Patents

Literature

576results about How to "Long application period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane reaction system having a blocked catalyst combination

InactiveUS6348121B1Long open timeFast curing timePolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentPolyolMetal catalyst

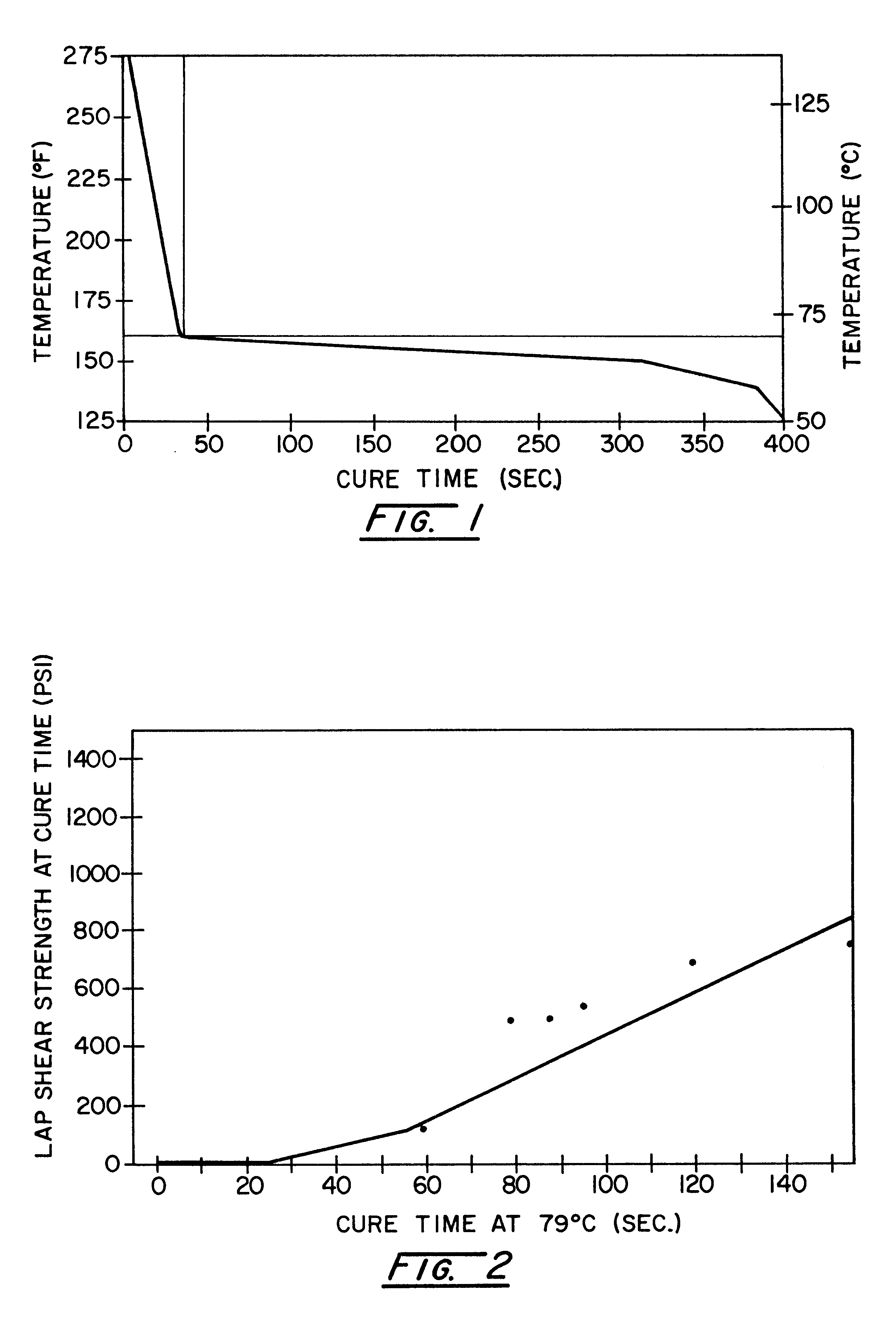

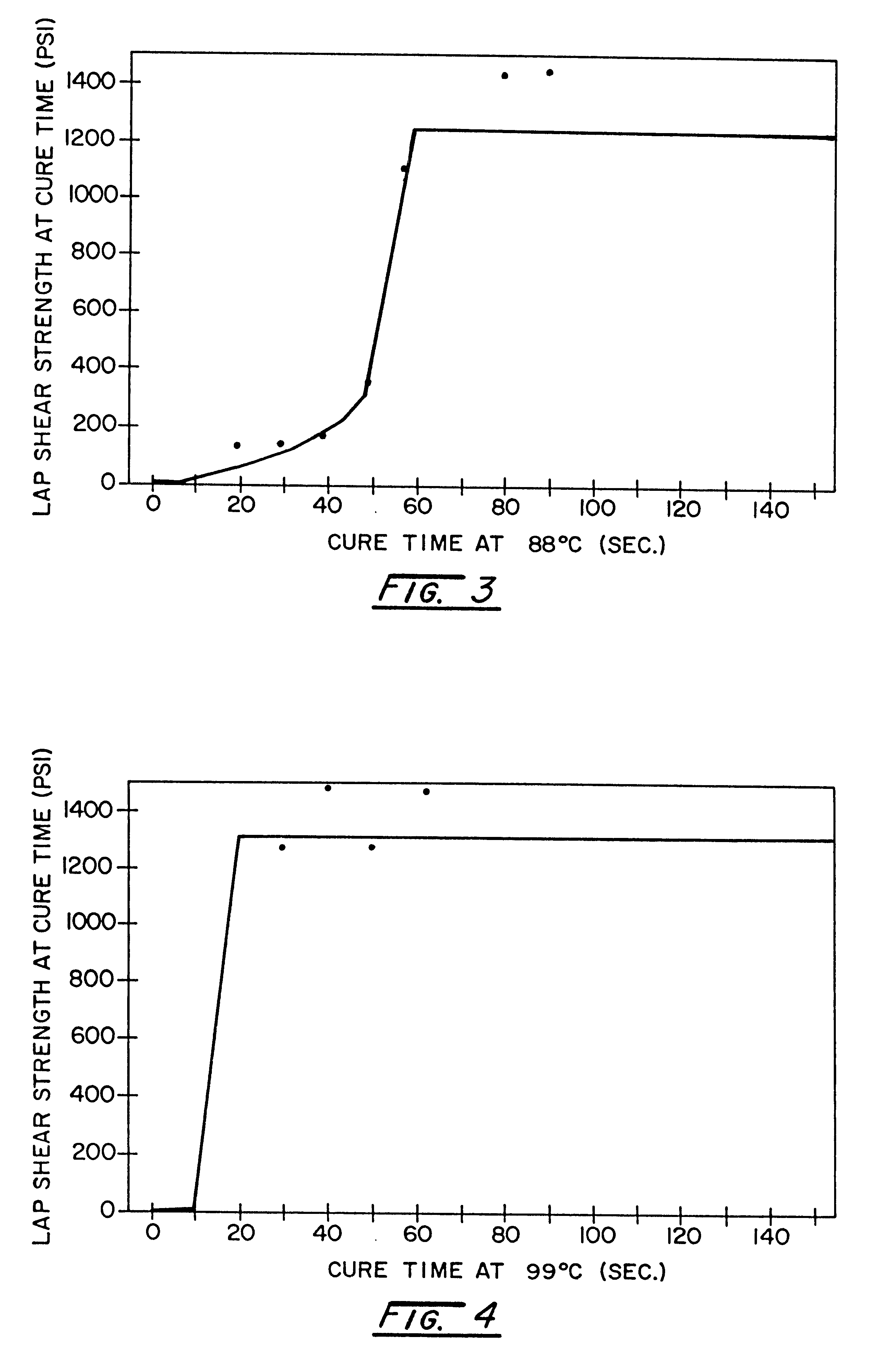

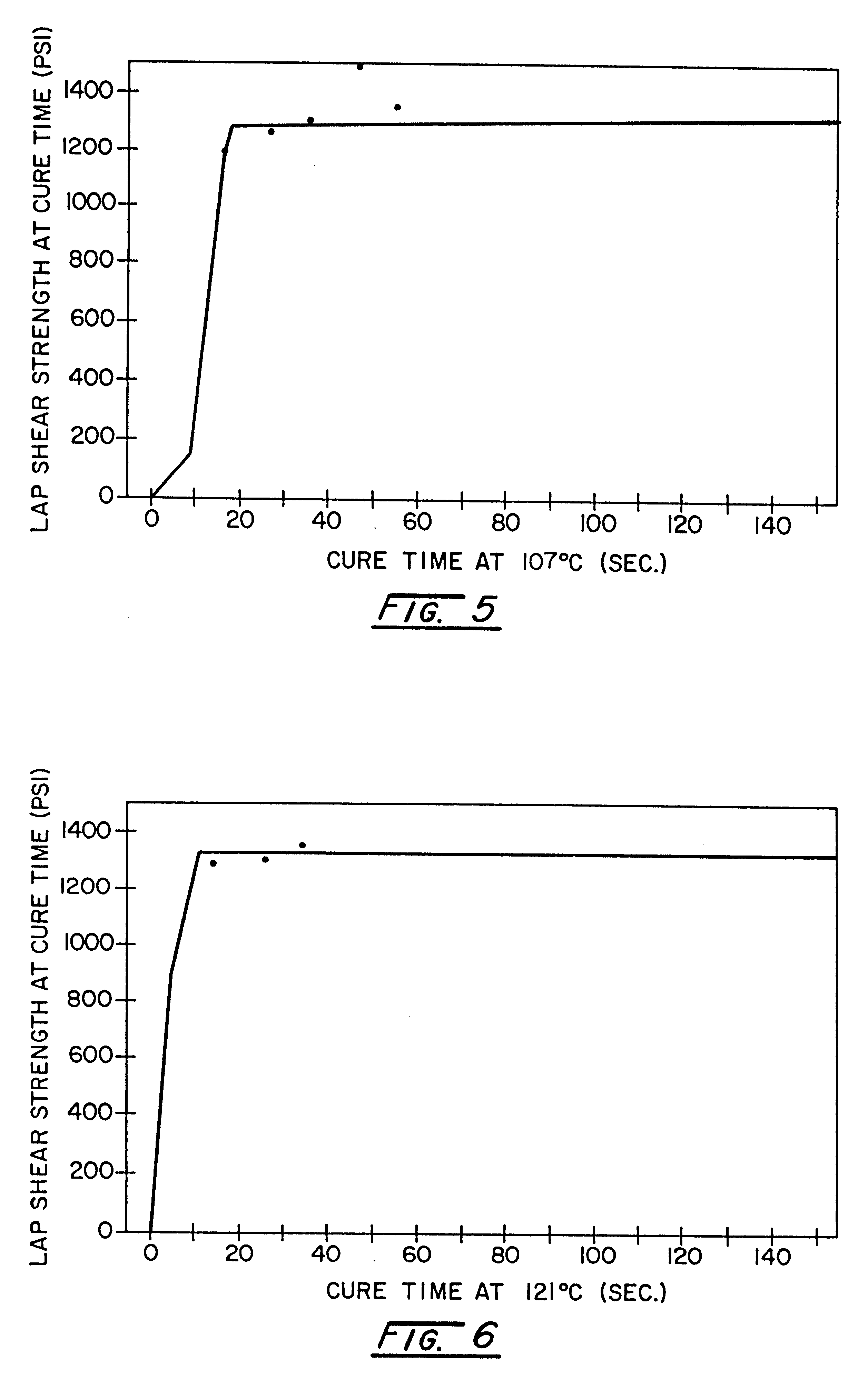

Disclosed is a polyol / polyisocyanate adhesive system having an isocyanate component and a catalyzed component which form a heat-cured composition when admixed and heated above a threshold temperature. The catalyzed component has a hydroxyl-functional component catalyzed with a catalyst combination of a heat-activatable amine or amine-like catalyst which is activated at temperatures above the threshold temperature, and an activatable complexed metal catalyst comprising the reaction product of tin or bismuth catalysts, or a mixture thereof, and a molar excess of a mercapto compound complexing agent. The catalyst combination is effective to maintain the processibility of the system at ambient temperatures while promoting the rapid cure of the system when heated above the threshold temperature.

Owner:ASHLAND LICENSING & INTPROP LLC

Polyether ester-based adhesive agent for solvent-free double-component polyurethane composite membrane and preparation method thereof

ActiveCN102174308AHigh bonding strengthImprove hydrolysis resistancePolyureas/polyurethane adhesivesVegetable oilPolyol

The invention relates to a polyether ester-based adhesive agent for a solvent-free double-component polyurethane composite membrane and a preparation method thereof. The preparation method of the adhesive agent comprises the following steps of: firstly, mixing 100 parts of polyisocyanates and 30 to 150 parts of polyol, and then raising temperature for reacting; secondly, adding a stabilizing agent to prepare a component A of the adhesive agent; and then, synthesizing a polyether ester polyol, and matching with 0.5 to 2 parts of polyether polyol, 0.1 to 1.0 part of vegetable oil polyol and 0.01 to 0.2 part of micromolecular polyol to prepare a component B of the adhesive agent. When the components A and B are in use, the functional group mole ratio of NCO to OH is (1.0 -2.0):1. The invention has the following advantages: the preparation method is safe and environmentally-friendly without solvent discharge; and the adhesive agent has low sizing quantity, high base material wetting property, wide serviceable range, high bonding strength and long usable life, and can be boiled at a high temperature (100 DEG C) for 40 minutes.

Owner:WANHUA CHEM BEIJING +1

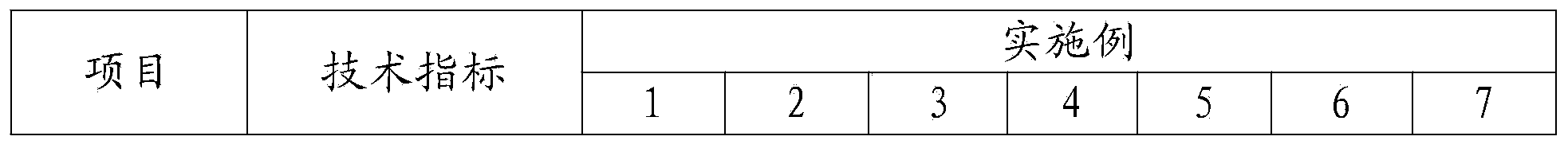

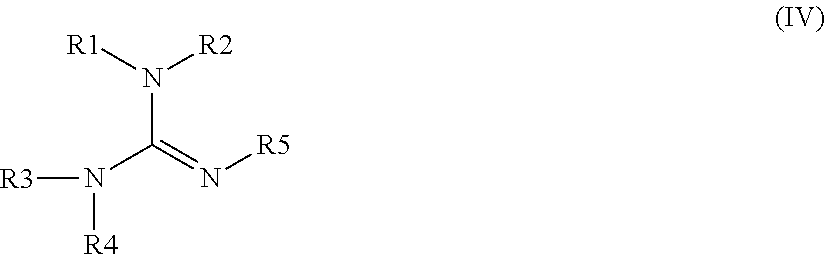

Crosslinkable composition crosslinkable with a latent base catalyst

ActiveUS8962725B2Reduce environmental burdenEffective use timeOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemistryPolymer chemistry

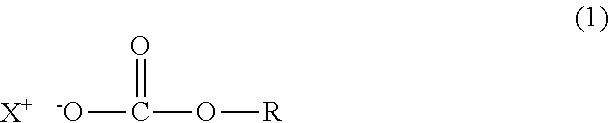

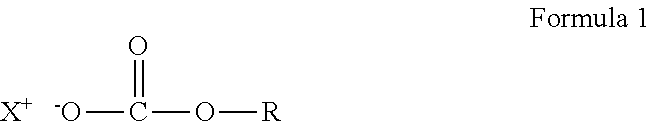

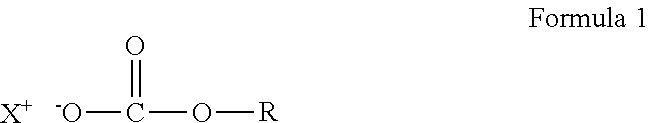

The present invention relates to a crosslinkable composition comprising at least one crosslinkable component crosslinkable by a latent base crosslinking catalyst comprising a substituted carbonate salt according to formula 1 wherein X+ represents a cation and wherein R is hydrogen, alkyl, aryl or aralkyl group, and wherein the crosslinkable composition comprises 0.1-10 wt %, preferably 0.1-5, more preferably 0.2-3 and most preferably 0.5-1.5 wt % water (relative to total weight of the crosslinkable composition). The invention further relates to a coating composition comprising the crosslinkable composition according to the invention, a novel catalyst composition and to the use of said catalyst composition according to the invention as a latent base crosslinking catalyst in coating compositions, preferably in RMA crosslinkable compositions.

