Patents

Literature

2715 results about "Digital printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital printing refers to methods of printing from a digital-based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers. Digital printing has a higher cost per page than more traditional offset printing methods, but this price is usually offset by avoiding the cost of all the technical steps required to make printing plates. It also allows for on-demand printing, short turnaround time, and even a modification of the image (variable data) used for each impression. The savings in labor and the ever-increasing capability of digital presses means that digital printing is reaching the point where it can match or supersede offset printing technology's ability to produce larger print runs of several thousand sheets at a low price.

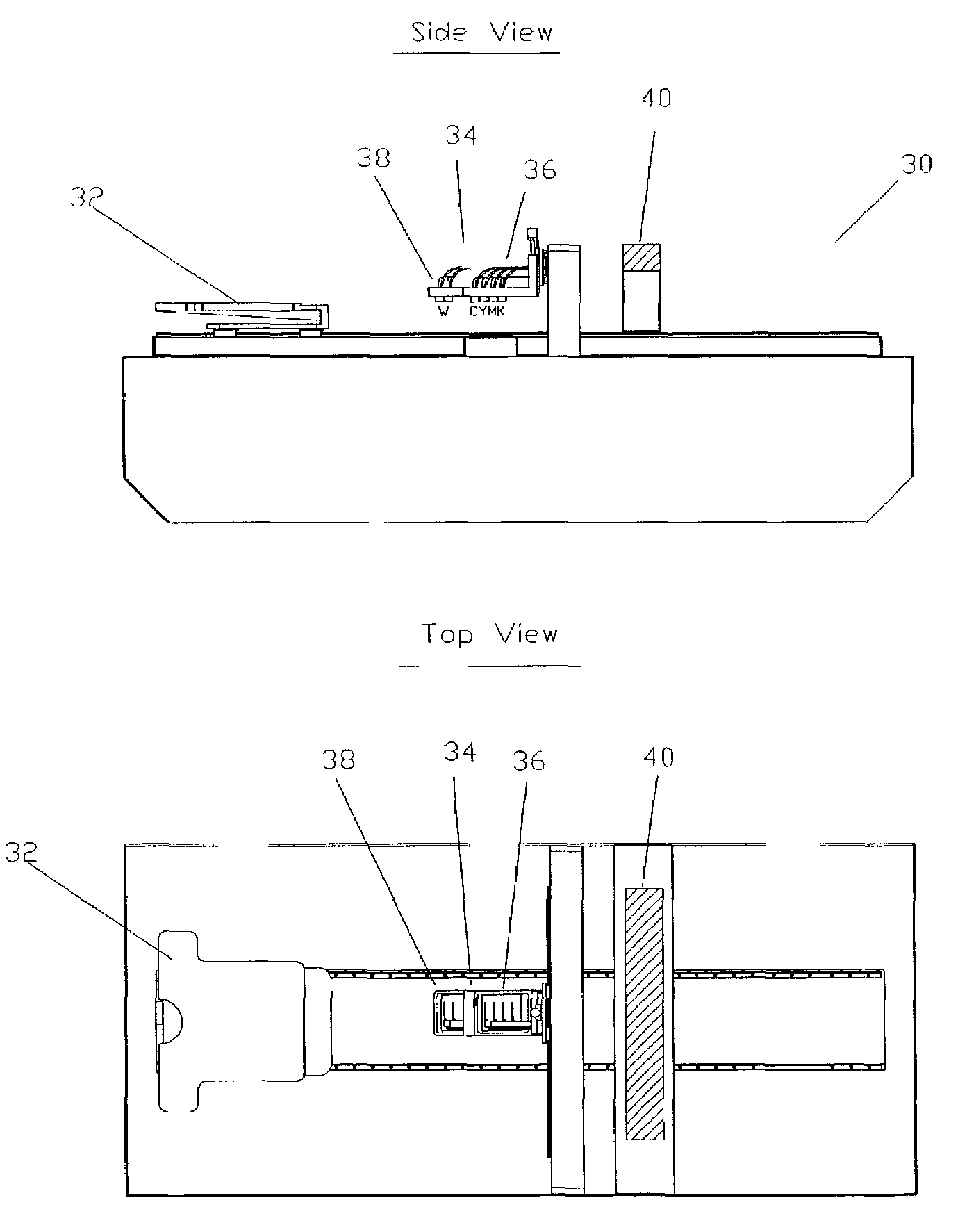

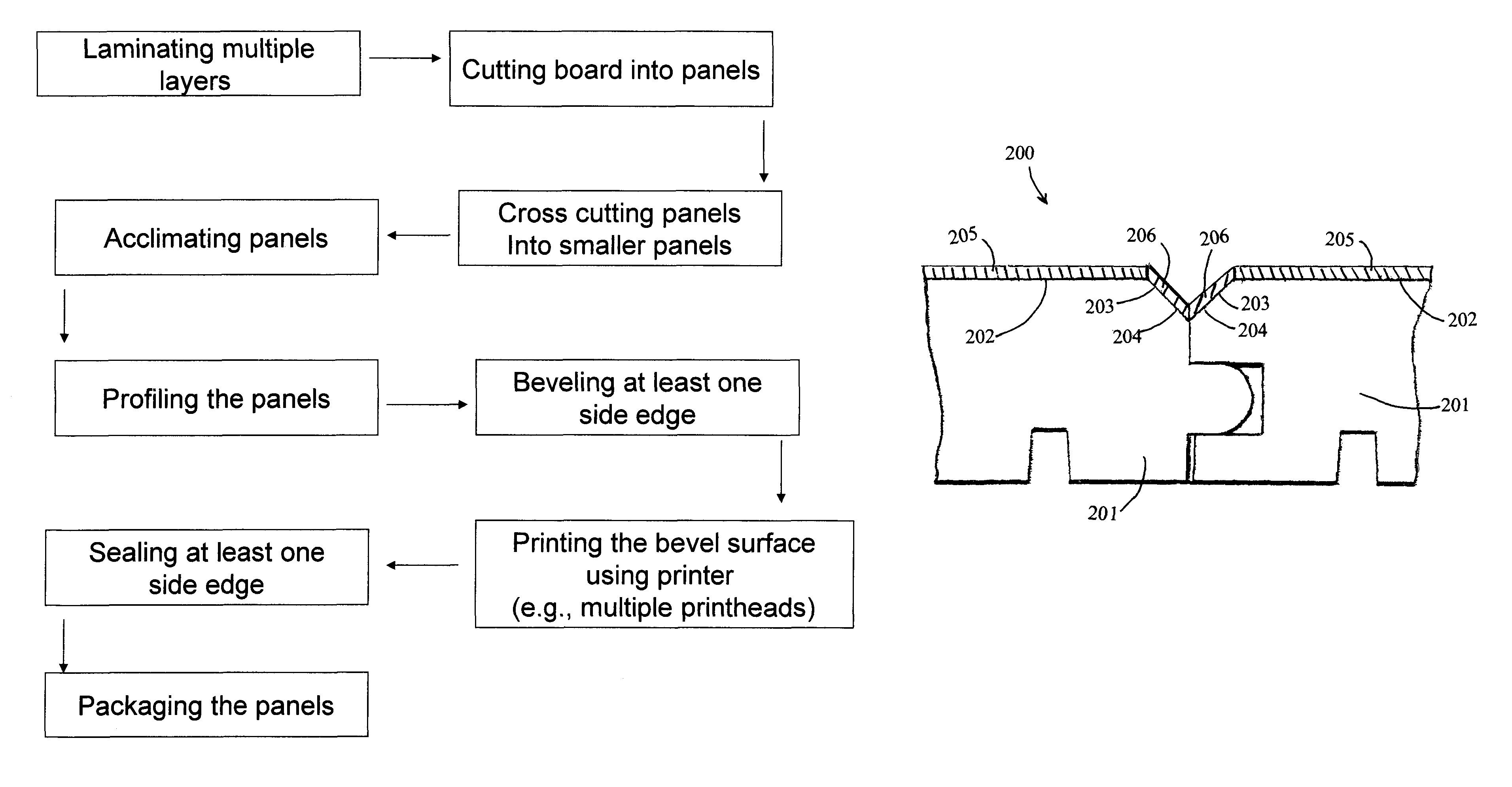

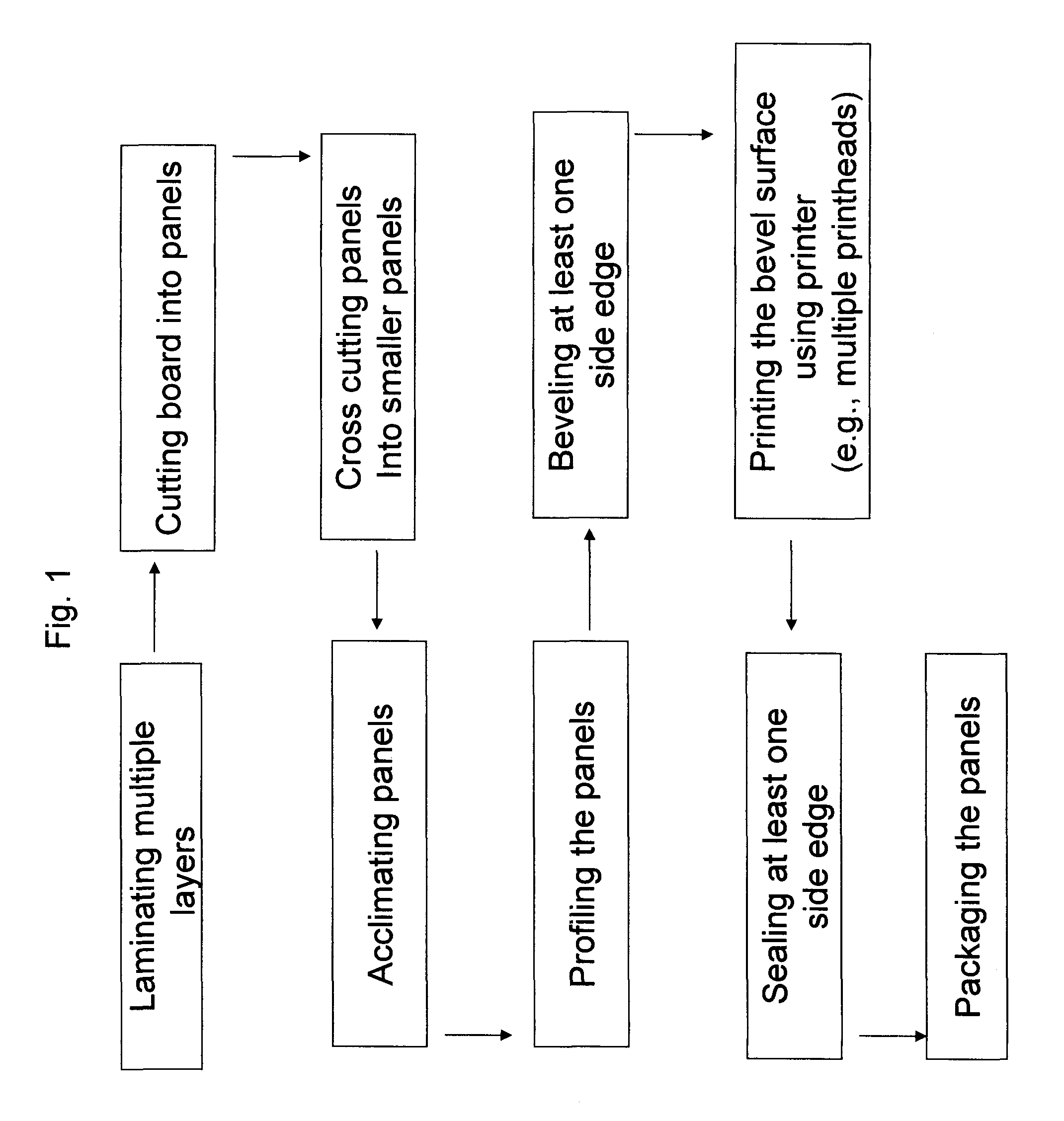

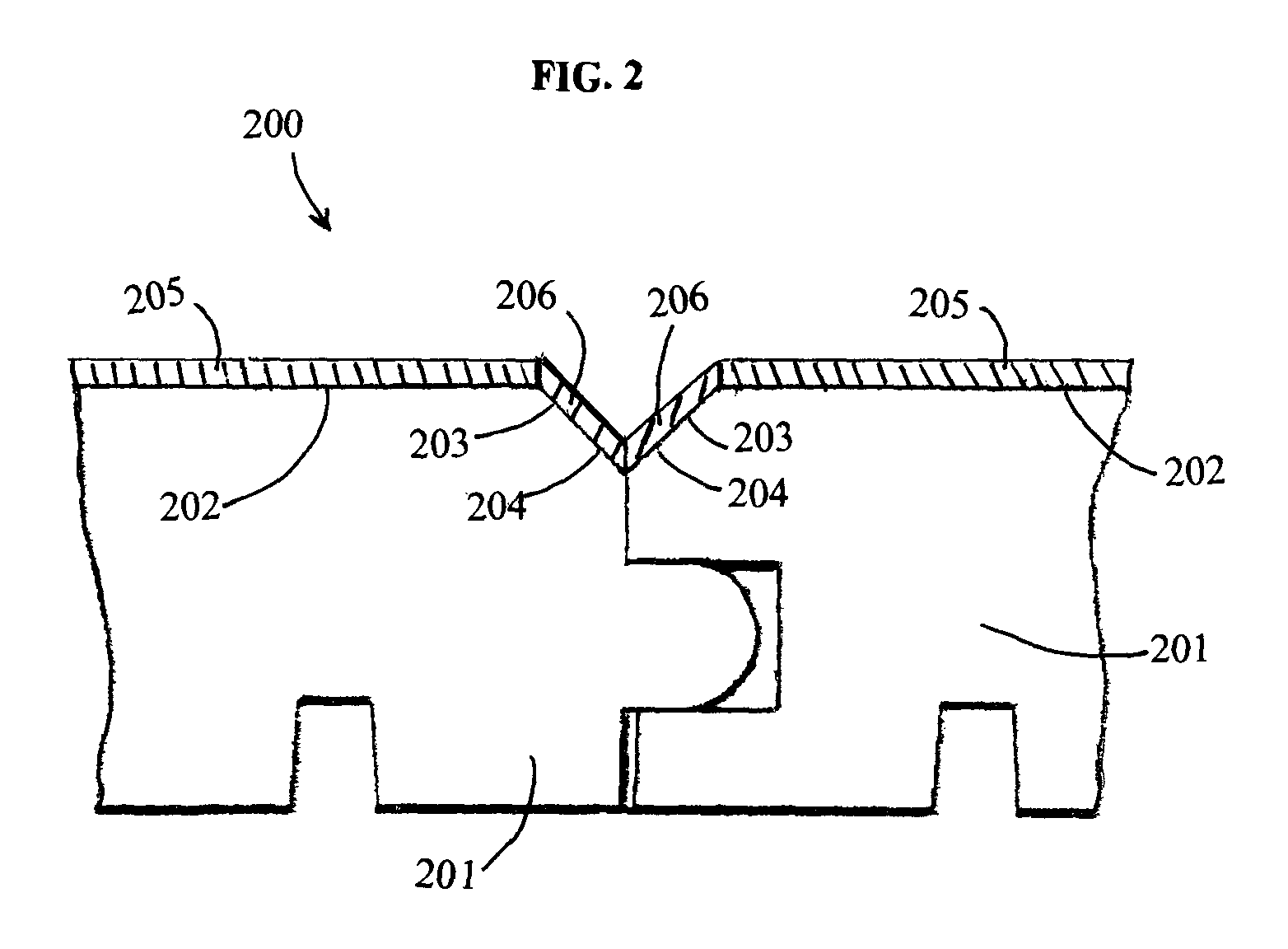

Methods and systems for decorating bevel and other surfaces of laminated floorings

ActiveUS20070283648A1Eliminate needEnhance the imageCovering/liningsWallsEngineeringDigital printing

Methods and systems for decorating at least one bevel surface or other surface of a laminated flooring are described. The bevel surface can be decorated by non-transfer printing such as digital printing. The digital printer can be an ink jet printer such as a piezoelectric drop-on-demand (DOD) printer that allows a color and pattern to be placed on the bevel surface that matches the print design (décor pattern or face design) of the laminated flooring. Other devices are provided such as a device that takes a picture of or scans an image of the print design, and modifies the taken picture or the scanned image so that the edge pattern thereof matches with an edge pattern of the print design.

Owner:FLOORING IND LTD

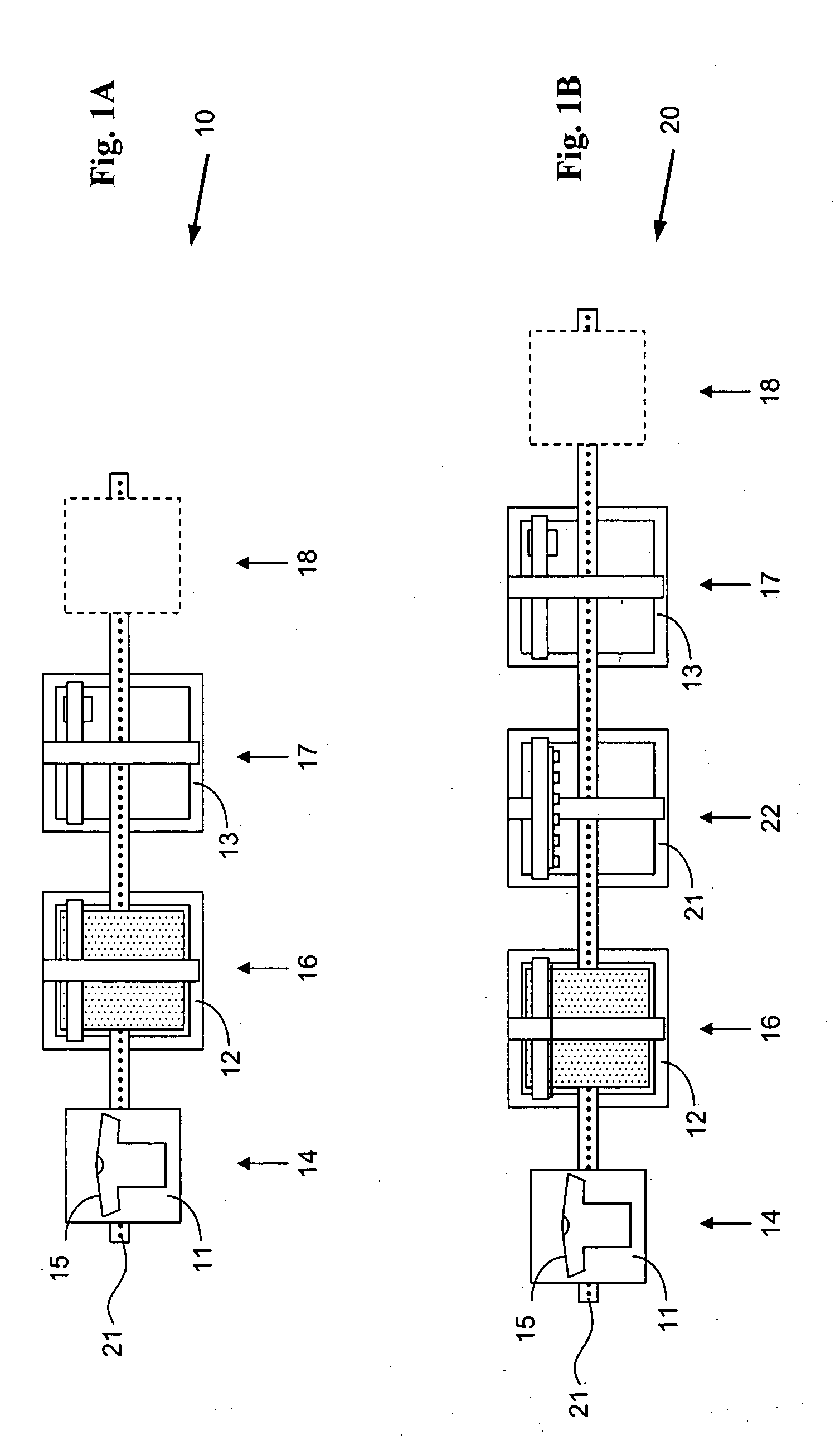

Digital printing machine

ActiveUS20050179708A1Accurate and high resolution printingImprove efficiencyTypewritersOther printing apparatusLinear motionEngineering

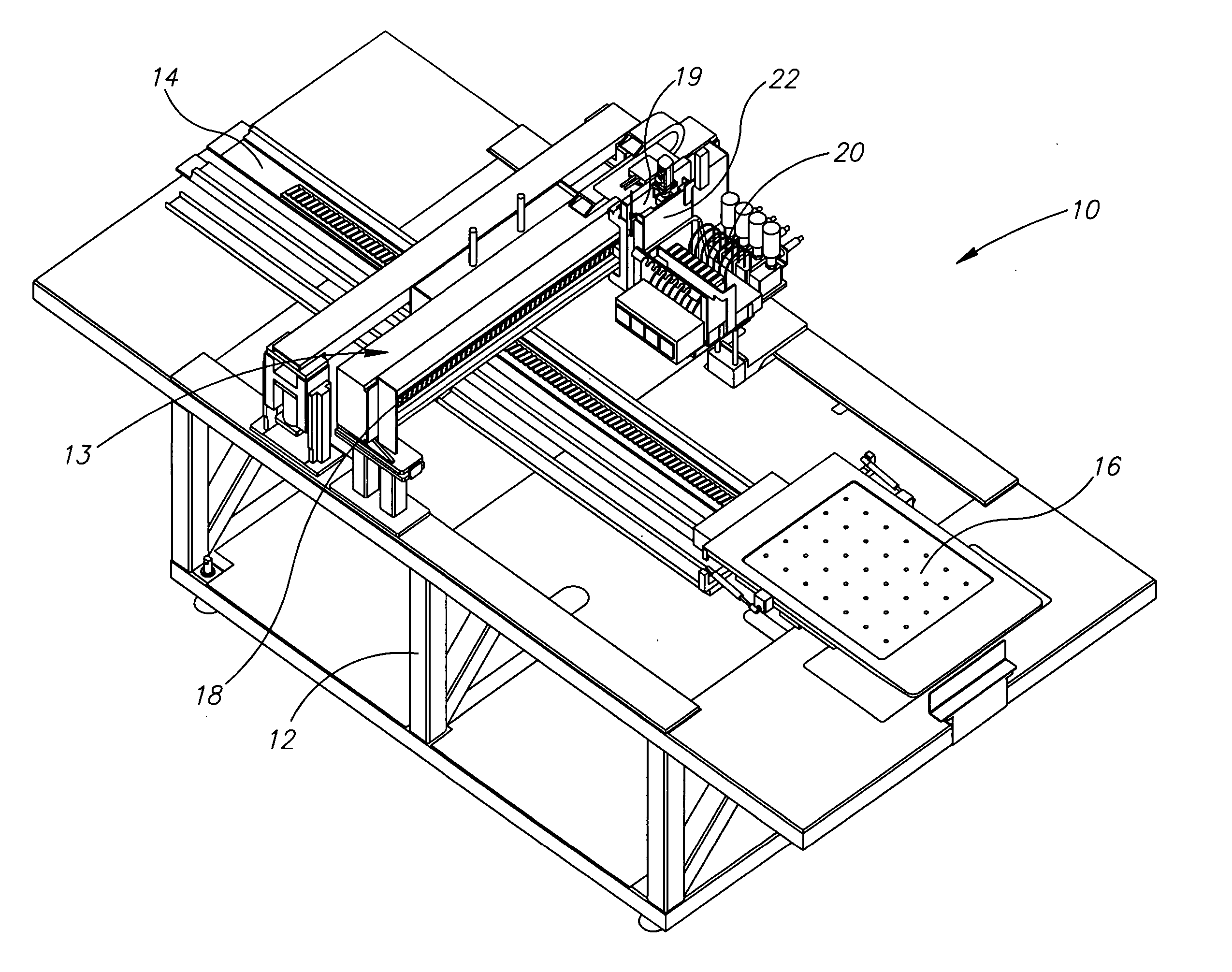

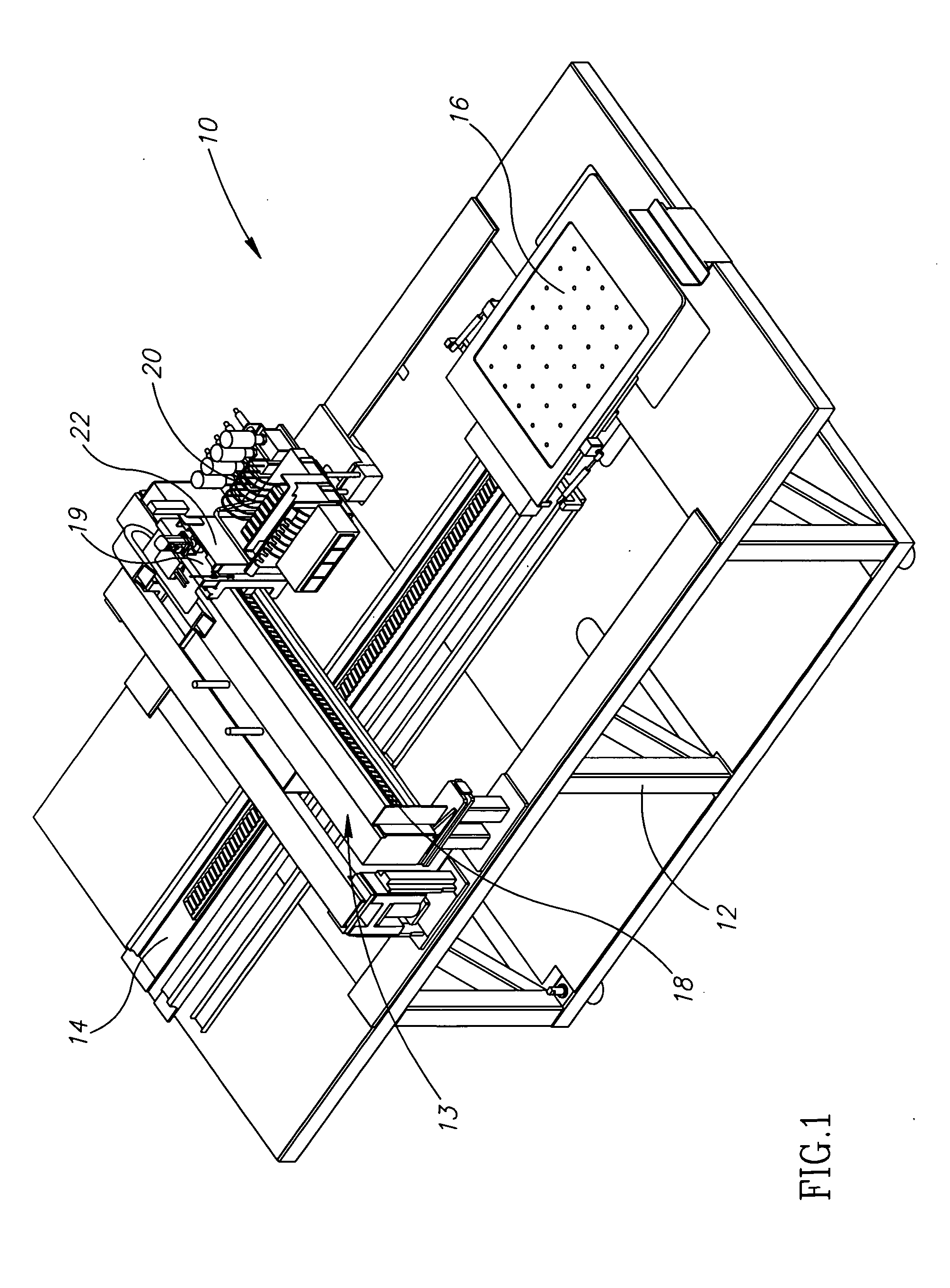

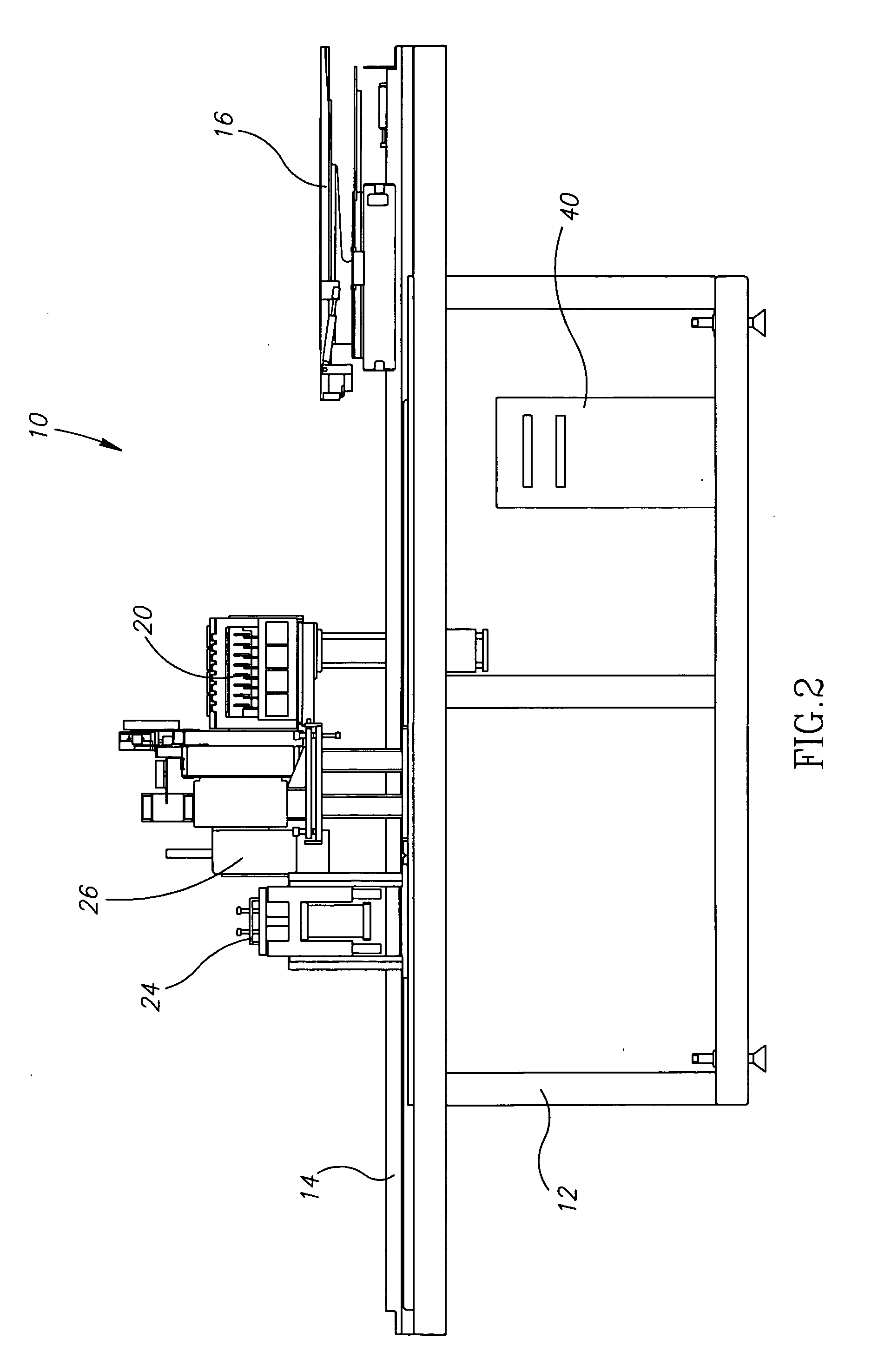

A digital printing machine including a rigid frame, a first linear motion X axis stage mounted on the frame, a printing table assembly movable on each linear X axis stage, a linear motion Y axis stage mounted on the frame perpendicular to the linear X axis stages, above the printing table assemblies, and an array of inkjet nozzles mounted on the linear Y axis stage for linear motion perpendicular to the X axis stage. The printing machine may include a second linear motion X axis stage mounted on the frame parallel to the first axis stage and arranged for operation independently of the first axis stage, and / or a curing unit located above the printing table assembly and arranged to cure ink on media on the printing table assembly and / or an ironing unit located above the printing table assembly and arranged to iron media on the printing assembly before printing thereon, or a first printing table assembly movable on the base of the linear X axis stage and a second printing table assembly movable on the linear X axis stage base independently of the first printing table assembly.

