Patents

Literature

539results about How to "No looseness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

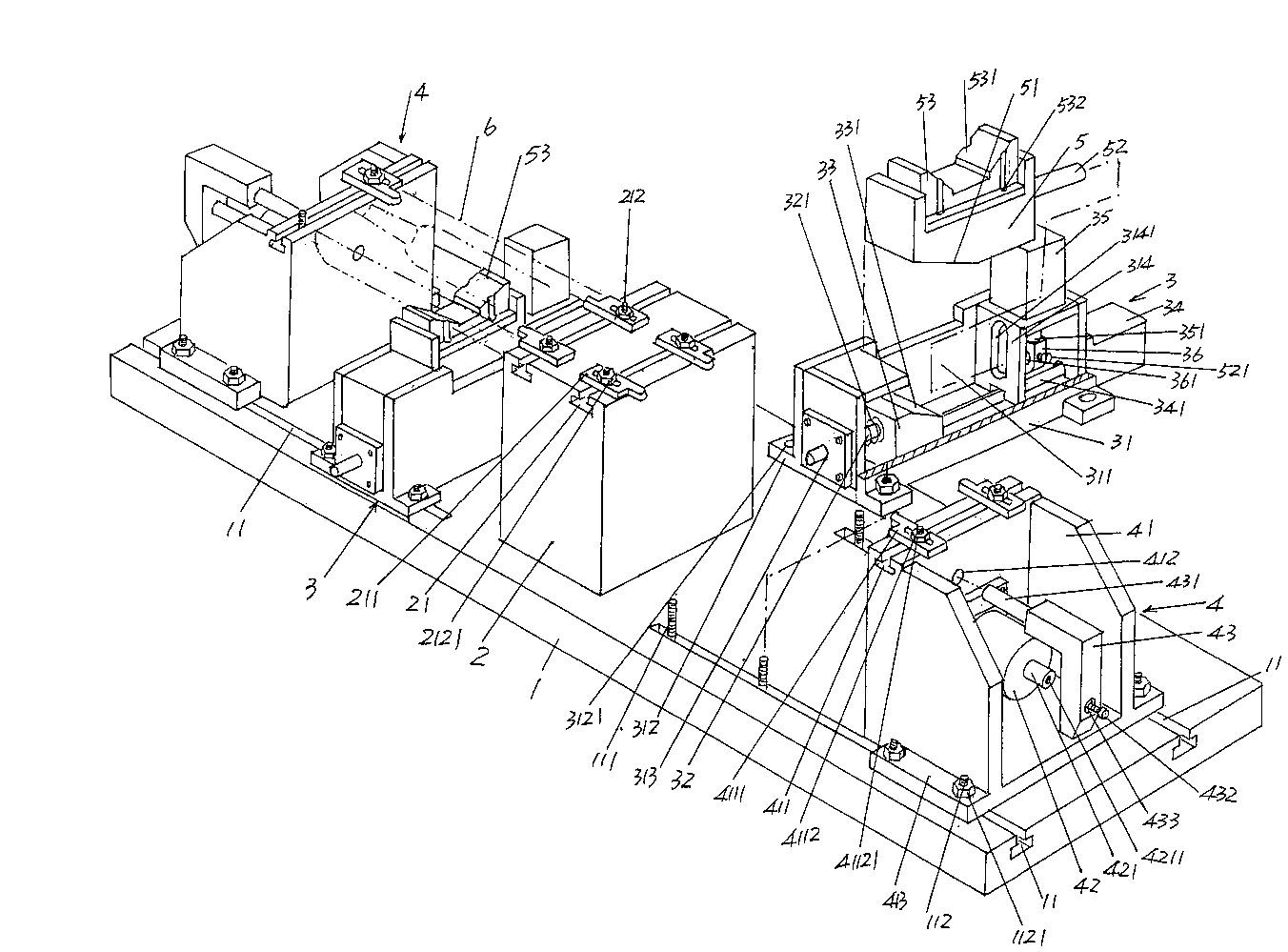

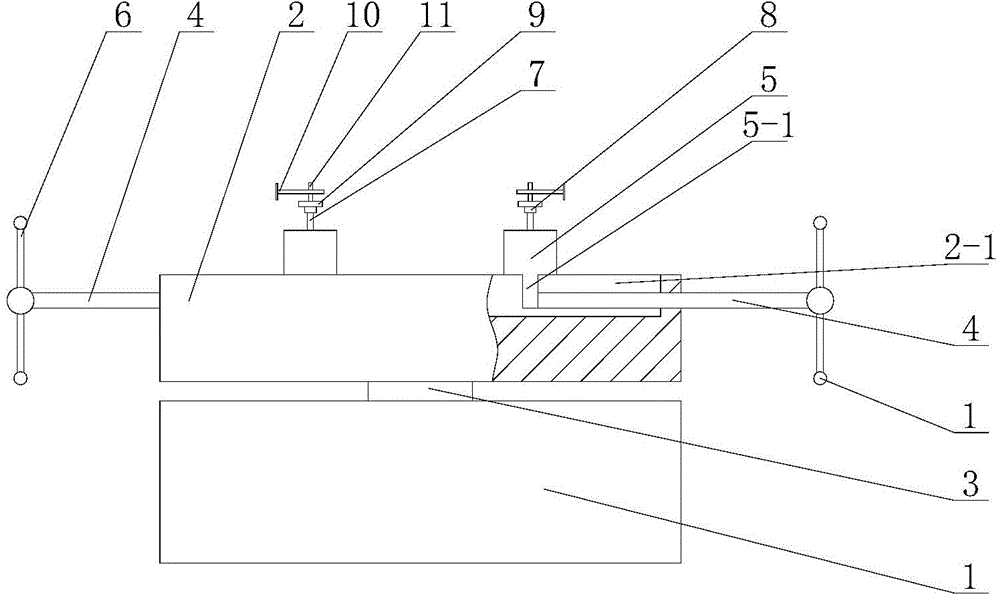

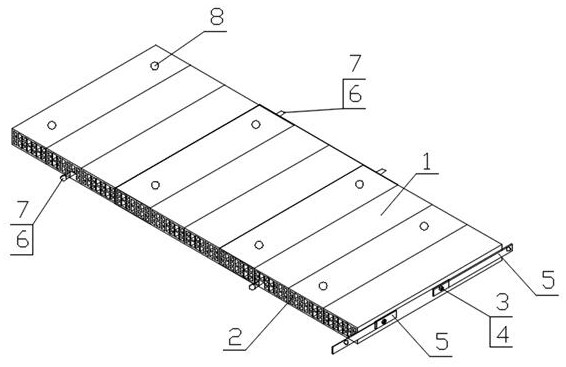

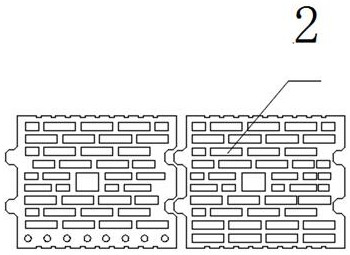

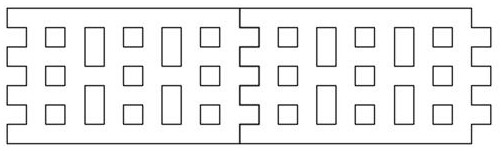

Fixture structure for machining inner cavities and joint closing surfaces of glass molds

ActiveCN103056695AEasy to settleReduce work intensityPositioning apparatusMetal-working holdersLocking mechanismEngineering

