Patents

Literature

80 results about "Ebonite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ebonite is a brand name for a material generically known as hard rubber, and is obtained by vulcanizing natural rubber for prolonged periods. Ebonite may contain from 25% to 80% sulfur and linseed oil. Its name comes from its intended use as an artificial substitute for ebony wood. The material has also been called vulcanite, although that name formally refers to the mineral vulcanite.

Rapid prototyping and filling commercial pipeline

InactiveUS20050247216A1Cheap and quickFast formingAdditive manufacturing apparatusMechanical working/deformationEngineeringDigital printing

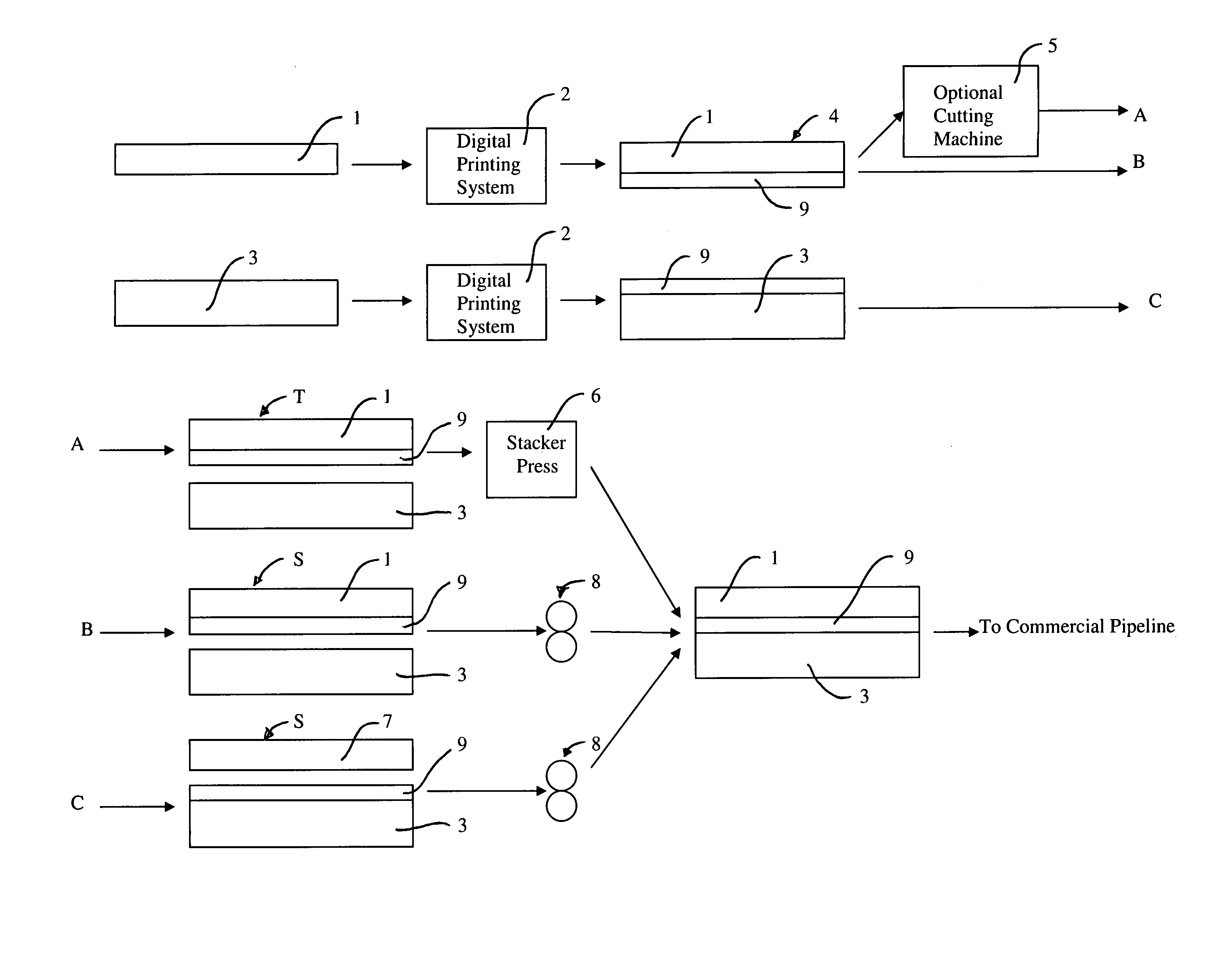

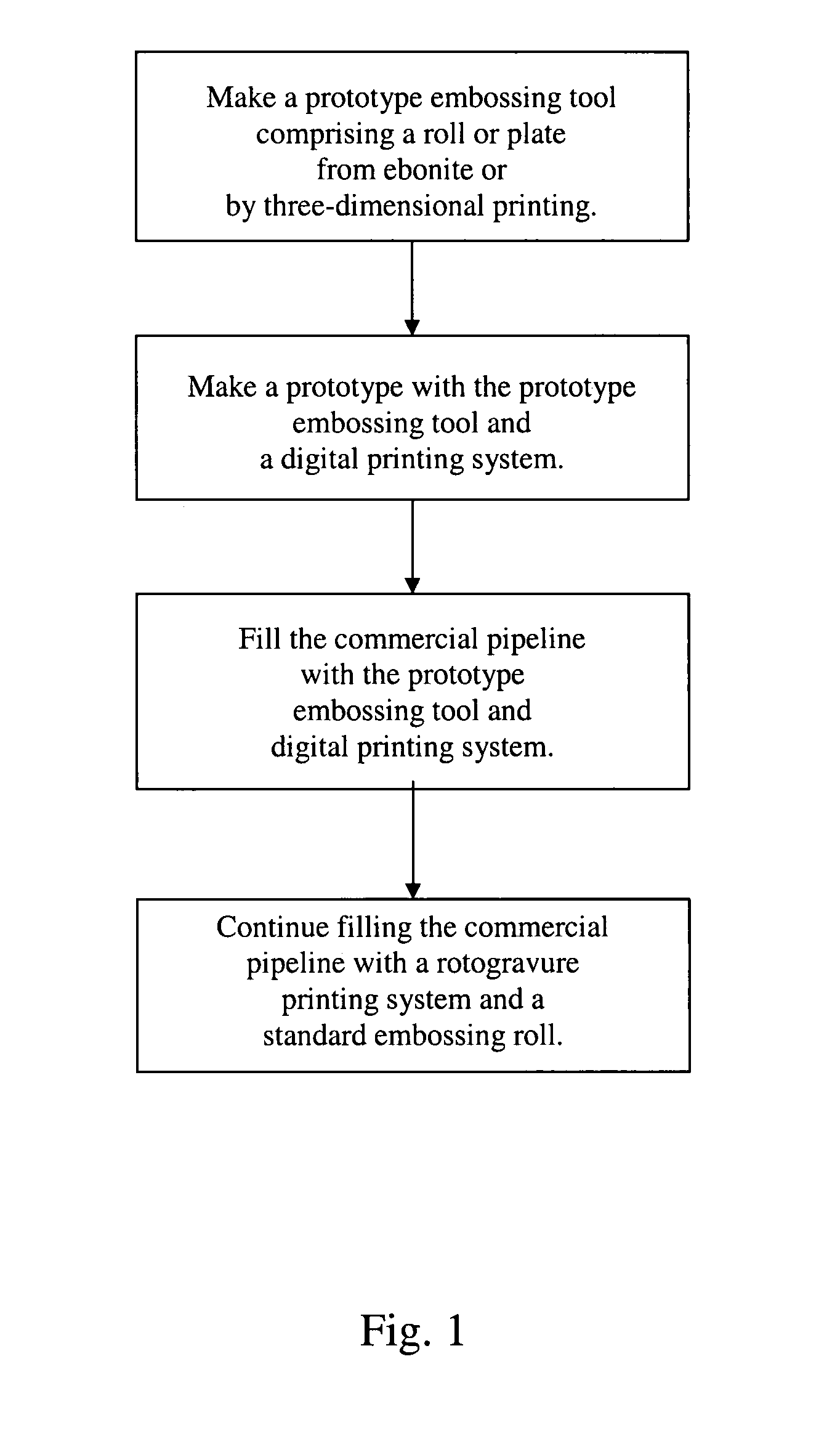

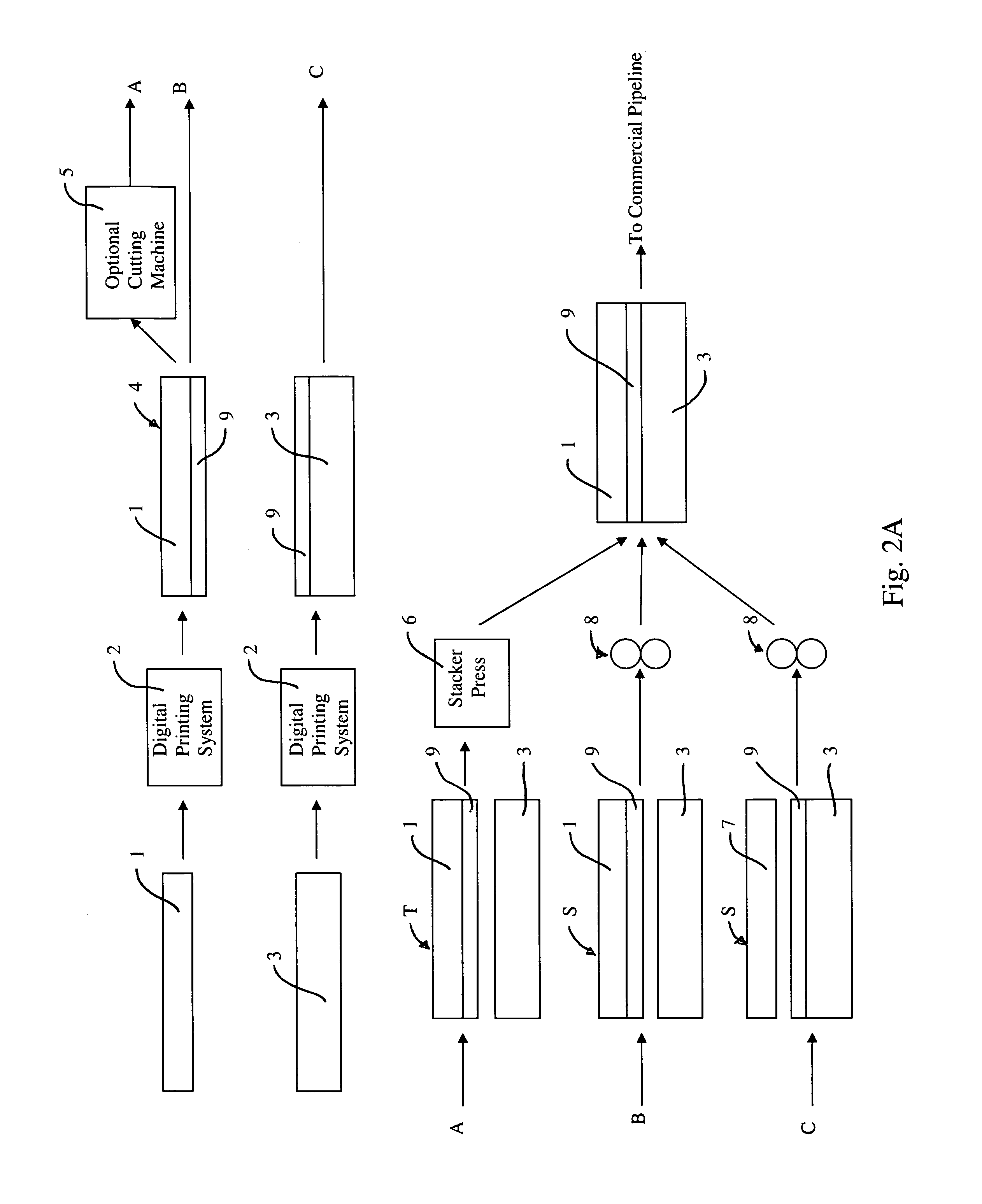

Methods and apparatus provide a means to rapidly develop and modify prototype surface coverings for customer review and approval, and fill the commercial pipeline while more conventional production equipment is obtained, installed and tested. The present apparatus to rapid prototype and fill the commercial pipeline includes a digital printing system to print a film and a press for laminating and embossing the printed film to a substrate. The press uses an embossing plate or roll, which is made from ebonite or by three-dimensional printing equipment. These plates and rolls can be produced within two or three days or less.

Owner:AFI LICENSING

Rapid prototyping and filling commercial pipeline

InactiveUS7383768B2Quick changeCheap and quickAdditive manufacturing apparatusMechanical working/deformationEngineeringPrinting press

Methods and apparatus provide a means to rapidly develop and modify prototype surface coverings for customer review and approval, and fill the commercial pipeline while more conventional production equipment is obtained, installed and tested. The present apparatus to rapid prototype and fill the commercial pipeline includes a digital printing system to print a film and a press for laminating and embossing the printed film to a substrate. The press uses an embossing plate or roll, which is made from ebonite or by three-dimensional printing equipment. These plates and rolls can be produced within two or three days or less.