Owner:ALLNEX NETHERLANDS BV

Modified benzoxazine resin capable of using for RTM and process for preparing same

A modified benzoxazine resin able to be used for RTM is prepared through feeding low-voscosity benzoxazine intermediate and epoxy resin (or arylacetylene resin) proportionally into a reactor, mixing,reaction at 50-100 deg.C for 5-10 min, adding catalyst, and reaction for 5-10 min. It can also be prepared from low-viscosity benzoxazine intermediate and bimaleimide resin.

Owner:SICHUAN UNIV

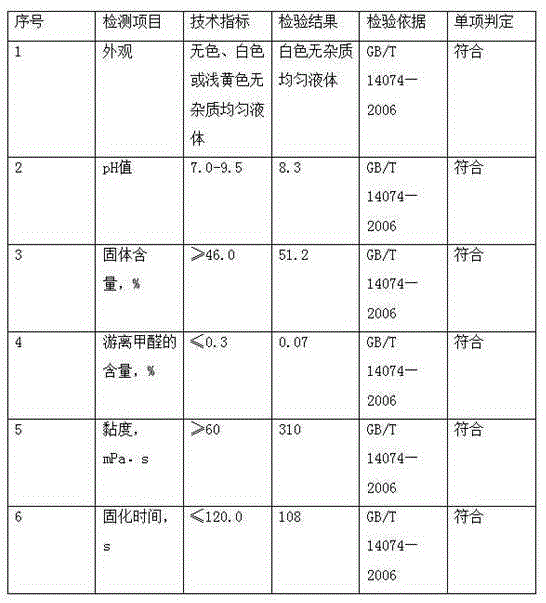

Water-soluble insulating varnish and preparation method thereof

InactiveCN101270256AGood transparency and stabilityLong application periodPolyurea/polyurethane coatingsEmulsion paintsWater basedDiluent

The invention relates to water-soluble insulating varnish and a preparation method thereof. The water-soluble insulating varnish of the invention consists of water-soluble resin, water-borne curing agent, water-base defoamer, water-base flow agent, water-base catalyst and water; the proportion of the components is as below: 30 percent to 50 percent of water-soluble resin; 10 percent to 30 percent of water-base curing agent, 1 percent to 1.0 percent of water-base catalyst, 0 percent to 0.5 percent of water-base defoamer, 0 percent to 0.5 percent of water-base flow agent and 20 percent to 60 percent of water; the water-soluble insulating varnish has the advantages of environmental protection and safety; no harmful solvent released to the atmosphere; no inflammability and explosion, no corrosion; no transparent or translucent paint liquid, good stability, long application service life under normal temperature; simple solidifying process, good insulating performance of the paint film after solidification, high strength and strong toughness; technical indexes meeting or exceeding the technical indexes of the prior solvent-type insulating varnish; the most important is that the insulating varnish takes water as solvent or diluent, which does not bring pollution and reduces the cost.

Owner:SHANGHAI BAOQING TONGYONG ELECTRICAL

Bi-component epoxy zinc rich primer

InactiveCN101407690AReduce zinc dust contentLow costAnti-corrosive paintsEpoxy resin coatingsEpoxyRoom temperature

The invention discloses a dual-component epoxy zinc-rich primer with excellent mechanical performance of a coating layer, low construction cost, high efficiency and prominent anti-corrosion performance. The dual-component epoxy zinc-rich primer comprises A and B components; wherein, the A component comprises the following components by parts by weight: 14 parts of epoxy resin, 54 to 71 parts of zinc powder, 4 to 20 parts of filler, 1 to 3 parts of anti-settlement auxiliary agent and 9 parts of solvent; the B component comprises the following components by weight percentage: 40 percent curing agent and 60 percent solvent; and the mixture ratio by weight of the A component to the B component is 8:1 to 15:1. The dual-component epoxy zinc-rich primer has the advantages of low content of the zinc powder in a paint film, low cost, simple technology and no need of special equipment; the use of the dual-component epoxy zinc-rich primer can realize the curing at room temperature, the paint film has excellent adhesion, flexibility and anti-corrosion effect, the applicable period is long and can achieve 4 hours, the construction is convenient, and the dual-component epoxy zinc-rich primer can be applied in anti-corrosion primers of pipelines, plant facilities, ships, bridges and other steel structures.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION

