Patents

Literature

45results about How to "Short firing cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

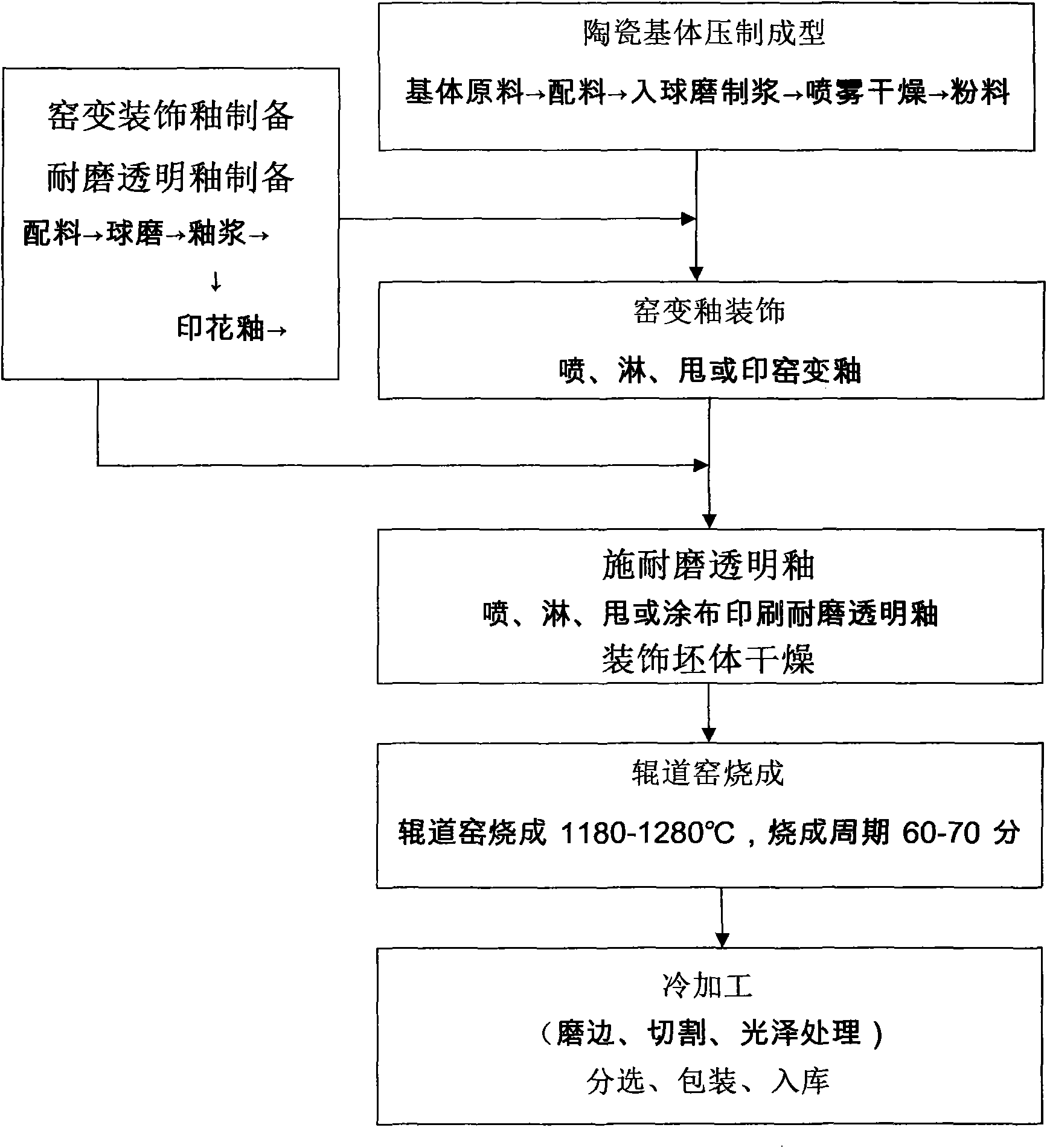

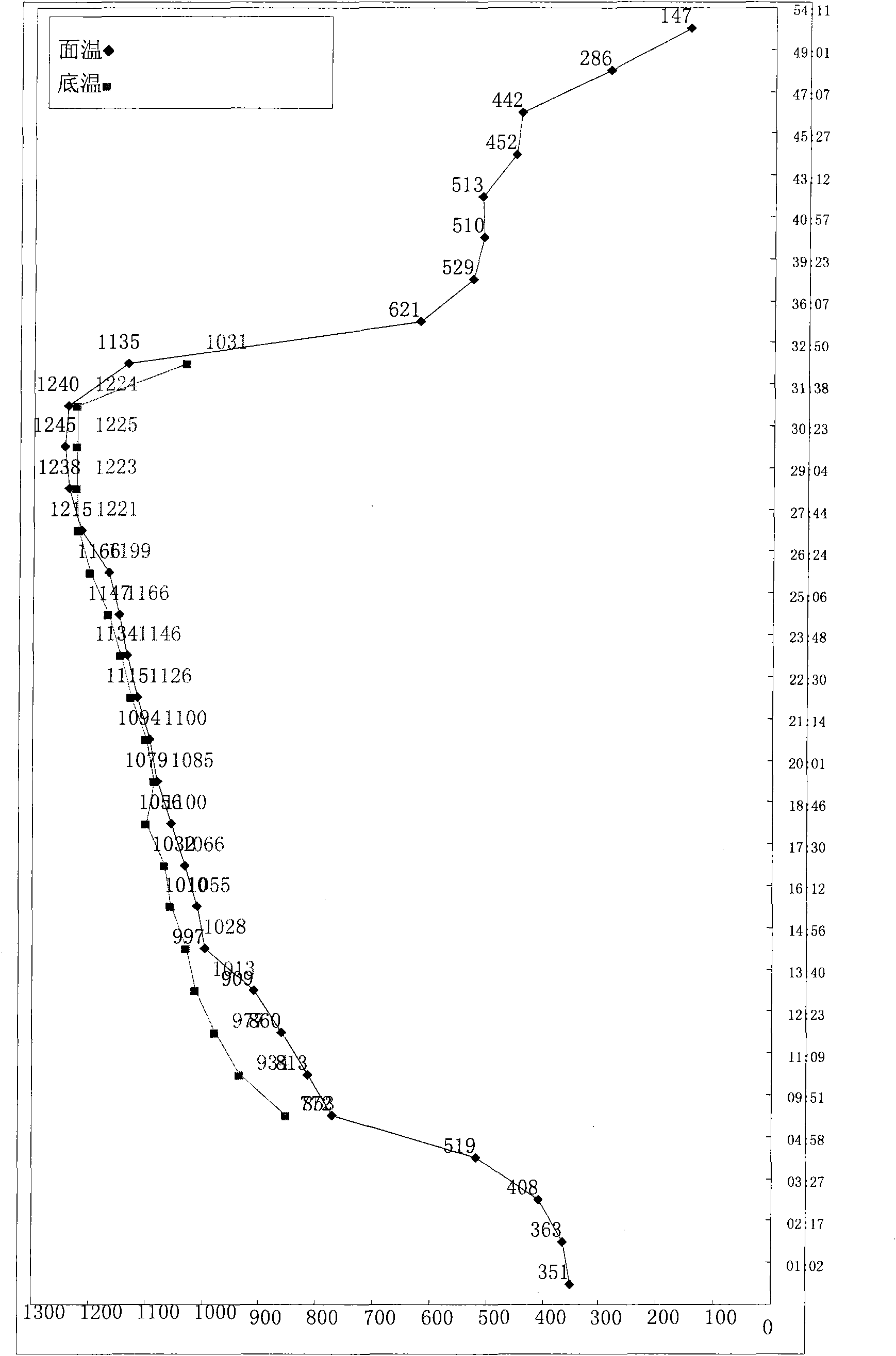

Furnace transmutation decoration glazed brick and production technology

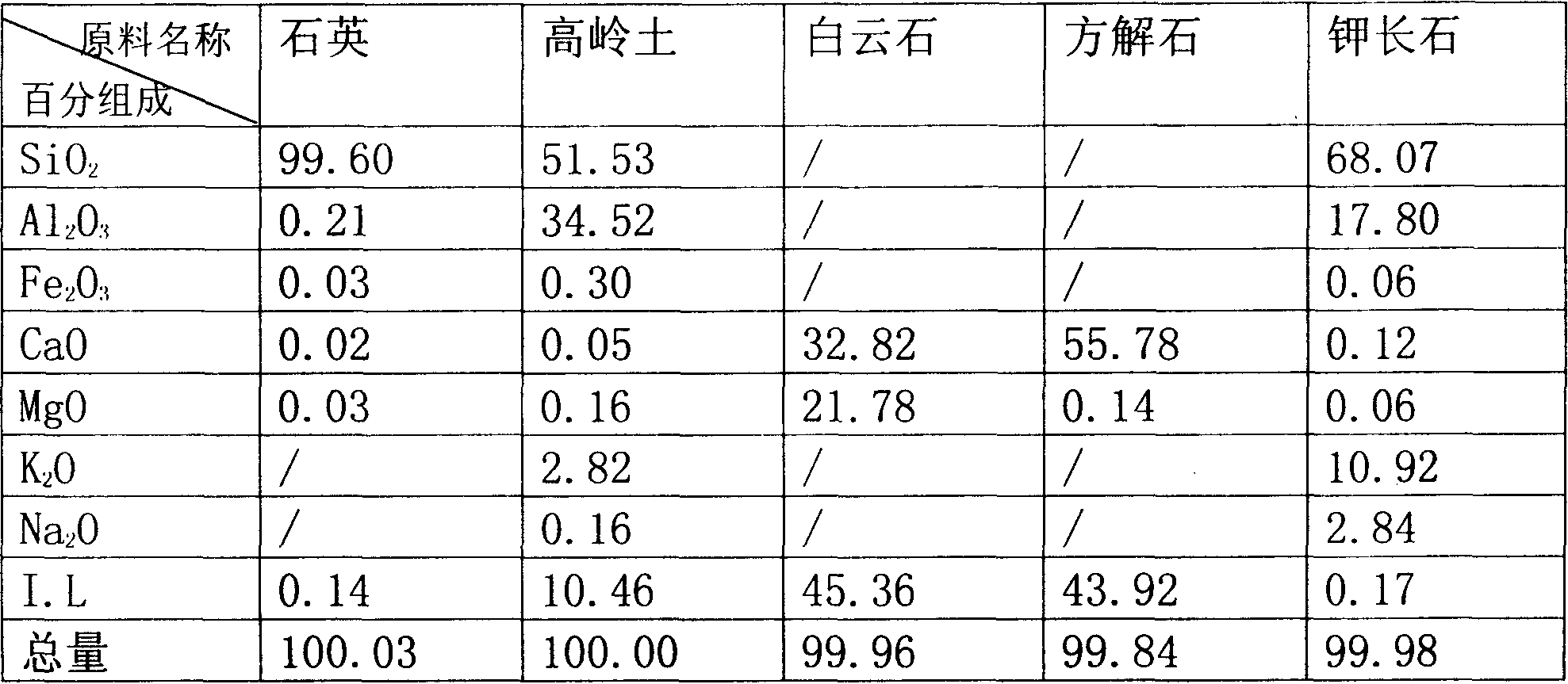

The invention relates to a furnace transmutation decoration glazed brick and a production technique thereof. The furnace transmutation decoration glazed brick is prepared from the following componentsin percentage by weight: 10-30% of albite, 3-10% of spodumene, 5-10% of kaoline Al2O3.2SiO2.2H2O, 8-30% of zinc oxide ZnO, 3-10% of talc 3MgO.4SiO2.H2O, 0-20% of titanium TiO2, 3-10% of zirconite ZrSiO, and 1-10% of coloring metallic oxide MnO2, V2O5, Fe2O3 and CoO2. The production technique of the furnace transmutation decoration glazed brick comprises the following steps: (1) shaping the substrate of the furnace transmutation decoration glazed wall and floor bricks; (2) decorating the wall and floor brick substrate surface or anti-abrasion transparent glaze layers and drying; and (3) sintering the furnace transmutation decoration glazed wall and floor bricks once in a high-temperature roller kiln.

