Patents

Literature

144 results about "Primary operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

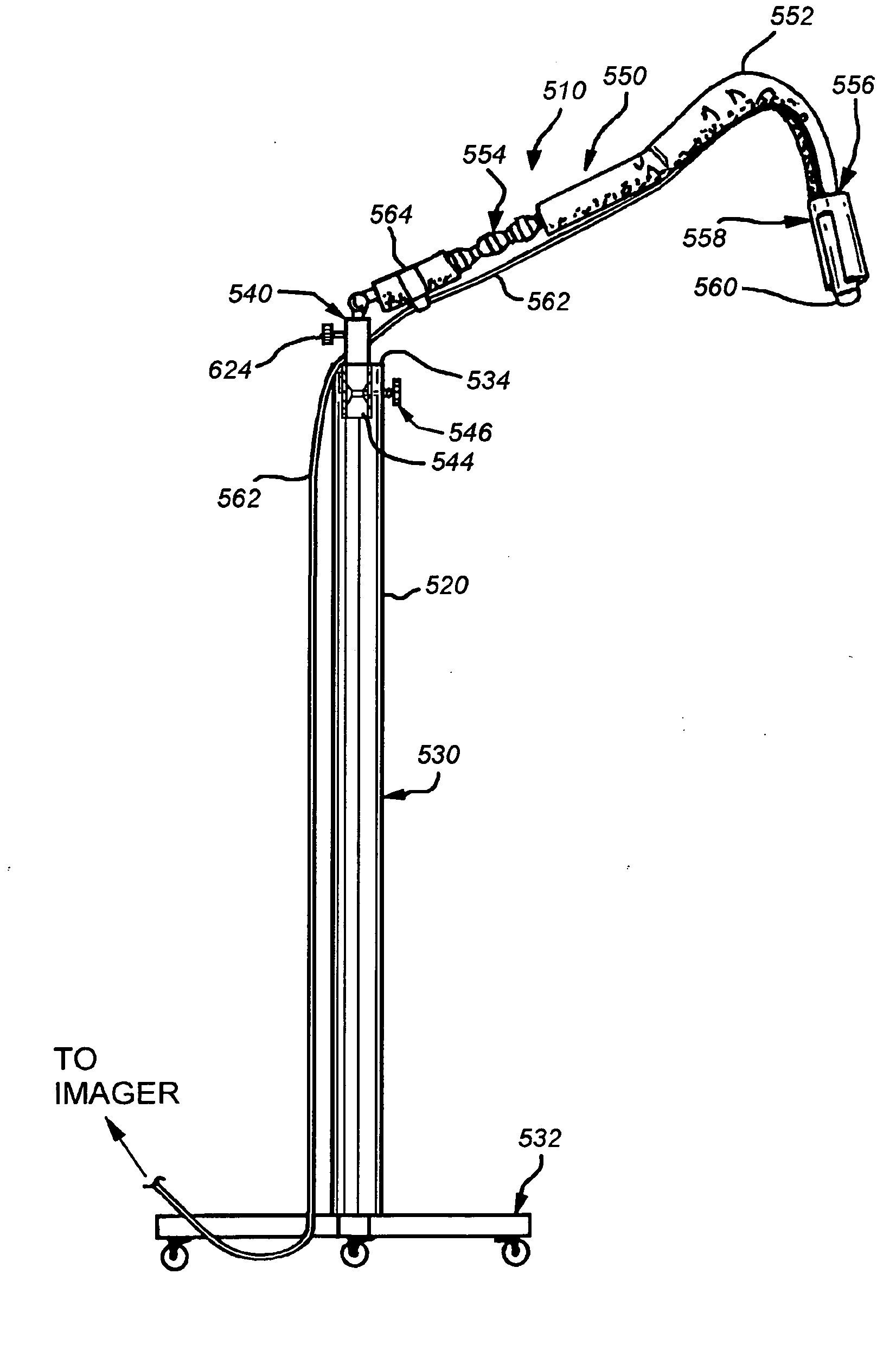

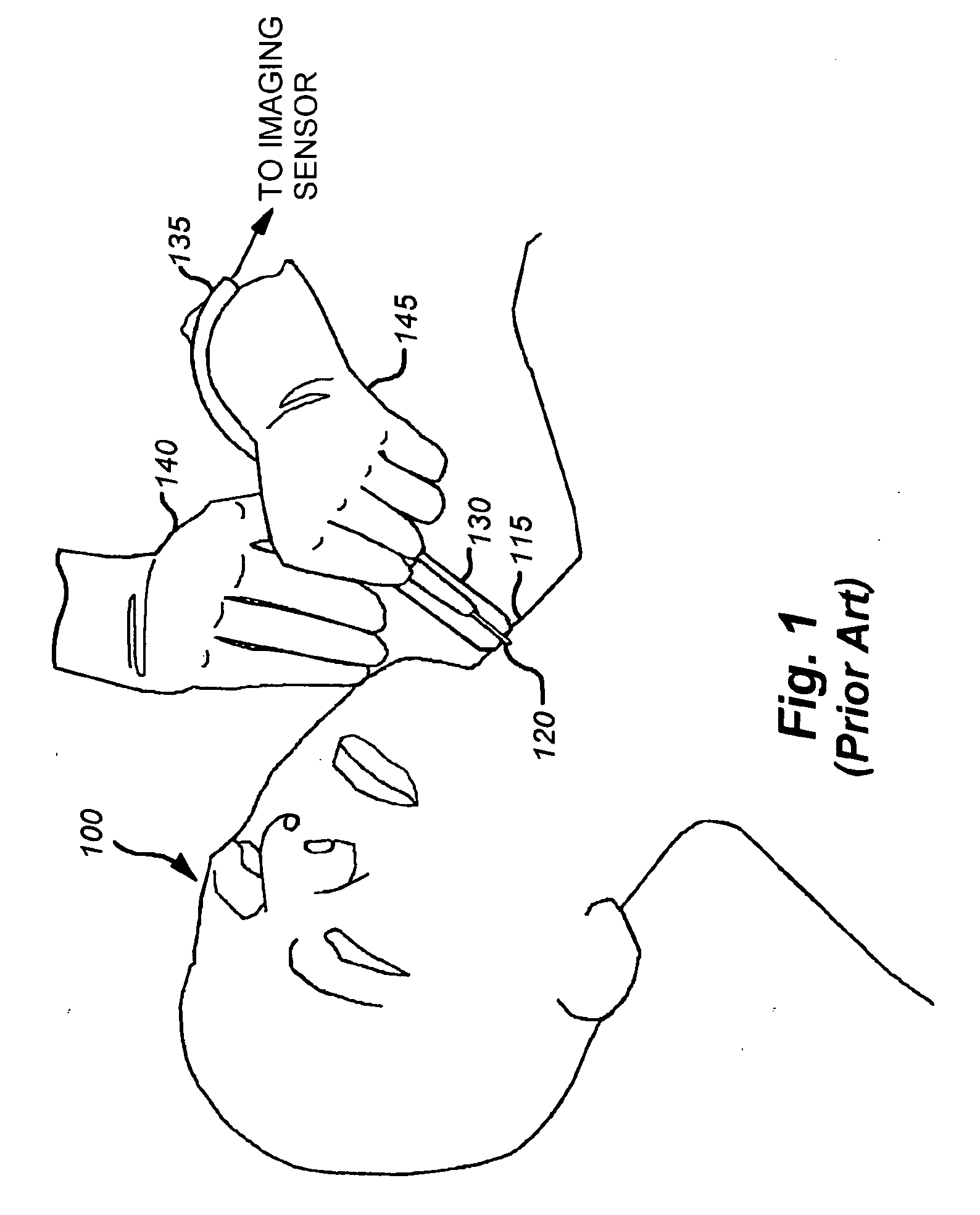

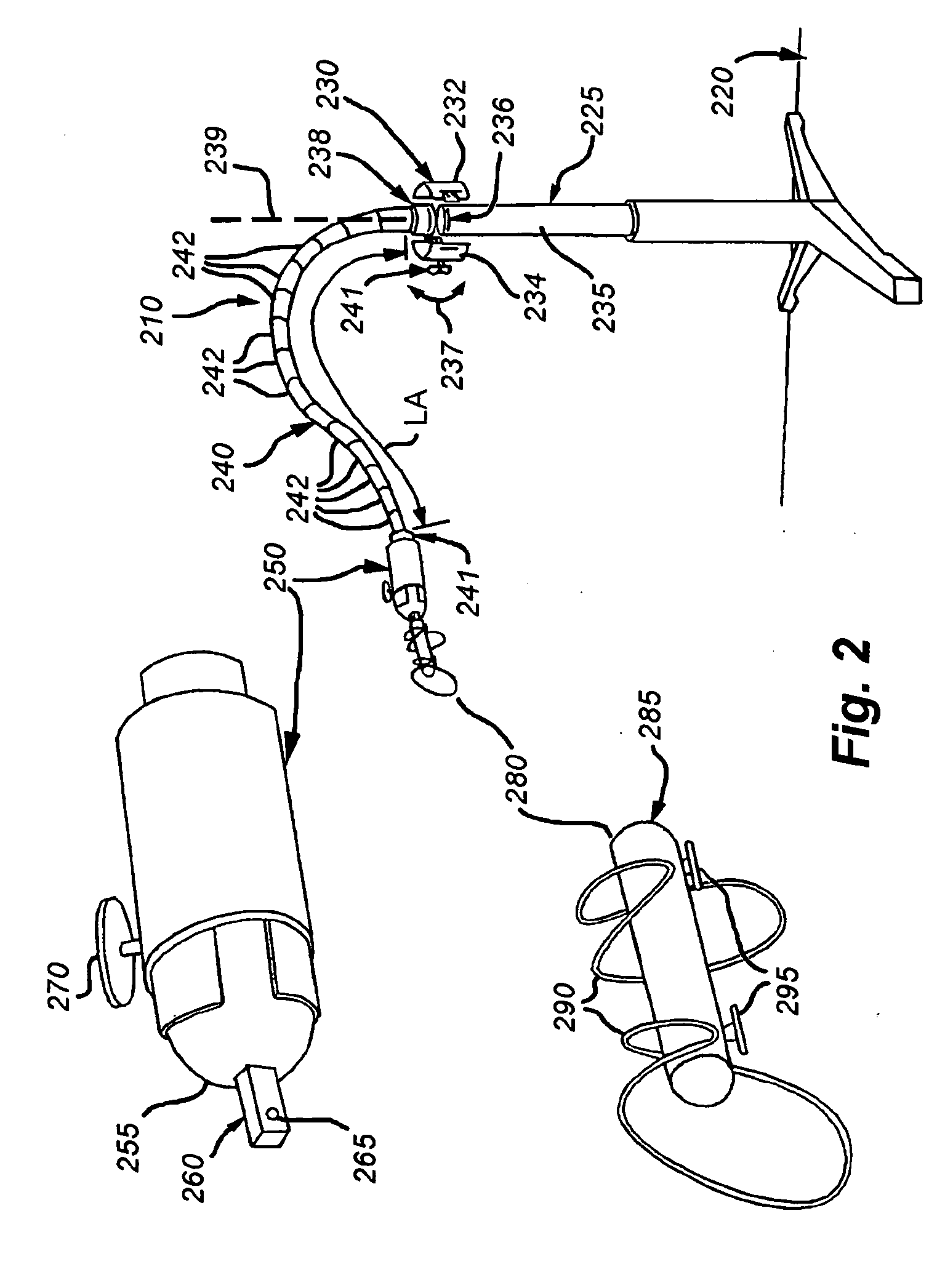

Biomedical positioning and stabilization system

InactiveUS20070129634A1Minimal effortGood flexibilityUltrasonic/sonic/infrasonic diagnosticsSurgical needlesAnatomical structuresPrimary operation

This invention provides a support device that allows the adjustable, yet rigid placement of a probe or other medical instrument against a region of interest / treatment on a patient. The system and method of rigid fixation, positioning, and adjustment contemplated herein is useful for a broad array of medical procedures including, but not limited to, ultrasound-guided anesthetic delivery. In an exemplary embodiment of the present invention, a flexible armature is attached to a rigid stand placed upon the floor, or attached to another stable surface such as a bed rail, wall, ceiling or piece of equipment. A joint connects the armature to an instrument holder able to accommodate and rigidly attach an ultrasound sensing probe or other medical device. The medical device then remains rigidly attached to the described invention during the procedure. Furthermore, this set position is resistant to minor patient motion or other disturbances. If required, small alterations can be made by the operator during the procedure with minimal effort. Such adjustment may be desirable, for example, if access to a new anatomical structure is needed. In this manner, the primary operator is able to maintain a ‘hands-free’ approach.

Owner:WELLAN MEDICAL SOLUTIONS +1

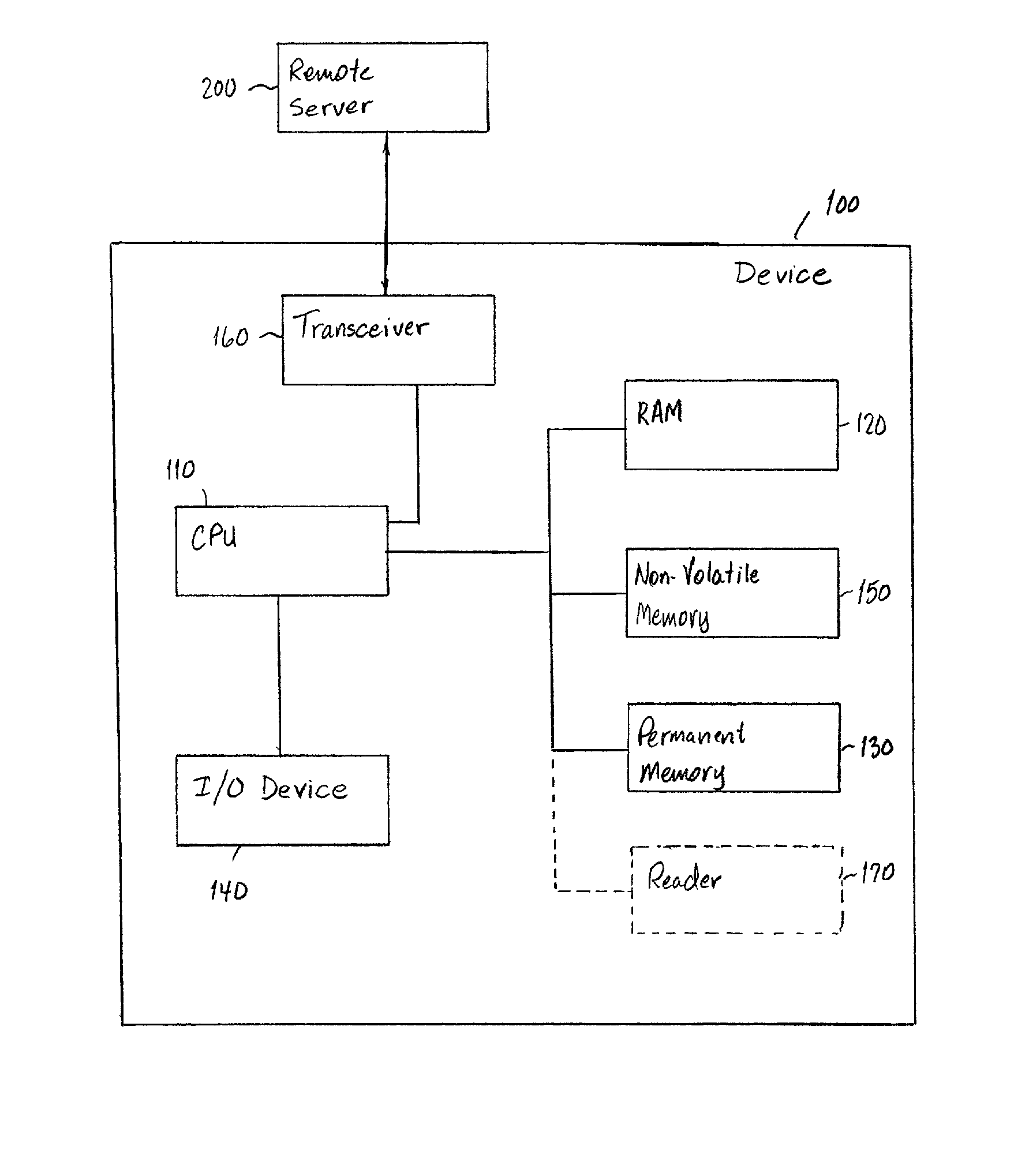

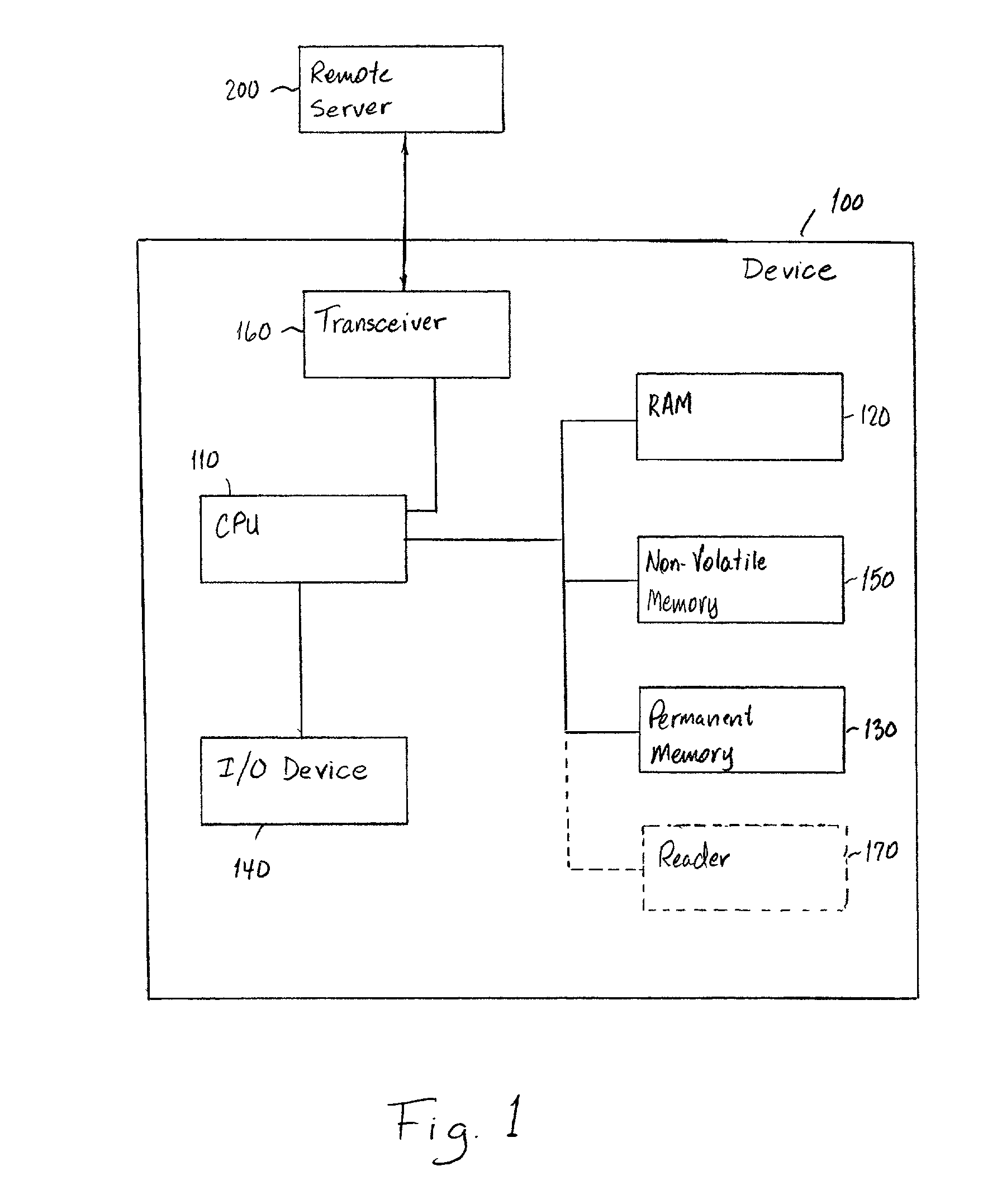

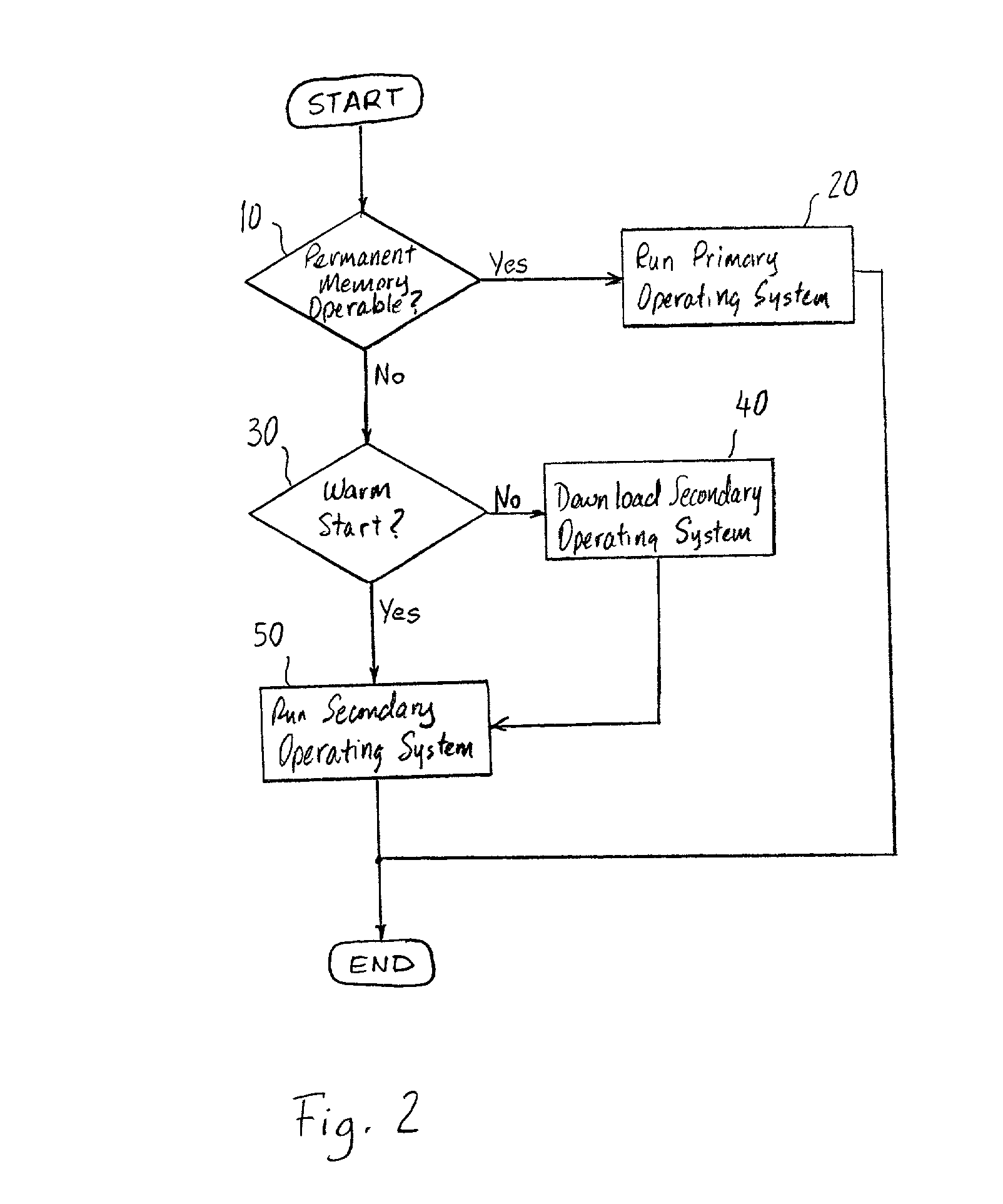

Crash recovery system

A set top box for a television includes a hard drive, a random access memory, and a non-volatile memory. To maintain functionality of the device after a crash of the hard drive, the non-volatile memory includes an executable program for downloading a secondary operating system from a remote server or other secondary storage during a startup when the primary operating system in the hard drive is not accessible. The secondary operating system is stored in the random access memory and is a functional subset of the primary operating system to allow the use of the primary functionality of the set top box until the hard disk drive is repaired or replaced.

Owner:NOKIA TECHNOLOGLES OY

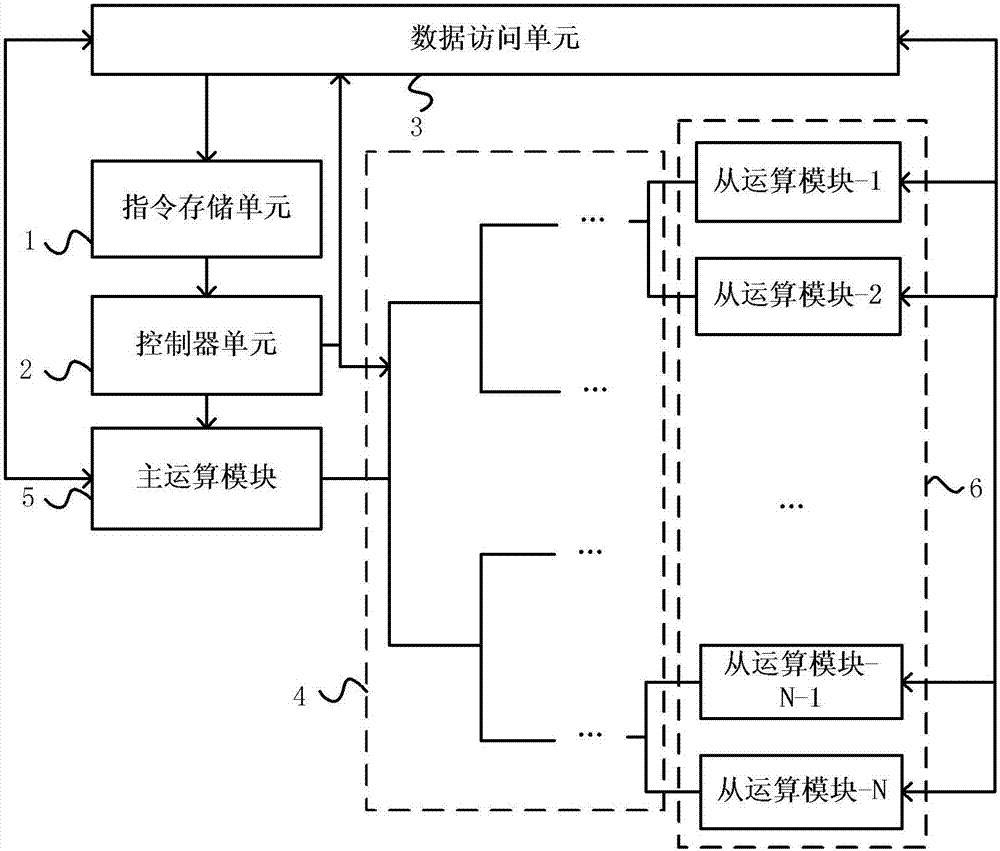

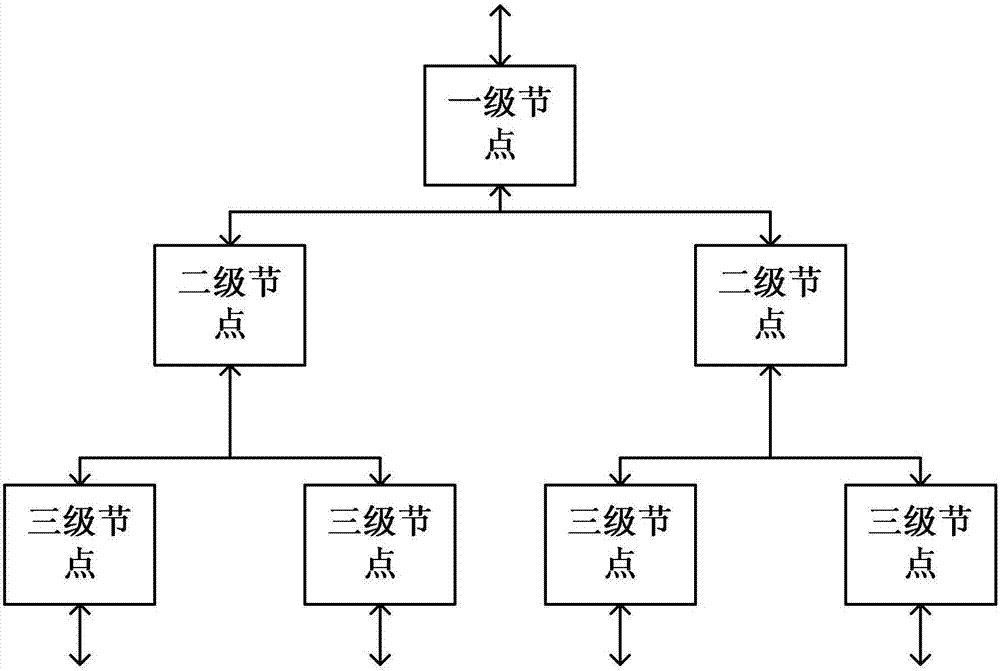

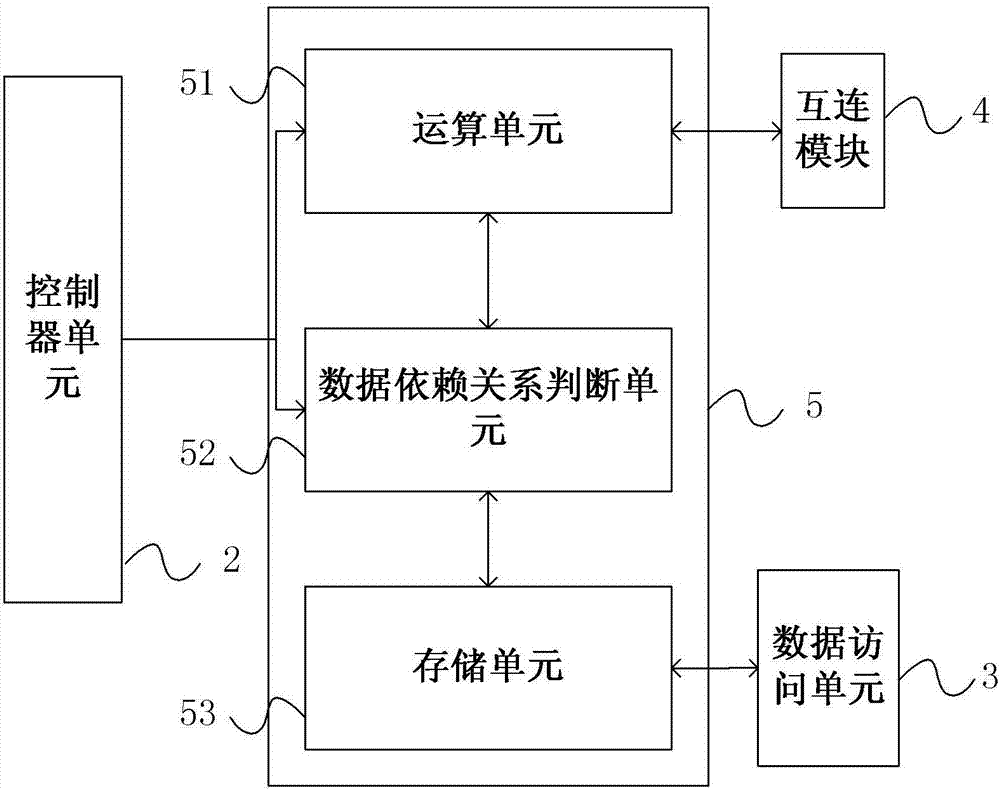

Device and method for executing artificial neural network self-learning operation

ActiveCN107316078ASimplified front-end decoding overheadHigh performance per wattPhysical realisationNeural learning methodsHidden layerNerve network

The invention discloses a device and method for executing artificial neural network self-learning operation. The device comprises an instruction storage unit, a controller unit, a data access unit, an interconnection module, a primary operation module and a plurality of secondary operation modules. According to the device and method, the self-learning pre-training of a multilayer neural network can adopt a layer-by-layer training manner; for each layer of network, the self-learning pre-training is completed after multiple operations are iterated until the weight is updated to be smaller than a certain threshold value. Each iteration process can be divided into four stages, calculation is carried out in the first three stages to respectively generate a first-order hidden layer median, a first-order visible layer median and a second-order hidden layer median, and the weight is updated in the last stage by utilizing the medians in the first three stages.

Owner:CAMBRICON TECH CO LTD

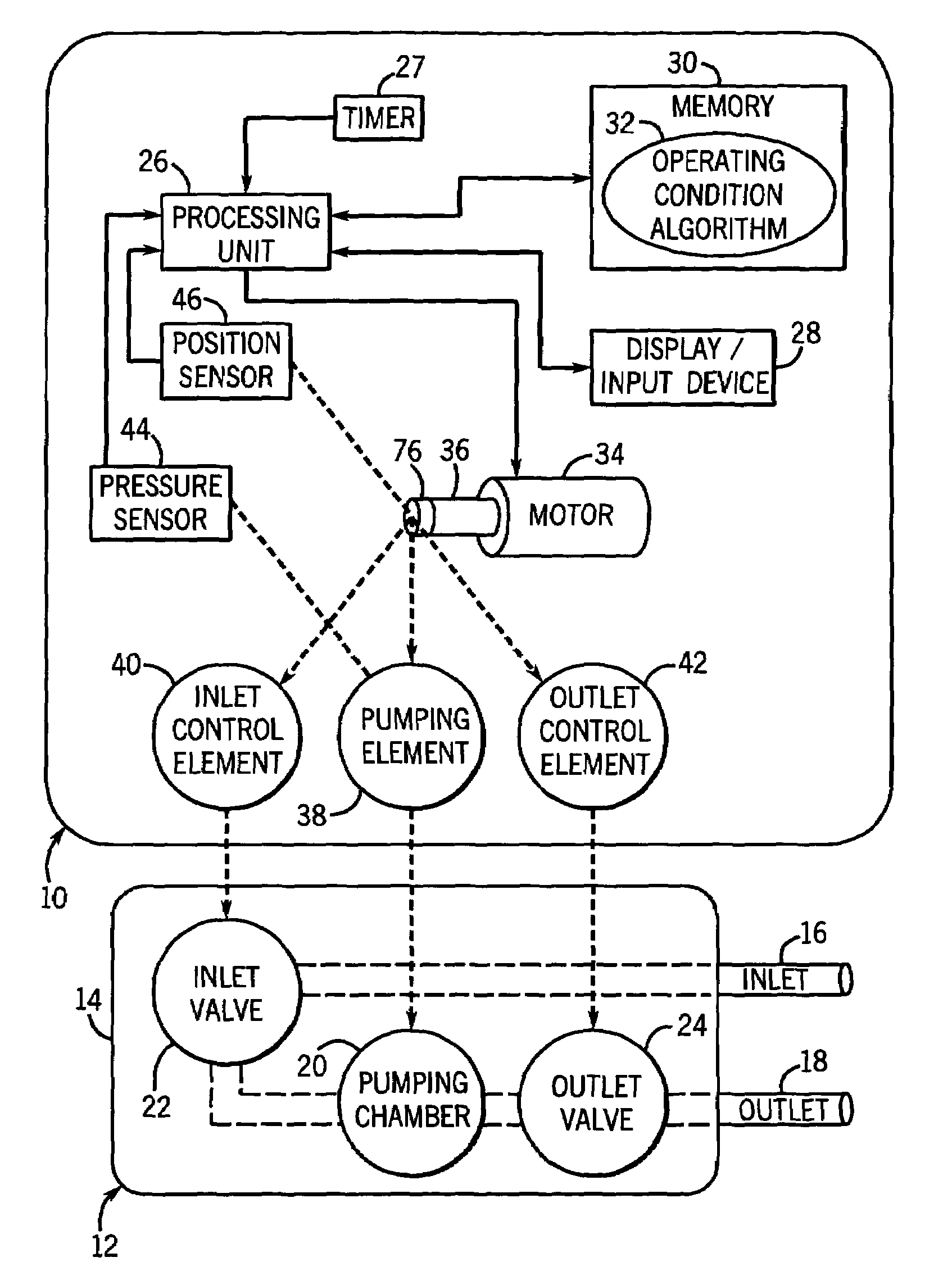

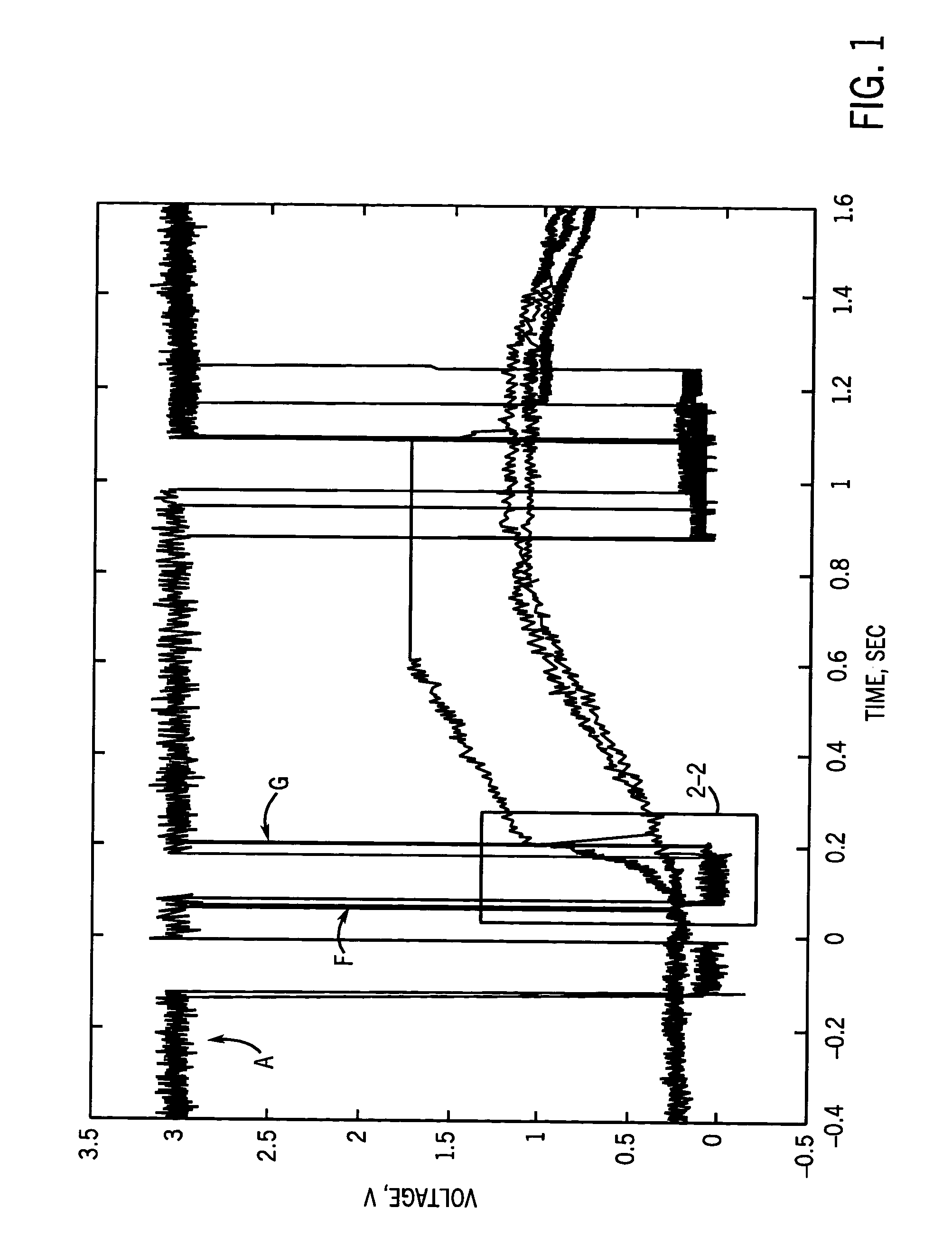

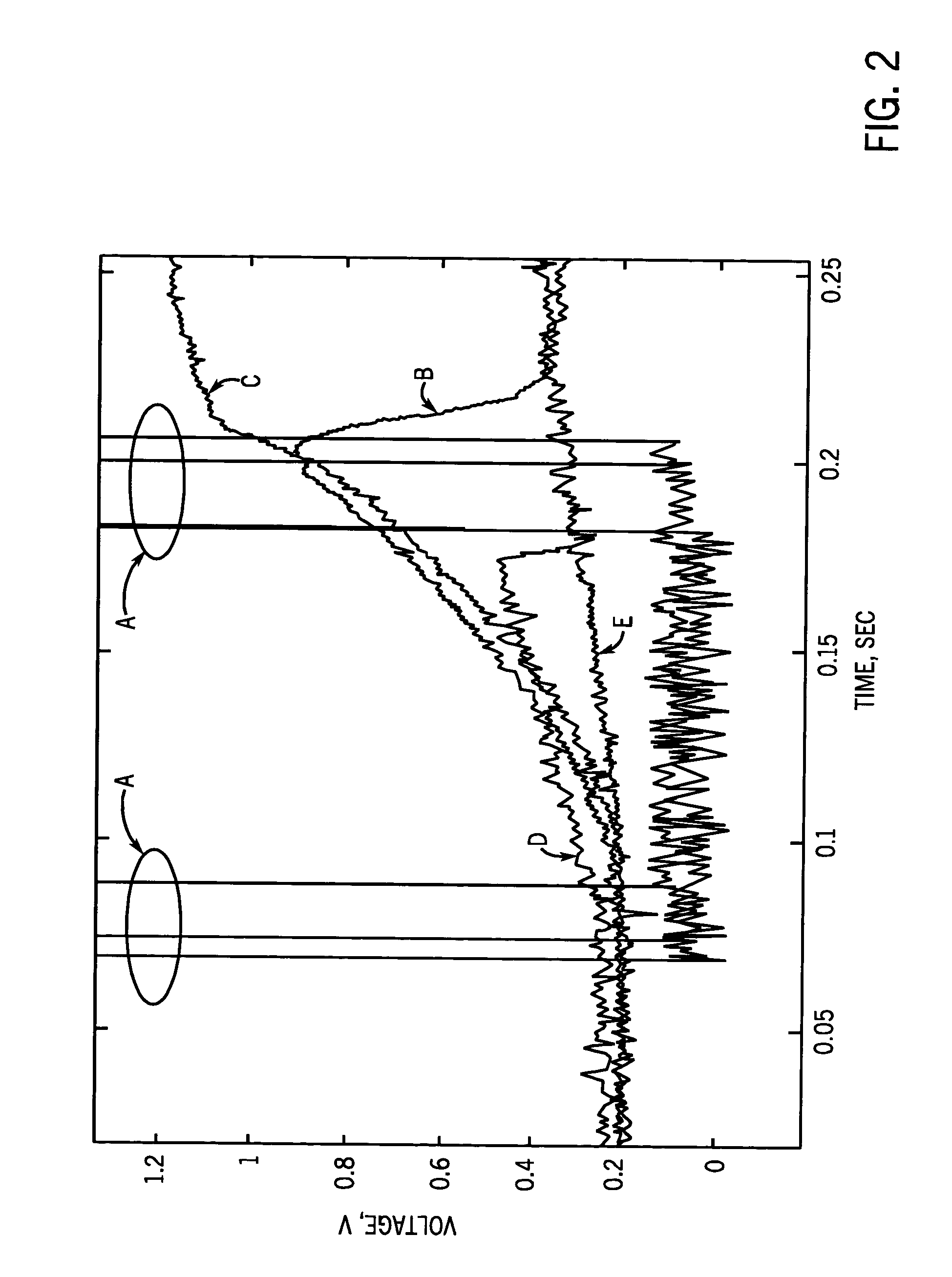

Method for discriminating between operating conditions in medical pump

A method is disclosed for determining the operating condition of a medical pump based on data derived from a pressure sensor and a position sensor. The pressure sensor generates pressure data by sensing the force on the pumping element. The position sensor generates position data by tracking the pumping cycle and determining the position of the pumping element. The pump pressure data and pump position data are processed and the calculated results compared with a pre-determined threshold value to determine the operating condition of the pump. The three main types of operating conditions of concern are the following: normal condition, where liquid is present and no leaks exist in pumping chamber; leak condition, where liquid is present but a leak exists in the pumping chamber; and air stroke condition, where the chamber contains some air.

