Patents

Literature

5076 results about "Batch manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Batch manufacturing refers to the production of a specific quantity of identical items in a series of processes. This style of manufacturing may be driven by the steps necessary to produce a completed product or it may be a function of the amount of materials that can be handled at one time by a set of machinery.

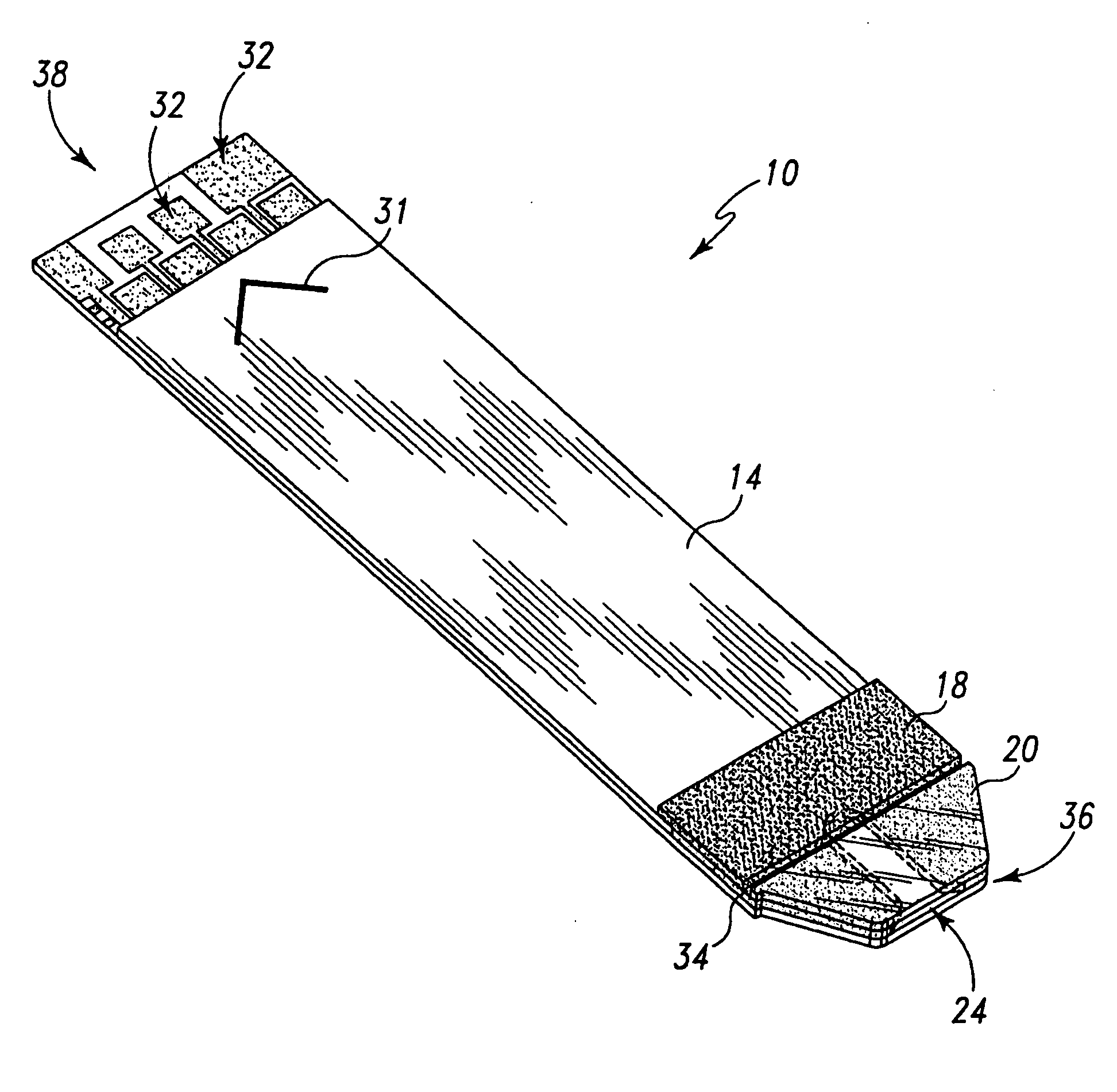

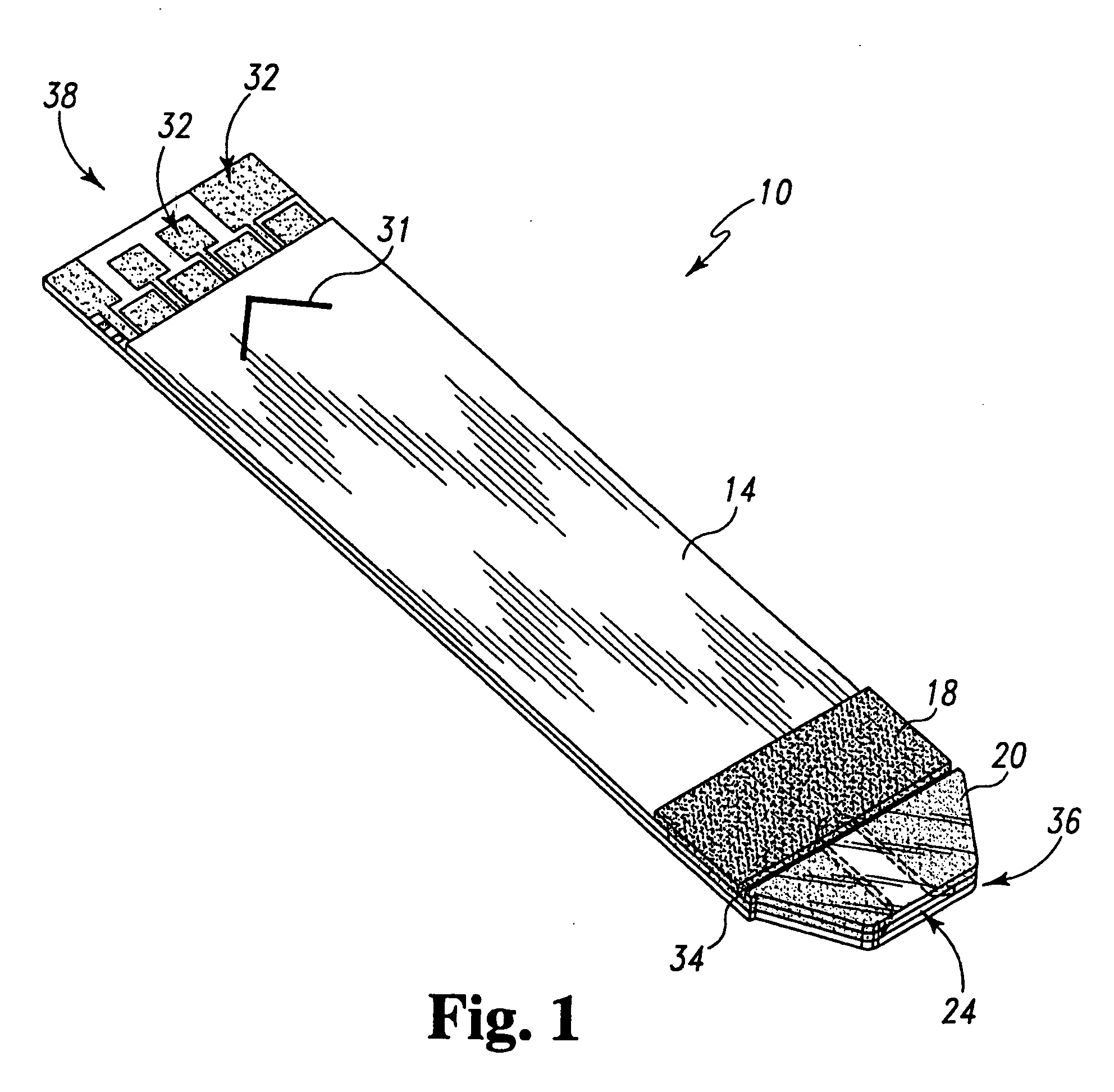

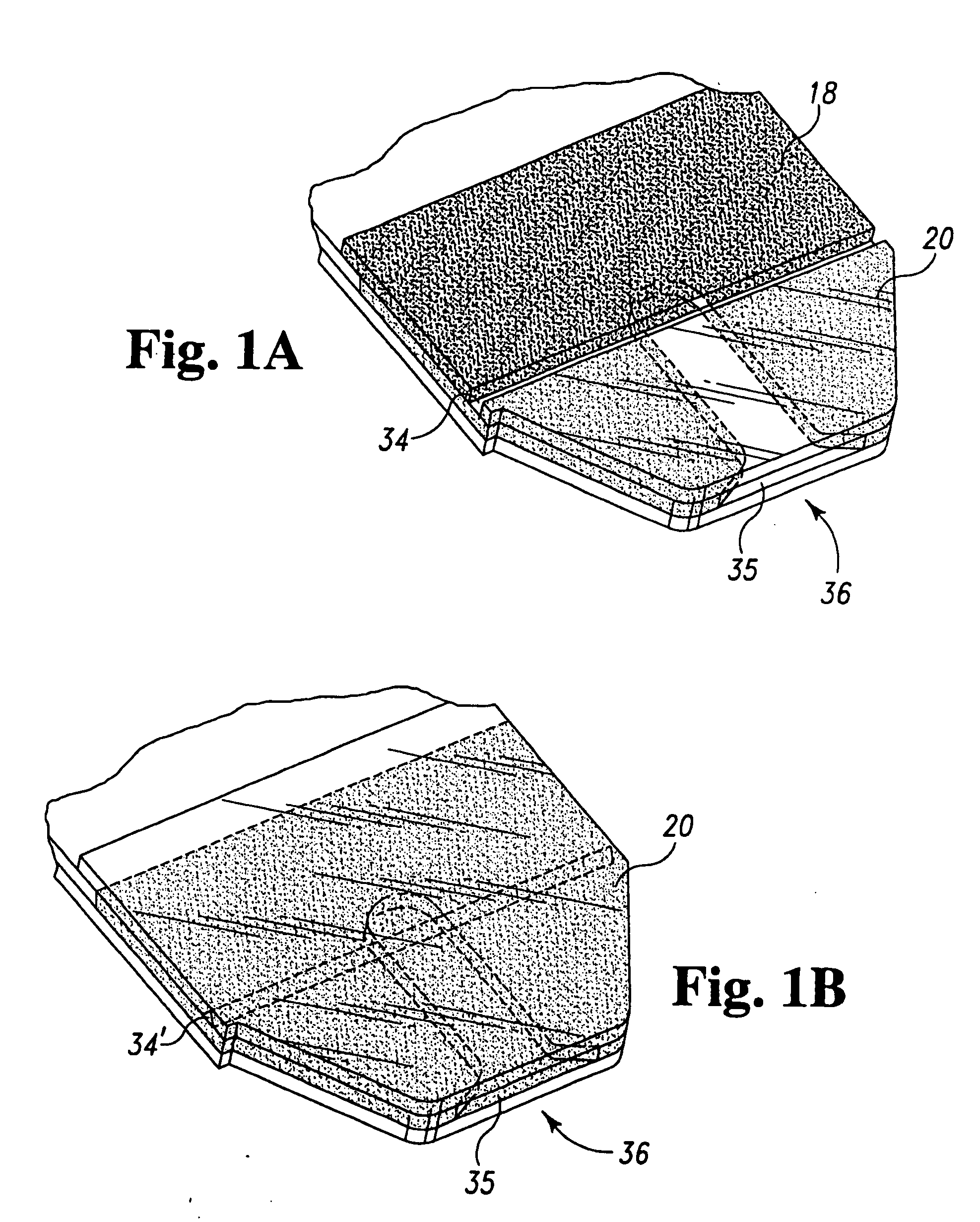

Test strip with slot vent opening

ActiveUS20050013731A1Easy doseRobust manufacturing processAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionMechanical engineeringTest strips

A test strip with a covering layer having a novel slot. The slot divides the inventive covering layer into two parts and provides a vent opening that allows air to escape as fluid enters a cavity or sample receiving chamber formed in the test strip. In preferred embodiments, the covering layer is clear such that the user can see through it and the slot doubles as a “fill line.” The user can thus watch the fluid sample enter the test strip, progress through the capillary cavity, and then stop at the slot or fill-line. This provides positive assurance to the user that the sample size is sufficient and the test strip has been filled properly. The present invention also provides an advantageous method of mass-producing the inventive test strips without having to align the slot or vent opening laterally with respect to the test strips and without having to punch a vent opening. The method is also well suited to mass production by roll processing techniques.

Owner:ROCHE DIABETES CARE INC +1

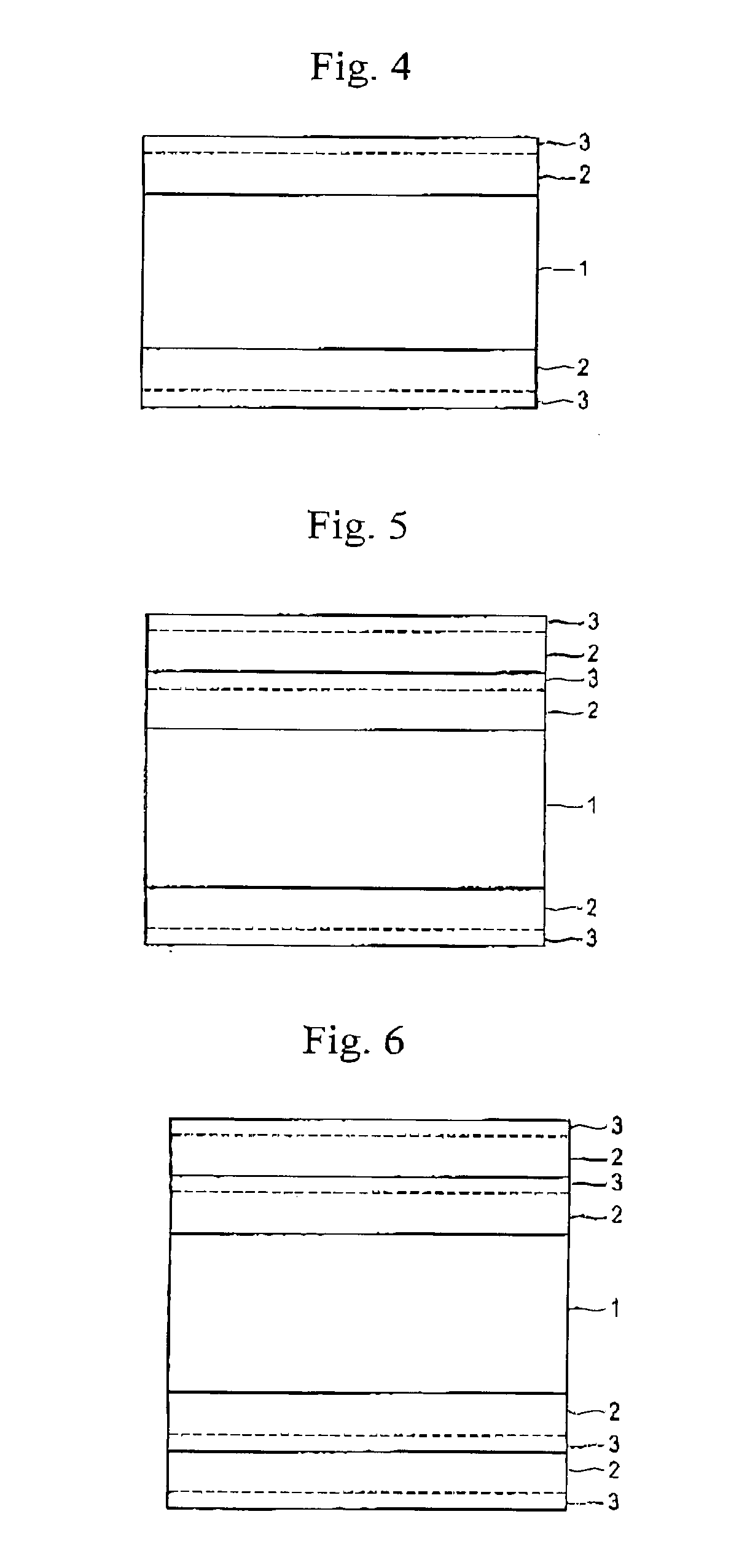

Method for fabrication of transparent gas barrier film using plasma surface treatment and transparent gas barrier film fabricated thereby

InactiveUS20100285319A1Excellent gas barrier performanceEconomical and simple methodSynthetic resin layered productsPretreated surfacesOptoelectronicsInorganic layer

The present invention relates to a method of fabricating a transparent gas barrier film by using plasma surface treatment and a transparent gas barrier film fabricated according to such method which has an organic / inorganic gradient interface structure at the interface between an organic / inorganic hybrid layer and an inorganic layer. Since the method of the present invention is capable of fabricating a gas barrier film by plasma surface treatment instead of deposition under high vacuum, it can mass-produce a transparent gas barrier film with excellent gas barrier properties in an economical and simple manner. Further, since the transparent gas barrier film fabricated according to the method of the present invention shows excellent gas barrier properties and is free of crack formation and layer-peeling phenomenon, it can be effectively used in the manufacture of a variety of display panels.

Owner:KOREA INST OF SCI & TECH

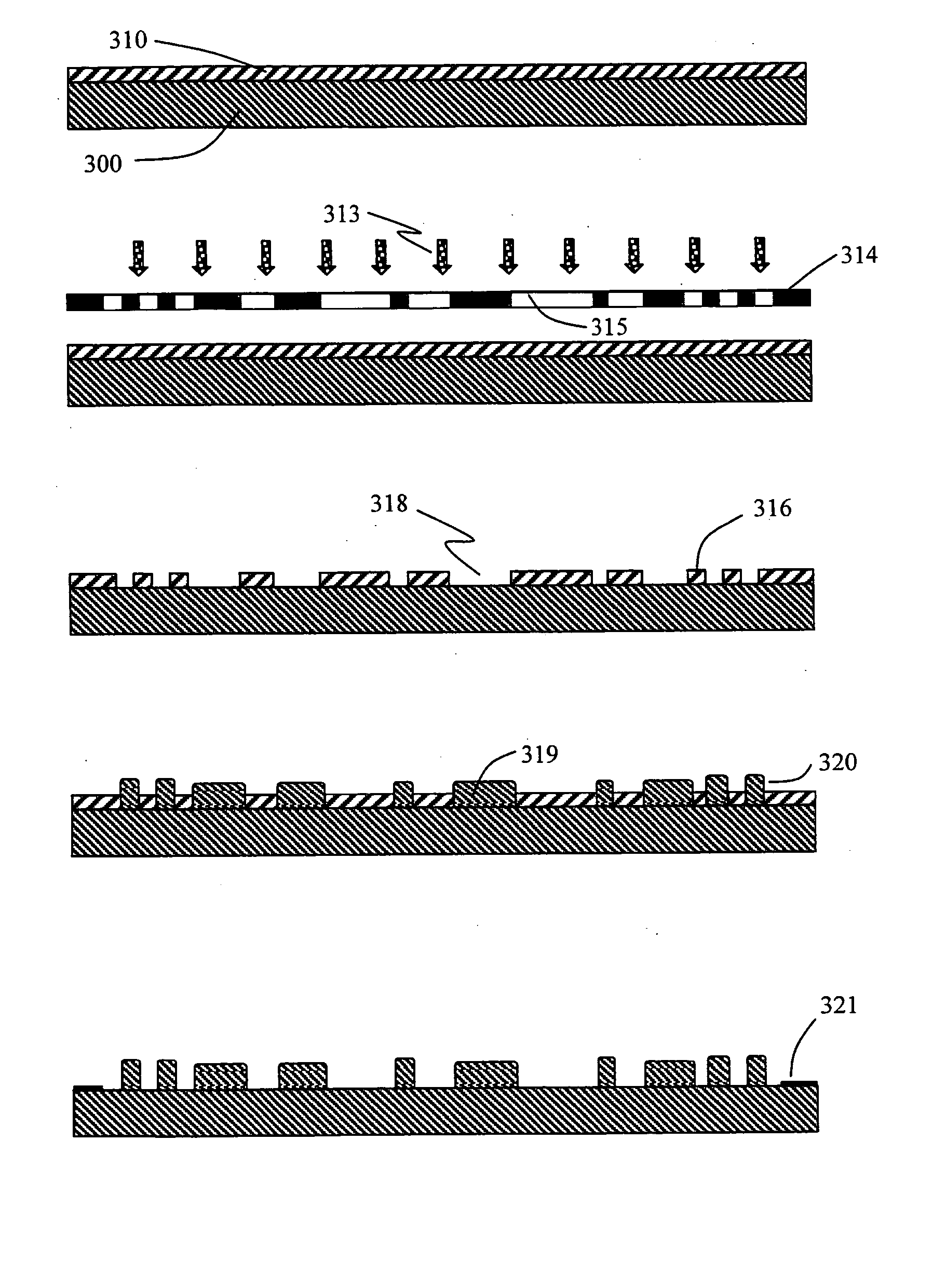

Microfabricated structures and processes for manufacturing same

InactiveUS20050067286A1Minimize surface roughnessEasy to controlElectroforming processesMicroelectromechanical systemsManufacturing technologyCompound (substance)

Various techniques for the fabrication of highly accurate master molds with precisely defined microstructures for use in plastic replication using injection molding, hot embossing, or casting techniques are disclosed herein. Three different fabrication processes used for master mold fabrication are disclosed wherein one of the processes is a combination of the other two processes. In an embodiment of the first process, a two-step electroplating approach is used wherein one of the metals forms the microstructures and the second metal is used as a sacrificial support layer. Following electroplating, the exact height of the microstructures is defined using a chemical mechanical polishing process. In an embodiment of the second process, a modified electroforming process is used for master mold fabrication. The specific modifications include the use of Nickel-Iron (80:20) as a structural component of the master mold, and the use of a higher saccharin concentration in the electroplating bath to reduce tensile stress during plating and electroforming on the top as well as sides of the dummy substrate to prevent peel off of the electroform. The electroforming process is also well suited towards the fabrication of microstructures with non-rectangular cross sectional profiles. Also disclosed is an embodiment of a simple fabrication process using direct deposition of a curable liquid molding material combined with the electroforming process. Finally, an embodiment of a third fabrication process combines the meritorious features of the first two approaches and is used to fabricate a master mold using a combination of the two-step electroplating plus chemical mechanical polishing approach and the electroforming approach to fabricate highly accurate master molds with precisely defined microstructures. The microstructures are an integral part of the master mold and hence the master mold is more robust and well suited for high volume production of plastic MEMS devices through replication techniques such as injection molding.

Owner:CINCINNATI UNIVERISITY OF THE

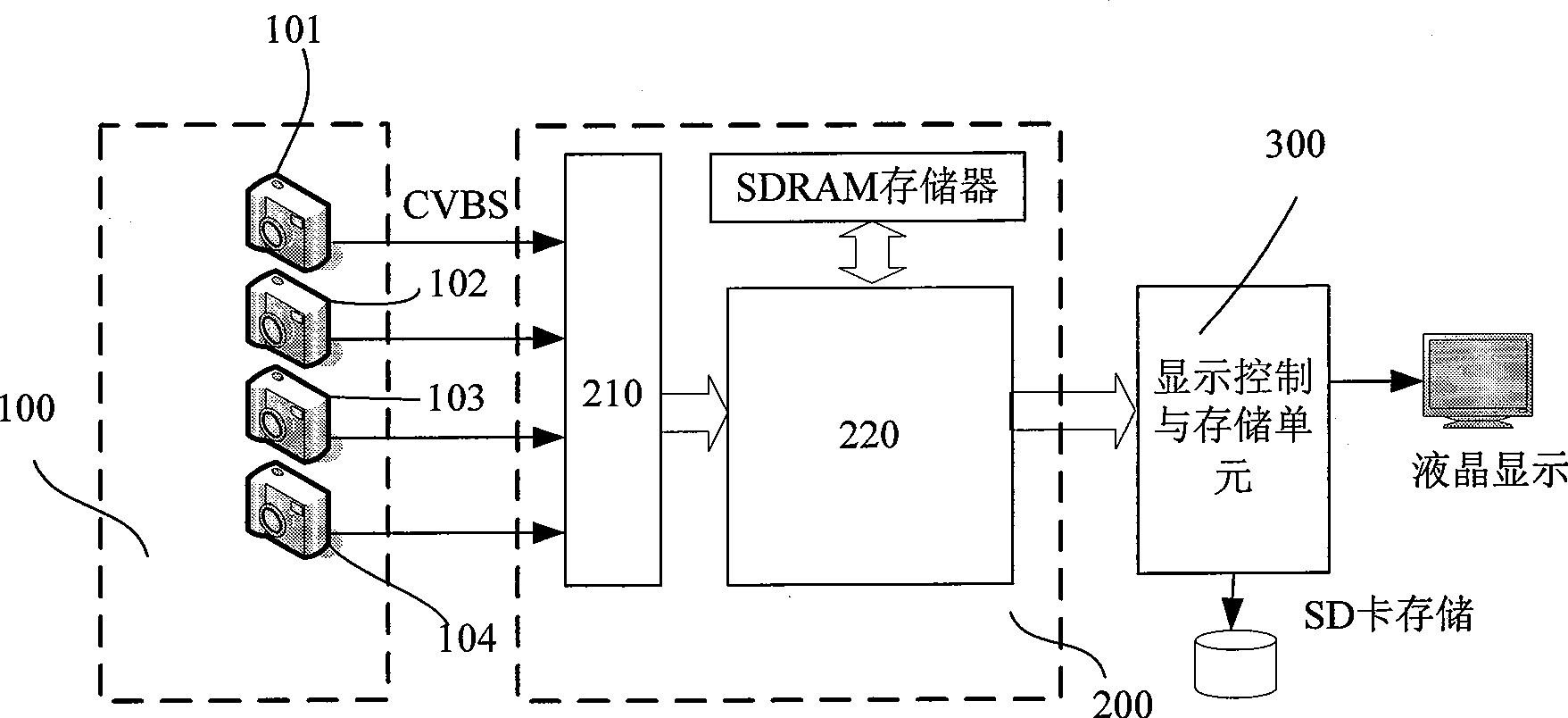

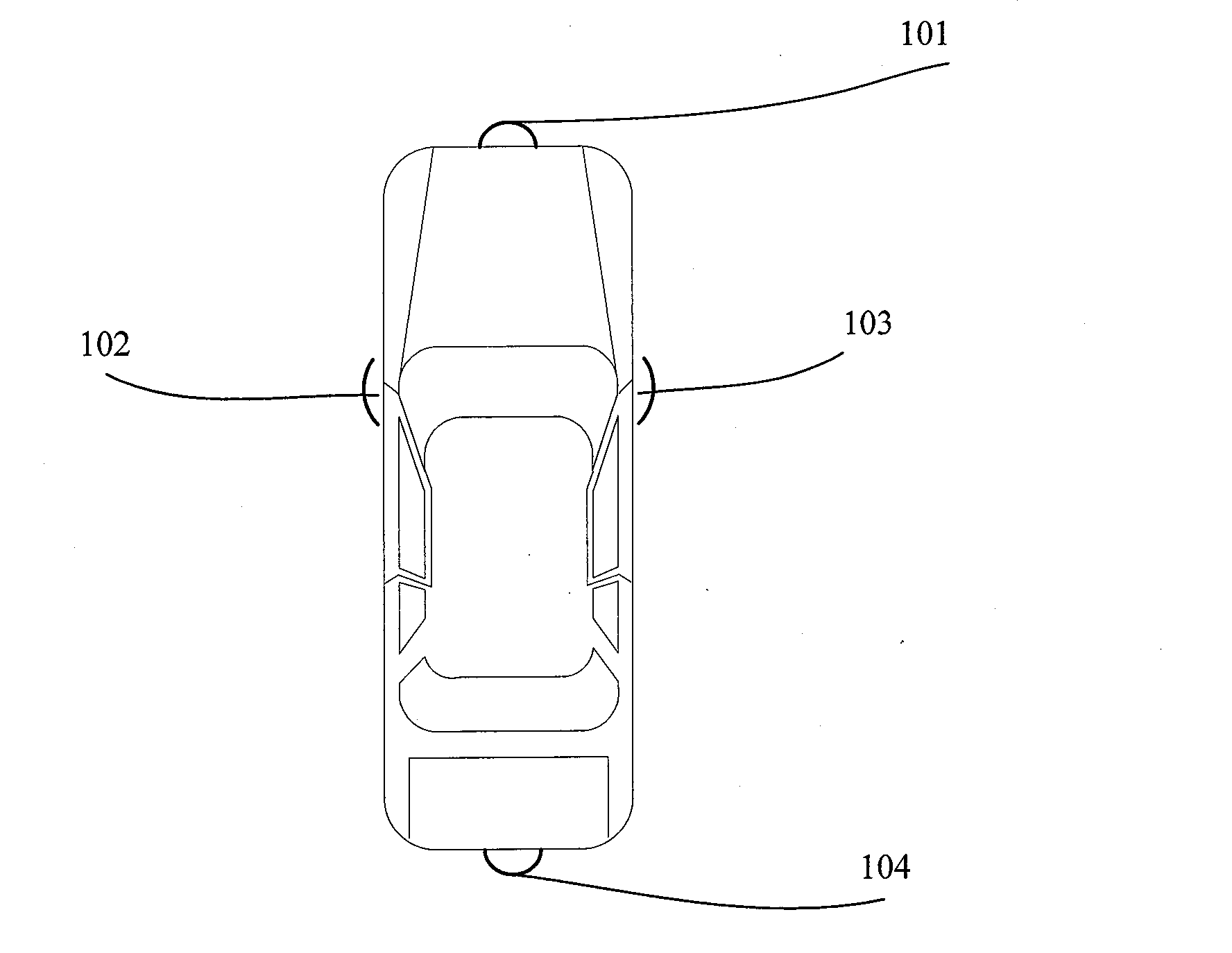

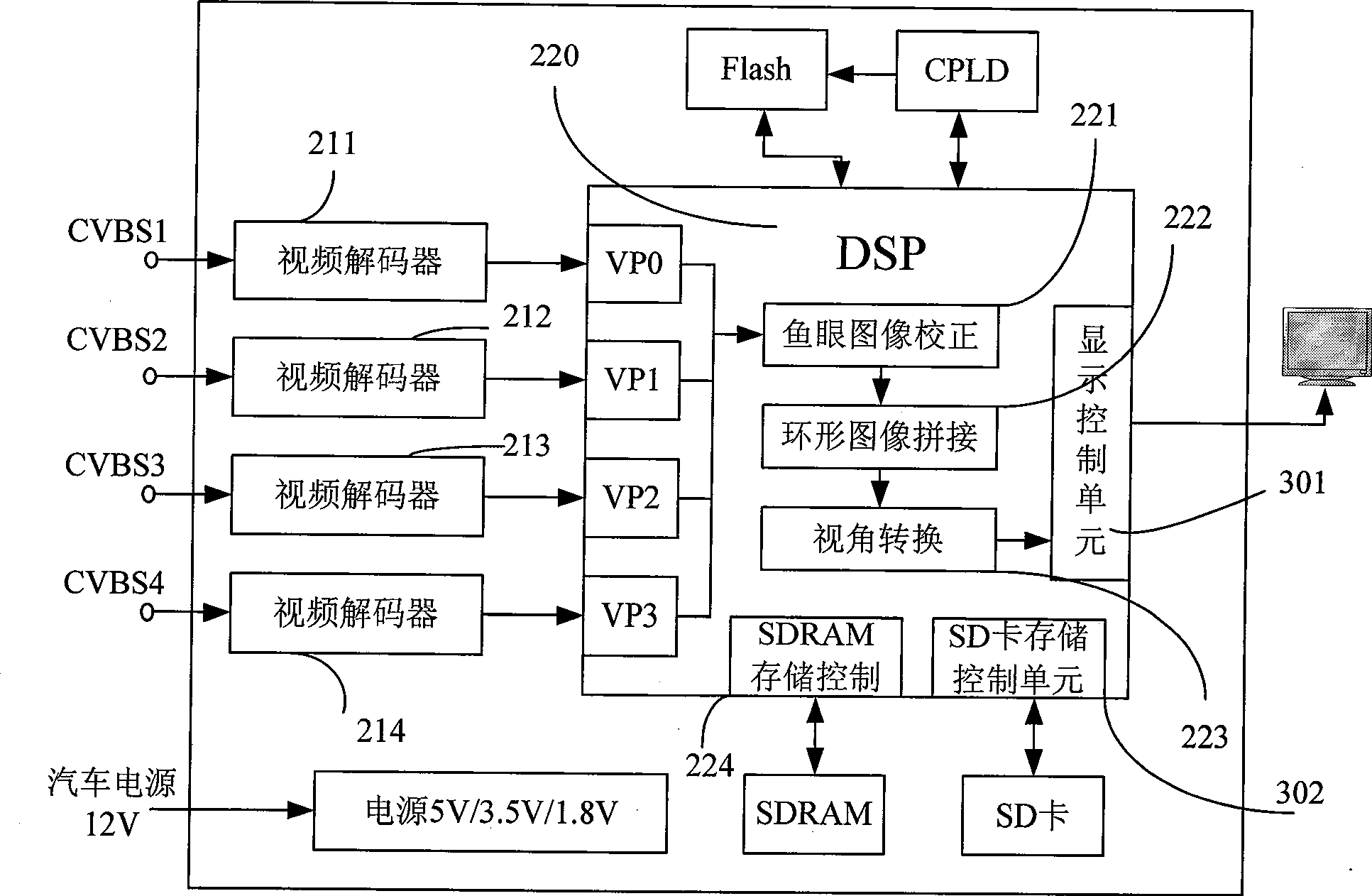

Method for synthesizing 360 DEG ring-shaped video of vehicle assistant drive

InactiveCN101442618ALow costSuitable for mass productionTelevision system detailsColor television detailsBlind zoneDriver/operator

The invention discloses a method for synthesizing annular video of 360 degrees for assistant drive of a vehicle. The method adopts a video acquisition unit, an annular video synthesis unit and a display control and storage unit, and has the characteristics of reliable stability, low cost and suitable batch production. The method can acquire video signals in real time for four super-wide-angle fish-eye cameras arranged at front, back, left and right of the vehicle, carries out treatment of fish-eye image correction, annular image mosaic and vision angle conversion on four channels of the video signals through a video decoding unit and a video synthesizing control unit to generate a panoramic displayed plan view of 360 degrees, achieves multiple display modes through the display control and storage unit, and can selectively store correlated video information. The method can provide surrounding scenes for a driver, and eliminate vision blind area thereof, and is favorable for the driver to achieve safe and accurate vehicle driving operations. The method is used for assistant drive for sedans, business vehicles and heavy trucks of various grades, and passenger coaches of different types.