Owner:黄建平

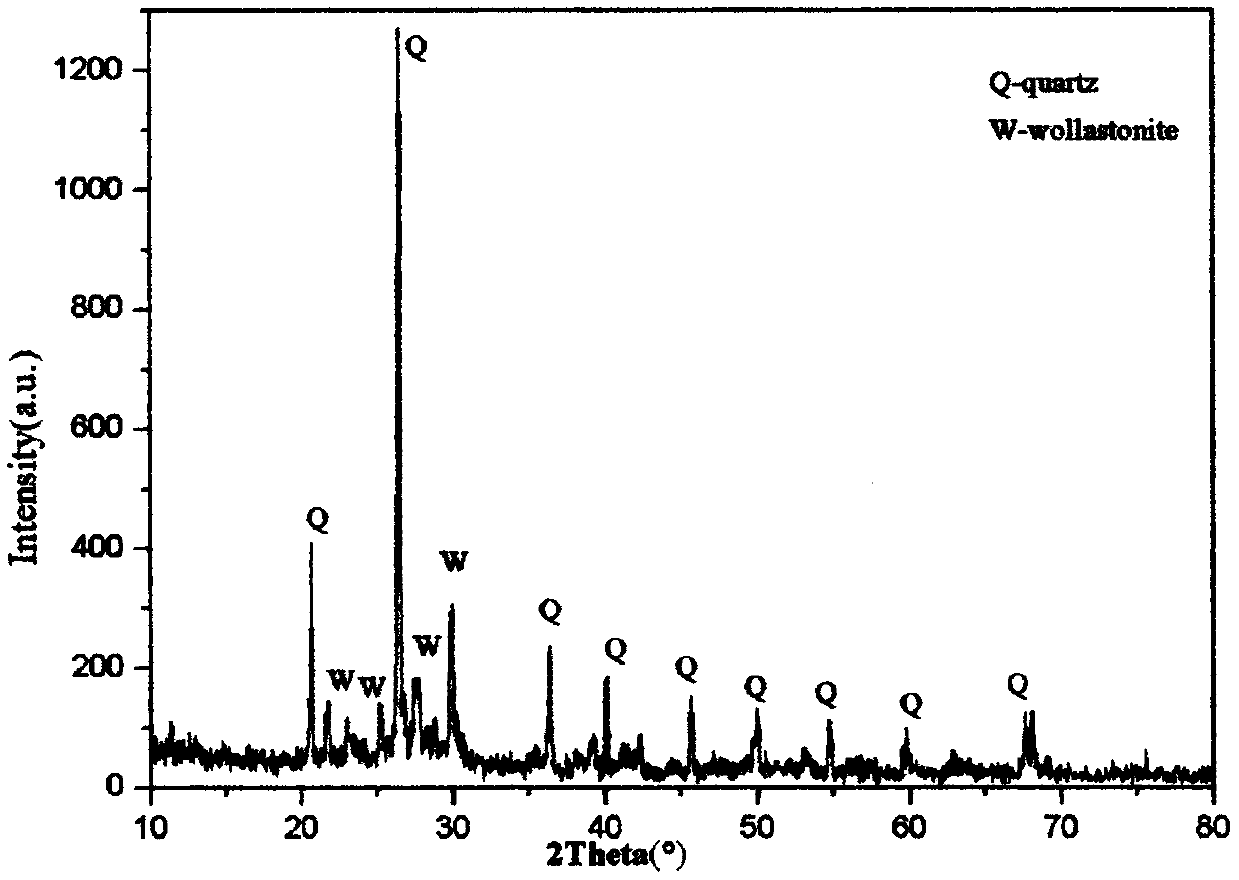

Quick fired fine ceramics made in open flame roller hearth kiln and technical method

The present invention is a new ceramic material and new producing technology. The quick fired fie ceramic is produced with the material including kaolin 20-55 wt%, feldspar 10-20 wt%, and quartz 35-60 wt%, and through quick high temperature biscuit firing in an open flame roller hearth kiln and low temperature glaze firing. The low temperature glaze firing in reducing atmosphere can obtain bright and soft glaze with high transmittance, and product with high impact strength, high heat impact strength and high acid and alkali resistance; and the low temperature glaze firing in oxidizing atmosphere can obtain bright glaze without pinhole. The present invention has simple technological process, low cost, great output and low power consumption, and may be applied widely in ceramic industry.

Owner:张民

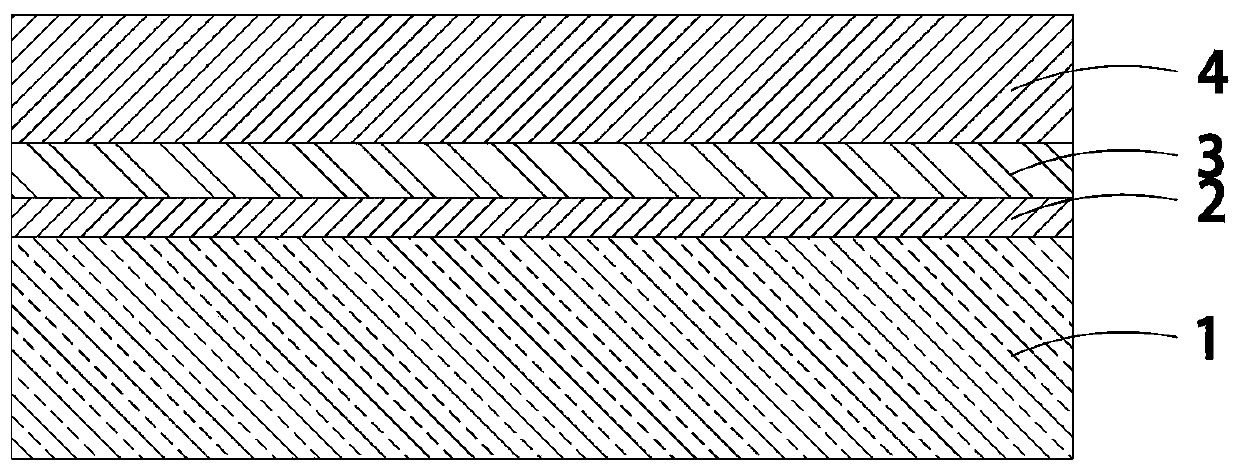

Preparation method of wet-process dry-grain polished crystal brick and polished crystal brick

ActiveCN110981197AEasy to recycleEasy to adjust the glaze amountCeramic shaping apparatusTextile printerProduction line

The invention discloses a preparation method of a wet-process dry-grain polished crystal brick and the polished crystal brick. The preparation method comprises the following steps: preparing a green brick; performing drying for the first time; applying surface glaze; performing ink-jet printing; applying dry particle protective glaze; performing drying for the second time; and performing firing and molding. The wet-process dry-grain polished crystal brick sequentially comprises a green brick layer, a cover glaze layer, a printing layer and a dry-grain protective glaze layer from bottom to top.The polished crystal brick with excellent performance is prepared by controlling production process parameters and the setting of proper components and proportion of dry particles and dry particle protective glaze. The method is suitable for existing production equipment, and a production line does not need to be modified; a glaze spraying process is adopted, a glaze layer is more uniform, and abell jar is adopted for glaze spraying, so that the glaze amount is more convenient to adjust, and the recycle is easy; the required glaze layer is thinner and is only 1 / 5 of the dosage of dry-processdry particles, so that the dosage is lower, the firing period is shorter, the production cost is reduced, and the production efficiency is improved; meanwhile, compared with a dry method, the defectsof bubbles, pinholes and the like of the glaze layer are fewer, and color development is finer and richer.

Owner:FOSHAN OCEANO CERAMICS

Novel microcrystallite glass-ceramic composite brick and production method thereof

The invention discloses a novel microcrystallite glass-ceramic composite brick and a production method thereof. The production method comprises the following steps of: (1) preparing low-viscosity glass clinker and high-viscosity glass clinker; (2) preparing microcrystallite glass-ceramic composite brick blank powder for later use by the conventional method; (3) preparing a microcrystallite glass-ceramic composite brick substrate by using the obtained microcrystallite glass-ceramic composite brick blank powder for later use; (4) preparing the microcrystallite glass-ceramic composite brick; and (5) performing aftertreatment. The prepared microcrystallite glass-ceramic composite brick is low in firing temperature, and short in firing period; energy consumption can be reduced greatly, emission is reduced, and preparation cost is saved; the surface of the prepared microcrystallite glass-ceramic composite brick has a small amount of blowholes; and the prepared microcrystallite glass-ceramic composite brick is high in soil resistance, and abrasive resistance, and can fully meet the requirement of using performance.

Owner:HANGZHOU NABEL CERAMIC

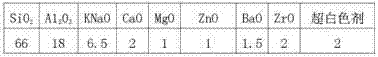

Formula for environment-friendly energy-saving low-temperature white semi-porcelain and method for preparing the same

ActiveCN104944912ASolve the problem of high firing temperatureReduce energy consumptionClaywaresThermal stabilityDolomite

The invention relates to the technical field of low-temperature white semi-porcelains and preparation thereof and discloses a formula for an environment-friendly energy-saving low-temperature white semi-porcelain and a method for preparing the same. In the formula of the low-temperature white semi-porcelain, the low-temperature white semi-porcelain comprises, by weight parts, 6-10 parts of spodumene, 13-17 parts of albite, 8-12 parts of talc, 3-7 parts of dolomite, 8-12 parts of quartz, 18-22 parts of washed kaolin, 10-14 parts of black soil, 18-22 parts of clay and 0.0002-0.0003 part of brightener. The formula and the preparation method for preparing the low-temperature white semi-porcelain not only reduce sintering temperature and sintering time of porcelain products, but also improve thermal shock resistance and thermal stability of the porcelain products; the low-temperature white semi-porcelain is low in water absorption and high in strength, the unit energy consumption is reduced, national environmental resources are protected, and the low-temperature white semi-porcelain is green and environmentally friendly.

Owner:JIEDONG COUNTY YI CHENG CERAMIC IND

Method for producing microcrystalline jade panel with iridescent entire body by utilization of roller kiln

A method for producing a microcrystalline jade panel with the iridescent entire body by the utilization of a roller kiln comprises the following steps: (1) microcrystalline glass frits in multiple colors are prepared; (2) a chromophoric auxiliary agent is prepared; (3) a kiln furniture is manufactured; and (4) the above microcrystalline glass frits in all colors are distributed through an automatic distribution device on a fireproof backing plate according to a predetermined mode for 1-5 times, and the chromophoric auxiliary agent is applied occasionally to make the total thickness of the frits reach 12-40 mm; and the frits are fired in a roller kiln. The firing period is 2-8 hours. The firing curve is as follows: the temperature rises from normal temperature to 800-1050 DEG C within 30-120 min; the temperature rises to 1000-1250 DEG C within 60-240 min; the temperature cools to 850-580 DEG C within 90-360 min; and the temperature cools to normal temperature within 120-480 min before drawing. By the method, the produced microcrystalline jade panel with the iridescent entire body has natural iridescent patterns and entire texture effect as natural stones. The method has advantages of low production cost and high production efficiency.

Owner:范国雄

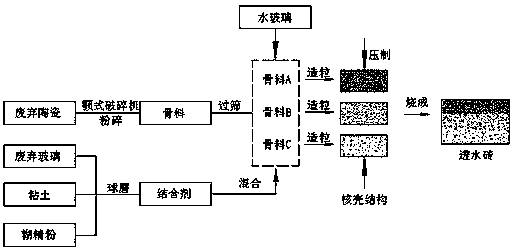

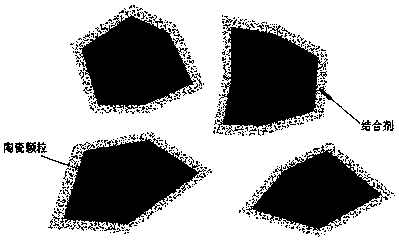

Preparation method of ceramic water-permeable brick suitable for low-temperature fast firing

ActiveCN108585781AHigh strengthImprove product qualityCeramic materials productionClaywaresPorosityBrick

The invention discloses a preparation method of a low-cost ceramic water-permeable brick suitable for low-temperature fast firing. The preparation method includes the steps that (1), after waste glassis subjected to batching, breaking, mixing and ball-milling, a uniform powder mixture is obtained, a small amount of dextrin powder, water and clay are used in assistance, prilling is carried out, and obtained materials serve as a binding agent of the water-permeable brick; (2), architectural ceramic and domestic ceramic waste and waste residues are broken to a certain granularity, and the obtained materials serve as aggregate of the water-permeable brick; (3), sodium silicate water glass is prepared to a certain concentration, then the sodium silicate water glass and the aggregate are fullymixed according to a certain proportion, and sodium silicate water glass coated aggregate is obtained; (4), after the prilled binding agent and the coated aggregate are batched according to a certainproportion, mixed and prilled, distributing-forming and sintering are carried out, finally, surface finishing is carried out, and the ceramic water-permeable brick is obtained. The surface hole diameter and porosity of the water-permeable brick are small, but the internal hole diameter and porosity of the water-permeable brick are large, the situation that surface pores are blocked is greatly reduced, and it is guaranteed that the water-permeable brick can continuously keep a high permeability rate.