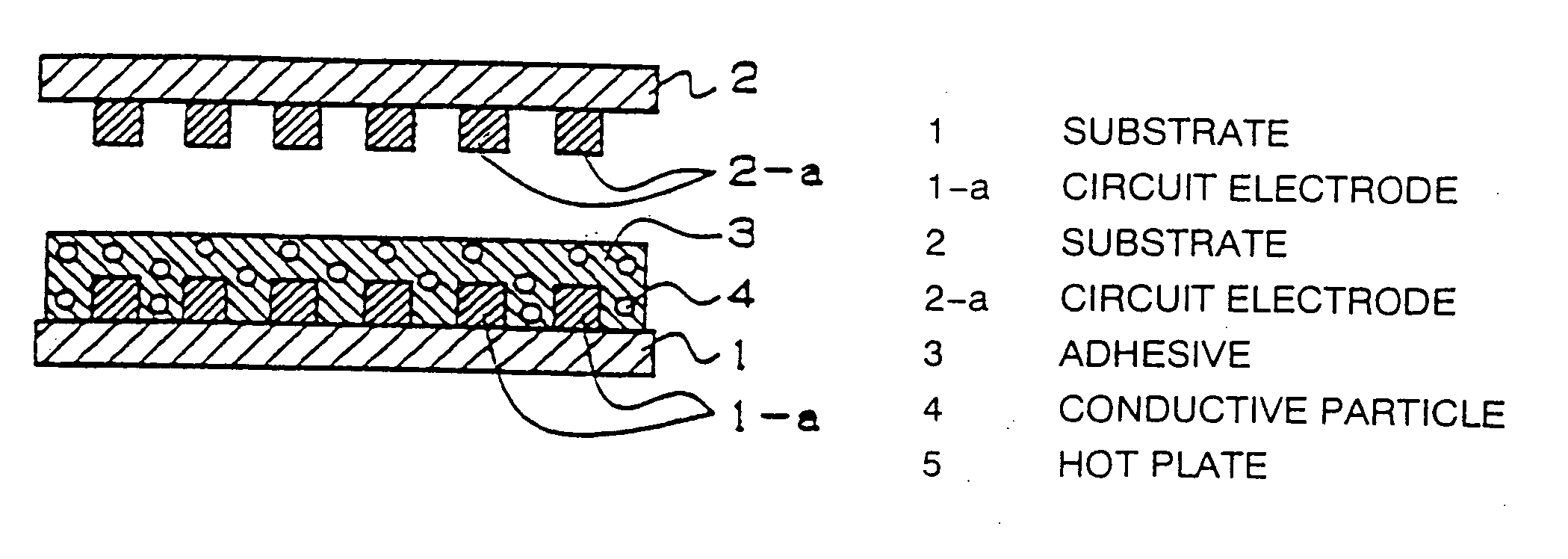

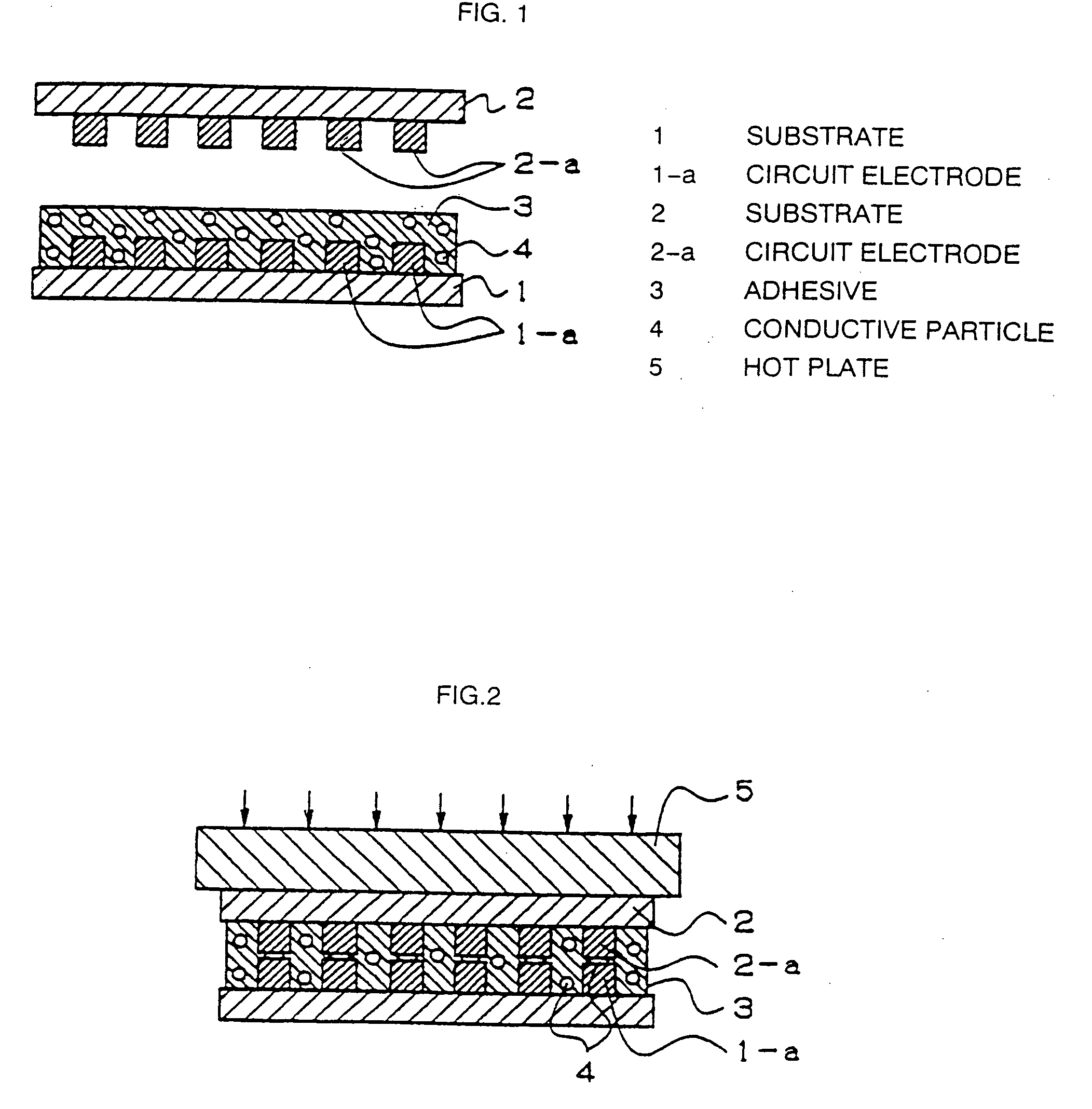

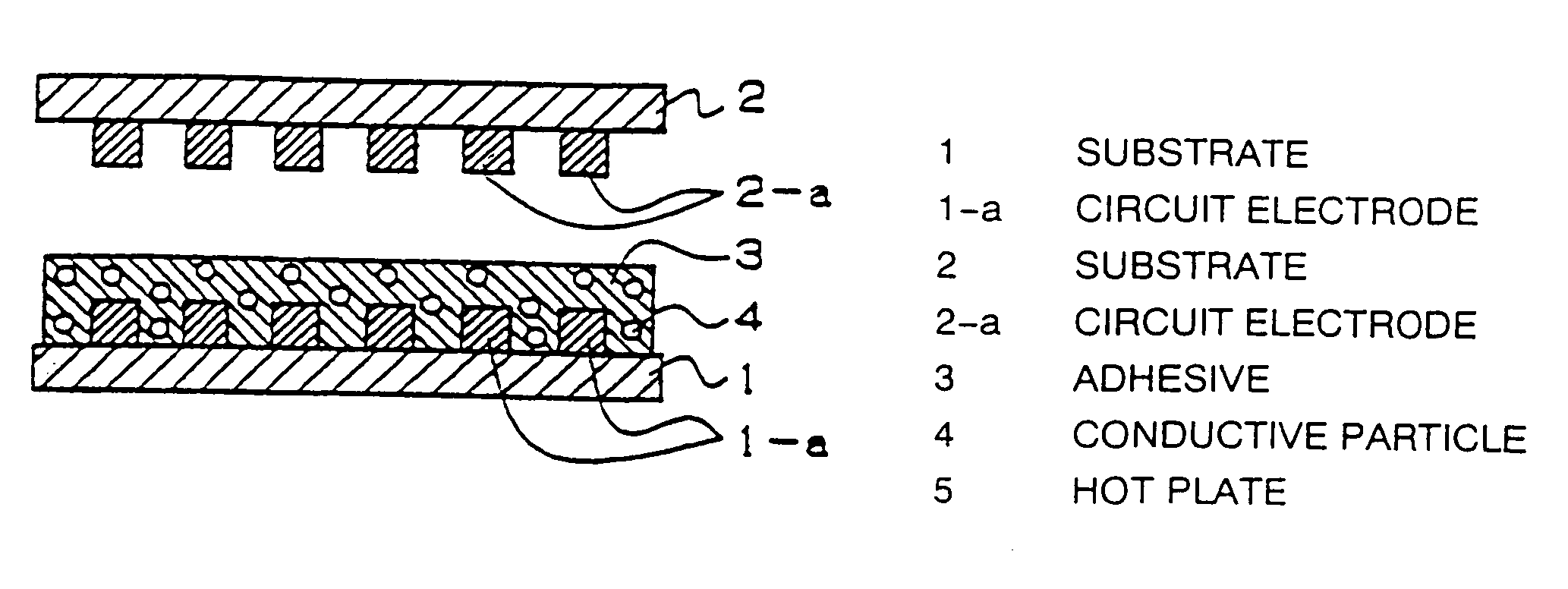

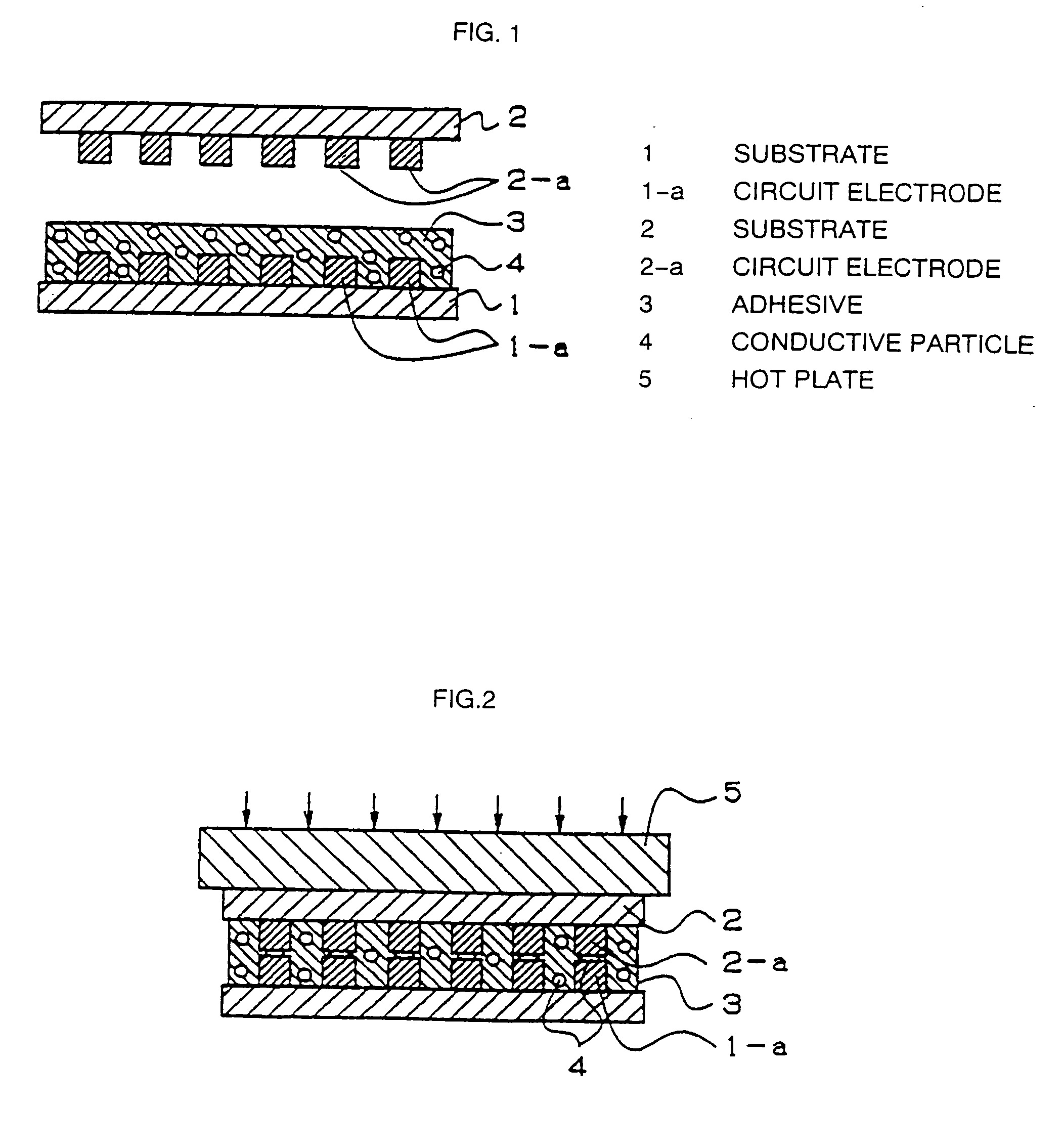

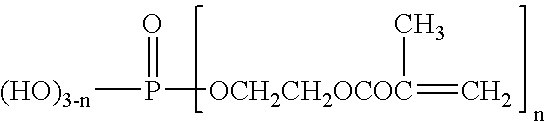

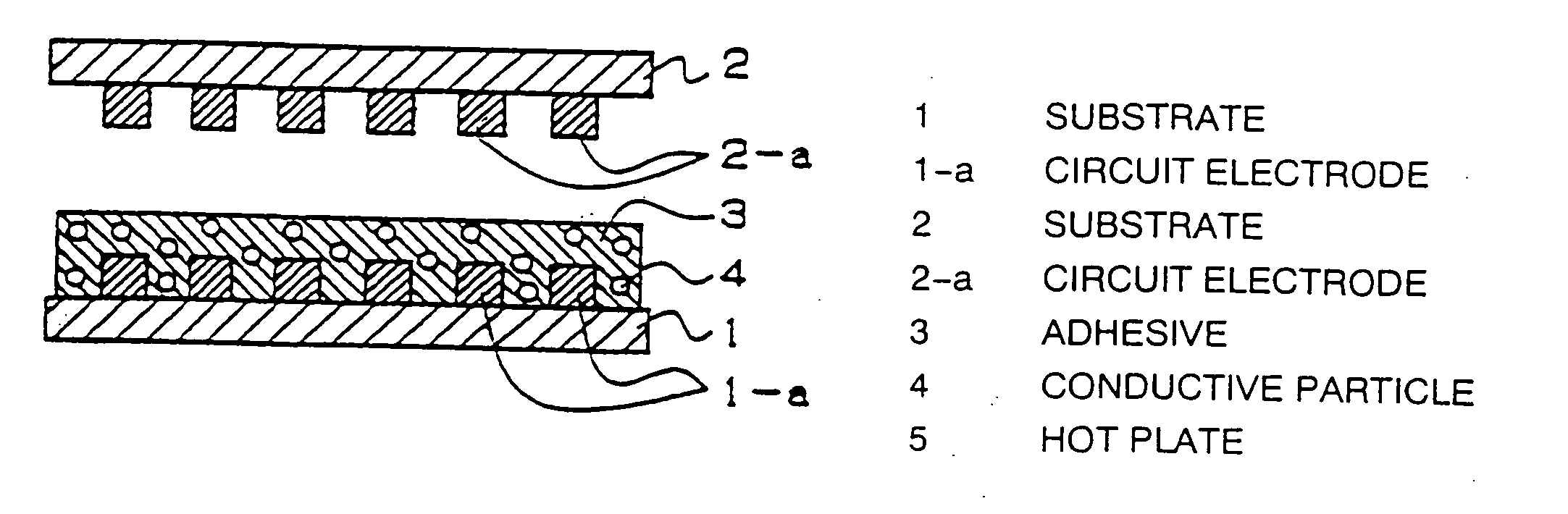

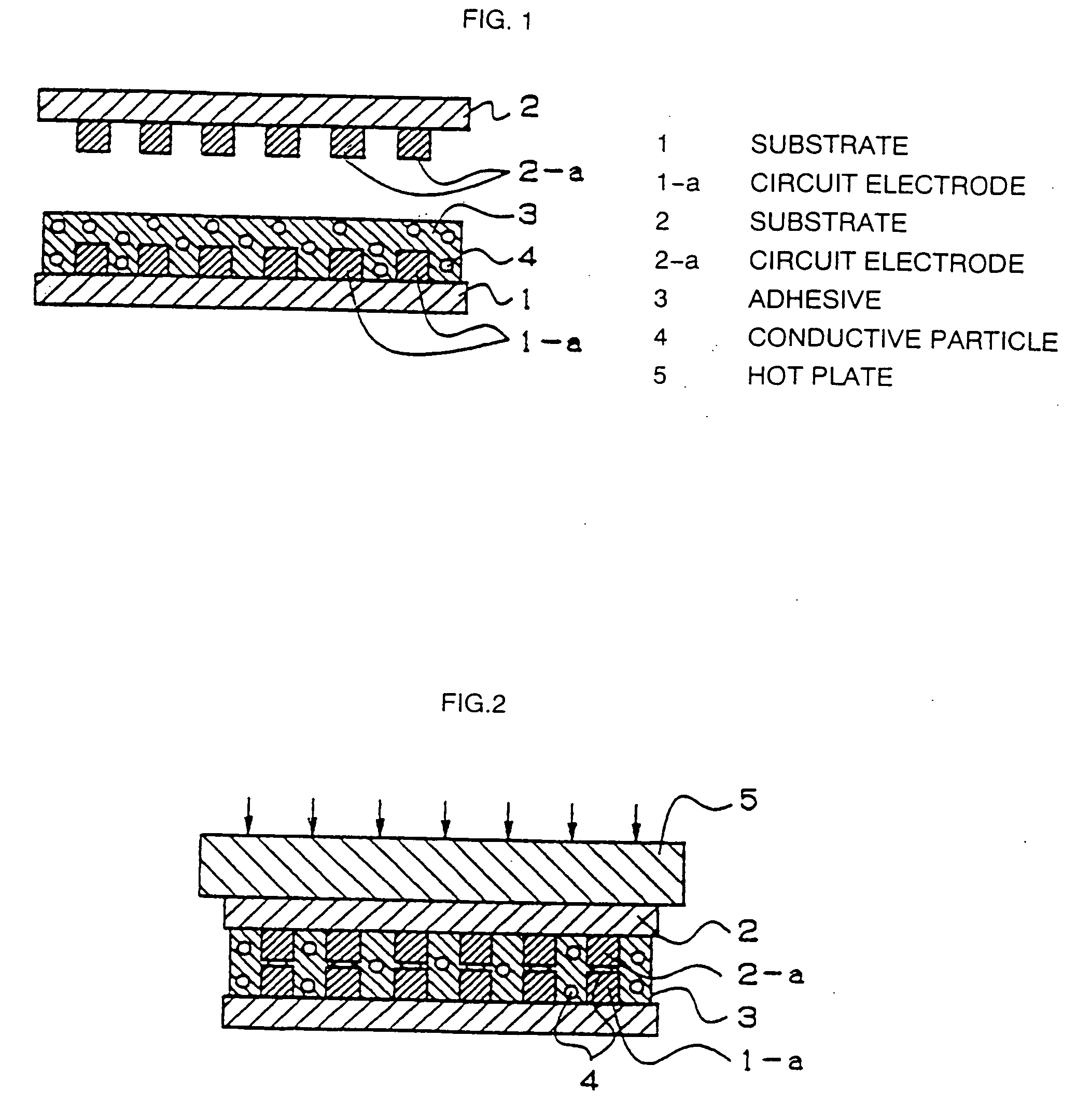

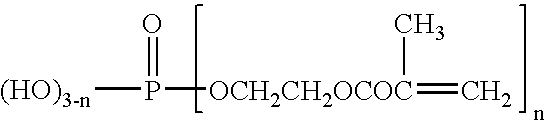

Circuit-connecting material and circuit terminal connected structure and connecting method

InactiveUS20060014860A1Superior low-temperature rapid curabilityLong application periodPrinted circuit assemblingSemiconductor/solid-state device detailsElectricityHydroxy compound

Owner:HITACHI CHEM CO LTD

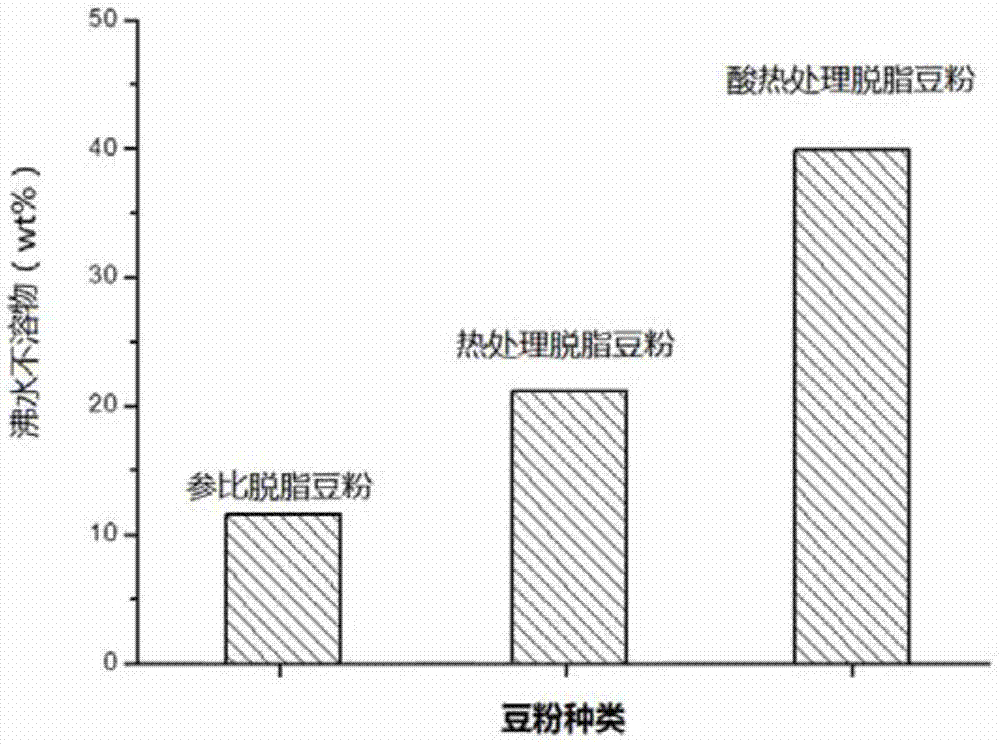

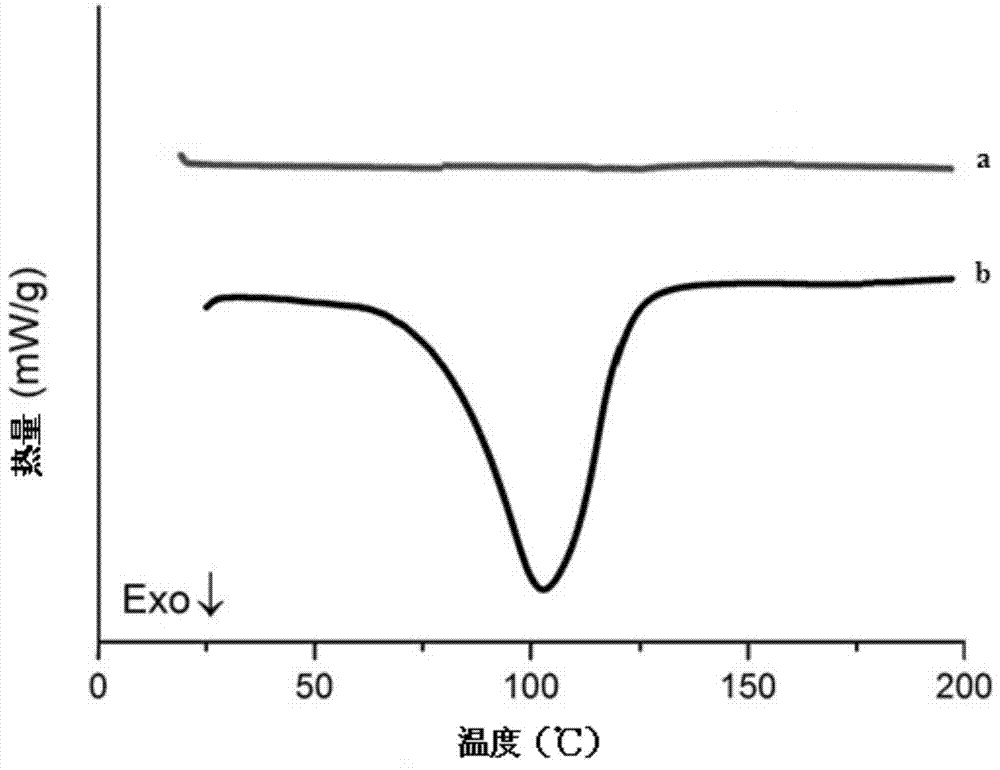

Waterproof-level soy protein adhesive and preparation method thereof

ActiveCN104497965AFacilitate cross-linkingImprove water resistanceProtein adhesivesGlue/gelatin preparationAdhesiveWorking life

The invention provides a waterproof-level soy protein adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof, in particular to a modified soyabean protein adhesive for waterproof-level plywood. The waterproof-level soy protein adhesive aims at solving the technical problem that an existing adhesive for plywood is not waterproof. The preparation method comprises the steps of beam flour acid heat treatment, beam flour liquidation, polyamide solution synthesis and adhesive modulation. Degreased beam flour or soya bean meal left after soybean oil expelling is used as a main raw material, the water resisting property of the beam flour and the solid content of the soy protein adhesive are improved through acid heat treatment, the cross-linking efficiency, cementing effect and process usability of the soy protein adhesive are improved through liquidation, the water resisting property of the soy protein adhesive is improved through cross-linking of polyamide polyamine resin, and finally the soy protein adhesive high in beam flour content, low in viscosity, long in working life and good in water resisting property and used for the waterproof-level plywood is prepared. The waterproof-level soy protein adhesive and the preparation method belong to the field of adhesive preparation.

