Patents

Literature

795 results about "Laser heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser processing for heat-sensitive mesoscale deposition

InactiveUS7294366B2Low damage thresholdElectric discharge heatingRadiation applicationsLaser processingHeat sensitive

A method of depositing various materials onto heat-sensitive targets. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts.

Owner:OPTOMEC DESIGN CO

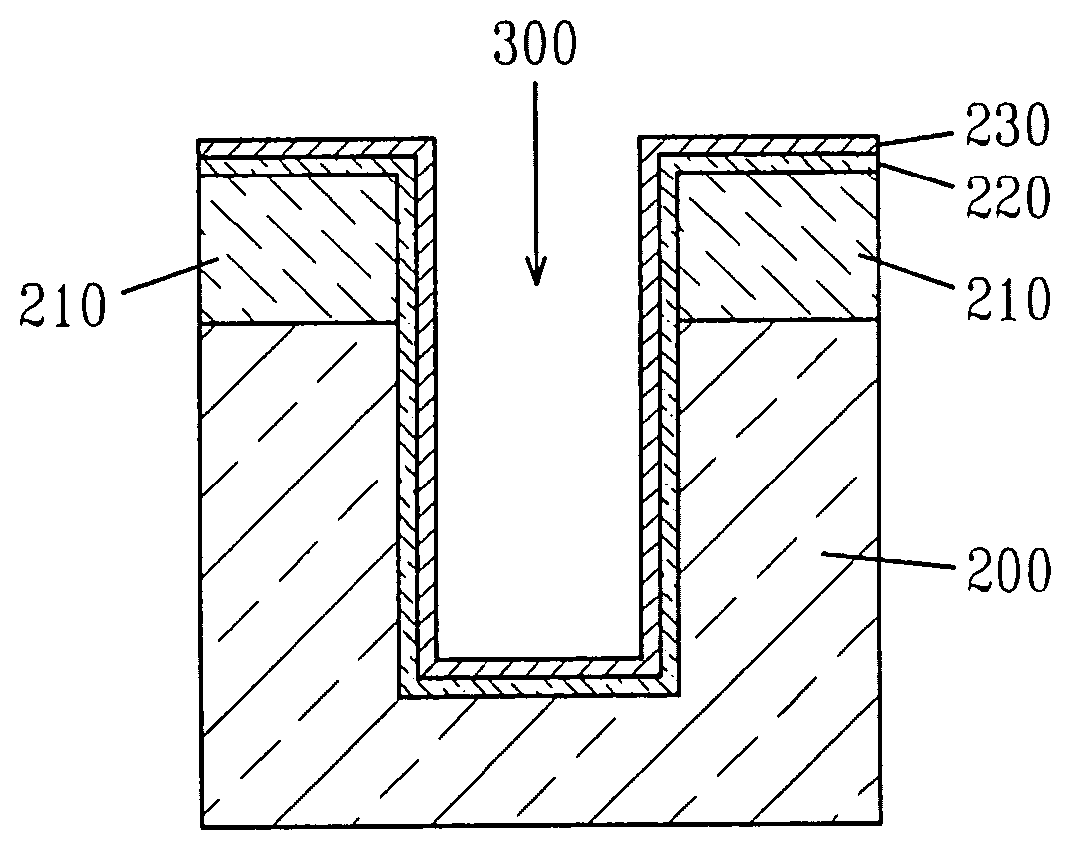

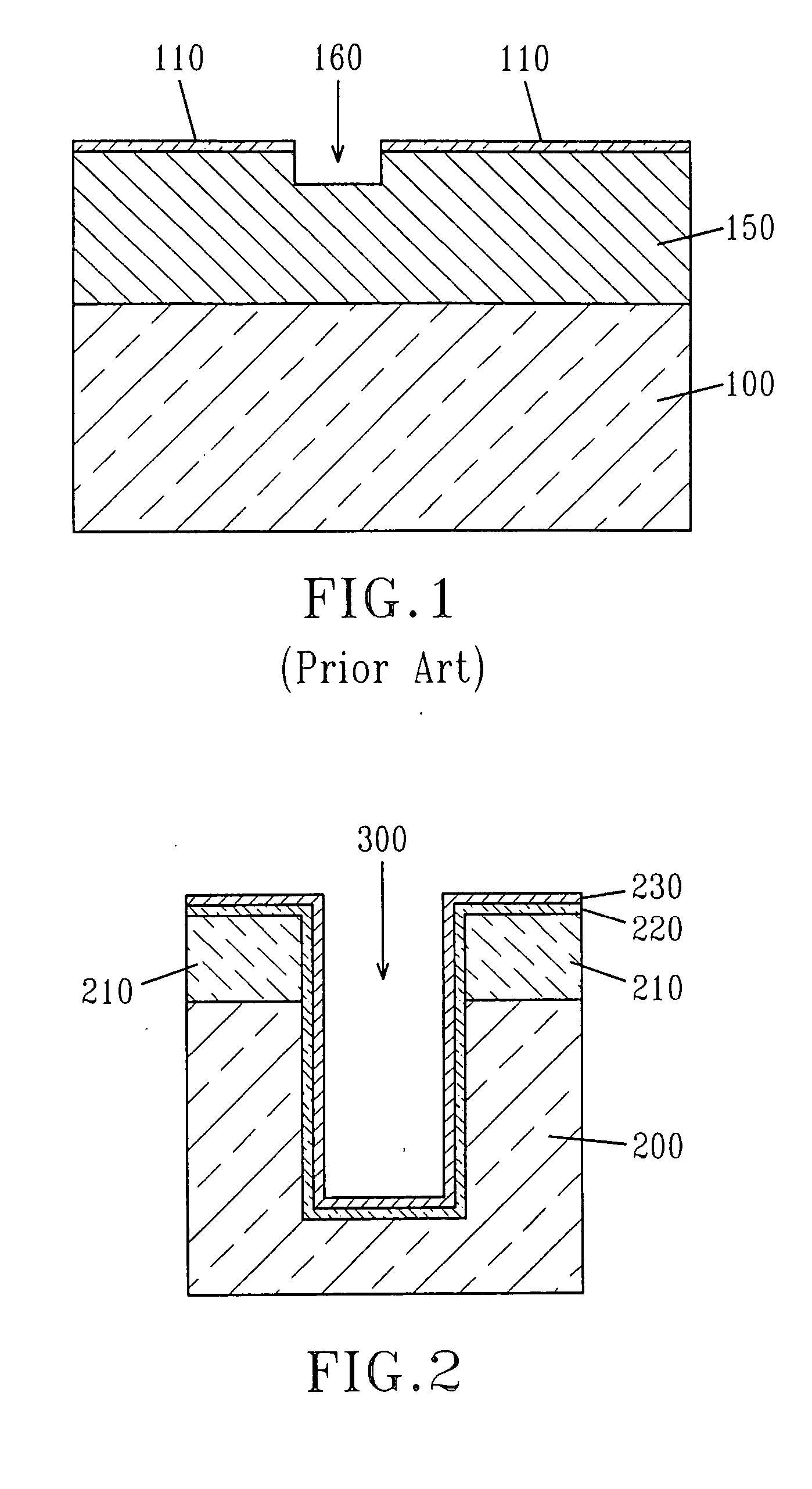

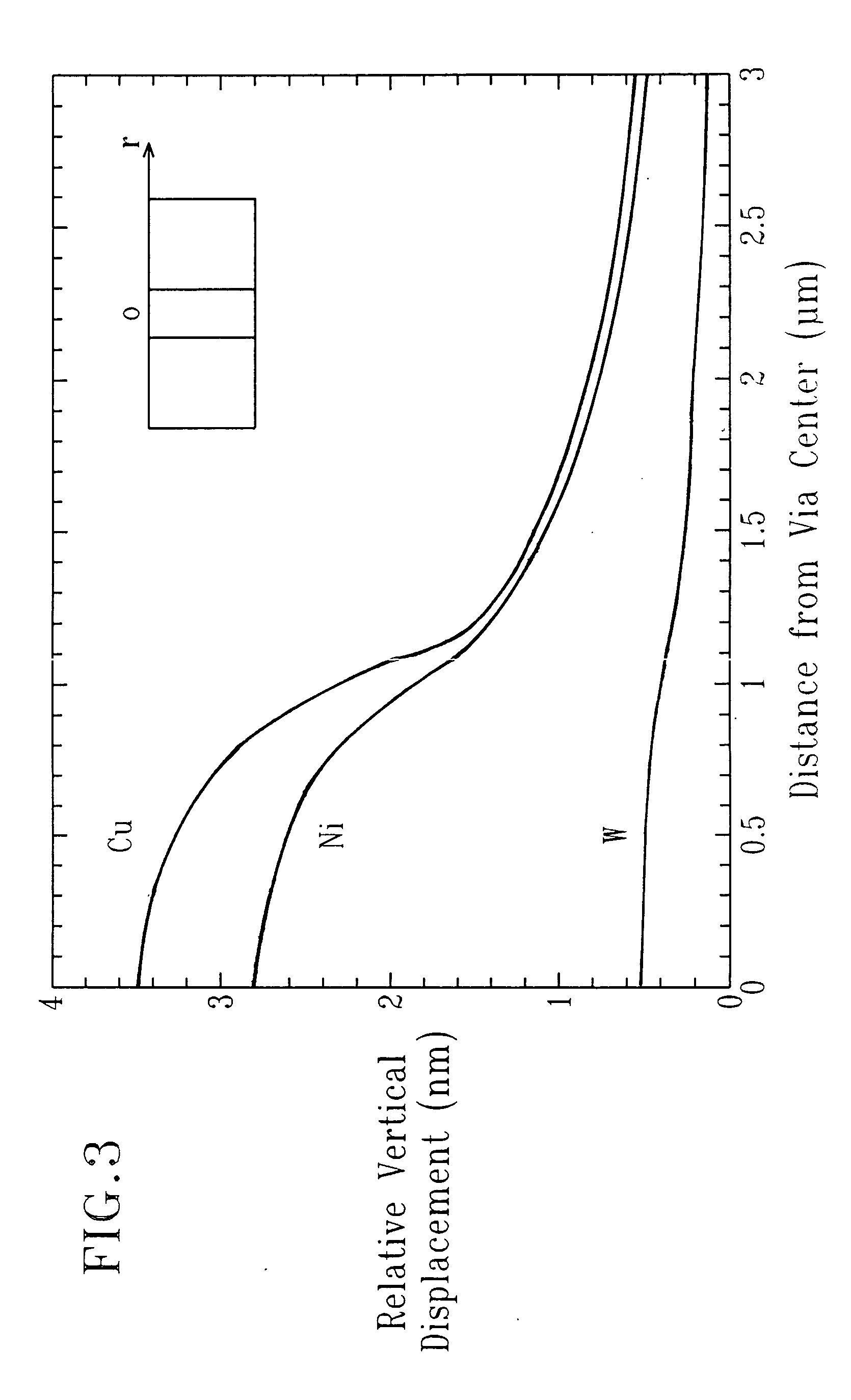

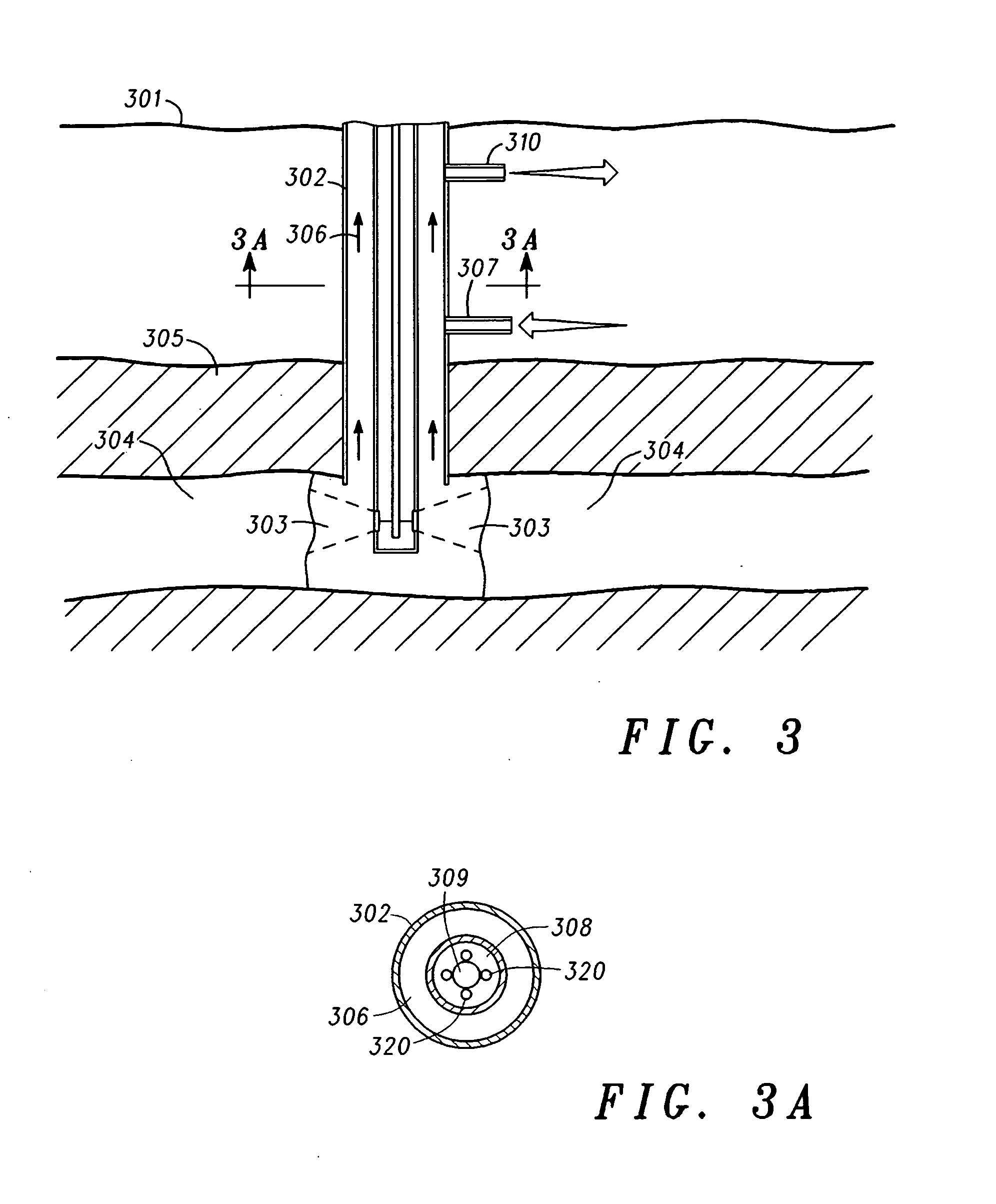

Silicon chip carrier with through-vias using laser assisted chemical vapor deposition of conductor

ActiveUS20050082676A1High aspect ratioSemiconductor/solid-state device detailsSolid-state devicesControl mannerGas phase

This disclosure teaches a method of filling deep vias or capping deep conducting paste filled vias in silicon or glass substrate using laser assisted chemical vapor deposition of metals. This method uses a continuous wave or pulsed laser to heat the via bottom and the growing metal fill selectively by selecting the laser wavelength such that silicon and / or glass do not absorb the energy of the laser in any appreciable manner to cause deposition in the field. Alternatively holographic mask or an array of micro lenses may be used to focus the laser beams to the vias to fill them with metal. The substrate is moved in a controlled manner in the z-direction away from the laser at about the rate of deposition thus causing the laser heating to be focused on the surface region of the growing metal fill.

