Patents

Literature

2509 results about "Glaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A glaze is a thin transparent or semi-transparent layer on a painting which modifies the appearance of the underlying paint layer. Glazes can change the chroma, value, hue and texture of a surface. Glazes consist of a great amount of binding medium in relation to a very small amount of pigment. Drying time will depend on the amount and type of paint medium used in the glaze. The medium, base, or vehicle is the mixture to which the dry pigment is added. Different media can increase or decrease the rate at which oil paints dry.

Cooking surface for cooking food having a glass ceramic surface with a glass coating thereon

InactiveUS6525300B1Reduction factorEasy to processCoil arrangementsHot plates heating arrangementsGlazeThermal expansion

The invention relates to lead- and cadmium-free glass for glazing, enamelling and decorating glasses or glass-ceramics which have a low coefficient of thermal expansion of less than 2x10-6 / K, having the composition (in % by weight) 0-6 Li2O, 0-5 Na2O, 0 to less than 2 K2O, where the sum Li2O+K2+Na2O is between 2 and 12, 0-4 MgO, 0-4 CaO, 0-4 SrO, 0-1 BaO, 0-4 ZnO, 3 to less than 10 Al2O3, 13-23 B2O3, 50-65 SiO2, 0-4 TiO2, 0-4 ZrO2 and 0-4 F, as replacement for oxygen and containing up to 30% by weight of a pigment which is resistant at the firing temperature, where the glass is suitable for glazing, enamelling and decoration in both primary and secondary firing, and both the full-area and sparse glaze, enamel or decoration layers have low abrasion susceptibility after firing, and it relates to processes for the production of a glass-ceramic coated therewith.

Owner:SCHOTT AG

Ceramic tile with dry particle glaze-decorated surface and manufacturing method thereof

The invention relates to a ceramic tile with a dry particle glaze-decorated surface. The structure of the ceramic tile comprises a blank layer, a base glaze layer, a cover glaze layer, a printing layer and a dry particle layer from bottom to top, wherein the dry particle layer comprises the same kind of dry particles or the combination of more than two different kinds of dry particles; the different kinds of dry particles are different in particle size and refractoriness; and the particle size of the middle dry particles in the dry particle layer is (-60)-(-120) meshes. The invention also provides a preparation method of the ceramic tile with a dry particle glaze-decorated surface, which sequentially comprises the following steps: (a) producing a blank by using a press; (b) drying the blank by using a drying kiln; (c) applying the base glaze; (d) applying the cover glaze; (e) printing; (f) applying the dry particle glaze; (g) firing; (h) polishing; and (i) edging. The ceramic tile shows unique third dimension of light in the change of different lights and different heights so that the decorative pattern of the ceramic tile has a perfect texture; and moreover, the ceramic tile has good effects in slip resistance, wear resistance, dirt prevention and the like. The preparation method is easy to operate, the cost is low, and the product has a good effect.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

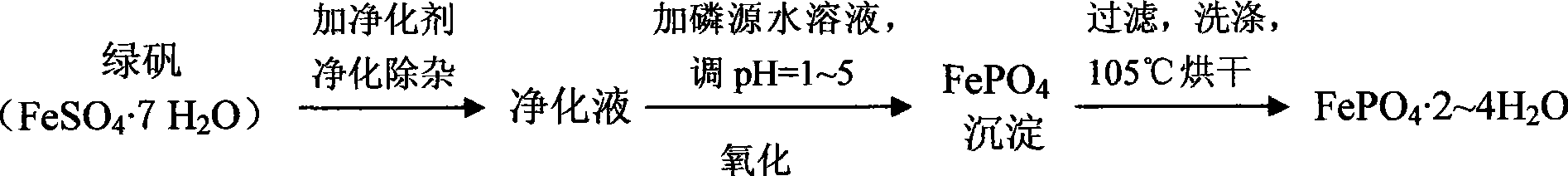

Method for preparing high purity ferric phosphate using ferrous sulfate as by-product of white titanium pigment

InactiveCN101531355AEasy to oxidizeSolve the use problemPhosphorus compoundsLithium iron phosphateGlaze

The invention relates to a preparation method of pure ferric phosphate, characterized in that: iron vitriol, phosphorus source as by-product of white titanium pigment are used as reactant and purificant and oxidant are added into the reactant and the reaction temperature is controlled at 25-100 DEG C and the reaction time is 0.5-10 hours, thus white ferric phosphate powder (FePO[4]2-4H[2]O) with 2-4 crystal water is obtained. The technological process has features of simple process, low production cost, high product purity, increased added value of ferrous sulfate as by-product of white titanium pigment and the product can be used as ceramic metal glaze-color glaze material and raw material for producing lithium iron phosphate as lithium ionization cell anode material.

Owner:GUANGXI UNIV +1

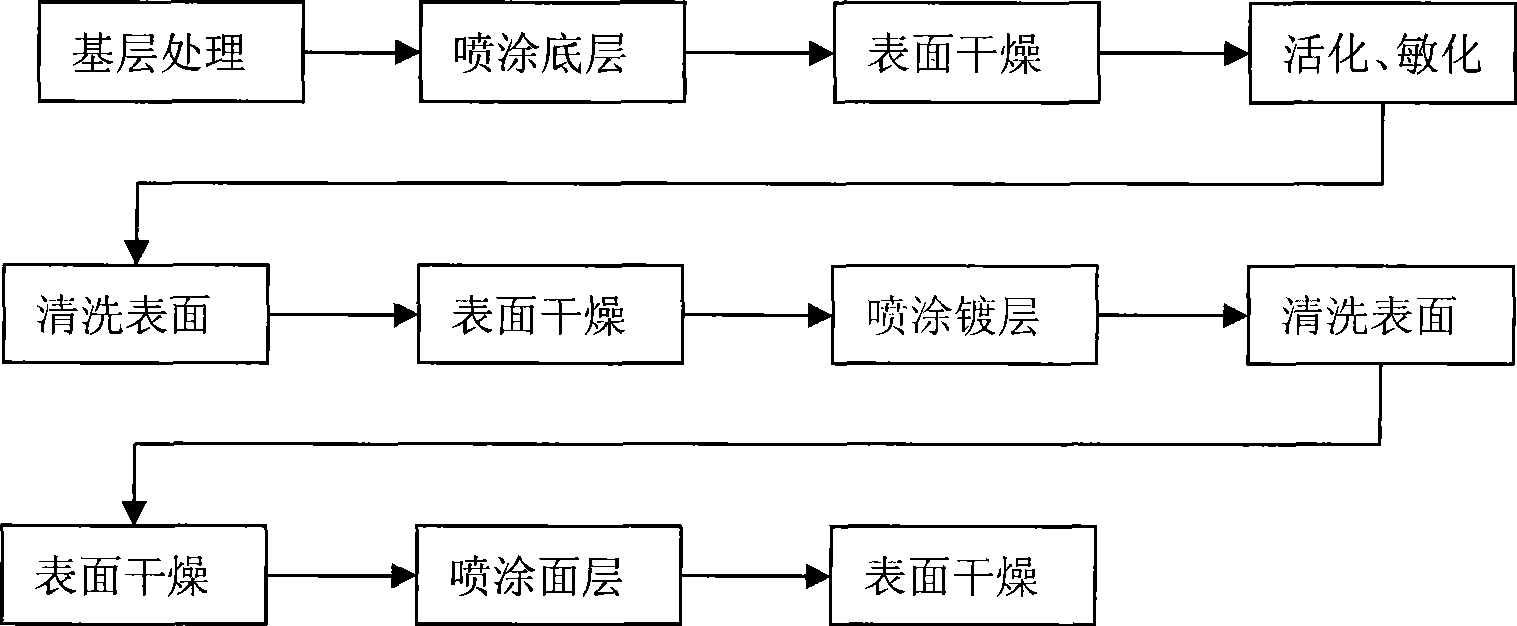

Nano spray plating technique for silver mirror

InactiveCN101469427AAvoid processing powerAvoid environmental problemsLiquid/solution decomposition chemical coatingSuperimposed coating processSurface layerWeather resistance

The invention provides nanometer spray plating for a silver mirror, namely obtain a high glaze metal mirror face by adopting coating technique, which is similar to the brand new decorative effect of plating. The whole technique consists of a paint bottom layer, a metal reflecting layer (spray plating layer) and a paint surface layer. The coating has excellent adhesive attraction, shock resistance, corrosion resistance, weather resistance and marresistance, has rich colors and is bright like a mirror. The nanometer spray plating can be used to various materials such as metal, resin, ABS, PC, PP+PS carbon element resin, plastic, glass, pottery and porcelain, acrylic, wood, plastic wood and calcium plastic.

Owner:汪正红

Production method of imitated natural marble polished glazed brick

The invention provides a production method of an imitated natural marble polished glazed brick. The method comprises the following steps: 1, mixing a widely-known rough body raw material with a pigment, and granulating the obtained mixture to obtain granular colored powder; 2, mixing and distributing the colored powder and the widely-known rough body powder, and carrying out stamping forming to make a green ceramic brick wholly having finishing texture; 3, applying a transparent glaze to the green brick obtained in step 2; and 4, adding the glazed green brick to a kiln, sintering the glazed green brick, and polishing the sintered brick to obtain the imitated natural marble polished glazed brick. The production method of the imitated natural marble polished glazed brick allows the green brick with a whole texture effect to be formed through mixing the widely-known green body raw material with the pigment to prepare slurry, granulating the slurry to obtain the granular colored powder, and mixing and distributing the colored powder and the rough body raw material, and allows the texture of the cross section of the produced polished glazed brick to be same to that of natural stones.

