A kind of preparation method of fast-fired ceramic tile and product thereof

A ceramic tile, pressing and forming technology, applied in the field of building ceramics, can solve the problems of inability to quickly fire ceramic tiles, low production speed of fast-fired ceramic tiles, easy occurrence of roller stick marks, etc. Wide range, the effect of improving product productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method for fast-fired ceramic tiles, comprising the following steps:

[0036] A. Mix the green body raw materials evenly, and then make a green body powder after ball milling, pulping and drying granulation, and press the green body powder to obtain a green body;

[0037] Calculated according to mass percentage, the chemical composition of the green body raw material contains K 2 O 4.1~4.5%, Na 2 O 1.3~1.7% and MgO 1.4~1.7%;

[0038] B. Apply glaze on the surface of the green body;

[0039] The raw materials of the glaze include potassium feldspar, calcined alumina, kaolin, quartz, dolomite and zirconium silicate;

[0040] C. The body is fired in a short kiln to produce a fast-fired ceramic brick.

[0041] To realize energy-saving and fast burning, start with changing the chemical composition of the raw material system of the green body, the chemical composition of the green body raw material adopts K 2 O-MgO flux system, then Na 2 Supplemented by O,...

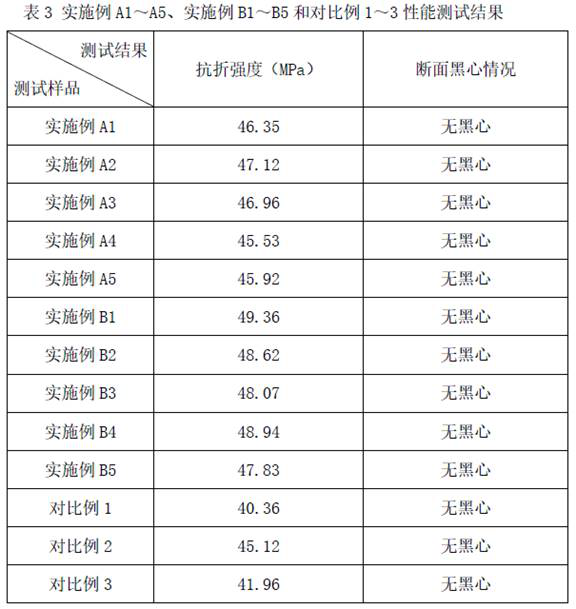

Embodiment A1~A5

[0081] A preparation method for fast-fired ceramic tiles, comprising the following steps:

[0082] A. Mix the green body raw materials (use the existing conventional ceramic green body raw materials, and the chemical composition of the green body raw materials is shown in Table 1) and mix them evenly, and then go through ball milling (the ball milling time is 18h, after ball milling and pulping) The fineness of the prepared slurry is 0.7-0.9% after passing through a 250-mesh sieve), drying and granulating to obtain a green body powder, and pressing the green body powder to obtain a green body;

[0083] B. Apply glaze on the surface of the green body;

[0084] Calculated in parts by weight, the raw materials of the glaze are 60 parts of potassium feldspar, 18 parts of calcined alumina, 6 parts of kaolin, 6 parts of quartz, 3 parts of dolomite and 15 parts of zirconium silicate.

[0085] C. The green body is fired in a short kiln. During the firing process, the firing temperatu...

Embodiment B1~B5

[0088] A preparation method for fast-fired ceramic tiles, comprising the following steps:

[0089] A, the green body raw material (using the green body raw material shown in Table 2, wherein the chemical composition of the green body raw material is Al 2 o 3 17~18%, SiO 2 68~70%, K 2 O 4.1~4.5%, Na 2 O 1.3~1.7%, MgO 1.4~1.7%, CaO 0~0.7% and IL 4~6%) mix evenly, and then go through ball milling (where the ball milling time is 18h, the pulp obtained after ball milling is The fineness is 0.7-0.9% after passing through a 250-mesh sieve), drying and granulating to obtain a green body powder, and pressing the green body powder to obtain a green body;

[0090] B. Apply glaze on the surface of the green body;

[0091] Calculated in parts by weight, the raw materials of the glaze are 60 parts of potassium feldspar, 18 parts of calcined alumina, 6 parts of kaolin, 6 parts of quartz, 3 parts of dolomite and 15 parts of zirconium silicate.

[0092] C. The green body is fired in a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com