Patents

Literature

293 results about "Parquetina" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing compressed charing poplar three-layer wood composite flooring

InactiveCN101486212ALow costHigh densityWood treatment detailsWood veneer joiningSolid woodSurface layer

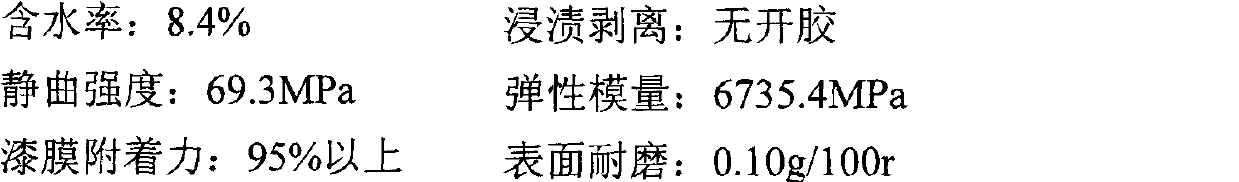

The invention discloses technology for producing compressed and carbonized poplar three-layer solid wood composite floor fully through utilization of a fast-growing material of poplar. A poplar sheet obtained by a special densification process is used as a surface layer; a common poplar core veneer is used as a core layer; a poplar veneer is used as a bottom layer to manufacture three-layer solid wood composite floor; each performance reaches the requirement of national standard GB / T 18103-2000 on the solid wood composite floor; the technology totally adopts the fast-growing material of the poplar as a raw material, does not add any chemical reagent in the special densification process of the poplar sheet, and does not cause any pollution to environment; after the poplar sheet is subjected to compaction treatment, the density and the hard sense of the wood are strengthened; the late high-temperature carbonization treatment solves the problem of rebounding after the poplar is compressed, changes luster of the wood, and strengthens high grade; and the technology is simple and feasible and has low manufacturing cost.

Owner:NANJING FORESTRY UNIV

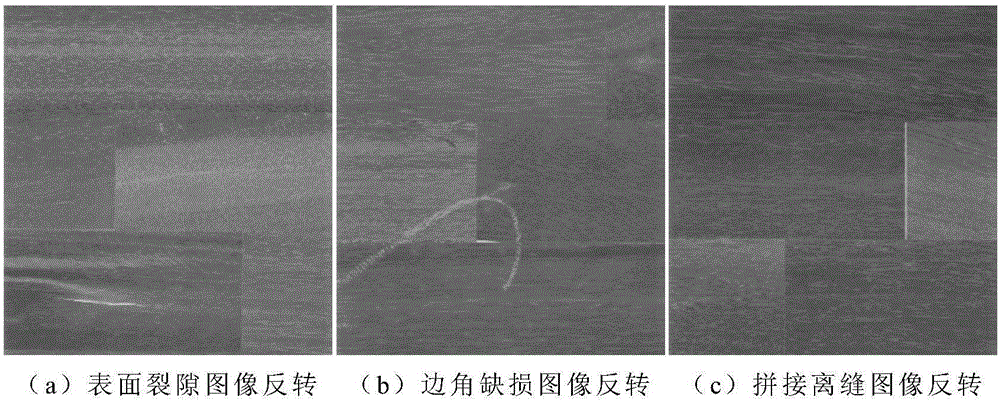

Recognition method of surface defects of multilayer solid wood composite floor with surface board being jointed board

InactiveCN106338520AImprove visual inspection efficiencyImprove the level ofOptically investigating flaws/contaminationSolid woodSupport vector machine

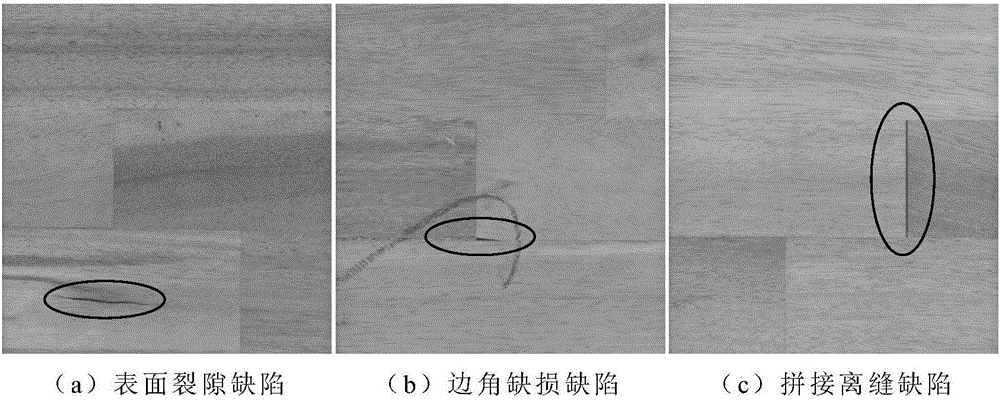

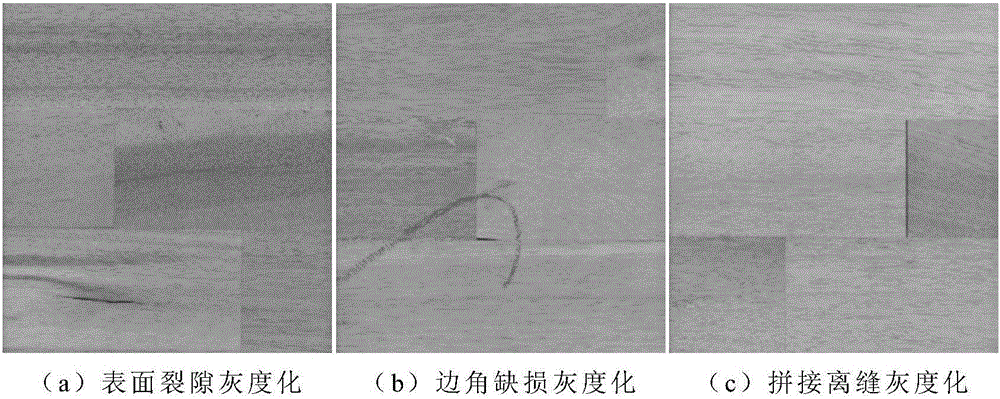

The invention provides an recognition method of surface defects of a multilayer solid wood composite floor with a surface board being a jointed board, which is basically the same in the classification standards, high in recognition rate and low in error rate, can realize industrial on-line detection, and can accurately recognize three types of defects of the multilayer solid composite floor: corner defects, surface fractures and splicing open joints. The recognition method comprises the following steps: performing image graying processing, image grey level transformation, image smoothing processing, image segmentation and image segmentation postprocessing on a collected RGB color image on the surface of the solid wood composite floor to extract target defects; adding characteristic values of the target defects, with defect characteristics being extracted, to a support vector machine, so as to be trained; after training, adding the characteristic values of the target defects, with defect characteristics being extracted, to the support vector machine, so as to be recognized.

Owner:NANJING FORESTRY UNIV

Non-formaldehyde solid wood composite floor using low-density cottonwood veneers as base materials and manufacturing method thereof

ActiveCN102423891AHigh densityEfficient value-added utilizationWood working apparatusWood layered productsSolid woodSurface layer

The invention provides a manufacturing method of a non-formaldehyde solid wood composite floor using low-density cottonwood veneers as base materials. The non-formaldehyde solid wood composite floor is at least a cottonwood base plate assembly manufactured by combining following two raw materials: first, cottonwood veneers formed by stewing cottonwood logs at a low temperature of 10 to 50 DEC C, then rotary-cutting or slicing the cottonwood logs and afterwards drying the cottonwood logs, and second, plastic adhesive films manufactured by adopting thermoplastic resin; the treated cottonwood veneers are coated with coupling agents and are then assembled with the plastic adhesive films, and after hot-pressing and setting treatment, a cottonwood base plate is manufactured; afterwards, decorative thin wood is adopted as a surface layer and is combined with the cottonwood base plate assembly, and after cold-pressing, a floor blank is manufactured; and finally, the floor blank is milled, tenoned, slotted, and subjected to paint curing, and then a product is manufactured. Through using high polymer materials, from which no harmful substance escapes, in both the machining process and the use process, the environmentally friendly solid wood composite floor is produced.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Wood multi-layer floor composed of cut-plate and veneer and method for making same

InactiveCN101139864ASave woodImprove product qualityWood working apparatusFlooringSolid woodSurface layer

The invention relates to a real-wood composite floor panel, which adopts a sheet-cut board with a sheet-cutting method as a core layer, a shave-cut single plate with a shave-cutting method as a surface layer, a rotary cut single plate with a rotary cutting method as a base layer, as well as all the other intermediate layers. The invention belongs to a real-wood composite floor panel, which is an artificial board in the industry of wood materials. The invention is characterized in that the core layer of the real-wood composite floor panel is a sheet-cut board that is produced with a sheet-cutting method; the surface layer of the real-wood composite floor panel is a shave-cut single-plate that is processed with a shave-cutting method; the base layer and all the other intermediate layers of the real-wood composite floor panel are rotary-cut single-plates produced with a rotary cutting method. The fabrication method is that the core layer of the real-wood composite floor panel is produced in a one-through mode covering adhesive coating, blank combination and glueing. The invention has advantages of perfect product quality, small deformation, needing no too much investment, saving wood materials, comprehensive utilization of wood materials and low cost. Except for pruducing real-wood composite floor panels, the invention can also be used to make such base material products as fine woodwork boards, real-wood doors and sheet-type furniture.

Owner:吴立忠

Preparation method of environmental protection type solid-wood composite floor

InactiveCN101396839ATake advantage ofReduce pollutionOther plywood/veneer working apparatusWood treatment detailsSolid woodEngineering

The invention relates to a preparation method for an engineered flooring, in particular to a preparation method for an environment-friendly engineered flooring, belonging to the wood manufacturing industry. The invention aims at providing a preparation method for an environment-friendly engineered flooring which has strong non-deformability, high processing efficiency and can fully use resources, thus overcoming the deficiencies of the prior art. Due to the adoption of the technical program, the invention has the advantages of making full use of wood resources, improving labor efficiency and relieving the pollution of formaldehyde to the environment.

Owner:汤可新

Process for printing and doping solid wood and wood composite floor boards

InactiveCN101591969ASatisfy the pursuitSave resourcesPretreated surfacesWood working apparatusSolid woodPulp and paper industry

The invention relates to the field of floor boards, in particular to a process for printing and doping solid wood and wood composite floor boards. The method comprises the following steps: material preparing; the material processing; wood grain preparing; special adhesive agent printing; UV drying; oil sands doping; bouncing putty doping; UV drying; the oil sand doping; printing special adhesive agent for the substrate board surface; printing mask primer; UV drying; printing special ink varnish; wood grain transfer printing; wearable primer printing; UV drying; sanding primer printing; UV drying; roller paint doping; curtain coating of finishing coat; and four lamp drying. The process can print various natural wood grains according to client requirement, and greatly save wood resources which are reduced day by day.

Owner:史海龙

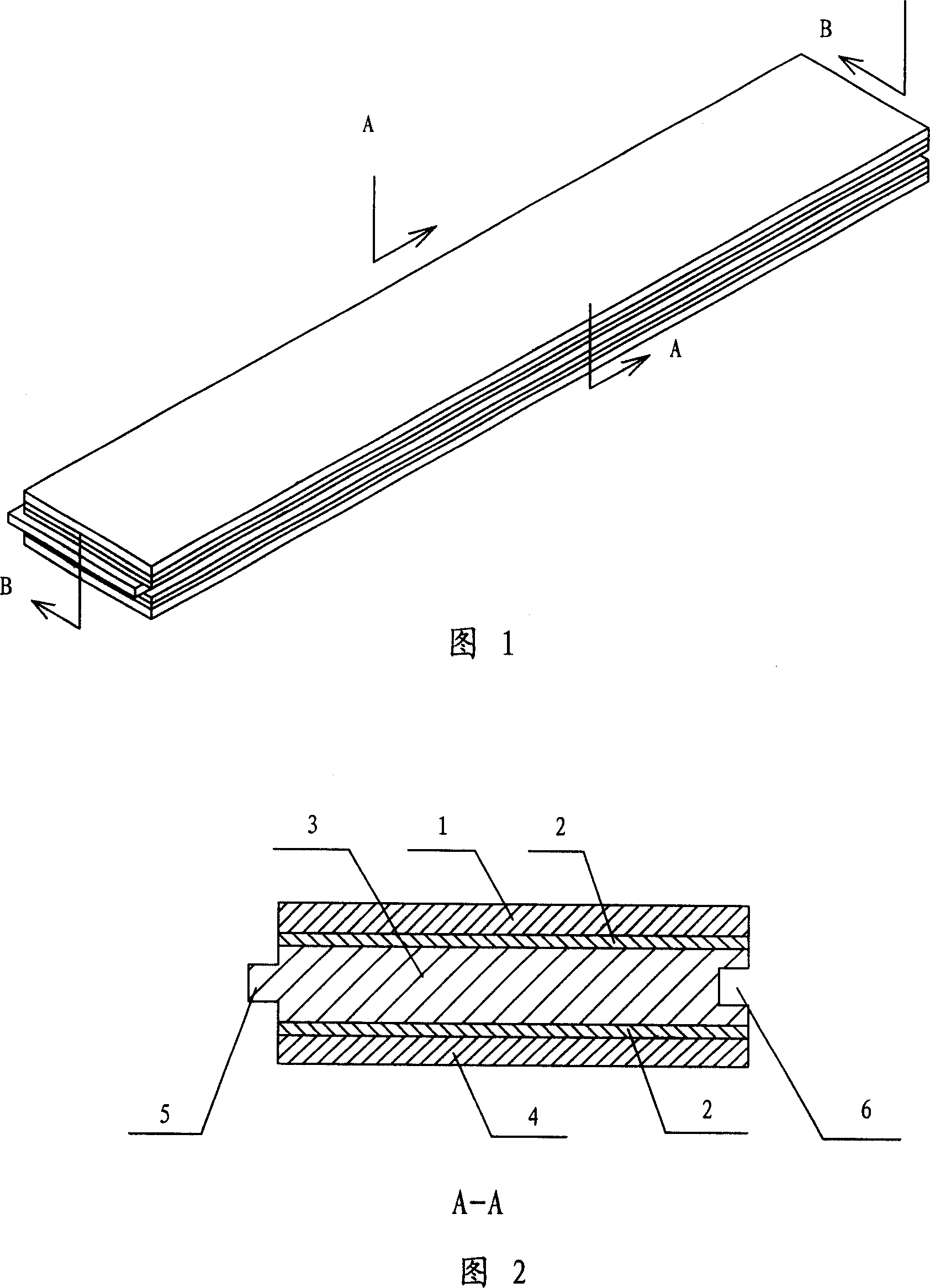

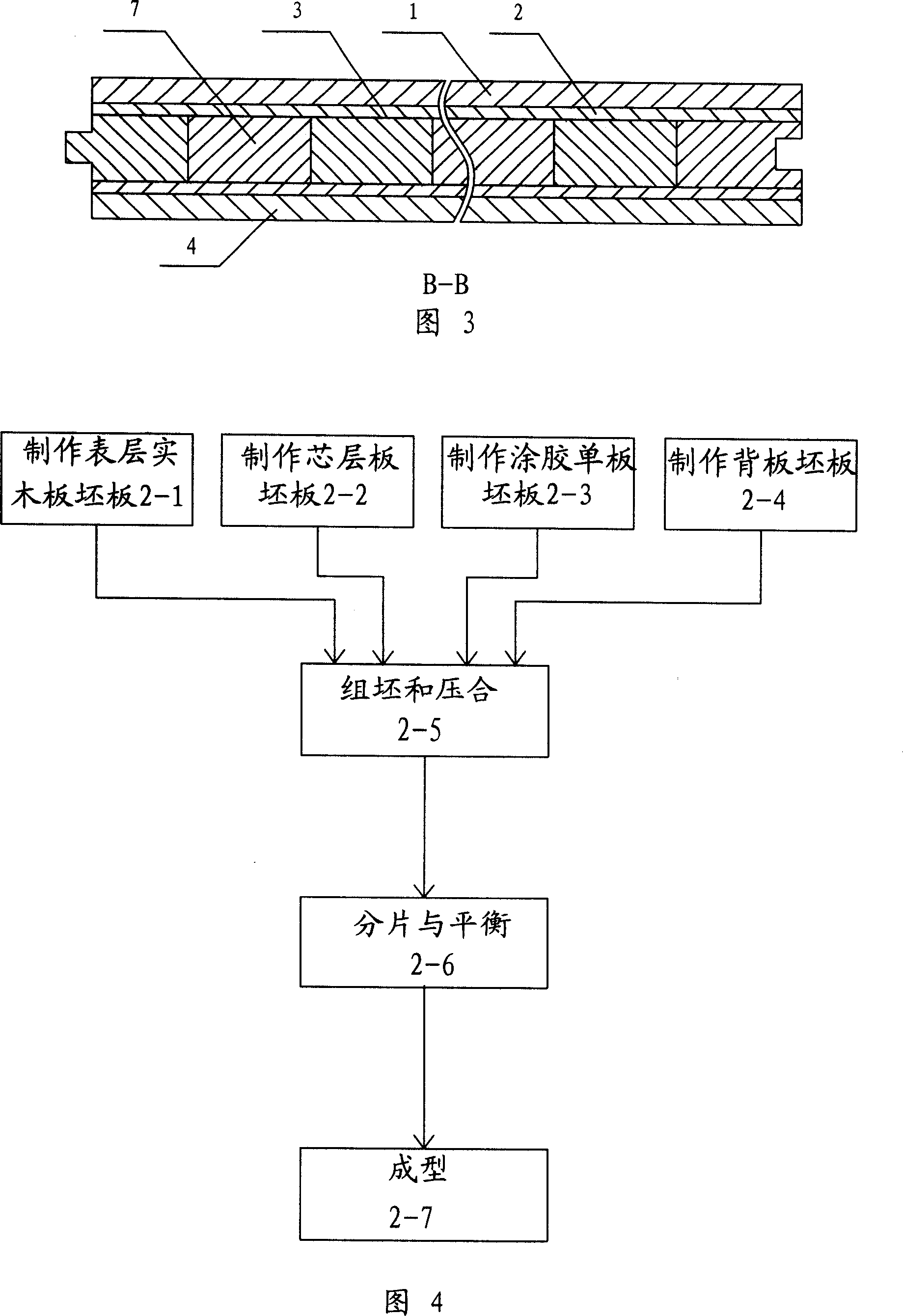

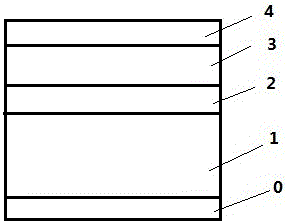

Strengthening type three-layered wood compound floor board and mfg. method thereof