Owner:AFI LICENSING

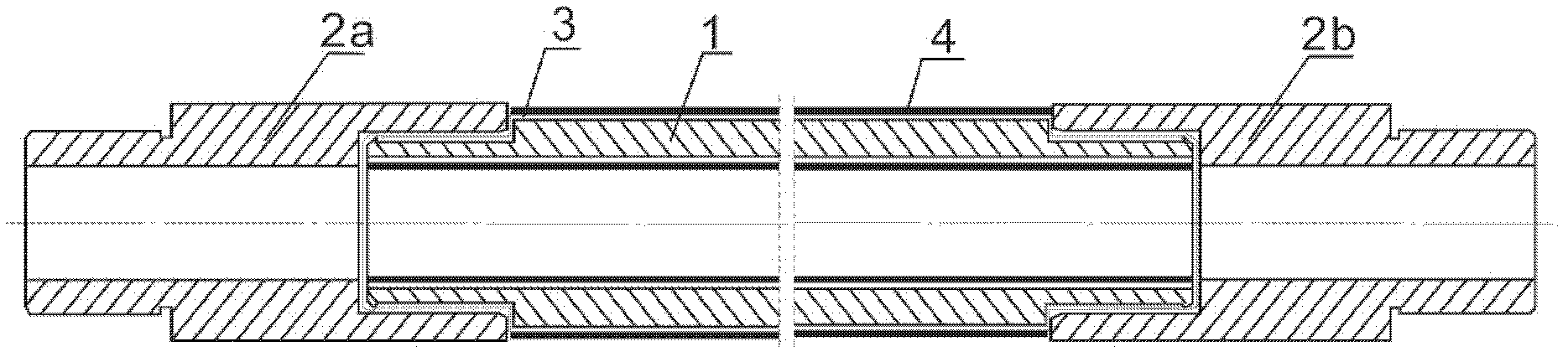

Insulating pup joint used for underground mine drilling and manufacture method thereof

InactiveCN102305029AAchieve insulationDrilling rodsLayered productsHybrid materialPetroleum engineering

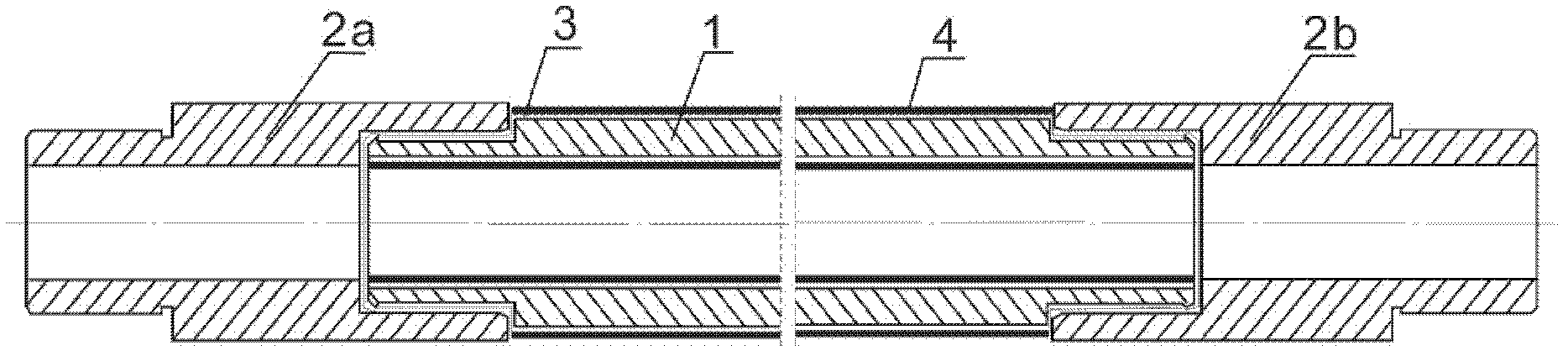

The invention discloses an insulating pup joint used for underground mine drilling and a manufacture method thereof. The insulating pup joint at least comprises a hollow pup joint body and two hollow protection joints, wherein the hollow protection joints are respectively arranged on two ends of the pup joint body and are fixedly connected with the pup joint body; the inner surface, the outer surface and the end surface of the pup joint body are all coated with a wear-resisting ceramic insulating material layer; and the wear-resisting ceramic insulating material layer of the inner surface of the pup joint body and the wear-resisting ceramic insulating material layer on the outer surface of the pup joint body, which does not contact with the protection joints are coated with a hybrid material layer of ebonite and diamond particles. In the manufacture method, the pup joint body and two protection joints are firstly manufactured, and then, the two protection joints are respectively fixedly connected to two ends of the pup joint body. The insulating pup joint can be applied to the underground electromagnetic wave measurement while drilling in the underground mine industry to cause an upper drill pipe and a lower drill pipe to insulate. The manufacture method can be used for manufacturing the insulating pup joint suitable for underground electromagnetic wave measurement while drilling in the underground mine industry.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Functional health care latex

InactiveCN103422357AGood health effectIn line with seeking health care materialsFibre treatmentMicrobial agentPotassium hydroxide

The invention provides functional health care latex, which is formed by the following materials in weight part: 49-51 parts of synthetic latex, 5-7 parts of ebonite, 2-5 parts of foaming agent, 5-7 parts of vulcanizing agent, 0.1-0.8 part of potassium pyrophosphate, 0.2-0.6 part of potassium hydroxide, 0.2-0.6 part of siloxane, 25-35 parts of calcium carbonate, 2-4 parts of functional materials, wherein the functional materials are magnetic powder particles and / or anti-fungus anti-microbial agent; preferably, the scheme is that the functional materials are 1-2 parts of magnetic powder particles and 1-2 parts of anti-fungus anti-microbial agent. According to the functional health care latex, the magnetic powder technology and / or anti-fungus anti-microbial technology are / is adopted, so that the health care properties of the latex material are greatly improved, and the latex conforms to the requirements for seeking of health care materials and pursuing of high quality life of the modern society better.

Owner:东莞市铨兴乳胶制品有限公司

Epoxy ebonite compositions

InactiveUS20050282960A1Good physical propertiesImprove curing speedUnspecified rubber coatingsSynthetic resin layered productsEpoxyAs Directed

Overall, ebonite coatings or elastomeric linings are not recommended for direct immersion in sulfuric acid with higher than 65% concentration. By blending a chemical resistant epoxy resin to an ebonite coating, the resulting epoxy ebonite composition can be employed in more severe environment such as direct immersion in >65% sulfuric acid. In particular, the present invention provides a blend of an epoxy coating with an ebonite coating with a mix ratio of 95 / 5 to 5 / 95, the resulting epoxy ebonite composition of which has greatly increased adhesion to steel and excellent resistance to undercut corrosion when subjected to salt spray. The epoxy ebonite composition according to the present invention can be used as coatings, adhesives, encapsulants or sealants and is particularly useful as industrial coatings that are subject to wide temperature variations, salt contamination or chemical attack.

Owner:3L&T

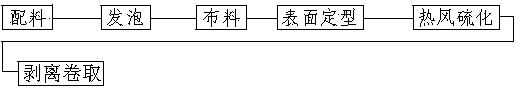

High-temperature ebonite foam for unbalanced drilling and preparation method thereof

ActiveCN103013477ATemperature resistantSalt resistantDrilling compositionSalt resistanceFoaming agent

The invention relates to the technical field of unbalanced drilling, and particularly relates to high-temperature ebonite foam for unbalanced drilling and a preparation method thereof. The high-temperature ebonite foam for unbalanced drilling comprises the following components in percentage by weight: 1-3% of bentonite, 3-6% of composite foaming agent, 0.3-0.6% of foam stabilizer and the balance of water. Through the synergistic effect of the composite foaming agent and the foam stabilizer, the high-temperature ebonite foam provided by the invention has the characteristics of dense foam, temperature resistance, salt resistance, strong oil resistance and stable foam performance; and the sand carrying ability is enhanced, and the requirements for drilling construction are met better.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Moisture activated single-component ebonite composition

ActiveUS20040254303A1Improve stabilityPrevents sagging, dripping or run-offPlastic/resin/waxes insulatorsConductive materialChemical LinkageVulcanization

A single component sag-free liquid ebonite composition having silane coupling agents selected to chemically bond and convert liquid unsaturated rubber to alkoxy functionality, to consume and scavenge moisture originally present in the mixture, and to react with sulfur during vulcanization. The single component liquid ebonite composition is moisture activated and is particularly useful for coating applications in protecting metal from corrosion and chemical attack. In some embodiments, the liquid ebonite composition having a total mass percentage of 100 is mainly composed of liquid unsaturated rubber, sulfur, a vulcanization activator, a vulcanization accelerator, a first silane, a second silane, and a third silane. With the right reactive functional group, the third silane can replace the first or second silane. In some embodiments, the liquid ebonite composition includes a catalyst, carbon black, fillers, additives, and a diluent or solvent.

Owner:3L&T

Fireproof long-acting sealant

InactiveCN104046306AImprove tightnessImprove air tightnessNon-macromolecular adhesive additivesPhosphateAluminium hydroxide

A disclosed fireproof long-acting sealant is prepared from the following raw materials in parts by weight: 20-30 parts of butyl rubber, 15-25 parts of polyisobutylene, 17-21 parts of liquid polybutene, 7-10 parts of ebonite, 15-25 parts of triaryl phosphate, 13-16 parts of nanometer calcium carbonate, 18-24 parts of magnesium hydroxide, 3-6 parts of barium sulfate, 15-18 parts of aluminium hydroxide, 10-20 parts of rutile titanium dioxide, 7-14 parts of a phosphate fire retardant, 6-9 parts of diatomite and 12-16 parts of polyisobutylene. The provided fireproof long-acting sealant is good in sealing property, air impermeability, water sealing property, flexibility, beneficial for construction and installation, resistant to high and low temperature, and good in fireproof effect.

Owner:QINGDAO CHENQING INFORMATION TECH

Sealant for electric vehicles

InactiveCN104046300AImprove sealingWatertightNon-macromolecular adhesive additivesConjugated diene hydrocarbon adhesivesFire retardantSealant

A disclosed sealant for electric vehicles is prepared from the following raw materials in parts by weight: 15-20 parts of cis-1,4-polybutadiene rubber, 6-9 parts of carbon black, 6-10 parts of sodium silicate, 10-18 parts of polyisobutylene, 5-8 parts of zinc oxide, 6-9 parts of ebonite, 4-7 parts of a lubricant, 10-15 parts of nanometer calcium carbonate, 9-18 parts of dioctyl phthalate, 3-7 parts of barium sulfate, 15-20 parts of thermoplastic synthetic resin, 4-8 parts of calcium carbonate, 11-18 parts of rutile titanium dioxide, 4-8 parts of a phosphate flame retardant and 5-10 parts of diatomite. The provided sealant for electric vehicles is good in stability, good in gumminess, not easy to crack in sun and fall off, and good in fireproof effect.

Owner:QINGDAO CHENQING INFORMATION TECH

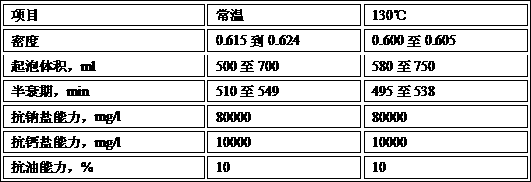

Method for recycling waste lead storage battery

The invention discloses a method for recycling a waste lead storage battery. The method comprises the following steps of 1, feeding the recovered waste storage battery into a drying chamber to be dried so as to evaporate the moisture inside the lead storage battery; 2, placing the dried waste lead storage battery into a smasher to be smashed, simultaneously sending the smashed articles into a screening machine to select the waste lead powder, and then placing the waste lead powder into a desulphurization pond to be desulphurized; and 3, sending the residual particles into the smasher to be smashed, sending the smashed articles into the screening machine, and recovering the selected plastic particles and the hard rubber particles respectively into a plastic collecting area and a hard rubber collecting area. The desulphurization agent used in the desulphurization pond is limestone-gypsum, a wet desulphurization method is used, the desulphurization product is gypsum which can be used as a building material, and the lead is also replaced. By adopting the method, the problem that the waste lead storage battery pollutes the environment can be solved, and the resource waste can be reduced.