Owner:ABBOTT LAB INC

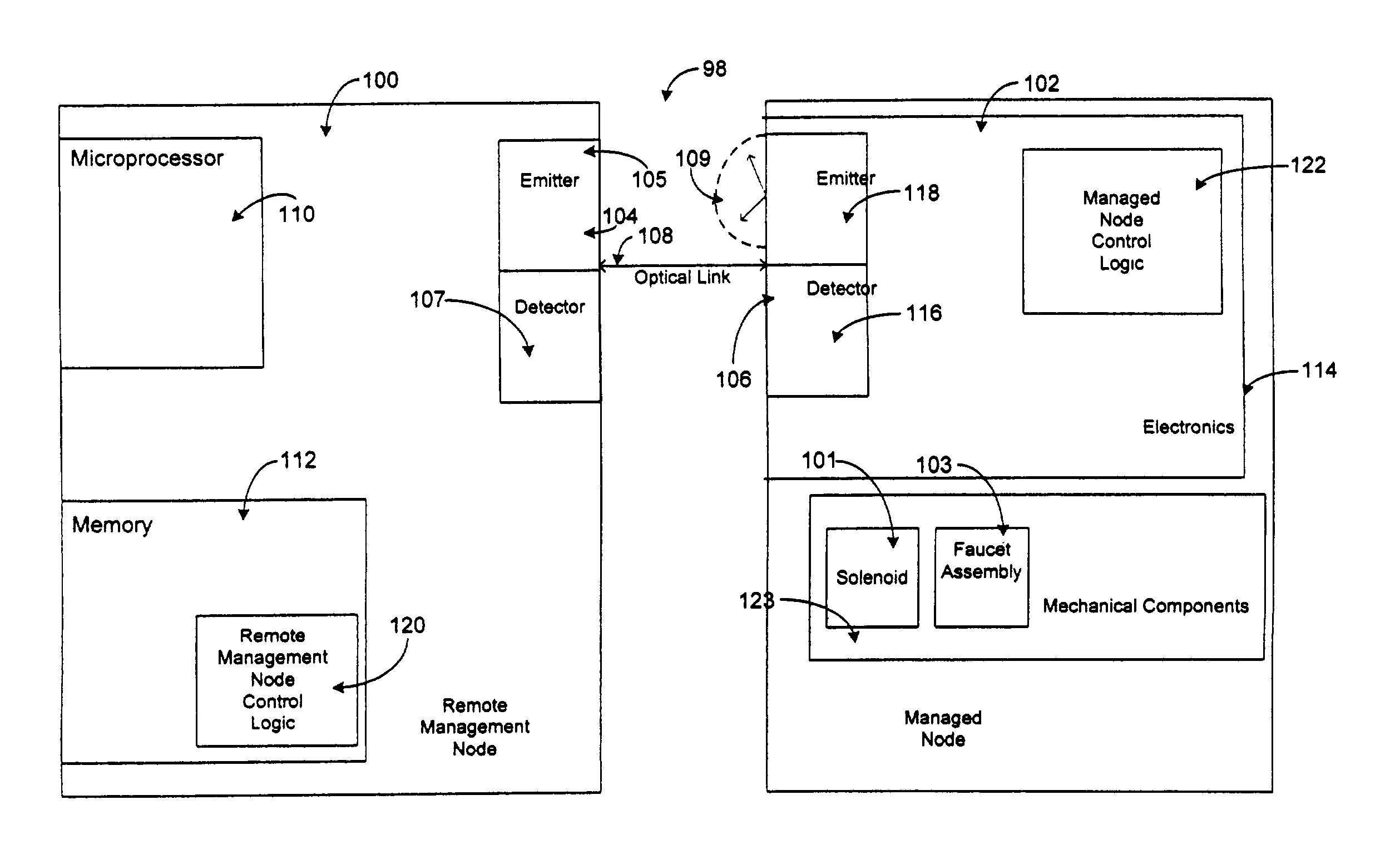

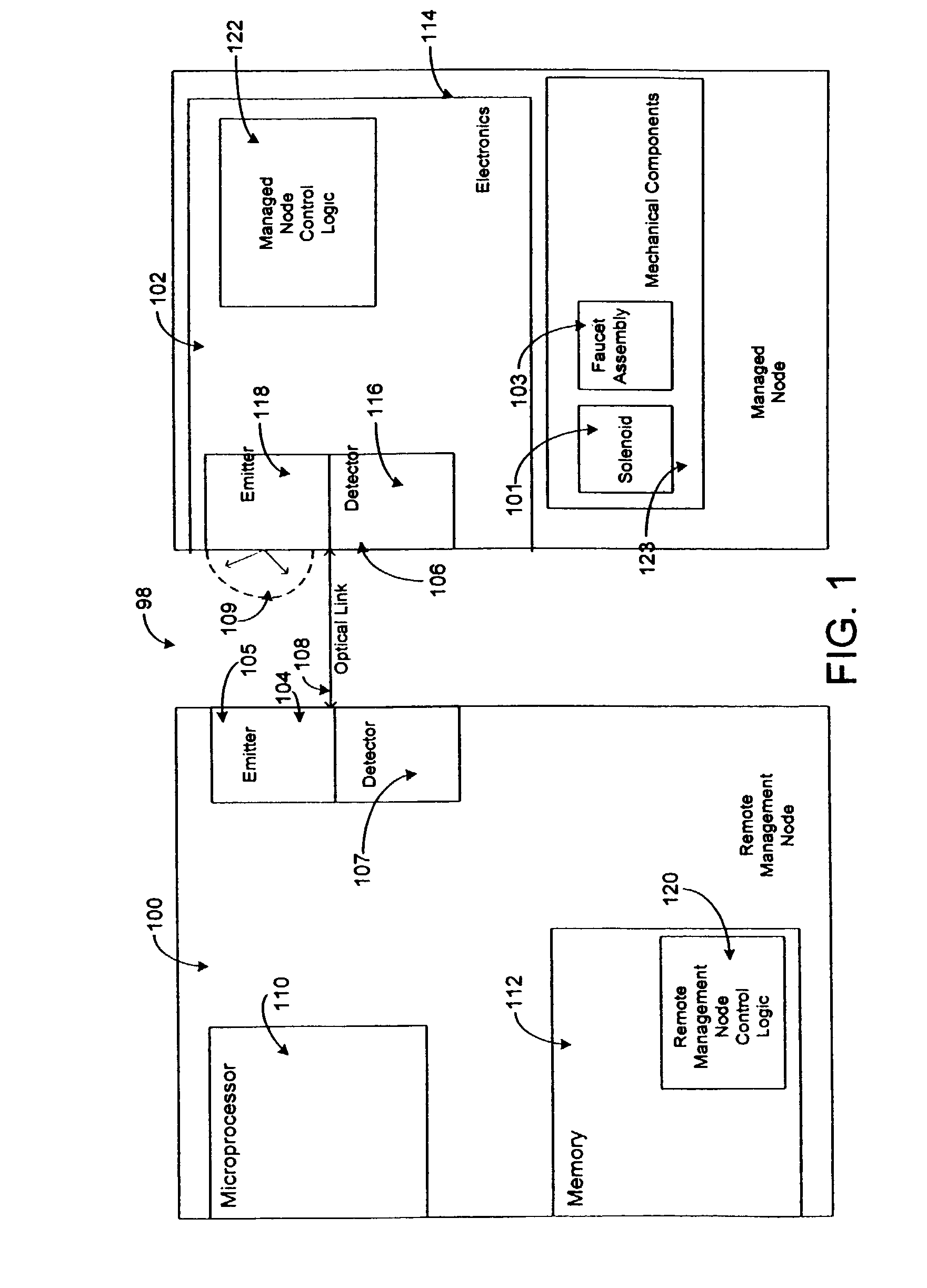

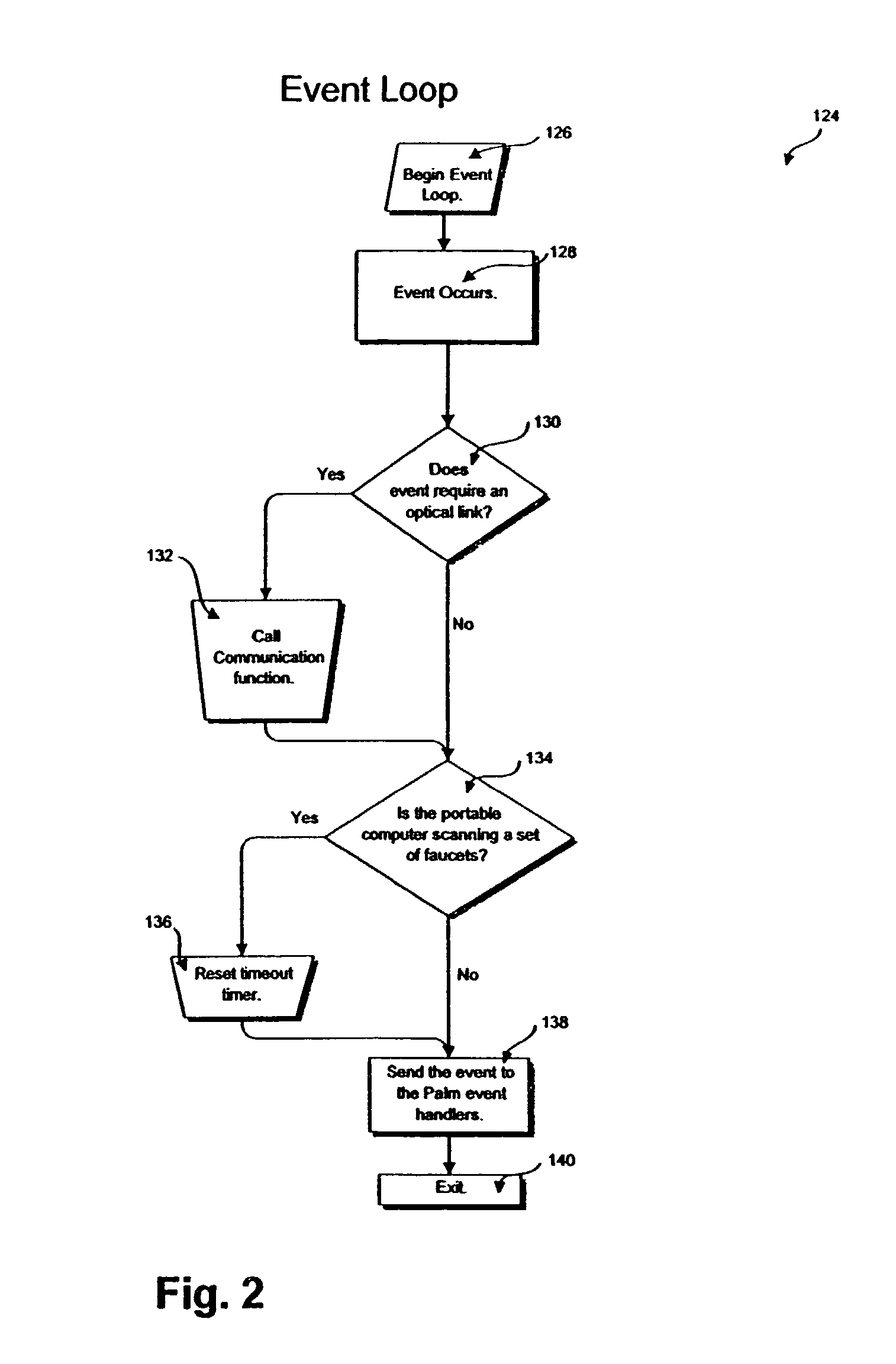

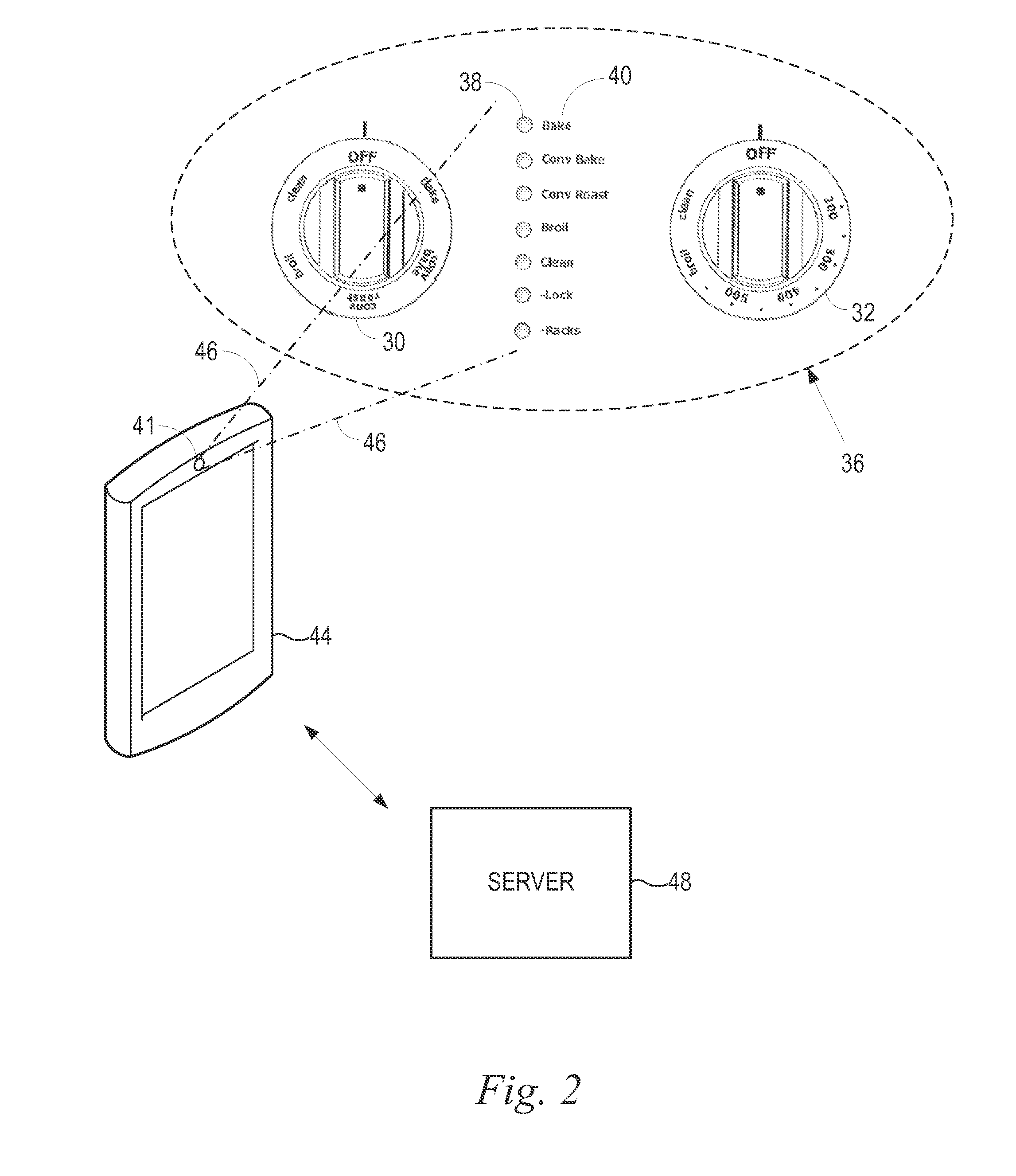

System and method for wireless data exchange between an appliance and a handheld device

InactiveUS7099649B2Reduce in quantityReadily apparentProgramme controlNon-electrical signal transmission systemsPrimary operationComputer module

A wireless data exchange system is disclosed. The system includes an electronically operated appliance including a transmitter, a receiver, and a control module configured to communicate with the transmitter and receiver. The control module provides a primary mode of operation and a secondary mode of operation and includes control logic configured to selectively change the mode of operation of the electronically operated appliance. A communication device adapted to be held in the hand of a user is configured to cooperate with the transmitter and the receiver to impart instructions wirelessly to the control logic in order to change the mode of operation of the electronically operated appliance upon receipt of a command from a user. A method of exchanging data wirelessly between an apparatus and a communication device is also disclosed.

Owner:GEBERIT INT AG

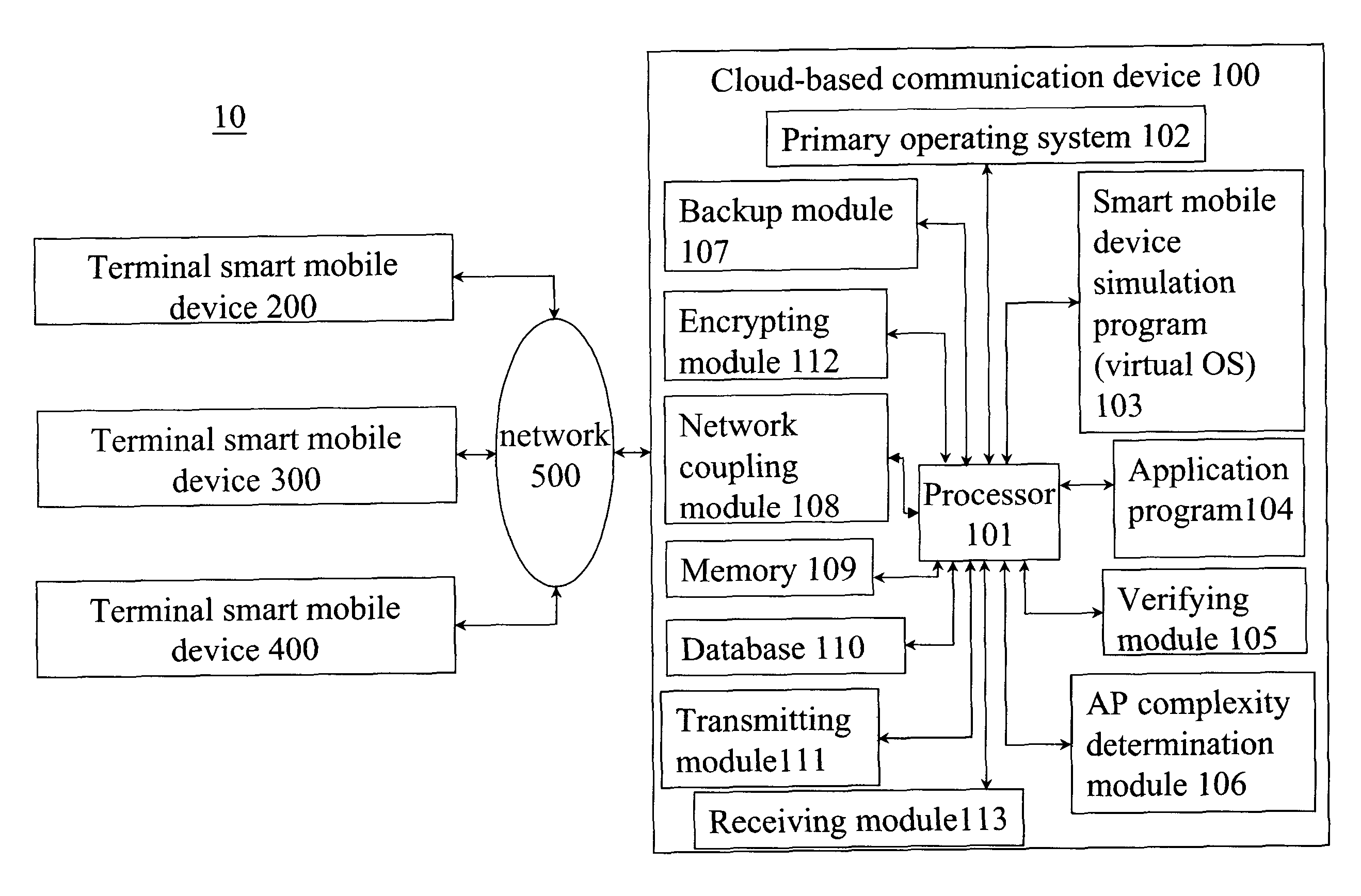

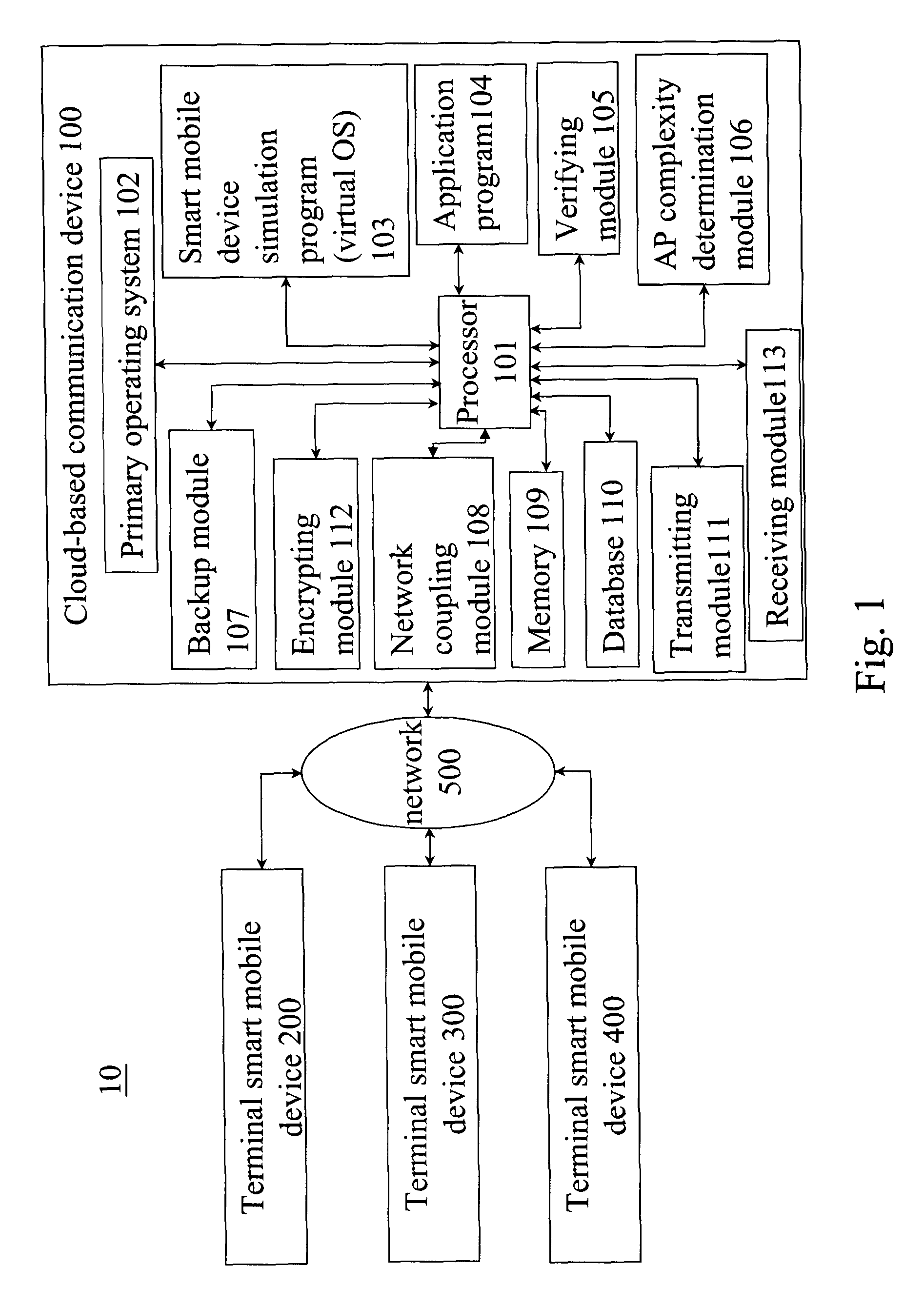

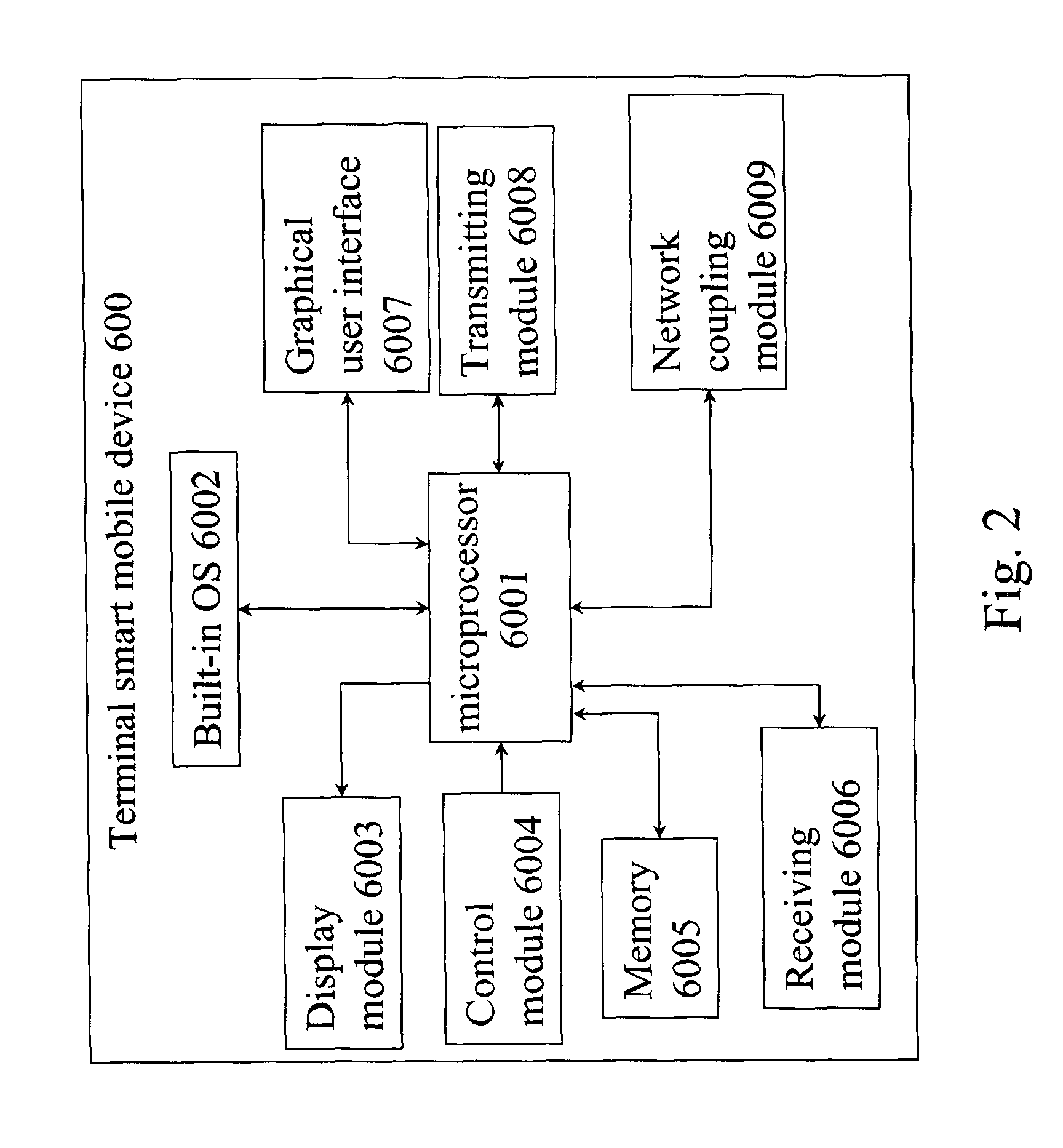

Cloud-based Communication Device and Smart Mobile Device Using Cloud-based Communication Device

InactiveUS20130007203A1Reduce power consumption rateExtended use timeService provisioningMultiple digital computer combinationsComputer hardwareGraphics

The present invention provides a cloud-based communication device, including a processor; a primary operating system implanted in the cloud-based communication device; a virtual operating system or program executed by the processor and generating display data, wherein the primary operating system is different from the virtual operating system or program, the display data instructing a smart mobile device to display a graphical user interface related to the operating system or the program of the smart mobile device simulated by the virtual operating system or program; a transmission module coupled to the processor to transmit the display data to the smart mobile device through a network; a receiving module coupled to the processor to receive the control signals transmitted from the smart mobile device though the network to control the graphical user interface of the virtual operating system or program.

Owner:GCCA

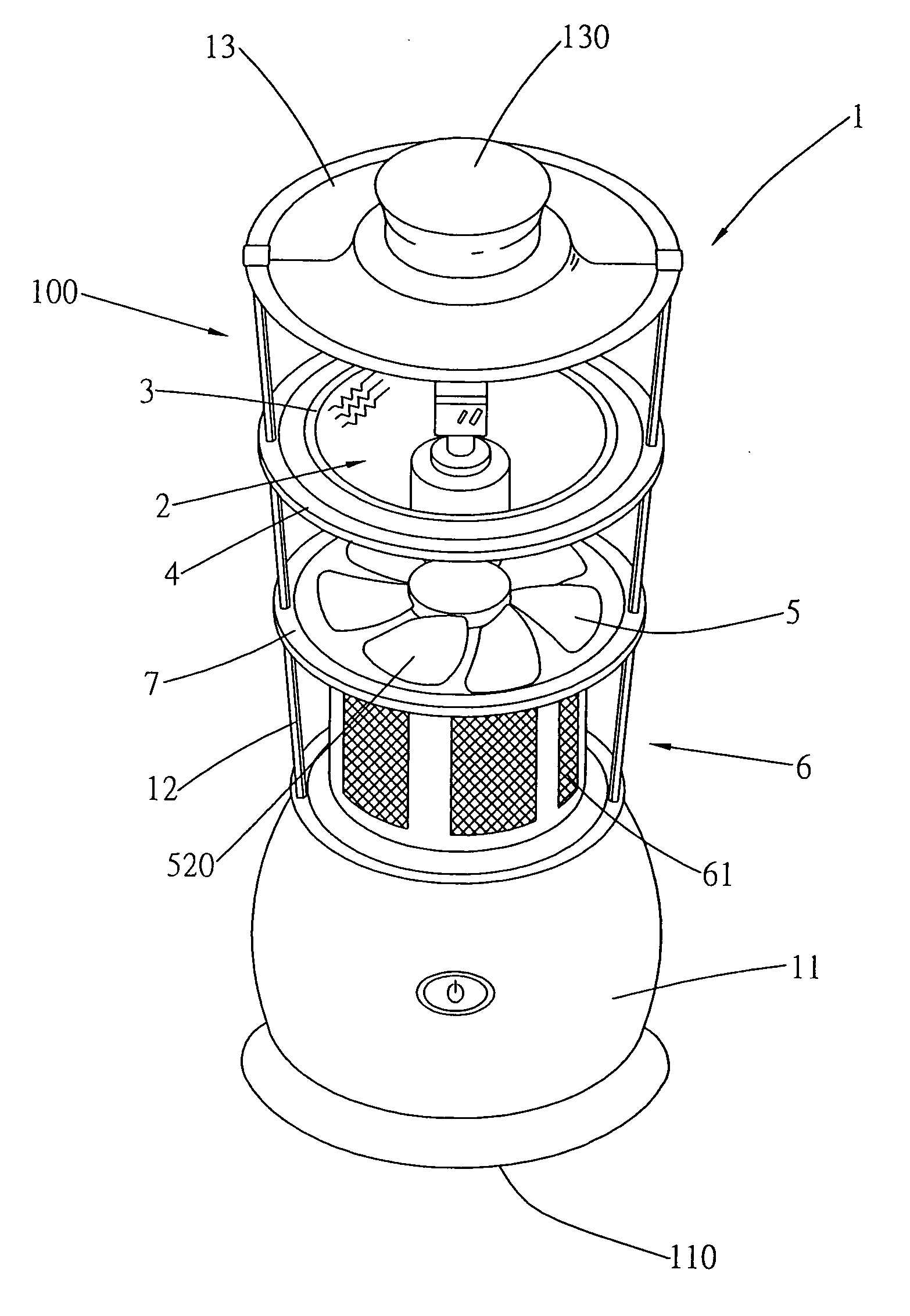

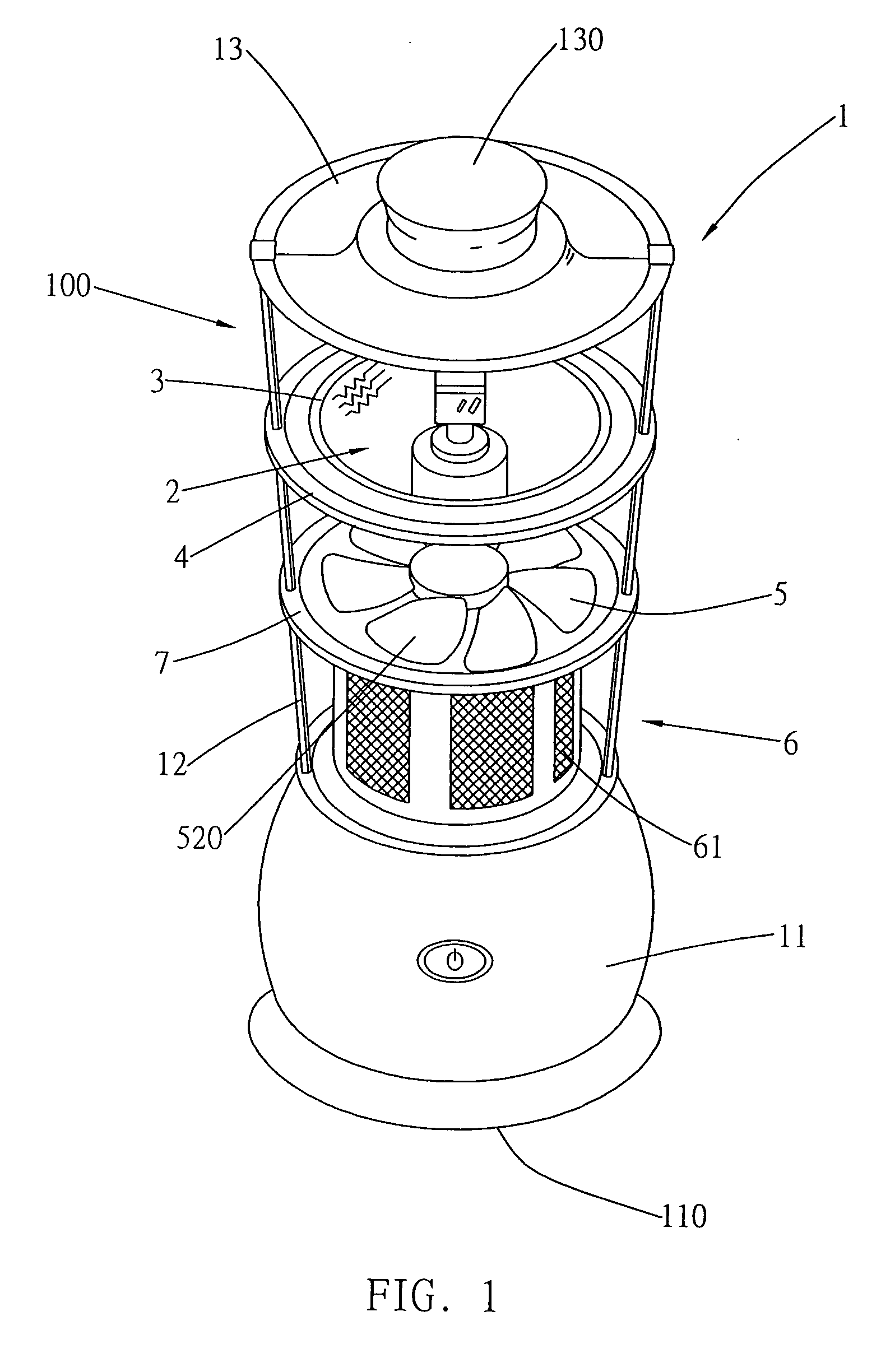

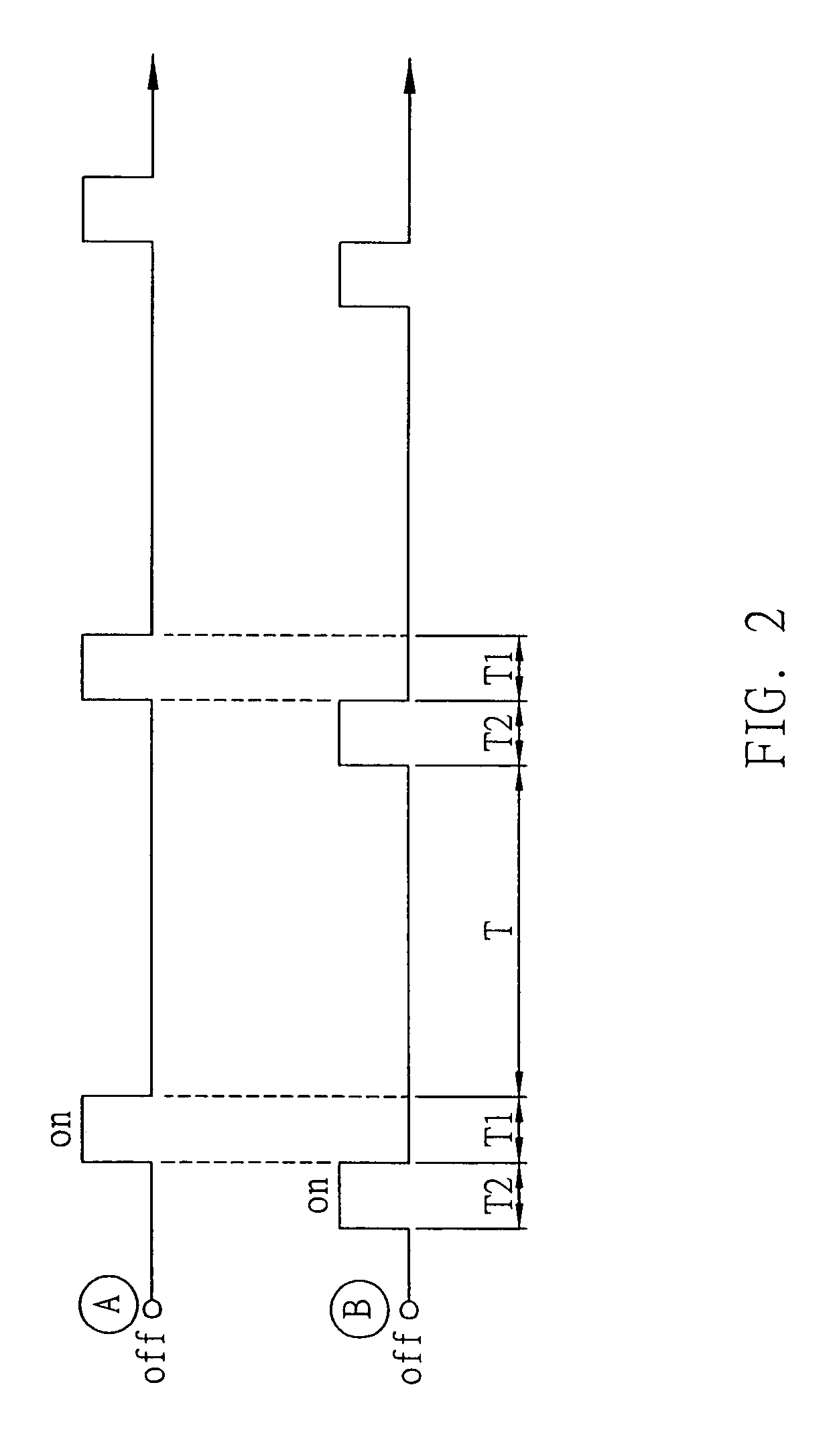

Intermittent insect trap

An intermittent insect trap, working time of which proceeds by alternating periods, and embodies two primary operations including actuation of ultrasonic waves to excite an attractant and form a mist and formation of a backpressure airflow, thereby ensuring that concentration of the mist is not disturbed and thus reduced by external forces during the course of vaporization, and thus preventing dilution of the attractant. Moreover, intermittent operation of a motor results in substantial savings in power. The insect trap primarily uses a mist excitation device to excite and disperse an insect attractant as attractant particles that suspend in the air and diffuse. After achieving a predetermined diffusion concentration, operation switches over to actuate a backpressure device, which pressures lured insects into a receiving chamber through a valve. The alternating working times and mechanical ensnaring of insects provide the insect trap with effective inducement and power saving features.

