Patents

Literature

256 results about "Puddle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A puddle is a small accumulation of liquid, usually water, on a surface. It can form either by pooling in a depression on the surface, or by surface tension upon a flat surface. A puddle is generally shallow enough to walk through, and too small to traverse with a boat or raft. Small wildlife may be attracted to puddles.

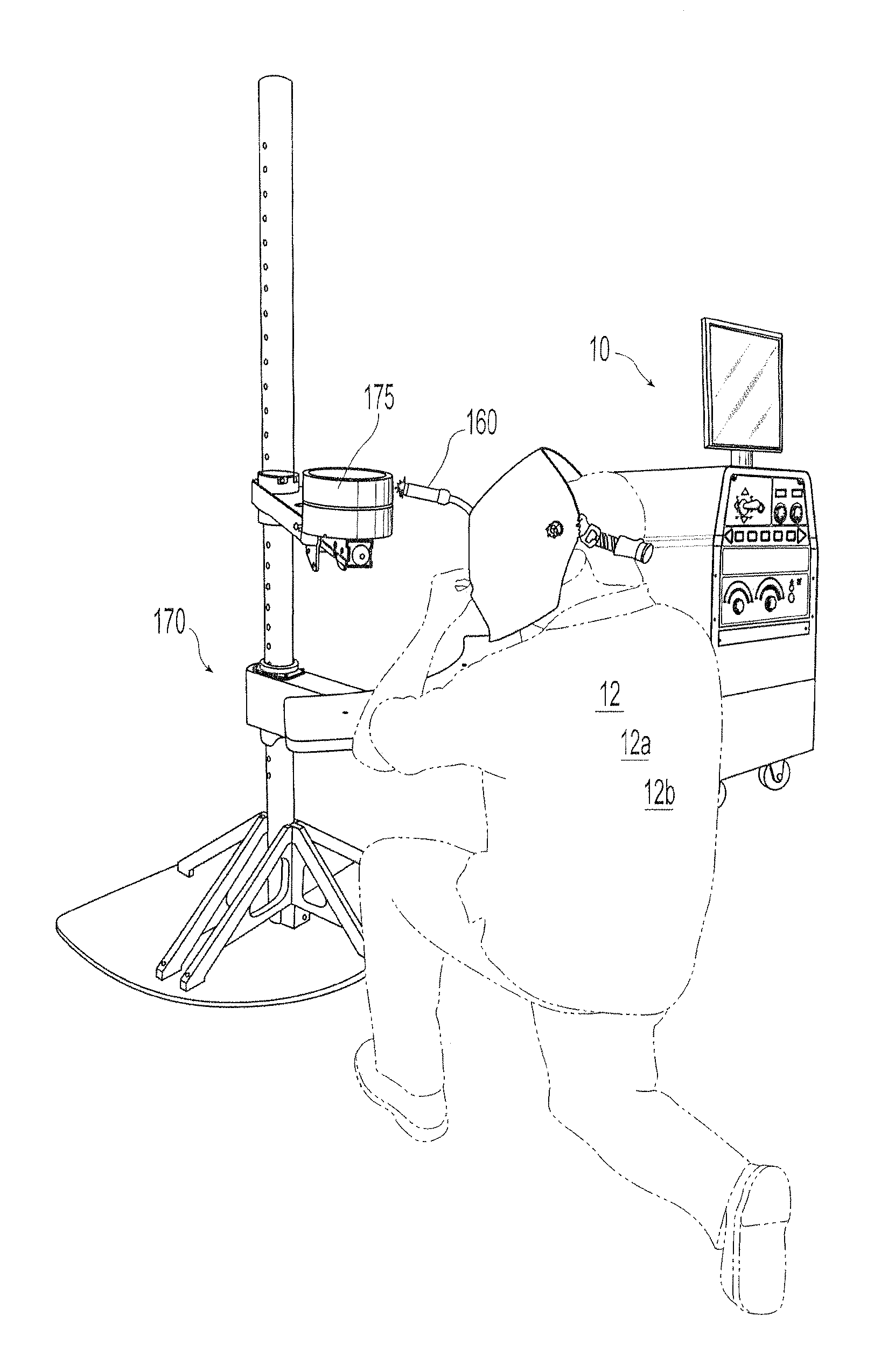

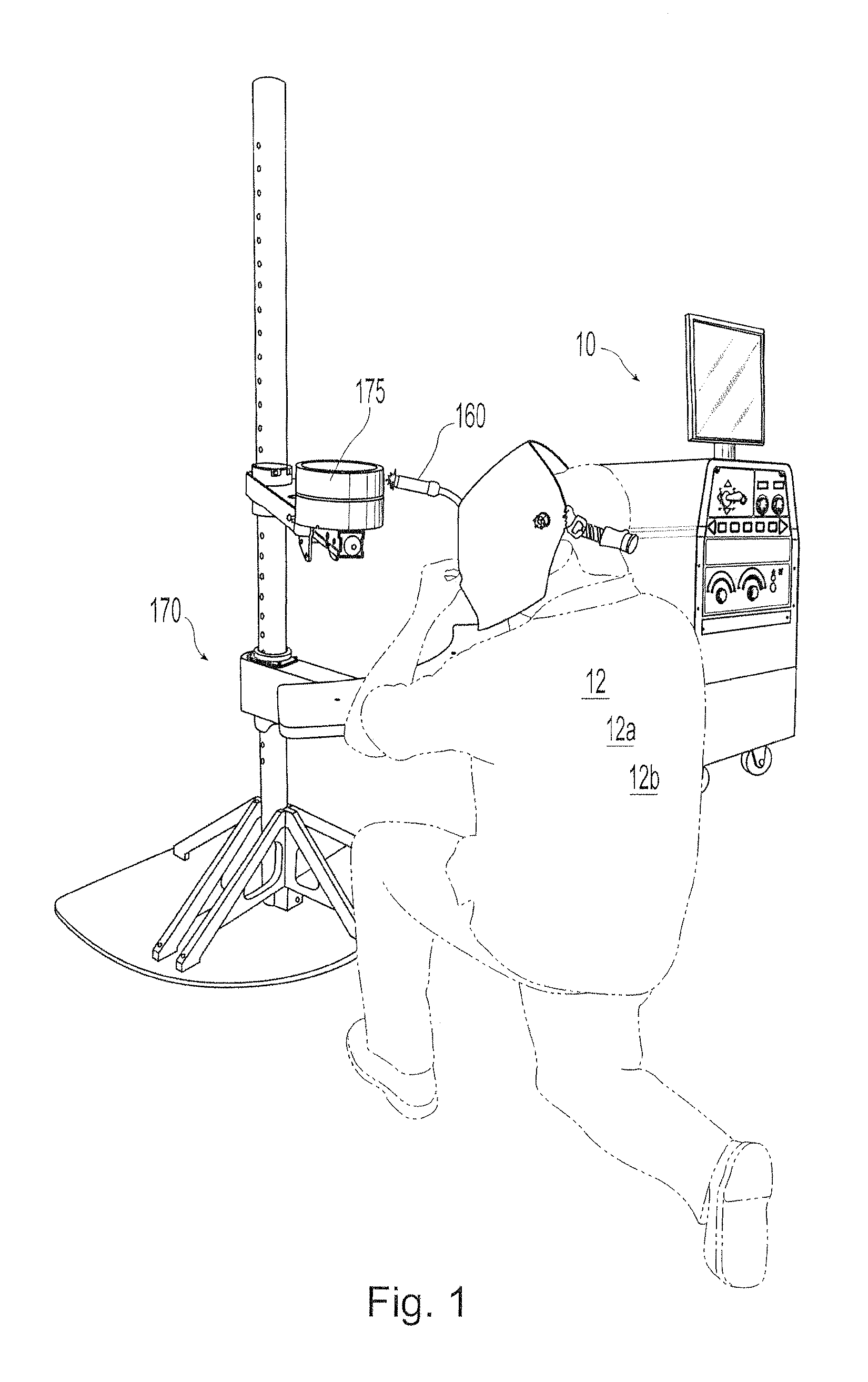

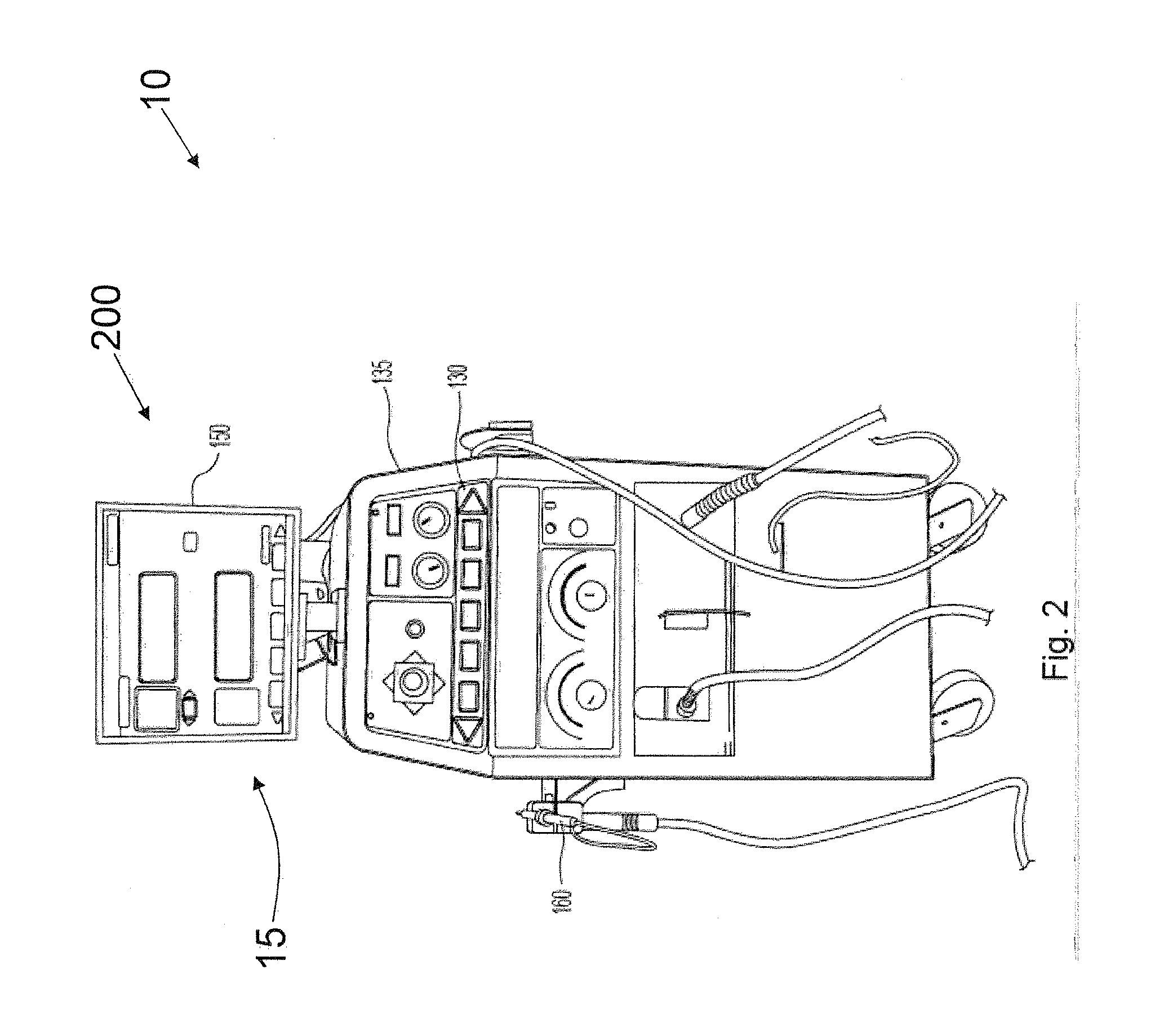

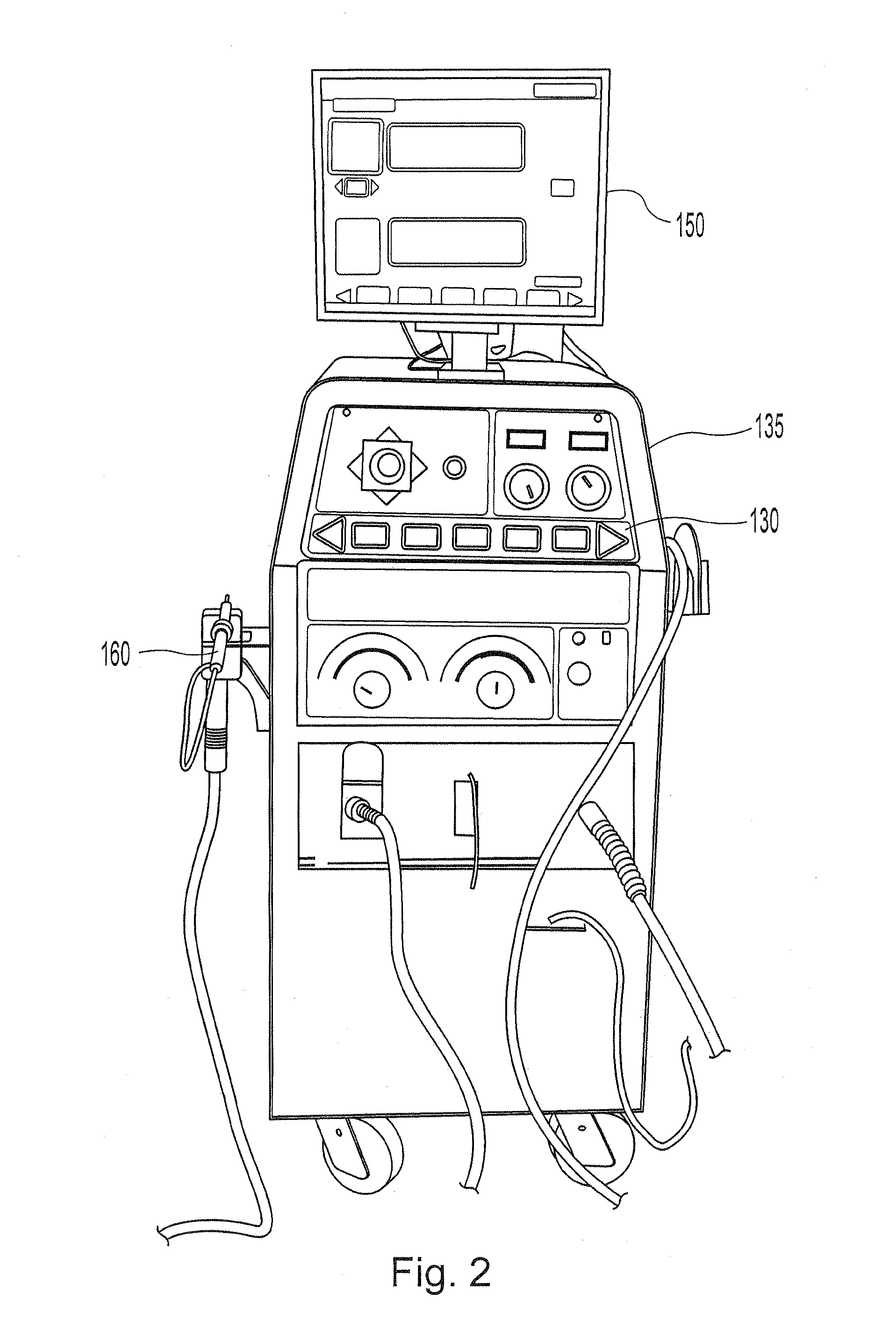

Virtual reality GTAW and pipe welding simulator and setup

A simulator facilitating virtual welding activity. The simulator may include a logic processor based subsystem operable to generate an interactive welding environment in virtual reality space that emulates welding activity by simulating a virtual weld puddle having dynamic, real time molten metal fluidity and heat dissipation characteristics, responsive to performing a simulated welding activity in real time. The simulator may include a foot pedal device in operative communication with the logic processor based subsystem and configured to affect a characteristic of the virtual weld puddle in real time, responsive to user control of the foot pedal device. The simulator may be configured to track the movements of a mock welding tool and a mock filler wire and determine interaction between the virtual weld puddle, a corresponding virtual welding tool, and a corresponding filler wire in virtual reality space that would result in the welding tool becoming contaminated.

Owner:LINCOLN GLOBAL INC

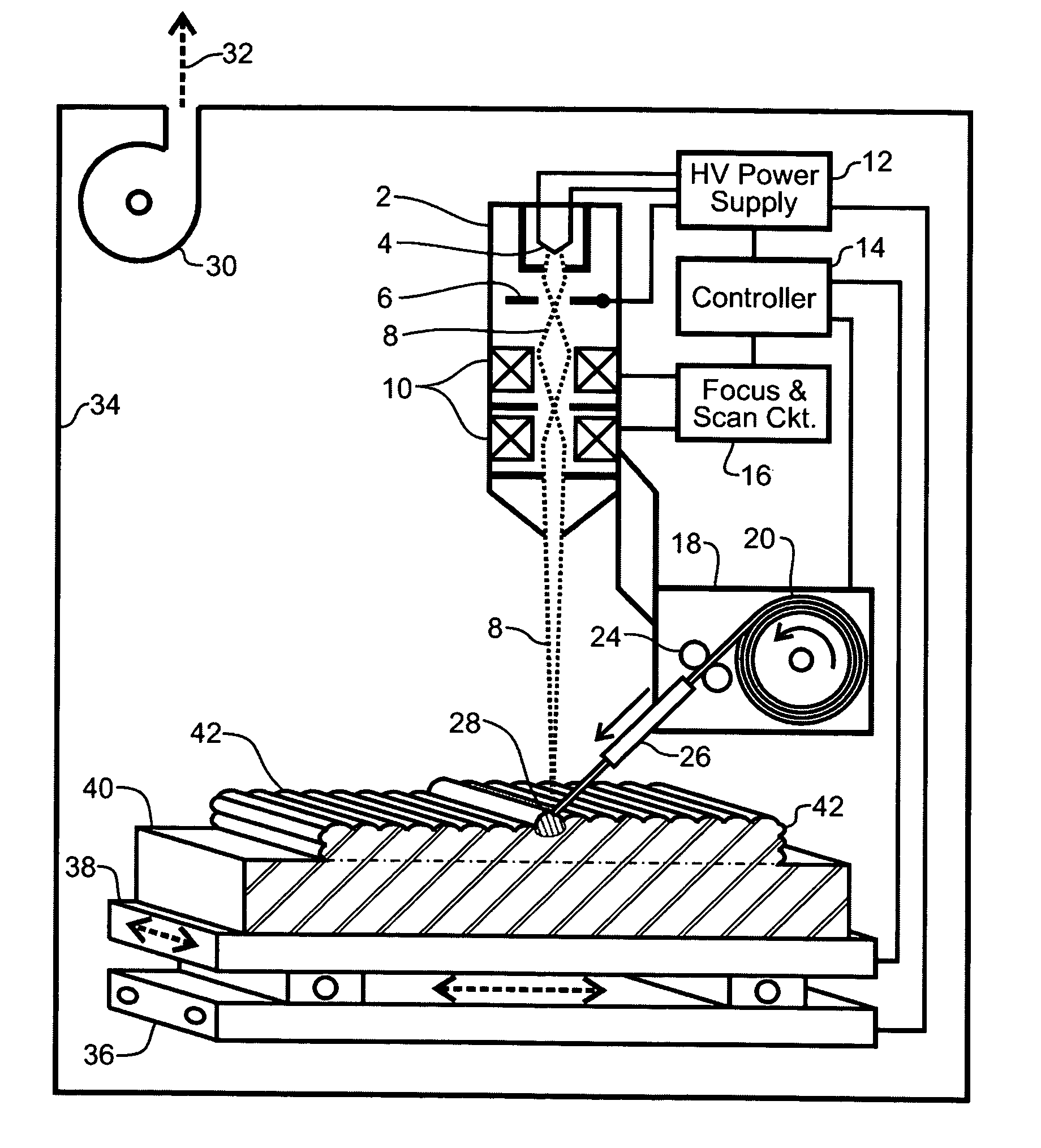

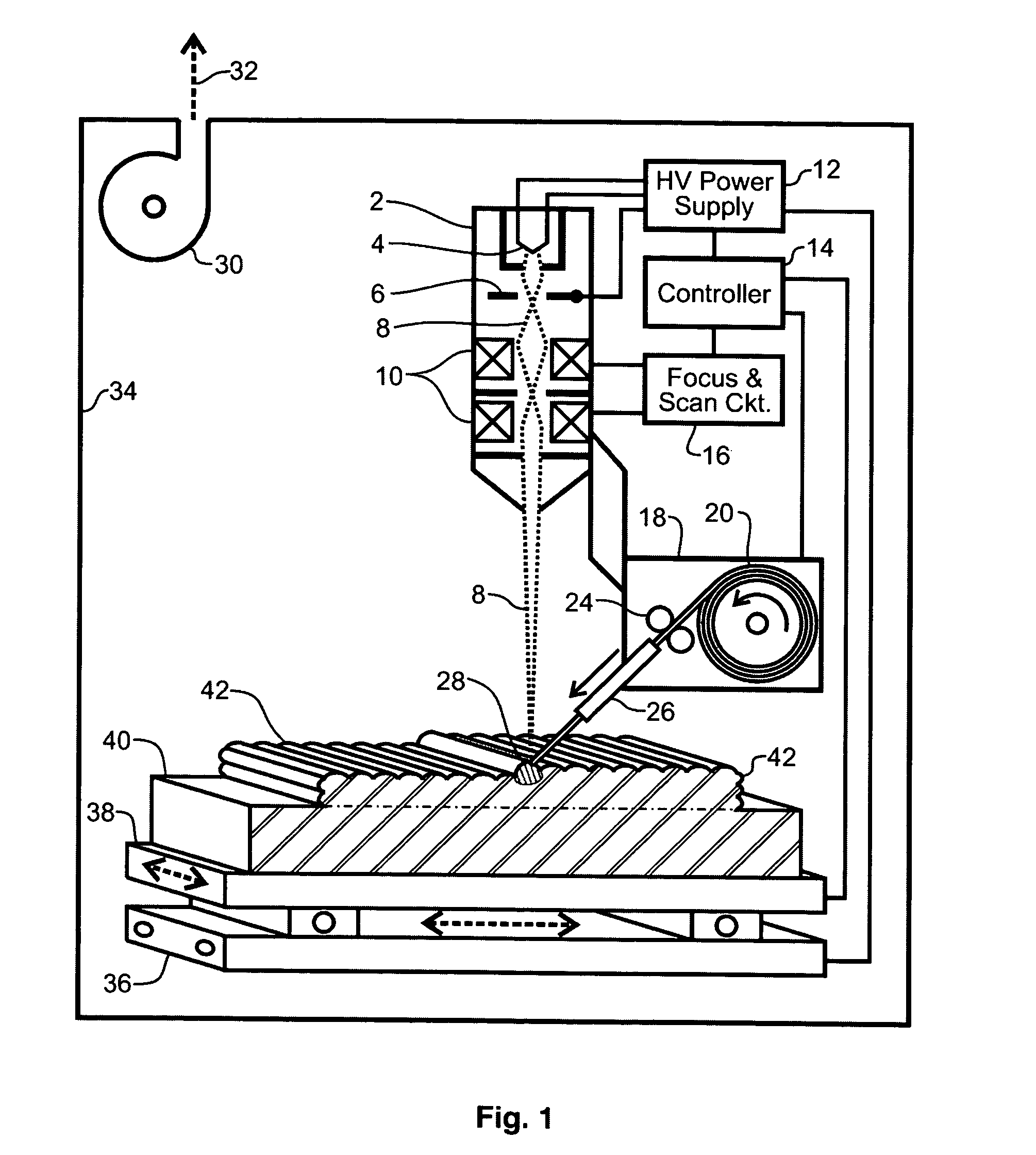

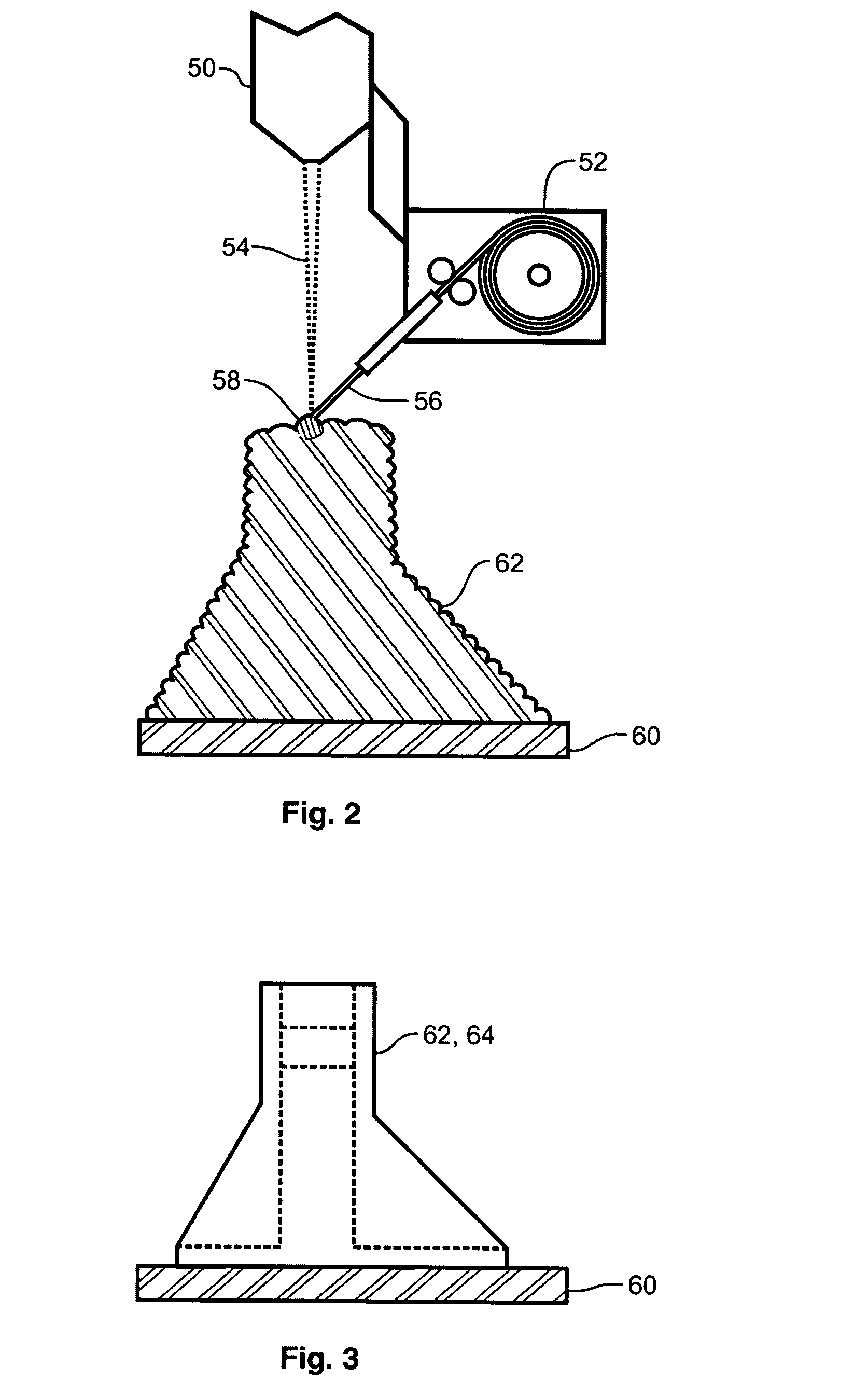

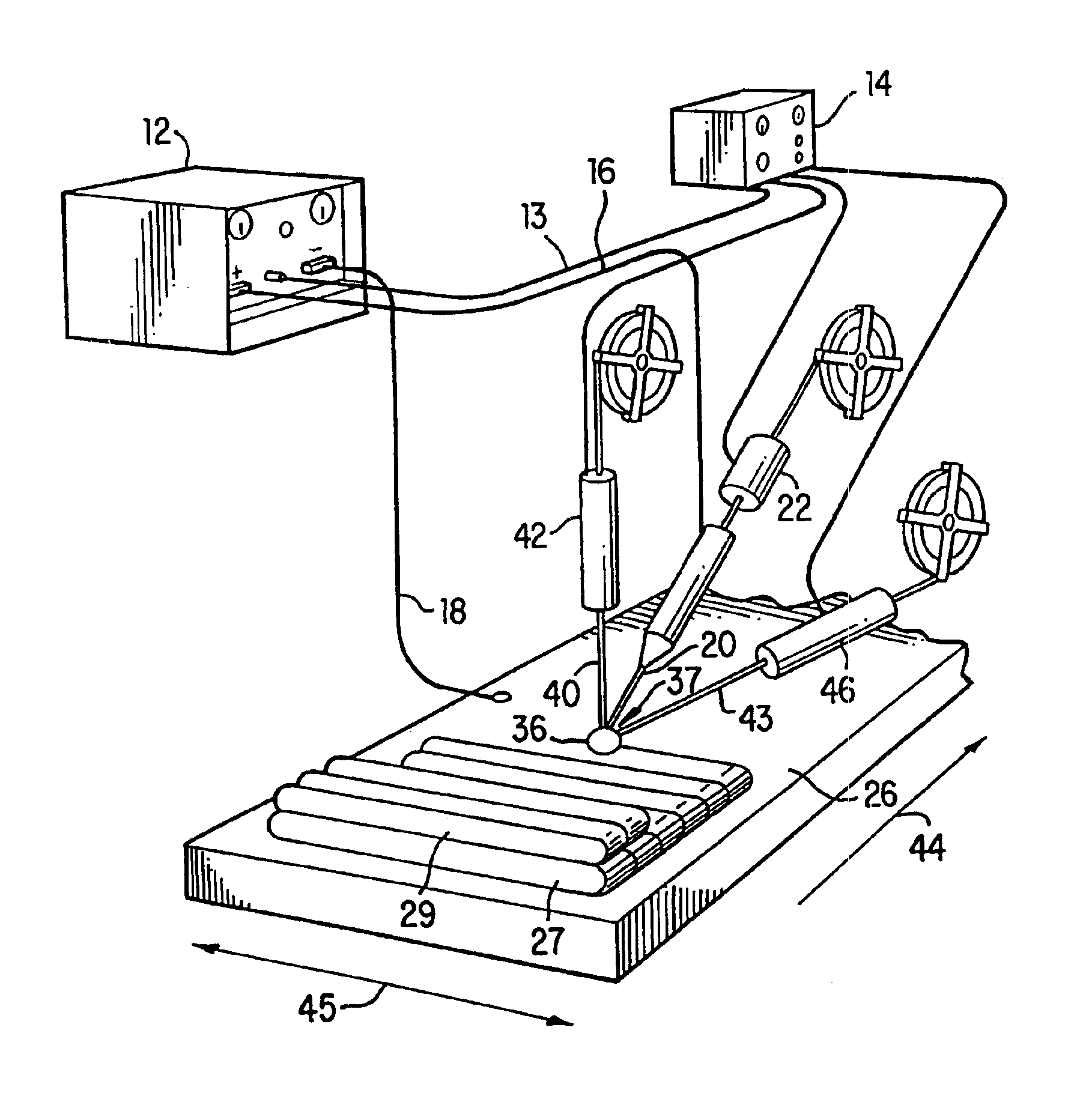

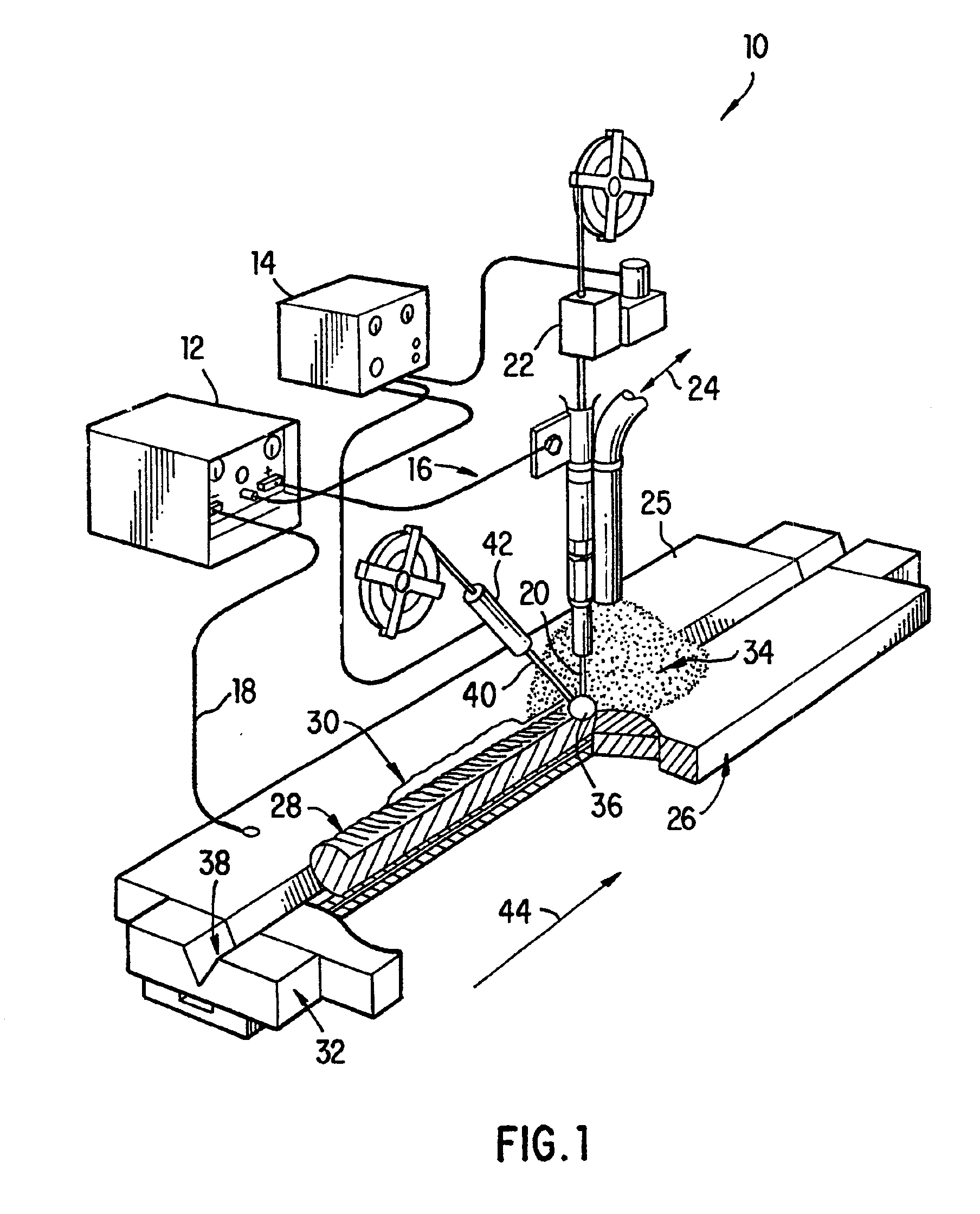

Solid freeform fabrication system and method

A system and method of solid freeform work piece fabrication through layered deposition of feedstock material on a mold structure. An energy beam and feedstock are fed to a feed point adjacent to a mold structure, thereby forming a molten puddle. The feed point is moved relative to the mold structure, thereby advancing the molten puddle of presently fed feedstock and rapidly solidifying previously fed feedstock. The feed point is sequentially advanced within a predetermined geometric volume containing at least a portion of the mold structure, thereby sequentially fusing the feedstock, by action of the advancing molten puddle, into a near net shape work piece built-up upon the mold structure.

