Patents

Literature

146results about How to "Realize power transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

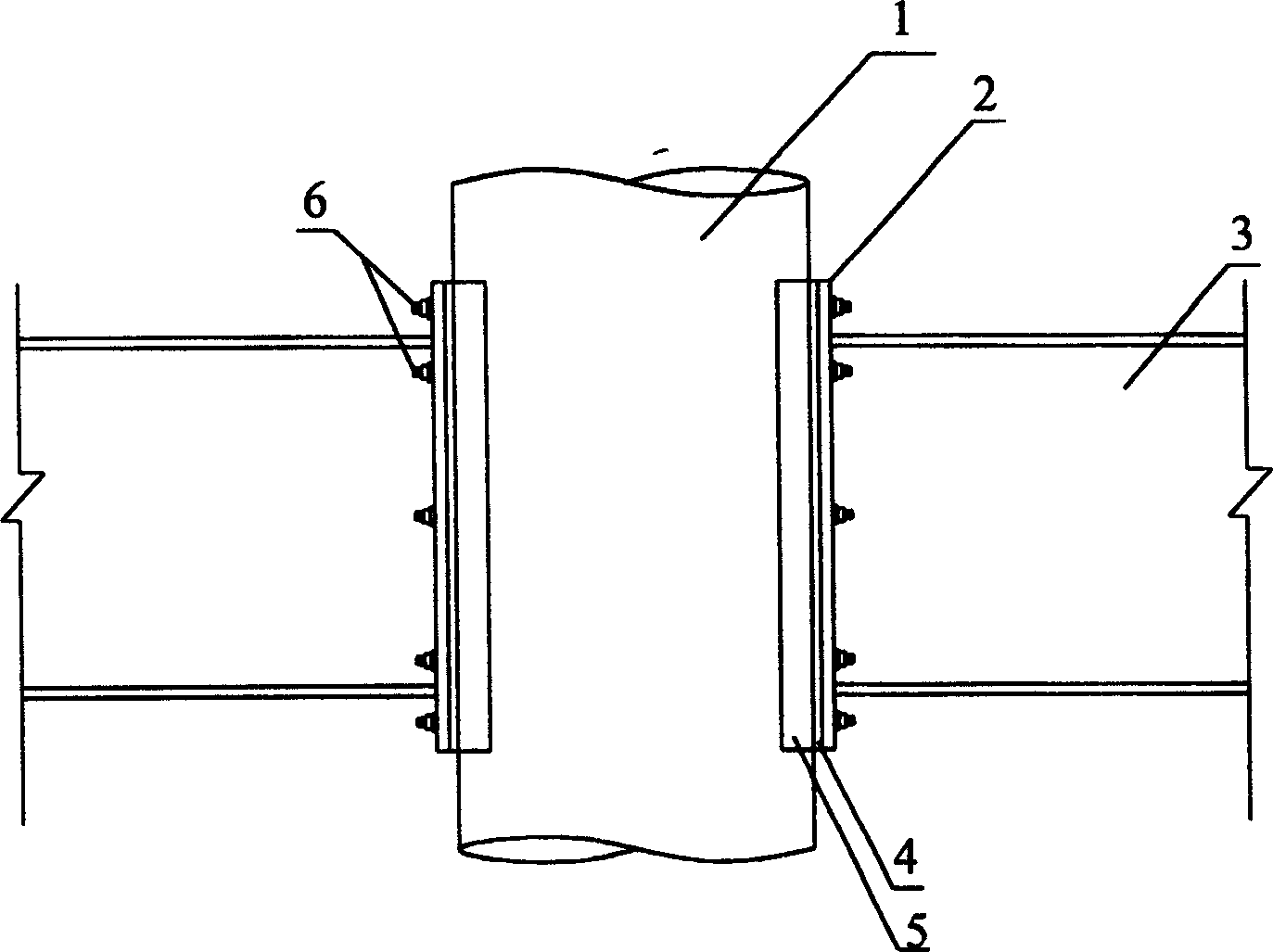

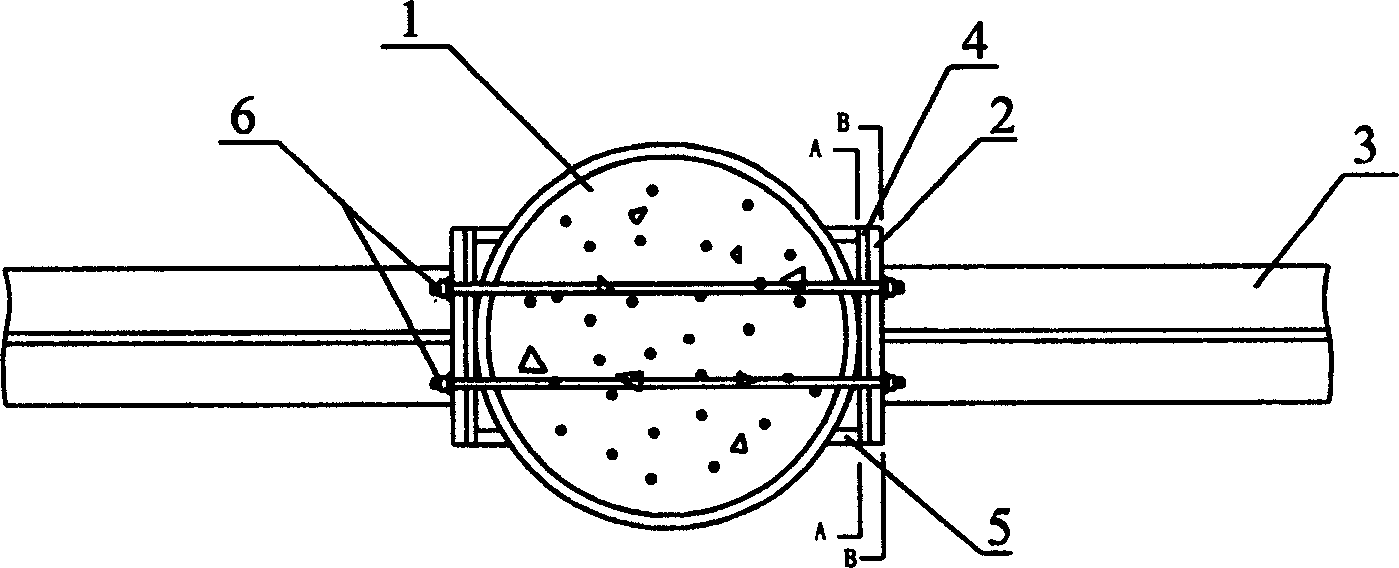

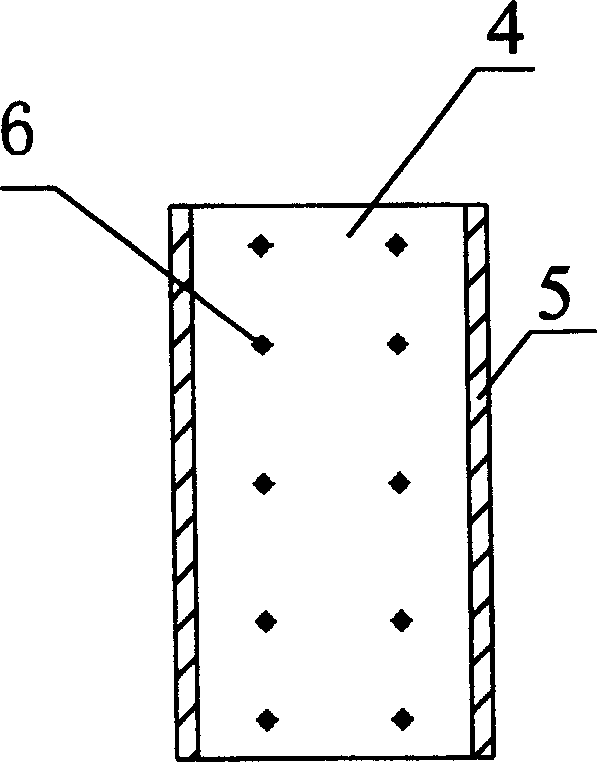

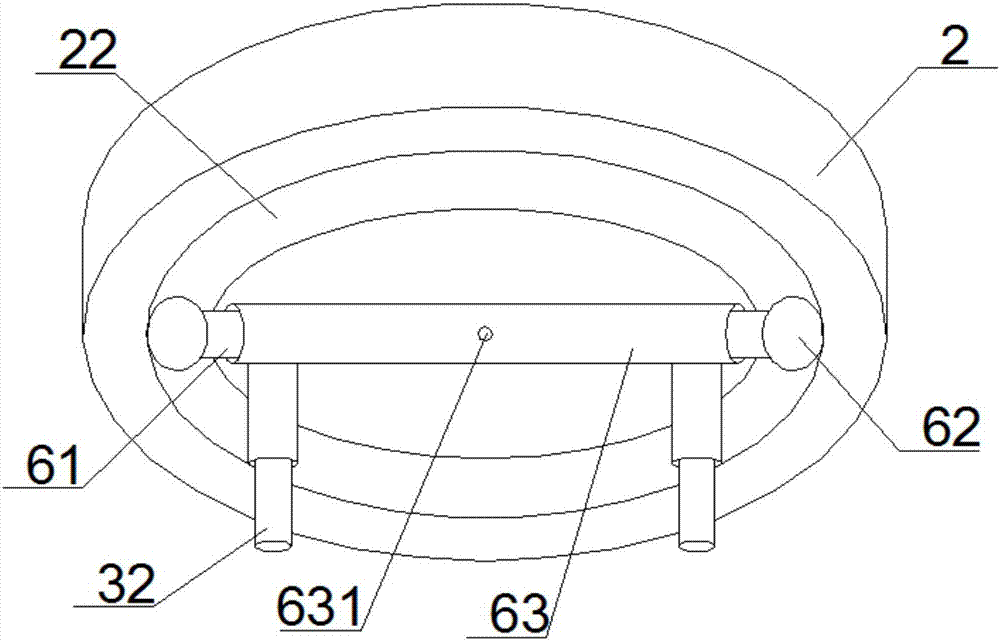

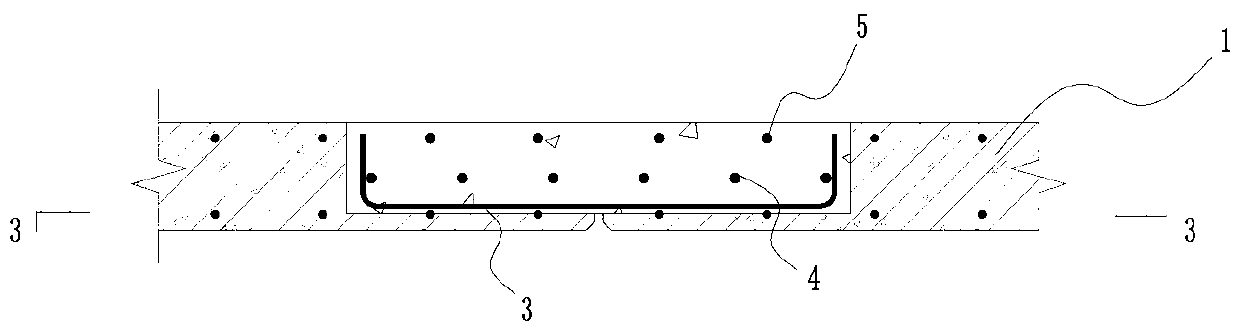

Round steel pipe concrete column joint for beam column connection and method for manufacturing the same

The invention discloses a kind to use in beam column the connection round steel pipe coagulation earth pyramid pitch point and its the manufacture method, it mainly included the round steel pipe coagulation earth pyramid and the steel girder which connected with this column, the round steel pipe coagulation earth pyramid and filled in in this round steel pipe including the round steel pipe the concrete, in carried with steel pipe coagulation earth pyramid connection steel girder Liang is equipped with an end board, this steel pipe coagulation earth pyramid with stated between the end board to be equipped with the belt rib level the steel plate, level the steel plate solidified on the round steel pipe, carried the board, level the steel plate as well as the round steel pipe through as soon as passed through core excels in the bold fastening in together. The invention cost inexpensive, mechanics performance good, design succinct convenient, the construction difficulty is small, also can avoid the scene welding, improves the connection quality and the construction benefit.

