Patents

Literature

403 results about "Line heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

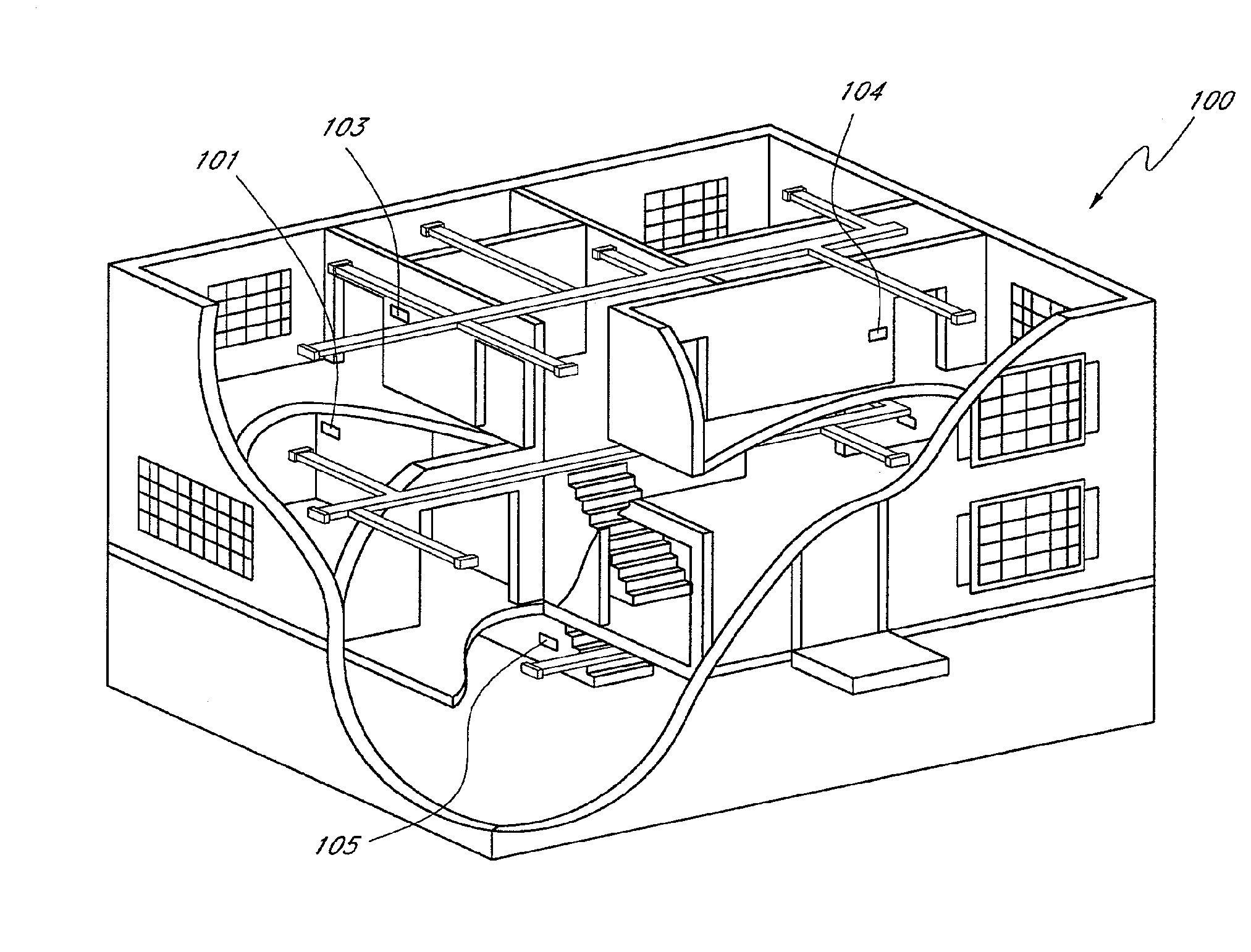

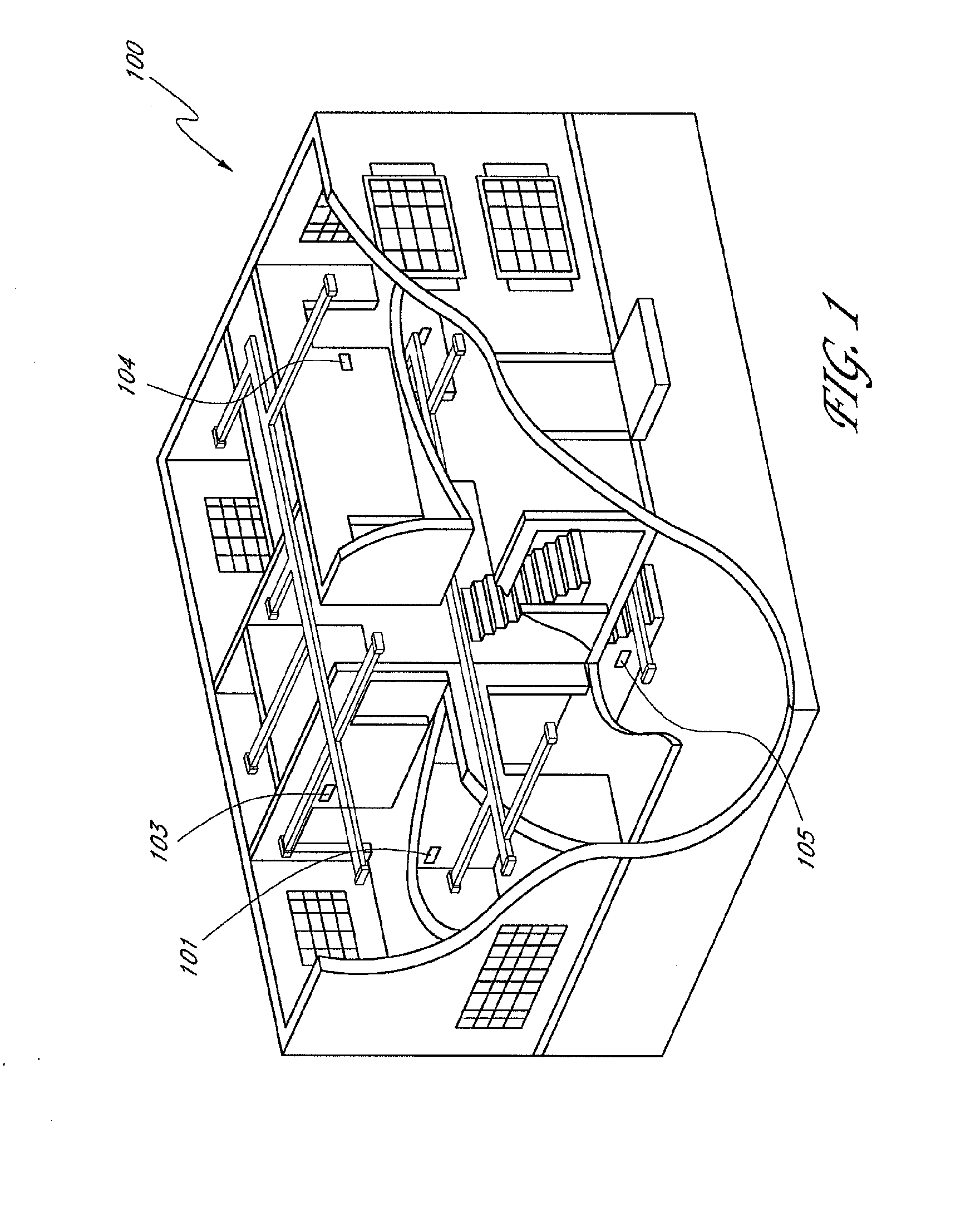

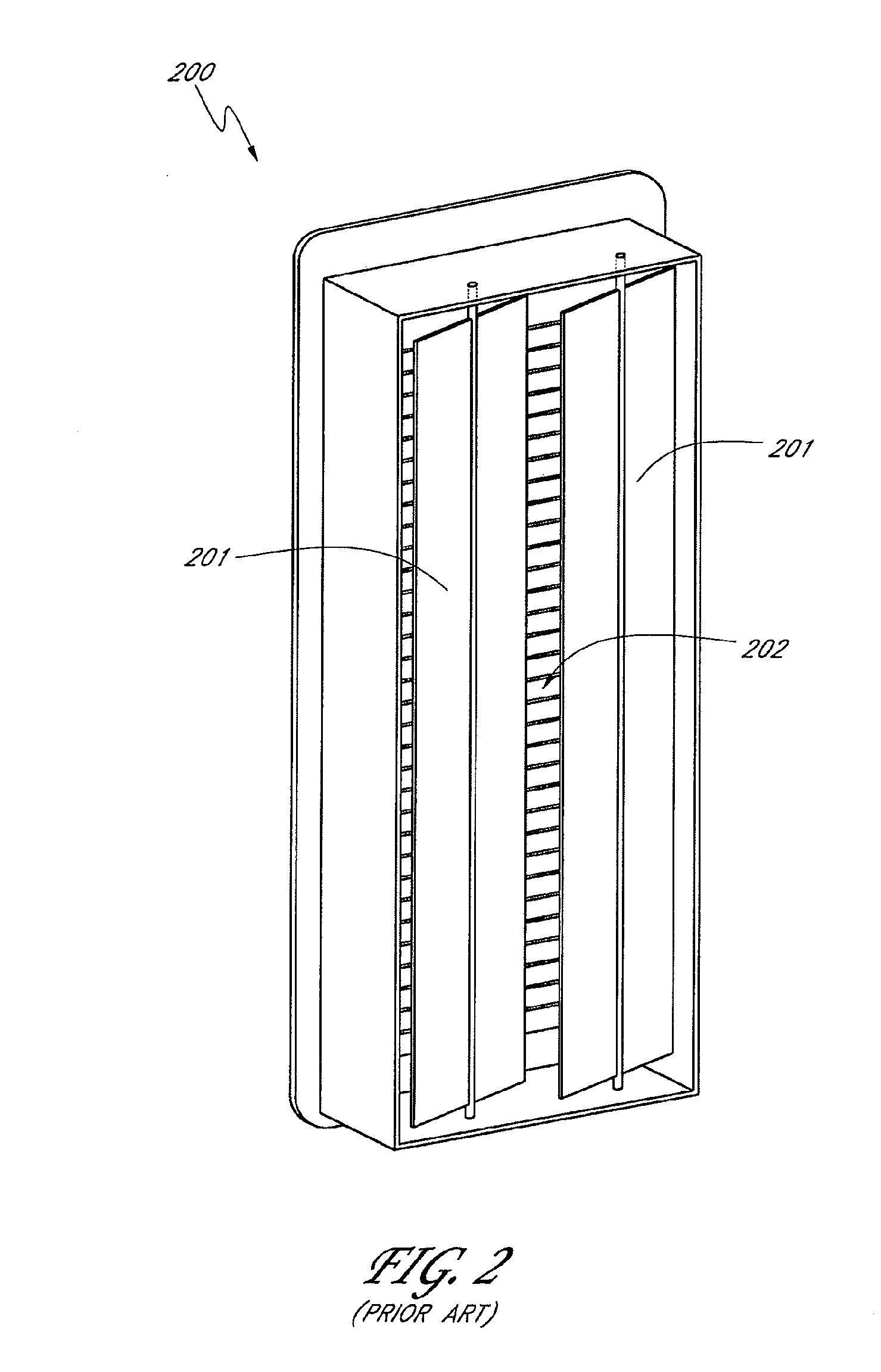

System and method for budgeted zone heating and cooling

ActiveUS20080179052A1Difficult to coolHeat is not easyMechanical apparatusAir-treating devicesZone SystemMonitoring system

An Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured to have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones and provides heating and cooling to the various zones according to a cost budget.

Owner:GOOGLE LLC

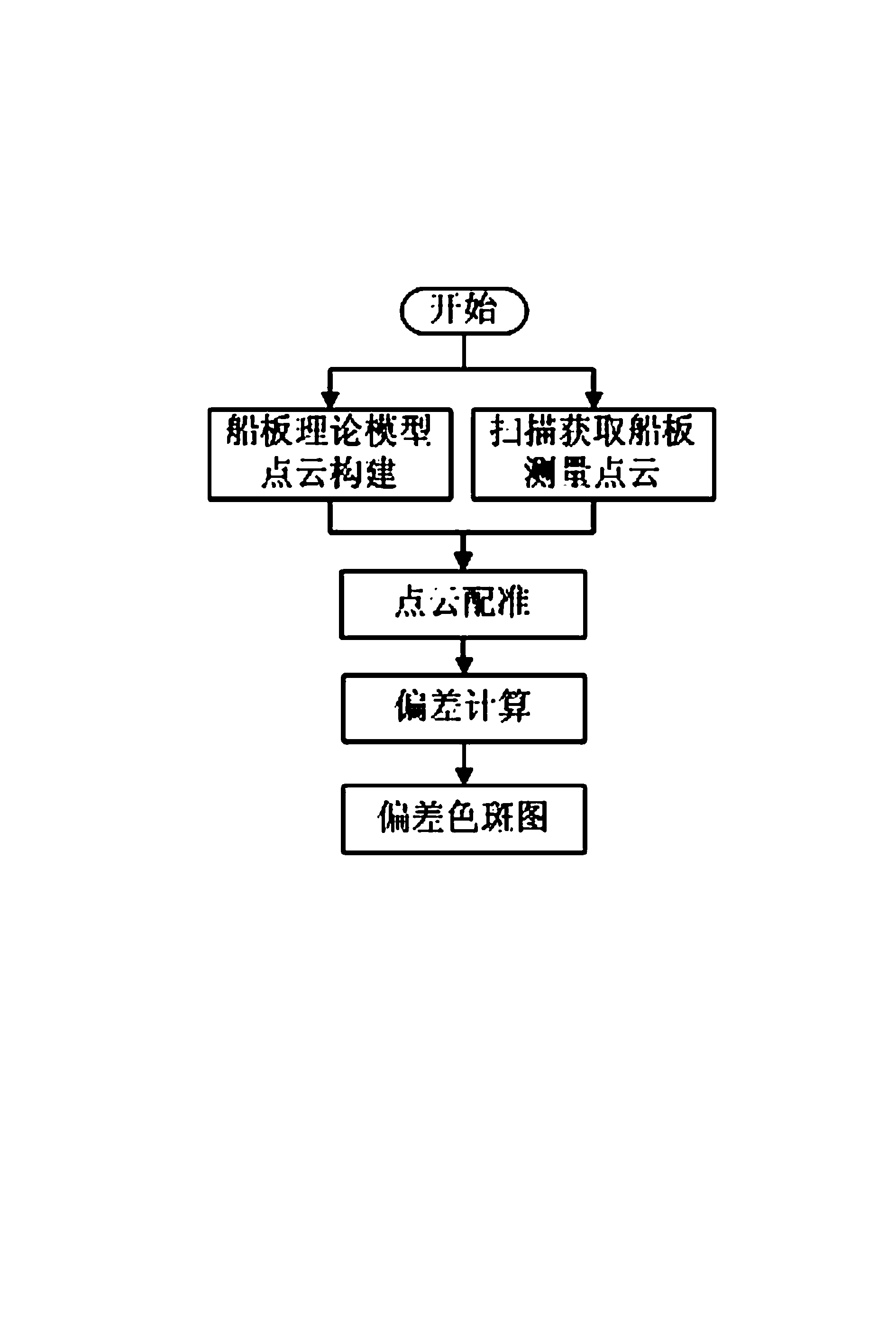

On-line detection method for line heating forming

The invention discloses an on-line detection method for line heat forming of a ship outer plate, and belongs to the field of shipbuilding technologies and optical measurement. The method comprises the following steps: A, establishing a ship theoretical model point cloud; B, scanning and obtaining a ship measurement point cloud; C, performing coordinate system registration for ship theoretical model point cloud and the ship measurement point cloud; D, calculating the distance between every point in the ship measurement point cloud and a theoretical curve surface so as to present the deviation between the measurement point cloud and the theoretical model point cloud; E, expressing the deviation value by a color map. Compared with a traditional sample case / sample plate detection method, the method is high in detection efficiency and precision, and the detection result can be quantized and is good in readability.

Owner:SHANGHAI SHIPBUILDING TECH RES INST +1

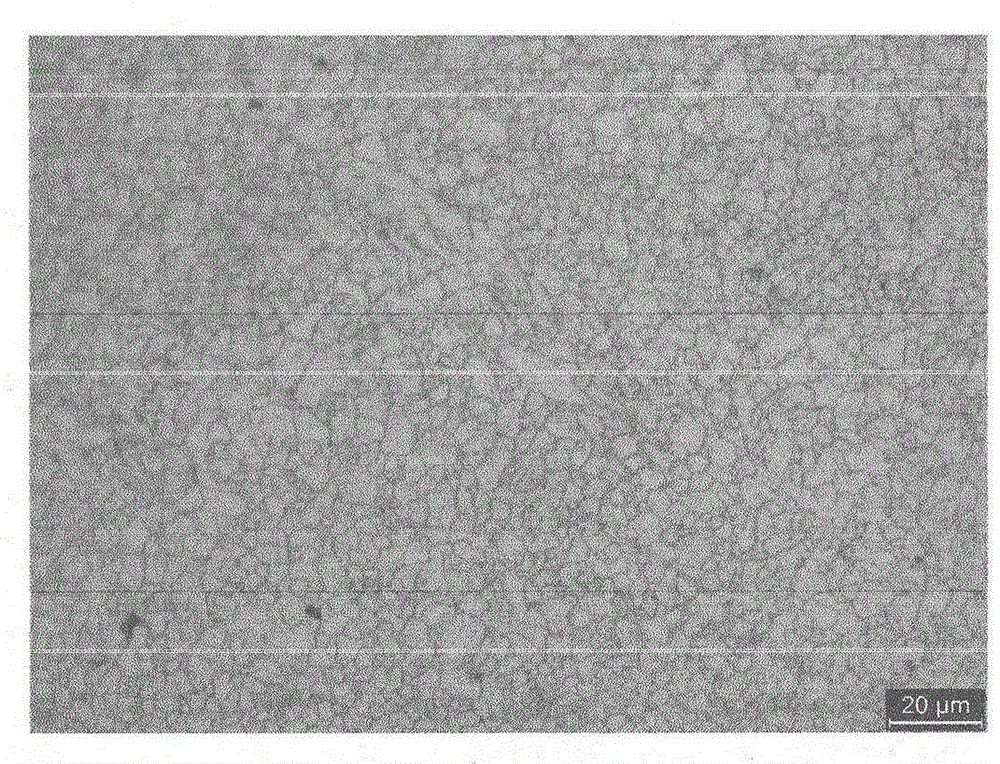

Titanium alloy TC4 hot-rolled tube and production method thereof

The invention relates to a titanium alloy, in particular to a titanium alloy TC4 hot-rolled tube and a production method thereof. By weight, the composition of the alloy is as follows: the balance of Ti, 5.5 percent to 6.75 percent of Al, 3.5 percent to 4.5 percent of V, less than or equal to 0.1 percent of Fe, less than or equal to 0.1 percent of C, less than or equal to 0.03 percent of N, less than or equal to 0.015 percent of H and less than or equal to 0.15 percent of O. A tube blank is heated and rolled on line, the on-line heating temperature is 600 DEG C to 1200 DEG C, and is kept for 1 to 45 minutes, the deformation at each pass is 15 percent to 85 percent, the rolling speed is 20 to 90 times / min, a finished product is produced after 1 to 10 times of rolling, the rolled finished product is annealed in oxygen or vacuum, the annealed finished product is washed by alkali and acid or acid and then by water, and thereby the product is obtained. The tensile strength of the titanium alloy tube is 895MPa to 1300MPa, the elongation of the titanium alloy tube is 8 percent to 25 percent, the metallographic structure is uniform, and a stress-relief annealed metallographic structure and a fully recrystalization annealed metallographic structure can be obtained.

Owner:忠世高新材料股份有限公司

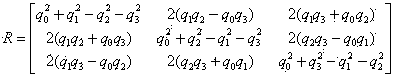

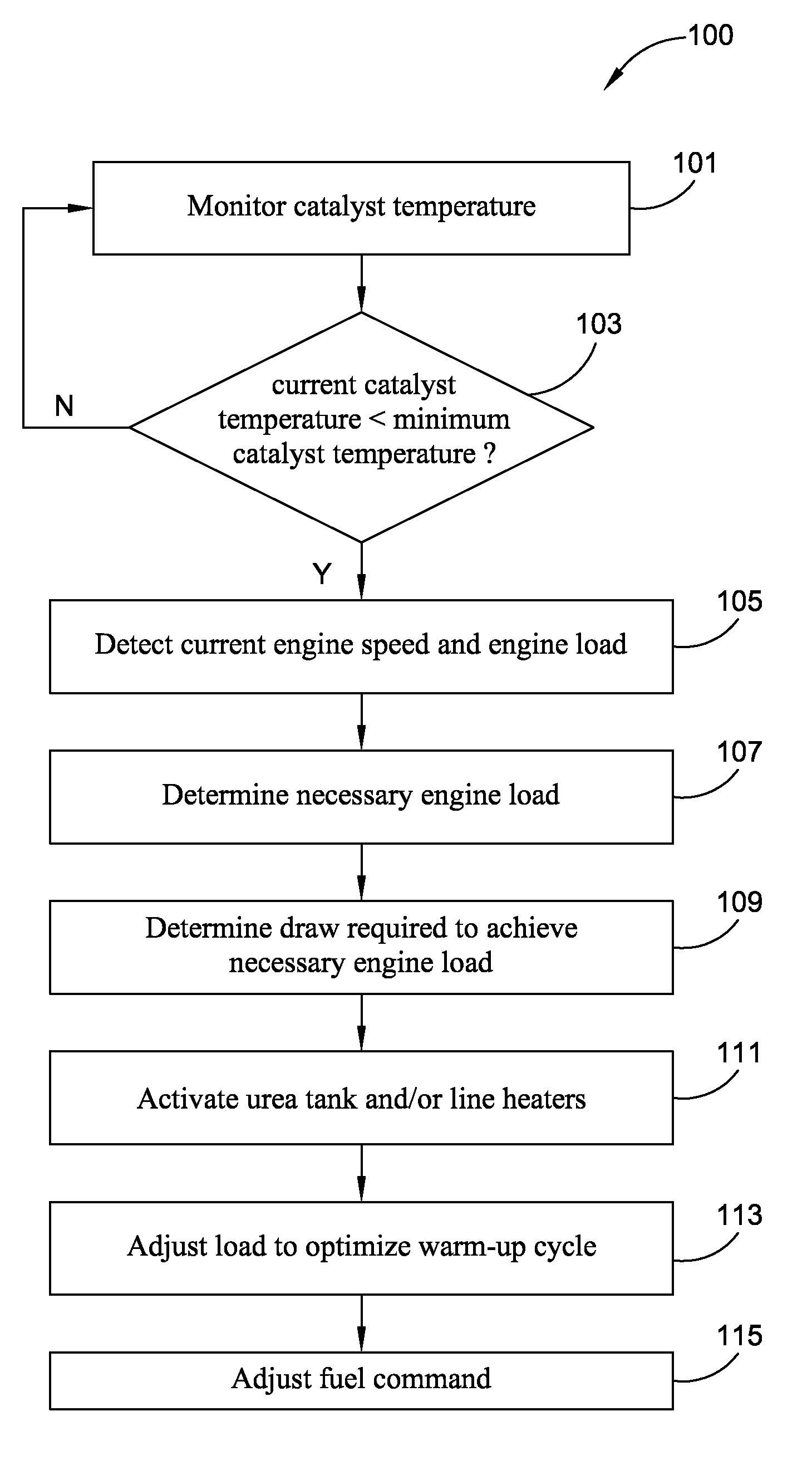

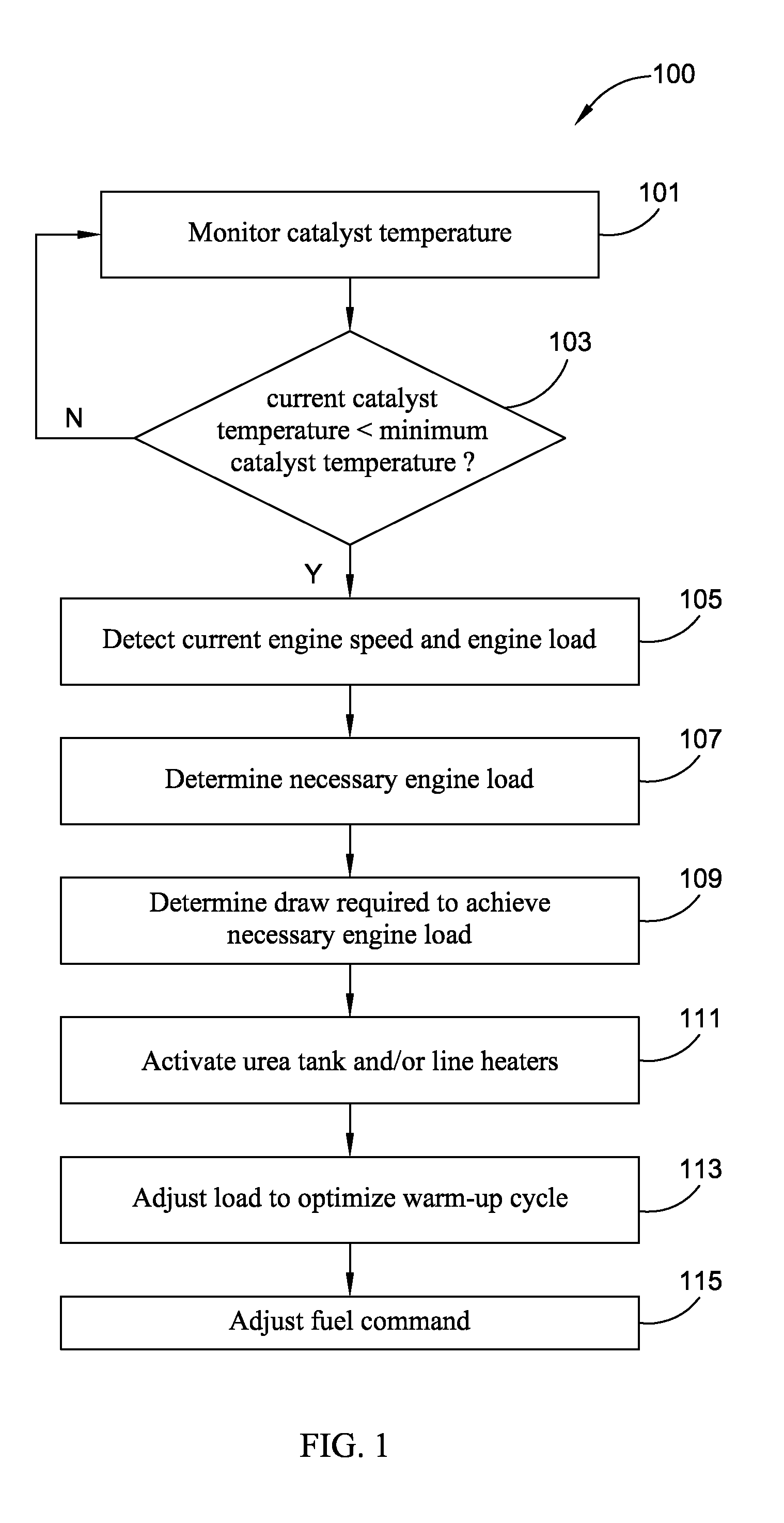

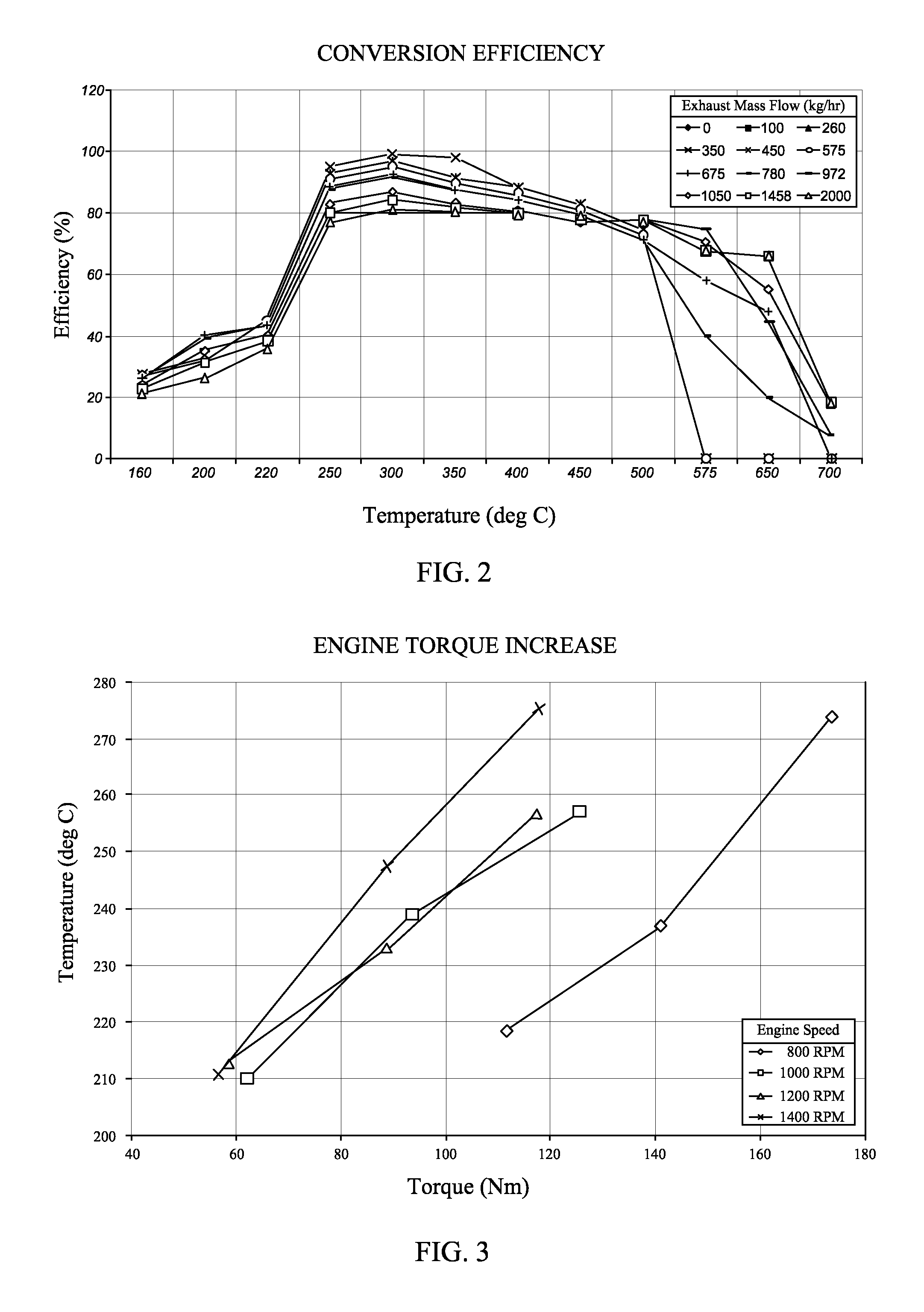

Cold-start engine loading for accelerated warming of exhaust aftertreatment system

InactiveUS20100122523A1Shorten light-off timeReduce nitrogen oxide emissionsInternal combustion piston enginesExhaust apparatusEngineeringLine heating

The methods of the present invention are adapted to adjust engine loading during catalyst warm up to accelerate heating of the exhaust aftertreatment system and thereby decrease catalyst light-off times. According to a preferred embodiment of the present invention, the method includes: monitoring the current catalyst temperature; determining if the current catalyst temperature is less than a predetermined minimum catalyst temperature; and, if the current catalyst temperature is less than the predetermined minimum catalyst temperature, increasing the current engine load. The current engine load is increased by activating a reducing agent tank heating device and / or a reducing agent line heating device.