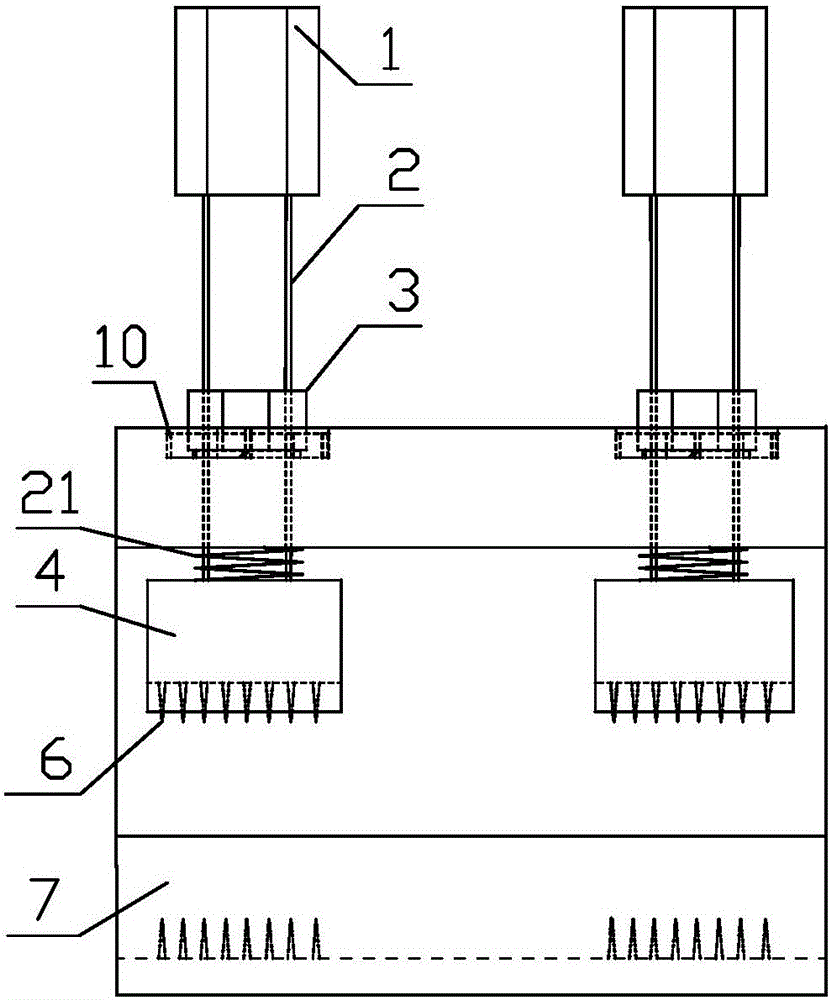

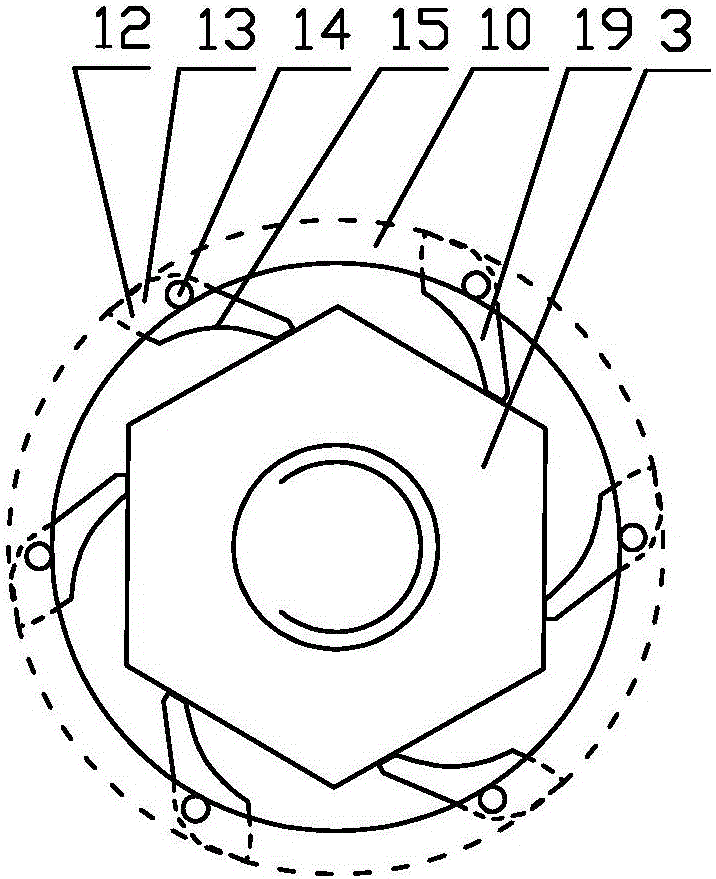

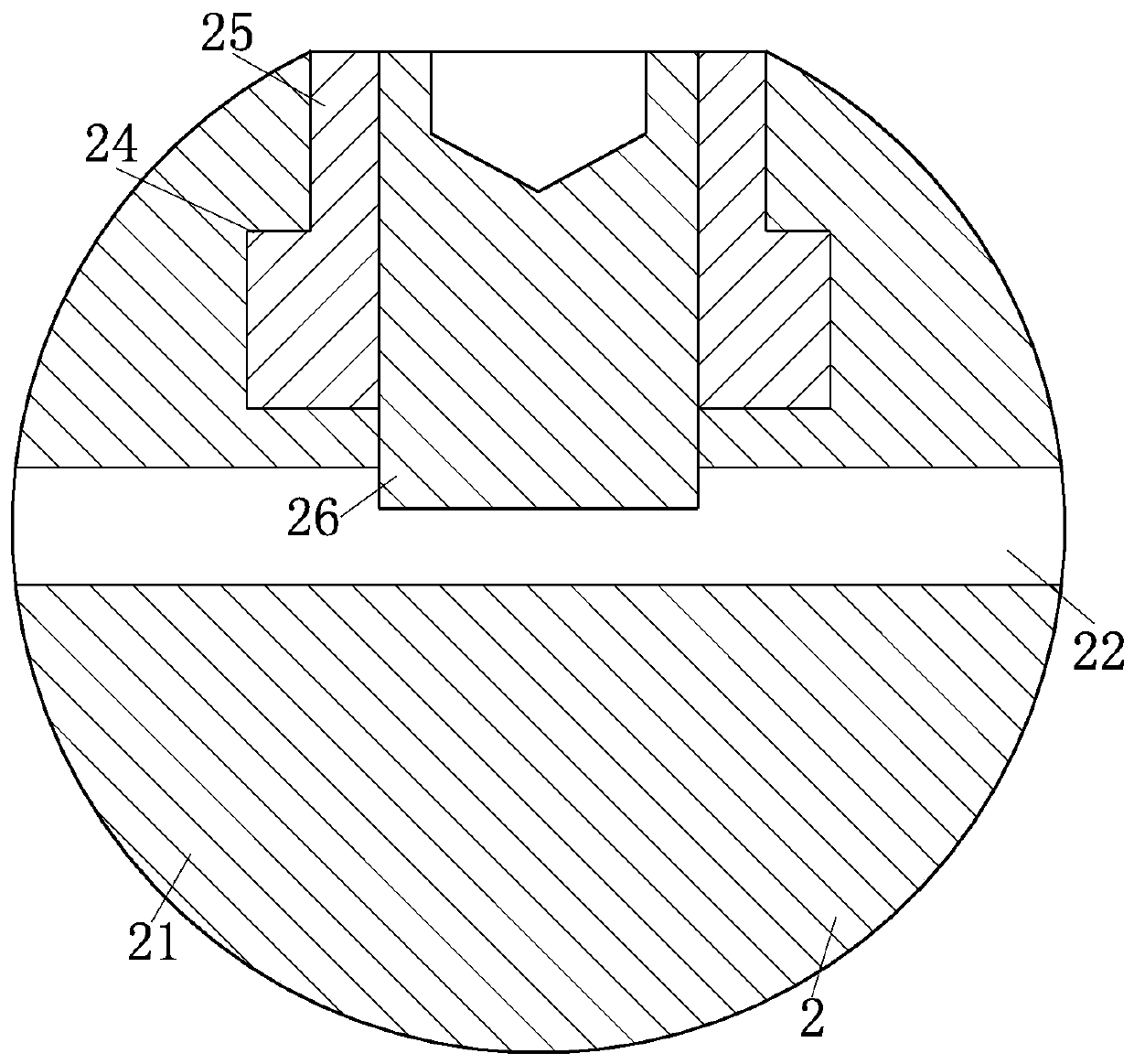

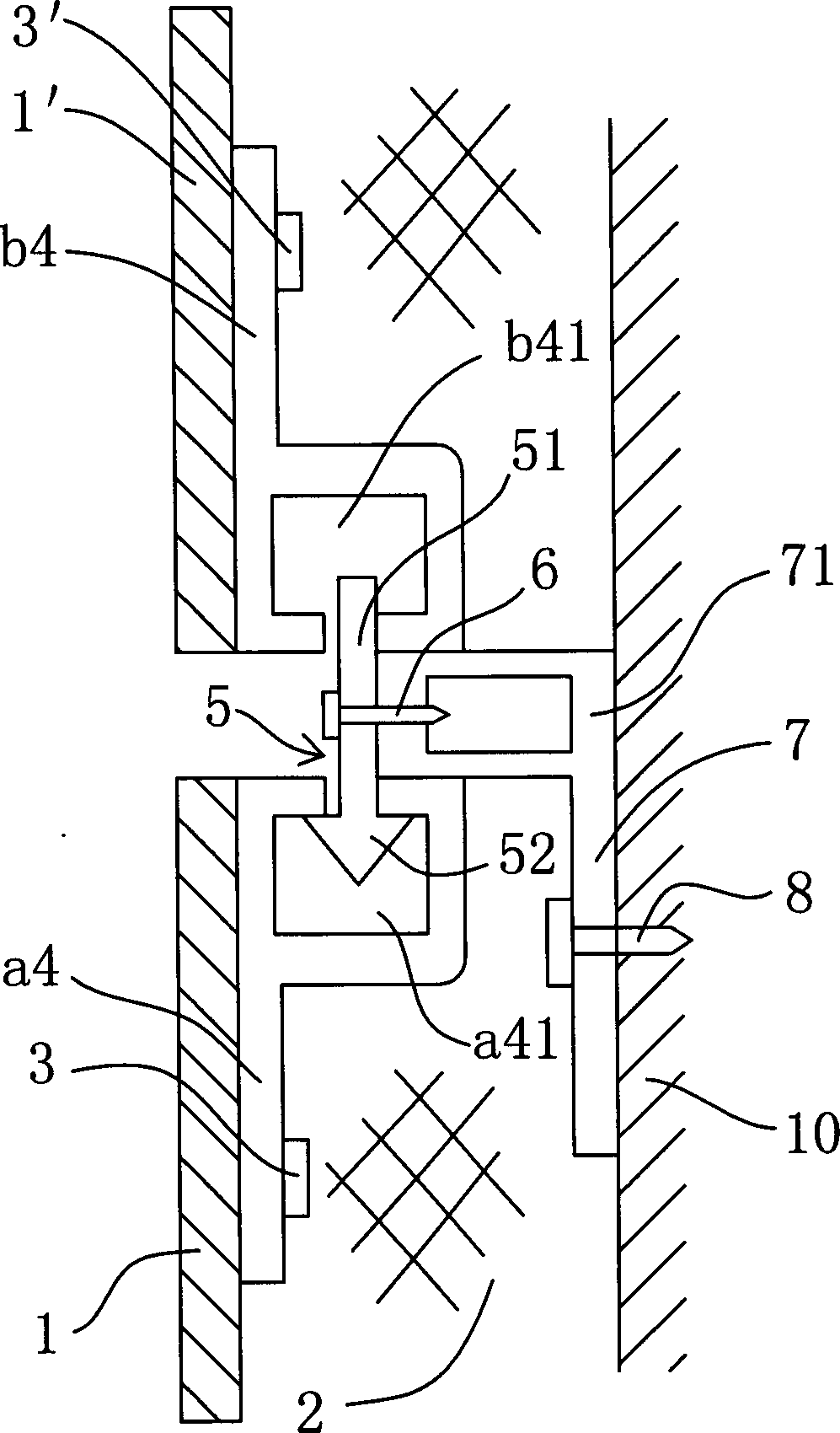

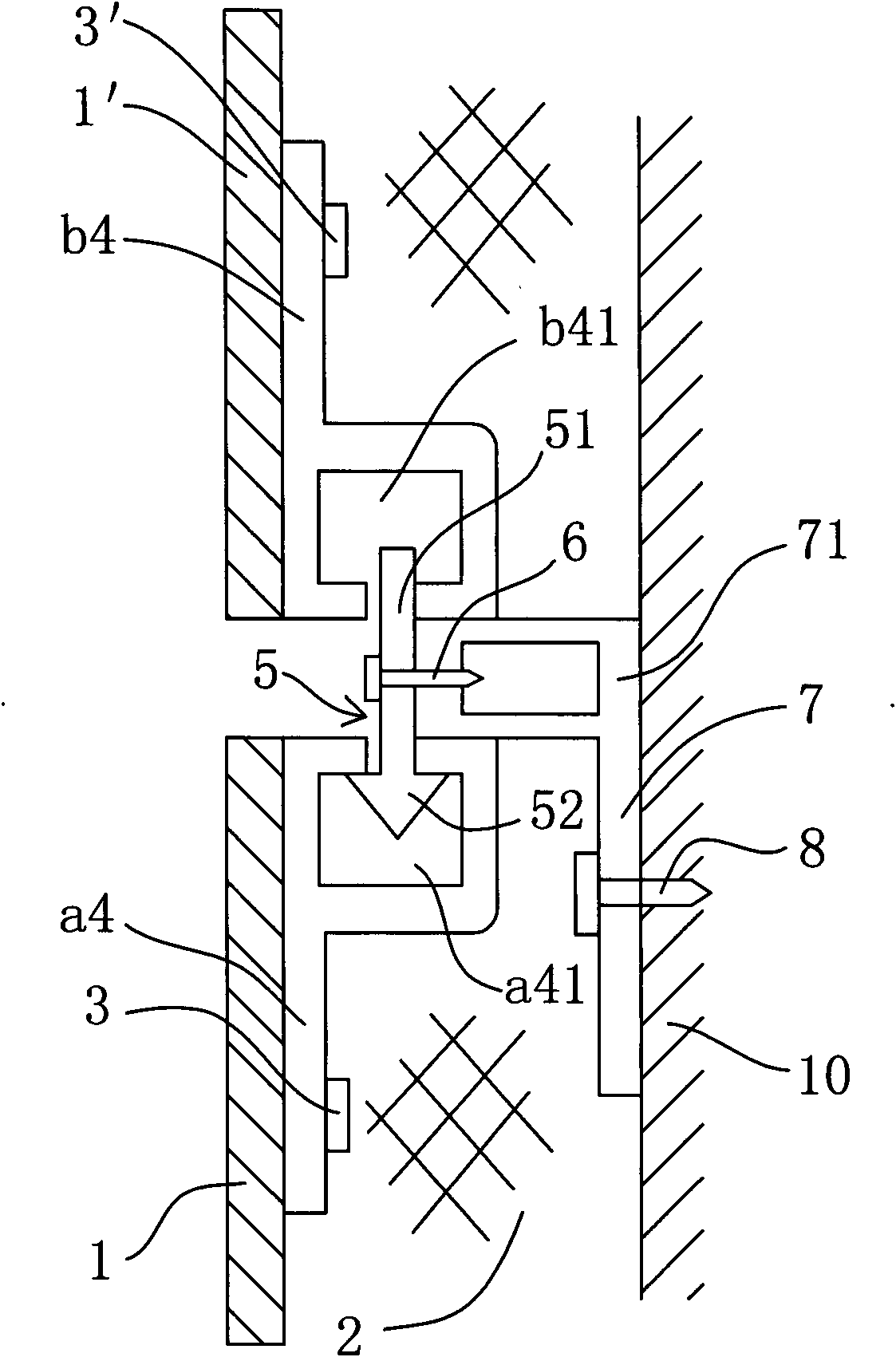

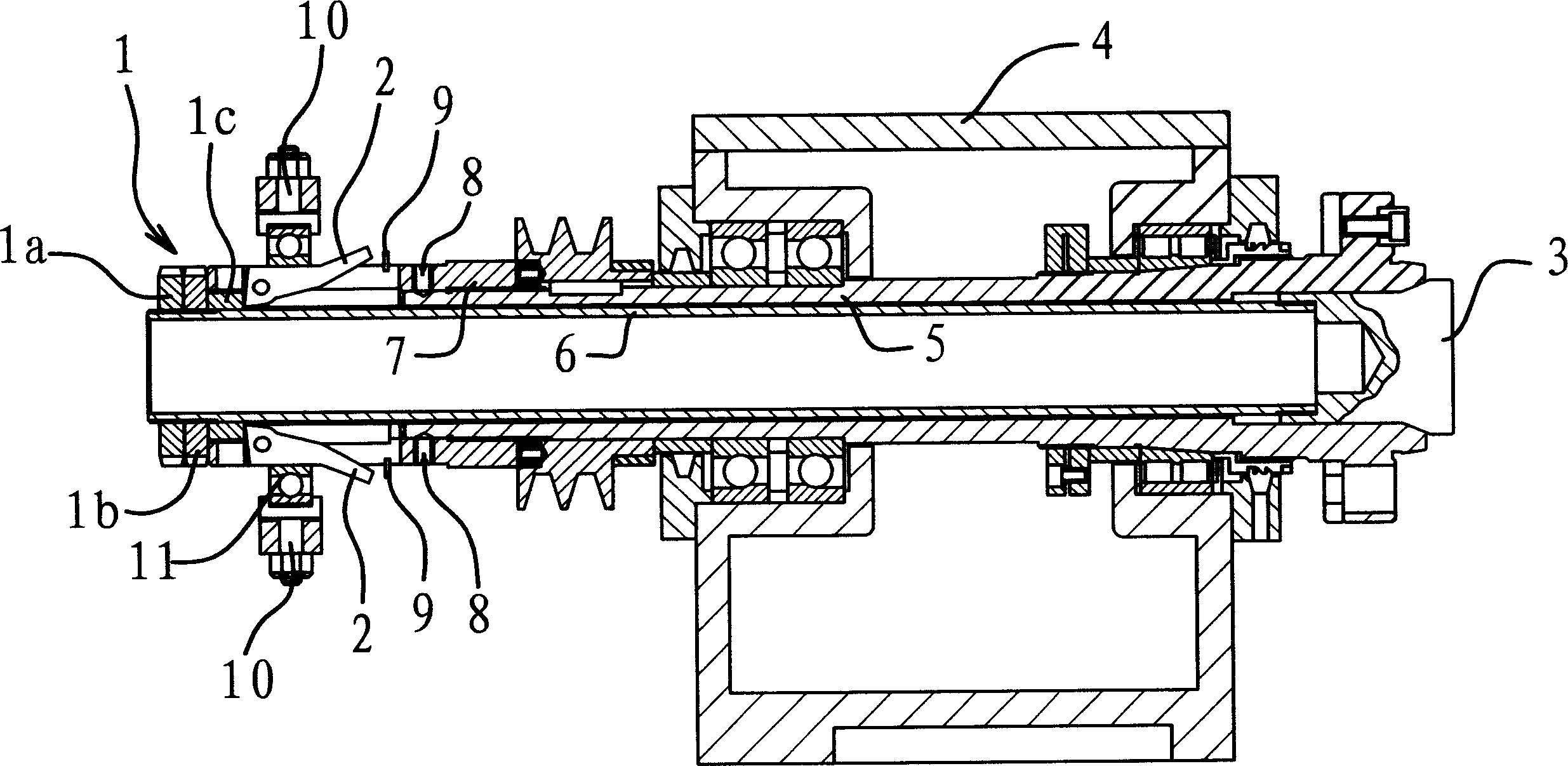

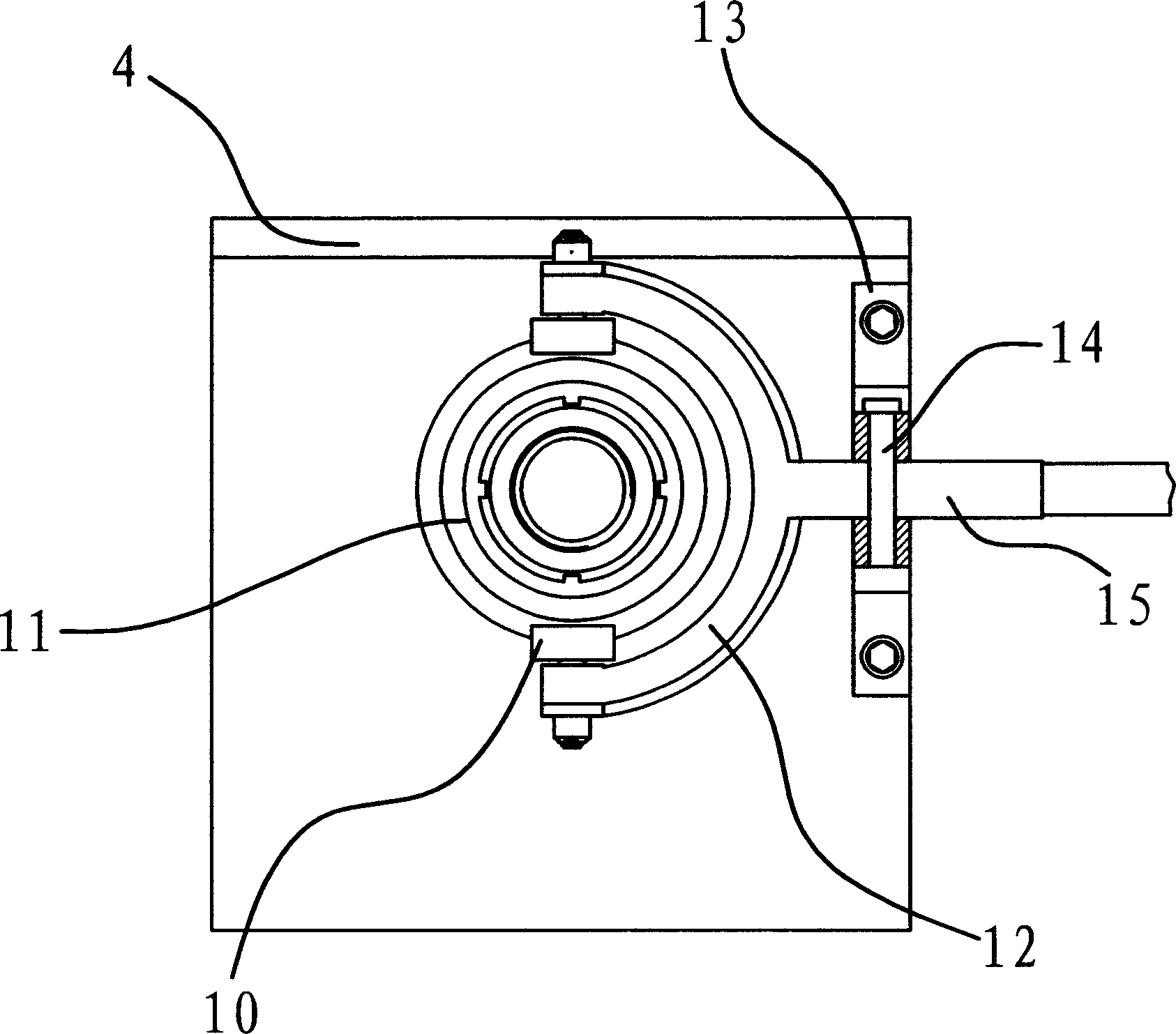

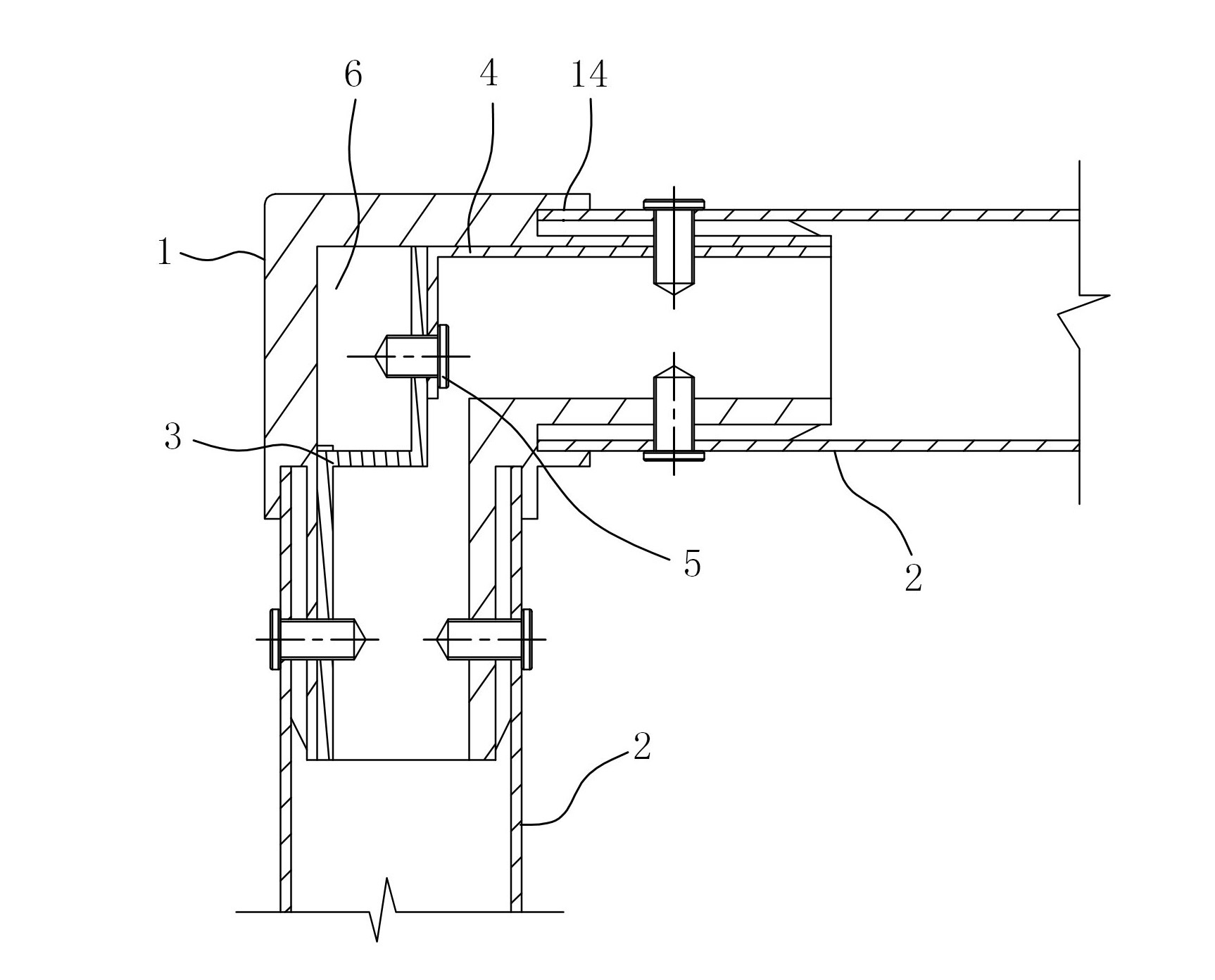

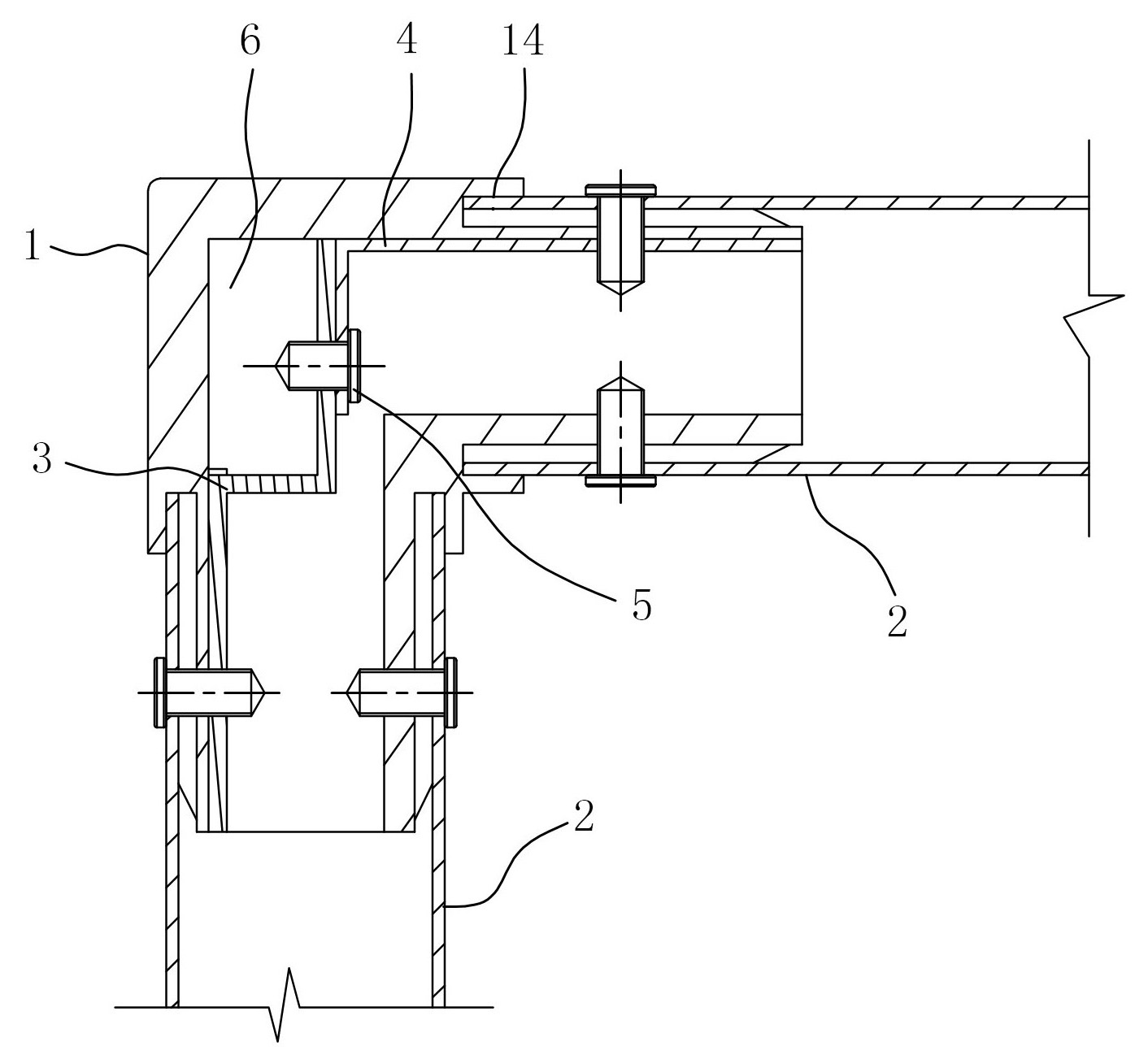

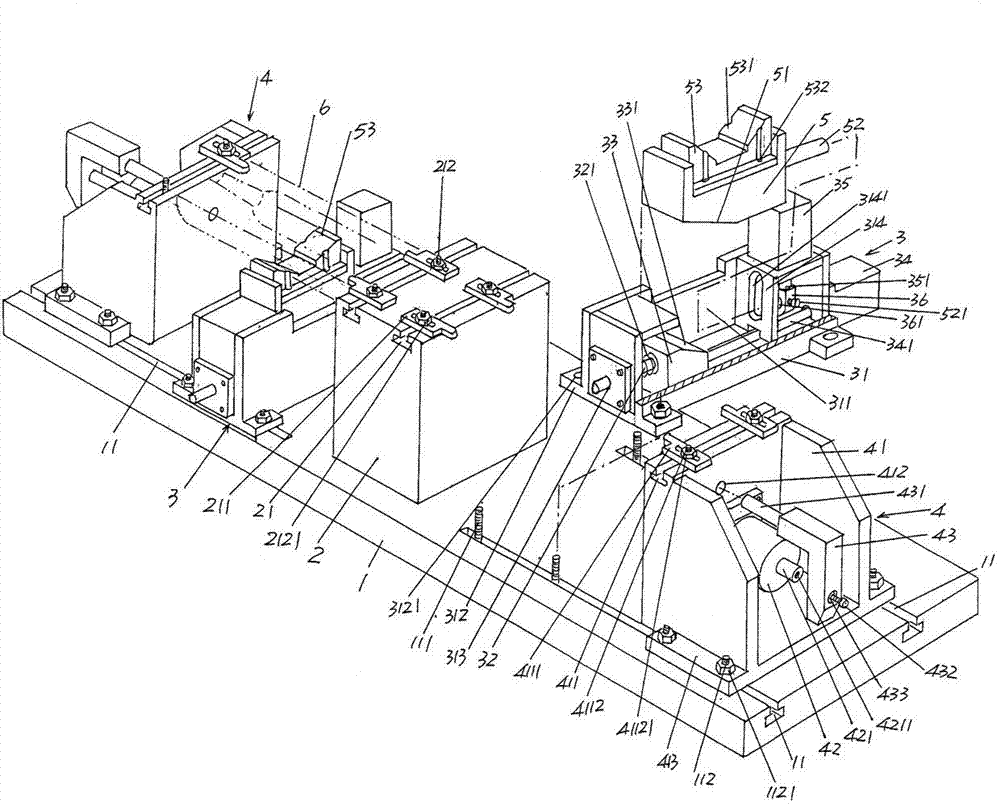

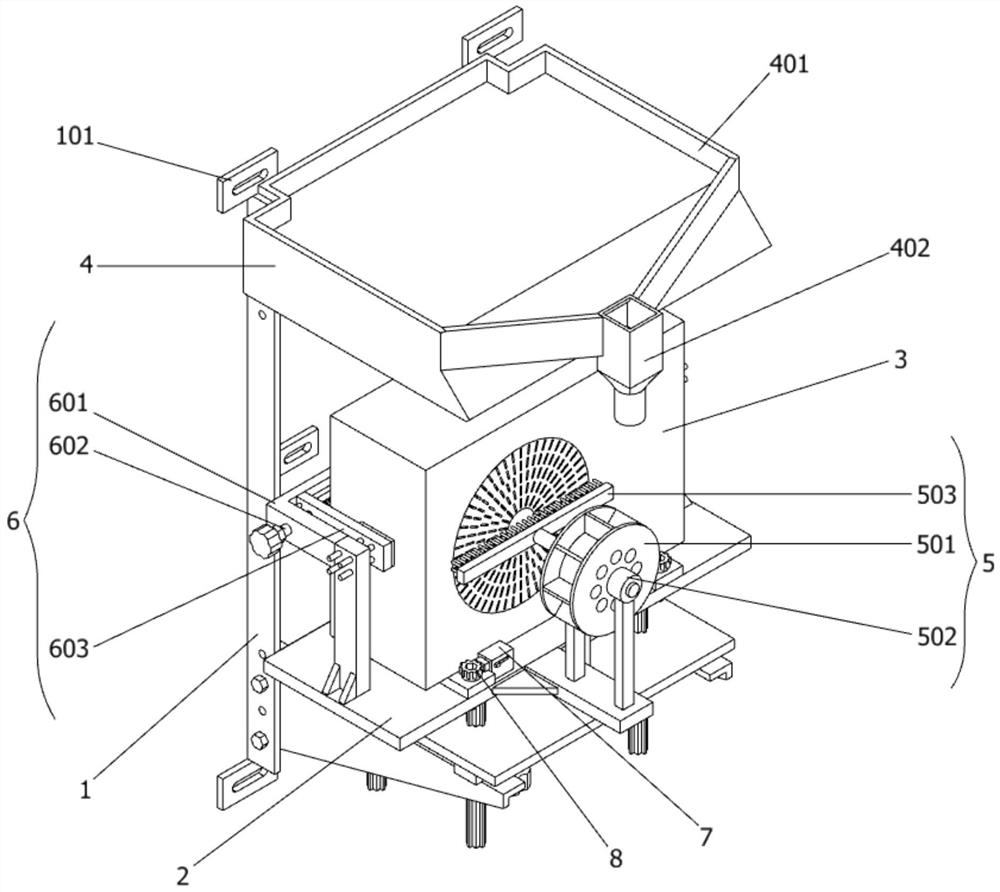

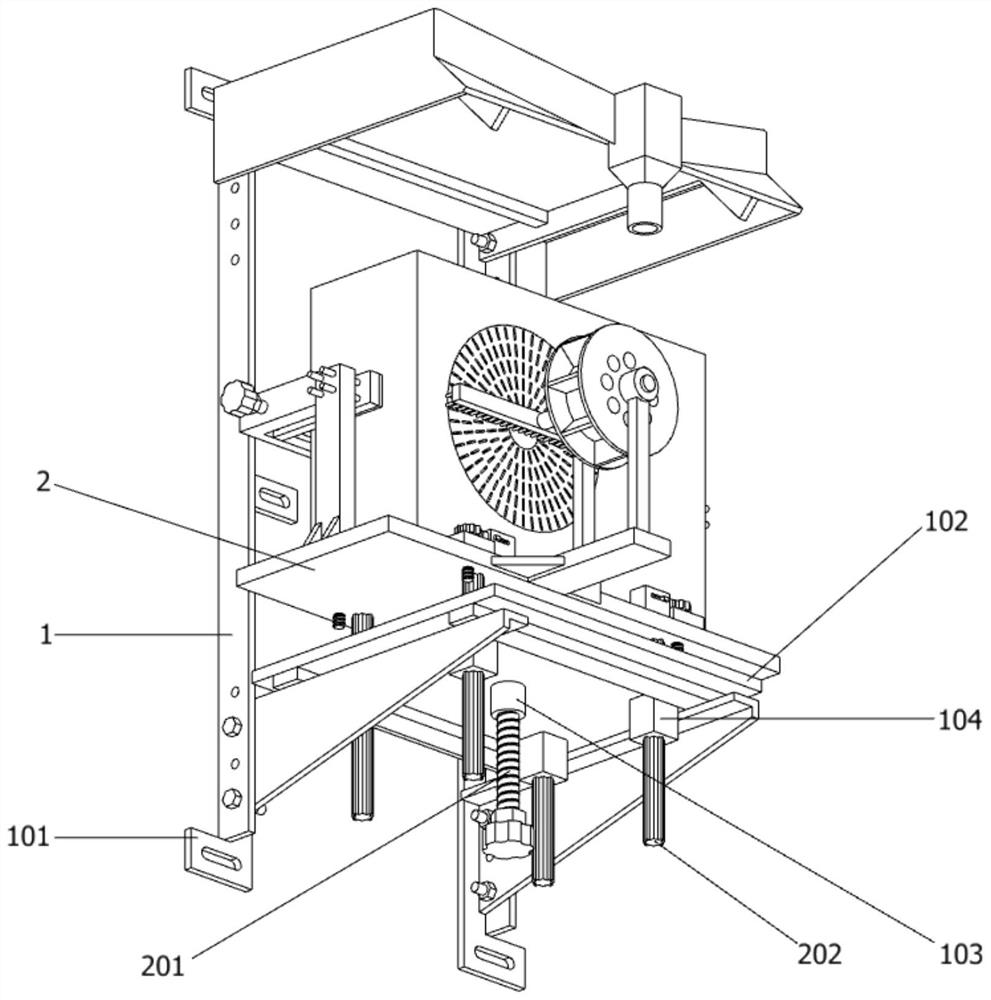

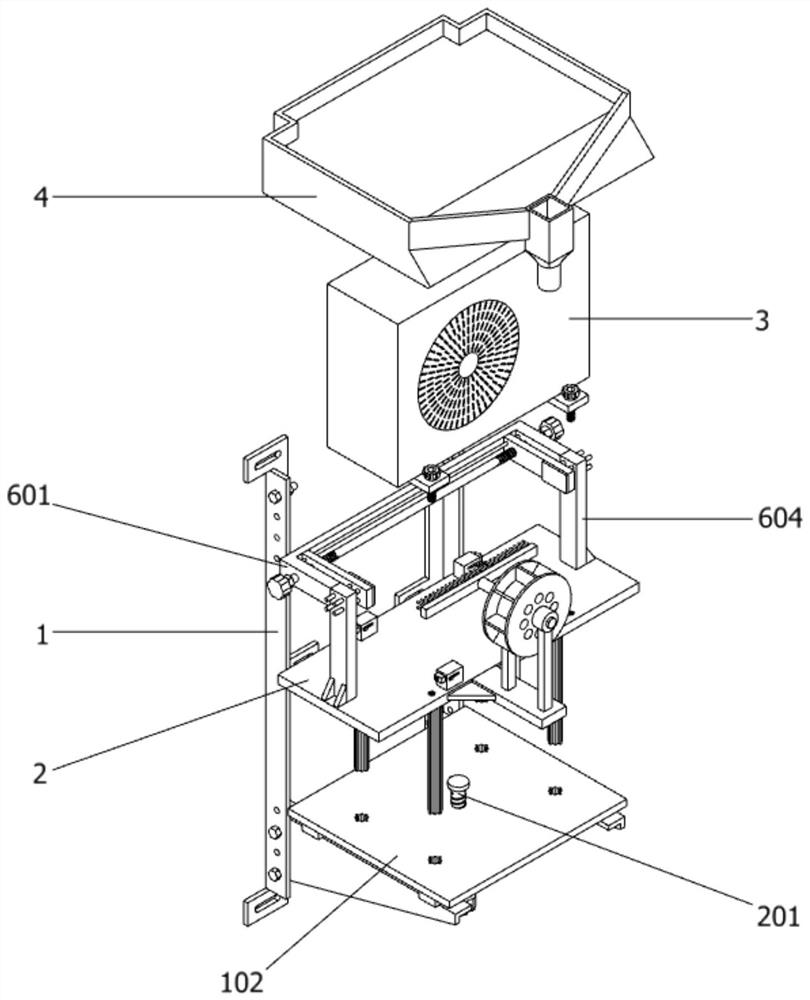

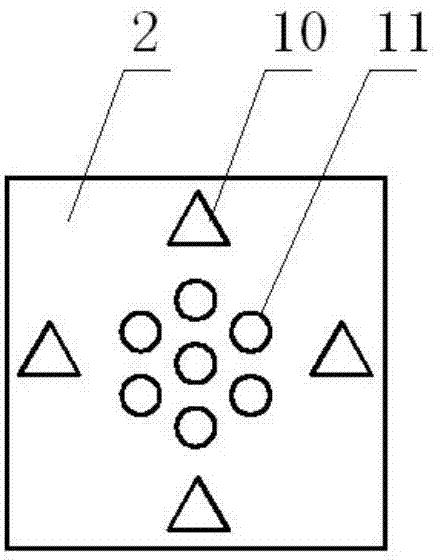

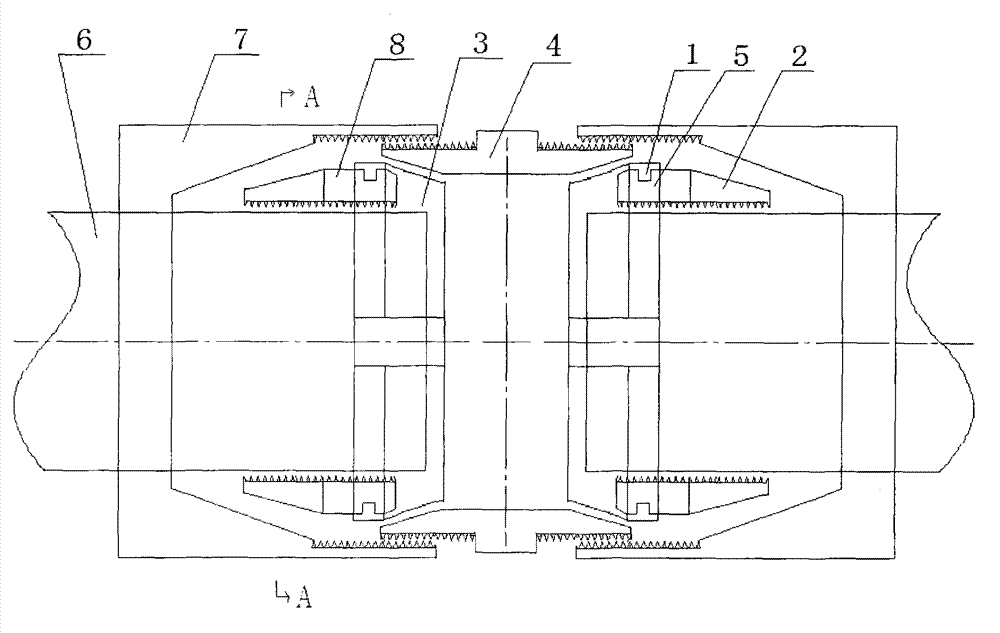

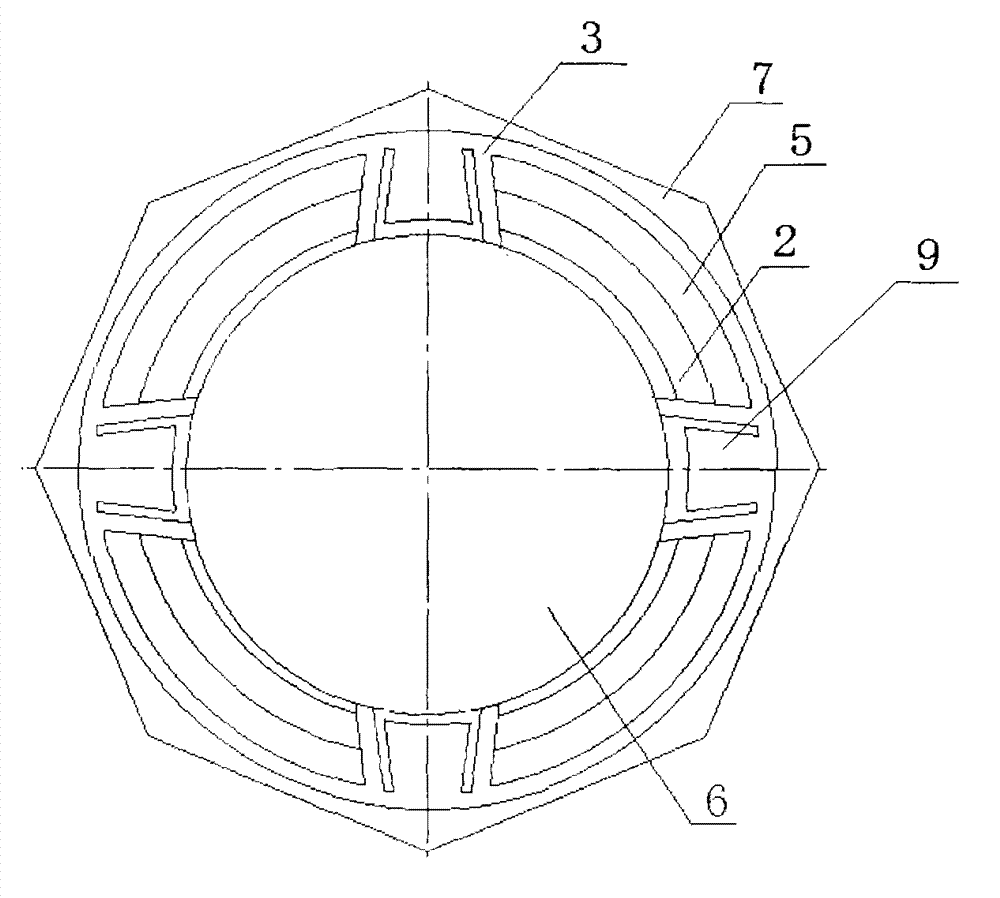

A fixture structure for machining inner cavities and joint closing surfaces of glass molds comprises a bottom seat plate, a center frame, two automatic mold supporting guide block lifting mechanisms and two automatic glass mold end surface locking mechanisms. Adjusting grooves are respectively arranged on surfaces of two ends of the bottom seat plate; adjusting grooves of mold pressing plates of the center frame are arranged on the top surface of the center frame, and the mold pressing plates of the center frame are respectively fittingly arranged on the adjusting grooves of the mold pressing plates of the center frame; the two automatic mold supporting guide block lifting mechanisms and the two automatic glass mold end surface locking mechanisms are respectively arranged at the two ends of the bottom seat plate, the automatic mold supporting guide block lifting mechanisms are positioned among the center frame and the automatic glass mold end surface locking mechanisms, a mold supporting guide block is arranged on the automatic mold supporting guide block lifting mechanism positioned at one end of the bottom seat plate, and another mold supporting guide block is arranged on the automatic mold supporting guide block lifting mechanism positioned at the other end of the bottom seat plate. The fixture structure has the advantages that the fixture structure is simple, and is convenient to manufacture and easy to use and maintain; the operation intensity is relieved for operators; loosening is prevented; and the machining efficiency of a machining center is improved, and the perfect matching precision between two half molds of a mold can be guaranteed.