Owner:FOSHAN DONGPENG CERAMIC +3

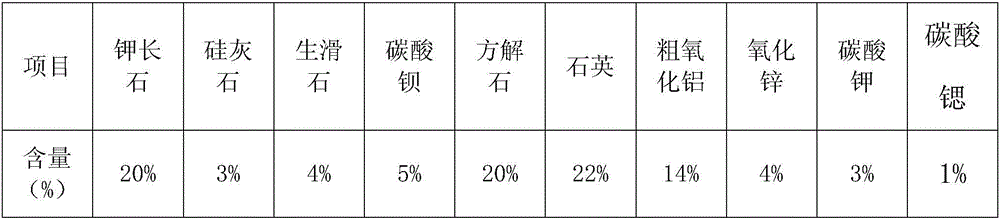

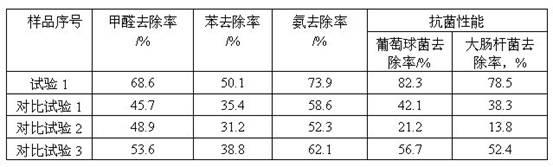

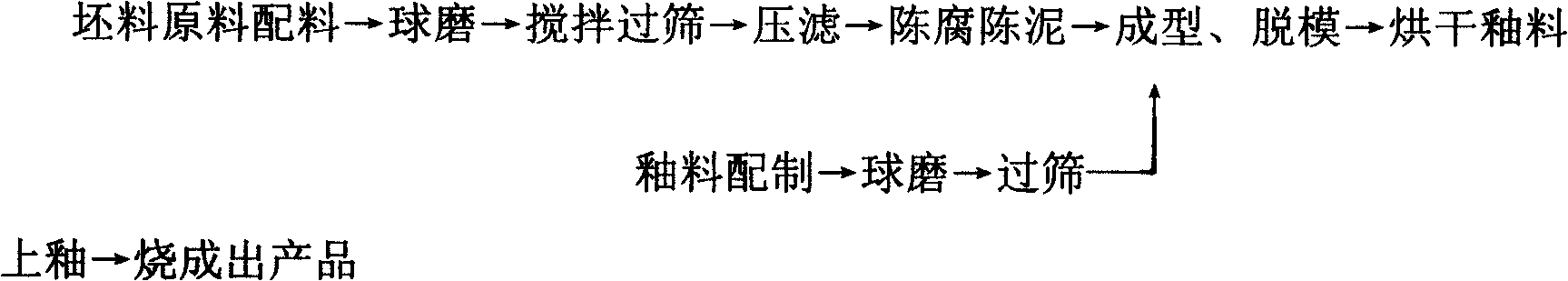

Diatomite-based environmentally friendly glaze for interior wall tiles and interior wall tiles prepared using the glaze

The invention belongs to the technical field of inorganic materials and in particular relates to a kieselguhr-based environmentally-friendly glaze material for an inner wall brick and the inner wall brick prepared by using the same as well as a preparation method. The kieselguhr-based environmentally-friendly glaze material for the inner wall brick comprises kieselguhr, a nano TiO2 / tourmaline composite material, a sintering adjuvant, ceramic pigment, a dispersing agent and water, wherein the weight ratio of kieselguhr to nano TiO2 / tourmaline composite material to sintering adjuvant to ceramic pigment to dispersing agent to water is (40-92):(6-40):(2-15):(0-8):(0.1-4):(60-250). According to the invention, a functional raw material nano TiO2 / tourmaline composite material is introduced in the environmentally-friendly glaze material for the inner wall brick, and the functional raw material has multiple functions of obviously dispelling poisonous and harmful gases such as formaldehyde, ammonia, benzene, volatile organic compound (VOC) and the like which are released by various decoration and finishing materials, furniture and the like, releasing negative ions, resisting bacterium and the like.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Low temperature ceramic color without lead on glaze, and preparation method

This invention relates to a low-temperature lead-free overglaze pigment, which is composed of lead-free pigment 8-30 wt.%, and lead- and cadmium-free flux 70-92 wt.%. The flux is composed of: SiO2 30-60 wt%, B2O3 5-35 wt.%, Al2O3 1.5-15 wt.%, K2O 1.5-10 wt.%, Na2O 1.5-10 wt.%, Li2O 0-8 wt.%, ZnO 0-15 wt.%, CaO 0-5 wt.%, CoO 0-10 wt.%, BaO 0-5 wt.%, MgO 1-5 wt.%, ZrO2 0-10 wt.%, SnO2 0-10 wt.%, and TiO2 0-5 wt.%. The low-temperature lead-free overglaze pigment has such advantages as no toxic or side effects, compact structure, high chemical stability, low baking temperature, beautiful color, high resistance to acid and base, appropriate thermal expansion coefficient, good luster, good decoration effect, and simple preparation.

Owner:淄博华为颜料有限公司

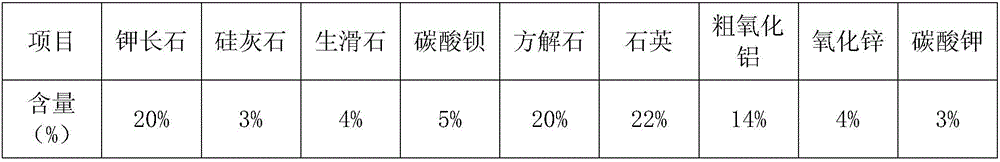

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

Colorful transparent polished-glazed brick and production method thereof

The invention discloses a colorful transparent polished-glazed brick and a production method thereof. The production method for the colorful transparent polished-glazed brick comprises the following steps: enameling a dried ceramic blank, spreading one or more glazes in different colors and with different burning temperature and different refractive indexes on the brick blank, and performing calcining and profiling soft polishing treatment to obtain the brick. According to the colorful transparent polished-glazed brick and the production method thereof, the layering effects and transition of the surface of the colorful transparent polished-glazed brick are closer to those of a natural stone, and the grade of the product is improved to a certain extent; original color effects can be achieved without adding a coloring material, so that process complexity is reduced, the labor intensity of a worker is reduced, and the production efficiency is favorably improved, and the colorful transparent polished-glazed brick and the production method thereof are suitable for popularization and application.

Owner:GUANGDONG JIA MEI CERAMIC

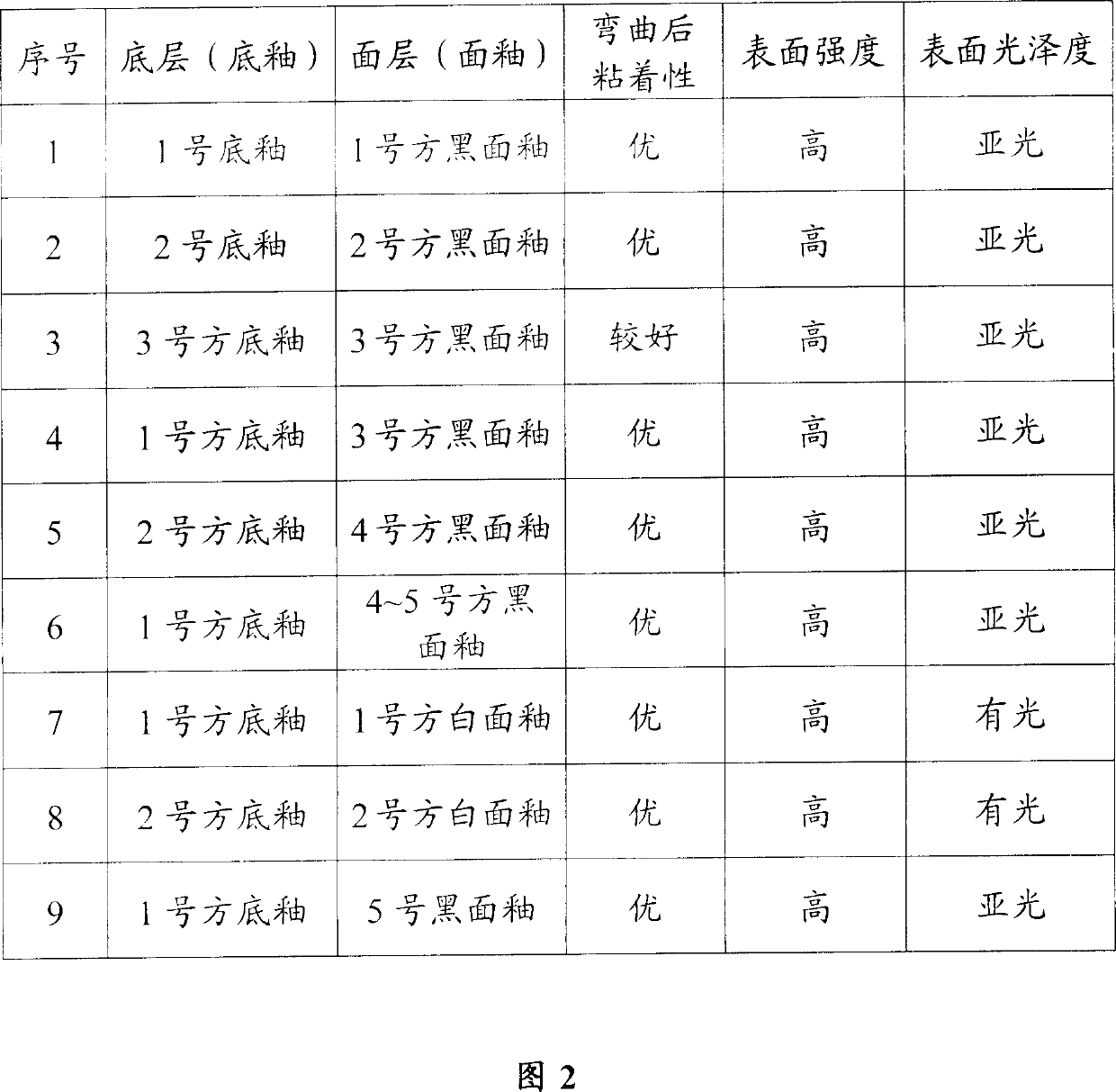

Method for producing blackboard and whiteboard made from enamel in super strength, and glaze of enamel

A process for preparing the super-strength enamelled black (or white) board includes such steps as praying the priming enamel, sintering at 680-740 deg.c for 3 min, spraying surficial enamel and sintering at 560-640 deg.C for 3-4 min. Its enamel contains Al2O3, B2O3, CaF2, Na2O or Li2O, BaO or PbO or CaO, and SiO2 or TiO2. Its advantages are super strength and high antiwear performance.