Owner:GM GLOBAL TECH OPERATIONS LLC

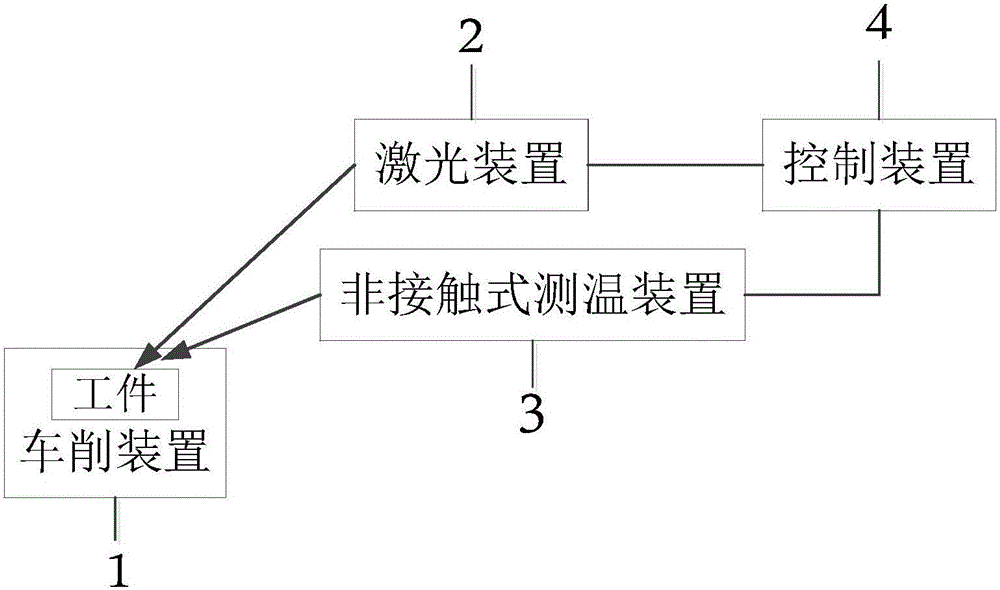

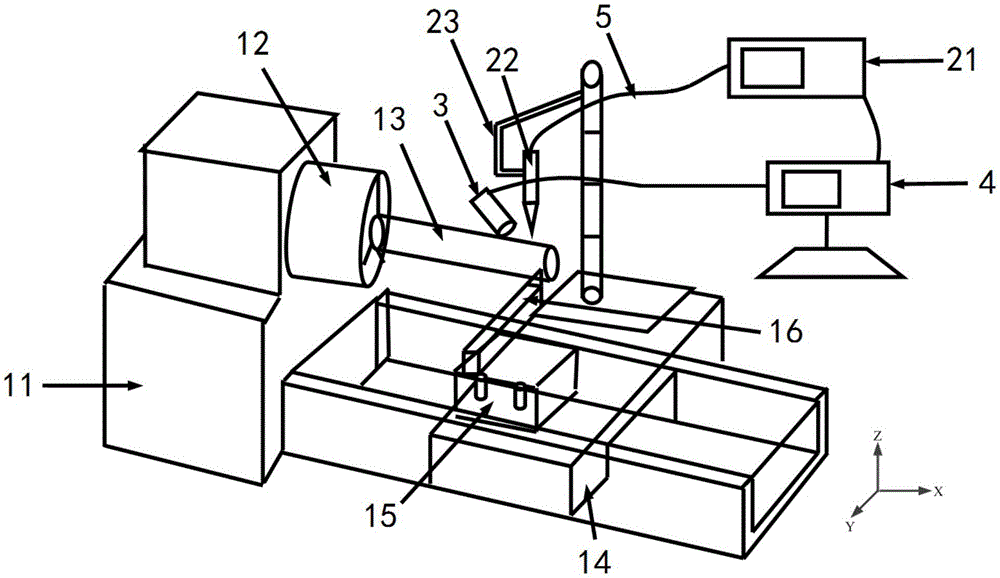

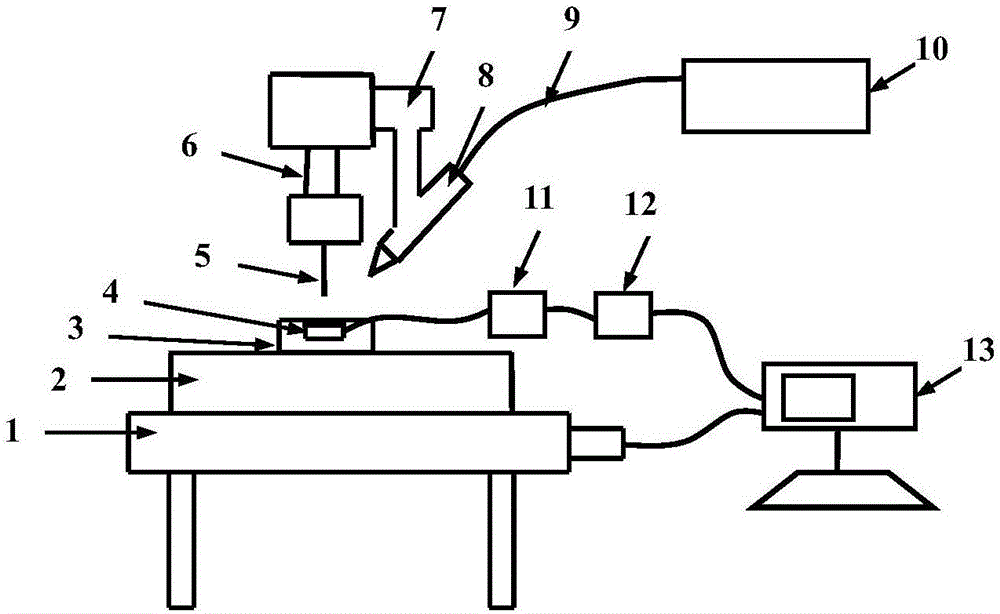

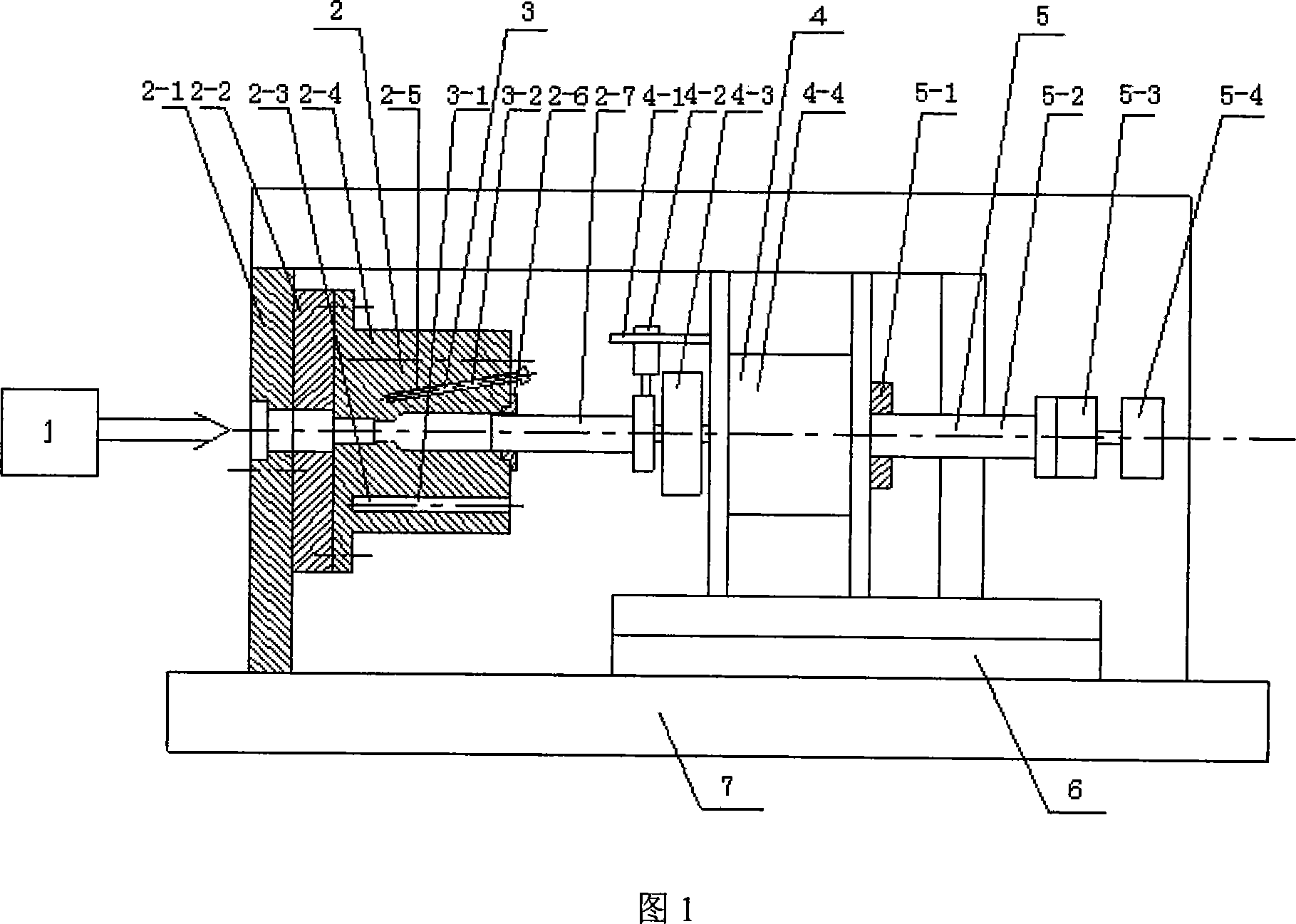

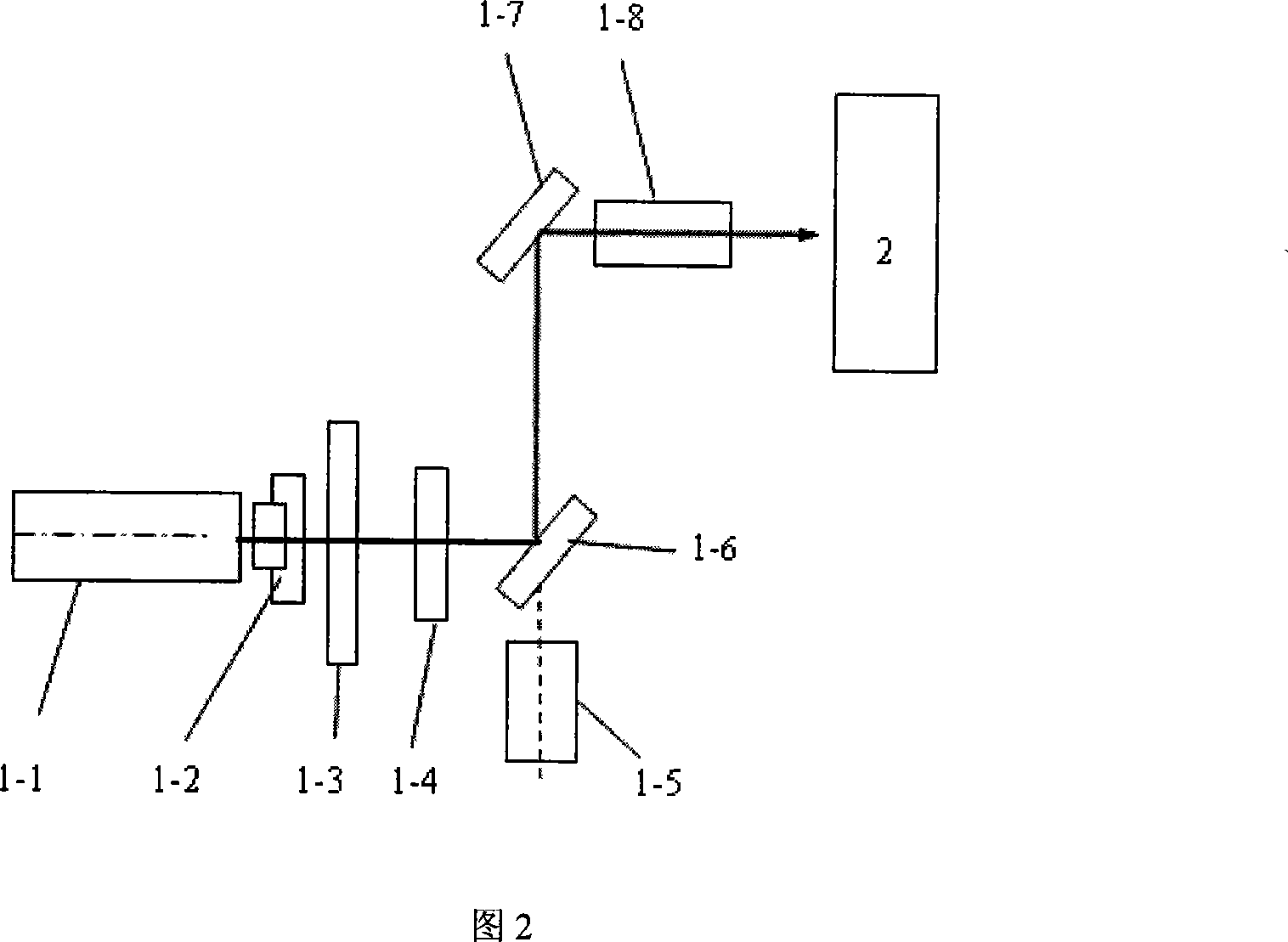

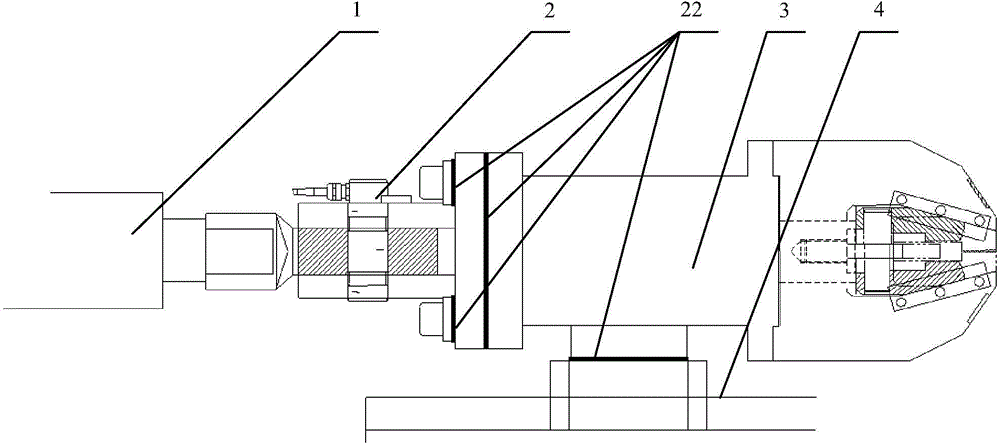

Laser heating assisted turning device and method

InactiveCN106001613ASolution to short lifeImprove surface qualityMeasurement/indication equipmentsMetal working apparatusData matchingMachined surface

The invention provides a laser heating assisted turning device and method. The laser heating assisted turning device comprises a turning device body, a laser device, a non-contact temperature measuring device and a control device, wherein a tool and a workpiece are fixed to the turning device body, the tool is detachably connected with the turning device body, the laser device is used for heating the workpiece through laser, the non-contact temperature measuring device is used for acquiring the temperature at the cutting position of the workpiece in real time, and the control device is used for comparing data of an optimum temperature field stored in the control device with temperature data acquired by the non-contact temperature measuring device in real time and controlling the laser device to adjust laser parameters so as to achieve the optimum temperature field if difference exists. The laser heating assisted turning device has the advantages that the laser parameters are adjusted in a data matching mode so that the temperature field at the cutting position of the workpiece can be always consistent to the optimum temperature field, the cutting performed in the temperature field makes the service life of the tool longest, the machined surface quality of the workpiece is the best, and the turning efficiency is the highest.

