Patents

Literature

389 results about "Axial strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

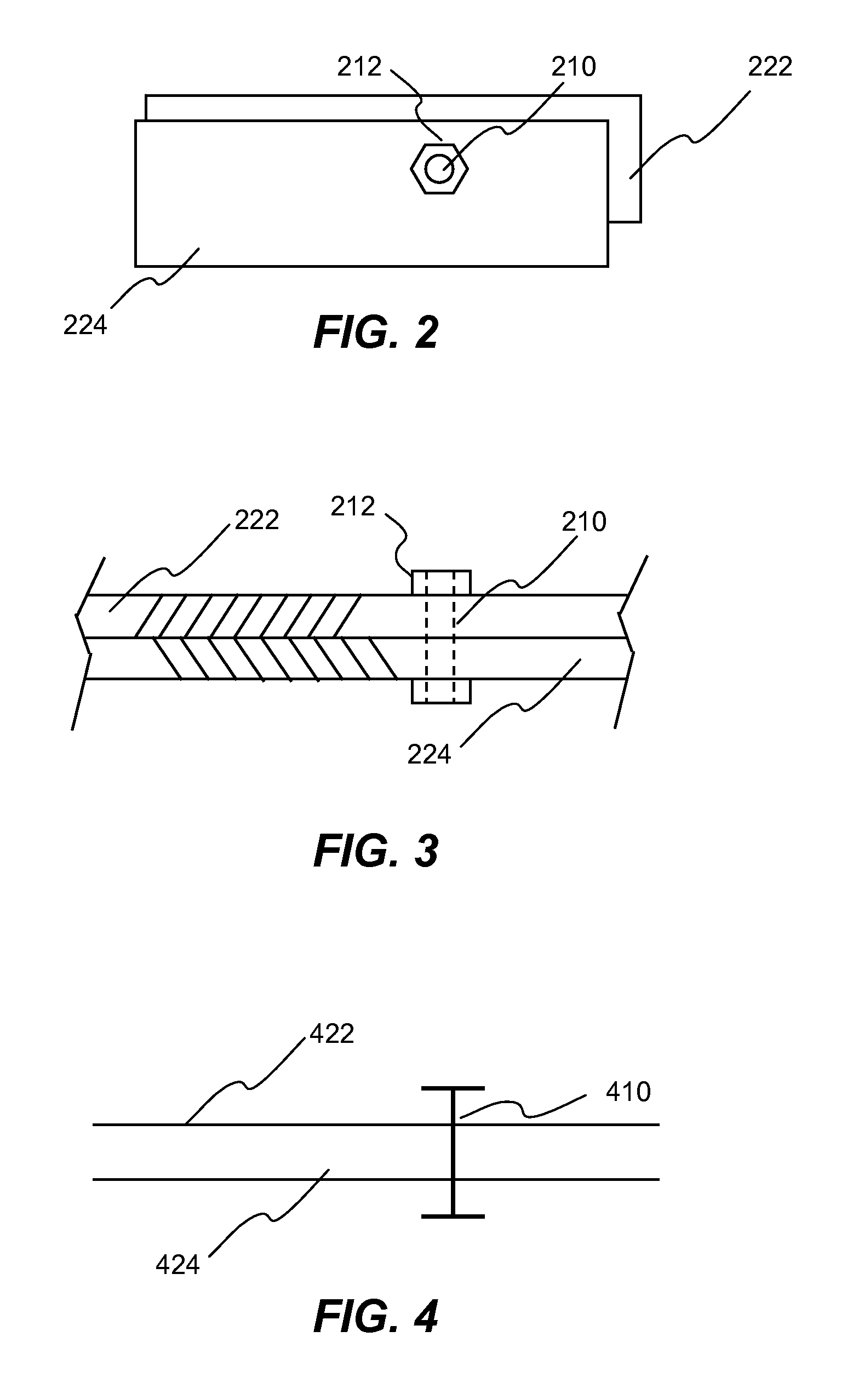

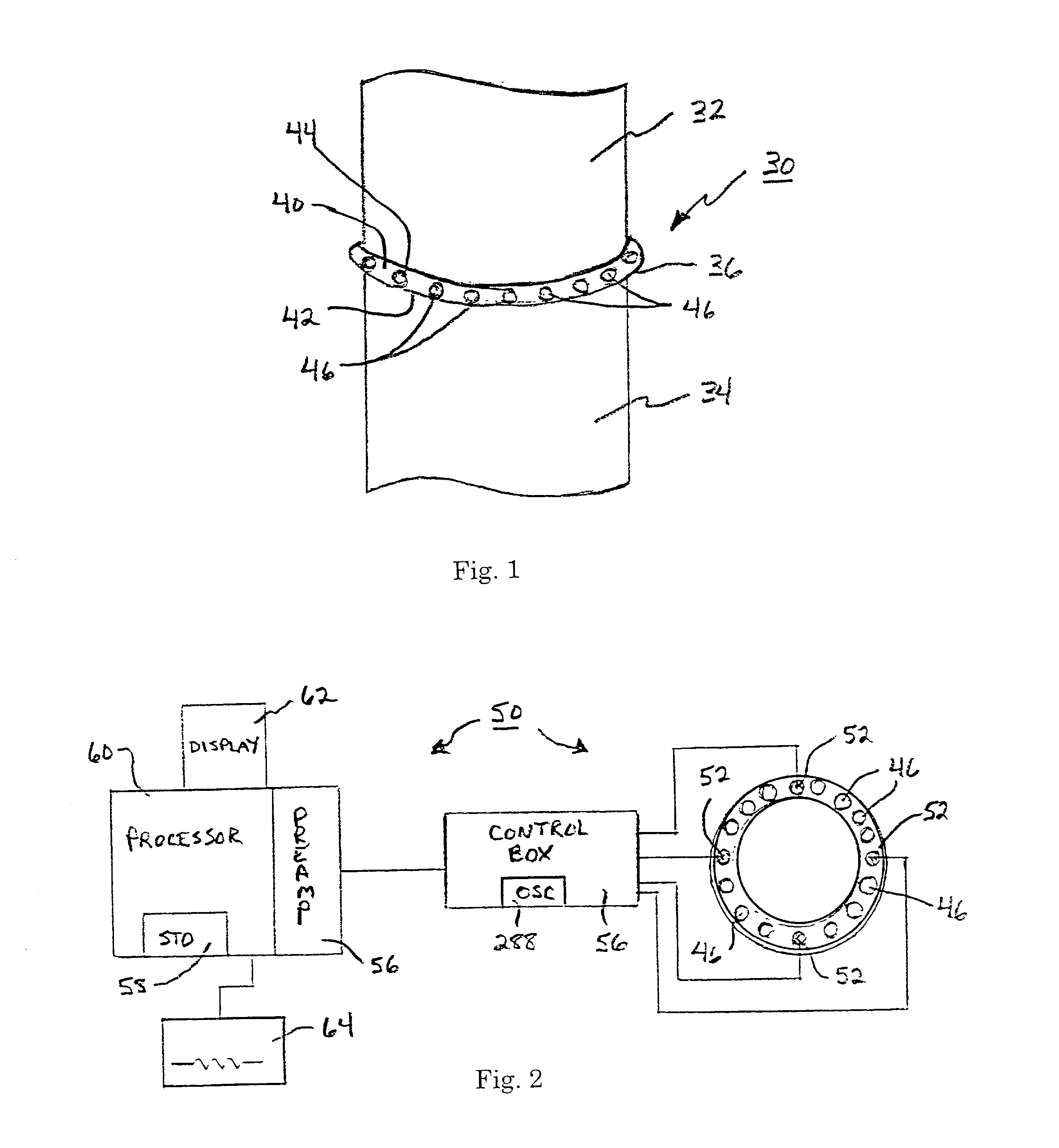

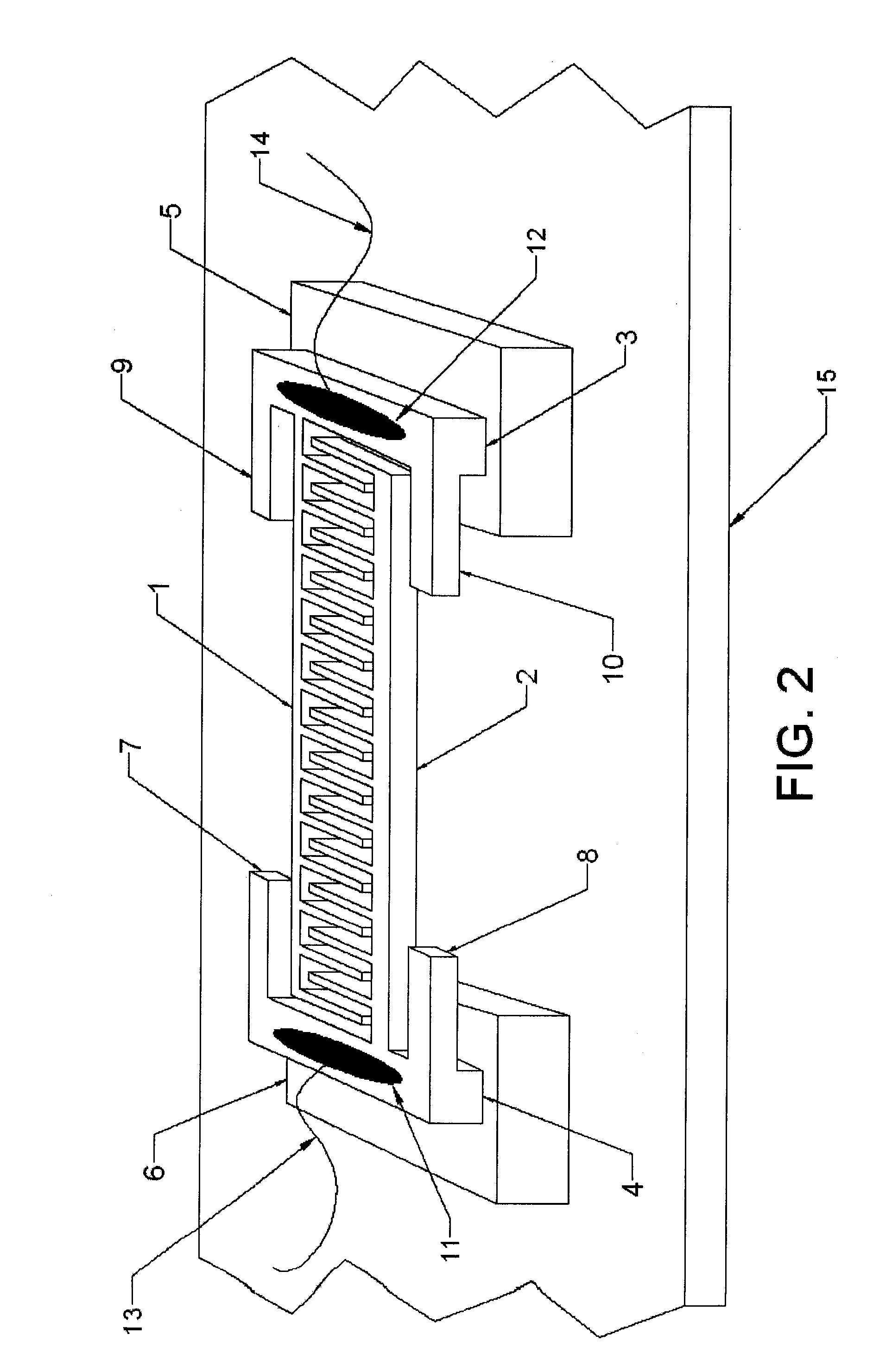

The four different types of strain are axial, bending, shear, and torsional. Axial and bending strain are the most common (see Figure 2). Axial strain measures how a material stretches or compresses as a result of a linear force in the horizontal direction.

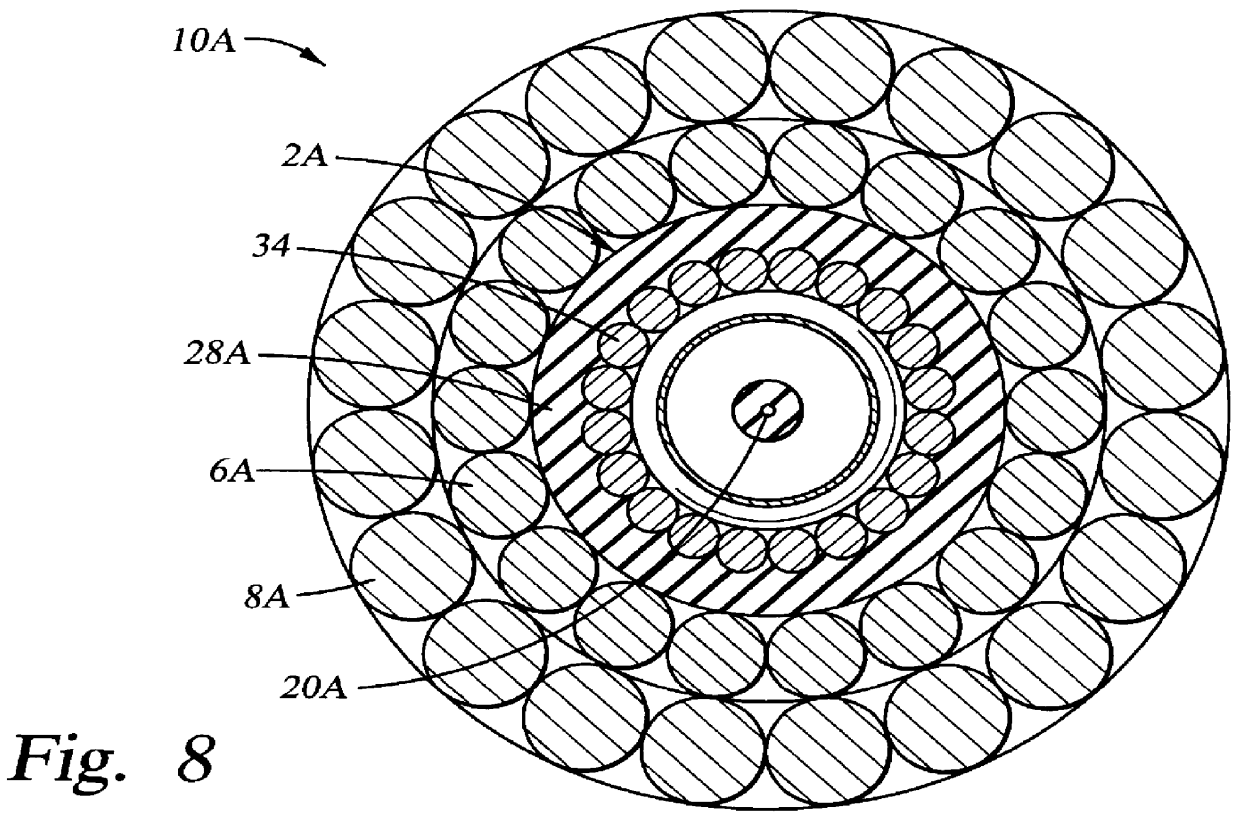

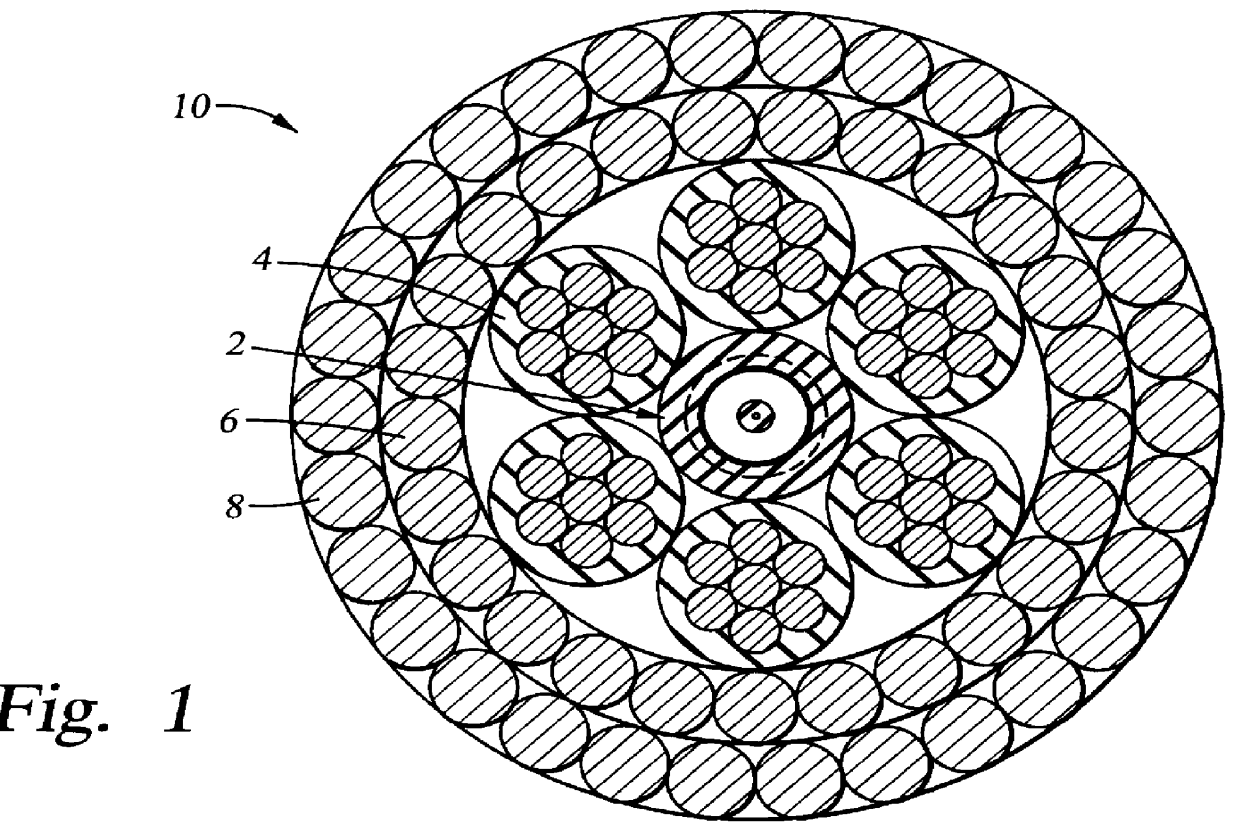

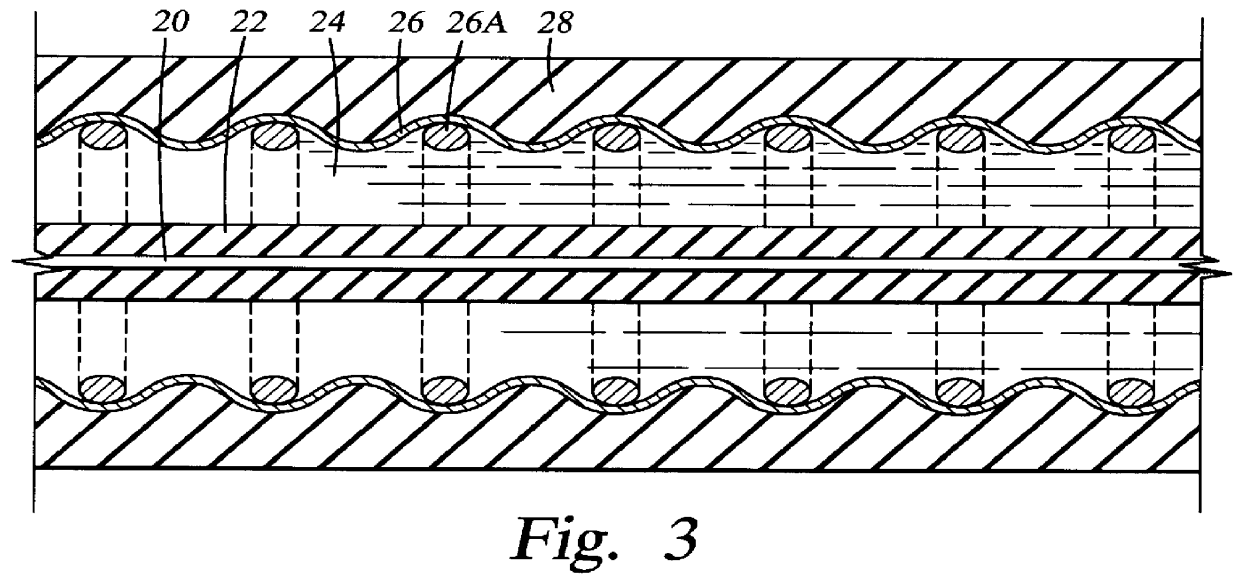

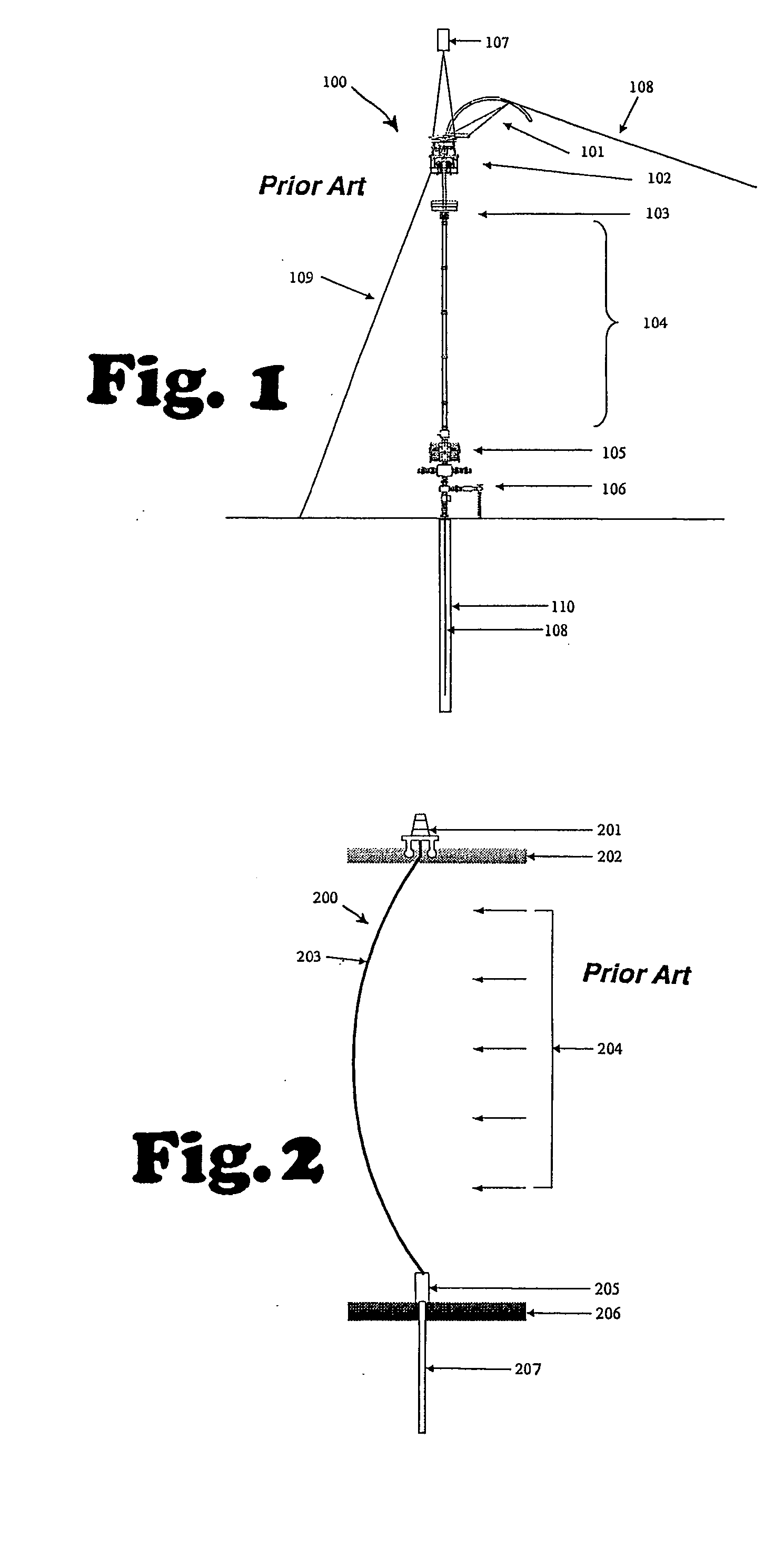

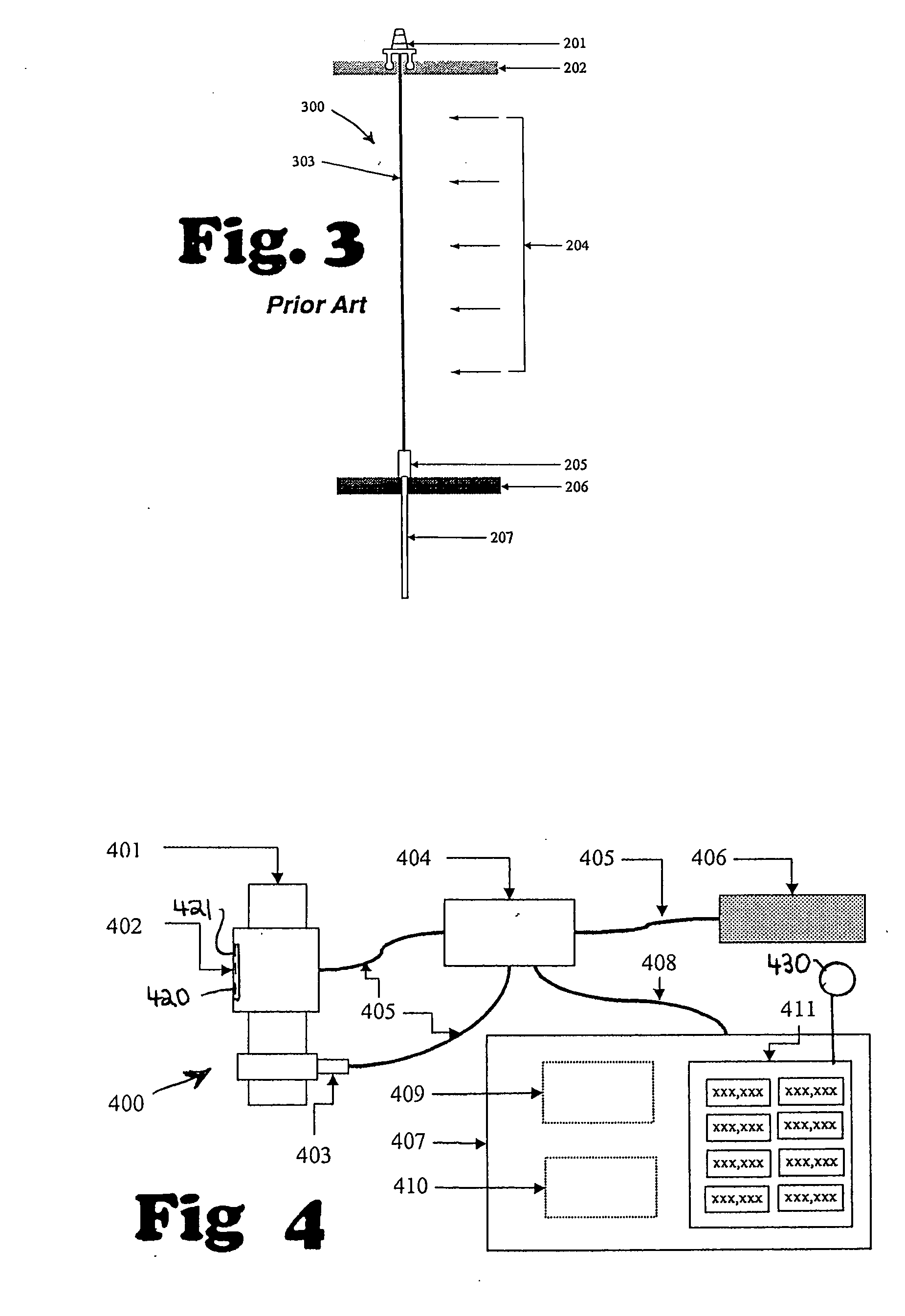

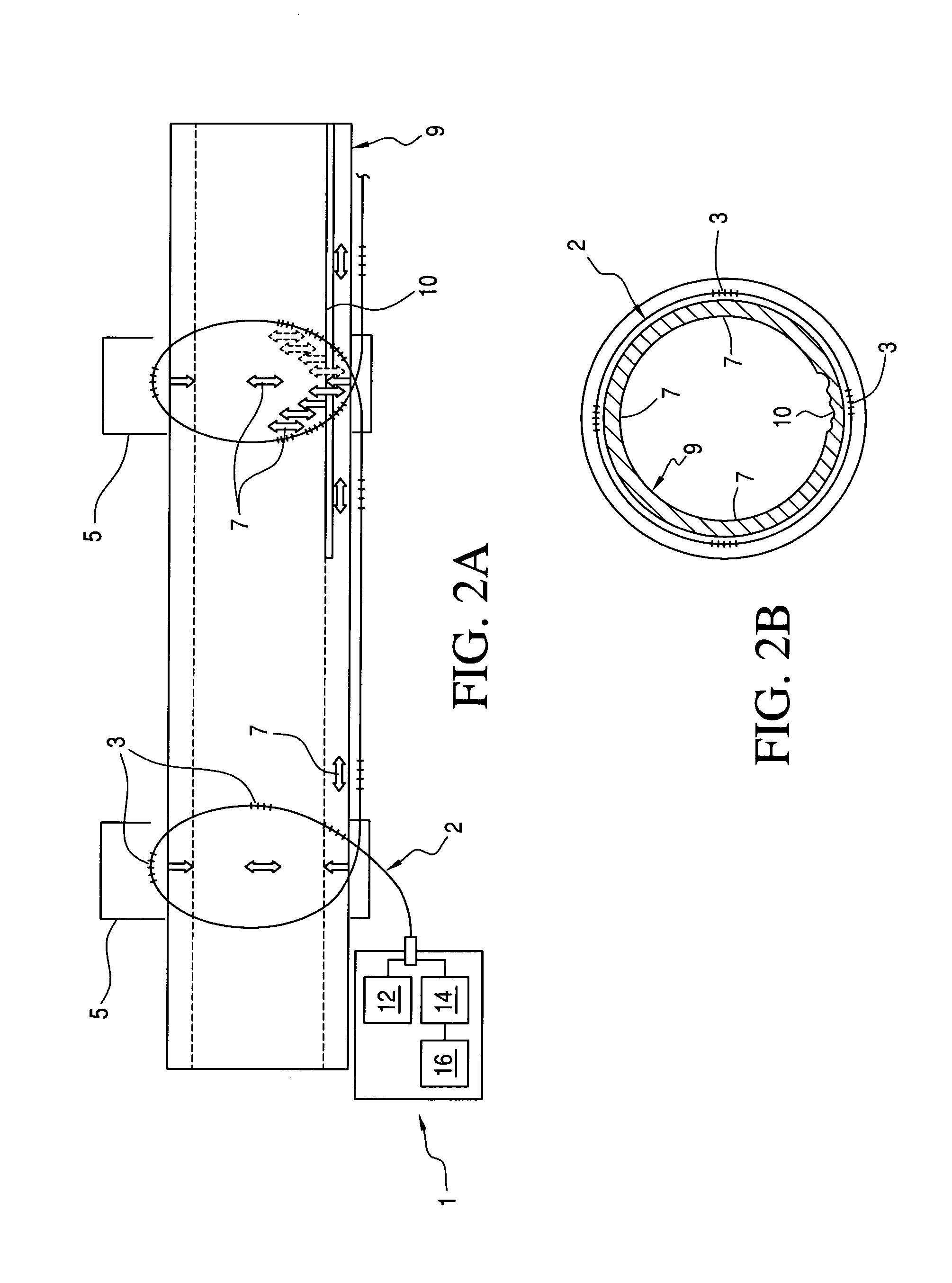

Fiber optic well logging cable

A well logging cable including an optical fiber and a pressure sealed enclosure surrounding the fiber. The enclosure is adapted to be able to be elongated to the maximum expected axial strain on the logging cable without permanent deformation. In one embodiment, the enclosure is a corrugated-wall tube surrounding the optical fiber. The tube contains toroidally shaped rings within the maximum diameter portions of the corrugations in the tube wall. The cable includes armor wires wound around the corrugated-wall tube. In the preferred embodiment, the tube is surrounded by an elastomeric jacket, and is filled with hydraulic oil or the like to prevent entry of wellbore fluids into the tube under hydrostatic pressure.