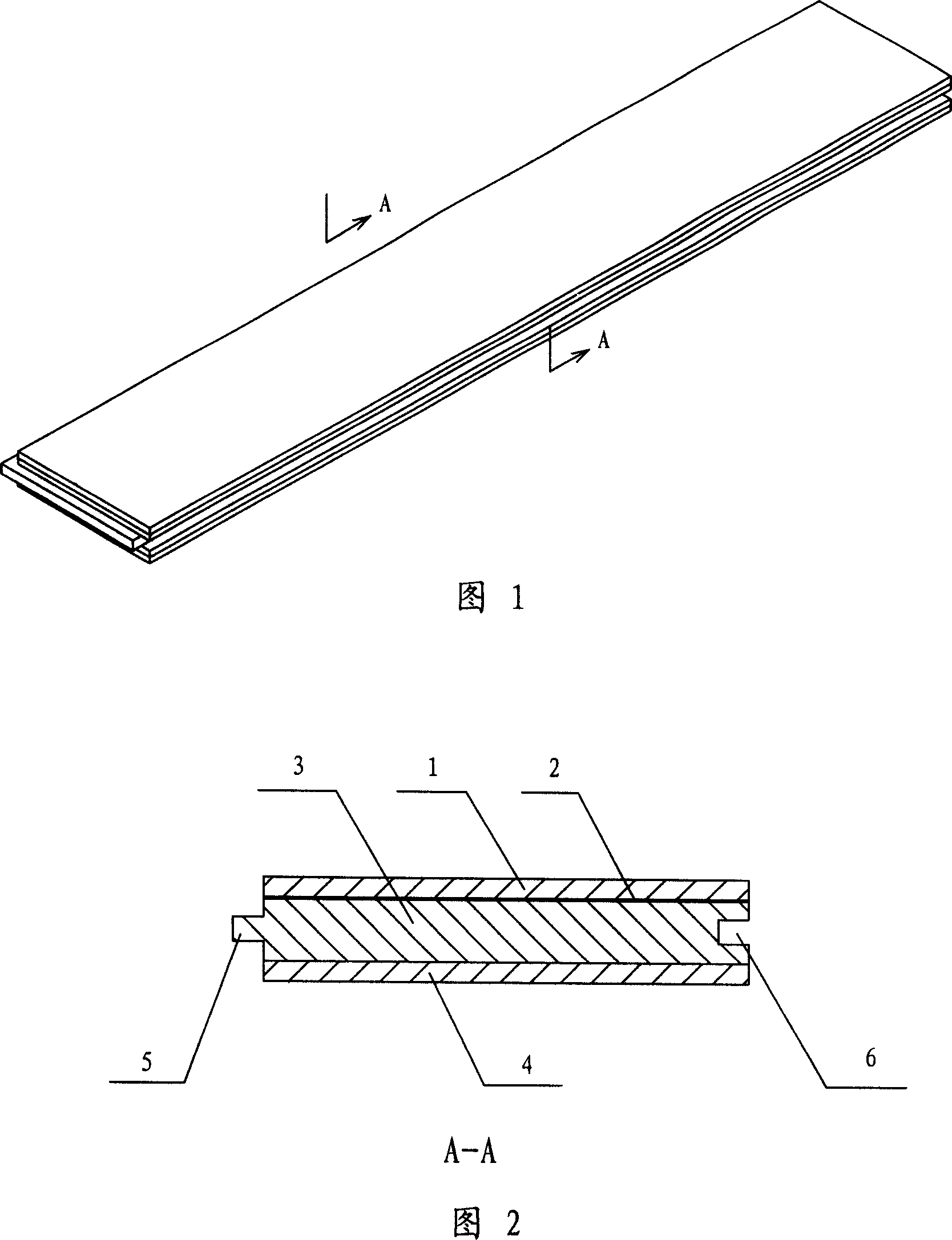

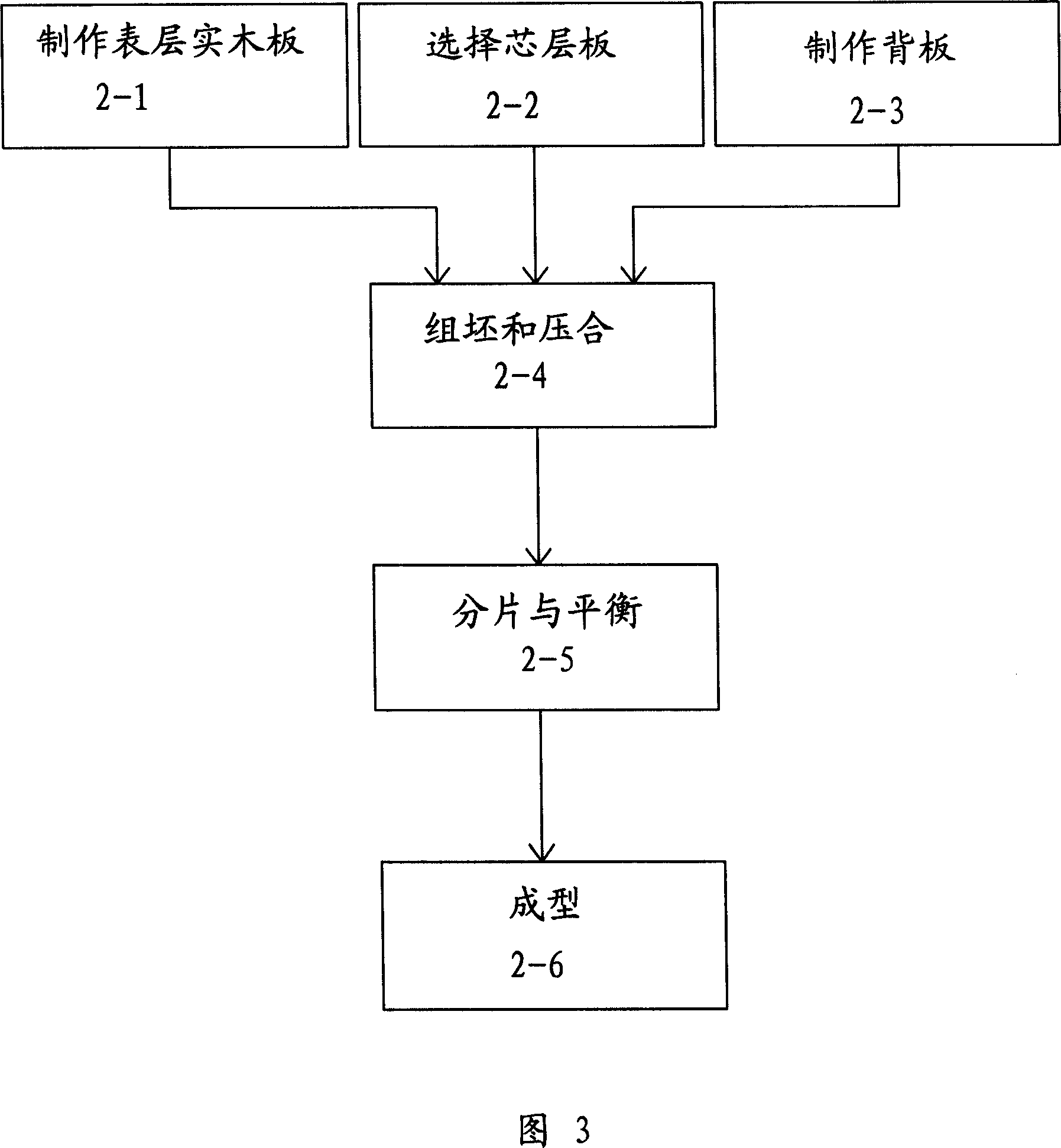

InactiveCN100999951AHigh bonding strengthReduce the chance of crackingWood working apparatusFlooringNonwoven fabricAdhesion strength

The present invention relates to one kind of three-layer reinforced laminated wooden floor board and its making process. The three-layer reinforced laminated wooden floor board includes one surface wood layer, one core layer and one back layer adhered to the core layer, and has one chemical fiber non-woven fabric layer adhered between the core layer and the surface wood layer. The making process of the three-layer reinforced composite wooden floor board includes the following steps: making surface wood board, selecting core layer board, making back board, combination and pressing, splitting and balancing, and forming. Compared with available technology, the present invention has the advantages of raised adhesion strength, less cracking and high stability.

Owner:上海新四合木业有限公司

Manufacturing method of flame retardant solid composite floor

InactiveCN102114656AImprove flame retardant performanceSimple production processLiquid surface applicatorsPressure impregnationEnvironmental resistanceSander

The invention discloses a manufacturing method of flame retardant solid composite floors. The method comprises steps of: performing flame retardant treatment on a natural rare tree veneer with the thickness of 0.5mm to 5mm by a vacuum pressure impregnation method, adhering the dried veneer to a glued floor substrate, and performing the processes of assembling, cold pressing, thermal pressing, health preserving, edge cutting, sanding, mortising and the like to obtain the solid composite floor blank; and then performing painting treatment on the surface of the solid composite plate blank, wherein the painting treatment adopts a process of twelve bottoms and two surfaces and the painting is performed according to the order: water primer, putty, elastic primer, wear resistant primer, transparent primer, sander, wear resistant primer, hardening primer, transparent primer, wear resistant primer, hardening primer, transparent primer, sander, finishing paint and finishing paint, and the wear resistant primer, the hardening primer and the sander are added with flame retardant agent. The flame retardant solid composite floor manufactured by the method has excellent flame retardant and fireproof performance and eco-friendly performance, and has excellent physics mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