Owner:HARBIN INST OF TECH

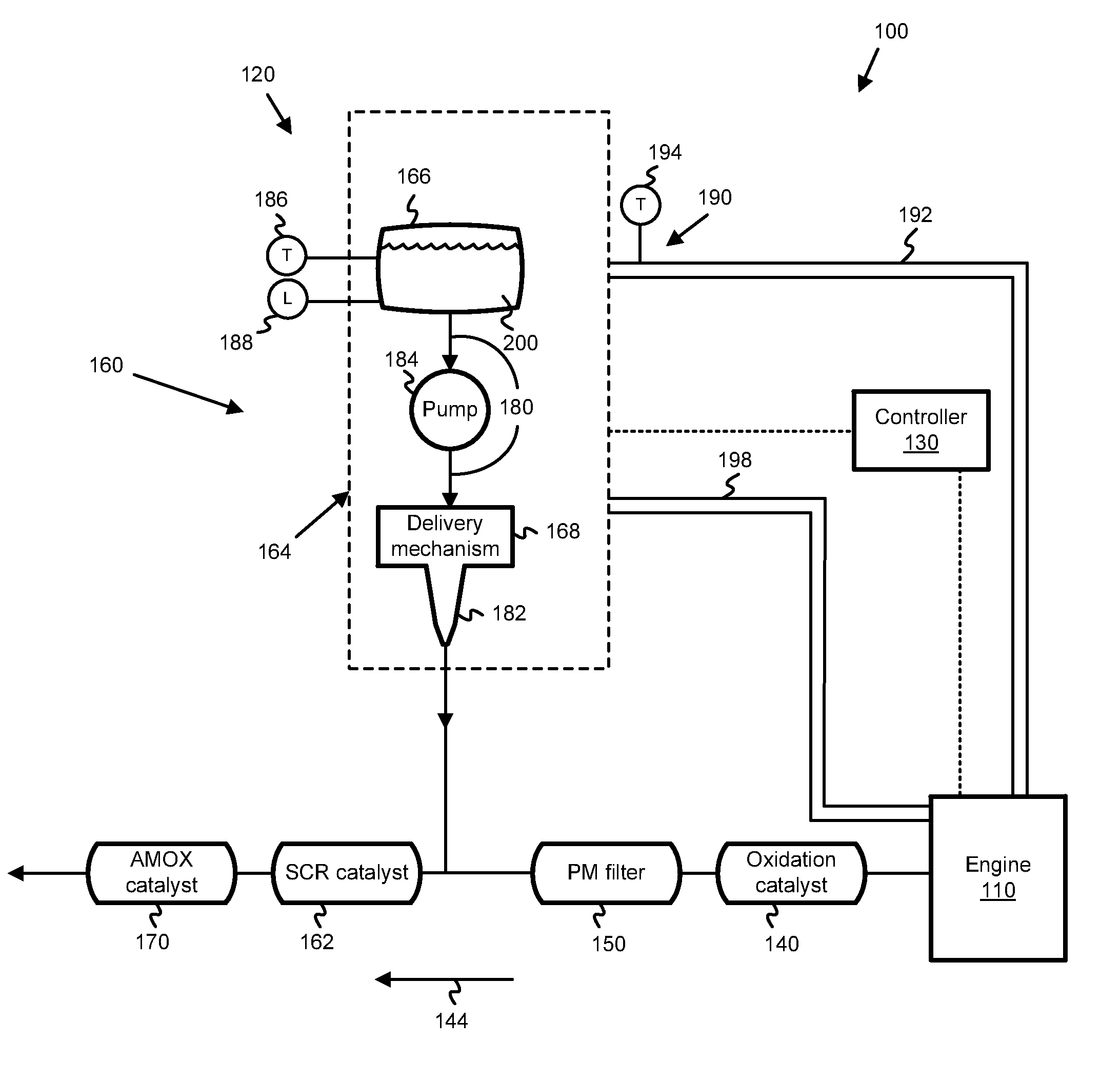

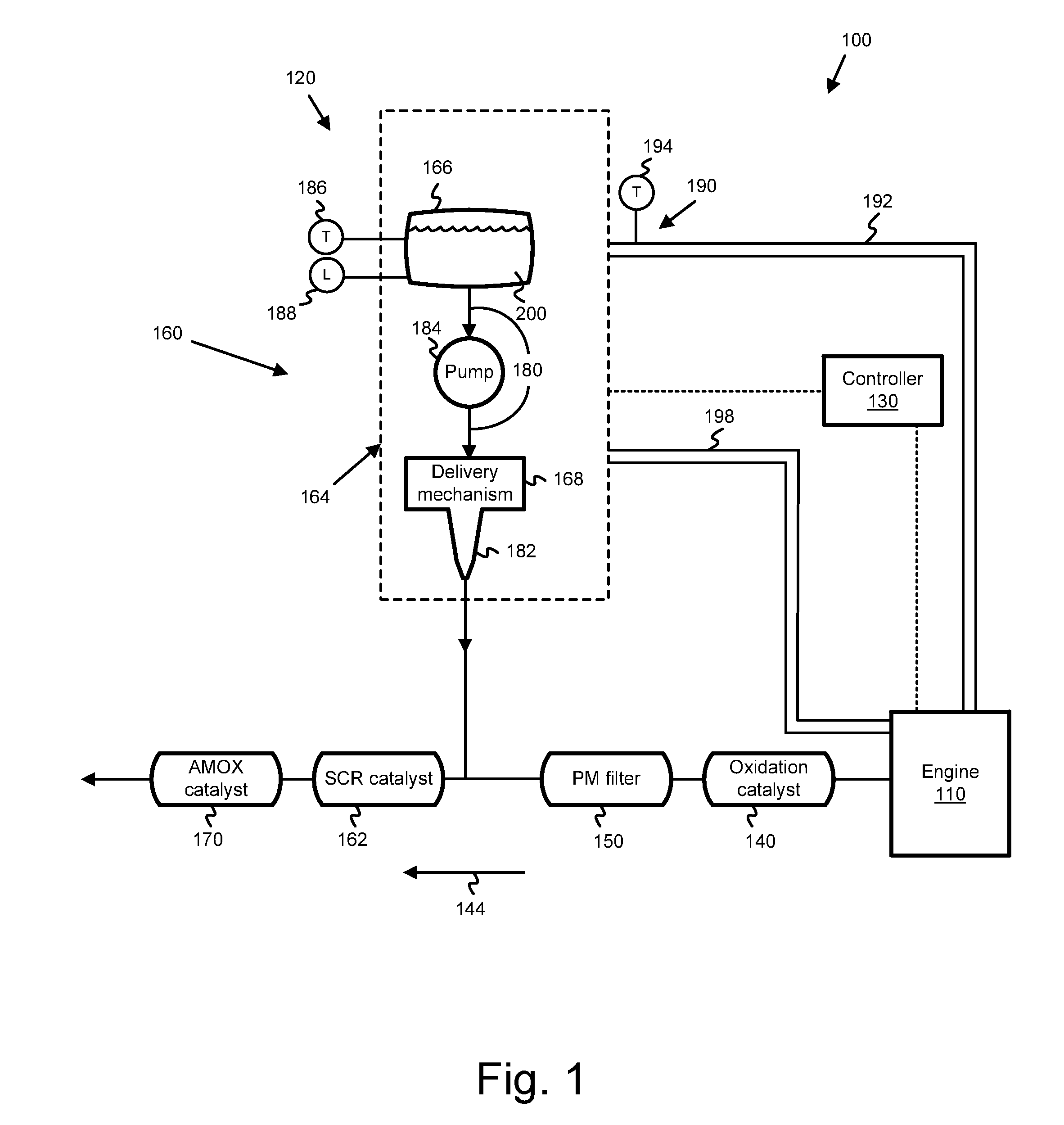

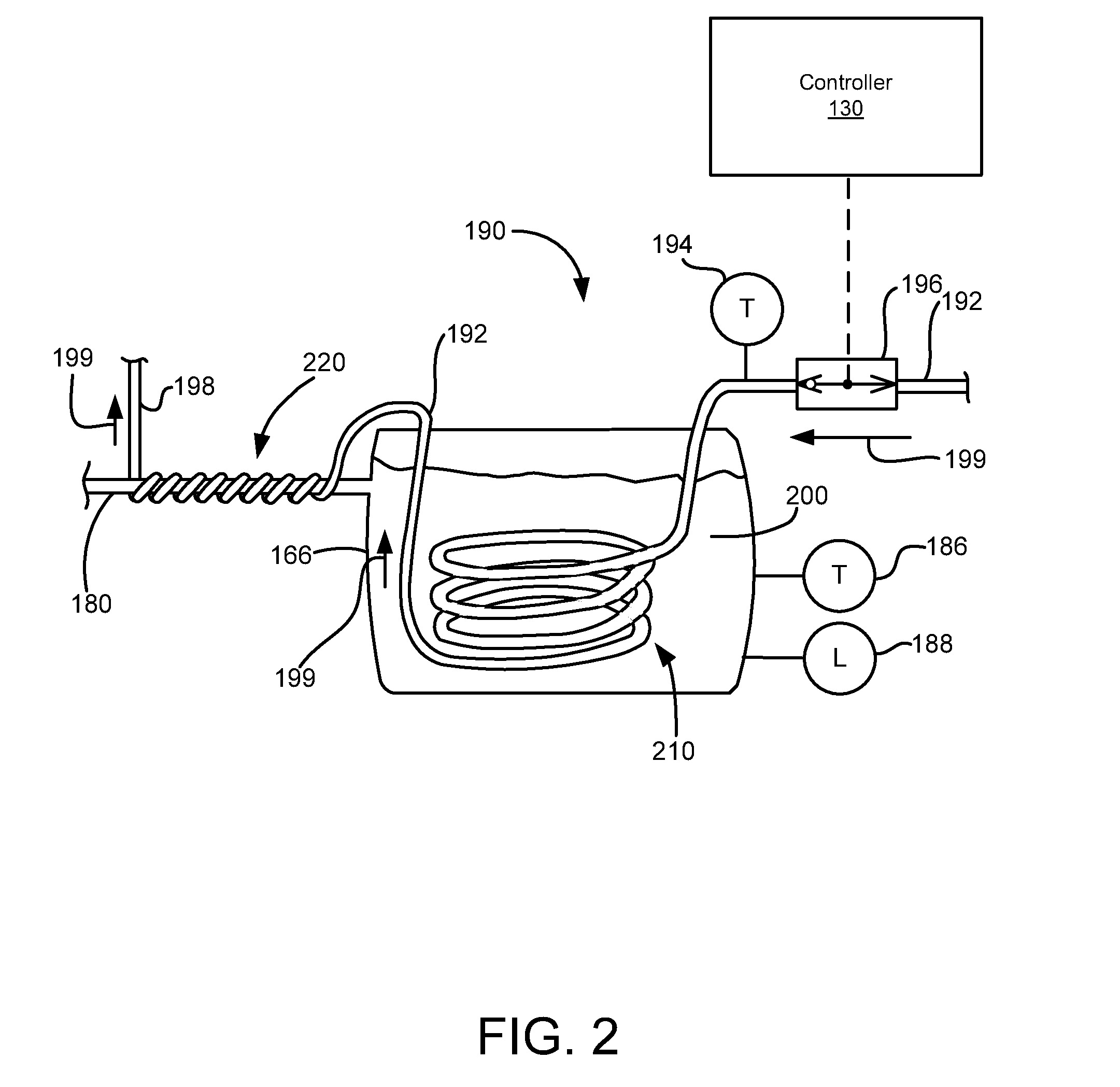

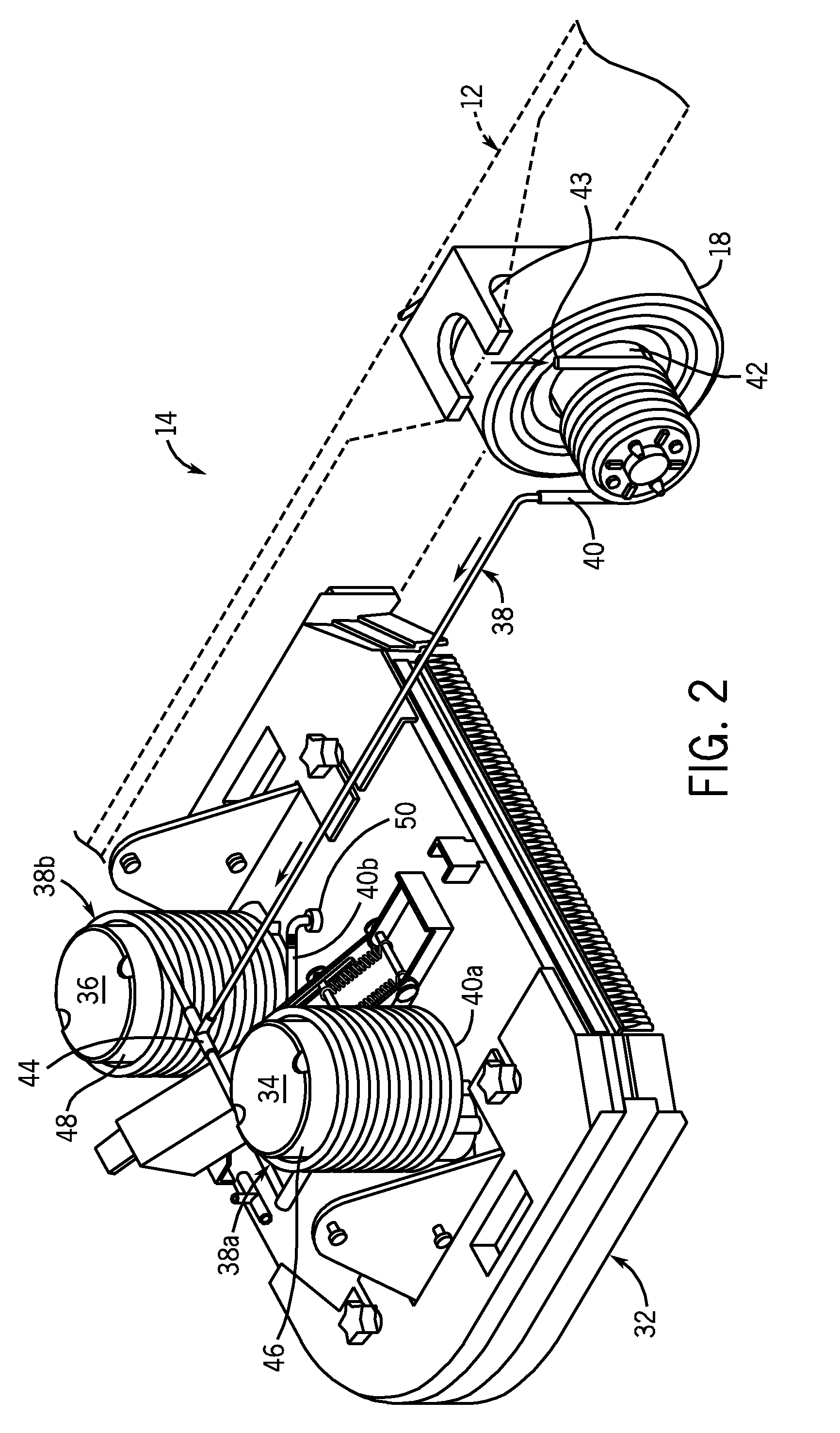

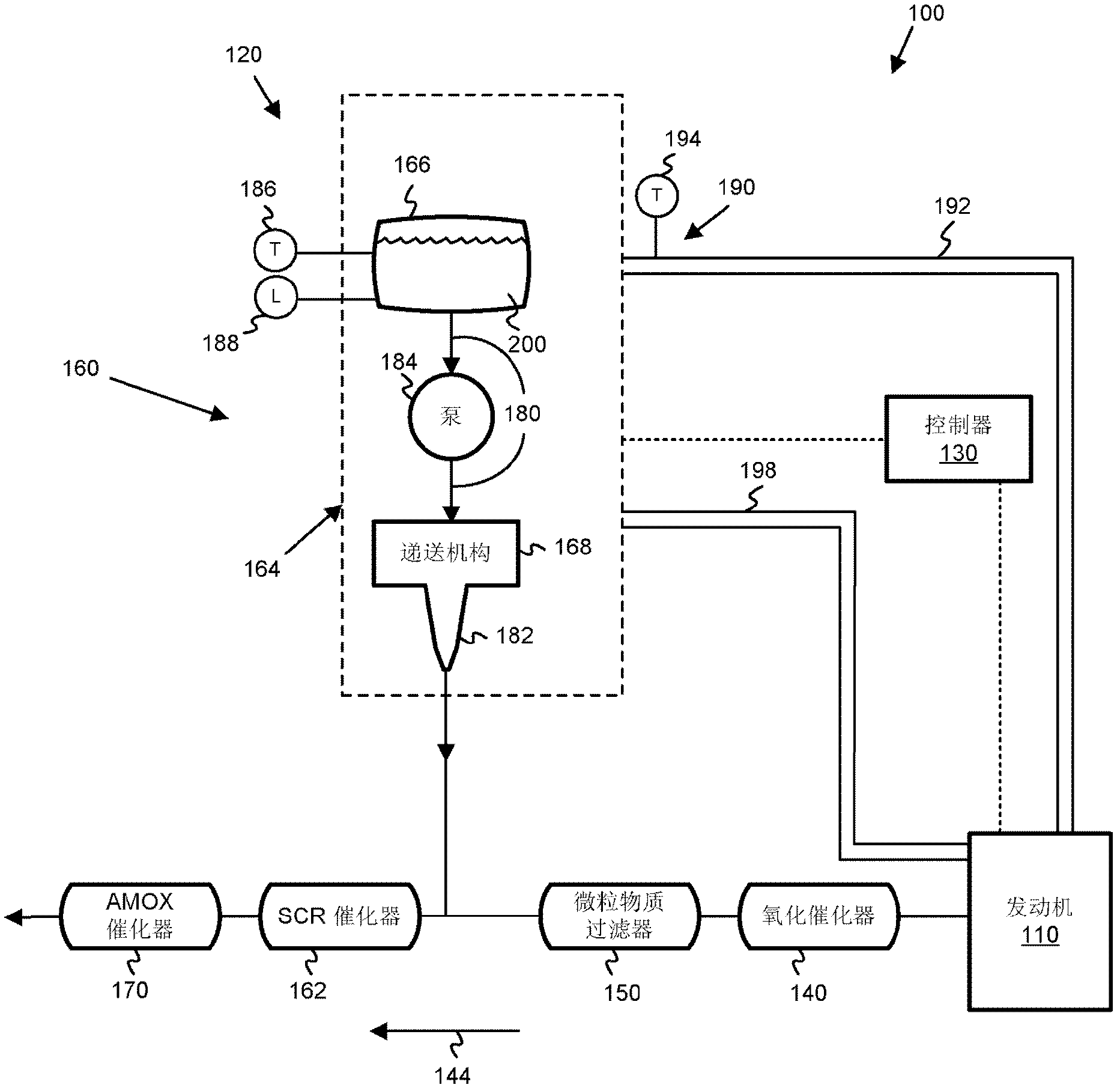

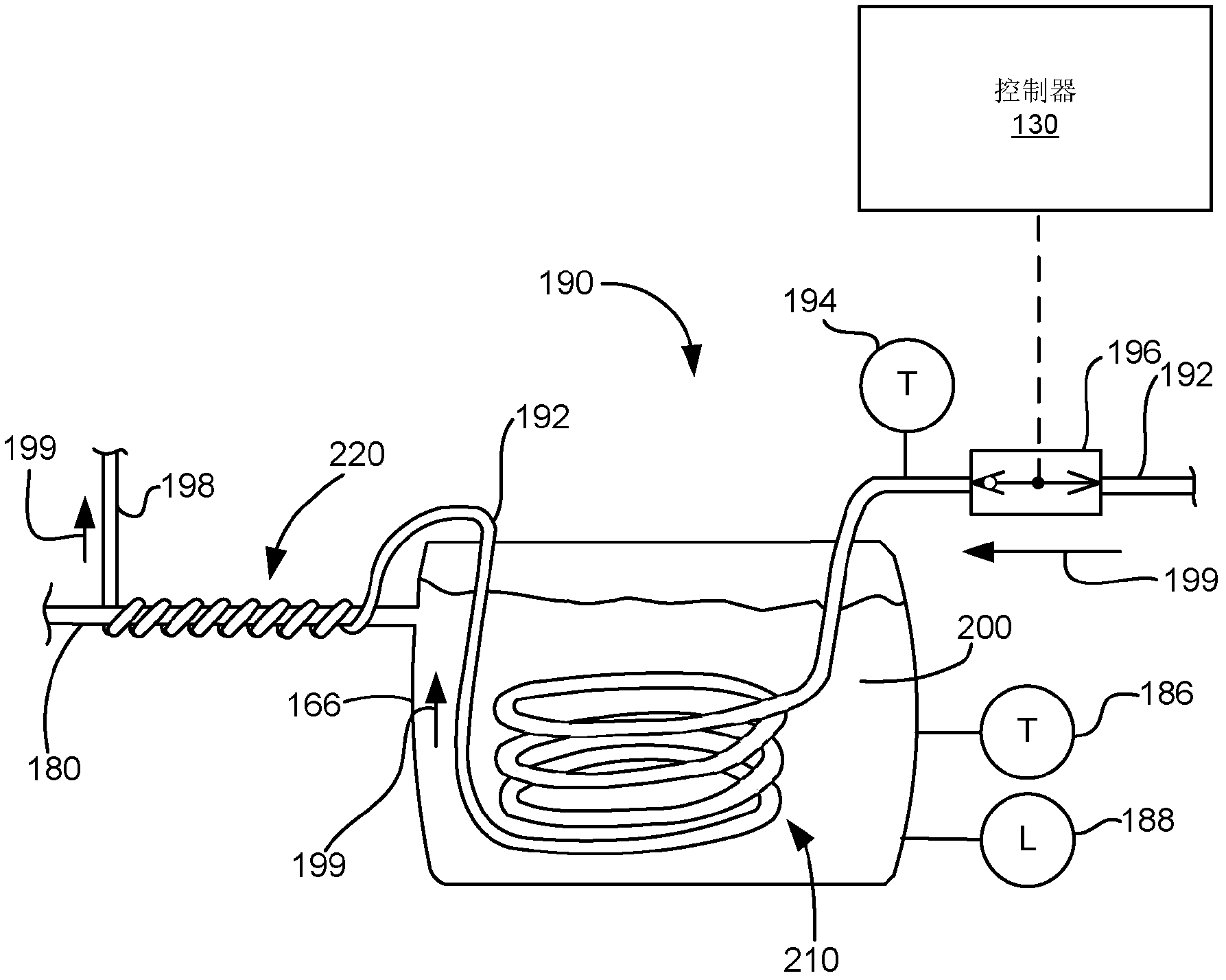

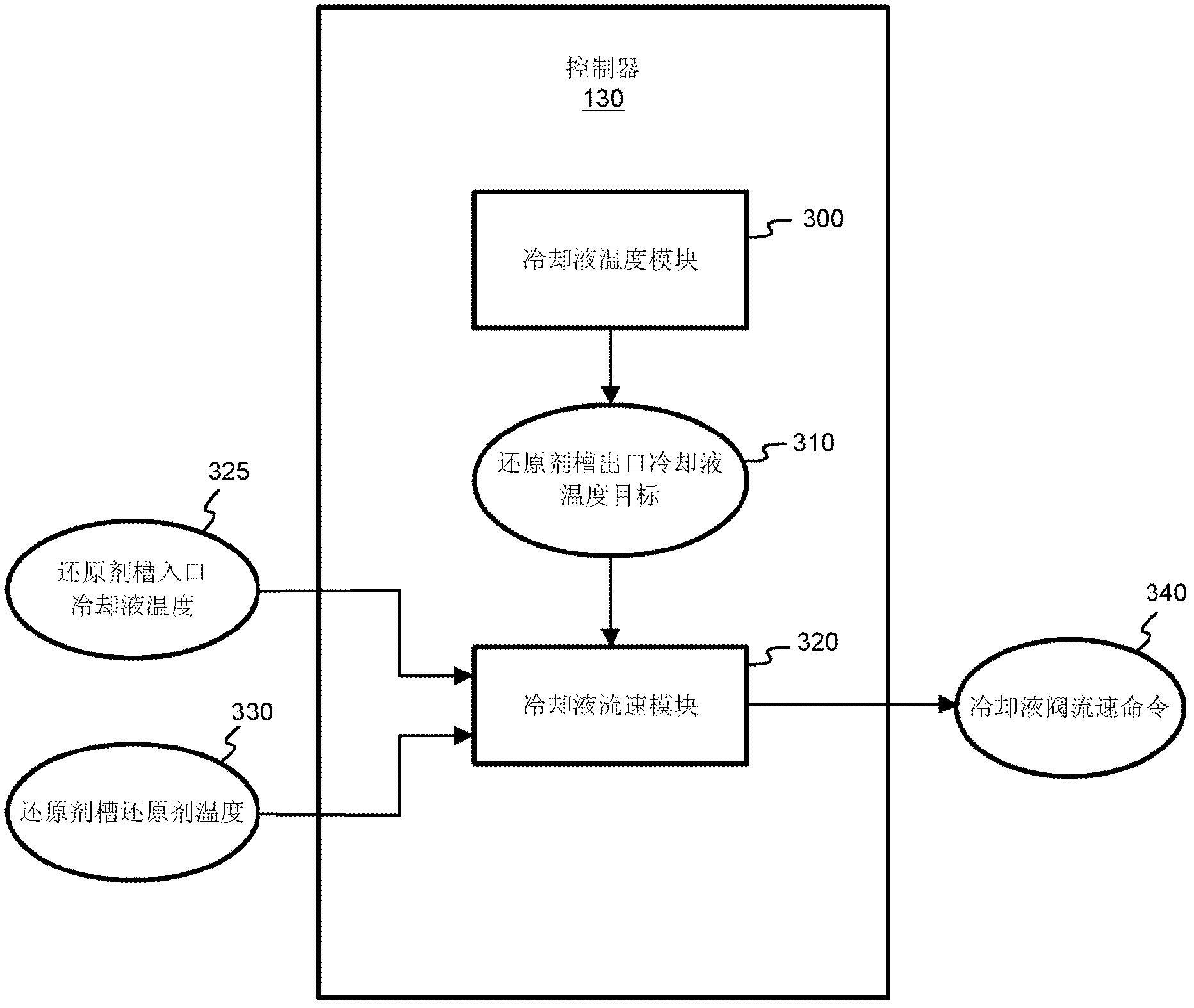

Apparatus, System, and Method for Reductant Line Heating Control

In one embodiment, an apparatus is disclosed for heating a reductant delivery line using coolant from an internal combustion engine where the reductant delivery line receives reductant from a reductant tank and a portion of a coolant line is positioned within the reductant tank. The apparatus includes a coolant temperature module that is configured to determine a reductant tank outlet coolant temperature target. Additionally, the apparatus includes a coolant flow rate module that is configured to generate a coolant valve flow rate command and transmit the command to a coolant valve. The coolant valve is controllable to regulate the flow rate of coolant through the coolant line. The coolant valve flow rate command is based on the reductant tank outlet coolant temperature target, a reductant tank inlet coolant temperature, and a reductant tank reductant temperature.

Owner:CUMMINS INTPROP INC

Laser heating-assisted milling device capable of real-time monitoring tool wear

ActiveCN106216745AEasy to monitor onlineImprove efficiencyMeasurement/indication equipmentsMilling equipment detailsNumerical controlMilling cutter

The invention discloses a laser heating-assisted milling device capable of real-time monitoring tool wear. The laser heating-assisted milling device capable of real-time monitoring tool wear comprises a milling device, a laser heating device and a real-time monitoring device. The milling device comprises a CNC (Computer Numerical Control) milling machine table, a milling cutter and a workpiece fixed to the CNC milling machine table; the laser heating device comprises a laser focus head; a laser light is incident on the surface of the workpiece through the laser focus head; the real-time monitoring device comprises a plurality of acoustic emission sensors, a signal processing module, a data acquisition processing module and an industrial personal computer; the acoustic emission sensors are arranged on the workpiece and are used for detecting acoustic emission signals of the milling cutter at a milling state; the acoustic emission signals are processed through the signal processing module and the data acquisition processing module and then are stored in the industrial personal computer; and through processing and analyzing, the real-time wear condition of the milling cutter is obtained.