Owner:HENN DAVID S

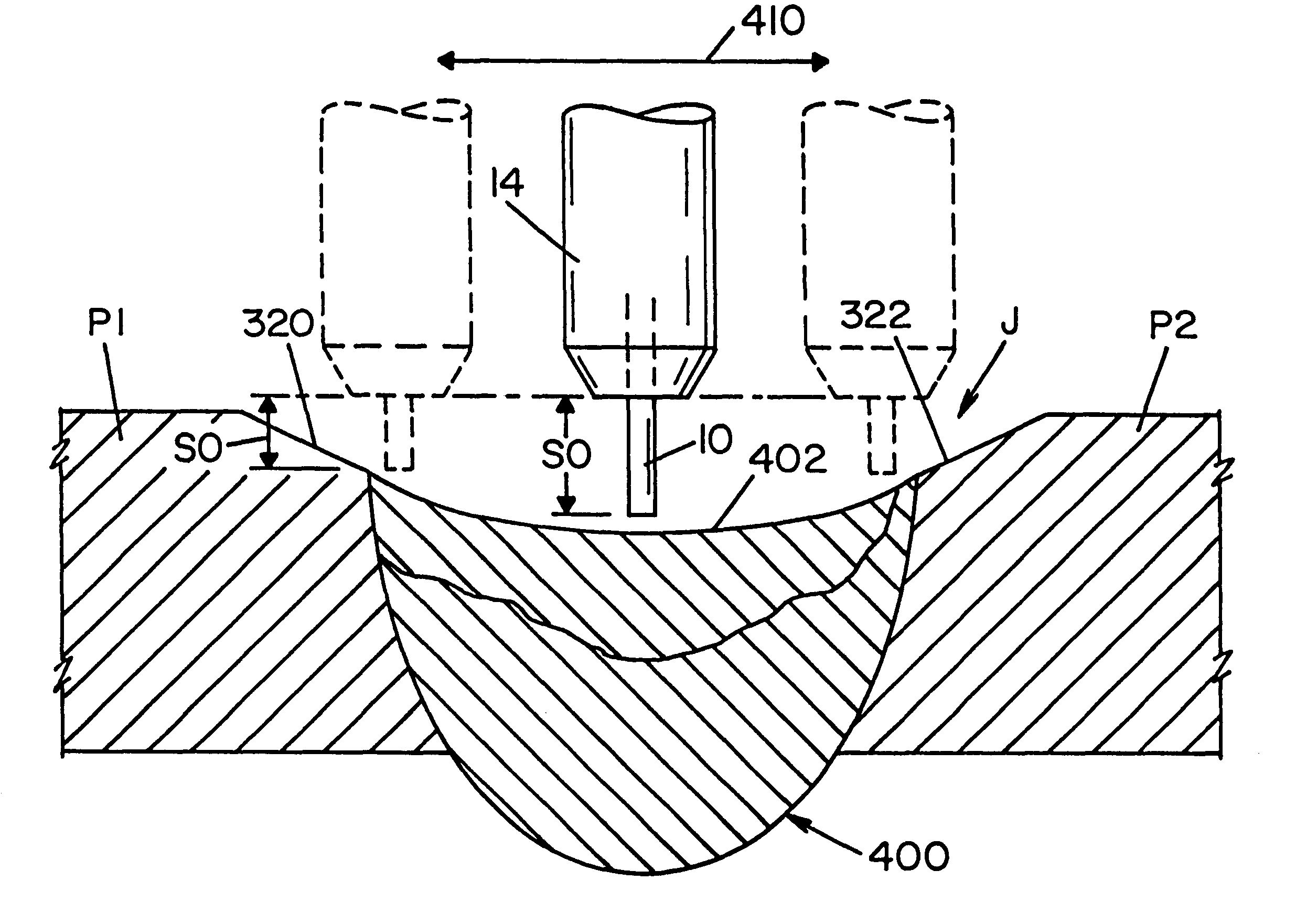

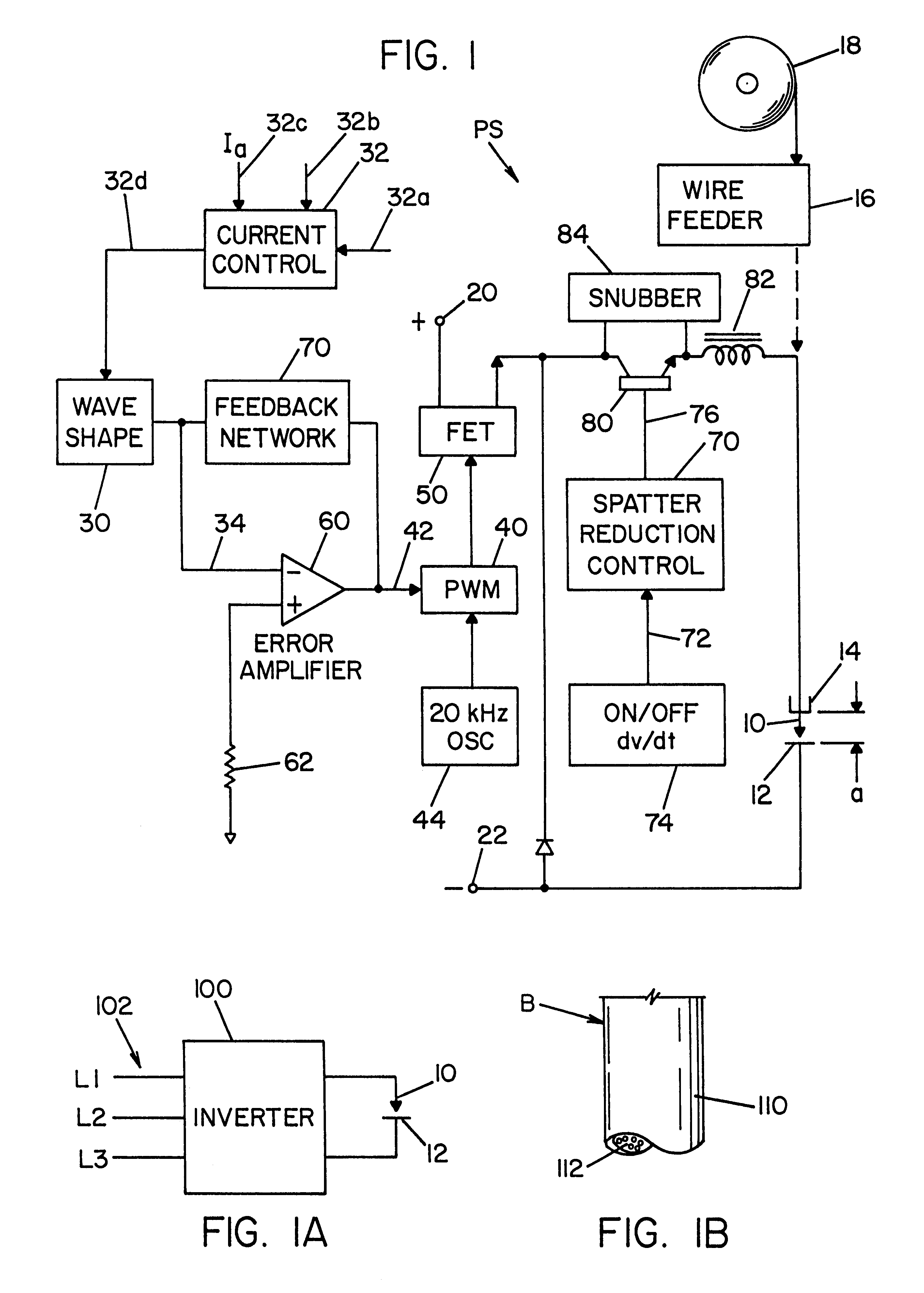

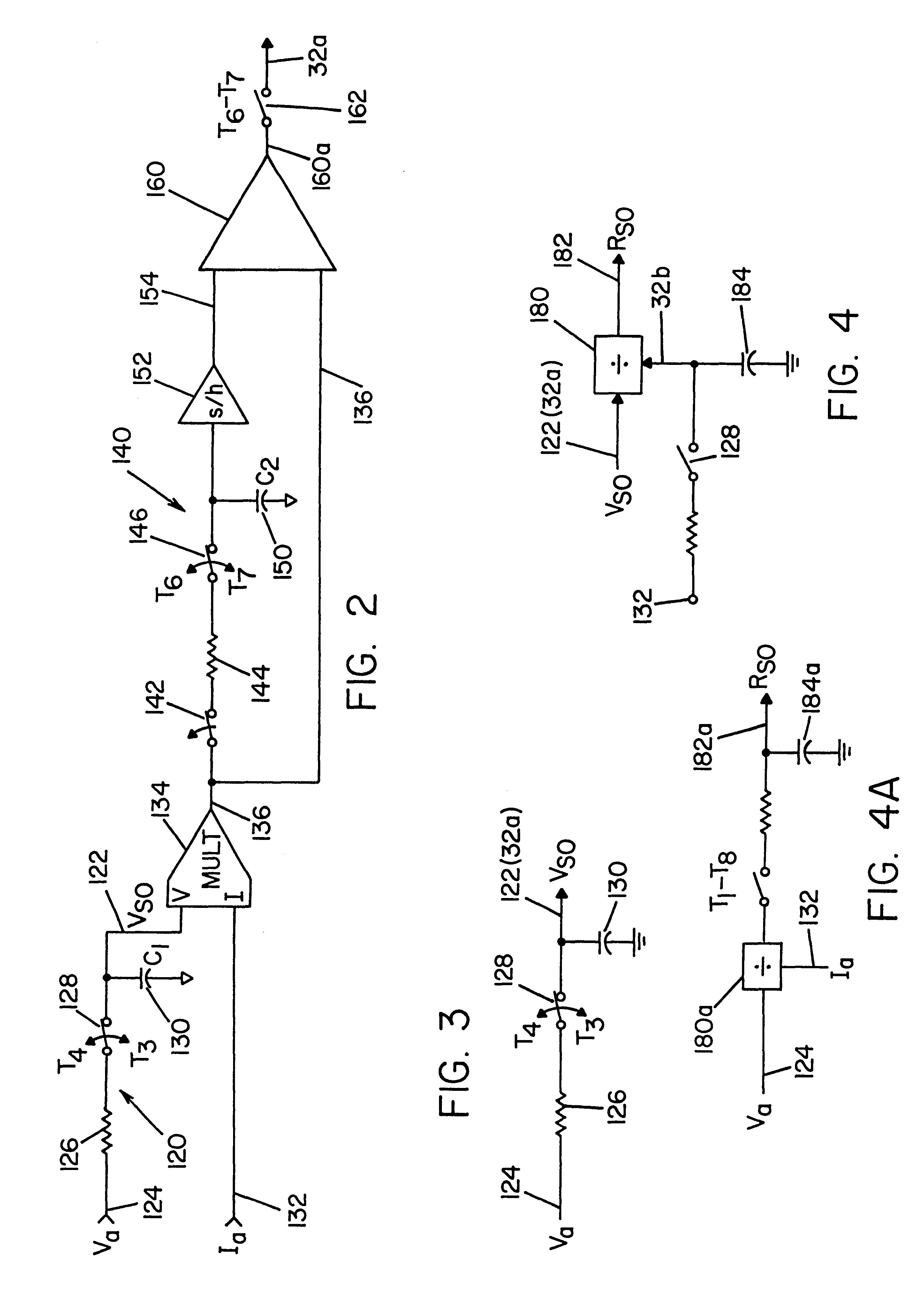

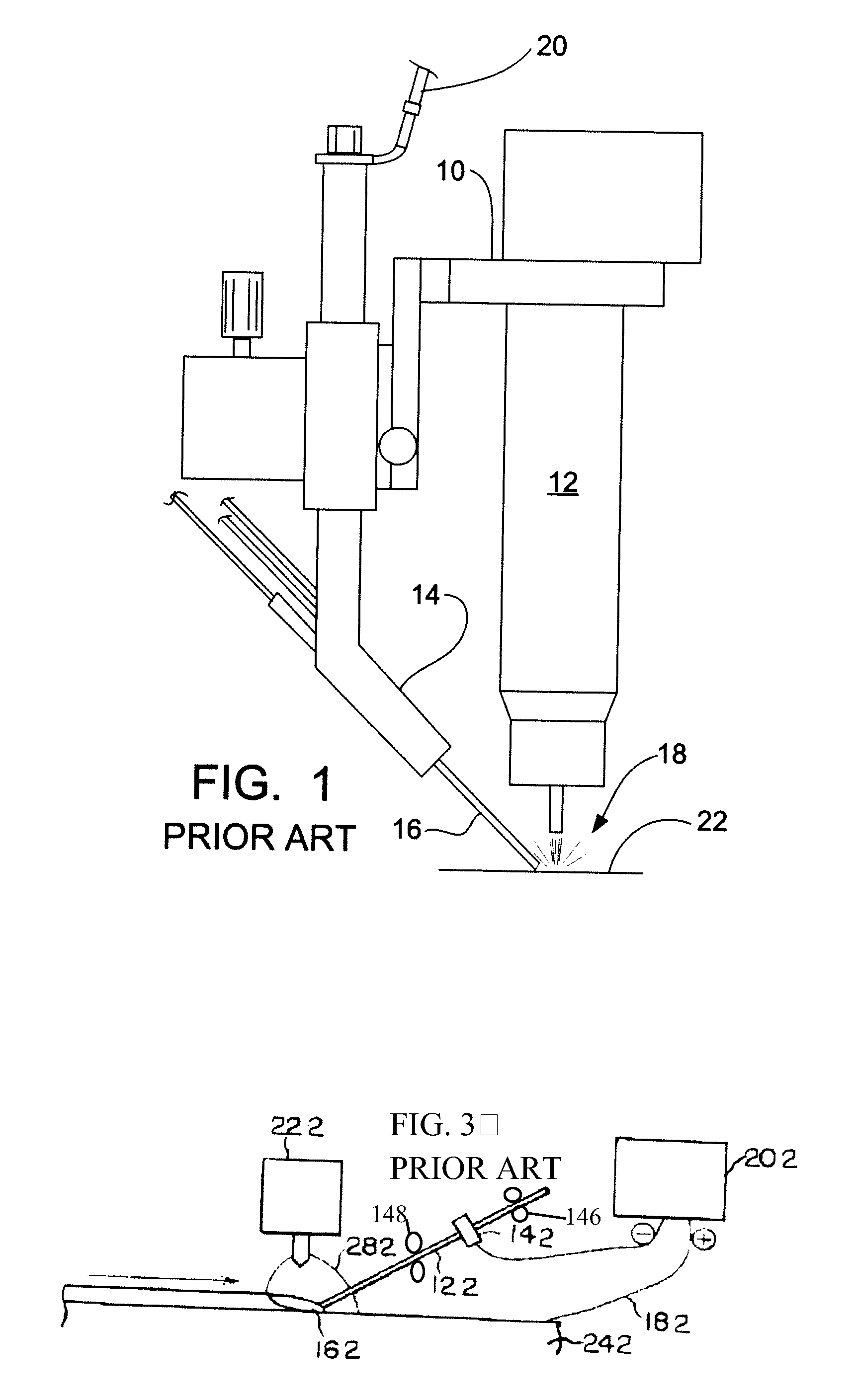

Method and apparatus for electric arc welding

An electric arc welding apparatus for depositing molten metal from an advancing welding wire into a weld puddle in an open root between two juxtapositioned plates where the root extends in a welding path and is formed by converging walls terminating in generally parallel walls spaced to define a gap, which apparatus comprises a contact holder with a wire outlet, a switching power supply directing welding current to the wire as the wire passes from the outlet toward the open root, with the advancing wire defining an electrode stick out between the contact holder and the weld puddle, a circuit for sensing the length of the stick out, and control means for adjusting the welding current as a function of the sensed stick out length.

Owner:LINCOLN GLOBAL INC

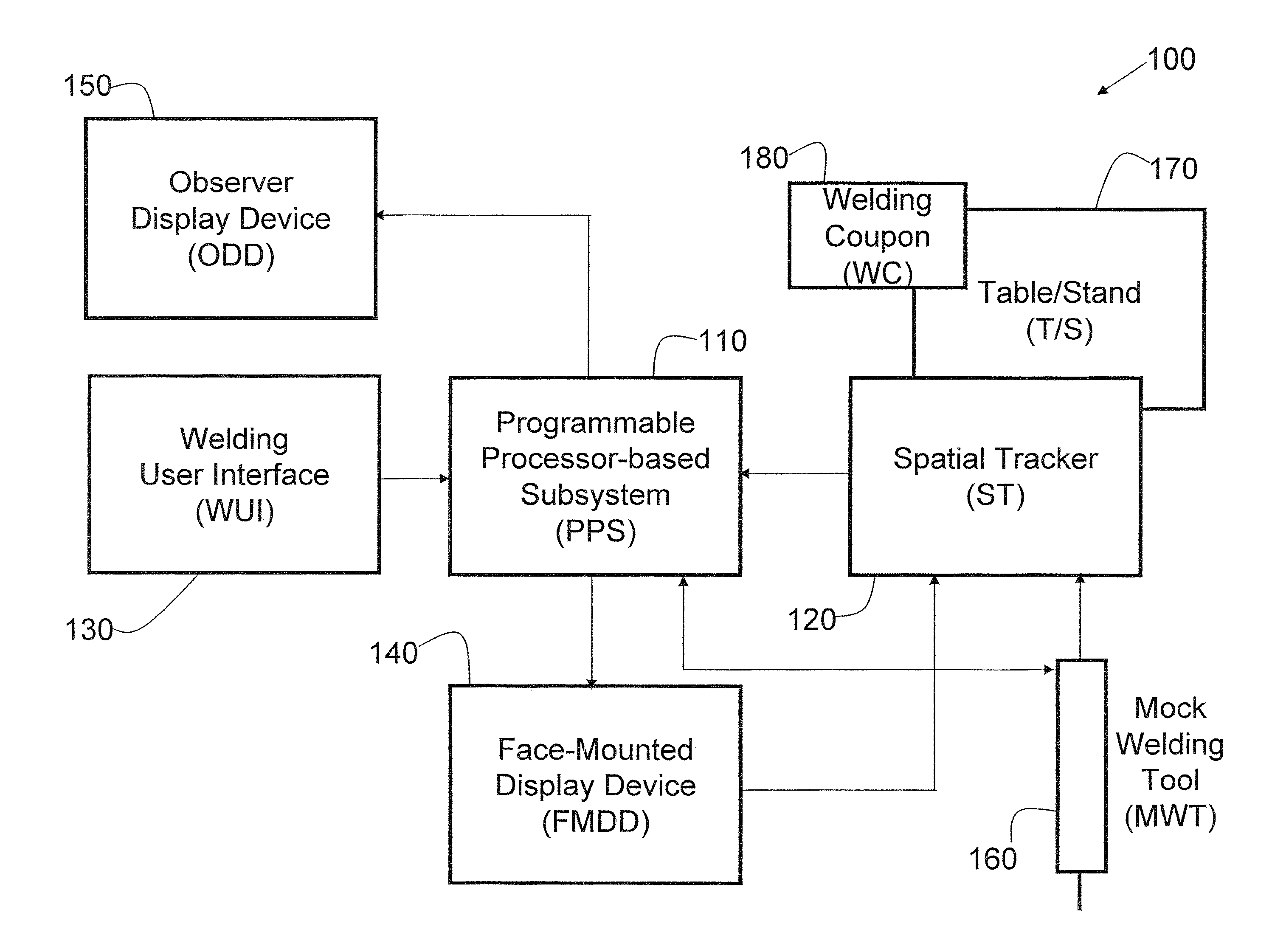

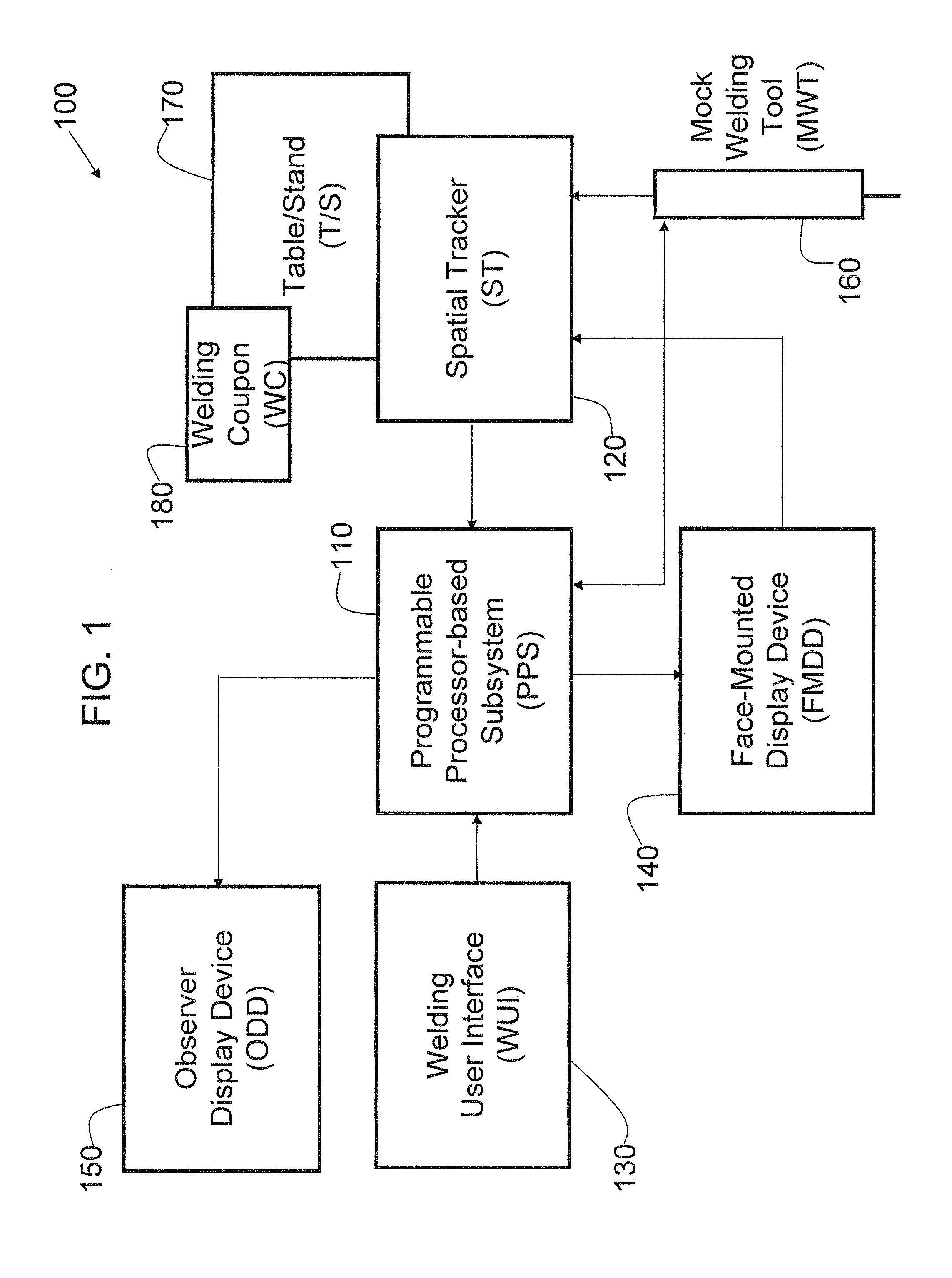

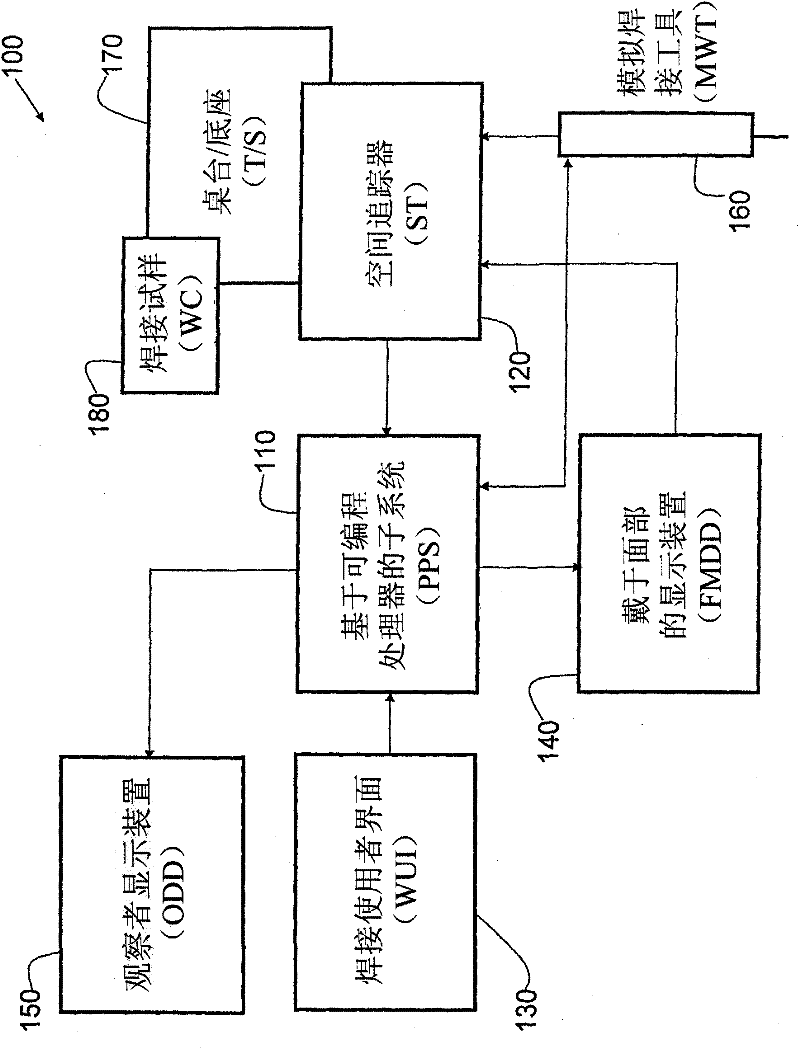

Importing and analyzing external data using a virtual reality welding system

A real-time virtual reality welding system including a programmable processor-based subsystem, a spatial tracker operatively connected to the programmable processor-based subsystem, at least one mock welding tool capable of being spatially tracked by the spatial tracker, and at least one display device operatively connected to the programmable processor-based subsystem. The system is capable of simulating, in virtual reality space, a weld puddle having real-time molten metal fluidity and heat dissipation characteristics. The system is further capable of importing data into the virtual reality welding system and analyzing the data to characterize a student welder's progress and to provide training.

Owner:LINCOLN GLOBAL INC

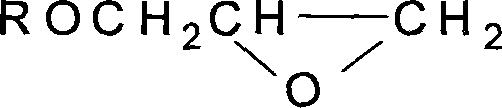

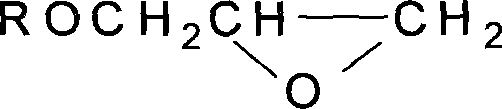

Developer/rinse formulation to prevent image collapse in resist

An apparatus and method are provided for developing photoresist patterns on electronic component substrates such as semiconductor wafers. The method and apparatus use a specially defined developer composition in sequence with a specially defined rinse composition to develop an exposed photoresist pattern and then to rinse the developed pattern. Both the developer composition and rinse composition contain an anionic surfactant and, when the solutions are used in sequence, have been found to provide a resist pattern which avoids pattern collapse even when small features such as line widths less than 150 nm with aspect ratios of greater than about 3 are formed. It is preferred to use a puddle developing and puddle rinsing process to develop and rinse the exposed wafer. Preferred anionic surfactants are ammonium perfluoroalkyl sulfonate and ammonium perfluoroalkyl carboxylate.