Owner:ORI MOLD TECH SUZHOU

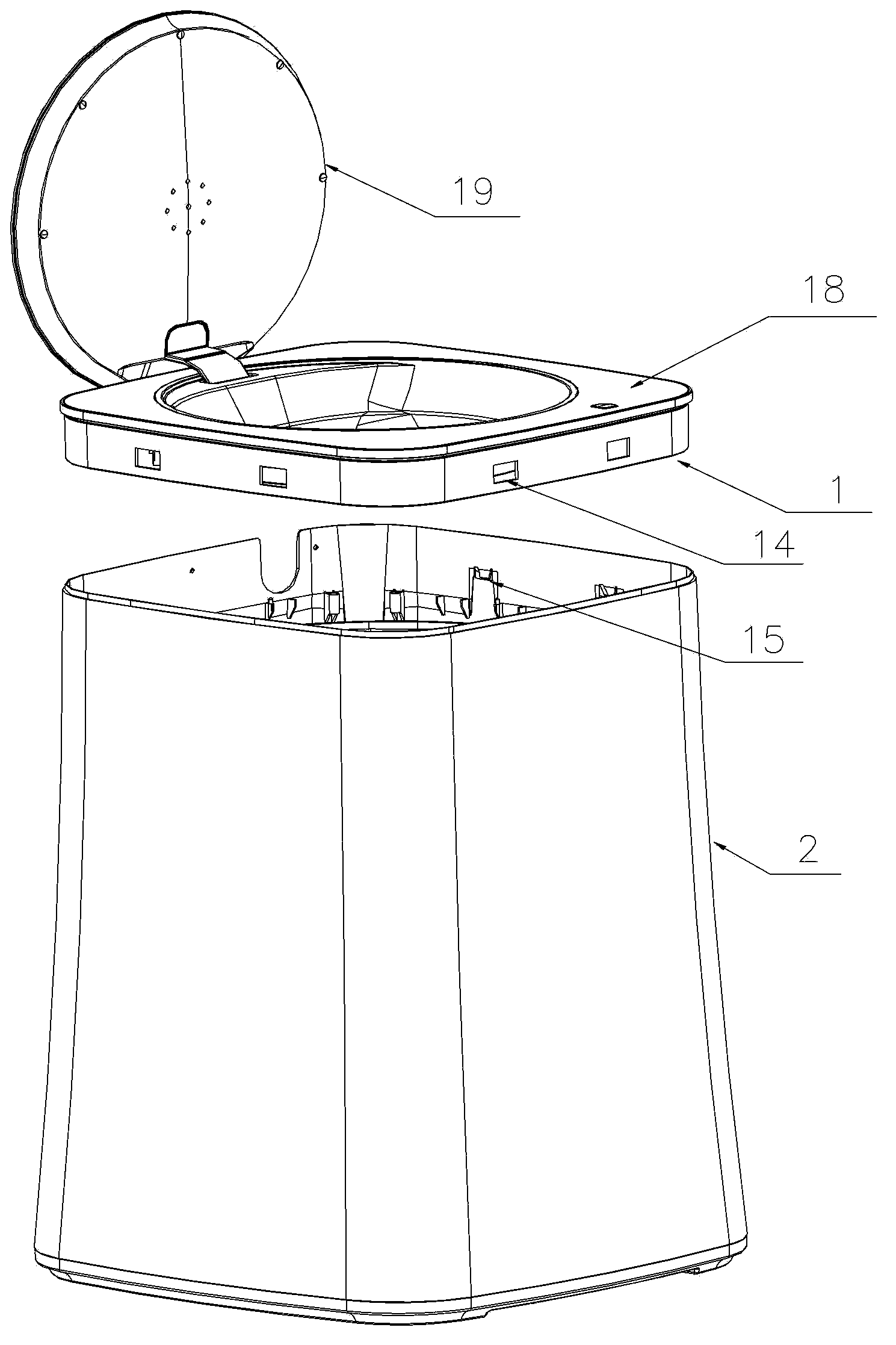

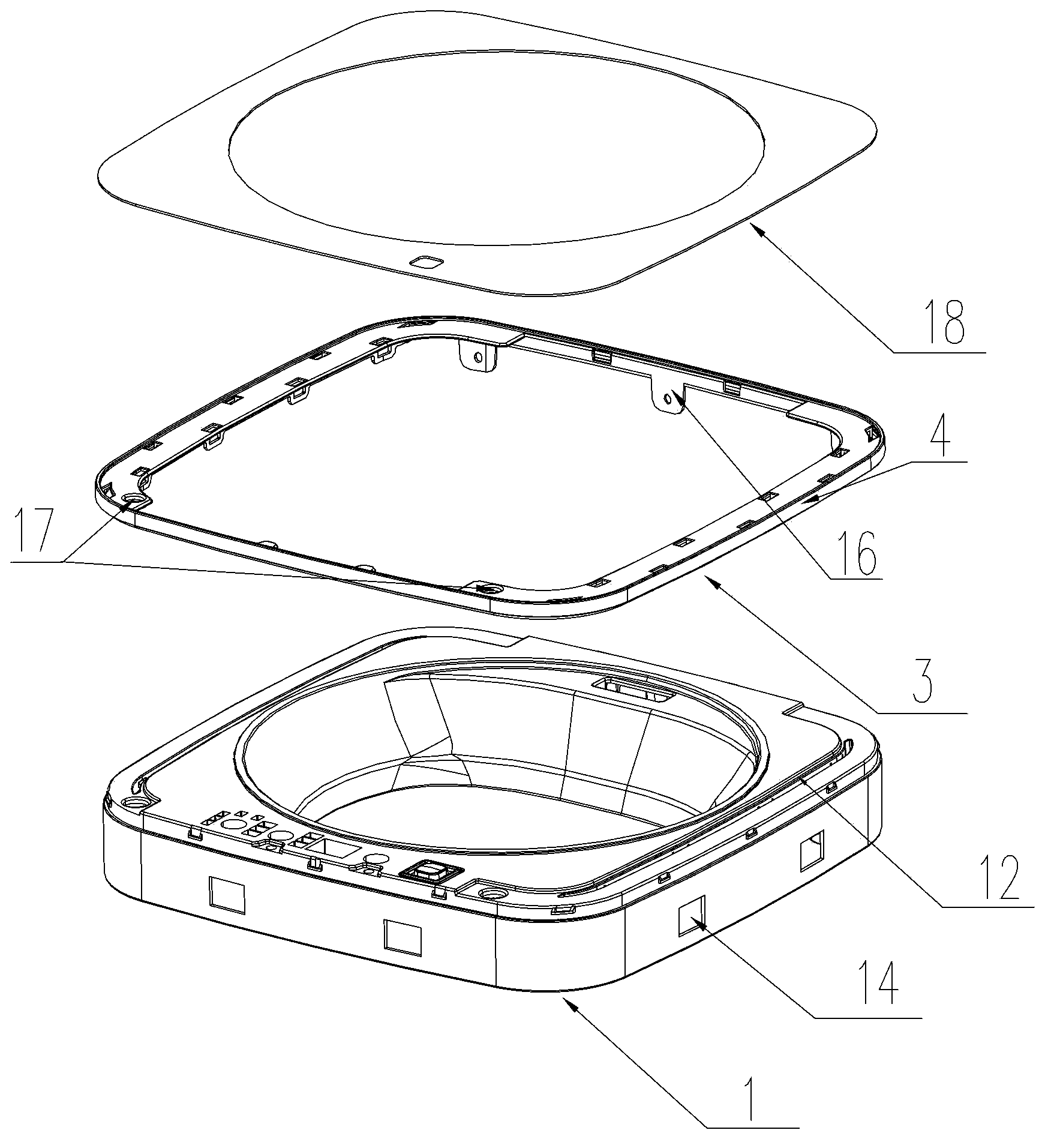

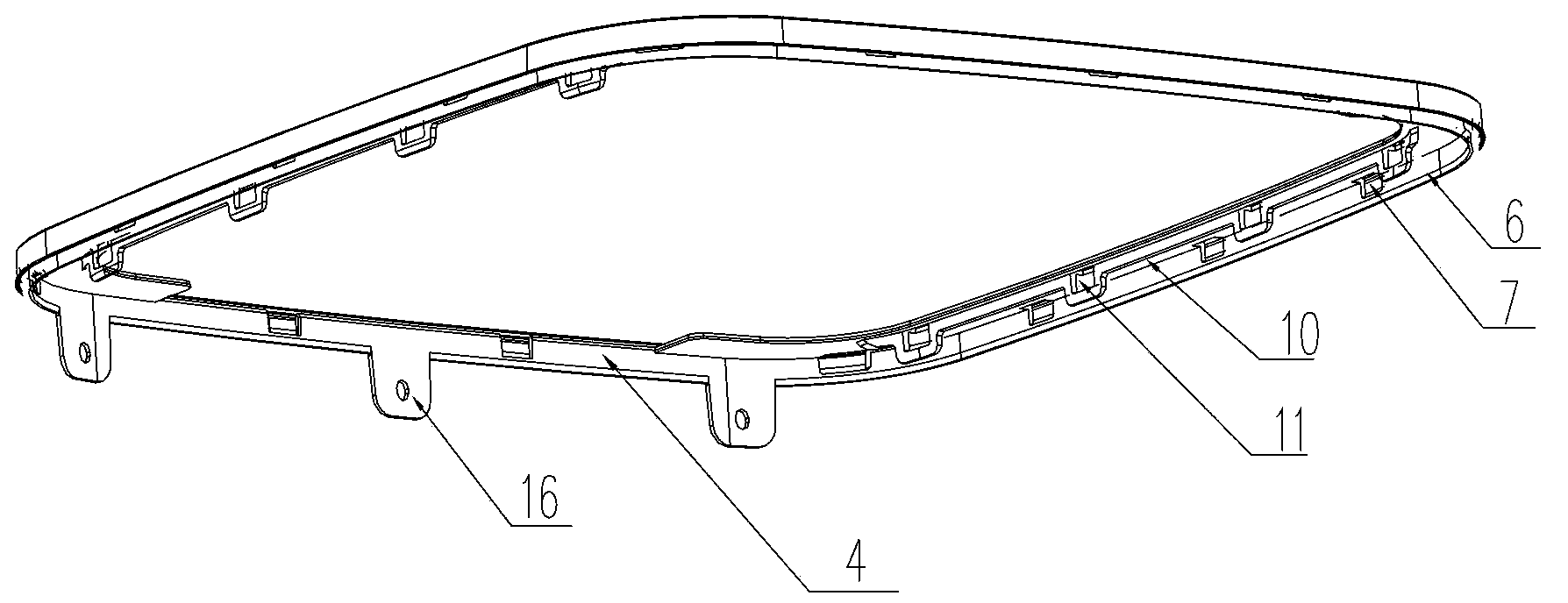

Washing machine control panel base and washing machine with same

ActiveCN103789974APrevent looseningFirmly connectedOther washing machinesTextiles and paperMachine controlEngineering

The invention belongs to the field of washing devices and particularly relates to a washing machine control panel base and a washing machine with the same. The washing machine control panel base comprises a control panel base body (1) and a decoration plate (16) arranged on the upper surface of the control panel base body. A decoration strip (3) is annularly arranged on the periphery of the control panel base body and extends downwards along the periphery to form a wrapping edge (4) which wraps an upper edge (5) of a washing machine box body. The washing machine control panel base and the washing machine box body are fixedly installed through a fastener, are further reinforced through the decoration strip and are firmly connected. The installation procedures are simplified, installation is convenient, time is saved, and the installation efficiency is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

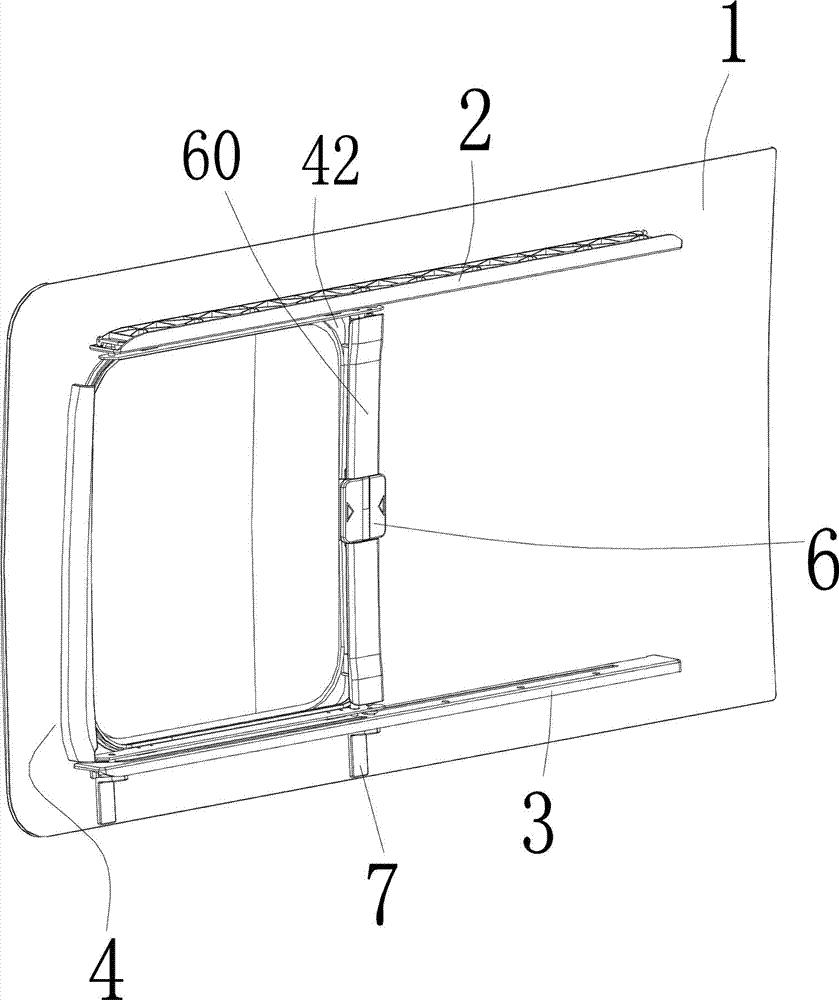

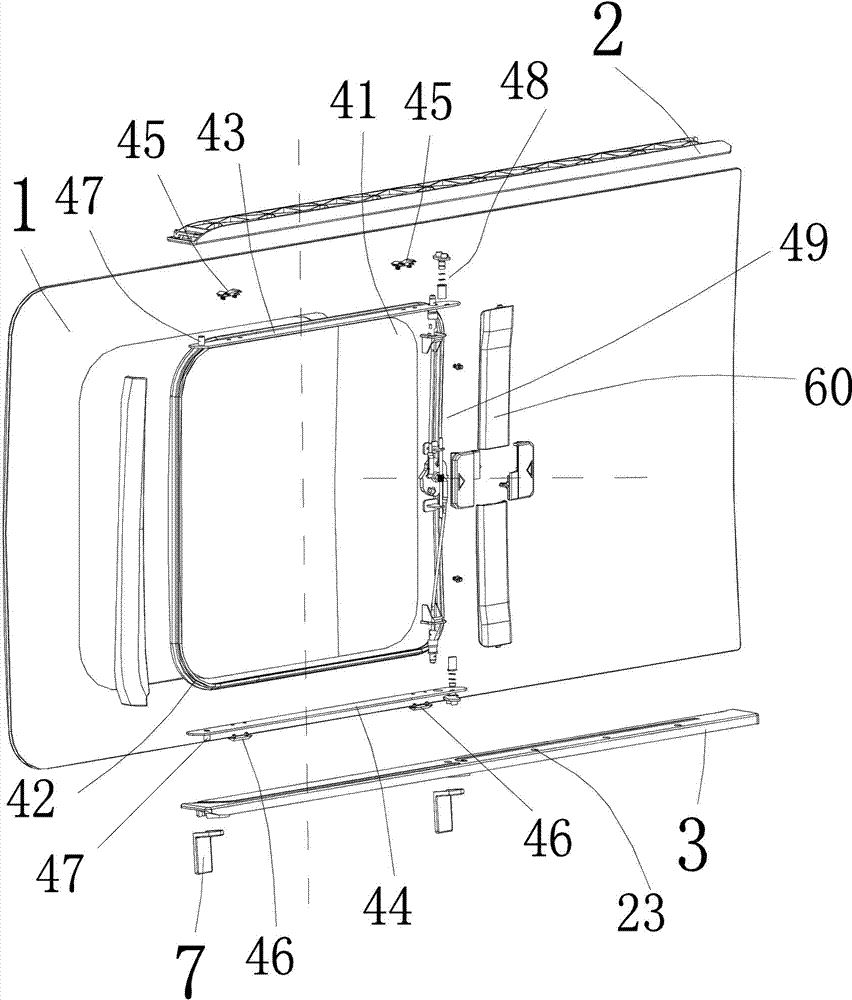

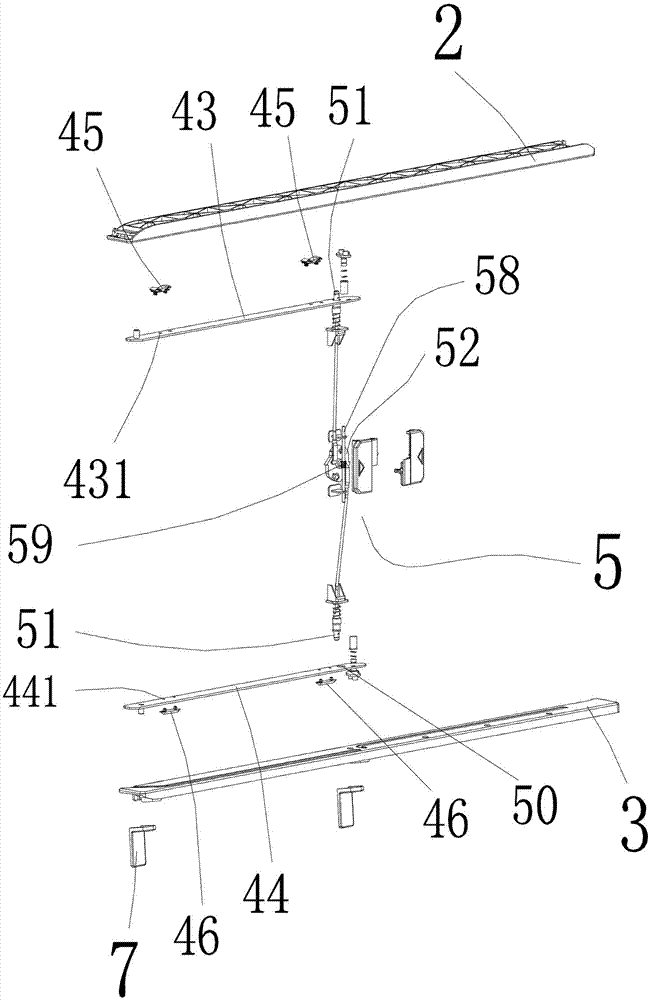

Built-in rail-changing sliding window

ActiveCN102828671ARaise the gradeImprove stabilityWindowsWindscreensSlide windowStructural engineering

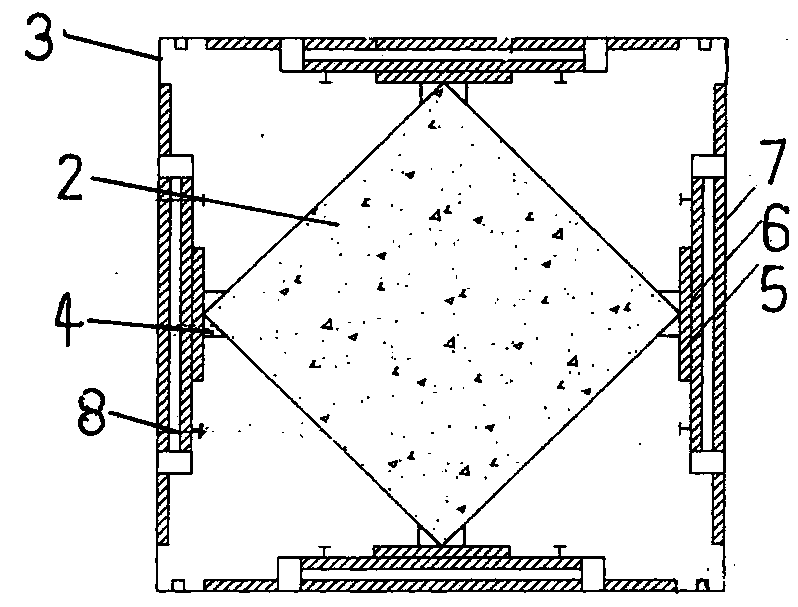

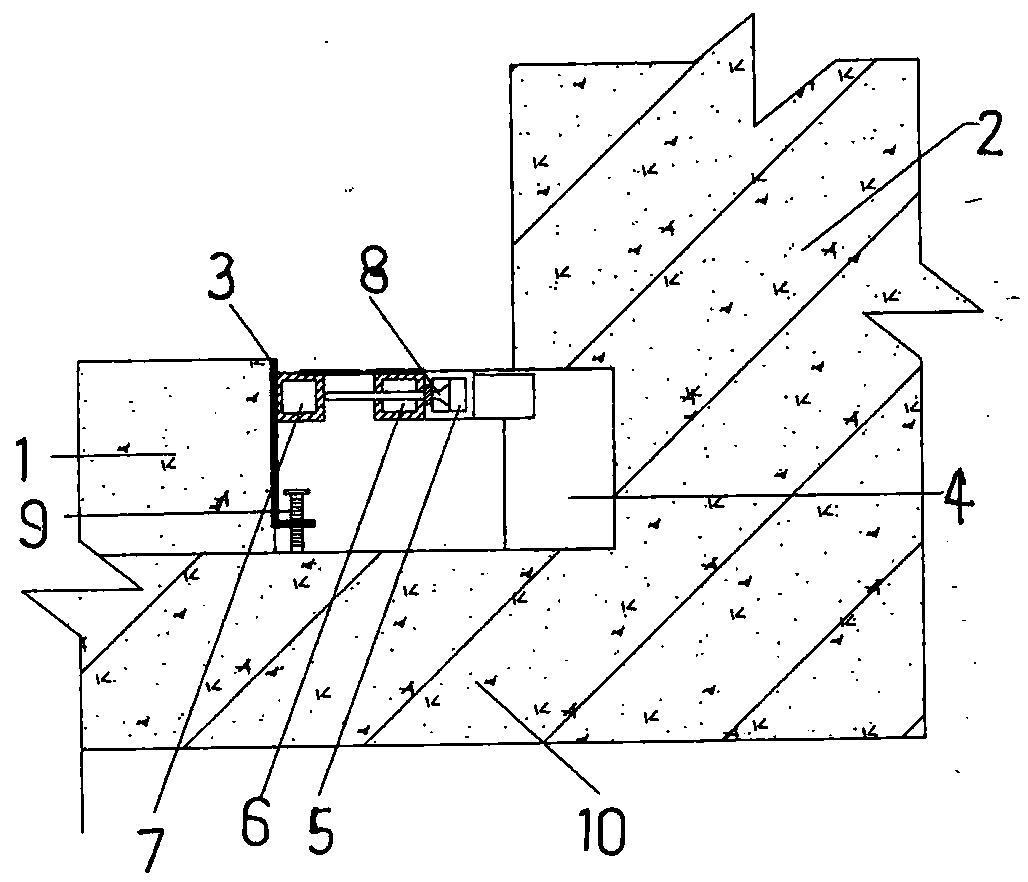

A built-in rail-changing sliding window comprises an upper sliding rail, a lower sliding rail and a moving window arranged between the upper and the lower sliding rails; the moving window comprises an upper window strip, a lower window strip, an upper liner, a lower liner, sliding pillars and rail-changing sliding bocks, wherein both the upper window strip and the lower window strop are arranged on a sliding glass fixing base, the upper liner is arranged on the upper window strip while the lower liner is arranged on the lower window strip, the sliding pillars are respectively arranged on the same ends of the upper window strip and one end of the lower window strip; the rail-changing sliding bocks are respectively arranged on the other same ends of the upper window strip and the lower window strip; each of the upper and the lower sliding rails is provided with two sections of sliding chutes, the end of each first section of sliding chute corresponding to each sliding pillar is of an arc shape, the end of each second section of sliding chute corresponding to each rail-changing sliding block is of a hook shape; and a lock hole matched with a bolt which is pushed out by a lock rotating mechanism in a lock box at the side of the sliding glass fixing base is respectively arranged on the surface of each of the upper and the lower sliding rails. The built-in rail-changing sliding window is long in service life and is more stable, more comfortable, good in overall appearance and excellent in waterproof property when in use; when the moving window is closed, sliding glass and outer window fixing glass can be realized on the same plane; with the adoption of an opening handle, the indoor comfortable degree is enhanced, and the vehicle grade is improved; and the window is beneficial to mass production and has higher practicability.