Owner:KAI CHIH IND

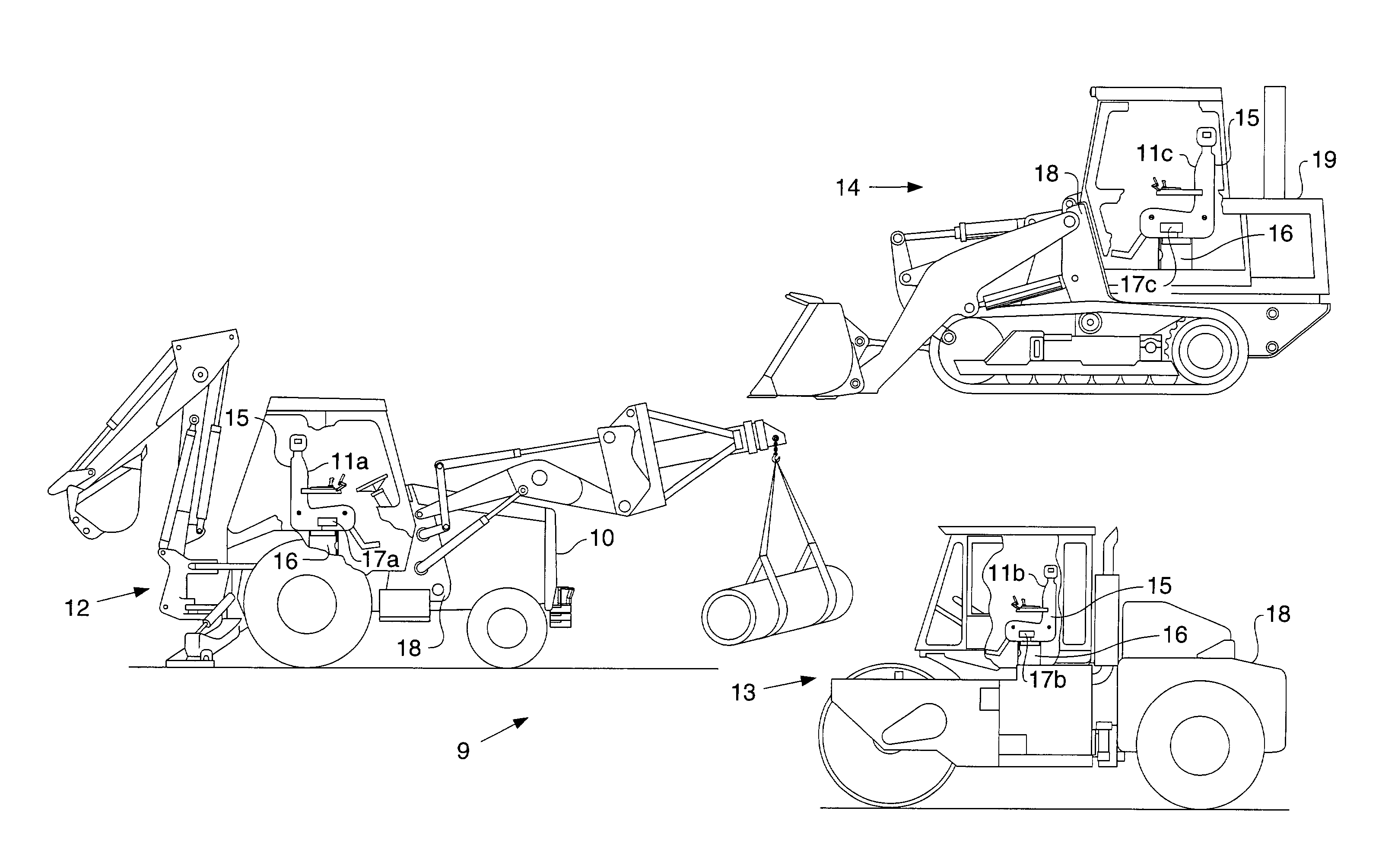

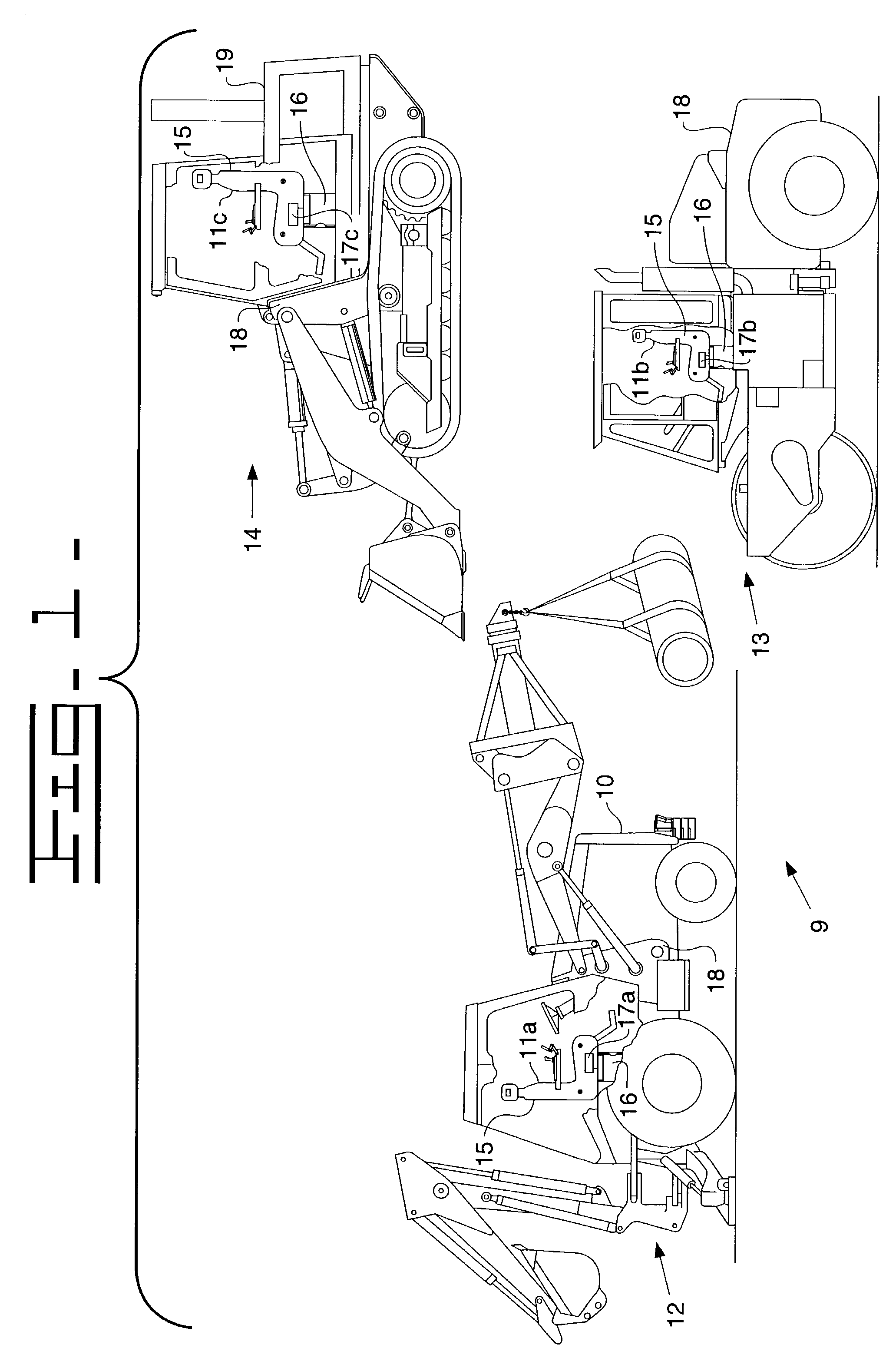

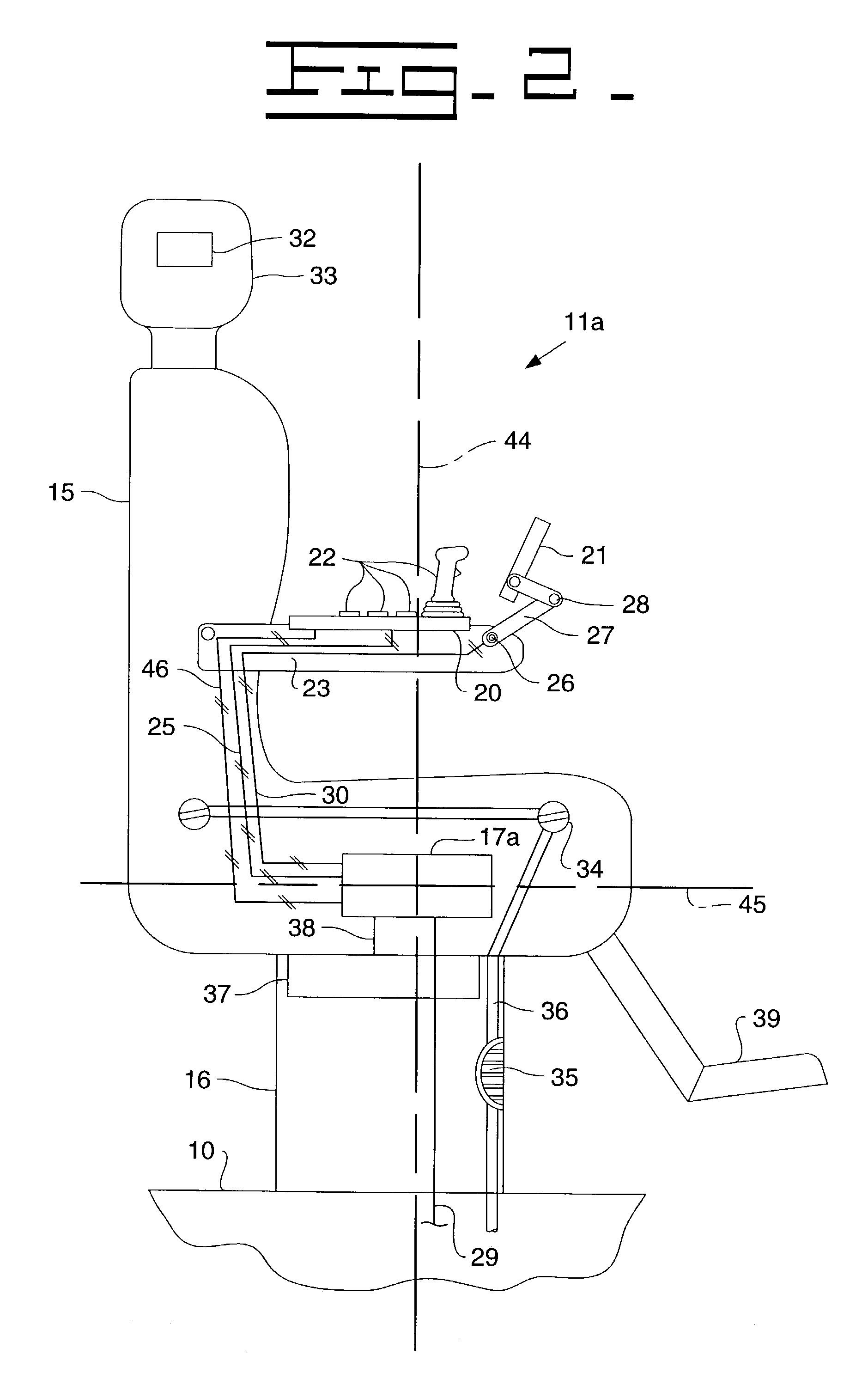

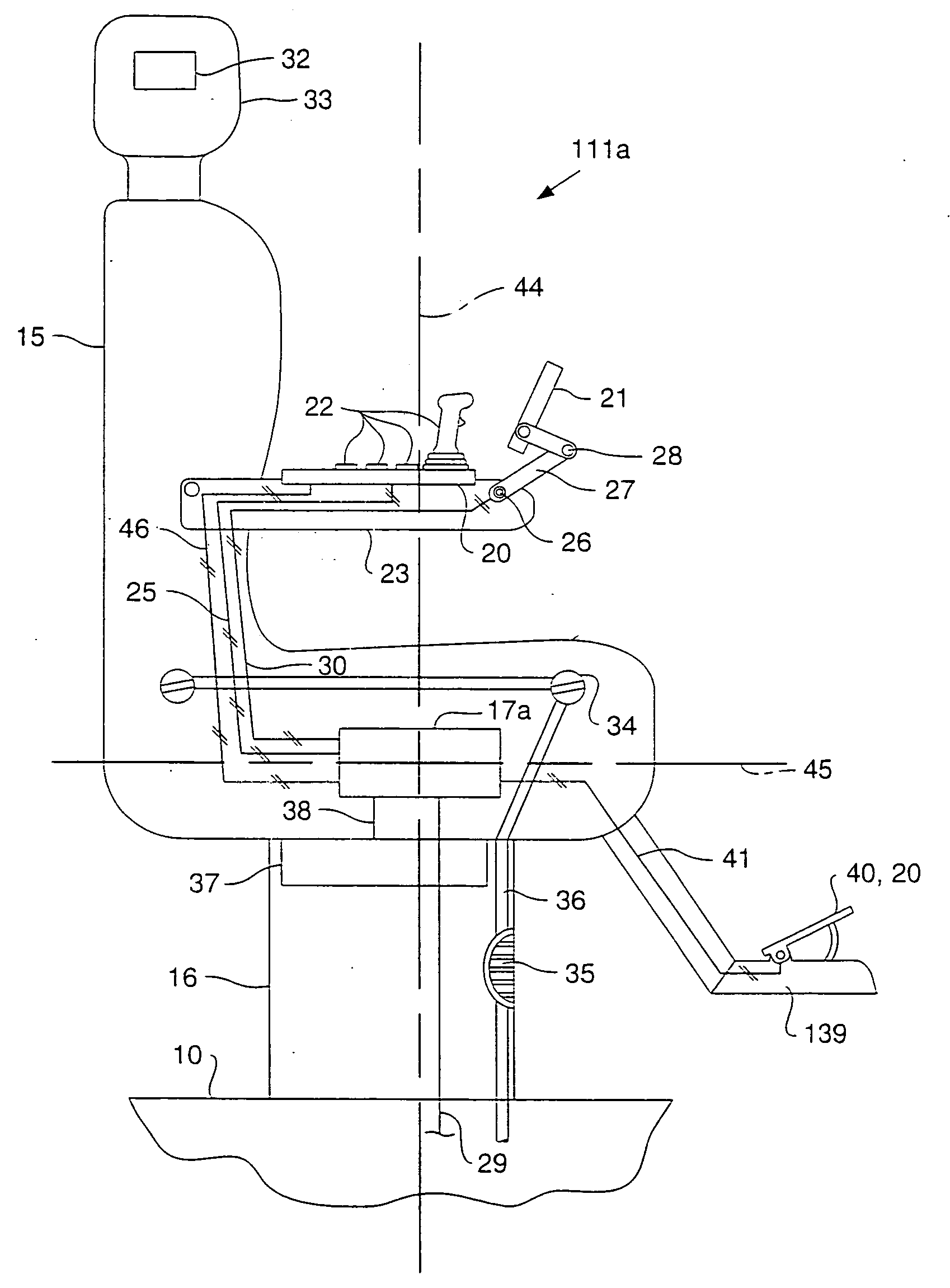

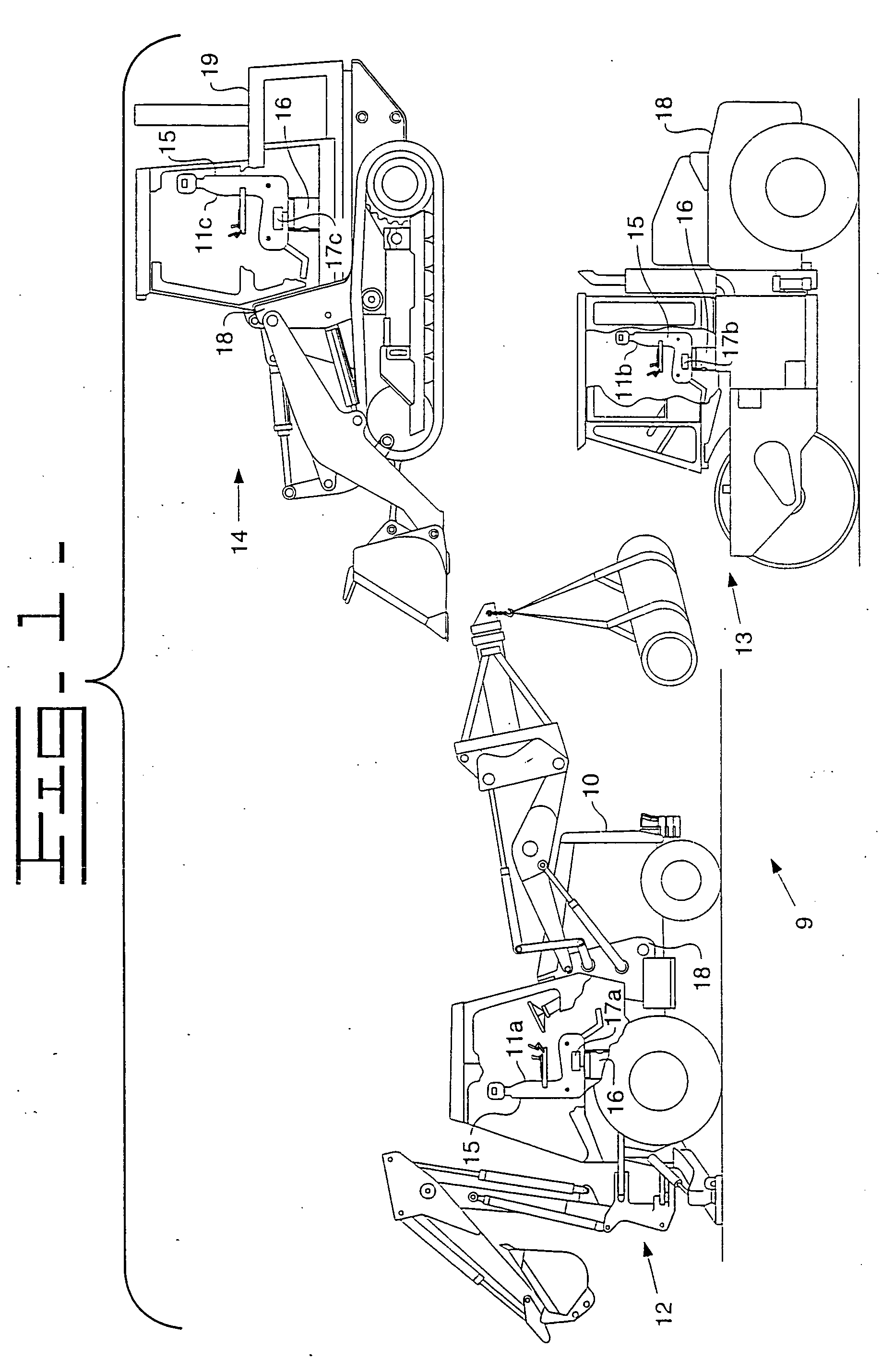

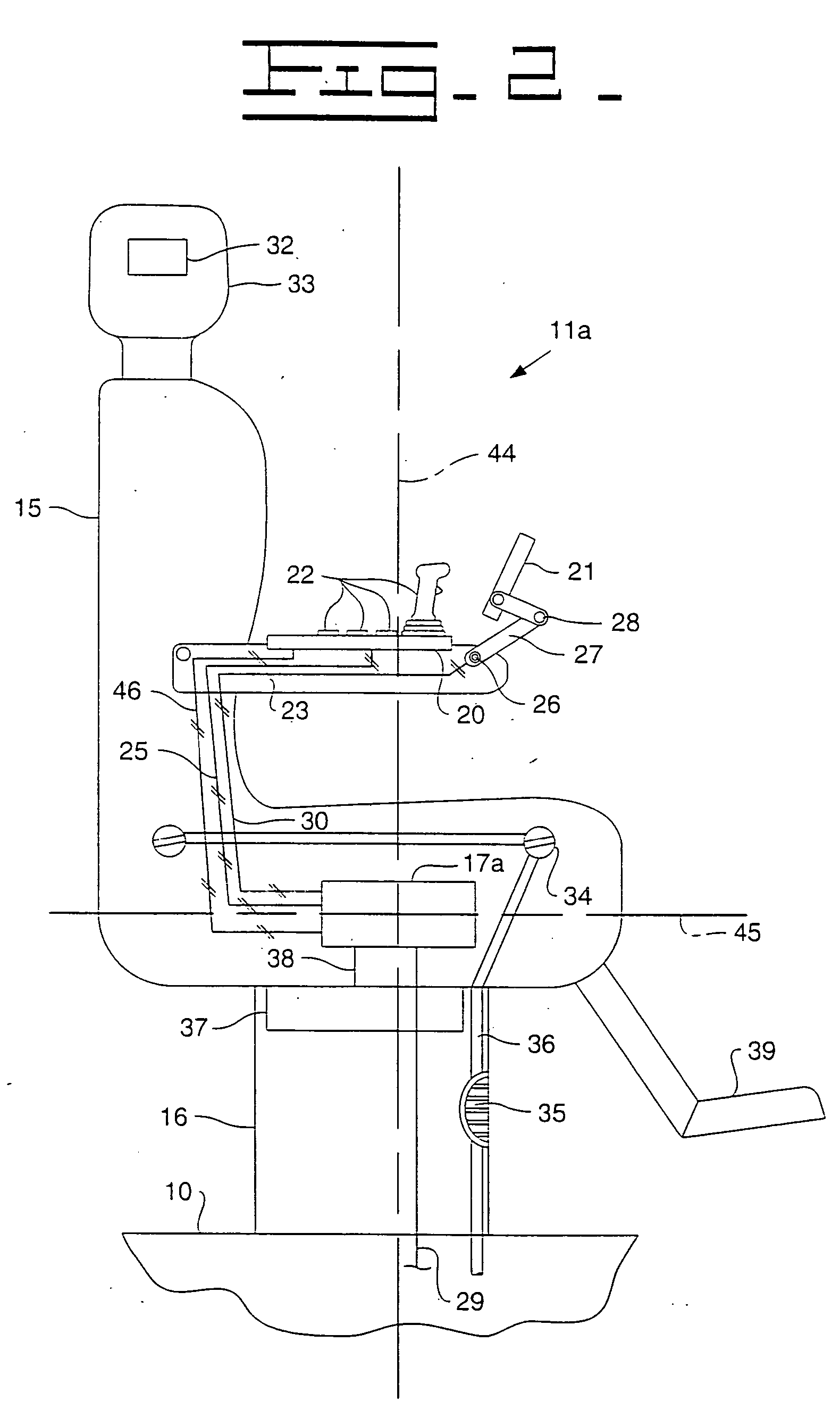

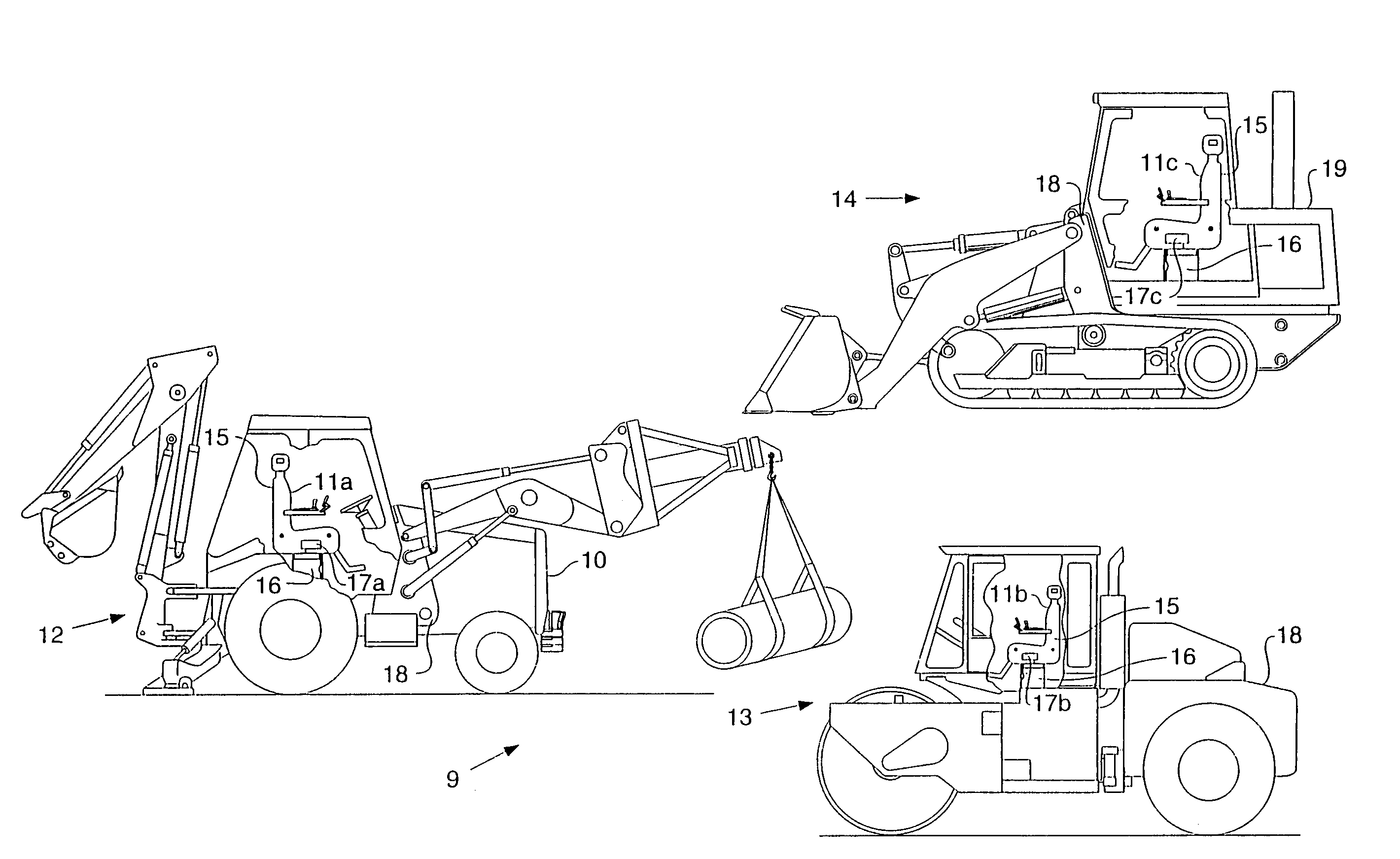

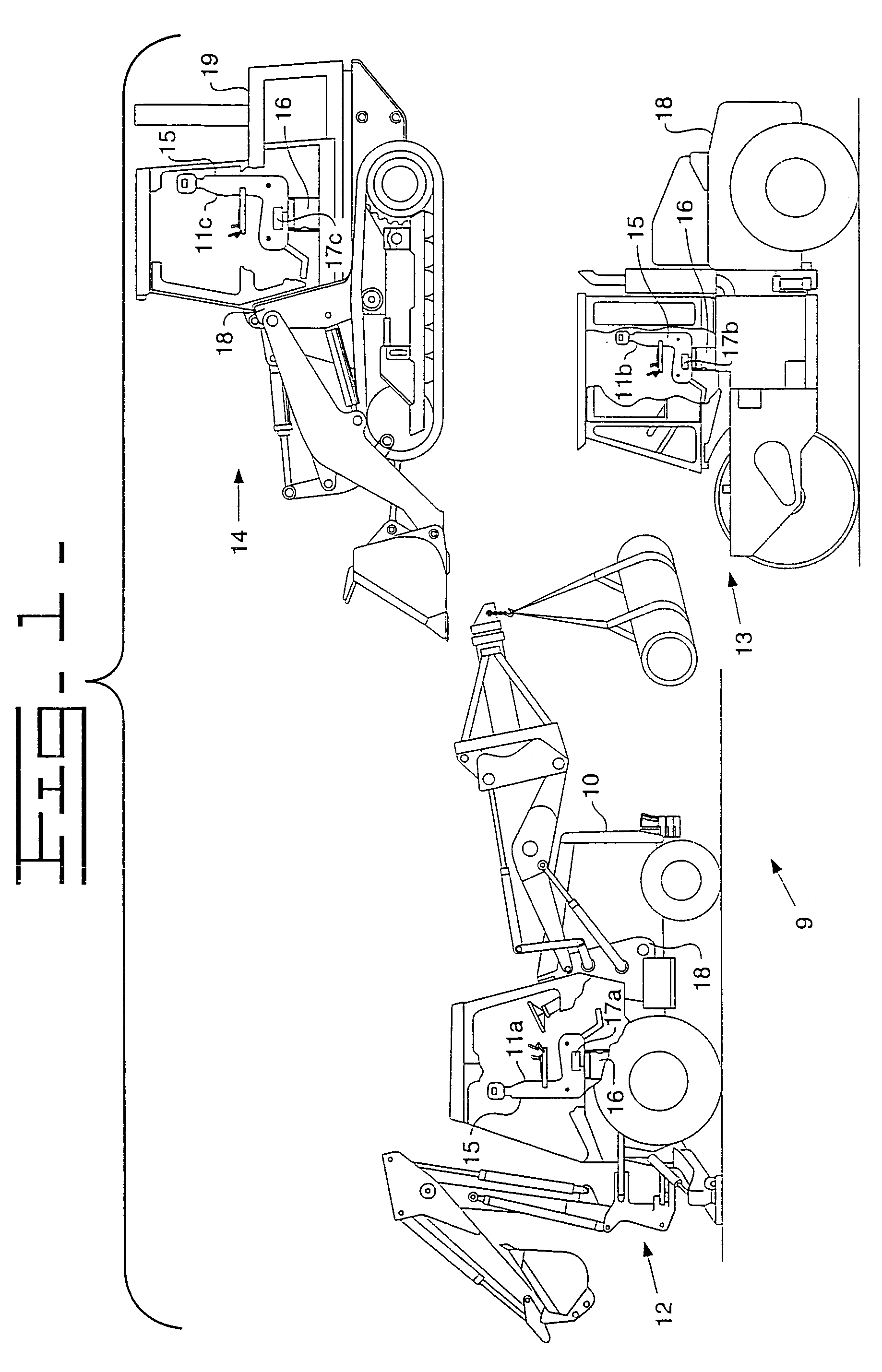

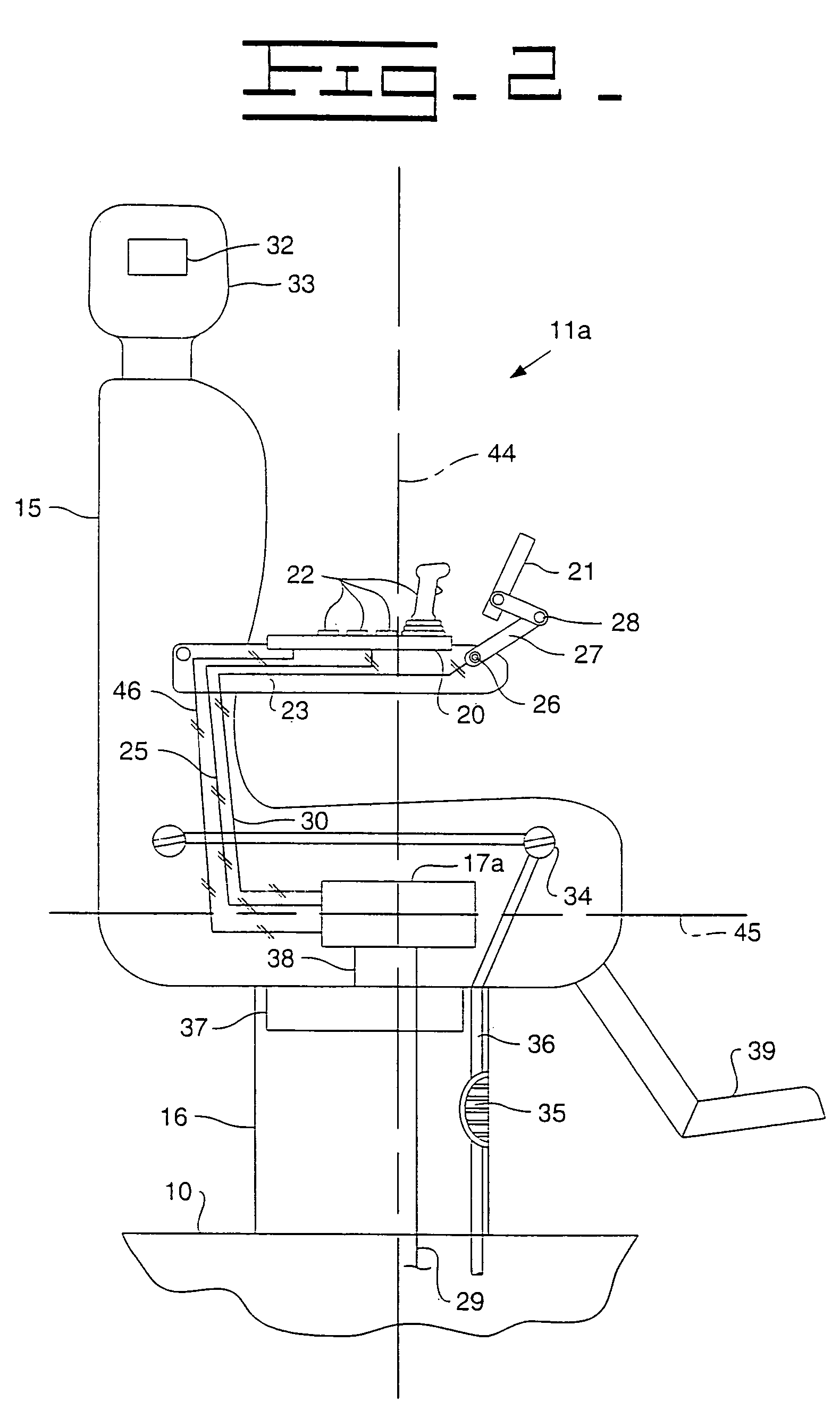

Operator control station for controlling different work machines

In order to enhance an operator's ability to control a work machine, an operator control station includes a seat assembly that is moveably mounted to a body of the work machine. The operator can control, at least in part, primary operator controllable aspects of the work machine by manipulating work machine operating controls attached to move with the seat assembly. The operator can monitor a work machine operating condition, at least in part, via a work machine operating condition display panel also attached to move with the seat assembly. In addition, the operator control station is interchangeable among a plurality of work machines of different types and sizes.

