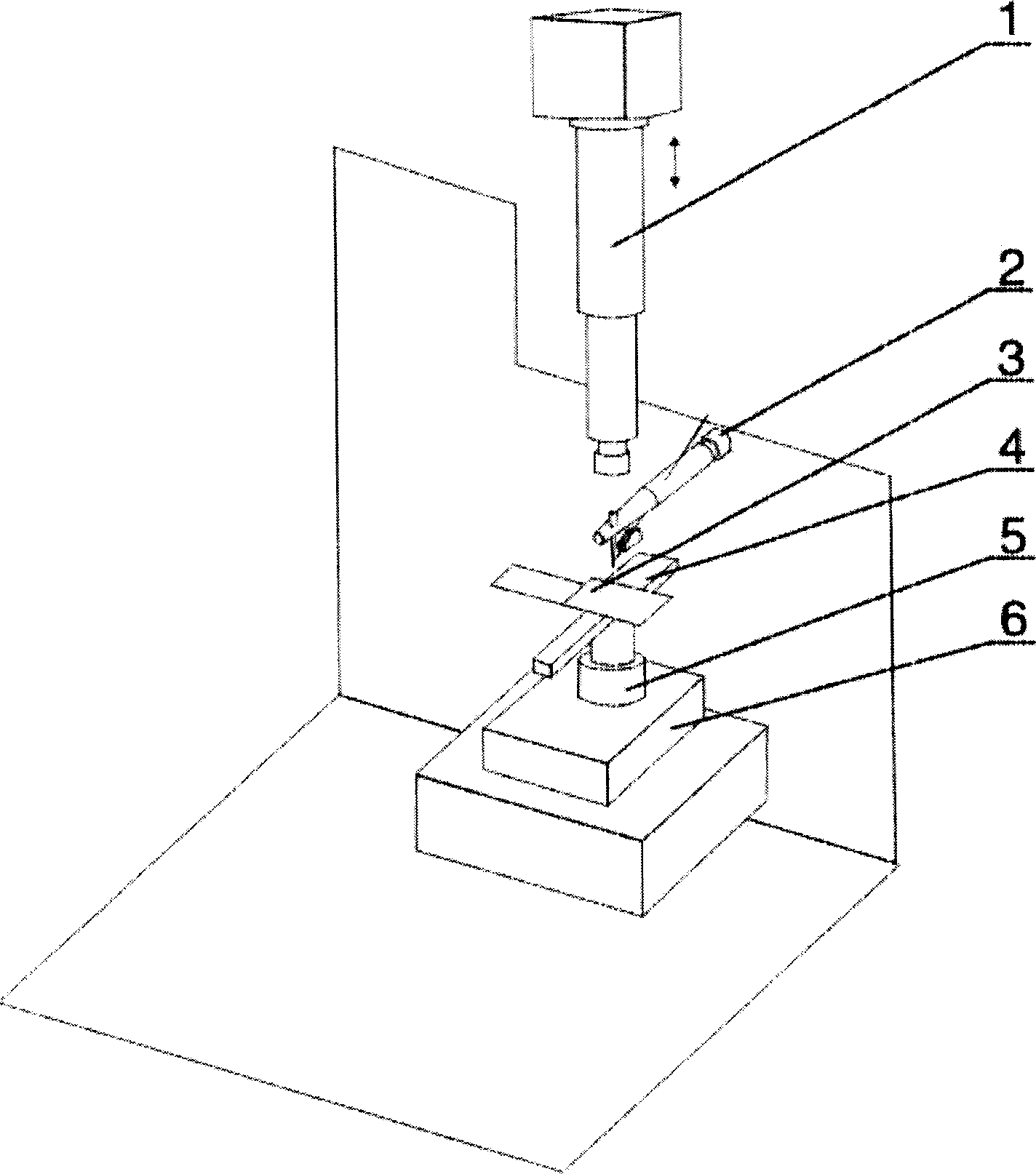

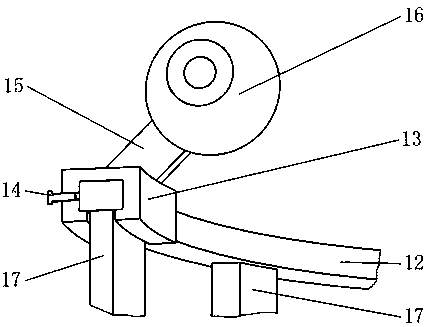

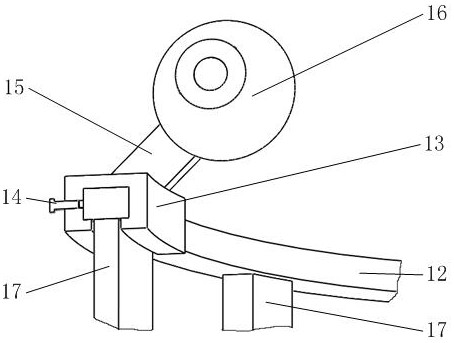

Dual-bonding wire head lead bonding device

InactiveCN102339771AIncreased wire speedImprove wire bonding efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLead bondingStructural engineering

The invention discloses a micro-electronic chip lead bonding device with dual bonding wire heads. The device comprises two sets of same welding wire heads, the position of a fastening bolt in a groove at the lower part of a base of the welding wire heads is adjusted manually, and the relative positions and the distance between the dual welding wire heads can be adjusted and changed. Under the coordination control action of a shared controller program, independent wire solder or simultaneous wire solder can be carried out on each welding wire head, the lead bonding efficiency of the micro-electronic chip lead bonding device is doubled compared with the lead bonding efficiency of a single-welding wire head bonding machine, and each welding wire head is fixedly connected with a welding wire head bearing by an attachment bolt. The lead bonding device formed by configuring two or more than two welding wire heads on one bonding machine can finish the wire solder task of lead interconnection jointly by division and cooperation of responsibilities of adjustment and programming aiming at different parts, so that the bonding efficiency of a chip can be improved manyfold.

Owner:CENT SOUTH UNIV

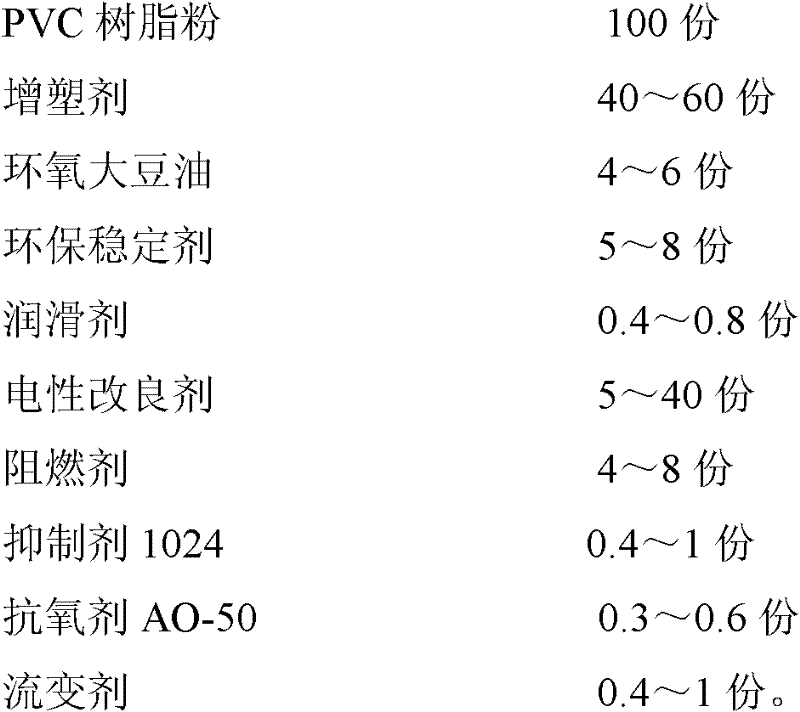

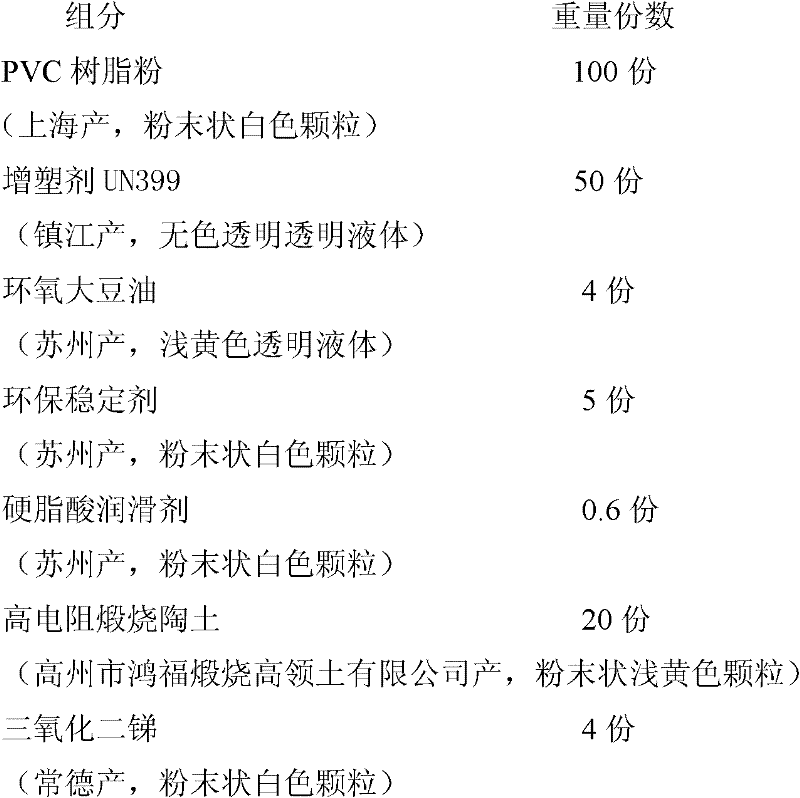

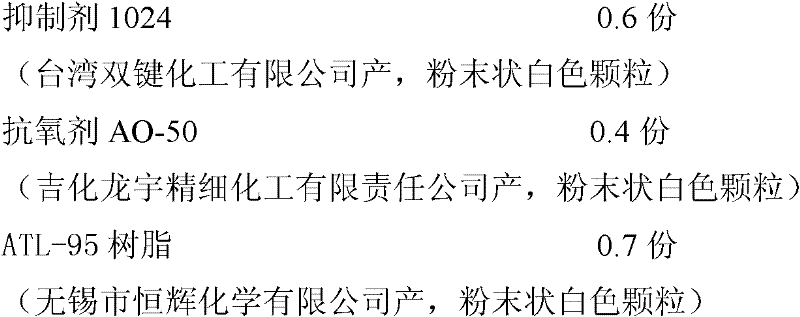

High humidity tolerance, high electric performance and environment-friendly polyvinyl chloride insulation material for electric wires and cables

InactiveCN102336987AExcellent high electrical propertiesPrevent agingPlastic/resin/waxes insulatorsPolyvinyl chlorideFire retardant

The invention discloses a high humidity tolerance, high electric performance and environment-friendly polyvinyl chloride (PVC) insulation material for electric wires and cables. The PVC insulation material is prepared by the following components by weight: 100 parts of PVC resin powder, 40 to 60 parts of a plasticizer, 4 to 6 parts of epoxy soybean oil, 5 to 8 parts of an environment-friendly stabilizing agent, 0.4 to 0.8 part of a lubricant, 5 to 40 parts of an electric performance modifier, 4 to 8 parts of a fire retardant, 0.4 to 1 part of inhibitor 1024, 0.3 to 0.6 part of the anti-oxidant AO-50 and 0.4 to 1 part of a rheological agent. The PVC insulation material for electric wires and cables in the invention, prepared by adopting a special raw material ratio, not only has excellent high humidity tolerance and high electric performance, but also enables a wire drawing speed of the material to be improved and environmental protection to be obtained. The PVC insulation material is applicable to wires used in temperature transmission devices for air-conditioners or to power lines, data lines or the like used in other high humidity environments.