Owner:HARBIN INST OF TECH

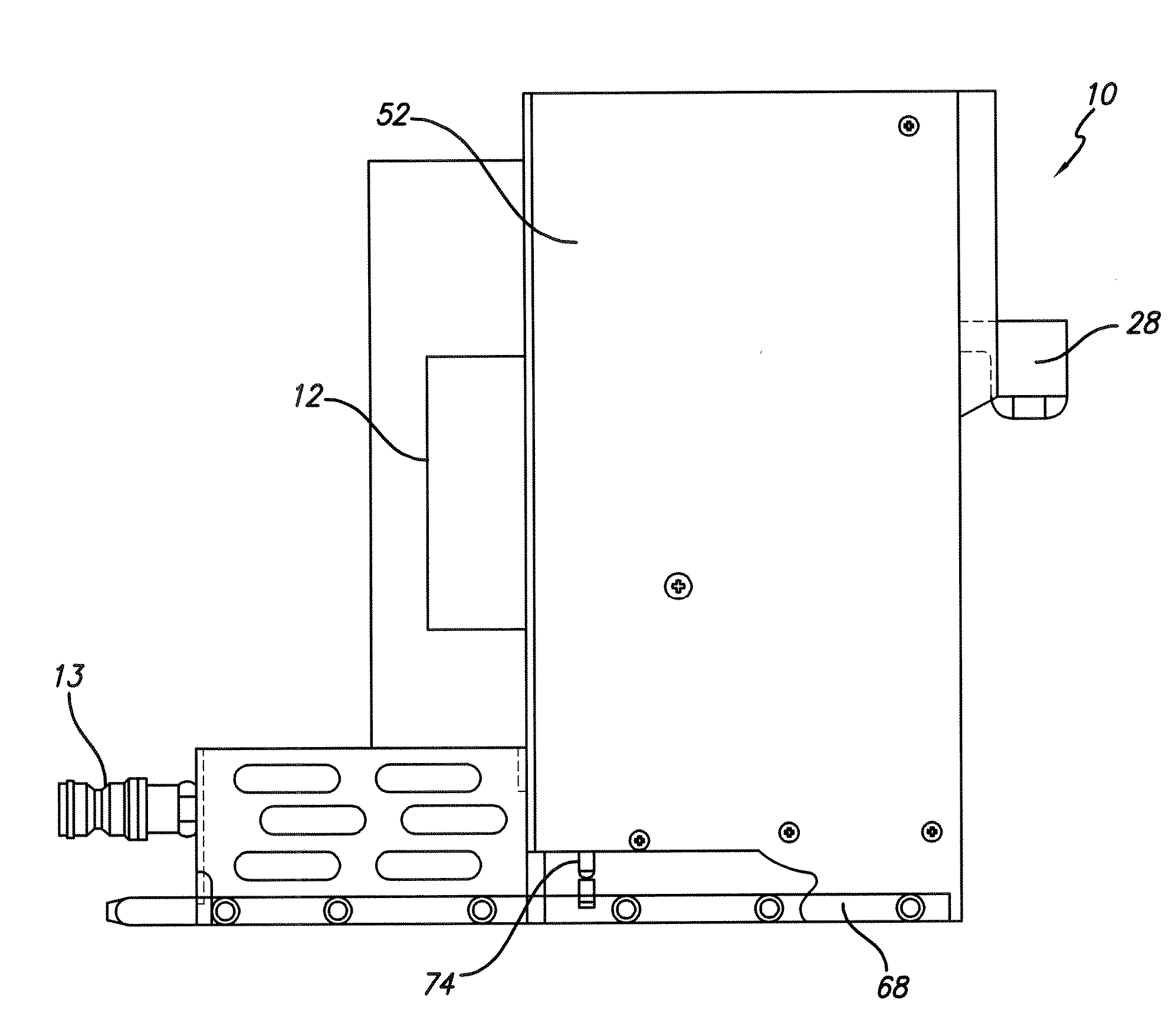

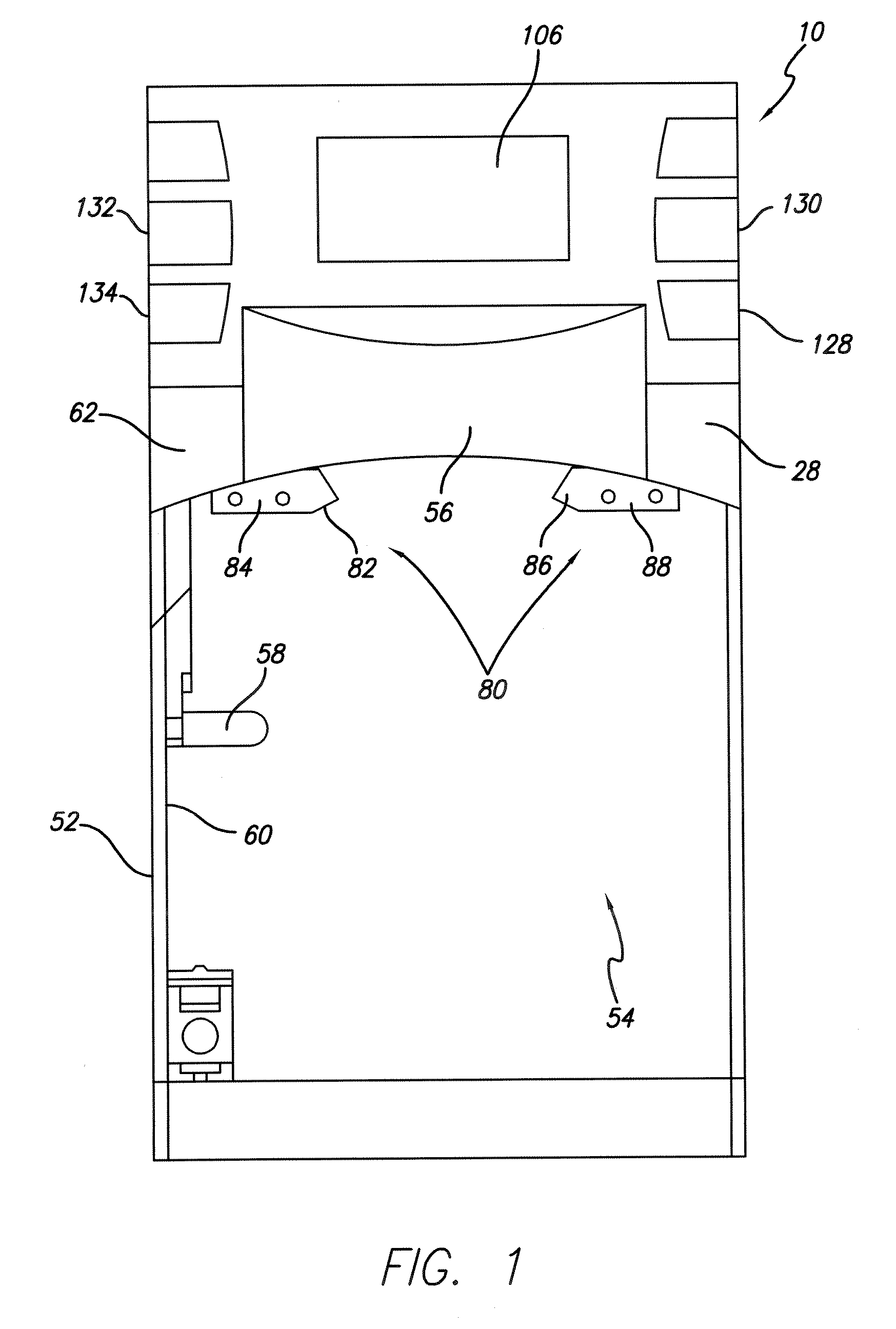

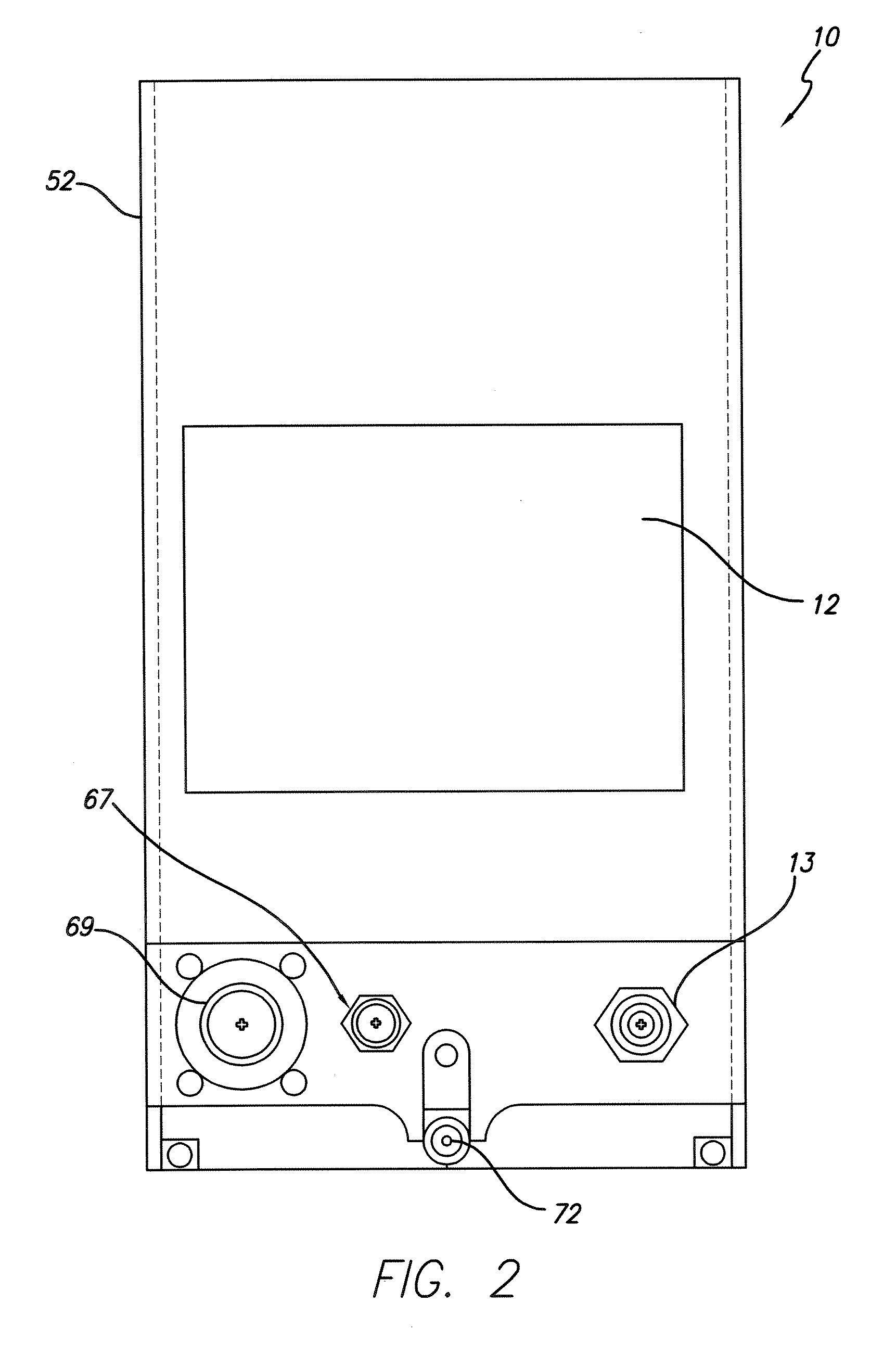

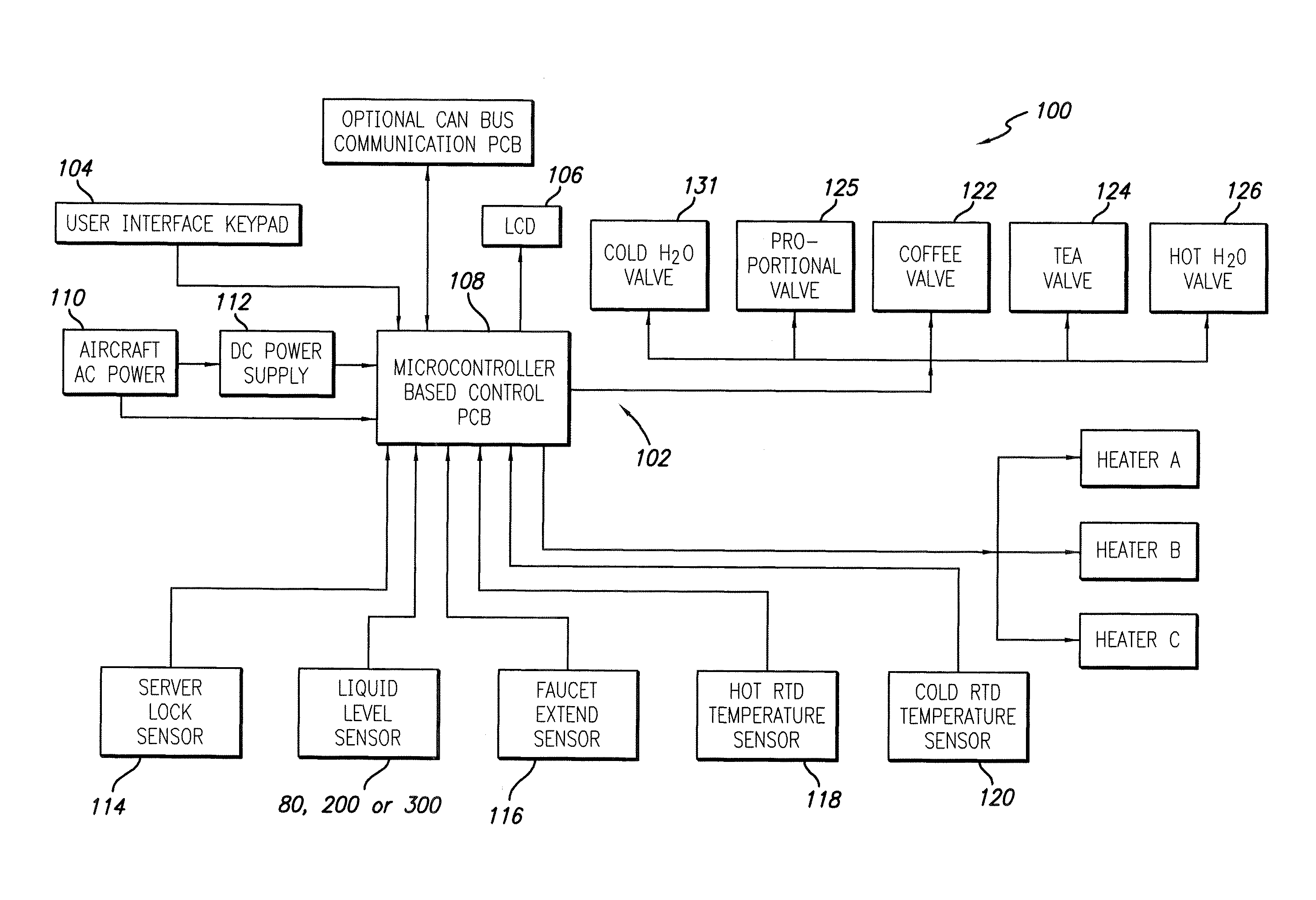

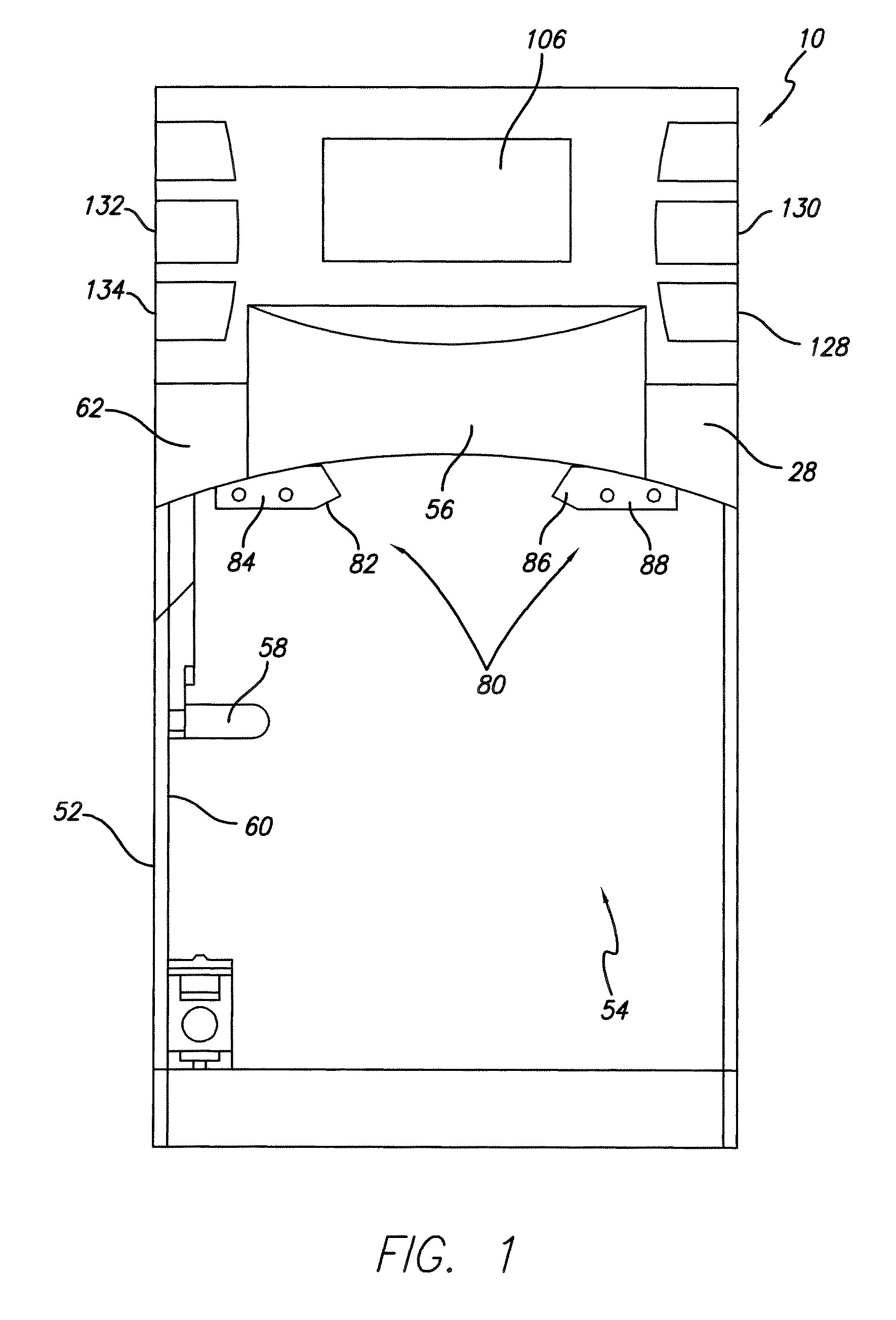

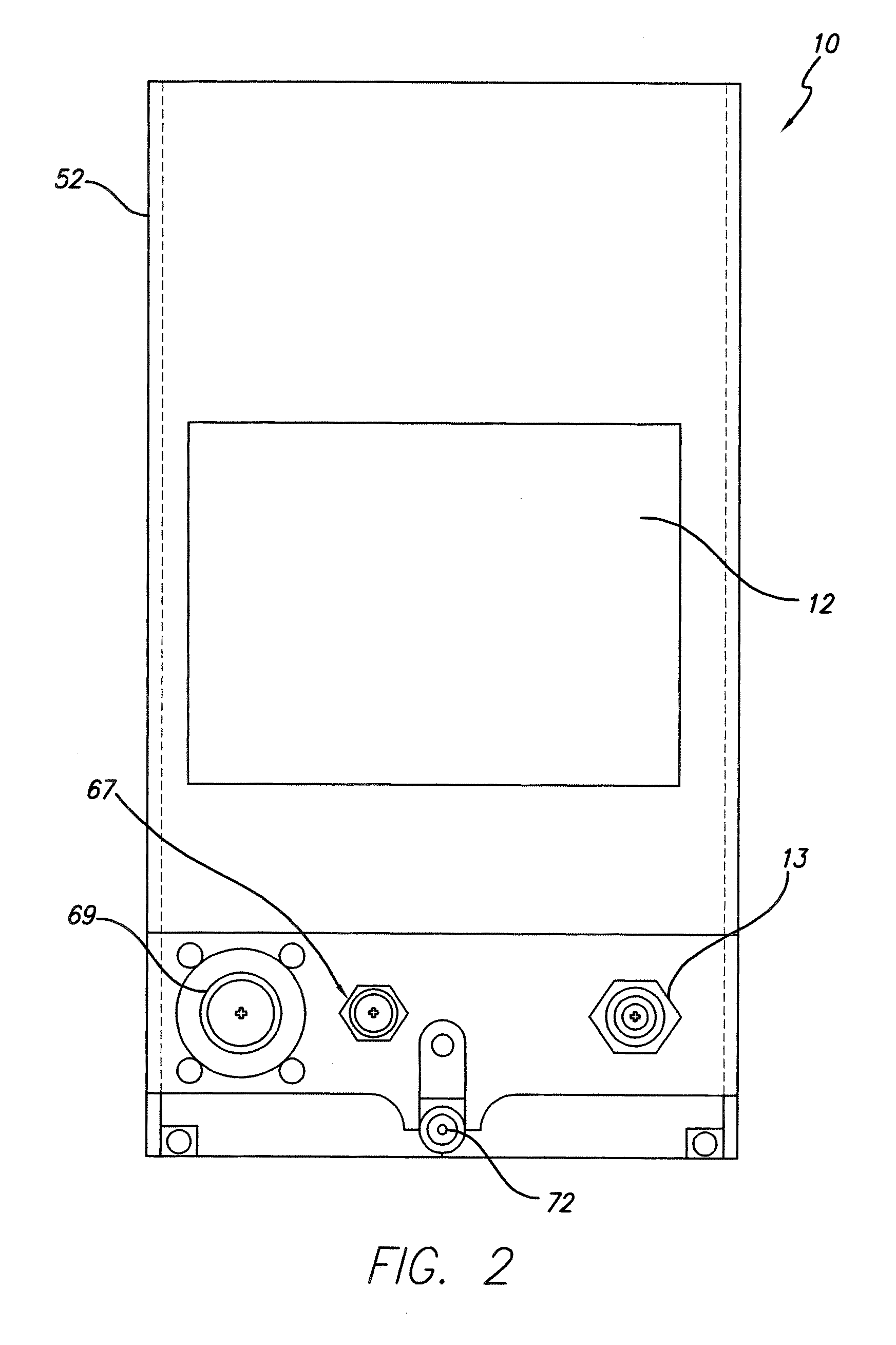

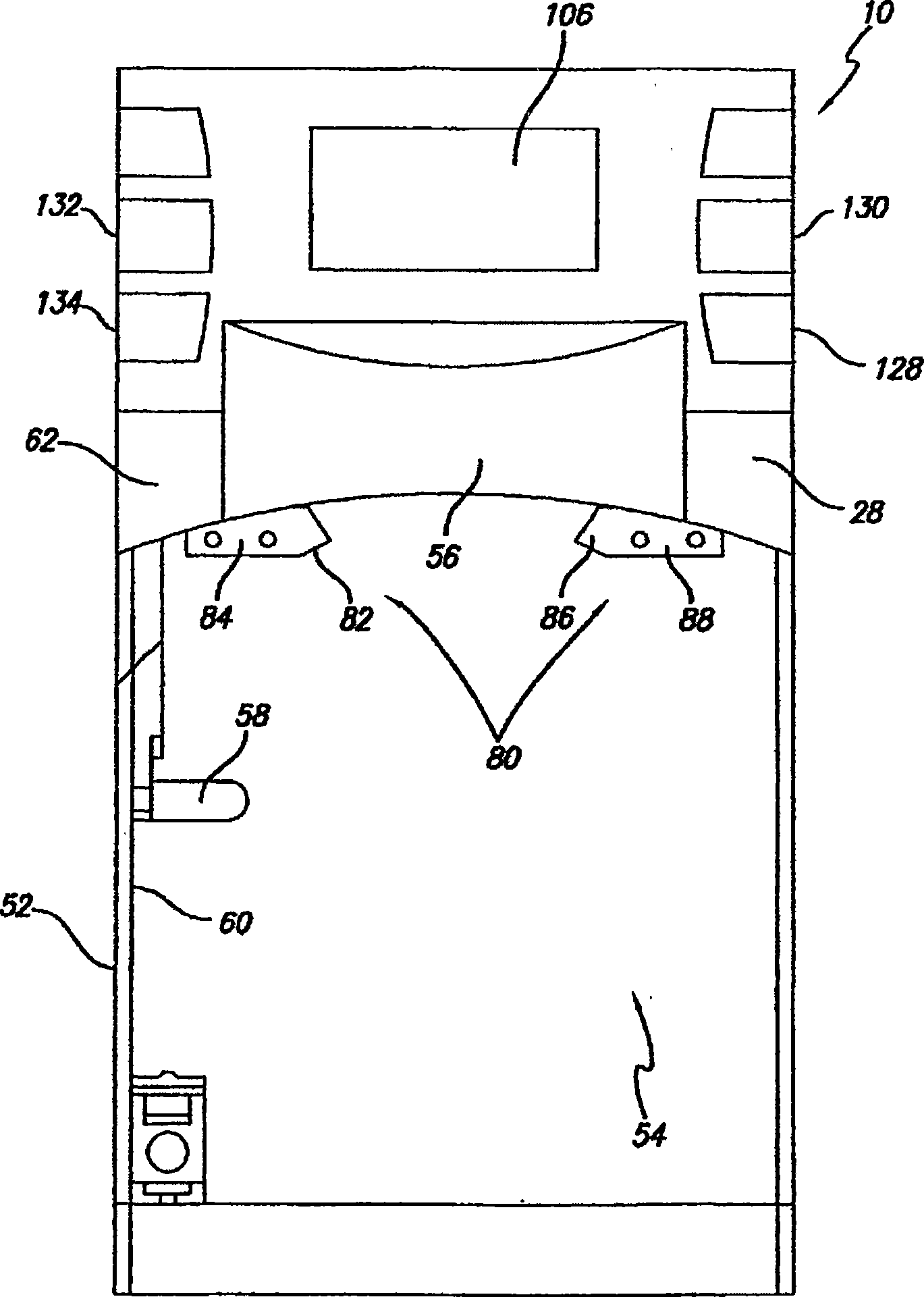

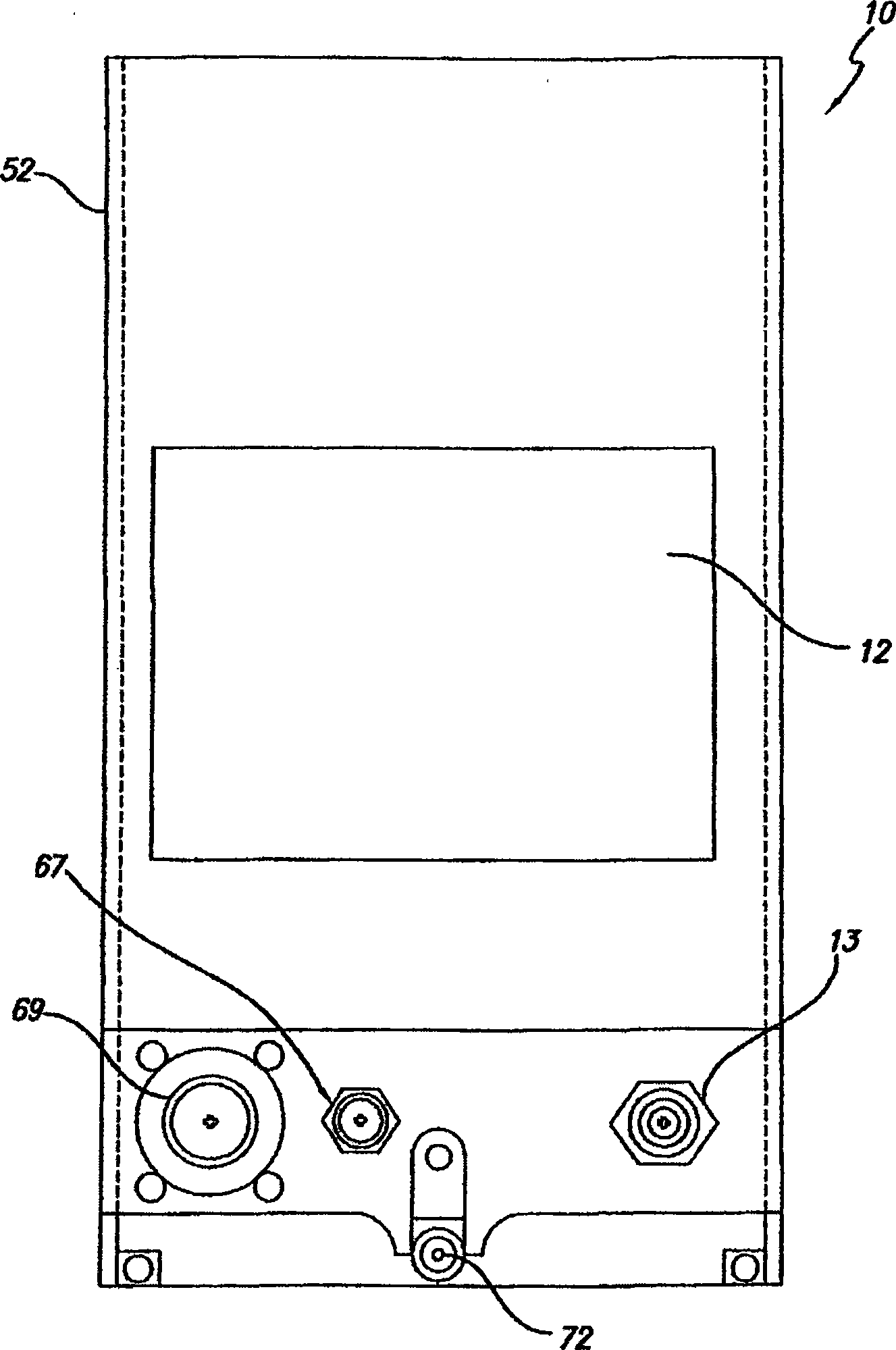

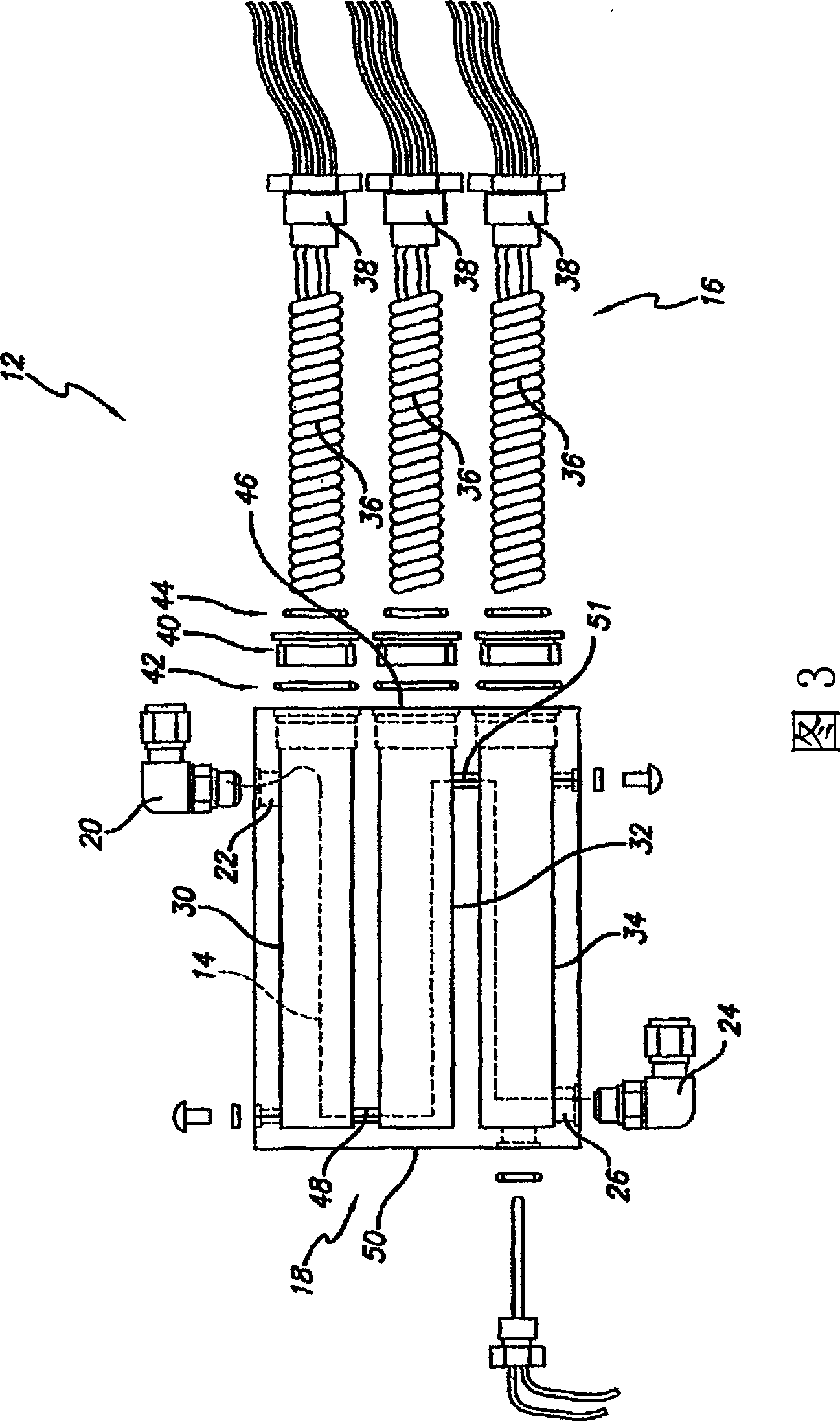

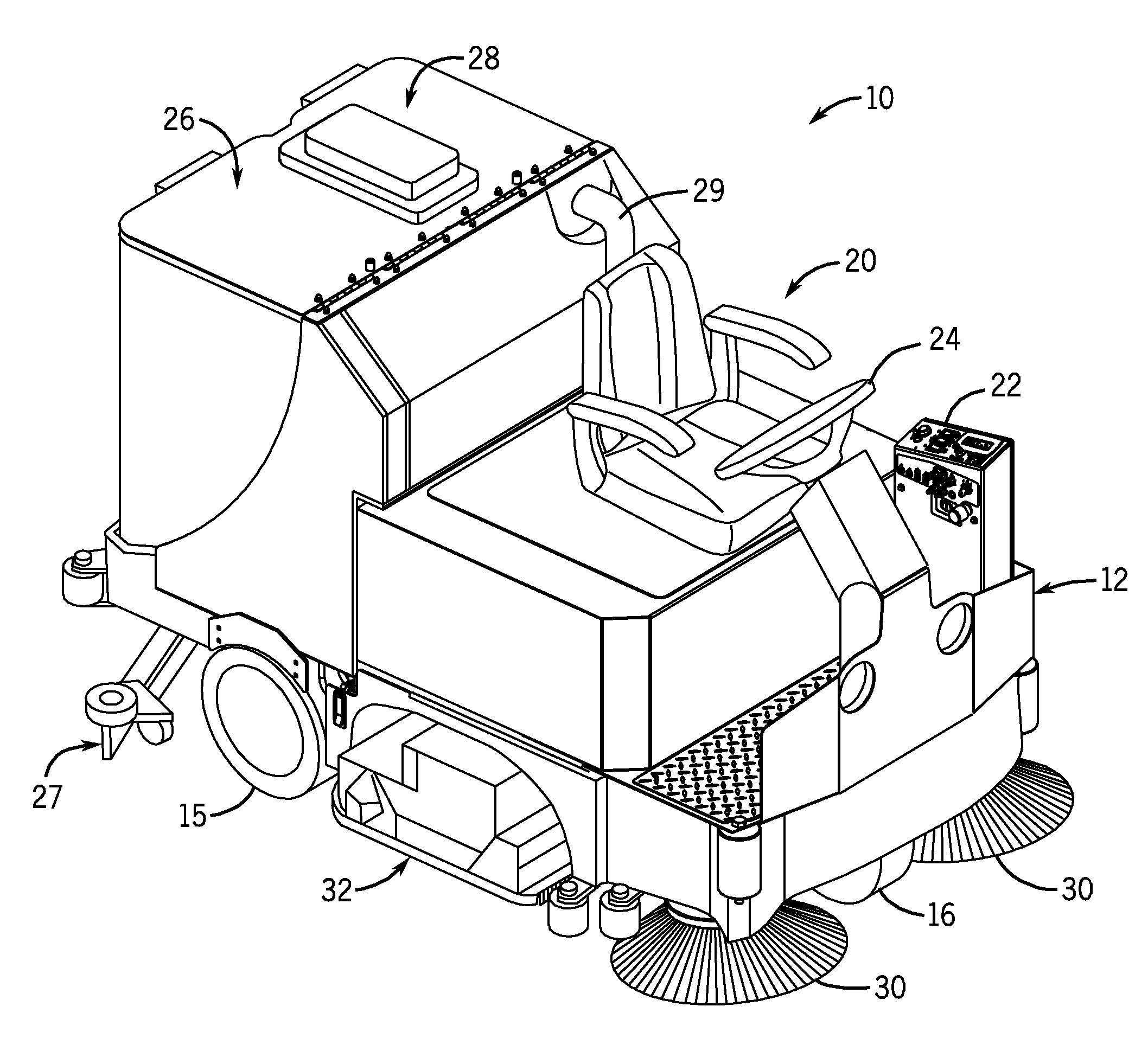

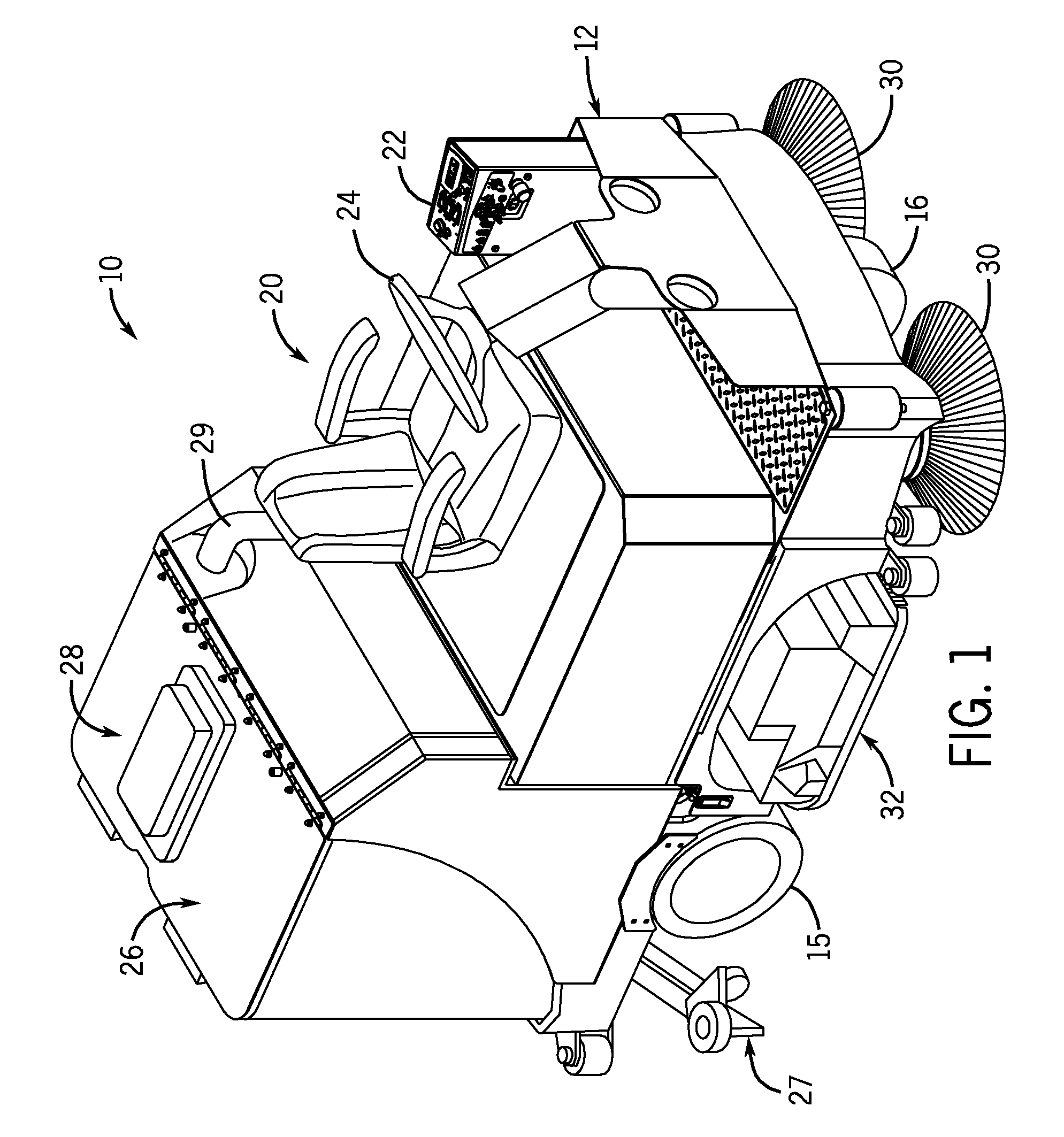

Beverage maker

The present invention provides a beverage maker having an in-line heating assembly for heating water to make hot beverages such as coffee and tea. The heating assembly defines a flow path that runs past a plurality of heaters for heating water to a desired temperature. In this manner, the beverage maker heats water as it travels, alleviating the need for a water tank or vessel, resulting in increased savings in weight and size, as well as reducing brew time. Additionally, an optical sensor assembly is provided to detect when a serving container of the beverage maker has a prescribed capacity of liquid within it. The sensor assembly includes at least one light source aligned to shine into the container and at least one detector aligned to detect light reflected off the liquid surface within the container. A drainage assembly is also provided that can drain liquid through either a connector port into an airplane's wastewater system or through a drainage port into a drainage sump.

Owner:SAFRAN CABIN GALLEYS US INC

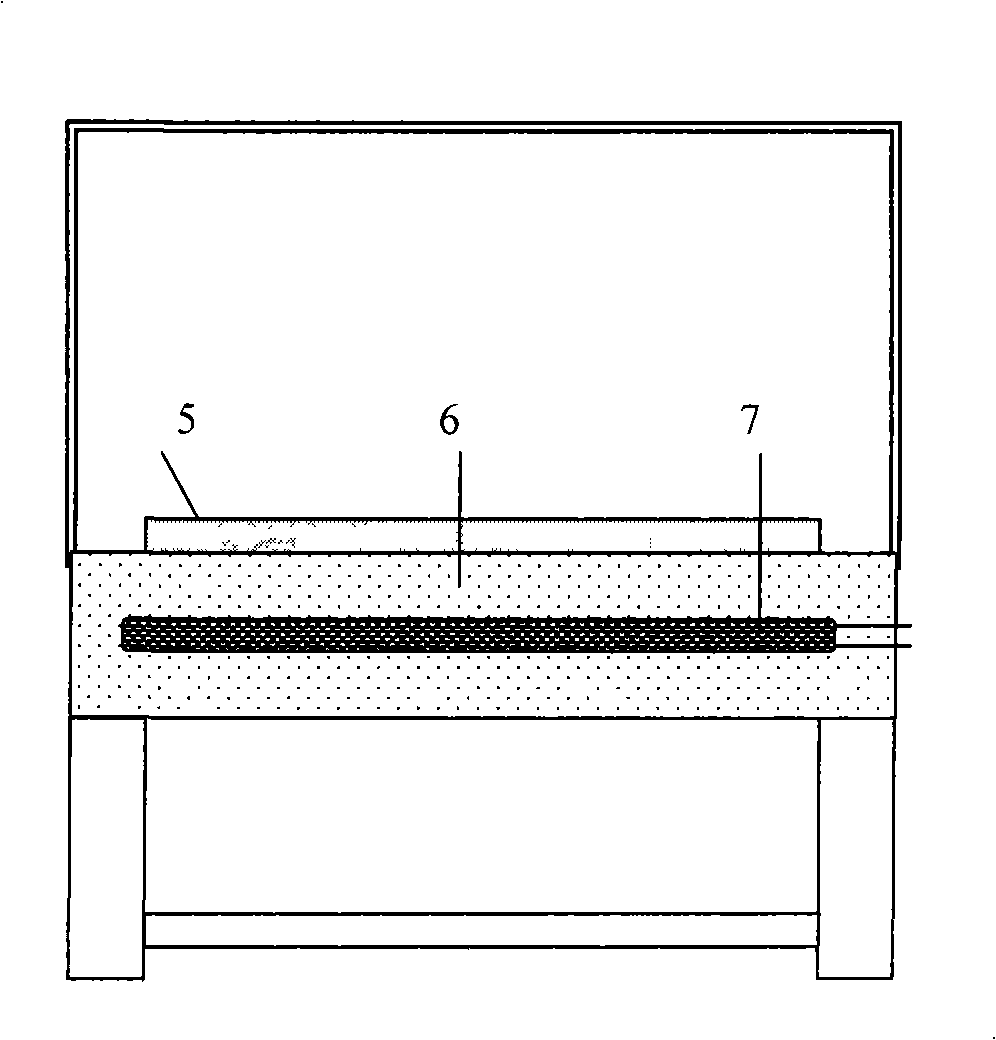

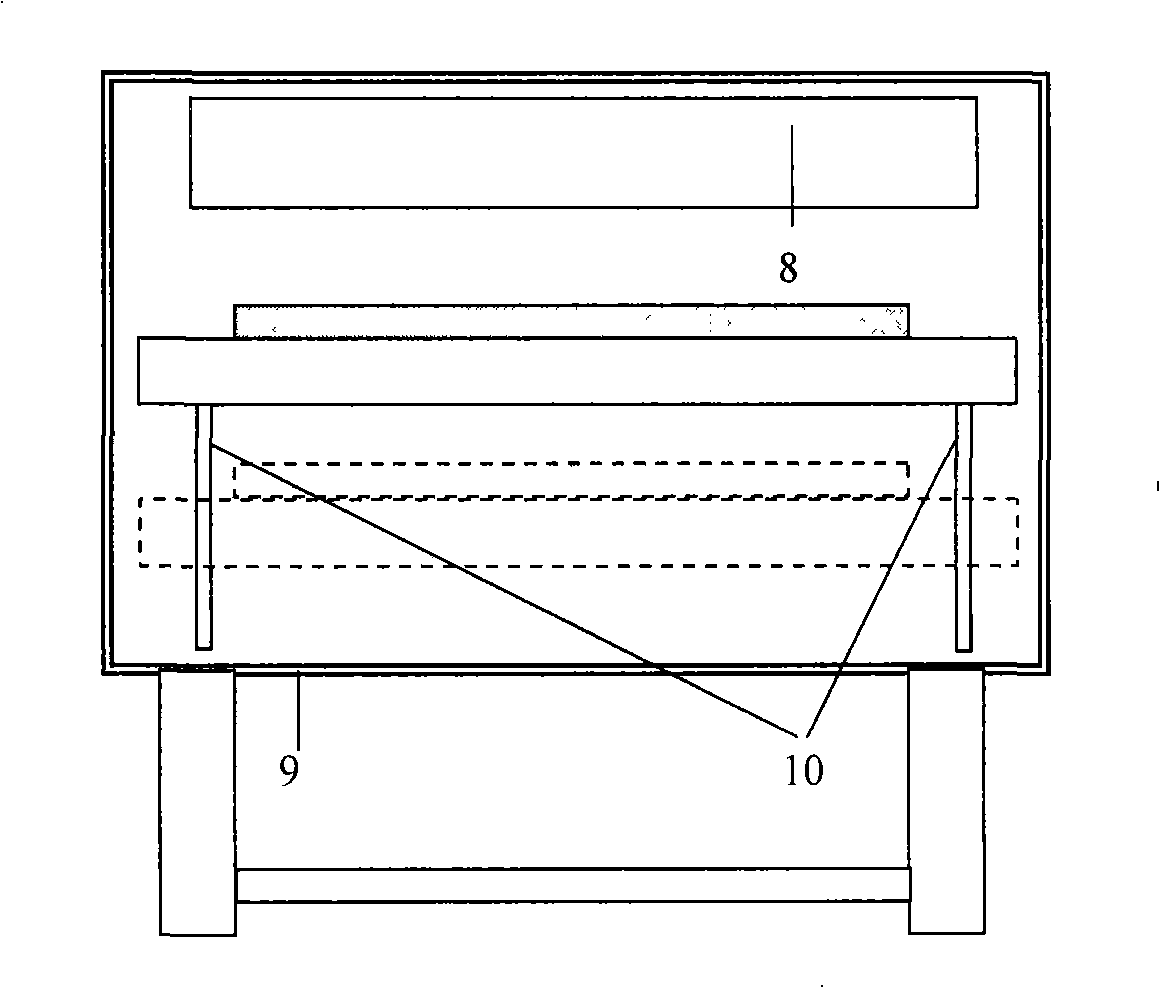

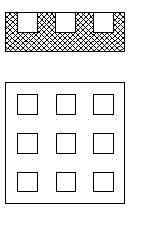

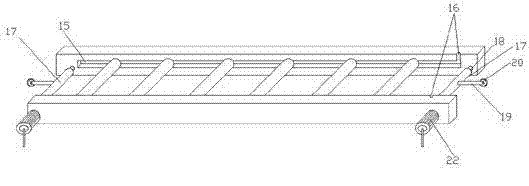

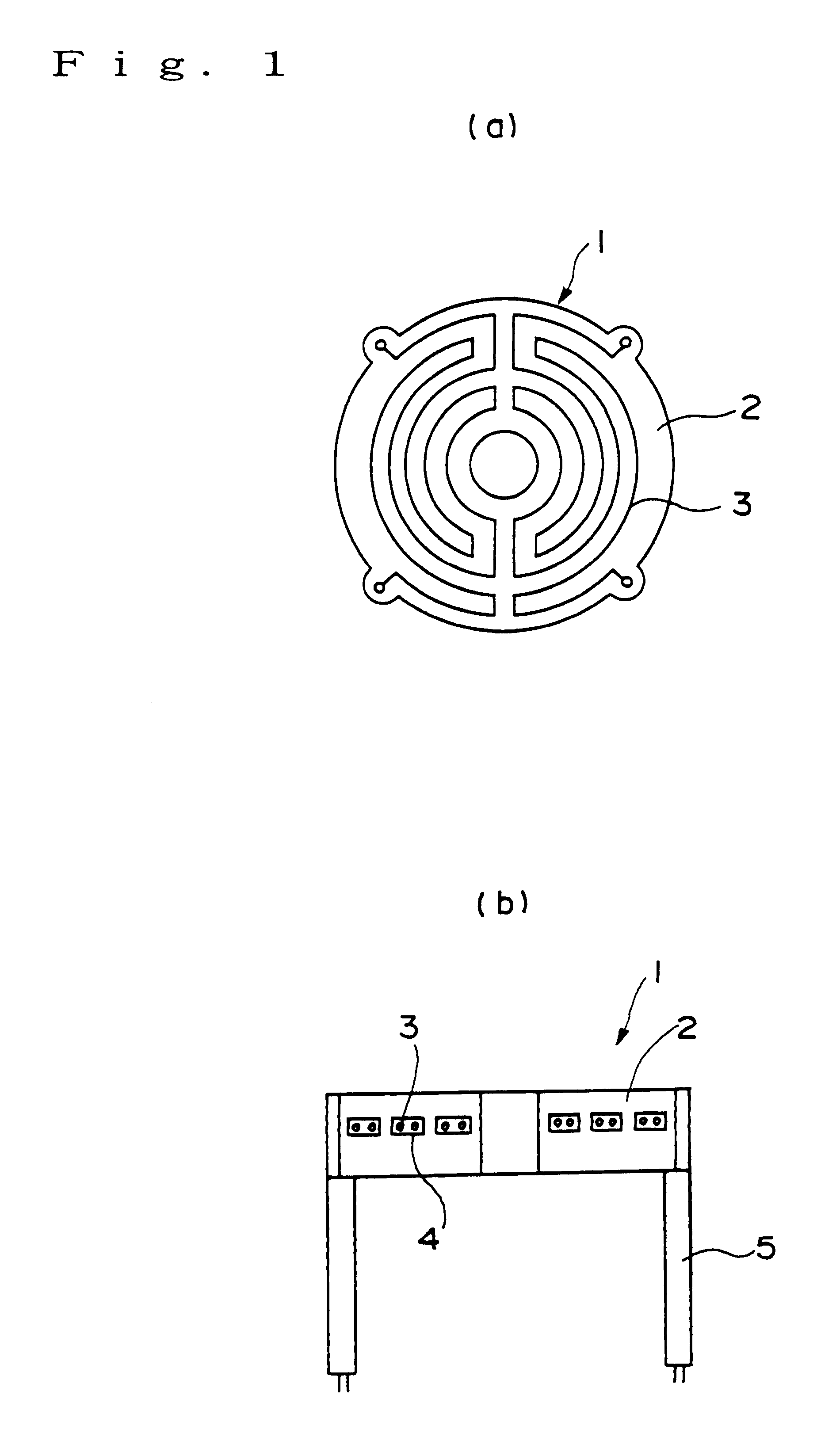

Alignment film precuring equipment

ActiveCN101308290AEvenly heatedIncrease temperature heatingHeating element shapesNon-linear opticsInfraredFar infrared

The invention discloses an orientation membrane pre-curing equipment, comprising a workbench and a heater arranged above the workbench; the heater is an infrared generating device which comprises a plurality of quartz glass far infrared ray heating tubes; wherein, a moving device is connected below the workbench and can drive the workbench to move up and down relative to the heater. The invention arranges the heating device on the upper part of the equipment and uses the infrared generating device to generate infrared so as to achieve panel heating to a substrate which has no contact with the heating device; the substrate has an air layer in the middle and can be evenly heated; besides, the workbench can move up and down; when the heating starts, the workbench has a longer distance from the infrared generating device on the upper part of the equipment, so the substrate is heated by less heat; during the heating process, the workbench automatically rises and is more and more close to the infrared generating device on the upper part of the equipment, so the substrate is heated by more and more heat so as to achieve a gradual increase in heating temperature to reduce the rate of unqualified products caused by uneven heating and improve the product yield.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

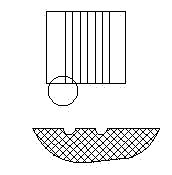

Method and device for forming plastic part microstructure based on laser heating

InactiveCN102962583AHigh processing flexibilityFast absorption of laser energyLaser beam welding apparatusLine heatingLaser heating