Owner:宁夏祺腾数据产业发展有限公司

Long-acting environment-friendly sealant

InactiveCN104046302AReduce manufacturing costImprove fire performanceNon-macromolecular adhesive additivesOther chemical processesAluminium hydroxidePolyvinyl chloride

A disclosed long-acting environment-friendly sealant is prepared from the following raw materials in parts by weight: 30-40 parts of cis-1,4-polybutadiene rubber, 4-7 parts of sodium hydroxide, 15-20 parts of polyisobutylene, 4-8 parts of organic bentonite, 6-10 parts of ebonite, 13-16 parts of nanometer calcium carbonate, 2-5 parts of phenolic resins, 3-9 parts of luting resin, 3-9 parts of polyvinyl chloride-polyvinylidene emulsion, 30-40 parts of thermoplastic synthetic resin, 4-8 parts of aluminium hydroxide, 10-20 parts of rutile titanium dioxide, 5-10 parts of portland cement, 5-15 parts of a phosphate flame retardant, 5-10 parts of diatomite and 50-80 parts of water. The provided long-acting environment-friendly sealant is low in production cost, good in fireproof performance, good in waterproof performance, smooth in surface and strong in adaptability.

Owner:QINGDAO CHENQING INFORMATION TECH

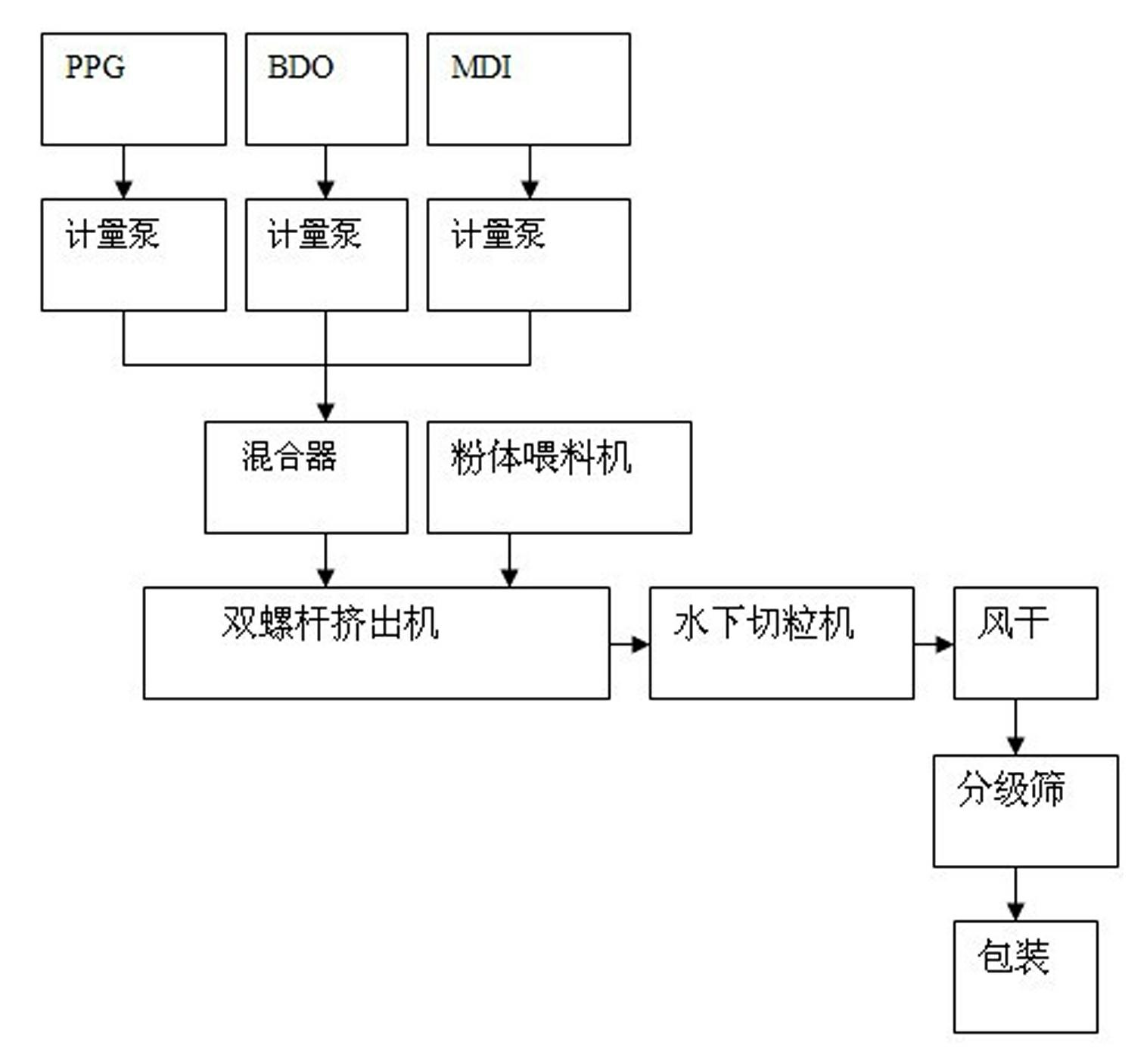

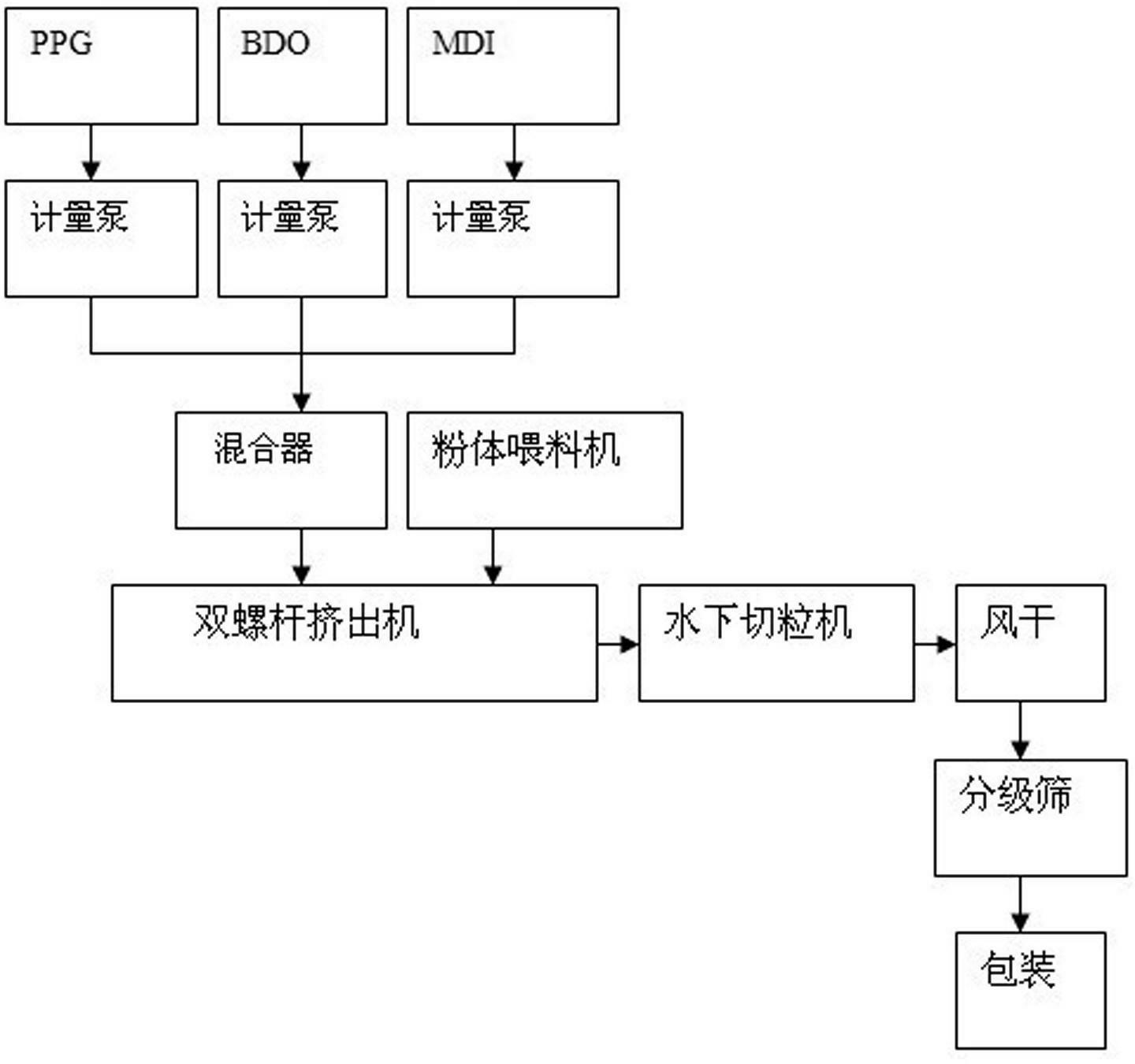

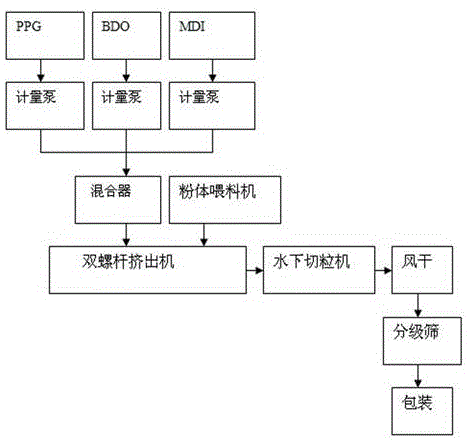

Polyurethane rubber composite material and preparation method thereof

The invention relates to a composite material and the preparation field thereof, in particular to a polyurethane rubber composite material. The polyurethane rubber composite material comprises the following components in percentage by weight: 50 to 70 percent of polyether glycol (PPG), 18 to 50 percent of isocyanate (MDI), 6 to 9 percent of crosslinking agent, 1 to 3 percent of catalyst, 4 to 5 percent of aid, 0.9 to 2 percent of water, 1 to 10 percent of surfactant, 1 to 4 percent of triisocyanate, 1 to 3 percent of sulfur accelerating agent, 2 to 4 percent of foaming agent, 1 to 3 percent of internal lubricant, 2 to 3 percent of external lubricant and 1 to 10 percent of coloring agent. The rubber composite material is prepared by the preparation method. Compared with the traditional hard rubber, the polyurethane rubber composite material has a low density and a stable size and can greatly save materials.

