Micro-plastic molding method and apparatus for micro-device

A micro-plastic and micro-device technology, applied in forming tools, metal extrusion control equipment, metal extrusion and other directions, can solve the problems of forming materials and forming process limitations, large deformation resistance of micro-cold forming, uneven material flow, etc. , to achieve the effect of easy automatic production, uniform micro-forming process and easy focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

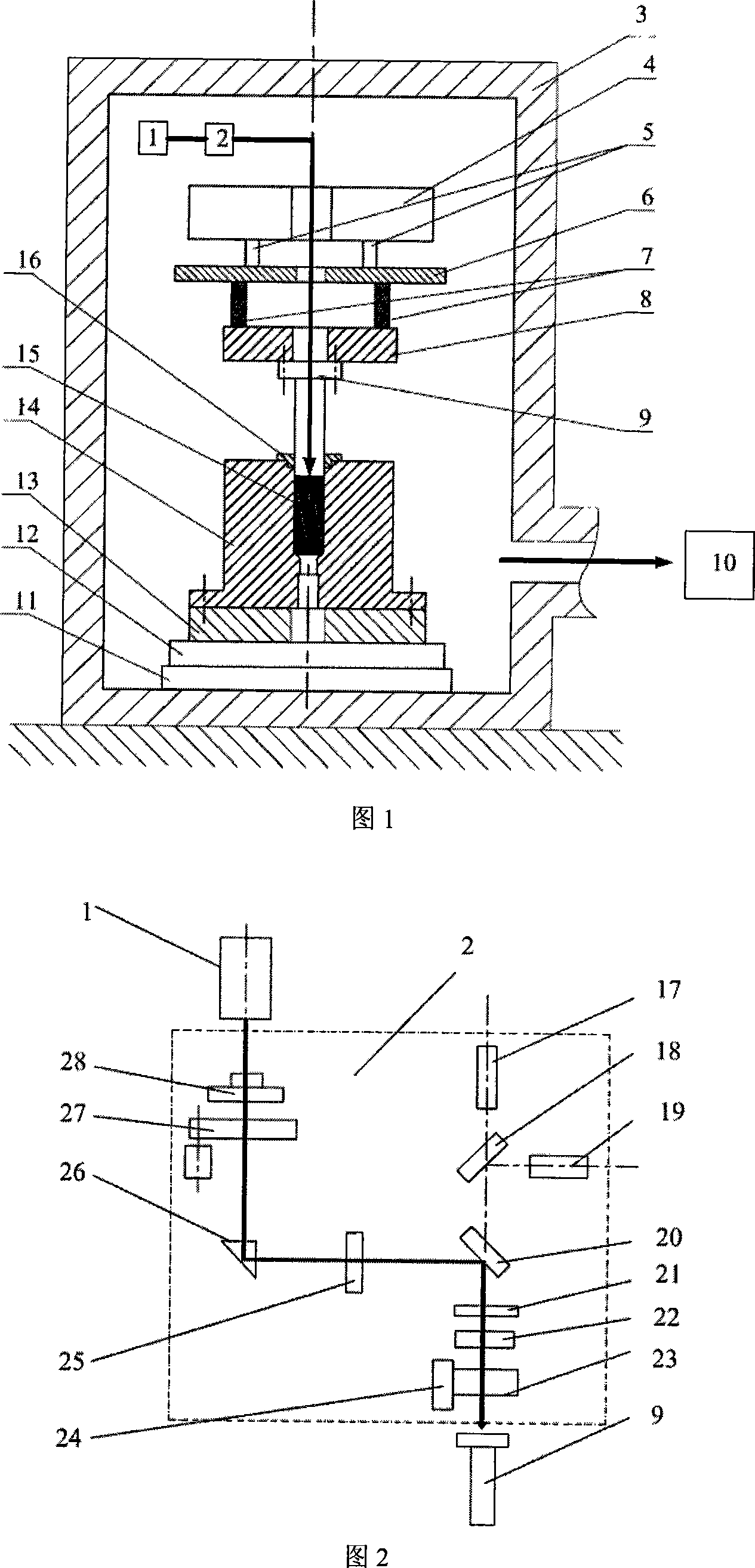

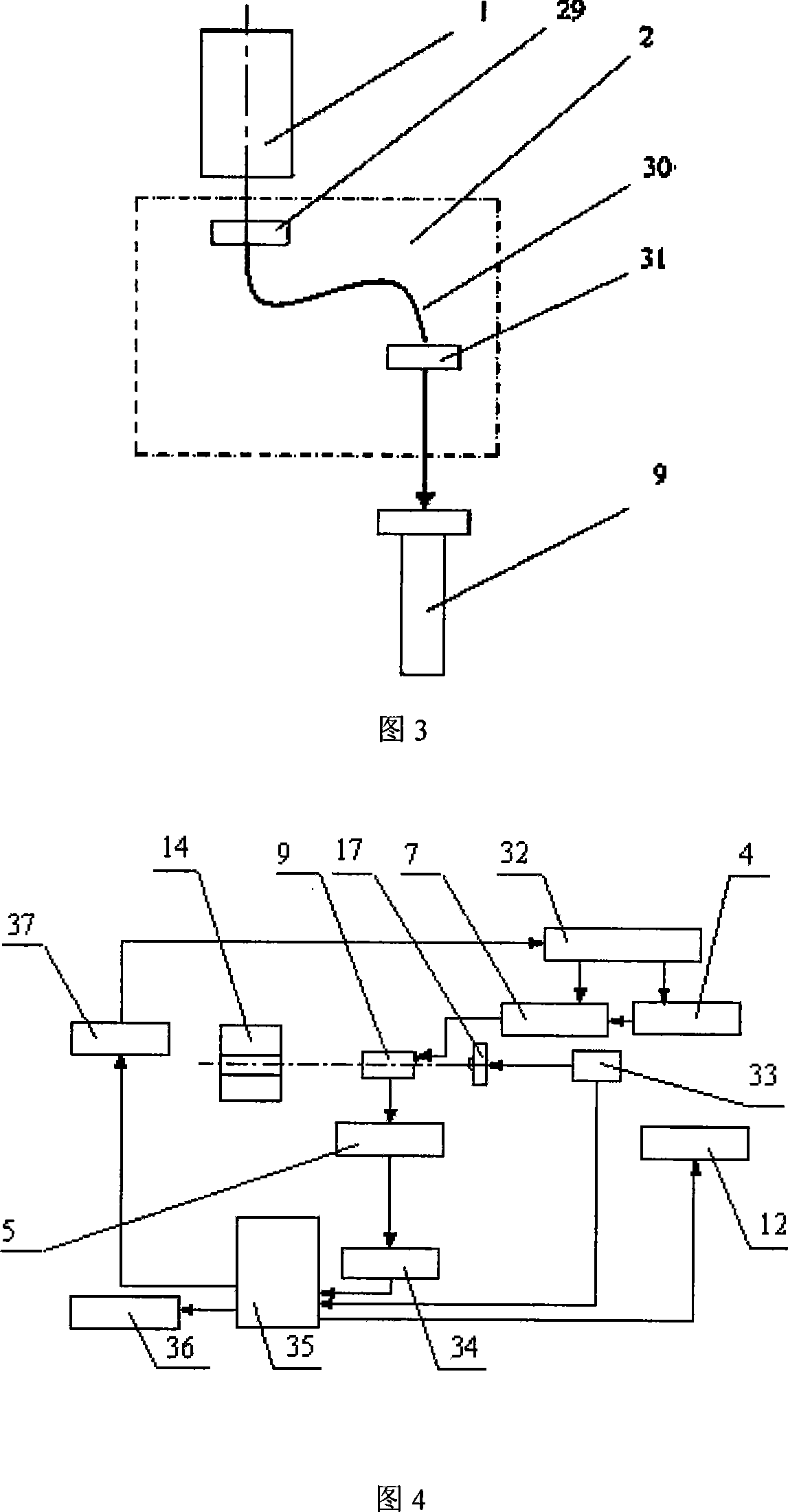

[0036] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with FIG. 1 , FIG. 2 , FIG. 3 and FIG. 4 .

[0037] The microplastic forming system of the whole micro device consists of five parts: laser heating system, micro forming system, loading system, control system and installation platform. The laser heating system consists of a laser 1 connected to an optical path system 2. The optical path system 2 consists of a laser 1, a beam expander 28, a laser safety shutter 27 with safety measures, a prism 26, a collimator 25, a half-transparent mirror 20, Optical filter 21, aperture 22, short-focus objective lens 23 for adjusting spot size, five-position adjustment frame 24 for adjusting objective lens, and observation subsystem composed of CCD17, half-transparent mirror 18 and white light source 19. The laser heating system may also consist of a laser 1 , an acousto-optic modulator 29 , a sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com