Owner:JINGDEZHEN CERAMIC INSTITUTE

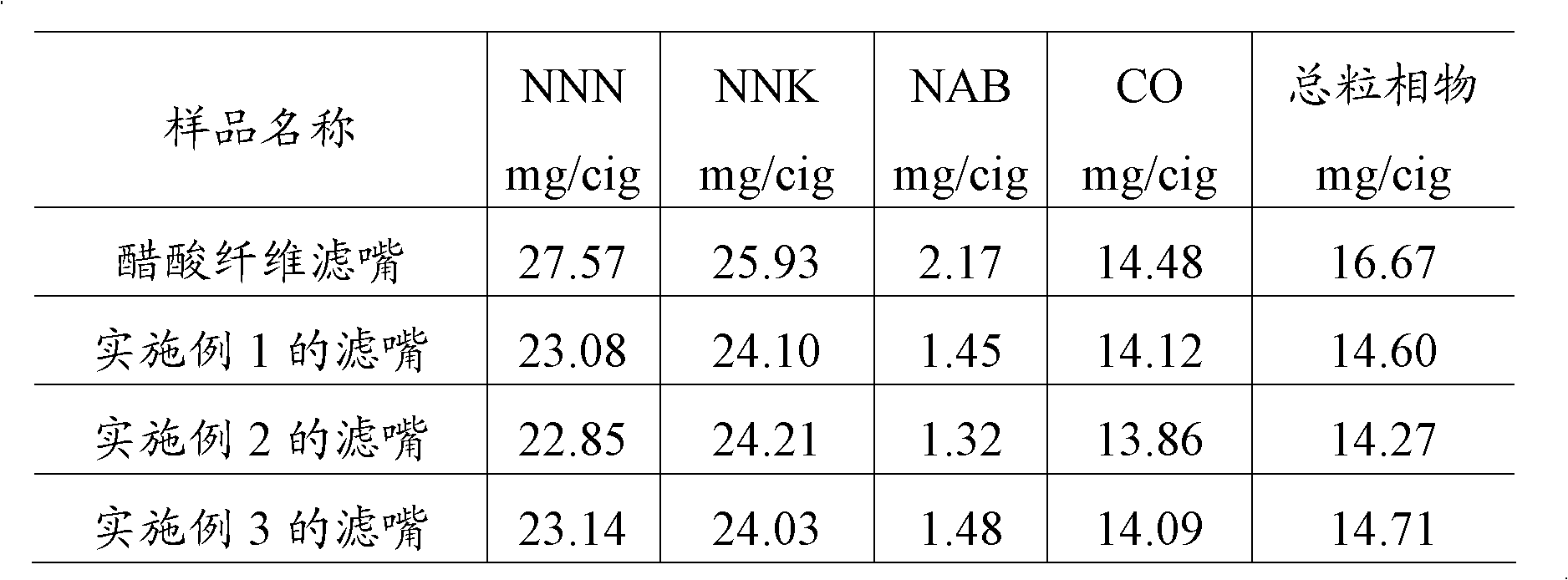

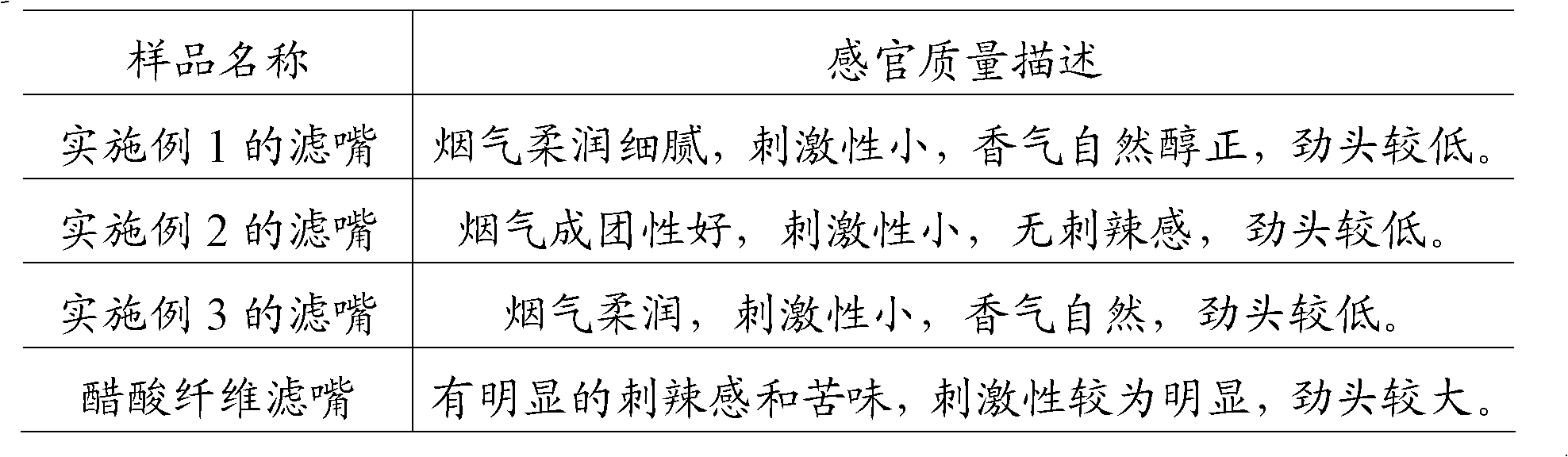

Bamboo charcoal fiber and preparation method thereof and application of bamboo charcoal fiber to cigarette filter tips

ActiveCN102302219AImprove adsorption capacityImprove adsorption efficiencyTobacco smoke filtersTarMaterials science

The invention relates to bamboo charcoal fiber and application of the bamboo charcoal fiber to cigarette filter tips. The bamboo charcoal fiber consists of superfine bamboo charcoal powder and a fiber formation material which are co-melted into filaments, wherein the superfine bamboo charcoal powder accounts for 0.1 to 15 percent based on the weight of the fiber formation material. The bamboo charcoal fiber is nontoxic and odorless, has strong adsorption capacity on tar in cigarette smoke, particularly small molecular harmful substances, and has high adsorption efficiency. The production process is simple and convenient, and additional equipment is not required to be arranged for the production and rolling connection of filter tips.

Owner:YUNNAN XINYUN TECH DEV CO LTD

Production method of microcrystalline glass-ceramic composite brick

ActiveCN104309215AImprove the decorative effectRaise the firing temperatureCeramic layered productsGlass/slag layered productsCeramic compositeBrick

The invention discloses a production method of a microcrystalline glass-ceramic composite brick. The production method comprises the following steps: (1) preparing a high-calcium raw material; (2) preparing a low-viscosity glass frit and a high-viscosity glass frit; (3) preparing powder of a green microcrystalline glass-ceramic composite brick through a conventional method; (4) preparing a microcrystalline glass-ceramic composite brick substrate from the powder of the green microcrystalline glass-ceramic composite brick prepared by the step (3) through a conventional method; (5) preparing a microcrystalline glass-ceramic composite brick; and (6) post-processing. The microcrystalline glass-ceramic composite brick prepared by the production method disclosed by the invention, through staggered distribution of crystallization regions and transparent and / or semitransparent regions, changes an original monotonous texture that has only crystallization patterns on the entire surface, and the brick is richer in pattern layering sense and better in decoration effect; the production method disclosed by the invention is lower in sintering temperature, shorter in sintering cycle, and capable of greatly reducing energy consumption, relieving emission and saving manufacturing cost; and the prepared composite brick has fewer surface pores, good anti-fouling performance and high wear resistance.

Owner:HANGZHOU NABEL CERAMIC

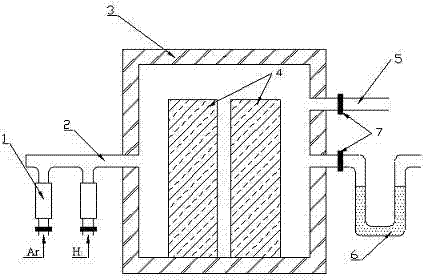

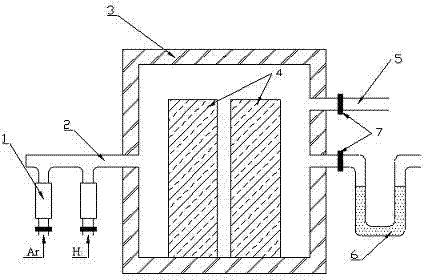

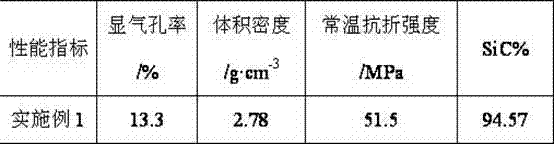

Sintering method of self-bonding SiC refractory material

The invention provides a sintering method of a self-bonding SiC refractory material. In the sintering method provided by the invention, pure H2 is introduced into a sintering furnace which is filled with a self-bonding SiC blank for serving as a protective atmosphere for material sintering, the sintering temperature is 1,400-1,500 DEG C, heat preserving time is not less than 5 hours, and a positive pressure difference in the furnace is not lower than that of a water column of 60 millimeters. The sintering method for a self-bonding SiC product provided by the invention has the advantages of safe and reliable operating process, capability of preparing a self-bonding SiC product with excellent performance and stable quality and capability of realizing large-scale production.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Technology for preparing ultra-low-temperature glaze and formula

The invention discloses a process for preparing an ultra-low-temperature glaze and a formula and belongs to the field of the development and application of glazes. The annealing temperature of the glaze is reduced by regulating the formula of the glaze. The process is characterized by preparing a novel low-temperature glaze by taking borax, weathered potassium-feldspar, calcium oxide and zinc oxide as raw materials. The glaze comprises the following components in percentage by mass: borax (0.3 to 0.9), weathered potassium-feldspar (0.05 to 0.35), calcium oxide (0.03 to 0.18) and zinc oxide (0.03 to 0.18). The sintering temperature can be adjusted between 700 and 1,050 DEG C by changing the content of the borax and keeping the content proportion of other components invariable. The preparation process comprises the following steps of: pre-treating a blank at first and then applying the glaze on the blank body to form a coating with the thickness of 0.3 to 0.8mm. The process and the formula have the advantages of no toxic or side effect of raw materials, low cost of raw materials, simple and practical preparation method, low sintering temperature, short temperature preservation time, great energy source conservation, high surface glossiness of the glaze and good decoration effect.

Owner:WUYI UNIV +1

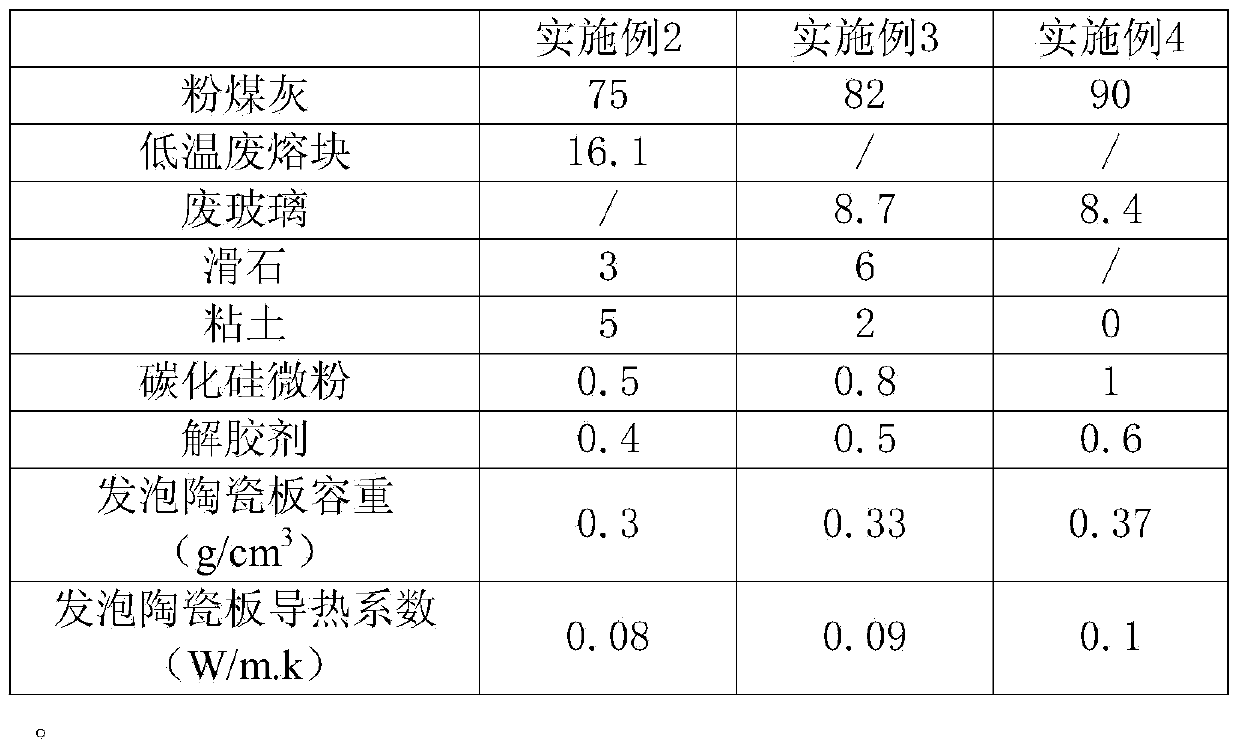

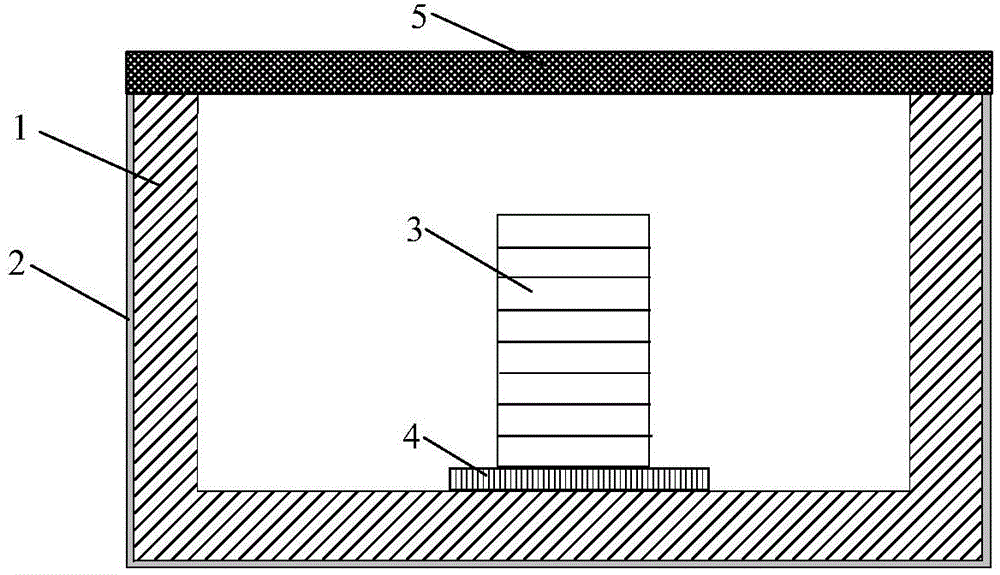

Method for preparing foamed ceramic plate by taking pulverized fuel ash as raw material via microwave sintering