Owner:浙江蓝歌新材料科技有限公司

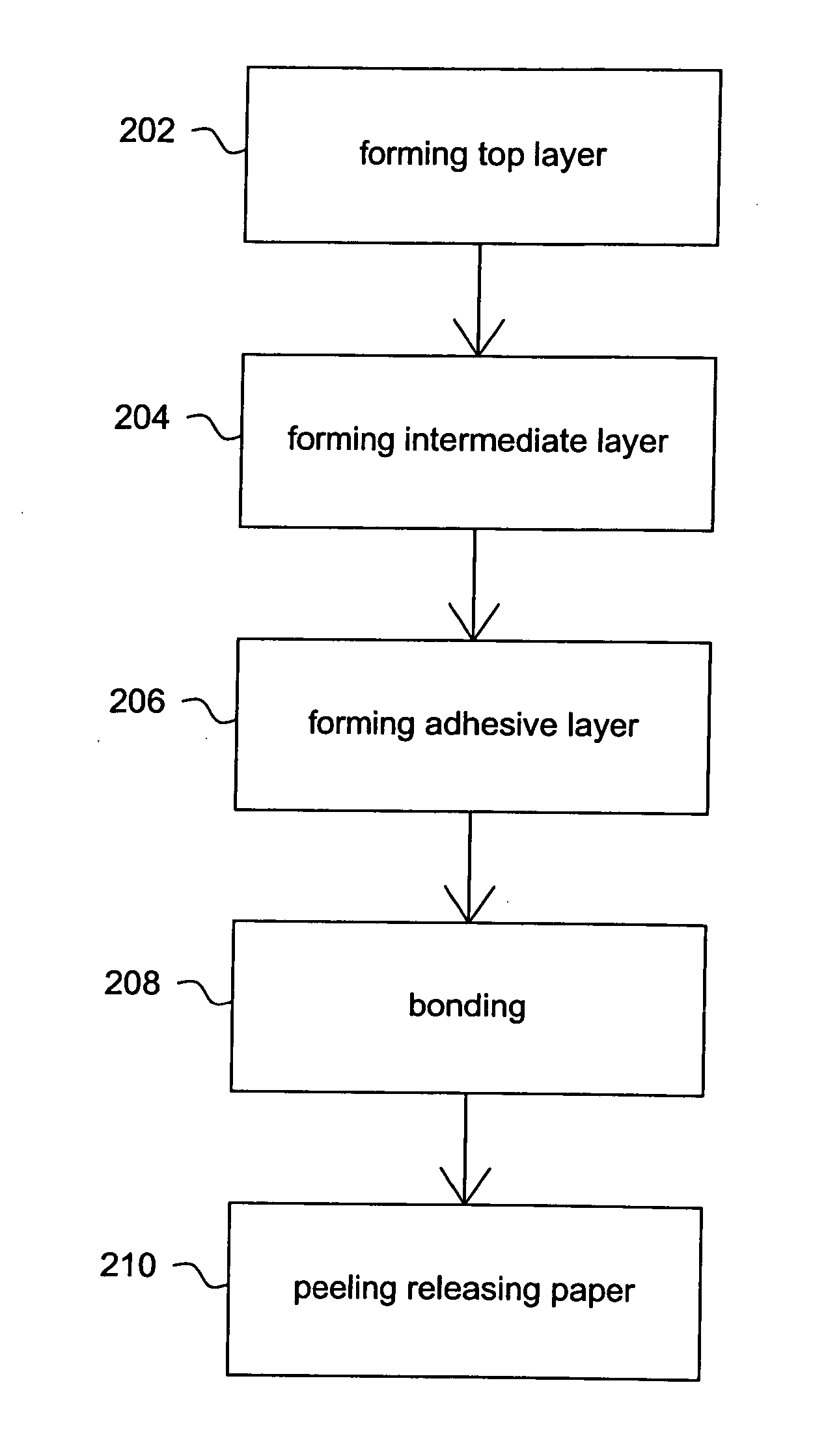

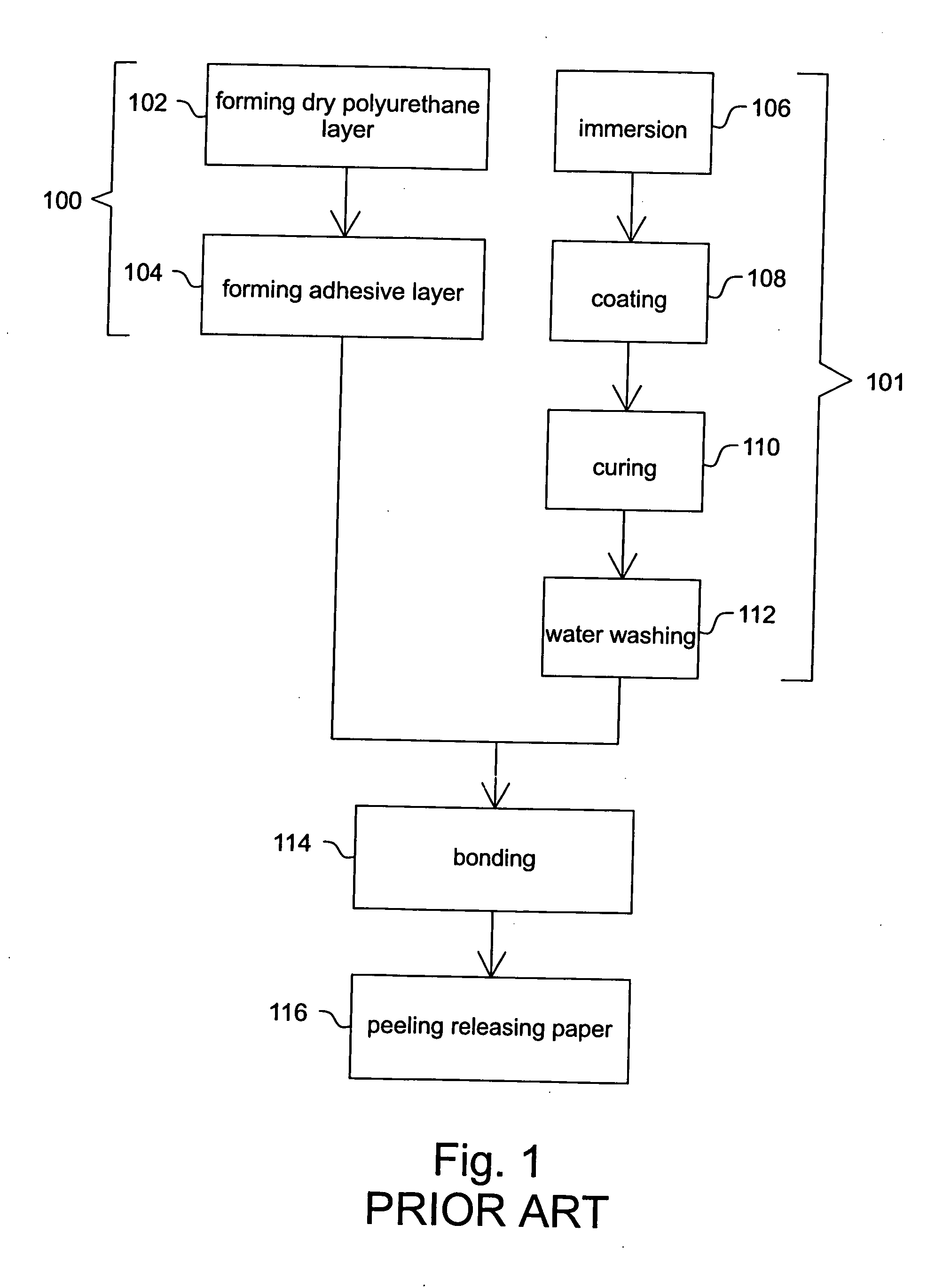

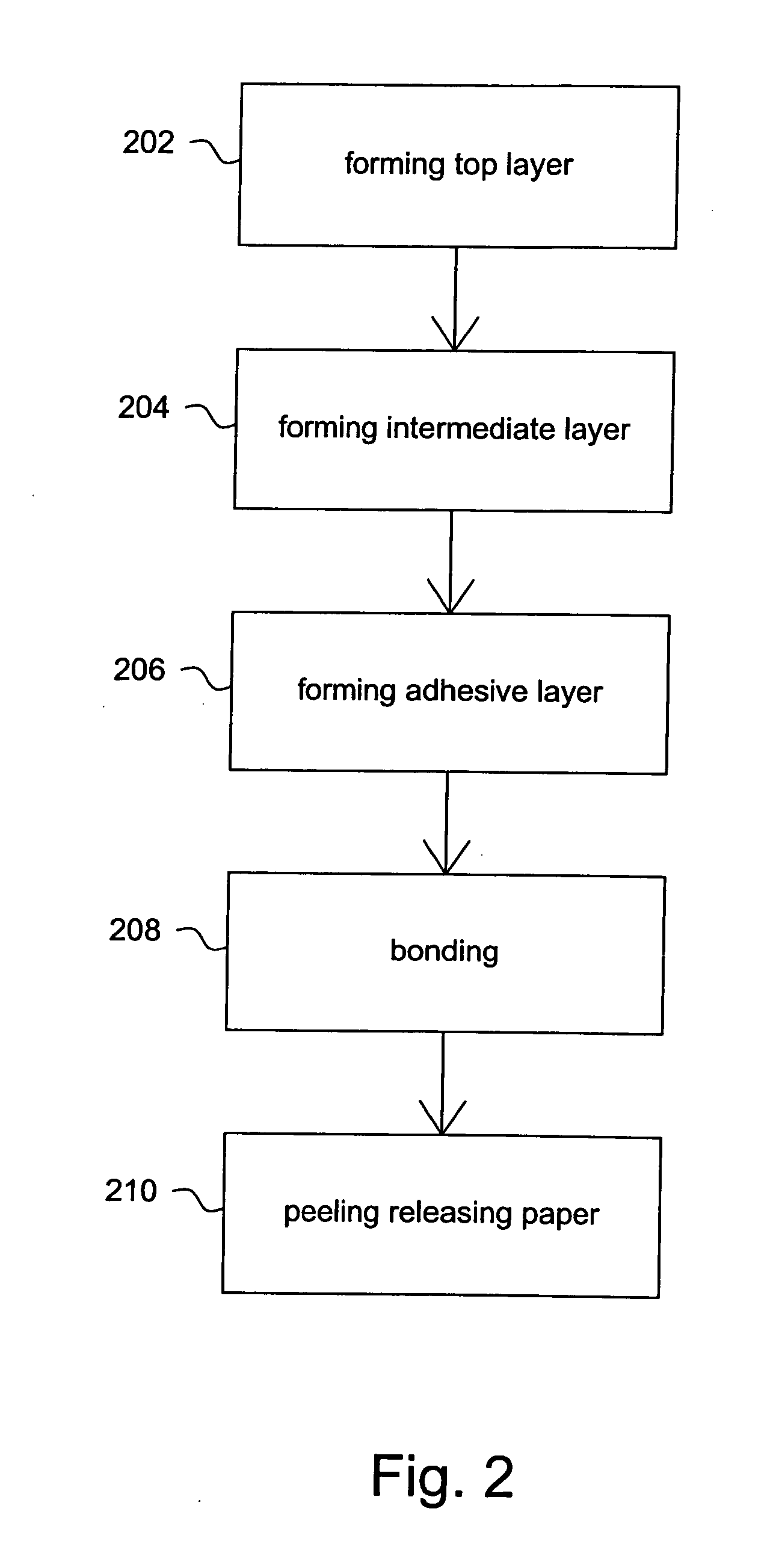

Method for producing environmental friendly artificial leather product

InactiveUS20060249244A1Reduce the amount requiredExtensive contentNatural patternsDecorative surface effectsElastomerSolvent free

A method for producing an environmental friendly artificial leather product includes coating a first solvent-free elastomer resin composition on a releasing paper to form a top layer, coating a polyurethane resin composition containing more than 50% by weight solid content on the top layer to form an intermediate layer, coating a second solvent-free elastomer resin composition on the intermediate layer to form an adhesive layer, and finally applying a substrate on the adhesive layer, and peeling the releasing paper.

Owner:SAN FANG CHEM IND

Epoxy resin dough moulding compound and preparation method thereof

The invention discloses an epoxy resin dough moulding compound and a preparation method thereof. The epoxy resin dough moulding compound is prepared by evenly kneading 35-40 parts by mass of epoxy resin paste, 4-5 parts by mass of curing agent mixture and 65-70 parts by mass of chopped fiber, wherein the epoxy resin paste comprises the following components in parts by mass: 80-120 parts of epoxy resin, 5-10 parts of plasticizer, 4-8 parts of filler, 3-6 parts of mould release agent and 0.5-2 part(s) of coupling agent; the curing agent mixture comprises the following components in parts by mass: 4-7 parts of latent curing agent, 1-3 part(s) of accelerator and 6-10 parts of amine curing agent, and the length of the chopper fiber is one eighth to one half inch. Compared with the traditional method, the preparation method eliminates the curing process, and the dough moulding compound is prepared by adding modifying components and different curing systems into the epoxy resin. The method has the advantages of simple operation, high production efficiency, long working life and easy formation. Since the baking oven and other heating equipment are not needed, the method can reduce the energy consumption. Moreover, the method is applicable to fields of structural materials and composite materials with high requirements for insulation and electrical properties, and can be easily promoted and implemented.

Owner:北京玻钢院复合材料有限公司

Bi-component polyurethane adhesive

ActiveCN102533200AQuick unblockSpeed up unblockingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses a bi-component polyurethane adhesive, which consists of a component A and a component B. The component A comprises the following raw materials in percentage by weight: 0-10% of monohydric alcohol, 30-90% of polyhydric alcohol, 8-60% of pigments and fillers, 1-10% of nano-filler, 0.01-1% of catalyst and 0.1-5% of silane coupling agent, wherein the sum of the raw materials is equal to 100%; the component B is isocyanate; and the weight ratio of the component A to the component B is 1-5:1. According to the bi-component polyurethane adhesive, the shelf life of the prepared bi-component polyurethane adhesive is obviously prolonged, and the curing speed is doubled.

Owner:GUANGZHOU RETAN NEW MATERIALS & HI TECH CO LTD

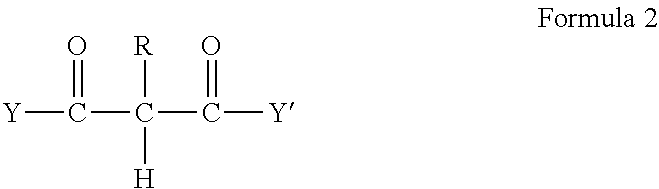

Amine epoxy resin curing agent, gas barrier epoxy resin composition comprising the curing agent, coating agent, and adhesive agent for laminate

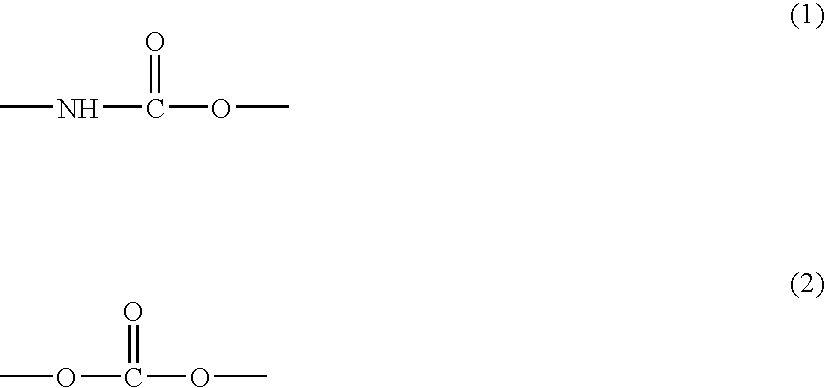

ActiveUS20100160494A1Excellent gas barrier performanceOvercome short pot lifeSynthetic resin layered productsDomestic containersCarbamateAdhesive

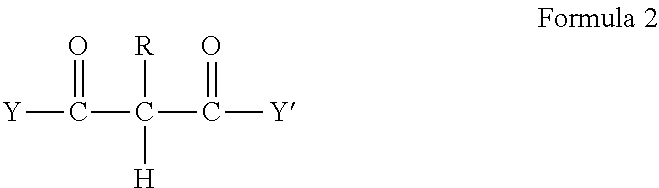

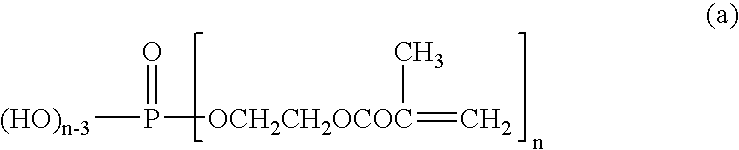

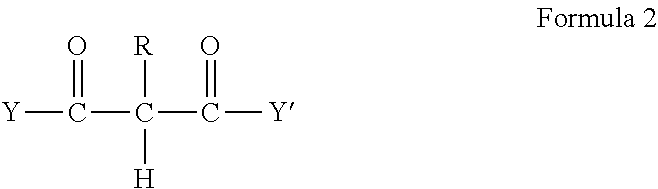

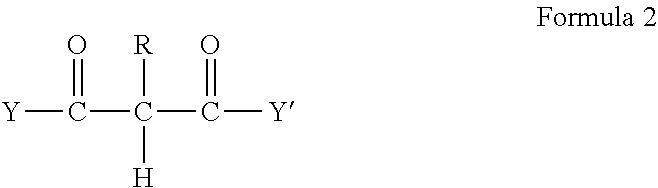

The present invention provides an amine based epoxy resin curing agent containing an epoxy resin and an amine compound capable of imparting a high gas barrier performance and a long pot life, in addition to excellent performances which an epoxy resin conventionally possesses, and an epoxy resin composition with a high gas barrier performance and a long pot life, which contains the subject curing agent. Also, the present invention provides an adhesive for laminate with excellent adhesiveness to various polymers, papers, metals, etc., which contains, as a main component, an epoxy resin composition containing an amine based resin curing agent with a high gas barrier performance and a long pot life.The amine based epoxy resin curing agent of the present invention is composed of a reaction product of the following (A), (B) and (D) or a reaction product of the following (A), (B), (C) and (D):(A) m-xylylenediamine or p-xylylenediamine,(B) a polyfunctional compound having at least one acyl group, which is capable of forming an amide group site through a reaction with a polyamine and forming an oligomer,(C) a monovalent carboxylic acid having from 1 to 8 carbon atoms and / or its derivative, and(D) a functional compound having at least one carbonate site represented by the formula (2), which is capable of forming a carbamate site represented by the formula (1) through a reaction with a polyamine:

Owner:MITSUBISHI GAS CHEM CO INC

Circuit-connecting material and circuit terminal connected structure and connecting method

InactiveUS20060063366A1Excellent curabilityLong application periodPrinted circuit assemblingSemiconductor/solid-state device detailsHydroxy compoundElectrical and Electronics engineering

Owner:HITACHI CHEM CO LTD

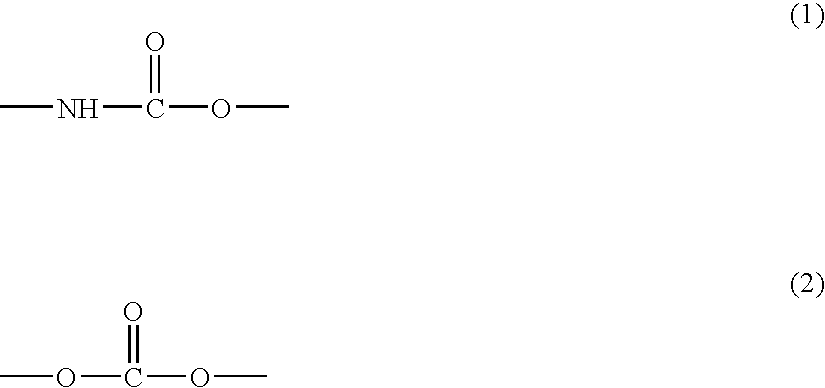

Crosslinkable composition crosslinkable with a latent base catalyst

ActiveUS9534081B2Effective use timeExtended validity periodOrganic-compounds/hydrides/coordination-complexes catalystsPolyester coatingsArylHydrogen

The present invention relates to a crosslinkable composition comprising at least one crosslinkable component and a latent base crosslinking catalyst, which crosslinkable composition has a solids content of typically at least 55 wt (dry weight after crosslinking relative to the total weight of the crosslinking composition) wherein the latent base catalyst is a substituted carbonate salt according to formula 1wherein X+ represents a non acidic cation, preferably a quaternary ammonium or phosphonium, and wherein R is hydrogen, alkyl, aryl or aralkyl group.