Owner:WESTERN ATLAS INTERNAIONAL INC

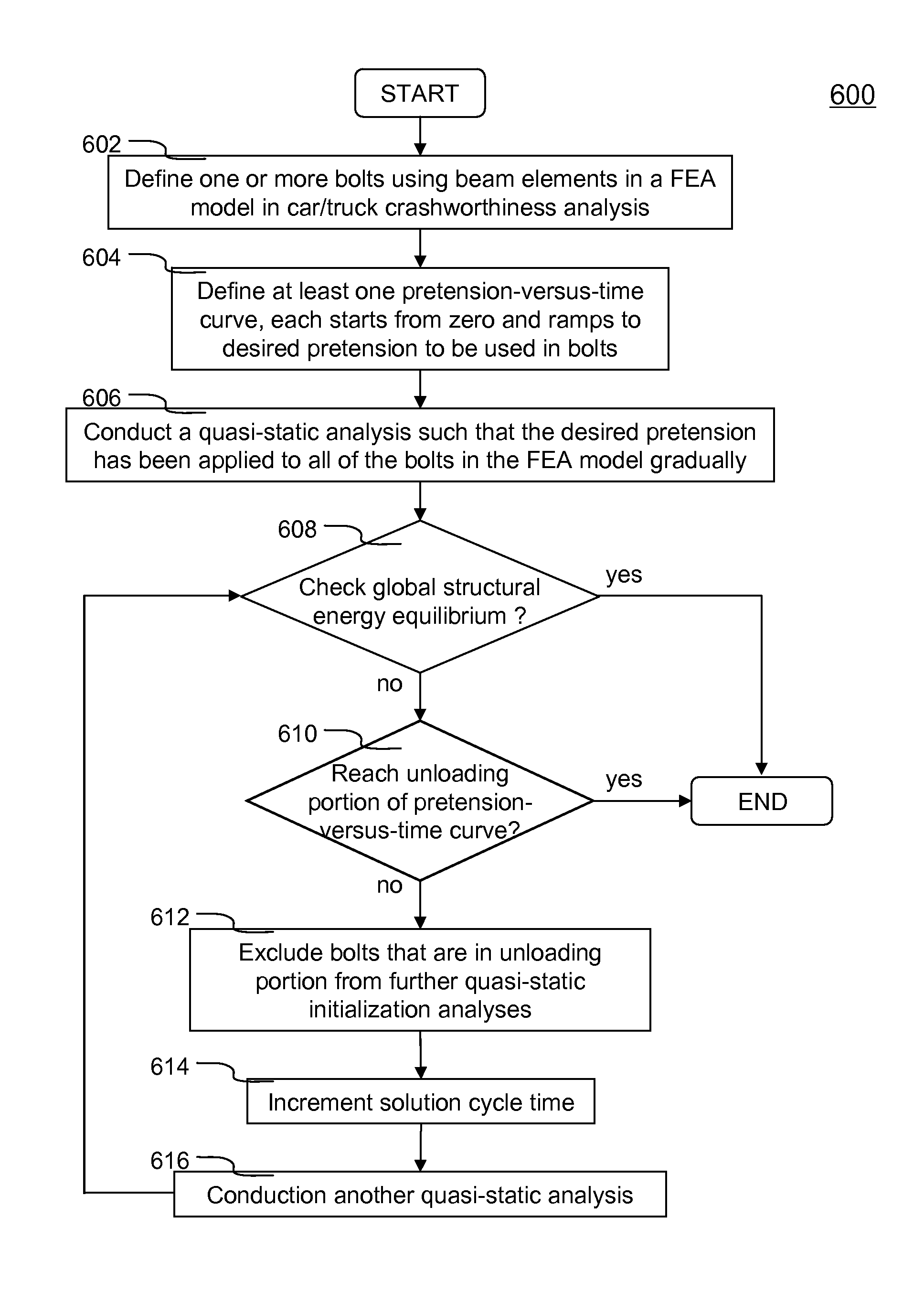

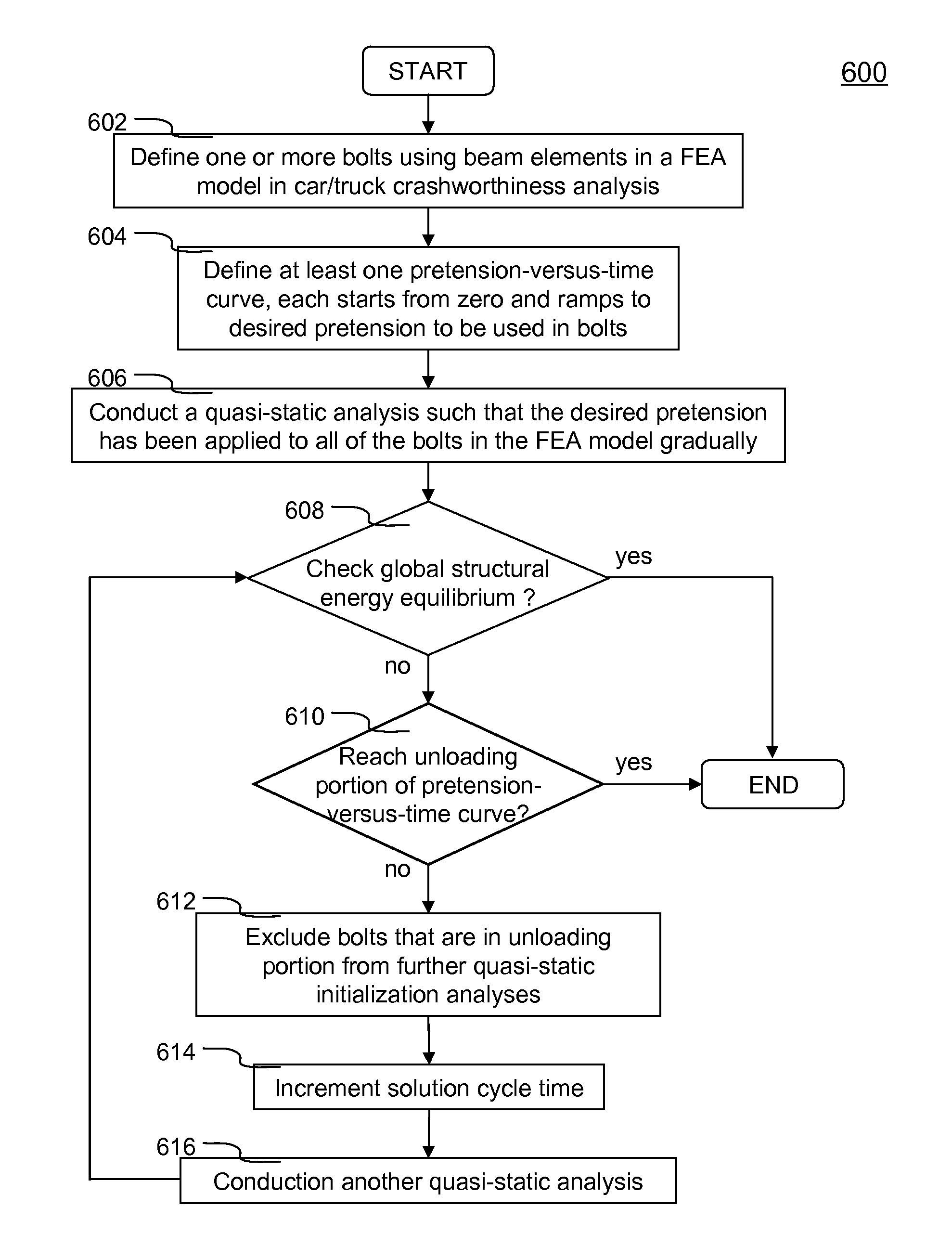

Method of initializing bolt pretension in a finite element analysis

ActiveUS8069017B2Small incrementAvoid the needDesign optimisation/simulationSpecial data processing applicationsElement analysisEngineering

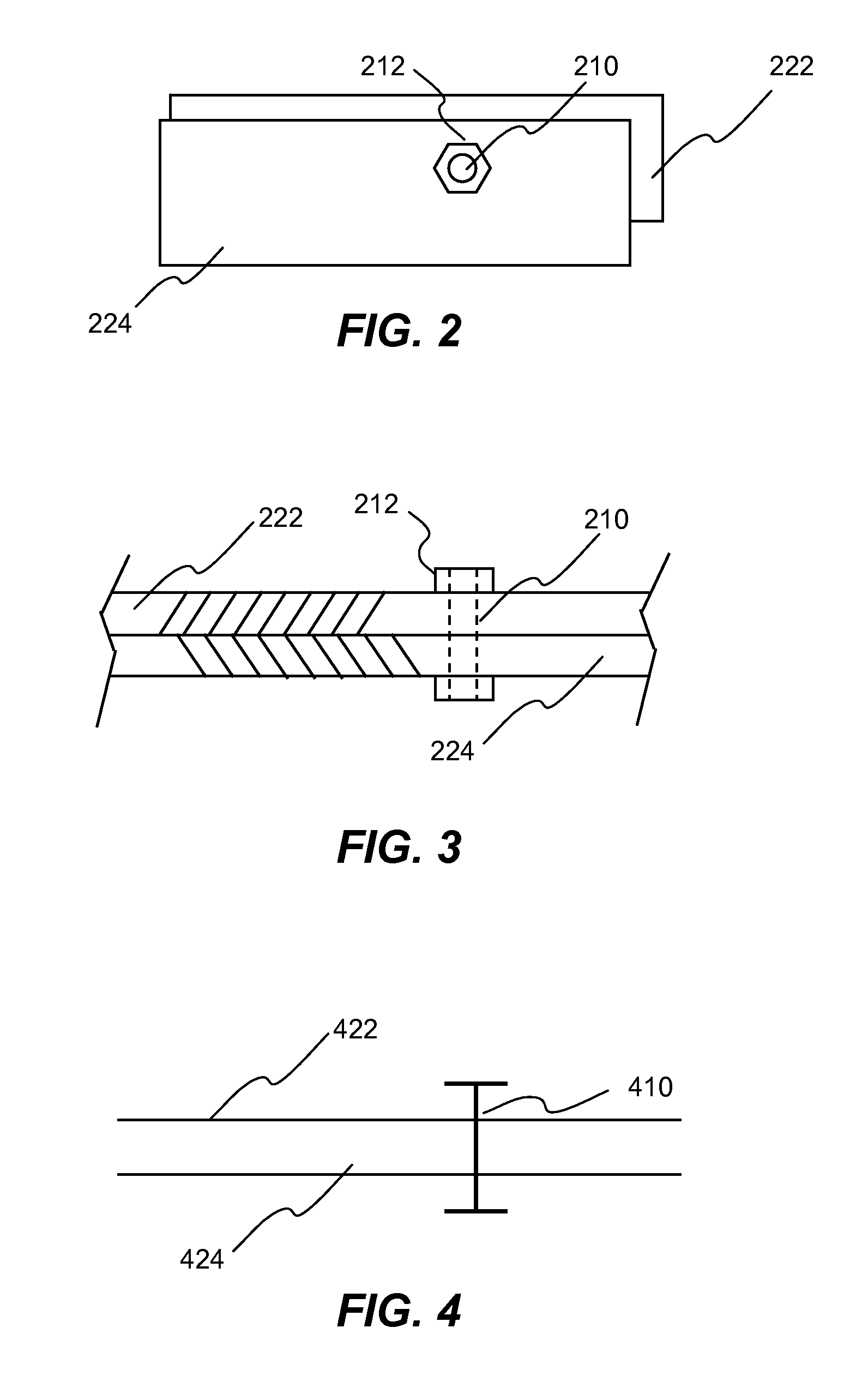

In one aspect of the invention, each bolt is modeled using a beam element in a FEA model. To apply desired pretension to one or more bolts, at least one pretension-versus-time curve is specified. Each pretension-versus-time curve includes ramp portion, desired pretension portion and optional unloading portion. Duration of the pretension-versus-time curve generally covers first 0.5-1% of total simulation time of a car crashworthiness analysis. Ramp portion starts from zero to desired pretension in a substantially linear manner, and hence being configured for applying desired pretension to a bolt gradually with smaller increments. Desired pretension portion is configured for ensuring the desired pretension can actually be applied to the beam element during an initialization process—a series of quasi-static analyses. Since the method is independent of the deformation of the beam, the method completely avoids the need to iteratively determine an axial strain or displacement that gives the desired pretension.

Owner:ANSYS

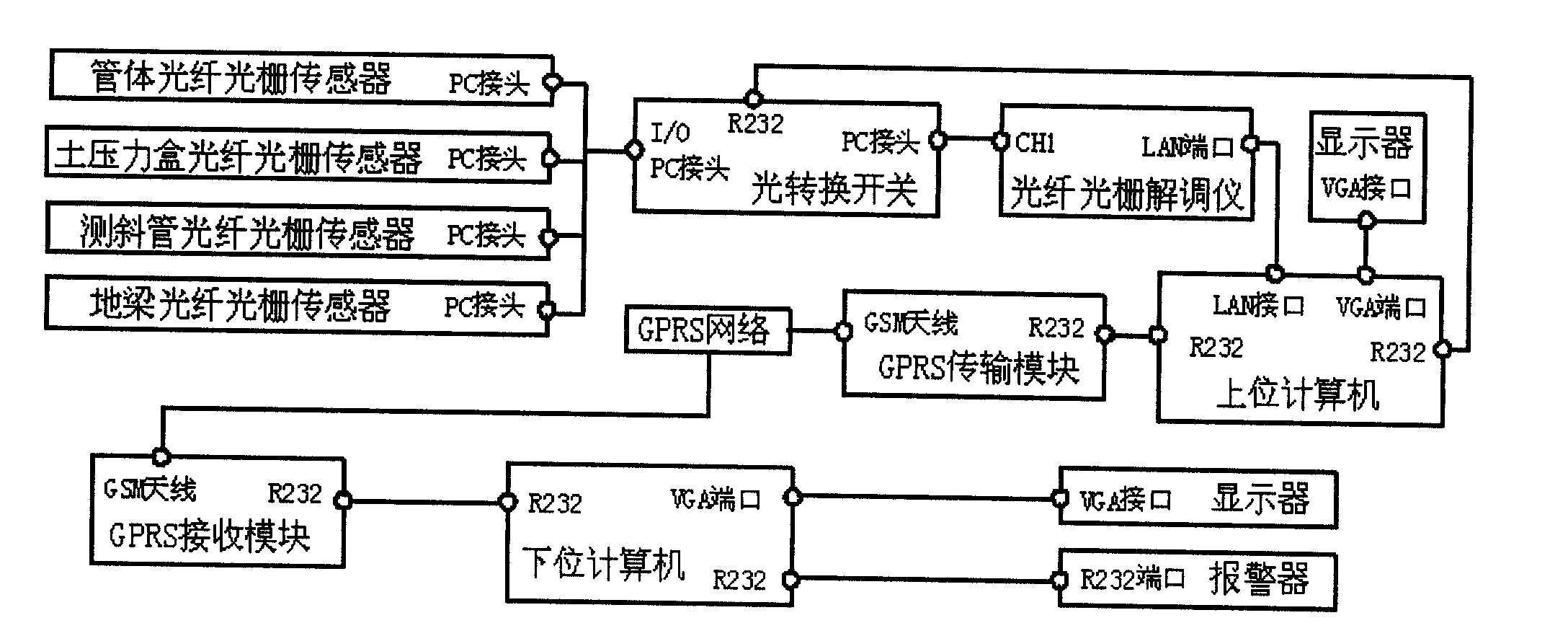

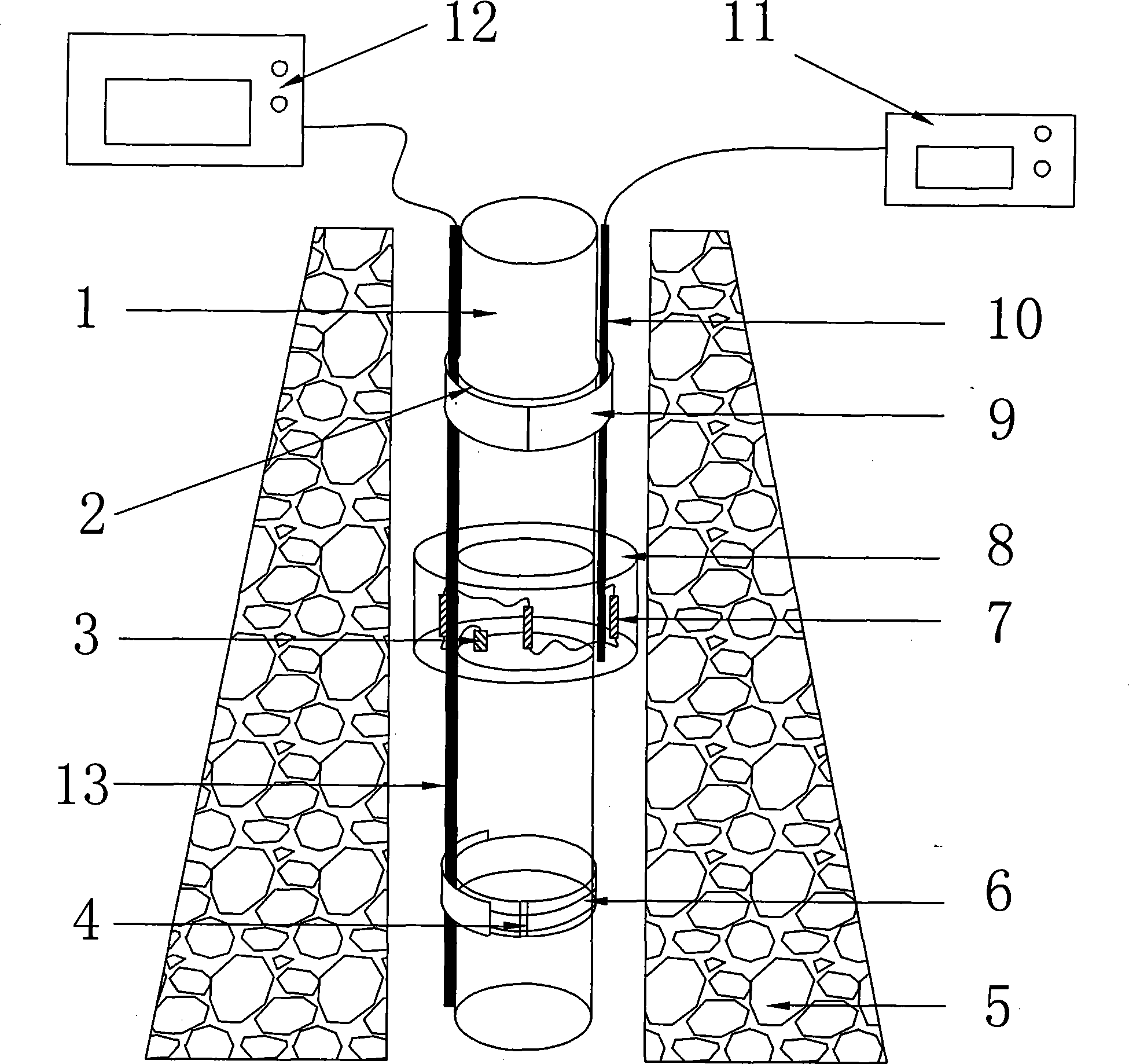

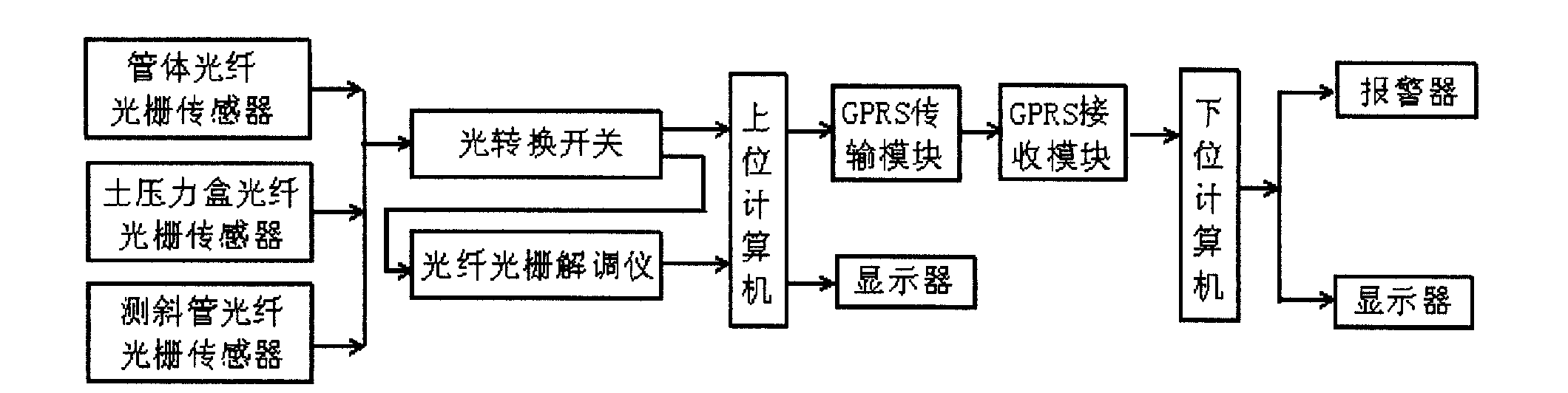

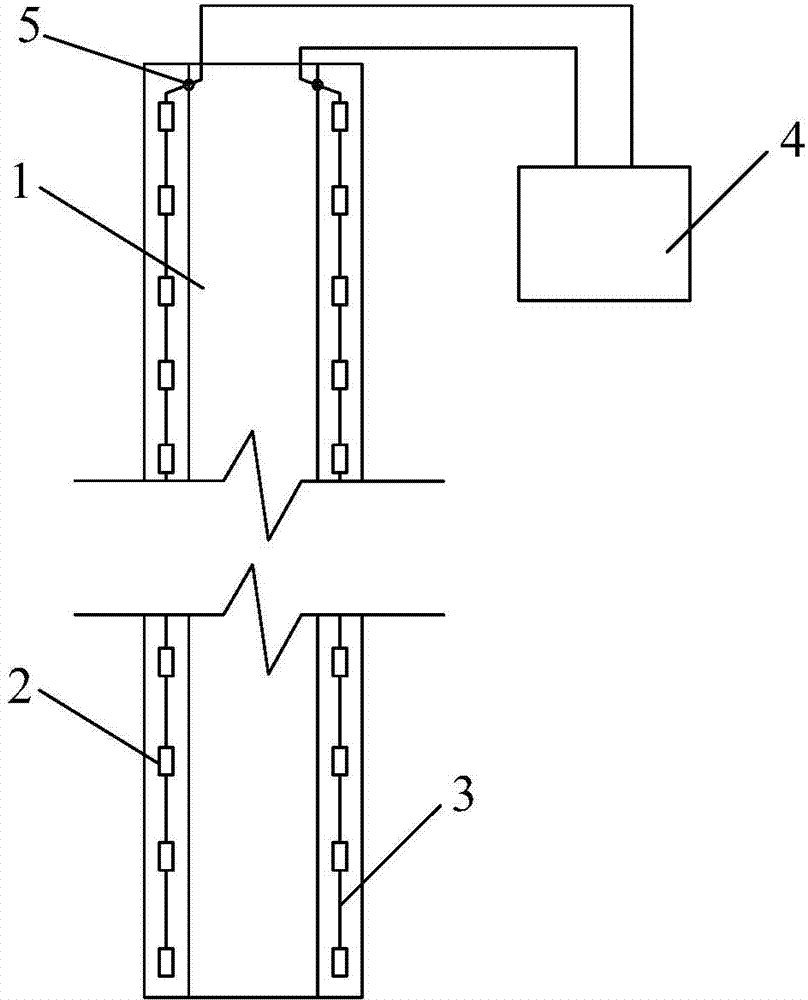

Method and system for monitoring and warning pipeline landslide and method for constructing system

ActiveCN101667324ASimple structureReduce volumeForce measurement by measuring optical property variationUsing optical meansFiberGrating