Owner:KORNIT DIGITAL LTD

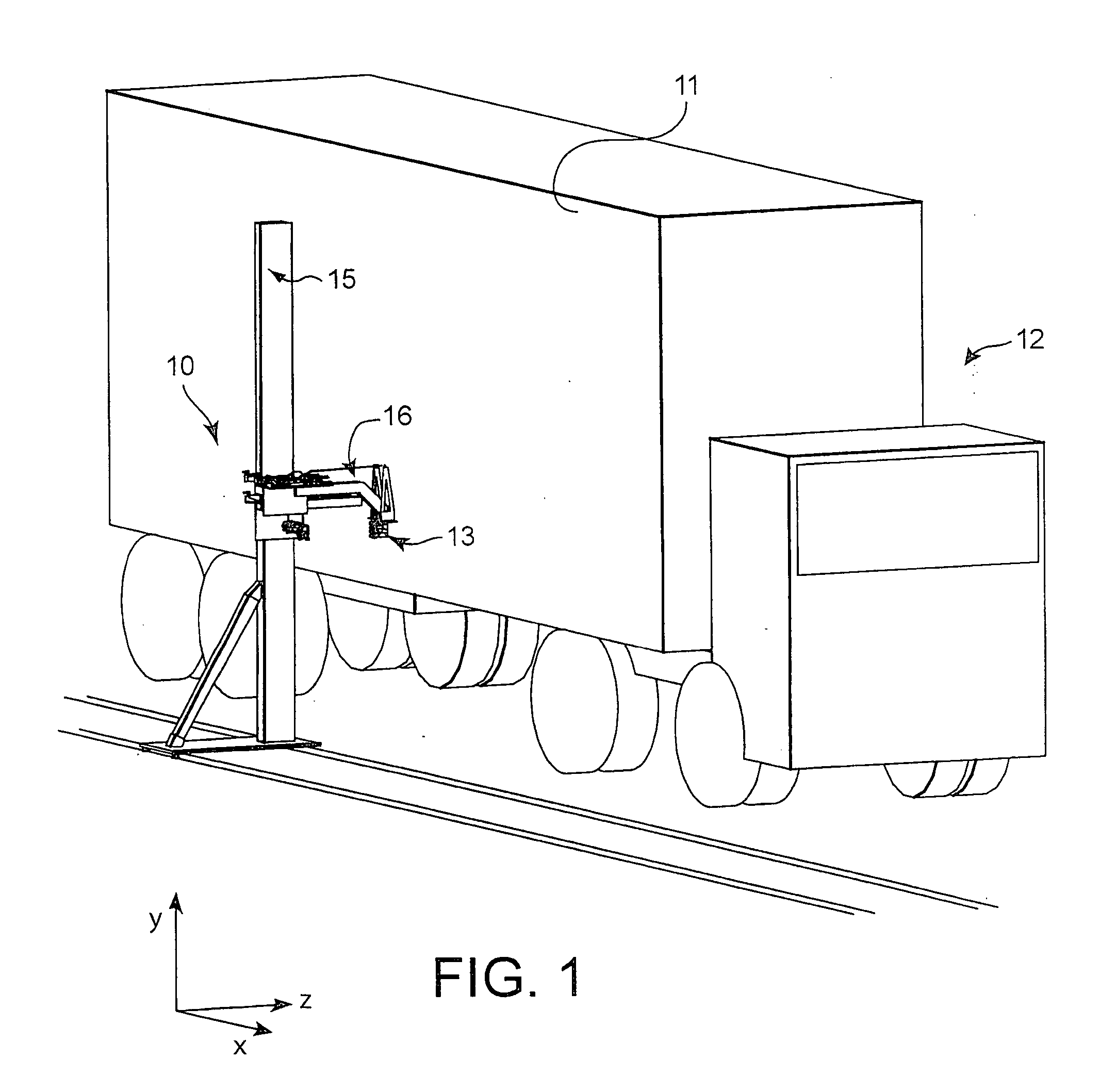

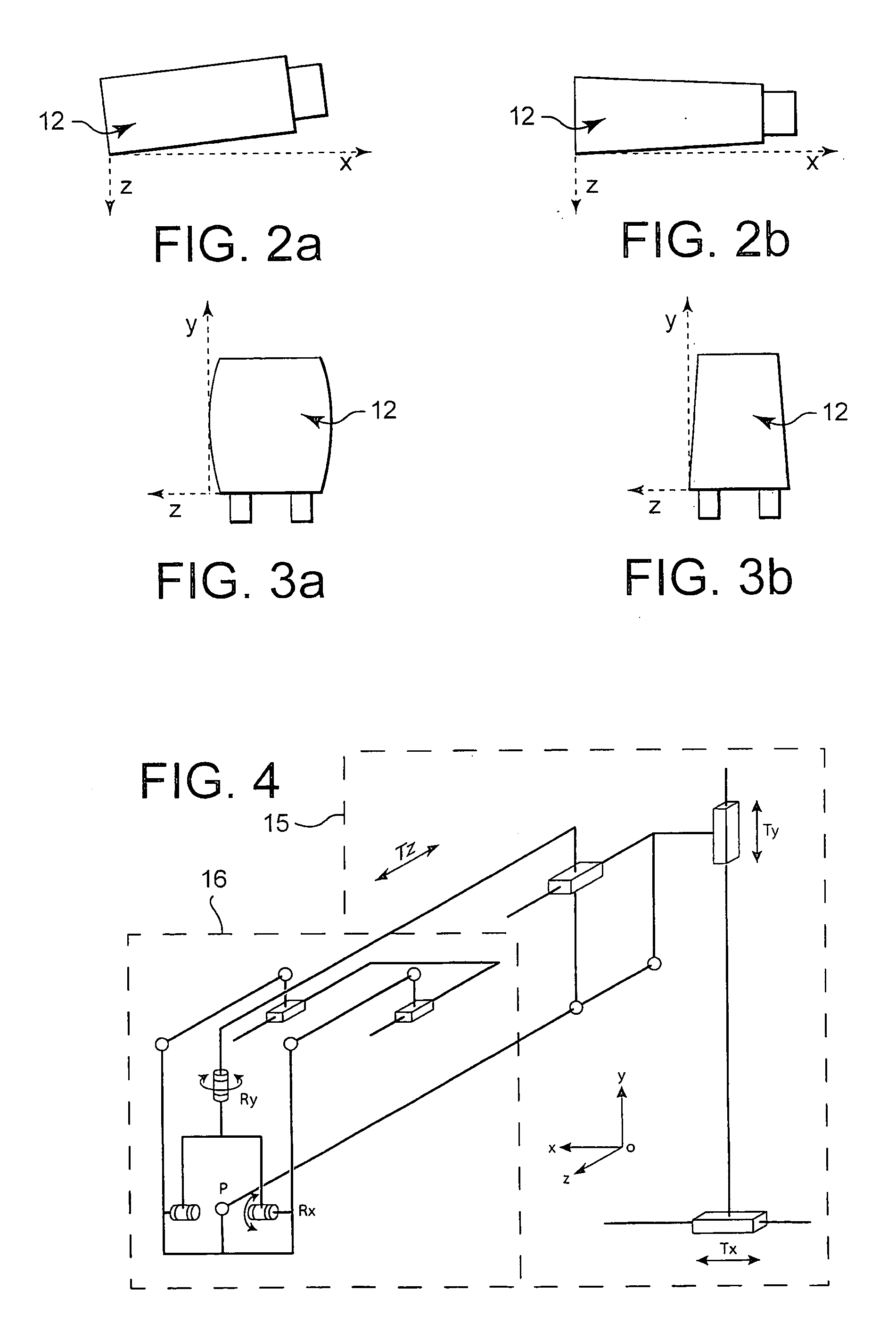

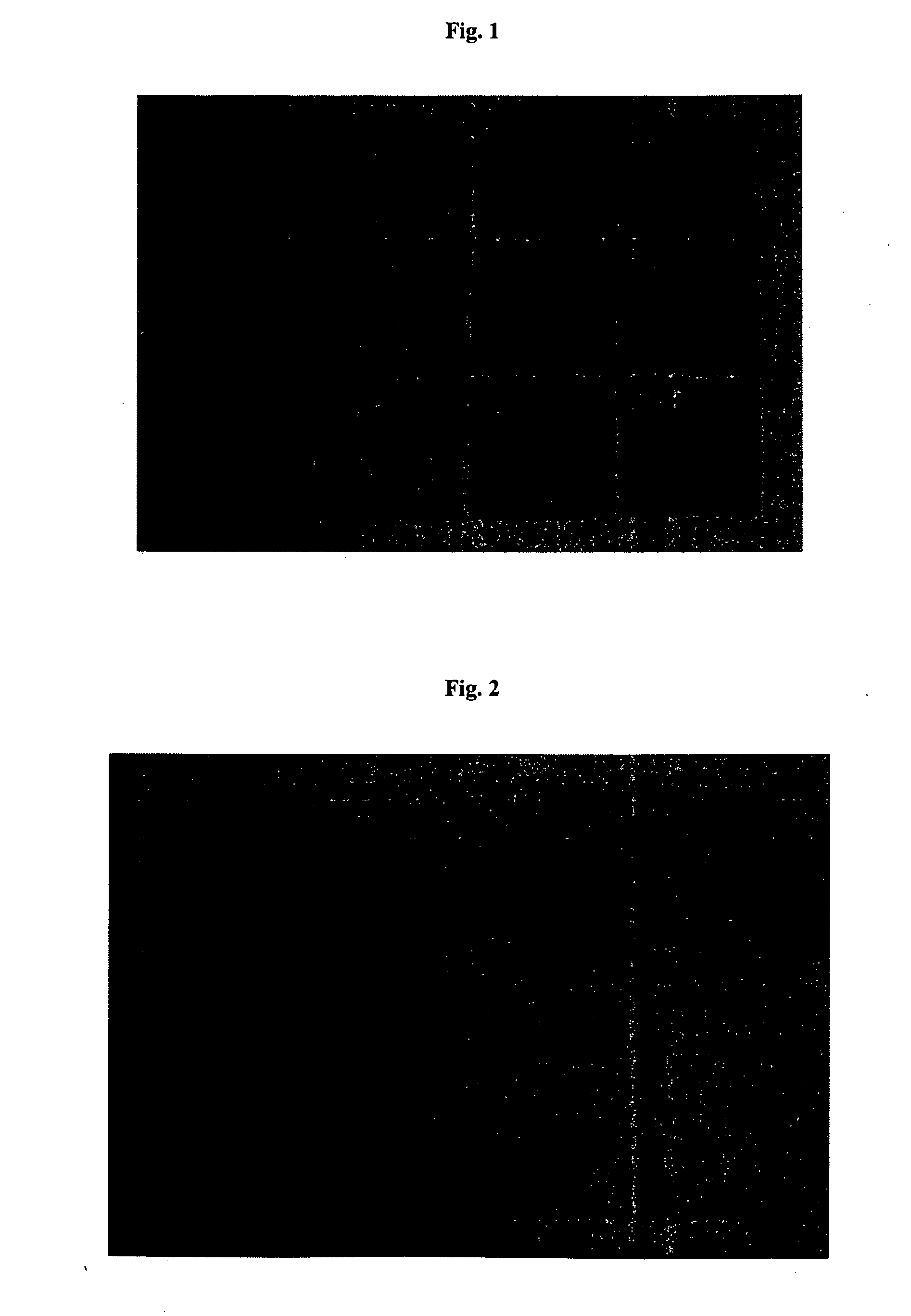

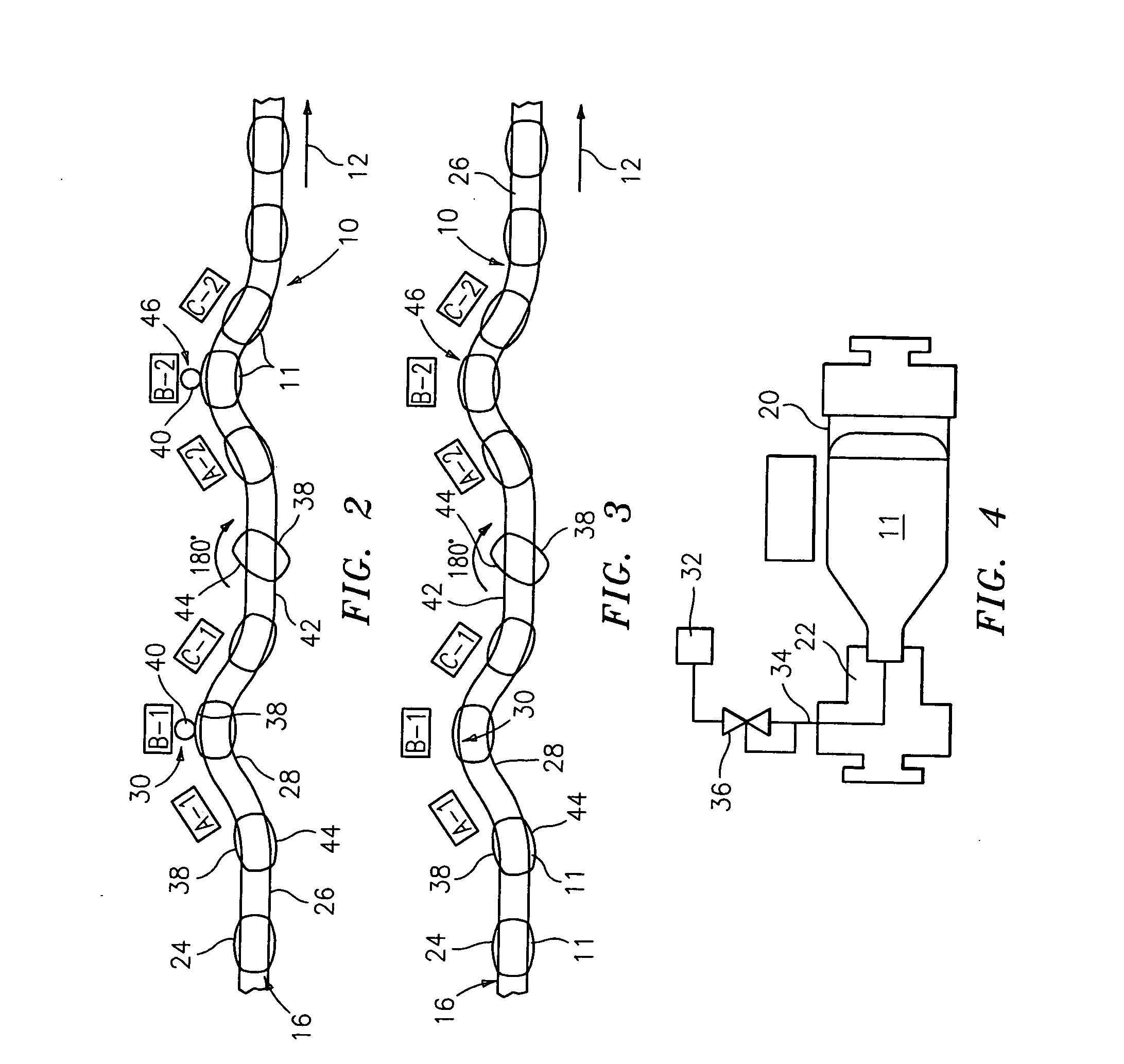

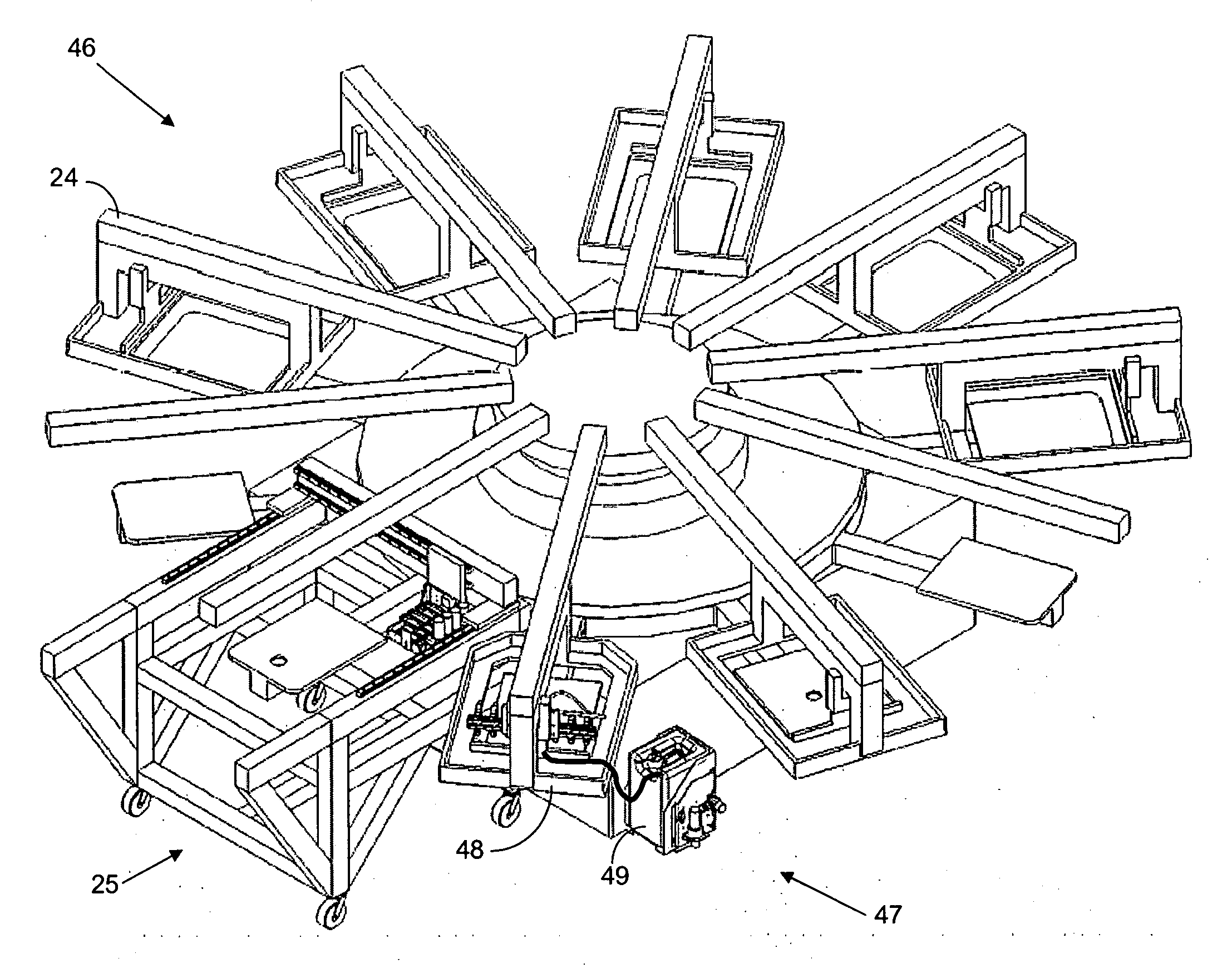

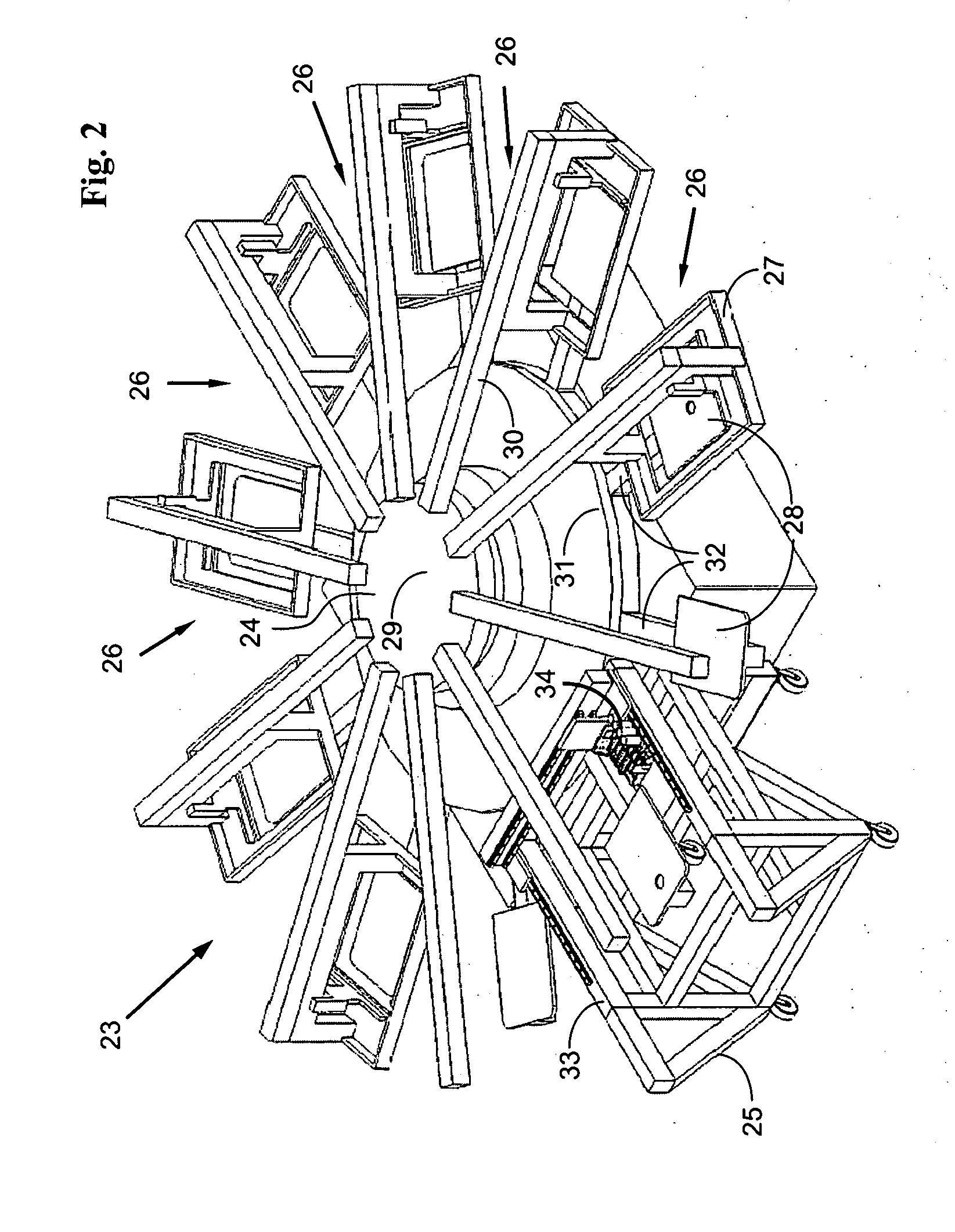

Robot for large-format, three dimensional digital printing on a fixed surface and printing method involving at least one such robot

InactiveUS20070062383A1Avoid couplingAdditive manufacturing apparatusDuplicating/marking methodsThree degrees of freedomEngineering

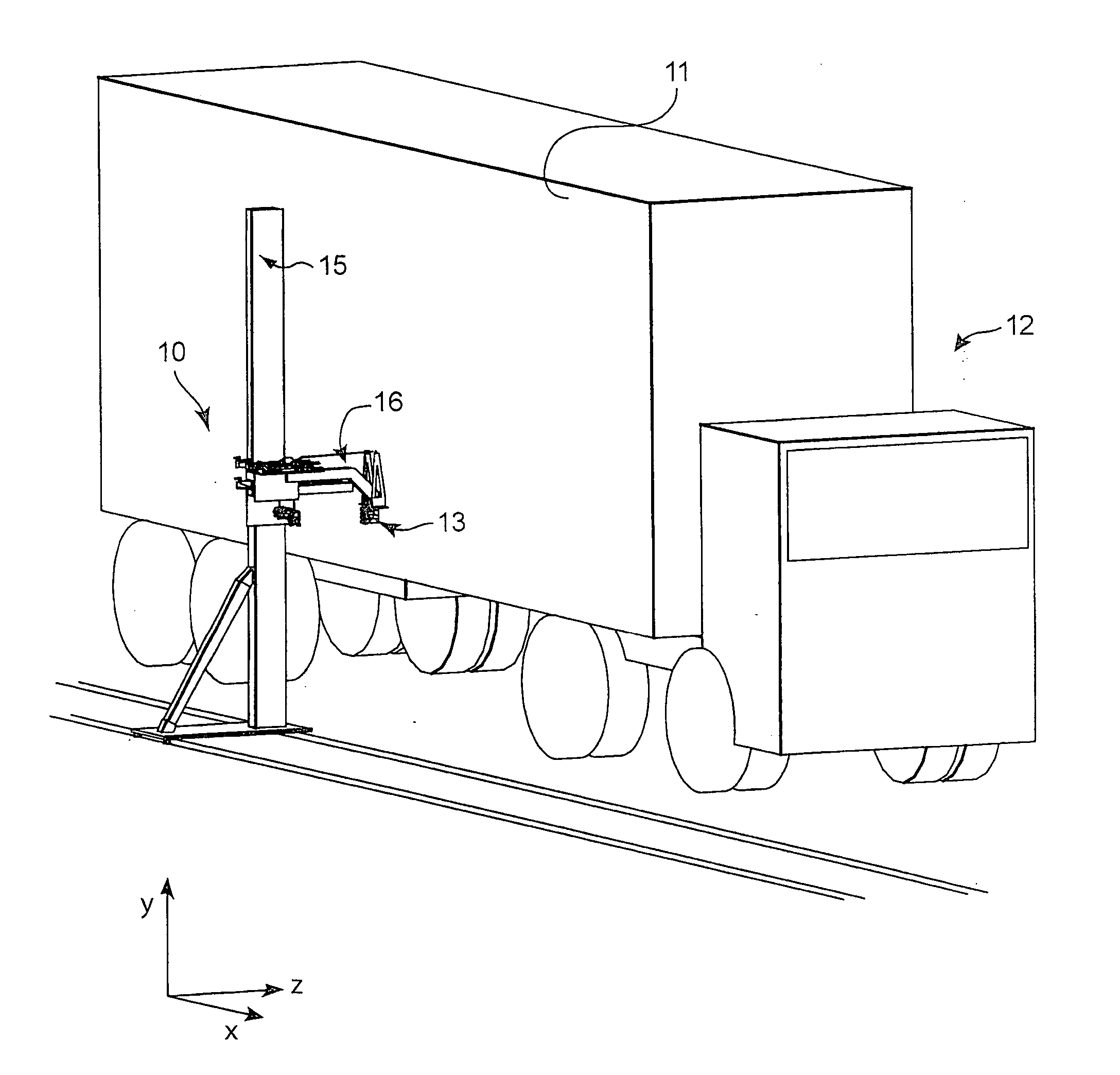

The invention concerns a print robot for large format three-dimensional printing on a fixed surface ( 11 ) having five motorized axes, comprising an inkjet printing block ( 13 ), means for displacing and orientating this printing assembly along several axes, at least one control unit controlling these means and a drying device to dry the ink sprayed onto said surface ( 11 ), wherein these means comprise: a carrier ( 15 ) with three degrees of freedom in translation, ensuring the positioning of the printing assembly allowing its horizontal, vertical and depth translation, a wrist ( 16 ) with two degrees of freedom which supports and orientates the printing assembly ( 13 ) allowing its rotations along two perpendicular axes. The invention also concerns a process implementing this robot.