Owner:ELPIS TECH INC

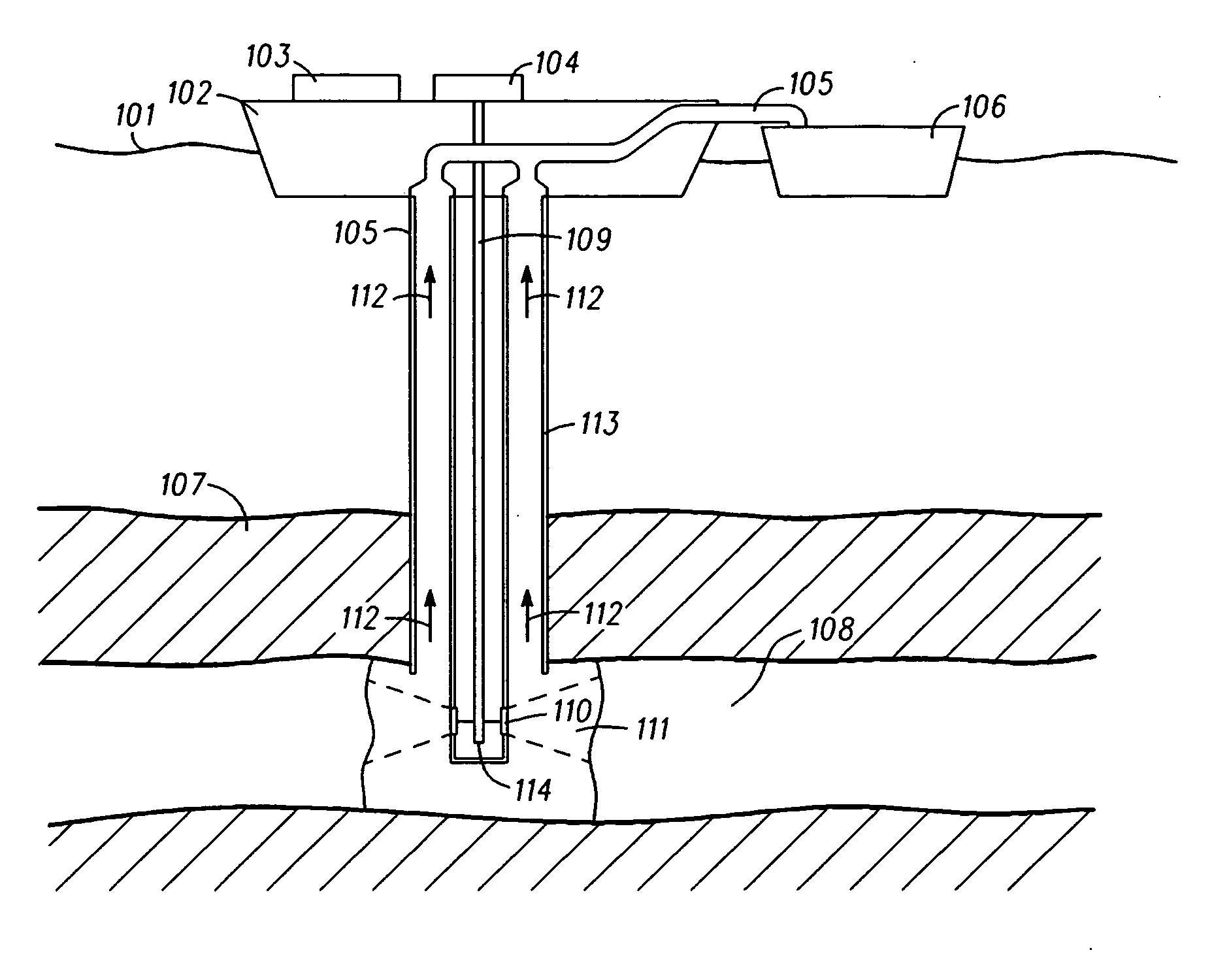

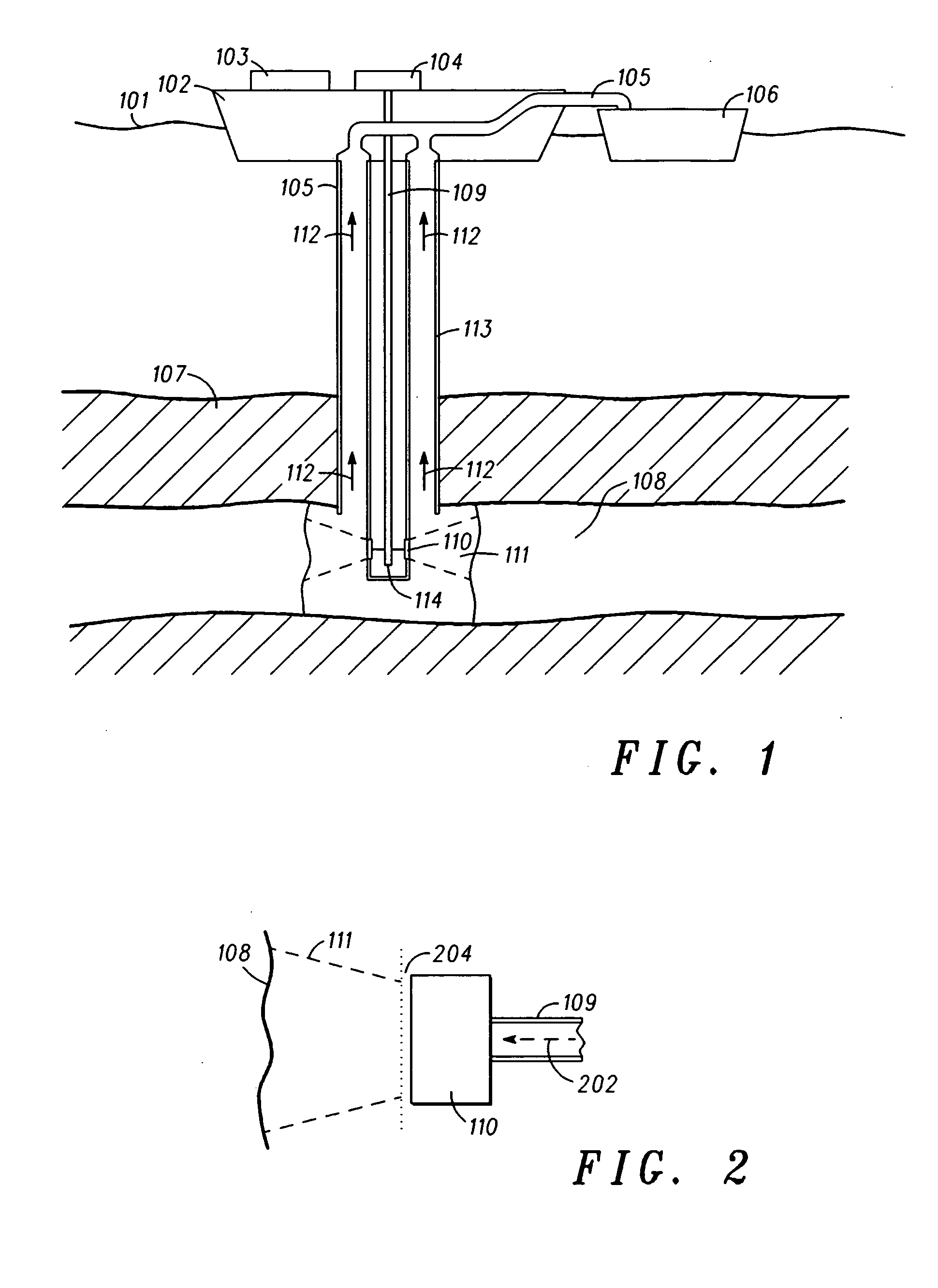

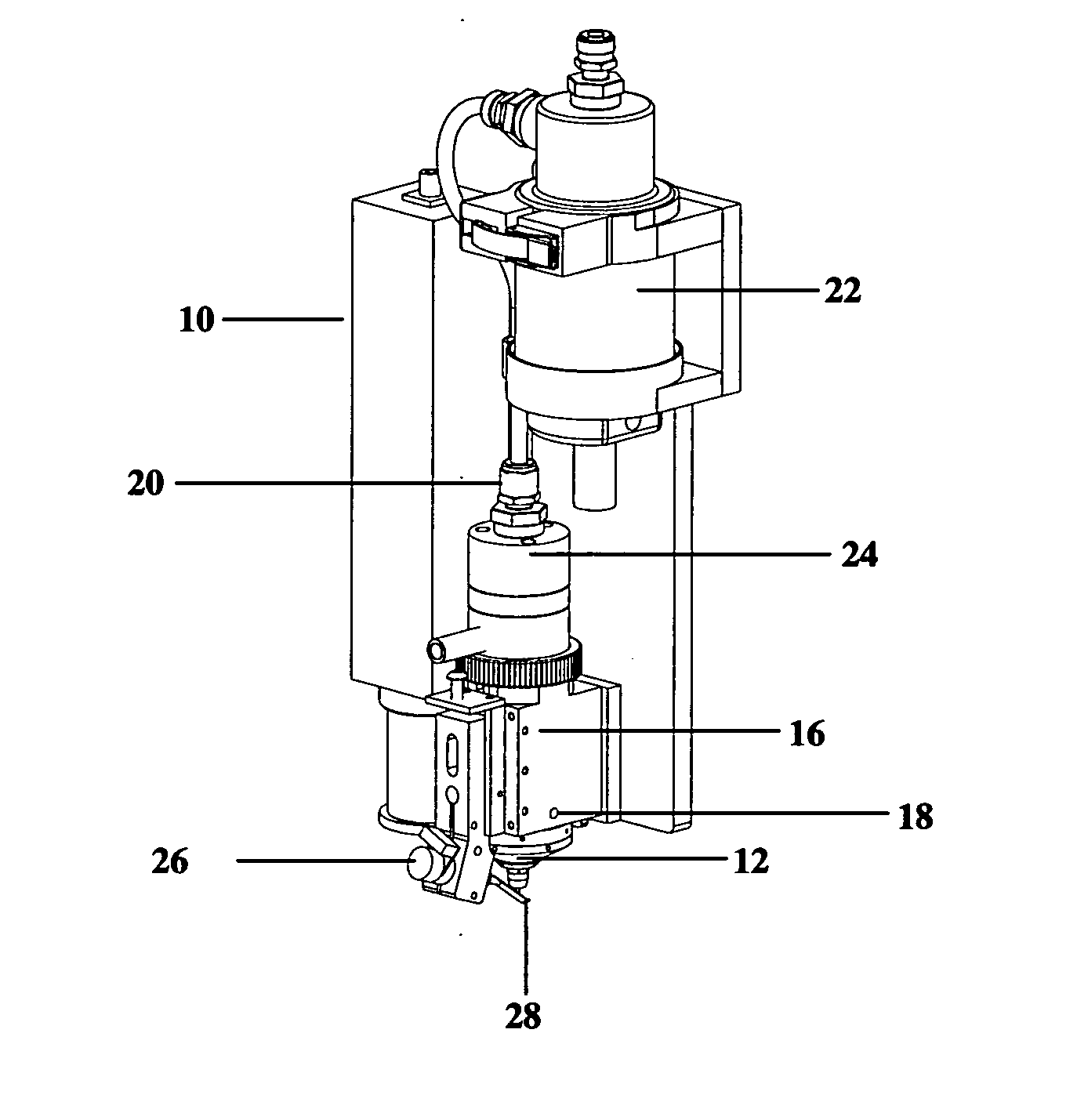

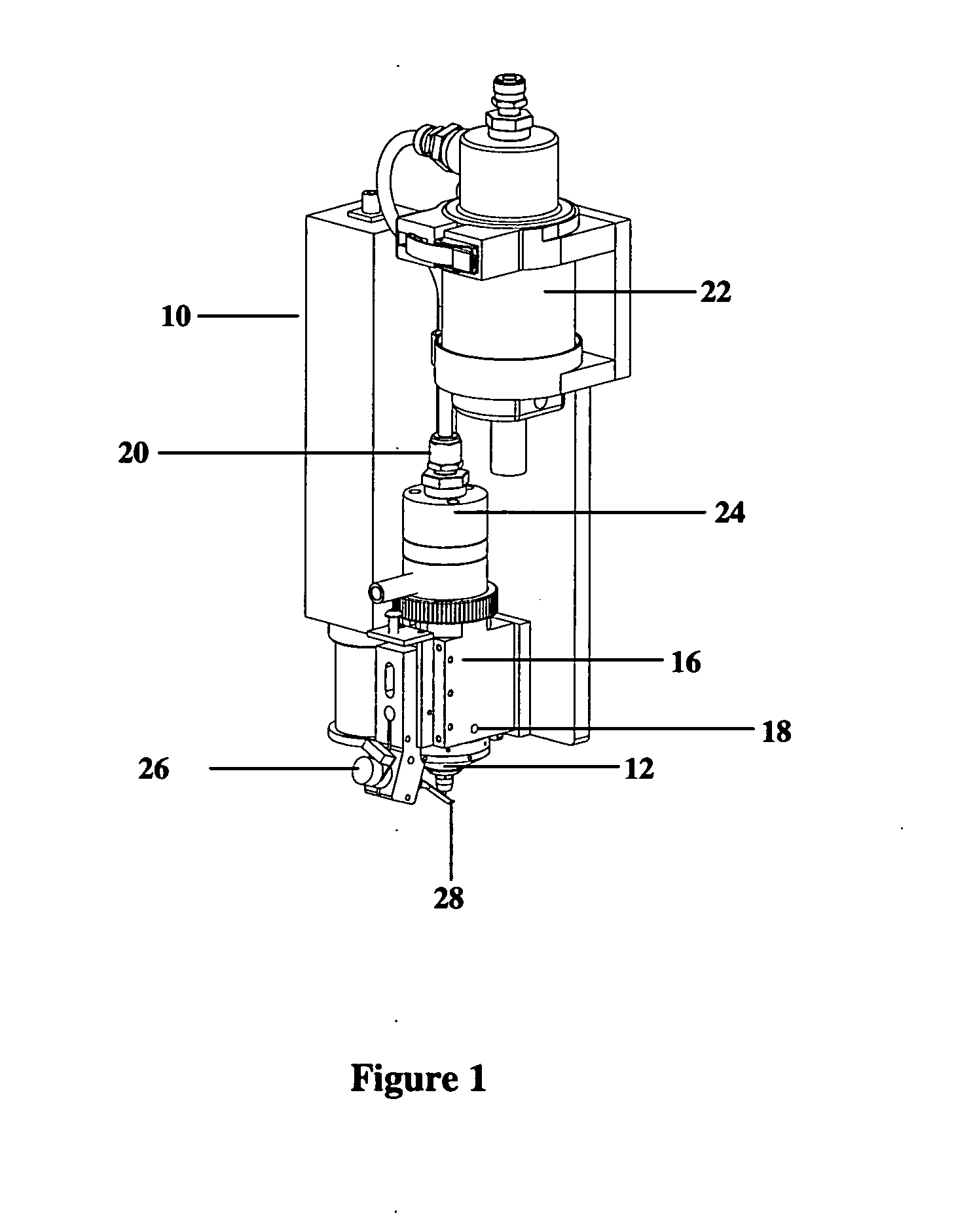

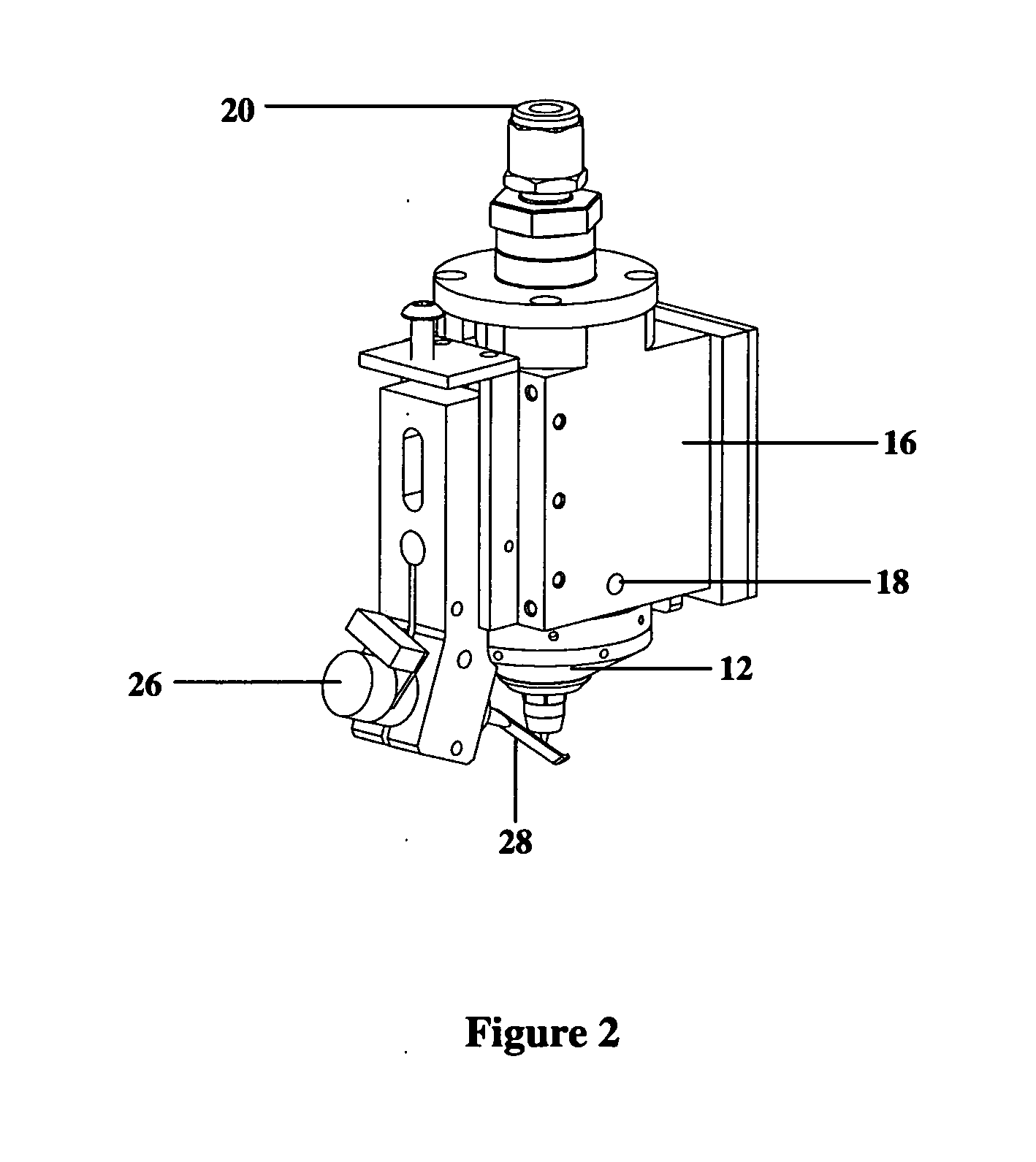

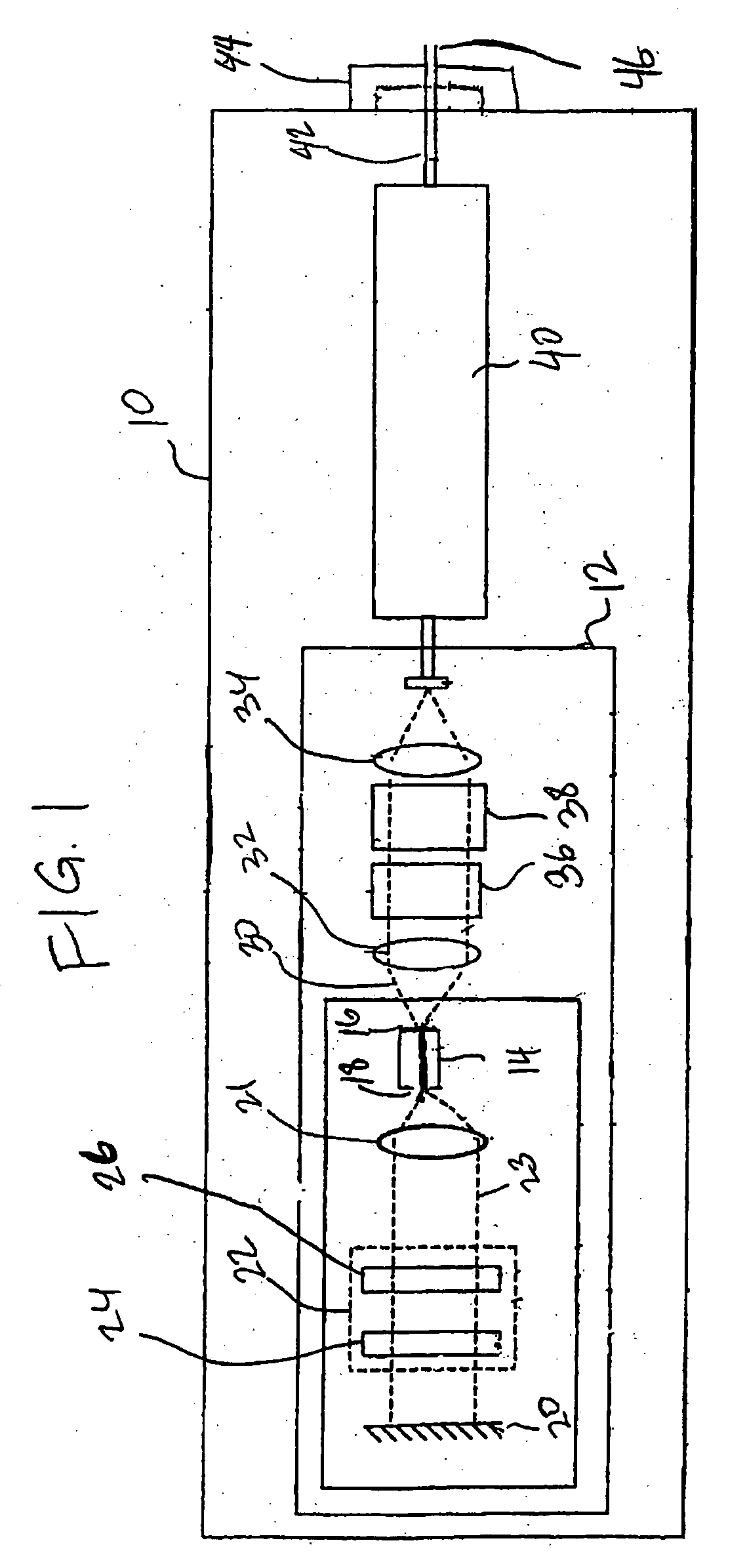

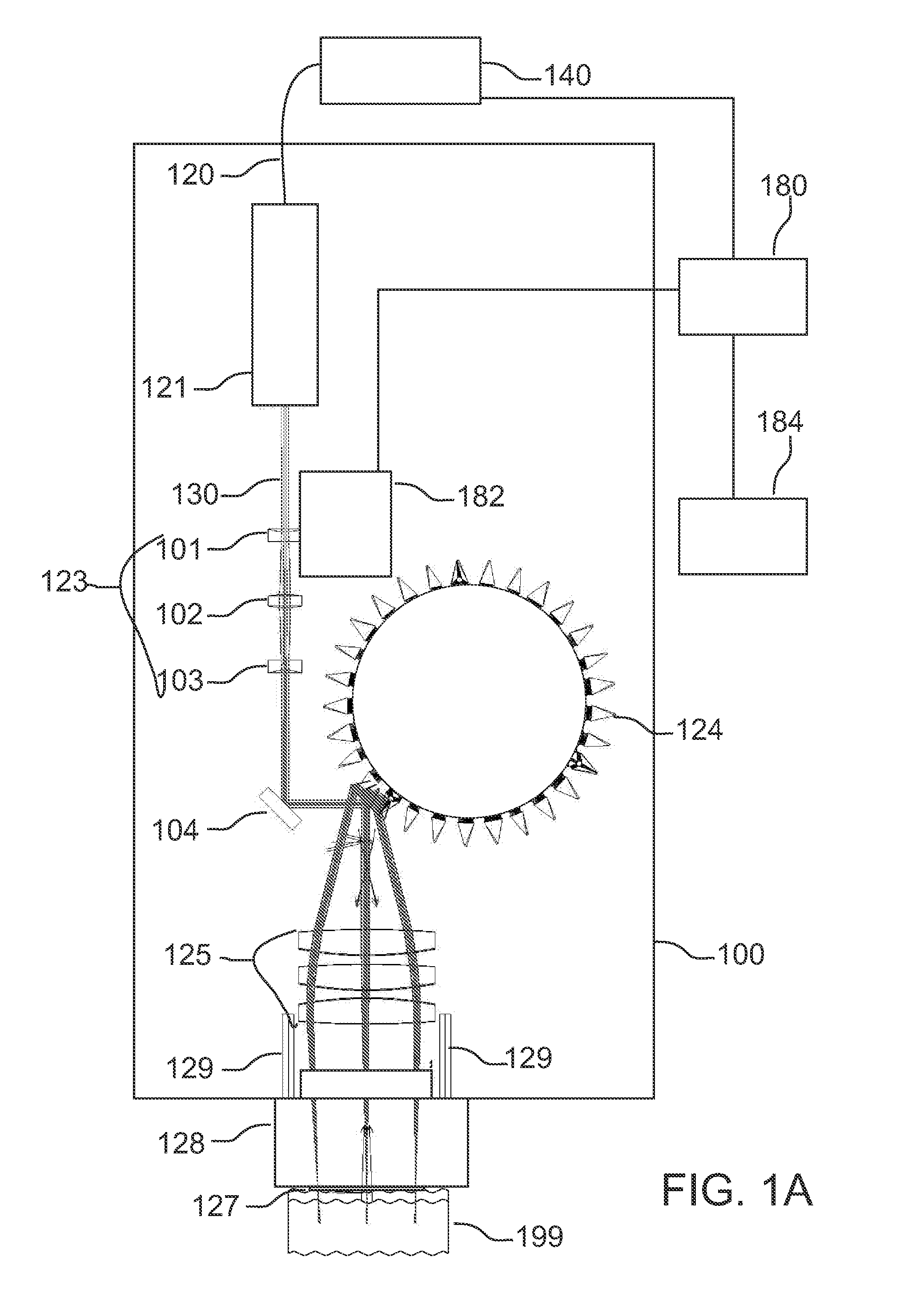

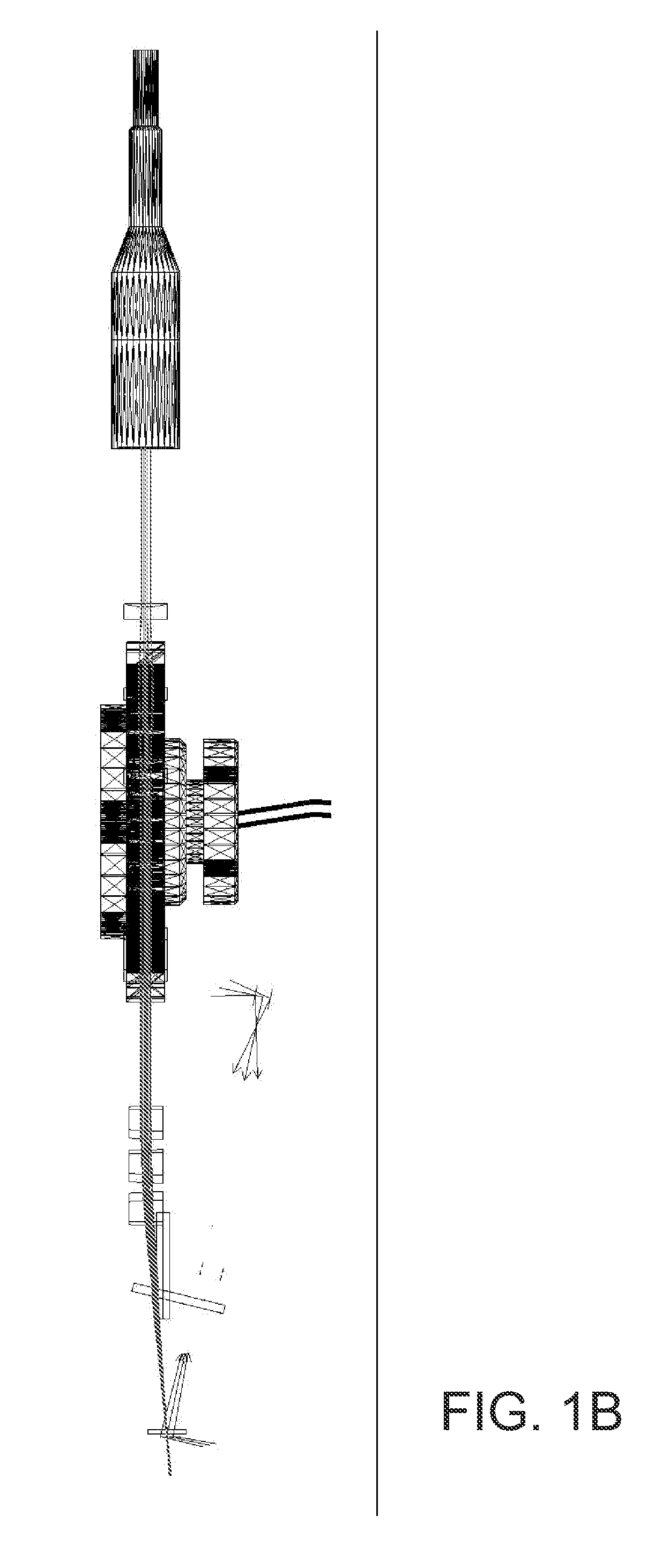

Methane extraction method and apparatus using high-energy diode lasers or diode-pumped solid state lasers

InactiveUS20070267220A1Efficient productionConstructionsDisloding machinesFiberDiode-pumped solid-state laser

A method and apparatus for extracting methane gas from methane hydrate. The method includes heating the methane hydrate with a laser apparatus. The laser apparatus includes a diode laser or a solid state laser that is pumped with a diode laser. The laser is guided to a working end of a tool with a fiber optic bundle. The tool is guided to heat the methane hydrate with the laser, which emanates from a beam expander at the working end of the tool. The tool can be modified for removing obstructions of methane hydrate in pipelines. Also, the tool can be modified for extracting methane from mined methane hydrate, which is in a container. The characteristics of diode lasers or diode-pumped solid state lasers such as efficiency, size, nature of operation, environmental impact and durability, make methane gas extraction from methane hydrate economically feasible.

Owner:NORTHROP GRUMAN CORP

Laser processing for heat-sensitive mesoscale deposition of oxygen-sensitive materials

InactiveUS20070019028A1Damage to materialRadiation applicationsPretreated surfacesForming gasHeat sensitive

A method of depositing various materials onto heat-sensitive targets, particularly oxygen-sensitive materials. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts. Cover gases and / or forming gases may be used during thermal processing to change the material properties, for example by preventing oxidation.

Owner:OPTOMEC DESIGN CO

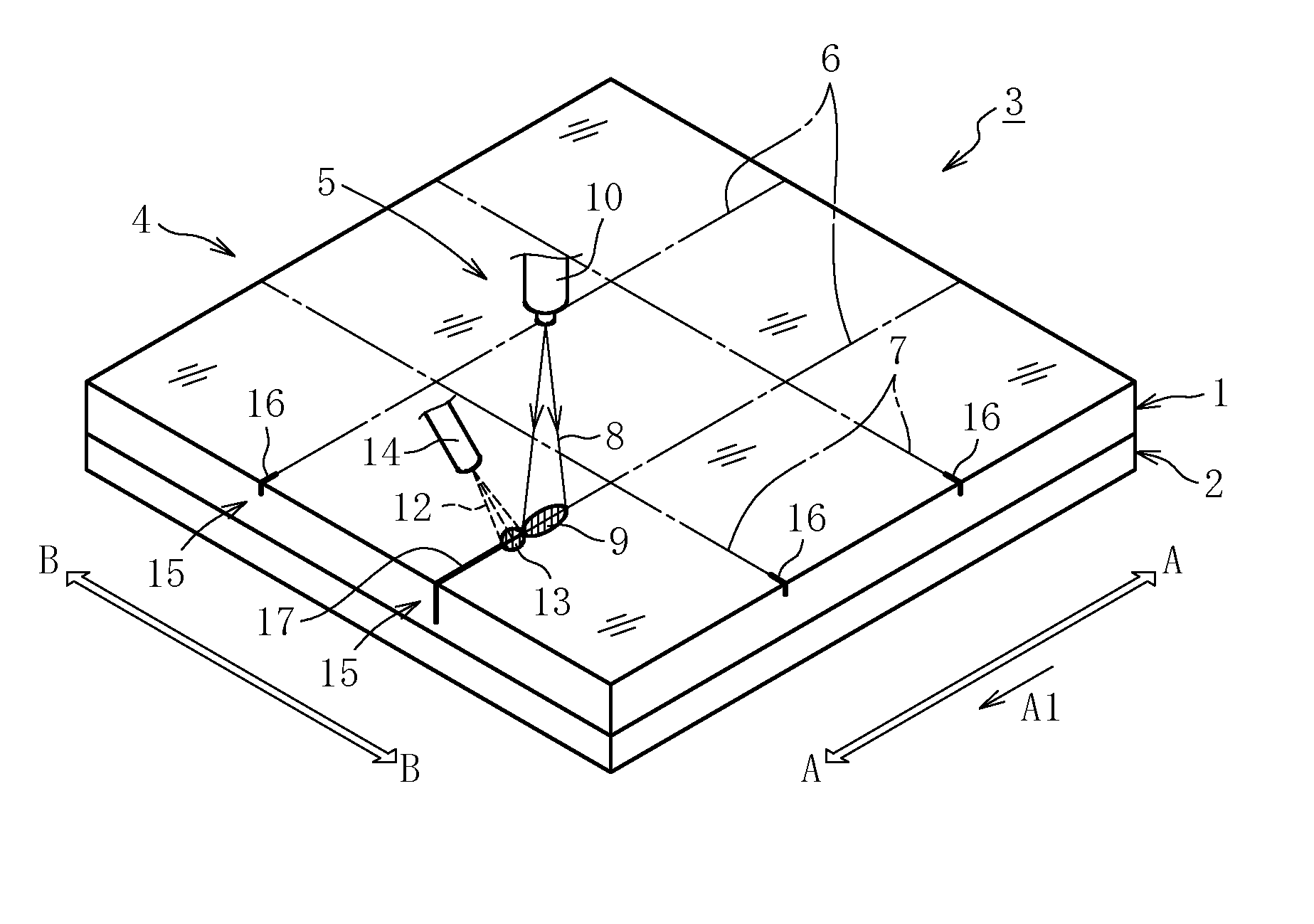

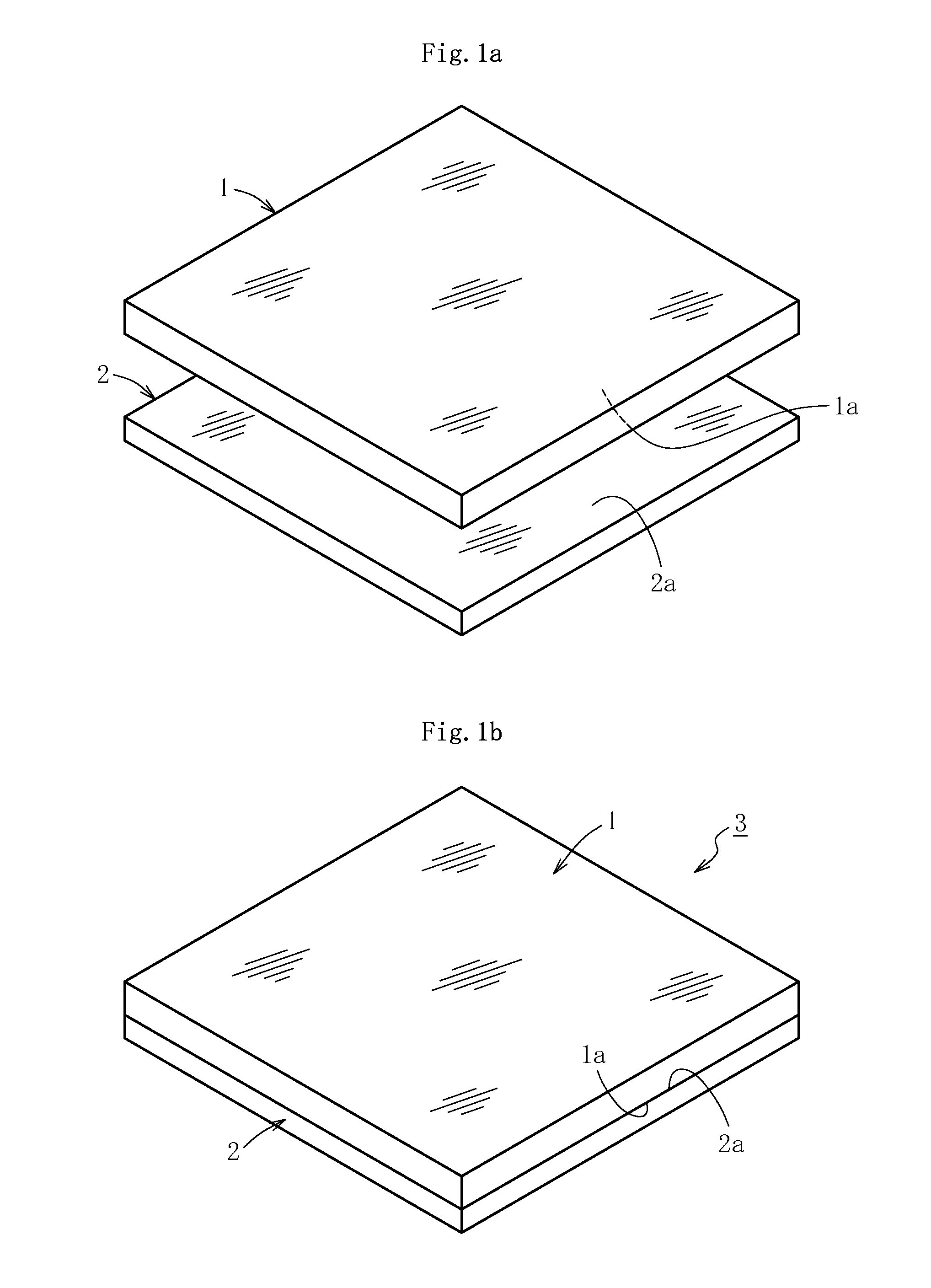

Glass film cutting method and glass film laminate

InactiveUS20130280495A1Appropriate adhesionGlass/slag layered productsGlass reforming apparatusSurface roughnessLaser scribing

Owner:NIPPON ELECTRIC GLASS CO LTD

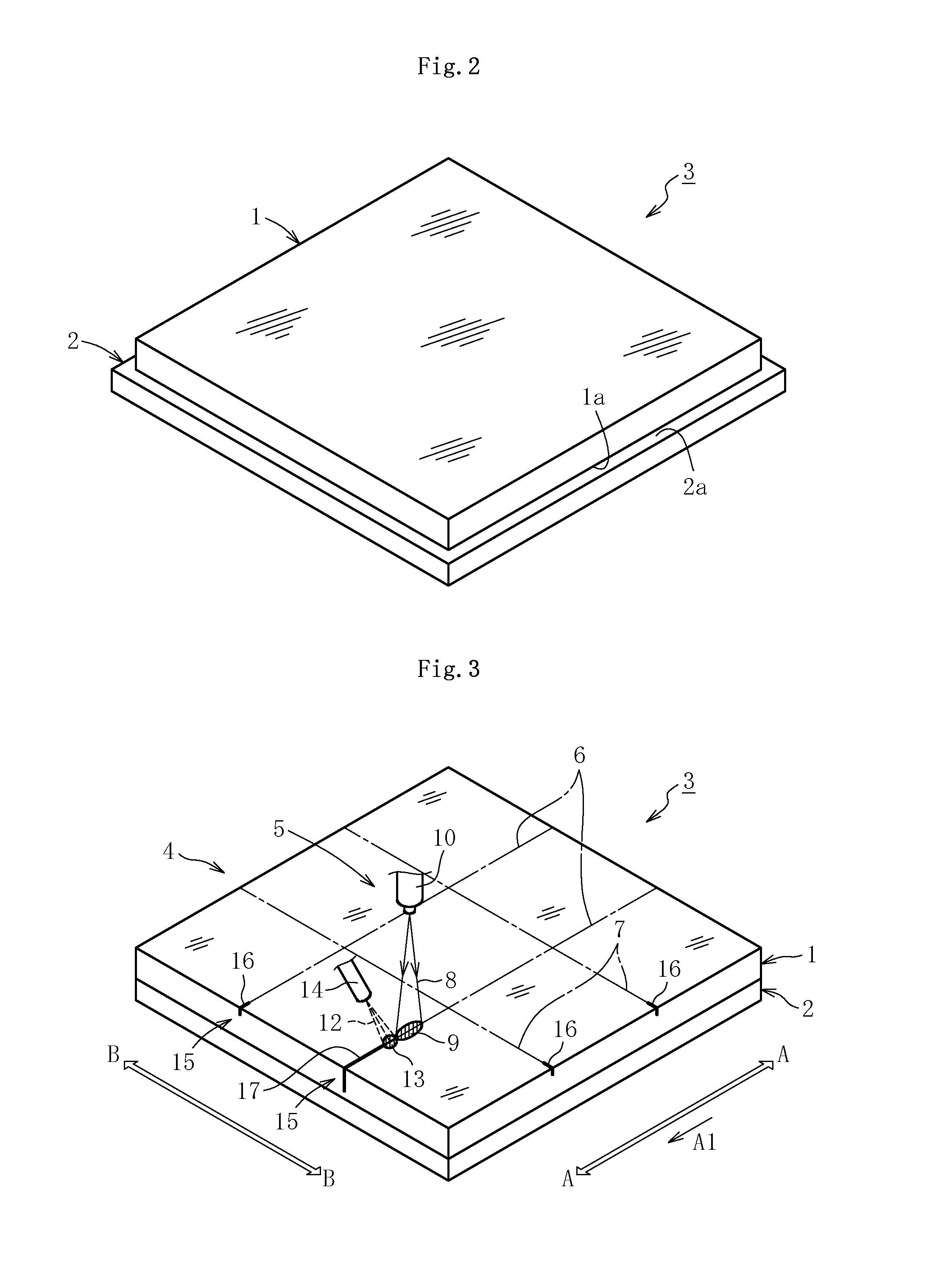

Method for laser-induced thermal separation of plate glass

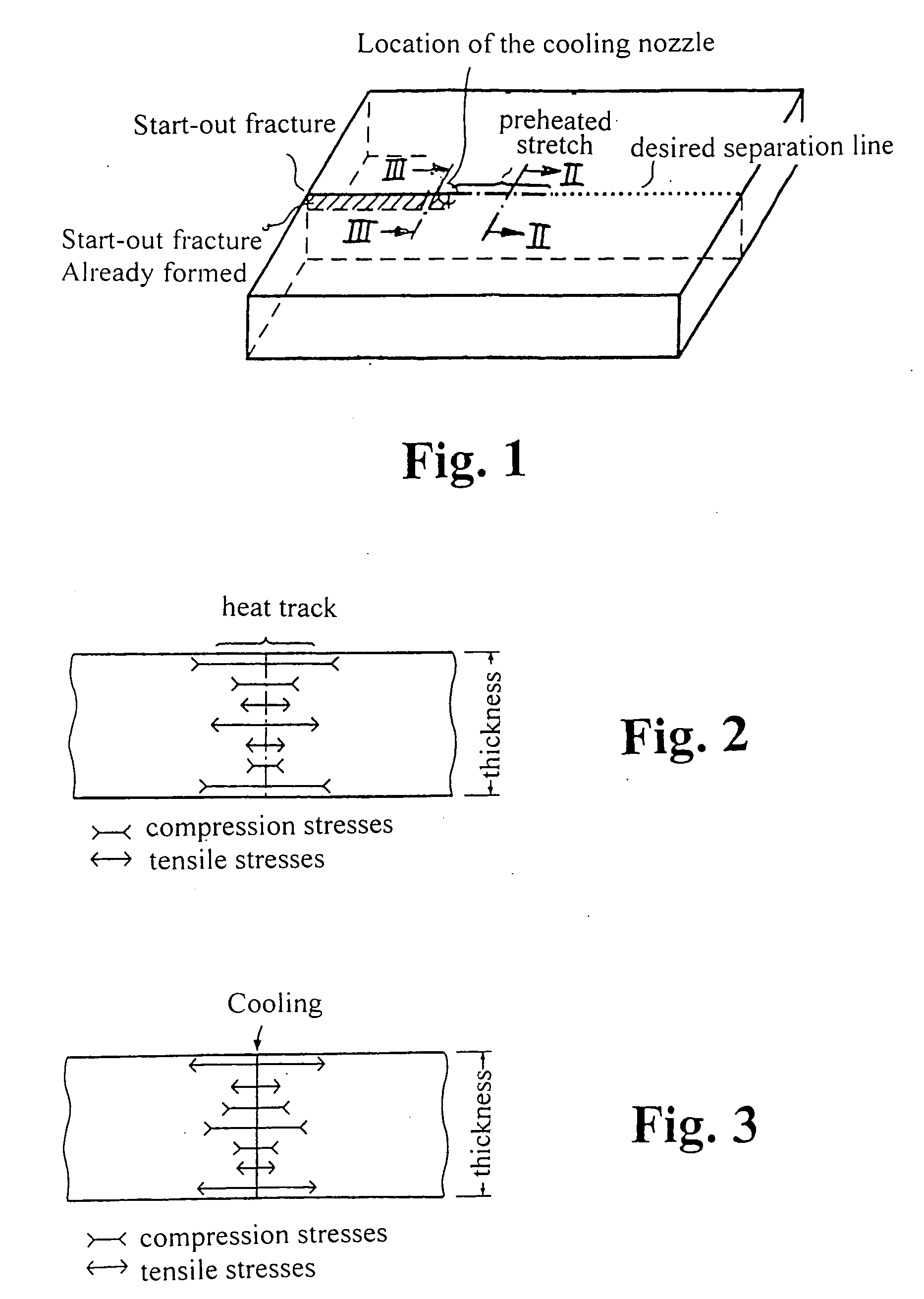

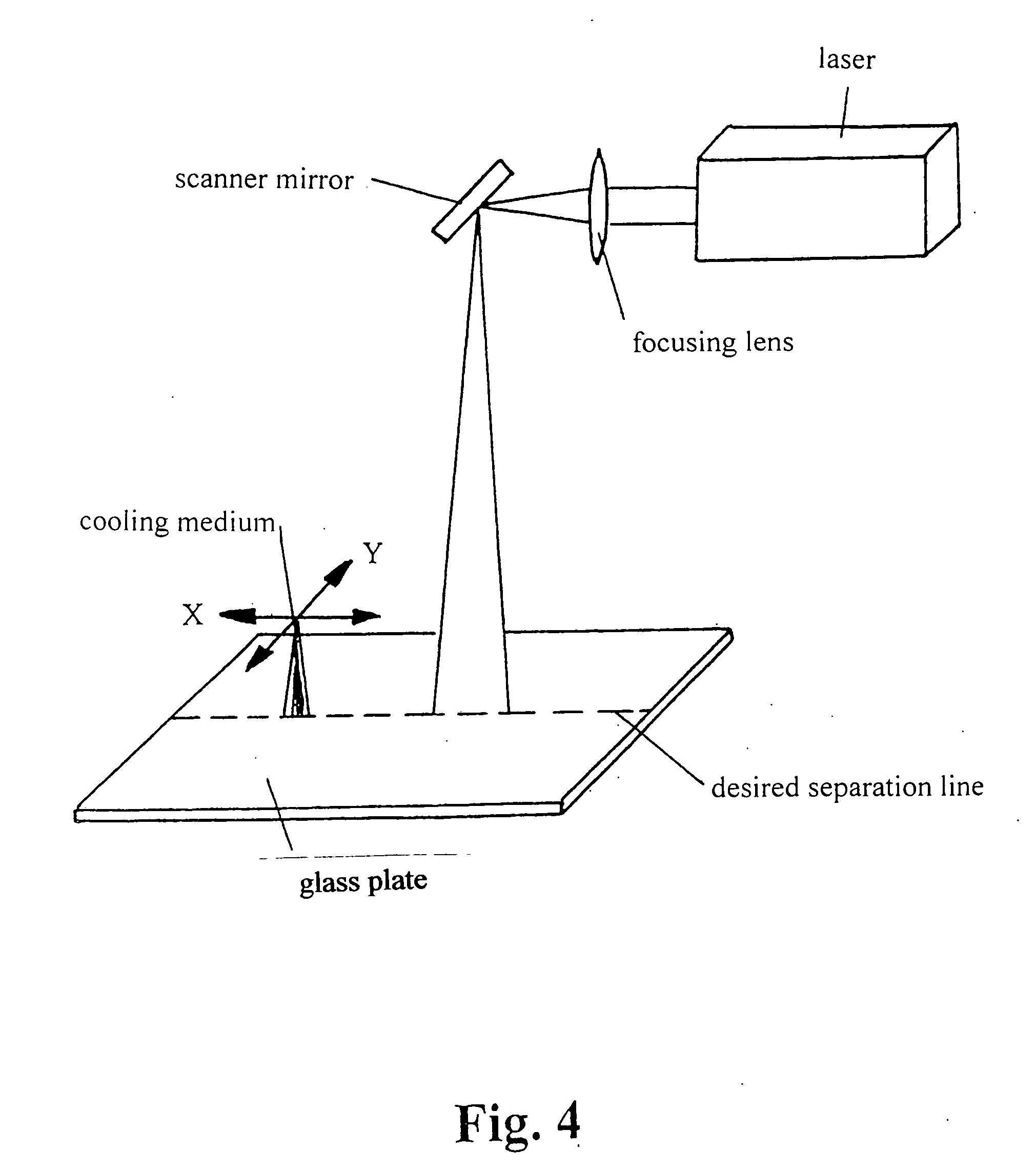

InactiveUS20070151962A1Reduce surface temperatureFast cutting speedGlass severing apparatusWelding/soldering/cutting articlesFlat glassLaser heating

In a method for a laser-induced thermal separation of plate glass by thermal scoring using a laser beam heating the glass along a desired separation line with subsequent cooling of the laser-heated line, wherein the heat is applied by the laser beam in a number of repetitive passes at intensities based on glass thickness and desired cutting speeds.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