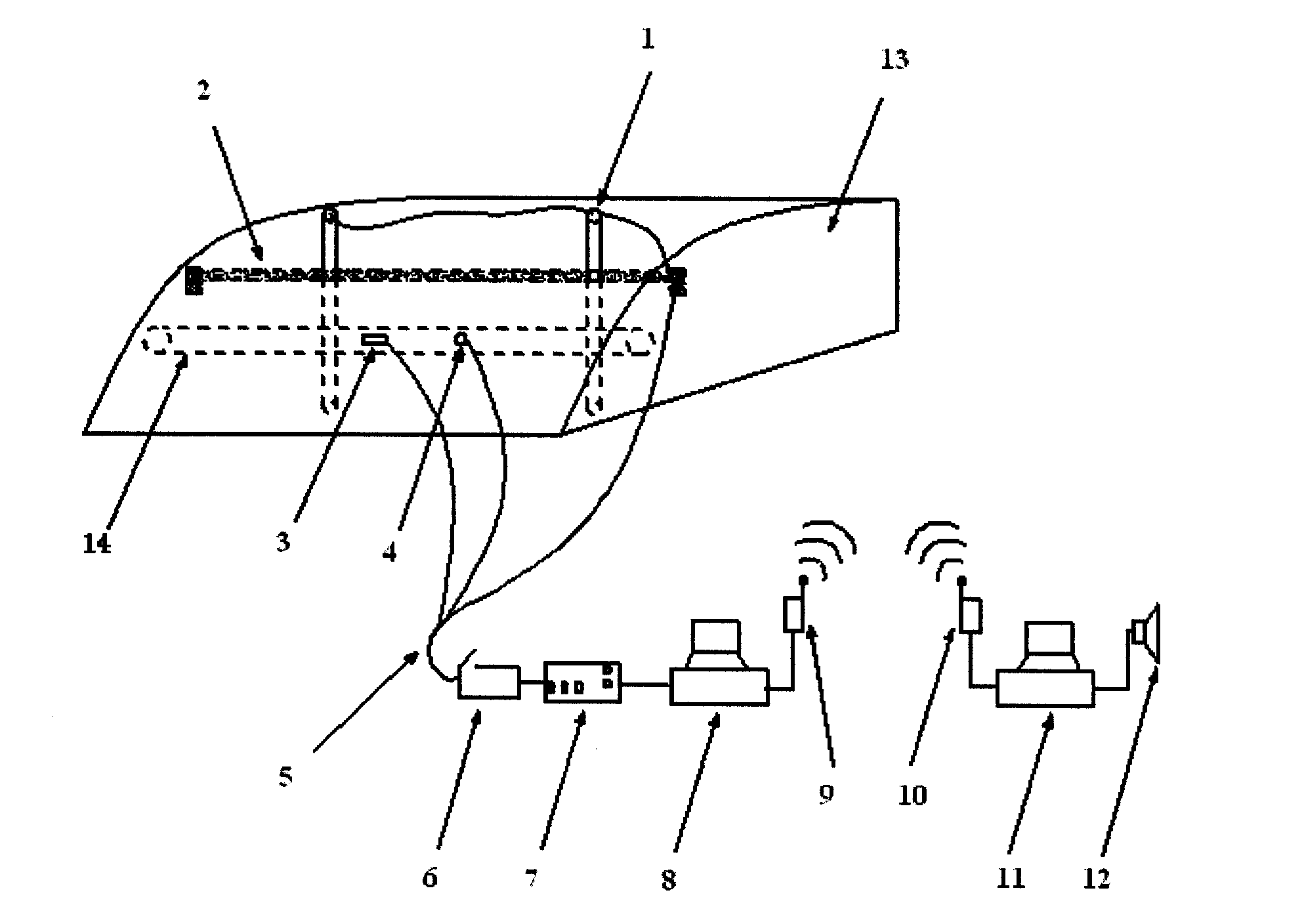

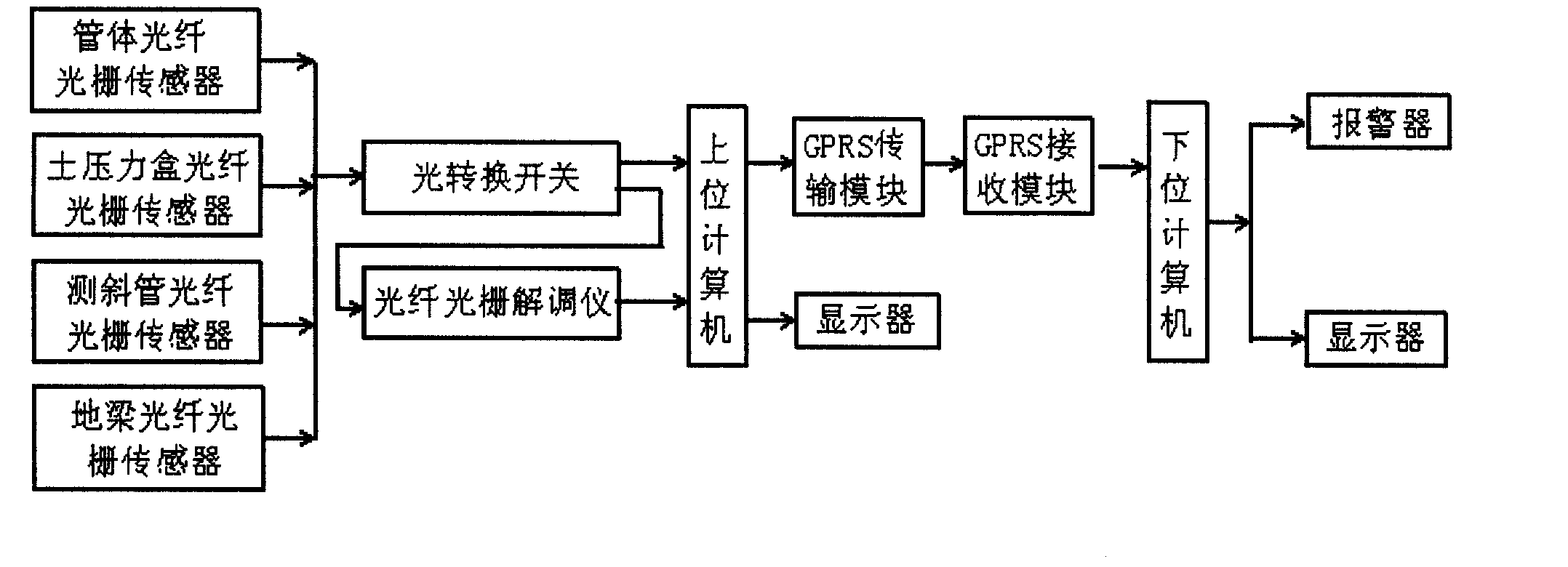

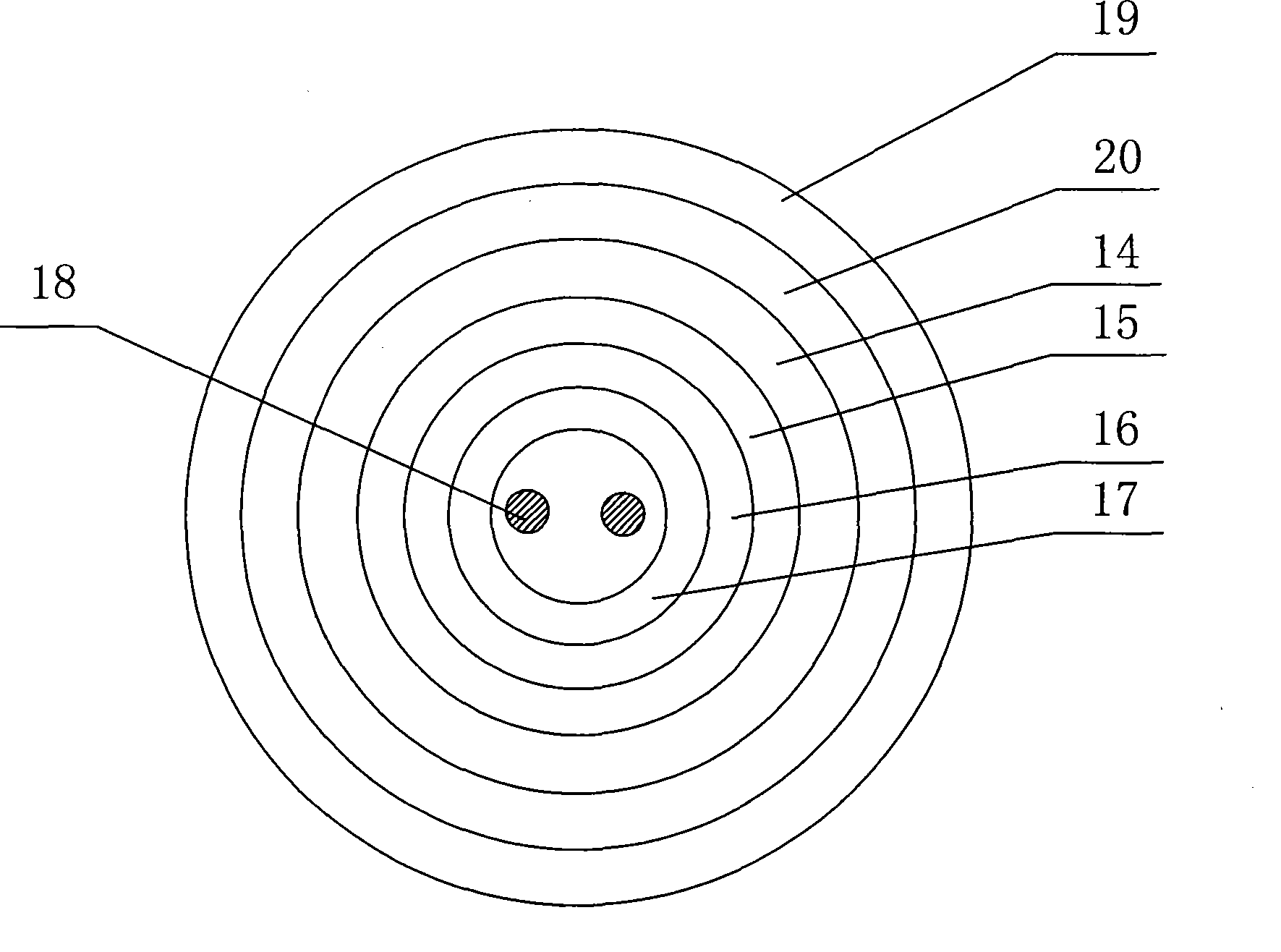

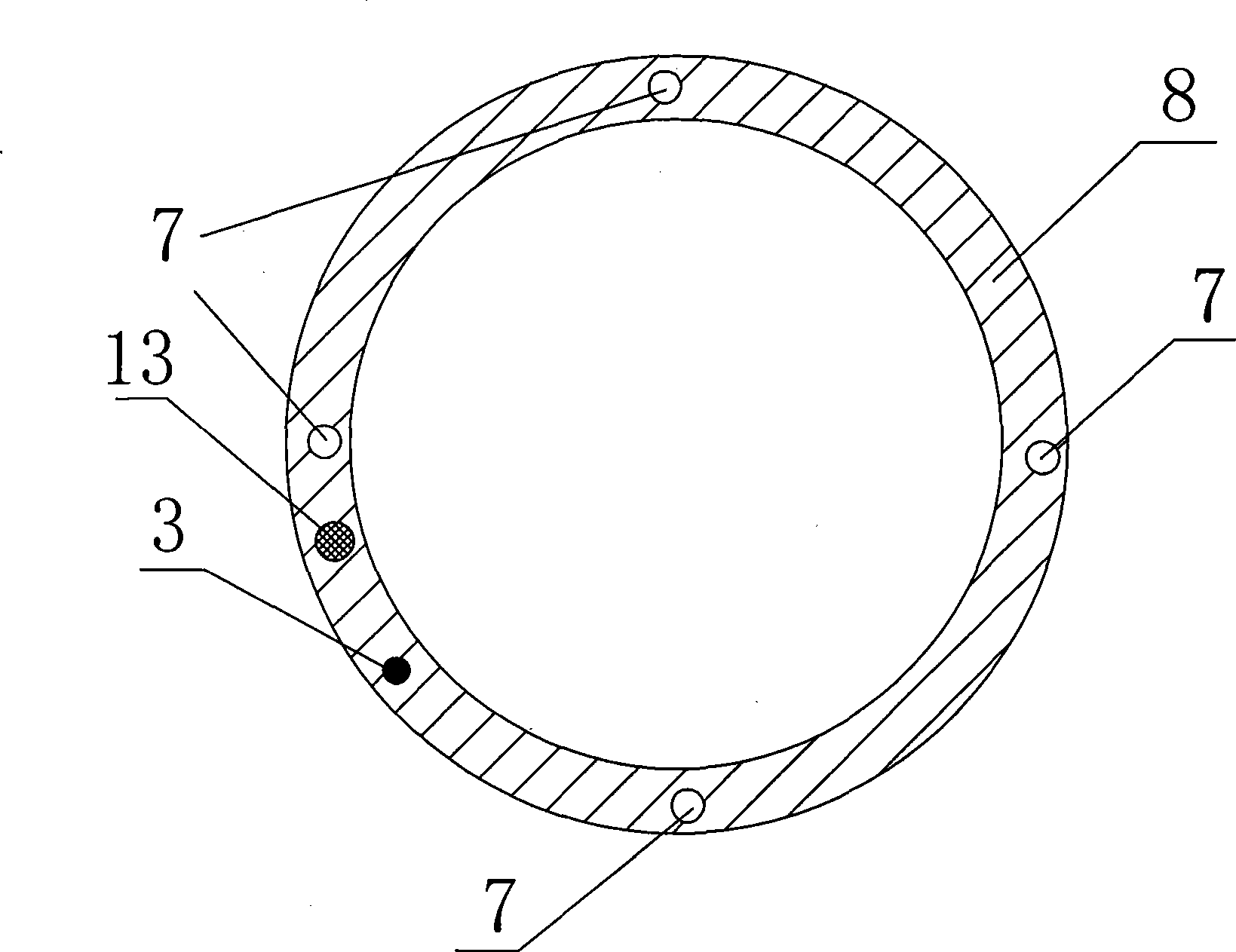

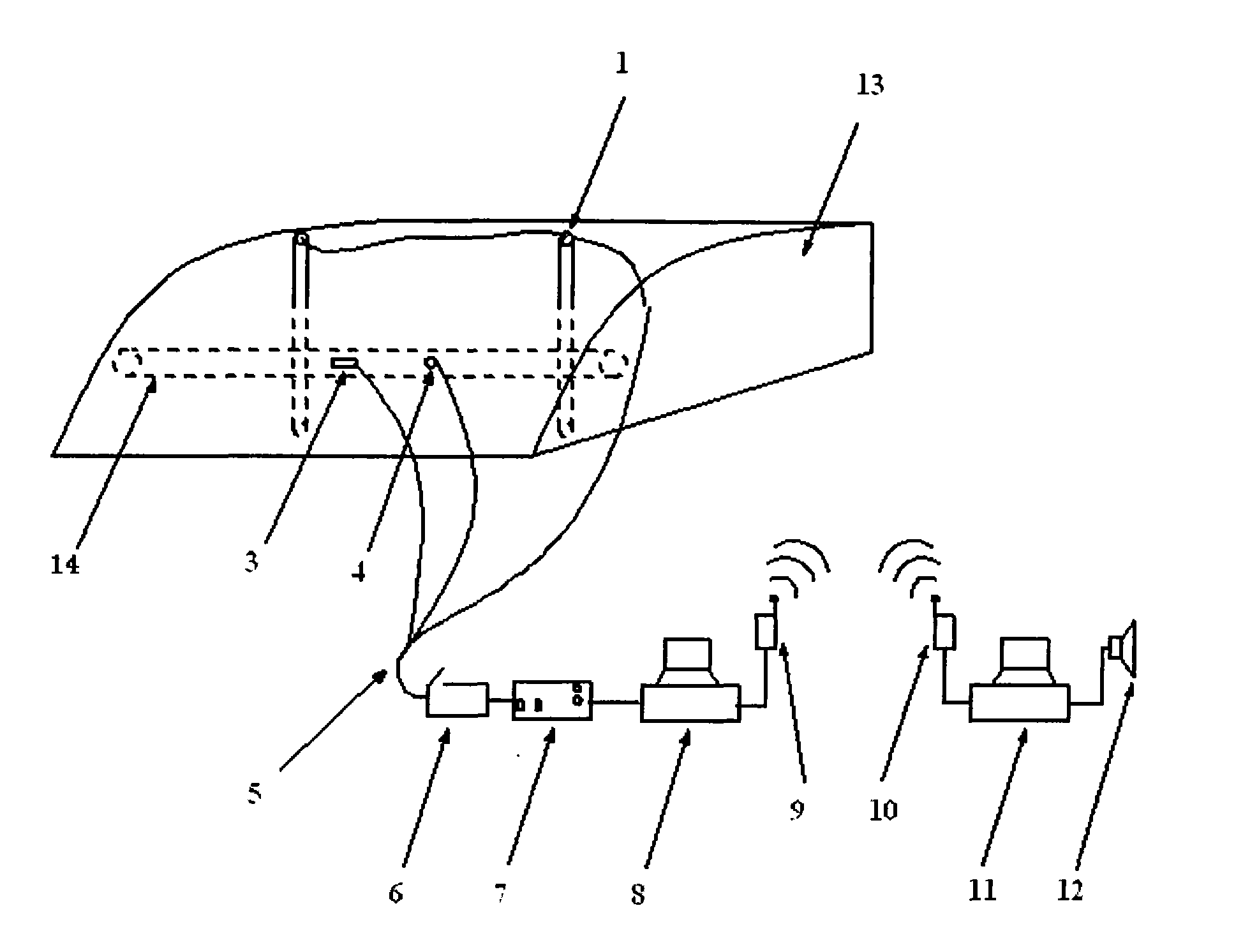

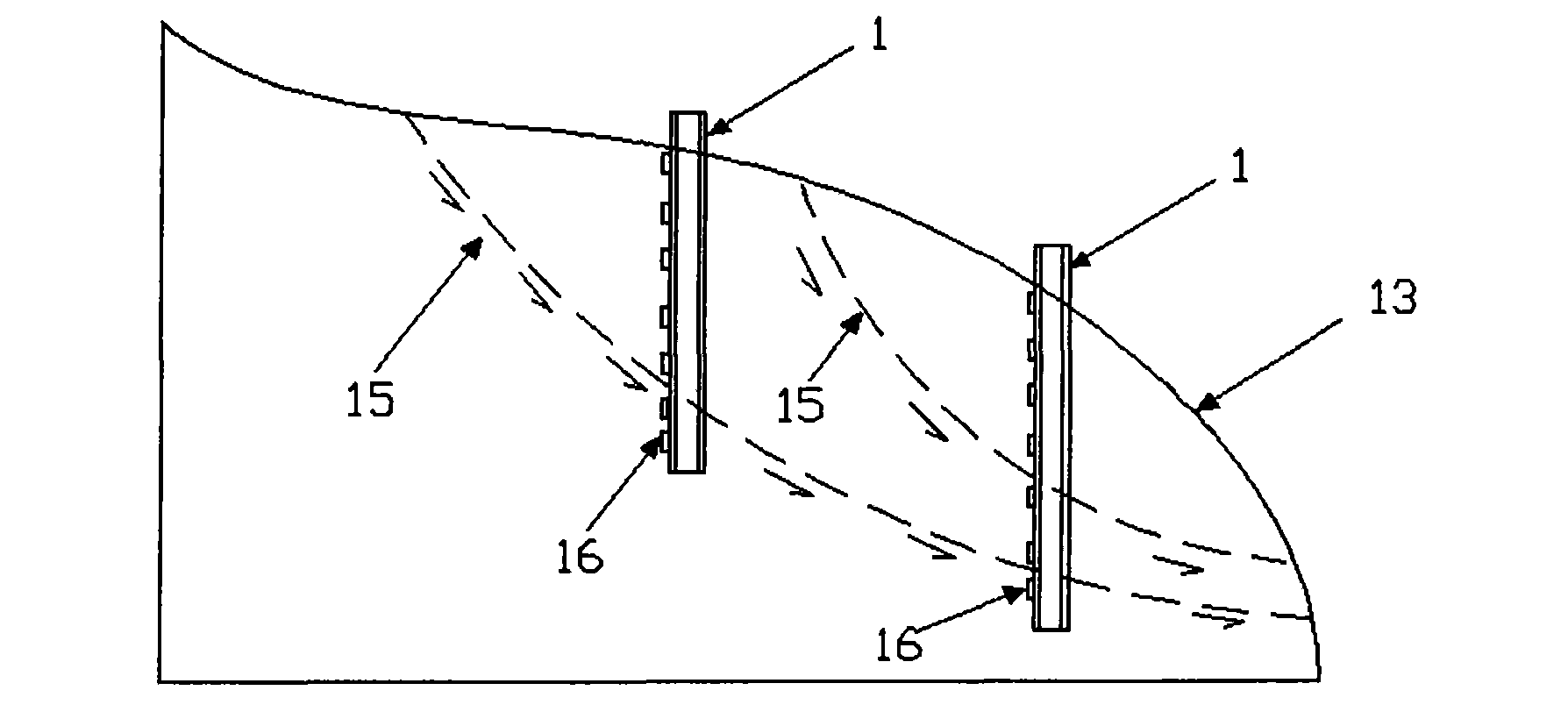

The invention relates to a method and a system for monitoring and warning a pipeline landslide based on a fiber Bragg grating and a method for constructing the system. The monitoring is performed on four parts including landslide depth displacement, landslide surface displacement, thrust of landslide on a pipeline and pipeline strain, and comprises the steps of: firstly, inserting an inclinometerpipe (1) pasted with a fiber Bragg grating sensor from the landslide (13) to all potential sliding surfaces (15); secondly, embedding a slender concrete ground beam (2) of which two ends are fixedly restrained and the axial direction of a central reinforced bar (17) is stuck to a ground beam fiber Bragg grating sensor (20) in a direction vertical to the deformation direction of the landslide (13)below the surface of the landslide (13); thirdly, measuring the thrust of the landslide (13) on the pipeline by using an earth pressure cell fiber Bragg grating sensor (4) fixed on the pipeline (14);and fourthly, arranging monitoring sections on edges on two sides and the pipeline (14) in the center of the landslide (13), and uniformly arranging three pipe strain fiber Bragg grating sensors (3) on each monitoring section to monitor the axial strain of the pipeline (14).

Owner:PIPECHINA SOUTH CHINA CO

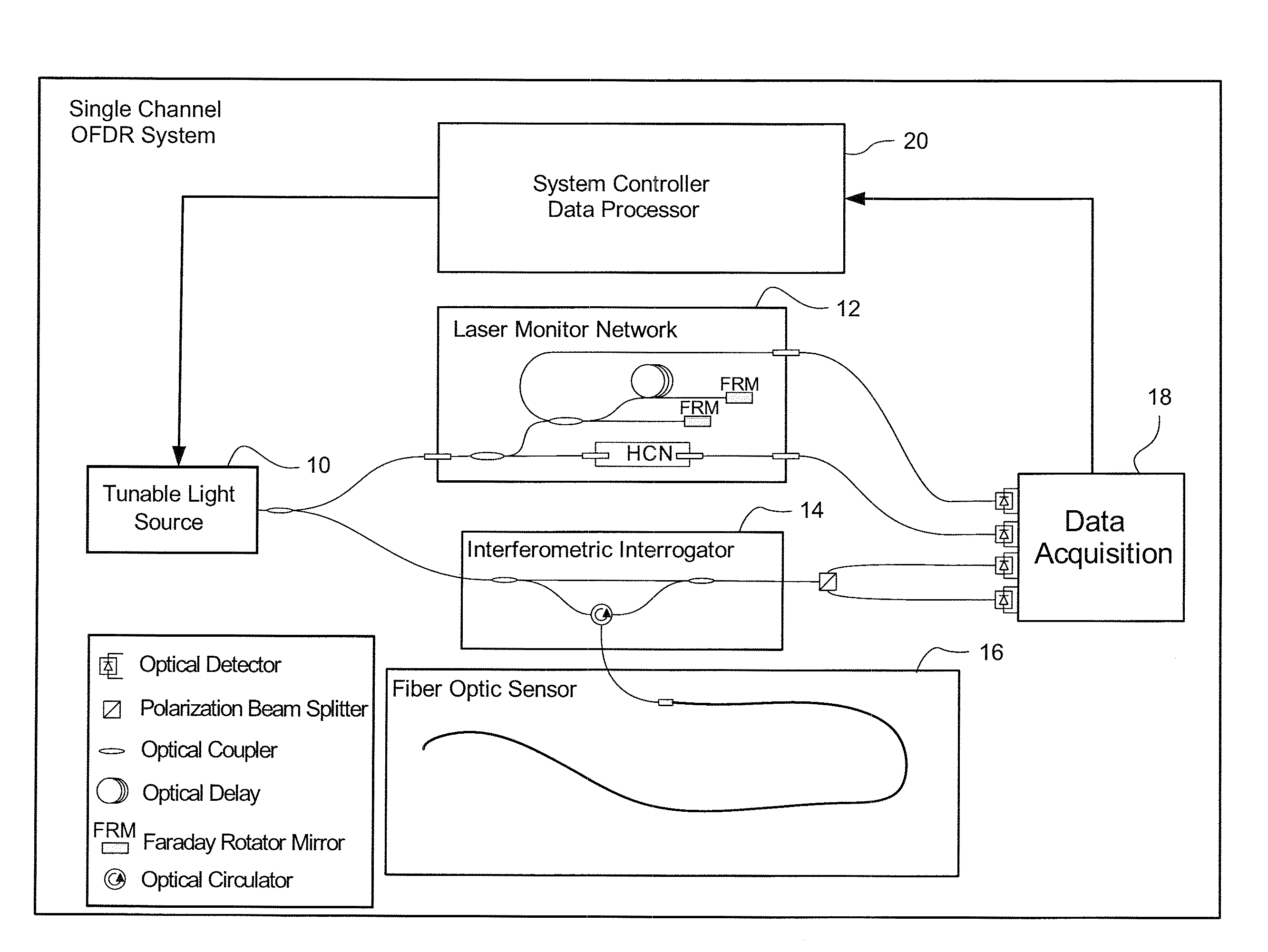

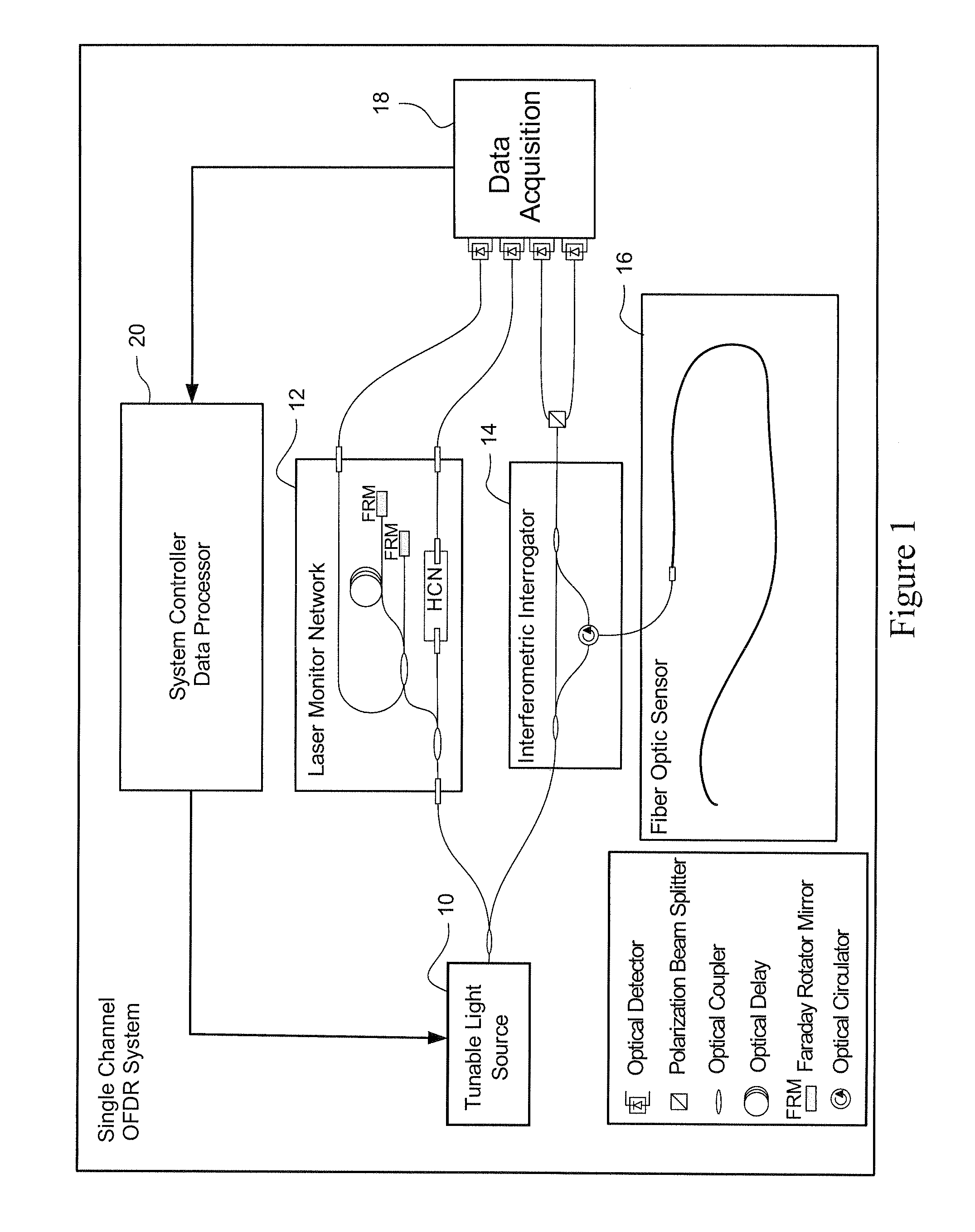

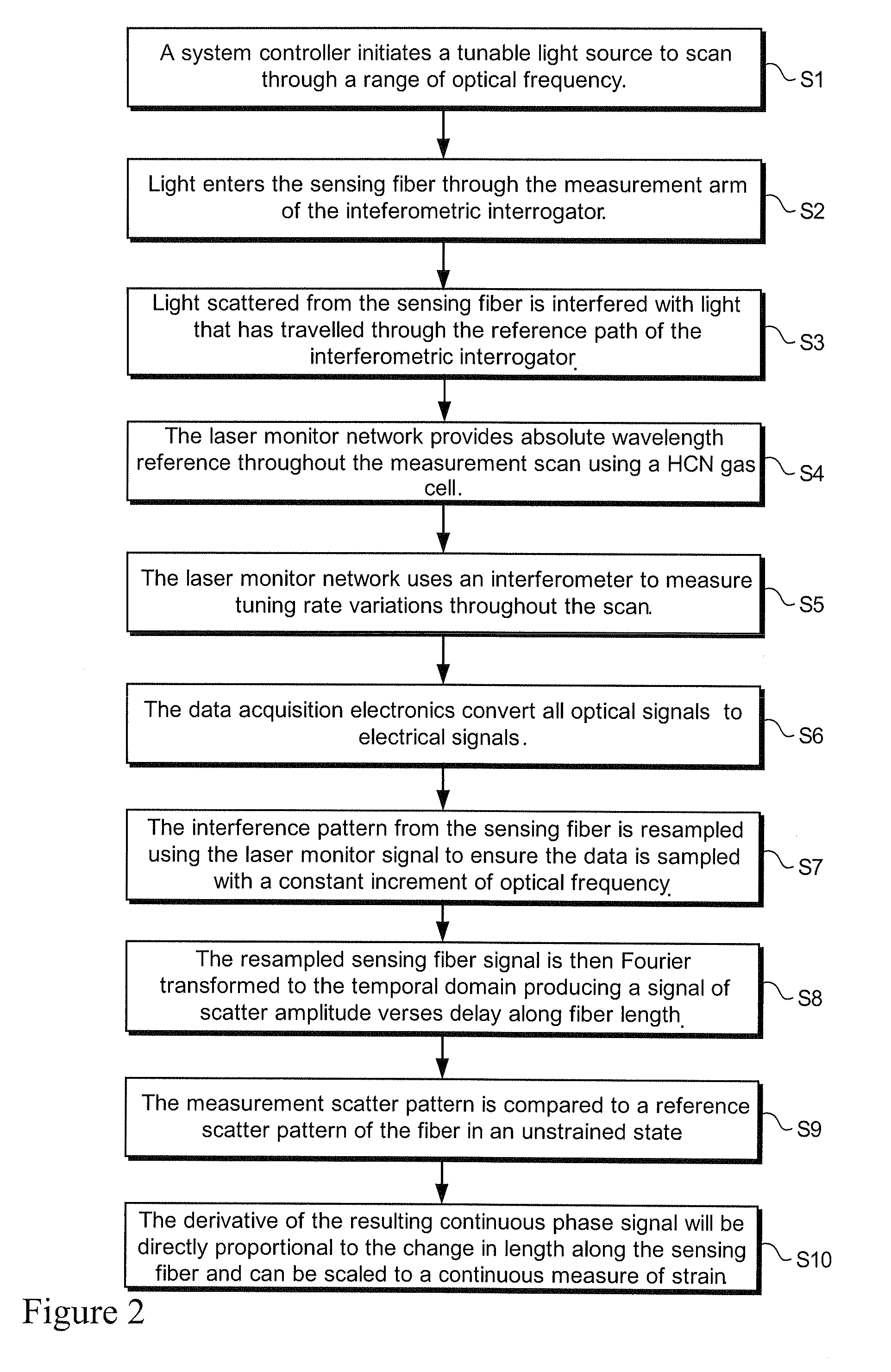

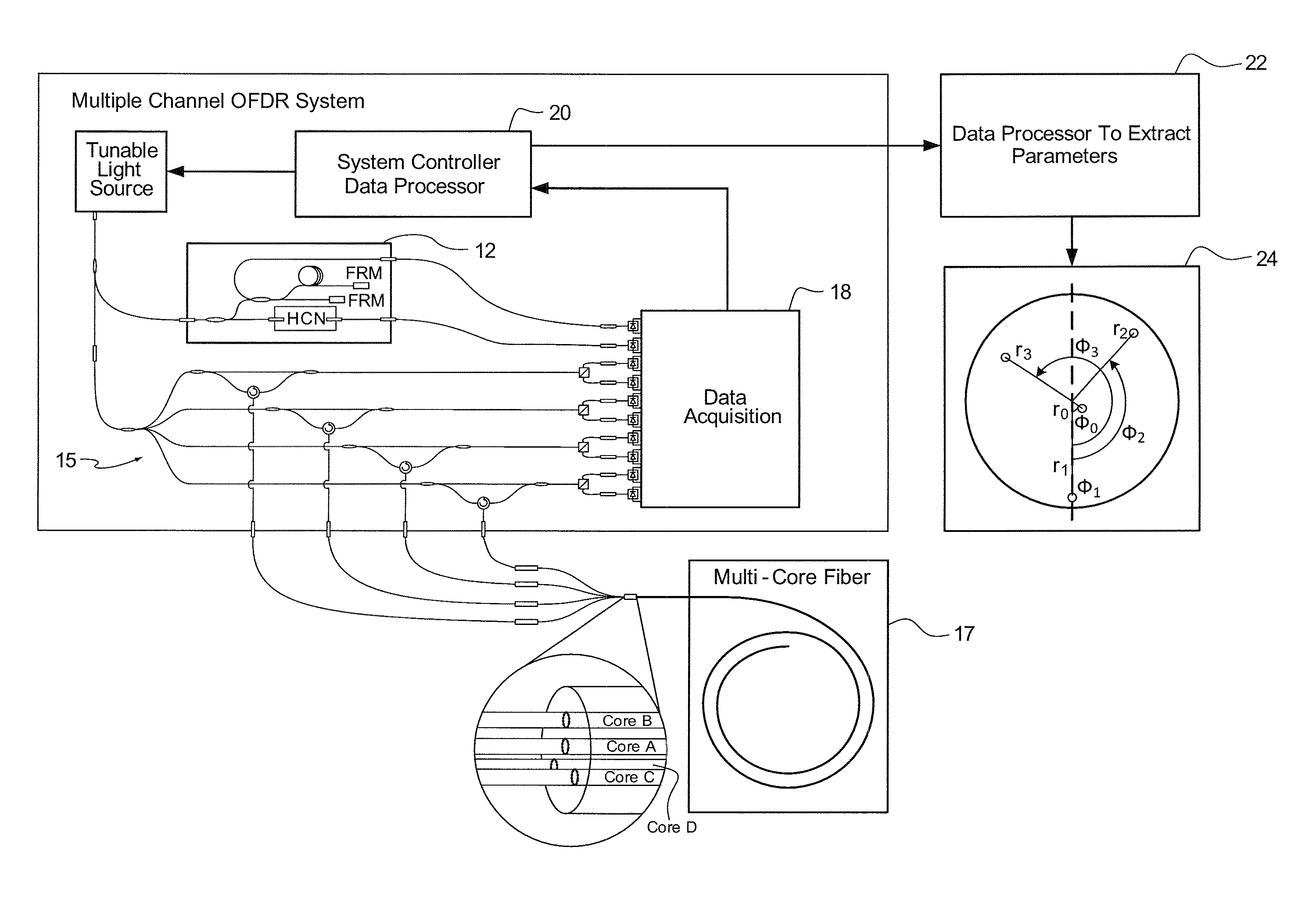

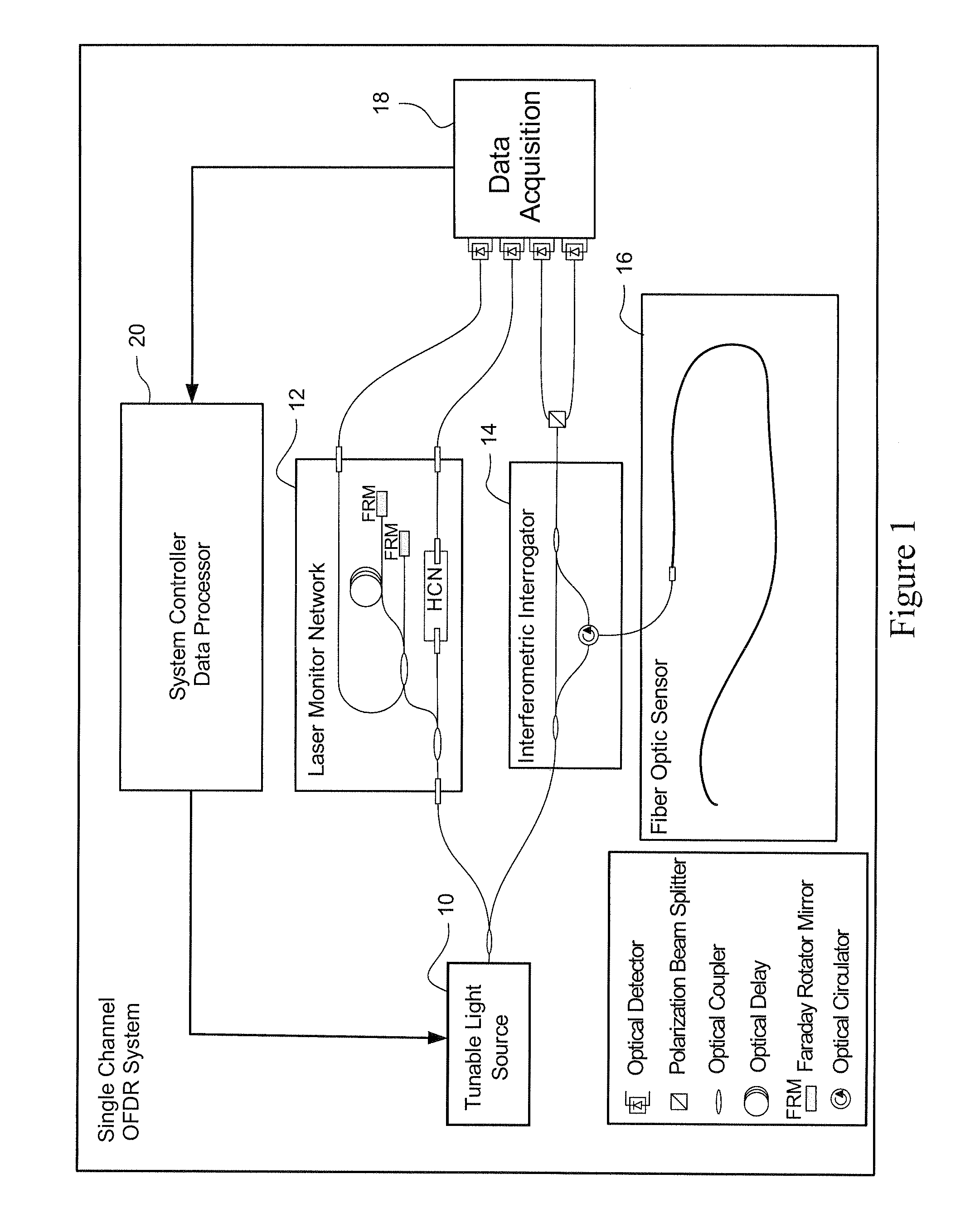

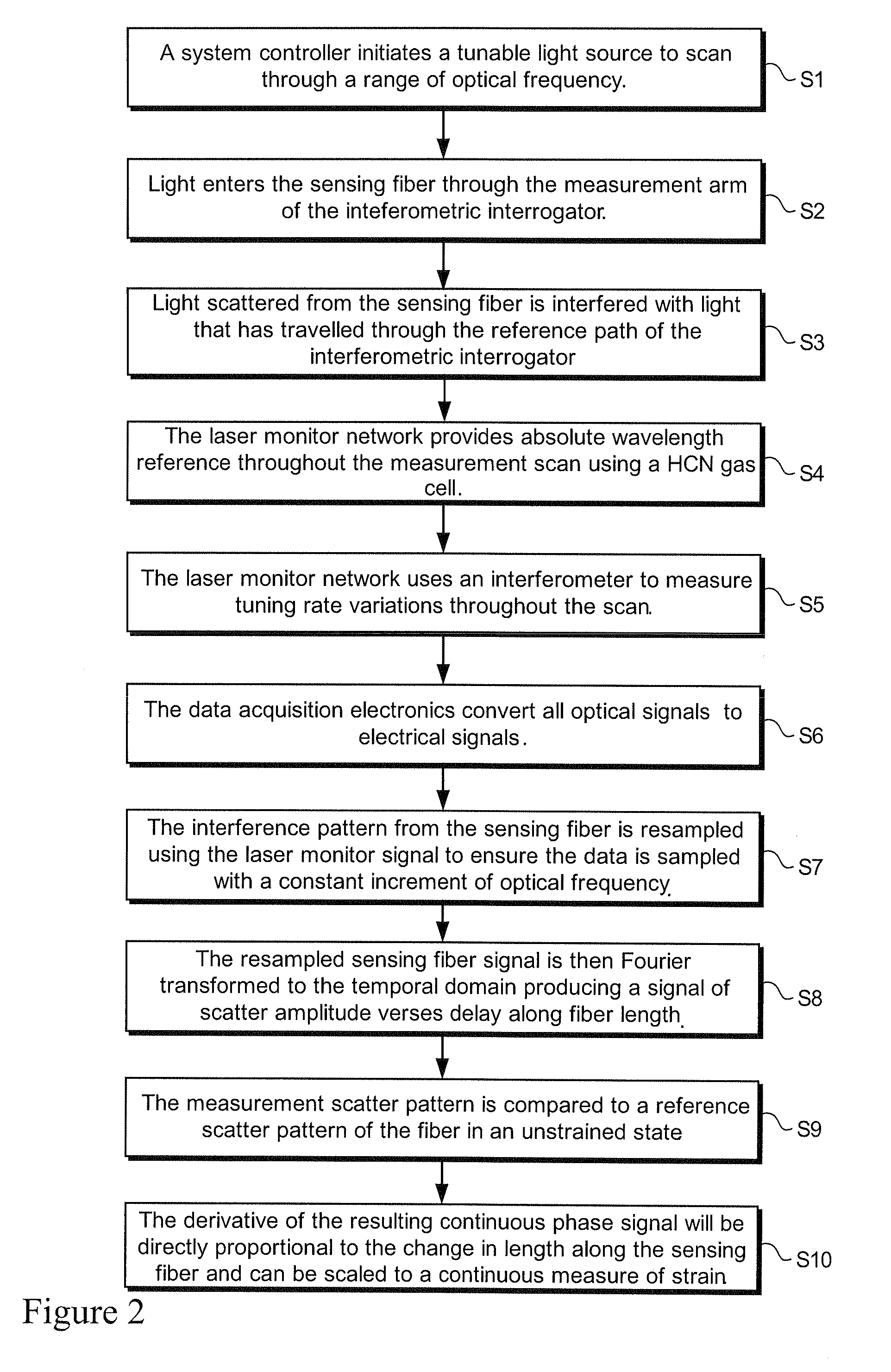

Compensating for non-ideal multi-core optical fiber structure

ActiveUS20120069347A1Accurately determineWithout loss in positional accuracyForce measurementMaterial analysis by optical meansEngineeringMechanical engineering

An interferometric measurement system includes a spun optical fiber including multiple optical waveguides configured in the fiber. Interferometric detection circuitry detects measurement interferometric pattern data associated with each of the multiple optical waveguides when the optical fiber is placed into a bend. Data processing circuitry determines compensation parameters that compensate for variations between an optimal configuration of the multiple optical waveguides in the fiber and an actual configuration of multiple optical waveguides in the fiber. The compensation parameters are stored in memory for compensating subsequently-obtained measurement interferometric pattern data for the fiber. The compensation parameters are applied to the subsequently-obtained measurement interferometric pattern data in order to distinguish between axial strain, bend strain, and twist strain on the fiber and to accurately determine one or more strain values for the fiber corresponding to one or more of the axial strain, bend strain, or twist strain on the fiber.