Owner:HUNAN UNIV

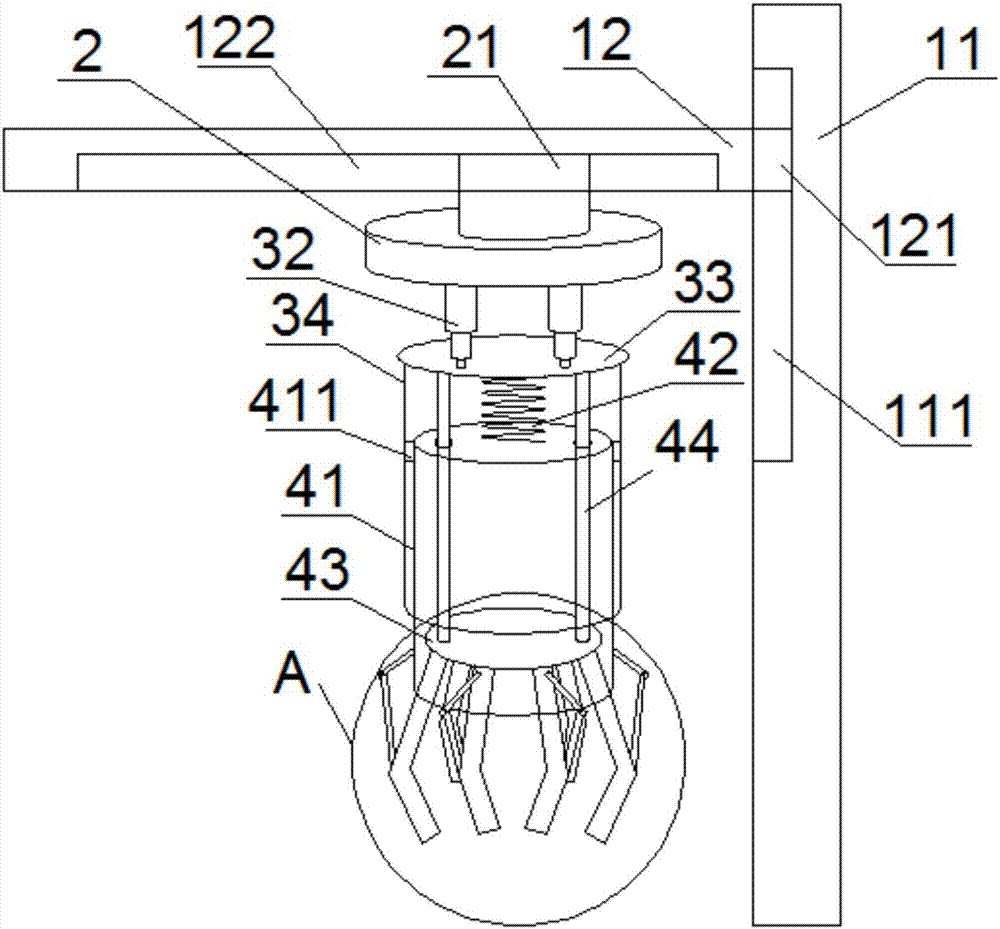

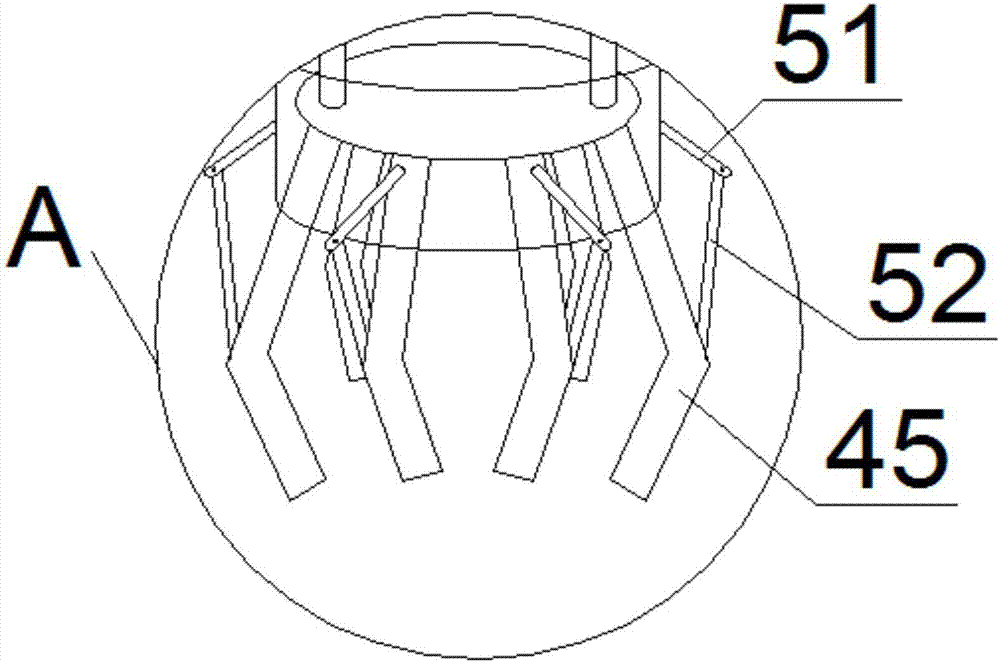

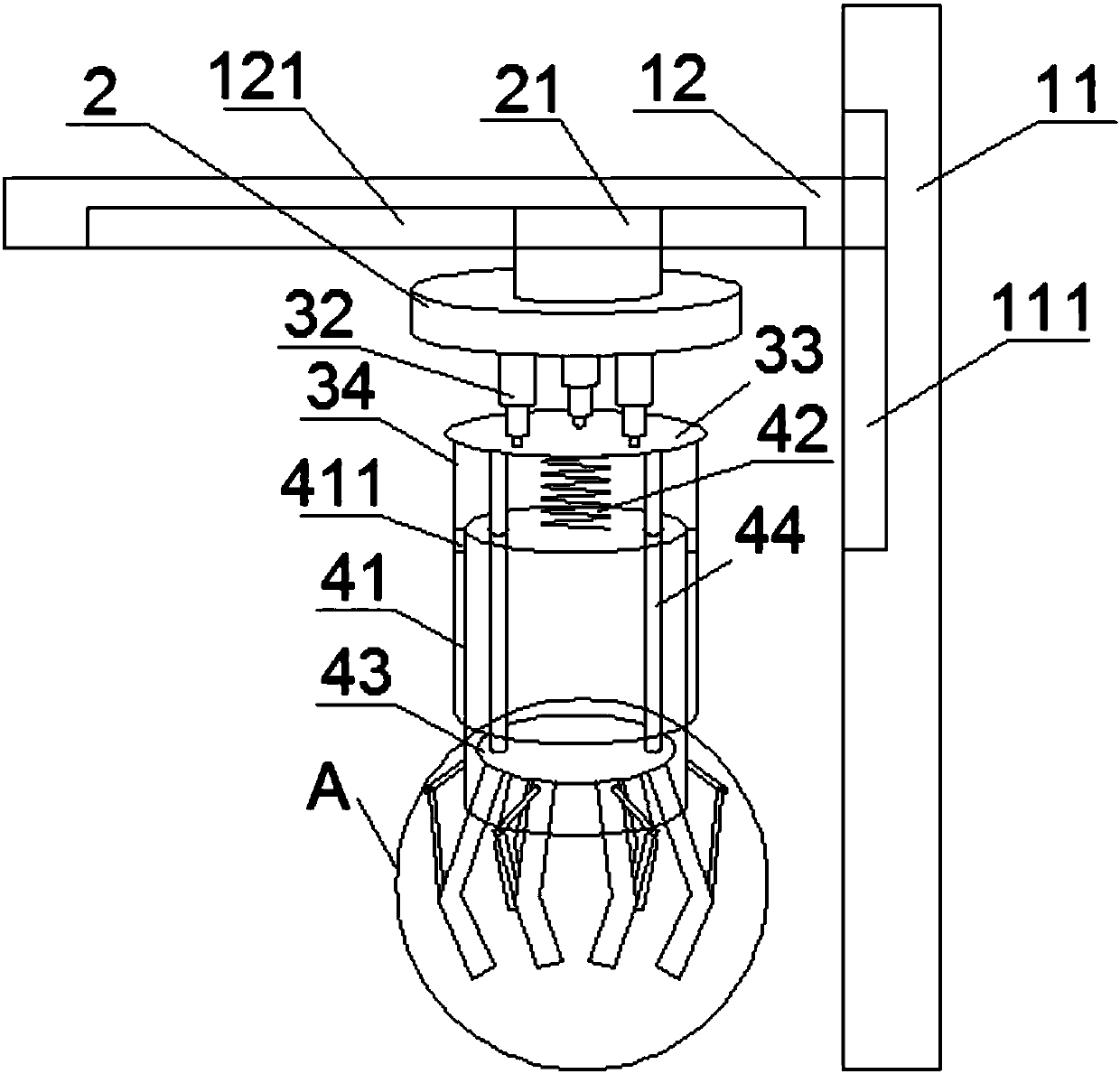

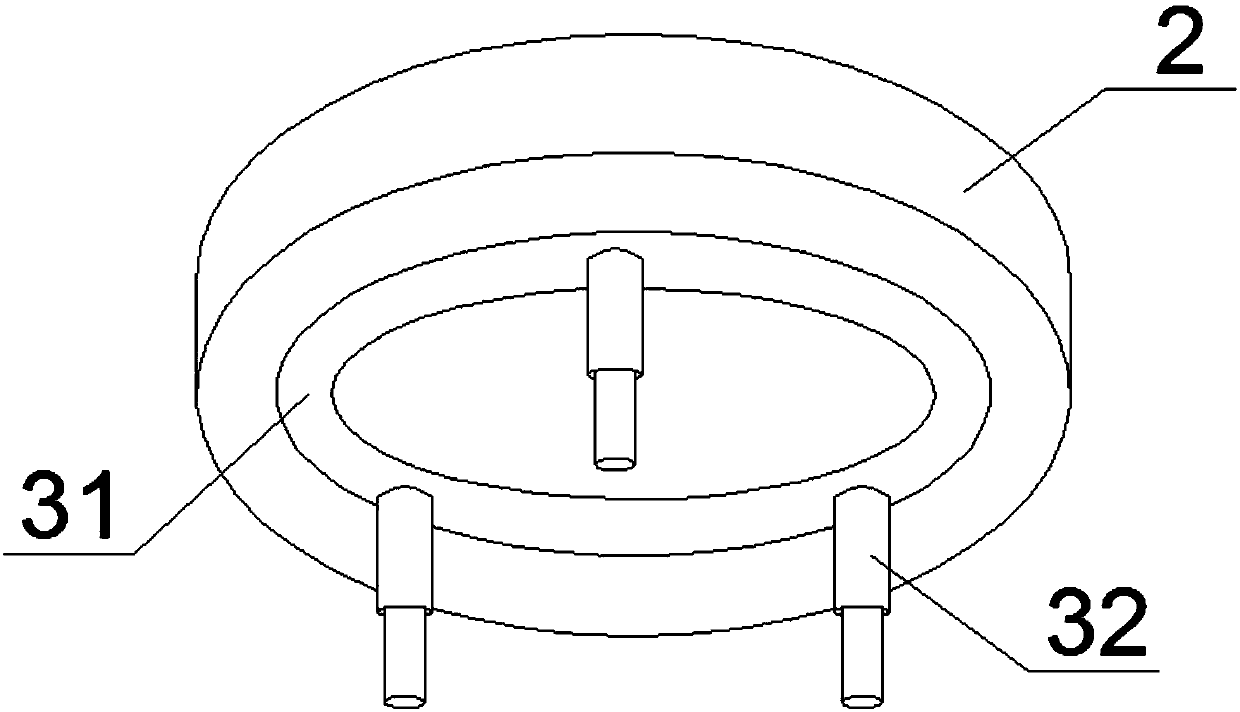

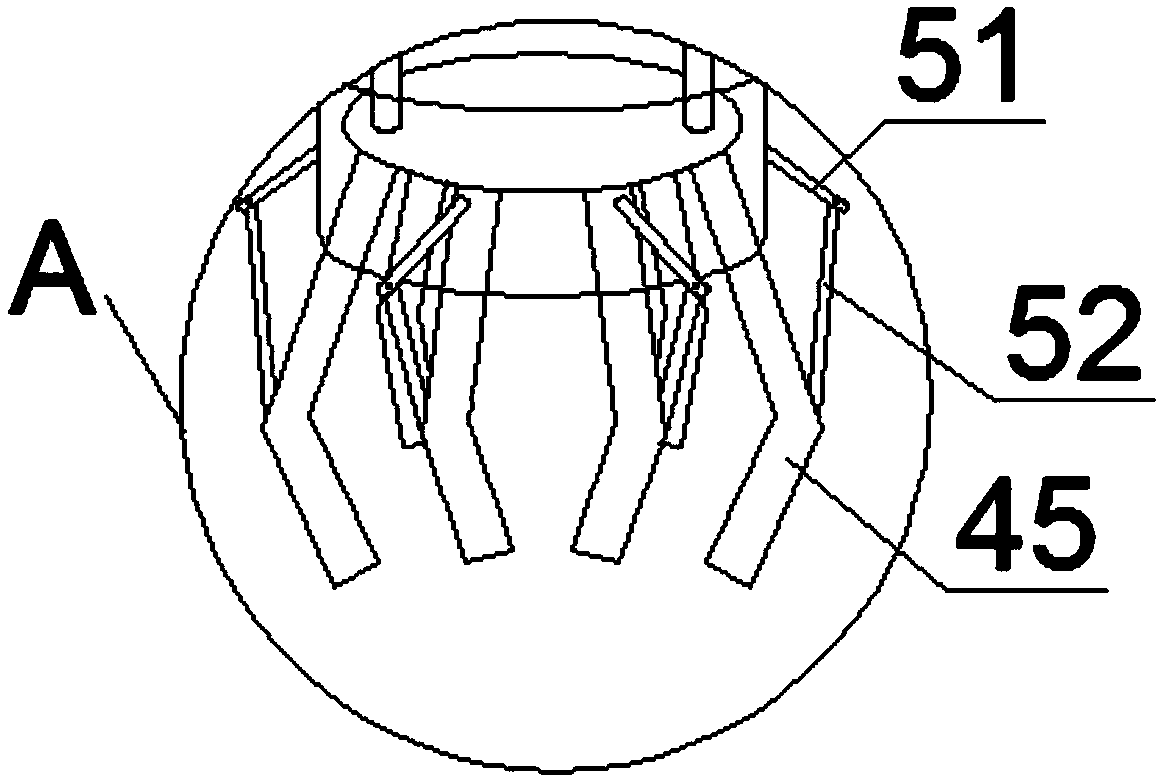

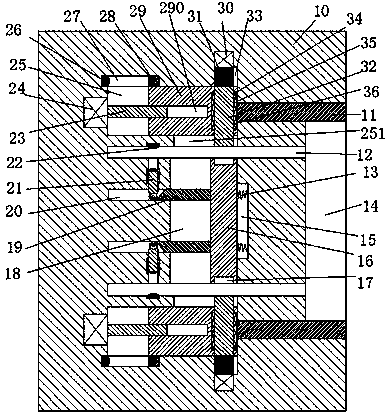

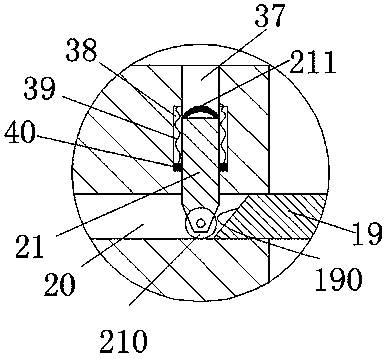

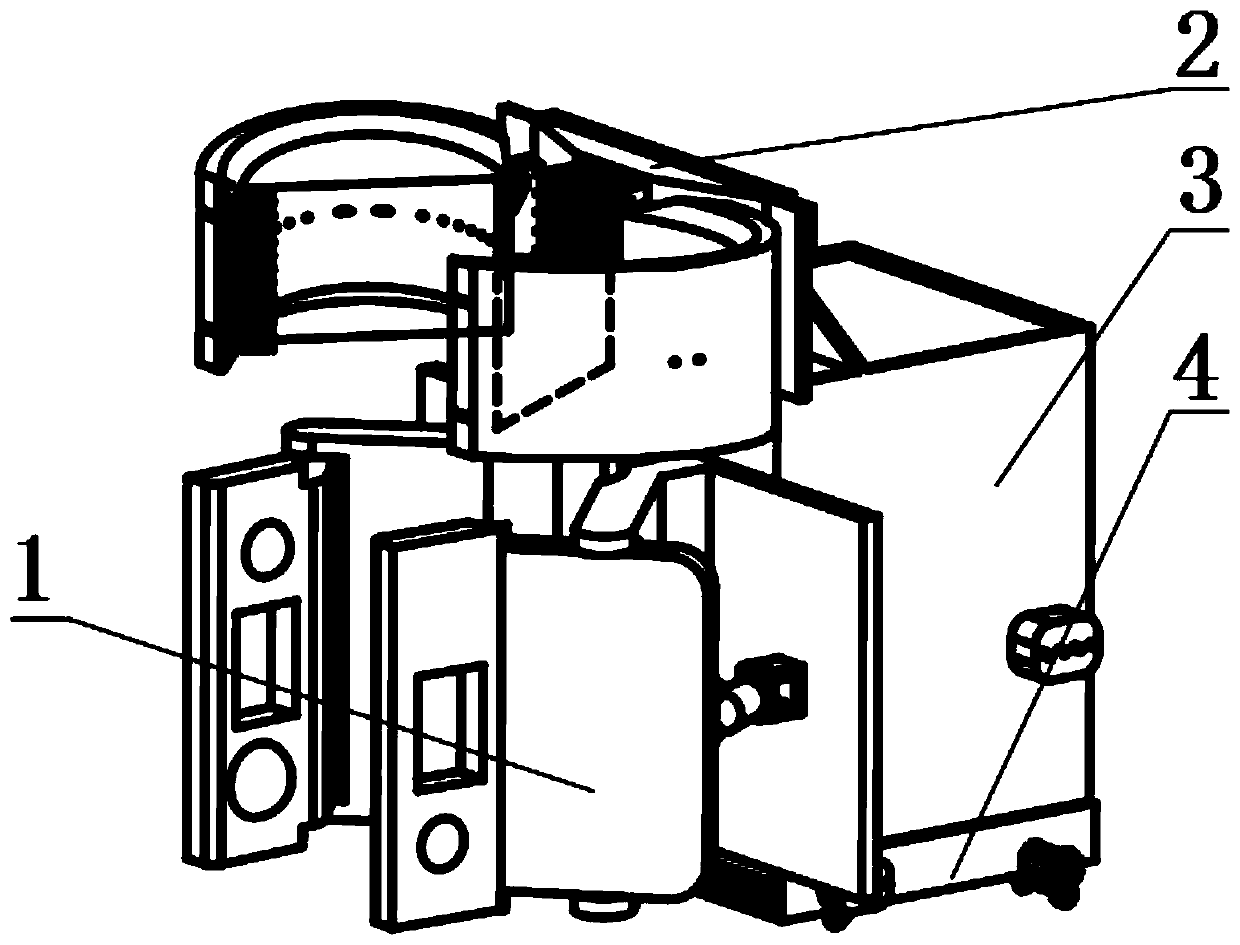

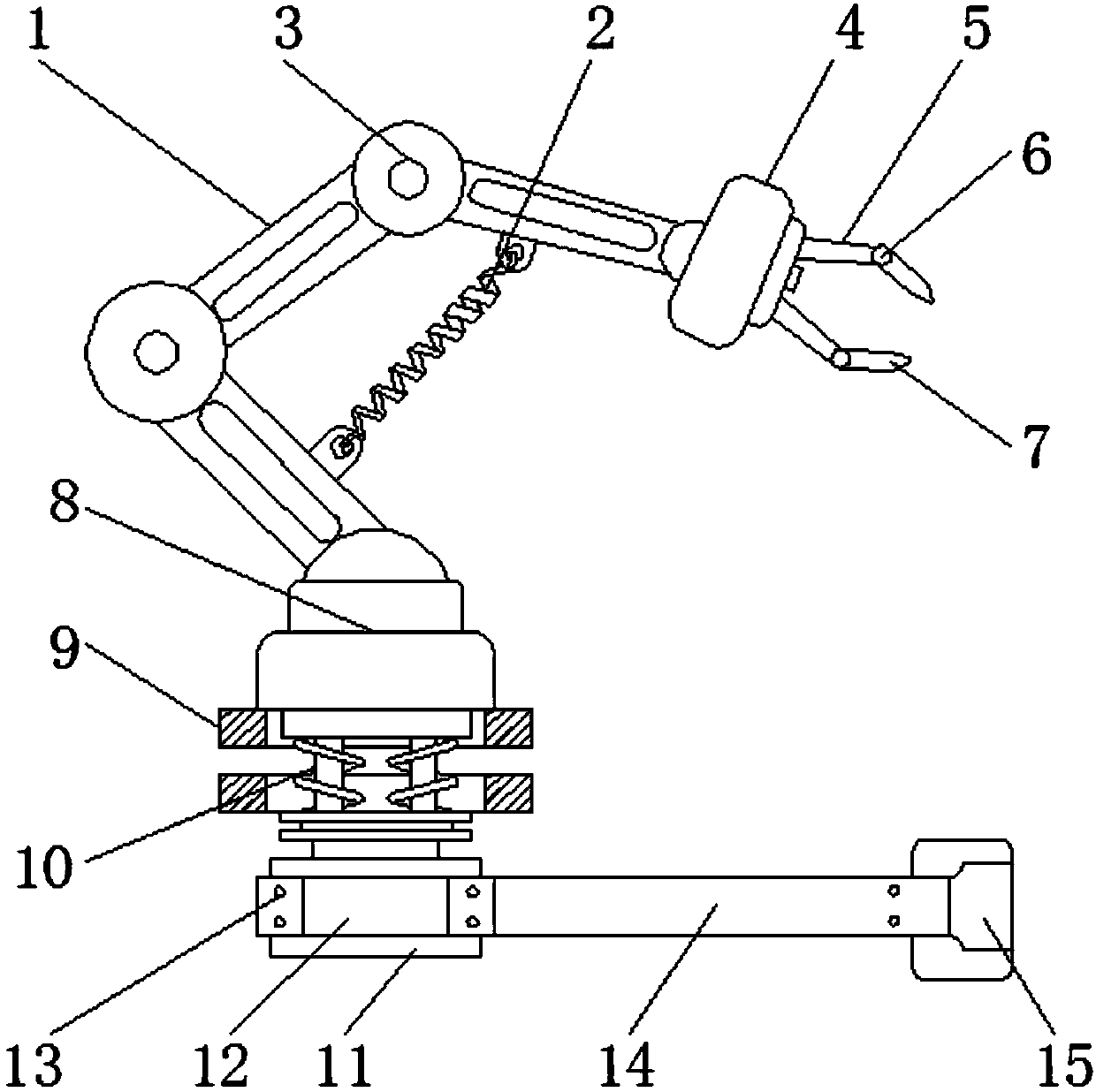

Industrial mechanical arm

InactiveCN107414796AAdjust the installation angleAffect normal progressProgramme-controlled manipulatorGripping headsCircular discEngineering

The invention discloses an industrial mechanical arm. The industrial mechanical arm comprises a rack, an adjusting mechanism, a grabbing mechanism and a plurality of connecting pieces; the rack comprises a vertical column and a cross rod; the adjusting mechanism comprises a horizontally arranged base, a first rod body rotationally connected with the base, a first sleeve rotationally arranged outside the first rod body in a sleeving manner, two telescopic rods symmetrically fixed to the lower portion of the first sleeve, a first disk fixedly connected with the lower ends of the two telescopic rods and a second sleeve fixedly connected with the lower surface of the first disk; the grabbing mechanism comprises a barrel body arranged in the second sleeve in a sleeved manner, a compression spring, a second disk, two second rod bodies and a plurality of jaw bodies; and the jaw bodies are movably connected to the peripheral face of the barrel body through the connecting pieces. The industrial mechanical arm can rotate at a plurality of angles and automatically lock and keep the firm grabbing state of the jaw bodies, and is simple in structure, flexible to rotate and capable of completing the construction operation of a complicated environment.

Owner:LIUZHOU FUNENG ROBOT DEV CO LTD

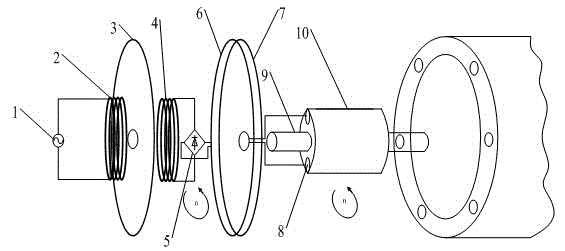

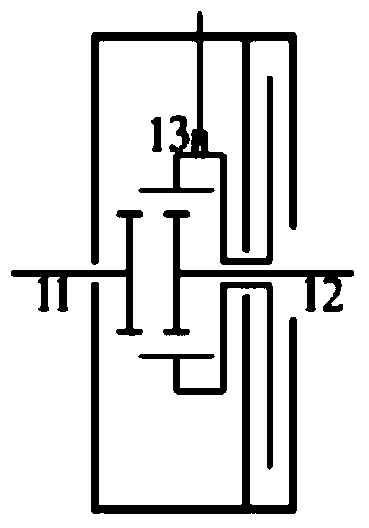

Brushless excitation mechanism based on wireless transmission of electric energy

InactiveCN103560632AOptimize the magnetic fieldRealize wireless excitationSynchronous generatorsElectromagnetic wave systemTransmitter coilMetallic materials

The invention discloses a brushless excitation mechanism based on wireless transmission of electric energy. The mechanism comprises a high frequency excitation source, an auxiliary excitation transmitting coil, an auxiliary excitation receiving coil, a rotating rectifier bridge, a soft magnetism optimization layer and a metal shielding layer, wherein the high frequency excitation source and the auxiliary excitation transmitting coil are arranged outside a motor, the auxiliary excitation receiving coil, the rotating rectifier bridge, the soft magnetism optimization layer and the metal shielding layer are arranged in the motor, an electromagnetic field of an excitation system is optimized and shielded through soft magnetism materials and metal materials, an excitation coil of a rotor of the alternating-current motor is supplied with power through the wireless transmission of the electric energy, mechanical connection between the rotor and external terminals is avoided, and brushless excitation of the motor is achieved.

Owner:SOUTHEAST UNIV

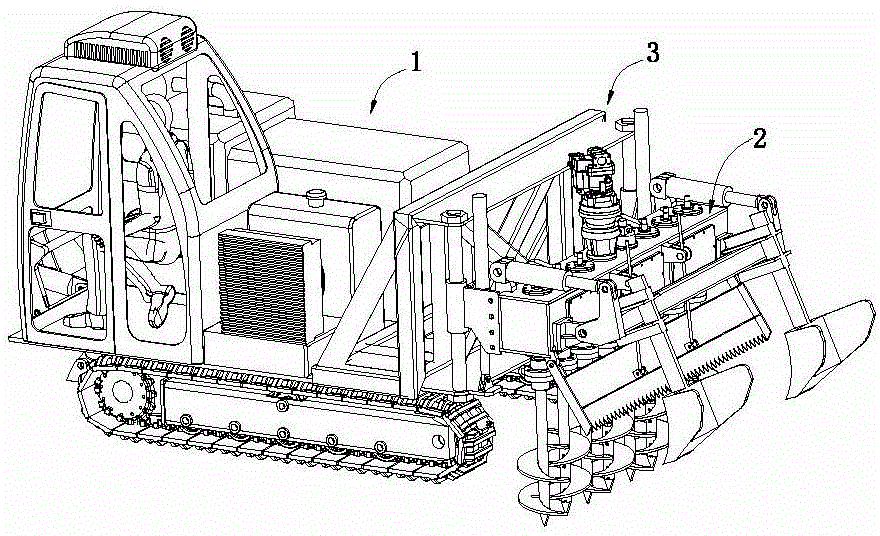

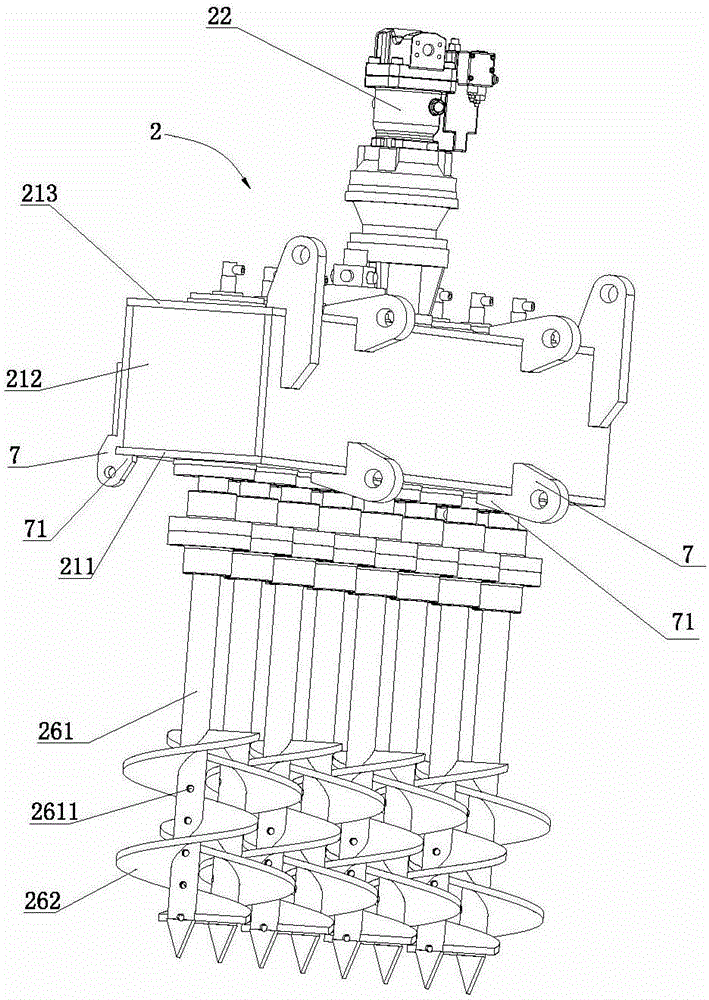

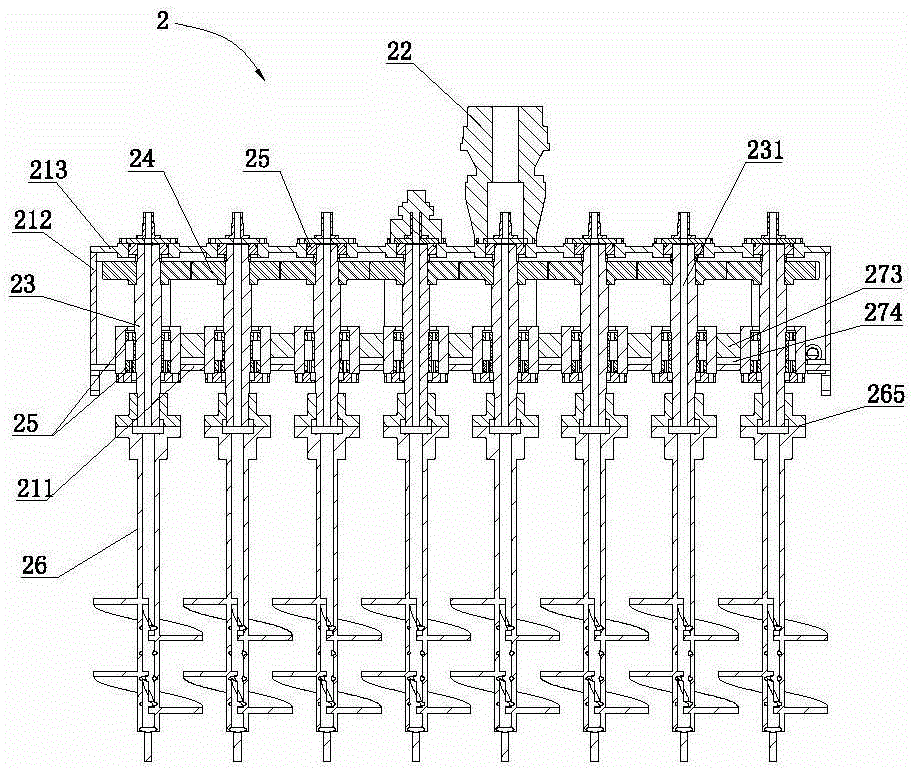

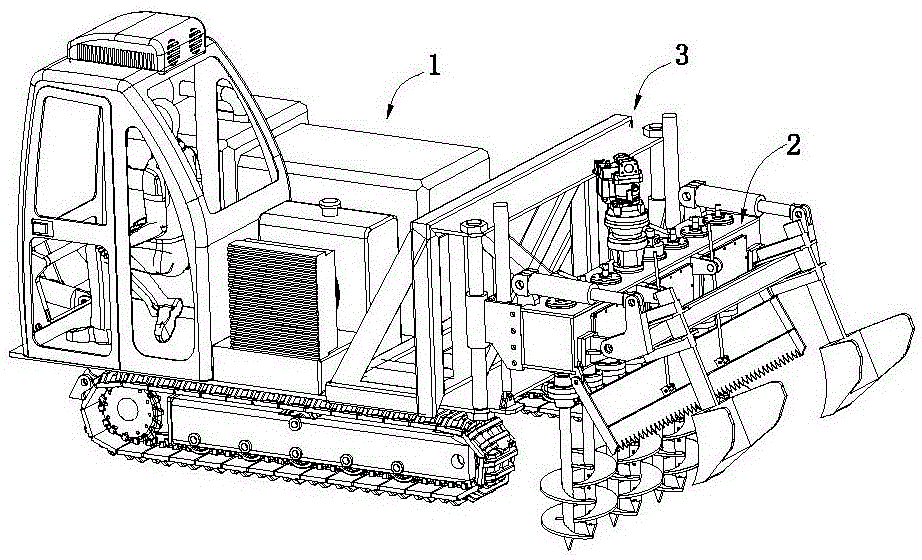

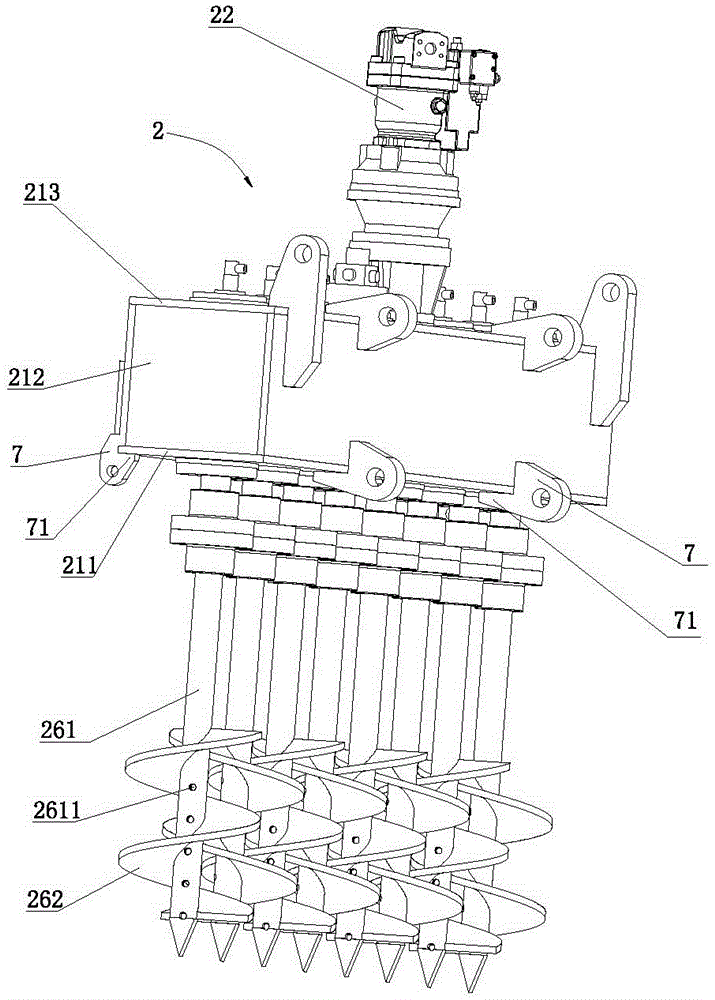

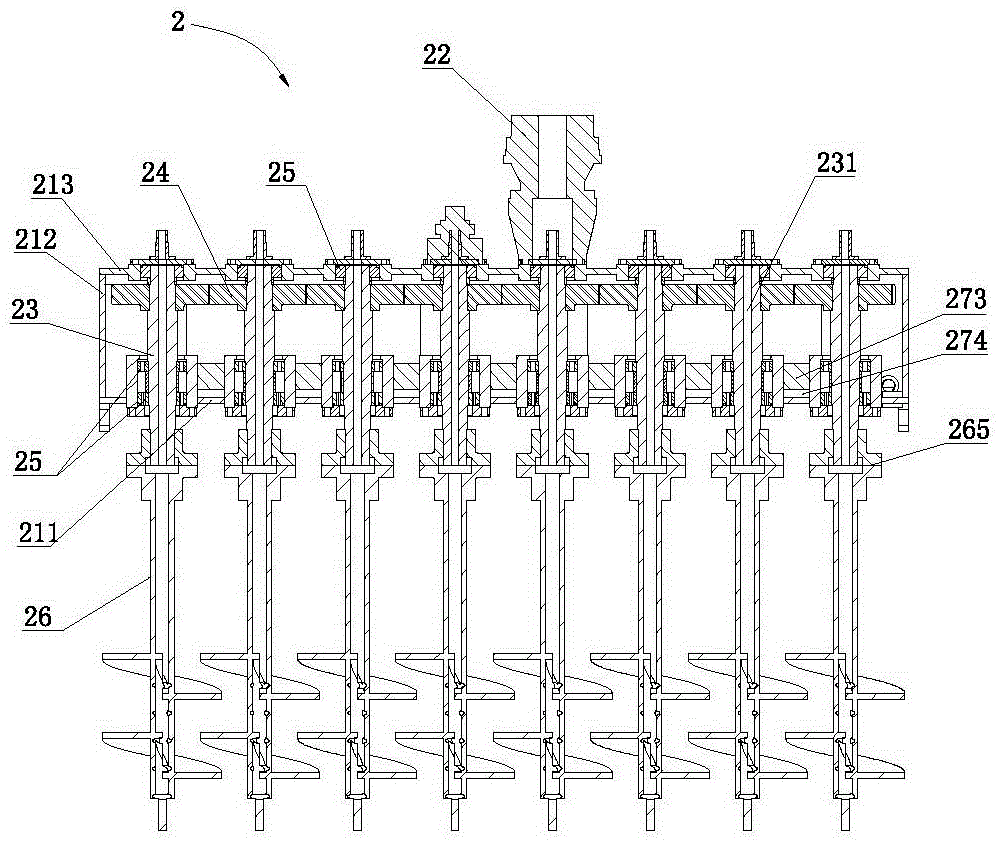

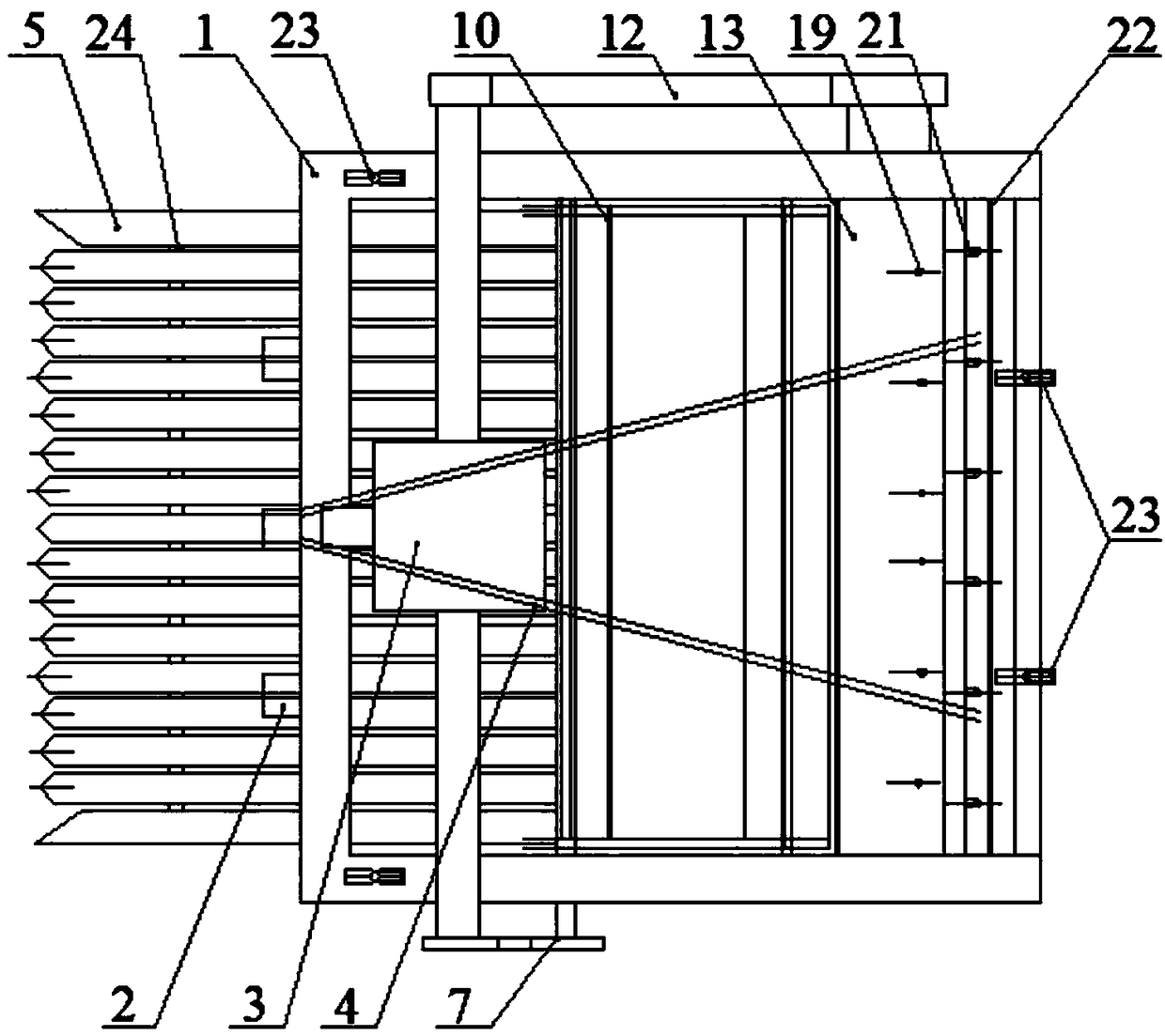

Ridge crusher for subsoiling and ridge crushing machine

InactiveCN104904348AIncrease the welding areaImprove connection strengthSpadesPloughsDrive shaftLow load

The invention discloses a ridge crusher for a subsoiling and ridge crushing machine. The ridge crusher comprises a ridge crushing box with a bottom plate, side plates and a top plate, rib plates are welded among lower bearing seats which are mounted on the bottom plate, a lubricating oil passage is reserved between each rib plate and the bottom plate, and upper bearing seats mounted on the top plate are longer than the lower bearing seats. The ridge crusher for the subsoiling and ridge crushing machine has the advantages that strength of the lower bearing seat can be improved, more bearings can be mounted at high-load-bearing positions while less bearings are mounted at low-load-bearing positions, and accordingly rigidity and transmission stability of a transmission shaft are improved, and cost is reduced; in addition, welding of the rib plates is facilitated, and smooth flow of lubricating oil in the ridge crushing box is guaranteed so as to improve lubrication effects.

