Patents

Literature

4898results about How to "Won't fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

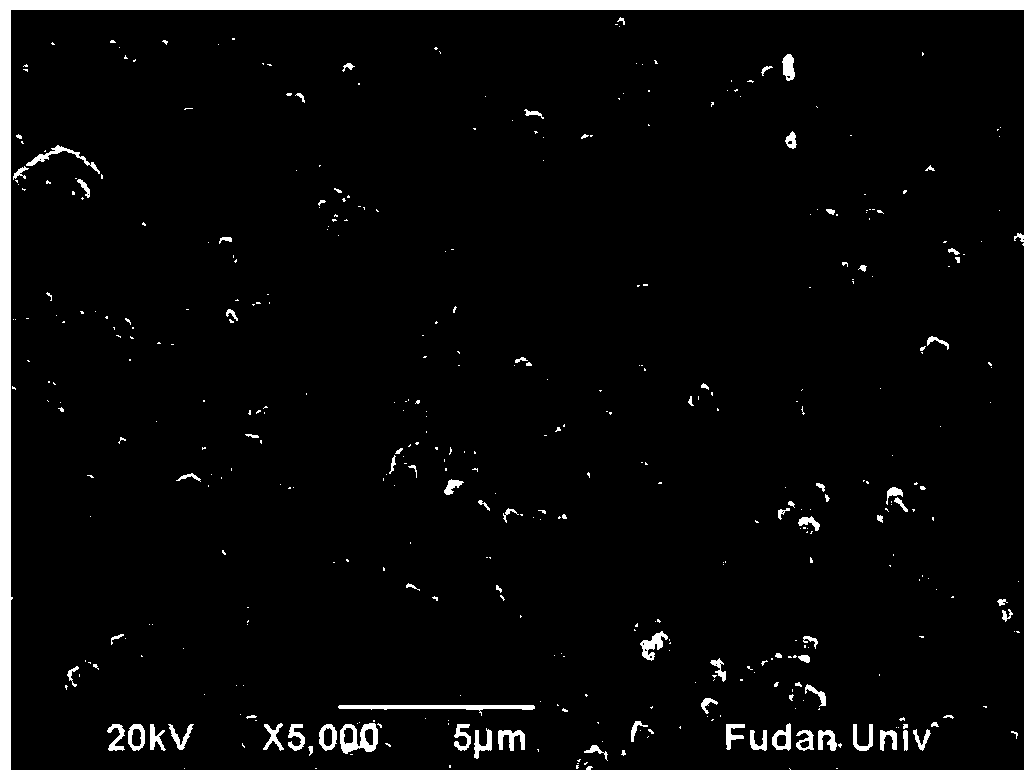

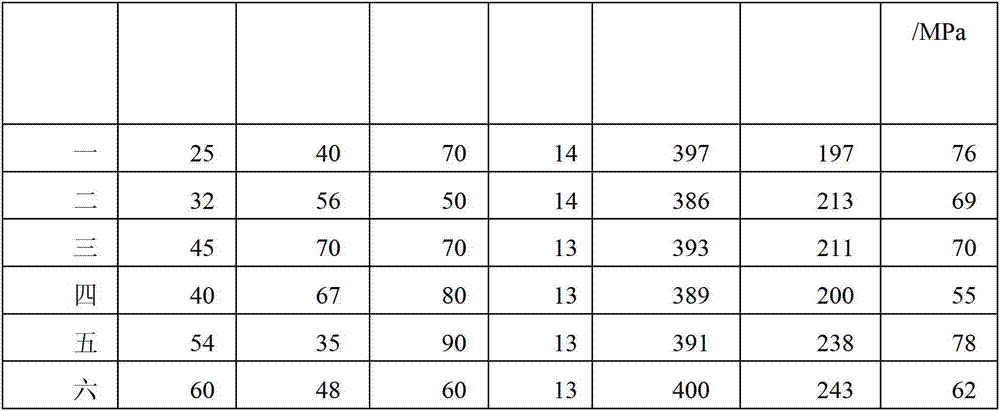

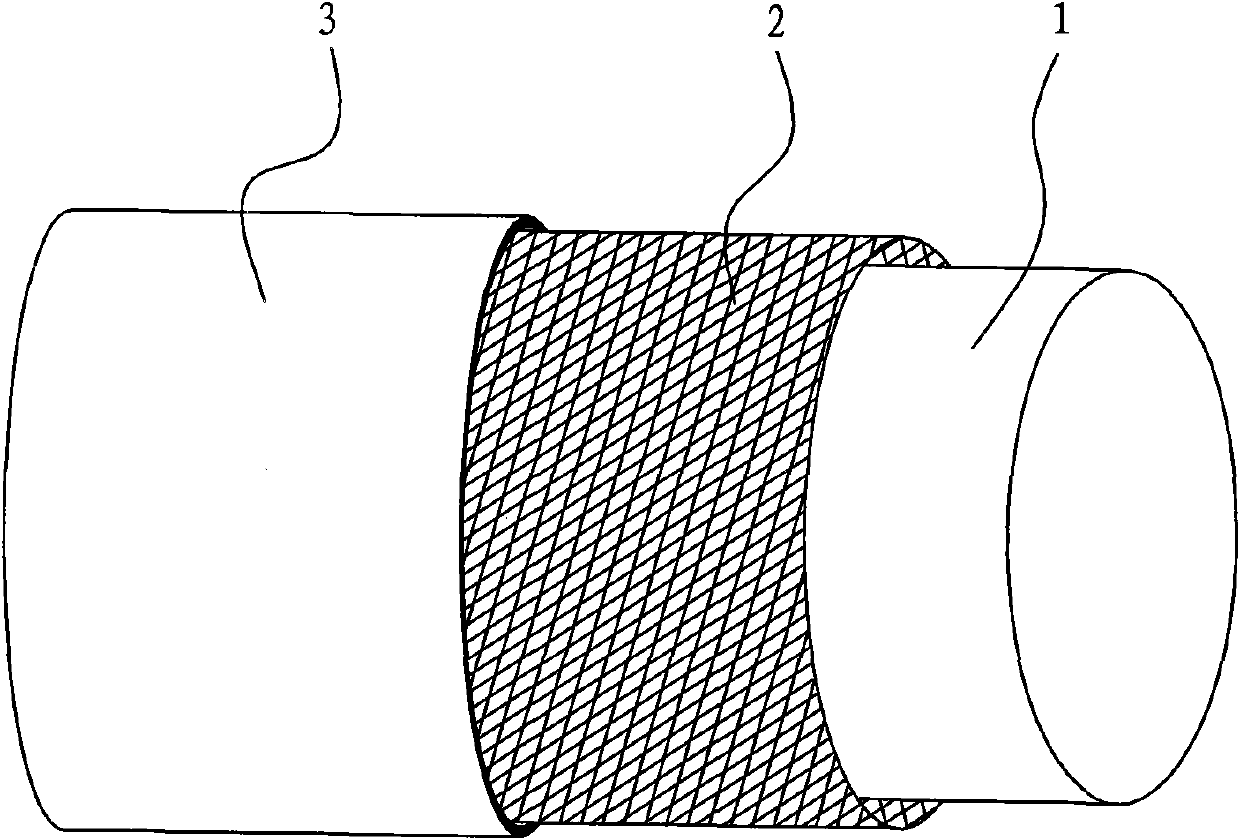

Graphene and carbon fiber composite material, and preparation thereof

The invention relates to a Graphene and carbon fiber-based composite material and a preparation method thereof. The composite material is prepared by taking the Graphene and the carbon fiber as raw materials, and coating a Graphene coating layer on the surface of the carbon fiber by a coating method, and the thickness of the coating layer is 1nm-5mum. The Graphene is taken as a surface coating material of the carbon fiber, and the Graphene and the carbon fiber are carbon materials and have high compatibility, thus Graphene solution coated on the surface of the carbon fiber can form the high-performance composite material and further improve the mechanical property, conductivity and heat resistance of the carbon fiber. The composite material has low cost, simple operation and strong applicability.

Owner:NANKAI UNIV

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

Thread-guiding-type pepper selfing fruit marking method

InactiveCN104115742ALess laborLess time consumingPlant genotype modificationCapsicum annuumPollination

The invention discloses a thread-guiding-type pepper selfing fruit marking method and belongs to the technical field of plant breeding. The thread-guiding-type pepper selfing fruit marking method comprises the following steps: firstly selecting selfing single plants, and marking by hanging a tag; secondly, selecting flowers about to bloom in the selected selfing single plants; threading a filament into a hand sewing needle with a certain specification (0.2-0.4mm), and tieing a knot at one end close to a needle hole; threading a guiding thread of the hand sewing needle through a pedicel part of each flower to be bloomed; leaving the tail end, about 2-3cm long, of the filament into the pedicel part as a marker of a selfing pollination flower; manually pollinating the marked flowers; and harvesting fruits with filament markers in the pedicel parts in a physiological mature period.

Owner:王红侠

Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

The invention discloses a composite reinforced wear-resistant part of a metal-ceramic prefabricated member and a manufacturing method of the composite reinforced wear-resistant part. The manufacturing method comprises the steps as follows: uniformly mixing ceramic particles with self-fluxing alloy powder to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, pressing by pressure, forming and demoulding, and placing biscuits and gaskets into a drying box for drying; placing the dried biscuits and gaskets into a vacuum furnace for sintering, cooling and discharging to obtain the metal-ceramic composite prefabricated member; carrying out sand blasting on the prefabricated member, and spraying a layer of nickel-based self-fluxing alloy powder onto the surface of the prefabricated member; and placing the processed fabricated member onto the end surface of a cast cavity, and pouring metal liquid formed by smelting metal matrix materials into the bottom of the cast cavity to obtain the composite reinforced wear-resistant part of the metal-ceramic prefabricated member. According to the manufacturing method, the wear resistance and the impact resistance of the composite wear-resistant part are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

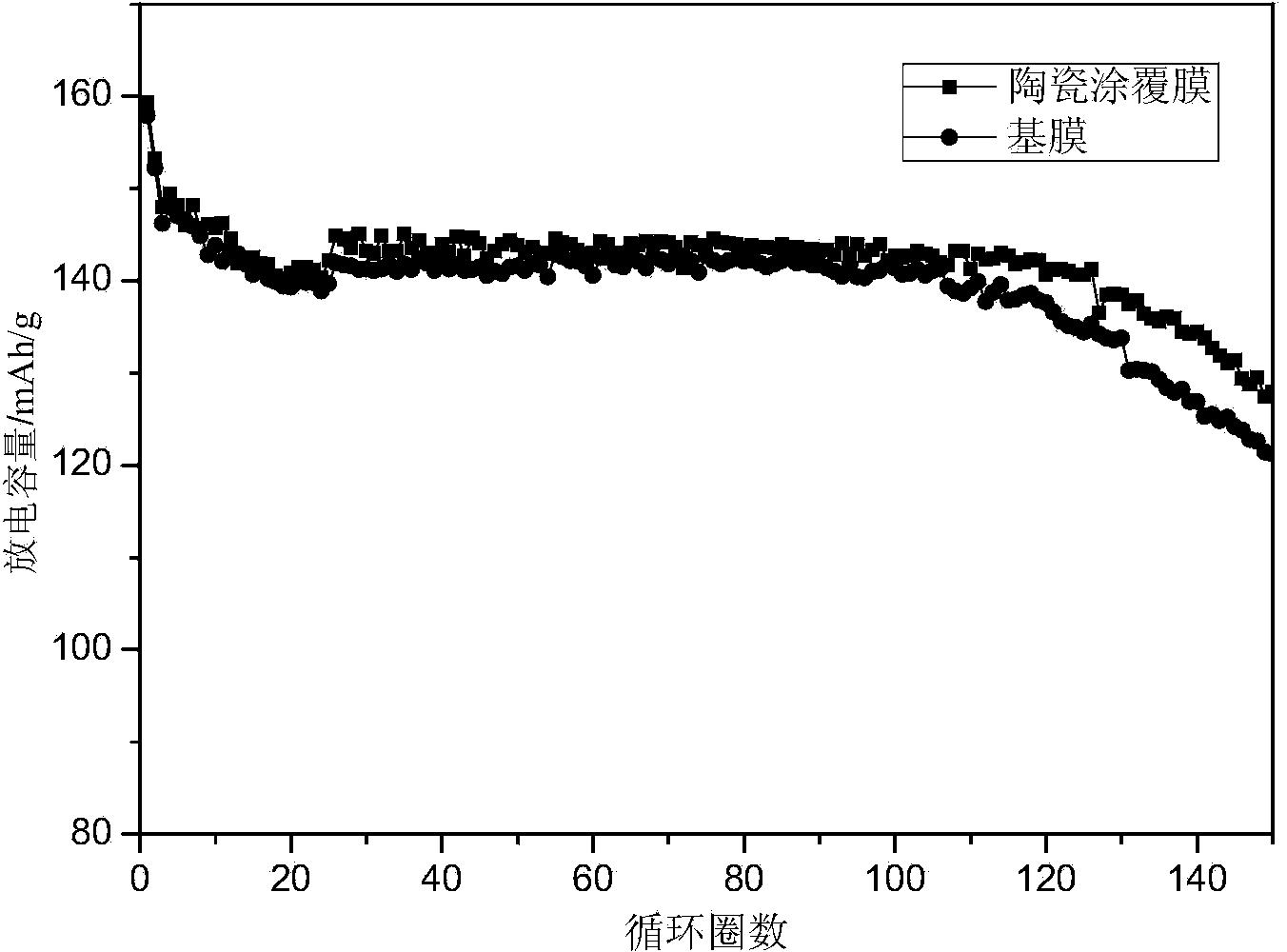

Ceramic coating diaphragm for lithium battery and preparation method of ceramic coating diaphragm

InactiveCN104269509AGood air permeabilityImprove peel forceCell component detailsCeramic coatingDiameter ratio

The invention discloses a ceramic coating diaphragm for a lithium battery and a preparation method of the ceramic coating diaphragm, and belongs to the technical field of batteries. The ceramic coating diaphragm comprises a ceramic coating and a substrate diaphragm, wherein the ceramic coating is prepared by uniformly coating the substrate diaphragm with water-based ceramic coating slurry; the ceramic coating slurry comprises components in percentage by weight as follows: 10%-30% of aluminum oxide, 0.5%-3% of a bonding agent, 0.2%-1.0% of an additive and 0.01%-0.1% of an auxiliary; and the aluminum oxide is nanometer aluminum oxide powder with the grain diameter ratio D1 / D2 of 0.10-0.20. According to the technical scheme, the safety of the ceramic coating diaphragm is improved, the wetting ability of electrolyte is improved, and the cycle life of the battery can be prolonged when the ceramic coating diaphragm is applied to the lithium battery.