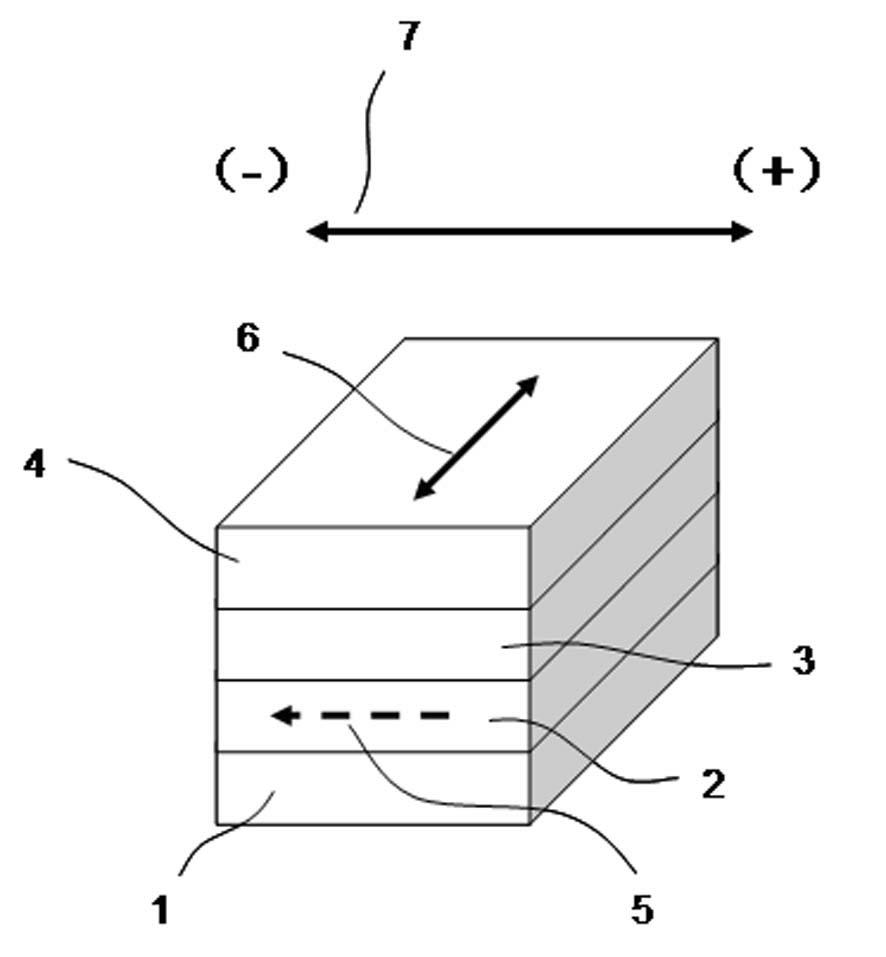

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

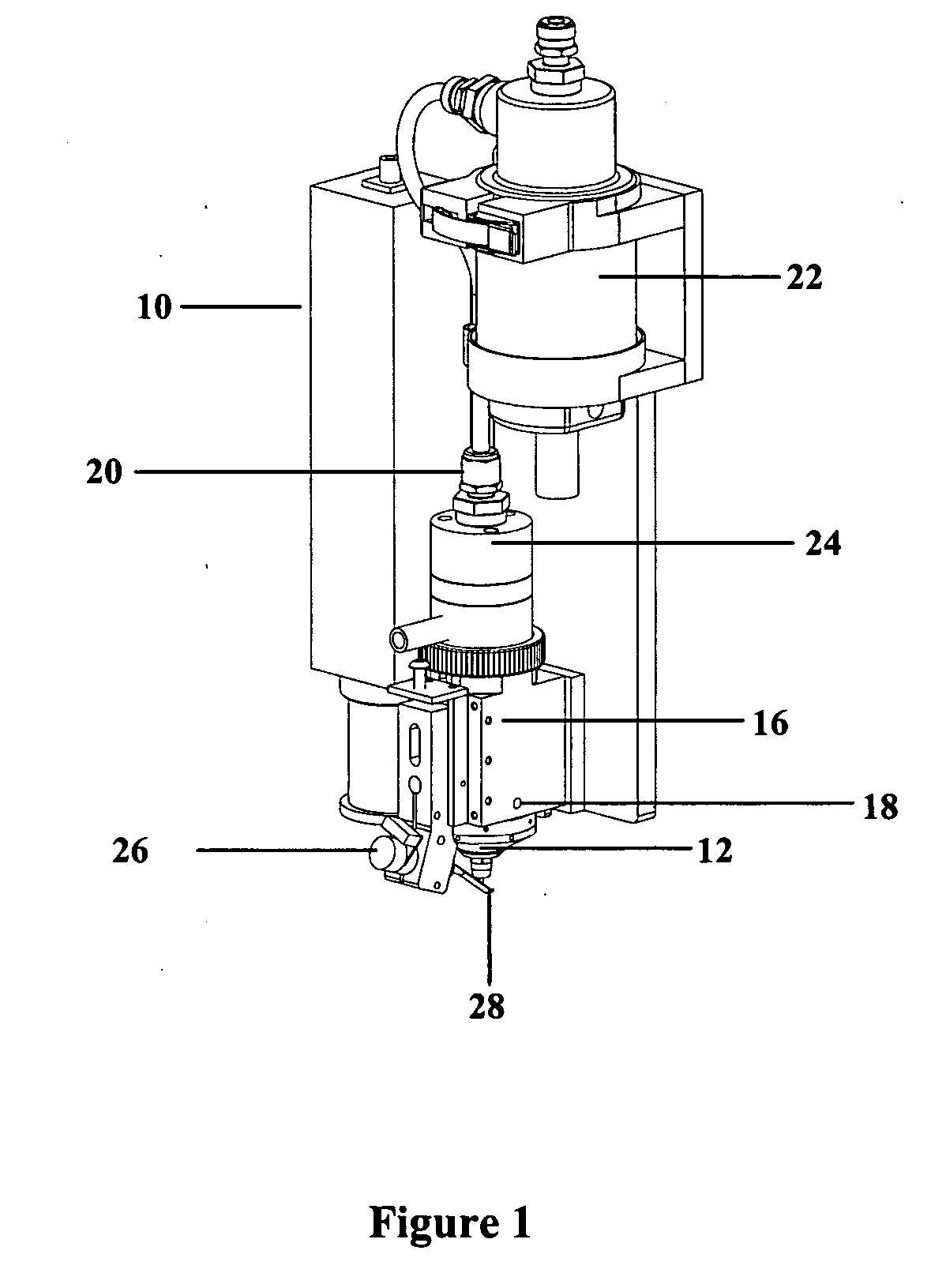

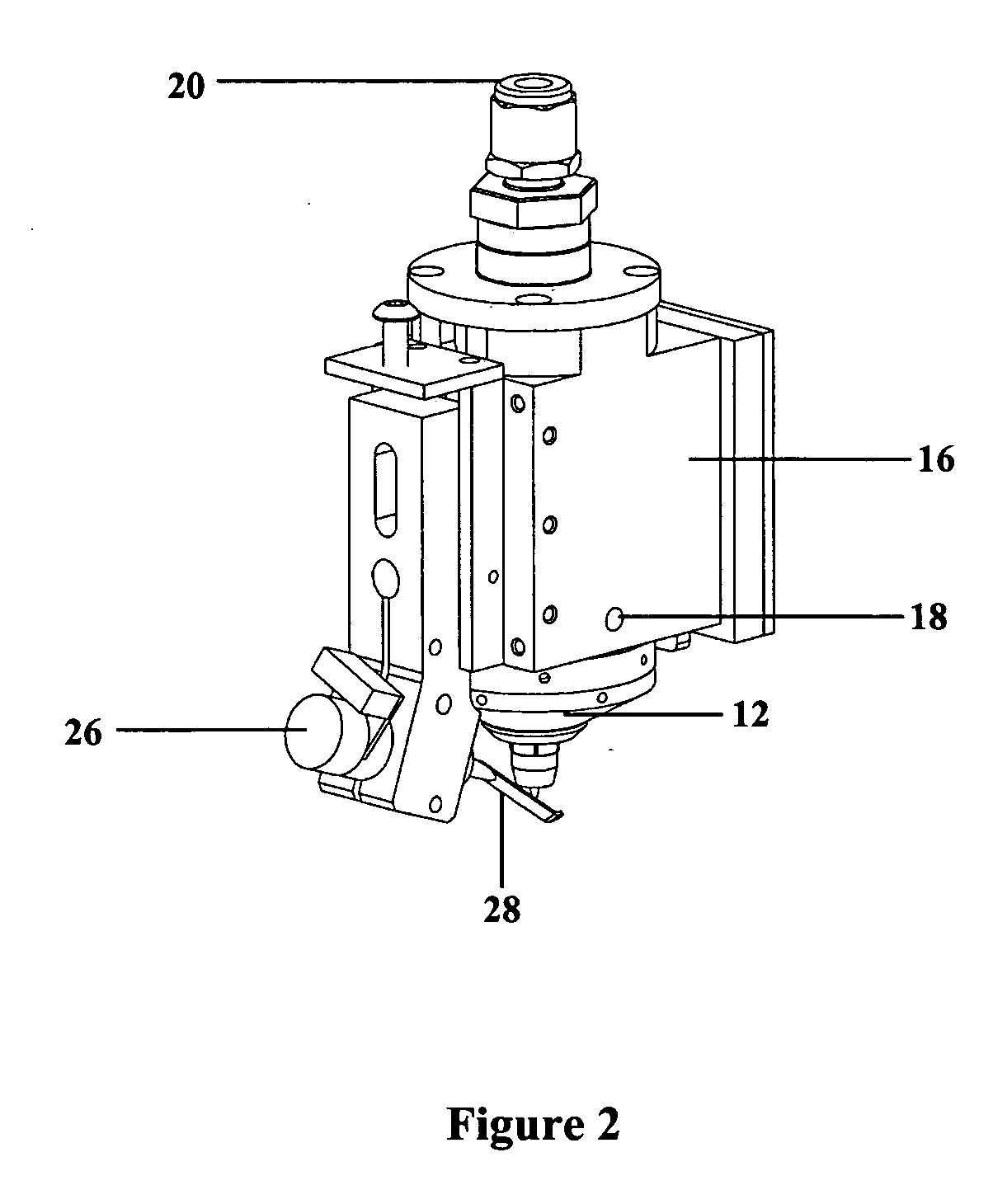

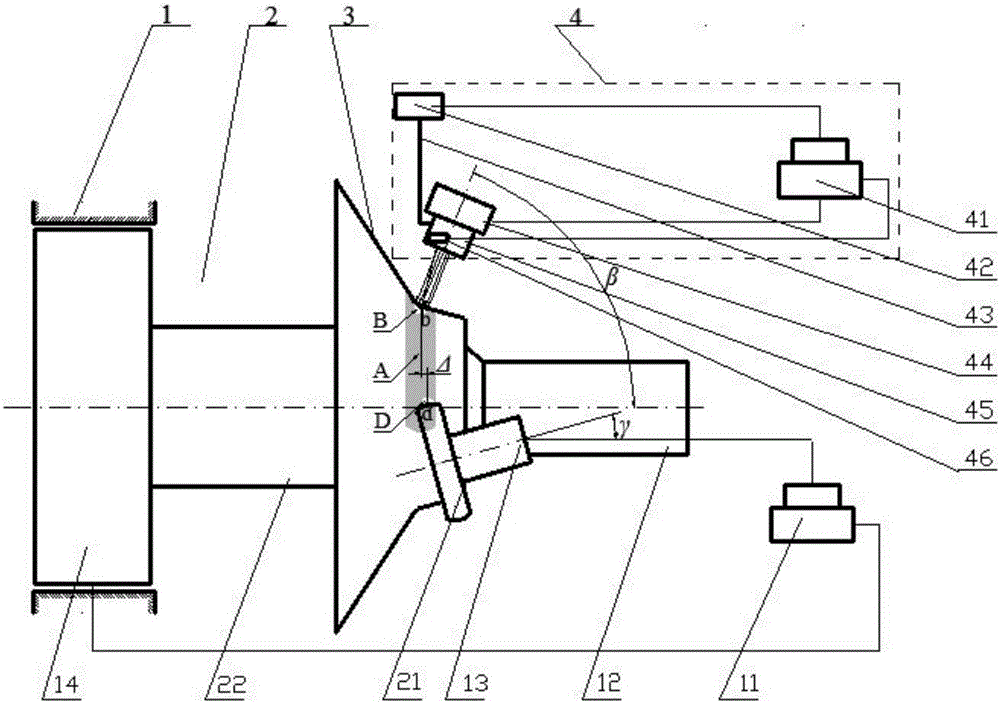

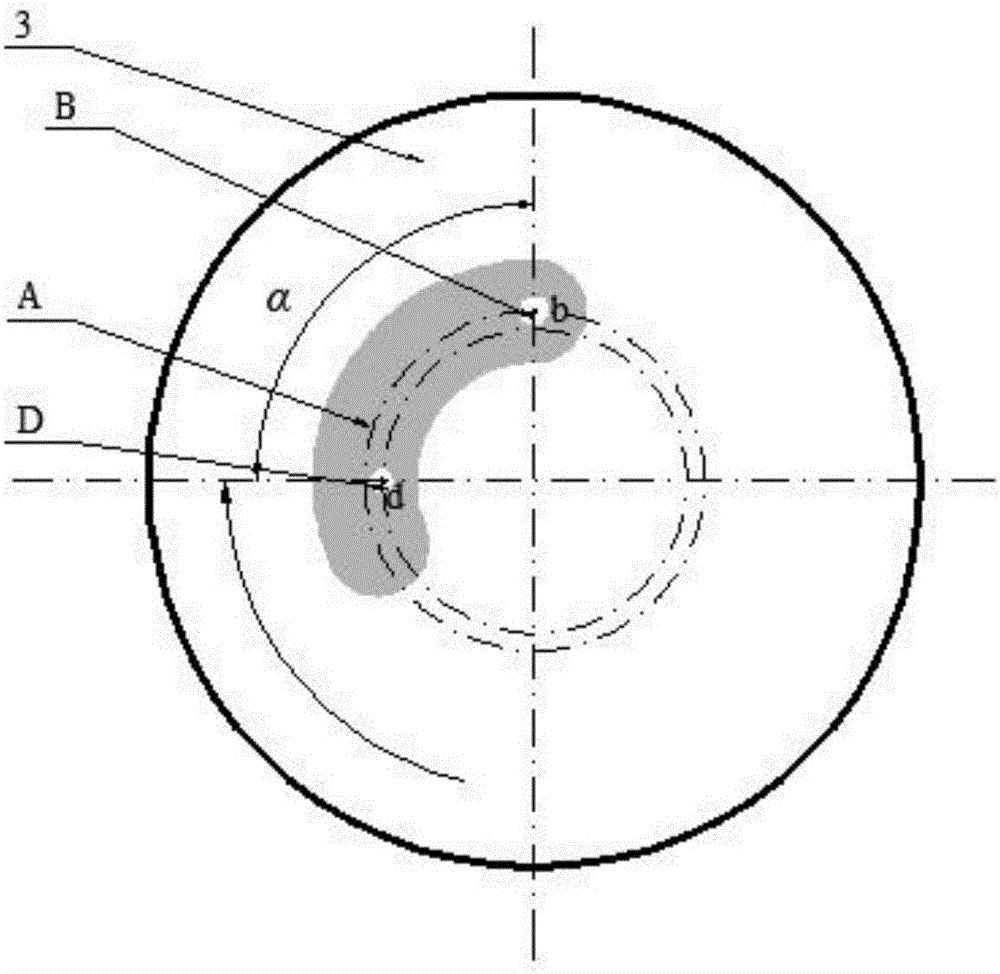

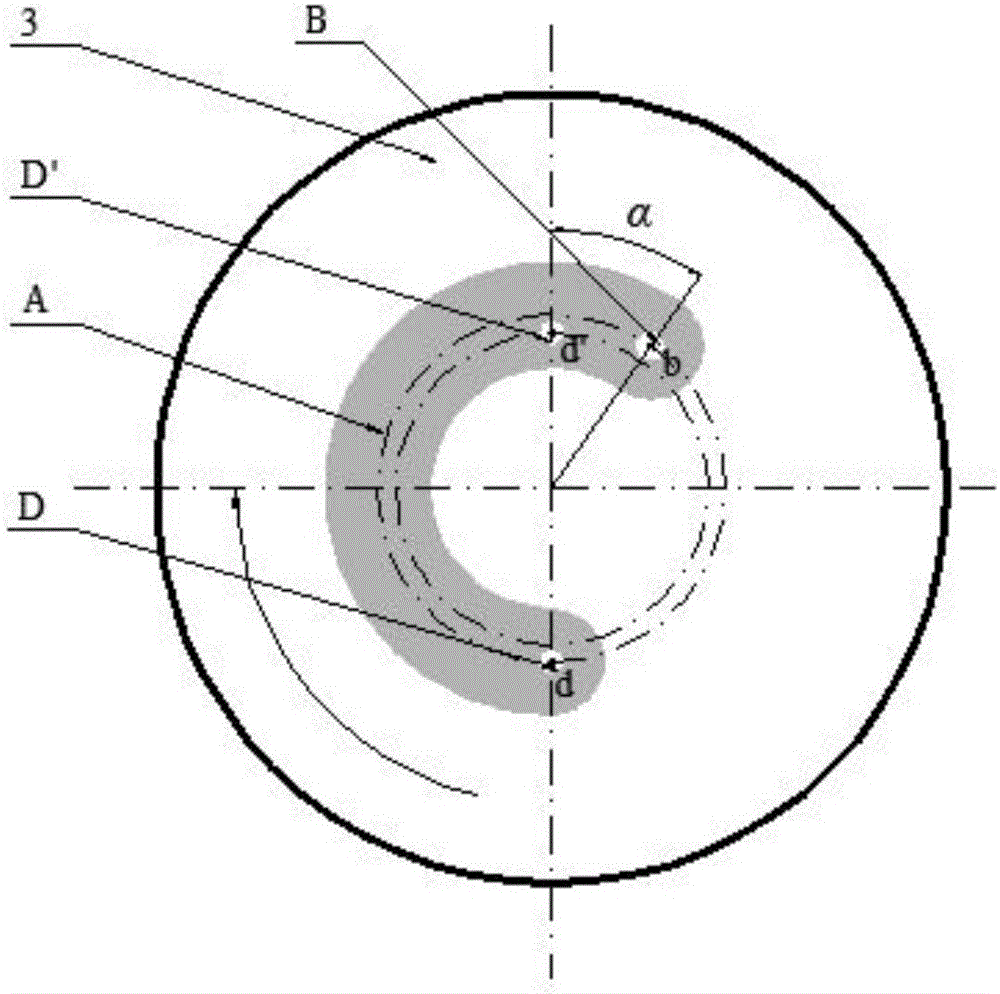

Auxiliary laser heating milling device and method

InactiveCN102430904AEasy to set upEasy to operateMilling equipment detailsNumerical controlMilling cutter

The invention discloses an auxiliary laser heating milling device and method. A laser focusing head is arranged on the traditional numerical control milling machine, and laser is introduced in through optical fiber to increase the local workpiece temperature so as to achieve the purpose of improving the material processability. A rotating workbench is additionally arranged on the condition that the laser focusing head and a milling cutter are fixed relatively, and the method of rotating a workpiece is adopted so that the workpiece direction relative to the laser incidence direction is changed and the auxiliary laser heating milling of the complex workpiece is hereby realized. The invention overcomes the defect that the auxiliary heating milling direction can not be changed and provides a new method for processing the complex workpiece made of the material which is difficult to process.

Owner:HARBIN INST OF TECH

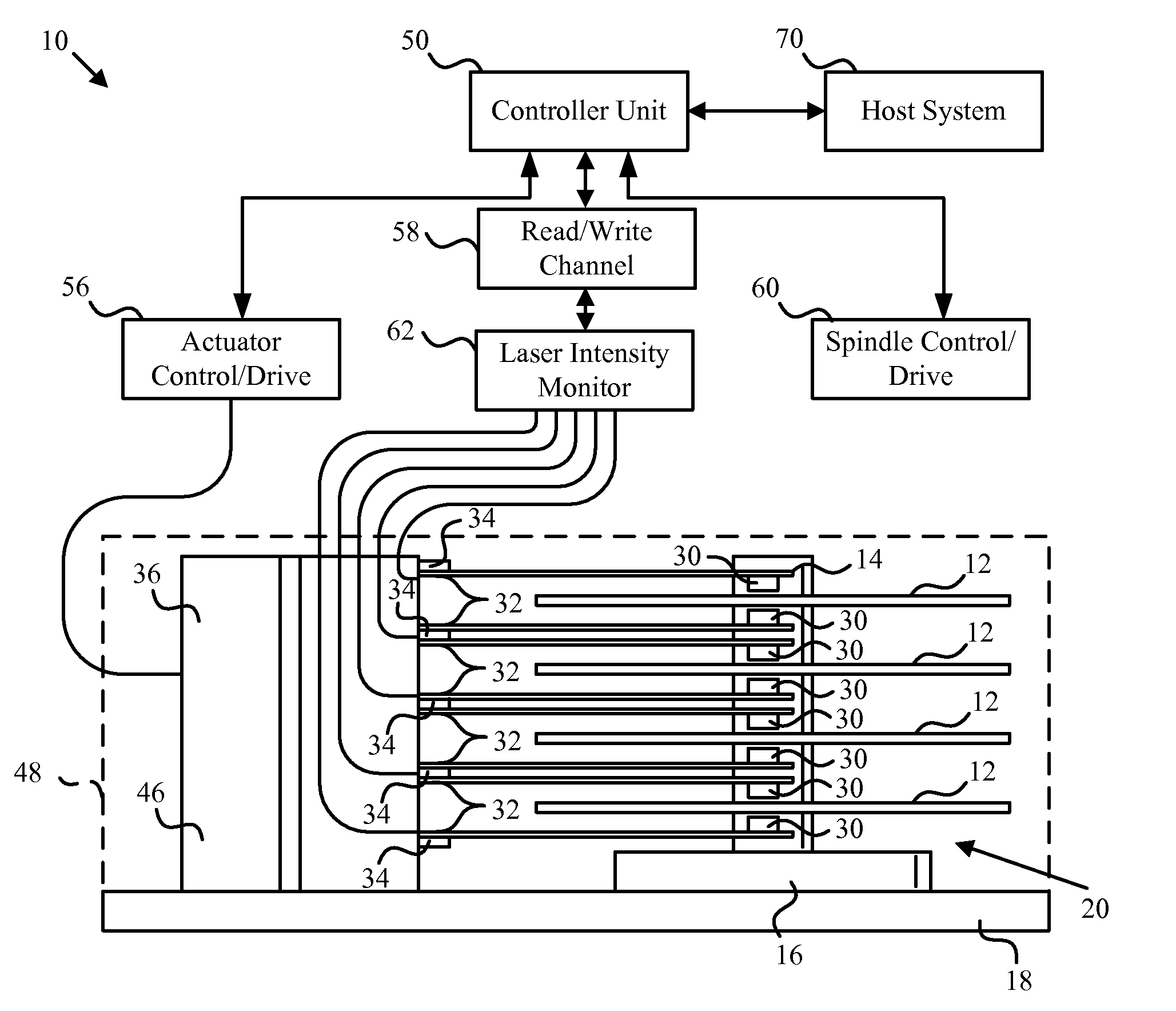

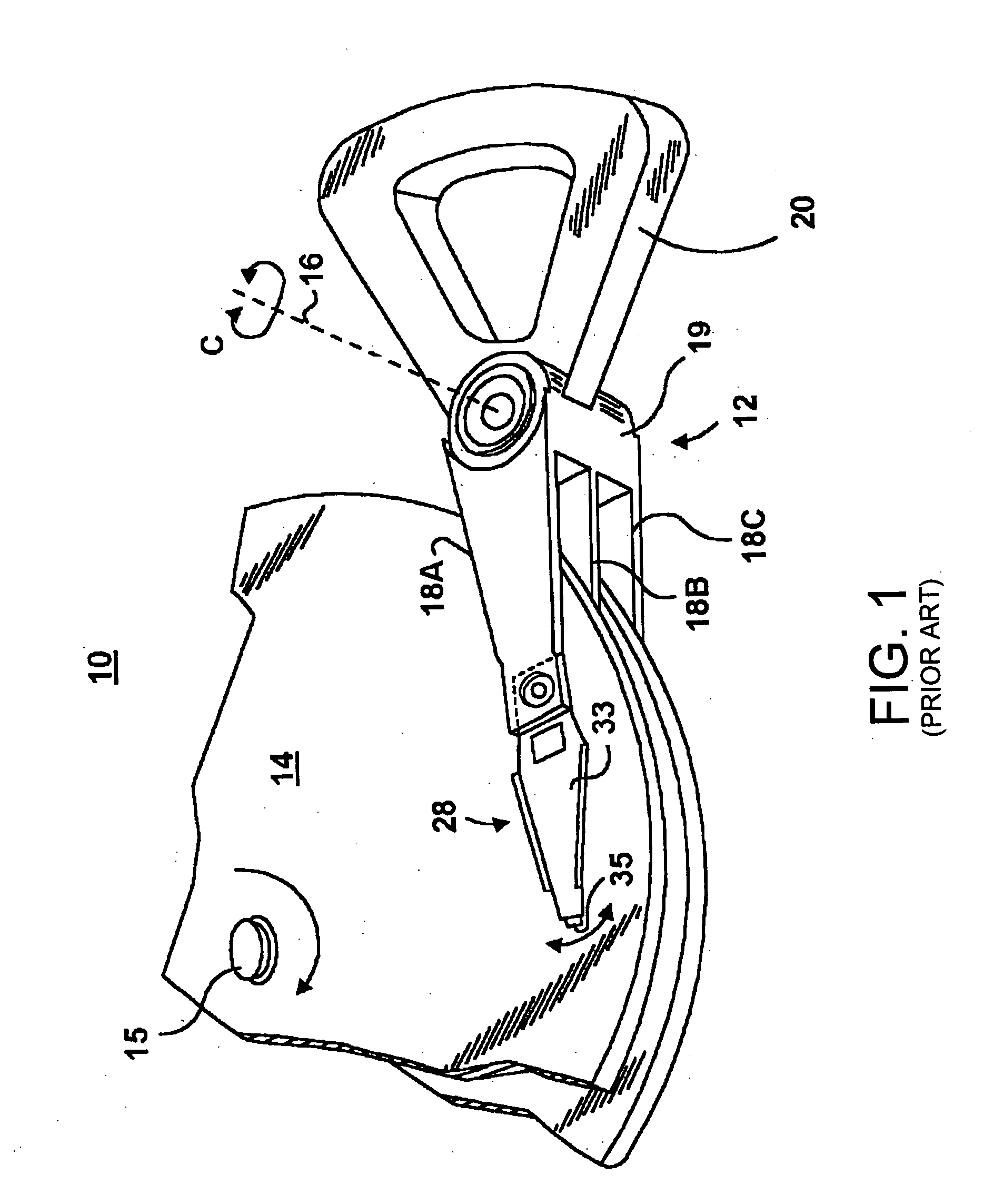

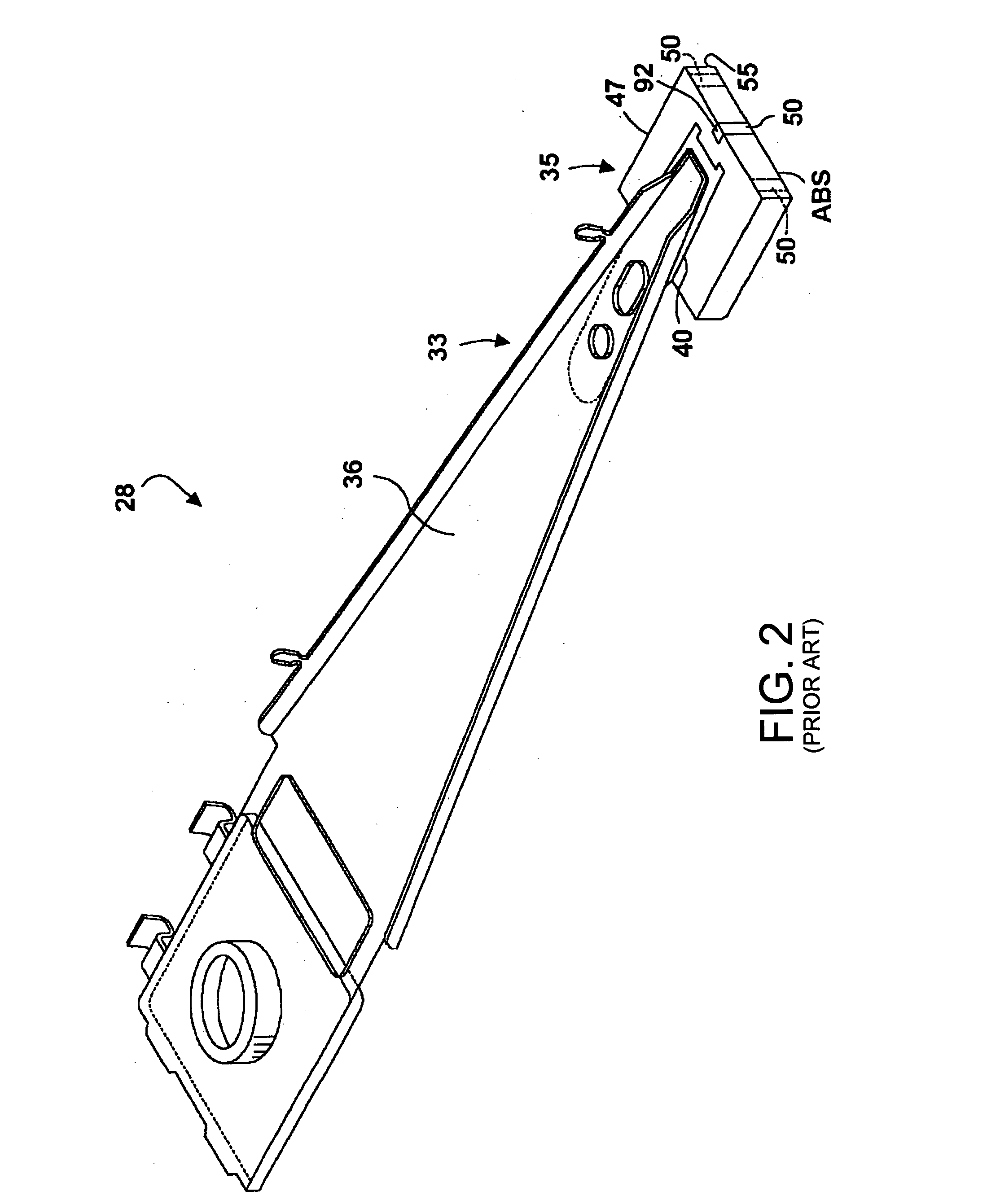

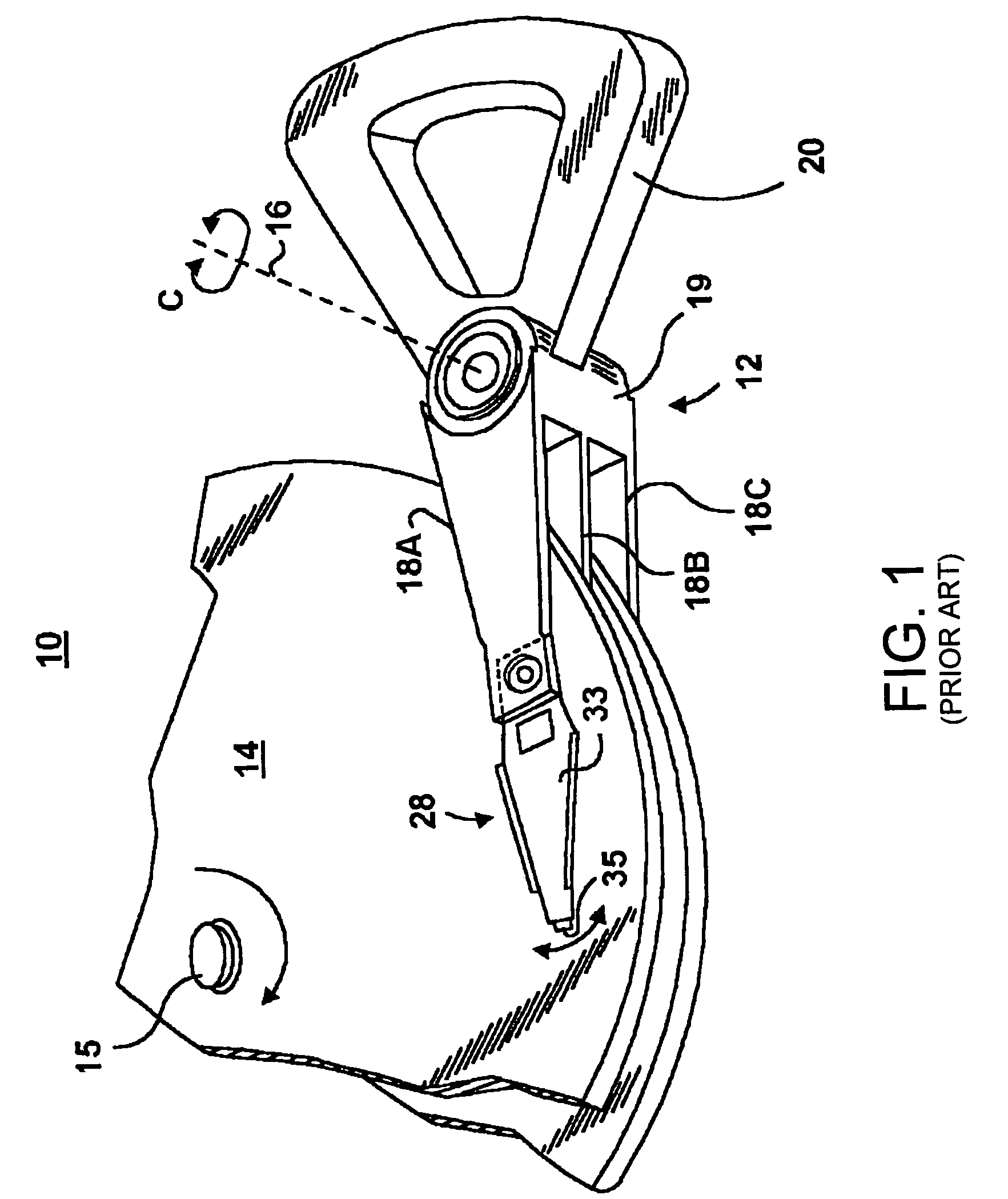

Laser power sensor for thermally assisted magnetic recording

ActiveUS20090225464A1Record information storageRecording/reproducing/erasing methodsPower sensorHeat-assisted magnetic recording

An apparatus, system, and method for measuring thermally induced electric resistance changes in thermally assisted magnetic recording are disclosed for monitoring laser light output in thermally assisted magnetic recording disk drives. An electrical lead is coupled to a read / write head element. A first electrical resistance in the read / write head element is measured. The read / write head is heated by a laser and a second electrical resistance in the read / write head element is measured. The electrical resistance may be monitored at regular intervals when the read / write head element is on the ramp or the electrical resistance measurements may be continuously monitored as the read / write head flies over the magnetic media.

Owner:WESTERN DIGITAL TECH INC

Laser ignition for gas mixtures

ActiveUS20100147259A1Reduce riskReliable ignitionCombustion enginesIgnition sparking plugsCombustion chamberInternal combustion engine

Owner:MULTIFLASHLIGHT

Laser processing for heat-sensitive mesoscale deposition

InactiveUS20050129383A1Low damage thresholdDamage to materialSolid-state devicesMetal-working apparatusLaser processingHeat sensitive

A method of depositing various materials onto heat-sensitive targets. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts.