Owner:谢秋鸿

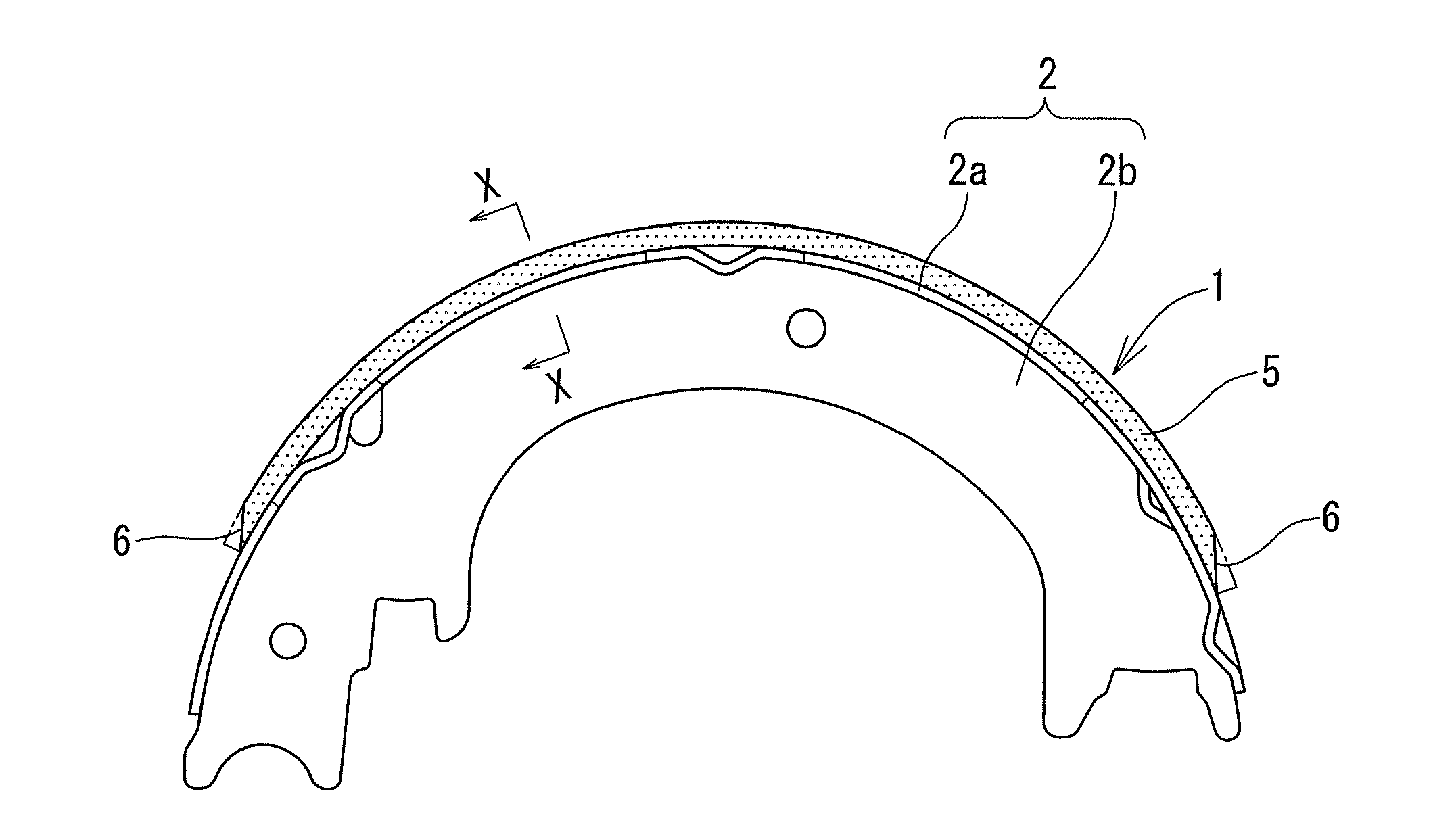

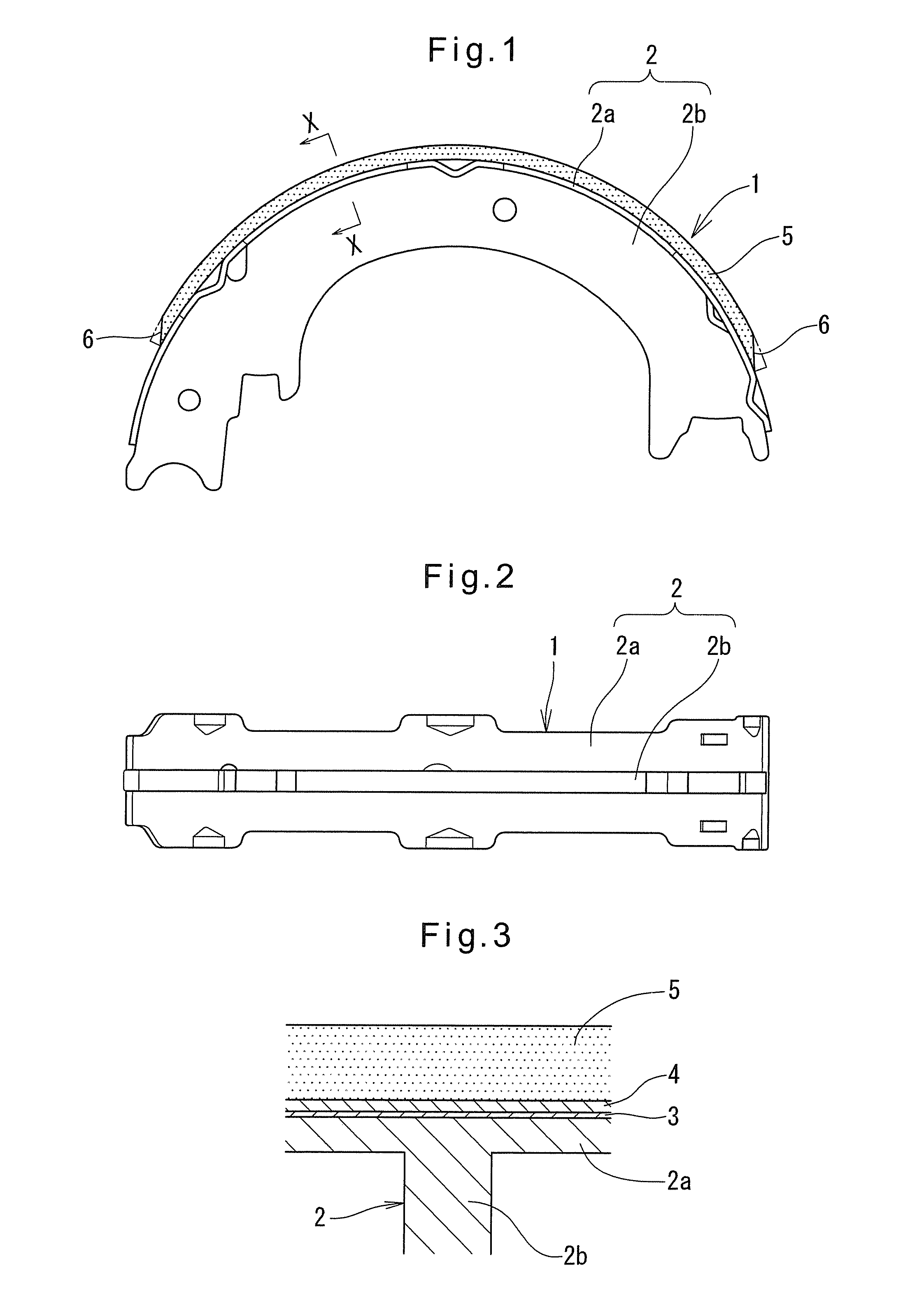

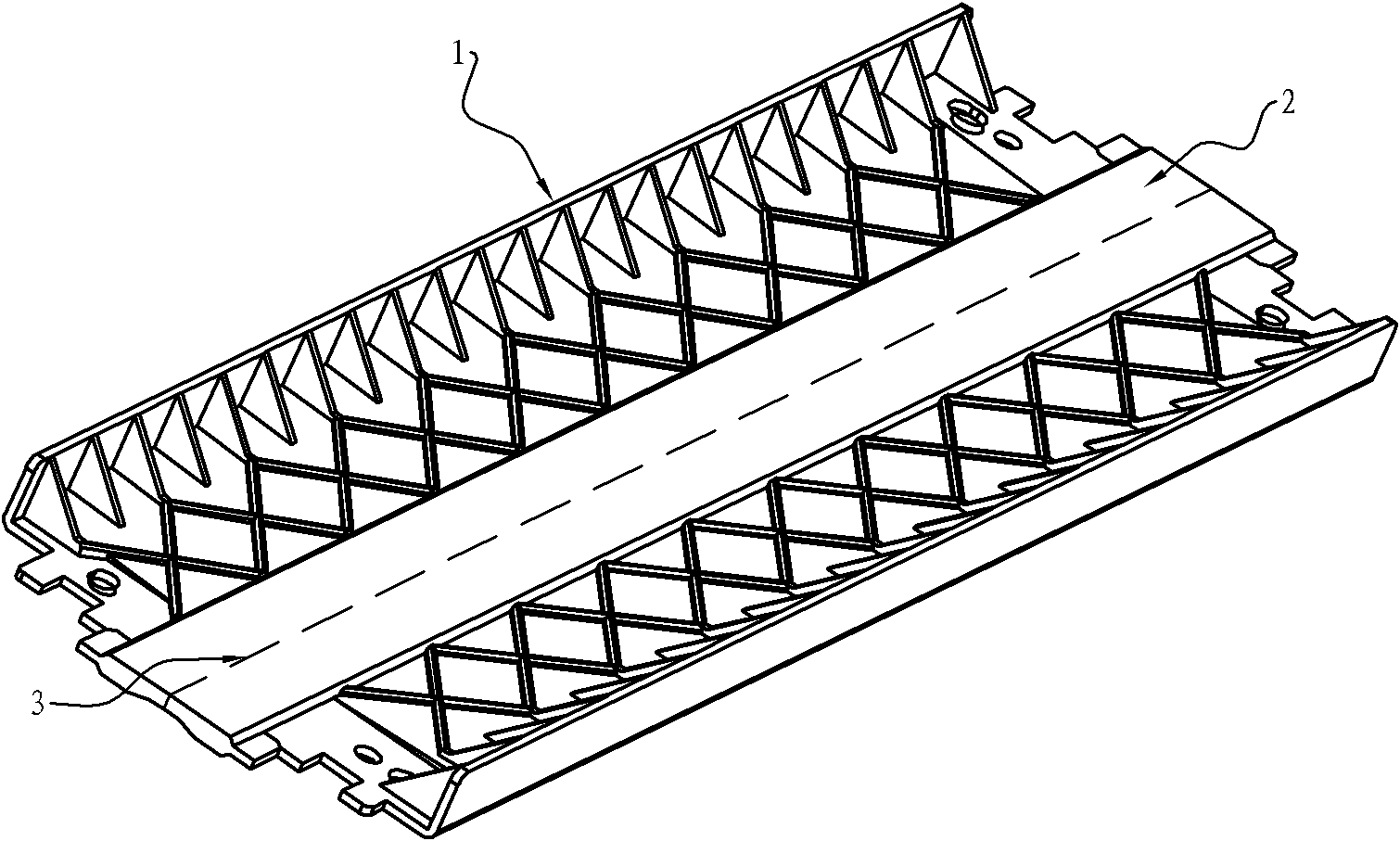

Brake Shoe

InactiveUS20080251330A1Speed up preparationLow costBraking membersFriction liningEngineeringStress relief

A brake shoe is proposed which includes a lining containing a rubber of the type which becomes ebonite when vulcanized. An elastic interlayer is disposed between the lining and an adhesive layer through which the lining is bonded to the shoe body. The interlayer serves as a stress relief layer, thereby preventing the lining from peeling off the shoe body when the brake shoe is subjected to thermal history.

Owner:ADVICS CO LTD

Epoxy ebonite compositions

InactiveUS7005483B2Improves resistance to delamination and undercut corrosionUnspecified rubber coatingsEpoxy resin coatingsElastomerEpoxy

Owner:3L&T

Preparation method of conductive scanning metallographic sample

InactiveCN101718647ASolve uneven distributionEasy to makePreparing sample for investigationAqueous alcoholSoot

The invention relates to a preparation method of a scanning metallographic sample, particularly to a preparation method of a conductive scanning metallographic sample. The invention solves the problems of no conductibility of the scanning metallographic sample, homogeneous distribution of a conductive filling material and poor adhesive property between the conductive filling material and a base material. The method comprises the following steps of: selecting ebonite dust as the base material; selecting carbon soot as the conductive filling material, and adding the ebonite dust and the carbon soot in the volume proportion of 5:(2-3) into a container containing alcohol; heating the container to the temperature of 100DEG C, and stirring for 30 minutes; pouring out the mixture out offrom the container, and drying at the temperature of 50-100DEG C; pulverizing a dried composite material; putting the prepared powder into a mould, heating to the temperature of 130-150DEG C, simultaneously applying pressure to the mould, and retaining heat and pressure for 8-10 minutes; and taking out a sample to finish the preparation of the metallographic sample. The invention improves the adhesive property between the conductive filling material and the base material, and the conductive filling material is homogeneously distributed; the metallographic sample has stable physical-mechanical performance.