Owner:SHANGHAI ELECTRICGROUP CORP

Nano wave-absorption fibre and method for making same

InactiveCN101135071AImprove absorbing performanceInfluence of absorbing performanceMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentFiberMaterials science

The present invention belongs to the field of radiation resisting technology, and is especially one kind of nanometer wave absorbing fiber. The nanometer wave absorbing fiber consists of nanometer wave absorbing particle of 1-100 nm diameter of fine fiber of 30-2000 nm diameter in the weight ratio of 3-35 to 65-97. The nanometer wave absorbing fiber has wide wave absorbing range, powerful wave absorbing capacity, lasting wave absorbing effect and high flexibility. It has wave absorbing function, as well as antistatic, bacteriostasis, biochemical protection and other functions.

Owner:上海兰度科技有限公司

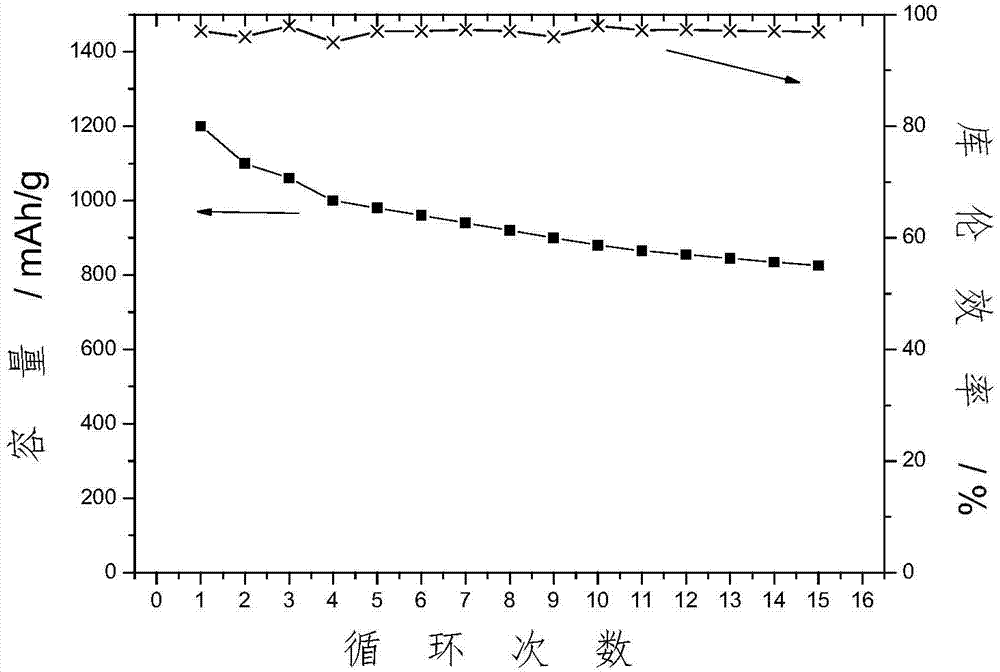

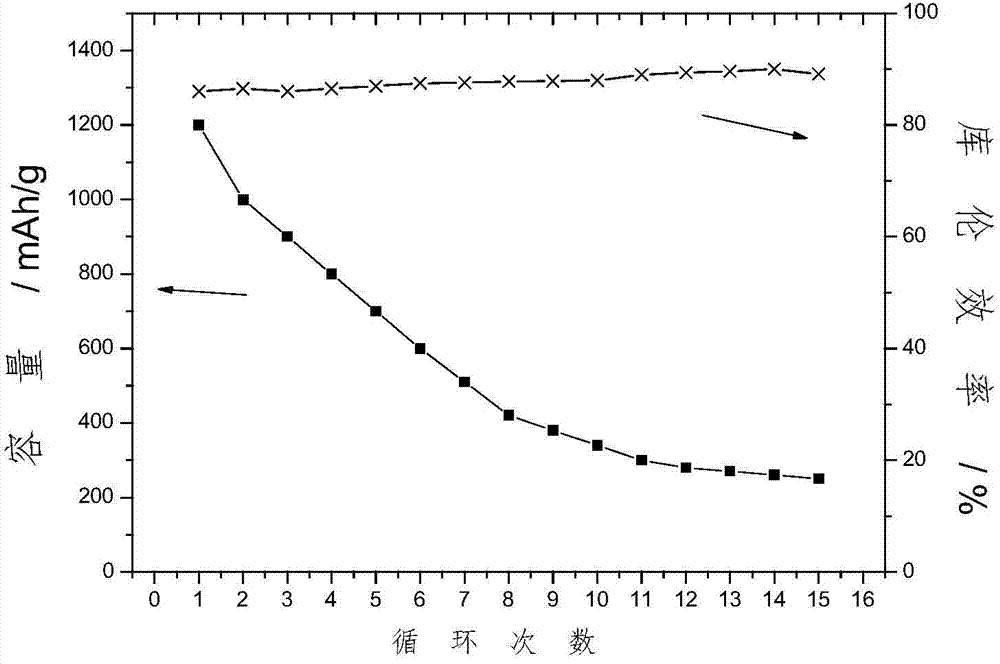

Method for protecting negative electrode of lithium sulfur battery

InactiveCN104716381ADoes not affect the assembly processPracticalFinal product manufactureLi-accumulatorsBorideLithium metal

The invention discloses a method for protecting the negative electrode of a lithium sulfur battery. A lithium sulfur battery negative electrode protection additive layer is adhered to the surface of the anode of the lithium sulfur battery. An additive component forming the protection additive layer can be an inorganic compound or an organic compound; the inorganic compound is one or above two of metal oxides, nonmetal oxides, sulfides, phosphides, nitrides, borides and fluorides; and the organic compound is one or above two of ionic liquid molecules, amino acids, polycation electrolytes, polyanion electrolytes, cationic surfactants, polyoxyether and polythioether. The morphology of the liquid metal protection layer is dynamically changing, and does not physically shed or crack due to continuous dissolution and deposition of the lithium metal in order to effectively protect the negative electrode.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of temperature-resistant and salt-tolerant nano oil displacement agent

ActiveCN103725278AWon't fall offImprove performanceMaterial nanotechnologyDrilling compositionActive agentSurface-active agents

The invention provides a preparation method of a temperature-resistant and salt-tolerant nano oil displacement agent. The preparation method comprises the following steps: modifying polyacrylamide to surfaces of silica nanoparticles through chemical bonds to obtain nano-composite particles with stable performance, and then using the nano-composite particles together with alkali and a surfactant to prepare the nano oil displacement agent. The nano oil displacement agent can solve the problem about high possibility of falling off of a polymer on the surface of a traditional nano oil displacement agent in the formation moving process, so as to achieve an excellent oil displacement effect. Especially in the high-temperature and high-salt formation, the nano oil displacement agent can overcome harsh formation conditions and cannot reduce the oil displacement effect.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

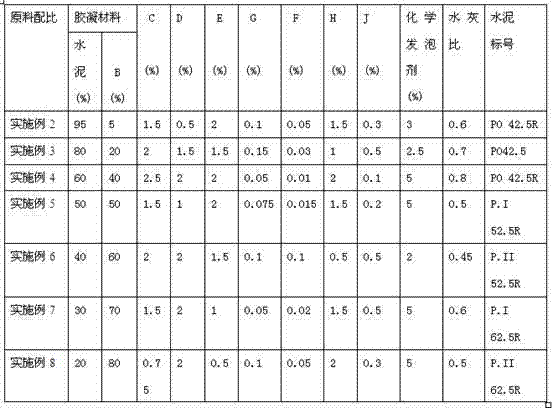

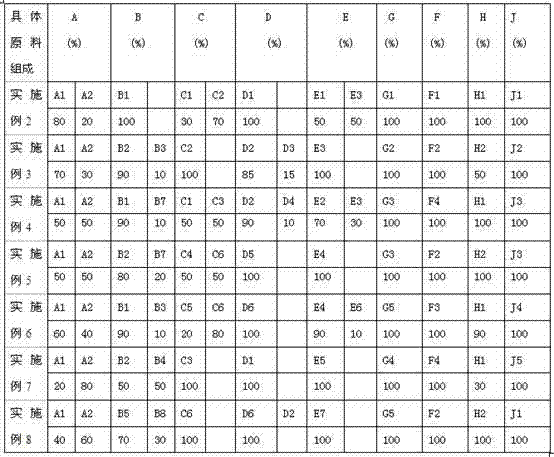

Inorganic foaming thermal-insulation mortar and preparation method thereof

The present invention provides an inorganic foaming thermal-insulation mortar and a preparation method thereof, and belongs to the technical field of building material preparation. The thermal-insulation mortar comprises a cementing material, expanded perlite particles, a macromolecule polymer, a coagulant, an early strength agent, a physical foaming agent, a chemical foaming agent hydrogen peroxide, a chemical foaming agent foaming catalyst, a hydrophobic agent, reinforced short fibers and water. According to the present invention, the inorganic foaming thermal-insulation mortar can be directly coated on the wall and the roof requiring the thermal-insulation treatment, the thickness of the inorganic thermal-insulation mortar layer can be adjusted within 10-100 mm, screeding finishing construction is performed before the cementing material is subjected to final setting, and hardening is performed to obtain the inorganic thermal-insulation mortar layer with characteristics of good durability, good water resistance and good heat insulation, wherein the inorganic thermal-insulation mortar layer never sheds, and has the same service life as the building being subjected to thermal-insulation by the inorganic thermal-insulation mortar layer; and the raw material cost is low, and significant economic benefits and environmental benefits are provided.