Owner:葛晨阳

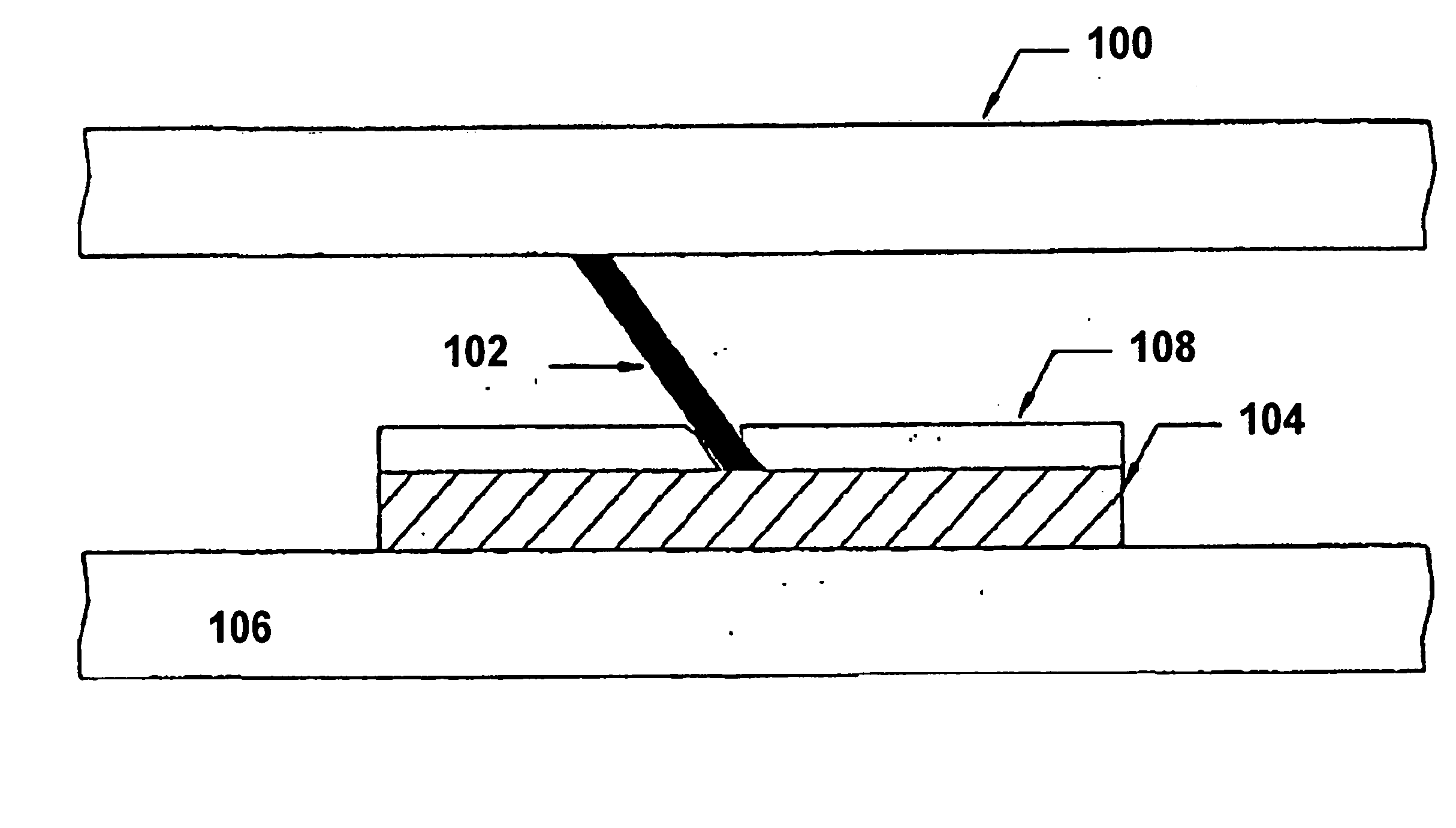

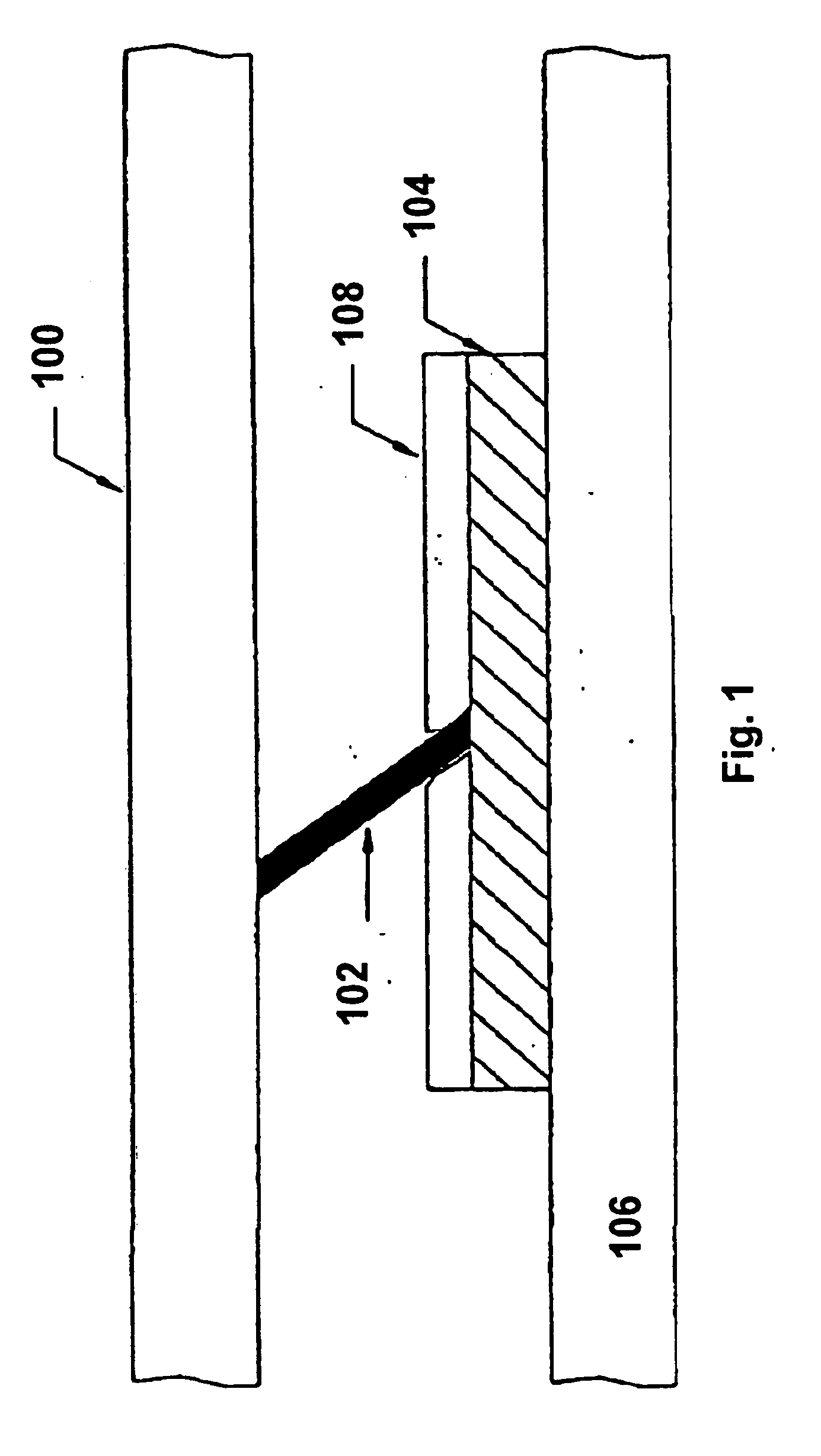

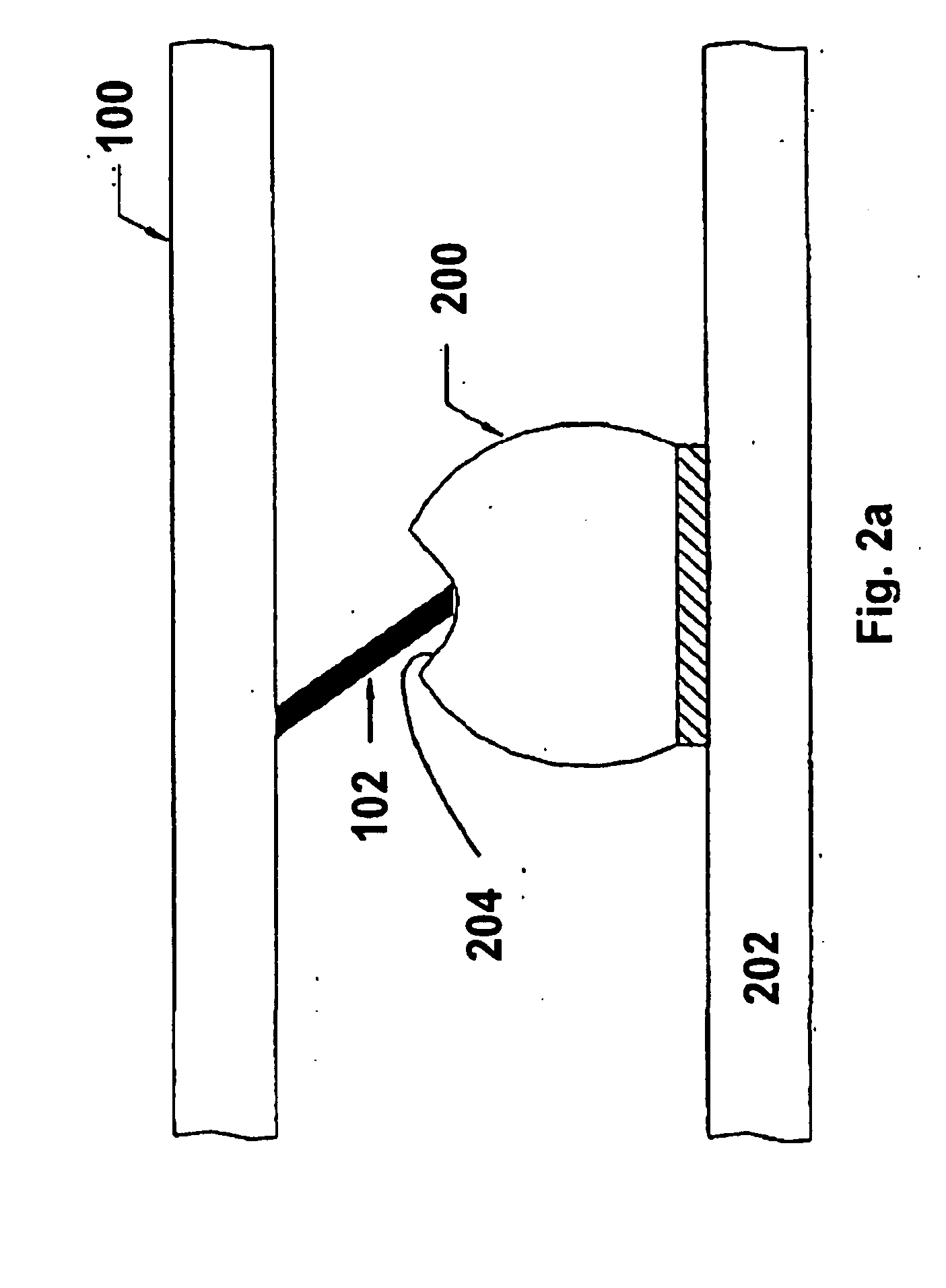

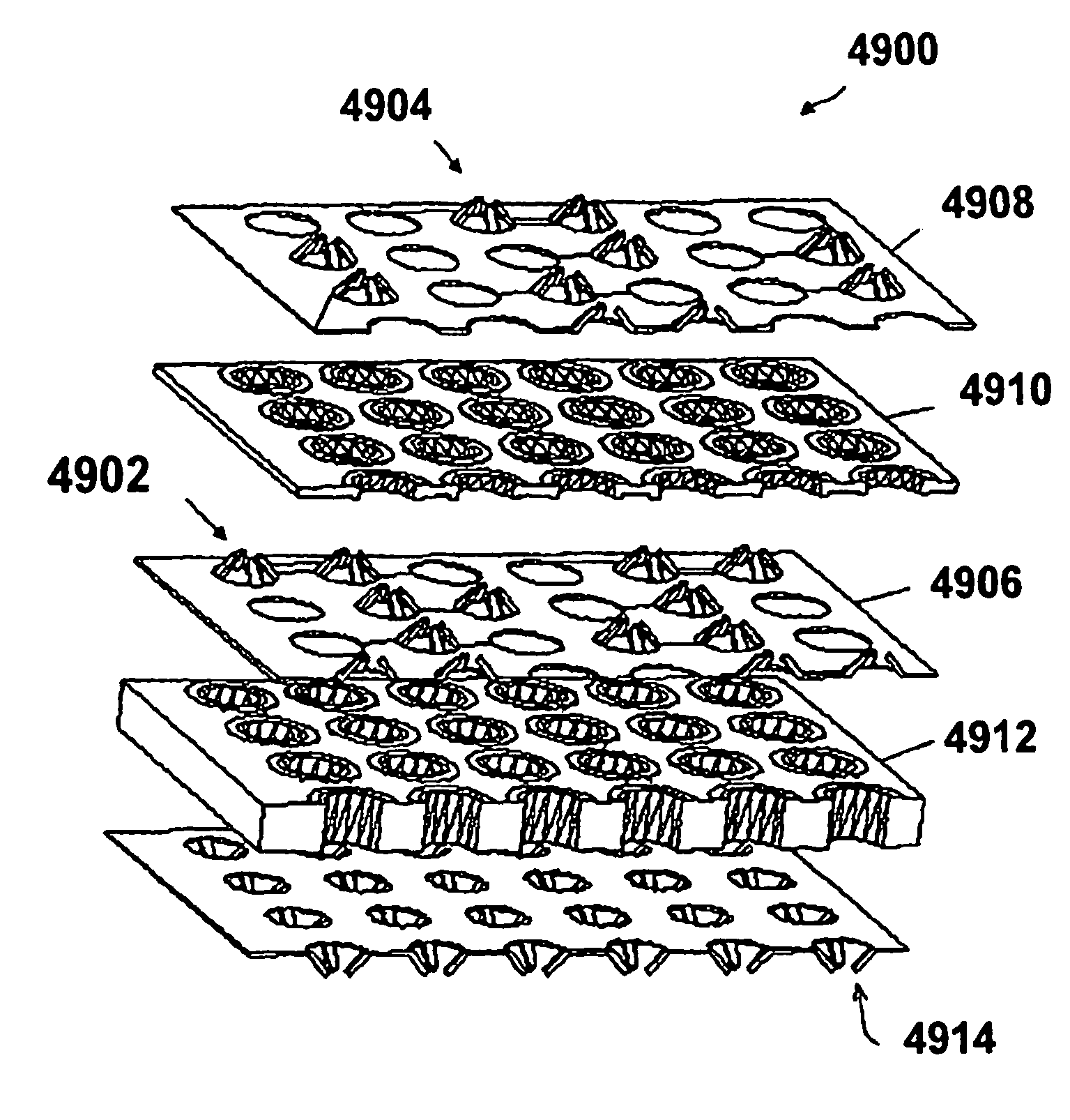

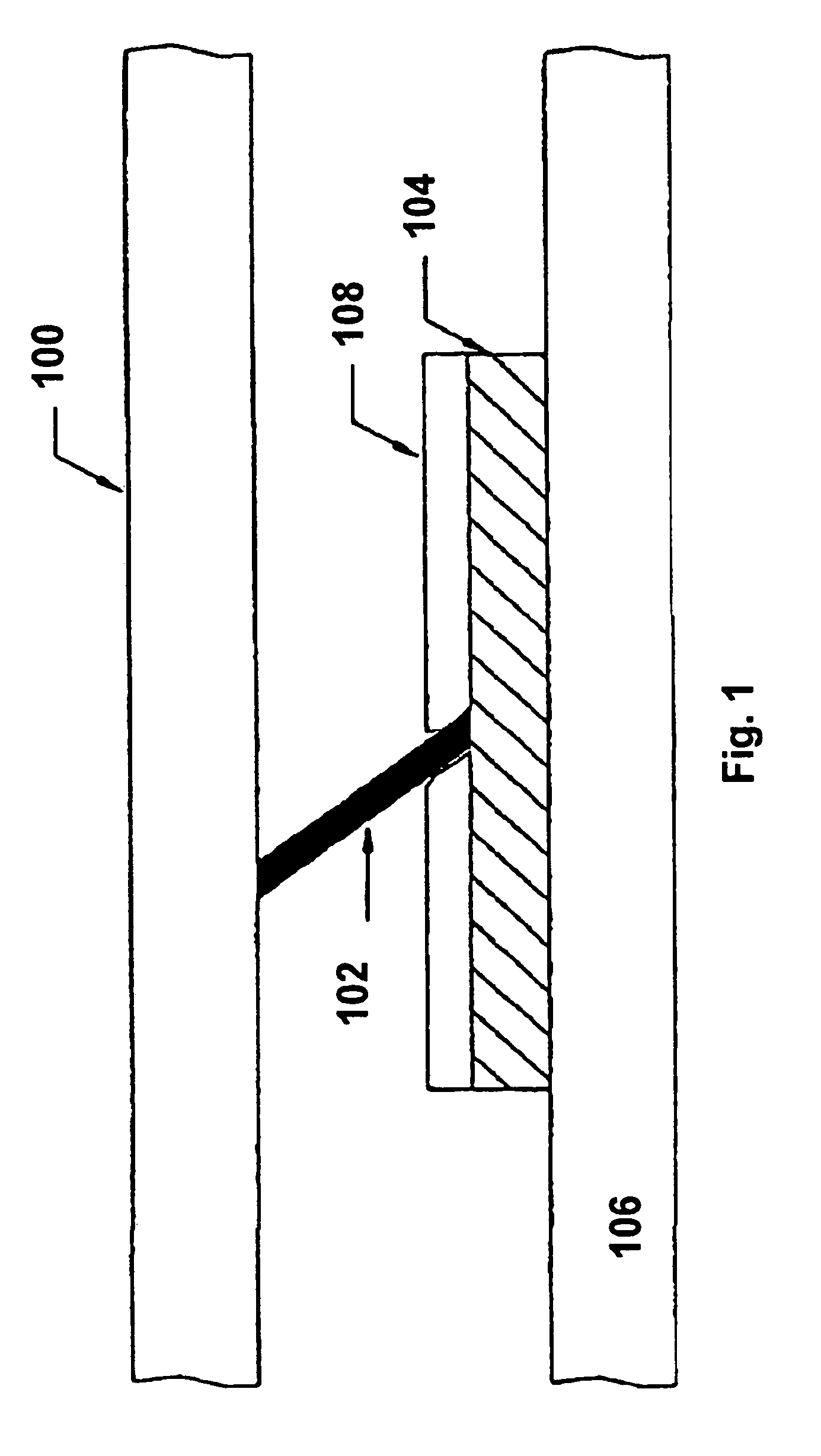

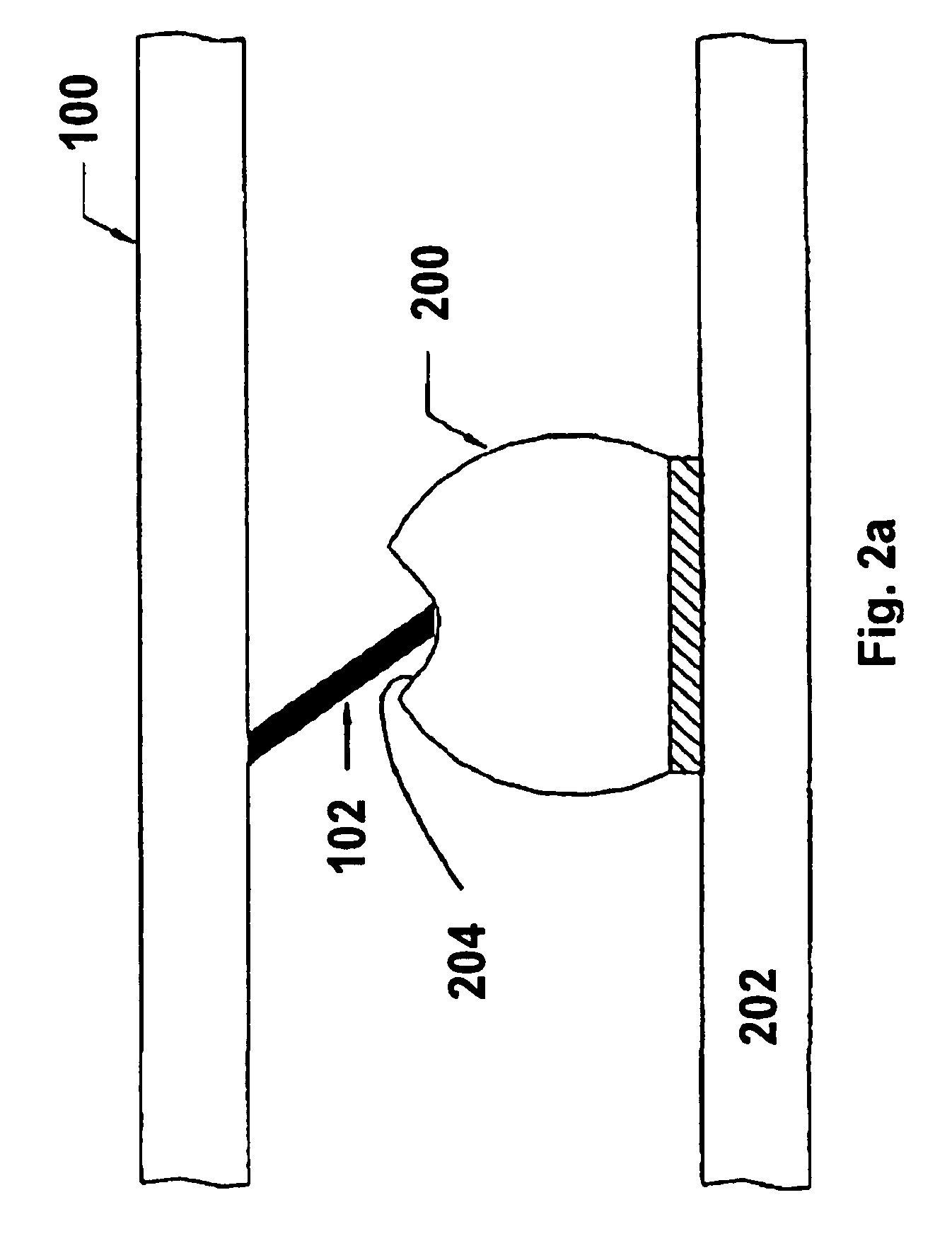

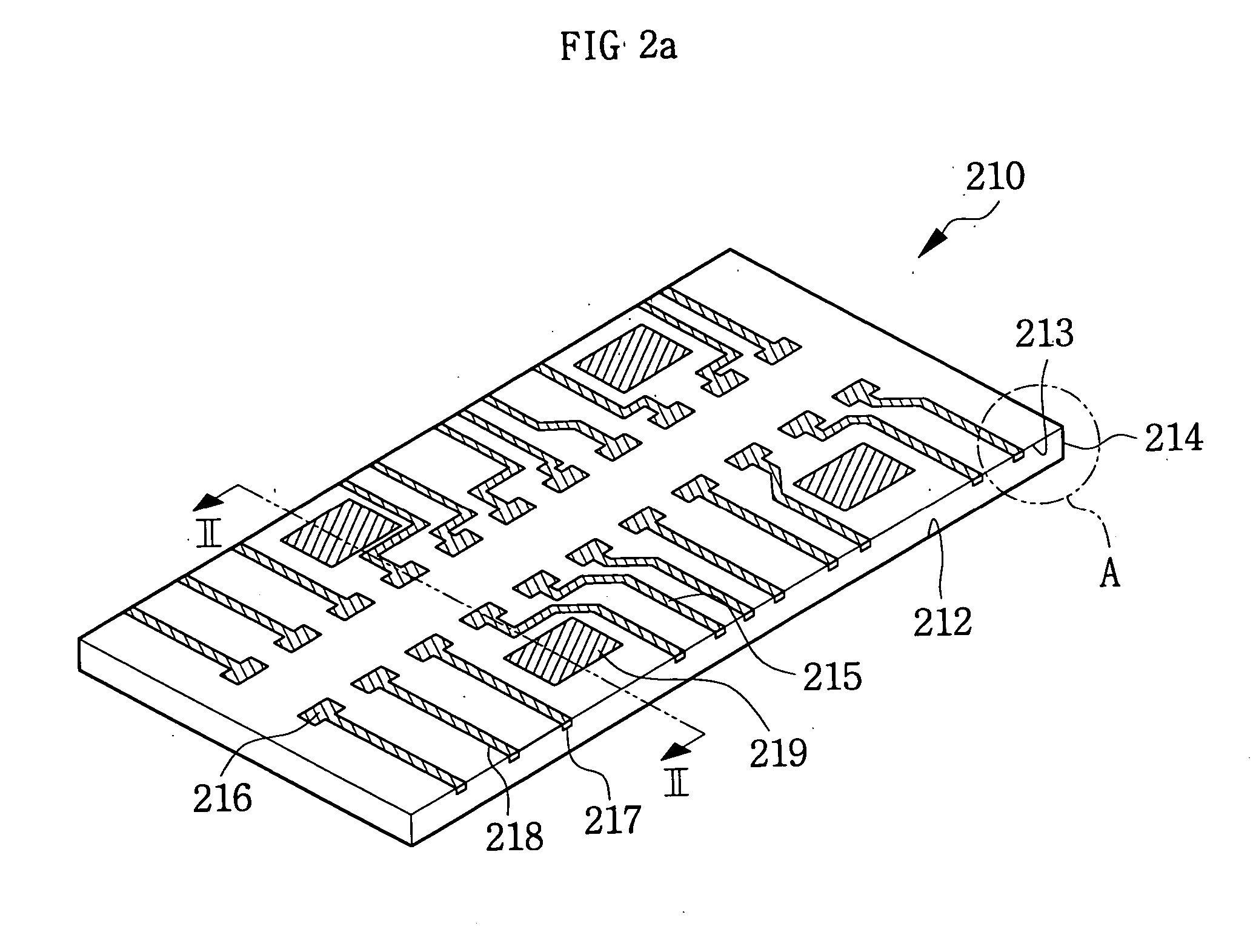

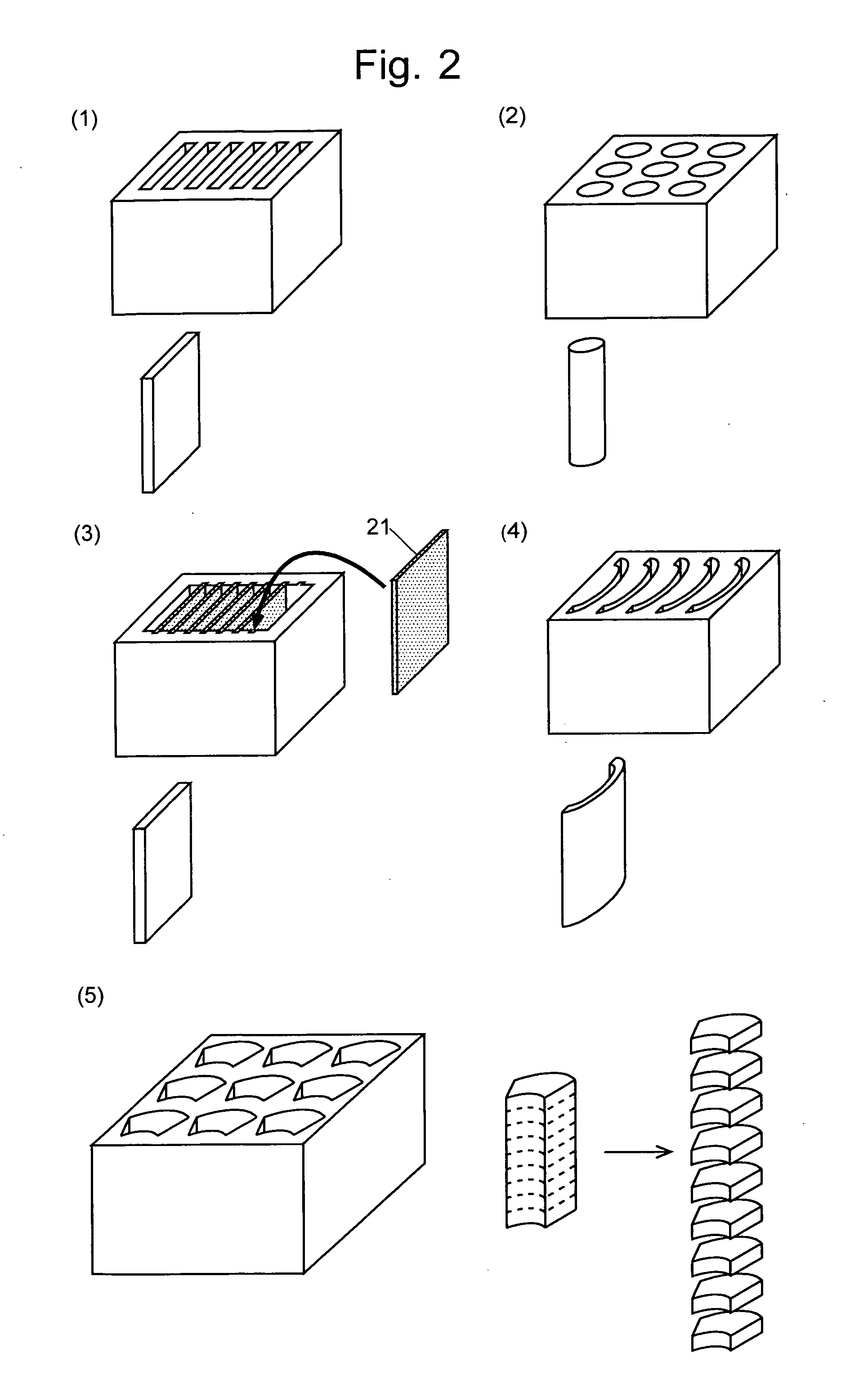

Method and system for batch manufacturing of spring elements

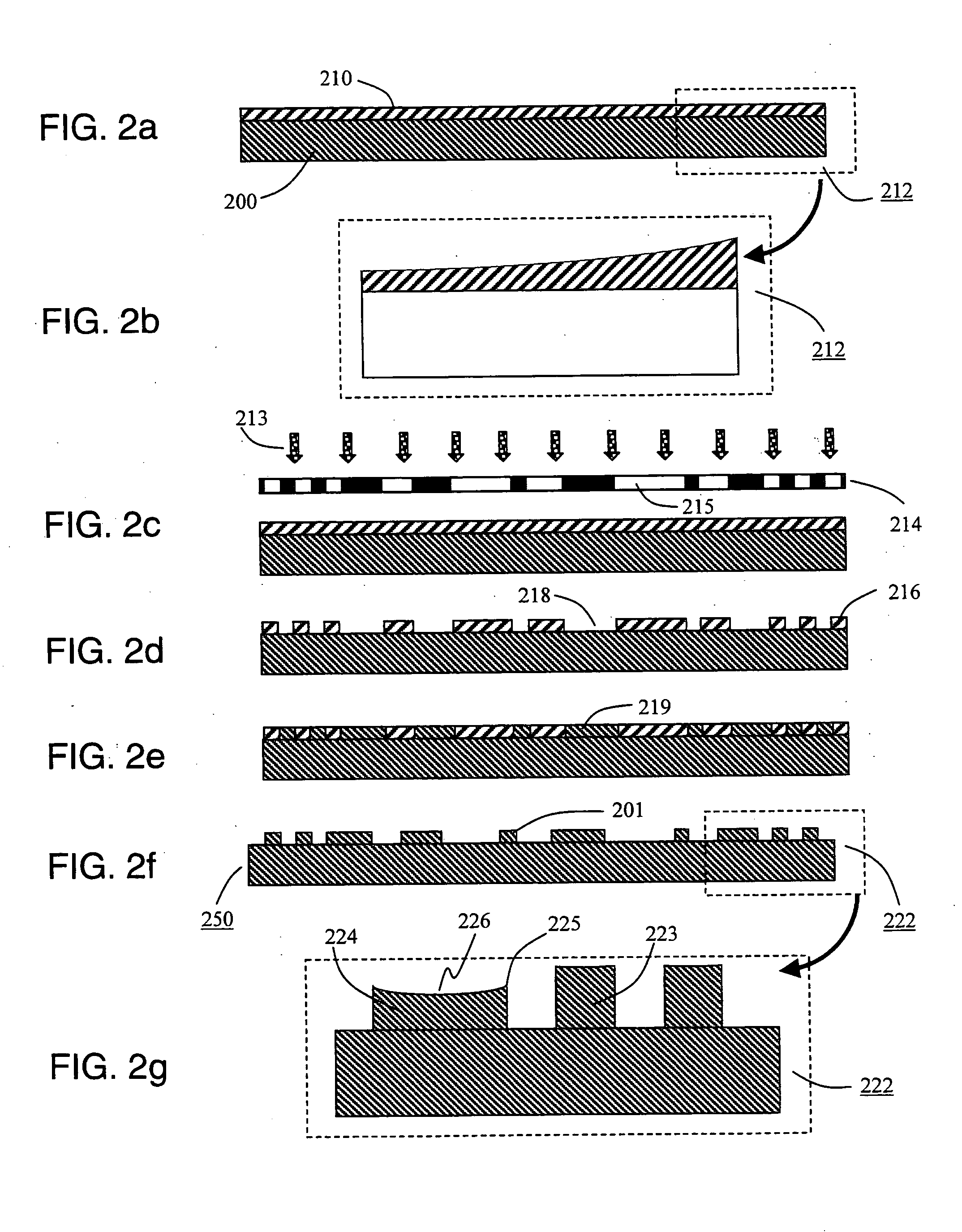

A system for batch forming a sheet of spring elements in three dimensions is described. A spring element sheet containing spring elements defined in two dimensions is arranged between two mating die press plates. A force is applied to the mating die press plates to form the two-dimensional spring contact elements into three dimensions. Alternatively, configurable die press plates are used to selectively form a two-dimensional spring element sheet into three-dimensional spring contacts.

Owner:NEOCONIX INC

Method and system for batch manufacturing of spring elements

A system for batch forming a sheet of spring elements in three dimensions is described. A spring element sheet containing spring elements defined in two dimensions is arranged between two mating die press plates. A force is applied to the mating die press plates to form the two-dimensional spring contact elements into three dimensions. Alternatively, configurable die press plates are used to selectively form a two-dimensional spring element sheet into three-dimensional spring contacts.

Owner:NEOCONIX INC

Method for forming mould-free gel with metal sizing agents through 3D printing

The invention provides a method for forming mould-free gel with metal sizing agents through 3D printing. A 3D printing technology is combined with a gel forming technology, the metal sizing agents are prepared through a gel forming process, the sizing agents are adopted as the raw materials of 3D printing, then layered printing is carried out through 3D printing equipment according to a data model, the metal sizing agents are solidified fast by controlling the additive number of initiating agents and catalysts, the initiating agents and the catalysts are accumulated layer by layer to form a metal blank, and the metal blank is dried and sintered to obtain a metal part product with a large size and in a complex shape. The method can be used for manufacturing a part including a sealed cavity and a complex inner cavity, the part cannot be manufactured through a traditional gel casting forming mode, the blank is directly formed through the 3D printing technology, mould development cost is saved, the method has obvious advantages in single part production and small scale production, requirements for powder materials are low, the process is stable and reliable, the operability is strong, consumed time is short, efficiency is high, cost is low, and the industrialization of manufacturing the metal part with the large size and in the complex shape through the 3D printing technology is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

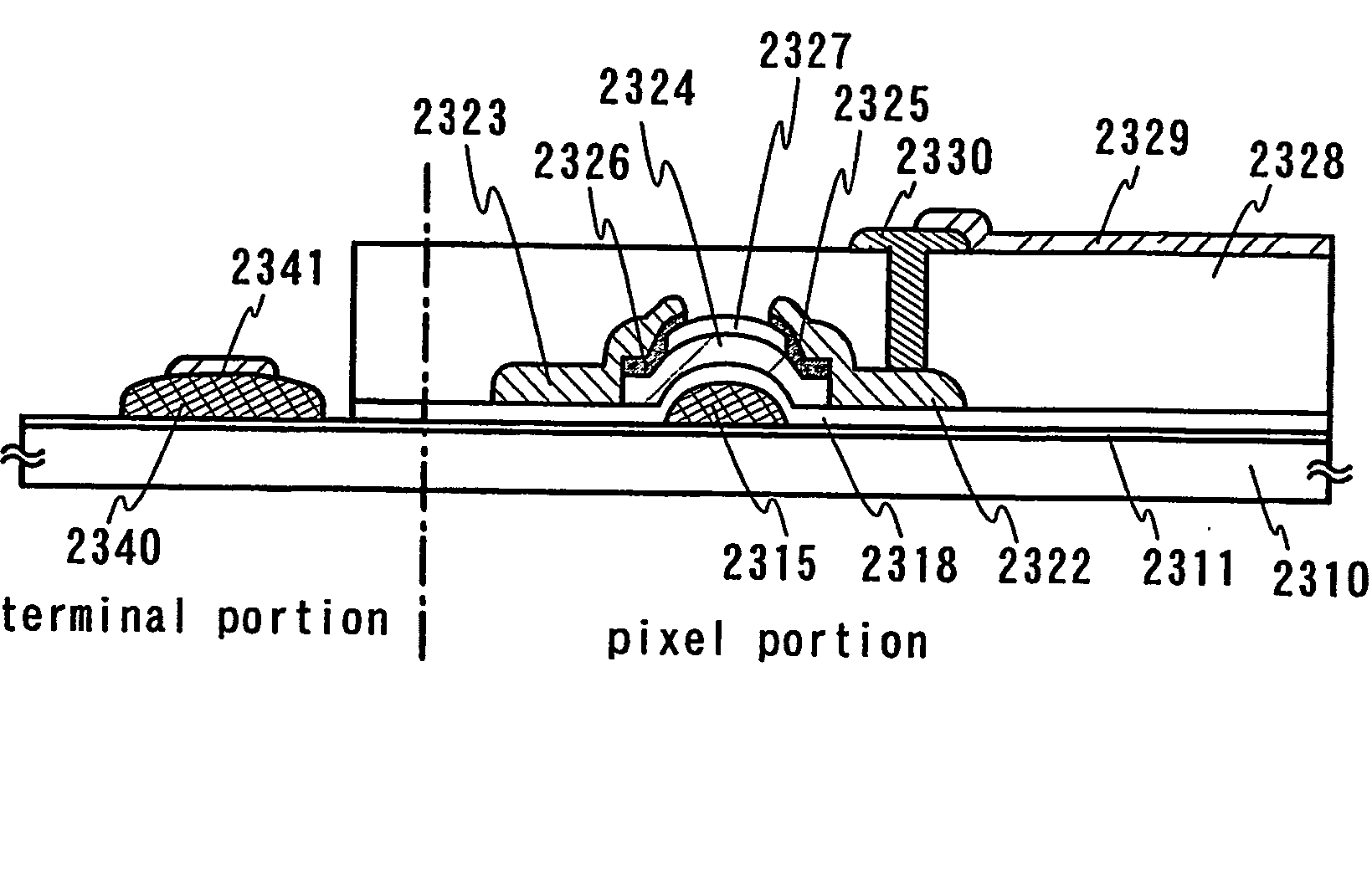

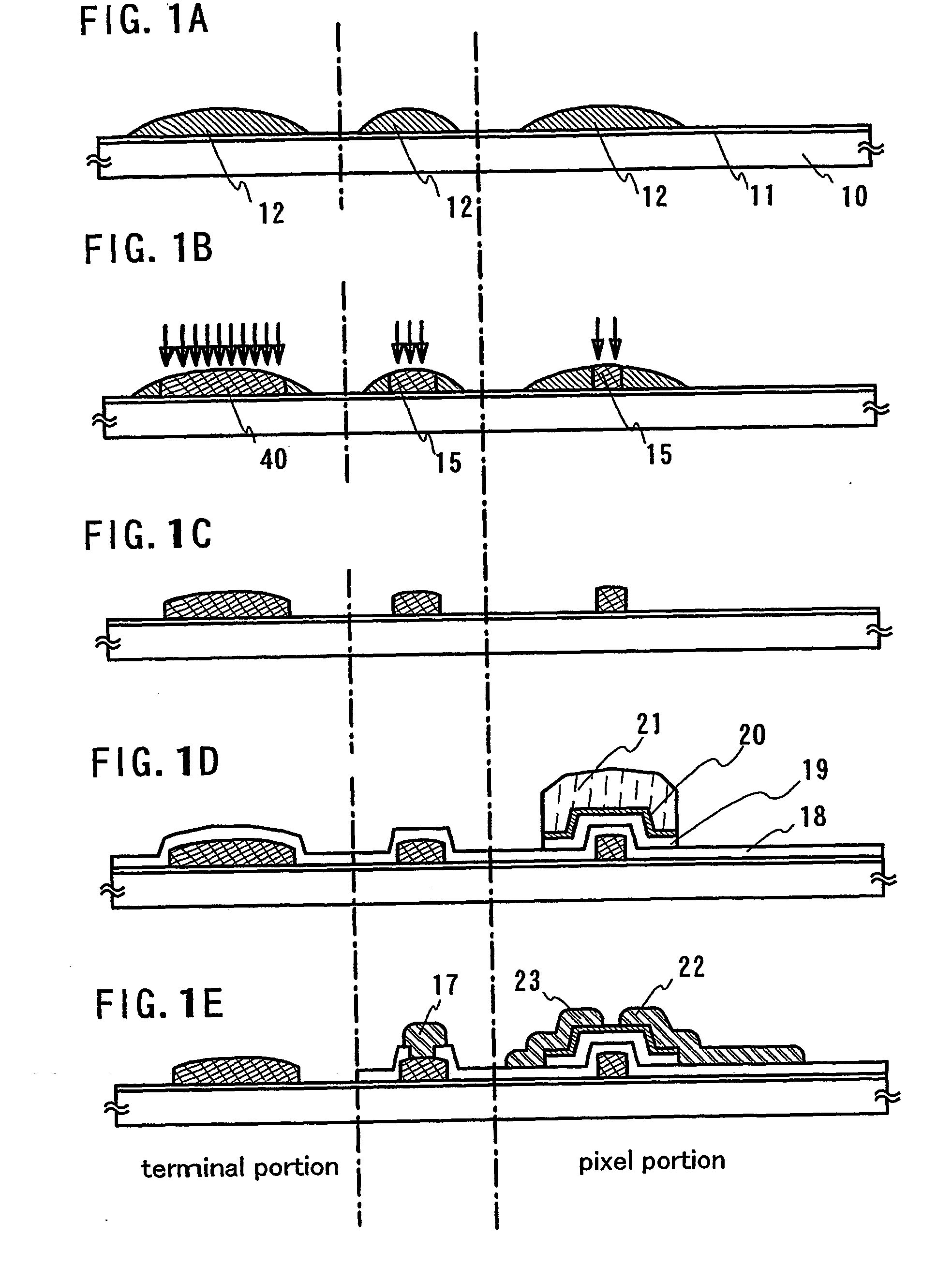

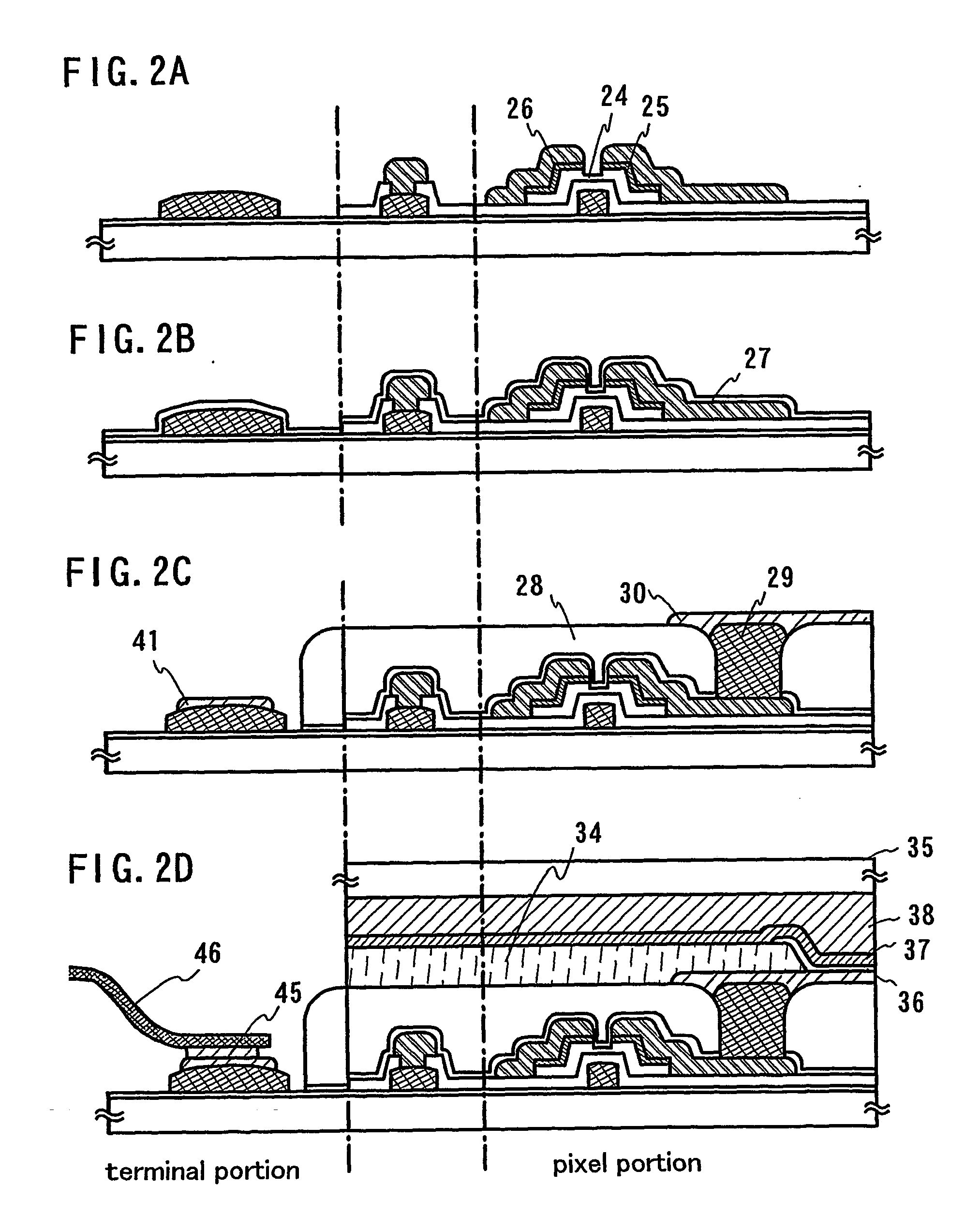

Electric appliance, semiconductor device, and method for manufacturing the same

InactiveUS20070093002A1Reduce drastically costReduce material usageTransistorElectroluminescent light sourcesDevice materialConductive materials