The invention discloses a method and a device for forming a plastic part microstructure based on laser heating, and relates to the field of formation of the plastic part microstructure, in particular to the method and the device for forming the plastic part microstructure based on laser heating. The surface of a base body of a plastic part with microstructure characteristics is quickly heated and molten by utilizing the heat effect of laser on a polymer and accurately controlling laser power and irradiation time as well as irradiation mode, and the plastic part microstructure is formed and processed through a laser heating extrusion forming device. The method and the device have the advantages of high forming precision, large scale range, good flexibility, high efficiency and low cost, are suitable for large-batch automatic forming and processing of the plastic part microstructure, and have higher application values.

Owner:JIANGSU UNIV

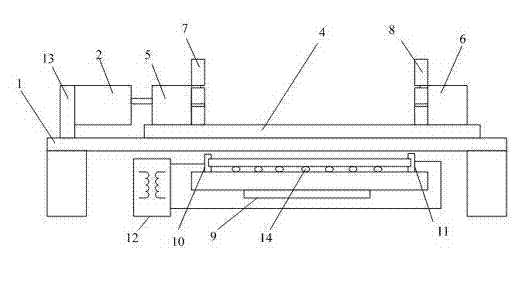

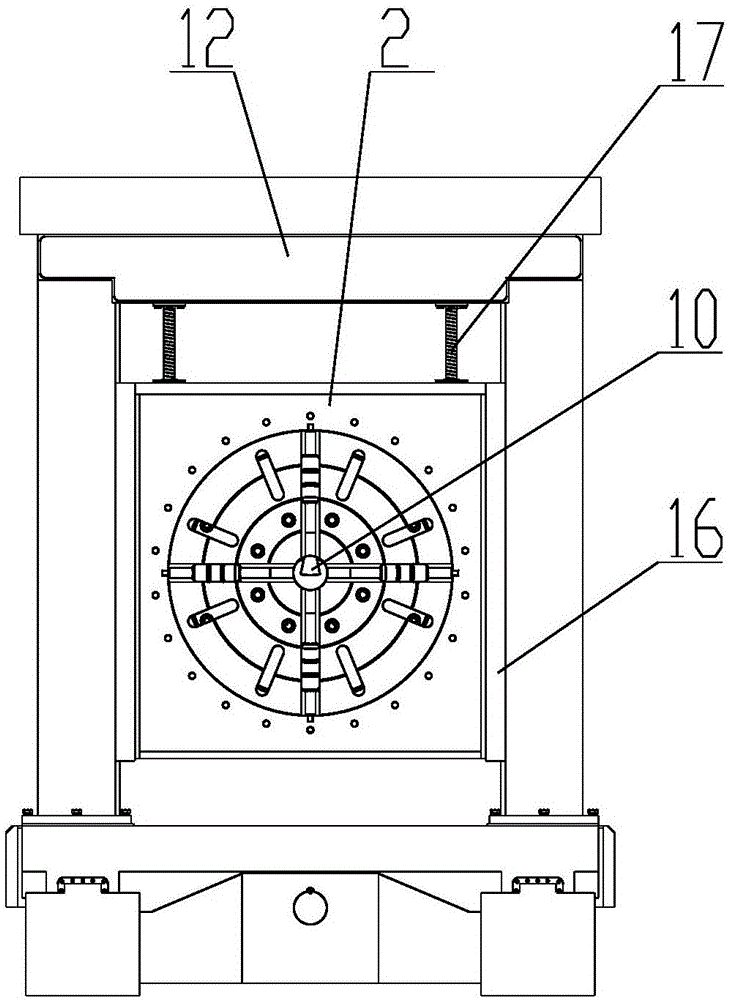

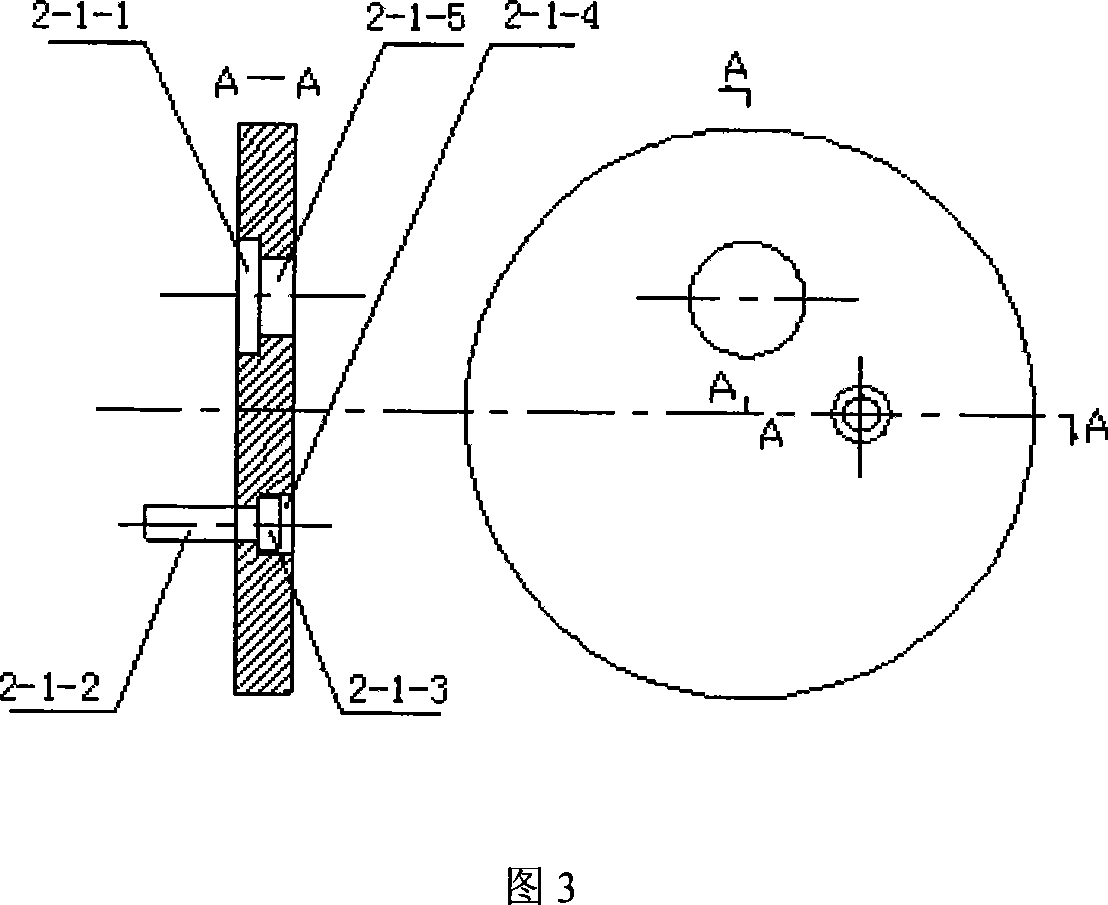

Tensile straightening device for on-line heating and straightening process of magnesium alloy extrusion

The invention discloses a stretching-straightening device for an online heating-straightening process of a magnesium alloy extrusion material, comprising a stretching-straightening device and a heating device. The stretching-straightening mechanism comprises a bracket, a stretching drive mechanism and a clamping drive mechanism. Double rails are arranged on the bracket. The rail is provided with a chuck I and a chuck II which are matched with the surfaces of the rails in a sliding manner. At least one chuck is capable of sliding forward and backward along the rail direction with the action ofthe stretching drive device. The chuck I and the chuck II are used for generating clamping forces via the clamping drive mechanism respectively. The heating device comprises a lifting mechanism and aheating mechanism. The heating mechanism comprises a positive clamping electrode, a negative clamping electrode and a transformer. The lifting mechanism is arranged under the double rails. The heating device of the stretching-straightening device is capable of guaranteeing that the extrusion material is expanded freely during heating without generating heat stress. The bending phenomenon caused by the heat stress and the instability phenomenon caused by the combined action of the heat stress and the self gravity are avoided via effective support during heating.

Owner:重庆昱华新材料科技有限公司

Beverage maker

The present invention provides a beverage maker having an in-line heating assembly for heating water to make hot beverages such as coffee and tea. The heating assembly defines a flow path that runs past a plurality of heaters for heating water to a desired temperature. In this manner, the beverage maker heats water as it travels, alleviating the need for a water tank or vessel, resulting in increased savings in weight and size, as well as reducing brew time. Additionally, an optical sensor assembly is provided to detect when a serving container of the beverage maker has a prescribed capacity of liquid within it. The sensor assembly includes at least one light source aligned to shine into the container and at least one detector aligned to detect light reflected off the liquid surface within the container. A drainage assembly is also provided that can drain liquid through either a connector port into an airplane's wastewater system or through a drainage port into a drainage sump.