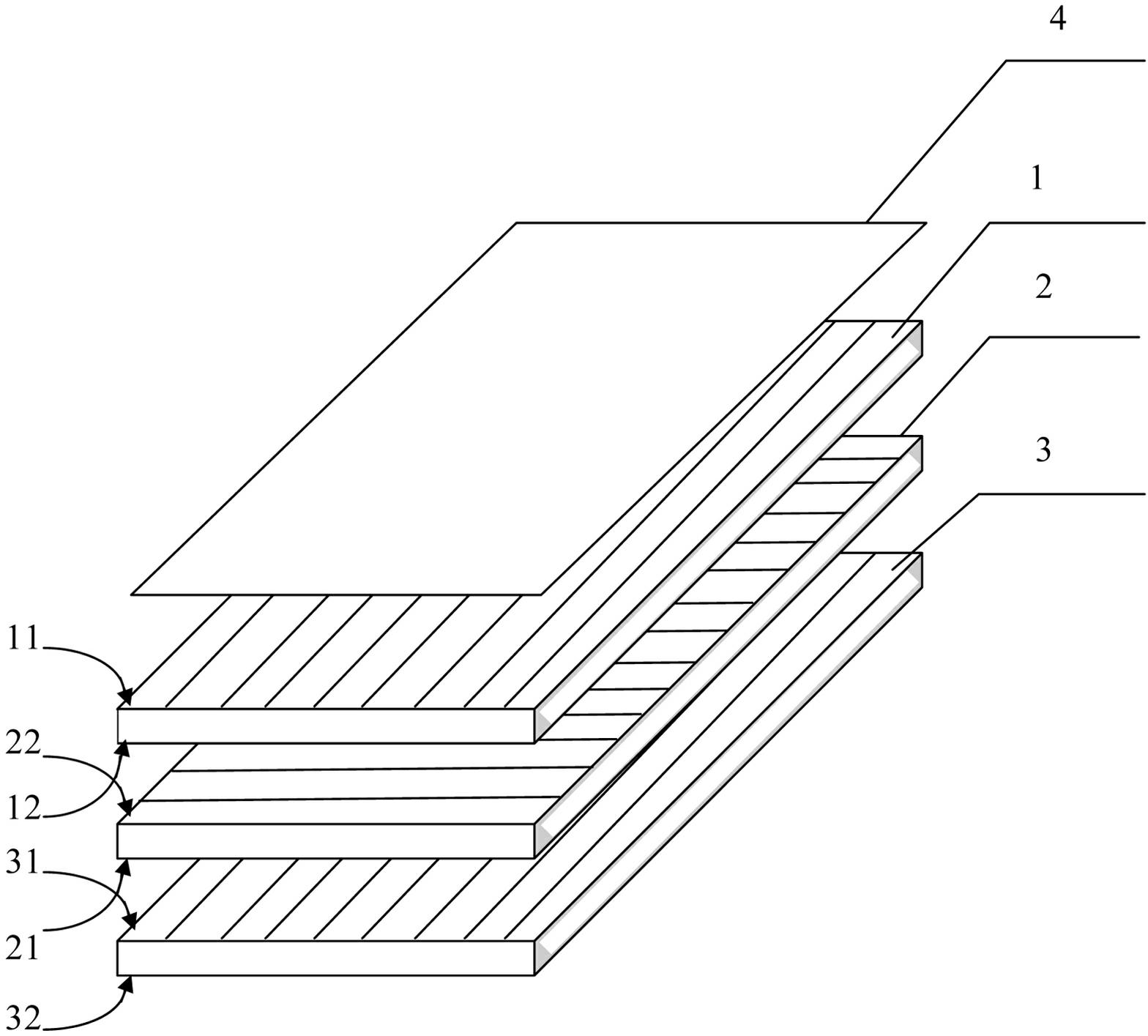

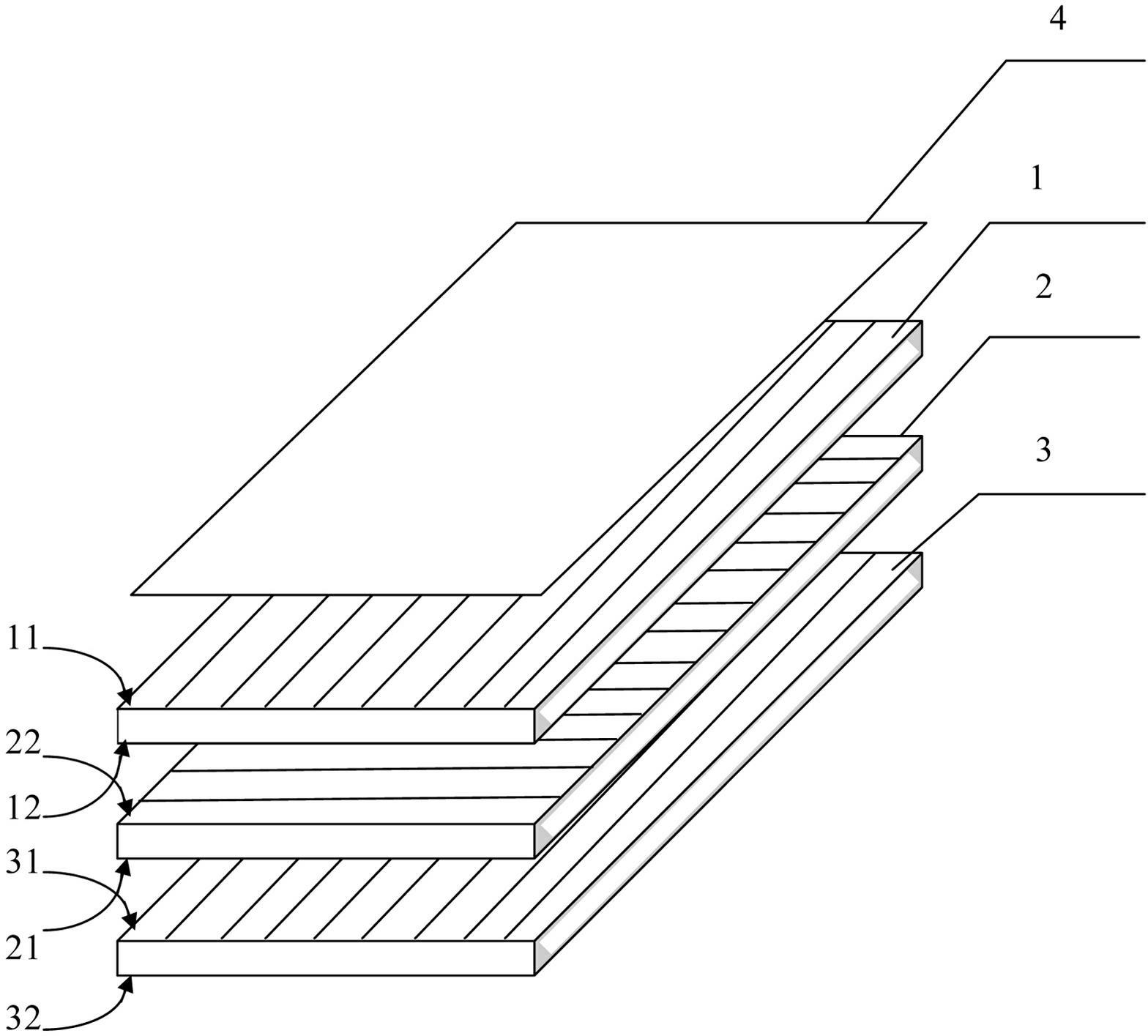

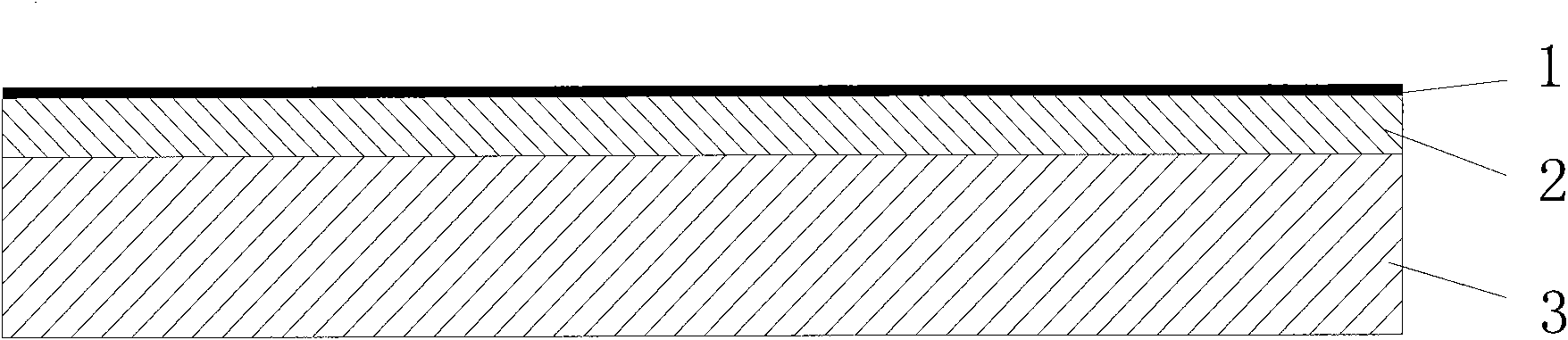

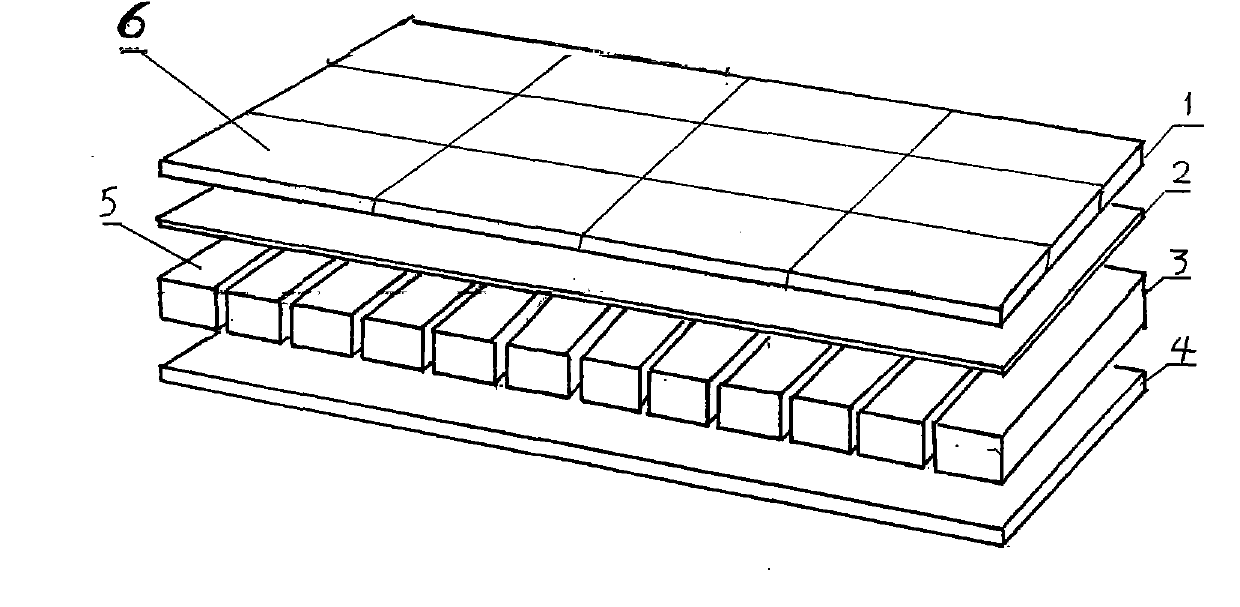

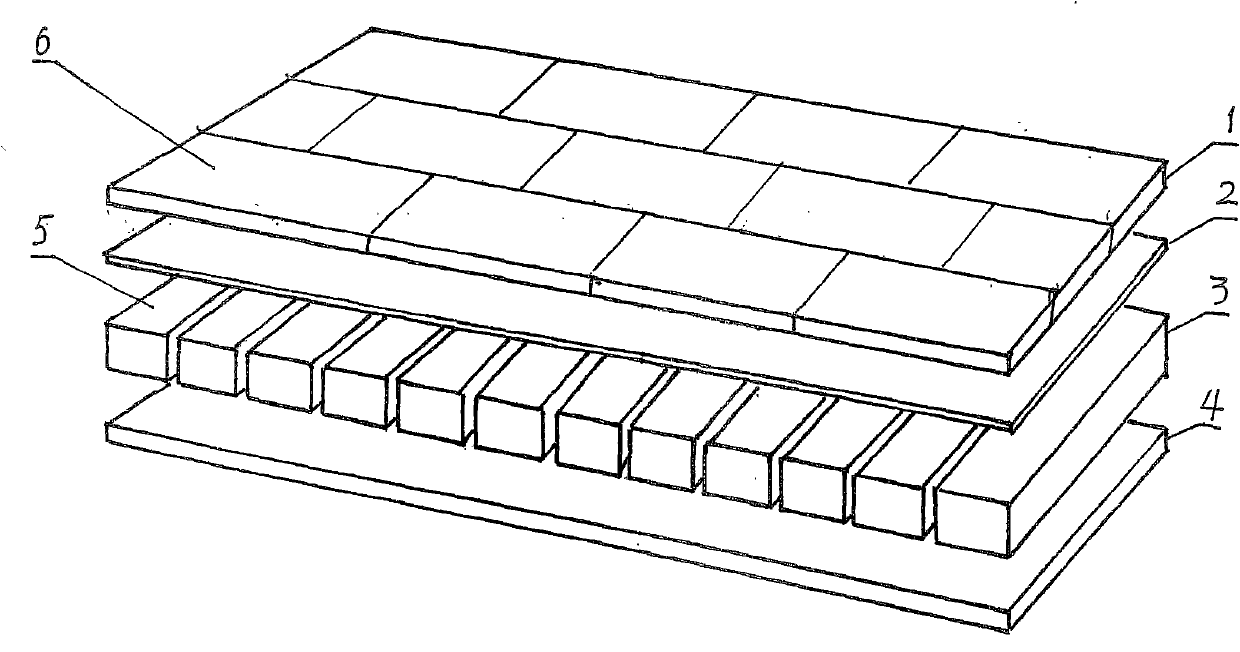

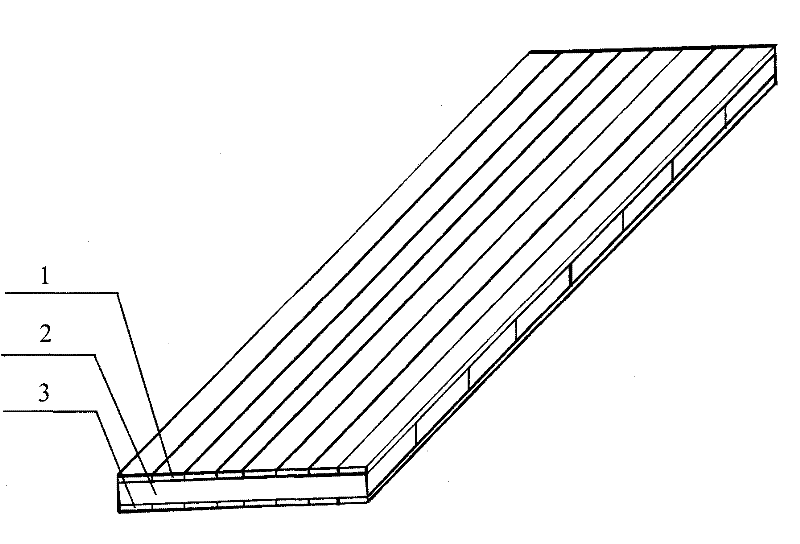

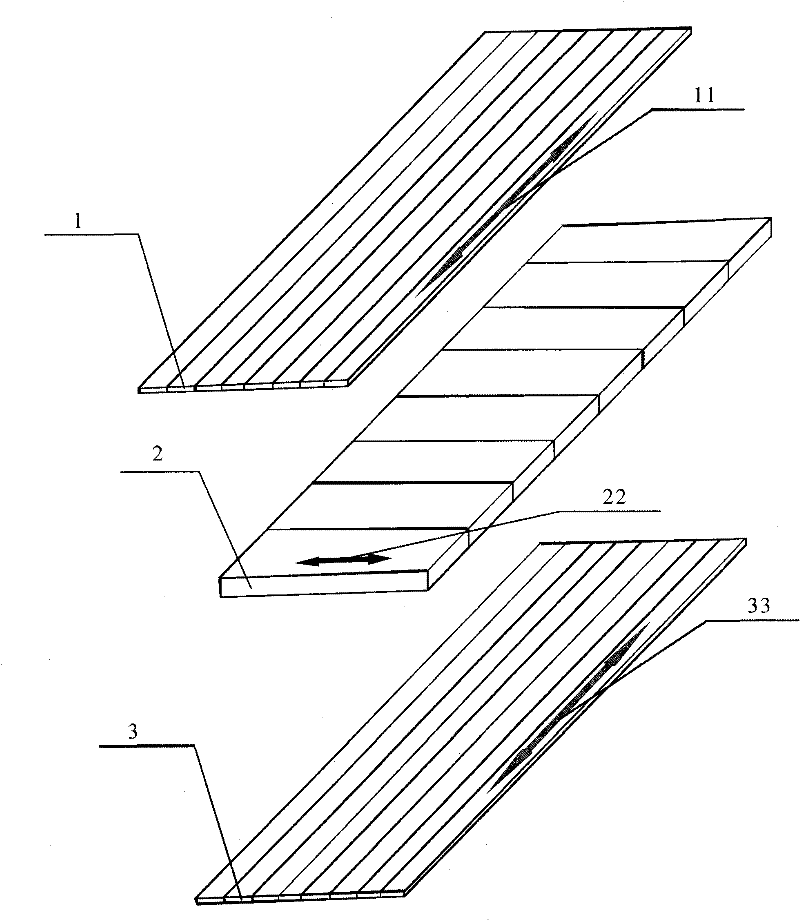

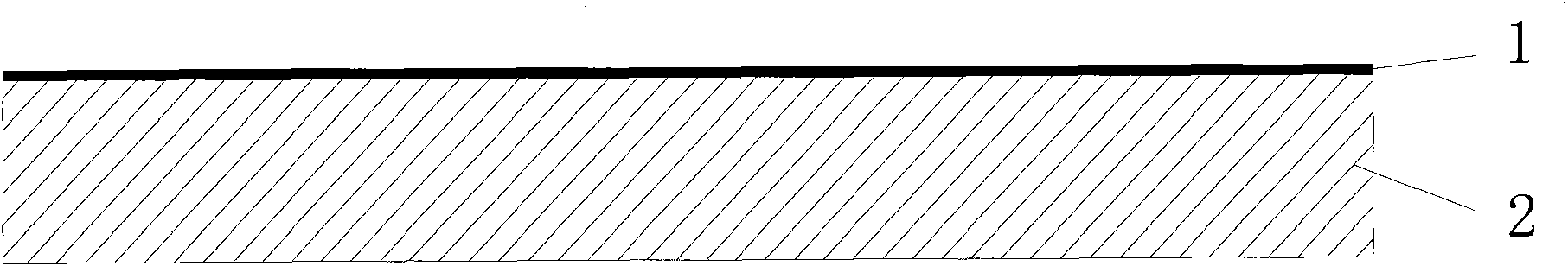

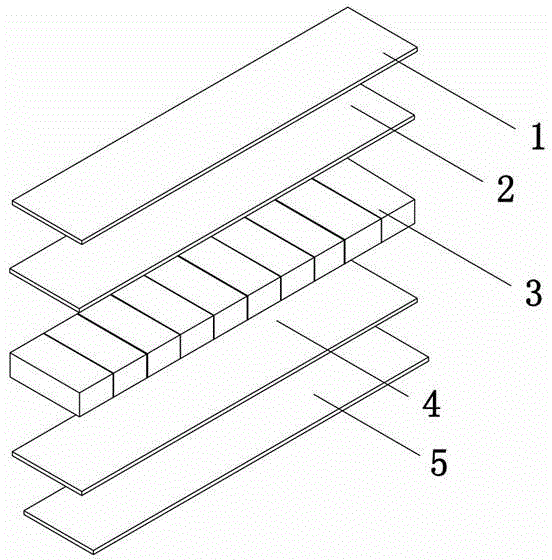

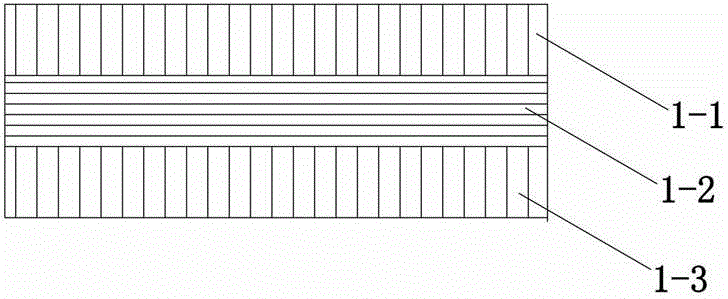

Production method of stabilized solid wood composite floor with buffer layer

InactiveCN102166775AImprove stabilityEasy to crackPlywood pressesVeneer pressesSolid woodSurface layer