Owner:INTUITIVE SURGICAL OPERATIONS INC

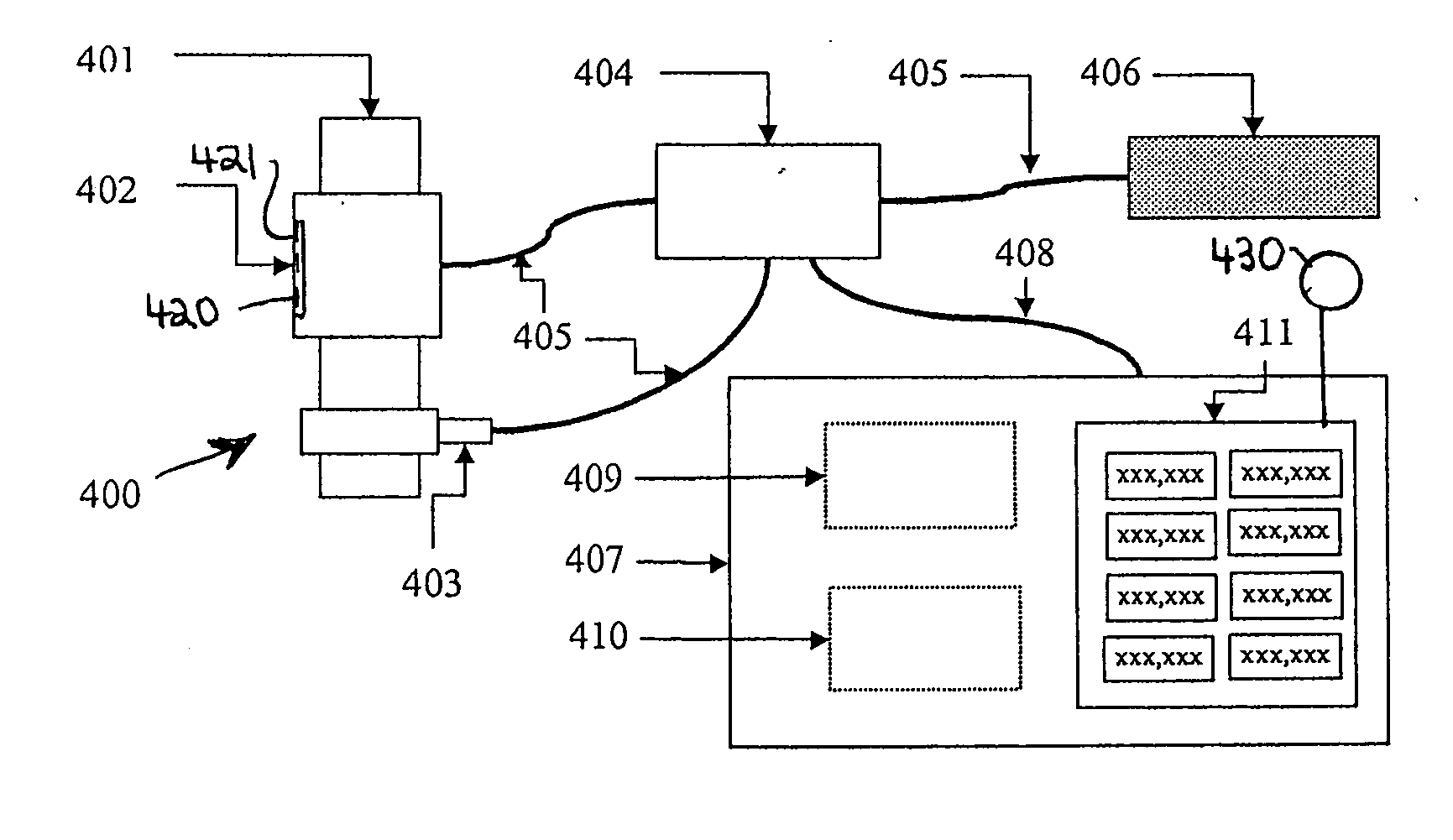

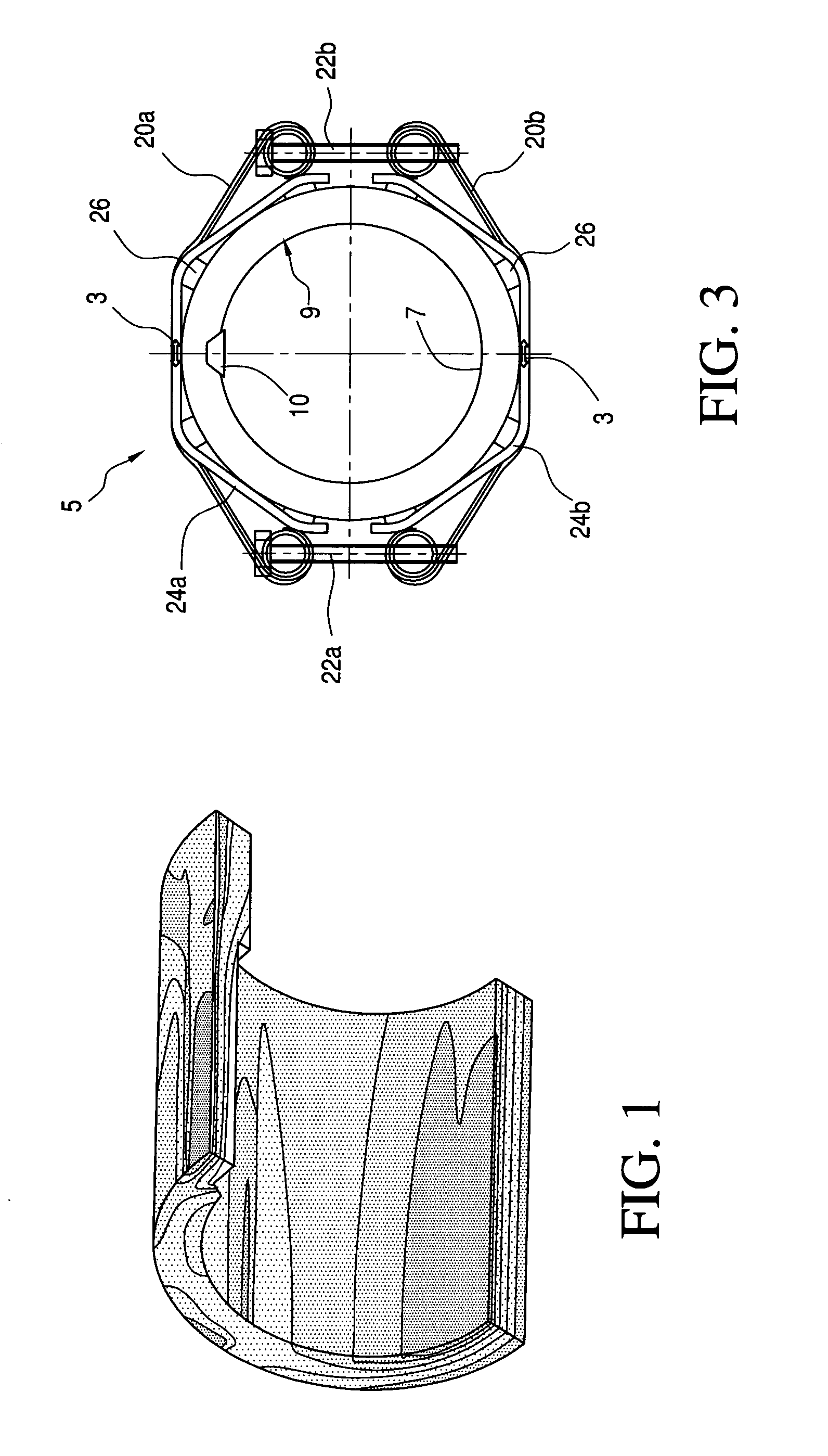

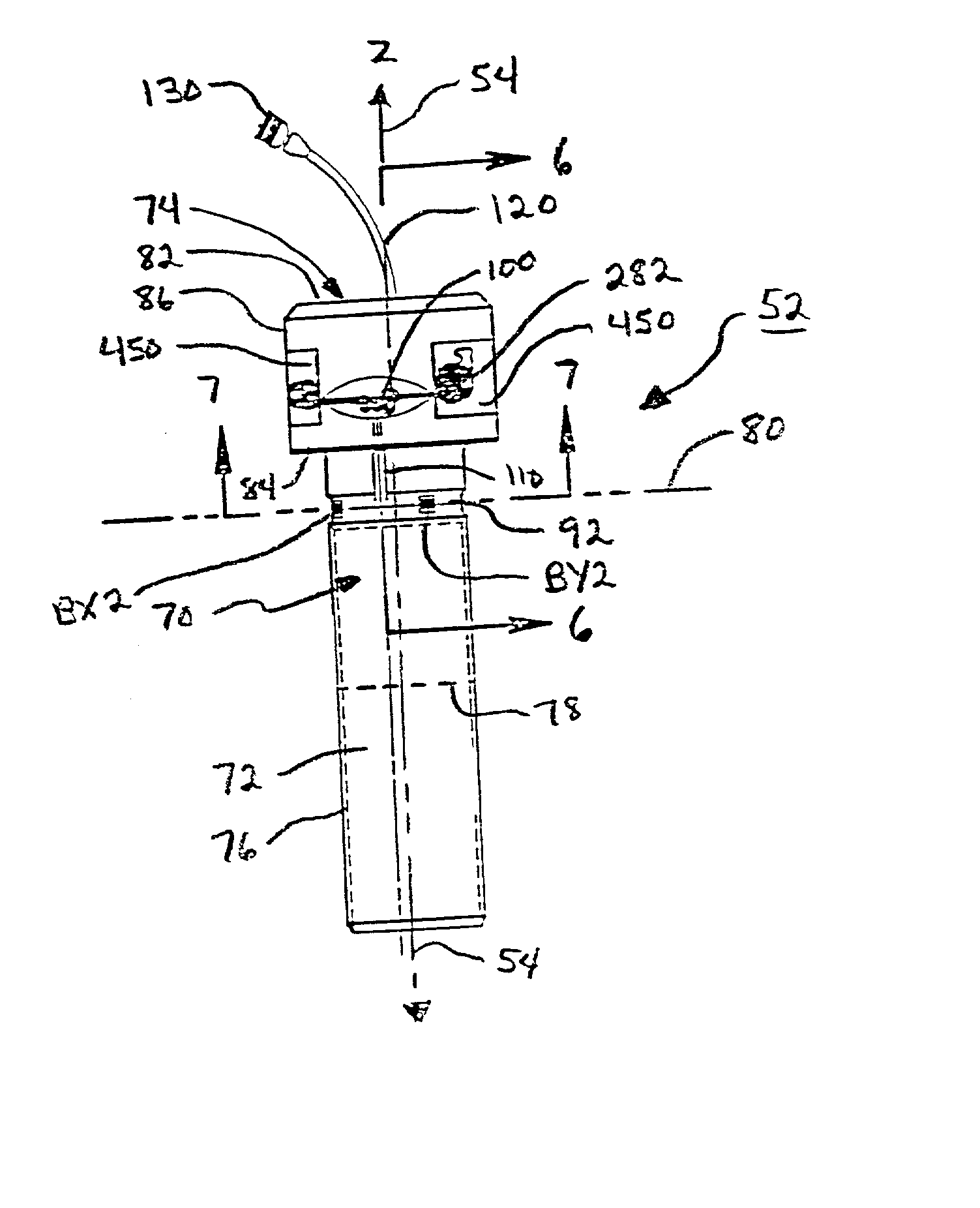

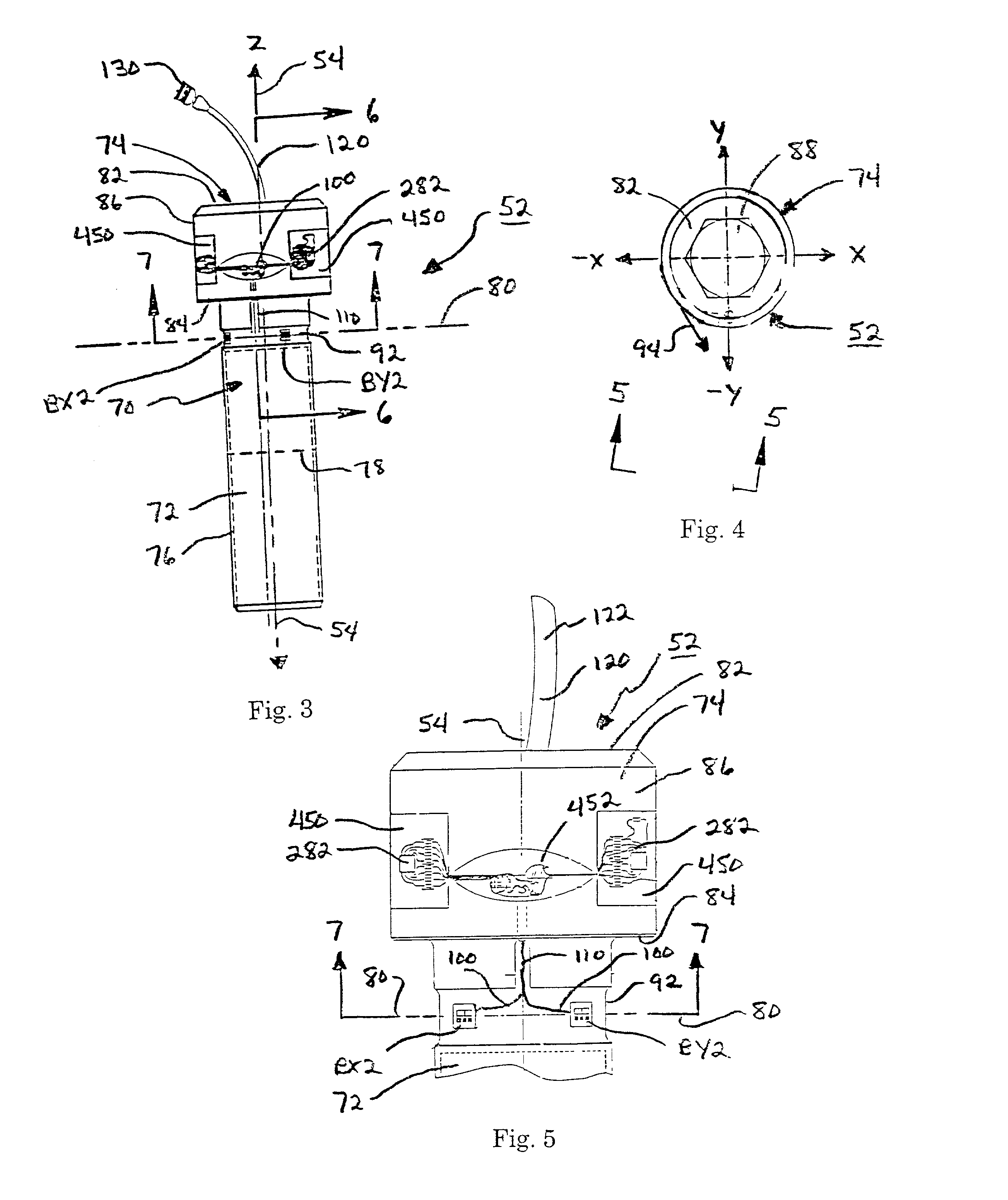

Tubular monitor systems and methods

A system for measuring parameters of a structure, the system in certain aspects having a plurality of strain gauges emplaceable on the structure, signal transmission apparatus associated with the plurality of strain gauges for transmitting signals therefrom indicative of gauge measurements to computer apparatus for processing the signals, the gauges, in one aspect, including at least three strain gauge apparatuses for providing axial strain measurements, and computer apparatus for receiving signals from the transmitting apparatus indicative of the measurements and for determining bending moment and bending direction of the structure at a location of the gauge apparatuses, and in one aspect wherein the computer apparatus is programmed to calculate internal pressure and / or bending direction of the structure based on the measurements, and in one aspect to do so in real time.

Owner:COILED TUBING ENG SERVICES

Method for monitoring downhole casing strain by using optical fibre sensor

InactiveCN101397904ARealize full well section monitoringAccurate measurementSurveyConstructionsGratingCircumferential strain

The invention relates to a method for monitoring the stress of a casing in a well by applying optical-fiber sensors, which mainly solves the problem that the existing research field of the casing erosion of an oil field and oil-water well does not have a direct method for monitoring the stress loading process of the casing in the well and the morphological characters of the casing erosion. The method is characterized in that: optical-fiber grating sensors are circumferentially arranged along the outer surface of the casing; a ground optical-fiber grating demodulation instrument connected with the optical-fiber grating sensors is utilized to monitor the circumferential strain Epsilon Theta of the casing and obtain the circumferential strain data of the casing; meanwhile, Brilliouin optical-fiber sensors are axially arranged along the outer surface of the casing; a ground Brilliouin optical-fiber demodulation instrument connected with the Brilliouin optical-fiber sensors is utilized to monitor the axial strain Epsilon Z of the casing and obtain the axial stain data of the casing; and the obtained circumferential strain Epsilon Theta and the axial strain Epsilon Z of the casing are utilized to obtain the stress of the outer layer of the casing in the well according to a ground stress explanation model. The method is characterized by being capable of permanently monitoring the deformation of the casing and obtaining corresponding stratum pressure under the condition without knowing the casing erosion and the stratum pressure.

Owner:DAQING OILFIELD CO LTD

Method and system for monitoring and warning pipeline landslide depth displacement and method for constructing system

ActiveCN101667327ASimple structureReduce volumeForce measurement by measuring optical property variationUsing optical meansFiberGrating

The invention relates to a method and a system for monitoring and warning pipeline landslide depth displacement and a method for constructing the system. The monitoring is divided into three parts including landslide depth displacement monitoring, monitoring of thrust of landslide on a pipeline and pipeline strain monitoring, and comprises the steps of: inserting an inclinometer pipe (1) pasted with a fiber Bragg grating sensor into the landslide (13), penetrating all potential sliding surfaces (15), extending the inclinometer pipe to a drilling hole 3 to 5m deep under a bedrock surface, and measuring the maximum tension strain born by the inclinometer pipe (1); measuring the front thrust of the landslide (13) on the pipeline by using a packaged earth pressure cell fiber Bragg grating sensor (4) fixed on the pipeline (14); and uniformly arranging pipeline (14) monitoring sections on edges on two sides of the landslide and the pipeline (14) in the center of the landslide (13), and uniformly arranging three pipe strain fiber Bragg grating sensors (3) on each monitoring section to monitor the axial strain of the pipeline (14).

Owner:PIPECHINA SOUTH CHINA CO

Compensating for non-ideal multi-core optical fiber structure

ActiveUS8531655B2Without loss in positional accuracyAccurately determinedForce measurementMaterial analysis by optical meansFiberBending strain

Owner:INTUITIVE SURGICAL OPERATIONS INC

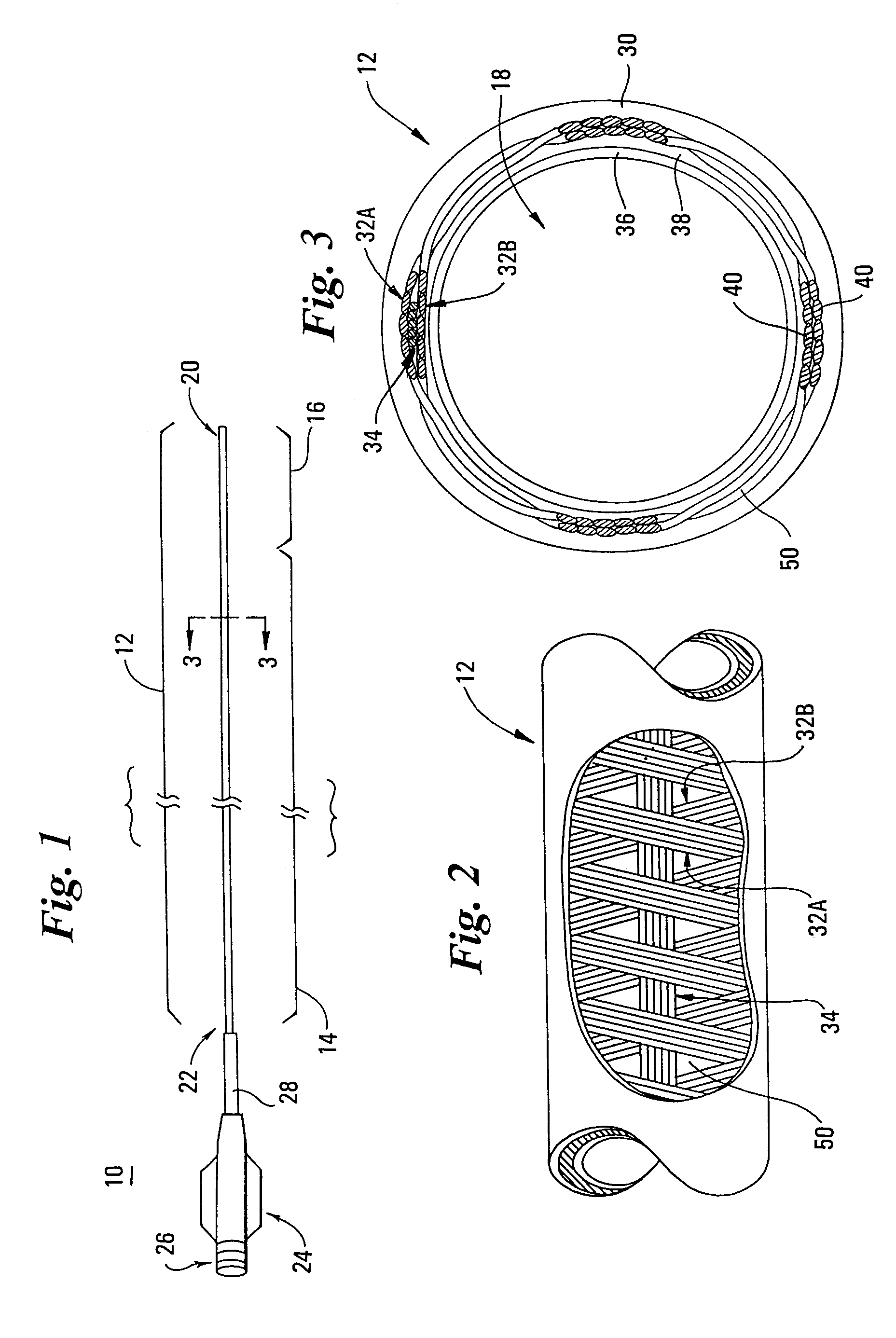

Intravascular catheter with axial member

InactiveUS6942654B1Without undesirable effect of frictionResists elongationCatheterFlexible pipesFiberFriction effect

An intravascular catheter having a shaft, at least a portion of which includes a braid reinforcement with an axial wire or fiber disposed between the helical members that form the braid. The axial member prevents the elongation of the shaft of the catheter thereby maintaining one-to-one correspondence in axial manipulation of the catheter, even when the shaft is placed in tension. By positioning the axial member between the helical members, the axial member does not create a protrusion and does not become fixed to any adjacent polymer layer. Thus, the axial member limits axial strain of the catheter, without creating the undesirable effects of friction caused by an axial protrusion and without creating the undesirable effects of limited flexure caused by an adjacent polymer layer becoming fixed to the axial member.

