Micro-device warm extrusion molding method and device based on laser heating

A laser heating and warm extrusion technology, applied in metal extrusion, metal extrusion dies, metal extrusion control equipment, etc., can solve the limitations of forming materials and processes, large resistance to cold extrusion deformation, and unstable process parameters and other problems, to achieve the effect of accurate and convenient control, precise control of thermal action, and reduction of deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

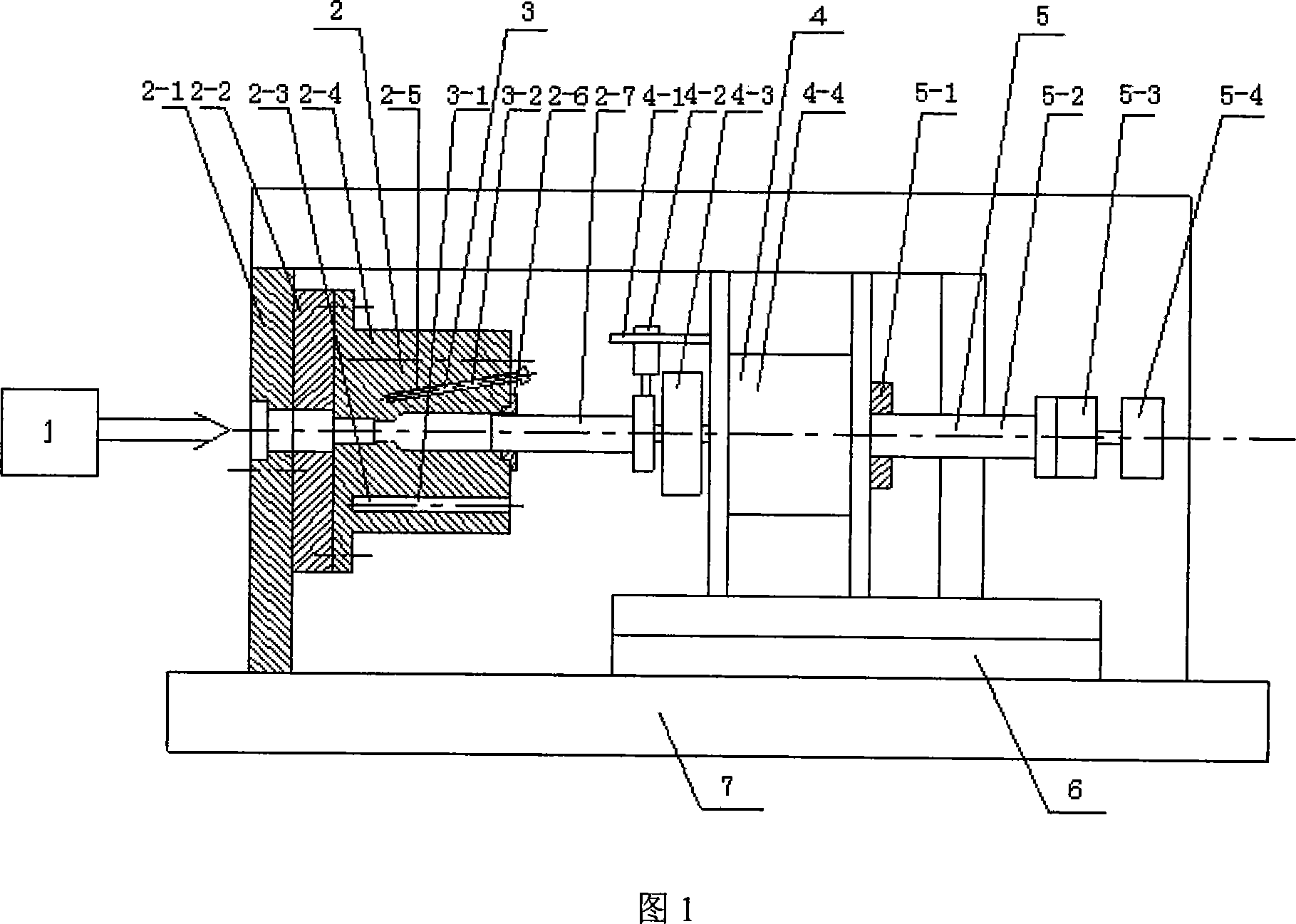

[0036] With reference to Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5, the entire device consists of a laser heating system 1, an extrusion die 2, a pressure applying mechanism 4, a feeding mechanism 5, a three-dimensional precision workbench 6, a support 7 and a control system composition.