Owner:OPTOMEC DESIGN CO

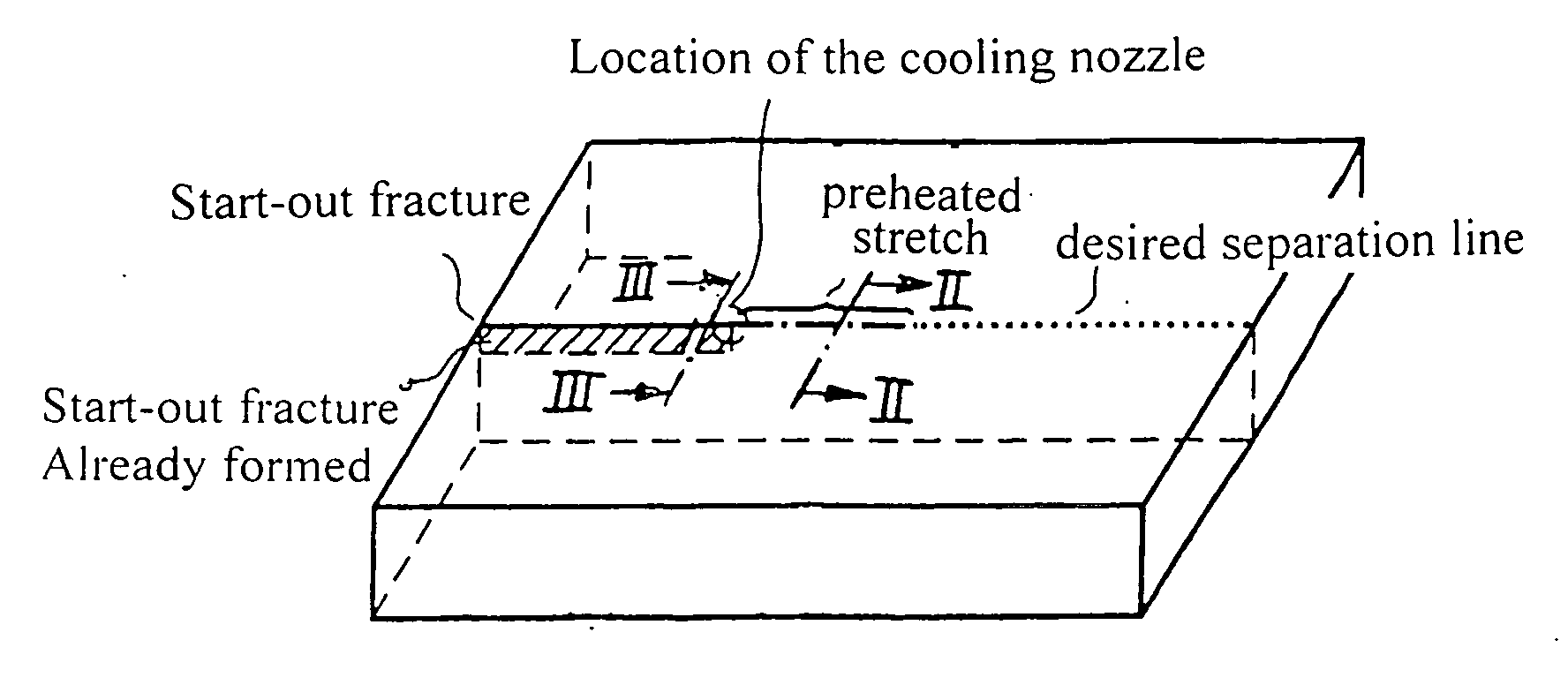

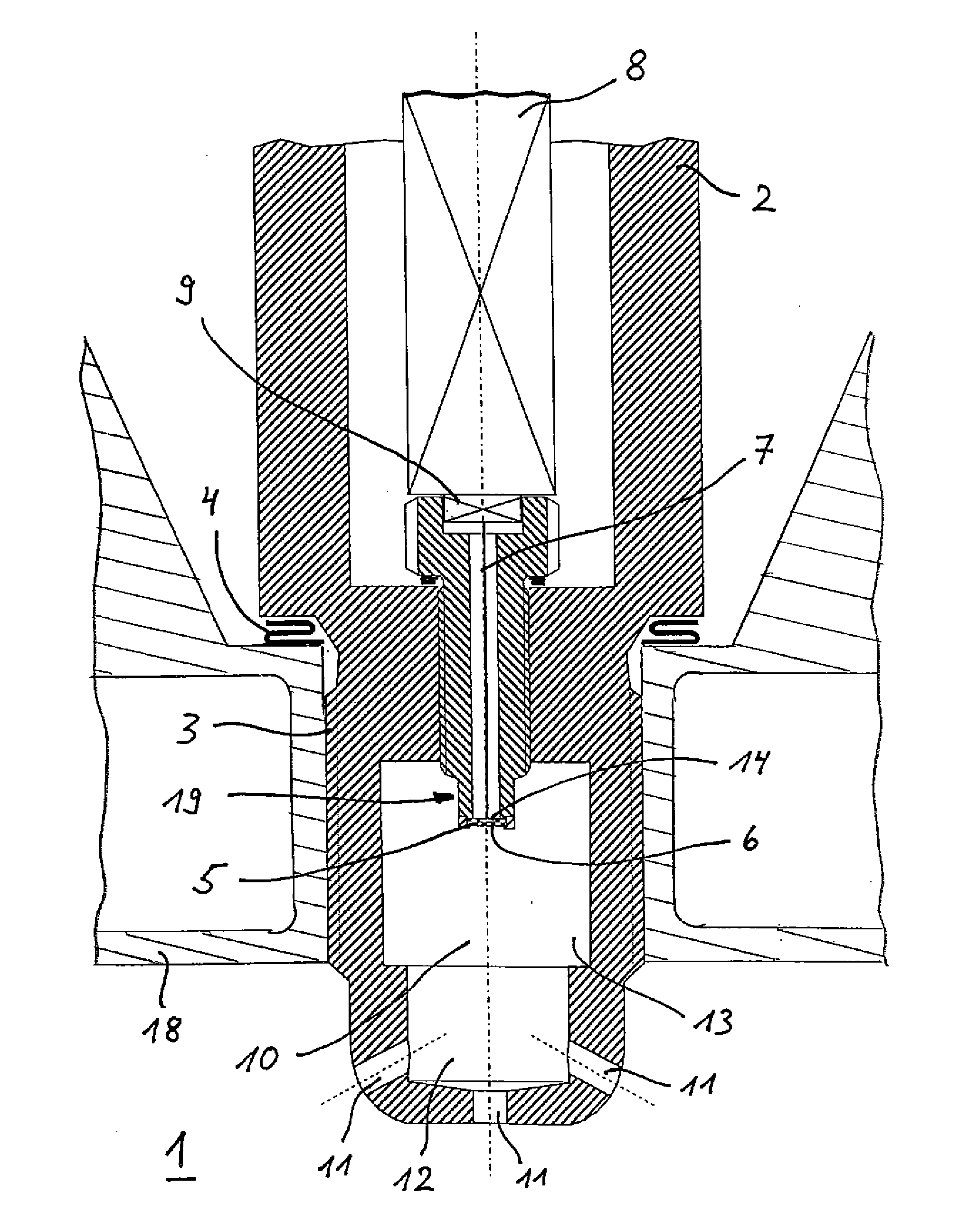

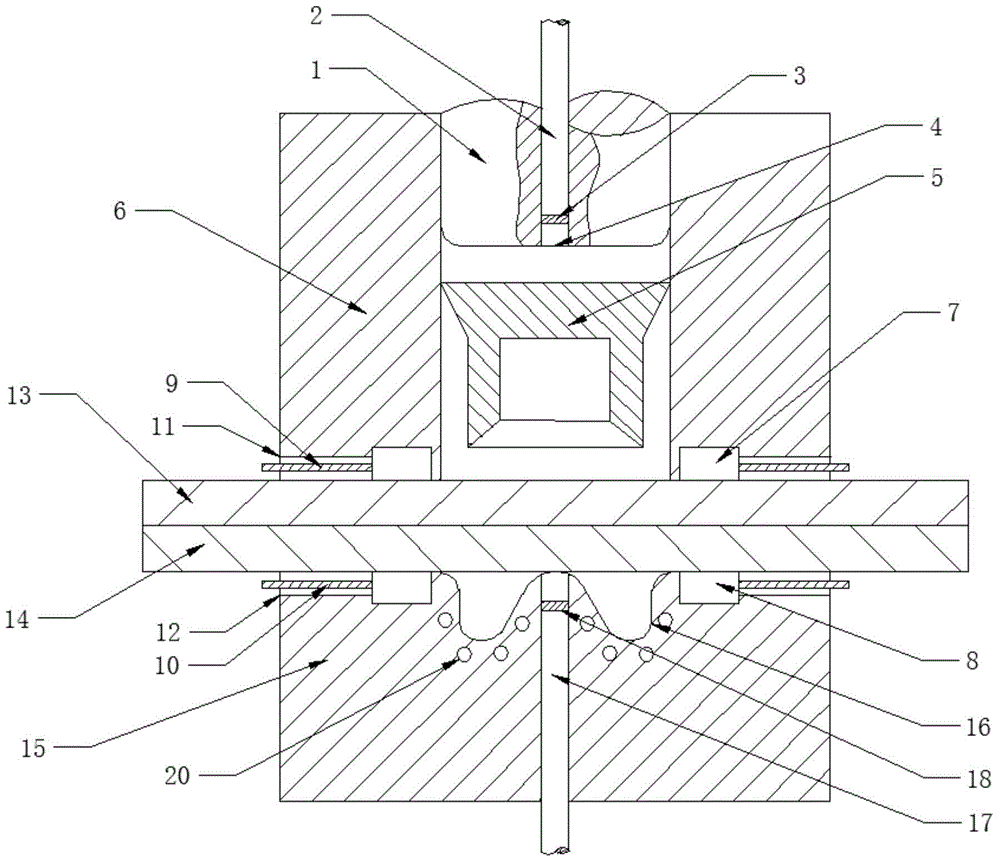

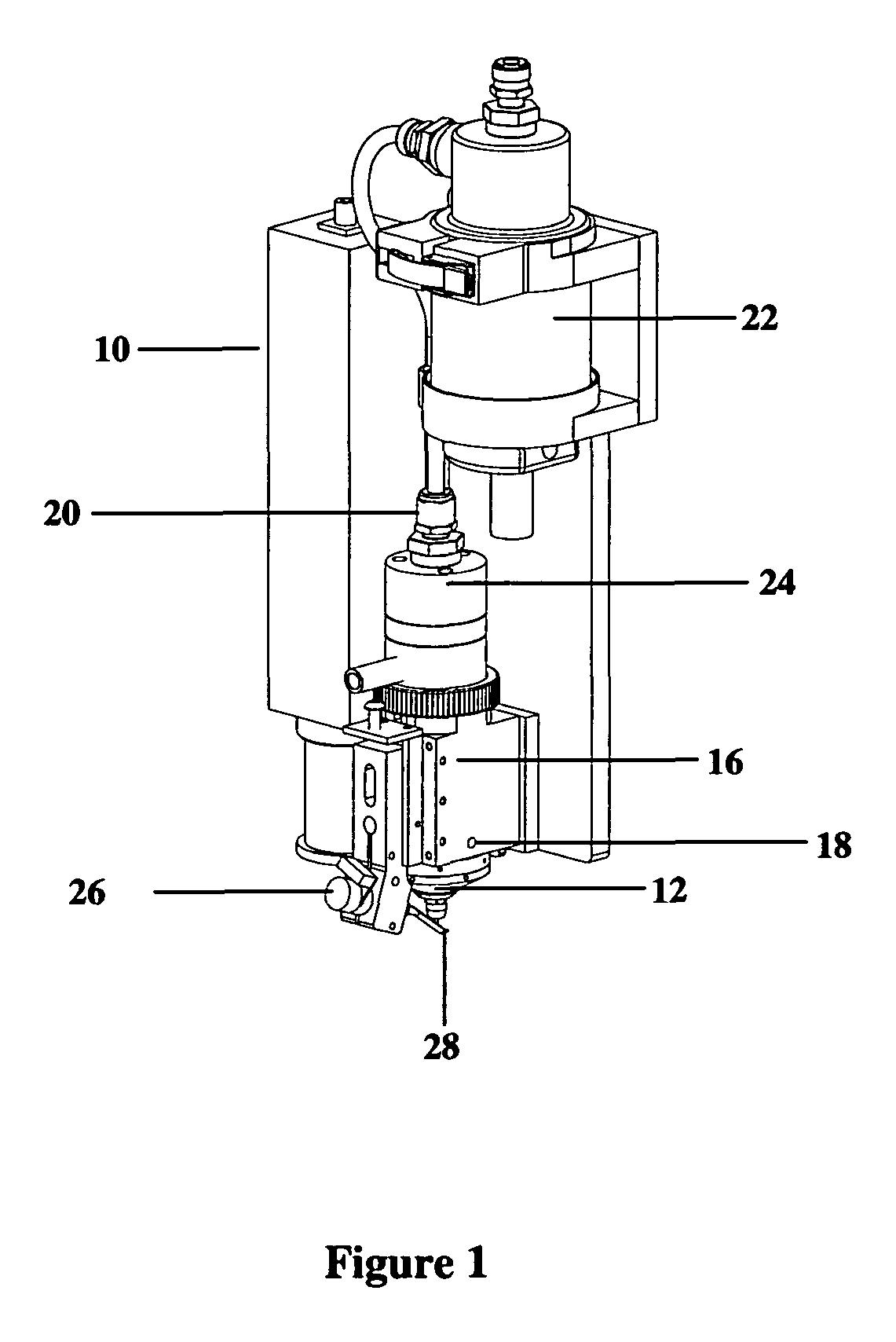

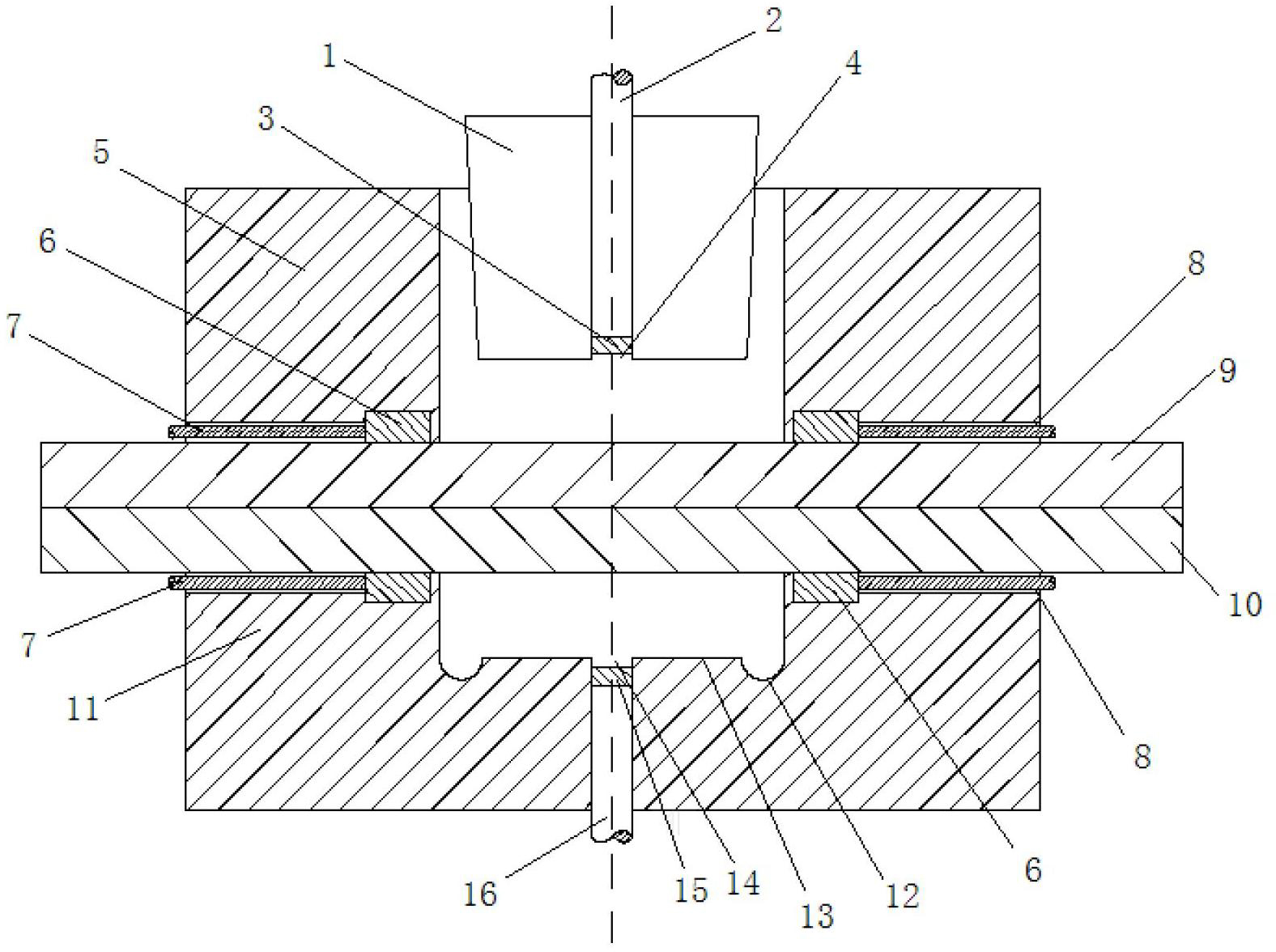

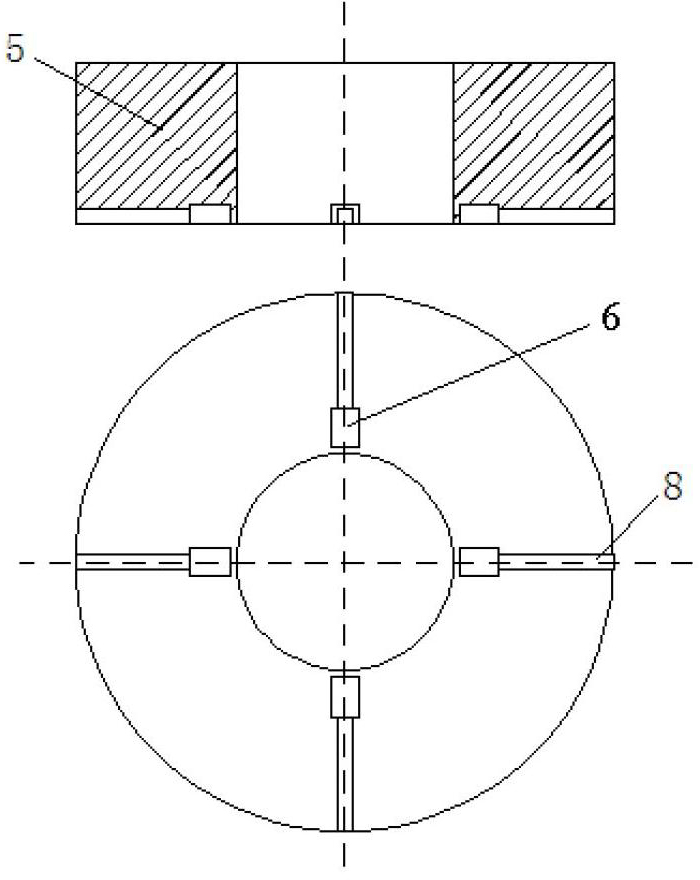

Self-piercing riveting device of ultrahigh strength steel plates or/and aluminum alloy plates

The invention discloses a self-piercing riveting device of ultrahigh strength steel plates or / and aluminum alloy plates and aims to solve the problem that the ultrahigh strength steel plates with high strength cannot be riveted. The self-piercing riveting device comprises a compound punch (1), a compound binder ring (6), a compound female die (15) and a laser heating control part. The compound binder ring (6) is stacked on the compound female die (15) by contact connection. The compound punch (1) is disposed in a central hole of the compound binder ring (6) by sliding connection. A first fiber tube (2) is mounted in a first hollow round hole (4) of the compound punch (1) by threaded connection. A first concave lens (3) is mounted in the first hollow round hole (4) below the first fiber tube (2). The bottom of the first concave lens (3) is 1-2mm away from the bottom of the compound punch (1). The first concave lens (3) is connected with the first fiber tube (2) in a threaded manner. Rotational axes of the compound punch (1), the compound binder ring (6) and the compound female die (15) are collinear.

Owner:JILIN UNIV

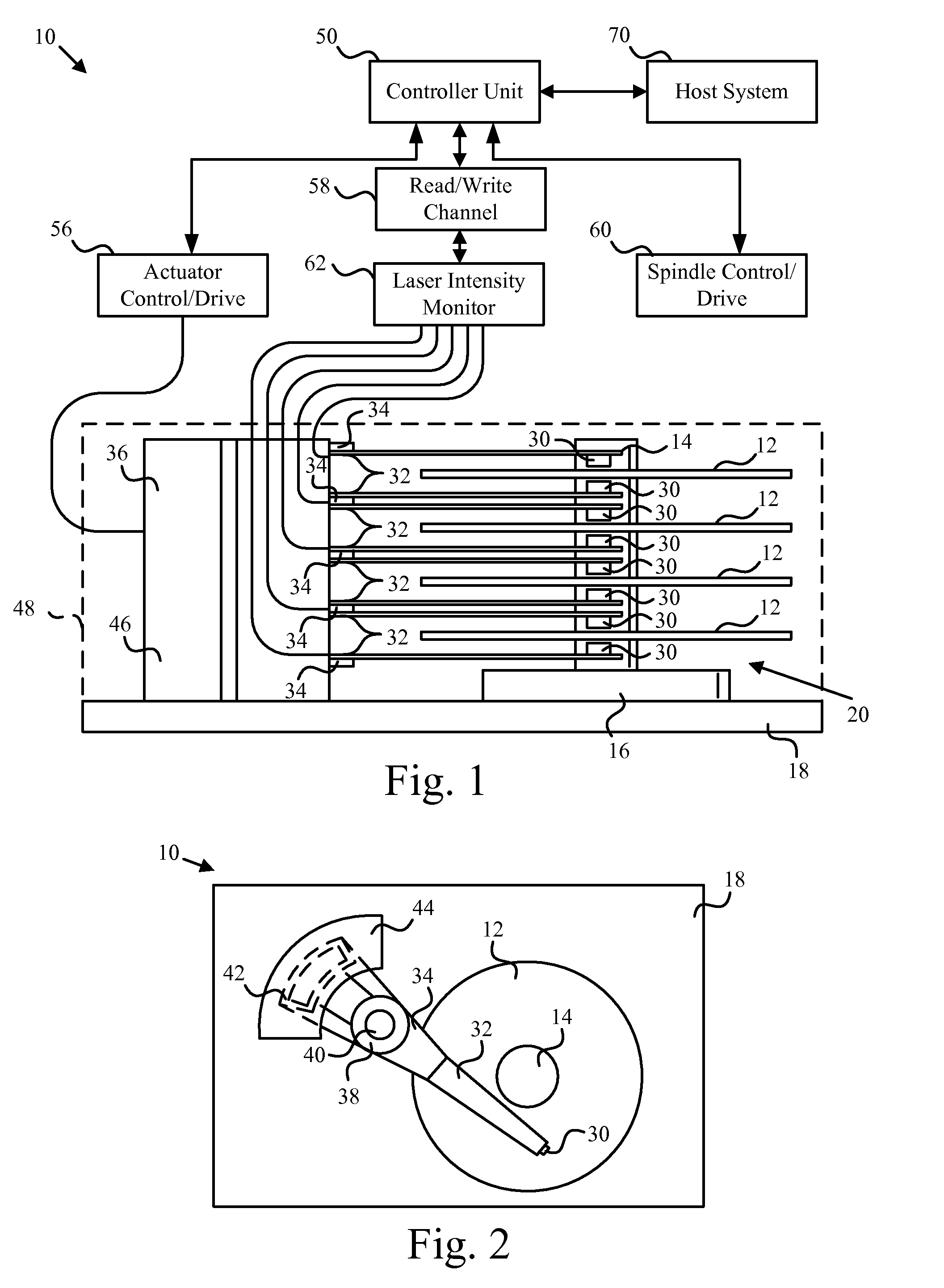

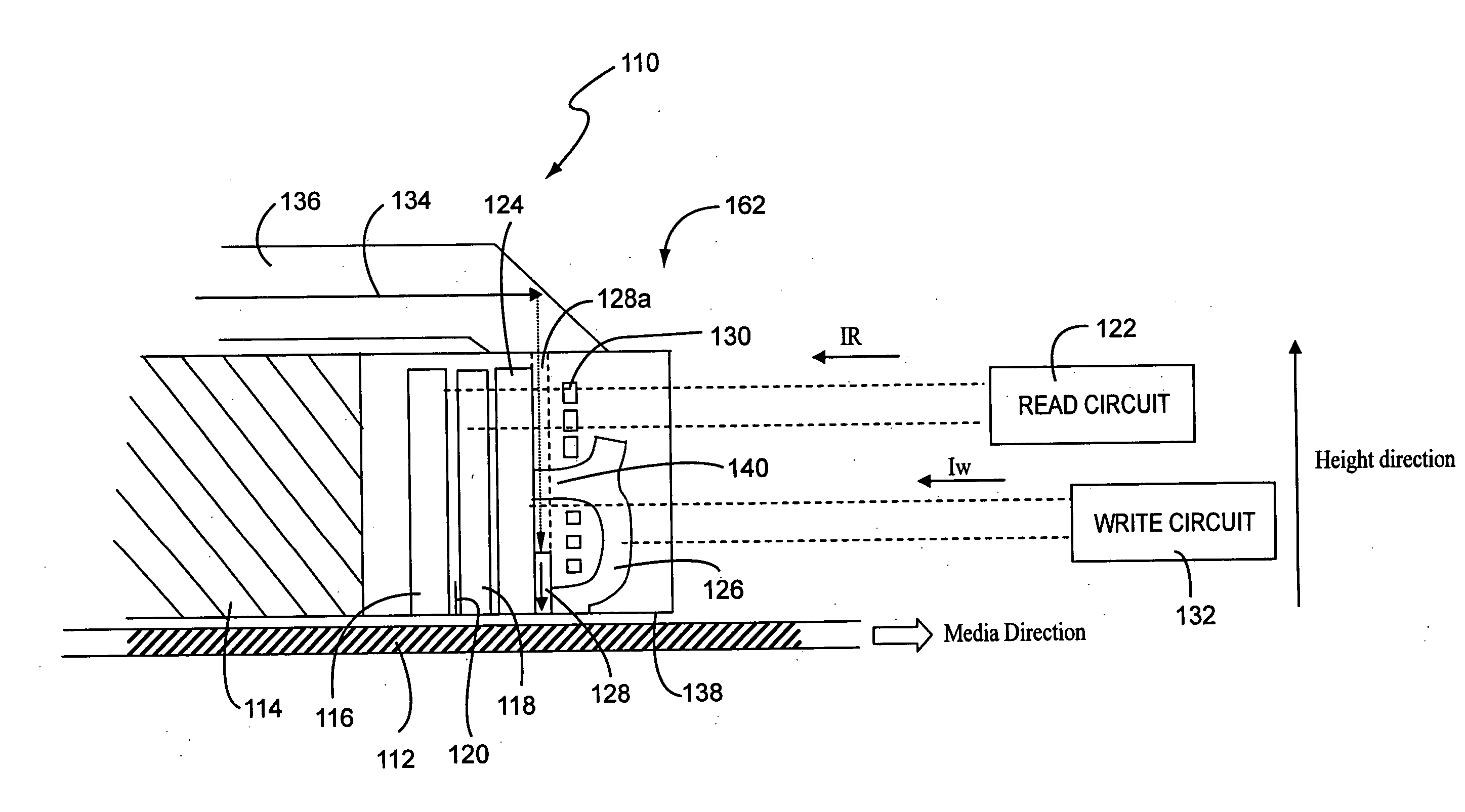

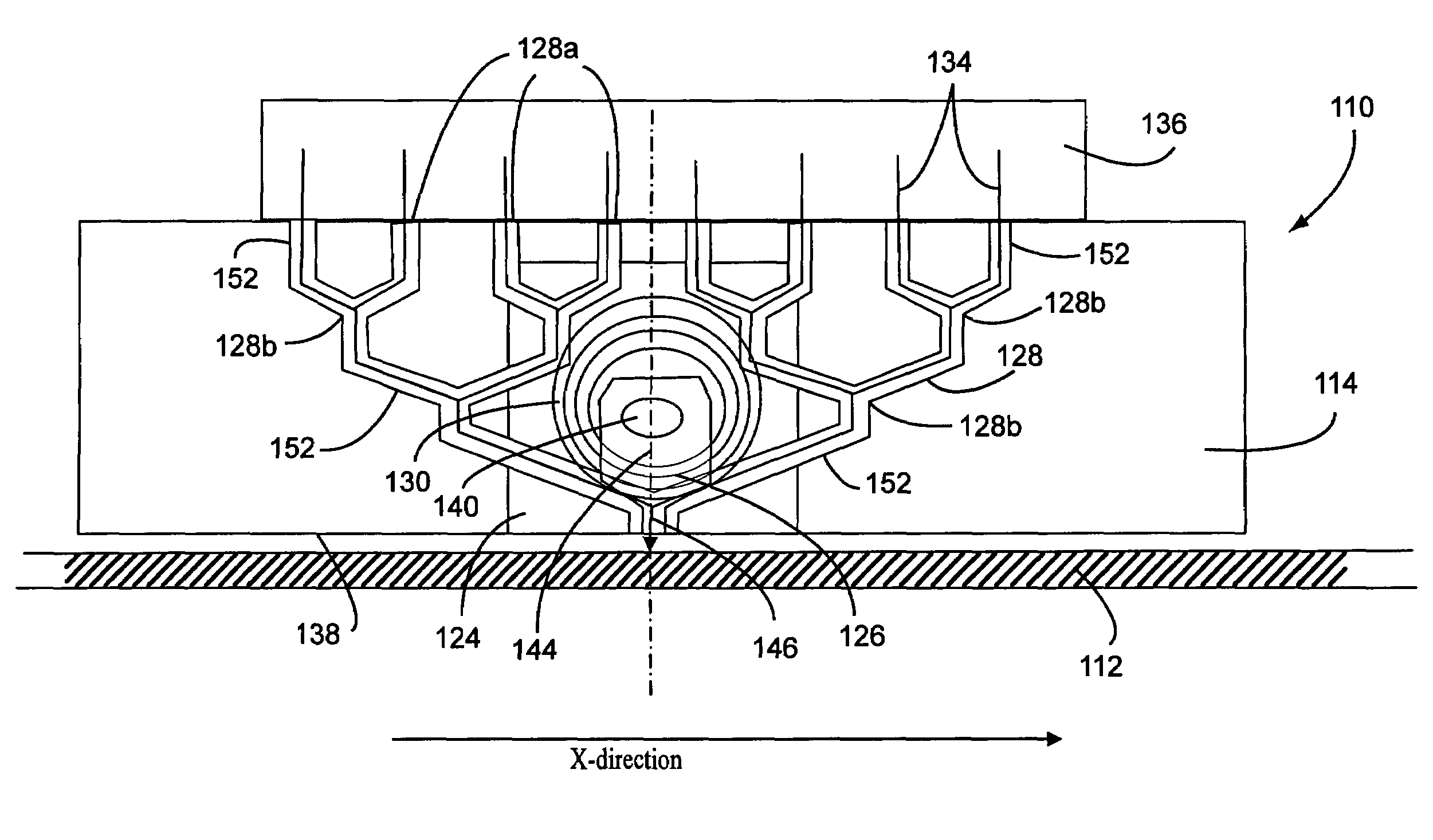

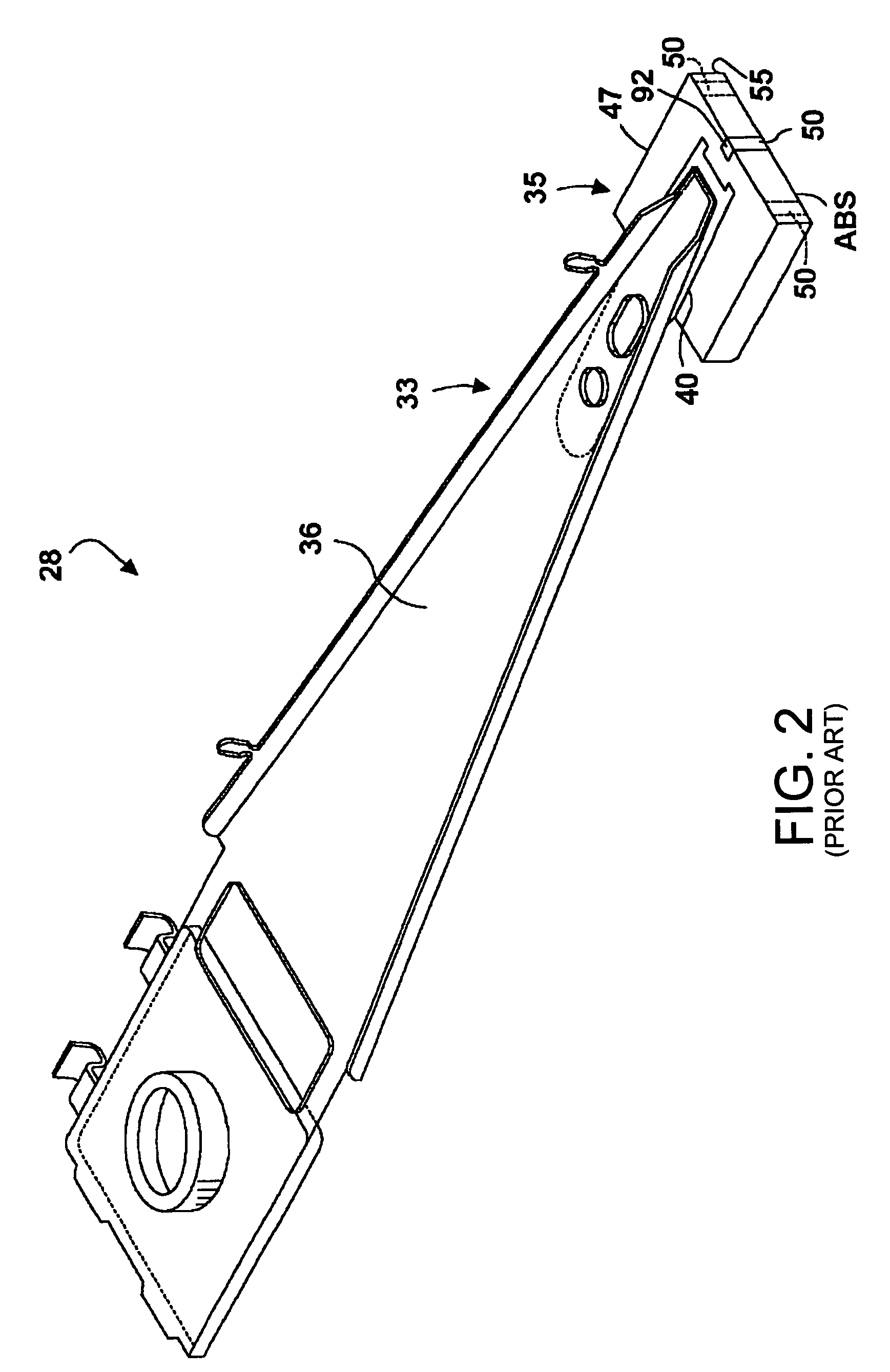

Magnetic thin film head with heat-assisted write section and hard disk drive incorporating same

InactiveUS20060143635A1High densityImproves servo writing processCombination recordingManufacturing heads with multiple gapsHard disc driveEngineering

A thin film magnetic read / write head for use in magnetic data storage systems to enable writing of data to a magnetic data storage medium with the assistance of laser heating. The read / write head allows magnetic reading of data from the storage medium, and thermally assisted magnetic writing of data on the storage medium. A waveguide is provided in a write gap in the form of an optical circuit having a plurality of inputs and a single output at the air bearing surface (ABS) for concentrating laser light used for heating the storage medium during the write operation. The thermally assisted magnetic writing improves the thermal stability of the recorded data and usefulness thereof throughout a wide temperature range.

Owner:SAE MAGNETICS (HK) LTD

Laser processing for heat-sensitive mesoscale deposition of oxygen-sensitive materials

InactiveUS8110247B2Low damage thresholdRadiation applicationsPretreated surfacesForming gasLaser processing