Owner:IBM CORP

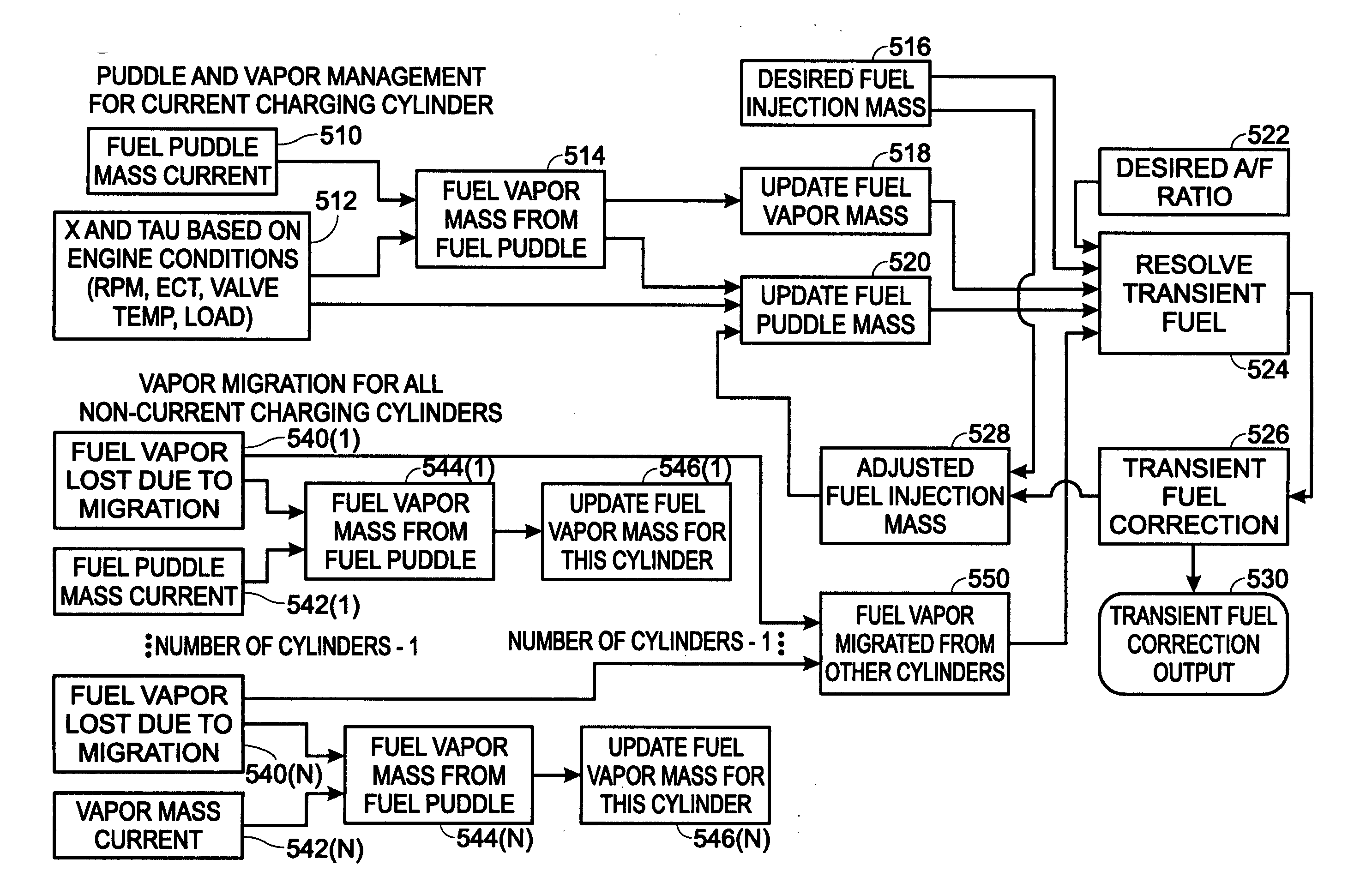

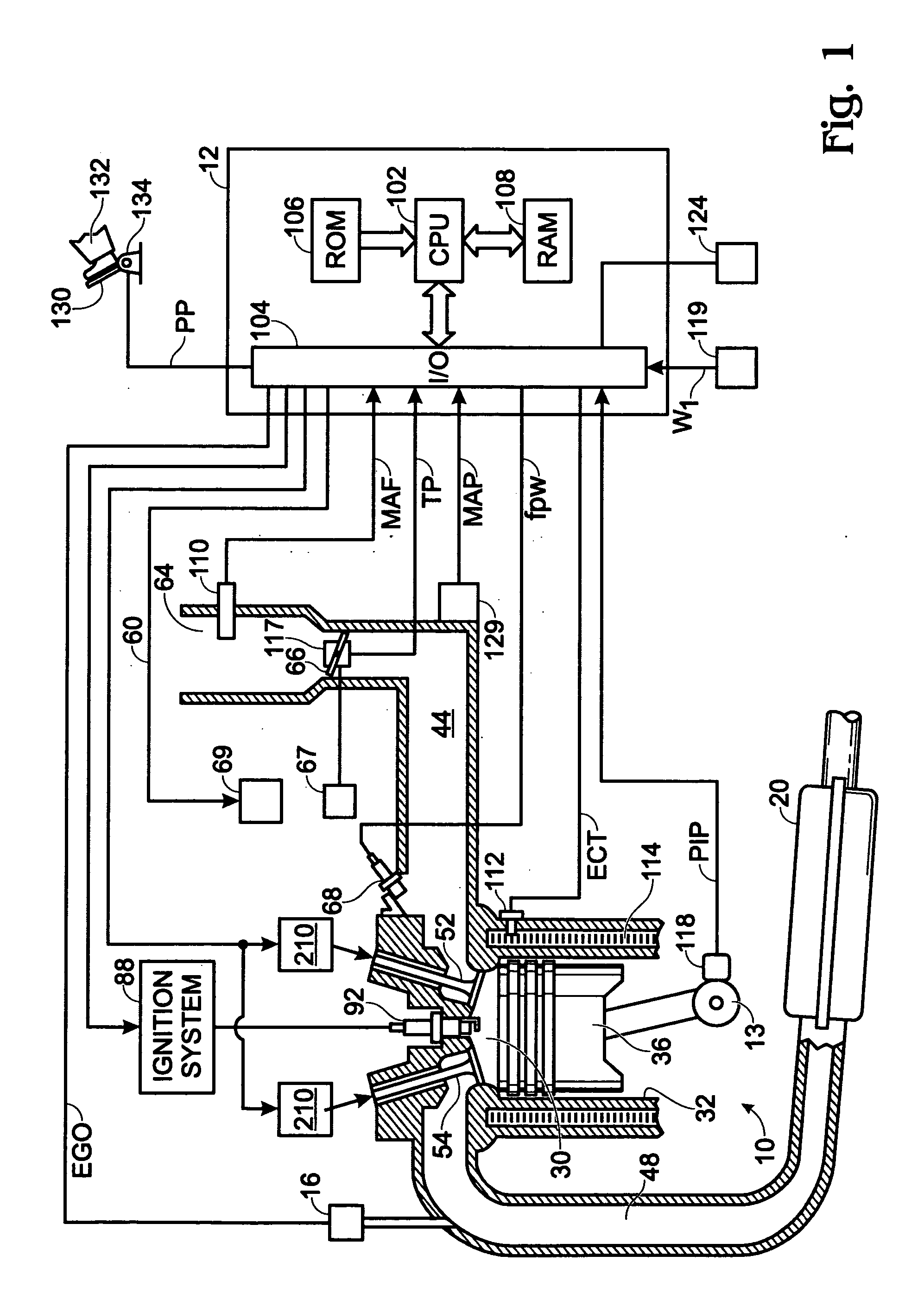

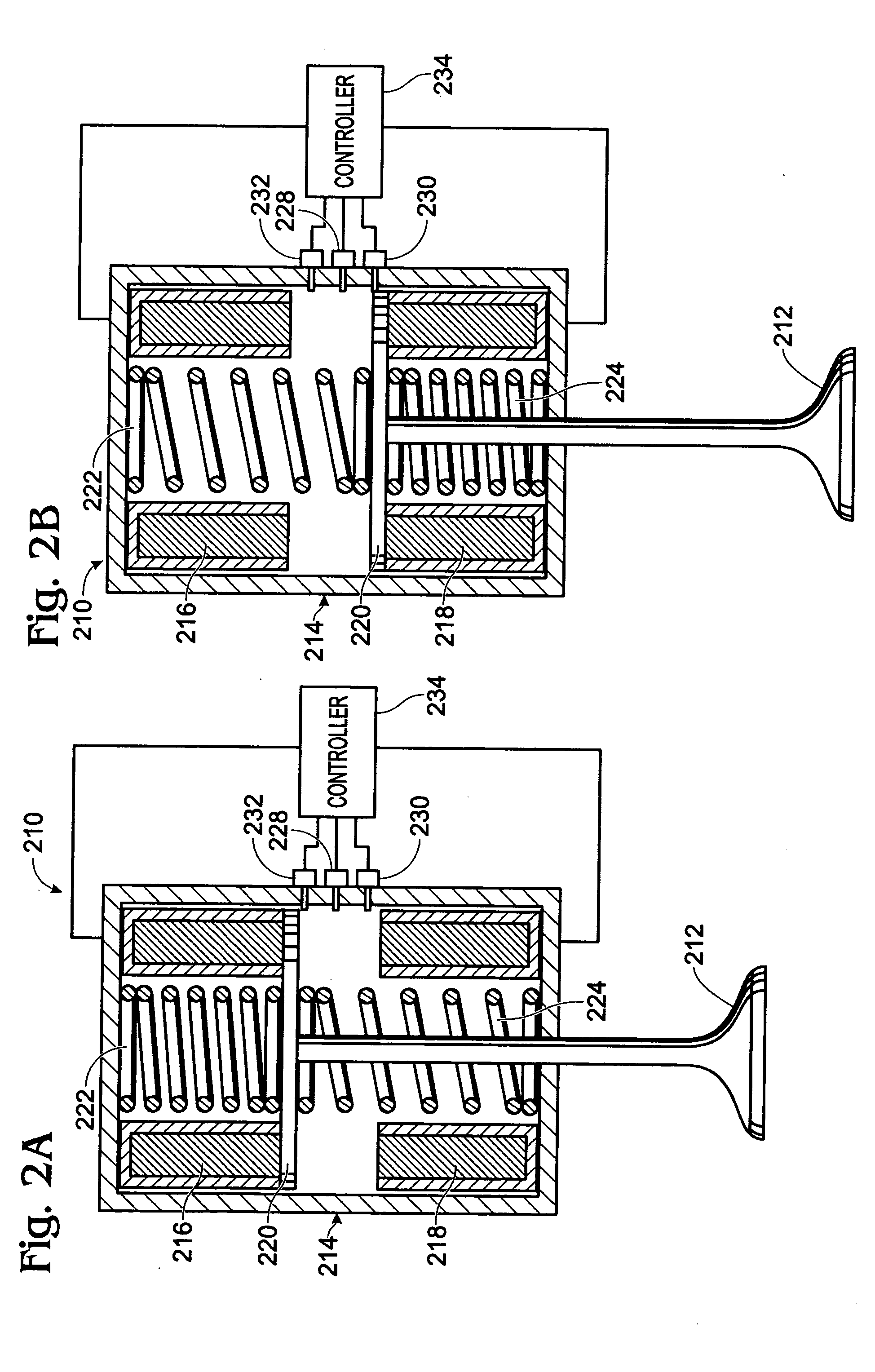

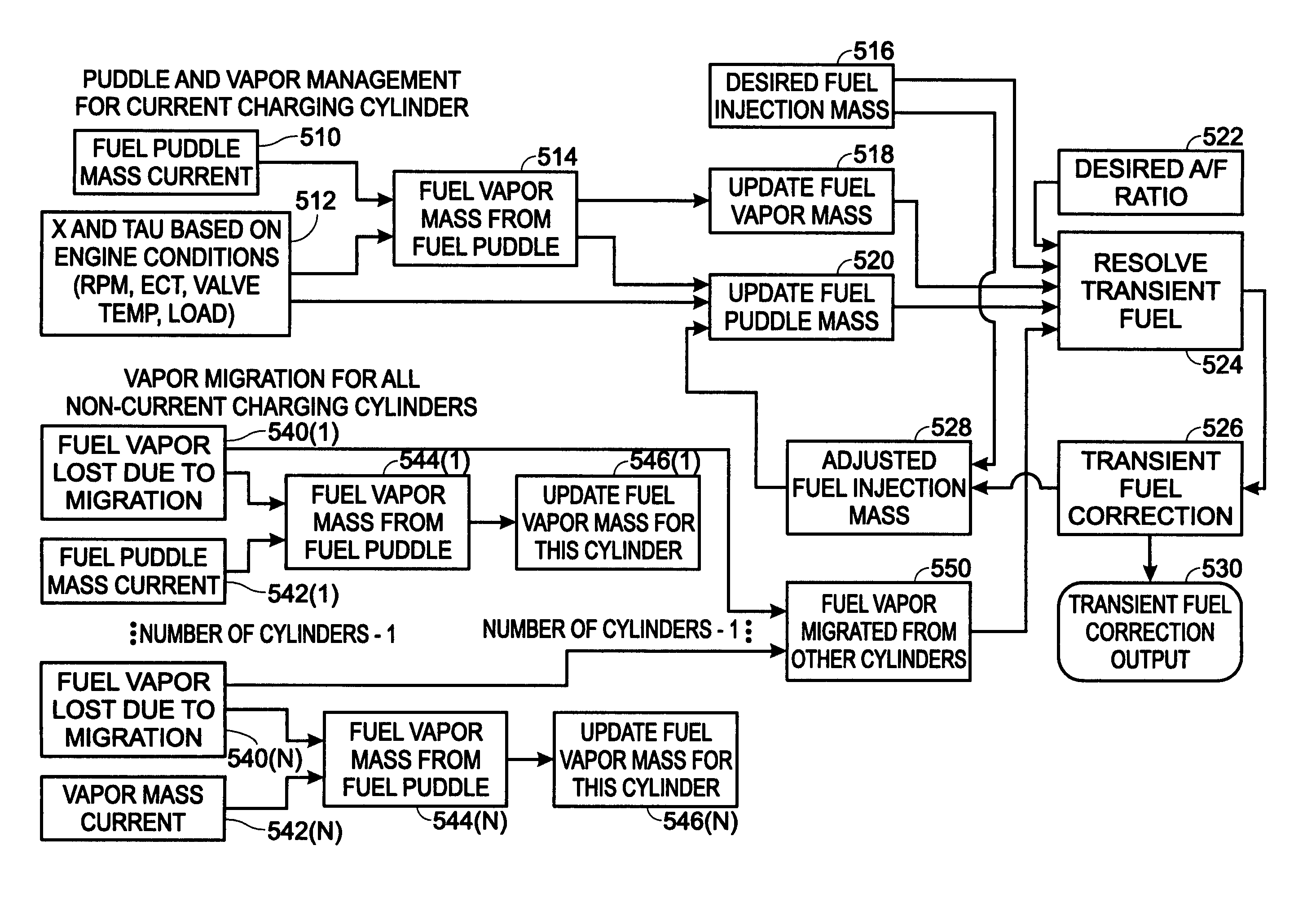

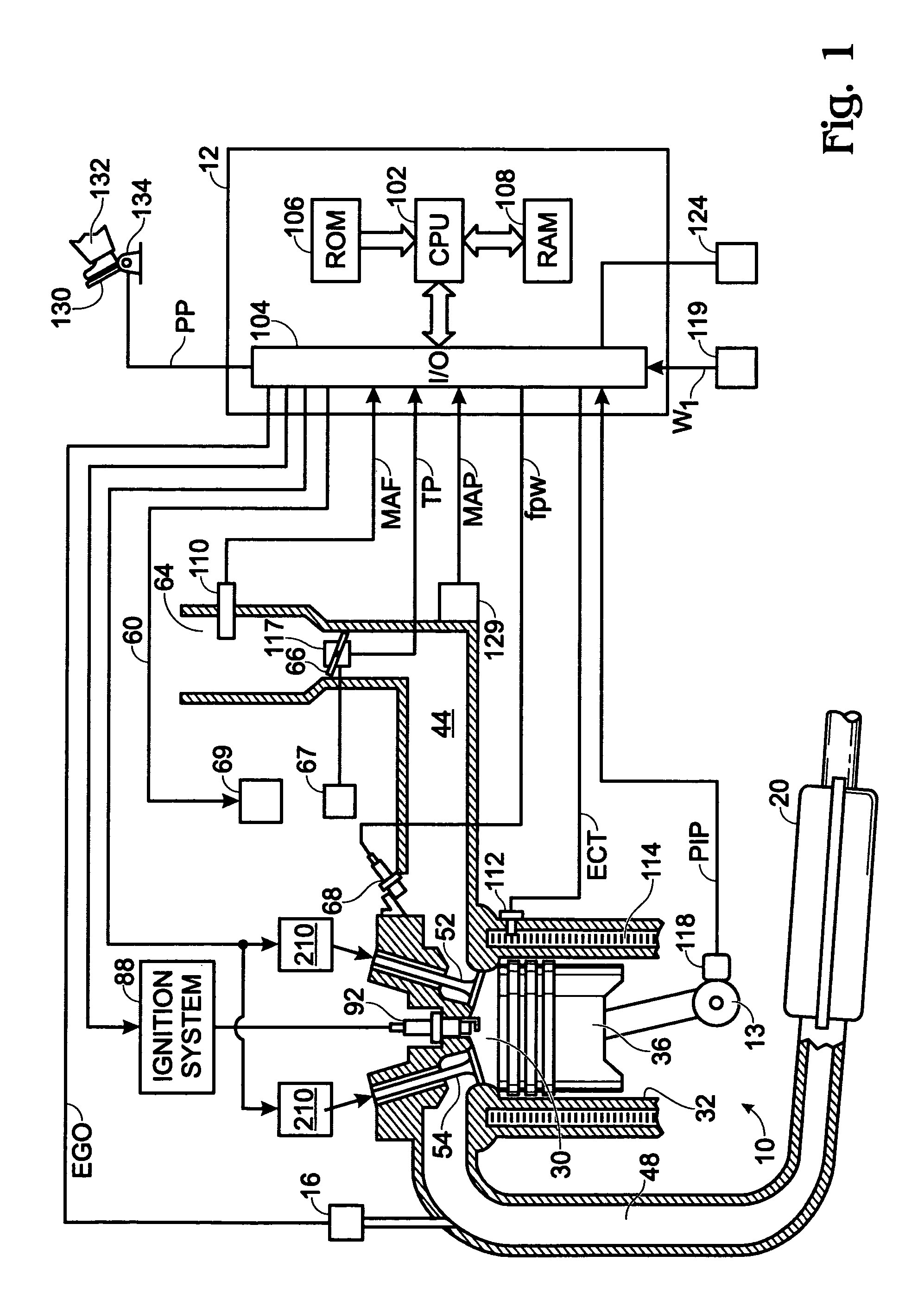

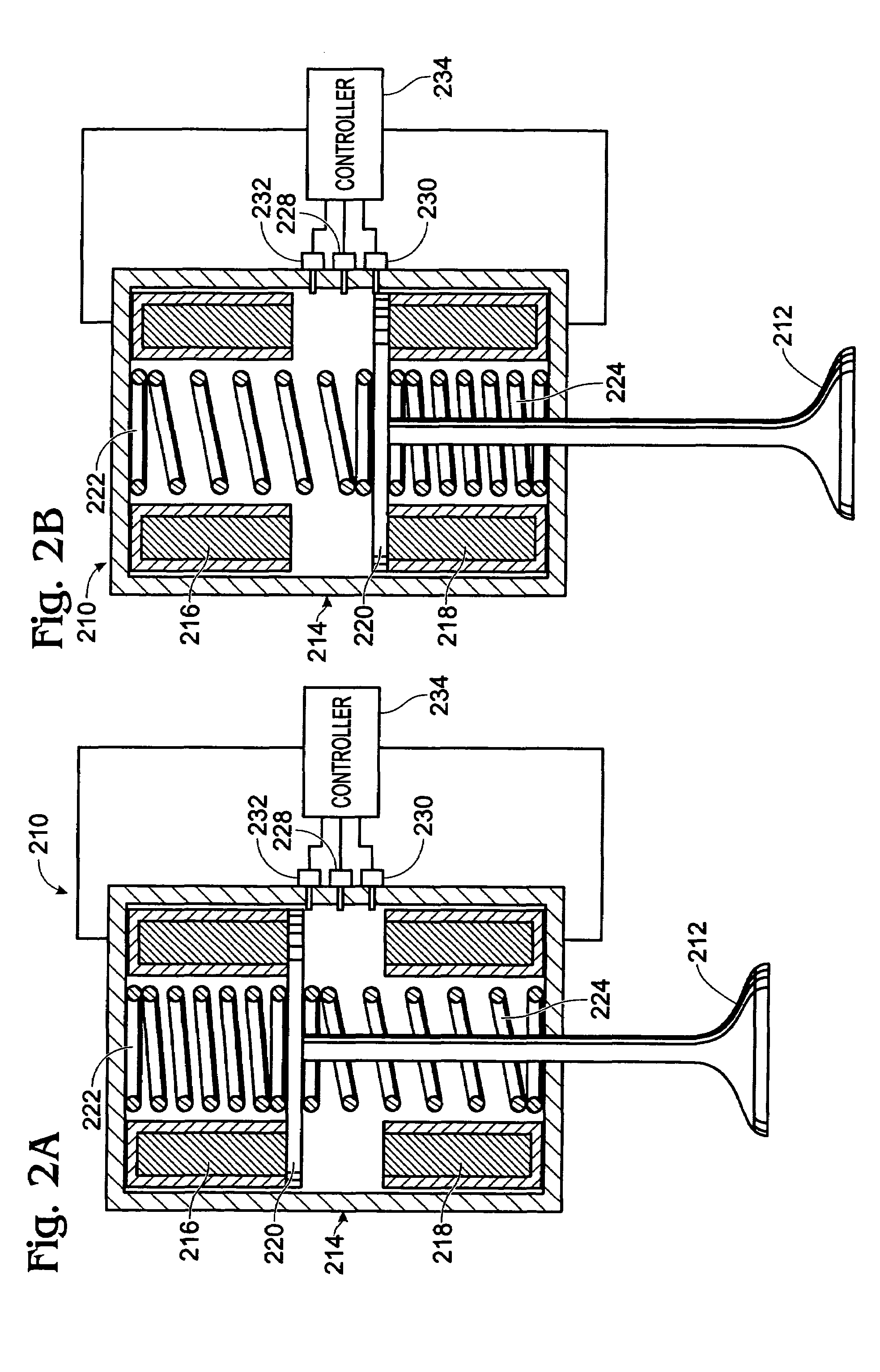

Engine control to compensate for fueling dynamics

ActiveUS20050166900A1Accurate air-fuel ratio controlEasy to controlElectrical controlInternal combustion piston enginesVaporizationCylinder Valve

A method for calculating transient fuel wall wetting characteristics of an operating engine is described. The method accounts for cylinder valve deactivation of cylinders in the engine in calculating the dynamic fueling compensation. In one example, fuel vaporization effects from fuel puddles in deactivated cylinders is considered when calculating the fueling compensation for active cylinders.

Owner:FORD GLOBAL TECH LLC

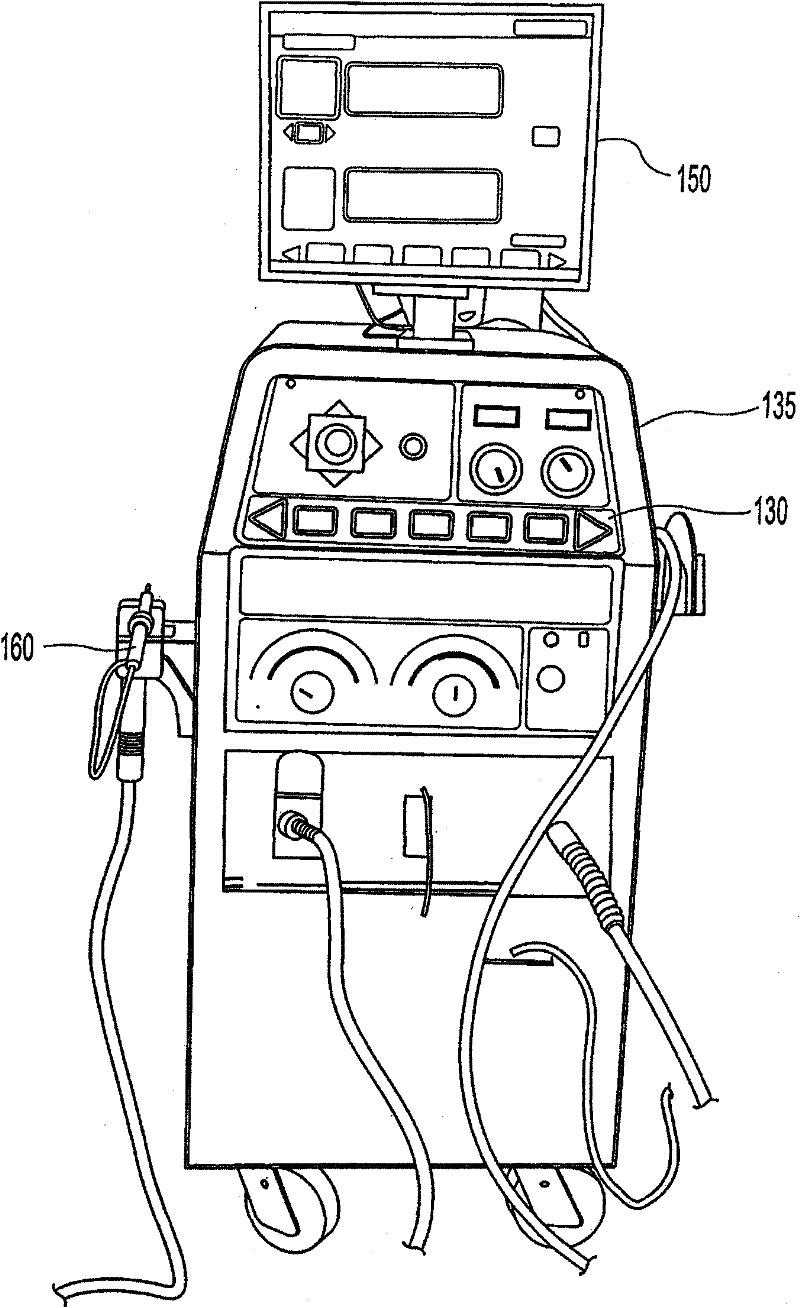

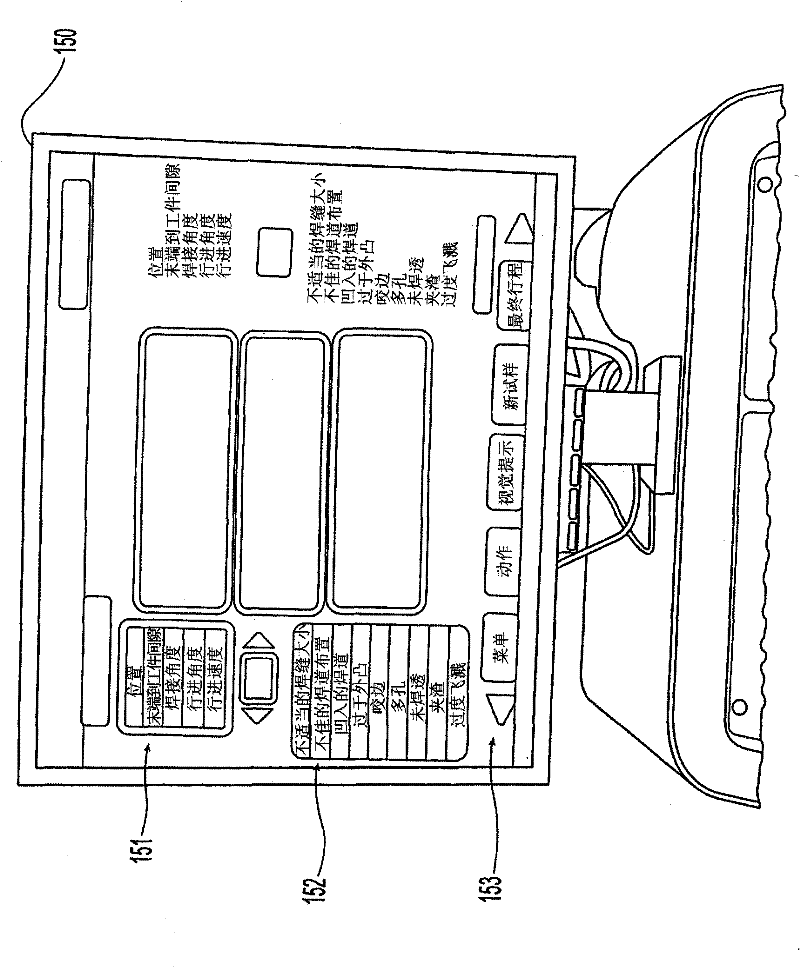

System and method providing arc welding training in a real-time simulated virtual reality environment using real-time weld puddle feedback

A real-time virtual reality welding system including a programmable processor- based subsystem, a spatial tracker operatively connected to the programmable processor- based subsystem, at least one mock welding tool capable of being spatially tracked by the spatial tracker, and at least one display device operatively connected to the programmable processor-based subsystem. The system is capable of simulating, in virtual reality space, a weld puddle having real-time molten metal fluidity and heat dissipation characteristics. The system is further capable of displaying the simulated weld puddle on the display device in real-time.

Owner:LINCOLN GLOBAL INC

Method and apparatus for electric arc welding

An electric arc welding apparatus for depositing molten metal from an advancing welding wire into a weld puddle in an open root between two juxtapositioned plates where the root extends in a welding path and is formed by converging walls terminating in generally parallel walls spaced to define a gap, which apparatus comprises a contact holder with a wire outlet, a switching power supply directing welding current to the wire as the wire passes from the outlet toward the open root, with the advancing wire defining an electrode stick out between the contact holder and the weld puddle, a circuit for sensing the length of the stick out, and control means for adjusting the welding current as a function of the sensed stick out length.