Owner:CENT NAT DE LA RECHERCHE SCI +1

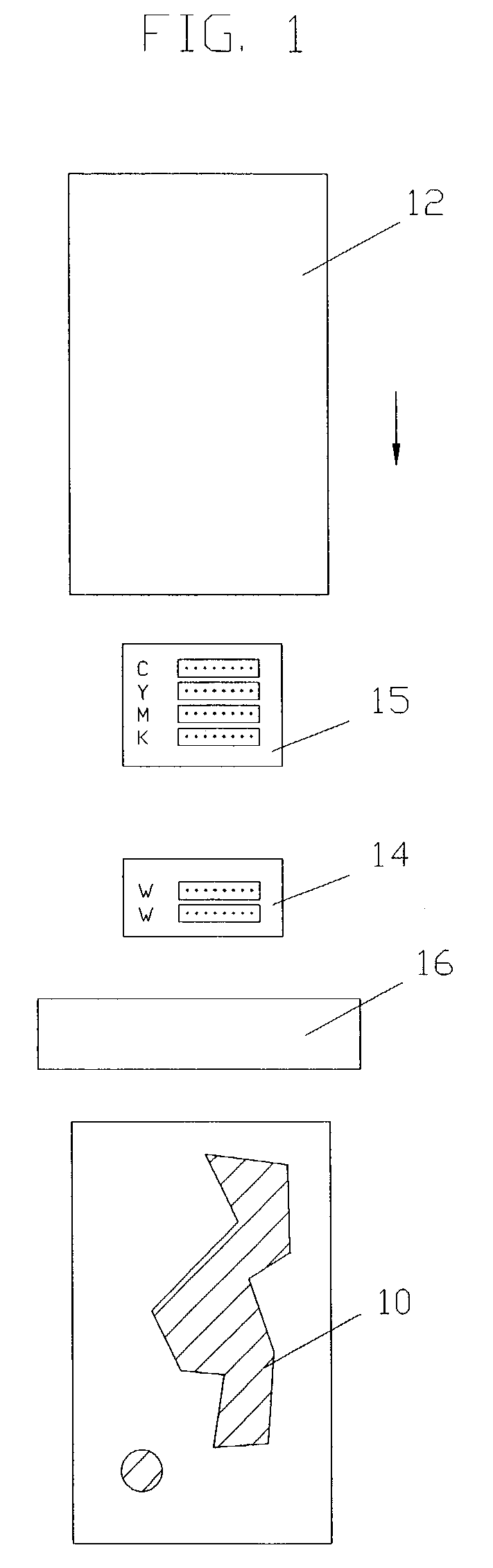

Process for printing images on dark surfaces

InactiveUS20070104899A1Quality improvementImprove adhesionDuplicating/marking methodsTransfer printing processColor imageFiber

Novel processes for printing high quality, high resolution, multi-color images on darkly colored fibrous or porous materials or other ink absorbing materials, is disclosed. The processes are effected by digitally printing a layer of an opaque, lightly colored ink composition, followed by digitally printing the colored image thereon, and optionally further involve applying a wetting composition prior to and / or subsequent to these printings. Processes utilizing wetting compositions and / or liquid ink compositions which can interact therebetween so as to effect a chemical and / or physical change in one or more of these compositions are further disclosed.

Owner:KORNIT DIGITAL LTD

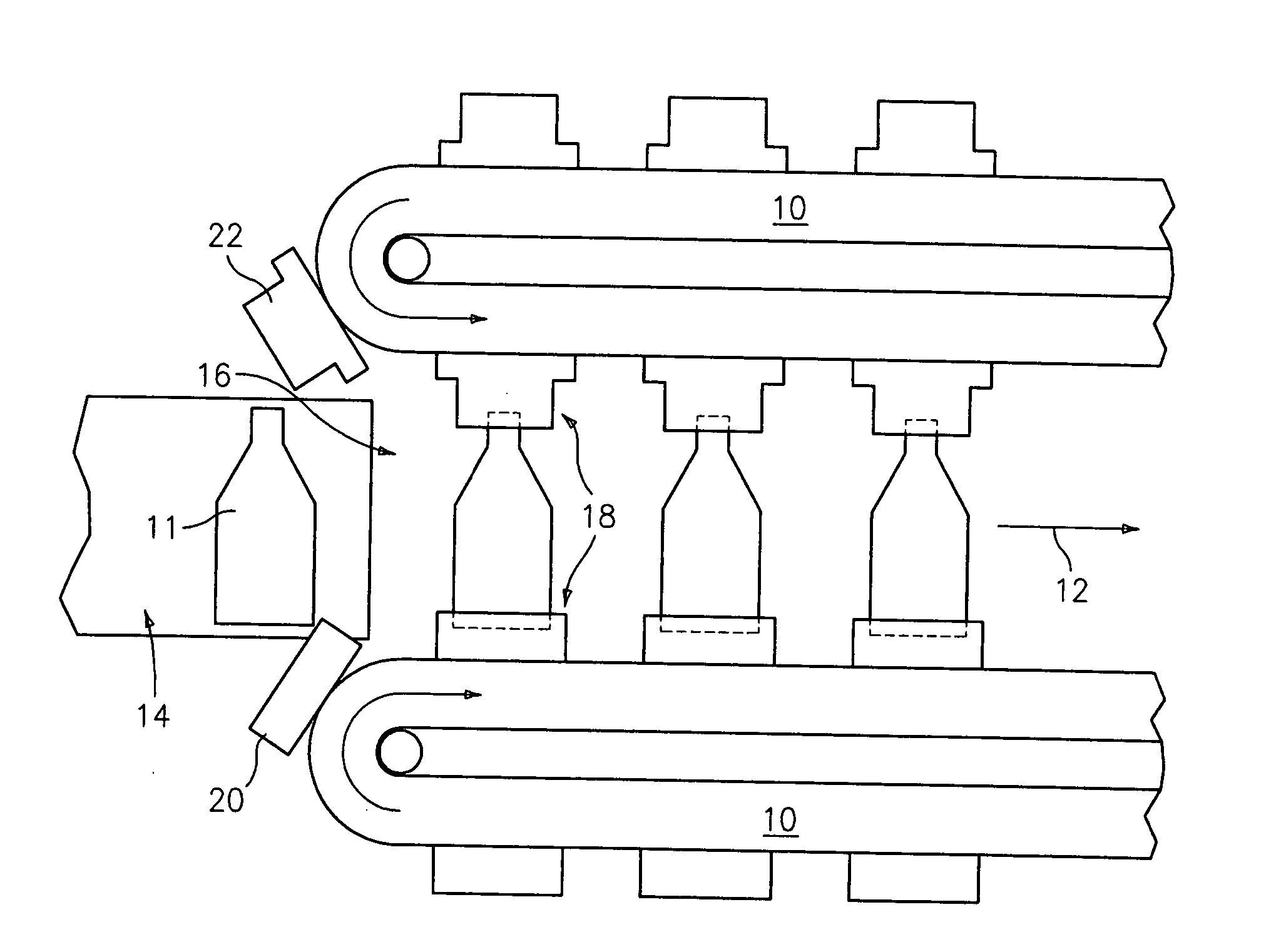

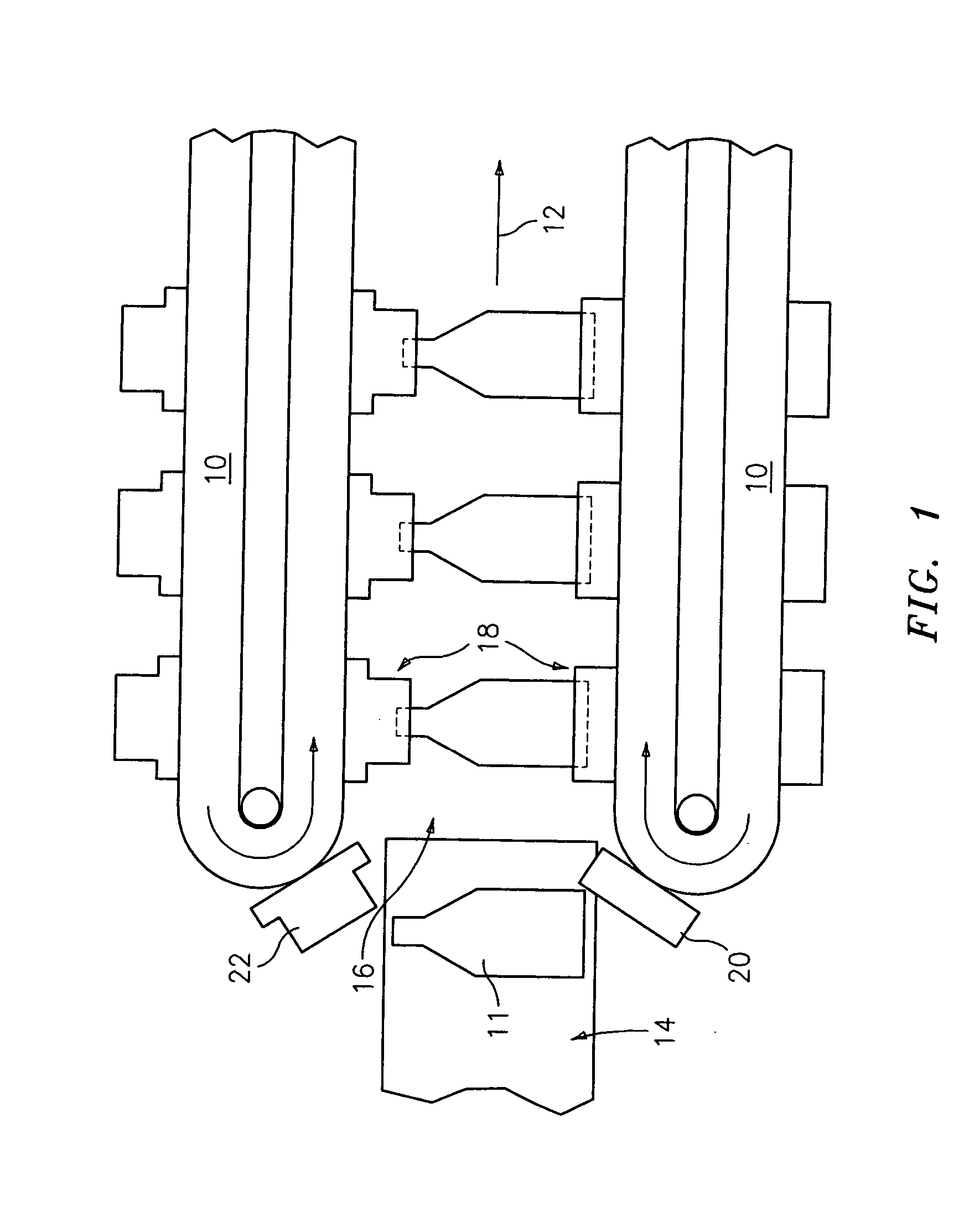

Printing plastic containers with digital images

A method for printing digital images on plastic containers having curved surfaces, including providing a series of hollow plastic containers, moving the containers along a track past first and second digital printing locations, and printing first and second digital images on the curved container surfaces while maintaining the container being printed under internal pressure and while firmly holding the container being printed at spaced locations thereon.

Owner:PLASTIPAK PACKAGING

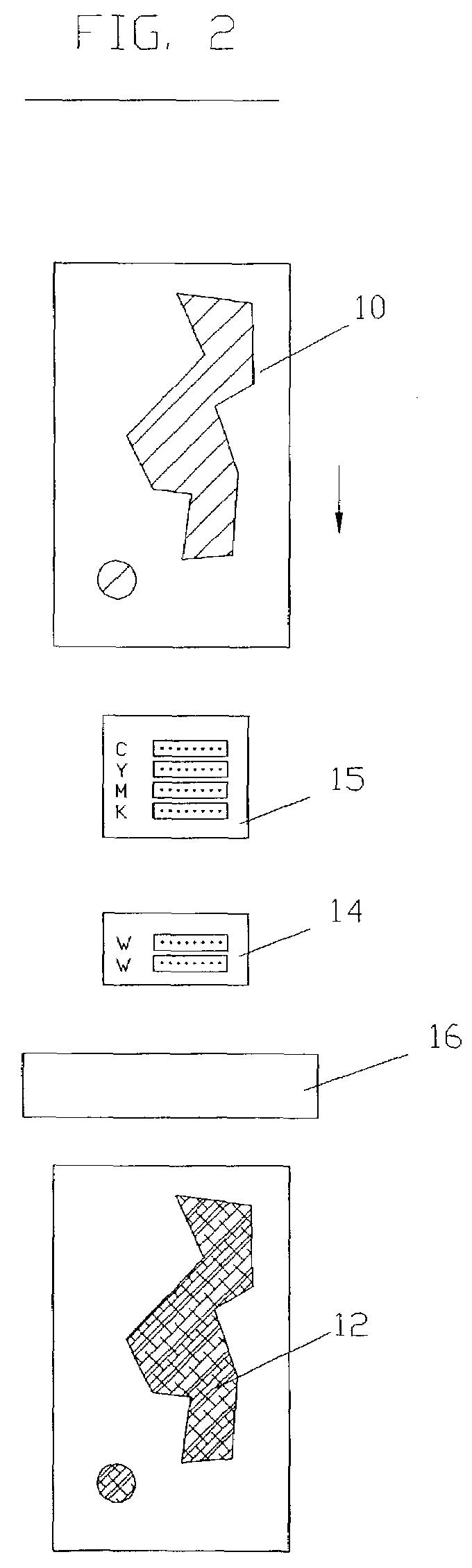

Method for image printing on a dark textile piece

InactiveUS7134749B2Measurement apparatus componentsTransfer printing processColored whiteColor printing

A method and apparatus for color printing on a dark textile piece, the method including the steps of digitally applying a white ink layer directly onto a textile piece, optionally curing the white ink layer, and digitally printing a colored image on said ink layer.

Owner:KORNIT DIGITAL LTD

Methods and systems for decorating bevel and other surfaces of laminated floorings

Methods and systems for decorating at least one bevel surface or other surface of a laminated flooring are described. The bevel surface can be decorated by non-transfer printing such as digital printing. The digital printer can be an ink jet printer such as a piezoelectric drop-on-demand (DOD) printer that allows a color and pattern to be placed on the bevel surface that matches the print design (décor pattern or face design) of the laminated flooring. Other devices are provided such as a device that takes a picture of or scans an image of the print design, and modifies the taken picture or the scanned image so that the edge pattern thereof matches with an edge pattern of the print design.

Owner:FLOORING IND LTD

Combined stencil and digital printing system

InactiveUS20060249039A1Increase surface tensionScreen printersTypewritersStencil printingEngineering

A printing system comprising a stencil printing apparatus and a digital printing apparatus for high speed printing of images having details of high resolution, rich colors, or variability, optionally also comprising a wetting apparatus operative to wet at least a part of the printed object prior to the digital printing.

Owner:KORNIT DIGITAL TECHNOLOGIES LTD

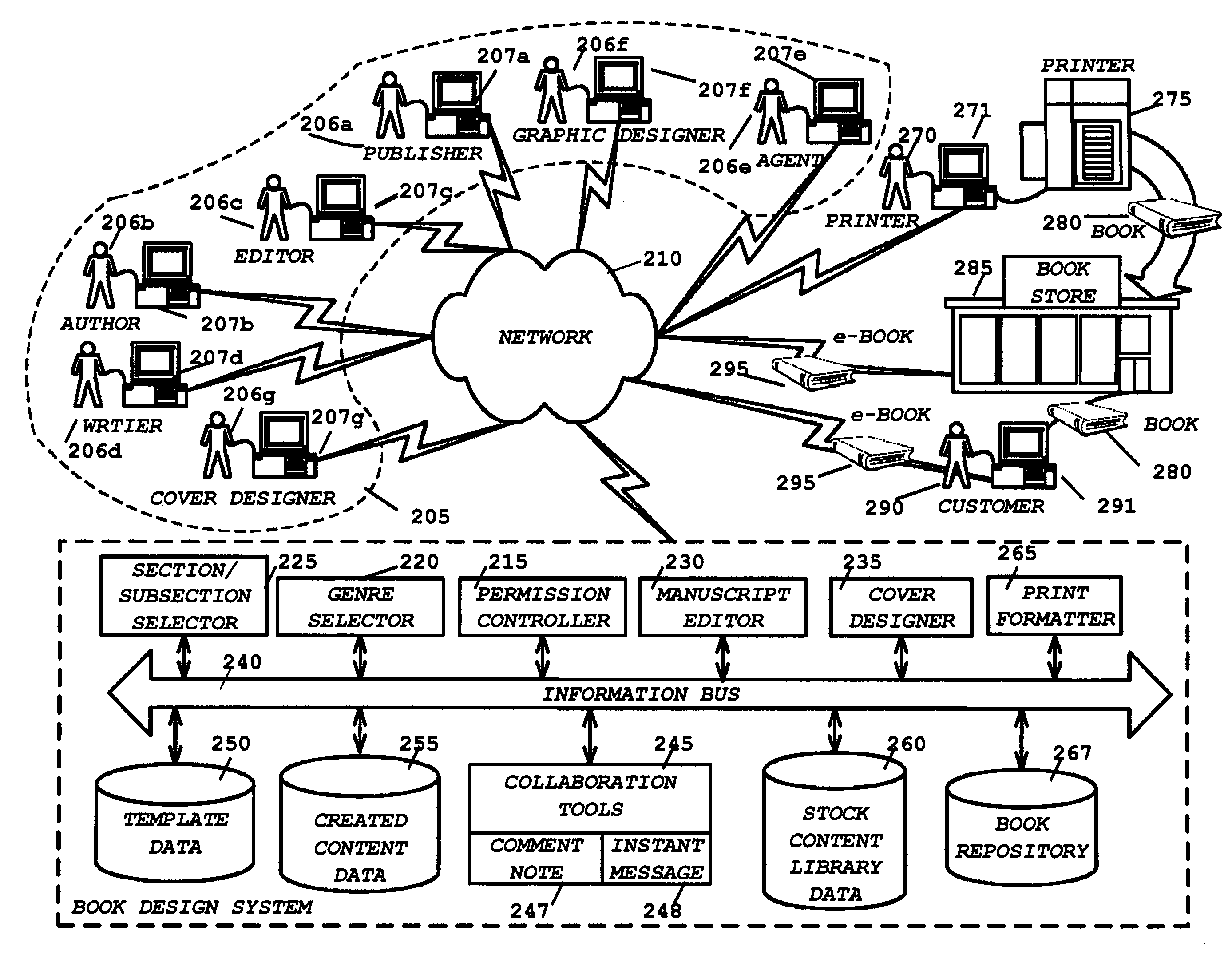

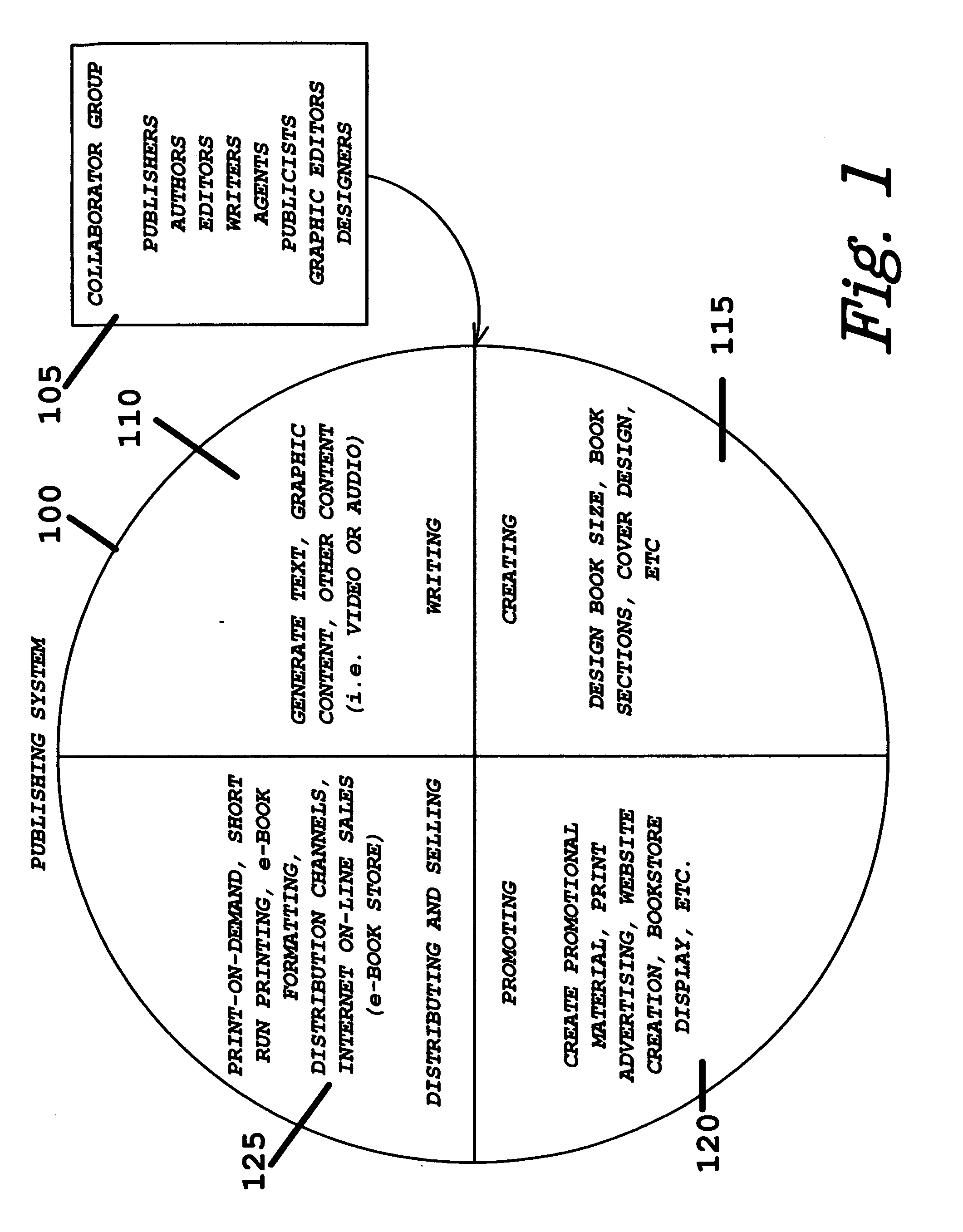

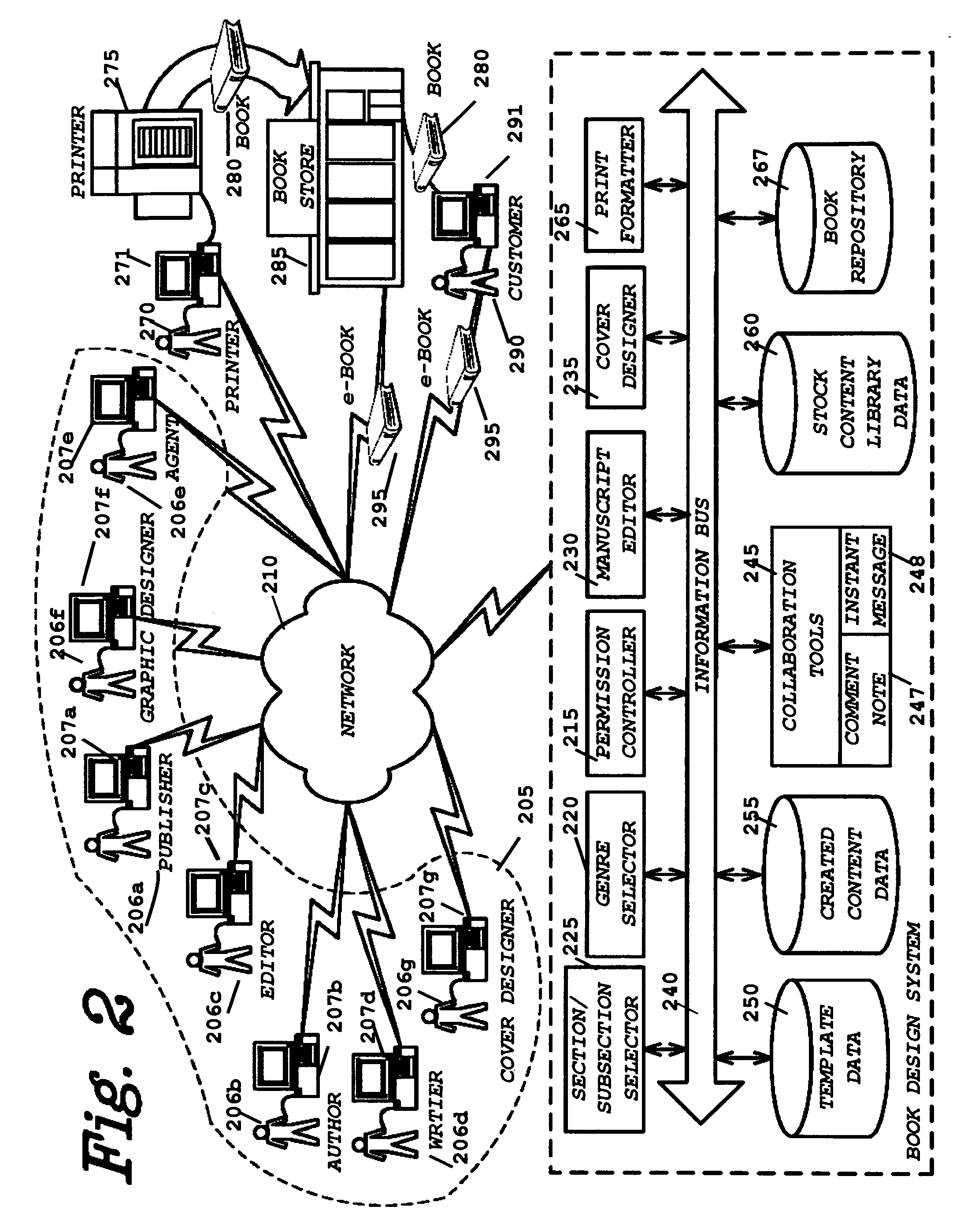

Publishing system and method that enables users to collaboratively create, professional appearing digital publications for "On-Demand" distribution in a variety of media that includes digital printing

InactiveUS20090254802A1Low costEasily assumeNatural language data processingMultiple digital computer combinationsGraphicsDigital printing

Apparatus and methods are provided for providing publishers and authors with the organizational and creative tools to professionally create books inclusive of writing, graphics and multi-media. The apparatus and methods further enable users to design and format their publication with minimal effort. A text editor is used to manipulate the input in a “What-You-See-Is-What-You-Get” (W.Y.S.I.W.Y.G.) environment. The user is able to professionally design a publication. The publication is previewed with images of the “print-ready” publication. Publishing resource tools are provided that allow the publisher, author and other collaborators to create and edit content. The publisher and authors can select from provided design styles and images or upload their own images to create professional looking publications. The publication is converted to a “print-ready file” and or an e-book and stored in a database. A bookstore associated with the apparatus and methods allow books to be viewed and purchased.