In the present circumstances, a film formation method of using spin coating in a manufacturing process is heavily used. As increasing the substrate size in future, the film formation method of using spin coating becomes at a disadvantage in mass production since a mechanism for rotating a large substrate becomes large, and there is many loss of material solution or waste liquid. According to the present invention, in a manufacturing process of a semiconductor device, a microscopic wiring pattern can be realized by delivering selectively photosensitive conductive material solution by droplet discharging, exposing selectively to laser light or the like, and developing. The present invention can reduce drastically costs since a patterning process can be shortened and an amount of material in a process of forming a conductive pattern can be reduced. Accordingly, the present invention can be applied to manufacture a large substrate.

Owner:SEMICON ENERGY LAB CO LTD

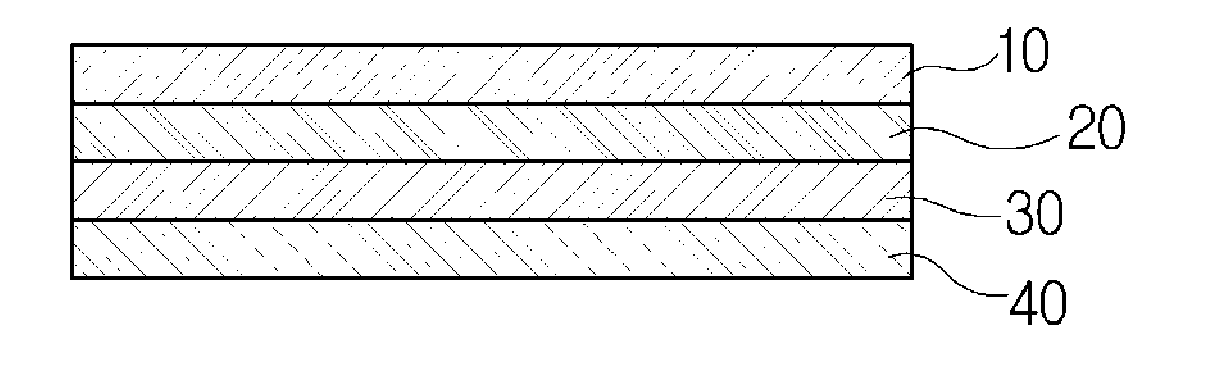

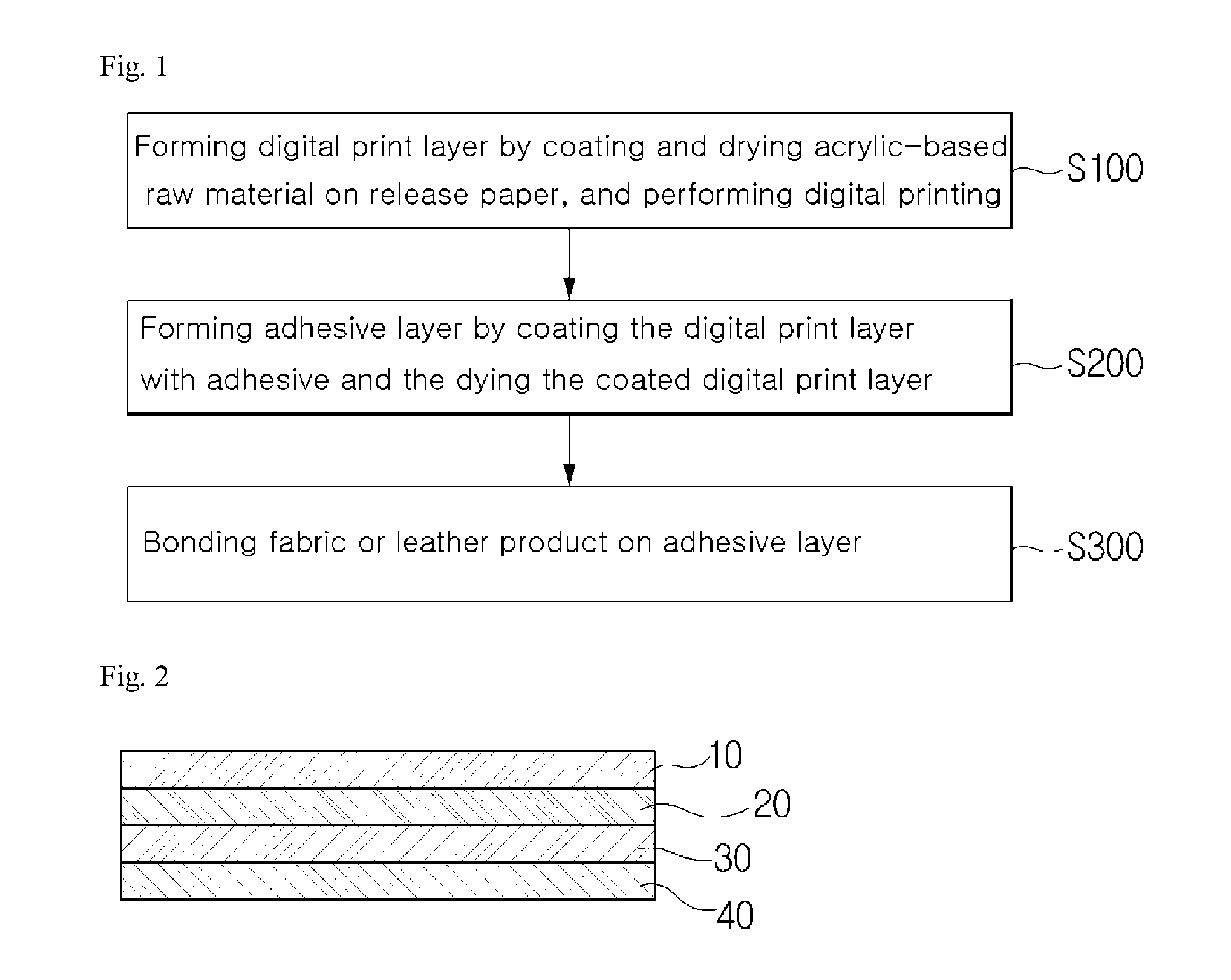

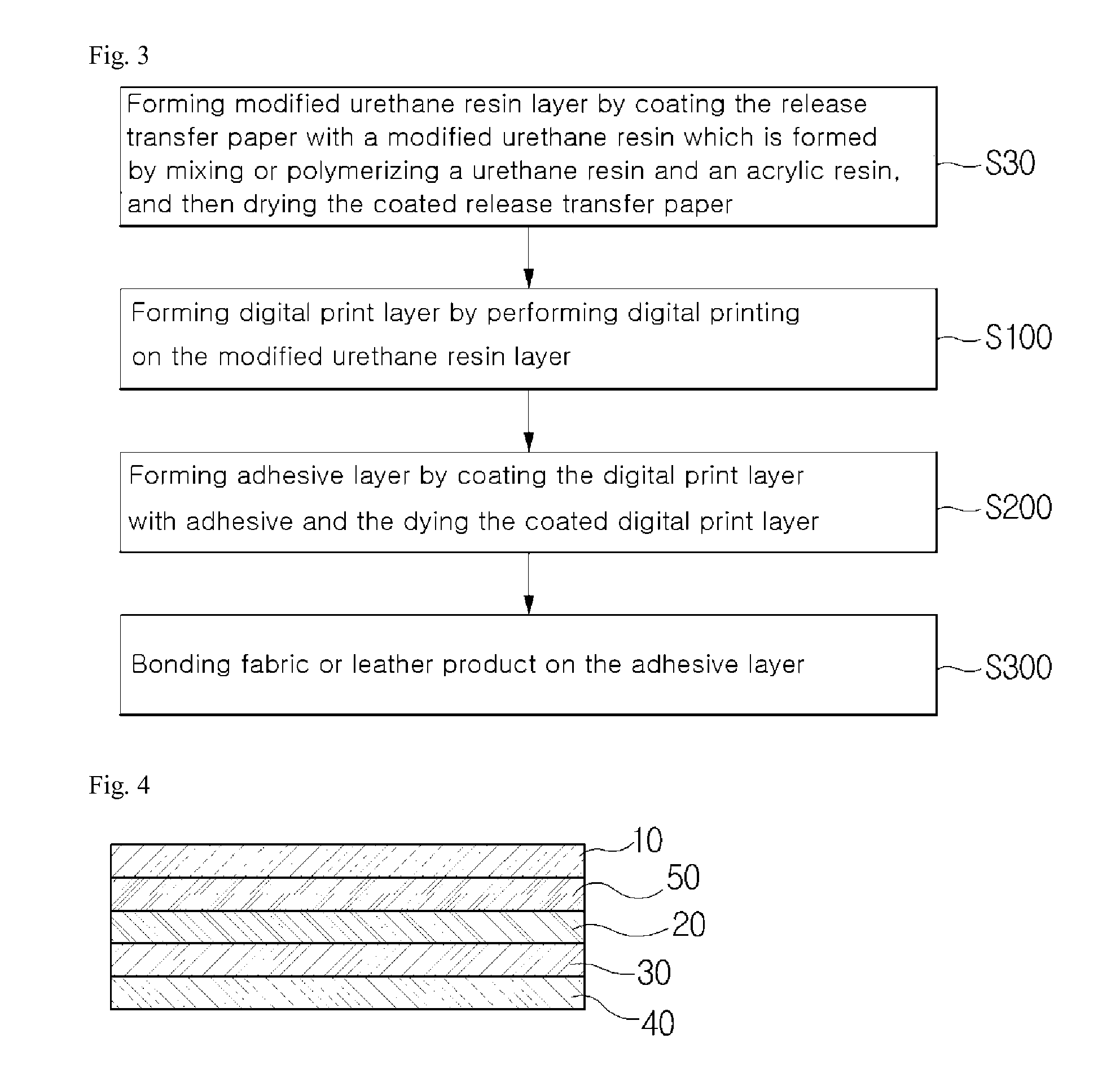

Method for printing fabric or leather product, and printed matter printed by using the same

ActiveUS20160067984A1Simple processReduce manufacturing costDecorative surface effectsDuplicating/marking methodsAdhesiveComputer printing

The present invention relates to a method for printing fabric or leather product, and printed matter printed by using the same, the method comprising the steps of: a) forming a digital print layer by performing digital printing on a release transfer paper by using an inkjet printer; b) forming adhesive layer by coating the digital print layer with an adhesive, and drying for a predetermined time; and c) bonding fabric or leather product to the adhesive layer. Thus, the present invention can precisely print fabric or leather product with high resolution and can enable customized printing so as to allow small quantity batch production.

Owner:CHUNG DOO HO

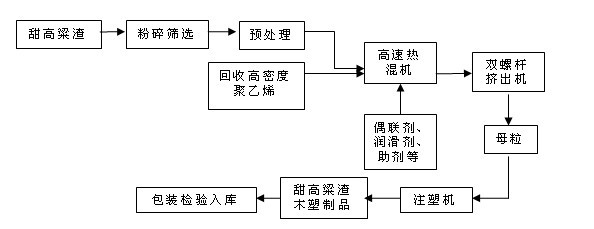

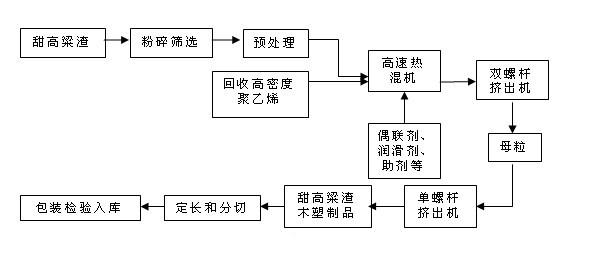

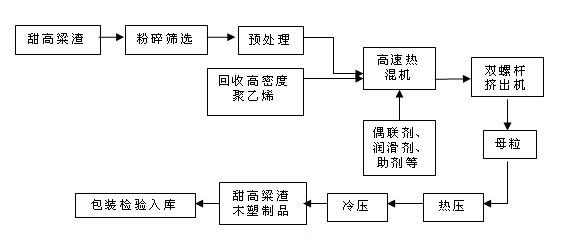

Wood-plastic composite material using sweet sorghum slag as enhanced phase and preparation method for wood-plastic composite material

InactiveCN102690525AGood mechanical propertiesImprove performanceCoatingsAgricultural engineeringMoisture resistance

The invention discloses a wood-plastic composite material using sweet sorghum slag as an enhanced phase and a preparation method for the wood-plastic composite material. The wood-plastic composite material comprises 10 to 80 parts of sweet sorghum slag and 20 to 90 parts of recycled plastic, wherein the sweet sorghum slag and the recycled plastic serve as a matrix phase; and the sweet sorghum slag is subjected to combined pretreatment by an alkali-oxygen method and a steam explosion method. Sectional materials such as a sweet sorghum slag wood-plastic four-pore board, a sauna board, garden protective process, walls and the like are manufactured by extruding a fixed die and forming, or sweet sorghum slag wood-plastic products are manufactured by formation such as injection molding, pressing and the like. The sweet sorghum slag wood-plastic products can be suitable for large-scale continuous batch production and has the advantages of high performance, low cost, moth resistance, moisture resistance, no formaldehyde and the like. Compared with the conventional wood powder fillings, the wood-plastic composite material has the advantages of light weight, high performance, low cost, high extrusion speed, low processing temperature and the like, wherein the mechanical performance of the sweet sorghum slag subjected to treatment is superior to that of wood powder. The sweet sorghum slag wood-plastic composite material has good economic benefits, social benefits and ecological benefits of reducing environmental pollution, protecting forest resource and promoting economic development.