Owner:GUANGXI WUFENG MACHINERY CO LTD

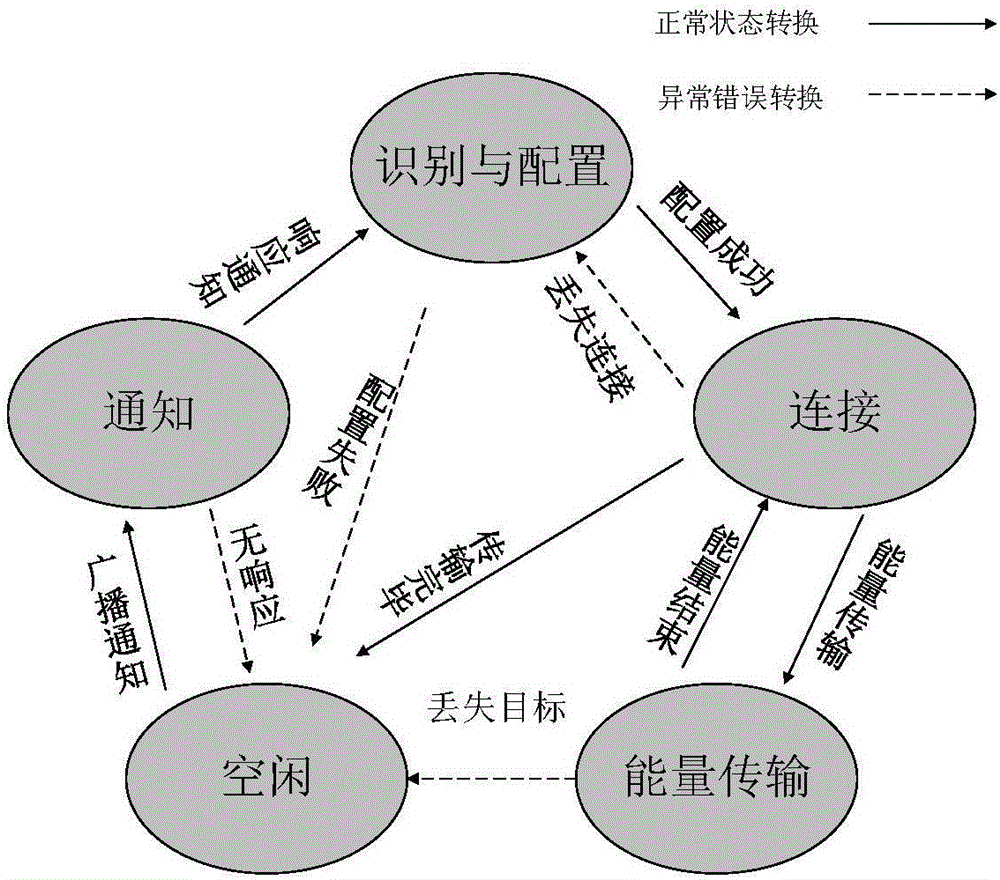

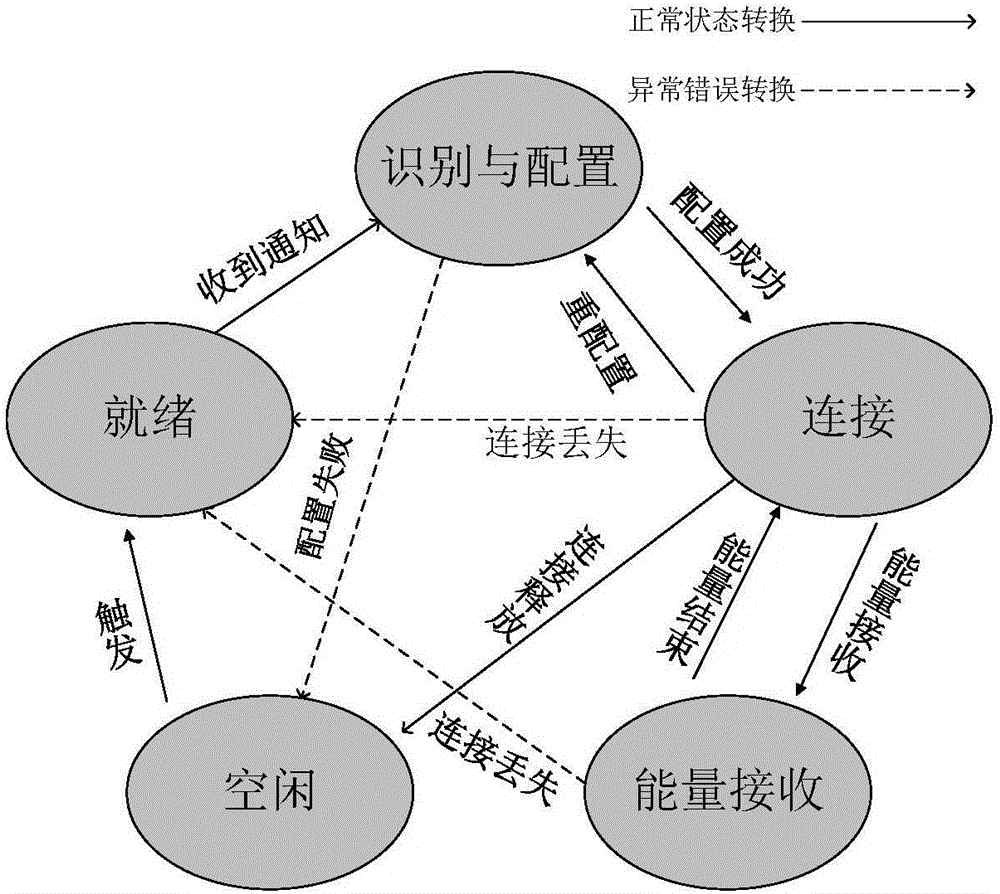

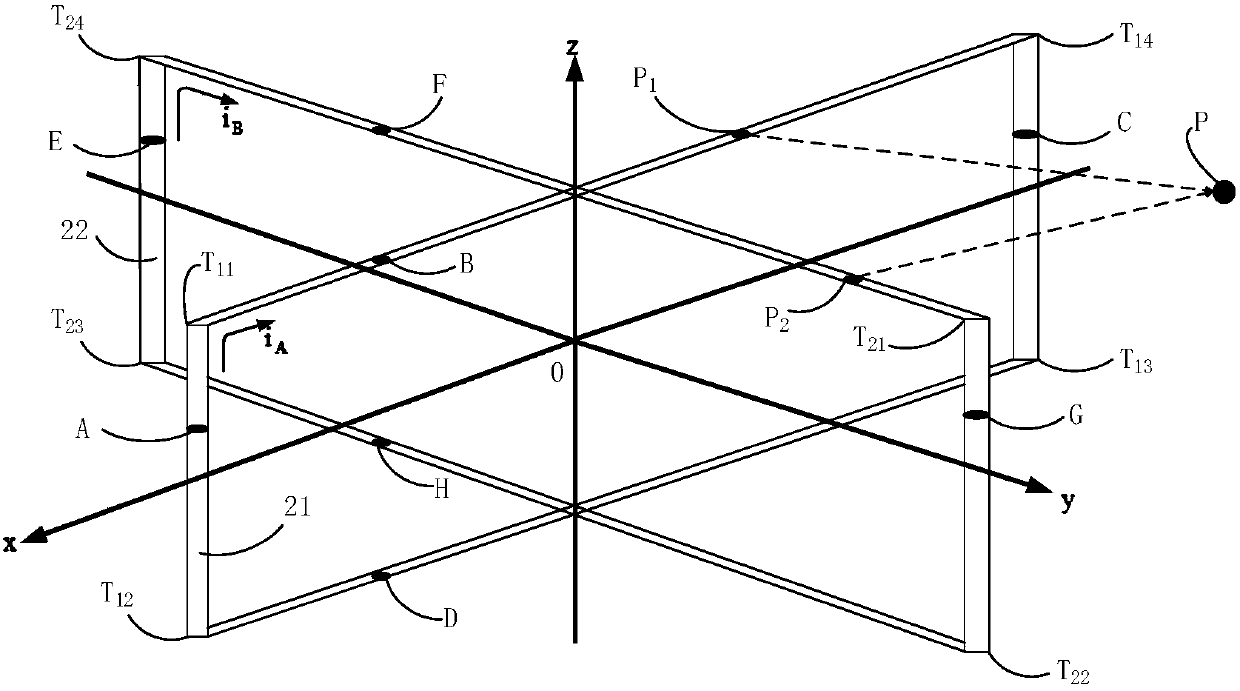

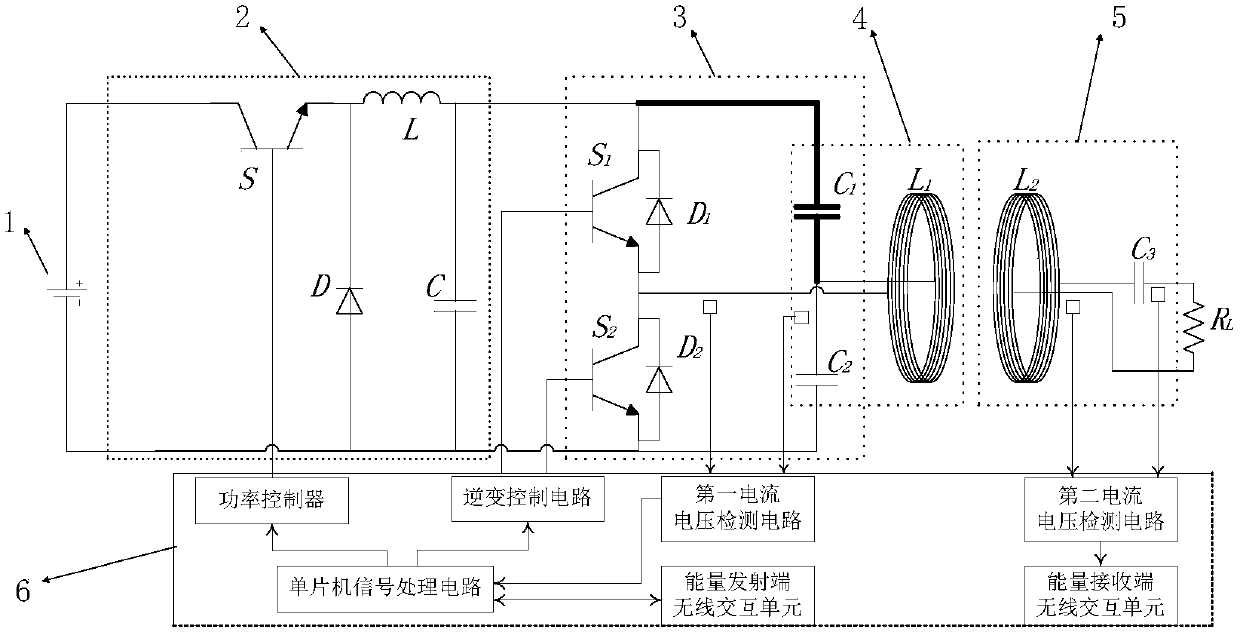

Interactive process state defining and converting method in radiation type wireless electric energy transmission system

ActiveCN105099007AAchieve interactionRealize power transmissionElectromagnetic wave systemState switchingProcess state

The invention discloses an interactive process state defining and converting method a radiation type wireless electric energy transmission system. Establishment of a control protocol for the radiation type wireless electric energy transmission system satisfies a function requirement and furthermore promotes an industrial standard process. The invention provides a defining and converting triggering condition for five states which are required in a system interaction process for aiming at the radiation type wireless electric energy transmission system, so that a receiving end and a transmission end can realize wireless communication interaction and electric energy transmission according to a state switching process.

Owner:UNIV OF SCI & TECH OF CHINA

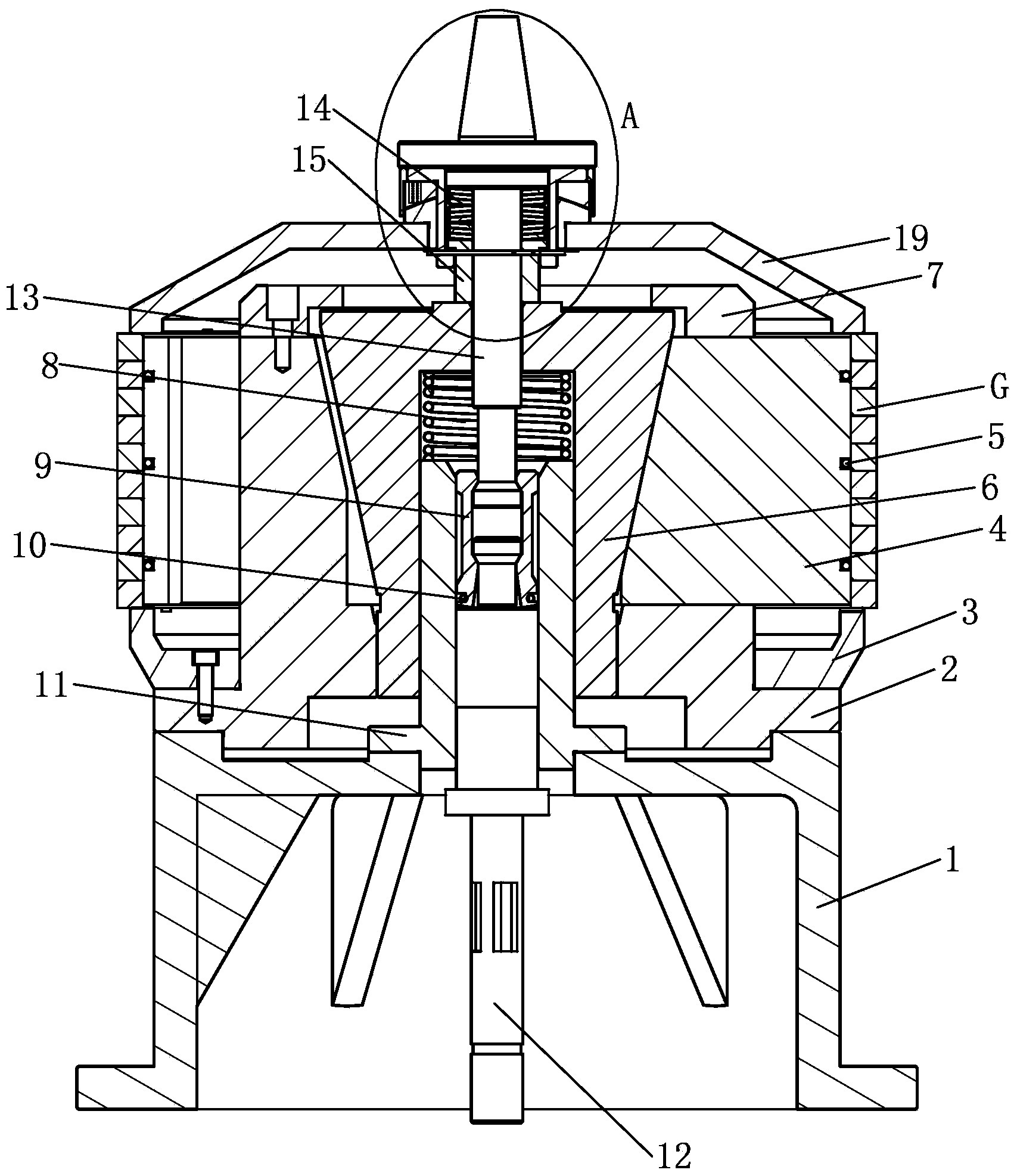

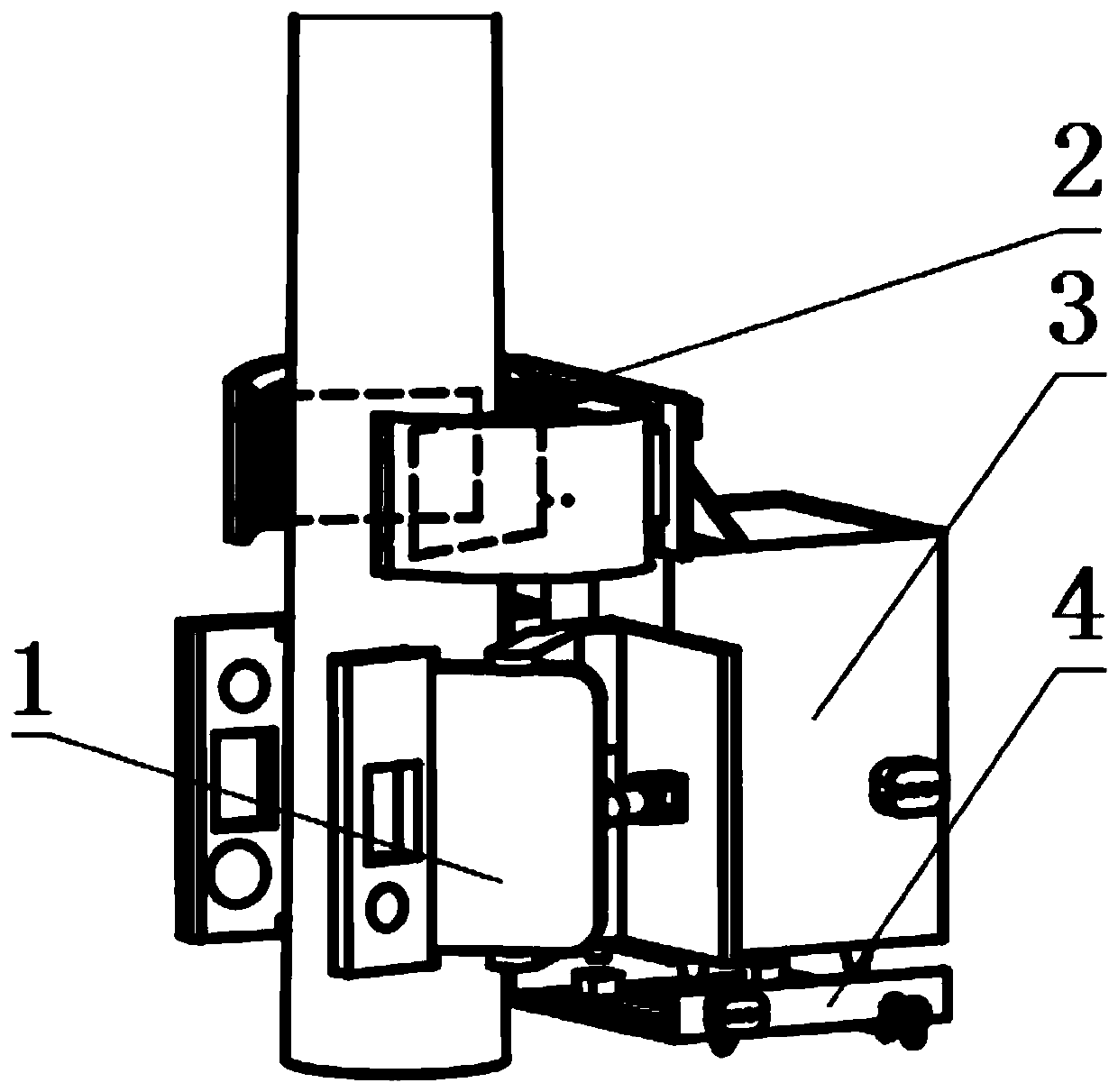

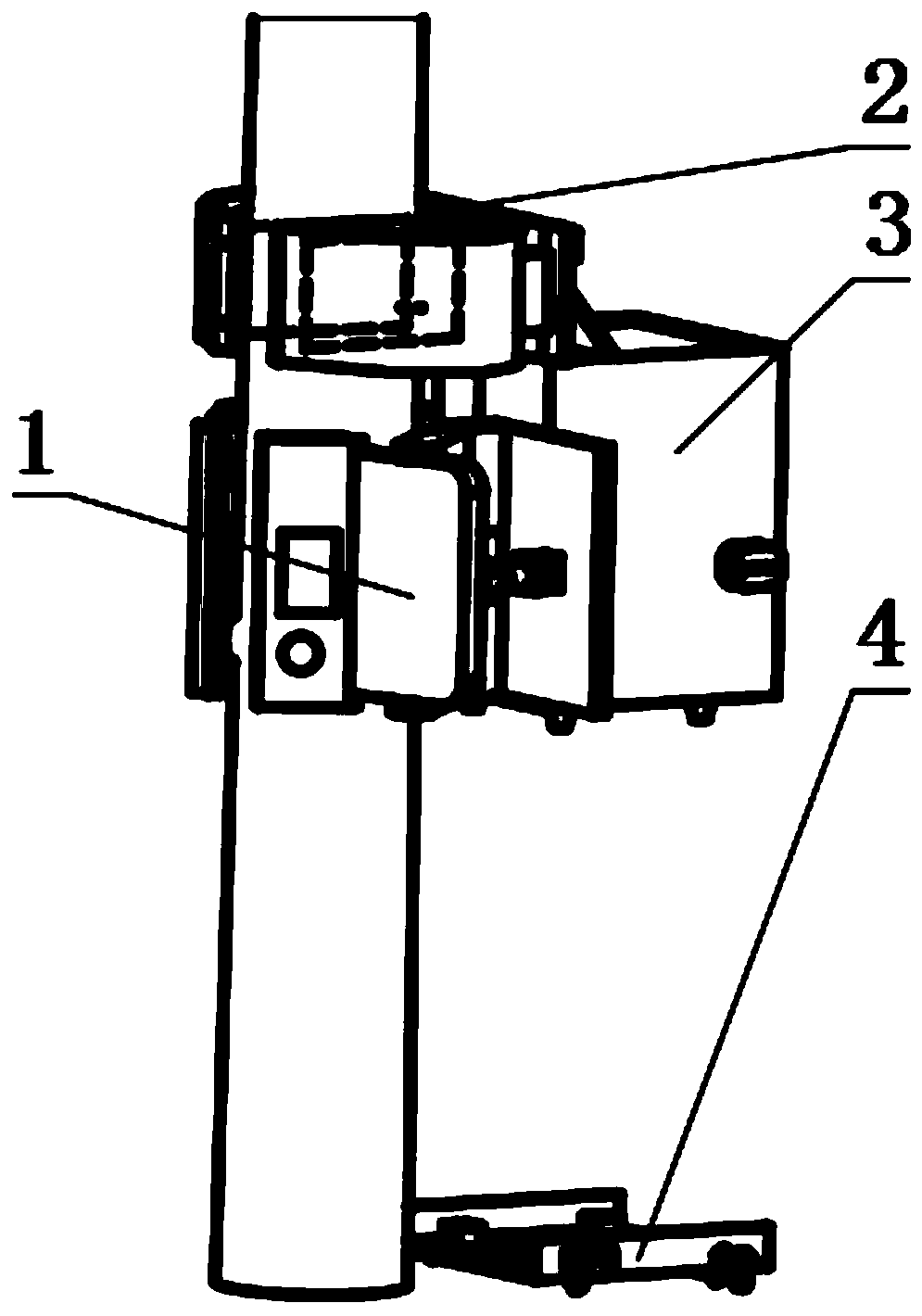

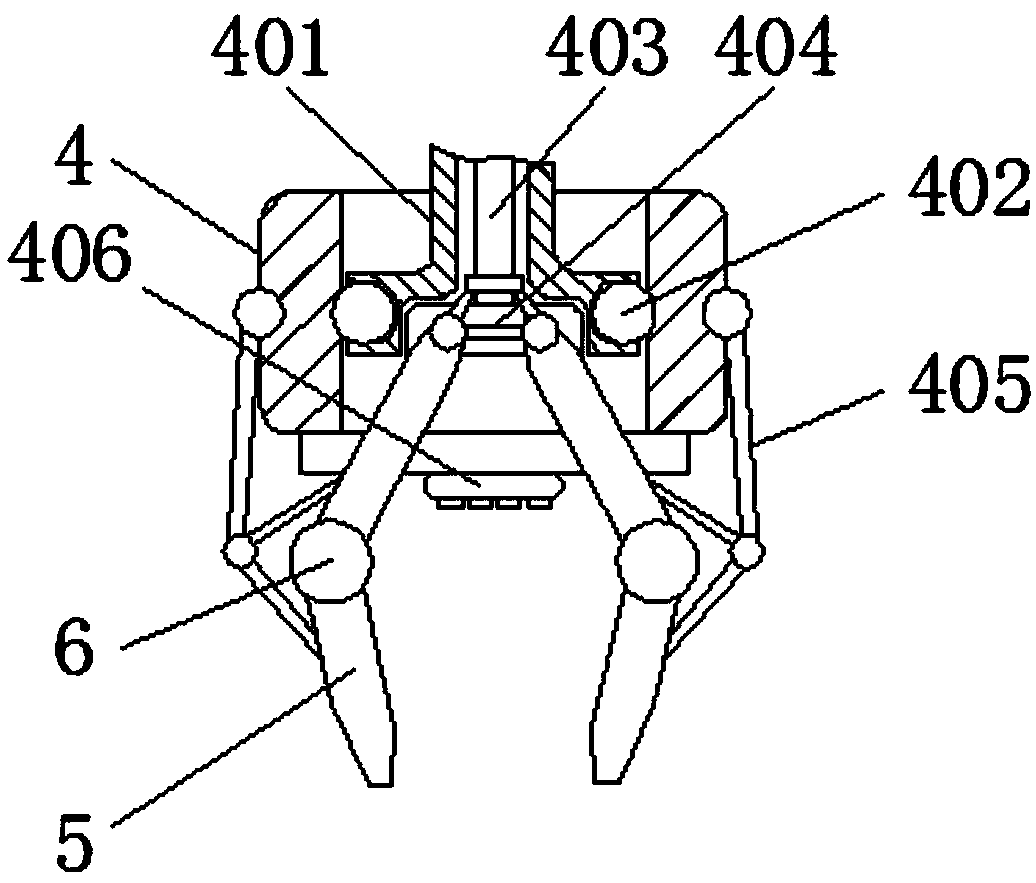

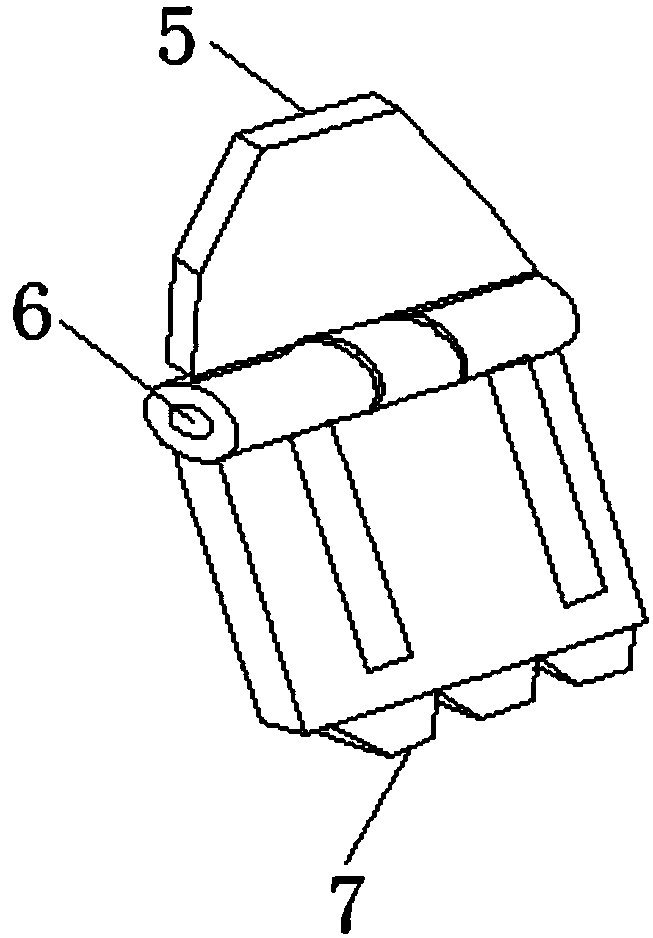

Automatic locking mechanical arm

ActiveCN107618873AImprove safety and reliabilitySimple structureGripping headsConveyor partsEngineeringLocking mechanism

The invention discloses an automatic locking mechanical arm. The automatic locking mechanical arm comprises a rack, a rotating mechanism and a locking mechanism, wherein the rotating mechanism comprises a base which is in sliding connection with the rack, an annular rotating base which is in bearing connection with the base, three telescopic rods which are in fixed connection with the annular rotating base, a first disk which is hinged to the lower ends of the three telescopic rods, a second disk and stand columns; and the locking mechanism comprises a sleeve which is fixedly arranged on the lower surface of the first disk, a cylinder which is sleeved by the sleeve in a sliding manner and connection pieces. According to the automatic locking mechanical arm, due to the fact that compressionsprings are designed between the first disk and the cylinder, the cylinder automatically locks grasping of claws under the elastic force action of the compression springs, and safety and reliabilityof the automatic locking mechanical arm are improved; and by adjusting the different lengths of the three telescopic rods, the first disk is driven to incline at all angles and in all directions, andtherefore the claws are driven to rotate at multiple angles, and completion of grasping operation of objects to be grasped on multiple planes and in all directions is achieved.

Owner:LIUZHOU FUNENG ROBOT DEV CO LTD

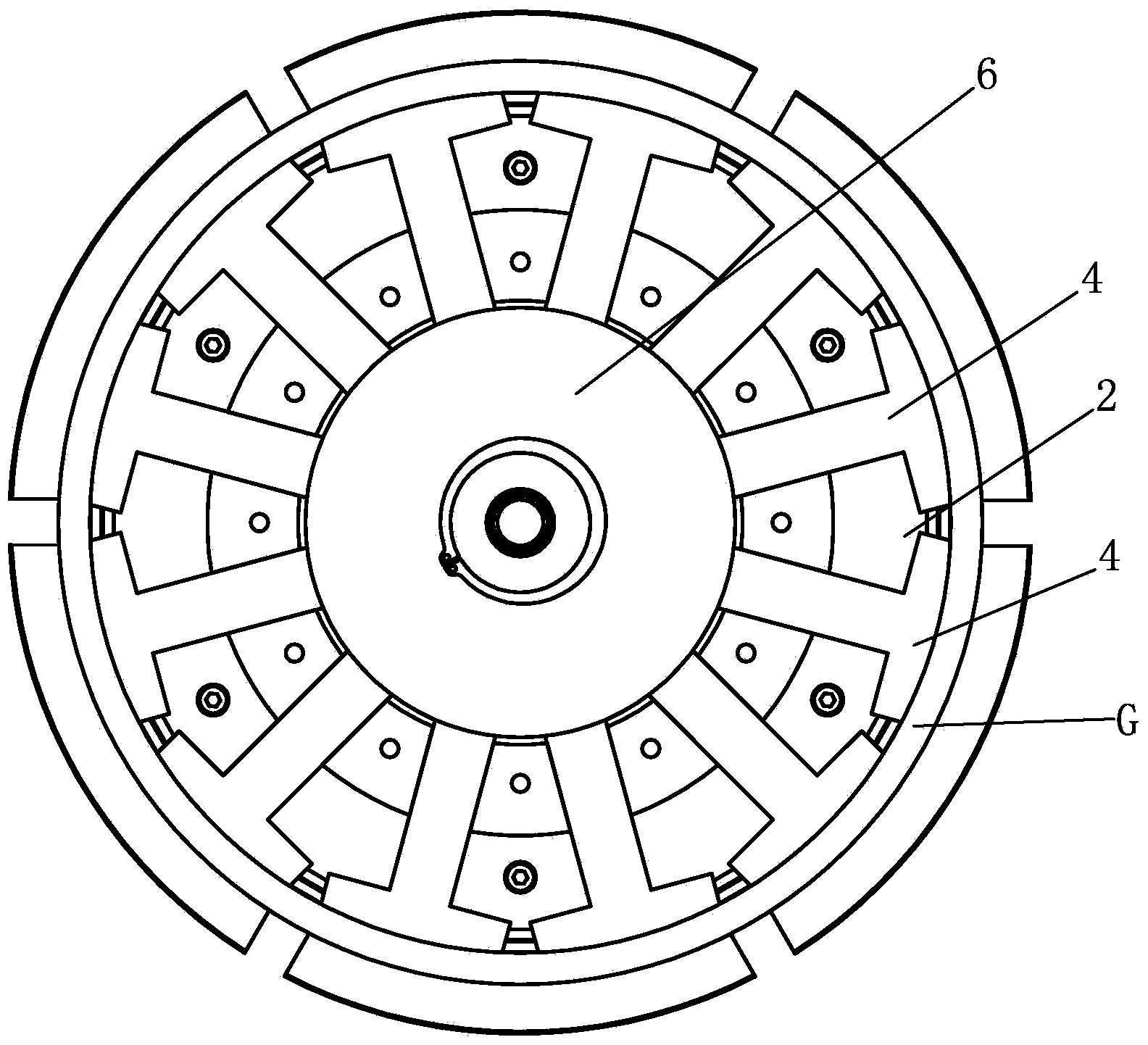

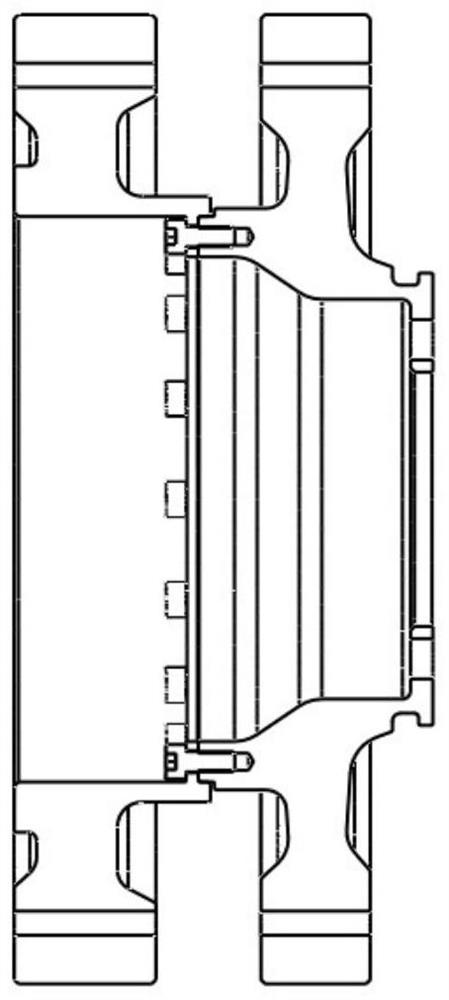

Hobbing clamp for clamping a plurality of parts with big gear rings

The invention discloses a hobbing clamp for clamping a plurality of parts with big gear rings. The hobbing clamp for clamping the parts with the big gear rings comprises a pressing portion and a centering portion, wherein the centering portion comprises a base, a first spring, a locating sleeve, force transmission blocks, a lower pull rod and the like, a support is arranged on the top surface of the base, the support is sleeved with a supporting disk, the pressing portion comprises an upper pull rod and a press plate, the upper pull rod is sleeve with a disk spring and a pressing sleeve in sequence from top to bottom, the disk spring and the pressing sleeve are sleeved with a bushing in a spaced mode, a supporting plate is arranged at the bottom of the press plate, the top surface of the supporting plate is a big-end-down conical surface, the conical surface is attached to the bottom surface of the press plate, the lower end of the supporting plate is fixedly sleeved with a gland, the lower end of the upper pull rod is provided with a T-shaped portion, and the T-shaped portion penetrates through a small-diameter section of a center hole of a taper sleeve and a center hole of a reset spring, and then is clamped into a large-diameter section of a cylindrical hole formed by inner surfaces of all the force transmission blocks. According to the hobbing clamp for clamping the parts with the big gear rings, centering of workpieces with big gear rings can be well carried out through expansion blocks, the workpieces can be tightly pressed at the same time, and centering accuracy can be ensured.