Owner:BOSTON SCI SCIMED INC

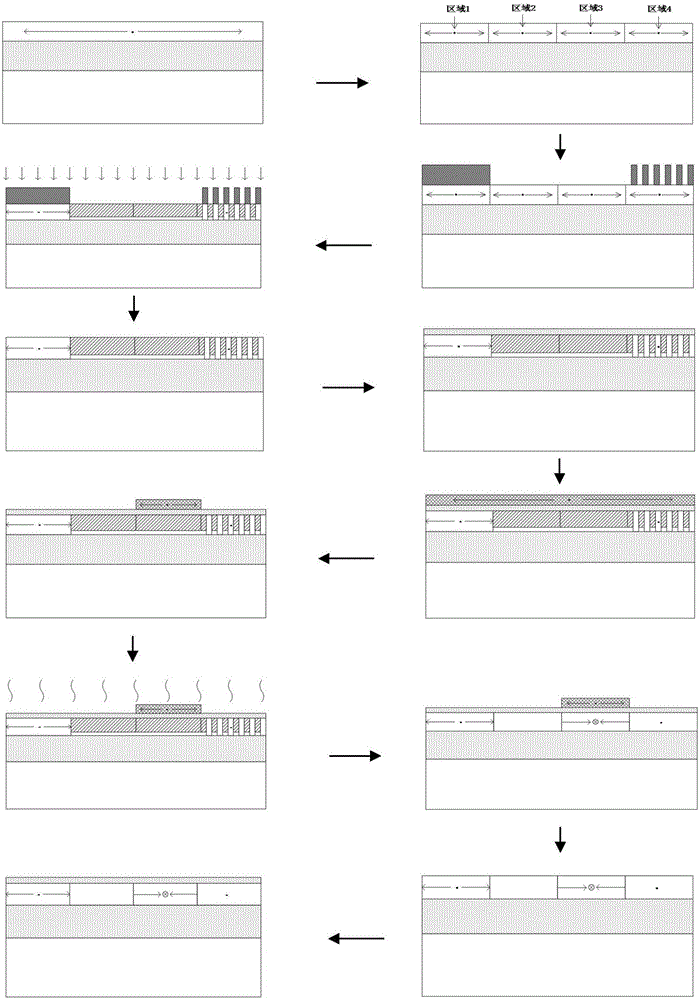

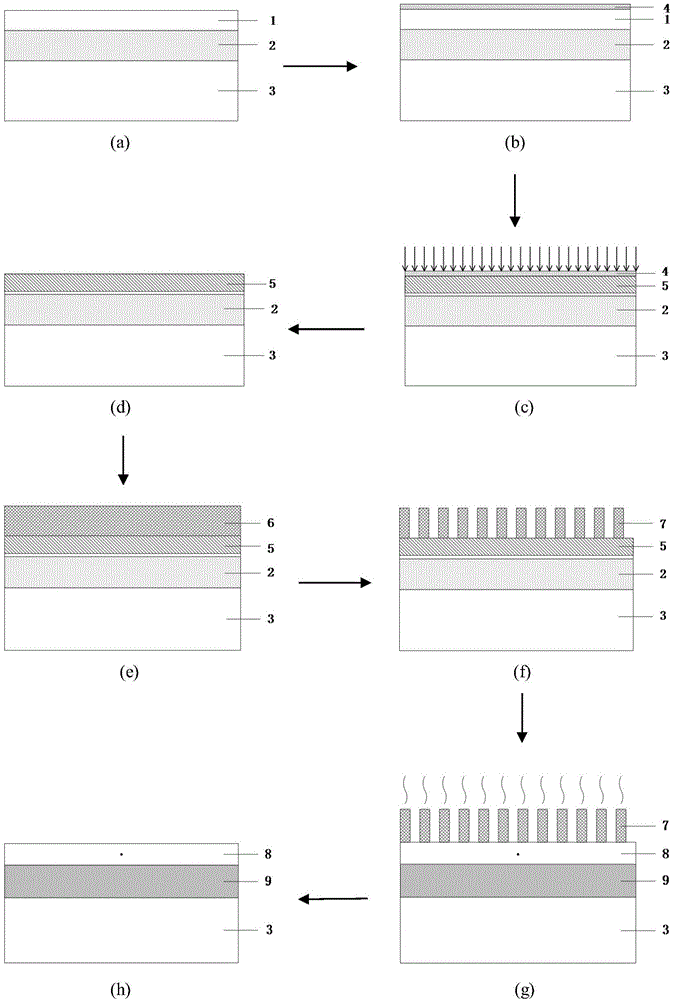

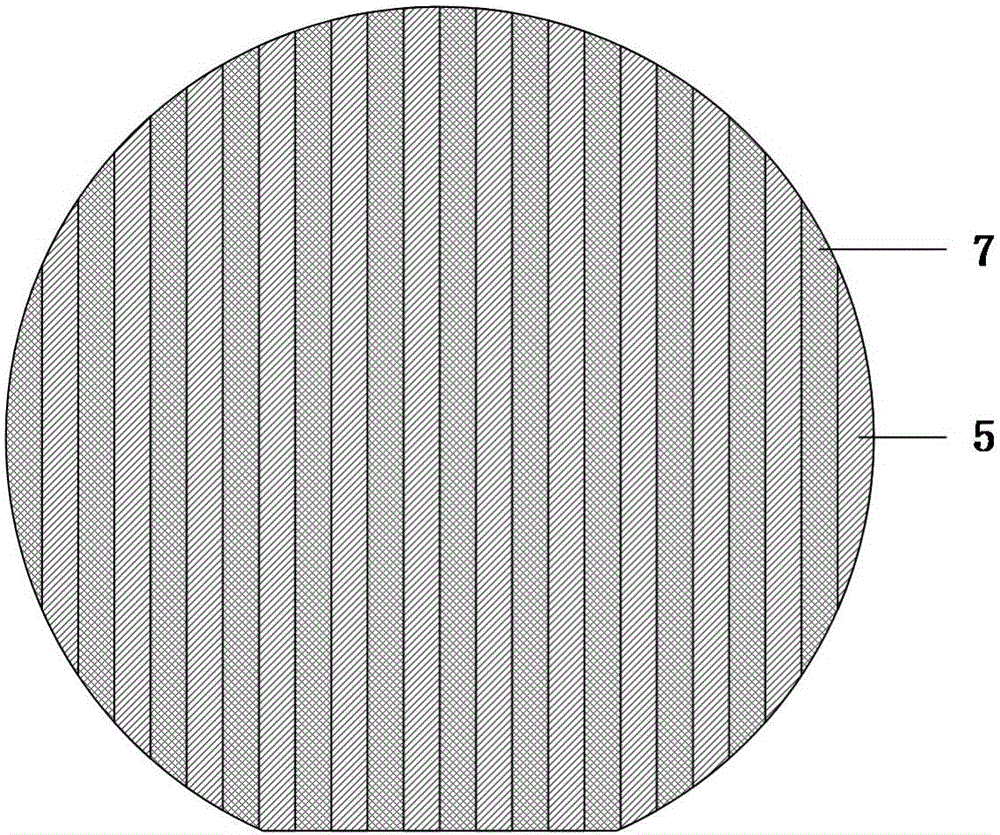

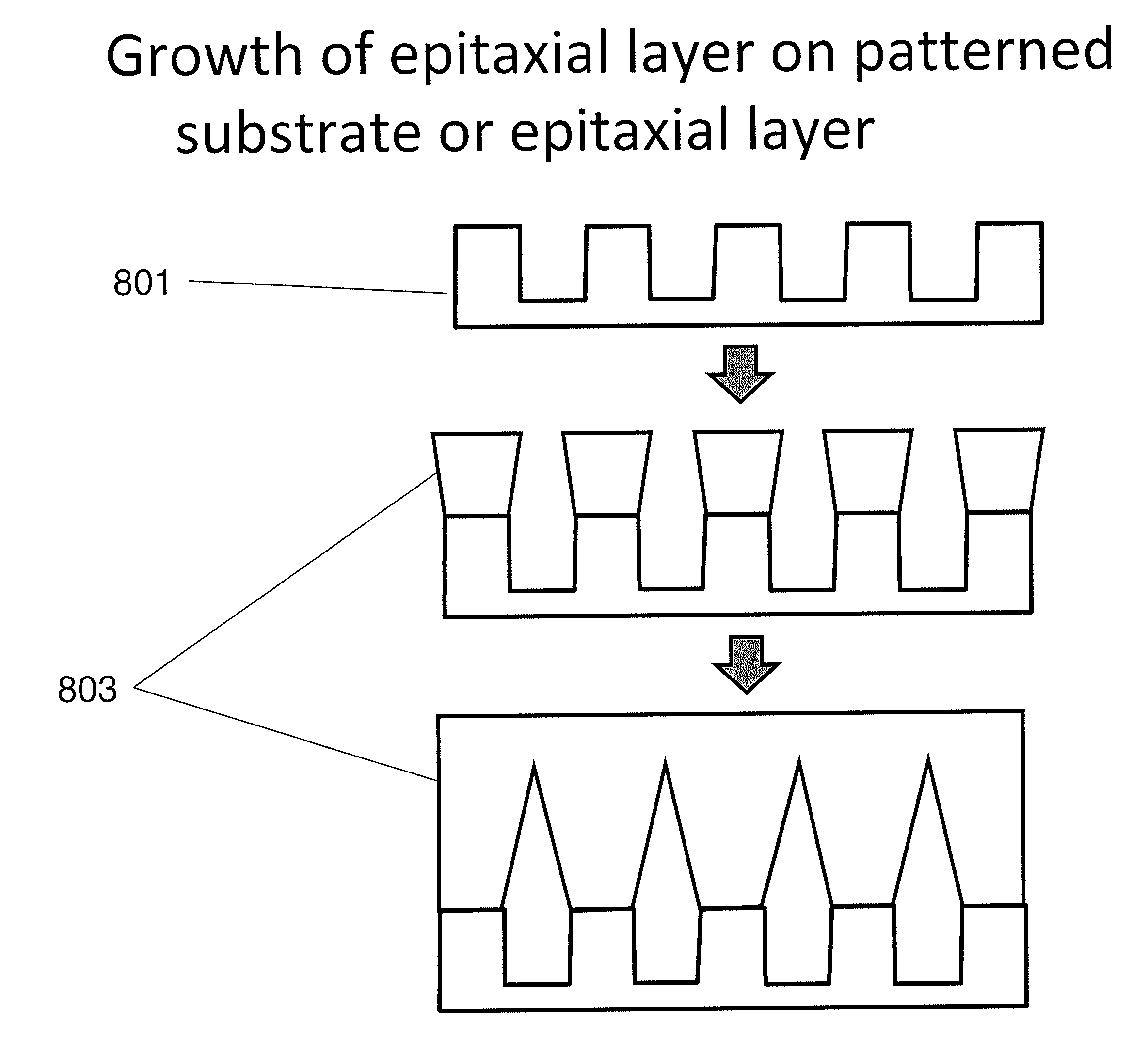

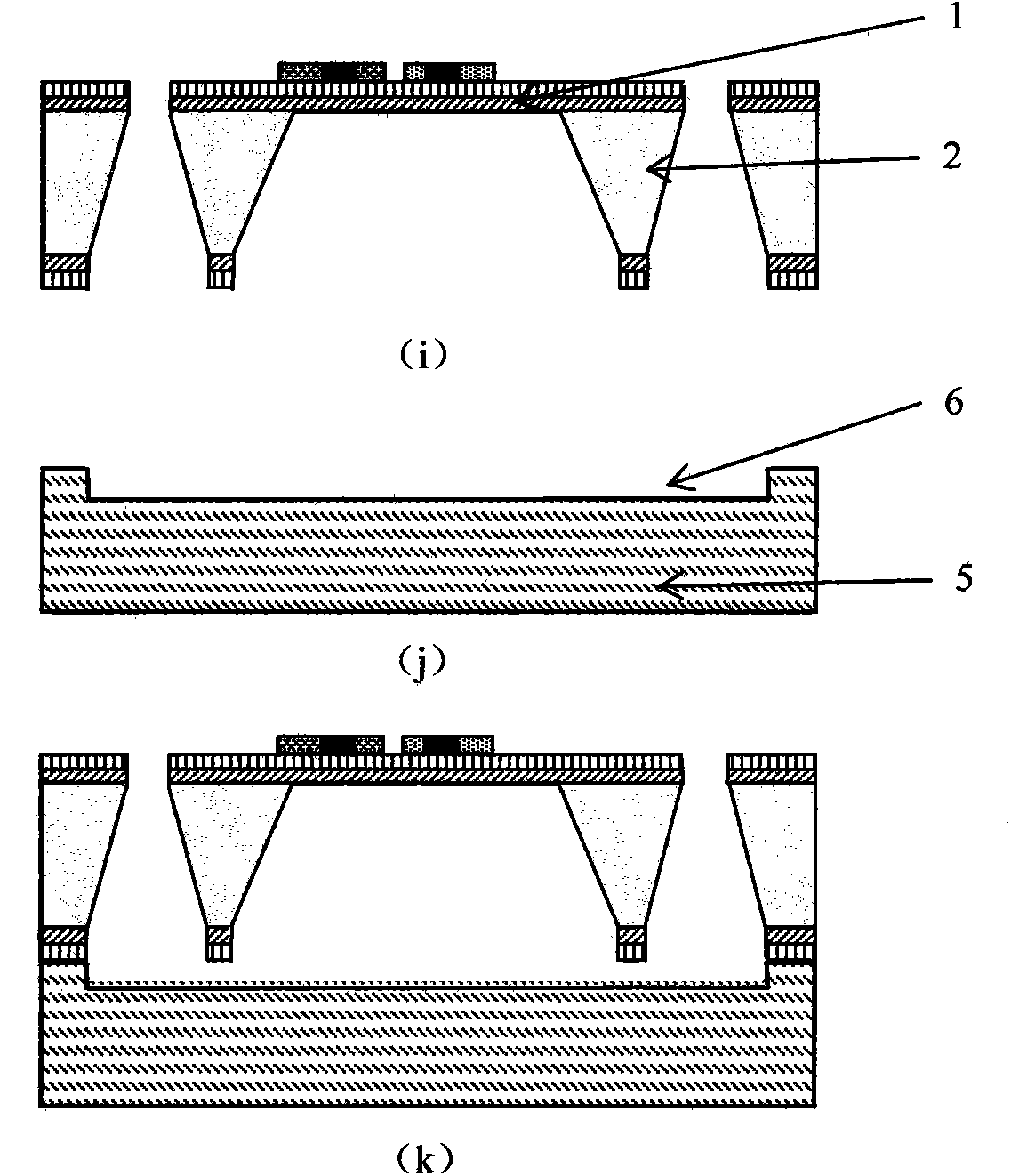

Fabrication method for wafer-level mono-axial strain Si on AlN-buried insulation layer based on non-crystallization and scale effect

ActiveCN106098609AImprove cooling effectImprove insulation performanceSemiconductor/solid-state device manufacturingInsulation layerScale effects

The invention discloses a fabrication method for wafer-level mono-axial strain Si on a AlN-buried insulation layer based on non-crystallization and a scale effect. The fabrication method is implemented according to the following steps of depositing a SiO2 layer at a Si layer at a top layer of a Si wafer on the cleaned AlN-buried insulation layer; performing ion injection on the Si layer at the top layer to form a non-crystallization layer, and removing the SiO2 layer on the non-crystallization layer; depositing a tensile stress SiN thin film or a press stress SiN thin film on the Si layer at the top layer, etching the SiN thin film to a mono-axial tensile stress SiN strip-shaped array or a mono-axial press stress SiN strip-shaped array, annealing the wafer to make the non-crystallization layer re-crystallized, and enabling the AlN-buried insulation layer to generate plastic deformation; and etching the SiN strip-shaped array to obtain the wafer-level mono-axial strain Si on the AlN-buried insulation layer. The wafer-level mono-axial strain Si has the advantages of high heat dissipation and large strain, and the fabrication method can be used for fabricating a wafer-level mono-axial strain Si material on the AlN-buried insulation layer.

Owner:XIDIAN UNIV

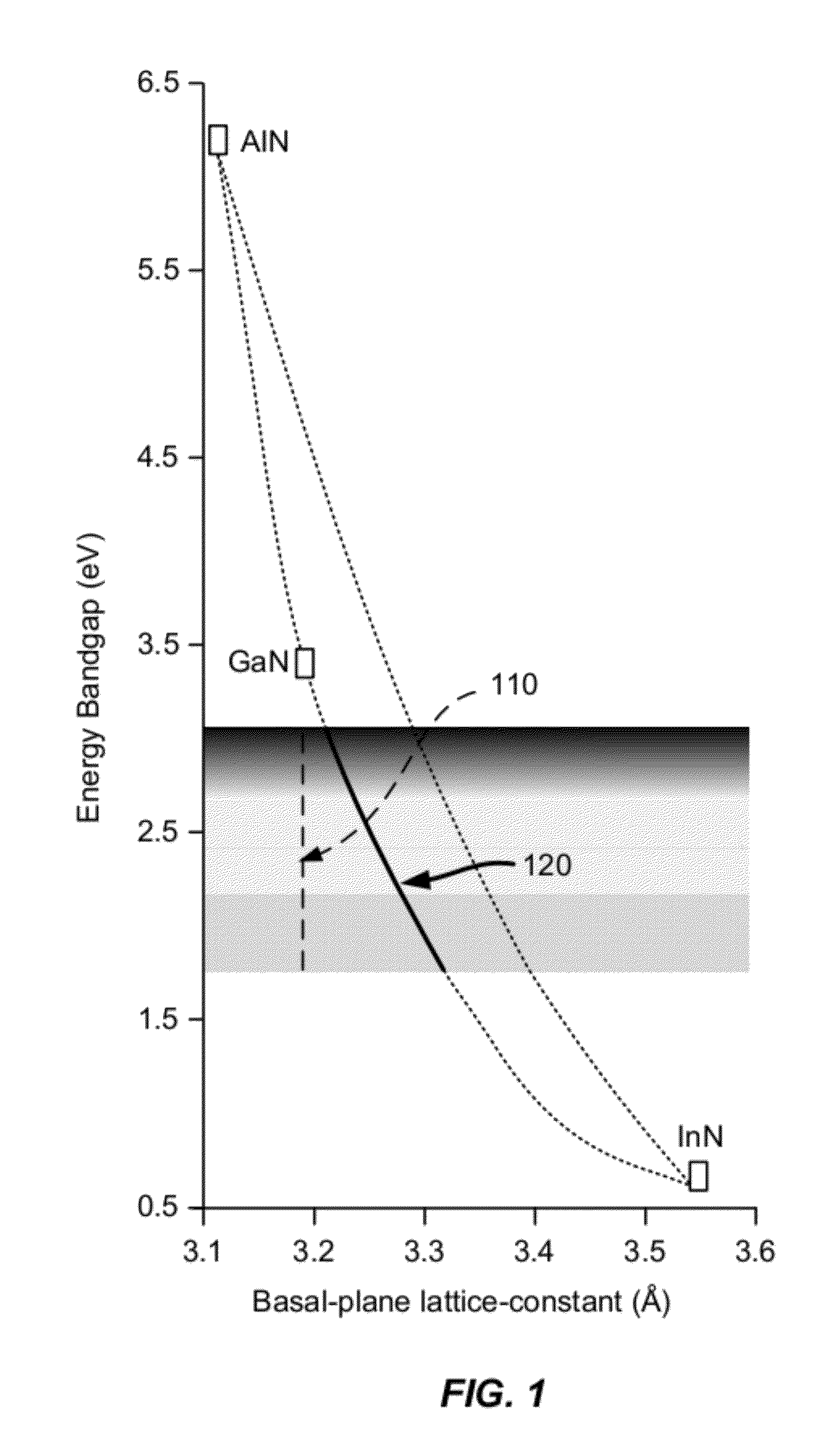

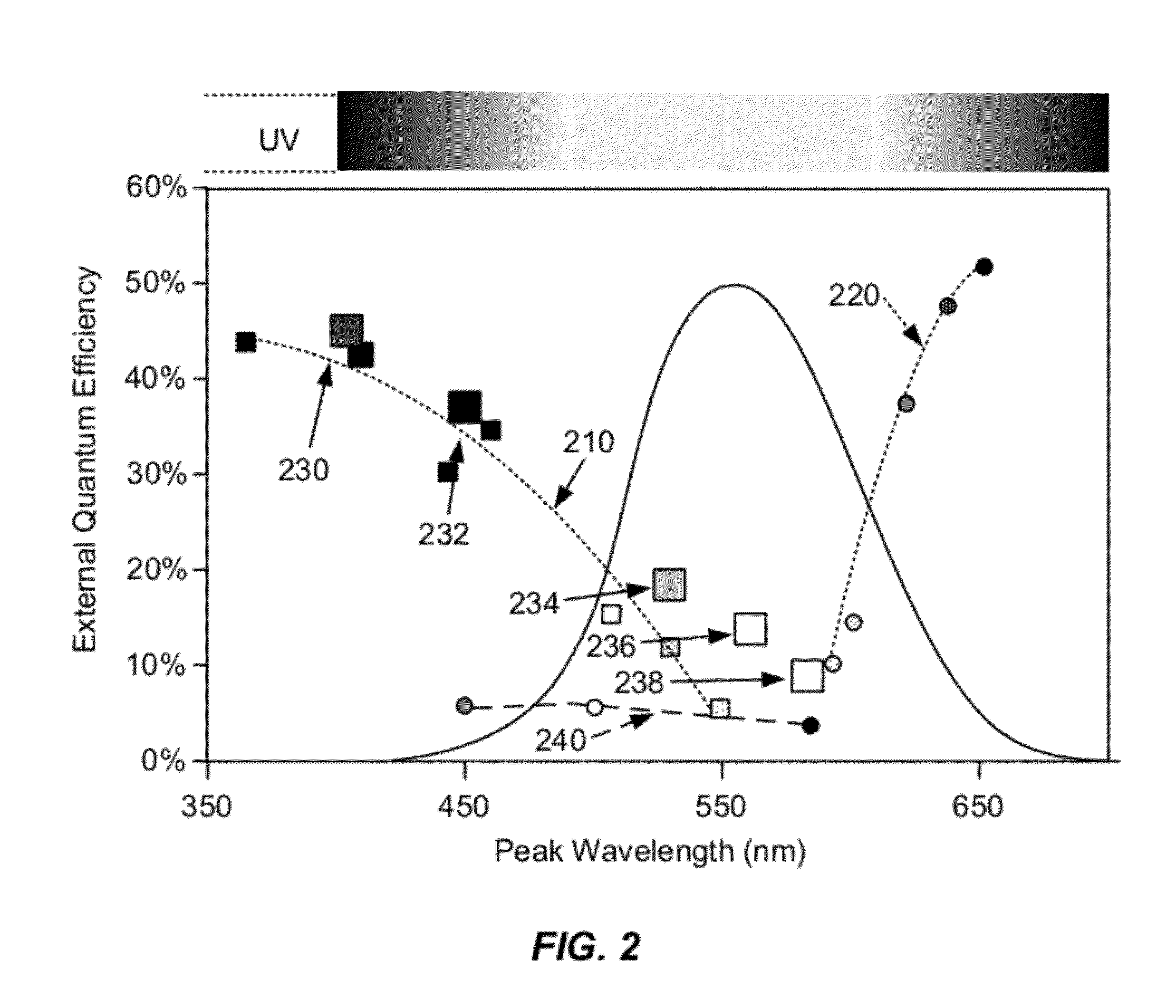

Method of making bulk InGaN substrates and devices thereon

ActiveUS8729559B2Relieve pressureCost effectivePolycrystalline material growthSemiconductor/solid-state device manufacturingOptoelectronicsAxial strain

Owner:SLT TECH

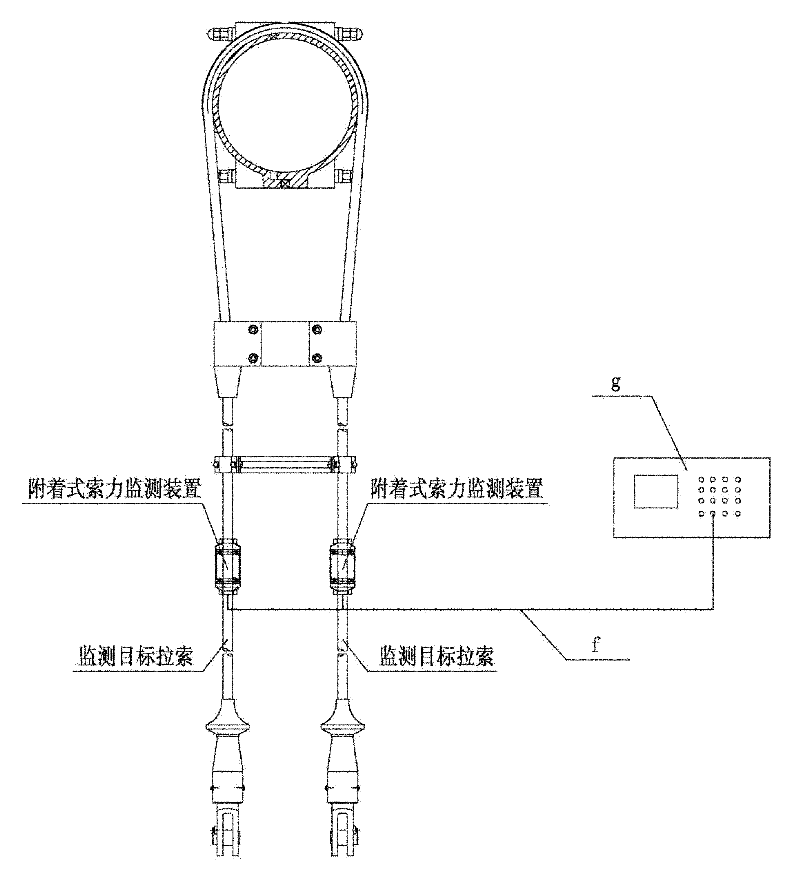

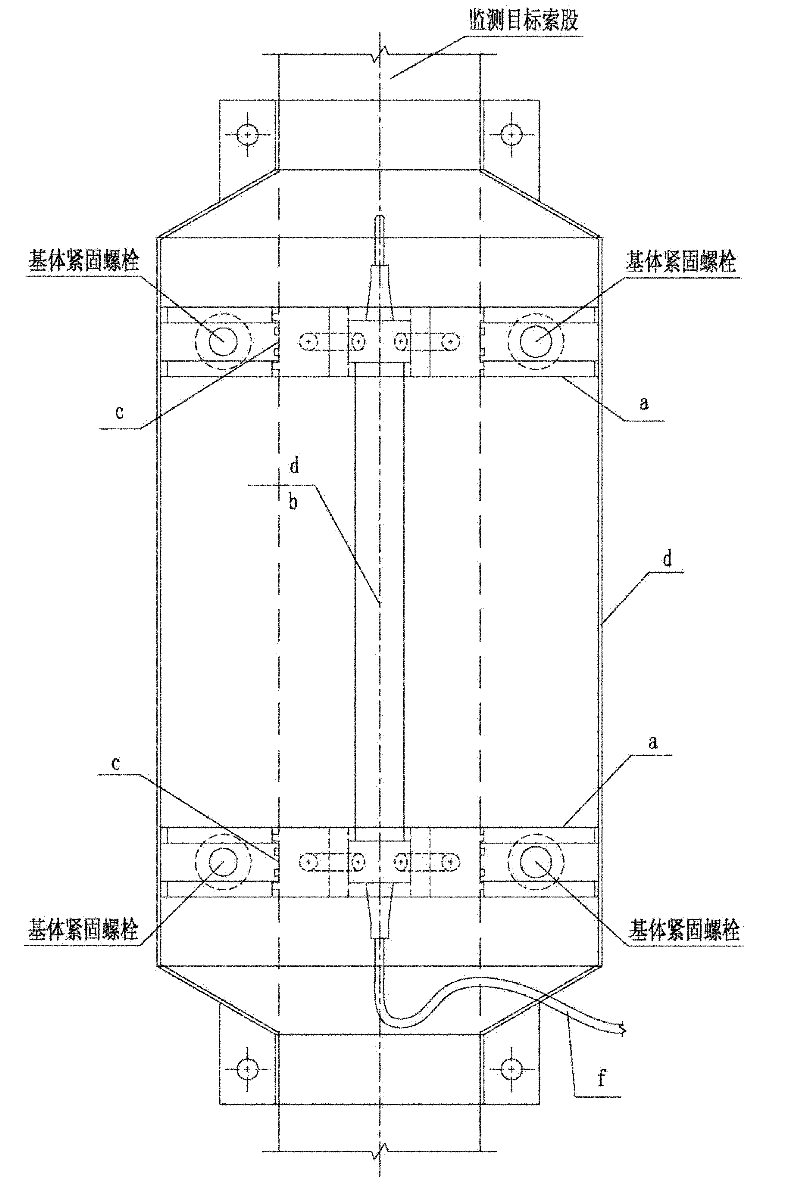

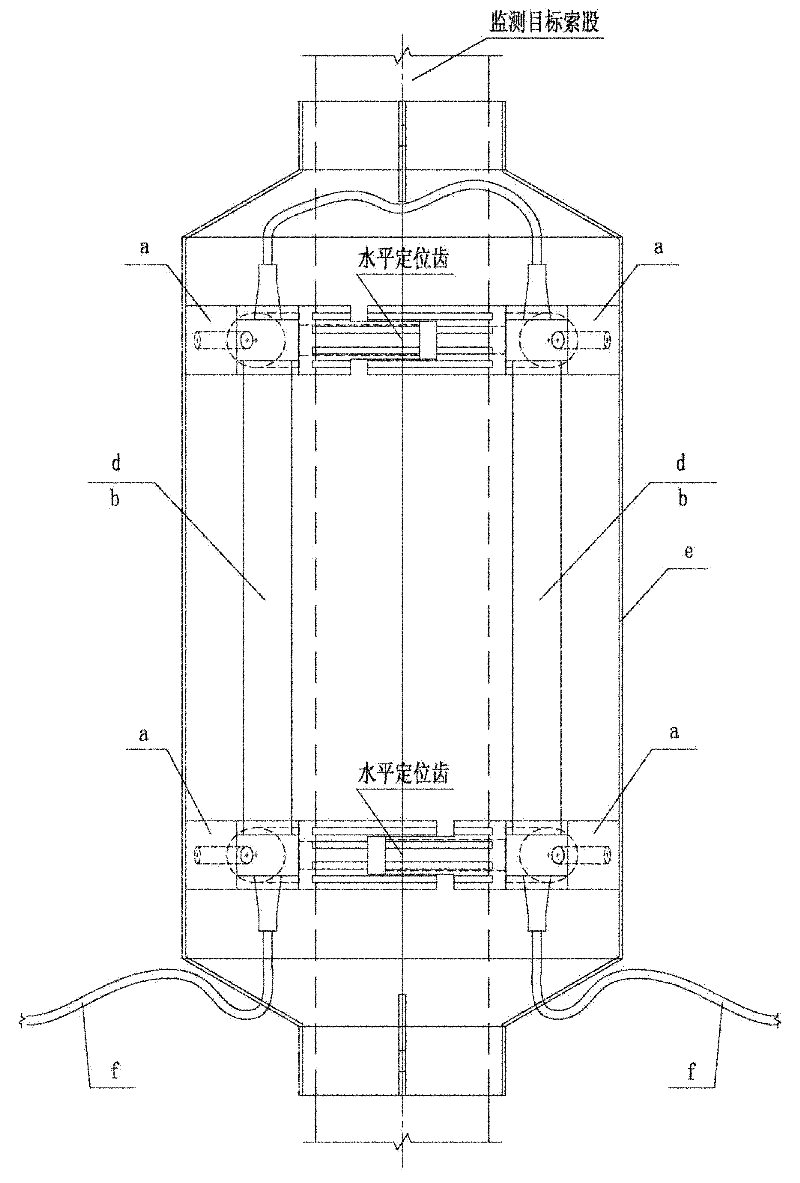

Cable force monitoring device for attached-type stay cable

ActiveCN102162760AImprove connection strengthFree from mechanical damageNon-electrical signal transmission systemsUsing optical meansFiberFiber gratings

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Method for testing pile shaft stress of static pressure high-strength pre-stressed concrete pipe pile

The invention belongs to the technical field of building construction stress testing and relates to a method for testing the pile shaft stress of a static pressure high-strength pre-stressed concrete pipe pile. When tensile force or pressure is received by a fiber Bragg grating sensor, the optical fiber grating period is changed due to the extension or the compression of the sensor, and therefore the effective refraction rate of the FBG sensor is changed. According to the axial strain of one section of the high-strength pre-stressed concrete pipe pile, the pile shaft stress of the static pressure high-strength pre-stressed concrete pipe pile is obtained, and therefore the axial force of a pile shaft, the side friction and the pile tip resistance are obtained. The method for testing the pile shaft stress of the static pressure high-strength pre-stressed concrete pipe pile is simple, convenient to operate, high in measuring accuracy, high in sensitivity, strong in electromagnetic field interference resistance, high in rate of survival, and capable of achieving quasi-distributed and automatic monitoring easier compared with a method of a traditional force testing element.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

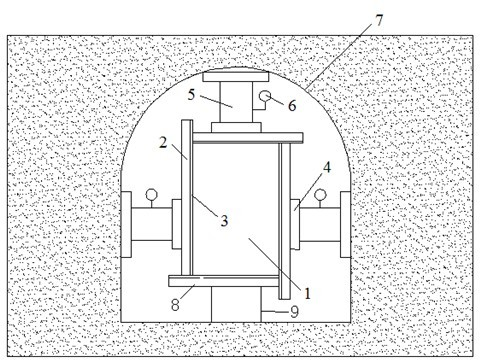

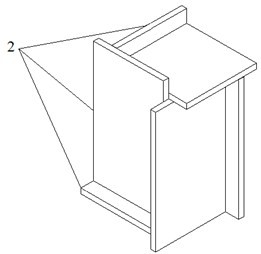

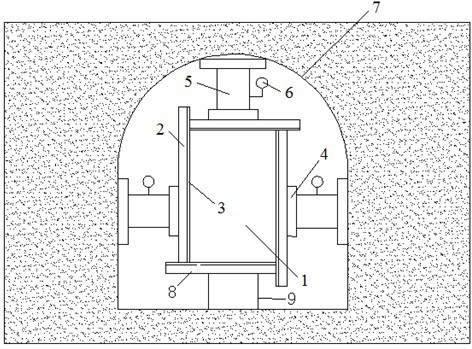

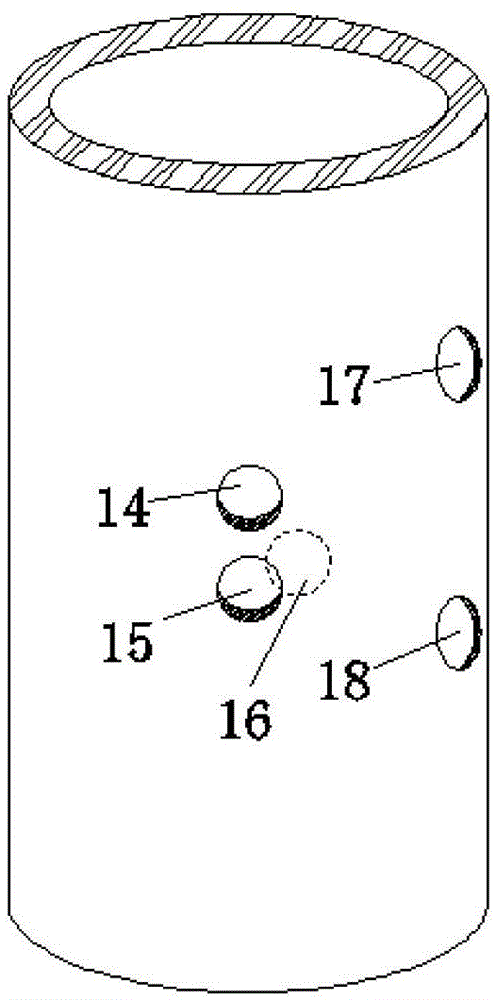

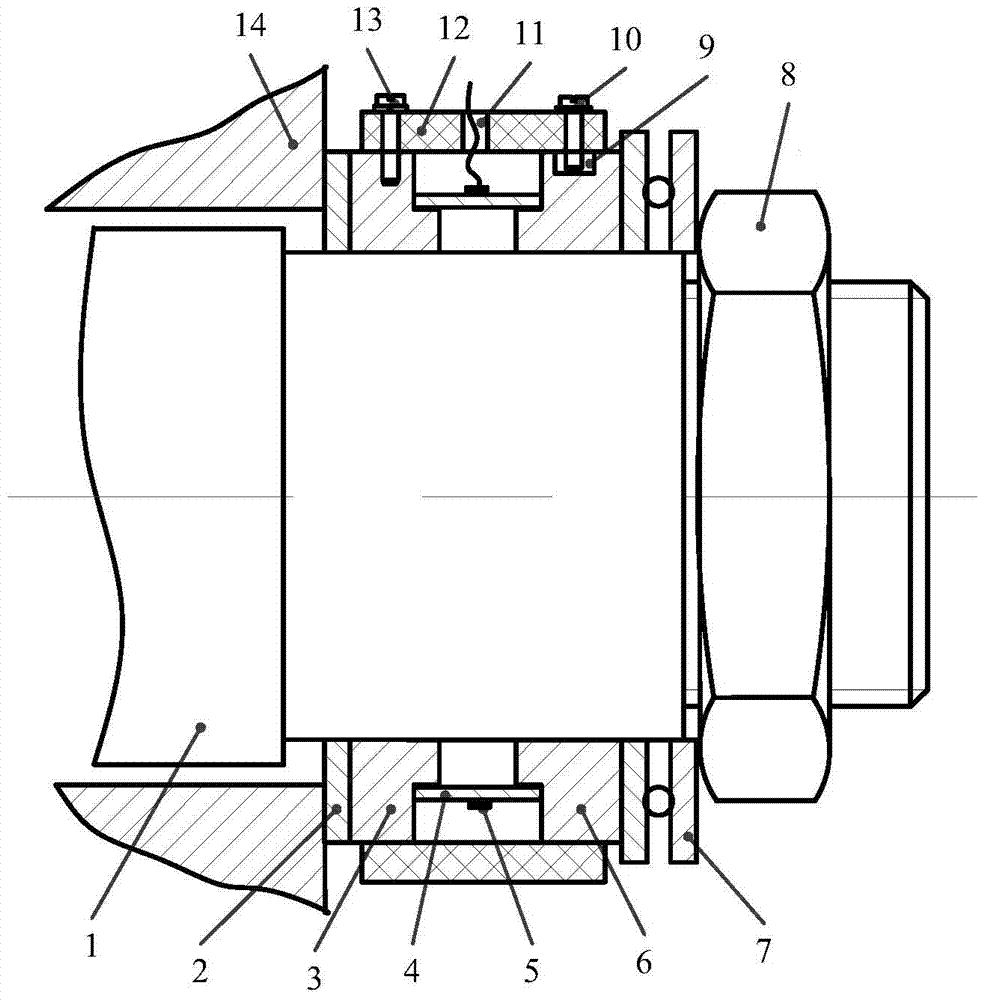

Device for large-scale true tri-axial test of original grading rockfill body and use method of method

ActiveCN102607946AFully reflect the mechanical propertiesReflect mechanical propertiesMaterial strength using tensile/compressive forcesRubber membraneTriaxial shear test

The invention discloses a large-scale true tri-axial test method and a large-scale true tri-axial test device, which can be used for carrying out the true tri-axial test on an original grading rockfill body. The device is arranged in a concrete cave chamber; six faces of a sample are loaded by rigid slabs; three directional main stress is applied by a hydraulic jack controlled by adopting a hydraulic system; two layers of rubber membranes are sleeved at the inner side of a steel plate so as to reduce friction; silicone grease is coated between the rubber membranes; and rigidity compression plates are respectively provided with a displacement sensor or a dialgage used for determining the deformation of the sample in all directions. The device can be used for testing a large-sized original grading sample of the rockfill body, therefore, the size effect can be completely avoided, larger axial strain can be achieved, and a complicated stress-strain path can be simulated.