Owner:ALLNEX NETHERLANDS BV

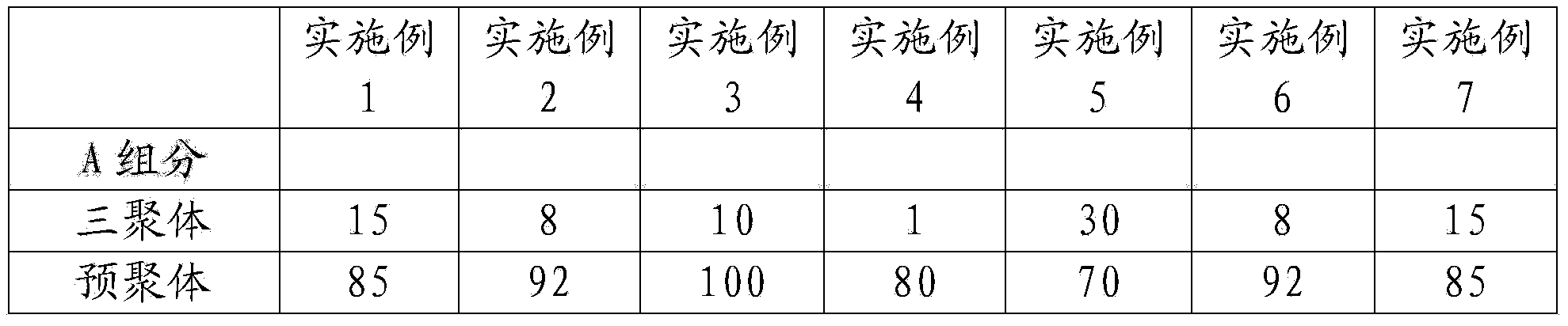

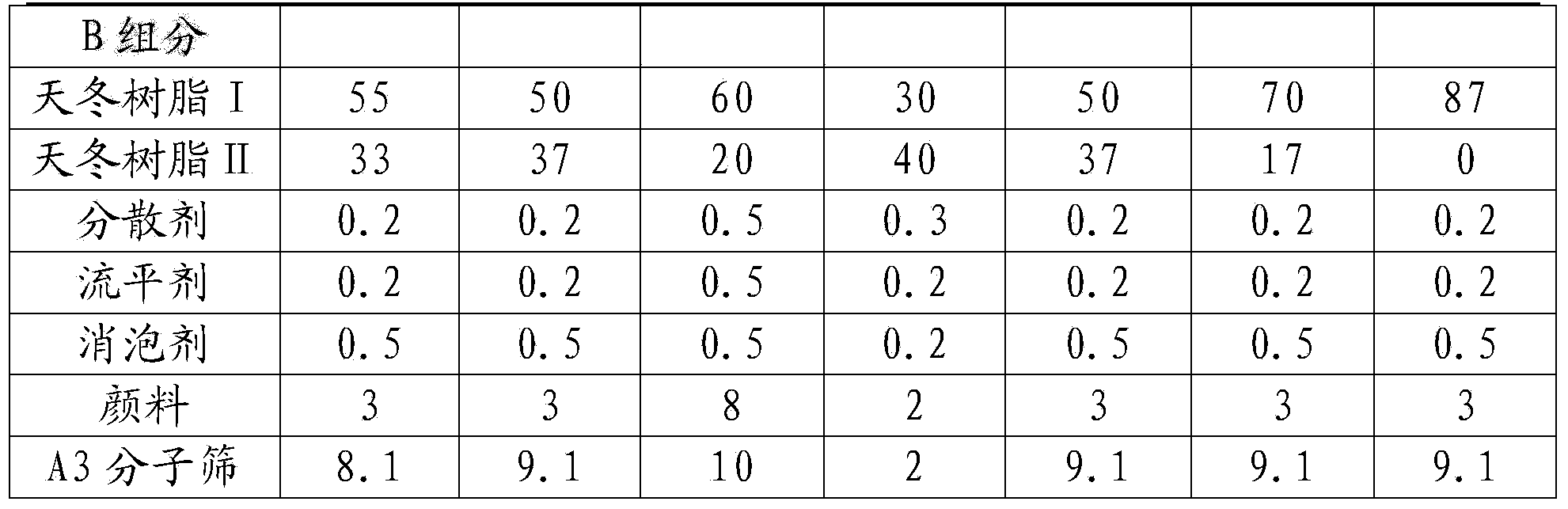

Elastic waterproof polyurea coating as well as preparation method and application method thereof

ActiveCN103820014ALow solvent contentLong application periodLiquid surface applicatorsPolyurea/polyurethane coatingsDisinfectantPolyurea

The invention belongs to the technical field of coating production and particularly relates to an elastic waterproof polyurea coating as well as a preparation method and application method thereof. The coating comprises a component A and a component B, wherein the component A comprises the main ingredients of aliphatic polyisocyanate trimer and an elastic isocyanate curing agent; the component B comprises the main ingredient of dimerization type asparaginic acid ester polyurea resin; the component A and the component B are packaged independently; a base coat layer is uniformly coated with the component A and the component B. The polyurea coating provided by the invention has the advantages as follows: the construction time of the polyurea coating is prolonged, the wettability is improved, and the performance of thick coating construction is provided, so that special polyurea coating equipment and special constructors are not required, the construction is facilitated, and the formed film has excellent elasticity. The polyurea coating can be dried after being coated for two hours, is high in curing speed, can be used outdoors, has excellent water resistance and chemical corrosion resistance of a swimming pool disinfectant, and can be soaked in water for a long time without cracking and leakage.

Owner:深圳市威尔地坪材料有限公司

Crosslinkable composition crosslinkable with a latent base catalyst

ActiveUS9181453B2Effective use timeExtended validity periodOrganic-compounds/hydrides/coordination-complexes catalystsInksHydrogenEvaporation

The present invention relates to a crosslinkable polymer composition comprising reactive components A and B each comprising at least 2 reactive groups wherein the at least 2 reactive groups of component A are acidic protons (C—H) in activated methylene or methine groups and the at least 2 reactive groups of component B are activated unsaturated groups (C═C) to achieve crosslinking by Real Michael Addition (RMA), wherein the component A is a malonate containing component and wherein components A and B react on drying of the crosslinkable polymer composition by deblocking of latent base catalyst C by evaporation of carbon dioxide, which latent base crosslinking catalyst, is a substituted carbonate salt according to formula 1wherein X+ represents a non acidic cation and wherein R is hydrogen, alkyl, aryl or aralkyl group.

Owner:ALLNEX NETHERLANDS BV

Crosslinkable composition crosslinkable with a latent base catalyst

ActiveUS9181452B2Effective use timeExtended validity periodOrganic-compounds/hydrides/coordination-complexes catalystsPolyester coatingsArylPhosphonium

The present invention relates to a crosslinkable composition comprising at least one crosslinkable component and a latent base crosslinking catalyst, which crosslinkable composition has a solids content of typically at least 55 wt (dry weight after crosslinking relative to the total weight of the crosslinking composition) wherein the latent base catalyst is a substituted carbonate salt according to formula 1wherein X+represents a non acidic cation, preferably a quaternary ammonium or phosphonium, and wherein R is hydrogen, alkyl, aryl or aralkyl group.

Owner:ALLNEX NETHERLANDS BV

Preparation method of nonionic waterborne epoxy curing agent

The invention provides a preparation method of a nonionic waterborne epoxy curing agent, which comprises the following steps: (1) heating and dissolving epoxy resin and polyether polyol, evenly mixing, dropwisely adding catalyst at 50-130 DEG C to carry out polymerization reaction, and after the reaction finishes, dissolving the product in the epoxy resin and solvent to prepare a mixed solution; (2) while stirring, dropwisely adding a monoepoxy compound into basic amine, and reacting at 10-100 DEG C; (3) dropwisely adding the mixed solution in the step (1) into the reaction product in the step (2) at 30-120 DEG C, and enabling the reaction at 10-90 DEG C; and after the reaction finishes, diluting by adding water until the solid content reaches 30-80%, thereby obtaining the nonionic waterborne epoxy curing agent. The method has the advantages of simple technique and mild reaction conditions; the adopted cosolvent has the advantages of low toxicity or no toxicity, and low VOC (volatile organic compound) content; and the substance cured by the product has the advantages of favorable compatibility with epoxy resin and high toughness of the paint film.

Owner:CHINA PETROCHEMICAL CORP

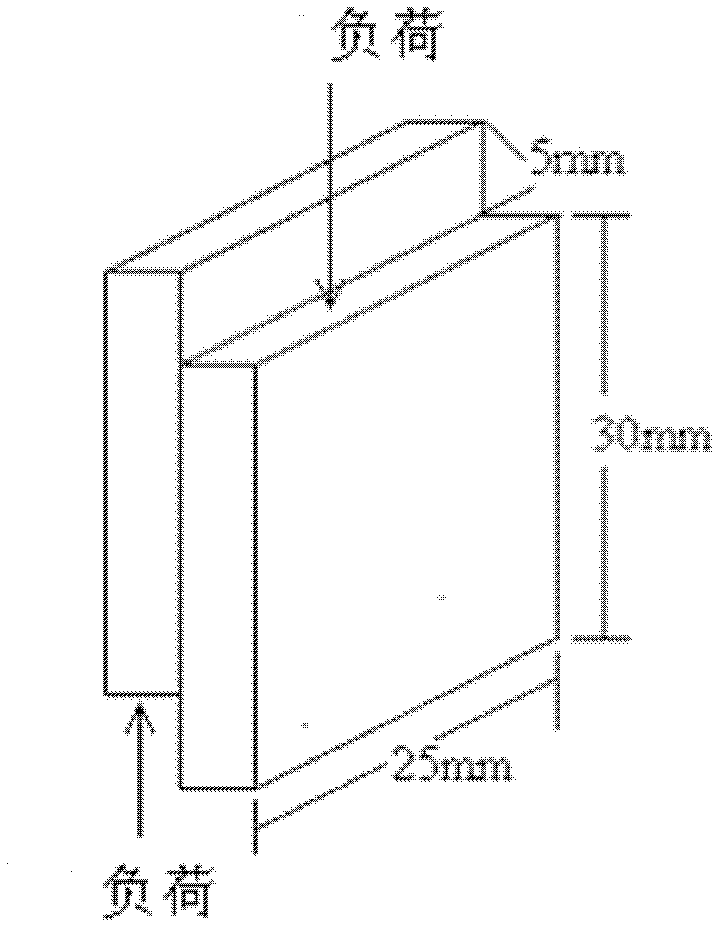

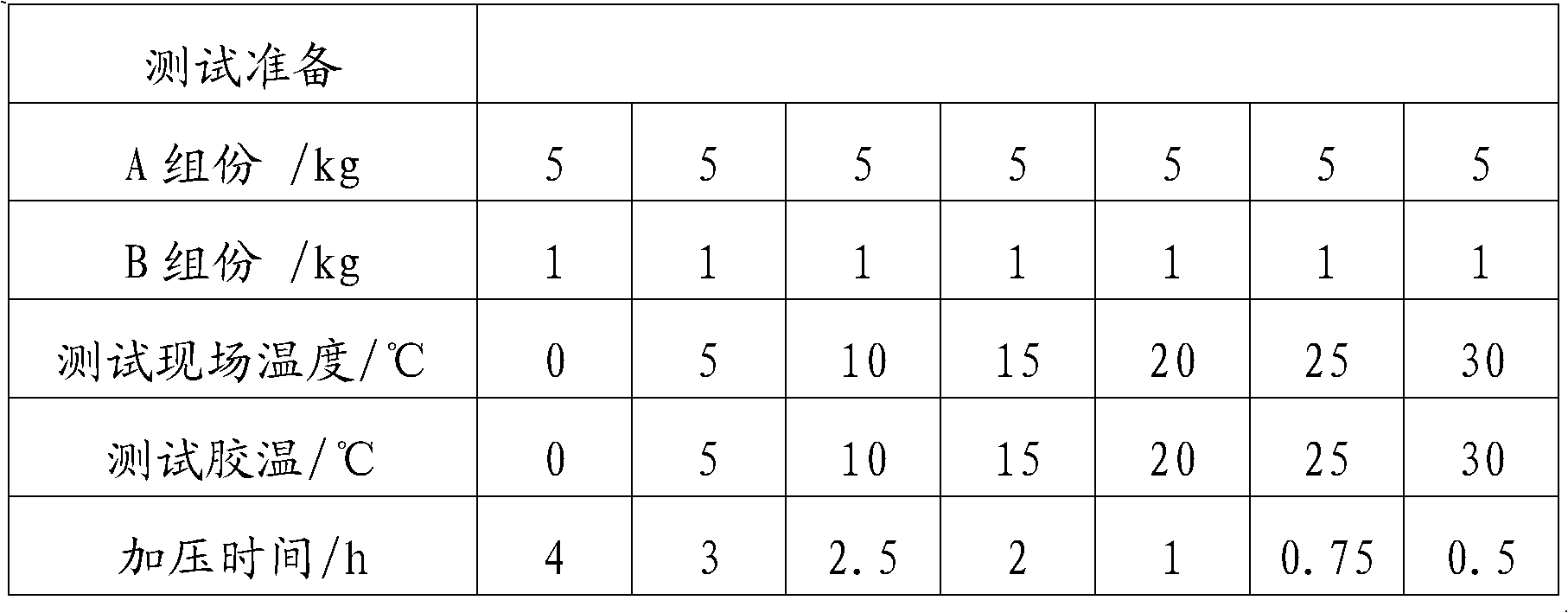

Low-viscosity epoxy resin system for resin transfer molding and preparation and using method thereof

The invention relates to a low-viscosity epoxy resin system for resin transfer molding and a preparation and using method thereof. The epoxy resin system consists of a component A and a component B, wherein in the component A, the weight ratio of epoxy resin to reactive diluent to antifoaming agent is 55-90: 10-45: 0.05-1; and the weight ratio of the component B (curing agent) to the component A is 100: 10-30. The preparation and using method comprises the following steps of: mixing and stirring the components A and B of the epoxy resin system uniformly in a ratio, pumping vacuum and removing bubbles at room temperature, and finally heating the components for 6 hours at the temperature of 80 DEG C to obtain a casting. The epoxy resin system can improve the gelling time and viscosity, meanwhile keeps good mechanical property and thermal property, and can be used for manufacturing large-sized composite structural members of automobiles, ships, wind-power blades, aerospace and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Polyolefin based hot melt adhesive having improved heat resistance

ActiveUS8476359B2High temperature resistanceEnvironmental durabilityLayered productsAdhesivesHeat resistancePlasticizer

A polyolefin based hot melt adhesive composition having improved heat resistance includes a blend of about 5% to 50% by weight of a glassy semicrystalline poly-alpha-olefin polymer, about 5% to 70% by weight of a soft or rubbery polymer, about 5% to 65% by weight of a tackifier, about 0% to 3% by weight of a stabilizer and optionally a wax and / or plasticizer. The composition can also contain other additives and fillers to further modify its properties. An application process for the adhesive composition and various articles assembled therewith are also disclosed. The composition is particularly suited for applications where complicated bonding needs exist that involve bonding of multiple components or parts fabricated from dissimilar materials ranging from steel to plastic to fabrics.