Owner:CHONGQING MACHINE TOOL GROUP

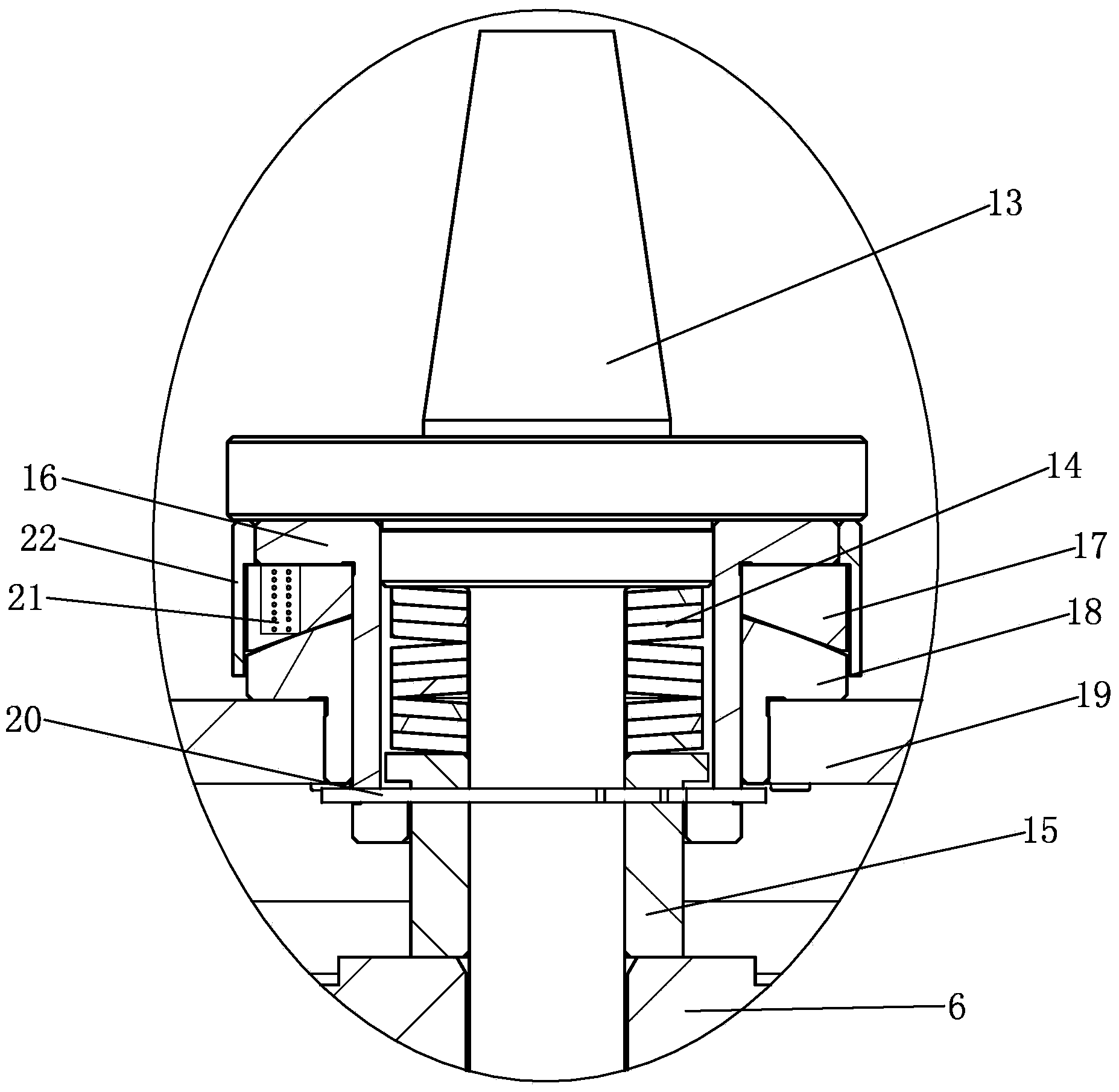

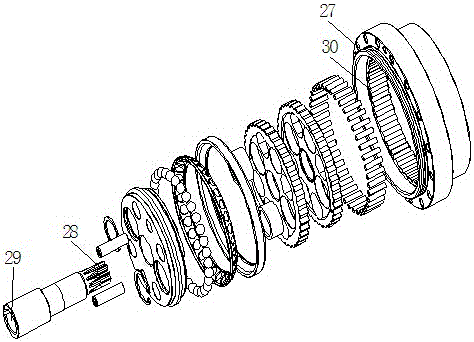

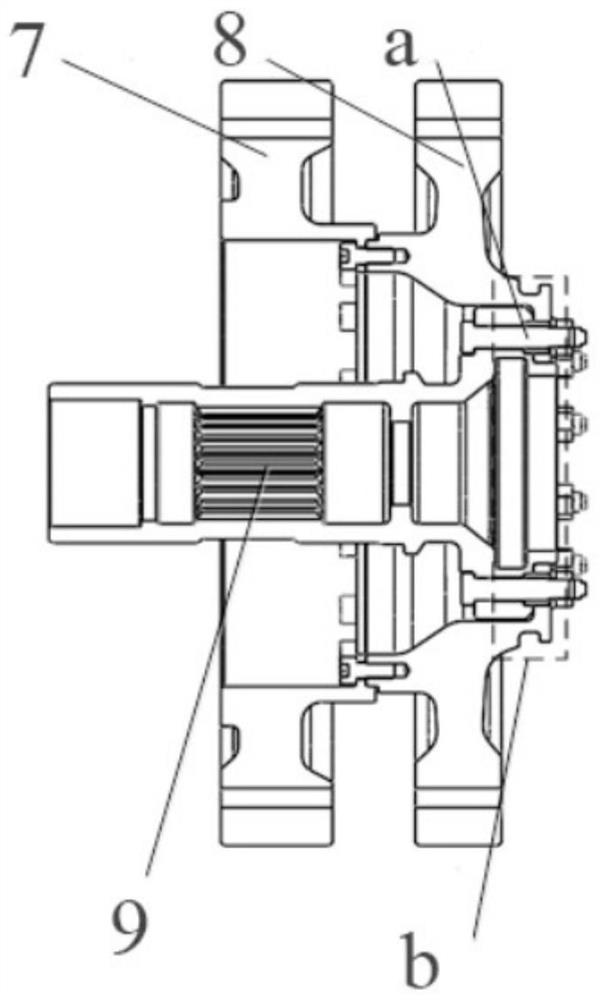

Normally engaged wet type clutch

InactiveCN103697080AAchieve separationRealize power transmissionFluid actuated clutchesThrust bearingPiston

The invention is applicable to various vehicles, and particularly relates to a normally engaged wet type clutch used on a car. The normally engaged wet type clutch comprises a motive power output shaft, an input shaft, a driven clutch hub, a driving clutch hub, a driven friction sheet, an active friction sheet and a thrust disc, wherein the motive power output shaft and the input shaft are respectively arranged on a casing and an end cover through bearings, the driven clutch hub and the driving clutch hub are respectively and fixedly arranged on the output shaft and the input shaft, the driven friction sheet is connected onto the driven clutch hub, the driving friction sheet is connected onto the driving clutch hub, the thrust disc is leaned and arranged on the end surface of the driven friction sheet, a diaphragm spring is arranged on the outer side of the thrust disc and is butted and connected onto the outer wall of the diaphragm spring through a pre-tightening screw bolt which is used as a lever fulcrum and is fixedly arranged on the driven clutch hub, a piston arranged on the input shaft diameter is butted and connected onto the inner edge of the diaphragm spring through the thrust bearing, and in addition, the pre-tightening screw bolt is regulated so that the driving and driven friction sheets are in the normally engaged states. The range of the torque transmitted by the wet type clutch is greater, the service life of the clutch can be prolonged, and the driving comfort is better.

Owner:CHANGCHUN YIDONG CLUTCH +1

Improved power connecting device for electrical equipment

InactiveCN108233010AAvoid Electric Shock AccidentsReduce security risksCoupling device detailsClamped/spring connectionsEngineeringCommunicating cavity

The invention discloses an improved power connecting device for electrical equipment. The improved power connecting device for the electrical equipment comprises a power supply seat fixedly mounted ina wall and a power connecting head connected with the electrical equipment, wherein an insertion slot having a rightward opening and matched with the power connecting head is formed in the right endsurface of the power supply seat; power supply slots with rightward openings are formed in the left end wall of the insertion slot in longitudinal symmetry; a communicating cavity communicated with the two power supply slots is formed between the two power supply slots; first sliding slots communicated with the communicating cavity are formed in the left end wall of the communicating cavity in longitudinal symmetry; second sliding slots communicated with the first sliding slots and the power supply slots are formed between the first sliding slots and the power supply slots; first sliding armsare mounted inside the second sliding slots in a sliding manner; rolling wheels are mounted on the end surfaces, facing the first sliding slots, of the first sliding arms; power supply sheets are fixedly mounted on the end surfaces, facing the power supply slots, of the first sliding arms; sliding cavities extending left and right are formed in the end walls, away from the communicating cavity, ofthe power supply slots; through slots communicated with the power supply slots are formed in the right sides of the end walls, near the power supply slots, of the sliding cavities.

Owner:广州爵诺医疗器械有限公司

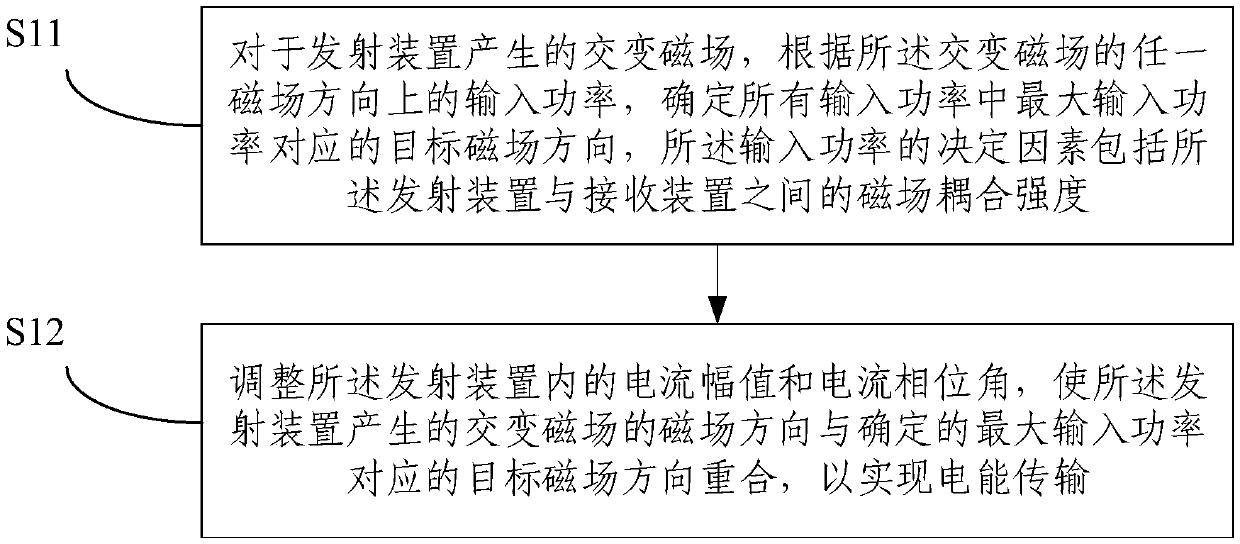

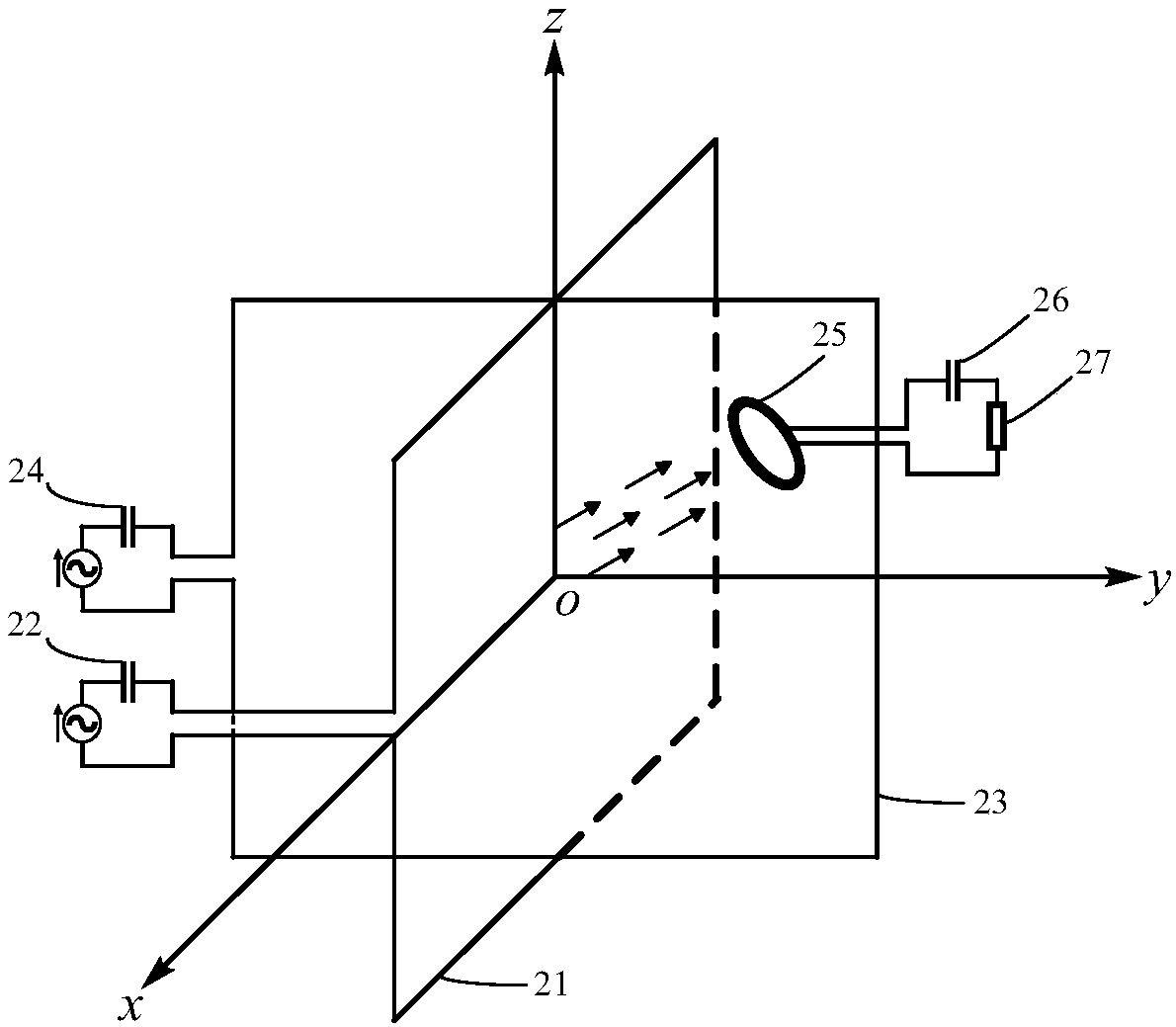

Wireless power transmission method and system

ActiveCN107623388ARealize power transmissionCircuit arrangementsElectric power transmissionMagnetic field coupling

The invention provides a wireless power transmission method and system. The method comprises: S11, for an alternating magnetic field generated by a transmitting device, according to an input power ofthe alternating magnetic field in any magnetic field direction, a target magnetic field direction corresponding to a maximum input power among all input powers is determined, wherein determining factors of the input powers include magnetic the magnetic field coupling strength between the transmitting device and a receiving device; and S12, a current amplitude and a current phase angle in the transmitting device are adjusted and thus the magnetic field direction of the alternating magnetic field generated by a transmitting device is overlapped with the target magnetic field direction corresponding to the determined maximum input power, thereby realizing power transmission. According to the wireless power transmission method, the orientation where the receiving device is located is tracked automatically; and establishment of communication connection between the transmitting device and the receiving device is not needed, so that a phenomenon that wireless power transmission can not be realized because no communication connection can be established in an environment with difficult communication is avoided.

Owner:CENT SOUTH UNIV

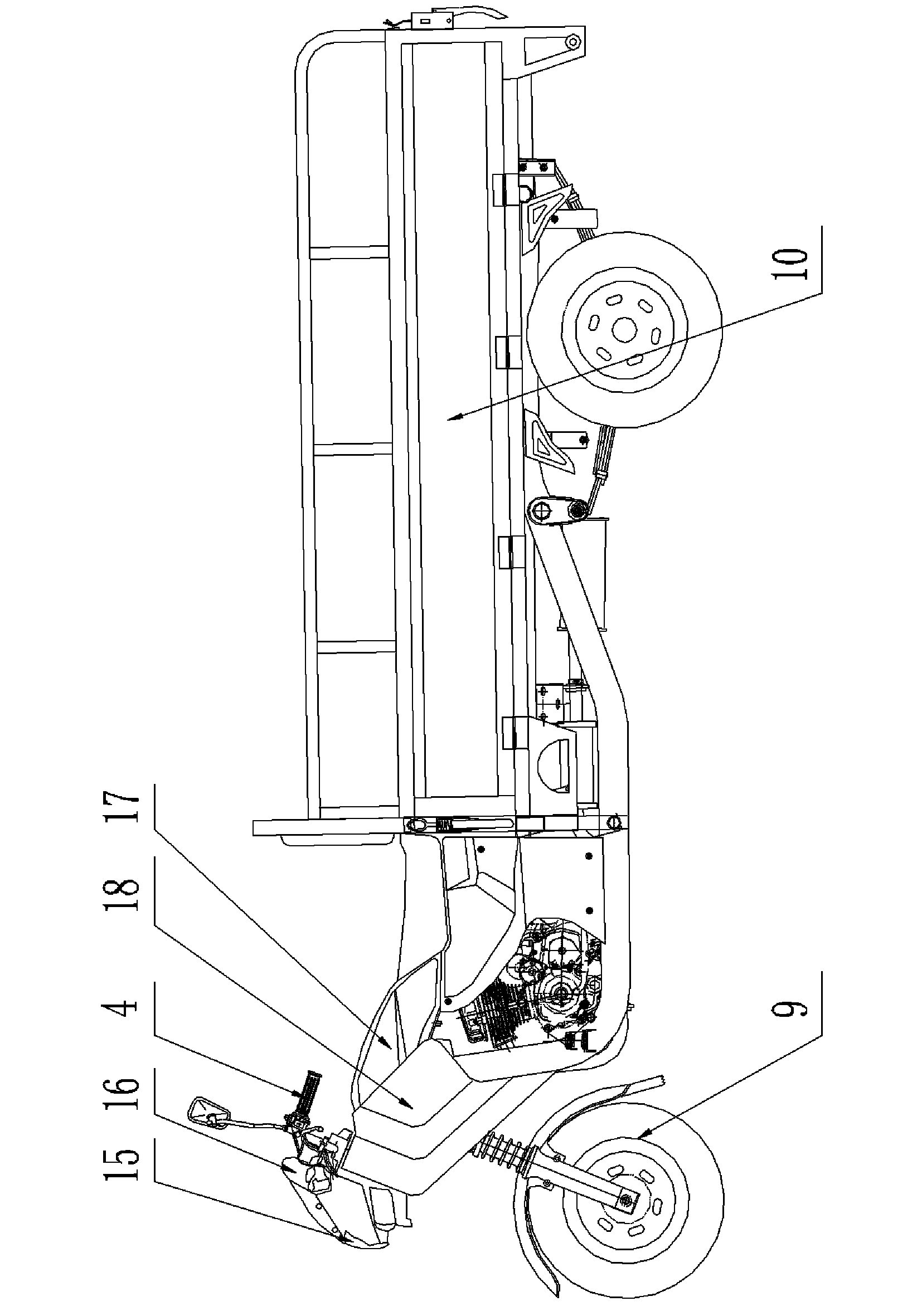

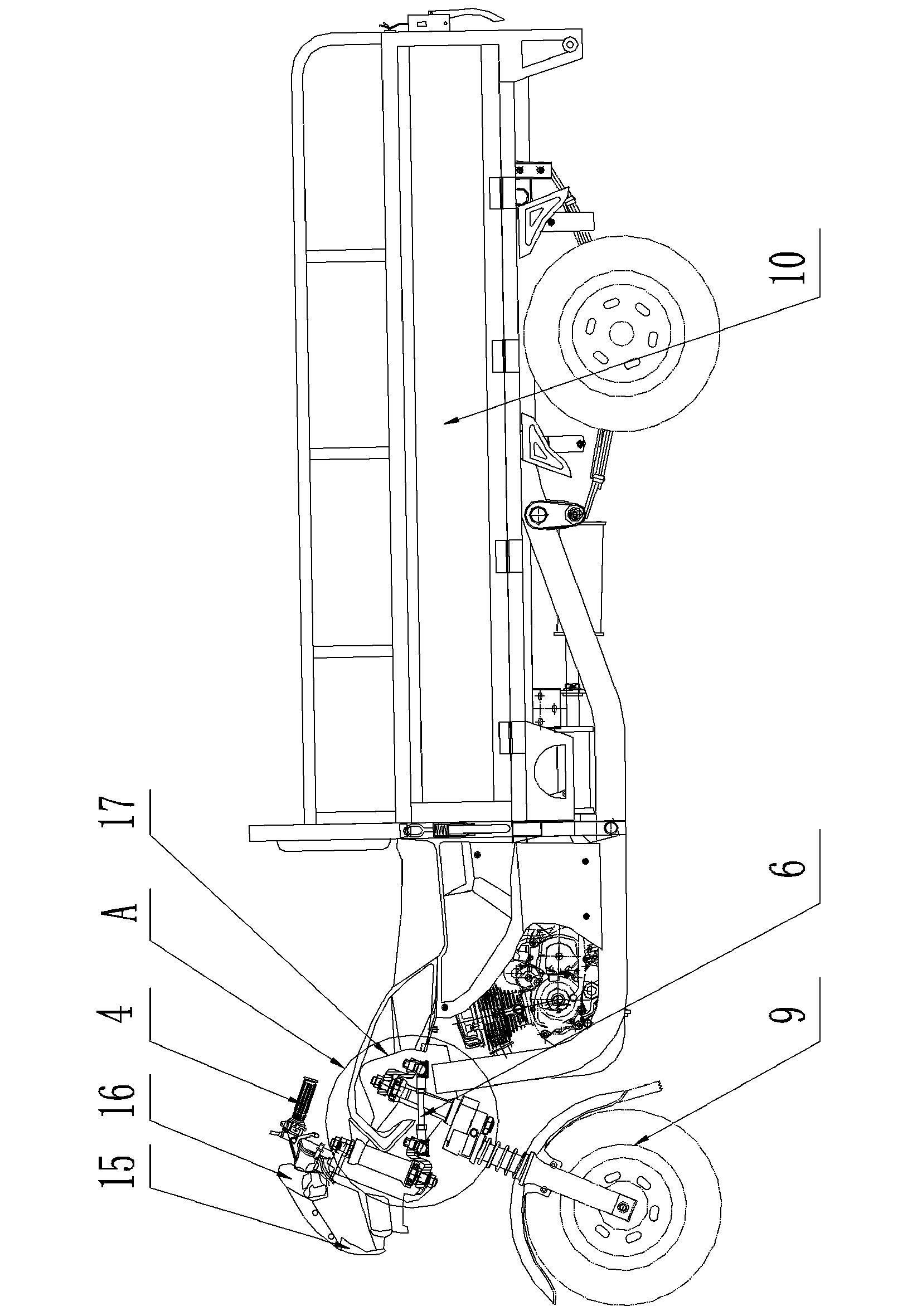

Right three-wheeled motorcycle

ActiveCN103192917AShorten invalid lengthConducive to driving safetyPassenger cyclesChain/belt transmissionVehicle frameControl engineering

The invention discloses a right three-wheeled motorcycle. The right three-wheeled motorcycle comprises a frame with a main beam and a container support beam, wherein a headstock stand pipe for installing a steering post is welded at the front end of the main beam; a handle pipe steering post for installing a handle pipe is rotatably matched in the headstock stand pipe; a handle pipe is arranged at the upper end of the handle pipe steering post; a front fork stand pipe for installing a front fork steering post is welded on the main beam at the back of the headstock stand pipe; a front fork steering post is rotatably matched in the front fork stand pipe; and the handle pipe steering post is connected with the front fork steering post through a linkage device. Compared with a conventional right three-wheeled motorcycle, the front fork steering post of the motorcycle moves backward, so that the invalid length between the front end of a front wheel and the front end of a head lamp of the right three-wheeled motorcycle is shortened; and therefore, a container of the right three-wheeled motorcycle can be lengthened within the specified overall length of the motorcycle, the transportation efficiency can be improved, and the requirements of customers can be met.

Owner:CHONGQING ASTRONAUTIC BASHAN MOTORCYCLE MFG

Street lamp cleaning device

PendingCN110813809AAchieve cleaningReduce volumeCleaning using toolsCleaning using liquidsEngineeringSmall footprint

Owner:CHANGAN UNIV

Subsoiling and smashing and ridging machine

InactiveCN104996014ANo loosenessPrevent looseningSpadesCrop conditionersDrive shaftUltimate tensile strength

The invention discloses a subsoiling and smashing machine. The subsoiling and smashing machine comprises a machine body, a smashing and ridging device, a connecting device, a ditching device, a leveling device and a device for returning straws to a field; the smashing and ridging device comprises a smashing and ridging box; the smashing and ridging box comprises a bottom plate, a side plate and a top plate; lower bearing bases are mounted on the bottom plate; a rib plate is welded between the lower bearing bases; a lubricating oil channel is arranged between the rib plate and the bottom plate; upper bearing bases are mounted on the top plate; and the lower bearing bases are arranged on the upper bearing bases. According to the subsoiling and smashing and ridging machine, the strength of the lower bearing bases can be improved; a plurality of bearings are conveniently mounted on places which with great stress, and less bearings are mounted on places with little stress; so that the rigidity and the transmission stability of a transmission shaft are improved, and the cost can be reduce; the rib plate is conveniently welded; and the lubricating oil is guaranteed to smoothly flow in the smashing and ridging box, thereby improving the lubricating effect.