Owner:BEIJING UNIV OF CHEM TECH

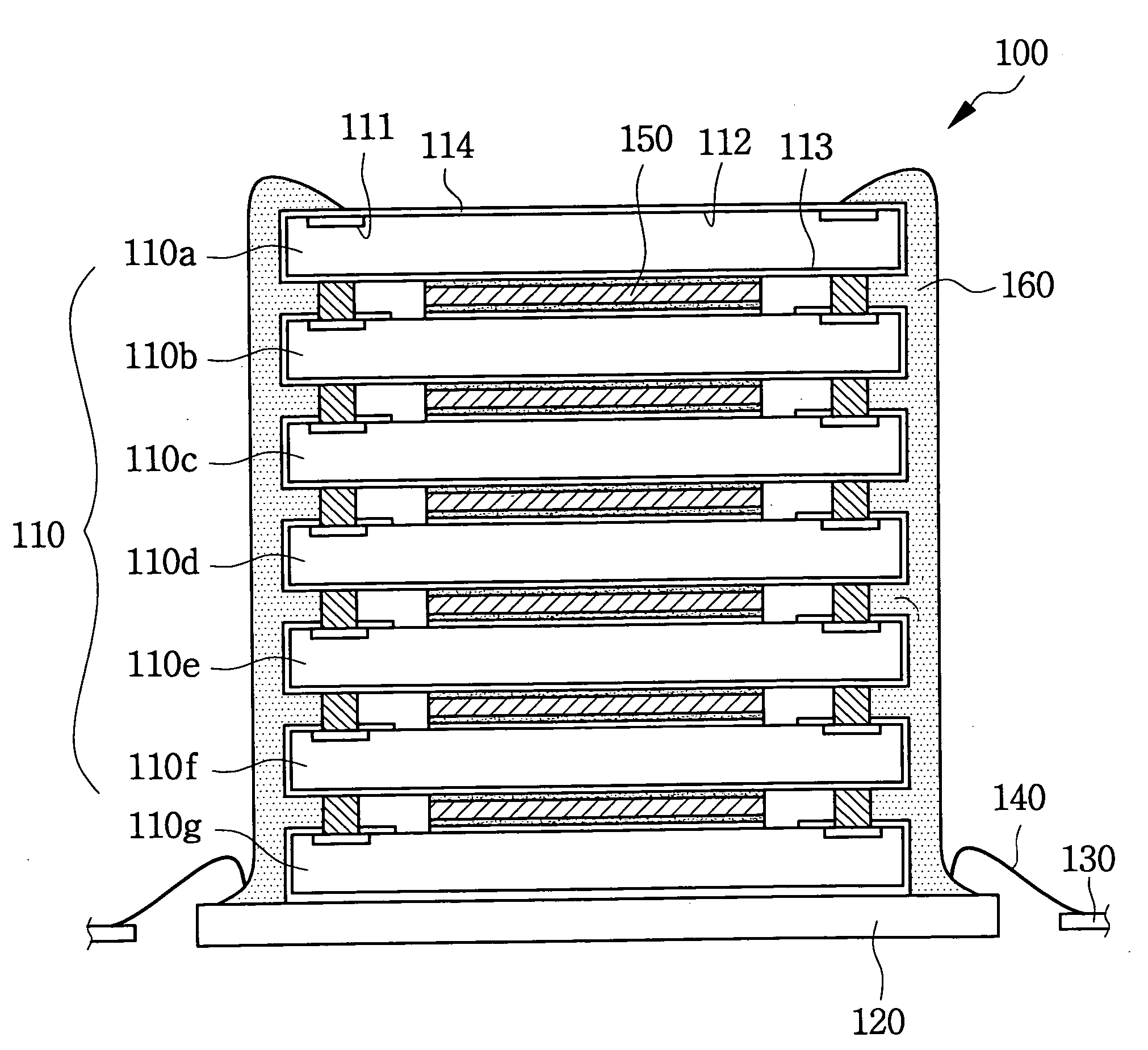

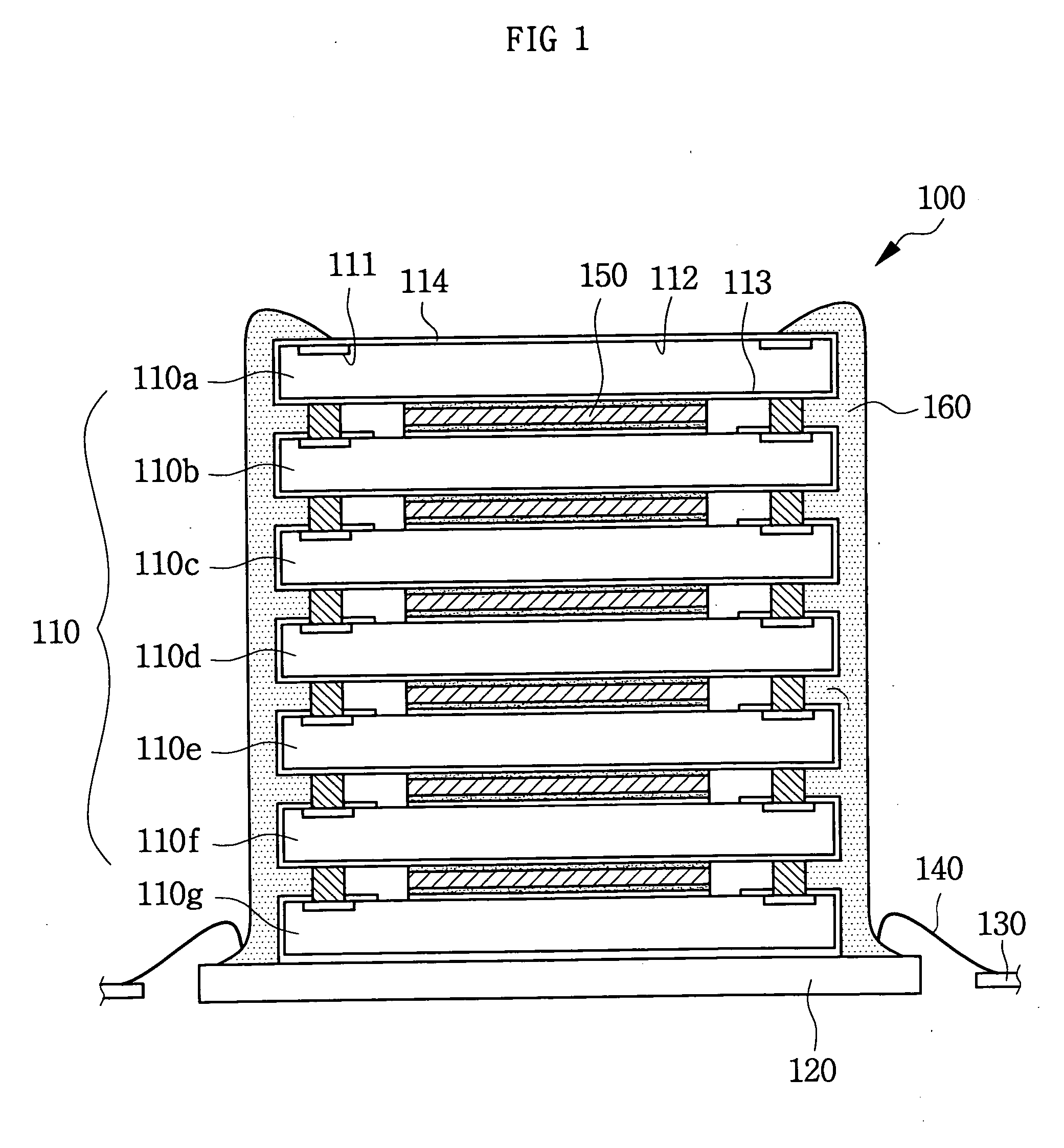

Semiconductor chip, chip stack package and manufacturing method

InactiveUS20050101056A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor chipConductive materials

A semiconductor chip with conductive wiring that is routed to the edge of the substrate from the chip's backside. A plurality of such semiconductor chips are stacked and electrically connected using a wiring element that is a circuit board or conductive adhesive strips. The wiring element connects the conductive wiring of each semiconductor chip along the sides of the chips to the package substrate. A method of manufacturing the semiconductor chip includes batch manufacturing a plurality of die on a wafer with an active surface on which a plurality bonding pads are formed, and a backside which is the rear side of the active surface; forming a circuit groove on the backside; applying conductive wiring on the circuit groove using a conductive material; and separating the wafer into a plurality of semiconductor chips. A method of manufacturing the chip stack package with a plurality of such semiconductor chips having bump pads and connection pads routed to the side surface of the semiconductor chip includes stacking and bonding the bonding pad of the upper semiconductor chip on the bump pad of a lower semiconductor chip; electrically connecting the bonding pad of the lowest semiconductor chip to the substrate by bump bonding electrically connecting the wiring element to the connection pad of the semiconductor chip and the substrate; and connecting an external connection to the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for producing high-strength fasteners in batch by using 3D (three dimensional) printing technology

InactiveCN103612393AImprove efficiencyIncrease productivityElectrographic process apparatusGraphicsPunching

The invention discloses a method for producing high-strength fasteners in batch by using a 3D (three dimensional) printing technology. The method specifically comprises the following steps: carrying out computer modeling, segmenting layer by layer, converting a graph into a light beam loaded with graph information; charging a photosensitive drum to obtain a potential, scanning by the light beam to form an electro-static latent image; enabling the electro-static latent image to pass through a magnetic brush, absorbing powder to form an internal member; forming the internal member; and carrying out punching cutting and surface treatment. According to the method for producing the fasteners in batch, the production efficiency is high, the accuracy is high, and the obtained fasteners in batch are excellent in performance.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

Method and System for Manufacturing Sintered Rare-Earth Magnet Having Magnetic Anisotropy

ActiveUS20070245851A1Improve coercive forceEfficient productionFoundry mouldsInorganic material magnetismManufacturing efficiencyCrystallite

To improve the performance of a rare-earth magnet, it is effective to use a low-oxidized powder having a small grain size. One objective of the present invention is to provide a method for manufacturing a sintered rare-earth magnet having a magnetic anisotropy, in which a very active powder having a small grain size can be safely used in a low-oxidized state. Another objective is to provide a method capable of efficiently manufacturing products having various shapes. In a weighing and loading section 41 and a high-density loading section 42, a fine powder as a material of the sintered rare-earth magnet having a magnetic anisotropy is loaded into a mold until its density reaches a predetermined level. Then, in a magnetic orientation section 43, the fine powder is oriented by a pulsed magnetic field. Subsequently, the fine powder is not compressed but immediately sintered in a sintering furnace 44. The present method enables the mass-producing machine to be simple in its operation and its housing to be accordingly smaller, so that it will be possible to eliminate the danger of oxidization or burning of the powder, which has been a serious problem for a conventional method that uses a large-scale die-pressing machine. Furthermore, the manufacturing efficiency can be improved by using a multi-cavity mold for manufacturing a sintered rare-earth magnet having an industrially important shape, such as a plate magnet or an arched plate magnet.

Owner:DAIDO STEEL CO LTD

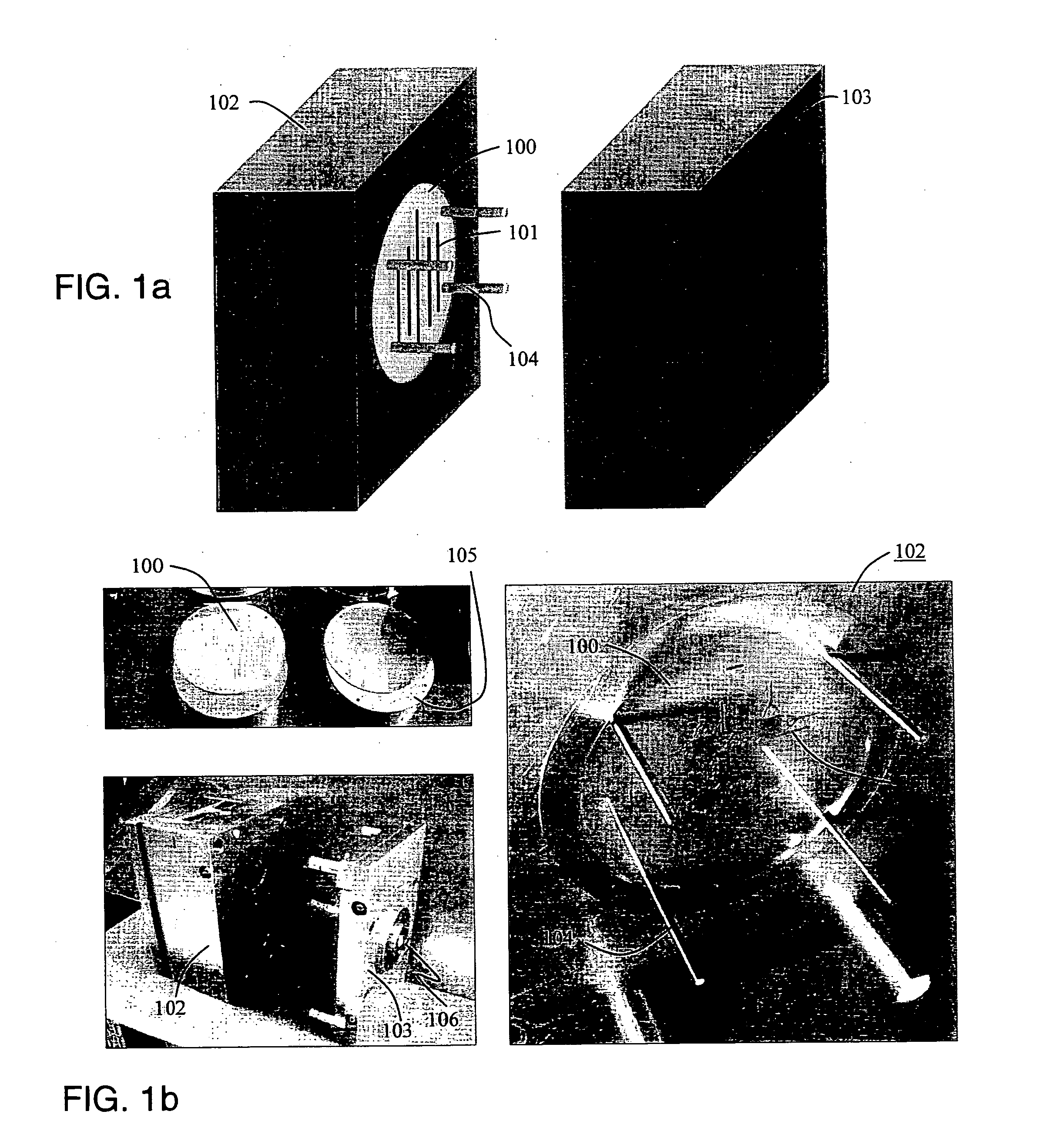

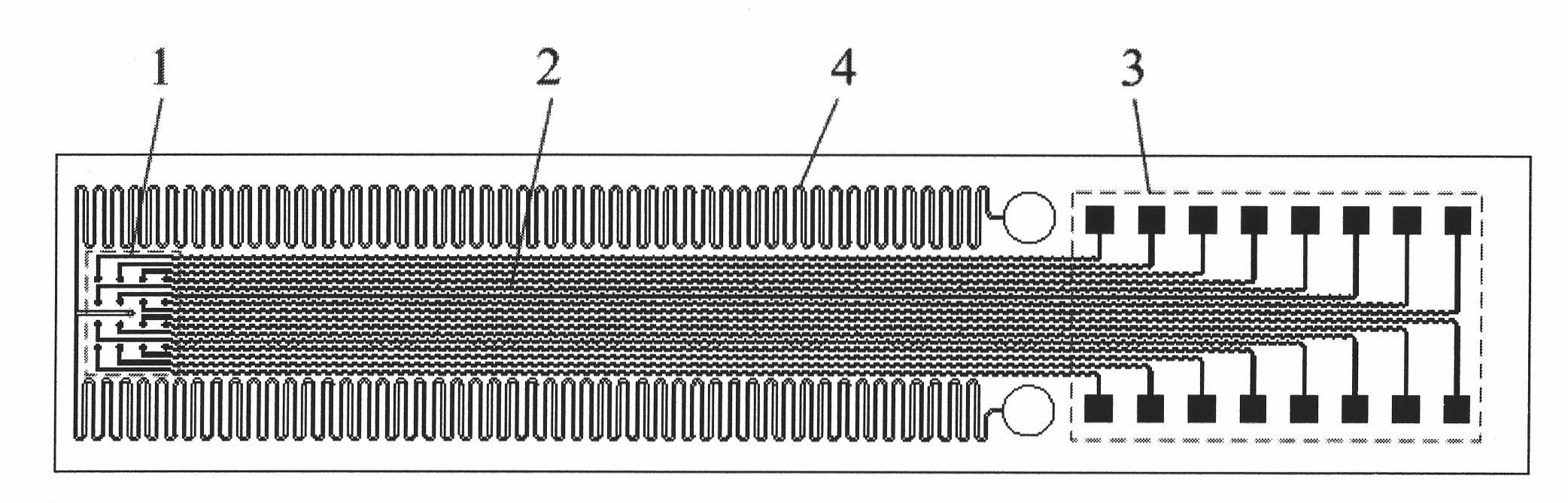

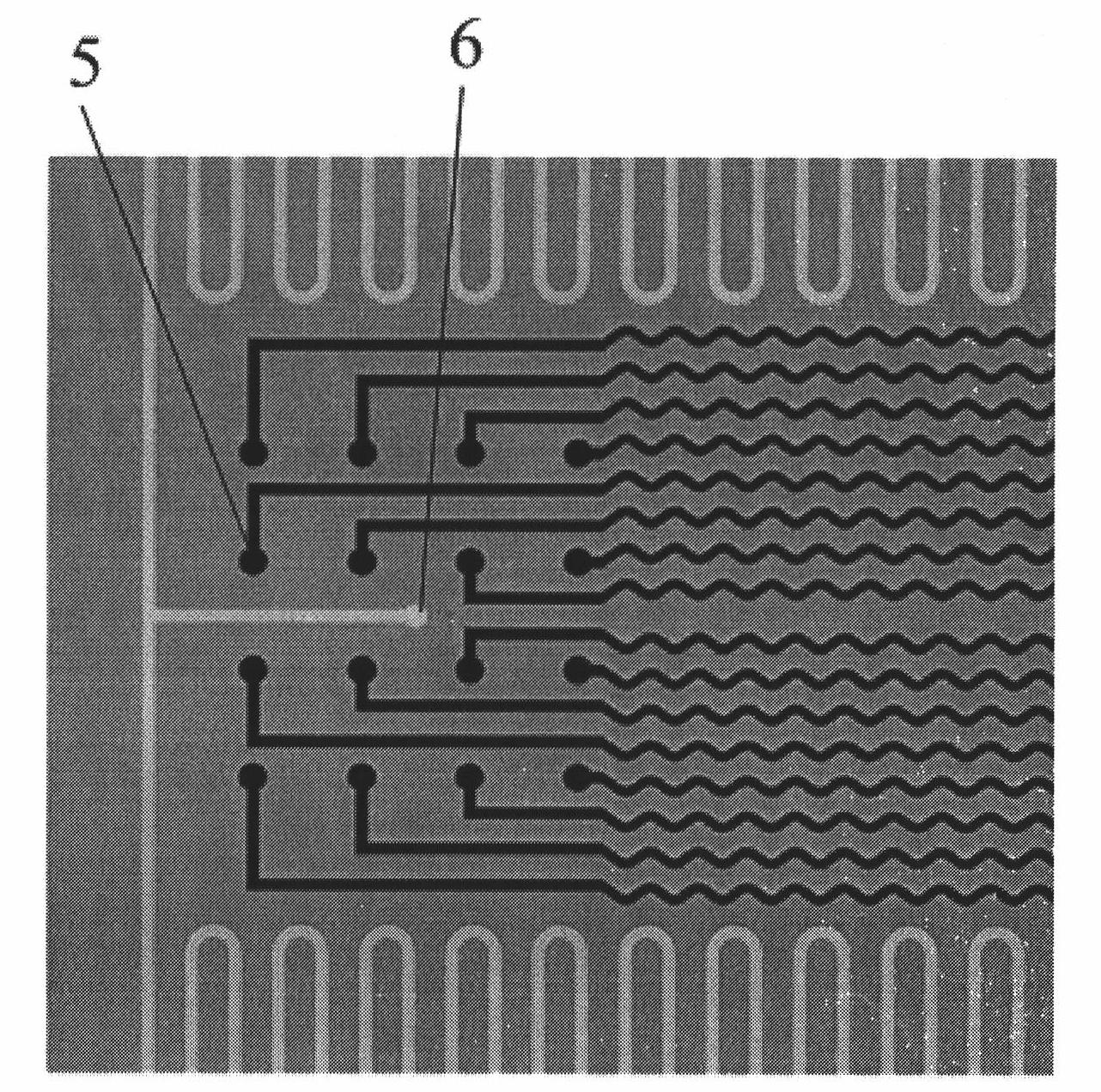

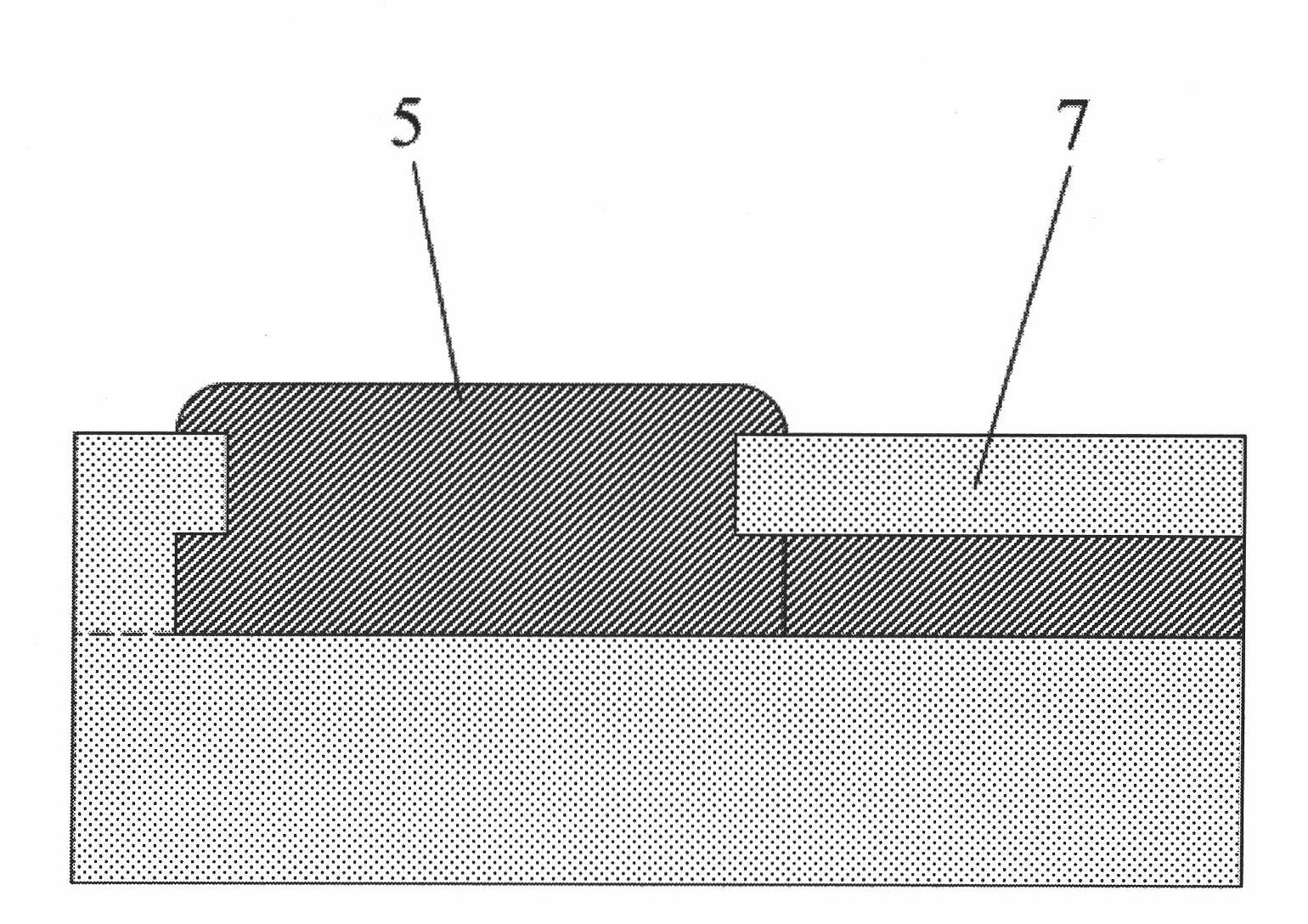

PDMS-based flexible implanted neural microelectrode and manufacturing method

ActiveCN101912666AGood biocompatibilityIncrease elasticityInternal electrodesMedical devicesBiocompatibility TestingMicroelectrode

The invention discloses a polydimethylsiloxane-based (PDMS) flexible implanted neural microelectrode and a manufacturing method. The electrode is characterized in that the PDMS with high biocompatibility and mechanical elasticity is used as a substrate material for the neural microelectrode, wherein the implanted flexible neural microelectrode which comprises an electrode site region, a connecting line region, a welding spot region and a micro-pipeline region is formed by electroplating technology, PDMS injection molding technology and bonding technology; the electrode site, the connecting line and the welding spot are structurally formed of an electroplated metal layer, so that the tensile resistance and the reliability of the metal structure of the PDMS microelectrode are enhanced; and the micro-pipeline integrated on the electrode can be used for pouring a curable liquid material which contains medicament or nerve growth factor, so that the operability of the operation implantation of the PDMS neutral microelectrode and the biocompatibility after the implantation are improved. Meanwhile, the preparation method of the PDMS microelectrode provided by the invention has the characteristics of simple process, low cost and standard batch manufacturing.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