Owner:PRINT ASSET MANAGEMENT

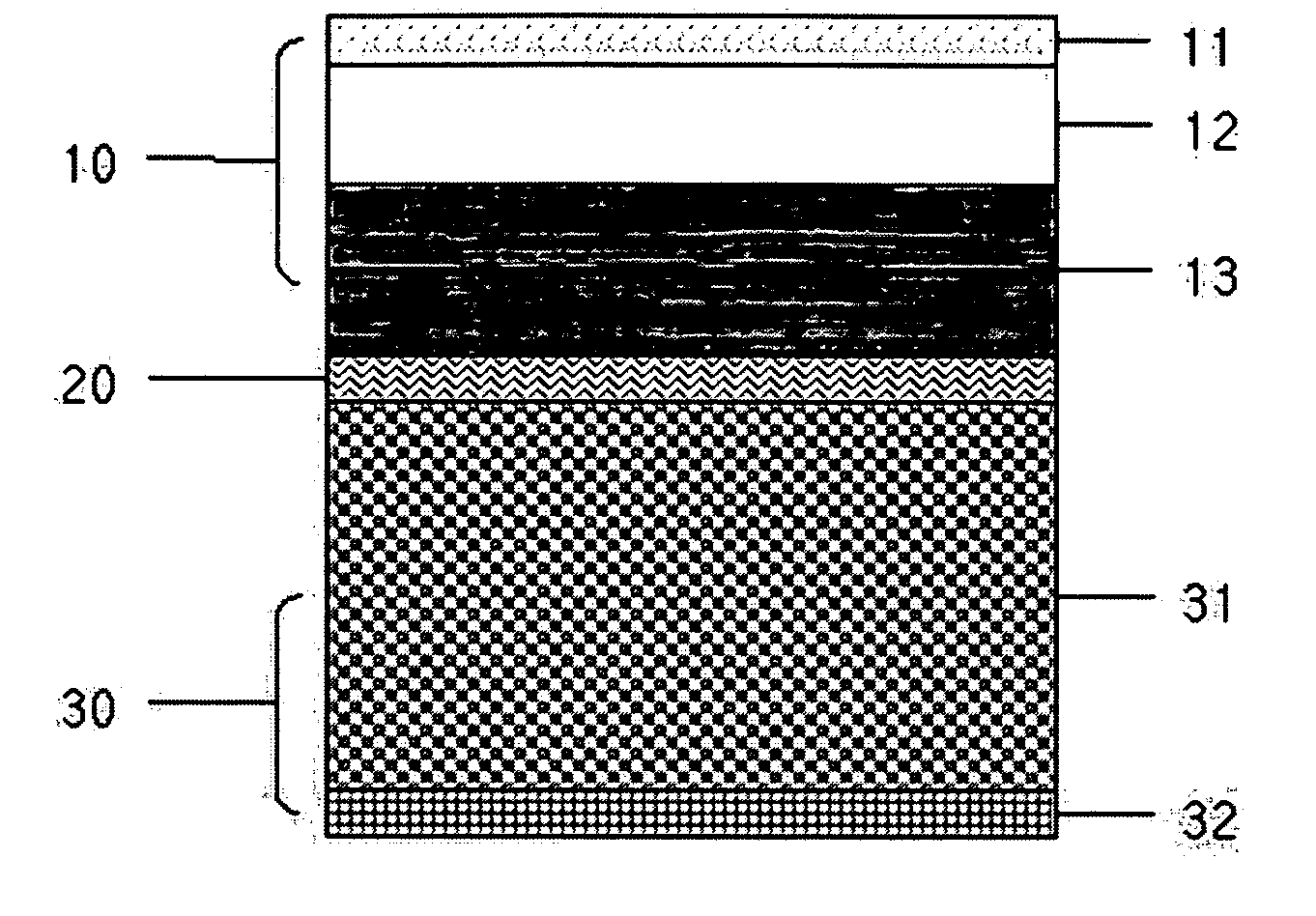

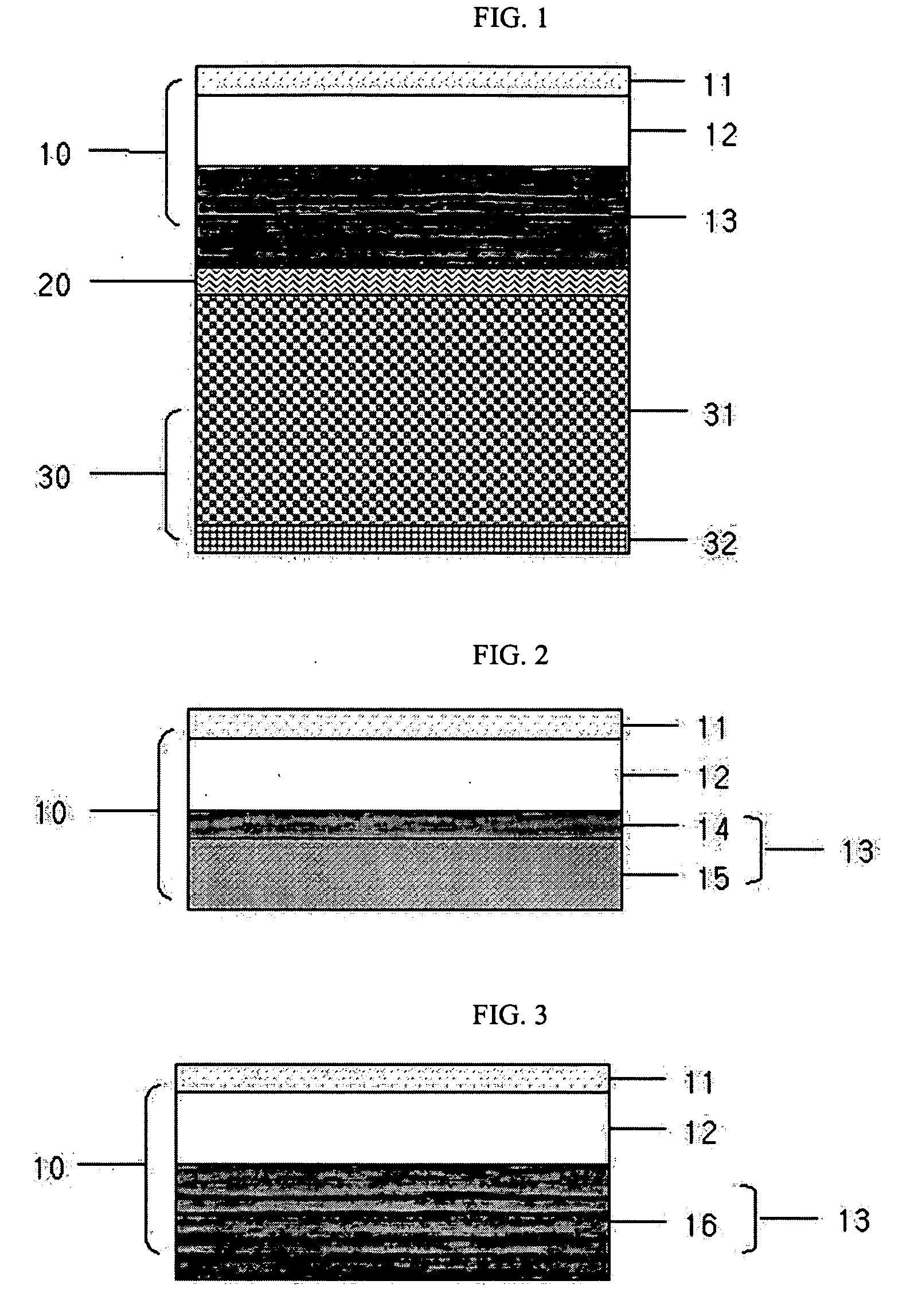

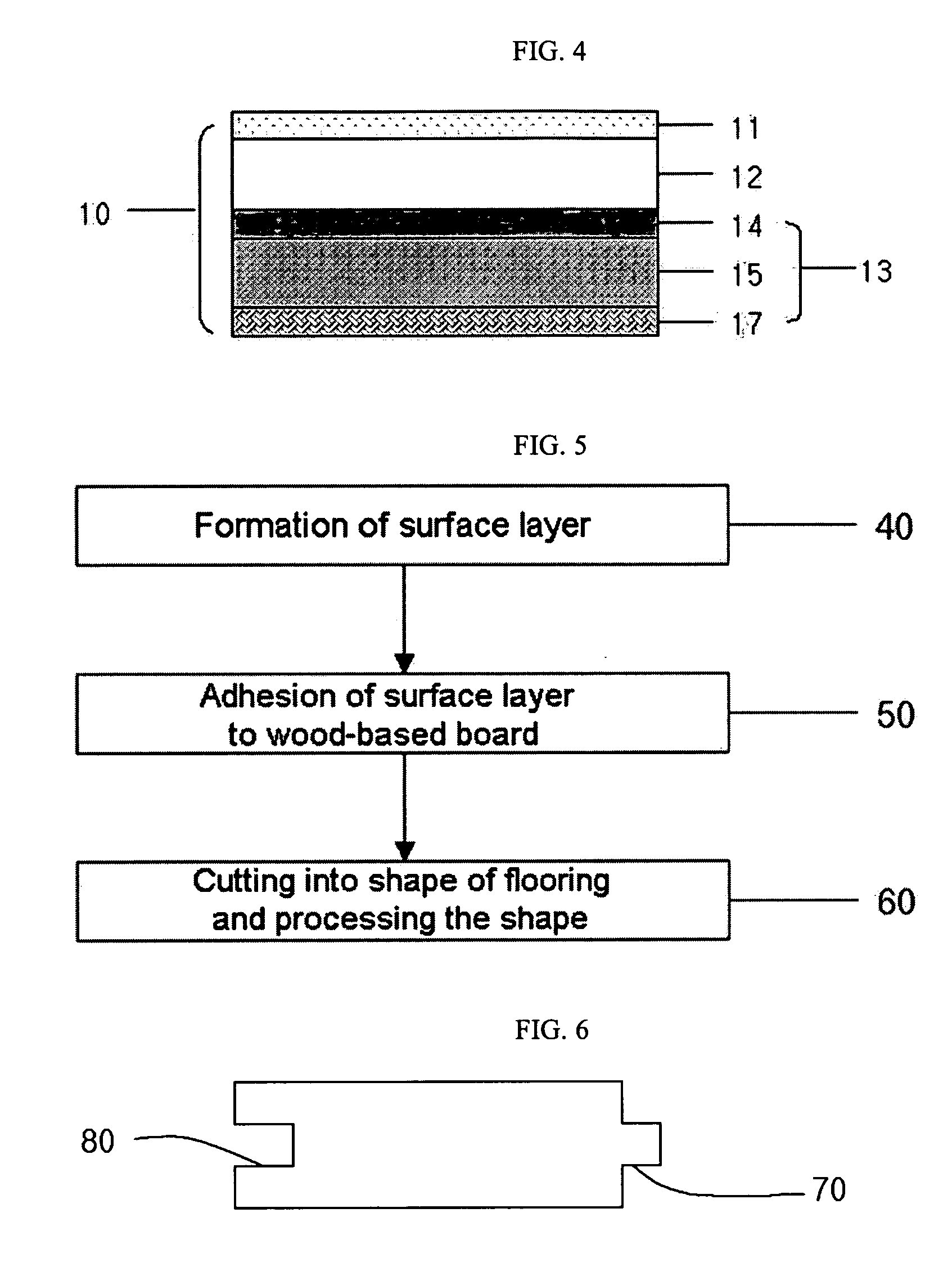

Flooring having surface layer of synthetic resin and wood-based board

InactiveUS20050281986A1Improve surface physical propertiesProtect the surfaceCovering/liningsSynthetic resin layered productsDigital printingTongue and groove

Disclosed herein is a flooring comprising a surface layer made of a synthetic resin, and a wood-based board as a base. Preferably, the surface layer includes a printed layer formed by general gravure, transfer, heat-sublimation, silk screen or digital printing using a printer, a protective made of a synthetic resin, and a UV-curable or heat-curable surface treatment layer. The wood-based board is selected from plywood, medium-density fiberboard (MDF), high-density fiberboard (HDF), particle board, and resin-wood flour composite board. The flooring may further comprise a bottom layer laminated under the wood-based board for protecting the flooring against moisture from the bottom. The flooring is cut into pieces having an appropriate size, and the pieces are processed into a finished product in a tongue and groove (T & G) shape.

Owner:LG CHEM LTD

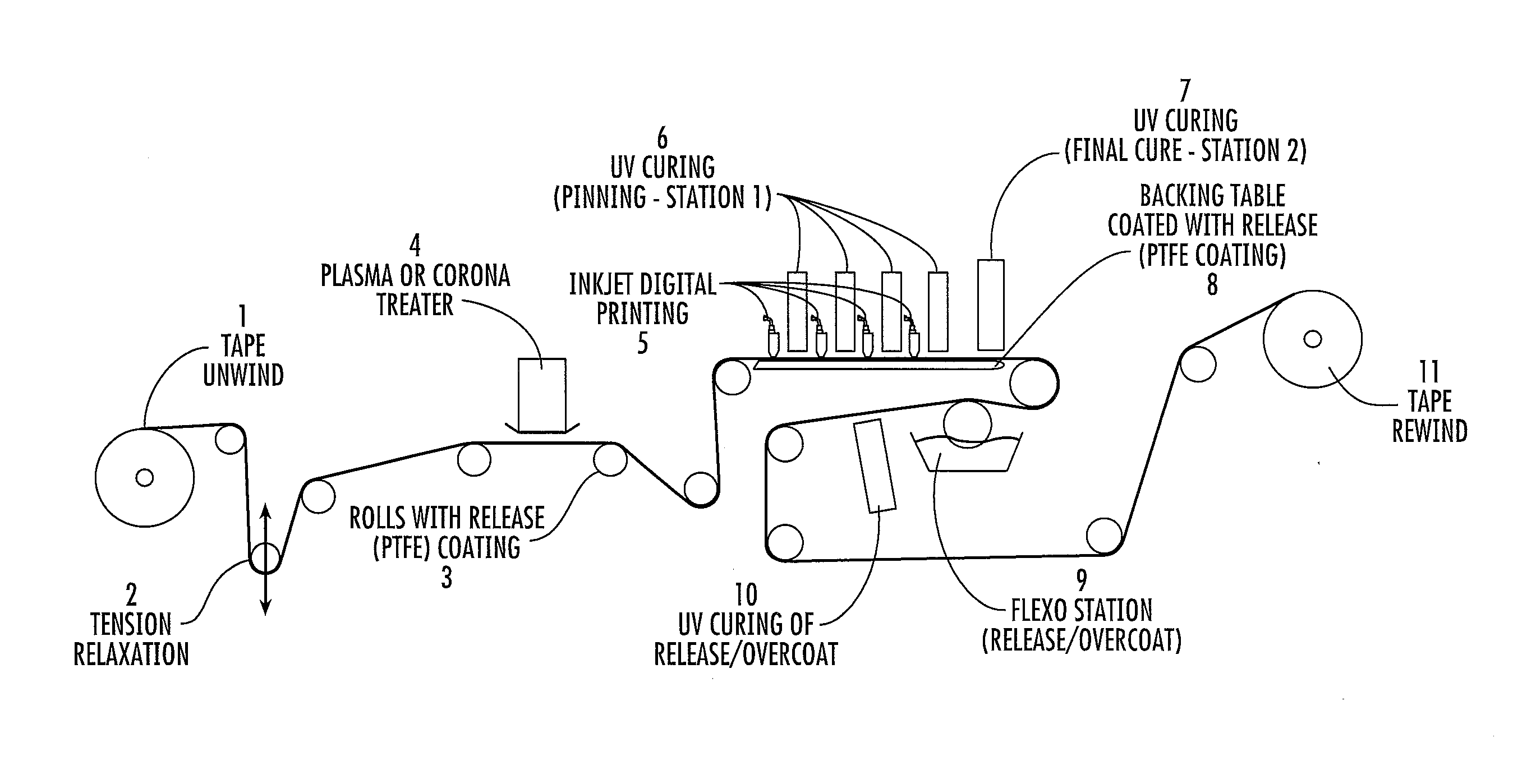

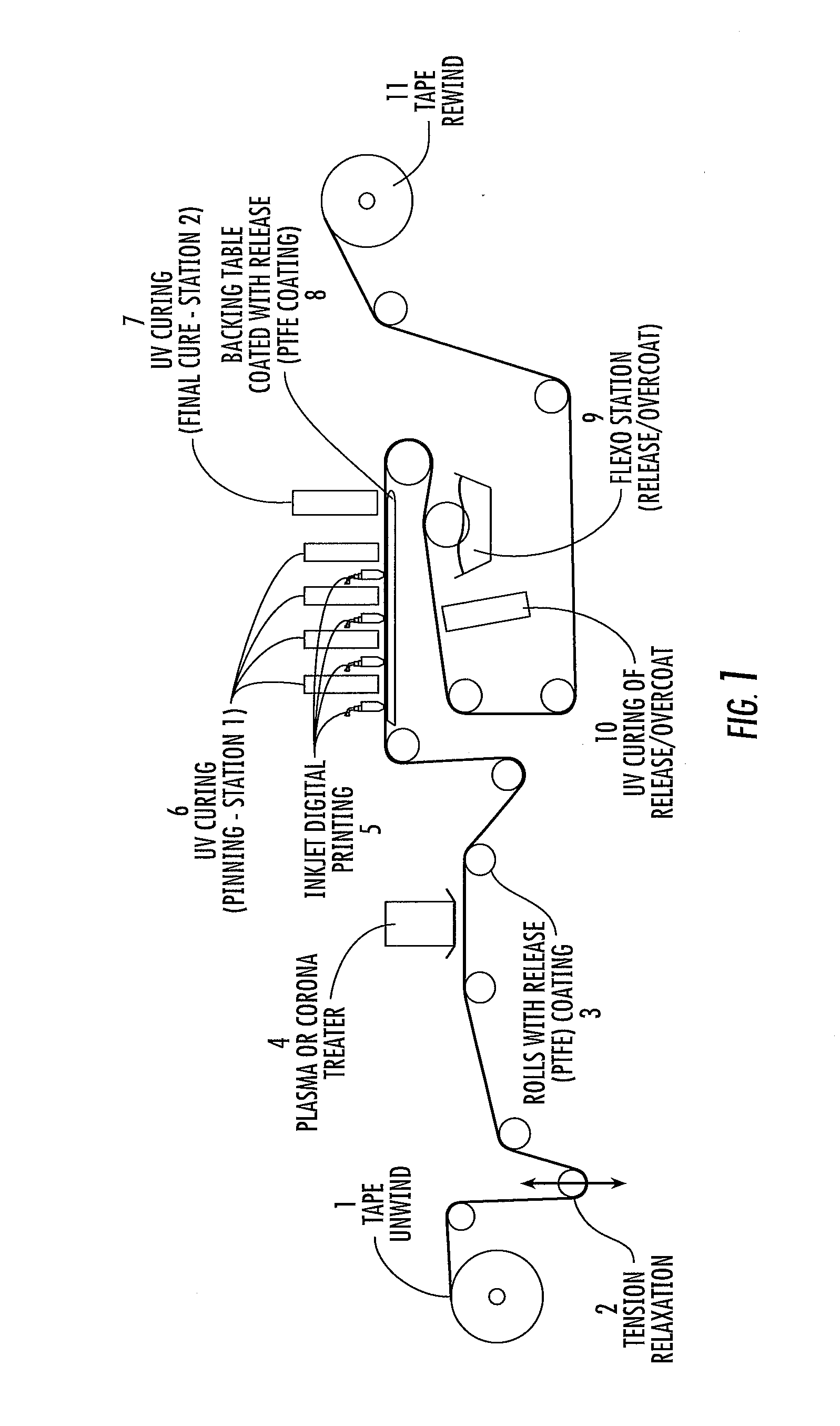

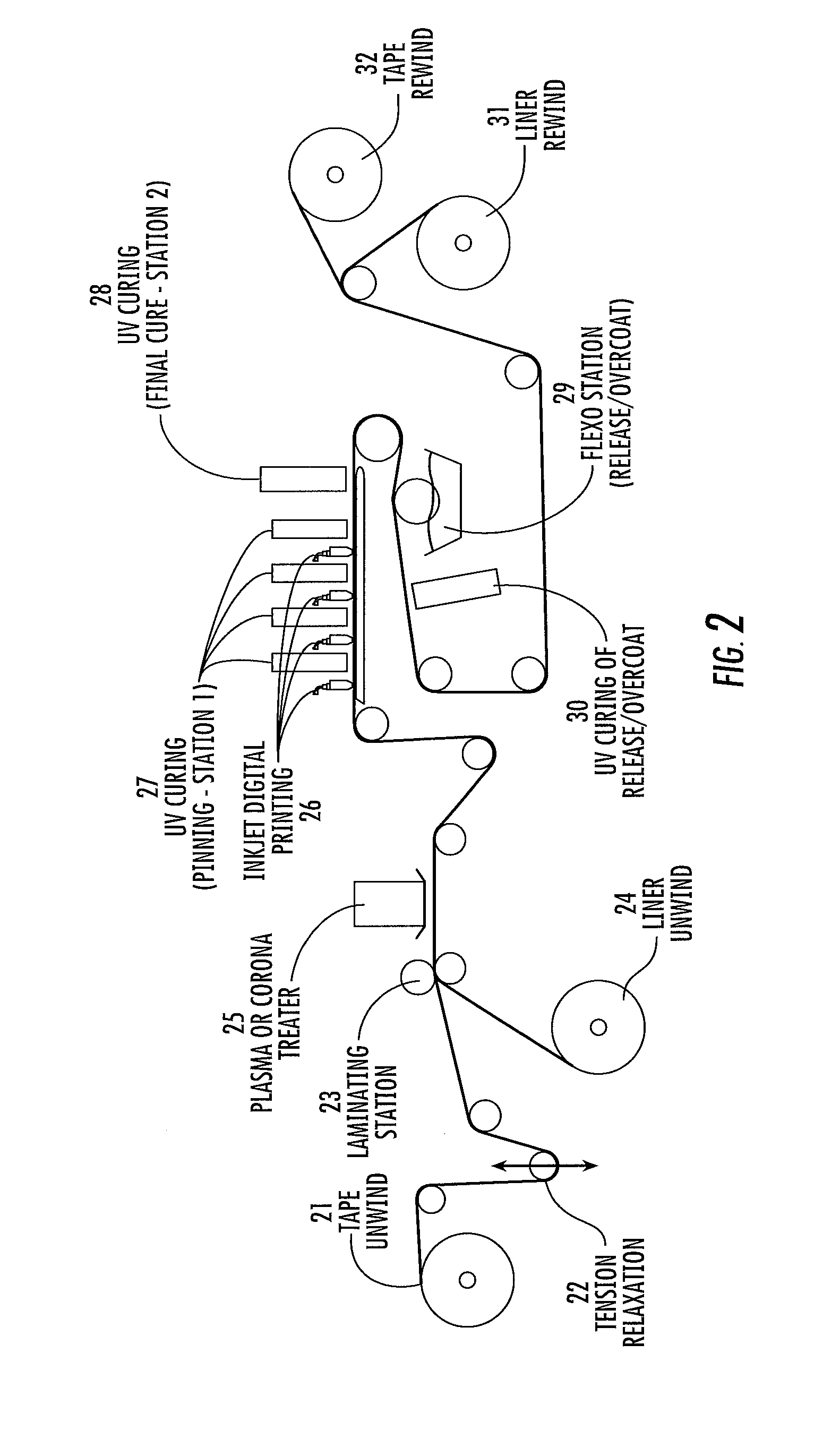

Digital printed duct tape

ActiveUS20150030823A1Fast and inexpensiveLayered productsFilm/foil adhesivesDual stageUltraviolet lights

A duct tape and a method of making a duct tape having a customized, printed design on a surface of the duct tape. The method comprises providing a design for printing on the duct tape, digitally printing the design on the surface of the duct tape, and curing the ink printed on the duct tape with ultraviolet light in dual stages. The method further comprises applying on the digitally printed duct tape a material or composition having overcoat properties, release properties, or a combination thereof.

Owner:SHURTAPE TECH LLC

Ultraviolet light curing printing ink for digital printing and dyeing preparation thereof

UV solidified printing ink for digital code printing and dyeing is composed of polyurethane acrylate, prepolymer, activity monomer, dyestuff, light initiator, dispersant agent and other addition agents. The prepolymer has the character of low viscosity and good flexibility. The ink doesn't contain organic solvent and has wide material adaptation, storage stability and softness.