Owner:SUZHOU HUAYING PLASTICS

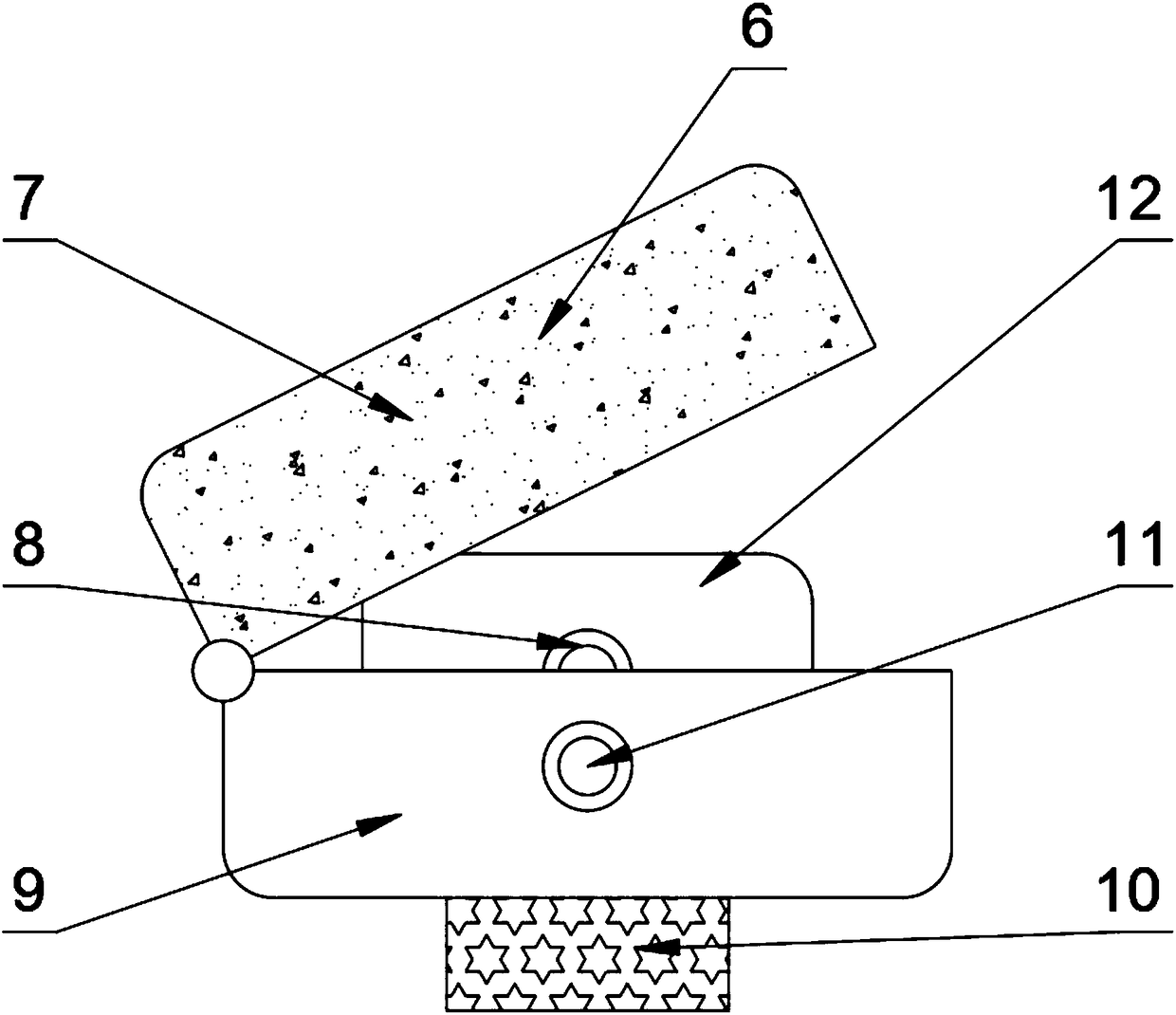

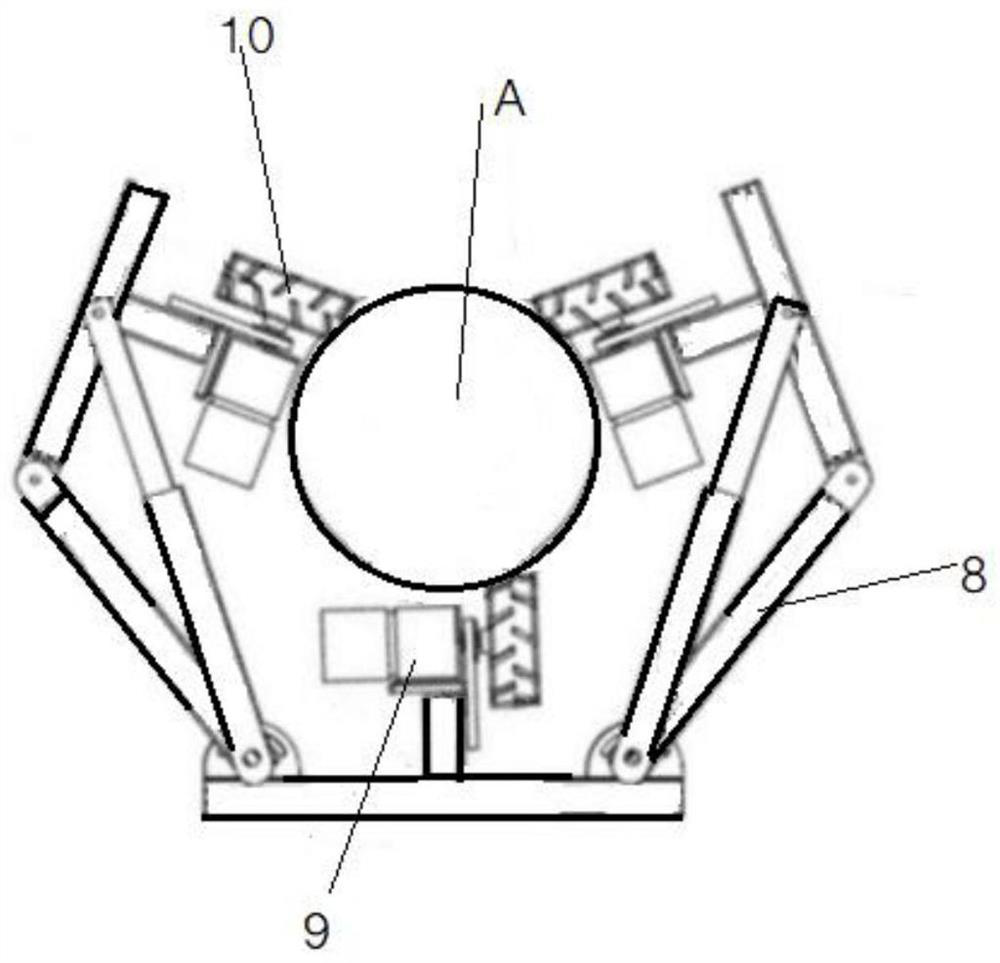

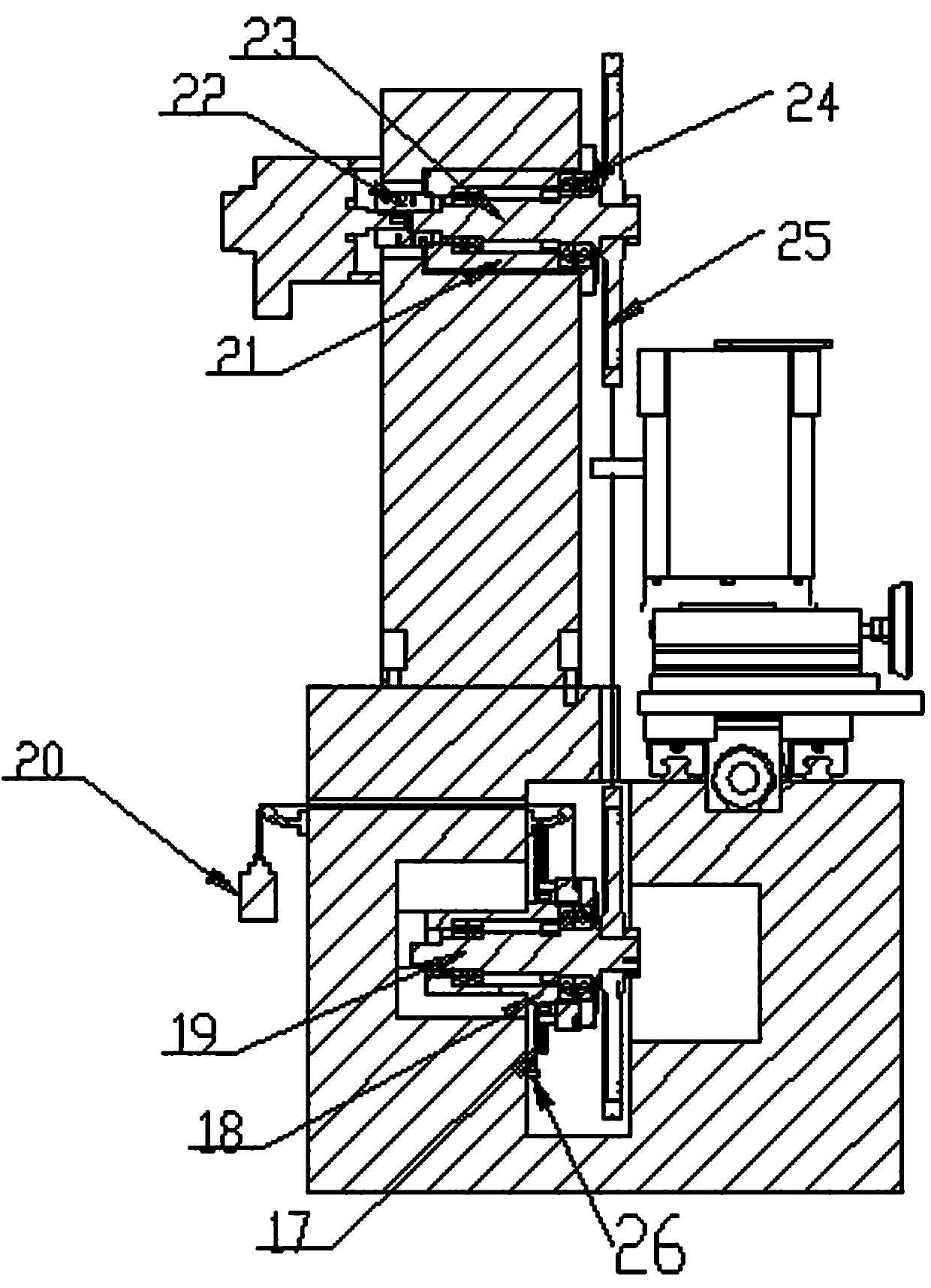

Wire surface rust removal polisher

ActiveCN104907907AAvoid dust pollutionReduce manufacturing costGrinding drivesBelt grinding machinesBelt grindingEngineering

The invention relates to a wire surface rust removal polisher. Rust removal polishing is performed on the surface of a wire in the mode that an abrasive belt moves to grind the wire and rotates around the circumference of the wire, the abrasive belt conducts helical motion on the surface of the wire due to linear movement of the wire, and therefore grinding dust removal can be performed on the whole surface of the wire. In addition, removed iron rust can be recycled, and therefore the production cost is lowered; a physical abrasive belt grinding method replaces a traditional chemical electrolysis pickling method, and therefore air pollution is reduced.

Owner:HANGZHOU XINGGUAN MACHINERY

Ultrasonic wave wire soldering method and wire soldering apparatus

InactiveCN1702847AImprove wire qualityIncrease wire speedSolid-state devicesSemiconductor/solid-state device manufacturingUltrasonic weldingEngineering

This invention discloses ultrasonic welding wire method and its device, which comprises welding probe system, positioning and testing cameral optics system, movable workbench, rotation bench in level direction and the clamper for welding parts fixed on the rotation bench. The method orderly comprises the following steps: setting initial positions, welding wire points; moving the initial points of welding mouth or moving the end points of welding mouth and wires; welding the wire end terminals.

Owner:ITM SHENZHEN

Method for producing high-strength high-modules carbon fibre and special equipment thereof

InactiveCN1385567AStable output powerReaction temperature control sensitiveFibre chemical featuresMicrowave heatingTemperature controlCarbon fibers

The present invention relates to a high-strength high-modules carbon fibre and its special equipment. It is characterized by that its high-frequency heating reaction pipe is formed from deoxygenationsection. cracking section, graphitizing section air-cooling section and water-cooding section. The carbon fibre can be continuously passed through said sectional reactino pipe, the reaction temp. of the graphitizing section is controlled at 2500-2650 deg.C, under the action of catalyst the graphitizing process of carbon fibre is completed. The drafting equipment is equipped with a drafting force display device, the drafting force can be controlled in the optimum state, it also has an optical temp.-measuring device, and the output power is controlled and regulated by computer. The strength of said fibre of greater than 3.5 GPa, and its modules is greater than GPa.

Owner:张蓬洲

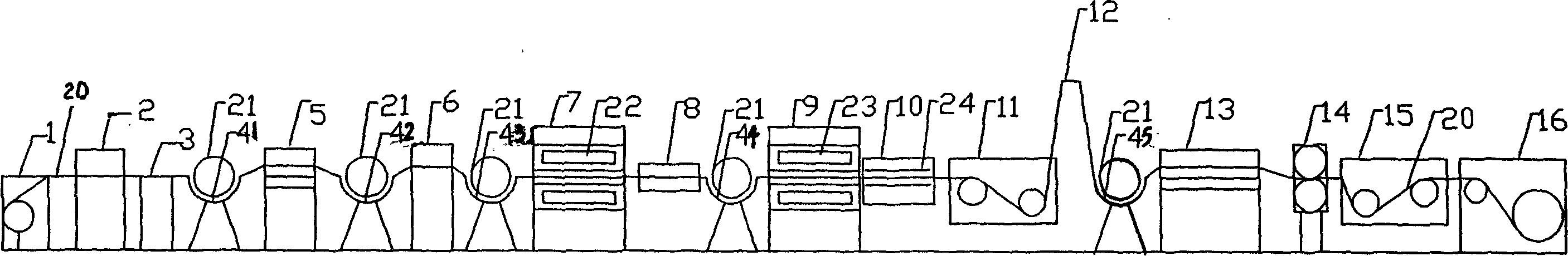

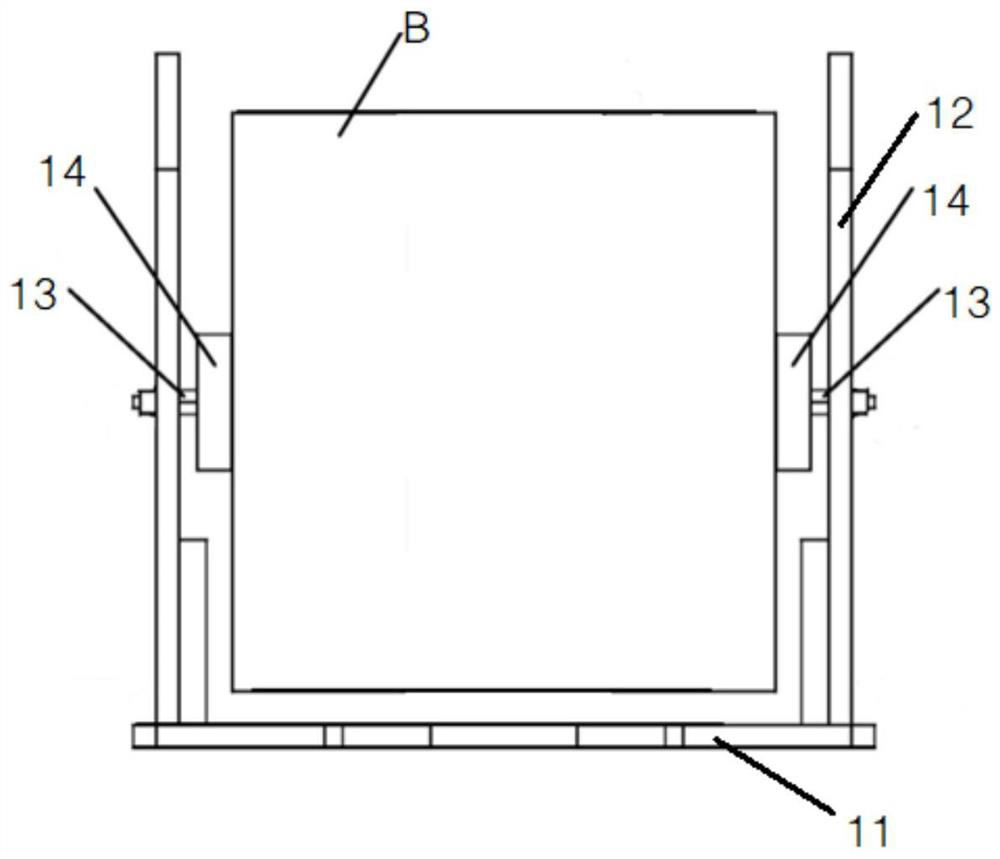

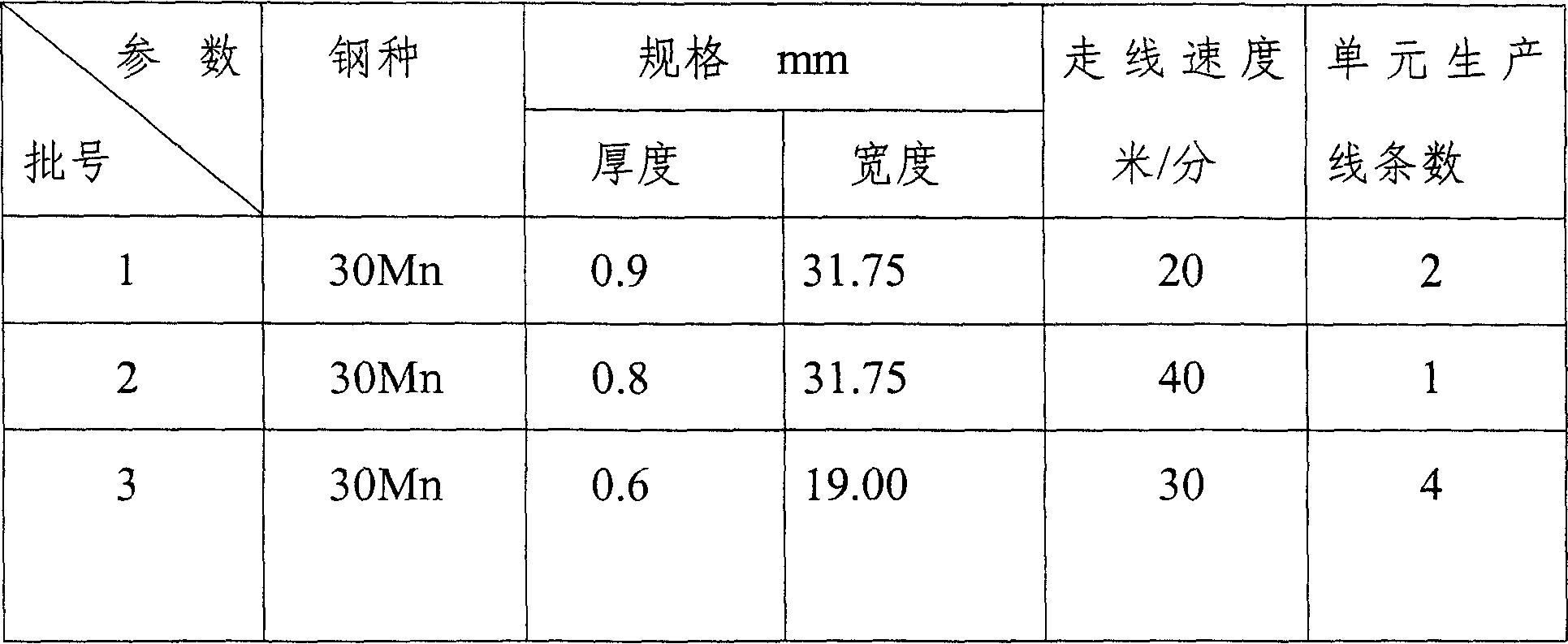

Manufacturing device for high strength bailing band

InactiveCN1631610AIncrease productivitySmall footprintOther manufacturing equipments/toolsProduction lineButt welding

The invention belongs to iron and steel field relates to packing steel belt production device. The invention high intensity steel packing belt producing device consists of unrolling machine, square joint machine, butt-welding machine, tractor, entrance loop machine, flat edge trimmer, quenching furnace, quenching water tank, tempering furnace, tempering water tank, leach drying stand, exit loop machine, tension machine, paraffin slot and rolling machine. The production device is adopted with an integral production line which has got on one line from unrolling machine, square joint machine, butt-linking machine, flat edge trimmer, to tempering insulation furnace, tempering water tank, quenching furnace, quenching water tank, paraffin slot and rolling machine all the devices all at the same level dragged by tractor and the production steel belt. The whole production line includes 1 to 10 production line unit namely installing 1 to 10 production line unit on the same line which means 1 to 10 high intensity steel packing belt can be producing at the same time on the same production line. The invention is of high efficiency, small area, low investment and non-polluting.

Owner:CENT IRON & STEEL RES INST

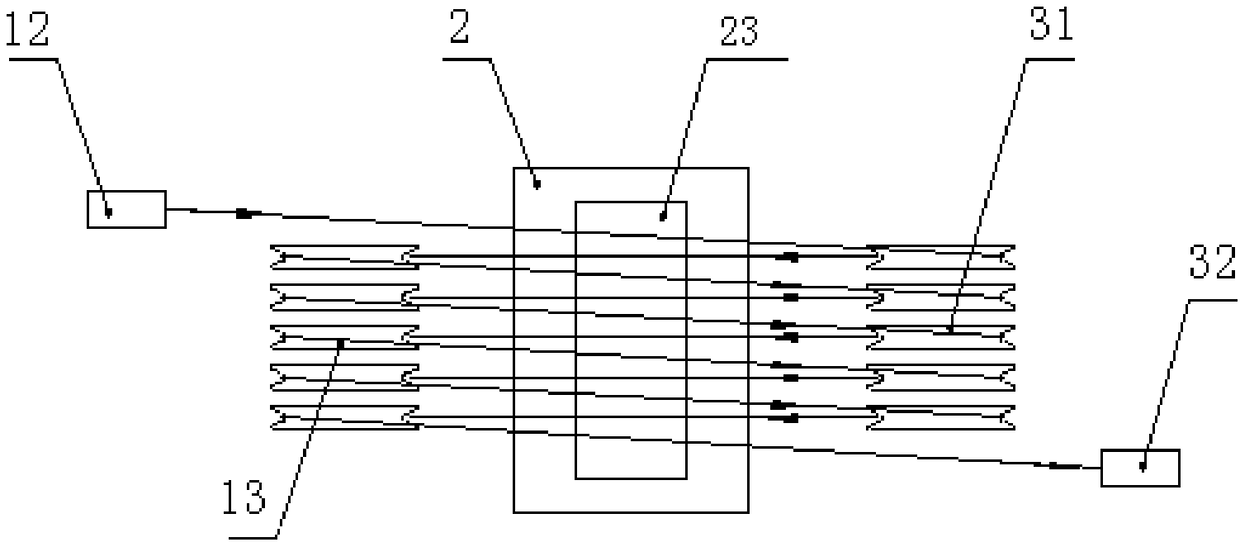

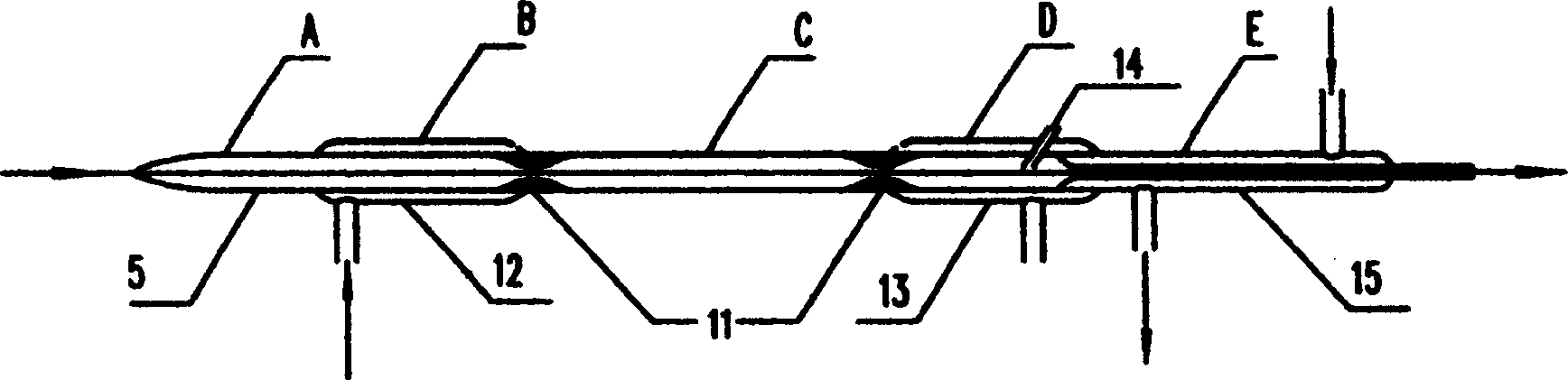

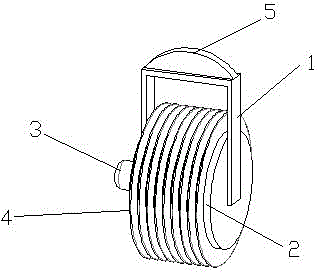

Method for continuously and quickly preparing SiC fiber surface BN coating

The invention discloses a method for continuously and quickly preparing a SiC fiber surface BN coating. By utilizing a yarn winding and unwinding device, after a SiC fiber is subjected to amorphous form BN interface deposition under movement, the crystal-state BN coating can be directly converted, so that the problem that in the prior art, no amorphous form BN is decomposed during a deposition-heat treatment conversion process is effectively avoided. A microwave heating manner is adopted during a heat treatment process, so that a uniform and flawless stable crystal structure is finally obtained; and in addition, the yarn winding and unwinding device adopts a multi-roller system, so that cyclic deposition is carried out during a deposition process, and the crystal-state BN coating with therequired thickness can be quickly obtained.