Owner:浙江瑾达汽车零部件股份有限公司

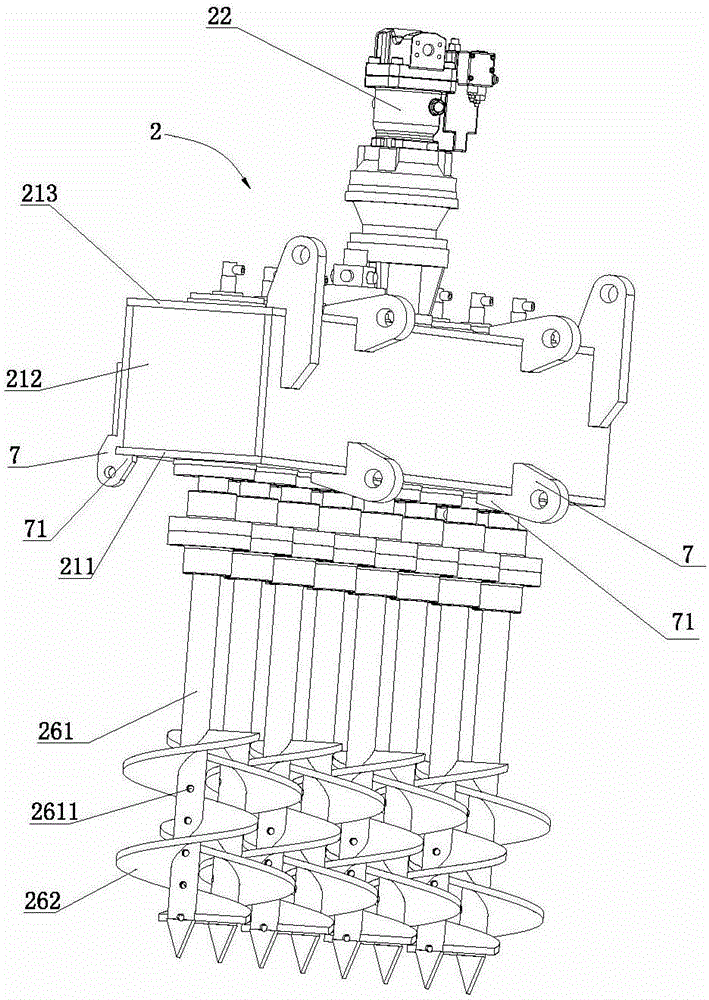

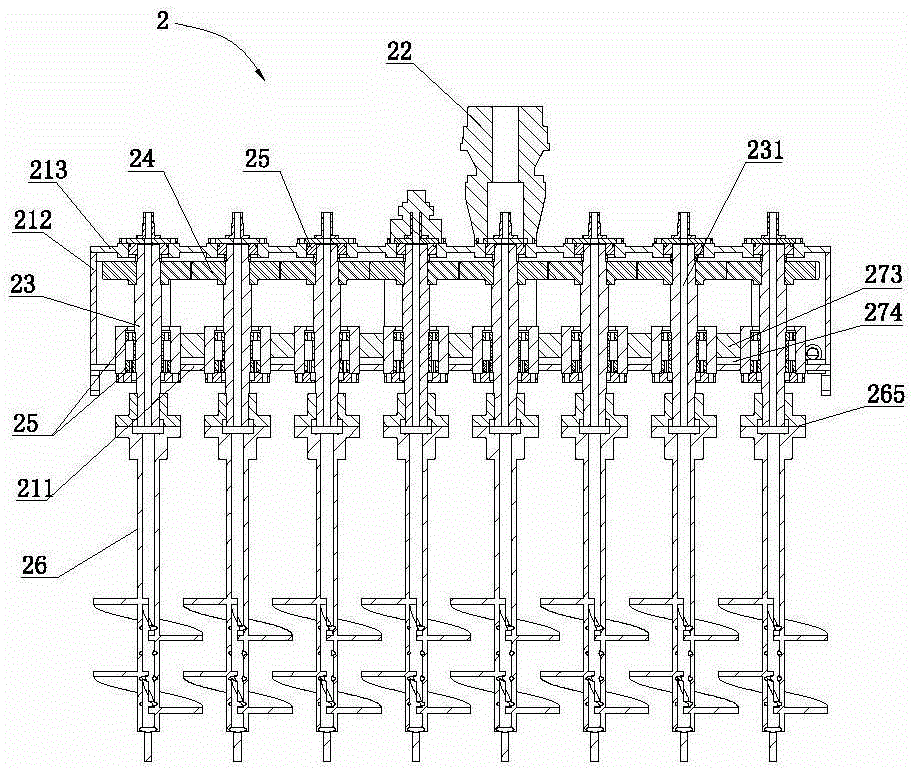

Ridge crusher for subsoiling and ridge crushing machine

InactiveCN104904348AIncrease the welding areaImprove connection strengthSpadesPloughsDrive shaftLow load

The invention discloses a ridge crusher for a subsoiling and ridge crushing machine. The ridge crusher comprises a ridge crushing box with a bottom plate, side plates and a top plate, rib plates are welded among lower bearing seats which are mounted on the bottom plate, a lubricating oil passage is reserved between each rib plate and the bottom plate, and upper bearing seats mounted on the top plate are longer than the lower bearing seats. The ridge crusher for the subsoiling and ridge crushing machine has the advantages that strength of the lower bearing seat can be improved, more bearings can be mounted at high-load-bearing positions while less bearings are mounted at low-load-bearing positions, and accordingly rigidity and transmission stability of a transmission shaft are improved, and cost is reduced; in addition, welding of the rib plates is facilitated, and smooth flow of lubricating oil in the ridge crushing box is guaranteed so as to improve lubrication effects.

Owner:GUANGXI WUFENG MACHINERY CO LTD

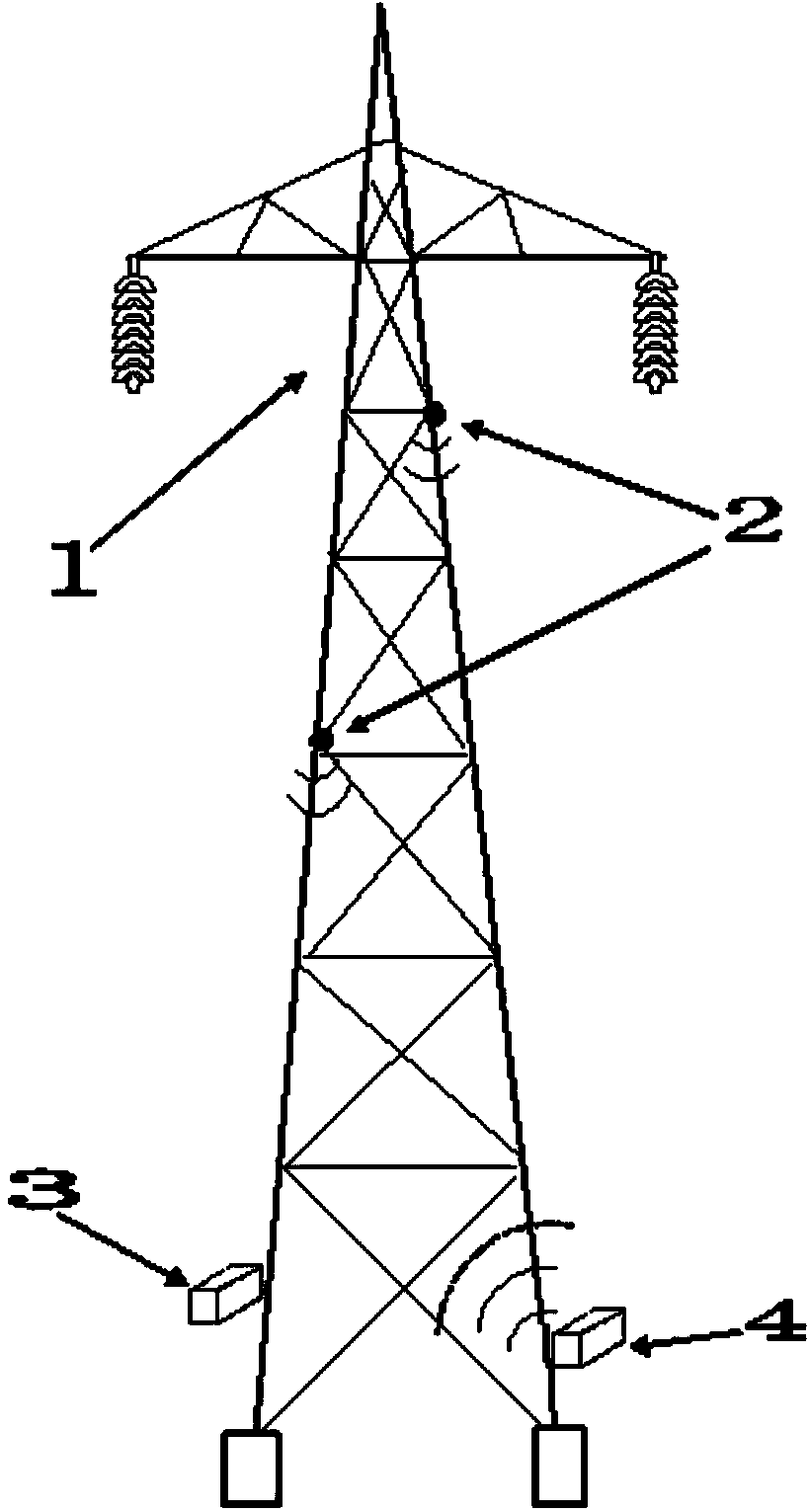

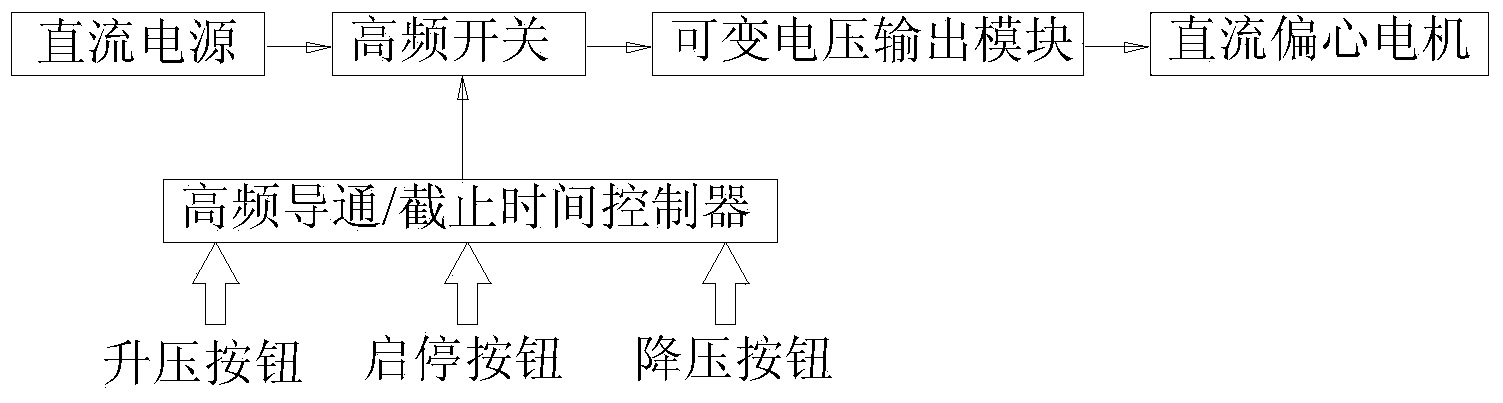

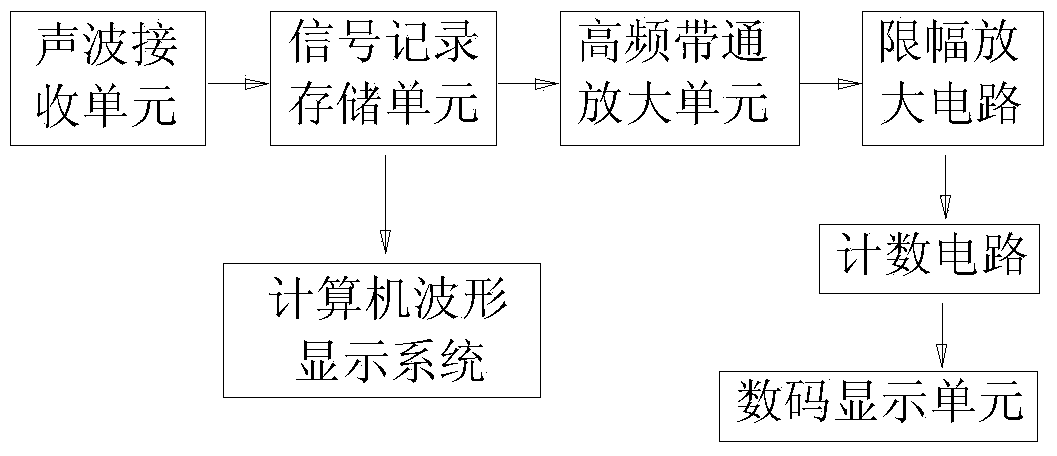

Method and device for rapidly detecting loosening of bolt of iron tower

ActiveCN103529471AMeet efficiency requirementsMeet accuracy requirementsSeismologyWaveform analysisResonance

The invention relates to the field of iron tower assembly quality detection, in particular to a method and a device for rapidly detecting the loosening of a bolt of an iron tower. An additional vibration source vibrates the iron tower, a loosened bolt and a tower part are excited to resonate or vibrate to produce secondary impact sounds, and sound waves are received and converted into electrical signals through a vibration frequency receiving device. Two methods are used for analyzing the electrical signals, wherein one method comprises the steps of displaying sound waveforms and performing waveform analysis by observing the waveforms, and the other method comprises the steps of performing counting and analyzing a count value, so that whether a certain bolt on the iron tower is loosened or not can be rapidly judged. Compared with the prior art, the method and the device have the beneficial effects that a sound wave detection technology is adopted for rapid detection after the assembly of the iron tower; the method and the device have the advantages of high detection speed, capability of greatly saving manpower and material resources and no requirements on tower climbing for detection; sound wave data can be analyzed to directly reflect whether the bolt of the iron tower is loosened or not by once comprehensive detection, so that requirements on the detection efficiency and accuracy of the iron tower are met.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +2

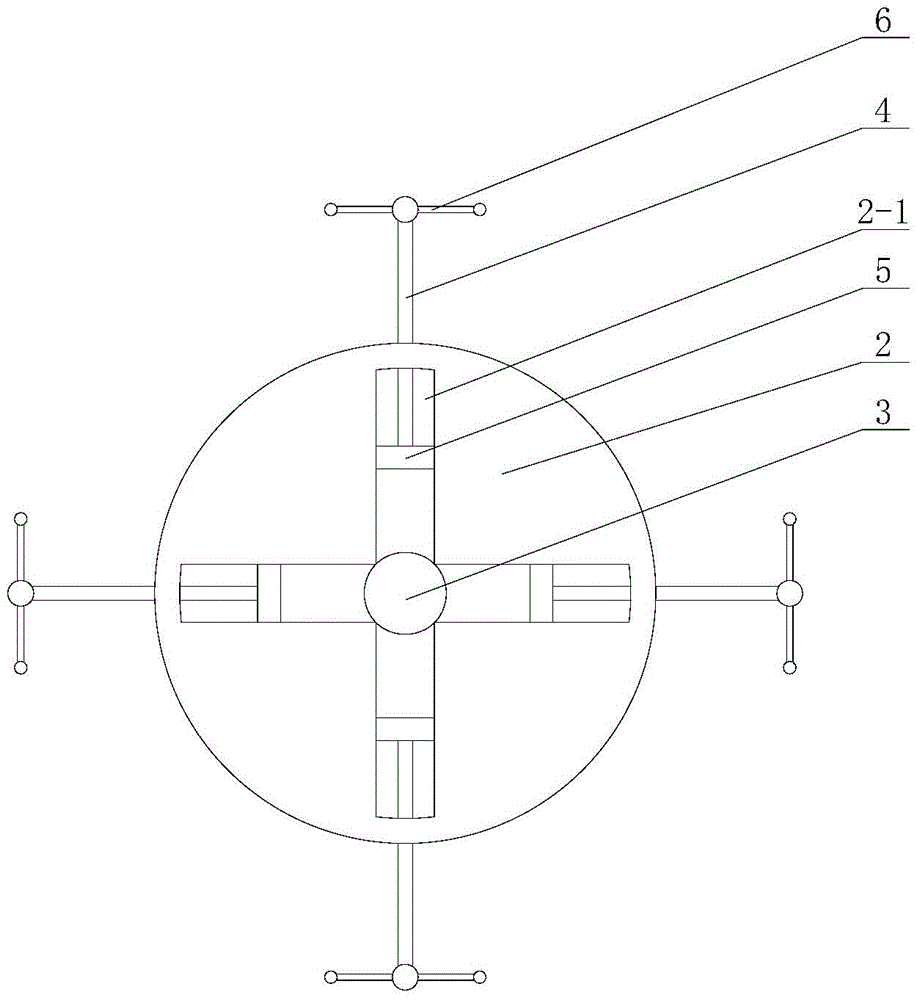

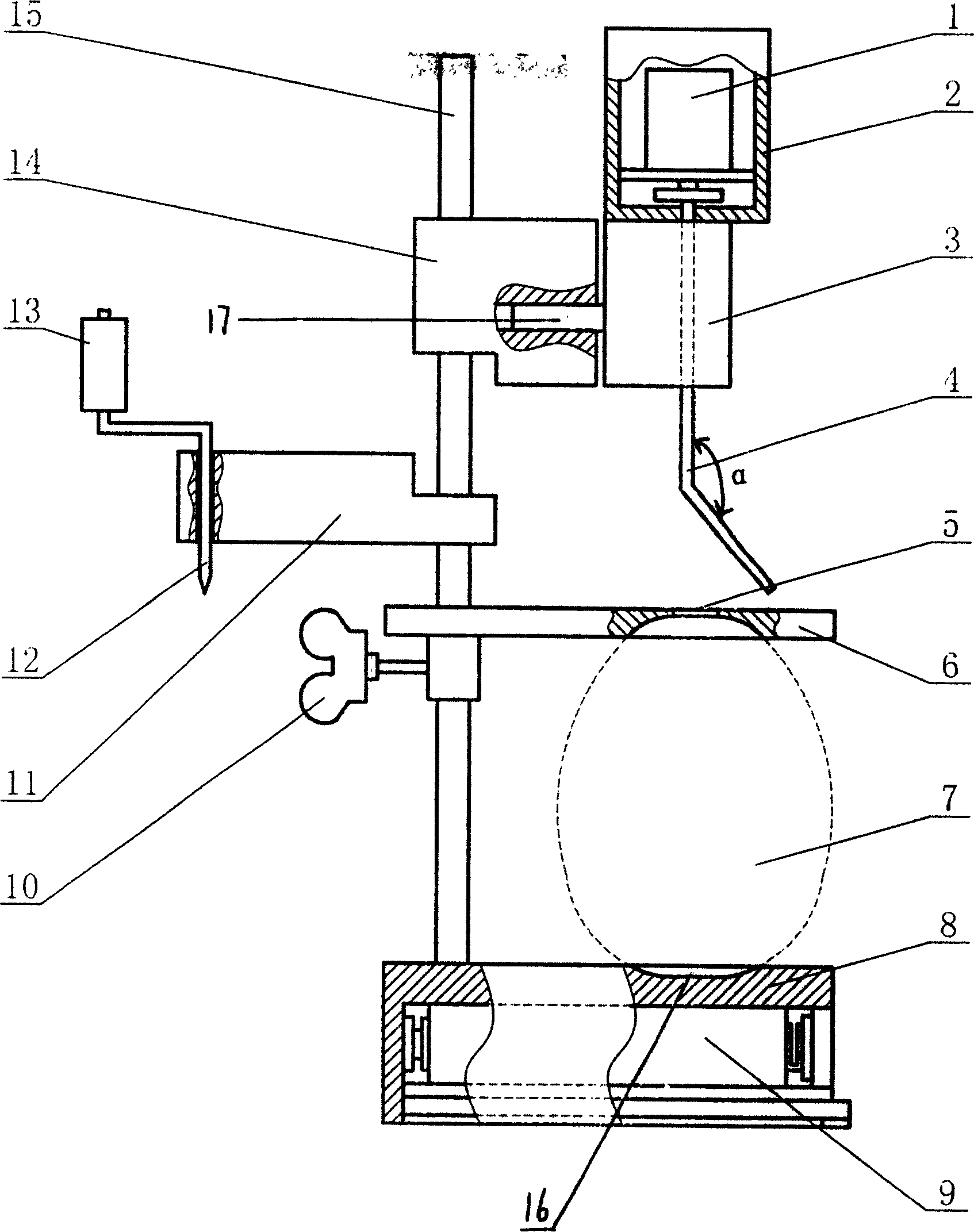

Clamping device for fixing work piece with irregular shape

InactiveCN105171458AStable clampingAvoid damagePositioning apparatusMetal-working holdersEngineeringMachining

A clamping device for fixing a work piece with an irregular shape relates to a clamping device and especially relates to the clamping device for fixing the work piece with the irregular shape. The objective of the invention is to solve the problem that a clamp on existing mechanical processing equipment cannot firmly clamp the work piece with the irregular shape and processing precision and work piece quality are thus influenced. In the clamping device for fixing the work piece with the irregular shape provided by the invention, a vertical shaft is successively sleeved by a rotation table and a base from top to bottom, each horizontal positioning mechanism is constituted of a screw rod and a horizontal moving block, four bar-shaped grooves are disposed uniformly in the upper surface of the rotation table, each bar-shaped groove passes through the center of the rotation table along the center line of the length direction, a boss on the lower surface of each horizontally moving slide block is respectively inserted in the corresponding bar-shaped groove, the four screw rods are inserted in the outer side wall of the rotation table, and a clamping body mechanism is installed respectively on the upper surface of each horizontally moving slide block. The clamping device for fixing the work piece with the irregular shape provided by the invention is applied to the field of mechanical processing.

Owner:TIANJIN TIANCHENG IND FURNACE MFG

Anti-drop insulation piercing connector

ActiveCN106025609AAchieve long runNo loosenessContact members penetrating/cutting insulation/cable strandsFastening/insulating connecting partsPower cableContinuous rotation

The invention provides an anti-drop insulation piercing connector. A J-shaped clamp which is in a columnar form in the transverse direction is arranged; a pair of screw rods is in threaded connection with a pair of screw holes in an upper platform of the J-shaped clamp respectively; the inner end of each screw rod is movably sleeved with a chuck; an upper wire slot is longitudinally arranged in the lower end surface of each chuck; a locking groove is arranged in the upper end surface of each screw hole of the upper platform; and a plurality of one-way locking claws are arranged on the side wall of each locking groove and can be pushed by a corresponding locking nut in the fastening and rotating direction to rotate around a rotating shaft and continuous rotation in the loosening direction is blocked by the front ends of the one-way locking claws. The target of long-time operation without loosening of a power cable clamp is achieved; vibration is effectively resisted; and loosening is prevented. Piercing teeth do not rotate; and the upper wire slots of the chucks can be provided with the piercing teeth, so that the conductivity is ensured; and the service lifetime is further prolonged under the action of pressure springs.

Owner:武汉阿尔普智能电气有限公司

Integral construction method of sealing and curing agent wear resistant floor

The invention discloses an integral construction method of sealing and curing agent wear resistant floor, including toolings mold design, construction preparation, cleaning of the concrete base, positioning and laying out, installation of elevation control of bolt angle steel, installation of construction joint template in the reserved area around the column, elevation survey, base wetting, layingwire mesh, pouring concrete with fine stones and leveling, mechanical plastering and pressing, removal of angle steel, concrete pouring for filling silos, maintenance, removal of peri-column formwork, dismantling line, slitting, round angle aluminum bars, manufacture of crack resistant reinforcement bar installation, installing, secondary concrete pouring at column edge, trowel light, floor cleaning, fine grinding process at the base, a first seal curing agent operation, water mill operation and cleaning the floor to dry, a second seal curing agent operation, water mill operation and cleaningthe floor to dry, secondary water grinding and polishing, the late maintenance and other steps. The integral construction method of the sealing and curing agent wear resistant floor has the advantages of convenient construction and good effect.