Owner:王强

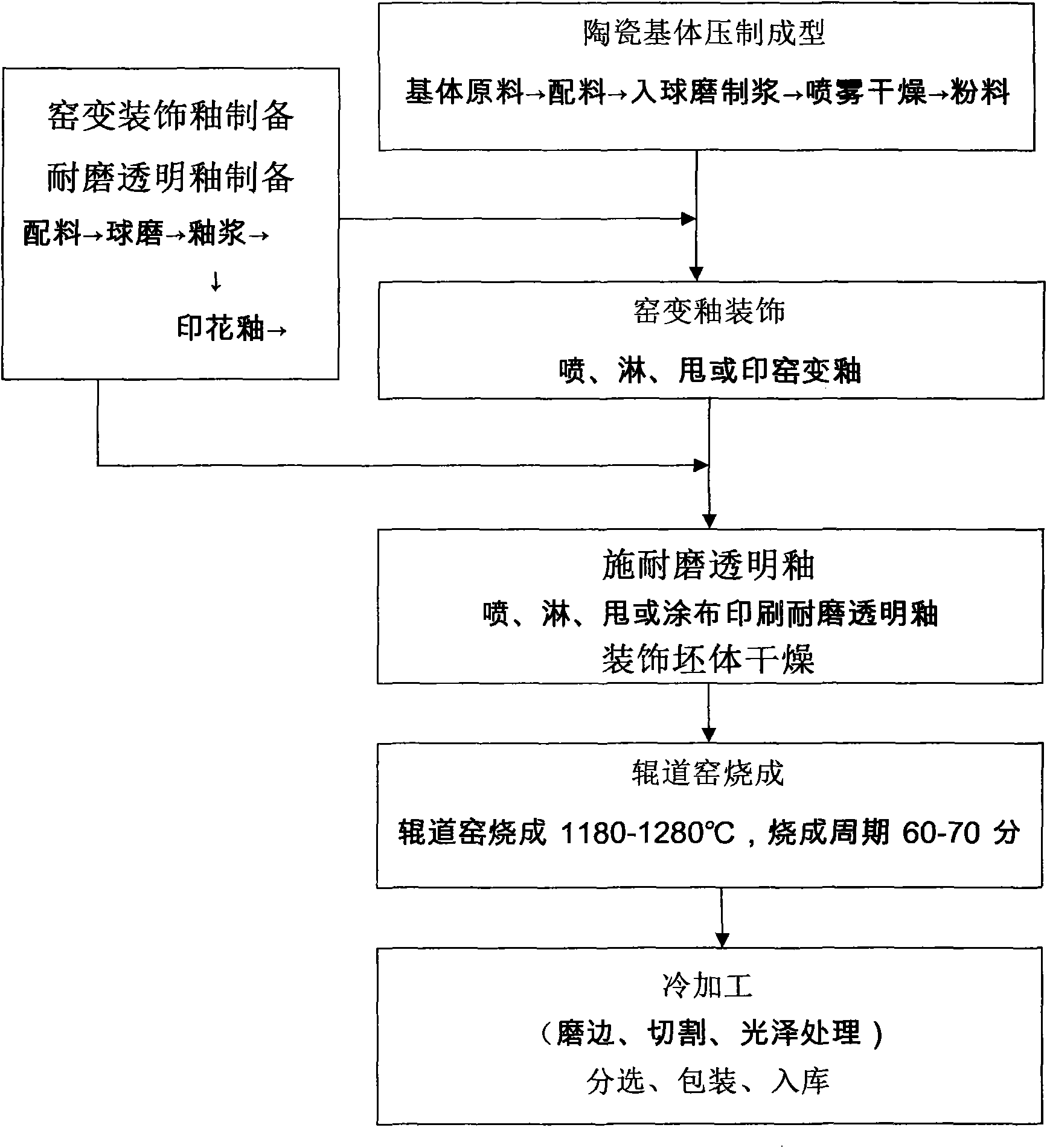

Furnace transmutation decoration glazed brick and production technology

The invention relates to a furnace transmutation decoration glazed brick and a production technique thereof. The furnace transmutation decoration glazed brick is prepared from the following componentsin percentage by weight: 10-30% of albite, 3-10% of spodumene, 5-10% of kaoline Al2O3.2SiO2.2H2O, 8-30% of zinc oxide ZnO, 3-10% of talc 3MgO.4SiO2.H2O, 0-20% of titanium TiO2, 3-10% of zirconite ZrSiO, and 1-10% of coloring metallic oxide MnO2, V2O5, Fe2O3 and CoO2. The production technique of the furnace transmutation decoration glazed brick comprises the following steps: (1) shaping the substrate of the furnace transmutation decoration glazed wall and floor bricks; (2) decorating the wall and floor brick substrate surface or anti-abrasion transparent glaze layers and drying; and (3) sintering the furnace transmutation decoration glazed wall and floor bricks once in a high-temperature roller kiln.