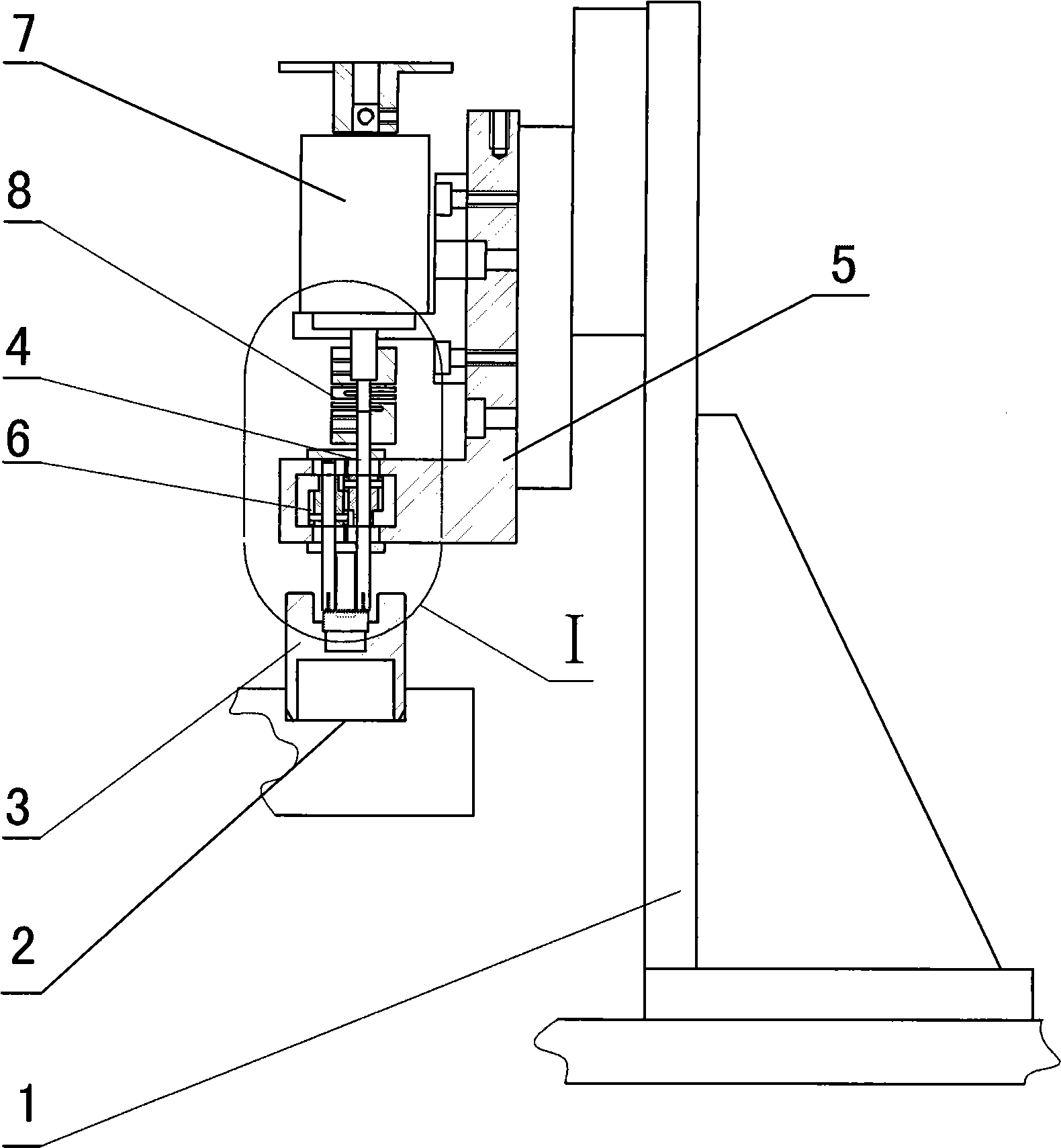

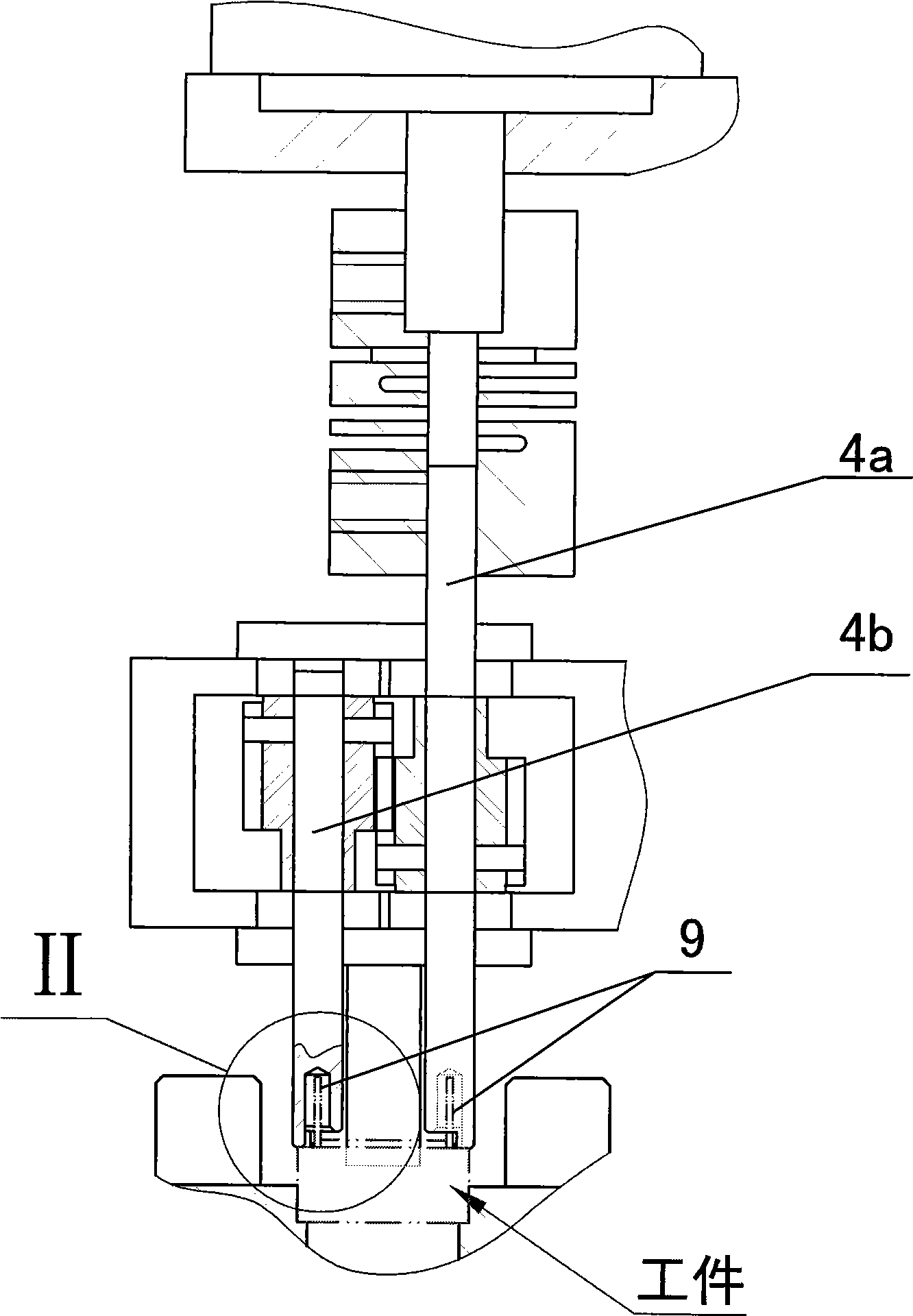

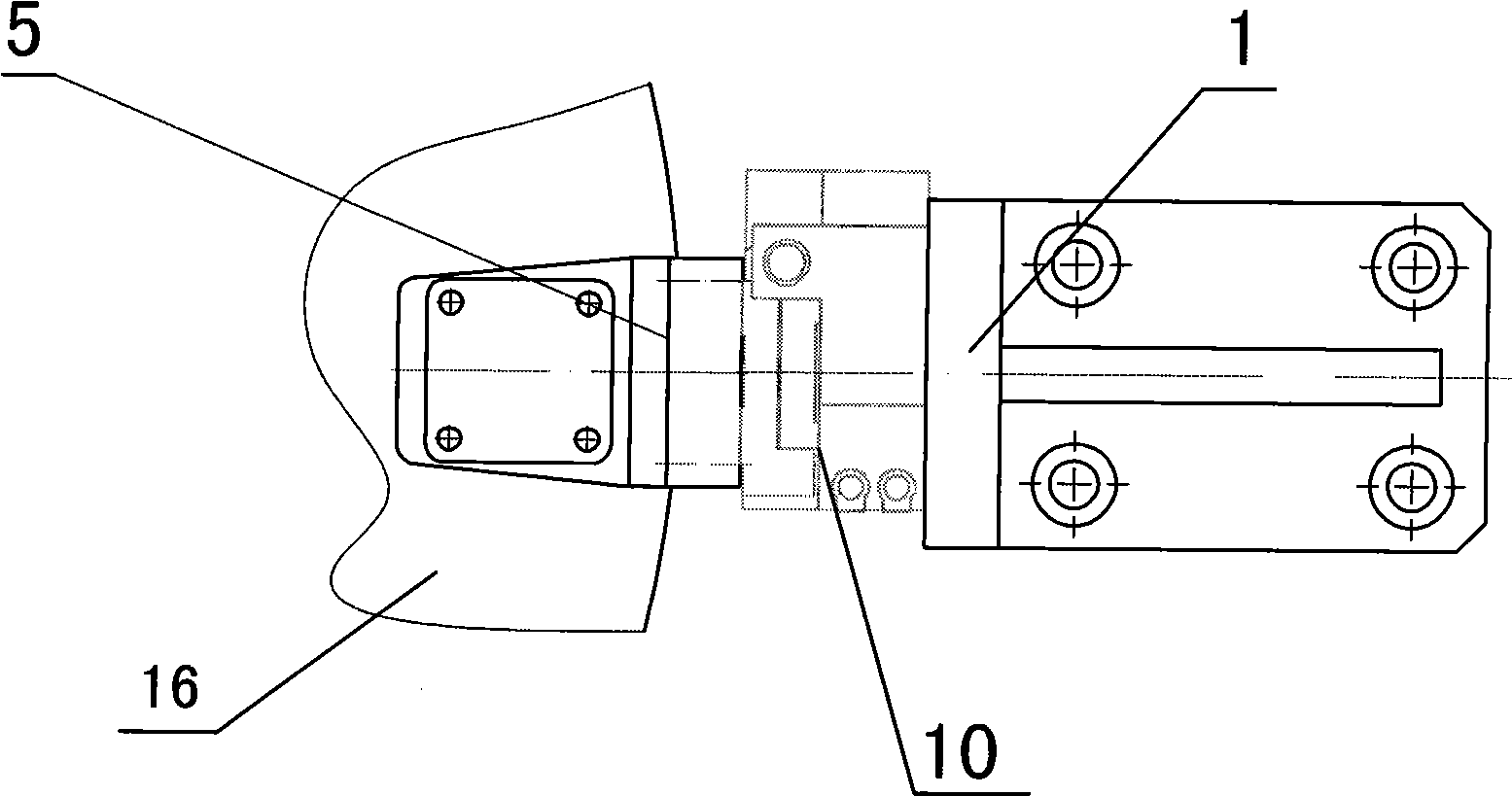

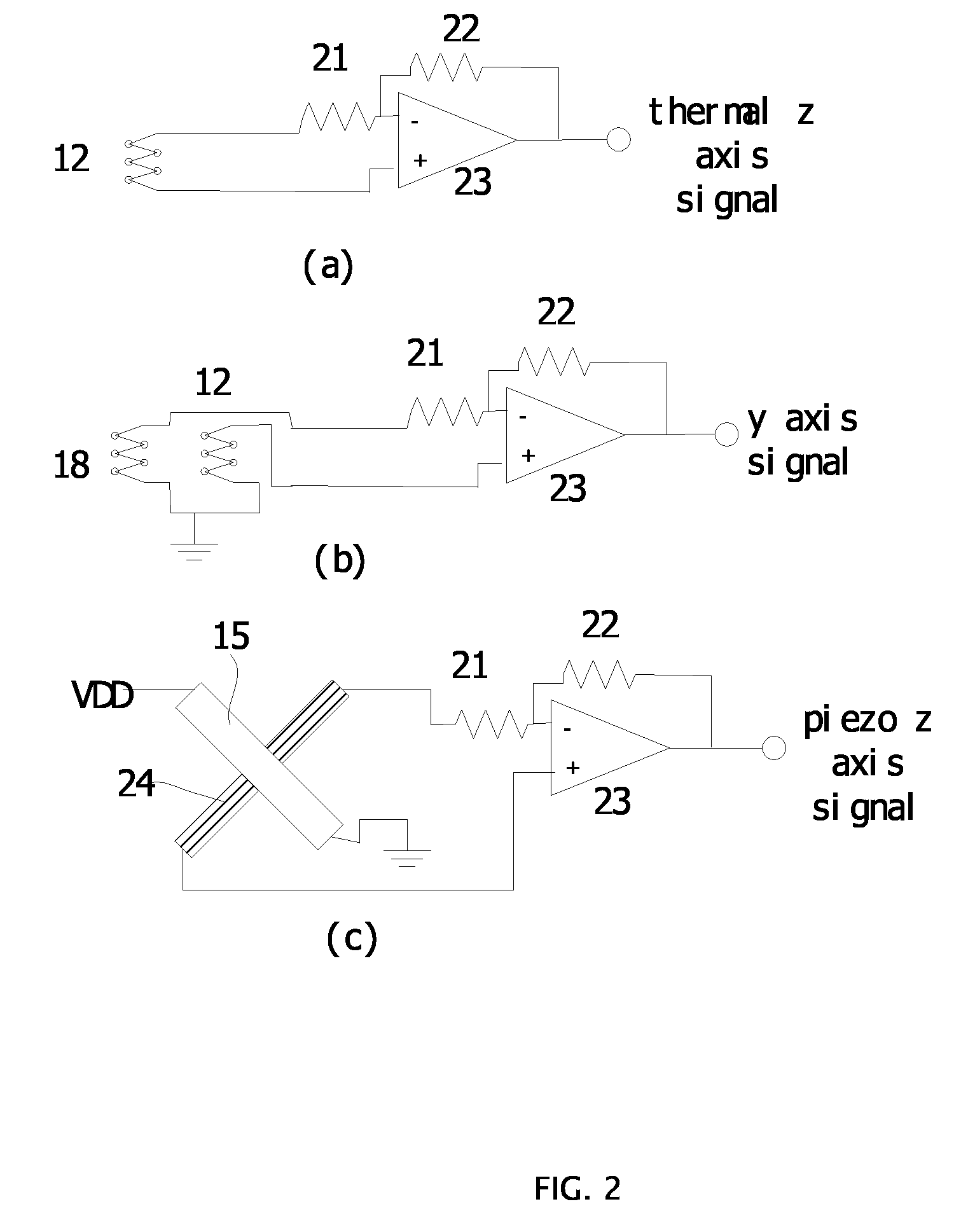

Winding device and winding machine

ActiveCN101533698AImprove efficiencyUniform number of turnsWinding capacitor machinesCoils manufactureAutomatic controlInductor

The invention discloses a high-efficiency winding device for winding stubs of electronic elements such as resistors, capacitors, inductors and the like, and a full automatic integrated winding machine. The winding machine comprises a rack (24) and a worktable (13). The worktable (13) is provided with a working turntable (16), the winding device, an upper fixture manipulator (21), a lower fixture manipulator (18), a charging conveyer belt (17), a cutting device (19), a clamping device (20), a discharging device (22) and the like. The winding device adopts a winding shaft (4) that has a kinking body (12) with the section being semicircle at the tail end to wind the stubs of workpieces. The winding machine realizes the full automatic control over the following process of: charging, cutting off thread ends, clamping by the fixture, installing the fixture, automatic winding, discharging and removing the fixture. The winding device and winding machine are suitable for the batch production of large-scale enterprises and have good market prospect.

Owner:东电化电子(珠海)有限公司

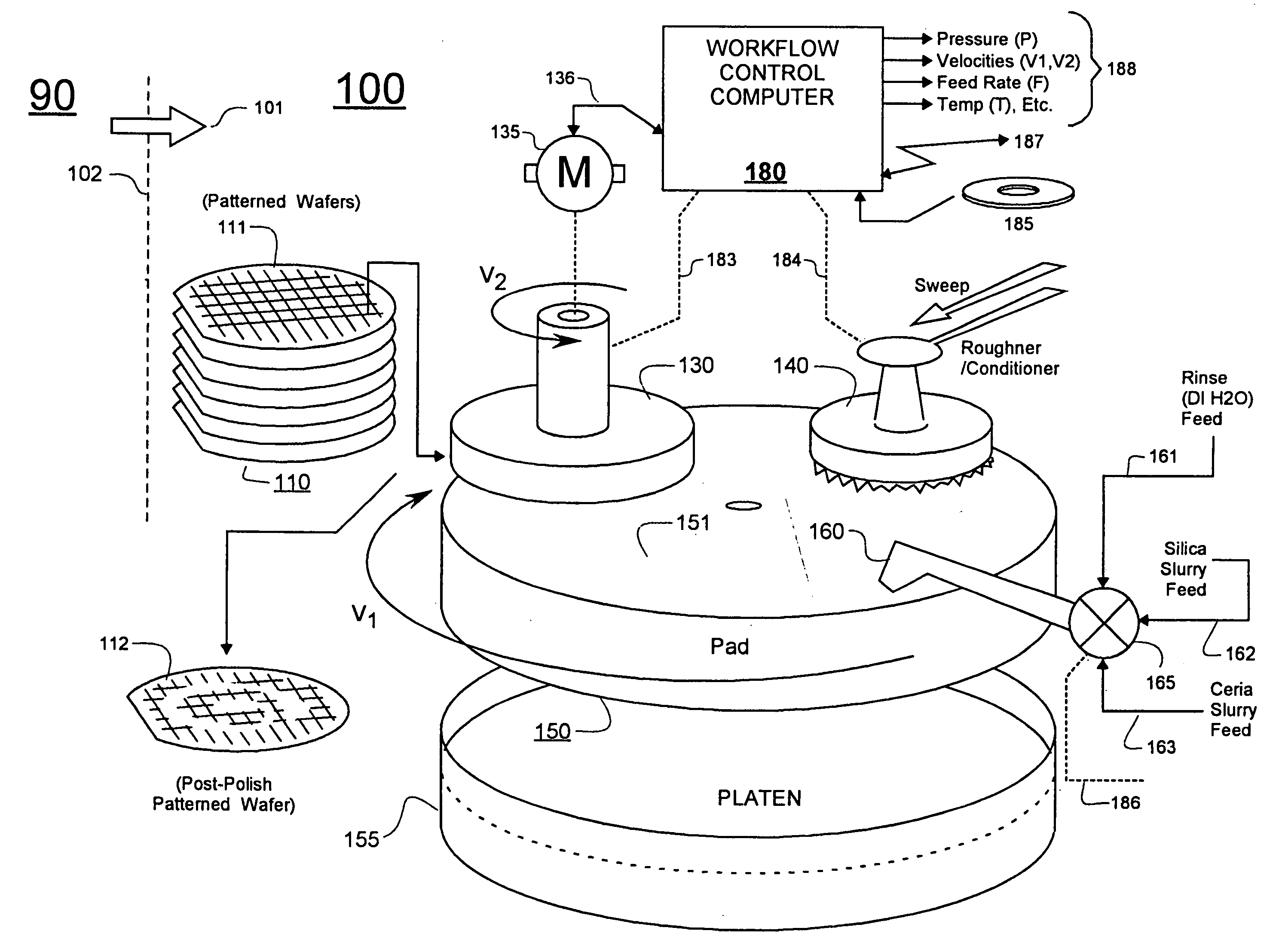

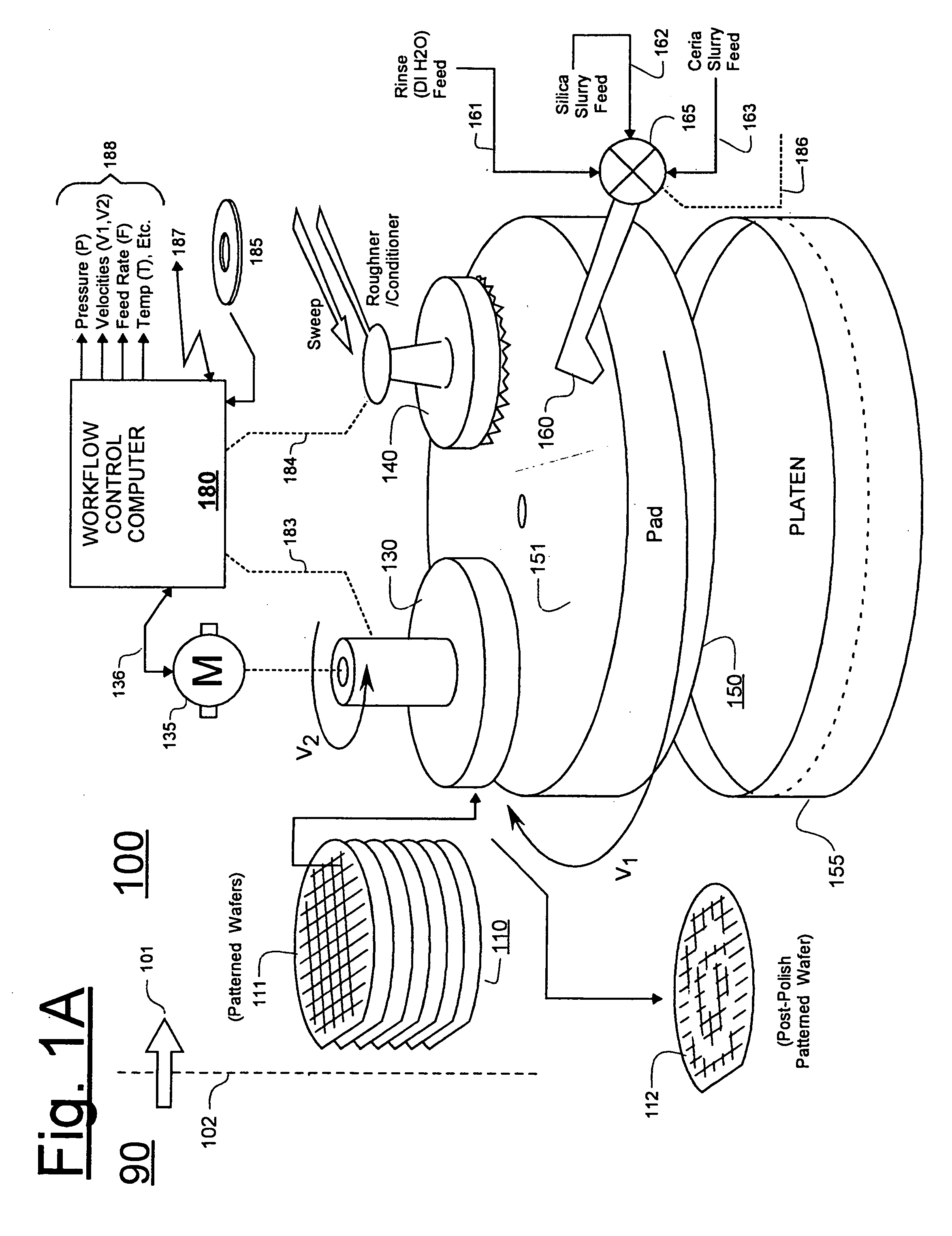

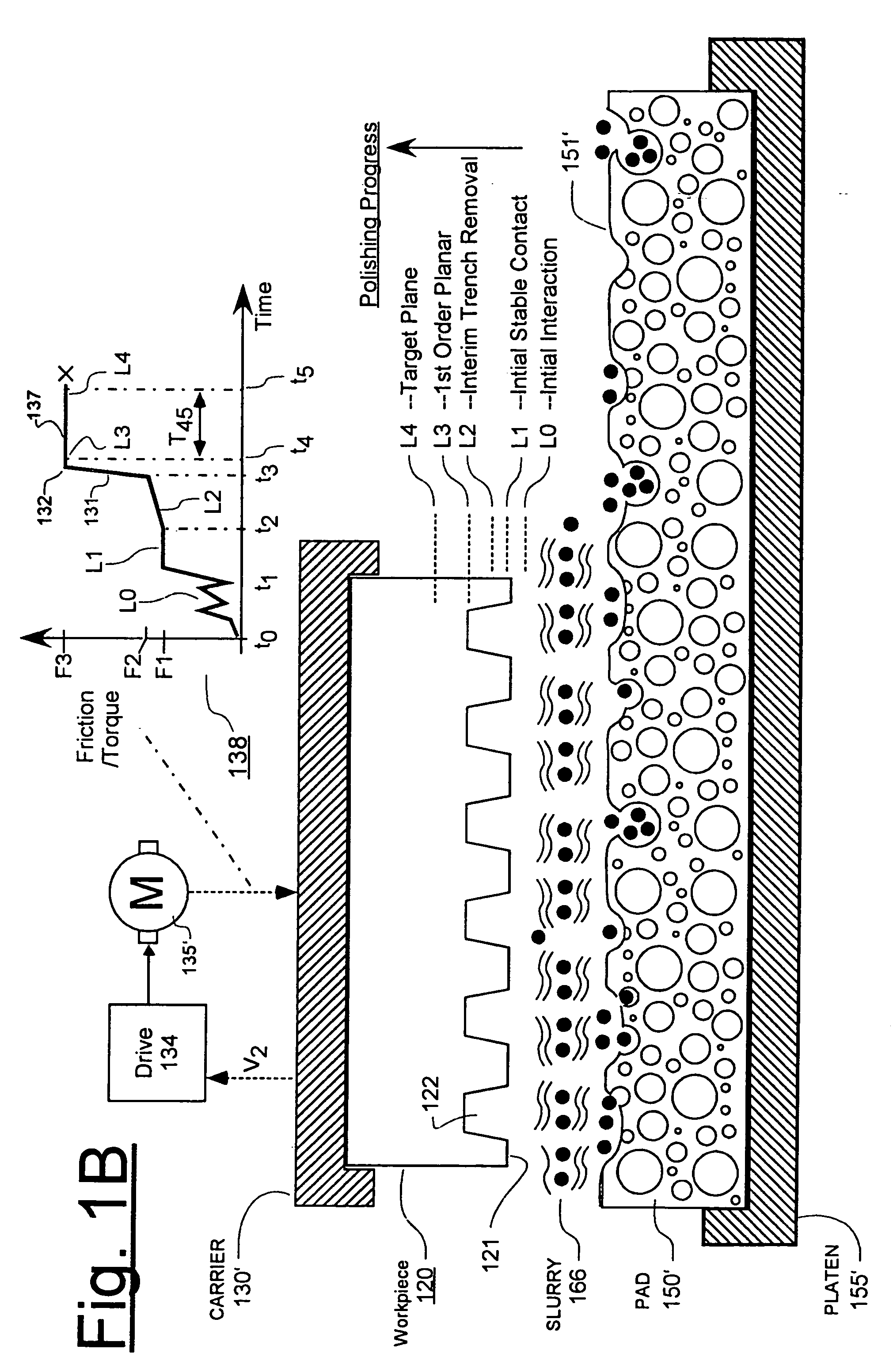

Torque-based end point detection methods for chemical mechanical polishing tool which uses ceria-based CMP slurry to polish to protective pad layer

A chemical mechanical polishing (CMP) method is disclosed in which a torque-based end-point algorithm is used to determine when polishing should be stopped. The end-point algorithm is applicable to situations where a ceria (CeO2) based CMP slurry is used for further polishing, pre-patterned and pre-polished workpieces (e.g., semiconductor wafers) which have a high friction over-layer (e.g., HDP-oxide) and a comparatively, lower friction and underlying layer of sacrificial pads (e.g., silicon nitride pads). A mass production wise, reliable and consistent signature point in the friction versus time waveform of a torque-representing signal is found and used to trigger an empirically specified duration of overpolish. A database may be used to define the overpolish time as a function of one or more relevant parameters.

Owner:PROMOS TECH INC

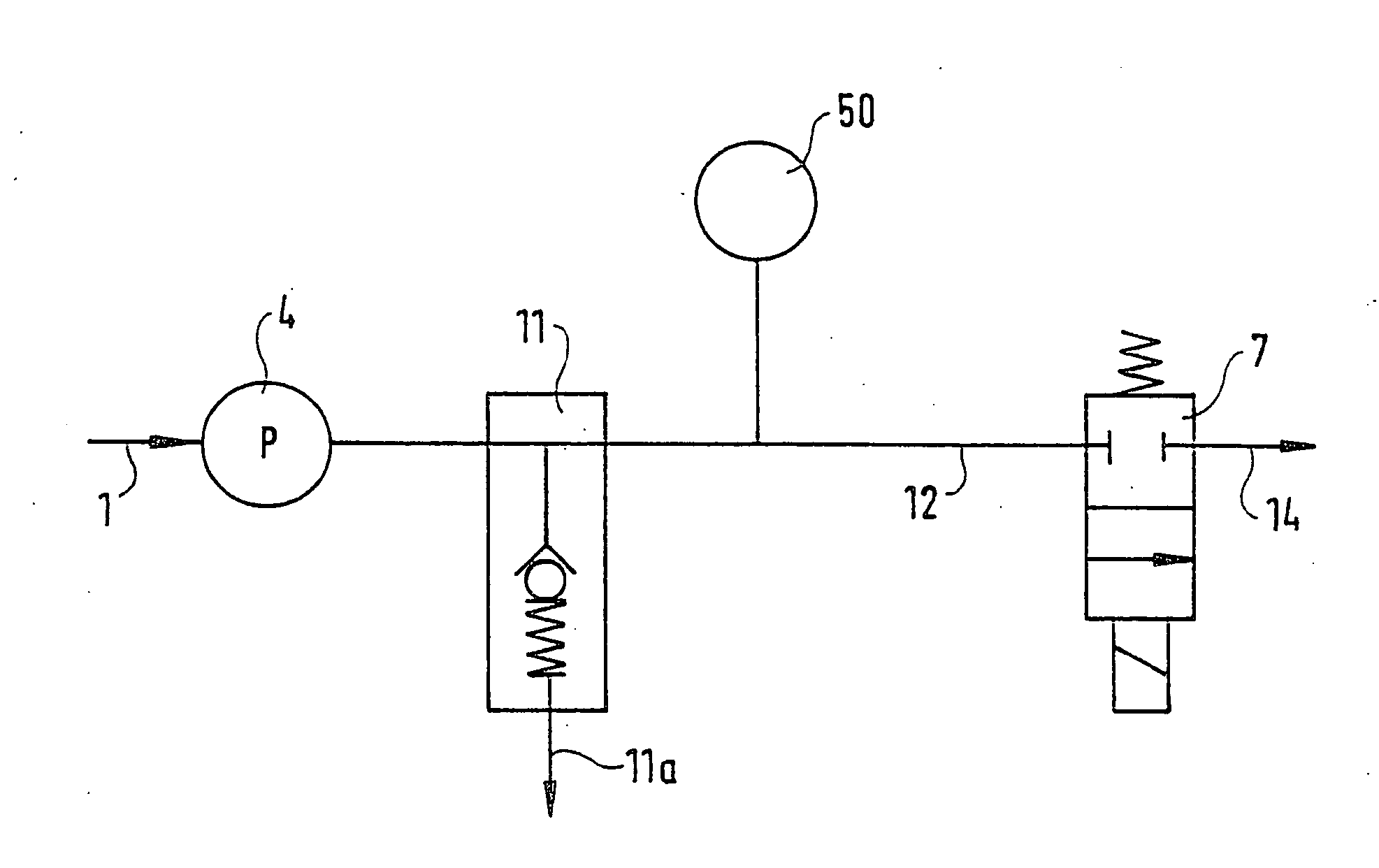

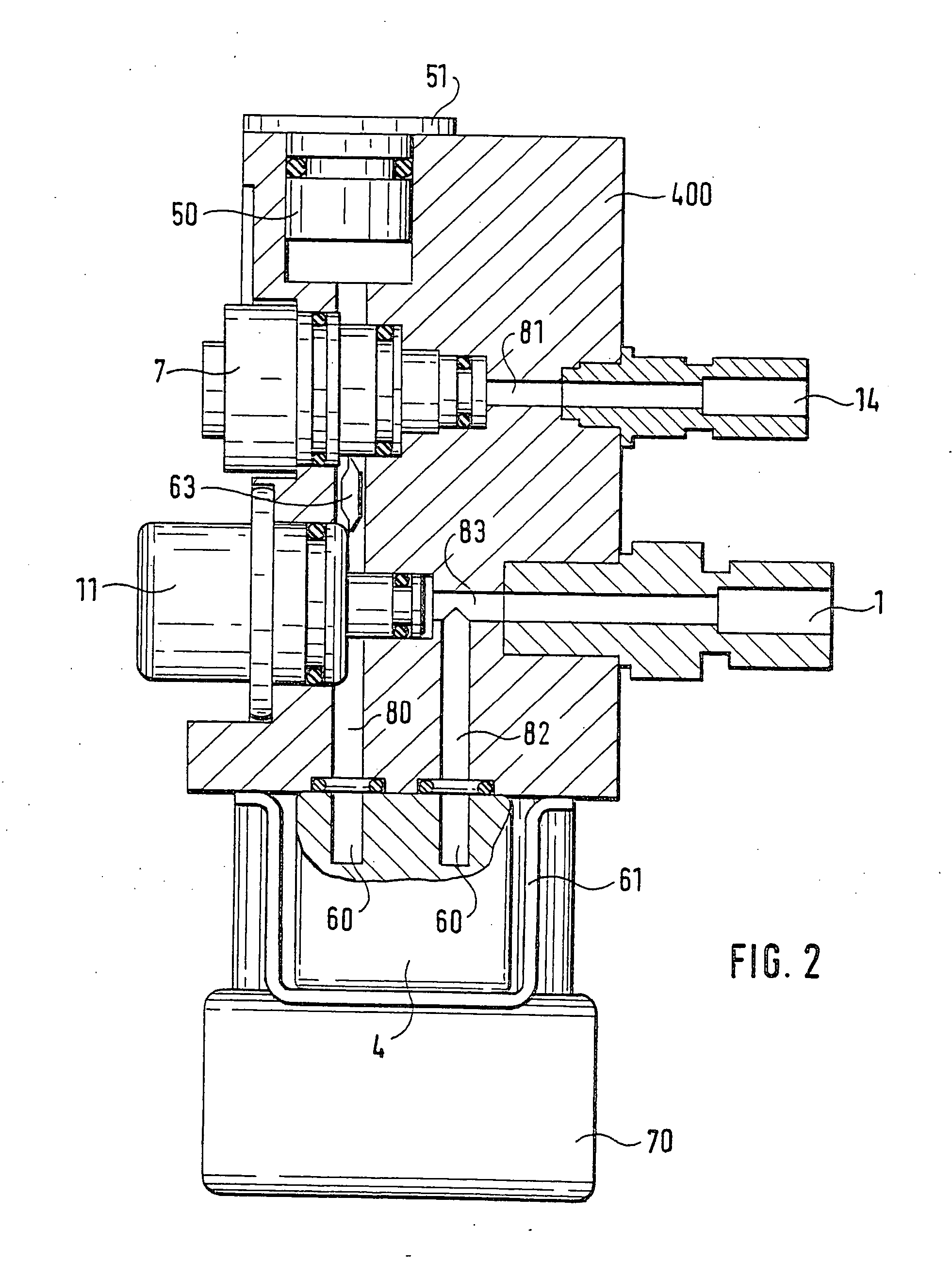

Device for the dosing of a reducing agent

An apparatus for metering a urea or a urea-water solution for delivery to a catalytic converter assembly for removing nitrogen oxides from the exhaust gases of a Diesel engine, includes a housing block supporting function components communicating via a line, formed by recesses in the housing block, for transporting the reducing agent, and the walls of the line are formed by the housing block. This apparatus assures a simple line layout for reducing agent with a minimum number of sealing points that is accordingly appropriate for large-scale mass production.