Owner:启东建筑集团有限公司

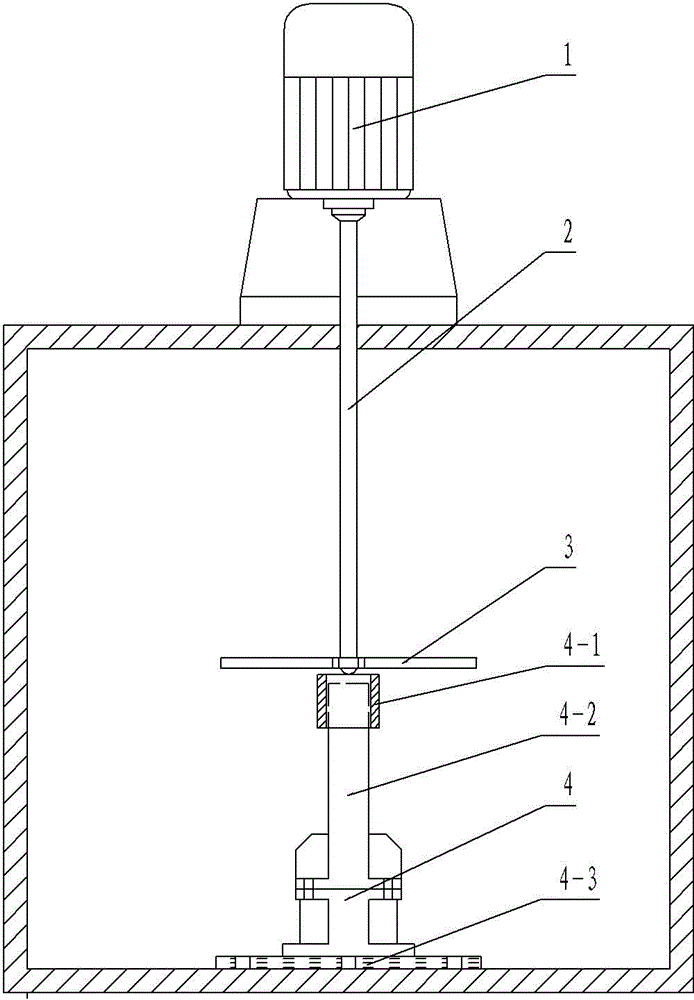

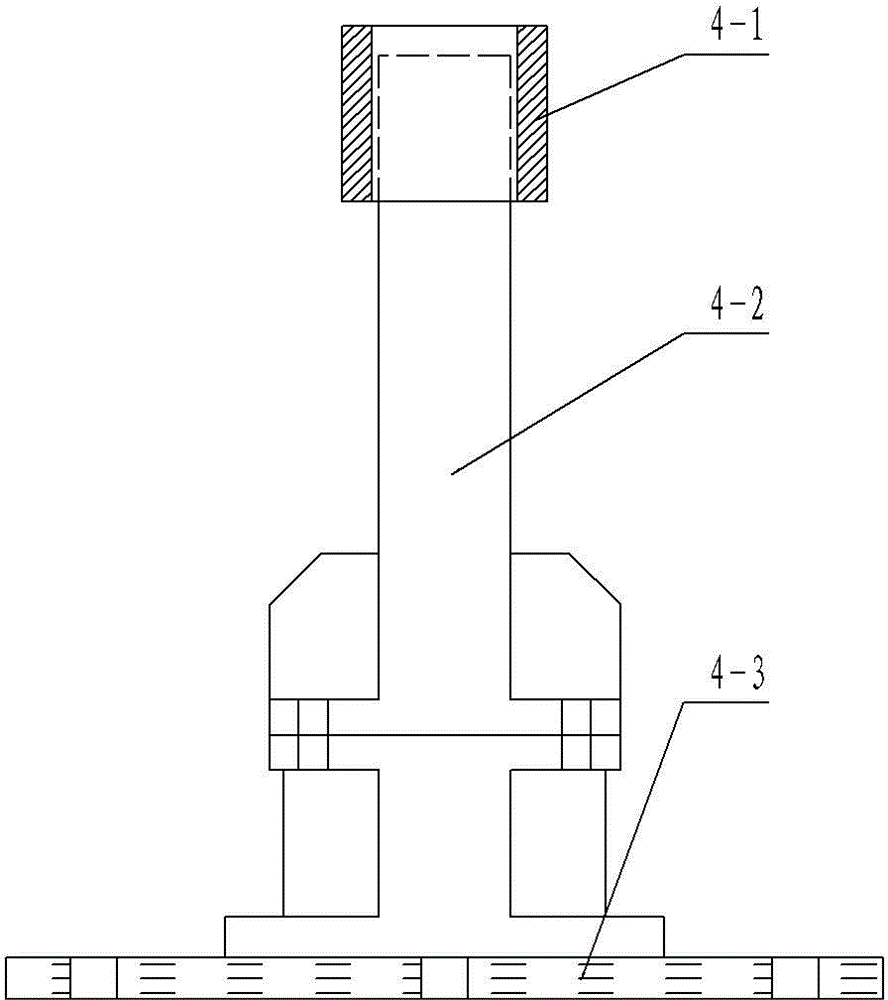

Stirrer

Owner:GUANGXI YUFENG CEMENT

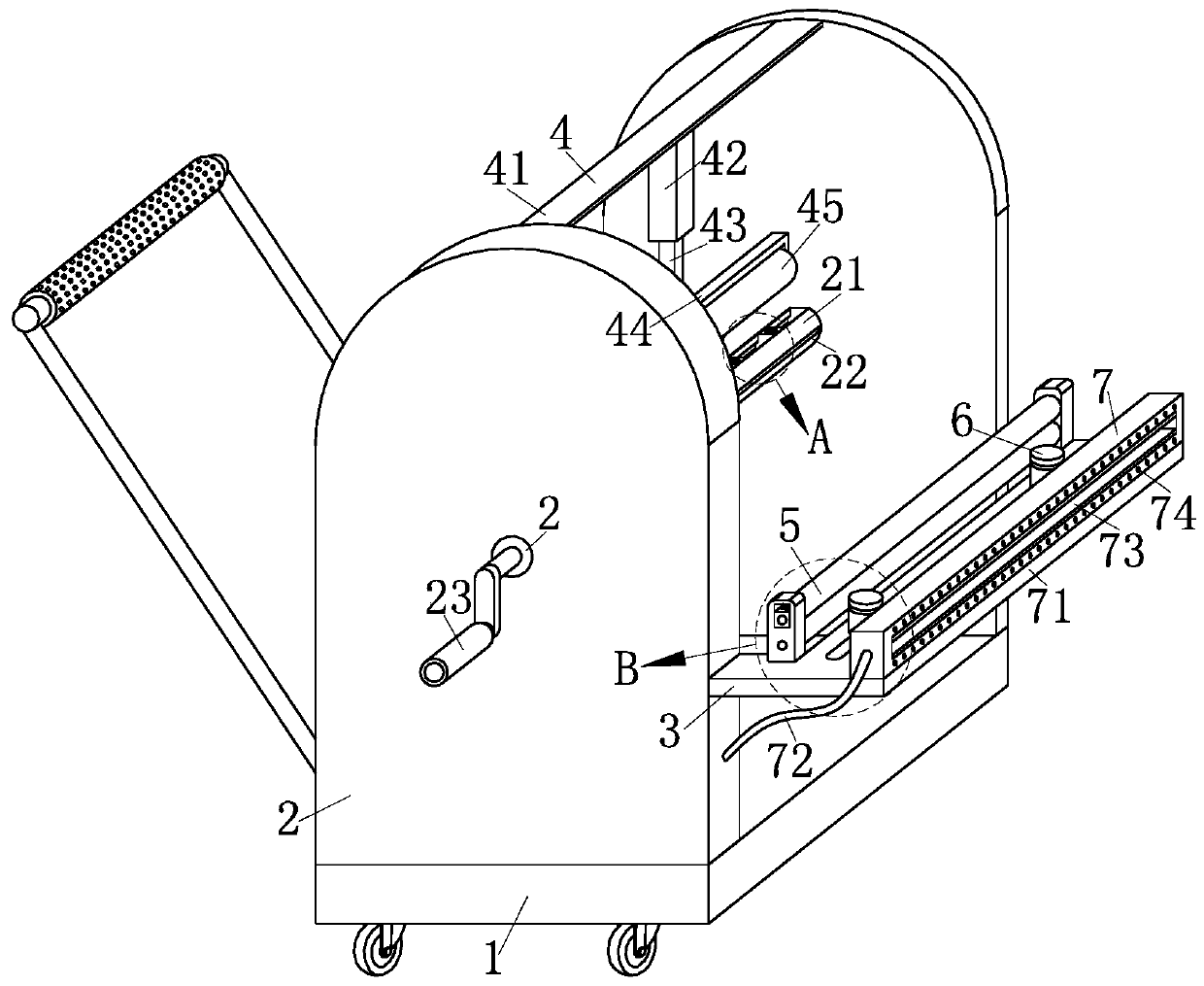

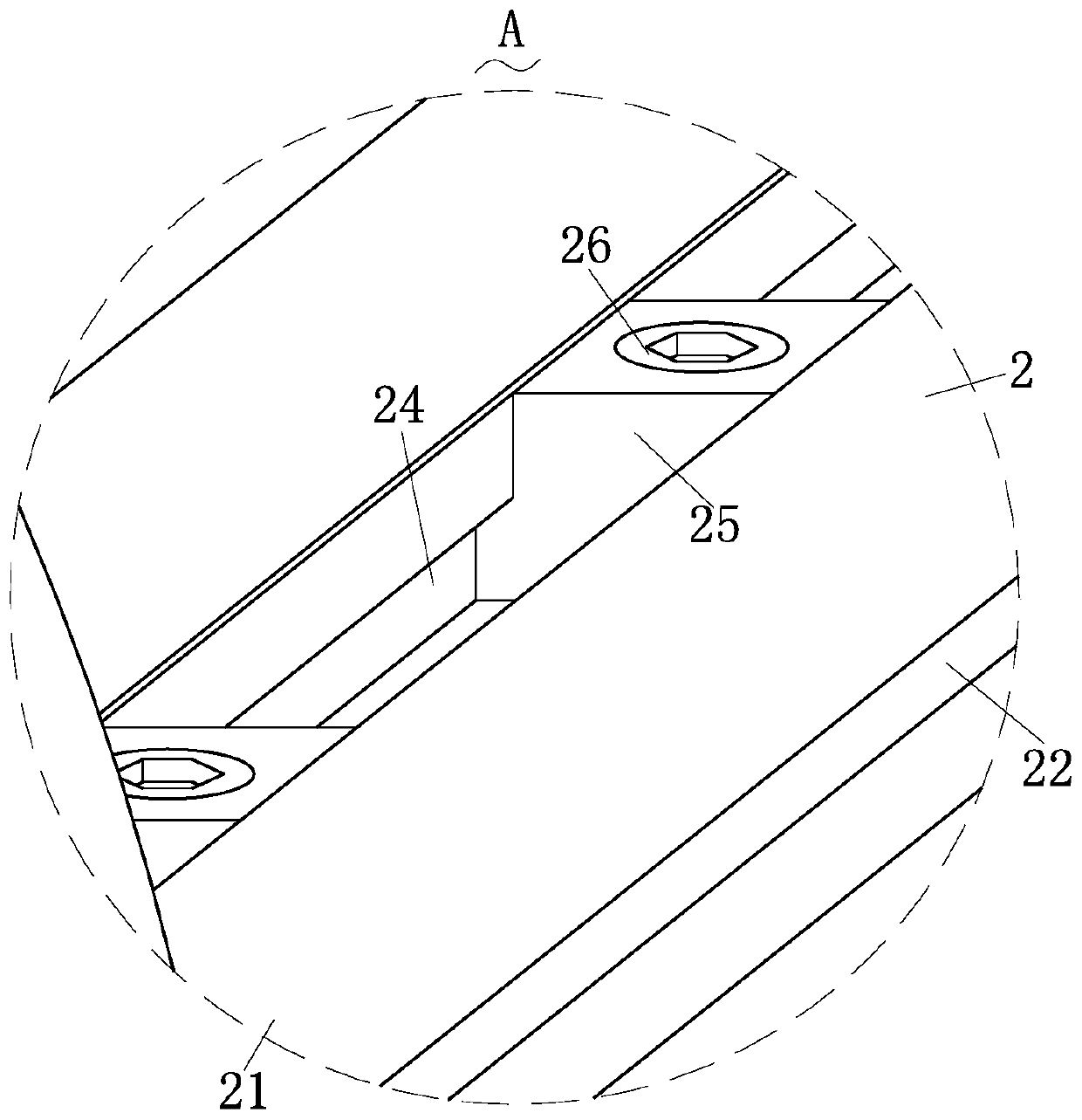

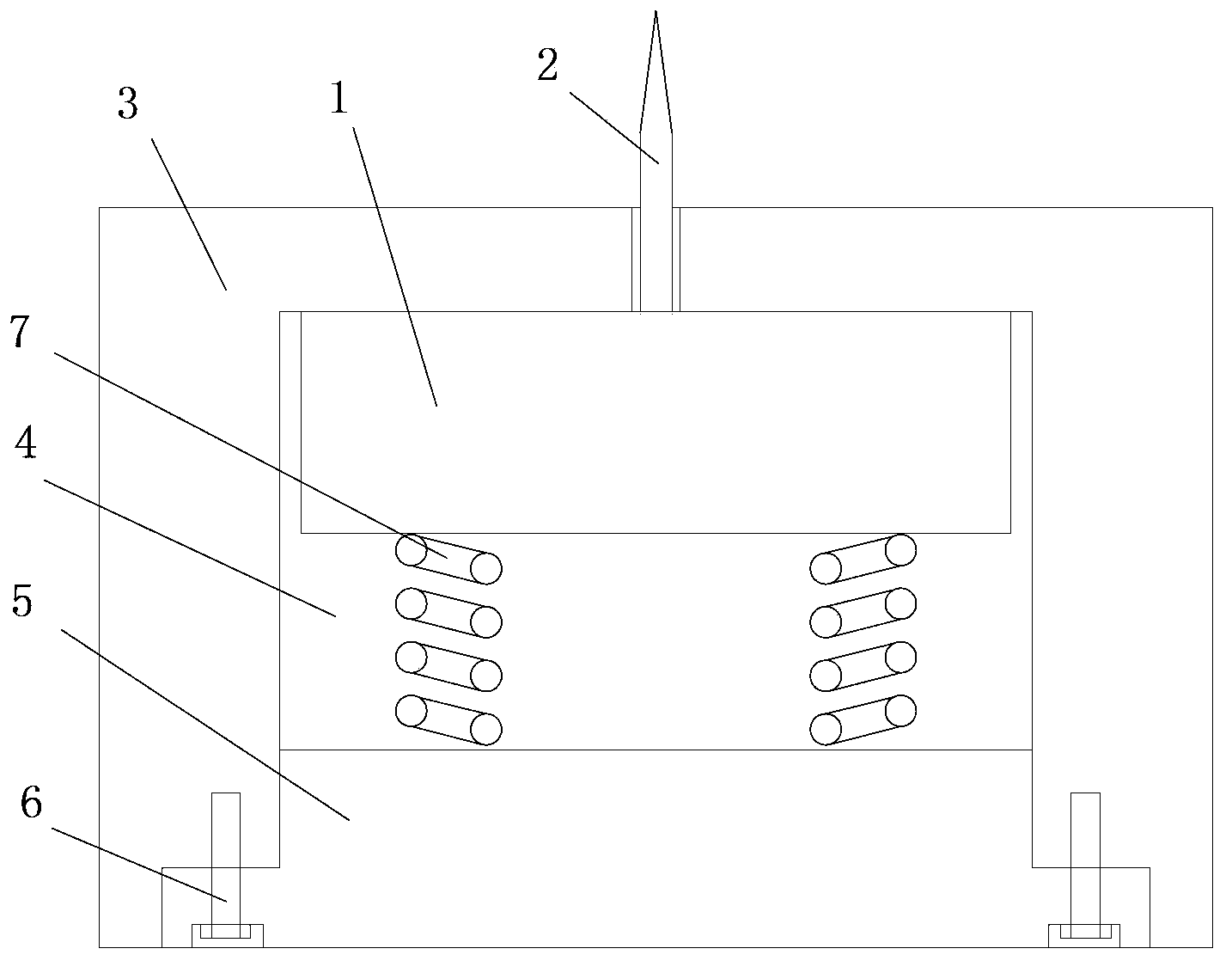

Temporary winding device with cleaning function and used for gauze production and machining

InactiveCN110626838AGood cleaning effectGuaranteed cleanlinessCleaning using toolsCleaning using gasesMachiningBlow out

The invention relates to the field of gauze production and machining devices, and specifically relates to a temporary winding device with a cleaning function and used for gauze production and machining. The temporary winding device with the cleaning function and used for gauze production and machining comprises a bottom plate, a winding structure, a fixed plate, a compression structure, a flatly-laying structure, a guide structure, a cleaning structure and a side plate. The winding structure is capable of synchronously driving the cleaning structure to work during working, so that a better cleaning effect of the cleaning structure can be achieved; two oppositely-arranged brush plates are fixed into a cleaning sleeve, and cleaning working can be carried out on a gauze being wound, so that impurities on the surface of the gauze can be cleaned, and then the cleanliness of the wound gauze can be ensured; gas blowing holes communicate with the interior of a gas storage groove separately, and therefore, gas in the gas storage groove is blown out via the gas blowing holes, so that ash blowing cleaning working can be carried out before the gauze enters the two brush plates, and then the cleanliness of the wound gauze can be ensured.

Owner:LIXIN FUYA GAUZE CO LTD

Improved battery

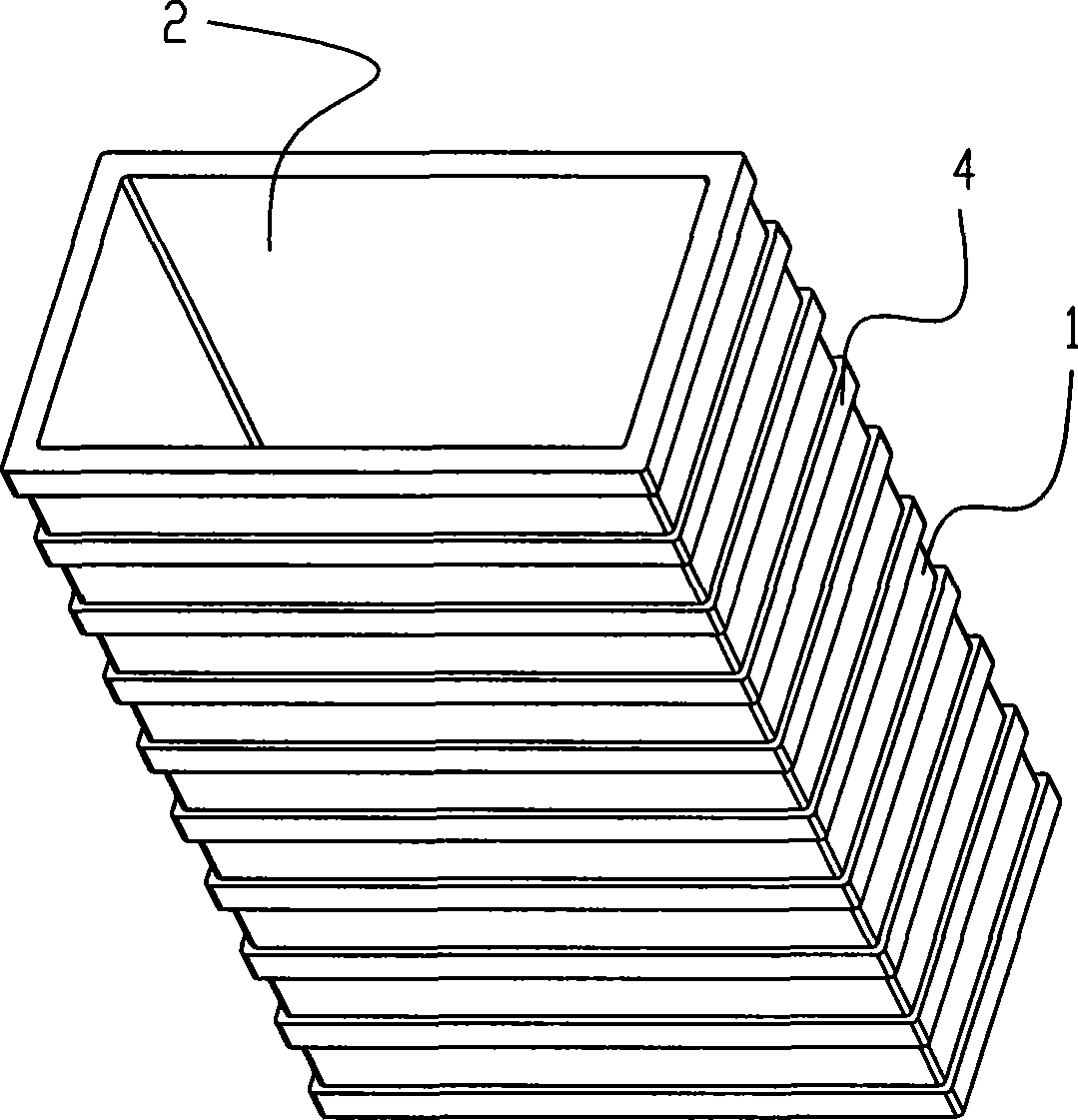

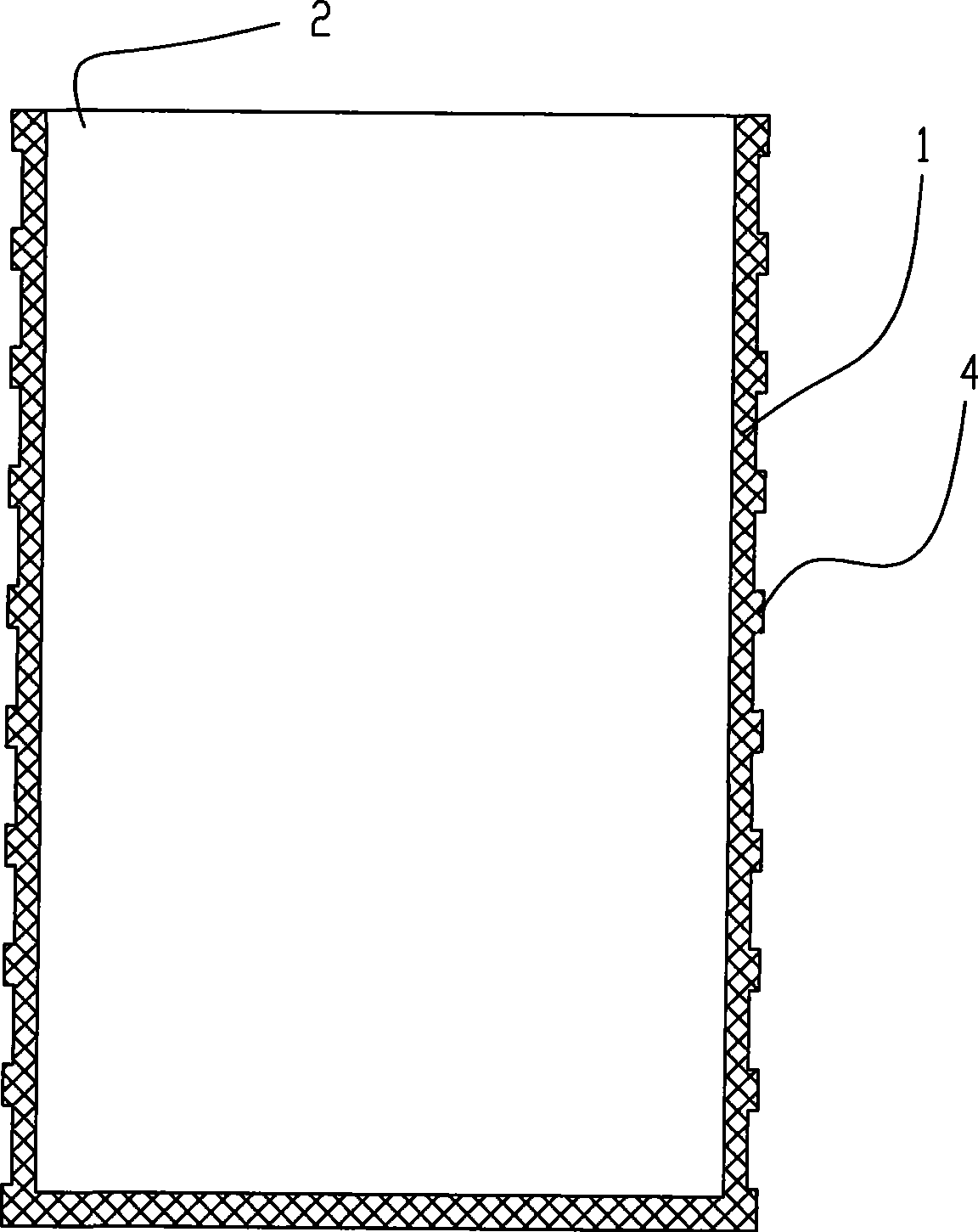

ActiveCN101465412AImprove cooling effectDo not change shapeSmall-sized cells cases/jacketsManufacturing technologyEngineering

The invention belongs to the technical field of battery manufacturing of electric motor cars and in particular relates to an improved battery; the battery comprises a shell, an upper cover, a pole rod, a lithium battery and an electric conducting bar; the shell is a cuboid shape, and the opening of the shell is sealed by the upper cover, and a strengthening rib is formed by the outer wall of the shell forms, and the lithium battery is arranged in the shell; the pole rod is embedded on the upper cover, and the outer end of the pole rod is connected with the electric conducting bar; the strengthening rib is transversely and uniformly distributed by the way that the strengthening rib is parallel to the edge of the opening of the shell. The improved battery has the advantages of high-strength shell, good heat radiating performance, simple structure, high using safety, high sealing property, long service life and the like.

Owner:ZHEJIANG GBS ENERGY

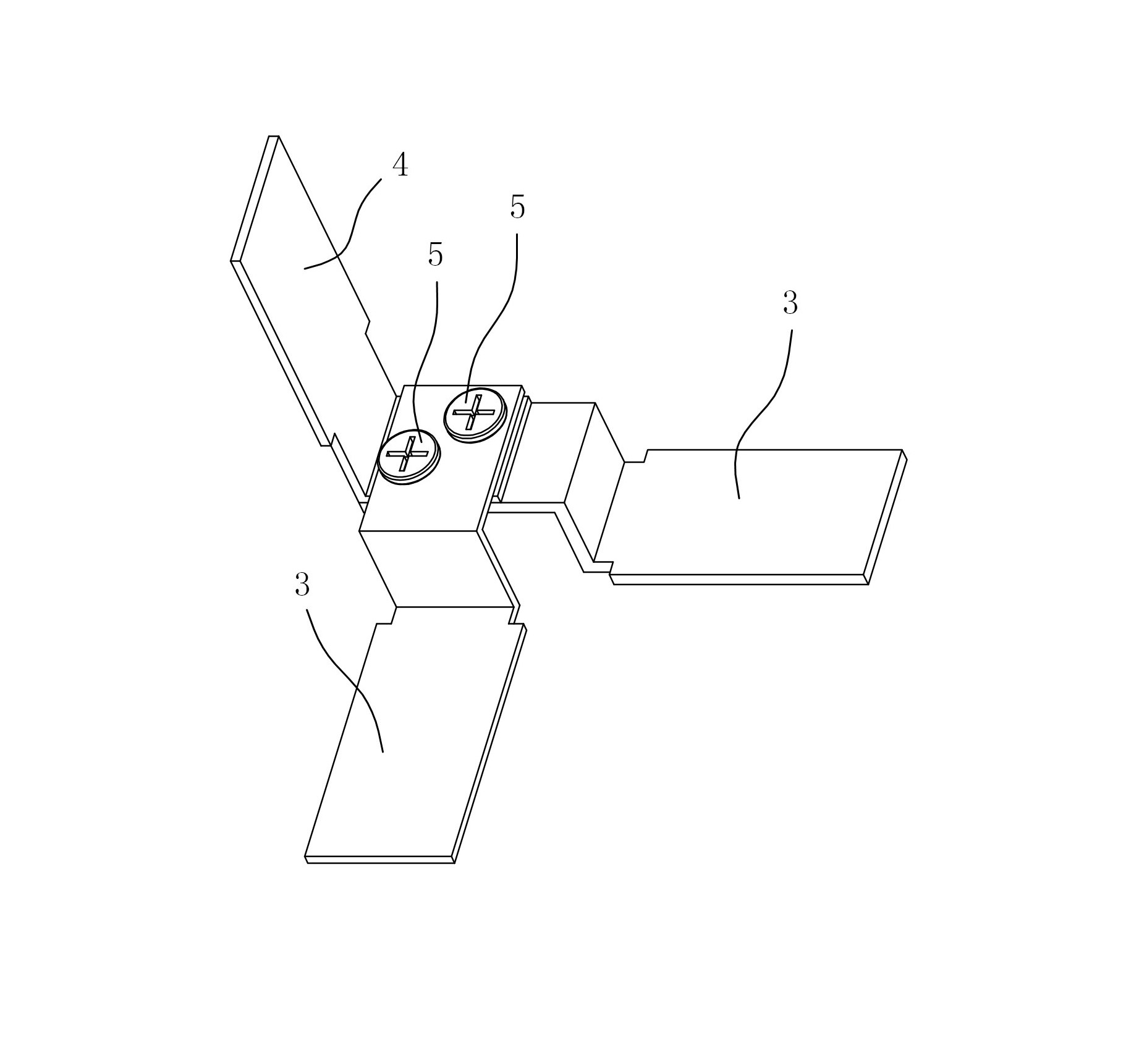

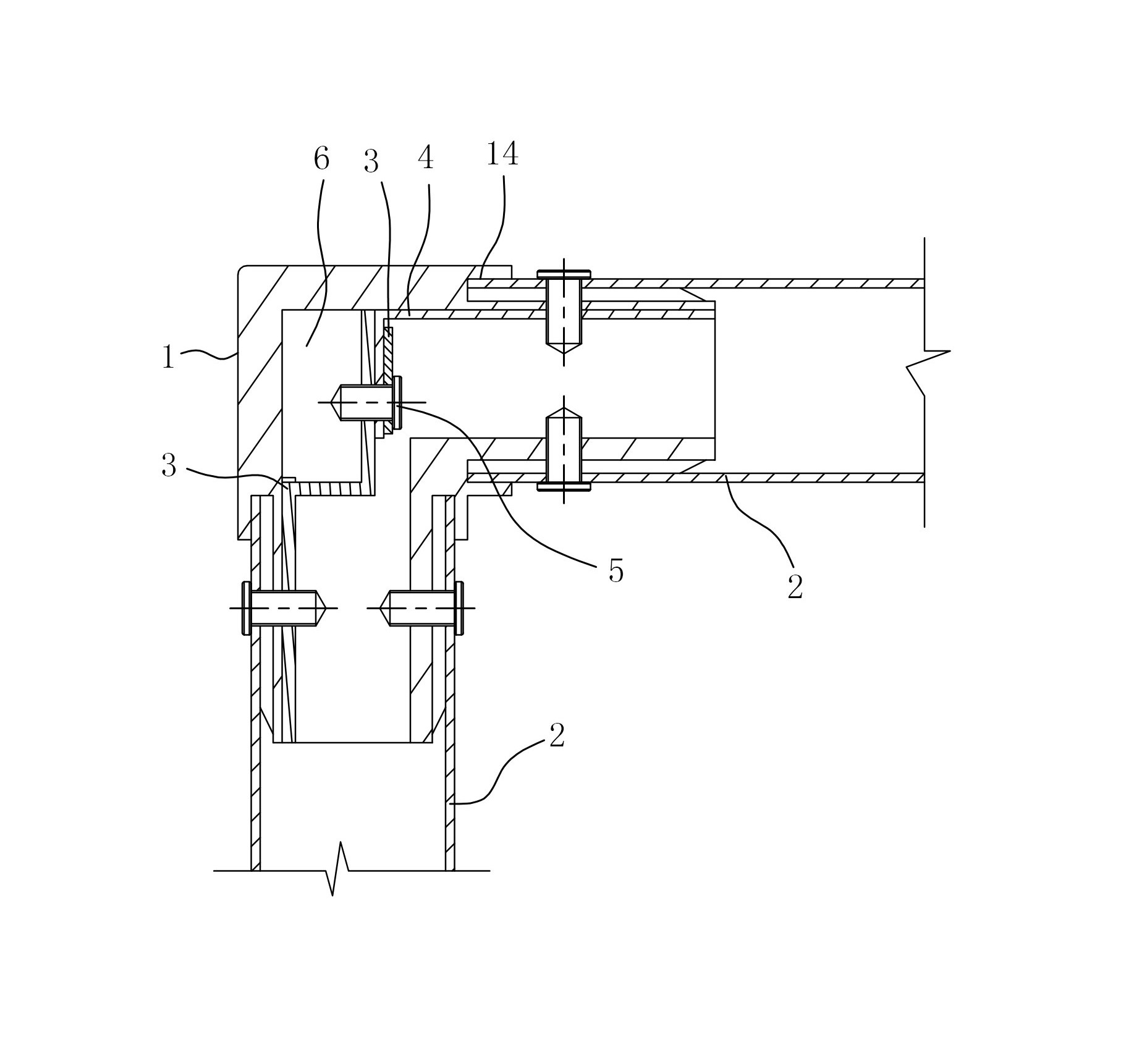

Stone ceramic plate hanging buckle component and mounting process thereof

The invention relates to a stone ceramic plate hanging buckle component which comprises a first pendant and a second pendant respectively mounted at the back part of a stone ceramic plate, a positioning corner fastener with a support part for fixing with the wall surface, and a fastener for respectively limiting the second pendant and the first pendant on the upper side and the lower side of the support part, wherein the fastener comprises a pressure plate and a hanging hook positioned at the lower end of the pressure plate; and the first pendant comprises a T-shaped groove which comprises anupward opening and is matched with the hanging hook, the hanging hook is inserted into the T-shaped groove of the first pendant for lifting the first pendant, the second pendant comprises a groove with a downward opening, and the upper end of the pressure plate is inserted into the groove and leans on the groove wall on one side of the groove, which is near to the wall surface. The stone ceramic plate hanging buckle component has simple structure, a keel framework does not need to be mounted, the dry hanging is not required, the positioning is fast, the stress on all plate blocks is more uniform through hanging (lifting)-supporting-leaning-adhering combination, the seismic performance is better, the detachment, the mounting and the replacement are more convenient, the mutual interference can be avoided, the problem of a cold / thermal bridge of a stone ceramic plate curtain wall can be thoroughly solved, and the stone ceramic plate hanging buckle component has better economic benefits and energy-saving effect.