Owner:黄建平

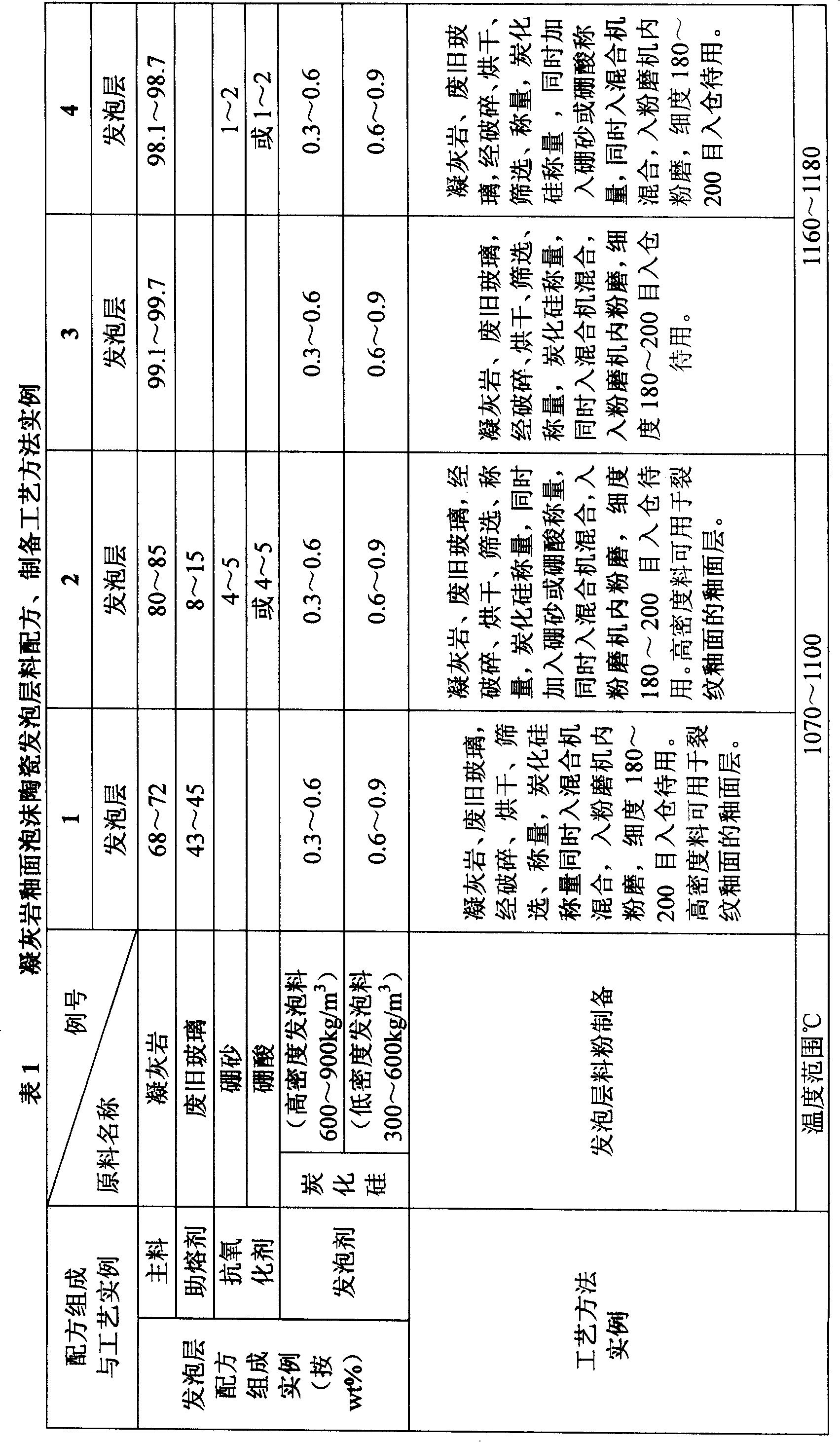

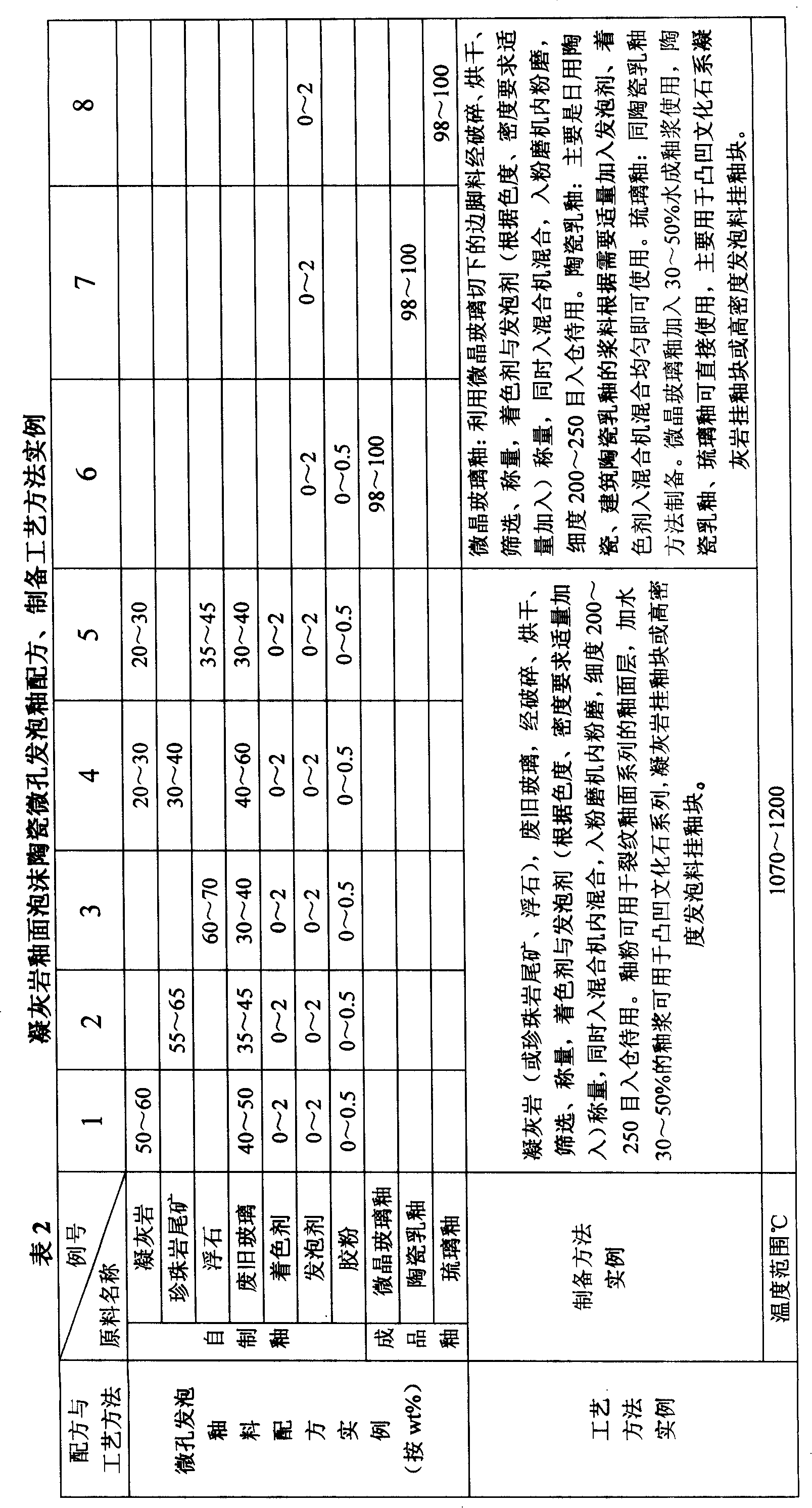

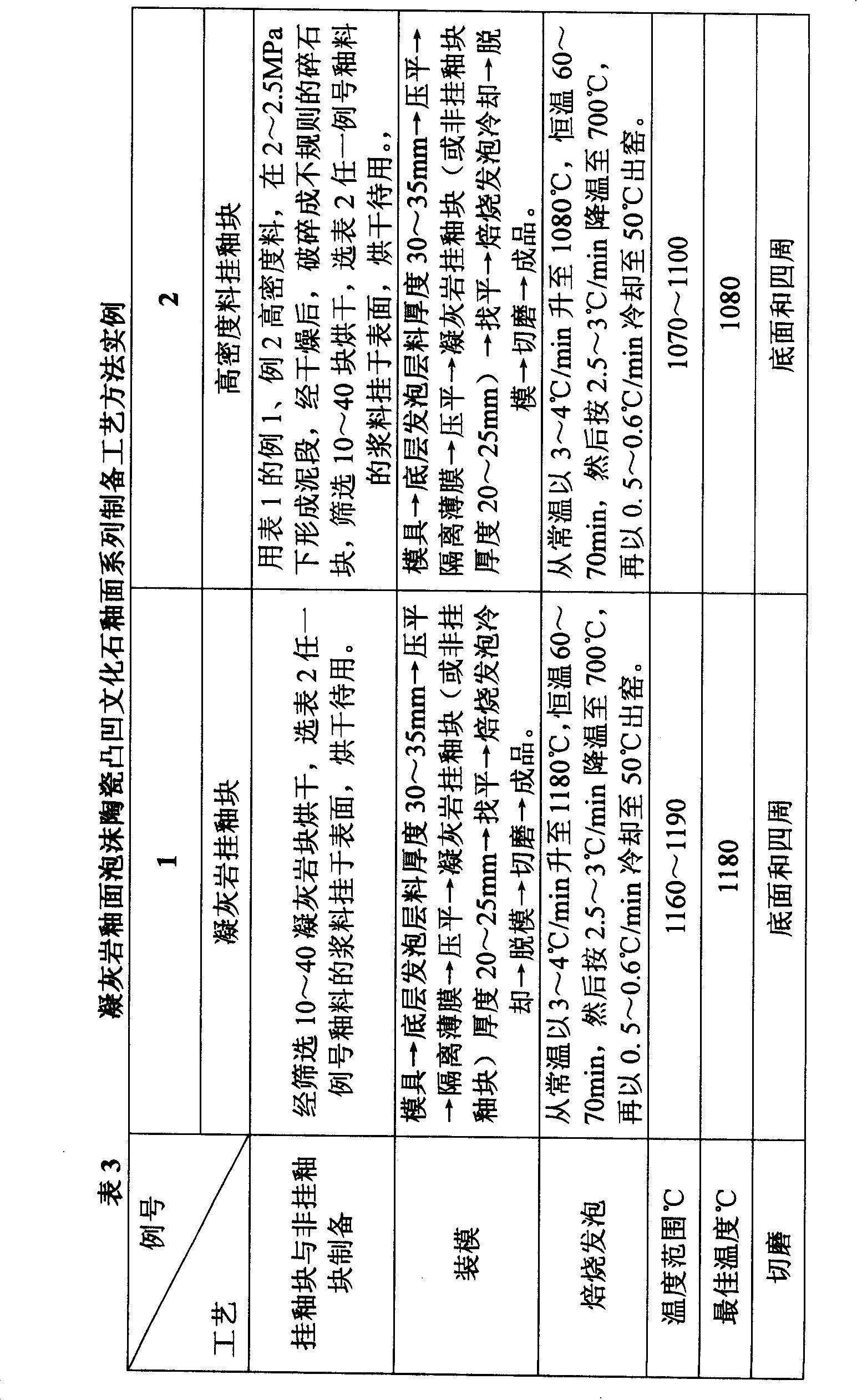

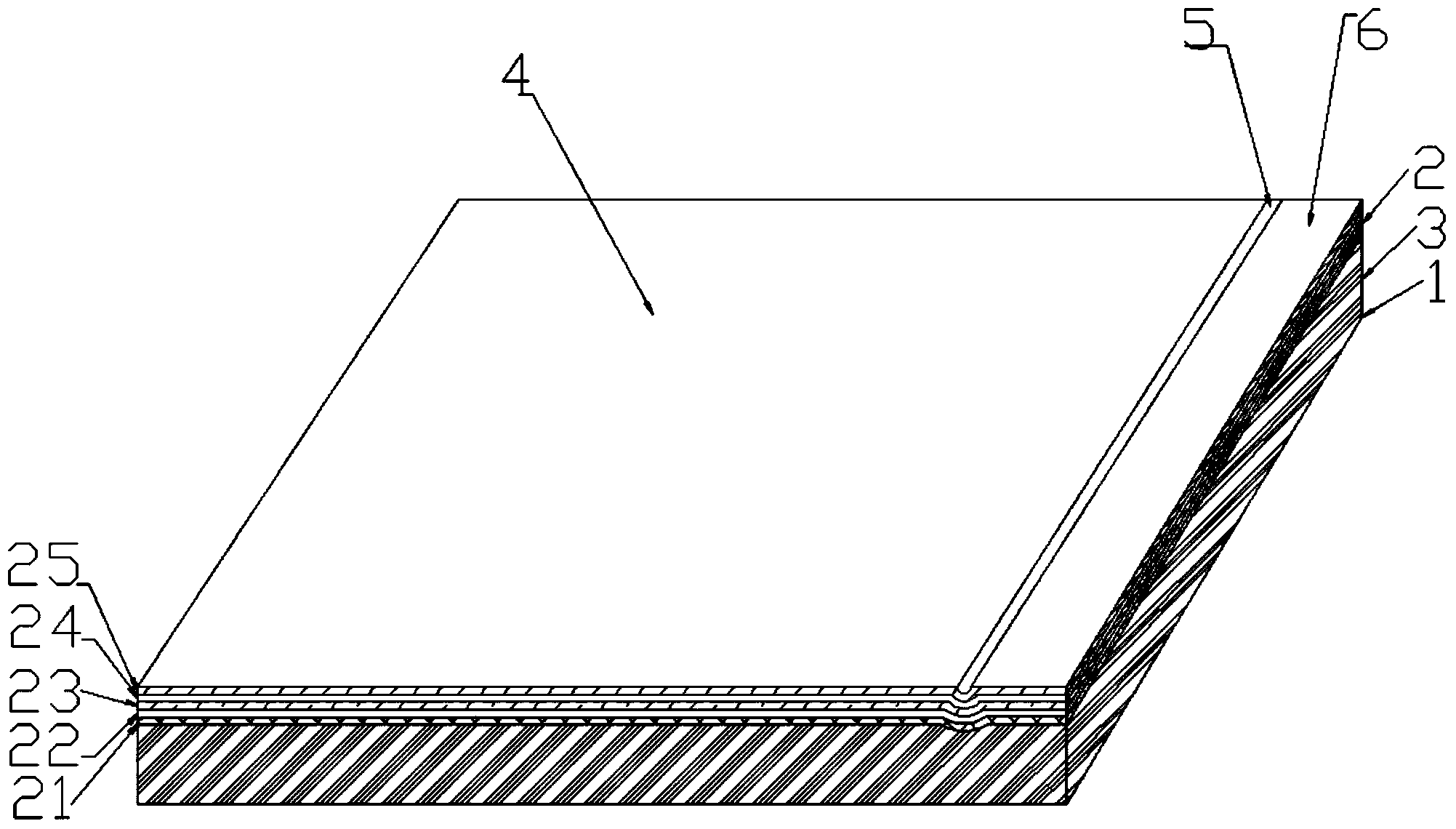

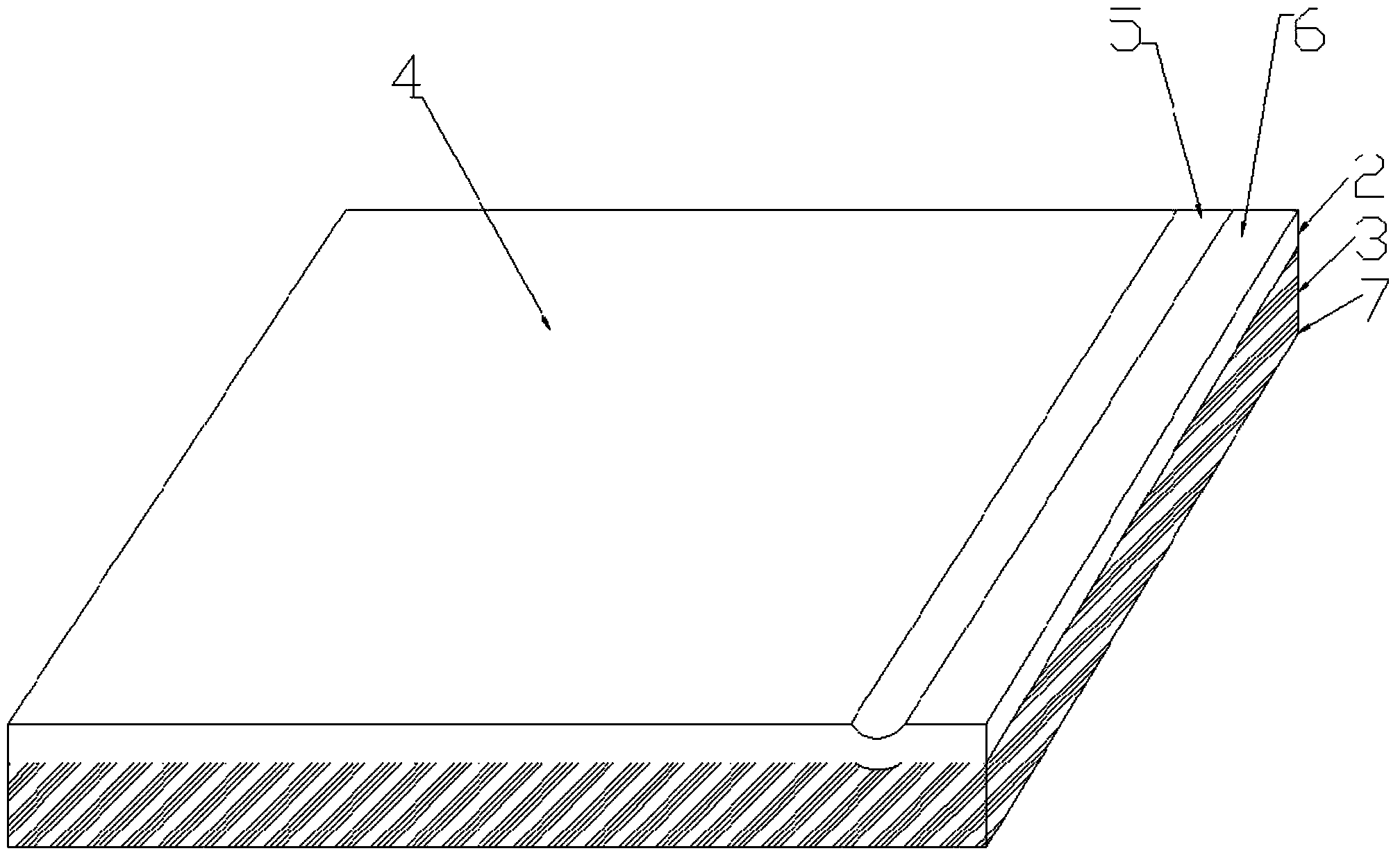

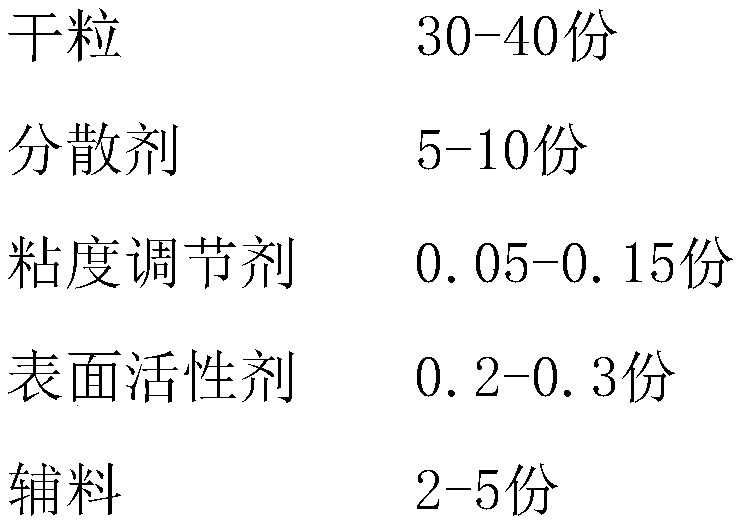

Tuff glaze foam ceramic thermal insulation decoration brick and manufacturing technique

The invention relates to a foam ceramic formed by adopting the rich tuff as the raw material and fluxing agent, foaming agent, and antioxidant as the additives at a temperature of 1,050 DEG C to 1,200 DEG C. The density of the foaming layer ranges from 300kg / m to 500kg / m<3>. The invention can form the following glazed ceramic series products after one-time calcinations: (1) the uneven culture glazed series are prepared by placing tuff blazing block or high-intensity foaming blazing block on the foaming layer; (2) the crystallite glass glazed series are formed by placing water quenched crystallite glass granules below the foaming layer; (3) the crack glazed series are formed by placing micro-hole foaming glazed powder on or below the foaming layer; the product can be produced in a crystallite glass crystallization kiln or an internal-combustion air brick tunnel kiln; with the unique decoration effect and good thermal insulation performance effect, the foam ceramic can be used for thermal insulation decoration, scenery decoration, etc.

Owner:邓家平

Ceramic tile preparation method and product thereof

ActiveCN103833423ANo complicated color separationNo tedious workCovering/liningsBrickMaterials science

The invention discloses a ceramic tile preparation method, which comprises the following steps in order: performing mold design and molding, applying ground glaze to form a ground glaze layer, then performing ink-jet printing to form an ink-jet decorative layer; performing roller printing decoration on the ink-jet decorative layer to form a printing decorative layer; spraying a layer of transparent glaze on the printing decorative layer to form a transparent glaze layer; decorating the transparent glaze layer to form a decorated