Owner:SAFRAN CABIN GALLEYS US INC

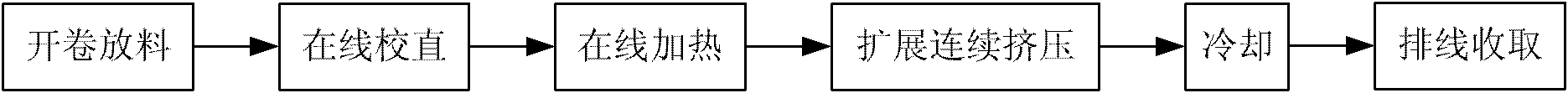

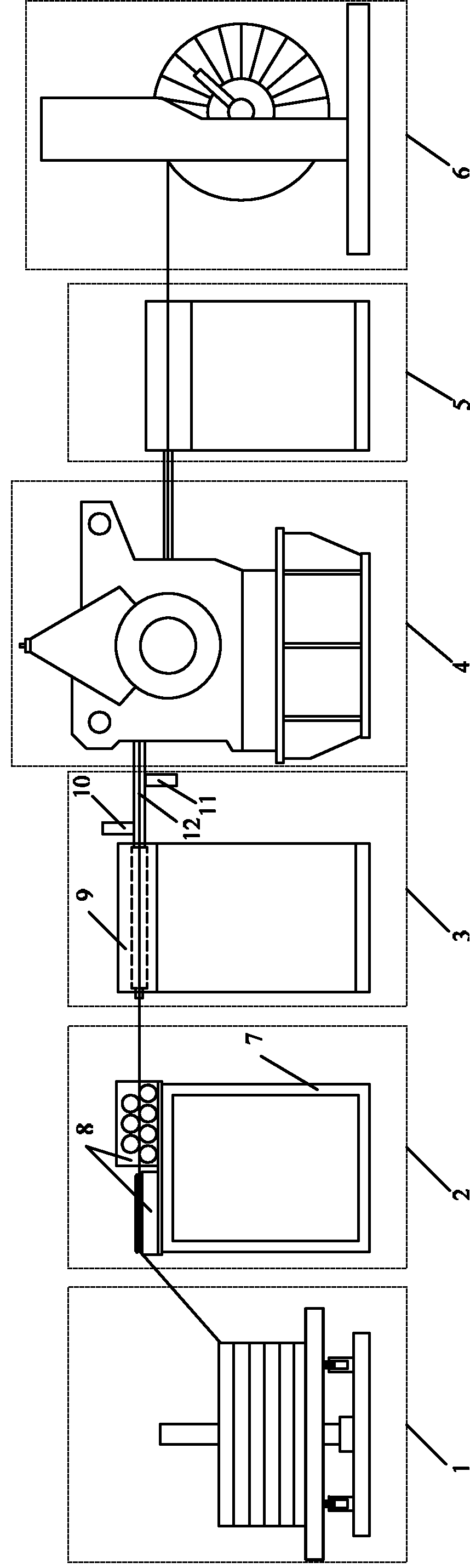

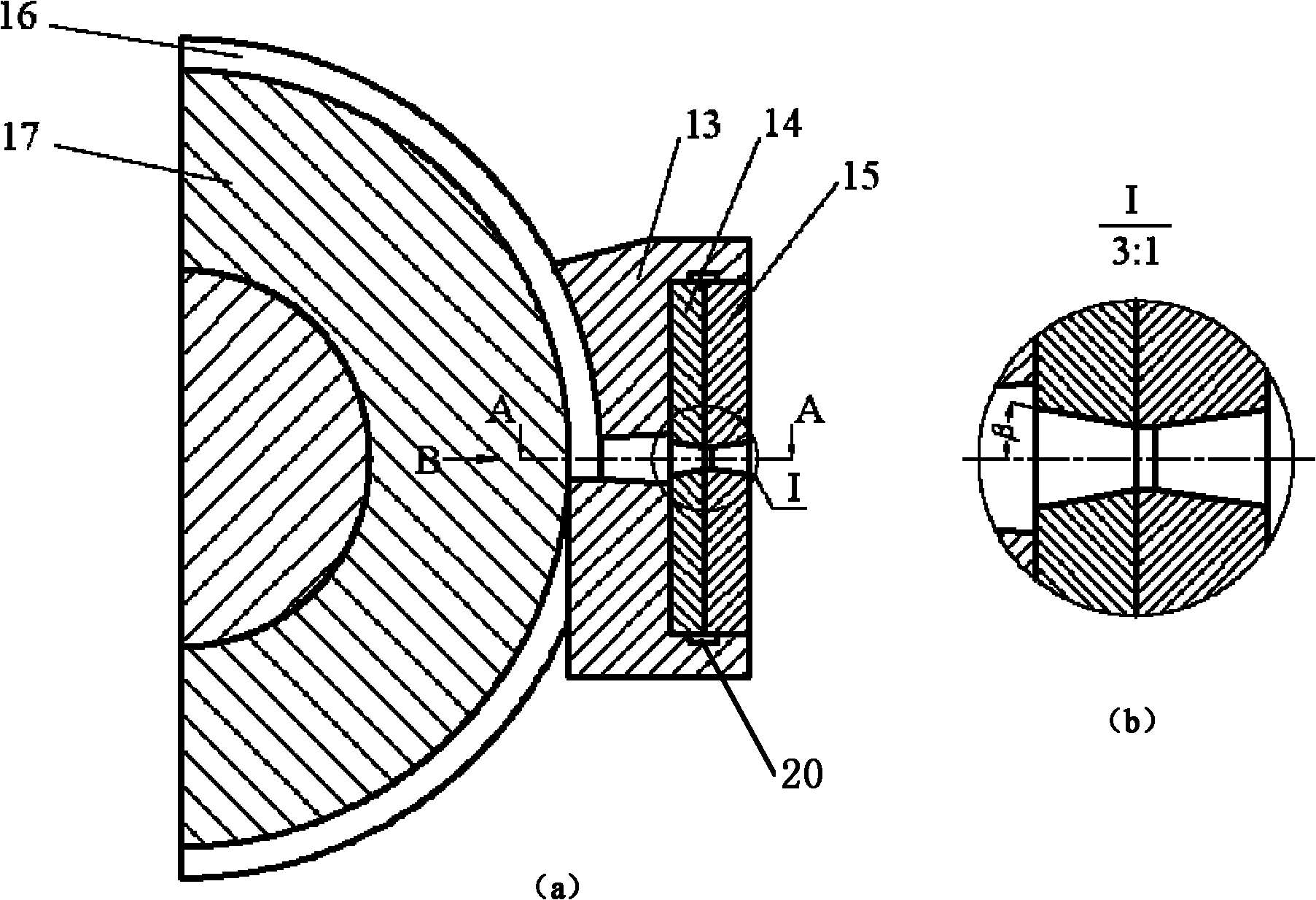

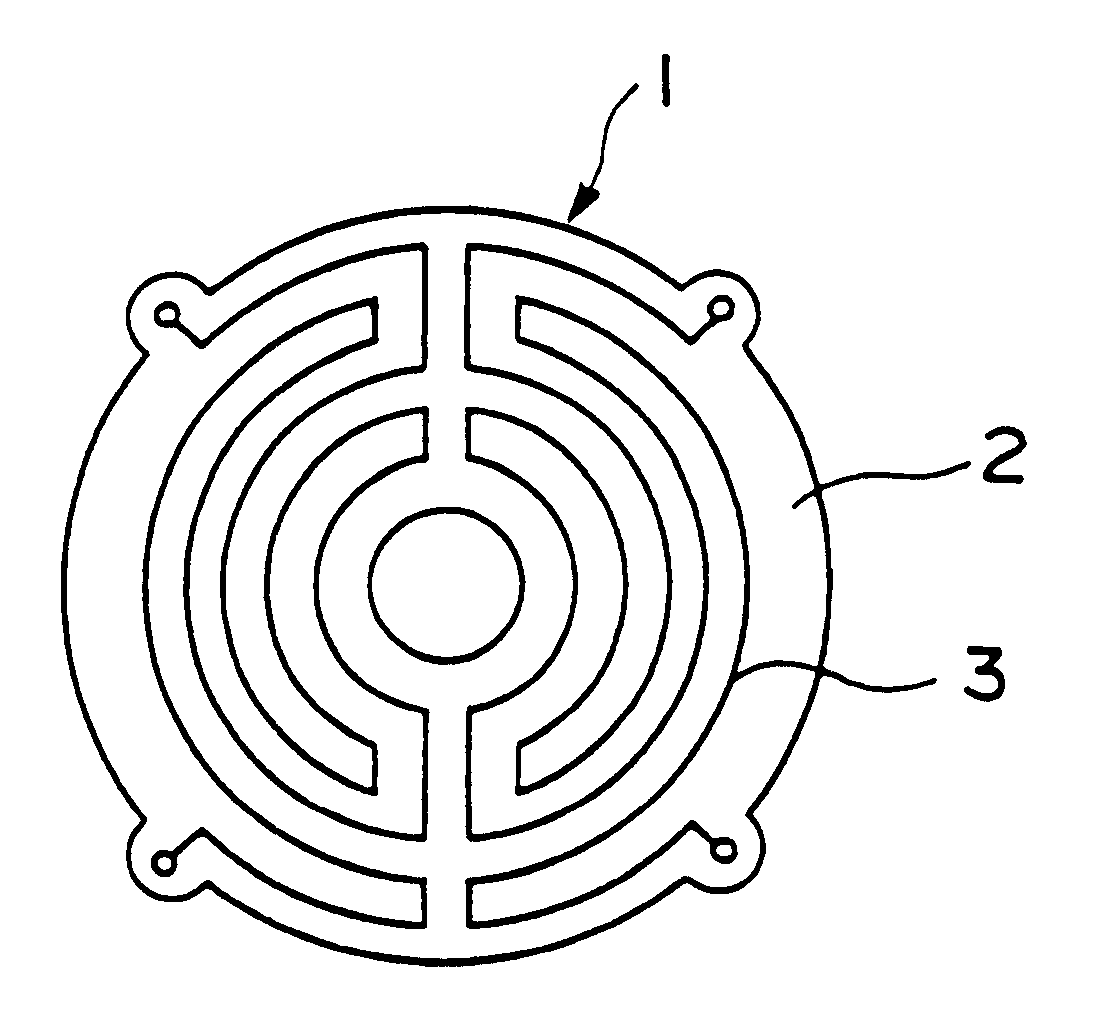

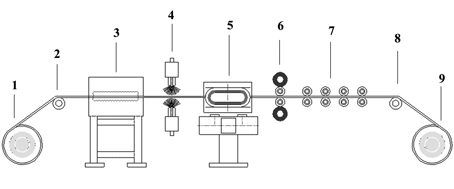

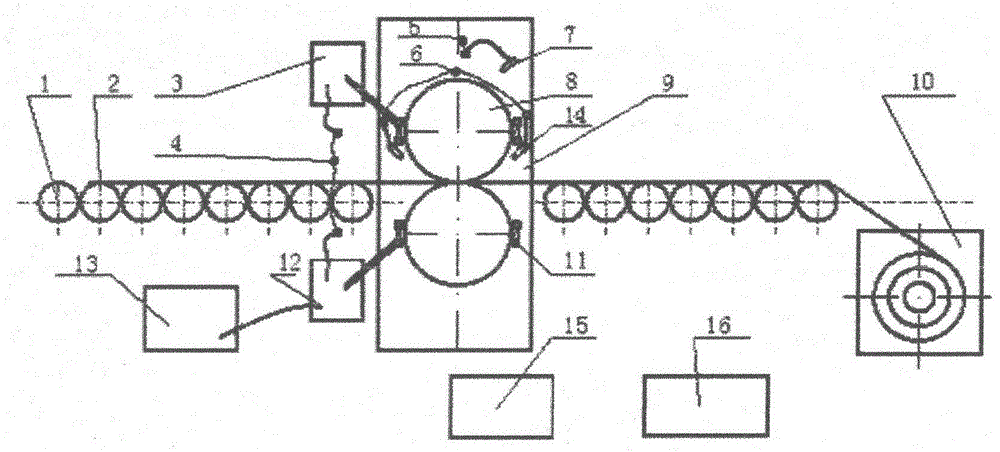

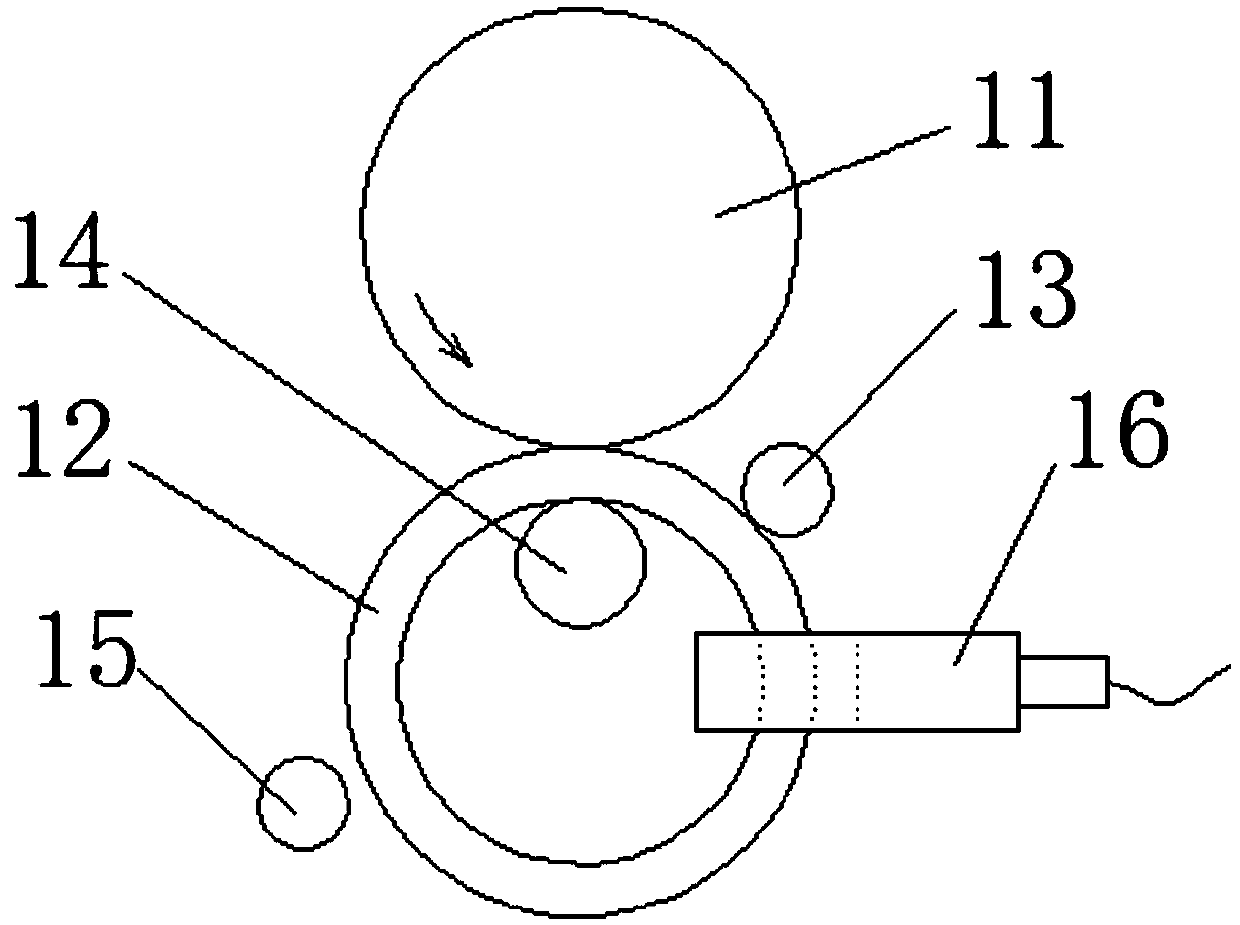

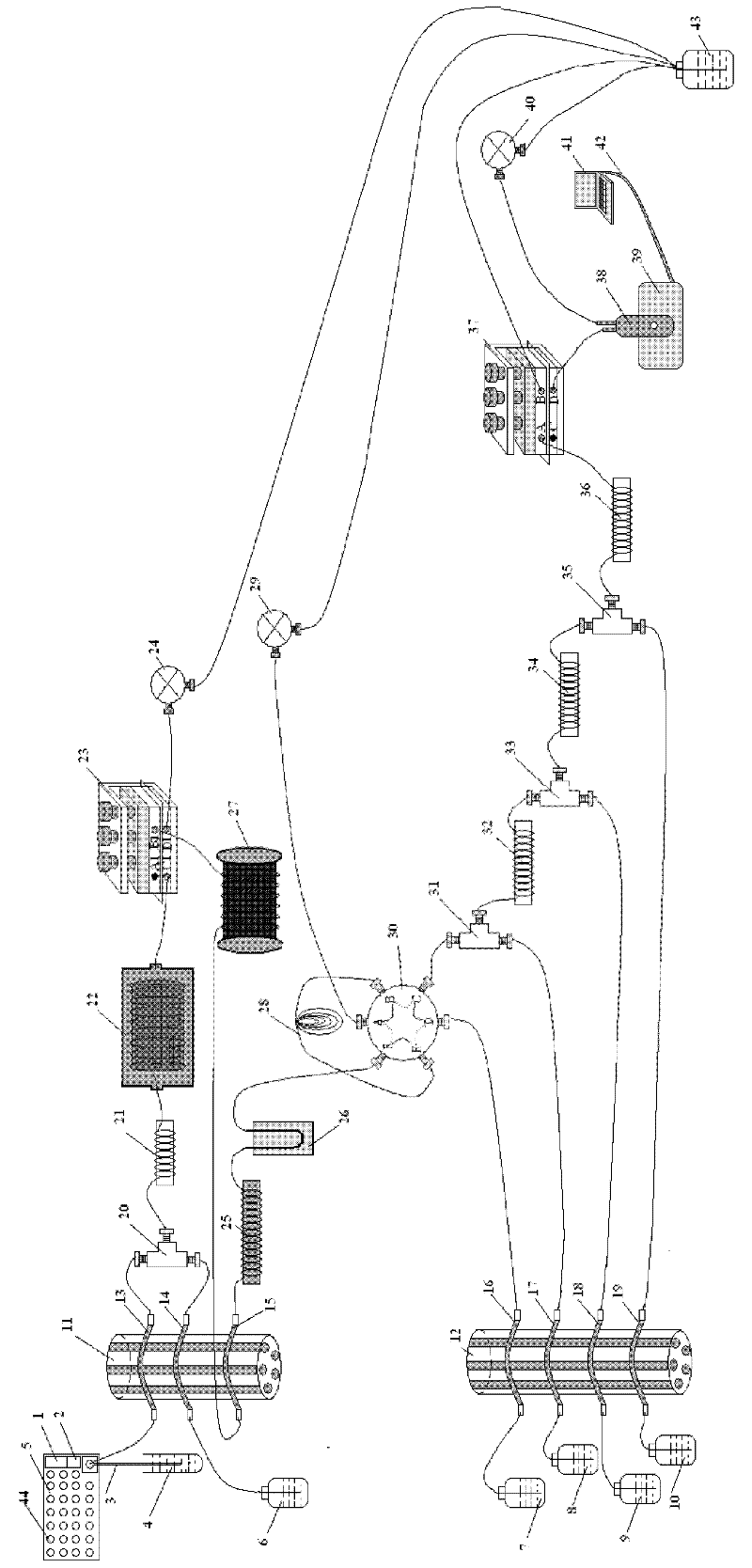

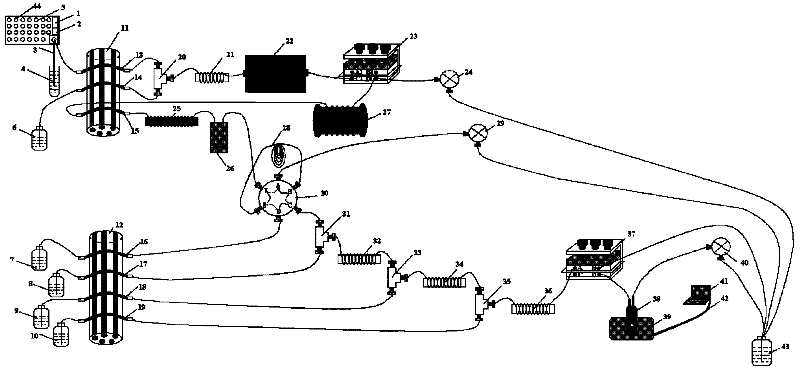

System and method for continuous extrusion production of fine-grain magnesium alloy strip

ActiveCN102688907AShort processIncrease productivityExtrusion control devicesProduction lineLine heating

The invention discloses a system and a method for continuous extrusion production of a fine-grain magnesium alloy strip. The system comprises a decoiling emptying device, an on-line straightening device, an on-line heating device, a continuous extrusion device, a cooling device and a winding displacement collection device. Through control of a temperature of a rod, a good extrusion driving force is produced between the rod and an extrusion wheel groove. Through an expansion mold cavity and a flow-blocking mold, magnesium alloy expansion flowing in a width direction is realized. In order to extrude a plate having larger width, the system adopts a two / three rod feeding-type extrusion mode so that joining and intermetallic welding of multiple rods in a corresponding multi-rod mold cavity are realized. The system and the method have the advantages that a process route is short; production efficiency is high; a grain refinement degree of a product microstructure is high; plate formability is good; and a continuous production line provided by the invention is suitable for industrial application.

Owner:DALIAN JIAOTONG UNIVERSITY

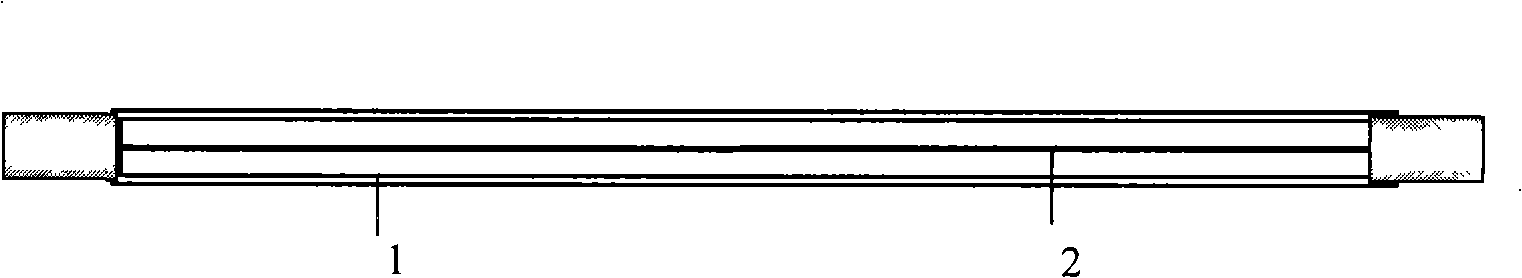

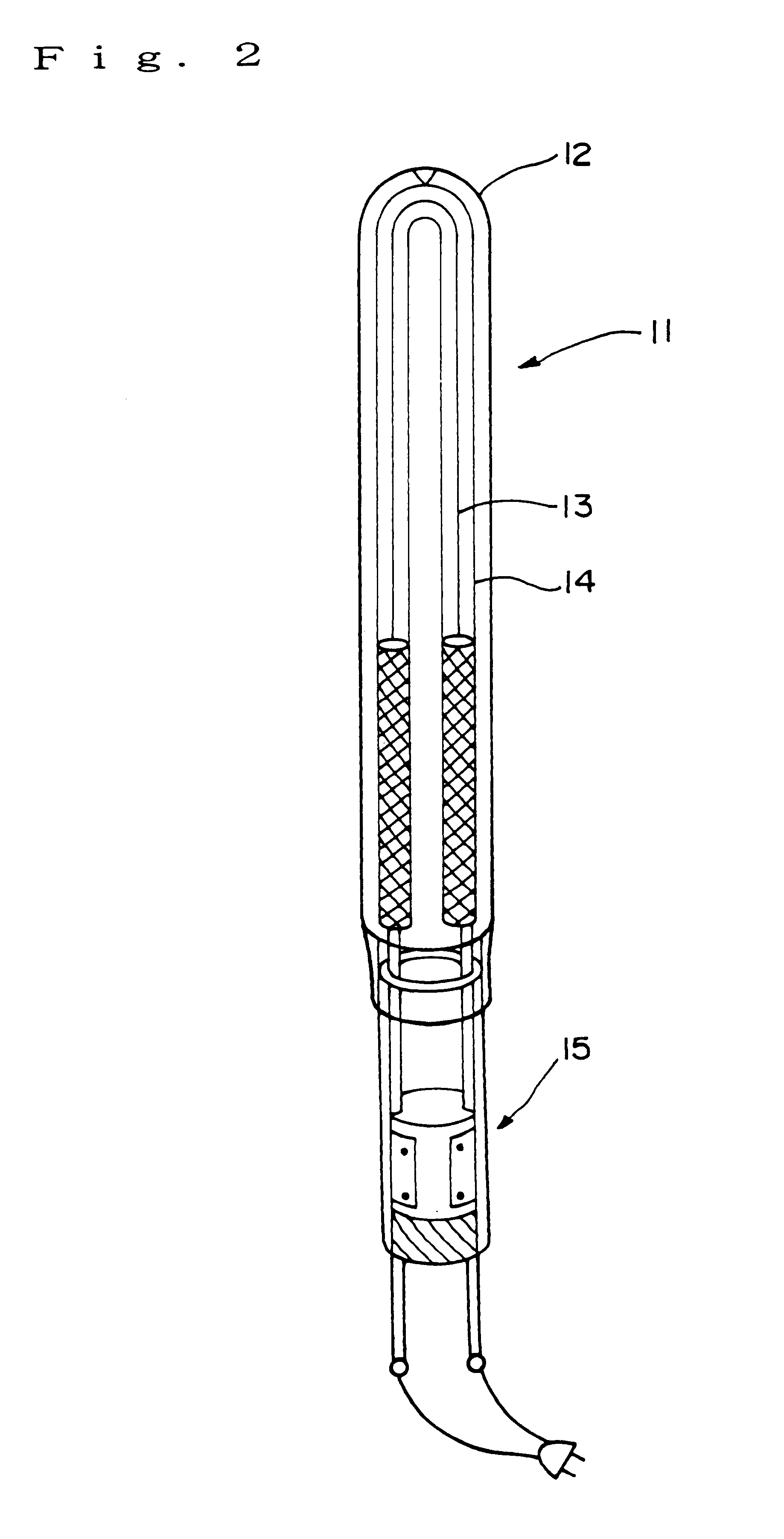

Heater sealed with carbon wire heating element

InactiveUS6584279B2Quality improvementExcellent anti-aging stability of electric resistanceDomestic stoves or rangesIncandescent ignitionSingle fiberCrystal structure

A heater sealed with carbon wire heating element has a carbon wire heating element sealed with a quartz glass member, the carbon wire being prepared by knitting carbon single fibers into a knitted cord of a braid, each wire having a crystal structure with a interlayer spacing d (002) thereof being 0.343 or less and crystallite size Lc (002) thereof being 4.0 nm or more.