Owner:WUHAN UNIV

System and method for uniform and localized wall thickness measurement using fiber optic sensors

ActiveUS20120099097A1Accurately determineClean and high signal to noise ratioFluid pressure measurement by electric/magnetic elementsUsing optical meansRelative strainFiber Bragg grating

A system and method are provided for determining wall thickness of a structure such as a metallic pressurized pipe. The system includes an optical fiber having a plurality of Fiber Bragg Gratings (FBGs), and a mounting for securing the FBGs over discrete portions of the exterior surface of the pipe such that strain in the pressurized pipe wall is transmitted to the FBGs. The system further includes a light source and a light sensor coupled to an end of the optical fiber. The light sensor converts light reflected back from the FBGs into electrical signals that a digital processor converts into strain measurements. The FBGs are mounted around portions of the pipe expected to have significant metal loss as well as portions of the pipe expected to have negligible metal loss. The method includes at least one of comparing relative strains at locations with negligible metal loss to those with significant metal loss to accurately determine the thickness of the wall with metal loss; compensating for temperature effects by considering relative strains at areas of the pipe with and without metal loss; and measuring axial strain on the pipe with one or more of the FBGs to correct for at least one of bending and torsion effects on hoop strain.

Owner:SCHLUMBERGER TECH CORP

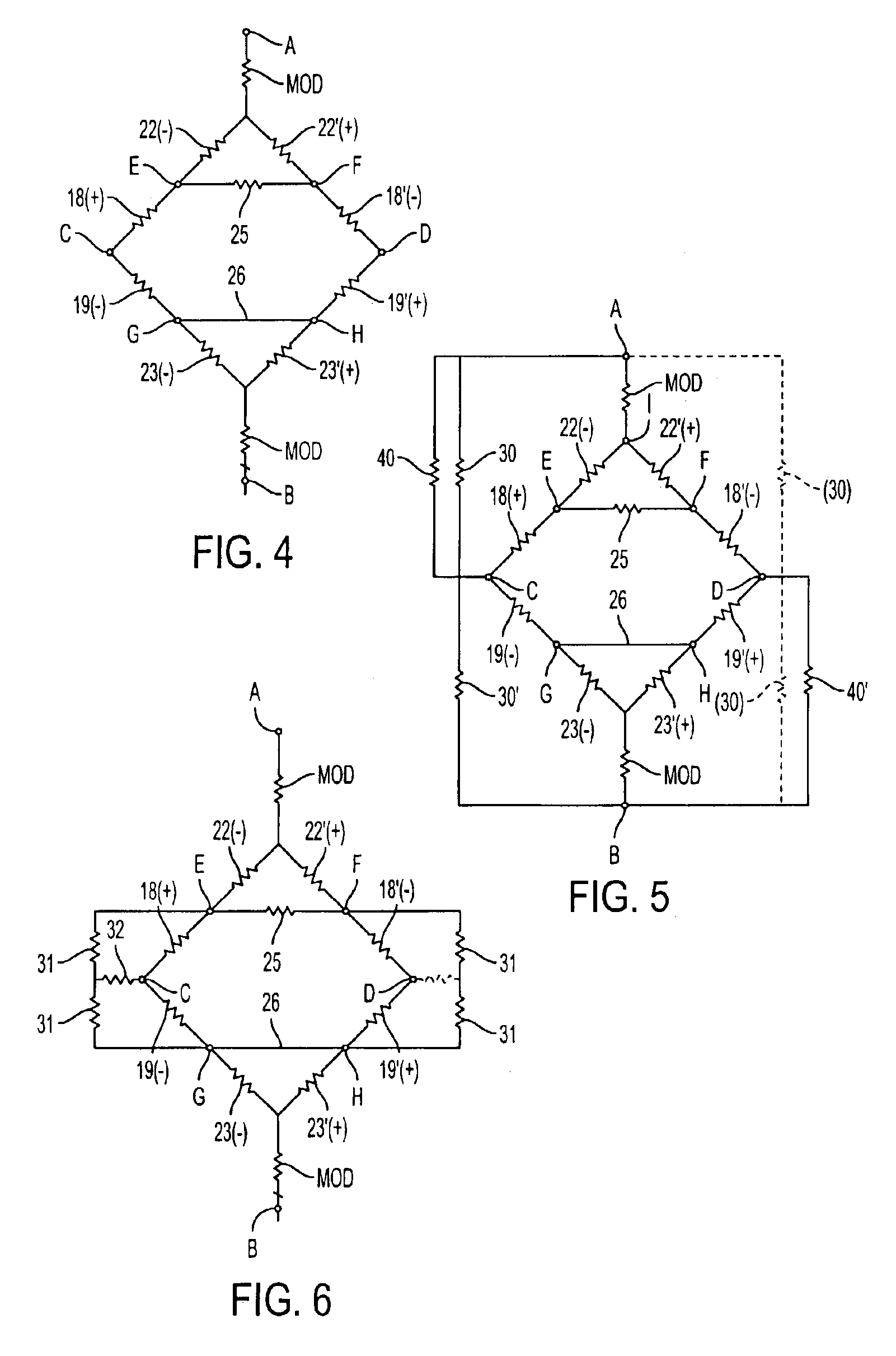

Bending beam load cell with torque sensitivity compensation

InactiveUS6910392B2Weighing apparatus using elastically-deformable membersApparatus for force/torque/work measurementElectricityBending strain

A bending beam load cell can be compensated for side-to-side off center load sensitivity by simple electrical adjustments if a pair of shear sensing strain gages are bonded to each bending beam midway between axial strain gages used to measure bending strains. The shear sensing strain gages measure torque on the load cell, and are incorporated in bridge circuits that make it possible to vary the amount of torque sensitivity correction by changing the value of a trimming resistor. The bridge circuits also include circuit components for compensation of front-to-back off center load error and for zero adjustment. Four strain gages on each bending beam can be part of a single composite strain gage element, so the shear sensing strain gages do not add any cost to the load cell. Such a load cell can also be hermetically sealed before any compensation of offset load errors is done.

Owner:FLINTEC GROUP

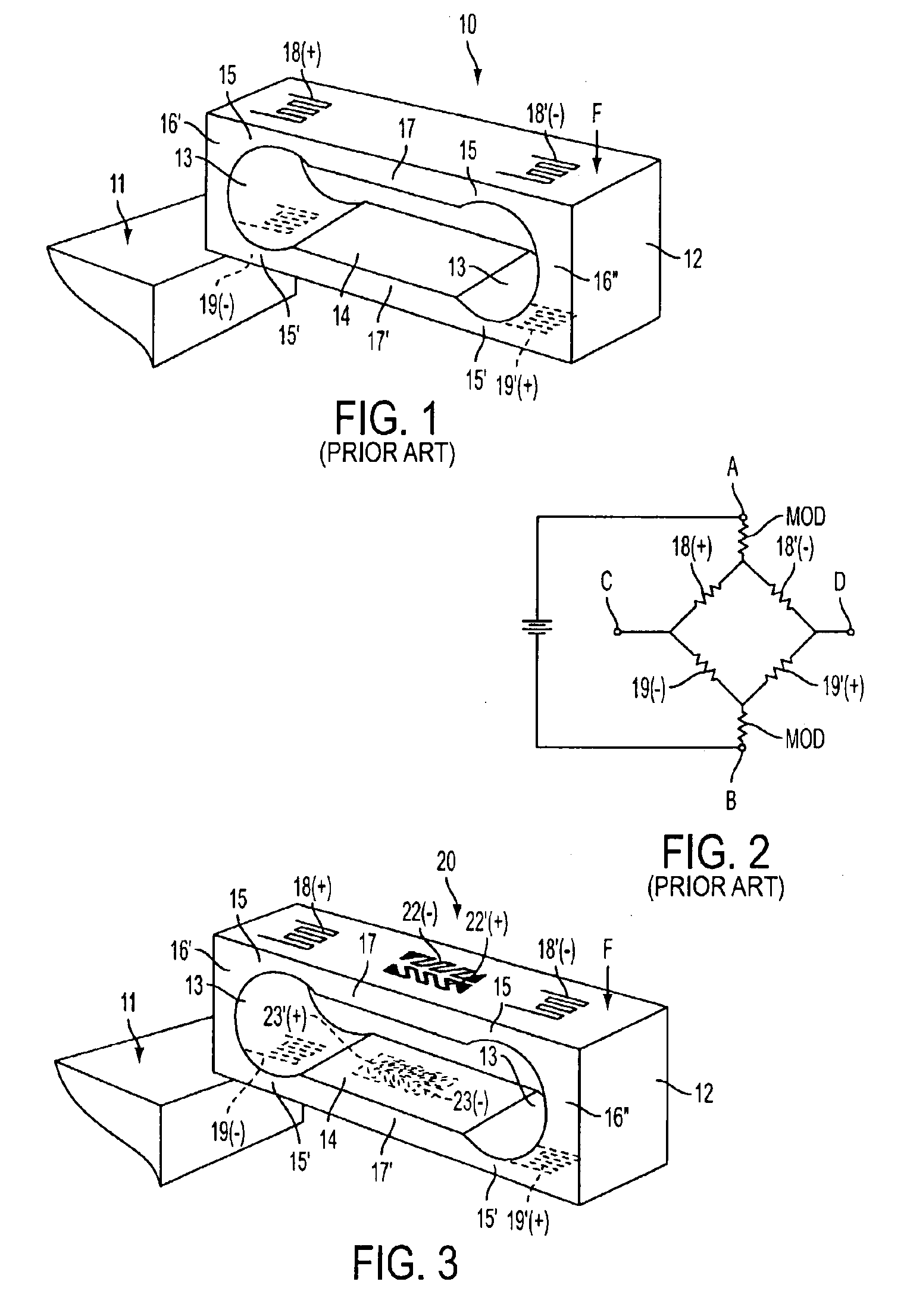

MEMS capacitive bending and axial strain sensor

ActiveUS7509870B2Easily be incorporated into current semi-conductor fabrication processLow powerForce measurementUsing electrical meansCapacitancePrimary operation

Owner:GLOBUS MEDICAL INC

System and method for measuring bending in a pin member

InactiveUS20030000314A1Reliably accurately measureHighly accurate bending moment informationLoad modified fastenersForce measurementOutput deviceBending strain

An instrumented pin member is provided that is capable of measuring bending moments, and optionally of measuring bending and axial strain in real or near real time. The instrumented pin member includes a pin member body disposed about a pin member axis, wherein the pin member body includes a bending portion. A sensing device is positioned at the pin member body within the bending portion for sensing a bending strain in the bending portion exclusive of a net axial strain, and for outputting a sensor measurement signal representative of the bending strain. A sensor measurement signal output device is provided for outputting the sensor measurement signal from the sensor device. A related system includes a plurality of pin members, among other things. Related methods also are disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

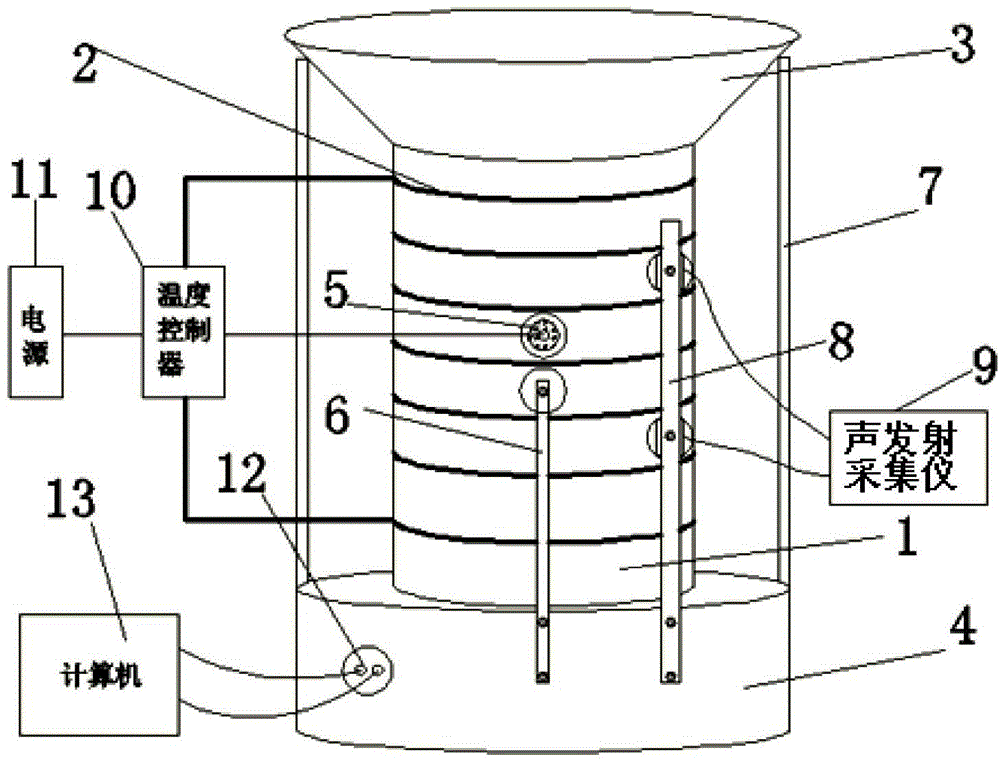

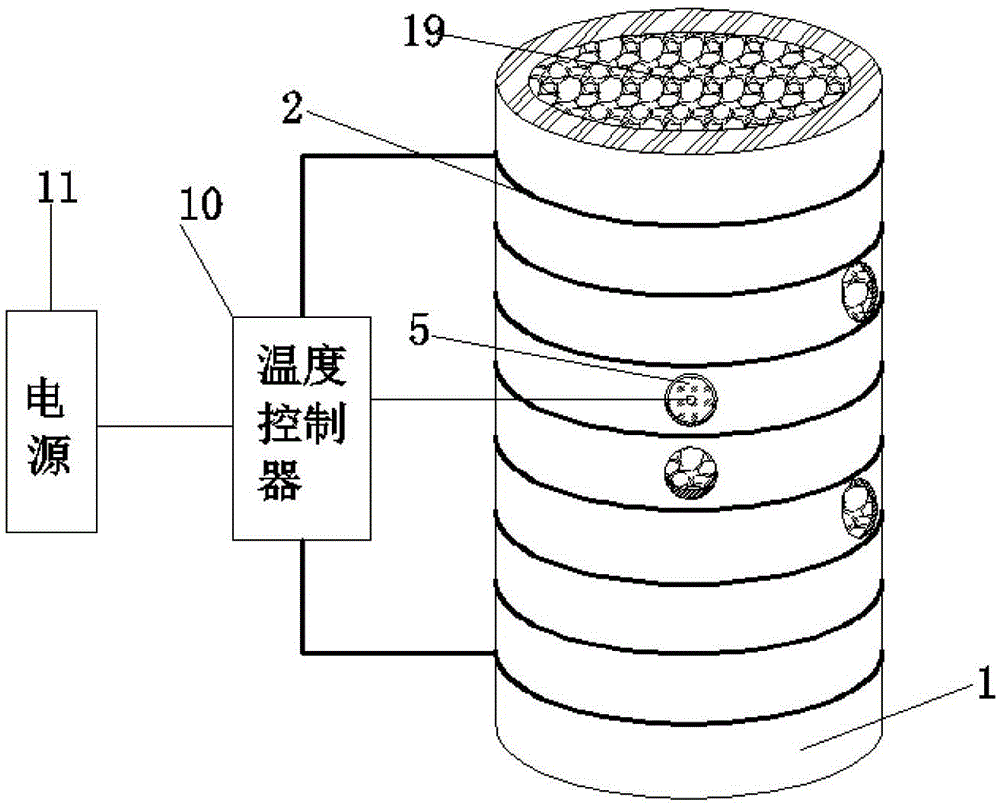

Temperature-controllable rock uniaxial compression sound emission test device and temperature-controllable rock uniaxial compression sound emission test method

InactiveCN104913976AReal-time temperature changeReduce omissionsMaterial strength using tensile/compressive forcesUniaxial compressionTemperature control

Owner:UNIV OF SCI & TECH BEIJING

Operational method for measuring creep parameters and infiltration parameters of smashed rocks simultaneously

InactiveCN102620996ALow costEasy to operateMaterial strength using tensile/compressive forcesPermeability/surface area analysisAxial LoadingsAxial pressure

The invention relates to an operational method for measuring creep parameters and infiltration parameters of smashed rocks simultaneously, which realizes loading of axial pressure and infiltration pressure difference by the aid of a smashed rock creep-infiltration full-process coupling testing device. The operational method includes: firstly, determining initial height of rock in a cylinder before loading, starting an axial loading device then, starting an electric test pump to saturate rocks, applying axial load, injecting water to the rocks to infiltrate according to set water pressure, finally changing the axial load to perform the creep-infiltration test of the next-grade stress stage. The infiltration characteristic parameters are obtained by matching of a scatter diagram of hole pressure gradient and average infiltration speed and the Forchheimer formula, and the creep parameters are obtained by matching of Kelvin-Volgt creep model and an axial strain time curve. The operational method has the advantages that creep model during creep and infiltration full-process couple of the smashed rocks can be acquired, mutual affection of creep and infiltration can be indicated through the parameters, operation results can provide theoretical basis for theoretical analysis and numerical value simulation of creep-infiltration of the smashed rocks.

Owner:XUZHOU NORMAL UNIVERSITY

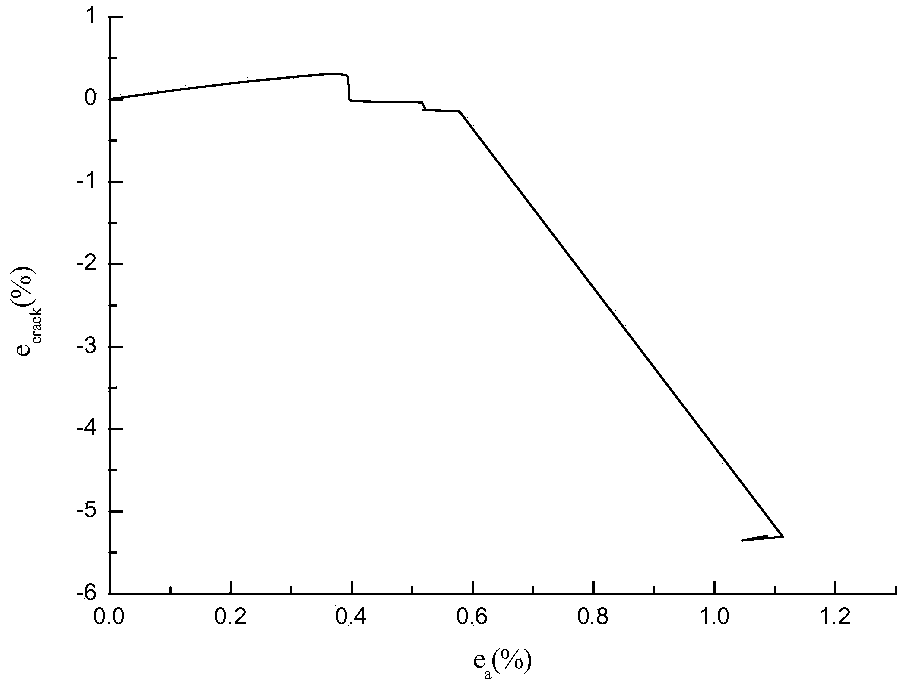

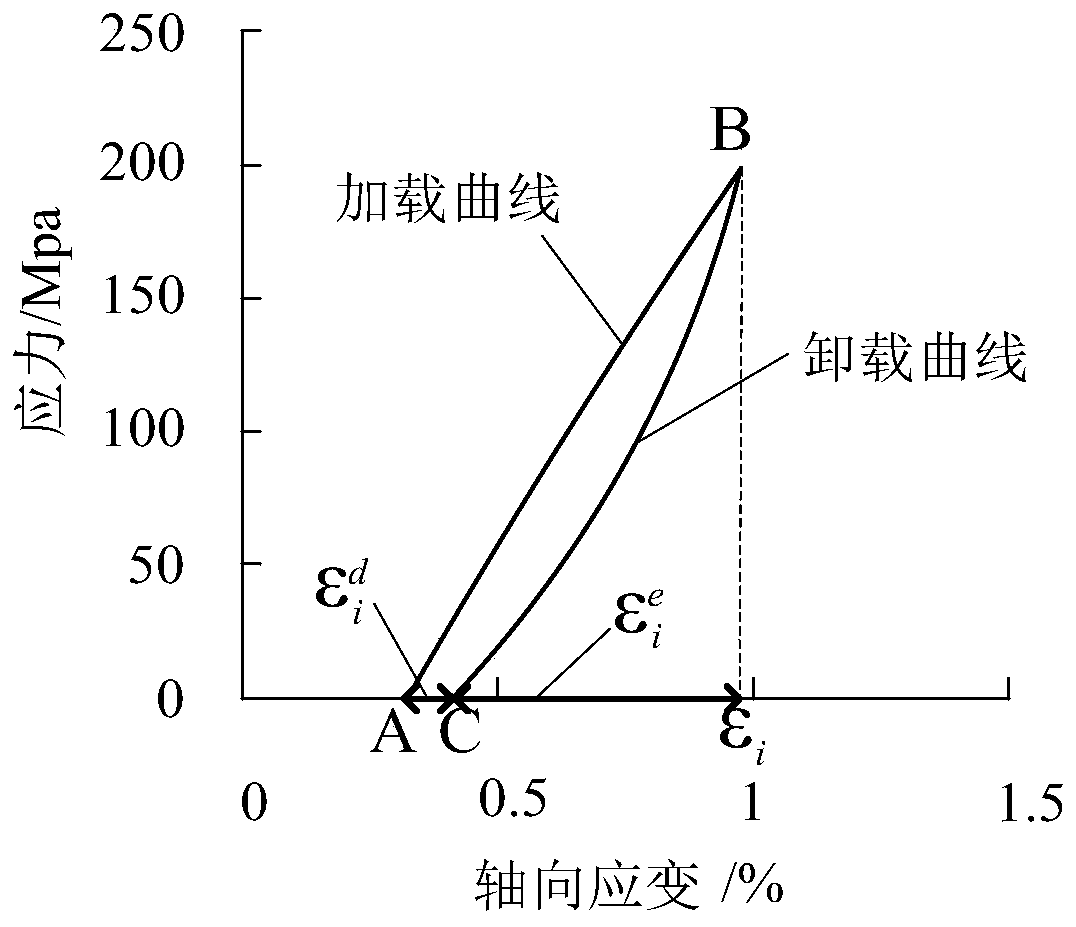

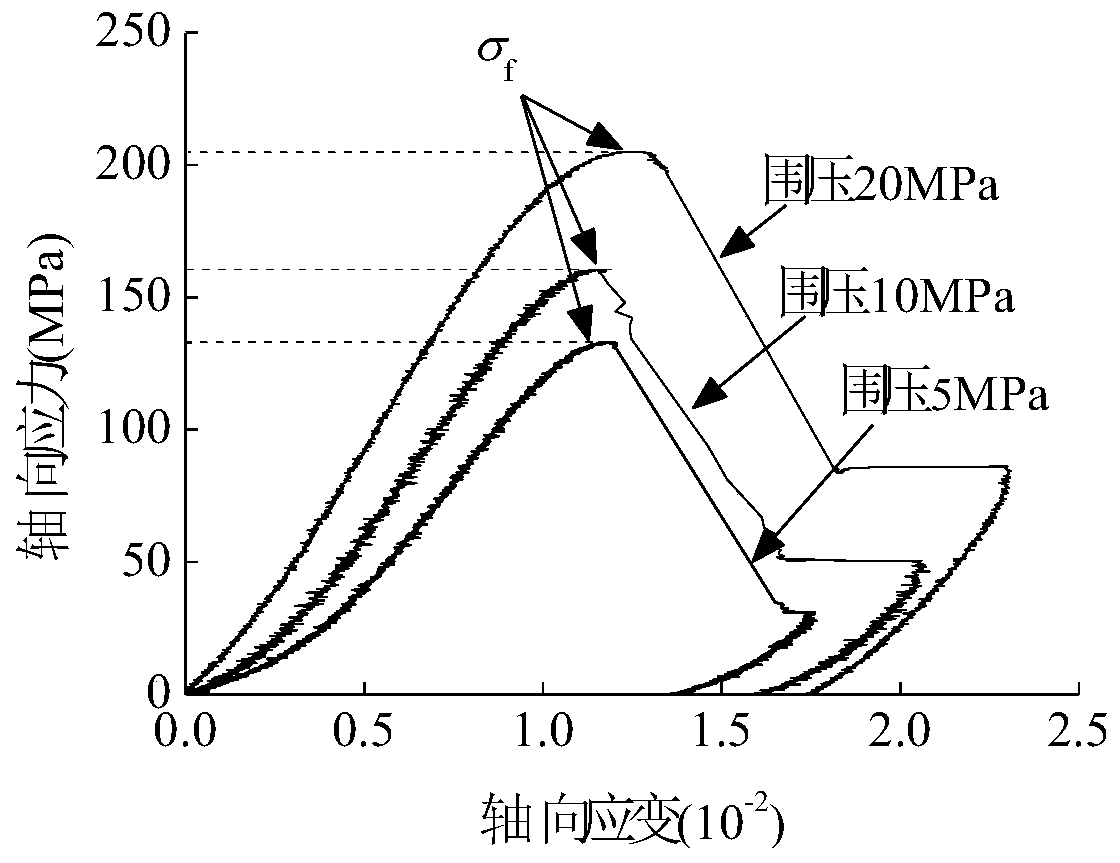

Method for evaluating compressibility of tight reservoir based on stress-strain curve

ActiveCN108593436AMaterial strength using tensile/compressive forcesMathematical modelStress–strain curve

The invention discloses a method for evaluating compressibility of a tight reservoir based on a stress-strain curve. The method comprises the following steps: testing the stress-strain curve of a rocksample under a certain confining pressure to obtain elasticity modulus and Poisson's ratio of an elastic deformation stage so as to obtain the volumetric strain of the elastic deformation stage and obtain crack volume strain; determining an expansion point of the rock sample according to an axial strain-crack volume strain relationship curve and obtaining the strain energy size through the stress-strain curve envelope area formed from the expansion point to the break point in an enclosing way; and establishing a compressibility index mathematical model of the surrounding rock by performing nondimensionalization on the change numerical value of the parameter, and calculating and comparing the size. The experimental evaluation method provided by the invention is suitable for the unconventional resources such as shale gas, coal bed gas, compact oil gas and a hot dry rock, and can be applied to the conventional oil and gas reservoir with low permeability and ultralow permeability. The confining pressure effect is considered and the artificial fracture density formed after the rock is expanded is considered, so the method can be used for evaluating the artificial joint network formingcapability of the formation condition and guiding the volumetric fracturing construction to select wells and select formations.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

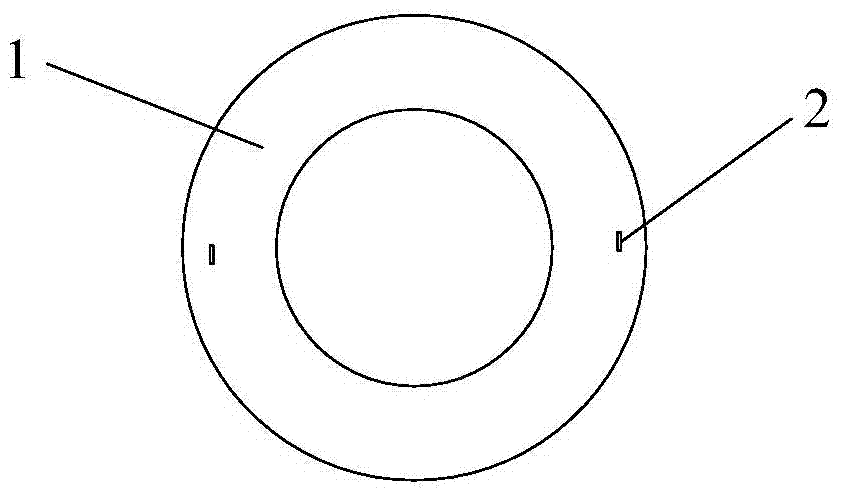

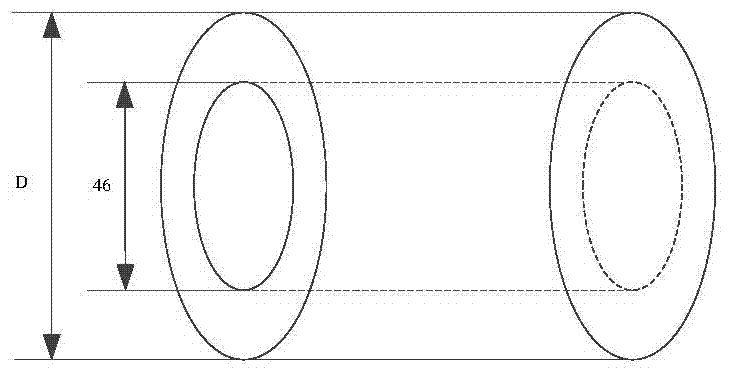

Measuring device of tubular part inner wall processing stress and measuring method thereof

InactiveCN103411711ALow costThe results are reliableForce measurementBiochemical engineeringTangential strain

The utility model provides a measuring device of a tubular part inner wall processing stress and a measuring method thereof, relating to the technical field of a measuring method of a tubular part inner wall processing stress. The device comprises a measured tubular part, and the outer peripheral surface of the measured tubular part is respectively provided with an axial strain piece and a tangential strain piece. The axial strain piece and the tangential strain piece are respectively connected with a strain gauge through conductive wires. The strain gauge is connected with a PC through a conductive wire. According to the device and the method, the measuring device has a simple structure, the measurement result is accurate, and the device is suitable for different tube diameters.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