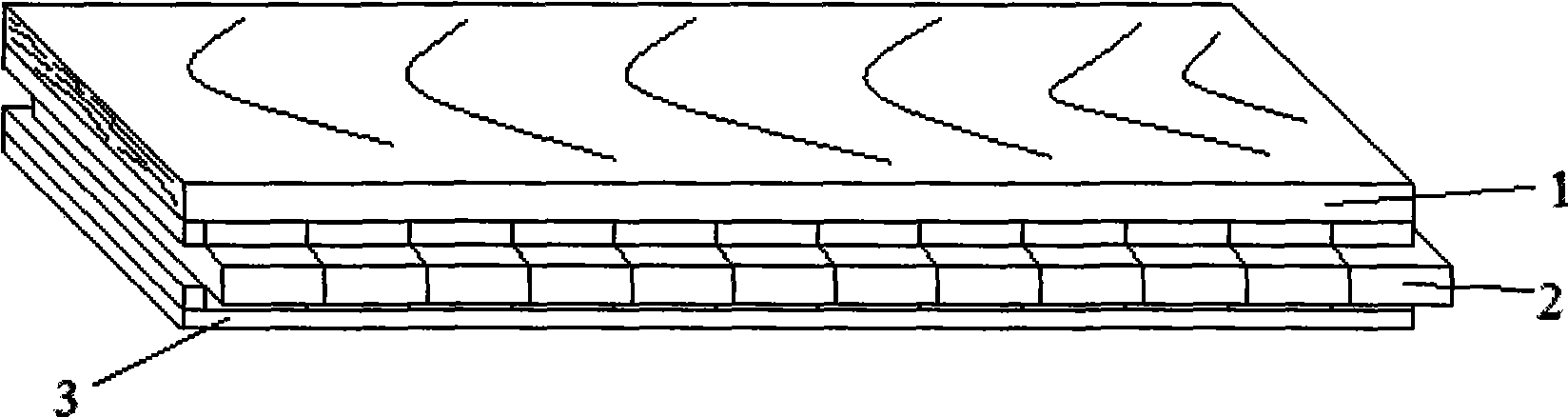

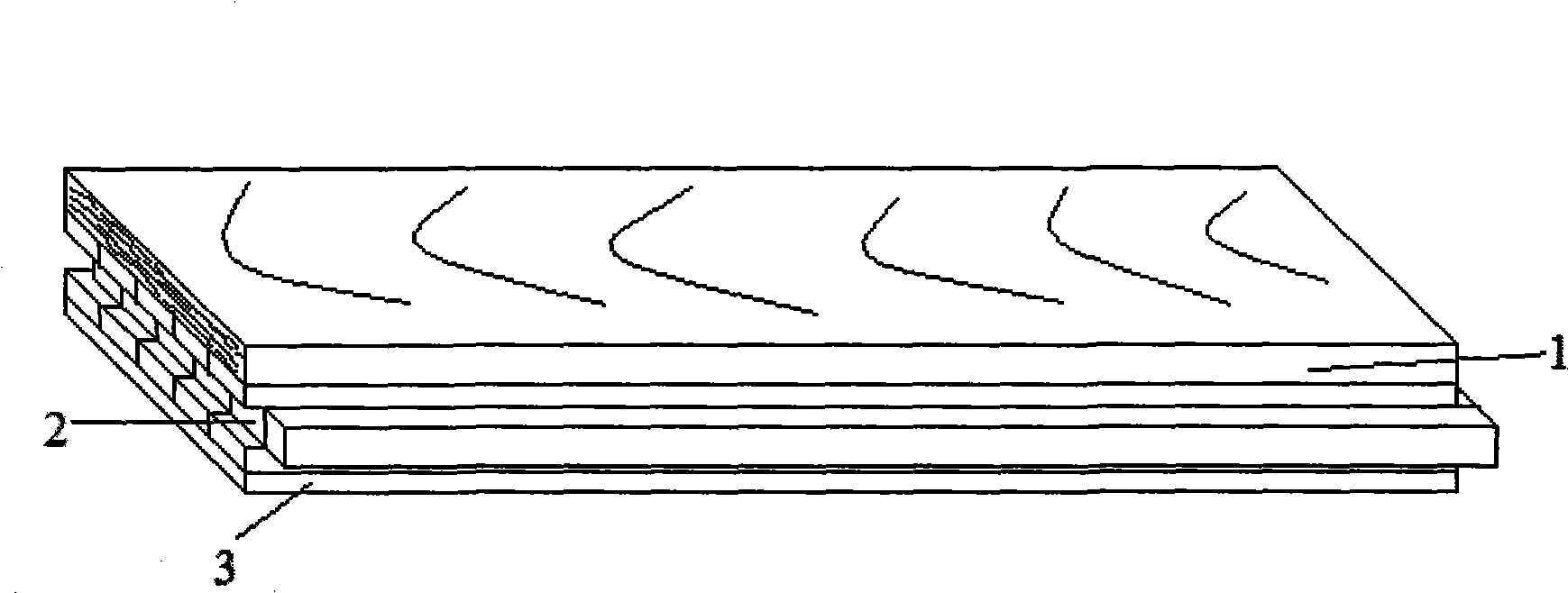

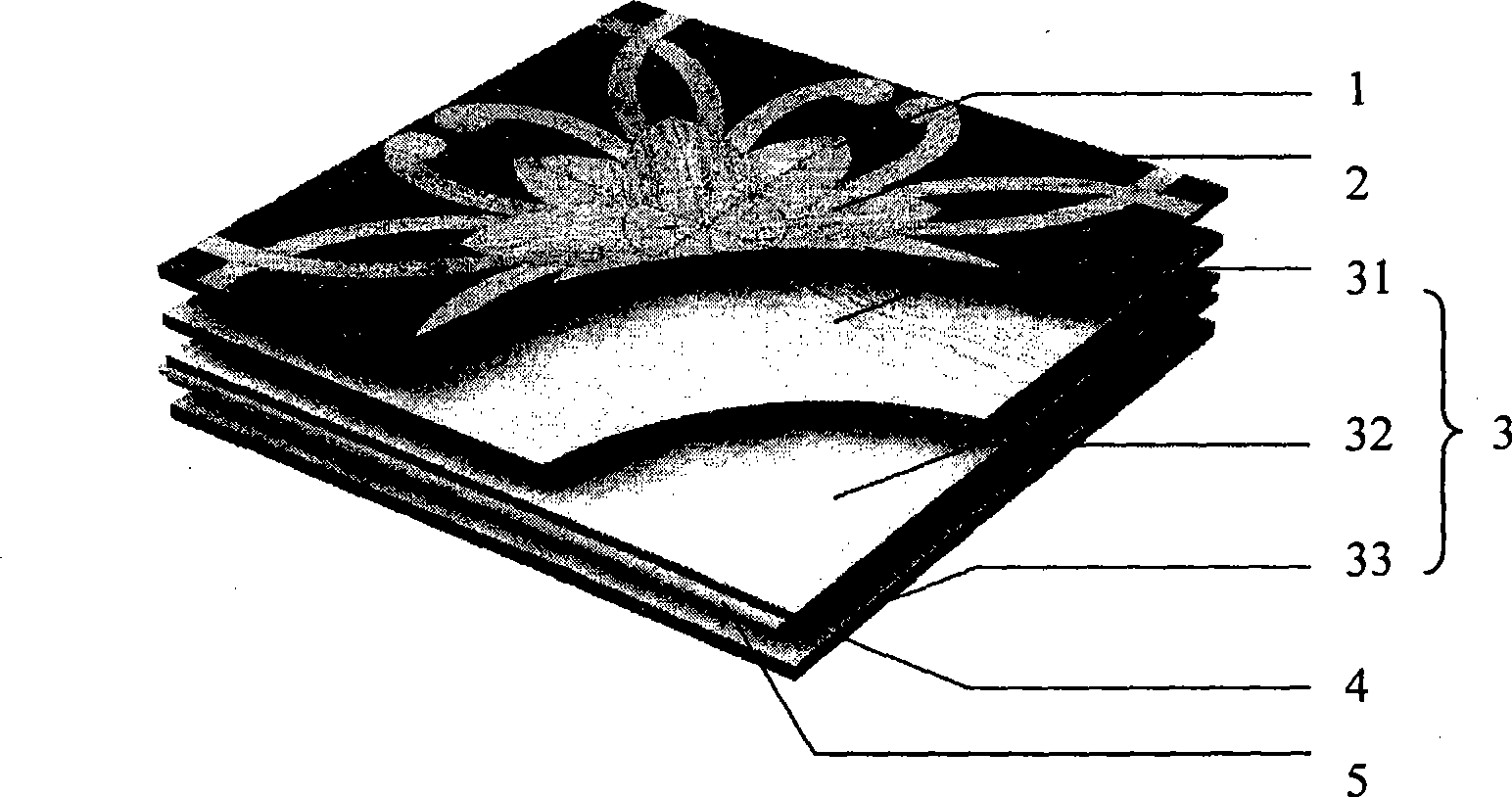

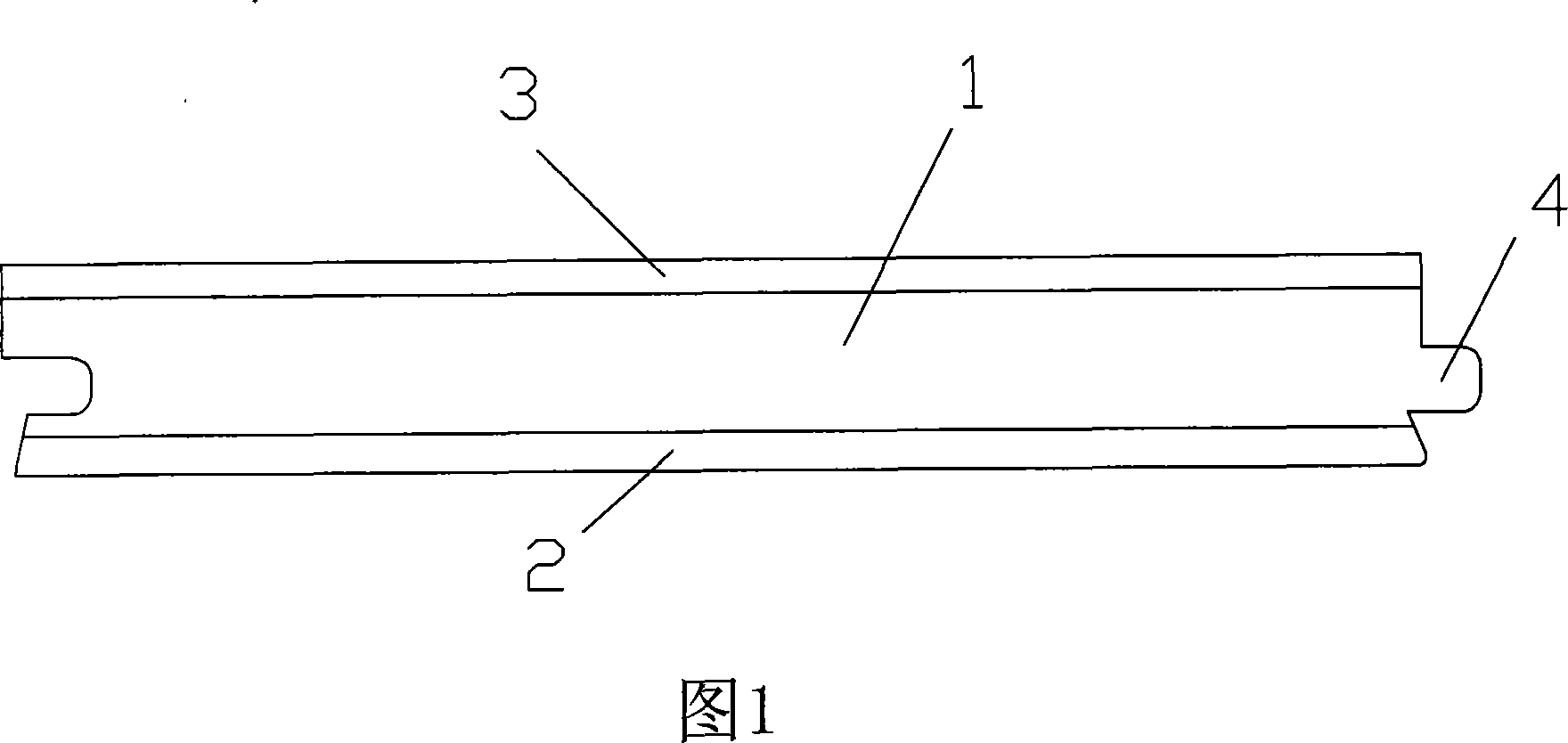

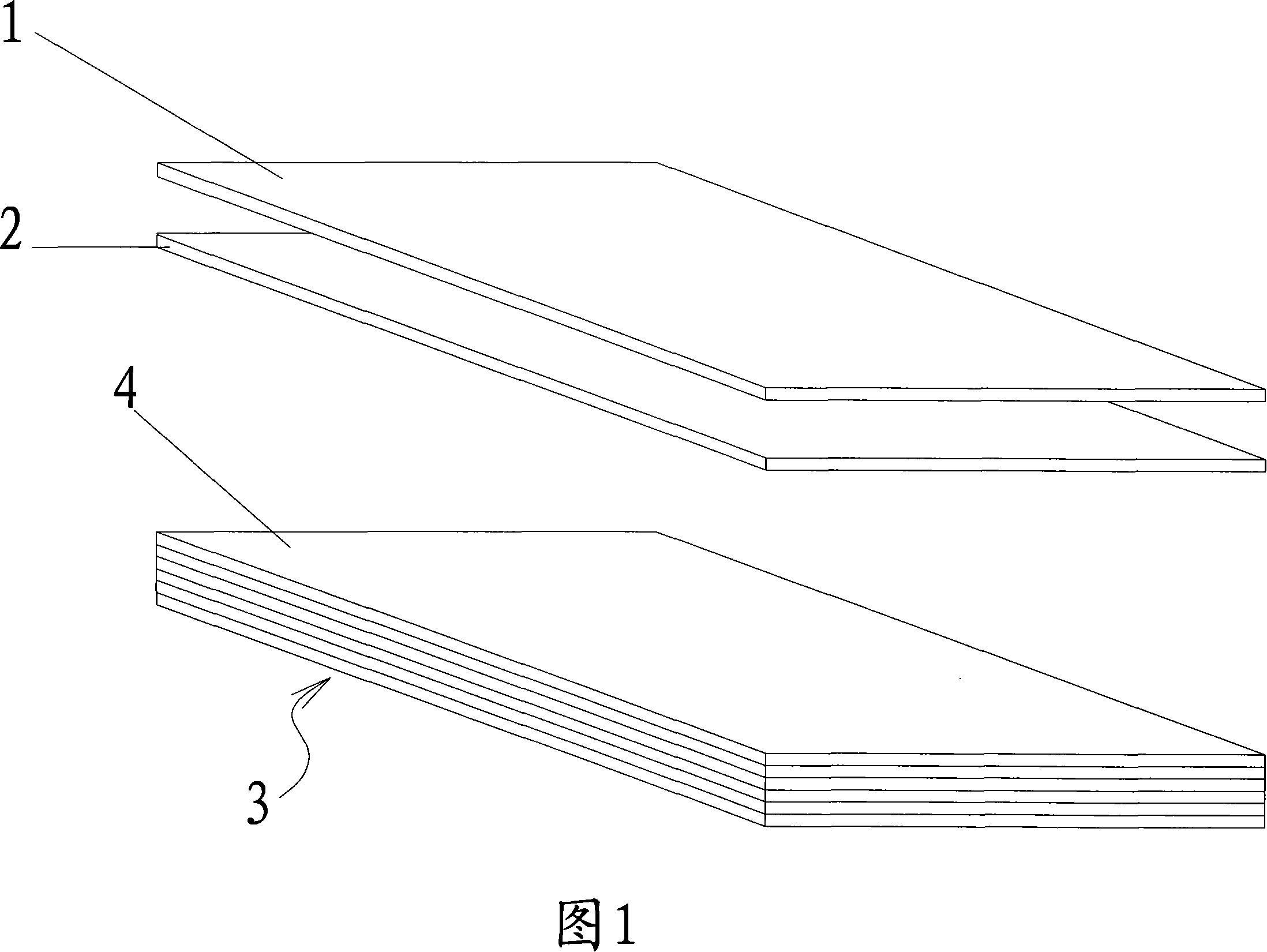

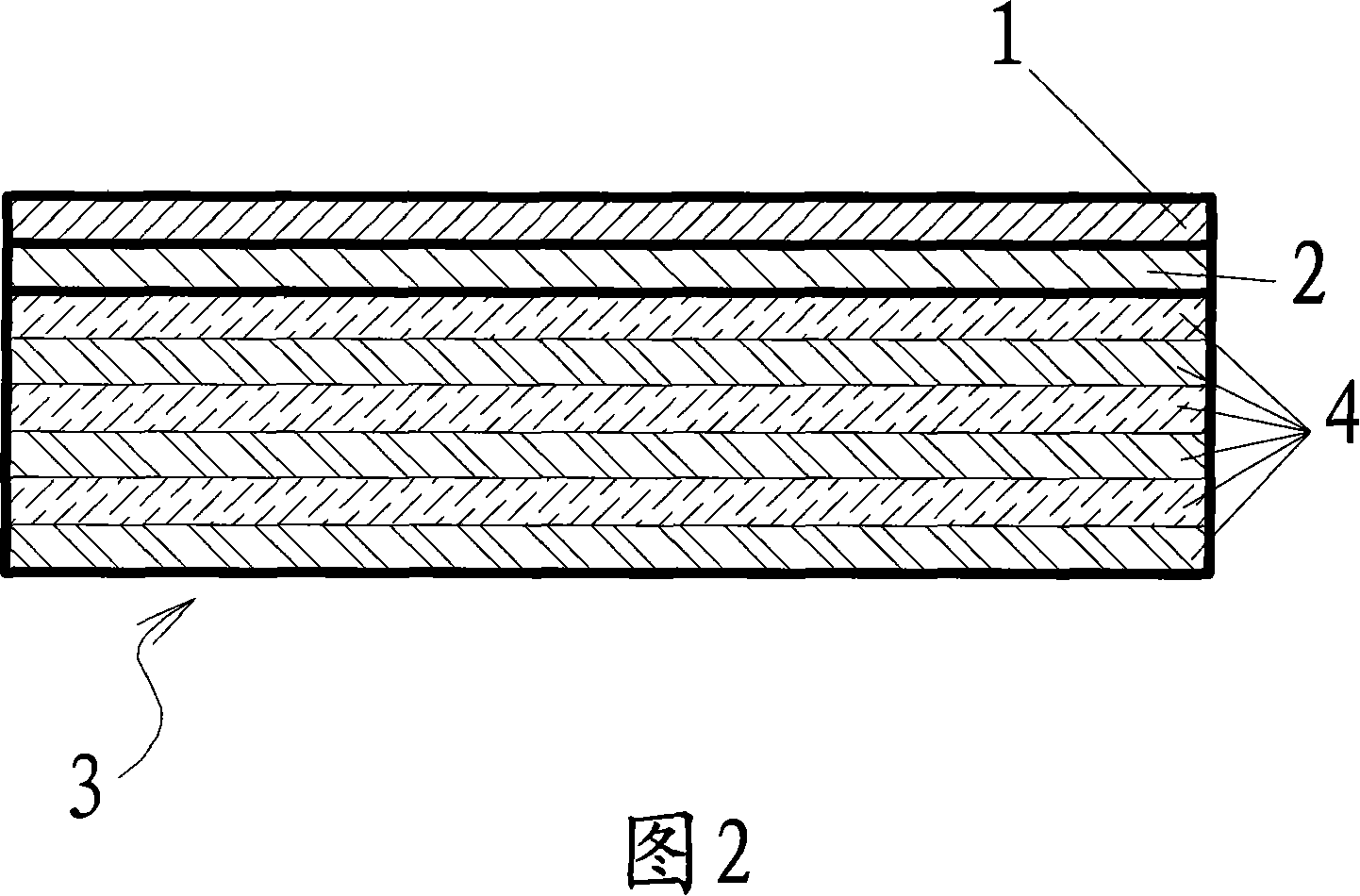

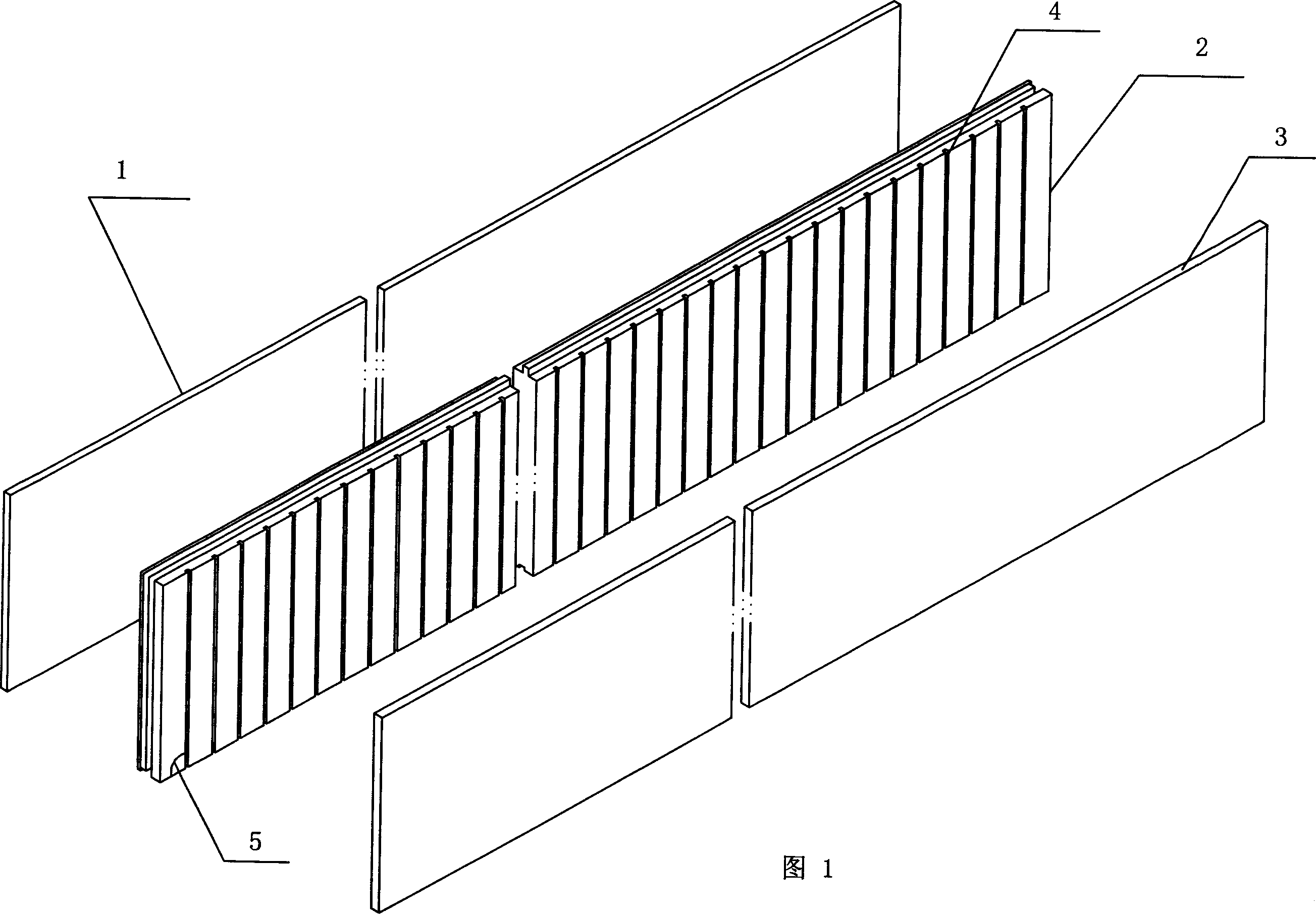

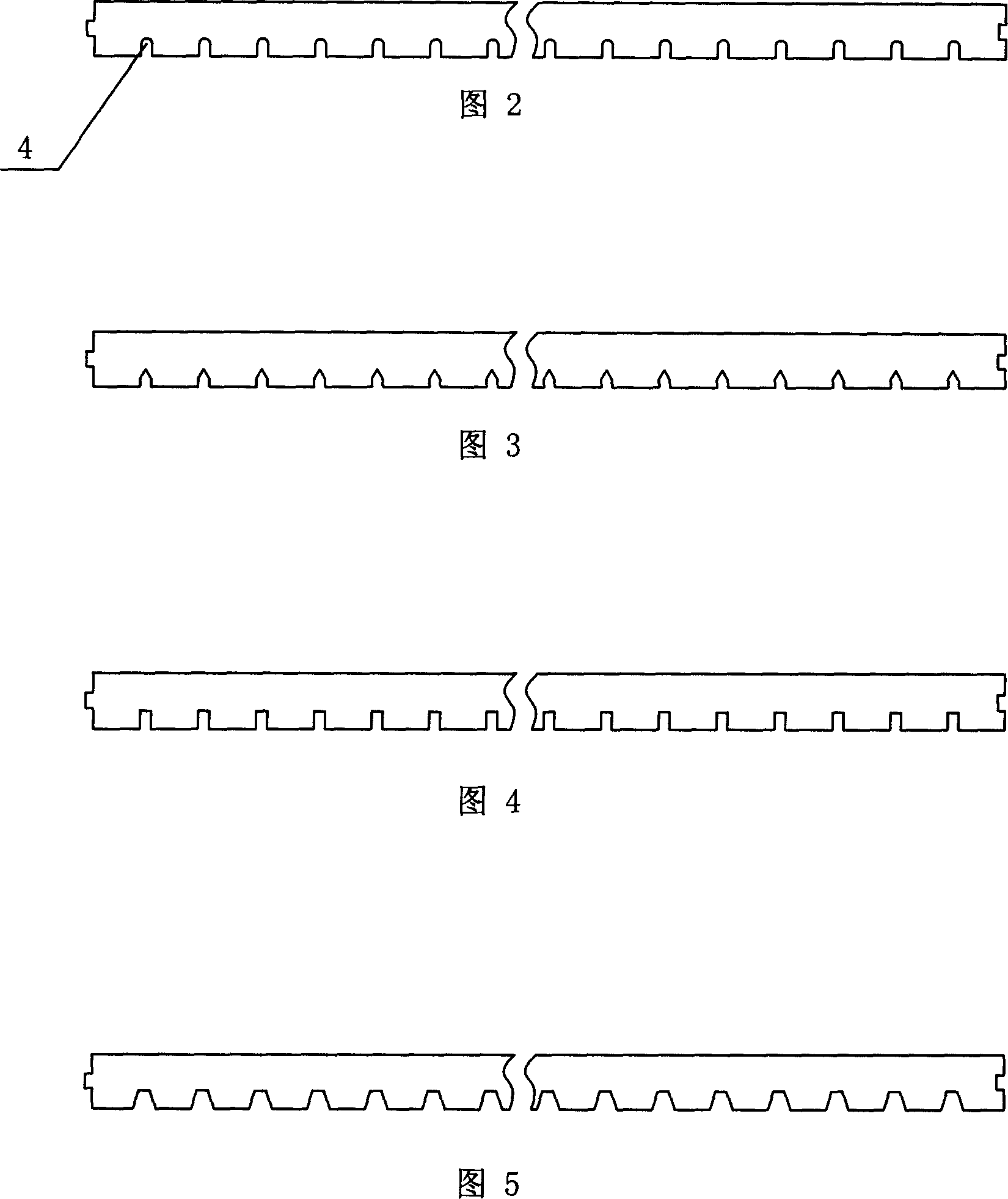

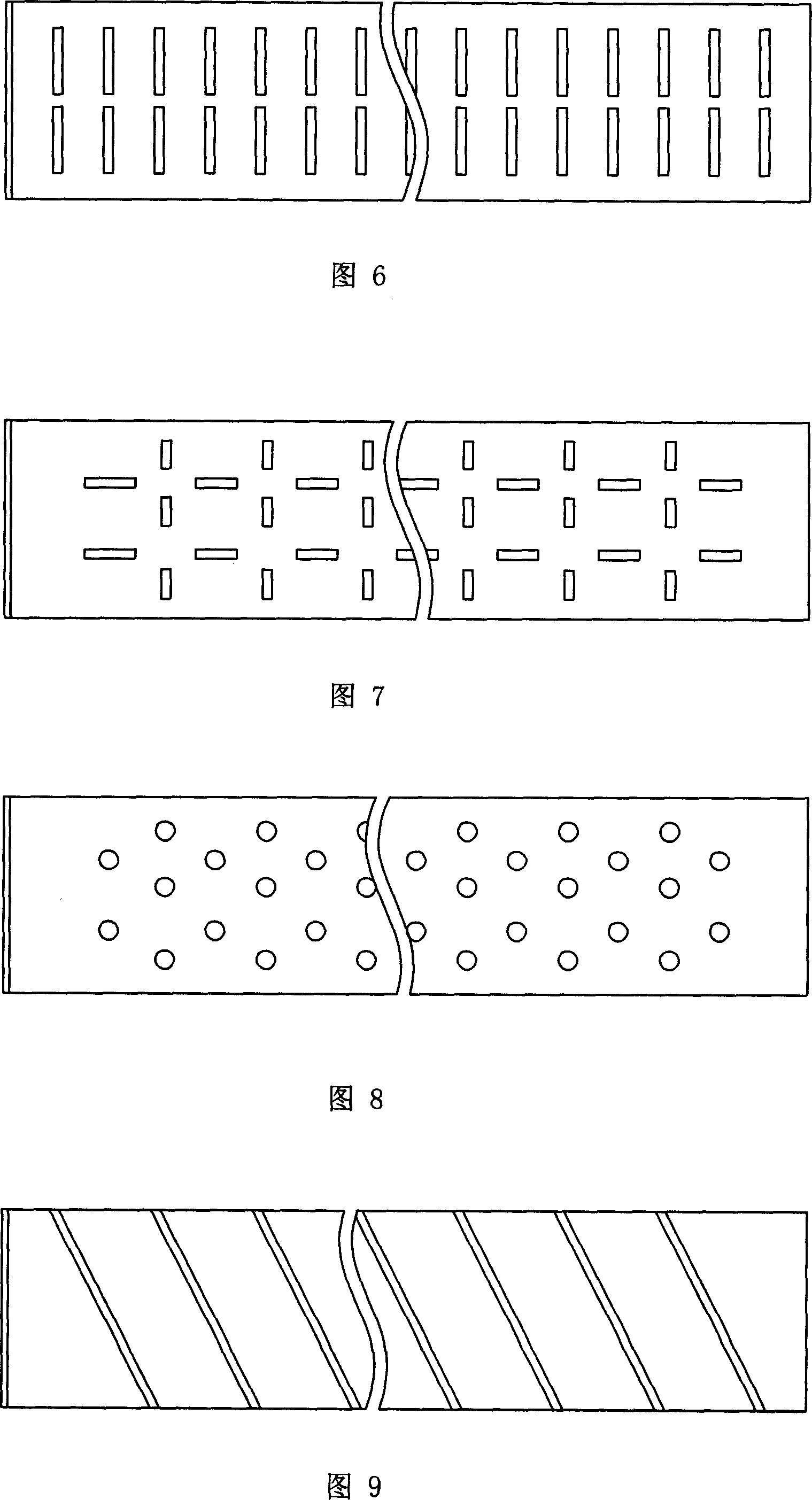

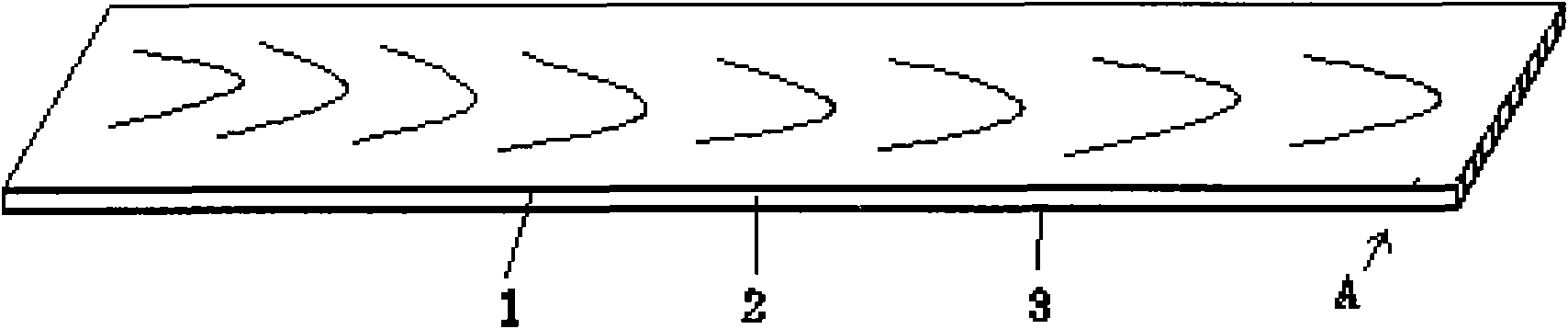

The invention discloses a production method of a stabilized solid wood composite floor with a buffer layer, comprising four steps of preparing materials, gluing, preparing blanks and hot pressing. The composite floor comprises a surface layer (1), a core layer (3) and a base layer (4); the buffer layer (2) is arranged between the surface layer (1) and the core layer (3); the wood grains of three layers of the surface layer (1), the buffer layer (2) and the base layer (4) are all arranged longitudinally consistently; and only the wood grains of the core layer (3) which is formed by parallelly arranged rectangular battens (5) at intervals are laterally distributed. The composite floor produced by the method is specially used for the floor or the wall plate to decorate the house, compared with the general three-layer solid composite floor, because of adding the buffer layer, the cracking phenomena that wavy stripes and the surface-layer wood appear in the original three-layer solid composite plate are improved; a continuous binding interface is formed on the surface of the core layer; the surface-layer binding area is increased; the bonding strength is improved; and the deformation of the surface-layer wood is impeded, thus the stability of the floor is improved.

Owner:ZHEJIANG FUDELI WOOD IND +1

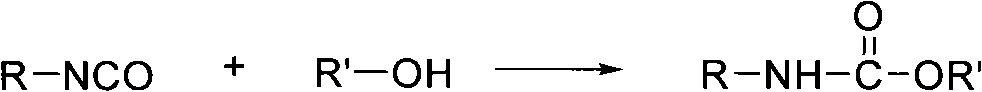

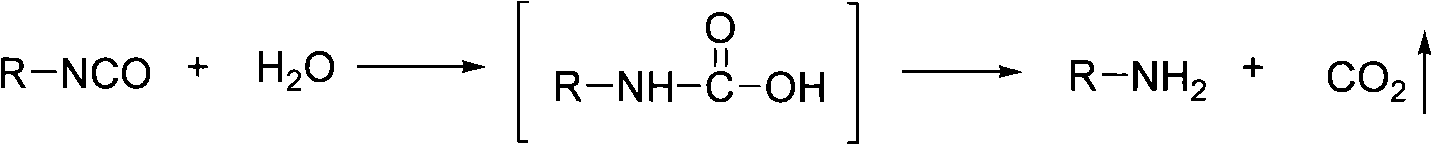

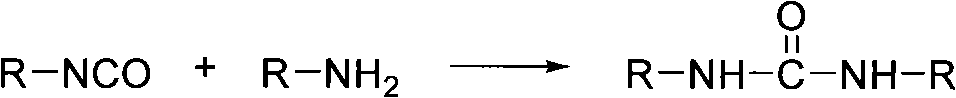

Plate alignment adhesive for surface plate lamination of engineered wood flooring and preparation method thereof

ActiveCN102086367AHigh strengthImprove water resistancePolyureas/polyurethane adhesivesFlooringAdhesivePolyvinyl alcohol

The invention relates to plate alignment adhesive for the surface plate lamination of the engineered wood flooring. The plate alignment adhesive contains main agent and curing agent, wherein the main agent consists of the following raw materials: polyvinyl alcohol, acrylic acid, butyl acrylate, hydroxyethyl acrylate, vinyl acetate, silane coupling agent, emulsifier, ammonium persulfate, deionizedwater and inorganic filler. The plate alignment adhesive of the invention has the advantages of high bonding strength, good water resistence, environmental friend, no solvent and no formaldehyde.

Owner:SHANGHAI JINQIANG ADHESIVE

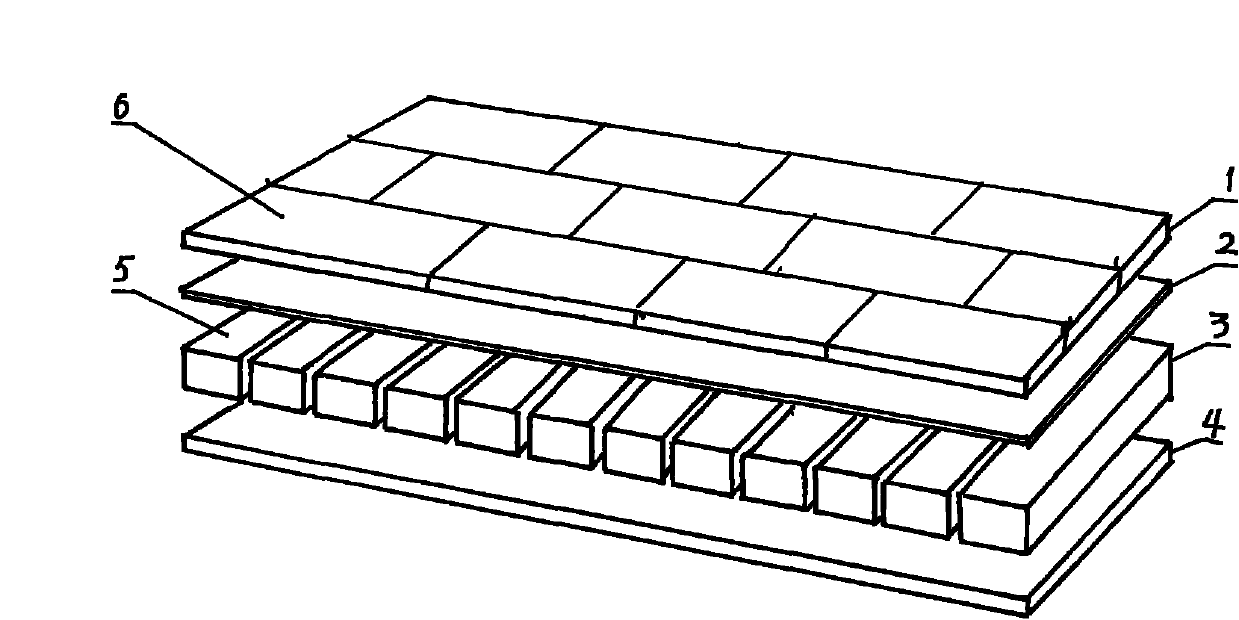

Five-layered thick core wood compound floor board and mfg. method thereof

InactiveCN100999952AStress constraintsAvoid deformationLaminationWood working apparatusSolid woodWood fibre

The present invention relates to one kind of five-layer thick-core wooden floor board and its making process. The five-layer thick-core wooden floor board includes one surface wood layer, one gummed sheet layer, one core layer, one other gummed sheet layer and one back layer adhered together successively. The making process of the five-layer thick-core wooden floor board includes the following steps: making surface wood board, making core layer board, making gummed sheet, making back board, combination and pressing, splitting and balancing, and forming. The five-layer thick-core wooden floor board of the present invention has the advantages of less deformation caused by environment temperature and humidity, reduced surface wood layer thickness resulting in saving in high quality wood, and raised adhesion strength and high stability.

Owner:上海新四合木业有限公司

Method for producing wood composite floor heating floorboard

InactiveCN101323128AGrowth inhibitionImprove corrosion resistanceWood treatment detailsWood veneer joiningWood veneerWeather resistance

The invention discloses a method for manufacturing engineered geothermic floors. The invention comprises the following procedures that: a cotton wood veneer or an imported miscellaneous tree veneer undergoes the process of deep steaming charring treatment under the pressure of 0.3 to 0.5MPa within 3 hours to obtain floor base materials; a hardwood plate with a thickness of 2 to 4mm is used as a surface course and the hardwood plate also undergoes the process of deep steaming charring treatment; the hardwood plate and the floor base material are made into a blank; after being glued, the obtained blank is made into the engineered floor suitable for geothermy after being notched and lacquered. The engineered floor suitable for geothermy has good corrosion resistance, weather resistance, stability and wearing resistance. In addition, the engineered geothermic floor accords with the modern idea of environmental protection and is easy to be maintained.

Owner:NANJING FORESTRY UNIV

Process for manufacturing multi-layer solid wood composite floor