Owner:安徽融博科技有限公司

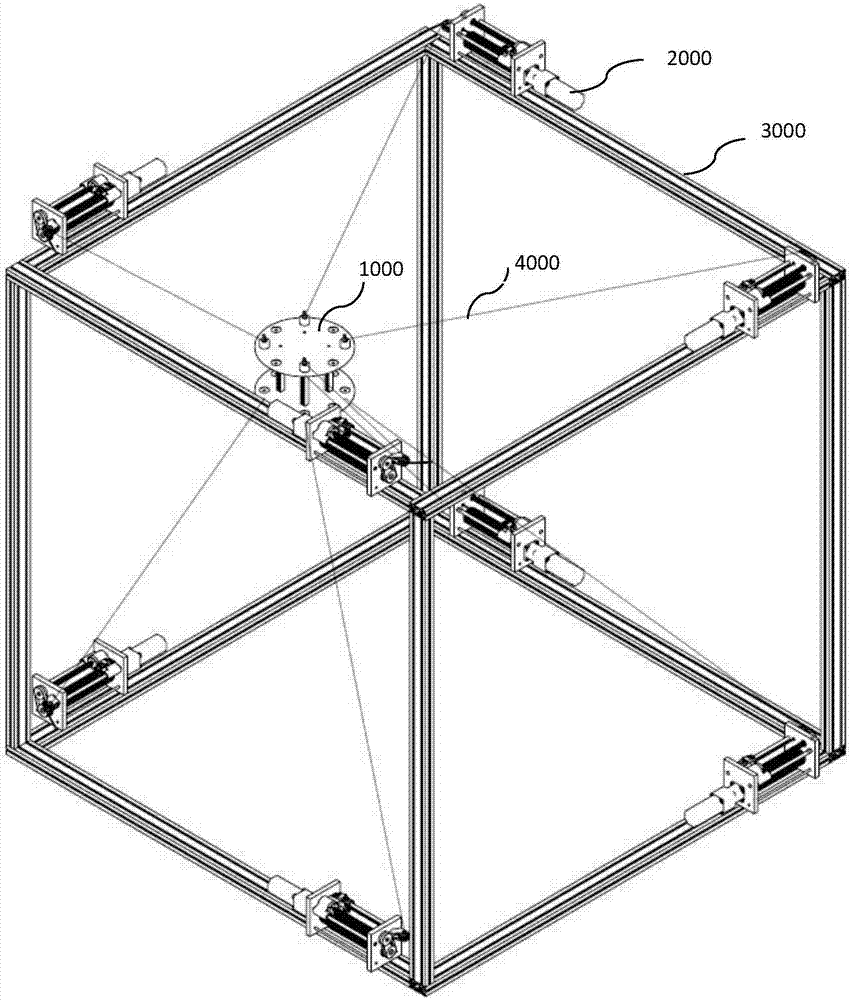

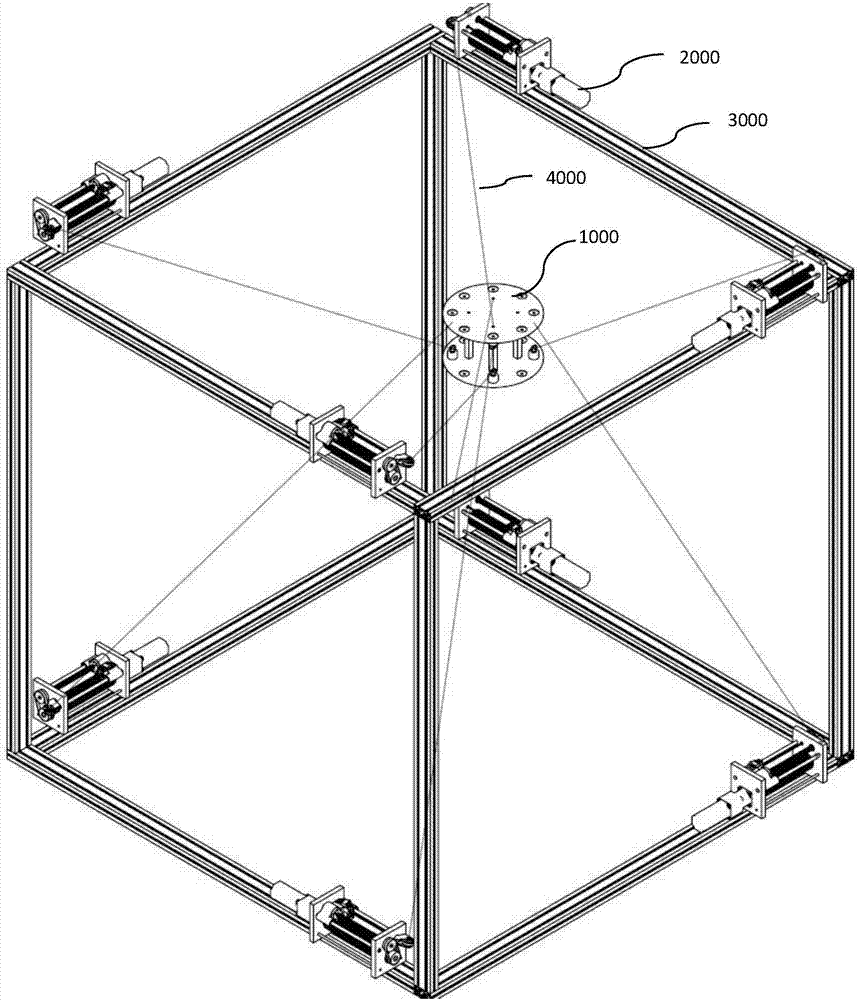

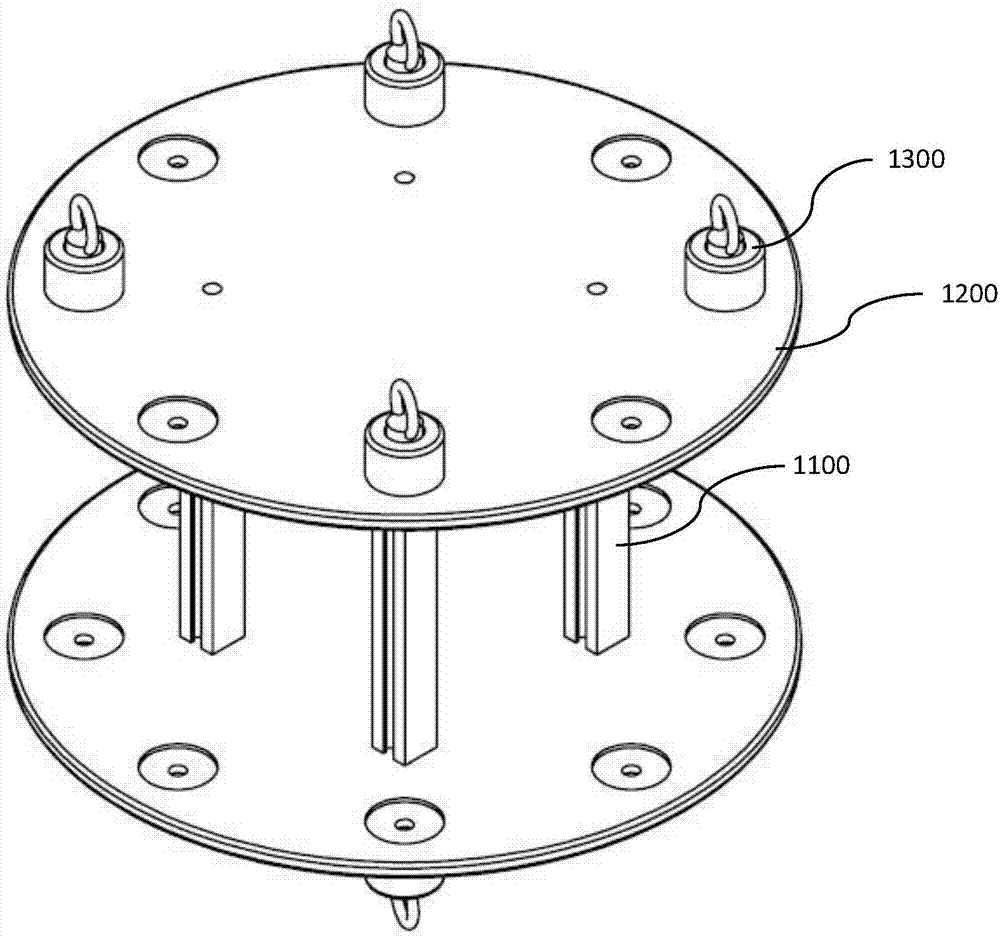

Multi-configuration rope drive parallel robot and space position and posture solution method thereof

ActiveCN107009348ASolve the problem that the spatial pose cannot be solved in real timeGuaranteed pose control accuracyProgramme-controlled manipulatorInterior spaceControl theory

The invention discloses a multi-configuration rope drive parallel robot and a space position and posture solution method thereof. The multi-configuration rope drive parallel robot is characterized by comprising a movable platform, a plurality of rope drive devices, a main rack and a plurality of ropes, wherein the rope drive devices can be arranged in an arbitrary position of the main rack according to task requirements; the movable platform is in an inner space of the main rack, and positions and postures of the movable platform can be freely changed in the inner space; the flexible ropes connected with the rope drive devices are arranged on the movable platform; and the rope drive devices pull the movable platform through the self ropes to move in arbitrary positions of the space in the main rack. According to the multi-configuration rope drive parallel robot, position and posture control precision of the rope drive parallel robot and utilization efficiency of robot devices can be improved.

Owner:UNIV OF SCI & TECH OF CHINA

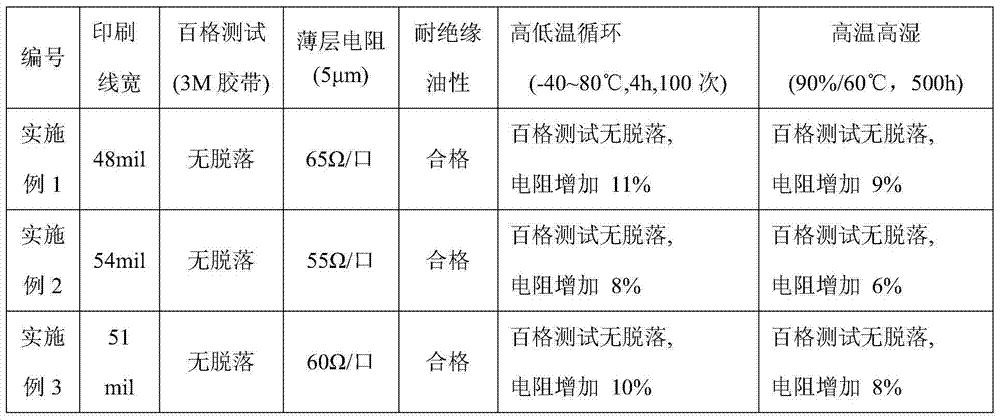

Silver paste used for grapheme touch screen, and preparation method thereof

ActiveCN103500596AHigh resolutionGood printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteWeather resistance

The invention discloses silver paste used for a grapheme touch screen, and a preparation method thereof. The silver paste is prepared from flake-like silver powder, spherical silver powder, inorganic electric conduction additive, organic carrier, accessory ingredient and diluent of residual percentage by weight. The preparation method comprises the following steps of: firstly, preparing the organic carrier; adding the flake-like silver powder, the spherical silver powder, the inorganic electric conduction additive, the accessory ingredient and the diluent into the organic carrier; fully and evenly mixing; finally, grinding by a three-roller machine, and carrying out vacuum defoaming. The silver paste disclosed by the invention has the advantages of good overall performance, convenience in printing, good adhesion property, good bending resistance, good weather resistance, good stability and good electrical conductivity and insulating oil performance and can pass a long-time high-temperature high-moisture aging test and thermal shock tests for more than hundred times, and the requirement on the conductive silver paste by the grapheme touch screen can be satisfied.

Owner:广州市尤特新材料有限公司

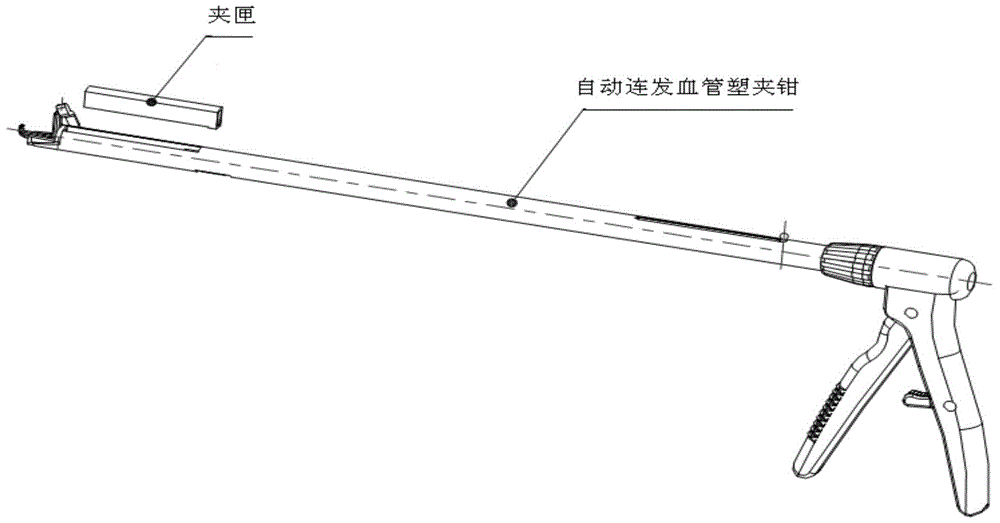

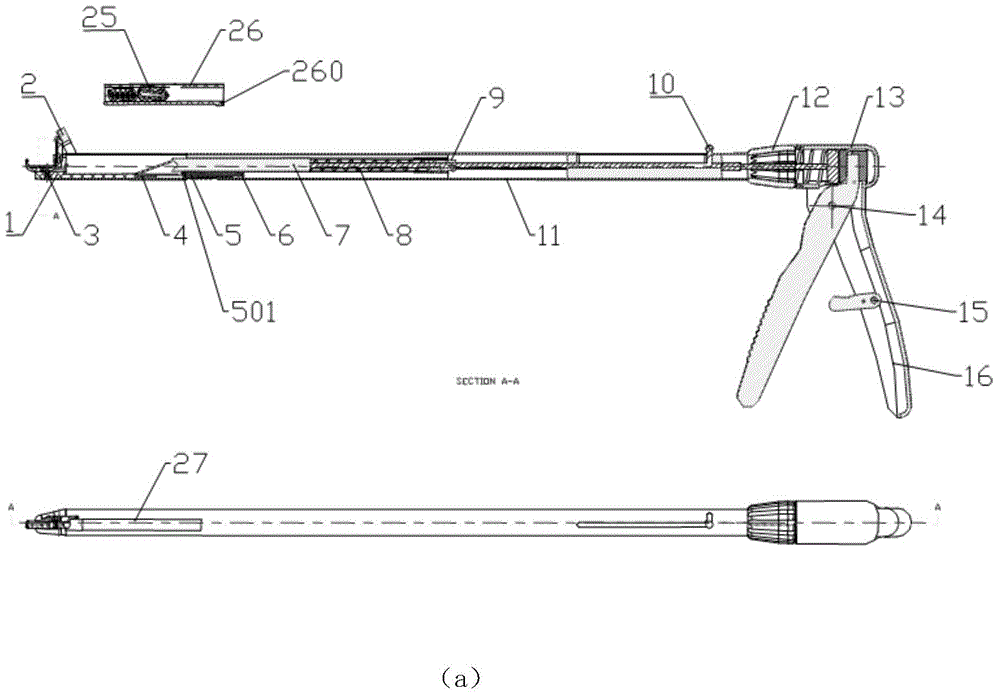

Automatic multi-shot plastic blood vessel serrefine and serrefine case

ActiveCN104523316AIncrease the speed of surgeryShorten the procedureWound clampsSingle useEngineering

The invention discloses an automatic multi-shot plastic blood vessel serrefine and a serrefine case. The automatic multi-shot plastic blood vessel serrefine comprises a serrefine mouth mechanism, a case containing mechanism, an automatic serrefine delivery mechanism, a serrefine applying mechism and a handle mechanism. By means of the automatic multi-shot plastic blood vessel serrefine and the serrefine case, the operation speed can be obviously and effectively improved, namely a doctor only needs to put an automatic multi-shot applied serrefine into a human body in one time to perform multiple-time continuous serrefine applying and does not need to take an instrument from the human body in the operation process. In addition, the operation time waste for instrument transfer between the operation doctor and a nurse and installation is avoided by means of the structure, operation risk is reduced, the multi-shot plastic blood vessel serrefine is capable of performing opening-closing motion and can be inversely buckled to achieve self locking, a large blood vessel ligation and closing are easy, blood vessel alignment is easier, operation is more convenient to perform, the closed blood vessel is firm, and quality is improved obviously. Furthermore, the automatic multi-shot plastic blood vessel serrefine can be disinfected for multiple times and repeatedly used, the serrefine case is disposable, and therefore product cost is low.

Owner:JIANGSU HAIZE MEDICAL TECH DEV

Functional viscose fiber containing Chinese medicinal component and its preparation method

InactiveCN1786300AKeep active ingredientsOvercome defectsArtificial filaments from viscoseAfter treatmentChinese drug

The invention discloses a traditional Chinese drug component containing functional viscose fiber and its manufacturing method. It is made up of traditional Chinese drug material, semi-finished products, finished products, part of dregs of decoction, and viscose fiber. Its components content is fiber: 85-99.9%, traditional Chinese drug: 0.1-15%. Its manufacturing method includes the following steps: dipping, mellowing, sulphidizing, dissolving, mixing, filtering, defoaming, ripening, spinning fore raw liquor mixing, traditional Chinese drug fiber spinning and drafting, and fiber after-treatment. Its traditional Chinese drug content can reach 10%. Thus the fiber has more effective health protection, sickness prevention, and auxiliary therapy. Thus it is fit for making underclothes, bedding, medical component, and so on.

Owner:张志伟

Chromium-free Dyclo paint

InactiveCN101260252AGood effectNo pollution in the processLiquid surface applicatorsAnti-corrosive paintsChromium freeZinc

The invention relates to a non-chromate Dacromet paint belonging to the metal anticorrosion technical field. The non-chromate Dacromet paint is prepared by the following steps that: after mixing a component B with a component C based on the weight ratio of 3-5:1.5-2.4, mixing the mixture with a component A based on the weight ratio of 1:16-32, stirring evenly and controlling pH value between 3.5 and 5.5; the non-chromate Dacromet paint has the characteristics of non-environmental pollution and non-public nuisance, high permeability, high adhesion, high antifriction, high weatherability, high chemical stability and so on. And the anticorrosion of the non-chromate Dacromet paint improves 7-10 folds of zinc electroplating.