Owner:CENT SOUTH UNIV

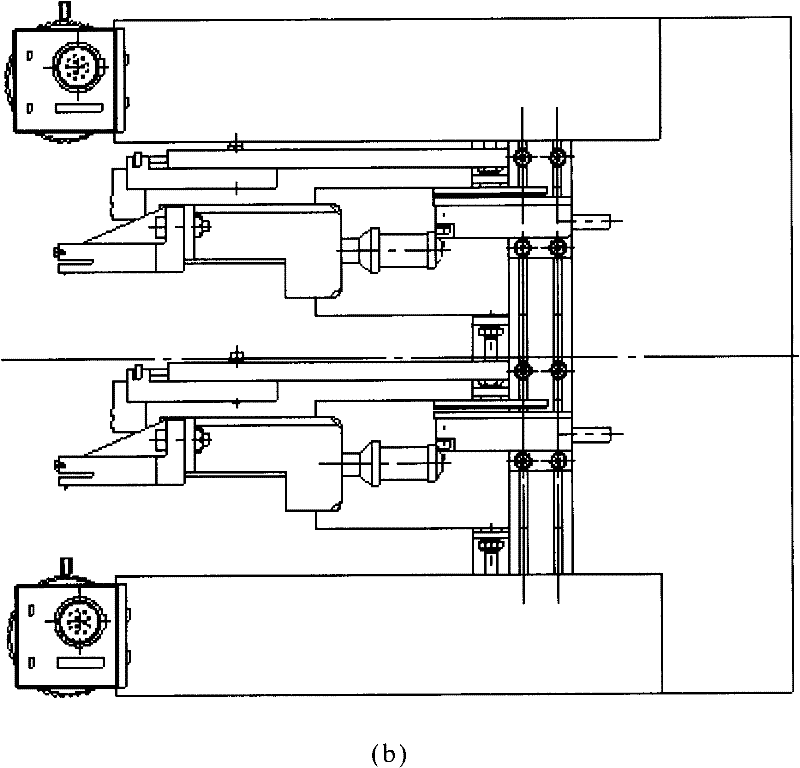

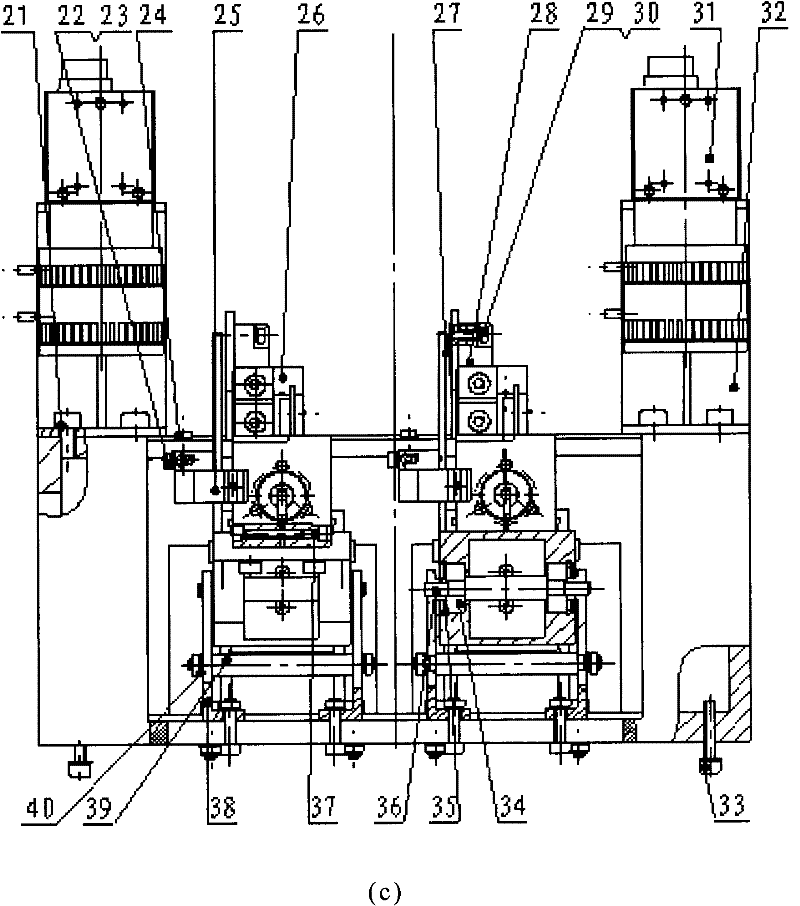

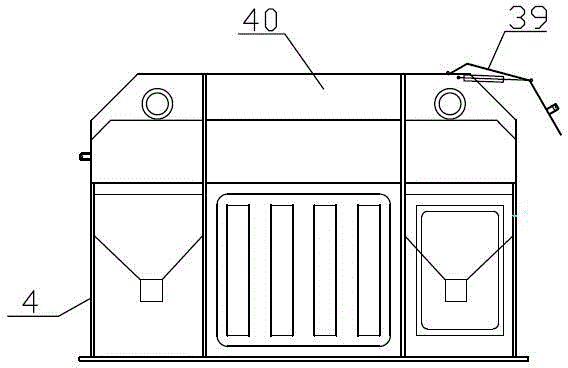

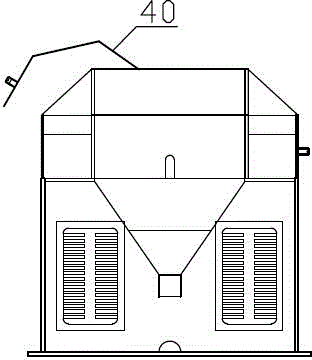

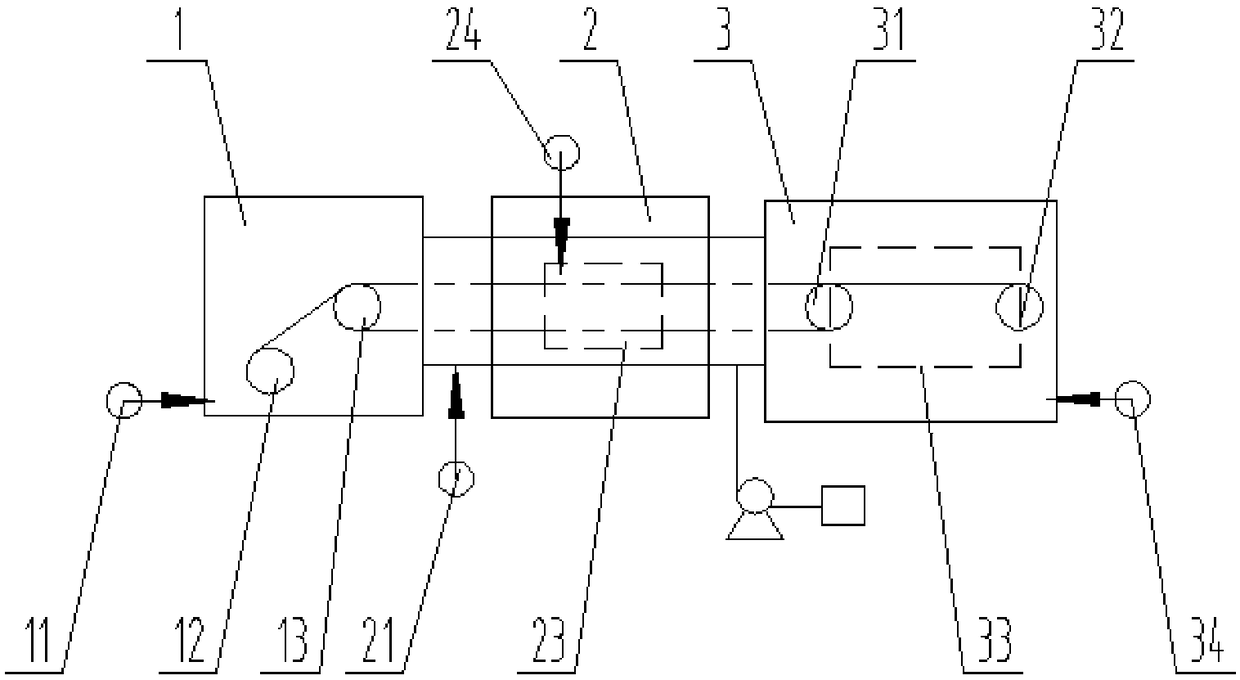

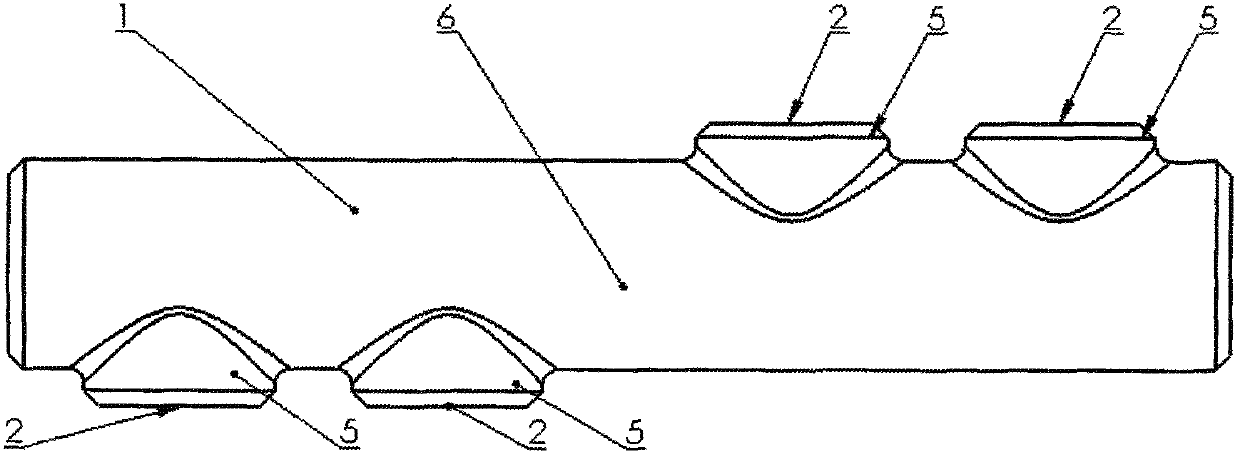

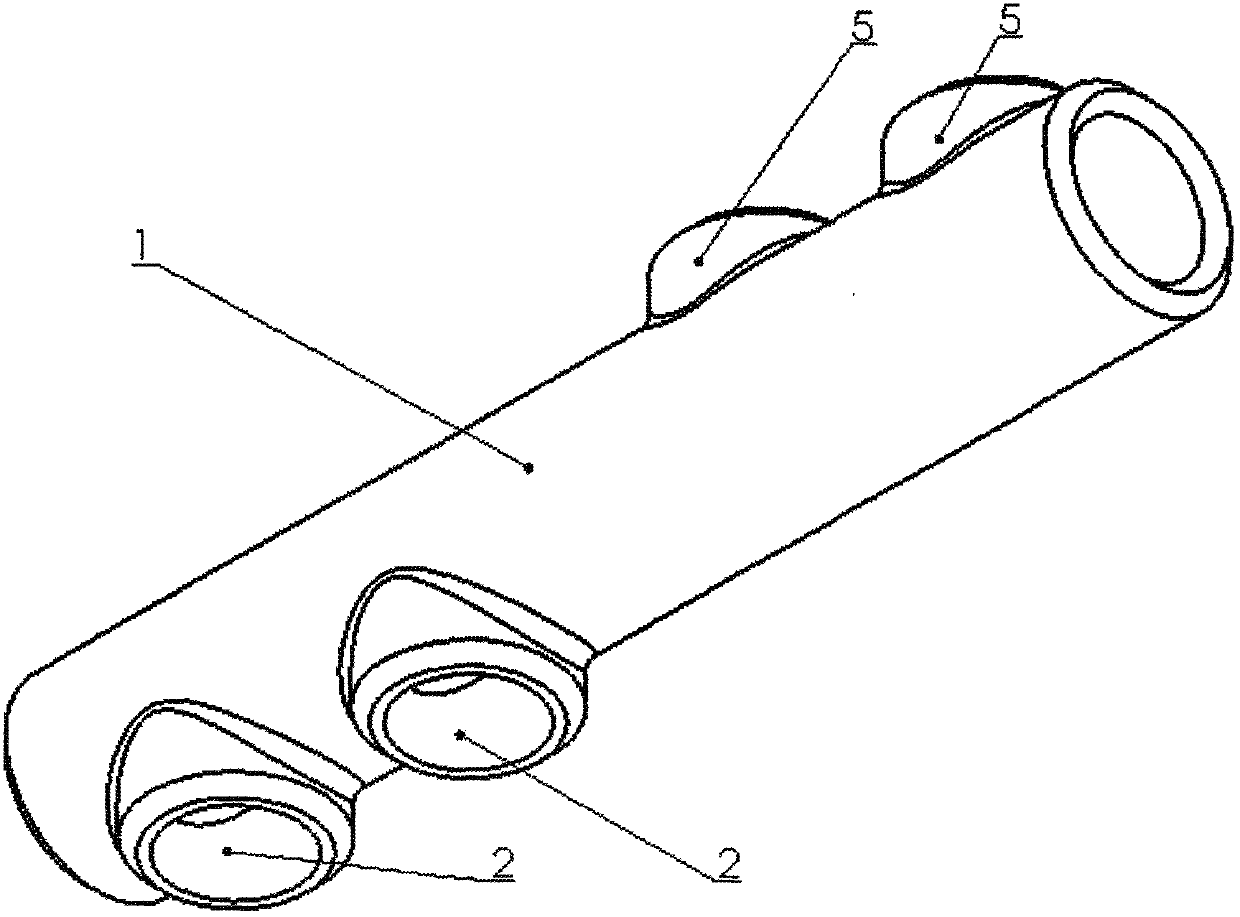

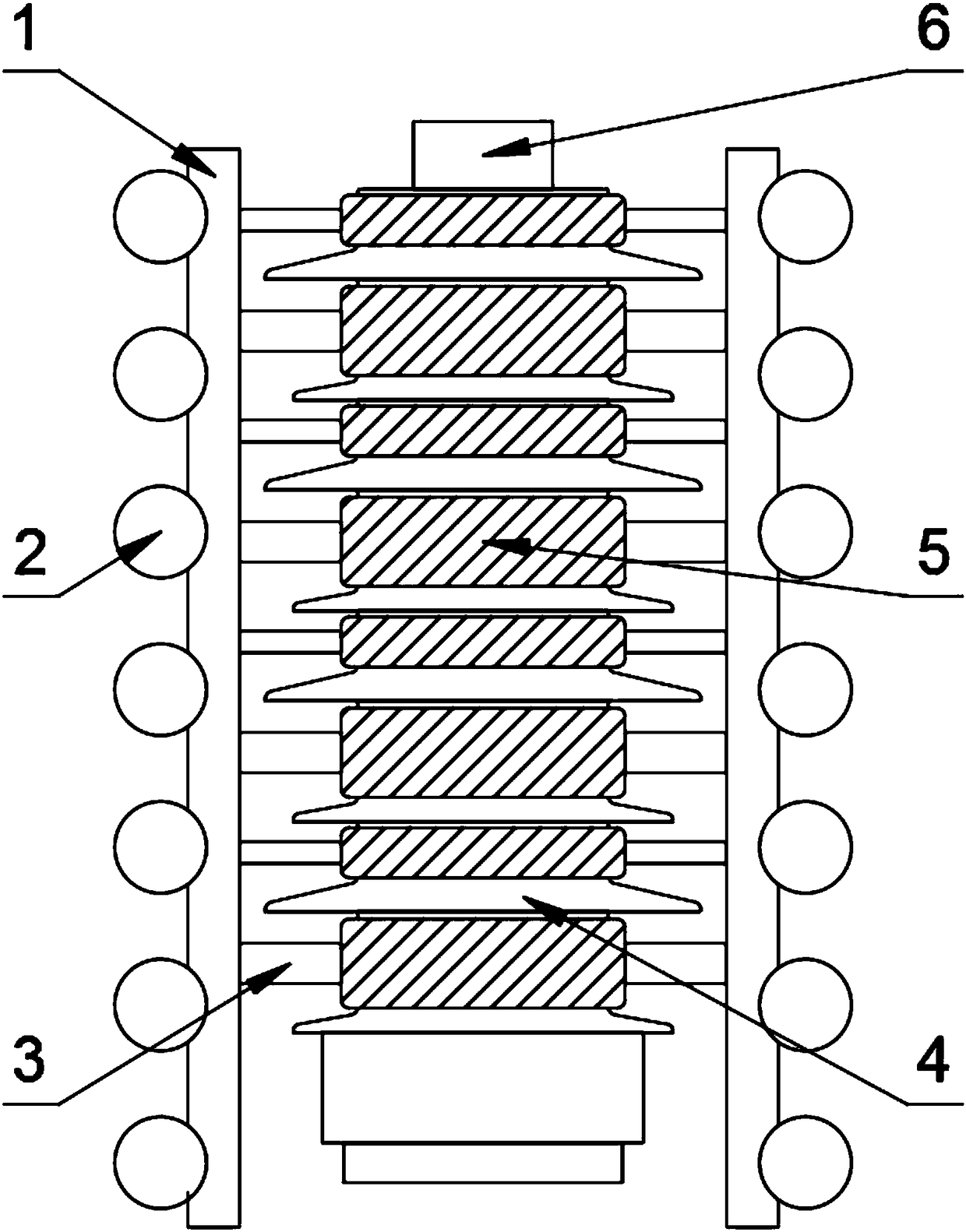

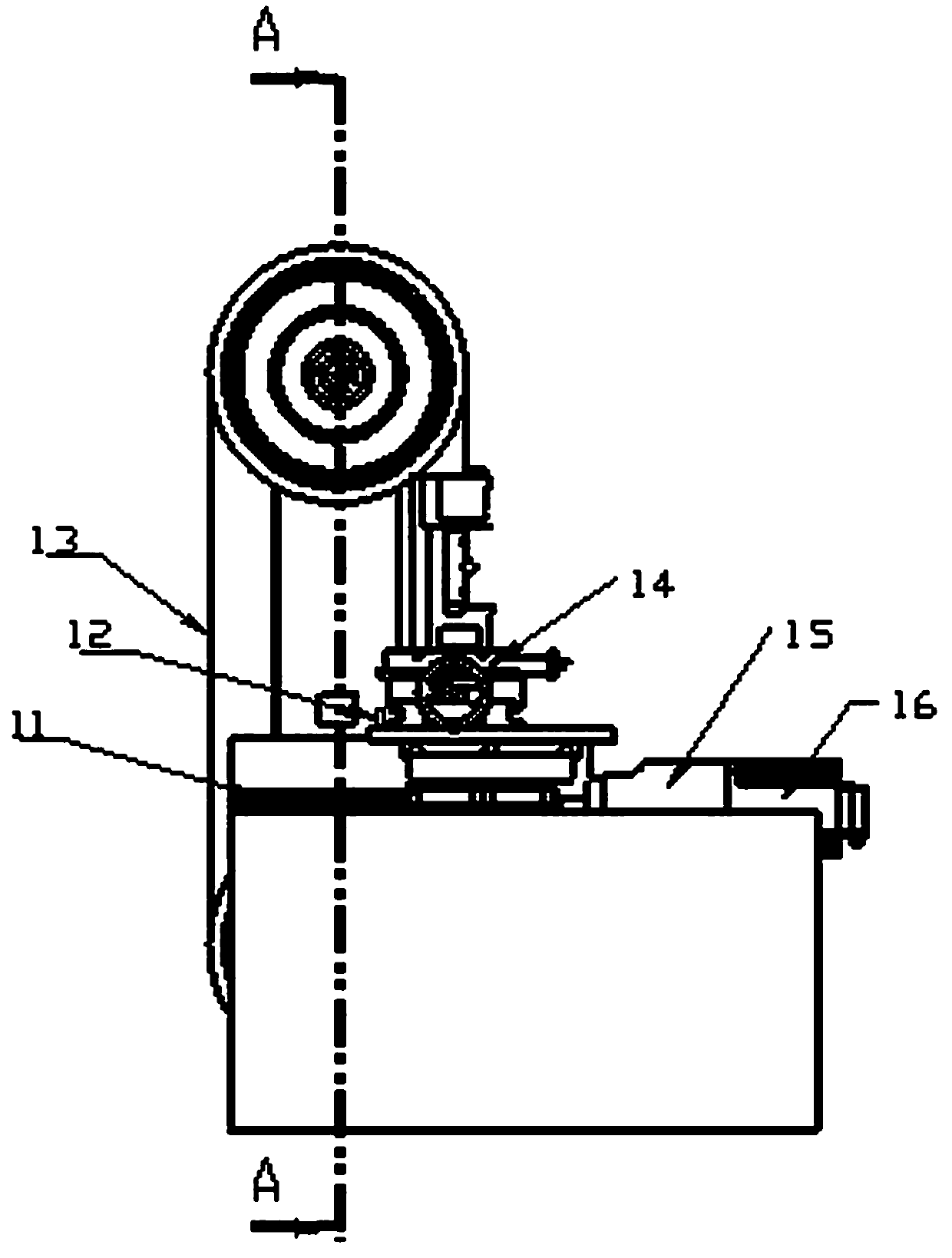

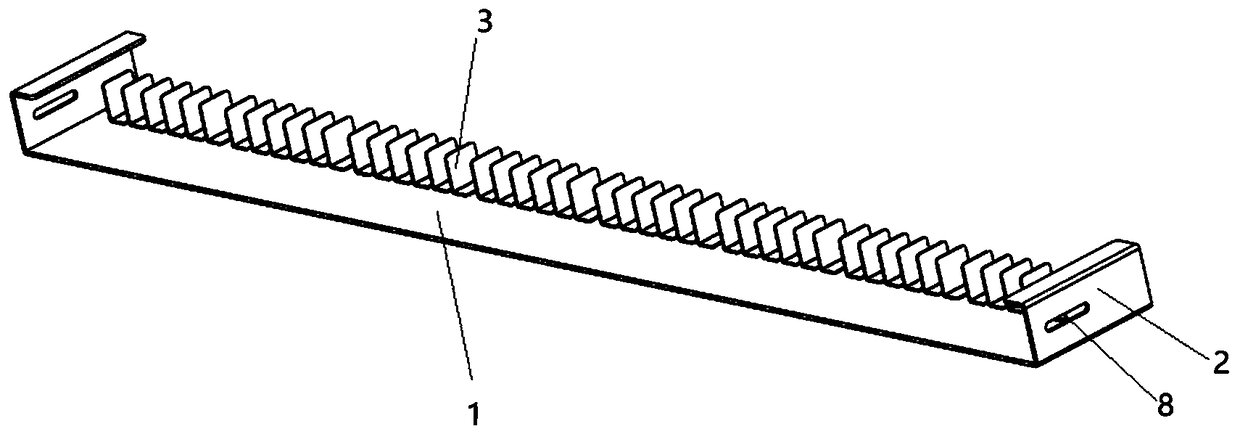

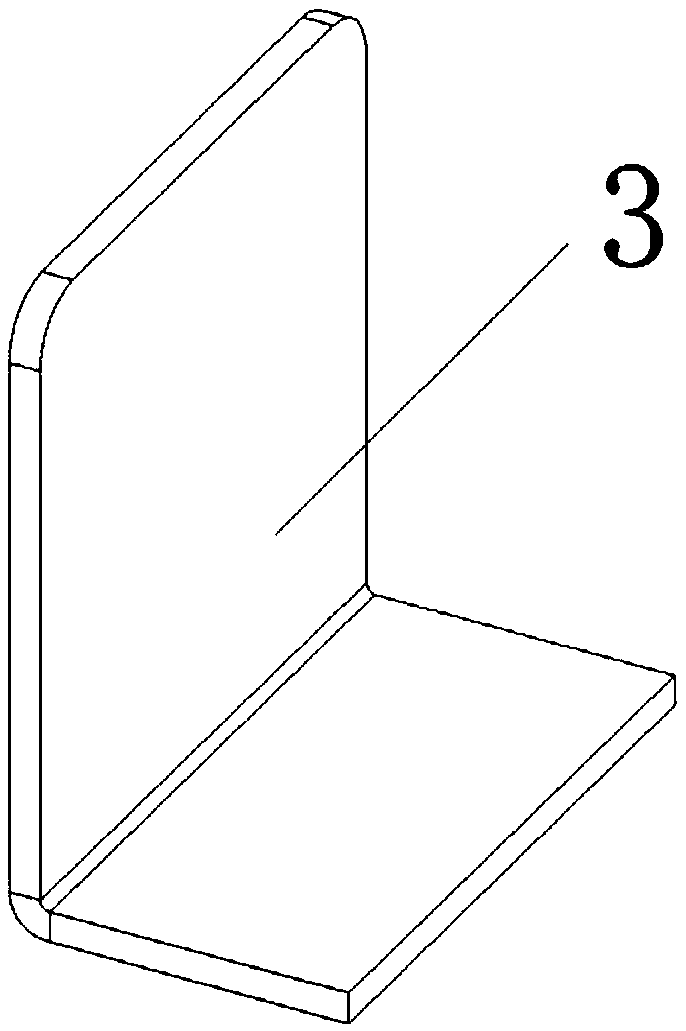

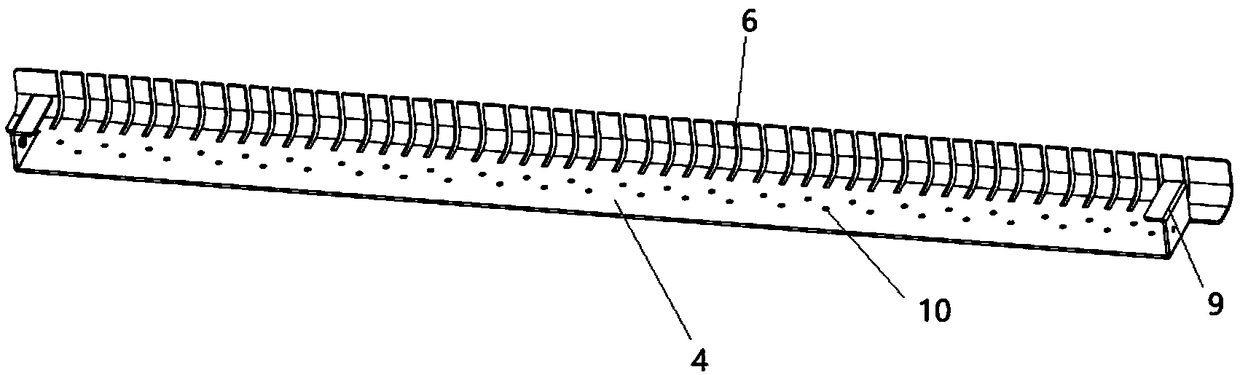

High-speed aluminum wire drawing machine

The invention relates to a high-speed aluminum wire drawing machine, and belongs to the technical field of an aluminum wire drawing machine. The high-speed aluminum wire drawing machine comprises a rack and a motor, wherein a low-speed guide wheel set, a low-speed mould base, a low-speed cone pulley set, a high-speed cone pulley set I, a high-speed mould base, a high-speed cone pulley set II and a constant-speed wheel are sequentially arranged on the rack; the motor is connected with a driving pulley, the driving pulley is connected with a driven pulley, and the driven pulley is connected with the high-speed cone pulley set I; the high-speed cone pulley set I, the high-speed cone pulley set II and the constant-speed wheel are connected and transmitted through synchronous belts; the high-speed cone pulley set I is connected and transmitted with the low-speed cone pulley set through a gear; and the low-speed guide wheel set is connected with the low-speed cone pulley set in a chain transmission mode. With the adoption of the technology, the gear or chain transmission among the constant-speed wheel, the high-speed cone pulley set I and the high-speed cone pulley set II is changed into synchronous belt transmission. The high-speed aluminum wire drawing machine has the advantages of simple transmission structure design, high wire drawing speed, low energy consumption, good economic benefit, strong practicality, greatly reduced transmission noises and prolonged service life, and brings security assurance to the personal safety of operating personnel.