Owner:OPTOMEC DESIGN CO

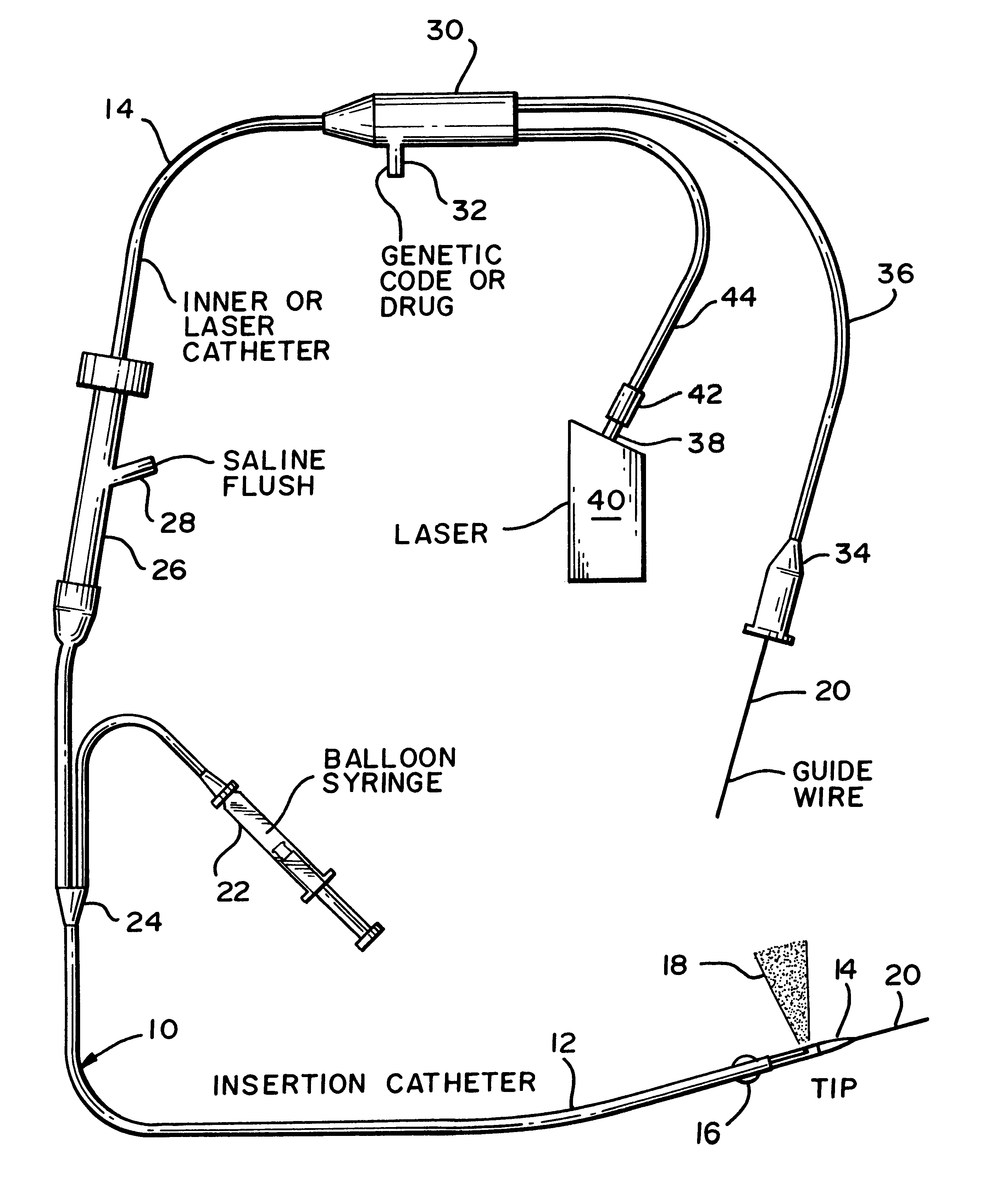

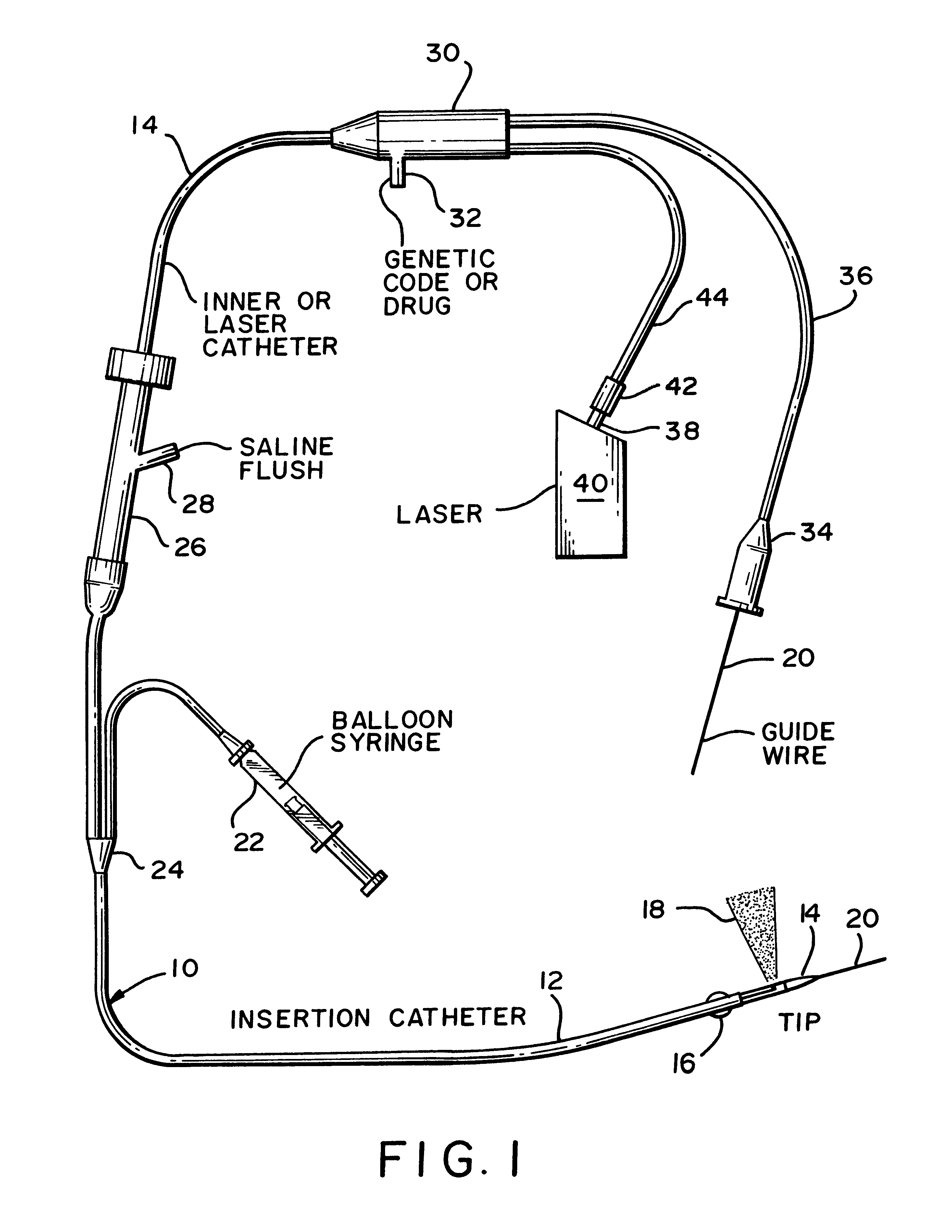

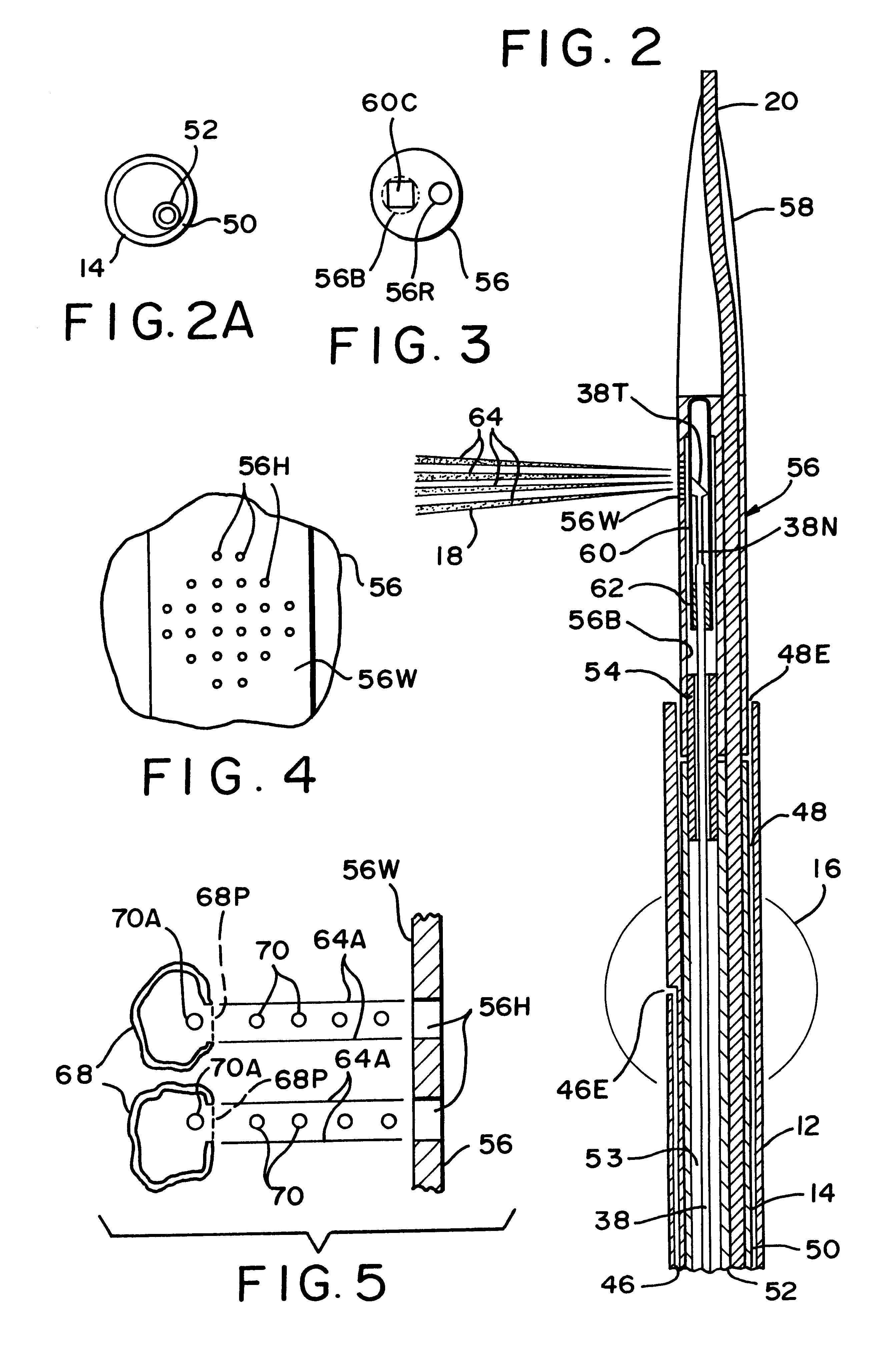

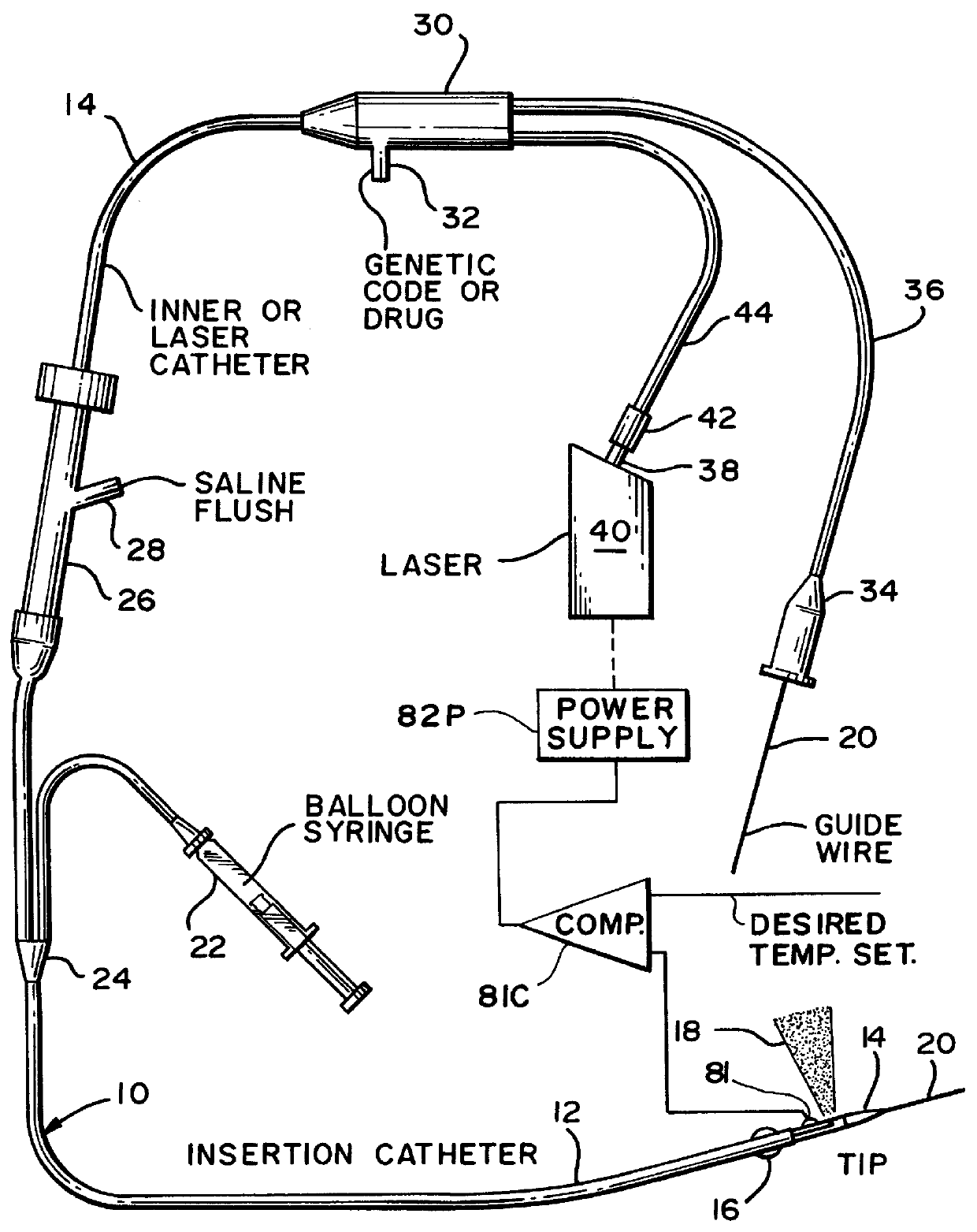

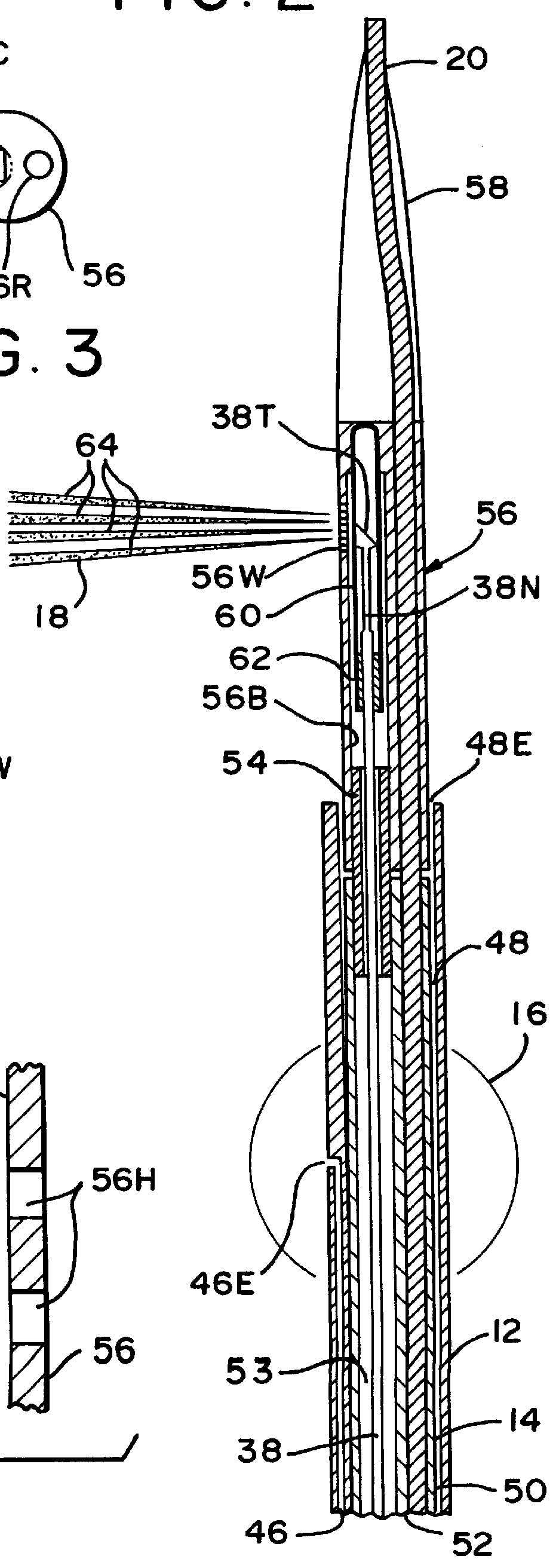

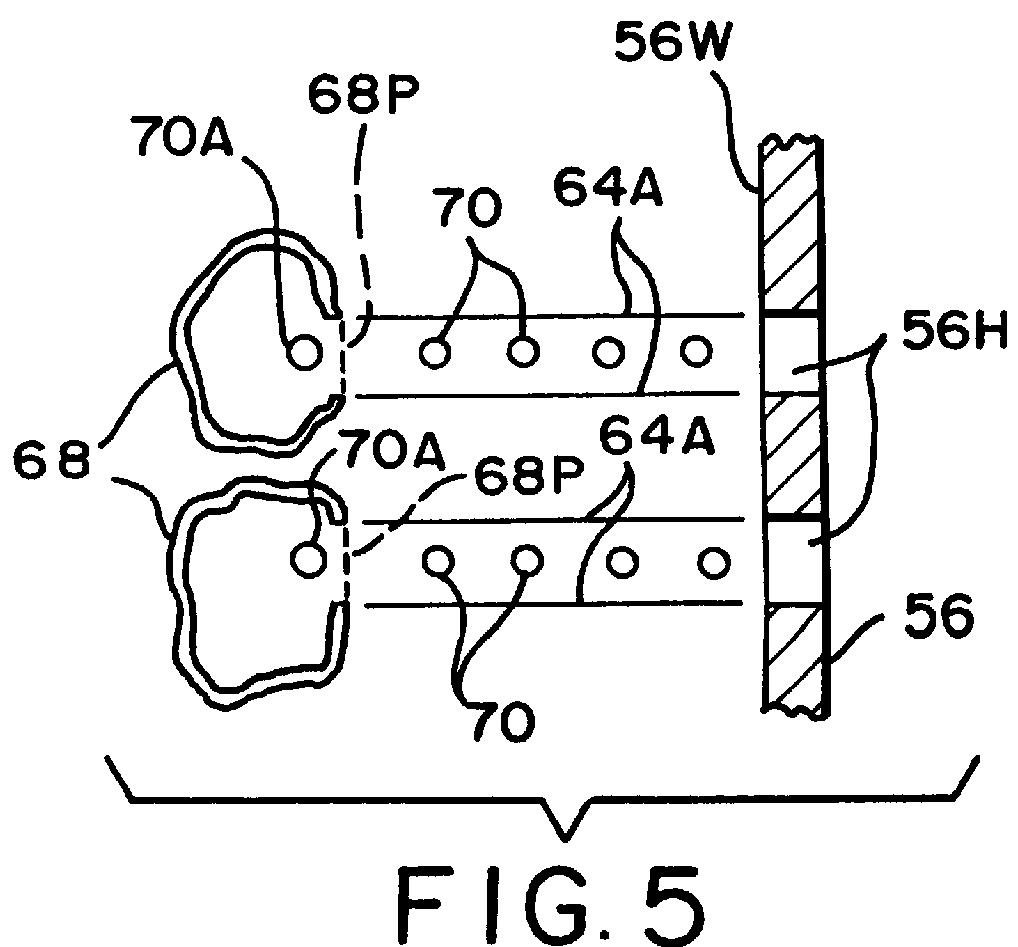

Cell transfection apparatus and method

InactiveUS6190380B1Transfection of cells in vivo relatively quicklyReduce amountCatheterSurgical instruments for heatingMicrowaveGenetic Materials

An apparatus and associated method provides for the application of a cell treatment agent, such as genetic material or drugs to be inserted within the cells of a patient in vivo. The apparatus may be a catheter arrangement with various embodiments for applying heat to a patient's cells in vivo in order to improve transfection efficiency or application efficiency. Laser beams may be applied directly to the cells. Alternately, the cells may be heated by electrical heating, chemical heating, radio frequency heating, microwave heating, infrared heating, ultrasound heating, or indirect laser heating. Further, the treatment agent may be heated prior to its application to the patient such that the treatment agent heats the cells of the patient.