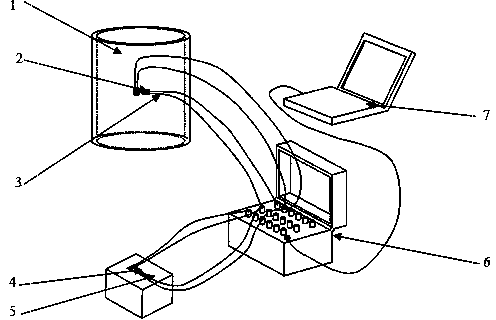

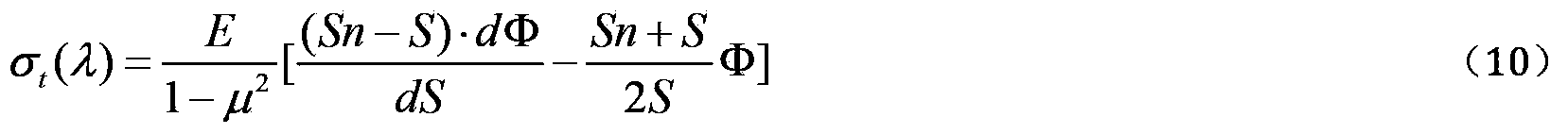

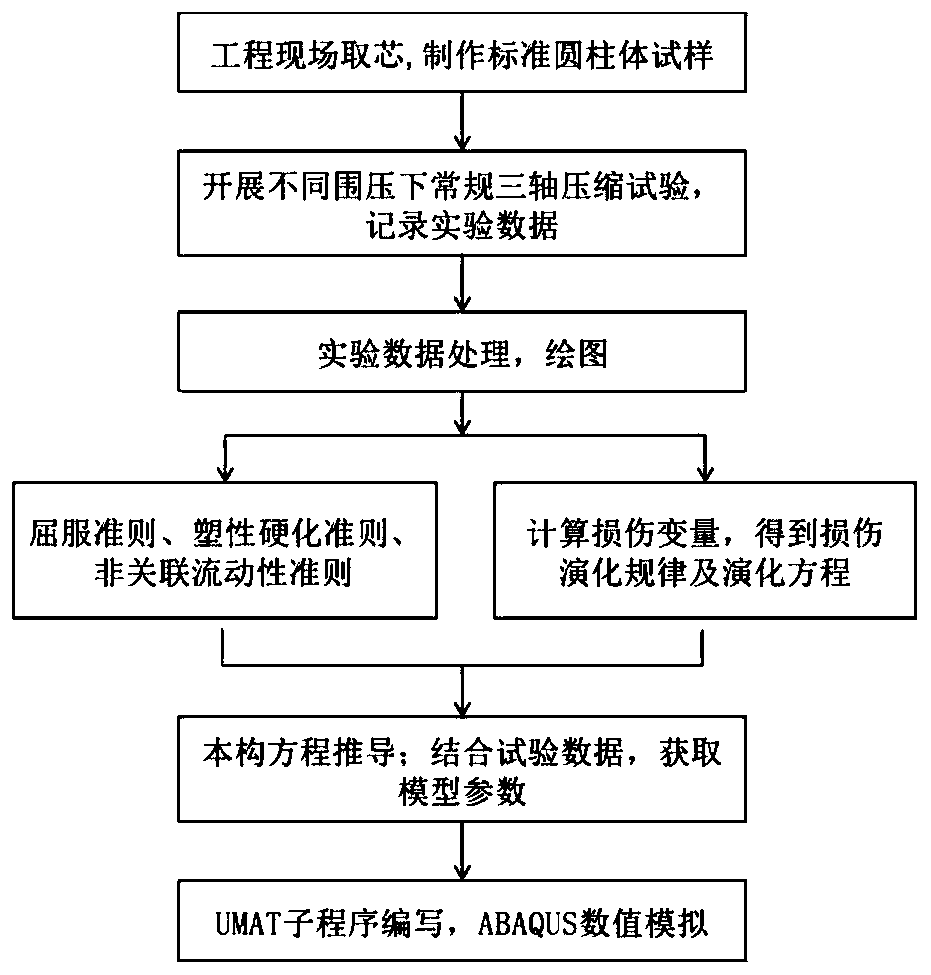

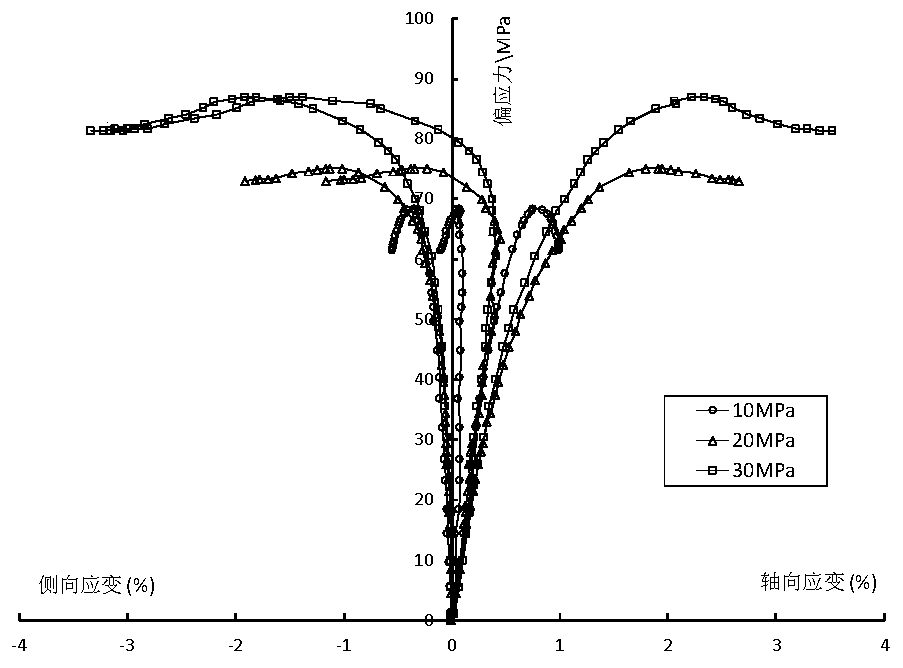

Method for constructing elastic-plastic-damage coupling mechanical constitutive model of rock material

PendingCN110705165AImprove accuracyWide applicabilityMaterial strength using tensile/compressive forcesDesign optimisation/simulationMechanical modelsElastic plastic

The invention discloses a method for constructing an elastoplasticity-damage coupling mechanical constitutive model of a rock material. The method comprises the following steps of obtaining the rock material on an engineering site, and manufacturing a standard cylinder sample; carrying out conventional triaxial compression mechanical tests under different confining pressures; obtaining a rock yield criterion, a plastic hardening criterion and a non-associated fluidity rule in combination with a test result; calculating a rock damage variable according to the stress-strain curve, and obtaininga rock damage evolution equation according to a damage variable-axial strain evolution rule; deriving a constitutive equation based on an elastic-plastic mechanics theory and an irreversible thermodynamic damage constitutive theory; combining the test data to obtain model parameters; writing the mechanical model into a UMAT subprogram, embedding the UMAT subprogram into ABAQUS finite element software, and carrying out triaxial test numerical simulation, so as to verify and improve the model. The method is clear in mechanical significance, simple in parameter acquisition, wide in application range and relatively high in accuracy.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

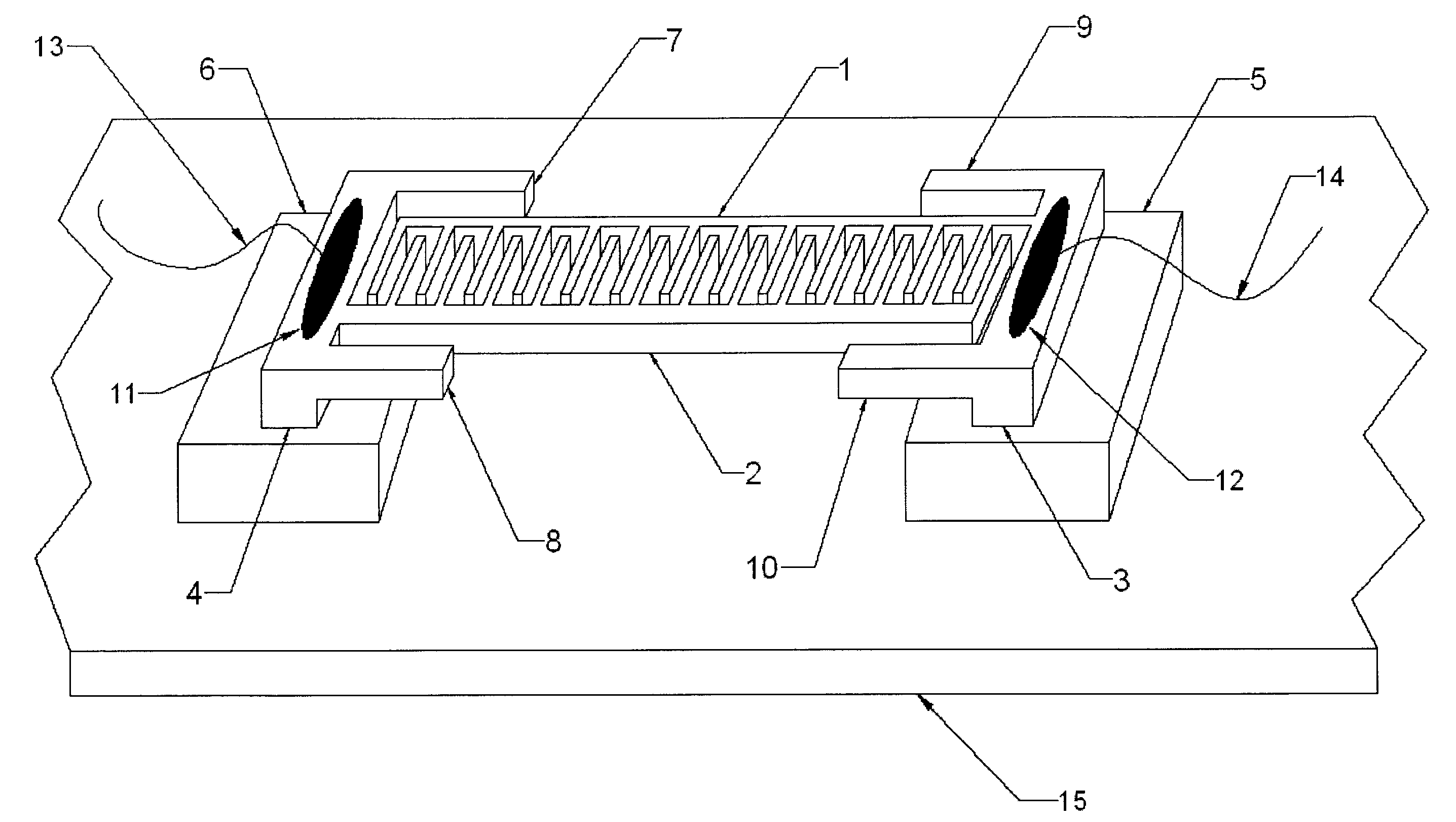

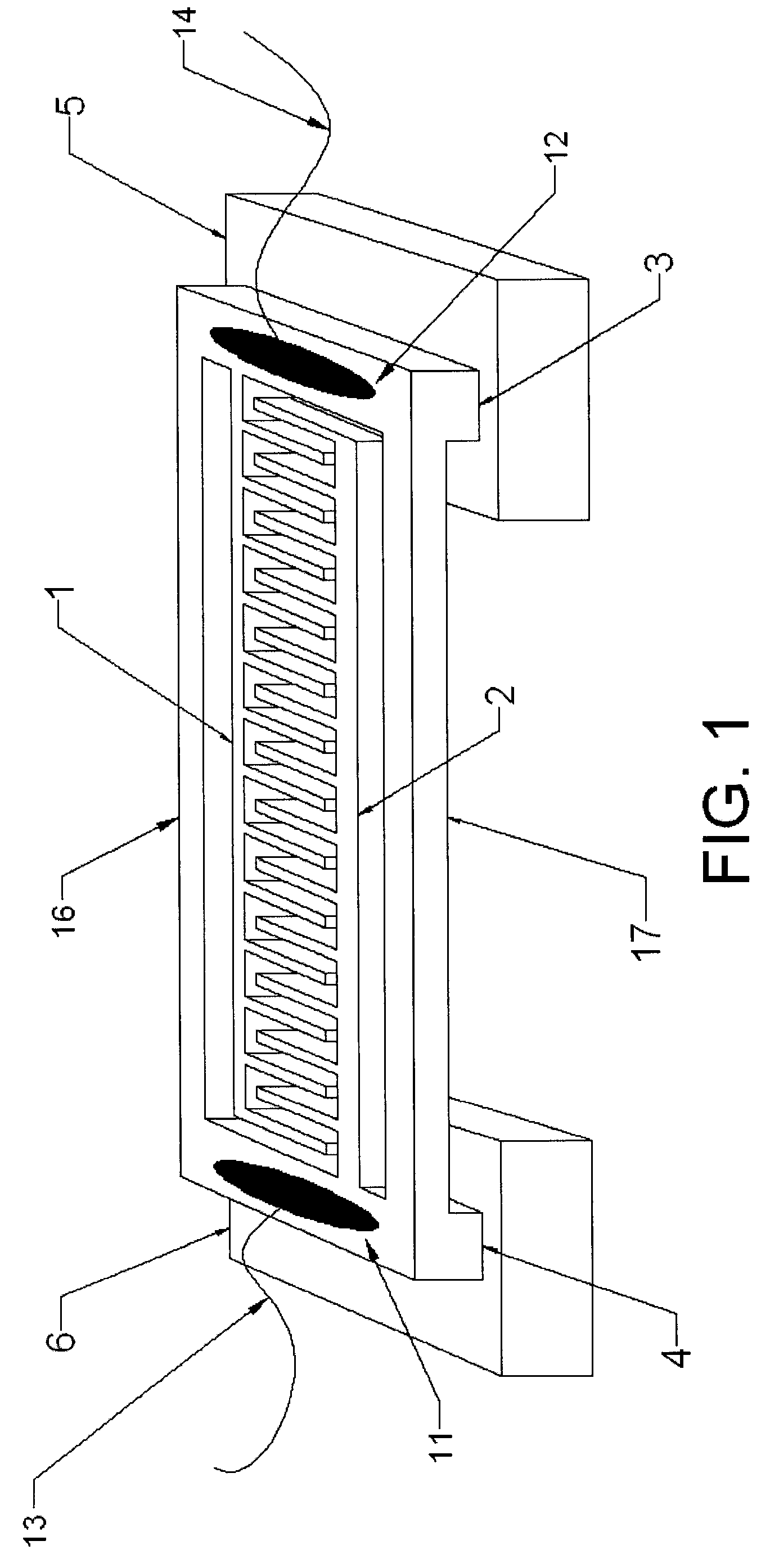

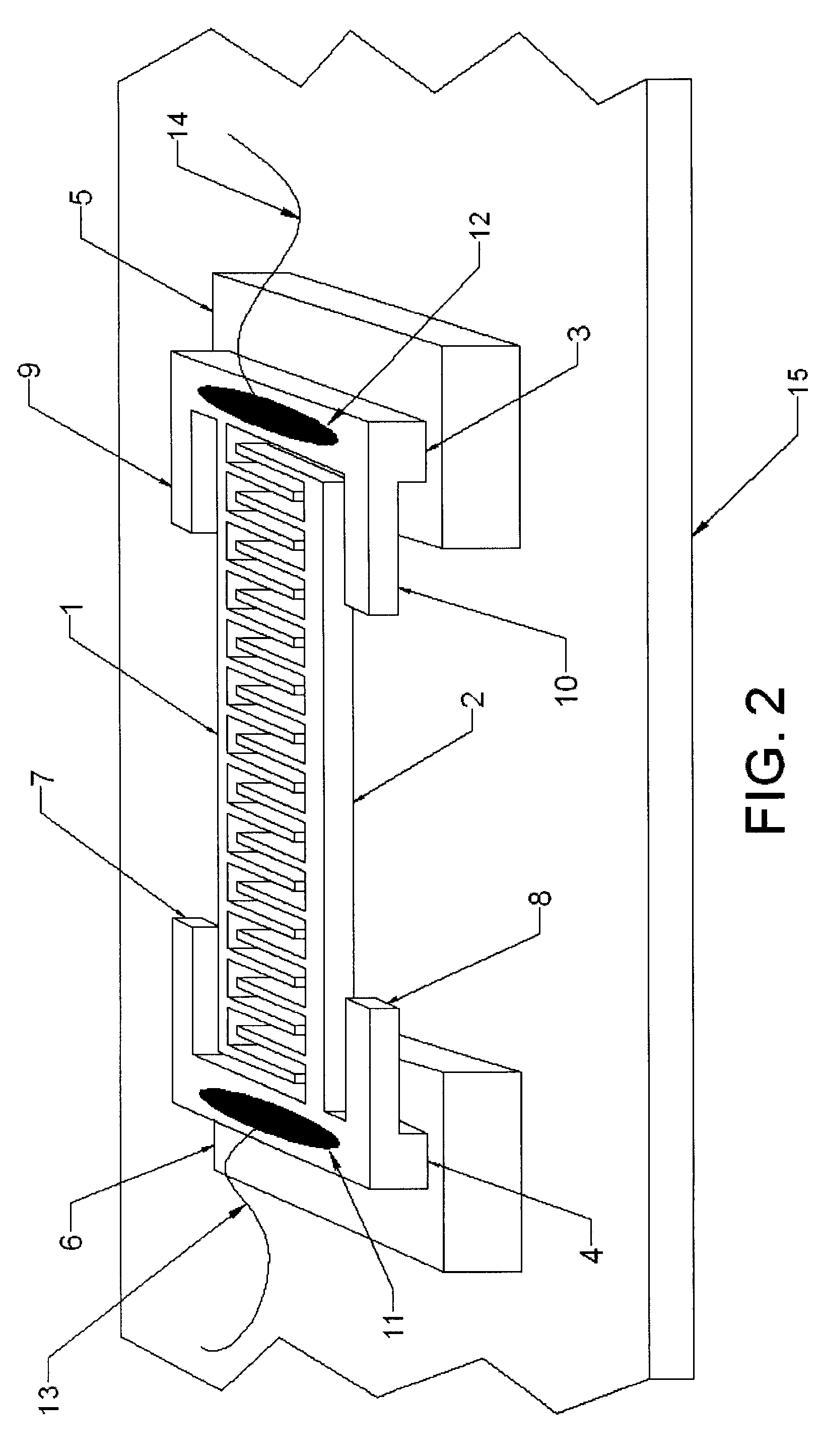

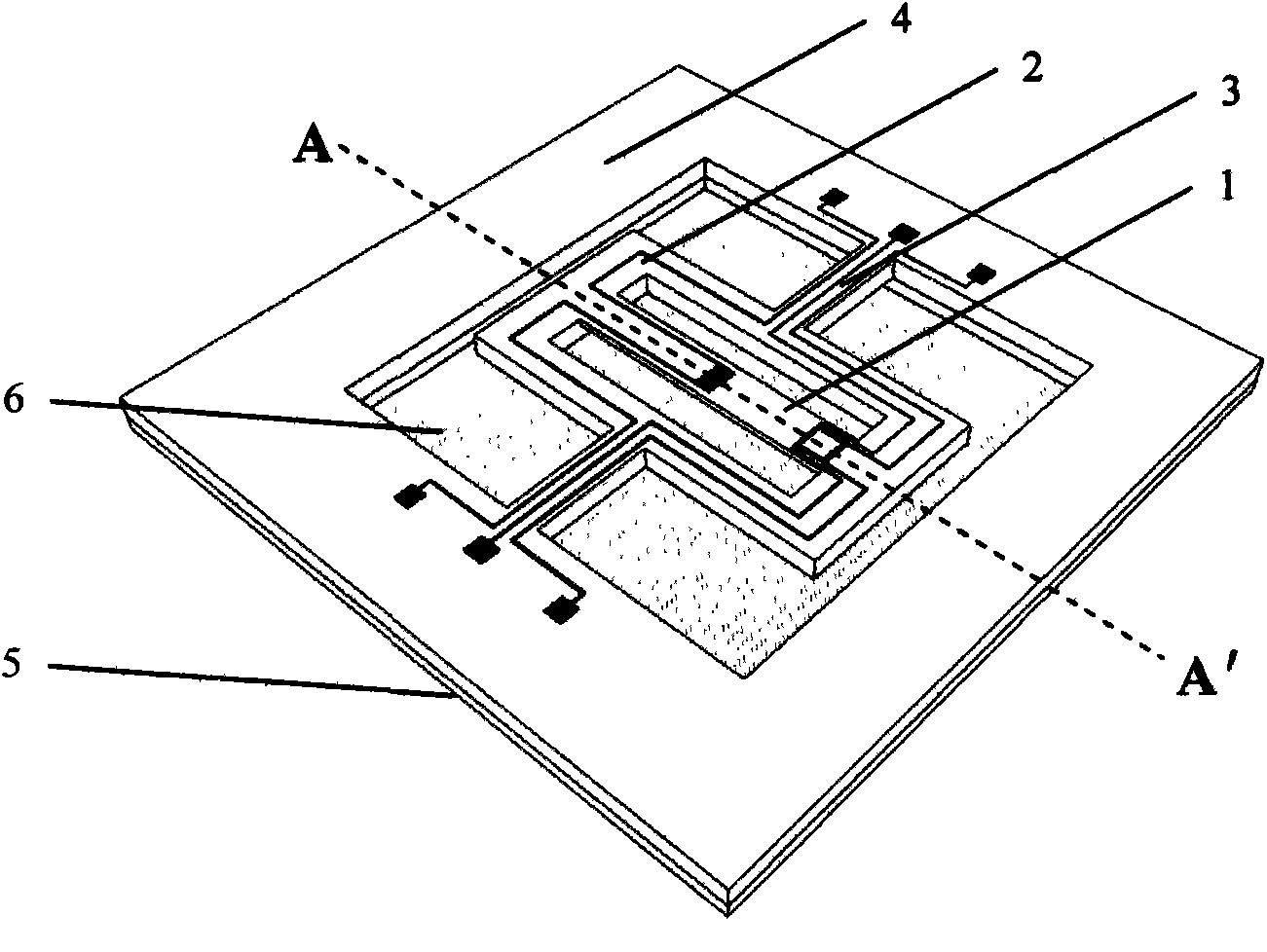

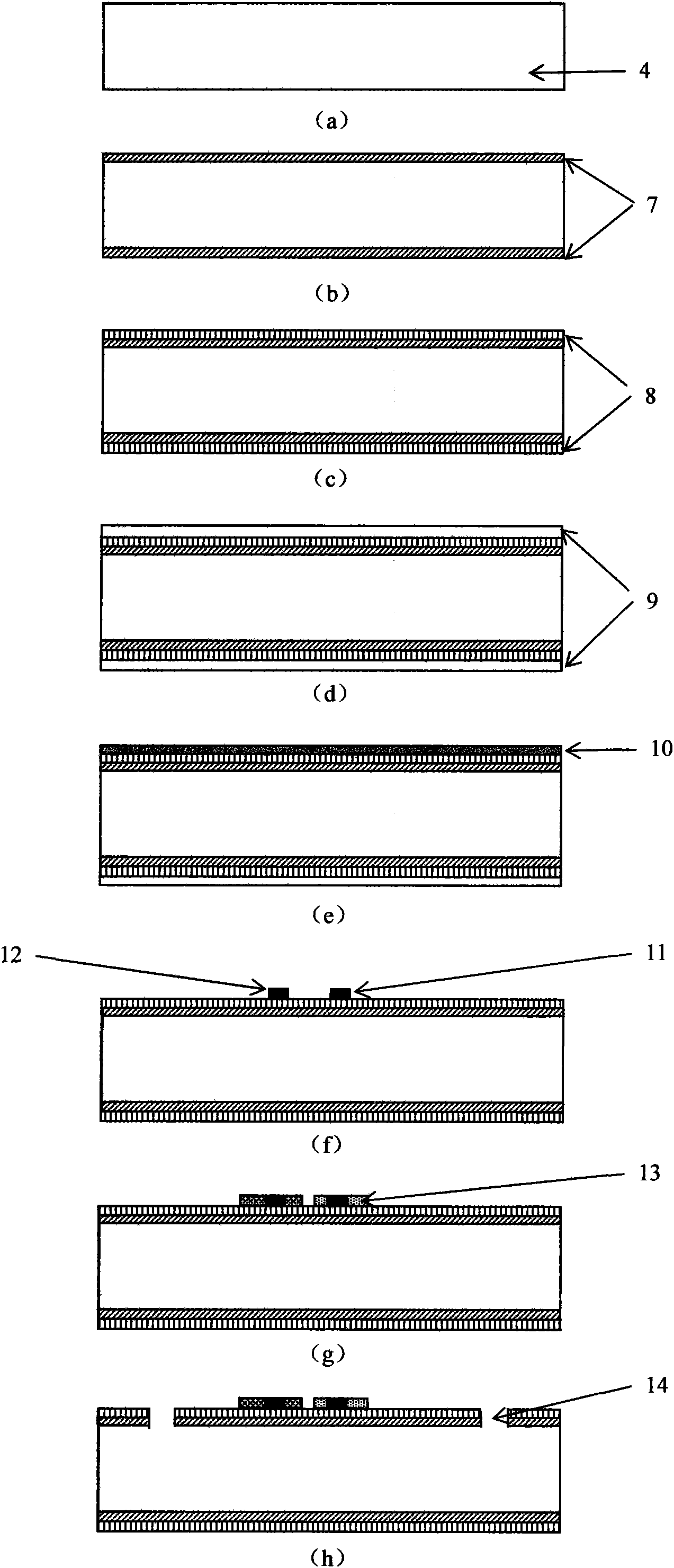

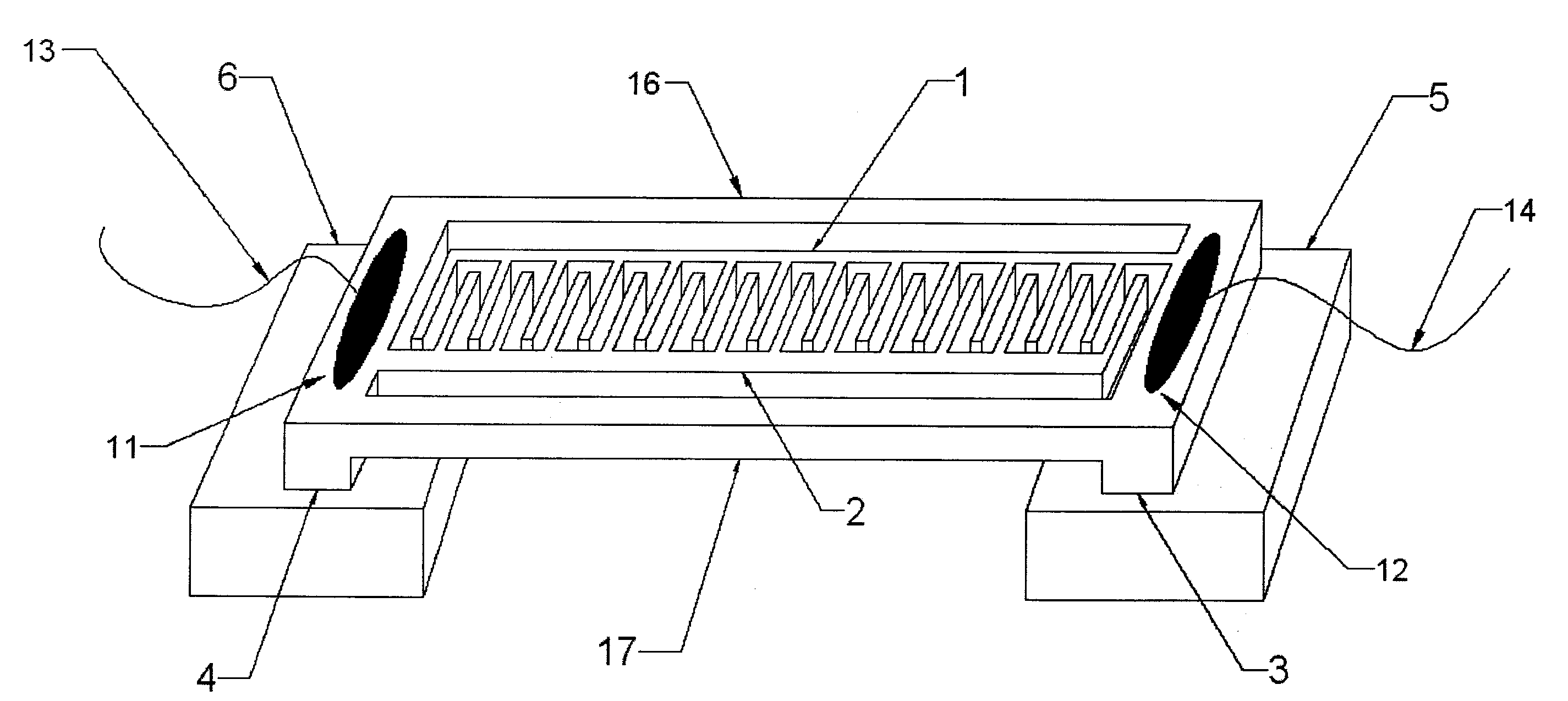

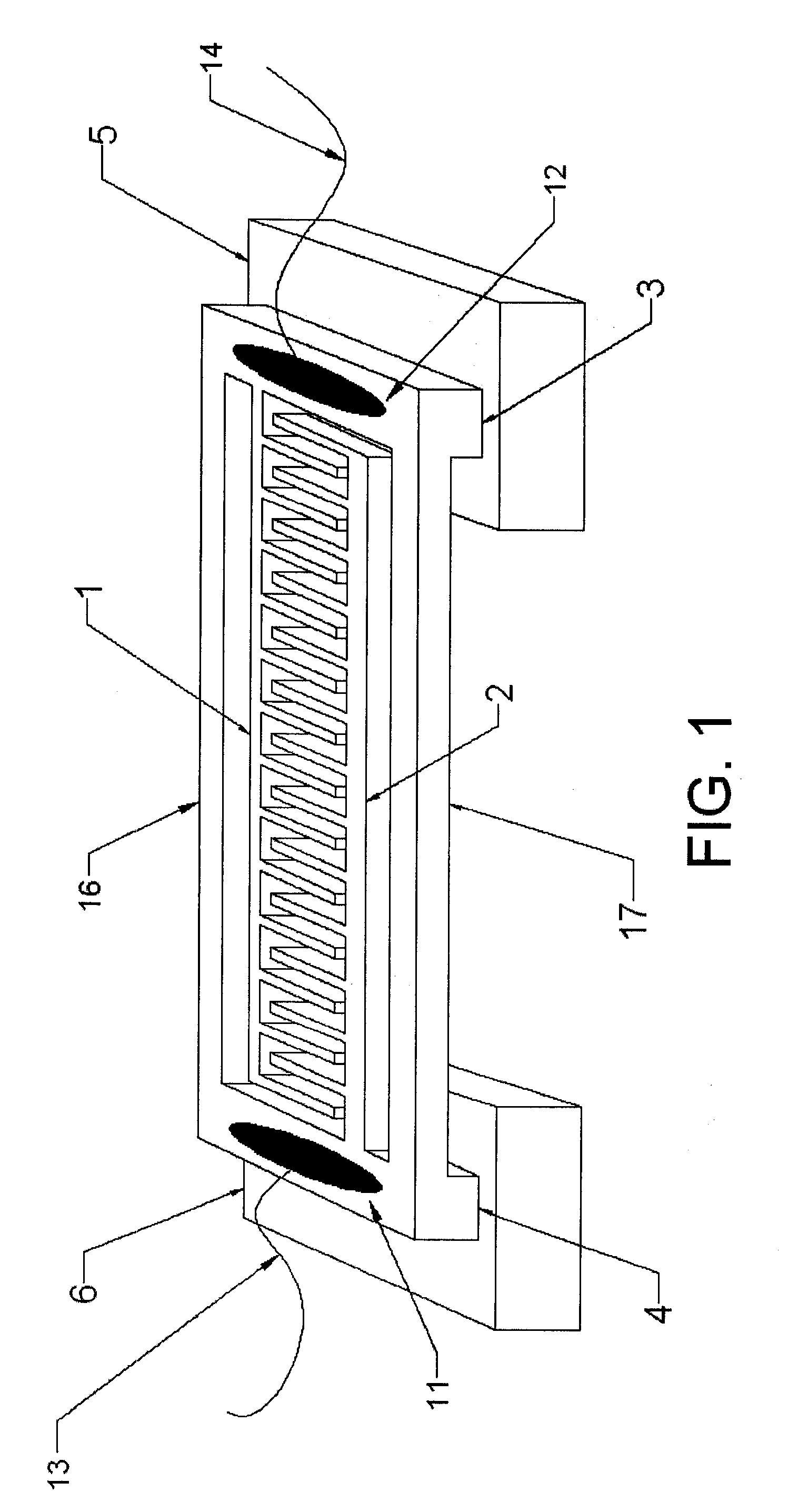

Resonant type infrared detector structure capable of isolating packaging stress and manufacturing method thereof

InactiveCN103708406ADoes not change lengthDoes not change axial strainDecorative surface effectsSolid-state devicesThermal expansionAxial strain

The invention discloses a resonant type infrared detector structure capable of isolating packaging stress and a manufacturing method thereof, and belongs to the field of micro-electronic mechanical systems. The resonant type infrared detector structure is characterized by being composed of a micro-bridge resonator chip and a lower bottom plate. The micro-bridge resonator chip is composed of a micro-bridge resonator (1), a rectangular framework (2), two supporting beams (3) and a substrate (4). One end of each supporting beam (3) is fixedly supported by the substrate (4), and the other ends of the supporting beams (3) are connected with a pair of opposite sides of the rectangular framework (2). The two ends of the micro-bridge resonator (1) are fixedly supported between the other pair of opposite sides of the rectangular framework (2). The micro-bridge resonator (1), the rectangular framework (2) and the supporting beams (3) are suspended above a lower bottom plate (5). The thermal expansion of the lower bottom plate (5) cannot change the distance between one pair of opposite sides, supporting the micro-bridge resonator (1), of the rectangular framework (2), and the length, the axial strain and the resonant frequency of the micro-bridge resonator (1) cannot be changed.