Owner:HARBIN INST OF TECH

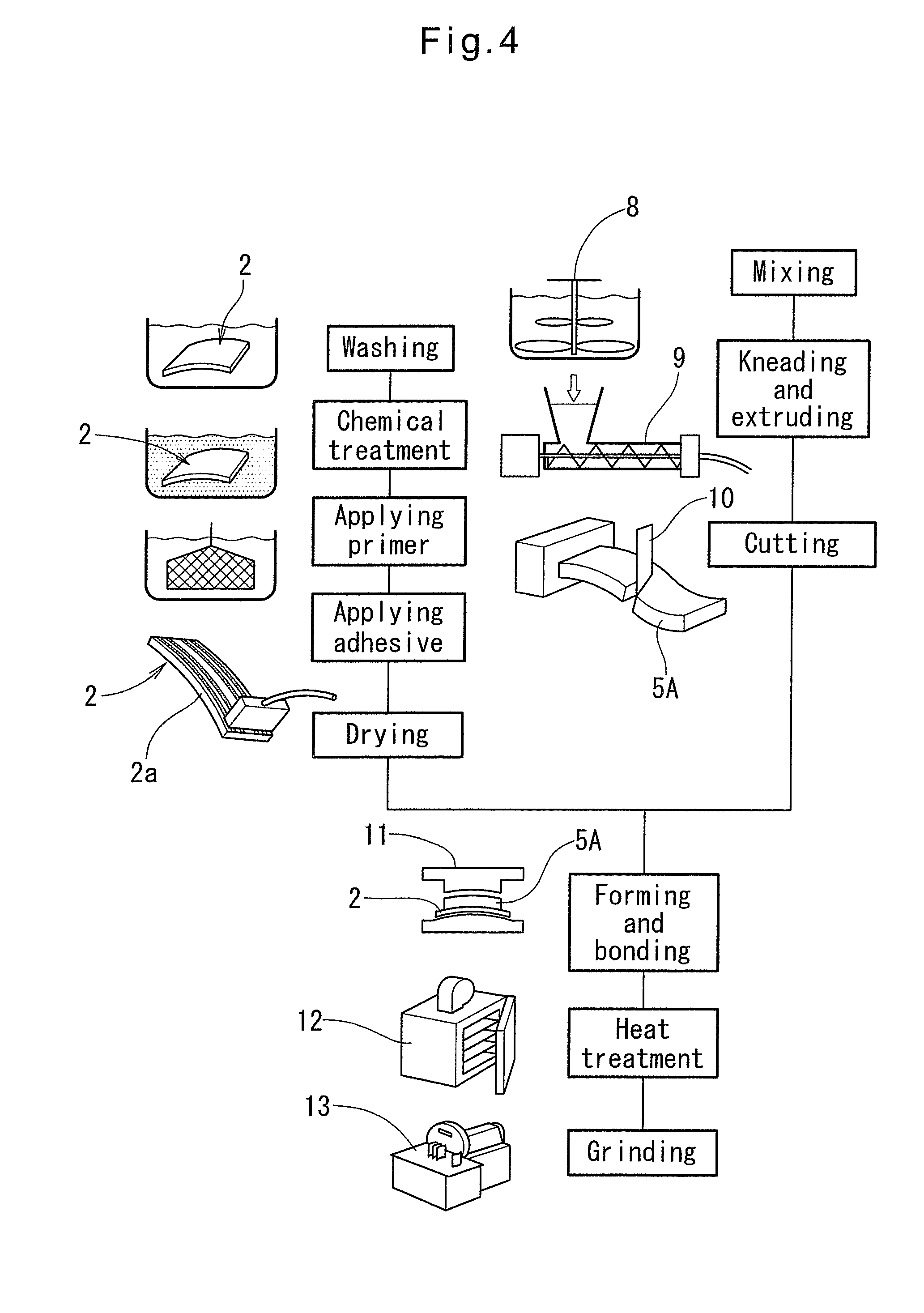

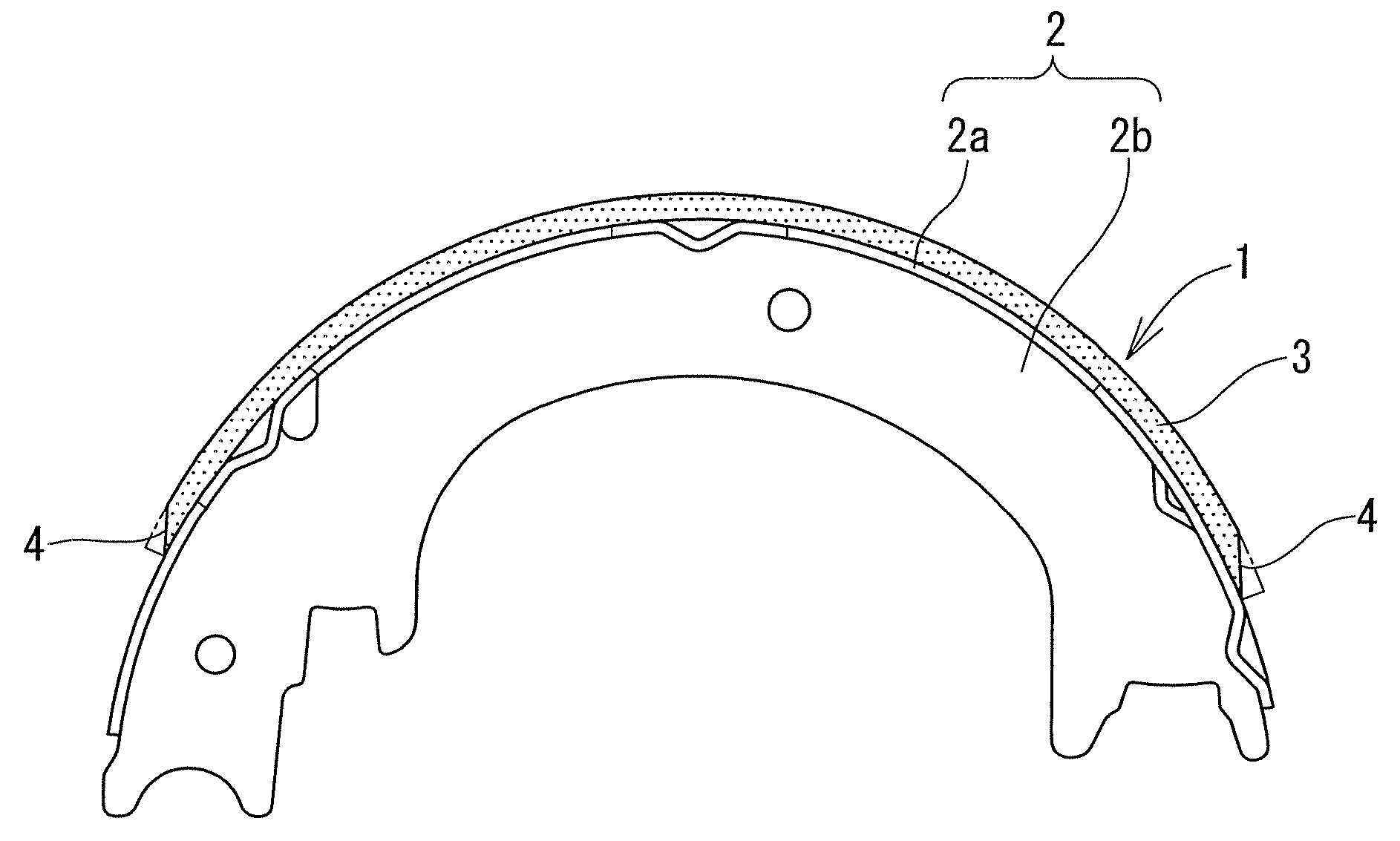

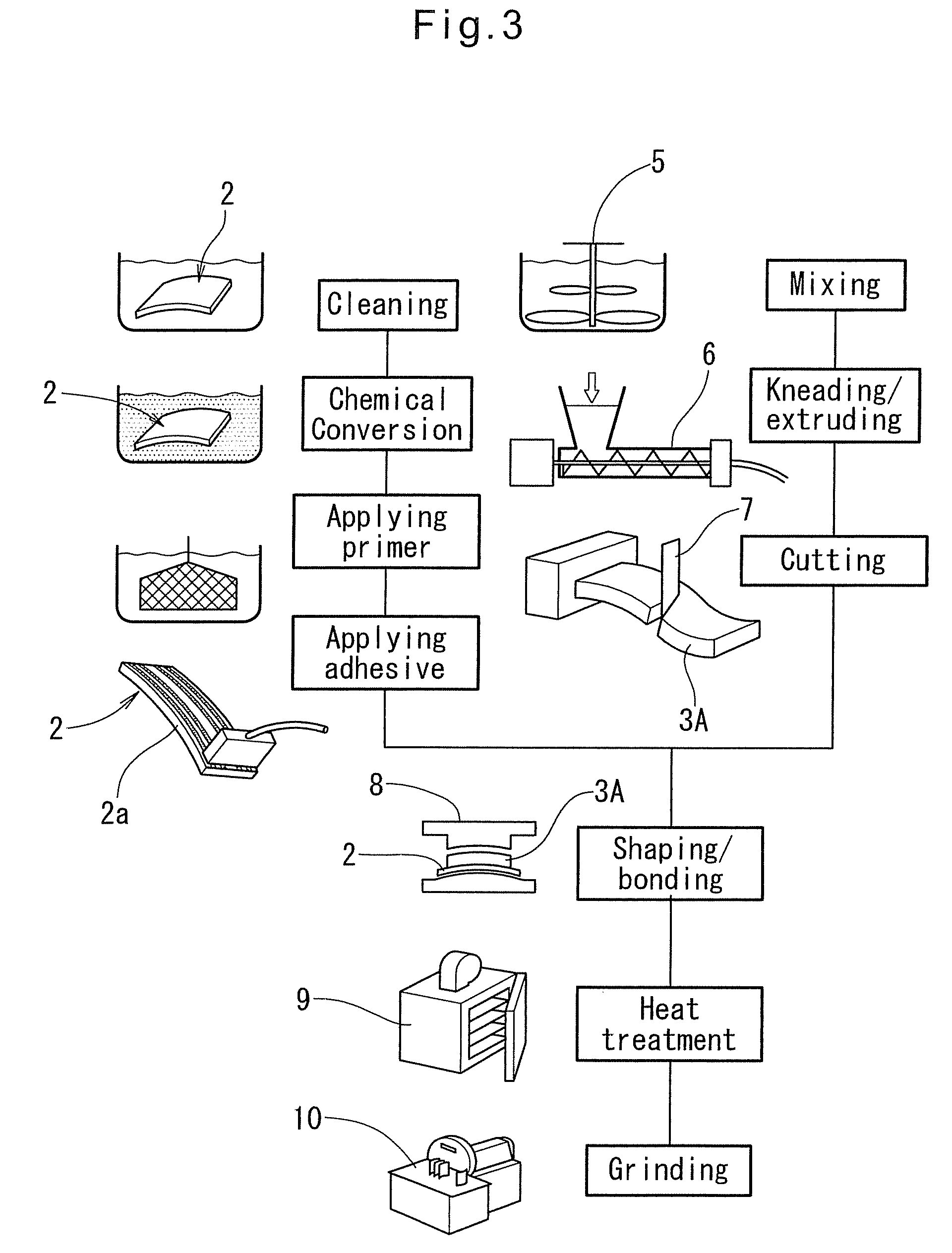

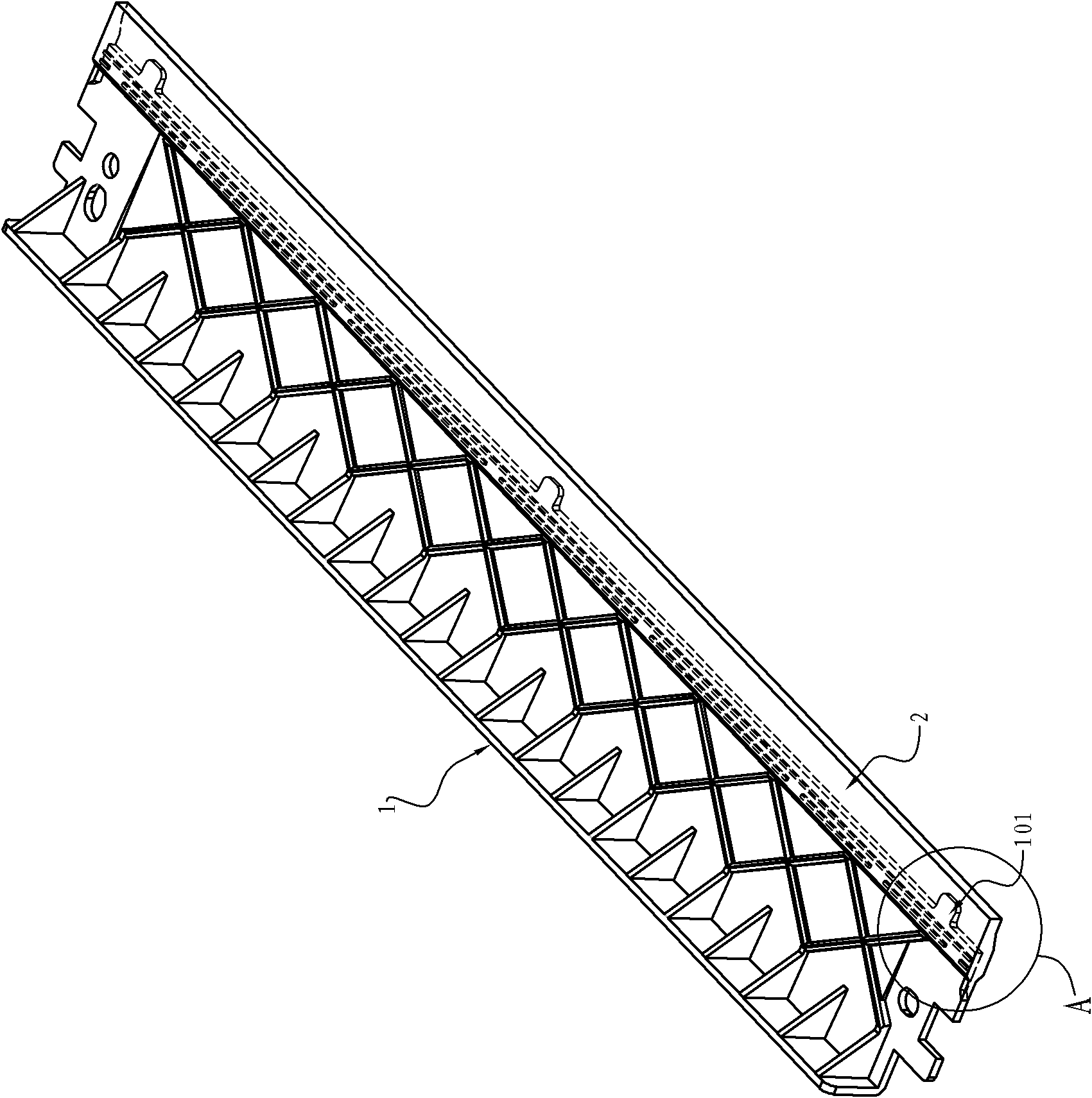

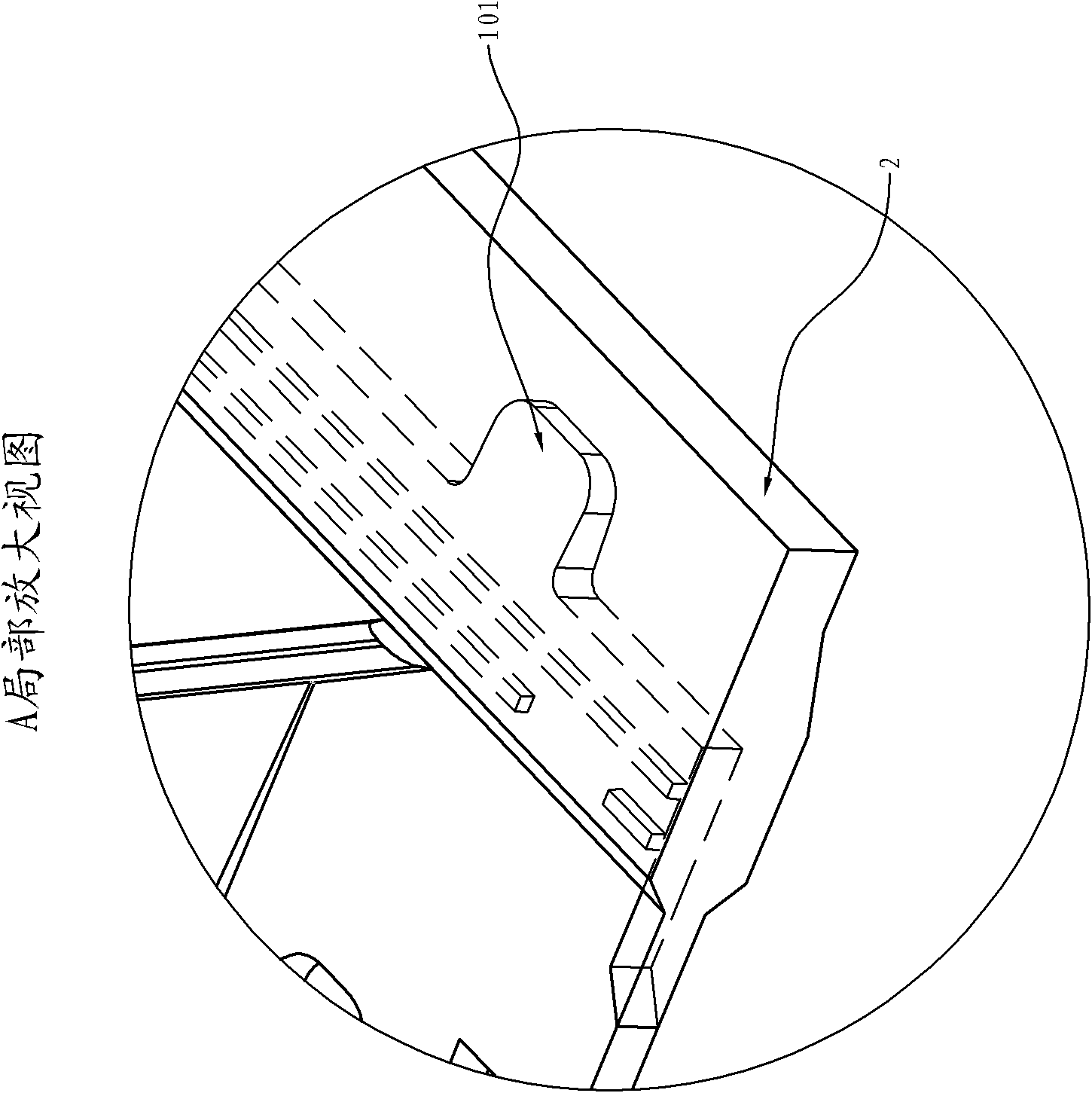

Brake Shoe and Method of Manufacturing the Same

InactiveUS20090159380A1Improve productivityReduce manufacturing stepsBraking membersFriction liningVulcanizationEngineering

An object is to provide a brake shoe which can be manufactured by a method comprising a reduced number of manufacturing steps, and such a method. A brake shoe 1 is manufactured by cutting a sheet blank formed by extrusion or calender sheeting into strips having a predetermined length, laying the strips on the shoe body 2, pressing and bonding the strips to the shoe body 2 and hardening the strips. The lining 3 is formed with tapered surfaces 4 at both ends thereof for facilitating release of the lining from a die. The lining 3 preferably contains as a binder a rubber that turns into ebonite when subjected vulcanization.

Owner:ADVICS CO LTD

Seal puddle

InactiveCN102993497ANot easy to spillNot easy to flowOther chemical processesPolymer scienceEngineering

The invention discloses a seal puddle. The seal puddle is characterized by comprising the following raw materials in percentage by weight: 50 to 60% of butadiene rubber, 10 to 25% of polyisobutene, 5 to 8% of carbon black, 2 to 5% of ebonite, 11 to 15% of nano calcium carbonate, 5 to 10% of connection resin, 0.3 to 1% of barium sulfate, and 2 to 5% of talcum powder. The seal puddle has the advantages that the component proportion in the prescription is optimized, and the glue hardly overflows, flows and moves, is high in water resistance and seal performance, smoother in surface and high in adaptability.

Owner:无锡昆成新材料科技有限公司

Hard rubber composition for hot water vulcanized anticorrosion lining of large equipment

The invention relates to a rubber composition, in particular to a rubber composition for hot water vulcanized anticorrosion lining of large equipment, which is characterized by comprising the following components in percentage by weight: 70 to 90 parts of natural rubber, 10 to 30 parts of high styrene, 10 to 40 parts of filler, 3 to 10 parts of zinc oxide, 20 to 50 parts of sulfur, 1 to 3 parts of promoter DM1 and 1 to 5 parts of promoter TT. In the invention, the vulcanization of the composition can be realized without using any vulcanizing boiler, the vulcanization is complete, and surface quality problems are avoided.

Owner:SHANGHAI SHUANGPU ANTICORROSION RUBBER LINING

Mobile phone protective cover and preparing technique thereof