Owner:ROBERT BOSCH GMBH

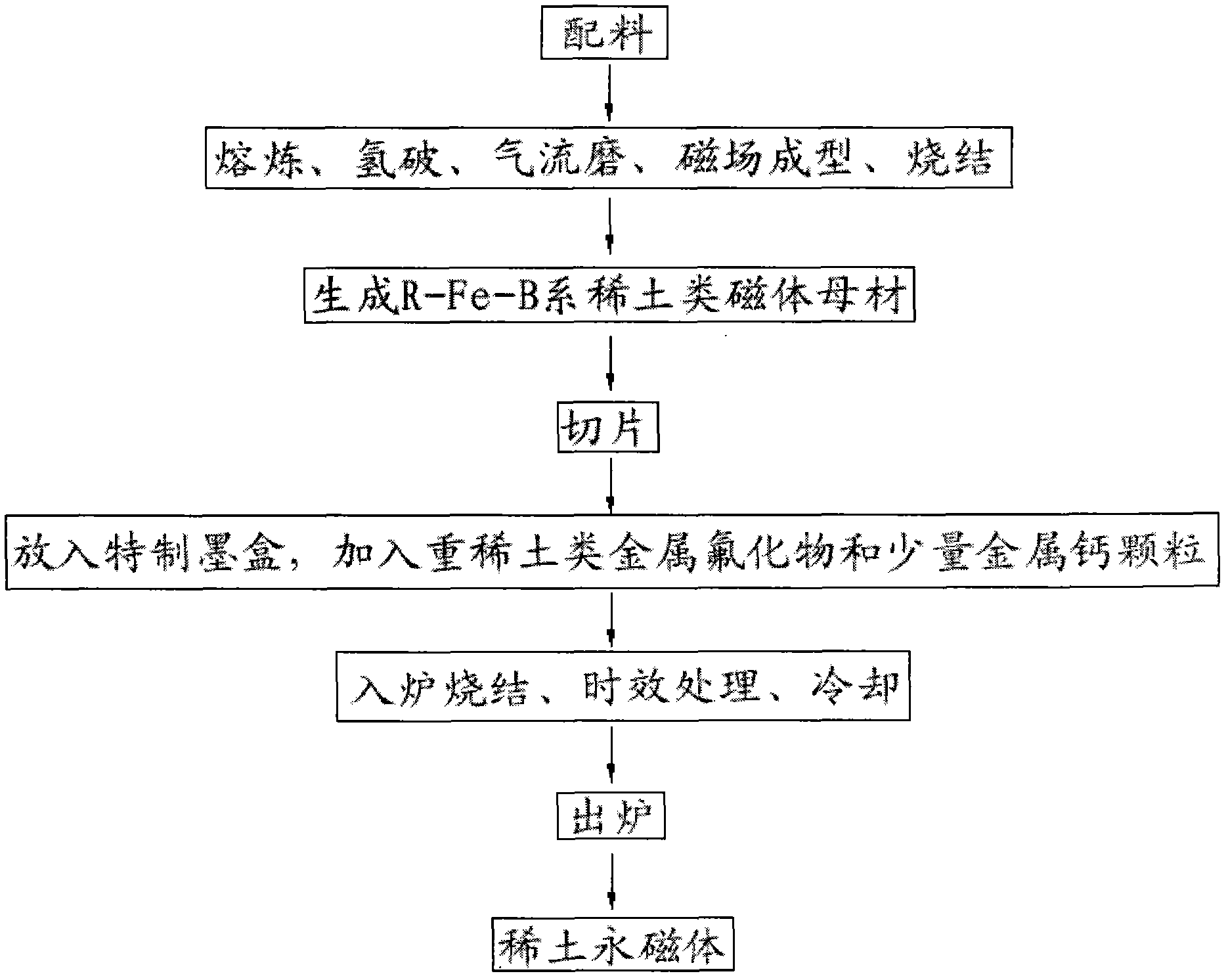

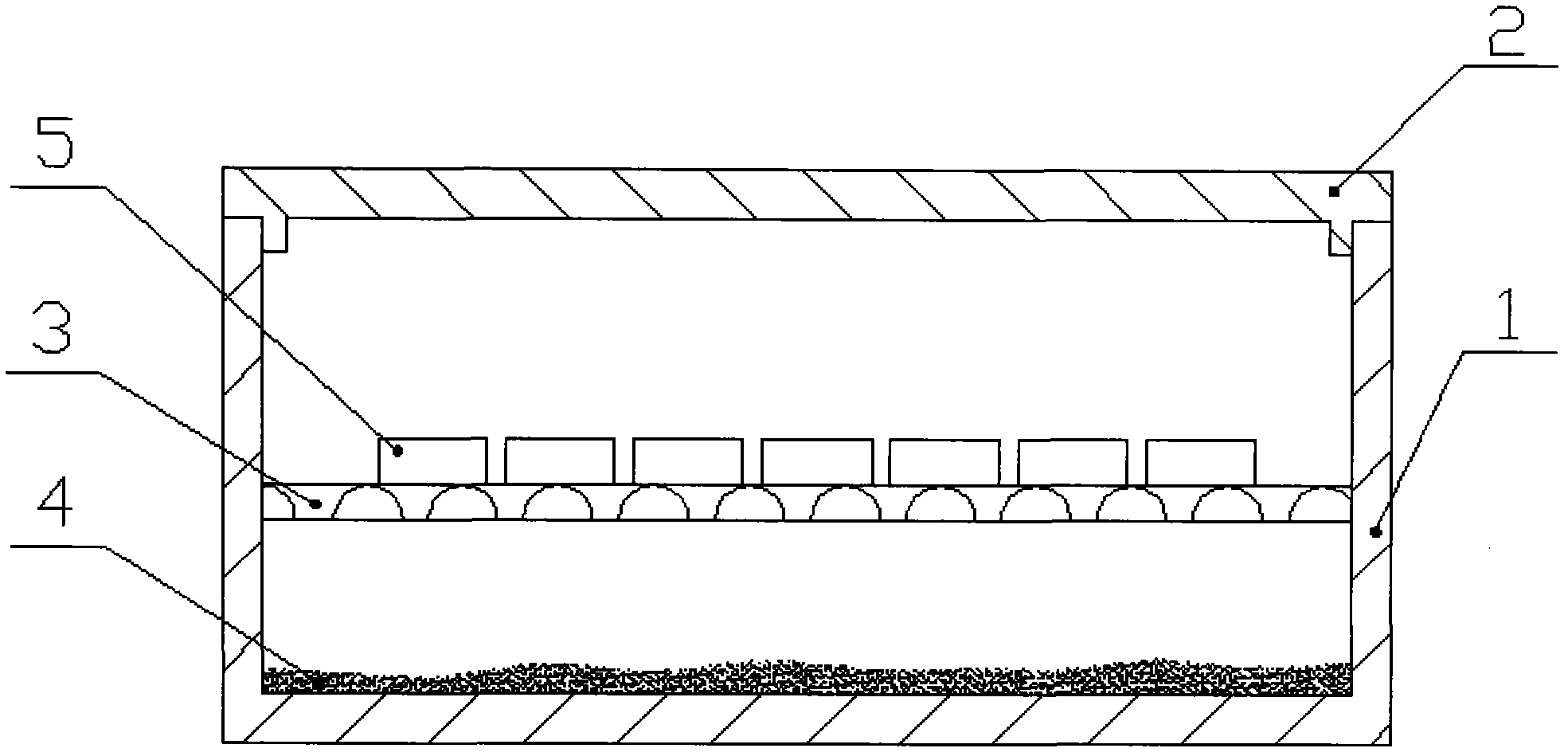

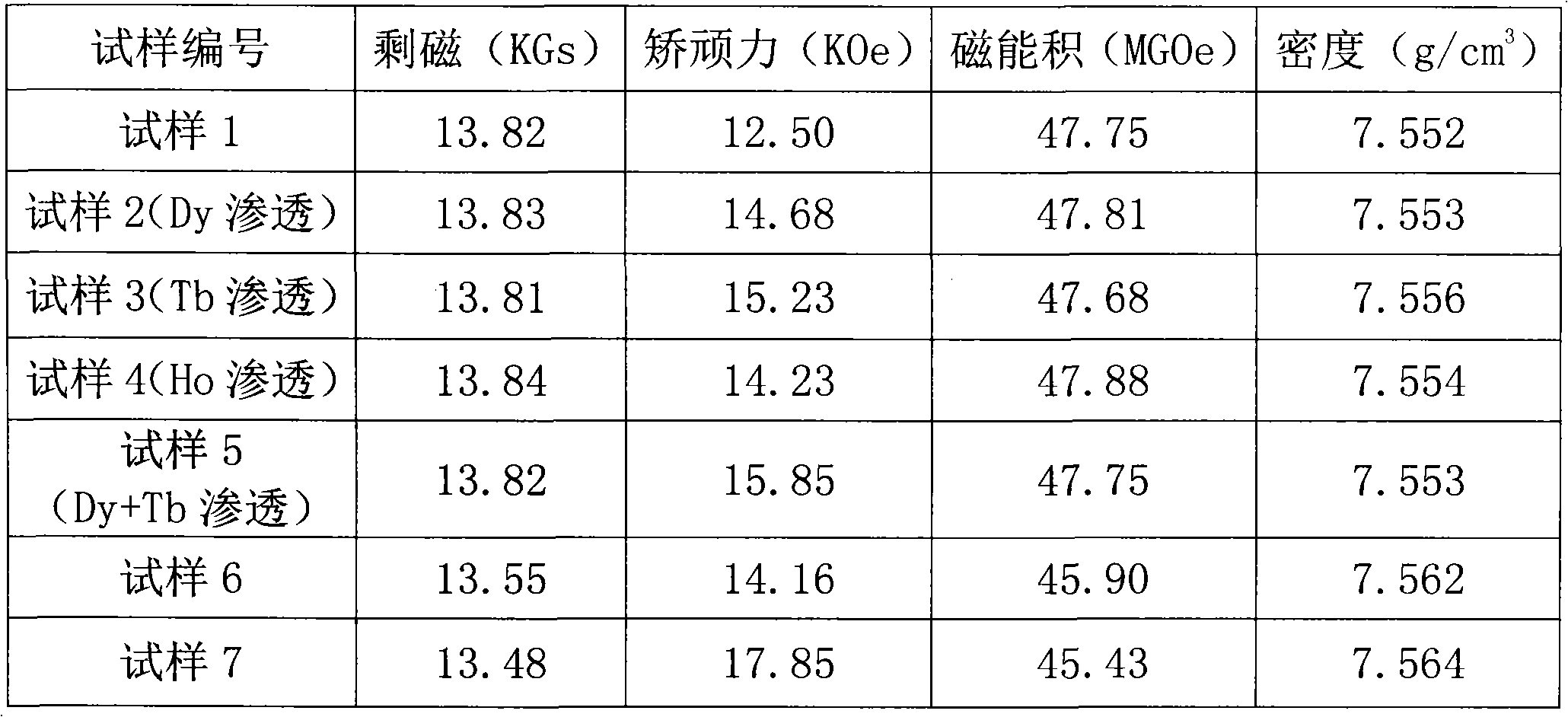

Method for preparing rare-earth permanent magnets by infiltration process and graphite box utilized in method

InactiveCN102568806AReduce manufacturing costReduce usagePermanent magnetsSolid state diffusion coatingRare earthMaterials science

Disclosed are a method for preparing rare-earth permanent magnets by the infiltration process and a graphite box utilized in the method. The method includes: preparing base materials of R (rare earth)-Fe (ferrum)-B (boron) rear earth magnets by prepared raw materials which are subjected to smelting, hydrogen decrepitation, magnetic field forming, sintering and the like; cutting the base material into slices with the thickness ranging from 2mm to 10mm; placing the slices into a specially-made graphite box and placing heavy rare earth type metal fluoride and a few of metal calcium particles into the bottom of the graphite box; sintering the graphite box in a sintering furnace, inflating air into the sintering furnace to cool the temperature to be lower than 60 DEG C, finally ageing magnets, then inflating Ar gas into the sintering furnace to cool the temperature to be lower than 60 DEG C after ageing, and finally obtaining the rare-earth permanent magnets. Elements including Dy (dysprosium), Tb (terbium), Ho (holmium) and the like are infiltrated into the crystal boundary of the R-Fe-B to prepare high-coercivity rare-earth permanent magnets by means of infiltration process, usage of heavy rare earth metal can be greatly reduced, and production cost of magnets can be effectively reduced. Additionally, the method for preparing rare-earth permanent magnets by the infiltration process is simple in operation and suitable for batch production.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

Carbon-ceramic brake material preparation method and carbon-ceramic brake disc preparation method

ActiveCN105565839AMeet the density requirementShort preparation cycleBraking discsActuatorsMaterials preparationFiber

The present invention provides a carbon-ceramic brake material preparation method comprising the following steps: 1) preparing a first carbon fiber preform; 2) preparing a phenolic resin solution; 3) preparing phenolic resin and ceramic powder mixed slurry; 4 ) preparing a second carbon fiber preform; 5) drying the second carbon fiber preform; 6) hot pressing and curing of the dried preform; 7) cracking a carbon / phenolic-ceramic composite; and 8) processing a first porous carbon / carbon-ceramic powder composite material at high temperature. The present invention also provides a carbon-ceramic brake disc preparation method including the above eight steps, and further comprising the following steps: 9) pre-processing; 10) silicon infiltration processing of a first brake disc; and 11) final processing. The carbon-ceramic brake material preparation method greatly reduces the manufacturing cycle and cost of a carbon-ceramic brake material, and is simple in process, well reproducible, and suitable for industrial mass production.

Owner:SHENZHEN LE MYTH TECH CO LTD

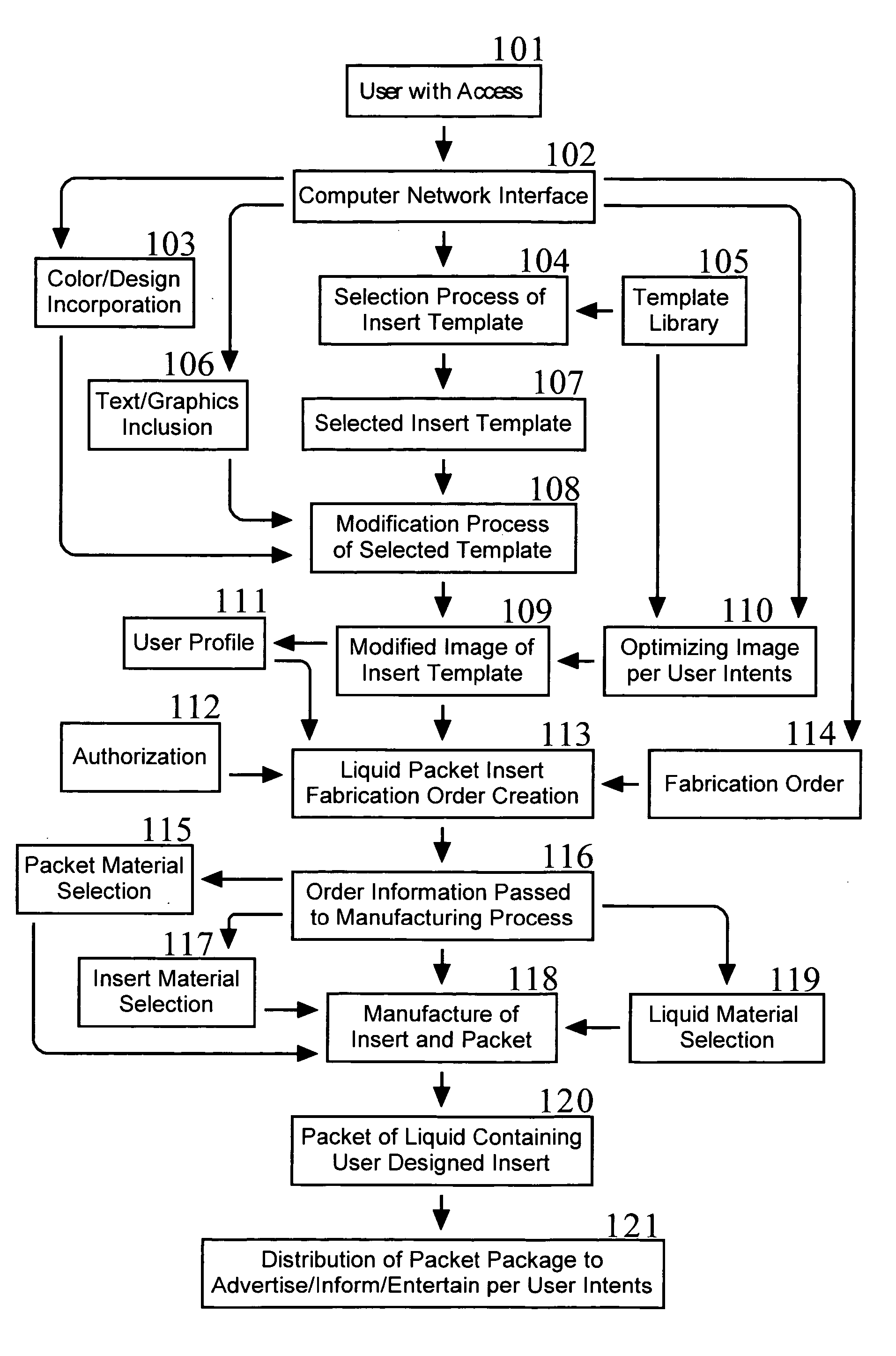

Mass customization of liquid packets

InactiveUS20060155561A1Facilitates online designEasy to orderMarketingExtensibilityMass customization

A method is provided comprising the online design of an insert by a user and the subsequent packaging of the custom insert with liquids. The insert is designed, approved, and ordered by the user through an internet interface that in turn supplies the insert design to an extremely scalable assemblage process within a high volume manufacturing operation which produces a custom finished product quickly, on demand, at low cost, and in quantities determined by the user. By incorporating the custom insert as a changeable modular component within an assembly line a mass produced product, specifically a packet package of hand sanitizer fluid, can be individually characterized by its insert as fully intended by the user who designed, ordered, and receives the packaged liquid packet insert.

Owner:HARPER WILLIAM ANTHONY

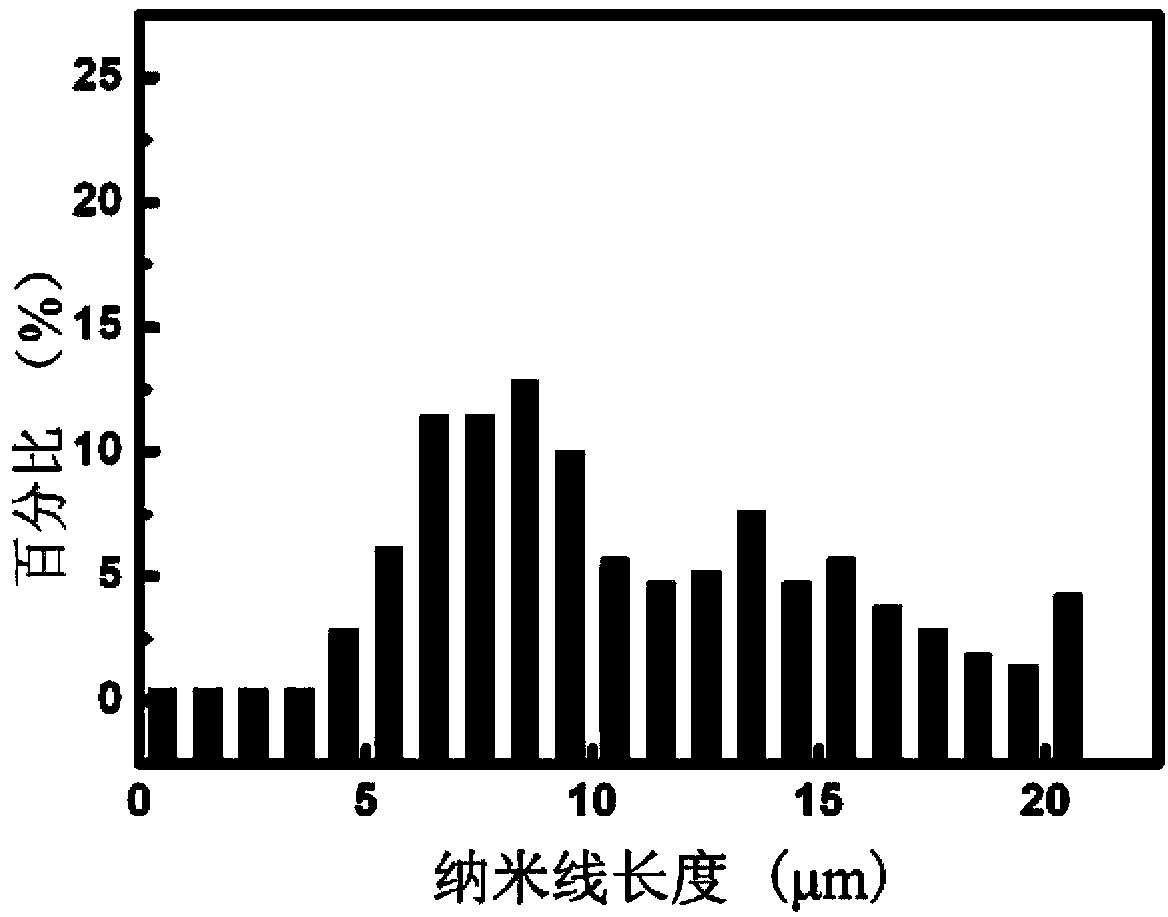

Preparation method and application of silver nanowire with high length-width ratio

ActiveCN103357889AGrowth inhibitionPrompt generation and lengthConductive layers on insulating-supportsMetal/alloy conductorsWidth ratioElectrically conductive

The invention discloses a method for compositing a silver nanowire with a high length-width ratio, that is, through a one-time addition of silver salt to carry out reduction reaction, the silver nanowire with the average length of more than 52 micrometers and the average length-width ratio of more than 400 can be acquired. The method does not need to accurately control the adding velocity of reactant, the composited silver nanowire is good in dispersity and high in uniformity, compared with the traditional polyhydric alcohol method, the average length-width ratio of the silver nanowire is improved by more than 5 times, through the preparation of a flexible transparent conductive film on a transparent flexible plastic substrate, the visible light penetration rate is more than 90 %, and the square resistance is lower than 10 Omega / square. Compared with the traditional polyhydric alcohol method, the method provided by the invention is simple in technology control and high in repeatability, and is in favor of the batch production of the silver nanowire with the high length-width ratio.

Owner:CENT SOUTH UNIV

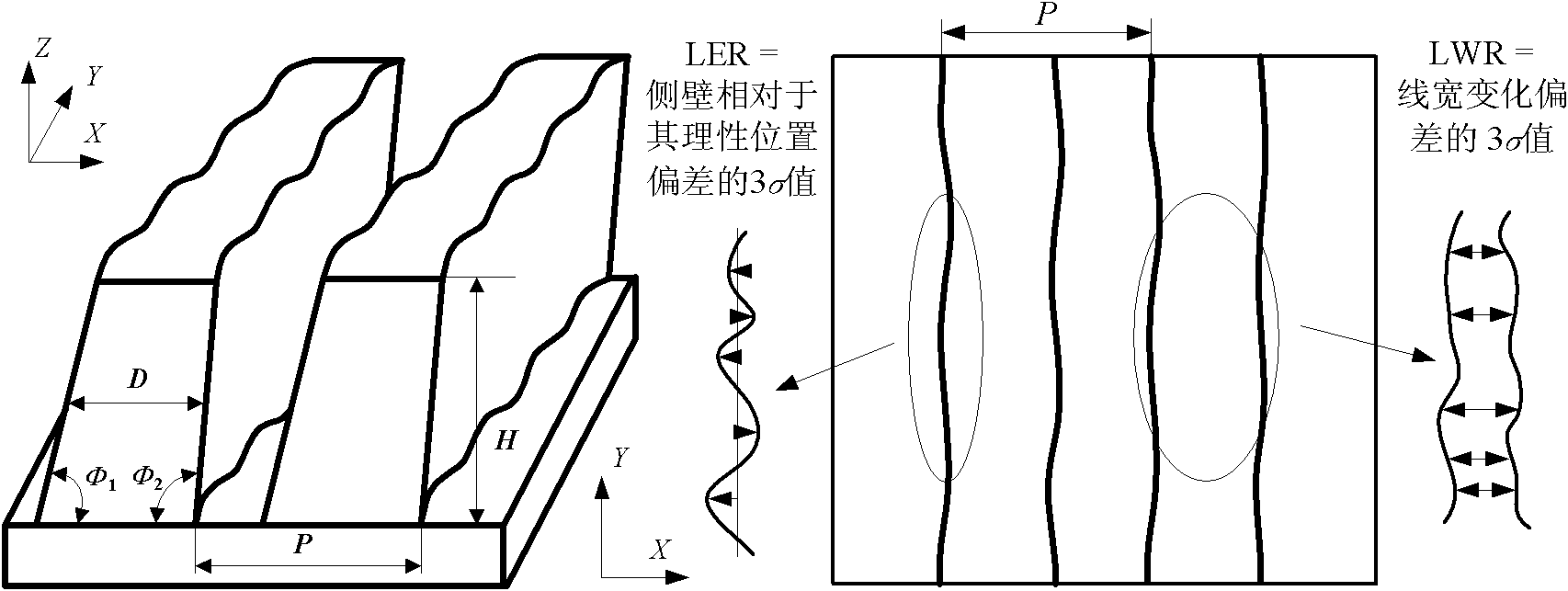

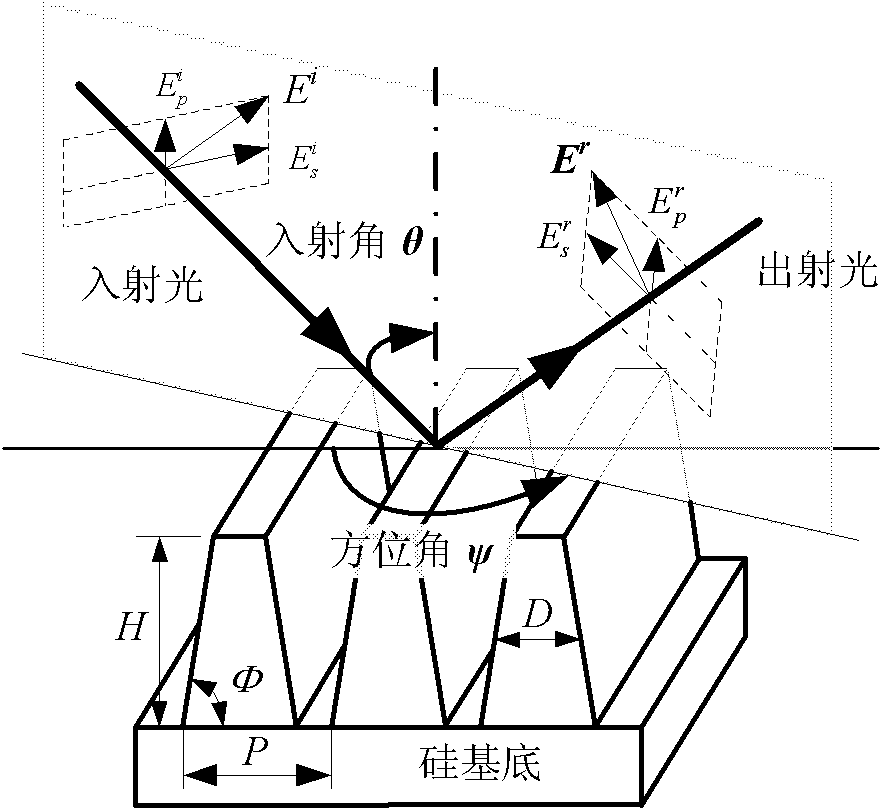

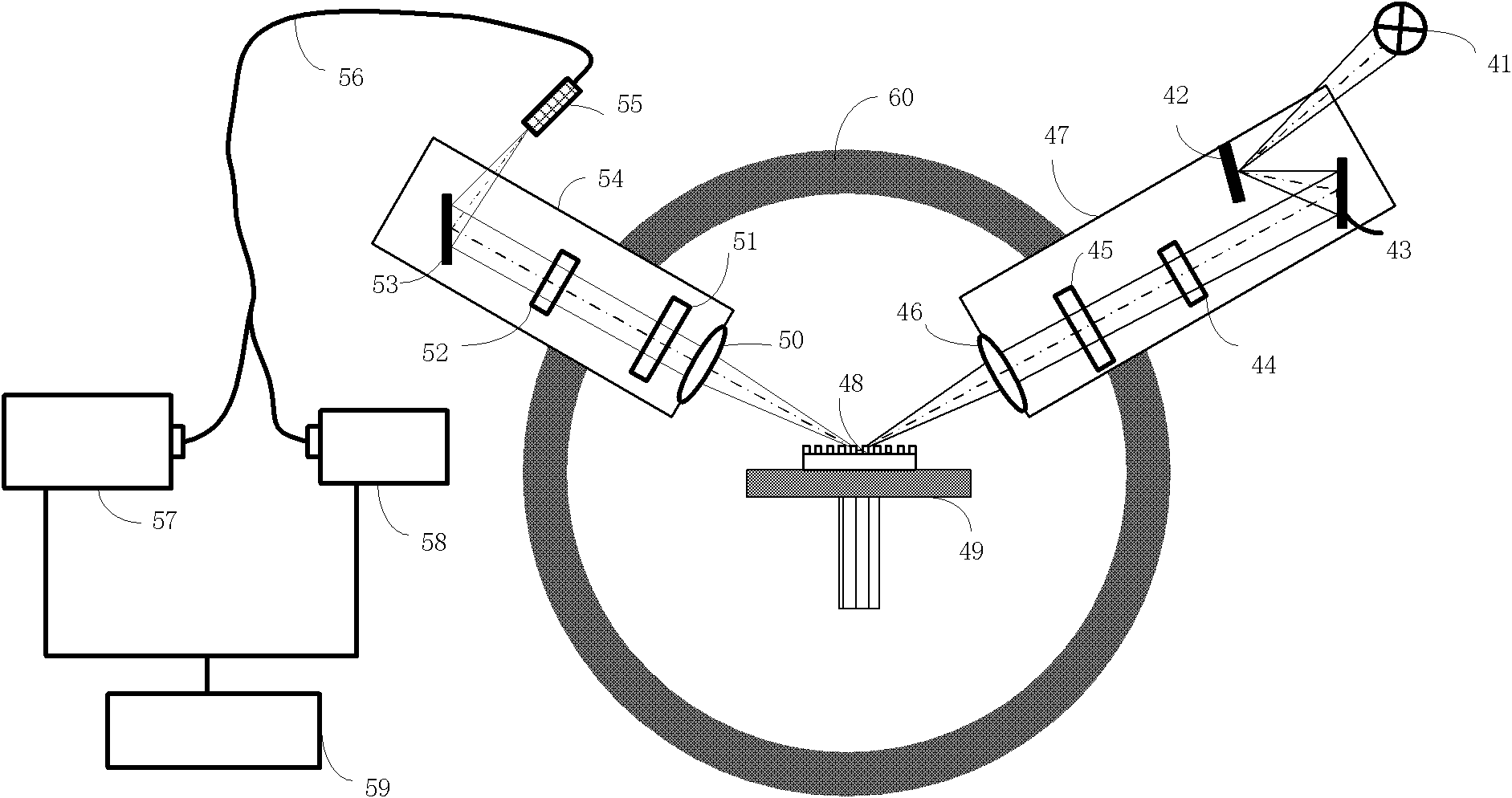

Method and device for measuring three-dimensional topography of nano structure

ActiveCN101881599AMeet measurement needsHigh spectral sensitivityUsing optical meansEtchingImage transfer

The invention discloses a method and a device thereof for measuring three-dimensional topography of a nano structure, which can simultaneously measure three-dimensional topography parameters such as line width, depth, side corner, line edge roughness, line width roughness and the like of the nano structure. The method comprises the following steps of: performing splitting, polarization and front and back phase compensation on light beams with wavelengths in ultraviolet to near-infrared wave band to obtain elliptical polarized light and projecting the elliptical polarized light for later measurement; acquiring surface reflected zero-level diffraction signals of the to-be-measured structure, and obtaining a measurement Mueller matrix of the nano structure by calculation; and matching the measurement Mueller matrix and a theoretical Mueller matrix, and obtaining a three-dimensional topography parameter value of the to-be-measured nano-scale structure. The device provided by the invention for measuring the three-dimensional topography parameter of the nano structure can provide a non-contact, nondestructive, low-cost and quick measurement means for one-dimensional and two-dimensional sub-wavelength periodic structures in processes of photo-etching, nano impressing and the like of an image transfer-based batch manufacturing method.