Owner:LINCOLN GLOBAL INC

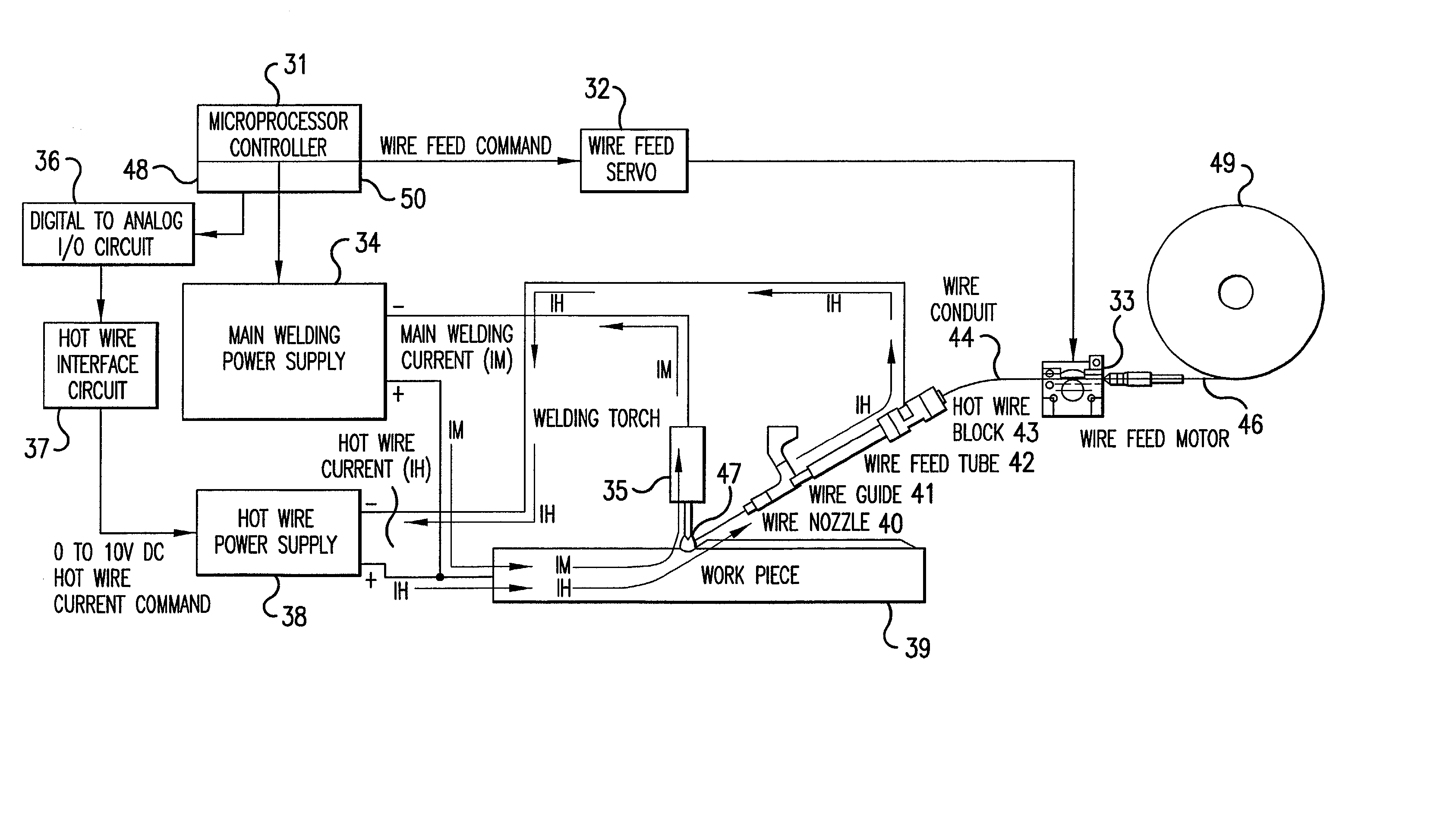

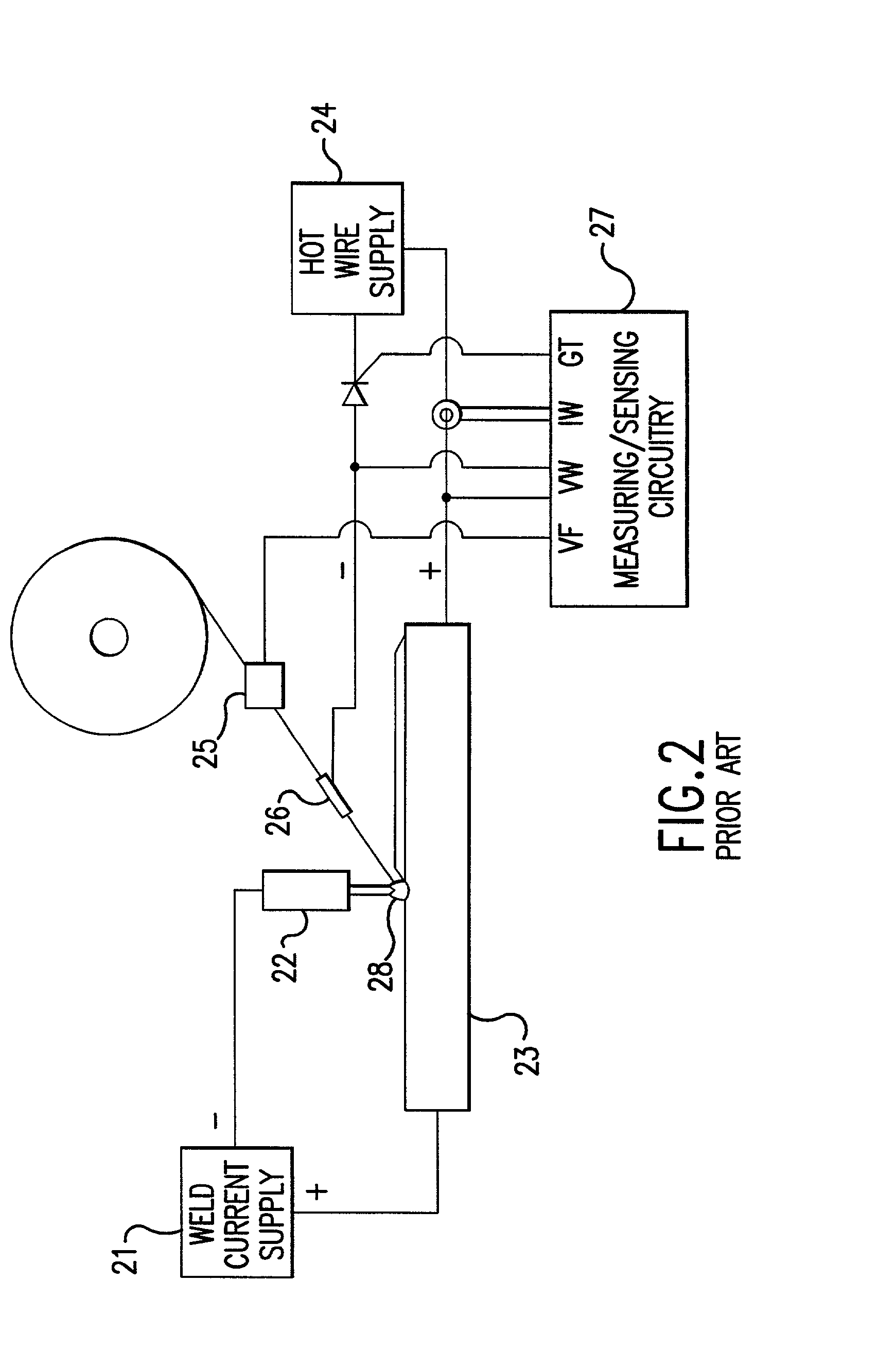

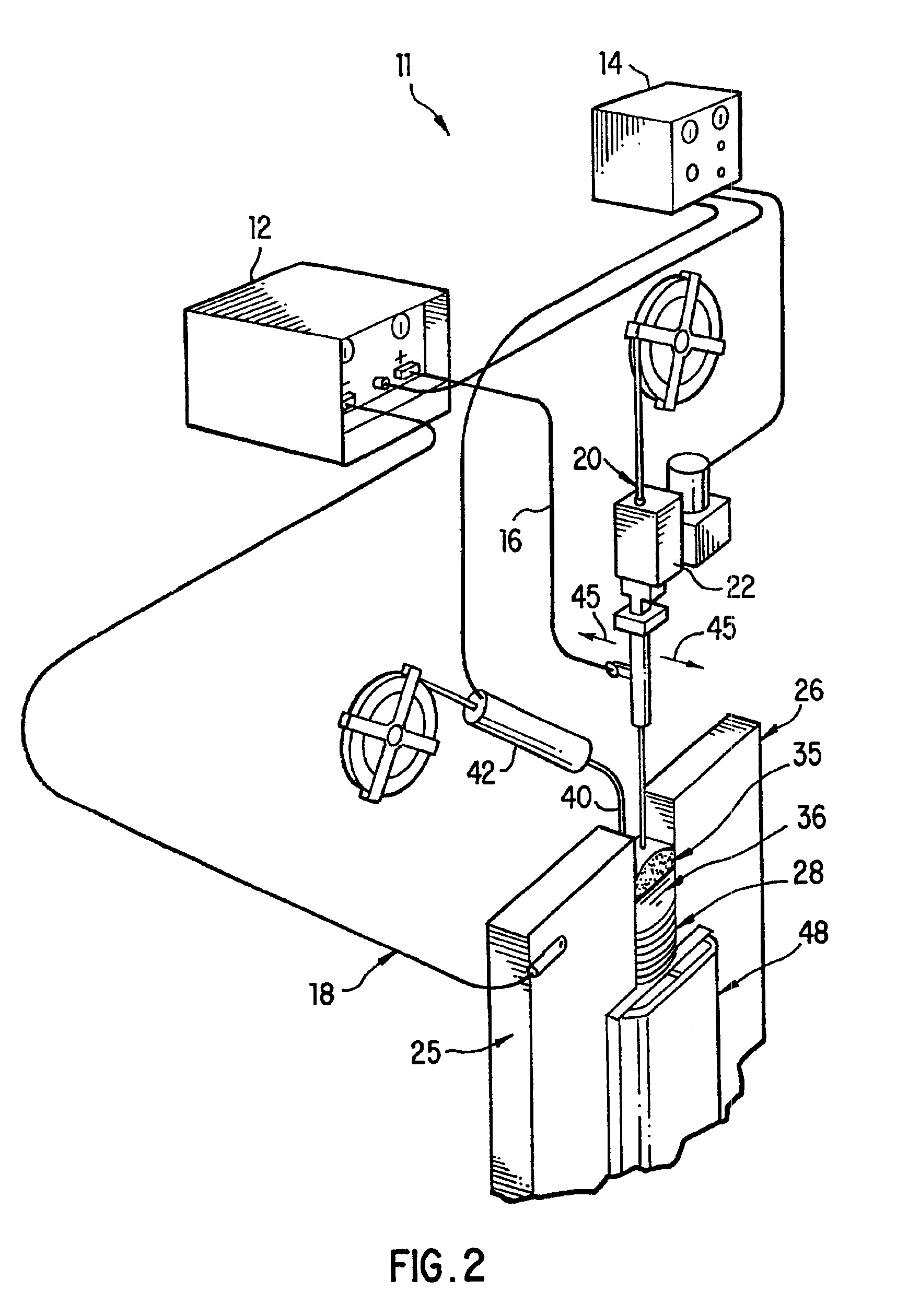

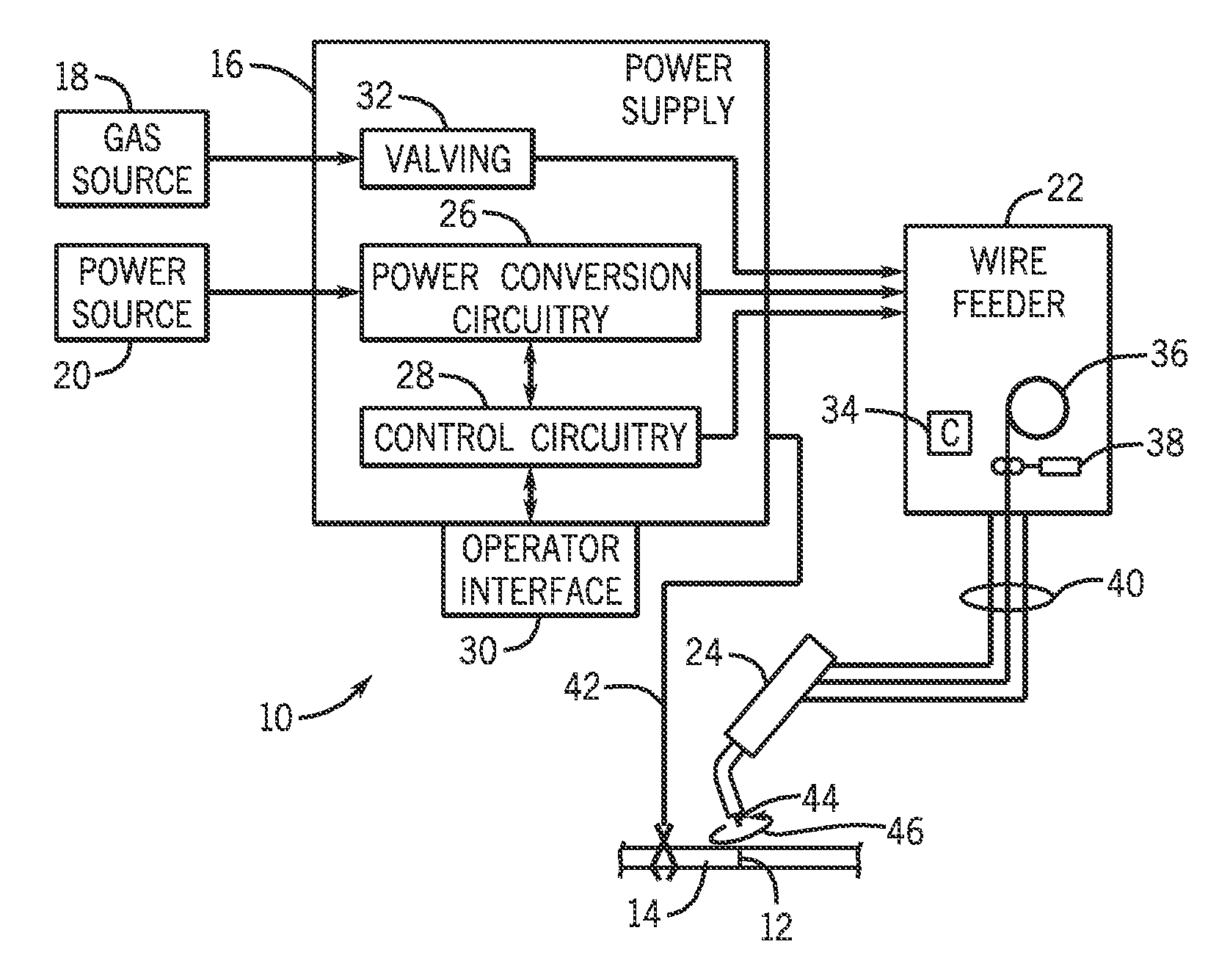

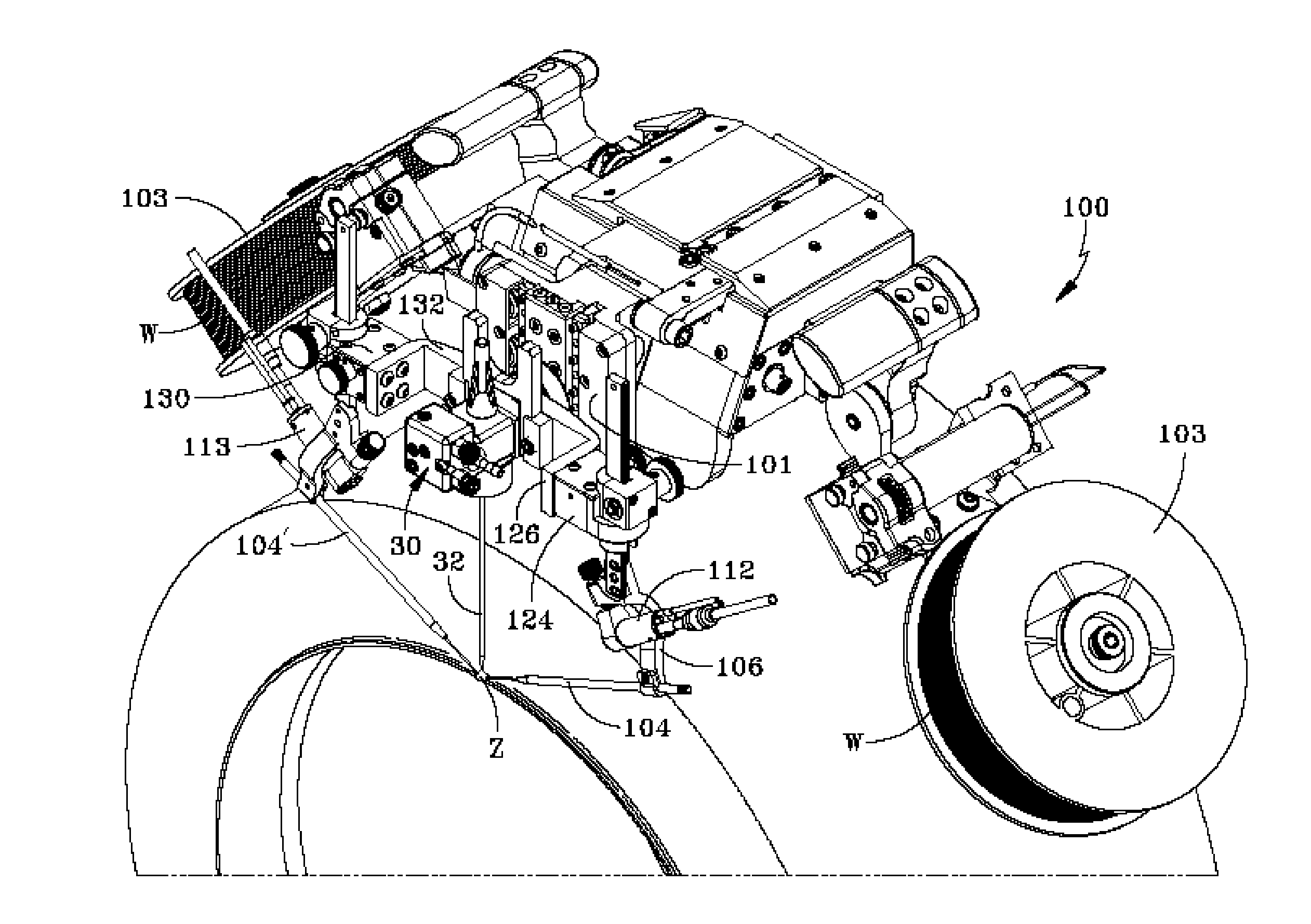

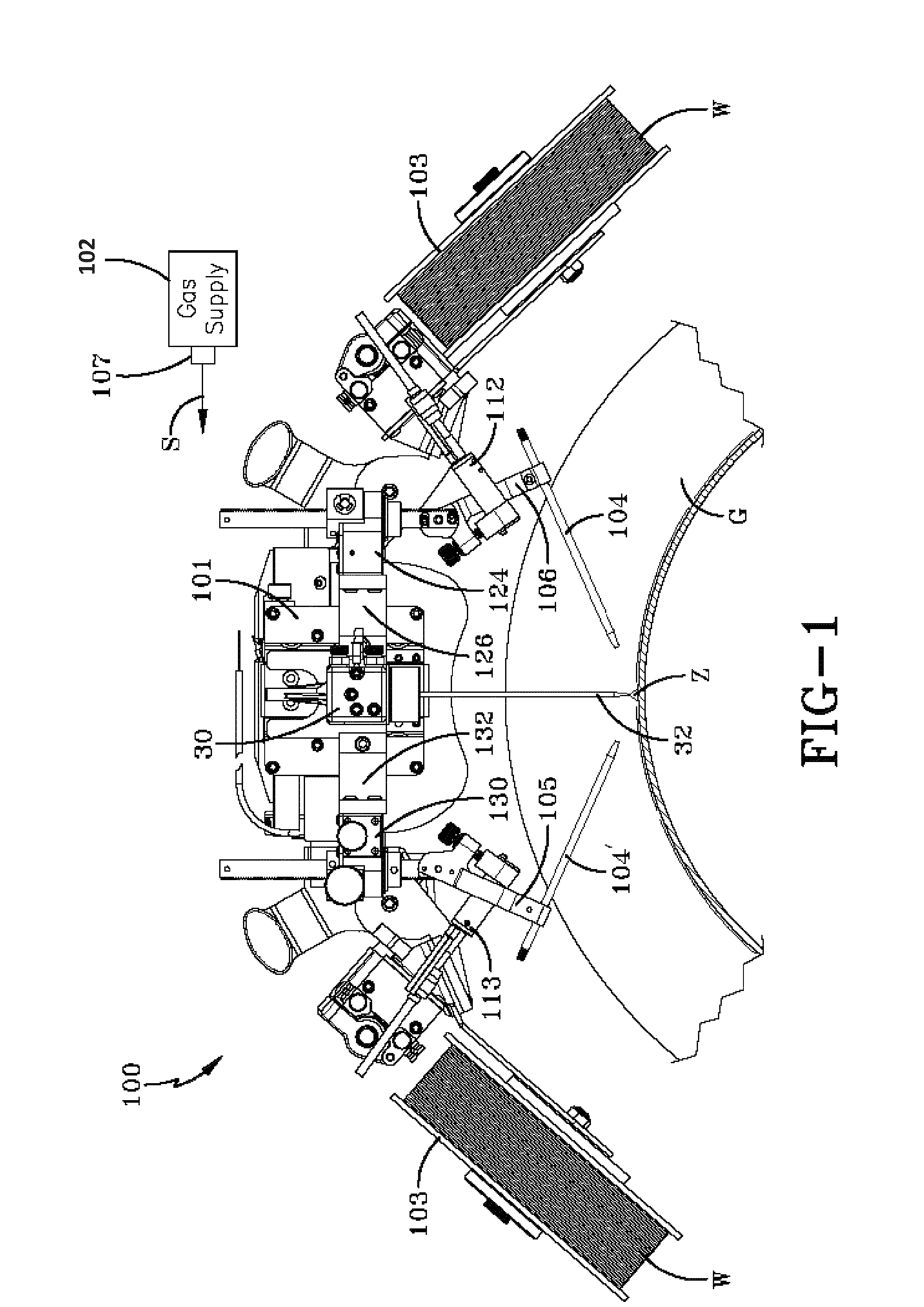

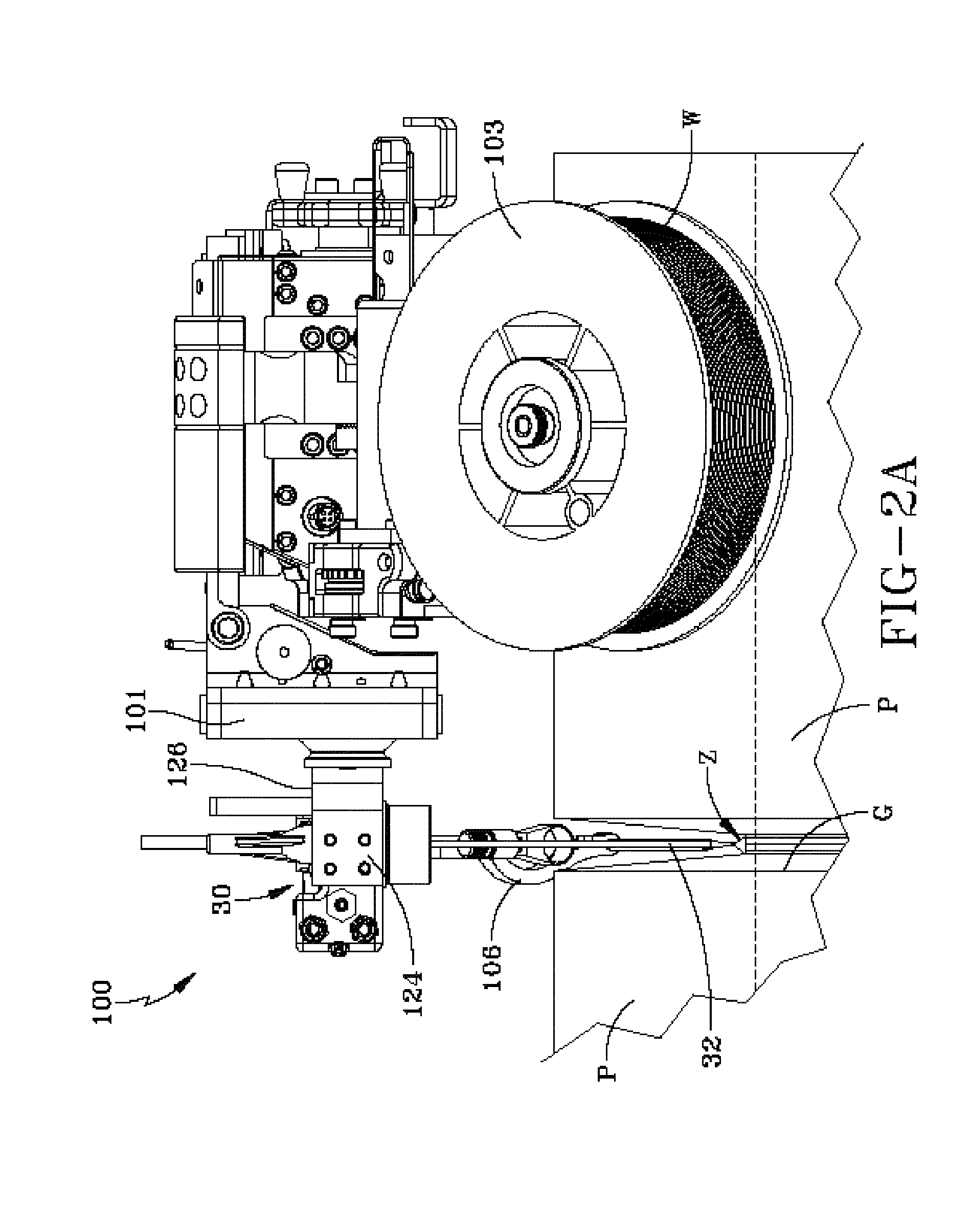

Method and system for hot wire welding

InactiveUS20020117489A1Welding/cutting media/materialsWelding electrode featuresPower flowWelding power supply

A hot wire welding method and system rely upon a welding torch with a non-melting electrode, a melting metal filler wire that is fed into a weld puddle created by welding arc, a microprocessor controller for controlling (i) current of the main welding arc, (ii) filler wire feed speed, and (iii) hot wire current for heating the filler wire. The method and system also rely upon a main welding power supply for supplying the main welding arc and a secondary DC supply for supplying the hot wire current. The hot wire current is automatically controlled by the microprocessor to supply the correct amount of current to the filler wire in response to changes in wire feed speed.

Owner:ARNDT TONY LEE +2

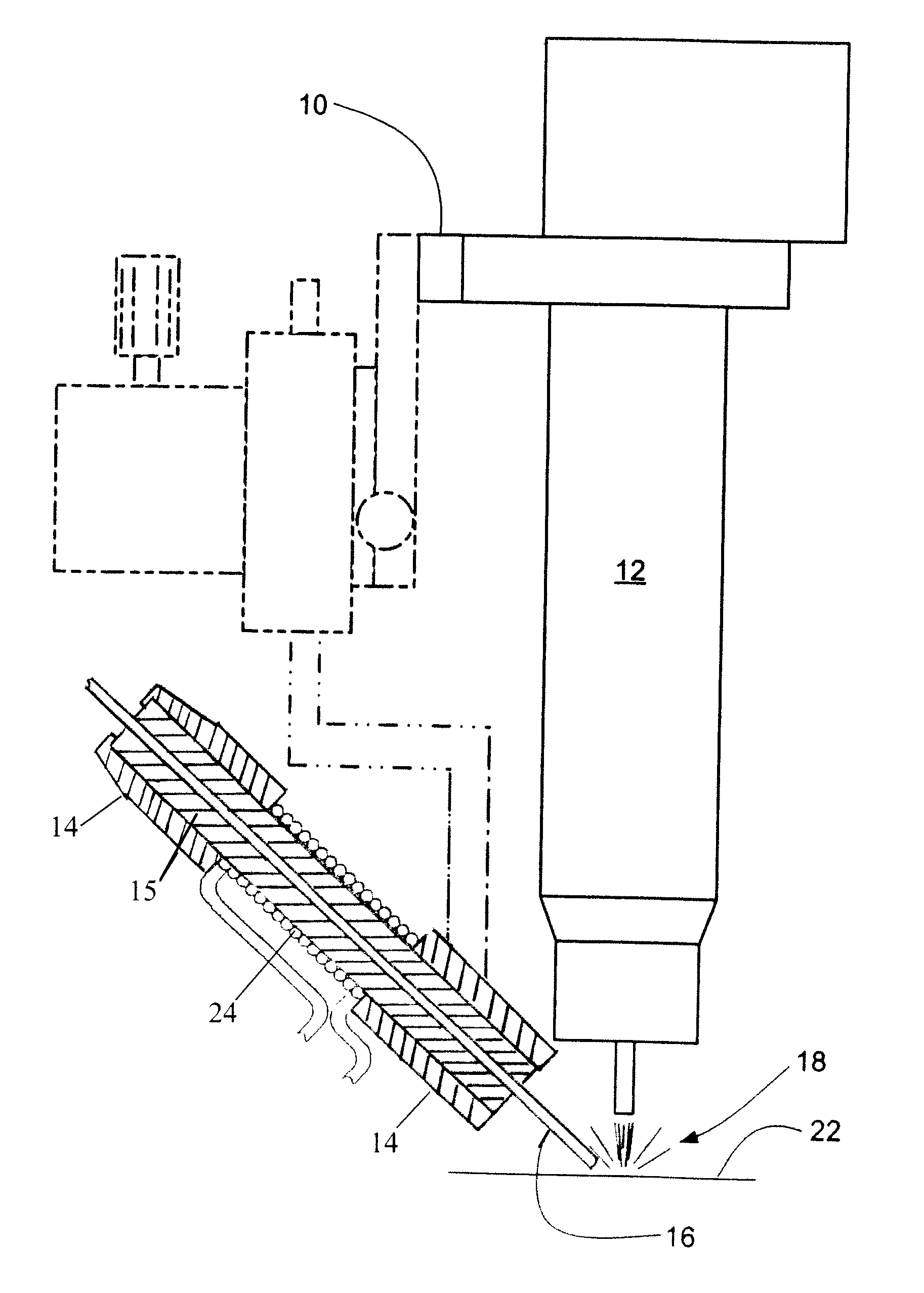

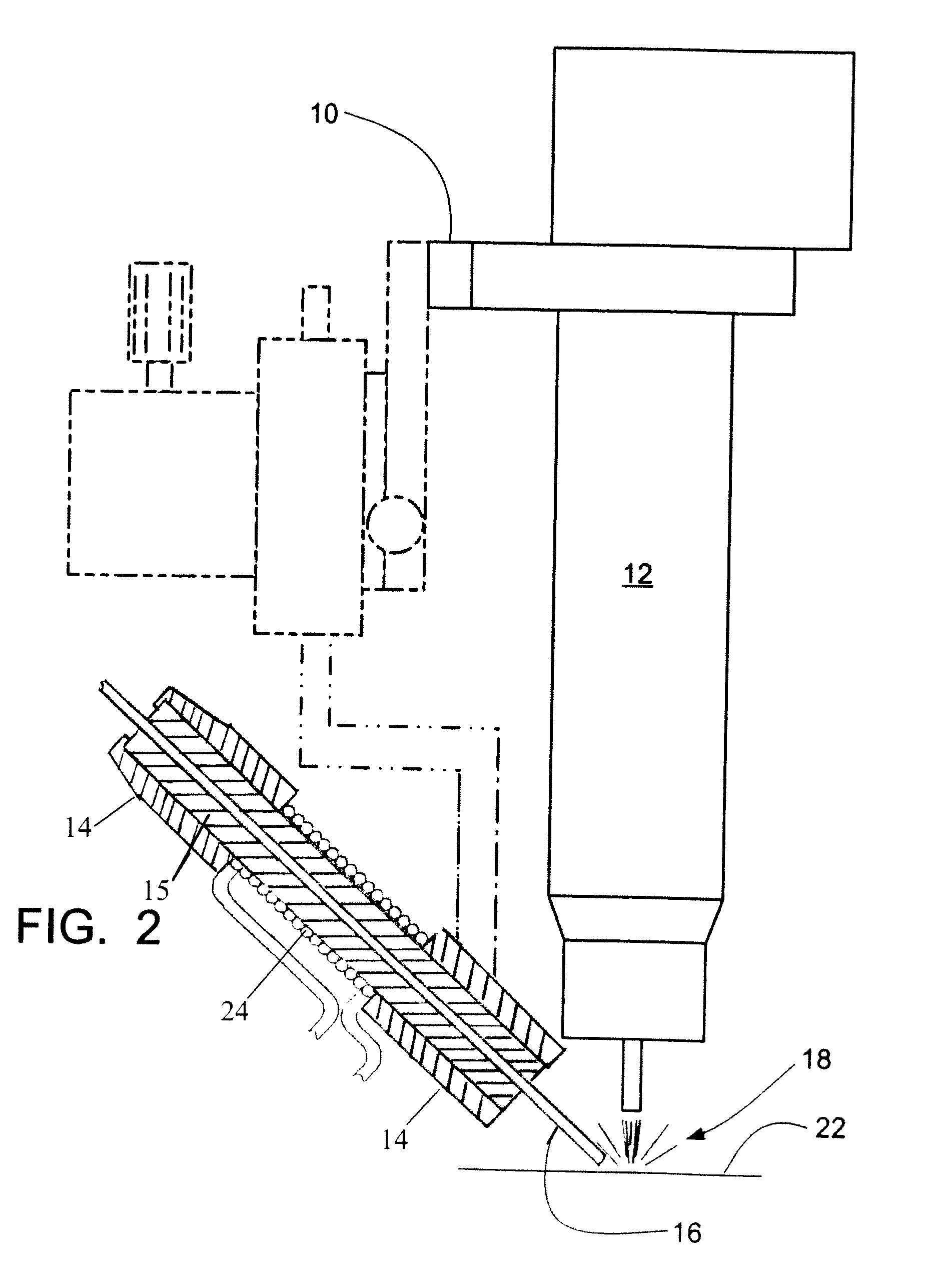

Induction heated, hot wire welding

InactiveUS20100059493A1Prevent heat lossImprove thermal shock resistanceArc welding apparatusLaser beam welding apparatusEngineeringElectric resistivity