Owner:CHINA JILIANG UNIV

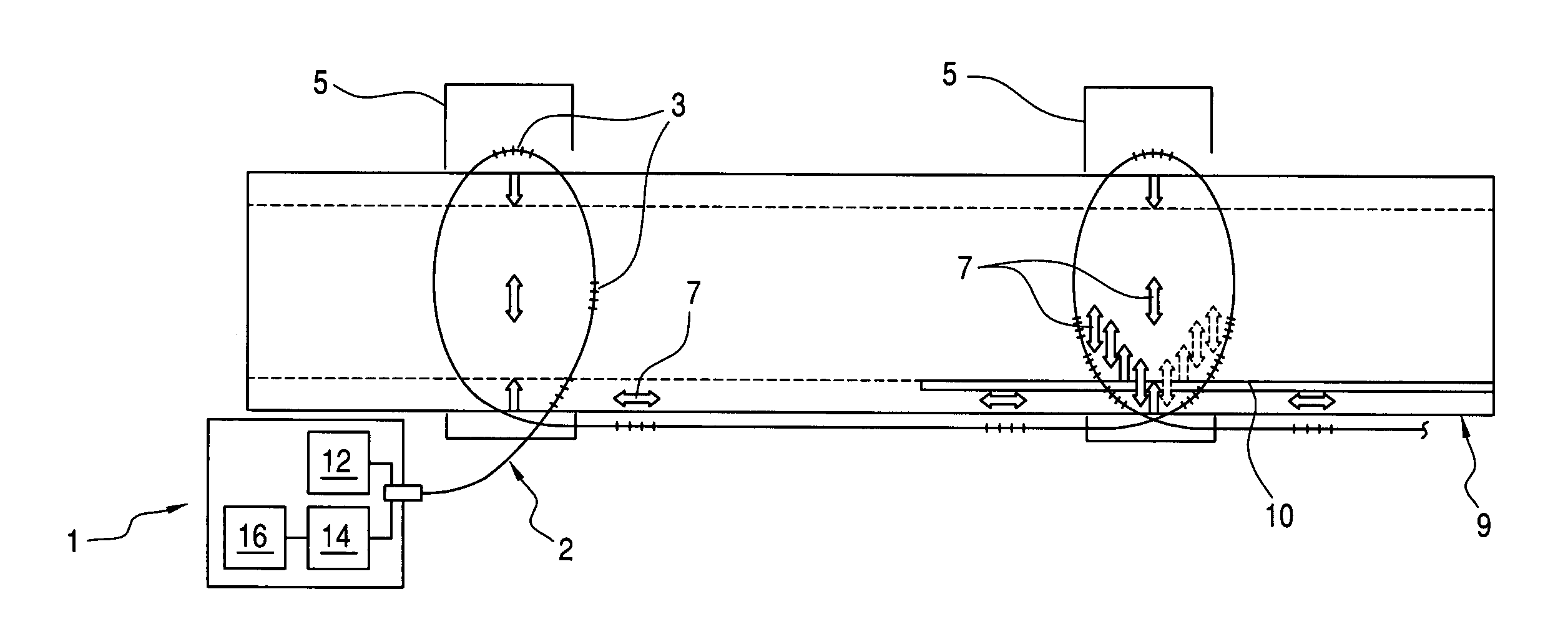

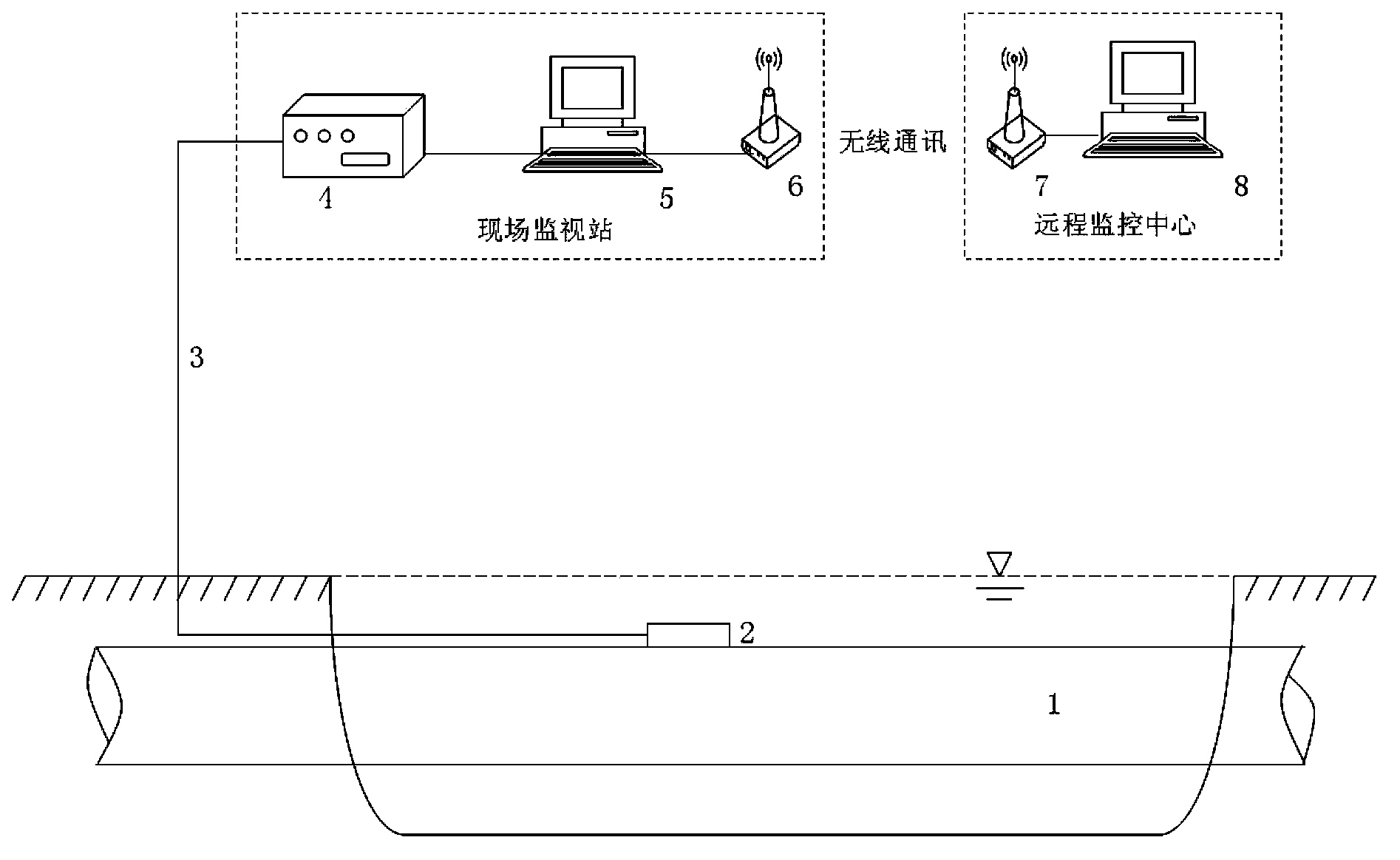

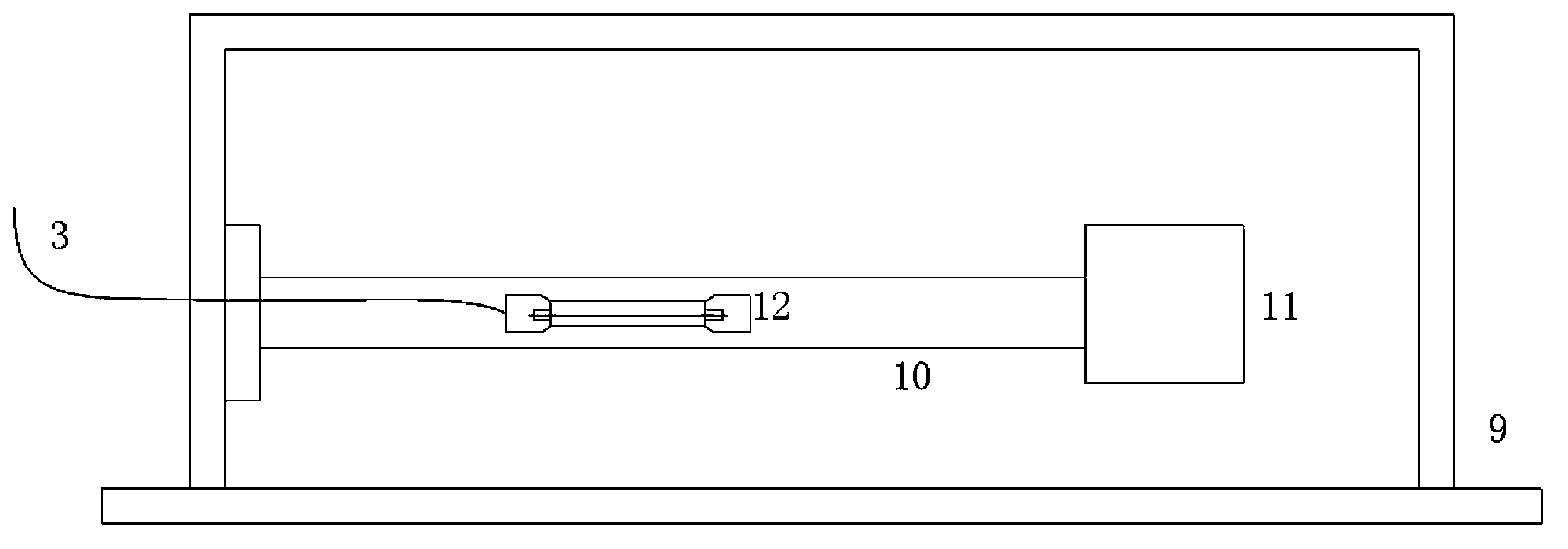

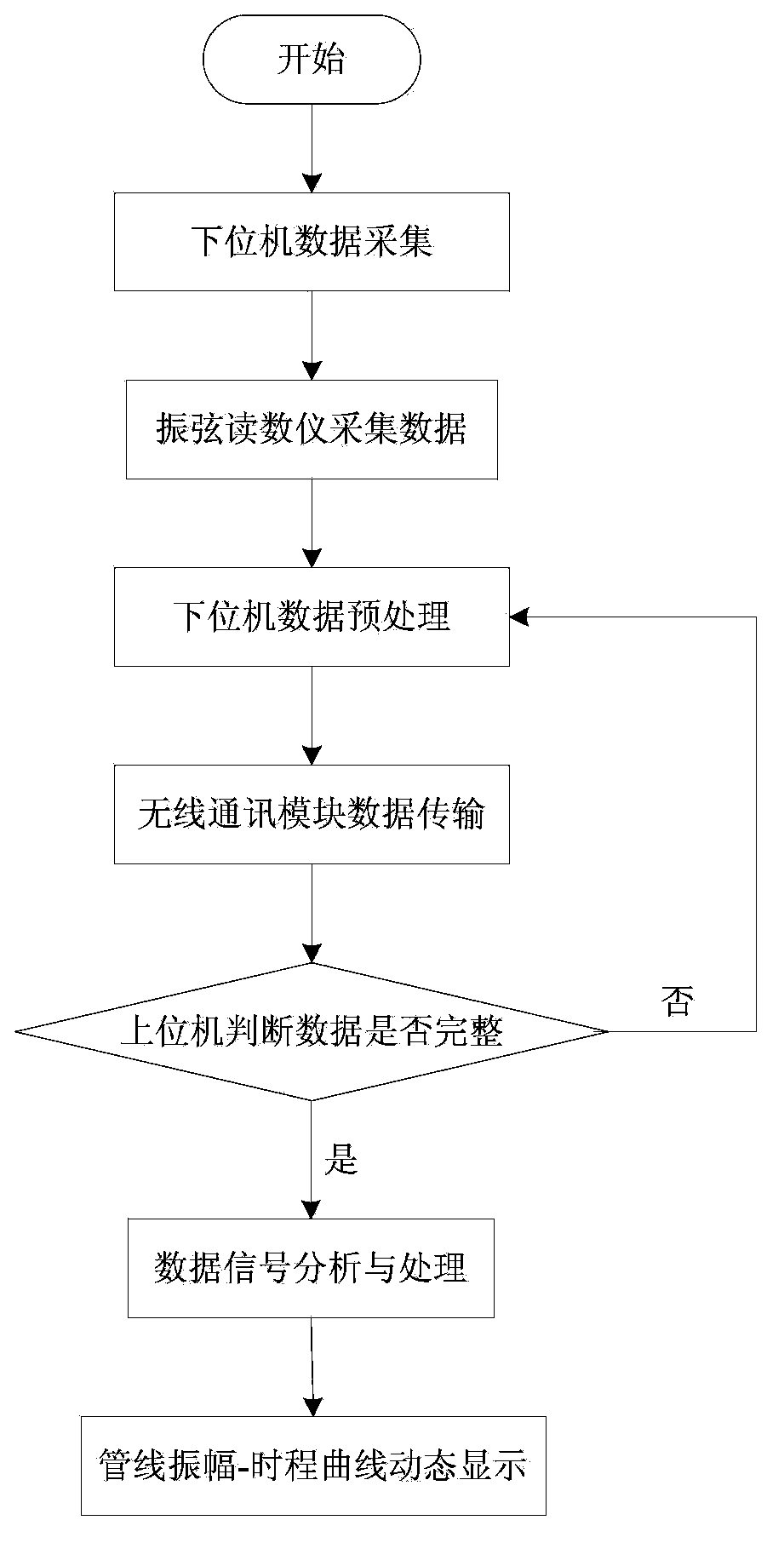

Oil-gas pipeline vibration monitoring method and device based on vibration wire type sensor

ActiveCN103808406AHigh measurement accuracyLess affected by electrical parametersSubsonic/sonic/ultrasonic wave measurementFast Fourier transformVibration acceleration

The invention relates to an oil-gas pipeline vibration monitoring method and device based on a vibration wire type sensor. According to the method, the parameters of amplitude and acceleration of a pipeline are converted into axial strain through stress on a metal bar (10) and further into the output frequency signals of the vibration wire type strain sensor (12), and by measuring the frequency change signals, measurement of the vibration acceleration of the oil-gas pipeline can be achieved; after fast Fourier transform (FFT) is performed on the vibration acceleration a (t), the vibration spectrum of the pipeline can be obtained and further the vibration period can be obtained; according to the number of waves within a quarter of the vibration period, the amplitude and the frequency in a measuring point can be obtained, and further the amplitude-time-history curve of vortex induced vibration of the pipeline can be drawn up. According to the oil-gas pipeline vibration monitoring method and device based on the vibration wire type sensor, the vibration frequency acceleration of the pipeline is converted into the strain of the vibration wire sensor, so that high-precision, anti-interference and stable-performance automatic monitoring of the vibration frequency of the oil-gas pipeline can be achieved.

Owner:PIPECHINA SOUTH CHINA CO

Method of initializing bolt pretension in a finite element analysis

ActiveUS20100076739A1Small incrementAvoid the needAnalogue computers for vehiclesDesign optimisation/simulationElement analysisMechanical engineering

In one aspect of the invention, each bolt is modeled using a beam element in a FEA model. To apply desired pretension to one or more bolts, at least one pretension-versus-time curve is specified. Each pretension-versus-time curve includes ramp portion, desired pretension portion and optional unloading portion. Duration_of the pretension-versus-time curve generally covers first 0.5-1% of total simulation time of a car crashworthiness analysis. Ramp portion starts from zero to desired pretension in a substantially linear manner, and hence being configured for applying desired pretension to a bolt gradually with smaller increments. Desired pretension portion is configured for ensuring the desired pretension can actually be applied to the beam element during an initialization process—a series of quasi-static analyses. Since the method is independent of the deformation of the beam, the method completely avoids the need to iteratively determine an axial strain or displacement that gives the desired pretension.

Owner:ANSYS

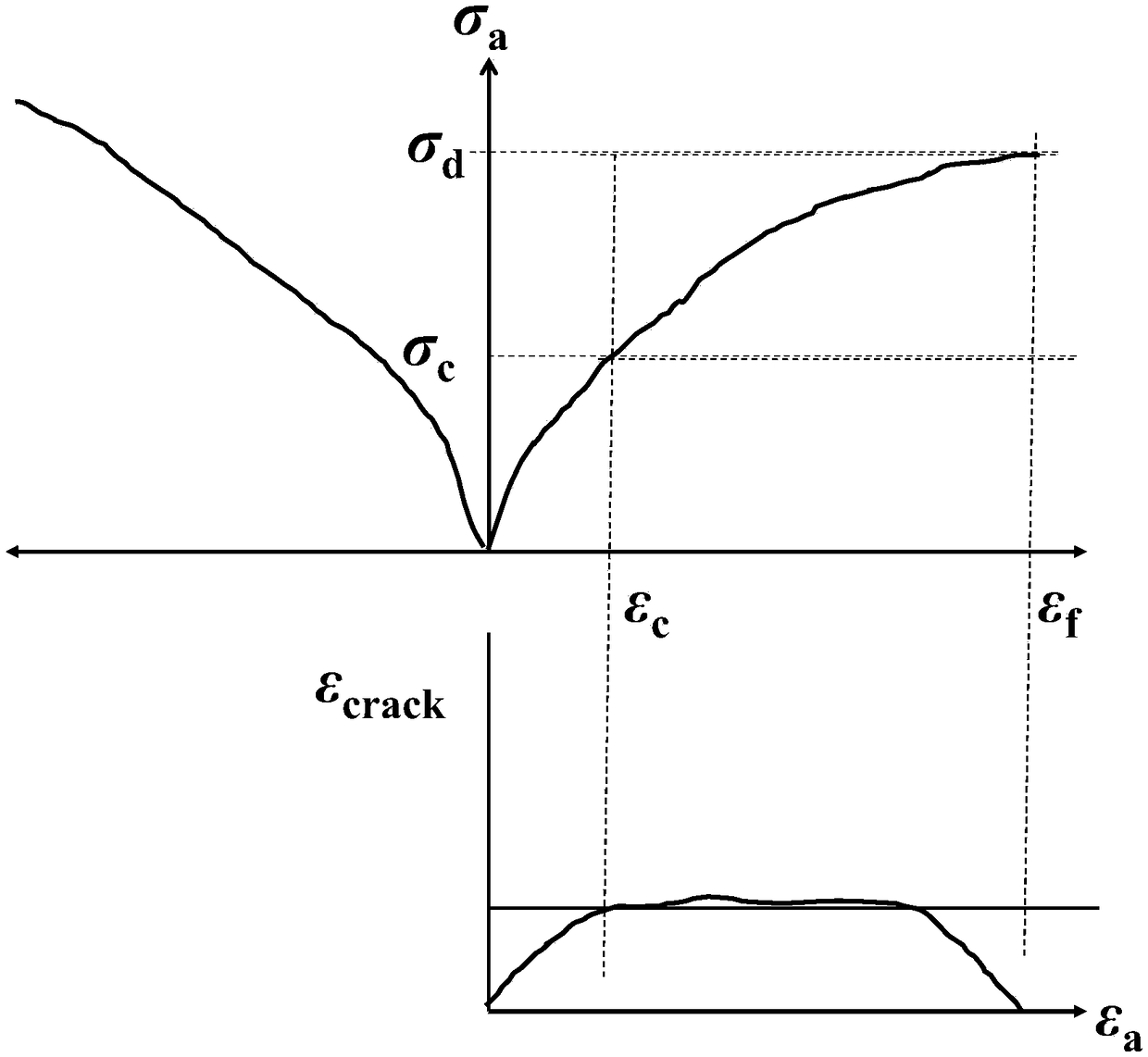

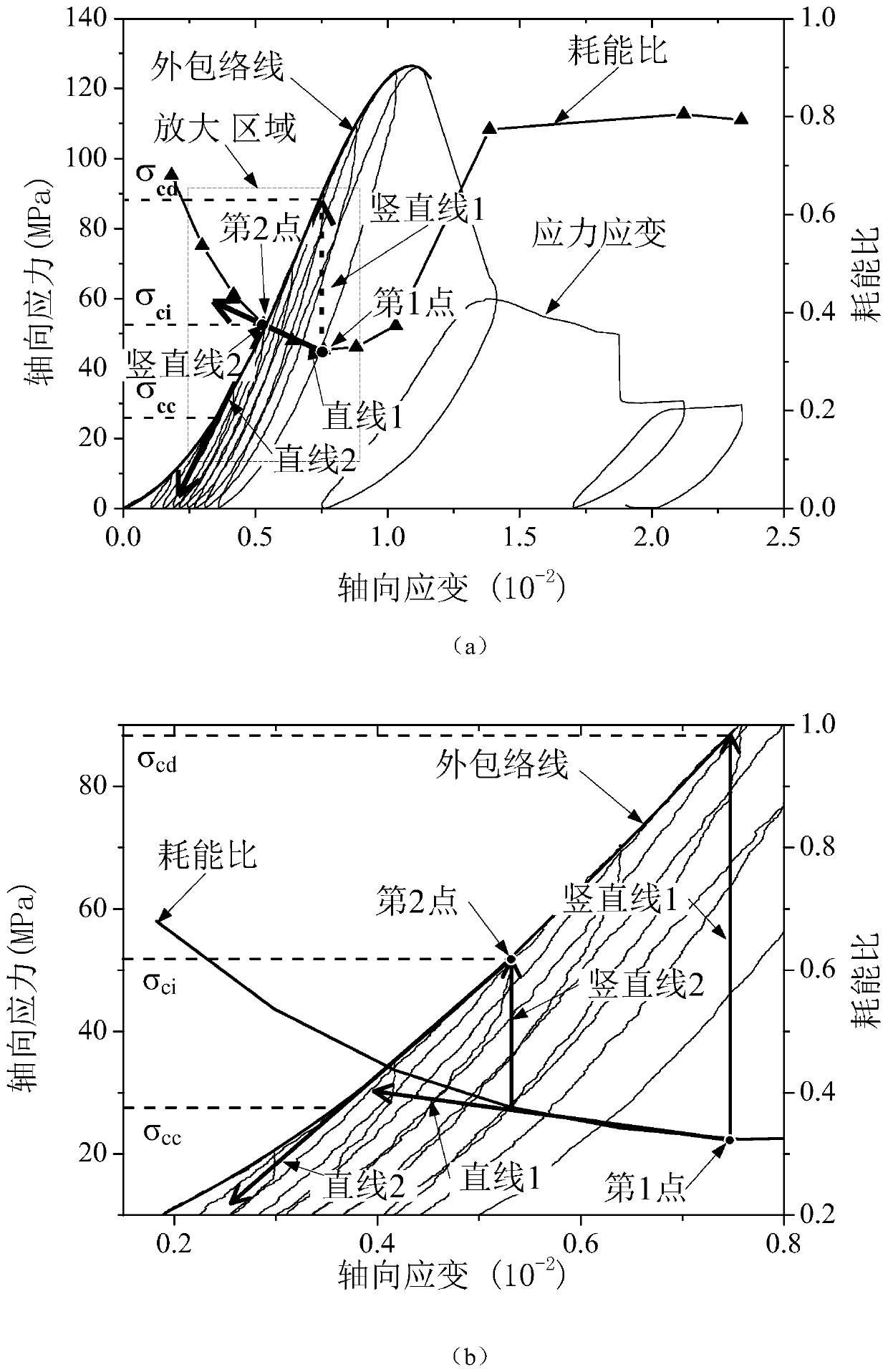

Method for determining characteristic stress in rock material damage evolution process based on energy analysis

InactiveCN110296892ACalculations are reliableEasy to operateWithdrawing sample devicesPreparing sample for investigationCrack closureStress–strain curve

The invention discloses a method for determining characteristic stress in a rock material damage evolution process based on energy analysis, and mainly relates to crack closure stress, initiation stress and damage stress in the rock material damage evolution. The minimum value of the energy consumption ratio on the energy consumption ratio-axial strain curve is taken as a first point to draw a vertical line 1, and the rock damage stress can be found on the outer envelope line of the axial stress-strain curve; a straight line 1 is drawn from the point to the upper left along the energy consumption ratio-axial strain curve, a vertical line 2 is drawn at the position where the straight line 1 deviates from the energy consumption ratio-axial strain curve, and the intersection point on the corresponding axial stress-strain curve outer envelope line is the rock initiation stress; and the rock initiation stress is taken as a second point along the axial stress-strain curve outer envelope lineto draw a straight line 2, the straight line 2 is drawn towards the origin of coordinates, the position which deviates from the axial stress- strain curve outer envelope line is the rock crack closure stress. The method for determining characteristic stress in the rock material damage evolution process based on energy analysis has strong operability, further reduces human subjectivity; and the method for determining characteristic stress in the rock material damage evolution process based on energy analysis is more advantageous in terms of operation process and determination of the amount ofcharacteristic stress.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

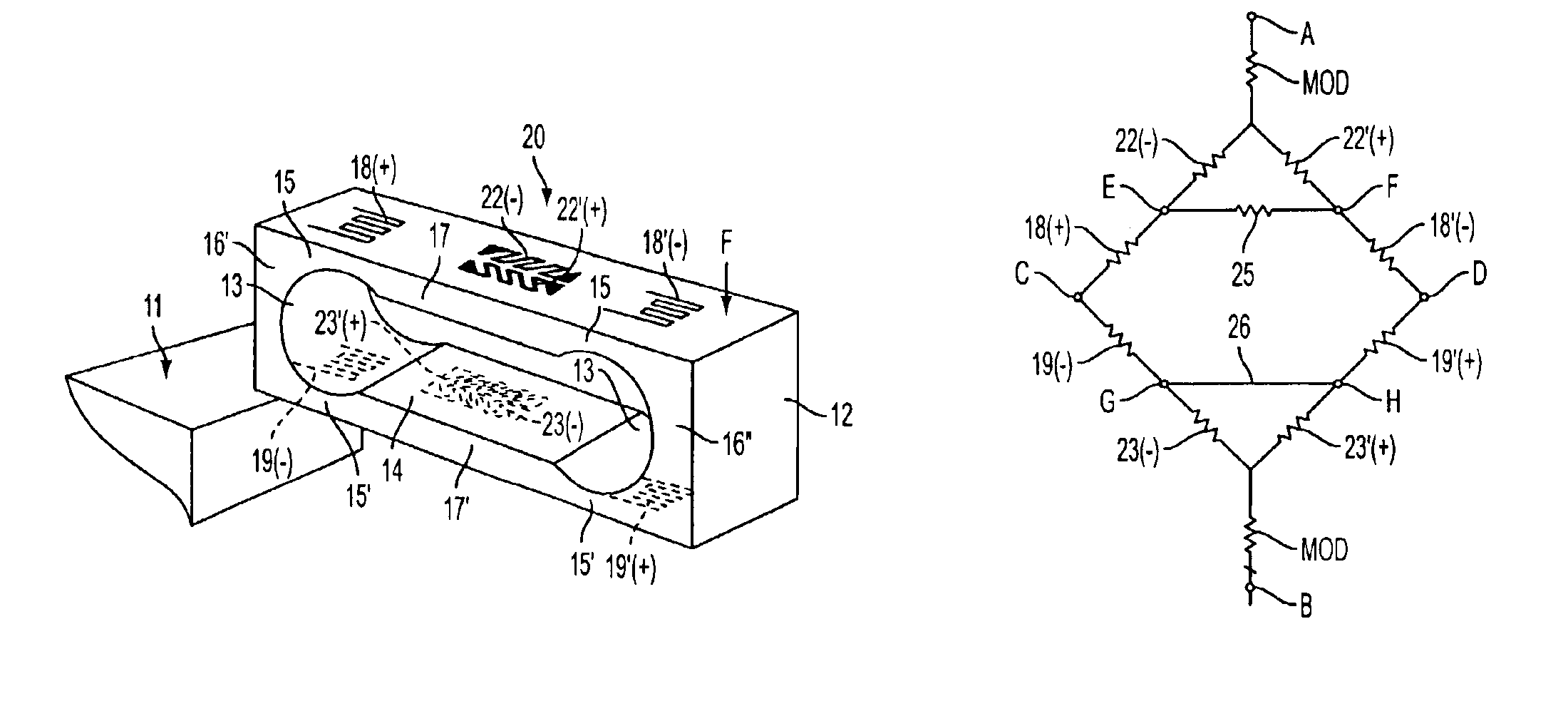

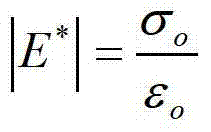

MEMS Capacitive Bending and Axial Strain Sensor

ActiveUS20090188325A1Easily be incorporated into current semi-conductor fabrication processLow powerForce measurementUsing electrical meansCapacitancePrimary operation

A three-dimensional micro-electro-mechanical-systems (MEMS) capacitive bending and axial strain sensor capacitor is described. Two independent comb structures, incorporating suspended polysilicon interdigitated fingers, are fabricated simultaneously on a substrate that can displace independently of each other while attached to a substrate undergoing bending or axial deformation. A change in spacing between the interdigitated fingers will output a change in capacitance of the sensor and is the primary mode of operation of the device. On the bottom and to the end of each comb structure, a glass pad is attached to the comb structure to allow for ample surface area for affixing the sensor to a substrate. During fabrication, tethers are used to connect each comb structure to maintain equal spacing between the fingers before attachment to the substrate. After attachment, the tethers are broken to allow independent movement of each comb structure.

Owner:GLOBUS MEDICAL INC

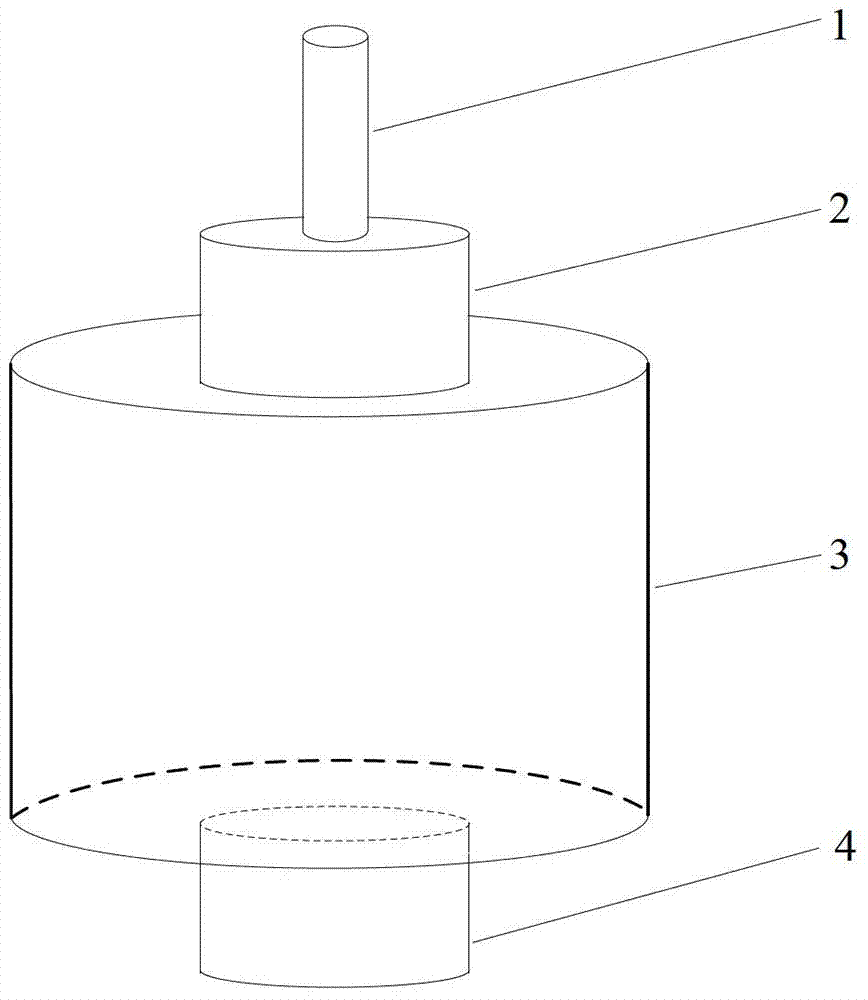

Asphalt mixture dynamic modulus testing method

InactiveCN103323350AEasy to operateMaterial strength using repeated/pulsating forcesEngineeringRoad surface

The invention discloses an asphalt mixture dynamic modulus testing method comprising the steps that: 1, with an asphalt mixture rotation compaction instrument, an asphalt mixture sample is formed; and through cutting, an asphalt mixture cylindrical sample with a fixed size is obtained; 2, two pressure heads are prepared; the sample and the two pressure heads are plated into an environment box with a target temperature; and the temperature is maintained for 5h; 3, the two pressure heads and the sample are fetched; the two pressure heads are respectively placed at central positions on two ends of the cylindrical sample; and sinusoidal axial compressive stress is applied to the sample with different frequencies under a specified test temperature; and 4, during the loading process, applied stresses and generated axial strains at corresponding times are determined, and the dynamic modulus is a ratio of the amplitude of sinusoidal load to the amplitude of generated sinusoidal strain. According to the method provided by the invention, with the local loading test, lateral restraint of the asphalt mixture in an actual pavement can be effectively simulated. The test device is simple, the operation is easy, and the method can be popularized.

Owner:SOUTHEAST UNIV +1

Axial pre-tightening force sensor

InactiveCN103592062AClear principleWide range of axial preloadForce measurementAxial displacementBall bearing

The invention relates to an axial pre-tightening force sensor. The axial pre-tightening force sensor comprises a regulating gasket 2, a left end cover 3, an elastic sensitive element 4, a strain gage 5, a right end cover 6, a thrust ball bearing 7, an axial hole groove 9, a right bolt 10, a fairlead 11, a package shell 12 and a left bolt 13. The regulating gasket is used for regulating the axial position of the sensor on a shaft, the left end cover and the right end cover support the elastic sensitive element through bosses, the elastic sensitive element generates axial strain because of bearing axial force, and the axial force can be measured through the resistance strain effect and a measuring circuit. The axial hole groove 9 in the right end cover 6 of the sensor is matched with the right bolt 10 to be used for preventing the elastic sensitive element from generating circumferential strain in a pre-tightening process, axial displacement of the right end cover 6 and axial strain of the elastic sensitive element 4 are allowed, and the thrust ball bearing is used for insulating circumferential twisting force generated when the pre-tightening force is exerted so that the axial twisting force can be prevented from being transmitted to the elastic sensitive element 4.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com