Owner:WUHAN EOPTICS TECH CO LTD

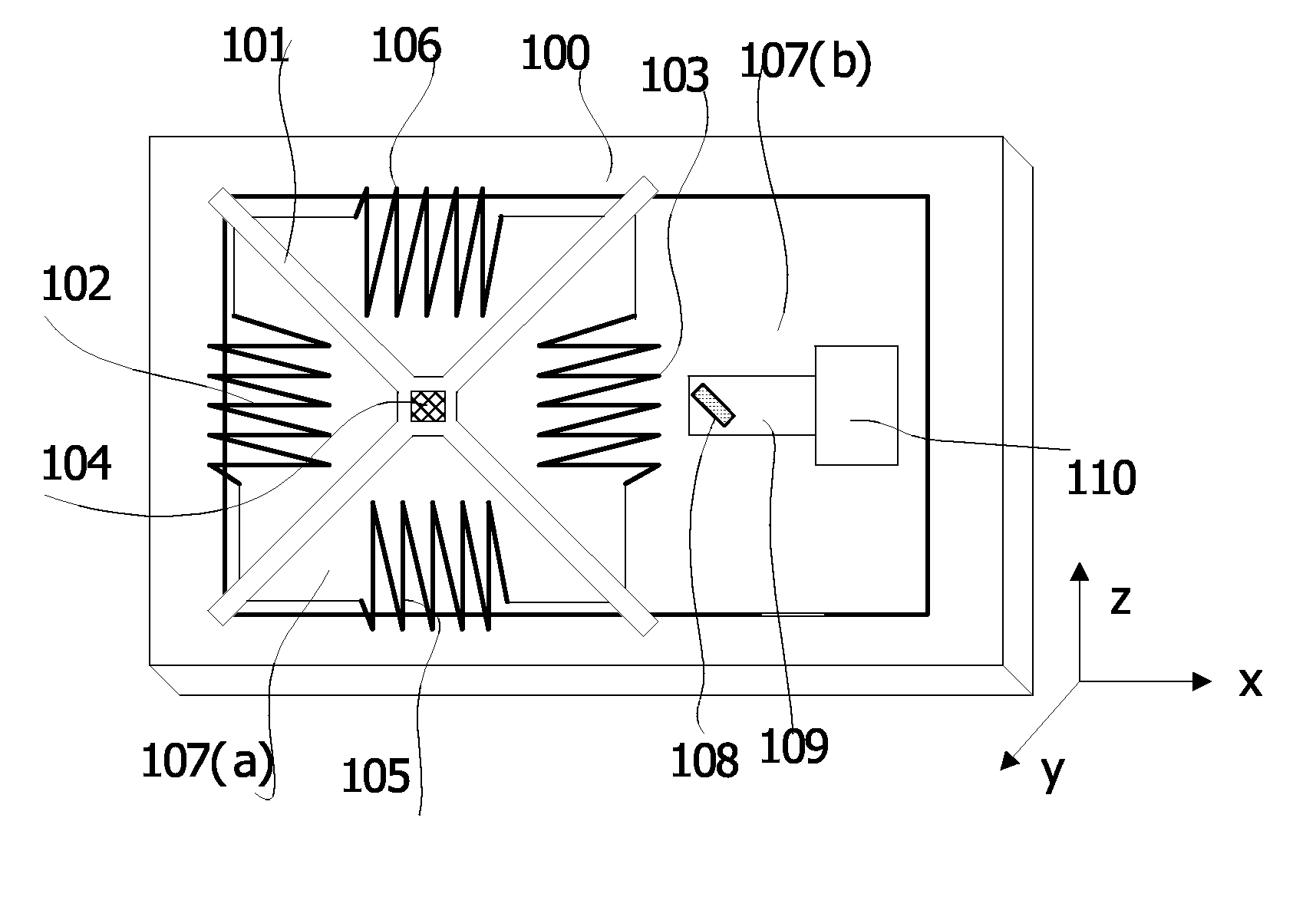

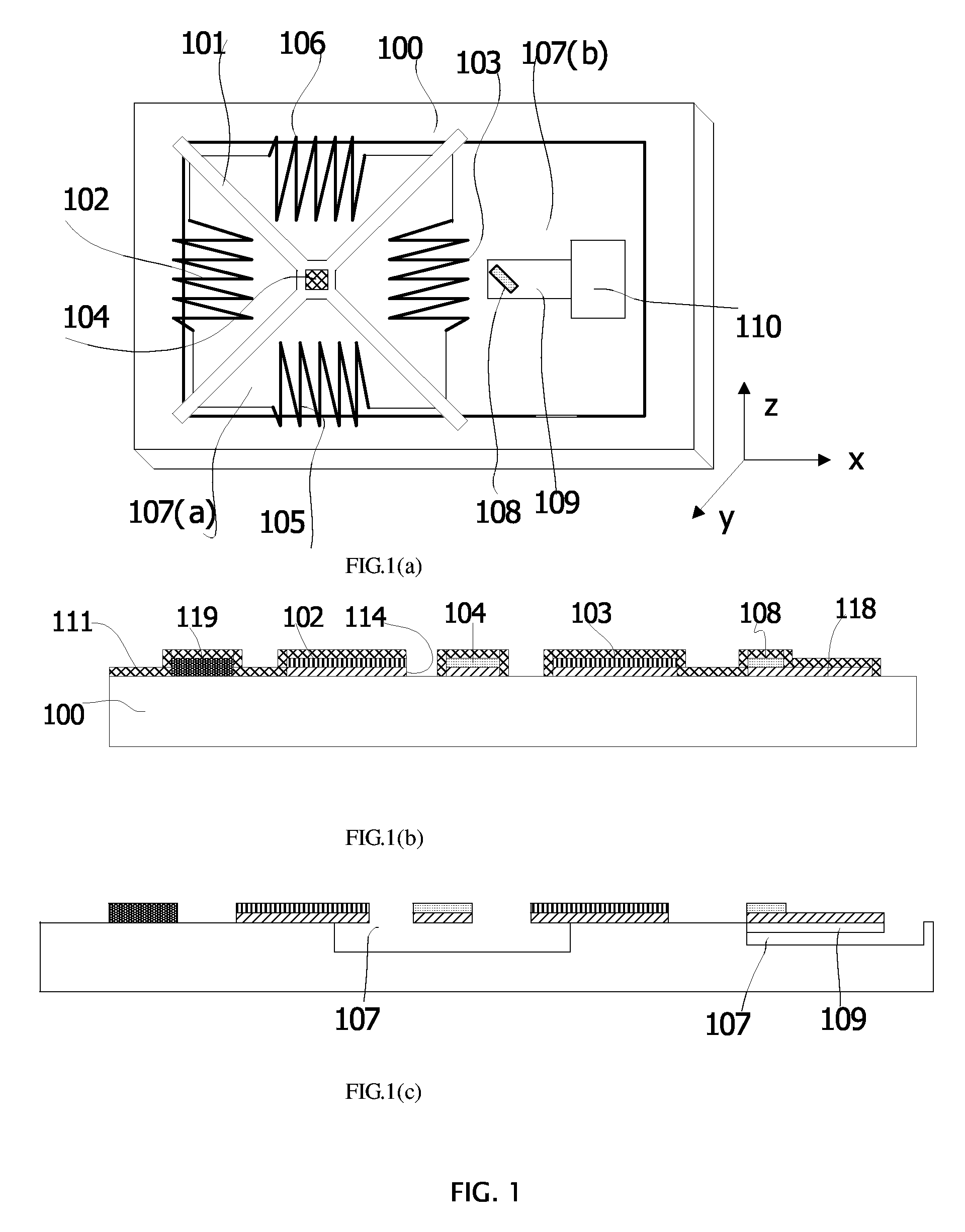

Ultra-small Profile, Low Cost Chip Scale Accelerometers of Two and Three Axes Based on Wafer Level Packaging

Several micro-machined, ultra-profile two-axis and three-axis accelerometers are fabricated by CMOS-compatible process, which makes them suitable for volume production. The x, y axis signal is based on natural thermal convection, and z-axis signal may be based on thermal convention or piezoresistive in nature. The bulk MEMS (Micro-Electro-Mechanical-Systems) process is based on Deep Reactive Ion Etching (DRIE). After the front-end fabrication process, the accelerometers are packaged at wafer level by glass frit and / or anodic bonding, which lowers the device cost.

Owner:WUHAN FINEMEMS

Device and process for mass production of nanometer fiber by melt electro-spinning method

ActiveCN102839431AMelt thinningFlexible arrangementSpinnerette packsFilament/thread formingMelt blowingNanofiber

The invention relates to a device and a process for mass production of nanometer fiber by a melt electro-spinning method, belonging to the field of electro-spinning. The device mainly comprises a base fabric unwinding device, a conveyor belt device, a high-voltage electrode net, a spinning die head assembly, a melt body metering pump, a static removal roller, base fabric, a base fabric winding device, a hot wind return path, an electrode net insulation support, a melt body transmission device, a high-voltage static generator and an air heating system, wherein by the application of a primary division runner in the spinning die head assembly, primary division and accurate partition temperature control of a melt body can be realized; with the creation of a nozzle on an airflow-assisted inner conical face and the assistance of high-speed hot air, secondary division thinning of a melt body layer is realized; by the whole device and the corresponding process, the problems of thick fiber and low yield of the traditional melt body spinning device and process are solved, the device and the process can substitute a melt blowing method to be the main production device and process for production of non-woven materials, and a new path is provided for the production of hundred-nanometer fiber products.

Owner:BEIJING UNIV OF CHEM TECH

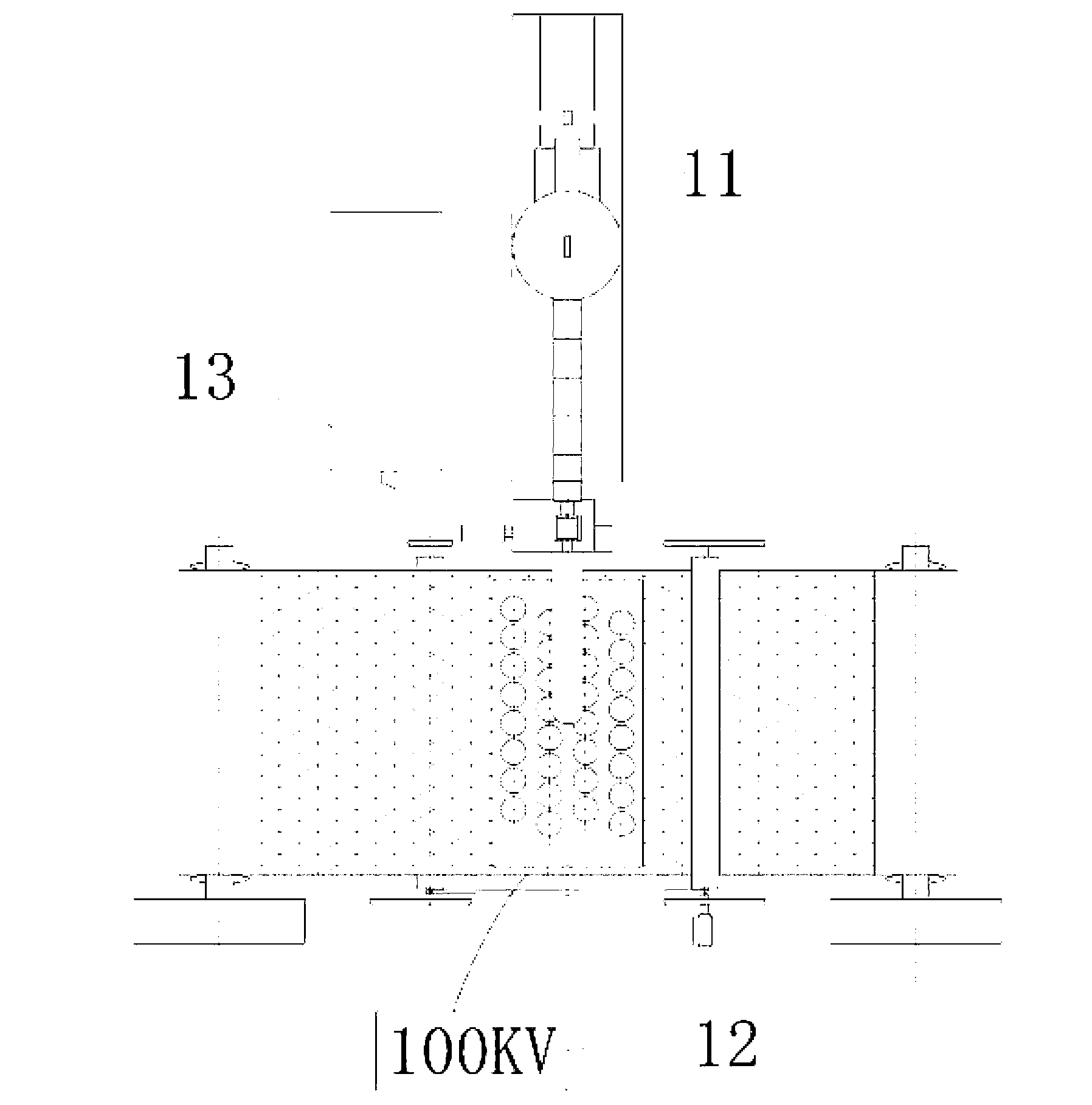

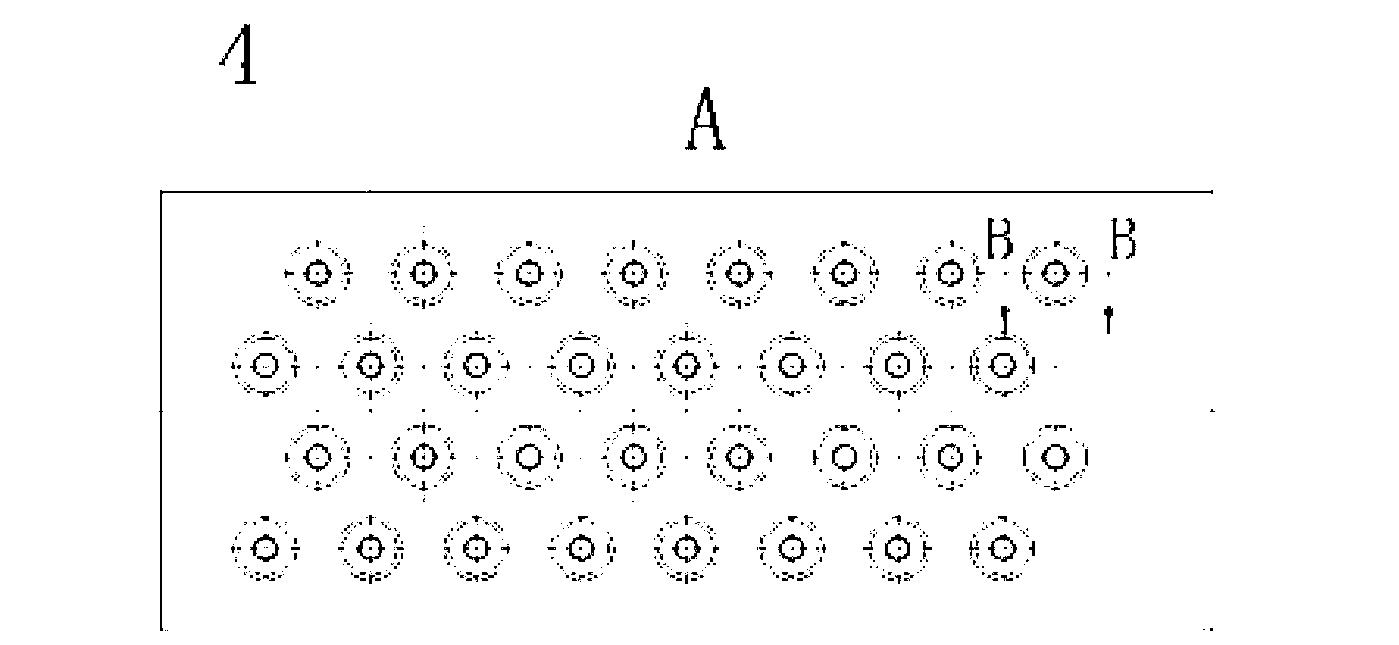

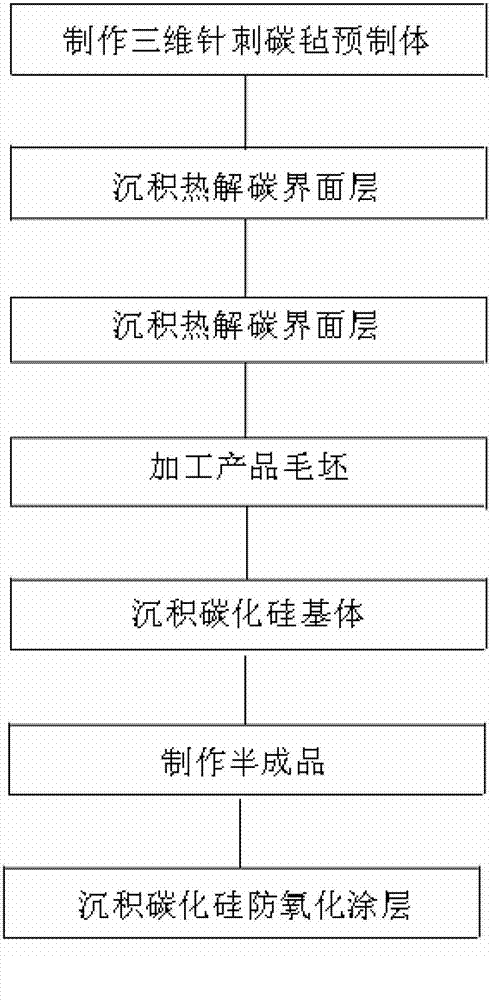

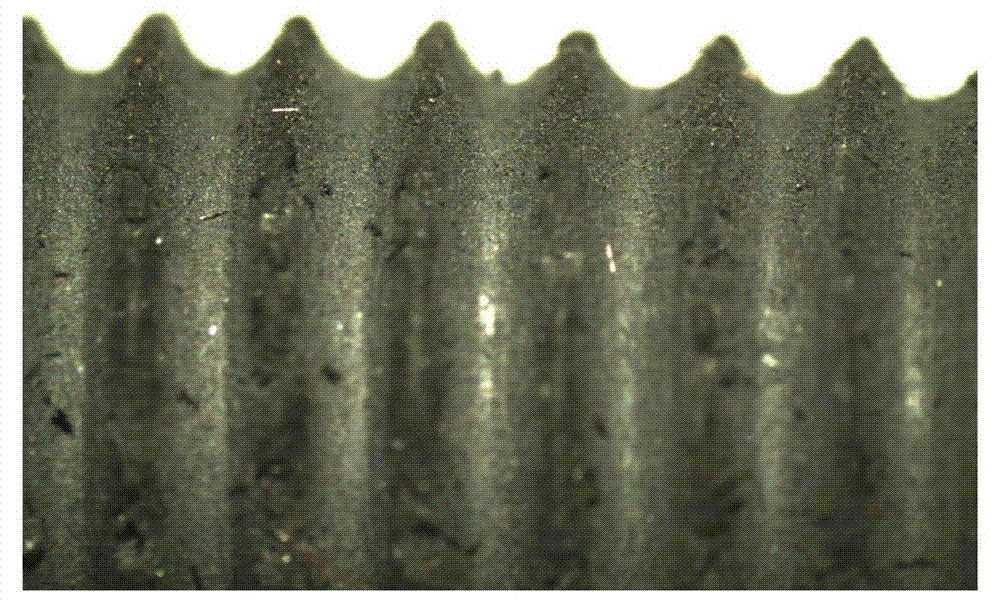

Preparation method of three-dimensional needling carbon/carborundum composite material bolt

ActiveCN102775176AIncreased shear strengthReduce wearScrewsChemical vapor infiltrationMaterials science

A preparation method of a three-dimensional needling carbon / carborundum composite material bolt adopts a three-dimensional needling fiber prefabrication body to prepare the composite material bolt. Pyrolytic carbon is deposited on the prefabrication body, carborundum substrates are deposited through chemical vapor infiltration (CVI), and a bolt bar blank and a bolt cap blank are obtained. The carborundum substrates of the bolt bar blank and the bolt cap blank which are obtained through machining are deposited through the CVI, a carborundum anti-oxidation coating is deposited through the CVI, and a three-dimensional needling C / SiC composite material bolt end product with the shear strength being 80-100MP is obtained. Compared with the prior art, the preparation method has the advantages that the number of times for getting into a furnace is reduced by 6-10, the densifying period is shorter, and the production cost is reduced. By means of a test of a CK6180-3000 numerically controlled lathe, the preparation method is small in diamond grinding wheel abrasion, hour norm for machining 30 bolt threads is reduced by about 10 hours, and as the abrasion of a grinding wheel is less, the working accuracy is improved, and industrialized batch production is achieved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

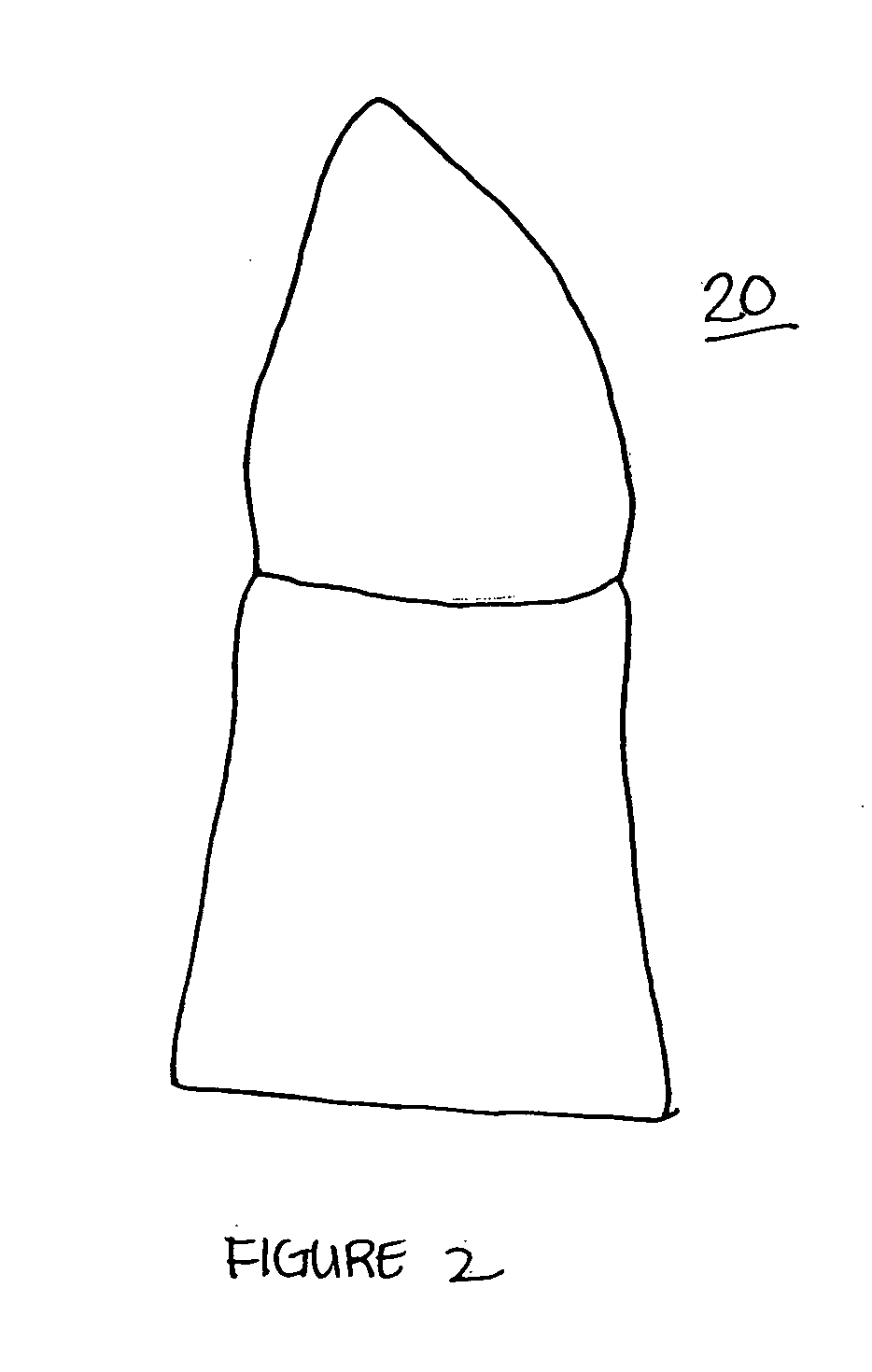

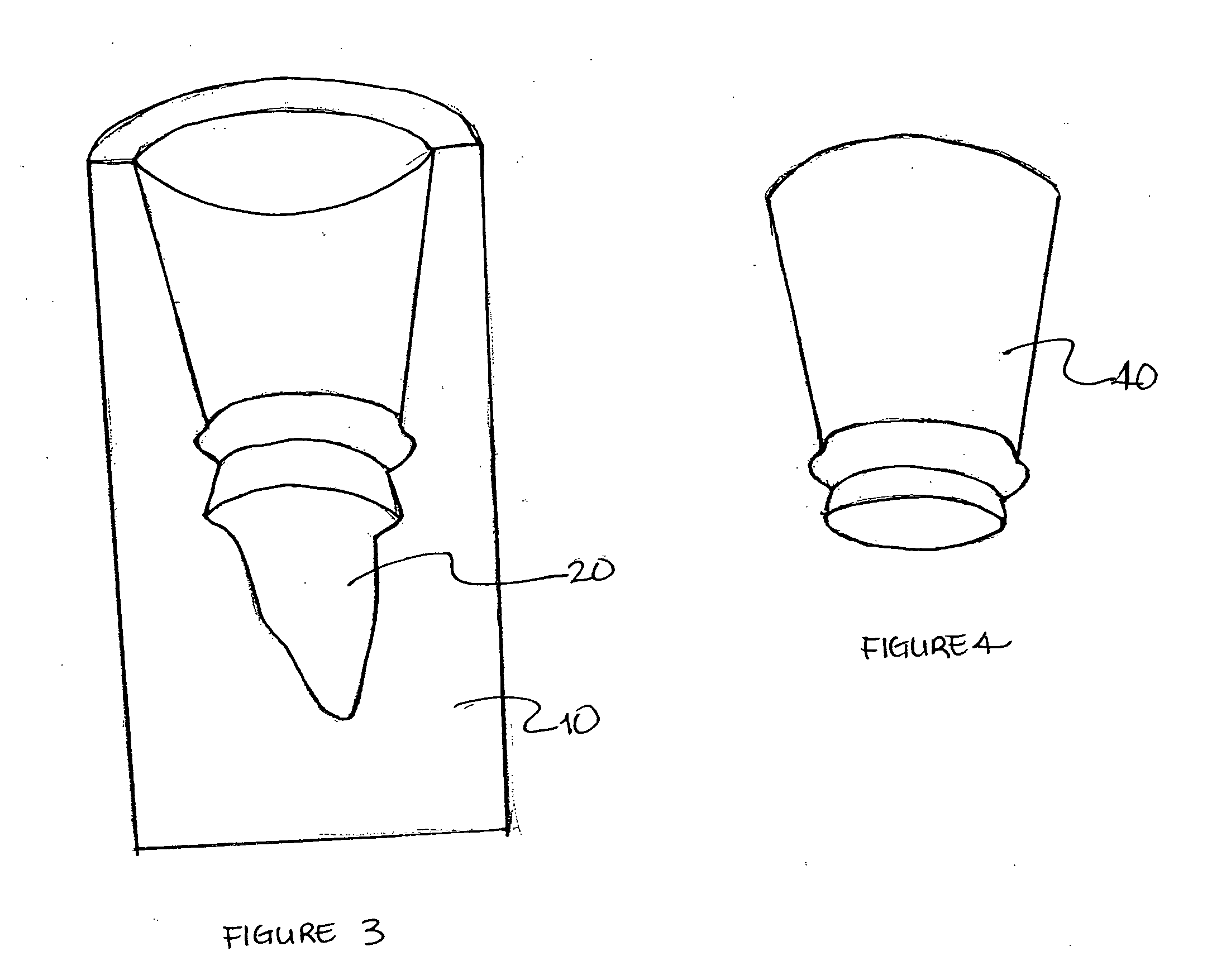

Mass production of shells and models for dental restorations produced by solid free-form fabrication methods

InactiveUS20050110177A1Improve bindingAdditive manufacturing apparatusImpression capsFree formThin layer

Solid free form fabrication techniques such as fused deposition modeling and three-dimensional printing are used to create a shell used in the manufacture of a dental restoration. Three-dimensional printing includes ink-jet printing a binder into selected areas of sequentially deposited layers of powder. Each layer is created by spreading a thin layer of powder over the surface of a powder bed. Instructions for each layer may be derived directly from a CAD representation of the restoration. The area to be printed is obtained by computing the area of intersection between the desired plane and the CAD representation of the object. All the layers required for an aesthetically sound shell can be deposited concurrently slice after slice and sintered / cured simultaneously. While the layers become hardened or at least partially hardened as each of the layers is laid down, once the desired final shaped configuration is achieved and the layering process is complete, in some applications it may be desirable that the form and its contents be heated, cooled or cured at a suitably selected temperature to further promote the integrity of solid free-form structures.