Owner:HANGZHOU XINGGUAN MACHINERY

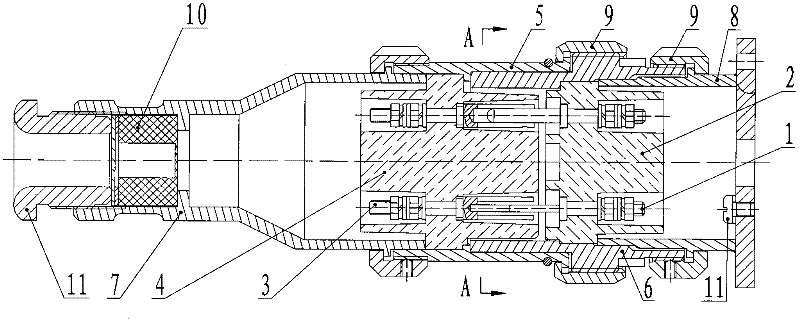

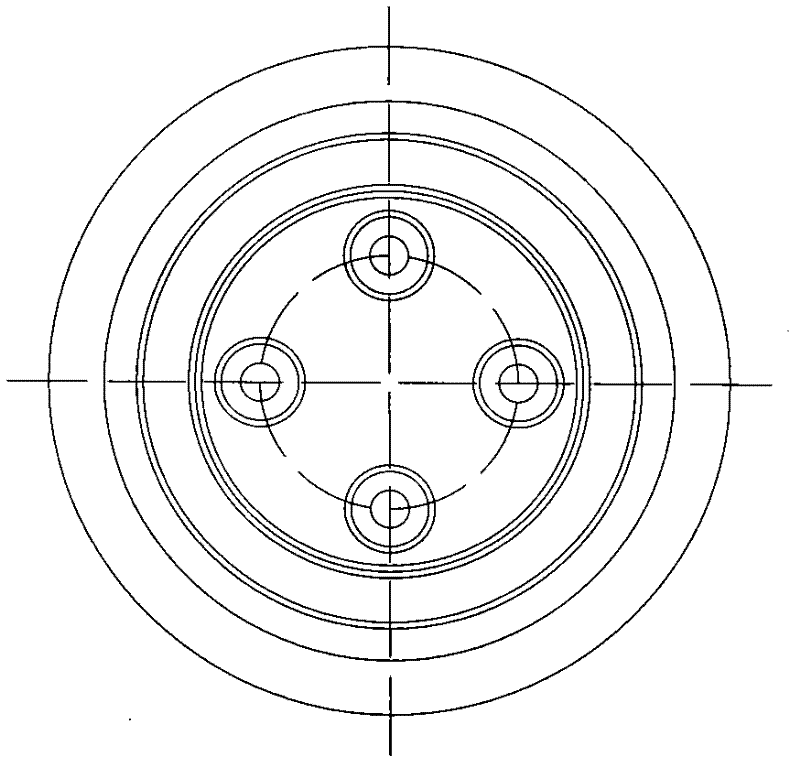

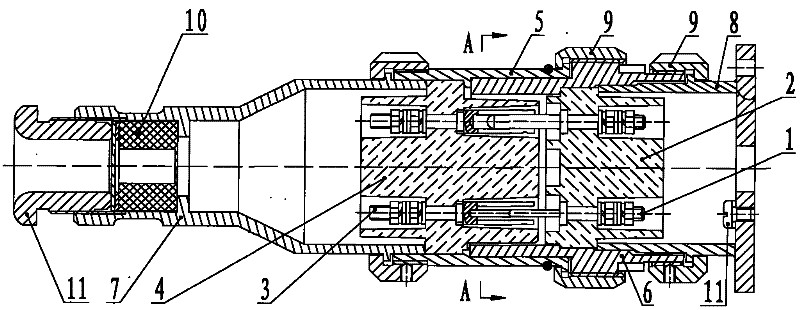

Mining explosion-proof latch with low voltage

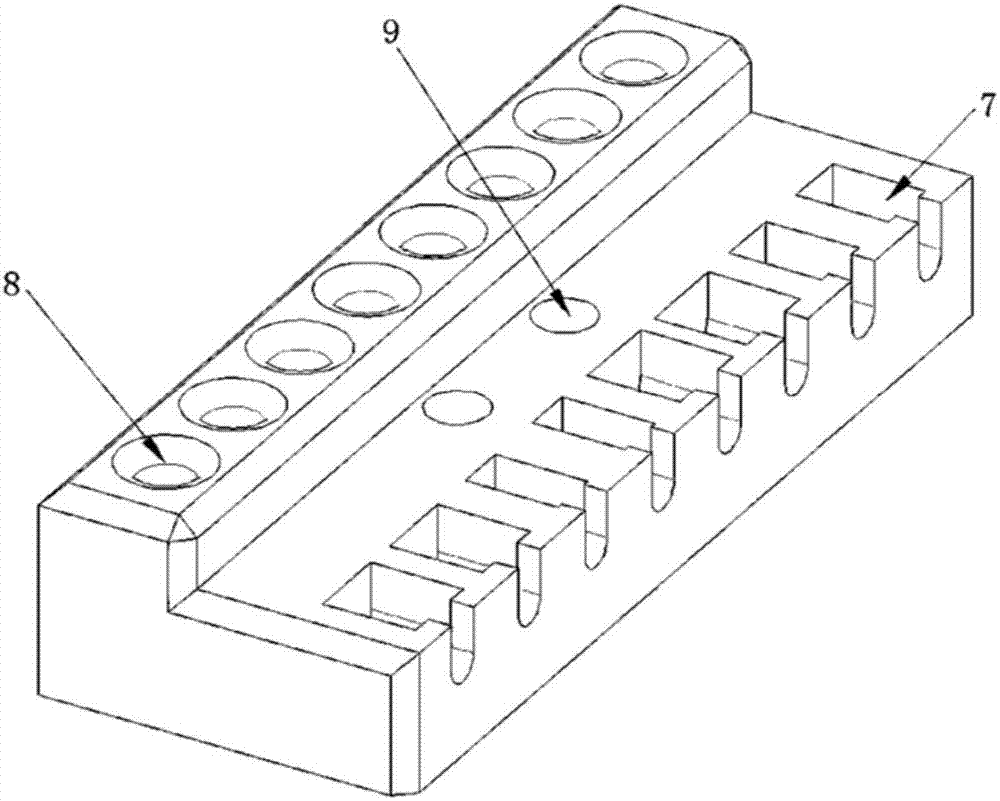

InactiveCN102394417AFast wiringEasy to disassembleCoupling contact membersCouplings bases/casesWater leakageLow voltage

The invention discloses a mining explosion-proof latch with a low voltage. The latch comprises a male inserted rod, a male inserted rod insulating base, a mother rod base, a mother rod base insulating base and an explosion-proof outer sleeve. The male inserted rod is arranged on the male inserted rod insulating base; and the mother rod base is arranged in the mother rod base insulating base. One end of the male inserted rod extruded outside the male inserted rod insulating base and is plugged with one end of the mother rod base; and the other ends of the male inserted rod and the mother rod base are used as terminals; and besides, the explosion-proof outer sleeve enables the male inserted rod insulating base and the mother rod base insulating base to be encompassed inside it. According to the invention, the mining explosion-proof latch with a low voltage is mainly used a cable introduction apparatus of a mining explosion-proof vulcanizer with an electric heating type; and problems of water leakage, electric leakage and production of spark during the using process of a current mining explosion-proof vulcanizer with an electric heating type and a wiring speed is slow are solved; besides, the provided mining explosion-proof latch has advantages of fast wiring speed, easy disassembly, good explosion-proof performance, and safe and reliable working performances.

