Manufacturing method for high strength bailing band

A production method and technology for steel strips, applied in the field of steel, can solve the problems of worker health and environmental hazards, slow running speed of steel strips, limited use range, etc., and achieve the effects of reducing investment, improving running speed, and heating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

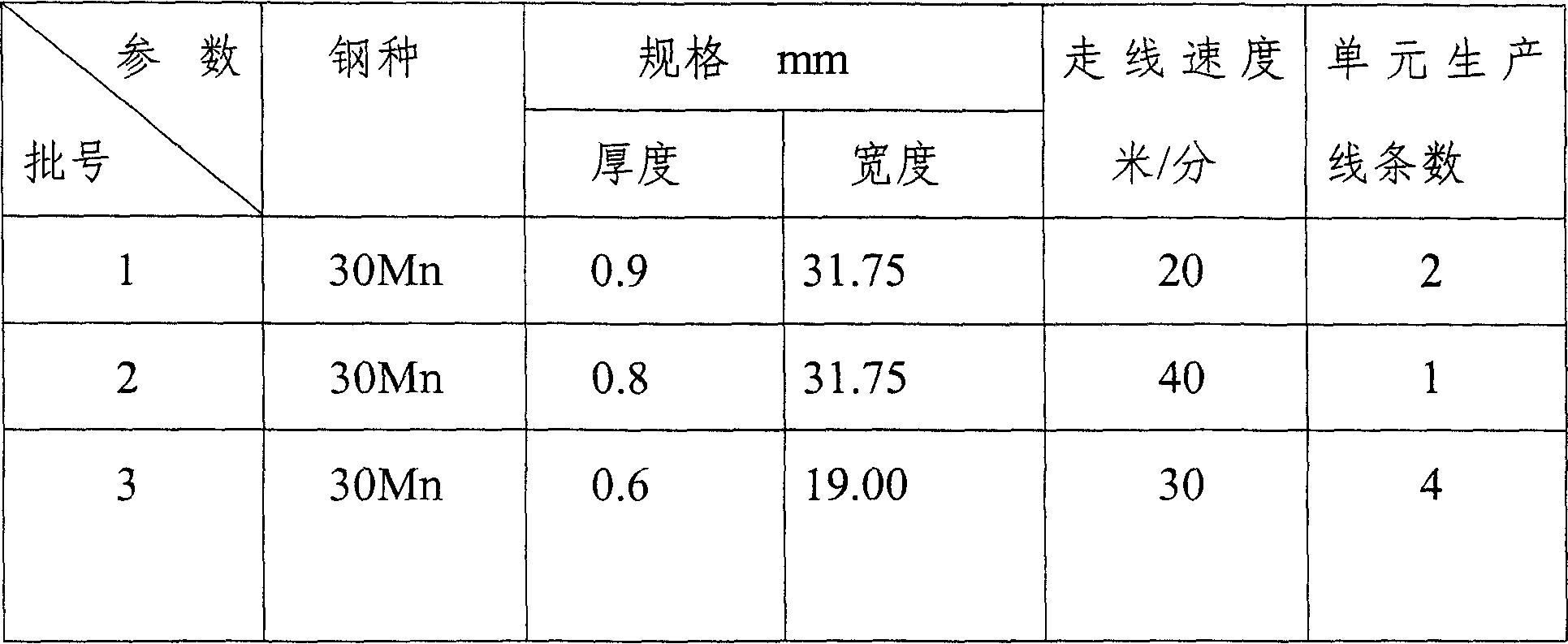

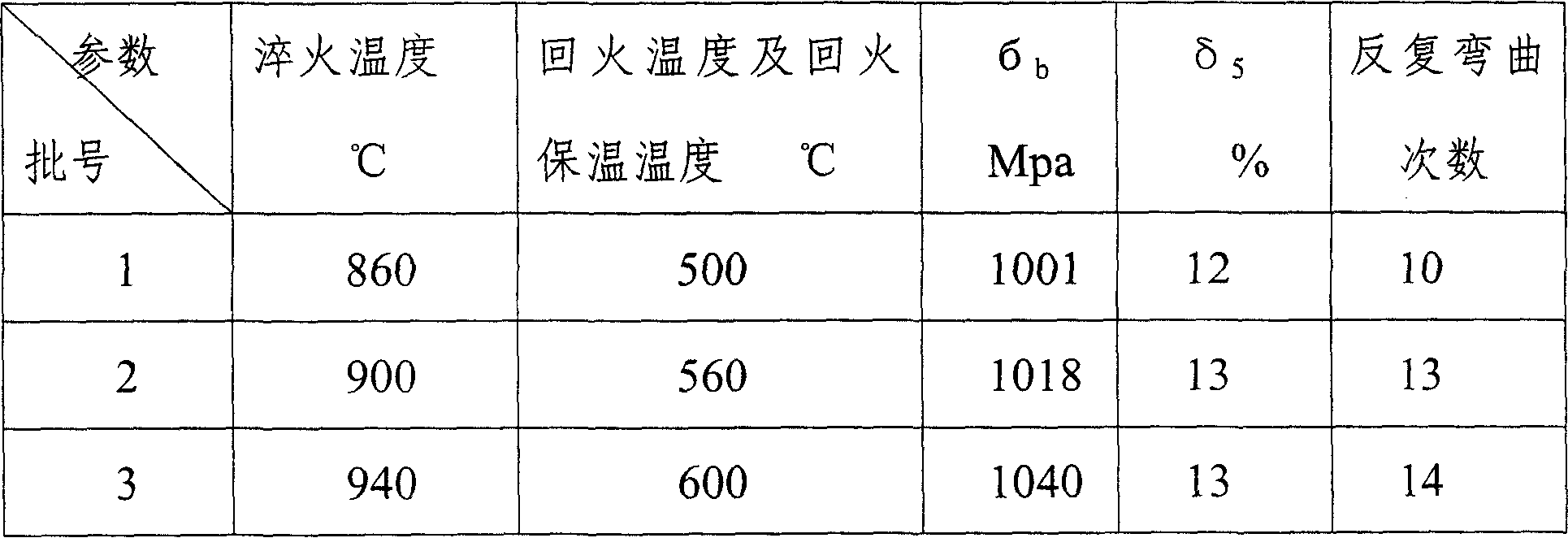

[0035] According to the production method of high-strength packing steel strip of the present invention, manufacture and test 3 batches of packing steel strips, in the process of trial production, steel strip uncoiling, flat head, butt welding, and entrance looper all adopt conventional methods to be respectively placed in conventional pay-off machines , flat head machine, butt welding machine, and entrance looper; steel strip trimming is carried out in a universal frame composed of two pairs of vertical rollers and two pairs of horizontal rollers by rolling deformation; heat treatment adopts quenching and tempering, quenching heating Heat preservation adopts high-frequency induction on-line heating and water quenching, tempering heating adopts medium-frequency induction on-line heating, and water cooling is used after tempering and heat preservation; then it is realized through rapid induction heating and heat preservation in the tempering heating furnace and tempering heat pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com