Owner:CATERPILLAR INC

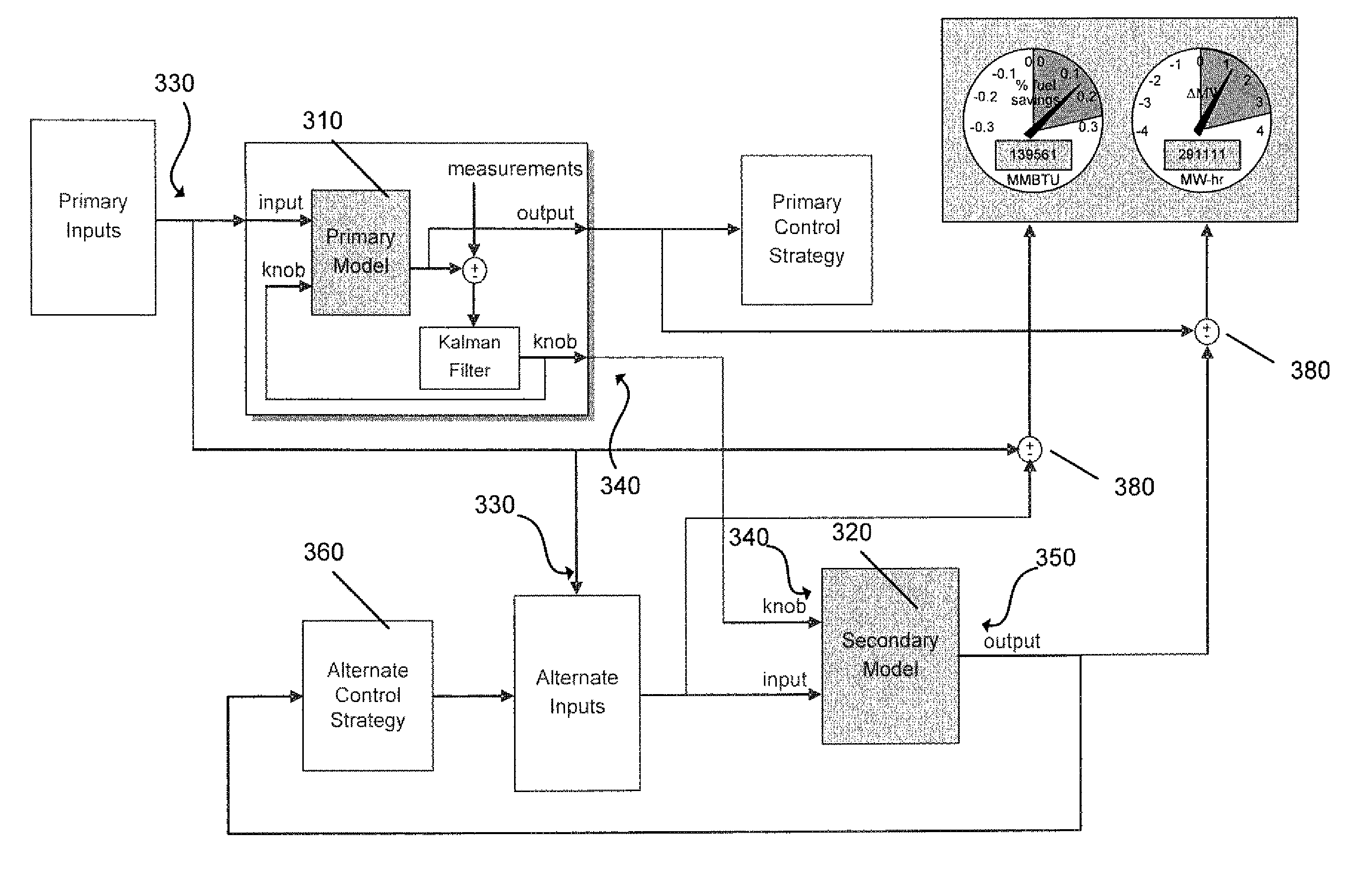

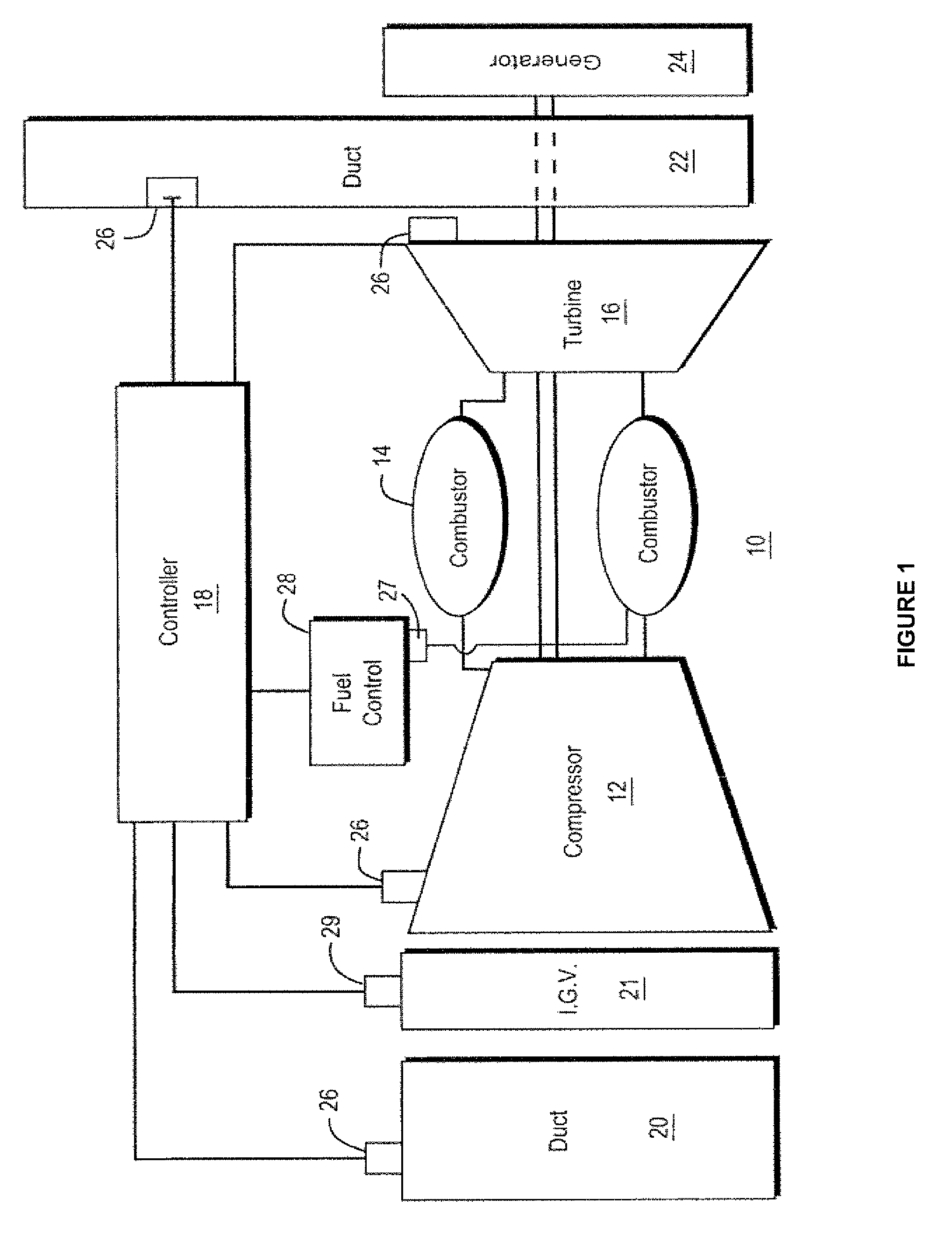

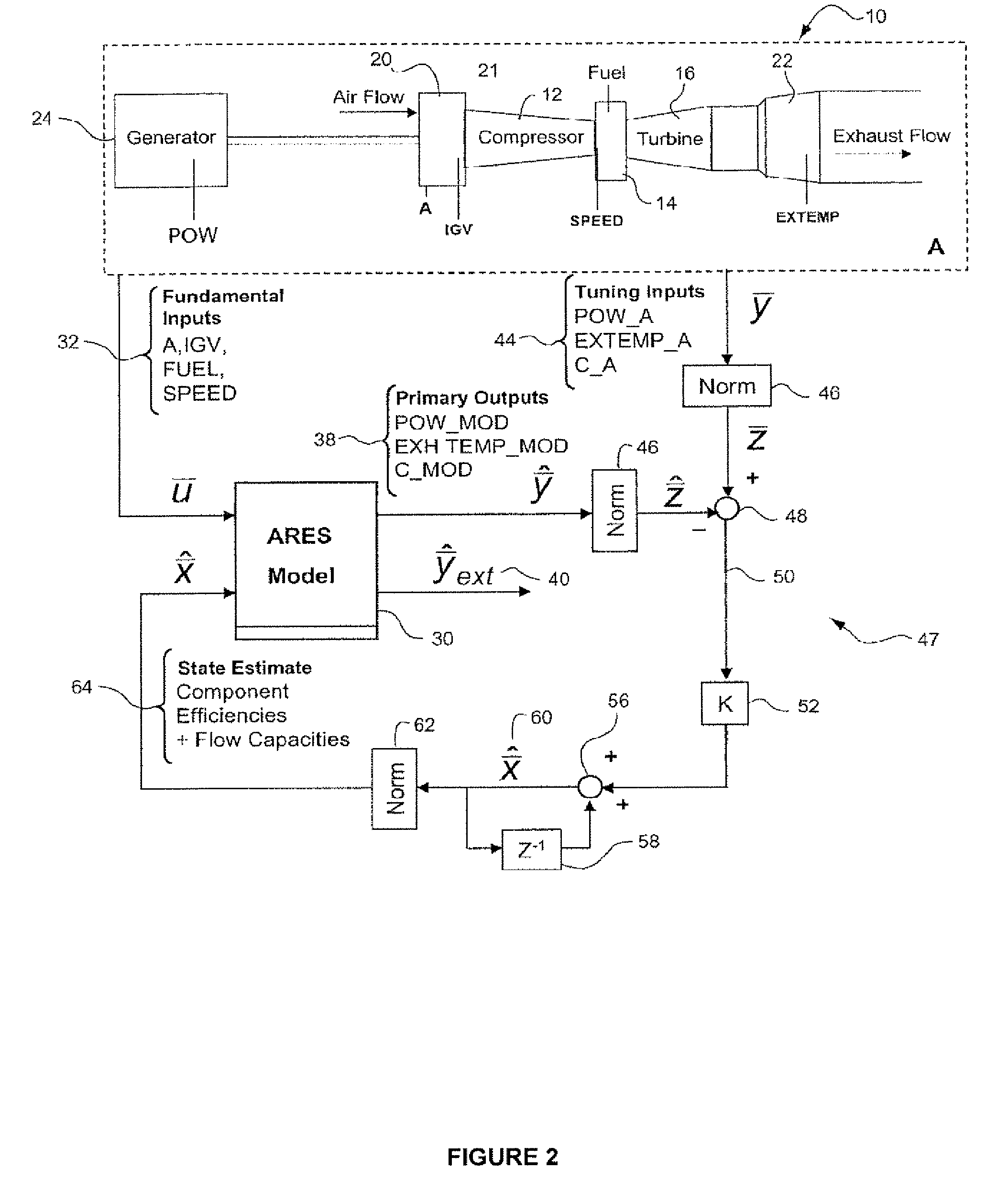

Methods and systems for providing real-time comparison with an alternate control strategy for a turbine

ActiveUS7822512B2Mechanical power/torque controlAnalogue computers for vehiclesPrimary operationSimulation

A method for controlling and modeling a turbine is provided. The method may include modeling the turbine by a primary adaptive turbine model that includes at least one primary operating parameter and modeling the turbine by an alternate adaptive turbine model that includes at least one alternate operating parameter. The method may also include determining a first output value from the primary adaptive turbine model that corresponds at least in part to the operation of the turbine based on a primary control strategy and adjusting the alternate operating parameter or parameters based on an alternate control strategy and based at least in part on the first output value. The method may further include determining comparison data based at least in part on a comparison between the primary control strategy and the alternate control strategy.

Owner:GE INFRASTRUCTURE TECH INT LLC

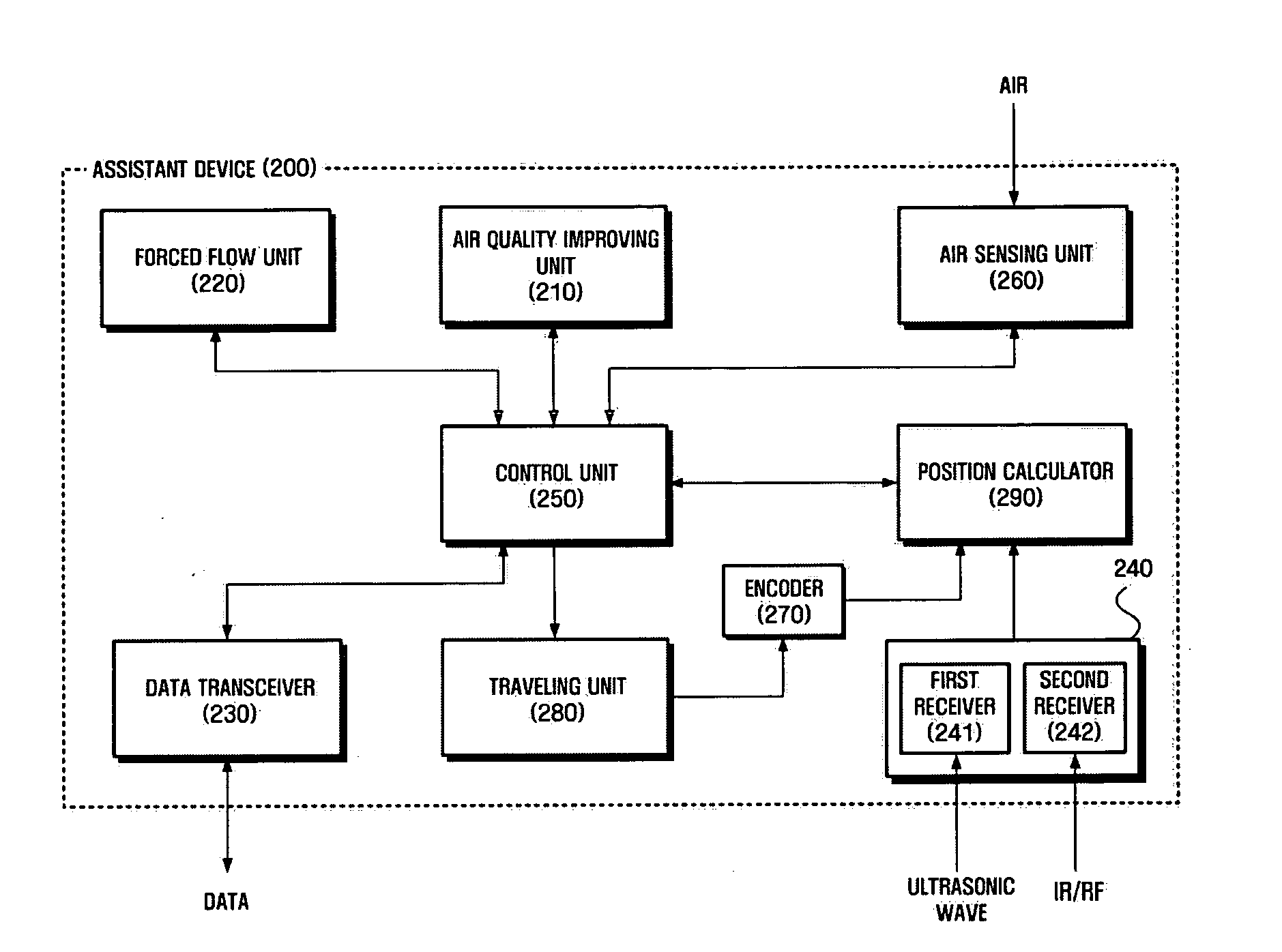

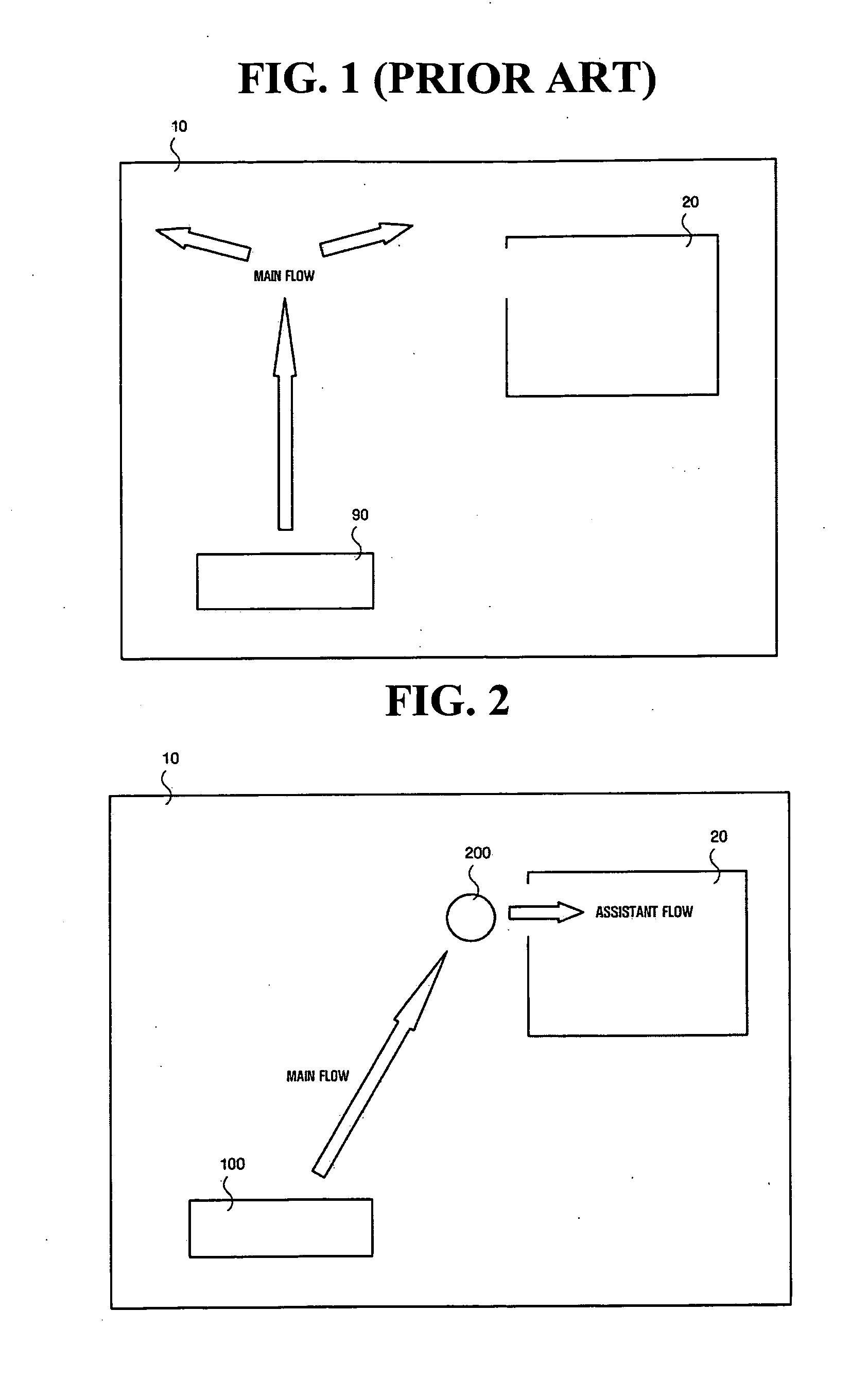

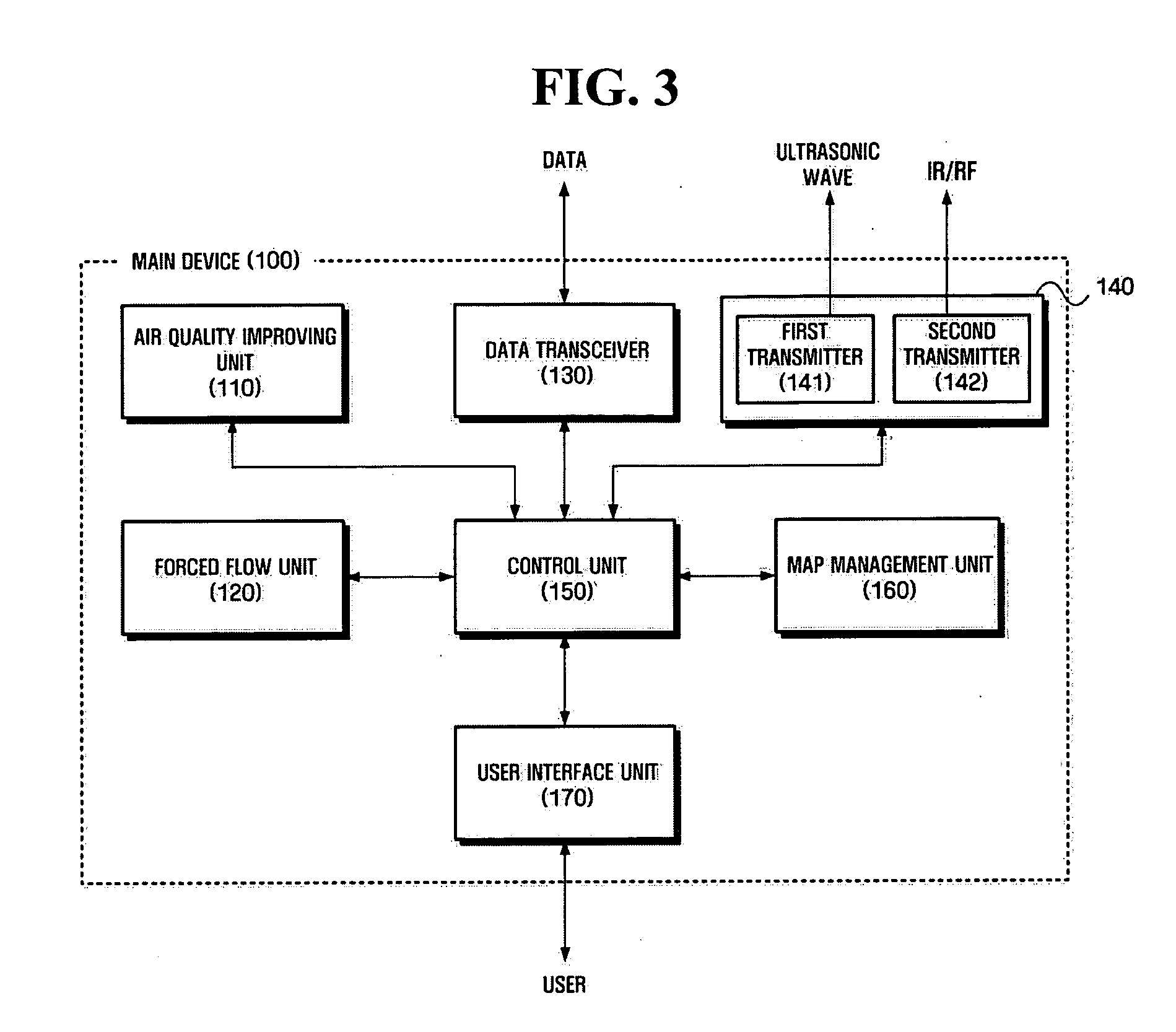

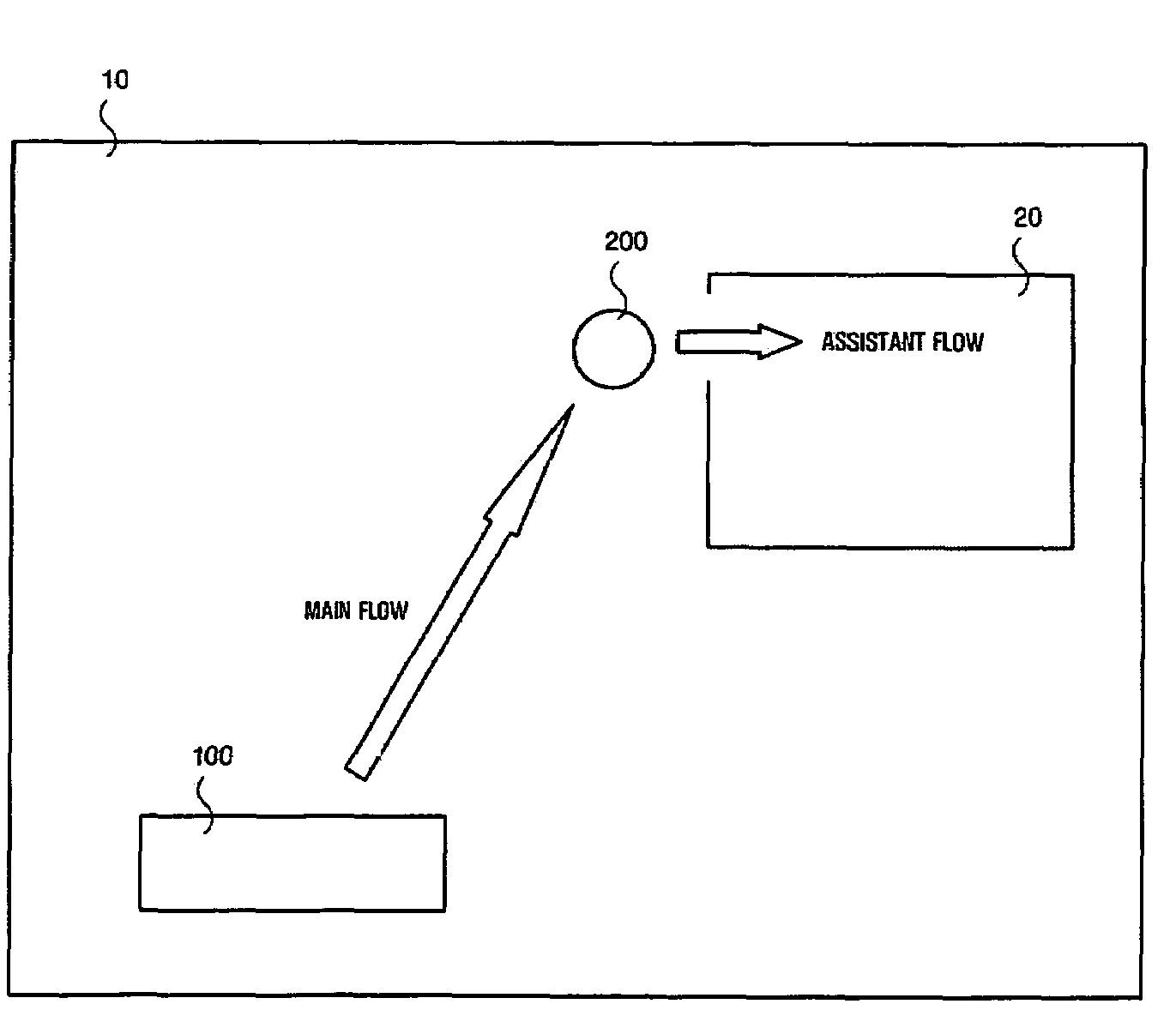

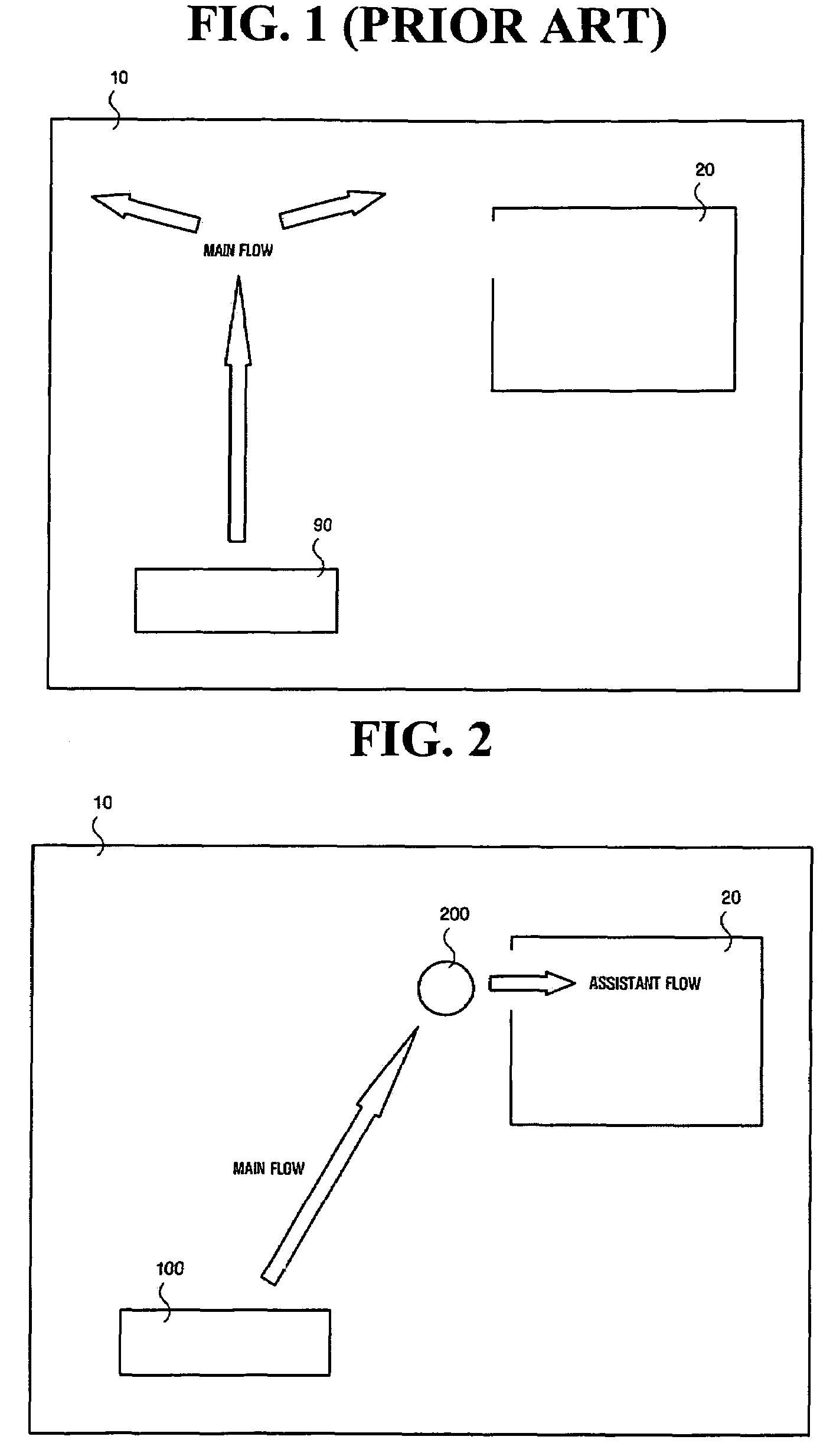

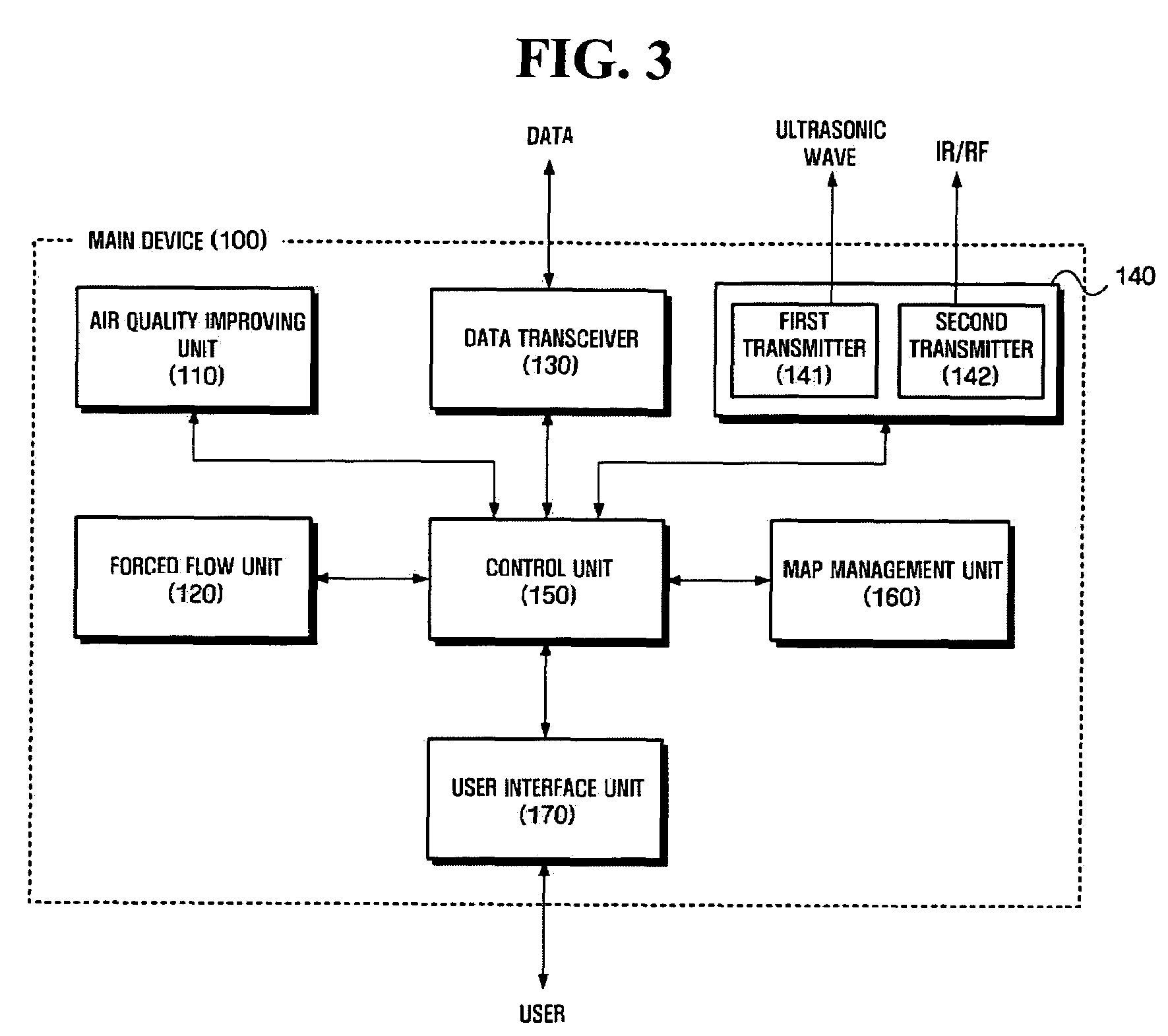

System and method for managing indoor air through cooperation between air conditioner and mobile assistant device

ActiveUS20060064204A1Improve air qualityIncrease valueMechanical apparatusLighting and heating apparatusPrimary operationAir quality index

A method and system for efficiently managing indoor air through cooperation between a mobile device and a stationary air conditioner. The system may include at least one stationary air conditioner and at least one mobile assistant device that move with a predetermined management area and cooperates with the air conditioner. The air conditioner may include an air quality improving unit improving a value of a predetermined air quality index into an appropriate range, a first forced flow unit generating a main flow to transport improved air toward the abnormal region, and a control unit controlling the air quality improving unit and the first forced flow unit to perform a main operation on the abnormal region and transmitting a command instructing the assistant device to perform an assistant operation on the abnormal region to the assistant device.

Owner:SAMSUNG ELECTRONICS CO LTD

Operator control station for controlling different work machines

In order to enhance an operator's ability to control a work machine, an operator control station includes a seat assembly that is moveably mounted to a body of the work machine. The operator can control, at least in part, primary operator controllable aspects of the work machine by manipulating work machine operating controls attached to move with the seat assembly. The operator can monitor a work machine operating condition, at least in part, via a work machine operating condition display panel also attached to move with the seat assembly. In addition, the operator control station is interchangeable among a plurality of work machines of different types and sizes.