InactiveCN101704263AQuality improvementRigorous workmanshipDomestic articlesFlooringSolid woodLacquer

The invention relates to a process for manufacturing a composite floor, in particular to a process for manufacturing a multi-layer solid wood composite floor. The process comprises twelve procedures of selecting a log, rotatably cutting and drying the log, sorting a solid wood core board, hot pressing and gluing the core board, fixing thickness and polishing a base material, sorting and preserving the base material, selecting solid wood skin, molding a floor blank, preserving the floor blank, cutting and slotting the floor, painting and drying for molding. The invention has strict process, good quality of the produced floor, smooth and flexible paint surface, no cracking, long service life and easy processing.

Owner:周广龙

Process for producing multifunctional solid wood composite floor

ActiveCN101927517AWith protectionFlame retardantBelt grinding machinesWood veneer joiningSolid woodSurface layer

The invention discloses a process for producing a multifunctional solid wood composite floor. The production process is mainly characterized in that: a PVC rubber layer is adhered between two layers of veneers, the veneer for the surface of the composite floor is soaked into aqueous solution compounded by phosphorus flame retardant and boron flame retardant and dried, and a nano-scale titanium dioxide photocatalyst is added into the paint brushed on the surface layer of the veer. Therefore, the floor processed by the process has good quake-proof and mute functions, the floor is effectively protected, and the noise is greatly reduced; and the floor also has flame-retardant and antibacterial functions, greatly improves the fireproof performance, and can be used for sterilization and deodorization and protect the human body from being invaded by bacteria.

Owner:浙江云峰莫干山地板有限公司

Photocatalyst antibacterial solid wood composite floor board and production process of photocatalyst antibacterial solid wood composite floor board

InactiveCN104989070APromote environmental protectionImprove performanceAntifouling/underwater paintsProtein adhesivesSolid woodLacquer

The invention relates to a photocatalyst antibacterial solid wood composite floor board, and belongs to the field of a functional environment-friendly healthy floor board. The formaldehyde release limited quantity of the solid wood composite floor board is smaller than 0.3mg / L; the antibacterial rate of the solid wood composite floor board is greater than or equal to 90 percent; the surface wear-resistant index of the solid wood composite floor board is smaller than or equal to 0.08g / 100r; a decoration layer, a wear-resistant primer layer and a photocatalyst antibacterial oil decoration layer are sequentially arranged on a substrate layer; the photocatalyst antibacterial oil decoration layer is a mixture layer consisting of nanoscale TiO2 photocatalyst materials, nanometer silver and UV (Ultraviolet) scratch-resistant finish paint according to a mass ratio being (1-2):(0.2-0.4):(15-20); and a balance layer is arranged under the substrate layer. A production process of the photocatalyst antibacterial solid wood composite floor board comprises the steps of: middle plate tidying, glue mixing, glue application and blank assembling for the first time, cold pressing for the first time, core trimming, glue application and blank assembling for the second time, hot pressing for the first time, fixed thickness sanding, edge cutting, puttying, polishing, sorting, maintenance, glue application and veneering, cold pressing for the third time, hot pressing for the second time, multi-blade sawing, sanding, two-end milling, primer application, finish paint mixing and finish paint application. The photocatalyst antibacterial solid wood composite floor board has the advantages of good antibacterial function, high strength, good wear-resistant performance and foot feeling comfort.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Solid wood composite floor fit for geothermal heat and manufacturing method thereof

InactiveCN1908345AGood biological durabilityGood weather resistanceWood working apparatusFlooringFiberSolid wood

The invention relates to a solid composite floor and relative production, wherein the surface plate is above the carbonized bottom plate that adhered by adhesive; the bottom plate has vertical ventilate holes; the bottom plate is sliced by carbonized blank, then adhered by adhesive into single-layer plate; then assembling the single-layer plate with grooved single-layer plate alternatively into blank, with odd layers; and the non-groove single-layer plates are two outer surfaces of bottom plate; the grooved single-layer plate is grooved along the fiber direction, and formed by several sheets; the lower layer of bottom plate is adhered with one layer of shear single plate. The invention has better size stability, with local diversion heat exchange between the ground and the surface plate.

