Taper-sleeve locking-type steel bar connection joint

A connecting joint and locking technology, which is applied to structural elements, building components, building reinforcements, etc., can solve problems such as time-consuming, labor-intensive, limited popularization and application, and hidden safety hazards, and achieve the effect of convenient use and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

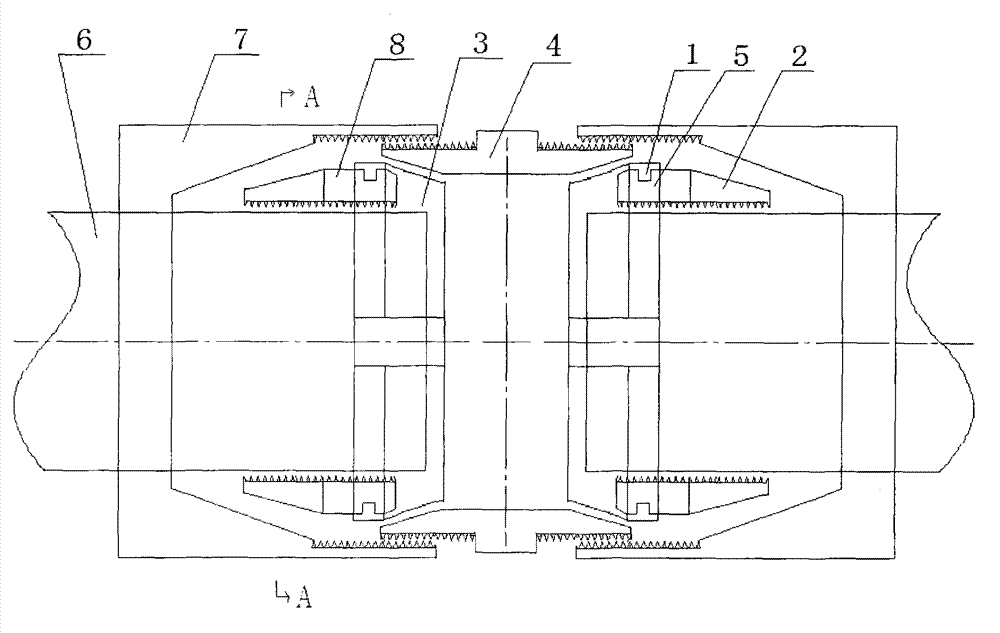

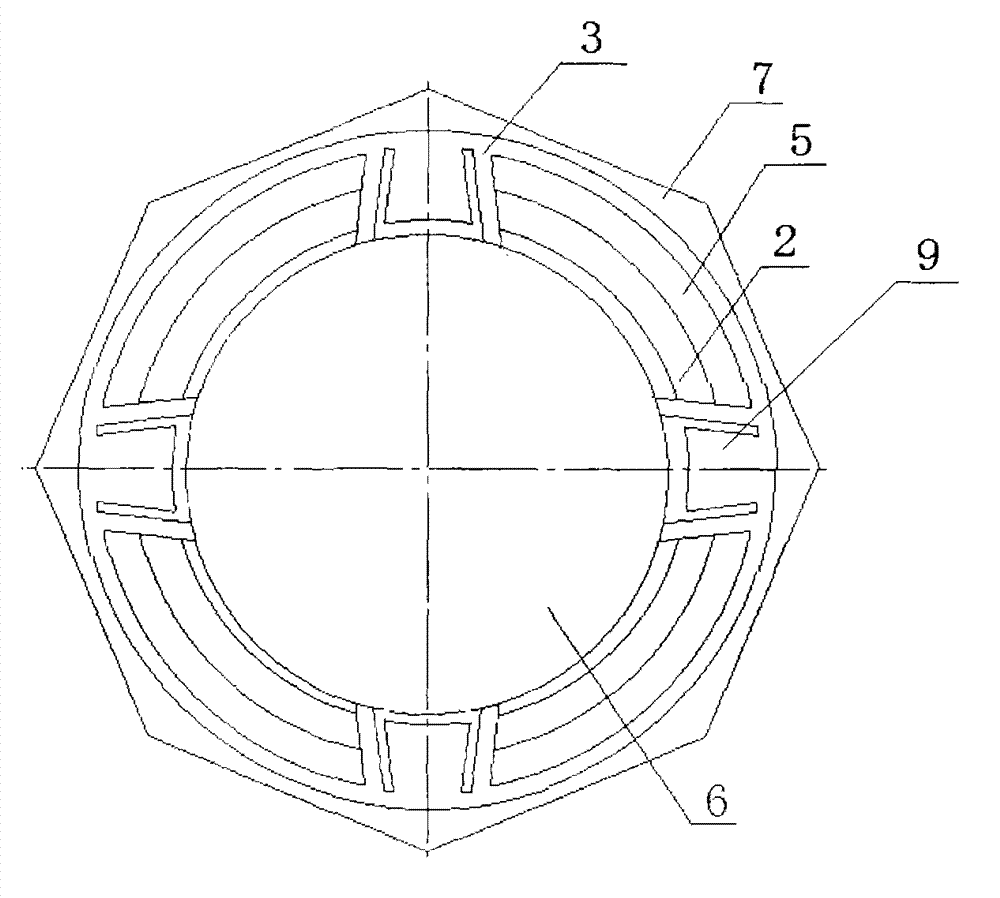

[0013] refer to Figure 1-Figure 2 , the taper sleeve locking type steel bar connection joint of this embodiment includes an outer sleeve and an inner core connector, the inner core connector is arranged in the outer sleeve, the inner core connectors are a pair, and the inner core connector includes Support seat 3, several locking parts 8, a pair of support seats 3 of inner core connectors are set back to back; locking parts 8 and outer sleeves are made of high-quality steel, and the locking parts include locking head 2, base end 5, The base end 5 is fastened to the supporting base 3 , and a buffer groove 9 is provided between two adjacent locking pieces 8 . The outer sleeve is an inner cone outer sleeve, and the inner cone outer sleeve includes the middle inner cone cylinder 4 and the inner cone nuts 7 that are symmetrically arranged at both ends of the inner cone cylinder 4, and the inner cone nut 7 and the inner cone The cylinders 4 are screwed together. The support seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com