Owner:BOSTIK INC

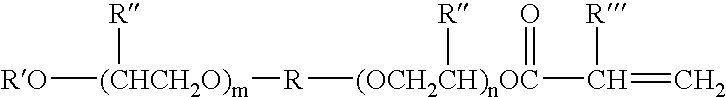

Adhesive useful for film laminating applications

InactiveUS20070088145A1Broaden applicationEasy to handleAdhesive processesPolyureas/polyurethane adhesivesPolyesterEpoxy

An adhesive that is capable of being curing in at least two stages is prepared by combining at least one isocyanate-functionalized polyurethane prepolymer, at least one hardener, and at least one (meth)acrylate-functionalized compound selected from the group consisting of polyester (meth)acrylates containing hydroxyl functional groups, adducts of epoxy-functionalized poly(meth)acrylic resins and (meth)acrylic acids, polybutadiene (meth)acrylates, and polyoxyalkylene ether mono(meth)acrylates. Such adhesives are particular useful as two part laminating adhesives in the assembly of flexible laminates.

Owner:HENKEL CORP

Hydrazide latency improving curing agent and preparation method thereof

The invention discloses a hydrazide latency improving curing agent comprising hydrazide compound and epoxy compound, wherein mol ratio between hydrazide radical and epoxy radical is 1: 0.5 to 2.5. The curing agent is prepared by mixing and dissolving the hydrazide compound and epoxy compound into a solvent, reacting for 1 to 24 hours at 60 to 150 DEG C, lastly depressurizing and removing the solvent. The prepared curing agent has good compatibility with liquid epoxy resin. The prepared single-component aqueous epoxy dope has six months storage period at room temperature, is stable below 40 DEG C, is cured at 100 to 150 DEG C to form a coat having flat and smooth surface and flexibility, and is applied to insulating coats of electronic elements and insulating coats of electric device coils.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE +1

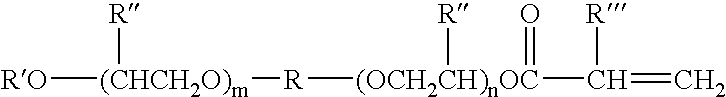

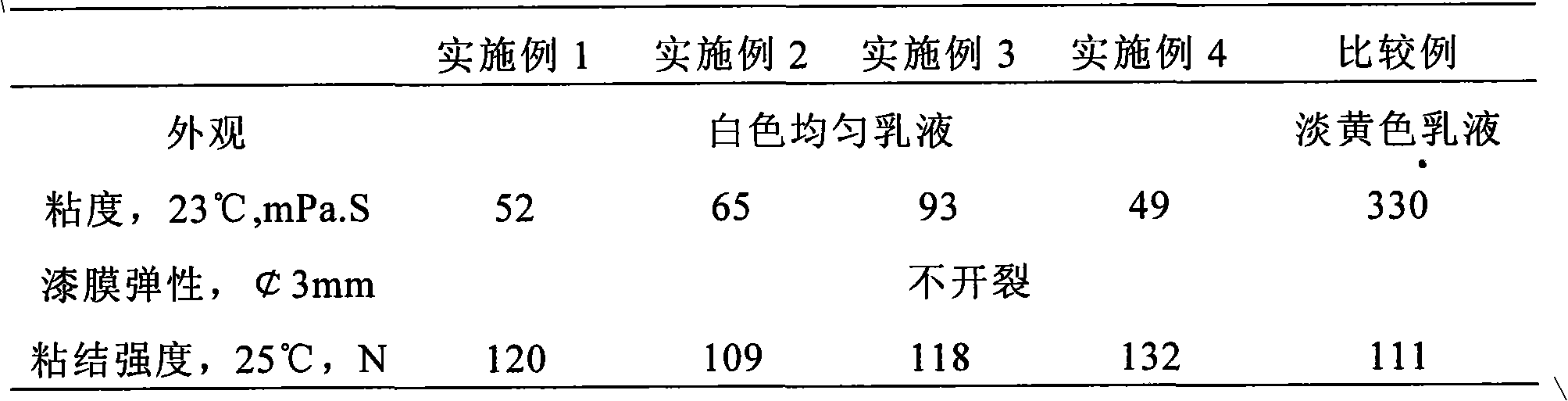

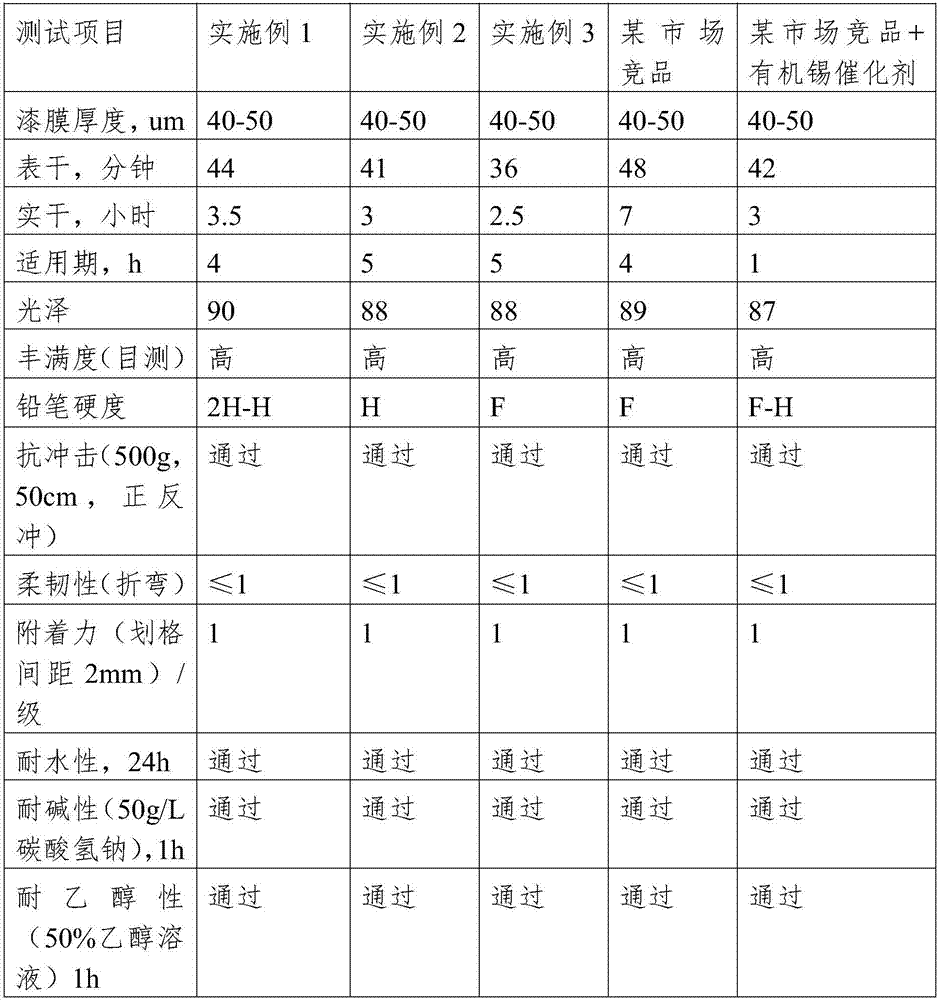

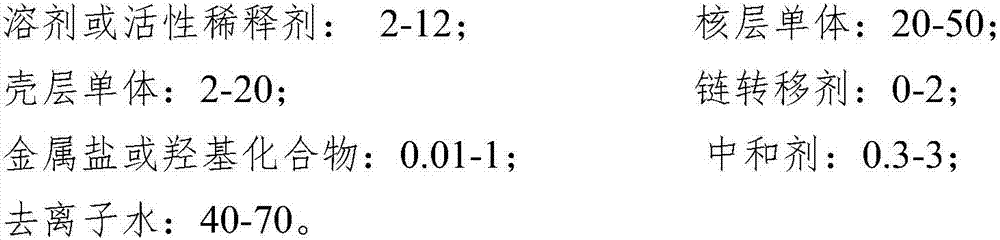

Quick-drying hydroxyacrylic resin aqueous dispersion with long working life and preparation method thereof

ActiveCN107163177AHigh glossImprove fullnessPolyurea/polyurethane coatingsWorking lifeMetal catalyst

The invention relates to a quick-drying hydroxyacrylic resin aqueous dispersion with long working life and a preparation method thereof. Metal ions are chelated in the aqueous dispersion and are used as a catalyst, and in an aqueous phase system, a catalyst component is wrapped by a hydrophobic core layer of the dispersion, but is not contacted with an isocyanate component, so that the activation period is not shortened; in the later stage of construction, moisture is basically evaporated completely, a hydrophobic part inside the dispersion is contacted and fused with the isocyanate component, and the metal catalyst starts to catalyze a reaction of the hydroxyl group and the isocyanate to promote curing of a coating film, so that the aqueous dispersion has the characteristics of long working life and quick drying. When the aqueous dispersion is applied to a waterborne double-component polyurethane coating, the coating film has excellent gloss and fullness, high hardness, good flexibility, excellent water resistance and solvent resistance; the aqueous dispersion can be widely applied to coating of wood furniture and large transporting tools, industrial coating and automobile repairing.

Owner:广东拓普合成科技股份有限公司

Acrylic acid modified water-based polyurethane adhesive and preparation method thereof

InactiveCN103242787ALong application periodExcellent shelf lifeGraft polymer adhesivesPolymer sciencePolyurethane adhesive

The invention belongs to the technical field of chemical adhesives and in particular relates to an acrylic acid modified water-based polyurethane adhesive and a preparation method thereof. The preparation method of the acrylic acid modified water-based polyurethane adhesive comprises the following steps of: preparing prepolymer; neutralizing and dispersing; and adding a bridging agent and an acrylic acid monomer for performing polymerization. The acrylic acid modified water-based polyurethane adhesive and a water-based curing agent are mixed to prepare a double-component water-based polyurethane adhesive. The double-component water-based polyurethane adhesive has the properties of low solvent consumption, high solid content, high viscosity, long and adjustable pot life of mixtures, excellent adhesive force, low price and the like, can be applied to base materials such as fabrics, foam, plastic, leather and the like, and has wide application prospect.

Owner:FUDAN UNIV

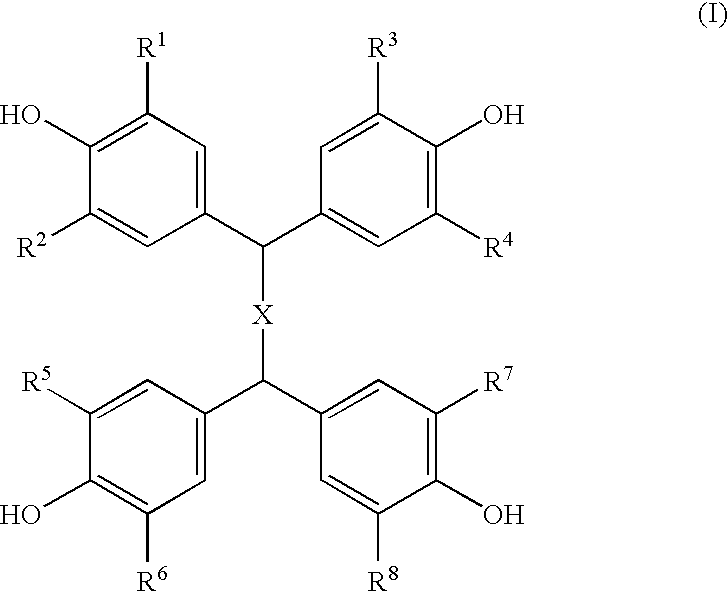

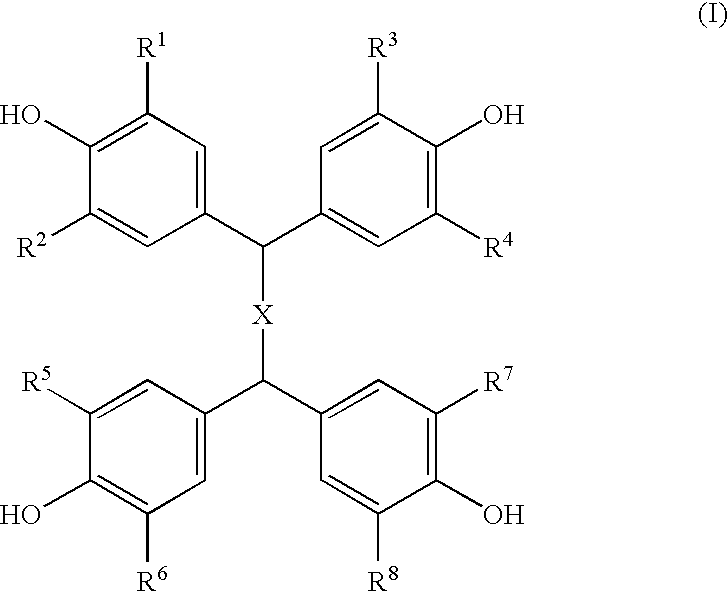

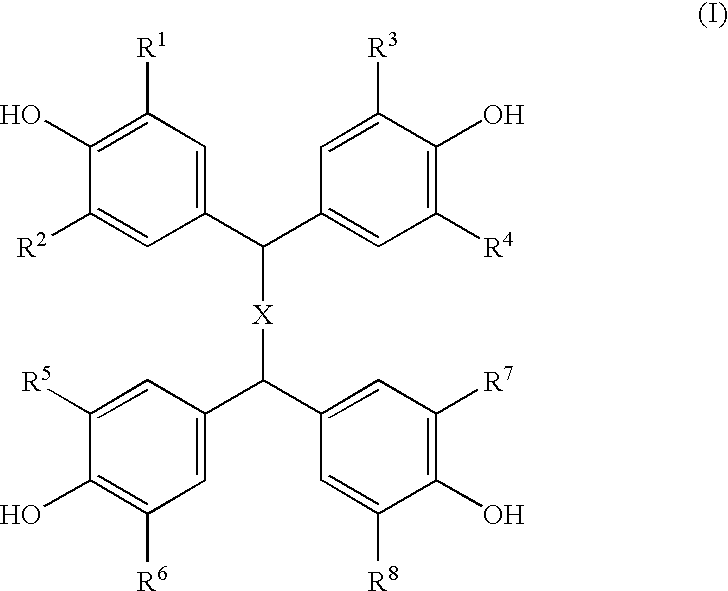

Composition of epoxy resin and clathrate of tetrakisphenol and epoxy-reactive curing compound

The present invention has an object to provide curatives for epoxy resins and curing accelerators for epoxy resins, which both have improved subliming and decomposing properties and which, when mixed with an epoxy resin, enable the mixture to be greatly improved in thermal stability that is extremely important for the control of a curing reaction and to have a prolonged pot life (stability as a one-pack mixture comprising the epoxy resin, curative, etc.) and improved curability at low temperatures.The curative is characterized by being a clathrate comprising a tetrakisphenol compound represented by a general formula [I];wherein X represents (CH2)n, wherein n is 0, 1, 2 or 3, and R<1 >to R<8 >each represents hydrogen, a lower alkyl, optionally-substituted phenyl, halogeno or a lower alkoxy, and the curing accelerator is characterized by being a clathrate comprising a tetrakisphenol compound represented by the general formula [I] shown above and a compound accelerating the curing of a compound which reacts with the epoxy group of an epoxy resin to cure the resin.

Owner:NIPPON SODA CO LTD

Electronic circuit including circuit-connecting material

InactiveUS20060060969A1Excellent curabilityLong application periodLiquid crystal compositionsSemiconductor/solid-state device detailsHydroxy compoundElectronic circuit

Owner:RESONAC CORPORATION

Production method for low-formaldehyde solid wood composite floor

ActiveCN105235024AAvoid gel effectLow residual formaldehydeLaminationLamination apparatusParquetinaSolid wood

The invention relates to a solid wood composite floor, in particular to a production method for a low-formaldehyde solid wood composite floor. The production method comprises the technological steps of wood plate slicing, drying, repairing, selecting, gluing, pre-pressing, hot pressing, edge cutting and sanding, and finished product obtaining. The key of the production method is that the residual amount of formaldehyde in adhesives is reduced by modifying the used urea-formaldehyde resin adhesives, so that the residual amount of the formaldehyde in the solid wood composite floor is reduced; by adopting high-quality plates and controlling process parameters in the production process, the quality of the produced solid wood composite floor is guaranteed. The content of the formaldehyde in the solid wood composite floor manufactured through the method is low, the quality of the floor is stable, and the floor is not prone to damage; the floor has the characteristics of being comfortable in foot feeling, resistant to abrasion, easy to install and clean, and high in stability.