Owner:CATERPILLAR INC

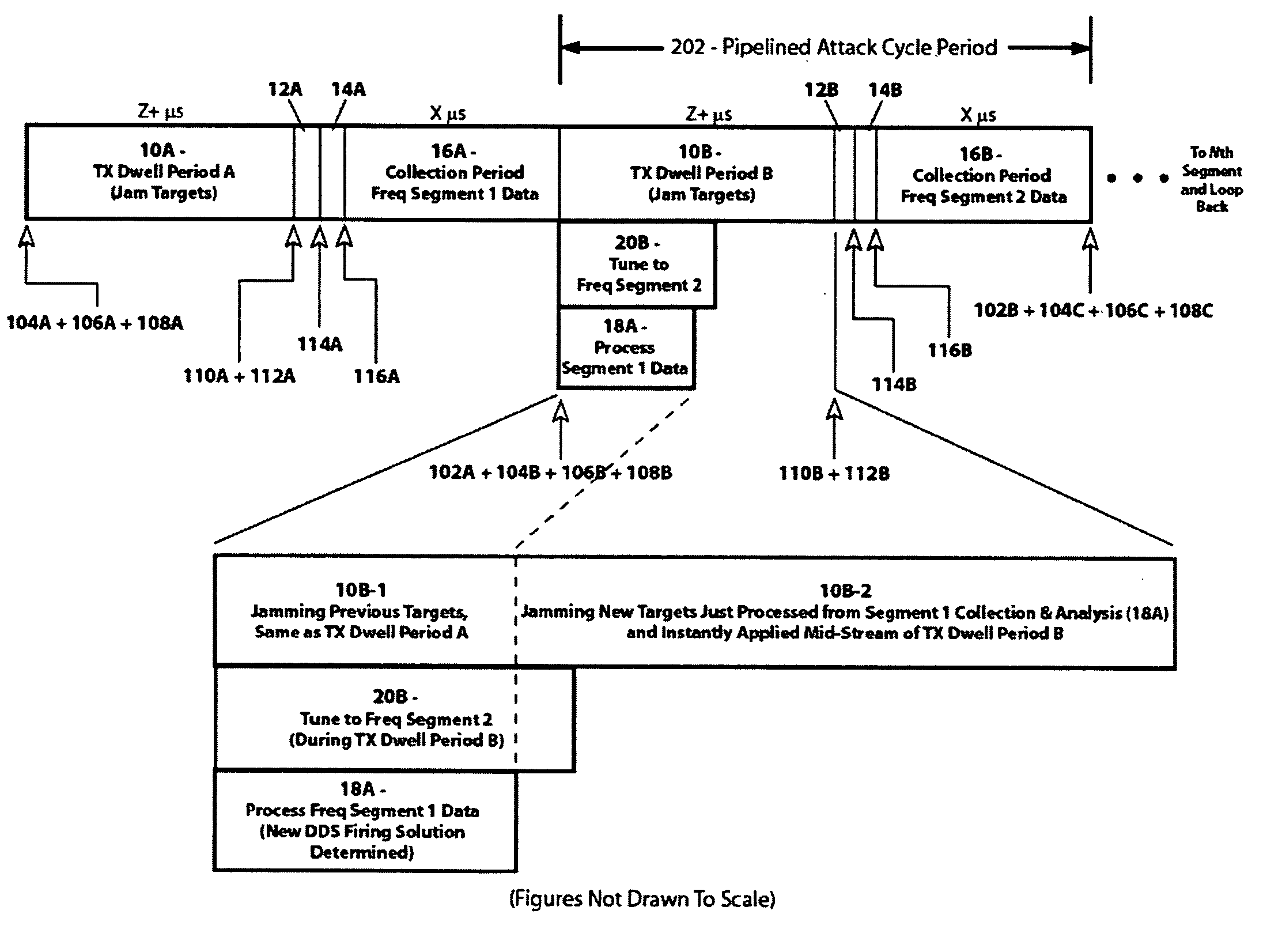

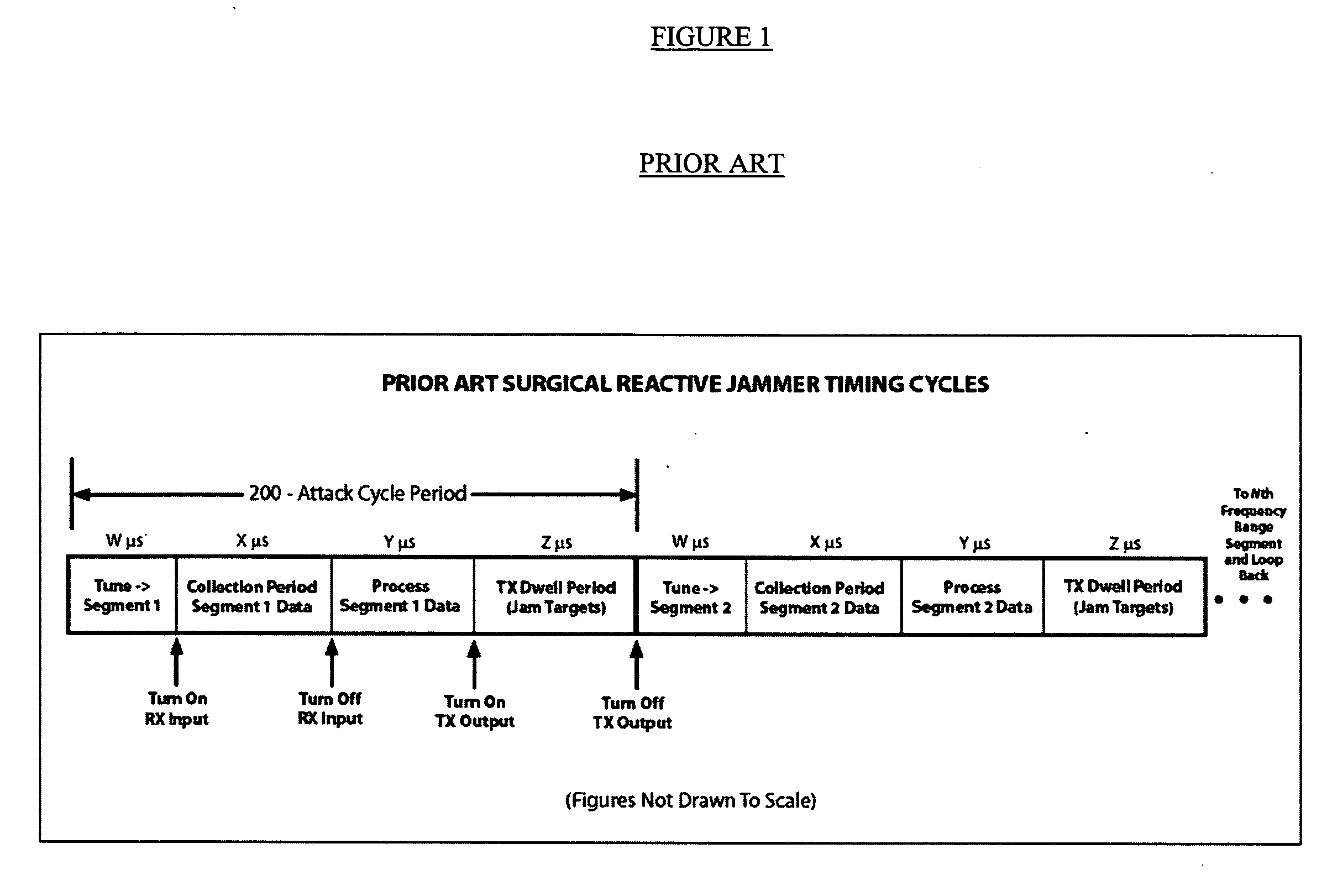

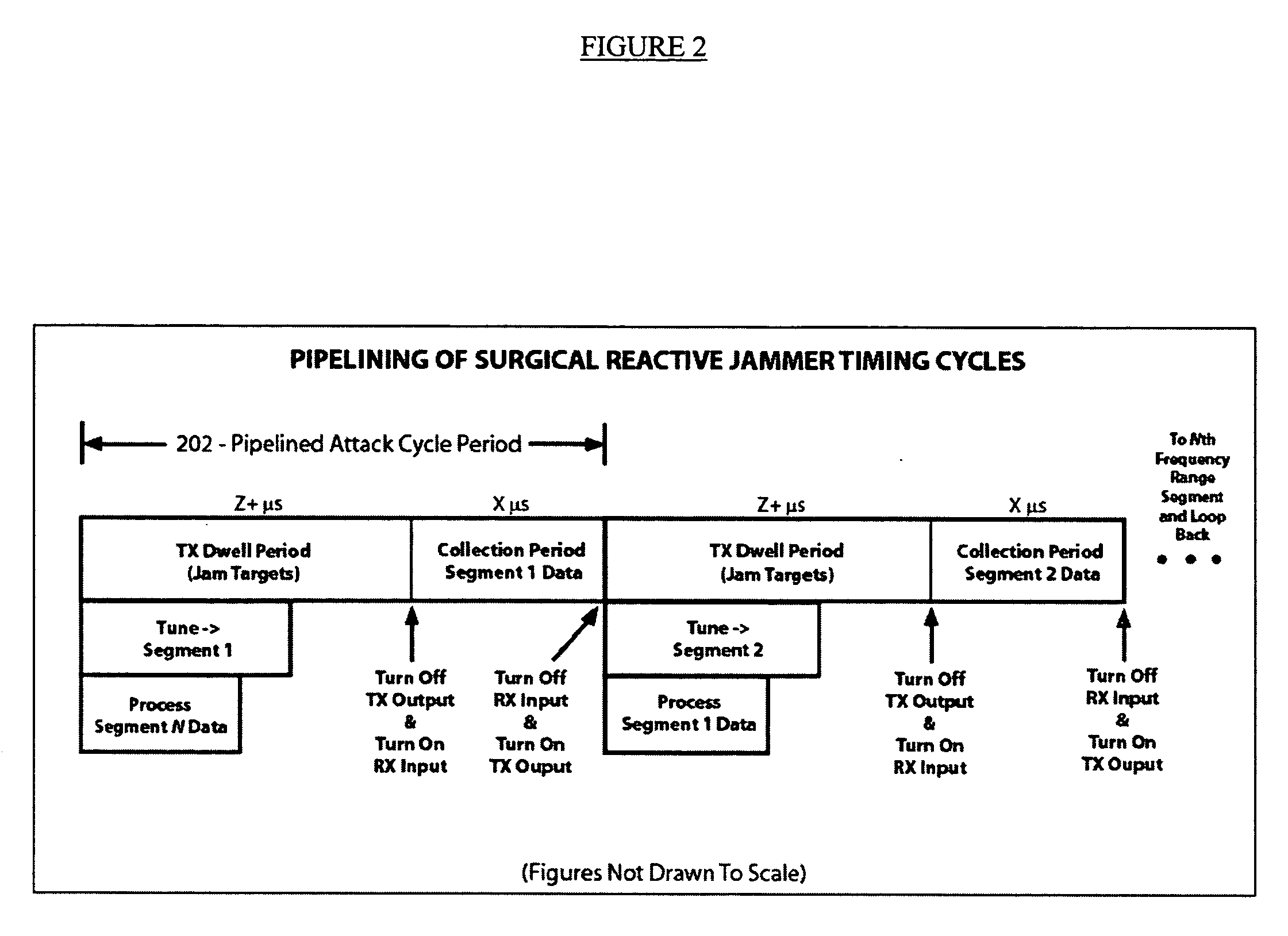

Method, system and apparatus for maximizing a jammer's time-on-target and power-on-target

InactiveUS20060164283A1Enhanced and efficient jammingTime-on-targets are maximizedWave based measurement systemsCommunication jammingMultiplexingElectricity

A Method, System and Apparatus for Maximizing a Jammer's Time and Power on Target is disclosed. System and method of the present invention provide an enhanced and more efficient jamming system that can address multiple simultaneous targets, such that the time-on-targets are maximized given a fixed amount of available system power. Such an enhanced surgical reactive jamming system allows users to more intelligently and efficiently address all targets that suddenly appear, without having to replicate more jamming system hardware which drastically raises the total overall costs. The system has the ability to do fast wideband scanning of the RF spectrum looking for RF signals such as those emitted by frequency hoppers and RCIED's, and then jam them instantaneously. Secondly, the system has the ability to pipeline the major operational functions so that more time can be spent putting energy on target (extends the TX Dwell Period effectively by allowing the jammer more time to apply energy, as opposed to spending time on calculations and re-tuning). Third, the system has the ability to change, mid TX Dwell Period, the output jamming frequencies so it can jam all the current targets with the maximum available power. Fourth and finally, the system has the ability to perform a real time evaluation of the DDS firing solutions such that the signals going to multiple DDS's in a jammer system can be multiplexed in a fashion that optimize time-on-target.

Owner:AGILENT TECH INC

Operator control station for controlling different work machines

In order to enhance an operator's ability to control a work machine, an operator control station includes a seat assembly that is moveably mounted to a body of the work machine. The operator can control, at least in part, primary operator controllable aspects of the work machine by manipulating work machine operating controls attached to move with the seat assembly. The operator can monitor a work machine operating condition, at least in part, via a work machine operating condition display panel also attached to move with the seat assembly. In addition, the operator control station is interchangeable among a plurality of work machines of different types and sizes.

Owner:CATERPILLAR INC

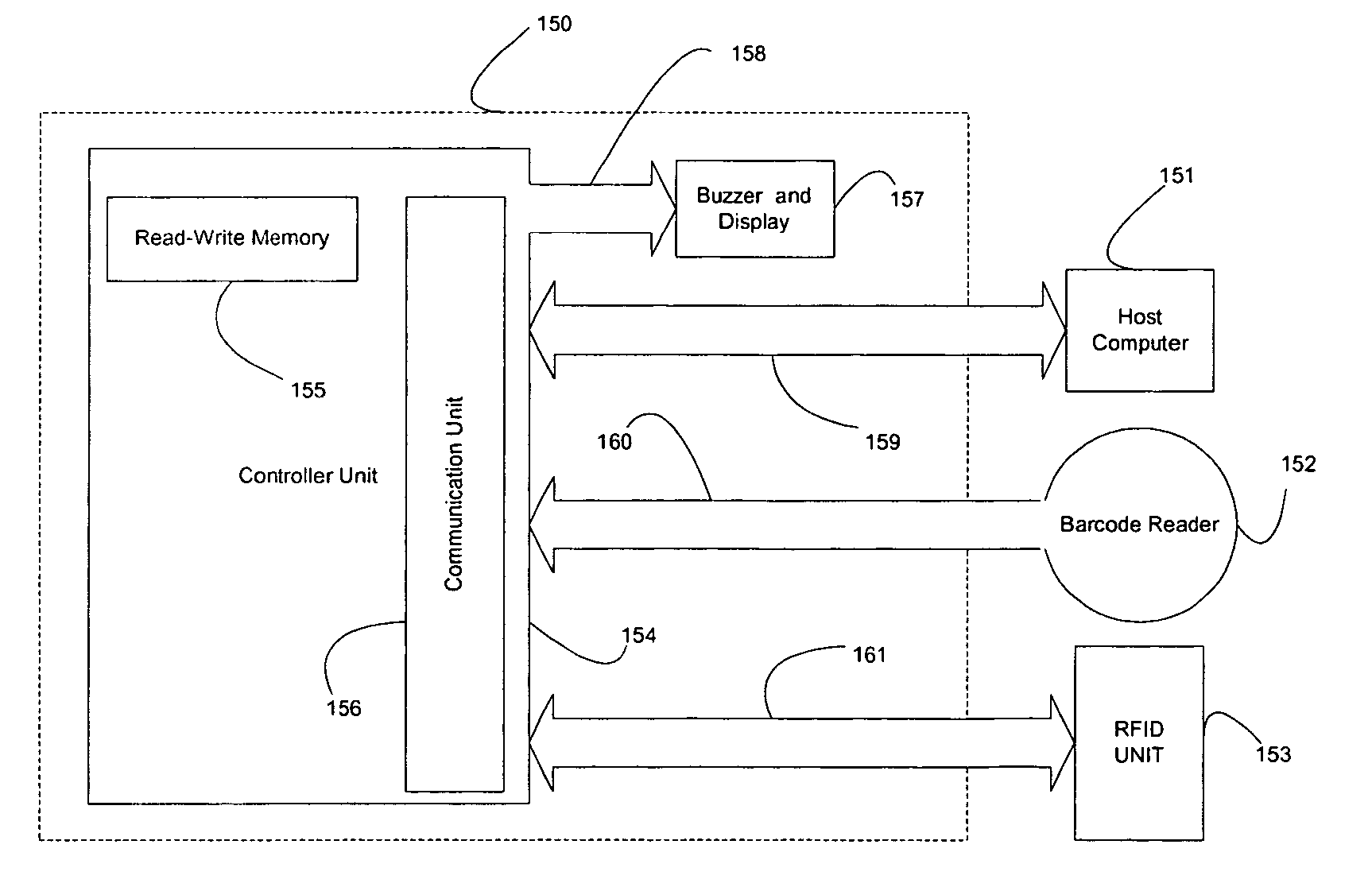

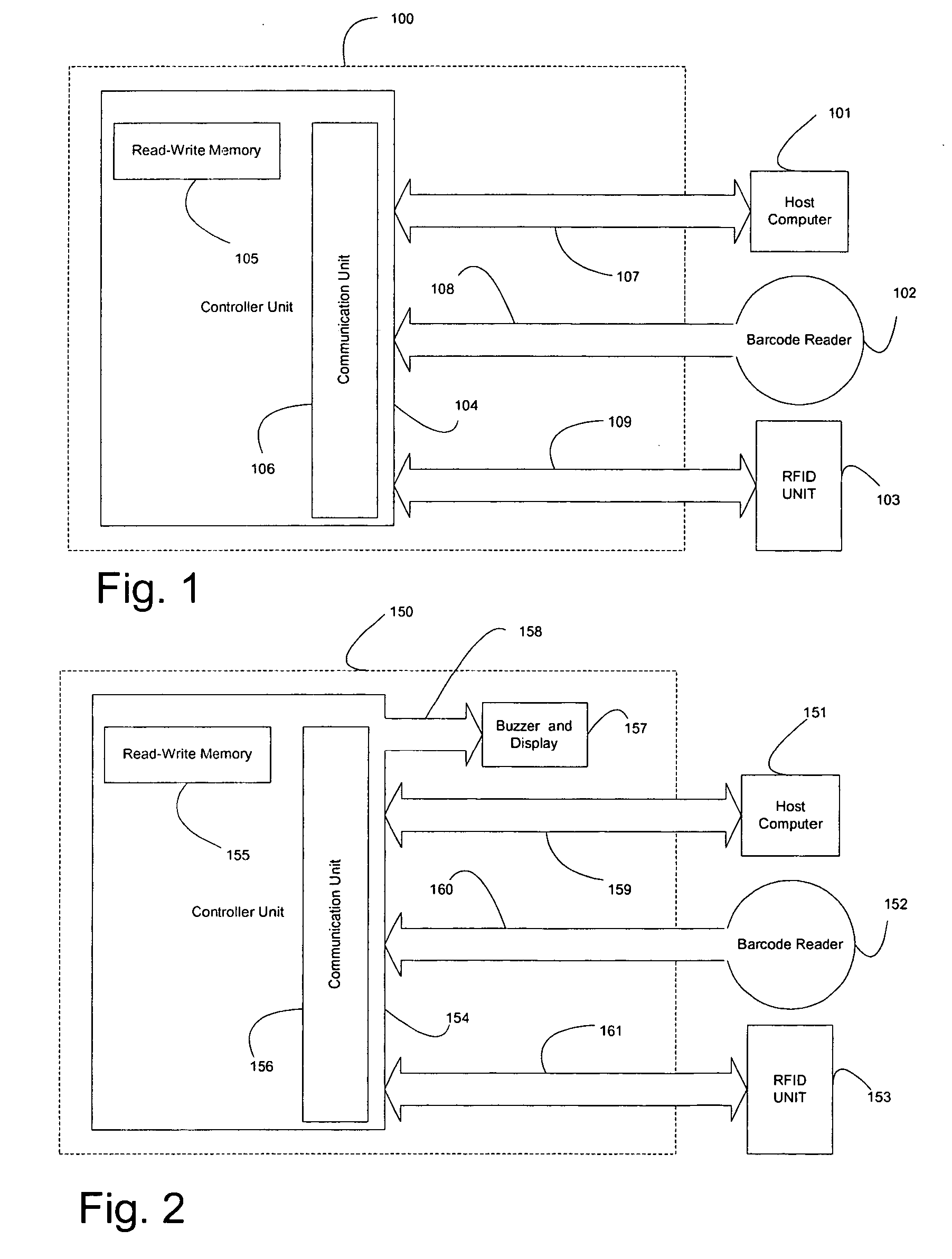

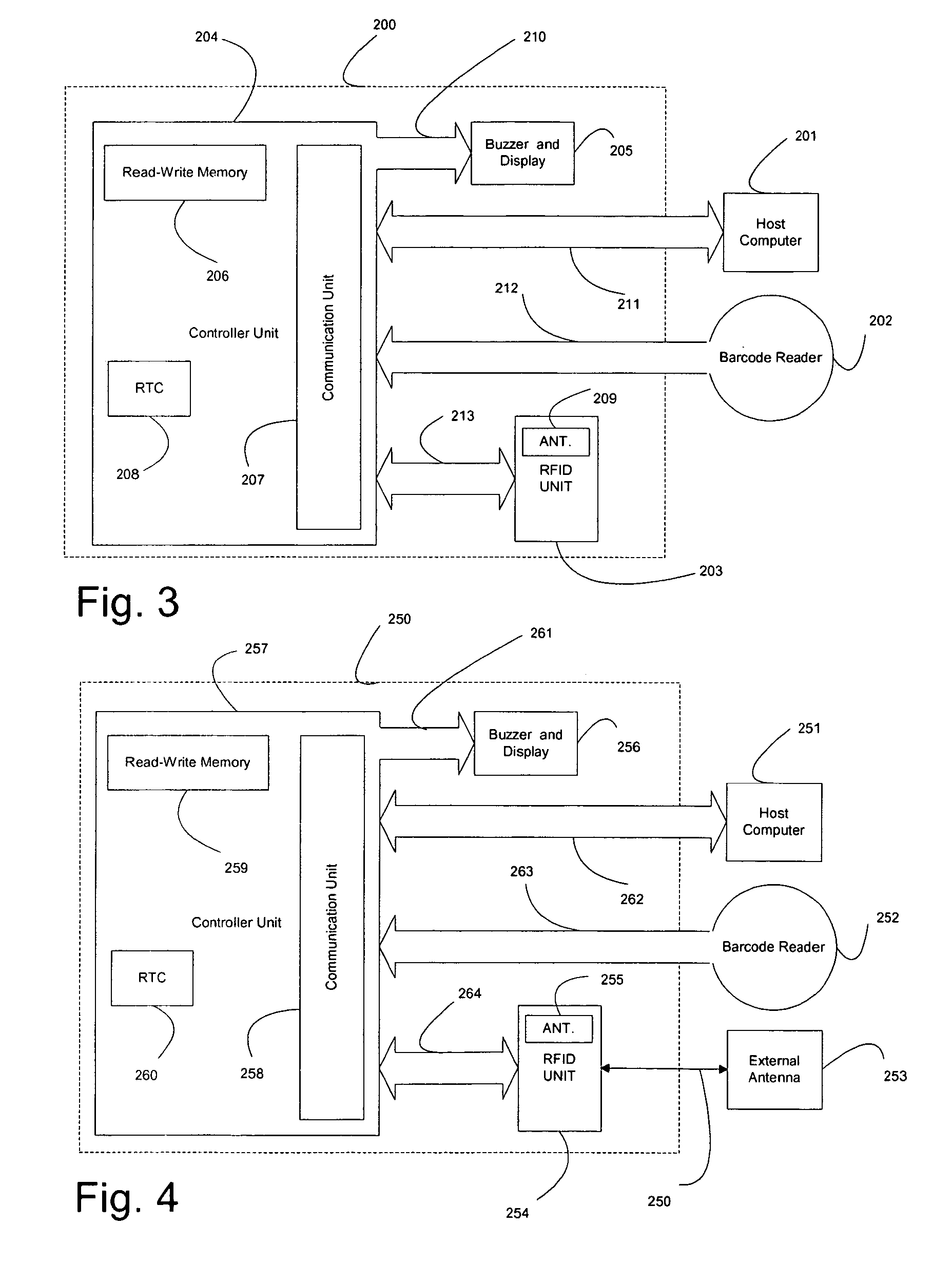

Multiple technology router for radio frequency identification (RFID) and barcode

InactiveUS20060213989A1Eliminate needCo-operative working arrangementsHybrid readersComputer hardwarePrimary operation

A multiple technology router for radio frequency identification (RFID) and barcode, the device has three ports, one to connect to an external barcode reader, and one to connect to an internal or external RFID reader / writer and finally one to connect to a host computer. The device constantly monitors port connected to barcode reader for intercepting a barcode symbol, sends request to RFID device and checks for RFID tag being sensed. Upon receiving data from either port, the device executes a pre-programmed series of actions. The action can be simply routing data from either port to the host computer or read one or many barcode symbols and write the information to a RFID tag without using a host computer. Additional actions such as EAS bit operation, incrementing / decrementing counters within a RFID tag and writing current time and date to an RFID tag can be done along with the main action of the device. The device can indicate the success or failure of operations audibly and visibly.

Owner:INTELLETTO TECH

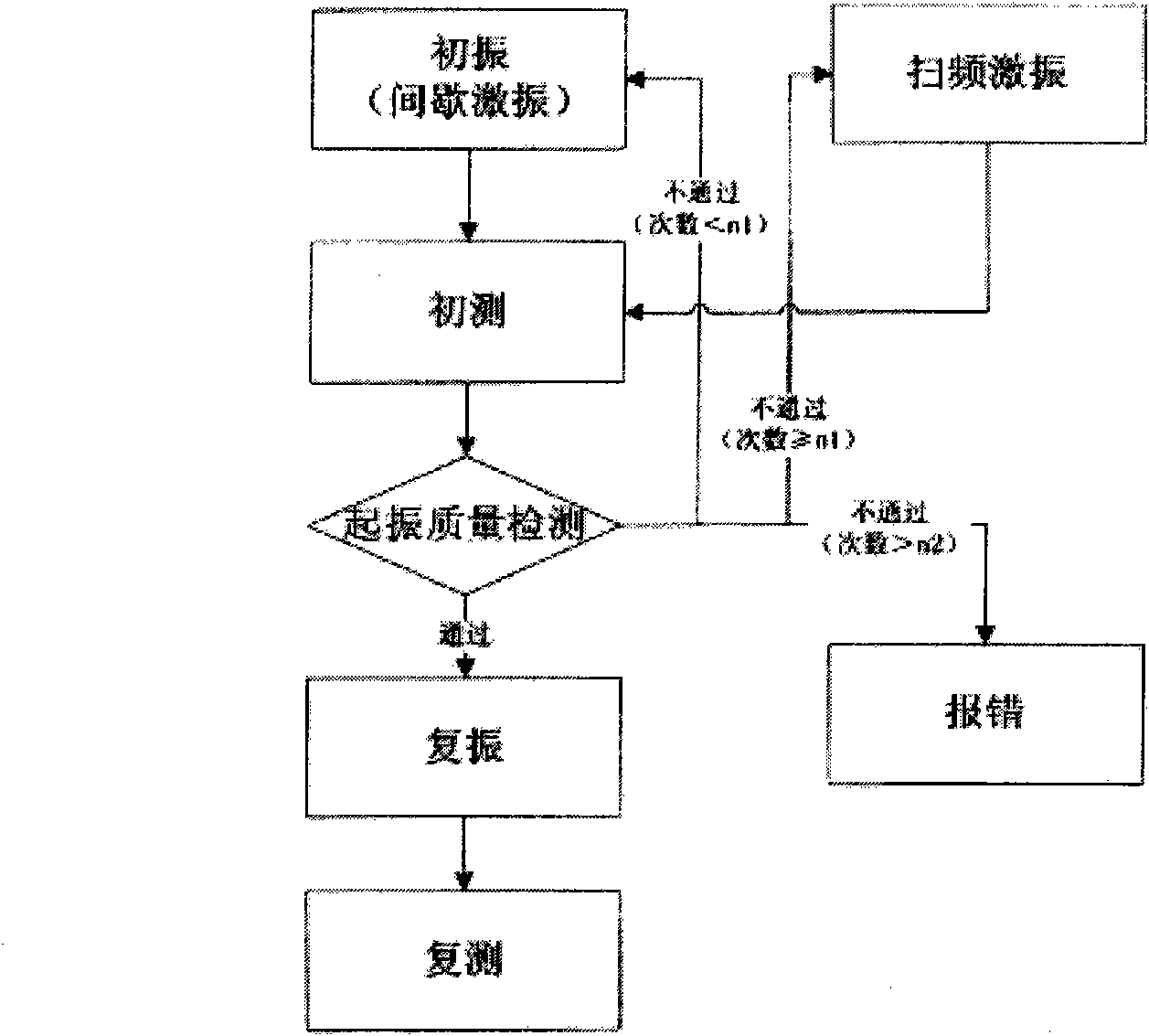

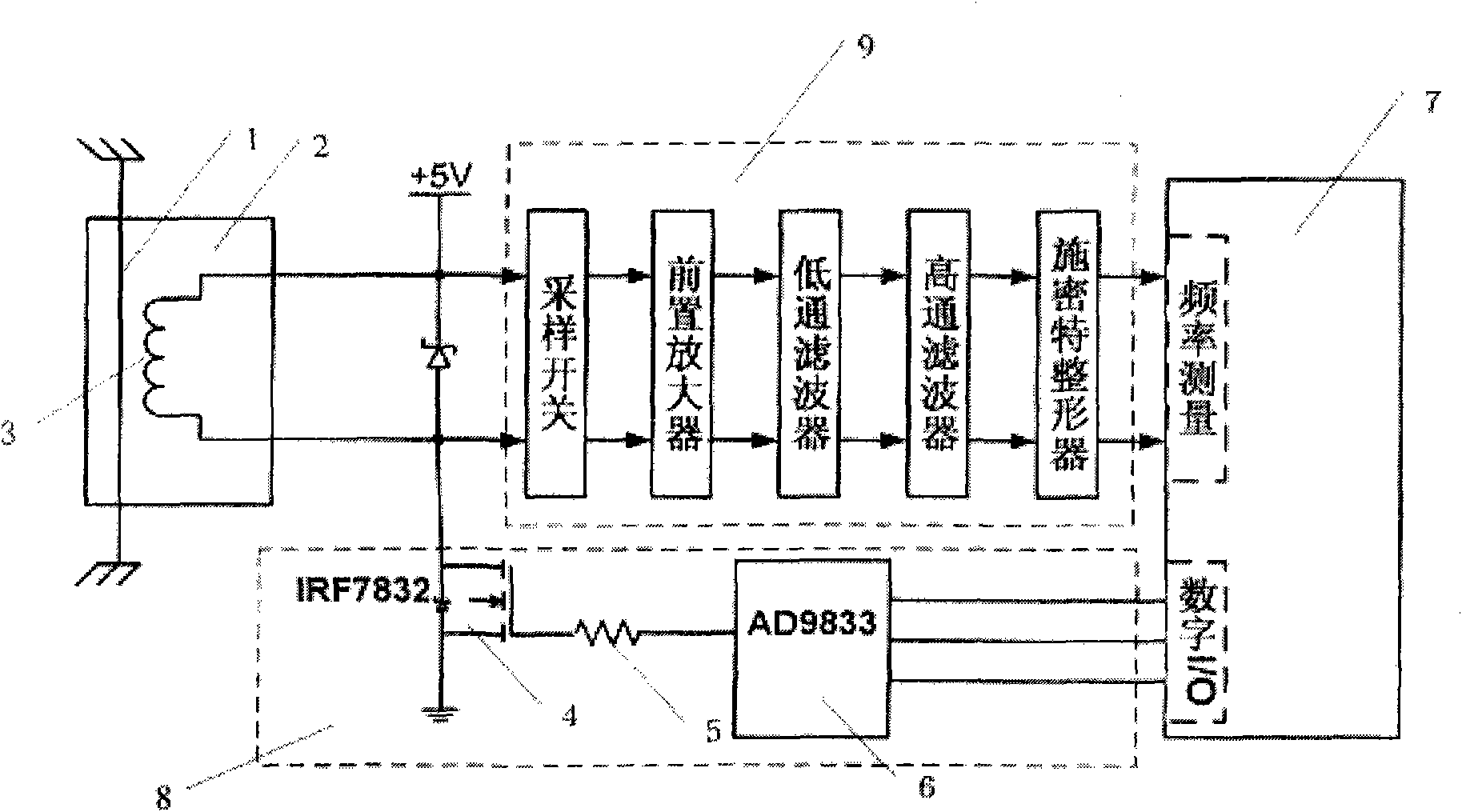

Excitation method of vibrating wire sensor

InactiveCN101571407AFast start-upShorten detection timeConverting sensor output electrically/magneticallyPrimary operationResonance

An excitation method of a vibrating wire sensor mainly comprises the following operating steps: performing single excitation for exciting coils of the vibrating wire sensor by an intermittent excitation mode to obtain a resonant frequency measured value f1 with low precision; calculating statistical characteristics of vibration signals during various periods, and inspecting the statistical characteristics; exciting the exciting coils of the vibrating wire sensor by adopting a signal with the frequency being f1 and stopping excitation after vibrating wire resonance, or performing frequency-sweep excitation at the position of a narrower bandwidth near the frequency f1; and finally processing signals from vibration pickup coils, and measuring the signal frequency to obtain a measured value f2 as an exact value of vibrating wire resonance frequency. The excitation method of the vibrating wire sensor has the advantages of fast starting of vibration, large amplitude, shortened detection time, improved working efficiency, improved excitation reliability and improved measuring precision. The excitation method of the vibrating wire sensor is applicable to observation on stress strain, deformation, seepage, liquid level, temperature and the like of the projects such as reservoir dams, bridges, foundation pits and the like.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

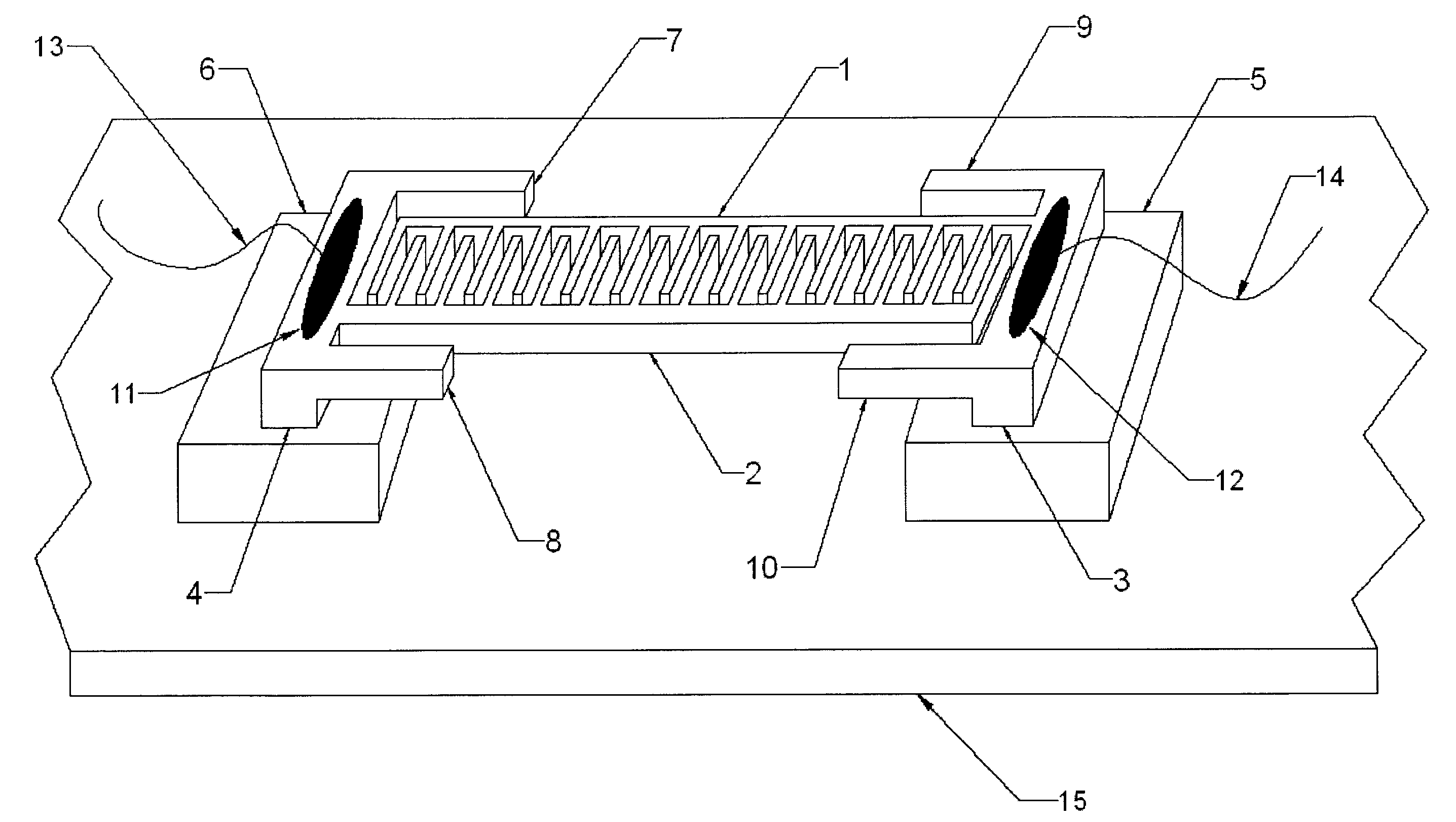

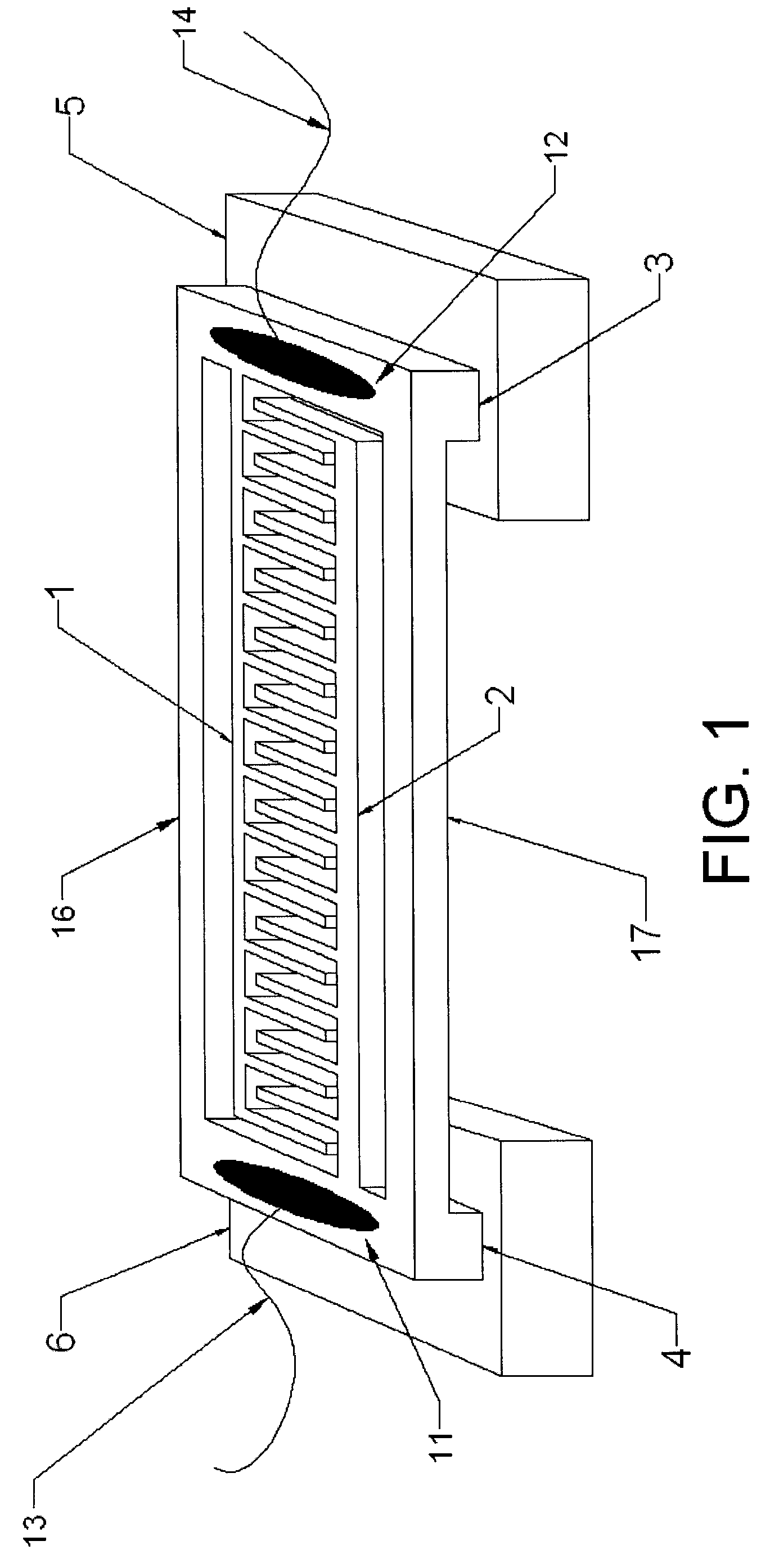

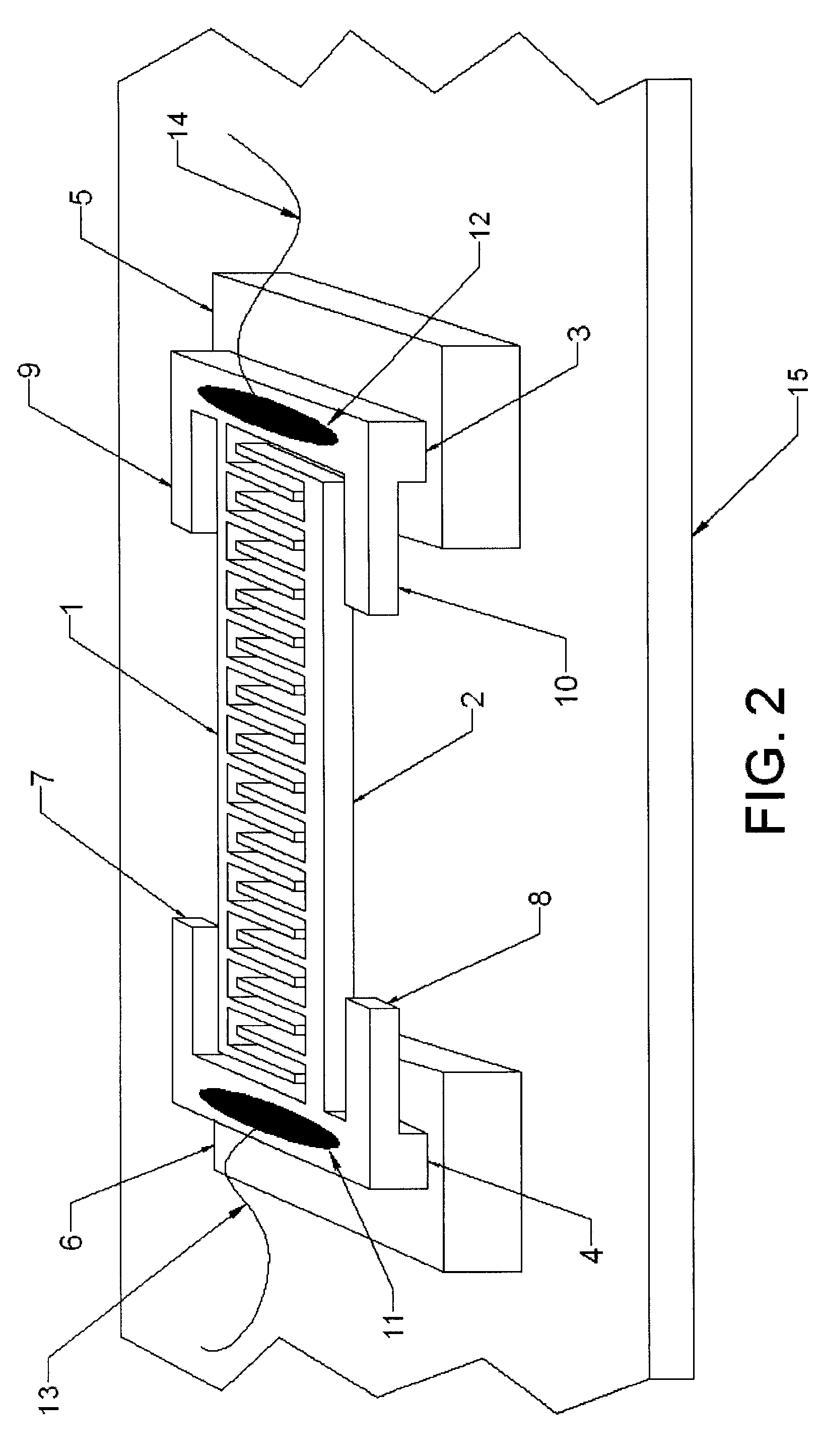

MEMS capacitive bending and axial strain sensor

ActiveUS7509870B2Easily be incorporated into current semi-conductor fabrication processLow powerForce measurementUsing electrical meansCapacitancePrimary operation

