Antimicrobial pearl viscose fiber, preparation method and application thereof

A technology of viscose fiber and viscose staple fiber, which is applied in the field of preparation of antibacterial pearl viscose fiber, and can solve problems such as the influence of human body comfort, complex process, and limited pearl dosage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

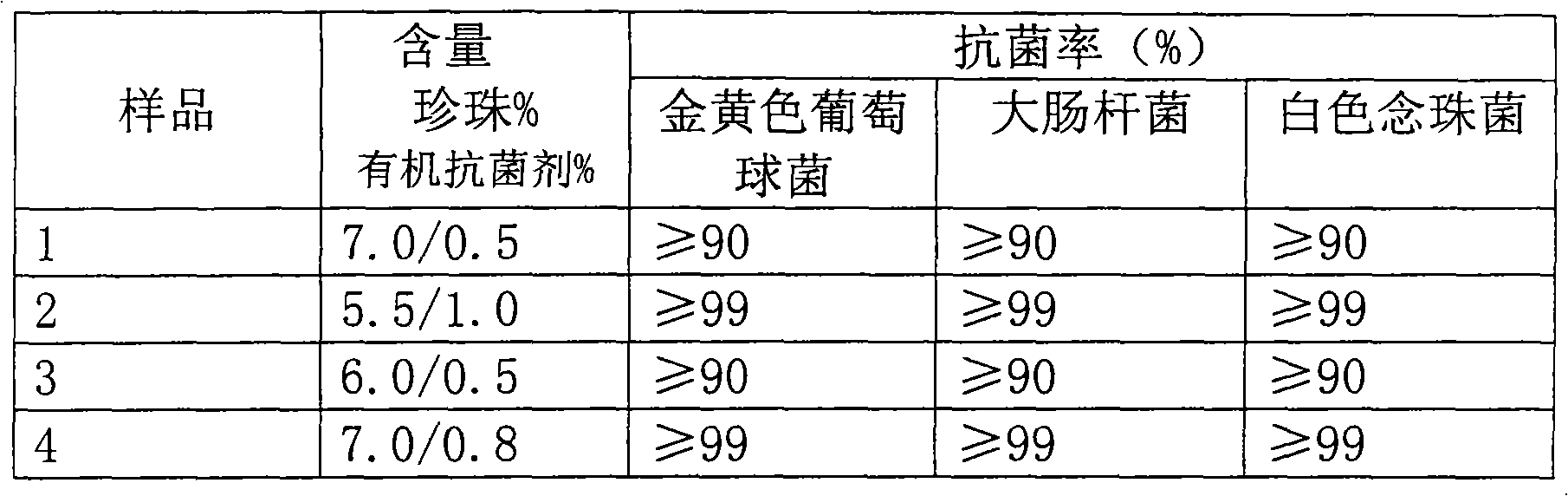

Examples

specific Embodiment 1

[0026] To prepare one ton of antibacterial pearl viscose filaments with a pearl content of 5.5% and an organic antibacterial agent content of 1.0%, the pearl mother liquor is first prepared.

[0027] Preparation of mother of pearl solution:

[0028] Pearl powder (average particle size: 1.0 μm, powder greater than 3 μm is less than 10%): 15-25wt%, dispersant: 10-15wt%, carrier solution: 56-73.5wt%.

[0029] Organic antibacterial agent: 1.5-4wt%. One of the organic antibacterial agents can be selected: triclocarban (TCC) (chemical name: trichlorodiphenylcarbamide, English name: Triclocarban), halogen compound (dichlorophenyl biguanide hexane hydrochloride), two Phenyl ethers (2,4,4'-trichloro-2'hydroxydiphenyl ether), phenylamide anionic compounds, organic nitrogen compounds (SCJ-2000) and chlorbendazole compounds (SCJ-126), etc.

[0030] The preparation method that contains 5.5wt% pearl powder and 1.0wt% organic antibacterial agent mother liquor: in stainless steel ax, add pe...

specific Embodiment 2

[0032]To prepare one ton of antibacterial pearl viscose short fibers with 6% pearl content and 0.5% organic antibacterial agent, first prepare pearl mother liquor.

[0033] Preparation of mother of pearl solution:

[0034] Pearl powder (average particle size: 1.0 μm, powder greater than 3 μm is less than 10%): 15-20 wt%, dispersant: 10-15 wt%, carrier solution: 56-73.5 wt%.

[0035] Organic antibacterial agent: 1.5-4wt%.

[0036] The preparation method that contains 6%wt% pearl powder and 0.5wt% organic antibacterial agent mother liquor: in stainless steel still, add pearl powder 60Kg (pearl 18.46wt%), add dispersant 48.75Kg (dispersant 15wt%), carrier 211.25Kg of solution (carrier solution 65wt%), organic antibacterial agent 5Kg (organic antibacterial agent 1.54wt%) were stirred, mixed, filtered and set aside.

[0037] The above mother liquor is blended with the dissolved viscose in a dissolving machine, and the blending ratio is 1:0.06:0.005 according to the weight of α-Ce...

specific Embodiment 3

[0038] To prepare one ton of antibacterial pearl viscose short fibers with a pearl content of 7.0% and an organic antibacterial agent of 0.8%, the pearl mother liquor is first prepared.

[0039] Preparation of mother of pearl solution:

[0040] Pearl powder (average particle size: 1.0 μm, powder greater than 3 μm is less than 10%): 15-20 wt%, dispersant: 10-15 wt%, carrier solution: 56-73.5 wt%.

[0041] Organic antibacterial agent: 1.5-4wt%.

[0042] The preparation method that contains 7.0wt% pearl powder and 0.8wt% organic antibacterial agent mother liquor: in stainless steel still, add pearl powder 70Kg (pearl 17.95wt%), add dispersant 58.5Kg (dispersant 15wt%), carrier solution 253.5Kg (carrier solution 65wt%), organic antibacterial agent 8Kg (organic antibacterial agent 2.05wt%) stirred, mixed, filtered, set aside.

[0043] The above mother liquor is blended with the dissolving viscose in a dissolving machine, and the blending ratio is 1:0.07:0.008 according to the wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com