Owner:DALIAN SHENGYU TECH DEV CO LTD

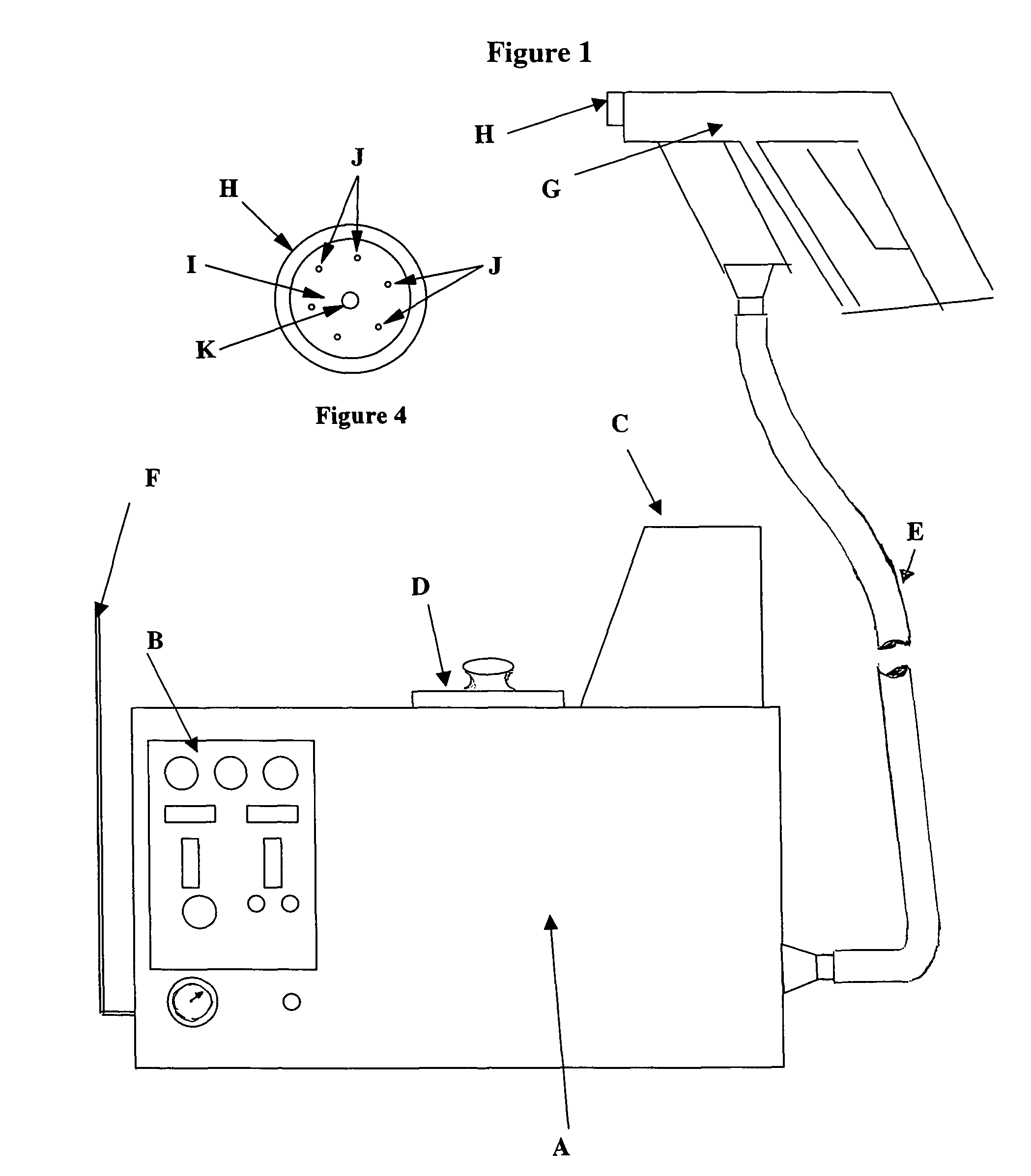

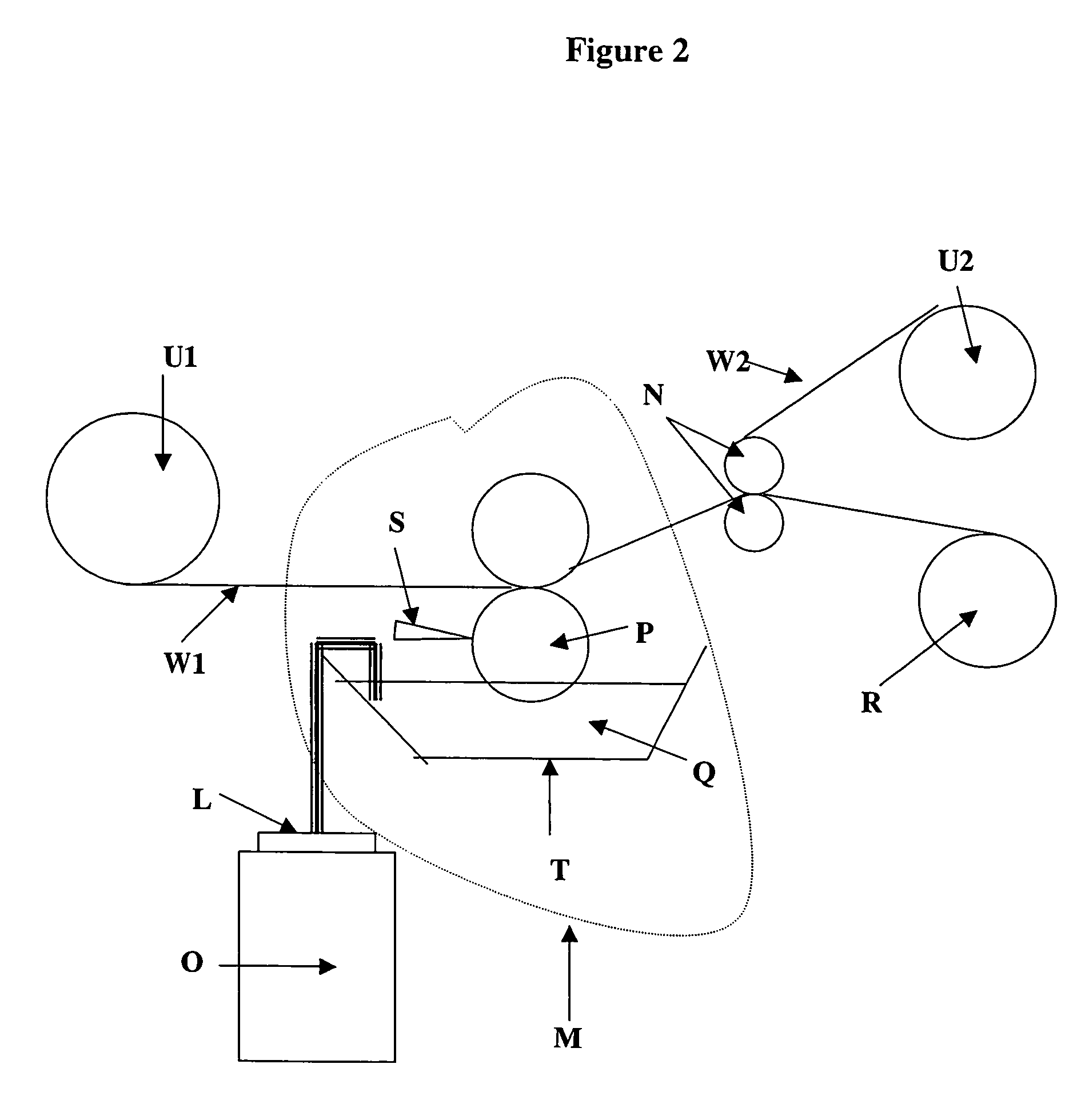

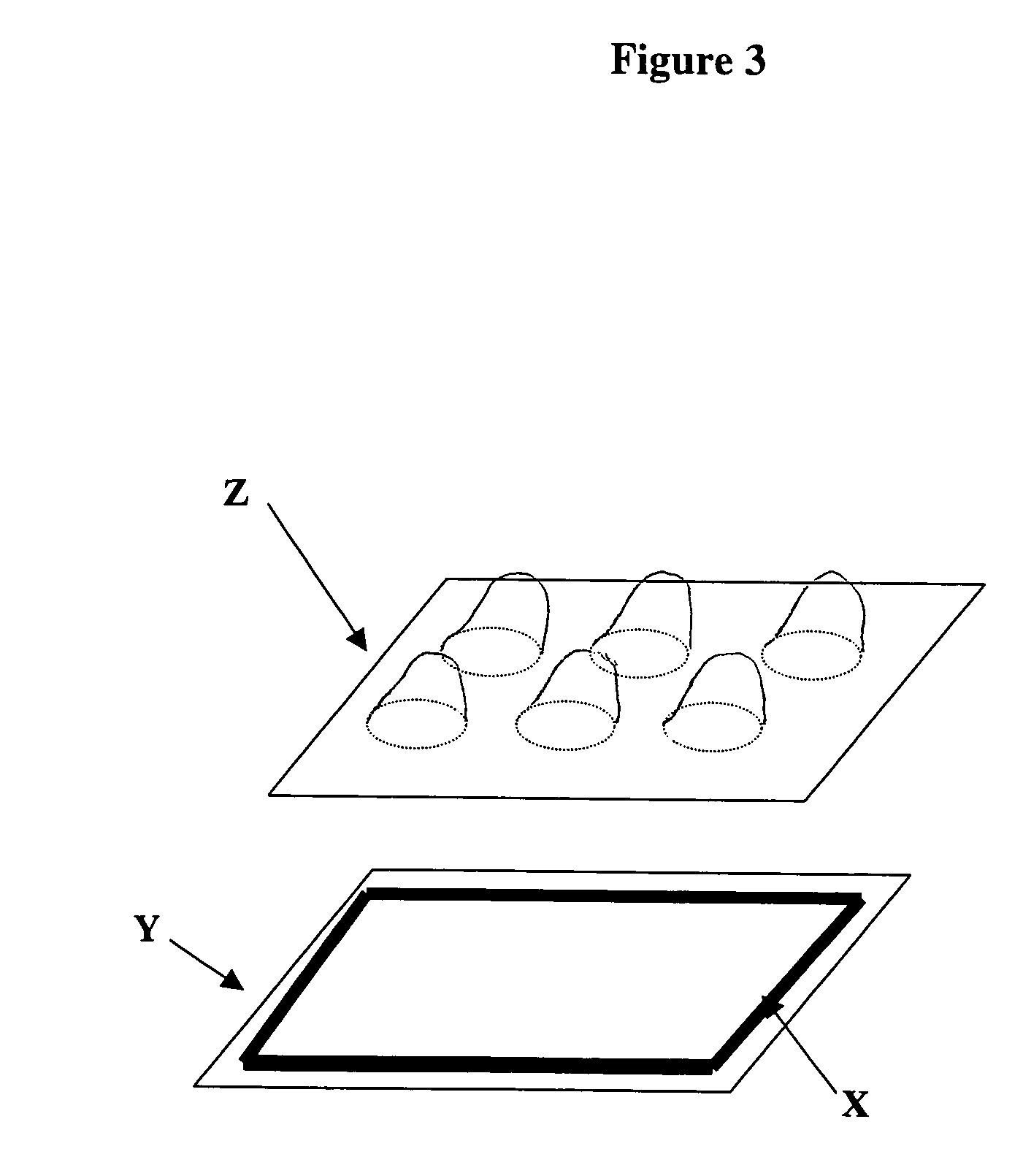

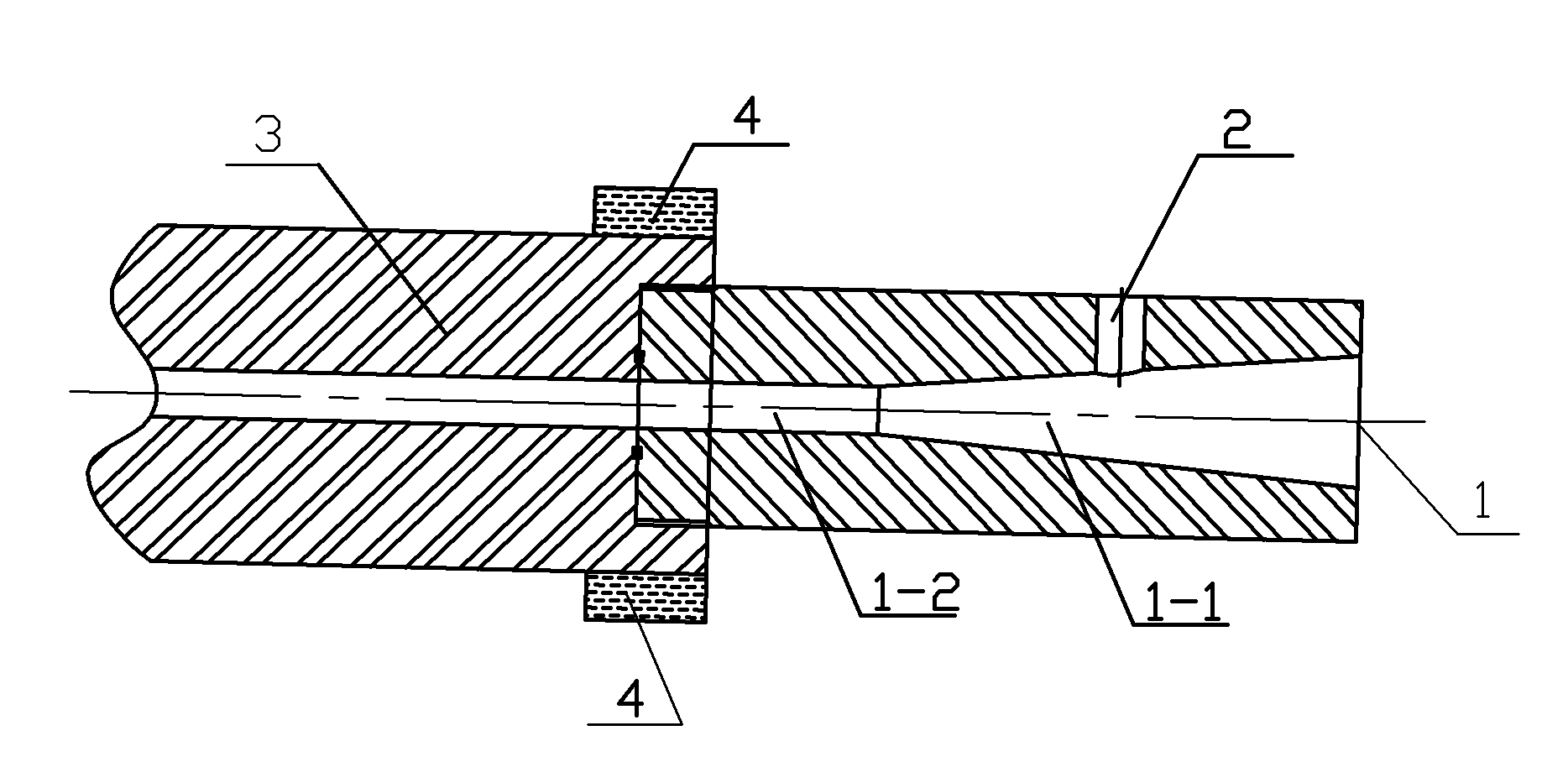

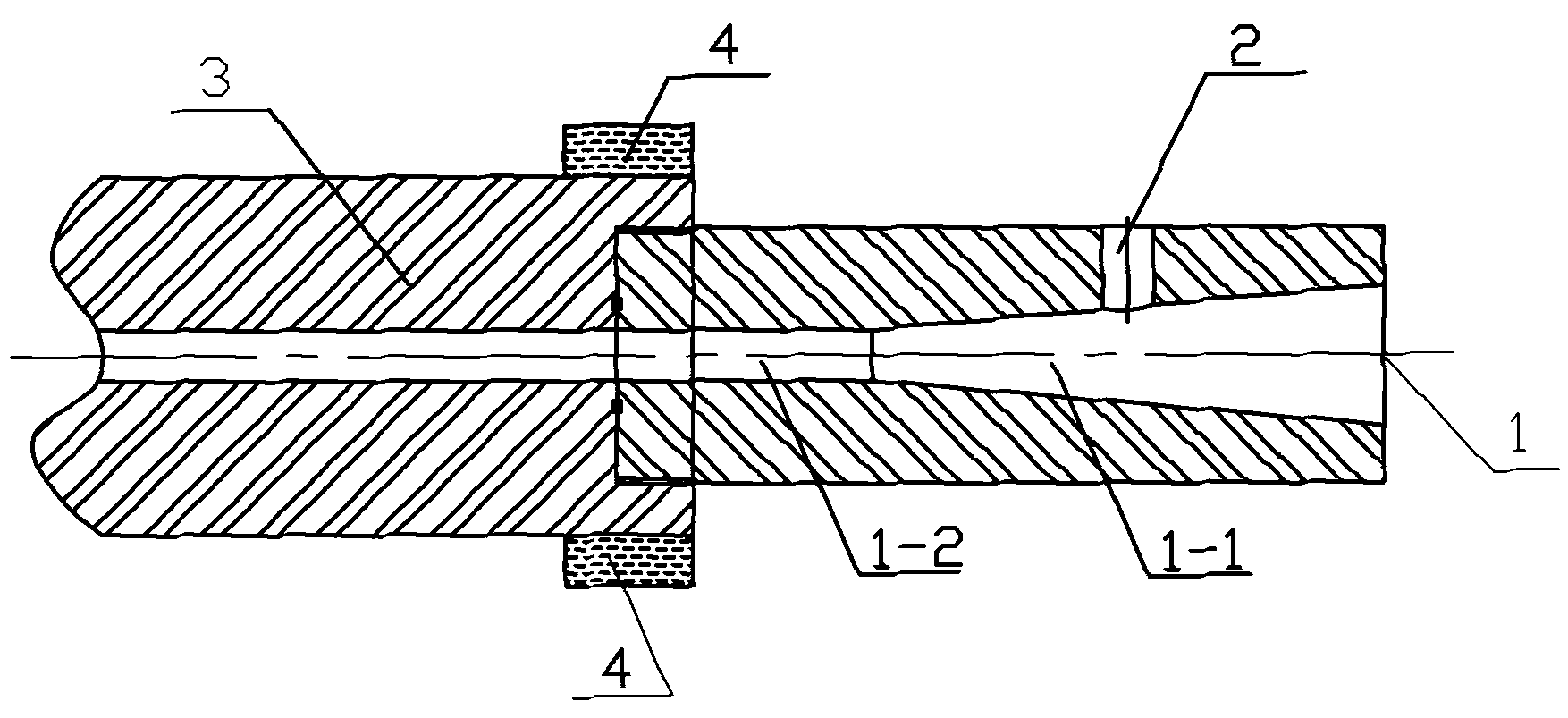

Injection die for injection and pull-extrusion process and method for preparing resin matrix composite by using same