Owner:ABELA GEORGE S

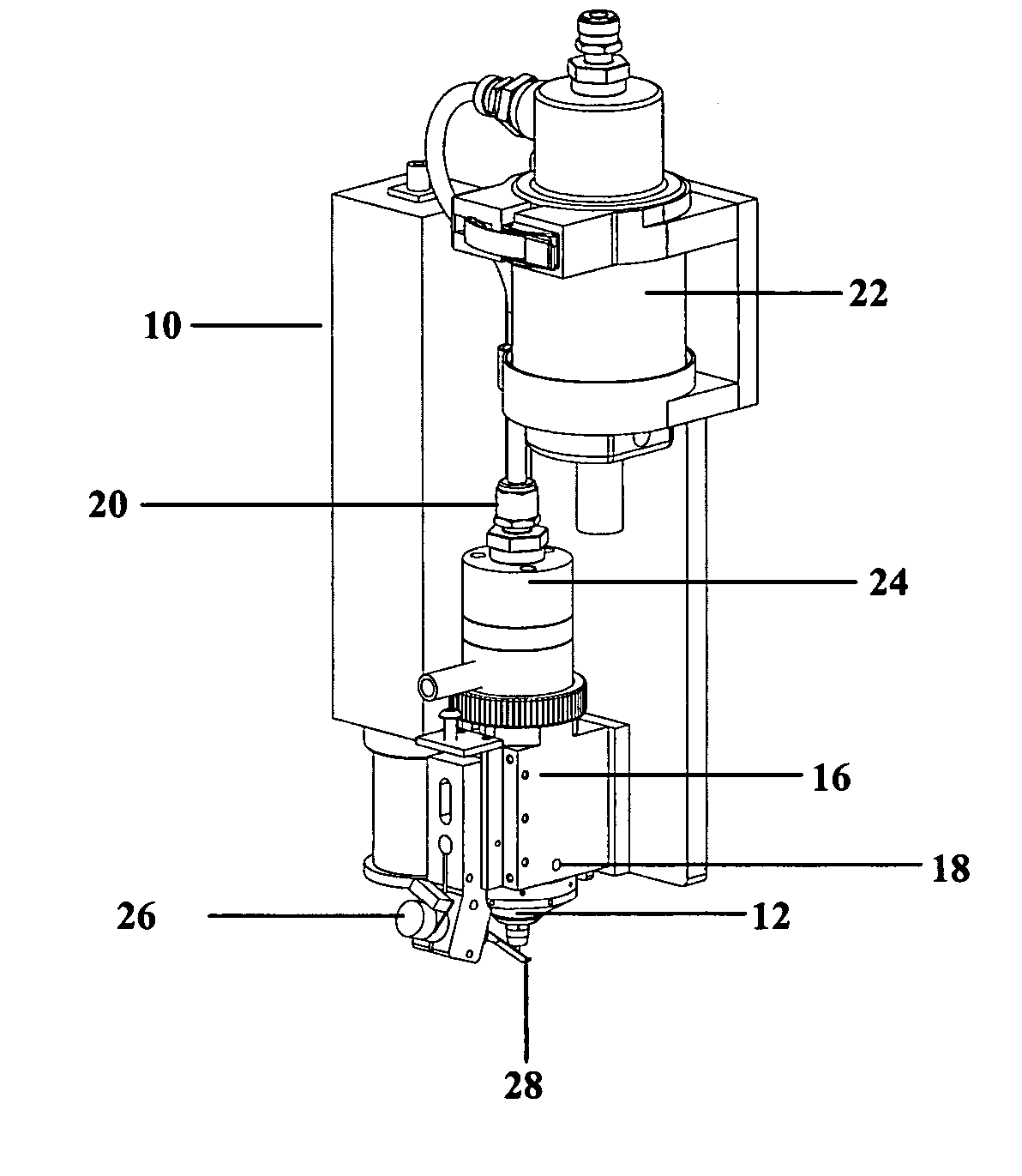

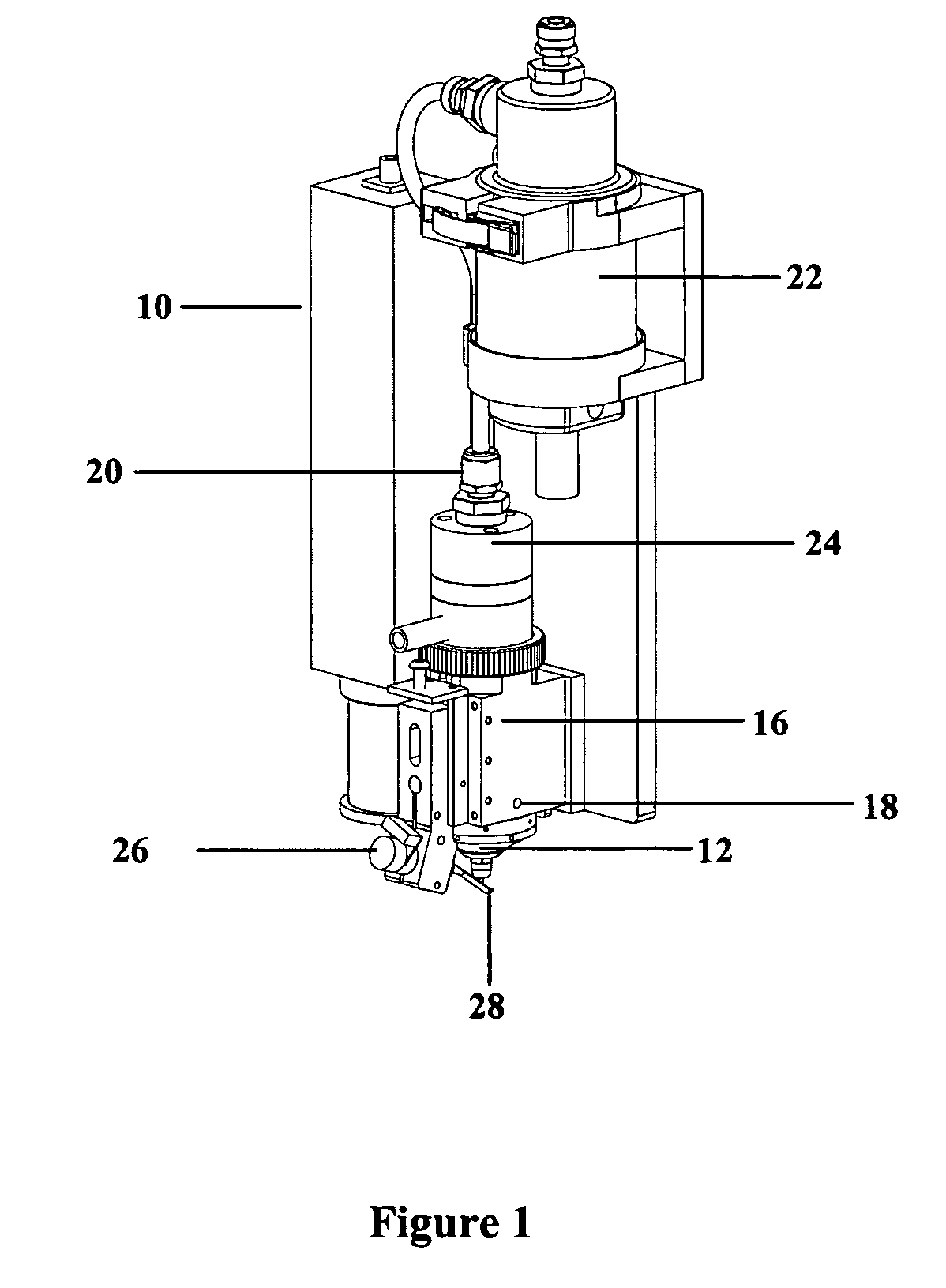

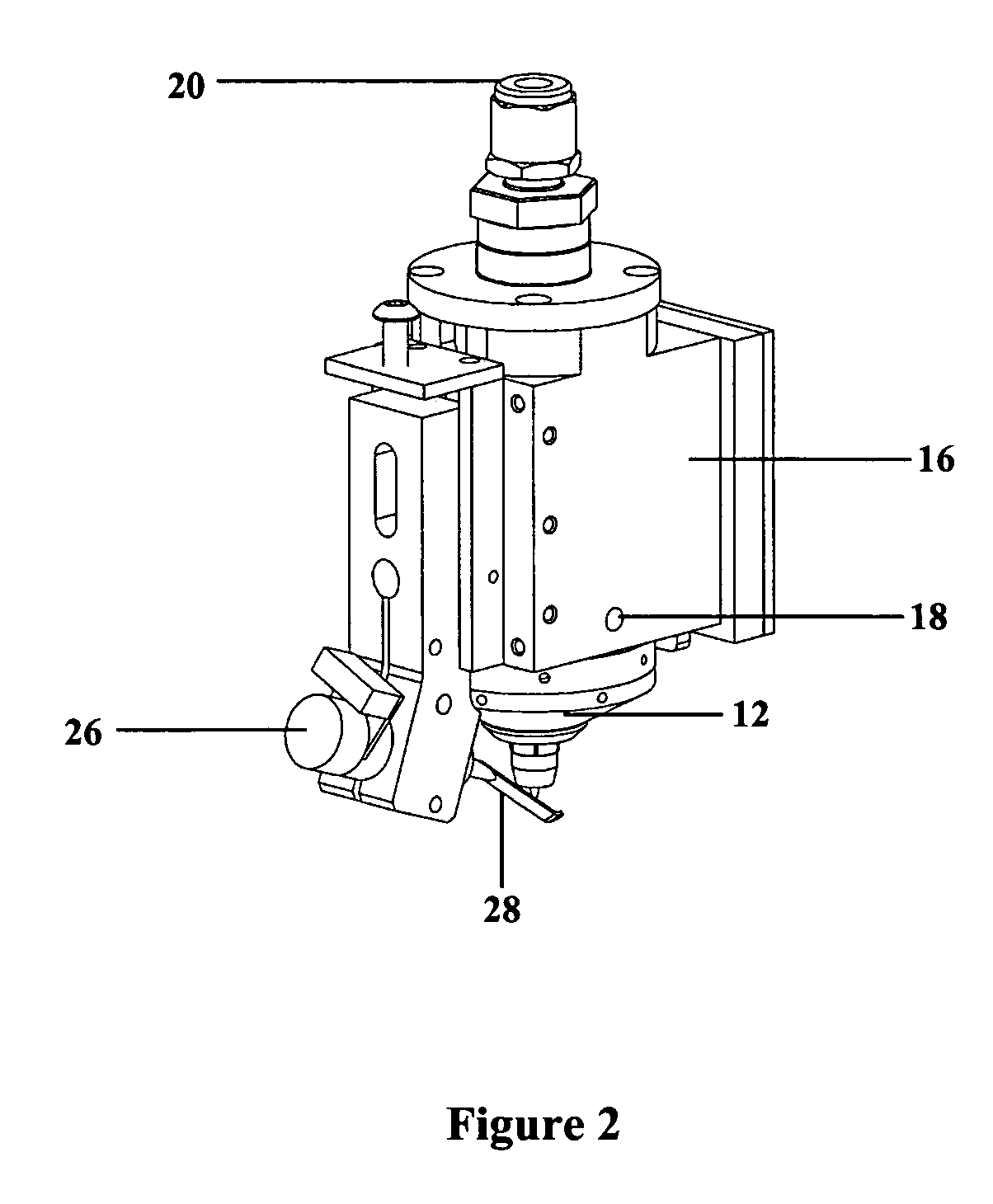

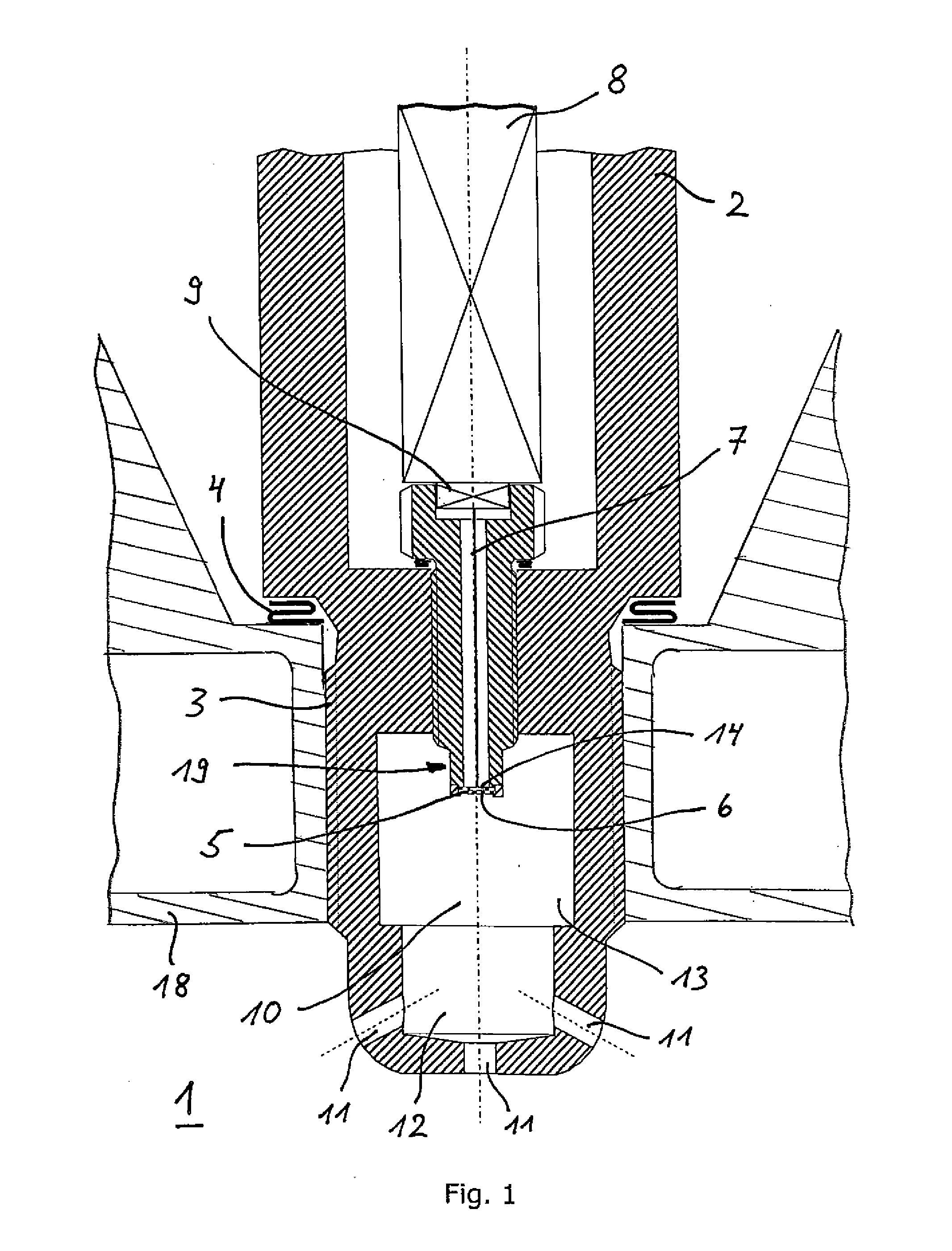

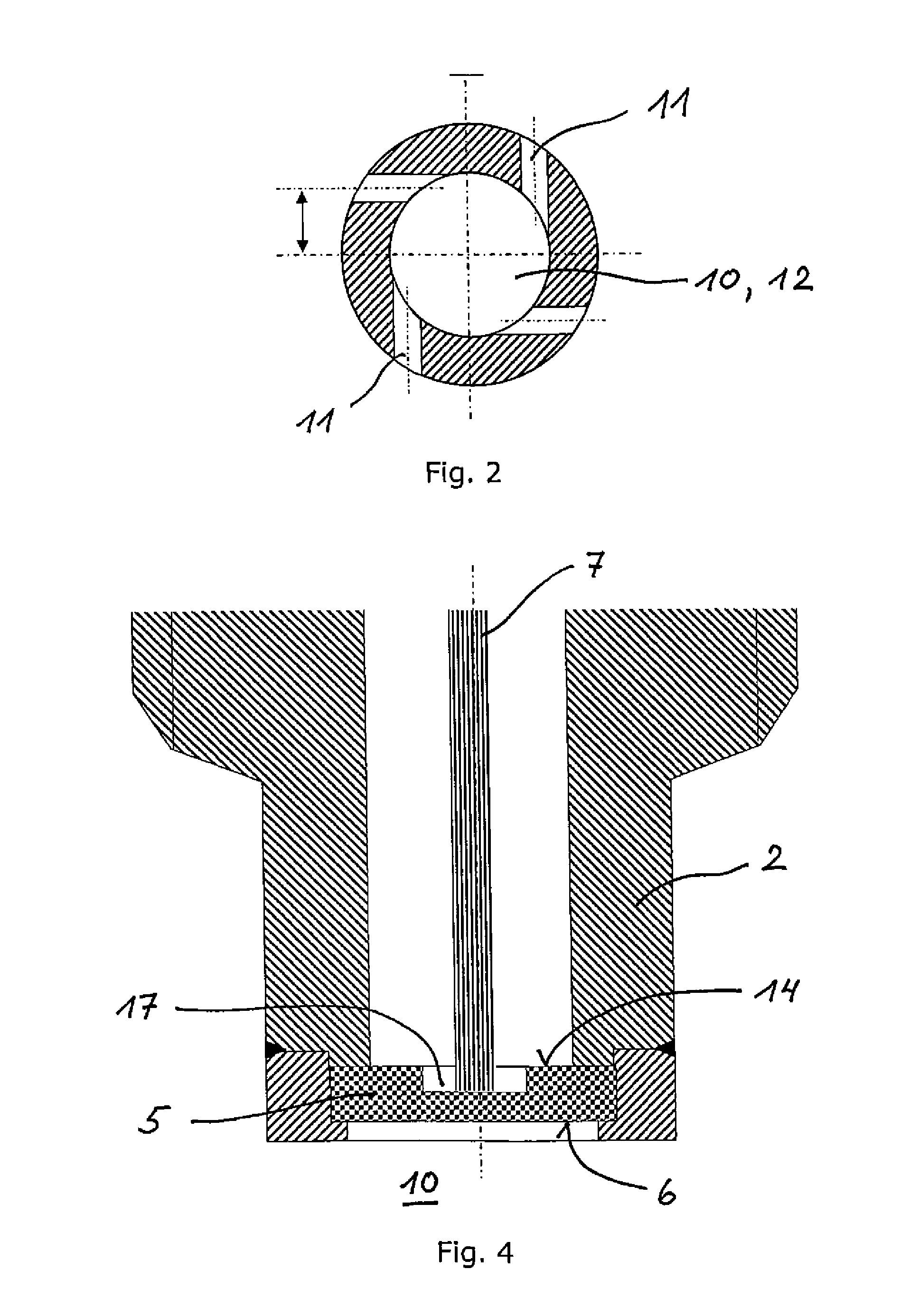

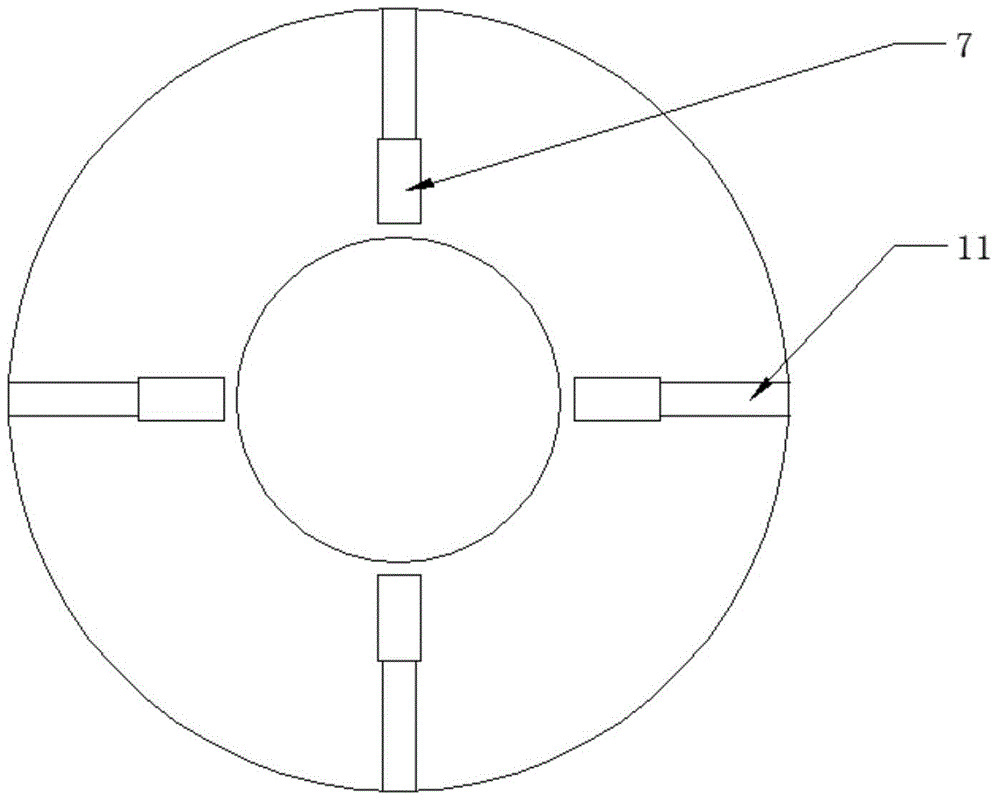

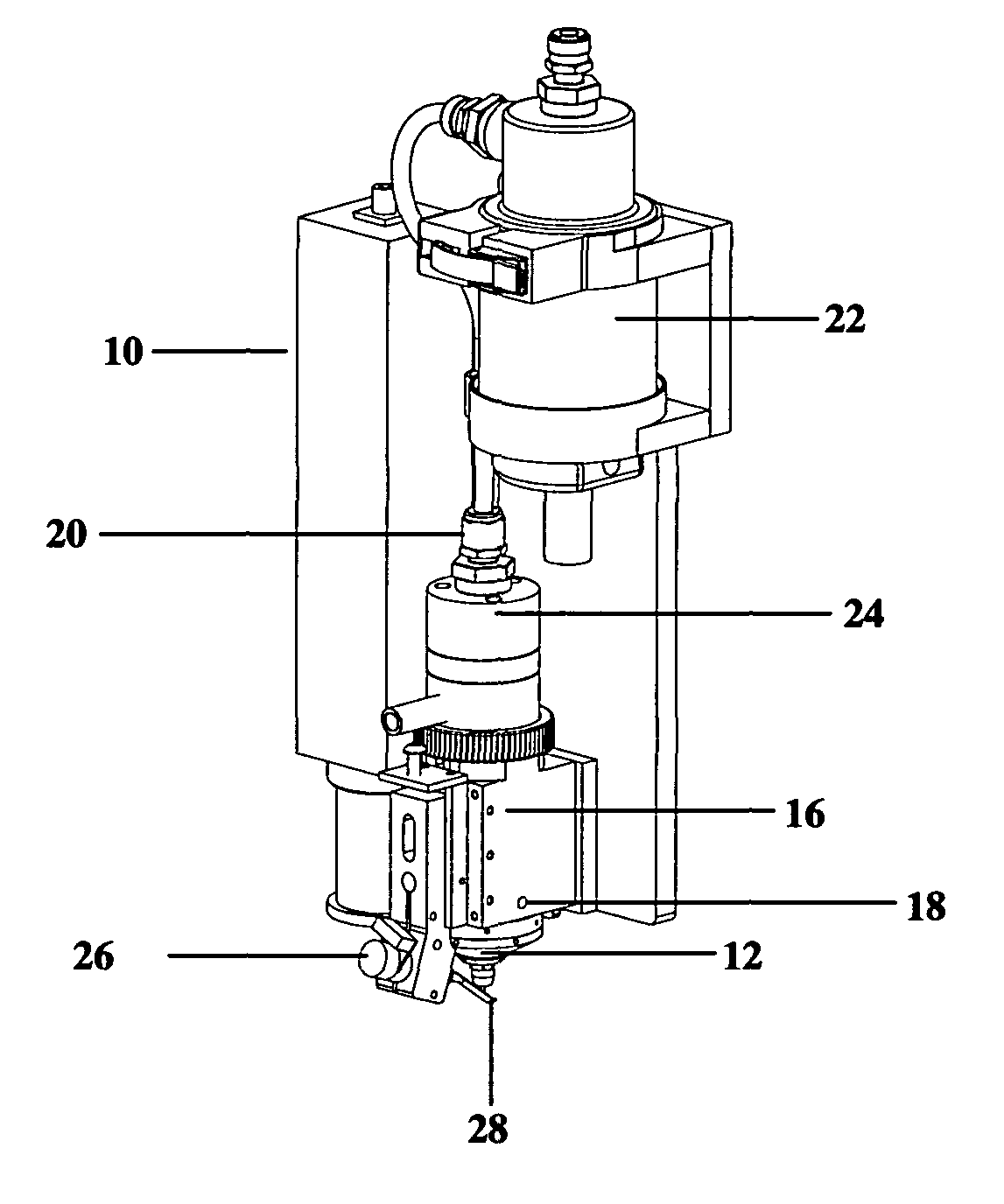

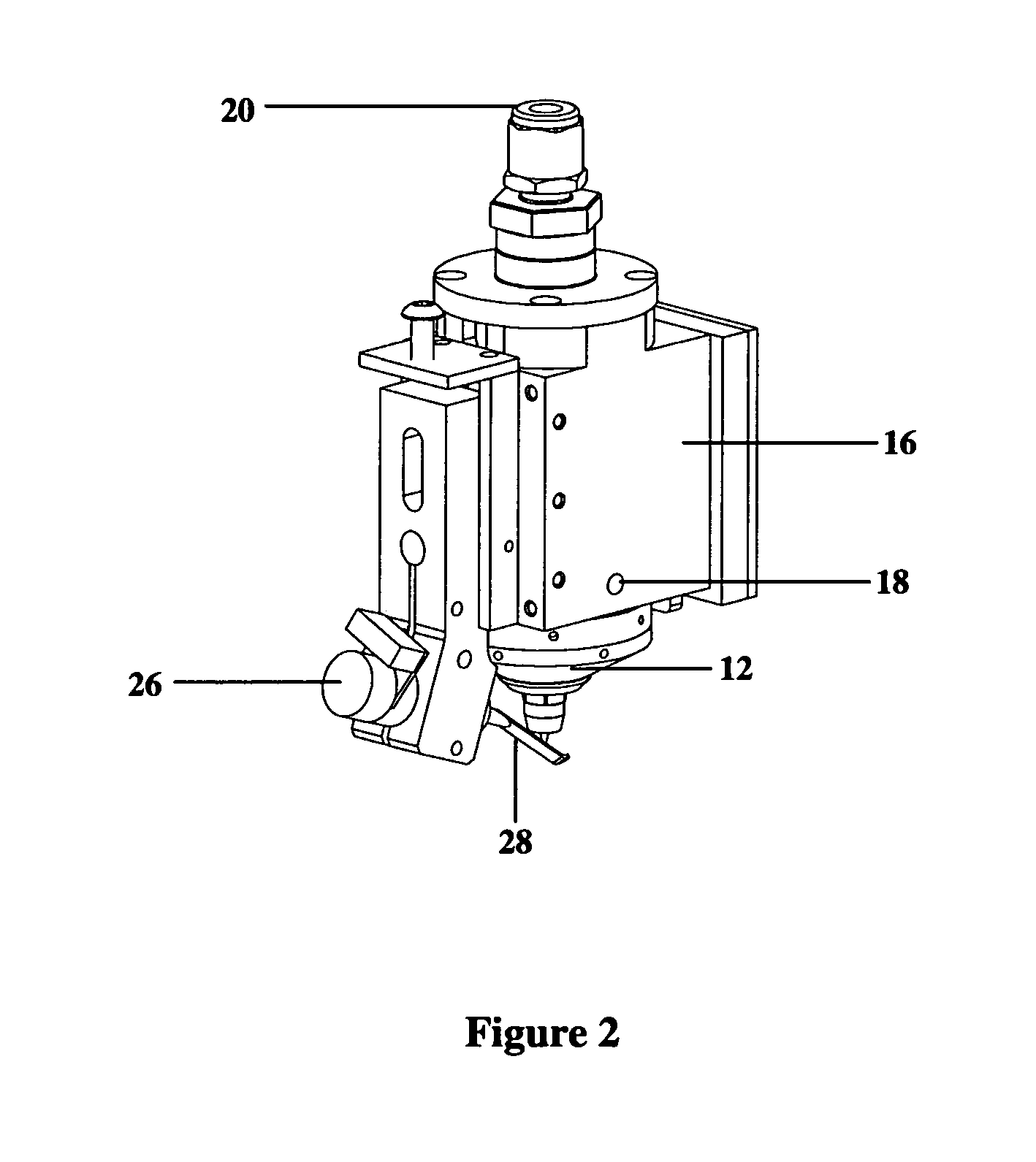

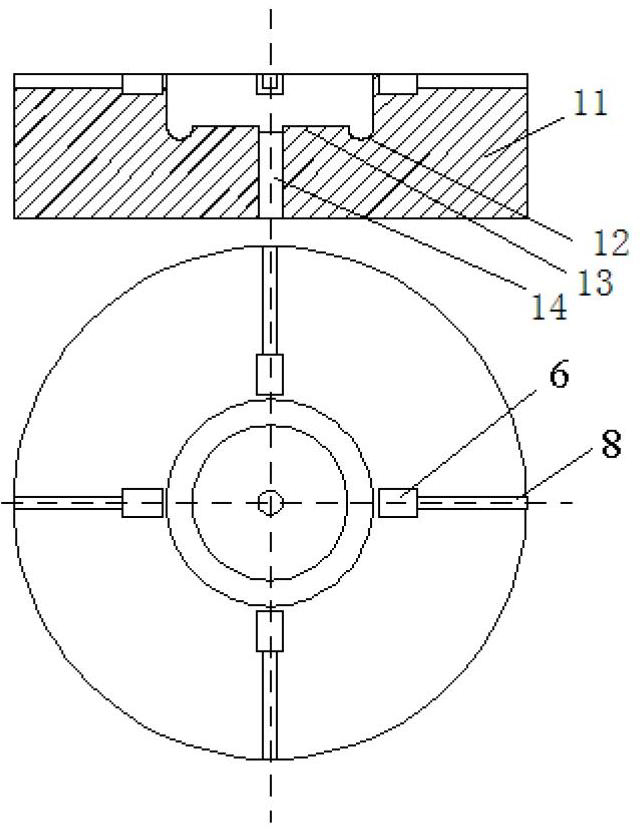

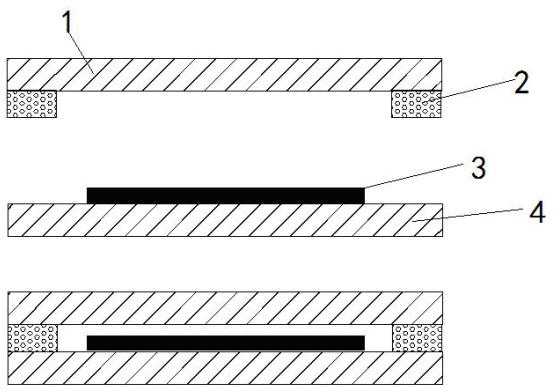

Laser heating rivetless riveting device

InactiveCN102672062AGood formabilityImprove ductilityShaping toolsElectrical resistance and conductanceControl system

The invention relates to a laser heating rivetless riveting device in the technical field of automobile manufacturing. The laser heating rivetless riveting device comprises a compound punch pin, a compound blank holder, a compound lower die and a laser control system, wherein, the compound punch pin is sheathed with the compound blank holder, and the compound punch pin, a workpiece and the lower die are arranged coaxially from top to bottom; hollow circular holes are formed at the center parts of the compound punch pin and the compound lower die; optical fiber tubes and concave lenses are arranged in the hollow circular holes; grooves are formed in the surfaces of the compound blank holder and the compound lower die in contact with a panel veneer, and are used for laying out thermistors that are lead wires; and the lead wires are connected with a laser control system. The laser heating rivetless riveting device heats a forming area of riveting material through laser before riveting forming so as to improve the forming performance of material, prevents fragile material from being easy to crack and fracture during the riveting process, reduces the plastic deformation resistance of material at the same time, enables the panel veneer to deform fully during the forming process, is easy to get a rivet joint with better quality, and reduces the requirements on riveting force and rigidity of riveting equipment at the same time along with the reduction of plastic deformation resistance of material.

Owner:JILIN UNIV

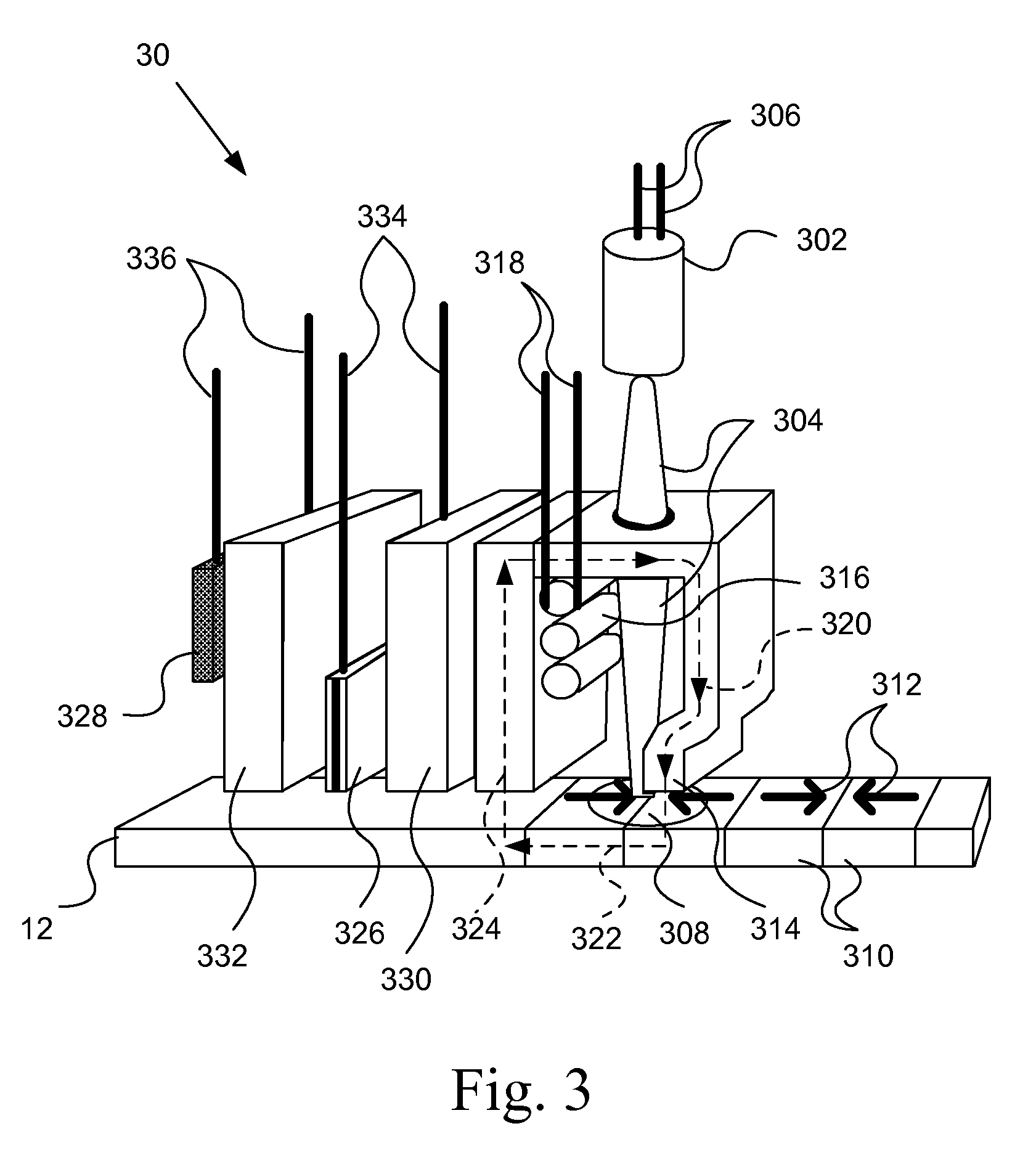

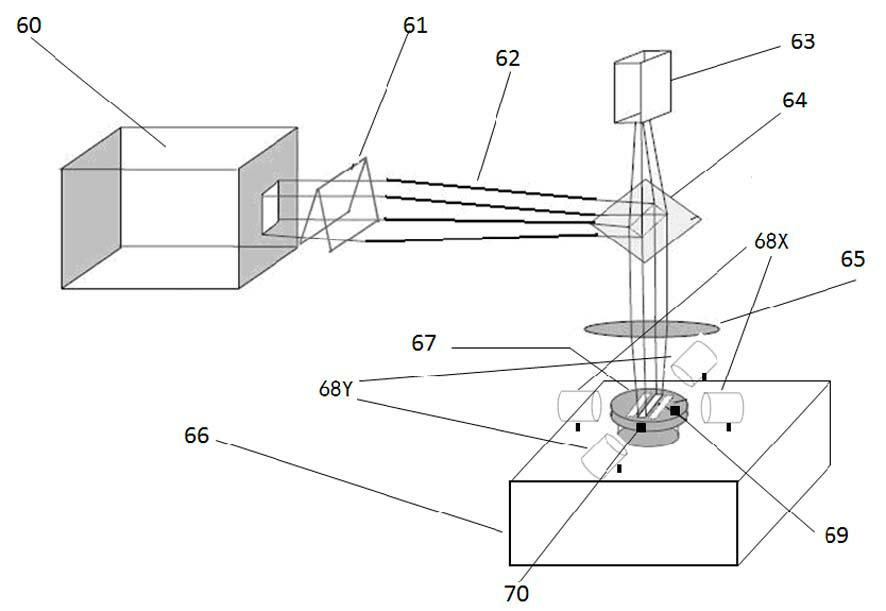

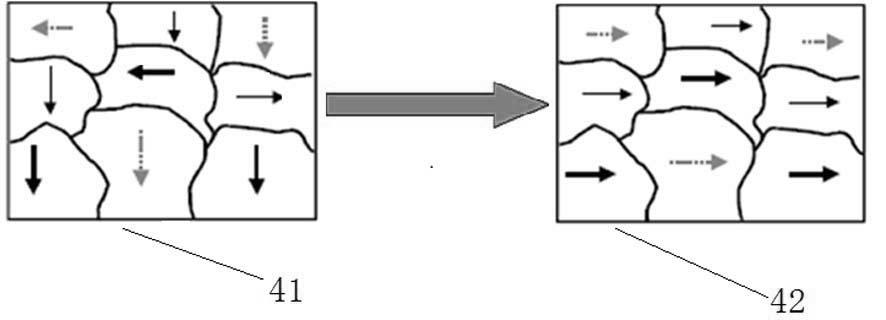

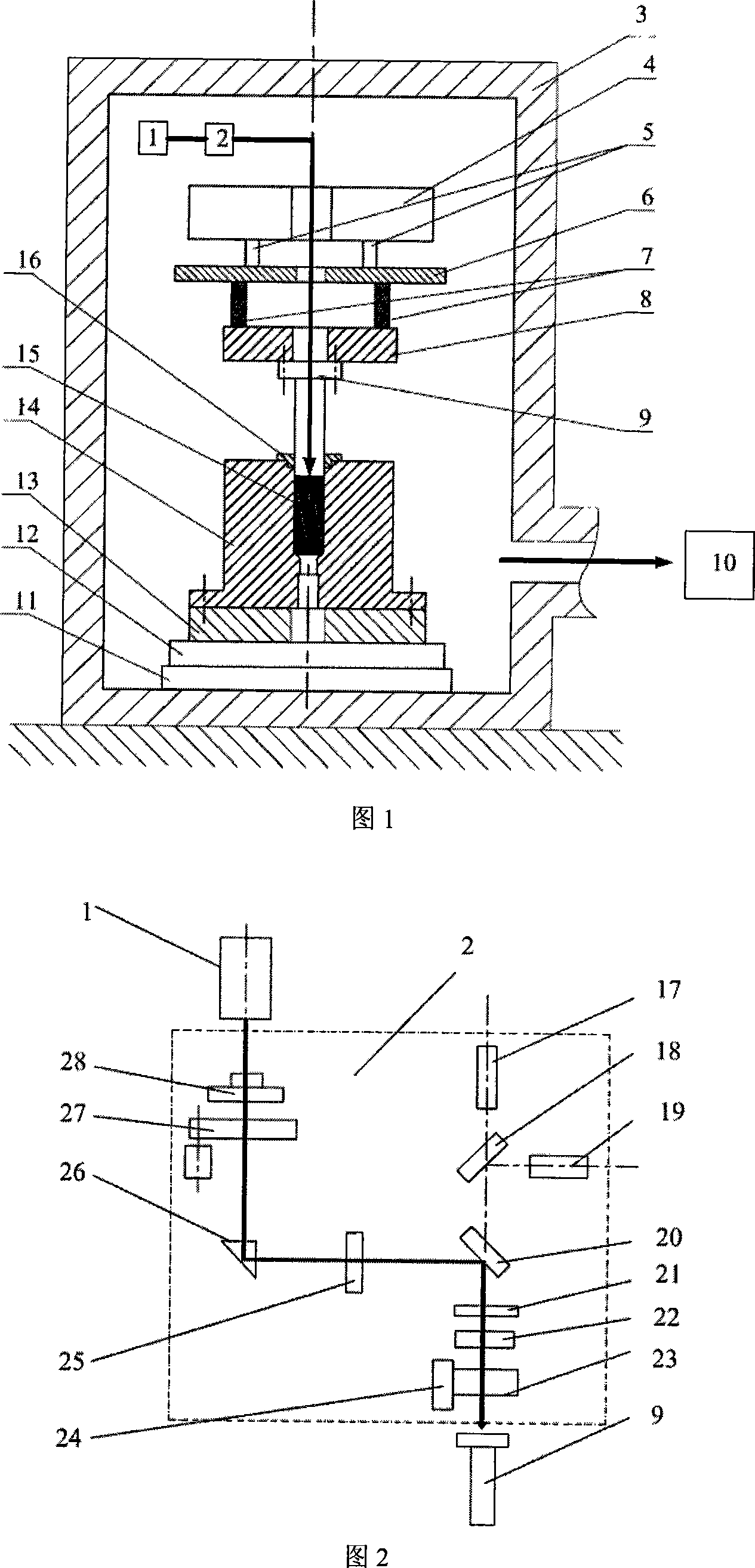

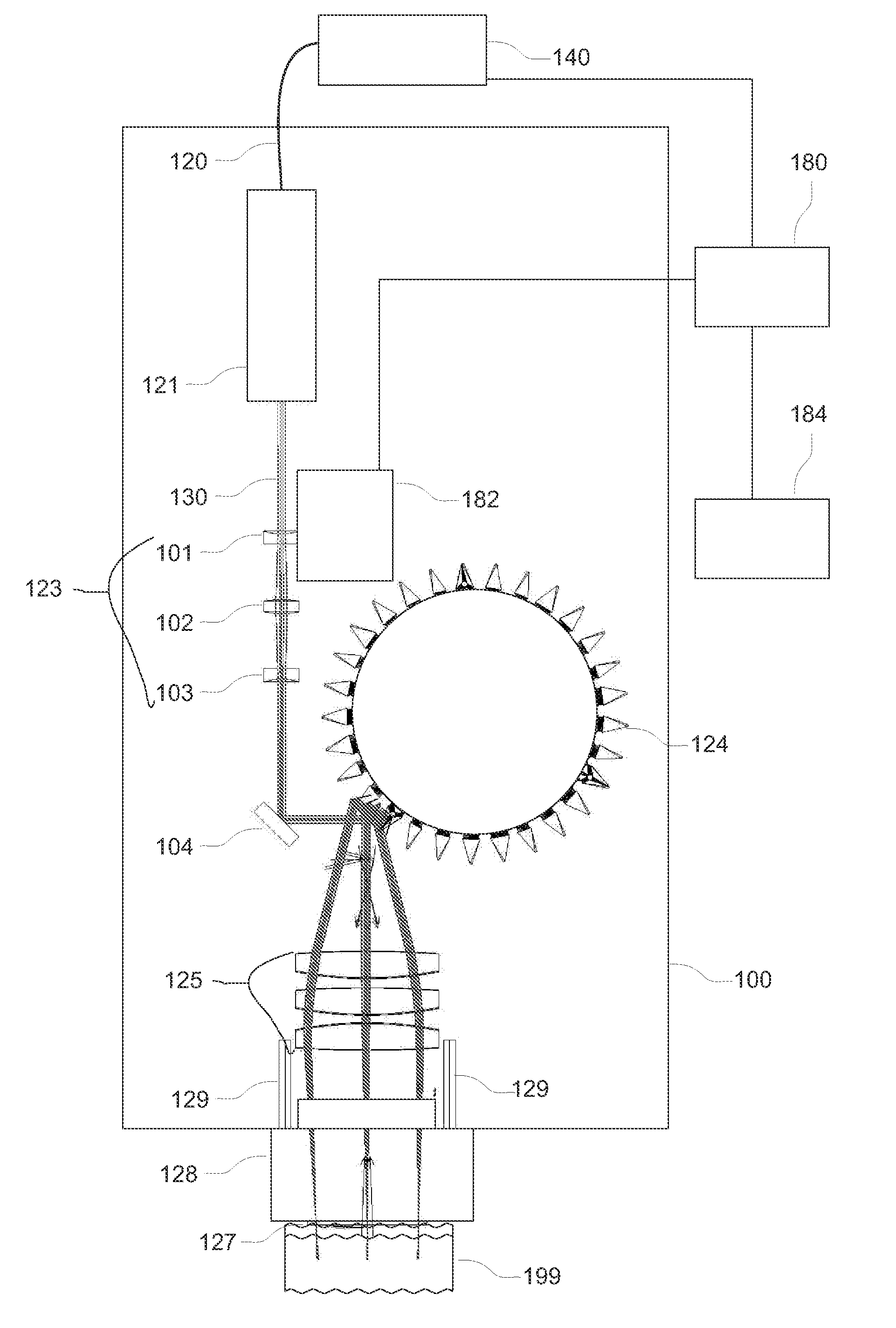

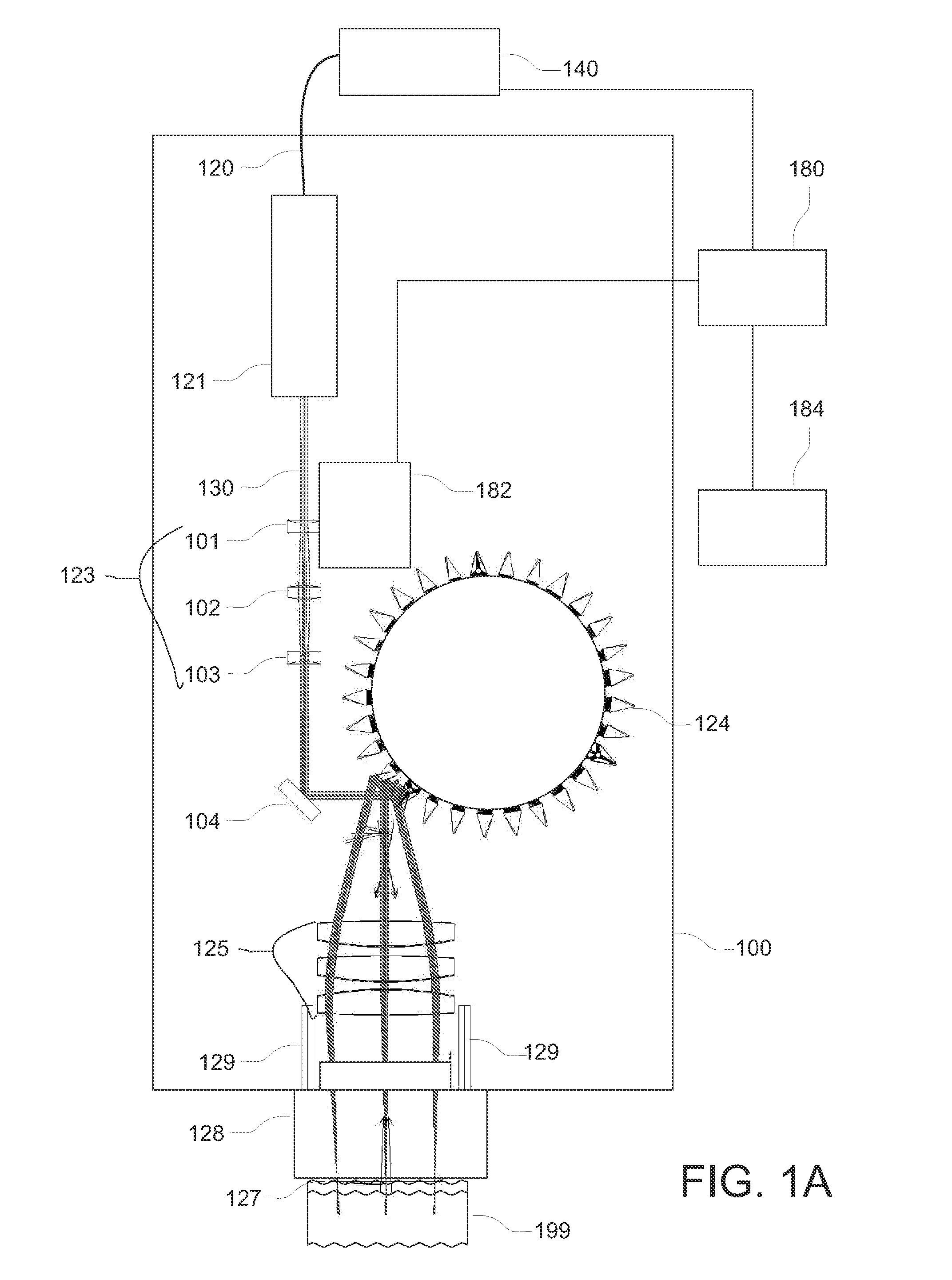

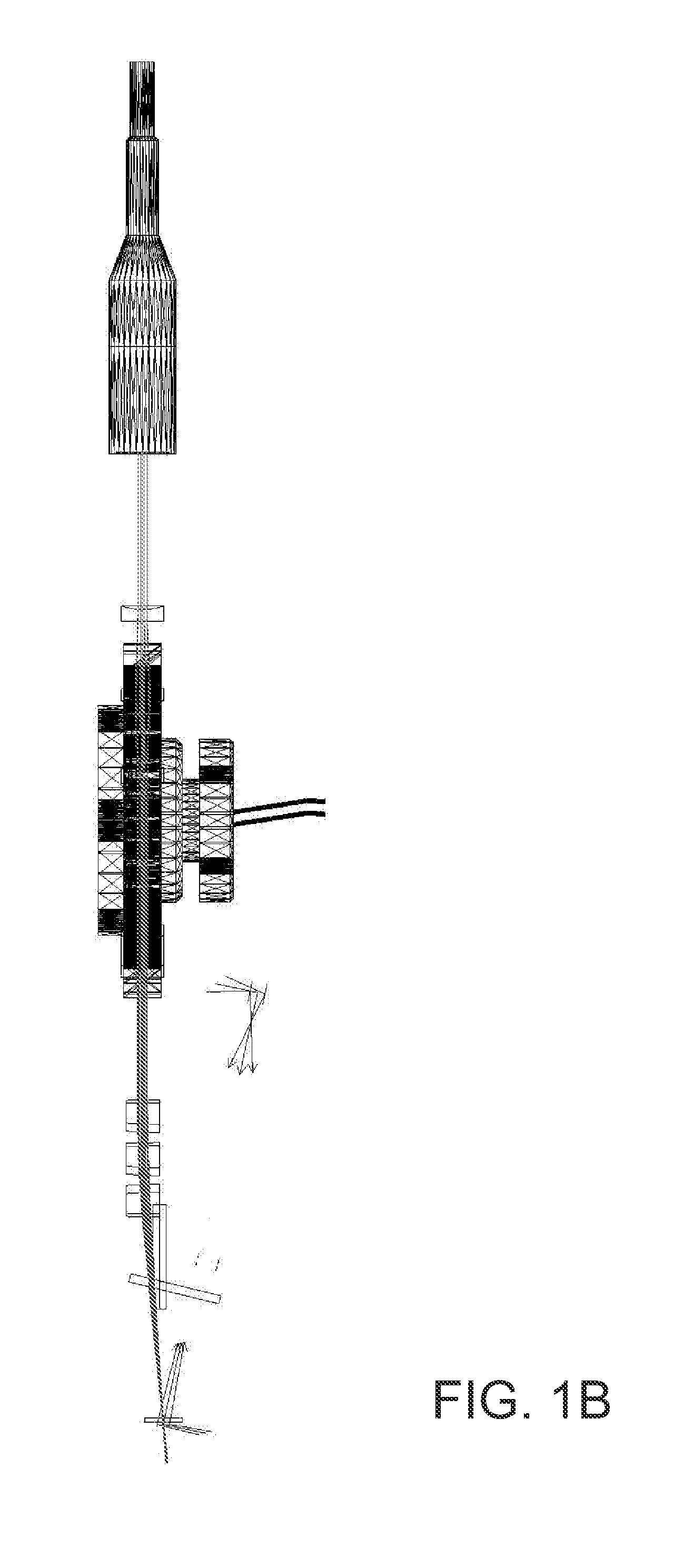

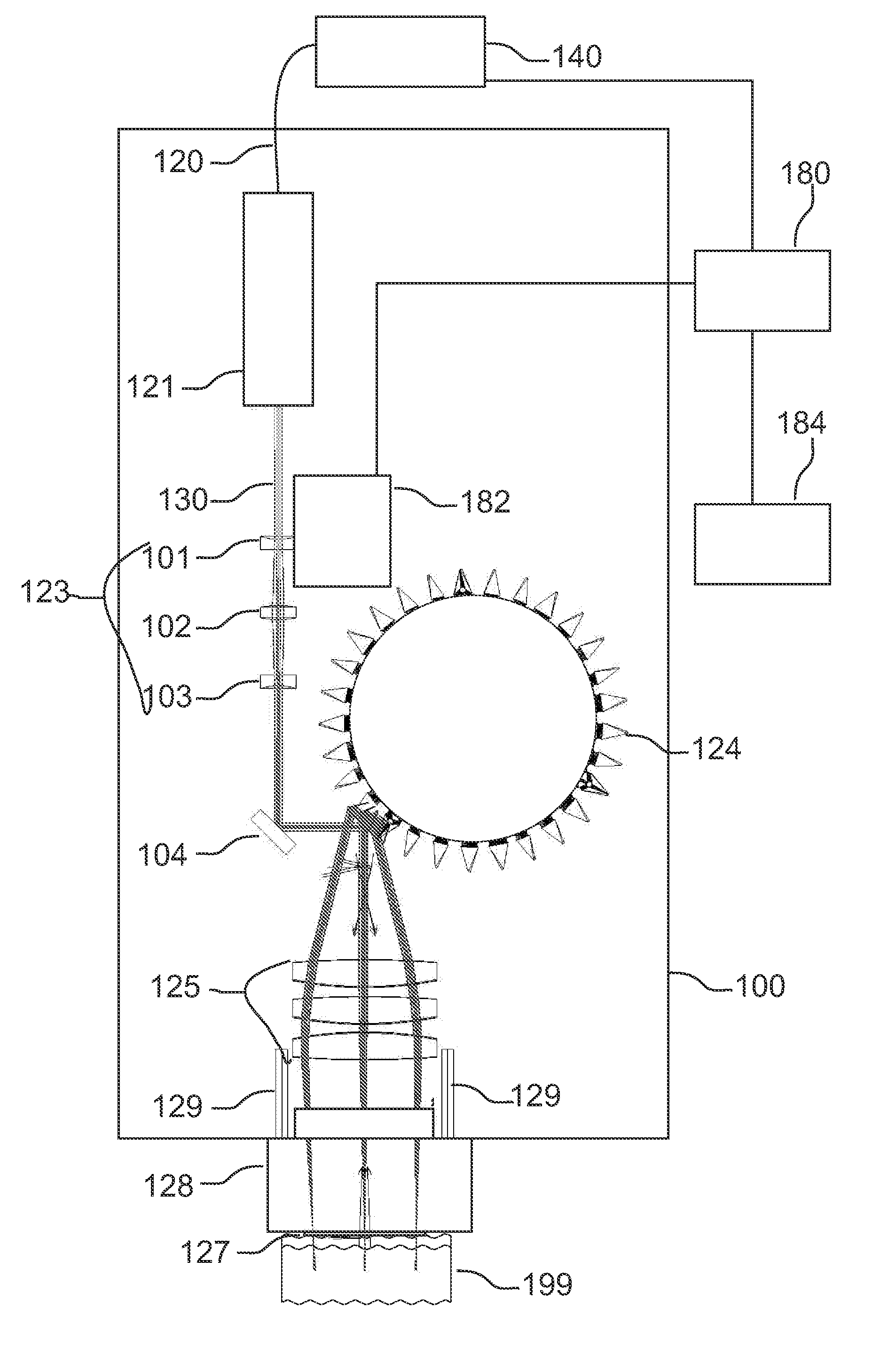

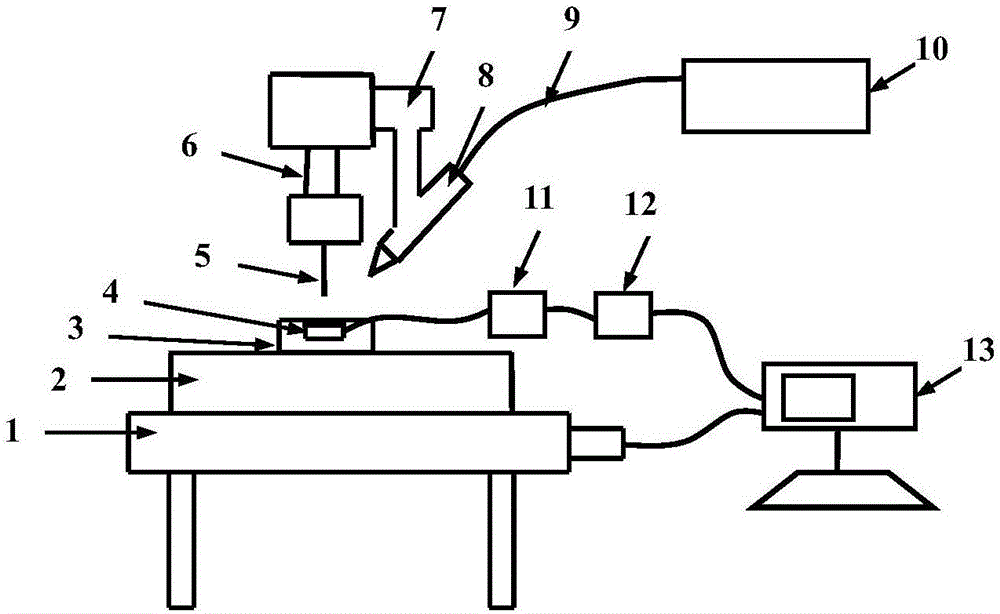

Single-chip magnetic sensor, and laser heating-assisted annealing apparatus thereof and laser heating-assisted annealing method thereof

ActiveCN102208530AHigh sensitivityGood magnetoresistance matchingMagnetic measurementsMagnetic-field-controlled resistorsOptoelectronicsOptical attenuator

The invention discloses a single-chip magnetic sensor, and a laser heating-assisted annealing apparatus thereof and a laser heating-assisted annealing method thereof. The laser heating-assisted annealing method comprises the following steps: (a), annealing is carried out on a magnetic thin film in a strong magnetic field, so that magnetic moments on a pinning layer of the magnetic thin film are towards a same direction; (b), the magnetic thin film is fixedly disposed on a clamp of a movable platform; (c), a laser source is opened to emit a laser beam, which is attenuated through an optical attenuator; the direction of the attenuated laser beam is changed through a reflective mirror; and the laser beam with the changed direction is focused into a light spot by a focusing objective lens; (d), the movable platform is moved, in order that the focused light spot of the laser beam is aimed at the magnetic thin film so as to enable the magnetic thin film to be heated by the laser beam; (e), a magnetic field intensity of an electromagnet arranged on the movable platform is adjusted, so that a magnetic domain of the heating area of the magnetic thin film can be overturned; and (f), the magnetic thin film is cut into slices, and the slices of the cut magnetic thin film are bound into one.