Owner:SHANDONG UNIV

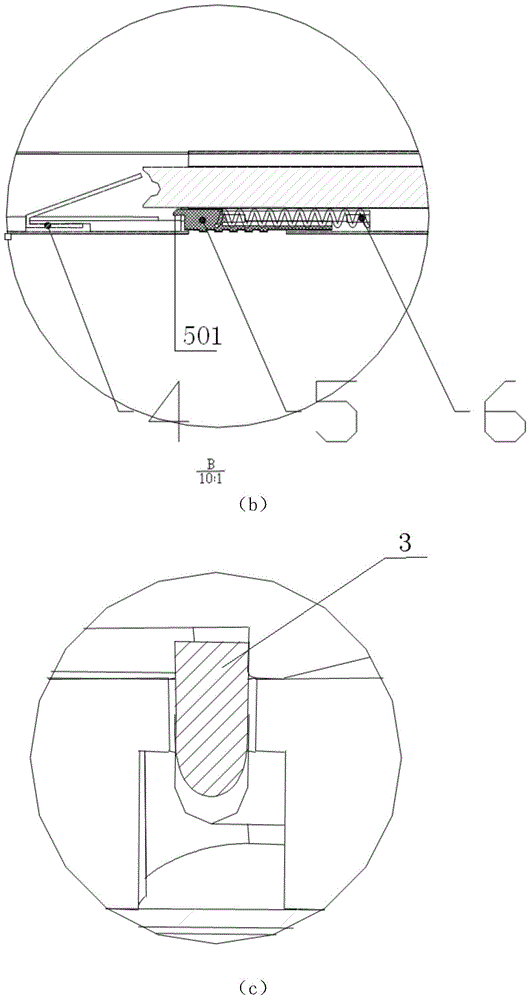

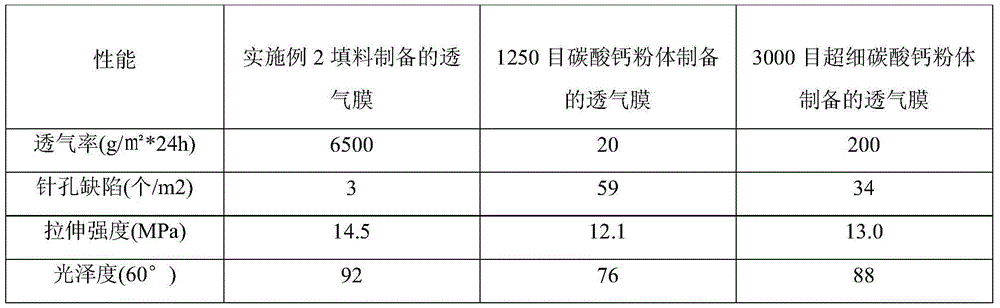

Coarse whiting filler for gas-permeable membrane and preparation method of coarse whiting filler

ActiveCN104530768AGood sphericityNo edges and cornersPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsMicrometerSURFACTANT BLEND

The invention belongs to the field of deep processing and utilization of nonmetal minerals, composite materials and functional materials, and particularly relates to coarse whiting filler for a gas-permeable membrane and a preparation method of the coarse whiting filler. The invention aims to provide the preparation method of the coarse whiting filler for the gas-permeable membrane. The preparation method comprises the following steps: crushing marble until the diameter is 40 to 70 micrometers; uniformly mixing marble powder, water and a high-molecular surfactant at a weight ratio of 1:(0.2-1.5):(0.001-0.1); ball-milling and filtering; dehydrating until the water content is not larger than 1%; dismissing gathered powder; drying until the water content is not larger than 0.2%; adding an activating agent of which the weight is 0.5% to 3% of the total weight of the dried powder material; fully reacting at the temperature of 110 to 140 DEG C; and cooling, uniformly mixing and packaging. The coarse whiting filler prepared by the method disclosed by the invention is good in performance and can be well applied to preparation of the gas-permeable membranes and relevant products.

Owner:SICHUAN SHIMIAN JUFENG POWDER

High-porosity epoxy resin pervious concrete

The invention provides high-porosity epoxy resin pervious concrete, which comprises the following components in part by mass: 100 parts of epoxy resin, 0-50 parts of reactive diluent, 20-80 parts of curing agent, 2,000-10,000 parts of aggregate and 0-30 parts of dye. The invention has the beneficial effects that (1) the pervious concrete with porosity of greater than 40% is prepared by using the epoxy resin as gel material; (2) the pervious concrete the maximum breaking strength of which is 12 MPa can be prepared, which can bear relatively large impact load and prevent the aggregate from falling compared with the cement-based pervious concrete; (3) when the steel slag is used as the aggregate, the steel slag can be used without special treatment; and (4) the pervious concrete with variouscolors can be prepared by adding the dye.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Ecological shell powder inorganic nanometer composite coating material and preparation method thereof

The present invention relates to an ecological shell powder inorganic nanometer composite coating material and a preparation method thereof. The ecological shell powder inorganic nanometer composite coating material comprises, by mass, 70-90% of shell powder and 10-30% of a composite glue adhesive, wherein the shell powder contains 1-3% by mass of titanium dioxide nanoparticles and 1-3% by mass of tourmaline powder, and the composite glue adhesive contains 80-90% by mass of water, 3-10% by mass of polyvinyl alcohol, and 0.5-3% by mass of cellulose. According to the present invention, natural shell powder is adopted as a main material, any toxic and hazardous substances are not added, and the ecological shell powder inorganic nanometer composite coating material has functions of indoor toxic gas absorption and decomposition, and has the following characteristics that: construction is simple, shedding due to scrubbing can not be generated, negative oxygen ions can be released for a long time so as to carry out a purification and sterilization treatment on indoor air.

Owner:山东贝壳屋新材料科技有限公司

Purification for stink and organic waste gas

ActiveCN1745883AImprove purification rateStable growth environmentDispersed particle separationAir quality improvementSorbentSewage

A process for treating the offensive smell in petrochemical sewage treating plant and cleaning the low-concentration waste organic gas features use of immobilized microbial membrane as filler and 1-3 stages of microbial treatment. It includes such steps as wet dusting for pre-treating, microbial treating and post-treating by absorbent.

Owner:CHINA PETROLEUM & CHEM CORP +1

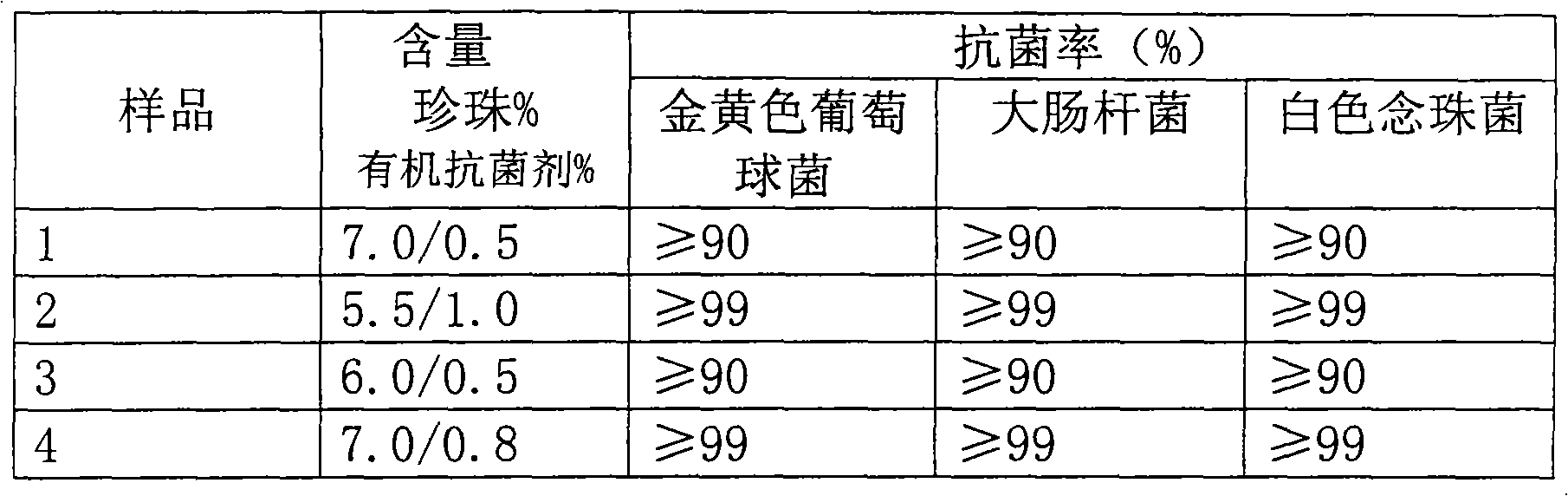

Antimicrobial pearl viscose fiber, preparation method and application thereof

InactiveCN101270508AExpand the range of dosageRaise the ratioMonocomponent cellulose artificial filamentArtifical filament manufactureAntibiosisViscose fiber

The invention discloses an antibiosis pearl mucilage glue fiber as well as a manufacture method and application thereof. The fiber is manufactured by mixing the mucilage glue, pearl powder accounting for 5.5 to 7.0 percent of the total weight of the fiber as well as organic antimicrobial accounting for 0.5 to 1.0 percent of the total weight of the fiber. The antibiosis pearl mucilage glue fiber of the invention not only has the advantages of pure savageness, being degradable and excellent chromaticity but also has the functions of smart appearance, smooth and cool hand feeling and being softer than pure cotton that are specifically owned by pearl; the fiber also has particularly comfort feeling when contacting with skin and the function of antibiosis and health care.

Owner:FUJIAN ZHONGHE

Flat varnish for waterborne wood

The invention discloses a flat varnish for waterborne wood, comprising the following components in parts by weight: 30-70 percent of waterborne acrylic emulsion, 0-30 percent of waterborne aliphatic polyurethane and mixture emulsion, 3-10 percent of film forming aid, 0.01-2 percent of antifoaming agent, 0.01-2 percent of dispersing agent, 0.1-5 percent of extinction powder, 0-2 percent of wettingagent, 0.01-2 percent of rheological additive, 0.01-2 percent of wax additive, 0.01-2 percent of hand-feeling addictive, 0.01-2 percent of thickening agent, 0.01-2 percent of ammonia water, 0.01-2 percent of coupling agent and 5-30 percent of water. The flat varnish for waterborne wood has the advantage of ensuring that a varnish film has better fullness, hardness, high chemical resistance, super-strong hand feeling and strong adhesive force on an oil primer. In addition, the flat varnish for waterborne wood can solve the compatibility between the aquosity and the oilness, ensure the varnish film cannot fall off after being dried and can meet the requirement for consumers on high environmental protection, low odor and less pollution.

Owner:HUIZHOU CHANGRUNFA PAINT

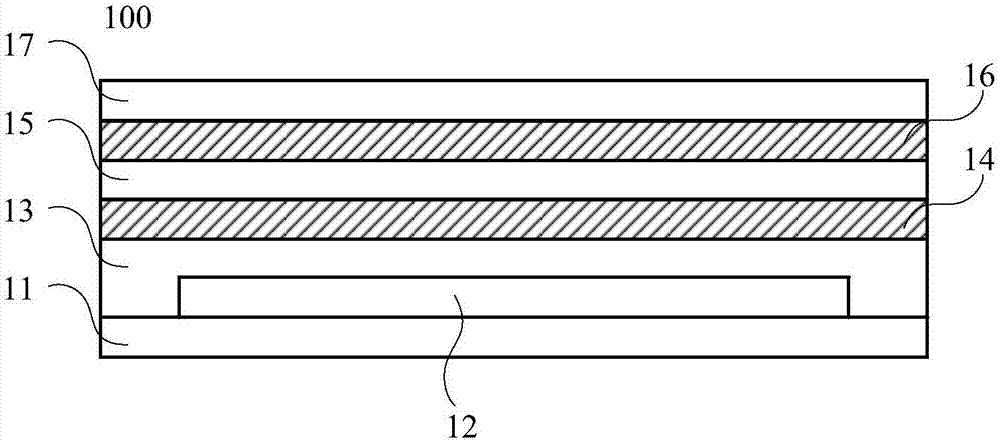

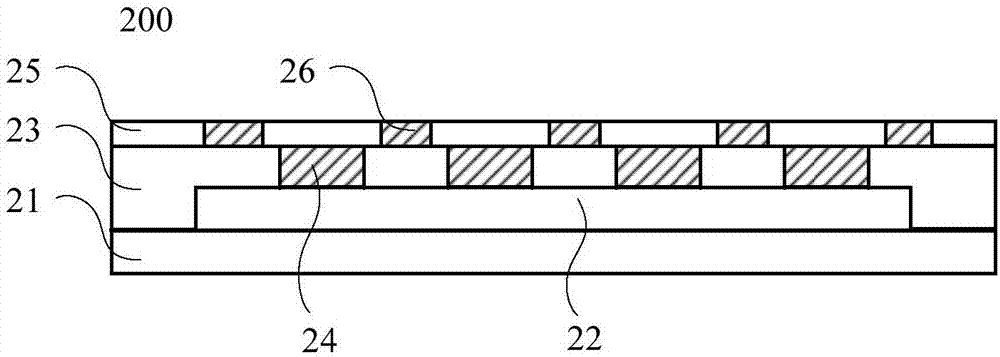

Packaging structure of OLED device and preparation method for packaging structure, and metal mask plate

InactiveCN106876612AImprove bending performanceReduce bending stressSolid-state devicesSemiconductor/solid-state device manufacturingMetalPhysics

The invention discloses a packaging structure of an OLED device and a preparation method for the packaging structure, and a metal mask plate. The packaging structure of the OLED device comprises a plurality of alternate barrier layers and buffer layers above the OLED device; at least one barrier layer adopts a patterned structure; and a patterned region of the barrier layer is filled with the corresponding buffer layer. By setting the barrier layer into the pattered structure and by filling the patterned region of the barrier layer with the corresponding buffer layer, when the OLED device is bent, the bending stress on the barrier layer can be released by the buffer layer is which is arranged in the patterned region of the barrier layer in a filling way, so that bending stress on the barrier layer can be lowered, the OLED device can be bent for a higher amplitude, and the bending performance of the OLED device is further improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

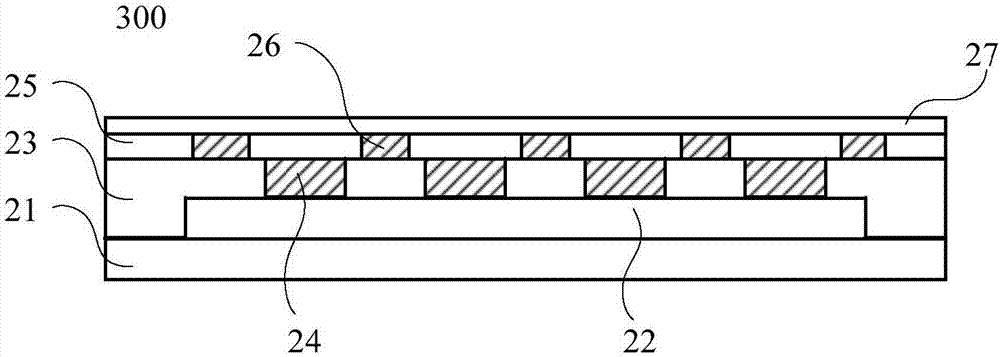

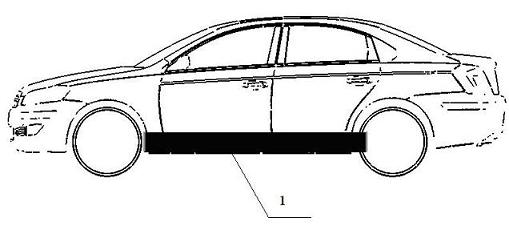

Mechanism and method for quickly exchanging power battery of electric automobile

ActiveCN102673361AEasy to replaceMeet driving needsElectric propulsion mountingElectric vehicle charging technologyPower batteryElectricity

The invention relates to a mechanism for quickly exchanging a power battery of an electric automobile. The mechanism is characterized in that: a power battery pack (1) of the electric automobile can be exchanged. A quickly-exchangeable battery structure is adopted, so that the battery of the whole automobile is easy to exchange. When the battery is low, the electric automobile quickly exchanges another set of battery by running to a battery exchange station and can drive continuously, so the driving requirement can be met completely. The invention also discloses a method for exchanging the power battery of the electric automobile.