Owner:王云飞

Method and device for monitoring transverse displacement of track

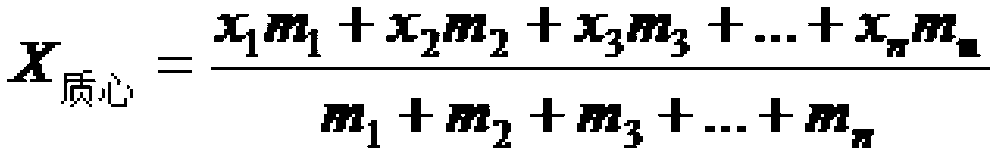

InactiveCN103217106ANo loosenessAchievement distanceUsing optical meansComputer hardwareImaging processing

Disclosed are a method and a device for monitoring transverse displacement of a track. The method for monitoring the transverse displacement of the track includes the following steps: collecting and processing image data through a video collection device, and sending the image data to a communication switching device through wire communication; receiving the image data through the communication switching device, and transferring and sending the image data to a host data processing unit through wireless communication; and figuring out the offset of the transverse displacement of the track through the host data processing unit according to data comparison, wherein the host data processing unit controls operation of the whole device. The device for monitoring the transverse displacement of the track comprises the video collection device located in a monitoring spot. The image data are collected by a camera of the video collection device, processed by a micro-control unit of the video collection device, and transferred to the host data processing unit through the communication switching device; and the offset of the transverse displacement of the track is figured out according to the data comparison. According to the method and the device for monitoring the transverse displacement of the track, the image processing technique is used for measuring the transverse displacement of the track, and distance control and data access on data collection monitoring and track displacement processing are achieved. The device is reliable, stable and low in power consumption.

Owner:BEIJING UNIV OF TECH

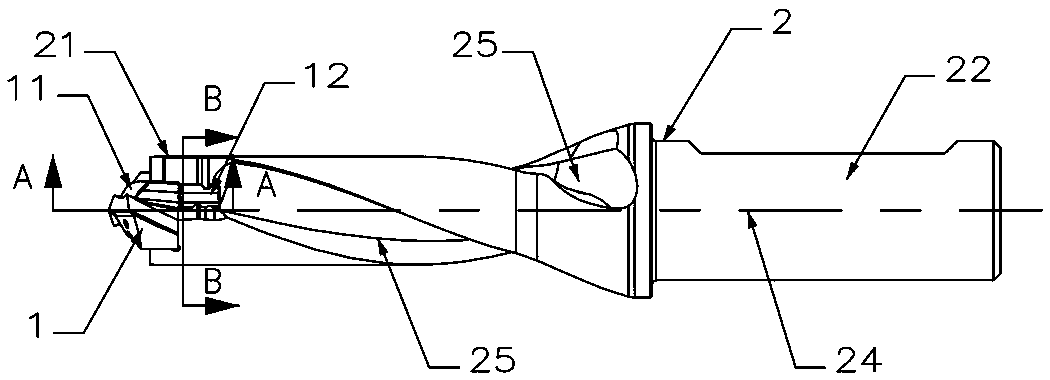

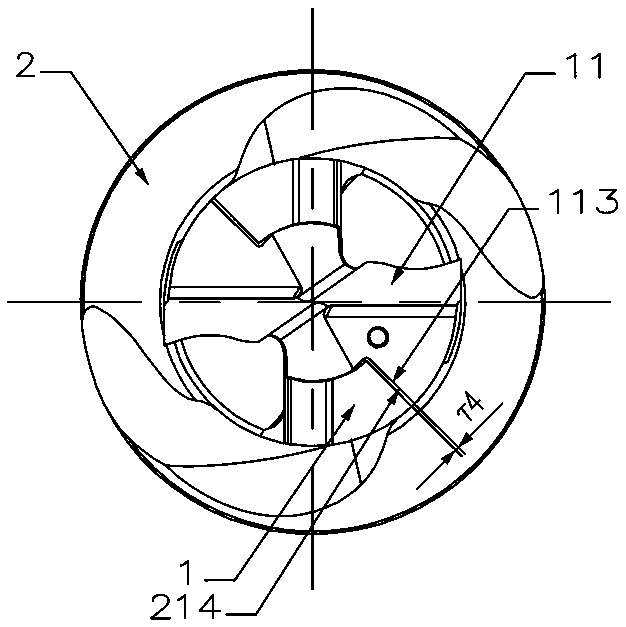

Lathe chuck

InactiveCN1748919ASimple structureGood stabilityChucksPositioning apparatusMechanical engineeringEngineering

The lathe chuck includes main shaft, pull tube and chuck head. The chuck head is fixed to the pull tube and installed in one end of the main shaft, and the pull tube extends beyond the other end of the main shaft. One clamping jaw seat is socked to the extending part of the pull tube, connected to the main shaft and hinged to several clamping jaws, each of which has one end pushing against the pull tube and the other end extending outside the clamping jaw seat. One locking sleeve is sleeved onto the clamping jaw seat, and one handle assembly is set to control the slide of the locking sleeve on the clamping jaw seat. The lathe chuck is easy to assemble and maintain, has simple structure, long service life, and high handle stability.

Owner:玉环龙生机床有限公司

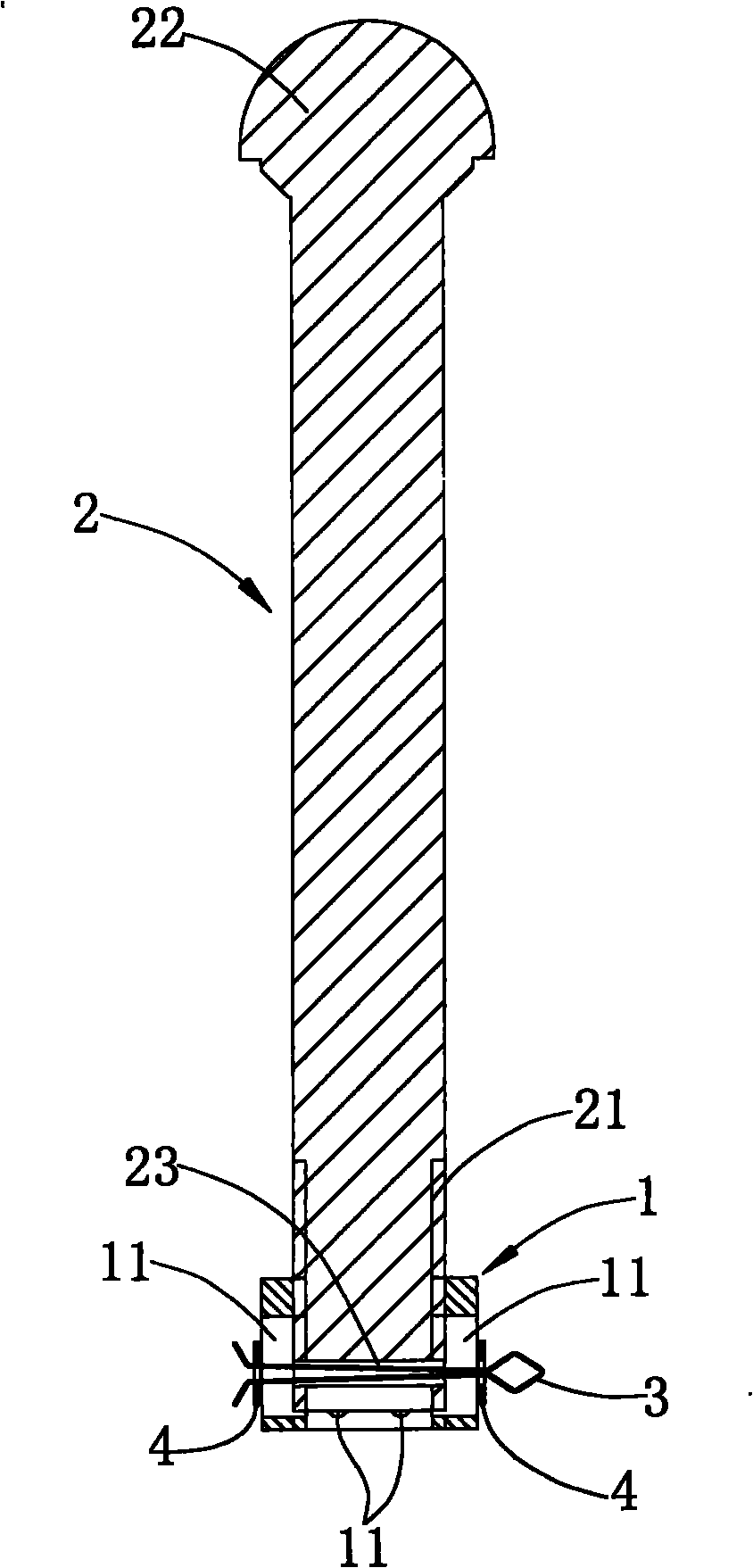

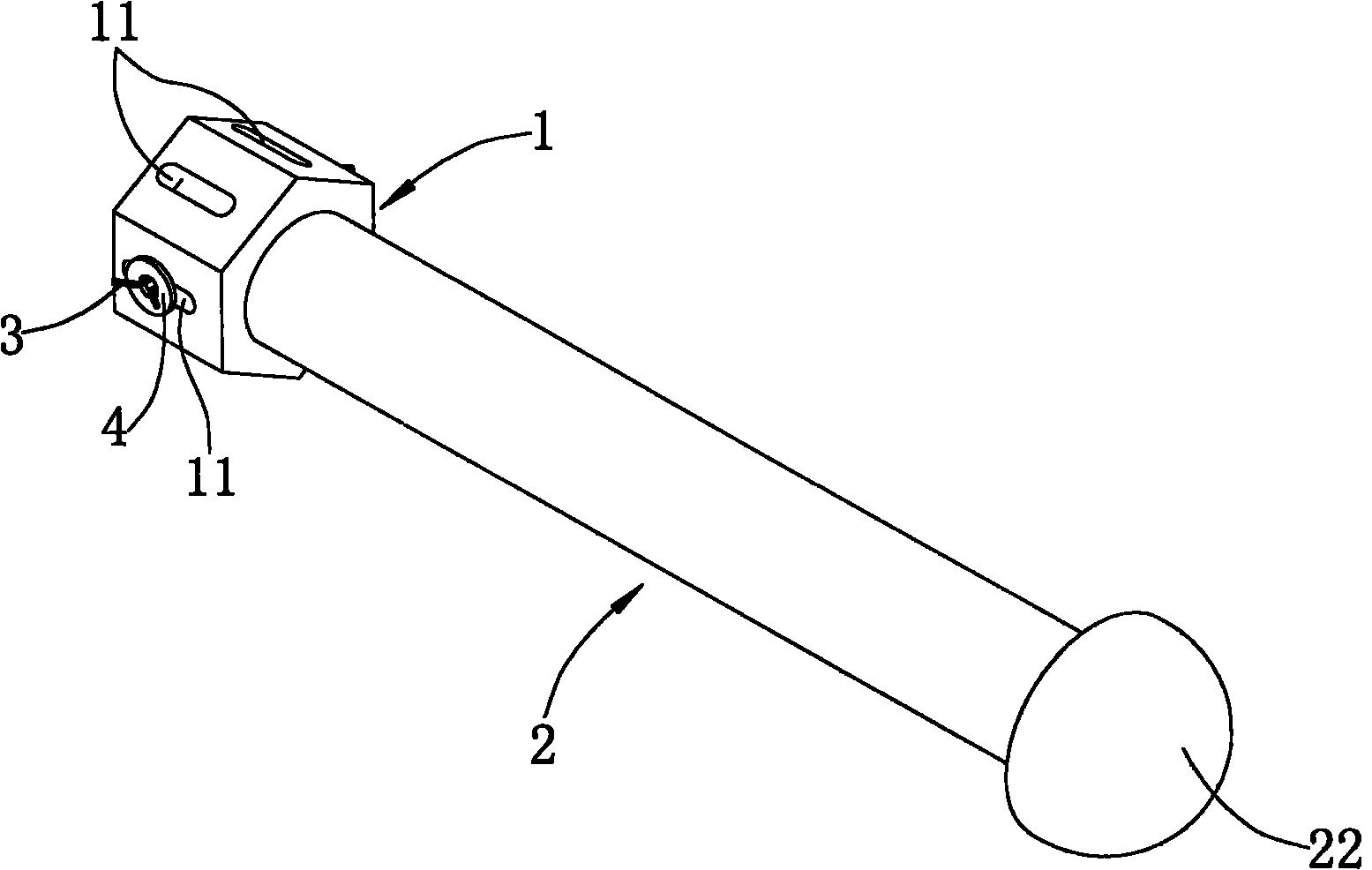

Textile yarn guide seat

InactiveCN104342840AGuaranteed smooth yarn guidanceNo loosenessWeft knittingWarp knittingTextile yarnEngineering

The invention relates to the technical field of textiles, in particular to a textile yarn guide seat. The textile yarn guide seat comprises a positioning plate, a plurality of yarn guide needles fixedly arranged on the upper end face of the positioning plate and a locking structure locking the positioning plate in a positioning seat, wherein the positioning plate is arranged in the positioning seat, and the yarn guide needles on the positioning plate penetrate through the positioning seat to be exposed out of the positioning seat. The positioning plate is locked in the positioning seat through a locking structure, the yarn guide needles extend out of the positioning seat to be used for yarn guide, the positioning plate is firmly limited in the positioning seat and does not loosen, and smooth yarn guide of the yarn guide needles is ensured.

Owner:常州市嘉翔纺织印染有限公司

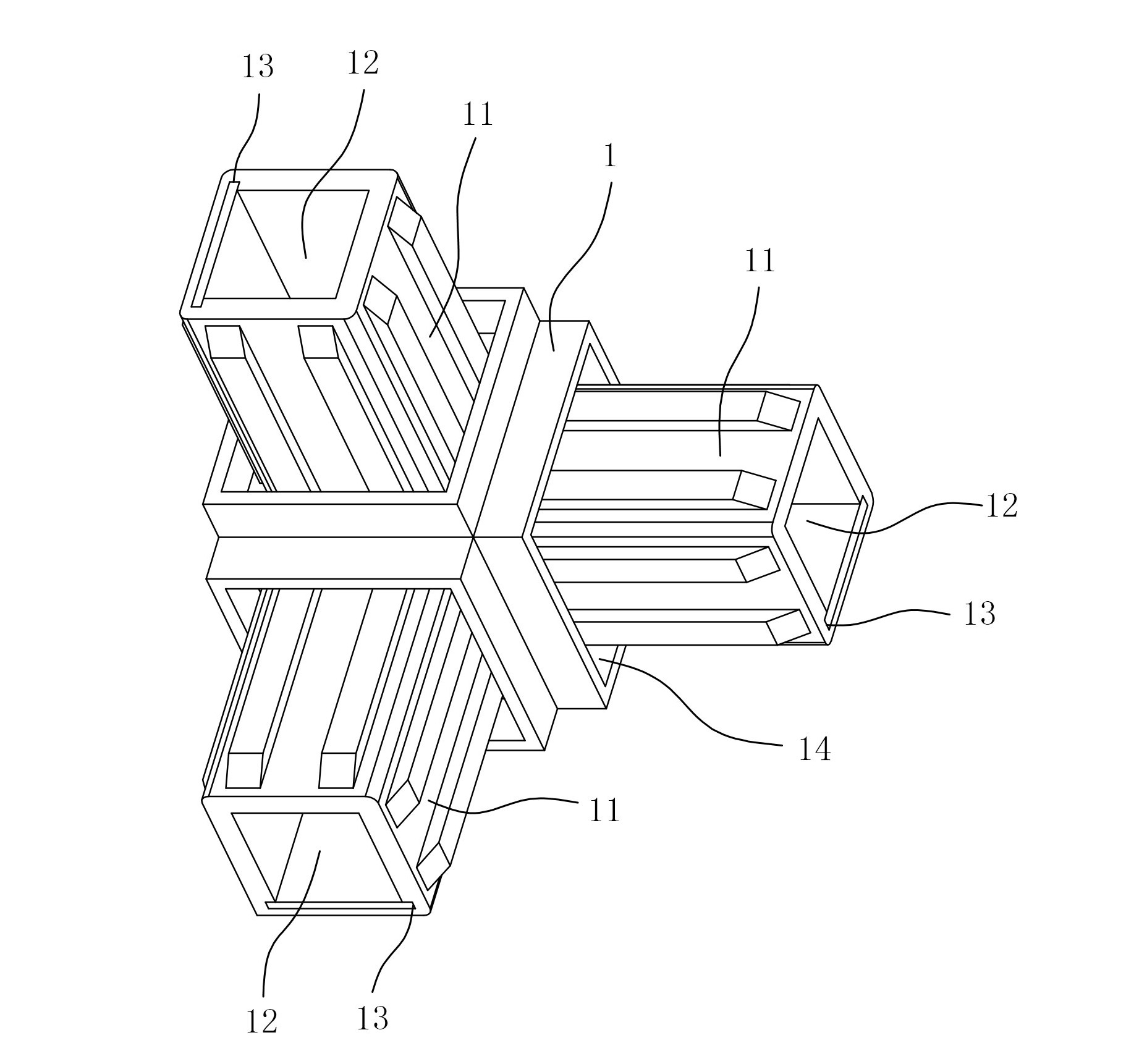

Three-way joint of protection net

The invention discloses a three-way joint of a protection net. The three-way joint comprises a nylon three-way joint body, wherein the nylon three-way joint body is provided with three sections of joints used for connecting the border of the protection net; the three sections of joints are respectively provided with an inner hole, and the three inner holes are mutually communicated; a metal plate is respectively inserted in each inner hole; and the three metal plates are tightly connected. The three-way joint of the protection net has the advantages of reliable connection, high safety coefficient, strong anti-theft capacity, simple structure, convenient manufacture and low cost.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

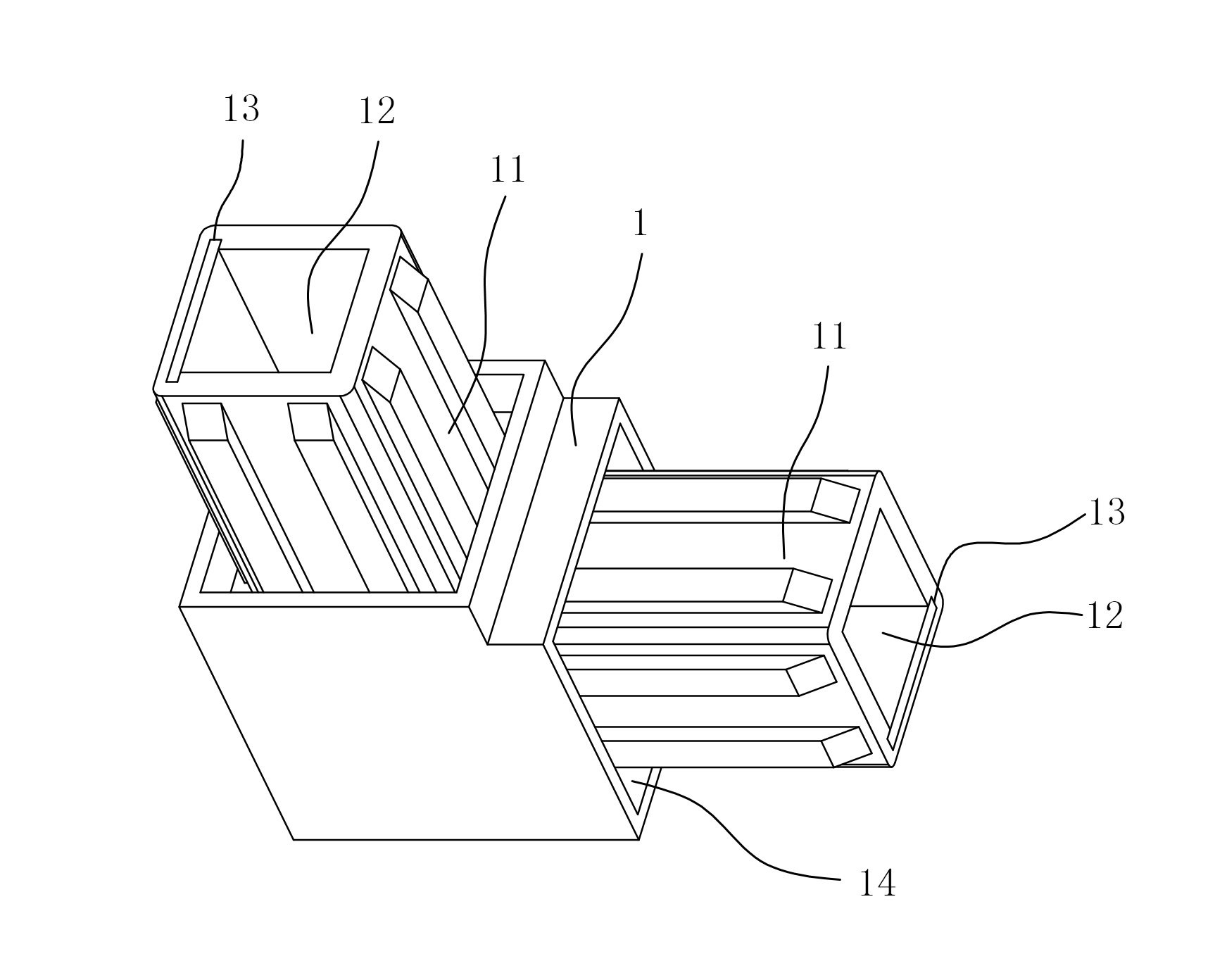

Two-way joint of protective net

ActiveCN101942958AImprove connection reliabilityEliminate potential safety hazardsFixed grillesEngineeringAnti theft

The invention discloses a two-way joint of a protective net. The two-way joint comprises a nylon two-way joint body, wherein the nylon two-way joint body is provided with two sections of joints used for connecting a border of the protective net; the two sections of joints are respectively provided with an inner hole, and the two inner holes are mutually communicated; and two metal plates are respectively inserted into the inner holes and tightly connected. The two-way joint of the protective net has the advantages of reliable connection, high safety factor, strong anti-theft capacity, simple structure, convenient manufacture and low cost.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

Elastic anti-knock anti-loose nut

The invention discloses an elastic anti-knock anti-loose nut. The elastic anti-knock anti-loose nut comprises a nut body, and connecting threads are machined on the nut body; an elastic gasket is arranged at the end of the nut body, and an elastic press-fit groove which can generate press-fit deformation along with pressing of the upper end of the elastic gasket is formed in the wall of the elastic gasket; through the improvement on the end of the nut body, the aim that a conventional spring gasket prevents looseness in the bolt connection process is achieved, a spring gasket is prevented from being placed at the end of the nut body, the space occupying at the position where the spring gasket is placed is reduced, it is ensured that when a bolt and the nut are connected, the enough effective length is achieved, and the connecting strength between the bolt and the nut is further ensured; and meanwhile, in the connecting process of the bolt, the elastic anti-knock anti-loose effect is achieved, the elastic gasket does not need to be additionally arranged, and the effective length of connection between the bolt and the nut is not shortened.

Owner:QUANZHOU LITAI AUTO PARTS MFG

Fixture structure for machining inner cavities and joint closing surfaces of glass molds

ActiveCN103056695BEasy to settleReduce work intensityPositioning apparatusMetal-working holdersStructural engineeringMechanical engineering

A fixture structure for machining inner cavities and joint closing surfaces of glass molds comprises a bottom seat plate, a center frame, two automatic mold supporting guide block lifting mechanisms and two automatic glass mold end surface locking mechanisms. Adjusting grooves are respectively arranged on surfaces of two ends of the bottom seat plate; adjusting grooves of mold pressing plates of the center frame are arranged on the top surface of the center frame, and the mold pressing plates of the center frame are respectively fittingly arranged on the adjusting grooves of the mold pressing plates of the center frame; the two automatic mold supporting guide block lifting mechanisms and the two automatic glass mold end surface locking mechanisms are respectively arranged at the two ends of the bottom seat plate, the automatic mold supporting guide block lifting mechanisms are positioned among the center frame and the automatic glass mold end surface locking mechanisms, a mold supporting guide block is arranged on the automatic mold supporting guide block lifting mechanism positioned at one end of the bottom seat plate, and another mold supporting guide block is arranged on the automatic mold supporting guide block lifting mechanism positioned at the other end of the bottom seat plate. The fixture structure has the advantages that the fixture structure is simple, and is convenient to manufacture and easy to use and maintain; the operation intensity is relieved for operators; loosening is prevented; and the machining efficiency of a machining center is improved, and the perfect matching precision between two half molds of a mold can be guaranteed.

Owner:ORI MOLD TECH SUZHOU

Anti-loosing fastener

The invention relates to an anti-loosing fastener, which comprises a nut body and a screw which are screwed mutually, wherein one end of the screw is provided with external screw threads, and the other end of the screw is provided with a chock plug; the cap body is a regular polygonal prism block with an internal threaded hole in the axial direction; an axial striped hole communicated with the internal threaded hole is formed in the centre area of each of at least two opposite sides in the cap body, and the axial central lines of the two striped holes and the axial line of the cap body are coplanar; a radial perforation which passes through the axial line is formed on one end with the external screw threads of the screw; and an opening pin is arranged in the striped hole on one side, the perforation and the striped hole on the other side to position the cap body on the screw. The two ends, positioned outside the cap body, of the opening pin are sleeved with a gasket respectively. The cap body is a regular hexagonal prism block, and an axial striped hole which is communicated with the through hole with the internal screw threads is positioned in the centre area of each of every two opposite sides in the cap body respectively, and axial centre lines of the opposite every two striped holes and the axial line of the cap body are coplanar. When used, the fastener is not loosed caused by vibration and the like.