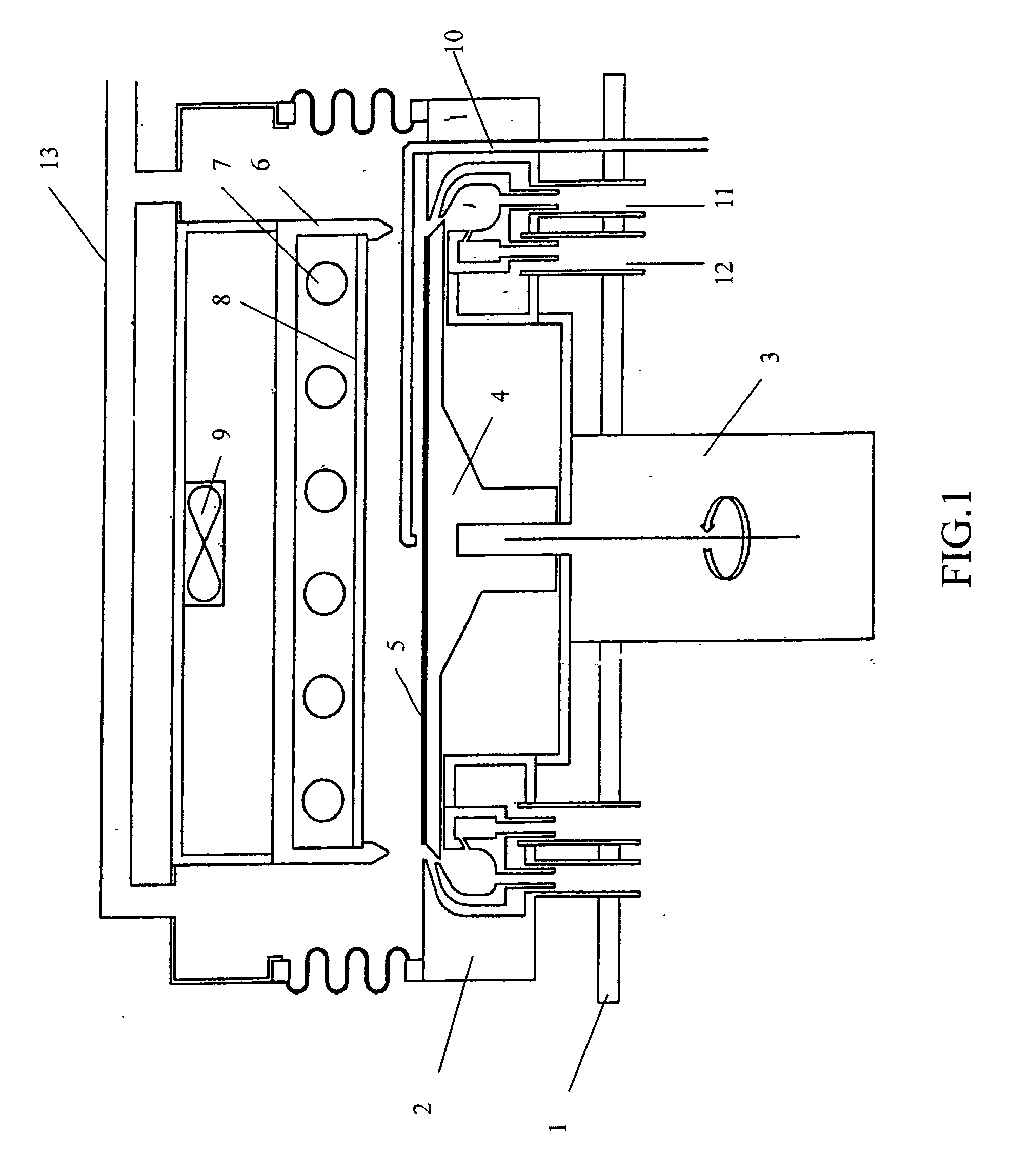

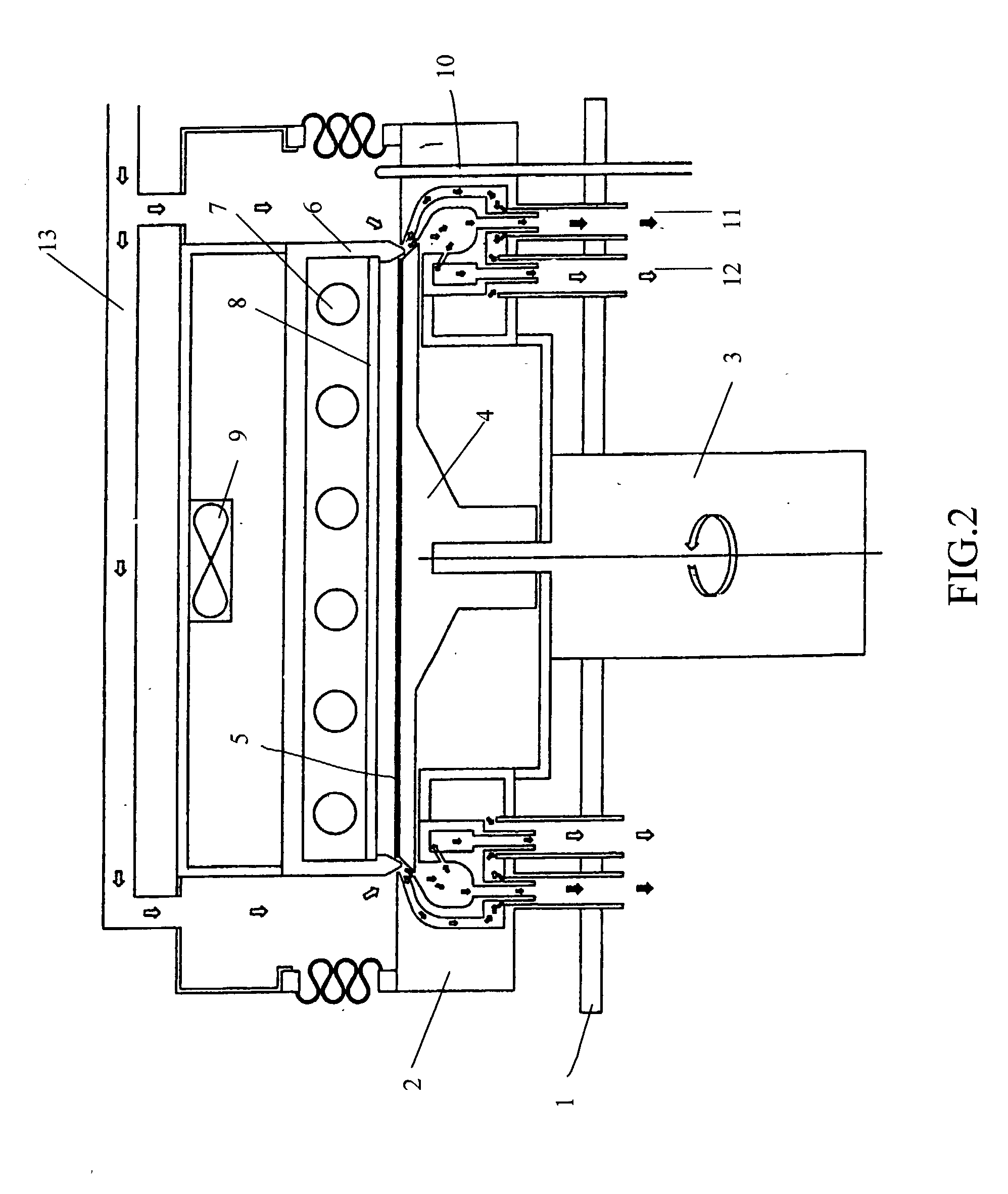

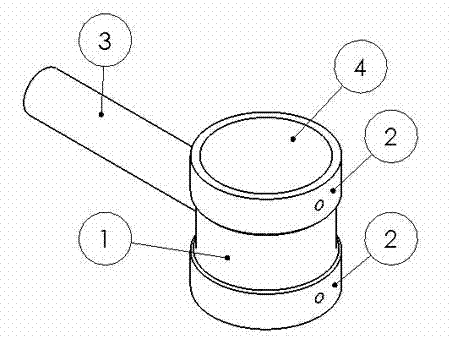

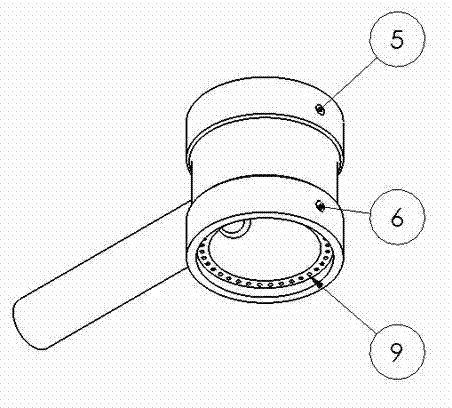

A hot wire welding process. An induction coil is used to preheat the filler metal wire prior to its entering the welding puddle / arc region. An induction coil is placed in close proximity to the welding arc. The filler wire is guided and supported by a delivery guide so that the filler wire passes through the center of, and is insulated from, the induction coil. The induction coil induces a current flow in the filler wire. The current produces heat as a result of the electrical resistivity of the filler wire. The heat produced raises the temperature of the filler wire just before it is fed into the weld arc region, thus reducing the energy required from the welding arc to melt the filler metal wire into the weld puddle.

Owner:BABCOCK & WILCOX TECHNICALSERVICES GRP INC

Engine control to compensate for fueling dynamics

ActiveUS7111593B2Easy to controlCompensation effectElectrical controlInternal combustion piston enginesVaporizationCylinder Valve

A method for calculating transient fuel wall wetting characteristics of an operating engine is described. The method accounts for cylinder valve deactivation of cylinders in the engine in calculating the dynamic fueling compensation. In one example, fuel vaporization effects from fuel puddles in deactivated cylinders is considered when calculating the fueling compensation for active cylinders.

Owner:FORD GLOBAL TECH LLC

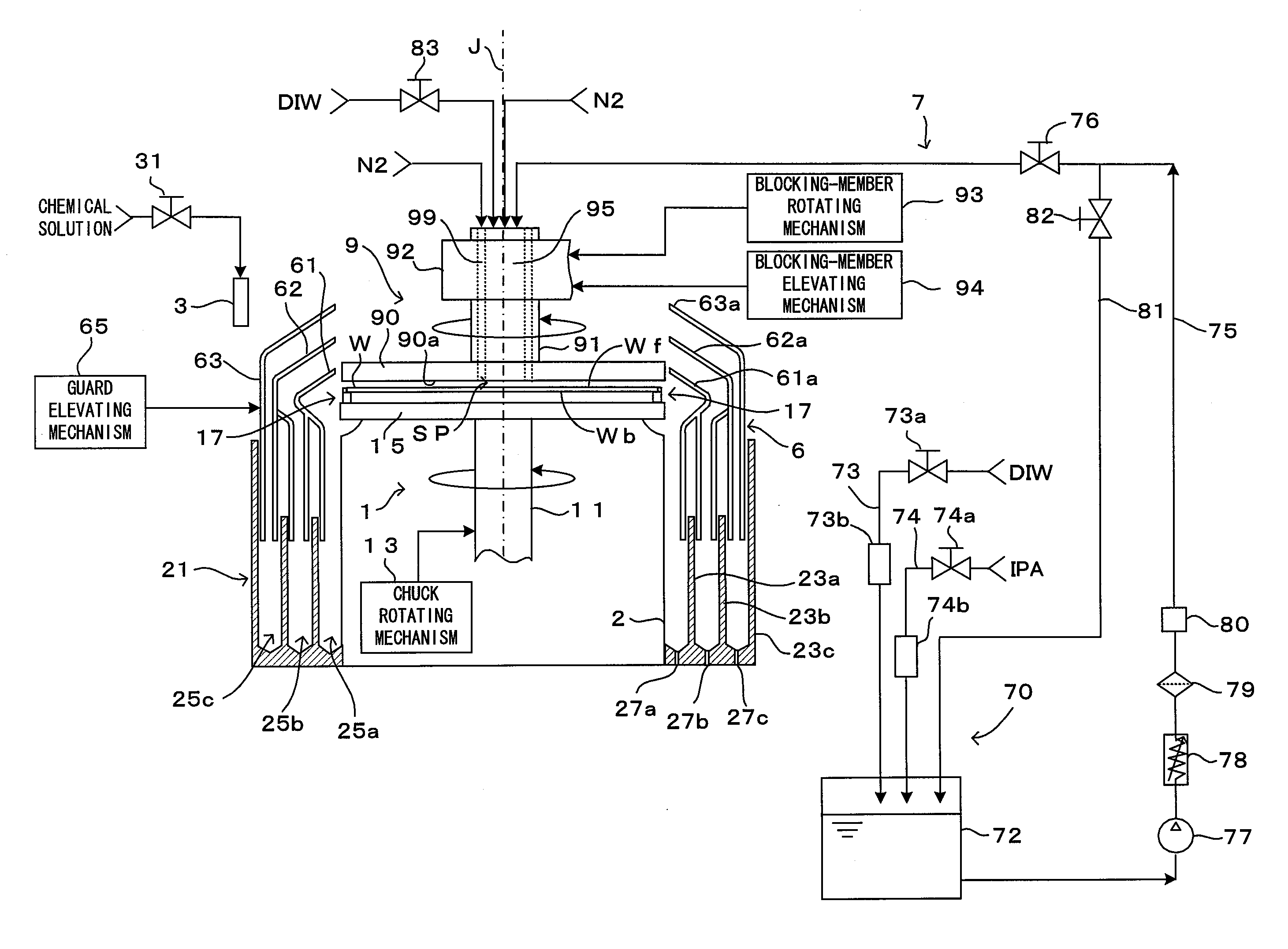

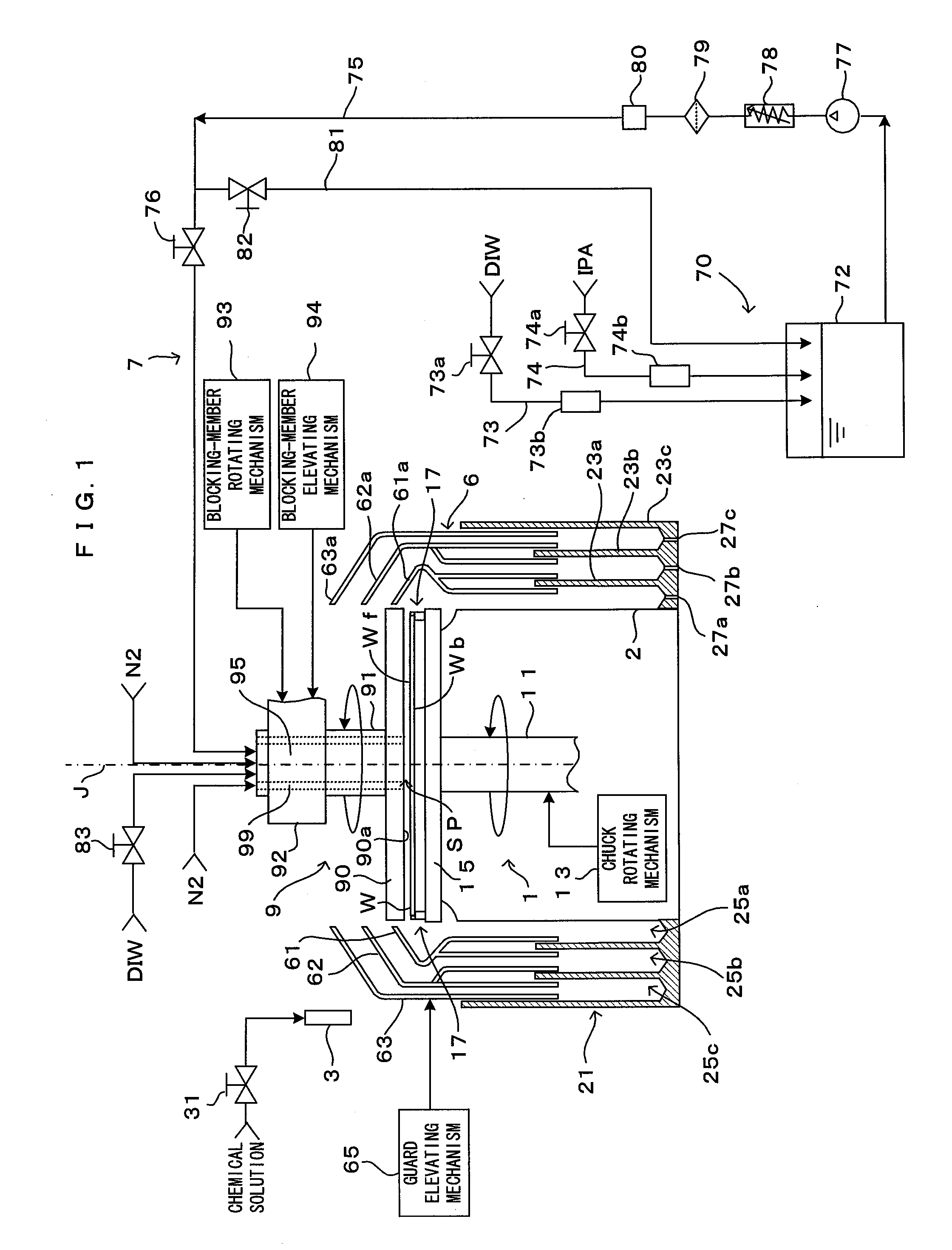

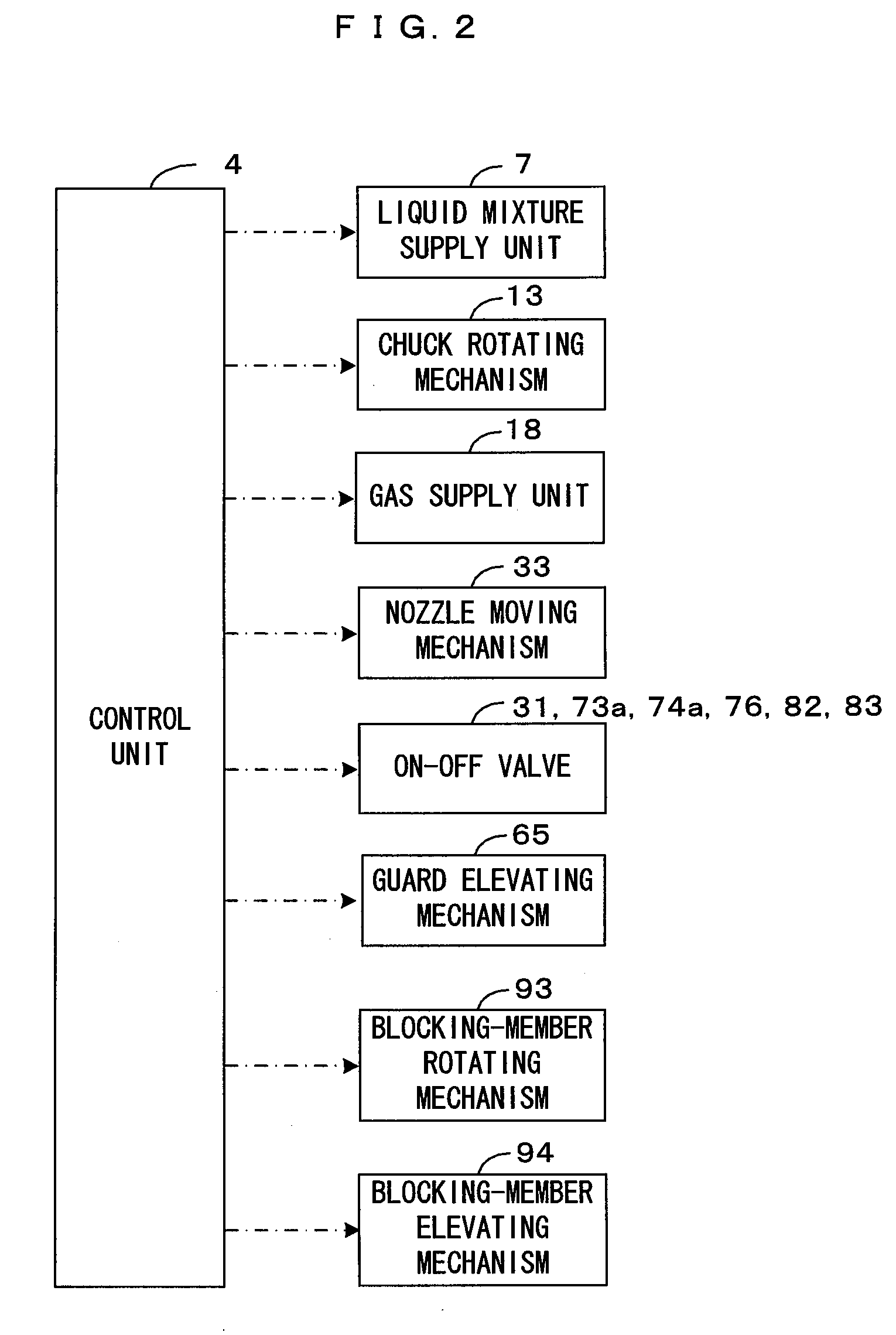

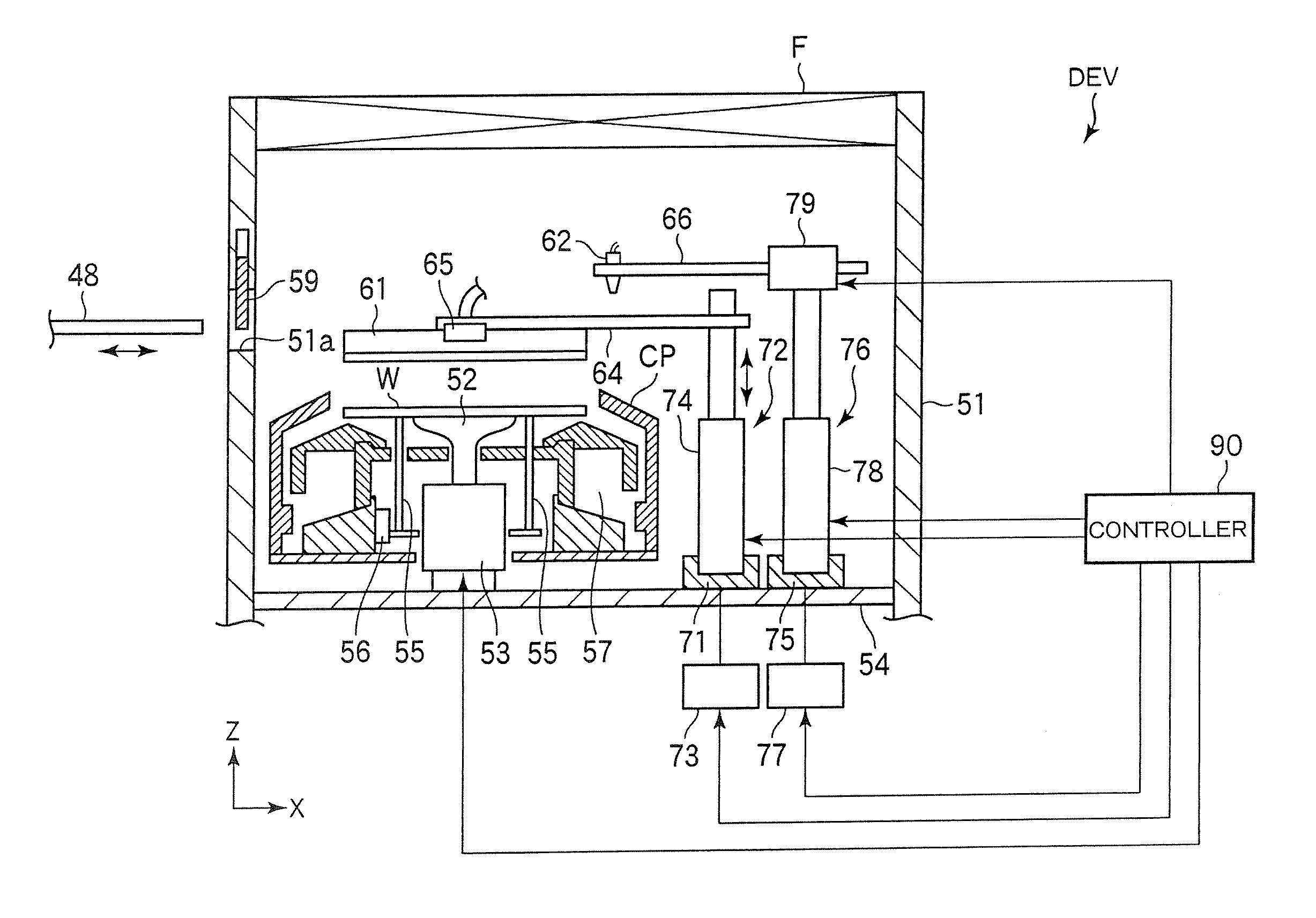

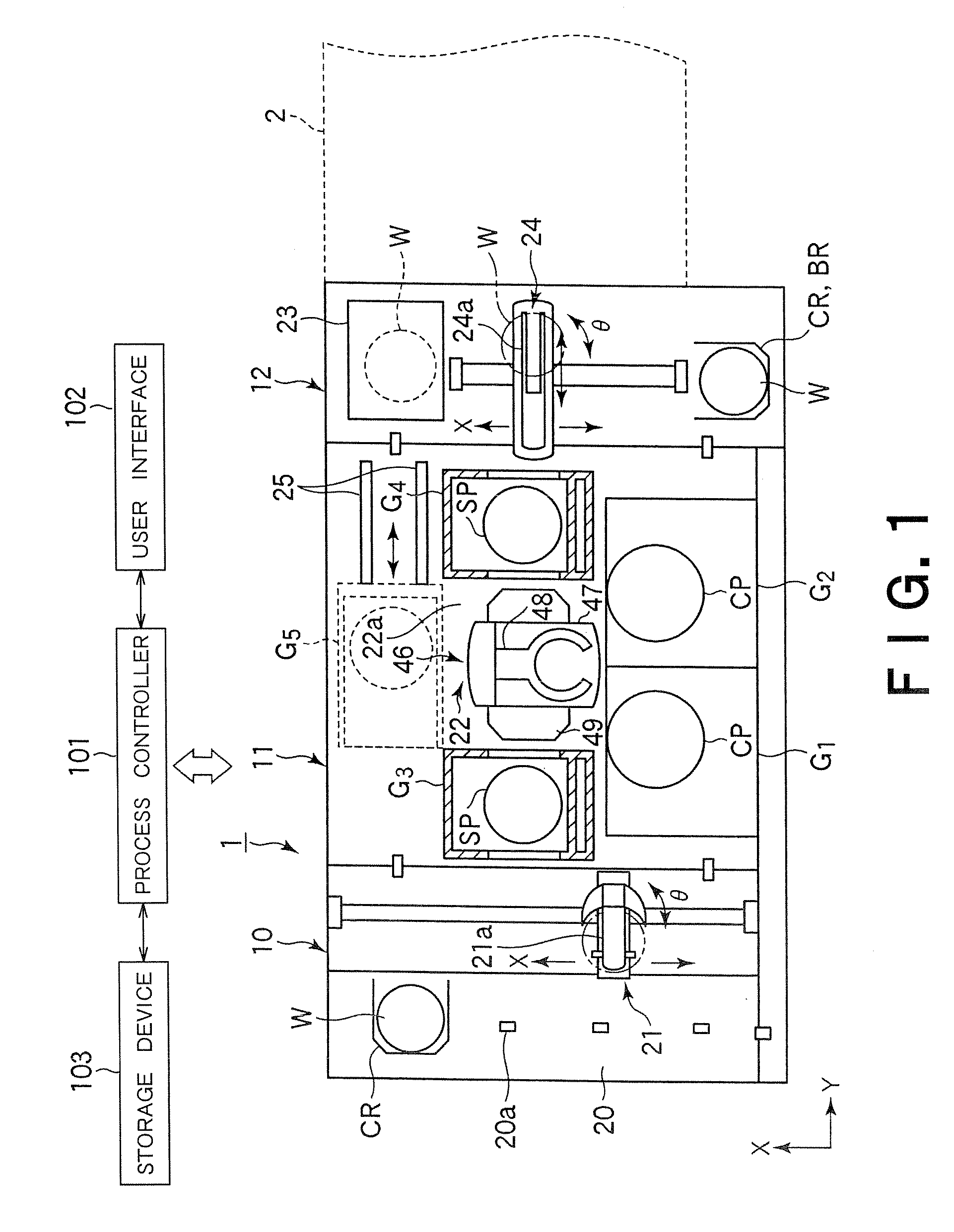

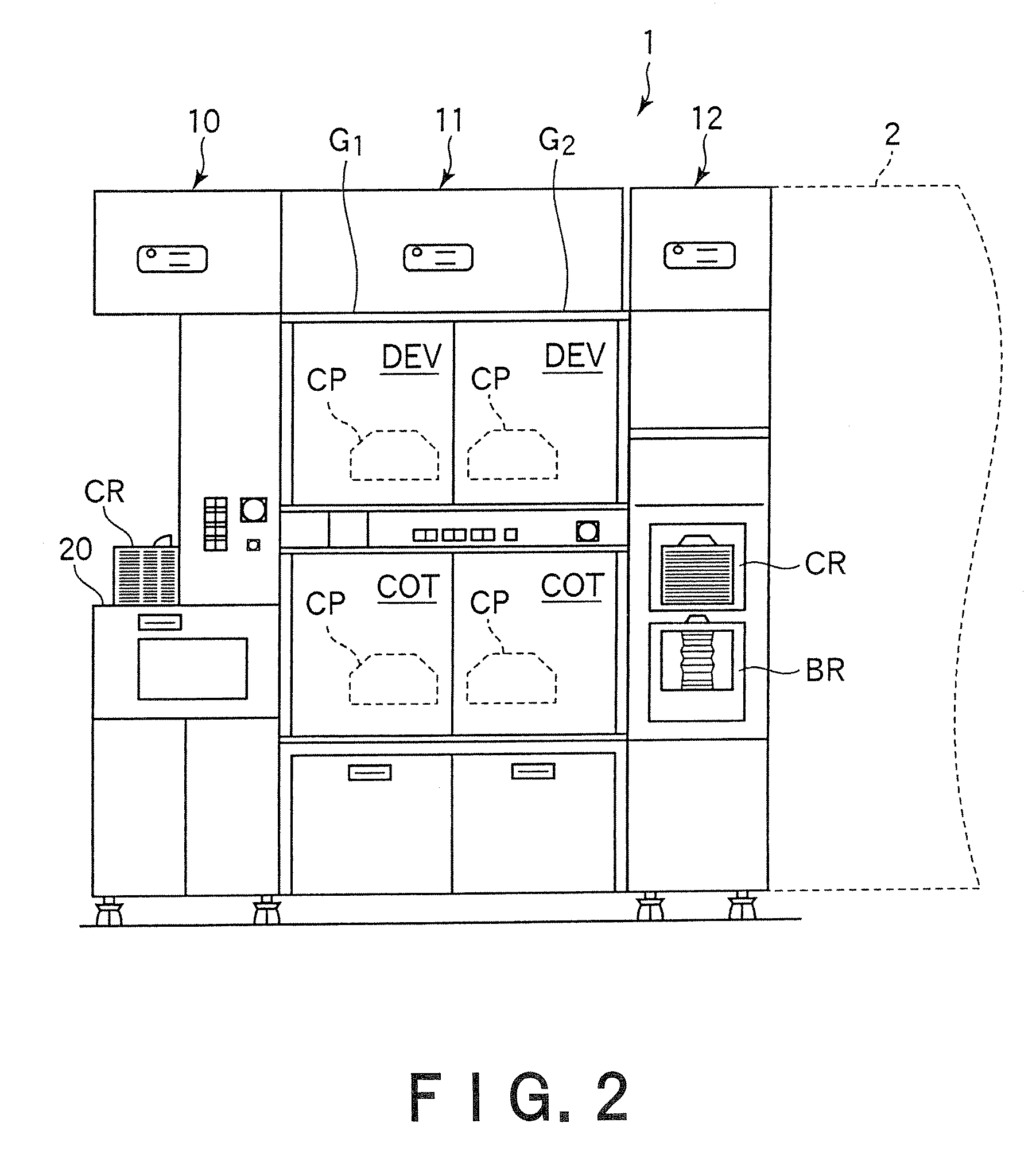

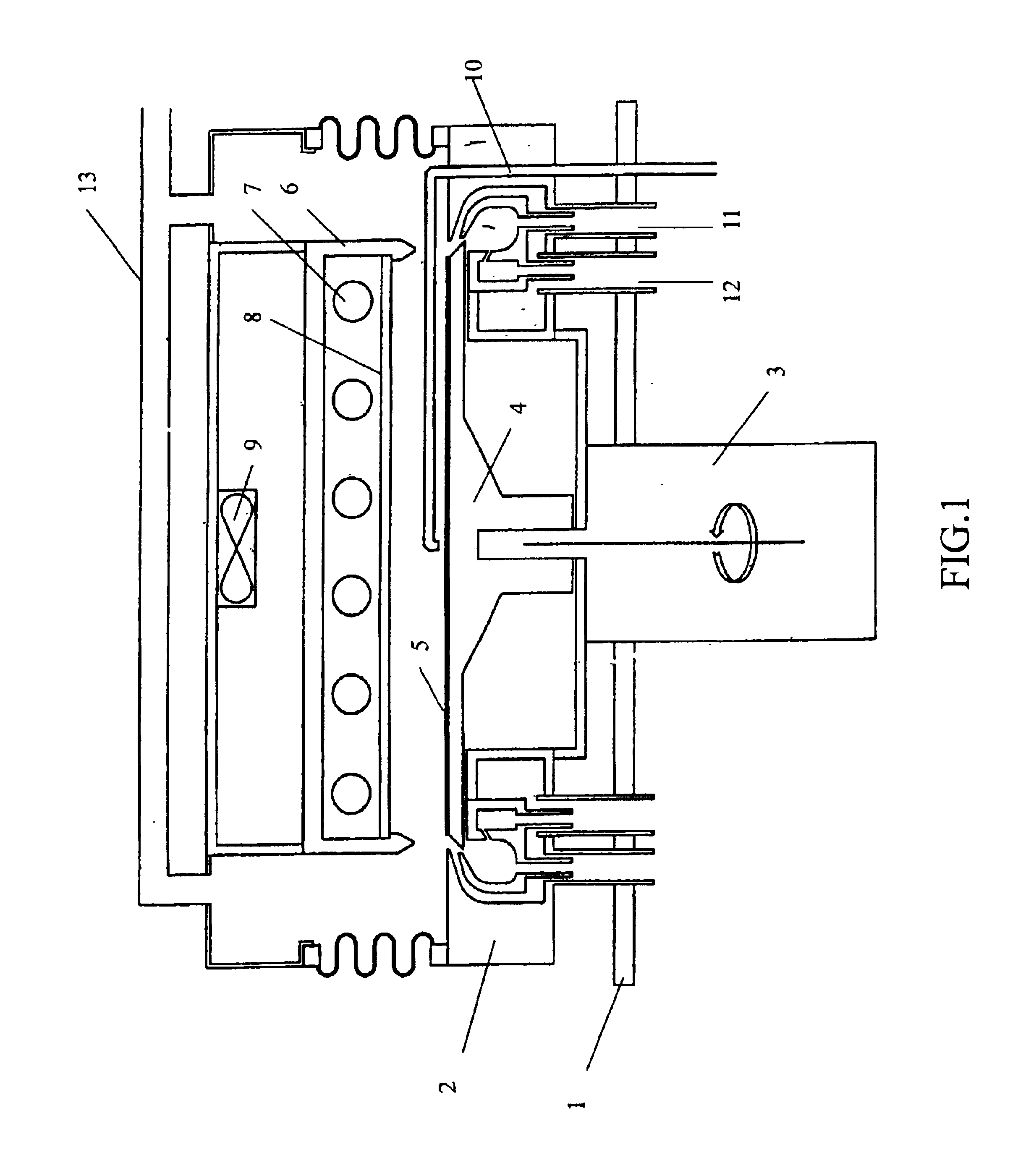

Substrate processing apparatus and substrate processing method

ActiveUS20090032067A1Reduce flow rateReduce usageSemiconductor/solid-state device manufacturingCleaning using toolsEngineeringSolvent

After the rinsing processing is completed, the rotation speed of the substrate is reduced from 600 rpm to 10 rpm to form a puddle-like DIW liquid film. After the supply of DIW is stopped, the control unit waits for a predetermined time (0.5 seconds) so that the film thickness t1 of the puddle-like liquid film becomes approximately uniform. Then, IPA is discharged to a central part of the surface of the substrate at a flow rate of 100 (mL / min) for instance. By the supply of IPA, DIW is replaced with IPA at the central part of the surface of the substrate to form a replaced region. Further, after three seconds of IPA supply, the rotation speed of the substrate is accelerated from 10 rpm to 300 rpm. This causes the replaced region to expand in a radial direction of the substrate so that the entire surface of the substrate is replaced with the low surface-tension solvent.