InactiveCN101238927ASignificant progressProminentlyOther accessoriesTelephone set constructionsEngineeringSynthetic resin

The invention provides a handset protective sleeve and preparation method thereof. The handset protective sleeve comprises 30-90% mass ratio of ebonite material and 10-70% mass ratio of flexible glue material, wherein the ebonite material is one material selected from ABS, PC, or PP or mixture of ABS and PC; the flexible glue material is one material selected from TPR, TPE, TPU or PU. The preparation method thereof comprises the following steps: pressing 30-90% mass ratio of synthetic resin of any one ebonite material selected from the ABS, PC, or PP or mixture of ABS and PC at 180-350 degree and pouring the flaky resin into the mould to form inner-layer hardshell; pressing 10-70% mass ratio of synthetic resin of any one flexible glue material selected from the TPR, TPE, TPU or PU at 150-260 degree and pouring the flaky resin into the mould to form outer-layer softshell; obtaining the finished product.

Owner:邓洪初

Raw material formula for plastic woven bag

The invention discloses a raw material formula for a plastic woven bag. According to the formula, the plastic woven bag comprises 30-38% of PP T30S, 15-20% of PP 045, 8-10% of PET, 10-18% of polystyrene ebonite, 4-5% of resin, 3-4% of bakelite and 5-30% of filling master batch. The filling master batch is nano calcium carbonate. The resin is silicon resin. The plastic woven bag manufactured according to the raw material formula for the plastic woven bag is environmentally friendly and resistant to tearing and stretching.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

Method for manufacturing scraping knife

InactiveCN102529013ALow costReduce processElectrographic process apparatusDomestic articlesEngineeringInjection molding machine

The invention provides a method for manufacturing a scraping knife. The scraping knife comprises a knife rest made of ebonite and a blade made of soft rubber. The method for manufacturing the scraping knife comprises the following steps of: preparing a die; adding the ebonite and the soft rubber; performing injection molding of the knife rest; performing the injection molding of the blade; and demolding. According to the method, the full-plastic scraping machine is produced by using a double-material injection molding machine, so that the cost of production raw materials is reduced, production processes are reduced, the planeness of the scraping knife is improved, namely the quality of products is improved, and environmental pollution caused by the conventional process for manufacturing the scraping knife is avoided.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