glaze layer, and performing high temperature sintering. With the method of the invention, prepared waistline and main tile parts are sintered integrally; the product has unified color, texture, and lines, has good decorative effect. When in use, not only is tedious work of tile alignment and tiling by colores and batches omitted, but also no customer complaint is generated, and the product has strong practicality; when compared with traditional methods in which waistlines and main tiles are produced and tiled respectively, the method of the invention can produce the integral product which omits tiling manpower, is simple in construction, and convenient for popularization.

Owner:FOSHAN DONGPENG CERAMIC +3

Ink-jet dry granular decorative ceramic tile and manufacturing method thereof

The invention relates to the technical field of ceramic tiles, in particular to an ink-jet dry granular decorative ceramic tile and a manufacturing method thereof. The manufacturing method includes the following steps: A. bottom glaze decoration; B. pattern decoration; C. drying for the first time; D. dry granular decoration; E. spraying a protective glaze; and F. calcining to obtain the product.The method for preparing the dry granular decorative ceramic tile has the advantages of simple operation steps, convenient control, simplified process flow, improved production efficiency, reduced production difficulty and production cost, so that the method is suitable for industrial large-scale production; by spraying with dry granular ink, spray printing can be carried out on a designated position on the surface of a blank body, so as to enable a spray printed texture to be accurately correspond to a pattern decorative texture, and thus the distribution uniformity and adhesion of dry granules on the surface of the blank body are improved, and the prepared ceramic tile product has clear and distinct patterns, low glaze gloss, good anti-skid effect, obvious dry granular feeling, strong stereoscopic impression, rich colors, stable physicochemical properties and wide temperature adaptation range.