Owner:CHERY AUTOMOBILE CO LTD

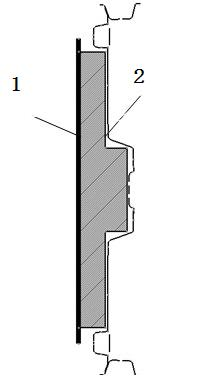

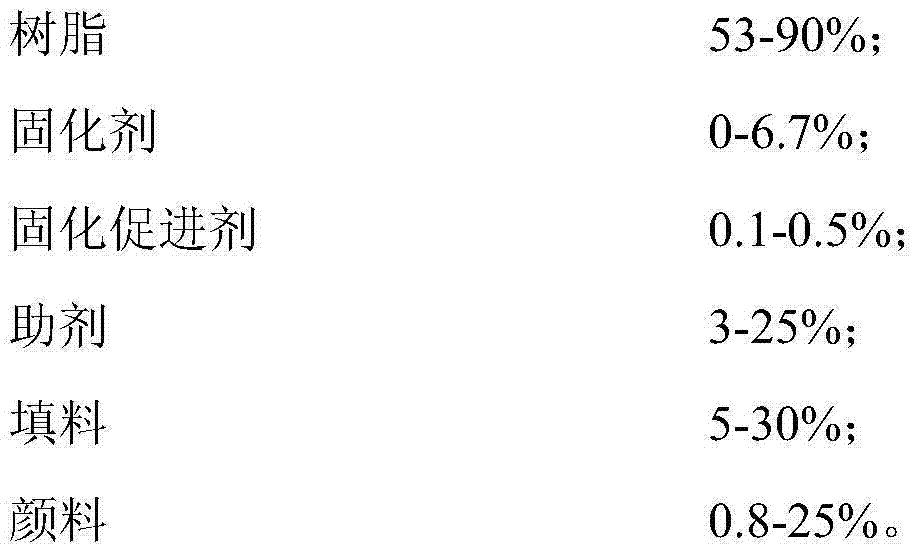

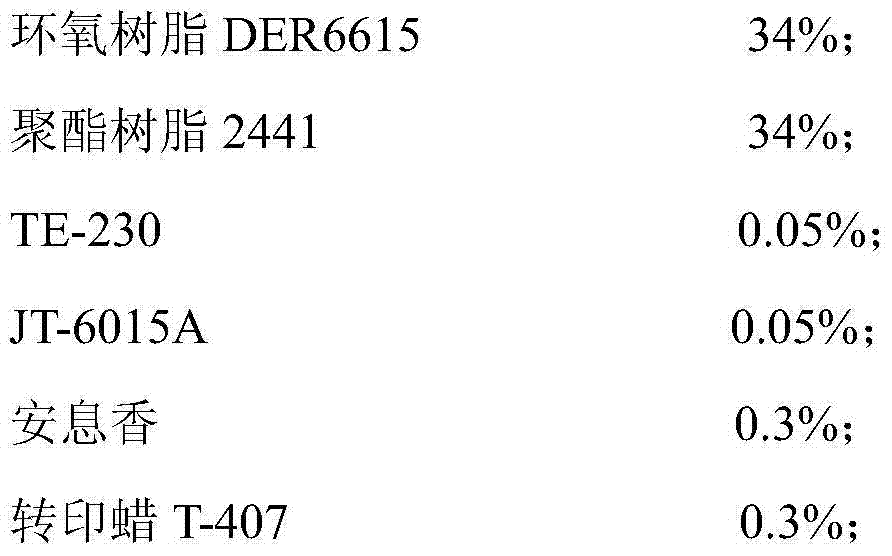

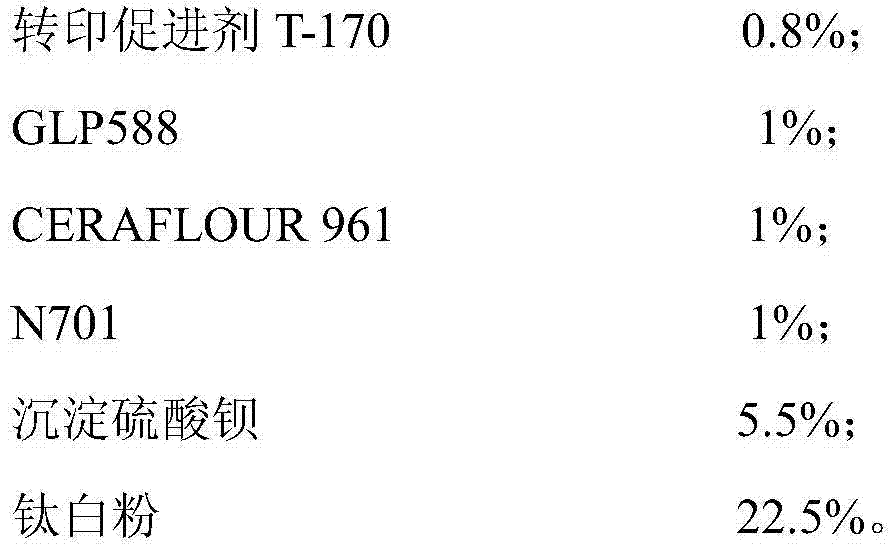

Powder coating for MDF transfer printing and application method of powder coating

PendingCN104497808AImprove texture clarityEasy to tear offDuplicating/marking methodsPowdery paintsWeather resistanceWear resistance

The invention relates to powder coating and particularly relates to powder coating for MDF transfer printing and an application method of the powder coating. The powder coating is prepared from the following raw materials in percentage by weight: 53-90% of resin, 0-6.7% of a curing agent, 0.1-0.5% of a curing accelerant, 3-25% of auxiliaries, 5-30% of filler and 0.8-25% of pigment. After the powder coating is used for transfer printing, the texture is clear, the penetration is deep, the third dimension is strong, the transfer printing paper can be easily uncovered, the thermal transfer printing product is durable in use, and the patterns are not dropped, cracked or faded; moreover, the thermal transfer printing only achieves a surface decoration effect without changing the characteristics of the original glossiness, the wear resistance, the weather resistance, the acid and alkali resistance, and the like of the product. The invention also provides an application method of the powder coating.