Owner:GLOBUS MEDICAL INC

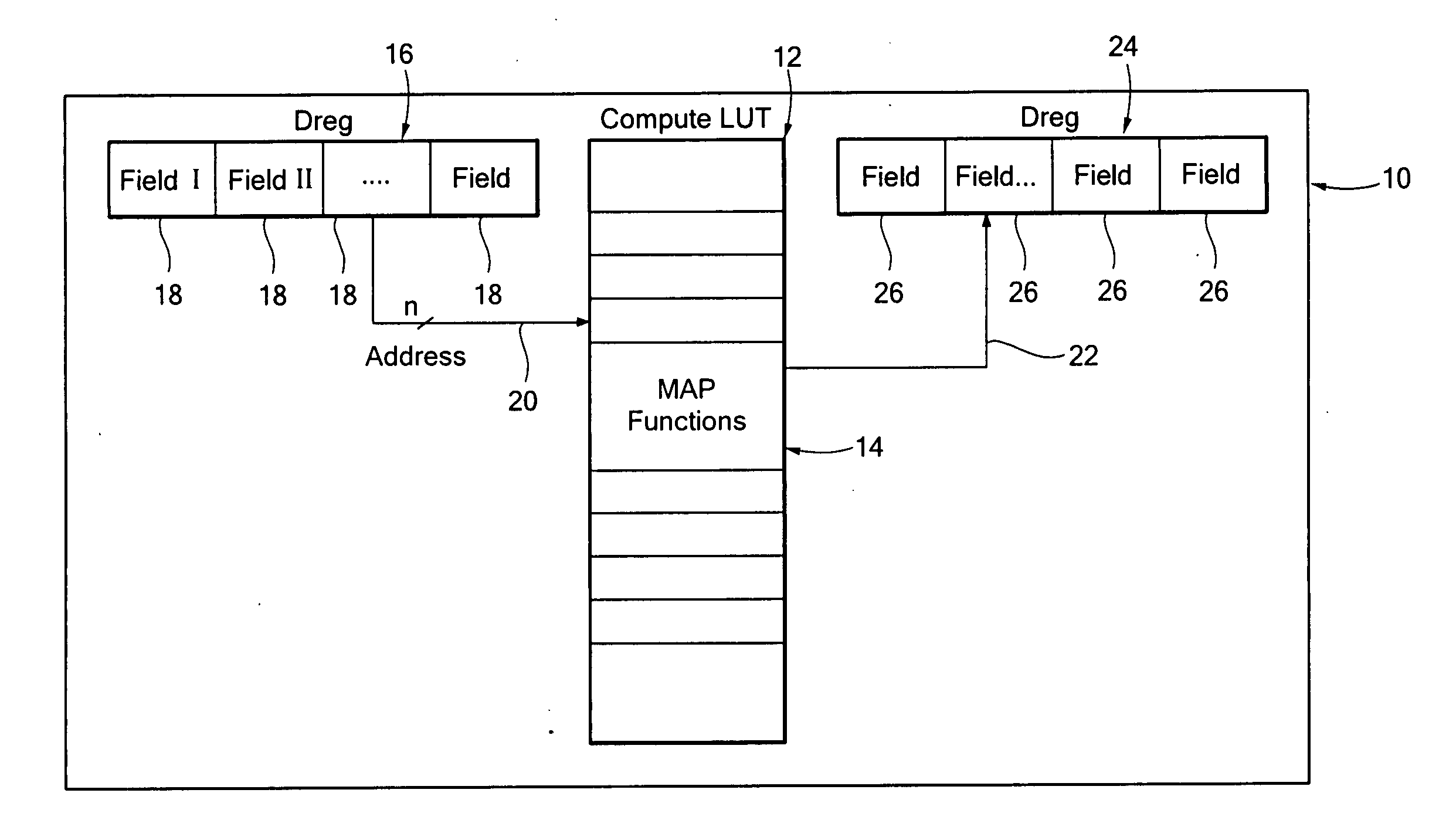

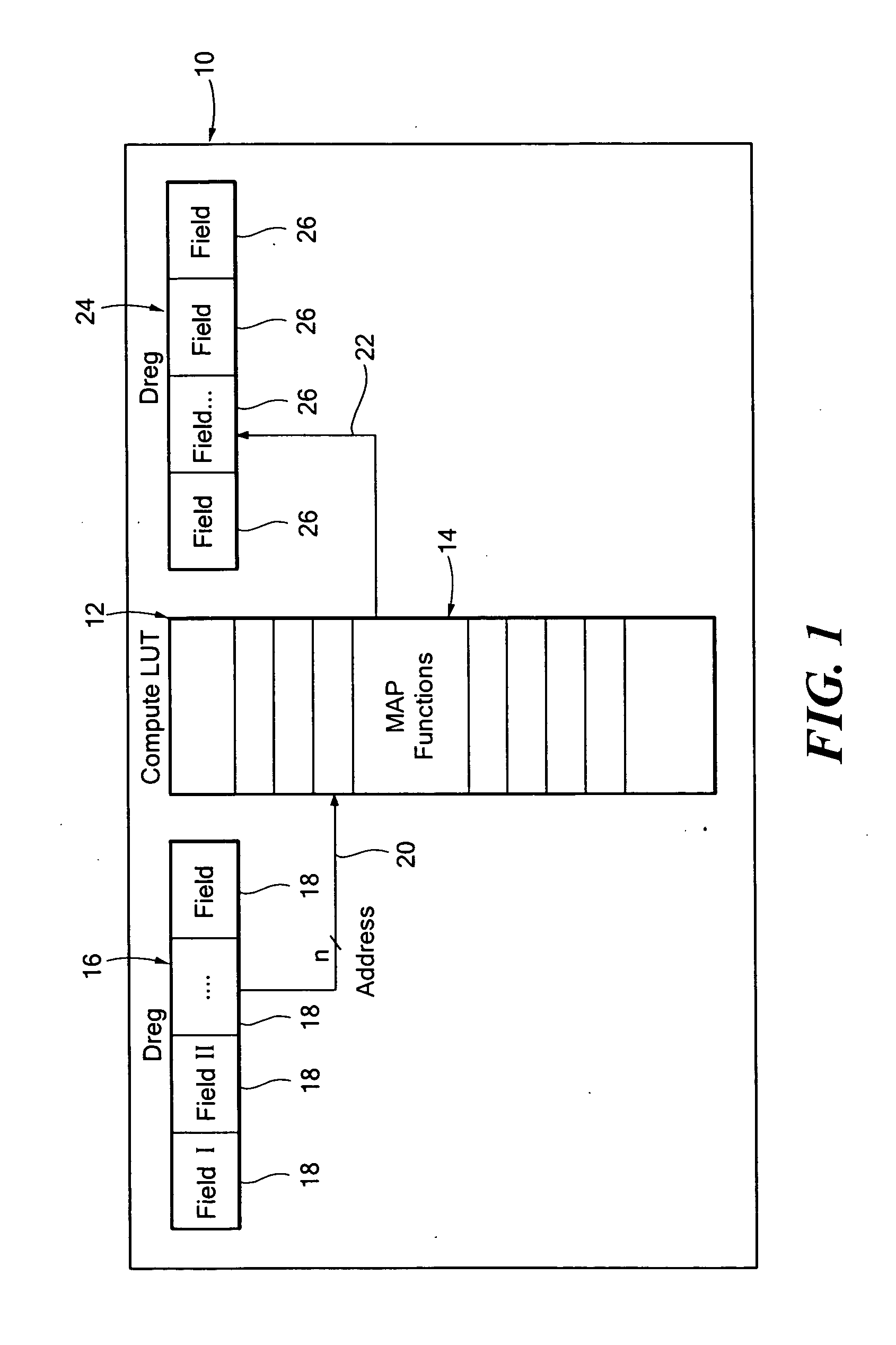

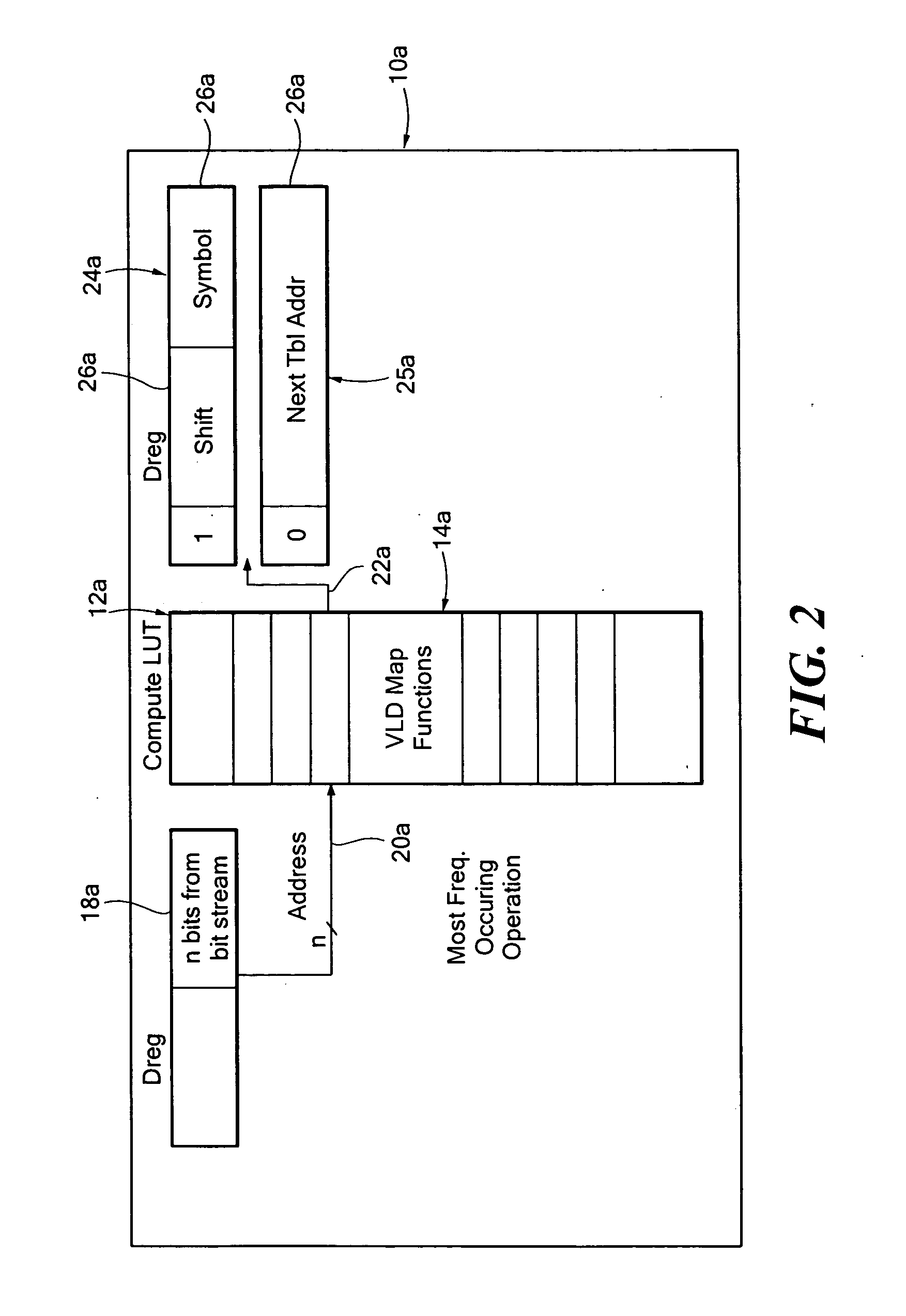

Method and apparatus for mapping the primary operational sequences of an algorithm in a compute unit having an internal random access memory

InactiveUS20080154803A1Improve efficiencyImprove performanceCode conversionDigital computer detailsStatic random-access memoryPrimary operation

A method and apparatus for direct mapping in a compute unit having an internal random access memory the primary operational sequences of an algorithm to related function including storing in an internal random access memory at least one predetermined direct mapped function value for each primary operational sequence of an algorithm; holding in an input data register the address in the random access memory of at least one mapped function value for a selected primary operational sequence of the algorithm and holding in an output register the at least one mapped function value for the selected primary operational sequence of the algorithm read out of the random access memory.

Owner:ANALOG DEVICES INC

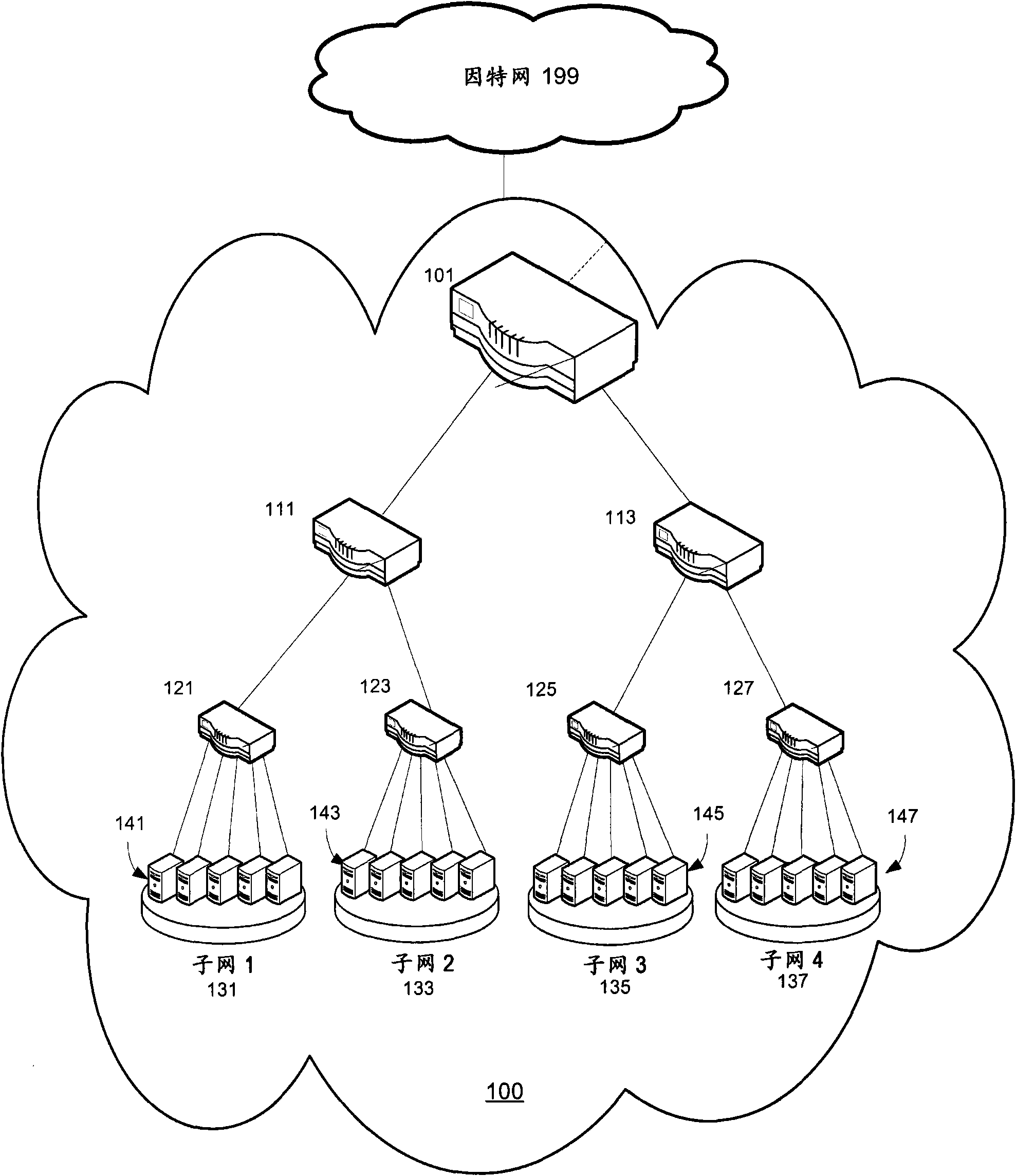

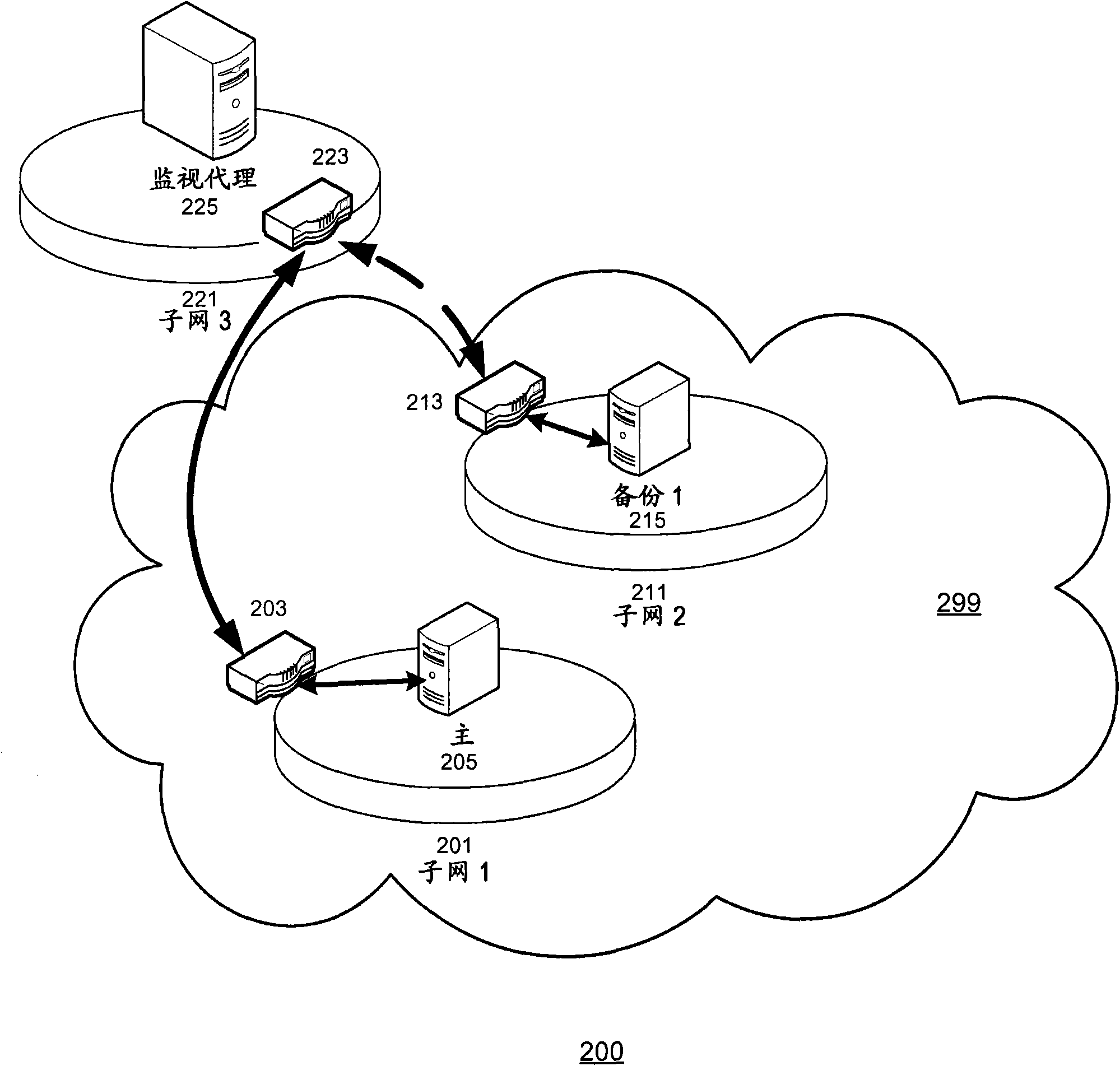

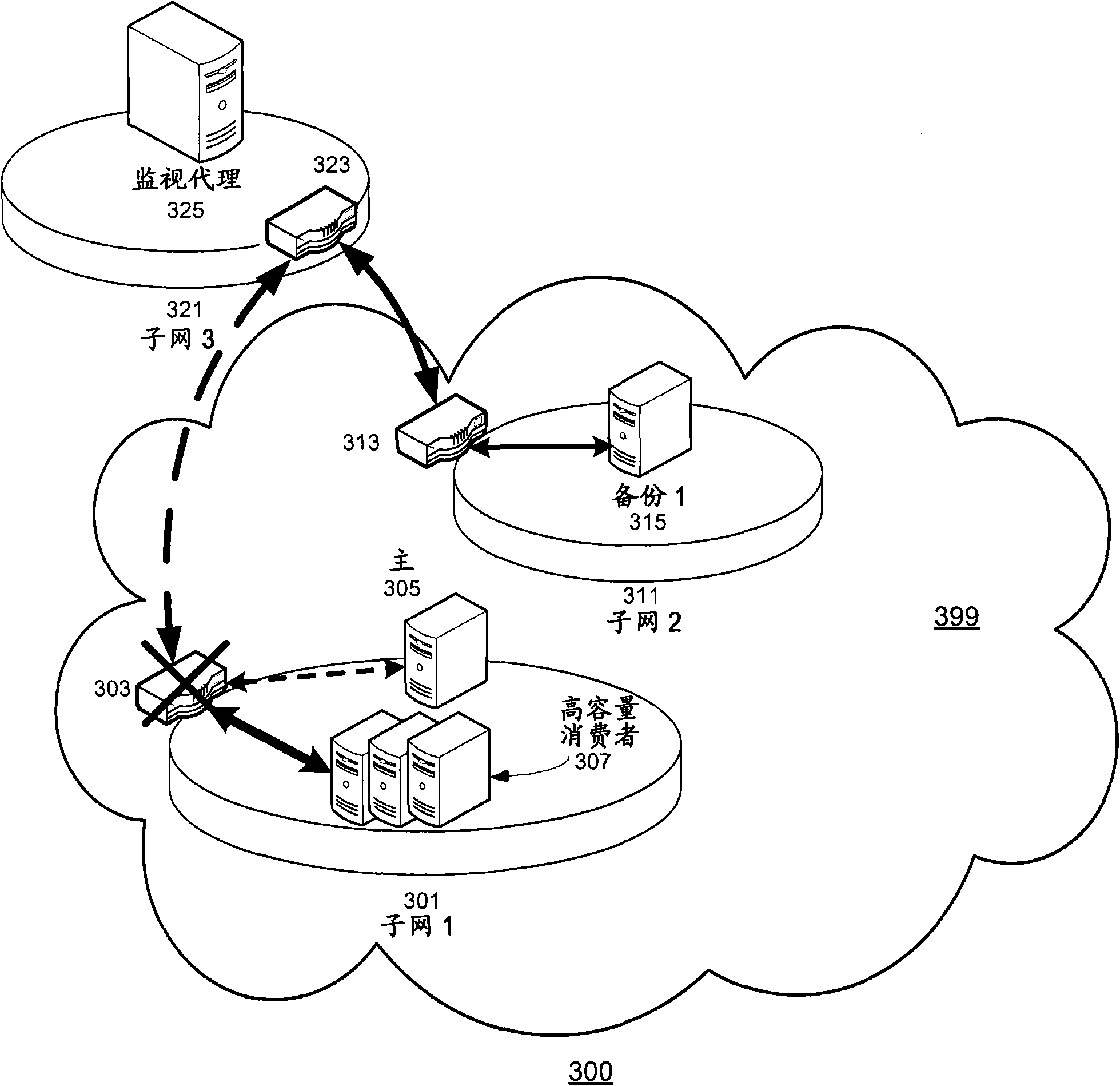

Method and system for application migration in a cloud

A method and system for managing an application in a cloud data center by monitoring the bandwidth of a subnet of which the primary operating instance of an application is a member. If a severe deterioration in the bandwidth caused by an over consumption of the subnet resources from other subnet constituents is detected, a suitable secondary instance in an alternate, uncompromised subnet is located and primary operation of the application is transferred from the former primary operating instance to the secondary instance. The secondary instance can be pre-launched or dynamically requisitioned in the cloud data center.

Owner:埃森哲国际责任有限公司

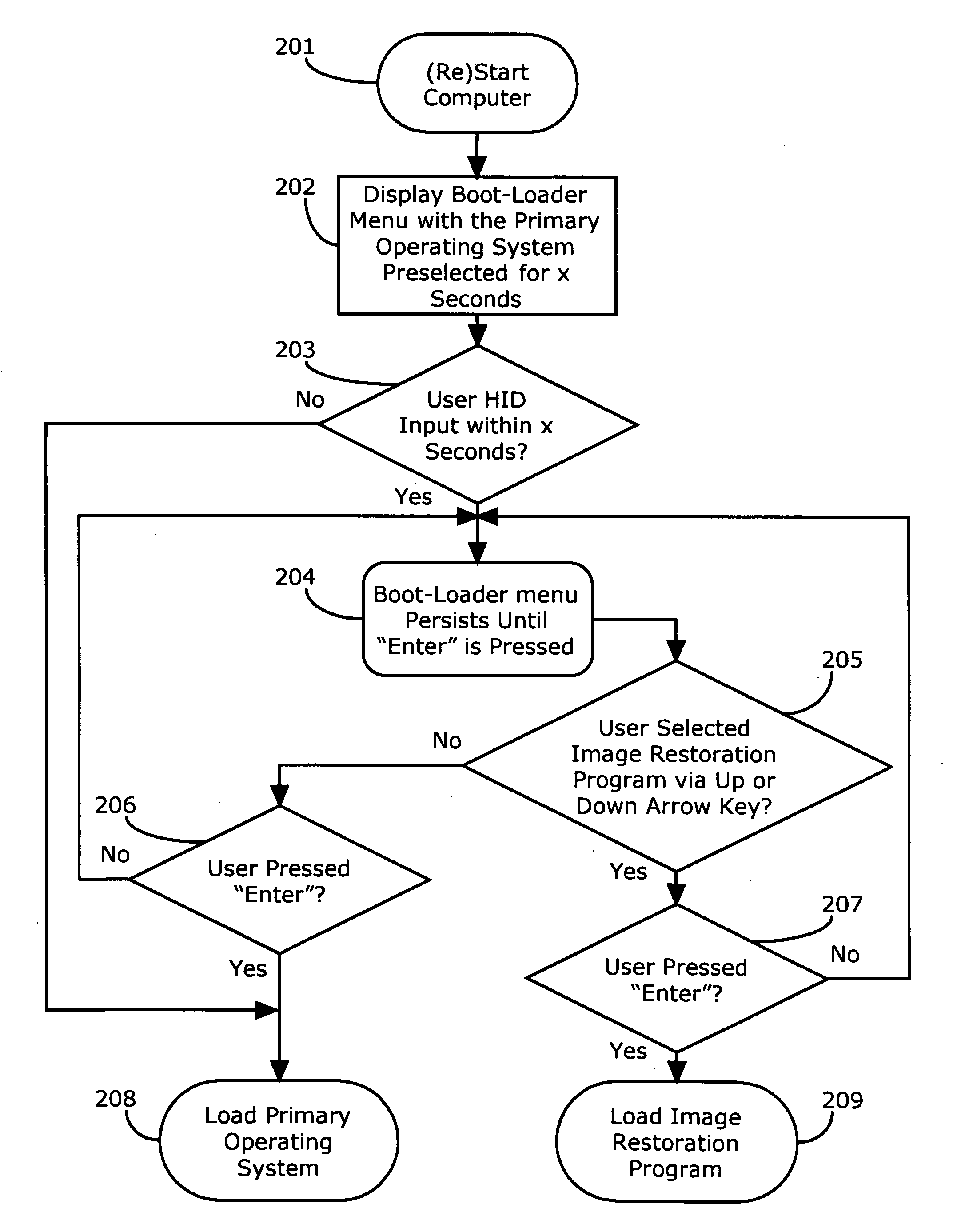

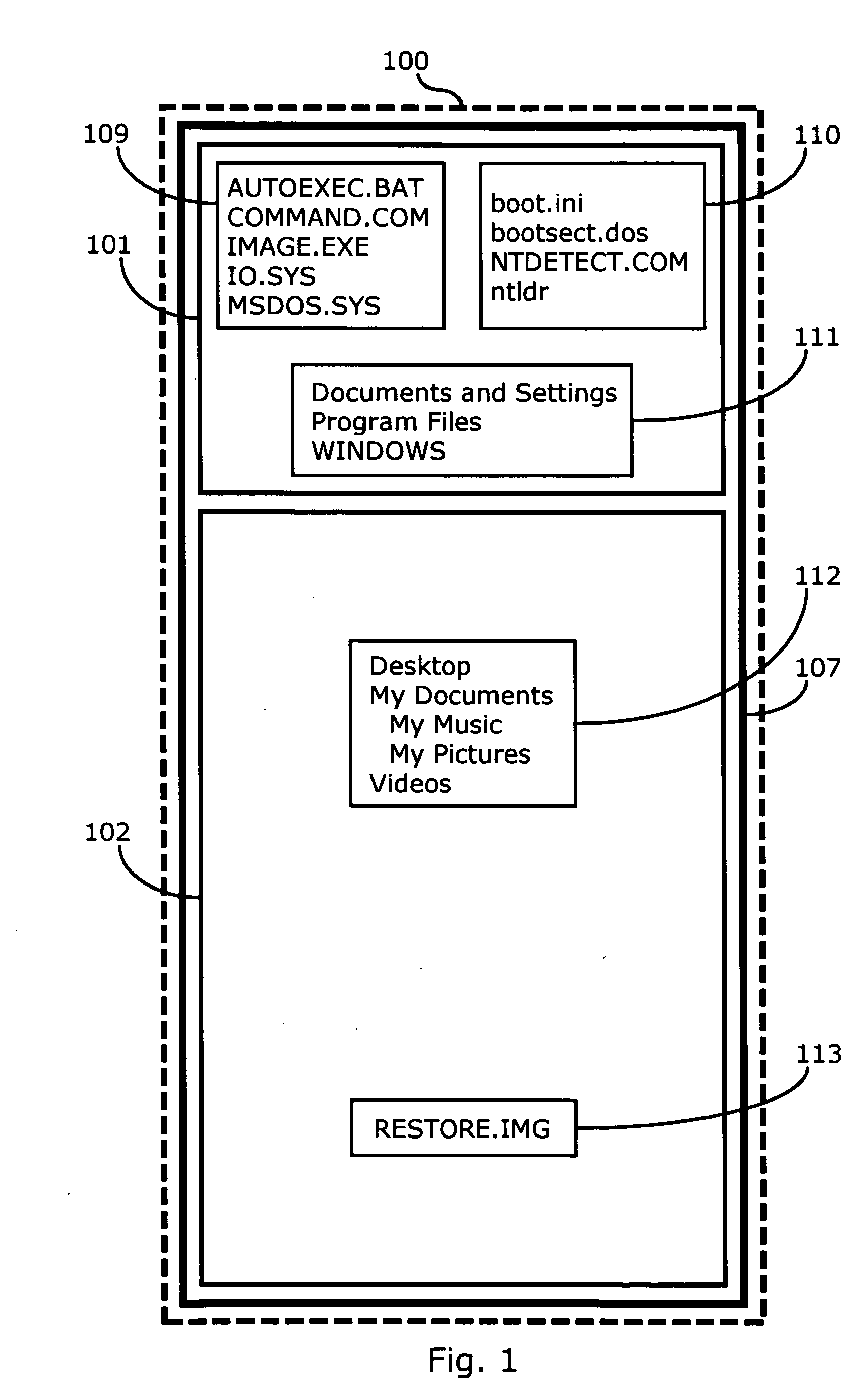

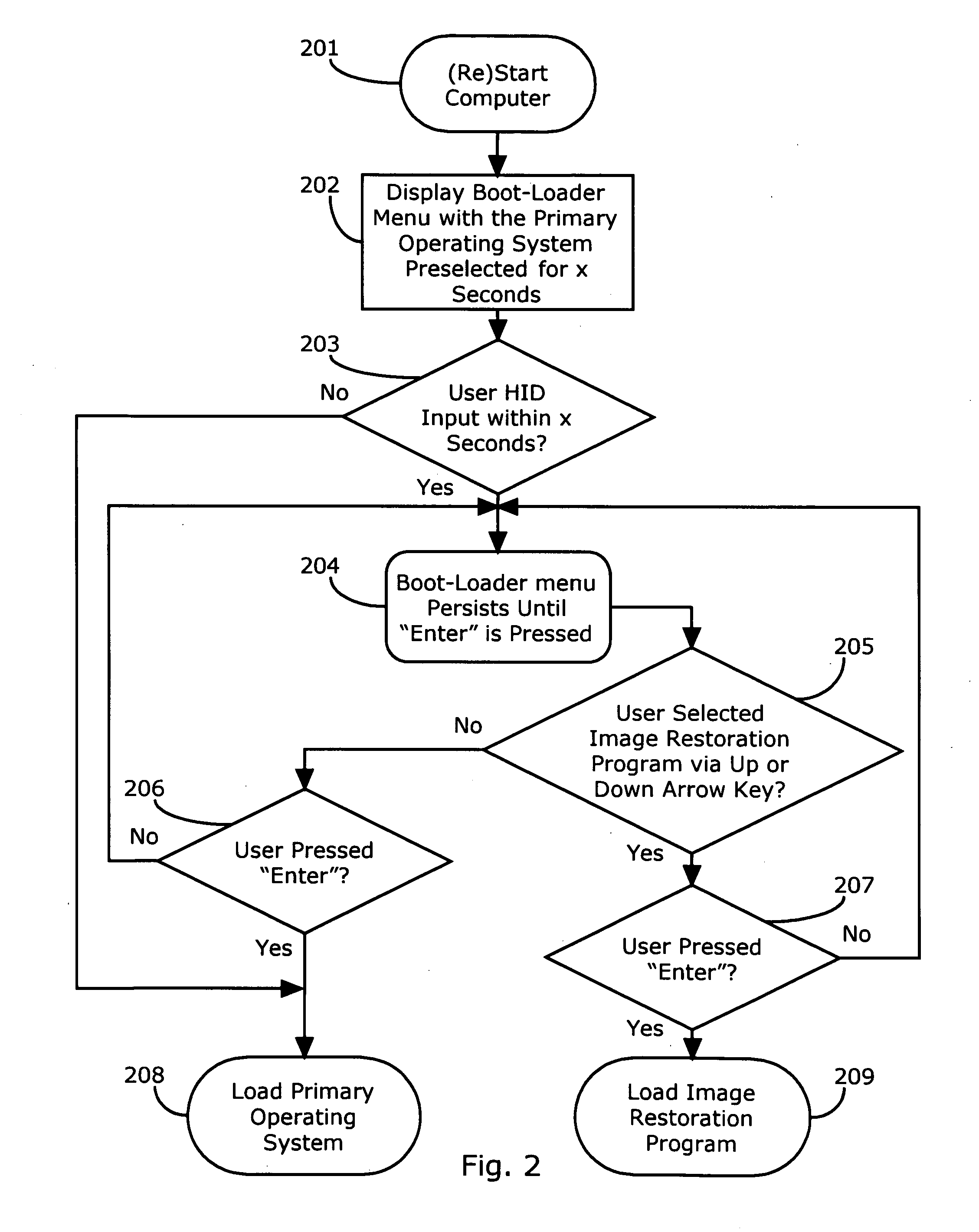

Computer with bootable restoration

ActiveUS20100241837A1Memory adressing/allocation/relocationDigital computer detailsMass storageGraphics

A bootable restoration computer includes: at least one mass storage device; at least two mass storage device partitions in the at least one mass storage device, including first and second partitions; a partition image restoration program; at least one partition image; at least one human interface device; a primary operating system with graphical user interface; a secondary operating system; and, a boot loader responsive to the human interface device that provides for selecting between the primary secondary operating systems. The primary operating system resides on the first partition and is configured so that its standard locations for storing user-created files are folders rooted on at least one of any partition other than the first partition. The at least one partition image is an image of the first partition, and resides on at least one of any partition other than the first partition. If no opportunity is taken to select the secondary operating system in a predefined time, the computer loads the primary operating system. If the opportunity is taken, the partition image restoration program restores the partition image to the first partition.