The invention discloses an injection die for an injection and pull-extrusion process and a method for preparing a resin matrix composite by using the same, relating to an injection die and a method for preparing a resin matrix composite by using the same. Through the invention, the problem that the existing injection dies for the injection and pull-extrusion process are complicated in structure is solved. The injection die is provided with a die cavity and a glue injection hole, wherein the die cavity consists of a round table-shaped die cavity and a cylindrical die cavity; and the glue injection hole is located on the die wall of the round table-shaped die cavity. The method comprises the steps of: injecting a resin matrix into the round table-shaped die cavity through the glue injectionhole; causing continuous fibers to enter the die cavity of the injection die from a large-diameter end of the round table-shaped die cavity of the injection die under the traction of a traction device and then enter a die cavity of a pull-extrusion molding die through the cylindrical die cavity; and carrying out sizing and curing. The die cavity of the injection die is conical in front part and flat in rear part, the fibers of a solvent impregnated resin are stressed by a small-diameter end of the round table-shaped die cavity and the die wall of the cylindrical die cavity and then air bubbles are discharged, therefore, the void ratio of the composite is reduced and the mechanical property is improved. The injection die is simplified and the application range of the injection and pull-extrusion process is enlarged.

Owner:HARBIN FRP INST

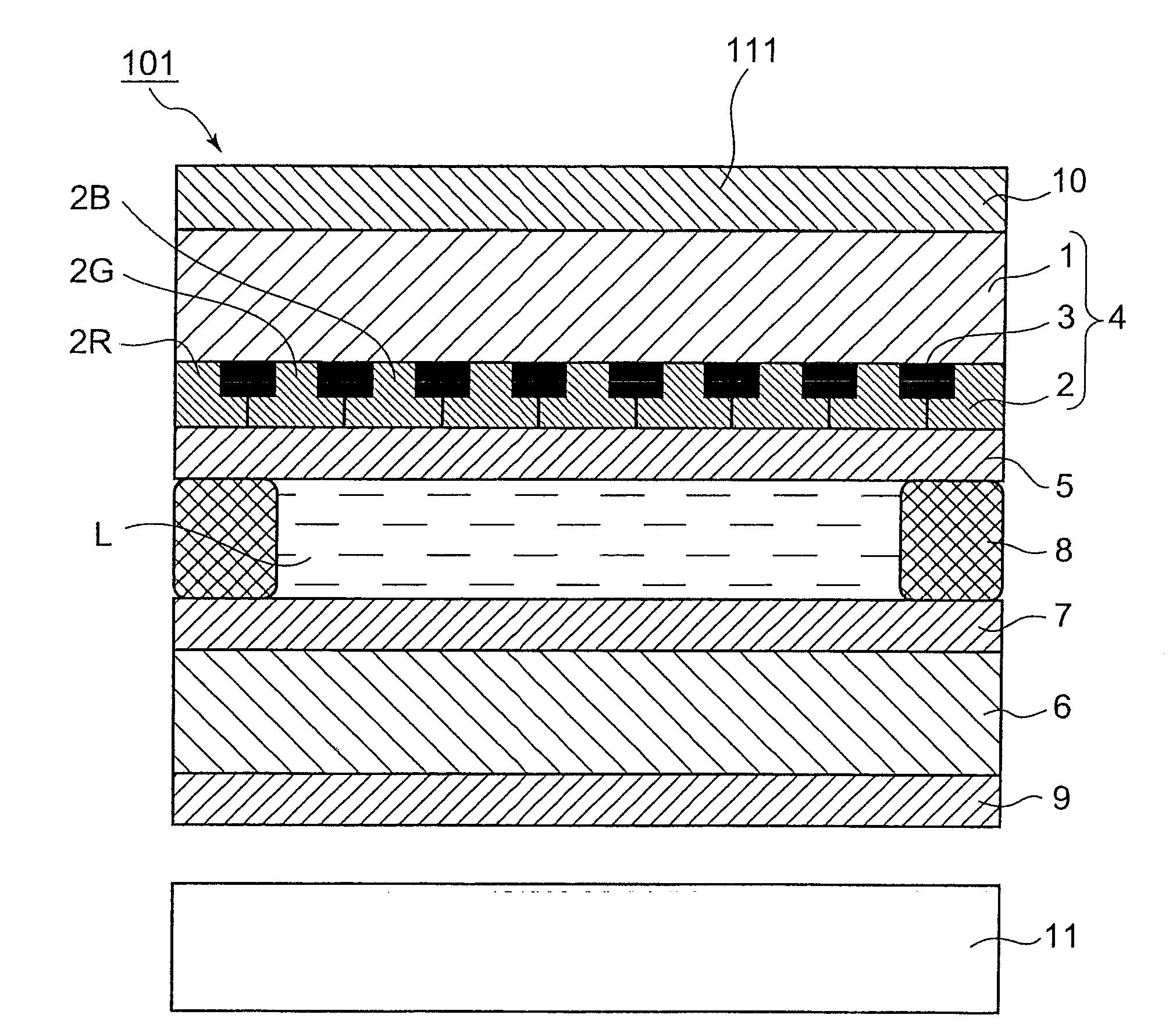

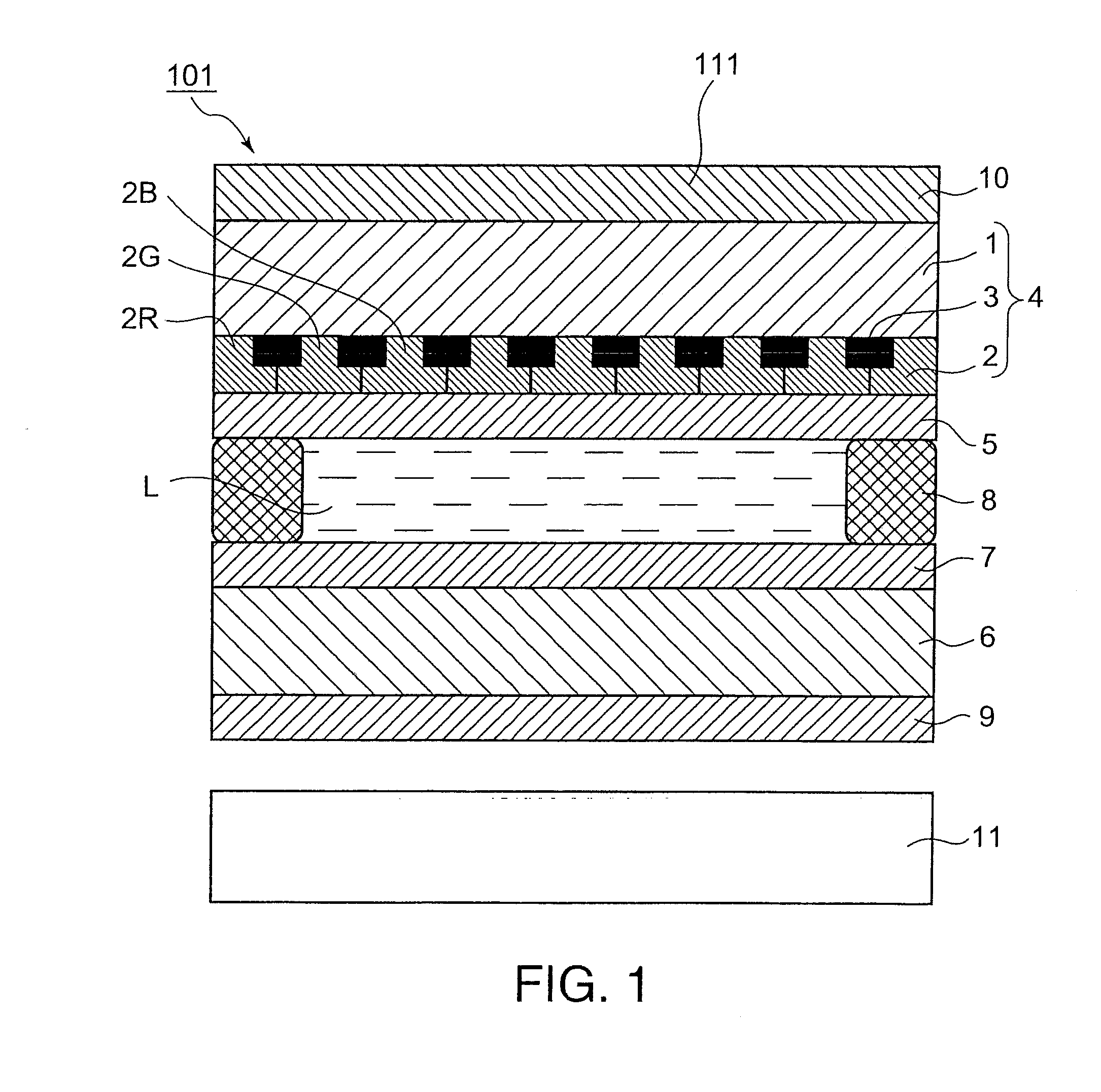

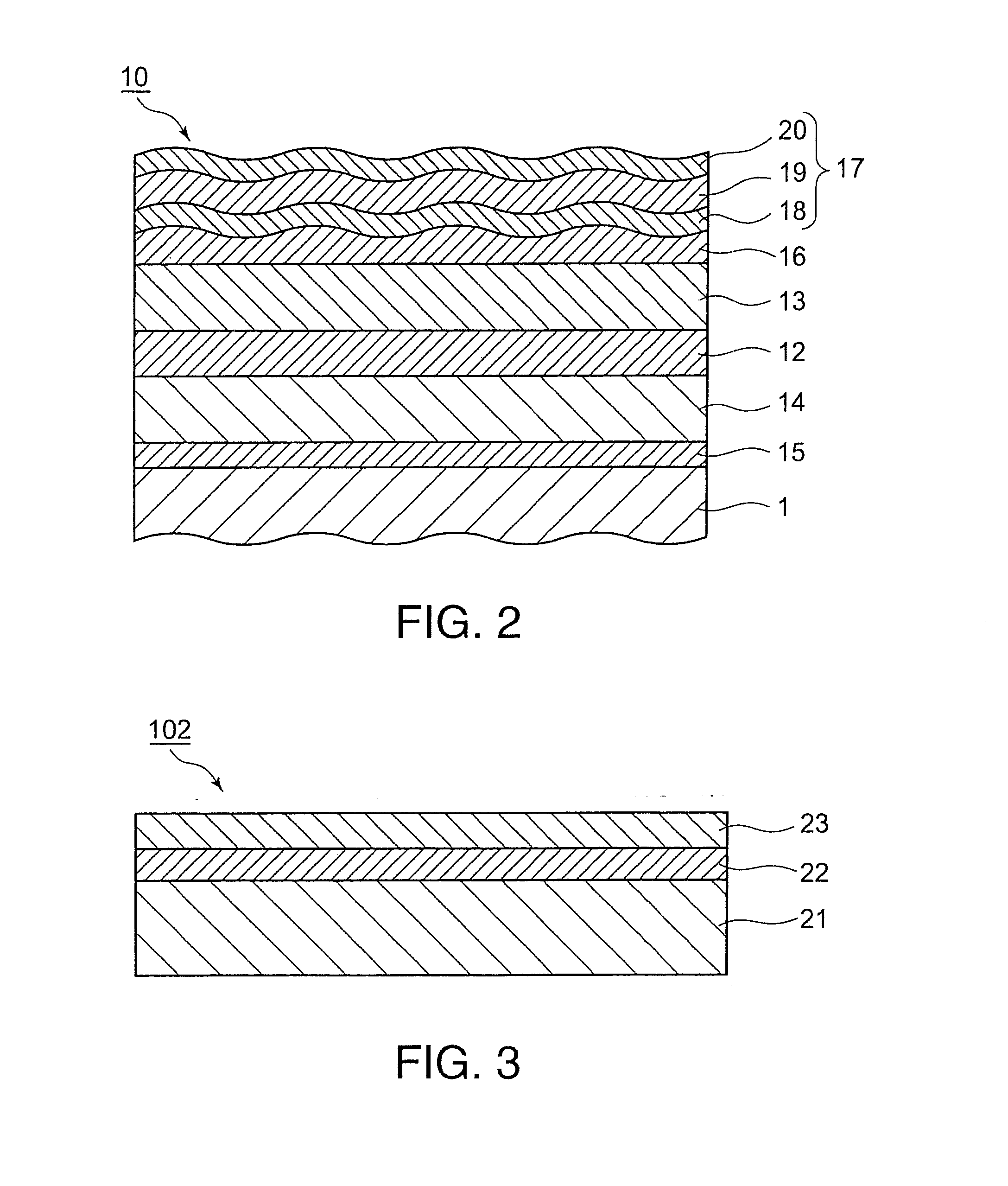

Coating Composition, Its Coating Film, Antireflection Film, and Image Display Device

ActiveUS20080187732A1Lowering in strengthReducing and eliminating activityGlass/slag layered productsWood layered productsCoated membraneElectron hole

This invention provides a coating composition that can form a coating film having an eliminated or reduced photocatalytic action-derived deterioration and can form a coating film having a lowered haze value, has excellent dispersibility and dispersion stability in a coating liquid form, has excellent storage stability, and also has excellent coatability. The coating composition is characterized by comprising at least the following four components (1) to (4): (1) titanium dioxide fine particles with eliminated or reduced photocatalytic activity which is obtained by surface treating titanium dioxide fine particles doped with cobalt capable of capturing free electrons and / or holes, with a zinc chelate compound capable of capturing free electrons and / or holes, (2) a binder component, (3) a dispersant, and (4) an organic solvent.

Owner:DAI NIPPON PRINTING CO LTD

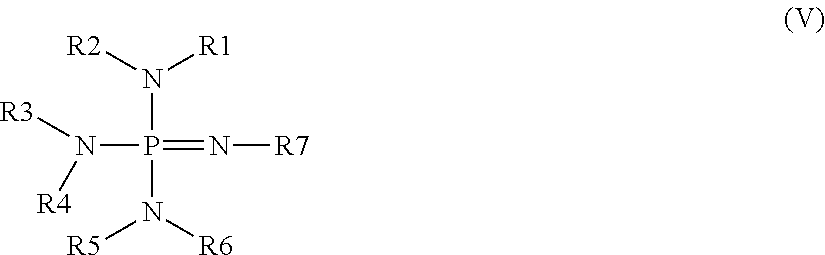

Curable composition comprising dual reactive silane functionality

InactiveUS20130102728A1Efficiently processableSolution stableGroup 5/15 element organic compoundsCoatingsHydrolysisOrganic compound

A curable composition comprises (a) at least one inorganic or organic compound comprising reactive silane functionality comprising at least one hydrosilyl moiety; (b) at least one inorganic or organic compound comprising reactive silane functionality comprising at least one hydroxysilyl moiety, the hydroxysilyl moiety optionally being generated in situ by hydrolysis of at least one hydrosilyl moiety; and (c) at least one base selected from amidines, guanidines, phosphazenes, proazaphosphatranes, and combinations thereof; with the proviso that, when component (a) is an organic polymer, then component (b) is different from component (a) and is not generated in situ by hydrolysis of component (a).

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com