Owner:DONGHUA UNIV

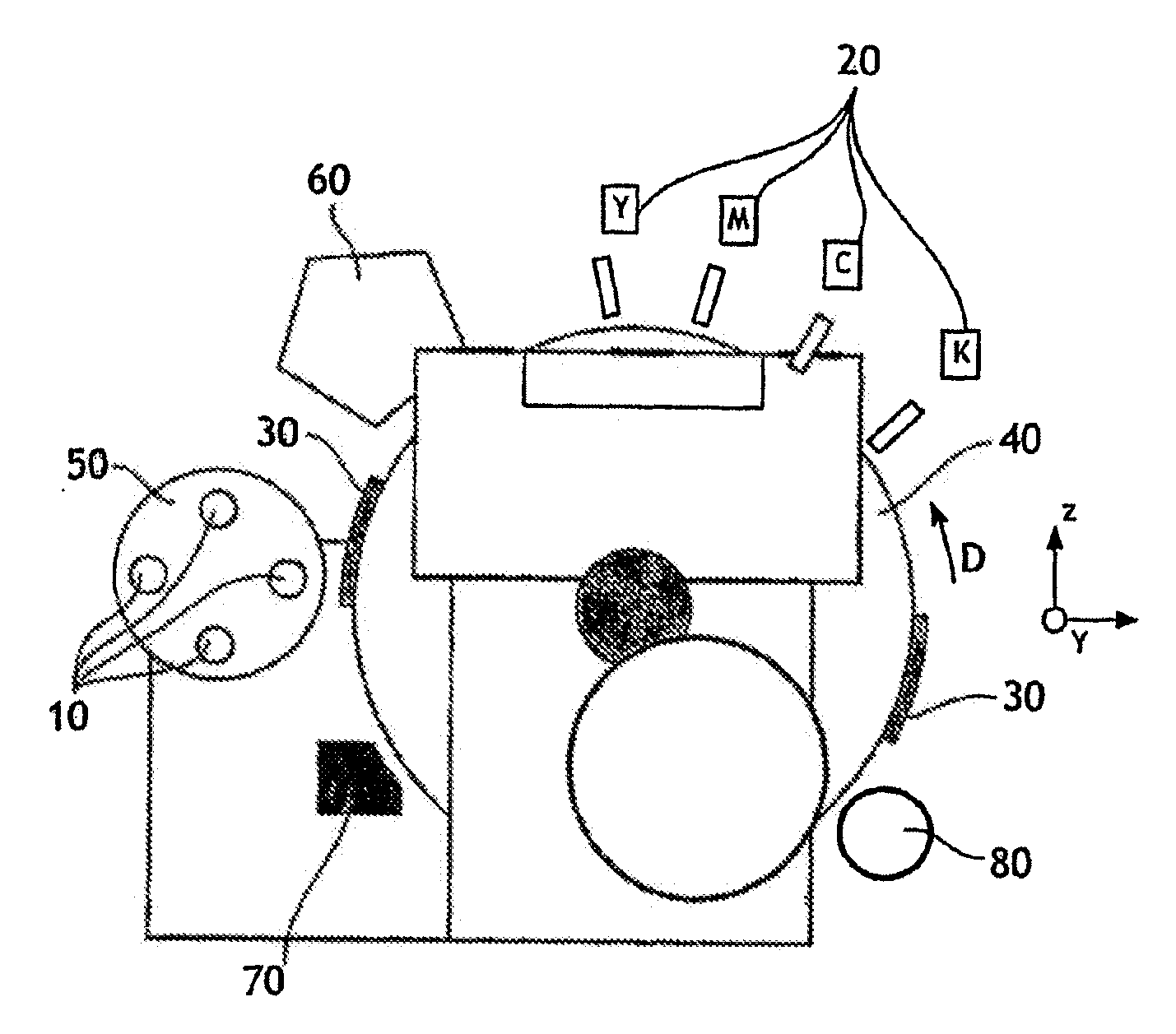

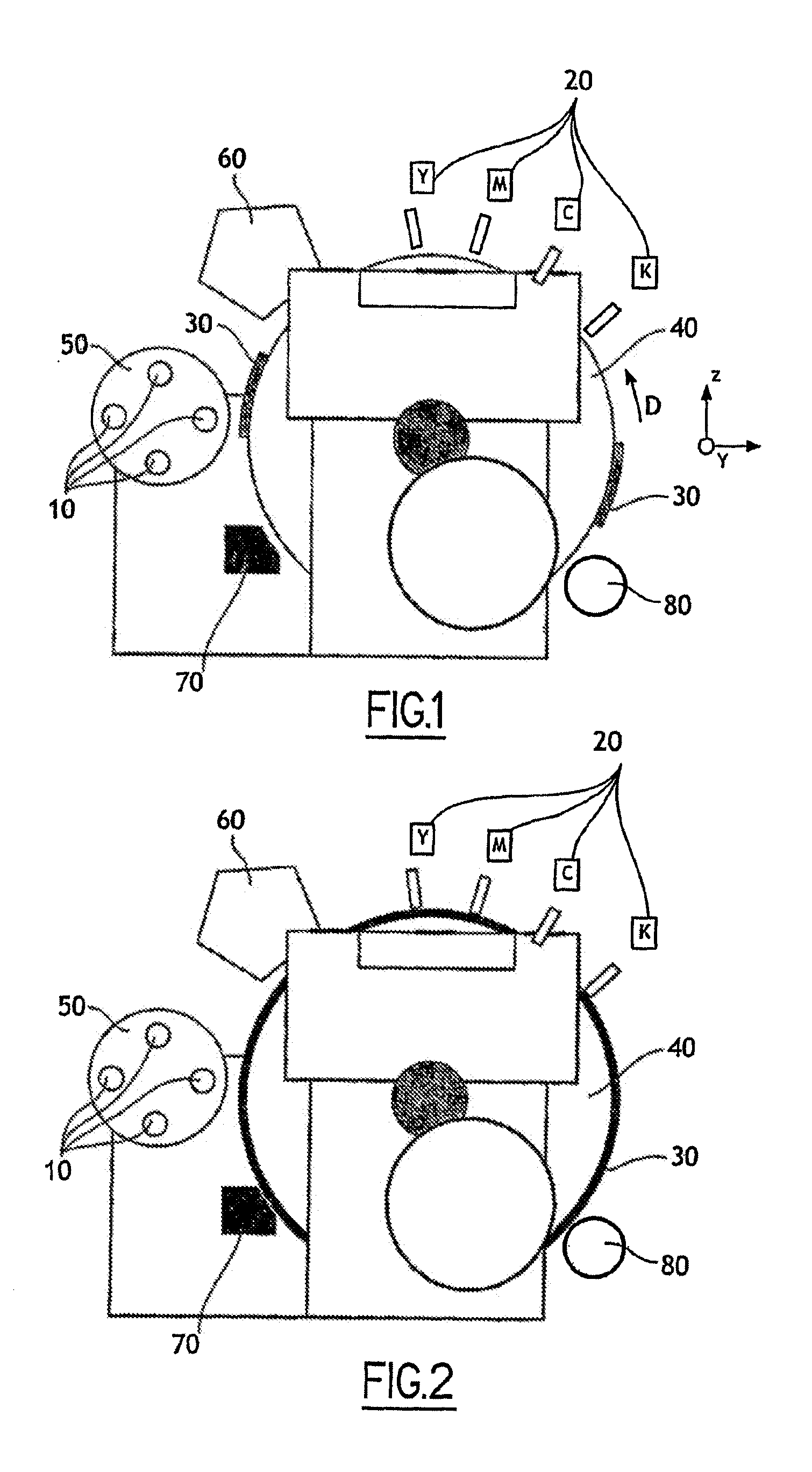

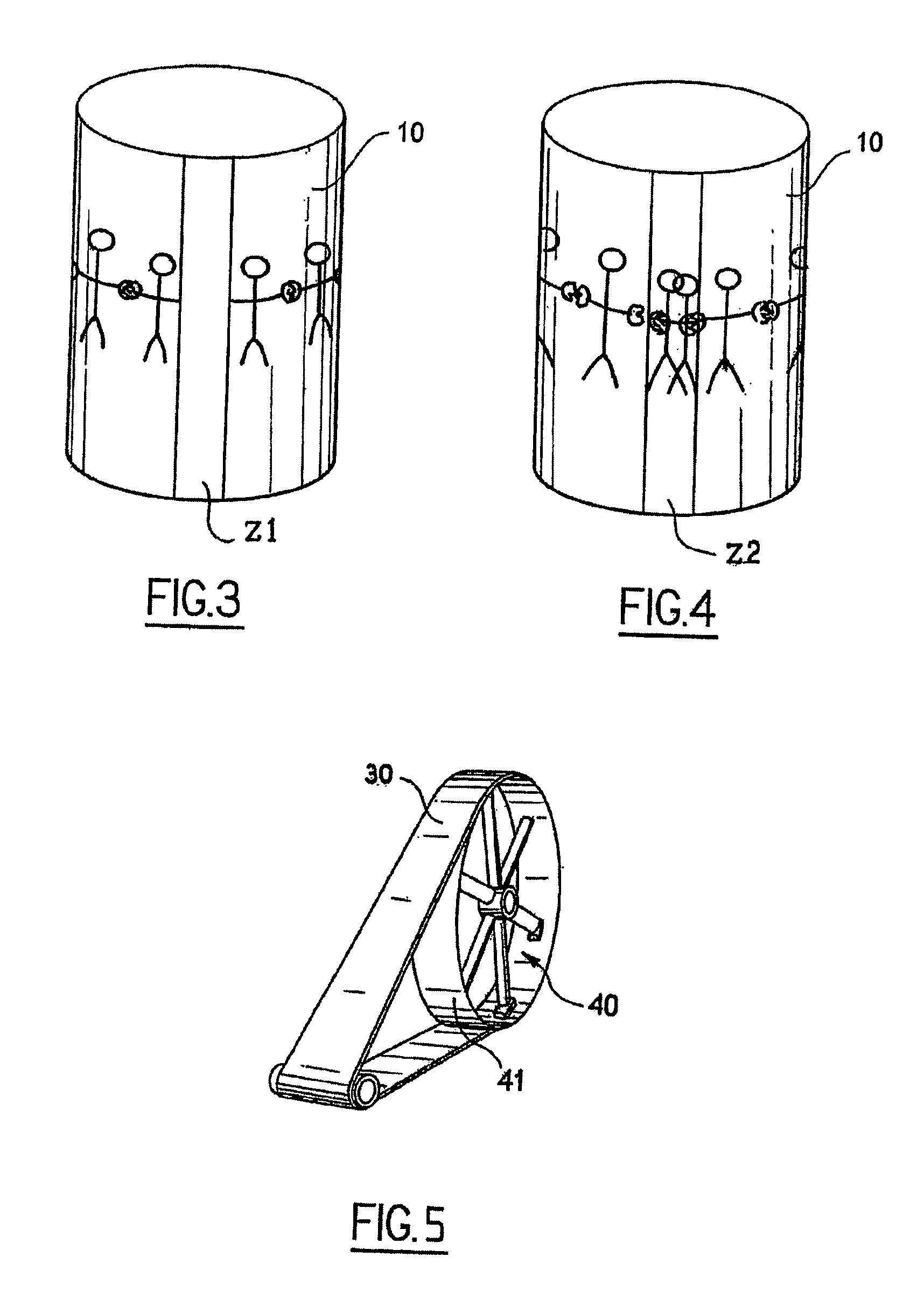

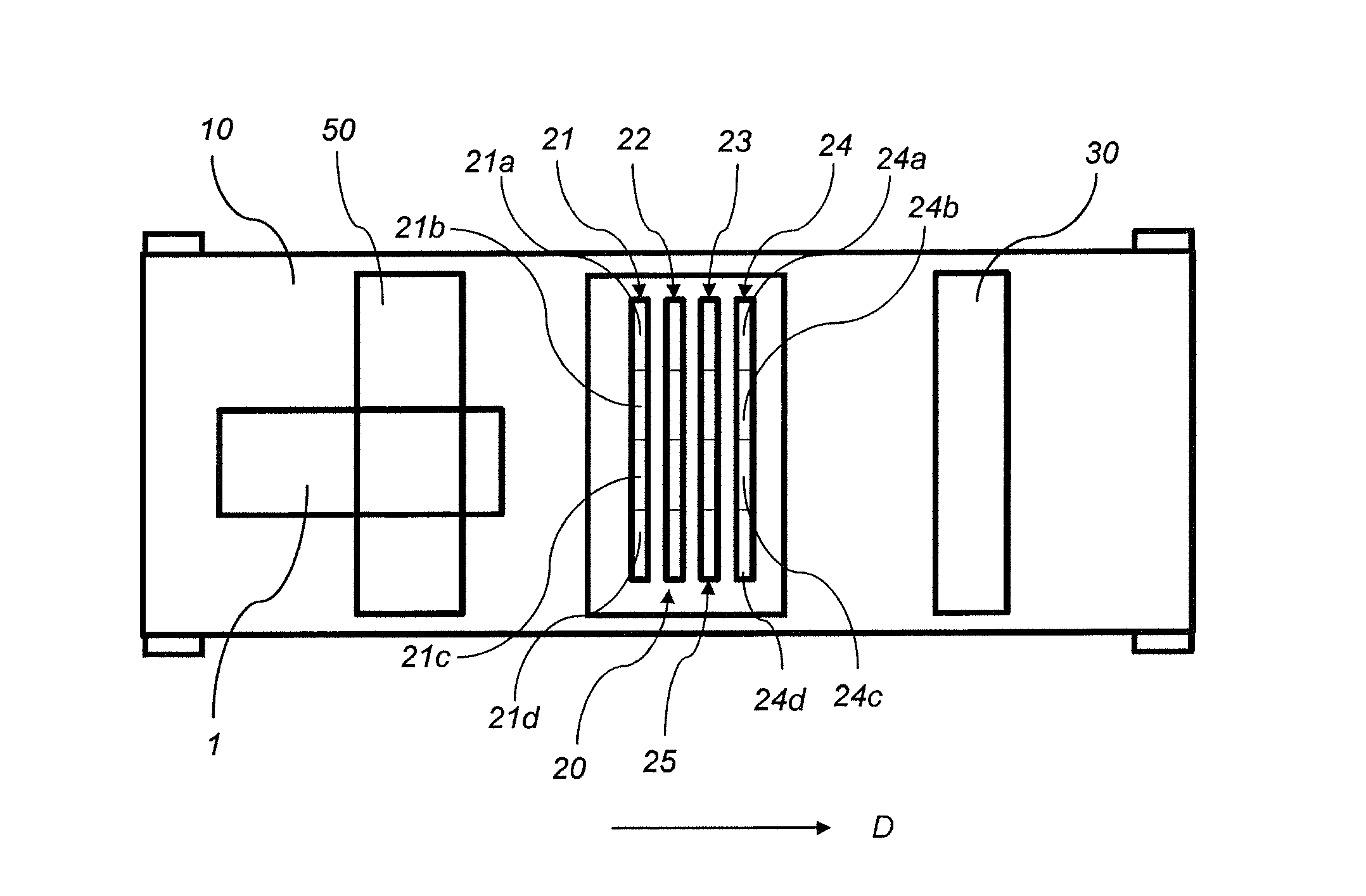

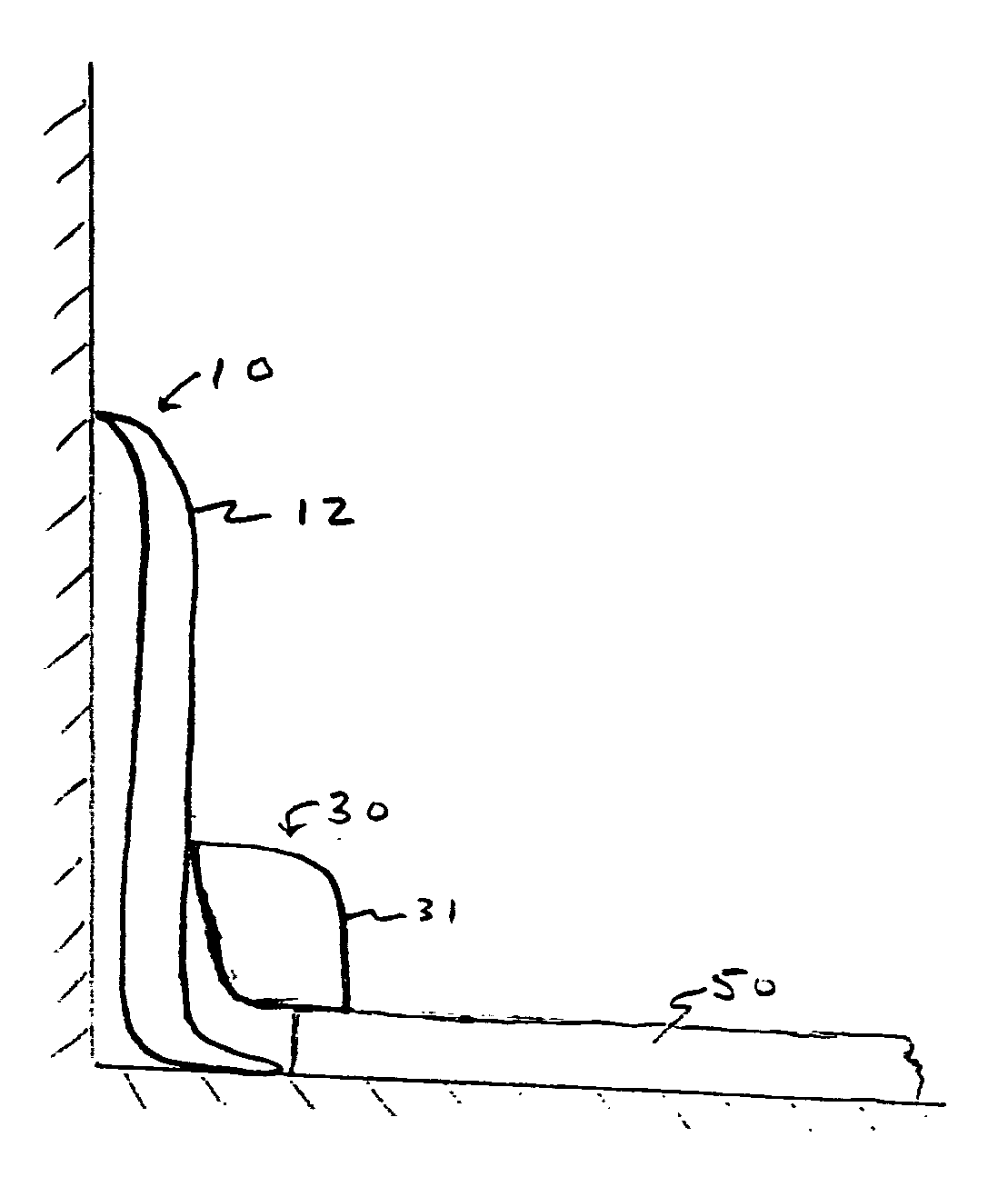

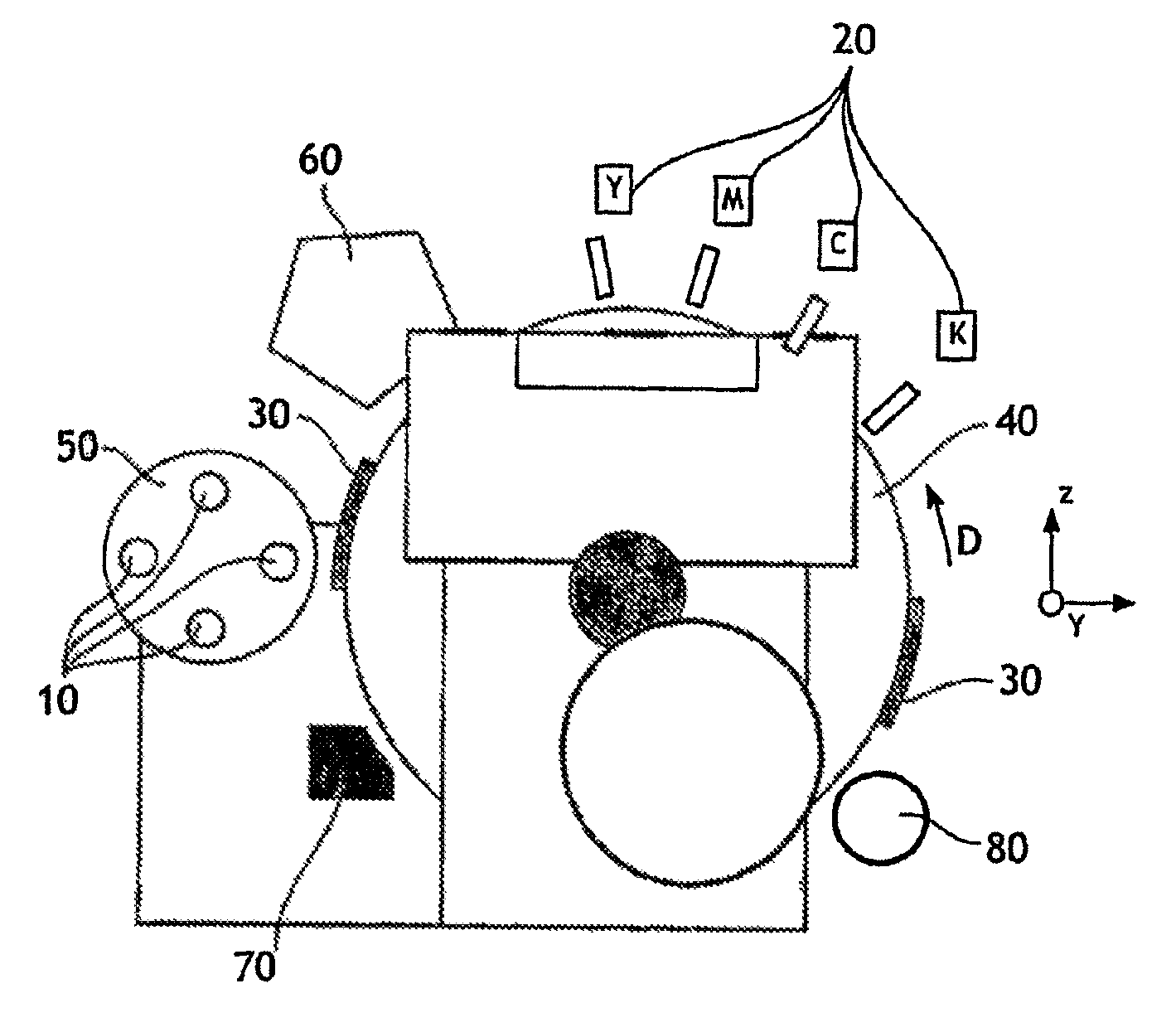

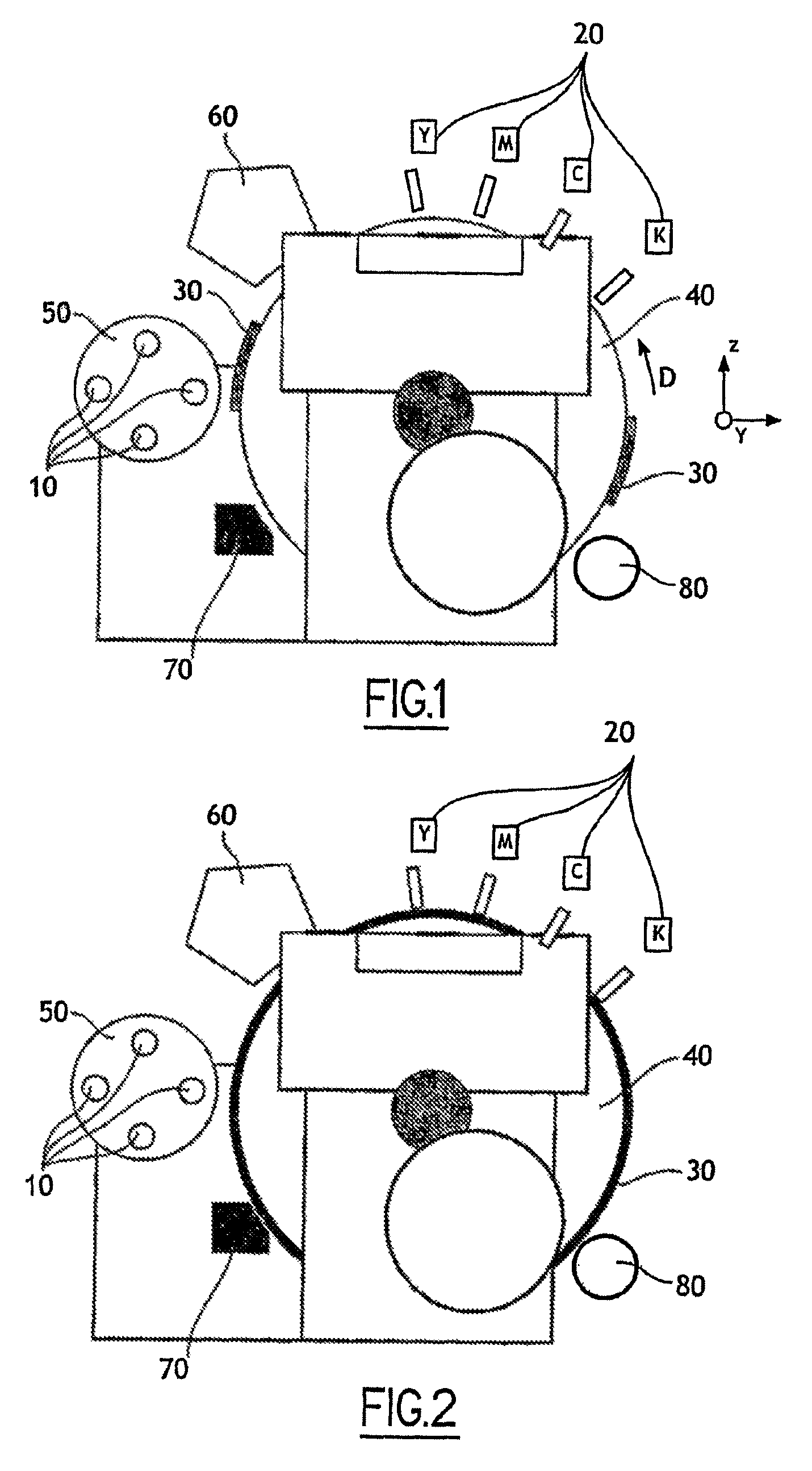

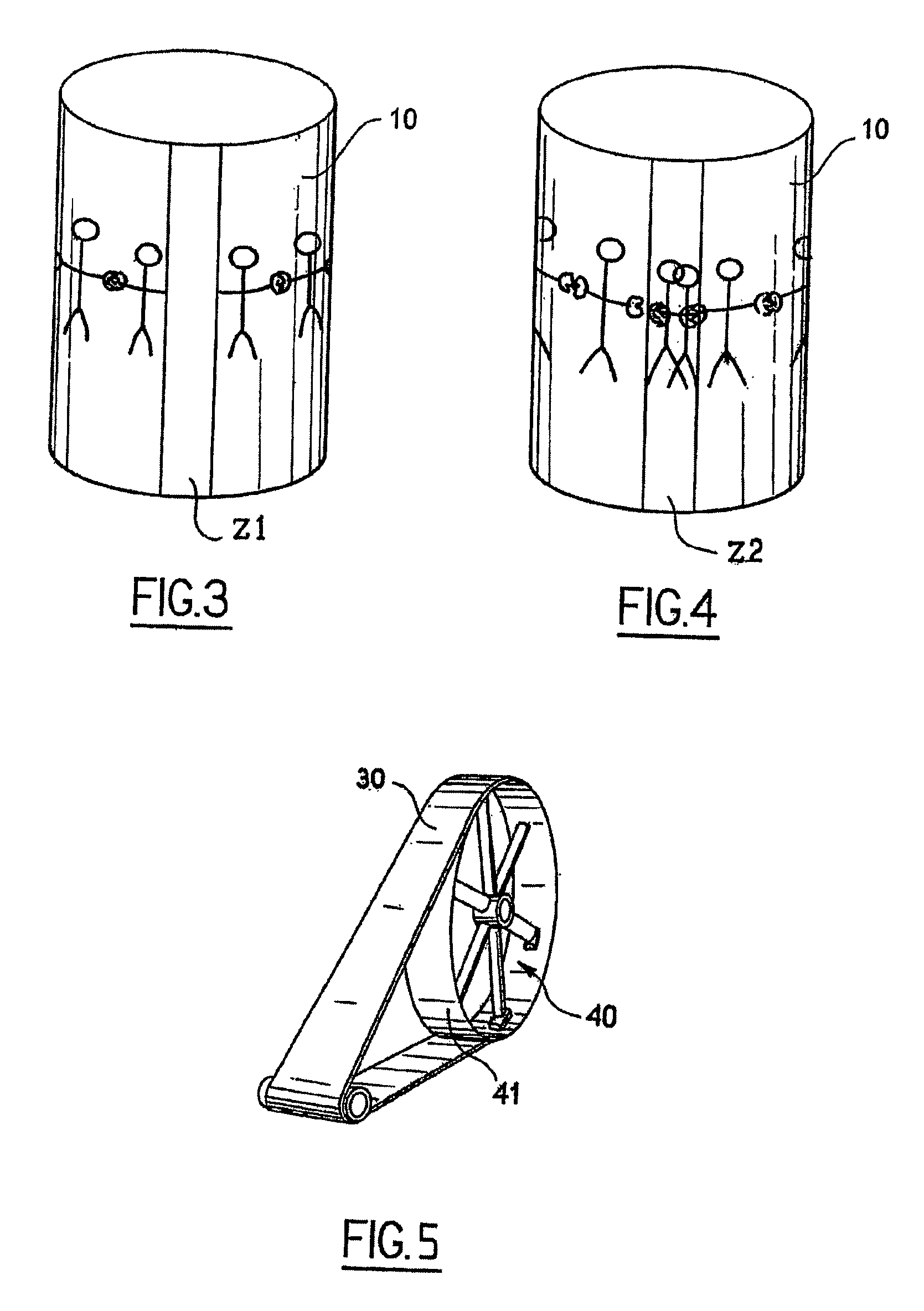

Device for printing by transfer onto a cylindrical printing medium

The invention relates to a device for printing by transfer onto a print support (10) comprising at least one blanket (30) driven in a sequential relative movement past a magazine (50) conveying the print supports (10), in which device the blanket (30) has a surface area greater than that of the print support (10), the device further comprising digital printing means (20) which print by spraying ink onto this blanket (30) over a variable area equal to that of the print support (10).

Owner:IMPIKA +1

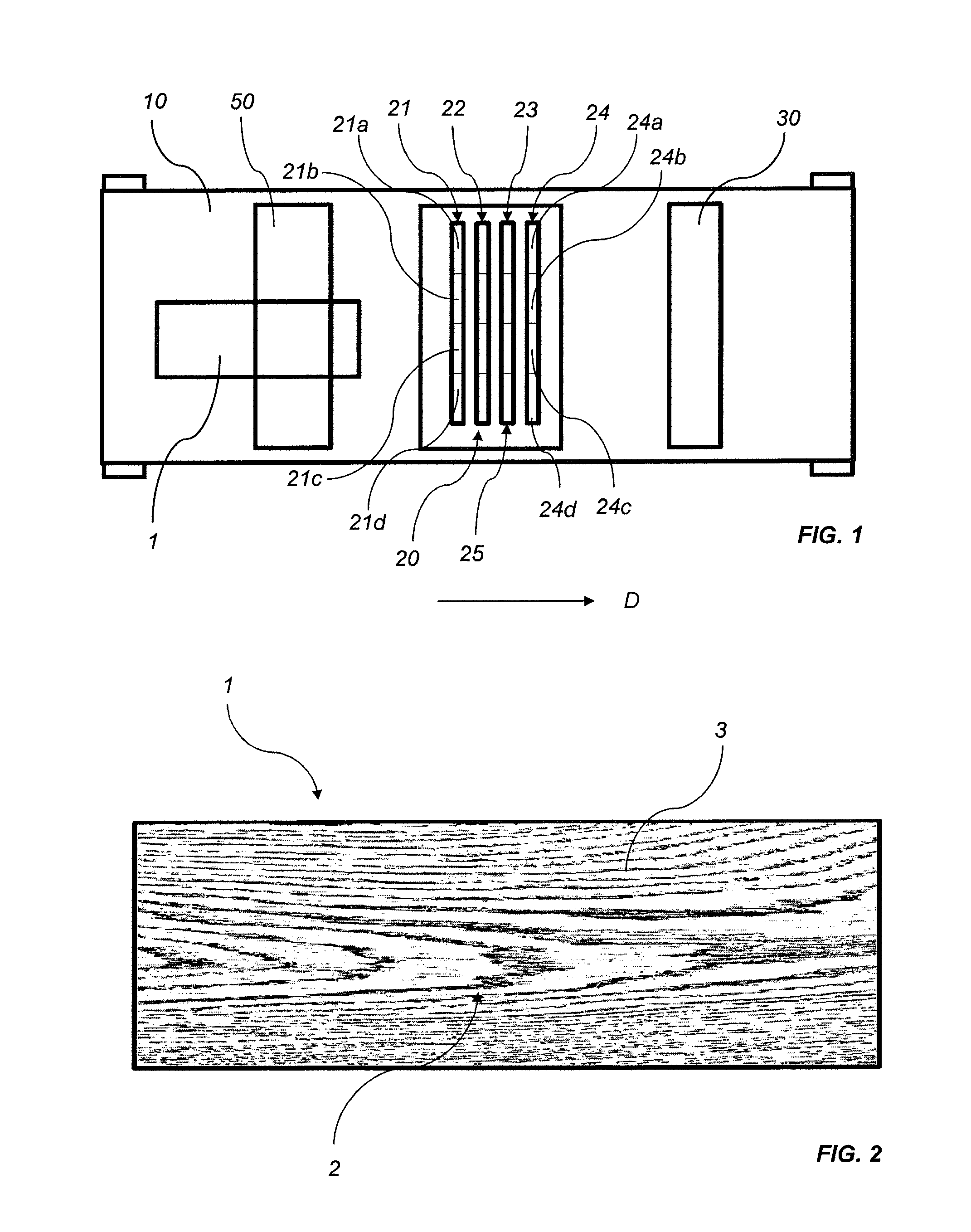

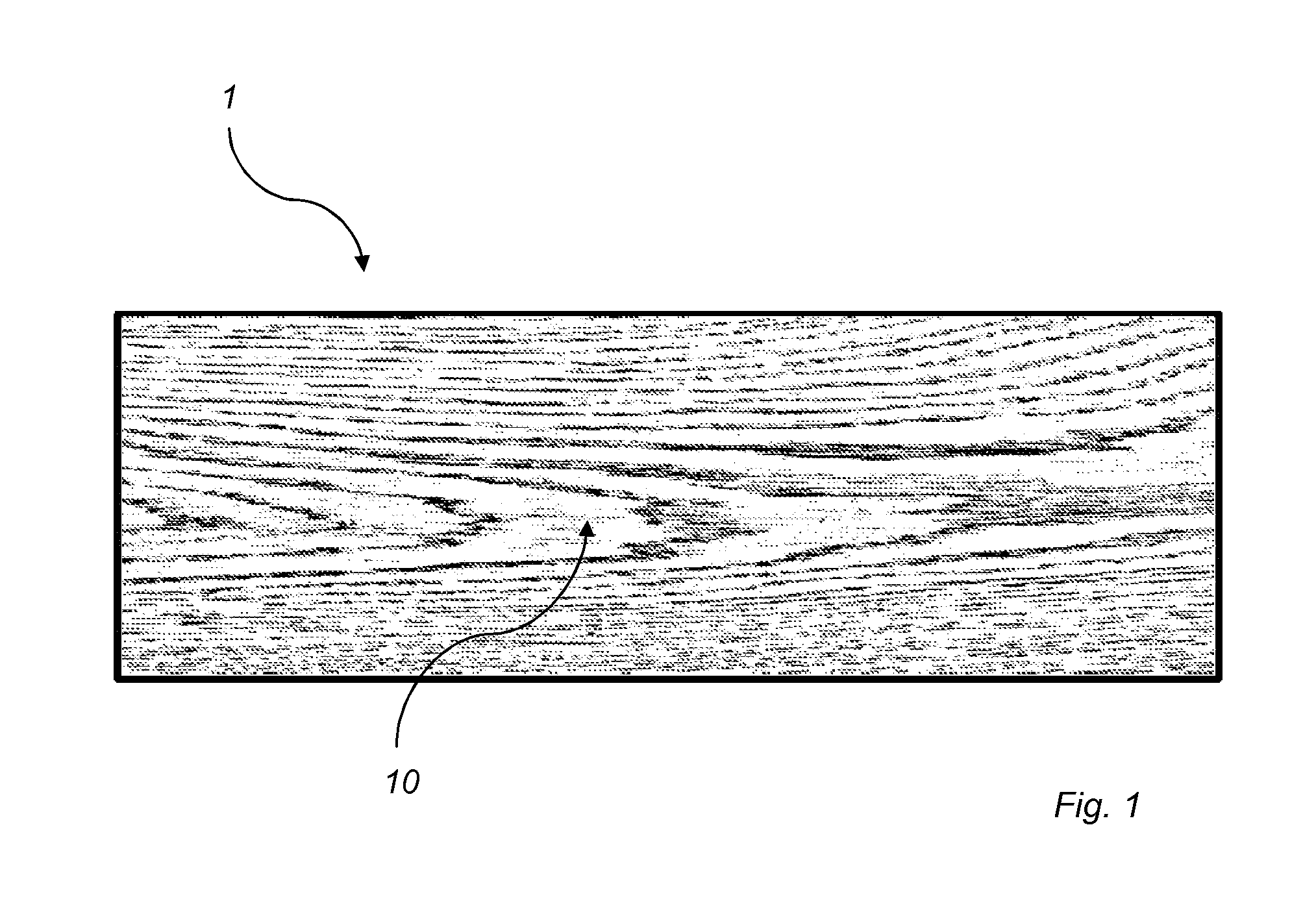

Method for forming a decorative design on an element of a wood-based material

ActiveUS20130286088A1Reduce curingNatural patternsDecorative surface effectsEngineeringDigital printing

A method for forming a decorative design (2) on an element (1) of a wood-based material, including providing an element (1) of a wood-based material having a surface (3), said surface (3) being solid and being formed of said wood-based material, and printing a decorative design (2) with an aqueous ink on at least a portion of said surface (3) by means of a digital printing device. Also, a building element including such an element.