ActiveCN104211435AShort firing cycleSave ceramic raw materialsCeramicwareMicrowave sinteringMaterials science

The invention relates to a method for preparing a foamed ceramic plate by taking pulverized fuel ash as a raw material via microwave sintering. The method comprises the following steps: carrying out burdening on the following raw materials by weight percent: 70% to 90% of pulverized fuel ash, 0% to 20% of low-temperature waste frits, 0% to 20% of waste glass, 0% to 8% of soapstone, 0% to 8% of clay, 0% to 1% of microwave absorbing material and 0.2% to 0.6% of dispergator, wherein the sum of the weight percent of all the components is 100%; carrying out ball grinding and spray granulation and putting the mixture into a mould to form a green body; and carrying out the microwave sintering on the green body within a firing period of 100 to 160 minutes at a temperature of 1080 DEG C to 1150 DEG C and under the microwave power of 20kW to 50kW and then carrying out heat preservation for 6 to 12 minutes so as to obtain the foamed ceramic plate.

Owner:MONALISA GRP CO LTD

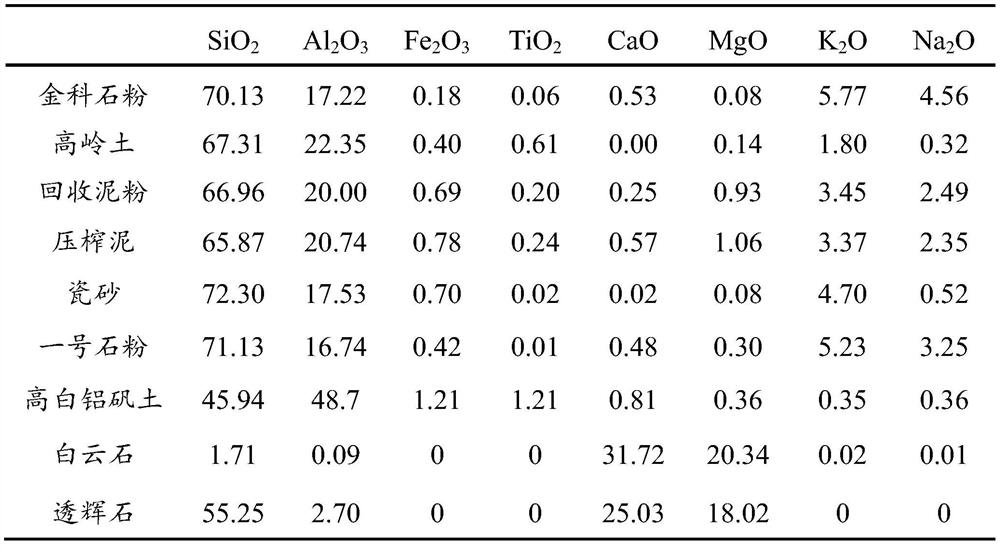

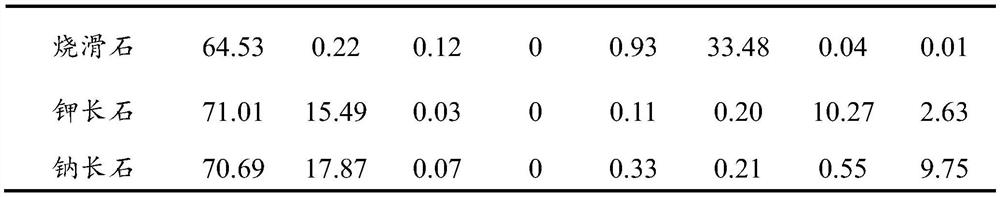

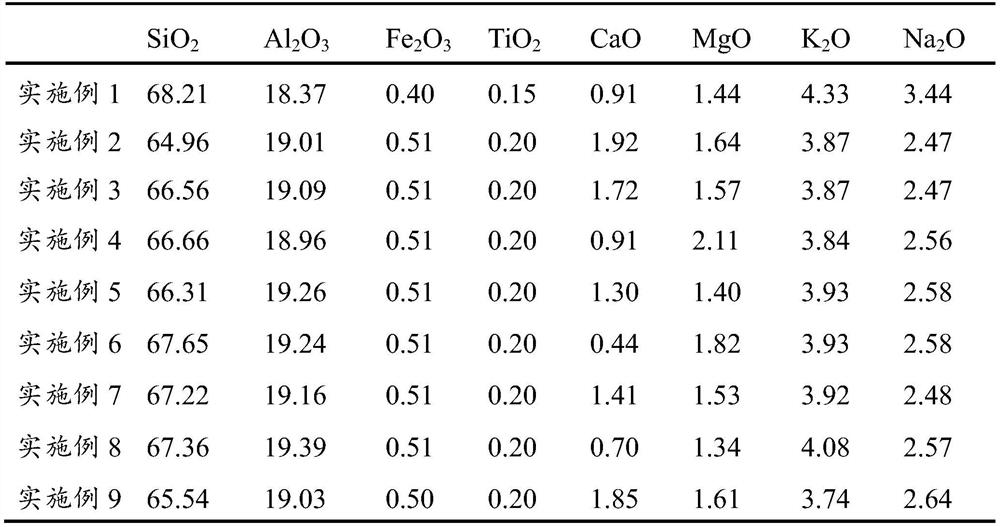

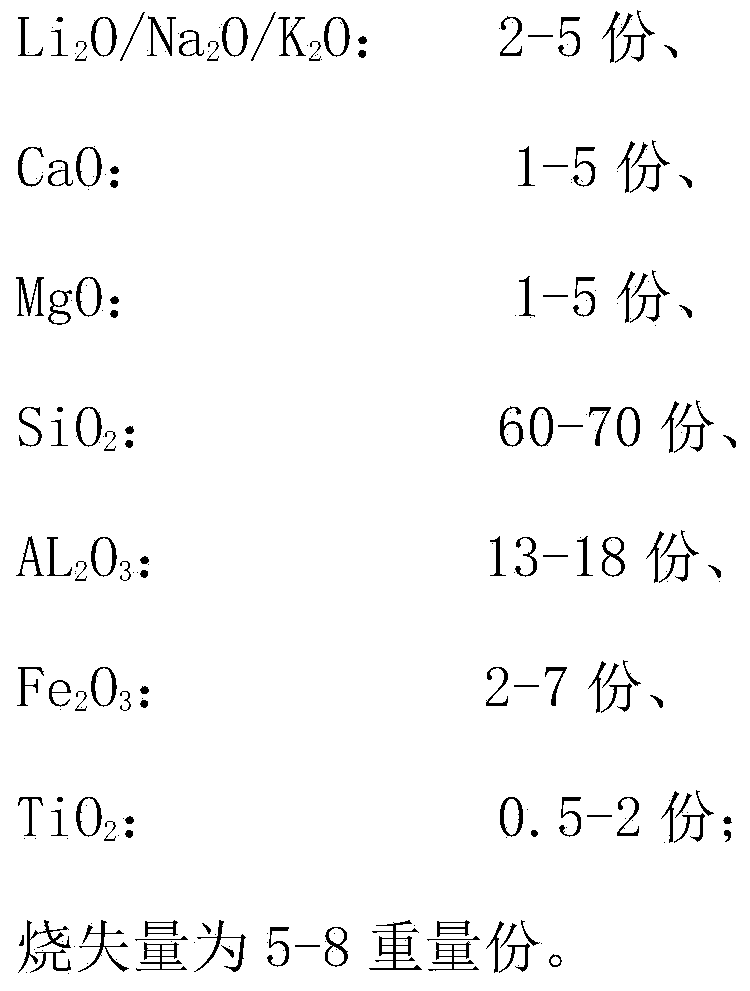

Marble tile blank sintered by using multi-component composite flux at low temperature and preparation method thereof

InactiveCN111892389ARealize low temperature fast burningShort firing cycleCeramic shaping apparatusLithium oxideBreaking strength

The invention discloses a marble tile blank sintered by using a multi-component composite flux at low temperature. The marble tile blank comprises the following components in percentage by weight: 64%-69% of SiO2, 18%-20% of Al2O3, 0.4%-0.6% of Fe2O3, 0.15%-0.2% of TiO2, 0.4%-2.0% of CaO, 1.4%-2.2% of MgO, 3.5%-4.5% of K2O and 2.0%-3.5% of Na2O. According to the blank, alkali metal and alkaline-earth metal oxide are compounded to serve as a fluxing agent, lithium oxide is not added, low-temperature fast firing of marble tiles can be achieved, a firing period is short, and the physical performance of fired products meets national standards in China. The invention further discloses a preparation method of the marble tile blank sintered by using the multi-component composite flux at low temperature. The preparation method is simple, the drying strength of a prepared marble tile is larger than or equal to 2.5 Mpa, the breaking strength of a sintered product is larger than or equal to 35 Mpa, and a water absorption rate is smaller than 0.1%.

Owner:清远市简一陶瓷有限公司

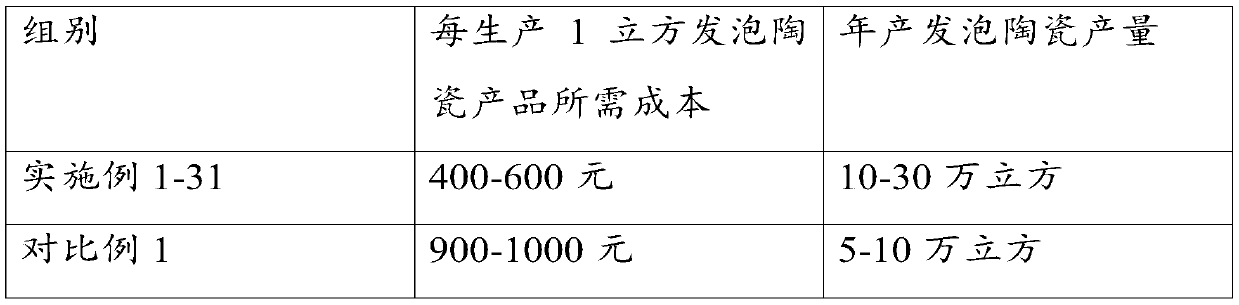

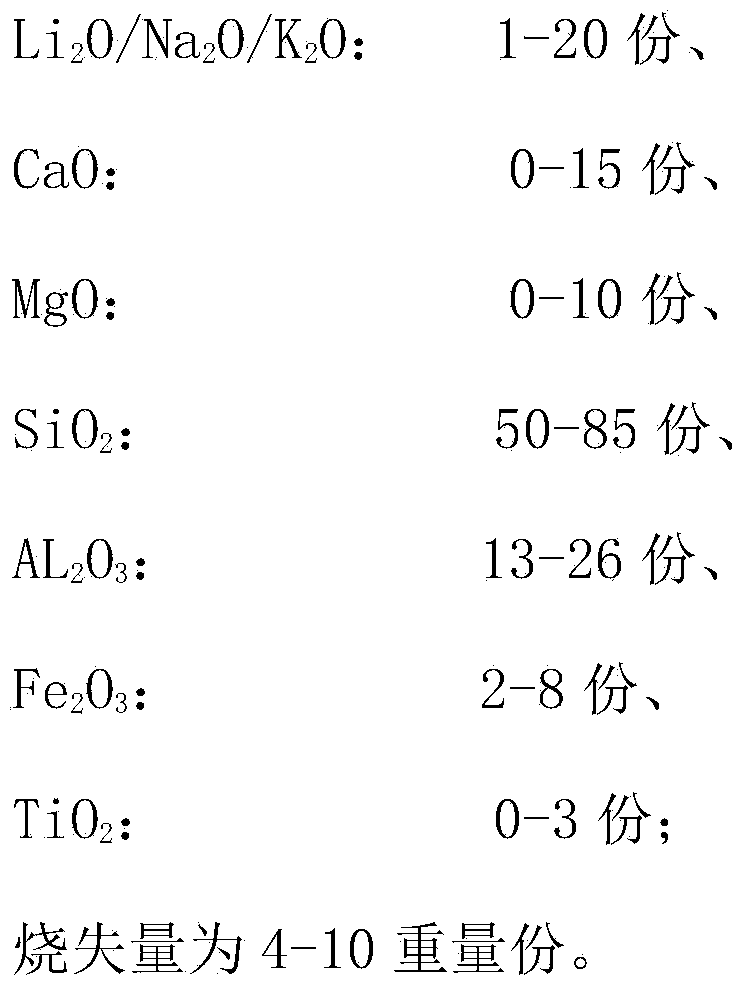

Novel process for industrial mass production of foamed ceramic, foamed ceramic, application of foamed ceramic and building component

