Microcrystal green glaze based on yijun sand and preparing method of microcrystal green glaze

A technology of microcrystalline and celadon glazes, applied in the field of ceramic glazes, can solve the problems of low maturation temperature, high cost of raw materials, poor hardness and wear resistance of microcrystalline glazes, and achieve high mechanical strength, low price, and wear resistance good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation steps of the present invention comprise:

[0025] 1) Mix 20-80% of Yijun sand, 20-30% raw loess, 0-25% cooked loess, and 0-30% feldspar powder according to mass percentage to obtain a mixture, and then add the mass of the mixture to the mixture 2-4% calcium phosphate, 0.3-0.5% sodium tripolyphosphate and 1-2% CMC are mixed evenly, finely ground to 250 mesh with a fine grinder to obtain a secondary mixture, and the specific gravity of the glaze slurry is adjusted by the secondary mixture 1.6-1.7g / cm 3 ;

[0026] 2) Apply the glaze slurry obtained above evenly on the green body, and then put the green body into a high-temperature furnace and use a reducing atmosphere for glaze firing. The glaze firing temperature is 1150-1250°C, keep it warm for 20-50 minutes, take it out, and cool it naturally That is, the microcrystalline green glaze is obtained.

[0027] Preparation of cooked loess: Grind the raw loess evenly in a mortar, put it into a crucible and p...

Embodiment 1

[0029] 1) By mass percentage, 80% Yijun sand and 20% raw loess are mixed uniformly to obtain a mixture, then in the mixture, add calcium phosphate of mixture quality 4%, 0.4% sodium tripolyphosphate as suspending agent and 1% as suspending agent The CMC of the dispersant is mixed evenly and finely ground to 250 mesh to obtain a secondary mixture;

[0030] 2) Use the secondary mixture to prepare the glaze slurry with a specific gravity of 1.7g / cm 3 ;

[0031] 3) Apply the above-mentioned glaze slurry evenly on the green body, and then place the green body in a high-temperature furnace for glaze firing in a reducing atmosphere at a temperature of 1250°C, keep it warm for 50 minutes and cool naturally to obtain a microcrystalline green glaze.

Embodiment 2

[0033] 1) Mix 70% Yijun sand and 30% raw loess uniformly by mass percentage to obtain a mixture, then add 3% calcium phosphate, 0.4% sodium tripolyphosphate and 2% CMC to the mixture and mix uniformly , finely ground to 250 mesh to obtain a secondary mixture;

[0034] 2) Use the secondary mixture to prepare the glaze slurry with a specific gravity of 1.7g / cm 3 ;

[0035] 3) Apply the glaze slurry obtained above evenly on the green body, and then place the green body in a high-temperature furnace for glaze firing in a reducing atmosphere at a temperature of 1230°C, keep it warm for 40 minutes and cool naturally to obtain a microcrystalline green glaze.

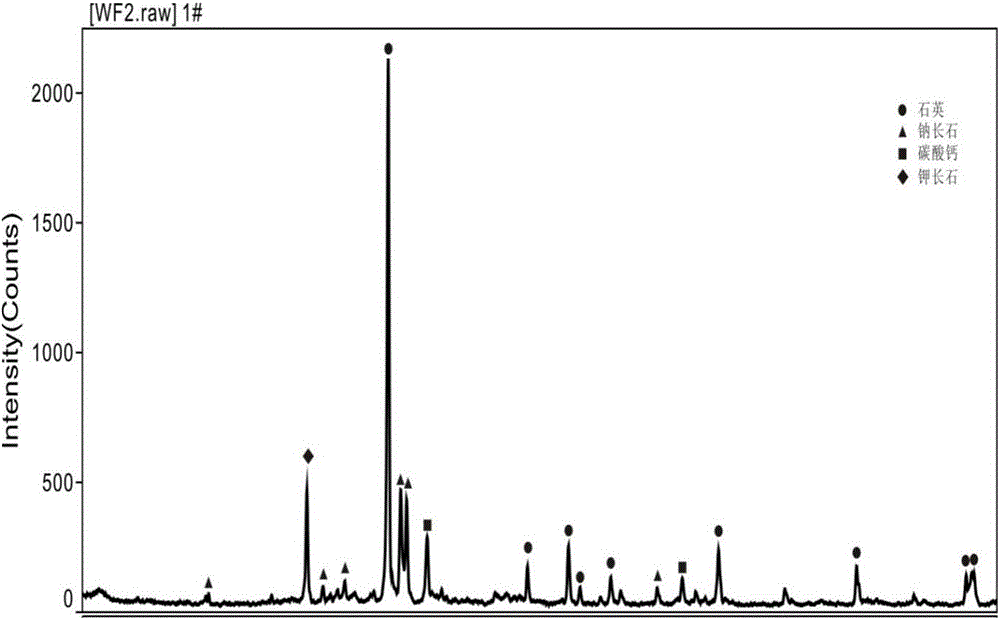

[0036] Depend on image 3 It can be seen from the photo that the present invention prepares microcrystalline green glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com