Stirrer

A stirrer and rotating rod technology, applied in the field of machinery, can solve problems such as damage to the stirrer, affecting production, etc., and achieve the effect of convenient movement, reasonable structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

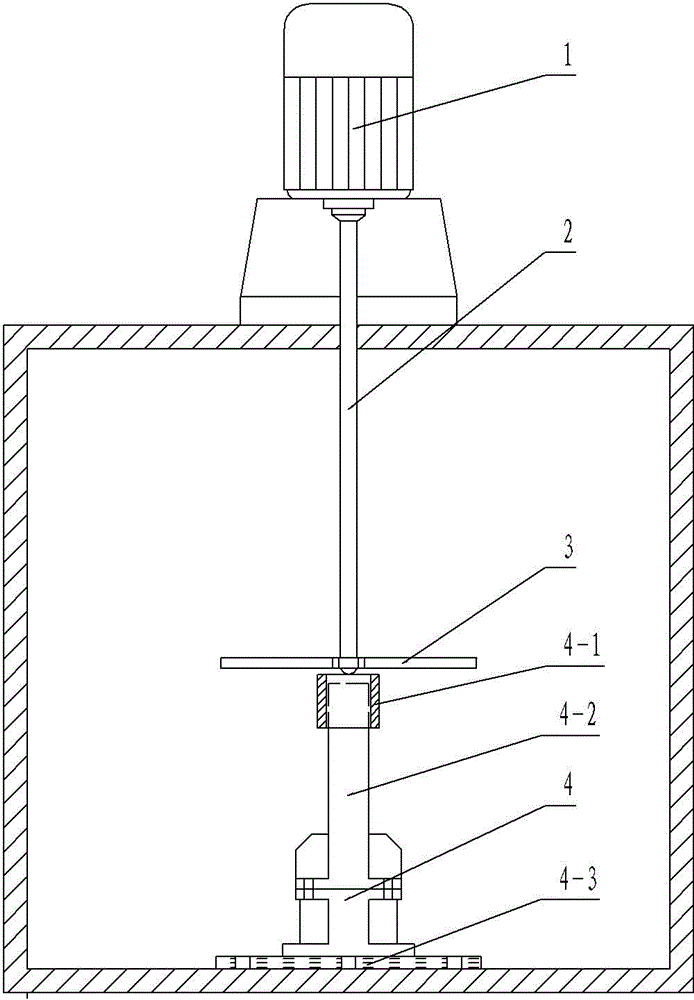

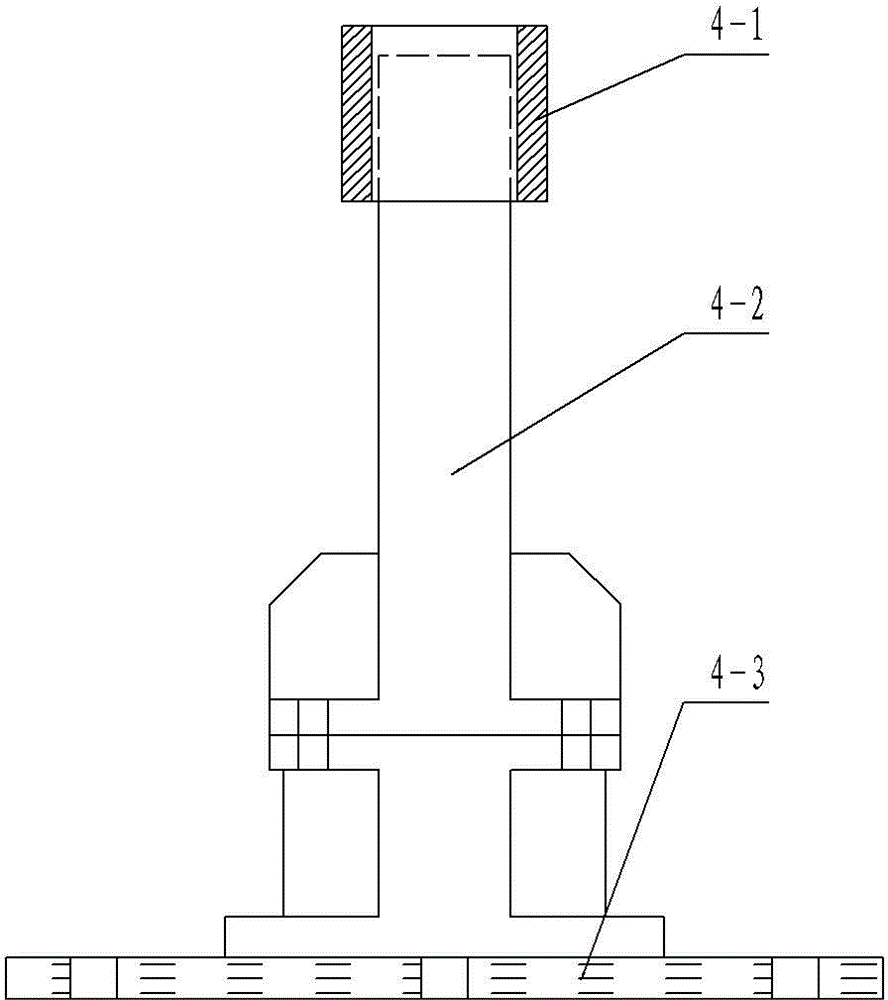

[0013] figure 1 The shown agitator includes a motor 1, the motor shaft is connected with a rotating rod 2, the lower part of the rotating rod 2 is equipped with a paddle 3, and the lower end surface of the rotating rod 2 is in contact with a support seat 4, as shown in FIG. figure 2 As shown, the support seat 4 has a base 4-3, the upper end of the base 4-3 is provided with a support rod 4-2 vertical to the horizontal plane, the upper outer wall of the support rod 4-2 is provided with threads, and the thread is sleeved with an adjustment support rod 4. -2 height nuts 4-1. Because the upper thread of the support rod 4-2 is covered with a nut 4-1 that can adjust the height of the support rod 4-2, the height of the nut 4-1 can be lowered during installation, so that the support base 4 is placed between the rotating rod 2 and the ground. Between, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com