Owner:PENTRON LAB TECH

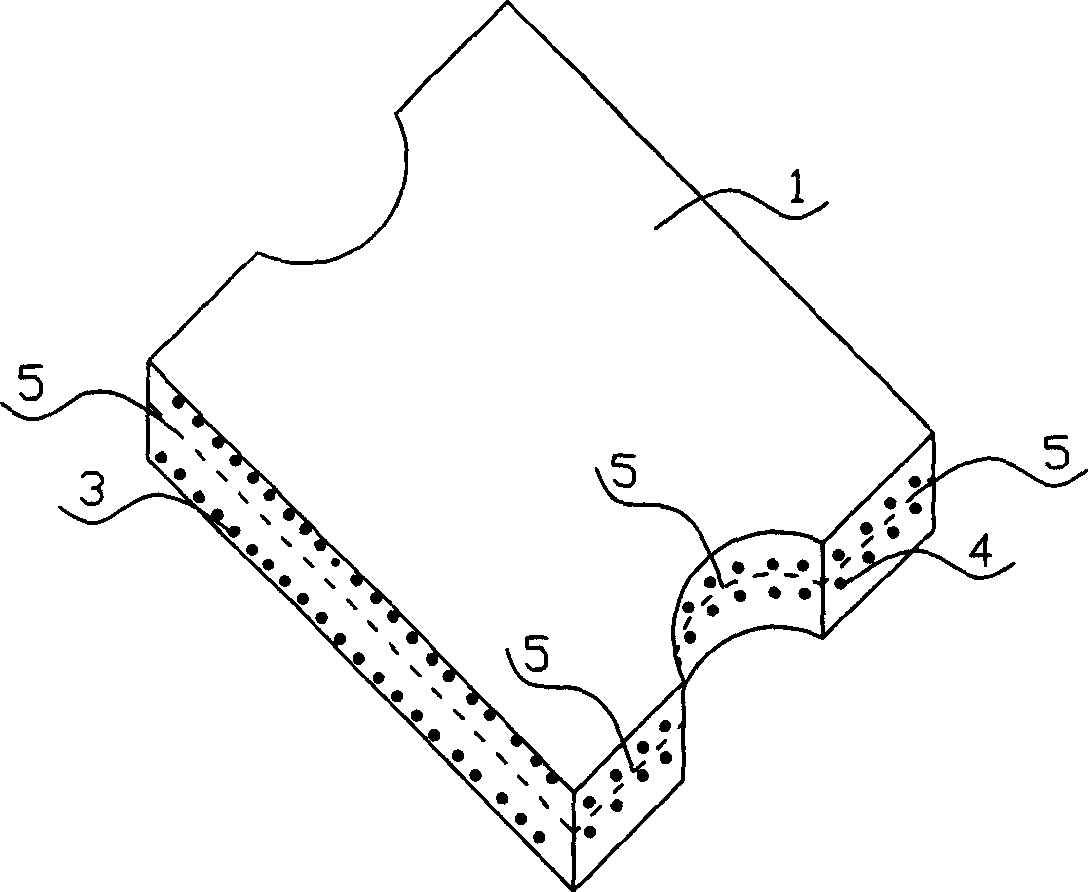

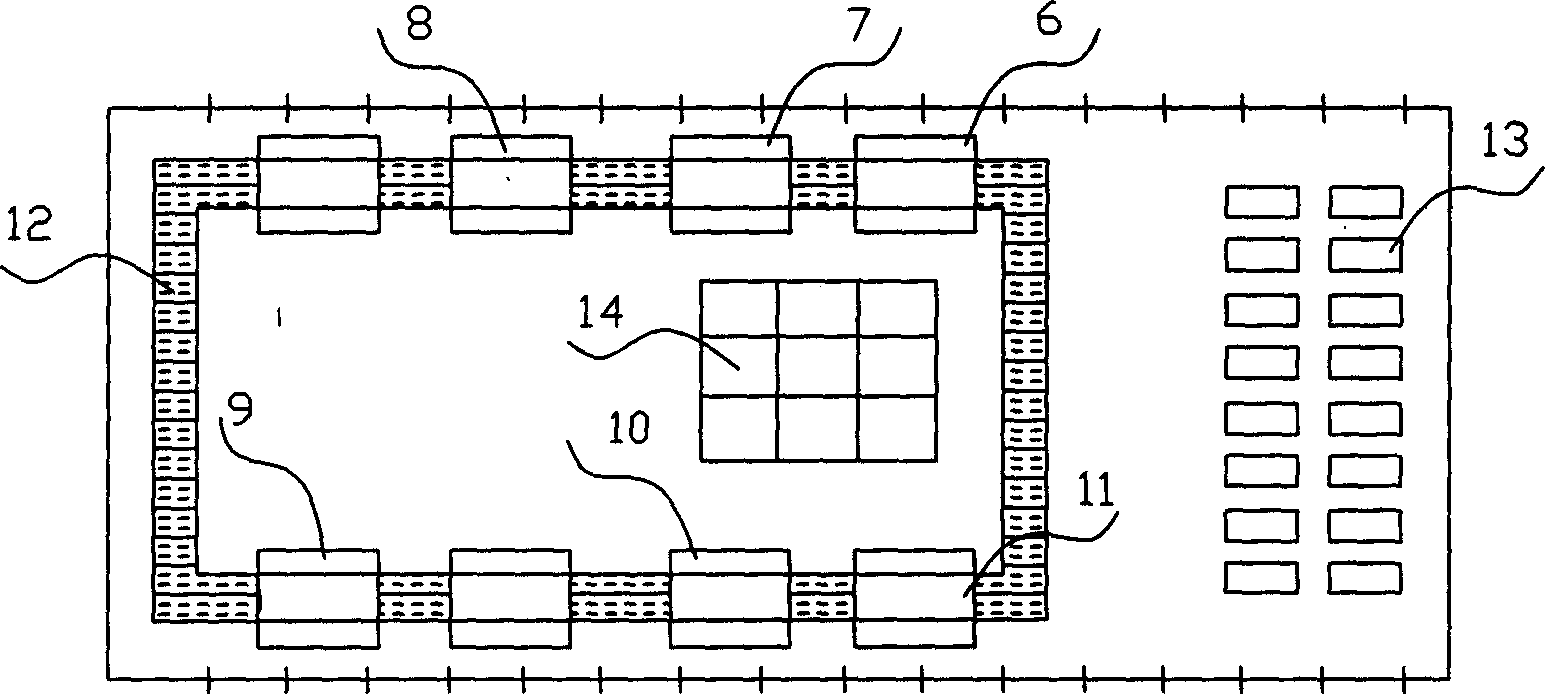

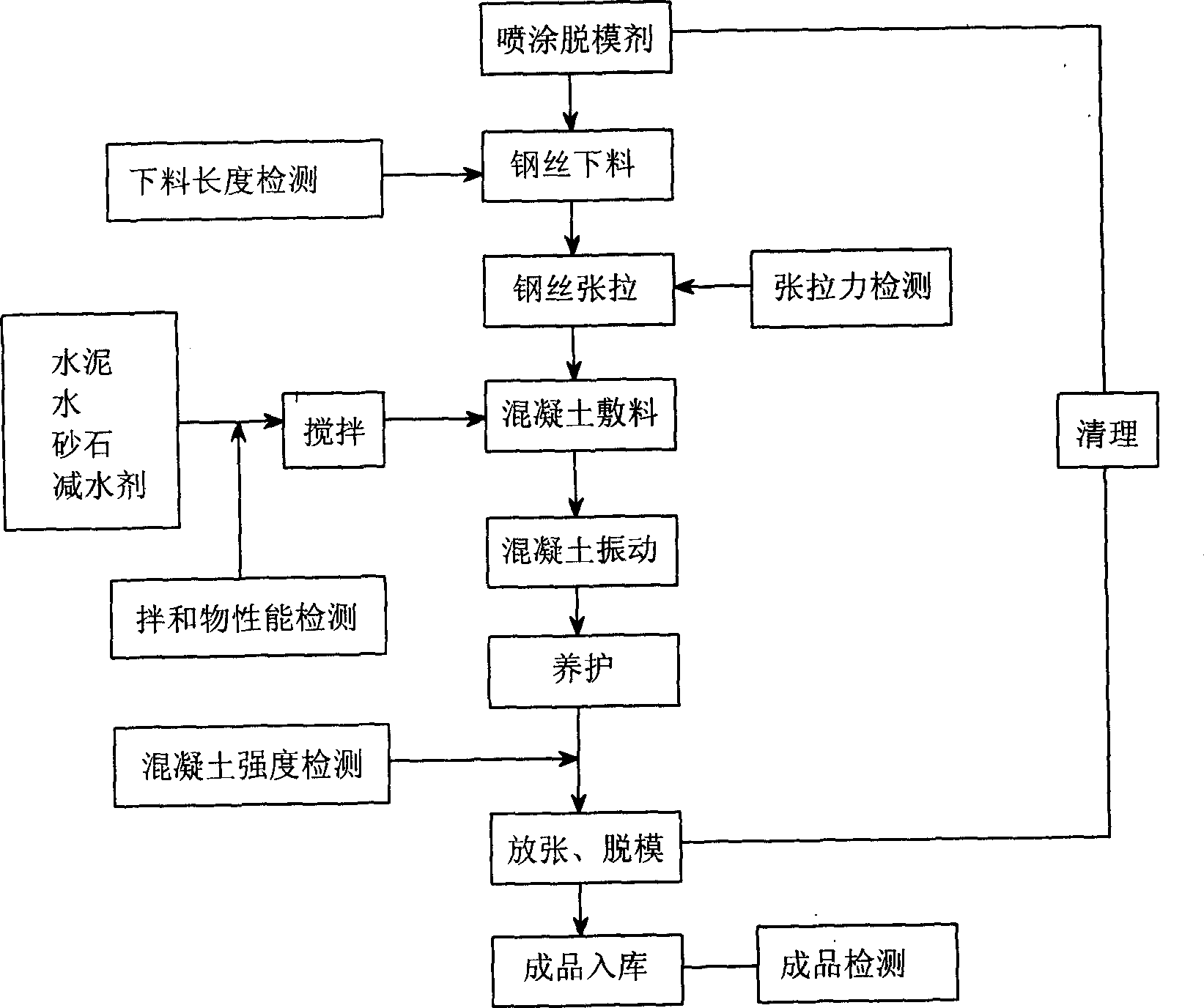

Bidirectional pretensioning method prestressed concrete railway board and assembly machine sets method production process

InactiveCN1865593AReduced creep warpageReduces the possibility of creep warpingBallastwayCeramic shaping plantsProduction linePre stress

The invention relates to a bidirectional pre-stress concrete track plate with significant electric property and lower producing cost, and relative production line. Wherein, the track plate is a cuboid, with several preset structures; there are at least two layers of steel wires inside the track plate along its length and width directions; the steel wires in said two directions do not contact each other; said pre-stress concrete track plate are tensioned along the length and width directions; the production method comprises: spraying demoulding agent, feeding material, tensioning, coating concrete, vibrating, maintaining, tensioning and demoulding. The invention can overcome the defects of present technique, with simple method, while it can be used to build high-speed railway.

Owner:欧阳炎

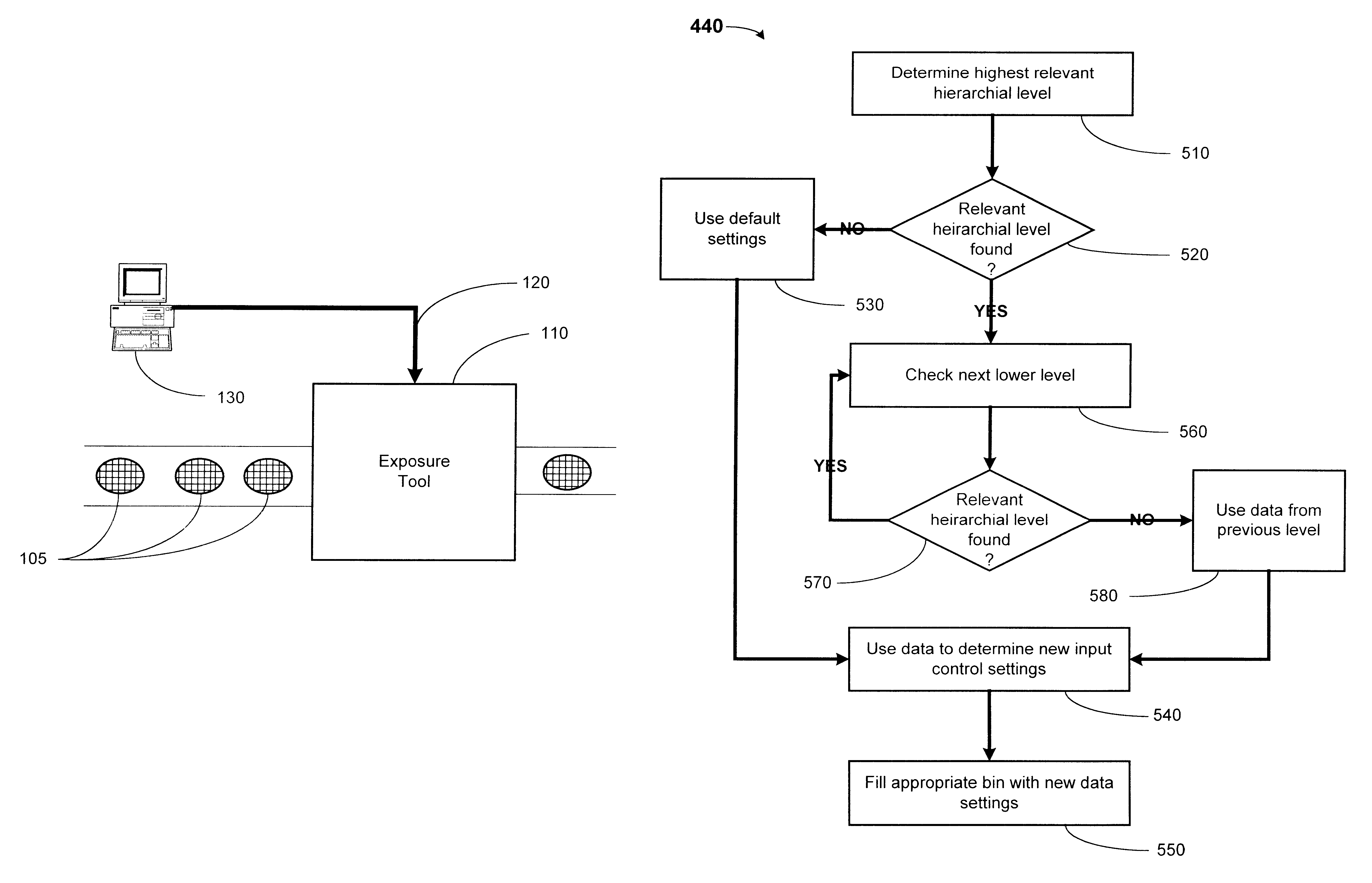

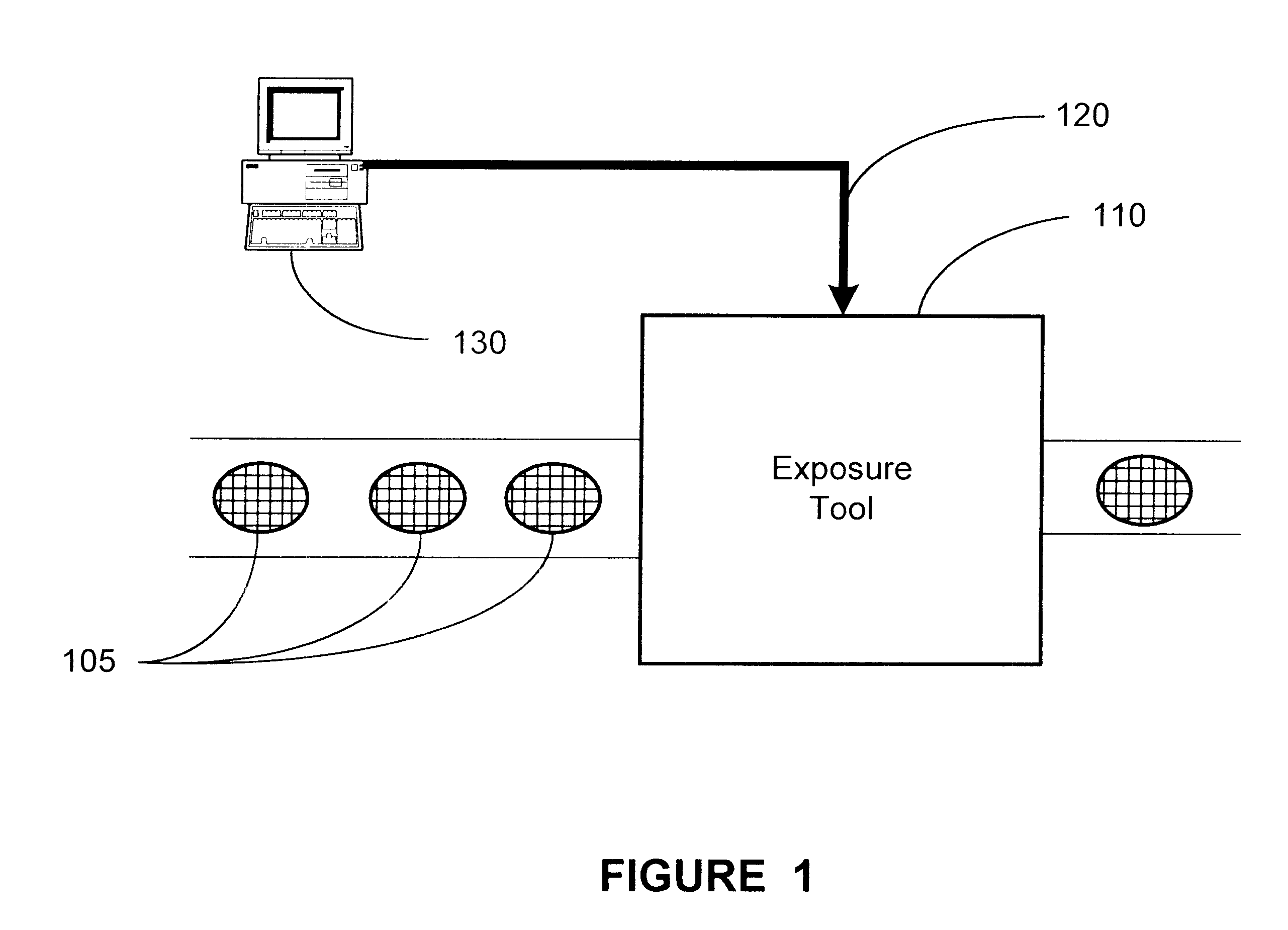

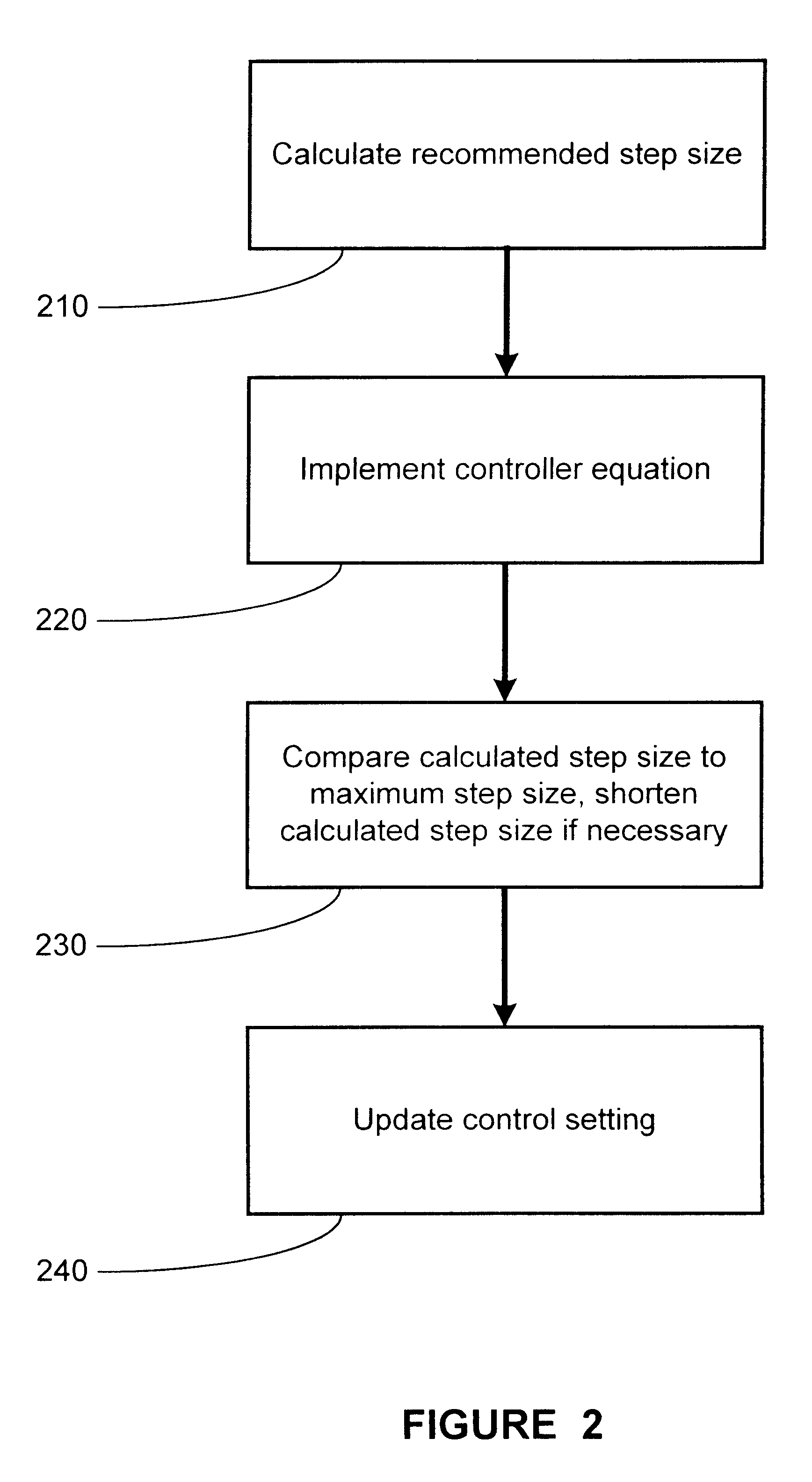

Method and apparatus for performing run-to-run control in a batch manufacturing environment

InactiveUS6607926B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention provides for a method and an apparatus for controlling manufacturing processes using a hierarchical system. A first lot of semiconductor devices is processed using a first set of control input parameters. The first set of control input parameters is stored in one of a plurality of hierarchical levels, the first set of control input parameters being available for processing of a second lot of semiconductor devices. Process data is acquired from the processing of the first lot of semiconductor devices. A second set of control input parameters is determined for a subsequent lot of semiconductor devices based upon the acquired process data. The second set of control input parameters is stored in one of a plurality of hierarchical levels, the first and second sets of control input settings being available for processing of a third lot of semiconductor devices.

Owner:GLOBALFOUNDRIES INC

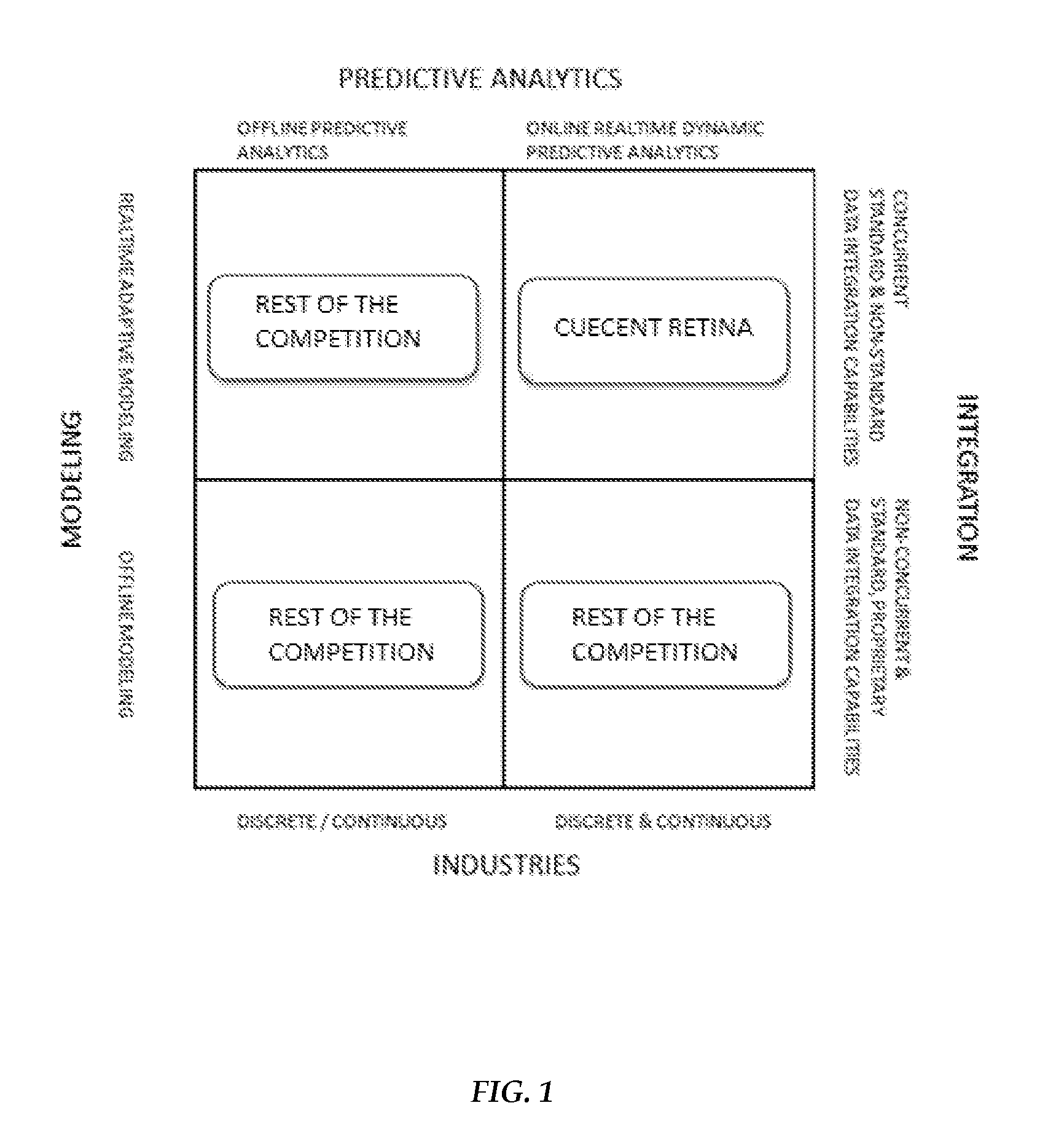

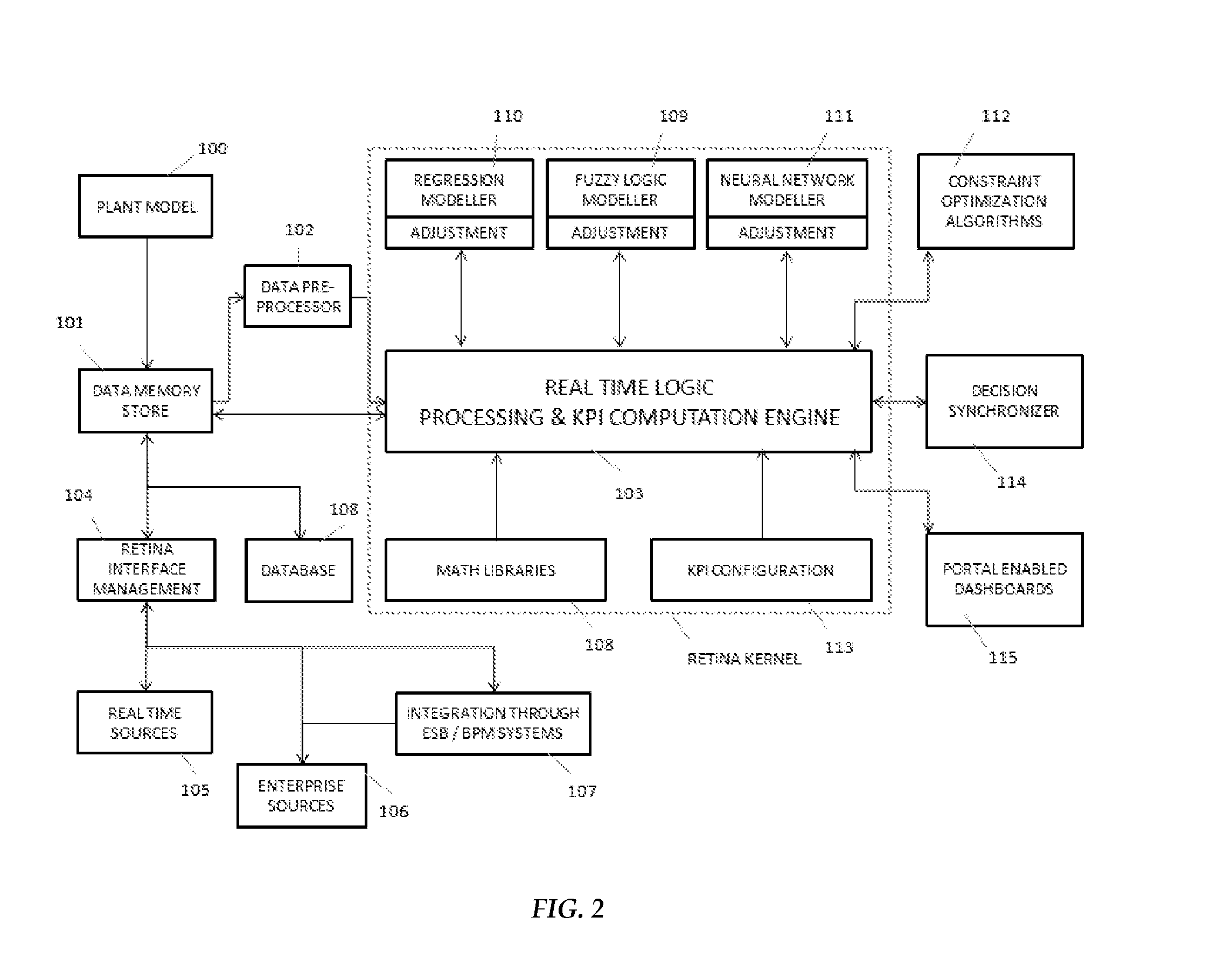

Intelligent Decision Synchronization in Real Time for both Discrete and Continuous Process Industries

A composite technology system RETINA that enables intelligent decision synchronization in real time for continuous, discrete and batch process industries is disclosed. RETINA generates and synchronizes the intelligent decisions that affect the performance and profitability of business operations in real time and helps in analysis that are essential for any successful business operations in any manufacturing industries. RETINA combines the real time integration capability; Predictive analytics capability and adaptive real time process modeling capability to generate intelligent risk-reduced business decisions for continuous, discrete and batch manufacturing processes. RETINA unifies the data from disparate sources or in silos, collates, comprehends and analyses the data, and then convert them into actionable information in real time. Correct decisions are generated, streamlined and shared at the appropriate instant of time with right amount of data to the pertinent personnel to eliminate inefficiencies in operations and performance resulting in tangible profitability.

Owner:BAHWAN CYBERTEK

Polishing film and method for making same

ActiveCN101225281AUniform performanceReduce manufacturing costOther chemical processesPolishing compositionsOrganic solventRoller Coating Method

The invention discloses a polishing film and the preparation method, which adopts the ultrafine micro mist as the grinding material and prepares in flow-casting coating method, namely the powdered or granular resin is dissolved into the organic solvent and then added in functional additive to make the resin adhesive, then the abrasive of surface-modified ultrafine micro mist is added into the resin adhesive and the spread coating liquid can be obtained after fully mixing, finally the paint is painted on the surface of soft base in flow-casting coating method and the polishing film can be obtained after drying and curing. The preparation method of the polishing film has the advantages of small equipment investment, simple operation, high productivity and automation level, steady craft, even film performance and low manufacturing cost. The polishing film can adjust the craft parameters of the flow-casting craft conveniently according to the different quality requirement and standards of the products, and can achieve production in multi-specification and small lot production and overcomes the problems that the rapid transformation of the product specification is difficult due to the limit of the equipment structure in roller coating method.

Owner:HENAN UNION ABRASIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com