Owner:MULTIDIMENSION TECH CO LTD

Cell transfection apparatus and method

InactiveUS6071276ATransfection of cells in vivo relatively quicklyReduce amountCatheterSurgical instruments for heatingIn vivoRadio frequency

An apparatus and associated method provides for the application of a cell treatment agent, such as genetic material or drugs to be inserted within the cells of a patient in vivo. The apparatus may be a catheter arrangement with various embodiments for applying heat to a patient's cells in vivo in order to improve transfection efficiency or application efficiency. Laser beams may be applied directly to the cells. Alternately, the cells may be heated by electrical heating, chemical heating, radio frequency heating, microwave heating, infrared heating, ultrasound heating, or indirect laser heating. Further, the treatment agent may be heated prior to its application to the patient such that the treatment agent heats the cells of the patient.

Owner:ABELA GEORGE S

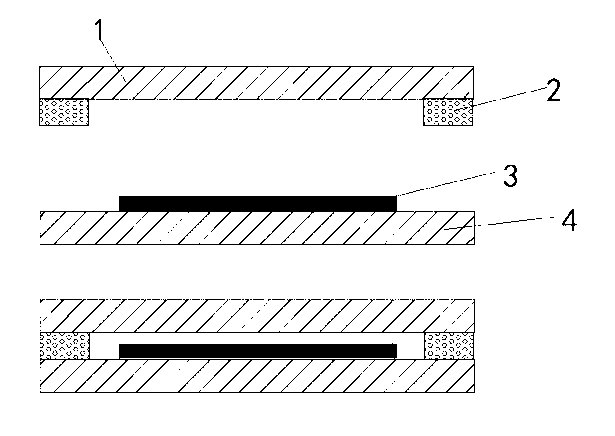

Laser packaged glass powder sealing material for photoelectric device packaging

InactiveCN102701591ASolid-state devicesSemiconductor/solid-state device manufacturingFritThermal expansion

The invention discloses a laser packaged glass powder sealing material for photoelectric device packaging, and belongs to the technical field of photoelectric device packaging. The sealing material is a combined material of laser packaged glass powder and high-temperature non-conductive ceramic powder added according to the proportion of 5 to 15%. All elements in the sealing material are easily available, so that the cost is low. The softening point of the packaged glass powder has the temperature of 420 to 450 DEG C and the coefficient of thermal expansion of 75*10 <-7> / DEG C. In the packaging of glass, the selection range of laser heating equipment is wider, the laser packaged glass powder sealing material adapts to various different packaging manners, the cost is lowered, and the efficiency is improved; the added ceramic powder plays a role in supporting frit bands, and the frit bands have relatively low flowability in packaging, the packaged bands are closer to the distribution of the frits in sedimentation, the displacement deformation generated in the frit heating process is easy to control to enable the packaged bands to be regular; the frit bands have no great displacement deformation, no remark air holes exit in the packaged bands, and the erosion of oxygen and moisture is blocked by the effective airtight.

Owner:SHANGHAI UNIV

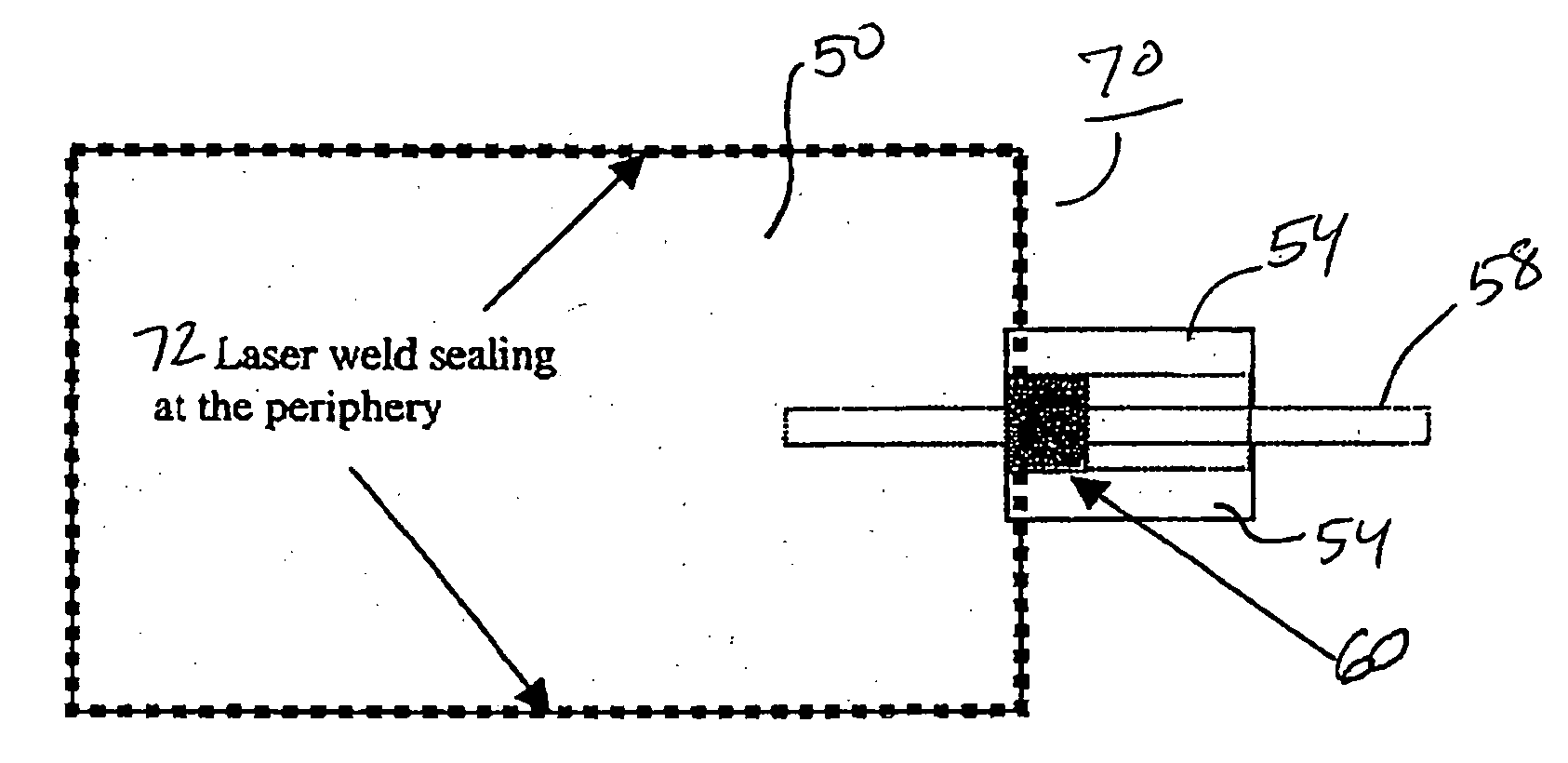

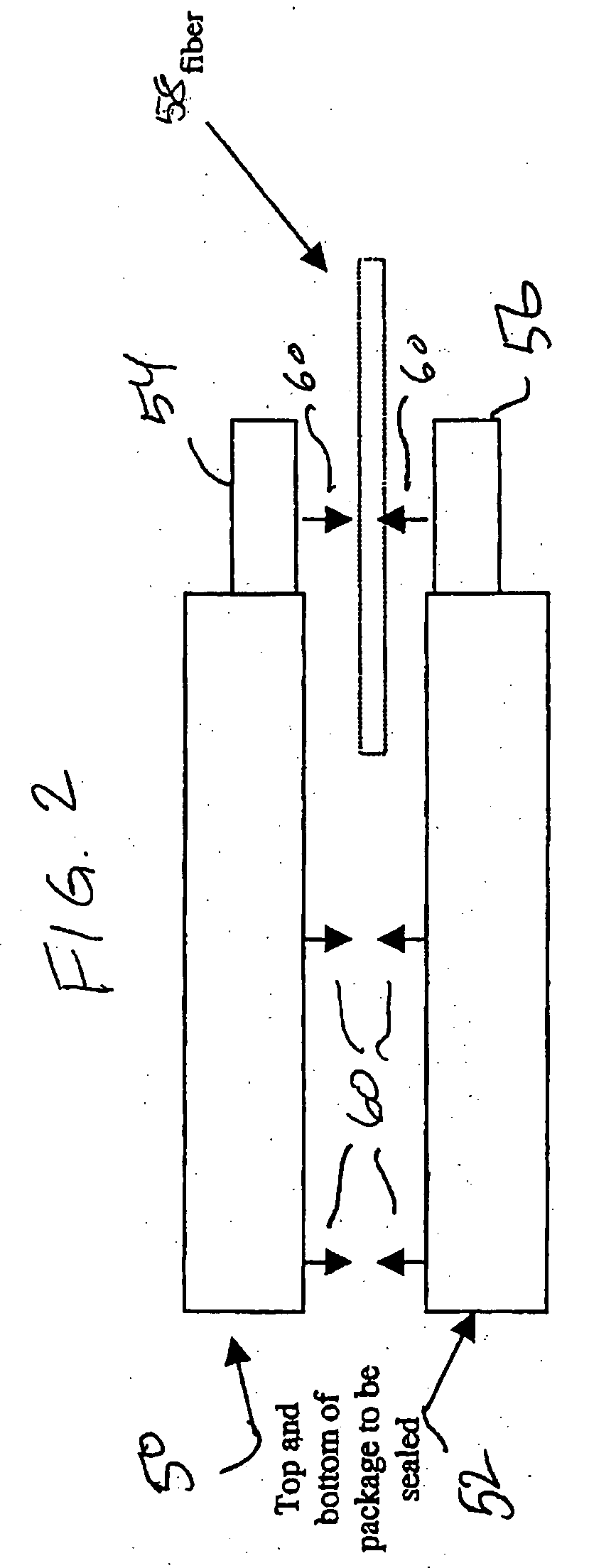

Hermetic sealing of optical module

A hermetically sealable package may be formed from a top portion and a bottom portion mated along a seam at or near a plane of an optical fiber. A completed pill assembly may be positioned directly into the enclosure base without requiring the fiber to be threaded through the feed through or “snout”. The top potion may then be mated with the bottom portion to form the package. A glass solder ring may be placed coaxial with the fiber in the feed through. The seam may be sealed by laser welding and the glass solder ring reflowed by laser heating, for example, with a same laser as used to weld the seam or by resistive or induction heating. In some embodiments a coupling tube around the fiber and snout or the snout itself may have holes to allow solder sealing within the snout and filling the remaining area with epoxy. Since the package is initially split in two pieces, module assembly may be facilitated without threading.

Owner:INTEL CORP

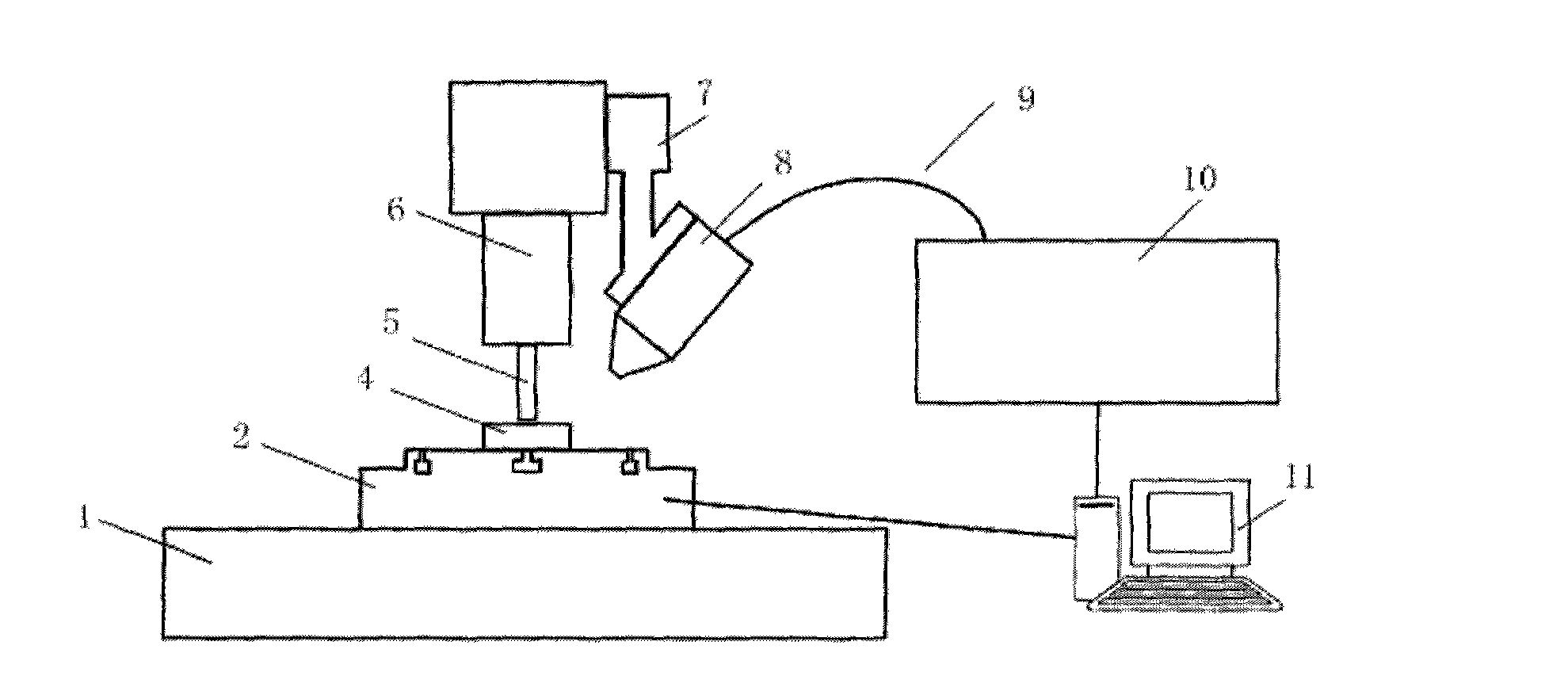

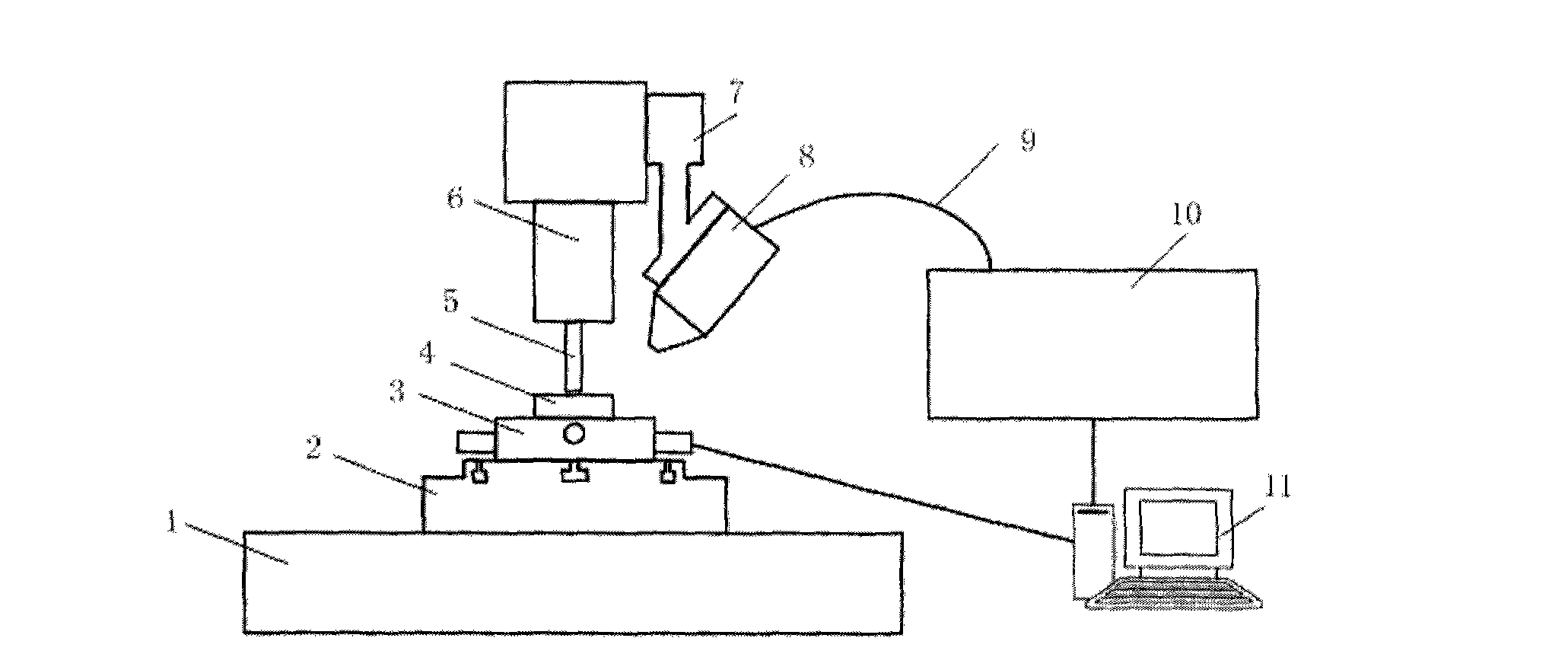

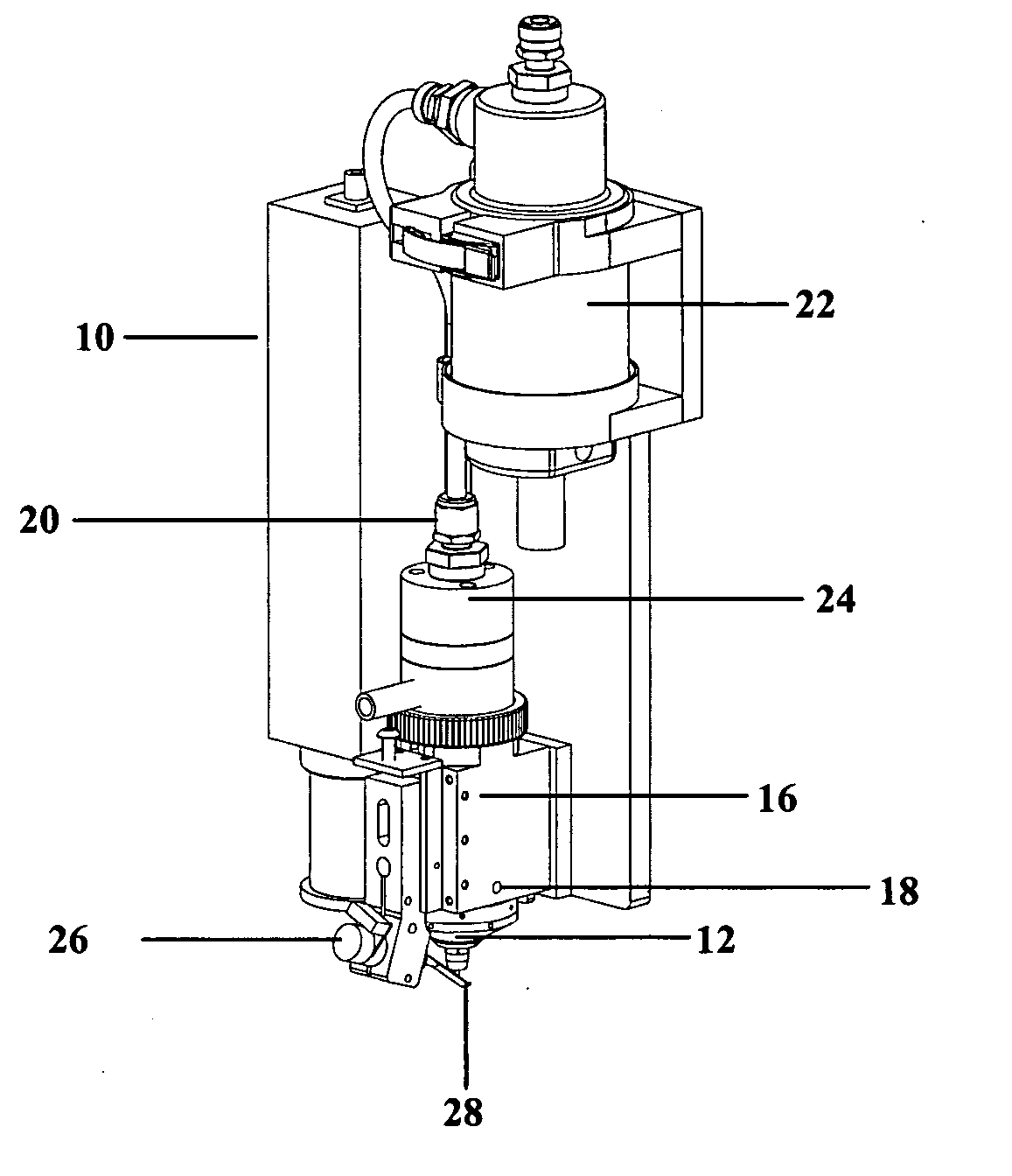

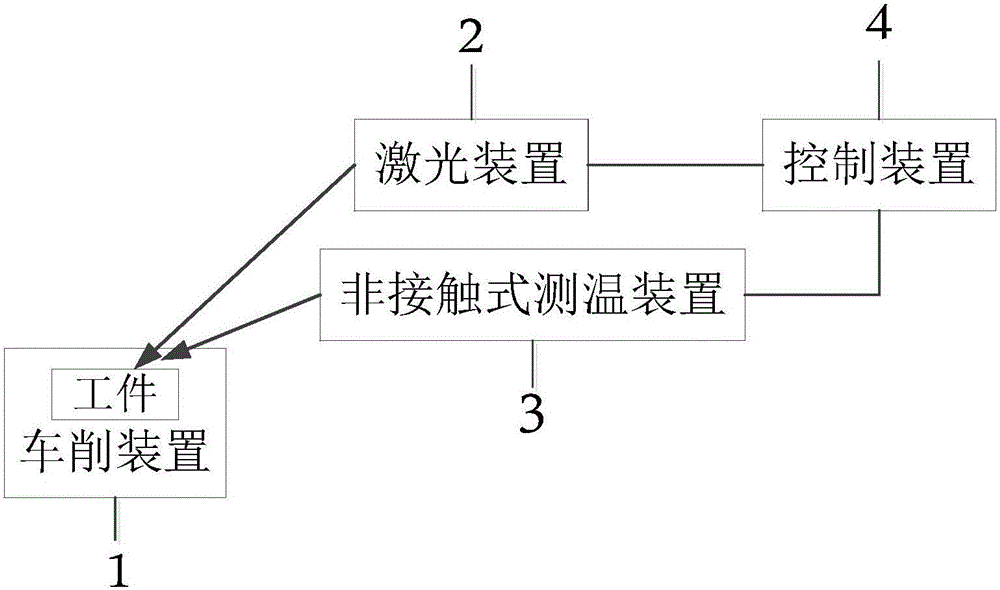

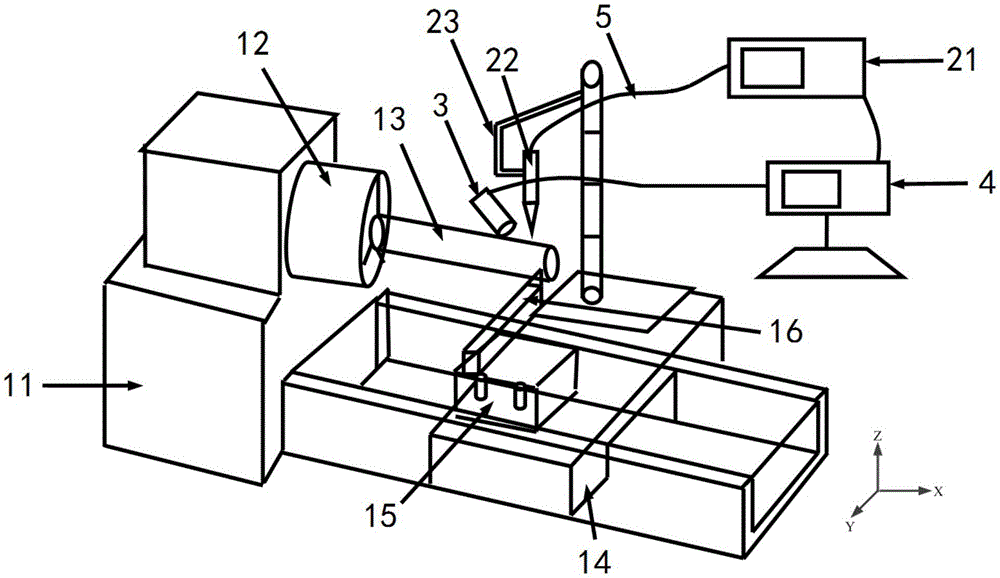

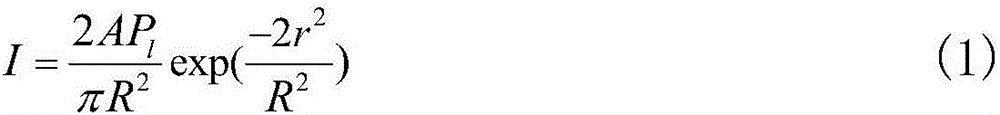

Laser heating assisted turning device and method

InactiveCN106001613ASolution to short lifeImprove surface qualityMeasurement/indication equipmentsMetal working apparatusData matchingMachined surface

The invention provides a laser heating assisted turning device and method. The laser heating assisted turning device comprises a turning device body, a laser device, a non-contact temperature measuring device and a control device, wherein a tool and a workpiece are fixed to the turning device body, the tool is detachably connected with the turning device body, the laser device is used for heating the workpiece through laser, the non-contact temperature measuring device is used for acquiring the temperature at the cutting position of the workpiece in real time, and the control device is used for comparing data of an optimum temperature field stored in the control device with temperature data acquired by the non-contact temperature measuring device in real time and controlling the laser device to adjust laser parameters so as to achieve the optimum temperature field if difference exists. The laser heating assisted turning device has the advantages that the laser parameters are adjusted in a data matching mode so that the temperature field at the cutting position of the workpiece can be always consistent to the optimum temperature field, the cutting performed in the temperature field makes the service life of the tool longest, the machined surface quality of the workpiece is the best, and the turning efficiency is the highest.

Owner:HARBIN INST OF TECH

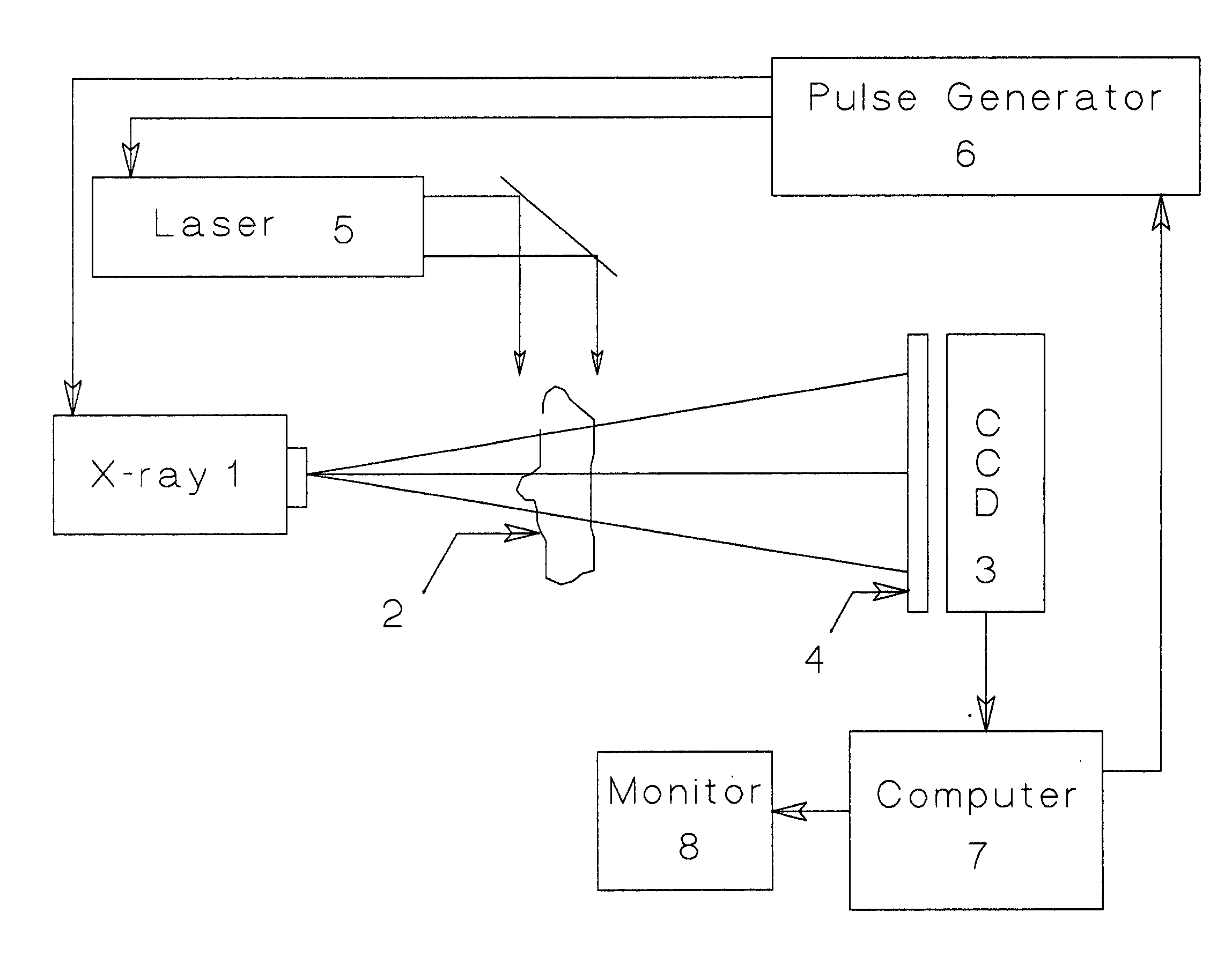

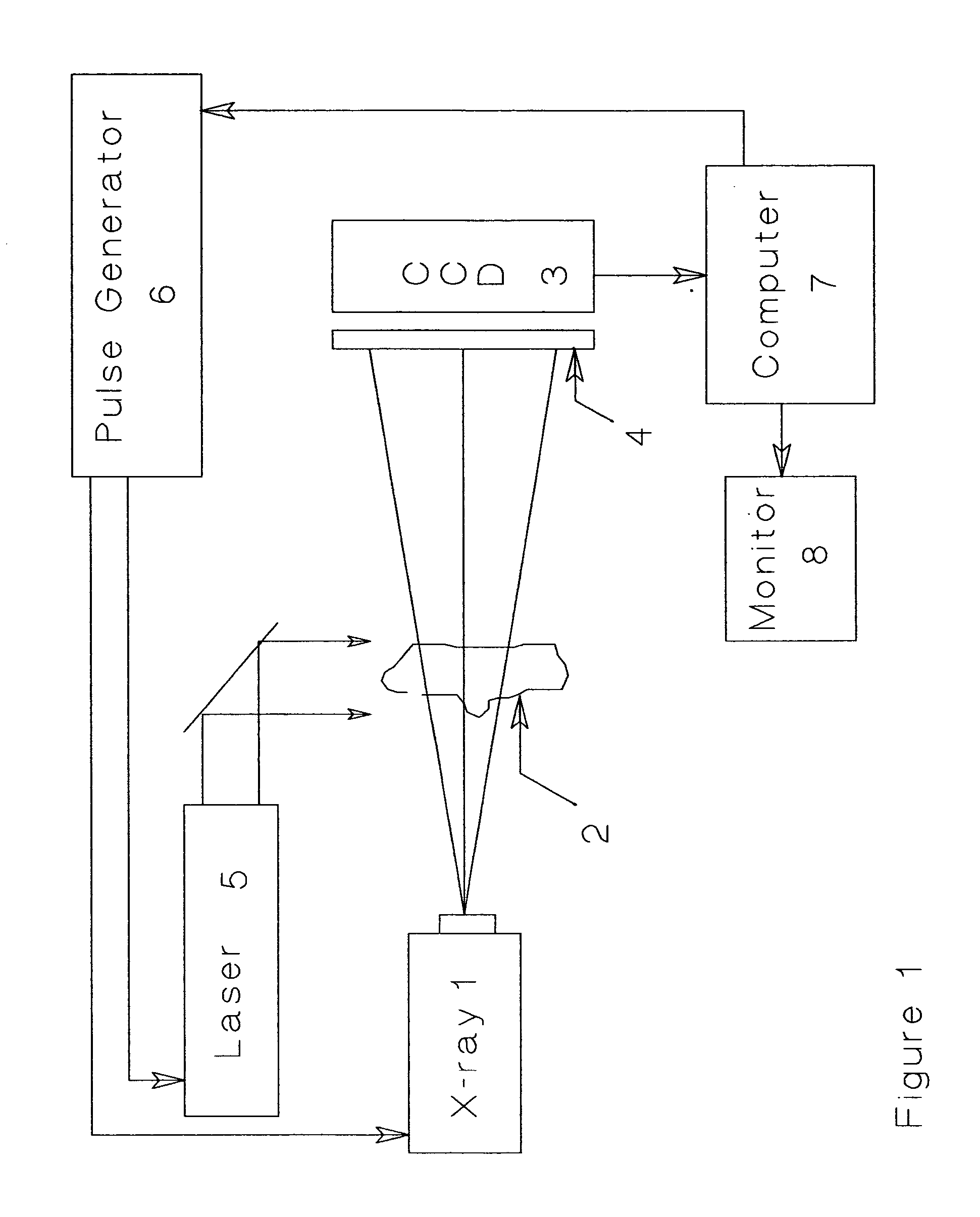

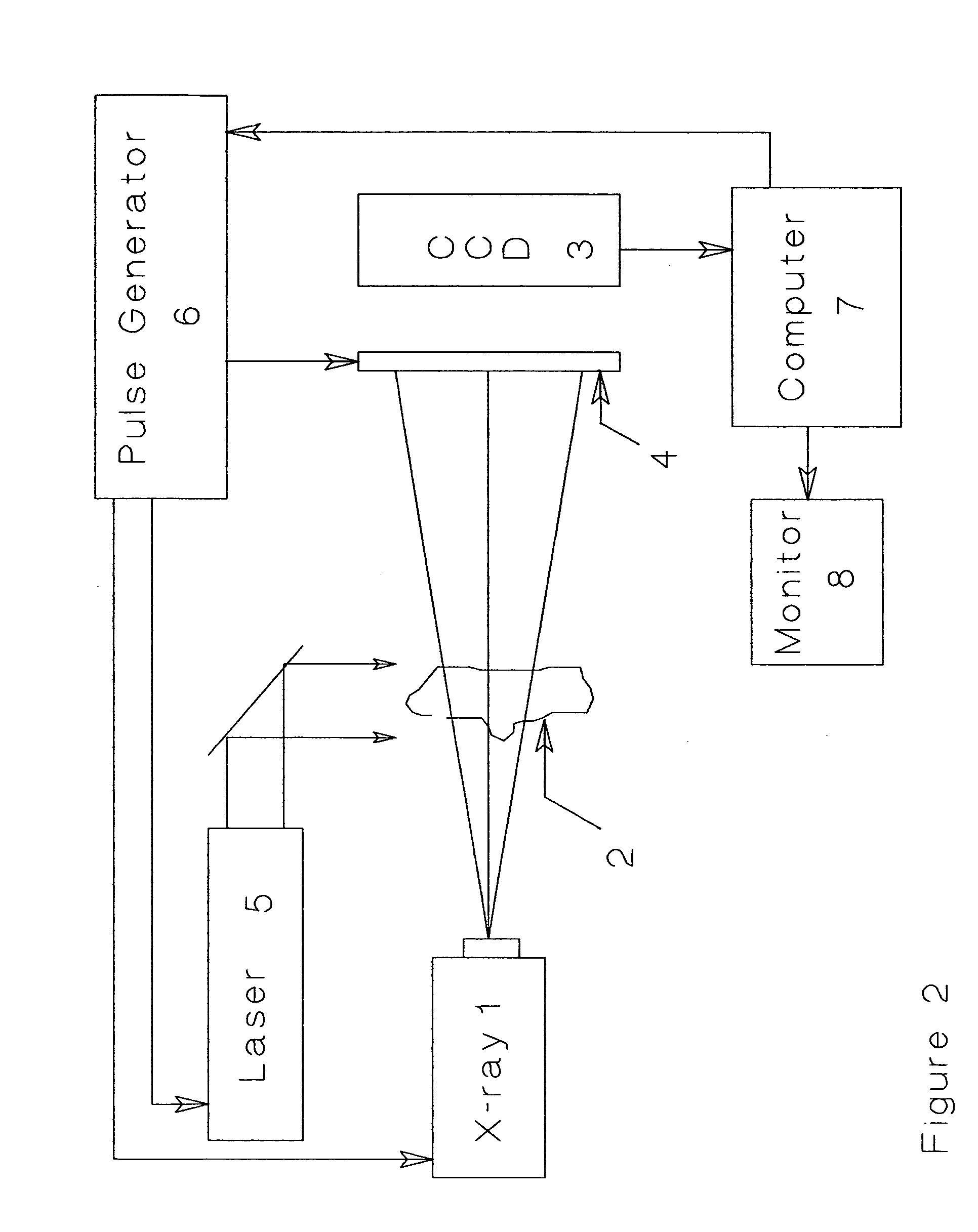

Method and apparatus for photothermal modification of x-ray images

InactiveUS20060262903A1Increase volumeLarge objectMaterial analysis by transmitting radiationAbnormal tissue growthX-ray

An x-ray image of a body can be modified by absorption of laser radiation that causes thermal gradients to be generated in portions of the body. If an object within the body has a higher optical absorption than the surrounding medium, the effect of absorption of the laser radiation is to cause the production of thermal gradients. Thermal gradients give rise to density gradients, which modify an x-ray image through changes in x-ray index of refraction at the site of the thermal gradient. The overall effect of the laser heating is to produce an x-ray contrast mechanism wherein the x-ray image becomes sensitive to differences in the optical absorption within a body. An application of the invention is for detection of tumors that are highly vascularized, using a laser operating in the near infrared.