Owner:GUANGXI WUFENG MACHINERY CO LTD

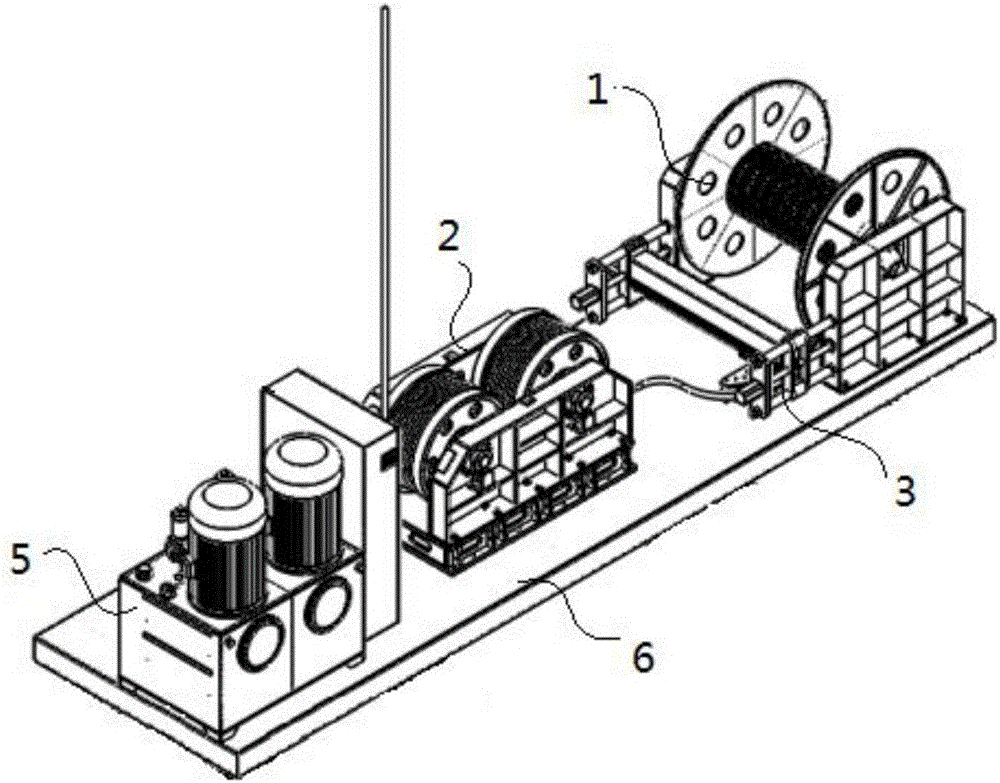

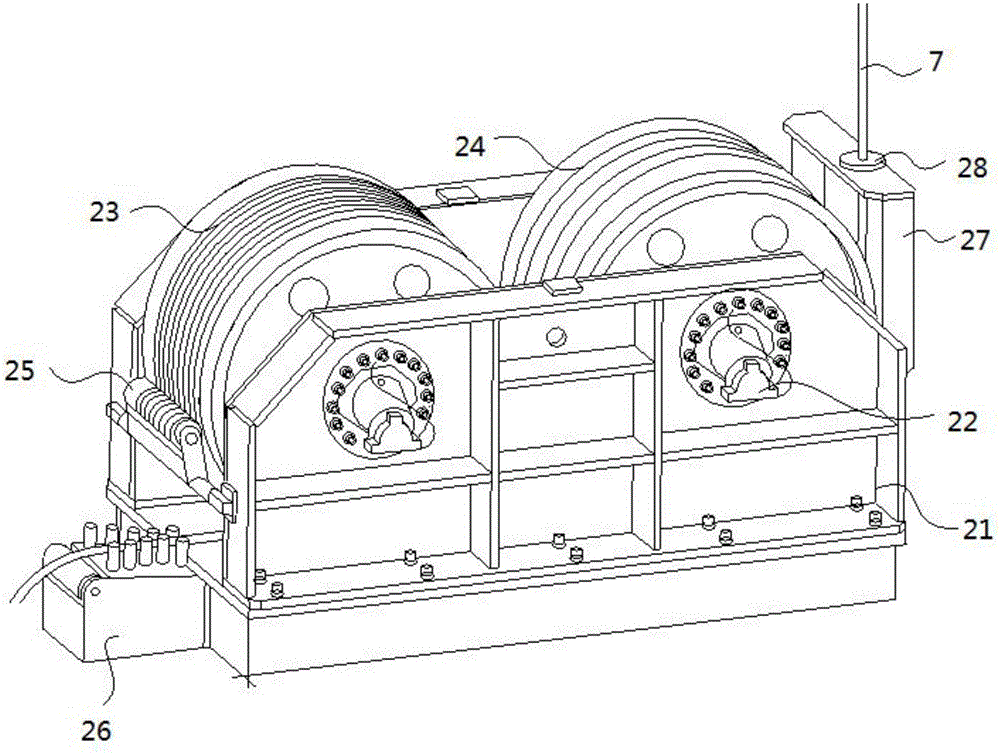

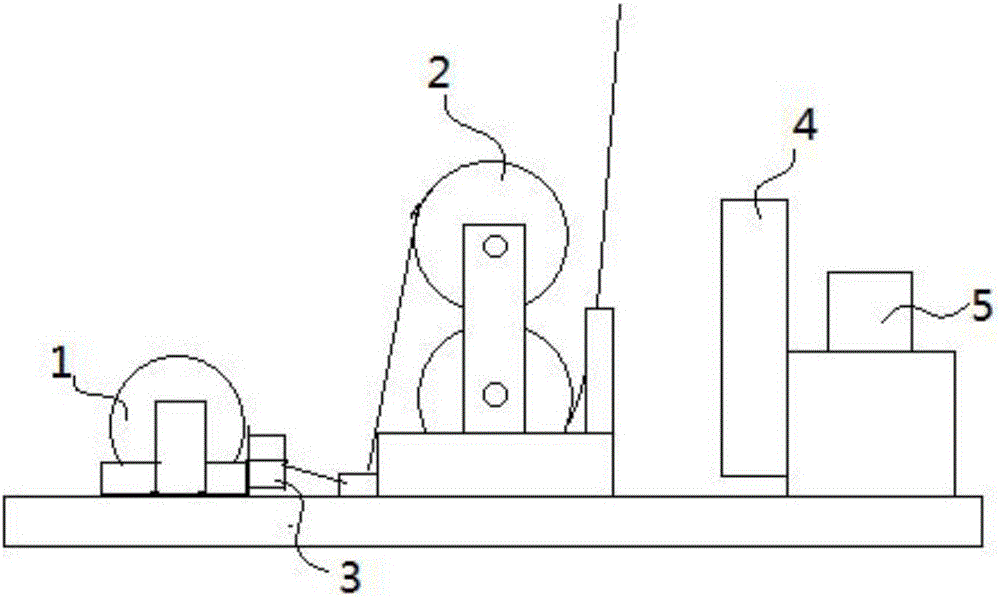

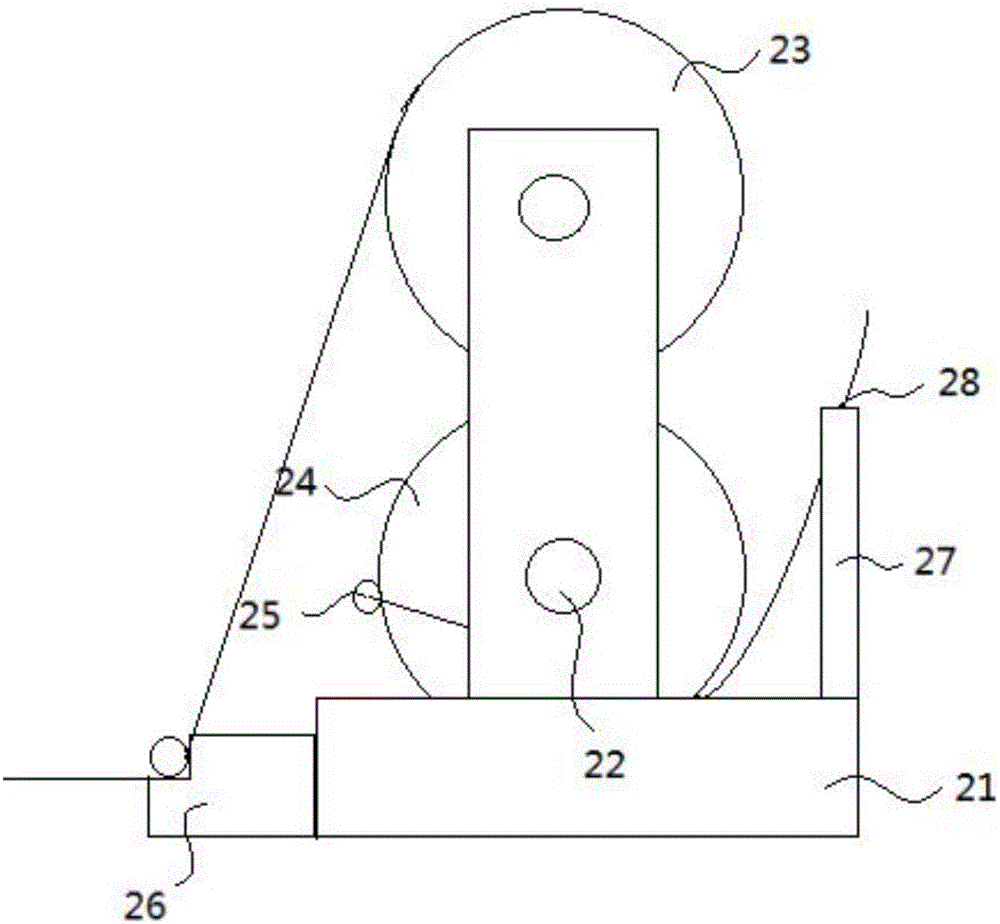

Tie-down rope winding and unwinding device

The invention discloses a tie-down rope winding and unwinding device, and belongs to the field of floating-observation platforms. The tie-down rope winding and unwinding device comprises a winding device, a traction device and an unwinding device, wherein the winding device comprises a winding drum connected with a hydraulic transmission device; the traction device comprises a first traction wheel and a second traction wheel which are connected with the hydraulic transmission device; skewed slots which correspond to each other are formed in the first traction wheel and the second traction wheel in an engraved manner; a mooring rope is wound on the first traction wheel and the second traction wheel in 8-shaped repeated, alternate, single-layer and multi-turn manner; the unwinding device is positioned between the winding device and the traction device; and the winding direction and force of the mooring rope are controlled by a plurality of servo motors of the unwinding device. By a hydraulic transmission mode, volume and weight are reduced, and energy consumption is lowered. Moreover, in a mooring rope winding and unwinding process of the device, stable control on winding and unwinding of the mooring rope and protection to the mooring rope are fully considered in the design, and use safety of a tie-down platform is ensured.

Owner:HUAINAN GUOLI HYDRAULIC MACHINERY MFG

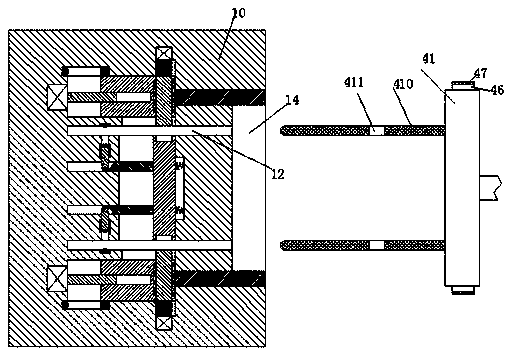

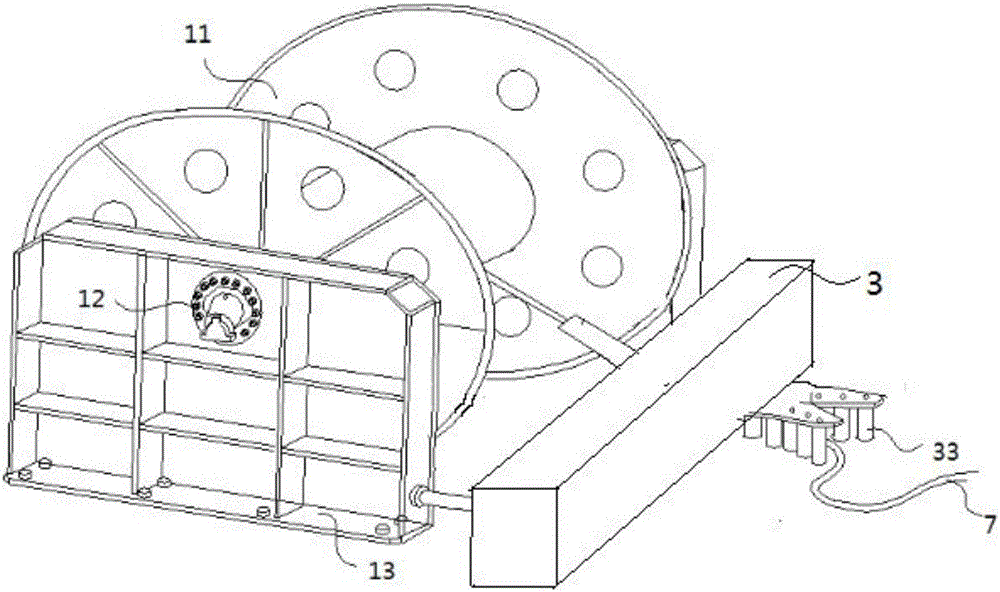

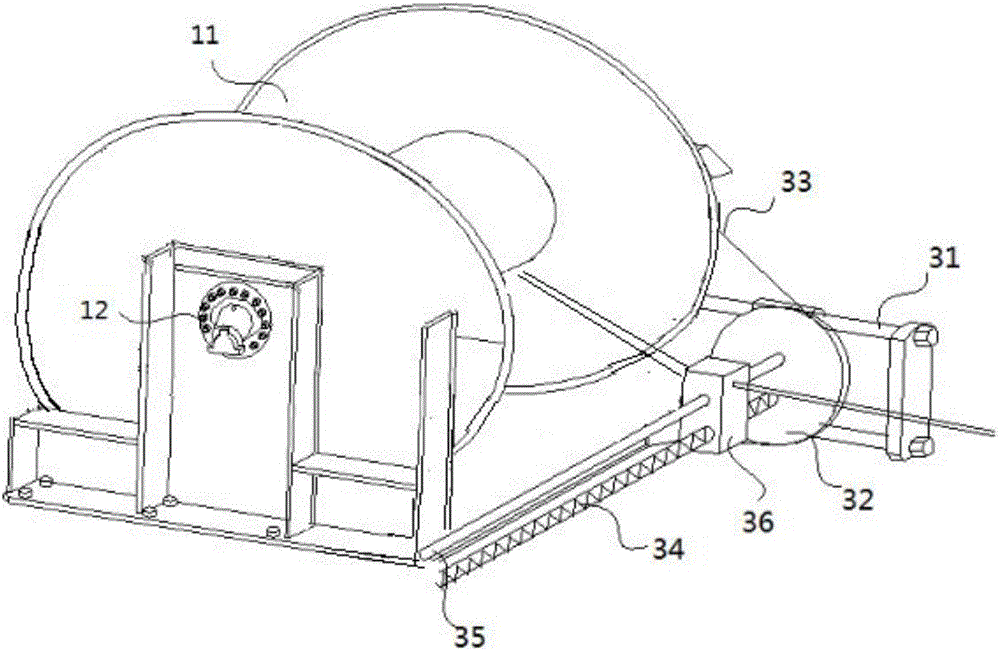

Cable winding and unwinding device based on cable arrangement by lead screw

The invention discloses a cable winding and unwinding device based on cable arrangement by a lead screw and belongs to the field of floating platforms. The cable winding and unwinding device comprises a cable winding system, a driving system and a cable arrangement system. The cable arrangement system is positioned between the cable winding system and the driving system and comprises a belt transmission mechanism, a belt, the reciprocating lead screw, a polished rod, a slider and a shifting fork, wherein the belt transmission mechanism is connected to a winding reel and the reciprocating lead screw, the polished rod penetrates through the belt transmission mechanism to be fixed on guide rails, the slider sleeves the polished rod and the reciprocating lead screw, the shifting fork is inlaid at the bottom end of the slider, and the spiral surface of the reciprocating lead screw is matched with the shifting fork. By adopting the cable arrangement system controlled by the lead screw, the cable winding and unwinding device based on cable arrangement by the lead screw has the advantages that a cable can be arranged on the winding reel orderly and compactly, twining of the cable is avoided, and use safety of a mooring platform is ensured.