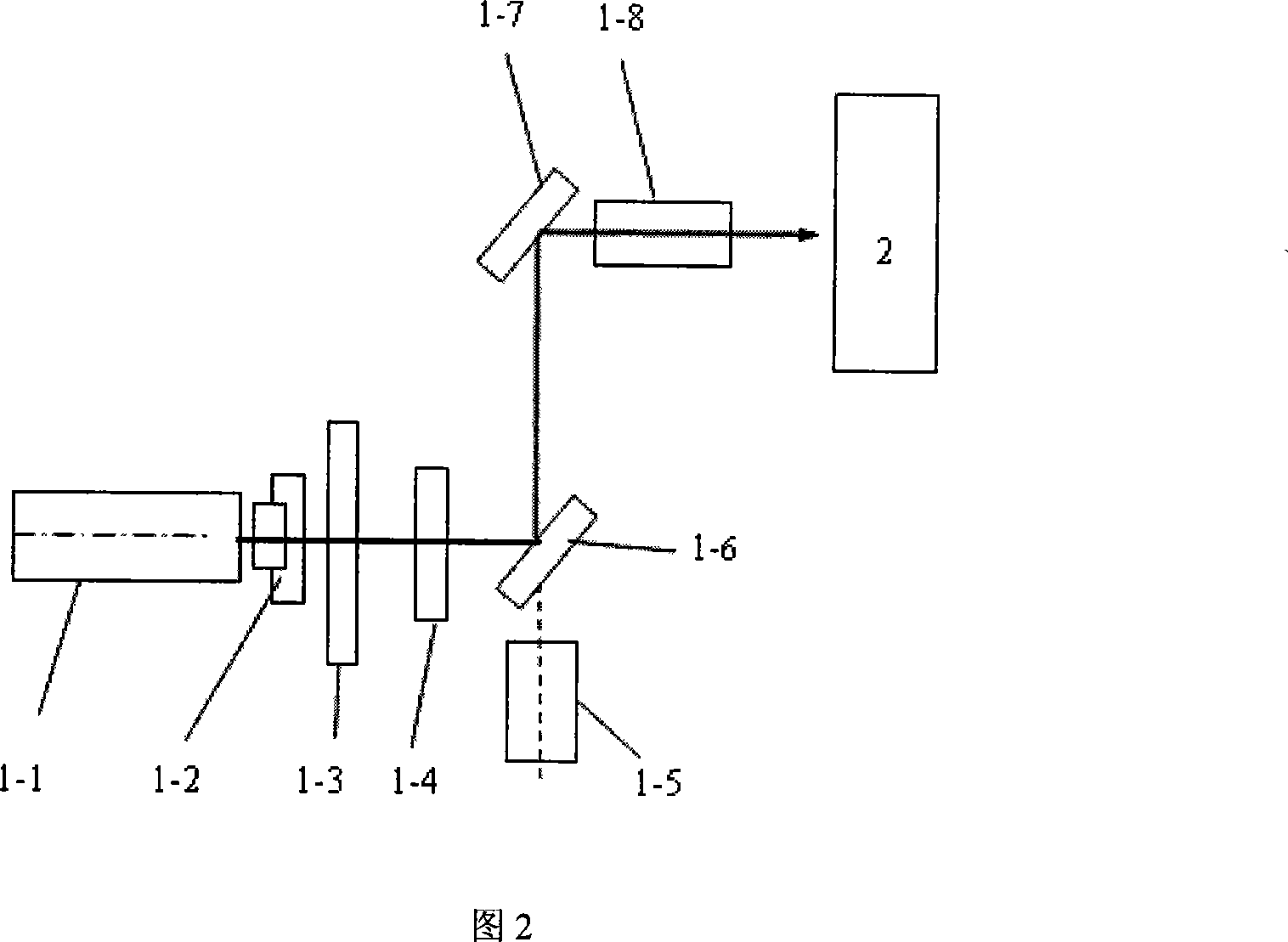

[0037] Figure 2 shows the laser heating system, the long-pulse infrared laser 1-1 passes through the expander 1-2, the adjustable diaphragm 1-3, the collimator 1-4, the light guide system 1-5, and the mirror 1-6 , 1-7, and short-focus objective lens 1-8, etc., the incident laser beam optical path system directly irradiates the blank, and uses the laser beam to perform quasi-static non-contact heating on the blank, and the laser beam forms a certain temperature distribution and gradient on the surface and inside of the blank , by changing the laser parameters such as laser pulse width, energy, beam diameter, and repetition frequency to adjust the temperature boundary conditions, so ...

specific Embodiment approach 2

[0045] If the dimensions of the blank to be formed are close to the diameter of the spot, or there is no special requirement for the temperature range of warm extrusion, because the heat loss is less in a short period of time, the mold temperature control component in the micro-temperature extrusion device based on laser heating 3. Electric heating Rod 3-1, thermocouple 3-2, PID feedback control circuit 3-3, thyristor 3-4, AC power supply 3-5, temperature controller 3-6 and control pole 3-7 can be omitted . The blank is directly heated by the laser heating system, and then the feed system 5 is used to feed the punch 2-7 in a short time. The combination of the loading system 4 and the feed system 5 realizes the extrusion action of the micro blank. The heat loss is very small, and micro-extrusion between room temperature and the recrystallization temperature of the material can be accomplished.

[0046] In summary, the laser heating-based warm extrusion forming method and devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com