Owner:JIANGXI HEMEI CERAMICS +3

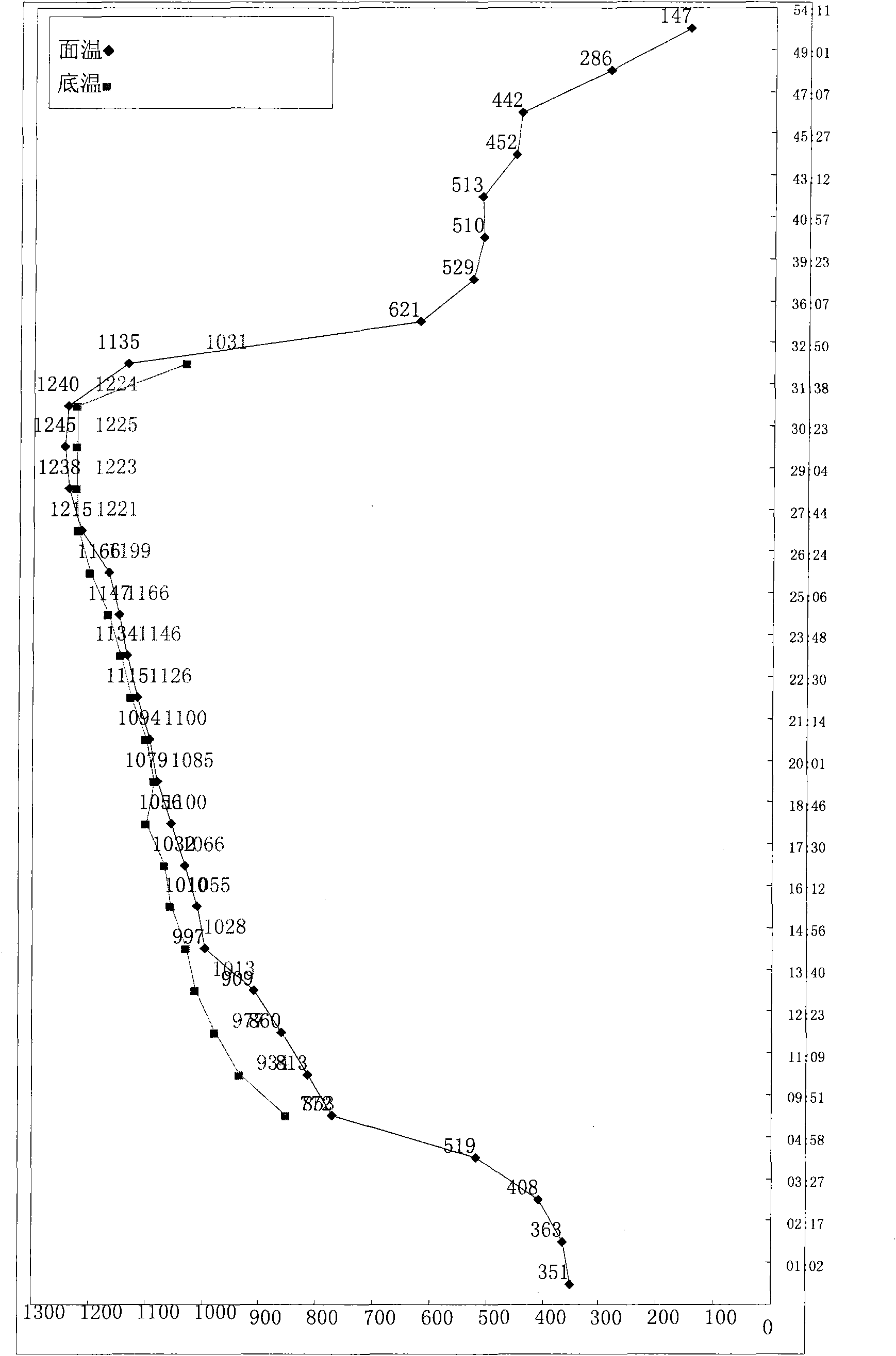

Preparation method of carbon-golden metallic luster crystalline glaze

The invention relates to a preparation method of a carbon-golden metallic luster crystalline glaze. The carbon-golden metallic luster crystalline glaze comprises the following component in parts by mass: 25-30 parts of MnO2 as crystallizing agent, 0.5-1.5 parts of MoO2, 0.5-1.5 parts of V2O5 as crystallization accelerator, 2-4.5 parts of CuO, 2.5-5 parts of Fe2O3, 3-7 parts of ZnO and 0.5-2.5 parts of NiO as colorants, 30-38 parts of potash feldspar produced in Pingjiang, 5-12 parts of quartz produced in Fengyang, 5-10 parts of talcum powder produced in Wuxi, and 5-12 parts of boron fusion cake produced in Yixing. The prepared glaze slip is applied onto a biscuited green body, and subjected to glaze firing according to the temperature curve in the invention. The carbon-golden metallic luster crystalline glaze has carbon-golden metallic luster, rainbow effect and beautiful appearance of crystals. Besides, the carbon-golden metallic luster crystalline glaze has the advantages of low cost, high glaze hardness, high wear resistance and high corrosion resistance, is a brand new glaze of ceramic art, and can be used for decorating ceramic artware.

Owner:山西高陶瓷业有限责任公司 +1

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

Ceramic rock plate and preparation method thereof

ActiveCN111470848AImprove plasticityGood molding effectCeramic materials productionClaywaresGlazeSpray dried

The invention relates to a ceramic rock plate and a preparation method thereof. A ceramic rock plate blank is composed of the following components in percentage by weight: 35-46.1% of mud; 50 to 60 percent of a water abrasive; 1-7% of a green body toughening material; 0.5 to 3 percent of a reclaimed material; and 0.1-0.8% of an additive. The preparation method comprises the following steps: preparing a green body, processing the green body, performing spray drying to prepare powder, performing dry pressing to form the green body (with a plane or concave-convex effect), drying, polishing the green body, blowing ash, spraying water, spraying white ink, spraying engobe, decorating patterns, decorating isolation glaze, decorating a transparent glaze layer, firing, polishing and edging.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD +3

Antiseep glaze material and glair for Ruyao kiln package container and preparing method thereof

InactiveCN101058476AImprove the anti-leakage effectGet rid of the status quo of pure handicraftsGlazeKaolin clay

The invention discloses an antiseptic glaze, slip and making method for herporcelain ash embryo, which comprises the following parts: 16-30% feldspar, 6-17% quartz, 12-26% calcite and 38-55% caoline, wherein the herporcelain packing container of antiseptic glaze slurry is composed of 5. 3% feldspar, 2-8. 5% quartz, 4-13% calcite, 12. 6-27. 5% caoline and 50-67% water. The invention can contain liquid material, which can also be ornamental craft.

Owner:王振芳

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

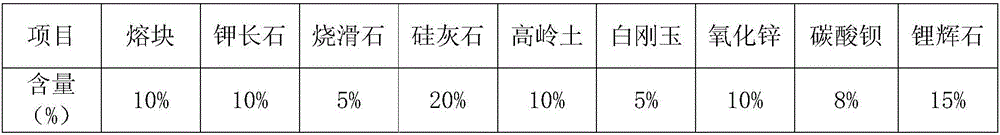

Magic star stone glazed brick with surface aventurine effect and preparation method thereof

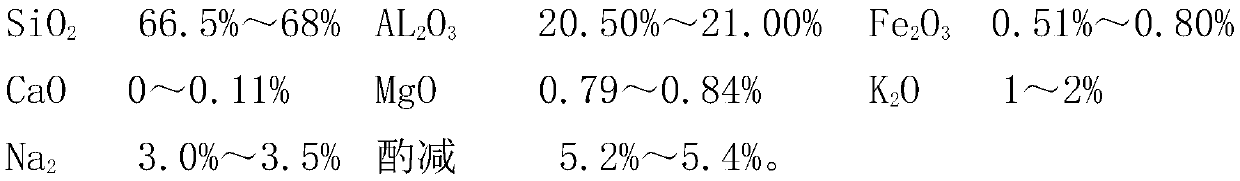

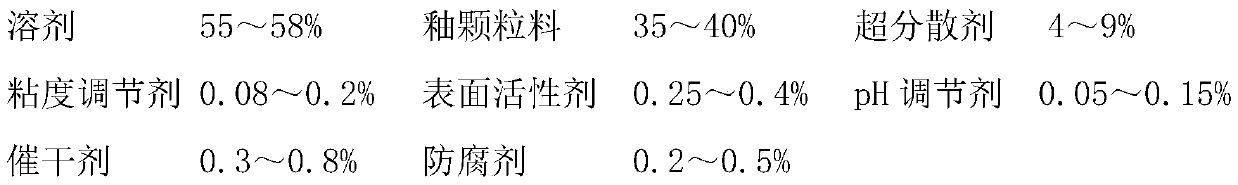

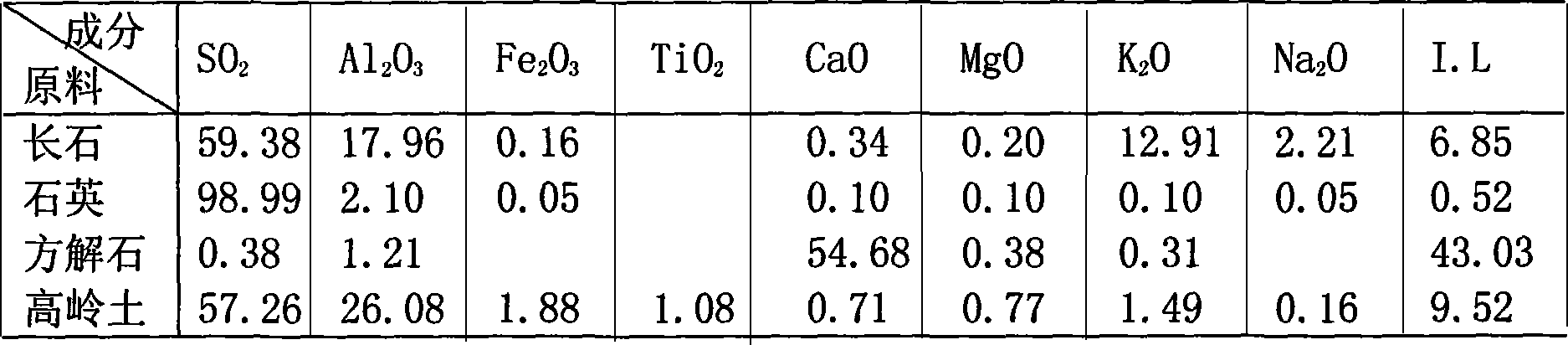

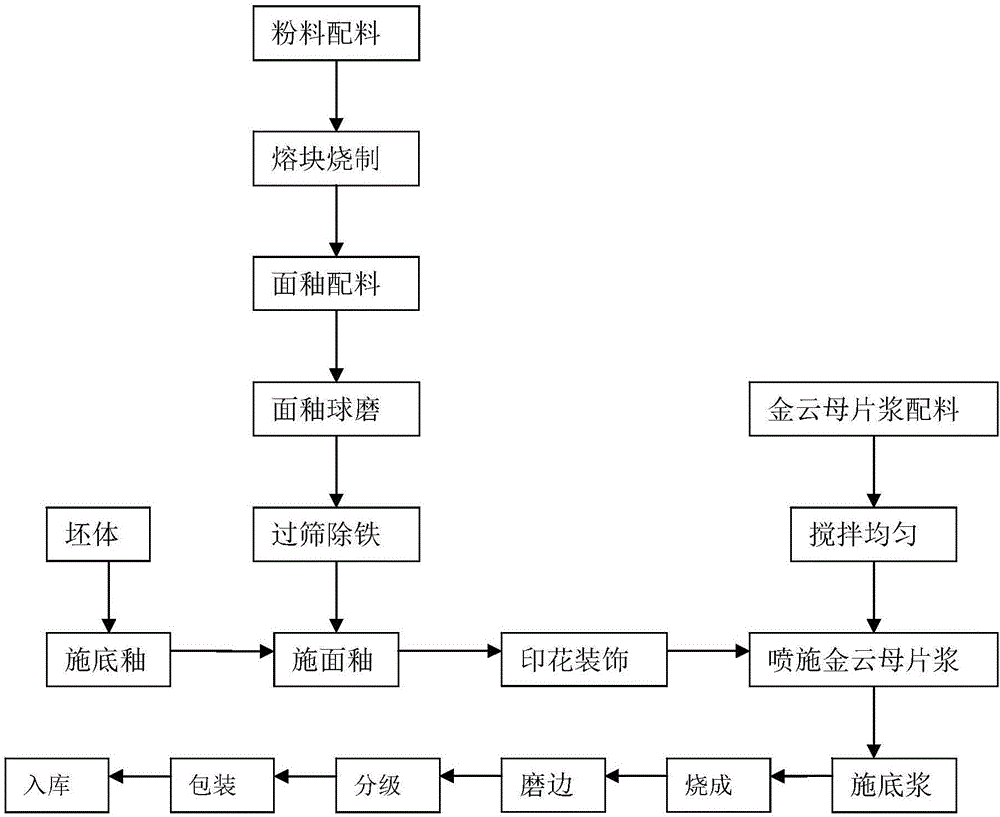

The invention relates to a magic star stone glazed brick with surface aventurine effect, and provides a magic star stone glazed brick with surface aventurine effect and a preparation method thereof. The magic star stone glazed brick comprises a frit, a surface glaze and a gold mica sheet slurry. The magic star stone glazed brick has the advantages that on the basis of not performing major change on the production technology of the existing glazed brick, the formula composition of the frit, the formula composition of the surface glaze, the formula composition of the gold mica sheet slurry, the optimum selection of granularity of gold mica sheet, the glaze applying technique, the slurry applying technique and the like are adjusted and optimized, so that the surface of the prepared magic star stone glazed brick is matte, and the luster of the surface of the product is measured by a WGG60-E4 luster meter and is 8 to 12; under the light radiation condition, the gold mica sheet at the surface of the product, such as mica or hematite small sheets in the aventurine, is glittering, magic and elegant, so that the special decorativeness and artistry are realized; the technique has higher universality, and is suitable for being popularized in industry.