Owner:从光梅

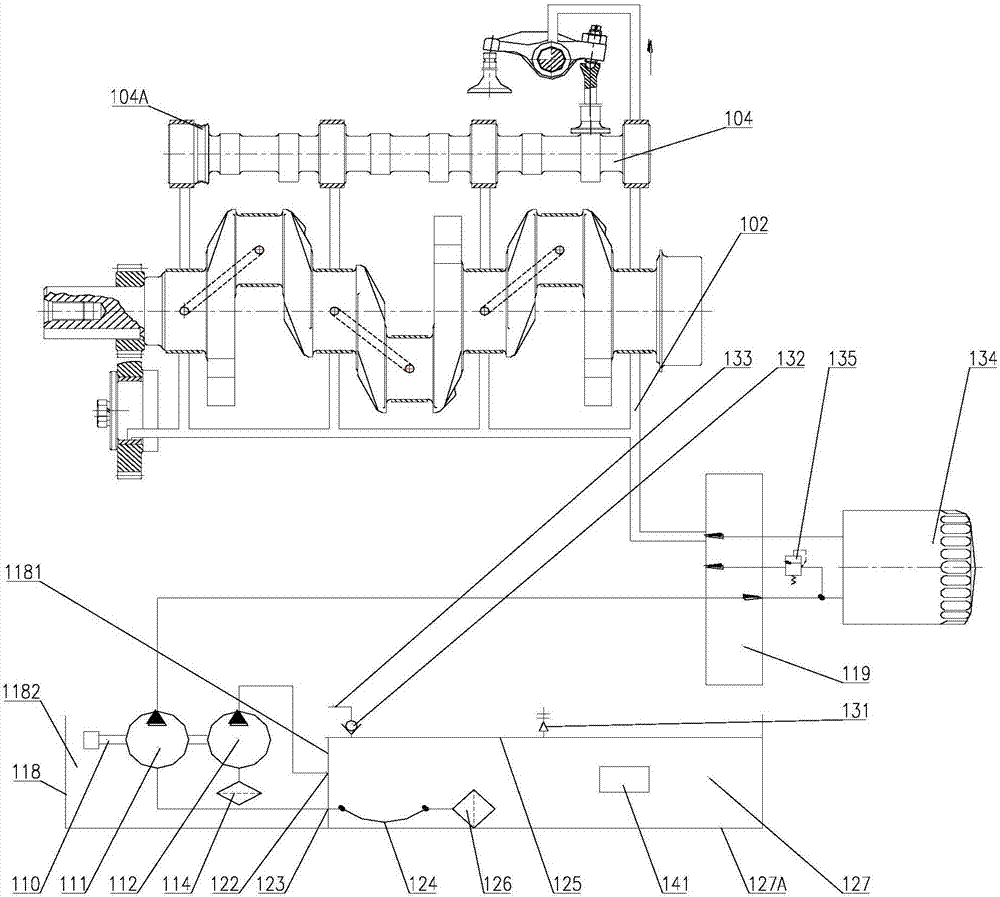

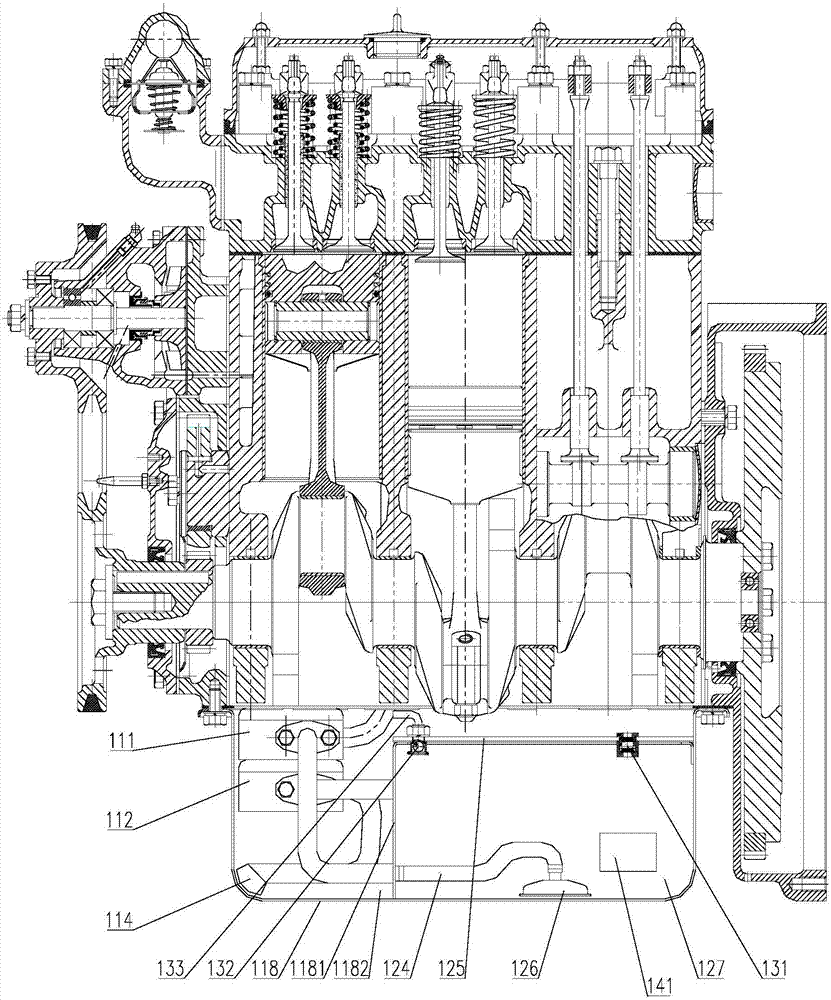

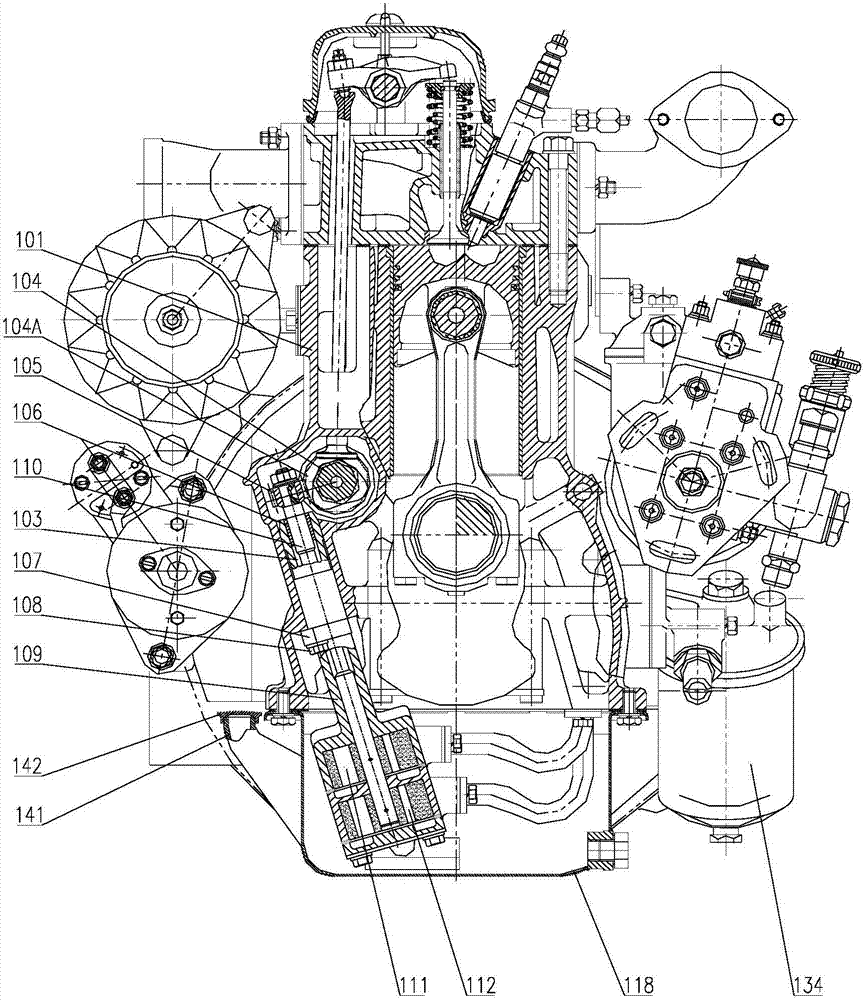

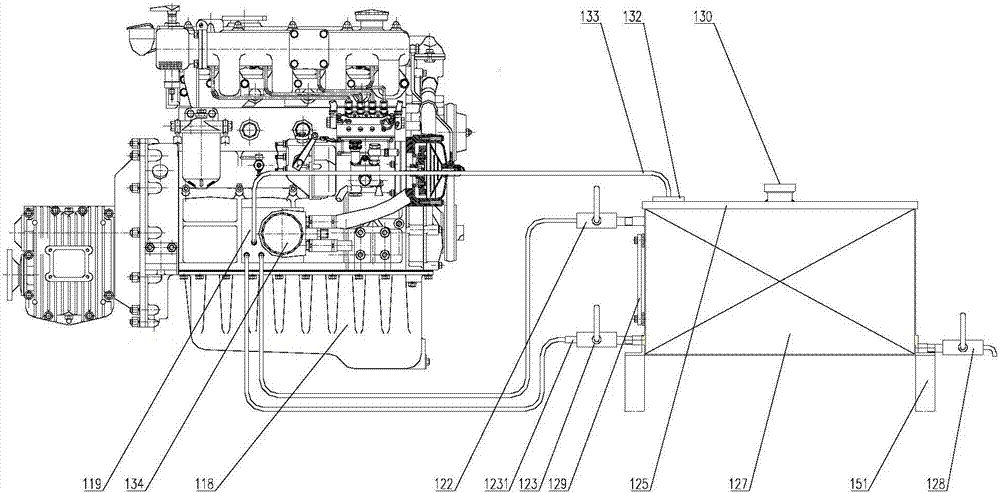

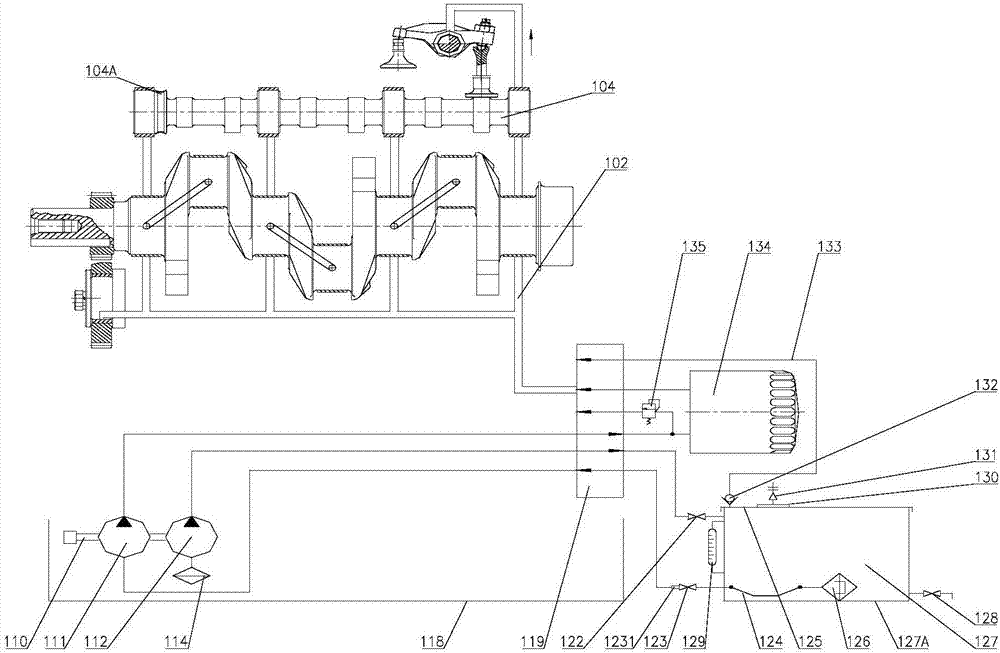

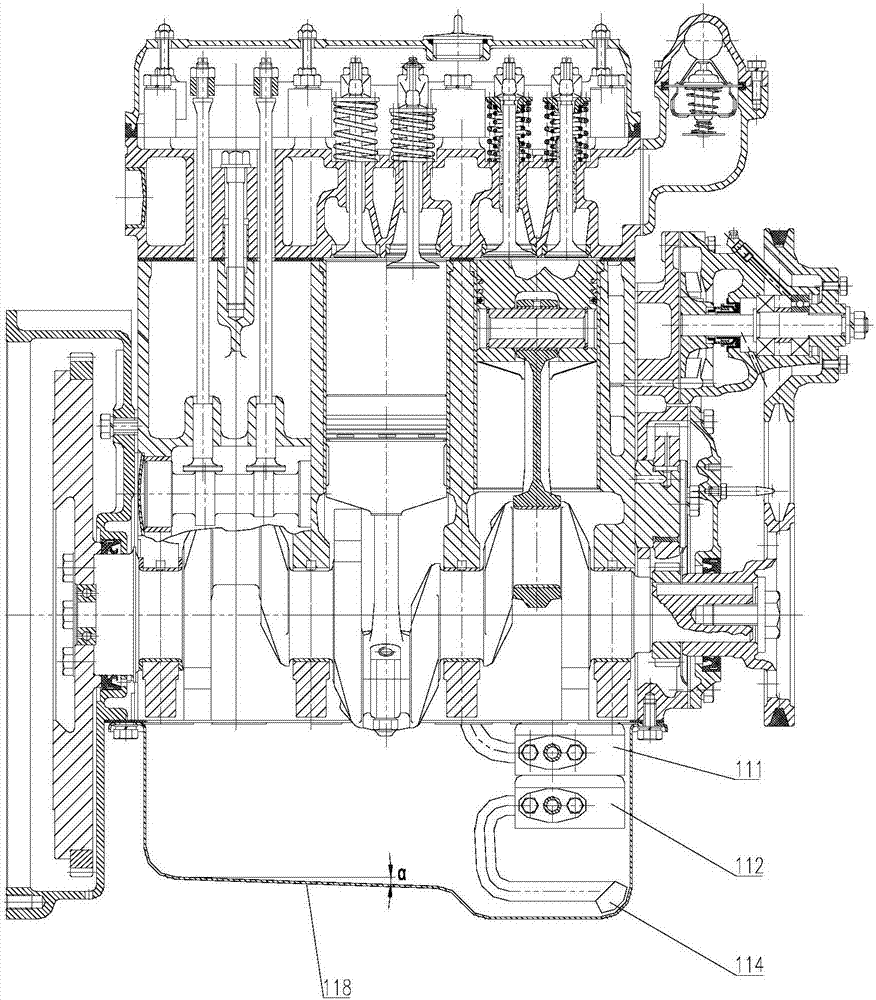

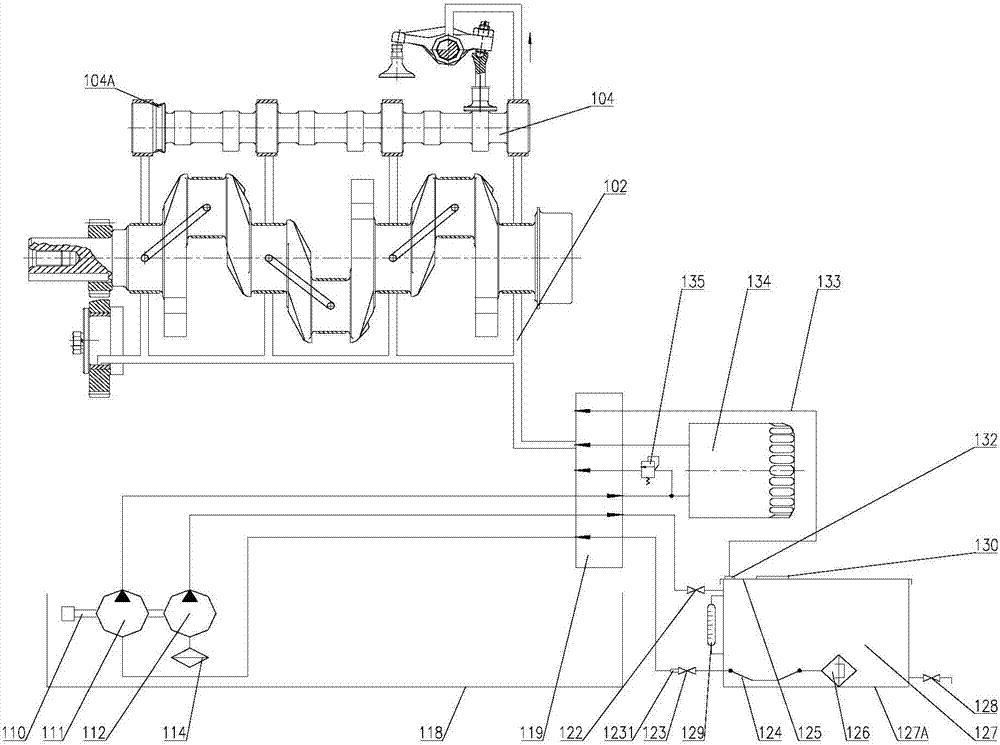

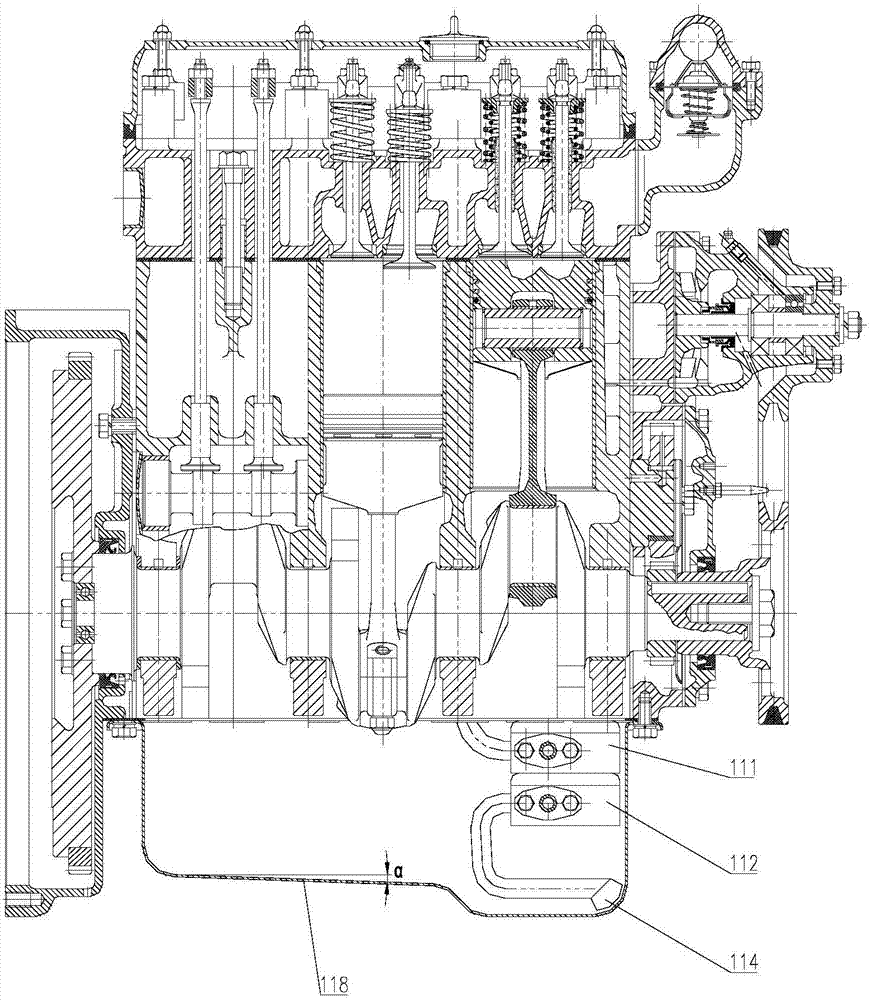

Multi-cylinder diesel engine inversion parking-free device for throwing down boat

ActiveCN107143395AFully lubricatedAchieve recyclingOilsumpsMachines/enginesBreathing systemAtmospheric pressure

Owner:镇江四洋柴油机制造有限公司

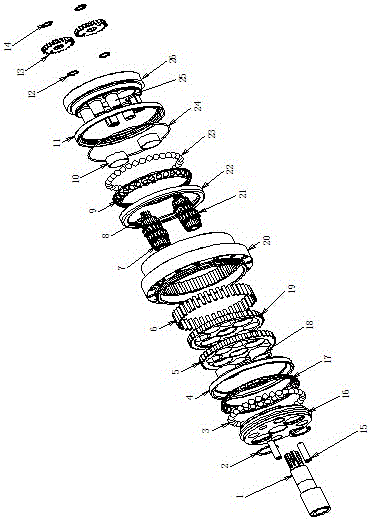

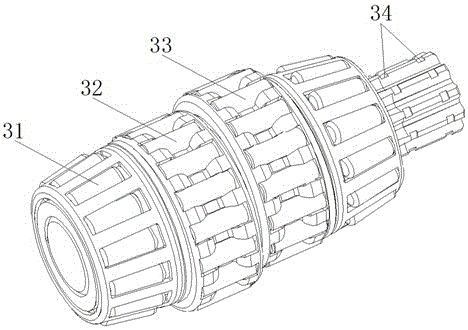

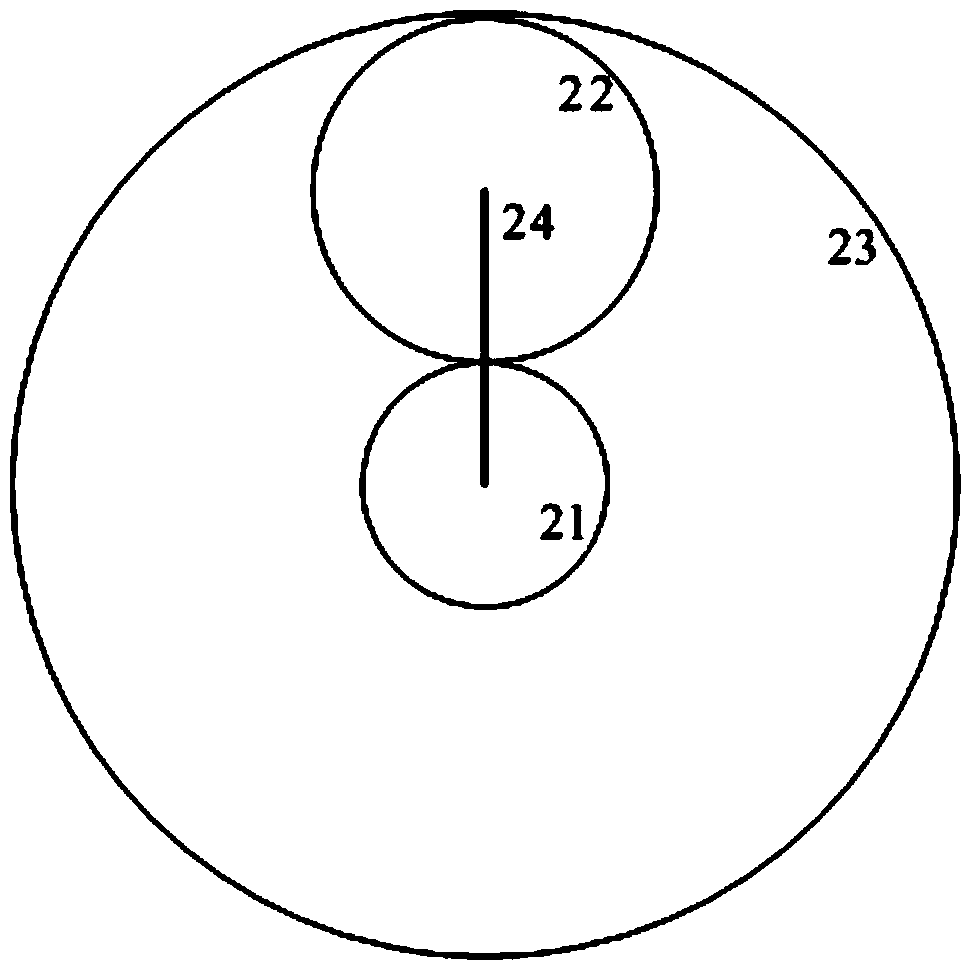

Bearing type RV speed reducer

InactiveCN105041985AStable structureSmooth driveToothed gearingsGearing detailsEngineeringPower transmission

Disclosed in the invention is a bearing type RV speed reducer. The structure of the speed reducer is stable and the power transmission process is smooth and reliable. The bearing type RV speed reducer comprises a body; and a through hole is formed in the center of the body. In addition, the speed reducer also includes a bearing seat and a foot-contained bearing seat, wherein the bearing seat and the foot-contained bearing seat are installed at the wall of the through hole of the body in a rotating mode. Two cycloidal gears are arranged between the bearing seat and the foot-contained bearing seat in parallel; and roller pins are arranged between the cycloidal gears and the wall of the through hole. Input shaft holes located at the centers as well as eccentric shaft holes symmetrically formed in the two sides of the input shaft holes are correspondingly formed in the bearing seat, the foot-contained bearing seat, and the cycloidal gears; and are symmetrically formed in the two sides of the input shaft hole. An input shaft is installed at the walls of the input shaft holes in a rotating mode. Eccentric shafts contain eccentric wheels cooperating with the eccentric shaft holes of the two cycloidal gears. Gear wheels engaged with each other are installed at end portions, approaching the foot-contained bearing seat, of the eccentric shafts and the input shaft. The diameter of the gear wheel of the input shaft is smaller than the gear wheel diameters of the eccentric shafts. A blind hole for assembling a power shaft is formed in one end, far away from the foot-contained bearing seat, of the input shaft; and a key groove is formed in the wall of the blind hole.

Owner:FUJIAN LIDONG PRECISION MACHINERY

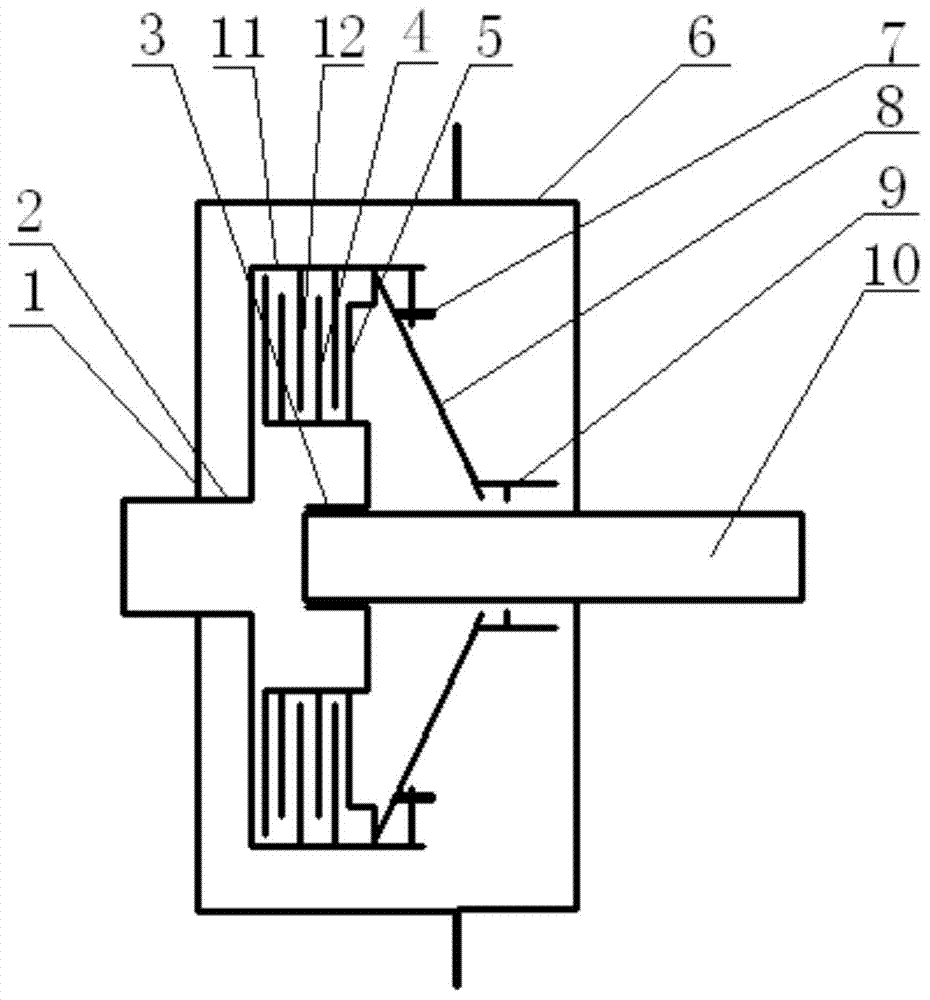

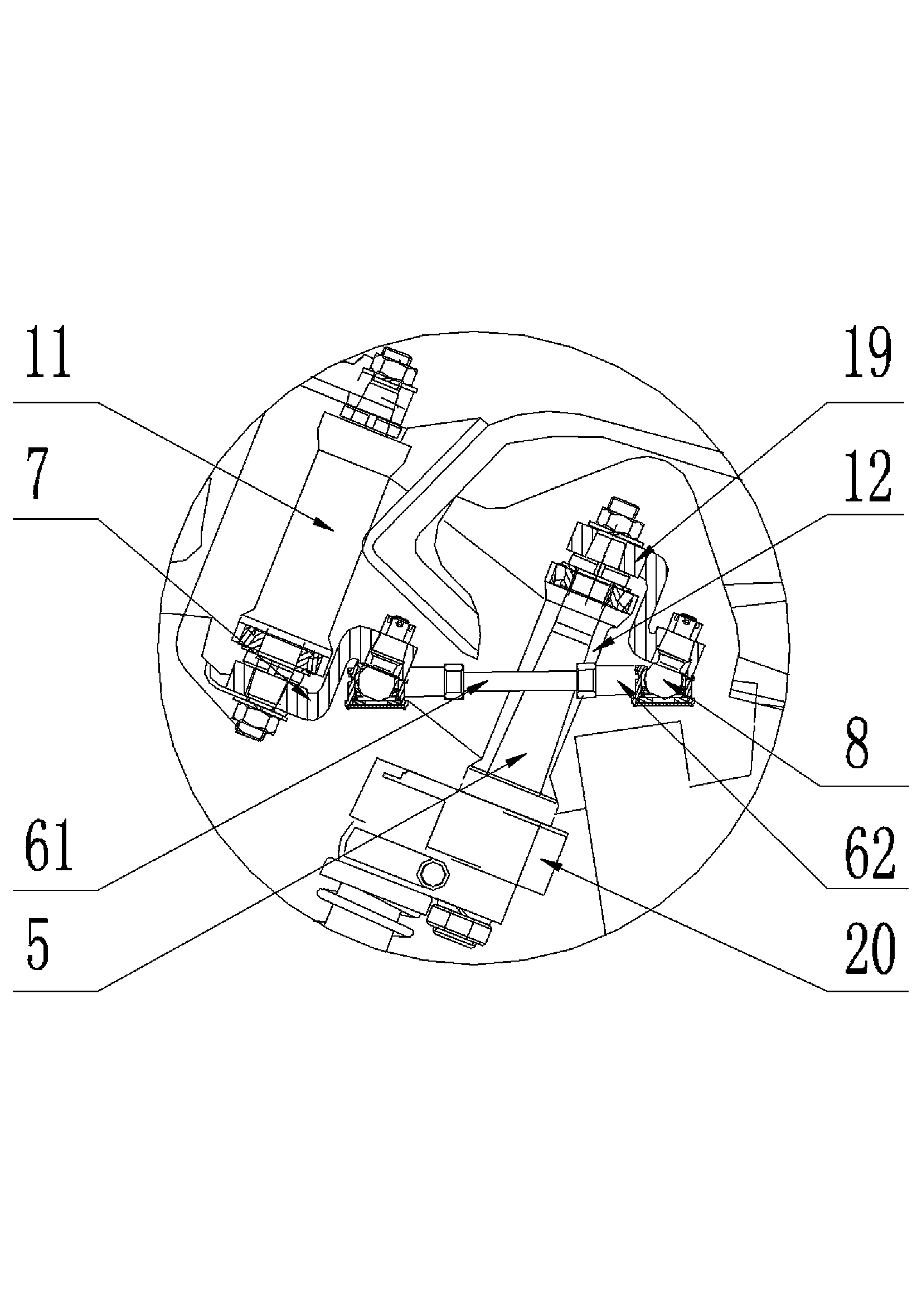

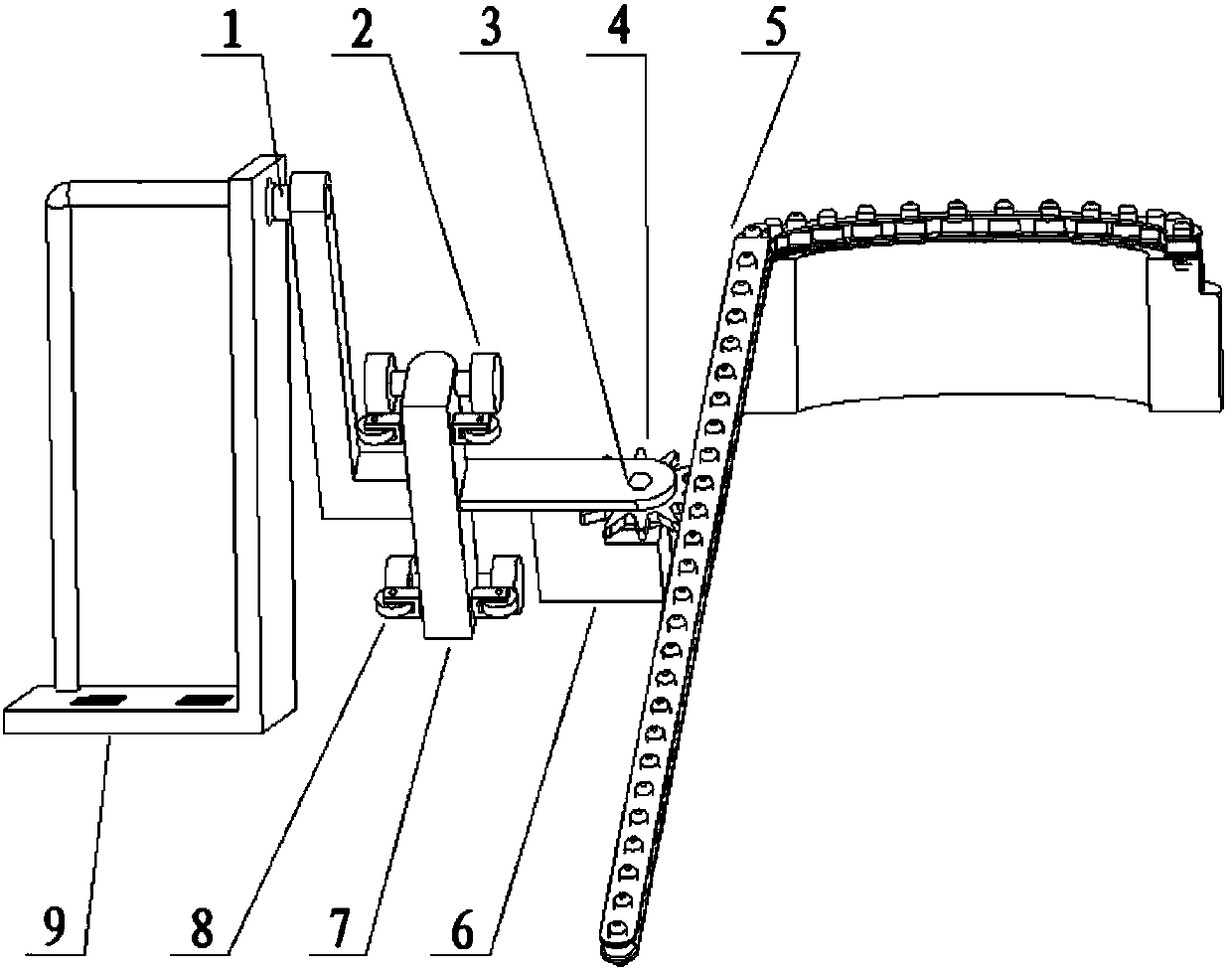

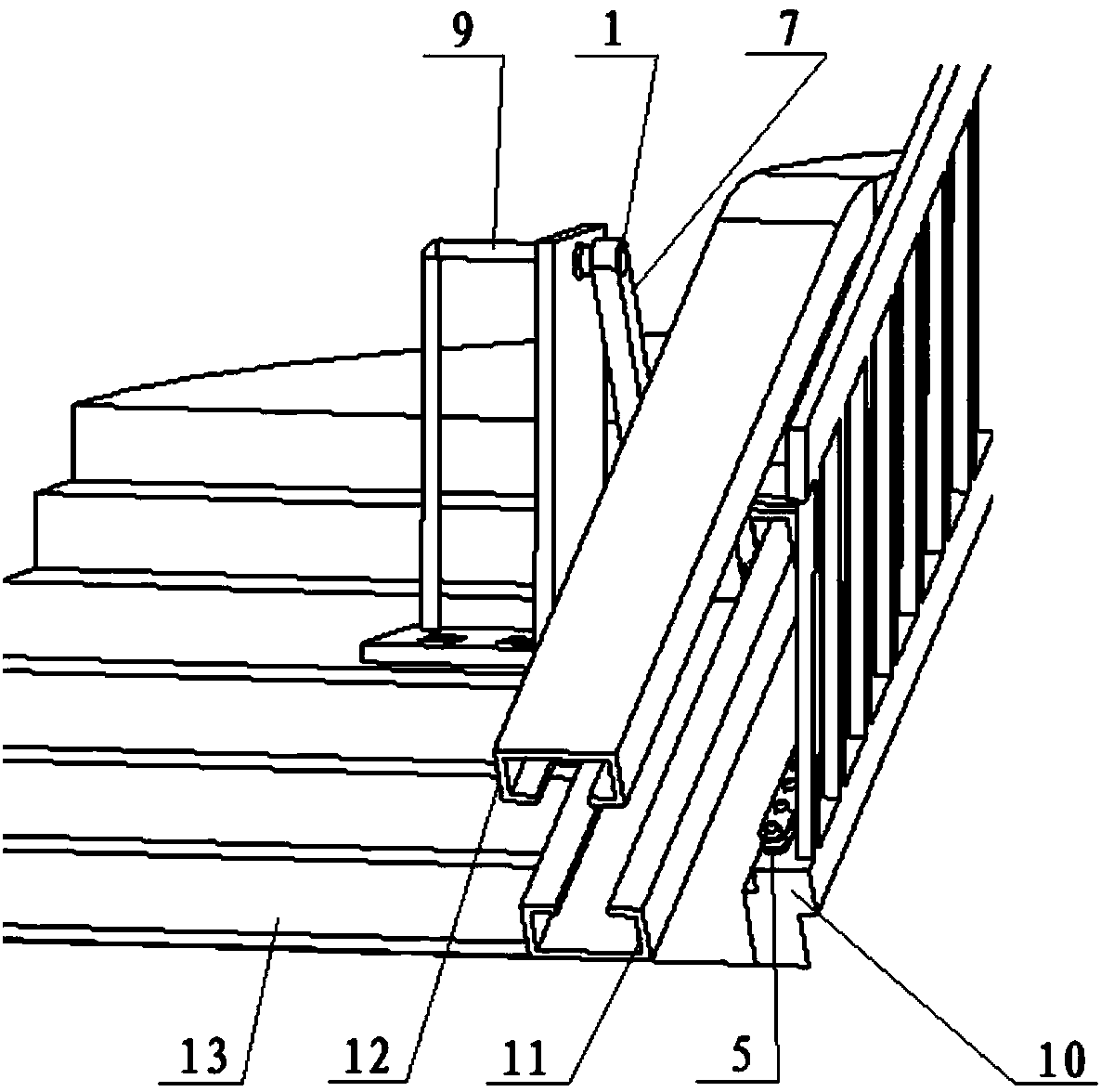

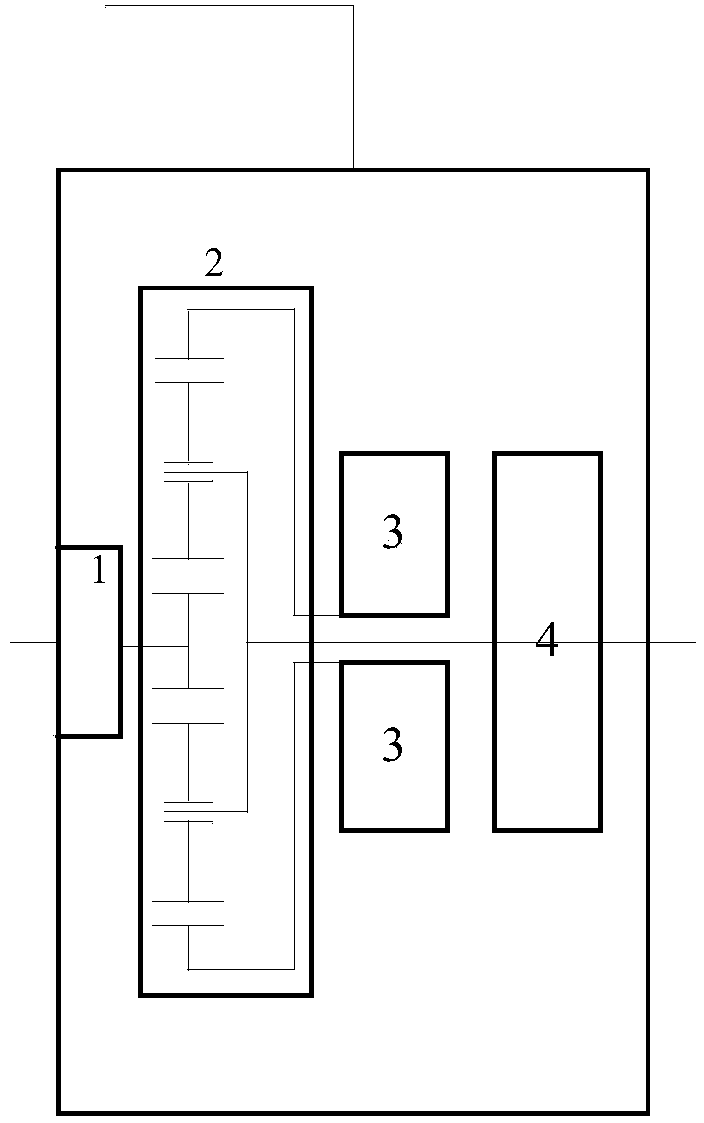

Novel portable passageway elevator

ActiveCN103787172ARealize power transmissionGuaranteed stabilityBuilding liftsElevator systemElectric machinery

The invention discloses a novel portable passageway elevator which comprises a power device, a guide device and a lift car (9). The power device is composed of a power chain wheel (4) and a driving motor (6), and the guide device is composed of a longitudinal guide wheel (2), a guide chain (5), a supporting body (7), a transverse guide wheel (8), an upper guide groove (11) and a lower guide groove (12). The passageway elevator is rapid and convenient to mount, and obvious in automatic lifting effect, the whole elevator system is small in occupied area, maintenance is convenient, and the elevator is quite suitable for being additionally arranged in an old building.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

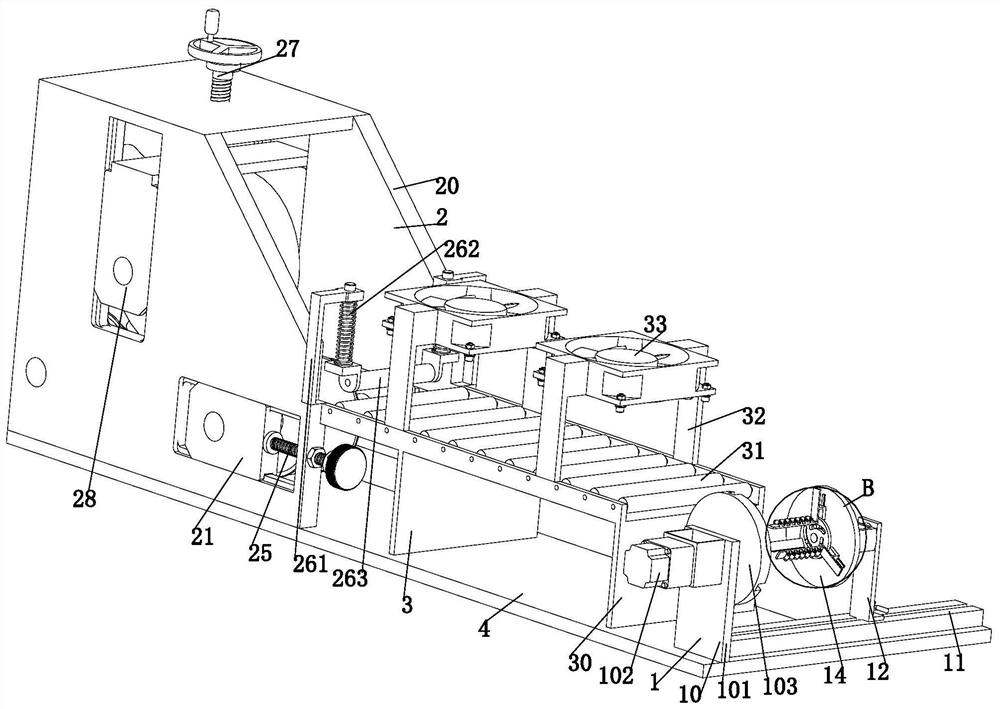

Production equipment of wood furniture

ActiveCN108857765AImprove processing efficiencyMeet the needs of different cutting anglesGrinding drivesBelt grinding machinesDrive wheelEngineering

The invention belongs to the field of furniture production, and particularly discloses production equipment of wood furniture. The production equipment comprises a rack. A supporting seat is arrangedon the rack. A driving wheel and a driven wheel are rotationally connected to the position, below the supporting seat, of the rack. A conveying belt is tensioned on the driving wheel and the driven wheel. A grinding face is arranged on the surface of the conveying belt. A mounting seat is rotationally connected to the supporting seat. An angle adjusting mechanism used for driving the mounting seatto rotate is arranged on the rack. A fixed part is fixedly connected to the mounting seat. The upper surface of the fixed part is in an arc shape, and the arc center of the arc shape coincides with the rotating center of the mounting seat. A pressing mechanism used for pressing the upper surface of the fixed part is arranged on the supporting seat. Through the adoption of the production equipment, corner cutting and grinding on a wood plate can be achieved at the same time.