Owner:WUXI ZHENHE MECHANICAL ELECTRIC APP

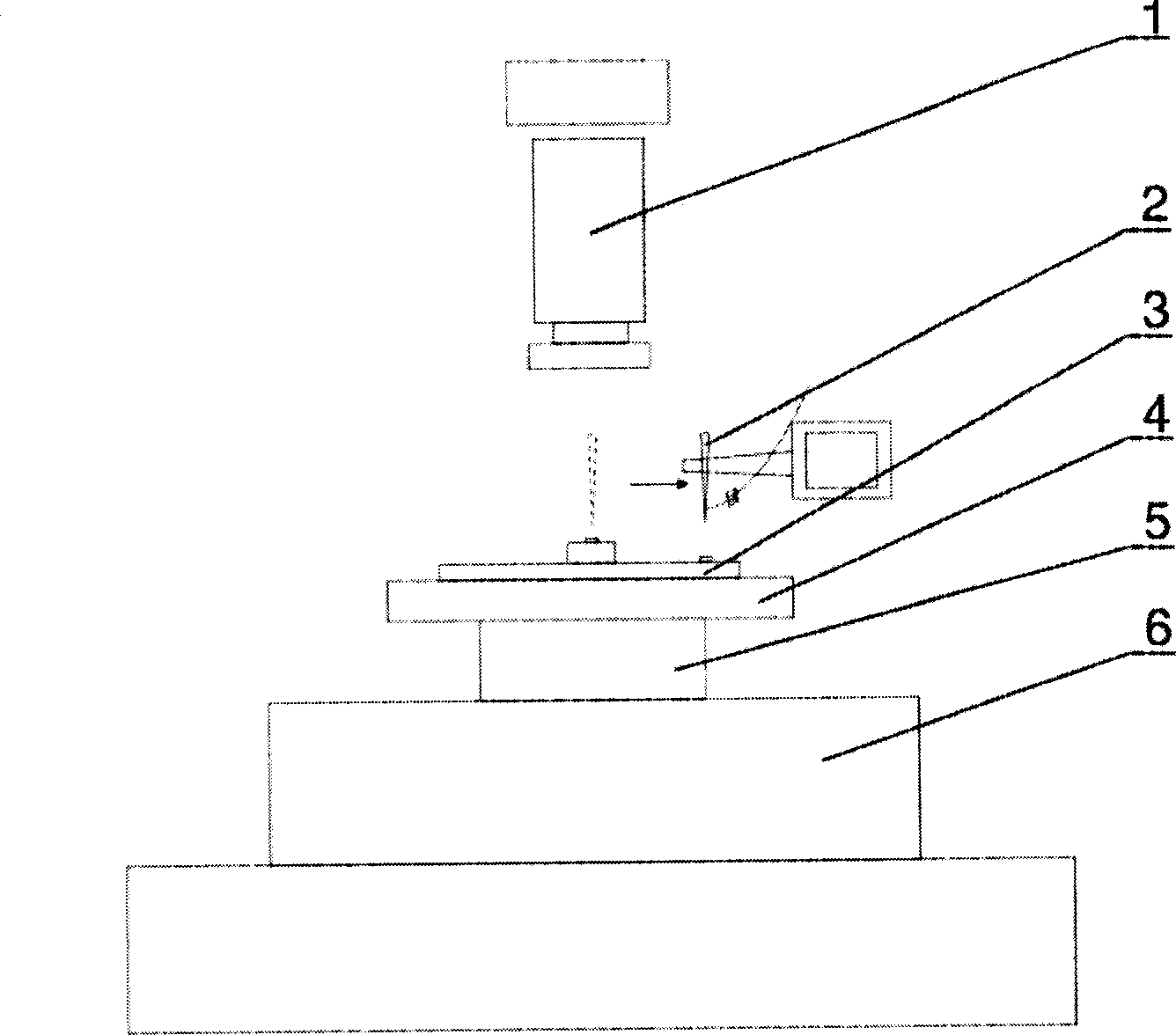

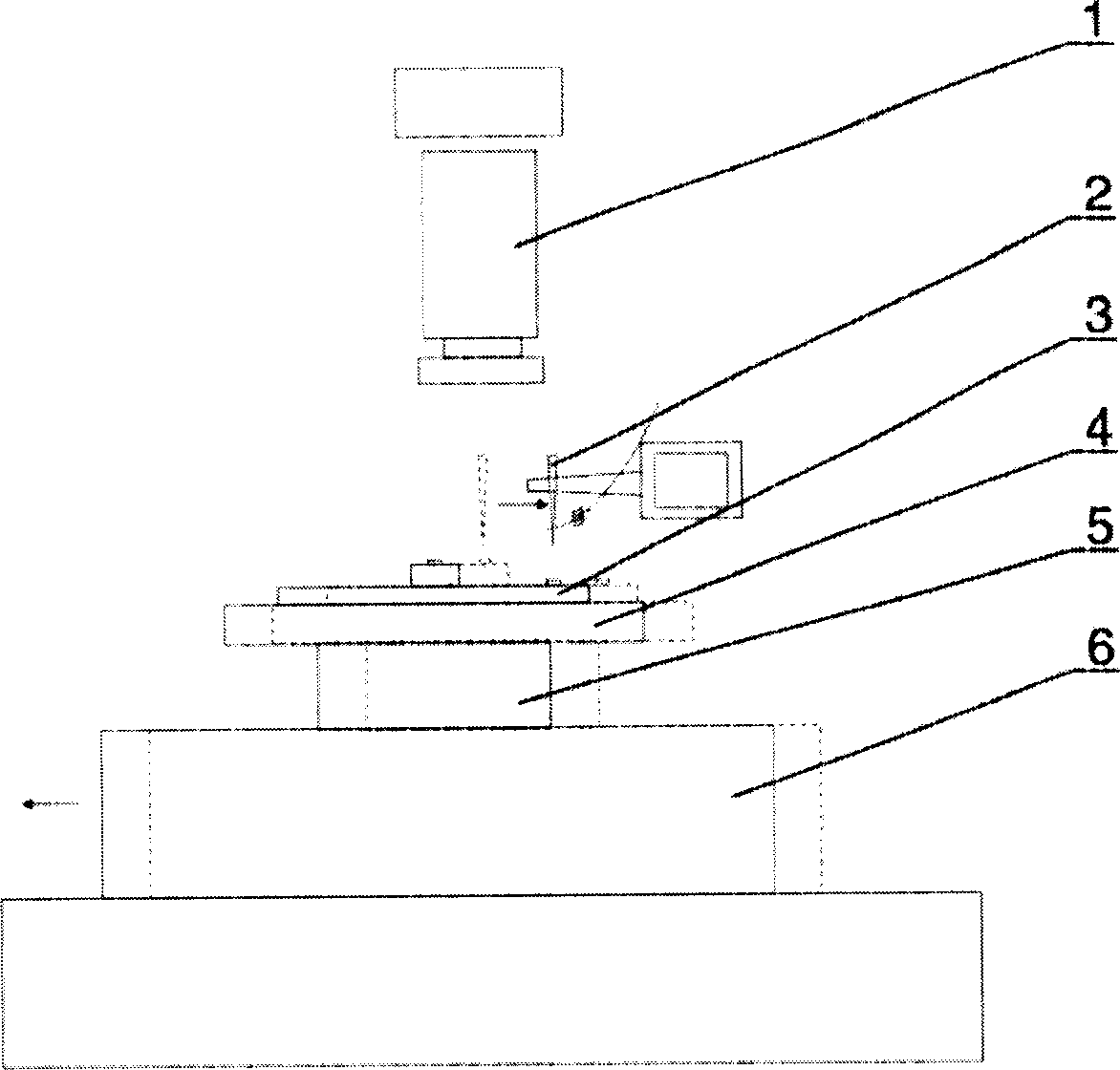

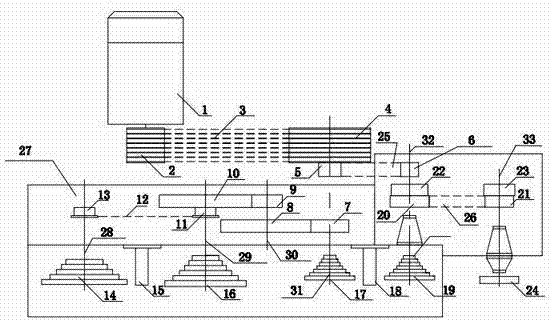

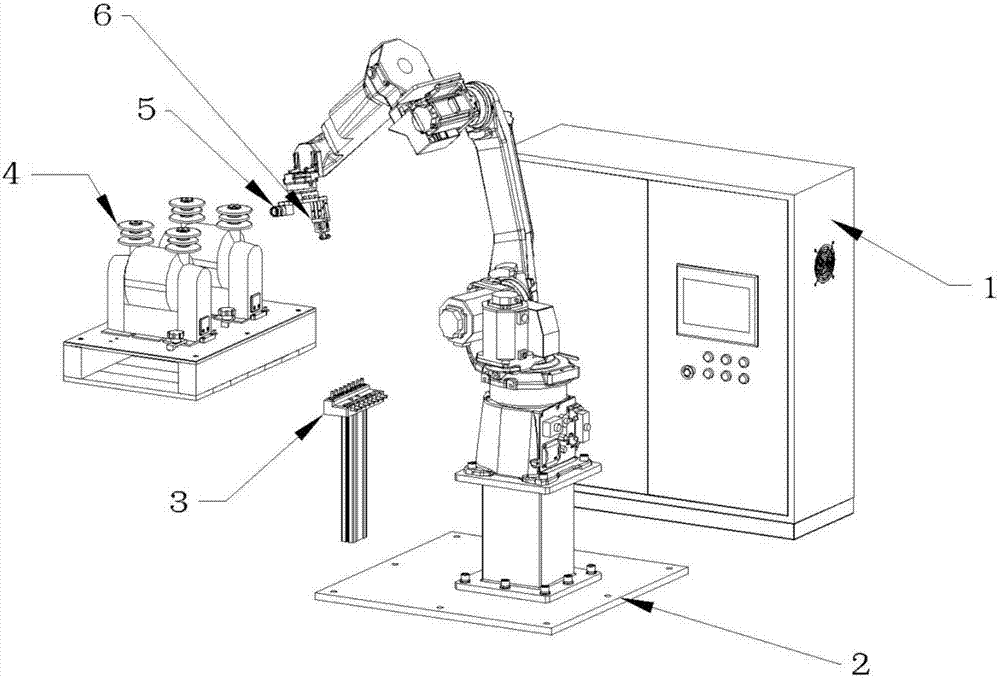

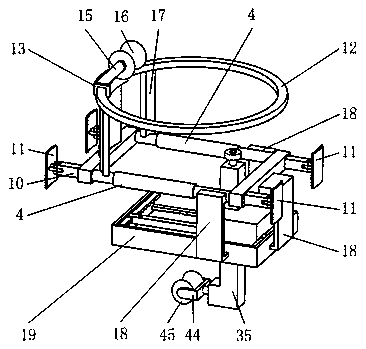

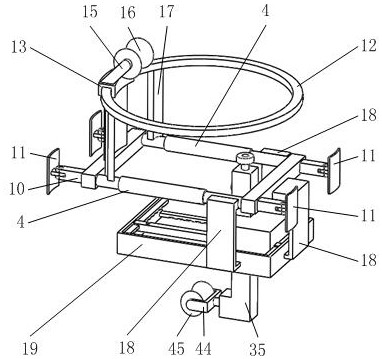

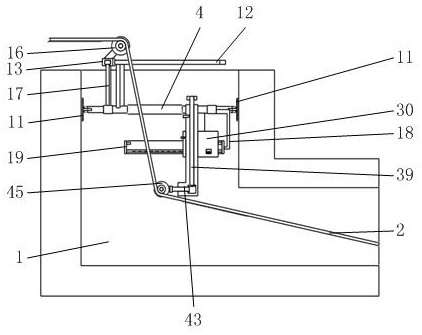

Voltage transformer automatic wiring device

InactiveCN107271728AReduce connection difficultyHigh precisionElectrical testingMeasurement instrument housingProduction lineTransformer

The invention relates to a voltage transformer automatic wiring device used for performing primary wiring and secondary wiring on a voltage transformer to be calibrated on a production line, and the device includes a robot located on a side face of the production line and used for performing precise recognition on the position of the voltage transformer and realizing primary wiring and secondary wiring of the voltage transformer; a clamp module mounted on the production line, connected with a test line and the voltage transformer during wiring and used for serving as an intermediate connecting device of the test line and the voltage transformer to improve wiring efficiency; and a controller connected with the robot and used for providing a wiring scheme for the robot and controlling an operation path of the robot. Compared with the prior art, the voltage transformer automatic wiring device has the advantages of accurate wiring, high degree of automation, cost saving and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

