Resonant type infrared detector structure capable of isolating packaging stress and manufacturing method thereof

An infrared detector and packaging stress technology, applied in the direction of microstructure devices composed of deformable elements, microstructure technology, microstructure devices, etc., can solve the problems of increasing response time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

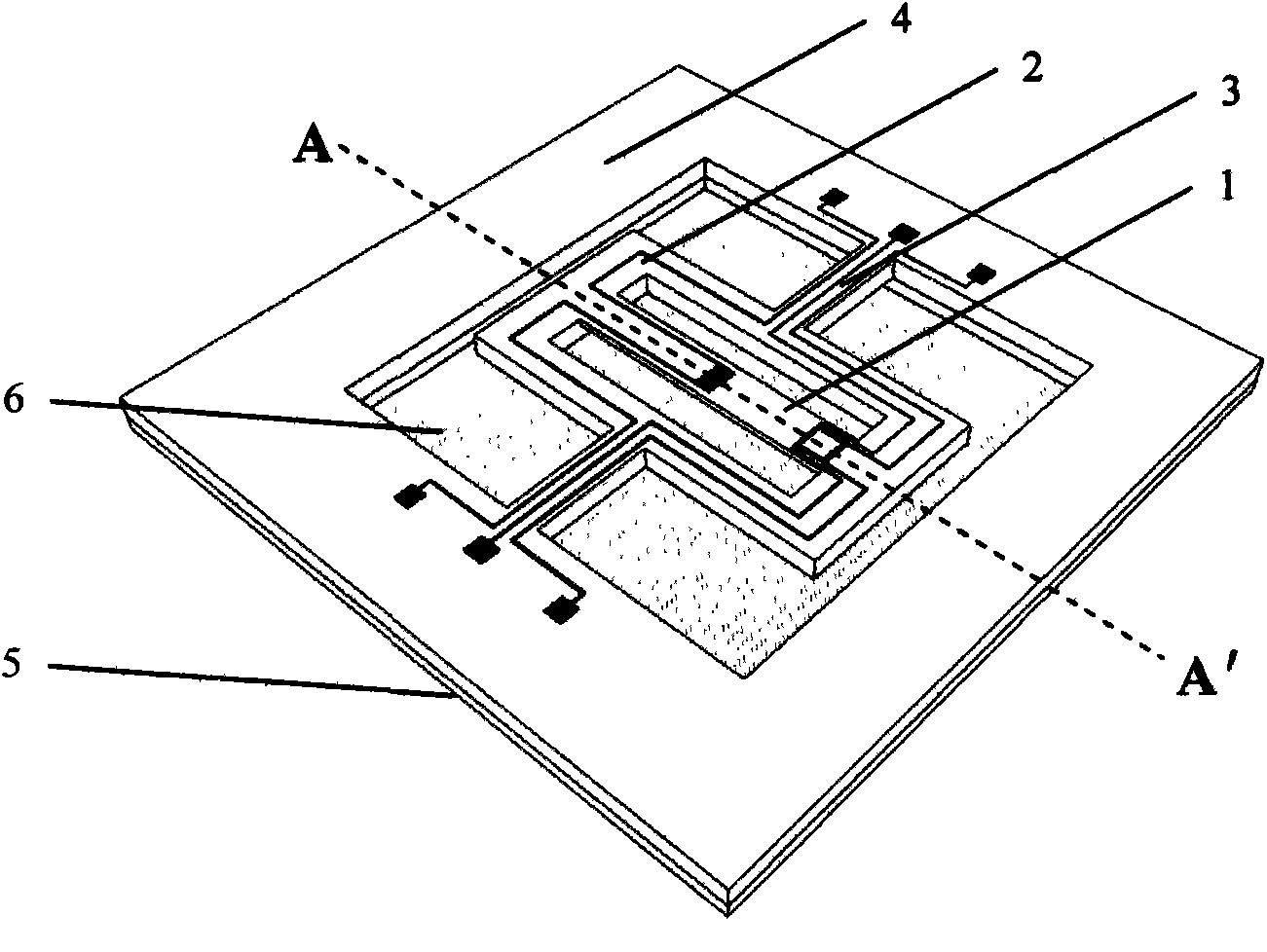

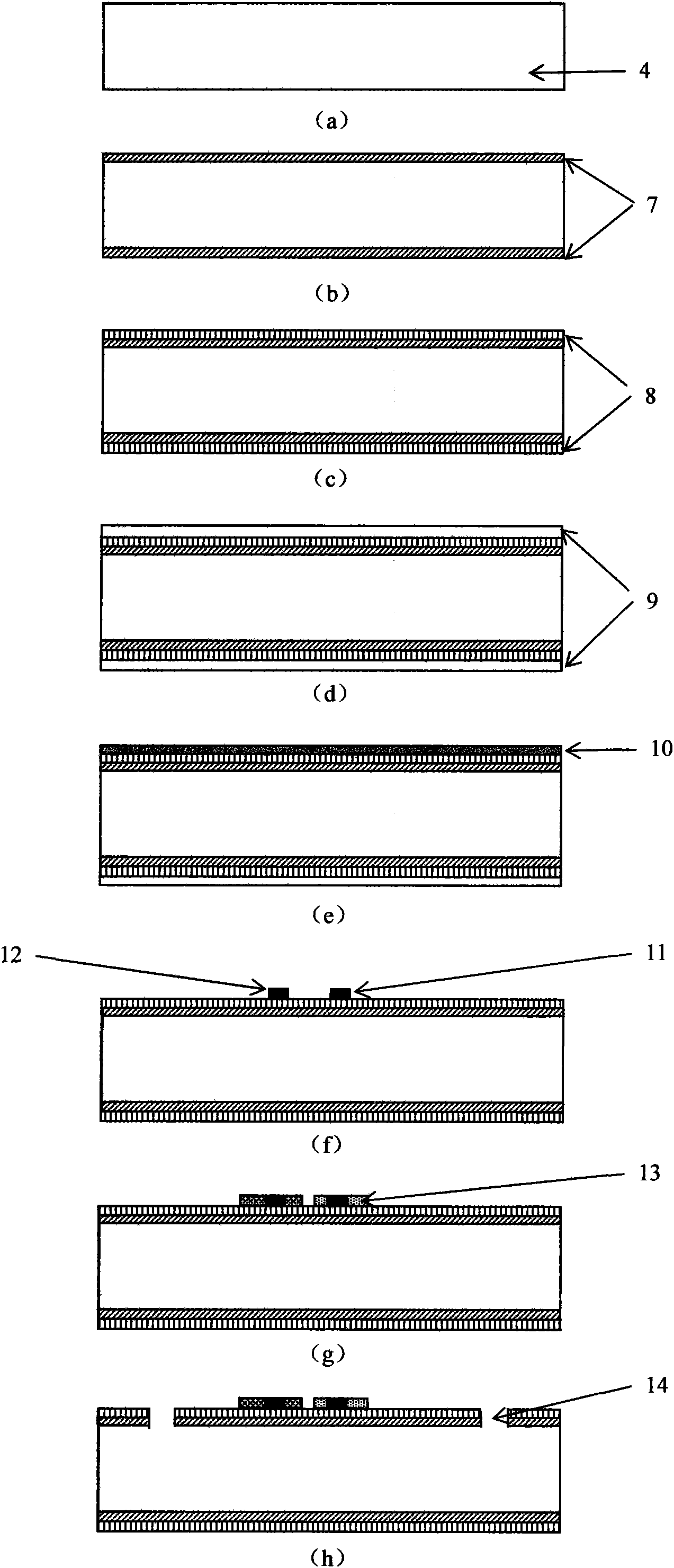

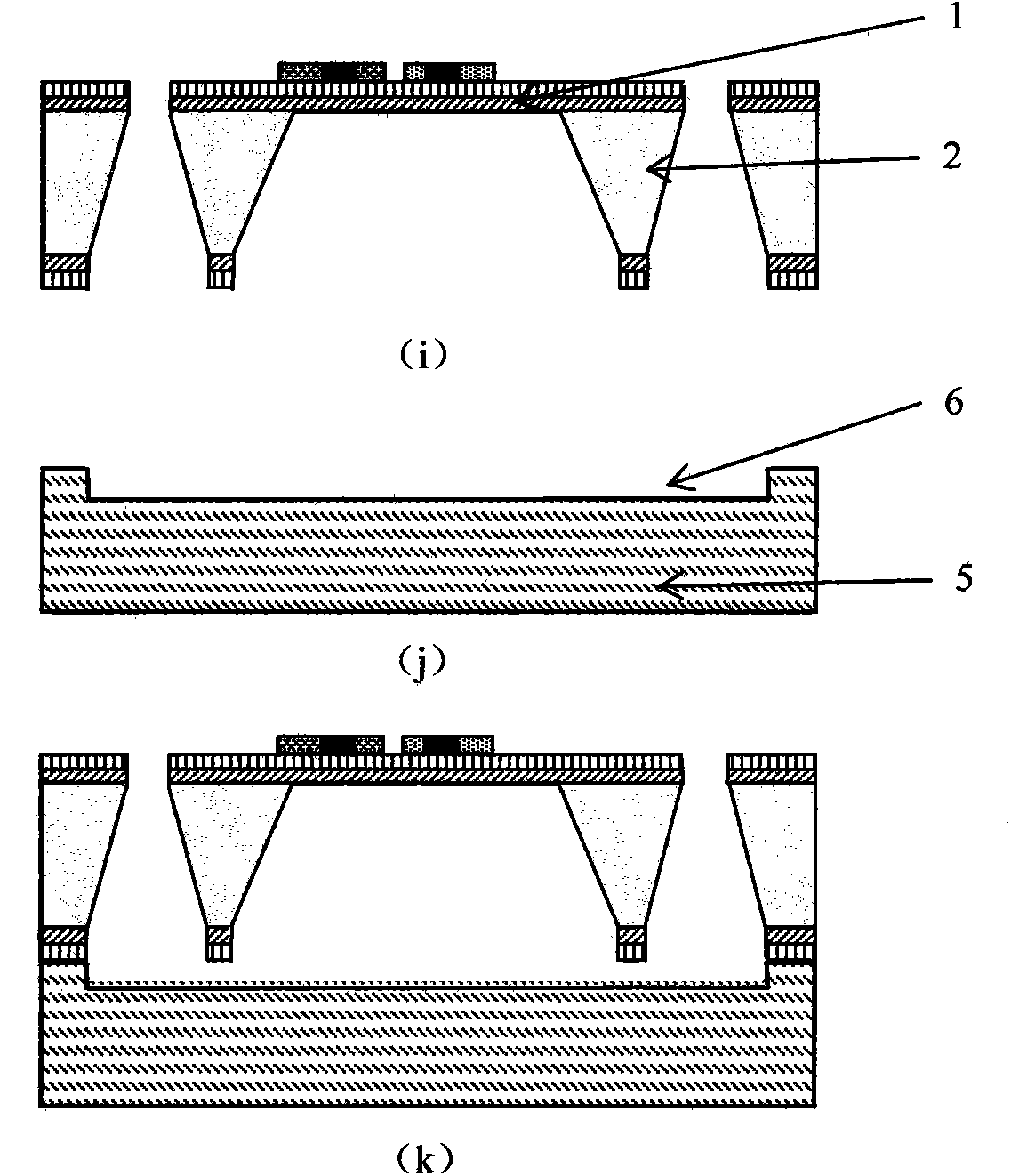

[0026] A resonant infrared detector capable of isolating packaging stress is manufactured by utilizing the technical scheme of the invention. Its micro-bridge resonator adopts polysilicon resistance electrothermal excitation and piezoresistive detection. Its production process is as follows:

[0027] (1) The original material is a double-sided polished silicon wafer of N-type, (100) plane, and resistivity 1-10Ω.cm. (see attached figure 2 (a))

[0028] (2) Thermally oxidize and grow a silicon dioxide film 7 with a thickness of 1 micron. (see attached figure 2 (b))

[0029] (3) A silicon nitride film 8 is deposited by a low-pressure chemical vapor deposition process (LPCVD), with a thickness of 0.3 microns. (see attached figure 2 (c))

[0030](4) Deposit a polysilicon film 9 with a thickness of 0.8 microns by a low-pressure chemical vapor deposition process (LPCVD). (see attached figure 2 (d))

[0031] (5) Ion implantation process Boron atoms are doped into the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com