Owner:VÄLINGE INNOVATION AB

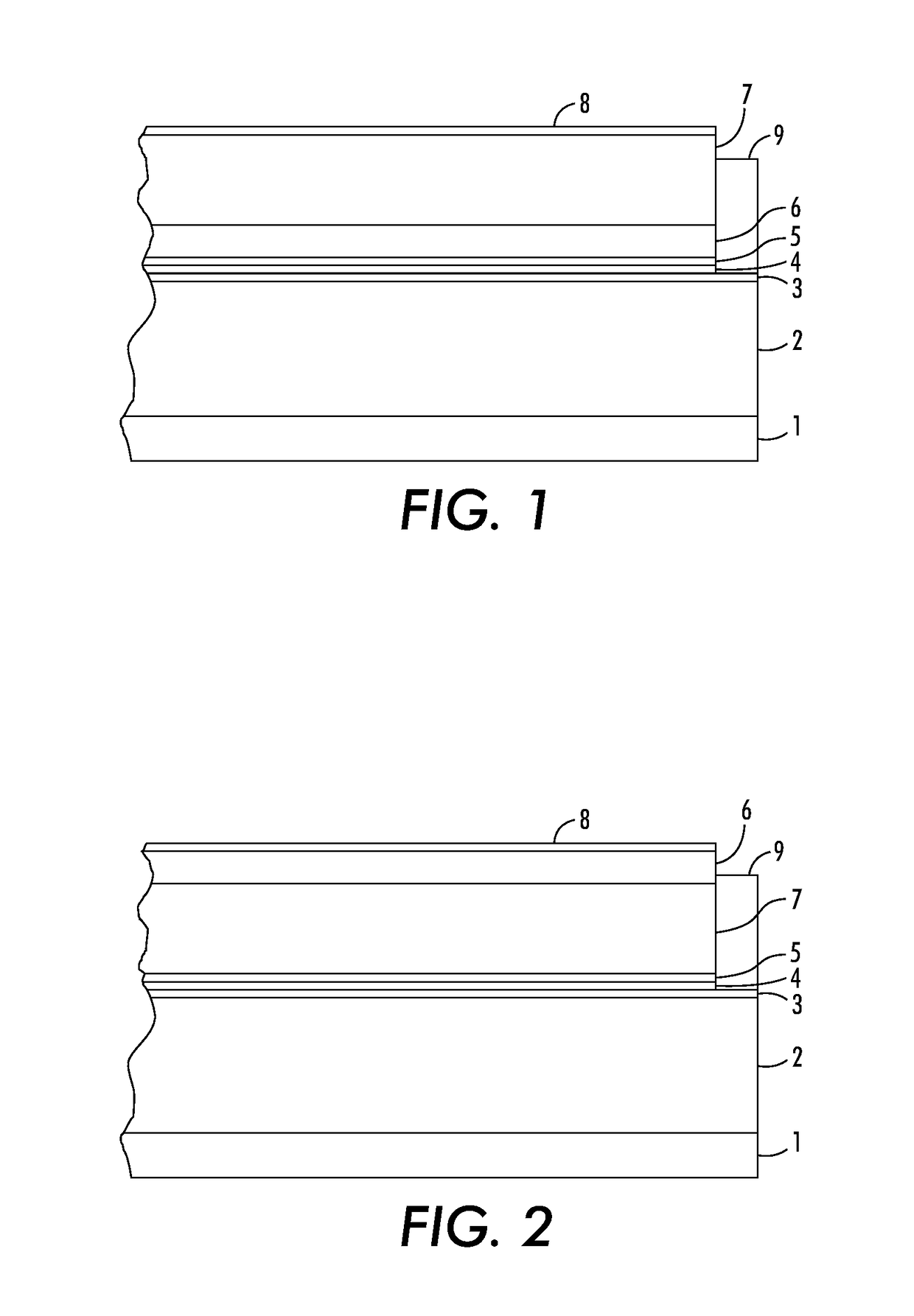

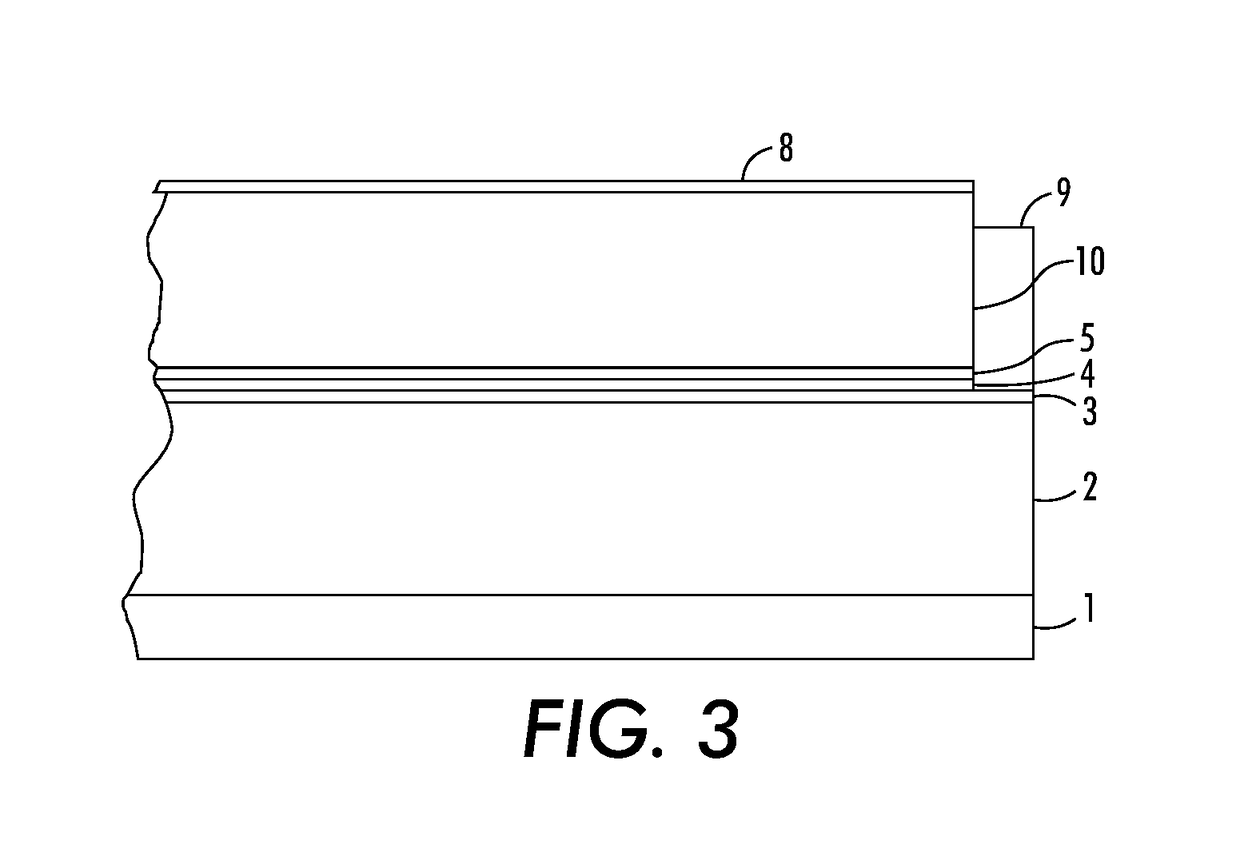

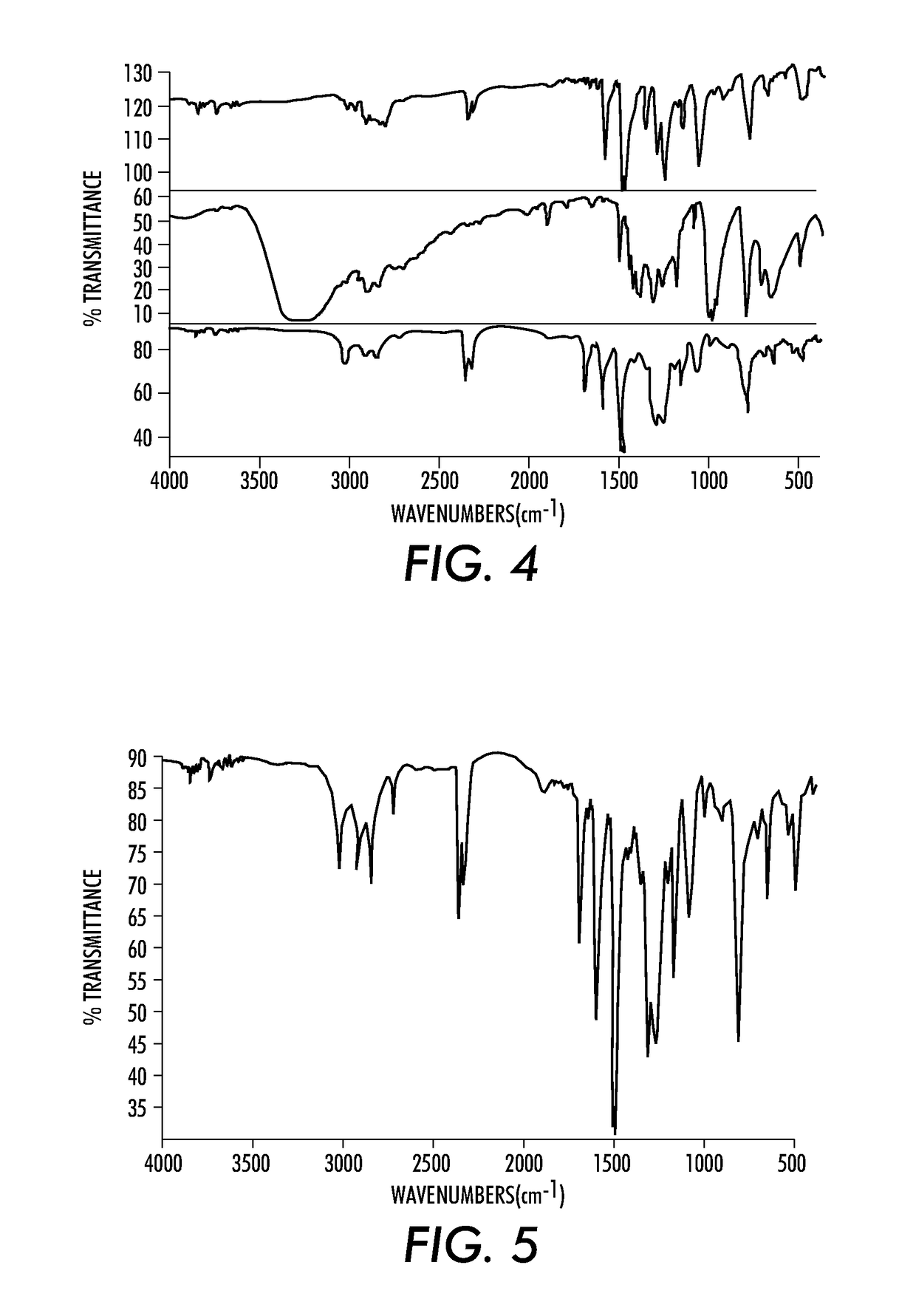

Imaging members for ink-based digital printing comprising structured organic films

ActiveUS8119315B1Electrographic process apparatusElectrographic processes using charge patternOrganic filmEngineering

An imaging member for ink-based digital printing having an outermost layer including a structured organic film (SOF) having a plurality of segments and a plurality of linkers arranged as a covalent organic framework, wherein the structured organic film may be multi-segment thick.

Owner:XEROX CORP

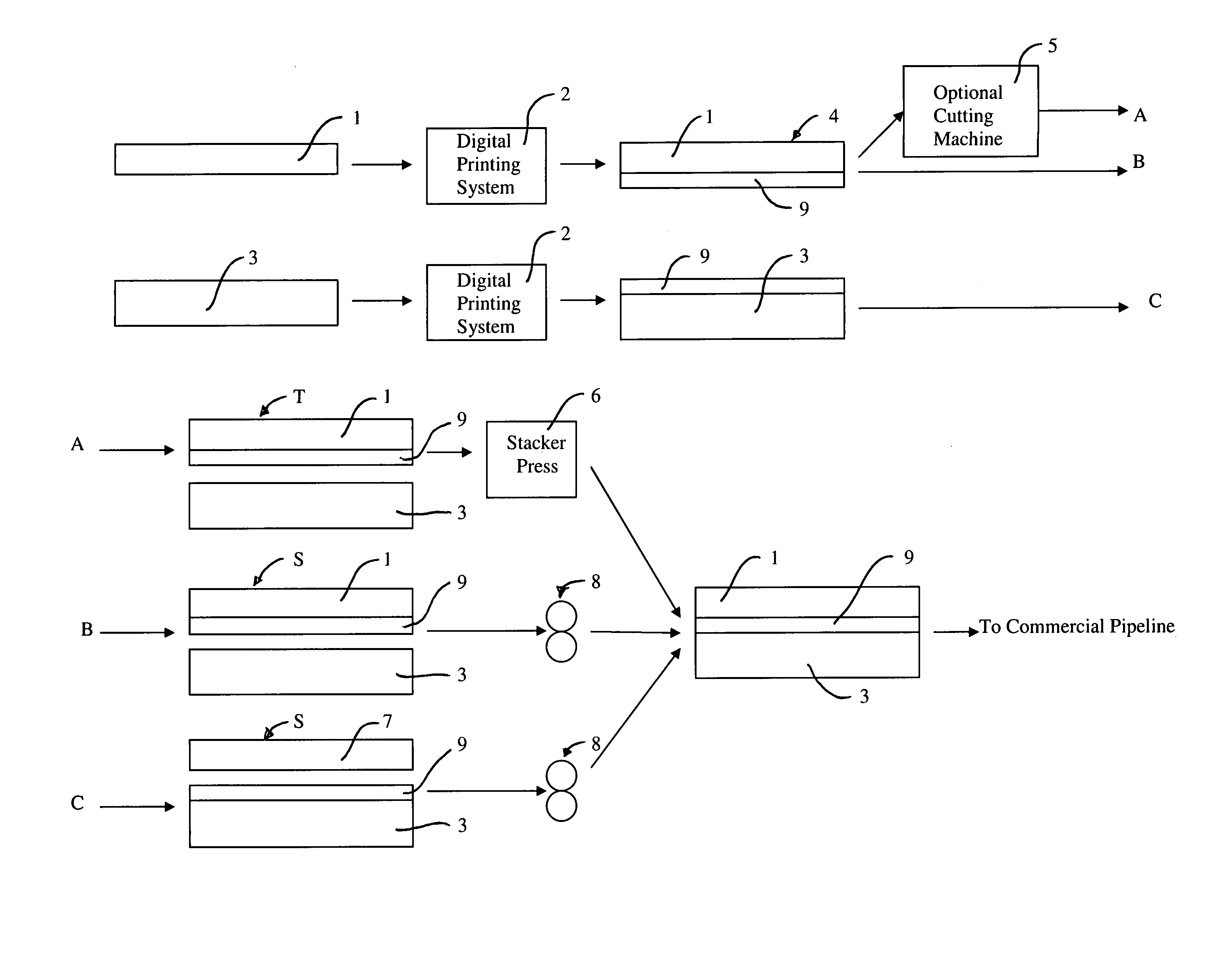

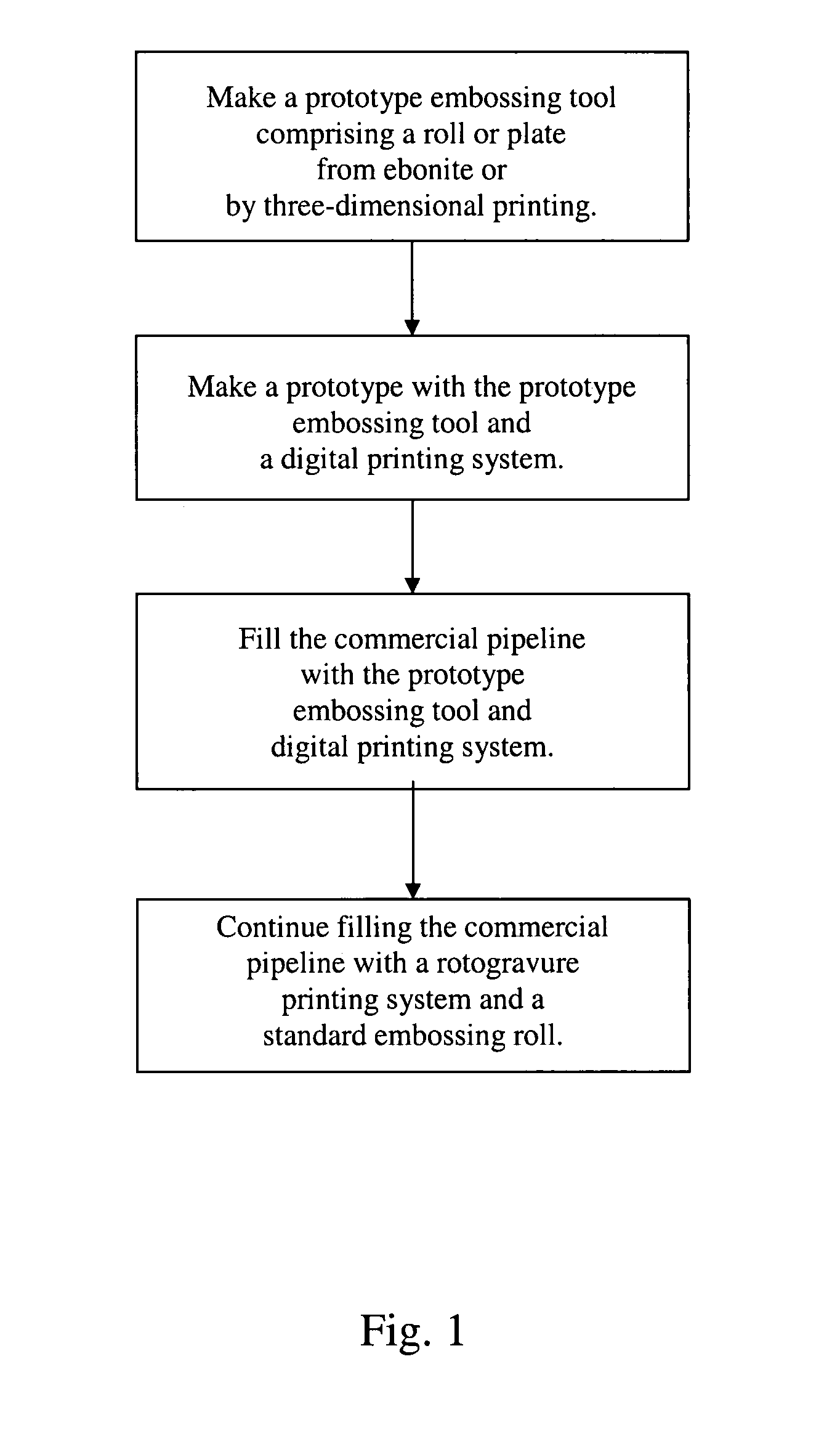

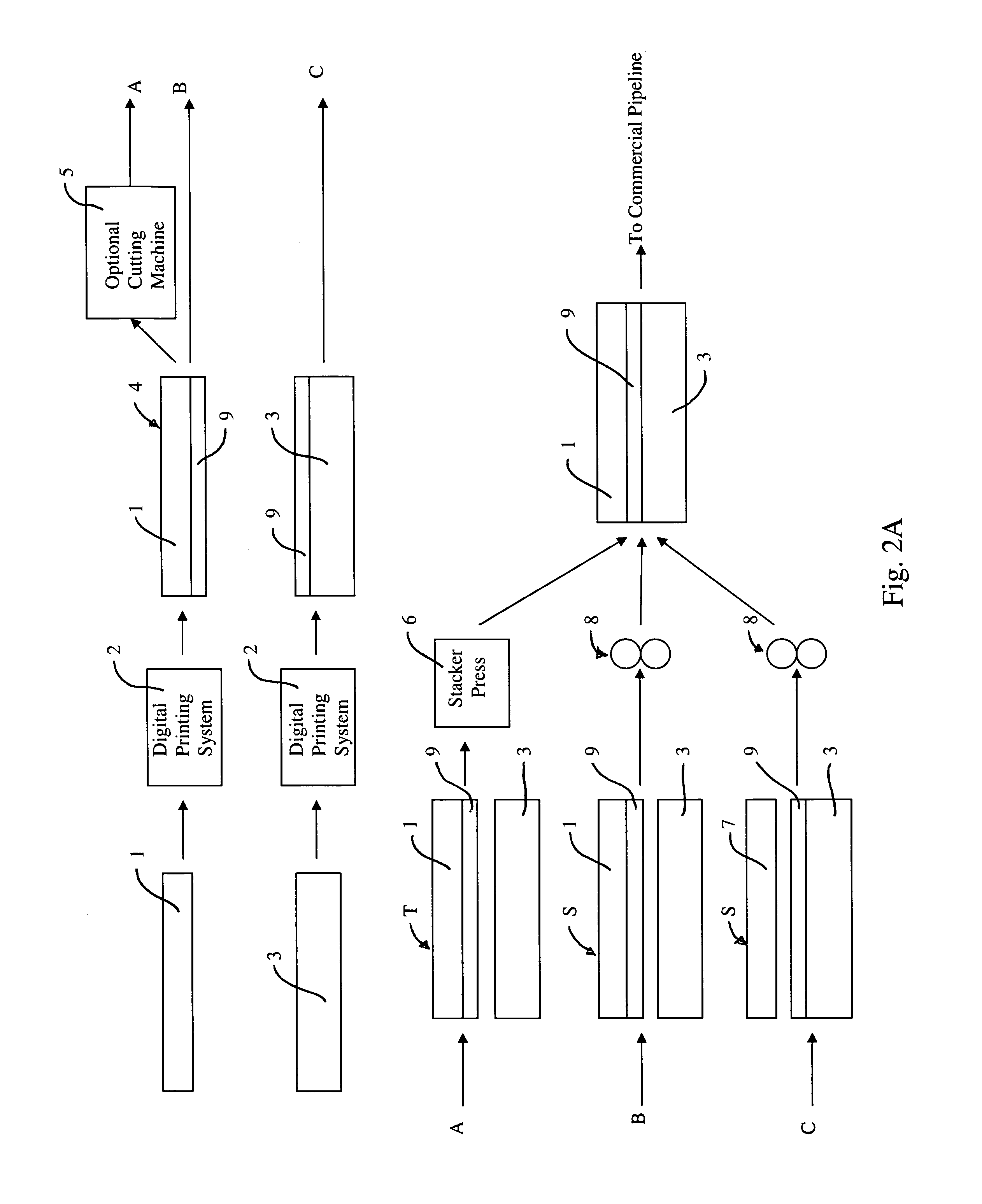

Rapid prototyping and filling commercial pipeline

InactiveUS20050247216A1Cheap and quickFast formingAdditive manufacturing apparatusMechanical working/deformationEngineeringDigital printing

Methods and apparatus provide a means to rapidly develop and modify prototype surface coverings for customer review and approval, and fill the commercial pipeline while more conventional production equipment is obtained, installed and tested. The present apparatus to rapid prototype and fill the commercial pipeline includes a digital printing system to print a film and a press for laminating and embossing the printed film to a substrate. The press uses an embossing plate or roll, which is made from ebonite or by three-dimensional printing equipment. These plates and rolls can be produced within two or three days or less.

Owner:AFI LICENSING

Pretreatment for low and non-porous media for inkjet printing

This invention pertains to inkjet printing on non-porous or low porous media and to a pretreatment solution for the non-porous or low porous media that allows high quality printing thereon. The preferred digitally printed inks are disperse dye or pigmented inks.

Owner:EI DU PONT DE NEMOURS & CO

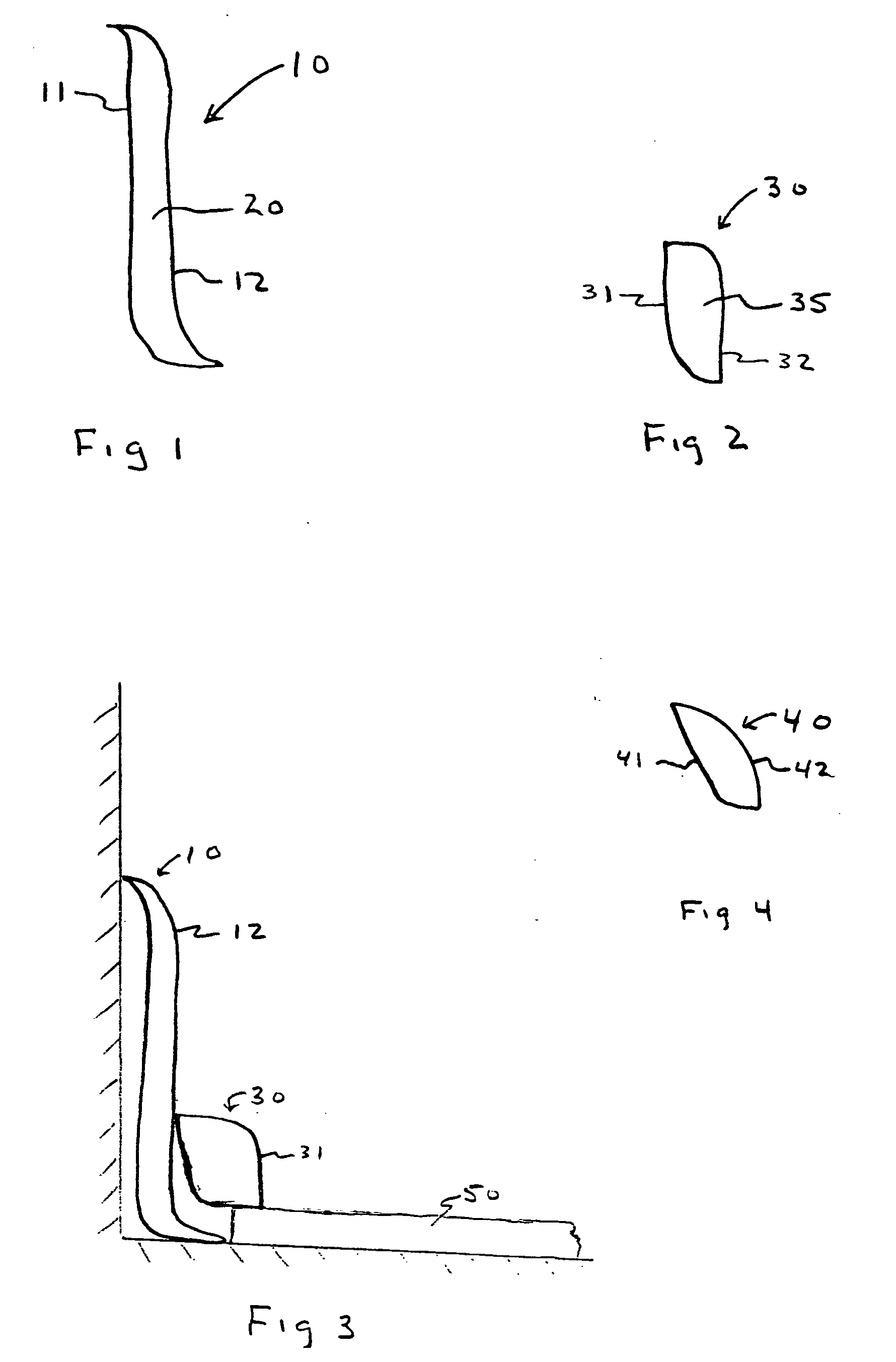

Reversible decorative moldings between floor and wall or wall and ceiling

A reversible molding is disclosed having multiple decorative face which differ from one another by at least one property. Such properties can include texture, color, pattern or design or shape. The molding can suitably be used at the joint between a wall and floor or between a wall and ceiling. In one embodiment, the moldings are manufactured from wood, MDF or HDF, with a decorative surface selected from foil, laminate, veneer, paint, stain or digital printing.