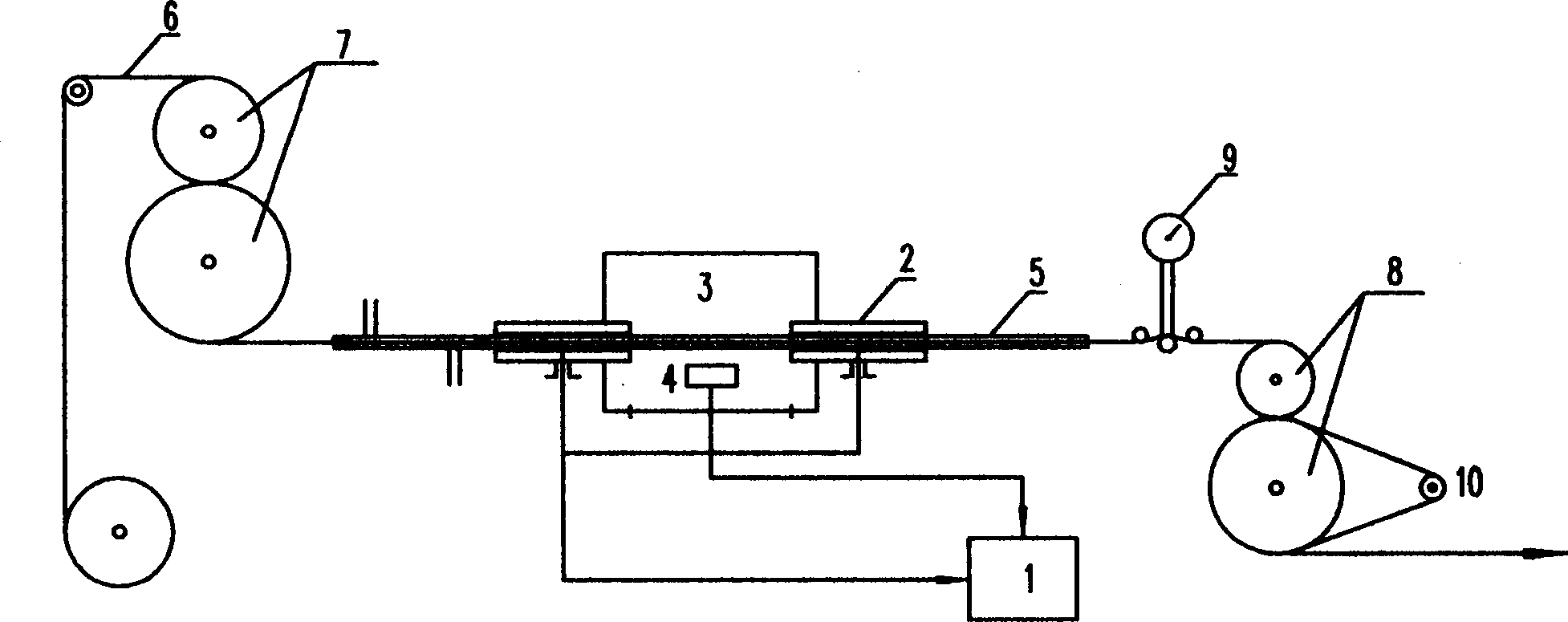

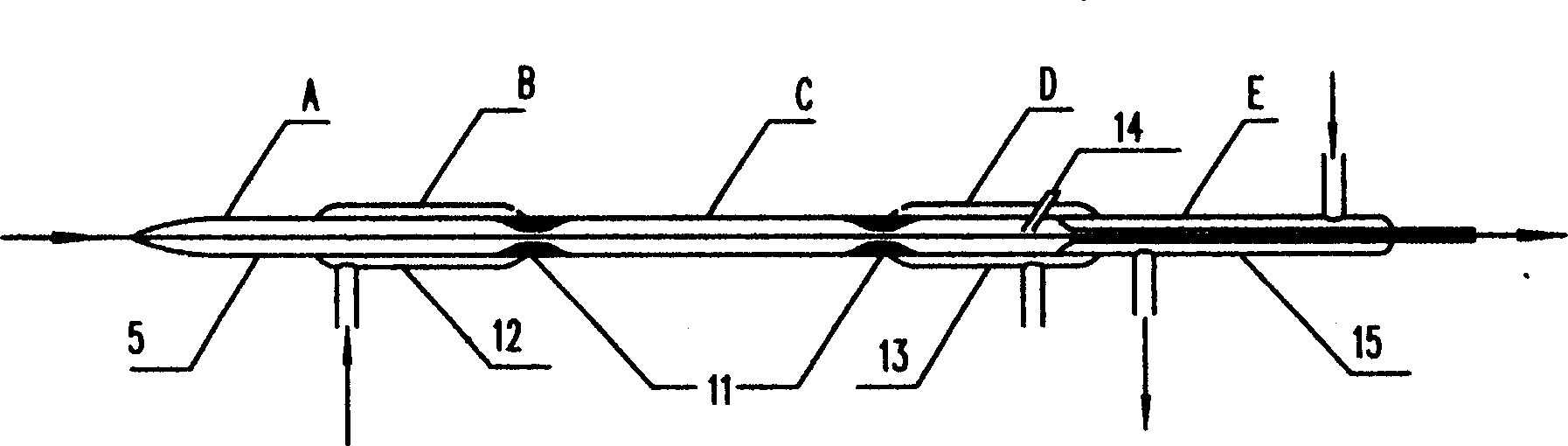

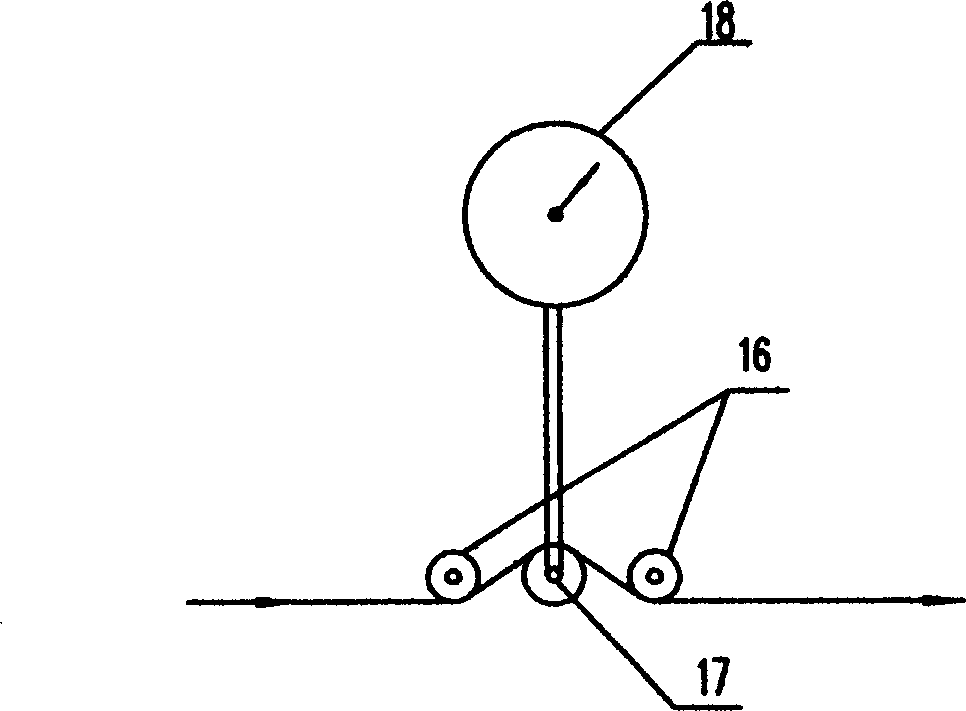

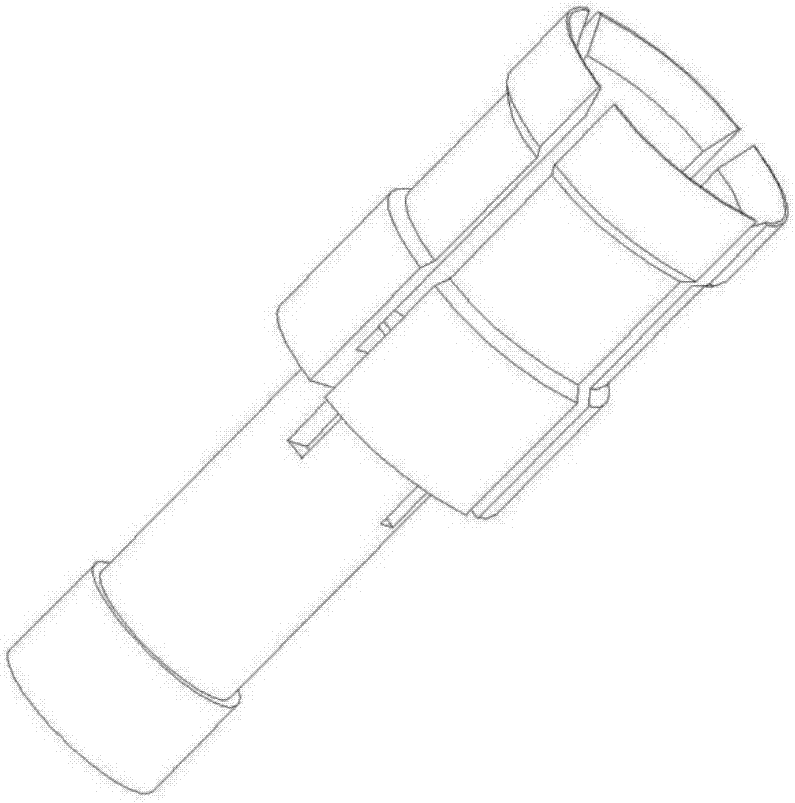

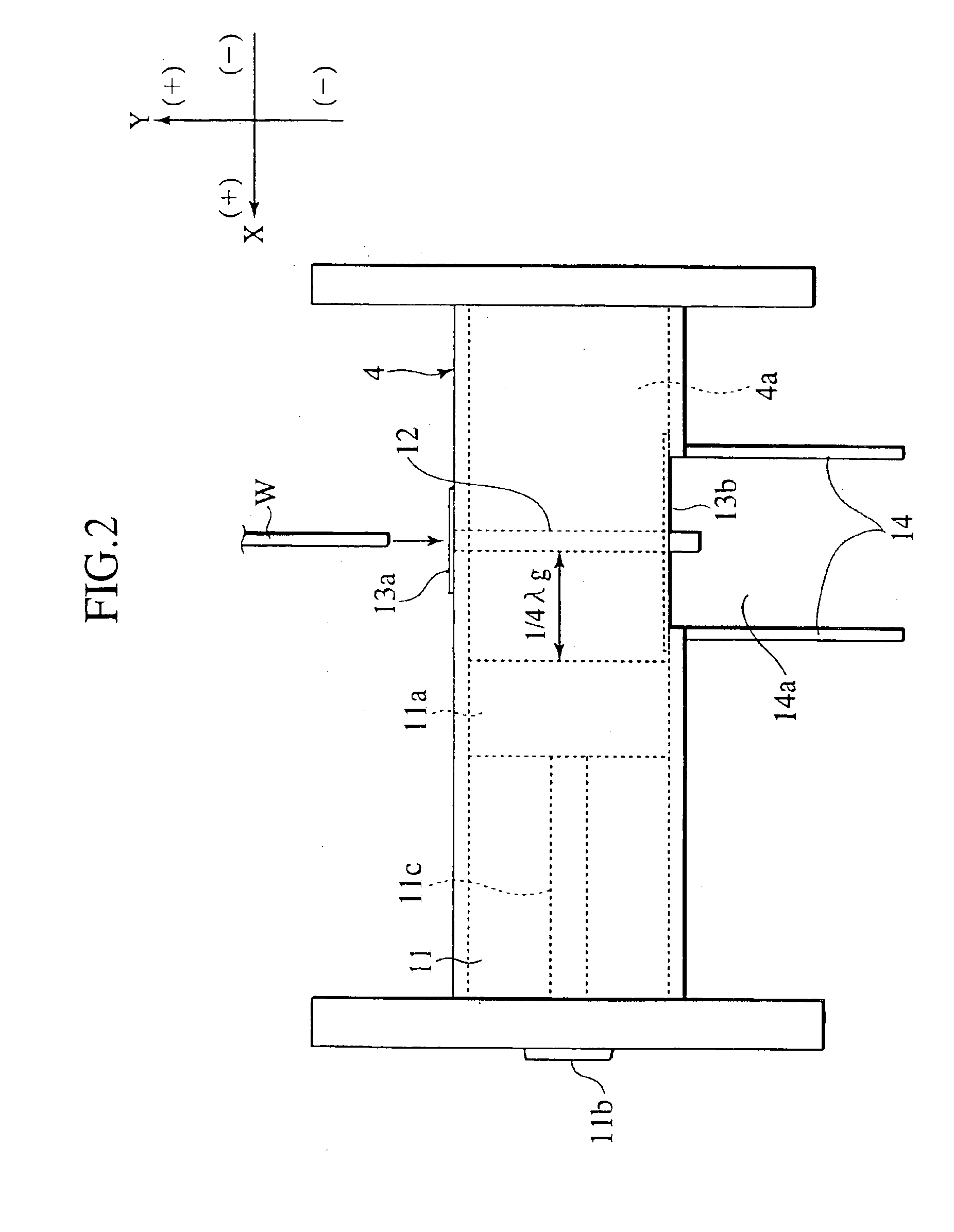

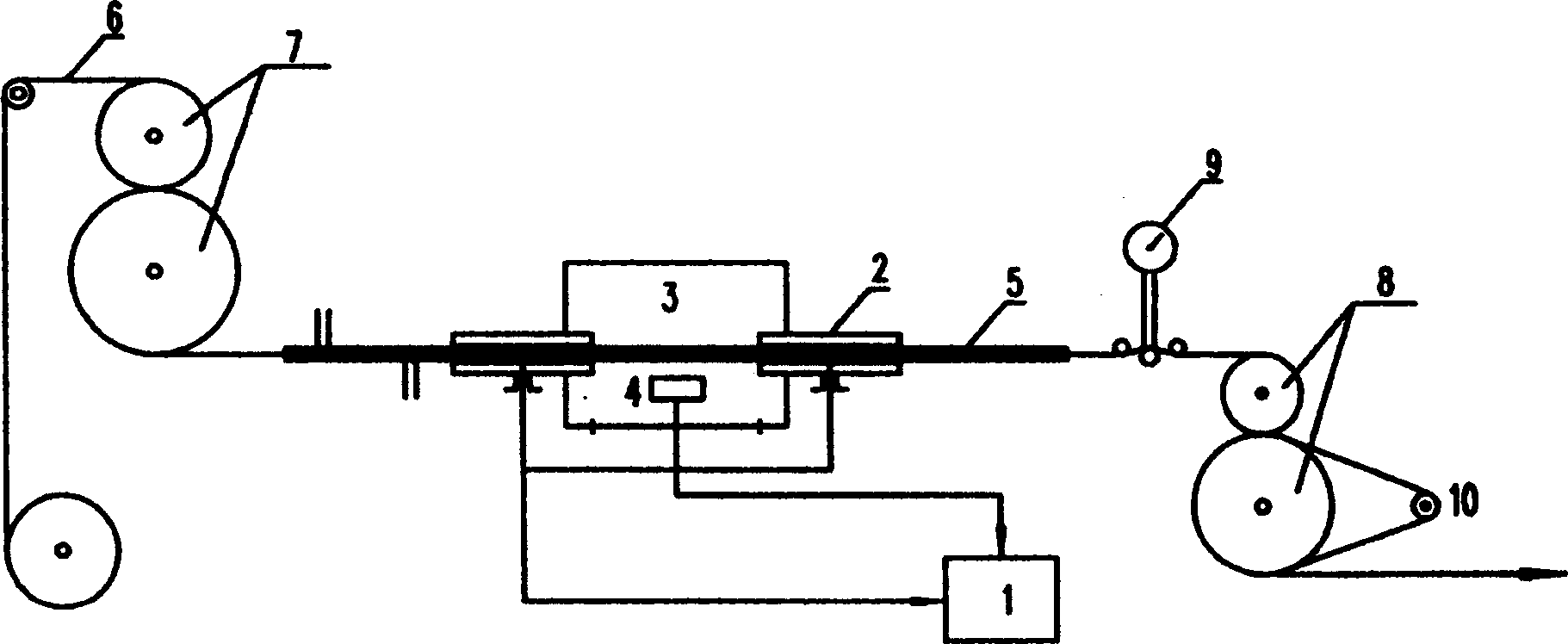

Wire processing apparatus and wire processing method

InactiveUS6868599B2Efficient separationEffective cross-linkingDielectric heatingRadiation applicationsCross-linkWire rod

A wire processing apparatus includes a microwave generator, a microwave transmitter, a waveguide coaxial converter and a wire insertion pipe, and the wire insertion pipe is disposed in the wireguide coaxial converter. In wire recycling process, after a tip end of a coated wire is inserted into the wire insertion pipe, microwave is launched into the inside of the waveguide coaxial converter. The tip end of the coated wire is separated into a decomposed coating insulator and a molten electric conductor by microwave. In wire cross-linking process, after microwave is launched into the inside of the waveguide coaxial converter, the coated wire is inserted into the wire insertion pipe. The coated wire is cross-linked by high frequency heat and a coating insulator is adhered well to an electric conductor by heat shrinking.