Owner:ZHEJIANG FORESTRY UNIVERSITY +1

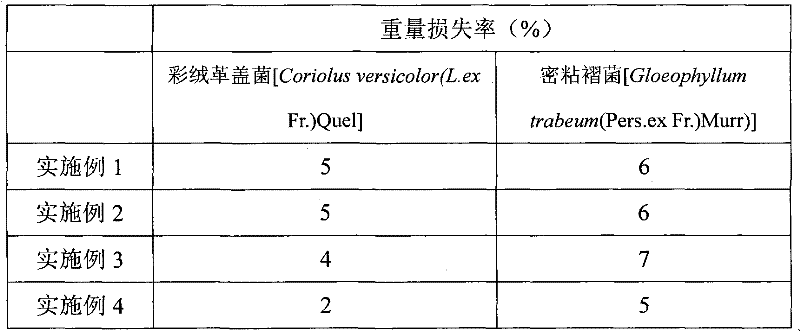

Bamboo-wood composite board and preparation method thereof

InactiveCN101745947AFully absorbedReach the designed drug loadingWood veneer joiningThermal compressionHigh surface

The invention relates to an anti-corrosion bamboo-wood composite board and a preparation method thereof. The preparation method of the anti-corrosion bamboo-wood composite board comprises the following steps: firstly preparing anti-corrosion bamboo strips and heat-treated wood; next, respectively assembling and compressing the anti-corrosion bamboo strips and the heat-treated wood into anti-corrosion bamboo wood and a heat-treated sheet material; and then carrying out assembling and hot compression on the anti-corrosion bamboo wood and the heat-treated sheet material to obtain the anti-corrosion bamboo-wood composite board. The bamboo-wood composite board prepared by the method of the invention has excellent corrosion resistance which reaches the corrosion resisting level specified in national standard GB / T13942.1-1992 Method for Laboratory Test of Natural Decay Resistance of Woods, and also has very high surface abrasion resistance and high mechanical strength which reach the national standards in GB / T 18103-2000 national composite floor.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Production method for flame-retardant solid wood flooring

InactiveCN102114655AImprove flame retardant performanceSimple production processLiquid surface applicatorsWood working apparatusWater basedSolid wood

The invention discloses a production method for a flame-retardant solid wood flooring. The production method comprises the steps as follows: solid wood flooring strips are processed through procedures such as reconditioning, sanding, mortise slotting and the like so as to obtain solid wood flooring slab molds; then surface courses of the solid wood flooring slab molds are processed through painting; the painting treatment adopts the process comprising nine layers of priming painting and two layers of finish painting; in addition, the painting comprises the following steps in sequence: water-based priming painting, puttying, elastic priming painting, wear resistant priming painting, wear resistant priming painting, back painting, transparent priming painting, sanding, wear resistant priming painting, stiffening priming painting, transparent priming painting, sanding, finish painting and finish painting, wherein, compound flame retardants are added in wear resistant priming painting, stiffening priming painting and finish painting. The compound flame-retardant solid wood flooring that is manufactured by adopting the production method achieves excellent flame-retardant fire-resistant performance, environment-friendly performance, and can also achieve excellent physical mechanical property.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Anti-cracking floor heating solid wood composite floor and production method thereof

ActiveCN104963481AImprove thermal conductivityBeautiful appearanceWood working apparatusWood layered productsEpoxySolid wood

The invention discloses an anti-cracking floor heating solid wood composite floor, and belongs to the technical field of wood floor production. The anti-cracking floor heating solid wood composite floor is formed by gluing a composite surface board, non-woven cloth, a core board, non-woven cloth and a bottom board in sequence. The composite surface board, the core board and the bottom board are arranged in a staggered mode in the longitudinal direction, the transverse direction and the longitudinal direction according to wood textures. The composite surface board is formed by assembling rotary-cut hardwood and softwood in a staggered mode in the longitudinal direction, the transverse direction and the longitudinal direction according to wood textures; longitudinal grooves are formed in the back surface of the hardwood surface board of the composite surface board, the depth of the longitudinal grooves ranges from 0.2 mm to 0.5 mm, the width of the longitudinal grooves ranges from 1 mm to 5 mm, and the length of the longitudinal grooves is equal to the length of the board; the surface is immersed with an epoxy resin layer. The anti-cracking floor heating solid wood composite floor has the advantages that the utilization rate of wood resources is increased, the cracking rate of the composite surface board is decreased, the loss of floor heating heat is reduced, and raised grain of the core board is avoided due to the composite surface board structure. The invention further discloses a production method of the anti-cracking floor heating solid wood composite floor.

Owner:DAYA JIANGSU FLOOR

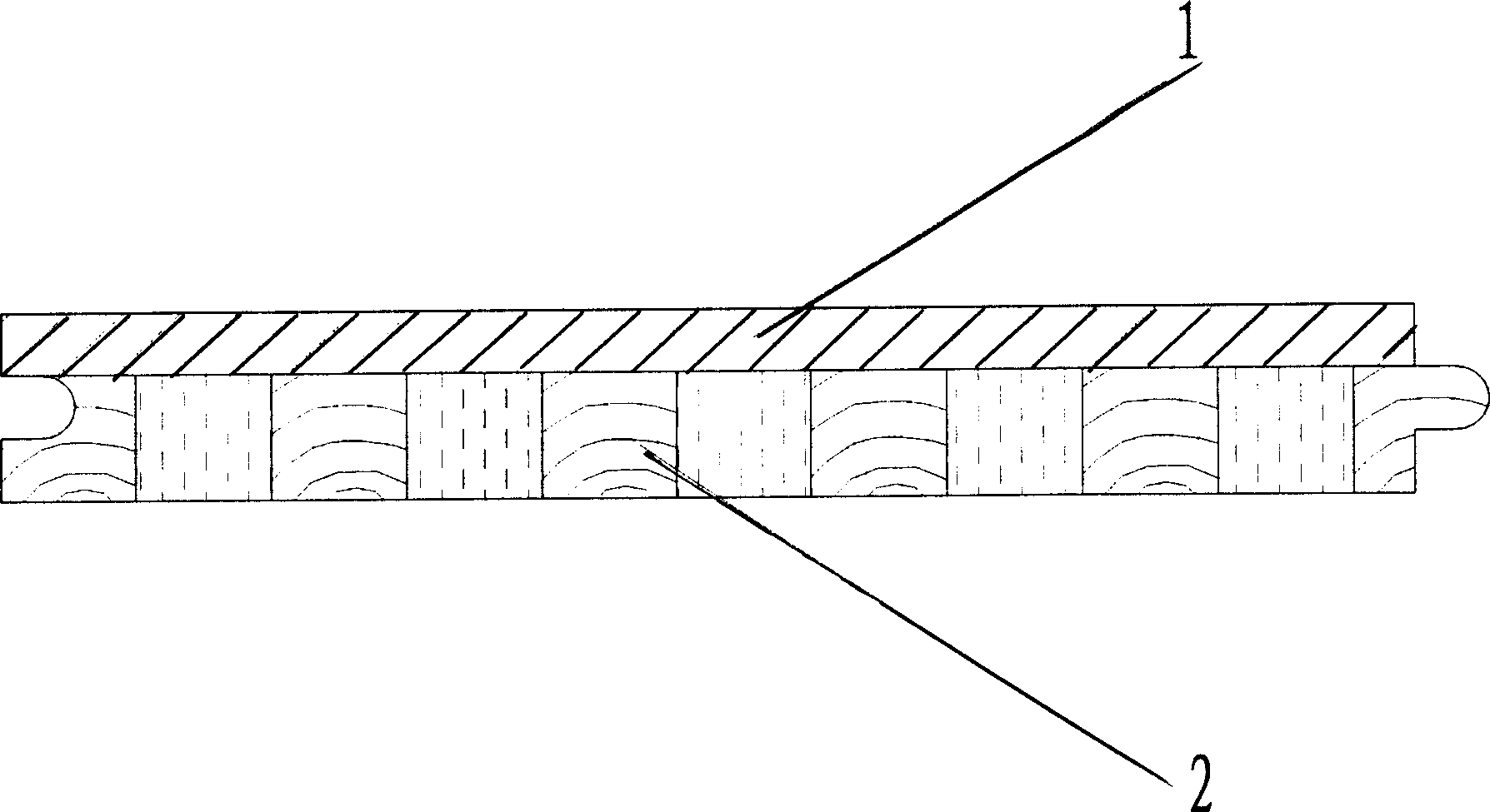

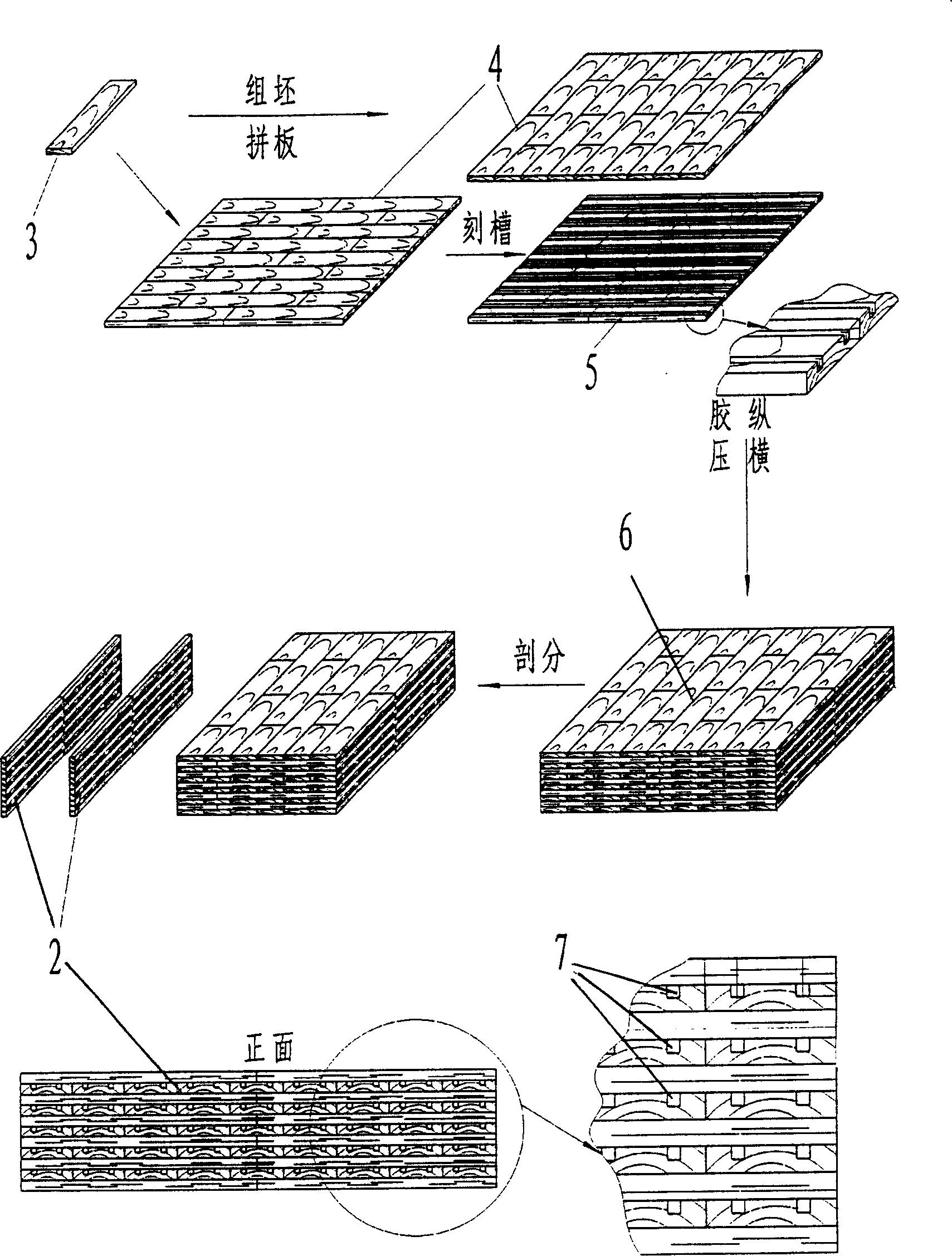

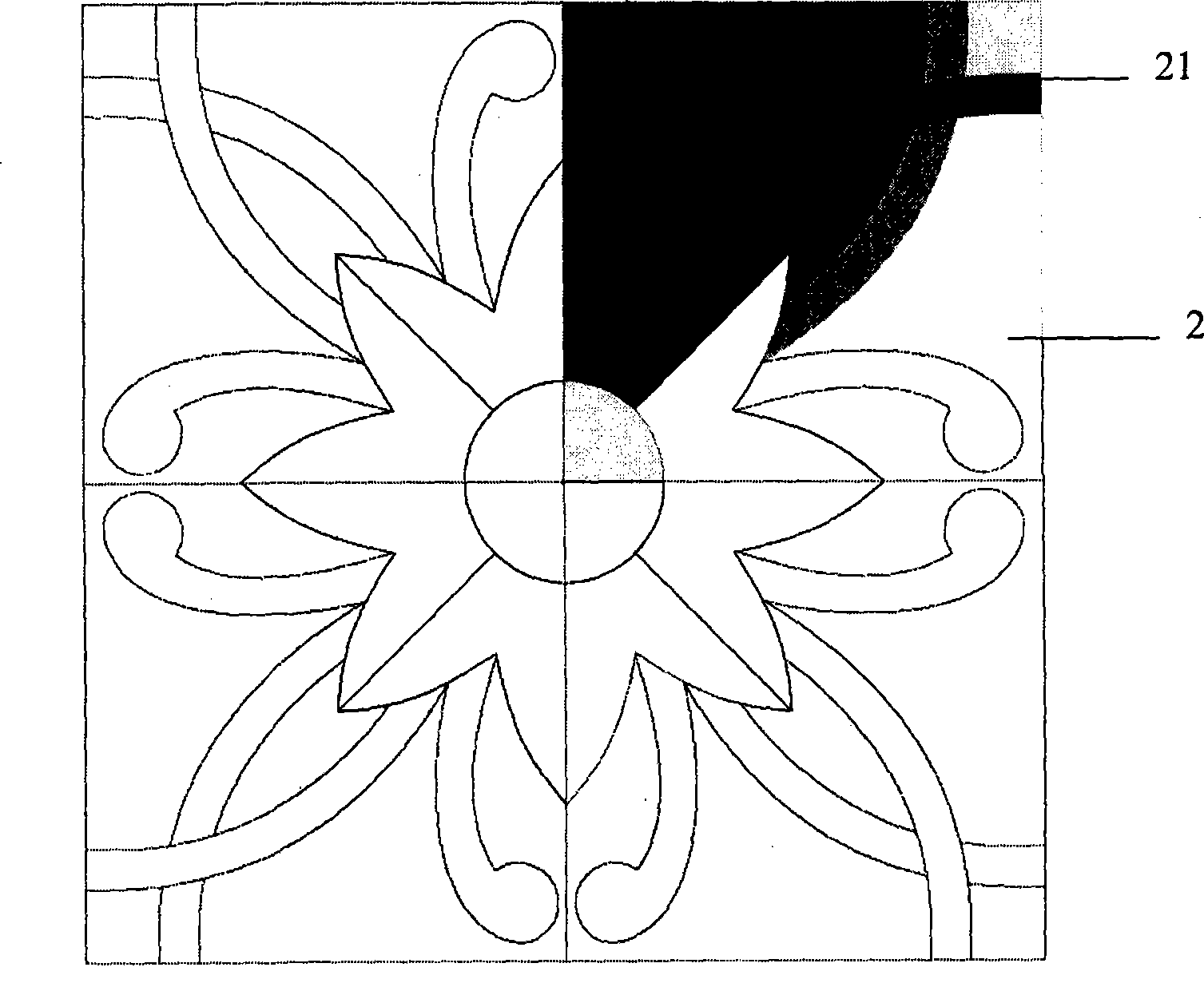

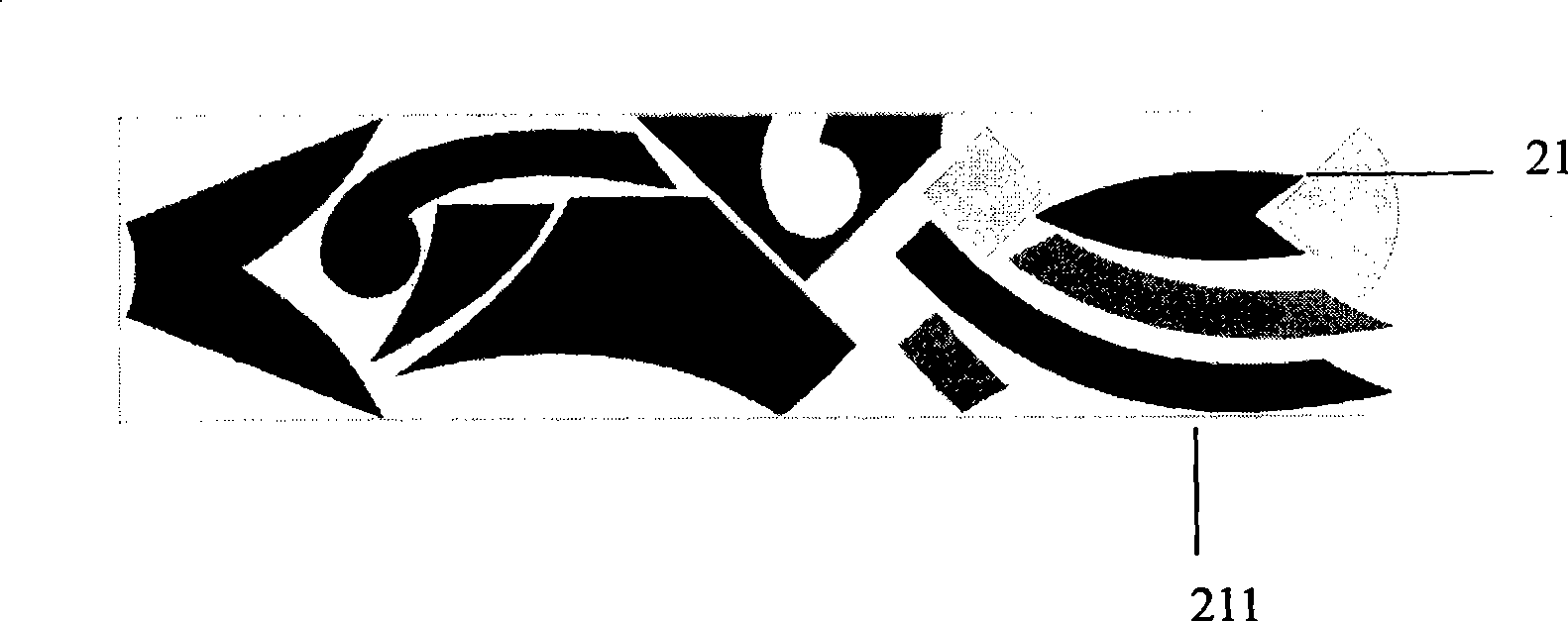

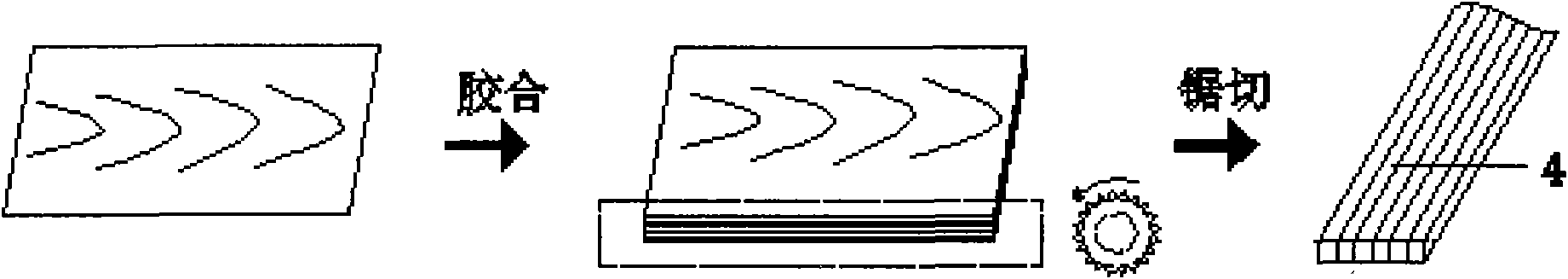

Thin woody combined floriation surface sliced veneer and method for producing the same