Owner:PERGO

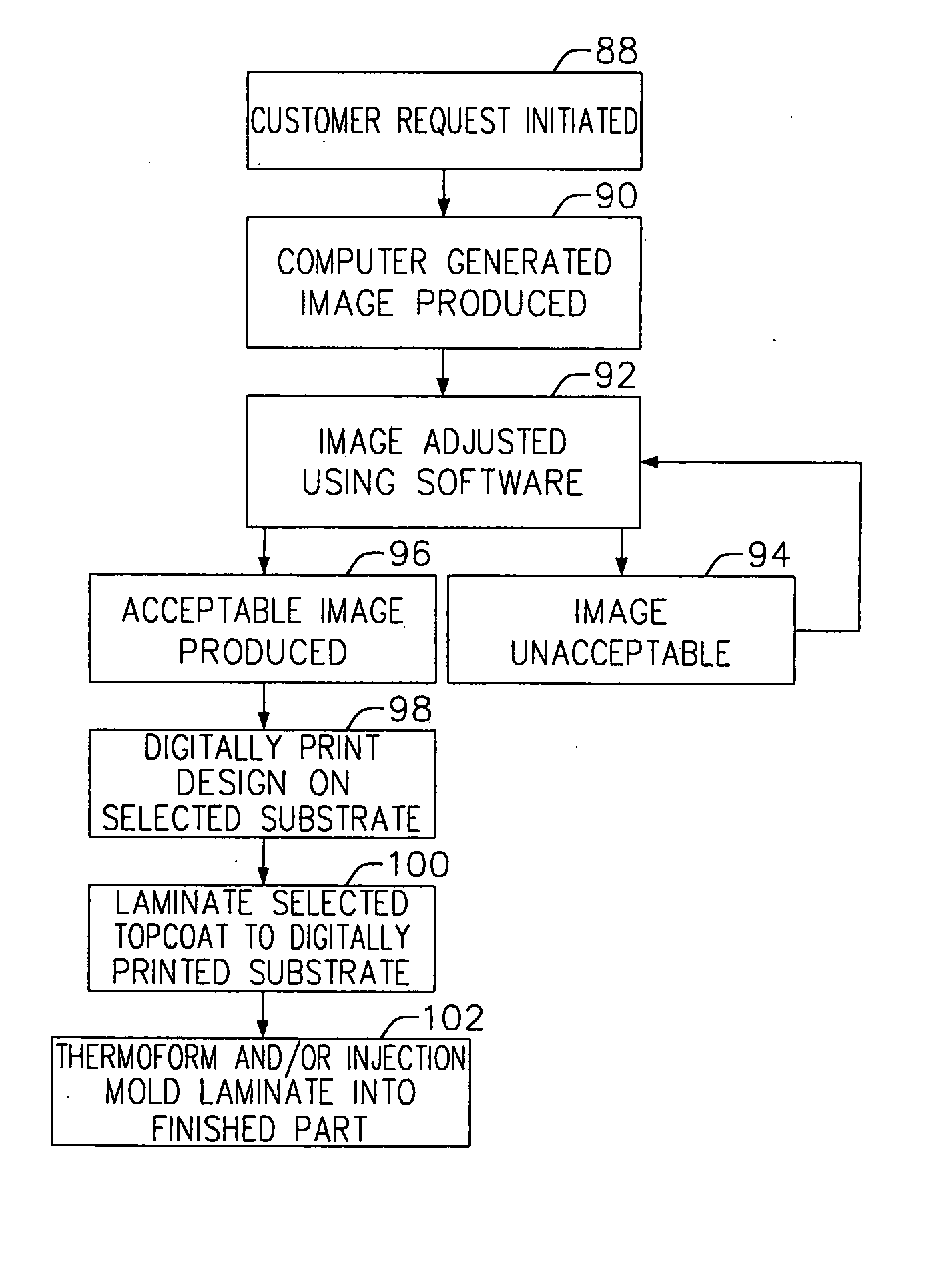

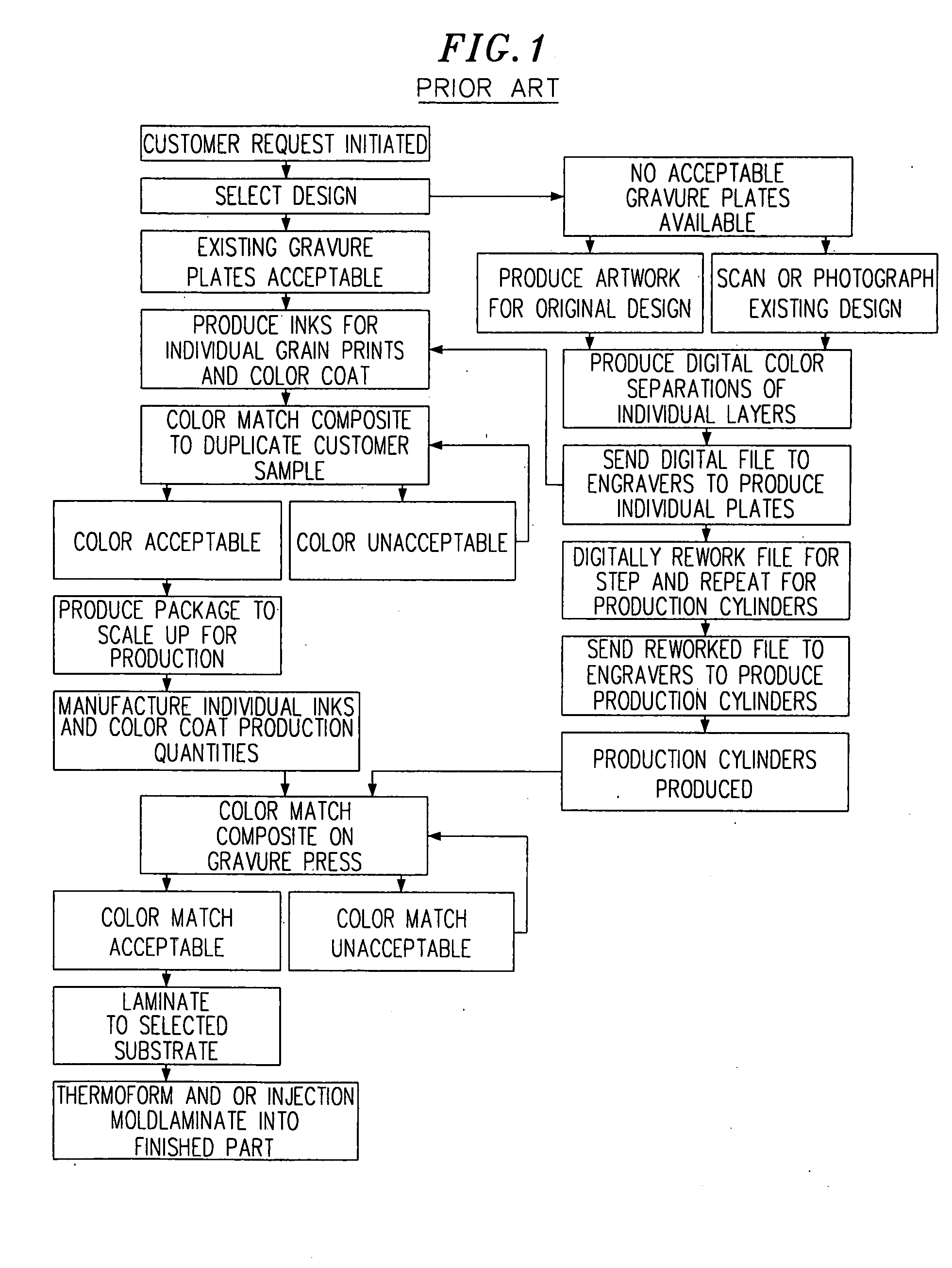

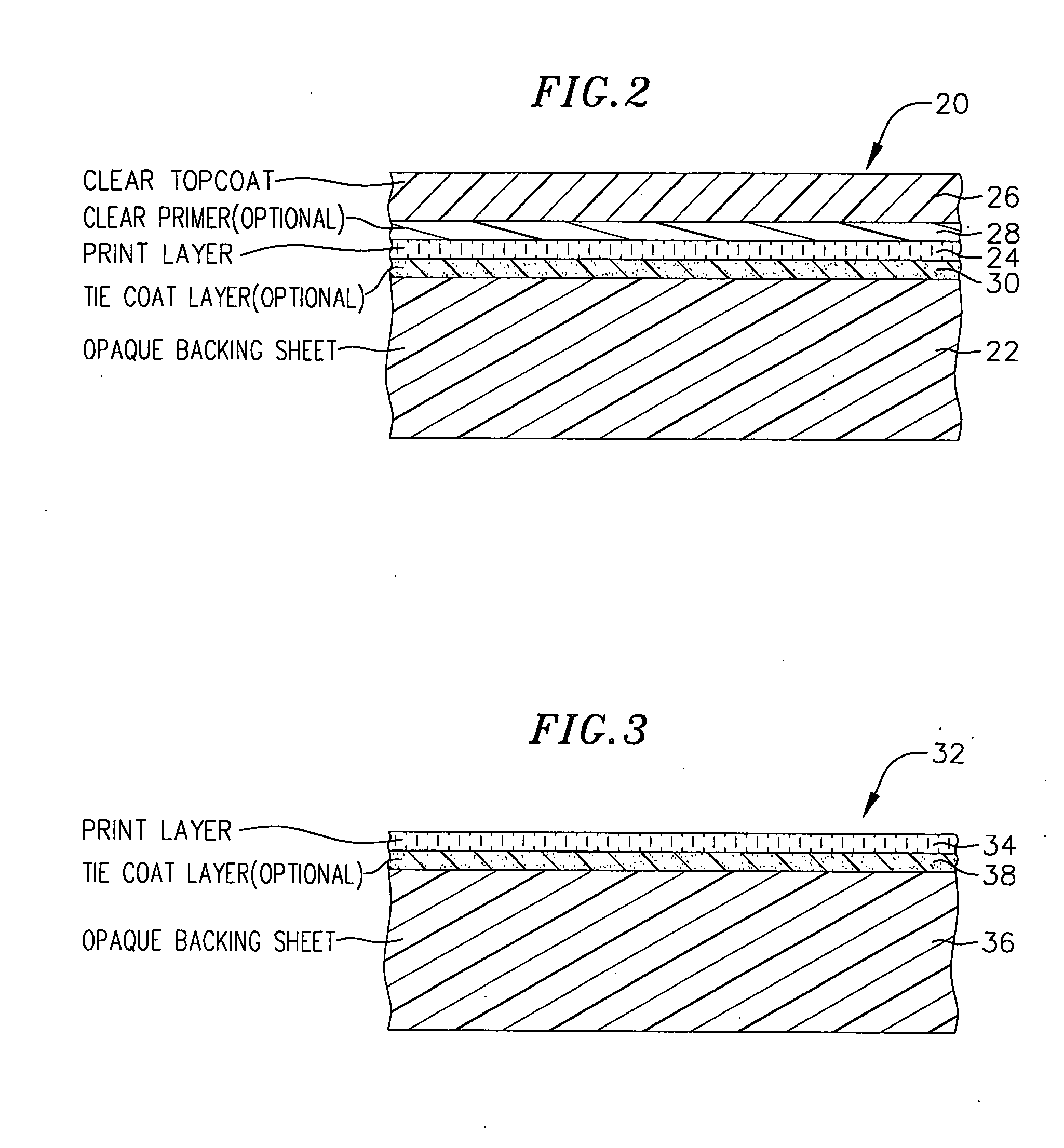

Digitally printed products and process

InactiveUS20070289705A1Speed color-matching processingExcellent abrasion resistanceLamination ancillary operationsDuplicating/marking methodsColor printingComputer printing

A process for manufacturing three-dimensionally shaped polymeric sheets and laminates with color-matched digitally printed full color ink jet images. A flexible thermoformable polymeric baseweb is placed in an ink jet printer and a solvent-based (non-aqueous) digital printing ink is applied directly to the baseweb, in the absence of an ink receptive layer on the baseweb, to form a decorative pattern in multiple colors in a single pass through the printer. The finished product can be thermoformed or injection molded to a three-dimensional shape. A protective topcoat can be laminated to the digitally printed sheet prior to the thermoforming and / or injection molding step. A process for making color-matched products comprises producing a software-driven image of a pattern on a screen representing a standard color print pattern; evaluating and adjusting the standard displayed on the screen using software-driven image related adjustments for hue, contrast, lightness / darkness, etc.; producing a test print by applying a decorative pattern to the baseweb by a digital ink jet printer and making an optional software-driven image-related adjustment in the standard to color match the standard to the test print image; and when the adjusted standard image displayed on the screen is acceptable, passing an image-related output to the digital ink jet printer for printing a decorative print color-matched to the accepted onscreen standard.

Owner:CCL LABEL INC

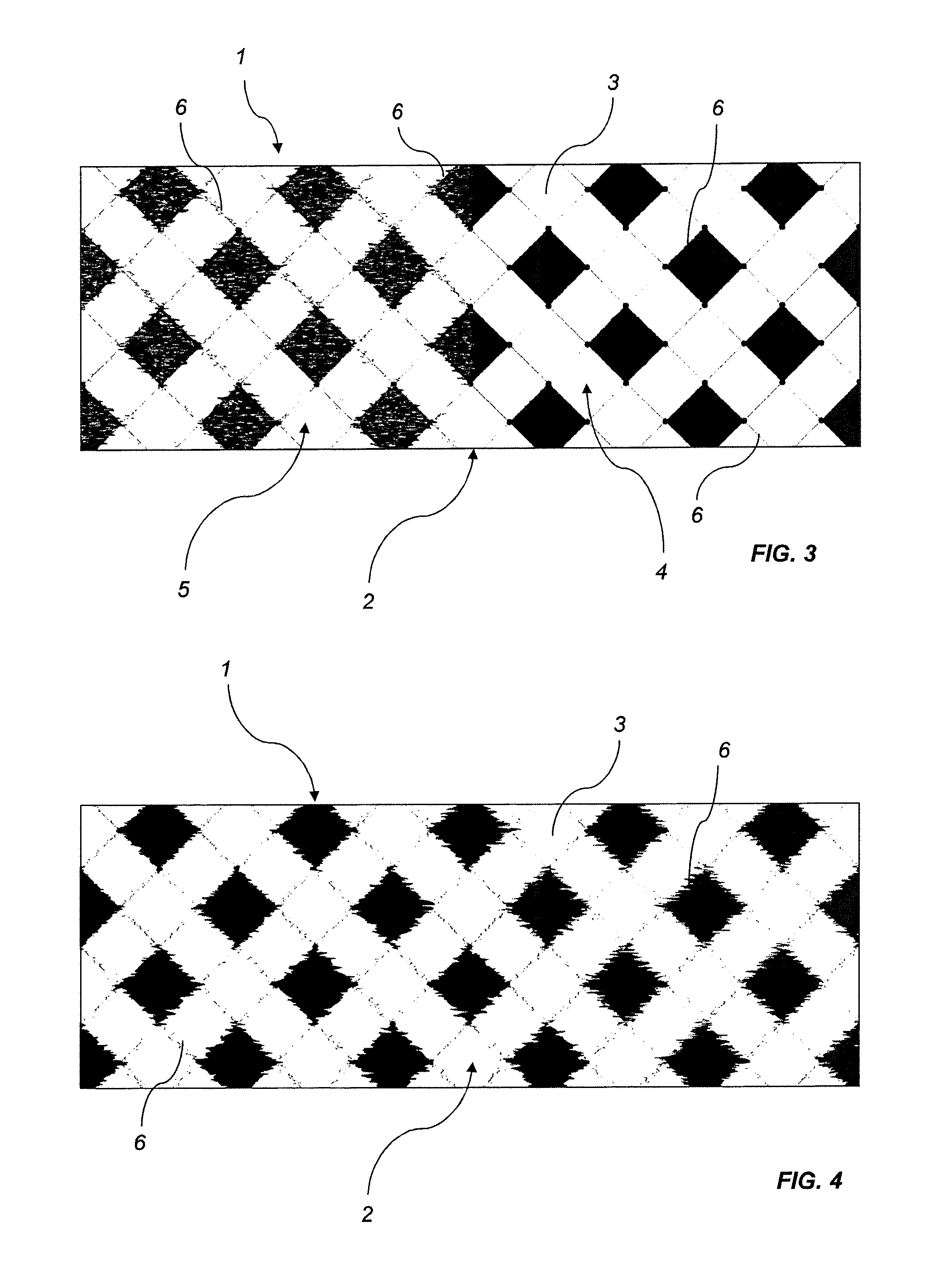

Method of producing a building panel

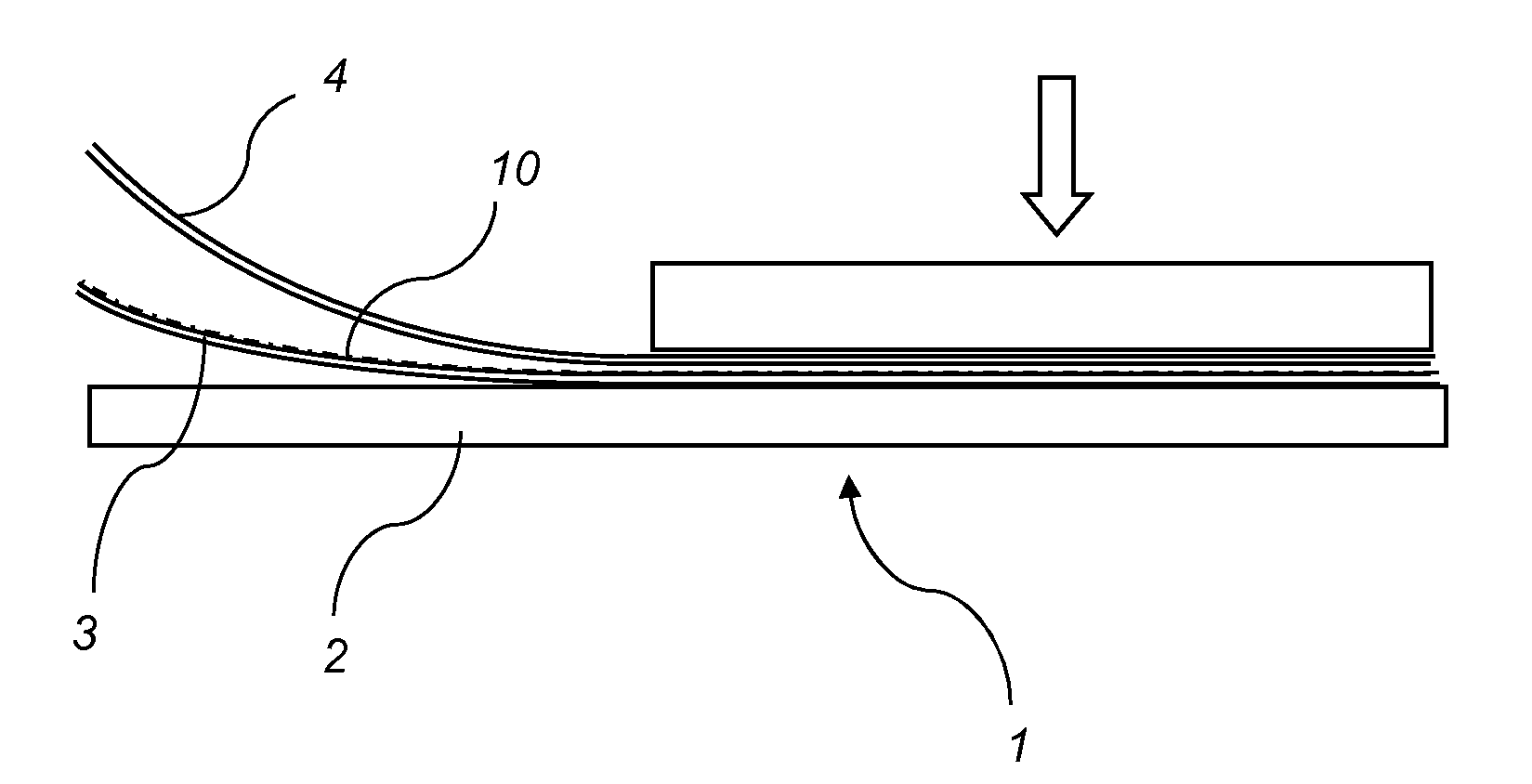

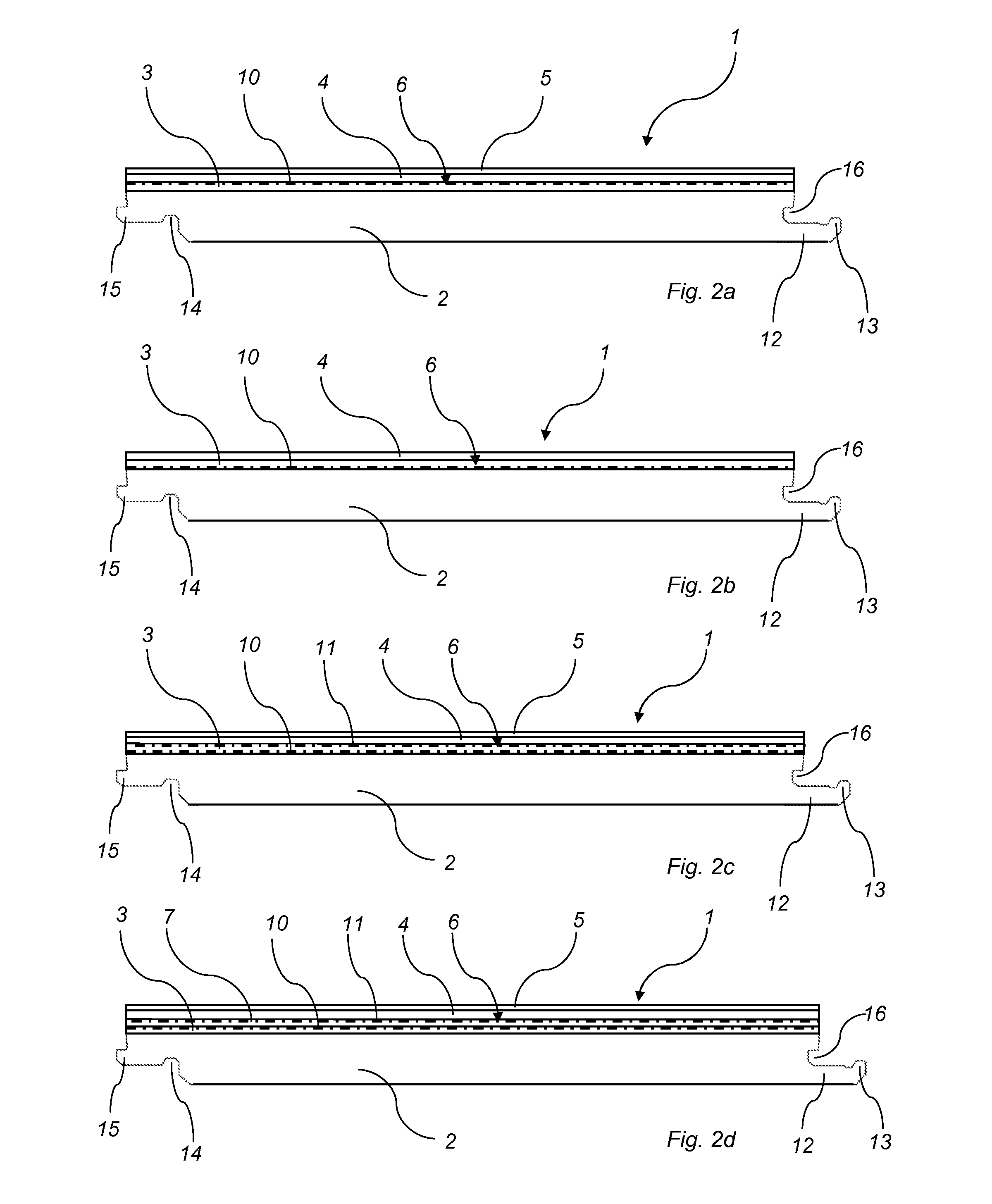

ActiveUS20140144583A1Fine surfaceEvenly distributedLamination ancillary operationsLaminationDigital printingProtection layer

A method of producing a floor panel (1), including providing a carrier (3) including a thermoplastic material, applying a primer comprising at least one salt, preferably a metal salt, on a first surface of the carrier (3), printing by means of digital printing a first print (10) on said first surface of the carrier (3) with an aqueous pigment ink composition, and applying a protective layer (4) on said first surface of the carrier (3) and applying the carrier (3) on a core (2) and pressing by applying heat and pressure the protective layer (4), the carrier (3) and the core (2) together to form a floor panel (1). Also, a method for forming a decorative substrate.

Owner:VÄLINGE INNOVATION AB

Digitally printed surface covering

InactiveUS20050249929A1Finite shelf lifeAvoid necessityNatural patternsLayered productsEngineeringDigital printing

Owner:ARMSTRONG WORLD INDUSTRIES

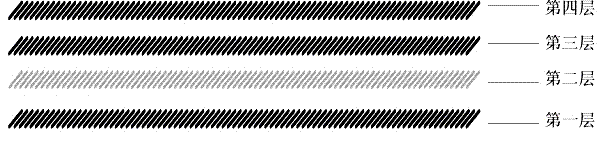

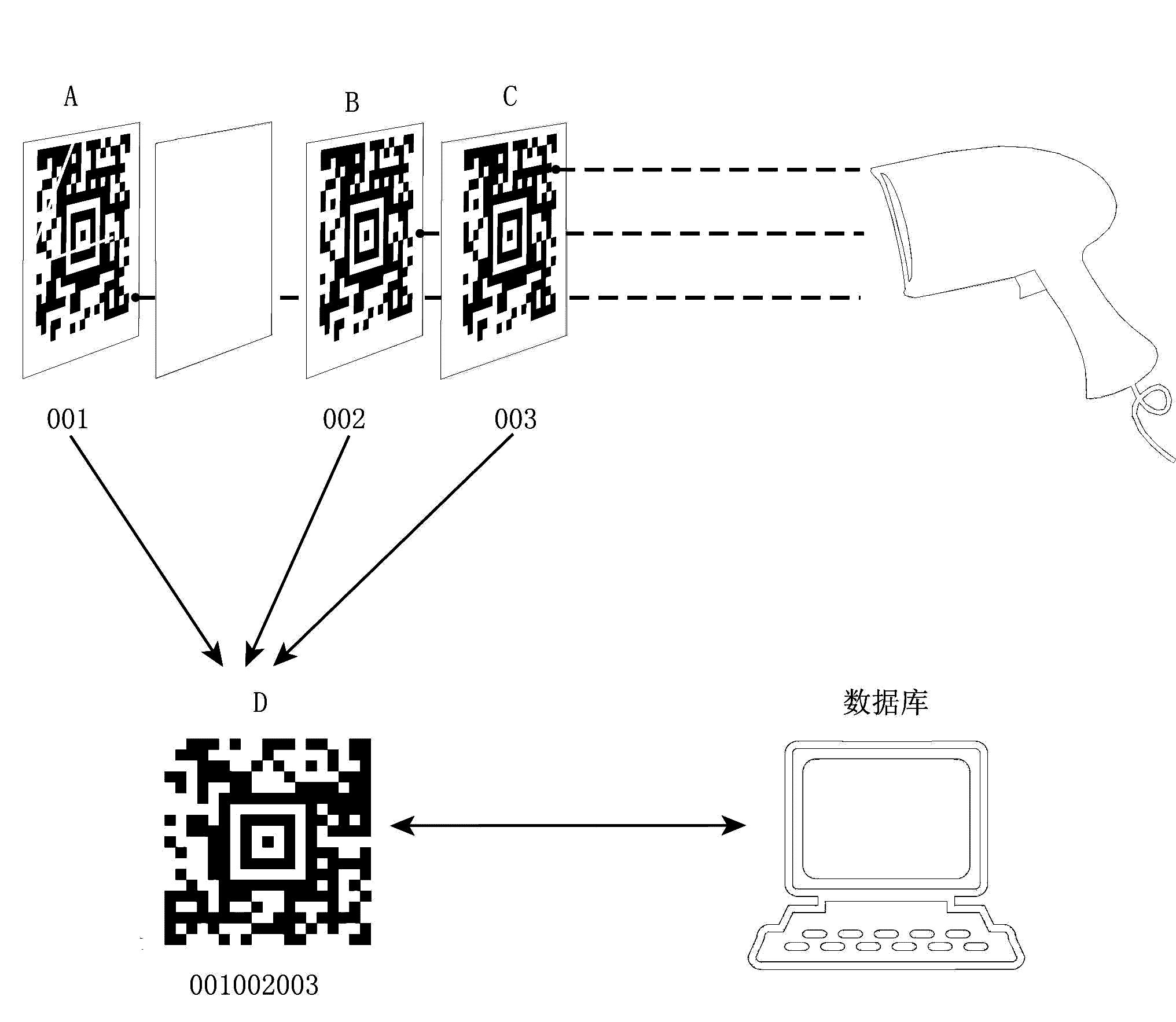

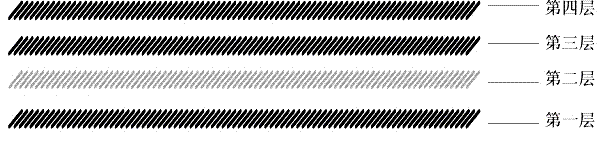

Anti-counterfeiting printing method by using invisible two-dimensional codes

InactiveCN101819647AEliminate the risk of imitationImprove use valuePattern printingRecord carriers used with machinesUltraviolet absorptionAbsorbent material

The invention relates to an anti-counterfeiting printing method by using invisible two-dimensional codes. The anti-counterfeiting printing method is characterized in that at least four printing layers for printing are adopted, and comprises the following steps of: firstly, providing a digital serial number and splitting the serial number into three fields of which information is assigned to three groups of two-dimensional codes; secondly, printing one group of two-dimensional codes on a first layer by using aqueous ink black materials; thirdly, overprinting a grey isolating layer on the first two-dimensional code layer by using infrared non-absorbent materials to form a second layer; fourthly, overprinting a second group of two-dimensional codes on the second layer of the grey isolating layer by using the infrared non-absorbent materials to form a third layer; and finally, overprinting a third group of two-dimensional codes on the third two-dimensional code layer by using ultraviolet absorption materials to form a fourth layer. The method has the advantages of eliminating the possibility of imitation by scanning the two-dimensional codes and achieving relatively higher use value because the overprinting is performed in the same area in an offset printing and digital jet printing way and the upper printing layer covers the lower layer naturally.

Owner:HONGBO CO LTD

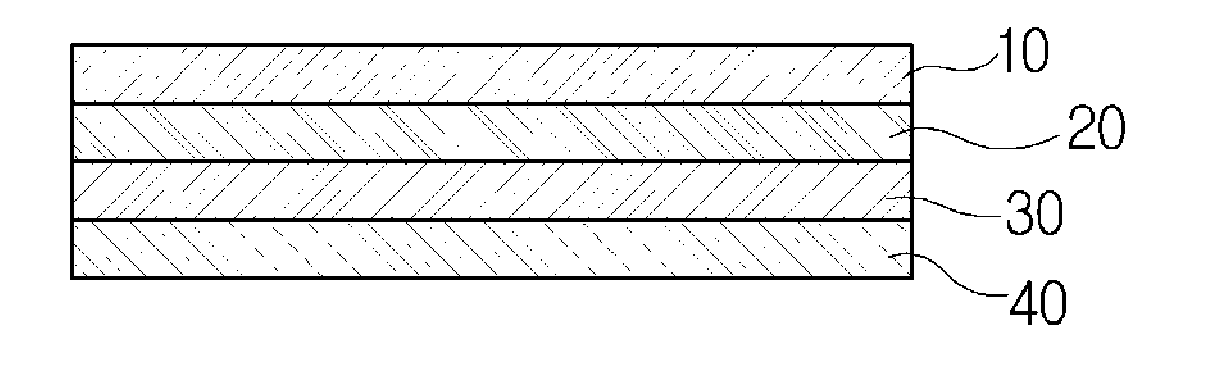

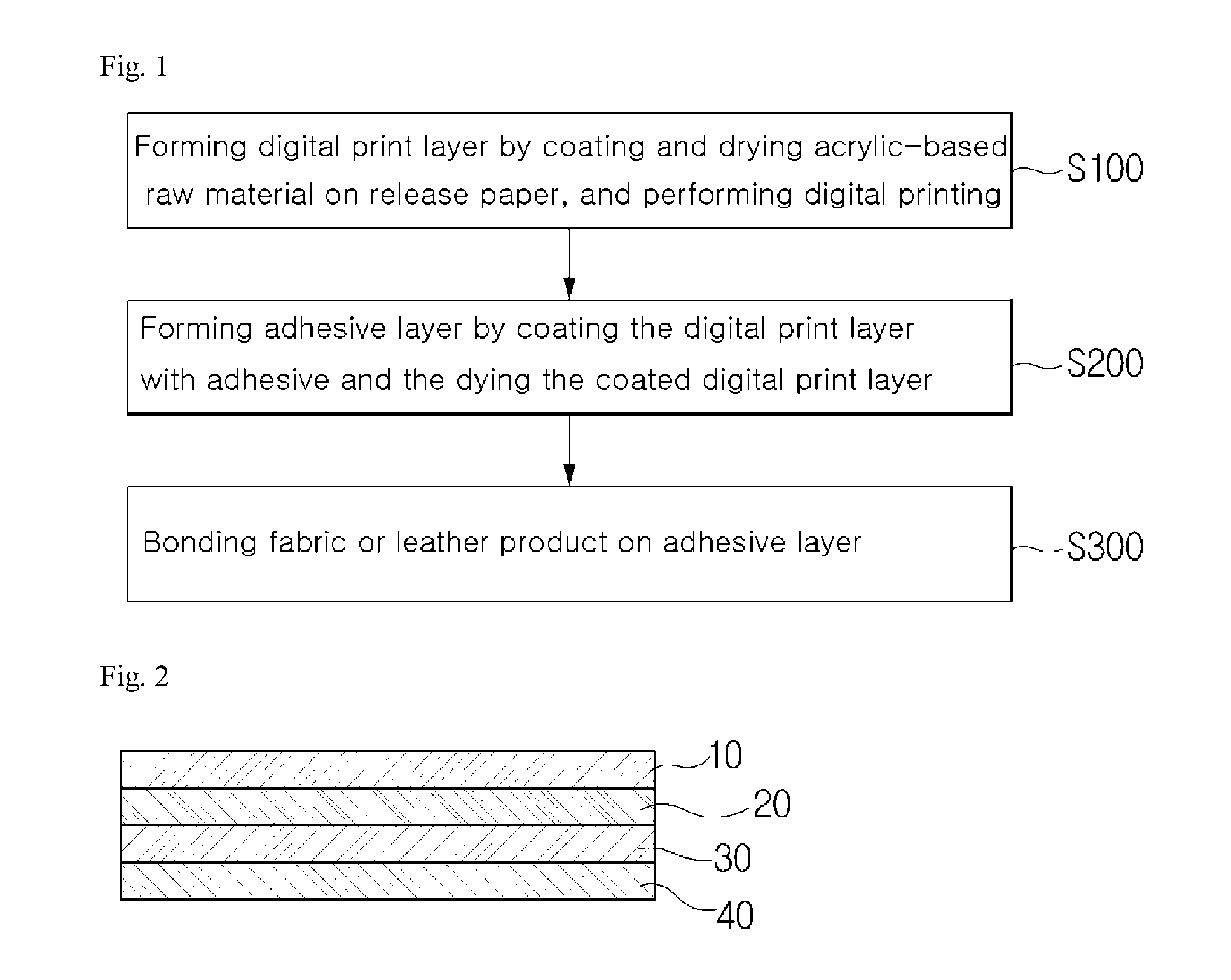

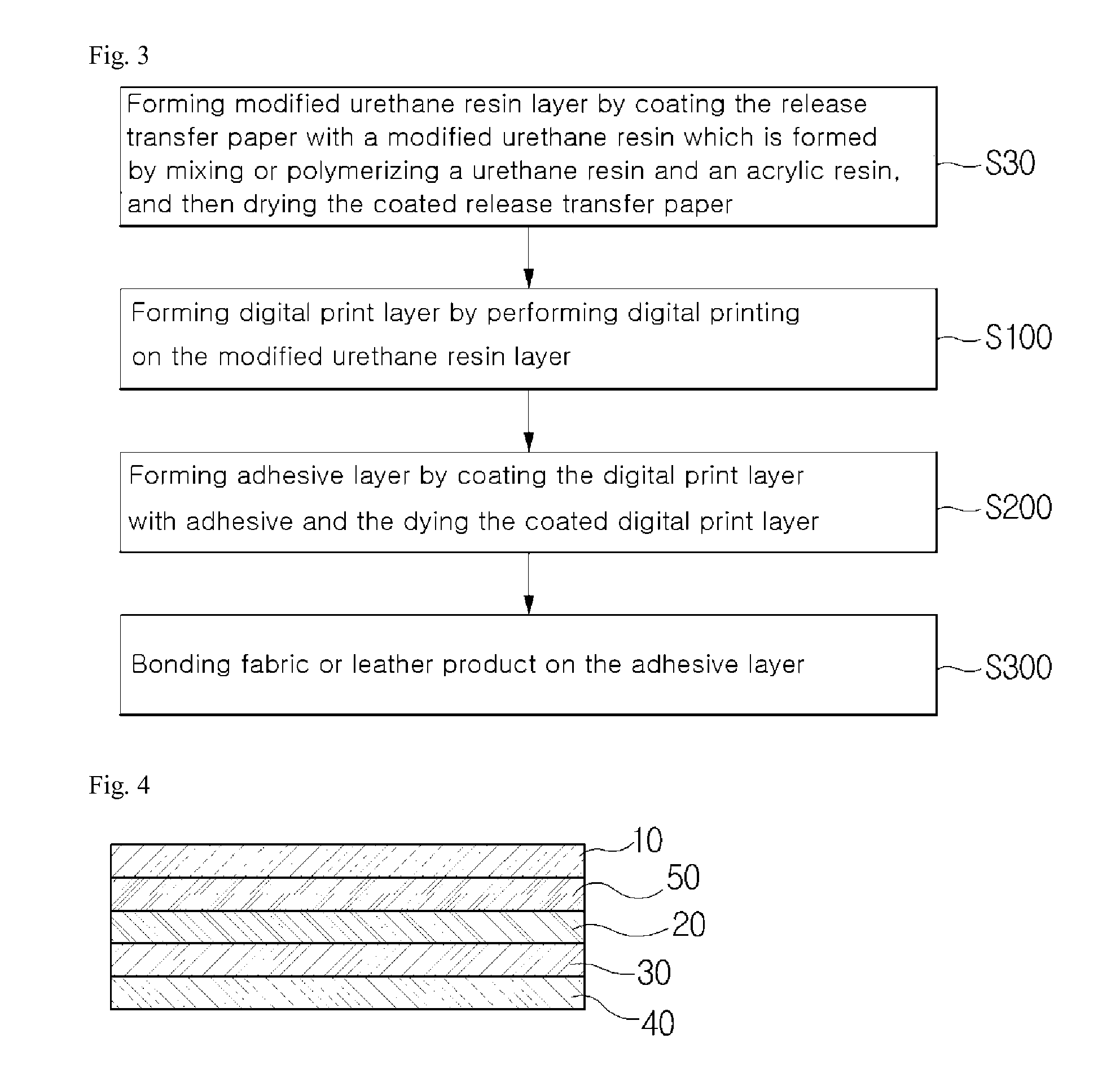

Method for printing fabric or leather product, and printed matter printed by using the same

ActiveUS20160067984A1Simple processReduce manufacturing costDecorative surface effectsDuplicating/marking methodsAdhesiveComputer printing

The present invention relates to a method for printing fabric or leather product, and printed matter printed by using the same, the method comprising the steps of: a) forming a digital print layer by performing digital printing on a release transfer paper by using an inkjet printer; b) forming adhesive layer by coating the digital print layer with an adhesive, and drying for a predetermined time; and c) bonding fabric or leather product to the adhesive layer. Thus, the present invention can precisely print fabric or leather product with high resolution and can enable customized printing so as to allow small quantity batch production.