Owner:DAINIPPON SCREEN MTG CO LTD

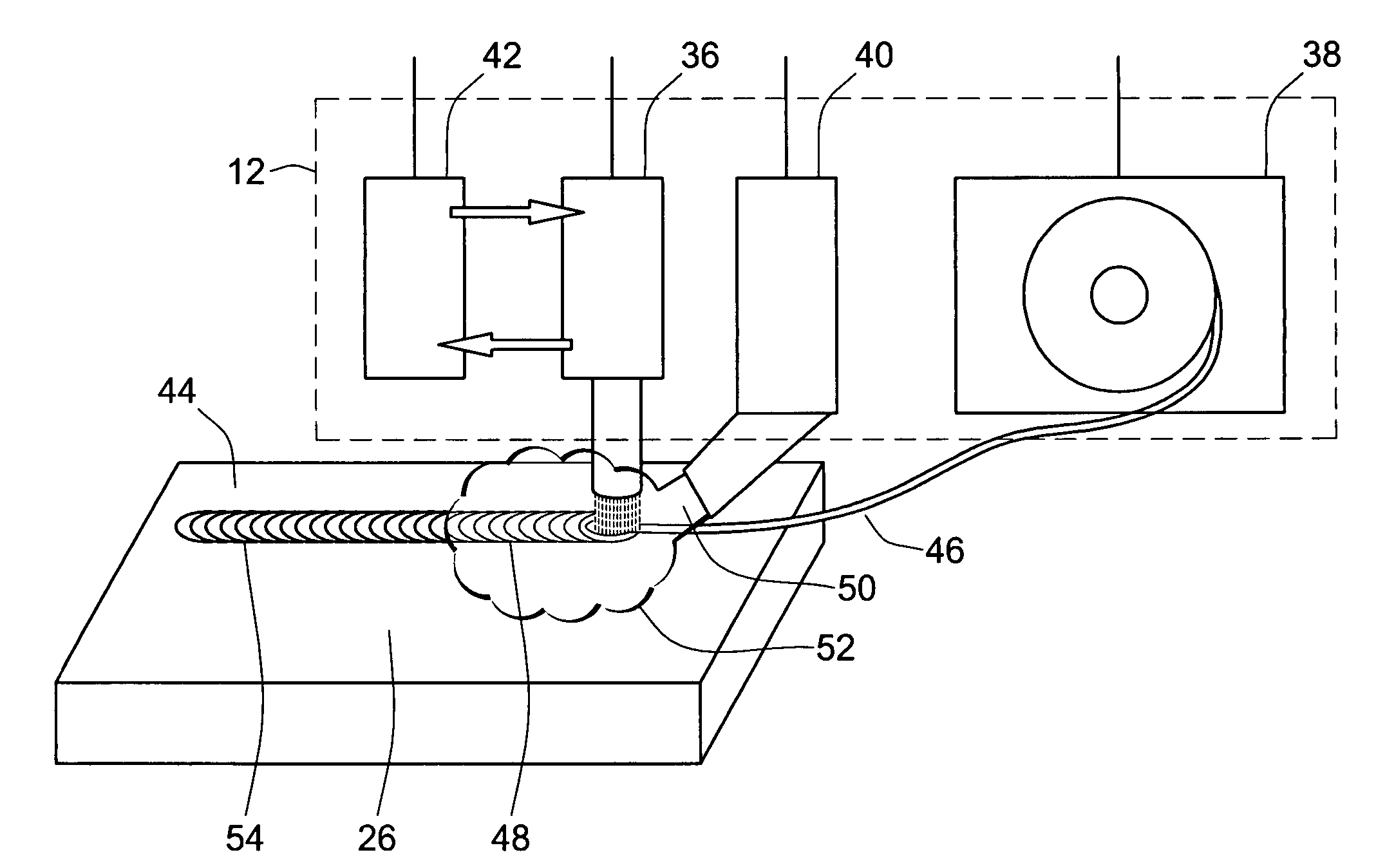

Controlled composition welding method

InactiveUS6884959B2Increase deposition rateMaintenance can be complicatedTurbinesGearingDeposition ratePuddle

This invention relates to a method and apparatus for controlling the composition of a weld. More particularly it relates to welding using an electric circuit, thereby creating a weld puddle, and adding at least one filler that is electrically independent from the electric circuit to the weld puddle at a controllable rate to obtain a target weld composition. The filler can be added to the extent limited by practical weld puddle geometry and, thus, the method and apparatus also facilitate increased weld deposition rates.

Owner:ELECTRIC POWER RES INST INC

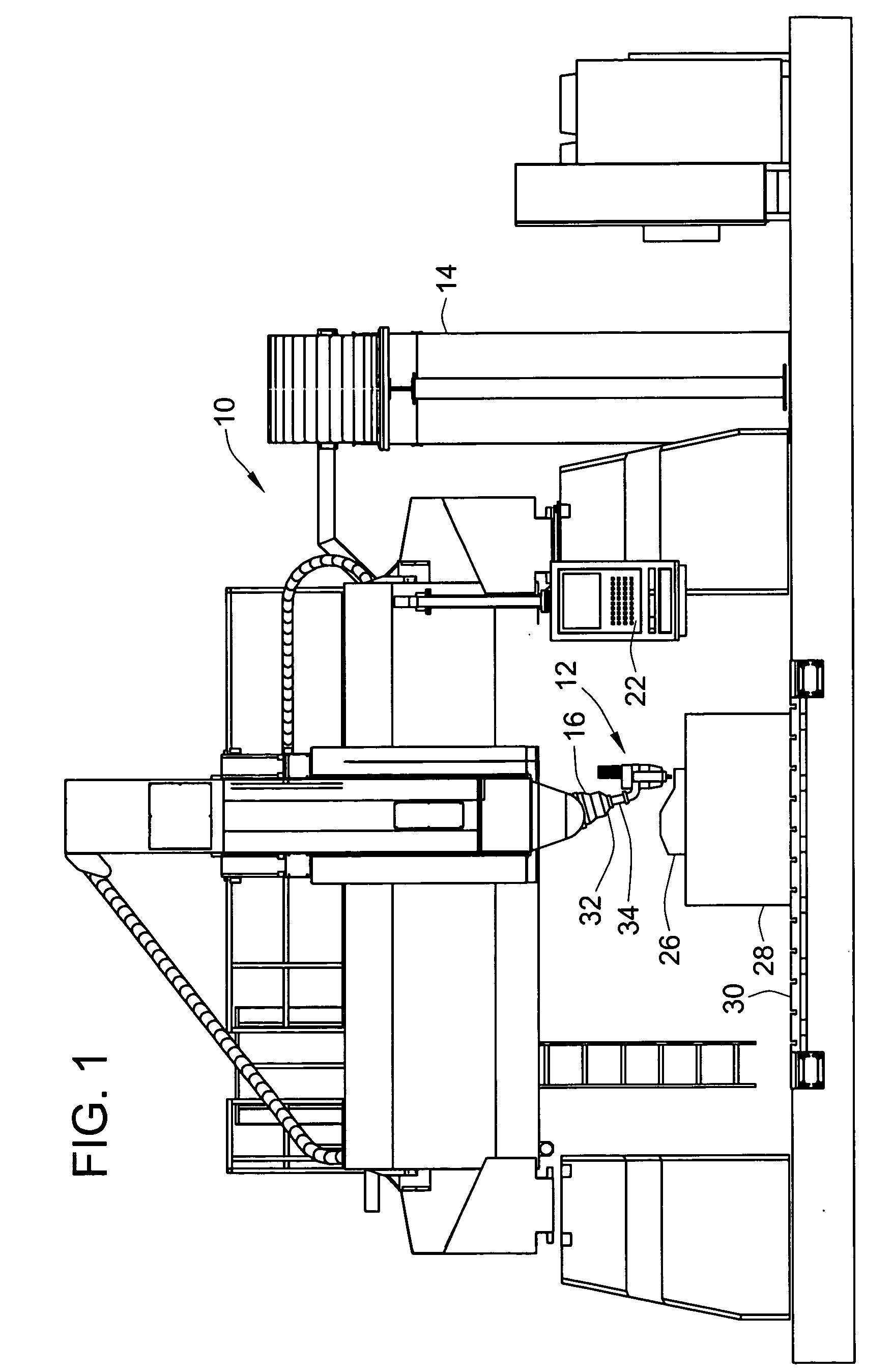

Method and apparatus for repairing or building up surfaces on a workpiece while the workpiece is mounted on a machine tool

A method and apparatus are provided for adding material to a workpiece mounted on a machine tool, while the workpiece is mounted on a machine tool, by melting a portion of the workpiece, in a zone of addition of the workpiece, using a material addition device including a laser, to form a puddle of molten material of the workpiece in the zone of addition, and feeding the material to be added into the puddle of molten material while continually applying heat with the laser. The melting and feeding are performed while the workpiece remains mounted in the same set-up that is used for machining the workpiece on the machine tool, except for replacing machining cutters used during machining operations with the material addition device. The machine tool may be a lathe, a grinder, a milling machine, a jig bore, or any other type of machine tool.

Owner:INGERSOLL MACHINE TOOLS

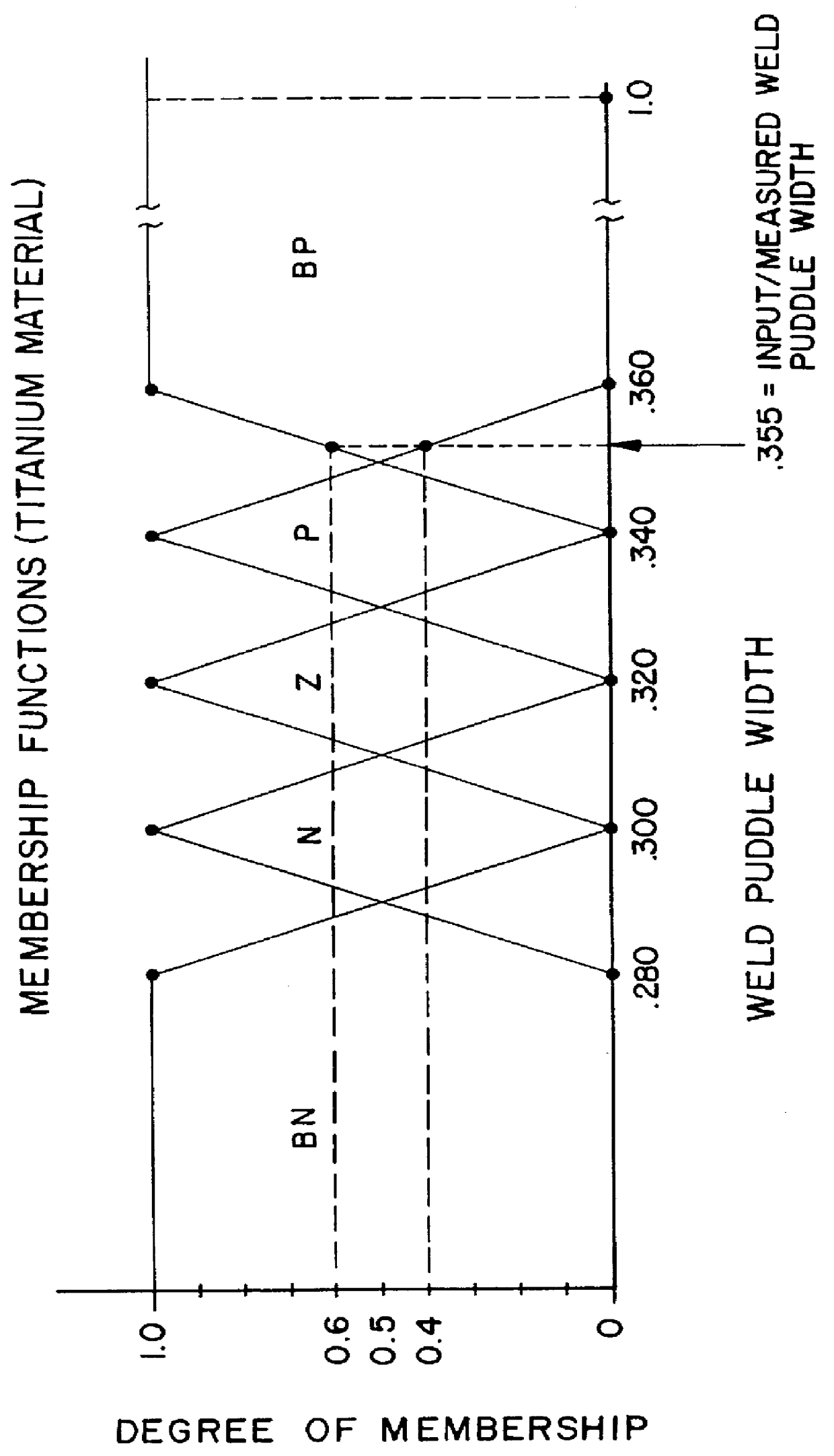

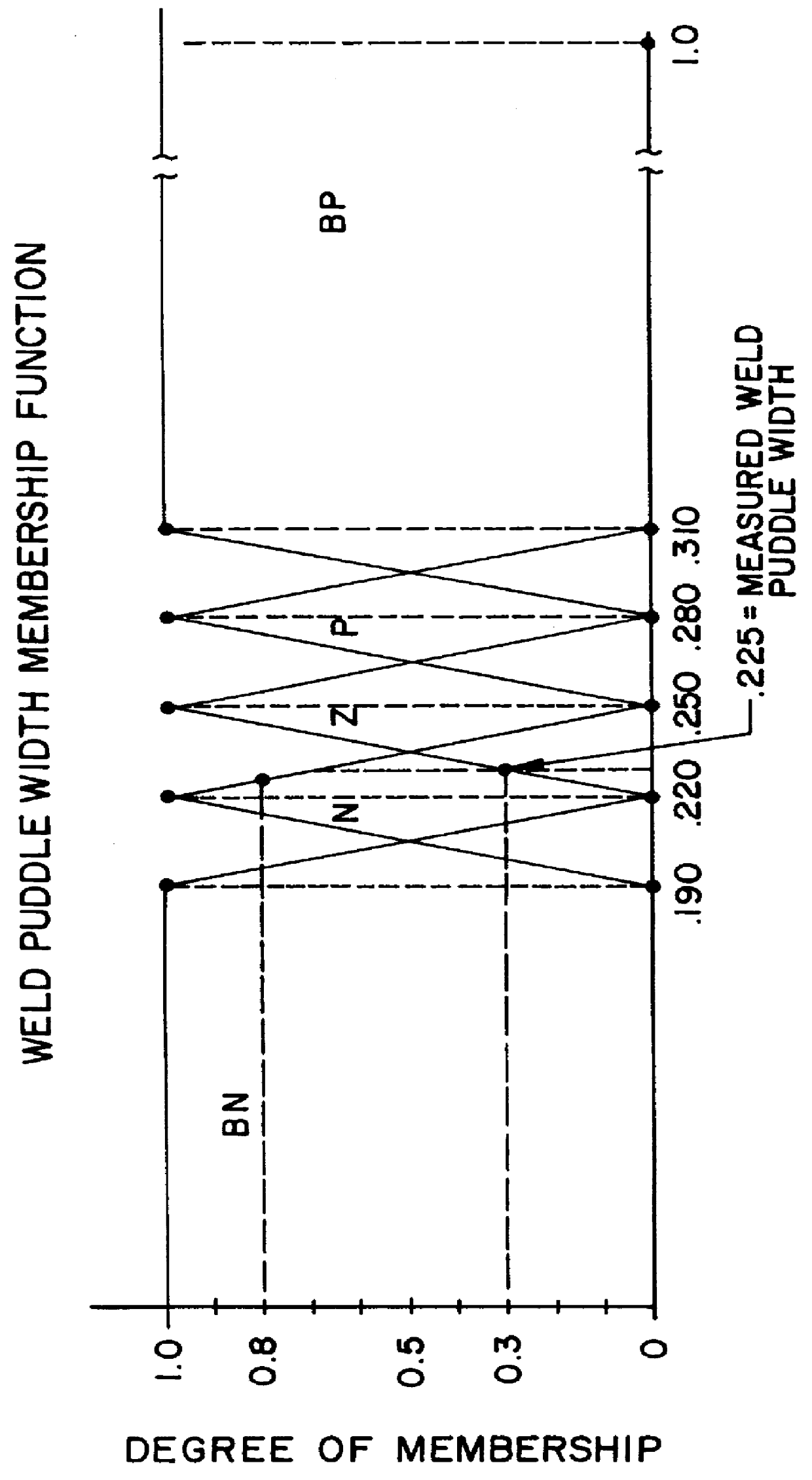

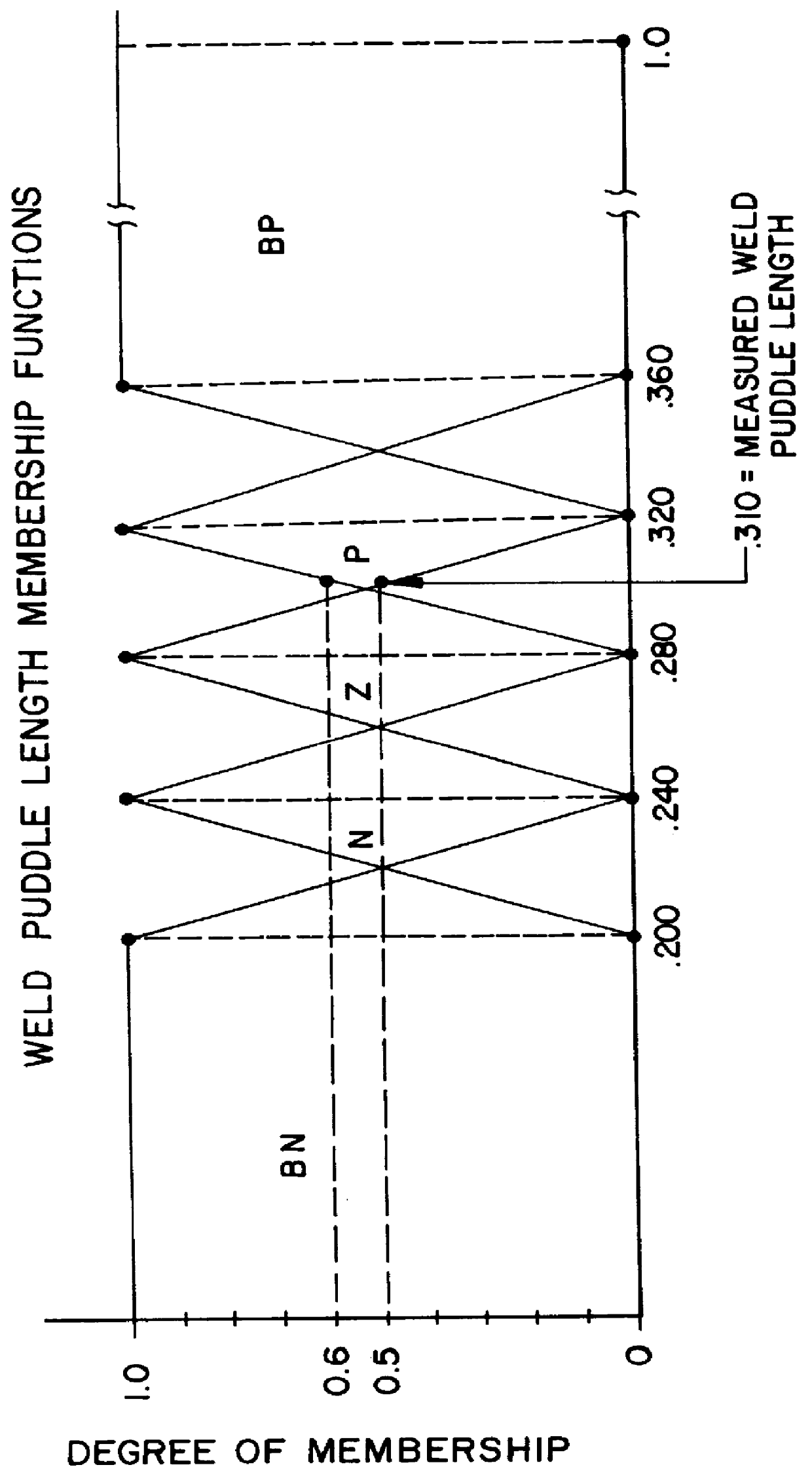

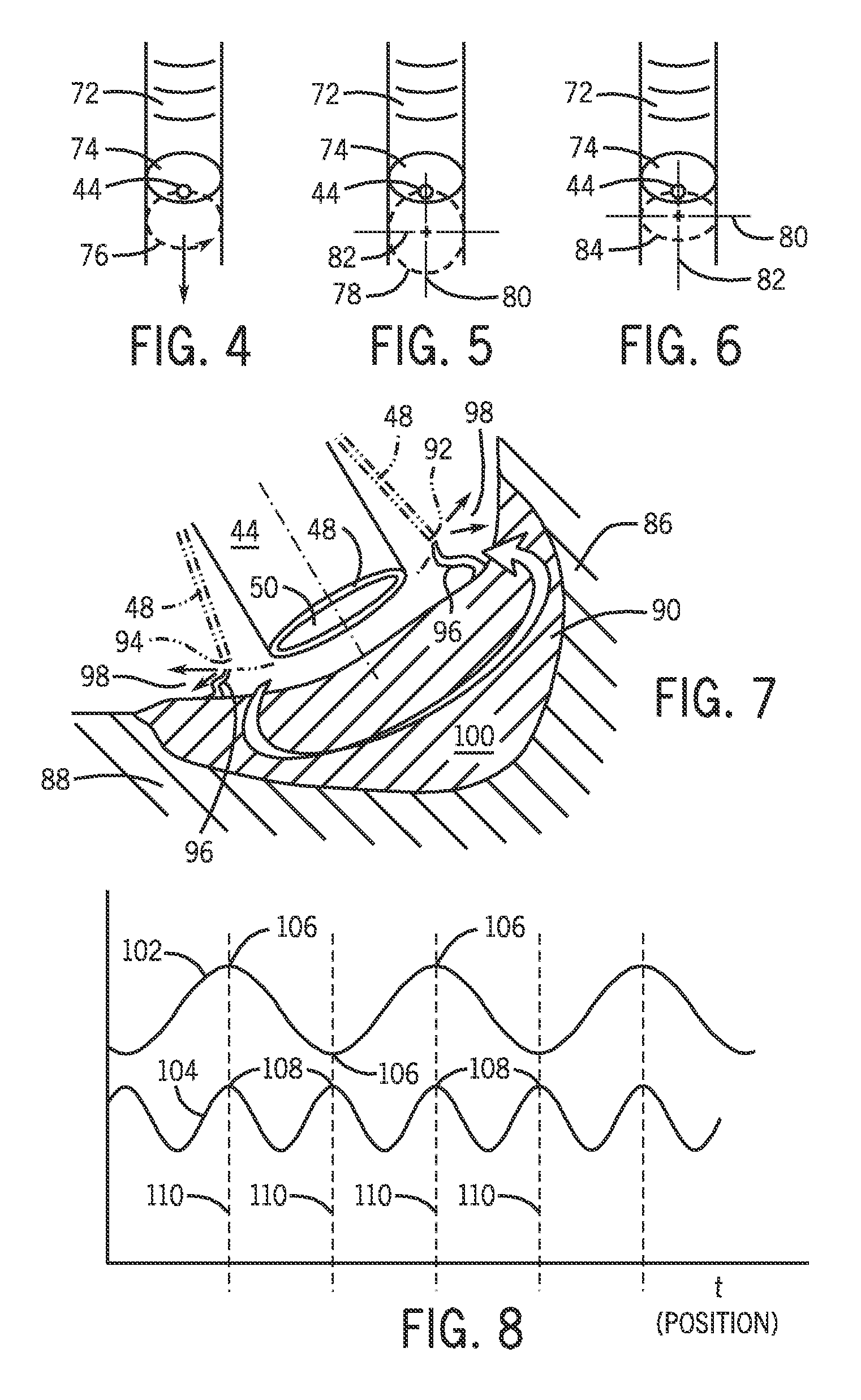

Welding control using fuzzy logic analysis of video imaged puddle dimensions

InactiveUSRE36926E1Reliable wayPrecise and repeatable weldProgramme-controlled manipulatorArc welding apparatusGear driveEngineering

A welding system includes an imaging system that takes frame by frame pictures of a weld puddle. The imaging system is located in the weld torch. From the images puddle length and width are determined. The length and width are applied against stored membership functions that cover a range of different weld current characteristics and the degree of membership of each dimension in those functions is determined, producing an alpha factor for each membership function. This provides a fuzzy current requirement. Stored values for moment and area for each membership function are multiplied by the alpha for the respective function. The total of the moments is divided by the total of the areas to produce a desired weld current. The weld head includes a weld wire feeder that is driven by a servo by which the wire can be feed along either side of the weld joint. The wire feeder is gear driven in such a way that it does not interfere with the optics in the weld torch. The optics include a strobe to illuminate the puddle. Signal processing includes a process for interpolating the puddle centerline from the range in puddle widths over successive strobed images of the puddle. The head is positioned automatically over the centerline.

Owner:UNITED TECH CORP +1

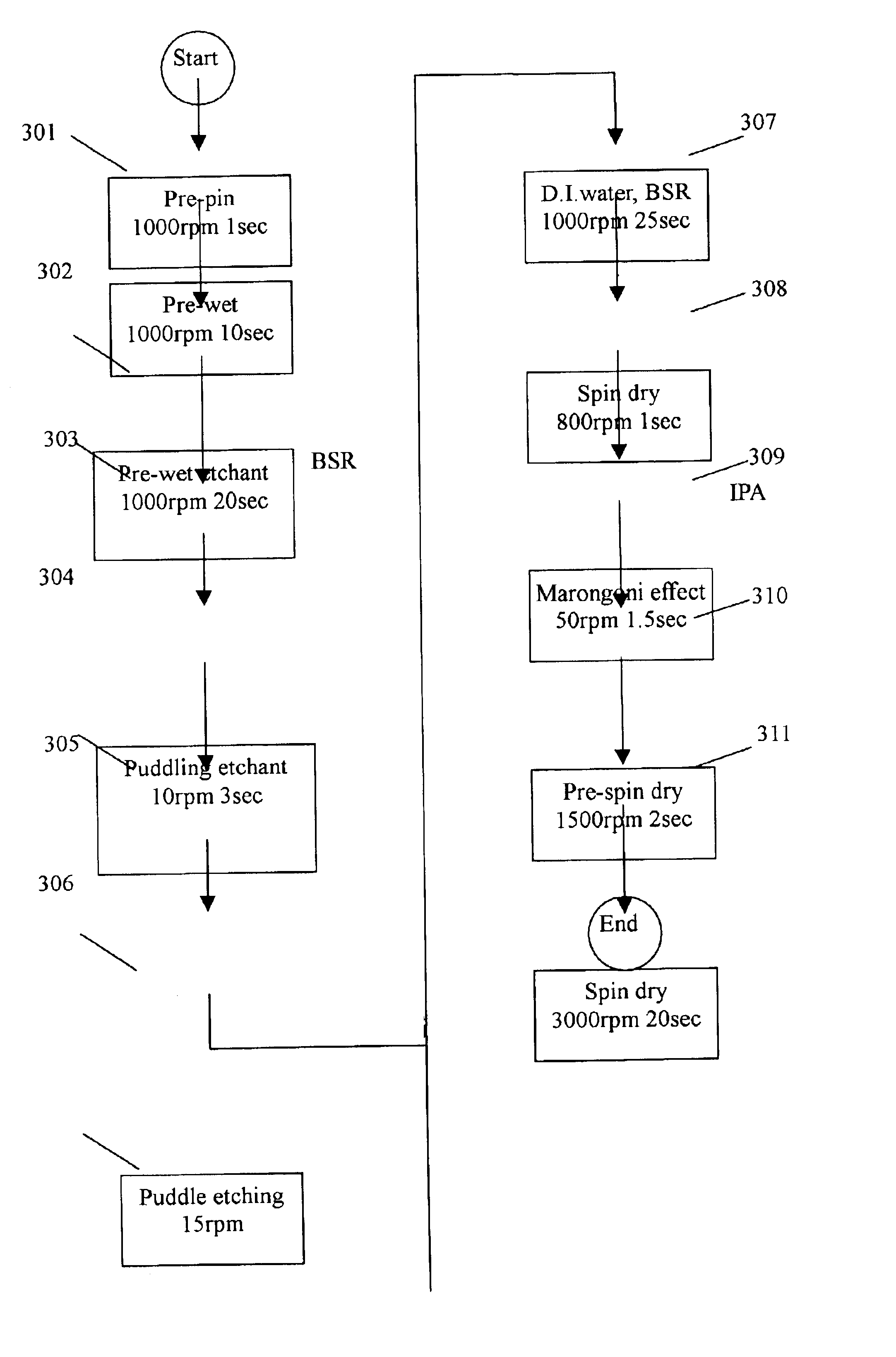

Puddle etching method of thin film by using spin-processor

The present invention discloses a puddle etching method of thin film. In a spin etching equipment, pre-wet the wafer by D.I. water and etch solution to remove the contamination and the upper layer of the film on the wafer. Then spin slowly (about 0-50 rpm) and inject etching solution to form a puddle of etching solution which will stay on the wafer, the wafer then keep spin slowly (about 0-50 rpm) such that the puddle of etching solution stay on the wafer and etching is going on by puddle etching. After the thin film is etched, the wafer is spin at higher speed, and D.I. water is injected to rinse. Then, IPA is used to remove the D.I. water by Marangoni effect. Finally raise the speed to dry the wafer.