Owner:山东朗法博粉末涂装科技有限公司

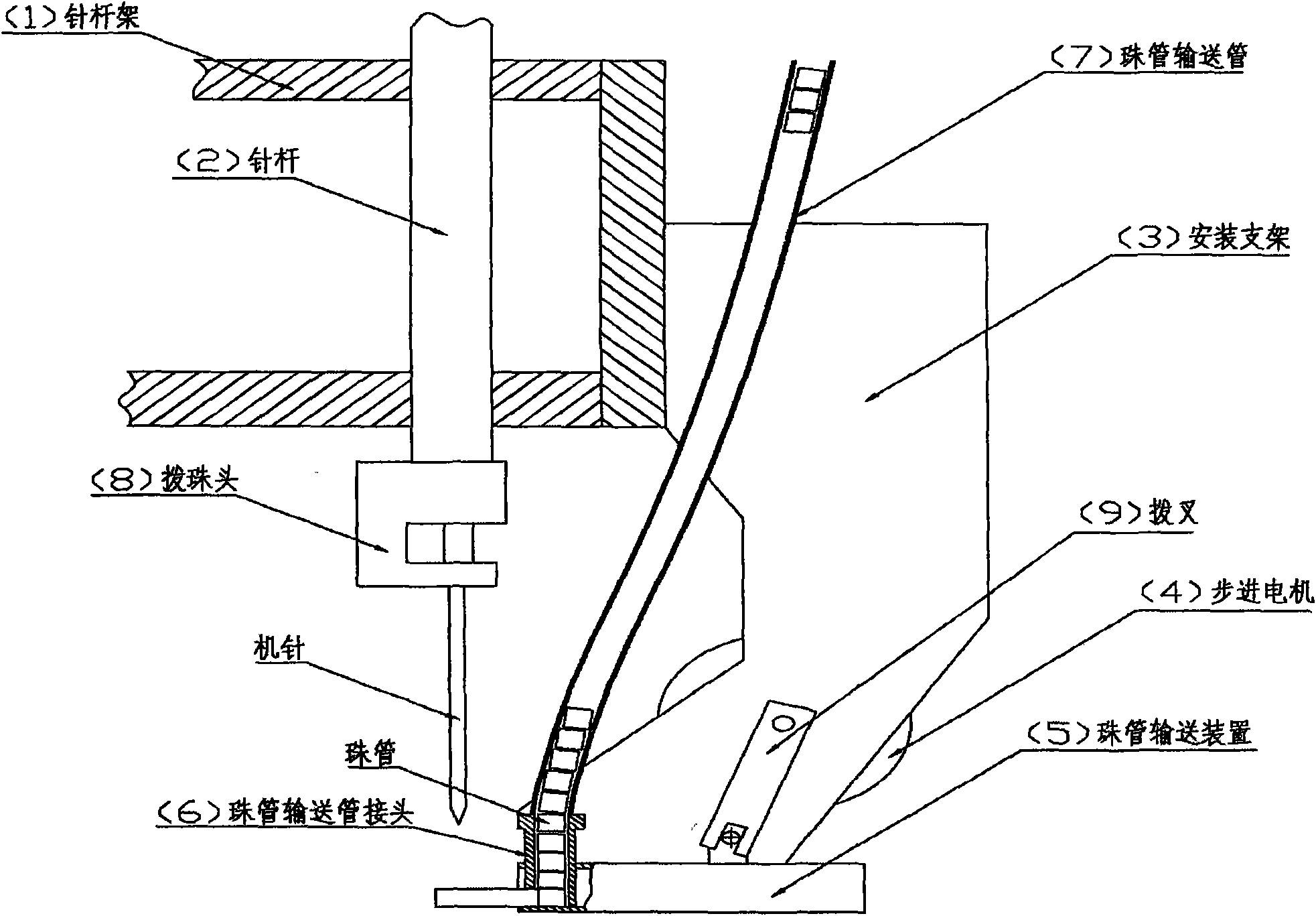

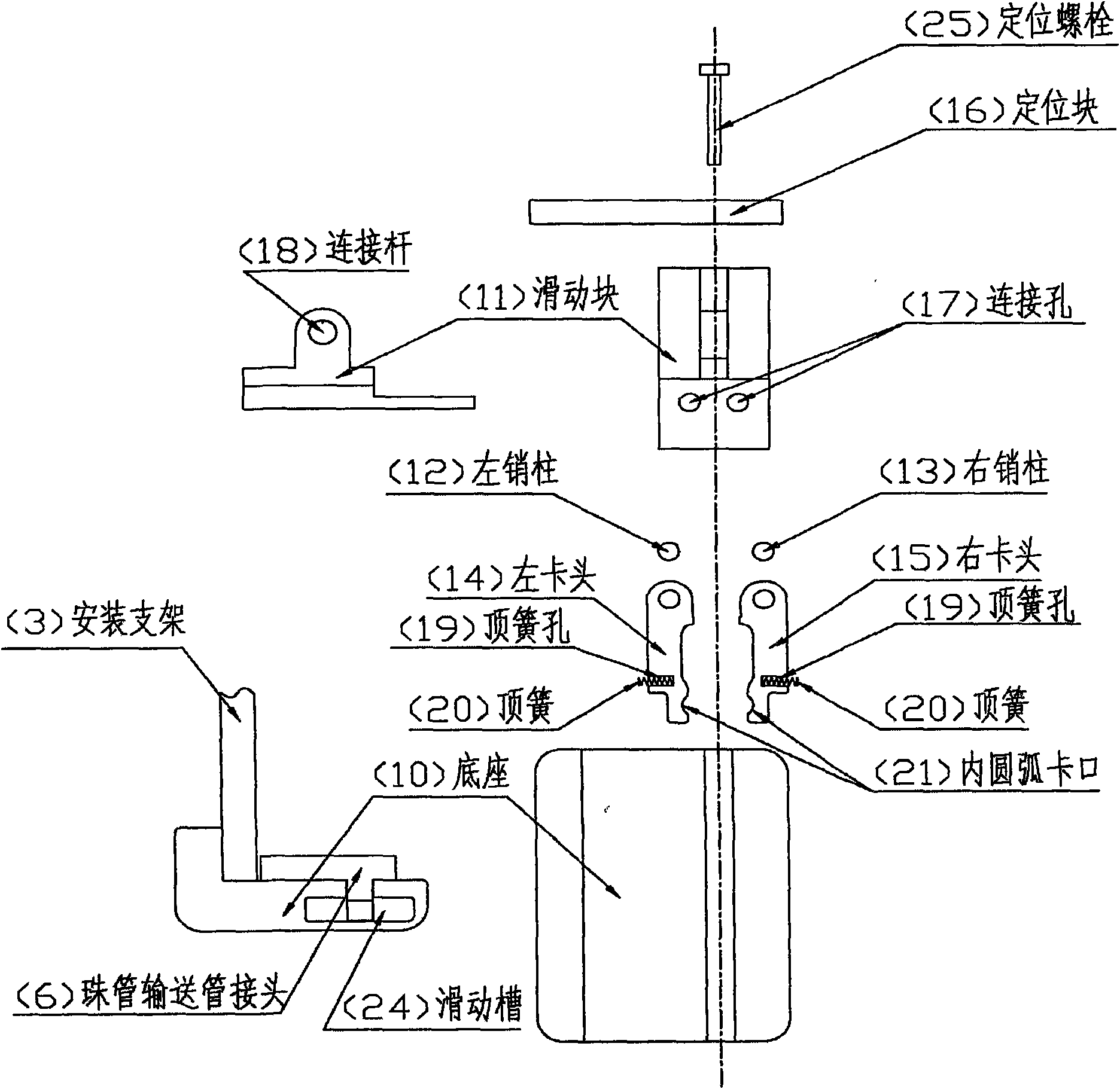

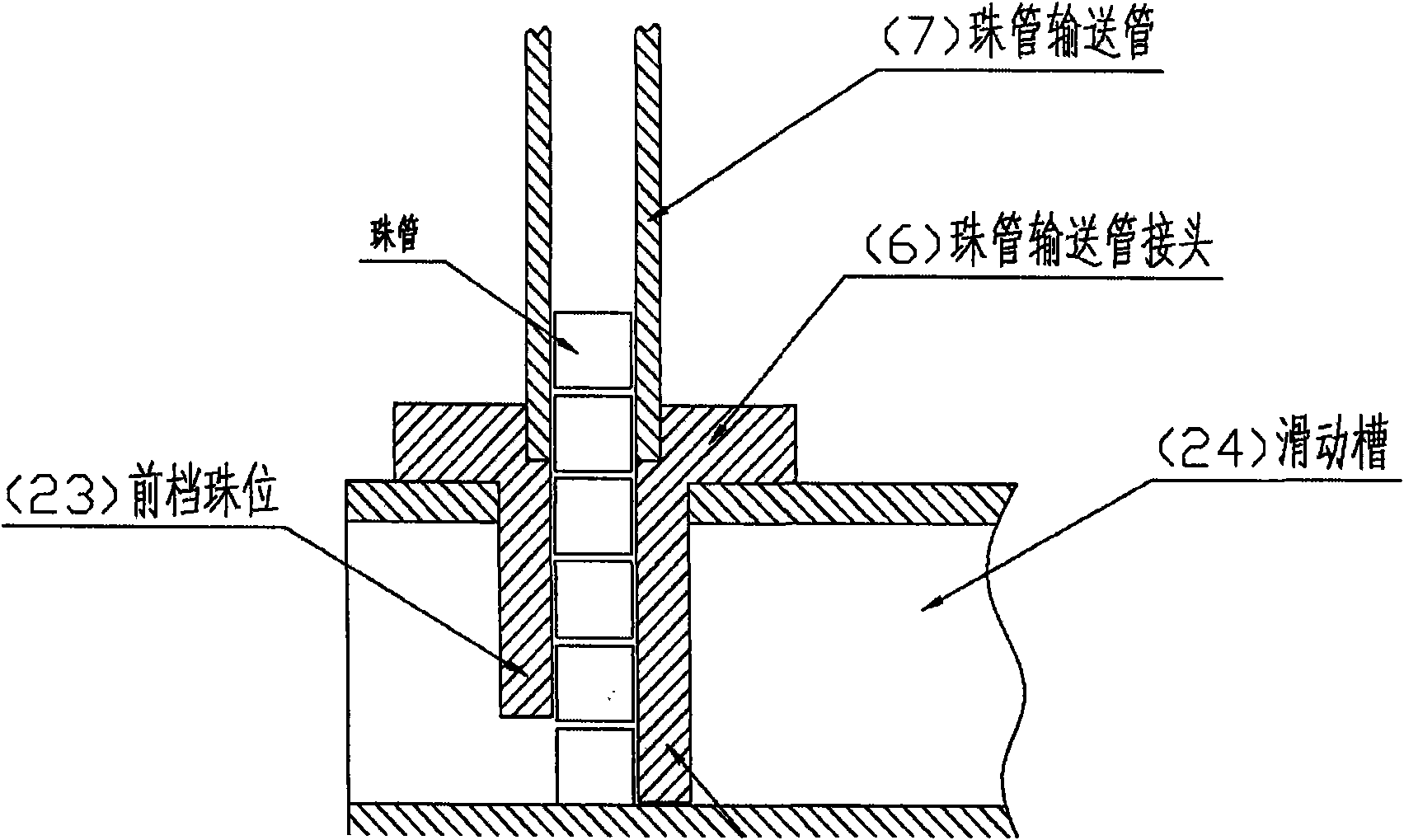

Device for arranging embroidering bead tube for common embroidery machine

InactiveCN101798732AAccurate penetrationBeautifully placedAutomatic machinesAuxillary devicesElectric machineryEngineering

The invention discloses a device for arranging an embroidering bead tube for a common embroidery machine, which comprises that: a bead shifting head and a machine needle are fixed on the lower part of a needle rod in a needle rod frame; a mounting bracket is fixed on the side face of the needle rod frame; a stepping motor is fixed in the middle of the mounting bracket; a bead tube conveying device is fixed on the lower part of the mounting bracket and is movably connected with the stepping motor through a shifting fork; a bead tube conveying pipe joint is arranged on the front plane of the bead tube conveying device; and the bead tube conveying pipe is connected with the bead tube conveying pipe joint. The device has the advantages that: the device has simple and reasonable structure and convenient operation, and can accurately feed unpackaged bead tubes to the underside of the machine needle of the common embroidery machine, so that the bead tubes are embroidered on shell fabrics according to the requirement on patterns through holes in the bead tubes by the machine needle, the production efficiency is high, the droppoints of the embroidered patterned bead tubes are accurate, the shell fabrics are brilliant and attractive, the level and ornamental property of the shell fabrics are greatly improved, and the like.

Owner:王仁坤

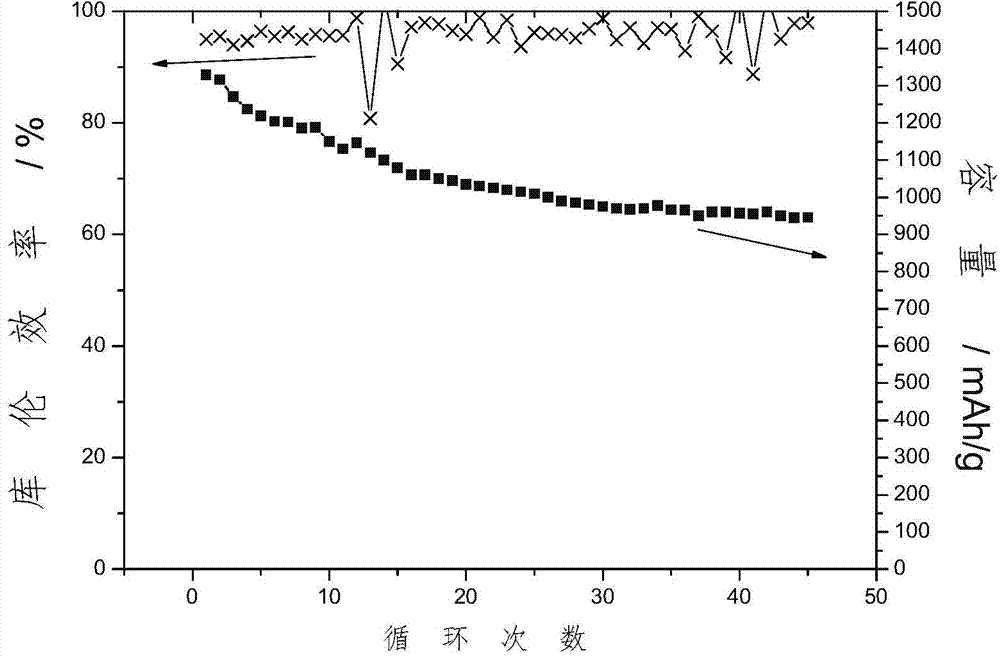

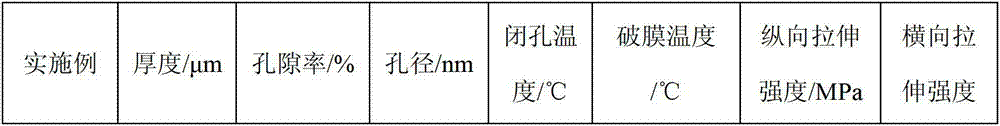

Inorganic composite microporous membrane serving as lithium ion battery diaphragm and preparation method thereof

InactiveCN102738427AImprove integrityWon't fall offMaterial nanotechnologySynthetic resin layered productsPolyolefinSilicon oxide

The invention relates to an inorganic composite microporous membrane serving as a lithium ion battery diaphragm and a preparation method of the inorganic composite microporous membrane. The inorganic composite microporous membrane is a co-extruded inorganic composite microporous membrane, and includes an intermediate layer and two outer layers, wherein the intermediate layer is mainly made of polyethylene, or the copolymer of ethylene and other olefins, or the mixture of polyethylene and other polyolefin; the two outer layers is mainly made of the mixture of polypropylene and inorganic nanoparticles; and the inorganic nanoparticles are selected from at least one of aluminum oxide, magnesium oxide, calcium oxide and silicon oxide. The inorganic composite microporous membrane provided by the invention has good unity, and can prevent shedding of the inorganic nanoparticles so as to ensure the stability of the battery performance during application of the inorganic composite microporous membrane. The preparation method provided by the invention can form the multilayer structure of the inorganic composite microporous membrane in one step by adopting co-extrusion method, thereby simplifying the production process, improving the production efficiency and improving the performance of the inorganic composite microporous membrane.

Owner:HENAN YITENG NEW ENERGY TECH

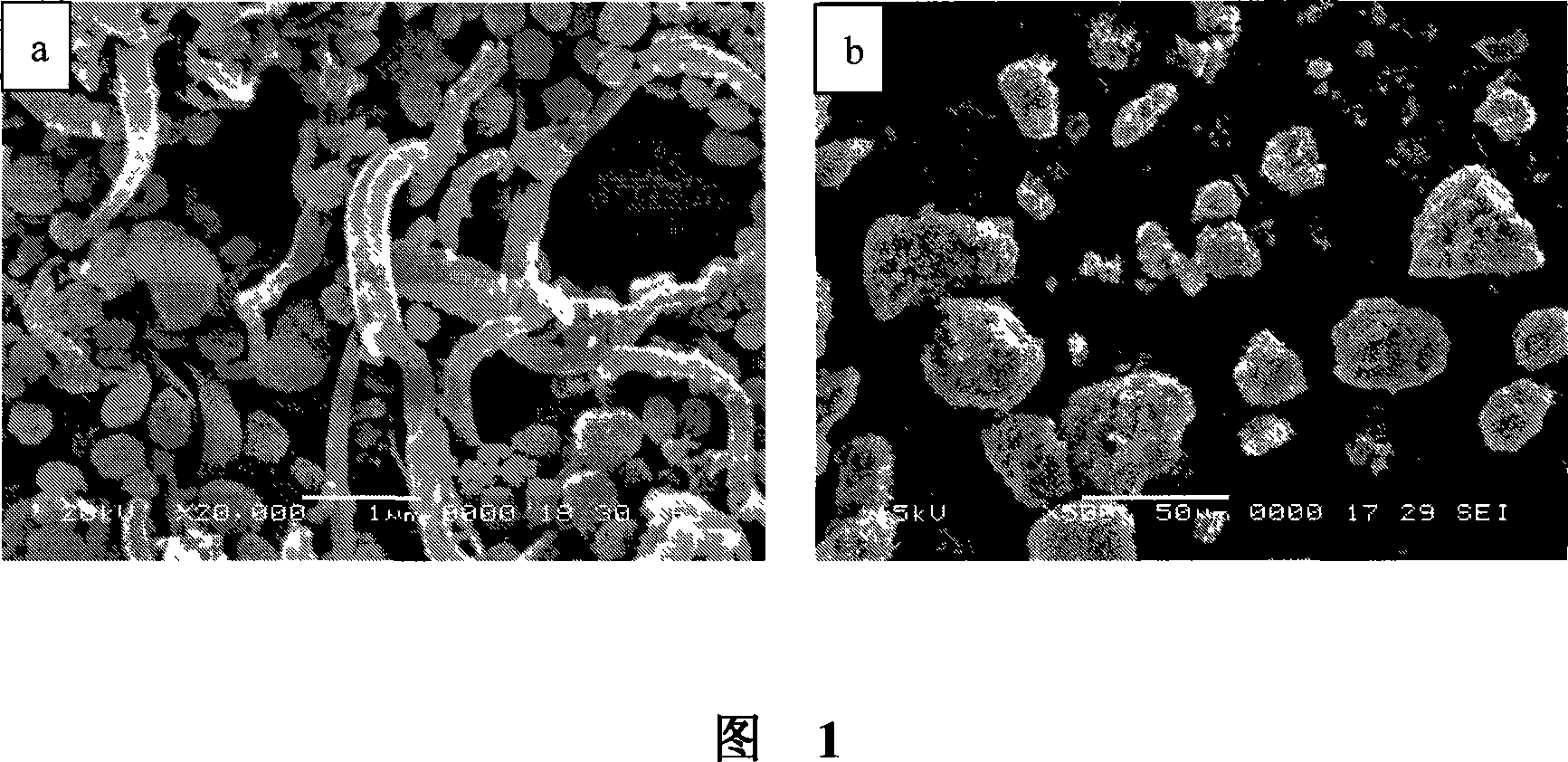

Process for preparing titanium-silicon molecular sieve/nano-carbon fiber fiber composite catalyst

InactiveCN101199941ADoes not affect diffusionDoes not affect catalytic activityMolecular sieve catalystsMicro nanoFiber

The invention relates to a preparation method of composite catalyst of the titanium silicate molecular sieve and the nano-carbon fiber. The composite catalyst of the titanium silicate molecular sieve and the nano-carbon fiber prepared by the method of the invention has strong bonding force between the active component of the titanium silicate molecular sieve and the nano-carbon fiber. Comparing with the industrial micro-nano TS-1 powder (100-500nm), the filtering quality is significantly improved. In the course of using the TS-1 catalyst, the problem of the solution dispersion and separation can be solved; the method is simple and the application range is wide. The catalytic performance of the made composite catalyst is excellent, and can be used for the cyclohexanone ammoximation, the conversion rate of the cyclohexanone and the cyclohexanone oxime selectivity can both reach over 98 percent.