Owner:COORSTEK INC +1

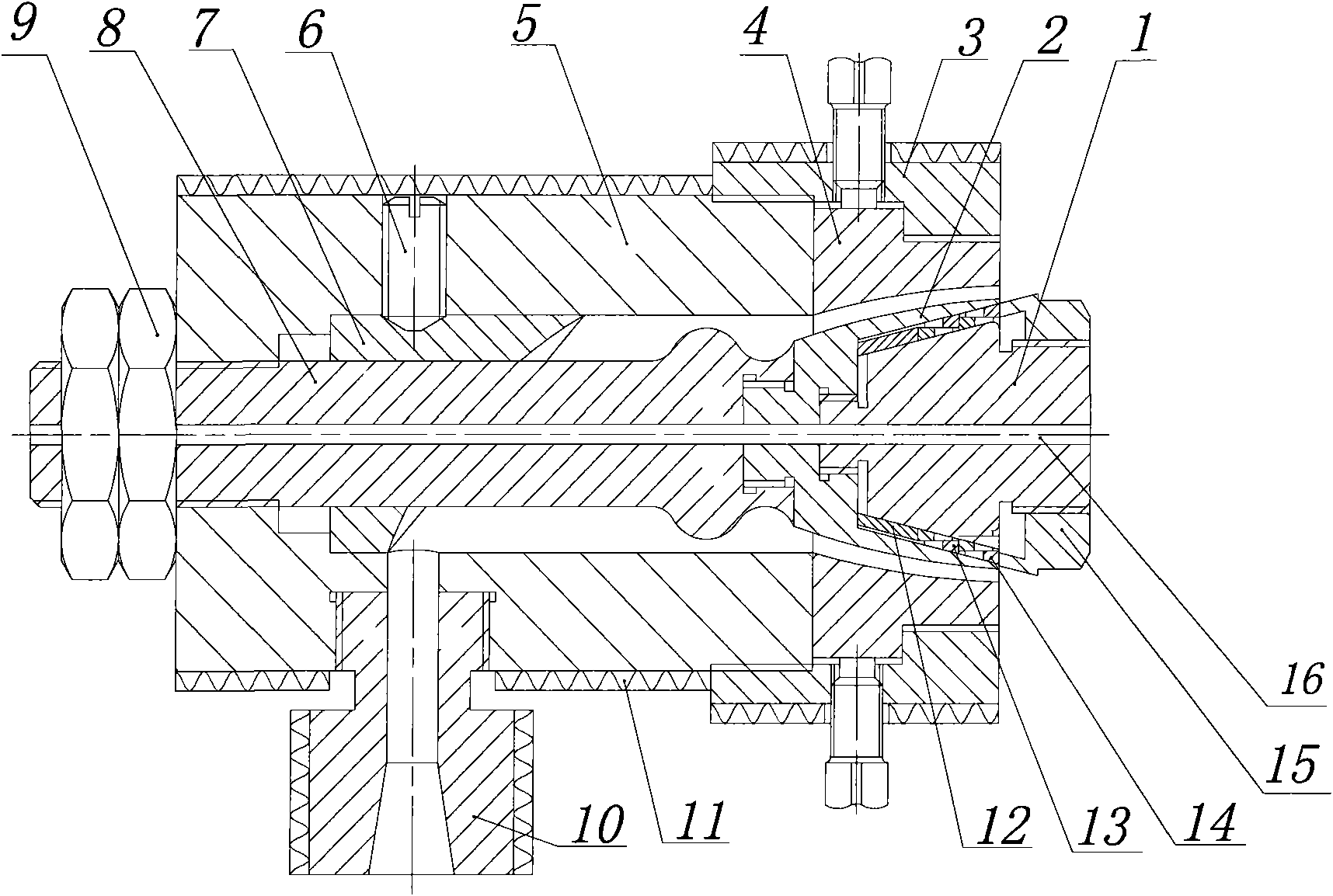

Machine head device capable of adjusting wall thickness of extrusion pipe

The invention belongs to a machine head device capable of adjusting the wall thickness of an extrusion pipe without dismantling a core mould in a neck ring mould in the technical field of polymer material processing mechanical equipment. A core mould inner shaft is sequentially provided with a lower expansion sleeve, an upper expansion sleeve and a core mould inner cushion block, a thread arranged at the right end of an adjusting nut is screwed into a nut arranged at the right end of the core mould inner shaft; a machine diameter is used for connecting the head part of an extrusion machine screw, the periphery of the machine diameter is provided with a wavy line heating ring, a transition block is arranged into a mandrel and a main mould body from a left port of the main mould body, the mandrel is connected with the main mould body into a whole; a thread arranged at the left end of a core mould body is connected with an inner thread arranged at the right end of the mandrel into a whole; the neck ring mould is arranged at the left end of a pressure sleeve, an inner thread at the left end of the neck ring mould is correspondingly assembled and connected with an outer thread at the right end of the main mould body; the neck ring mould and the main mould body form a runner inner wall of an extrusion machine head, the inner diameter of the neck ring mould is the outer diameter of the extrusion pipe, and the outer diameter of the core mould body is the inner diameter of the extrusion pipe. The machine head device capable of adjusting the wall thickness of the extrusion pipe has the advantages of simple structure, labor, financial resources and energy sources saving, and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Beverage maker

The present invention provides a beverage maker having an in-line heating assembly for heating water to make hot beverages such as coffee and tea. The heating assembly defines a flow path that runs past a plurality of heaters for heating water to a desired temperature In this manner, the beverage maker heats water as it travels, alleviating the need for a water tank or vessel, resulting in increased savings in weight and size, as well as reducing brew time. Additionally, an optical sensor assembly is provided to detect when a serving container of the beverage maker has a prescribed capacity of liquid within it. The sensor assembly includes at least one light source aligned to shine into the container and at least one detector aligned to detect light reflected off the liquid surface within the container. A drainage assembly is also provided that can drain liquid through either a connector port into an airplane's wastewater system or through a drainage port into a drainage sump.

Owner:C&D ZODIAC INC

Production technology method of low content alloy ultrahigh hardness wear-resistant steel plate

The invention provides a production technology method of a low content alloy ultrahigh hardness wear-resistant steel plate, belonging to the field of metal material; the production technology method is characterized in that: enhanced control cooling and once more off-line heating quenching process routes are carried out to the rolled steel plate; especially, enhanced control cooling is carried out to the rolled steel plate, the cooling starting temperature is 850-780 DEG C, the cooling speed is controlled to be 15-30 DEG C / s, and the final cooling temperature is 350-550 DEG C; then the temperature is naturally cooled to room temperature, and the steel plate is heated for 10-120min and is quenched to be at room temperature, and the quenching temperature is 950-900 DEG C; 100-400 DEG C tempering is carried out to the quenched steel plate, and the tempering time is 20-180min. the hardness of the wear-resistant steel plate produced by the invention is more than 500HB and the total alloy amount is less than 6 percent; therefore, the production technology method has the advantages of low cost, high additional value, stable process and easy realization.

Owner:UNIV OF SCI & TECH BEIJING

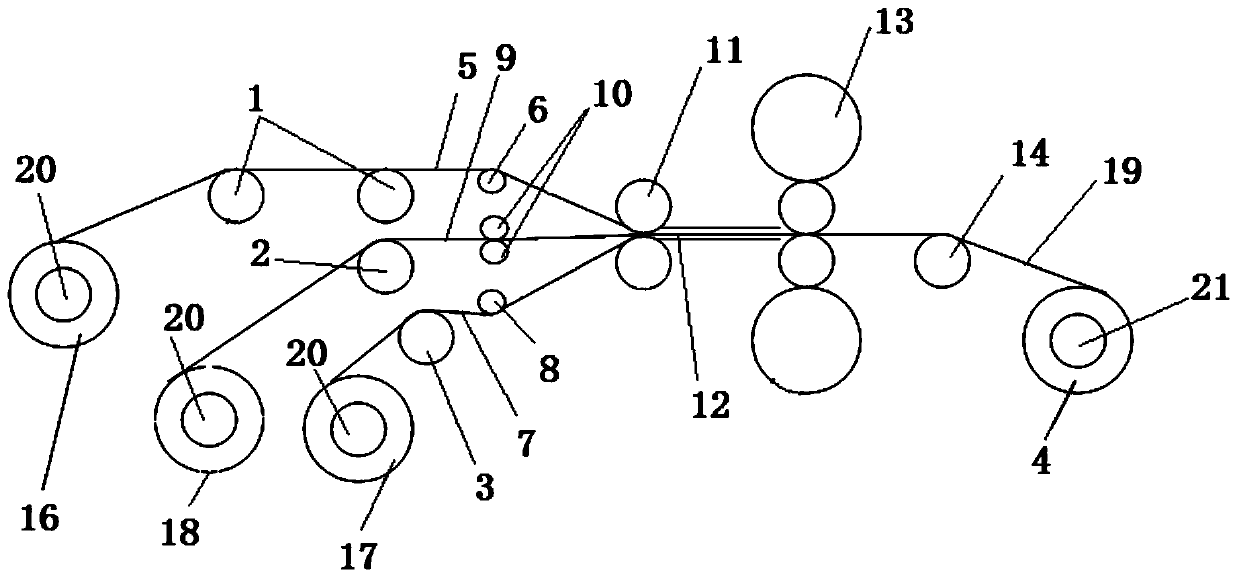

Preparation method of titanium-steel composite plate thin strip

InactiveCN102019292AReduce the degree of oxidationImprove bindingRoll mill control devicesMetal rolling arrangementsLine heatingComposite plate

The invention relates to the technical field of metallurgy, in particular to a preparation method of a titanium-steel composite plate thin strip, which is characterized by comprising the following steps of: firstly, uncoiling a cold rolled metal strip by using an uncoiling machine; secondly, sending the uncoiled strip to a heating furnace to be preheated; thirdly, thermally spraying the preheated strip, cooling to room temperature in air; fourthly, sending the cooled titanium-steel composite plate thin strip to an on-line heating device to ensure that the temperature of the sprayed titanium-steel composite plate thin strip raises to 200-1,000 DEG C at a temperature gradient of 30-300 DEG C / s; and fifthly, enabling the heated titanium-steel composite plate thin strip to enter a finishing mill at a speed of 0.3-2m / s to be rolled, wherein the primary down rate is more than 5 percent, the total down rate is more than 30 percent, the interface bond strength of the obtained titanium-steel composite plate thin strip is more than 300MPa and the surface roughness is less than 0.01mm.

Owner:沈阳科安捷材料技术有限公司

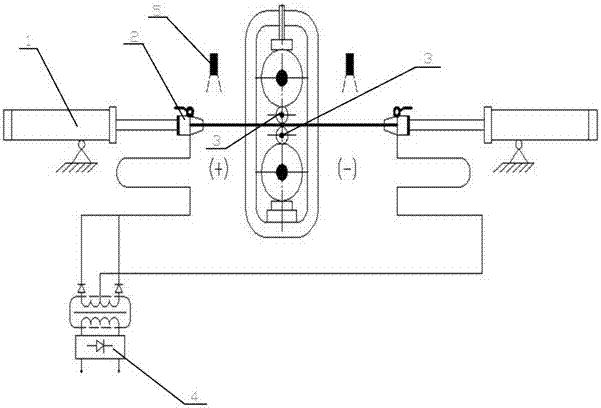

Device and method for producing high-frequency roll welding multilayer composite plate

The invention relates to a device and method for producing a high-frequency roll welding multilayer composite plate. The method comprises the following steps: feeding a strip coil into a corresponding uncoiling machine; performing tension control to ensure the flatness and favorable alignment of strips; feeding the strips into a conduction roll through a guide roll, and then performing on-line heating on the strips with high-frequency current, wherein the heating range is a loop from the conduction roll to the inlet of a guide and guard device, and the high-frequency current is introduced from the conduction roll to perform on-line quick heating on a shallow layer of the surface of the strips; when the strips reach a pinch roll, enabling that the strips are in contact with each other to achieve maximum heat, thus forming welding conditions; and welding the multiple layers of strips, then feeding into a rolling mill, and further rolling and compounding once to achieve optimal composite property of the different strips.

Owner:武汉钢铁有限公司

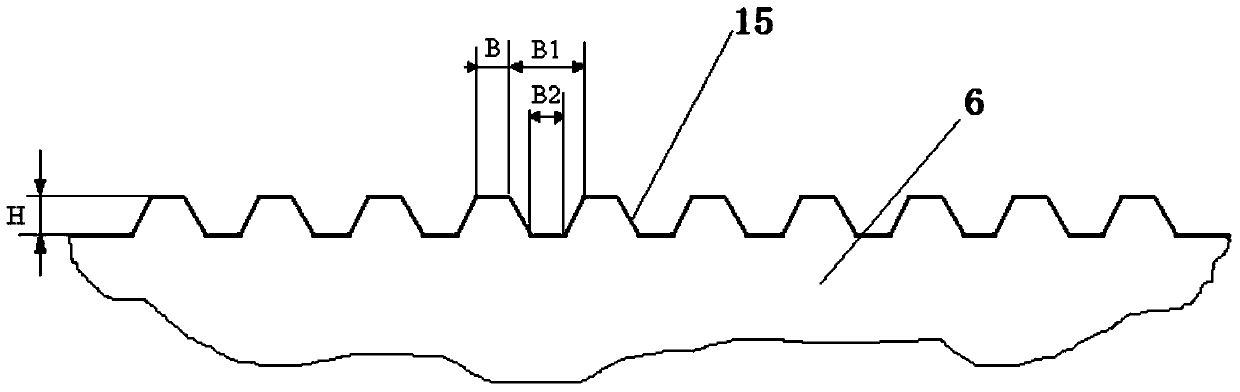

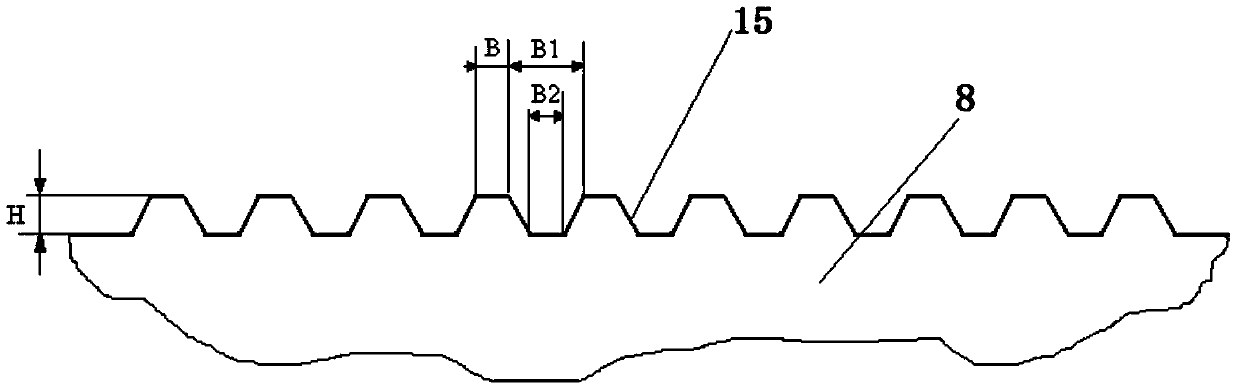

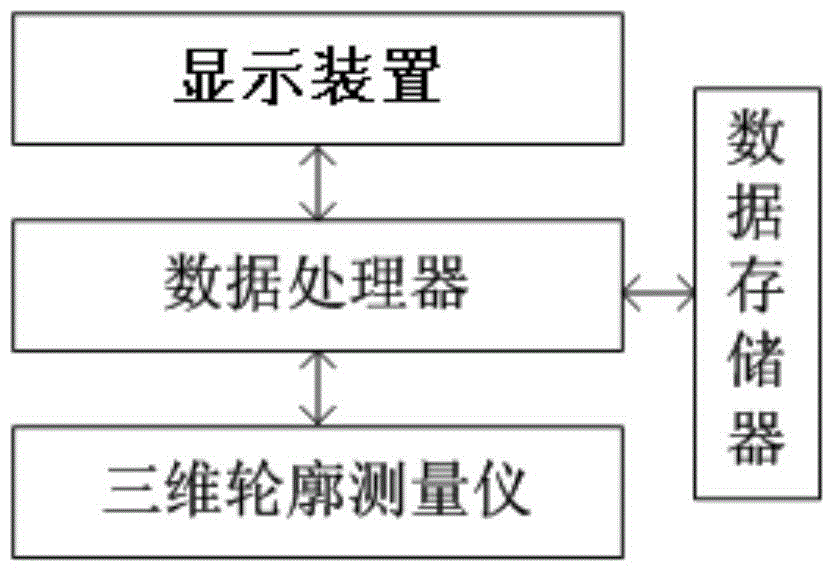

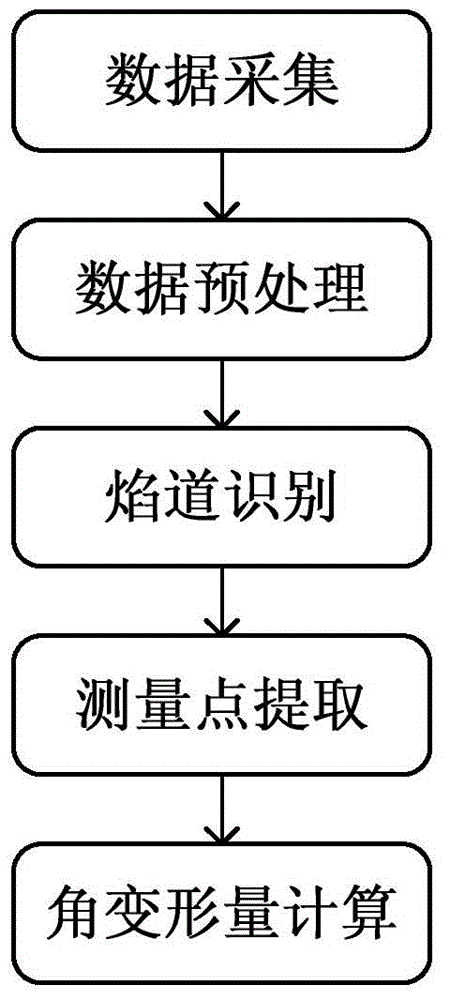

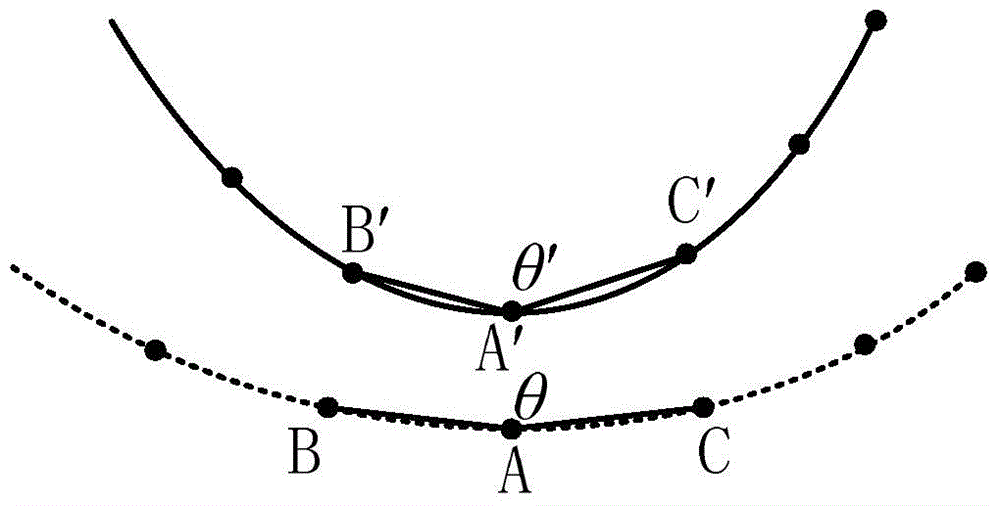

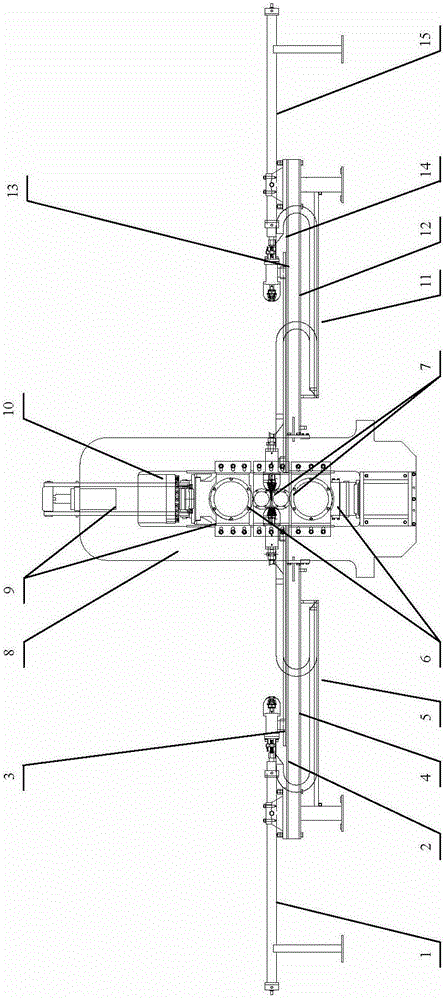

Measuring method and system of angular deformation for line heating and cooling

ActiveCN104359415AHigh measurement accuracyReduce labor costsImage analysisUsing optical meansPoint cloudDisplay device

The invention discloses a measuring method and system of angular deformation for line heating and cooling. A physical architecture used in the method comprises a display device, a data processor, a data storage and a three-dimensional profile measurer. The method is characterized in that three-dimensional point cloud data of a steel plate before and after line heating and cooling is processed, and angular deformation of a part near each flame path is calculated; specially, the method includes: target extraction of the point cloud data, denoising, data interpolation, flame path recognition, measuring point extraction and automatic calculation of angular deformation. Therefore, the measuring method and system has the advantages that automatic measurement of angular deformation of the flame path for line heating and cooling is provided, and basis for automatic correction of line heating and cooling process forecasting system is provided.

Owner:GUANGDONG UNIV OF TECH

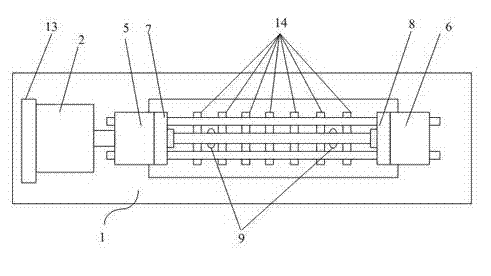

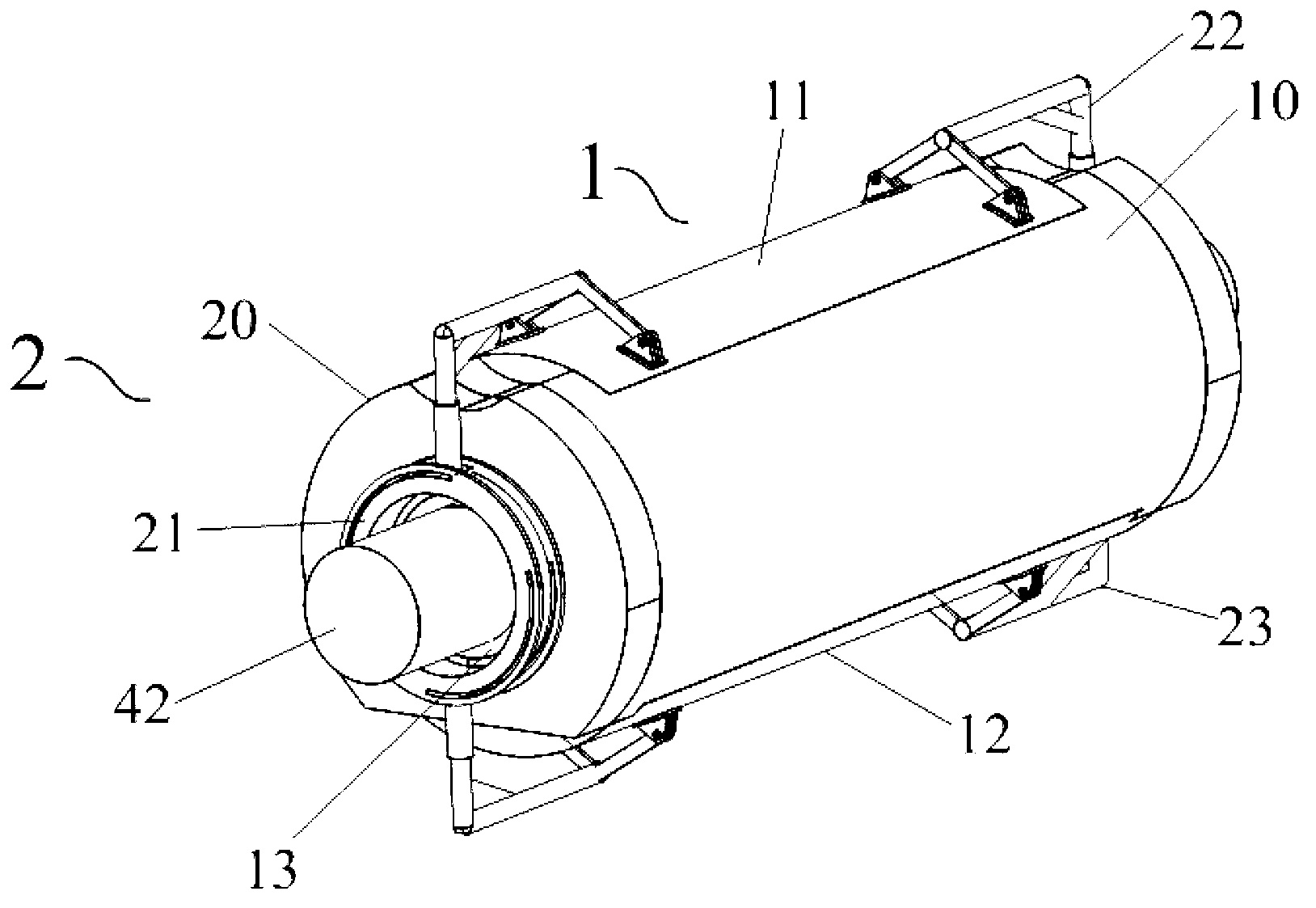

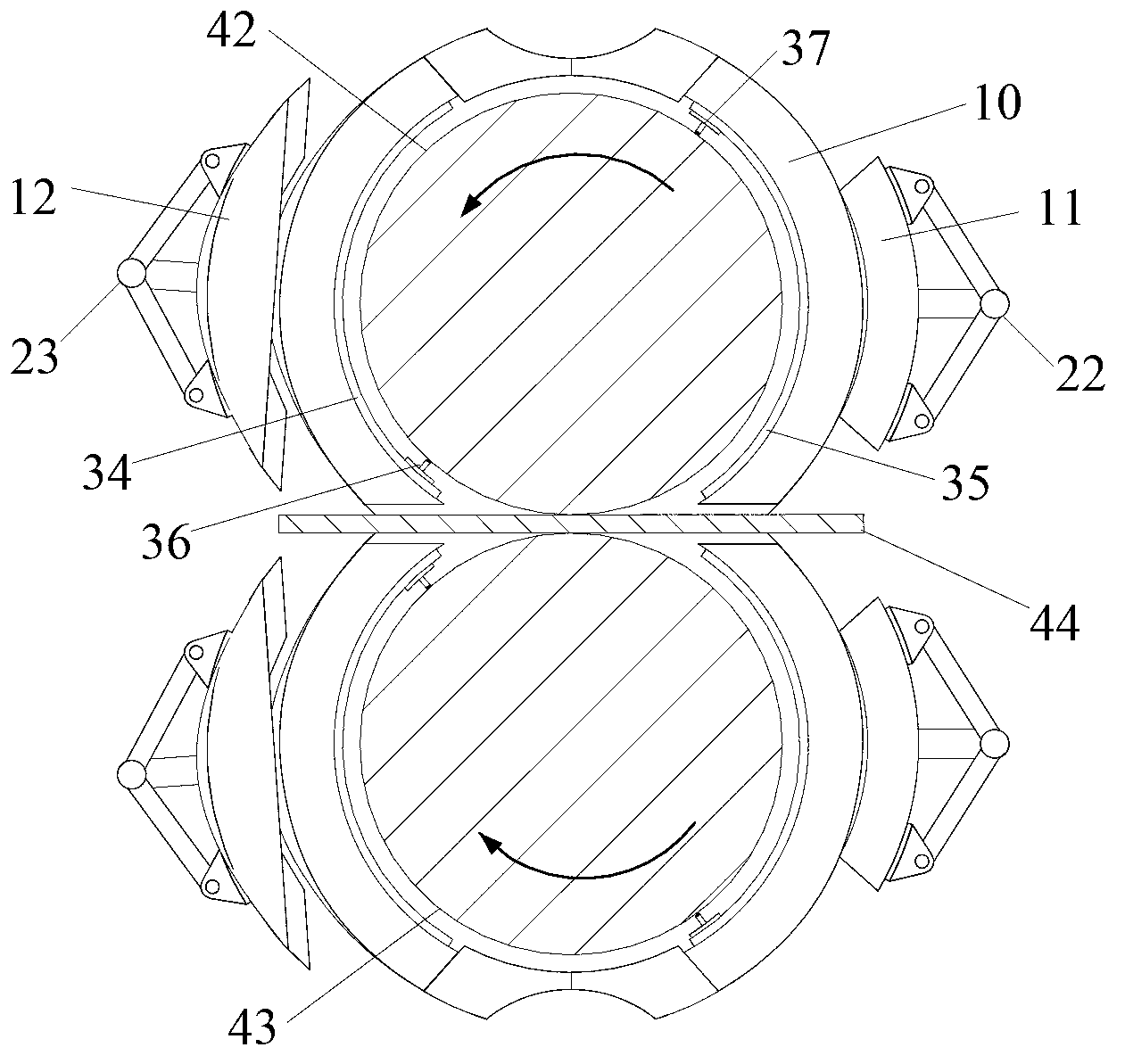

On-line heating device and heating method of magnesium alloy sheet warm rolling rollers

InactiveCN103240275AStrong reliabilityHeating fastRollsMetal rolling arrangementsTemperature controlThermal insulation

The invention discloses an on-line heating device and a heating method of magnesium alloy sheet warm rolling rollers. The on-line heating device is composed of a heating furnace, a positioning device and a temperature control module, the heating furnace is fixed on a rolling mill stand through the positioning device, and the temperature control module is used for detecting the temperature in the heating furnace and regulating heating power in real time. The heating method includes: firstly sealing preheating is performed on a working roller until the temperature on the surface of the working roller reaches a target value, and thermal insulation is performed; the heating device is positioned, and simultaneously all supporting rollers and the working roller are moved to the position where normal temperature rolling of magnesium alloy is performed; trial rolling is performed on magnesium alloy blanks to obtain the optimum temperature value; and finally normal rolling is started, and heating at the ideal temperature is achieved through feedback control. The structure of an existing roller does not need to be changed, and solid rollers with high rigidity and strong reliability can be used; a scheme that normal heating is performed after sealing preheating is adopted to achieve rapid heating of the rollers; and a temperature control strategy with double-target temperature is adopted to obtain the ideal roller surface temperature.