Owner:GRAND PLASTIC TECH

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

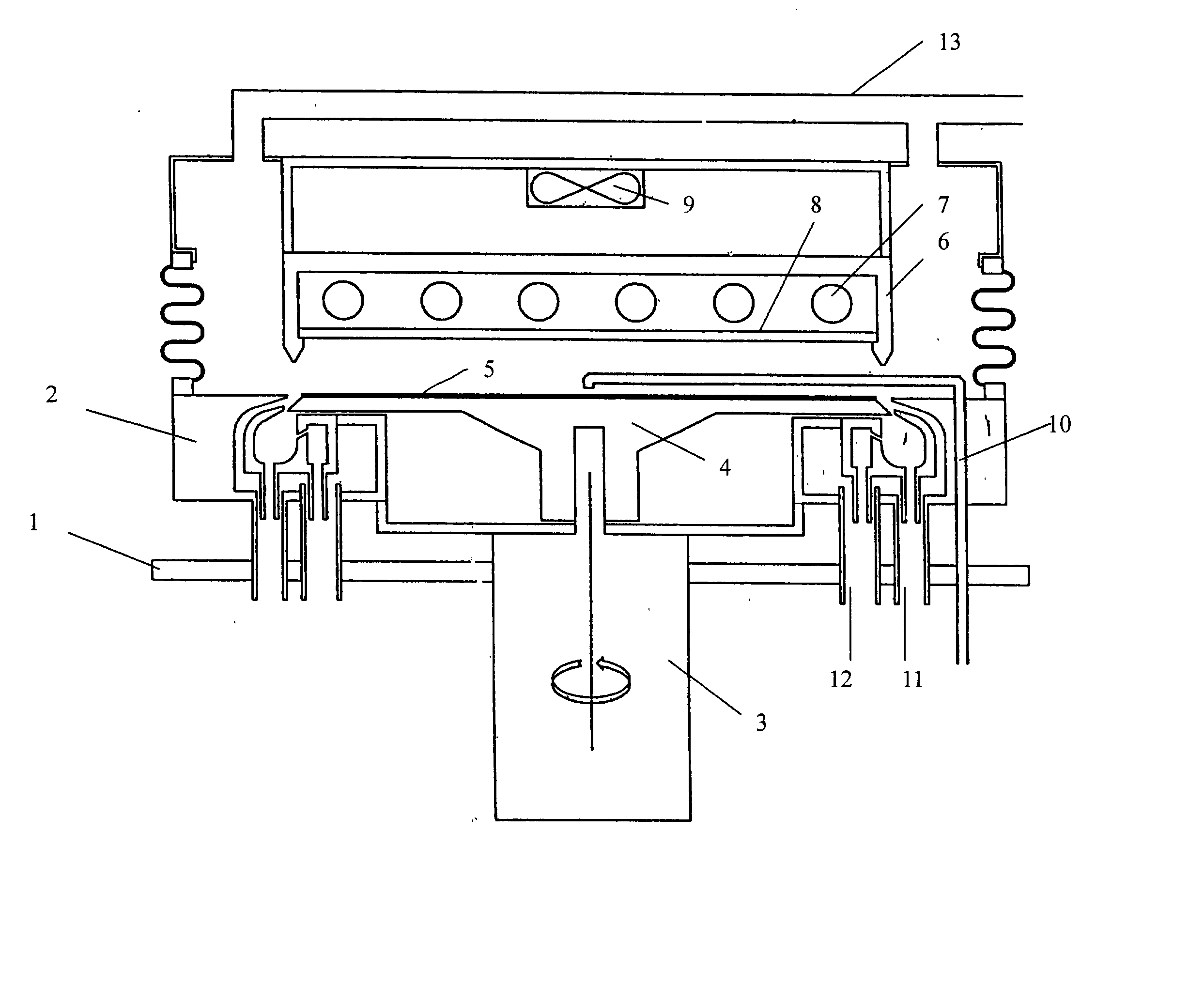

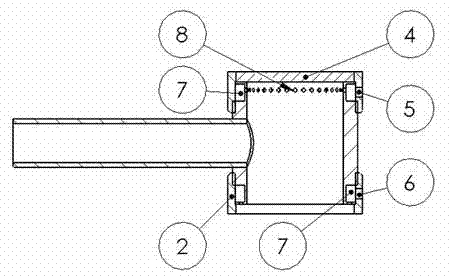

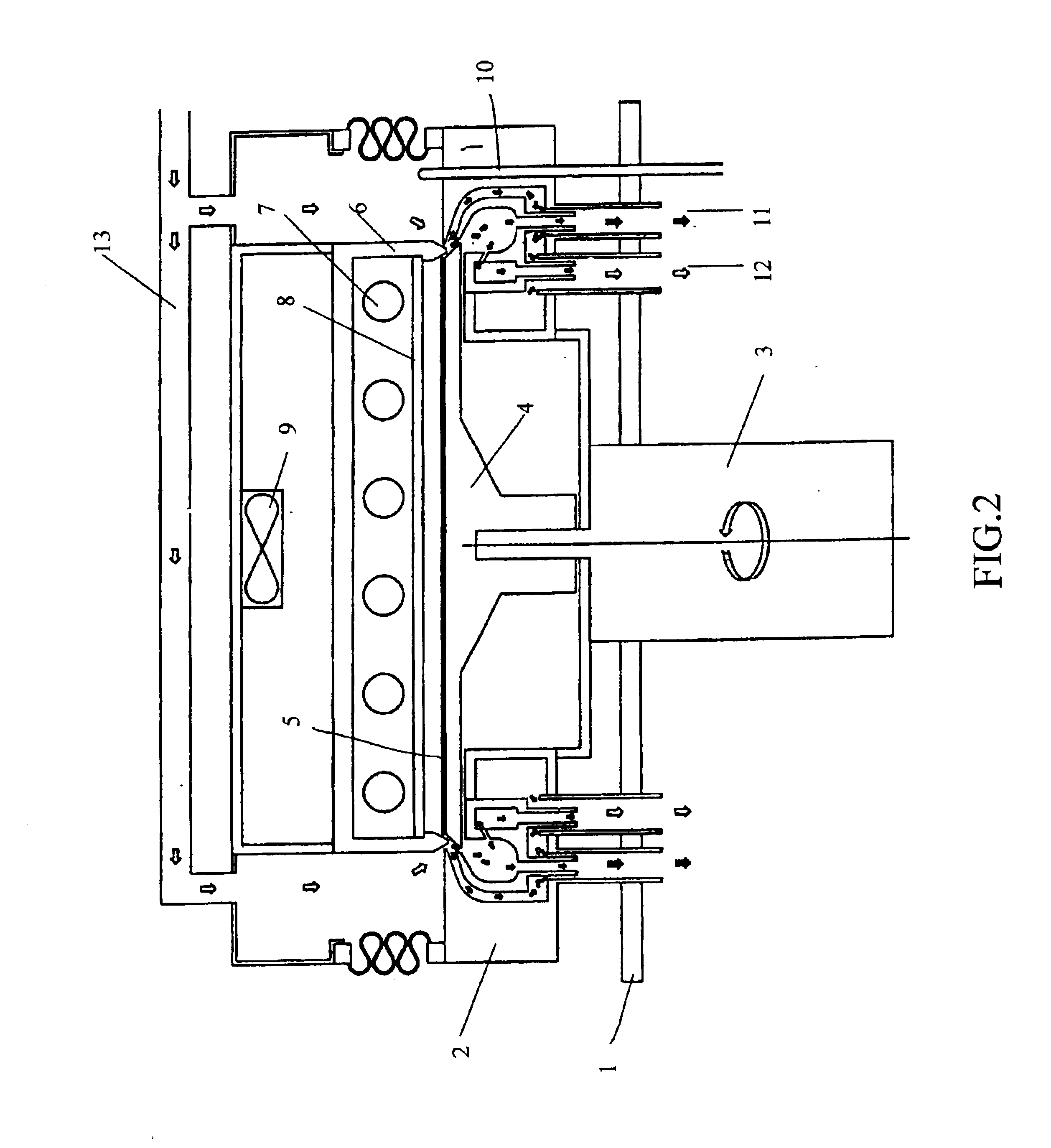

Plasma-side-suction negative pressure device for laser welding

InactiveCN102642085AUnlimited sizeImprove welding qualityLaser beam welding apparatusHigh power lasersClosed chamber

The invention relates to a plasma-side-suction negative pressure device for laser welding. The plasma-side-suction negative pressure device can be mounted on any laser welding gun head. A negative pressure chamber device is fixed with the laser welding gun head and can move relative to a workpiece to be welded; and the negative pressure chamber device is arranged above a welding puddle area on the surface of the workpiece to be welded and is used for quickly exhausting, so that local negative pressure lower than the normal atmospheric pressure is generated in a closed chamber fixed in the laser welding gun head, and a negative pressure environment can be formed around a welding puddle. With the adoption of the plasma-side-suction negative pressure device for laser welding, the plasma generation during the process of high-power laser deep penetration welding can be effectively inhibited, and the weld-seam deep-layer air holes caused by a keyhole effect are eliminated. The plasma-side-suction negative pressure device for laser welding has the advantages of no restriction of workpiece size, flexibility and convenience in use, good stability, higher welding quality and increased stability in a welding process.

Owner:SHANGHAI JIAO TONG UNIV

Method for fabricating door brick in coke furnace

The prodn. steps are: raw material with fixed size is matched according to fixed matching ratio and is weighed according to fixed matching ratio then is send into puddle mixer to be sturred 2-3 minutes by adding water, the mixed material is send into model with fixed size to be vibrated 2-3 minutes by vibrostand or vibrating stick to make injected material compacted; the material is natural maintained in proper time in the model, remaintained 3 days after form stripping, dried 7 days in drying room, then is used into kln to be fired 3 hours in temp. 1300 deg.C to produce the end product, thickness of the brick is more than 200 mm, evenly reach to 1200-1500 mm.

Owner:山东耐材集团中齐耐火有限公司

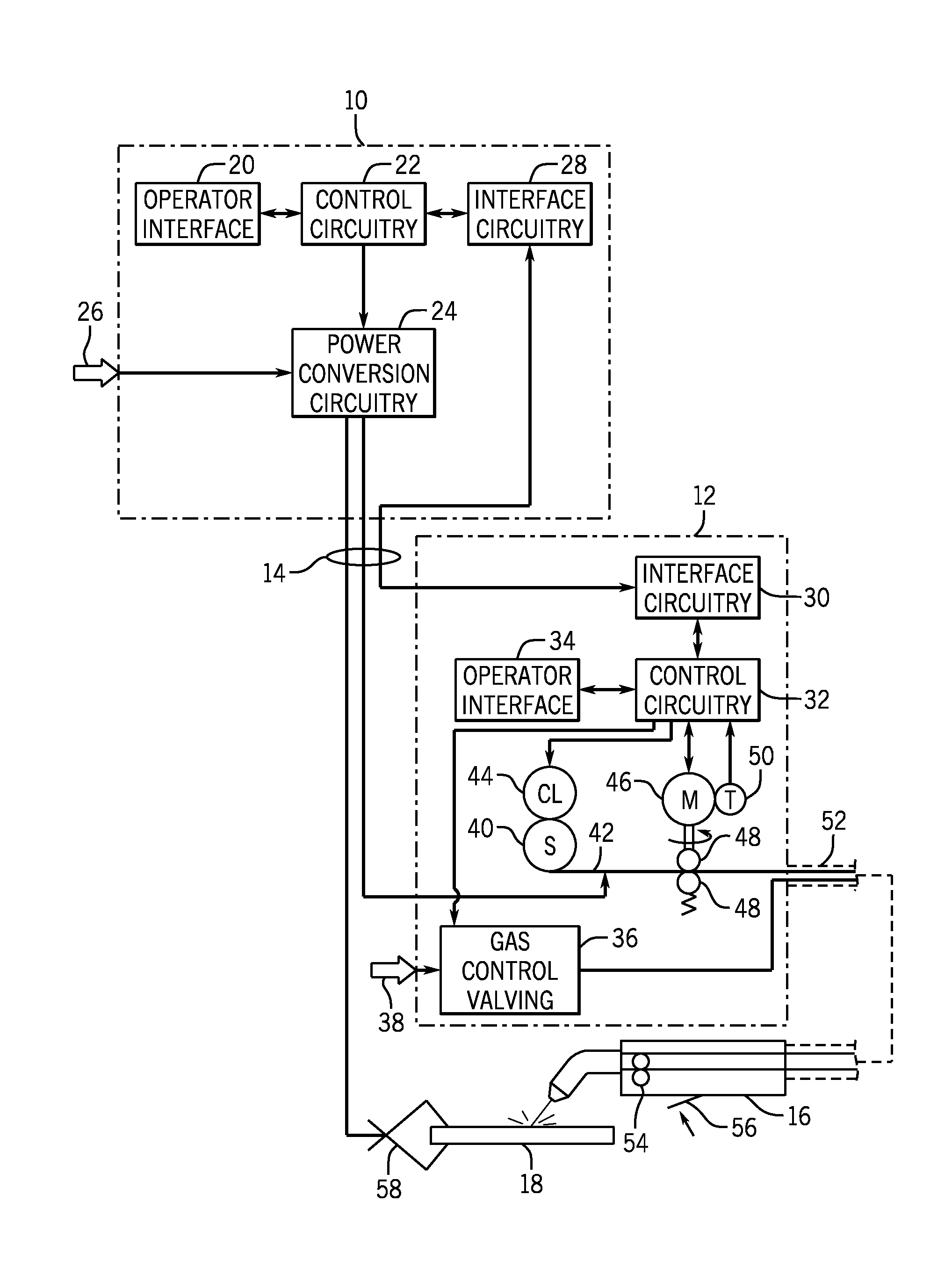

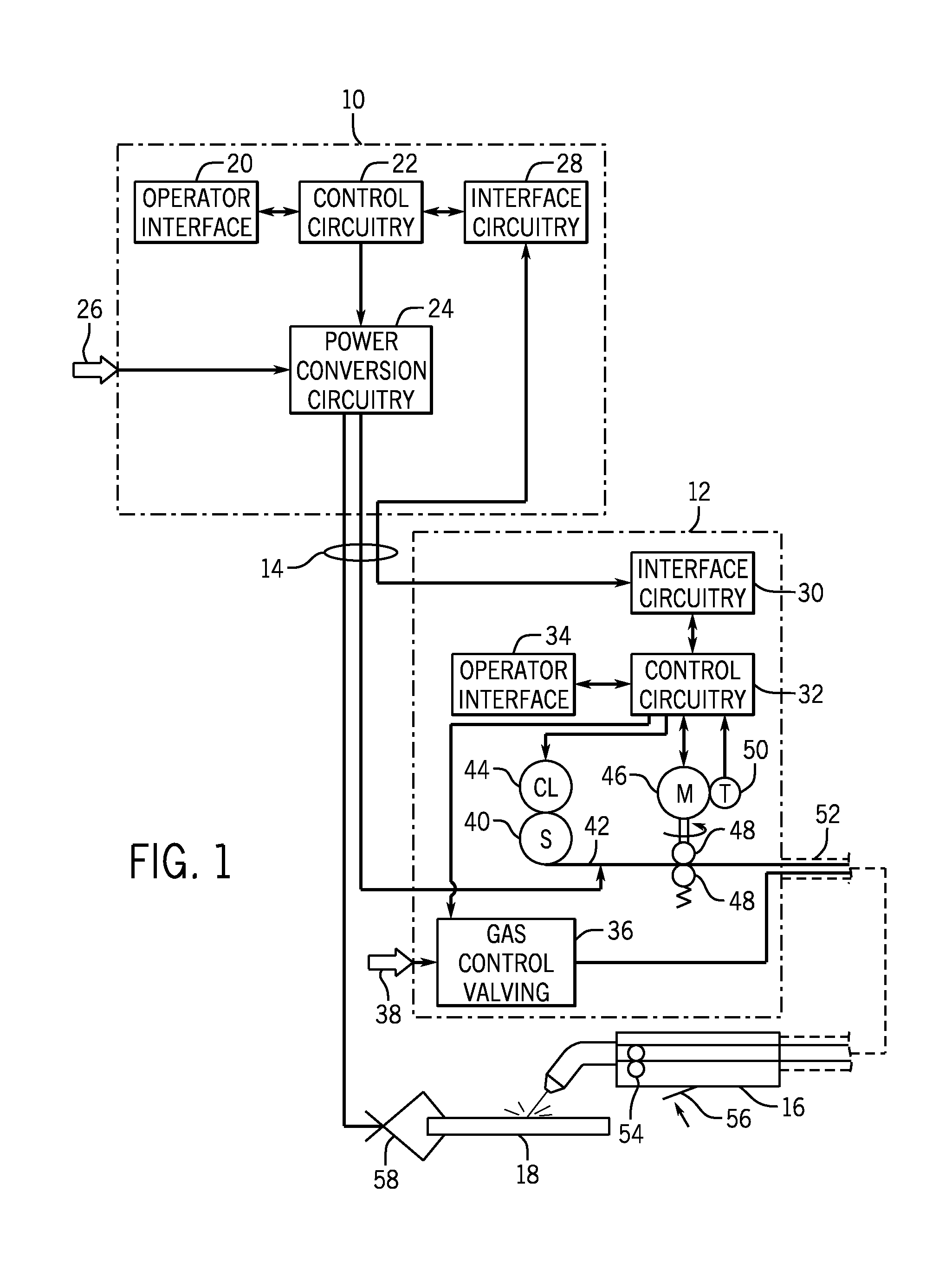

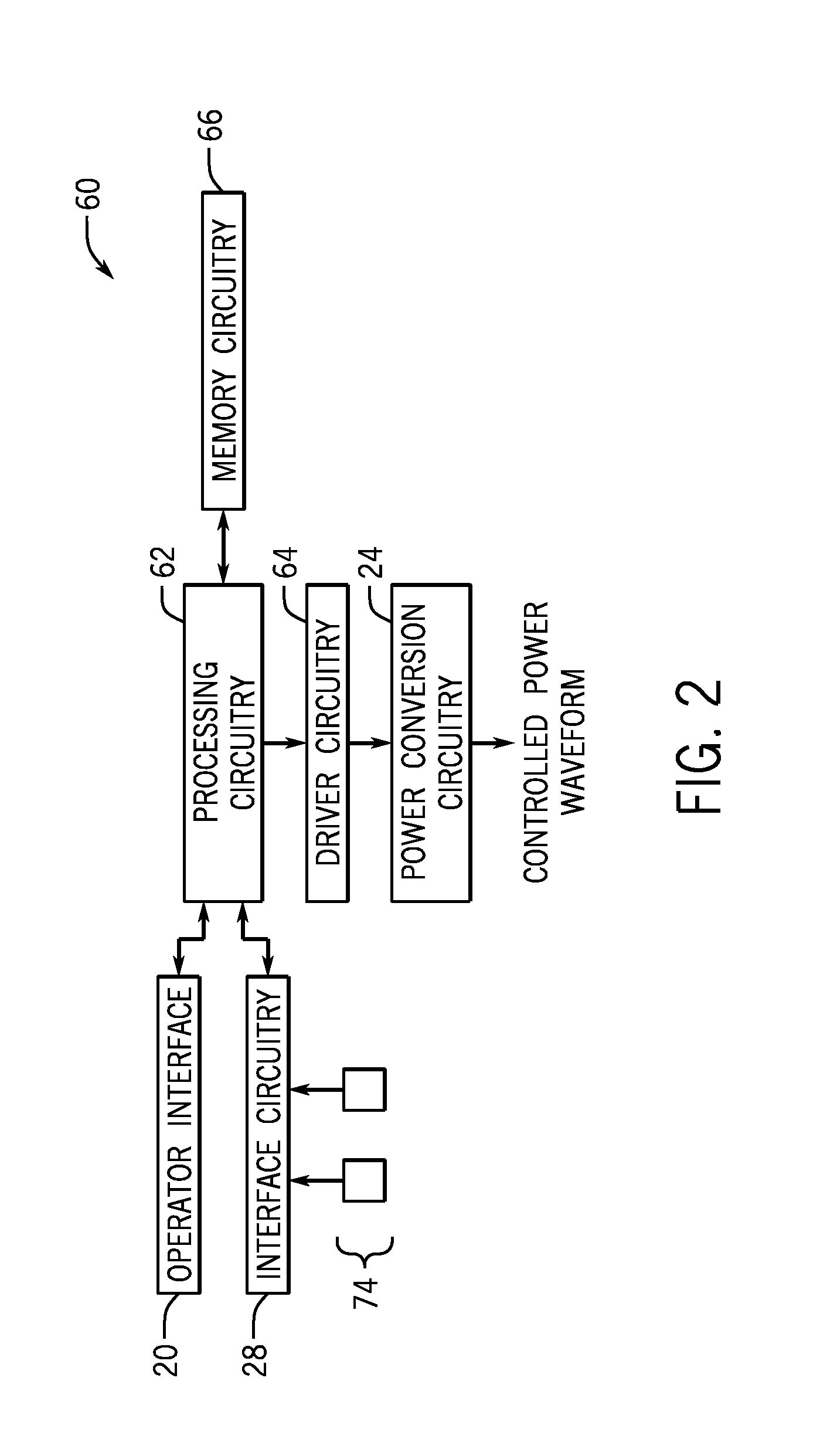

Controlled short circuit welding system and method

A welding system and method provide for generating a controlled waveform for welding power output, the waveform comprising a plurality of successive peak phases followed by a short circuit between a welding wire electrode and an advancing weld puddle. Each then present peak phase is regulated based upon at least the immediately preceding short circuit to control the short circuit that will occur following the then present peak phase. Some embodiments permit regulating at least one waveform phase based upon at least the immediately preceding short circuit to control the next short circuit that will occur, and regulating at least one short response phase based upon at least the immediately preceding short circuit to control the next short circuit that will occur.

Owner:ILLINOIS TOOL WORKS INC

Method for controlling water of seedbed of cured tobacco seedlings by floating cultivation

InactiveCN101699985AIncrease profitPromote growthClimate change adaptationAgriculture gas emission reductionNutrient solutionWater requirement

The invention discloses a method for controlling water of a seedbed of cured tobacco seedlings by floating cultivation, relating to soilless and waterless seedlings culture of crops. The method comprises two steps of: reconstruction of a nutrition pool: removing an earth stripe at one end of a conversional nutrition pool, digging a puddle for storing nutrient fluid, sequentially arranging two columns of bamboo splints in the nutrition pool, and placing a floating plate overhead after the nutrient fluid is discharged so as to form an air layer between the bottom of the floating plate and the liquid level; and water control of cured tobacco seedlings by dry-wet alternation and discontinuous water supply: moving the nutrient fluid in due time according to the water requirement pattern of thecured tobacco seedlings so as to ensure water for the growth of the cured tobacco seedlings. The method has the advantages that: (1) the water supply time and the supplying water are based on the water requirement pattern of the cured tobacco seedlings in growing so as to be beneficial to promoting the growth of the seedlings and improving the quality of the cured tobacco seedlings; (2) the nutrient fluid is reused, the utilization ratio of water and nutrients is greatly improved, and the collected nutrients can also be used for other plants so as to reduce pollution to the environment; and (3) the plate airing process caused by overmuch water in a floating cultivation substrate during latter hardening off is reduced, the labor intensity is lowered and the manpower is saved.

Owner:GUIZHOU TOBACCO SCI INST

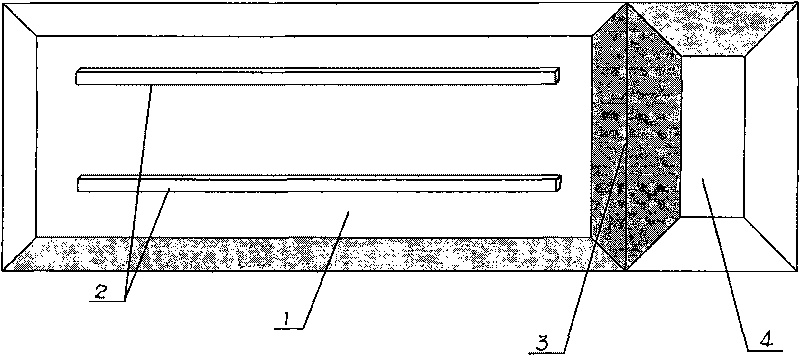

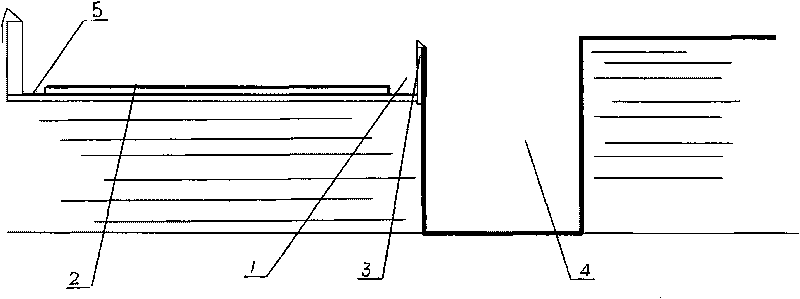

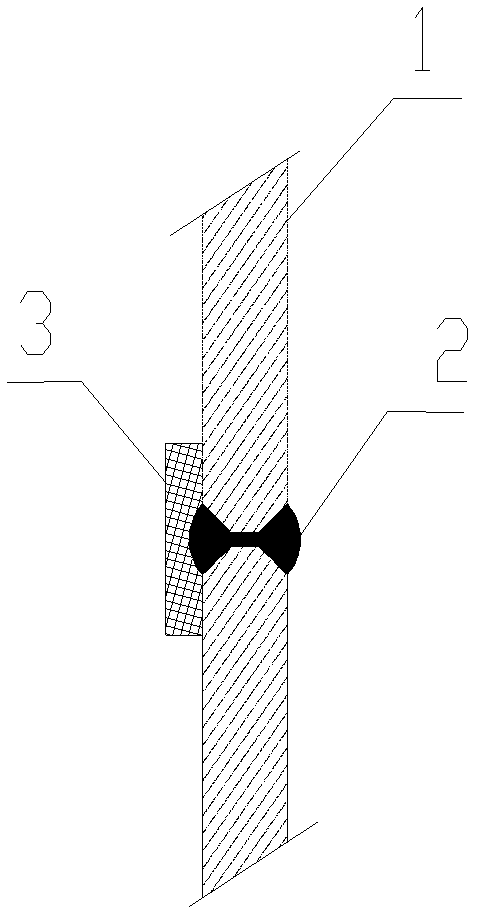

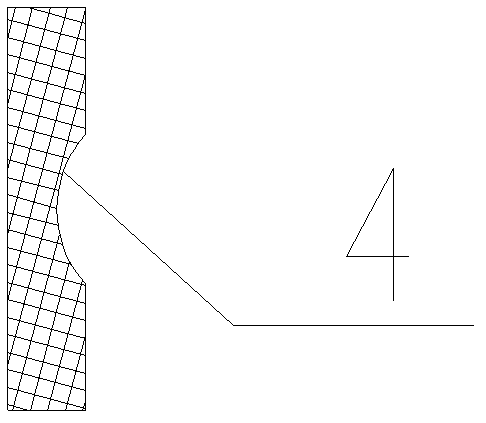

Large tank singe-face-weld double-face-forming method and weld joint forming pad

InactiveCN102489830AHigh technical levelReduce consumptionWelding accessoriesEngineeringWeld penetration

The invention provides a large tank singe-face-weld double-face-forming method, which comprises arranging a weld joint forming pad on the back face of a weld joint of a weld part, wherein the weld joint forming pad is provided with a weld joint forming groove with the shape matched with that of the weld joint; fixedly and tightly attaching the weld joint forming pad on the back face of the weld joint to enable the center of the weld joint to align at the center of the weld joint forming groove; welding the front face of the weld joint; using large weld current for weld penetration of a weld part at one step; and enabling a weld puddle to be cooled and solidified on the weld joint forming groove. Compared with a traditional double-face-weld method, the weld joint is formed by one step, weld quality is better, production efficiency is improved, and production cost is reduced.