InactiveCN101372111ARealize standardized productionImprove growth efficiencyOther plywood/veneer working apparatusWood veneer joiningSolid woodPunch press

The invention provides a thin-wood pattern facing layer facing plate and a preparation method thereof; the production process, which has high efficiency and low cost, is researched for a plurality of years by combining with the characteristic of the pattern floor on the basis of the production process of traditional solid wood composite floor; the plate is characterized in that the thickness of the wood of the pattern floor is 0.3-1mm; the structure of the pattern floor is a solid wood composite floor structure of multi-layers; the difference from normal multi-layer solid wood composite floor is that the surface decorative layer is not a single wood type but a pattern which is embedded by various woods; by adopting a tenon structure rather than a four-surface main trough, the installation is easier; the preparation of pattern part is not processed by a milling machine or a punch or laser type but die-pressed by a plane indentation tangent machine; the plate and the preparation method are characterized in that the preparation equipment of the pattern part has low investment and high daily yield.

Owner:ARMSTRONG (CHINA) INVESTMENT CO LTD

Health care mothproof wood composite flooring and manufacturing technique

The invention discloses a healthcare mothproof solid wood compound floor and the manufacturing technology thereof. The floor includes a base material plate layer, a common pine skin layer and a hardwood skin layer; the common pine skin layer and the hardwood skin layer are adhered on the upper part and the lower part of the base material plate layer by an adhesive. The structural characteristics are that the adhesive contains crystallized camphor powder, the weight ratio of the adhesive and the crystallized camphor powder is 500-600:1-1.5; the four sides of the floor are coated with a paint containing eucalyptus oil, and the weight ratio of paint and the eucalyptus oil is 400-600:5-8; the paint can also contain crystallized camphor powder, and the weight ratio of the paint, the crystallized camphor powder and the eucalyptus oil is 400-600:1-1.5:5-8; the final layer of the floor surface is roller coated with a UV paint containing aluminium sesquioxide particles and the weight ratio between the paint and the aluminium sesquioxide particles is 9-12:1.5-2. The invention has the advantages of good mothproof effect and is favorable for protecting vision and can prevent tumble in walking.

Owner:叶昌海 +1

Production process of formaldehydeless three-layer solid-wood composite floor

InactiveCN102345366AMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesSolid woodAdhesive

The invention relates to a production process of a formaldehydeless three-layer solid-wood composite floor, which is formed by hot pressing or cold pressing a core board, a bottom board and a panel through an adhesive. The production process is characterized in that the adhesive comprises the following components by weight: the ratio of primary agent, filler and curing agent is 1:0.01-0.50:0.01-0.50. The production process is mainly and technically characterized in that by a formaldehydeless adhesive technology, no free formaldehyde releasing resource exists, so that a formaldehydeless three-layer solid-wood composite floor product is obtained. The performance index of the product conforms to the F***8 requirements of the international highest standard JAS233-2003 specifications for The Japanese agriculture standard of the common plywood, and the release amount of formaldehyde is less than 0.3mg / L.

Owner:上海诺科化学油剂有限公司 +2

Multi-layer wood composite flooring and manufacturing method therefor

The invention discloses a multi-layer solid wooden compound floor board, which comprises from up to down an anti-wear layer, a decoration layer and a baseboard layer that are mutually glued. The baseboard layer comprises a plurality of mutually-glued single boards. The invention additionally discloses the method for making the floor board. The method comprises: selecting a plurality layers of single boards, coating glue on them, pressing the single boards to form the baseboard layer; coating glue between the baseboard layer and the decoration layer; pressing the decoration layer and the baseboard layer; sticking the anti-wear layer on the decoration layer; finally pressing the anti-wear layer, decoration layer and the baseboard layer to form a multi-layer solid wooden compound floor board. The multi-layer solid wooden compound floor board made by above method is furnished with appearance of a solid wood floorboard, is of steady structure, not liable to deformation, is of high surface strength, is wear and scraping proof, resistant to impact, burning and contamination, and is environmental friendly; the floorboard can be applicable for different environments, is economic, practical and durable.

Owner:捷伟实业有限公司

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804654AAvoid churnEasy to recycleLiquid surface applicatorsWood veneer joiningSolid woodPulp and paper industry

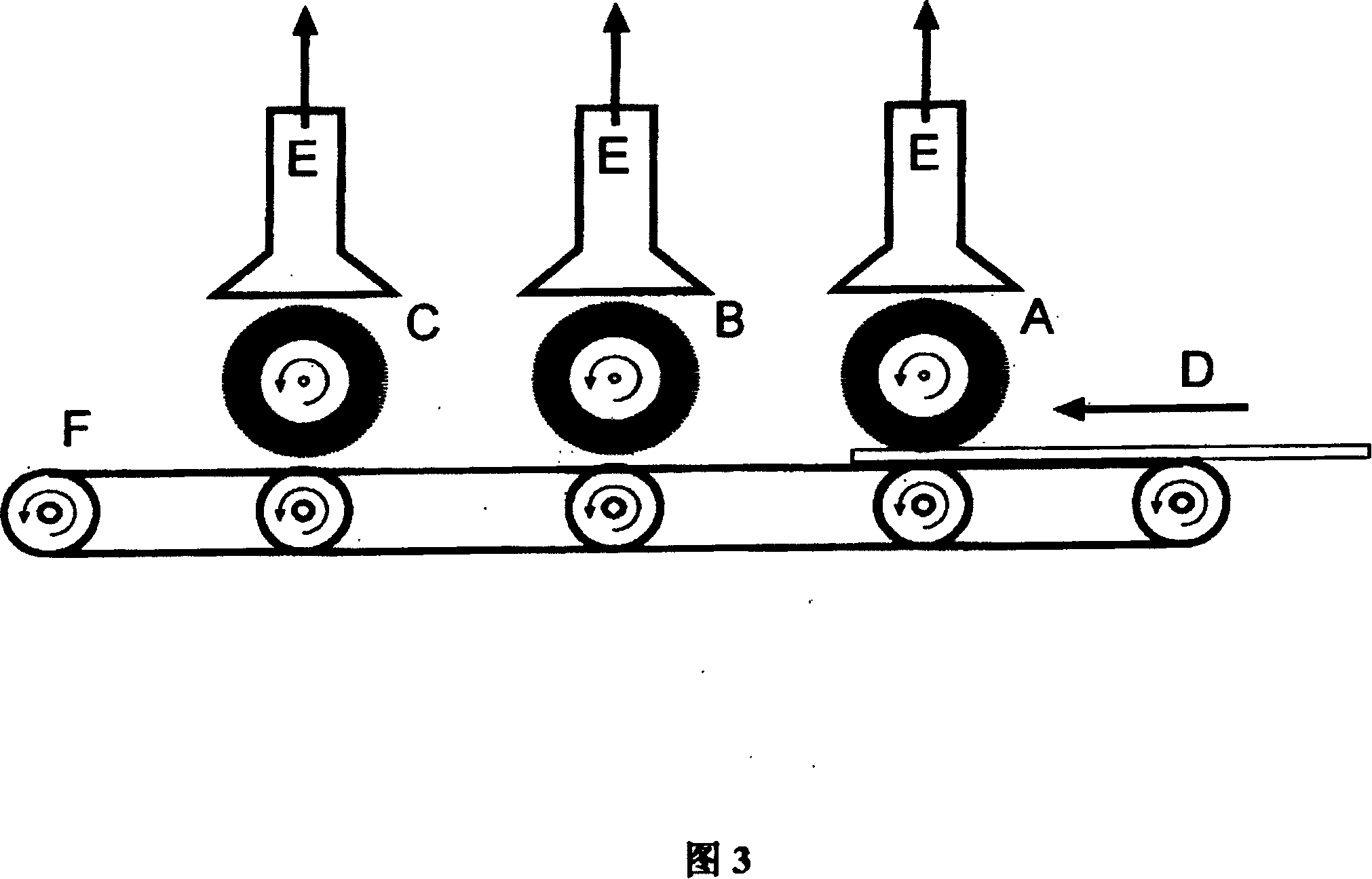

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: processing a surface board, processing a core board, processing a base board, glue pressing and compounding, fine processing, coating the surface, and forming the finished product. The process has the advantages of strong natural visual sensation, comfortable foot sensation, good material quality, easy processing, cyclic utilization, good geothermy adaptability, strong stability, more simple and convenient construction and installation, excellent environmental performance, great increase of comprehensive utilization ratio of timbers and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

Method for manufacturing flame-retarding mothproof solid wood composite floor

InactiveCN102120331AFlame RetardantAchieve smoke suppressionWood veneer joiningSolid woodProduction line

The invention discloses a method for manufacturing a flame-retarding mothproof solid wood composite floor and belongs to the technical field of building decorating materials. In the method, a multifunctional veneer laminated composite board is used as a substrate plate, a hardwood thin panel is used as a panel material, the hardwood thin panel is treated by a multifunctional wood protective agent treating solution to be formed into a multifunctional hardwood thin panel, the multifunctional veneer laminated composite board is coated with an adhesive, the multifunctional hardwood thin panel and the multifunctional veneer laminated composite board are formed into a blank, the blank is pre-pressed and thermally pressed till the multifunctional hardwood thin panel and the multifunctional veneer laminated composite board are well jointed and then is cured and treated by steps of edge aligning, cutting, sanding, processing in Homag production line and double-end milling, multi-pass base coating and surface coating are performed, fully curing is carried out and thus, the flame-retarding mothproof solid wood composite floor is manufactured. The invention has the advantages that: the process is simple and quick; the operation is easy; the production requirements can be met by sampling performing a process step of veneer immersing treatment before all process steps for producing the solid wood composite floor; the product update and upgrade of the existing artificial floor and solid wood composite floor enterprises can be realized easily; the added value of the product is high; and the method has a practical significance for guaranteeing fire safety in places where wood materials are used.

Owner:XUZHOU SHENGHE WOOD

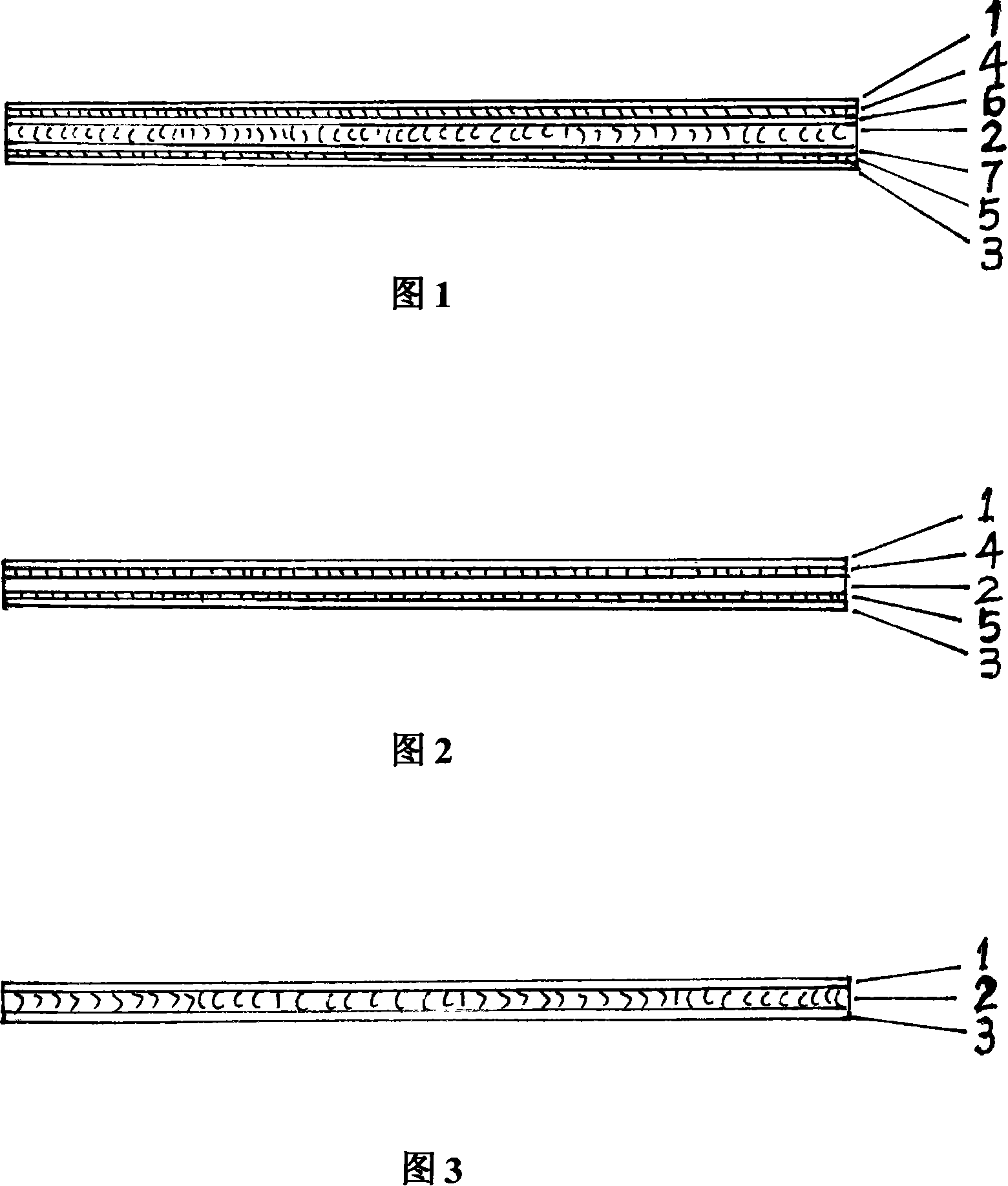

Four-layer solid wood composite floor with skin layer having horizontal-longitudinal split joint structure and method for making same

InactiveCN101012701ASolve the strength problemSolve problems such as cracking easilyWood veneer joiningFlooringSolid woodWood fibre

The invention relates to a four-layer solid wood composite floor and the manufacture method. The surface plate of four-layer solid wood composite floor is the horizontal and vertical stitching structure and the composite floor comprises a surface solid wood plate, a core plate and a back plate. It is characterized in that a gluing single plate is set between the surface solid wood plate and the core plate and said four-layer plates are bonded with each other; the surface solid wood plate is constituted by short solid blocks gluing in wood fiber direction along horizontal and vertical orders; the thickness of said gluing single plate is less than the one of said core plate. Compared with prior technologies, 1 the invention solves the problem that when the horizontal and vertical stitching thin plate is used as the surface plate to glue with the soft wood core plate, it is bad intensity and easy crack. 2 the invention avoids the floor deformation of wood generated by circumstance temperature and moisture changes so that the floor stability is improved by 6 to 8 times; because it is the gluing single plate under the surface plate, the bonding intensity of end stitching surface plate is strengthened effectively. At the same time the invention makes full use of short hard woods, which can not be used in producing the integral surface plate, and saves the resource of rare tree species.

Owner:上海新四合木业有限公司

Structured in three layer floorboard from composite solid wood reliev lock caught

InactiveCN100348811CAvoid deformationImprove stabilityWood layered productsFlooringSolid woodPulp and paper industry

The invention relates to a relief lock-fastened three-layer solid wood composite floor board, its production process and equipment. Said invention utilizes the combination of three-layer solid wood composition technique, notch lock-fastening technique and surface solid wood relief-making technique and adopts a swing type abrasive belt grinding steel brush dust-removing machine to implement said invention. Said invention also provides the concrete structure composition of said swing type abrasive belt grinding steel brush and dust-removing machine.