Owner:EAST CHINA UNIV OF SCI & TECH

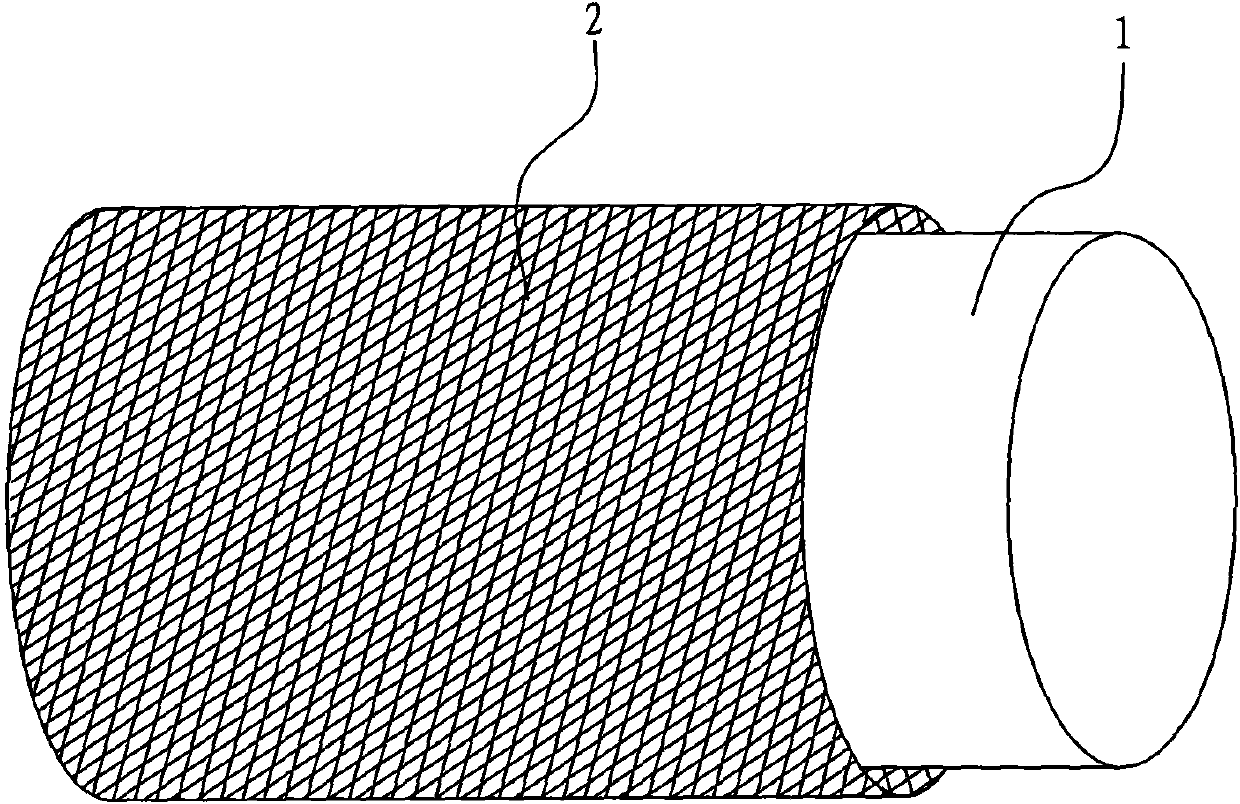

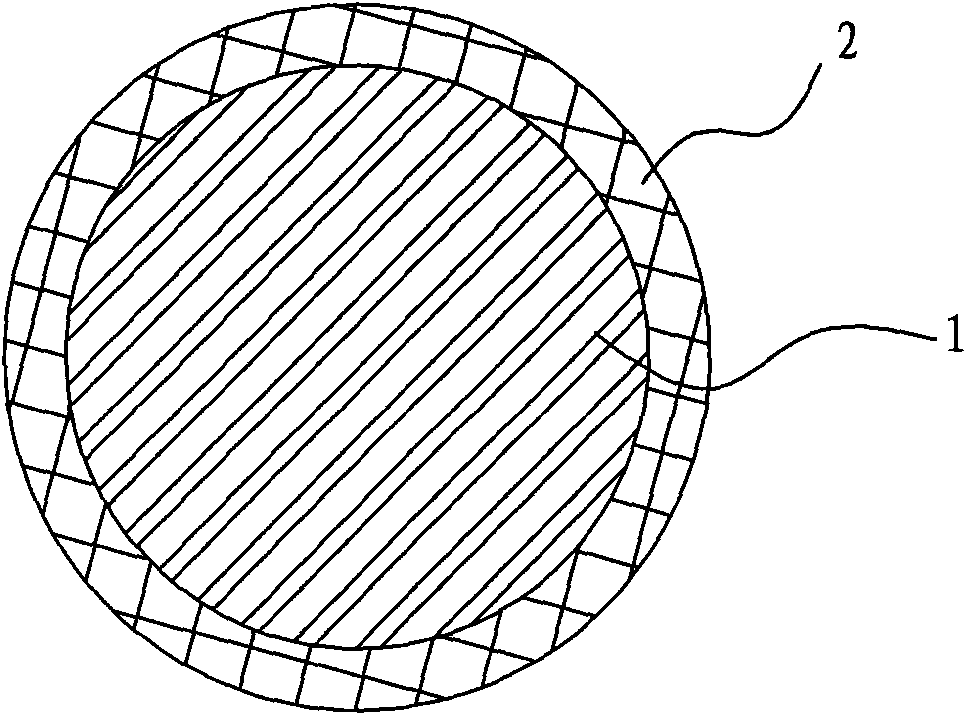

Composite material core used for enhanced cable, preparation process thereof and enhanced cable

InactiveCN102024517AImprove lateral strengthImprove fatigue resistance and fatigue resistanceInsulated cablesCable/conductor manufactureElectrical conductorFiber bundle

The invention relates to a composite material core used for an enhanced cable, a preparation process and the enhanced cable. The composite material core comprises an inner core and an outer layer, wherein the inner core is composed of fiber and thermosetting resin; the outer layer comprises a fiber woven pipe and thermosetting resin which are composited to form the outer layer; and the fiber woven pipe of the outer layer is a network structure which is woven by interlacing a plurality of fiber bundles. The transversal strength of the composite material core is greatly improved by the interlaced network structure, the fatigue resistance of the composite material core is greatly improved, and the service life of the composite material core and a power transmission cable is prolonged; and the problem that the composite material core is broken when the composite material core is stranded, wound and extruded by a conductor in the manufacturing process of the cable is completely avoided. As the fiber woven pipe is adopted by the outer layer, the flexibility of the outer layer is greatly increased by the interlaced and woven structure, thereby meeting the requirement of manufacturing composite material core with major diameter.

Owner:JIANGSU JIATAI TECH MATERIAL

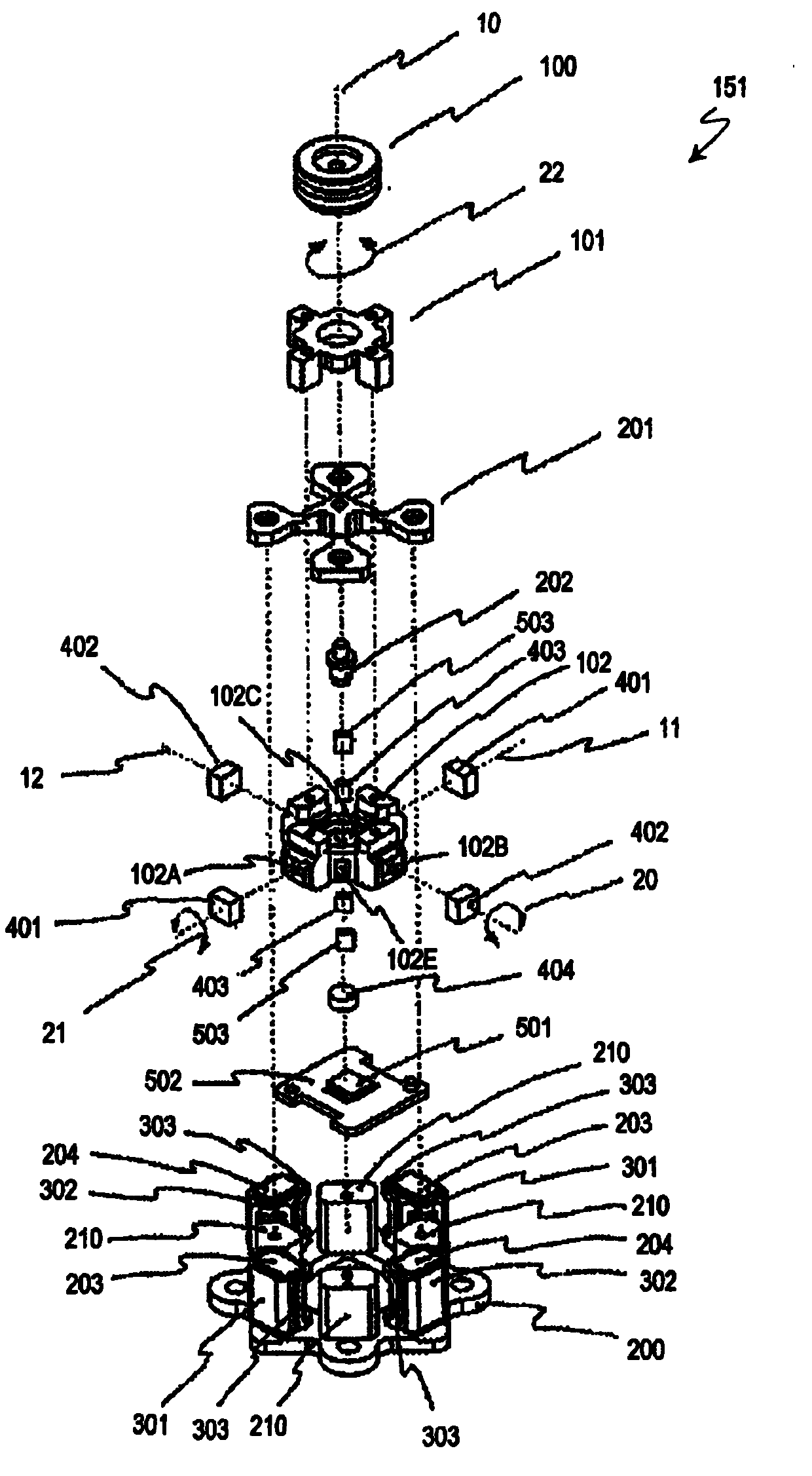

Camera driver

ActiveCN101772730AFree rotationWon't fall offProjector focusing arrangementCamera focusing arrangementFree rotationOptical axis

The camera driver is provided with a camera part that comprises an image pickup element, a lens that forms an object image on the image pickup surface of the image pickup element and a lens barrel that holds the lens; a fixed unit, at least a portion of which is made of a magnetic substance and which comprises a protruding part provided with a shape that is at least a portion of a spherical surface; a movable unit that comprises a first movable part comprising an attraction magnet that generates a magnetic attraction force on the magnetic substance and a contact surface with a conical shape into which the protruding part fits as a result of the magnetic attraction force, and which rotates freely with respect to the center of the sphere of the spherical surface of the protruding part, and a second movable part, which is equipped with the camera part and fixed to the first movable part, and which comprises a fall-off prevention regulating surface provided with a prescribed intervening gap that allows free rotation with respect to the fixed unit when the first movable part rotates; a detector that detects the slant angle of the camera part with respect to the fixed unit and the rotation angle of the camera part around the optical axis of the lens; a first driving part that slants the camera part with respect to the fixed unit; and a second driving part that rotates the camera part with respect to the fixed unit around the center of the optical axis.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