Owner:YUQING COUNTY XINGDA FURNITURE MFG

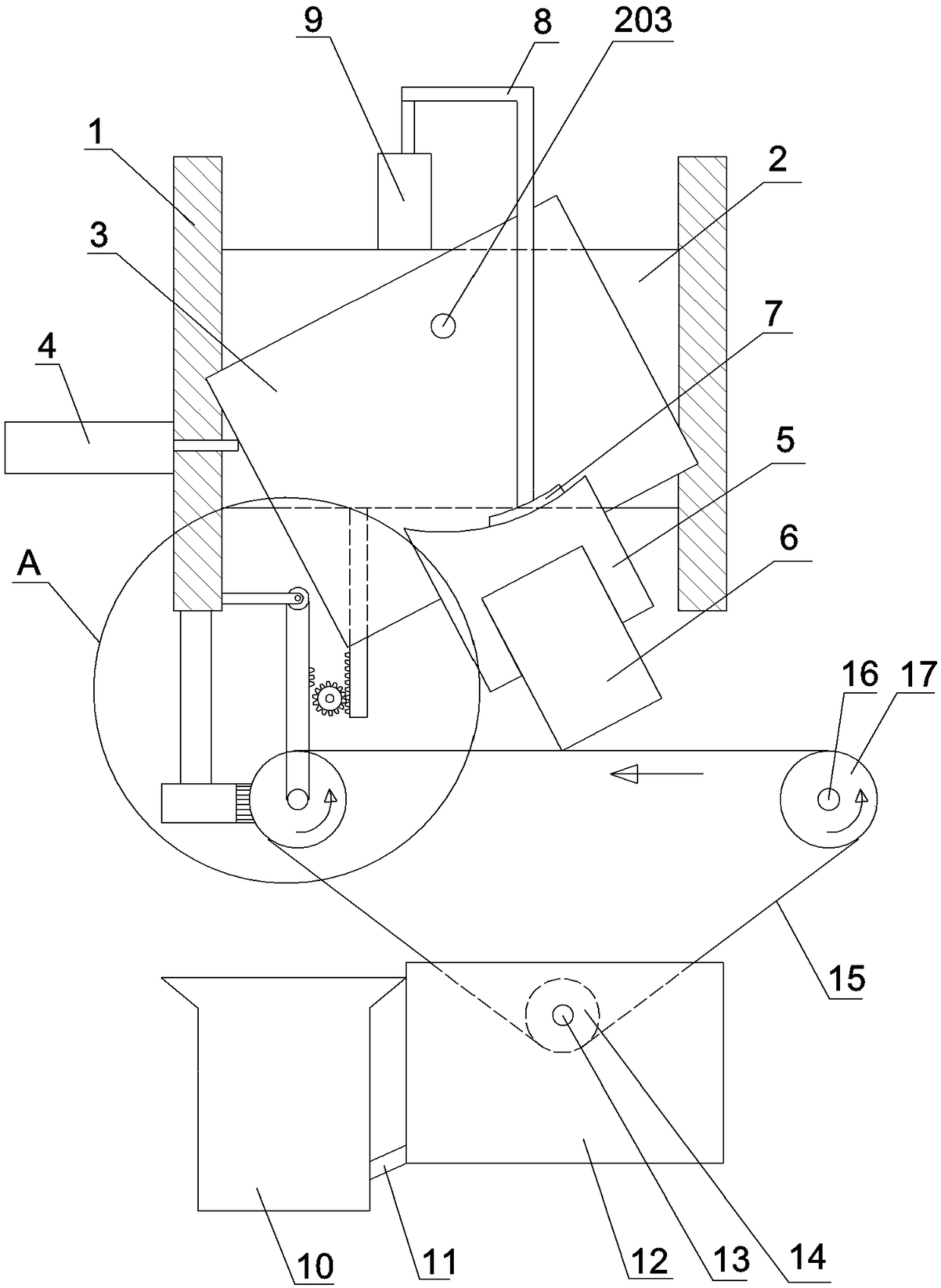

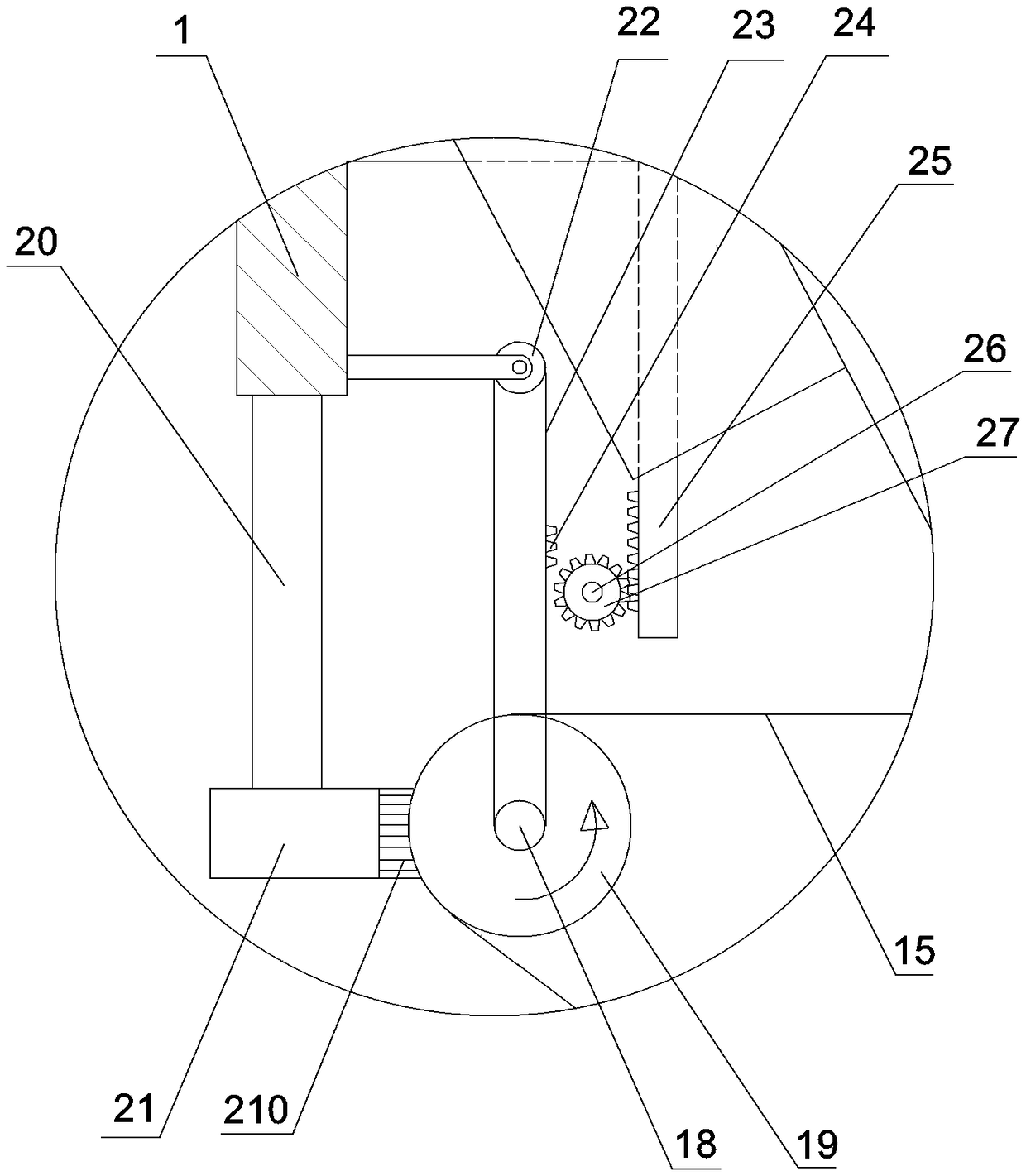

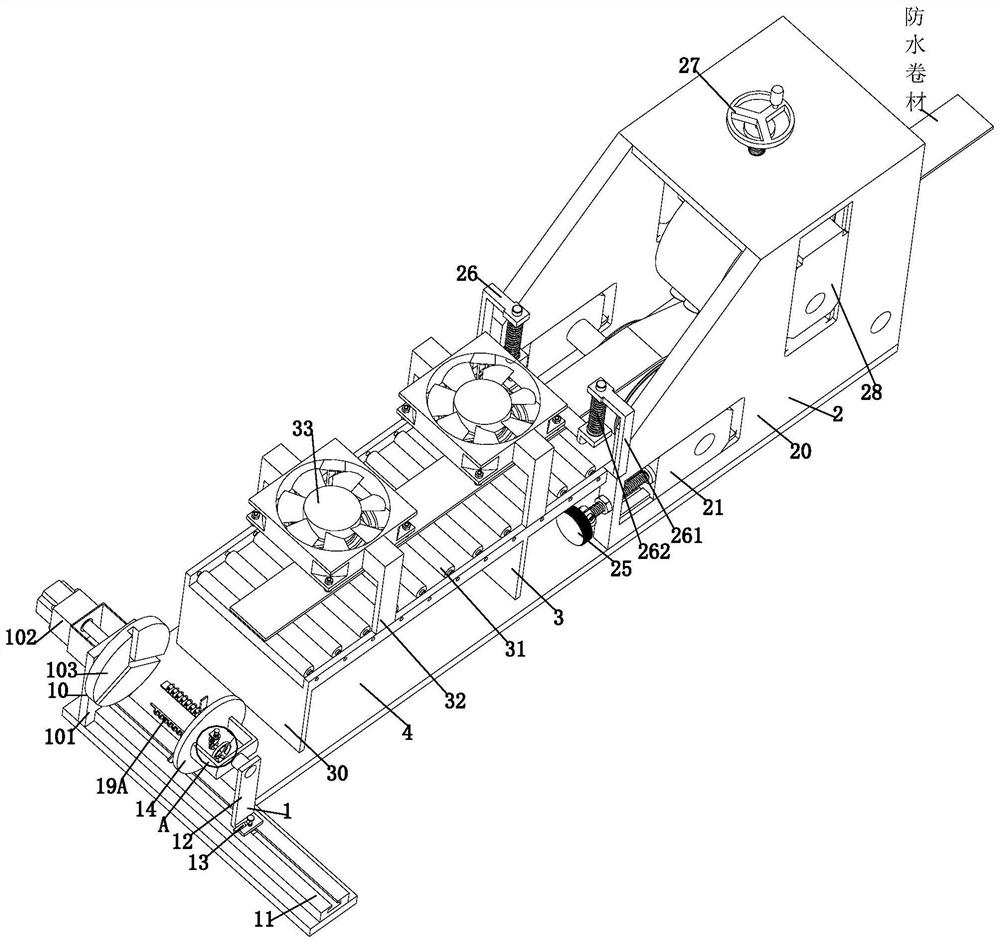

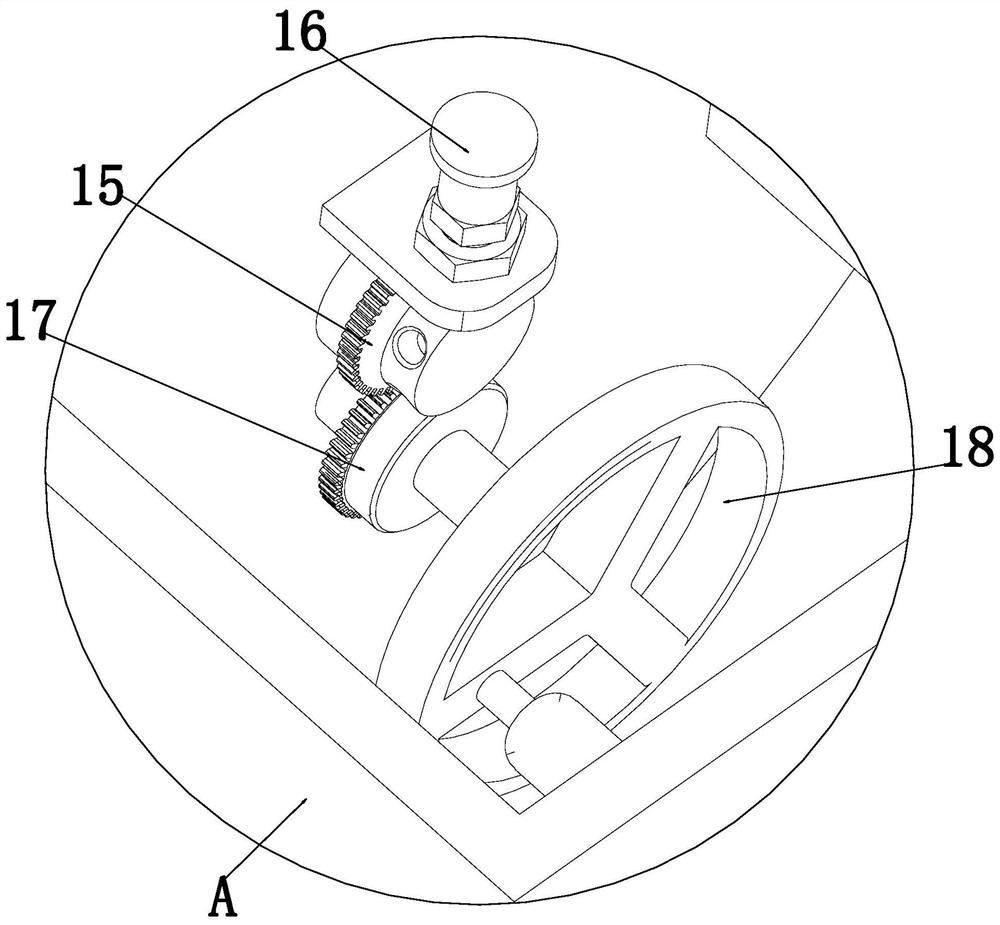

Coating device and method for waterproof roll coating

ActiveCN112295853AIncrease contact areaIncrease the coating area of the base surfacePretreated surfacesCoatingsComposite materialEngineering

The invention provides a coating device and method for a waterproof roll coating. The coating device comprises a winding mechanism, a roll coating mechanism, a drying mechanism and a bottom plate. Thewinding mechanism is mounted on the end face of the front portion of the bottom plate. The roll coating mechanism is mounted on the end face of the rear portion of the bottom plate. The drying mechanism is arranged between the roll coating mechanism and the winding mechanism and mounted on the bottom plate. The problems that in order to require uniform coating at present, a spray head large-areaspraying processing mode is adopted, so that an anti-corrosion coating material becomes highly-dispersed spray bodies, the spray bodies are prone to being exposed and dispersed in air, volatilized solvents are often pungent in taste, the processing environment is severe, the physical health of workers is threatened if the processing mode goes on like this, waste of coatings is prone to being caused by spraying, and economic losses are generated are solved; and in addition, natural airing needs to be conducted after spraying, so that the processing time is prolonged, an aired waterproof roll needs to be manually wound and collected, and the labor intensity of workers is increased.

Owner:WEIFANG HUAGUANG WATERPROOF MATERIALS

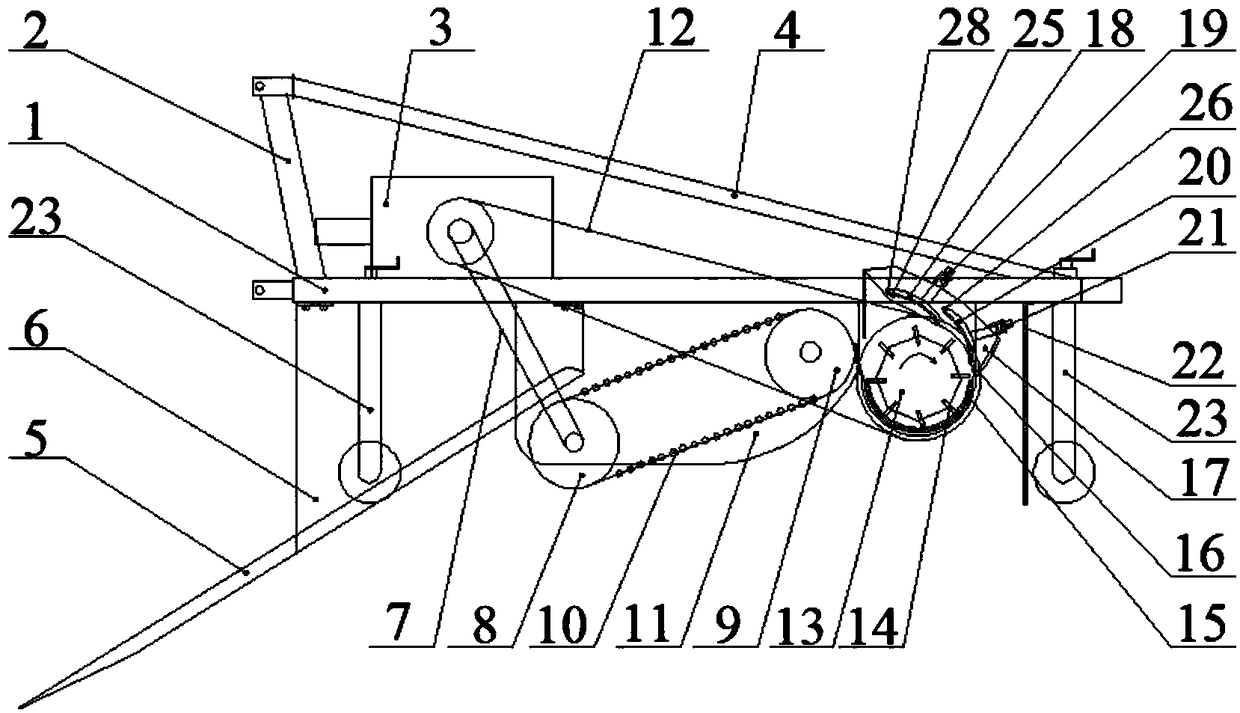

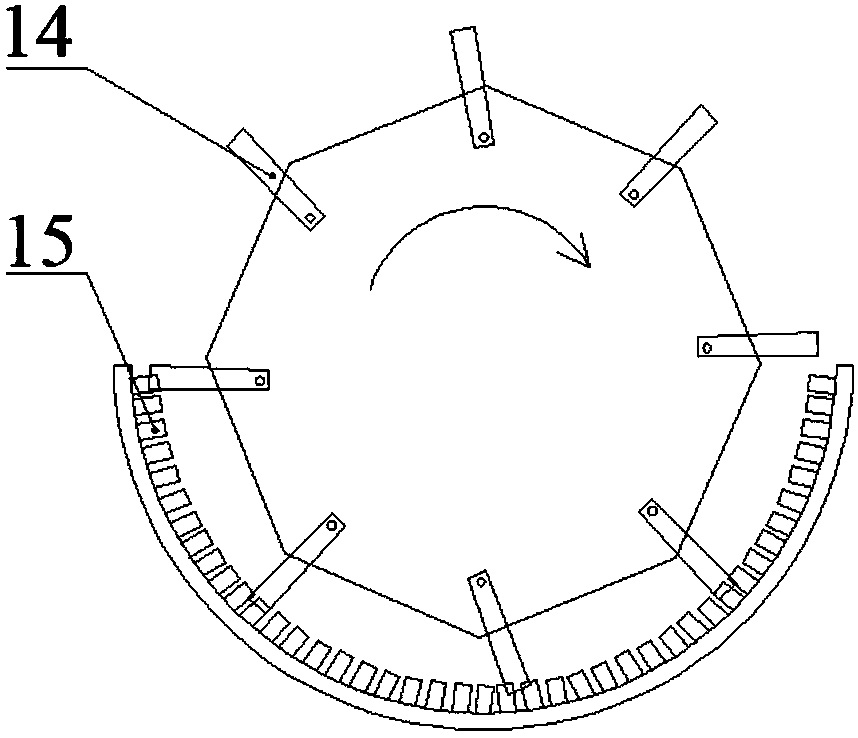

Farmland soil gravel picking, smashing and field returning device

PendingCN108184345ARealize power transmissionRealization of crushing and returning to fieldSievingScreeningSoil scienceAgricultural machinery

The invention relates to the technical field of agricultural machinery, in particular to a farmland soil gravel picking, smashing and field returning device. The device comprises a soil inserting part, a soil sieving part, and a smashing and field returning part, the soil inserting part comprises an soil inserting shovel, the soil sieving part comprises a soil sieving drive roller, a soil sievingdriven roller and a soil sieving bar screen, and the smashing and field returning part includes a soil smashing roller, a soil smashing roller fixing plate and first grade / second grade soil smashing baffles. The depth of soil insertion of the soil inserting shovel is adjusted by adjusting the depth of front limited depth wheel sets; a gap is reserved between the soil inserting shovel and the soilsieving bar screen to facilitate the sieving of fine soil particles; the soil sieving bar screen transports stones to the smashing and field returning part; the gaps between the first grade / second grade soil smashing baffles and the soil smashing roller are adjustable; the soil smashing roller and the soil smashing roller fixing plate are staggeredly provided with soil smashing moving blades and soil smashing fixed blades, the soil smashing moving blades and the soil smashing fixed blades are arranged staggeredly, the soil smashing roller fixing plate is provided with grid gaps, the broken stones drop to the ground through the grid gaps, and the stones which cannot drop to the ground continue to be broken in an inner cavity of the smashing and field returning part until all the stones dropto the ground.

Owner:CHINA AGRI UNIV

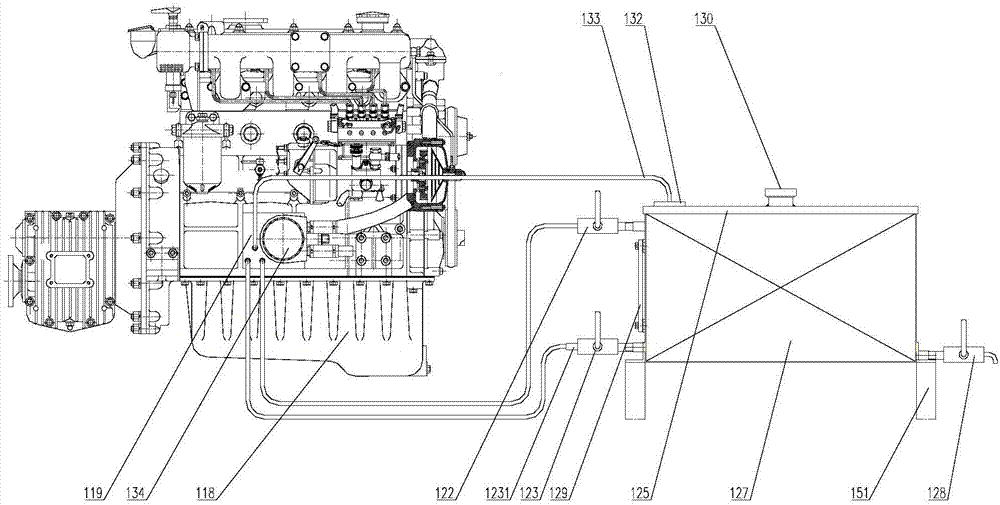

Multi-cylinder diesel engine lubricating system for lifeboat

ActiveCN107355280AAchieve recyclingTake advantage ofPropulsion power plantsLubricant conduit arrangementsFuel tankCrankcase

The invention discloses a multi-cylinder diesel engine lubricating system for a lifeboat. The lubricating system comprises an engine oil pump, a lubricating oil tank, a breathing tube, a machine body and an oil bottom shell, wherein the engine oil pump is a duplex pump with an oil inlet and an outlet which are separately independent, and is superposed up and down, the upper layer of the duplex pump is equipped with a lubricating pump and the lower layer of the duplex pump is equipped with an oil return pump; an oil inlet of the oil return pump extends to the bottom of an oil bottom shell mould cavity, and an oil outlet of the oil return pump extends to the lubricating oil tank; an oil inlet of the lubricating pump extends to the lubricating oil tank, an oil outlet of the lubricating pump extends to an inlet of a filter, and an outlet of the filter communicates with a machine body main oil path; a breathing one-way valve and an oil adding hole are arranged on an oil tank cover of the lubricating oil tank; an outlet of the breathing one-way valve communicates with one end of the breathing tube, and the other end of the breathing tube communicates with a crankcase; and meanwhile, an lubricating oil flow distributing method for a lifeboat diesel engine is set. According to the multi-cylinder diesel engine lubricating system disclosed by the invention, functions of collecting engine oil and storing the engine oil of an oil bottom shell of the lifeboat diesel engine are separated, so that the diesel engine can normally work regardless of being longitudinally and transversely turned over and reversed.

Owner:镇江四洋柴油机制造有限公司

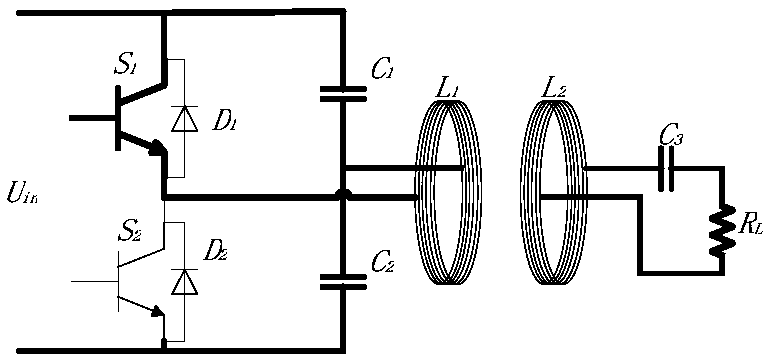

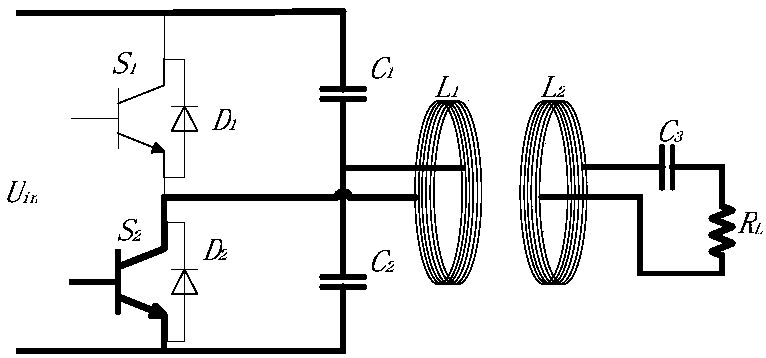

Half-bridge resonant wireless energy transmission system

ActiveCN107681791ARealize power transmissionHigh Efficiency Power TransmissionCircuit arrangementsElectric energyResonator

The invention discloses a half-bridge resonant wireless energy transmission system and relates to wireless energy transmission. The half-bridge resonant wireless energy transmission system is providedwith a DC power supply, a BUCK circuit, a half-bridge inverter circuit, a first resonator, a second resonator and an auxiliary circuit. A control method comprises the following steps of achieving adjustment of output power and achieving maintenance of resonant states of the system. Wireless transmission of electric energy is carried out through an inductive coupling mode; maintenance of the resonant states of the system under different power conditions is achieved through adding the BUCK circuit to a preceding stage of the half-bridge inverter circuit; and high-efficiency electric energy transmission is achieved.

Owner:厦门金固美能源科技有限公司

Anti-shake intelligent manipulator for feeding of packaging machine

InactiveCN107934023AReduce vibrationEasy to operateProgramme-controlled manipulatorGripping headsEngineeringOperability

The invention discloses an anti-shake intelligent manipulator for feeding of a packaging machine. The anti-shake intelligent mechanical arm comprises mechanical arms, a mechanical disc and mechanicalclaws; an extension spring is arranged at the inner side of the mechanical arms; rotating shafts are installed among the mechanical arms; the mechanical claws are arranged at the right side of the mechanical disc; the mechanical disc is positioned at the right side of the mechanical arms; each regulating shaft is installed inside the corresponding mechanical claw, and the mechanical claws are positioned below the mechanical disc; a connecting plate is installed below the mechanical arms; a shock absorbing plate is arranged below the connecting plate; a shock absorbing spring is installed at the inner side of the shock absorbing plate; a fixing disc is arranged below the shock absorbing plate; a fastening sleeve is installed at the outer wall of the fixing disc; and the left and right sidesof the fastening sleeve are each provided with a threaded hole. The anti-shake intelligent manipulator for feeding of the packaging machine can effectively weaken stop shock in actual running, the shrinkage range of the mechanical claws is obviously limited, and the manipulator can perform 360-degree large-amplitude rotation motion and has quite high operability.