Owner:CHONGQING POLYCOMP INT

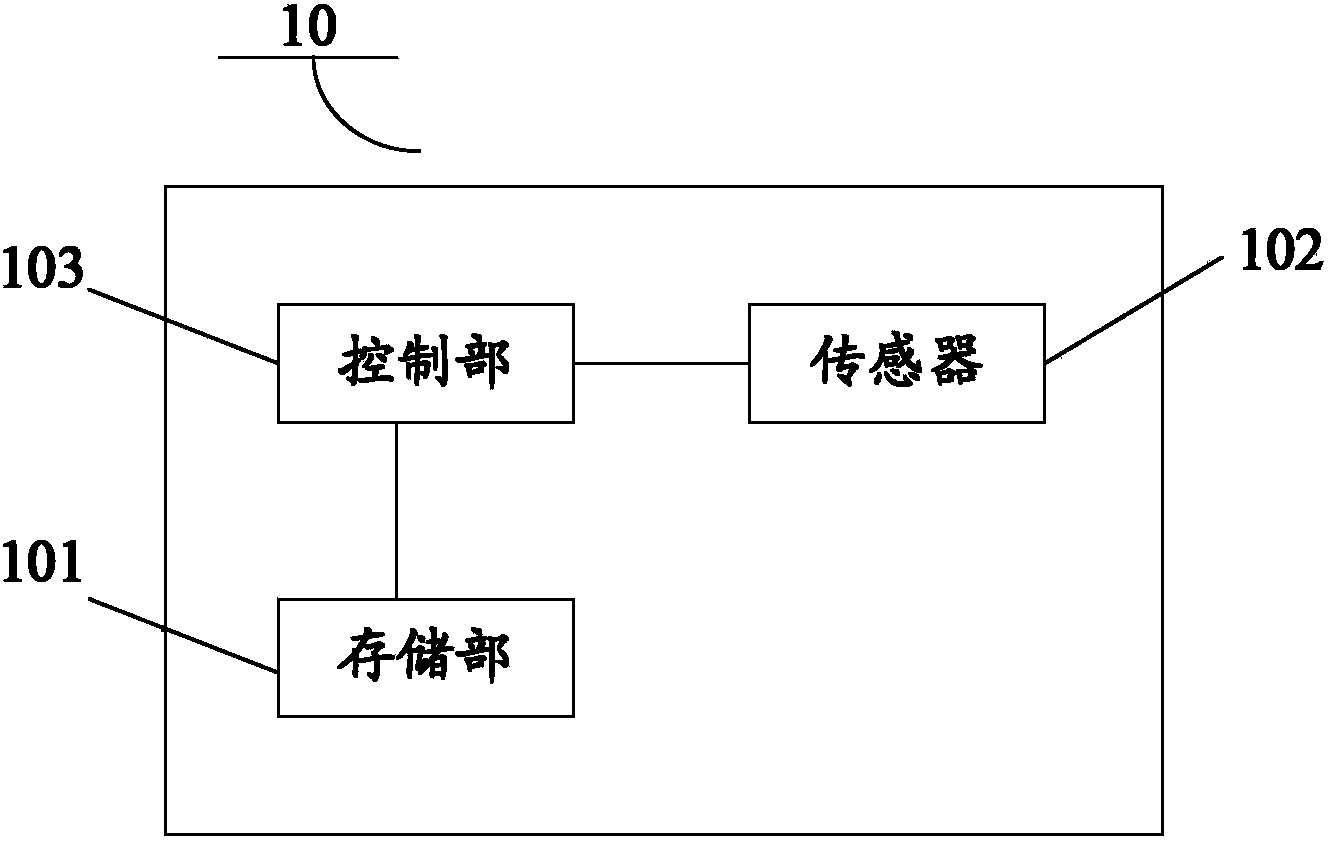

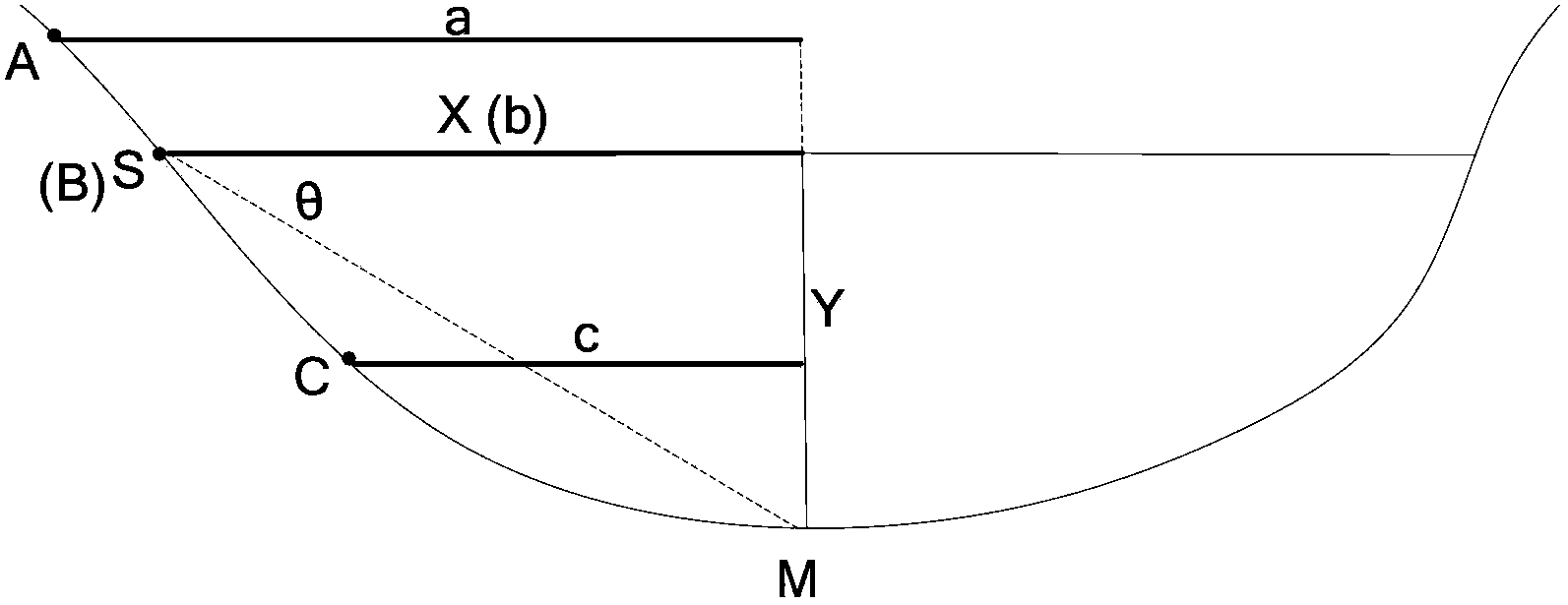

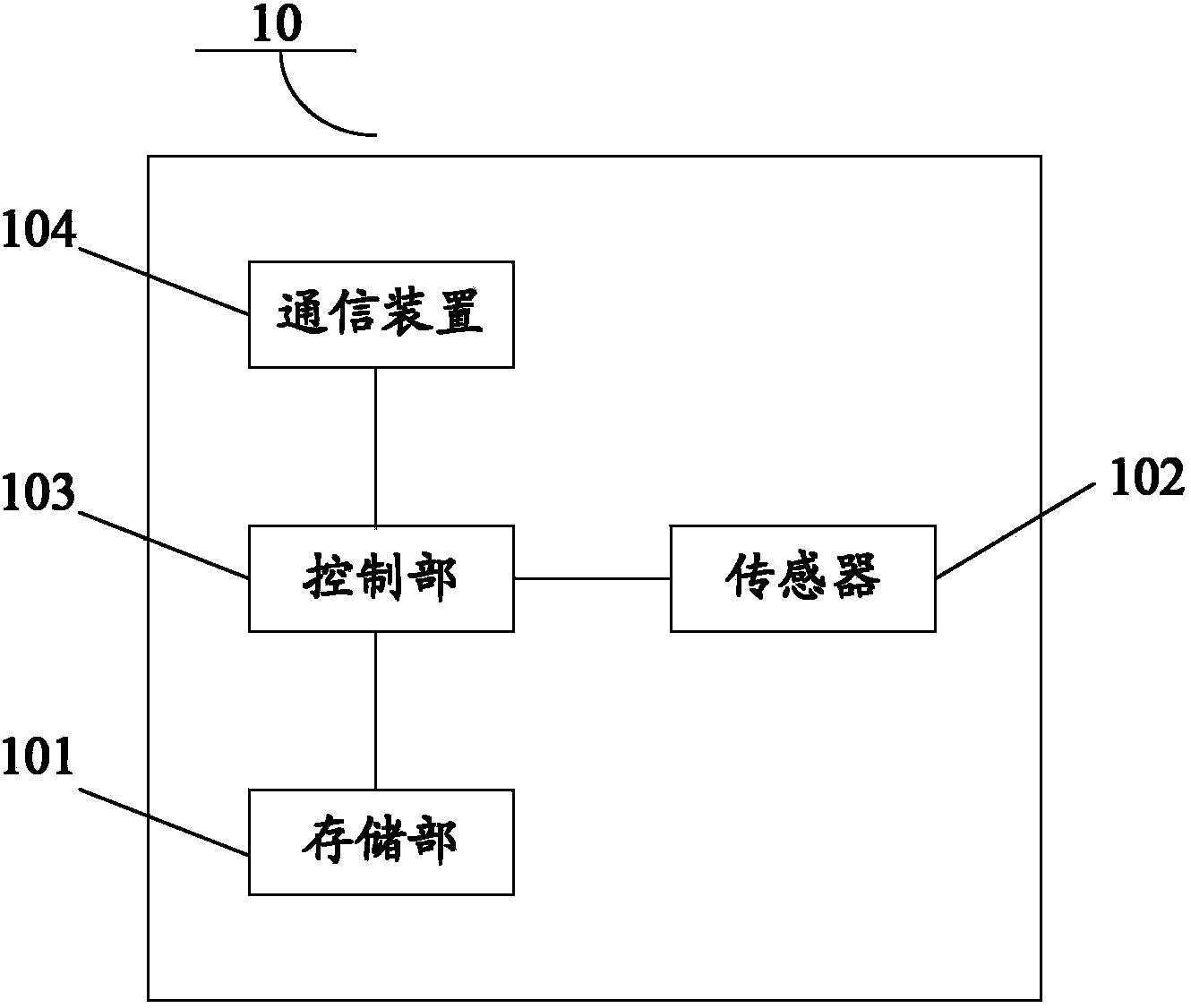

Terminal device carried at vehicle, vehicle, prompting method of puddle pavement

The embodiment of the invention, which relates to the technical field of the vehicle, provides a terminal device carried at vehicle, a vehicle, a prompting method of a puddle pavement, so that the potential safety hazard that a vehicle is trapped in or submerged in a puddle can be effective reduced or eliminated. The terminal device comprises: a storage unit, which is used for storing cartographic information and vehicle information of a vehicle itself; a sensor, which is arranged in front of the vehicle and is used for detecting a pavement condition of the vehicle driving path, particularly for detecting reflected wave information of the pavement ahead of the vehicle driving path, and sending the reflected wave information to a control unit; and the control unit, which is used for carrying out information processing including controlling of the storage unit and the sensor. The control unit determines whether a puddle exists at the pavement ahead according to the cartographic information, the vehicle information, and the pavement reflected wave information detected by the sensor and obtains maximum depth information of the puddle, thereby warning and reminding the driver. The provided terminal device can be applied to a vehicle.

Owner:FAURECIA CLARION ELECTRONICS (XIAMEN) CO LTD

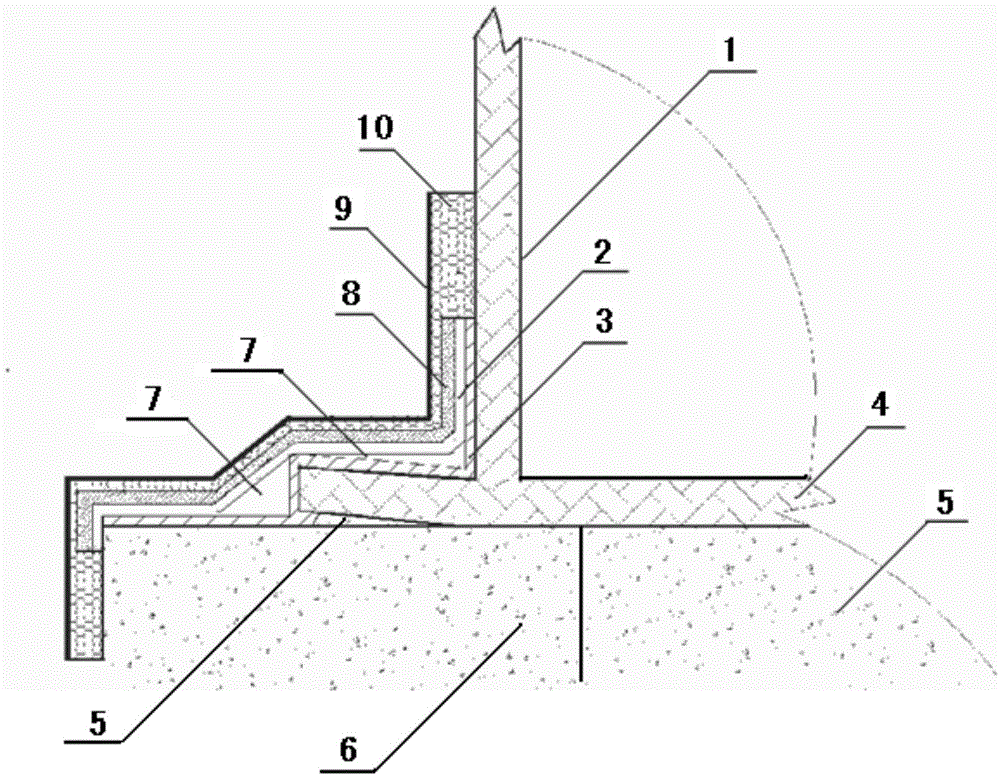

Cladding and corrosion control method for margin plate at bottom of vertical storage tank

ActiveCN103600941ALow surface treatment requirementsSimple construction methodLarge containersFiberPolyester

The invention relates to a cladding and corrosion control method for a margin plate at the bottom of a vertical storage tank. A cladding area covers the part 200mm above the bottom of the vertical storage tank, the part extending from a T-shaped joint of the margin plate at the bottom of the vertical storage tank to the edge of the margin plate, an asphaltic sand protective layer with a width of 100mm, and the part where a concrete base extends outward by 200mm. The cladding area sequentially comprises an anticorrosion paste layer (3), an anticorrosion puddle layer (6), an anticorrosion belt layer (2), polyester fiber cloth (7), an elastic macromolecule anticorrosion layer (9) and a weather-proof surface coating (8) from inside to outside; the polyester fiber cloth (7), the anticorrosion belt layer (2), the anticorrosion puddle layer (6) and the anticorrosion paste layer (3) on the inner layer are all isolated and sealed in an inner wall space formed by the elastic macromolecule anticorrosion layer (9) through the elastic macromolecule anticorrosion layer (9), so that a multi-layer cladding anticorrosion structure with a certain plastic deformation function is formed.

Owner:上海道盾科技股份有限公司

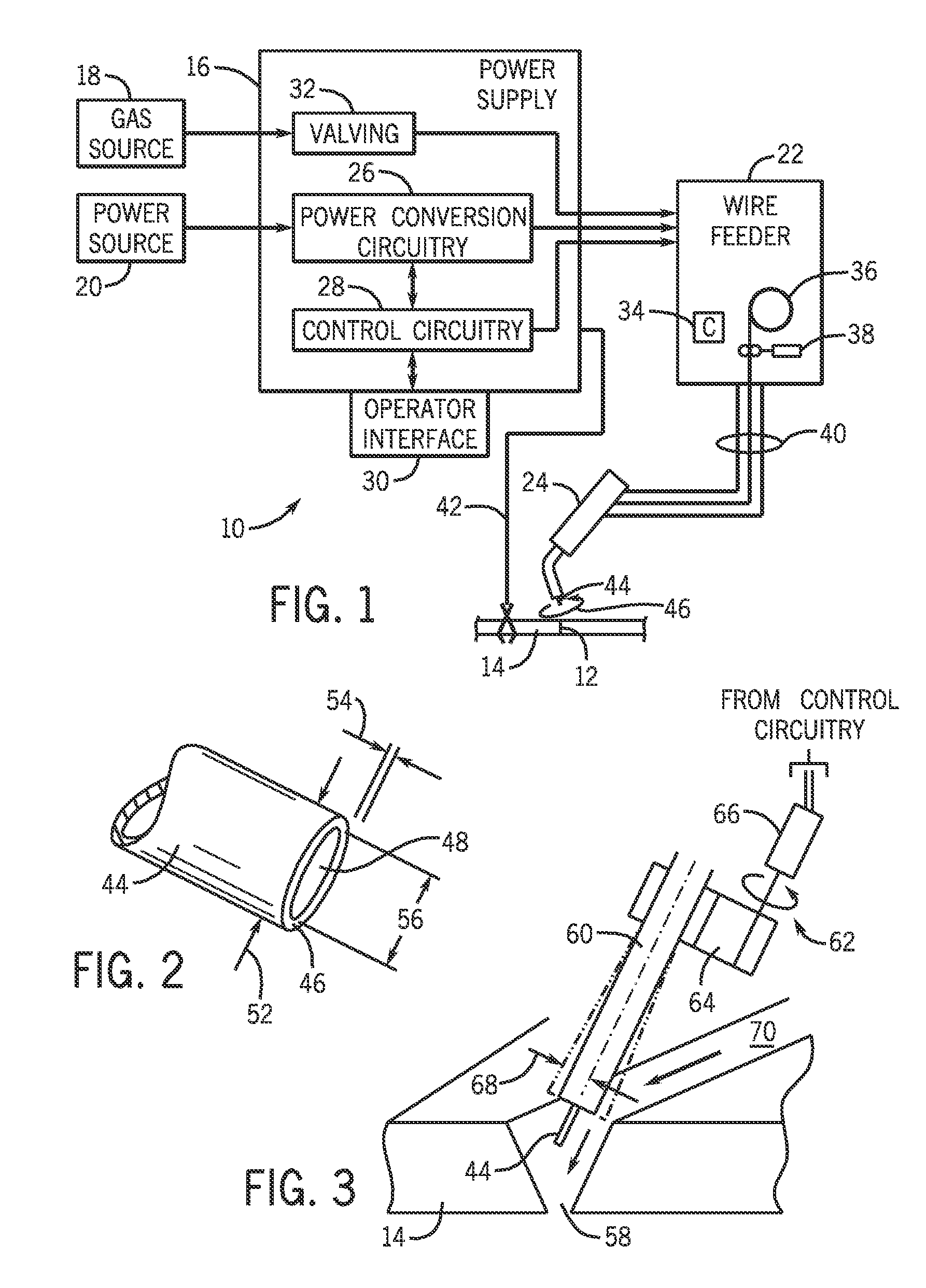

Metal cored welding method and system

InactiveUS20130001210A1Arc welding apparatusWelding/cutting media/materialsMelting tankTransfer mode

Methods and systems are disclosed for utilizing metal cored welding wire electrodes with forced movement of the electrode and arc. The electrode may be moved by a motion control assembly in a welding torch. The arc is established only between the sheath of the metal cored welding wire and the workpiece (or weld puddle), providing a unique transfer mode for enhanced deposition, travel speeds, and other weld and process characteristics.

Owner:ILLINOIS TOOL WORKS INC

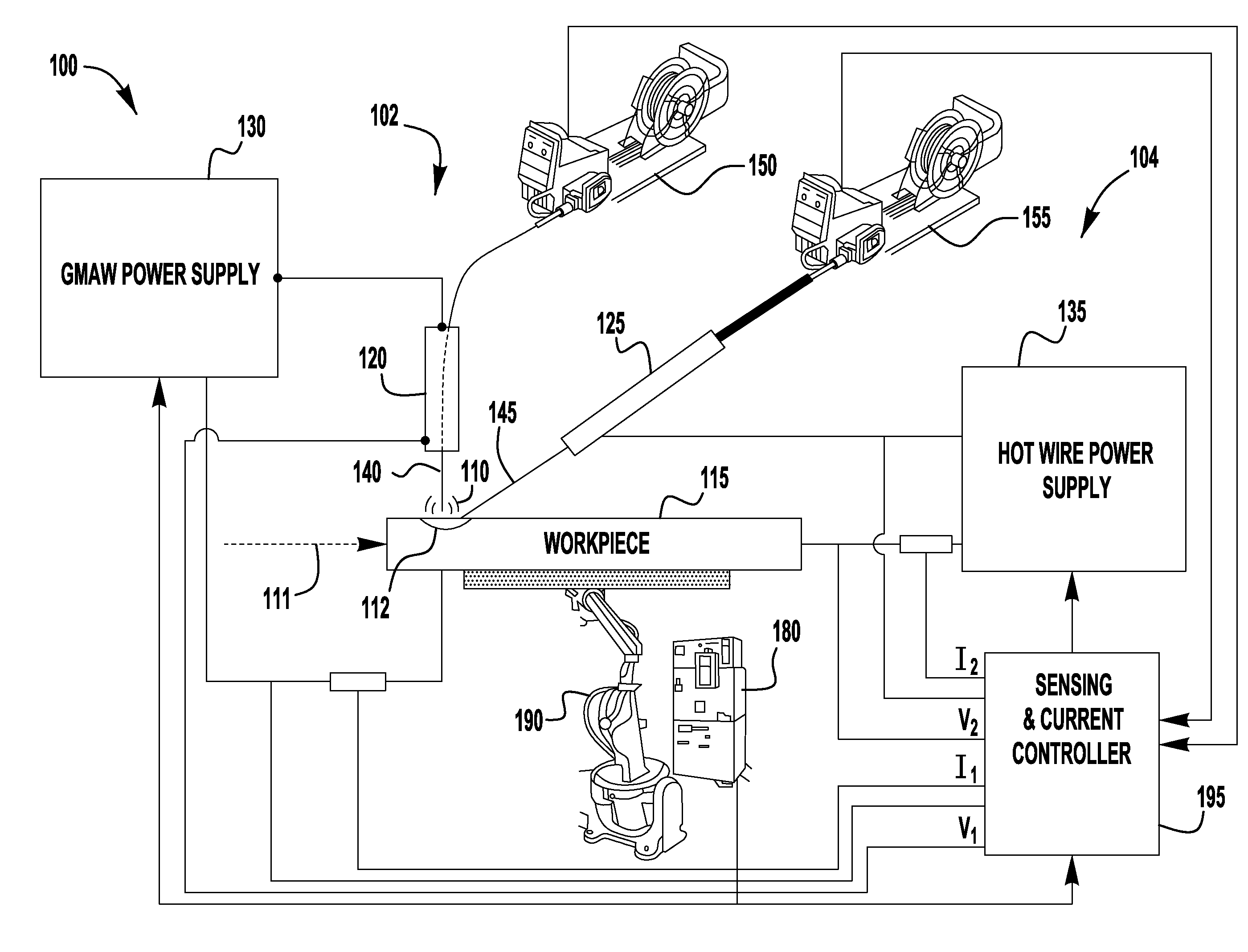

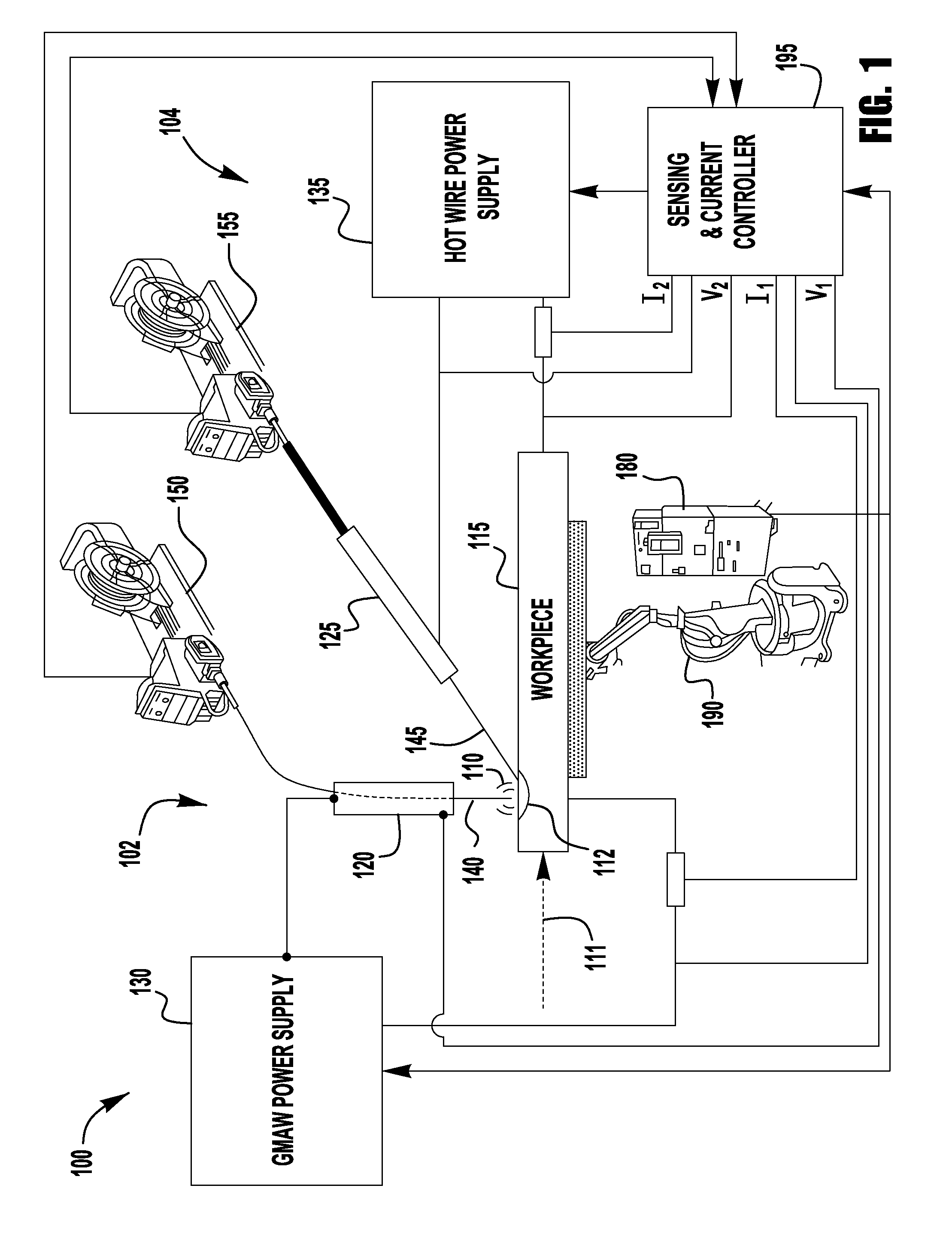

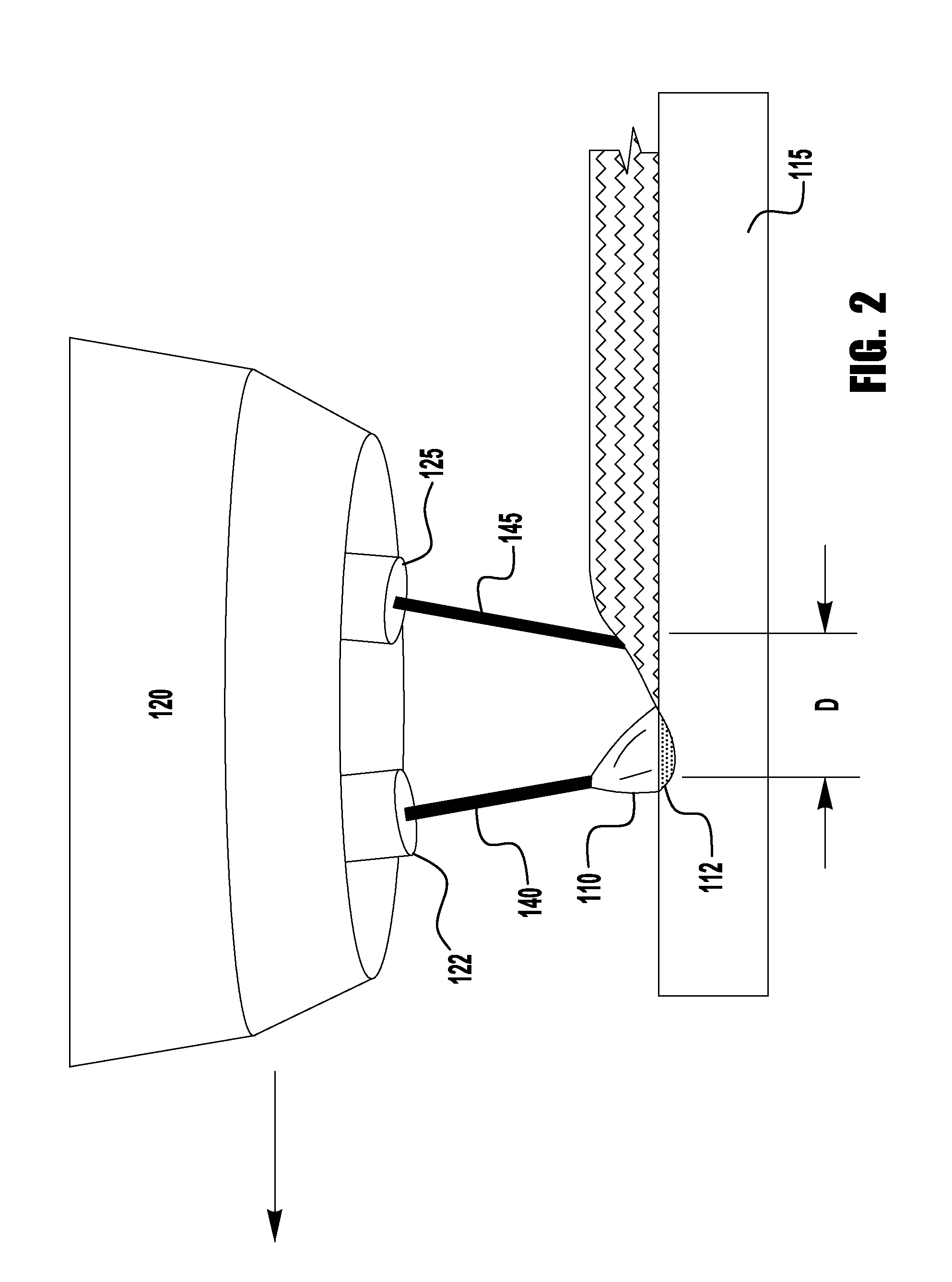

Tandem hot-wire systems

A system and method is provided. The system includes a first power supply that outputs a welding current that includes welding pulse currents and a background welding current. The system also includes a second power supply that outputs a heating current that includes first heating pulse currents at a first polarity and second heating pulse currents at an opposite polarity. The system also includes a controller that synchronizes at least one of the first heating pulse currents and the second heating pulse currents with at least one of the welding pulse currents and the background current to influence a position of an arc relative to a molten puddle based on magnetic fields created by the welding current and the heating current.

Owner:LINCOLN GLOBAL INC

Rinsing method, developing method, developing system and computer-read storage medium

The present invention provides a rinsing method capable of satisfactorily rinsing the surface of a resist film regardless of the condition of the surface of the resist film so that development defects caused by residuals produced by development may be reduced. A rinsing method of rinsing a substrate processed by a developing process for developing an exposed pattern comprises the steps of discharging a rinsing liquid onto a central part of the substrate processed by the developing process and coated with a developer puddle while the substrate is stopped or rotated (step 5), stopping discharging the rinsing liquid in a state where the developer puddle remains at least in a peripheral part of the substrate (step 6), and rotating the substrate at a high rotating speed to shake the developer remaining on the substrate off the substrate together with the rinsing liquid (step 7).

Owner:TOKYO ELECTRON LTD

Puddle etching method of thin film by using spin-processor

The present invention discloses a puddle etching method of thin film. In a spin etching equipment, pre-wet the wafer by D.I. water and etch solution to remove the contamination and the upper layer of the film on the wafer. Then spin slowly (about 0-50 rpm) and inject etching solution to form a puddle of etching solution which will stay on the wafer, the wafer then keep spin slowly (about 0-50 rpm) such that the puddle of etching solution stay on the wafer and etching is going on by puddle etching. After the thin film is etched, the wafer is spin at higher speed, and D.I. water is injected to rinse. Then, IPA is used to remove the D.I. water by Marangoni effect. Finally raise the speed to dry the wafer.

Owner:GRAND PLASTIC TECH

System and method for hot wire tig positioned heat control

The invention described herein generally pertains to a system and method related to energizing a welding wire based on a location of an electrode at an edge on a workpiece. An edge detector can be configured to identify an edge on the workpiece during a welding operation and a controller can be configured to mange a temperature of a puddle formed by the electrode by adjusting one or more welding parameters. The welding parameters can be, but are not limited to, an energizing of the welding wire, a wire feed speed, a temperature of a high intensity heat source (e.g., arc, a sub arc, a tungsten inert gas (TIG) arc, a metal inert gas (MIG) arc, a laser, a plasma arc, a metal core, or a flux core), movement speed, among others

Owner:LINCOLN GLOBAL INC

Dual-component bisphenol A epoxide-resin puddle for construction joint filling and preparation thereof

The invention discloses a bi-component bi-sphenol A-type epoxy resin clay for sealing in the construction, which is formed through mixing and modulating A-component and B-component at the allocated proportion of 1:0.8-1.2 according to the weight. The content of the components of A-component according to weight is as follows: bi-sphenol A-type epoxy resin 80-120, active dilution plasticizer 10-30, talcum powder 160-180; the content of the components of B-component according to weight is as follows: active dilution plasticizer 25-35, alicyclic amine firming agent 40-50, talcum powder 205-215. The preparation method comprises the preparation of both A-component and B-component, and then A-component and B-component are prepared through being agitated by the three roller machine or mixed by the direct manual. The invention has the advantages of low cost and easy operation. The raw materials of the A-component and B-component are put into the three roller machine for agitating for 8-10 min, or by the manual. The working period is long, the solidification is quick, the toughness is high, and the invention allows solidification under the moist environment.

Owner:湖北金叶新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com