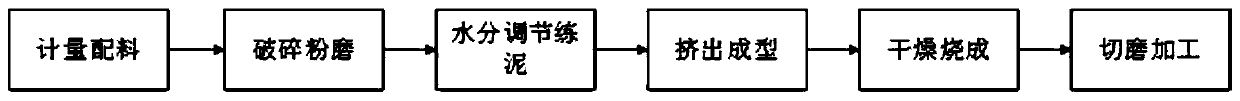

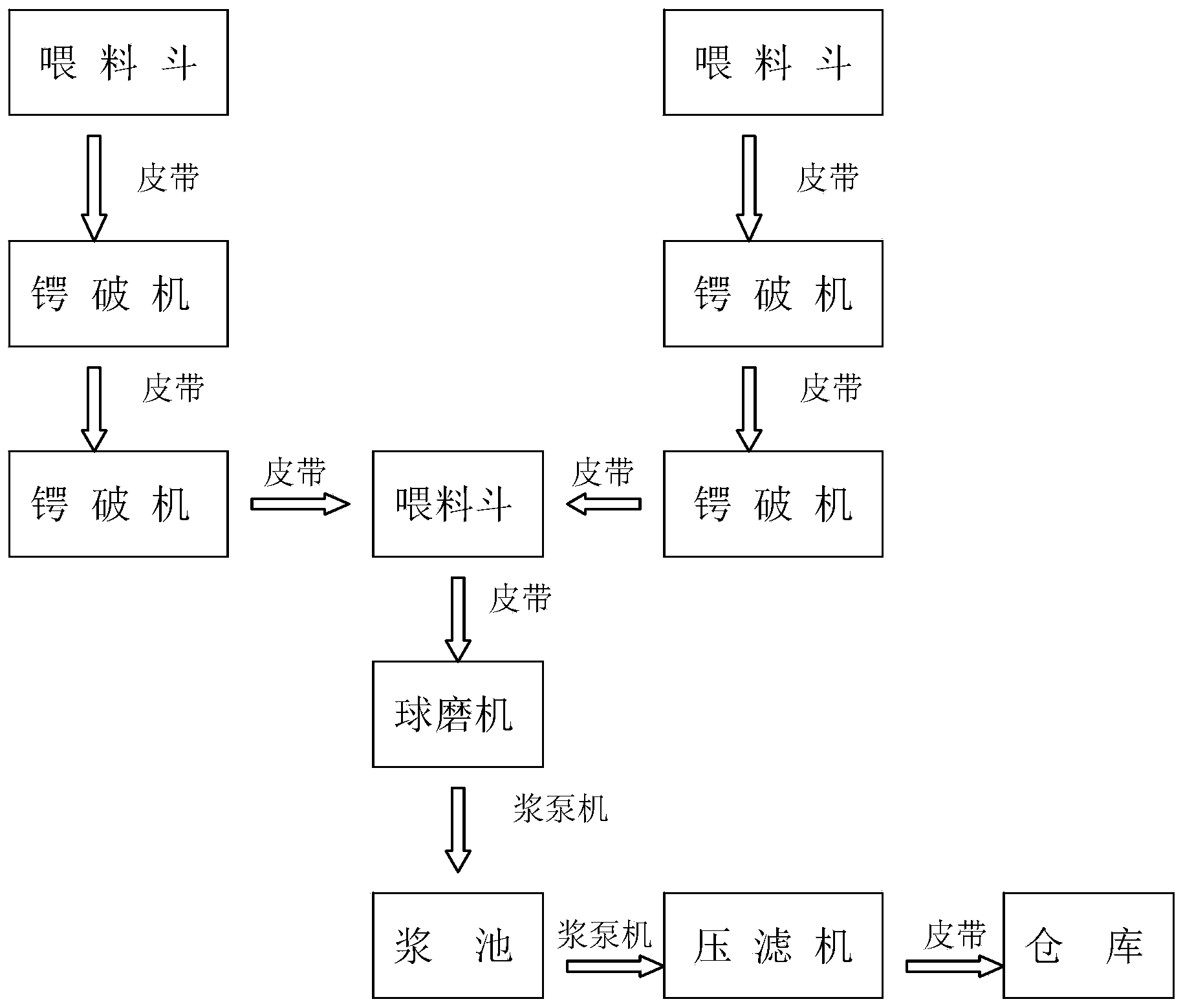

InactiveCN111004047AAvoid wastingReduce energy consumptionAuxillary shaping apparatusCeramic materials productionSpray driedKiln

The invention relates to the technical field of foamed ceramic production, and particularly provides a new process for industrial mass production of foamed ceramic, the foamed ceramic, application ofthe foamed ceramic and a building component. The new process for industrial mass production of the foamed ceramic comprises the following steps: sequentially crushing, grinding, pugging, performing extrusion molding, drying and sintering raw materials to obtain the foamed ceramic. According to the process, pugging and extrusion molding are adopted to replace the traditional wet ball milling and spray drying powdering process; the energy consumption required for drying, dehydrating and pulverizing is saved, a powder distribution system is not needed, kiln furniture such as a refractory surrounding edge, a silicon carbide bracket and refractory cotton of a kiln metering and batching furnace is omitted, and the gas energy consumption of the kiln is greatly reduced, so that the process is short in firing period and low in energy cost and equipment cost. Besides, the green body obtained by adopting the process is high in regularity, and components can be produced as required by adjusting the shape of an extrusion port, so that the cutting and grinding loss in the subsequent processing process is small, the waste of the raw materials is effectively avoided, and the yield is increased.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Low-temperature sintered terracotta blank and preparation method thereof

InactiveCN104230310ALower firing temperatureHigh strengthCeramic materials productionClaywaresMetallurgyCold weather

The invention discloses a low-temperature sintered terracotta blank and a preparation method thereof. The preparation method comprises the following steps: by taking waste terracotta, shale and clay as raw materials, uniformly processing, and mixing; the low-temperature sintered terracotta blank comprises the following raw materials in parts by weight: 0-80 parts of clay, 0-20 parts of waste terracotta and 15-50 parts of shale. The blank is fast in low-temperature sintering speed, high in sintering degree, low in water absorption, and high in strength, and sintered products can be used under severely cold weather condition.

Owner:FOSHAN RONGGUAN GLASS MATERIAL FOR BUILDING

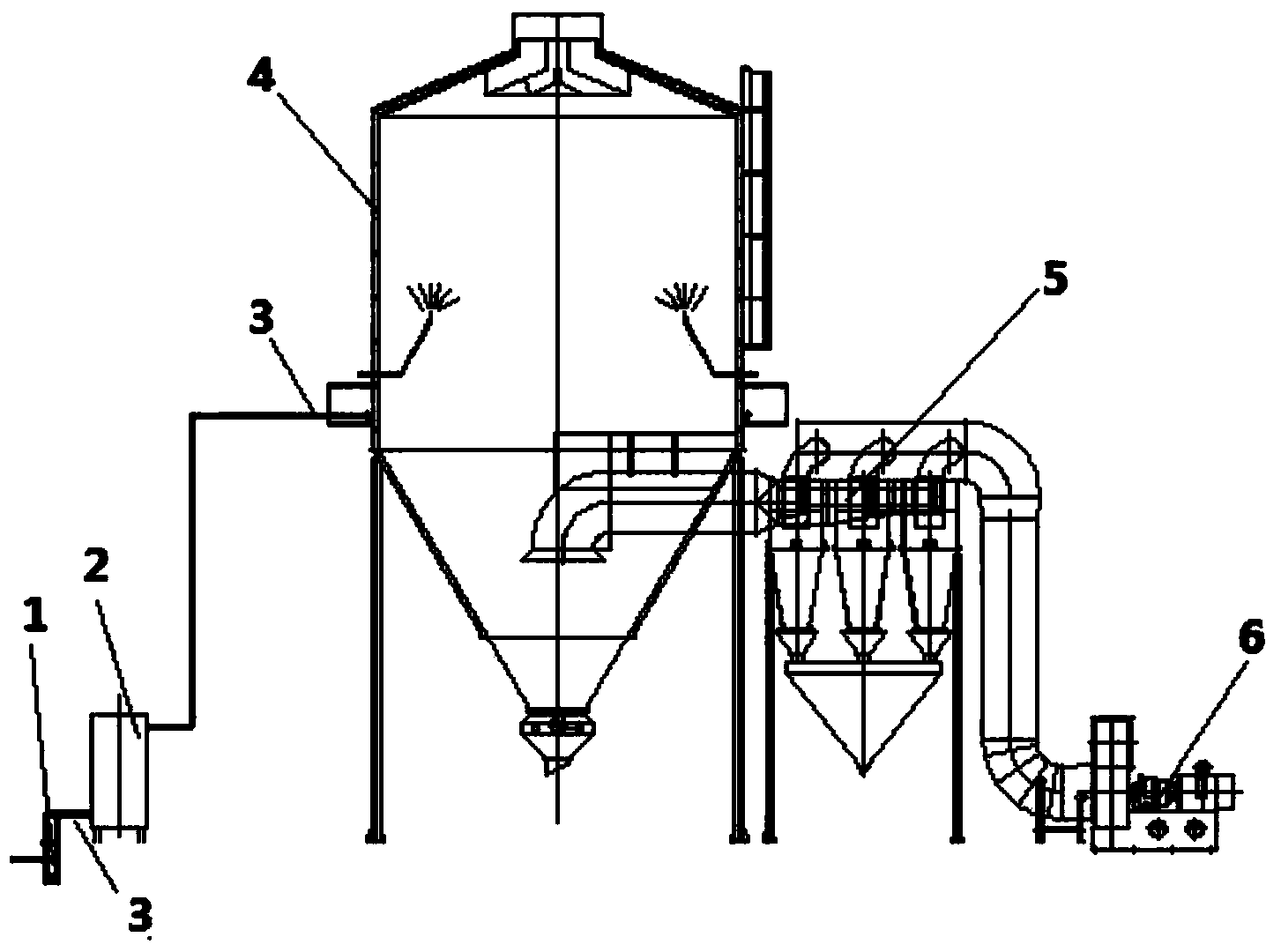

Energy-saving novel ceramic slurry granulation process and equipment for same

ActiveCN103551077AReduce energy consumptionGood liquidityGranulation by liquid drop formationExhaust gasSpray nozzle

The invention discloses an energy-saving novel ceramic slurry granulation process and equipment for the same. The process specifically comprises the steps of changing ceramic raw materials into ceramic slurry through ball milling, ageing, pumping into a slurry pipe in a high-pressure environment by a plunger pump, preheating to the temperature of 80-500 DEG C, and spraying into a spray tower by a spray nozzle. The equipment comprises the plunger pump, a heat exchanger and the spray tower, wherein the plunger pump is connected with the heat exchanger through the slurry pipe, and the heat exchanger is connected with the spray nozzle of the spray tower through the slurry pipe. According to the process and the equipment, the ceramic slurry is preheated to the temperature of 80-500 DEG C and then is sprayed into the spray tower, the moisture of the ceramic slurry can be evaporated through the heat of the ceramic slurry in a low-pressure environment in the spray tower, and the consumption of a lot of energy sources is reduced, so that the process and the equipment are energy-saving and environmental-friendly; ceramic granules produced by the process disclosed by the invention are solid granules and have the advantages that the fluidity is good, the molding speed is high, the firing cycle is short, a molding blank difficultly deforms and cracks, and the like; the preheating heat of the process can be residual heat generated by a kiln, namely heat contained in exhaust gases of the kiln, and energy sources can be recycled, so that the process is energy-saving.

Owner:GUANGDONG JUMPER THERMAL TECH

Ceramic plate

InactiveCN106866113AImprove drying pass rateExtrusion fastCeramic materials productionClaywaresPyrophylliteToxic industrial waste

The invention provides an argil plate and belongs to the technical field of building materials. The ceramic plate is prepared from the following materials in parts by weight: 10-35 parts of illite, 0-15 parts of kaolin, 5-15 parts of pyrophyllite, 5-30 parts of chinastone, 20-50 parts of iron ore smelting tailings, 5-30 parts of coarse poor materials, 0-5 parts of plasticizers, 20-40 parts of argil dry powder, 20-30 parts of chinaclay dry powder, 10-20 parts of feldspar powder and 20-30 parts of aggregate. The aggregate is prepared by crushing waste ceramic plates, ceramic tiles, pottery tiles and leftover materials; the fineness of the aggregate is 12-60 meshes. The argil plate is free of stone radiation and harm of organic materials of artificial stone to people; after the ceramic plate is fired under high temperature, the ceramic plate is high in strength, never fades and is free of influence of climatic environment; the coarse aggregate is added into the formula, so that the surface of the ceramic plate is rough and is not slippery; the argil plate is rapid to extrude and form, high in drying qualification rate and short in firing period; the cost is reduced; the iron ore tailings are used, so that the local industrial waste residues are reused.