Owner:上海四合木业有限公司

Equalizing three-layered wood compound floor board and mfg. method

InactiveCN100999954AImprove stabilityReduce the chance of crackingWood working apparatusFlooringEngineeringComposite plate

Owner:上海新四合木业有限公司

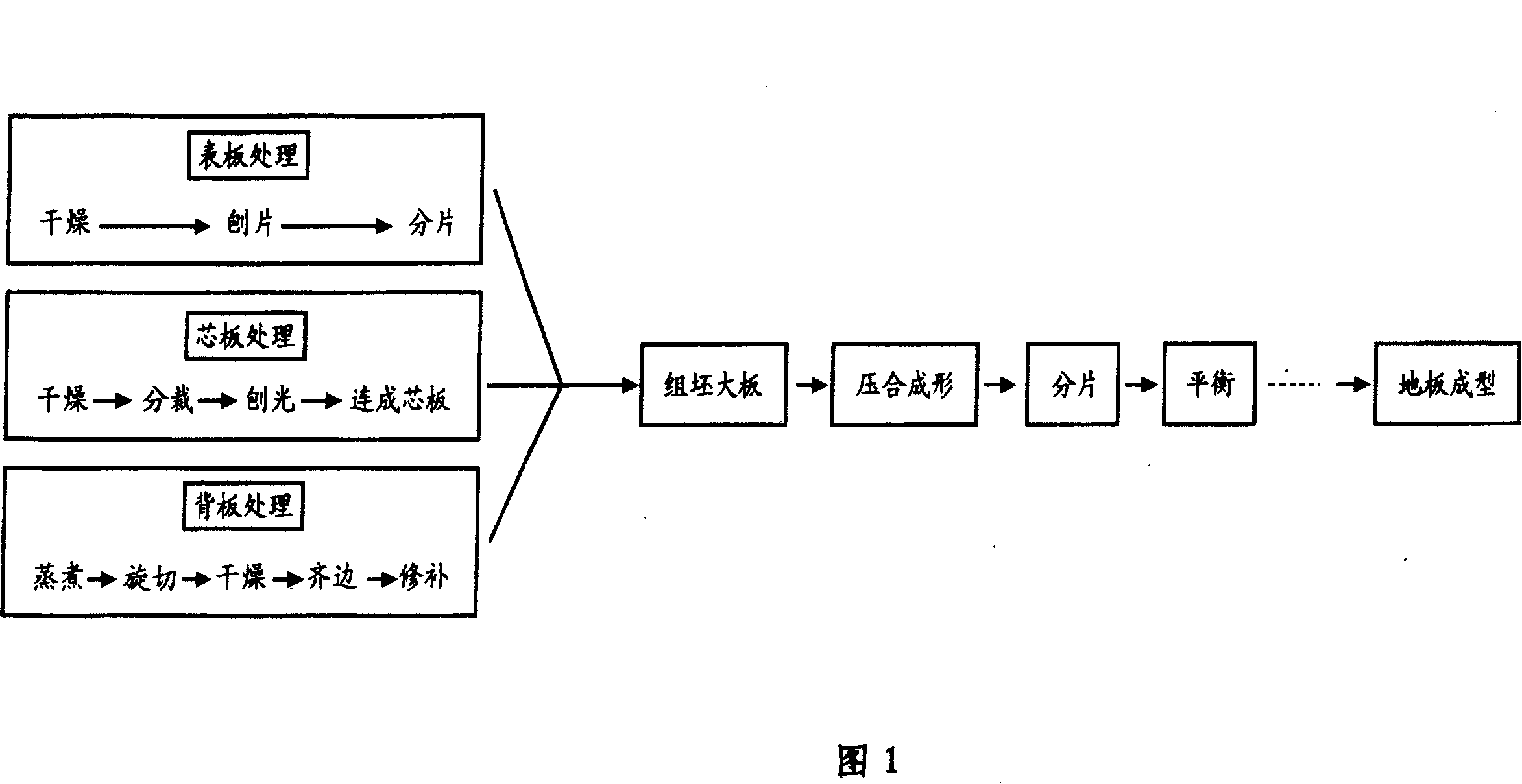

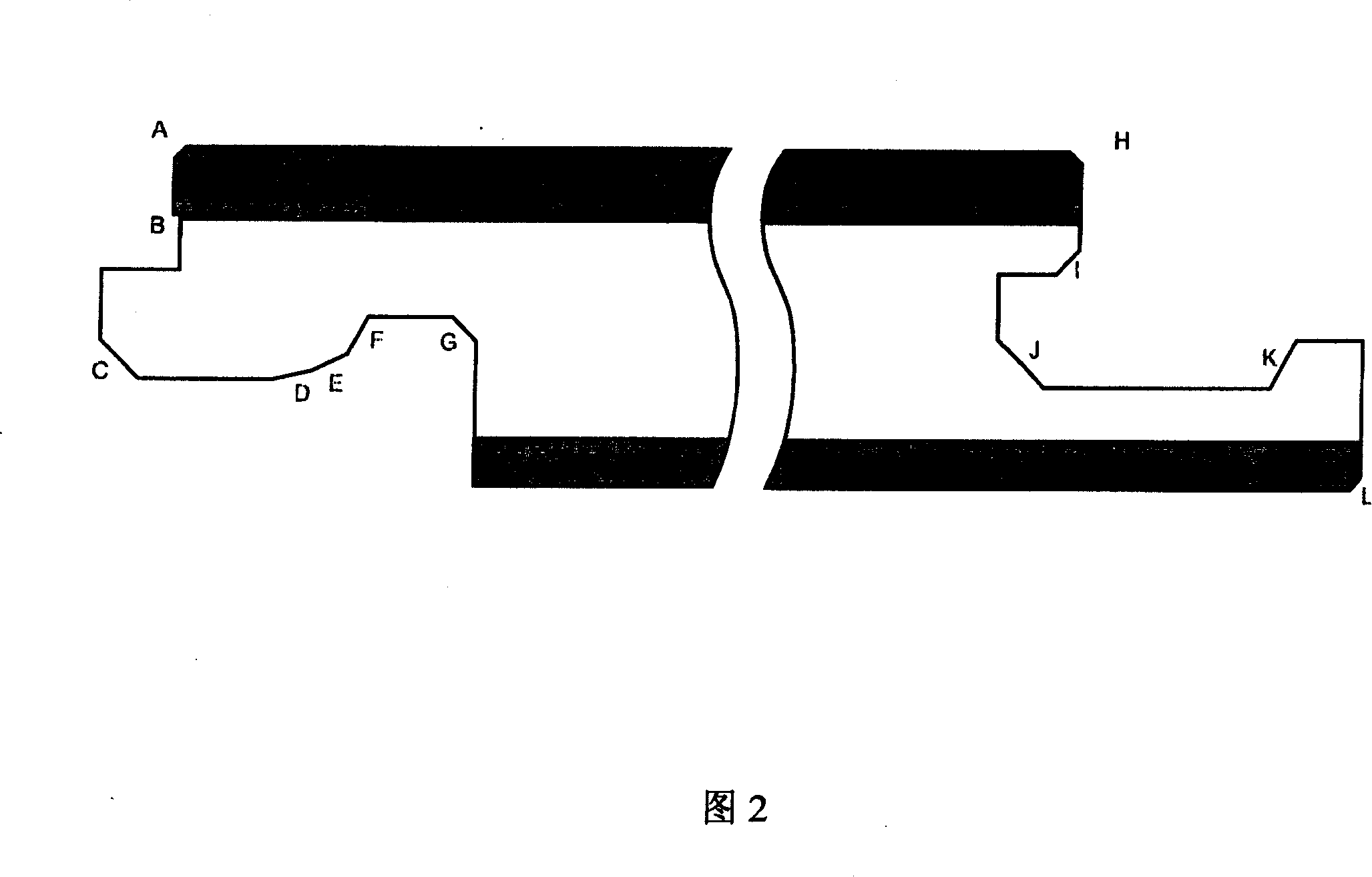

Parquet using laminated veneer lumber strip as base material and production method thereof

InactiveCN101550759AGood dimensional stabilitySolve the defect of warping deformationWood working apparatusFlooringParquetinaLaminated veneer lumber

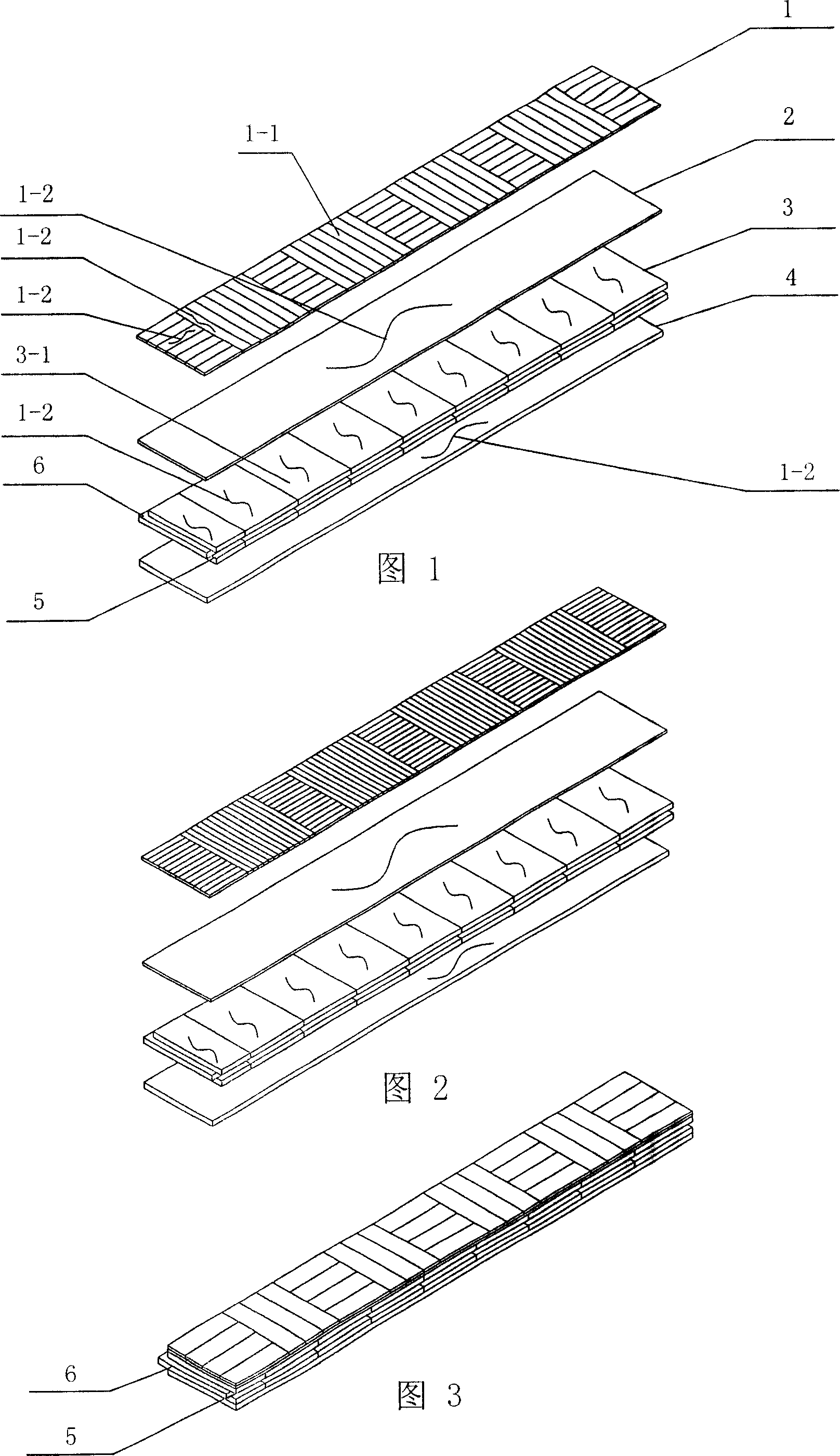

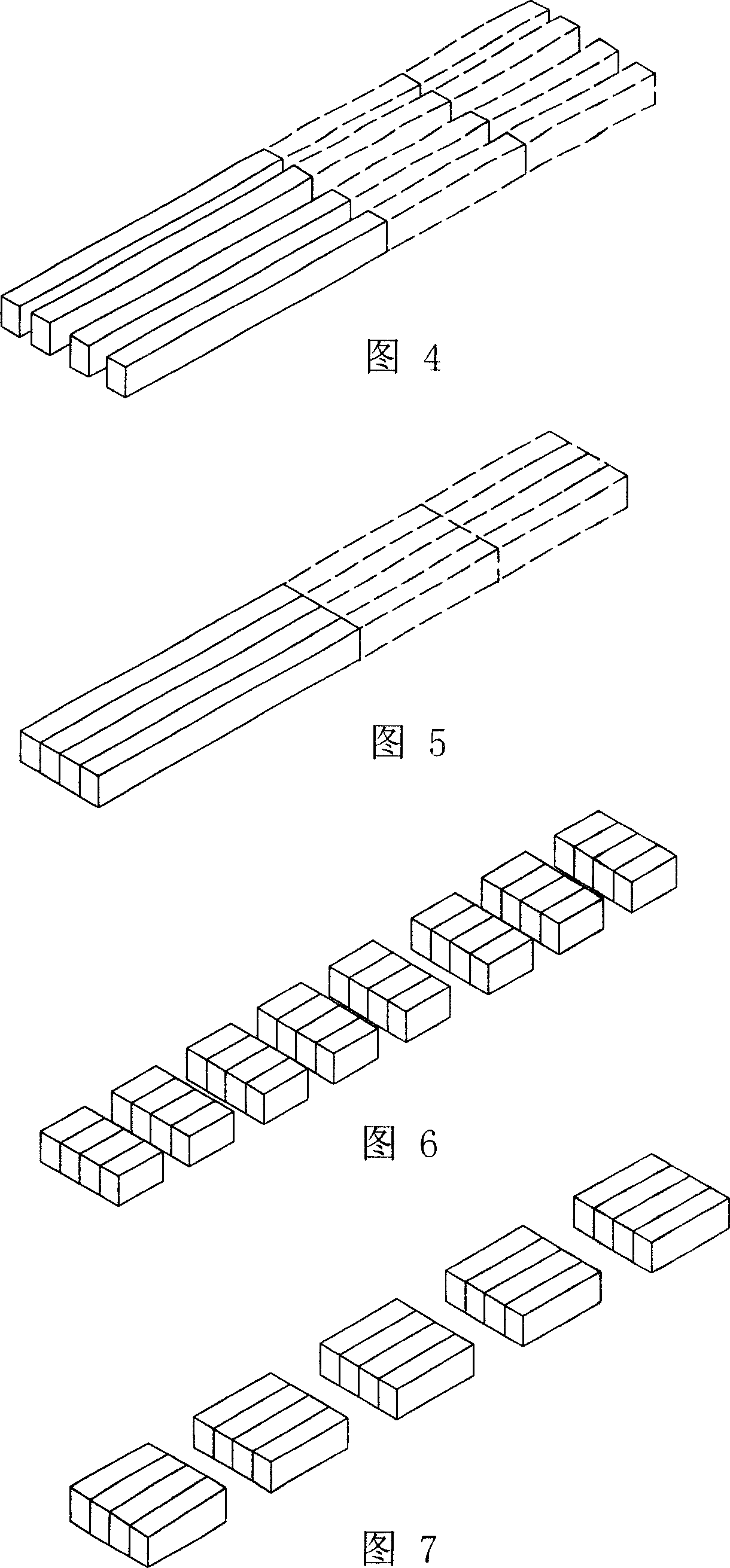

The invention discloses a parquet using laminated veneer lumber strip as base material and the production method thereof. The parquet is composed of a surface layer and base material or composed a surface layer, a bottom layer and base material there between. The base material is laminated veneer lumber strip which is manufactured by dividing the laminated veneer lumber into strips; In the dividing process, the sawing direction is perpendicular to the surface of the laminated veneer lumber while parallel with the fiber of the laminated veneer lumber; and the sawed surface while dividing is used as compounding surface to the surface layer. The parquet produced in the invention achieves the advantages of high size stability, excellent mechanical properties and low manufacturing cost.

Owner:冯桔红 +1

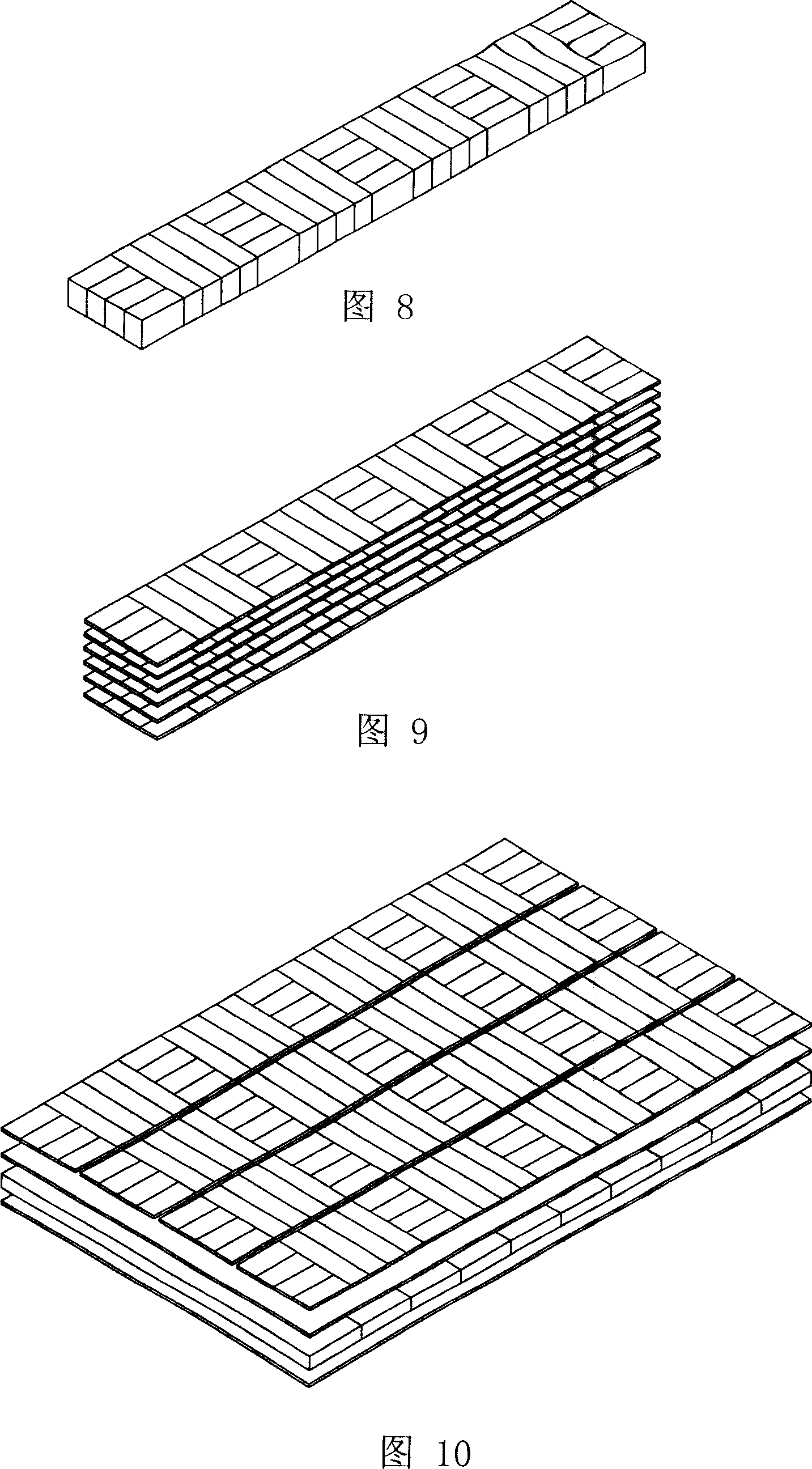

Method for producing multi-layer solid-wood composite floor by densified poplar single board

InactiveCN102179854ALow deformation rebound rateGood dimensional stabilityOther plywood/veneer working apparatusWood veneer joiningSolid woodNational standard

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com