Owner:GUANGDONG WINTO CERAMICS +3

Crystal glaze ceramic tile and production method thereof

The invention relates to a crystal glaze ceramic tile and a production method thereof. The method comprises the following steps: distributing a crystal clinker and seed crystal on a conventional ceramic tile blank, heating to 1130-1200 DEG C, and insulating for 10-30 minutes; then, cooling to 1000-1080 DEG C, and insulating at the temperature for 1-2 hours to prepare the crystal glaze ceramic tile with a remarkable crystal flower effect. An artistic decoration effect with large and round crystal flower and diversified patterns and colors can be achieved by utilizing the crystal glaze ceramic tile; a crystal glaze ceramic of which flowing stripes are arranged on the surface, and an artistic aesthetic value can be remarkably increased. When the crystal clinker is prepared, the smelting temperature is low, and the smelting time is short; when the crystal glaze ceramic tile is fired, the firing temperature is low, and the required crystallization time is short, so that the production energy consumption is remarkably reduced, the firing cycle is shortened, the production cost is reduced, the waste emission amount in the production process is reduced, and excellent economic and social benefits can be brought.

Owner:HANGZHOU NABEL CERAMIC

Anti-sliding glaze, anti-sliding brick and preparation method thereof

The invention discloses an anti-sliding glaze which contains the following chemical components by weight percent: 42.8%-48.5% of SiO2, 19.1%-22.8% of Al2O3, 0.1%-0.2% of Fe2O3, 7.0%-9.5% of CaO, 2.5%-5.2% of MgO, 2.1%-8.6% of Na2O, 0.9%-4.1% of K2O, 1.1%-3.3% of ZnO and 2.8%-6.2% of ZrO2. The invention also discloses an anti-sliding ceramic tile and a preparation method for the anti-sliding ceramic tile. The anti-sliding ceramic tile disclosed by the invention can achieve an excellent anti-sliding effect after a layer of anti-sliding glaze is applied to the surface of the anti-sliding ceramic tile, the technology is simple and the cost is low.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

Three-dimensional high simulation ceramic tile with matte glaze surface and preparation method thereof

ActiveCN108727037AExtended service lifeGood three-dimensionalCeramic shaping apparatusAdobeComputer printing

The invention discloses a three-dimensional high simulation ceramic tile with matte glaze surface and a preparation method thereof, the method comprising the following steps: 1) adopting a laser four-dimensional fine carving system to finely carve a digital mold; 2) Positively pressing green body molding; 3) Controlling the water absorption rate of the ceramic tile before glazing at 15%-20% by controlling the drying temperature of the ceramic tile adobe or the biscuiting temperature of the ceramic tile adobe; 4) spraying a small amount of high-titanium impervious ground coat under high pressure; 5) spraying a small amount of matte glaze under high pressure; 6) using a digital ink jet printer to print decorative ink and functional ink; 7) decorating the dry particle frit, and adopting a controllable negative pressure absorbing dry particle frit equipment to absorb excess dry particle frit; 8) sintering to obtain the three-dimensional high imitation ceramic tile with matt glaze surface,the preparation method provided by the invention obtains the three-dimensional high simulation ceramic tile with matte glaze surface with three-dimensional simulation, 2-6 glossy units of glaze surface gloss and lifelike surface decoration effect through the collaborative and innovative preparation including mold sculpture, glaze formula control, high-pressure glaze spraying and effect decoration.

Owner:广东协进陶瓷有限公司

Composite glaze, composite glaze slip and 4-8 degree soft-surface wear-resistant porcelain antique brick

The invention relates to a composite glaze, a composite glaze slip and a 4-8 degree soft-surface wear-resistant porcelain antique brick. The composite glaze slip comprises the following components inparts by mass: 51-55 parts of a high temperature matte transparent wear-resistant frit, 35-39 parts of matte transparent component glaze, and 7-11 parts of wear-resistant antiskid dry particles, and the sum of mass of the three components is 100 parts. After the composite glaze is sintered, a soft-surface wear-resistant glaze layer whose glossiness is 4-8 degrees is formed.

Owner:MONALISA GRP CO LTD

Basic glaze for ink jet printing, preparation method of basic glaze, and ceramic tile

The invention discloses a basic glaze for ink jet printing, a preparation method of the basic glaze, and a ceramic tile. The basic glaze for the ink jet printing comprises the following chemical components by weight percentage: 2.0-3.0% of igloss, 13.0-17.0% of aluminium oxide, 64.0-69.0% of silicon dioxide, 0.05-0.2% of ferric oxide, 0.3-0.9% of calcium oxide, 3.0-6.0% of magnesium oxide, 1.4-2.0% of potassium oxide, 1.4-2.0% of sodium oxide, 0.03-0.10% of titanium oxide, 5.0-10.0% of zirconium dioxide and hafnium oxide, 0.01-0.2% of lithium oxide, and 0.1-2.0% of zinc oxide. The basic glaze for the ink jet printing is free from such defects as deformation, bubbles, pin holes, sewage suction and poor color when an ink jet printing technique is used, and a fabricated product has good color, the surface of a glazed tile is fine and smooth, and the product quality and effect can be improved.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

Light-permeable tile and preparation method thereof

The invention relates to a light-permeable tile and a preparation method thereof. The light-permeable tile comprises a semi-light-permeable green body with light-impermeable colored particles inside, color emitting assistant clear glaze and patterns sequentially from bottom to top. Due to the light-impermeable colored particles in the green body of the light-permeable tile and in combination with appropriate colorful patterns, a ceramic product with a special hazy effect and strong stereoscopic impression can be formed. Moreover, with the color emitting assistant clear glaze, the emitted color of the patterns is brighter, and the color development effect is better. Compared with the non-transparency of common polished tiles and rustic tiles, the light-permeable tile provided by the invention can form a unique decoration effect in combination with certain light.

Owner:MONALISA GRP CO LTD

Wear-resistant antiskid glaze and preparation method thereof as well as preparation method of wear-resistant antiskid tile

The invention discloses a wear-resistant antiskid glaze and a preparation method thereof as well as a preparation method of a wear-resistant antiskid tile. The wear-resistant antiskid glaze comprises fused block glaze powder and Al2O3 with a corundum structure, and specifically comprises the following components in percentage by weight: 25-40% of SiO2, 40-60% of Al2O3, 1-5% of K2O+Na2O, 1-10% of CaO, 1-5% of MgO, 1-15% of BaO and 1-10% of ZnO. The wear-resistant antiskid glaze disclosed by the invention is simple to operate and the effect of the original decorative patterns is not influenced; by adopting the glaze produced by the preparation method to form a glaze layer on the surface of a ceramic tile body, after high-temperature firing, the tile has a good antifouling wear-resistant antiskid effect and a wide application range; wear-resistant antifouling antiskid glazes with different bases can be selected according to the firing temperature (1100-1230 DEG C) of ceramic tiles, and are matched with an original artwork design to produce wear-resistant antifouling antiskid tiles meeting requirements.

Owner:GUANGDONG SANSHUI TANDH GLAZE CO LTD

Glass ink for ink-jet printing and preparation method of glass ink

The invention discloses glass ink for ink-jet printing and a preparation method of the glass ink. The glass ink is prepared from the following main components: glass glaze, pigment, a solvent, a dispersing agent, a wetting agent and a stabilizing agent. The preparation method comprises the following steps: preparing the above raw materials, preparing the solvent, mixing the glaze and the pigment, grinding mechanically, thereby obtaining a finished product. The glass glaze and the pigment are crushed to be required particle sizes by using a step-by-step crushing method, and are further combined with additives to prepare the glass ink for ink-jet printing. The glass ink disclosed by the invention is stable in color, not easy to precipitate, good in stability, simple in process, low in requirement for equipment and applicable to industrialization production.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