Owner:CONCORSO JAMES A

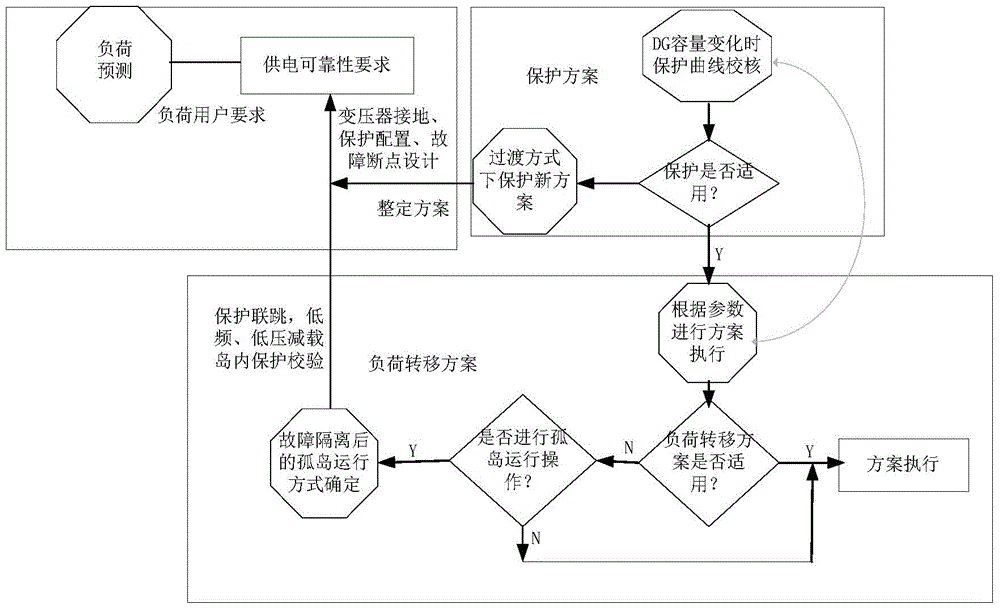

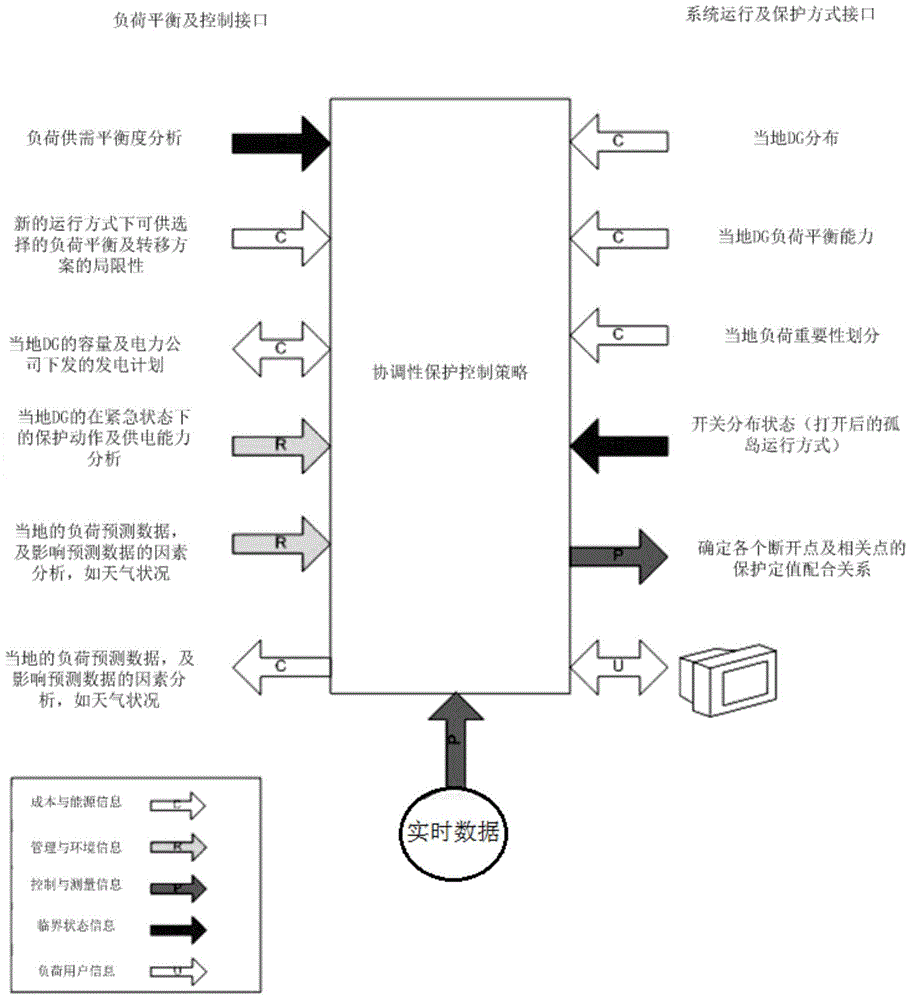

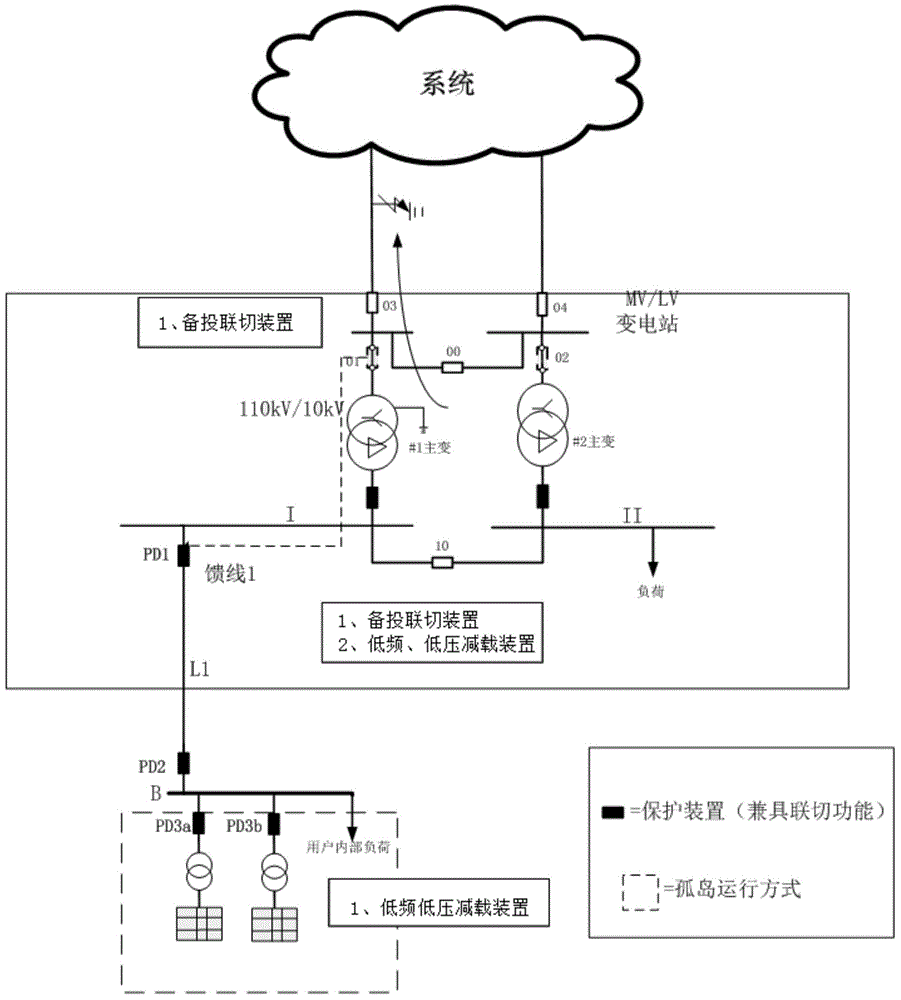

Distributed generation-based grid connection transition operation mode coordination comprehensive protection method

ActiveCN104836214AImplement Protection AdjustmentAchieve continuous power supplyEmergency protective circuit arrangementsPrimary operationIslanding

The invention discloses a distributed generation-based grid connection transition operation mode coordination comprehensive protection method. When the DG capacity is continuously increased, the short-circuit current level is improved, the DG is changed from a "pure load" into a "small power supply", and a problem that conventional protection and switching breakpoints cannot meet the transition condition is solved. Based on the conventional protection and the switching breakpoints, the scheme provided by the invention performs continuous matching with a primary operation model and is continuously optimized, and the information and the state quantity are continuously exchanged to form a protection control interface adapted to a primary system, so that dual purposes of safe operation of a system and continuous power supplying are achieved. The fault isolation range is determined by collecting a new boundary which is determined by the switching breakpoints, and that whether the system sectionalizing and the island operation mode generated as a boundary point is determined is stable or not is comprehensively considered.

Owner:STATE GRID CORP OF CHINA +1

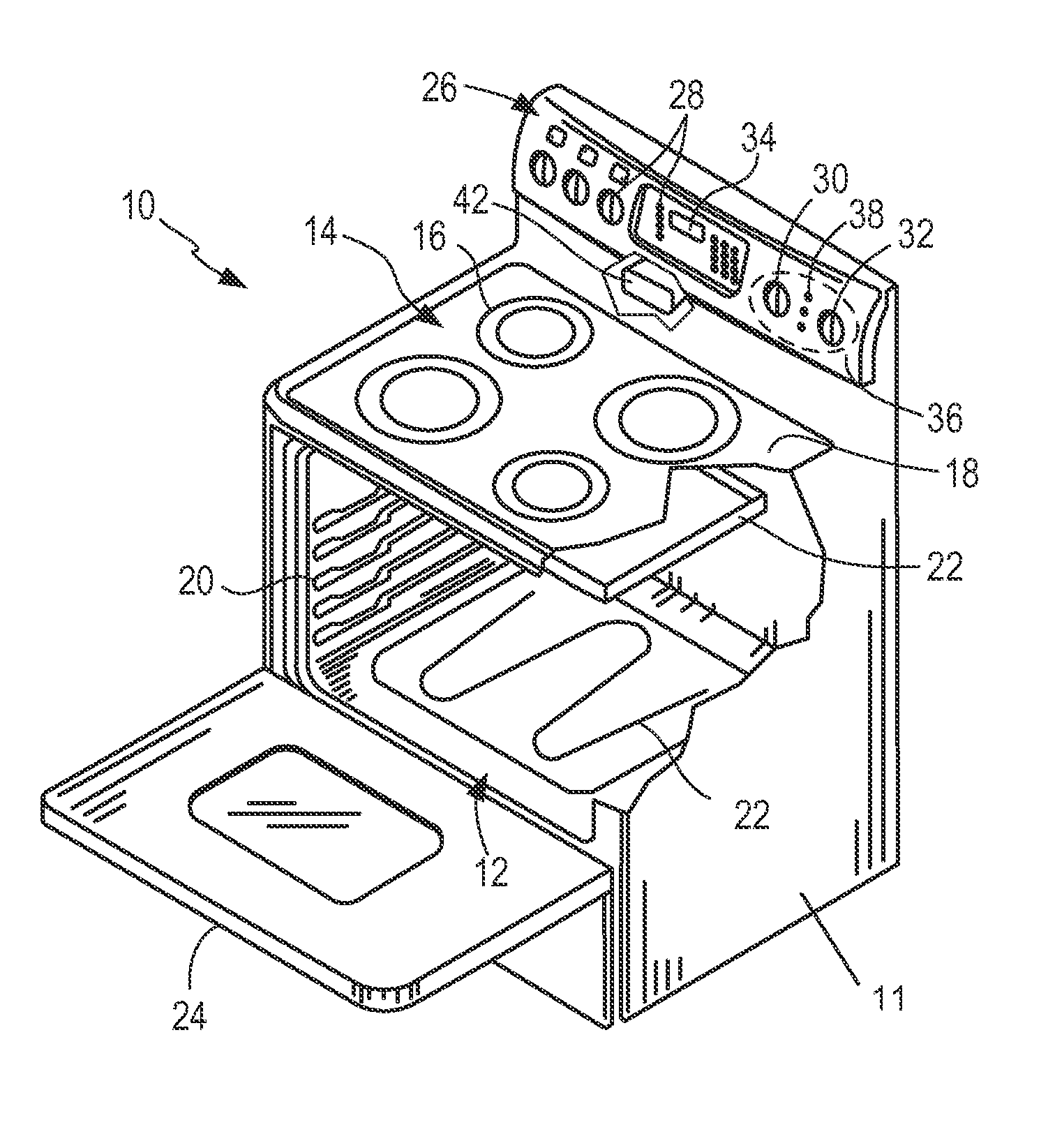

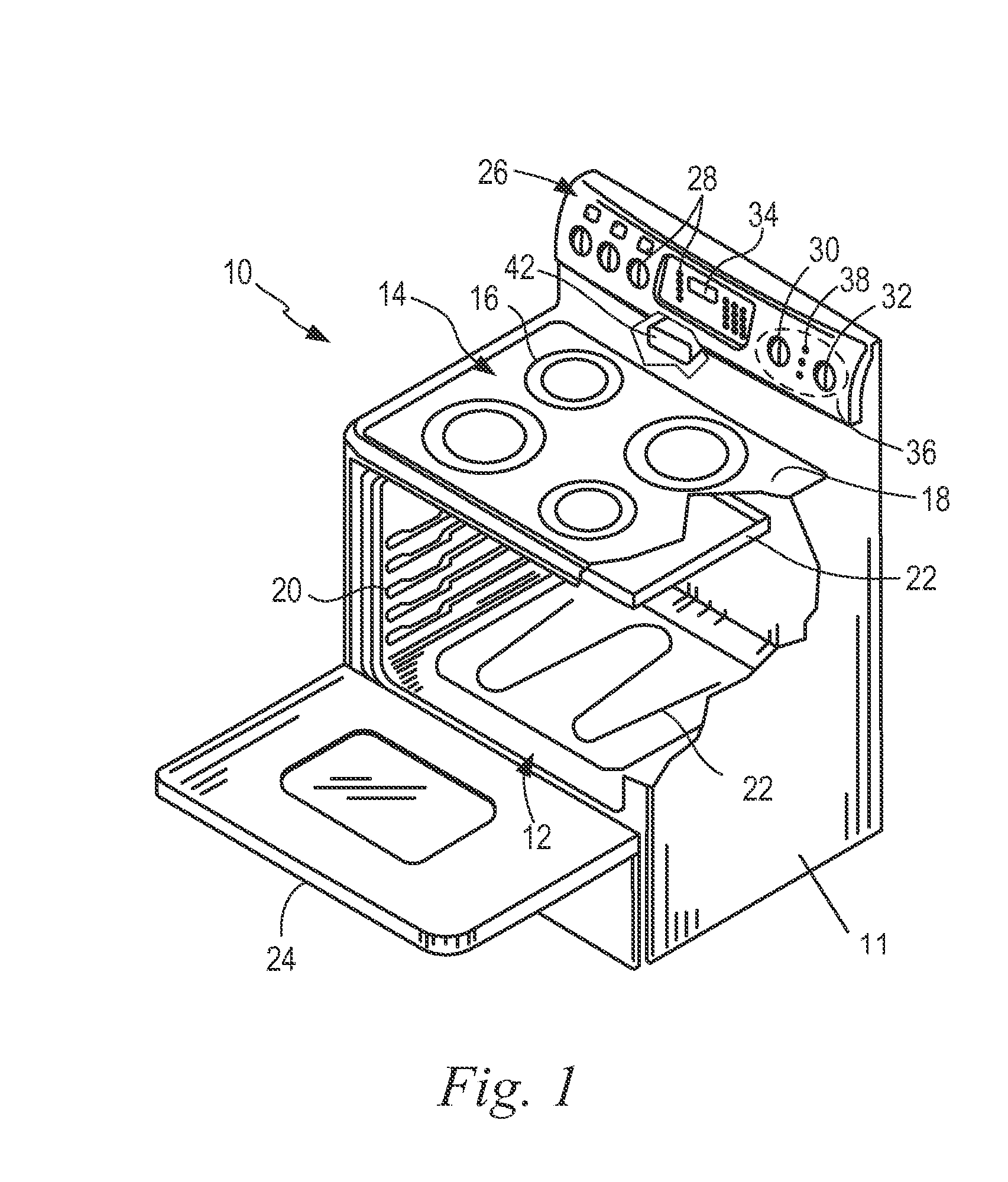

Appliance diagnostics utilizing visible indicators

InactiveUS20160123600A1Stoves/ranges foundationsDomestic stoves or rangesComputer assistancePrimary operation

A cooking appliance can include diagnostic information communication ability. The cooking appliance has a support for supporting a cooking vessel at a cooking location. A heating element is configured to heat the cooking vessel at the cooking location. A user interface of the cooking appliance includes a visible indicator that is operable to convey primary operational information indicative of an operational aspect of the cooking appliance to a user during normal operation of the cooking appliance. A controller receives sensed information indicative of a malfunction of the cooking appliance and controls an operation of the visible indicator to display an error signal that is incomprehensible to the user without computer assistance, but is readable by a portable code reader. The error signal comprises repeated illumination and deactivation of the visible indicator at a predetermined frequency.

Owner:ELECTROLUX HOME PROD CORP NV

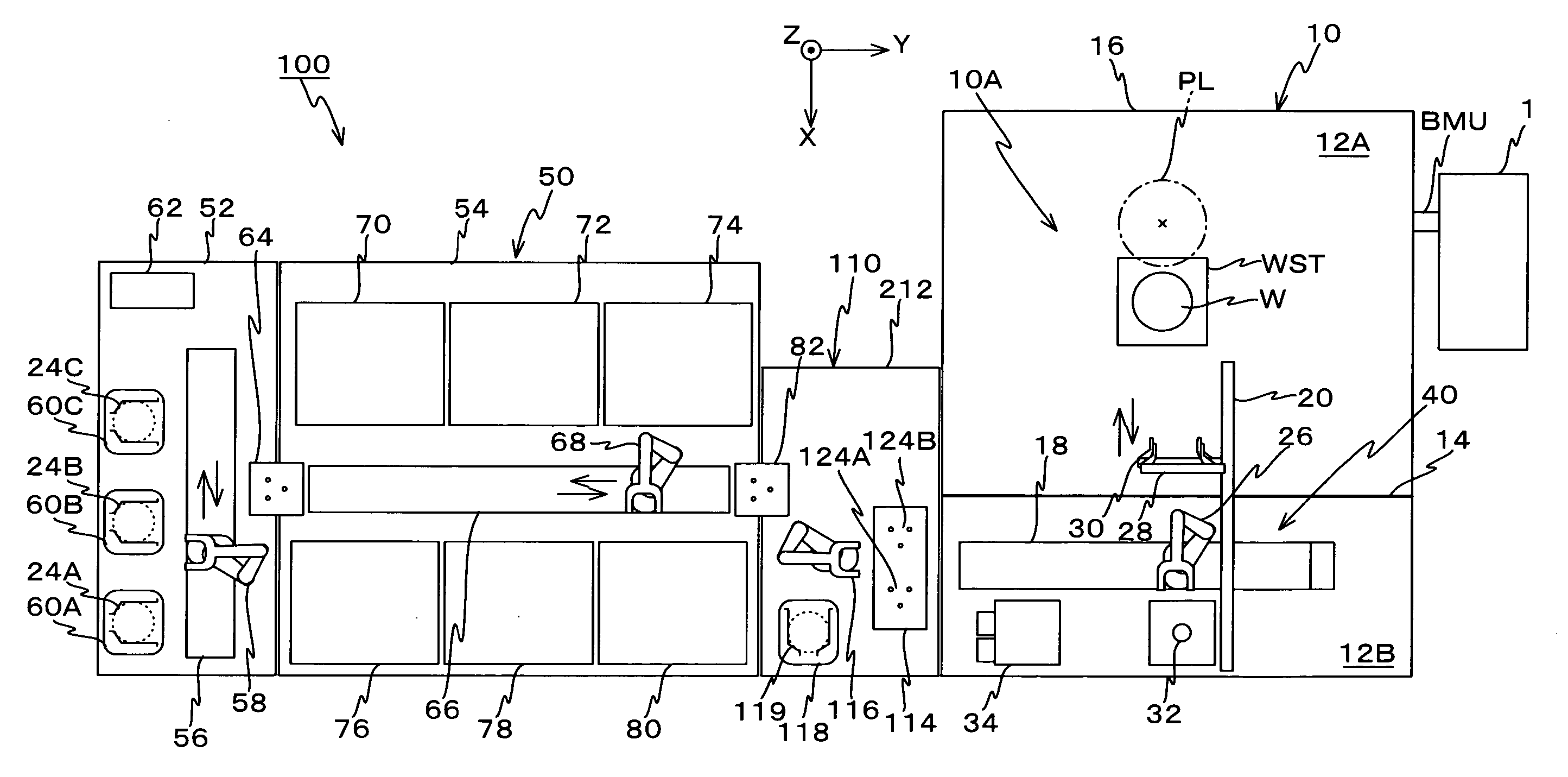

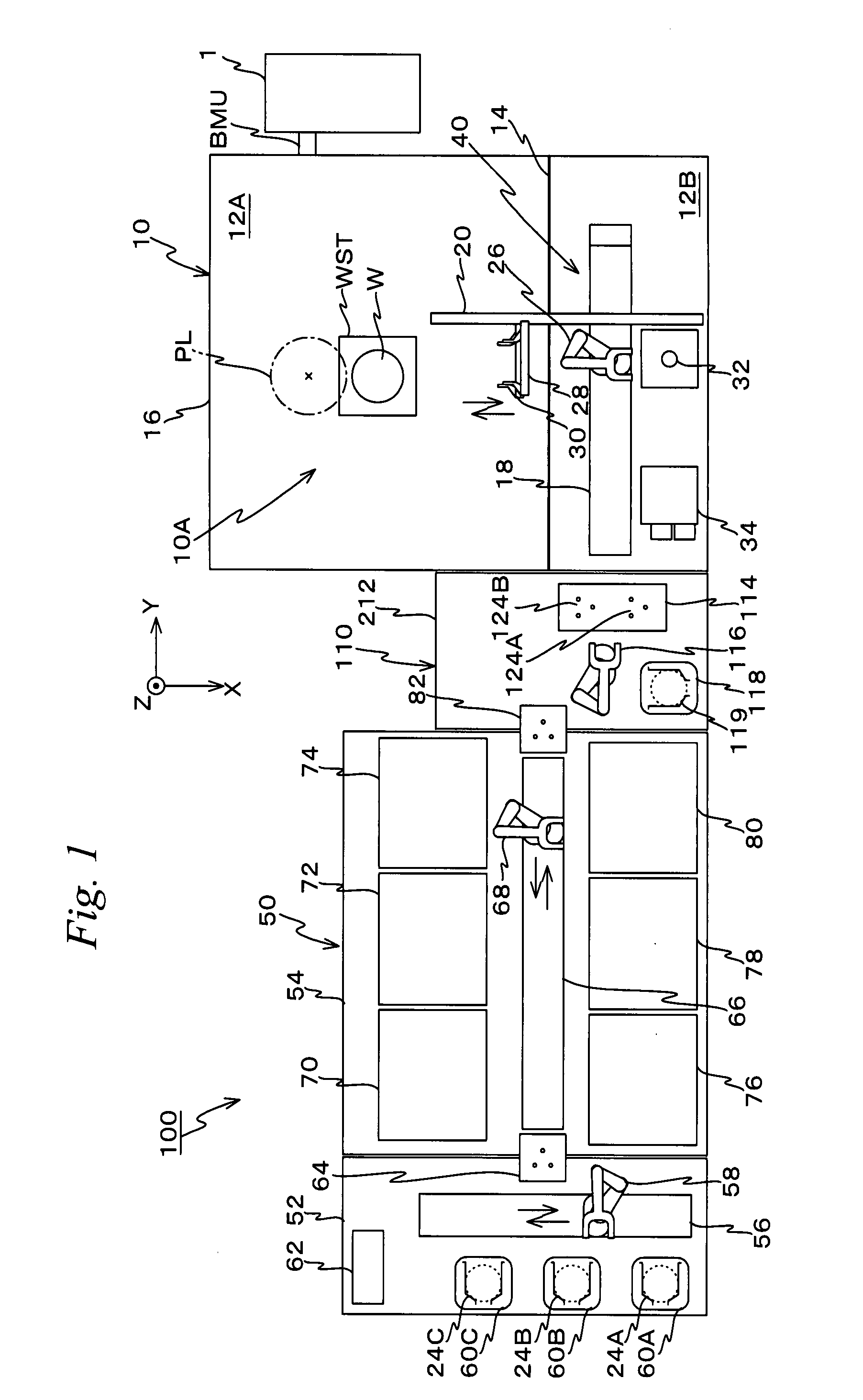

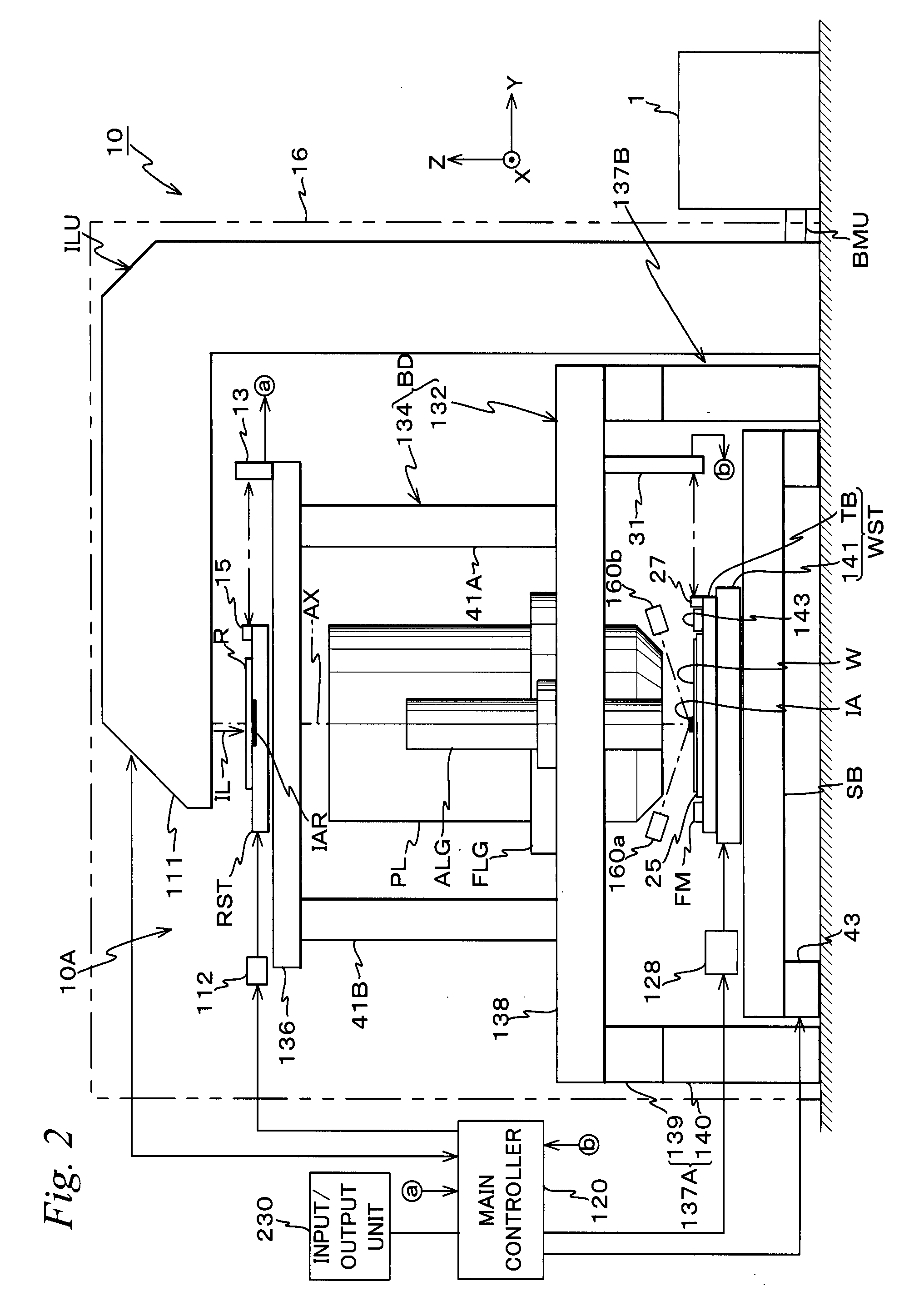

Exposure Apparatus, Operation Decision Method, Substrate Processing System, Maintenance Management Method, and Device Manufacuring Method

ActiveUS20070252966A1Improve productivityReduce equipment capacityLiquid processingPhotomechanical apparatusPrimary operationDowntime

An exposure apparatus is equipped with a main controller that decides an operation of the exposure apparatus based on information on maintenance from a C / D. Therefore, the main controller can decide to perform a specific operation, which is necessary for maintaining performance of the exposure apparatus and requires stop of the primary operation of the exposure apparatus, during maintenance of the C / D, that is, when the primary operation of the exposure apparatus has to be stopped by necessity, in parallel with the maintenance of the C / D. As a consequence, downtime of the exposure apparatus necessary for performing the specific operation can be decreased as a whole, which makes it possible to improve the operating rate without lowering apparatus performance of the exposure apparatus that is inline connected to a substrate processing apparatus.

Owner:NIKON CORP

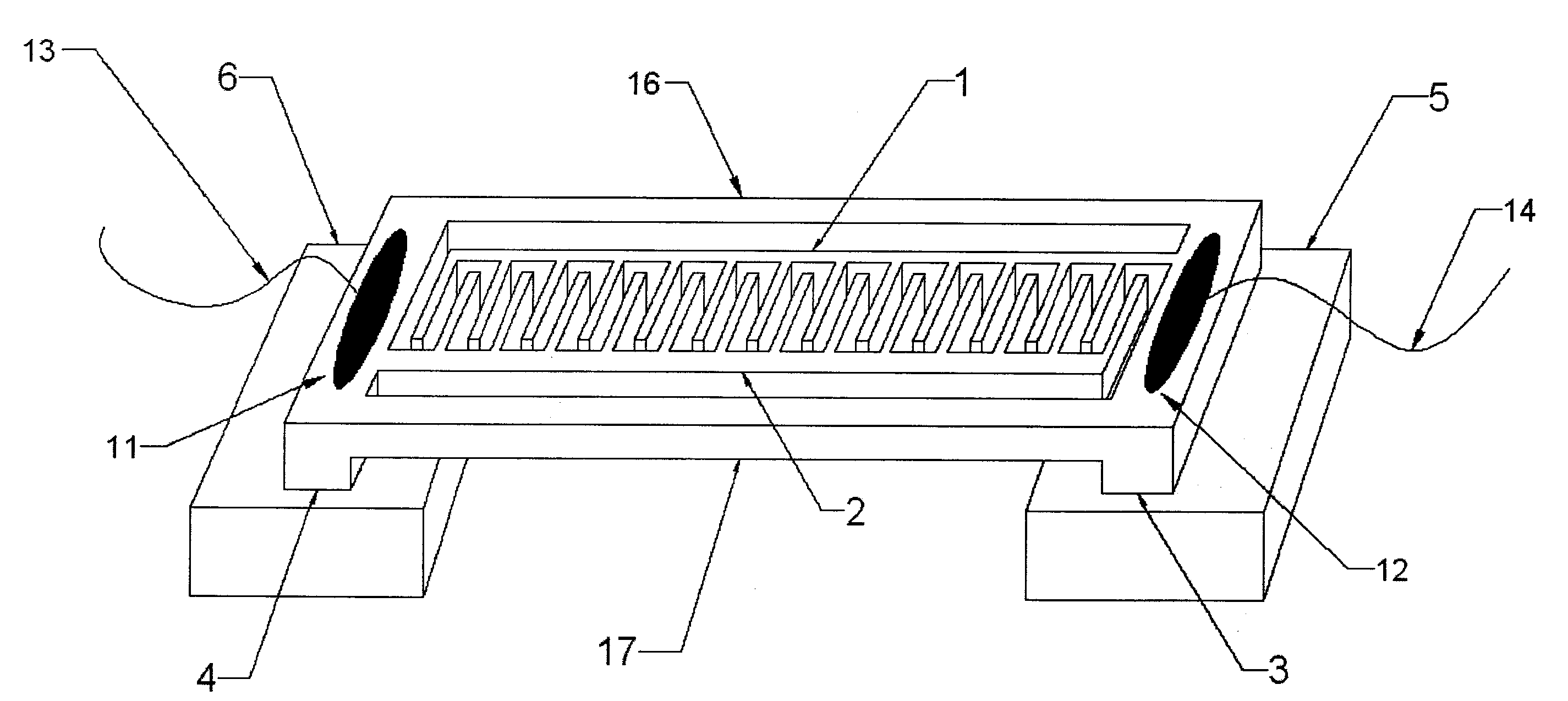

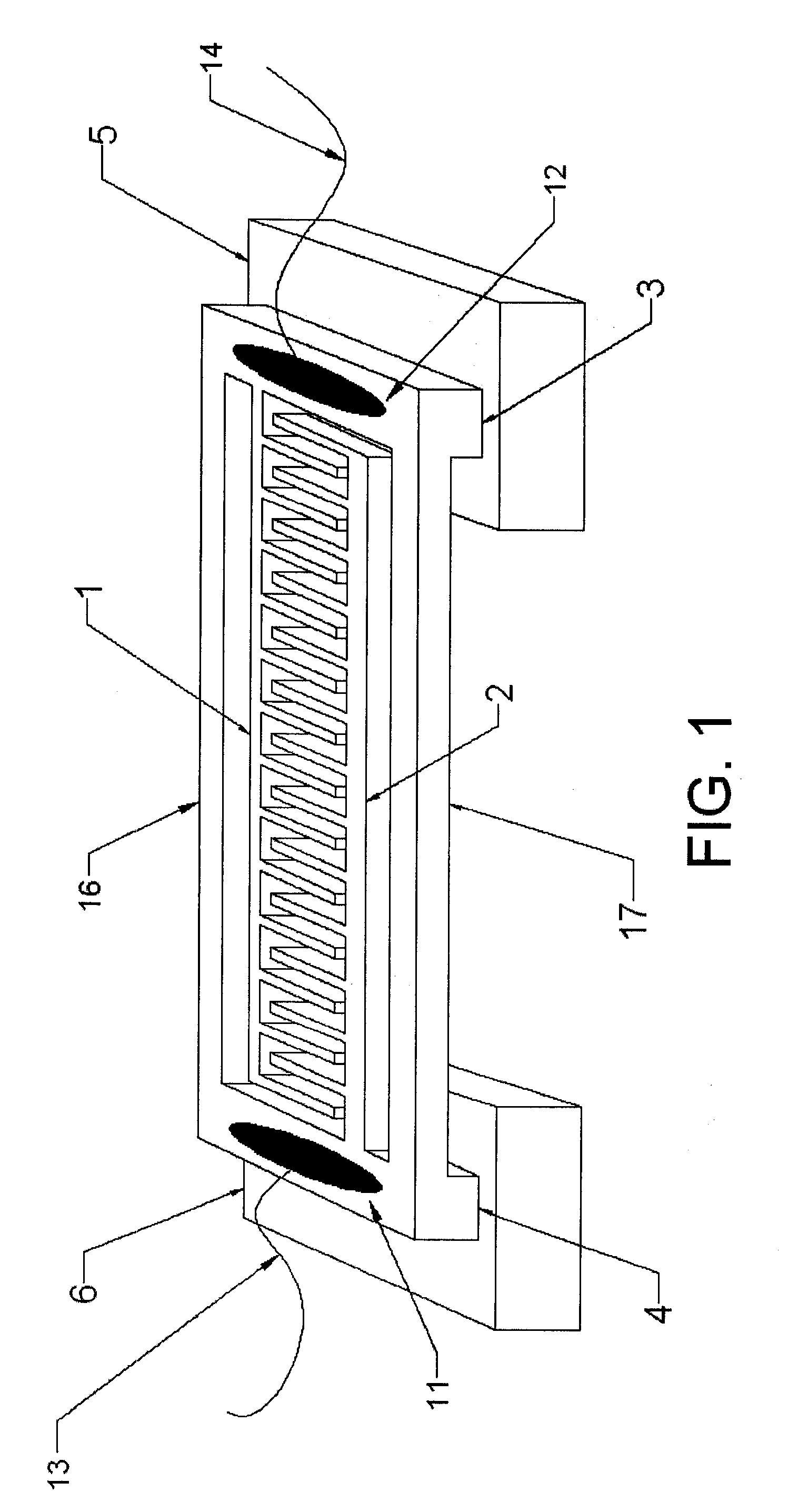

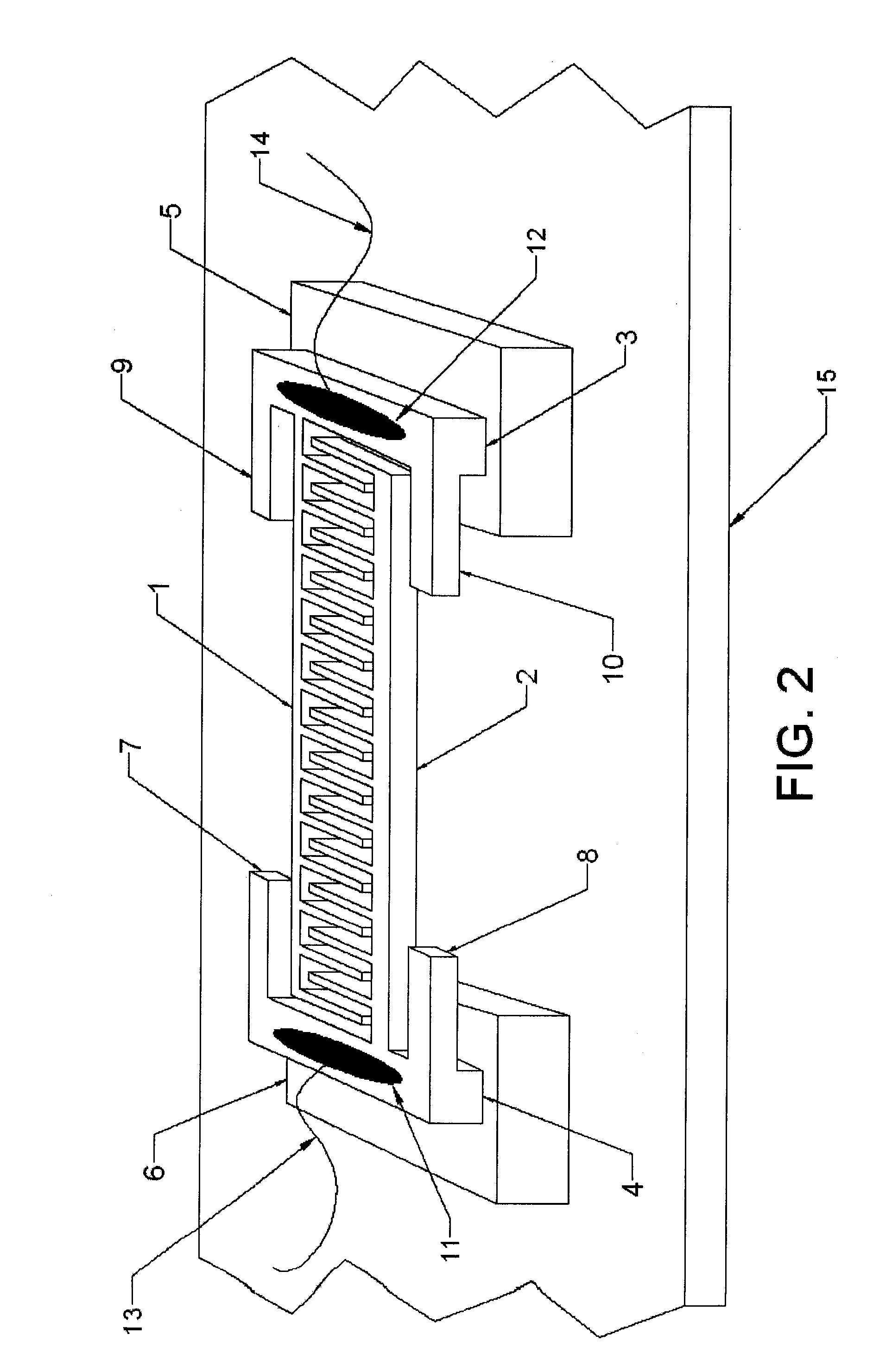

MEMS Capacitive Bending and Axial Strain Sensor

ActiveUS20090188325A1Easily be incorporated into current semi-conductor fabrication processLow powerForce measurementUsing electrical meansCapacitancePrimary operation

A three-dimensional micro-electro-mechanical-systems (MEMS) capacitive bending and axial strain sensor capacitor is described. Two independent comb structures, incorporating suspended polysilicon interdigitated fingers, are fabricated simultaneously on a substrate that can displace independently of each other while attached to a substrate undergoing bending or axial deformation. A change in spacing between the interdigitated fingers will output a change in capacitance of the sensor and is the primary mode of operation of the device. On the bottom and to the end of each comb structure, a glass pad is attached to the comb structure to allow for ample surface area for affixing the sensor to a substrate. During fabrication, tethers are used to connect each comb structure to maintain equal spacing between the fingers before attachment to the substrate. After attachment, the tethers are broken to allow independent movement of each comb structure.