Owner:YAZAKI CORP

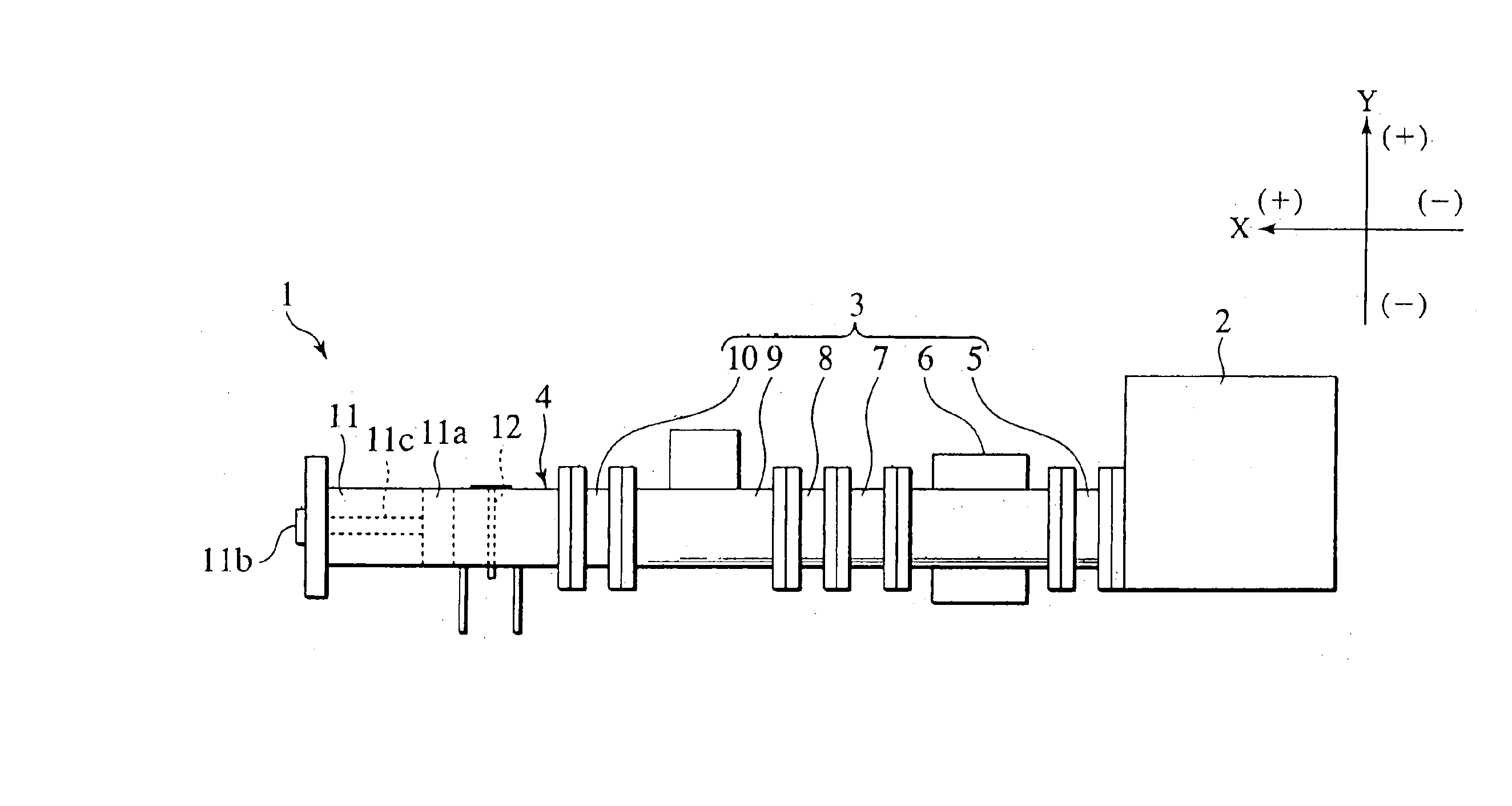

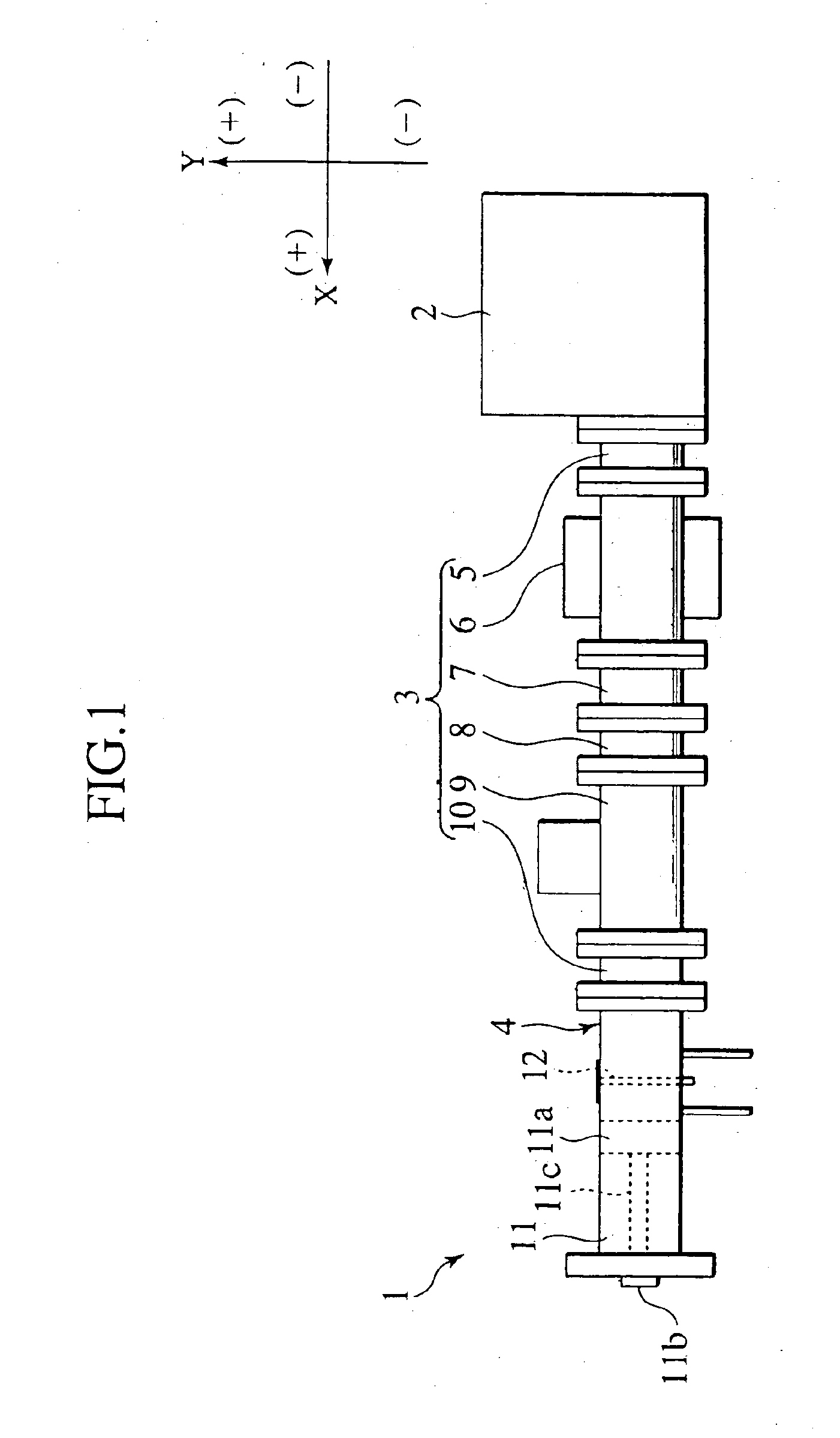

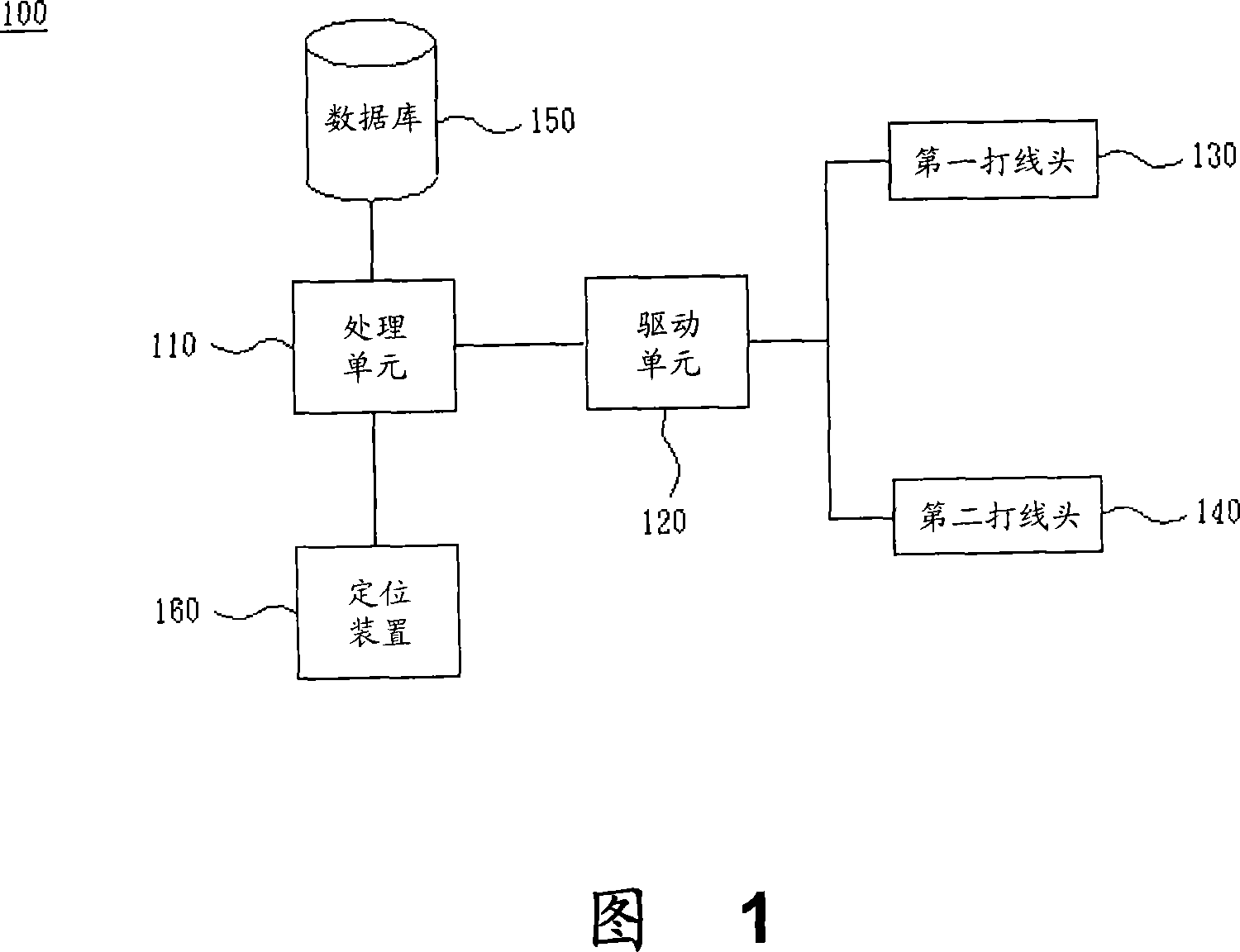

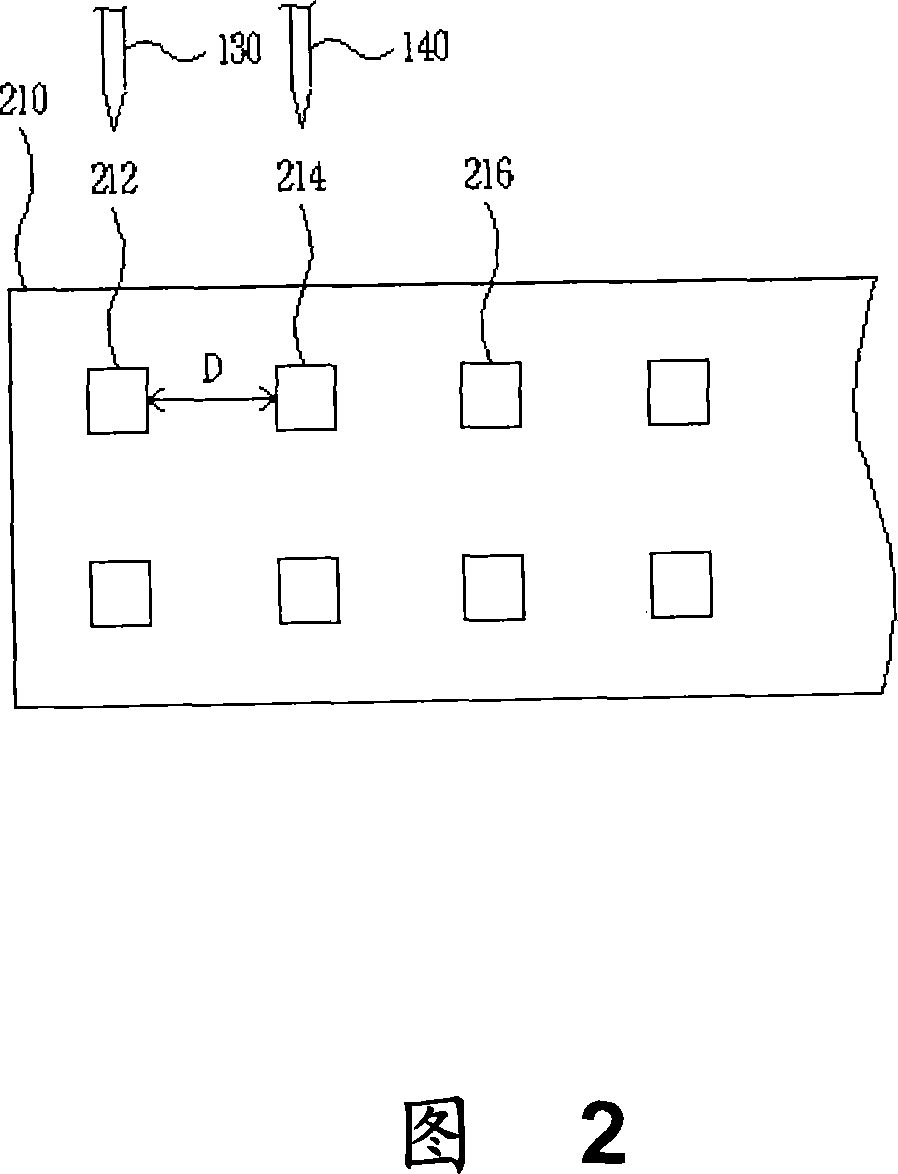

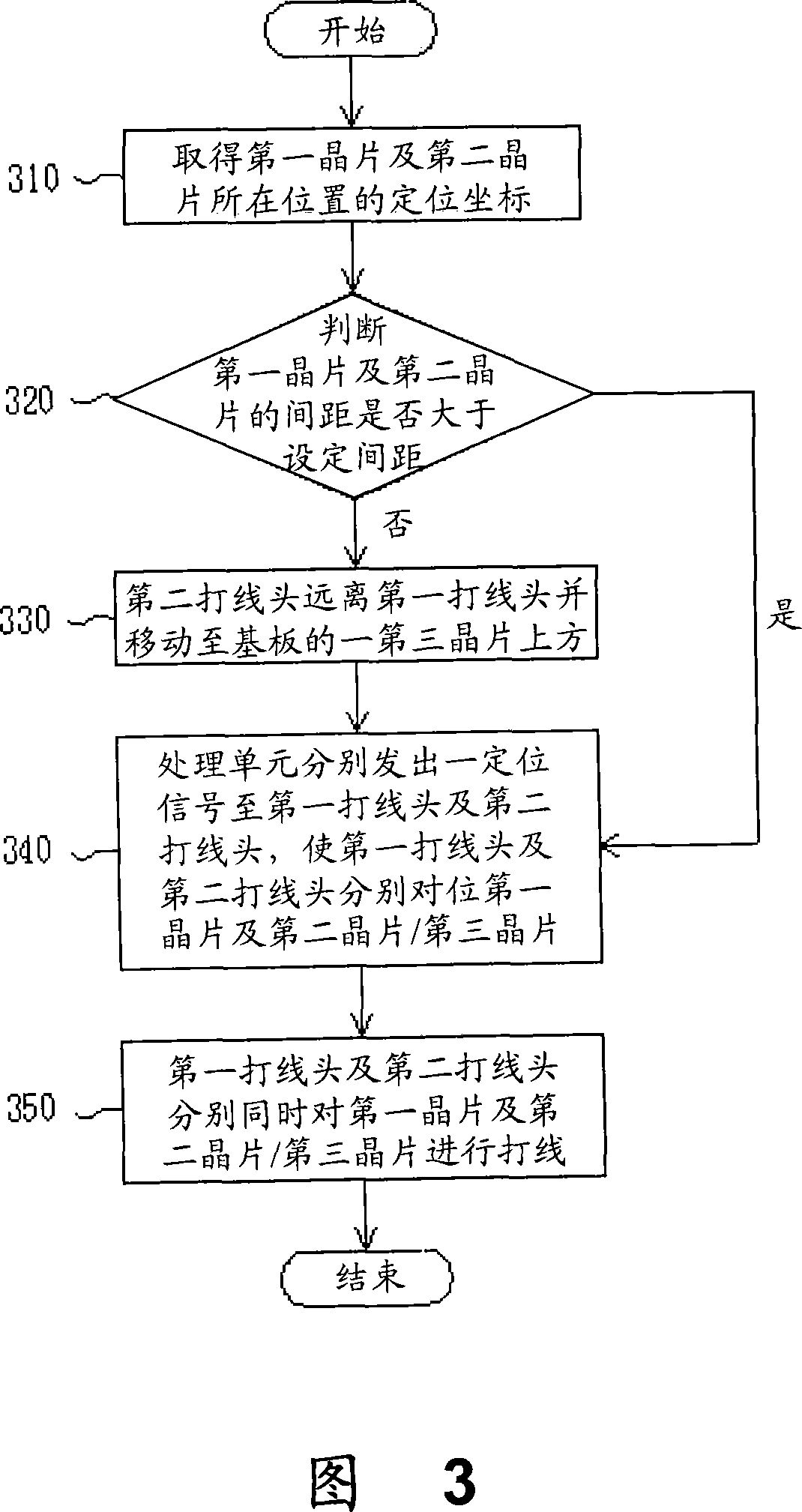

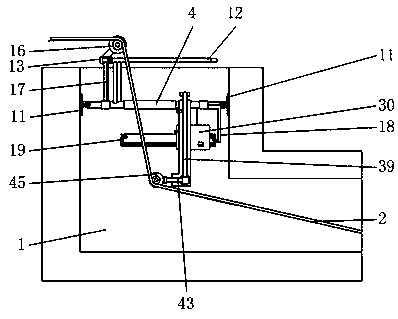

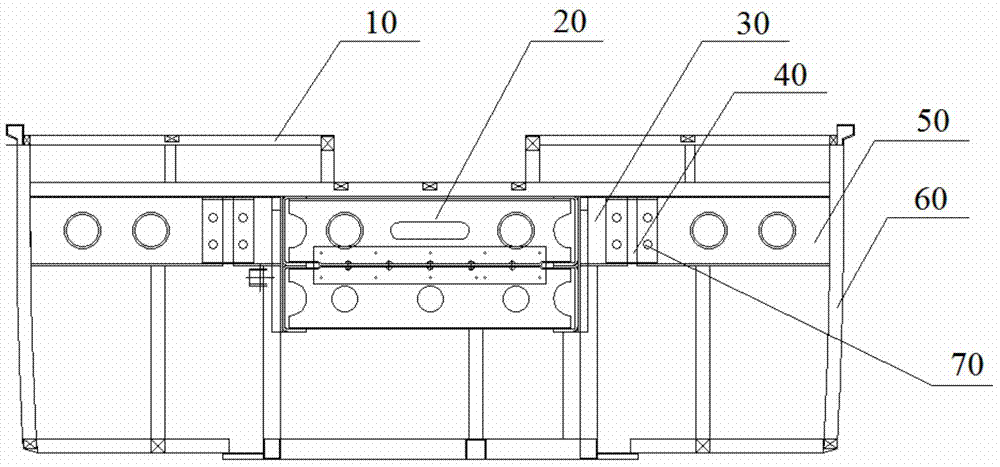

Wiring machine platform and wiring method

ActiveCN101101885AIncrease the speed of wiringImprove wiring speedSemiconductor/solid-state device manufacturingEngineeringEmbedded system

The invention is concerned with the thread feeder arm that is used to process thread to at least the first chip and the second chip on the basis synchronously, includes: at least the first thread head and the second thread head, the driving unit, the processing unit, the database. It is: the driving unit uses to move the first thread head and the second thread head; the processing unit uses to output the controlling order to the driving unit in order to control the first thread head and the second thread head; the database stores the operating parameter data, the processing unit control the first thread head and the second thread head according to the operating parameter data.

Owner:ADVANCED SEMICON ENG INC

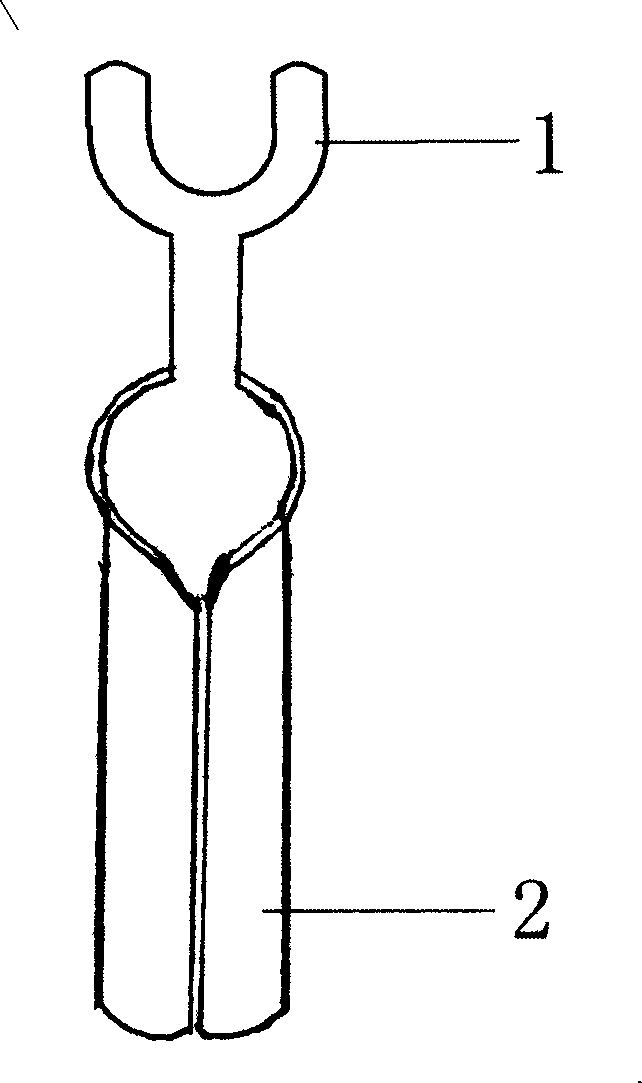

Lug

InactiveCN101202385ASave energyEasy to useElectric connection structural associationsConnections effected by permanent deformationEngineeringMetal

The invention provides a lug, comprising a wiring tongue and a pressing line terminal. The pressing line terminal is a round metal pipe which can just press a lead wire in size. The invention is characterized in that the pressing line terminal is provided with a V-shaped opening in the wiring tongue direction. The pressing line terminal is also provided with a plastic sleeve which sleeves the pressing line. When wiring, the lead passes through the bottom end of the lug and is clamped at the V-shaped opening; the lead is stripped off at the V-shaped opening; the lead wire is connected with a lug circuit and the lead and the pressing line terminal are sleeved by the plastic sleeve.

Owner:SHANGHAI QIYI HIGH SCHOOL

Energy-saving environment-friendly steel cord hot-dip coating copper-zinc alloy and thermal treatment production process thereof

The invention provides an energy-saving environment-friendly steel cord hot-dip coating copper-zinc alloy layer and a thermal treatment production process thereof in the process of steel cord production. The process comprises electrolytic degrading, washing, coating an assistant coating agent, drying, coating copper in hot-dip mode and austenitizing, coating zinc in hot-dip mode and isothermal treatment and diffusion annealing. The temperature for the process of coating the copper in hot-dip mode and austenitizing ranges from 1100 DEG C to 1140 DEG C, and the temperature for the process of coating the zinc in hot-dip mode and diffusion annealing ranges from 550 DEG C to 600 DEG C. After diffusion annealing, mass percentage of zinc in the copper-zinc alloy coating layer ranges from 30%-37%. The production process respectively utilizes the two procedures of coating the copper in hot-dip mode and austenitizing and coating the zinc in hot-dip mode and isothermal treatment to replace four procedures of austenitizing, copper coating, isothermal treatment and zinc coating, solves the problems of heavy metal iron sewage discharging, waste gas exhaust during austenitizing heating and lead and powder pollution during isothermal treatment in the existing production process, and has the advantages of being good in environment protection performance, high in production efficiency and low in production cost.

Owner:NANJING INST OF TECH

Municipal engineering cable equipment

ActiveCN111313329AImprove construction efficiencyImprove construction qualityCable installations on groundApparatus for laying cablesArchitectural engineeringStructural engineering

The invention belongs to the field of cable laying, and particularly relates to municipal engineering cable equipment which comprises rods A, telescopic rod structures, supporting feet, guide rings, idler wheels A, idler wheels B and the like. Four supporting feet matching the wall of a cable well are symmetrically installed on the two rods A connected through the two symmetrically-distributed telescopic rod structures. According to the invention, when the wire drawing direction is changed and is not consistent with the running direction of the underground cable of the cable, by adjusting thedirections of the idler wheels A and the idler wheels B, the cable is still located on the idler wheels A and the idler wheels under the condition that the pulling direction of cable pulling personnelon the ground is changed; therefore, abrasion caused by contact between the cable and the well edge or the corner in the cable well due to the fact that the cable is separated from the idler wheels Aand the idler wheels B when the pulling direction of the ground wire pulling personnel is changed is avoided; and the cable is prevented from being damaged while the cable construction efficiency isguaranteed.

Owner:山东宏远电力科技有限公司

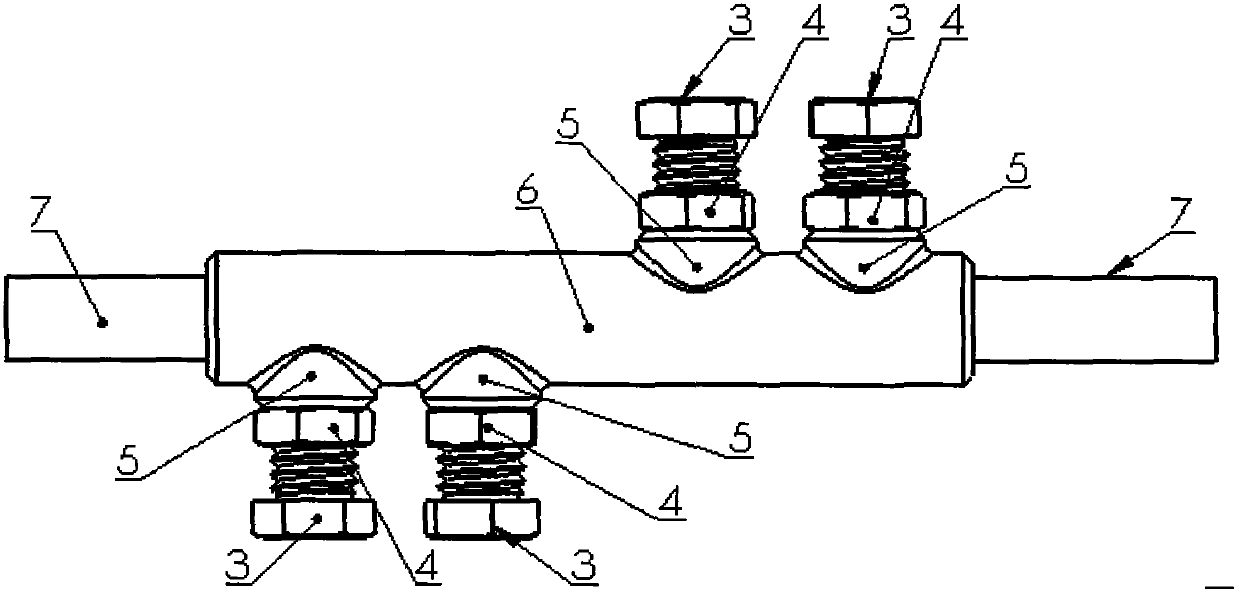

Quick joint for high-tension cables

InactiveCN102683915APrevent looseningShorten the timeElectric connection structural associationsClamped/spring connectionsEngineeringSelf locking

The invention relates to a quick joint for high-tension cables and belongs to a basic electric former piece. Each one of two ends of a wire passing pipe provided by the invention is at least provided with a thread hole; a screw rod is arranged on the thread hole; and the screw rod is fixed through a nut. By utilizing the quick joint for the high-tension cables provided by the invention, the time is saved, materials are saved, and the efficiency is improved, so that the cost is reduced, and the high-tension cables with different lengths can be sufficiently and reasonably used. The quick joint for the high-tension cables provided by the invention is simple and easy to know and simple and clear in operation. The screw rod is automatically locked by using a self-locking nut, so as to prevent from the release of the screw rod, caused by swinging. The operation time is greatly reduced, and the stringing speed is improved by using the lever principle, so that various electric devices are ensured to be efficiently operated. Meanwhile, the reasonable length is achieved by rapidly dismounting surplus wires of the quick joint, so that no material waste is caused, and the cost is reduced. Therefore, the purposes of reducing the cost and improving the efficiency can be achieved. The flexible quick joint provided by the invention is convenient to store, and is convenient in mechanical operation. The rapid quick joint has the advantages of low manufacturing cost and convenience in machining..