Owner:赵贺峰

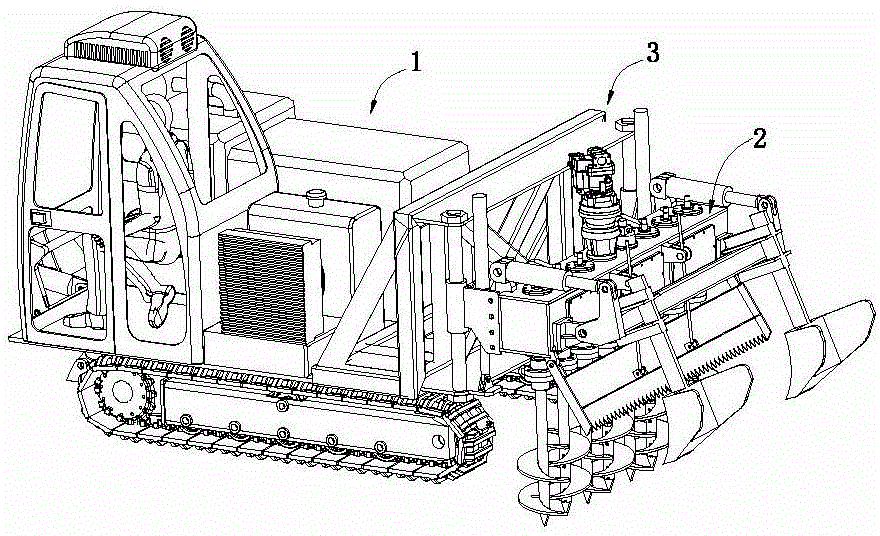

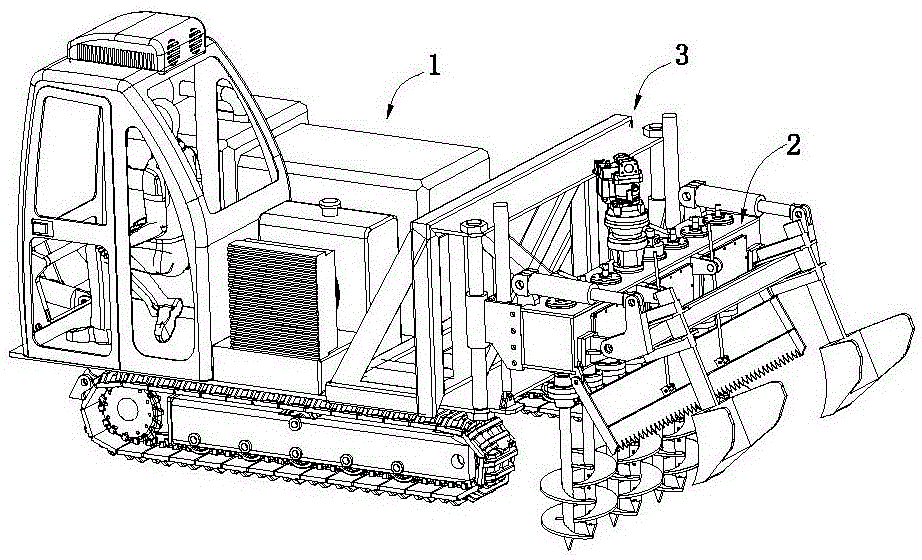

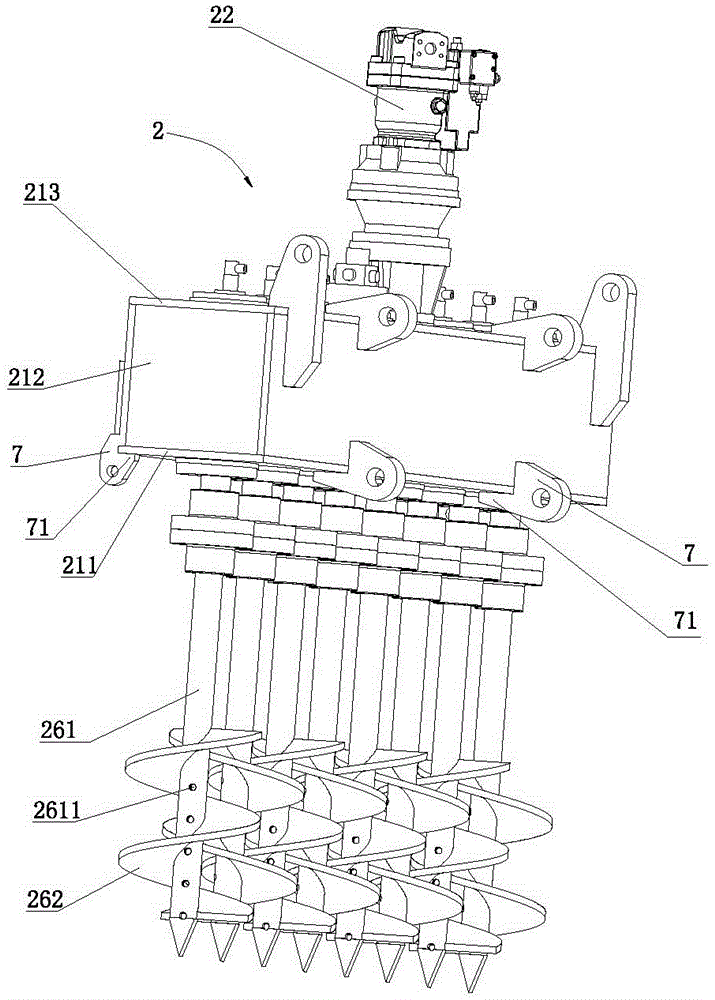

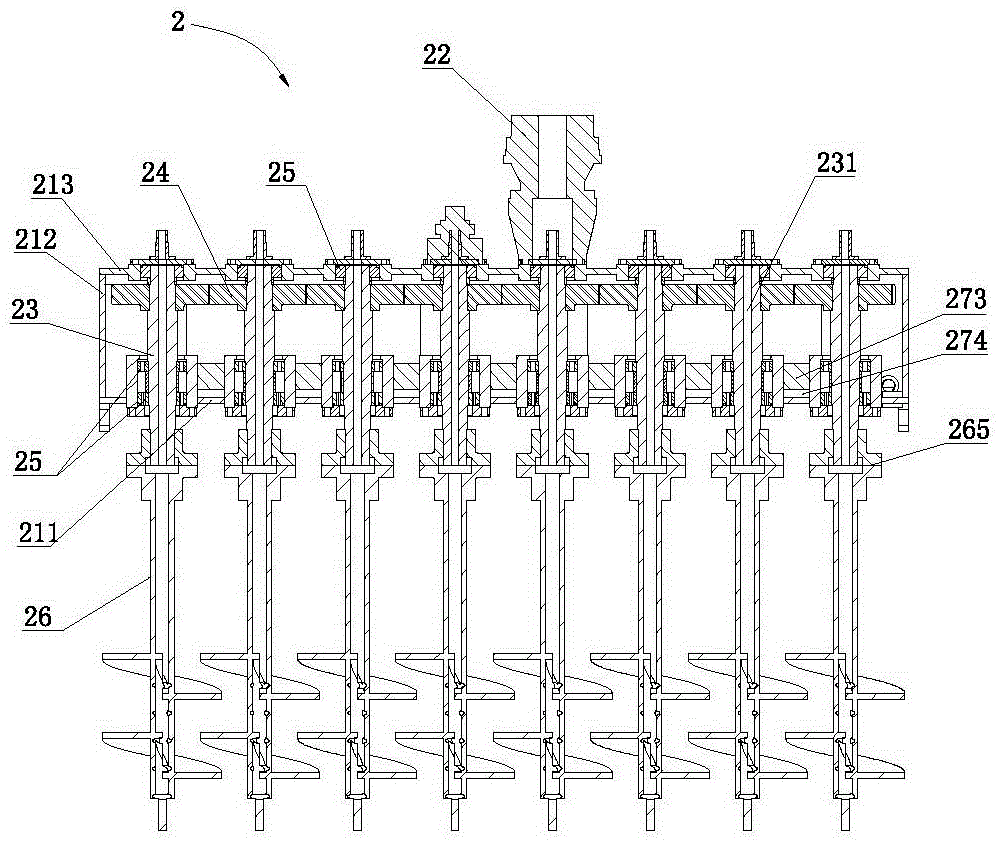

Subsoiling and smashing and ridging machine

InactiveCN104996014ANo loosenessPrevent looseningSpadesCrop conditionersDrive shaftUltimate tensile strength

The invention discloses a subsoiling and smashing machine. The subsoiling and smashing machine comprises a machine body, a smashing and ridging device, a connecting device, a ditching device, a leveling device and a device for returning straws to a field; the smashing and ridging device comprises a smashing and ridging box; the smashing and ridging box comprises a bottom plate, a side plate and a top plate; lower bearing bases are mounted on the bottom plate; a rib plate is welded between the lower bearing bases; a lubricating oil channel is arranged between the rib plate and the bottom plate; upper bearing bases are mounted on the top plate; and the lower bearing bases are arranged on the upper bearing bases. According to the subsoiling and smashing and ridging machine, the strength of the lower bearing bases can be improved; a plurality of bearings are conveniently mounted on places which with great stress, and less bearings are mounted on places with little stress; so that the rigidity and the transmission stability of a transmission shaft are improved, and the cost can be reduce; the rib plate is conveniently welded; and the lubricating oil is guaranteed to smoothly flow in the smashing and ridging box, thereby improving the lubricating effect.

Owner:GUANGXI WUFENG MACHINERY CO LTD

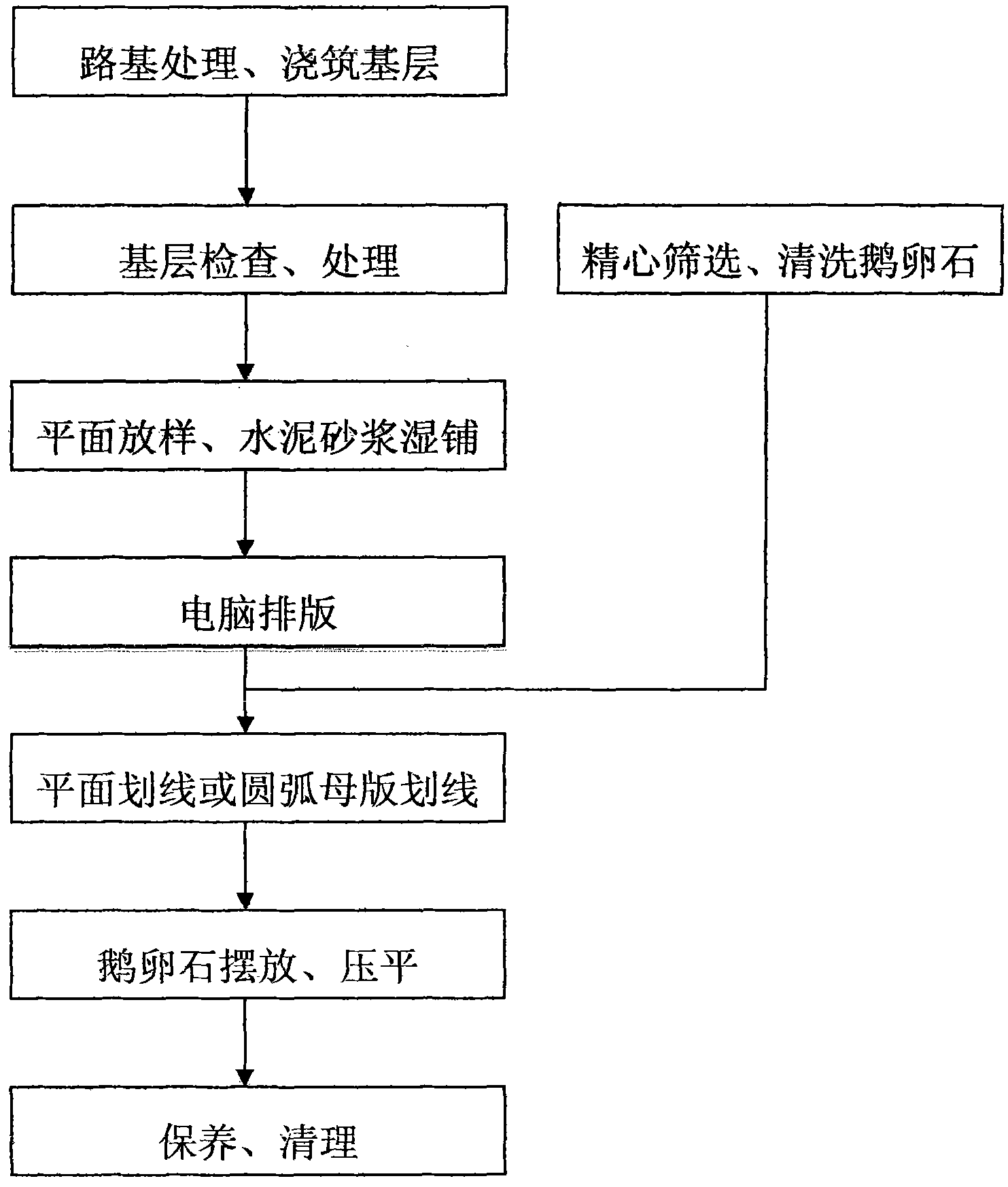

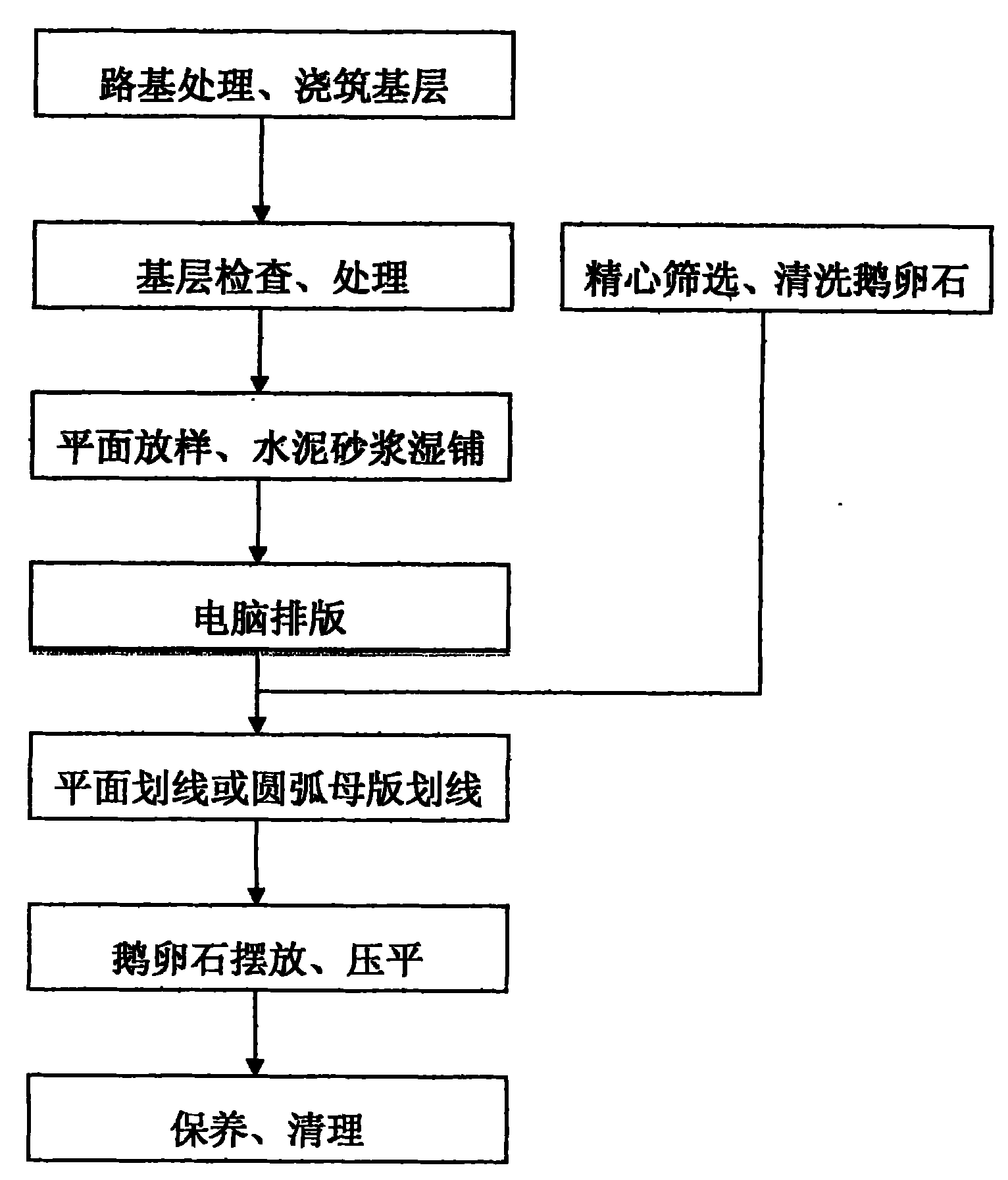

Wet-lime embedded once-molding construction process of cobblestone garden path and landscape floor

The invention relates to a wet-lime embedded once-molding construction process of a cobblestone garden path and a landscape floor, comprising the following steps of: (1) firstly carrying out roadbed treatment and basic layer casting, and detecting and treating a basic layer; (2) carrying out planer lofting and wetly paving cement mortar on the basic layer; (3) carrying out planer marking or circular-arc master plate marking when waiting prehardening and moisture dry-out of the cement mortar; (4) then carrying out on-site lofting, embedded setout and planishing on cobblestones according to patterns edited by a computer; and (5) clearing up and maintaining. The invention not only accelerates the construction speed, but also is firmly bonded after being embedded and solves the previous common quality fault that cobblestones become loose and peel off.

Owner:浙江中联建设集团有限公司

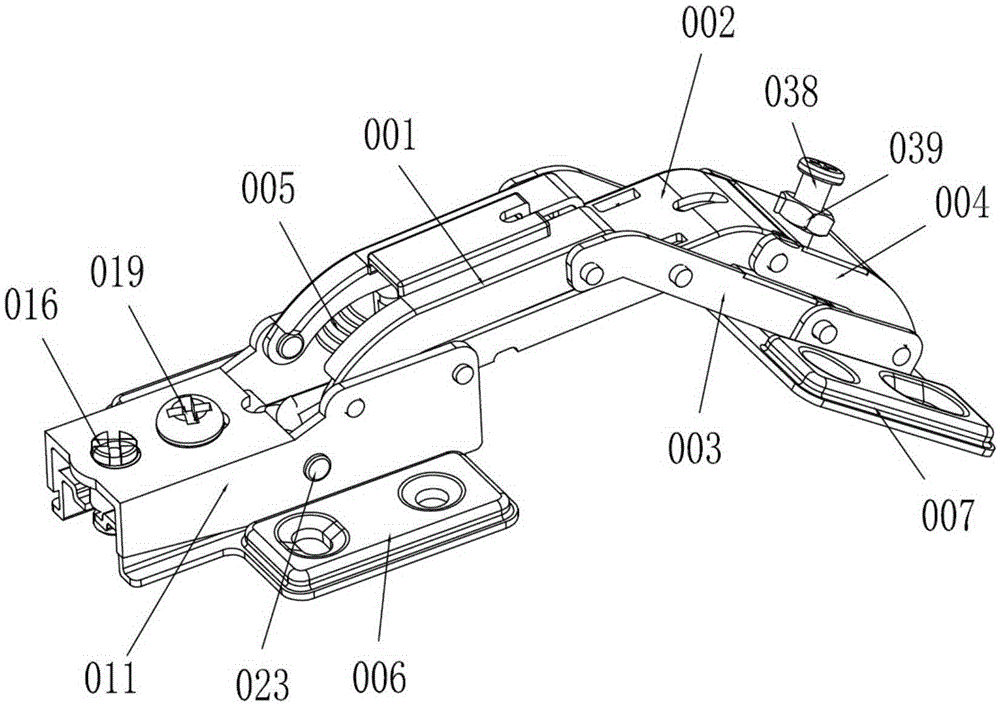

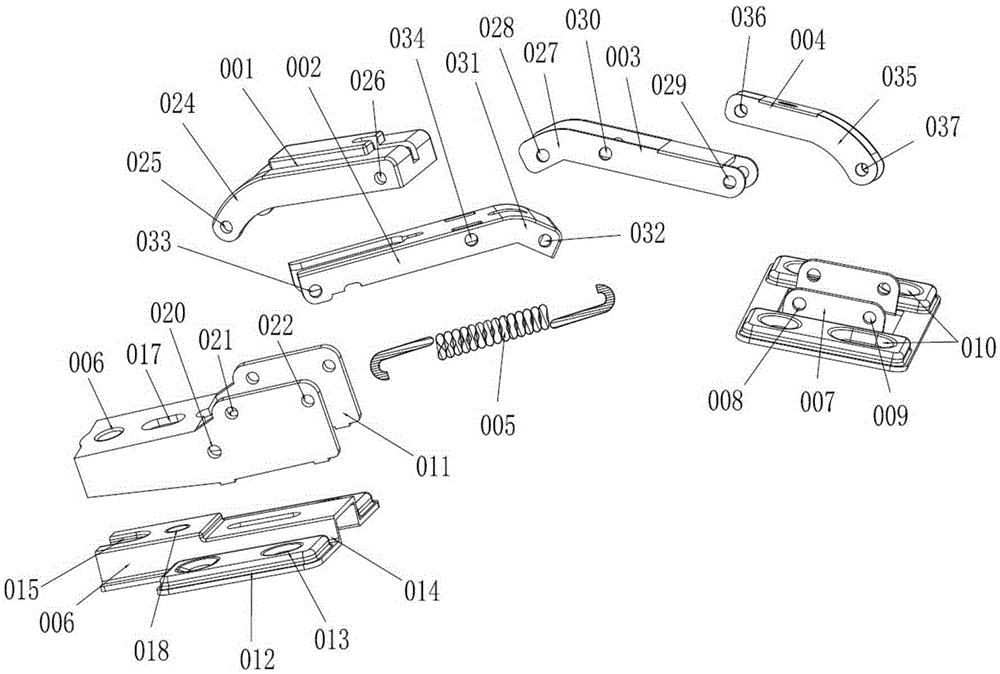

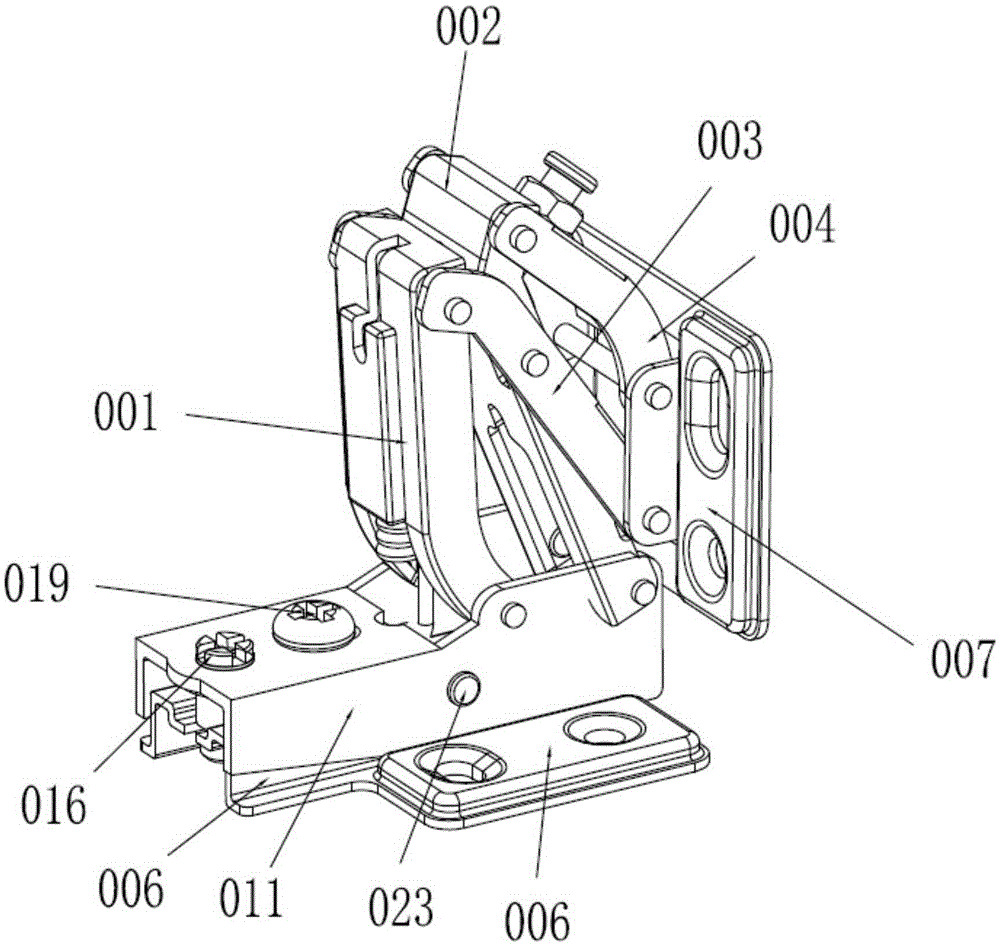

Multifunctional cabinet door hinge

InactiveCN105332584ATo achieve the purpose of multi-purposeEasy to assemblePin hingesWing openersEngineering

The invention discloses a multifunctional cabinet door hinge which comprises a main rotating pull rod, a main rotating connecting rod, a transmission connecting rod, a transmission pull rod, a tension spring, an inner frame base and an outer door base. An adjustable adjusting support is arranged on the inner frame base. The adjusting support is provided with a spring connecting hole. A first spring hook is arranged on the spring connecting hole. One end of the main rotating pull rod and one end of the main rotating connecting rod are connected with the adjusting support through shafts. The other end of the main rotating pull rod is connected with the transmission connecting rod, and the other end of the main rotating connecting rod is connected with the transmission pull rod. A first connecting hole is formed in the middle of the main rotating connecting rod. A second connecting hole is formed in the middle of the transmission connecting rod. The multifunctional cabinet door hinge is reasonable in structure, accurate, fast and easy to assemble, high in practicability and free of bad phenomena of noise, loosening, deformation, disengagement and the like during repeated starting.

Owner:DONGGUAN SUOMAILUO METAL TECH CO LTD

Mounting structure of intelligent air conditioner outdoor unit

ActiveCN111853968AIncrease flexibilityNo loosenessLighting and heating apparatusCleaning using toolsWater wheelEnvironmental engineering

The invention provides a mounting structure of an intelligent air conditioner outdoor unit, and belongs to the technical field of mounting structures. The mounting structure aims at solving the problems that as an effective cleaning mechanism is not available on an existing mounting structure, automatic cleaning cannot be carried out when impurities are attached to a ventilation net on the air conditioner outdoor unit, and then the ventilation effect of the air conditioner outdoor unit is reduced. The mounting structure comprises an angle steel mounting frame. A height adjusting mechanism is arranged on the front side of the angle steel mounting frame, and the height adjusting mechanism is of a rectangular plate structure. Through the cooperation of a rain shading part and a cleaning mechanism, when it rains outside, rainwater flows into a drain port through the upper end face of the rain shading part, then the rainwater is washed to a water wheel through the lower end of the drain port, as the rainwater drained from the lower end of the drain port has certain washing force under the effect of gravity, the water wheel starts to rotate, then a rotary shaft on the water wheel drivesa cleaning brush to rotate, thus, automatic cleaning can be carried out when the impurities are attached to the ventilation net on the air conditioner outdoor unit, and then the ventilation effect ofthe air conditioner outdoor unit is improved.

