Health care mothproof wood composite flooring and manufacturing technique

A technology of solid wood composite flooring and manufacturing technology, which is applied in the direction of wood layered products, floors, layered products, etc., and can solve the problem that pests cannot be prevented, mothproof effects cannot be achieved, and camphor wood odor cannot be released from the bottom and other problems, to achieve the effect of protecting vision and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

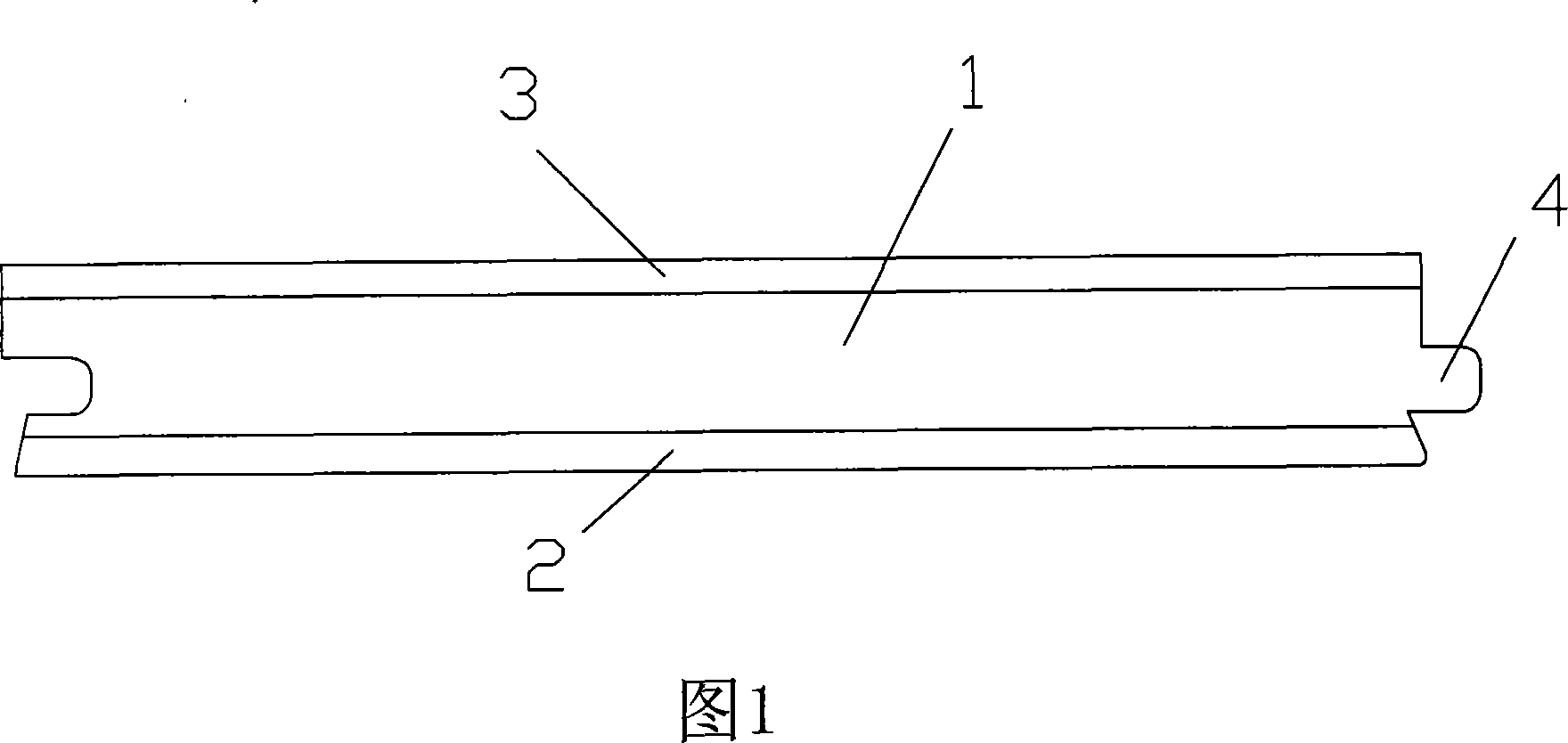

[0017] Referring to Fig. 1, present embodiment is made up of substrate plate 1, camphor wood cortex 2 and hardwood cortex 3, and base material plate 1 is multi-layer plywood, camphor wood cortex 2 adopts camphor wood, hardwood cortex 3 adopts hardwood, can be Balsam dal, maple, oak, teak or elm etc.

[0018] The camphor wood cortex 2 and the hardwood cortex 3 are bonded to the bottom and the top of the substrate ply 1 by isocyanate glue containing crystalline camphor powder respectively, i.e. the back and front of the substrate ply 1; the weight of the isocyanate glue and the crystalline camphor powder The ratio is 600:1. There is groove 4 around the floor, and its four sides are sprayed with paint containing eucalyptus oil, the concentration of eucalyptus oil is 80%, and the weight ratio of paint and eucalyptus oil is 500:5; crystallized camphor can also be added in the paint Powder, such as adding crystalline camphor powder, the weight ratio of paint, crystalline camphor po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com