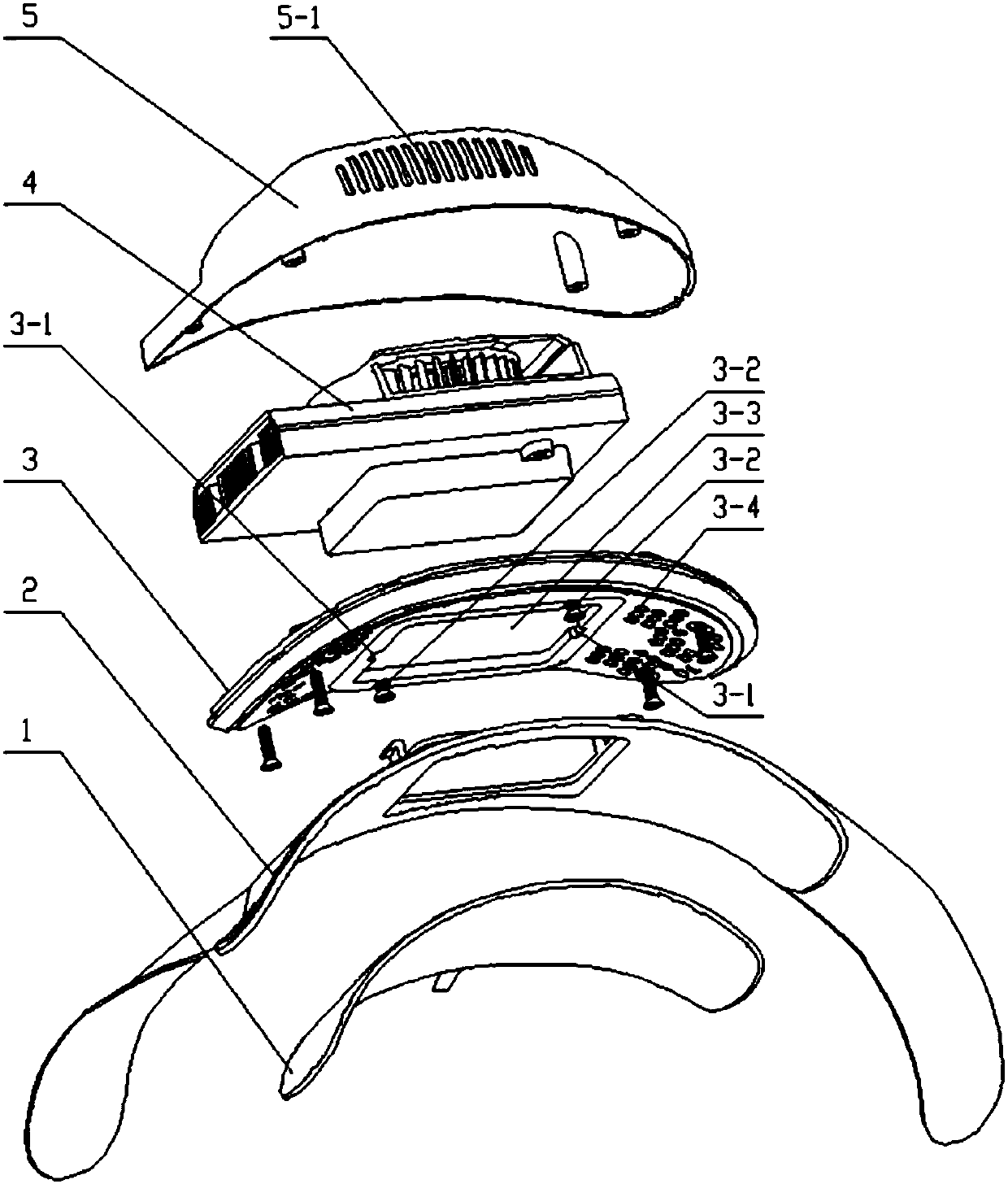

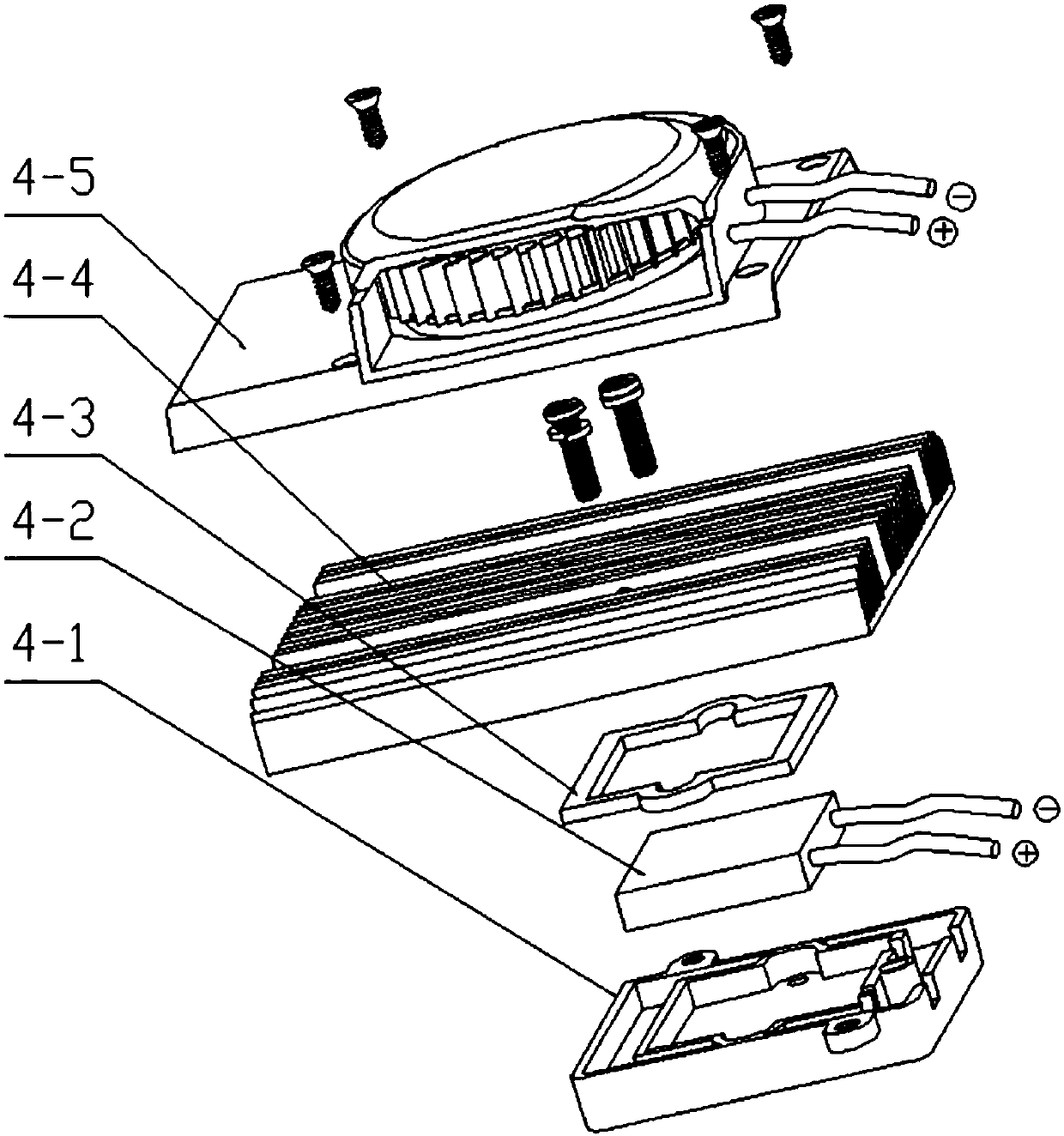

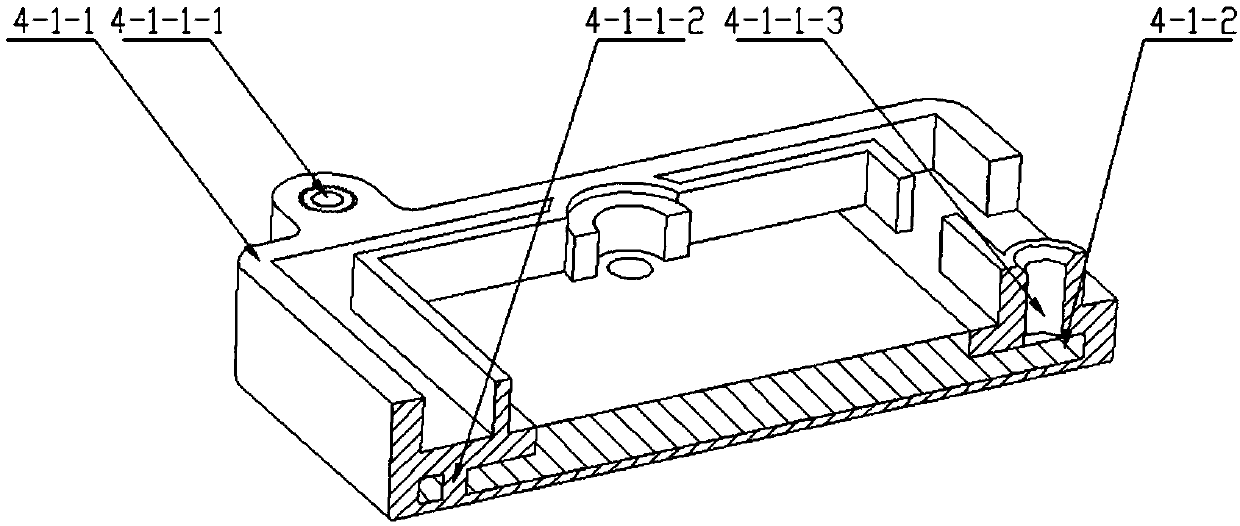

Main machine refrigeration module for a wearable physical temperature decreasing instrument

PendingCN110495987ASmallIncrease productivityMachines using electric/magnetic effectsTherapeutic coolingComputer moduleRefrigeration

The invention provides a main machine refrigeration module for a wearable physical temperature decreasing instrument. The main machine refrigeration module is characterized in that the main machine refrigeration module is composed of a refrigeration module body, a bottom shell, a face shell, a soft and hard plastic body and a water bag; the refrigeration module body is composed of a cold conducting body, a refrigeration sheet, a sponge ring, a heat radiator and a fan which are assembled into a whole; the cold conducting body is composed of a cold conducting plate and an ebonite square frame which are injected into a whole, wherein one face of the center cold conducting plate of the cold conducting body is exposed, the other face of the center cold conducting plate is covered with a layer of thin plastic ebonite, and a threaded hole connected with the bottom shell is formed in the refrigeration module body; a square hole is formed in the center of the bottom shell, and a through hole connected with the refrigeration module body and a buckle position hole connected with the soft and hard plastic body are formed in the face of the bottom shell; the soft and hard plastic body is composed of an ebonite hollow square frame and long-strip-shaped flexible glue which are injected into a whole, the soft and hard plastic body is connected with a wearing belt, the ebonite hollow square frame is provided with a buckle position connected with the bottom shell, and a center square hole of the ebonite hollow square frame is used for allowing the cold conducting body to overall being inserted in a penetrating mode so as to make contact with the surface of the water bag. According to the main machine refrigeration module, the overall industrial manufacturing level in the technical fieldcan be effectively improved, the research and development cycle of new products is greatly shortened, and a new industry of the refrigeration module can be extended.

Owner:SHENZHEN TIANFUJIAN MEDICAL DEVICE TECH +2

Adhesive for hot water-cured lining hard rubber and preparation method thereof

ActiveCN102127378ALower vulcanization temperatureFully vulcanizedNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention relates to an adhesive for lining hard rubber, in particular to an adhesive for hot water-cured lining hard rubber, which is a mixture of components A and B in a weight part ratio of 4:1. The component A comprises 100 parts of natural rubber, 1 to 3 parts of pigment, 20 to 40 parts of sulfur, 50 to 150 parts of zinc oxide, 15 to 40 parts of tackifying resin, 1 to 3 parts of accelerator DM1, 2 to 5 parts of mixed oil 933 and 400 to 700 parts of mixed solvent, wherein the mixed solvent is 2 or 3 of toluene, dimethylbenzene and gasoline. The component B comprises solution of polyisocyanate. Before use, the component B is added into the component A, the components are mixed uniformly (for at least 1 minute), and the adhesive for brushing can be obtained. The adhesive is applicable to hot water-cured lining hard rubber and has big adhesion force.

Owner:SHANGHAI SHUANGPU ANTICORROSION RUBBER LINING

Polyurethane rubber PTMEG-F composite material and preparation method thereof

The invention relates to the fields of composite material and preparation thereof, and particularly relates to a polyurethane rubber PTMEG-F rubber composite material including polyether polyol (PPG), isocyanate (MDI), a crosslinking agent and foaming auxiliary agents, wherein the foaming auxiliary agents include a catalyst, auxiliary agents, water, a surfactant, triisocyanate, a sulfur promoting agent, a foaming agent, an internal lubricant, an external lubricant and a colorant; with the use of the preparation method, the composite material has low density and stable size compared with traditional hard rubber, and can greatly save materials.

Owner:黄文鹏

Improved method and device for high water pressure difference gate sealing

The invention discloses an improved method and a device for high water pressure difference gate sealing. The improved method and the device are characterized in that the section of a water seal is in a blunt-nosed epsilon shape and is of a dual-layer structure; one protruded surface of the water seal is a soft rubber layer, and the other surface of the water seal is a hard rubber layer; a U-shaped cavity is formed in an interface between the soft rubber layer and the hard rubber layer; a water inlet hole is formed in one side of the U-shaped cavity and communicates with an upstream water body or a downstream water body; by means of the upstream water body or the downstream water body entering the U-shaped cavity, the soft rubber layer of the water seal generates expansive deformation deflecting towards the downstream direction, a round head of the water seal is enabled to tightly extrude the surface of a water seal sitting board, thereby improving the sealing effect of the water seal; and for preventing excessive deformation of the head of the water seal, a warping boss is arranged at a position, close to the head of the water seal, of a water seal inner pressing plate, and the condition of water leakage due to creepage of a water seal head caused by excessive deformation of the head of the water seal is limited. According to the improved method and the device disclosed by the invention, the technical problem of water leakage due to unclosed contact between the water seal head and the water seal sitting board in a two-side stressed state of a gate is well solved.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