Owner:河北天辰机电设备安装有限公司

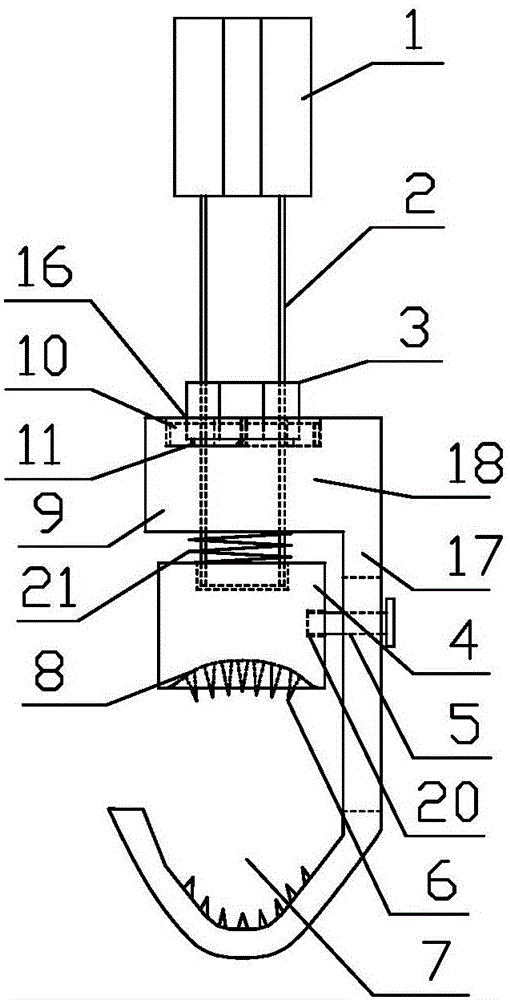

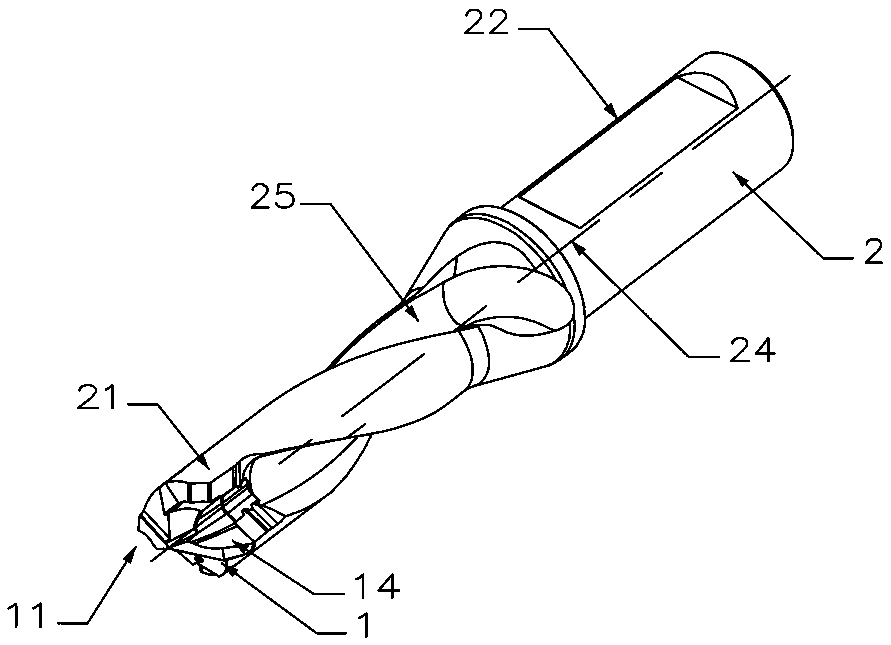

Stably clamping drilling tool

ActiveCN109262027AEasy clampingReduce manufacturing difficultyTransportation and packagingChucksBiomedical engineeringLambda

The invention discloses a stably clamping drilling tool. A projection is spirally twisted into a recess along the direction of a center shaft, an outer circumferential surface is matched with an innercircumferential surface to achieve changing interference magnitude lambda in the cutting part clamping process of a clamping component, and -0.1mm<=lambda<=0.05mm. The drilling tool has the advantages of rapidness in assembly and disassembly, no axial looseness, high positioning precision, simplicity in manufacture, good interchangeability and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Making method of yolkless poultry egg

InactiveCN1650754ANo loosenessIncrease food varietyKitchen equipmentFood preparationNutrient contentYolk

Owner:周贵章

Manufacturing method of shale sintered composite plate for prefabricated building

InactiveCN111663710AImprove construction efficiencyShorten the construction periodWallsHeat proofingBrickThermal insulation

The invention discloses a manufacturing method of a shale sintered composite plate for a prefabricated building. A plurality of thermal insulation holes are formed in a hollow brick body. One or morepenetrating reinforcing steel bar holes for reinforcing steel bars to penetrate through are formed in the direction perpendicular to the direction of the thermal insulation holes. A viscose for connection is sprayed or painted quantitatively between ends of every two adjacent hollow brick bodies, and a reinforcing steel bar penetrates into each overall reinforcing steel bar hole; the viscose fulfills gaps between every two adjacent hollow brick bodies under extrusion; and the ends of the hollow brick bodies are provided with connecting blocks correspondingly, each connecting block is at leastprovided with two connecting holes, one connecting hole is connected with one end of the corresponding reinforcing steel bar, other holes serve as bolt connecting holes for fixing bolts, and the sintered composite plate is formed. Platy wall board structures of various areas are prefabricated in a factory and then transported to a construction site to be overall installed on site, so that construction efficiency is greatly improved, operators for on-site bricklaying construction are greatly reduced, a construction period is shortened, and construction cost is reduced.

Owner:重庆金彧新型环保建材有限公司

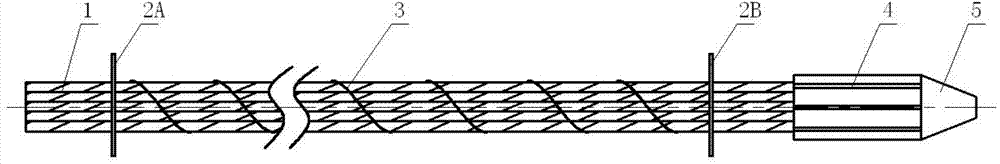

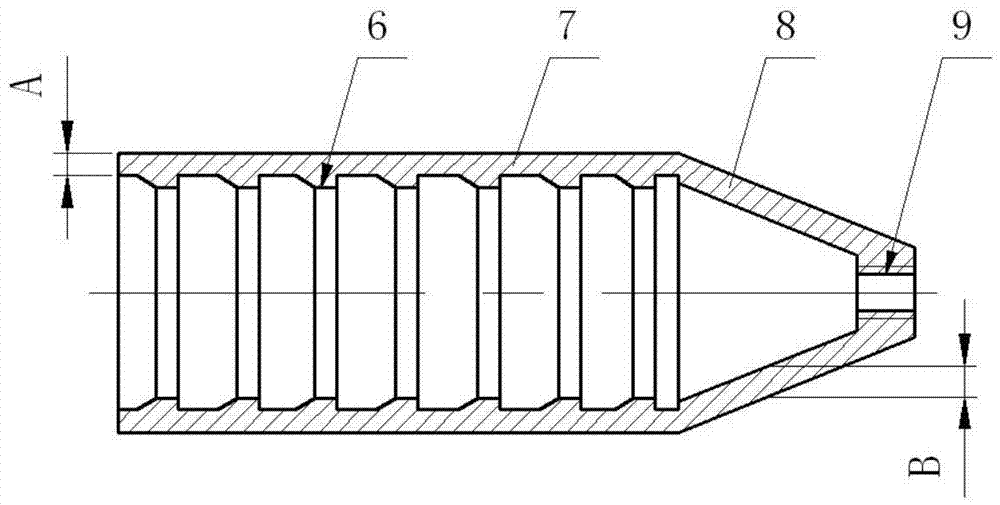

Finished prestressed steel stranded wire harness convenient for construction

InactiveCN104499652ANo loosenessSimple structureBuilding reinforcementsPre stressArchitectural engineering

The invention relates to a finished prestressed steel stranded wire harness convenient for construction. The finished prestressed steel stranded wire harness comprises a steel stranded wire harness, an extruding sleeve, a front marking board, a rear marking board and a binding wire, wherein the steel stranded wire harness is composed of a plurality of steel stranded wires through combing and twisting in an ordered manner, the extruding sleeve is coaxially buckled at the pulling end of the steel stranded wire harness, the front end and the rear end of the steel stranded wire harness penetrate through the front marking board and the rear marking board, respectively, the binding wire is spirally wound on the outer edge of the steel stranded wire harness between the two marking boards, the extruding sleeve comprises a connecting section and a pulling section, wherein the pulling section is integrated at one end part of the connecting section, the pulling section is of a cone-frustum shaped structure, a threaded hole is formed coaxially in the minor-diameter end of the cone-frustum shaped structure, and a plurality of barb bulge loops are uniformly and integrally arranged on the inner wall of the connecting section in a spacing manner. The steel stranded wire harness can penetrate into a corrugated pipe of a construction hole safely, twisting and deformation among the single steel stranded wires are avoided during penetrating, the pulling section of the extruding sleeve is of a conical structure design and has the strong guiding property, and the construction efficiency is effectively improved.

Owner:TIANJIN SHINKUNTAI ADVANCED PRESTRESSING TECH

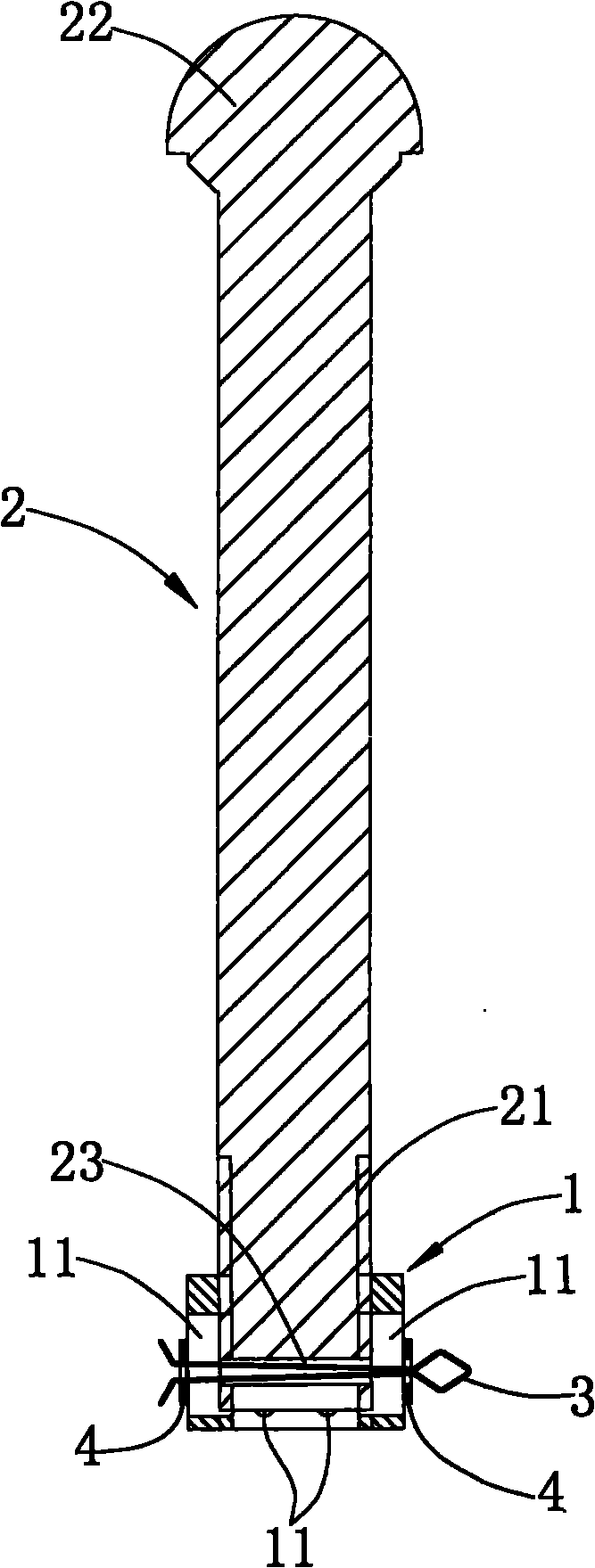

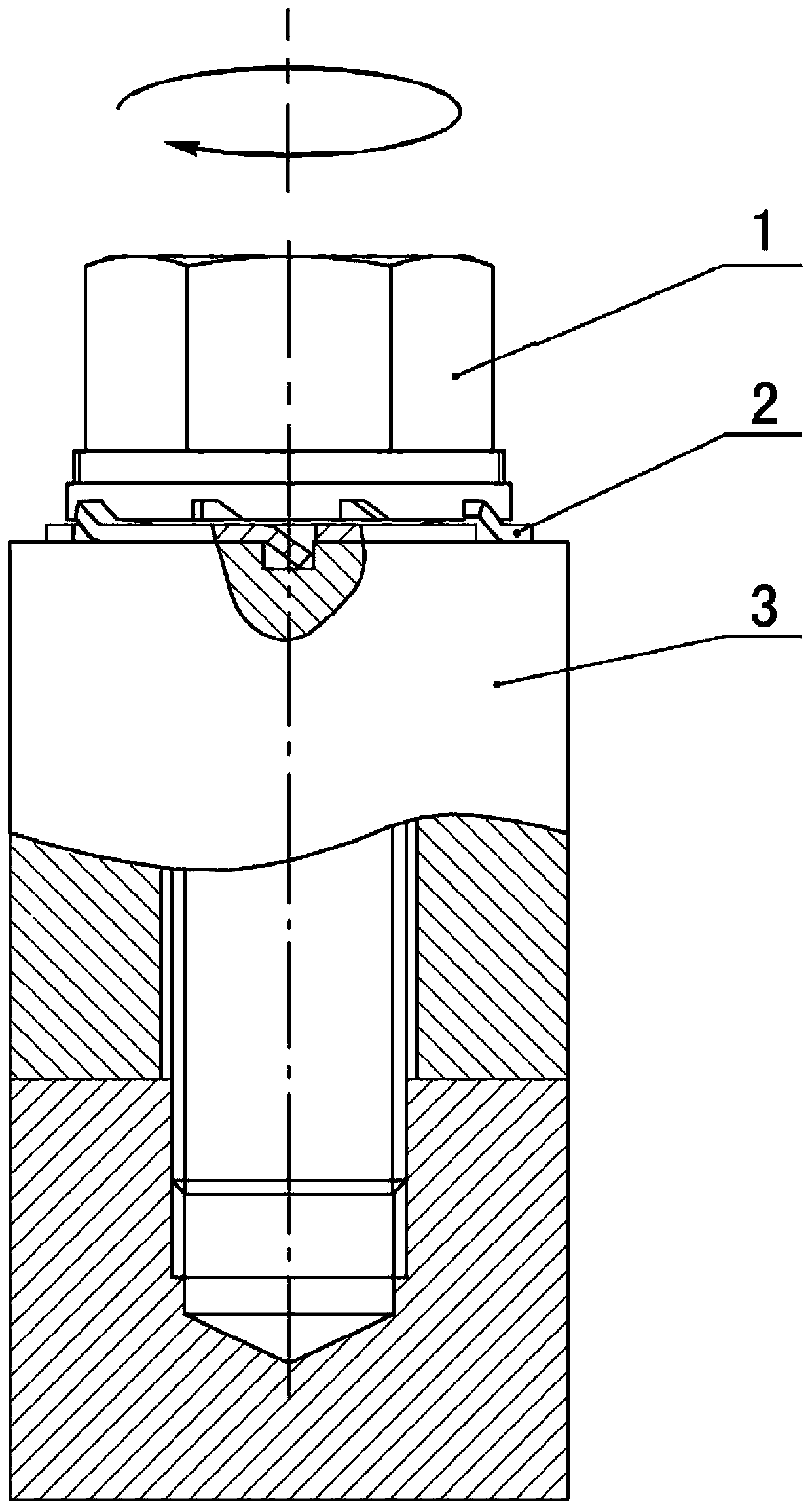

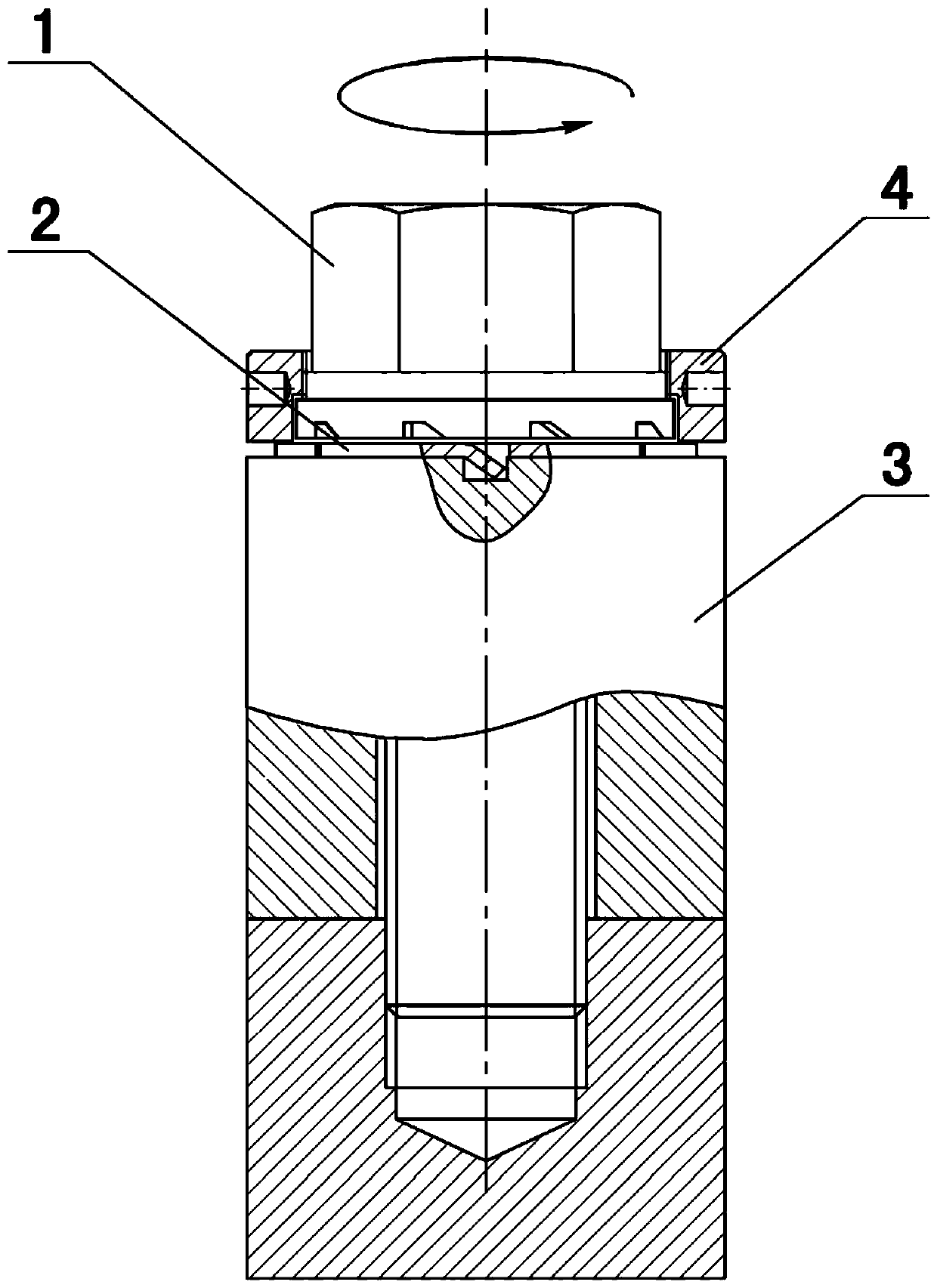

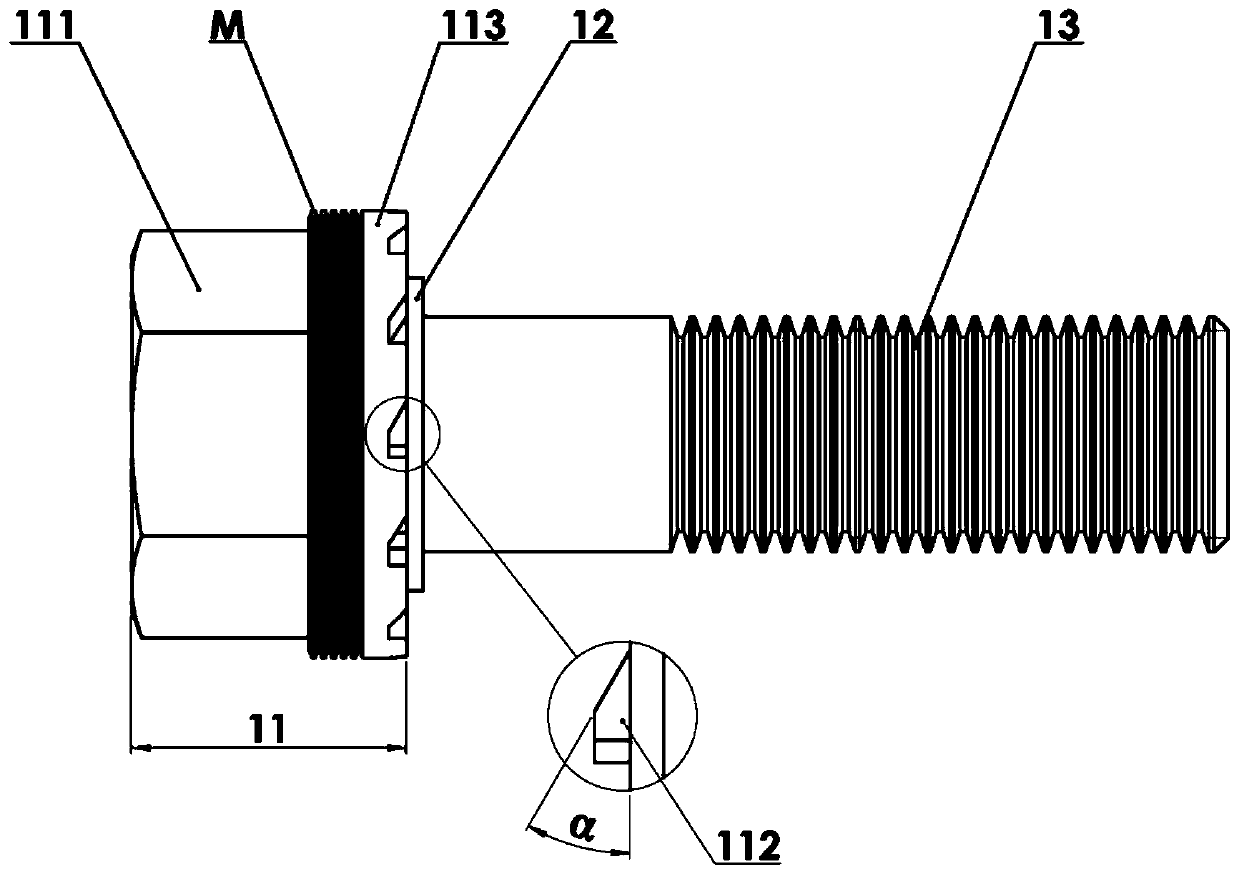

Anti-loose bolt device

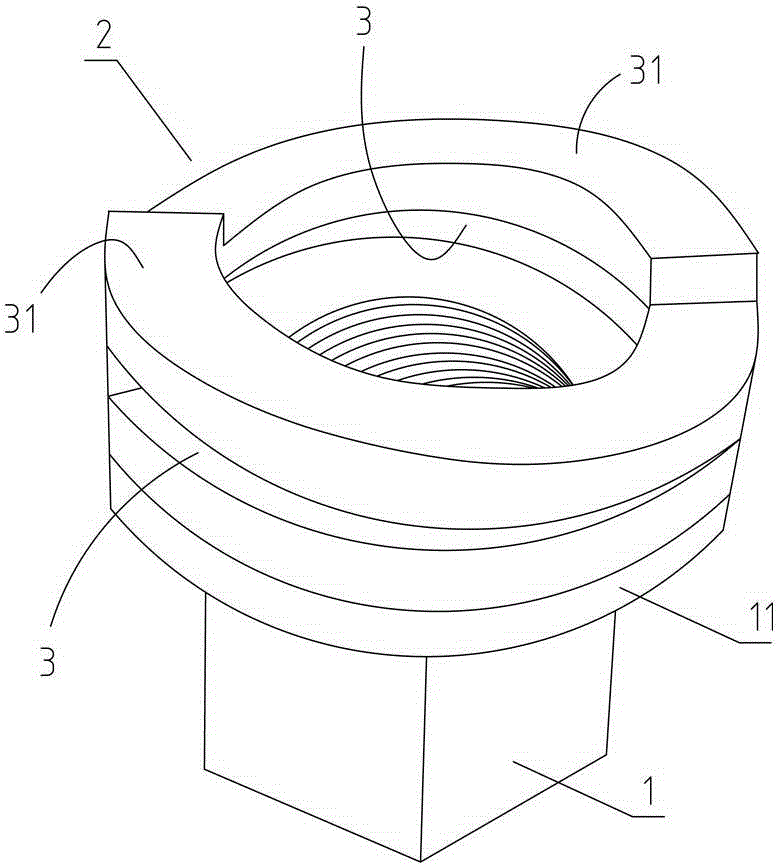

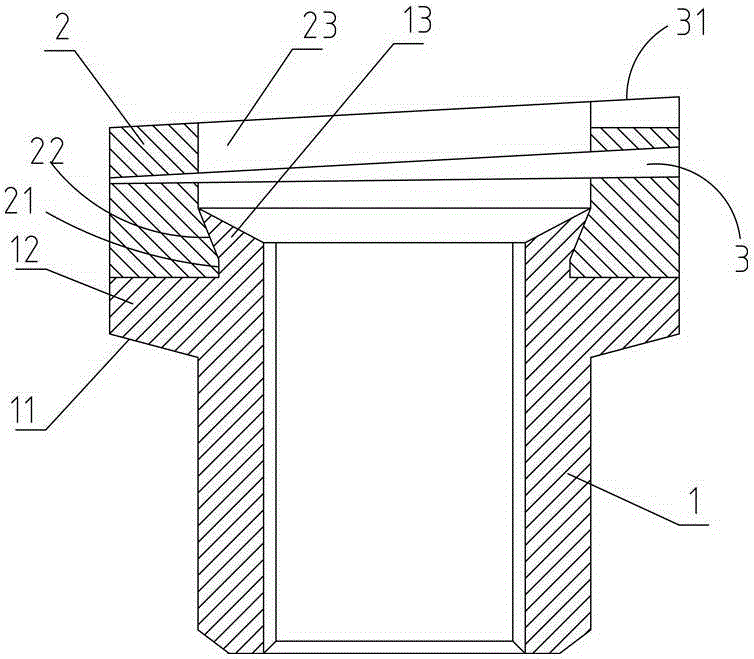

The invention discloses an anti-loose bolt device and a use method thereof. The anti-loose bolt device comprises a non-return flange bolt (1), a non-return gasket (2), a through hole part (3), a disassembly compression ring (4) and a threaded hole part, wherein the non-return flange bolt (1) comprises a flange section (11) and a screw (13) connected with the lower end of the flange section (11); the screw (13) is sleeved with the non-return gasket (2), the upper end of the non-return gasket (2) is provided with upper teeth (21), the lower surface of the flange section (11) is provided with non-return grooves (112) matched with the upper teeth (21), and the lower end of the non-return gasket (2) is provided with lower teeth (22); the through hole part (3) is arranged on the screw (13) in asleeving manner and located at the lower end of the non-return gasket (2), and the upper surface of the through hole part (3) is provided with through hole part groove bodies (31) matched with the lower teeth (22); the lower end of the screw (13) is connected with the threaded hole part; and the flange section (11) is sleeved with the disassembly compression ring (4), and the disassembly compression ring (4) can move up and down relative to the flange section (11). The anti-loose bolt device has a good anti-loose effect at high temperature and high frequency, the strength of the bolt is high,and the anti-loose bolt device has the advantages of being convenient to disassemble, energy saving and environment friendly.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Taper-sleeve locking-type steel bar connection joint

The invention discloses a taper-sleeve locking-type steel bar connection joint. The connection joint comprises an outer sleeve cylinder and inner core connection parts. The inner core connection parts are arranged in the outer sleeve cylinder. The inner core connection parts form a pair. The inner core connection parts comprise supporting seats and a plurality of locking part. The supporting seats of the pair of the inner core connection parts are arranged back-to-back. The outer sleeve cylinder is an inner-cone outer sleeve cylinder. The inner-cone outer sleeve cylinder comprises an inner-cone column cylinder and inner-cone nuts symmetrically arranged on two ends of the inner-cone column cylinder. The inner-cone nuts are threadedly connected with the inner-cone column cylinder. According to the invention, a locking structure in which the outer sleeve cylinder cooperates with the inner core connection parts is adopted. The connection joint is convenient to use. With the connection joint, unidirectional clamping or different-diameter connection can be realized with no assistance of any device, no welding, and no thread sleeve. Connection can be realized with manual screwing. The connection is firm, and has no loosening. As a result of a tensile strength experiment, a tensile strength after fastening connection is greatly higher than that of a welded structure.

Owner:青岛森林金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com