Owner:深圳市创信包装材料科技有限公司

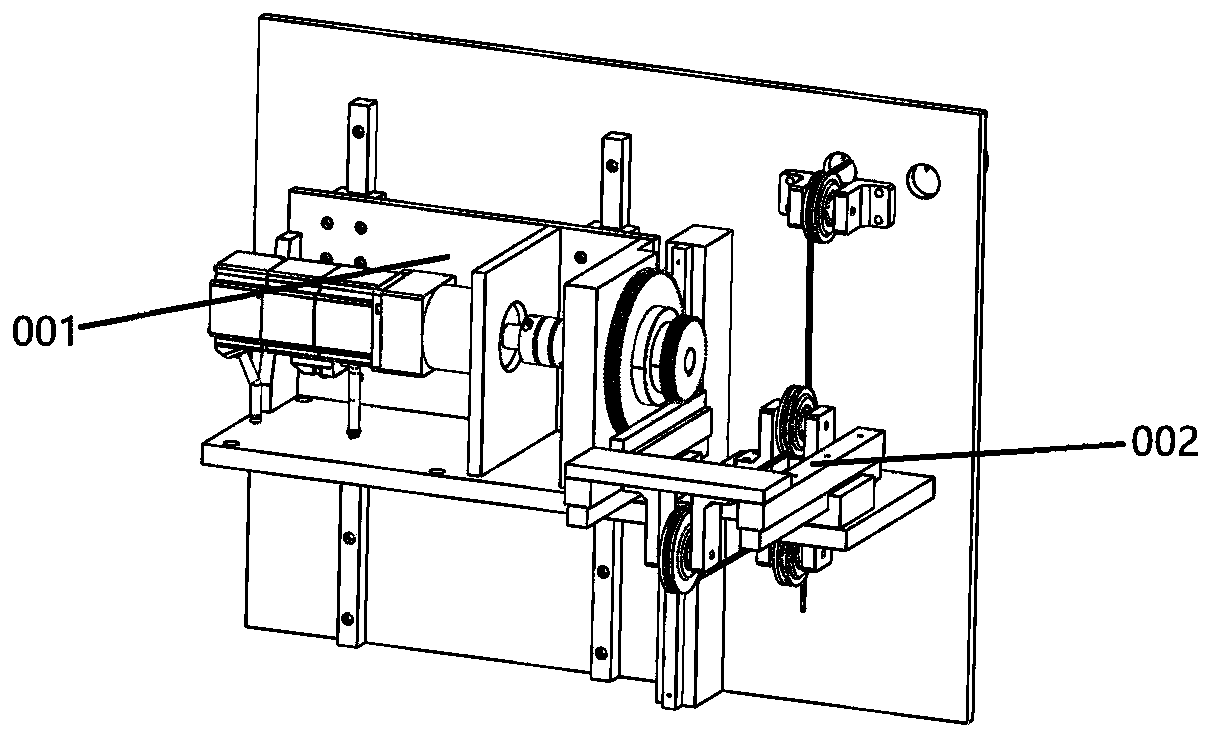

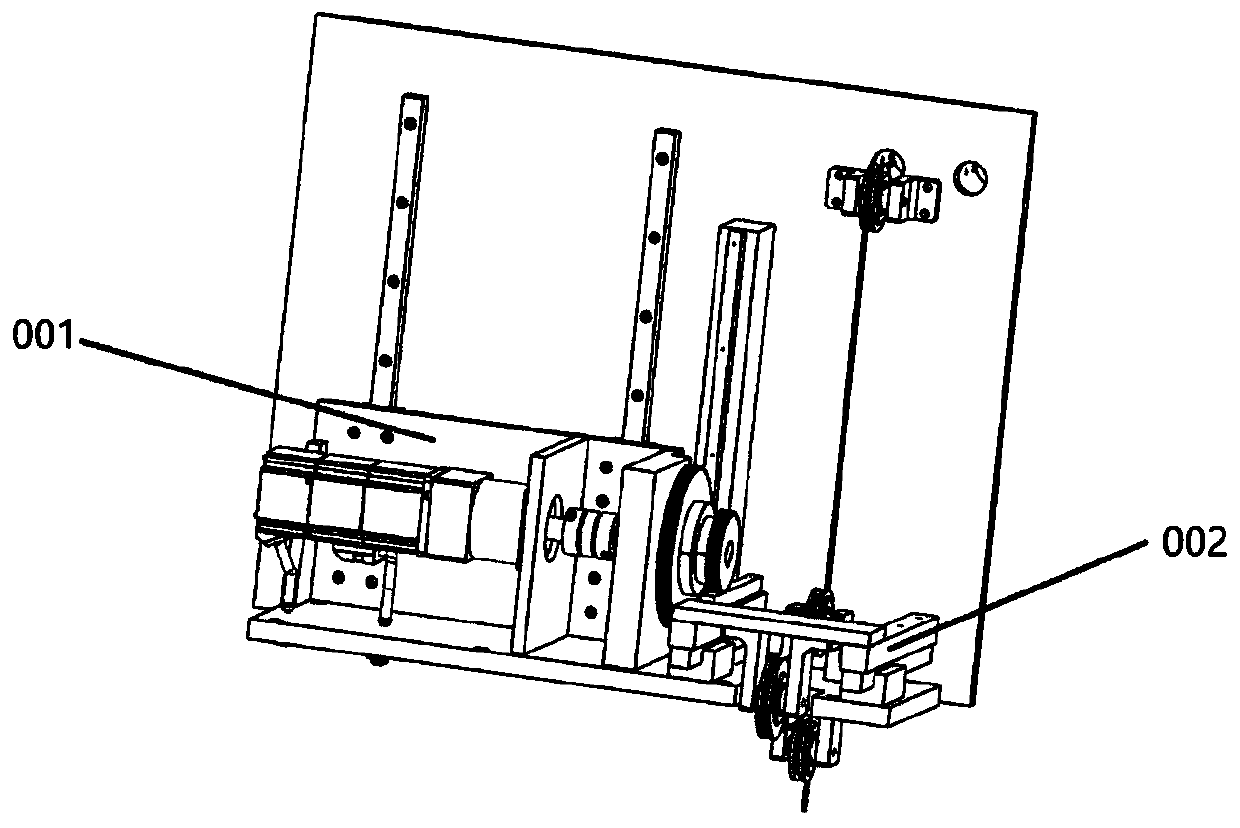

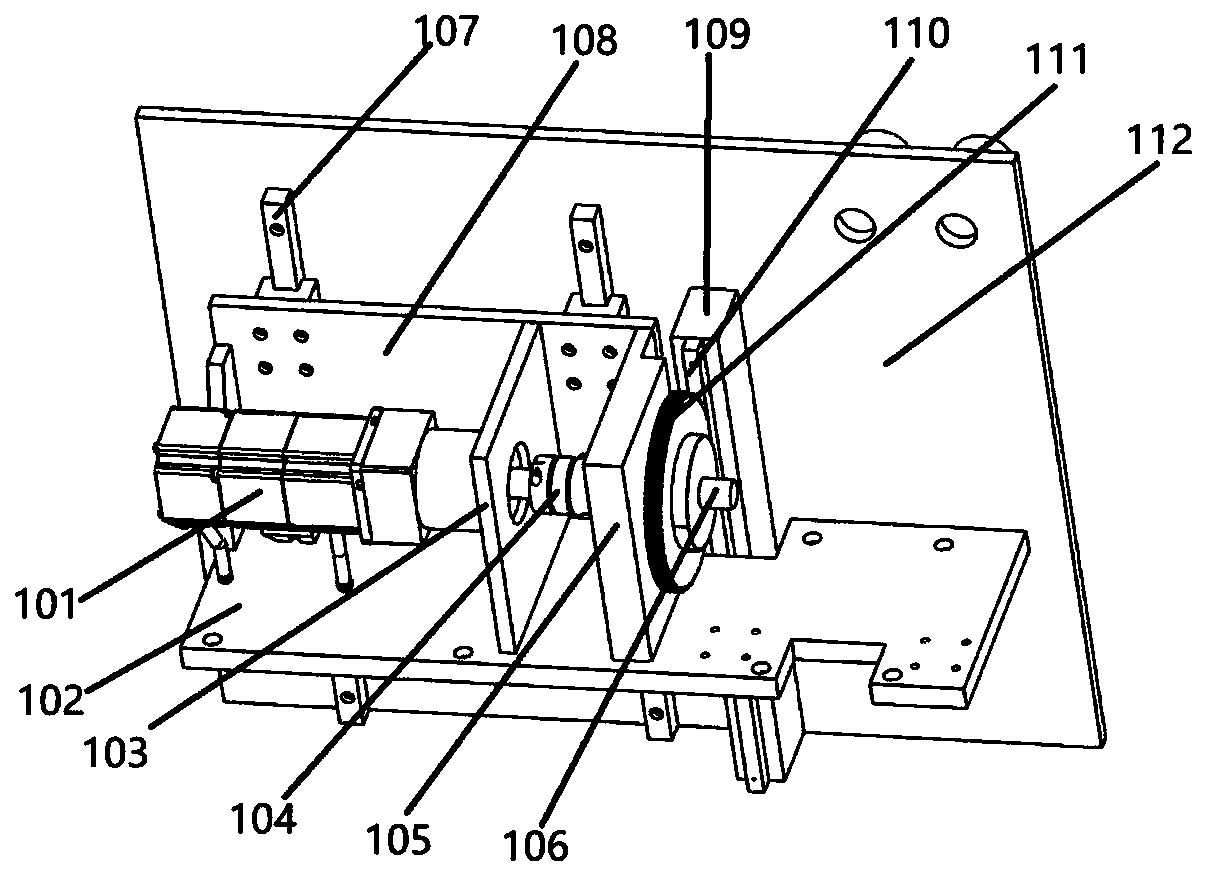

Stretchable motion device with rope automatic tensioning function

ActiveCN111571574ARealize automatic tensioningRealize power transmissionProgramme-controlled manipulatorChiropractic devicesGear wheelReduction drive

The invention relates to a stretchable motion device with a rope automatic tensioning function. The device comprises a stretchable motion mechanism and a steel wire rope length compensation mechanism,wherein the stretchable motion mechanism comprises a bottom plate and a motor-reducer arranged on the bottom plate, the output end of the motor-reducer is provided with a gear rack mechanism I, and the output end of the gear rack mechanism I is fixed on a lifting plate; the steel wire rope length compensation mechanism comprises a gear rack mechanism II mounted at the output end of the motor-reducer, the gear rack mechanism II is slidably connected with the bottom plate through a wire rail sliding block assembly II, and the second wire rail sliding block assembly II is connected with the lifting plate through a pulley block; and one end of a steel wire rope is connected with a counterweight module, and the other end of the steel wire rope is connected with an arm of a patient through thepulley block. According to the stretchable motion device with the rope automatic tensioning function, the gear rack mechanisms and the pulley block structure are adopted to realize automatic tensioning of the steel wire rope.

Owner:湖北英特搏智能机器有限公司

Mobile equipment with wireless charging and discharging function and device

InactiveCN105262233AImprove wireless transmission efficiencyStable and reliable wireless communicationBatteries circuit arrangementsElectric powerCapacitanceInductor

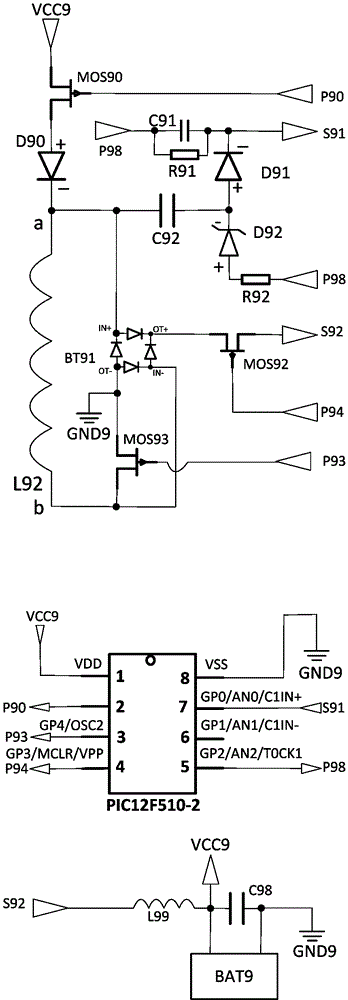

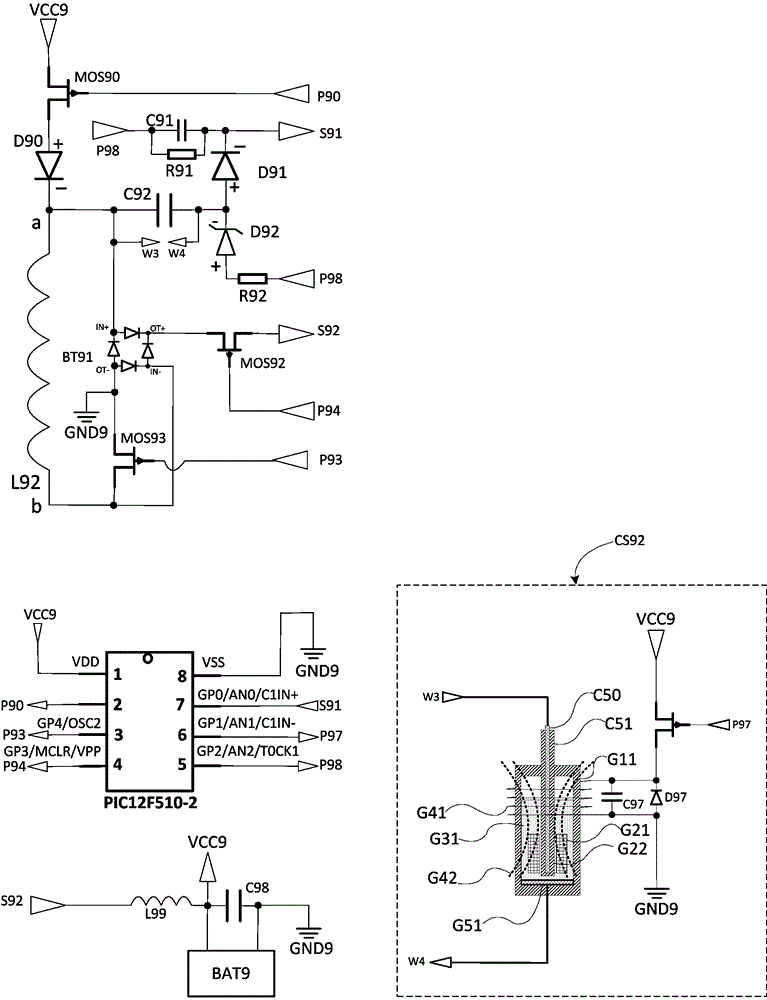

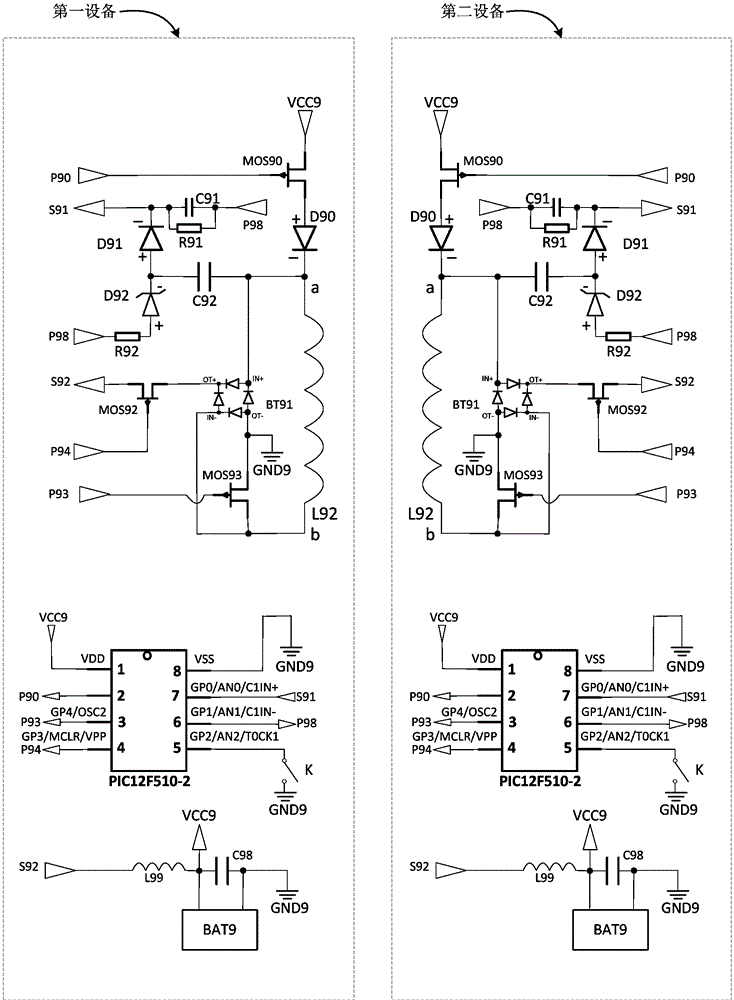

The invention relates to mobile equipment with a wireless charging and discharging function, which is characterized by further comprising a transmitting switch (MOS90), a protection diode (D90), a high-pass filtering capacitor (C92), a sampling site (P98), a voltage stabilizing tube (D92), a half-wave rectification diode (D91), a sampling resistor (R91), a current-limiting resistor (R92), a sampling capacitor (C91), a rectifier bridge (BT1), an electric energy receiving switch (MOS92), an electric energy receiving control point (P94), a change-over switch (MOS93), a coil (L2), a power supply point (VCC9), a ground point (GND9), a transmission control point (P90), an electric energy receiving point (S92), a switching control point (P93), a sampling output point (S91), a single chip microcomputer (PIC12F510-2), a rechargeable battery (BAT), a low-pass filtering inductor (L99) and a power supply output capacitor (C98). The invention further relates to a device, which is additionally provided with a control program on the basis of the solution. The mobile equipment and the device provided by the invention are low in cost, flexile in application, long in service life and capable of mutually transmitting electric energy and information.

Owner:NINGBO LIKETEK INFORMATION TECH

Lifeboat diesel engine lubricating system

ActiveCN107143399AAchieve recyclingTake advantage ofMachines/enginesLubricant filling/drainingFuel tankCrankcase

A lifeboat diesel engine lubricating system comprises an oil pump and a machine body. A crank case is arranged in the machine body. An oil sump is arranged at the bottom of the machine body. The lubricating system further comprises a lubricating oil tank and a breathing pipe, wherein the lubricating oil tank is arranged beside the machine body, and the bottom of the lubricating oil tank is provided with a support. The oil pump is a double pump with an oil inlet and an oil outlet which are independent and includes a lubricating pump body and an oil return pump body. The oil inlet of the oil return pump is formed in the bottom of an oil sump cavity, and the oil outlet is led to the lubricating oil tank. A lubricating pump oil inlet is formed in the lubricating oil tank, an outlet is led to a machine filter inlet, and a machine filter outlet communicates with a machine body main oil way. The lubricating oil tank comprises an oil tank cover and an oil tank body. The oil tank cover is provided with a breathing port and an oil adding port. An oil discharging valve is arranged at the bottom of an oil tank body, and an oil level indicator is arranged on the side face of the oil tank body. The engine oil collecting function and the engine oil storage function of the lifeboat diesel engine oil sump are separated, and a diesel engine can normally work when the diesel engine is longitudinally or transversely overturned and inverted.

Owner:镇江四洋柴油机制造有限公司

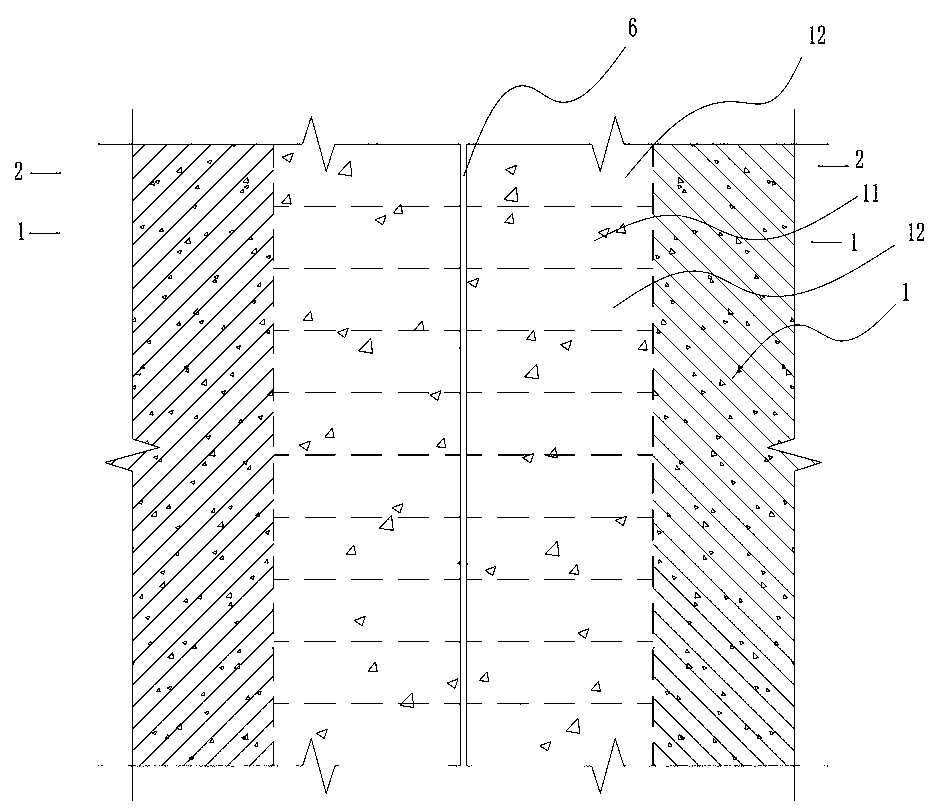

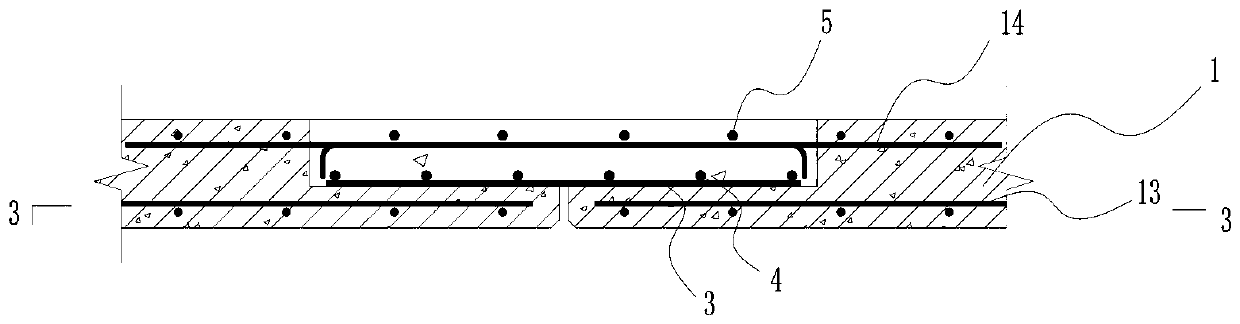

Local laminated slab connection joint and construction method thereof

ActiveCN110344530AIncreased bearing capacity and stiffnessRealize power transmissionFloorsSteel barBearing capacity

The invention provides a local laminated slab connection joint. The connection joint includes two prefabricated plates. The end parts of the prefabricated plates are provided with grooves. Bottom grooves are arranged in the grooves. The bottom grooves in the two prefabricated plates are arranged opposite to each other and form a through groove. First reinforcing ribs are arranged in the bottom grooves. Second reinforcing ribs are arranged in the grooves. The upper sides of the second reinforcing ribs are provided with third reinforcing ribs perpendicular to the second reinforcing ribs. The prefabricated plates are provided with top steel bars. The top steel bars extend from the side walls of the grooves to the upper ends of the grooves of the corresponding prefabricated plates. The upper sides of the top steel bars are provided with fourth reinforcing ribs. The local laminated slab connection joint can meet force transmission requirements of a two-way slab, and the rigidity and the bearing capacity of a connecting part are large.

Owner:ZHEJIANG DADONGWU CONSTR TECH CO LTD

Mechanical-electric hybrid energy change device and control method thereof

ActiveCN104029672ASimple structureLow costHybrid vehiclesPlural diverse prime-mover propulsion mountingElectric machineMechanical energy

The invention discloses a mechanical- electric hybrid energy change device and a control method thereof. The device mainly comprises a planet line (2), a clutch structure and two motors, wherein an input end of a sun wheel is connected with an output end of an engine through the clutch structure, a gear ring is connected with a rotating shaft of the first motor, a planet carrier is connected with a rotating shaft of the second motor, and the rotating shaft of the second motor is a power output end of the mechanical-electric hybrid energy change device. According to the control method disclosed by the invention, through control of the motors under various working conditions, the normal operation of vehicles under various working conditions is realized. The device disclosed by the invention is simple in structure and lower in cost; the comprehensive high-efficient output of mechanical energy and electric energy can be realized, the braking energy of the vehicles can be recycled, the power performance of the vehicles is greatly improved, and at the same time, the economic performance and the environmental protection performance of the vehicles while running are improved; a goal of stepless speed change can be realized; in addition, the requirement of a special function that the vehicles run purely electrically can be realized.

Owner:CHINA NORTH VEHICLE RES INST

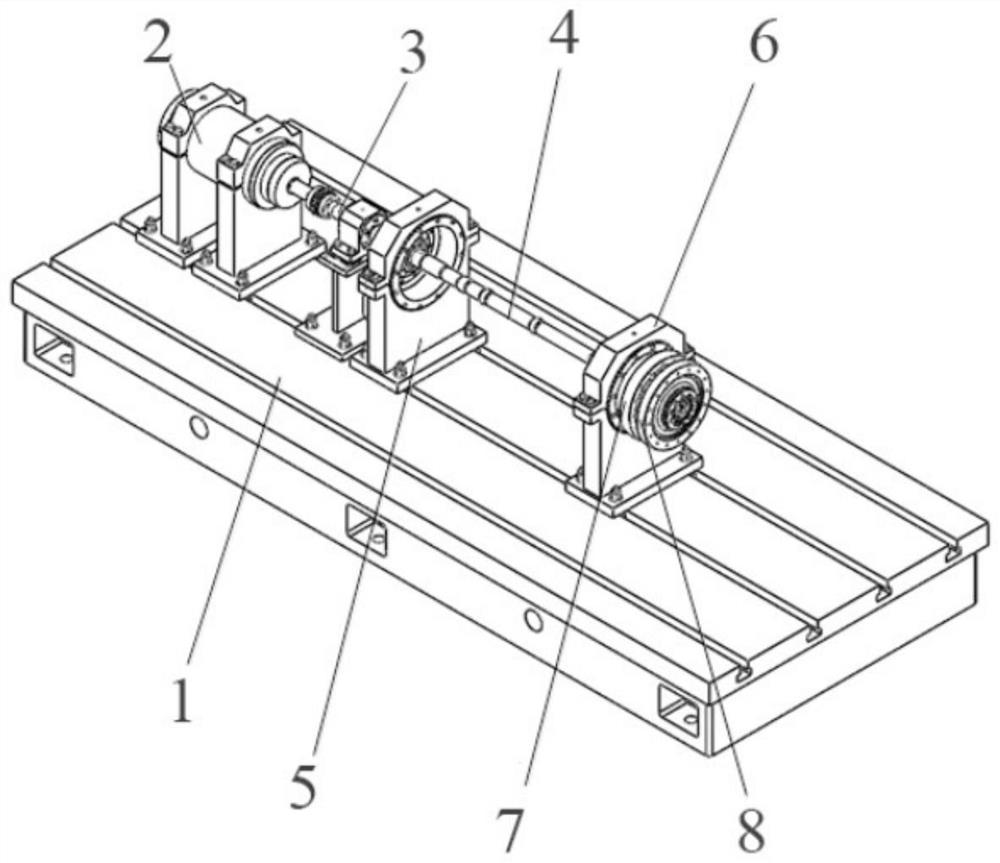

Aero-engine rotor simplified equivalent test device for high-speed dynamic balance

ActiveCN113432784AProcessing and manufacturing advantagesReduce computational difficultyEngine testingStatic/dynamic balance measurementElectric machineryDynamic balance

The invention relates to an aero-engine rotor simplified equivalent test device for high-speed dynamic balance. The aero-engine rotor simplified equivalent test device comprises a T-shaped groove platform, a high-speed motor, a spline transmission shaft, a slender shaft, a short shaft, a movable turbine disc and a supporting device. The high-speed motor, the spline transmission shaft, the slender shaft, the short shaft and the movable turbine disc are arranged on the T-shaped groove platform through the supporting device. The high-speed motor is in transmission connection with one end of the slender shaft through the spline transmission shaft; the other end of the slender shaft is in interference fit connection with the short shaft; the movable turbine disc is arranged on the short shaft; and the high-speed motor can drive the movable turbine disc to rotate by means of the slender shaft so as to simulate the dynamic evolution of an aero-engine rotor during operation. According to the simplified test device provided by the invention, complex parts are equivalent to simple disc and shaft parts through a certain simplification mode, so that the calculation difficulty can be greatly reduced, and meanwhile, the simplified test device also has great advantages in the aspect of processing and manufacturing of test pieces.

Owner:NORTHEASTERN UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com