Owner:GLOBUS MEDICAL INC

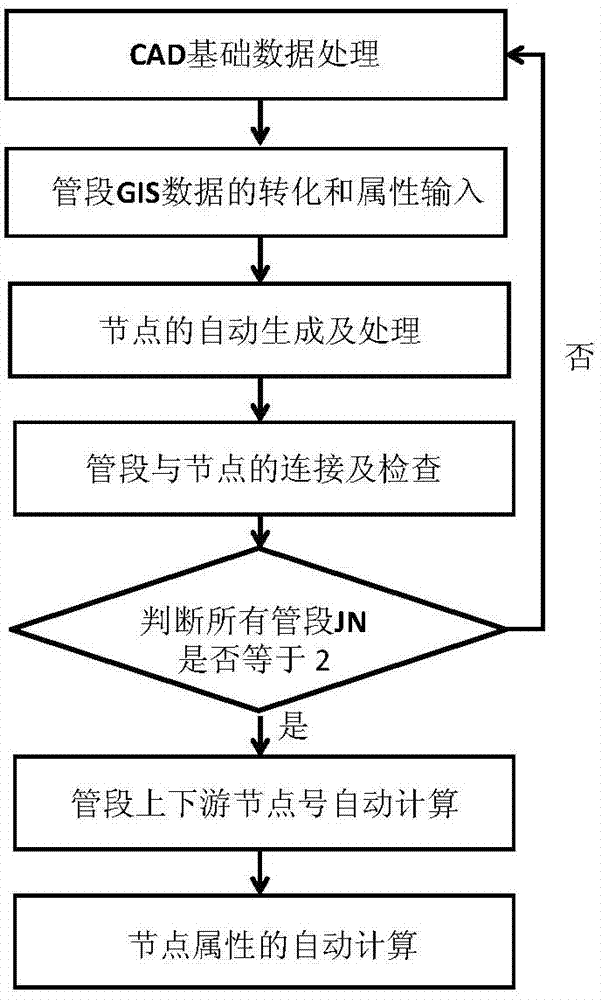

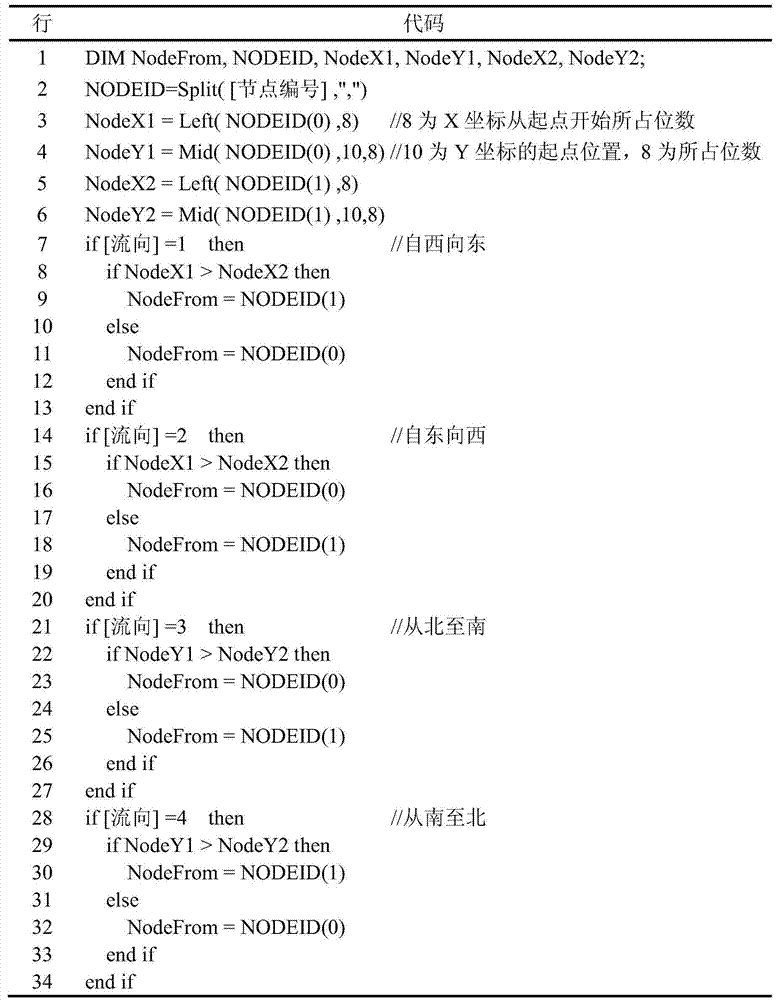

Hydraulic model building demands based digital processing method for drainage pipeline network

ActiveCN103927417AQuick buildImprove reliabilitySpecial data processing applicationsDigital signal processingPrimary operation

The invention relates to a hydraulic model building demands based digital processing method for a drainage pipeline network and belongs to the crossing field of the municipal engineering information technology and the geographic information system technology. Started with hydraulic model building demands, GIS (geographic information system) operation of standard CAD (computer-aided design) vector data is greatly simplified, main operation steps are automatically implemented through computers, errors of original data can be authenticated in time by the aid of a debugging mechanism, and digital processing of the drainage pipeline network system can be quickly and accurately realized. The hydraulic model building demands based digital processing method has the advantages that data size inputted manually by conventional processing methods is greatly simplified, flow direction information of pipeline sections is the only thing to determine, and complicated operations of inputting upstream and downstream node numbers of the pipeline sections are eliminated. Meanwhile, operability of various steps is taken into consideration, the steps can be implemented only by the aid of simple operations on the GIS platform instead of complicated procedural programming, and implementation of the digital processing method is guaranteed.

Owner:平行数字科技(江苏)有限公司

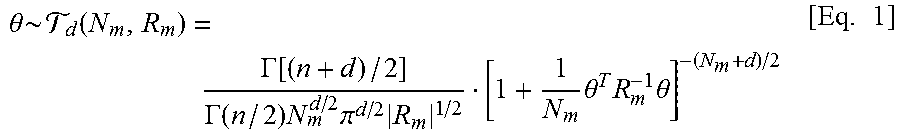

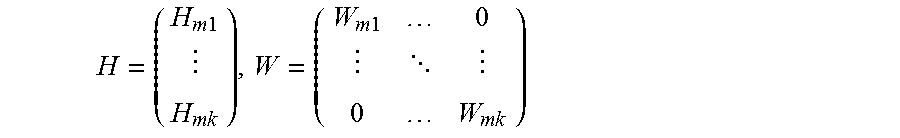

Device and method for computing an error bound of a kalman filter based GNSS position solution

The invention relates to a method for computing a bound B up to a given confidence level 1-4, of an error in a state vector estimation KSV of a state vector TSV of a physical system as provided by a Kalman filter. The method decomposes the errors of the Kalman solution as a sum of the errors due to each of the measurement types used in the filter, In addition, the contribution of each type of measurement is bounded by a multivariate t-distribution that considers the error terms from all the epochs processed. Then, the method implements three main operations:computing a probability distribution of the measurement errors for each epoch and measurement type;summing the previous distributions to obtain a global distribution that models the Kalman solution error; andcomputing the error bound B for a given confidence level from the resulting distribution.

Owner:GMV AEROSPACE & DEFENCE

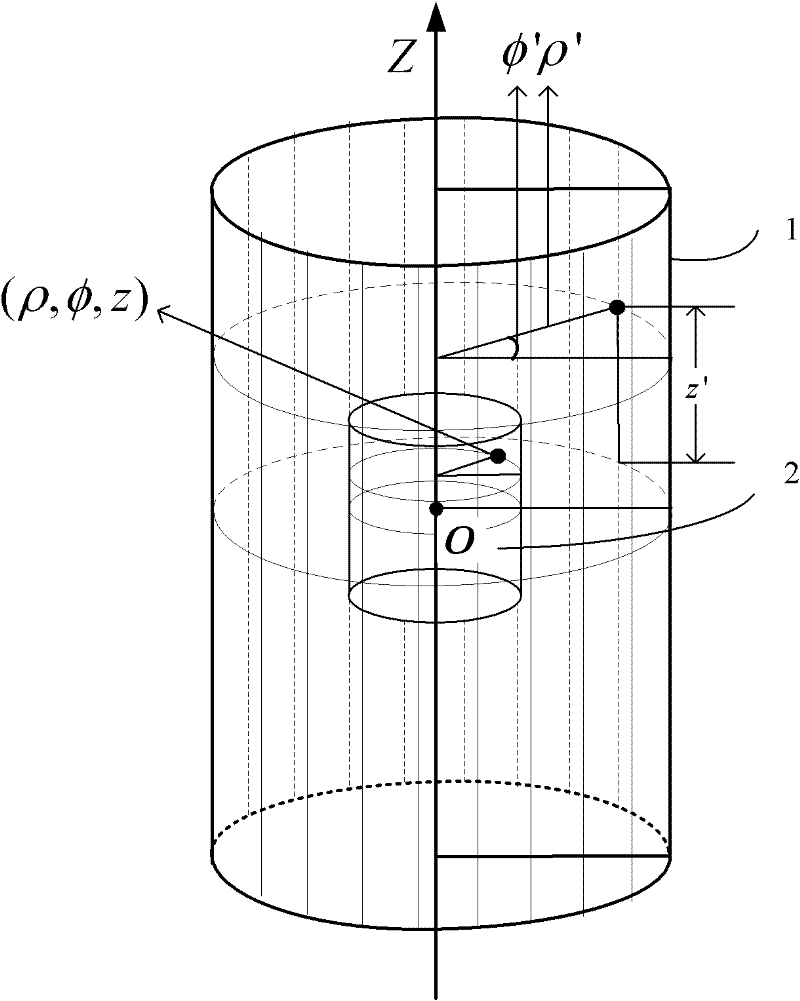

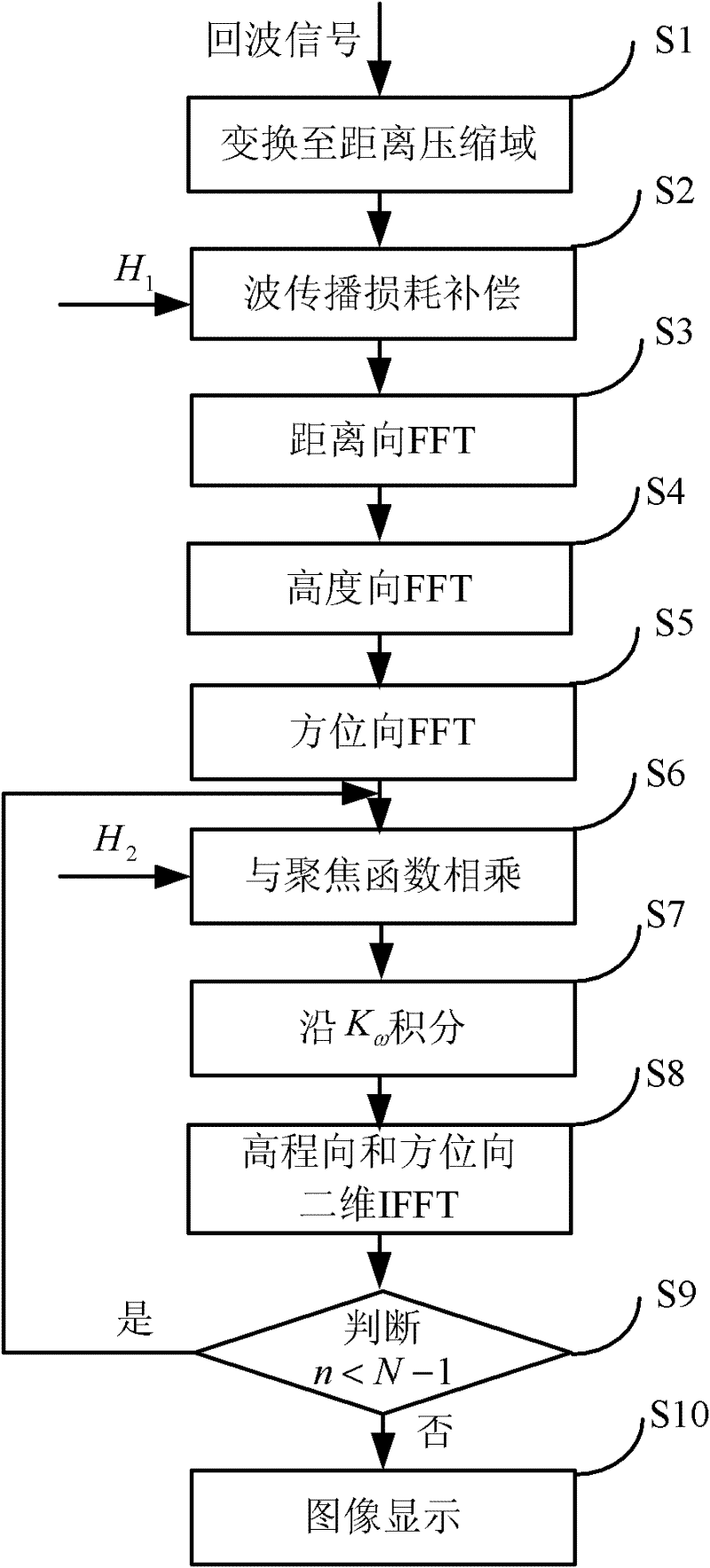

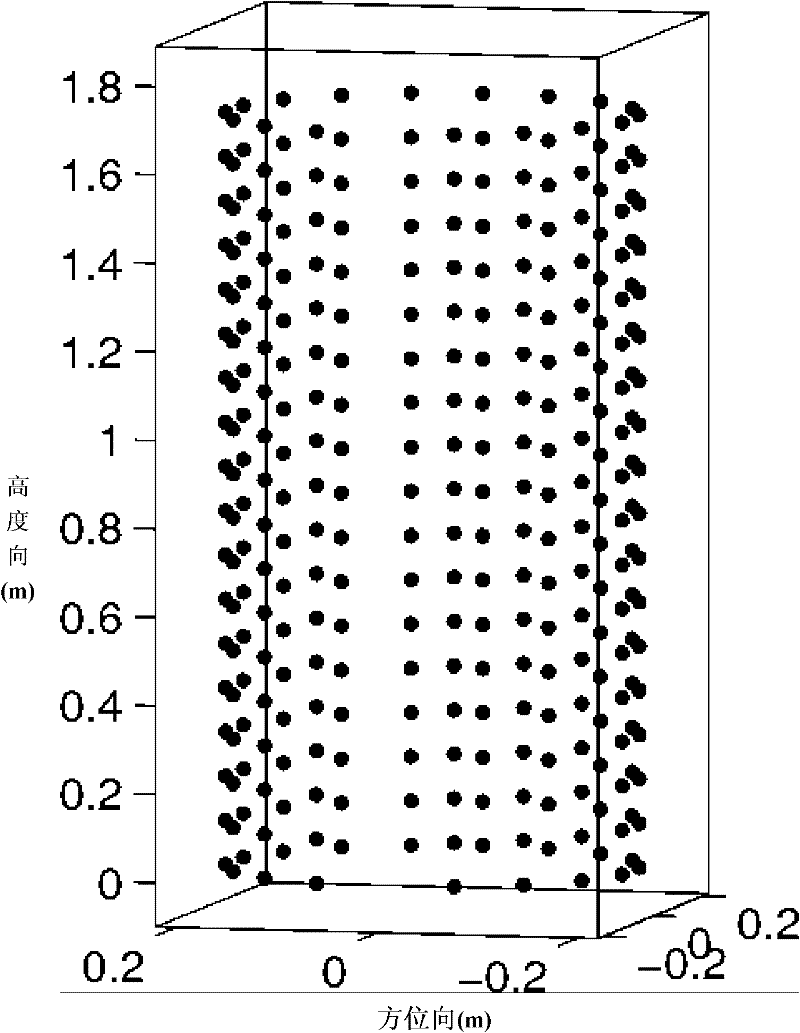

Three-dimensional microwave imaging method based on cylinder geometry

InactiveCN102540183AFast 3D Microwave Imaging3D Microwave Imaging AccurateRadio wave reradiation/reflectionPrimary operationEngineering

The invention discloses a three-dimensional microwave imaging method based on cylinder geometry, which relates to the microwave imaging technology. The three-dimensional microwave imaging method includes successively completing two-dimensional imaging on different cylinder surfaces by means of designing focusing functions corresponding to various imaging cylinder surfaces, and finally realizing three-dimensional imaging of a total objective region. The three-dimensional microwave imaging method avoids approximation in a processing process, main operations are carried out in a height wave number field and an orientation wave number field, interpolation is not required in a three-dimensional wave number field, and accordingly accurate and high-efficient three-dimensional imaging can be realized.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

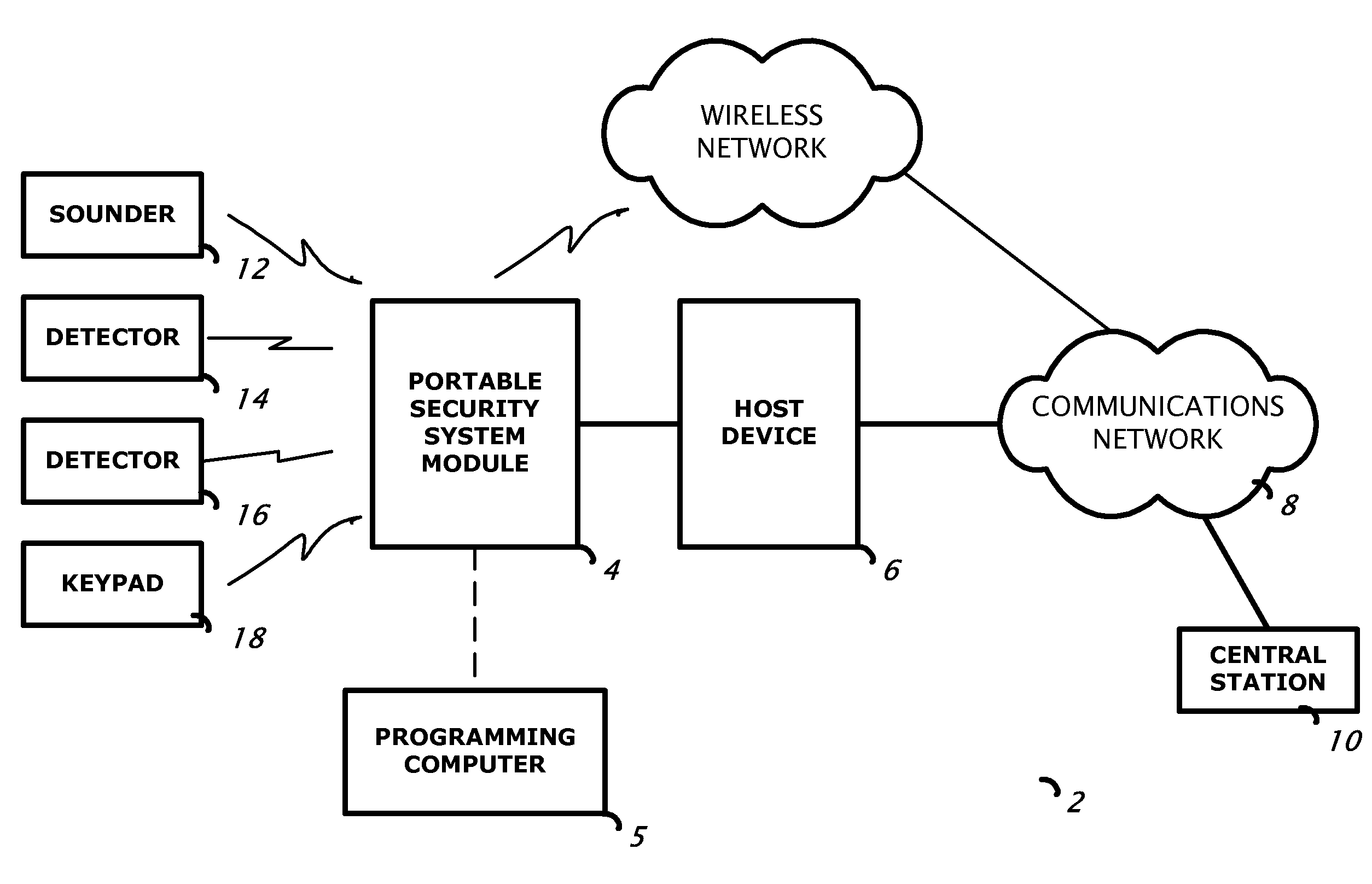

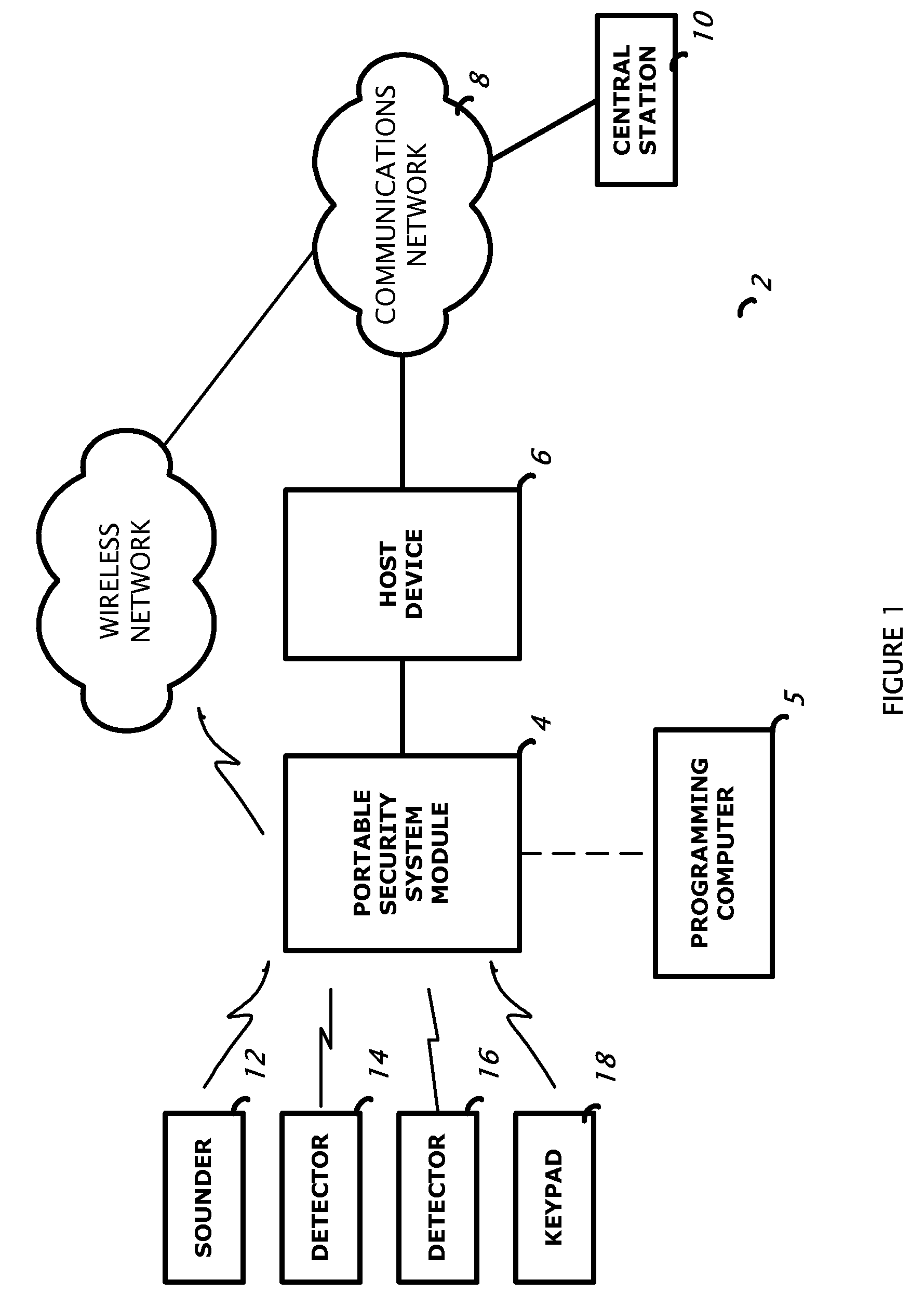

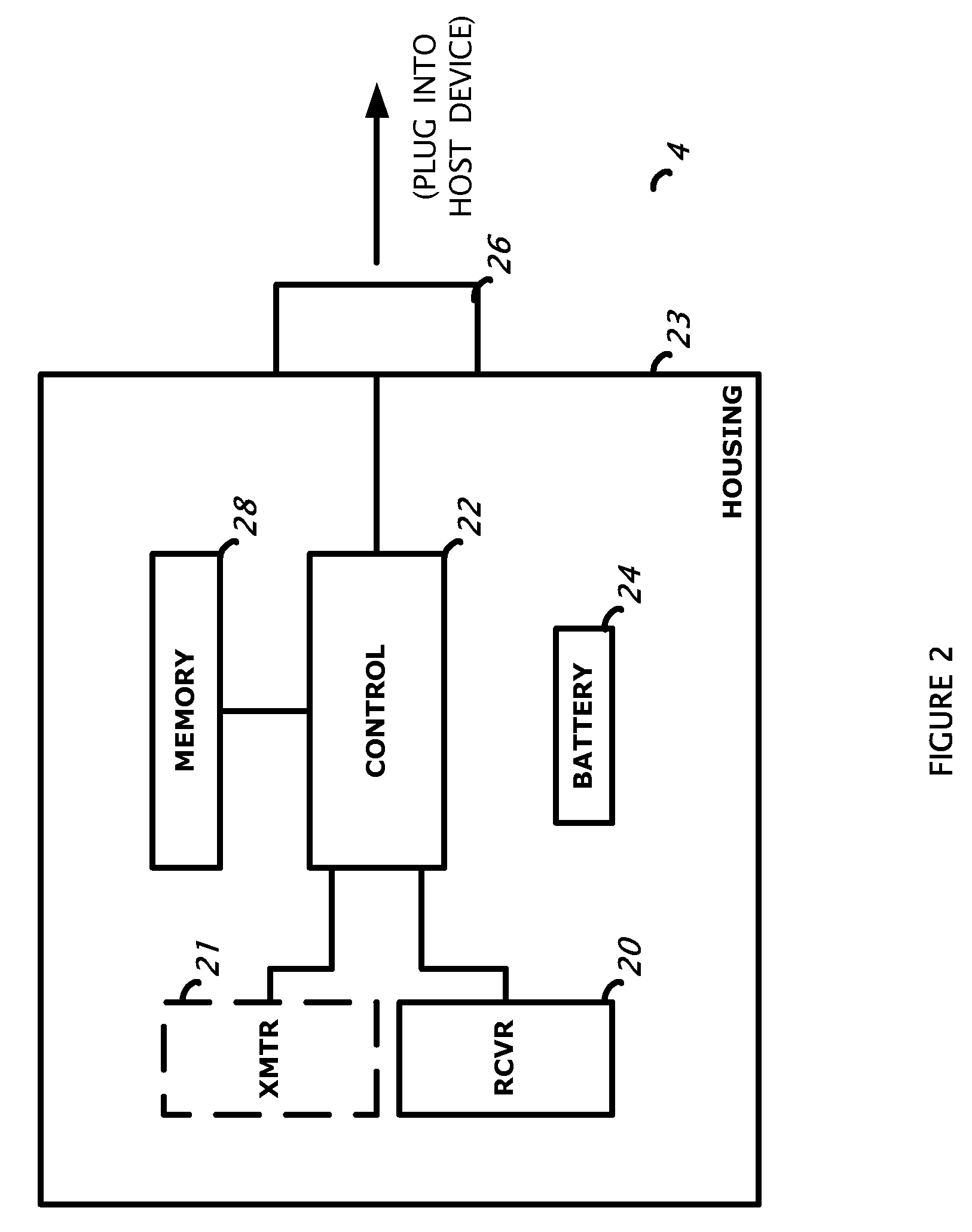

Security system control module

ActiveUS7804403B2Easy to installFrequency-division multiplex detailsTime-division multiplexData connectionPrimary operation

A security system control module with a portable housing including a wireless receiver, control circuitry, nonvolatile memory, and a data connector. The receiver receives data transmissions from at least one wireless security device that monitors a condition of a premises in which the wireless security device is installed. The data connector exchanges data between the control circuitry and an external host device, and it also accepts from the external host device primary operating power for operating the wireless receiver, the control circuitry, and the nonvolatile memory. The control circuitry is adapted to process signals in accordance with a preprogrammed configuration file stored in the nonvolatile memory, the signals received via the wireless receiver from a wireless security device, and to communicate with an external computer located remotely from the external host device via the data connector using a first communications protocol.

Owner:HONEYWELL INT INC

System and method for managing indoor air through cooperation between air conditioner and mobile assistant device

ActiveUS7366588B2Quick controlAccurate detectionMechanical apparatusLighting and heating apparatusPrimary operationAir quality index

A method and system for efficiently managing indoor air through cooperation between a mobile device and a stationary air conditioner. The system may include at least one stationary air conditioner and at least one mobile assistant device that move with a predetermined management area and cooperates with the air conditioner. The air conditioner may include an air quality improving unit improving a value of a predetermined air quality index into an appropriate range, a first forced flow unit generating a main flow to transport improved air toward the abnormal region, and a control unit controlling the air quality improving unit and the first forced flow unit to perform a main operation on the abnormal region and transmitting a command instructing the assistant device to perform an assistant operation on the abnormal region to the assistant device.

Owner:SAMSUNG ELECTRONICS CO LTD

Inspection of cylinder cap leakage of diesel engine

InactiveCN1746647AImprove safety and reliabilityAvoid misjudgmentMachine part testingDetection of fluid at leakage pointPrimary operationWater source

A method for detecting tightness of cylinder cover on diesel engine cylinder includes positioning and clamping closely cylinder or cylinder cover in clamp and sealing water channel to reserve air inlet only, transmitting high pressure air of 300 ¿C 400 Kpa into water channel internal cavity of work piece by air piping, utilizing water storage device or lifting mechanism to submerge work piece into water, observing whether there is air bubble in water or not for judging whether work piece tightness is qualified or not.

Owner:YANGDONG CO LTD

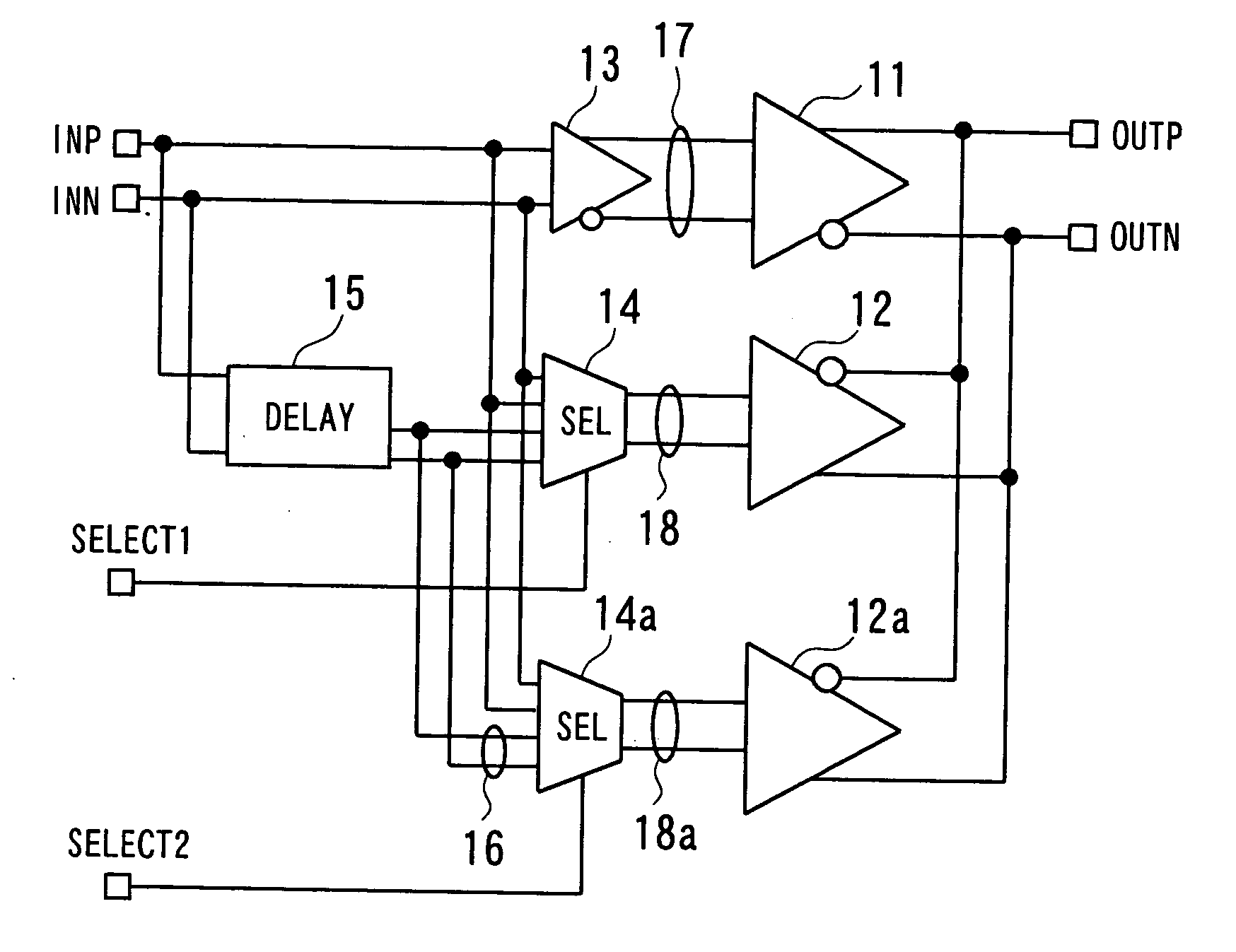

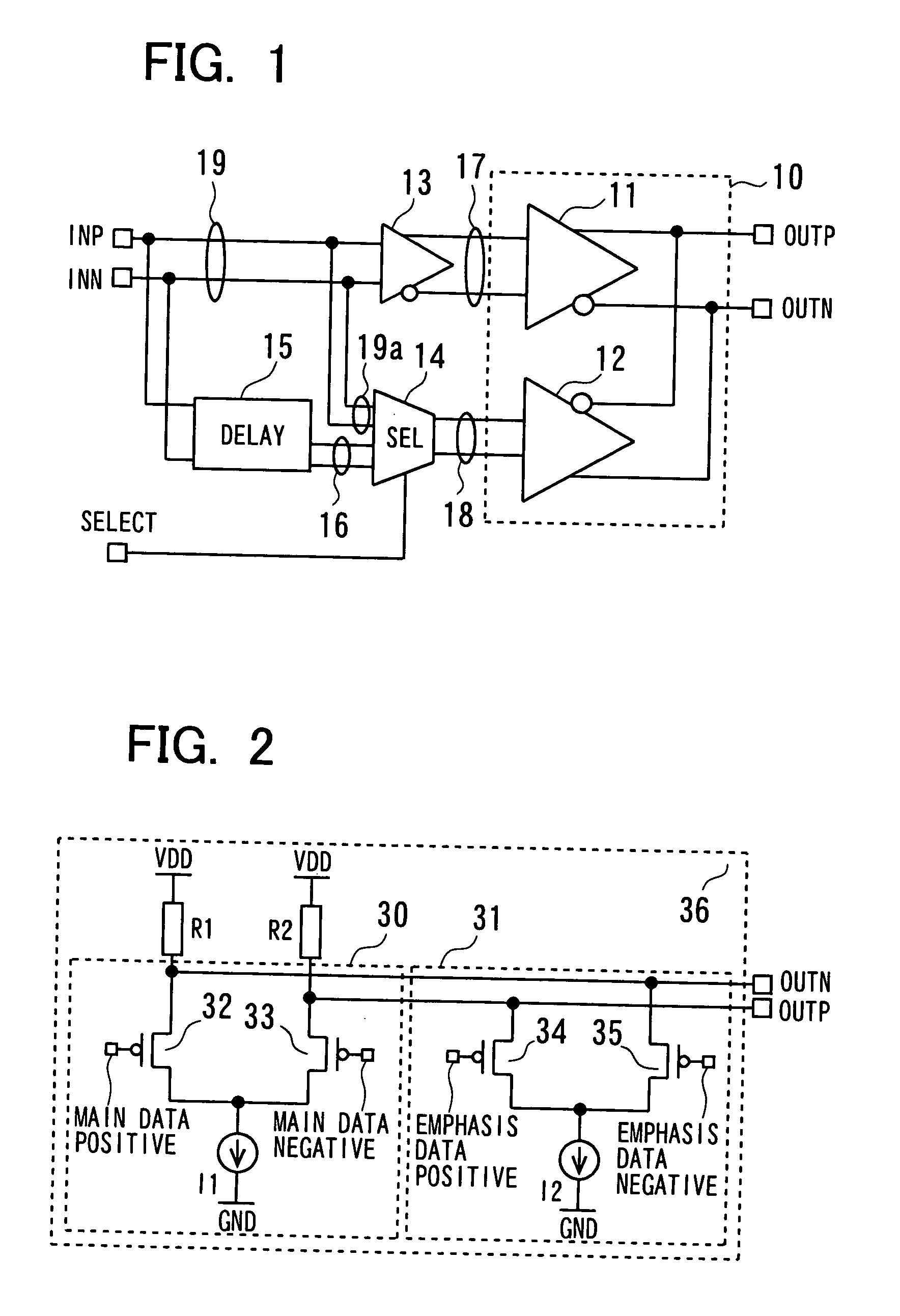

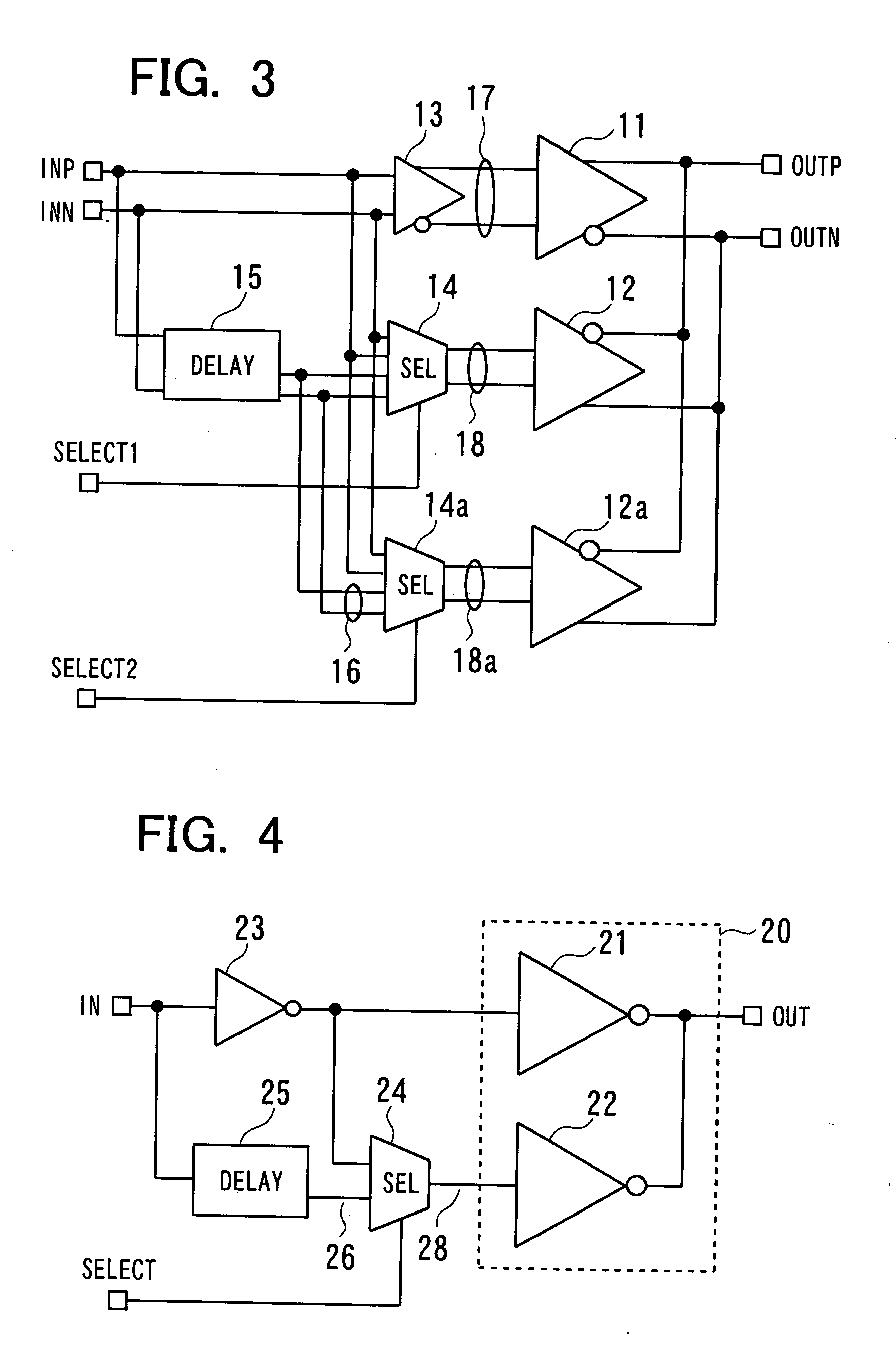

Output buffer circuit with de-emphasis function

InactiveUS20070050572A1Reduce in quantityReduce power consumptionElectric pulse generatorOscillations generatorsPrimary operationControl signal

Disclosed is an output buffer circuit including main-data output buffers; a de-emphasis output buffer; and a selector that performs switching control in such a way that, based on a control signal indicating whether de-emphasis is to be enabled or disabled, main data is supplied to the de-emphasis output buffer to make the buffer operate as a main-data output buffer when the control signal indicates that de-emphasis is to be disabled, while emphasis data obtained on delaying the main data by the delay circuit is supplied to the de-emphasis output buffer to make the buffer operate as a de-emphasis output buffer when the control signal indicates that de-emphasis is to be enabled.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com