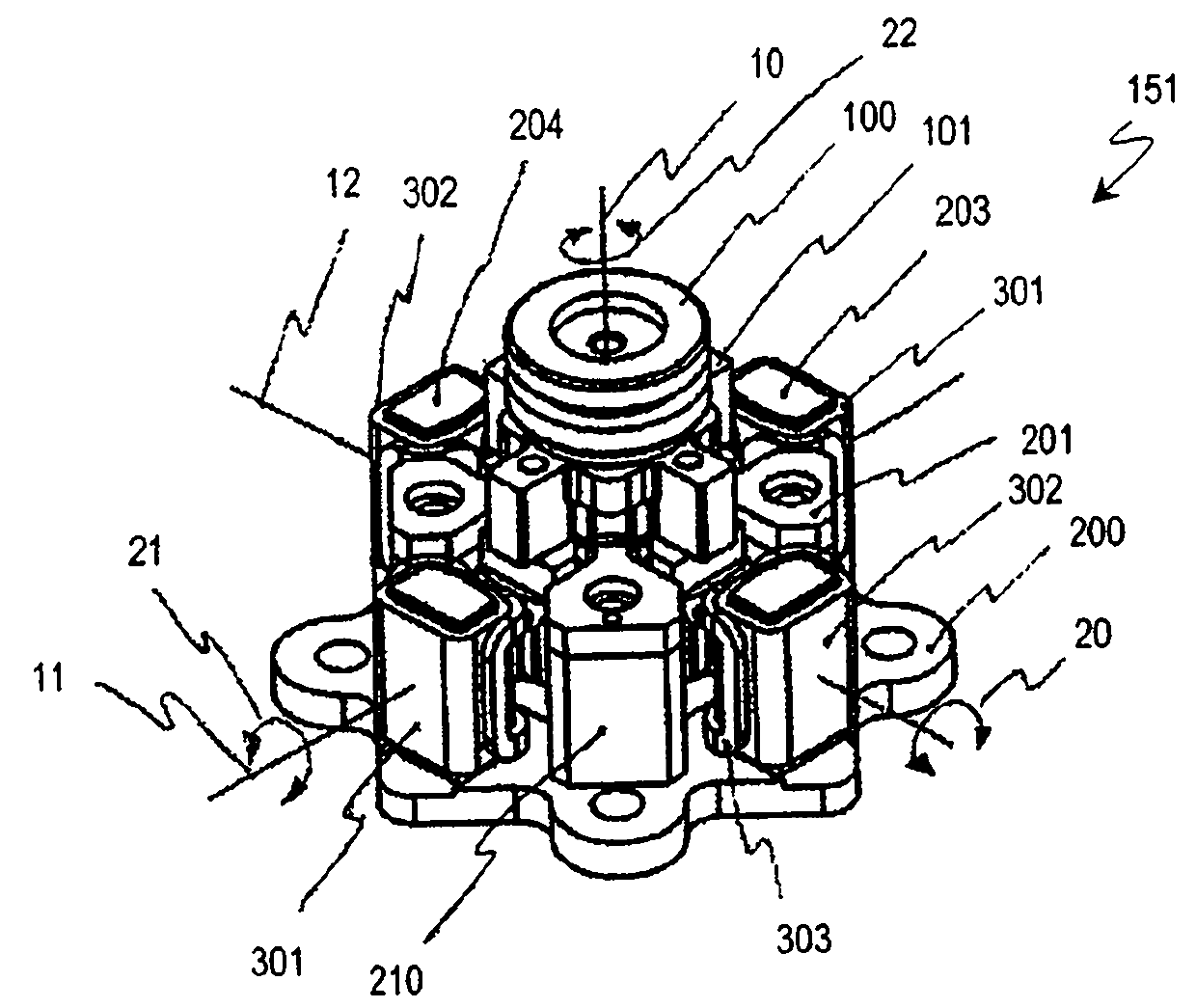

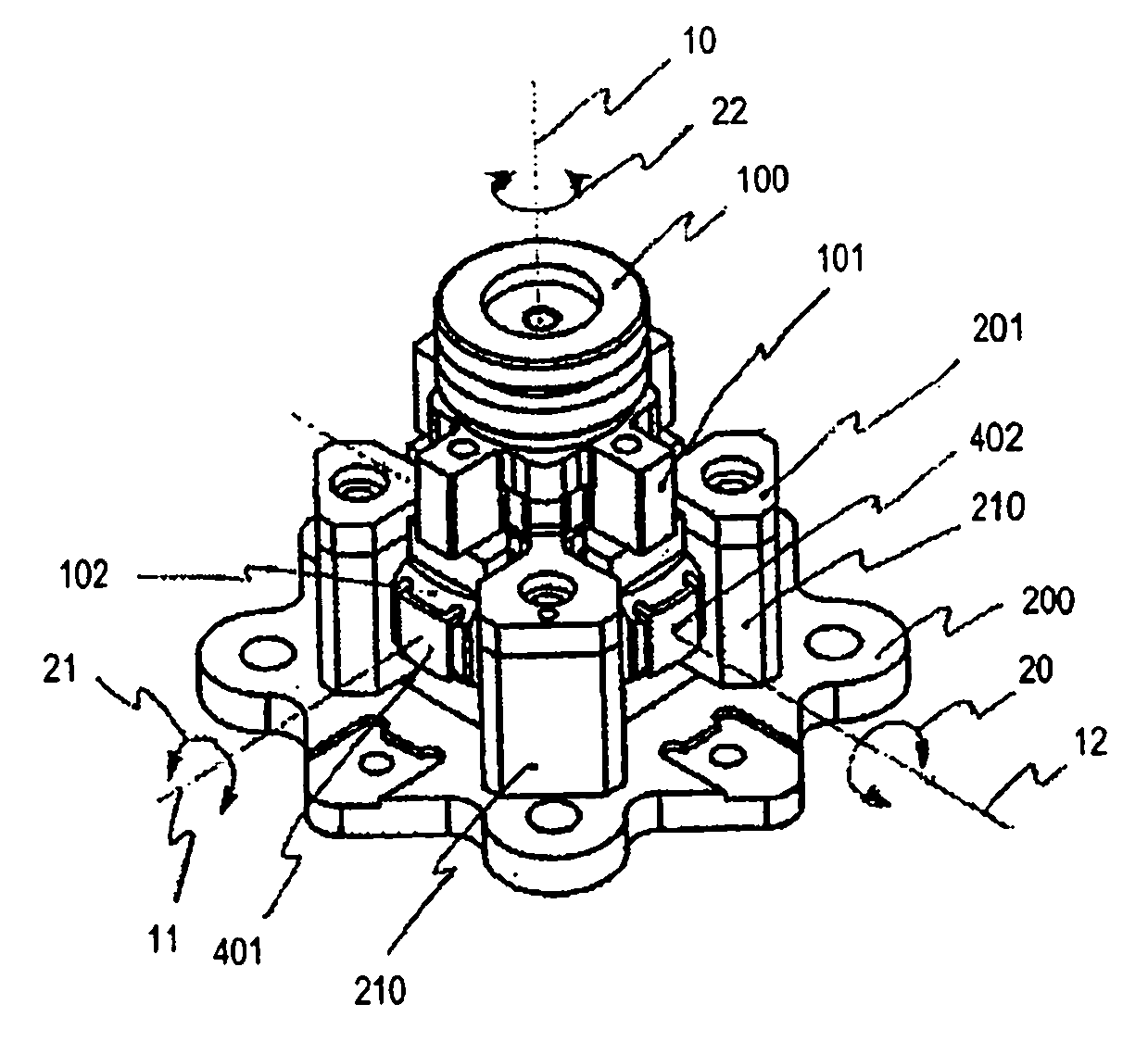

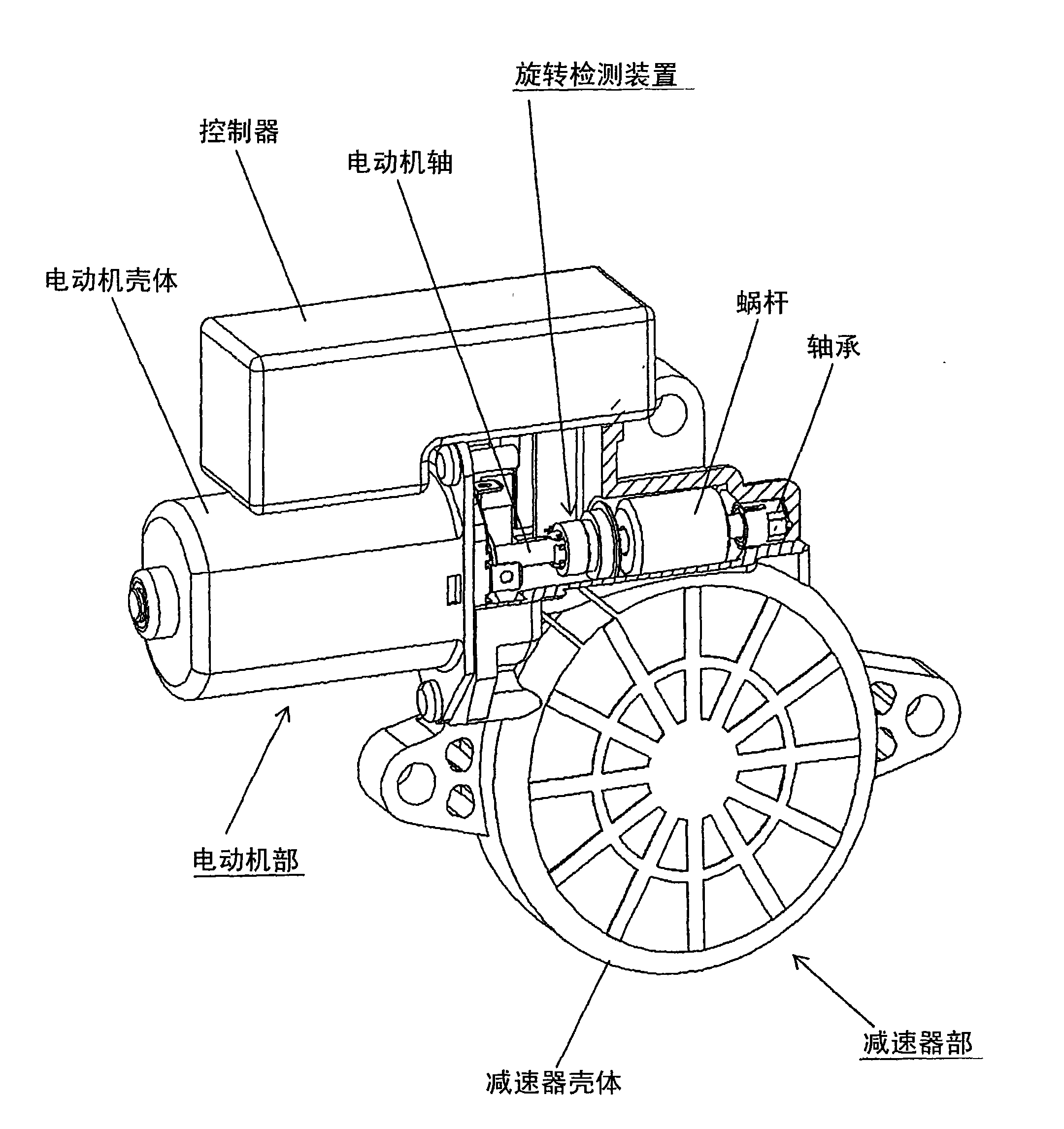

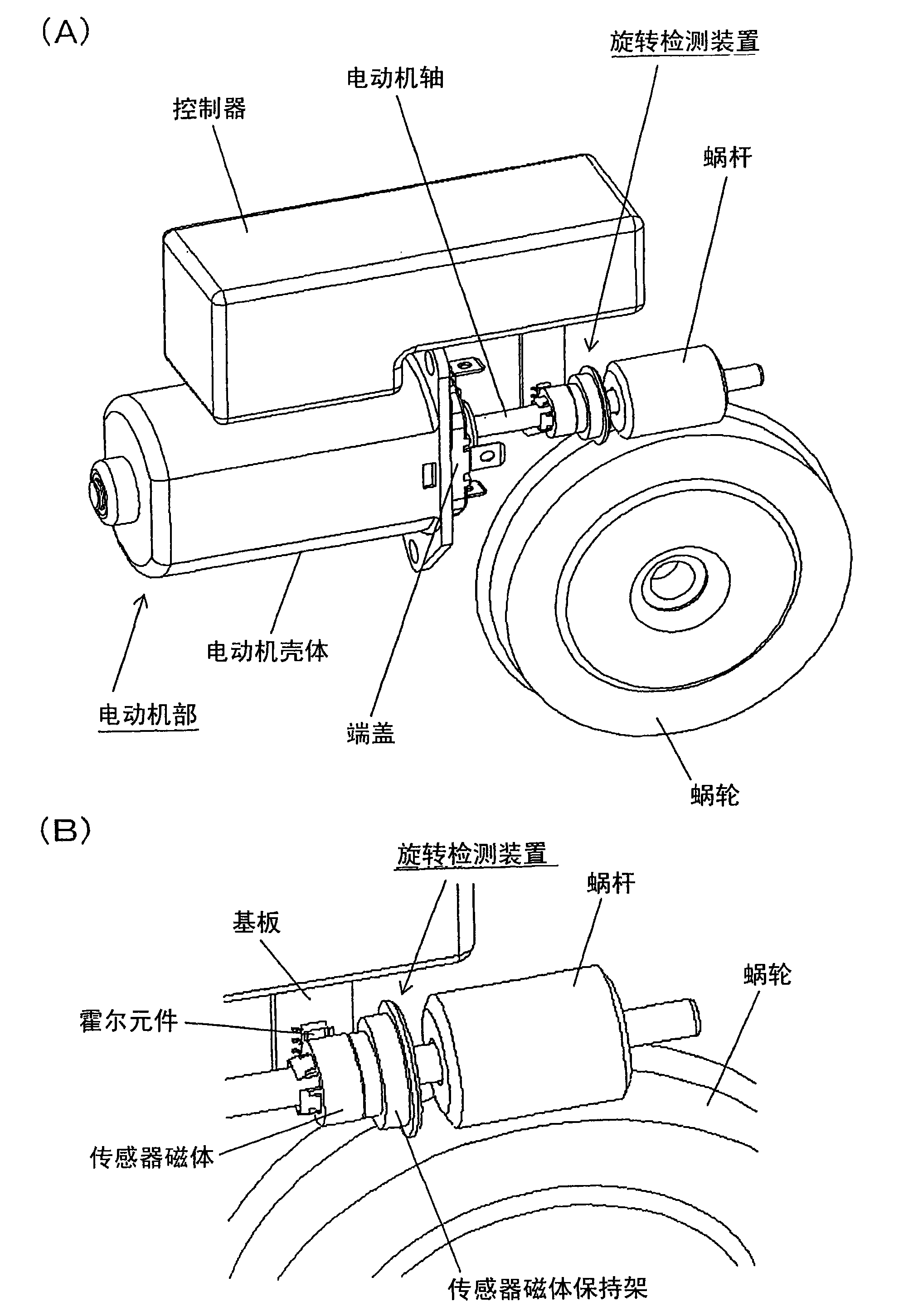

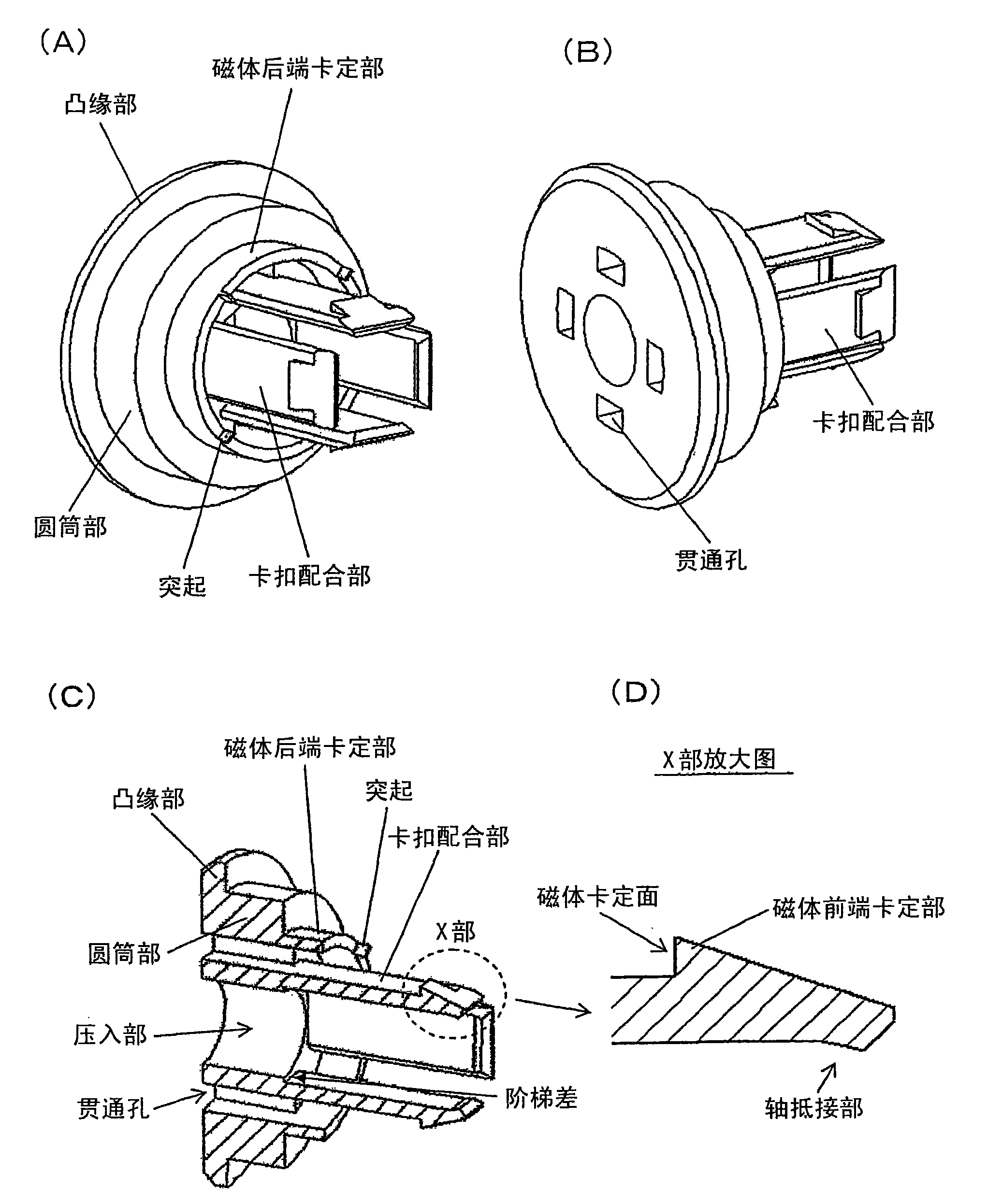

Sensor magnet holder, motor having the holder incorporated therein, and method of manufacturing the motor

ActiveCN101630888AAvoid crackingImprove resistance to movementManufacturing dynamo-electric machinesDC commutatorEngineeringMotor shaft

A sensor magnet holder is formed such that a cylindrical portion, a flange portion formed by increasing the diameter of one end part of the cylindrical portion, a magnet rear-end engagement portion formed at the other end part of the cylindrical portion, and four plate-like snap fit tongues are formed integral with one another. The cylindrical portion including the flange portion has, on its inner diametral side, a press fit portion to be press-fitted to a motor shaft. The four plate-like snap fit tongues have respective magnet front-end engagement portions formed on an outer diametral side of their tip portions. The four snap fit tongues are brought into contact with respective flat inner surfaces of the sensor magnet having four flat inner surfaces, by utilizing elasticity of the snap fit tongues. The sensor magnet is retained between the magnet rear-end engagement portion and the magnet front-end engagement portions.

Owner:MABUCHI MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com