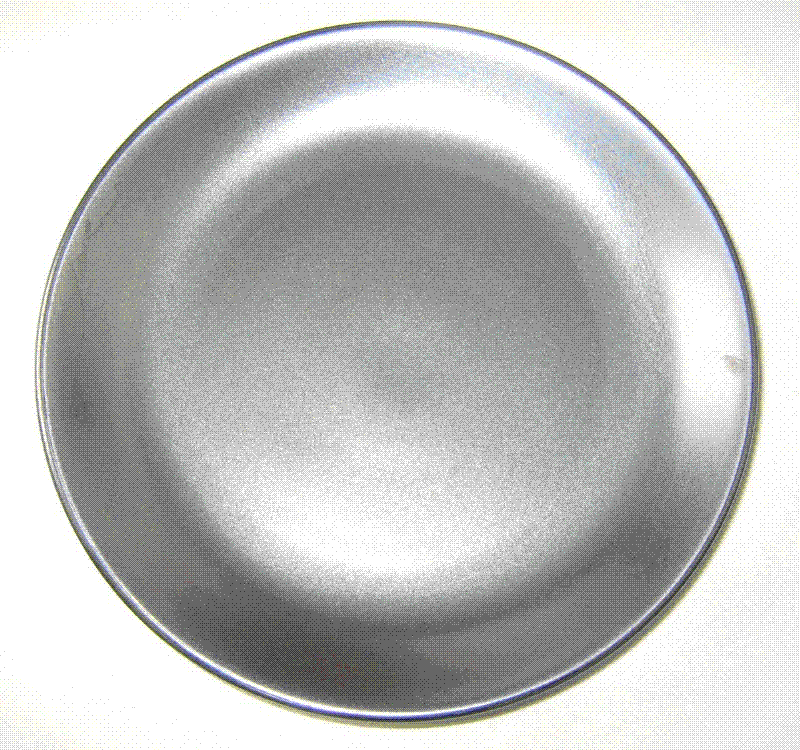

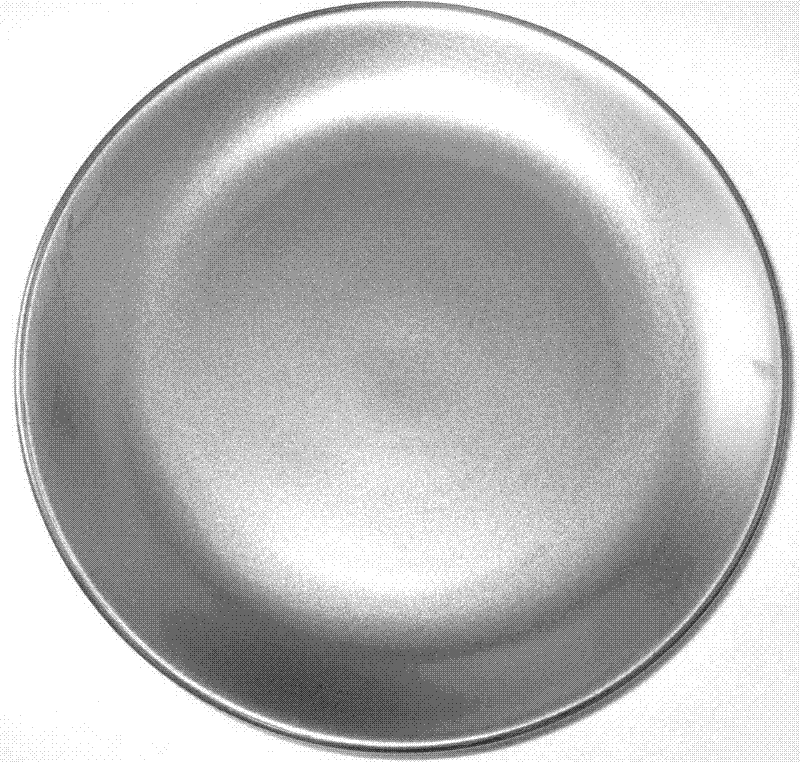

Low-gloss transparent glaze, ceramic tile using low-gloss transparent glaze and preparation method of ceramic tile

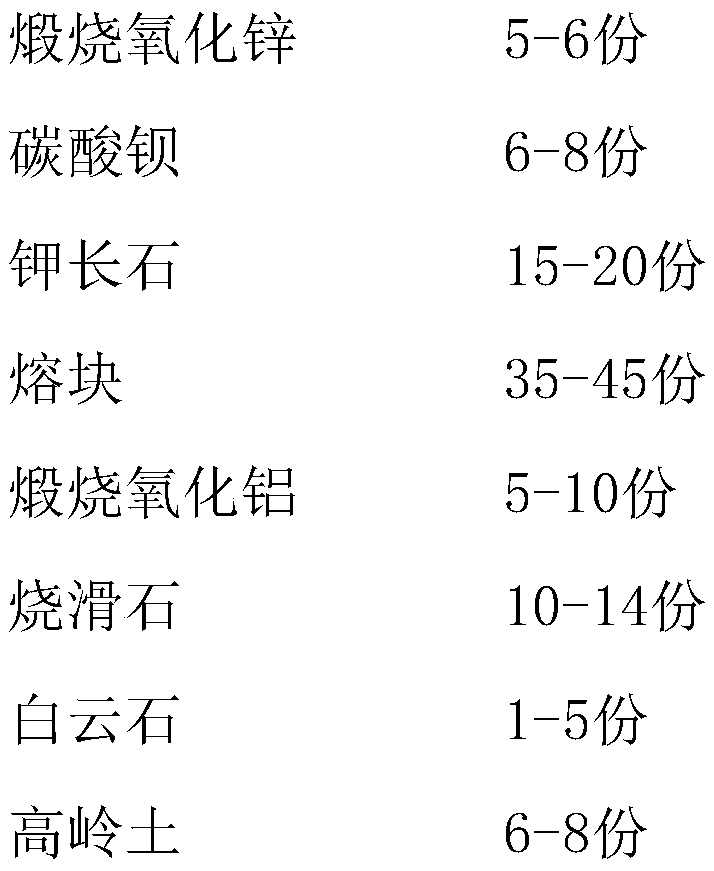

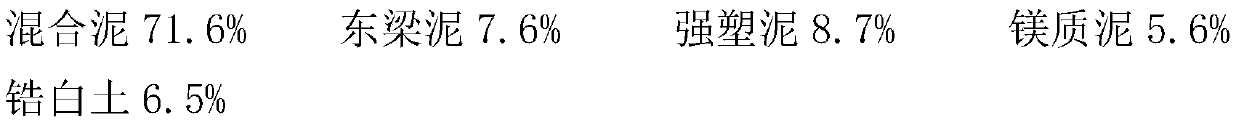

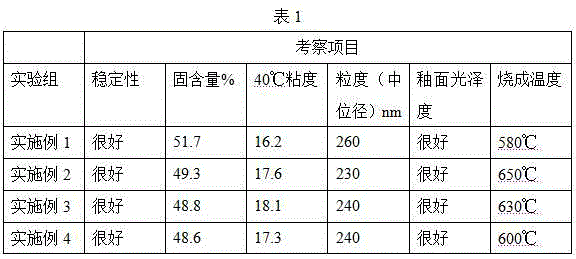

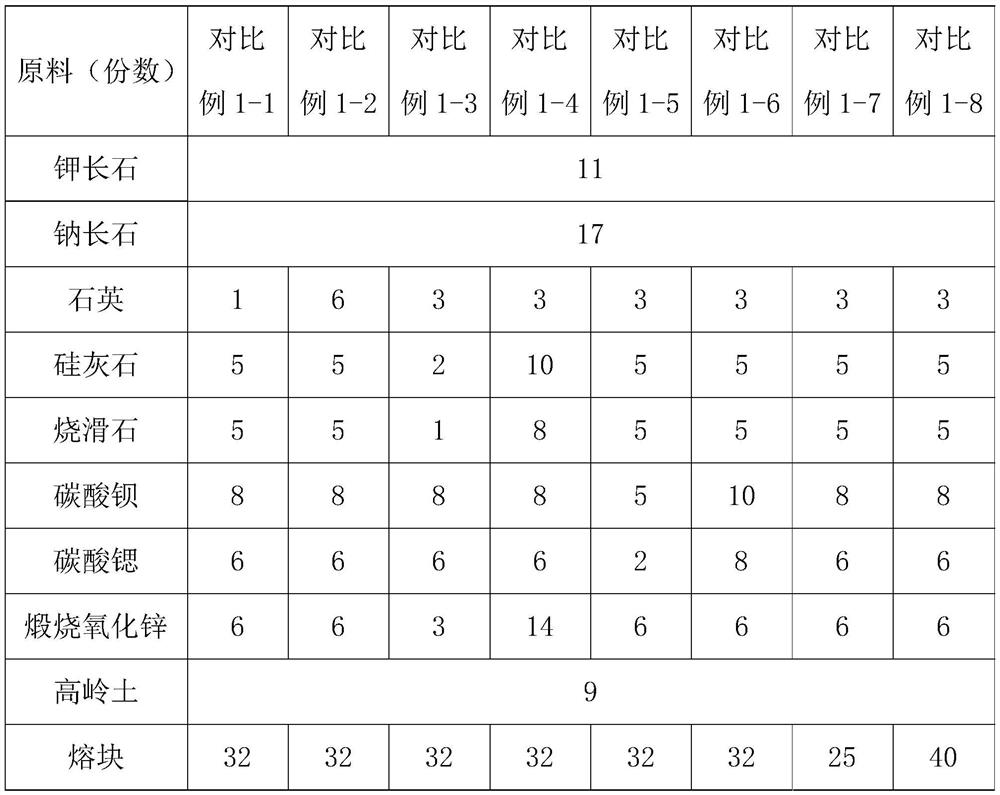

The invention discloses low-gloss translucent glaze, a ceramic tile using the low-gloss translucent glaze and a preparation method of the ceramic tile. The low-gloss transparent glaze is prepared from the following raw materials in parts by mass: 26-30 parts of feldspar, 2-4 parts of quartz, 4-6 parts of wollastonite, 4-6 parts of calcined talc, 7-9 parts of barium carbonate, 5-7 parts of strontium carbonate, 5-7 parts of calcined zinc oxide, 8-10 parts of kaolin and 30-33 parts of frit. According to the low-gloss transparent glaze provided by the technical scheme, the surface gloss of a fired glaze layer is low, the 3D layering sense is clear, the color development range of the glaze is wide, the production cost is low, and the defects in the prior art are overcome. The invention further provides a preparation method of the ceramic tile using the low-gloss transparent glaze, which has the advantages of simple steps and high operability, and is beneficial to ensuring the stable color development of the ceramic tile and enhancing the 3D stereoscopic effect of the ceramic tile. The technical scheme further provides the ceramic tile prepared by the preparation method of the ceramic tile, and the ceramic tile is stable in color development and strong in transparency.

Owner:肇庆乐华陶瓷洁具有限公司

Glaze capable of releasing negative ion, preparation and use method thereof

The invention discloses a glaze which can generate negative ion and is characterized in that: the prescription of the glaze also contains a stimulating material that can generate tourmaline microcrystalline structures and an energy transferring material. The main composing scope (proportion by weight) of the prescription of the glaze is as follows: SiO2: 40 percent to 70 percent, Al2O3: 5 percent to 15 percent, K2O+Na2O: 5 percent to 10 percent, CaO: 0.1 percent to 12 percent, MgO: 0.1 percent to 10 percent, ZnO: 0.1 percent to 10 percent, B2O3: 0.1 percent to 10 percent; the stimulating material: 0.1 percent to 10 percent and the energy transferring material: 0.1 percent to 10 percent. The preparation method of the invention comprises the following steps: first, fusion cakes is prepared; the materials of the prescription are mixed in mixture ratio and fused and then quenched rapidly to prepare into the fusion cakes; second, sintering is carried out after the fusion cakes are prepared; finally, finished products are obtained by grinding. The application method of the glaze is that: 2 percent to 15 percent of the glaze is added to a glaze of a building sanitary ceramics and goes through glaze application and then is sintered into glaze at 800 DEG C to 1300 DEG C. The glaze of the invention has the advantages of having good release effect of the negative ion, and being environmental-friendly, etc.

Owner:GUANGDONG SANSHUI TANDH GLAZE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com