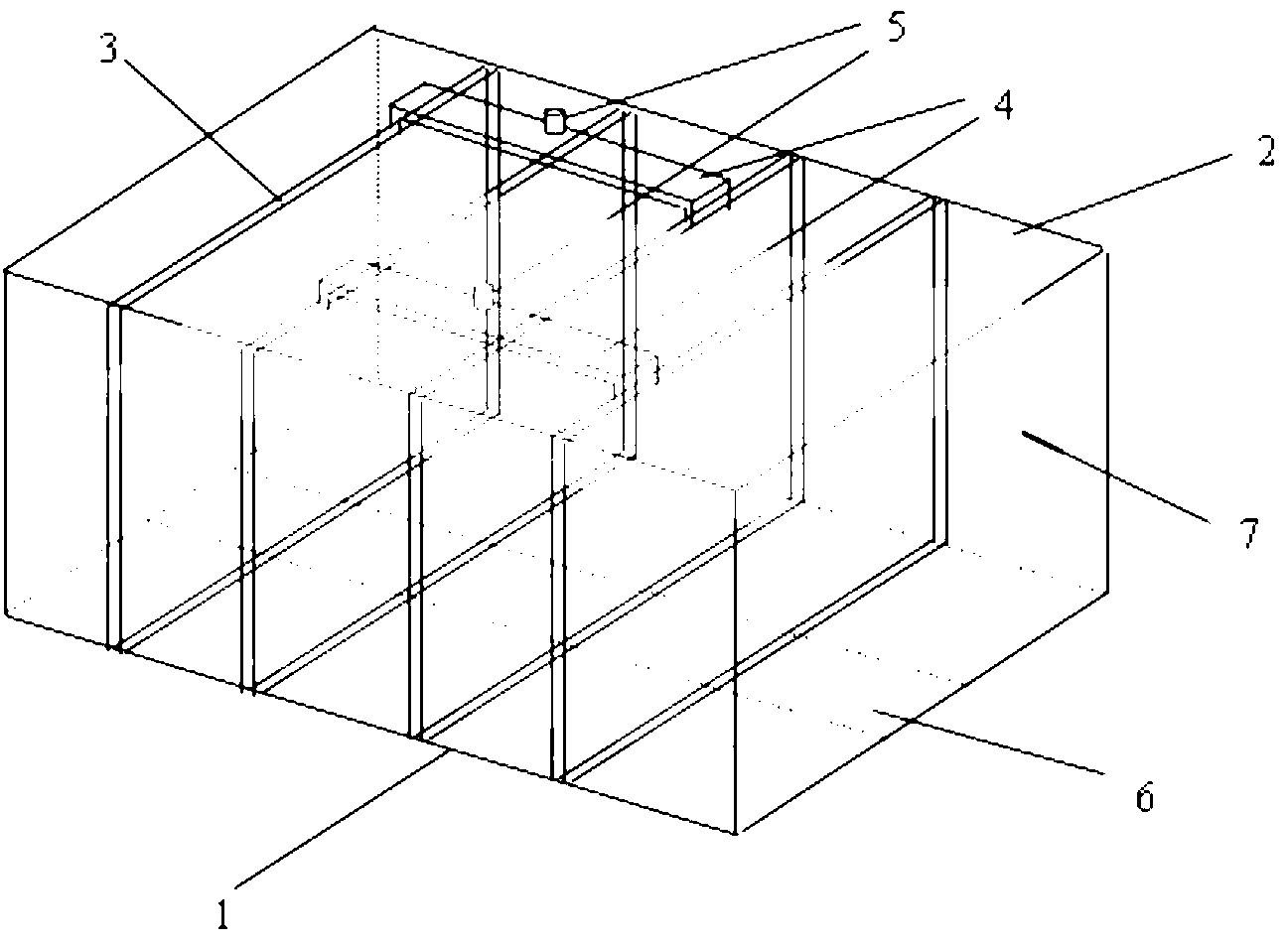

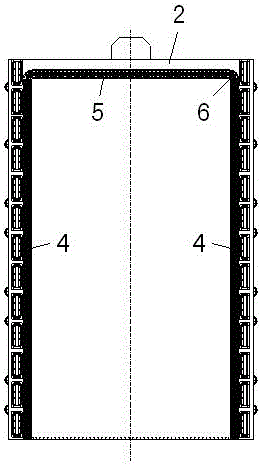

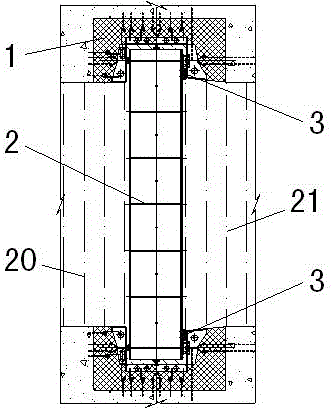

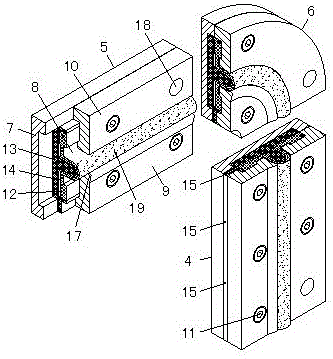

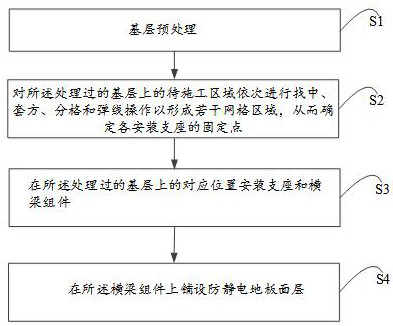

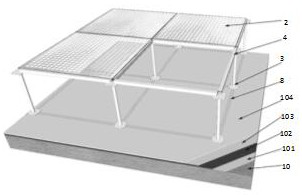

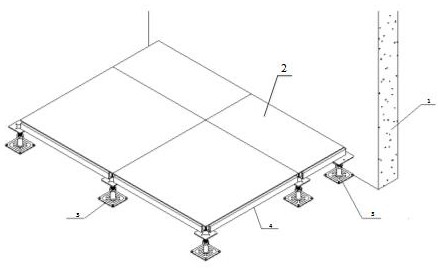

Construction method of anti-static floor

InactiveCN112459392AThe construction method is simpleEasy to operateFlooring insulationsFalse floorsAdhesiveArchitectural engineering

The invention provides a construction method of an anti-static floor. The construction method comprises the following steps that 1, pretreating a base layer; 2, sequentially carrying out centering, square sleeving, grid dividing and line snapping operations on a to-be-constructed area on the treated base layer to form a plurality of grid areas, so as to determine fixing points of each mounting support; 3, installing a support and a cross beam assembly at the corresponding positions of the treated base layer; and 4, laying an anti-static floor surface layer on the cross beam assembly. Accordingto the construction method of the anti-static floor, the process is simple, operation is easy, the construction efficiency is greatly improved, meanwhile, on-site materials can be utilized to the maximum extent, and the cost is saved. Furthermore, an adhesive is added in the construction process, so that the construction quality is ensured; Flame-retardant hard rubber, insulating paint, copper foil strips and the like are laid to achieve the fireproof and electricity-proof effects.

Owner:上海宝冶建筑装饰有限公司 +1

Novel resin sealant

InactiveCN104046301AImprove sealingGood weather resistanceNon-macromolecular adhesive additivesOther chemical processesEpoxyCrack resistance

A novel resin sealant is prepared from the following raw materials in parts by weight: 20-40 parts of epoxy resin, 30-50 parts of cis-1,4-polybutadiene rubber, 25-35 parts of thermoplastic synthetic resin, 3-8 parts of diatomite, 15-20 parts of polyisobutylene, 4-8 parts of xylene solution of raw rubber, 8-14 parts of xylene, 6-10 parts of ebonite, 9-18 parts of dibutyl phthalate, 11-16 parts of asbestos powder, 10-15 parts of nanometer calcium carbonate, 7-14 parts of m-phenylenediamine, 3-6 parts of barium sulfate, 11-17 parts of rutile titanium dioxide and 6-12 parts of a phosphate fire retardant. The novel resin sealant is good in sealing property, resistant to water seepage, airtight, good in weatherability, good in low-temperature crack resistance, excellent in heat-insulation shock-proof performances, beneficial for construction and installation, and good in fireproof effect.

Owner:QINGDAO CHENQING INFORMATION TECH

High-temperature resistant and highly-condensed type waterproof seal puddle

InactiveCN102993578AOptimizing the Group Distribution RatioNo overflowOther chemical processesEngineeringButyl rubber

The invention discloses a high-temperature resistant and highly-condensed type waterproof seal puddle. The seal puddle is characterized by comprising the following raw materials in parts by weight: 30 to 45 parts of butadiene rubber, 30 to 45 parts of polyisobutene, 5 to 10 parts of carbon black, 0.5 to 1 parts of ebonite, 5 to 10 parts of nano calcium carbonate, 5 to 10 parts of superfine talcum powder, 0.3 to 1 part of antioxidant 1010, and 0.3 to 1 parts of anti-aging agent RD. The high-temperature resistant and highly-condensed type waterproof seal puddle has the advantages that the component proportion in the prescription is optimized, and the nano calcium carbonate is prepared, thus the puddle cannot overflow, flow and move at high temperature of 130 to 150 DEG C or under the external force of the type mentioned above, and has higher resistance to high temperature and high coagulative power.

Owner:无锡昆成新材料科技有限公司

High-quality middle-high pressure insulated ethylene propylene rubber

InactiveCN104419083AImprove cleanlinessMass production quality is stableVulcanizationPolymer science

The invention discloses a high-quality middle-high pressure insulated ethylene propylene rubber, comprising ethylene-propylene diene copolymer rubber, zinc oxide, ebonite acid, paraffin, paroline, calcined clay, dicumyl peroxide, triallyl isocyanurate, 2,2,2,4-trimethyl-1,2-hydro-quinoline polymer, 2-thiol benzimidazole and light calcium carbonate. The invention also provides a preparation method of the high-quality middle-high pressure insulated ethylene propylene rubber. Ethylene propylene rubber is adopted as a basic material; surface-treated calcined clay is selected to fill; a peroxide vulcanization system is adopted; and the high-quality middle-high pressure insulated ethylene propylene rubber has characteristics of excellent electric property, good processing process and the like, also has good water resistance and low-temperature flexibility, and is suitable for pavement on a mine.

Owner:SHANGHAI MINING CABLE FACTORY

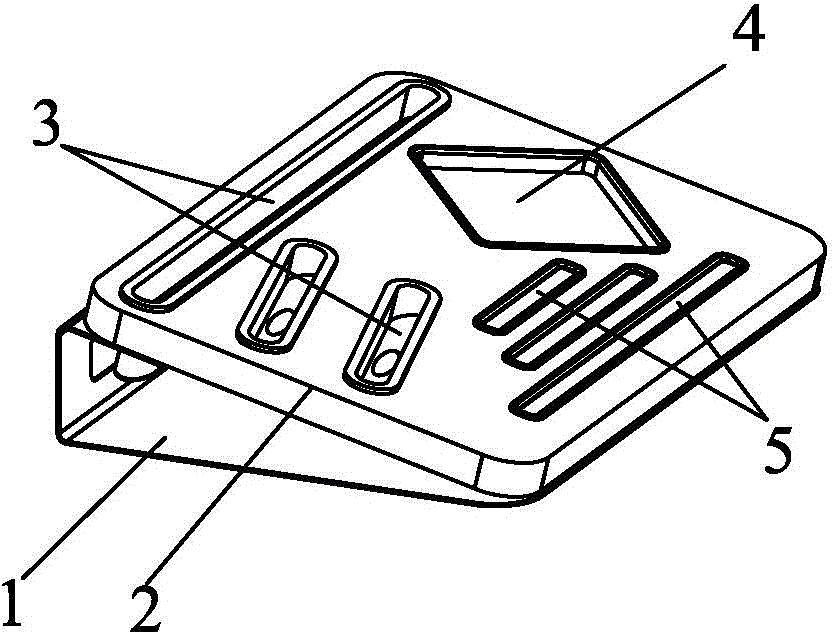

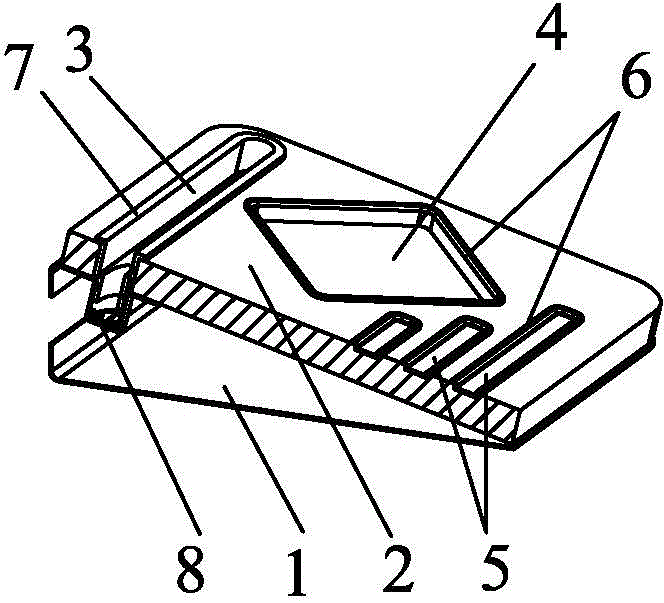

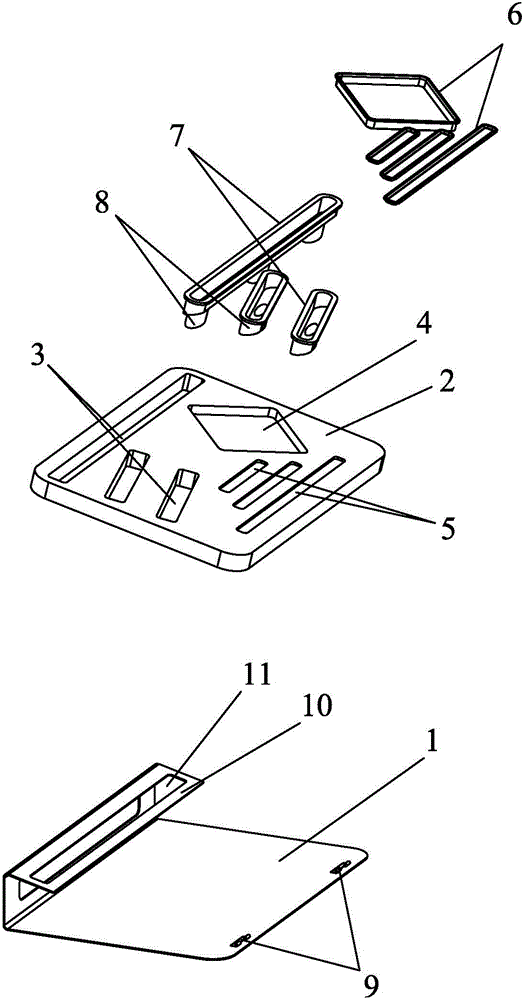

Bracket for mobile phone and tablet computer

The invention discloses a bracket for a mobile phone and a tablet computer. The bracket comprises a base and a panel, wherein the base adopts a horizontal L-shaped structure; an inward inclined extending structure is arranged at the tail end of the L-shaped structure; the panel is fixed on the base; the head end and the tail end of the L-shaped structure respectively support the two ends of the panel; a clamping groove is formed in the panel; ebonite is embedded in the clamping groove. The bracket is simple and convenient to use, has a simple structure, and is low in cost, small in size, and convenient for vast crowd to use; a soft rubber gasket can prevent a mobile phone or a tablet computer from being scrapped or bumped by the panel, and is beneficial to protecting the appearance of the mobile phone or the tablet computer.

Owner:珠海宏声科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com