Owner:史晓强

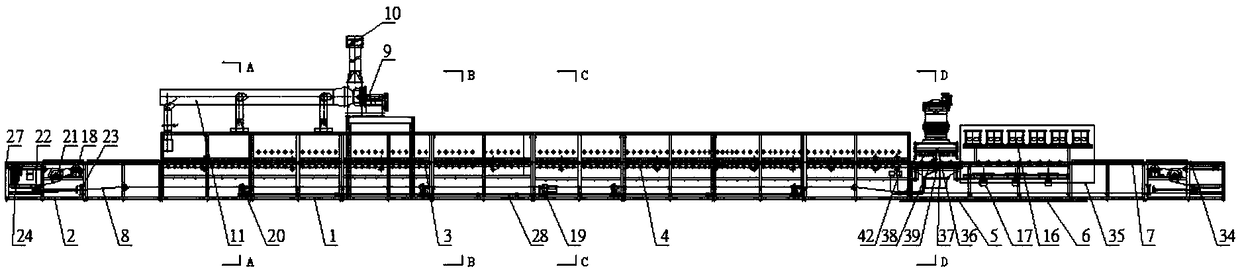

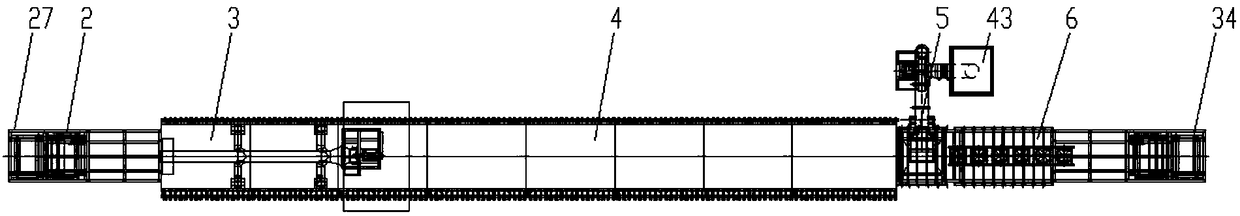

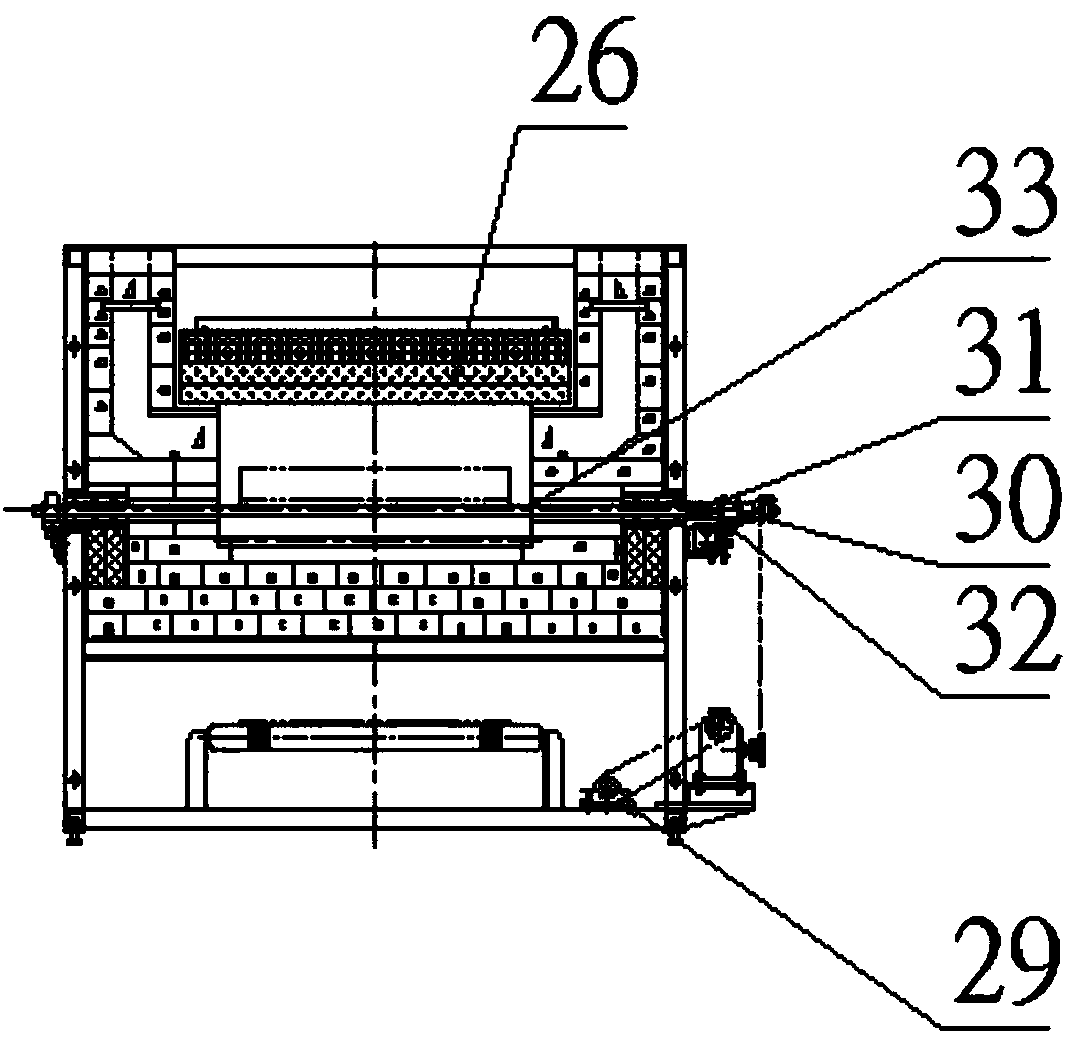

Electric-heating continuous glass tableware decorating firing and toughening furnace

InactiveCN108218209AReasonable structureReasonable control designGlass shaping apparatusGlass tempering apparatusFire controlEconomic benefits

The invention discloses an electric-heating continuous glass tableware decorating firing and toughening furnace. The electric-heating continuous glass tableware decorating firing and toughening furnace comprises a furnace body steel frame, a preheating adhesive discharging system, a decorating firing system, a tableware toughening system and an outlet cooling system, wherein two ends of the furnace body steel frame are respectively provided with a kiln inlet and a kiln outlet, the preheating adhesive discharging system is arranged inside the furnace body steel frame at one side of the kiln inlet, the decorating firing system is arranged in the furnace body steel frame at one side, away from the kiln inlet, of the preheating adhesive discharging system, the tableware toughening system is arranged inside the furnace body steel frame on one side, away from the preheating adhesive discharging system, of the decorating firing system, and the outlet cooling system is arranged inside the furnace body steel frame on one side, away from the decorating firing system, of the tableware toughening system. The electric-heating continuous glass tableware decorating firing and toughening furnace is reasonable in structure design, thermotechnical design and control design and short in firing period; and various production steps are combined with the continuous streamline production, and the clean energy is used, so that the electric-heating continuous glass tableware decorating firing and toughening furnace is environment-friendly, energy-saving, high in production capacity, low in production cost, apparent in economic benefit, automatic in firing control, and simple and easy in operation.