Owner:JILIN UNIV

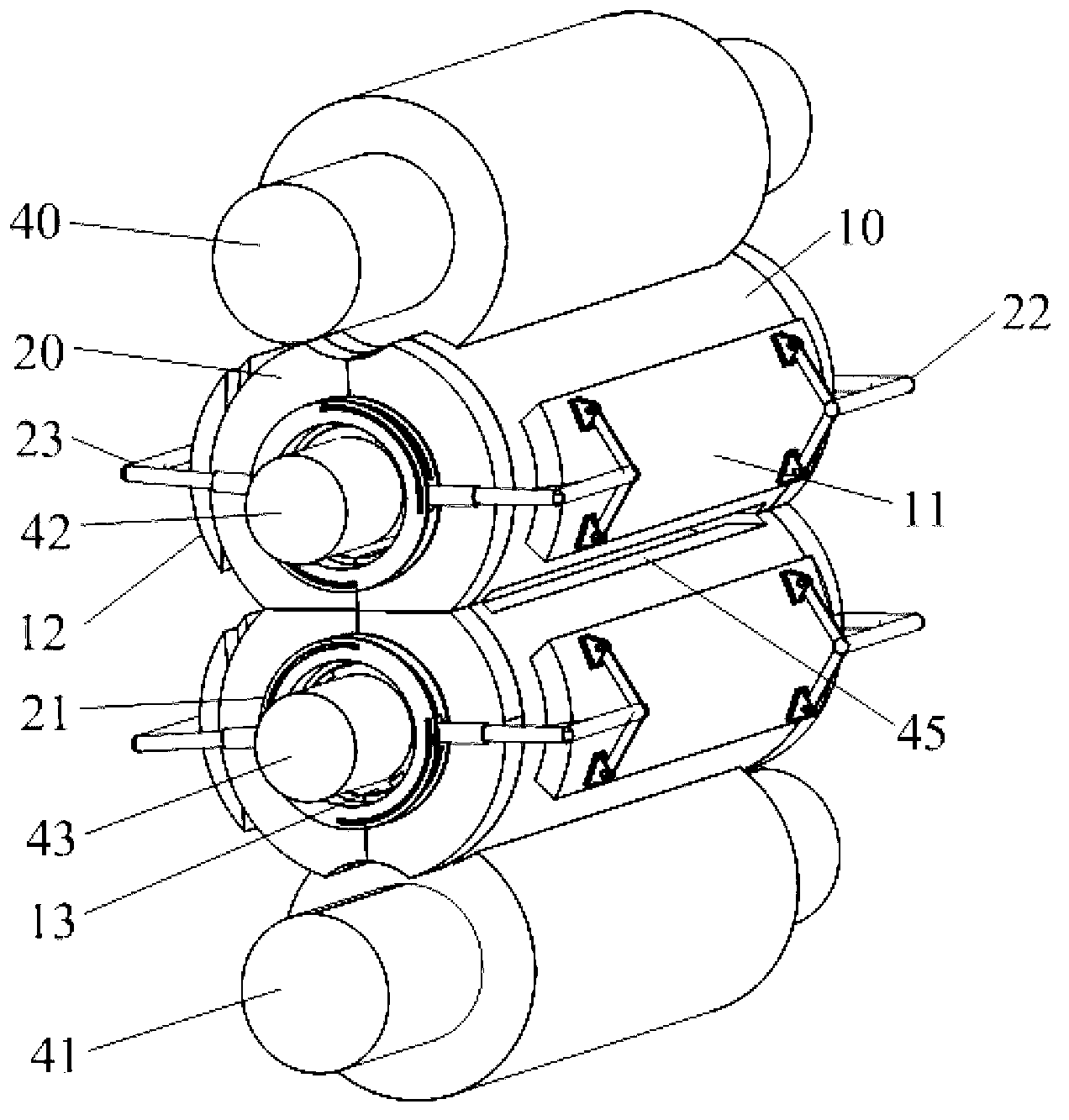

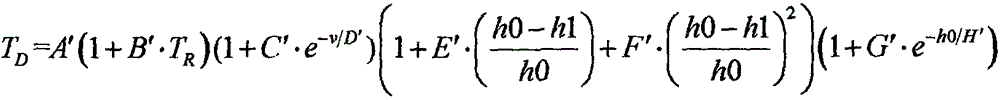

Hot roller heating and rolling device and method for magnesium alloy strips

ActiveCN105521996AAchieve large strain continuous rollingImprove thermal conductivityTemperature control deviceRollsLine heatingRolling mill

The invention discloses a hot roller heating and rolling device and method for magnesium alloy strips. The device comprises a conveying roller way, one or more rolling mill stands, one or more rollers, a first infrared thermometer, a second infrared thermometer, induction coils, a PLC and a rolling parameter operation table, wherein the conveying roller way is composed of one or more conveying rollers, and the magnesium alloy strips are arranged between the rollers; in the rolling process of the magnesium alloy strips, the rollers transfer heat to rolled pieces for realizing the on-line heating and rolling technology of magnesium alloy on the basis that the magnesium alloy has the advantages that the heat conduction coefficient is high, heat transfer is fast and the high-frequency induction heating efficiency is high, the outlet temperature of the rolled pieces can be accurately controlled by controlling the surface induction heating temperature of the rollers, heating and rolling can be carried out on normal-temperature strips, temperature compensating and rolling can be carried out on hot strips, the temperature drop rate of the strips in the rolling process can be lowered, the occurrence probability of edge cracks can be lowered, and the quality of finished products can be improved.

Owner:NORTHEASTERN UNIV

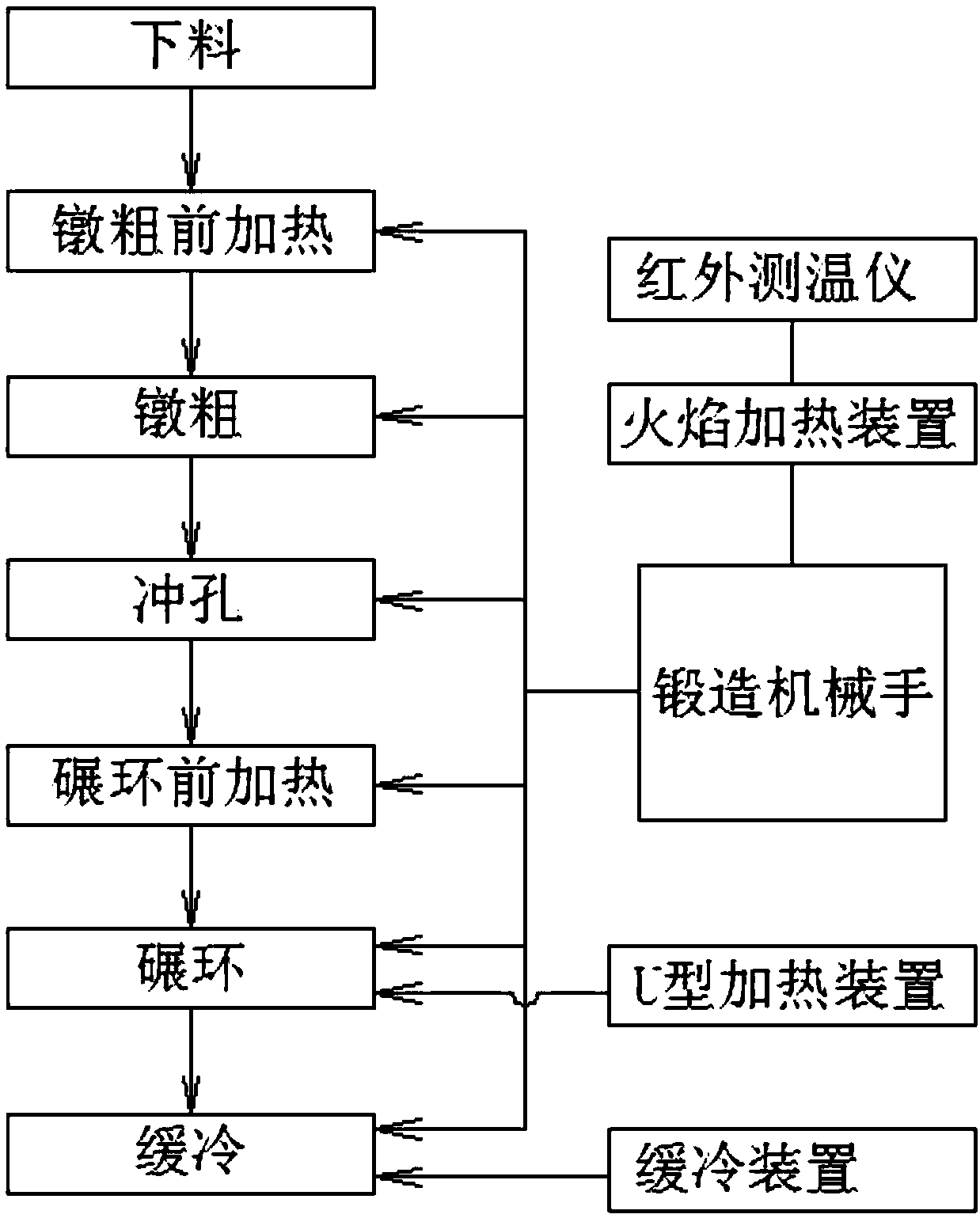

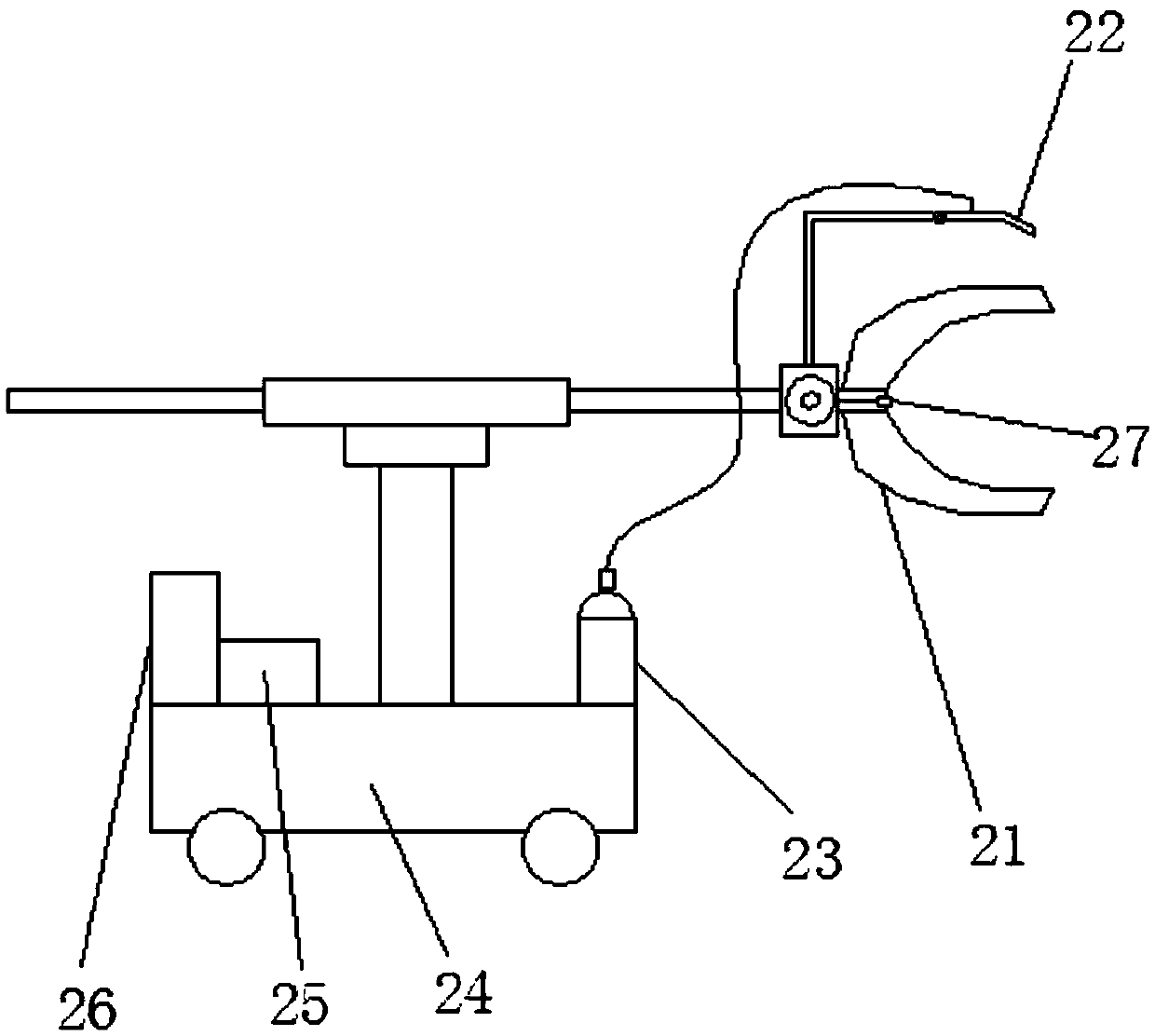

Forging process and equipment for high-temperature-resistant and high-pressure-resistant stainless steel ring

InactiveCN109590417ARealize the heating effectRealize the insulation effectPiercing pressesHeating/cooling devicesPunchingForging manipulator

The invention relates to the technical field of forging and discloses forging process and equipment for a high-temperature-resistant and high-pressure-resistant stainless steel ring. The forging process comprises the following process steps of step 10, blanking, step 20, heating before upsetting, step 30, upsetting, step 40, punching, step 50, heating before ring milling, step 60, ring milling andstep 70, slow cooling. The stainless steel ring is transferred in each forging workstage and between workstages by using a forging manipulator, the front end of the forging manipulator is provided with an infrared thermometer for online measuring of the temperature of a blank and a flame heating device for online heating and heat preservation of the blank, and the forging manipulator turns on theflame heating device in the process of transferring the blank to carry out heating and heat preservation on the blank of the stainless steel ring. By the adoption of the forging process and equipment, good control over the temperature of the blank of the stainless steel ring in the forging process is realized, so that the forging quality is improved, and the forging energy consumption is reduced.

Owner:JIANGYIN HENGRUN RING FORGING

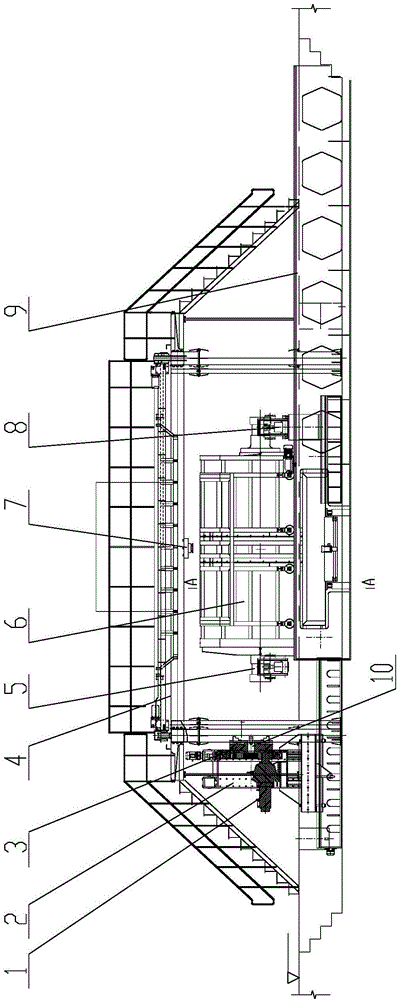

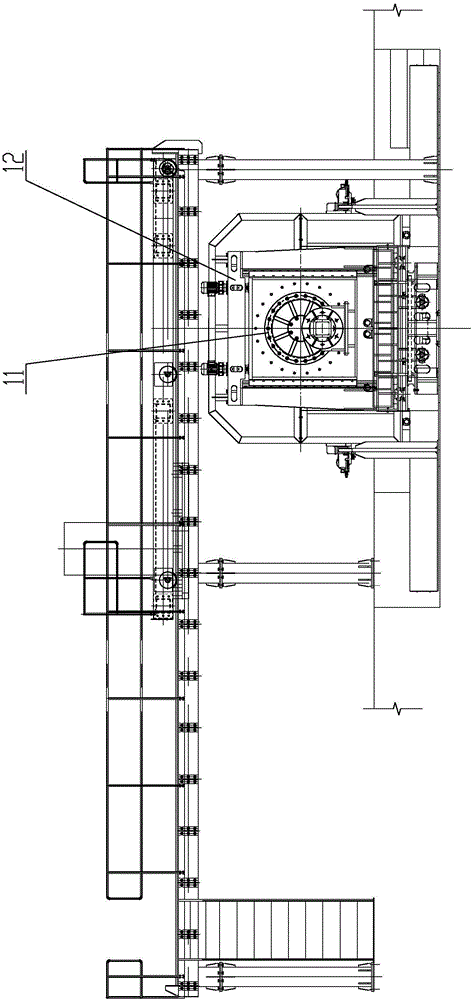

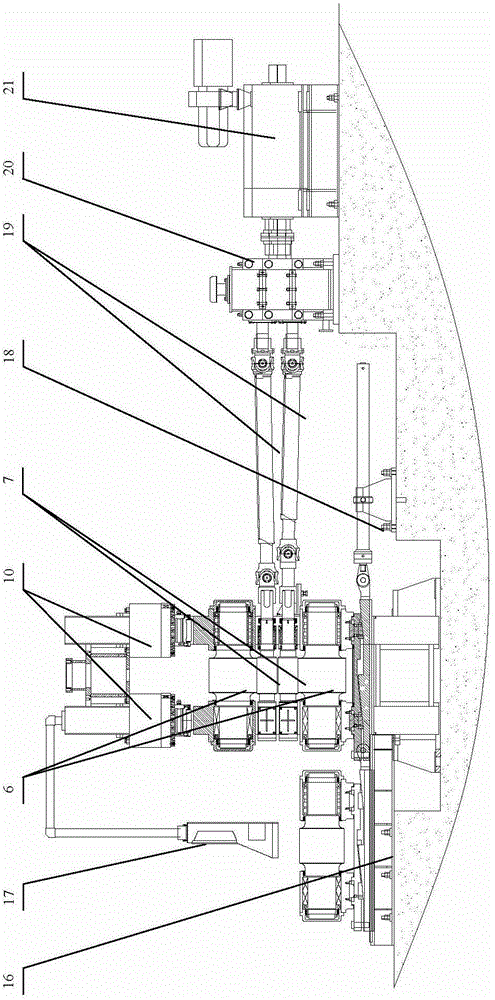

Large support roller overlaying workstation and operation method thereof

ActiveCN106141375ASmooth rotationAvoid affecting the quality of surfacingWelding/cutting auxillary devicesArc welding apparatusTemperature controlInsulation layer

The invention relates to a large support roller overlaying workstation and an operation method thereof. The large support roller overlaying workstation comprises a roller support device, a roller driving device, an online heating system, a welding system and a flux recovery system; a support roller is supported and positioned by the roller support device, and can be driven by the roller driving device to rotate; a door type heating cover of the online heating system covers the support roller to form a closed cover body; an insulation layer and an induction electric heating device are arranged on the inner wall of the cover body; a welding gun can vertically move to extend into the door type heating cover body; and the flux recovery system is arranged at the bottom of the door type heating cover. The support roller is heated and insulated in the closed cover body; multiple sets of welding mechanisms can synchronously perform welding; a flux can be automatically recovered; the continuous process of the large support roller as online preheating, welding, insulation and tempering can be realized; and the large support roller overlaying workstation is convenient for operation, high in automation degree and precise in temperature control, facilitates improvement of the overlaying quality of the support roller, improves the repair efficiency, and fills the blank of the technology.

Owner:辽宁天利再造科技股份有限公司

Fluid heating system for a cleaning device

Owner:RPS ,

Automatic analyser for volatile phenolic compound in water

The invention relates to an automatic analyser for volatile phenolic compound in water, which comprises a sample pretreatment device and a developing detection device, wherein the sample pretreatment device comprises an automatic sampling device and a first peristaltic pump; the first peristaltic pump is provided with a first pump pipe, a second pump pipe and a third pump pipe; a sampling needle of the automatic sampling device is connected to a first tee joint through the first pump pipe; the first tee joint is connected to a container bottle of distillation reagent through the second pump pipe; the first tee joint is connected to a first knotted reactor; and the first knotted reactor is sequentially connected to an on-line heating module, an on-line distilling module, an on-line condensation module, the third pump pipe, a second knotted reactor, an on-line degasser and an F port of a multi-ported valve with at least six ports. The automatic analyser can be used for continuously and automatically testing the sample accurately and quickly.

Owner:BEIJING JITIAN INSTR CO LTD

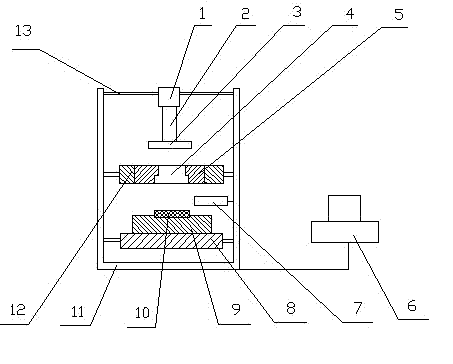

Micro-device warm extrusion molding method and device based on laser heating

InactiveCN101077507AAccurate temperatureGood formabilityExtrusion diesExtrusion control devicesManufacturing technologyEngineering

The present invention relates to micro plastic forming technology and micro device manufacturing technology, and is especially micro device warm extruding process and apparatus based on laser heating. Long pulse infrared laser beam is applied onto quasi-static micro blank, so that the micro blank has temperature distribution suitable for micro warm extrusion. The warm extruding apparatus includes a heating laser system, an extruding mold, a pressure applying mechanism, a feeding mechanism, a 3D precise worktable, a support and a control system. The present invention realizes feeding and extruding by means of combining ultra magnetostriction micro displacement actuator and step motor, constant temperature heating mold with electric heating rod and temperature control module, and centering with 3D micro platform and image treating device, and controlling with the control system. The present invention has high forming performance.

Owner:JIANGSU UNIV

Rolling method of magnesium alloy ultra-thin sheet

InactiveCN107030112AImprove mechanical propertiesRoll force/gap control deviceTemperature control deviceLine heatingMechanical property

The invention discloses a rolling method of a magnesium alloy ultra-thin sheet. The rolling method of the magnesium alloy ultra-thin sheet is characterized by comprising the following steps: A, clamping two ends of a magnesium alloy sheet to be rolled and making the magnesium alloy sheet generate tension; B, heating the magnesium alloy sheet; C, carrying out first pass rolling on the magnesium alloy sheet by a rolling roll; and D, repeating the step B and the step C, till the magnesium alloy sheet is rolled to reach a preset thickness. With adoption of the rolling method of the magnesium alloy ultra-thin sheet having the steps, on-line heating and rolling are carried out on the magnesium alloy sheet and finally the magnesium alloy sheet is rolled into an ultra-thin sheet of 0.8 mm, and the rolling temperature, rolling speed, percentage pass reduction and applied tension of each pass are all constantly changed. The magnesium alloy ultra-thin sheet has higher mechanical property.

Owner:CHONGQING ACADEMY OF SCI & TECH

Hydraulic tension warm-rolling machine

InactiveCN104148386ARealize the purpose of warm rolling with tensionRealize industrial productionTemperature control deviceTension/compression control deviceMetal stripsLoop control

The invention discloses a hydraulic tension warm-rolling machine which comprises a four-roller reversible mill, tension devices distributed on the two sides of the four-roller reversible mill, a sample heating device, a hydraulic system and an electric control system. According to the hydraulic tension warm-rolling machine, the tension devices are used for exerting tension on samples, the samples are heated online in a resistance heating mode, through a power adjustment control unit and closed-loop control over the heating temperature, different metal strips which are not prone to deformation at normal temperature can be subjected to strip tension rolling experiments within the temperature range from indoor temperature to 800 DEG C, and technical conditions are created for developing different warm-rolling technologies and industrially producing metal thin strips which are not prone to deformation at normal temperature; the samples are single metal strips, compared with a traditional winding type rolling mill, experiment materials can be saved, and experiment cost is lowered.

Owner:NORTHEASTERN UNIV

Apparatus, system, and method for reductant line heating control

ActiveCN102575551AInternal combustion piston enginesExhaust apparatusNuclear engineeringLine heating

In one embodiment, an apparatus is disclosed for heating a reductant delivery line (180) using coolant from an internal combustion engine (110) where the reductant delivery line receives reductant (200) from a reductant tank (166) and a portion (210) of a coolant line (192) is positioned within the reductant tank. The apparatus includes a coolant temperature module (300) that is configured to determine a reductant tank outlet coolant temperature target (310). Additionally, the apparatus includes a coolant flow rate module (320) that is configured to generate a coolant valve flow rate command (340) and transmit the command to a coolant valve (196). The coolant valve is controllable to regulate the flow rate of coolant through the coolant line. The coolant valve flow rate command is based on the reductant tank outlet coolant temperature target, a reductant tank inlet coolant temperature (325), and a reductant tank reductant temperature (330).

Owner:CUMMINS INTPROP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com