Owner:CHUNG DOO HO

Device and method for printing by transfer onto a cylindrical printing medium

The invention relates to a device for printing by transfer onto a print support (10) comprising at least one blanket (30) driven in a sequential relative movement past a magazine (50) conveying the print supports (10), in which device the blanket (30) has a surface area greater than that of the print support (10), the device further comprising digital printing means (20) which print by spraying ink onto this blanket (30) over a variable area equal to that of the print support (10).

Owner:IMPIKA +1

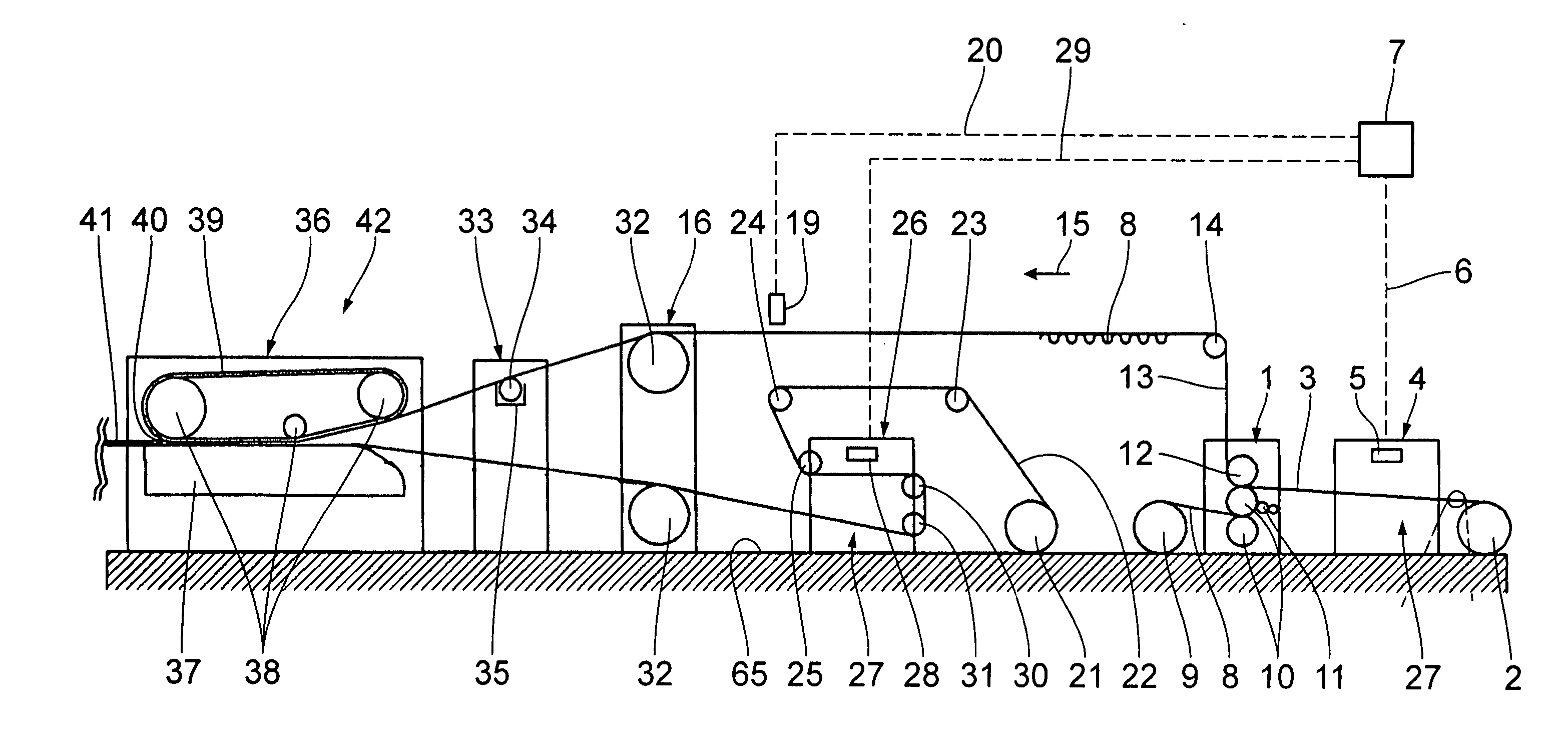

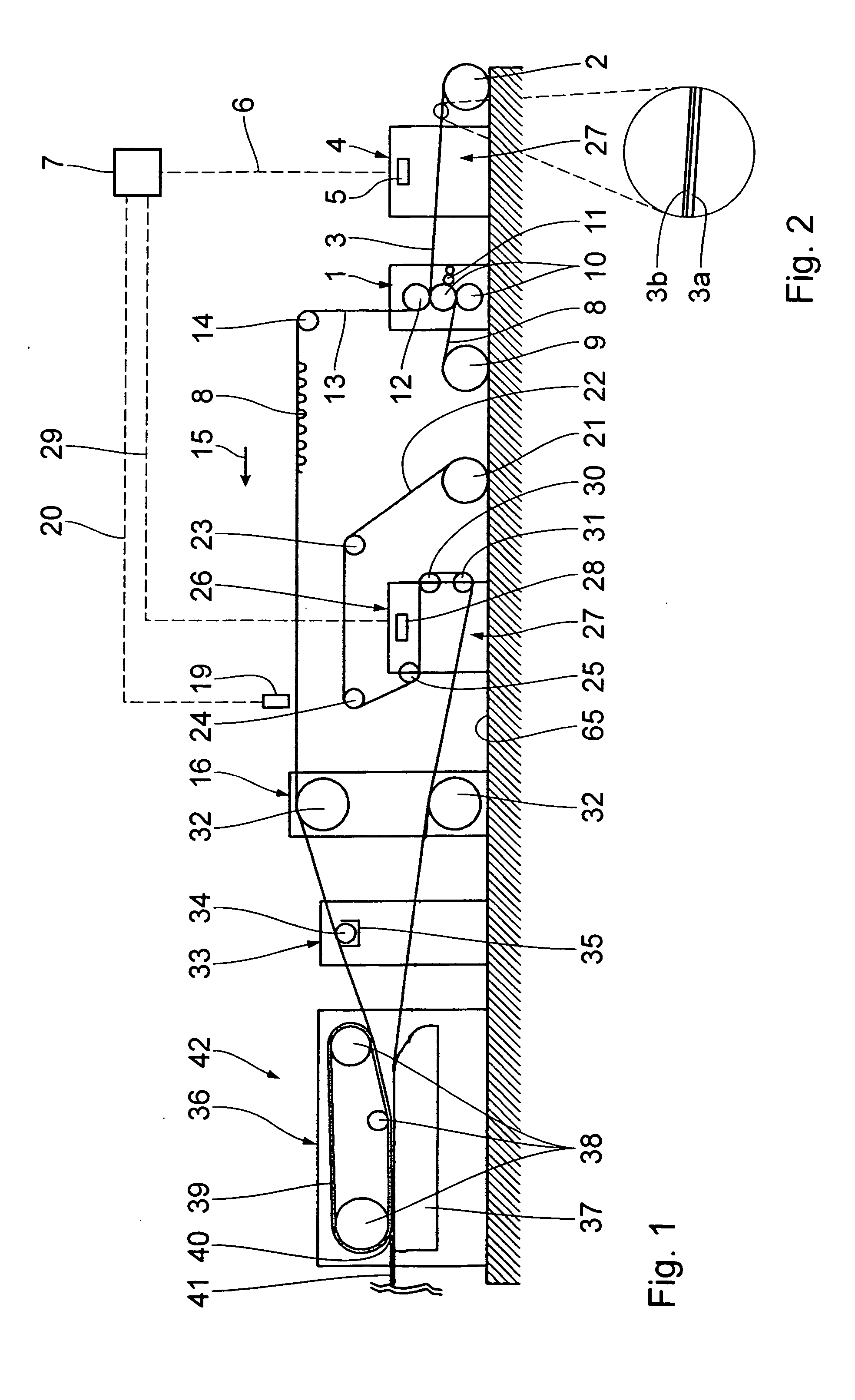

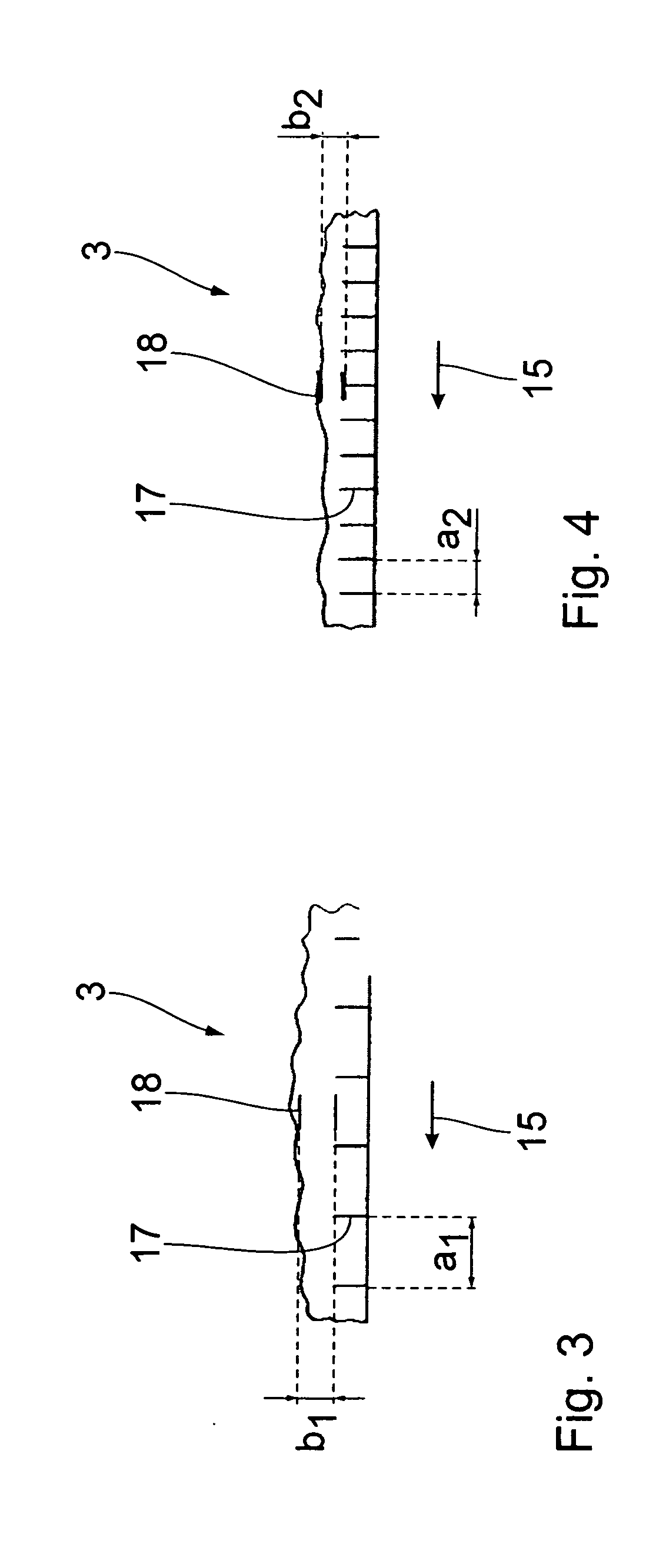

Corrugating machine and method for the manufacture of sheets of corrugated board

InactiveUS20040182503A1Reduce demandSmall thicknessMechanical working/deformationLamination ancillary operationsPrinting pressDigital printing

A corrugating machine serves for the manufacture of sheets of corrugated board. It comprises at least two unroll stands for unwinding webs of material. A fluting unit is provided for producing at least one corrugated medium from one of the webs of material. A processing equipment serves for uniting the webs of material to form a web of corrugated board. The sheets of corrugated board are cut to size in a cutting station. At least one digital printing system for printing at least one of the webs is disposed between the unroll stands and the cutting station. One of the webs of material can have a coating for improved printing quality. Methods are specified for digitally printing within the corrugating machine, which, upon printing, allow for any modification of dimensions during manufacture of the web of corrugated board; and which enable synchronized printing of opposite sides of the web of corrugated board to take place; and which enable the sheets of corrugated board to be cut in dependence on a printing job. This ensures rather flexible high-quality printing of the sheets of corrugated board.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

Rapid prototyping and filling commercial pipeline

InactiveUS7383768B2Quick changeCheap and quickAdditive manufacturing apparatusMechanical working/deformationEngineeringPrinting press

Methods and apparatus provide a means to rapidly develop and modify prototype surface coverings for customer review and approval, and fill the commercial pipeline while more conventional production equipment is obtained, installed and tested. The present apparatus to rapid prototype and fill the commercial pipeline includes a digital printing system to print a film and a press for laminating and embossing the printed film to a substrate. The press uses an embossing plate or roll, which is made from ebonite or by three-dimensional printing equipment. These plates and rolls can be produced within two or three days or less.

Owner:AFI LICENSING

High elongation vacuum formable digital ink

ActiveUS20060222831A1Additive manufacturing apparatusDecorative surface effectsFunctional monomerDigital printing

The present invention includes a curable ink composition for digitally printing onto plastic substrates and three dimensional objects comprising an ink composition comprising a pigment, an oligomeric component, a diluent, additives and a mono-functional monomer having a molecular weight of 10 g / mole to 600 g / mole. The curable ink composition adheres to the plastic substrate to thereby allow elongation of 100% to 900% of the printed ink image during thermal processing of the plastic substrate.

Owner:DONALD D SLOAN TRUSTEE OF THE DONALD D SLOAN TRUST AND HIS SUCCESSOR & SUCCESSORS UNDER THE FOURTEENTH AMENDMENT TO & COMPLETE RESTATEMENT OF THE DONALD D SLOAN TRUST DATED JUNE 28 2012 +1

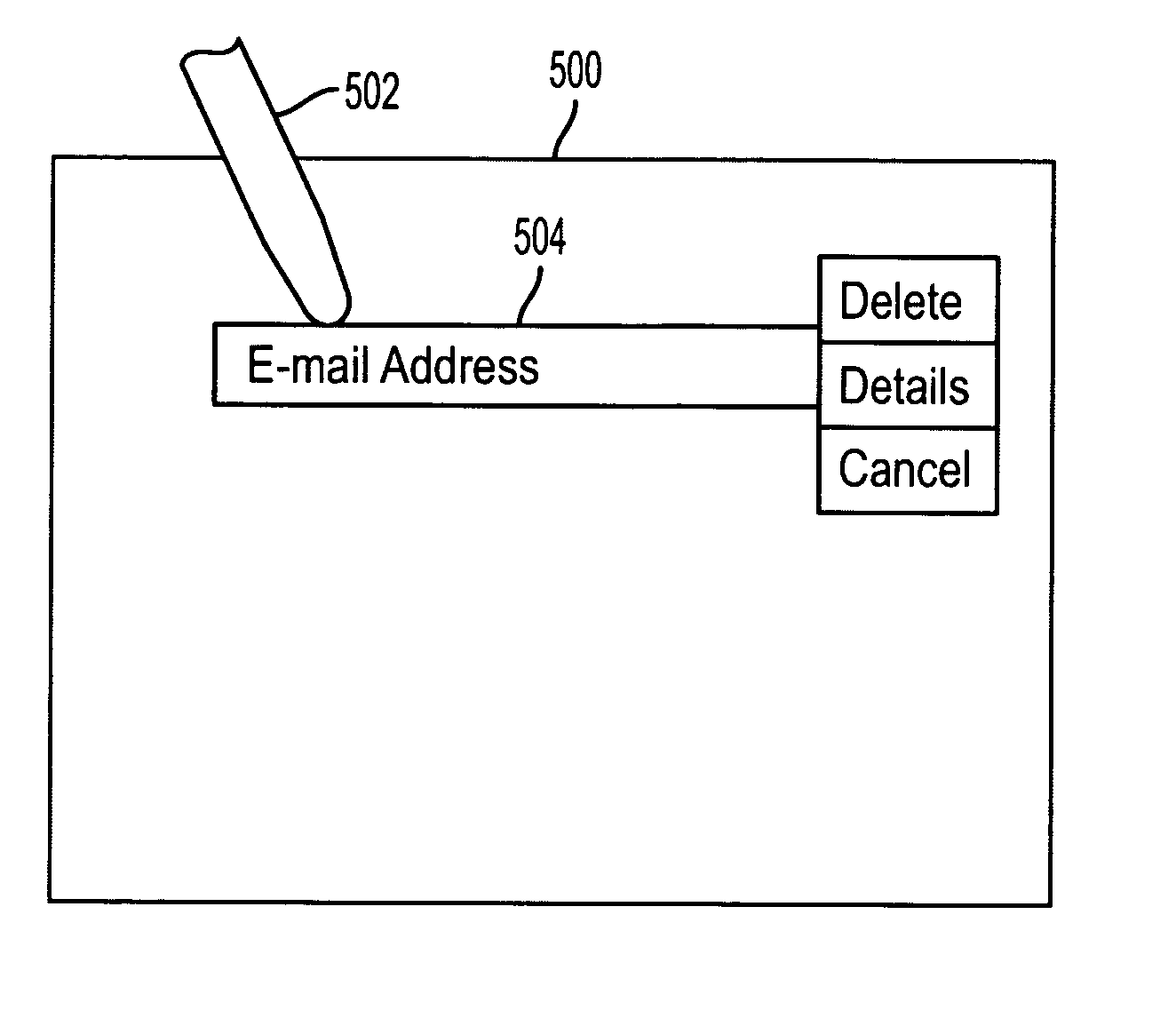

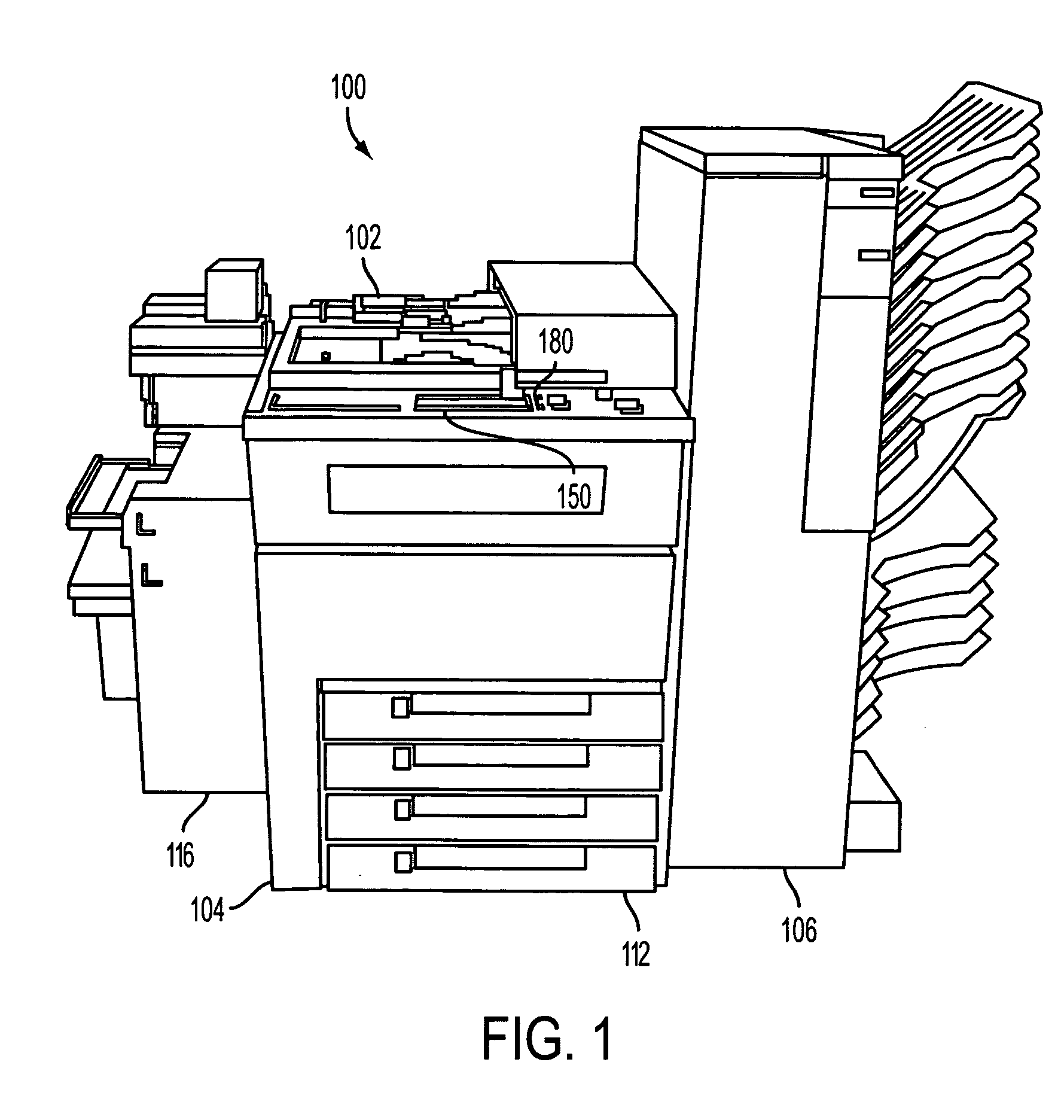

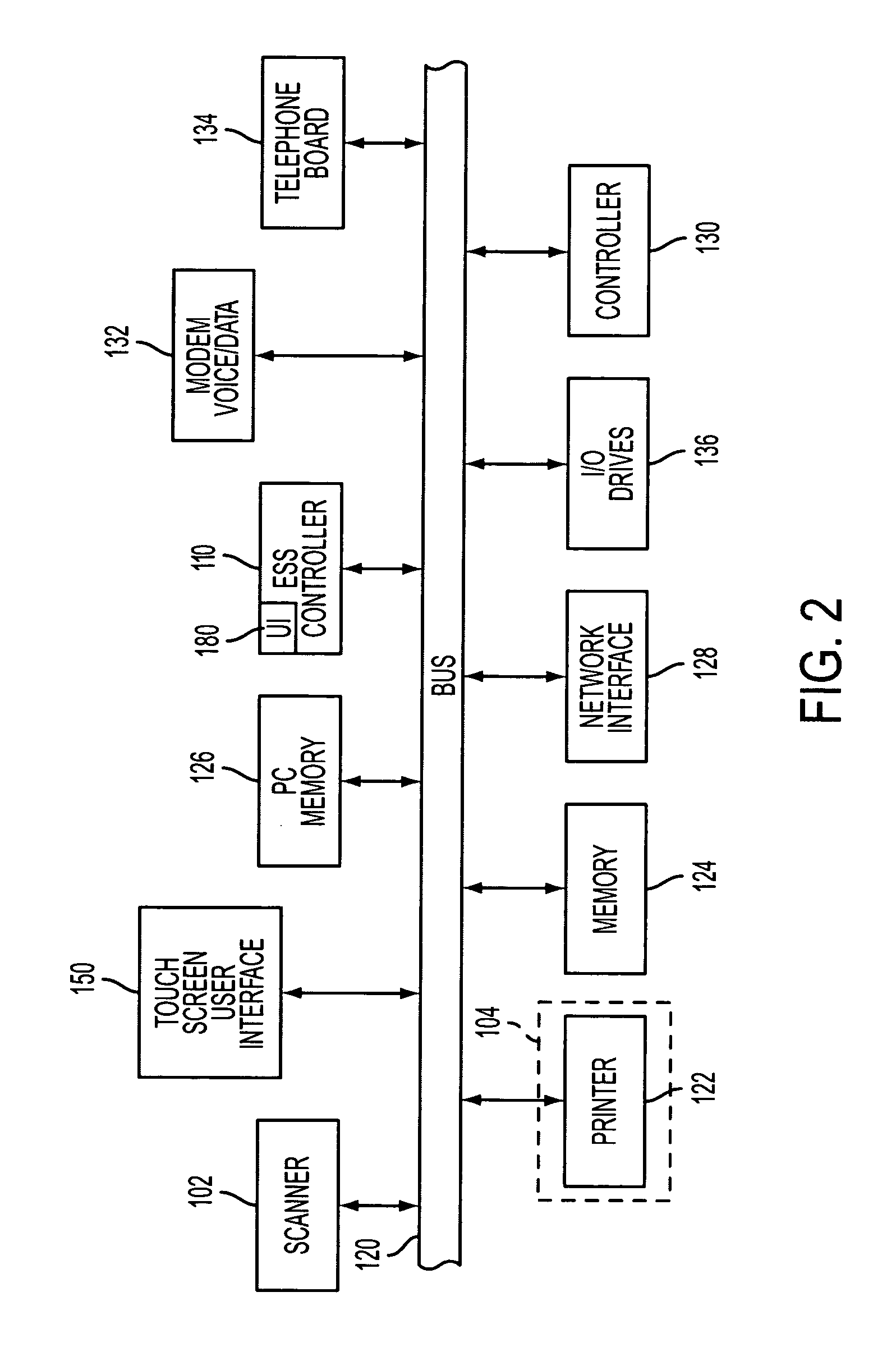

Touch screen user interface for digital reprographic device with pop-up menu display

InactiveUS20070139386A1Cathode-ray tube indicatorsInput/output processes for data processingTouchscreenDigital printing

Embodiments of the present invention provide methods, apparatus, and systems for an efficient user interface implemented on a touch screen for a digital reprographic machine. In particular, the touch screen may display various objects, such as icons or command buttons. In response to a user selecting one of these objects, a pop-up window is then provided on the touch screen. The pop-up window may comprise a list box or menu and its contents may be determined by the functions corresponding to the selected object. The pop-up window may remain open until the user selects one of the items, or touches an area of the touch screen that is outside of the pop-up window, or after a certain amount of time has elapsed, such as 10-15 seconds. When the user touches an item in the pop-up window, the pop-up window may close and a corresponding operation may be performed by the digital printing machine.

Owner:XEROX CORP

Fabric pretreatment for inkjet printing

This invention pertains to a method of inkjet printing on fabric, comprising the steps of pretreatment, printing with a white underprint of substantially the same shape as the colored image and printing an image on the fabric. The preferred digitally printed inks are pigmented inks.

Owner:DUPONT ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com