Owner:东莞市茂裕工业窑炉有限公司

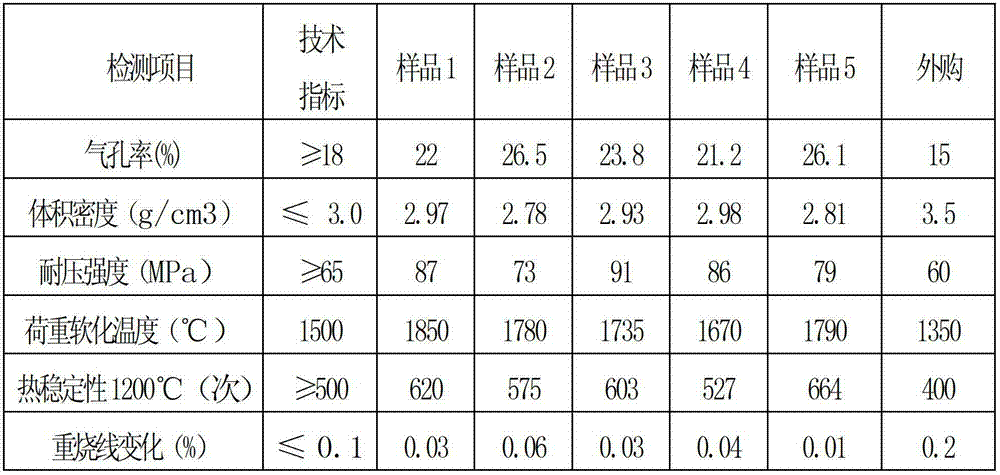

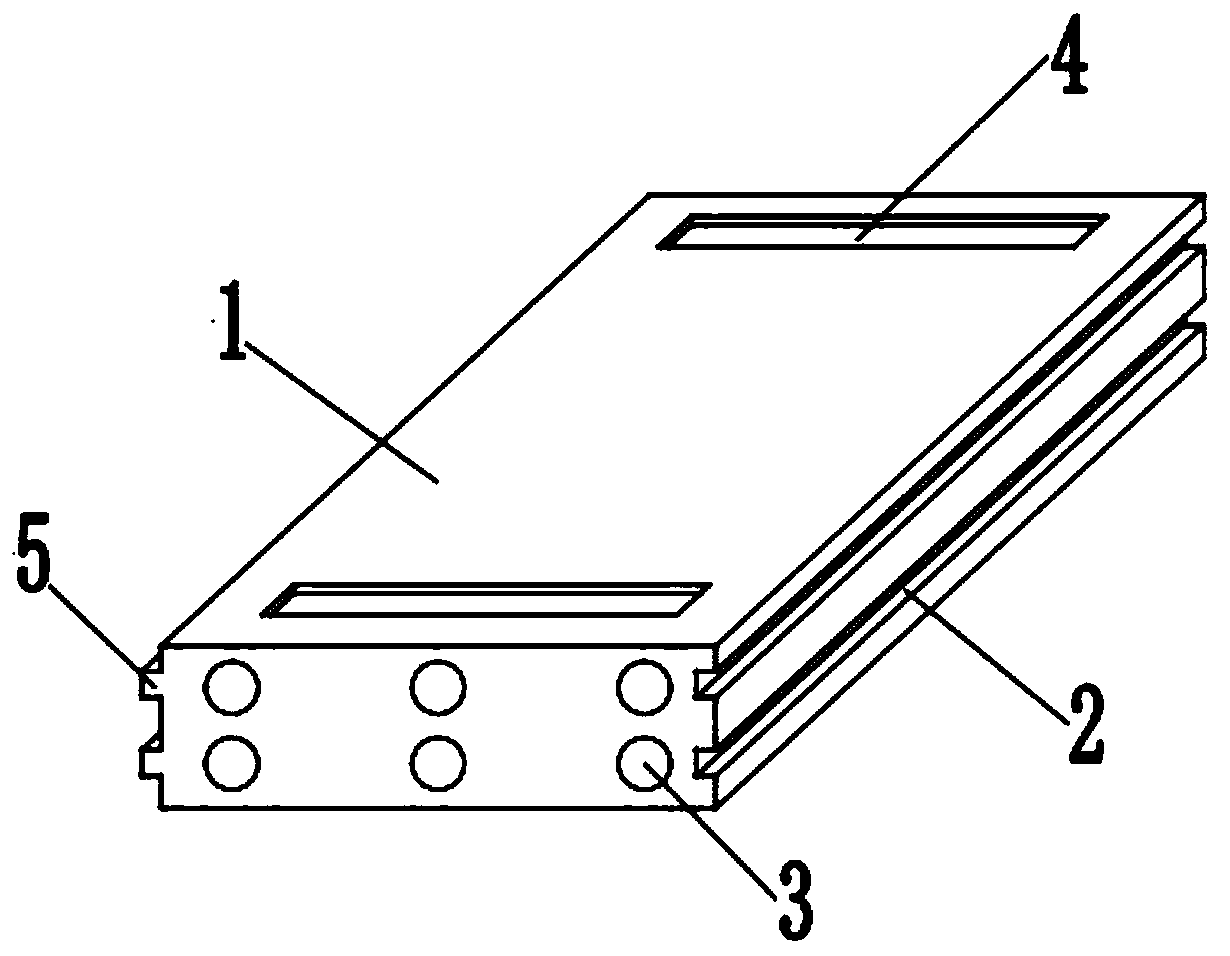

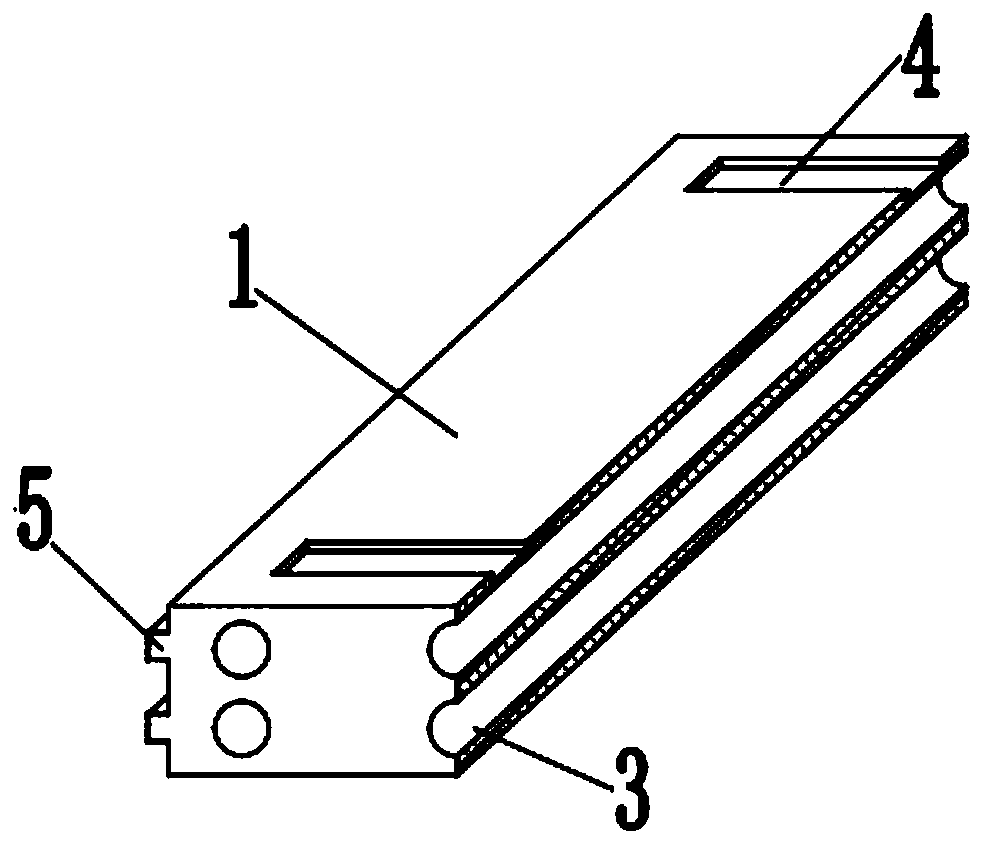

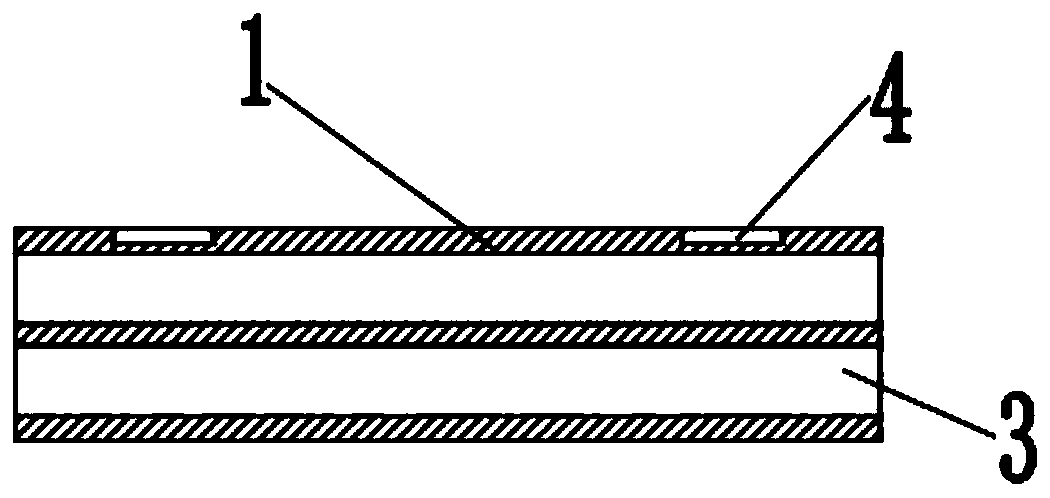

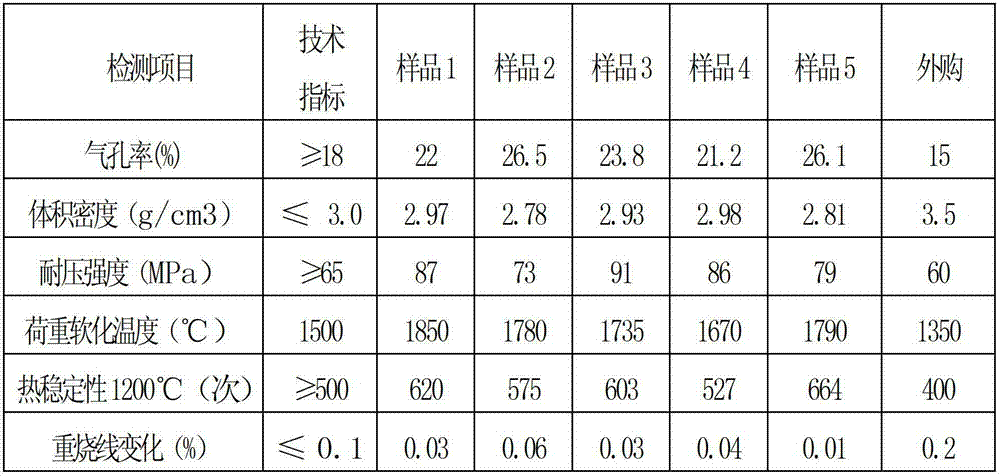

Backing plate for roller kiln

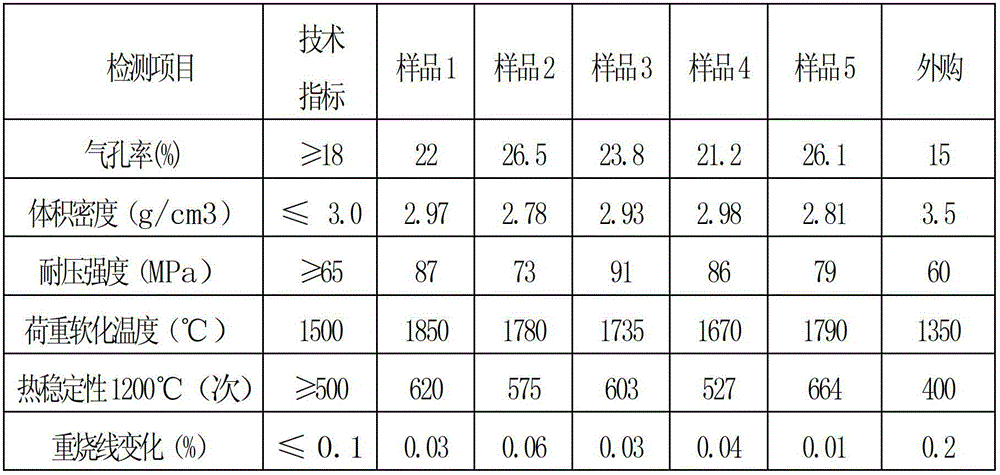

InactiveCN102731116AReduce manufacturing costShort firing cycleRefractoryCarboxymethylcellulose Sodium

The invention relates to a backing plate for a roller kiln and also relates to a fireproof hard material. Main points of the technical scheme are as follows: raw materials comprise, by weight, 5-7 parts of a material A and 3-5 parts of a material B; the two materials are mixed, compacted and sintered to obtain the backing plate; the material A is powders and comprises, by weight, 20-30 parts of a high temperature resistant matrix, 30-45 parts of alumina, 5-15 parts of calcine talcum, 15-30 parts of clay, 0.3-0.5 part of sodium tripolyphosphate and 0.2-0.5 part of carboxymethylcellulose sodium; and the material B is granules and comprises, by weight, 75-80 parts of high temperature resistant matrix particles and 20-25 parts of cast bauxitic clay particles. The backing plate provided by the invention has advantages of short sintering period, low temperature and high production efficiency, is an energy-saving environmentally-friendly low-cost high-performance refractory material product, and has wide industrial applications.

Owner:重庆歌德陶瓷玛赛克制造有限公司

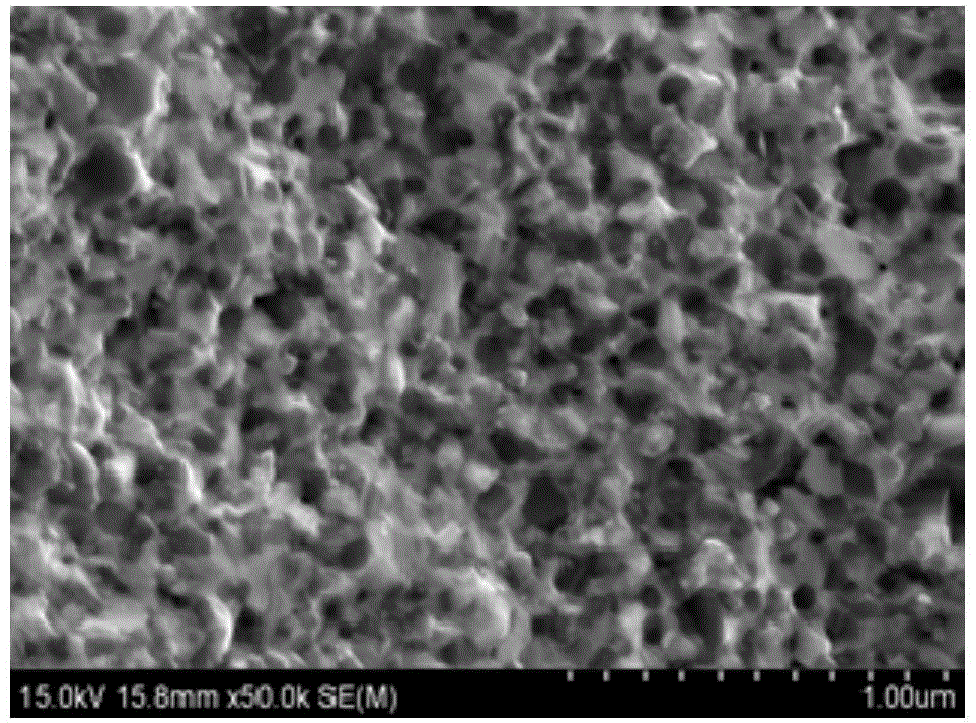

Method for preparing MgO-Y2O3 nanoceramics by two-step microwave sintering

The invention relates to a method for preparing MgO-Y2O3 nanoceramics by two-step microwave sintering. The method comprises the steps of proportioning, ball-milling and granulating, pressing a green piece, placing the green piece in an aluminum-oxide-made sagger of which the outer surface is coated with a heating-assistant material, then placing into a microwave sintering furnace, carrying out microwave sintering in two steps, and cooling to obtain MgO-Y2O3 nanoceramics, wherein in the first sintering step, the first-step sintering temperature T1 is 1320-1400 DEGC and the heat preservation time is 1-10 minutes, and in the second sintering step, the second-step sintering temperature T2 is 1250-1300 DEGC and the heat preservation time is 10-90 minutes. The method disclosed by the invention has the advantages of simple preparation process, short firing cycle and low energy consumption and can be used for preparing samples with larger size and complex shapes and is suitable for industrial production.

Owner:SHANDONG UNIV

Sintered brick prepared from waste paper papermaking sludge and preparation method thereof

The invention relates to the technical field of papermaking sludge recycling, in particular to sintered bricks prepared from waste paper papermaking sludge and a preparation method thereof. The sintered brick comprises a sintered brick body, a plurality of communicating holes are formed in the sintered brick body, two grooves are formed in the outer wall of one side of the sintered brick body, twoprotrusions are arranged on the outer wall of the side, away from the grooves, of the sintered brick body, and limiting grooves are formed in the two sides of the top of the sintered brick body. Thepreparation method of the sintered brick is simple; the waste paper papermaking sludge can be used for preparing sintered bricks; the sintered brick prepared by mixing the waste paper papermaking sludge is not easy to crack and good in use performance, resources are fully utilized, the environmental protection property is good, the waste paper papermaking sludge is stirred before the waste paper papermaking sludge is used, impurity waste in the waste paper papermaking sludge is taken out, a bactericide is added, mixing of the waste paper papermaking sludge and the sintered material is facilitated, bacterium breeding is reduced, the cement amount generated when the sintered brick bodies are piled into a wall through cement is reduced, and part of cost is saved.

Owner:上海永玺环境科技有限公司

Production method of backing plate for roller kiln

The invention relates to a backing plate for a roller kiln and also relates to a fireproof hard material. Main points of the technical scheme are as follows: raw materials comprise, by weight, 5-7 parts of a material A and 3-5 parts of a material B; the two materials are mixed, compacted and sintered to obtain the backing plate; the material A is powders and comprises, by weight, 20-30 parts of a high temperature resistant matrix, 30-45 parts of alumina, 5-15 parts of calcine talcum, 15-30 parts of clay, 0.3-0.5 part of sodium tripolyphosphate and 0.2-0.5 part of carboxymethylcellulose sodium; and the material B is granules and comprises, by weight, 75-80 parts of high temperature resistant matrix particles and 20-25 parts of cast bauxitic clay particles. The backing plate provided by the invention has advantages of short sintering period, low temperature and high production efficiency, is an energy-saving environmentally-friendly low-cost high-performance refractory material product, and has wide industrial applications.

