Marble tile blank sintered by using multi-component composite flux at low temperature and preparation method thereof

A composite flux, low-temperature firing technology, applied in the field of ceramic materials, can solve the problems of long firing time, high firing temperature, narrow melting temperature range, etc., and achieve the effects of short firing cycle and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

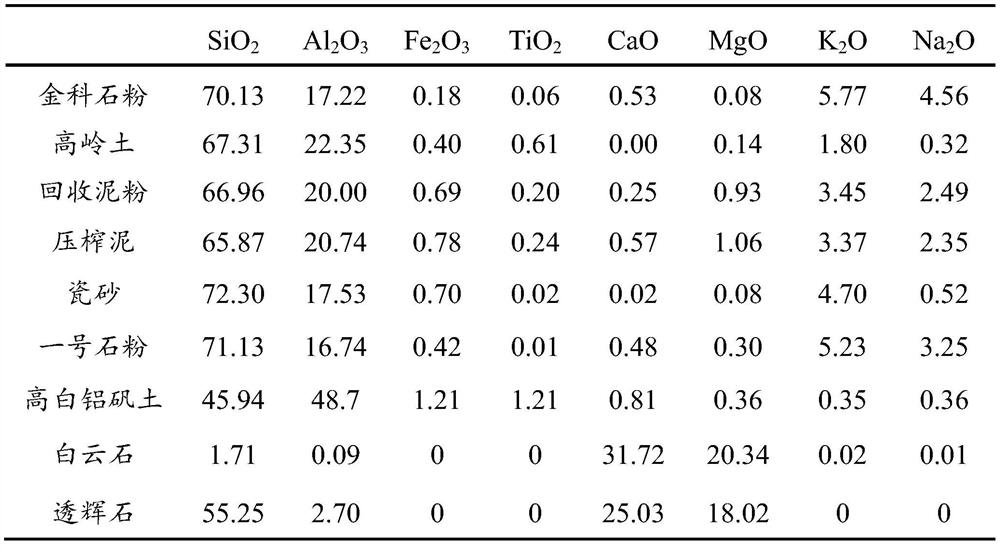

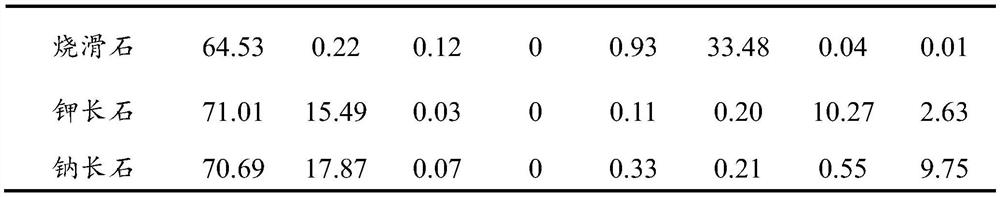

[0028] The blank described in this embodiment contains the following raw materials in parts by weight: 25 parts of Jinke stone powder, 6 parts of kaolin, 4 parts of recycled mud powder, 25 parts of pressed mud, 4 parts of porcelain sand, 10 parts of No. 1 stone powder, high white bauxite 2 parts, 2 parts of diopside, 2 parts of calcined talc, 10 parts of potassium feldspar and 10 parts of albite.

[0029] The raw material of the billet also contains 0.2wt% of solid debonding agent, 0.25wt% of water reducing agent and 0.32wt% of liquid degumming agent.

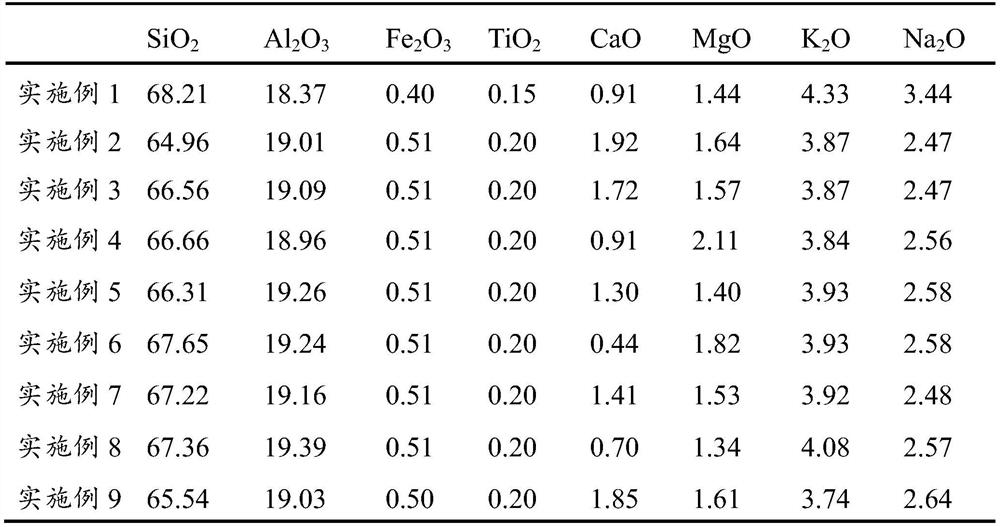

[0030] The chemical composition of the billet is shown in Table 2. The preparation method of the billet includes the following steps: ball mill each raw material, sieve the ball milled slurry to filter out large particles, and then enter the large pond to stale, so that the slurry is hydrated evenly, and the homogenized slurry After the material is sieved to remove iron, it enters the spray tower for granulation, and after the ...

Embodiment 2

[0034]The blank described in this embodiment contains the following raw materials in parts by weight: 25 parts of Jinke stone powder, 10 parts of kaolin, 8 parts of recycled mud powder, 30 parts of pressed mud, 8 parts of porcelain sand, 10 parts of No. 1 stone powder, high white bauxite 3 parts of dolomite, 4 parts of diopside, 1 part of diopside, 0.5 part of burnt talc and 0.5 part of potassium feldspar.

[0035] The raw material of the billet also contains 0.2wt% of solid debonding agent, 0.25wt% of water reducing agent and 0.32wt% of liquid degumming agent.

[0036] The chemical composition of the billet is shown in Table 2. The preparation method of the billet is the same as in Example 1, the particle size distribution of the billet powder is the same as in Example 1, and the firing rate of the billet is 1175° C. / 67 min.

Embodiment 3

[0038] The blank described in this embodiment contains the following raw materials in parts by weight: 25 parts of Jinke stone powder, 10 parts of kaolin, 8 parts of recycled mud powder, 30 parts of pressed mud, 8 parts of porcelain sand, 10 parts of No. 1 stone powder, high white bauxite 3 parts, 1 part of dolomite, 4 parts of diopside, 0.5 part of burnt talc and 0.5 part of potassium feldspar.

[0039] The raw material of the billet also contains 0.2wt% of solid debonding agent, 0.25wt% of water reducing agent and 0.32wt% of liquid degumming agent.

[0040] The chemical composition of the billet is shown in Table 2. The preparation method of the billet is the same as in Example 1, the particle size distribution of the billet powder is the same as in Example 1, and the firing rate of the billet is 1185° C. / 67 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com