Owner:BAOTOU STEEL GRP BARUN MINING CO LTD

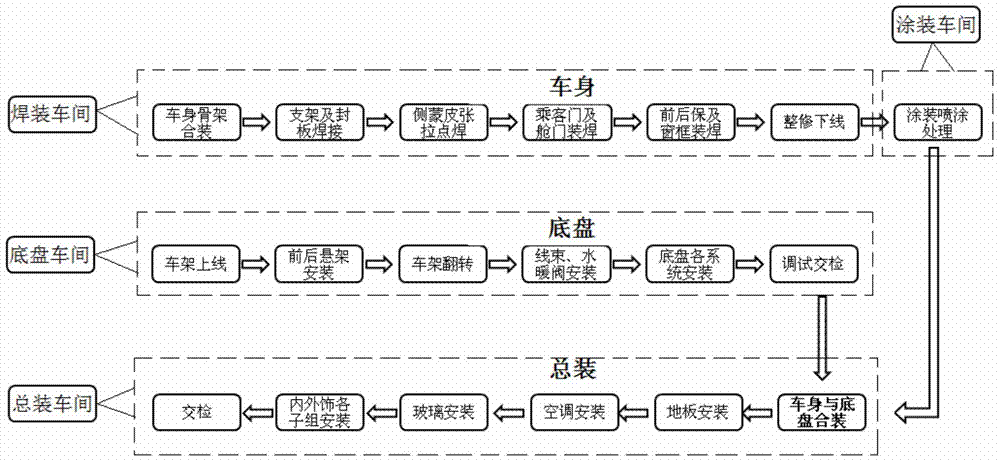

Half-loading passenger car and shell removing method thereof

InactiveCN104709352AImprove surface qualityImprove wiring speedVehicle body-frame connectionsVehiclesCoatingAutomotive engineering

The invention discloses a half-loading passenger car and a shell removing method thereof. The half-loading passenger car comprises a car body and a chassis, wherein car body connecting pieces are arranged on side stand columns of the car body, chassis connecting pieces are arranged on the chassis, and the chassis connecting pieces and the car body connecting pieces are fixed through combination connecting pieces. The shell removing method includes the steps that first, the car body and the chassis are separately manufactured; second, coating is performed on the car body manufactured in the first step; third, the chassis manufactured in the first step and the coated car body processed in the second step are connected into a whole in a buckled mode. In the first step, when the car body is manufactured, the car body connecting pieces are welded to the side stand columns of the car body; meanwhile, when the chassis is manufactured, the chassis connecting pieces are connected to the chassis in a riveted mode; the third step further includes the sub steps that one ends of the combination connecting pieces are fixed to the car body connecting pieces, and the other ends of the combination connecting pieces are fixed to the chassis connecting pieces. Due to the face that the car body connecting pieces are additionally arranged, after the car body and the chassis are buckled, the combination connecting pieces do not need to be welded to the side stand columns, and the surface quality of the car body is improved.

Owner:BEIQI FOTON MOTOR CO LTD

Liquid soldering flux for soldering electrical products

InactiveCN101829863APrevent oxidationQuality assuranceWelding/cutting media/materialsSoldering mediaWater bathsCopper conductor

The invention discloses a liquid soldering flux for soldering electrical products, which is characterized by being prepared from the following raw materials in percentage by weight: 70-85 percent of ethanol, 2.0-5.0 percent of ethylene glycol monobutyl ether, 1.0-4.0 percent of mixed acid with the volume ratio of hydrochloric acid to phosphoric acid of 2:1, 10-20 percent of colophony, 0.5-2.0 percent of benzotriazole and 0.5-3.0 percent of glycerol stearate. The liquid soldering flux for soldering the electrical products is prepared by the following steps of: respectively placing the components in a container for sufficiently mixing, heating in a water bath for 3h, keeping a temperature of 40-50 DEG C, and stirring and mixing to be uniform while heating; and naturally cooling to the room temperature. The liquid soldering flux is coated on an electric appliance wiring terminal so that a soldering surface is rapidly activated, a copper conductor is soldered on an activated surface of a large electric appliance wiring terminal by an electric soldering iron through soldering tin, thus a firm, smooth and bright soldered dot can be obtained, and the oxidation of the surface of the electric appliance wiring terminal is avoided. The soldered dot can keep firm, smooth and bright for a long time, and the quality of an electric appliance wiring product is ensured.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

High-speed metal wire drawing machine

The invention relates to a high-speed metal wire drawing machine, and belongs to the technical field of a metal wire drawing machine. The high-speed metal wire drawing machine comprises a rack and a motor, wherein a low-speed guide wheel set, a low-speed mould base, a high-speed guide wheel set, a high-speed mould base and the like are arranged on the rack; the motor is sequentially connected with a driving pulley, a driven pulley and a high-speed cone pulley set; the high-speed cone pulley set is in transmitted connection with a constant-speed wheel and is in meshed and transmitted connection with a low-speed cone pulley set; the low-speed guide wheel set is connected with the low-speed cone pulley set. The chain or gear transmission of the constant-speed wheel and the high-speed cone pulley set is changed into synchronous belt transmission, synchronous belt wheels are connected with shafts through taper locks, the replacement is convenient, and therefore the different speed ratios between the constant-speed wheel and the high-speed cone pulley set is obtained, so that only one mould is needed when customers draw a variety of specifications of metal wires. The mould cost is greatly reduced. The high-speed metal wire drawing machine has the advantages of simple design, high wire drawing speed, low energy consumption, good economic benefit and strong practicality, greatly reduces transmission noises, and brings security assurance to the personal safety of operating personnel.

Owner:HANGZHOU XINGGUAN MACHINERY

Method for producing high-strength-modules carbon fibre and speical equipment thereof

InactiveCN1172040CStable output powerReaction temperature control sensitiveFibre chemical featuresMicrowave heatingTemperature controlCarbon fibers

Owner:张蓬洲

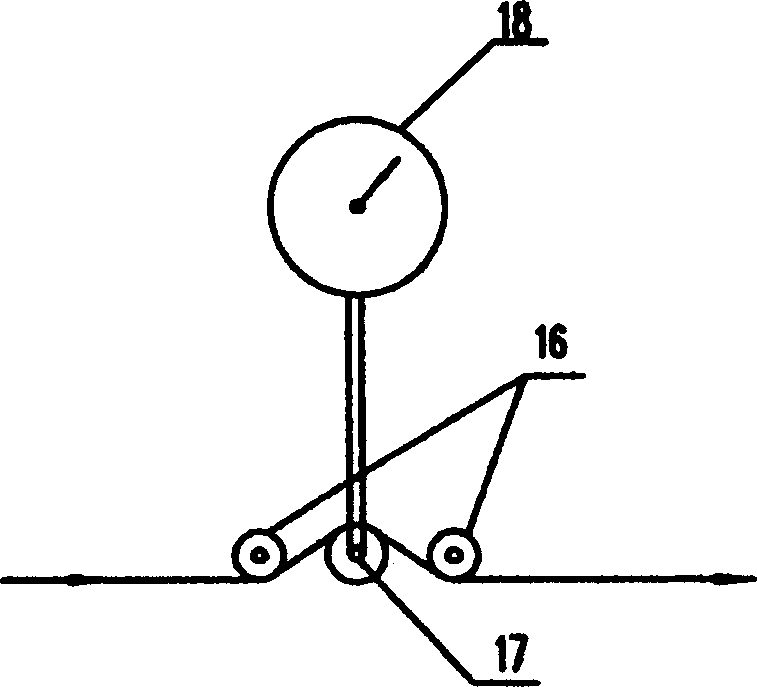

Power-dispersed cable erecting method and device thereof

InactiveCN104682255AEffort-saving erectionImprove wiring speedApparatus for overhead lines/cablesFriction forcePower transmission

The invention discloses a power-dispersed cable erecting method and a power-dispersed power transmission cable sheave. The power-dispersed cable erecting method and the power-dispersed power transmission cable sheave have the advantages that the increasing of friction force of conveying process caused by the cable rolling on the crossing frame and being tangled with the crossing frame can be prevented, the conducting wire transmitting speed is increased, and the labor intensity is decreased in the cable erecting process; a motor is fixedly arranged on a bracket, the sheave is used as a driving wheel in the cable erecting process, and the movement power of the cable is dispersed just like each carriage of a rail car provides the power, so the labor is saved in the erecting process of the power transmission cable, and the cable erecting speed is increased.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ANYANG POWER SUPPLY

Zinc oxide arrester

PendingCN108492952AImprove wiring speedSimplify wiring stepsOvervoltage protection resistorsResistor detailsEngineeringOxide

The invention discloses a zinc oxide arrester which comprises support racks, protection balls, connecting rods, ceramic umbrella skirts, protection jackets and a wiring device, wherein eight ceramic umbrella skirts are mutually fixed in a welded manner; the outer sides of the ceramic umbrella skirts are sleeved by the protection jackets; the connecting rods are correspondingly arranged on two sides of each protection jacket; the support racks are fixed at ends of the connecting rods through bolts; the protection balls are uniformly embedded into one side of each support rack; the wiring deviceconsists of a wiring cover, a first through hole, a wiring base, a binding post, a second through hole, a wiring button, a first circular groove, a third through hole, a first telescopic spring, a second circular groove, a connecting shaft, a gear, a first rack, a chute, a second telescopic spring, a sliding block and a second rack; the third through hole is formed in one side of the binding post; the wiring base is fixed on the outer side of the binding post in an adhesion manner. The zinc oxide arrester has the characteristics of being rapid in wiring speed and good in protection effect.

Owner:路任斯电气有限公司

Cable equipment for field of municipal engineering

InactiveCN112436442AImprove construction efficiencyImprove construction qualityApparatus for laying cablesArchitectural engineeringIdler-wheel

The invention belongs to the field of cable laying, and particularly relates to cable equipment for the field of municipal engineering, which comprises rods A, telescopic rod structures, support legs,guide rings, rollers A, rollers B and the like, and is characterized in that four support legs matched with the shaft wall of a cable well are symmetrically mounted on the two rods A connected through the two symmetrically distributed telescopic rod structures; when the cable pulling direction is changed and is not consistent with the running direction of the underground cable of the cable, the cable is still located on the roller A and the roller B under the condition that the pulling direction of a cable pulling person on the ground is changed by adjusting the directions of the roller A andthe roller B; and therefore, abrasion caused by contact between the cable and the well edge or the corner in the cable well due to the fact that the cable is separated from the idler wheel A and theidler wheel B when the pulling direction of ground wire pulling personnel is changed is avoided, and the cable is prevented from being damaged while the cable construction efficiency is guaranteed.

Owner:钱根新

Electric power construction method

PendingCN114006310AImprove wiring speedEasy to operateApparatus for overhead lines/cablesPower towerMonitor equipment

The invention discloses an electric power construction method. The electric power construction method comprises the following construction steps of: (1) simultaneously carrying out wire taking operation in two directions by utilizing lead wire drawing equipment and a special transport vehicle; (2) carrying out moving path planning and adjustment in real time in the moving process of the lead wire drawing equipment; (3) enabling lead wire drawing equipment to reach a specified position for erecting a high-voltage power line on a high-voltage power tower; (4) enabling the special transport vehicle to arrive at the position of the high-voltage power tower on the other side, and enabling the lead drawing equipment to arrive at the designated position for erecting the high-voltage power line on the high-voltage power tower on the other side in the mode the same as that in the step (3); and (5) tensioning the high-voltage power line according to the requirements to enable the high-voltage power line to meet the erection requirements. In the implementation process of all the steps, monitoring equipment is arranged for construction monitoring in the whole process, so that the construction safety and accuracy are met. By means of the electric power construction method, it is guaranteed that all the steps are connected and matched with one another, and the construction quality, efficiency, accuracy and safety are improved to the maximum extent.

Owner:山西泰尔达工程有限公司

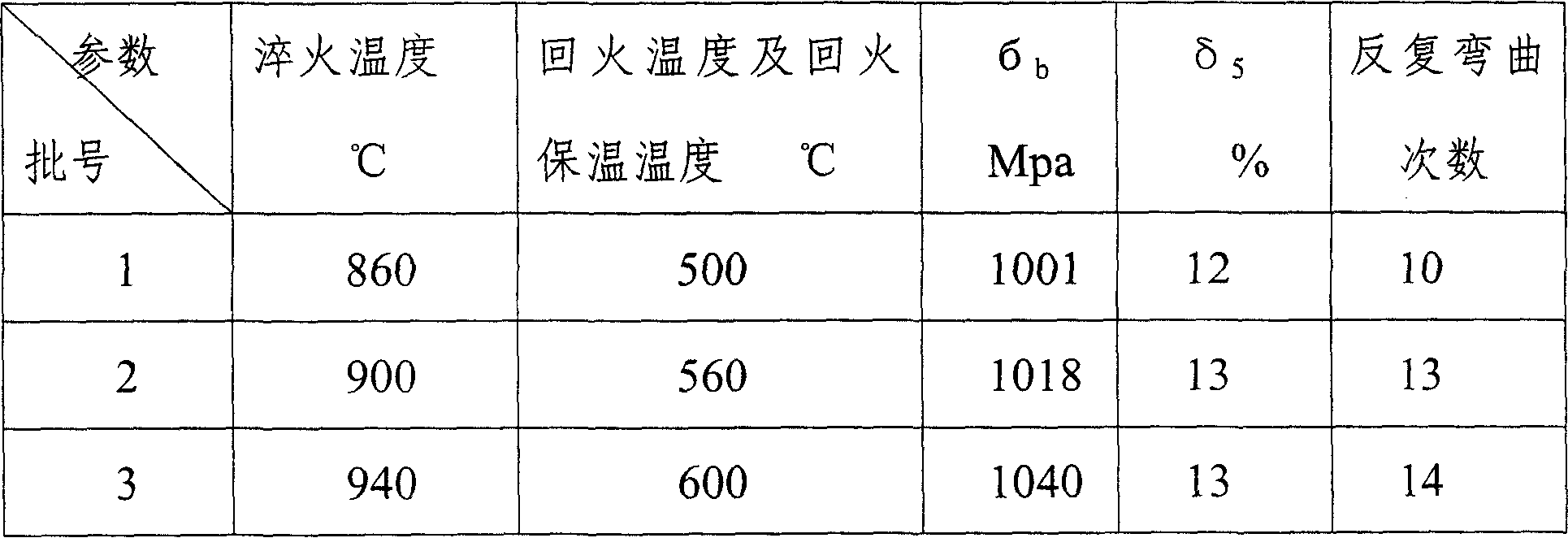

Manufacturing method for high strength bailing band

InactiveCN100344406CIncrease productivitySmall footprintOther manufacturing equipments/toolsProduction lineButt welding

The invention belongs to iron and steel field and relates to steel packing belt production technique. The technics steps includes unrolling, squaring head, butt-welding, entrance looping, flatting edge, heat treatment, blueing, leach drying, exit looping, paraffin coating and rolling. Above processes is done continuously on one production line which contains 1 to 10 production line unit namely producing 1 to 10 high intensity steel packing belts on the same production line. Heat treatment includes quenching and tempering which quenching with water and water cooling after tempering. Quenching heat the belt in quenching furnace with high frequency sensing heating at 800 to 960 deg. C and tempering heat the belt in tempering furnace with middle frequency sensing heaing at 450 to 650 deg. C. The invention is of high production efficiency, small area, low investment and nonpolluting.

Owner:CENT IRON & STEEL RES INST

Vertical loop diamond cutting equipment

InactiveCN108177259BSimple structureCompact structureWorking accessoriesFine working devicesDiamond cuttingMotor drive

Owner:刘文涛

Switch wiring template detachably adapted to different configurations

PendingCN108879504AReduced Skill Requirement Level RequirementsReasonable structural designSupport structure mountingEngineeringElectrical and Electronics engineering

Owner:ELECTRICAL ENG CO LTD OF CTCE GRP +1

Liquid soldering flux for soldering electrical products

InactiveCN101829863BPrevent oxidationQuality assuranceWelding/cutting media/materialsSoldering mediaWater bathsCopper conductor

The invention discloses a liquid soldering flux for soldering electrical products, which is characterized by being prepared from the following raw materials in percentage by weight: 70-85 percent of ethanol, 2.0-5.0 percent of ethylene glycol monobutyl ether, 1.0-4.0 percent of mixed acid with the volume ratio of hydrochloric acid to phosphoric acid of 2:1, 10-20 percent of colophony, 0.5-2.0 percent of benzotriazole and 0.5-3.0 percent of glycerol stearate. The liquid soldering flux for soldering the electrical products is prepared by the following steps of: respectively placing the components in a container for sufficiently mixing, heating in a water bath for 3h, keeping a temperature of 40-50 DEG C, and stirring and mixing to be uniform while heating; and naturally cooling to the room temperature. The liquid soldering flux is coated on an electric appliance wiring terminal so that a soldering surface is rapidly activated, a copper conductor is soldered on an activated surface of a large electric appliance wiring terminal by an electric soldering iron through soldering tin, thus a firm, smooth and bright soldered dot can be obtained, and the oxidation of the surface of the electric appliance wiring terminal is avoided. The soldered dot can keep firm, smooth and bright for a long time, and the quality of an electric appliance wiring product is ensured.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com