Owner:重庆歌德陶瓷玛赛克制造有限公司

Andesite tailing-based foamed ceramic

PendingCN110937918AEasy to useRealize resource utilizationCeramic materials productionCeramicwareCarbide siliconAndesite

The invention discloses foamed ceramic with andesite tailing mud and fly ash as main raw materials. The foamed ceramic is characterized by comprising the following components in percentage by mass: 50-90% of the andesite tailing mud, 8-48% of the fly ash and 2-5% of silicon carbide. A preparation method for the foamed ceramic comprises the following steps: S1, preparing powder; S2, forming and drying a green body; and S3, sintering a sample. The foamed ceramic prepared by the method is short in firing period, simple in formula and preparation process, low in equipment requirement, and excellent in performance. The use amount of solid waste reaches 98%, so production cost is effectively reduced; resource utilization of the solid waste, namely the andesite tailing mud, and the hazardous waste, namely the fly ash is achieved; land occupation of the tailings is reduced; and environmental problems caused by the tailings are relieved.

Owner:HUZHOU COLLEGE

A kind of ceramics with brown crystalline glaze layer on the surface and its preparation method

The invention relates to a ceramic with a coffee crystal glaze layer on a surface and a preparation method therefor. The ceramic surface coffee crystal glaze layer comprises the following ingredients, by weight, 15-30% of SiO2, 10-20% of Al2O3, 4-8% of F, 0.1-0.5% of K2O, 3-5% of Na2O, 20-35% of WO3, 6-10% of P2O5, 8-15% of MnO, 6-10% of CuO, and 0.5-2% of Fe2O3. The coffee crystal glaze employs a glaze spraying mode, the technology is simple, crystal flowers are ice-crystal-shaped and uniformly distributed, the stereo perception is strong, good decorative effects are achieved and the firing period is short.

Owner:MONALISA GRP CO LTD

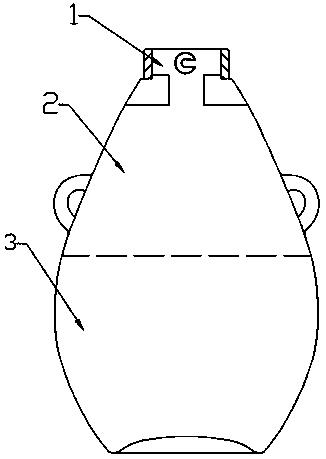

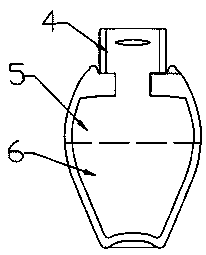

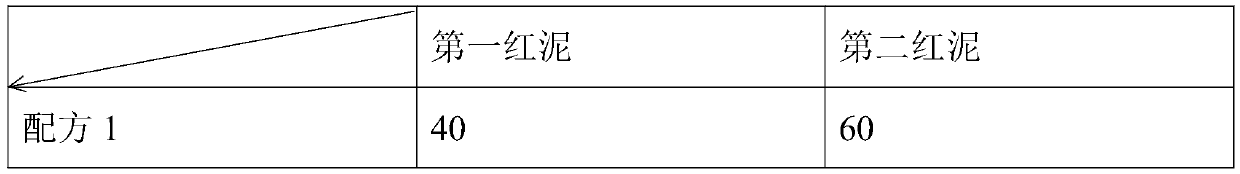

Red mud fine ceramic winebottle blank, and preparation process for manufacturing winebottle from same

The invention discloses a red mud fine ceramic winebottle blank, and a preparation process for manufacturing a winebottle from the same. The preparation process comprises the following steps: mixing 40-55% by weight of first red mud and 60-45% by weight of second red mud, and carrying out ball milling, sieving, filter-pressing dehydration and mud squeezing successively so as to obtain a mud cake;then, according to the shapes of a winebottle body and a winebottle head, carrying out separate and segmented moulding for the winebottle body and the winebottle, and then carrying out bonding to obtain a rough winebottle body and a rough winebottle head; and finally, separately subjecting the rough winebottle body and the rough winebottle head to natural drying, baking, blank washing, baking, biscuiting, inner-glaze preparation, inner-glaze pouring, outer-glaze preparing, outer-glaze soaking, glaze firing, color baking after overglaze decoration, sorting and packaging sequentially. Accordingto the red mud fine ceramic winebottle blank, and the preparation process for manufacturing the winebottle from the same in the invention, the prepared winebottle looks like pottery, but detection indexes shows the winebottle belongs to porcelain; the winebottle has excellent glaze surface with no or low gloss; and the cost of raw materials is low.

Owner:CHONGQING JINHUI CERAMICS

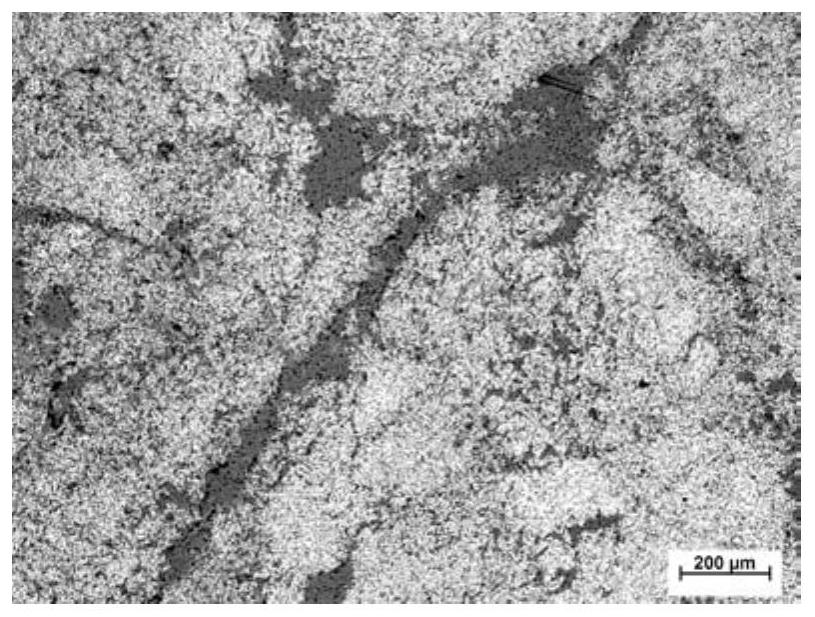

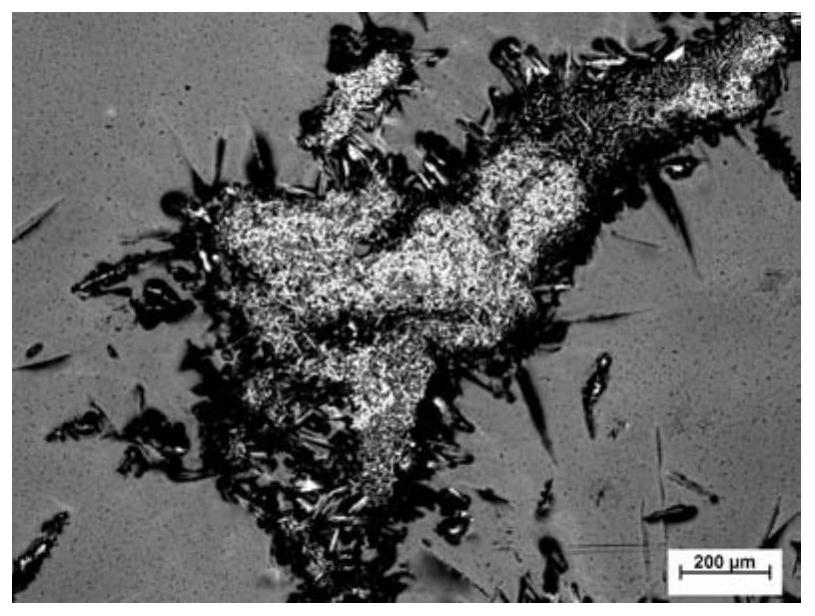

Method for producing phase-separated kiln-changing decorative composite material through roller kiln using red mud

The invention belongs to the technical field of building ceramic production, and in particular relates to a method for producing phase-separated kiln-transformed decorative composite materials by using red mud through a roller kiln. Use red mud, feldspar, vanadium-titanium slag, quartz, borax, lepidolite and talc as raw materials, put it in a frit furnace, melt it at 1400-1500°C, water quench, crush and sieve, and take the sieved residue The materials are mixed together, which is the raw material for phase-separation kiln transformation; feldspar, clay, coke gemstone, pyrophyllite and avenzu stone are used as raw materials, put them in a ball mill, after 36 hours of ball milling, spray granulation, and put the granules in the mold , through pressing and forming to obtain a green body; the prepared phase-separation kiln transformation raw material is spread on the green body, and then dried and fired in a roller kiln to produce a phase-separation kiln transformation decorative composite material. The phase-splitting kiln-changing decorative composite material produced by the invention can meet all the performance and decoration properties of traditional ceramics, and does not use glaze pigments in the production process, which is a green and environment-friendly production process.

Owner:ZIBO GOLD LION KING TECH CERAMICS CO LTD

Backing plate for roller kiln

InactiveCN102731116BReduce manufacturing costShort firing cycleRefractoryCarboxymethylcellulose Sodium

Owner:重庆歌德陶瓷玛赛克制造有限公司

Ornamental stone porcelain base and preparation method thereof

PendingCN114644511AImprove plasticityVarious scenesSpecial ornamental structuresKaolin clayOxidation resistant

The invention discloses an ornamental stone porcelain base and a preparation method thereof, and relates to the technical field of ceramic material preparation, the ornamental stone porcelain base comprises the following raw material components by weight: 35-60 parts of alumina, 15-40 parts of silica, 15-30 parts of high alumina ore, 1-5 parts of kaolin, 5-15 parts of calcium oxide, 3-5 parts of magnesium oxide, 1-3 parts of iron oxide, and 0.3-1 part of zirconium oxide. The ornamental stone porcelain base provided by the invention has the beneficial effects of strong plasticity, various placement scenes, prominent artistic effect, hard texture, water resistance, corrosion resistance, aging resistance, heat resistance, flame retardance, high melting point, thermal shock resistance, oxidation resistance, no volatilization, high stability, no wind, solarization, wind, sand, salt and alkali, repeated use of leftover materials, no paint and the like.

Owner:平顶山市三瓷源文化传播有限公司

A formula of environment-friendly energy-saving low-temperature white semi-ceramic and its preparation method

ActiveCN104944912BSolve the problem of high firing temperatureReduce energy consumptionClaywaresThermal stabilityDolomite

The invention relates to the technical field of low-temperature white semi-porcelains and preparation thereof and discloses a formula for an environment-friendly energy-saving low-temperature white semi-porcelain and a method for preparing the same. In the formula of the low-temperature white semi-porcelain, the low-temperature white semi-porcelain comprises, by weight parts, 6-10 parts of spodumene, 13-17 parts of albite, 8-12 parts of talc, 3-7 parts of dolomite, 8-12 parts of quartz, 18-22 parts of washed kaolin, 10-14 parts of black soil, 18-22 parts of clay and 0.0002-0.0003 part of brightener. The formula and the preparation method for preparing the low-temperature white semi-porcelain not only reduce sintering temperature and sintering time of porcelain products, but also improve thermal shock resistance and thermal stability of the porcelain products; the low-temperature white semi-porcelain is low in water absorption and high in strength, the unit energy consumption is reduced, national environmental resources are protected, and the low-temperature white semi-porcelain is green and environmentally friendly.

Owner:JIEDONG COUNTY YI CHENG CERAMIC IND

Method for producing split-phase furnace transmutation decorative composite materials from red mud by roller kilns

The invention belongs to the technical field of building ceramic production, and particularly relates to a method for producing split-phase furnace transmutation decorative composite materials from red mud by roller kilns. The method includes placing raw materials, which include the red mud, feldspar, vanadium and titanium slag, quartz, borax, lepidolite and talc, in frit furnaces, melting the rawmaterials at the temperatures of 1400-1500 DEG C, then carrying out water quenching and crushing, carrying out sieving to obtain sieve residues and mixing the sieve residues with one another to obtain split-phase furnace transmutation raw materials; placing raw materials, which include feldspar, clay, flint clay, pyrophyllite and aragonite, in ball mills, carrying out ball milling for 36 h, thencarrying out spray granulation, placing granules in dies and carrying out compression molding to obtain green bodies; arranging the obtained split-phase furnace transmutation raw materials on the green bodies and drying and firing the green bodies with the split-phase furnace transmutation raw materials by the roller kilns to obtain the split-phase furnace transmutation decorative composite materials. The method has the advantages that all the requirements on the usability and the decorativeness of the traditional ceramic can be met by the split-phase furnace transmutation decorative compositematerials produced by the aid of the method, glaze coloring materials are omitted in production procedures, and accordingly the method is a green and environment-friendly production process.

Owner:ZIBO GOLD LION KING TECH CERAMICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com