Owner:DIEBOLD ROGER M

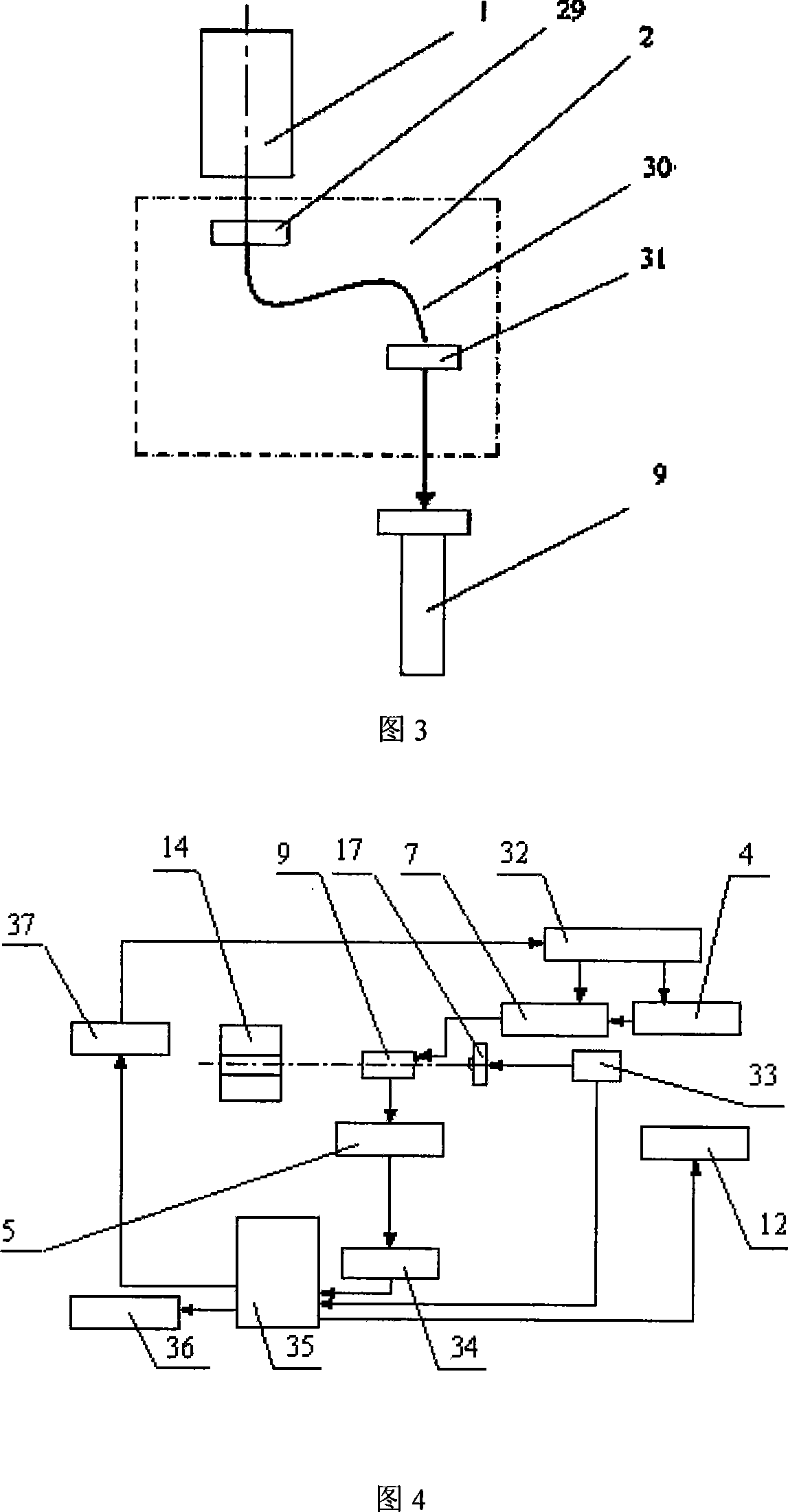

Micro-plastic molding method and apparatus for micro-device

InactiveCN101130196AAccurate temperatureReduce deformation resistanceShaping toolsExtrusion diesControl systemLaser heating

The invention discloses a microplastic shaping method and device of microelement in the microplastic piece preparing and shaping technical domain, which comprises the following parts: laser heating system, microshaping system, loading system, control system and assembling platform, wherein the flat-top laser beam emitted by laser is loaded on the surface of microelement surface through transmittable terrace die, which utilizes laser to do non-contact heating of working piece and heat conductivity; the heat work piece material is below recrystallizing temperature for shaping temperature scale; the terrace die does feeding movement towards female die through microdriving system; the loading system combines the microdriving system to realize loading action for microblank to finish microplastic shaping. The invention reduces the deformation resistance of material at non-contact heating on the upper surface of working piece through laser, which increases the evenness of material fluidity for batching manufacturing of microelement to realize automation manufacturing easily.

Owner:JIANGSU UNIV

Apparatus and Method for Adjustable Fractional Optical Dermatological Treatment

ActiveUS20080015556A1System can be further enhancedControlling energy of instrumentLight therapyLight beamLasing wavelength

A fractional treatment system can be configured with a laser wavelength that is selected such that absorption of the laser wavelength within the tissue increases as the tissue is heated by the laser (e.g., 1390-1425 nm). Desirably, the laser wavelength is primarily absorbed within a treated region of skin by water and has a thermally adjusted absorption coefficient within the range of about 8 cm−1 to about 30 cm−1. An adjustable mechanism can be used to adjust the beam shape, beam numerical aperture, beam focus depth, and / or beam size to affect the treatment depth and or the character of the resulting lesions. The system may be designed to be switchable between a treatment mode that is semi-ablative and a treatment mode that is not semi-ablative. Adjustment of these parameters can improve the efficiency and efficacy of treatment. Illustrative examples of adjustable mechanisms include a set of spacers of different lengths, a rotatable turret with lens elements of different focal distances, an optical zoom lens, and a mechanical adjustment apparatus for adjusting the spacing between two optical lens elements.

Owner:SOLTA MEDICAL

Apparatus and Method for Adjustable Fractional Optical Dermatological Treatment

ActiveUS20080015557A1Control over selected characteristicOvercome limitationsControlling energy of instrumentLight therapyLight beamLasing wavelength

In a fractional treatment system, an adjustable mechanism can be used to adjust the beam shape, beam numerical aperture, beam focus depth, and / or beam size to affect the treatment depth and or the character of the resulting lesions. Adjustment of these parameters can improve the efficiency and efficacy of treatment. Illustrative examples of adjustable mechanisms include a set of spacers of different lengths, a rotatable turret with lens elements of different focal distances, an optical zoom lens, and a mechanical adjustment apparatus for adjusting the spacing between two optical lens elements. In one aspect, the fractional treatment is configured with a laser wavelength that is selected such that absorption of the laser wavelength within the tissue decreases as the tissue is heated by the laser (e.g., 1480-1640 nm). Desirably, the laser wavelength is primarily absorbed within a treated region of skin by water and has a thermally adjusted absorption coefficient within the range of about 7 cm−1 to about 26 cm−1.

Owner:SOLTA MEDICAL

Laser heating-assisted milling device capable of real-time monitoring tool wear

ActiveCN106216745AEasy to monitor onlineImprove efficiencyMeasurement/indication equipmentsMilling equipment detailsNumerical controlMilling cutter

The invention discloses a laser heating-assisted milling device capable of real-time monitoring tool wear. The laser heating-assisted milling device capable of real-time monitoring tool wear comprises a milling device, a laser heating device and a real-time monitoring device. The milling device comprises a CNC (Computer Numerical Control) milling machine table, a milling cutter and a workpiece fixed to the CNC milling machine table; the laser heating device comprises a laser focus head; a laser light is incident on the surface of the workpiece through the laser focus head; the real-time monitoring device comprises a plurality of acoustic emission sensors, a signal processing module, a data acquisition processing module and an industrial personal computer; the acoustic emission sensors are arranged on the workpiece and are used for detecting acoustic emission signals of the milling cutter at a milling state; the acoustic emission signals are processed through the signal processing module and the data acquisition processing module and then are stored in the industrial personal computer; and through processing and analyzing, the real-time wear condition of the milling cutter is obtained.

Owner:HARBIN INST OF TECH

Spinning forming method and device based on laser heating

InactiveCN106424286AImprove heating efficiencyGood process flexibilityShaping toolsProcess equipmentSpinning

The invention discloses a spinning forming method and device based on laser heating. The spinning forming device is characterized by comprising a numerically-controlled spinning machine, spinning process equipment, a laser device, a light guide system, a six-degree-of-freedom robot machining system, a laser machining head, a temperature measuring device and the like. The spinning forming device conducts high-accuracy flexible control over a heating area according to the characteristics of high laser heating speed, accurate and controllable heating parts and temperatures and high degree of freedom and accurate control of the six-degree-of-freedom robot machining system, and spun blanks can be dynamically and locally heated while the spinning process equipment is not heated. The purposes of improving the material spinnability and reducing damage to the spinning machine are achieved. Meanwhile, closed-loop control over the heating temperature and laser output is realized, and realization of production automation is realized. The spinning forming method and device based on laser heating have the advantages of being high in production efficiency, good in process stability, high in forming precision, convenient to operate and the like.

Owner:JIANGSU UNIV OF TECH

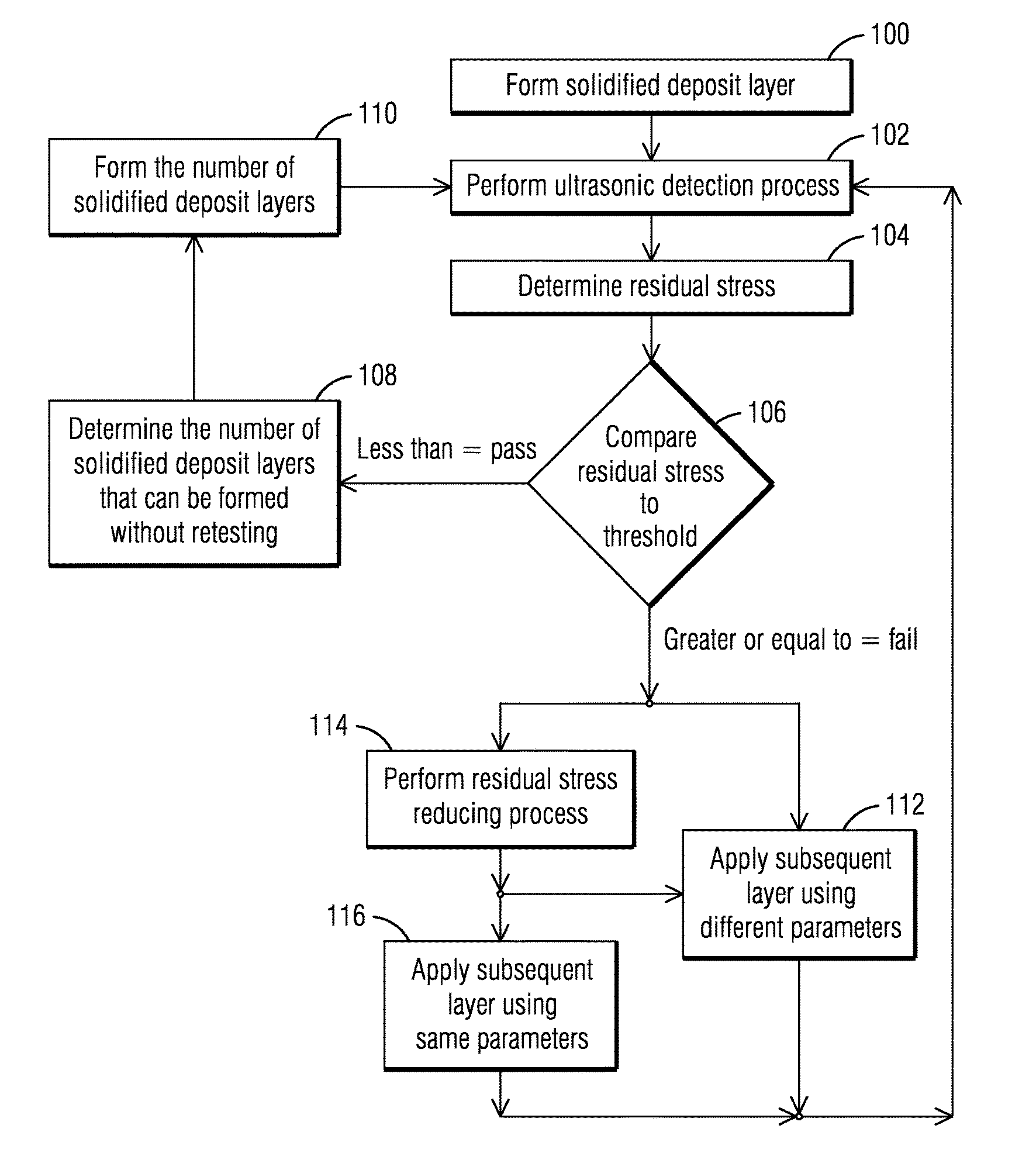

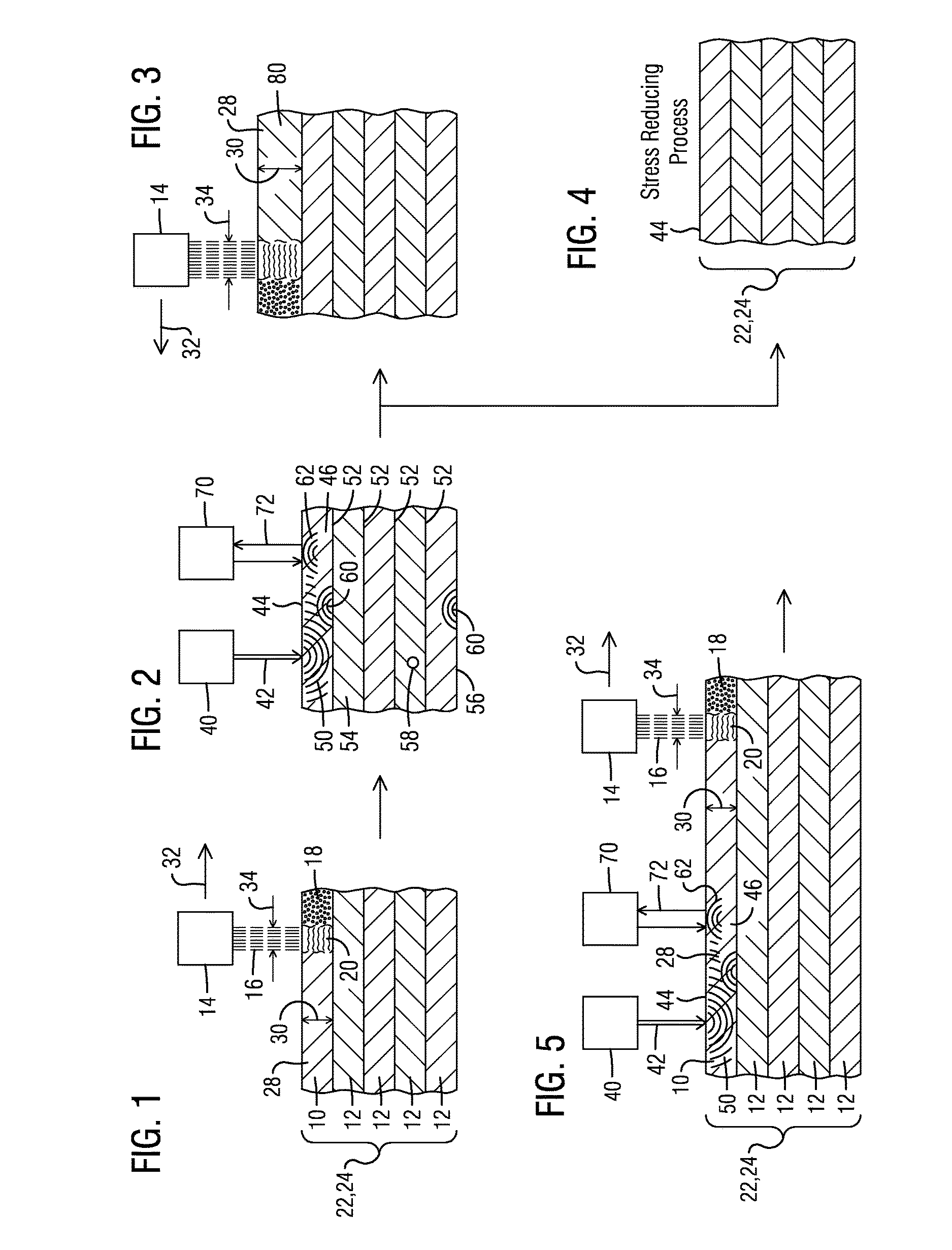

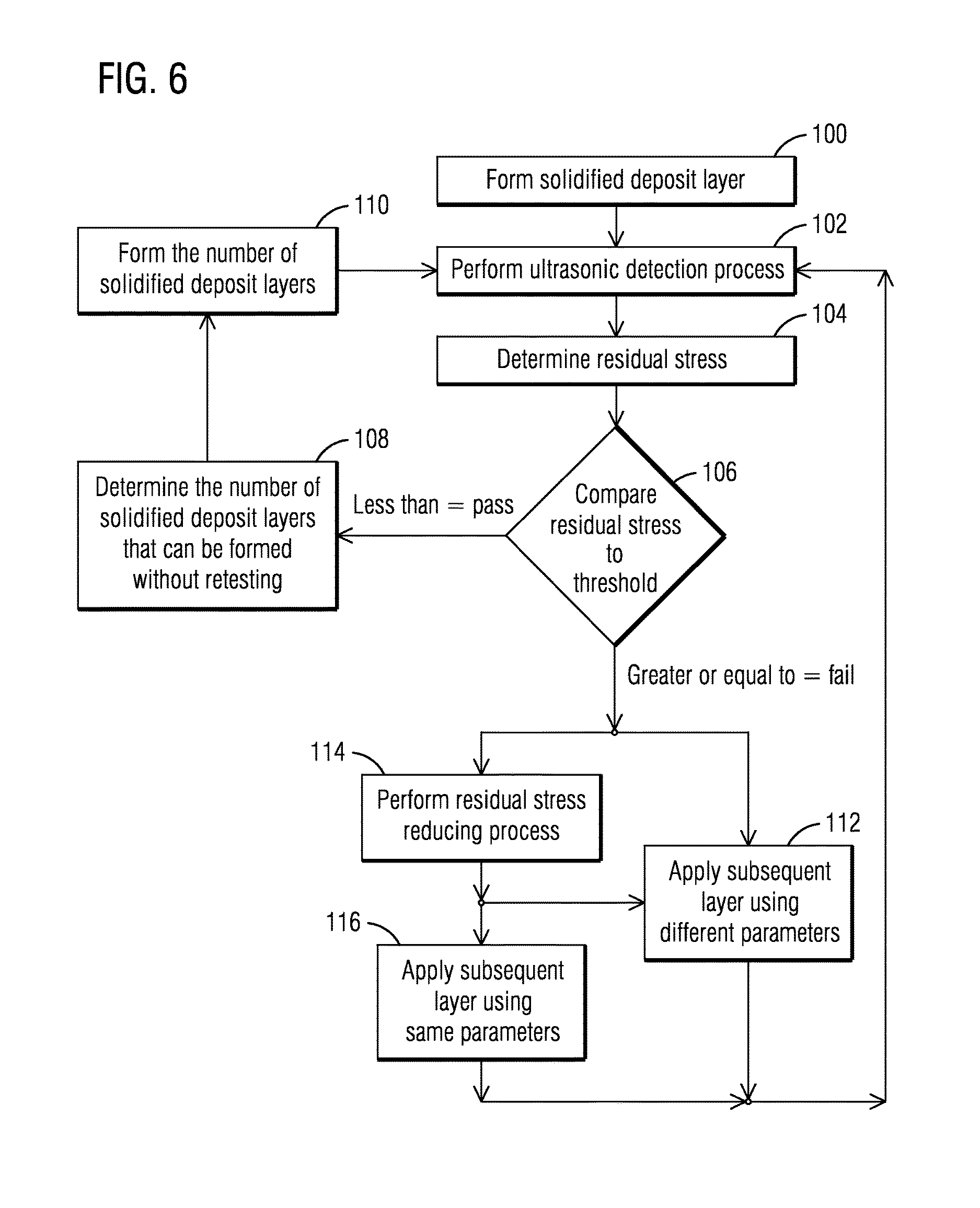

Adaptive additive manufacturing process using in-situ laser ultrasonic testing

InactiveUS20170059529A1Additive manufacturing apparatusAnalysing solids using sonic/ultrasonic/infrasonic wavesManufacturing technologyLaser heating

An additive manufacturing process, including: selectively-heating a layer of powder (18) to form a solid deposit layer (10) having a solid deposit (28), where the solid deposit layer constitutes part (24) of a component, via a selective laser heating process; propagating ultrasonic energy waves (50, 60) through the solid deposit prior to completion of the component by using a wave generating laser (40) set apart from a surface (44) of the solid deposit to direct a wave-generating laser beam (42) at the surface; detecting propagated ultrasonic energy waves (62); assessing the propagated ultrasonic waves for information about a physical characteristic of the solid deposit; and forming another solid deposit layer (80) in response to the information obtained about the solid deposit.

Owner:SIEMENS ENERGY INC

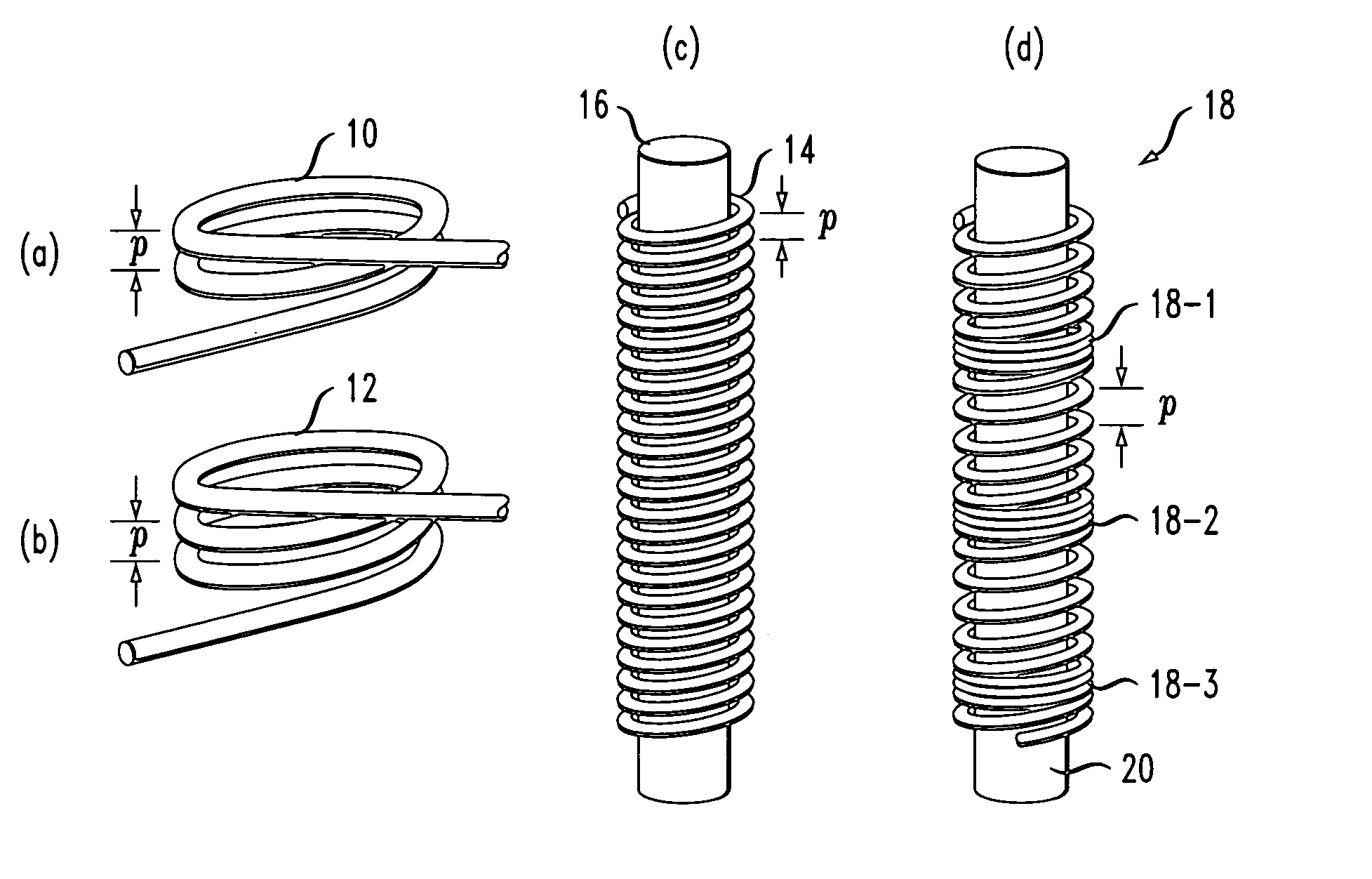

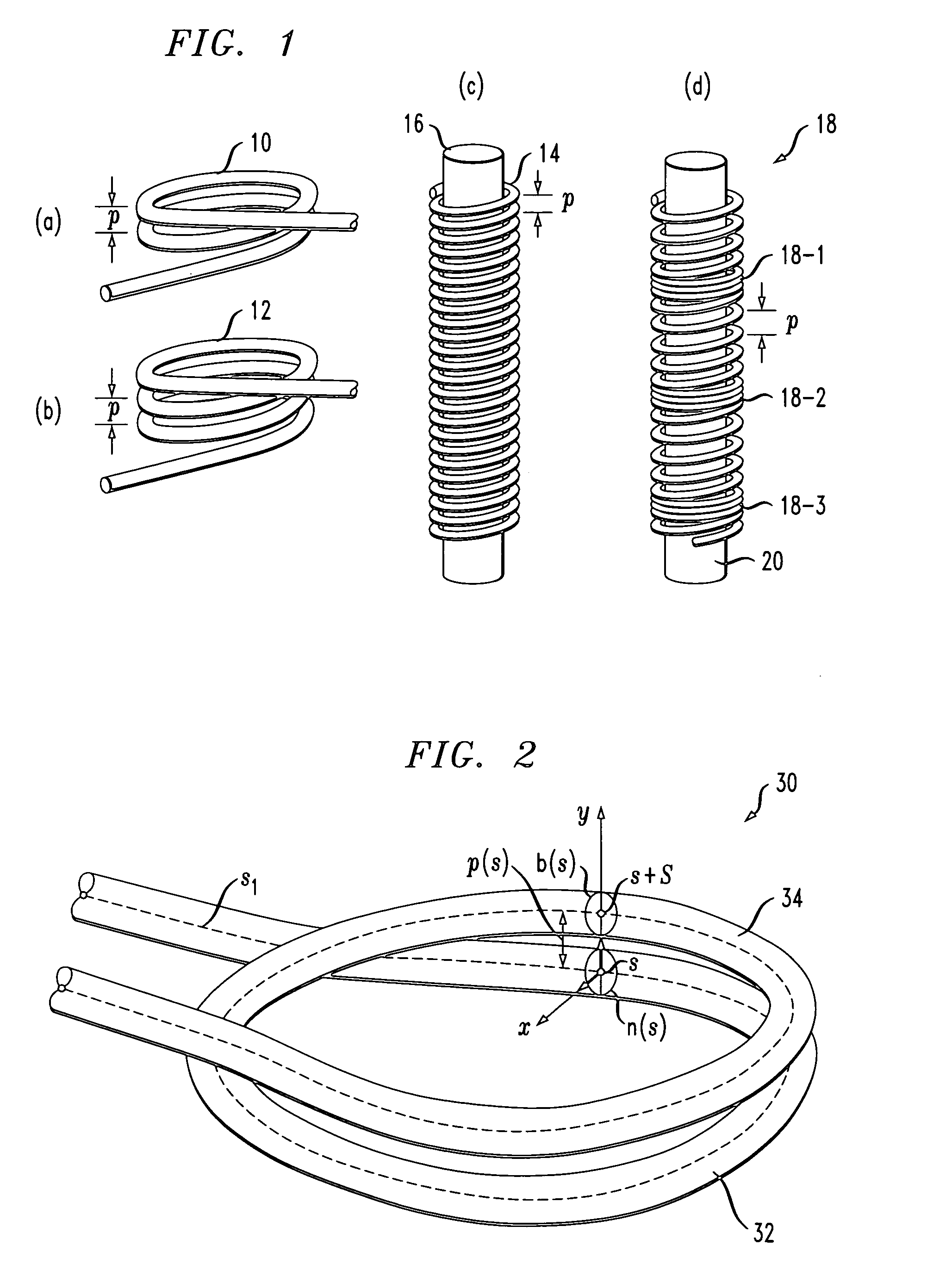

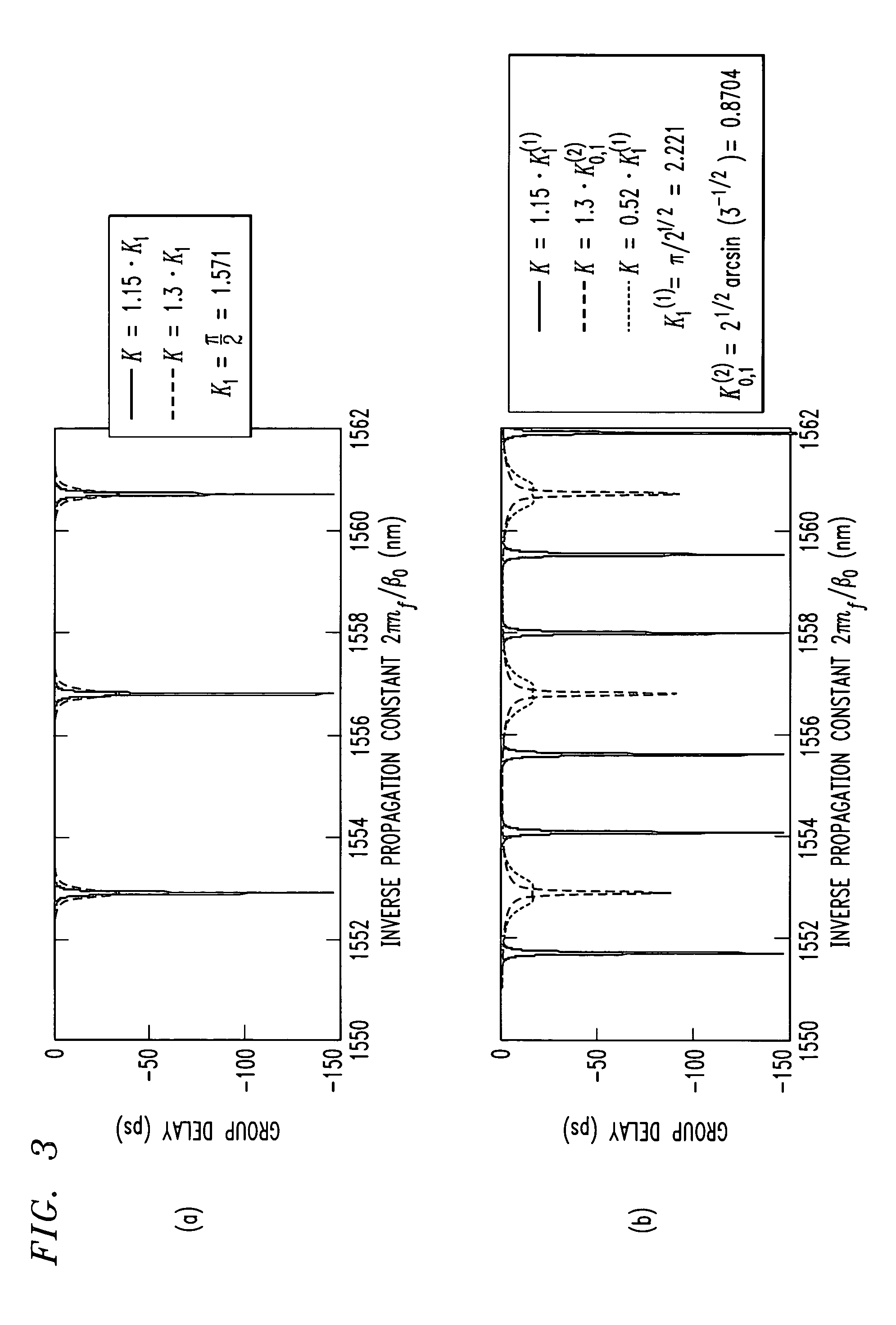

Optical fiber microcoil, resonant structure and method of making the same

ActiveUS7266259B1Transmission characteristicWell formedLaser detailsCladded optical fibreResonanceFiber diameter

An optical fiber coil of sub-micron diameter is shown to exhibit self-coupling between adjacent turns so as to form a three-dimensional optical resonator of relatively low loss and high Q. As long as the pitch of the coil and propagating wavelength remain on the same order (or less than) the fiber diameter, resonance may occur. Resonances can be induced by allowing adjacent turns of the coil to touch each other. Optical devices such as resonators and interferometers may then be formed from such “microcoils” that exhibit superior characteristics to conventional planar devices. A method of forming such a microfiber using indirect laser heating is also disclosed.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

Magnetic thin film head with heat-assisted write section and hard disk drive incorporating same

InactiveUS7310206B2Thickness minimizationHigh densityCombination recordingRecord information storageHard disc driveLaser light

A thin film magnetic read / write head for use in magnetic data storage systems to enable writing of data to a magnetic data storage medium with the assistance of laser heating. The read / write head allows magnetic reading of data from the storage medium, and thermally assisted magnetic writing of data on the storage medium. A waveguide is provided in a write gap in the form of an optical circuit having a plurality of inputs and a single output at the air bearing surface (ABS) for concentrating laser light used for heating the storage medium during the write operation. The thermally assisted magnetic writing improves the thermal stability of the recorded data and usefulness thereof throughout a wide temperature range.

Owner:SAE MAGNETICS (HK) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com